Patents

Literature

986 results about "Single crystal growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ß-Ga2o3 single crystal growing method, thin-film single crystal growing method, Ga2o3 light-emitting device, and its manufacturing method

InactiveUS20060150891A1Trend downHigh crystallinityPolycrystalline material growthBy zone-melting liquidsDopantInfrared

Owner:WASEDA UNIV

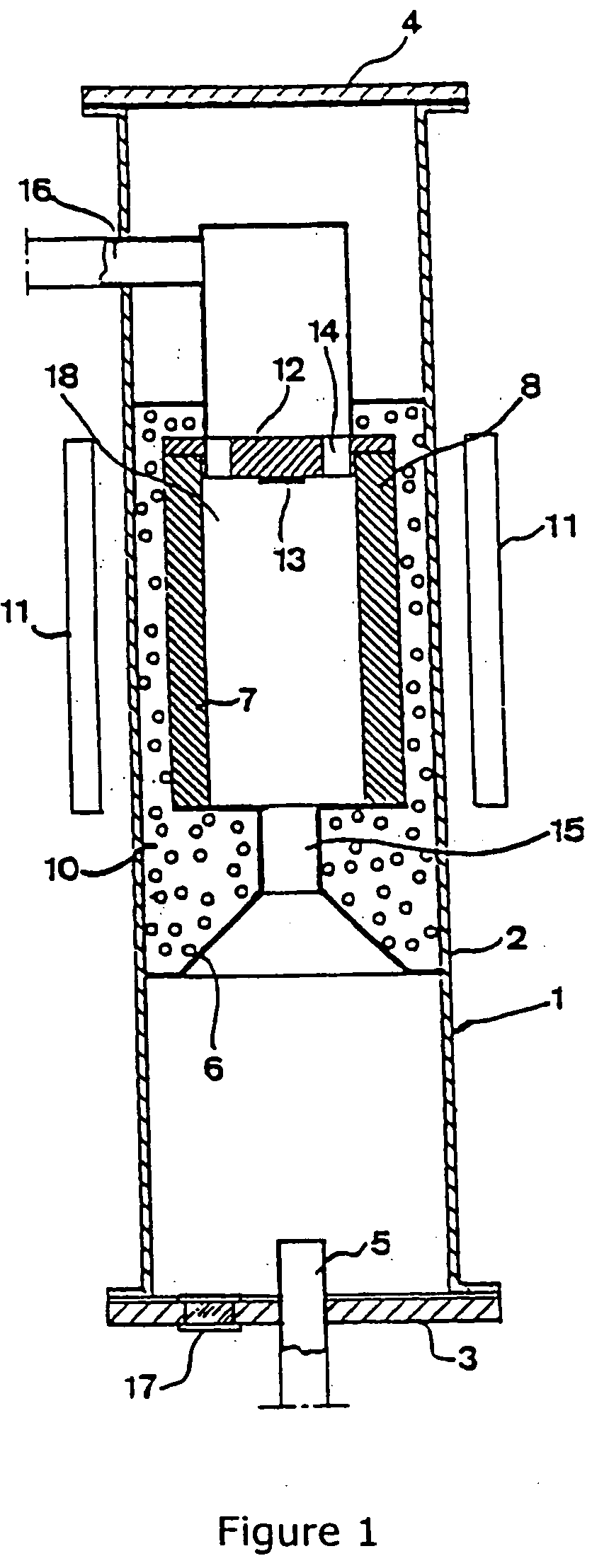

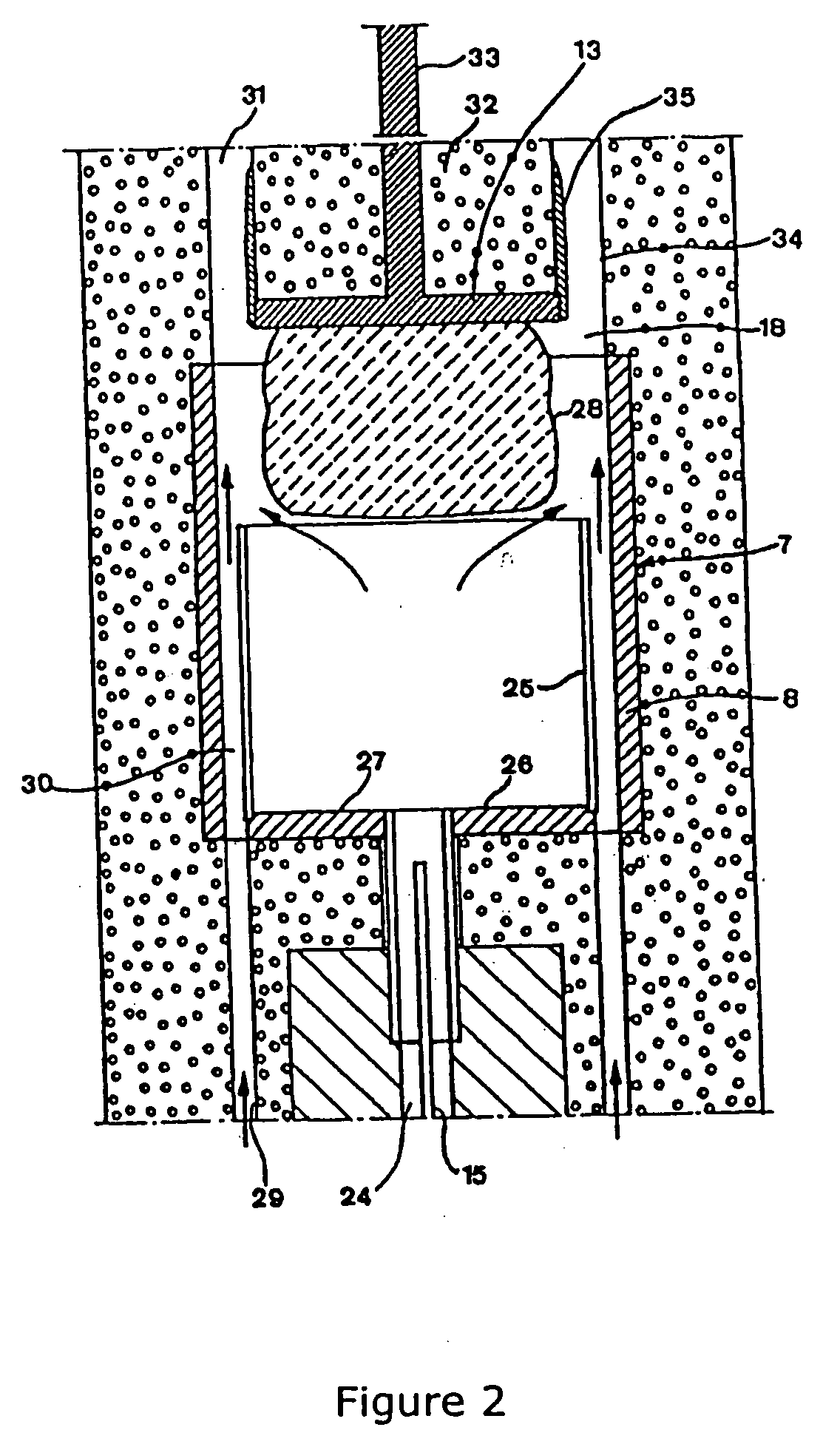

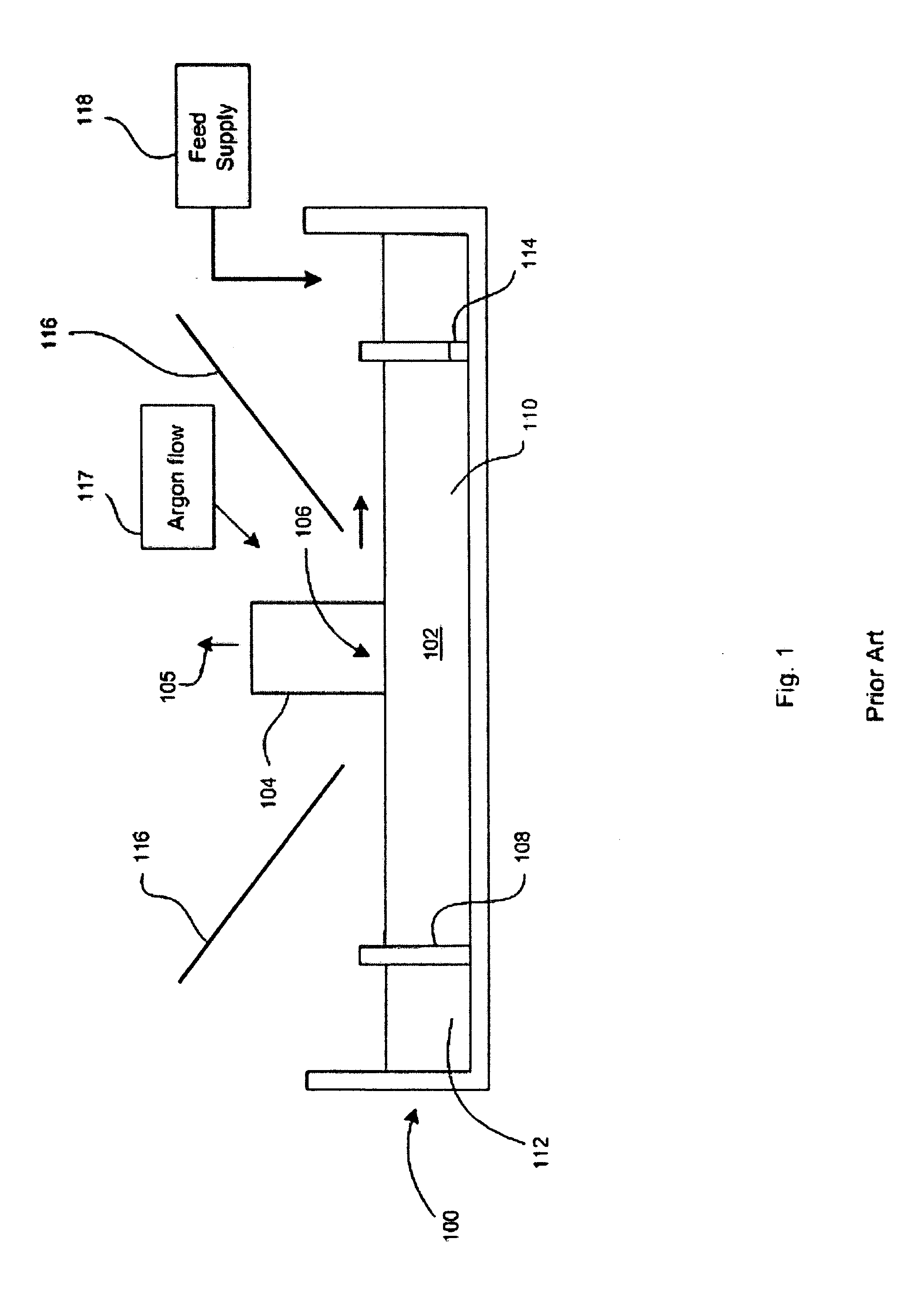

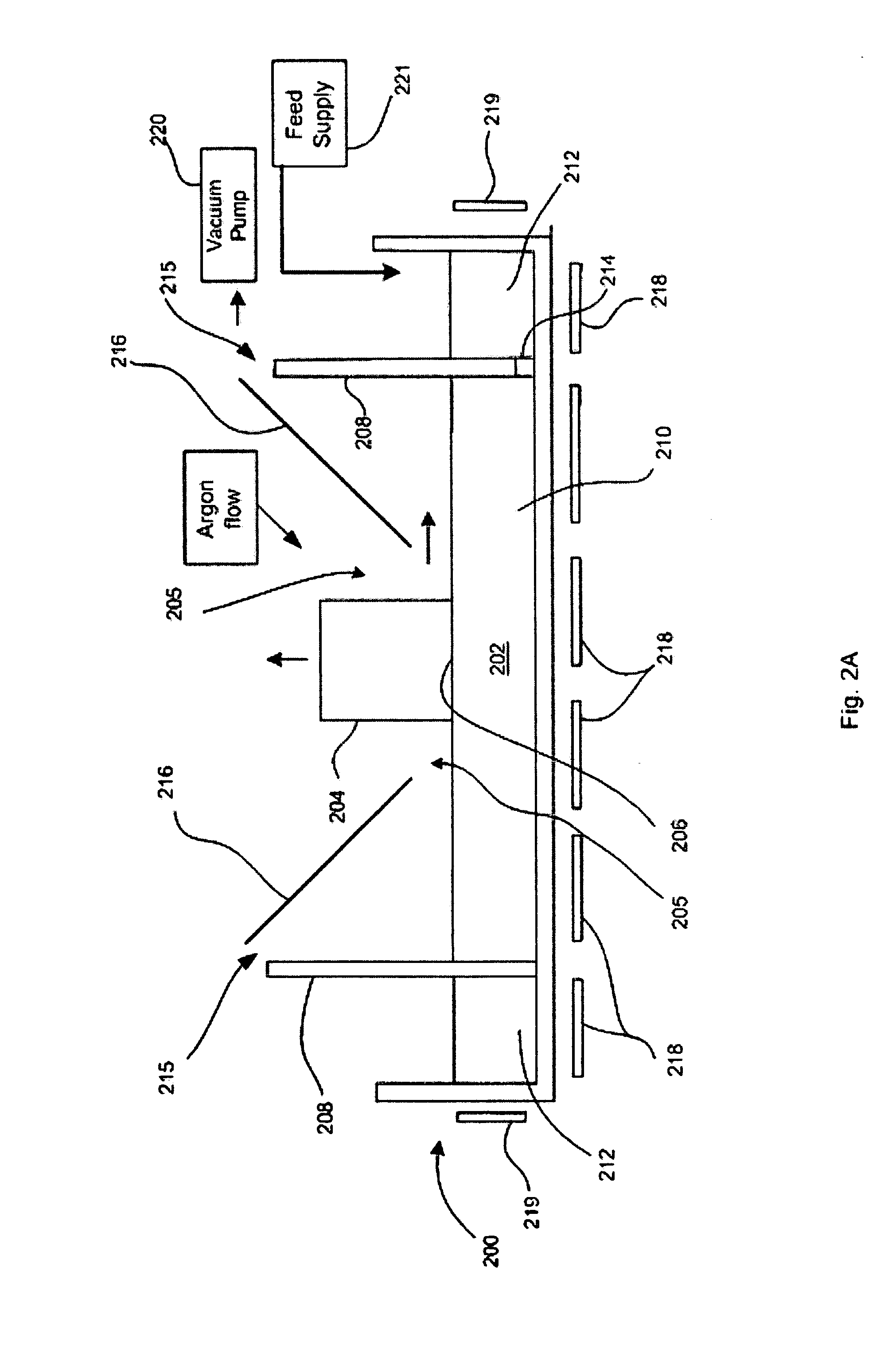

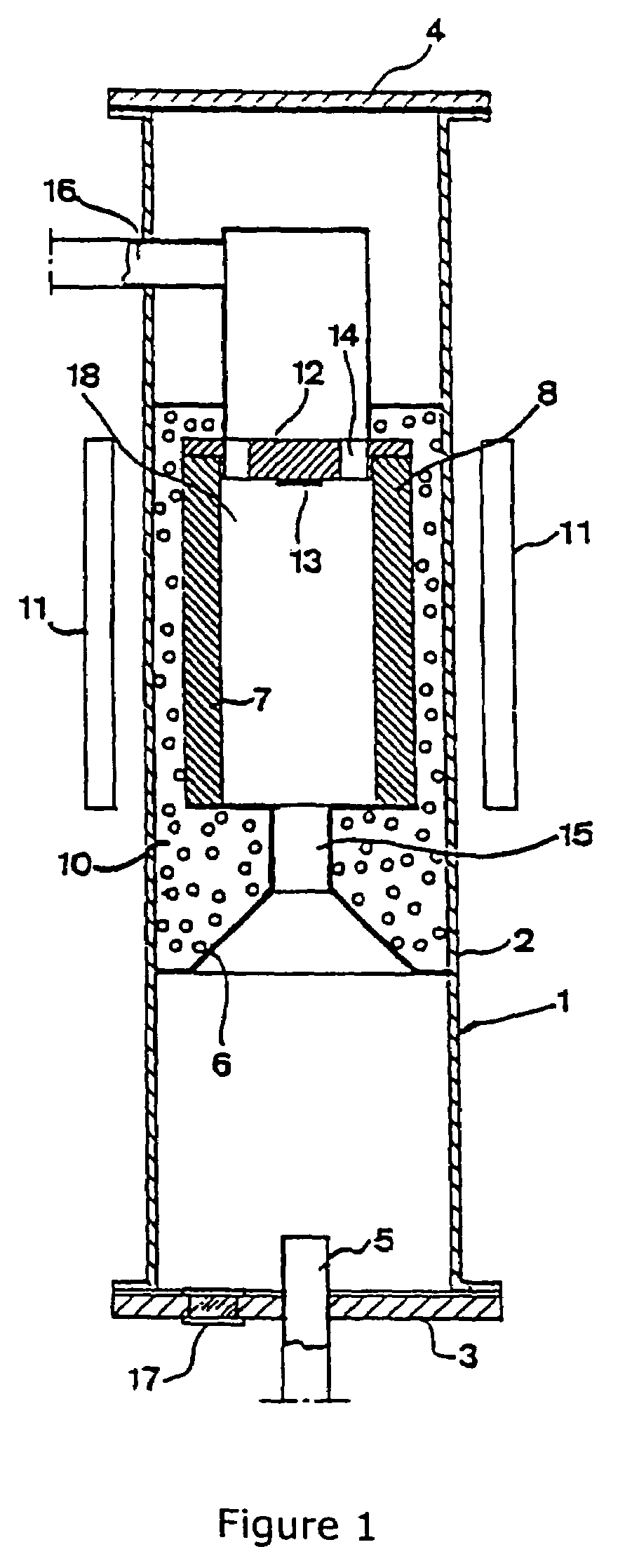

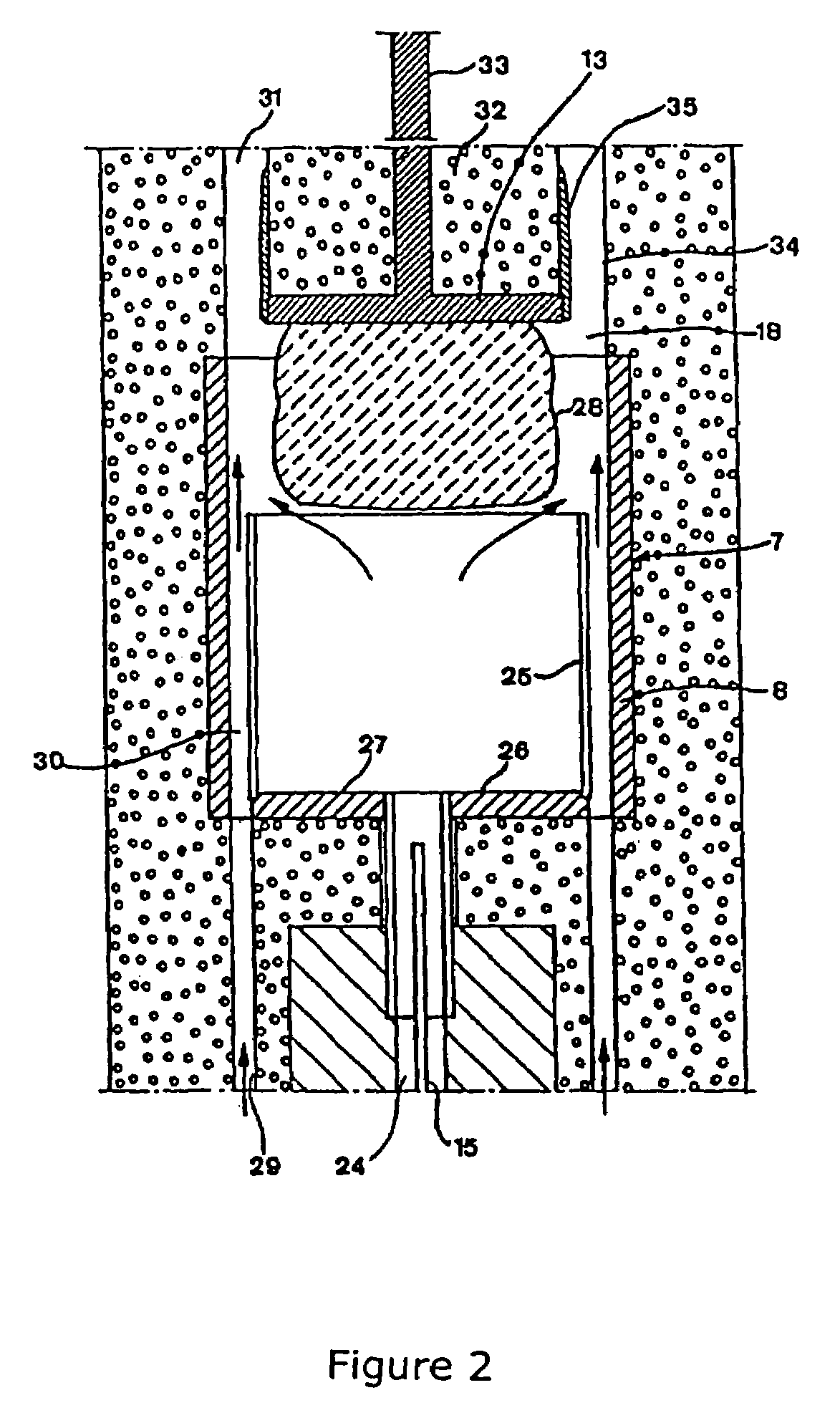

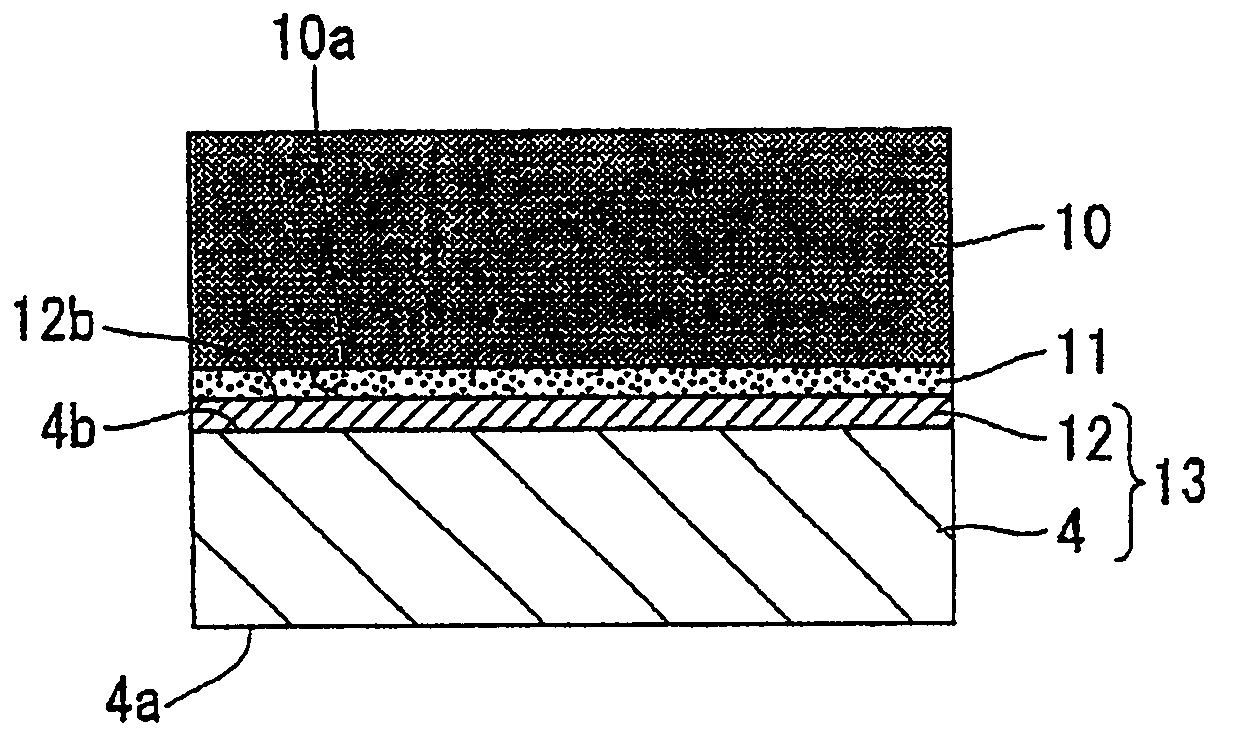

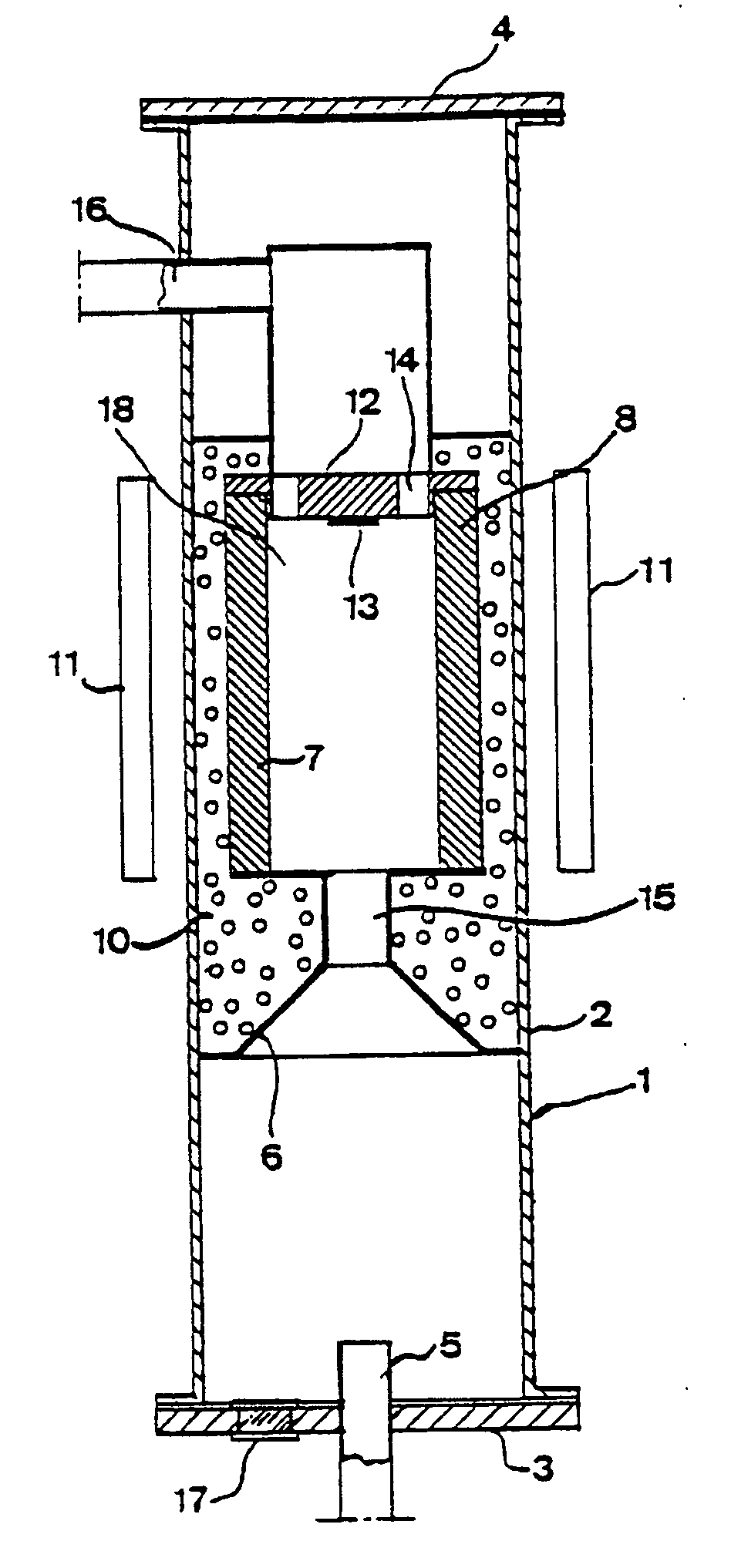

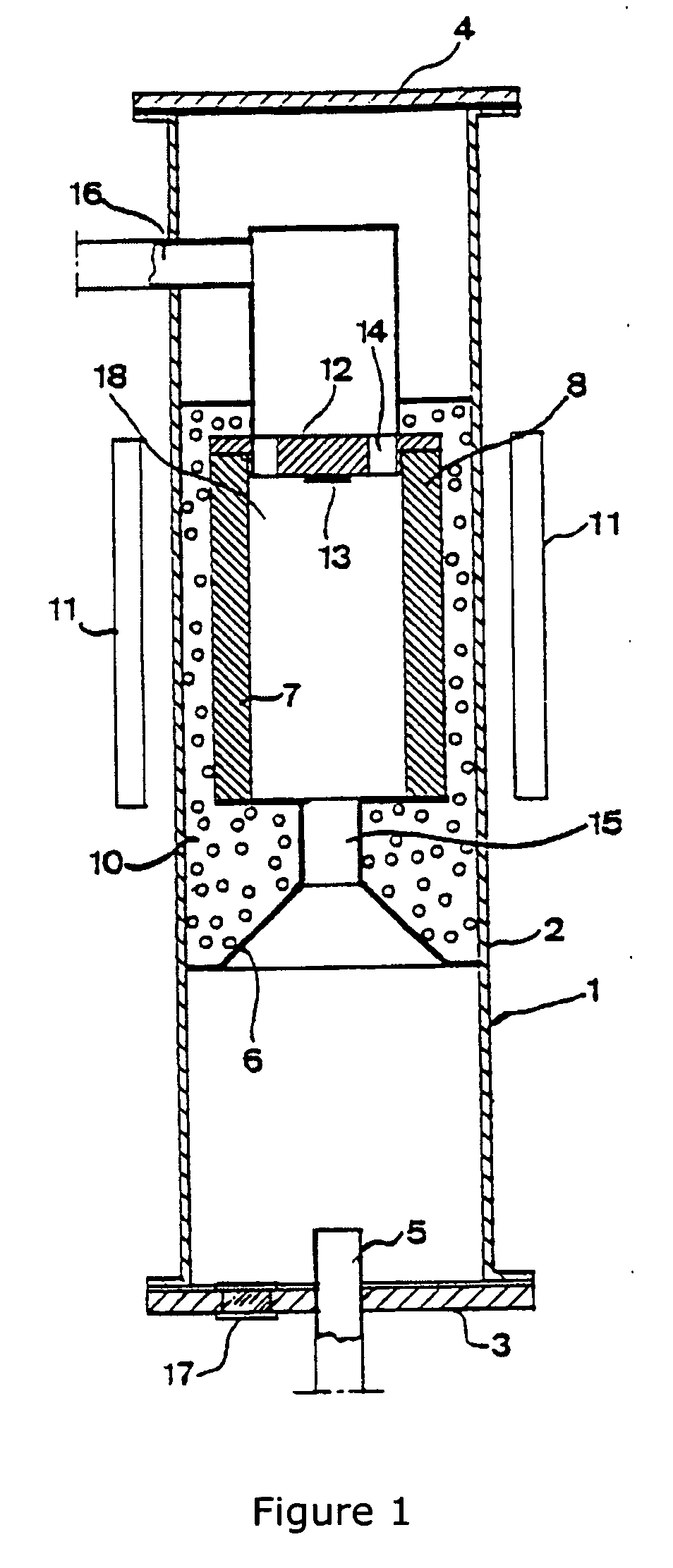

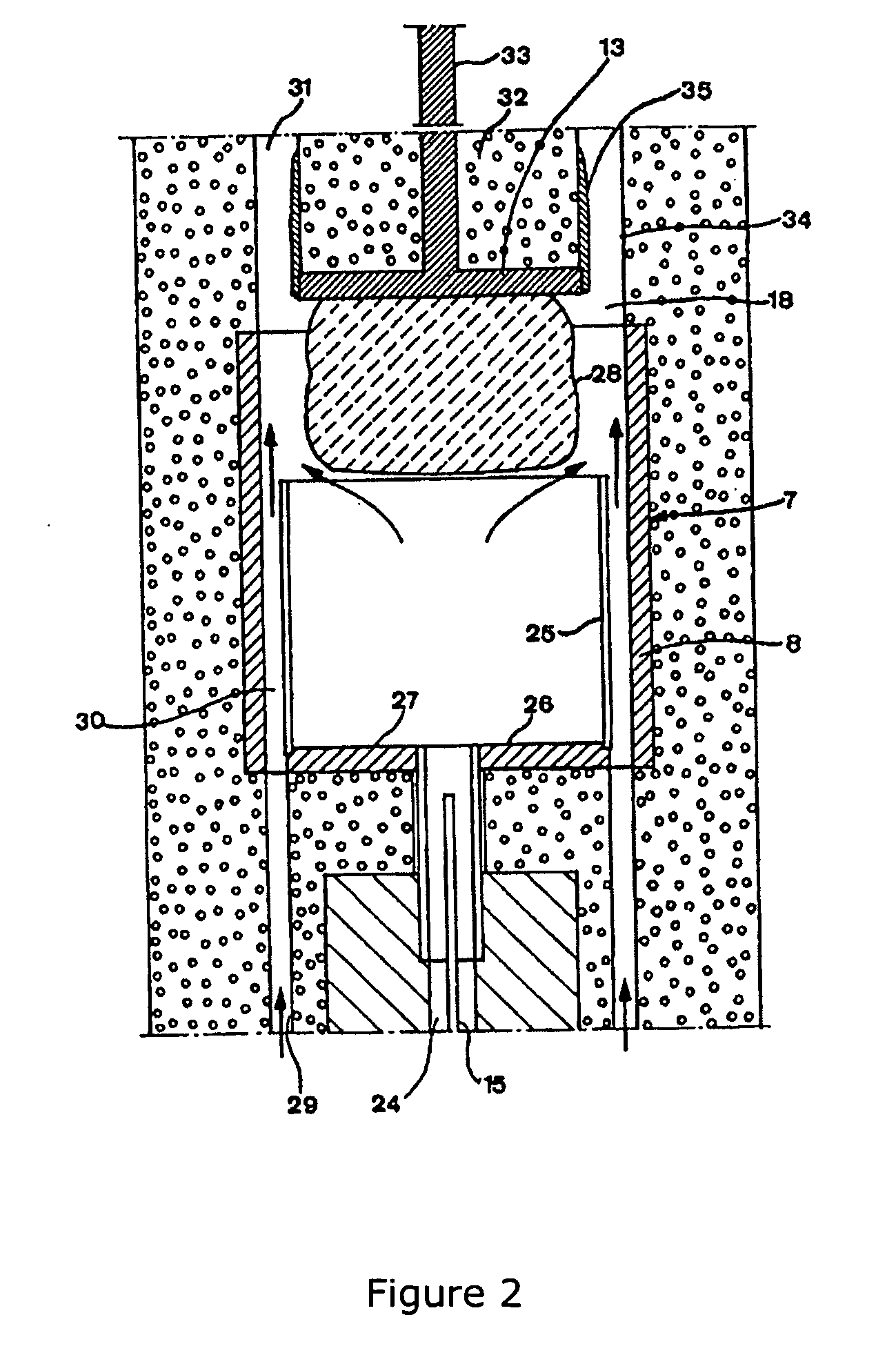

Device and method for producing single crystals by vapor deposition

ActiveUS20050000406A1Down and eliminate formationPreventing structural defect generationFrom gel statePolycrystalline material growthGas phaseSingle crystal

