Patents

Literature

57259results about How to "Improve toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

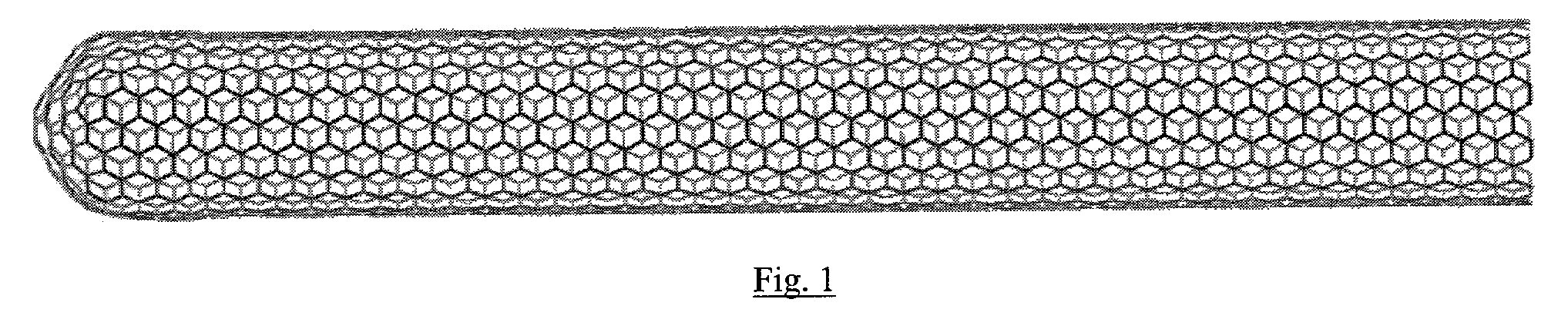

Bioabsorbable Polymer, Bioabsorbable Composite Stents

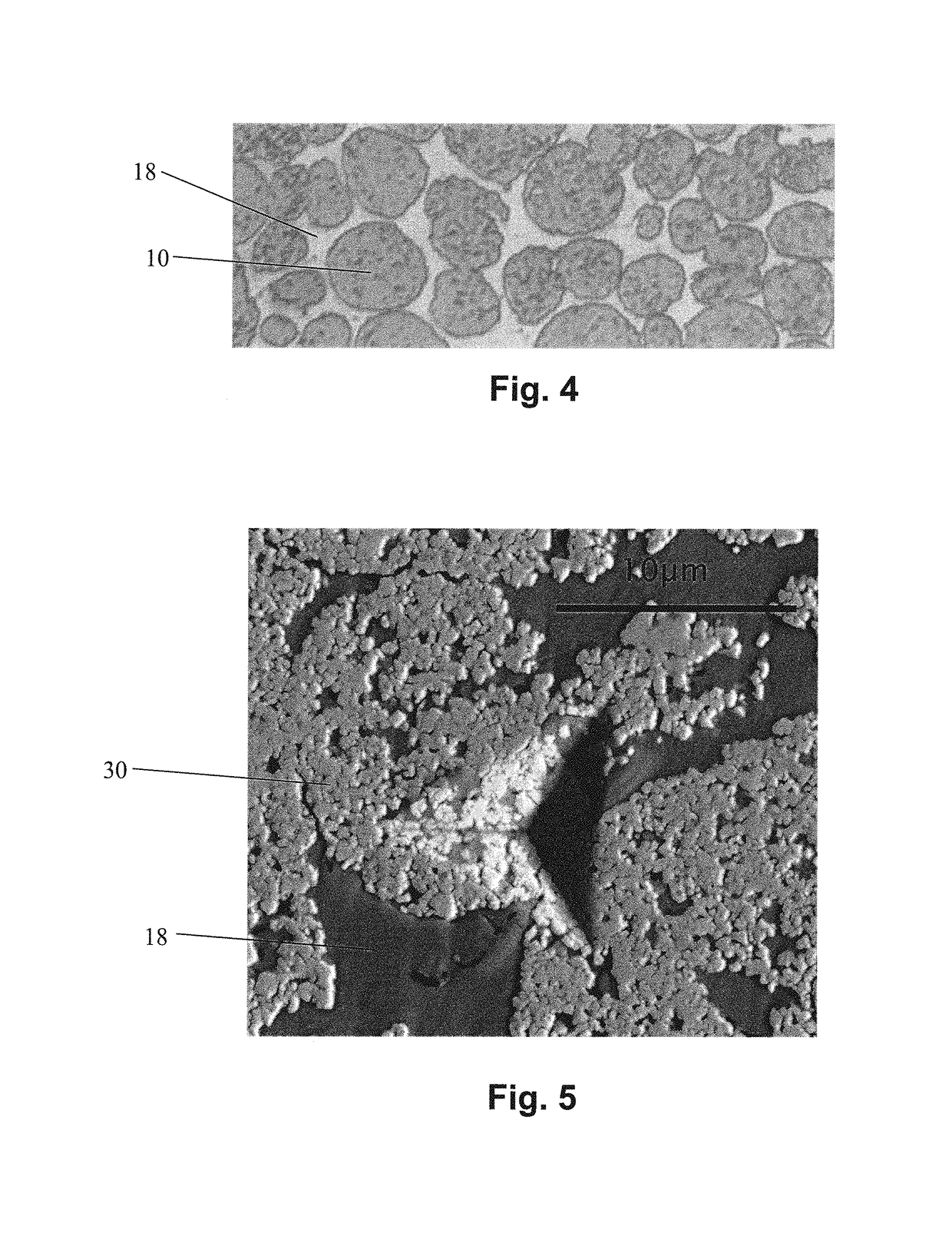

InactiveUS20080249608A1Simple and inexpensive to manufactureVarying of ductilityStentsSurgeryMetallic materialsMedical device

