Multi-phase combined lightweight aggregate concrete and preparation method thereof

A technology for lightweight aggregate concrete and raw materials, which is applied in ceramic products, other household appliances, sustainable waste treatment, etc. High density and other problems, to achieve the effect of light weight, good thermal insulation performance and good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment one, this heterogeneous composite lightweight aggregate concrete, described its raw material ratio by weight is as follows:

[0051] 1 part of cement;

[0052] 0.43 parts of fly ash;

[0053] Pumice sand 2.028 parts;

[0054] Corn straw fiber 0.038 parts;

[0055] 0.007 parts of polystyrene particles;

[0056] 0.280 parts of rubber particles;

[0057] Admixture 0.015 parts;

[0058] Foaming agent 0.006 part;

[0059] 0.53 parts of water.

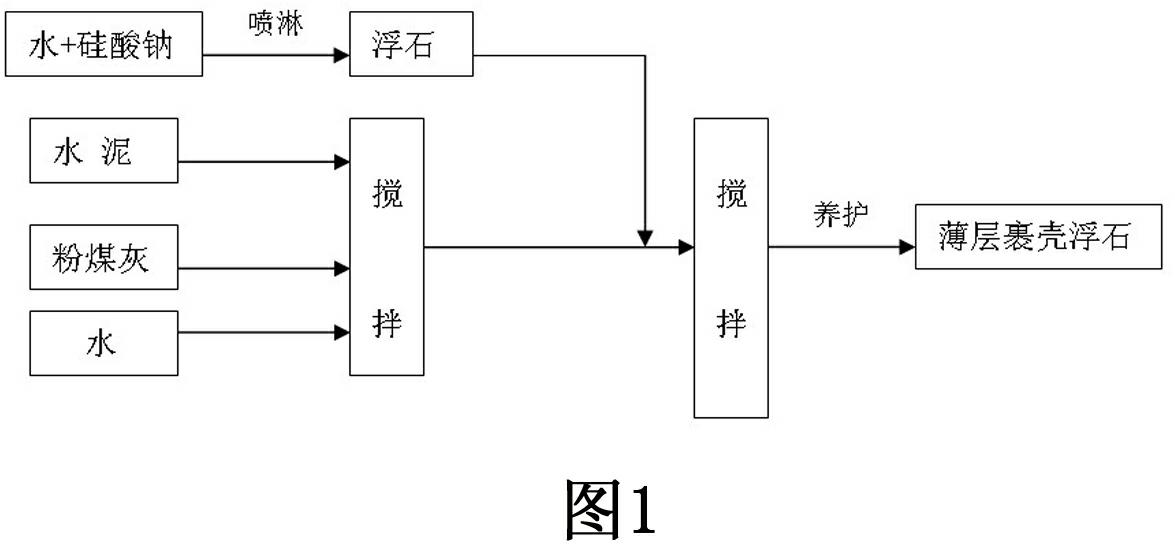

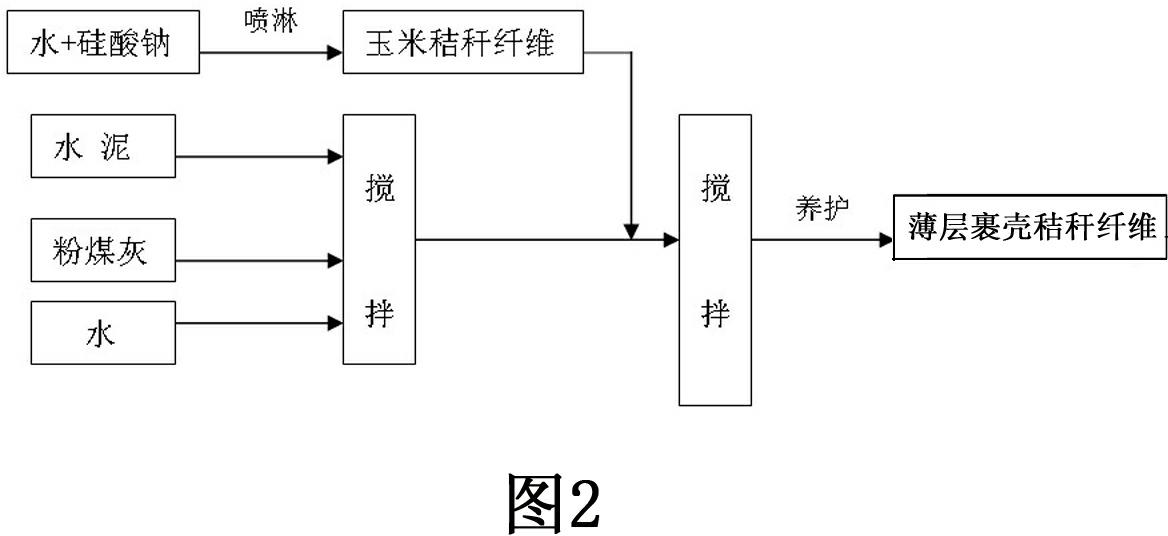

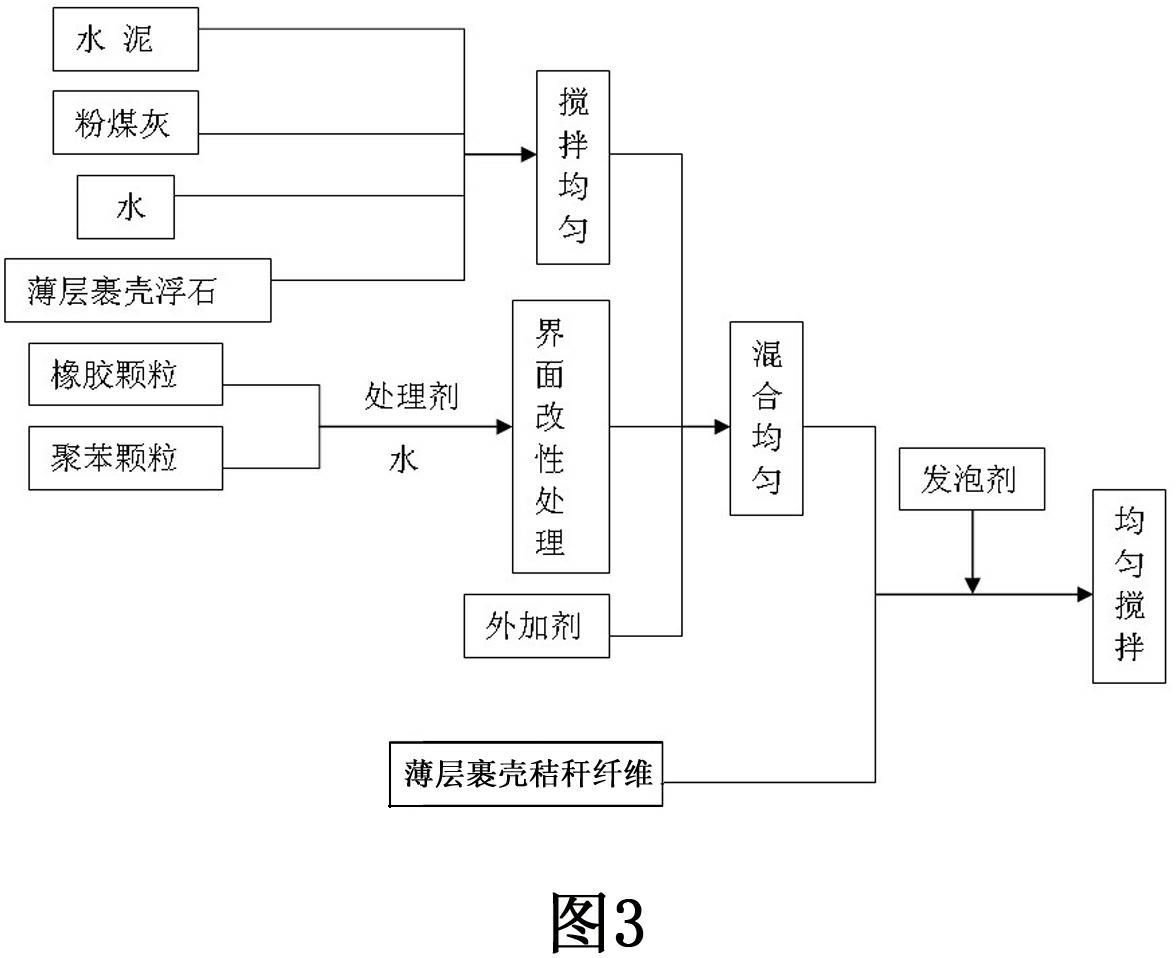

[0060] The pumice sand and corn stalk fibers are processed into thin-layer shell-coated pumice sand and thin-layer shell-coated straw fibers respectively, and the polystyrene particles and rubber particles are polystyrene particles and rubber particles that have been treated with an interface treatment agent. The treatment agent is prepared by diluting silane coupling agent with sodium silicate aqueous solution.

Embodiment 2

[0061] Embodiment two, this heterogeneous composite lightweight aggregate concrete, described its raw material proportioning by weight is as follows:

[0062] 1 part of cement;

[0063] 0.42 parts of fly ash;