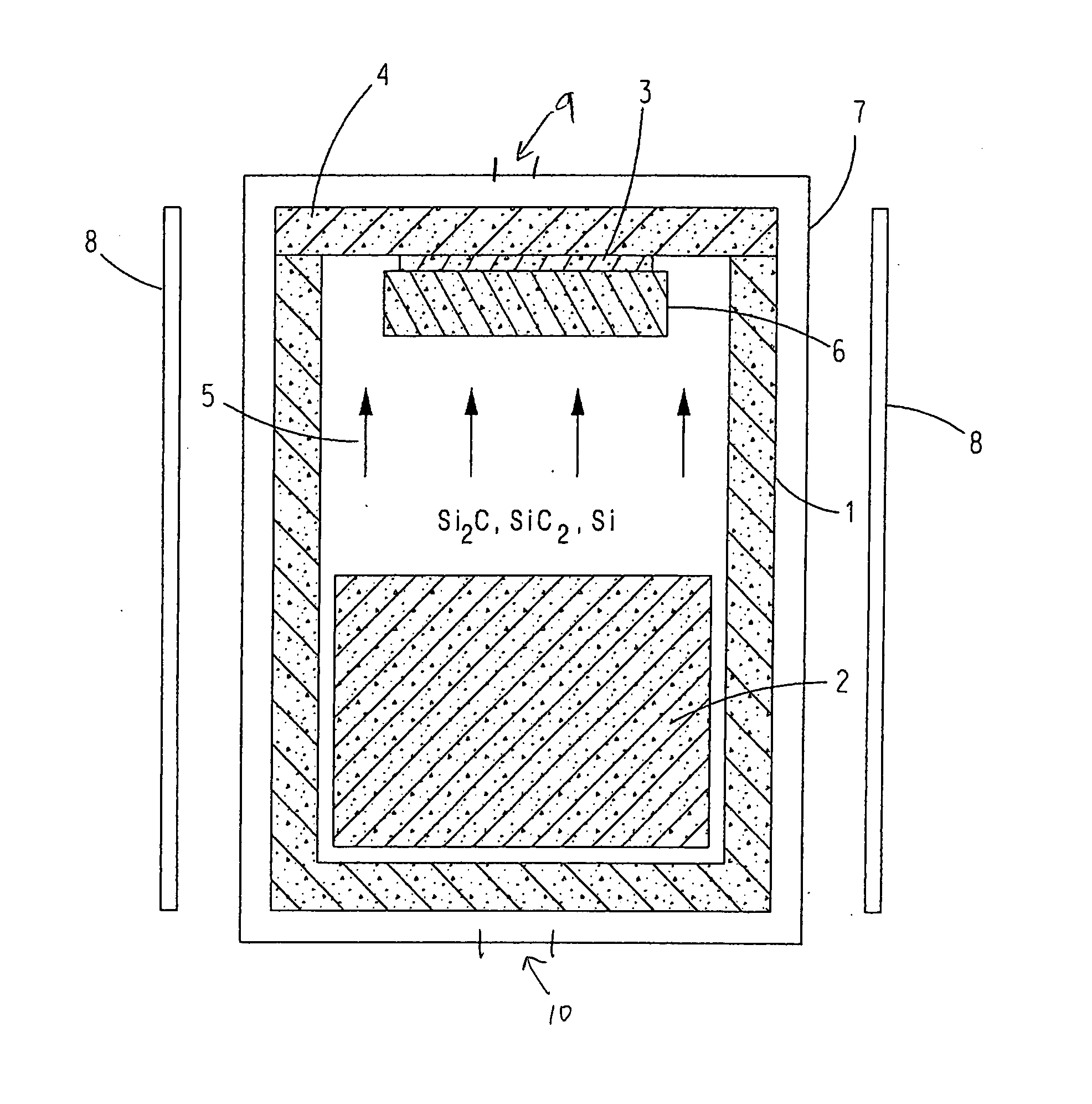

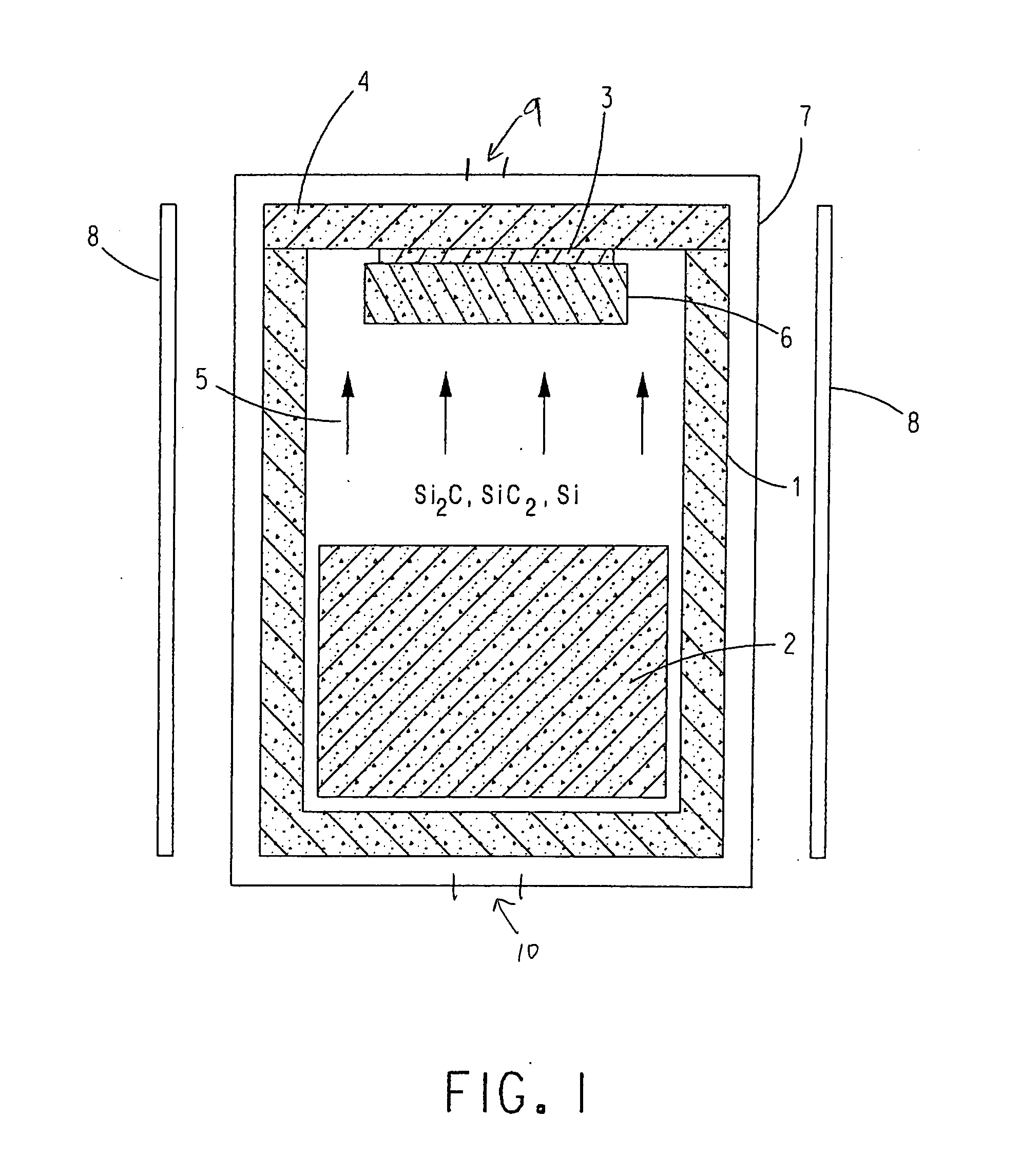

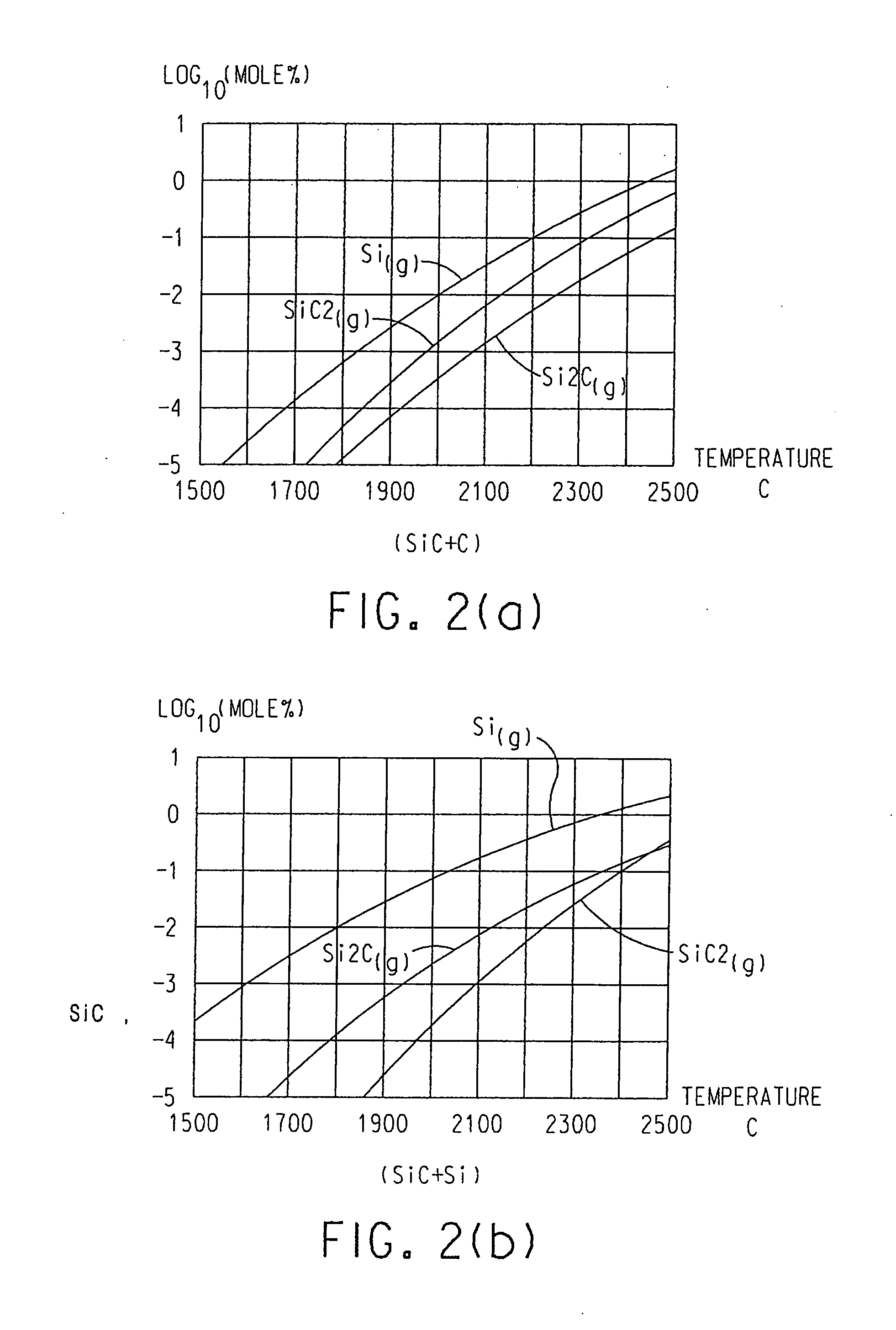

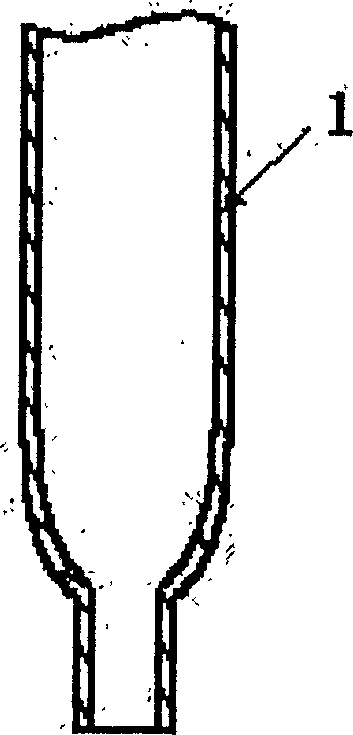

A method and a device to grow from the vapor phase, a single crystal of either SiC, a group III-nitride, or alloys thereof, at a growth rate and for a period of time sufficient to produce a crystal of preferably several centimeters length. The diameter of the growing crystal may be controlled. To prevent the formation of undesirable polycrystalline deposits on surfaces in the downstream vicinity of the single crystal growth area, the local supersaturation of at least one component of the material grown is lowered by introducing a separate gas flow comprising at least one halogen element or a combination of said halogen and hydrogen species.

Owner:NORSTEL

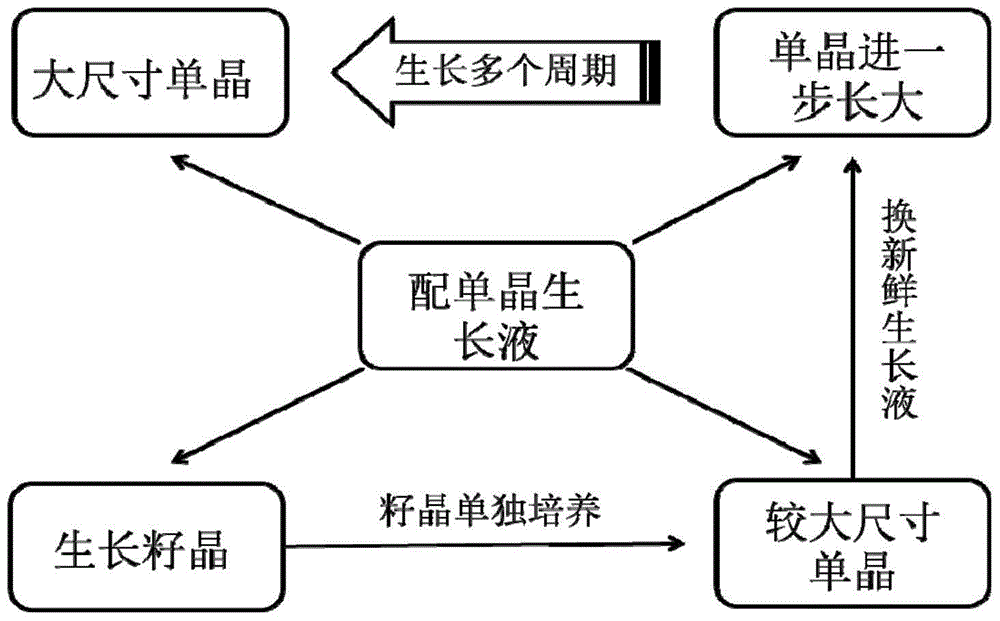

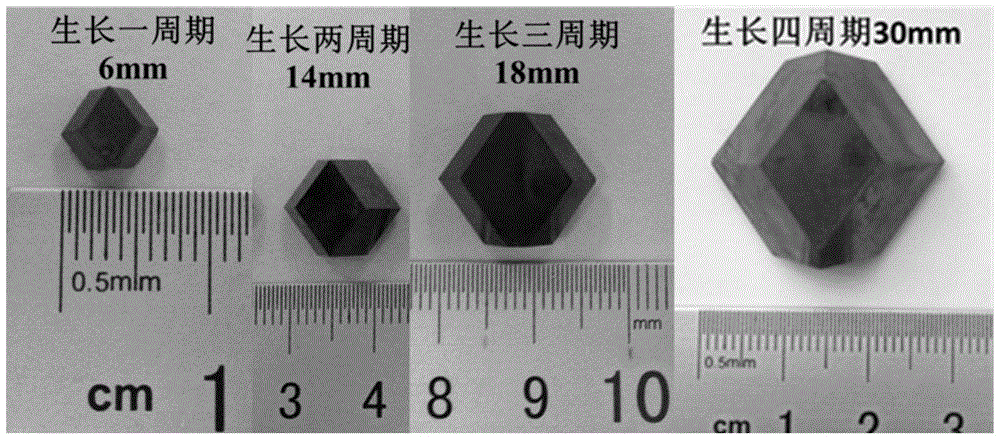

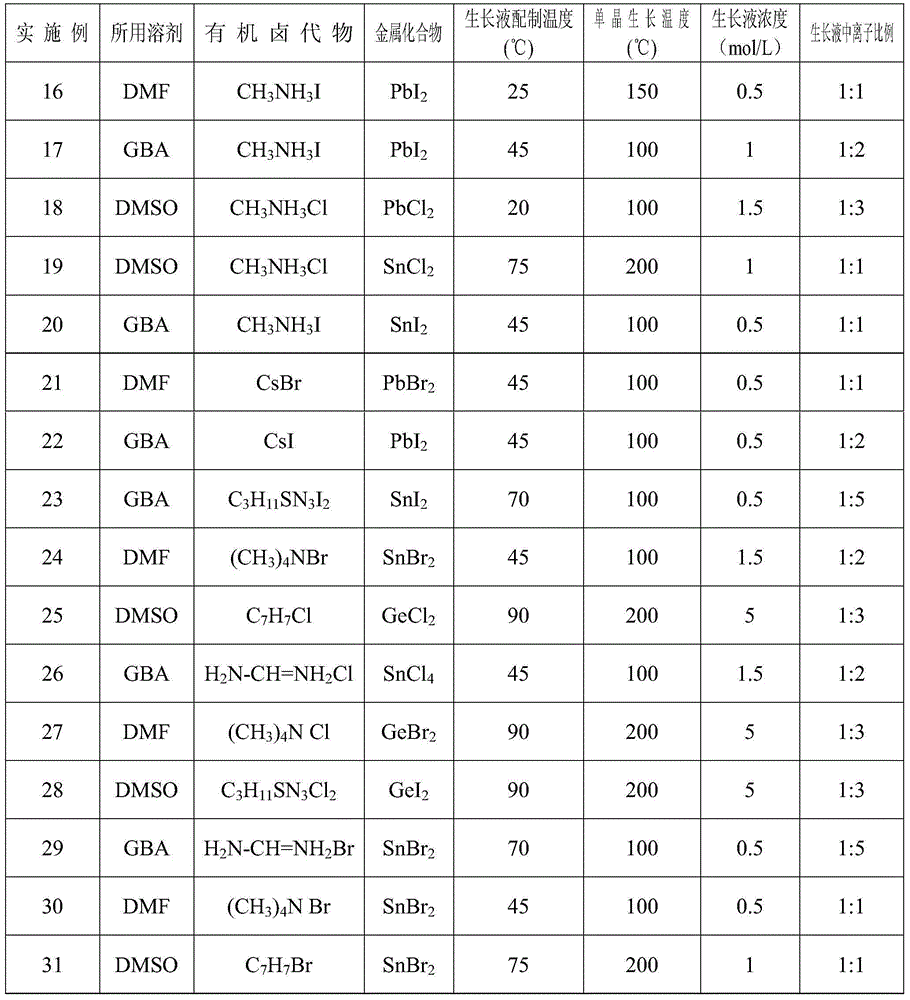

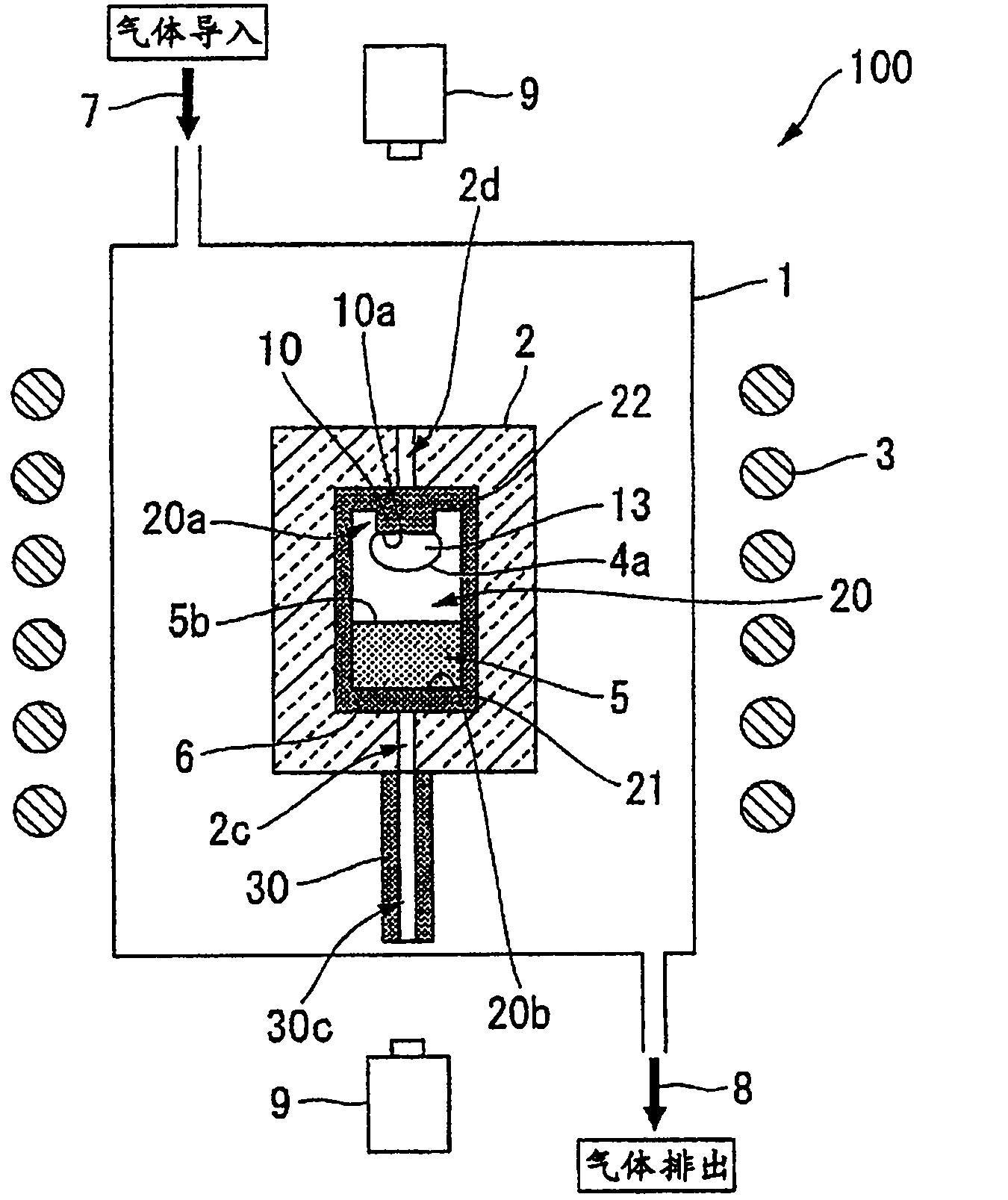

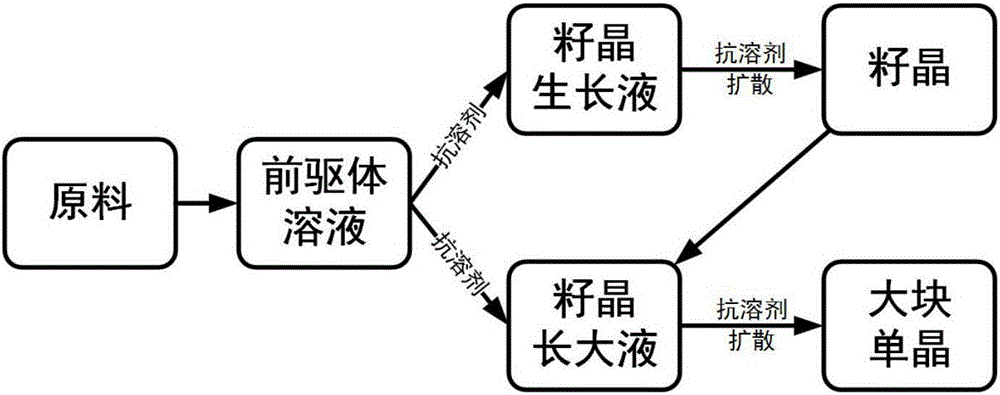

Method for growing ABX3 perovskite single crystals in low-temperature solution

ActiveCN104911705ARegular shapeModerate shapePolycrystalline material growthFrom normal temperature solutionsPhotodetectorSingle crystal growth

The invention provides a method for growing ABX3 perovskite single crystals in a low-temperature solution. According to the invention, a continuous growing method is adopted, and the ABX3 perovskite single crystals are rapidly grown in the low-temperature solution continuously with multiple periods and different stages. The concentration of the solution is high, and the raw materials required by growing are uniformly dissolved. Growing periods are added, and growing conditions are finely controlled, such that ABX3 perovskite single crystals with large sizes, regular shapes and high quality can be easily obtained. The method has the advantages of simple process, high operability, mild growing conditions, low required temperature, low energy consumption, low equipment requirement, low cost, high success rate, fast single crystal growth speed, fewer defects, good stability, large single crystal size (>10mm)*(>10mm)*(>10mm), and the like. Therefore, basic mechanism theoretical researches on perovskite materials and related optoelectronic devices (including solar cell, photodetector, LED and laser) are promoted.