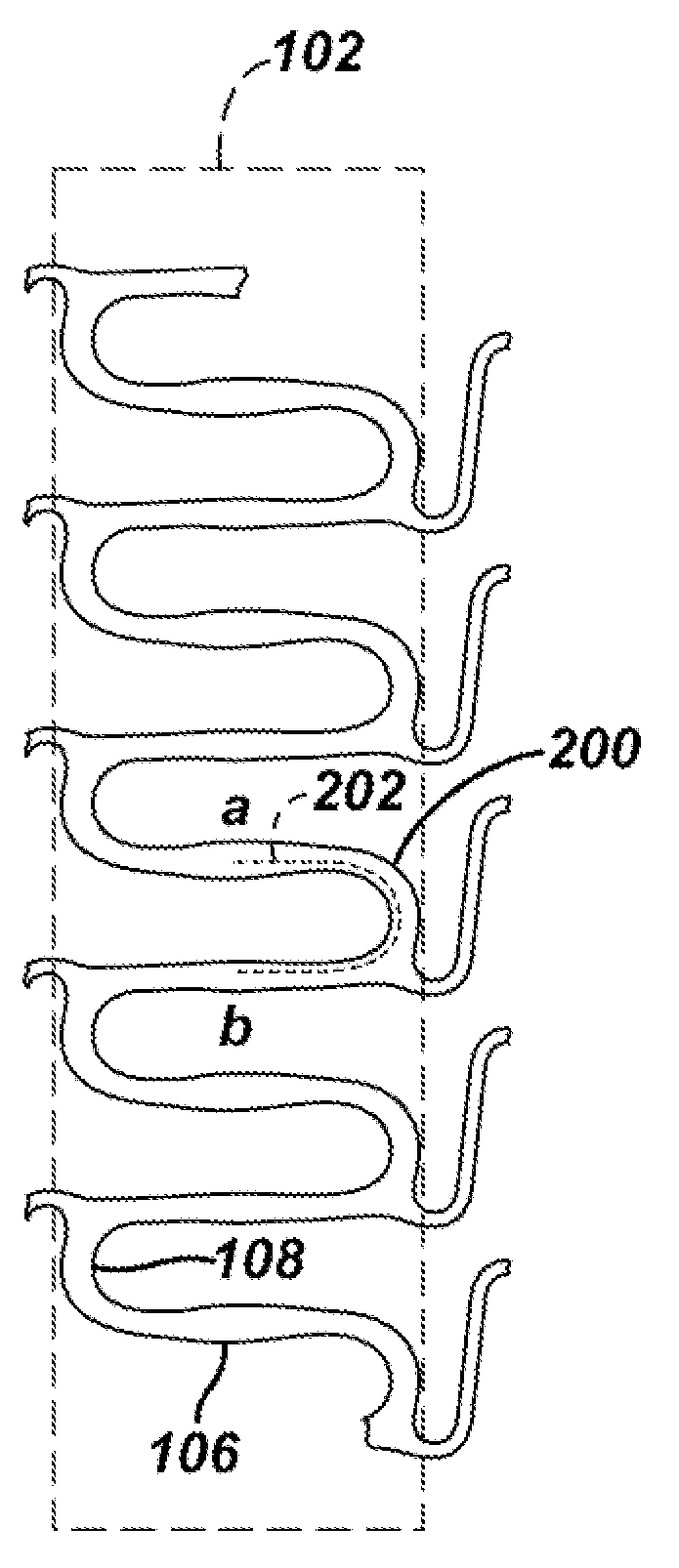

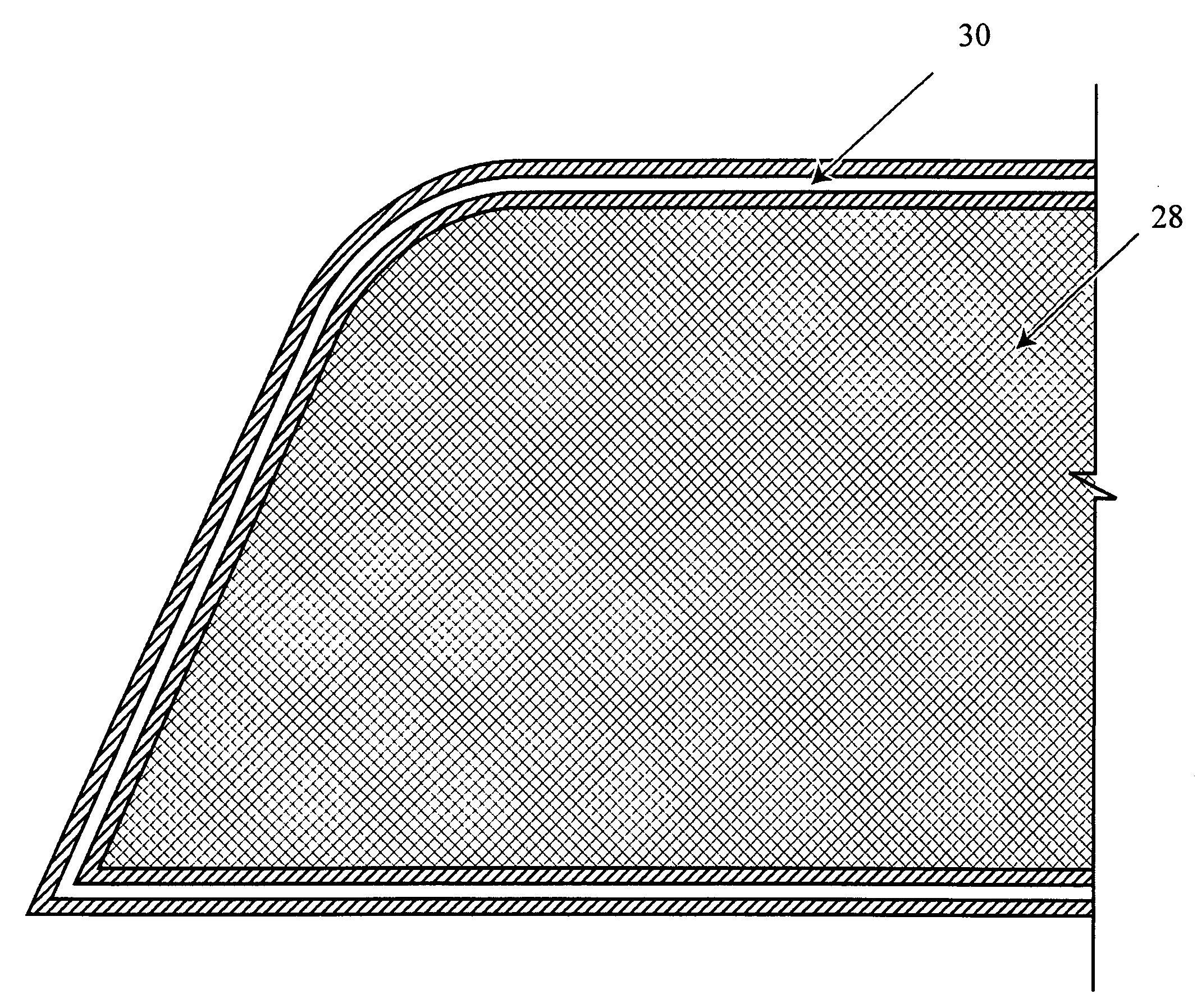

Biocompatible materials may be configured into any number of implantable medical devices including intraluminal stents. The biocompatible material may comprise metallic and non-metallic materials in hybrid structures. In one such structure, a device may be fabricated with one or more elements having an inner metallic core that is biodegradable with an outer shell formed from a polymeric material that is biodegradable. Additionally, therapeutic agents may be incorporated into the microstructure or the bulk material.

