Method and apparatus for preparing major diameter single crystal

A single crystal and heating device technology, applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as insufficient, and achieve the effects of low preparation cost and reduced material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

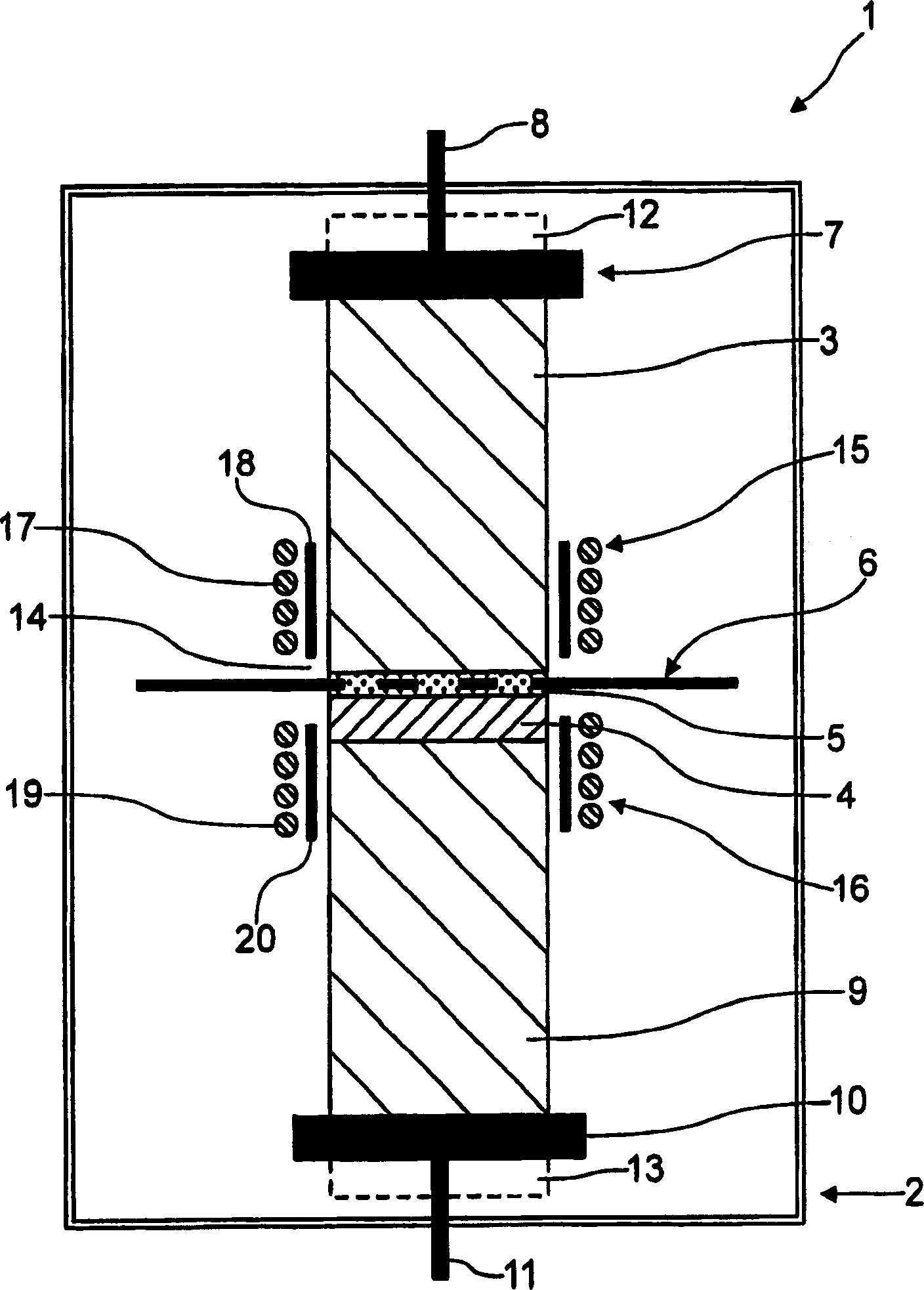

[0034] figure 1 Schematic representation of the apparatus used to grow high melting point single crystals with a diameter > 50 mm. Usually all kinds of crystals can be grown in this device and all common materials for crystal growth can be used. In addition, single crystals of any size can also be prepared with this device. The currently used preforms have a diameter of 10 mm to 100 mm, and the numerical values given here are only exemplary values, not upper or lower limit values of the method.

[0035] With the help of figure 1 Described for growing sapphire (Al 2 o 3 ) embodiment of the device.

[0036] First, the culture rod 3 with a diameter of 100mm used in the embodiment is installed inside the processing container 2 with a clamp 7, wherein the clamp 7 passes through at a speed of 0-100 minutes -1 The rotation drive / translation drive 12 can rotate around the rotation axis 8 and perform vertical processing at 0-40mm / h. Culture rod 3 is made of high-purity Al si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com