Owner:SHAANXI NORMAL UNIV

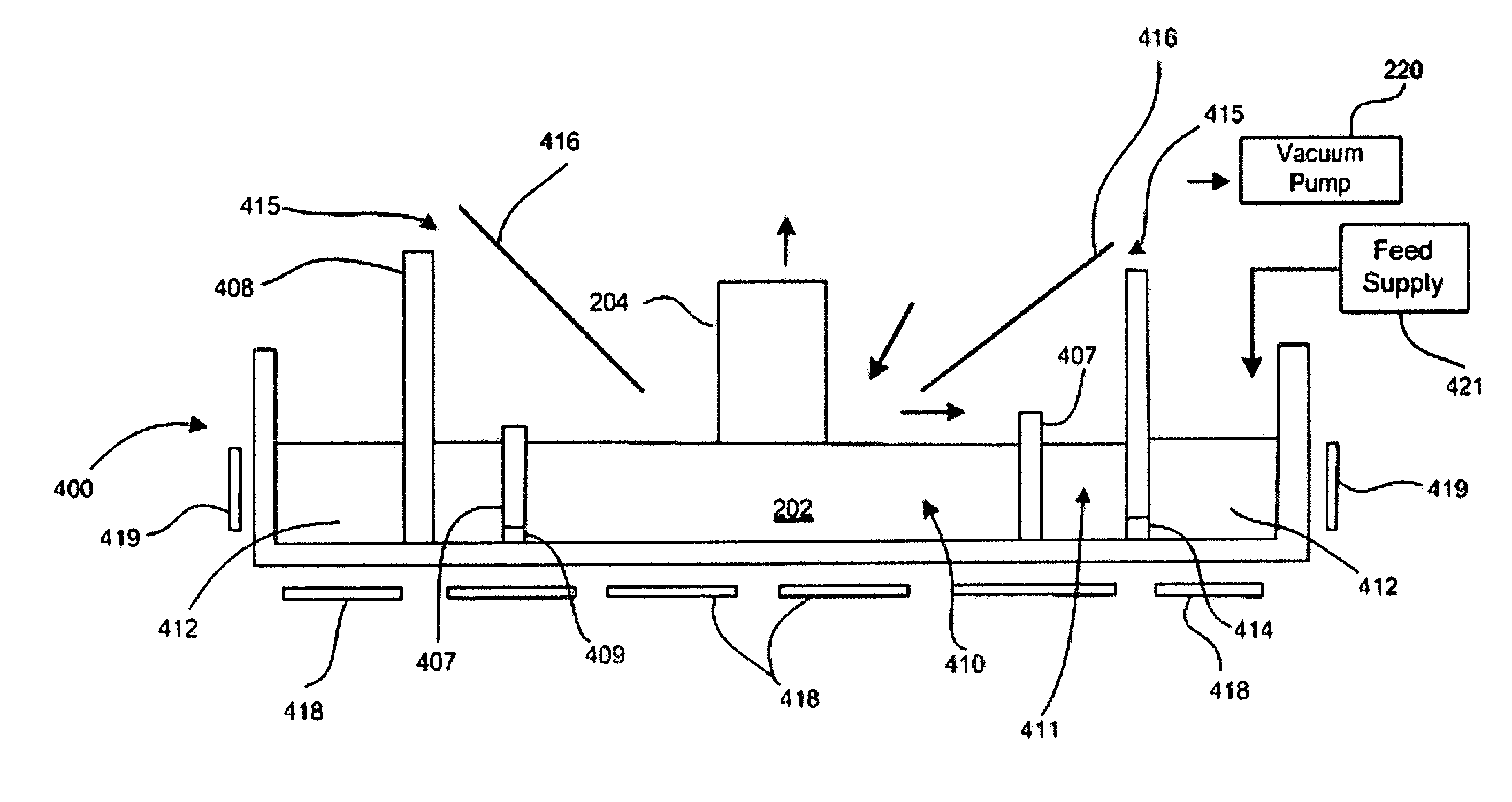

Weir design providing optimal purge gas flow, melt control, and temperature stabilization for improved single crystal growth in a continuous Czochralski process

ActiveUS8262797B1Increase path lengthExtended transit timePolycrystalline material growthBy pulling from meltSingle crystalEngineering

A weir is extended vertically to define an optimal annular gap between the top of the weir and the underside of a super-adjacent heat shield. The annular gap provides a high velocity stream of argon gas to be directed from the growth region to the melt region to substantially eliminate the transport of airborne particles from the melt region to the growth region. The tall weir may be configured as a modular, reusable weir extension supportably engaged with an outer (and / or inner) weir.

Owner:CORNER STAR LTD

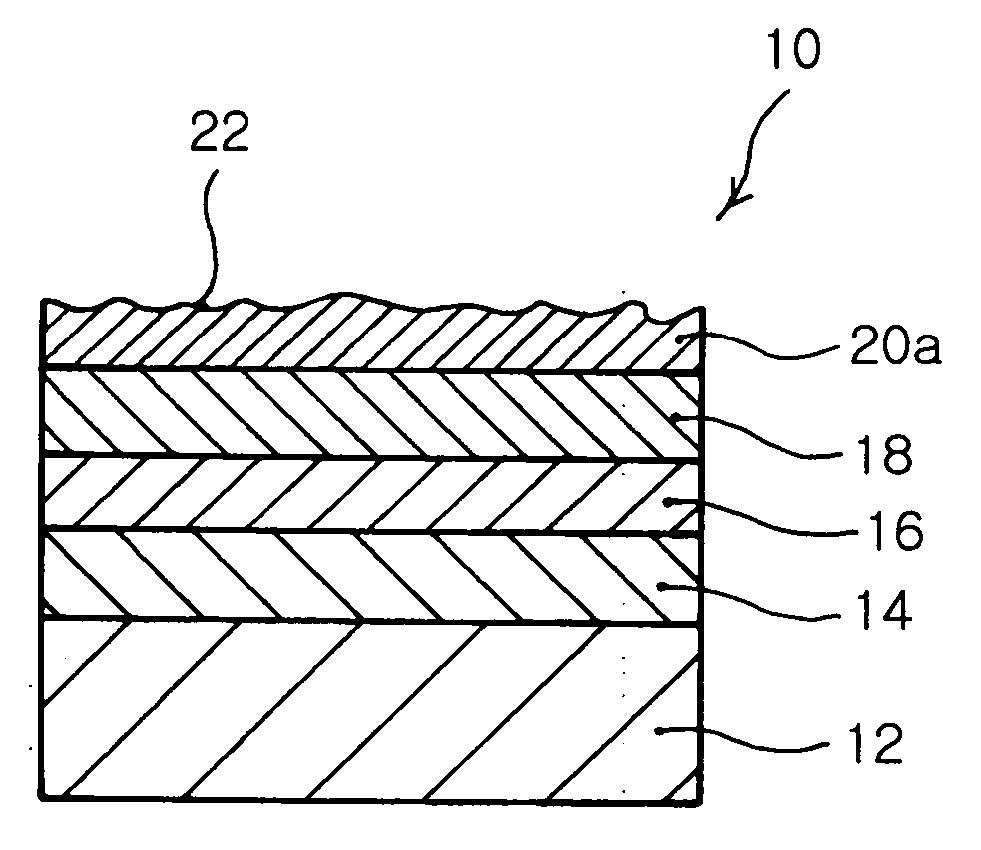

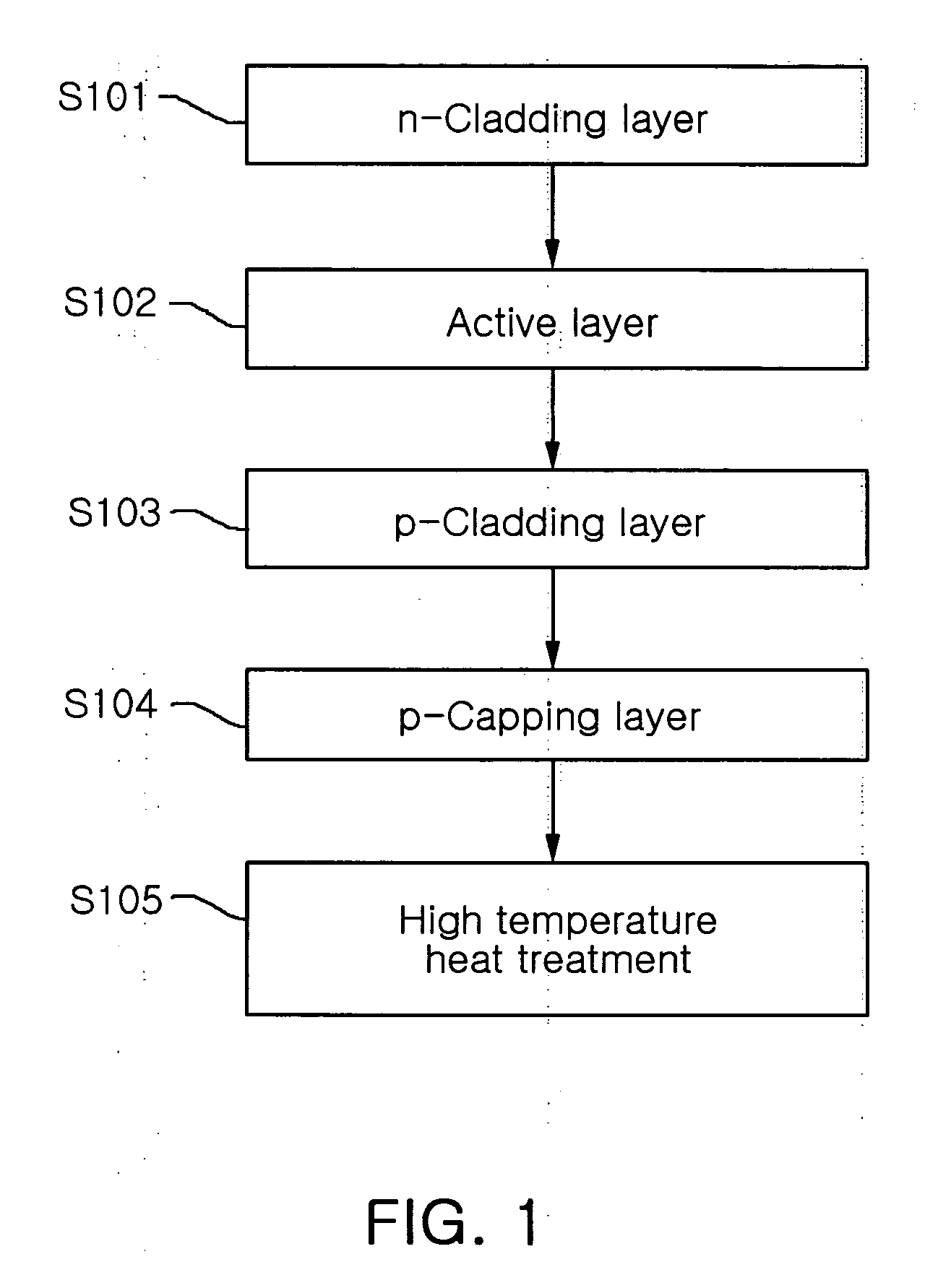

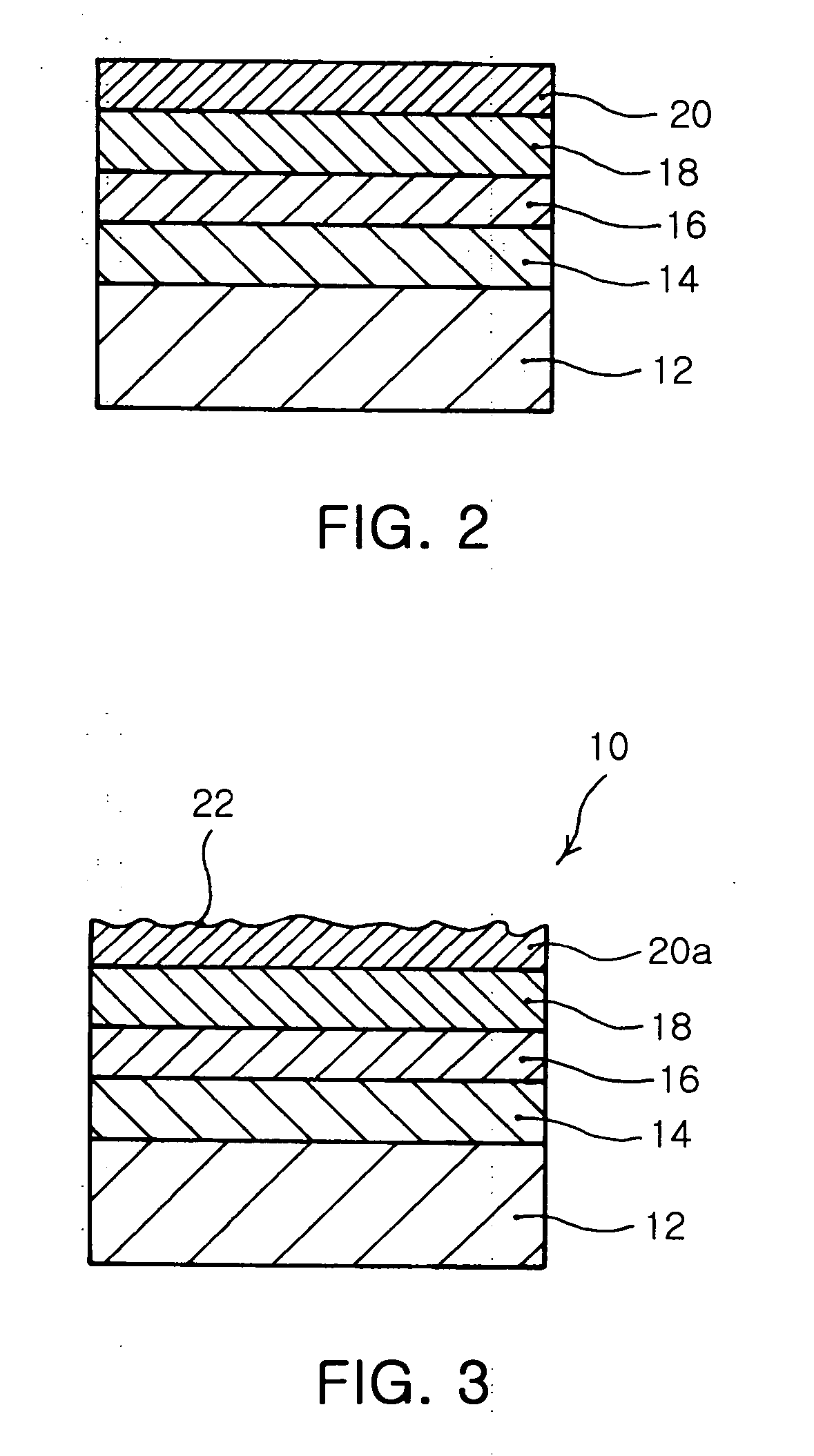

Nitride based semiconductor having improved external quantum efficiency and fabrication method thereof

InactiveUS20050224816A1Reduce internal reflectionsImprove external quantum efficiencyConveyorsSolid-state devicesSingle crystalSingle crystal growth

A surface treated nitride semiconductor in use for a light emitting diode, in which an n-cladding layer is formed on a substrate. An active layer having a multiple quantum well structure is formed on the n-cladding layer. A p-cladding layer is formed on the active layer. A p-capping layer is formed on the p-cladding layer in a low temperature range in which single crystal growth does not take place. The p-capping layer has a nanoscale roughened structure formed in an upper surface thereof via heat treatment in a high temperature range in which at least partial crystallization takes place. The nanoscale roughened structure reduces total internal reflection of the nitride semiconductor thereby improving external quantum efficiency thereof.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

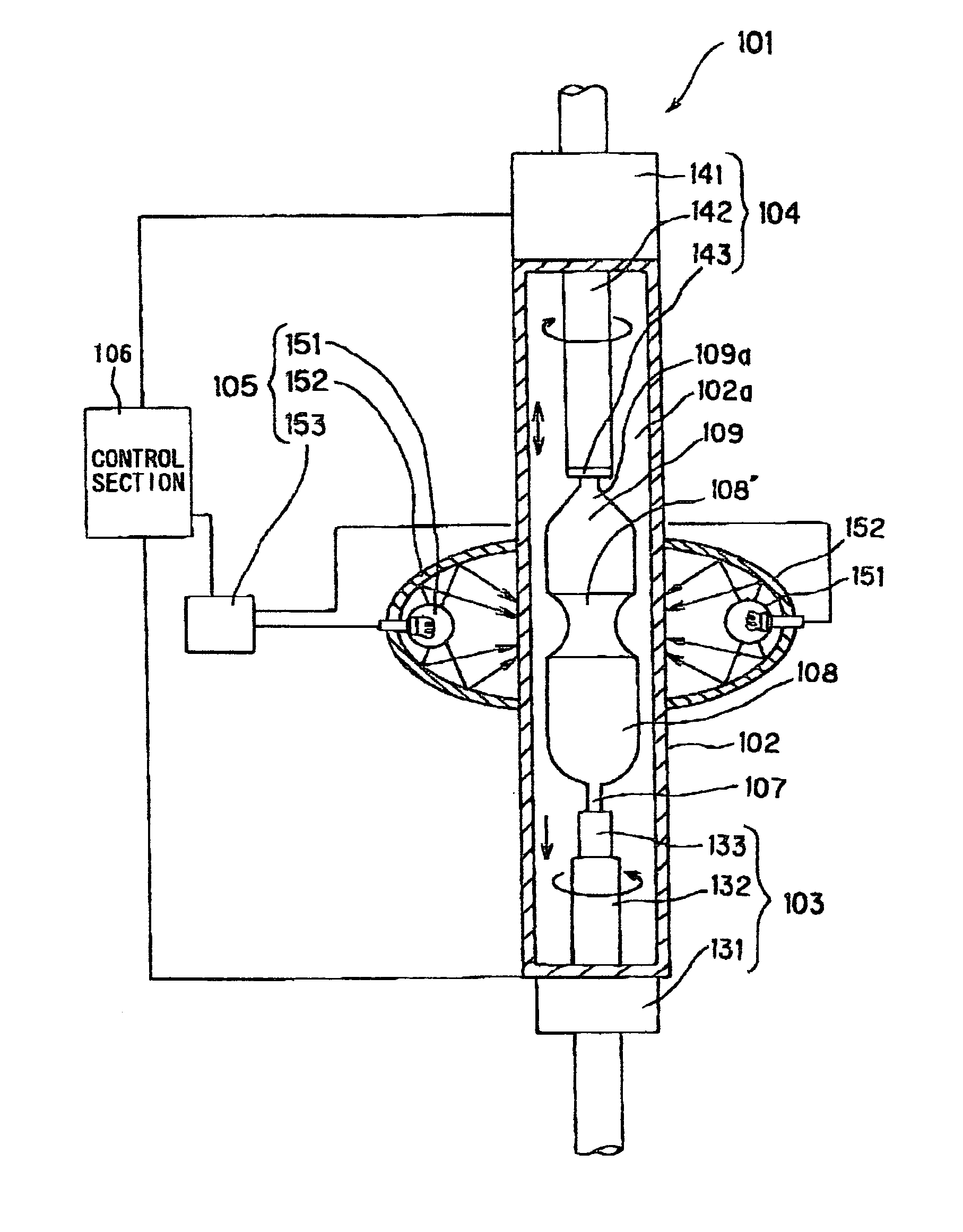

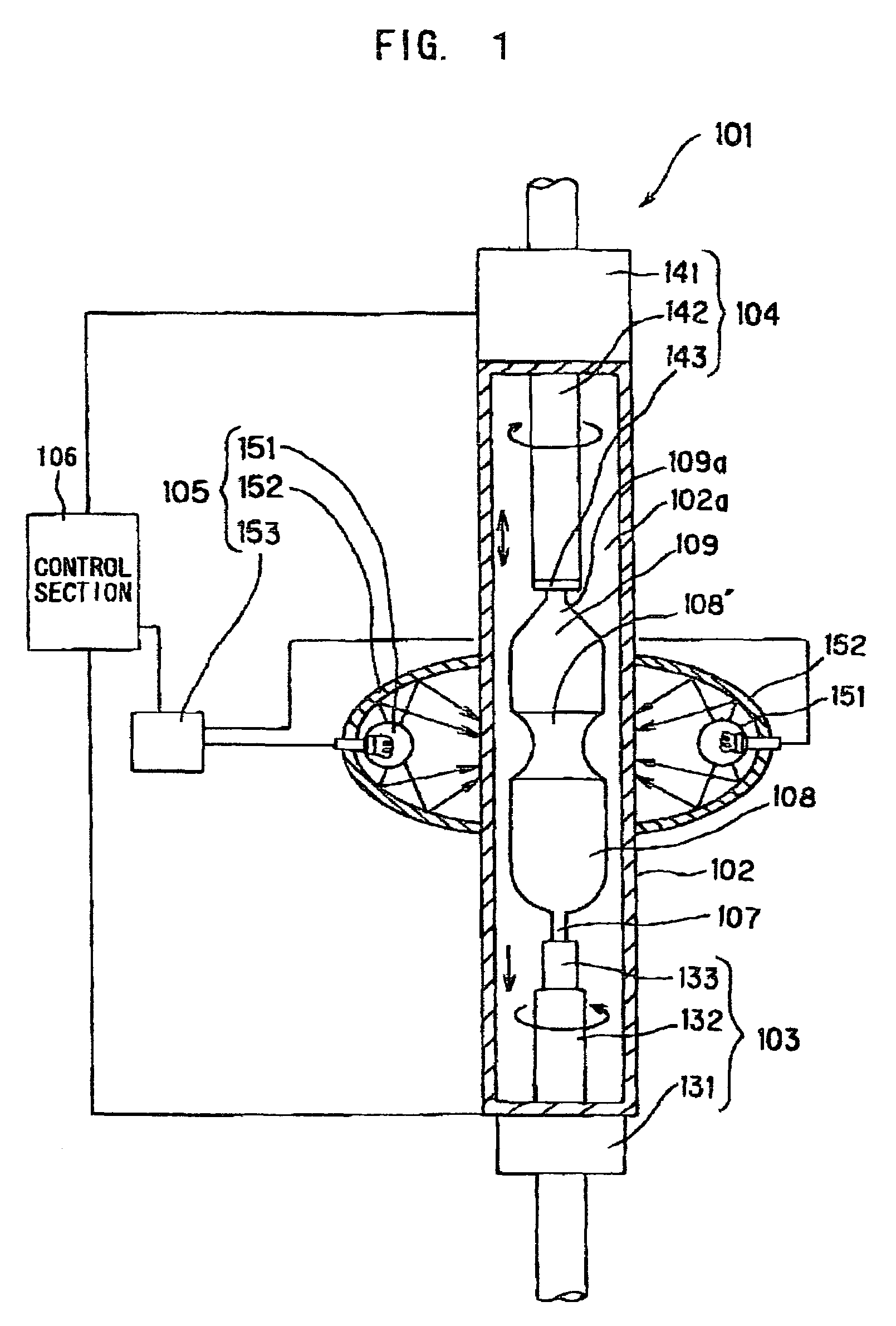

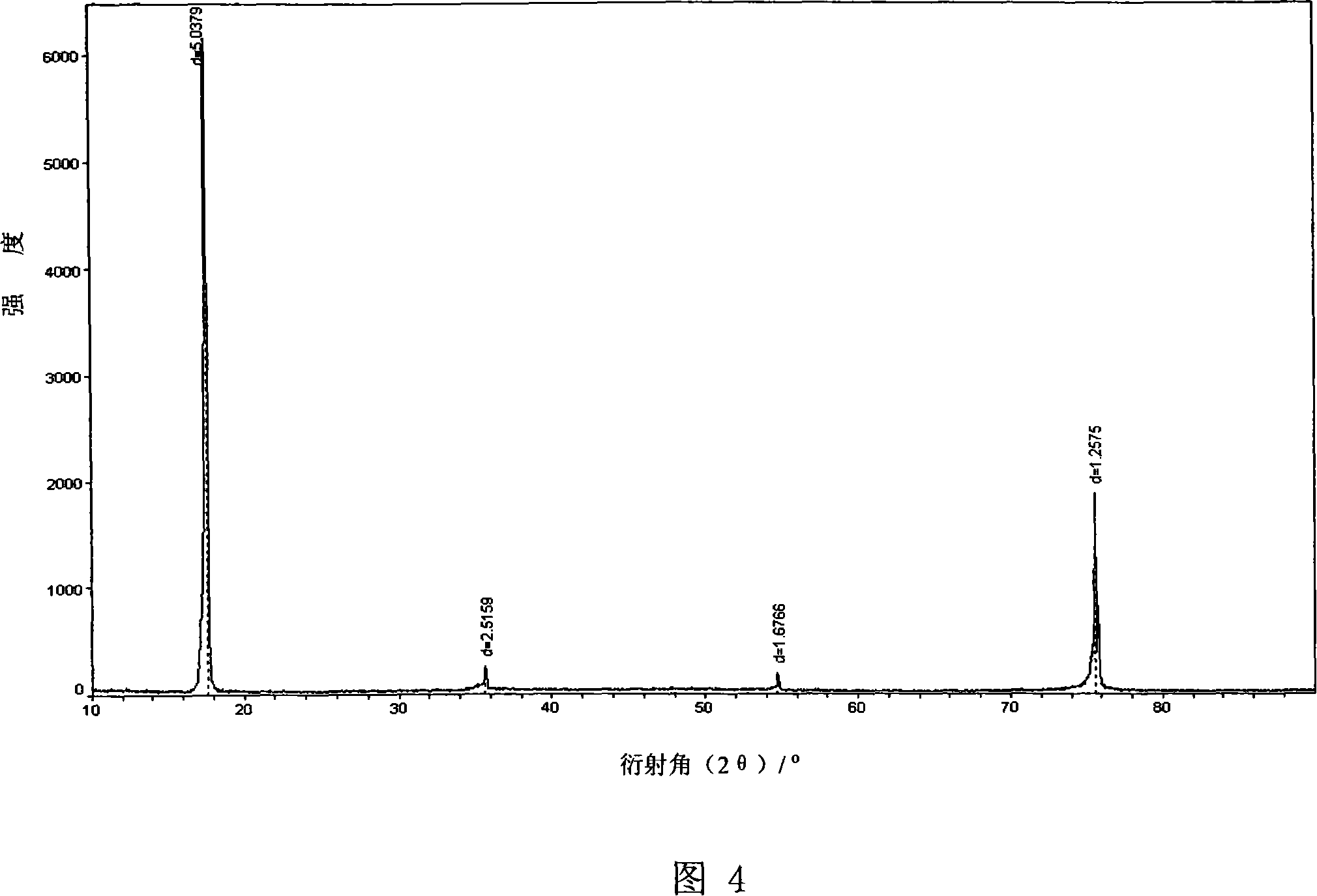

β-Ga2O3 single crystal growing method, thin-film single crystal growing method, Ga2O3 light-emitting device, and its manufacturing method

InactiveUS7393411B2Trend downImprove machinabilityPolycrystalline material growthBy zone-melting liquidsInfraredDopant

A method for growing a β-Ga2O3 single crystal hardly cracking and having a weakened twinning tendency and an improved crystallinity, a method for growing a thin-film single crystal with high quality, a GazO3 light-emitting device capable of emitting a light in the ultraviolet region, and its manufacturing method are disclosed. In an infrared-heating single crystal manufacturing system, a seed crystal and polycrystalline material are rotated in mutually opposite directions and heated, and a β-Ga2O3 single crystal is grown in one direction selected from among the a-axis <100> direction, the b-axis <010> direction, and the c-axis <001> direction. A thin film of a β-Ga2O3 single crystal is formed by PLD. A laser beam is applied to a target to excite atoms constituting the target Ga atoms are released from the target by thermal and photochemical actions. The free Ga atoms are bonded to radicals in the atmosphere in the chamber. Thus, a thin film of a β-Ga2O3 single crystal is grown on a substrate of a β-Ga2O3 single crystal A light-emitting device comprises an n-type substrate produced by doping a β-Ga2O3 single crystal with an n-type dopant and a p-type layer produced by doping the β-Ga2O3 single crystal with a p-type dopant and junctioned to the top of the n-type substrate. The light-emitting device emits a light from the junction portion.