Owner:CORDIS CORP

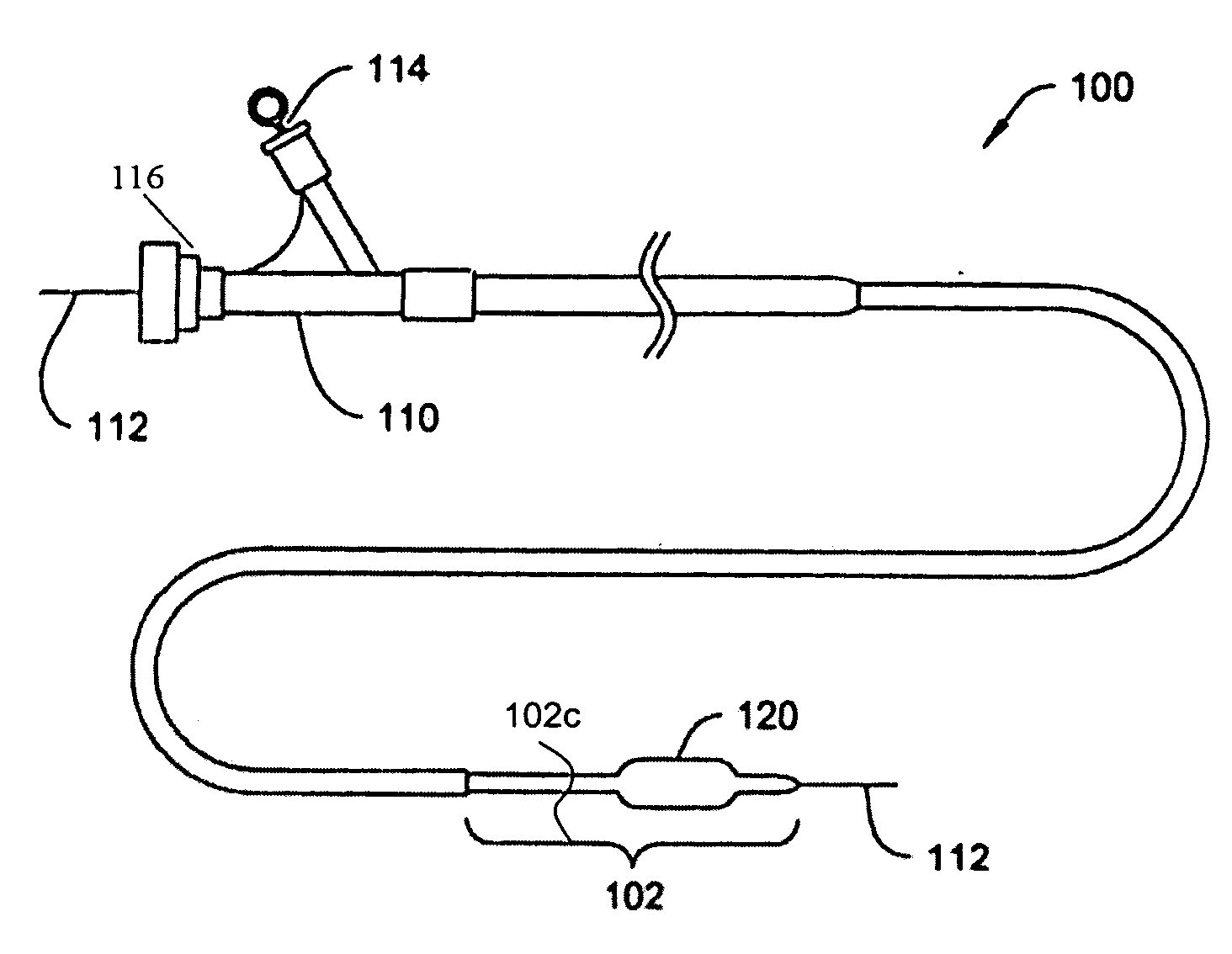

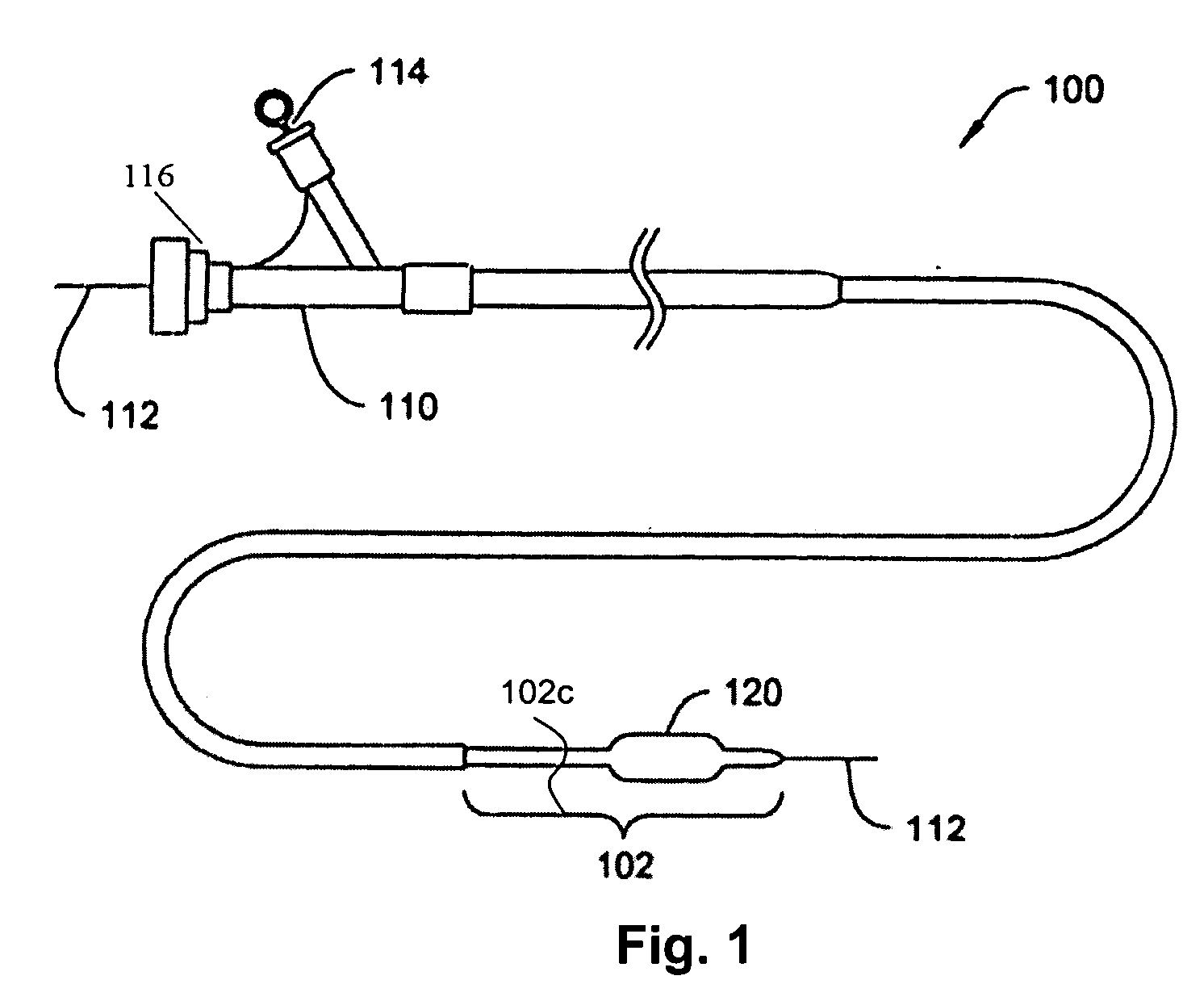

Access device with insert

ActiveUS8226553B2Reduce coefficient of frictionImprove puncture resistanceCannulasCatheterMedical deviceBiomedical engineering

Various devices and methods are provided with respect to inserting multiple surgical instruments through a single surgical access device. A medical device including a flexible tissue retractor and a releasable insert having multiple instrument openings is disclosed. The insert can be in the form of an insert assembly including multiple components. A method of using the insert is also described.

