Belt casting machine for preparing lead belts for battery grids

A battery and belt casting machine technology, applied in the field of heavy metal casting and rolling, can solve the problems of high fluidity requirements of lead liquid, lead oxide inclusions in lead belts, and easy formation of lead oxides, etc., and achieve low flow performance requirements, low lead smoke pollution, The effect of avoiding the generation of lead oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

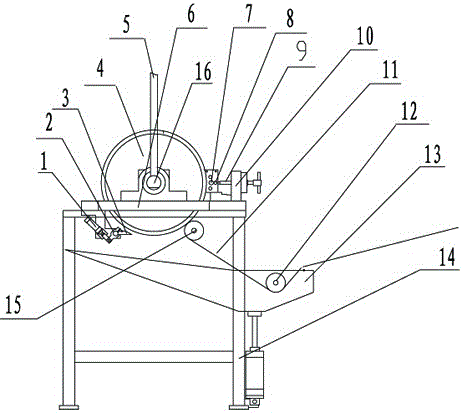

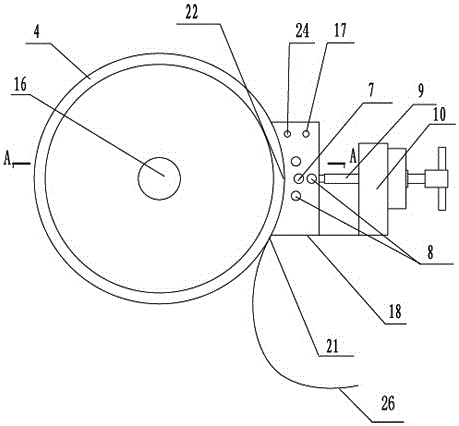

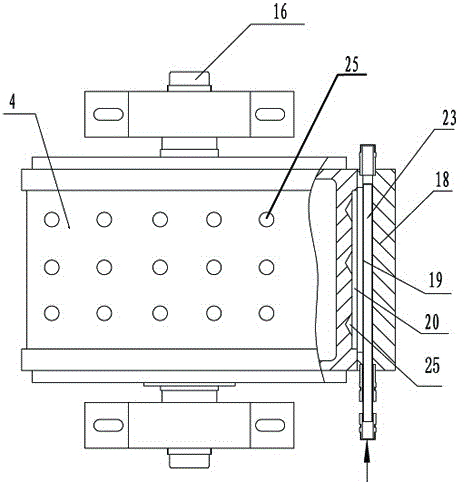

[0018] Such as figure 1 , figure 2 and image 3As shown, the present invention includes a frame and a casting system installed on the frame 14, a lead liquid supply system, a lead belt export device, a lead belt guide device, a lead belt cooling device and a control system. The casting system is composed of a rotary mold 4, a fixed mold 18, a fixed mold loading device and a temperature-controlled circulating cooling system 5. The rotary mold 4 is a cylinder with two end covers on the outer surface of the inner cavity, which is rotatably connected to the shaft 16 fixed on the frame 14; one end of the end cover has a cooling medium inlet, and the other end has a cooling medium At the outlet, there is a casting groove 20 at the position corresponding to the fixed mold 18 on the outer circle. When it is closed with the fixed mold 18, the castin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com