Owner:WASEDA UNIV

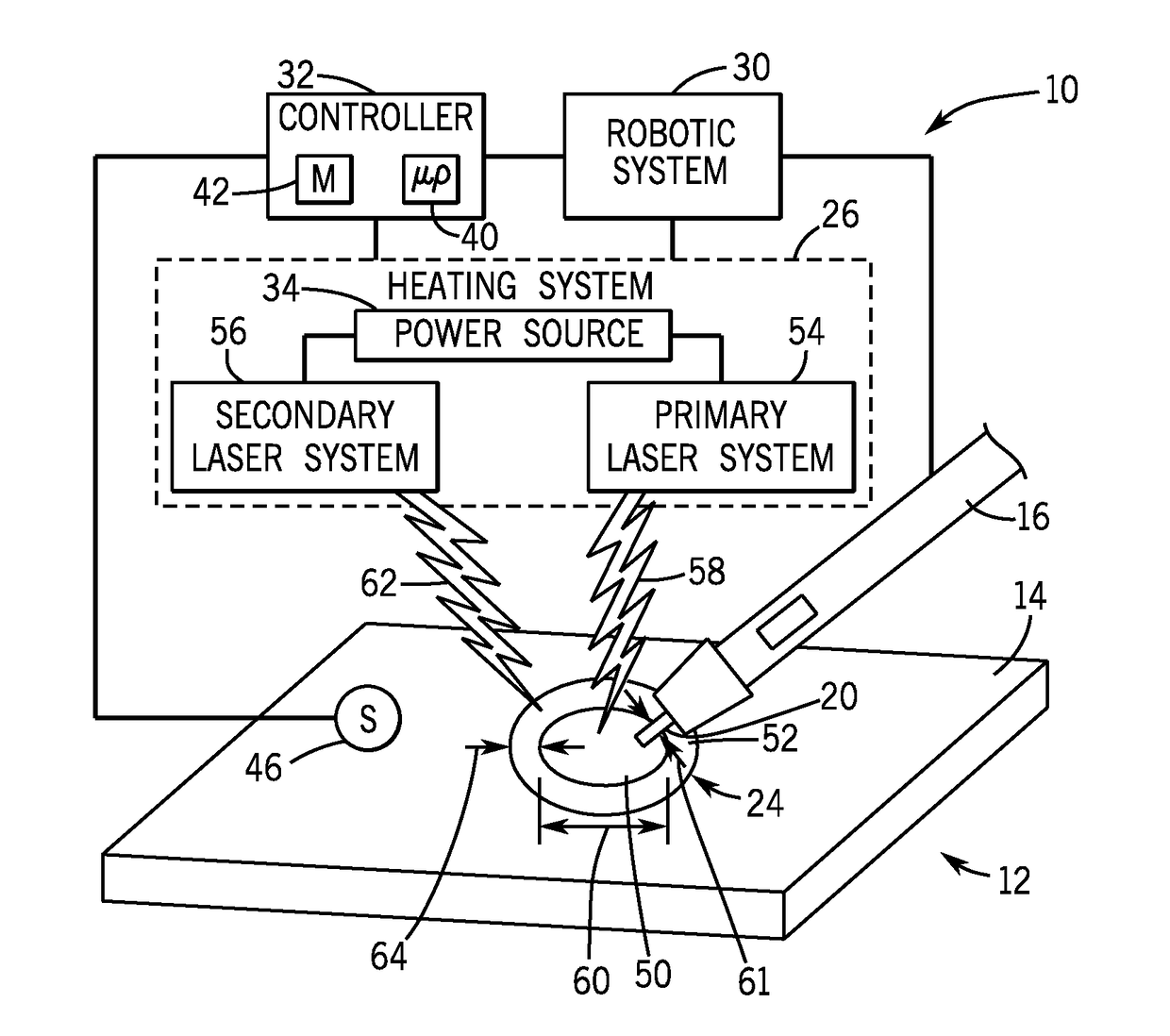

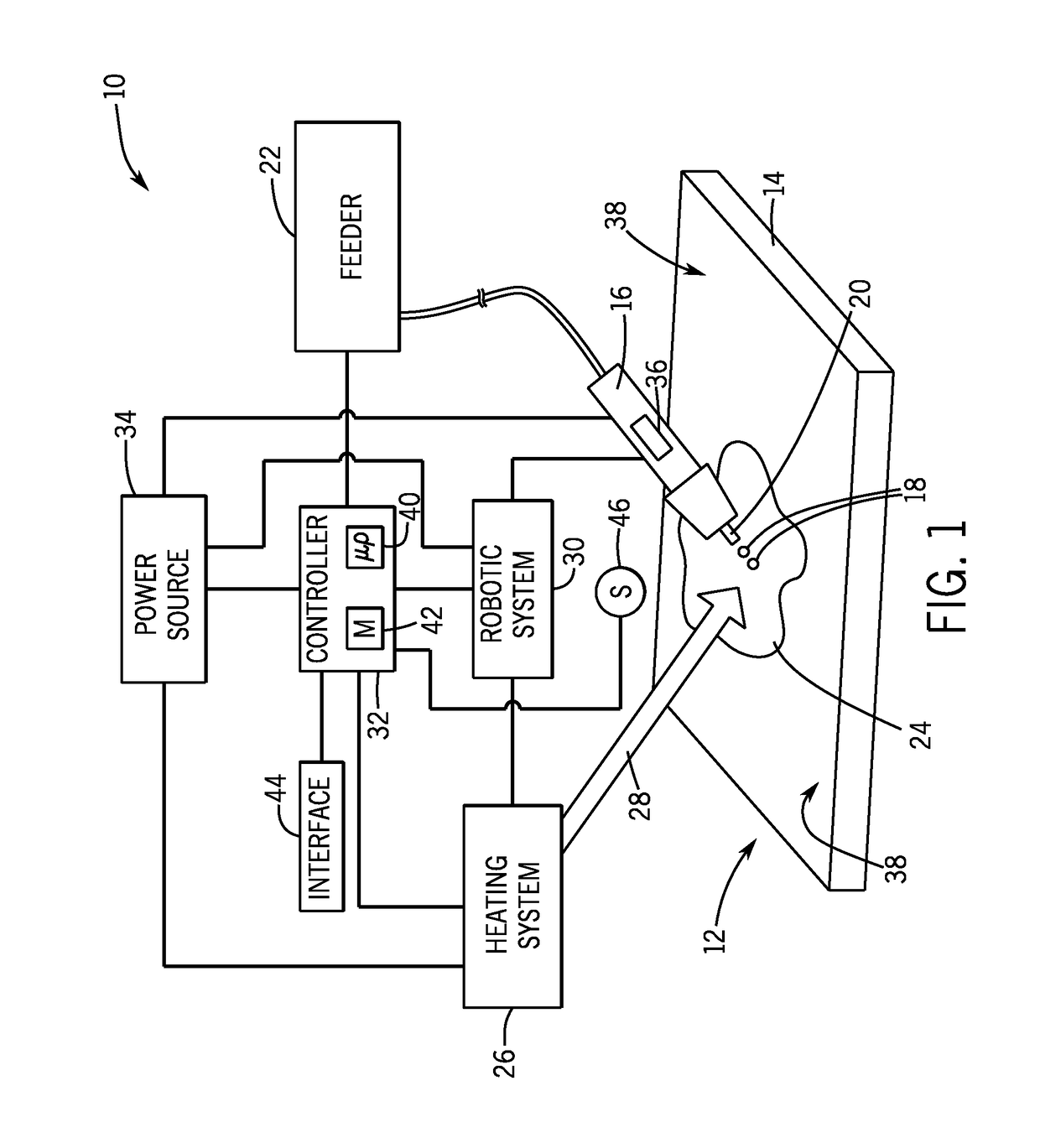

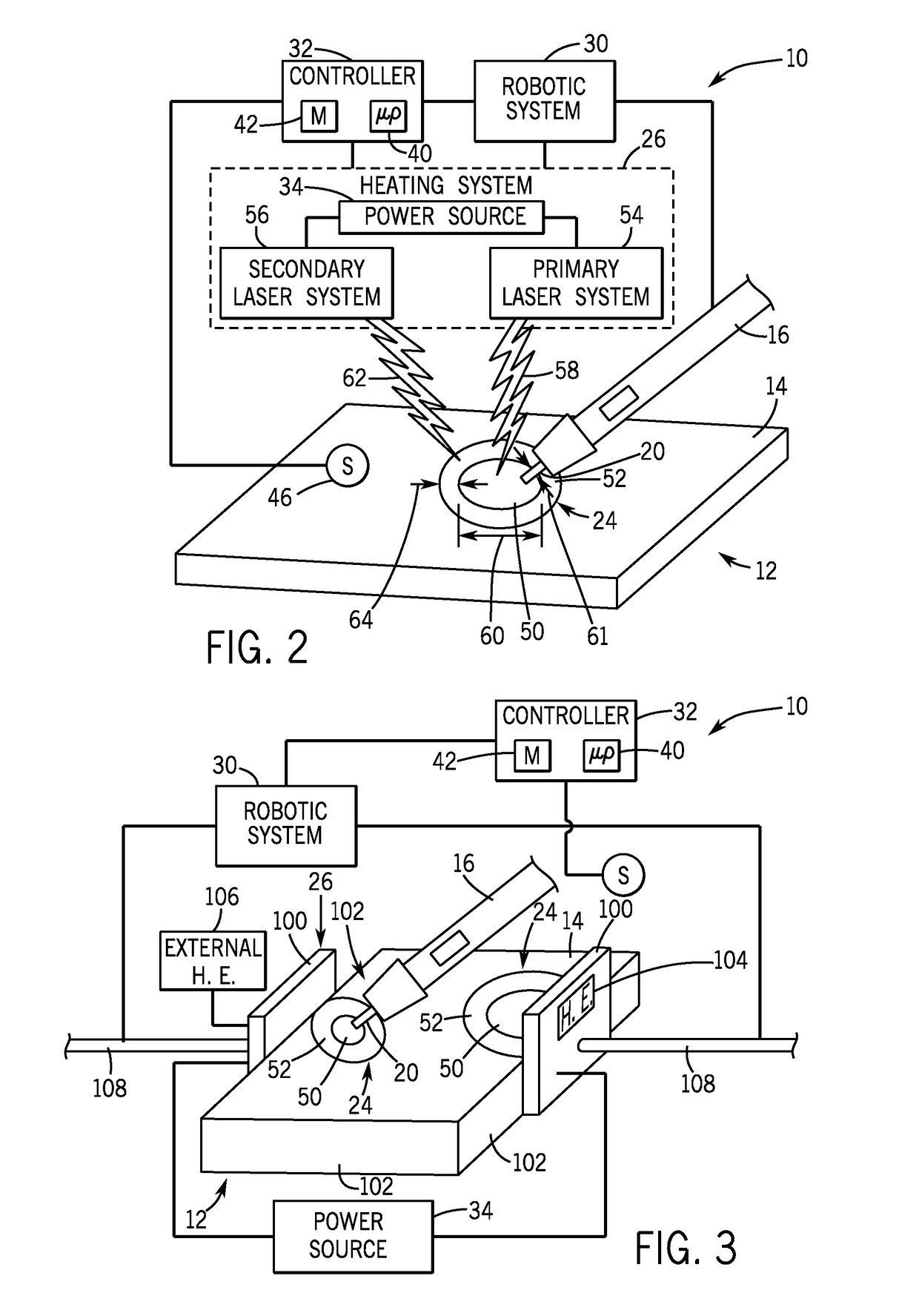

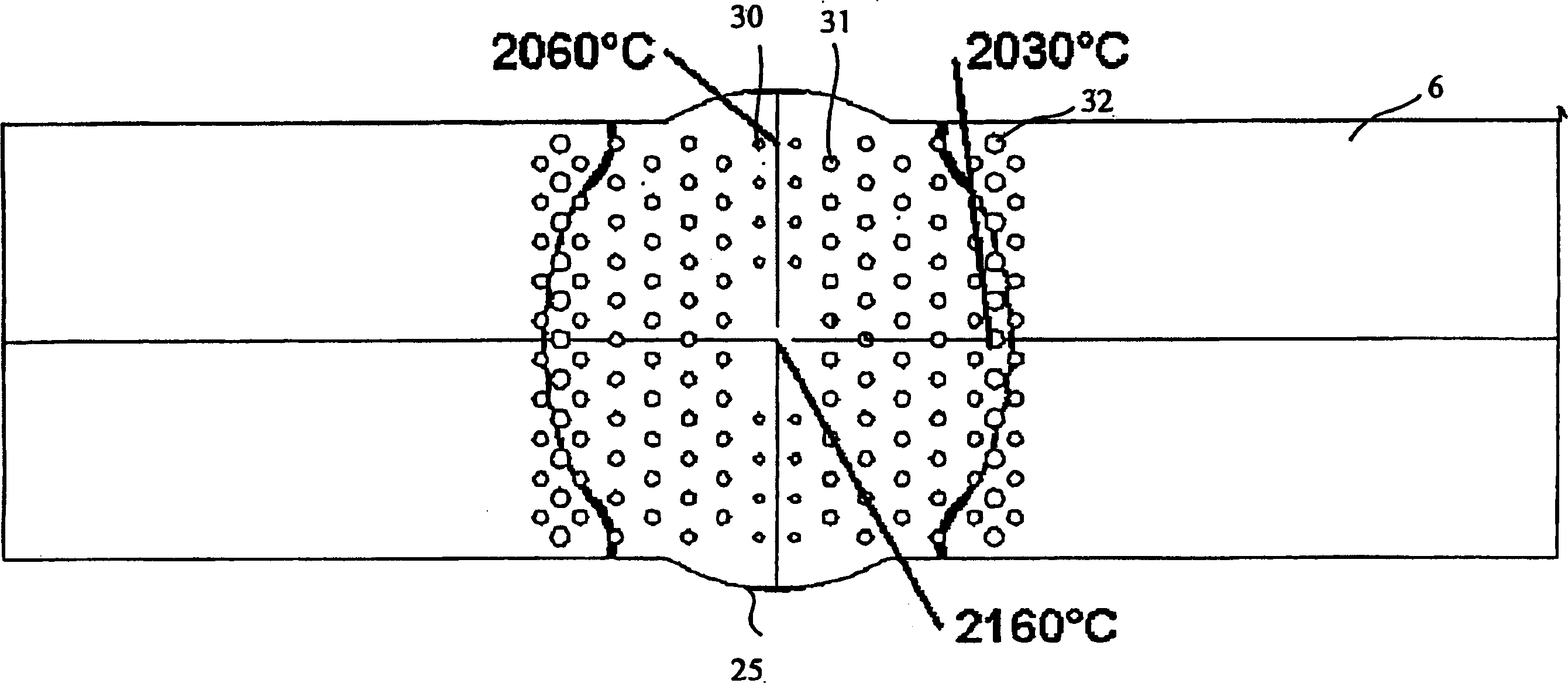

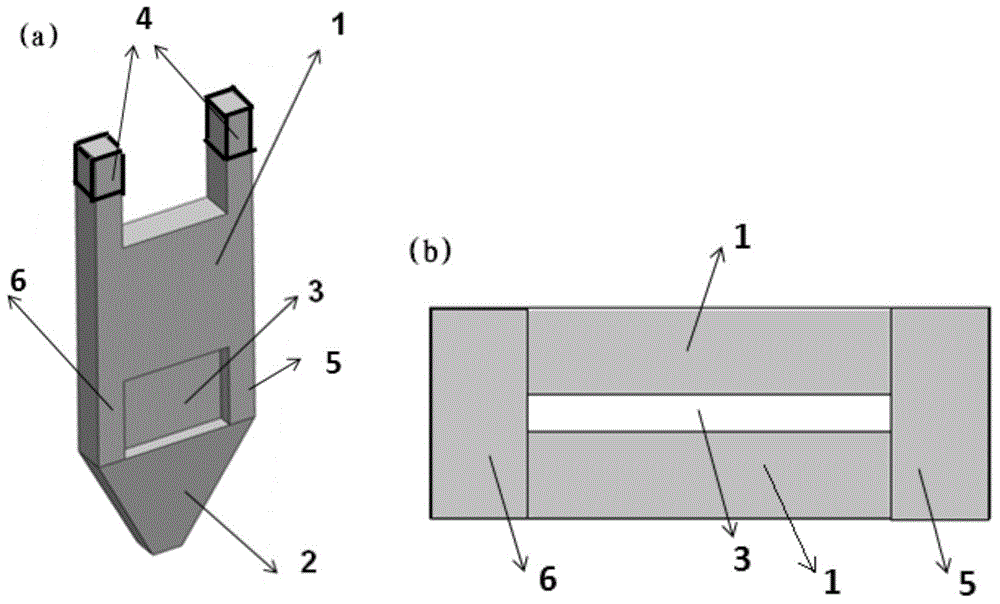

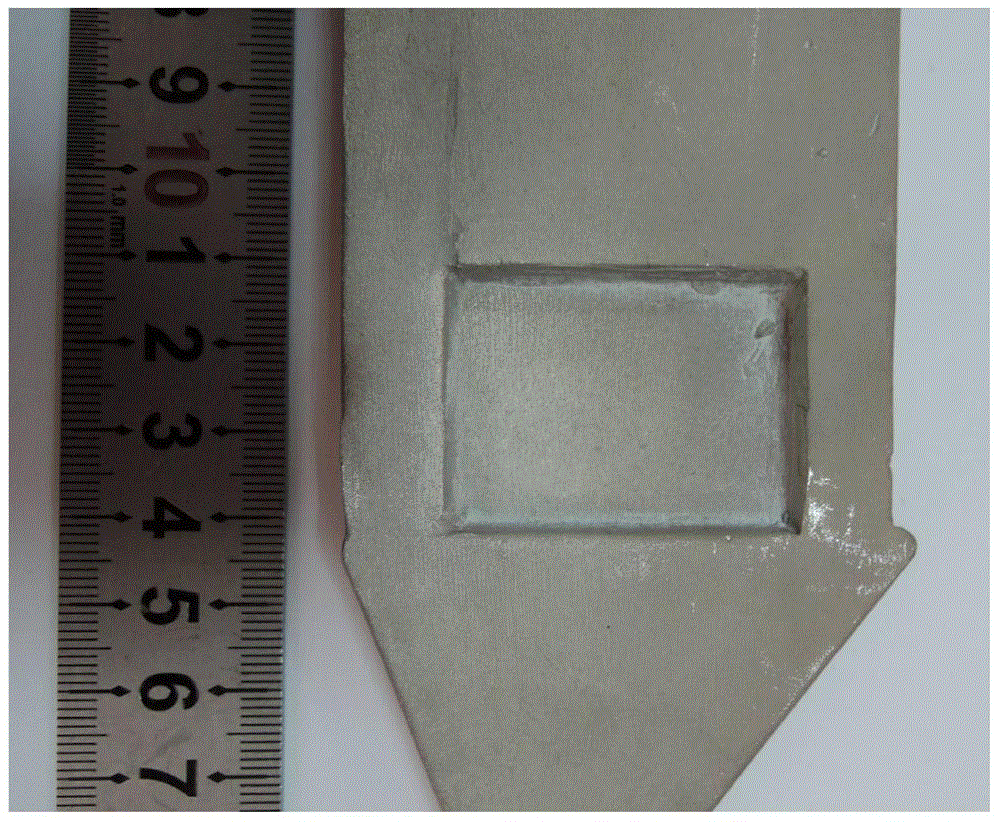

System and method for single crystal growth with additive manufacturing

InactiveUS20170145586A1Polycrystalline material growthAdditive manufacturing apparatusMetallic materialsSingle crystal

Present embodiments include an additive manufacturing tool configured to receive a metallic material and to supply a plurality of droplets to a part at a work region of the part, wherein each droplet of the plurality of droplets comprises the metallic material and a heating system comprising a primary laser system configured to generate a primary laser beam to heat a molten zone of a substrate of the part and a secondary laser system configured to generate a secondary laser beam to heat a transition zone of the substrate of the part, wherein the molten zone and the work region are colocated, and wherein the transition zone is disposed about the molten zone.

Owner:HOBART BROS

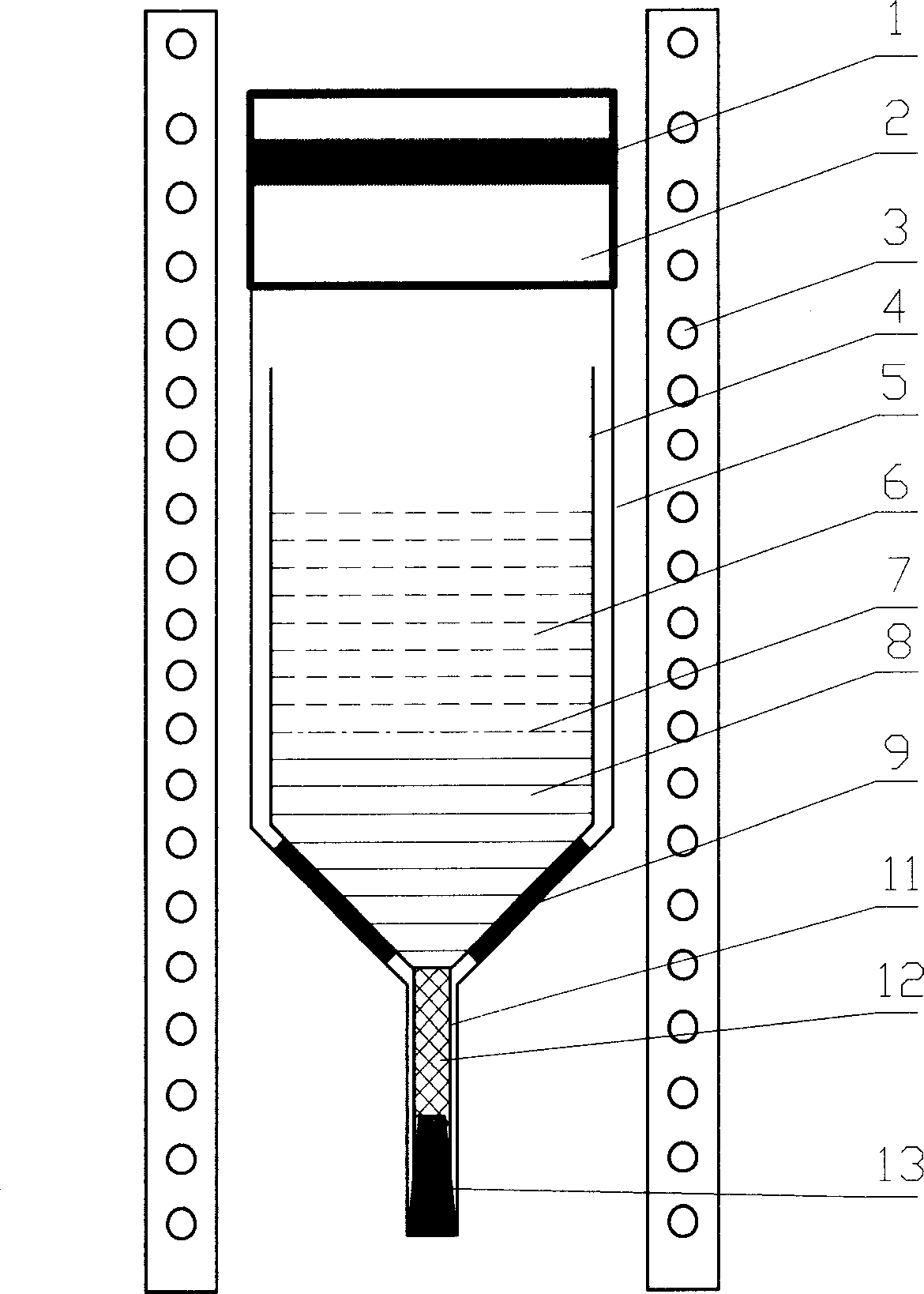

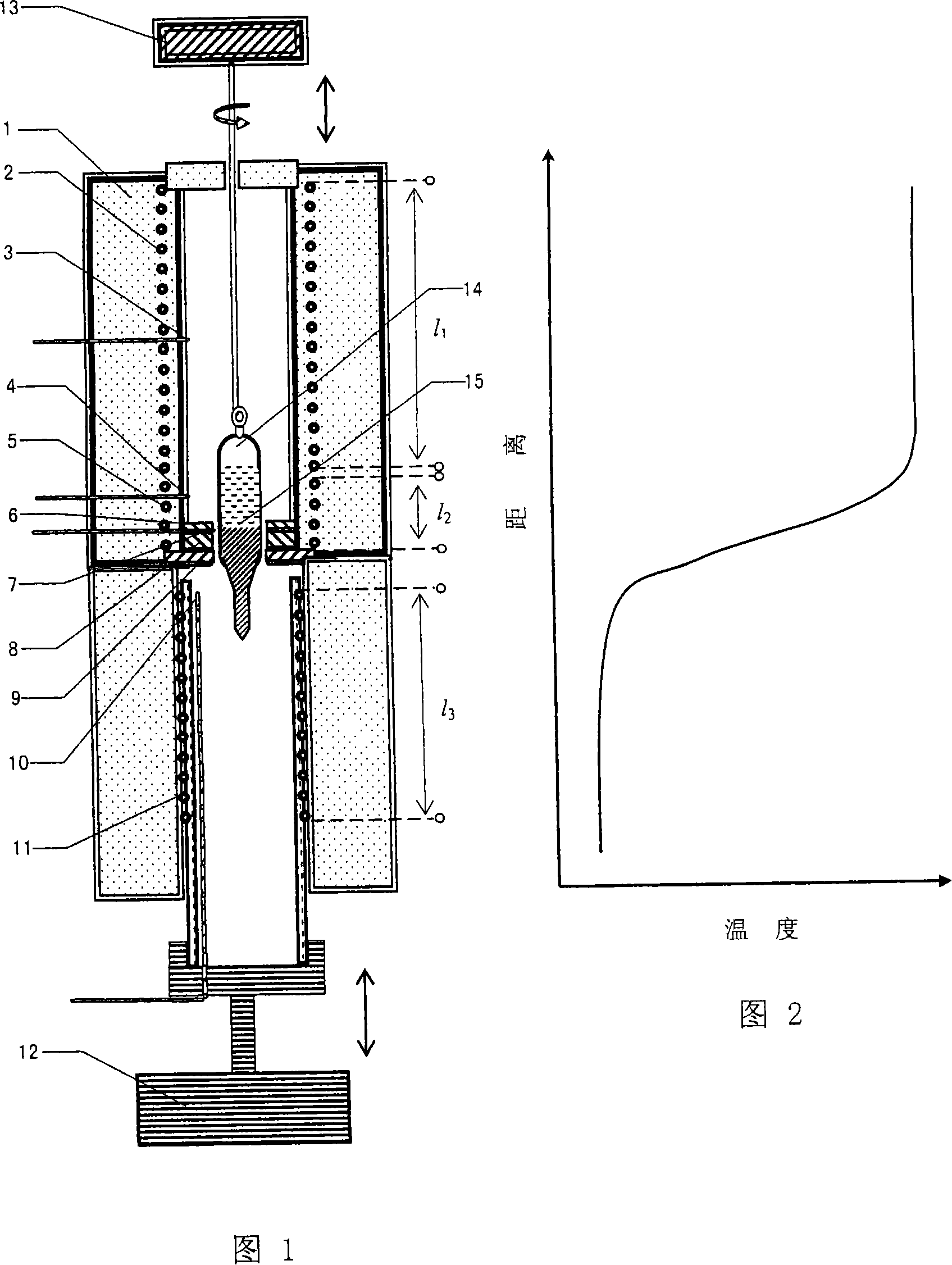

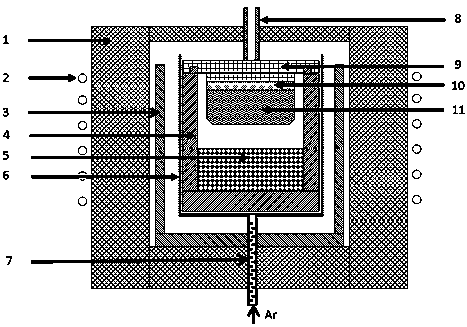

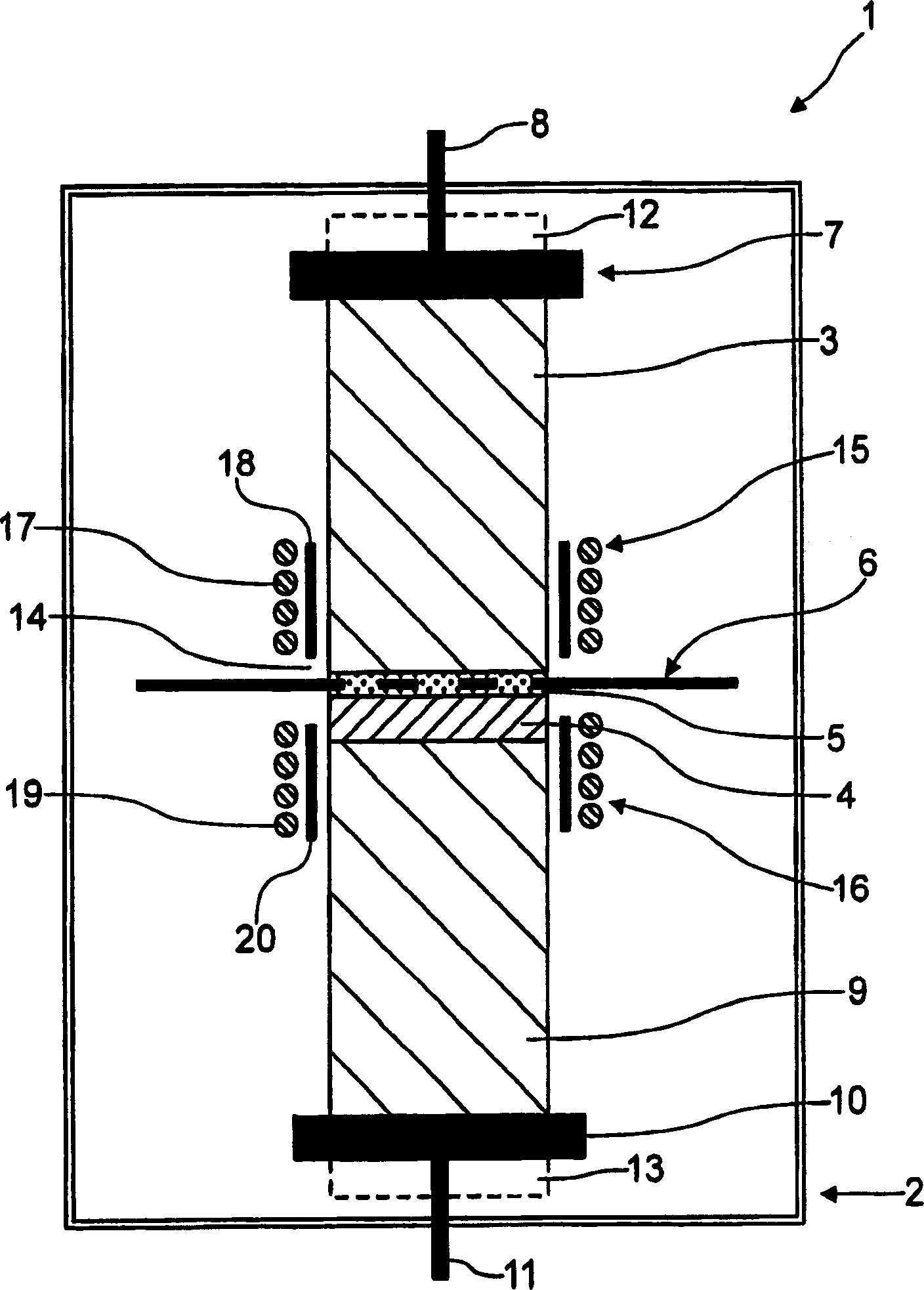

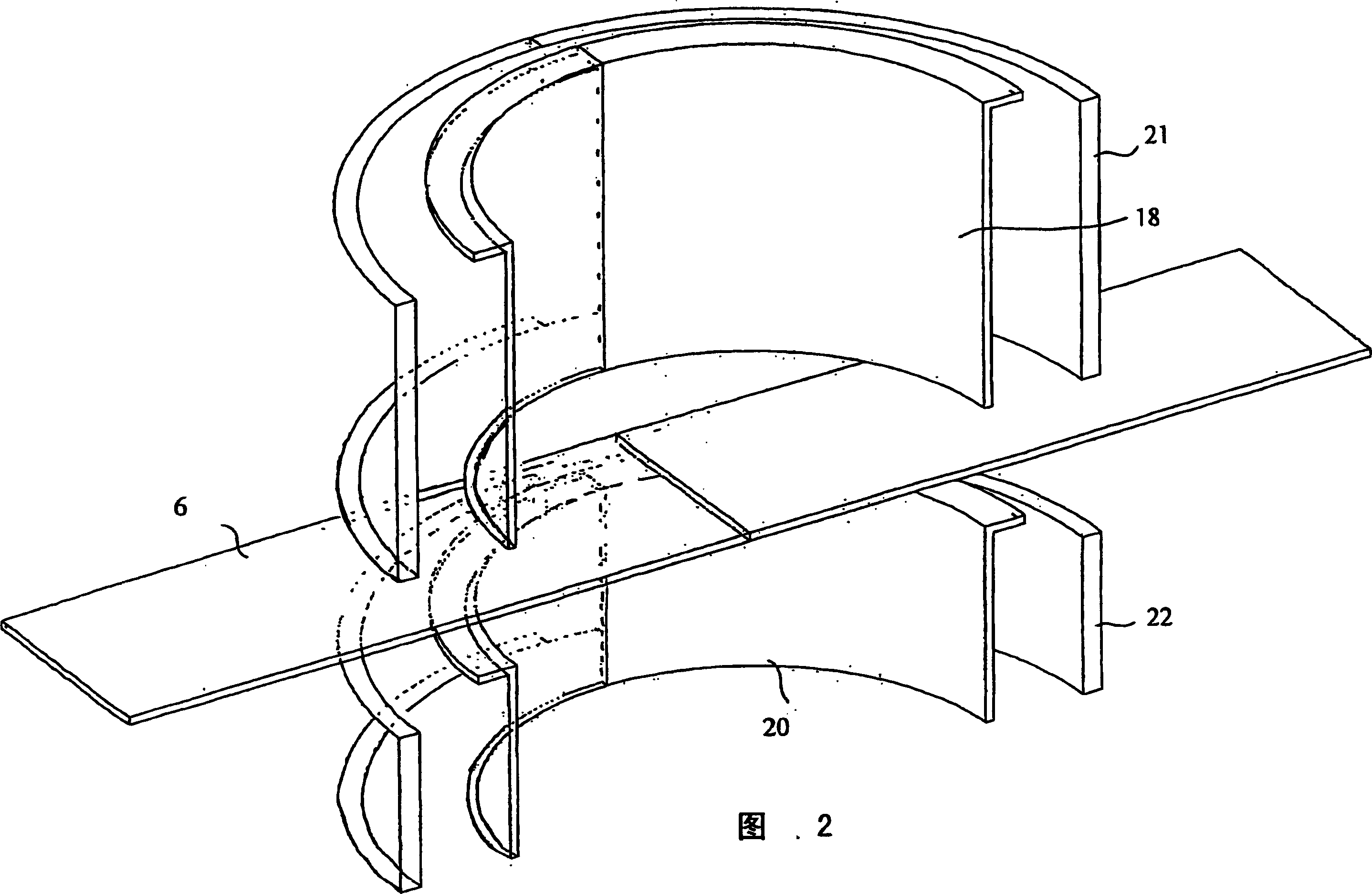

Precise vertical temperature-difference gradient condensation single crystal growth device and method thereof

InactiveCN1865527ALow temperature gradientReduce defect densityPolycrystalline material growthFrom frozen solutionsSemiconductor materialsEngineering

The invention discloses a growing device and method of precise vertical differential temperature gradient condensate monocrystal, which is characterized by the following: the heating element of heating device distributes evenly around the peripheral of copple, which is started from copple conversing point; the heating element attaches and distributes evenly along copple cone until covering the mouth position of copple, which makes temperature detecting couple touches quartz container wall through heating element. The invention improves eh quality and production rate of crystal, which is fit for III-V or II-IV composition semiconductor material.