Owner:CILAG GMBH INT

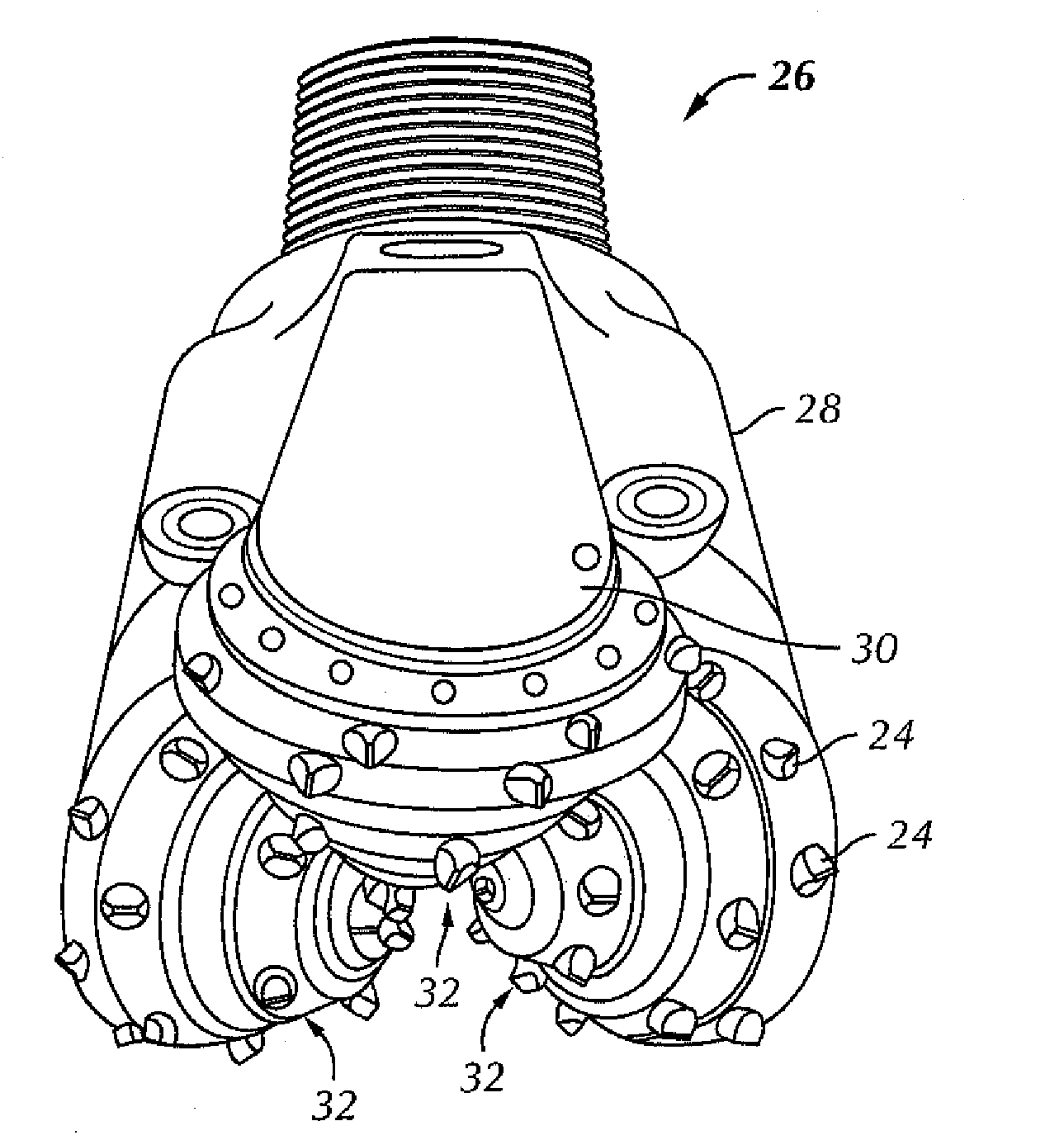

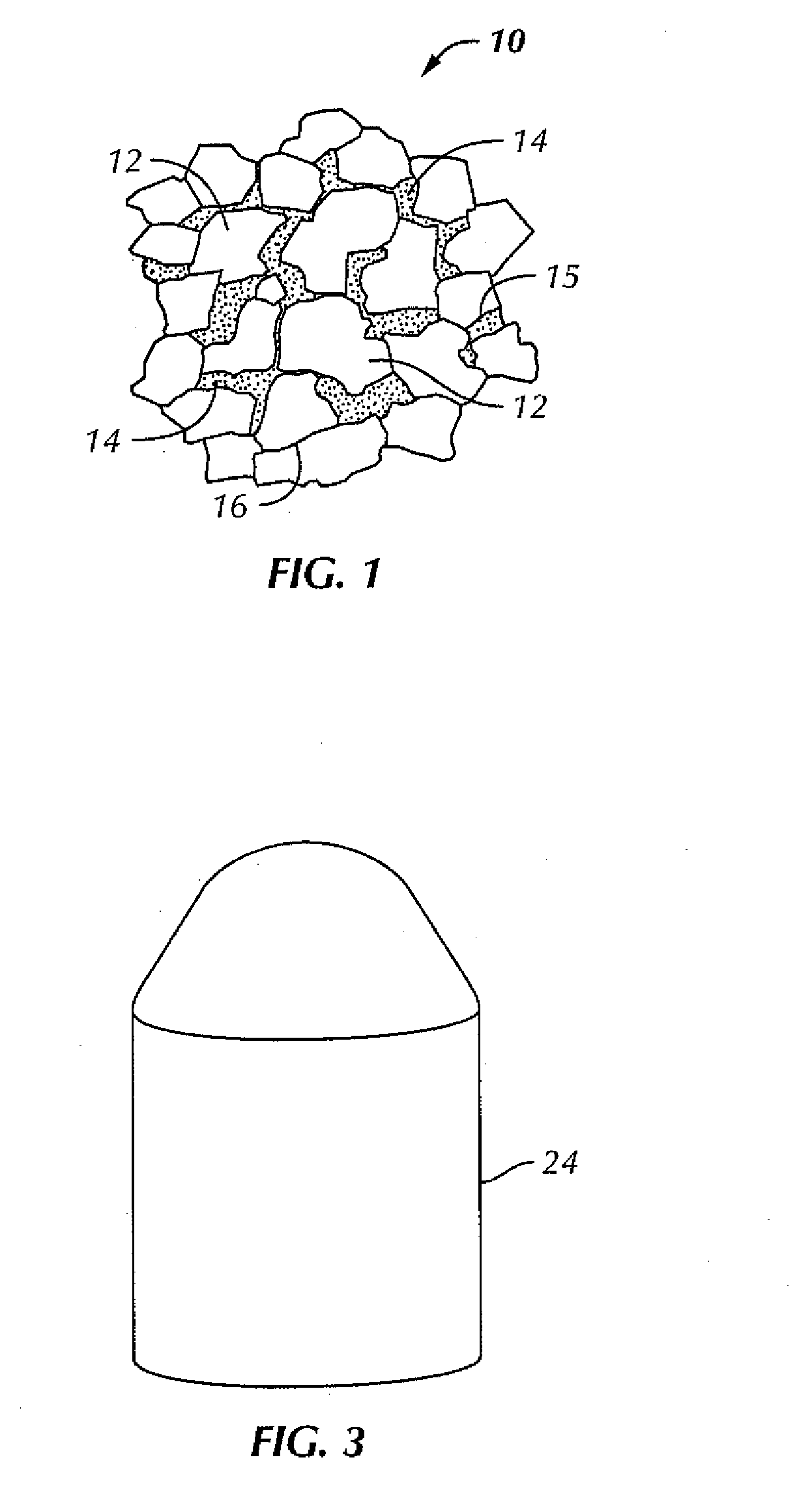

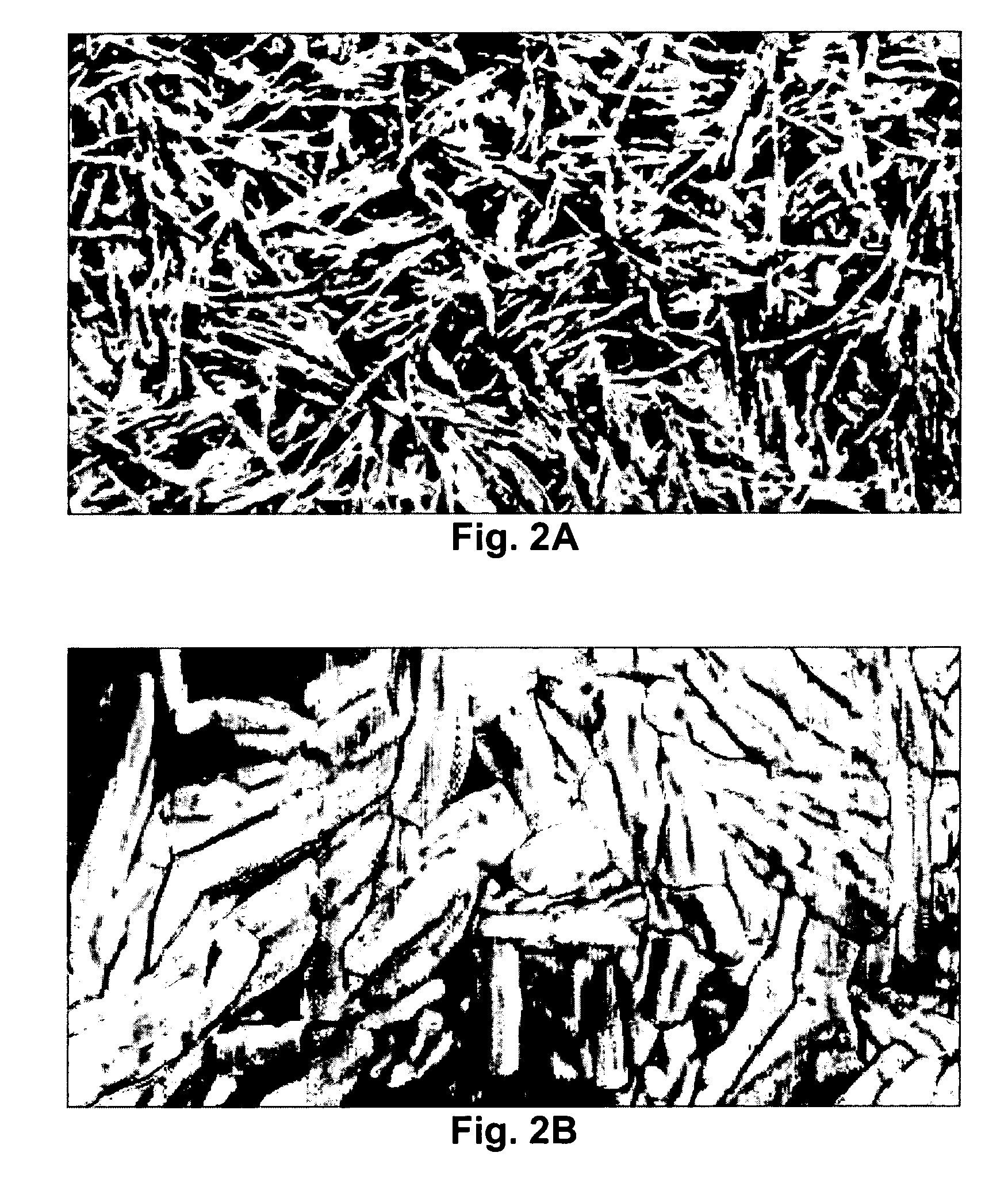

Nano-reinforced wc-co for improved properties

InactiveUS20080179104A1Increase resistanceImprove toughnessMaterial nanotechnologyDrill bitsCarbideNanometre

A drill bit that includes a bit body; and at least one cutting element for engaging the formation disposed on the bit body, the at least one cutting element comprising: a ductile phase; a plurality of carbide particles dispersed in the ductile phase; and a plurality of nanotubes integrated into the cutting element is disclosed.