[0064] Pumice sand 2.219 parts;

[0065] Corn straw fiber 0.043 part;

[0066] 0.006 parts of polystyrene particles;

[0067] 0.23 parts of rubber particles;

[0068] Admixture 0.012 parts;

[0069] Foaming agent 0.007 part;

[0070] 0.55 parts of water.

[0071] The pumice sand and corn stalk fibers are processed into thin-layer shell-coated pumice sand and thin-layer shell-coated straw fibers respectively, and the polystyrene particles and rubber particles are polystyrene particles and rubber particles that have been treated with an interface treatment agent. The treatment agent is prepared by diluting silane coupling agent with sodium silicate aqueous solution.

Embodiment 3

[0072] Embodiment three, this heterogeneous composite light aggregate concrete, described its raw material ratio by weight is as follows:

[0073] 1 part of cement;

[0074] 0.50 parts of fly ash;

[0075] 1.836 parts of pumice sand;

[0076] Corn straw fiber 0.028 parts;

[0077] 0.008 parts of polystyrene particles;

[0078] 0.33 parts of rubber particles;

[0079] Admixture 0.010 parts;

[0080] Foaming agent 0.005 parts;

[0081] 0.55 parts of water.

[0082]The pumice sand and corn stalk fibers are processed into a thin layer of shell-coated pumice sand and a thin layer of shell-coated straw fiber before use. Both the polystyrene particles and the rubber particles are polystyrene particles and rubber particles that have been treated with an interface treatment agent. The treating agent is prepared by diluting titanate coupling agent with sodium silicate aqueous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com