Owner:长治虹源科技晶片技术有限公司

Device and method for producing single crystals by vapor deposition

ActiveUS7361222B2Down and eliminate formationInhibition of defect generationPolycrystalline material growthNitrogen-metal/silicon/boron binary compoundsHalogenPhysical chemistry

Owner:NORSTEL

Nitride ceramics to mount aluminum nitride seed for sublimation growth

An apparatus and method for fabricating a mount for an aluminum nitride (AlN) seed for single crystal aluminum nitride growth is provided. A holder having a proximal base and wall portions extending therefrom is fabricated from crystal growth crucible material, and defines an internal cavity. An AlN seed is placed within the holder, and placed within a nitrogen atmosphere at a temperature at or exceeding the melting point of a suitable material capable of forming a nitride ceramic by nitridation, such as aluminum. Pellets fabricated from this material are dropped into the holder and onto the seed, so that they melt and react with the nitrogen atmosphere to form a nitride ceramic. The seed is effectively molded in-situ with the ceramic, so that the ceramic and holder forms a closely conforming holder for the seed, suitable for single crystal AlN growth.

Owner:CRYSTAL

High-strength hot-corrosion-resistant Ni-based single crystal superalloy and preparation method

InactiveCN103966671AImprove high temperature mechanical propertiesExcellent hot corrosion resistancePolycrystalline material growthFrom frozen solutionsSingle crystal superalloySingle crystal

The invention relates to the field of single crystal superalloys, particularly to a high-strength hot-corrosion-resistant Ni-based single crystal superalloy and a preparation method, and is mainly applied to high-temperature components applied to various marine environments and turbine high-temperature components of ground industrial gas turbines. The superalloy comprises chemical components in percentage by weight as follows: 11-15% of Cr, 5-9% of Co, 0.5-2.0% of Mo, 3.0-5.0% of W, 4.5-7.0% of Ta, 3.5-5.6% of Al, 2.3-3.7% of Ti and the balance of Ni. A vacuum induction furnace is used for smelting, a mother alloy is cast firstly, and then the high-strength hot-corrosion-resistant single crystal superalloy is prepared according to a single crystal growth technology and a heat treatment system. The Cr and refractory metallic elements with higher content are selected, but the content of the Ti element is reduced. Meanwhile, the crystal boundary is eliminated through a single crystal technology, so that the hot corrosion resistance, the high-temperature mechanical property and the structure stability of the alloy are further improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

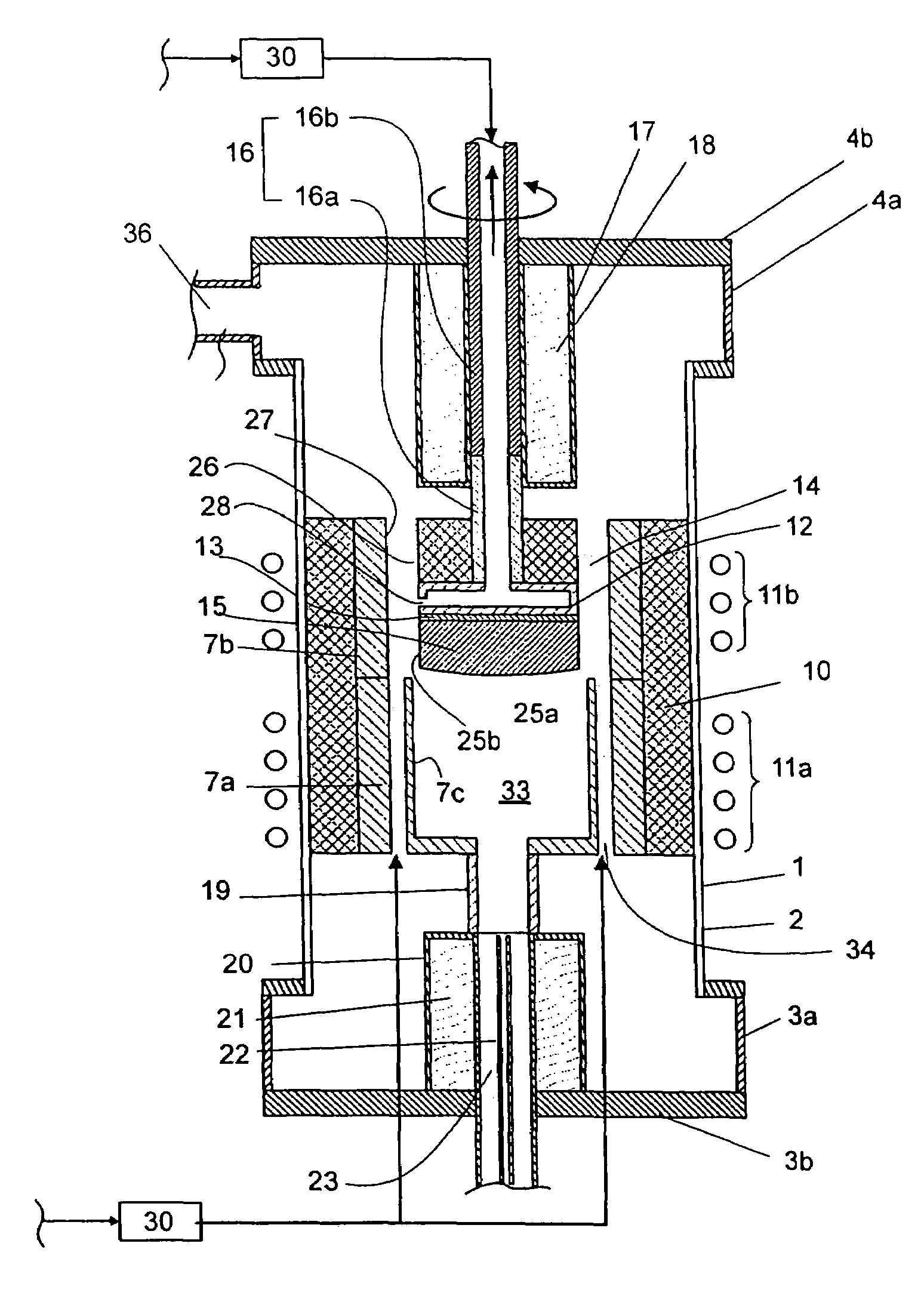

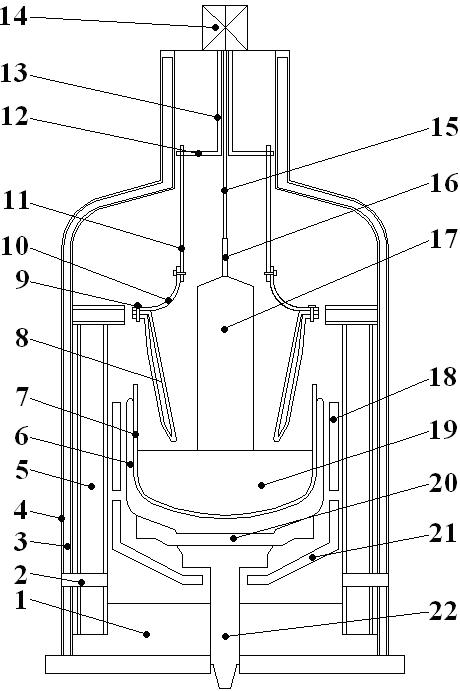

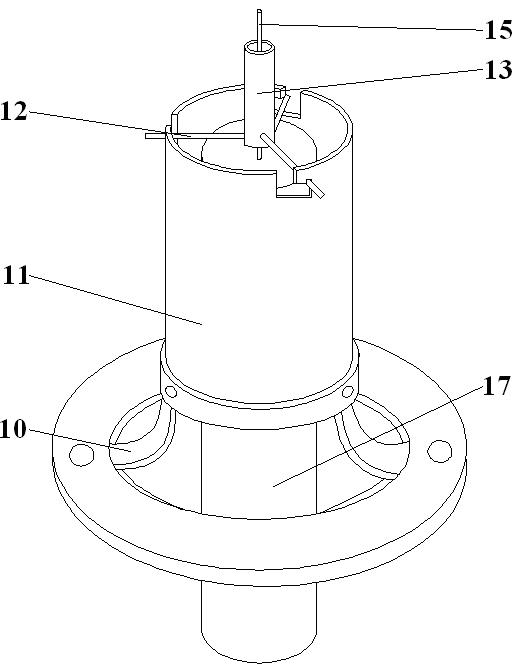

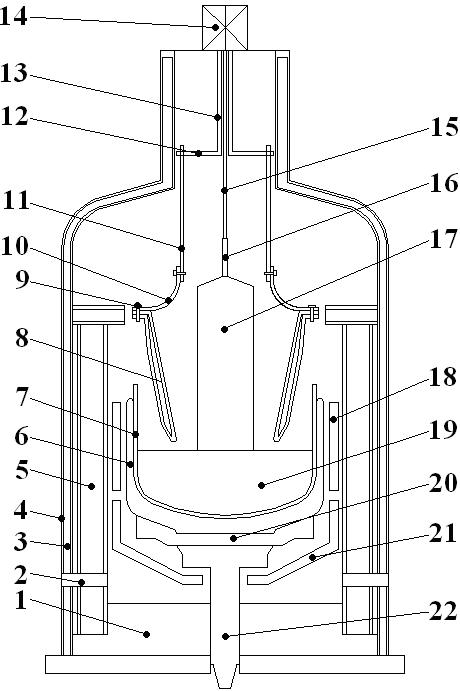

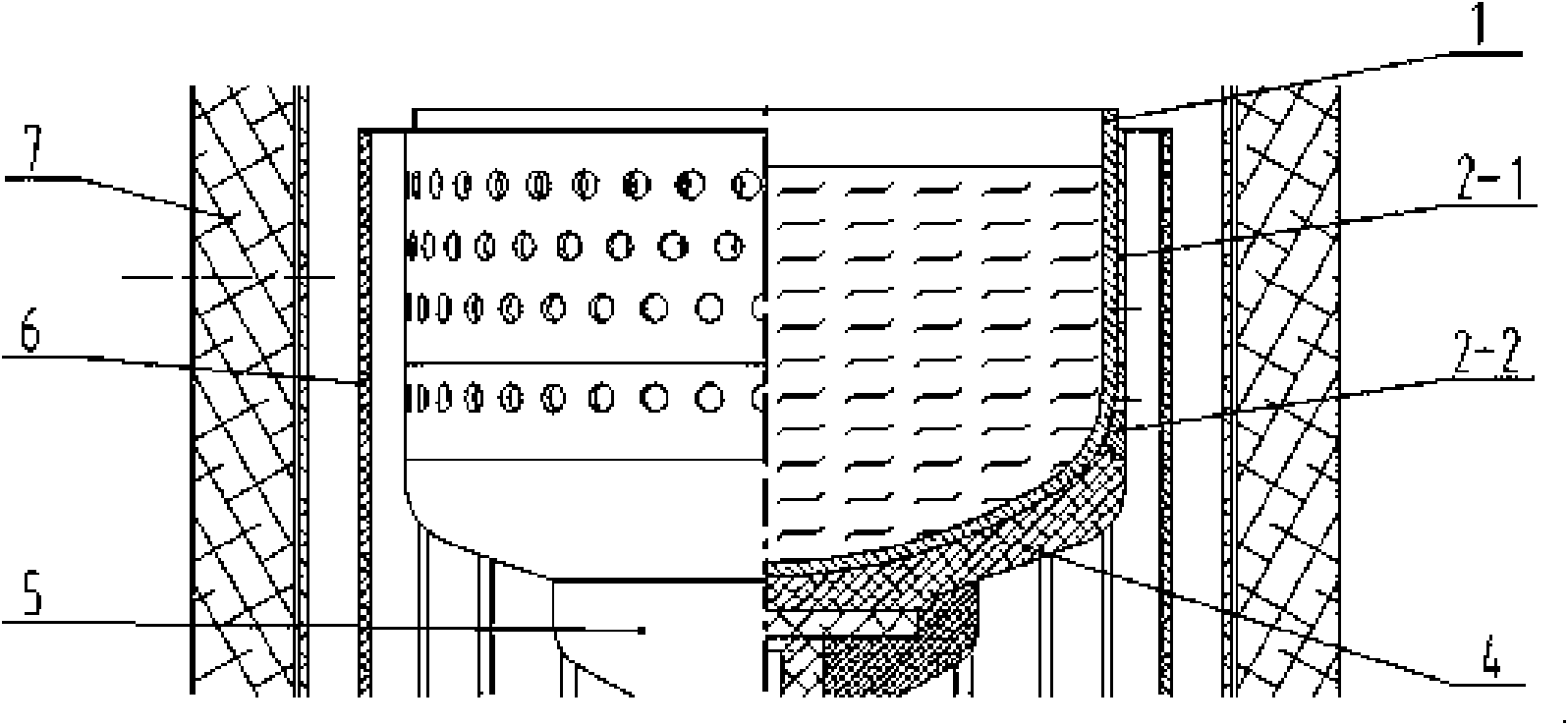

Dual-heater mobile-heat-shield type Czochralski crystal growing furnace

ActiveCN102162123AReduce the presence of impuritiesReduce microdefectsBy pulling from meltSemiconductor materialsSingle crystal

The invention discloses semiconductor material growing equipment, and in particular relates to a Czochralski crystal growing furnace for semiconductor single crystal growth. In the invention, the downward motion of a heat shield is used to replace the upward motion of a crucible, so that the crucible can only rotate and not ascend any more, thus, one degree of freedom is reduced and the system complexity is decreased; by adopting dual heaters respectively located at the bottom and the side face of the crucible respectively to control the growth of a crystal by aiming at different stages respectively, the temperature gradient control of the crystal and melt is more convenient; the relative positions between the crucible and the heaters are kept parallel and unchanged, and the heat radiation of the heaters is directly used for baking the crucible, so that the heat transfer efficiency is greatly improved in comparison with that in a traditional method in which the crucible in the traditional single crystal furnace is constantly away from a heating zone; and a flow guiding cylinder is used for guiding argon gas to carry out enhanced heat exchange on the crystal, so that an convection vortex of the argon gas above the melt is inhibited, thus, impurities and micro-defects in the crystal are favorably reduced and the consumption level of the argon gas is decreased.

Owner:JIANGSU UNIV

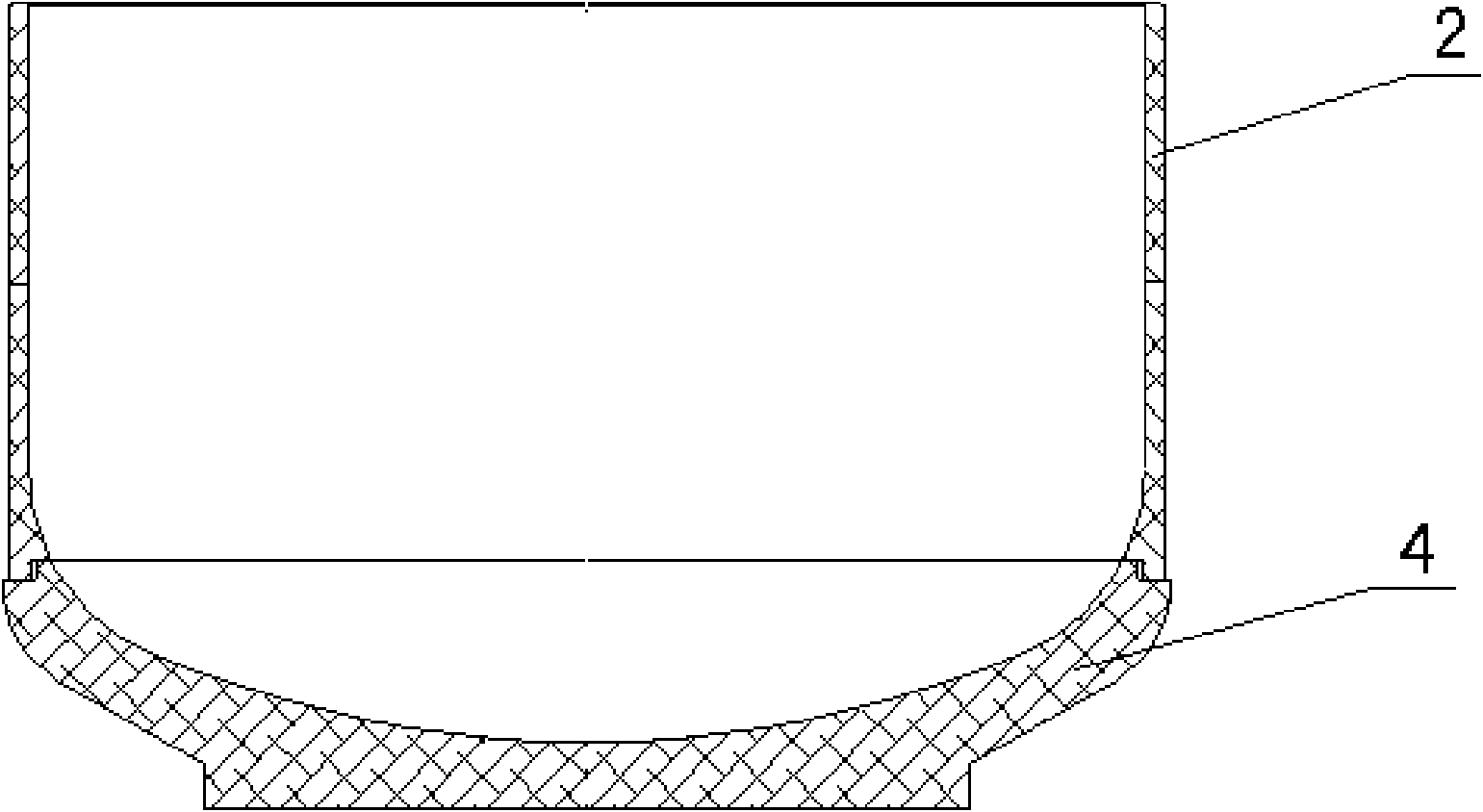

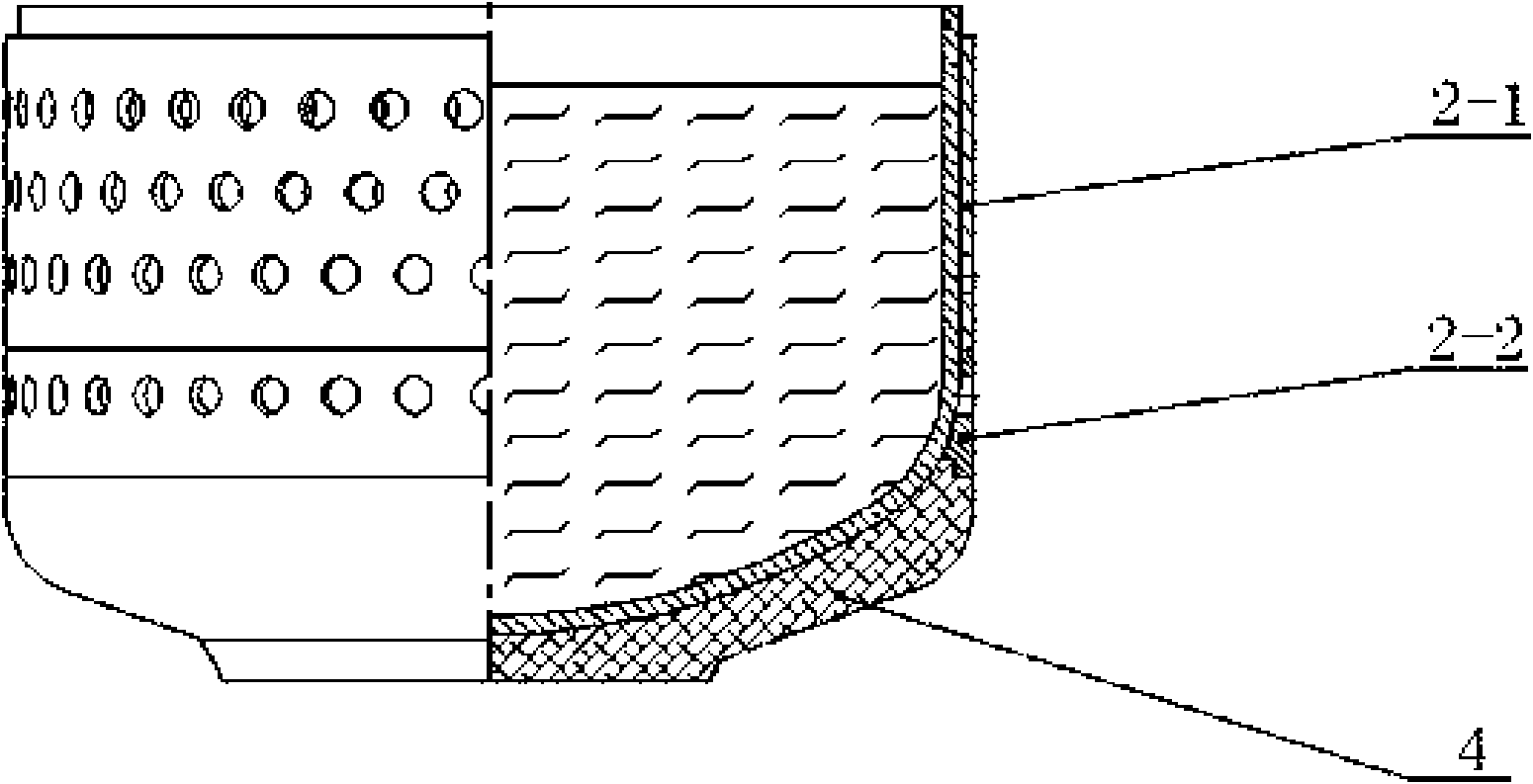

CZ method silicon single crystal growth furnace quartz crucible carbon protection crucible and manufacturing process thereof

InactiveCN101643933AExtended service lifeGuaranteed radiationBy pulling from meltCarbon coatingFiber

The invention relates to a CZ method silicon single crystal growth furnace quartz crucible carbon protection crucible and a manufacturing process thereof. The CZ method silicon single crystal growth furnace quartz crucible carbon protection crucible comprises an upper crucible edge, a lower crucible edge and a crucible support, wherein the upper crucible edge and the lower crucible edge comprise green bodies and matrix carbon, the surface is provided with a silicon carbide coating, each green body is formed by the superposition of two-dimensional carbon fiber fabrics or is formed by a quasi-three-dimensional punched carbon fiber felt body, and the weight is not lower than 40 percent of weight of the protection crucible; the matrix carbon comprises carbon resin and chemical vapor depositioncarbon, wherein the content of the chemical vapor deposition carbon is not higher than 30 percent of total weight of the product; the density of materials of the upper crucible edge and the lower crucible edge is higher than or equal to 1.3g / cm <3>; holes with the diameters ranging from 5 to 30 mm are uniformly distributed on the upper crucible edge and the lower crucible edge, the walls of the holes and the inner surfaces of the crucible edges are provided with silicon carbide coatings, and the thickness ranges from 10 to 100 mu m; and the crucible support comprises high strength and high purity graphite and surface deposited carbon coatings, the density thereof is higher than or equal to 1.7g / cm <3>, and the thickness of the surface deposited carbon coatings ranges from 10 to 100 mu m.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

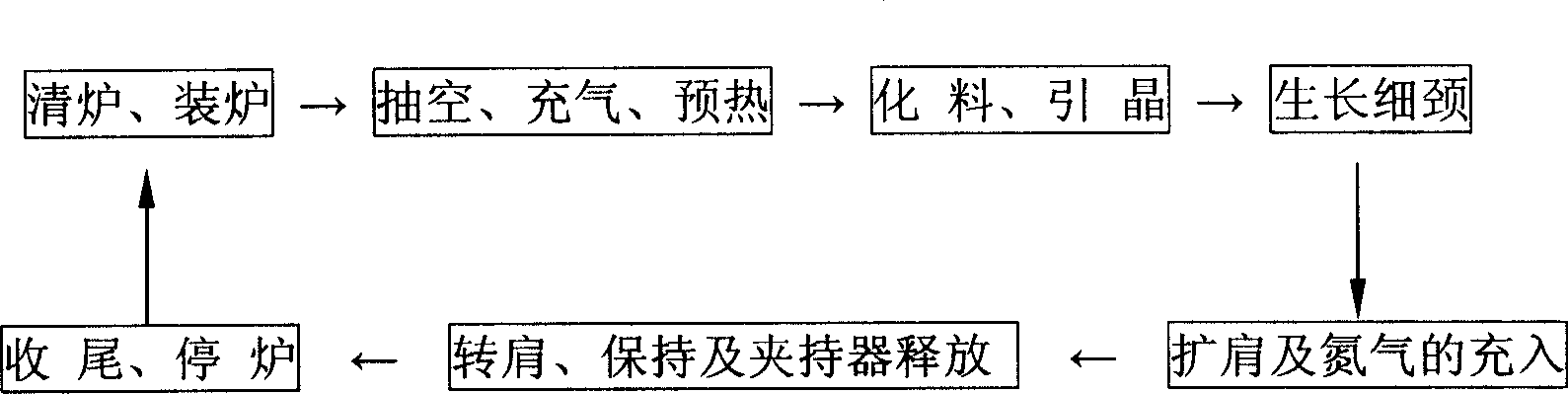

Large-diameter zone-melting silicon single crystal growth method

ActiveCN1865528AMeet the needs of large diameter zone molten silicon single crystalPolycrystalline material growthBy zone-melting liquidsNitrogenZone melting

The invention discloses a manufacturing method of silicon monocrystal, which comprises the following steps: 1. clearing furnace; loading furnace; 2. extracting; aerating; preheating; 3. digesting material; introducing seed; 4. growing thin neck; 5. expanding shoulder; aerating nitrogen; 6. transmitting; keeping; releasing clamper; 7. ending; stopping furnace. The invention realizes the large diameter zone melting silicon monocrystal, which reaches SEMI standard.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

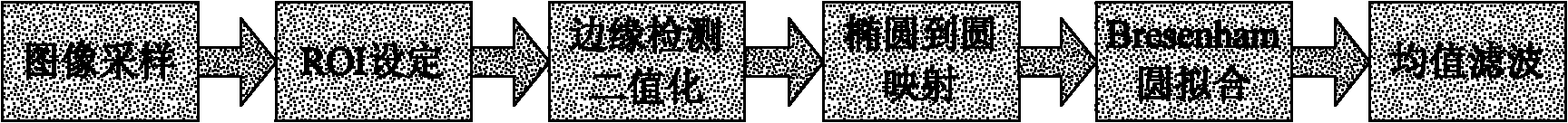

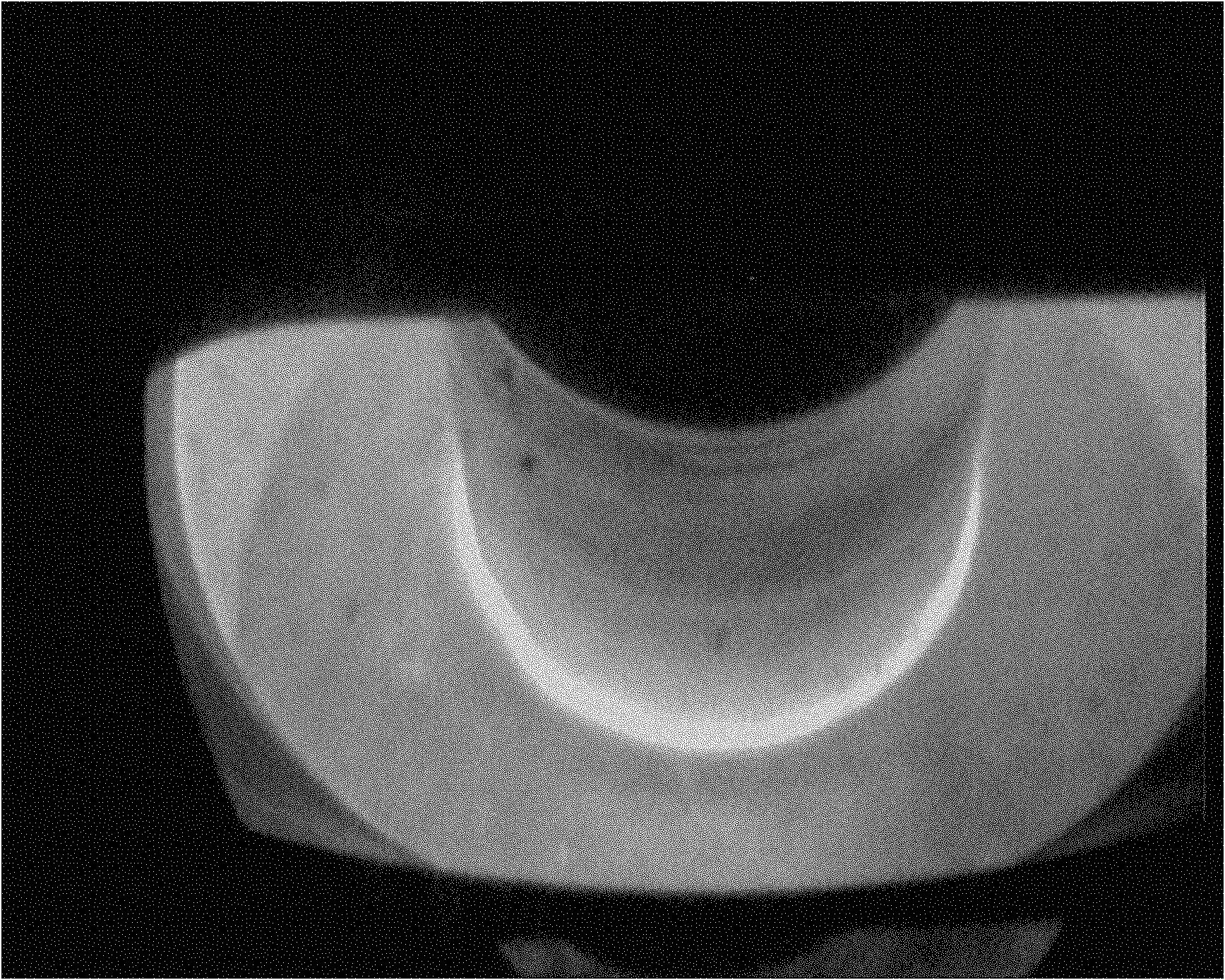

Czochralski single crystal silicon diameter measurement method

InactiveCN102061517AGuaranteed measurement accuracyLow costBy pulling from meltSingle crystalComputer vision

The invention discloses a Czochralski single crystal silicon diameter measurement method, which comprises the following steps of: synchronously acquiring single crystal growth images by using a camera, performing pre-processing and edge detection on the acquired images of each frame, performing sub-pixel optimal approximation and fit of a circle on the images of each frame by adopting a midpoint Bresenham circle drawing algorithm, and performing mean filter on the basis of a fit arc to acquire the accurate diameter of single crystal. The method can perform the sub-pixel optimal approximation of the circle by adopting the midpoint Bresenham circle drawing algorithm and can accurately calculate the diameter of the single crystal by using the common analog industrial camera so as to achieve the measurement effect of the high-resolution industrial camera.