Owner:SMITH INT INC

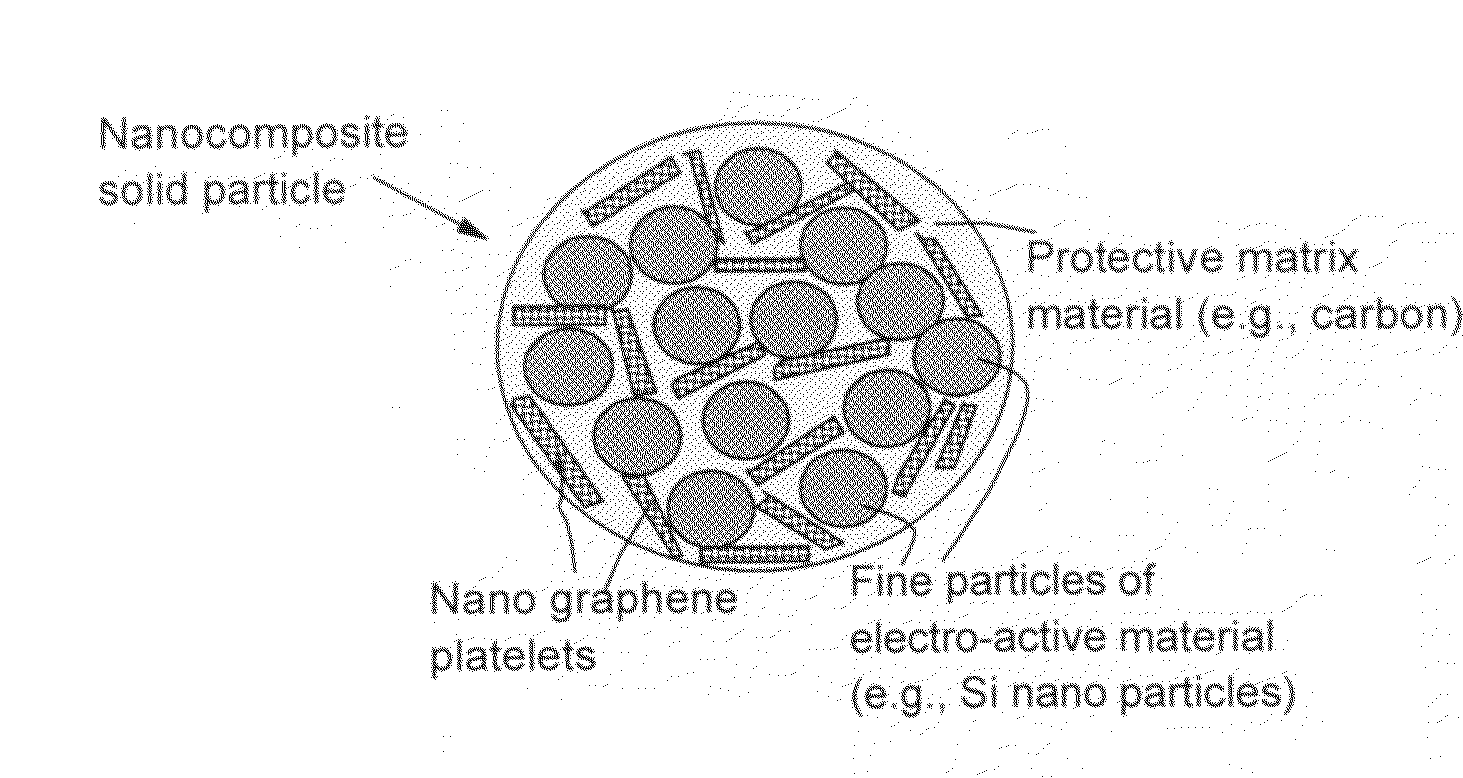

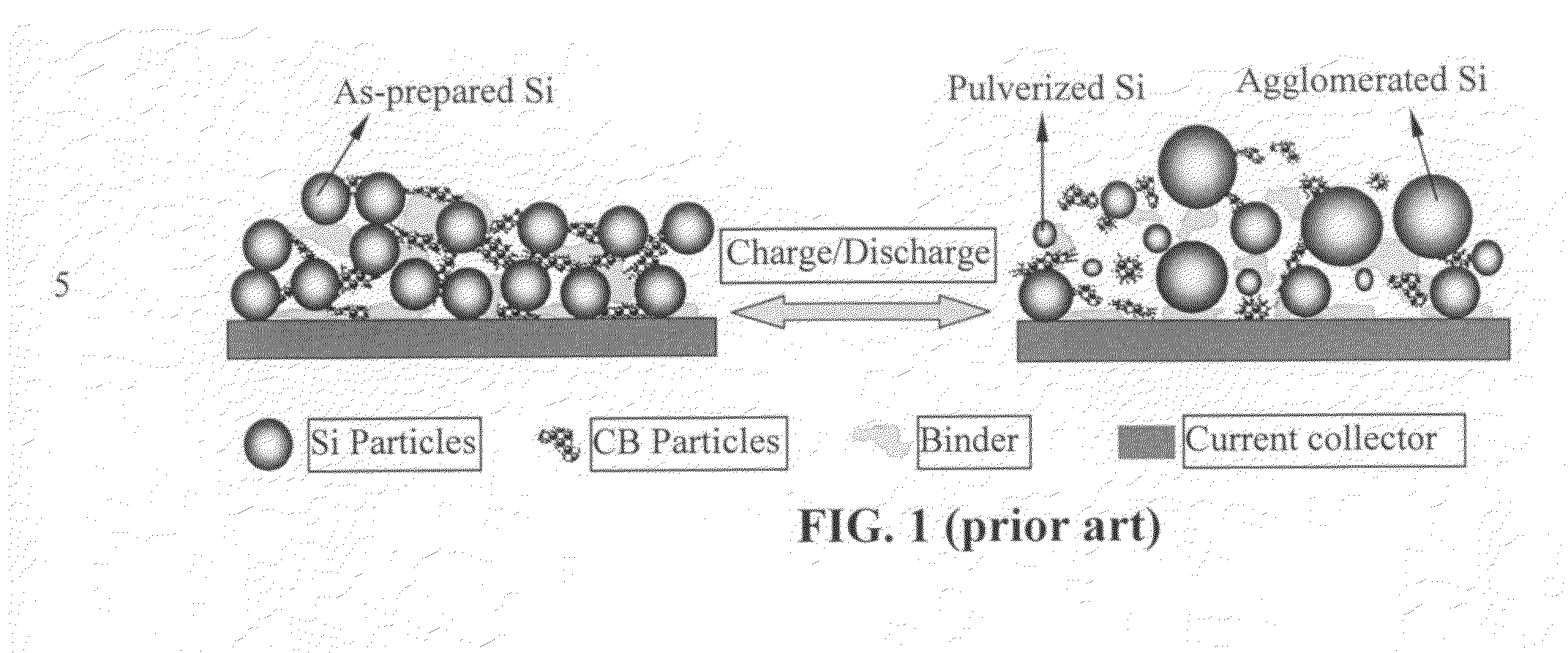

