A method for continuous melting and casting of high-quality zirconium-containing magnesium alloy

A high-quality, magnesium alloy technology, applied in the field of continuous smelting and casting of high-quality zirconium-containing magnesium alloys, and the preparation of cast magnesium alloys, can solve the problems of failure to meet the quality requirements of zirconium-containing magnesium alloy castings, the quality of the alloy melt, and the quality of the castings. It is difficult to improve the efficiency and other problems, and achieve the effect of strong product quality control, less inclusions, and avoiding oxidation and air absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

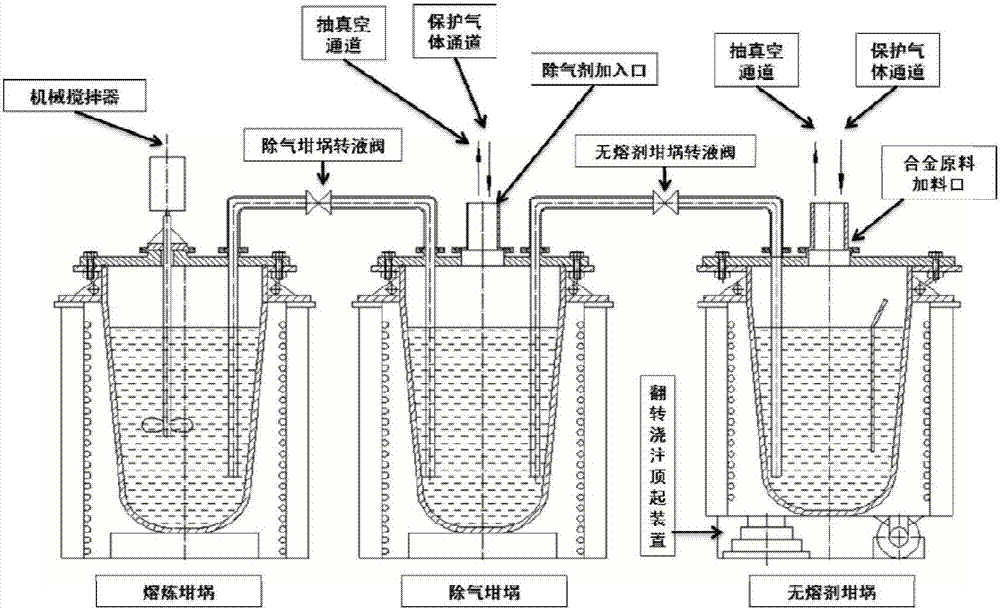

Image

Examples

Embodiment 1

[0022] Embodiment 1: (ZE41A)

[0023] A high-quality zirconium-containing magnesium alloy continuous melting casting method, comprising the following steps:

[0024] (1) Put 89kg of pure magnesium ingots with a magnesium content greater than 99.5% in a low-carbon steel smelting crucible, and evenly sprinkle RJ-2 flux into the bottom of the magnesium ingots and in each stacking layer. The amount of RJ-2 flux accounts for The mass fraction of magnesium ingot is 1%, and then the temperature of the melting furnace is set to 830°C to melt the magnesium ingot rapidly, and the melt temperature is adjusted to 750°C, and then the formula is 46wt% MgCl 2 +40wt%KCl+14wt%CaF 2 The self-made high-density refining agent, combined with a low-carbon steel mechanical stirrer with a rotation speed of 260 rpm, refined the melt for 10 minutes, and then adjusted the melt temperature to 706°C.

[0025] (2) When the temperature of the melt in the melting crucible reaches 706°C, use a vacuum suctio...

Embodiment 2

[0028] Embodiment 2: (ZE63A)

[0029] A high-quality zirconium-containing magnesium alloy continuous melting casting method, comprising the following steps:

[0030] (1) Put 162kg of pure magnesium ingots with a magnesium content greater than 99.5% in a low-carbon steel smelting crucible, and evenly sprinkle RJ-2 flux into the bottom of the magnesium ingot and in each stacking layer. The amount of RJ-2 flux accounts for The mass fraction of magnesium ingot is 1.5%, and then the temperature of the melting furnace is set to 850°C to melt the magnesium ingot rapidly, and the melt temperature is adjusted to 760°C, and then the formula is 44wt% MgCl 2 +38wt%KCl+18wt%CaF 2 The self-made high-density refining agent, combined with a low-carbon steel mechanical stirrer with a rotation speed of 400 rpm, refined the melt for 15 minutes, and then adjusted the melt temperature to 710°C.

[0031] (2) When the melt temperature in the smelting crucible reaches 710°C, use a vacuum suction meth...

Embodiment 3

[0034] Embodiment 3: (ZK61A)

[0035] A high-quality zirconium-containing magnesium alloy continuous melting casting method, comprising the following steps:

[0036] (1) Put 160kg of pure magnesium ingots with a magnesium content greater than 99.5% in a low-carbon steel smelting crucible, and evenly sprinkle RJ-2 flux into the bottom of the magnesium ingot and in each stacking layer. The amount of RJ-2 flux accounts for The mass fraction of magnesium ingot is 1.3%, and then the temperature of the melting furnace is set to 840°C to melt the magnesium ingot rapidly, and the melt temperature is adjusted to 755°C, and then the formula is 45wt% MgCl 2 +39wt%KCl+16wt%CaF 2 The self-made high-density refining agent, combined with a low-carbon steel mechanical stirrer with a rotation speed of 330 rpm, refined the melt for 12 minutes, and then adjusted the melt temperature to 700°C.

[0037] (2) When the temperature of the melt in the melting crucible reaches 700°C, use a vacuum suct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com