Owner:ZHEJIANG COWIN ELECTRONICS

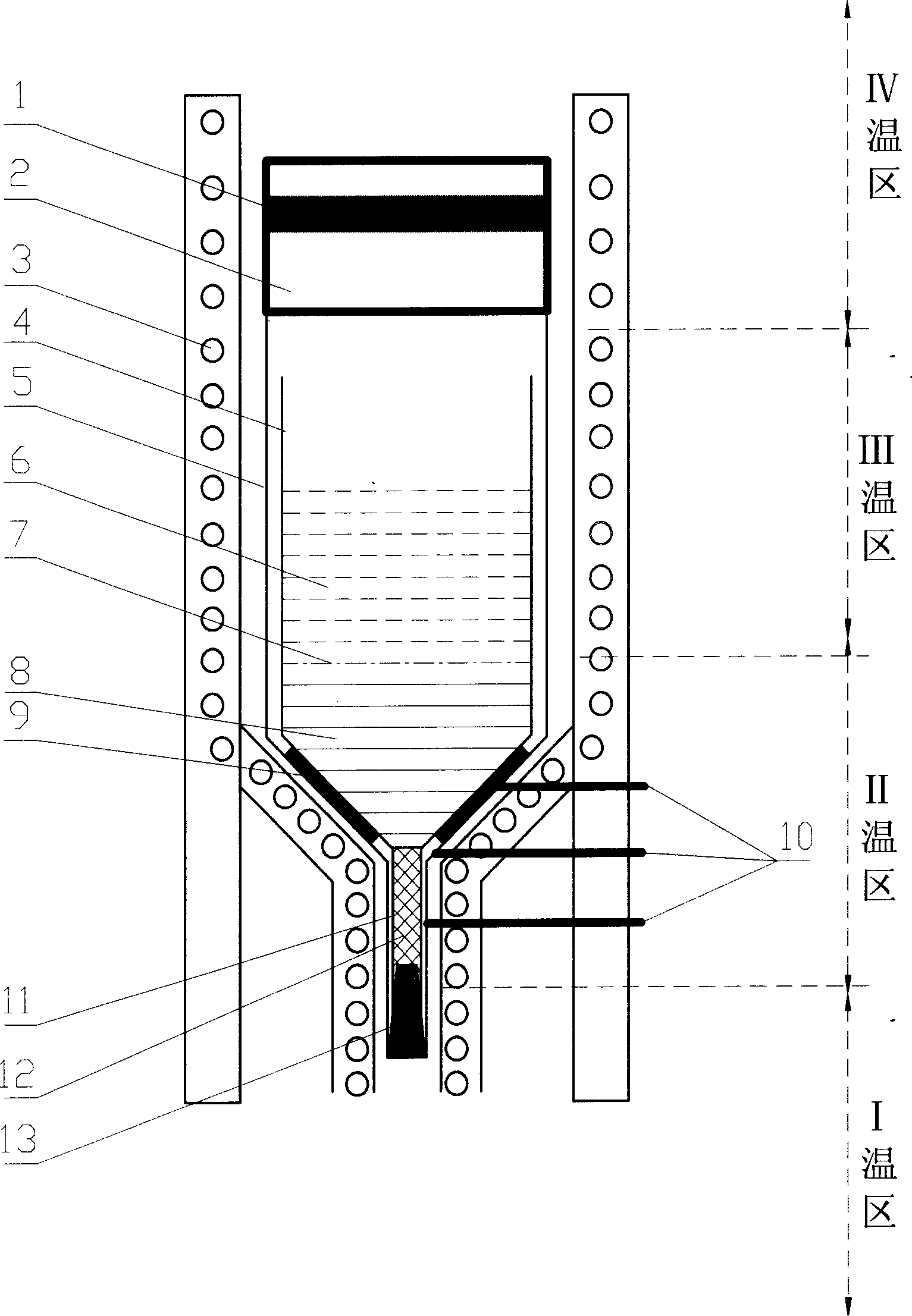

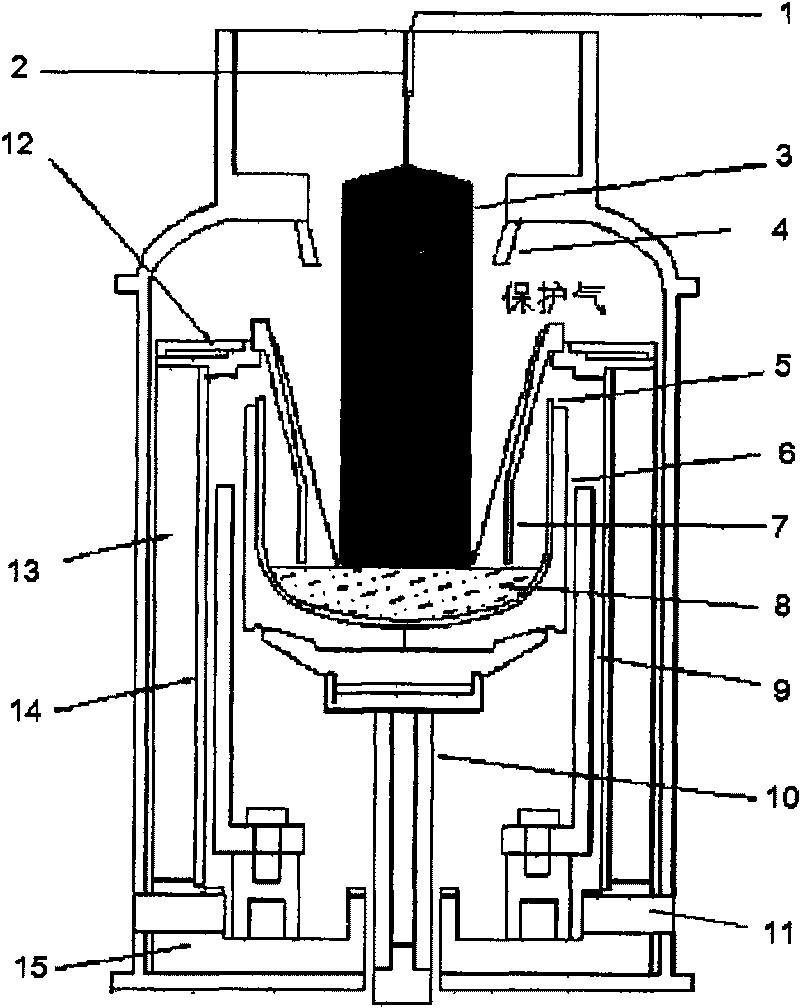

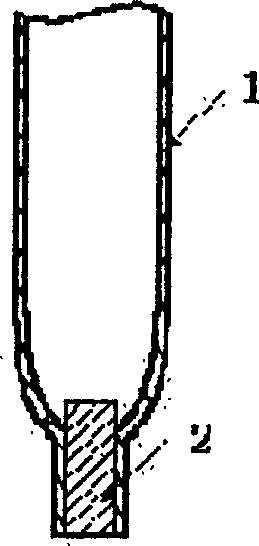

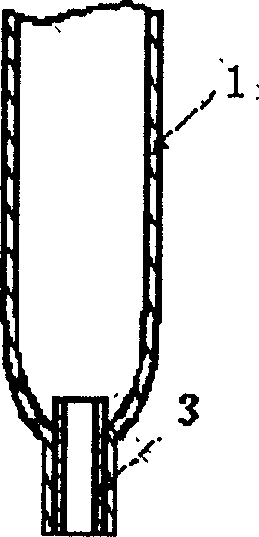

Preparation method for multi-element compounds semiconductor single-crystal and growth device thereof

InactiveCN101122045ARealize temperature field adjustmentComplete appearanceFrom frozen solutionsCrucibleSingle crystal

A method for preparing a multi-component semiconductor single crystal, the process steps are: (1) cleaning a crucible, (2) charging and degassing and sealing, (3) crystal growth, and (4) annealing and cooling. The single crystal growth device matched with this method includes a movable lower furnace heater and a single crystal growth furnace with an auxiliary heater in the middle, which can flexibly adjust the temperature field in the crystallization temperature gradient area according to the crystallization habit of the multi-component compound, and obtain The narrow temperature zone and large temperature gradient crystallization temperature field distribution required for the growth of compound single crystals maintain the stability of the solid-liquid interface and realize the flat interface growth of single crystals. Using the growth device, various multi-element compound semiconductor single crystals with complete appearance and good crystallization performance can be successfully grown by adopting the crucible descending method.

Owner:SICHUAN UNIV

Polycrystalline synthesis and single-crystal growth method for germanium zinc phosphide

InactiveCN101235542AIncrease synthesis rateHigh purityPolycrystalline material growthFrom solid stateForeign matterCrucible

A method for synthesizing poly-crystal and growing single-crystal of zinc germanium phosphide relates to a method for synthesizing and the growing the zinc germanium phosphide. The method solves the problem of low synthesizing rate of the current method for synthesizing the zinc germanium phosphide poly-crystal, and the problem of uneasy to exclude foreign matter of the method for growing the zinc germanium phosphide single-crystal. The synthesis of the zinc germanium phosphide poly-crystal of the invention comprises the following steps: firstly, defining the quantity, secondly, increasing the temperature, namely obtaining the zinc germanium phosphide poly-crystal material; the growth of the zinc germanium phosphide single-crystal protocaryon of the invention has the following steps: firstly, defining the quantity, secondly, increasing the temperature, thirdly, decreasing the copple and reducing the temperature, namely obtaining the zinc germanium phosphide single-crystal, the growth of the zinc germanium phosphide single-crystal with seed crystal of the invention has the following steps: firstly, defining the quantity, secondly, increasing the temperature, thirdly, decreasing the copple and reducing the temperature, namely obtaining the zinc germanium phosphide single-crystal. The method of the invention has the advantages that the synthesizing rate of the poly-crystal synthesis is high, the growth of the single-crystal is easy to exclude the foreign matter, and the direction of the crystal is accordant.

Owner:HARBIN INST OF TECH

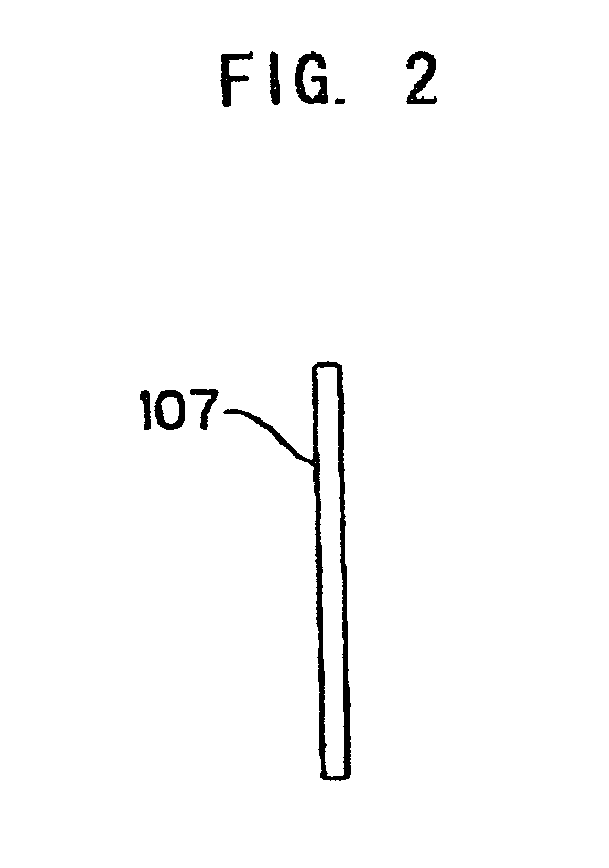

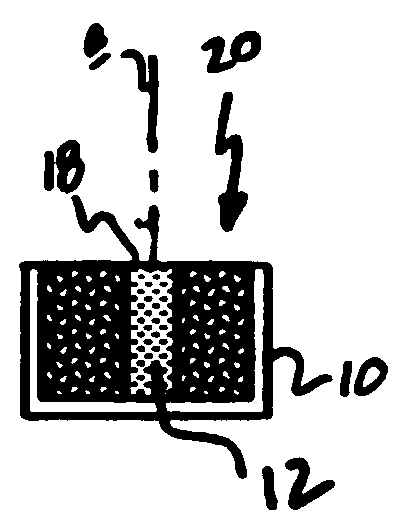

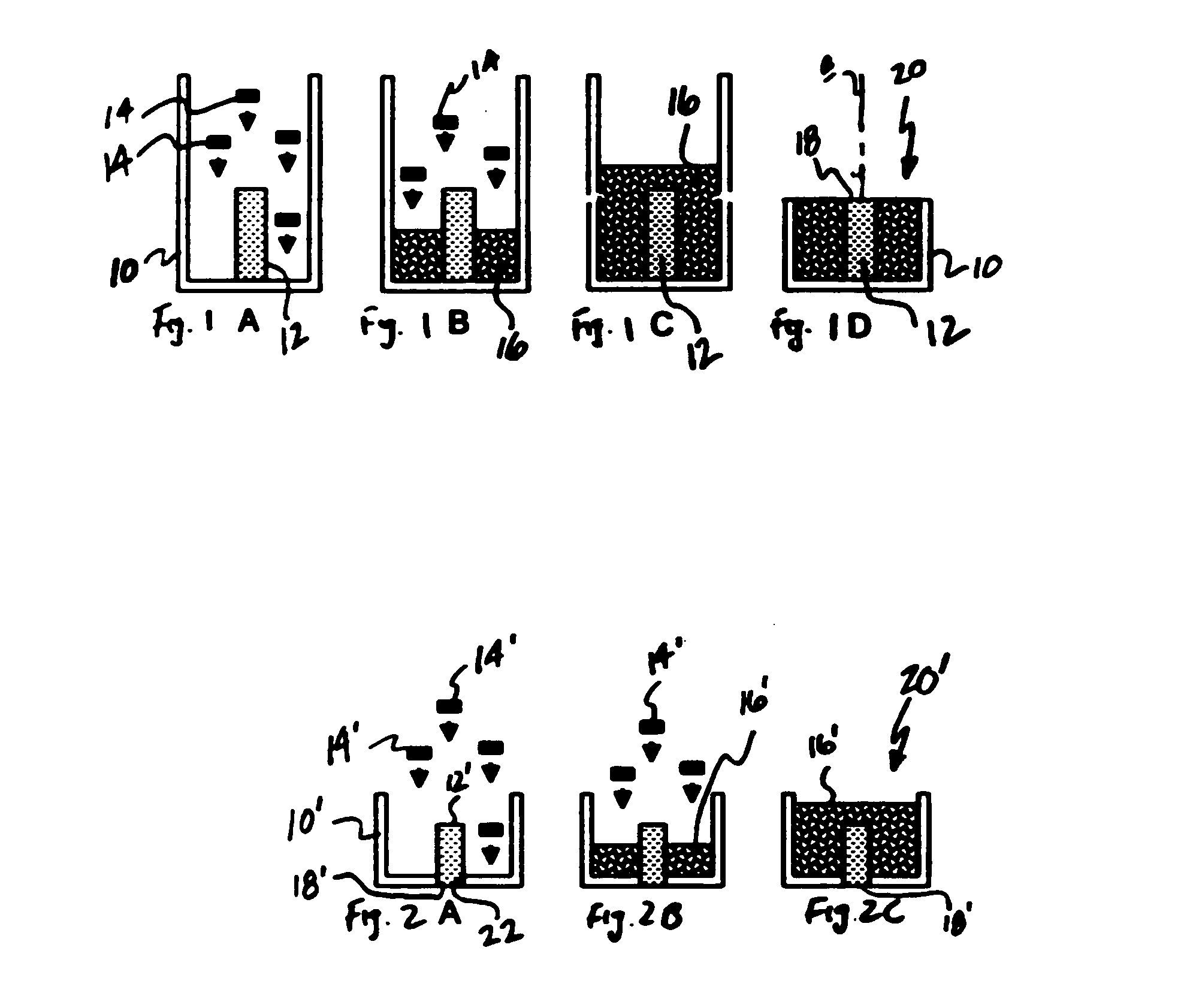

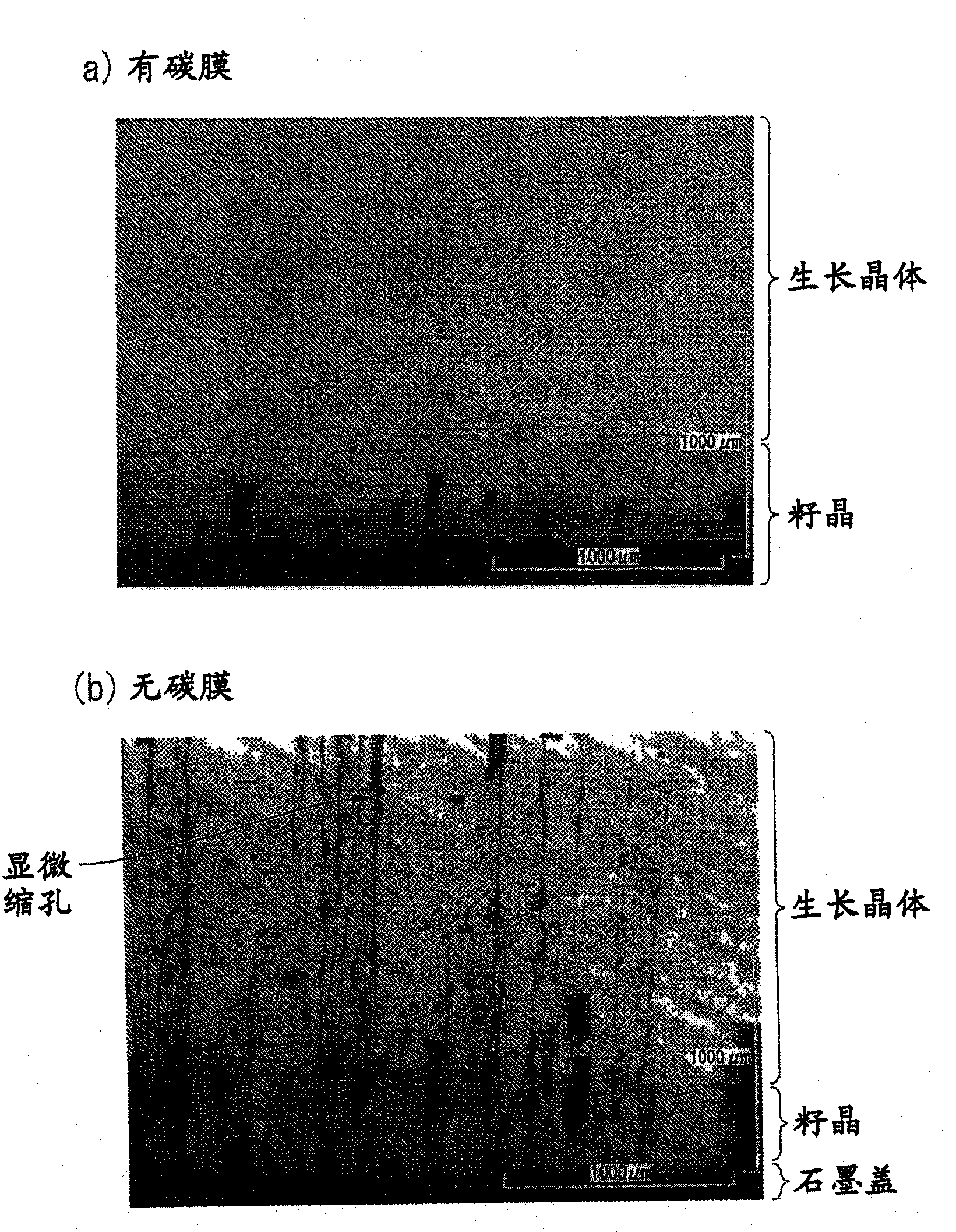

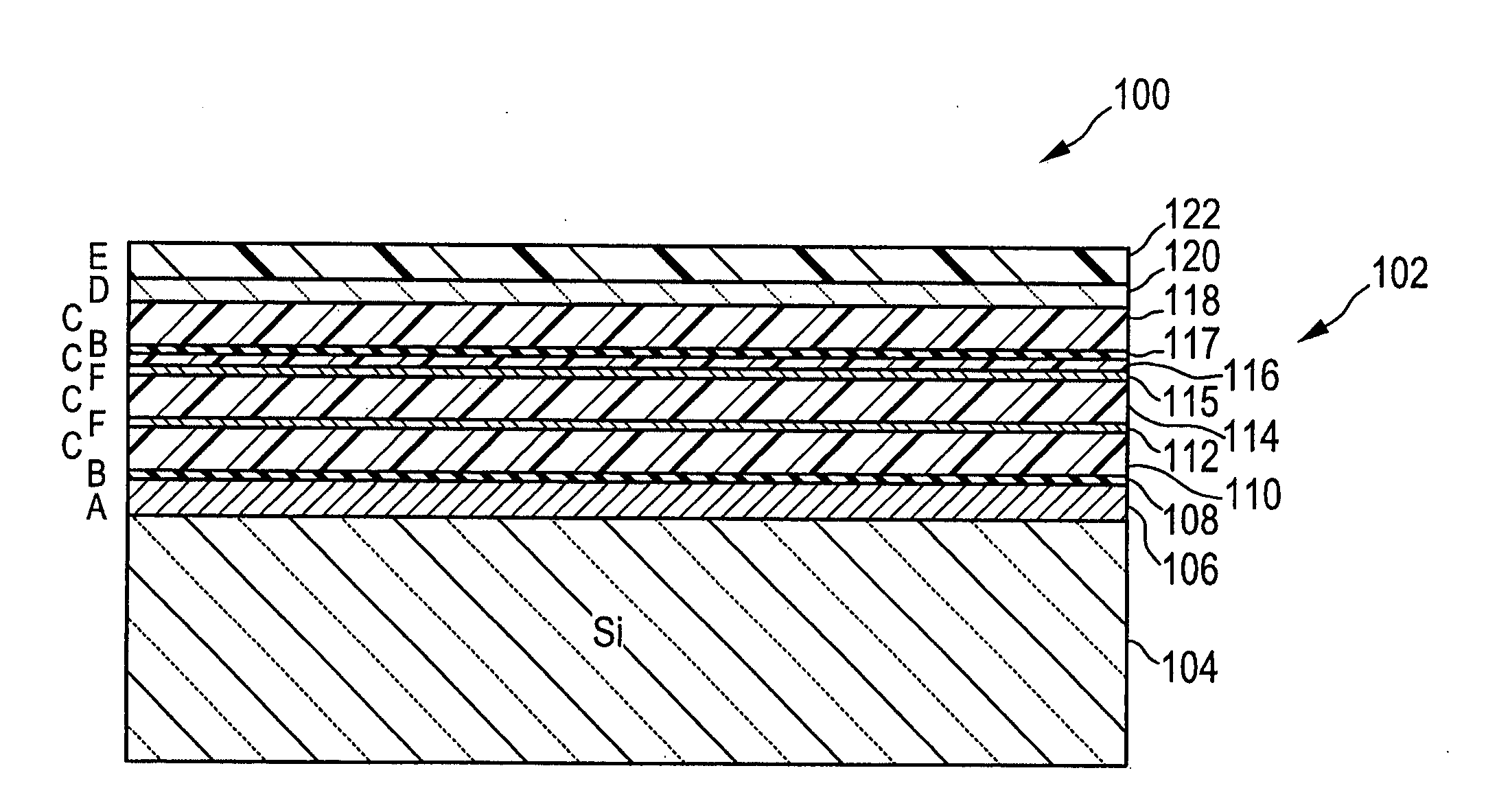

Seed crystal for growth of silicon carbide single crystal, process for producing the same, and silicone carbide single crystal and process for producing the same