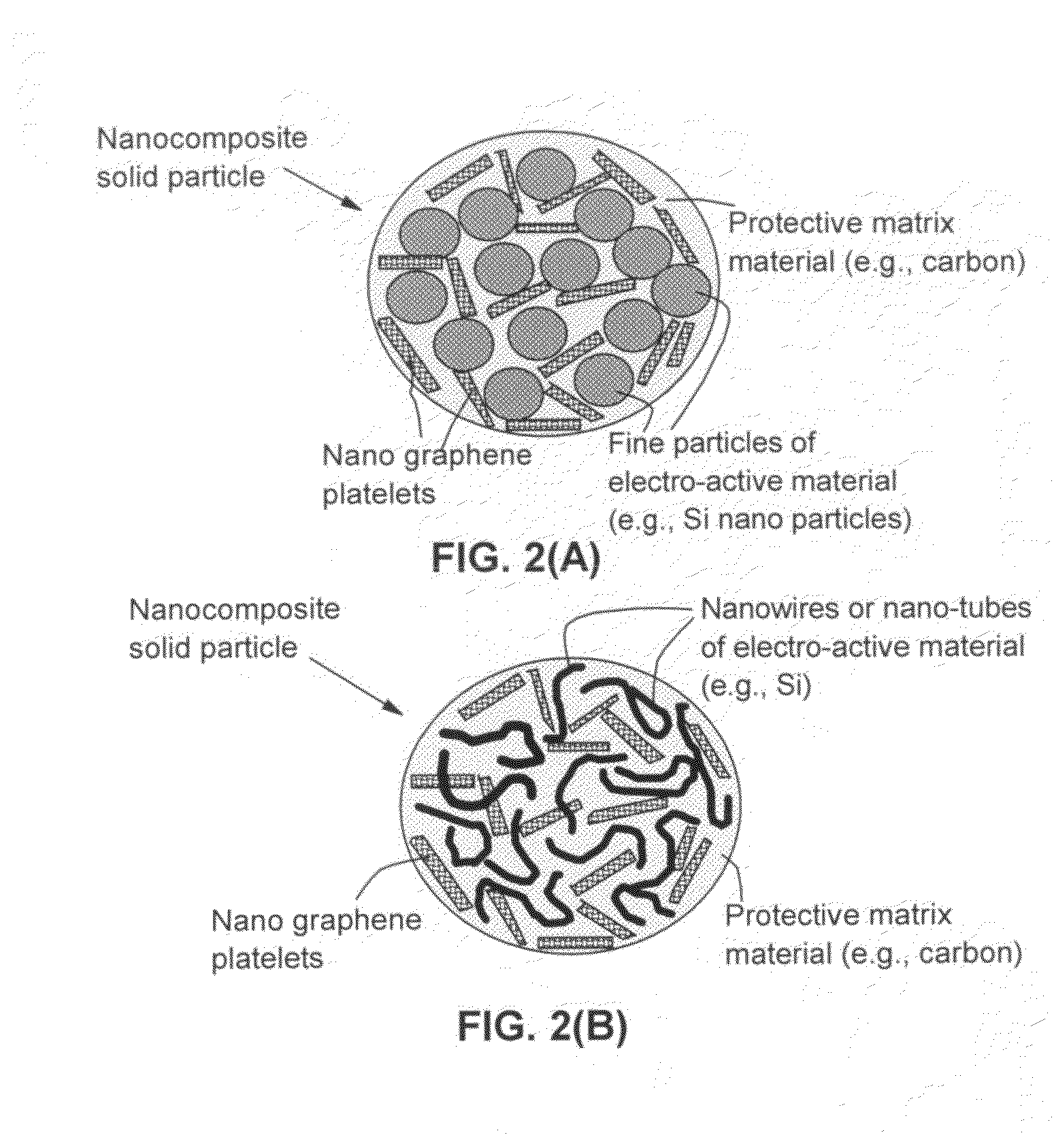

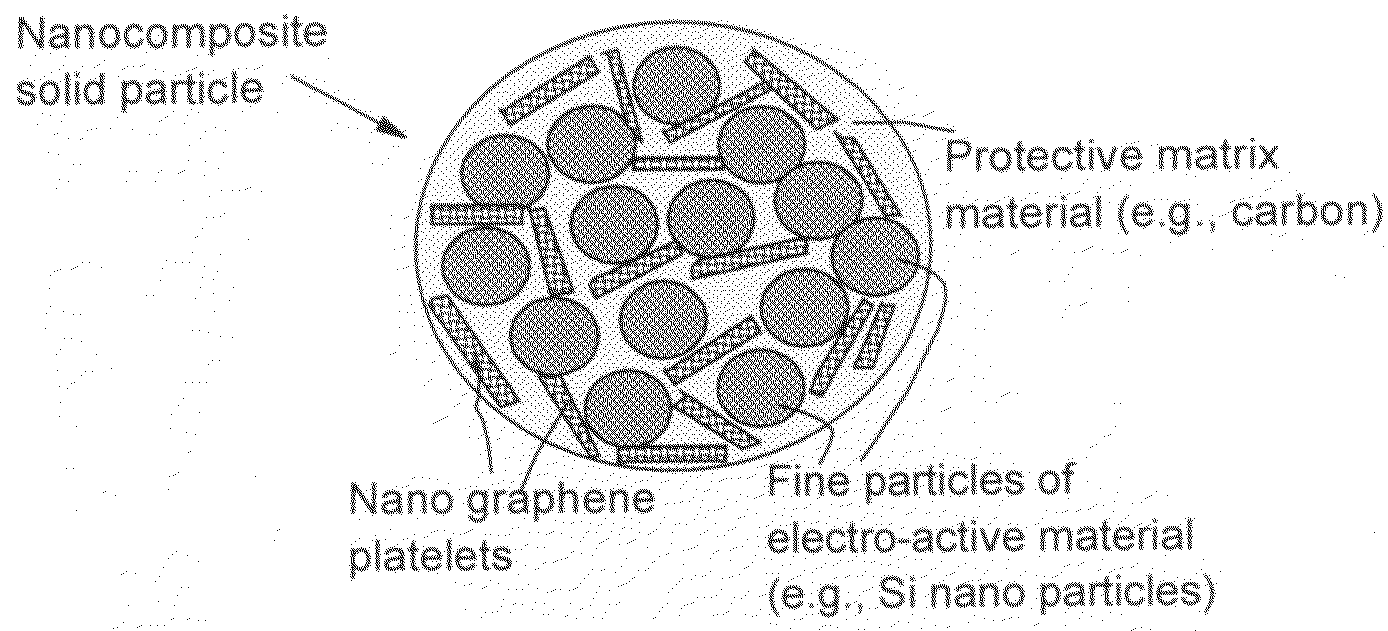

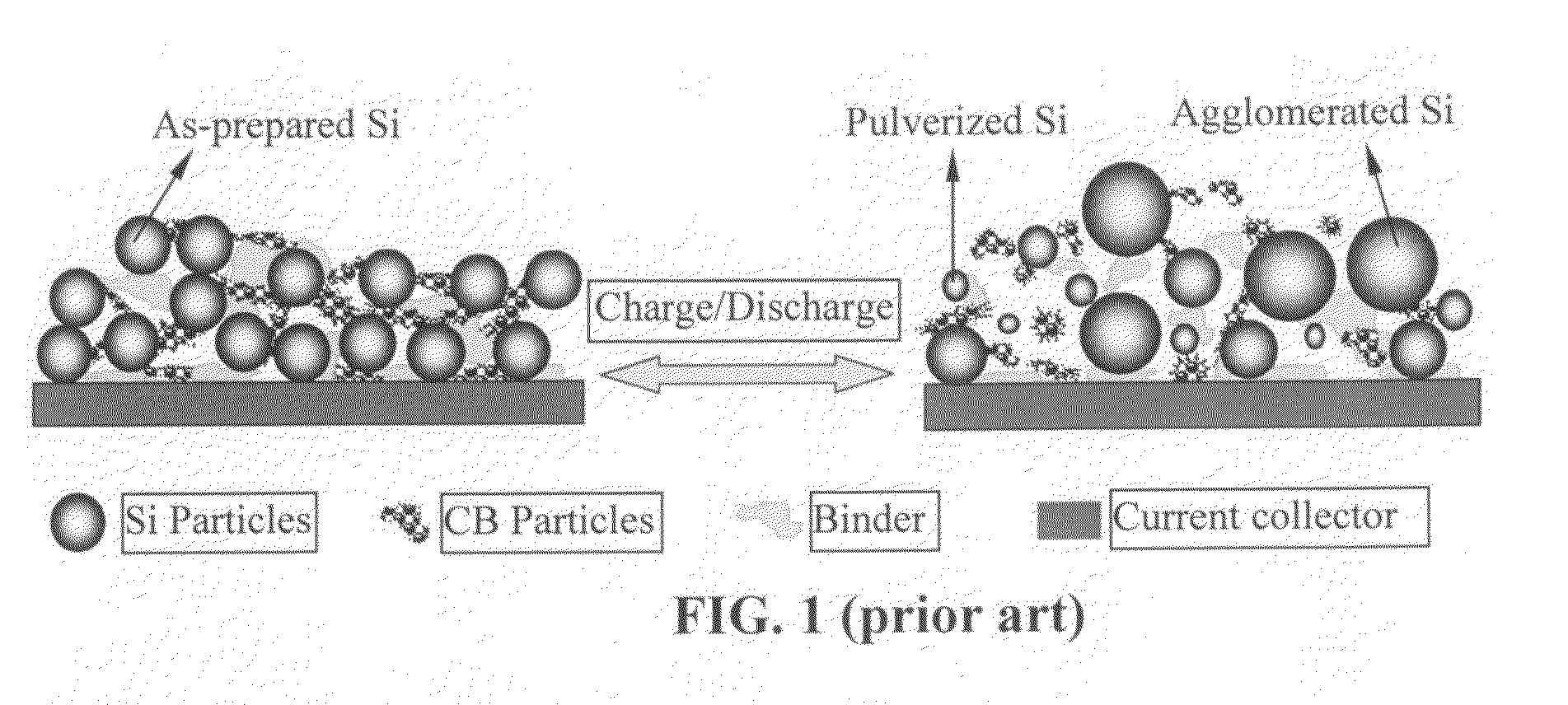