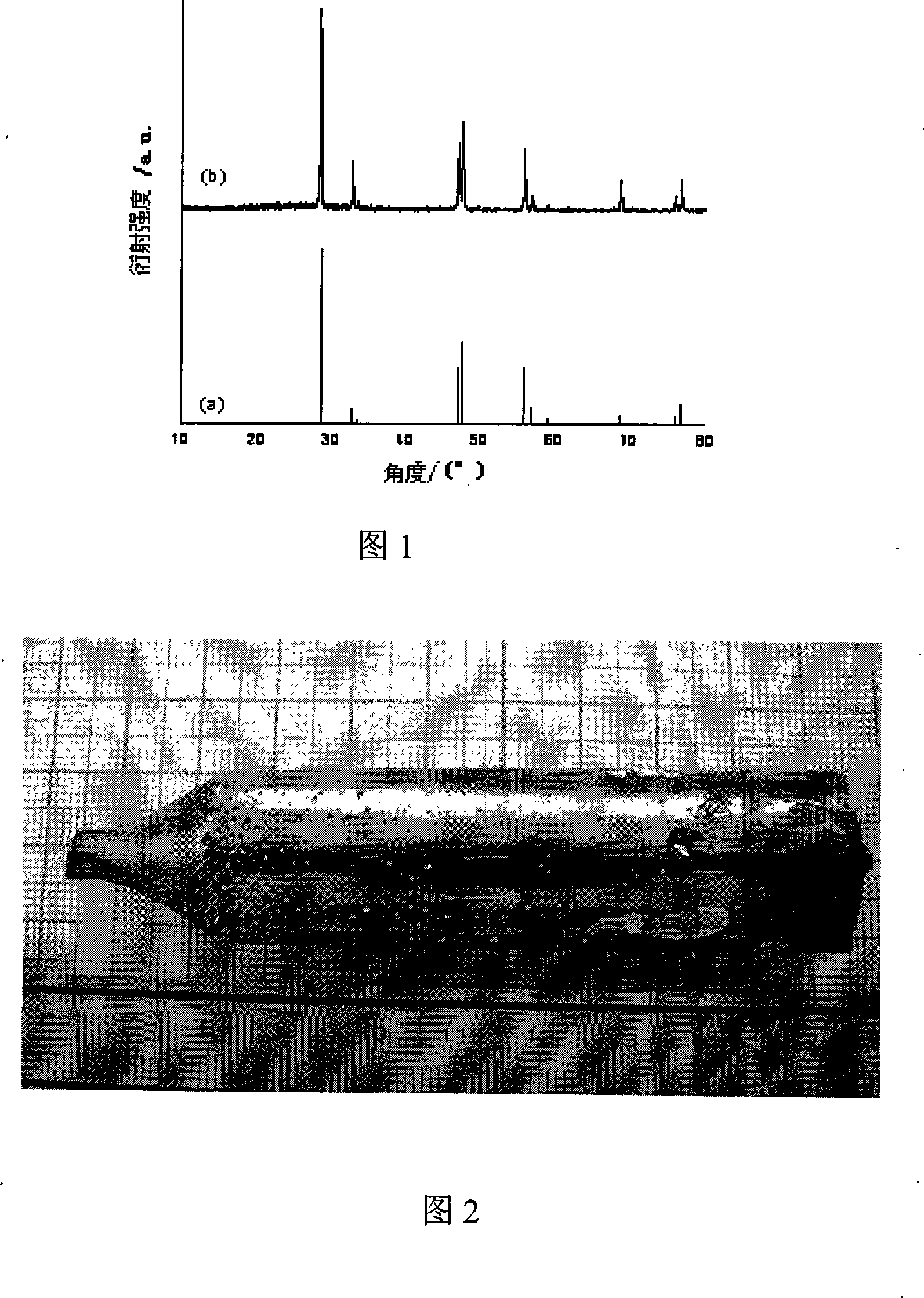

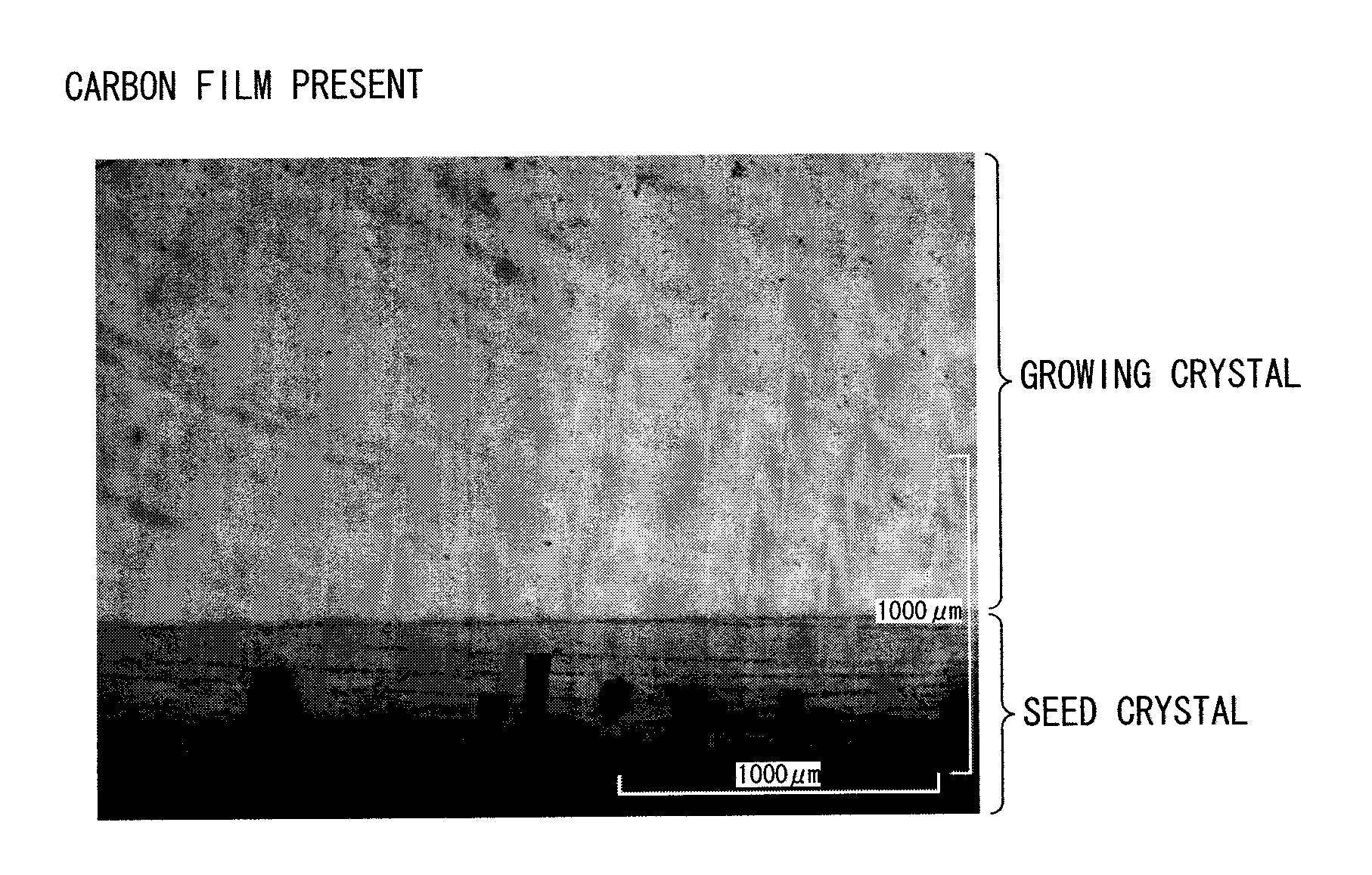

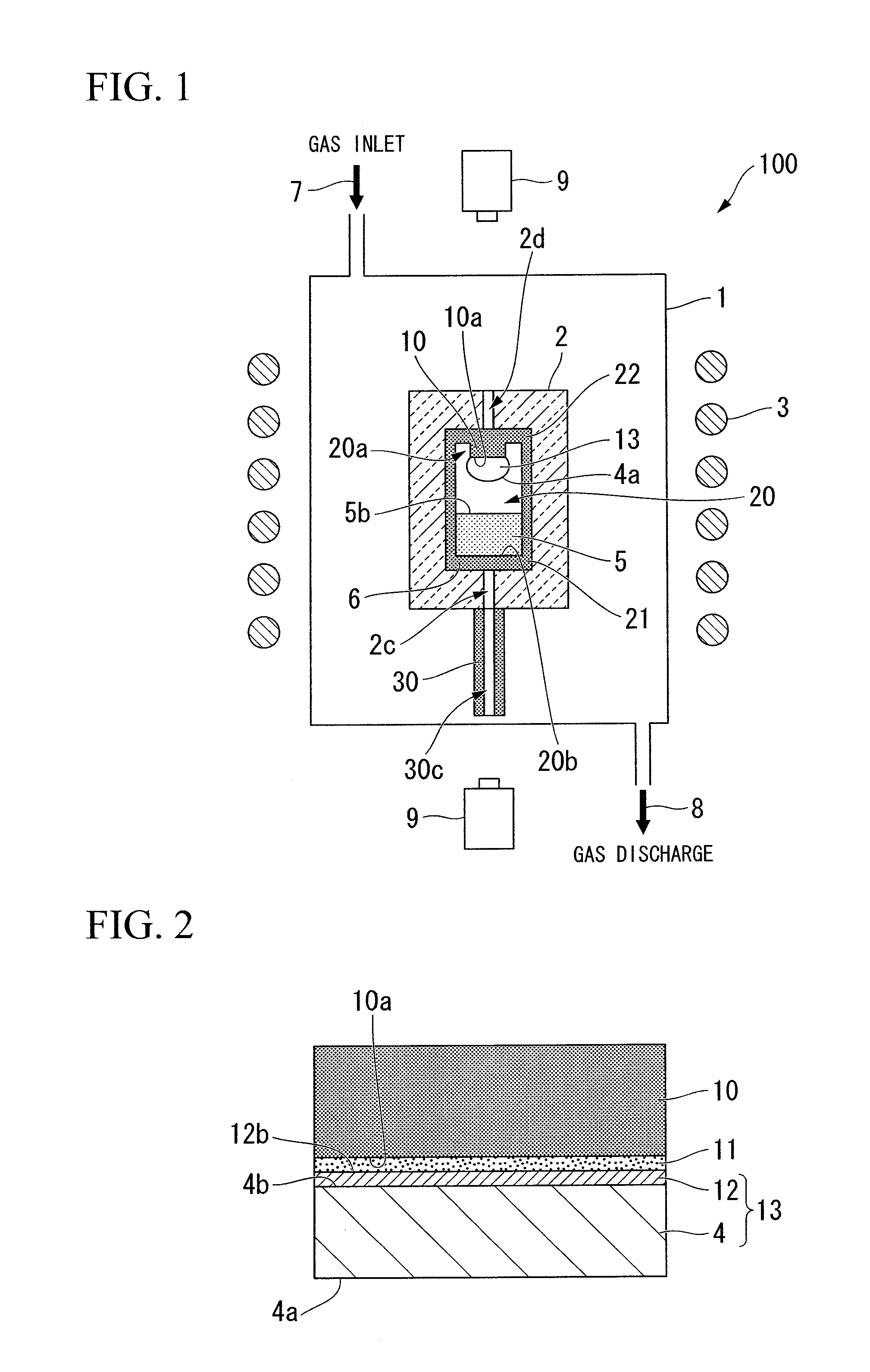

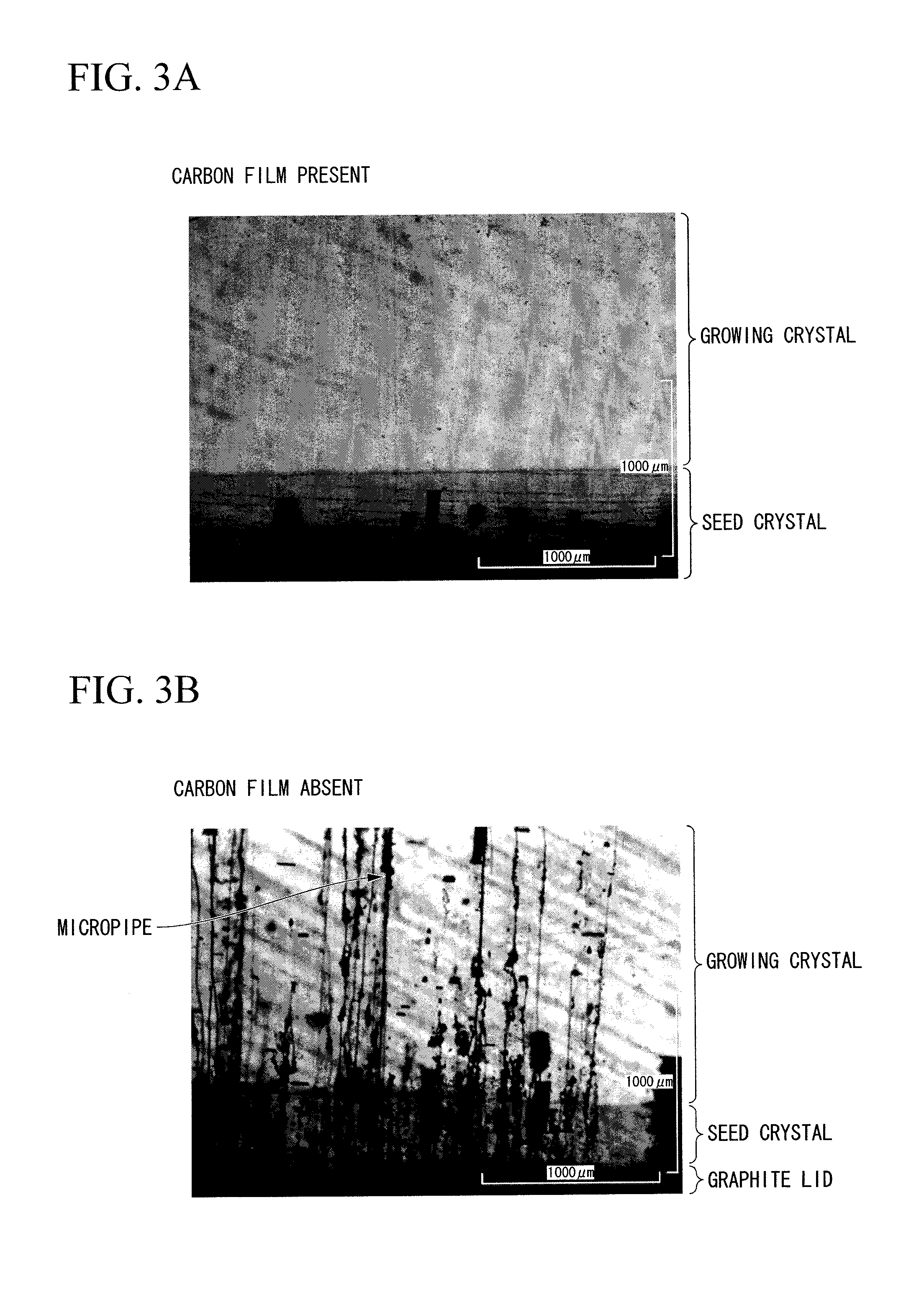

ActiveCN102057084ASuppression of crystal defectsHigh strengthPolycrystalline material growthFrom condensed vaporsCarbon filmCarbide

A seed crystal for the growth of a silicon carbide single crystal is provided which inhibits crystal defects from generating at the interface between the seed crystal and graphite and with which a high-quality silicon carbide single crystal having a low crystal defect density can be produced with satisfactory reproducibility. The seed crystal for the growth of a silicon carbide single crystal is a seed crystal (13) for silicon carbide single-crystal growth which is to be attached to the lid of a graphite crucible filled with a raw silicon carbide powder. The seed crystal (13) comprises: a seed crystal (4) which is constituted of silicon carbide and one side of which is a growth surface (4a) where a silicon carbide single crystal is to be grown by the sublimation method; and a carbon film (12) formed on the side (4b) opposite to the growth surface of the seed crystal (4), the carbon film (12) having a density of 1.2-3.3 g / cm3.

Owner:RESONAC CORPORATION

Seed crystal for silicon carbide single crystal growth, method for producing the seed crystal, silicon carbide single crystal, and method for producing the single crystal

InactiveUS20110111171A1Good reproducibilityQuality improvementVacuum evaporation coatingSputtering coatingCarbon filmOptoelectronics

A seed crystal for silicon carbide single crystal growth (13) which is attached to the lid of a graphite crucible charged with a raw material silicon carbide powder. The seed crystal includes a seed crystal (4) formed of silicon carbide having one surface defined as a growth surface (4a) for growing a silicon carbide single crystal by a sublimation method, and a carbon film (12) formed on the surface (4b) opposite to the growth surface of the seed crystal (4). Further, the film density of the carbon film (12) is 1.2 g / cm3 to 3.3 g / cm3.

Owner:SHOWA DENKO KK

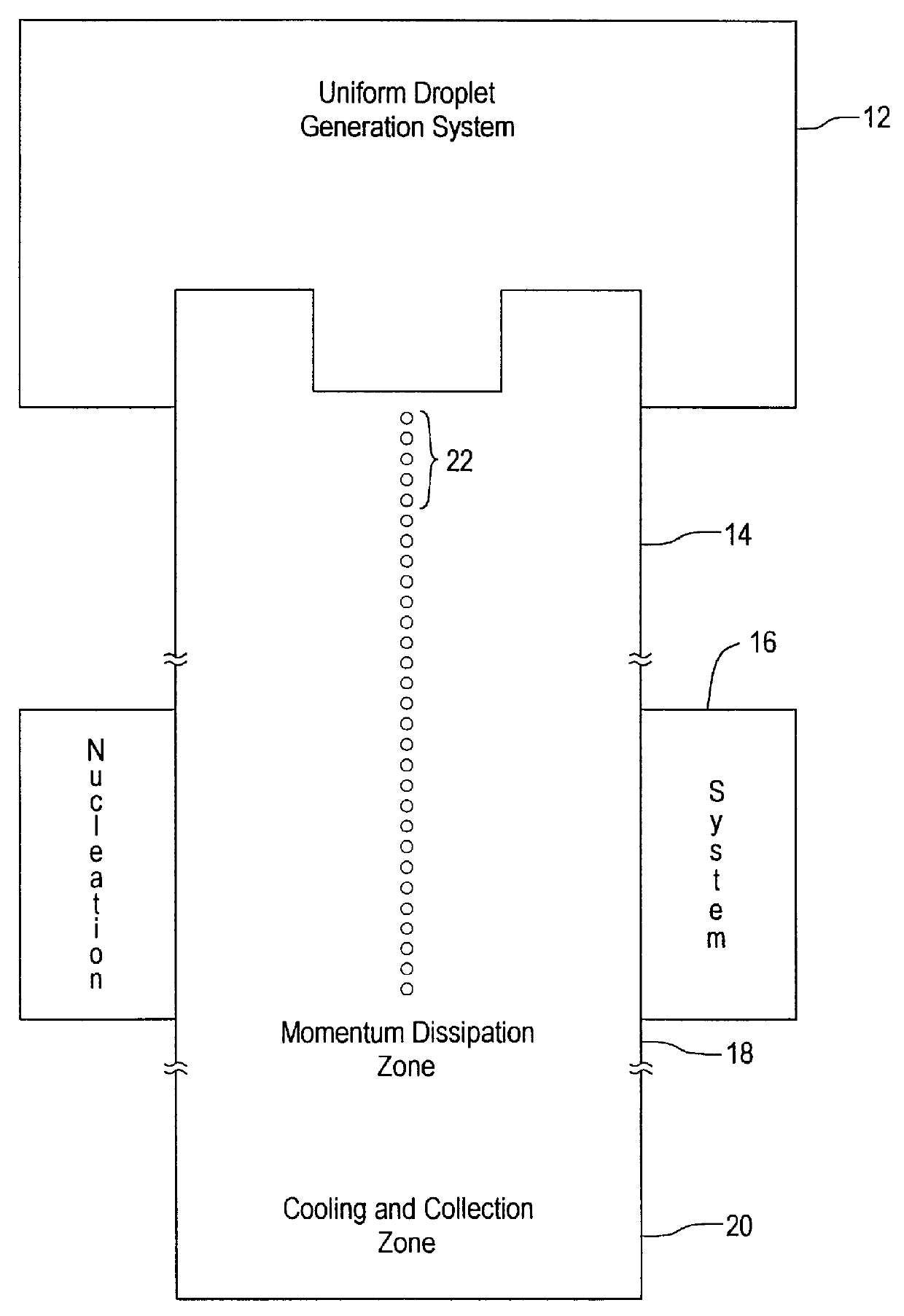

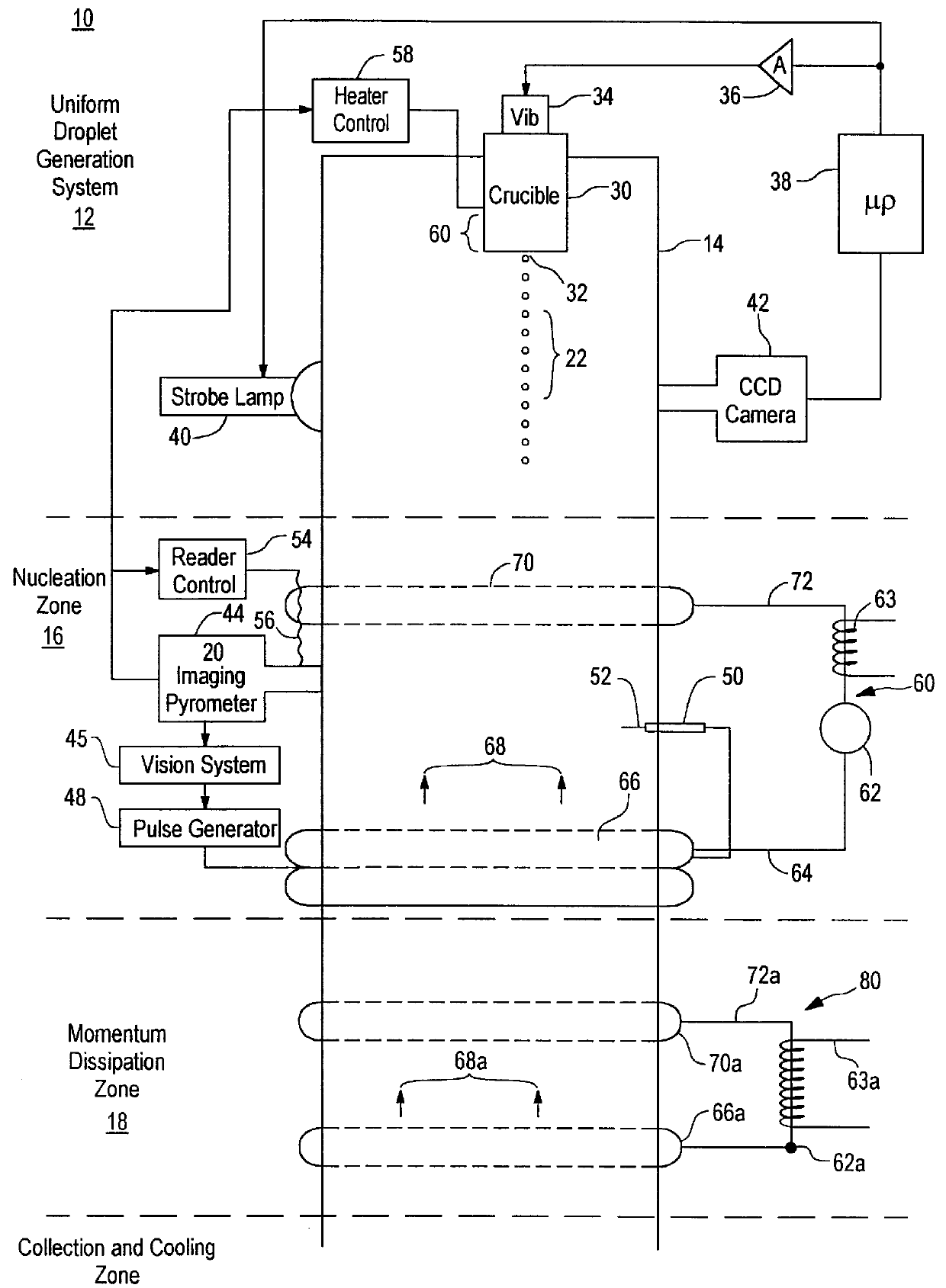

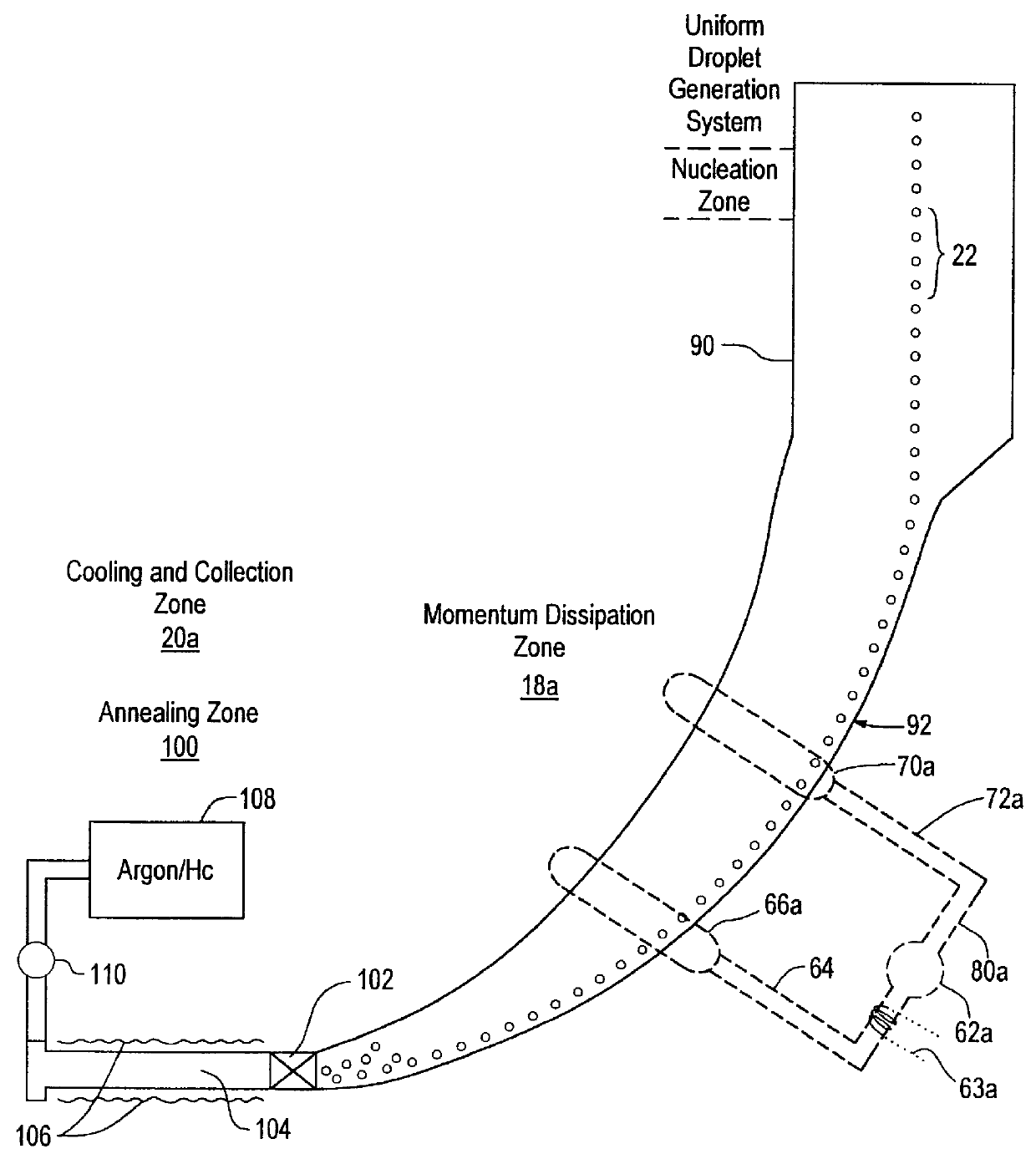

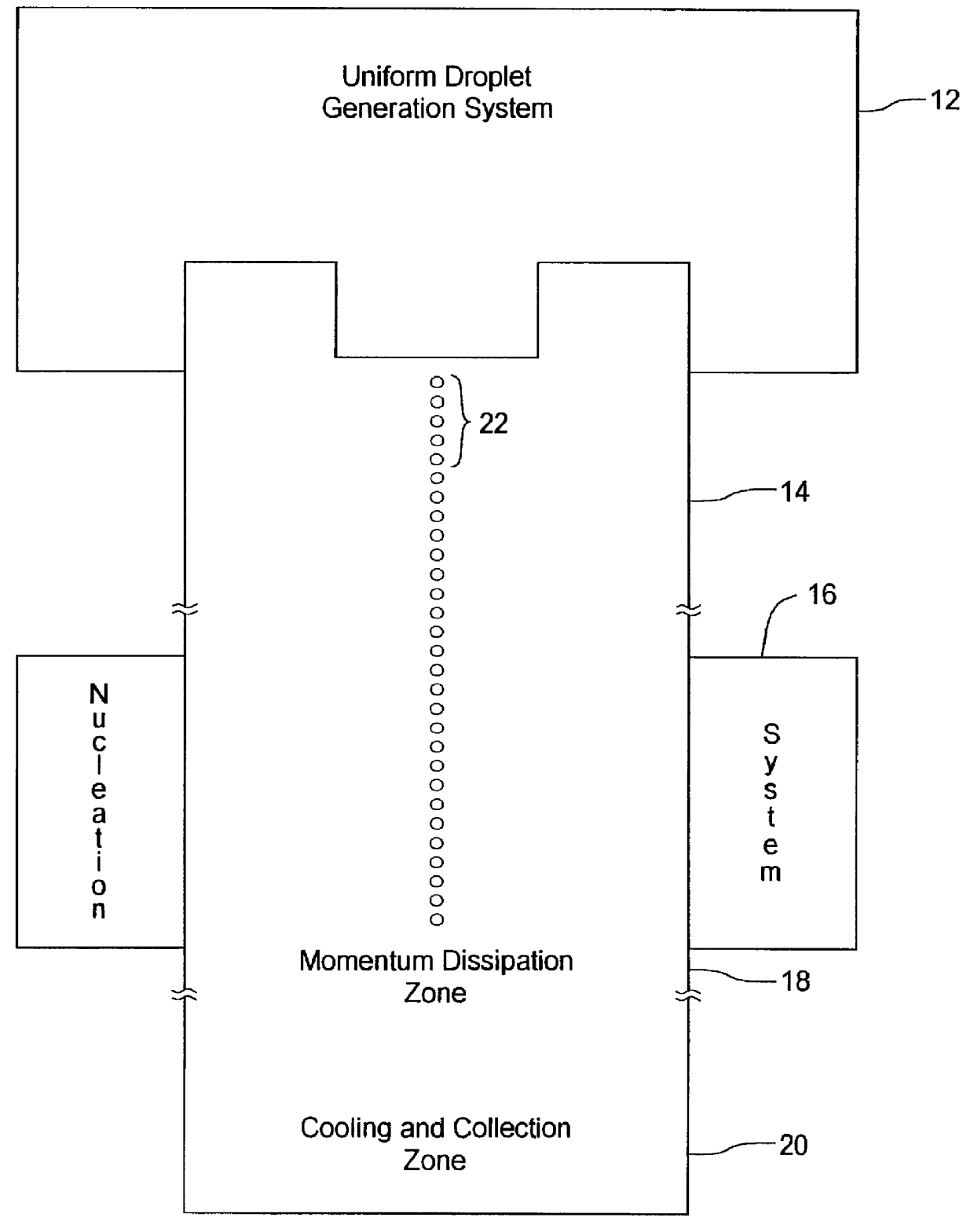

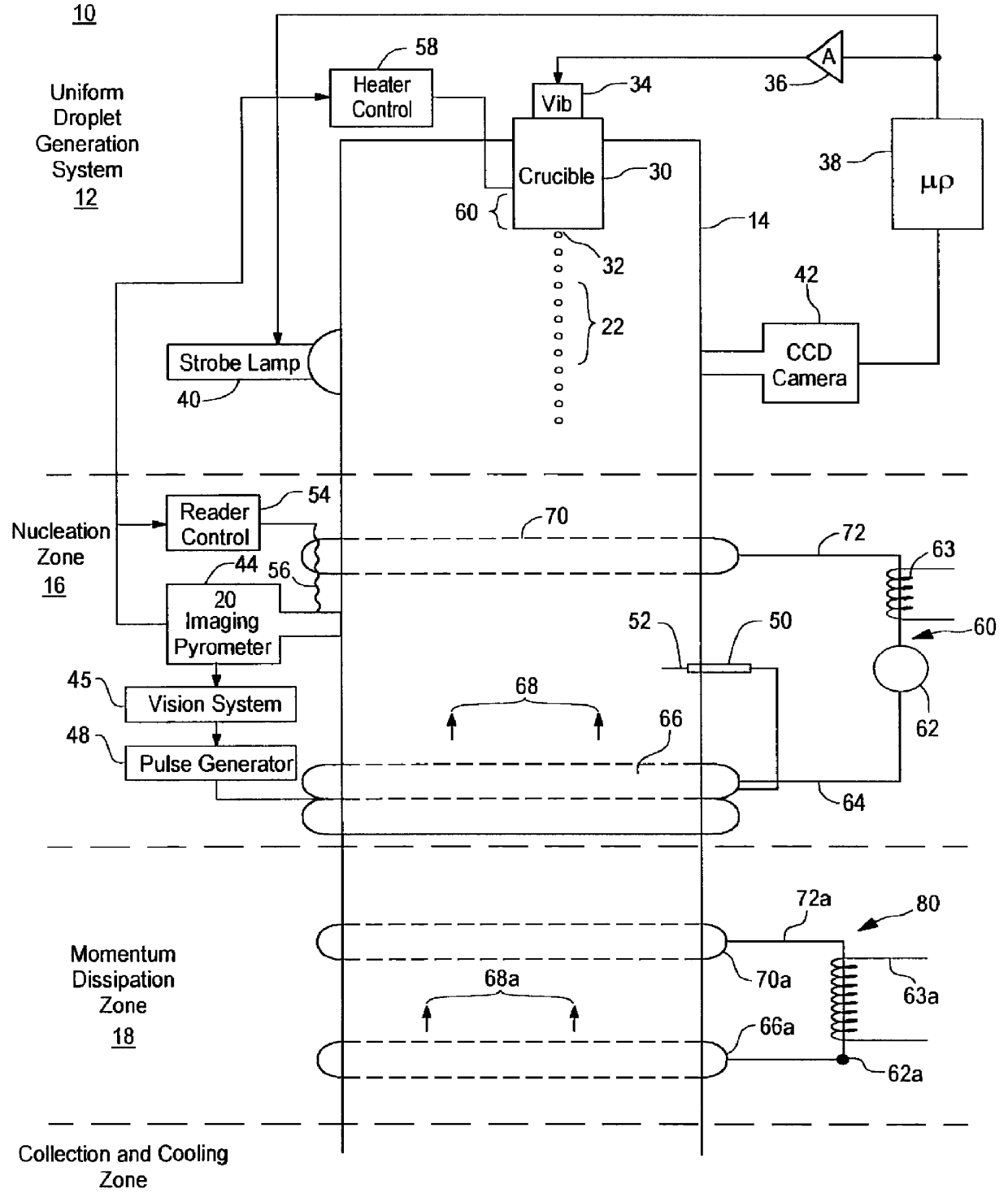

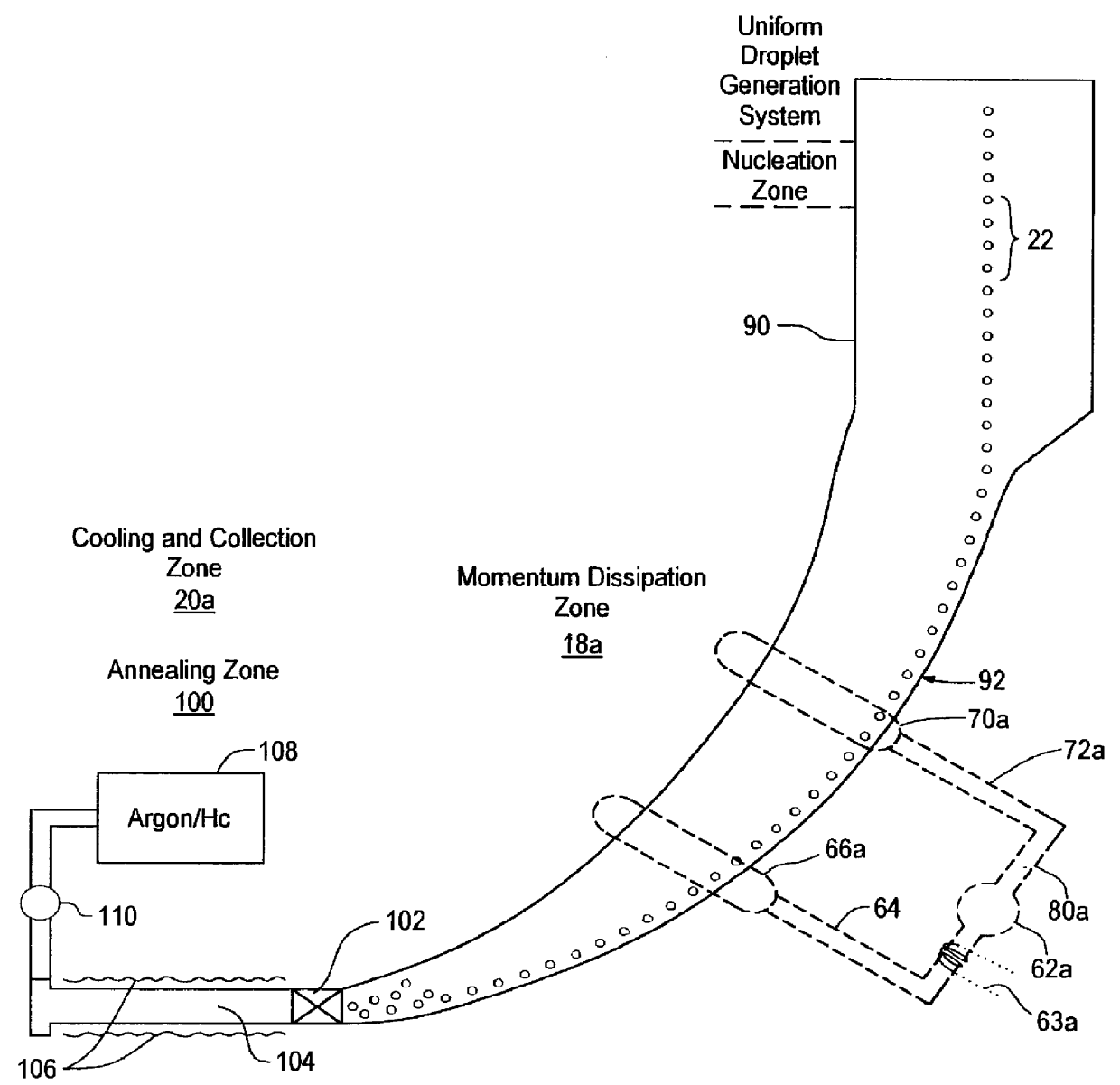

Method and apparatus for fabricating near spherical semiconductor single crystal particulate and the spherical product produced

InactiveUS6120602AExcellent propertySimpler and quicker and less-expensiveAfter-treatment apparatusPolycrystalline material growthParticulatesSingle crystal

An apparatus and a method for producing single crystal semiconductor particulate in near spherical shape and the particulate product so formed is accomplished by producing uniform, monosized, near spherical droplets; identifying the position of an undercooled droplet in a nucleation zone; and seeding the identified droplet in the nucleation zone to initiate single crystal growth in the droplet.

Owner:STARMET

Method and apparatus for fabricating near spherical semiconductor single crystal particulate and the spherical product produced

InactiveUS6106739AMaintain good propertiesSimpler and quicker and less-expensiveFinal product manufactureMetal-working apparatusParticulatesSingle crystal

An apparatus and a method for producing single crystal semiconductor particulate in near spherical shape and the particulate product so formed is accomplished by producing uniform, monosized, near spherical droplets; identifying the position of an undercooled droplet in a nucleation zone; and seeding the identified droplet in the nucleation zone to initiate single crystal growth in the droplet.

Owner:STARMET

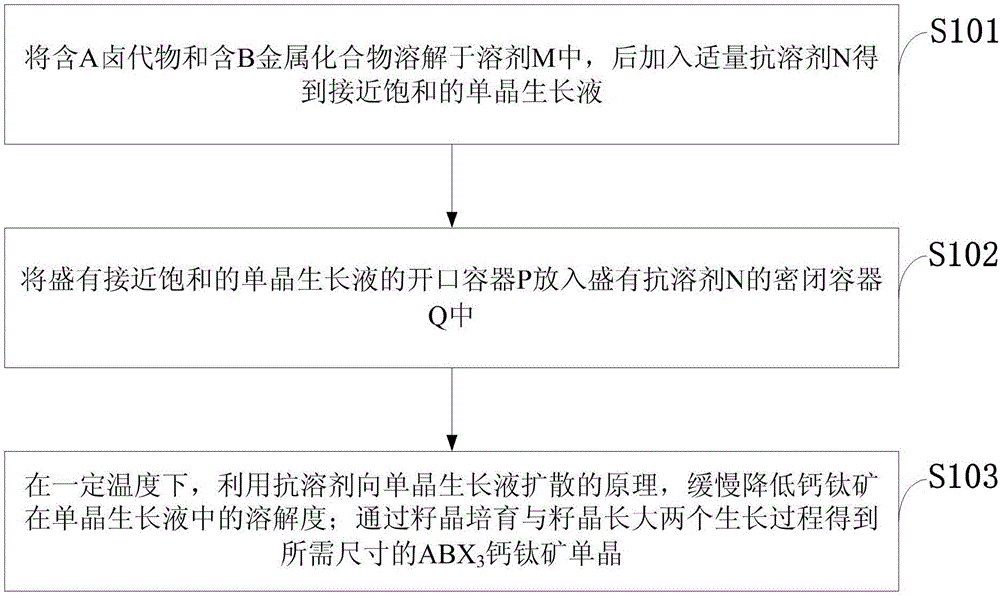

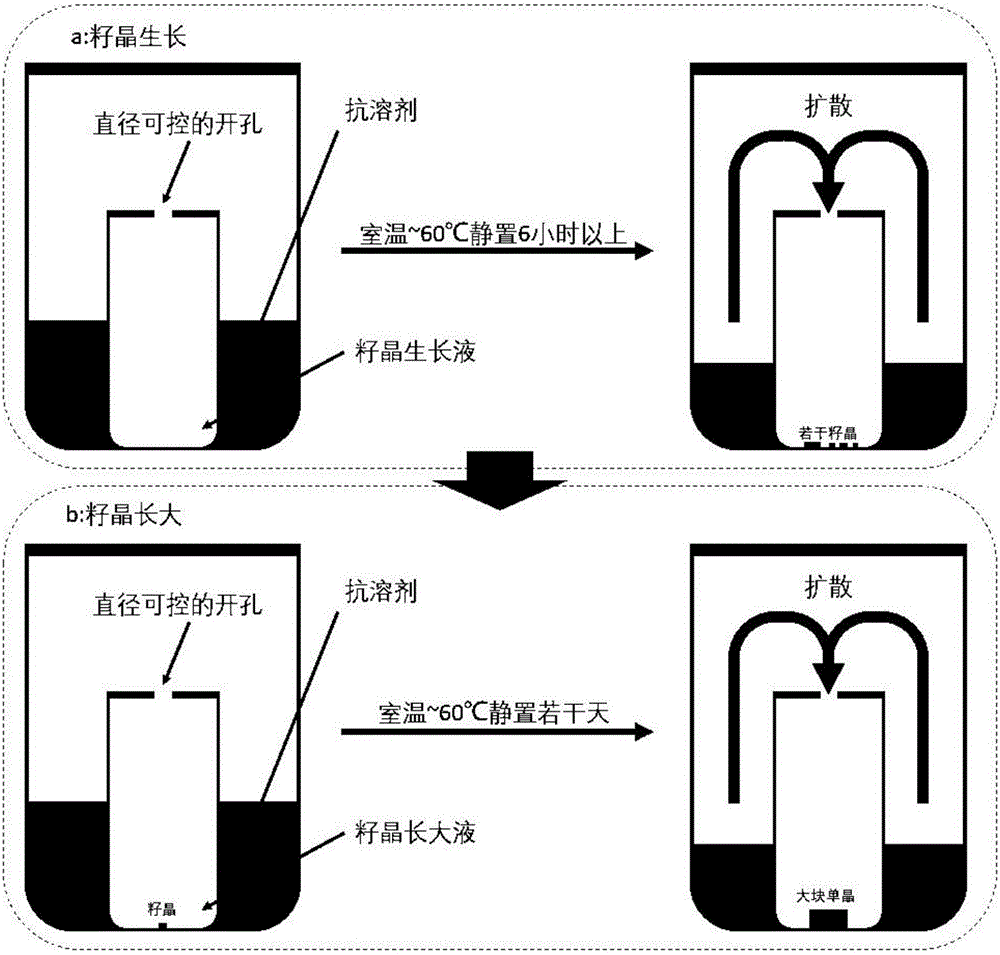

Method for growing ABX3 perovskite single crystal by antisolvent diffusion

InactiveCN106757342AReduce solubilitySmall sizePolycrystalline material growthFrom normal temperature solutionsSolubilitySolvent

The invention discloses a method for growing an ABX3 perovskite single crystal by antisolvent diffusion. The method comprises the following steps: dissolving an A-containing halide and a B-containing metal compound in a solvent M, and adding a right amount of antisolvent N to obtain an approximately saturated single crystal growth solution, wherein the mole ratio of the A-containing halide to the B-containing metal compound is 1:(0.1-2); putting the open container P containing the approximately saturated single crystal growth solution into the closed container Q containing the antisolvent N; and at a certain temperature, carrying out seed crystal culture and seed crystal growth (two growth processes) to obtain the ABX3 perovskite single crystal with required size. According to the method for preparing the high-quality perovskite single crystal, the principle that the antisolvent diffuses to the single crystal growth solution is utilized to slowly lower the solubility of perovskite in the single crystal growth solution, so that the solution precipitates the perovskite single crystal. The method has the advantages of large size and high quality of the obtained single crystal, high utilization ratio of raw materials, simple facility request, simple technique, low environmental hazard and the like.

Owner:KUNMING UNIV OF SCI & TECH

Device and method to producing single crystals by vapour deposition

InactiveUS20080149020A1Down and eliminate formationInhibition of defect generationAfter-treatment apparatusPolycrystalline material growthHalogenHydrogen

A method and a device to grow from the vapor phase, a single crystal of either SiC, a group III-nitride, or alloys thereof, at a growth rate and for a period of time sufficient to produce a crystal of preferably several centimeters length. The diameter of the growing crystal may be controlled. To prevent the formation of undesirable polycrystalline deposits on surfaces in the downstream vicinity of the single crystal growth area, the local supersaturation of at least one component of the material grown is lowered by introducing a separate gas flow comprising at least one halogen element or a combination of said halogen and hydrogen species.

Owner:NORSTEL +1

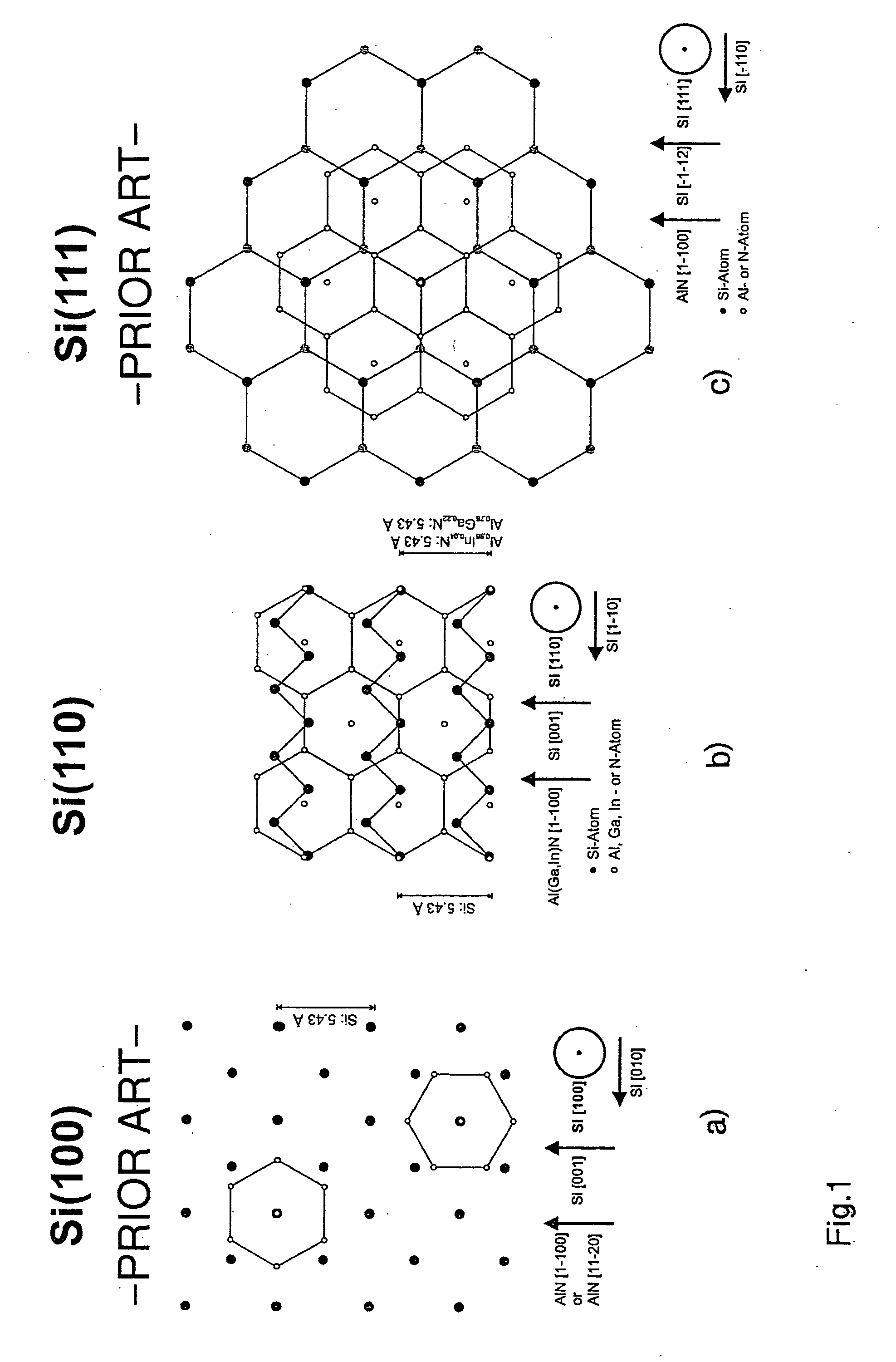

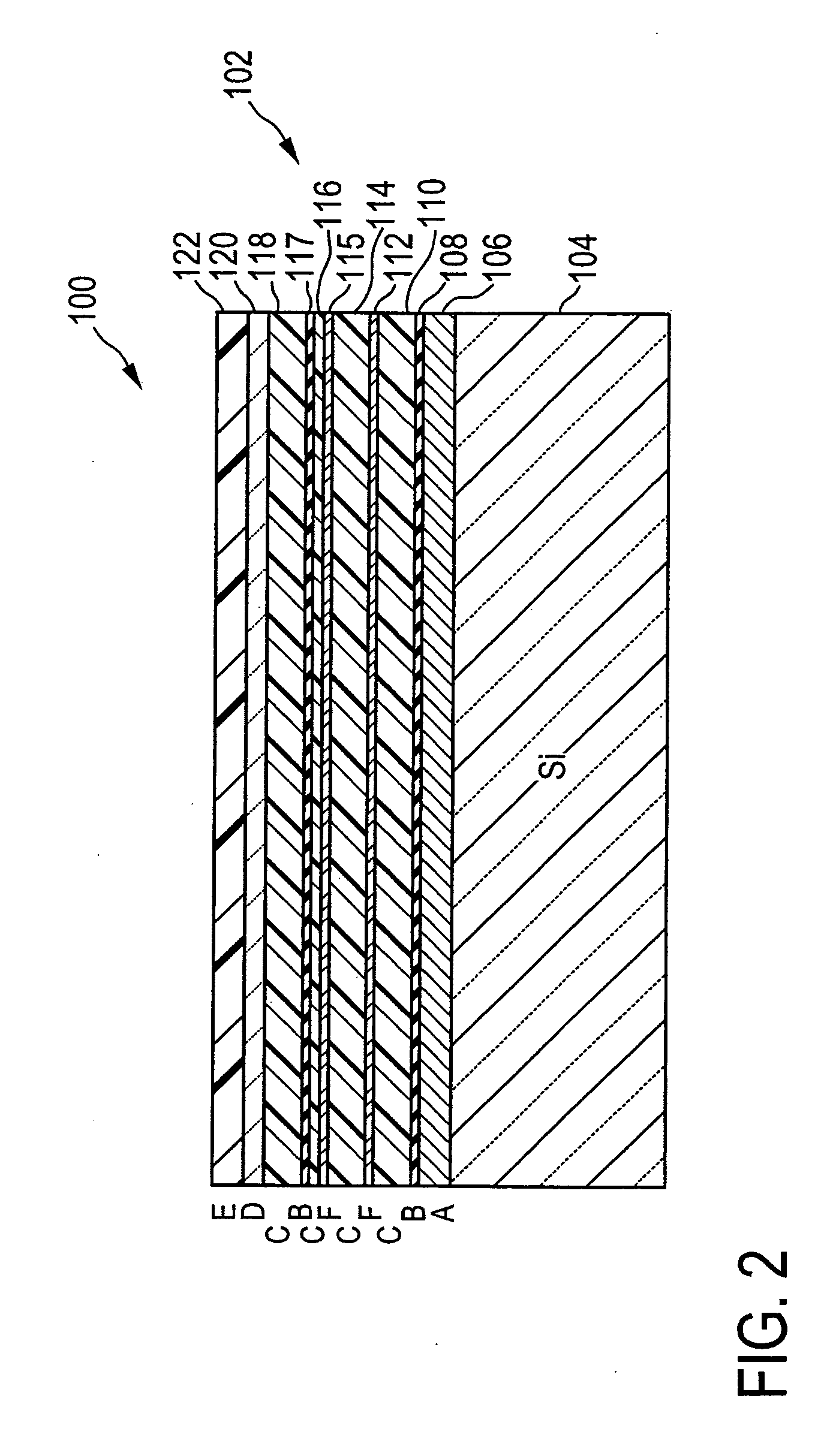

Nitride semiconductor component layer structure on a group iv substrate surface

InactiveUS20100133658A1Good lattice matchingReduce the possibilityPolycrystalline material growthSemiconductor/solid-state device manufacturingCrystal structureSingle crystal

The invention relates to nitride semiconductor component having a Group III nitride layer structure which is deposited on a substrate having a Group IV substrate surface made of a Group IV substrate material with a cubical crystal structure. The Group IV substrate surface has an elementary cell with C2 symmetry, but not with a higher rotational symmetry than C2 symmetry, when any surface reconstruction is ignored. The Group III nitride layer structure has a seeding layer of ternary or quaternary Al1-x-yInxGayN, where 0≦x, y<1 and x+y≦1, immediately adjacent to the Group IV substrate surface. High-quality monocrystalline growth is achieved as a result. The advantage of the invention consists in the high level of crystal quality that can be achieved, in the growth of c-, a- and m-plane GaN and above all in the ease with which the silicon substrate can be wholly or partially removed, since this is easier to do in a wet chemical process than on (111)-oriented substrates.

Owner:AZZURRO SEMICON

Growth device and growth method for preparing high-purity semi-insulating carbonized silicon single crystals efficiently

ActiveCN107723798AReduce nitrogen impurity contentImprove efficiencyPolycrystalline material growthAfter-treatment detailsSingle crystalNitrogen gas

The invention discloses a growth device and a growth method for preparing high-purity semi-insulating carbonized silicon single crystals efficiently. The growth method is implemented by the carbonizedsilicon single crystal growth device with a structure of an inert gas graphite flow guide tube and a graphite current-limiting cover. Inertia gases generate forced convection under the action of thestructure, and a forced convection layer is formed on the outer wall of a graphite crucible. When speed and flow of the gas convection are high, influences of diffusion on concentration distribution can be inhibited. In the method, directional movement of the forced convection layer can prevent nitrogen molecules outside the graphite crucible from dispersing into the graphite crucible, so that theproblem that adsorption nitrogen serves as a pollution source in a heat insulating system is solved. According to the method, an inertia-gas atmosphere isolation room system is not needed, and a long-term nitrogen removal process based on furnace vacuumizing is also not needed. The growth device and the growth method have the advantages of high efficiency and equipment simplicity, and can be widely applied to multiple carbonized silicon single crystal furnace systems in the field.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

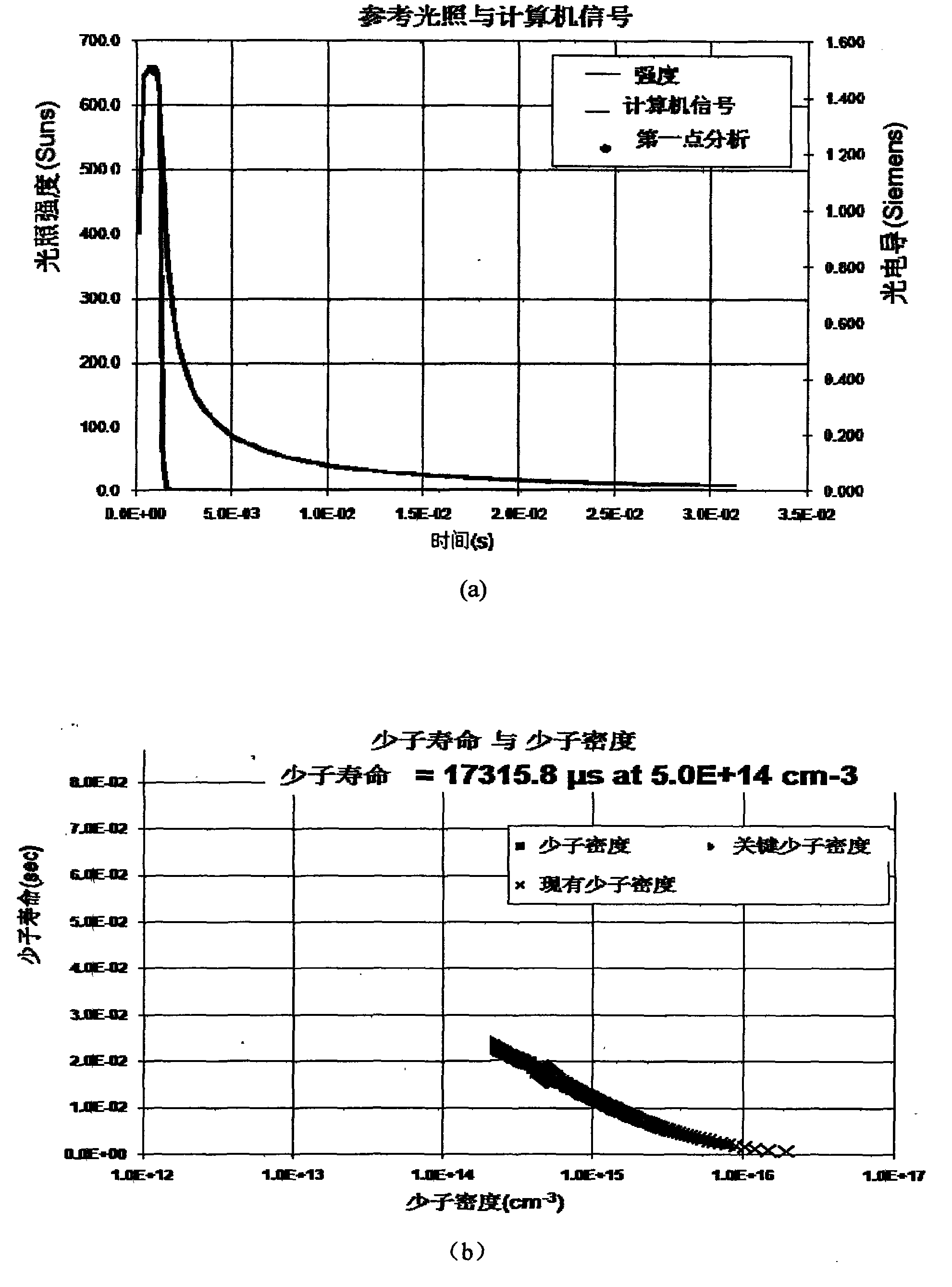

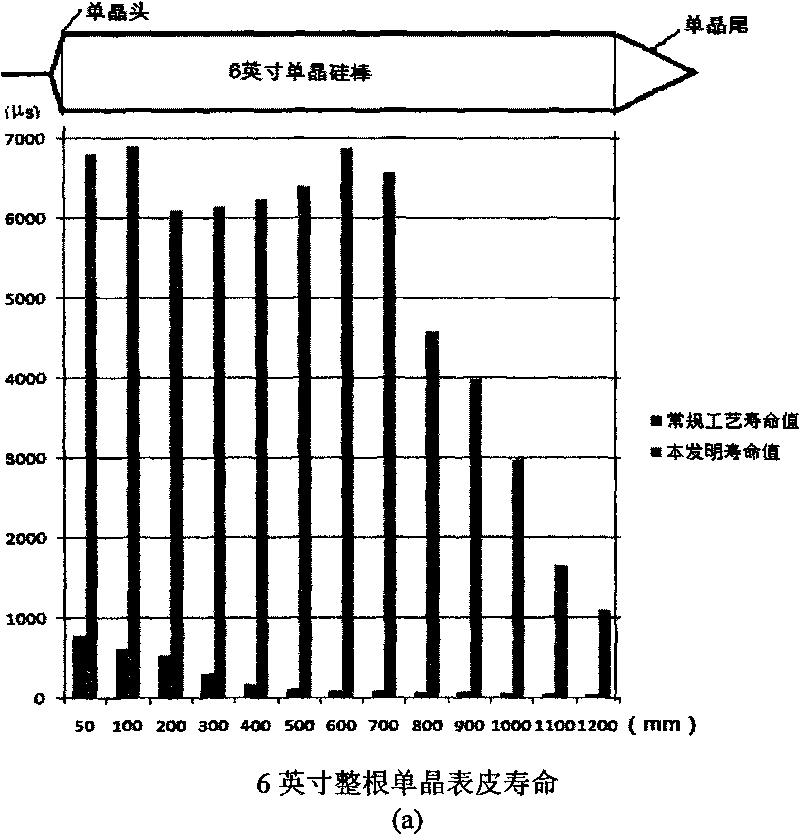

Growth process for N-type solar energy silicon single crystal with minority carrier service life of larger than or equal to 1,000 microseconds

InactiveCN101724899ASolve the problem of low lifespanPractical growing methodPolycrystalline material growthBy pulling from meltCrystal orientationSingle crystal

The invention relates to a growth process for N-type solar energy silicon single crystal with minority carrier service life of larger than or equal to 1,000 microseconds. The appearance is in 6-8 inches, the (100) crystal orientation resistivity range is between 1 omega.cm and 20 omega.cm, the minority carrier service life of the surface and the section is larger than or equal to 1,000 microseconds, the clearance oxygen content [Oi] is smaller than or equal to 17.5ppma, and the substituted carbon content [Cs] is smaller than or equal to 0.5ppma. Phosphorus-doped block-shaped polycrystalline silicon is used as a raw material to prepare the N-type solar energy silicon single crystal. The process comprises the steps of: charging, heating, leading diameter, maintaining equal diameter, collecting, cooling, heating by a program, stably heating and melting the material; after a thermal field in melting silicon is stable, leading the thin diameter, lifting the tail part of a single crystal to the upper edge of a guide cylinder with the cooling time of not larger than three hours. The crystal growth process is practical, has high efficiency and low cost, can prepare the N-type single crystal silicon which is completely larger than or equal to 1,000 microseconds from the head part to the tail part by a CZ method, and creates an industrialized foundation for efficiency improvement of an efficient solar battery.

Owner:任丙彦 +1

Method and apparatus for preparing major diameter single crystal

InactiveCN1847468AMake up for heat lossHigh Inductive Heat InputPolycrystalline material growthBy zone-melting liquidsSingle crystalEngineering

Owner:SCHOTT AG

Preparation technology for monocrystal turbine guide vane

ActiveCN105268916AAvoid miscellaneous crystals and surface porosityImprove yieldPolycrystalline material growthFoundry mouldsWaxDirectional solidification

The invention aims at providing a preparation technology for a monocrystal turbine guide vane. The preparation technology is characterized by employing a longitudinal monocrystal growing technology for preparing the monocrystal turbine guide vane. The preparation steps comprise firstly preparing a wax mold, combining the wax mold and a spiral crystal selector, making a shell by using a coating, removing wax, performing directional solidification, shelling and cleaning, removing the core, and removing a seeding thin sheet and a pouring system, so as to finally obtain a complete monocrystal turbine guide vane. The wax mold is composed of a turbine vane wax mold, a seeding-thin-sheet wax mold and a monocrystal-selector transition-segment wax mold; the turbine vane wax mold comprises a vane body, an upper margin plate, a lower margin plate and a feeding segment, the feeding segment is at the upper end faces of the margin plates, the monocrystal-selector transition-segment wax mold is connected with the lower end faces of the upper margin plate and the lower margin plate, and the seeding-thin-sheet wax mold is arranged in the space formed by the vane body, the upper margin plate, the lower margin plate and the monocrystal-selector transition-segment wax mold. The method is simple, low in cost and high in efficiency, and is suitable for large-scale production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Reduction of carbon inclusions in sublimation grown SiC single crystals

InactiveUS20080115719A1Avoid introducingPolycrystalline material growthFrom chemically reactive gasesSource materialCrucible

In a method of SiC single crystal growth, a SiC single crystal seed and polycrystalline SiC source material are provided in spaced relation inside of a graphite growth crucible along with at least one compound capable of forming SiO gas in the growth crucible. The growth crucible is heated whereupon the gaseous SiO forms and reacts with carbon in the growth crucible thereby avoiding the introduction of carbon into the SiC single crystal before and during the growth thereof and the SiC source material vaporizes and is transported via a temperature gradient in the growth crucible to the seed crystal where it precipitates and forms a SiC single crystal.

Owner:II VI

Method for suppressing stray crystal forming and growing at seed crystal starting end, and casting case construction thereof

InactiveCN1570224AIncrease success rateGuaranteed OrientationLiquid-phase epitaxial-layer growthNeck structureCrystal orientation

The invention relates to a technology for preparing a single crystal high-temperature alloy and especially provides a method for inhibiting stray crystal formation and growth in seed crystal initiating terminal and the shuttering structure. The preparing method based on seed crystal method comprises: preplacing the seed crystal in the shuttering, arranging a necking structure in the initiating terminal, forming stray crystal in the initiating terminal of inhibiting the seed crystal growth, and growing into the single crystal from the alloy melt on the unmelted interface of the seed crystal in the form of the epitaxial growth. The shuttering structure in the invention is the shuttering structure for preplacing the seed crystal, a necking structure is arranged on the bottom of the shuttering over the initiating terminal of seed crystal growth. The invention combines the seed crystal method initiating terminal design with the necking crystal-selecting device for inhibiting and removing the stray crystal in the process of the single crystal growth, controlling the crystal orientation, and improving the single crystal yield.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com