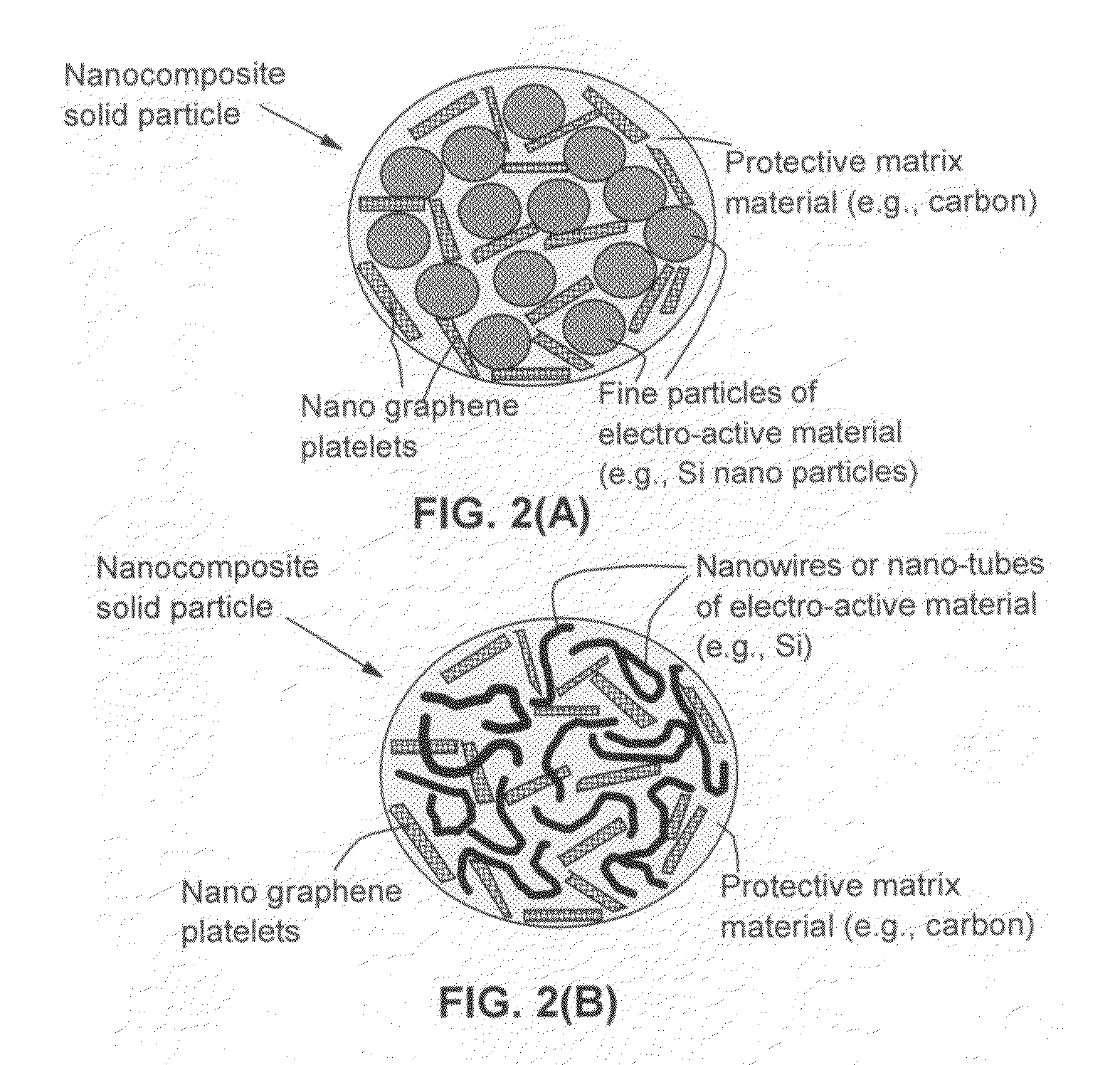

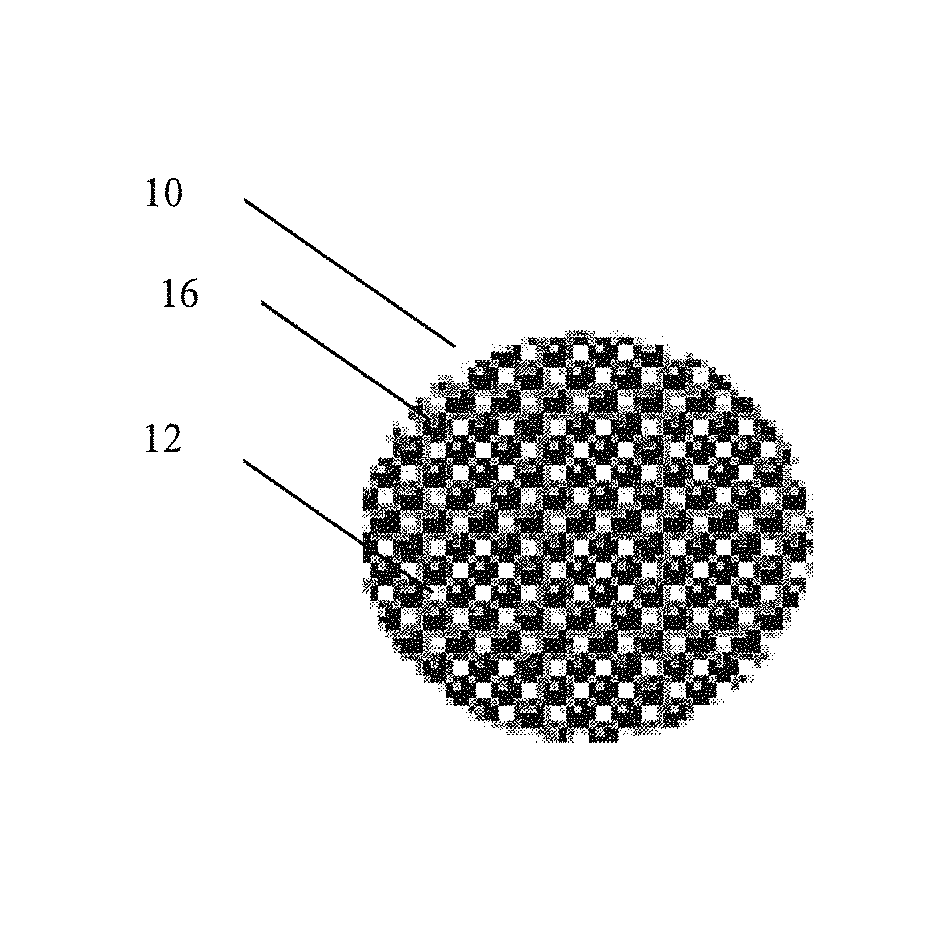

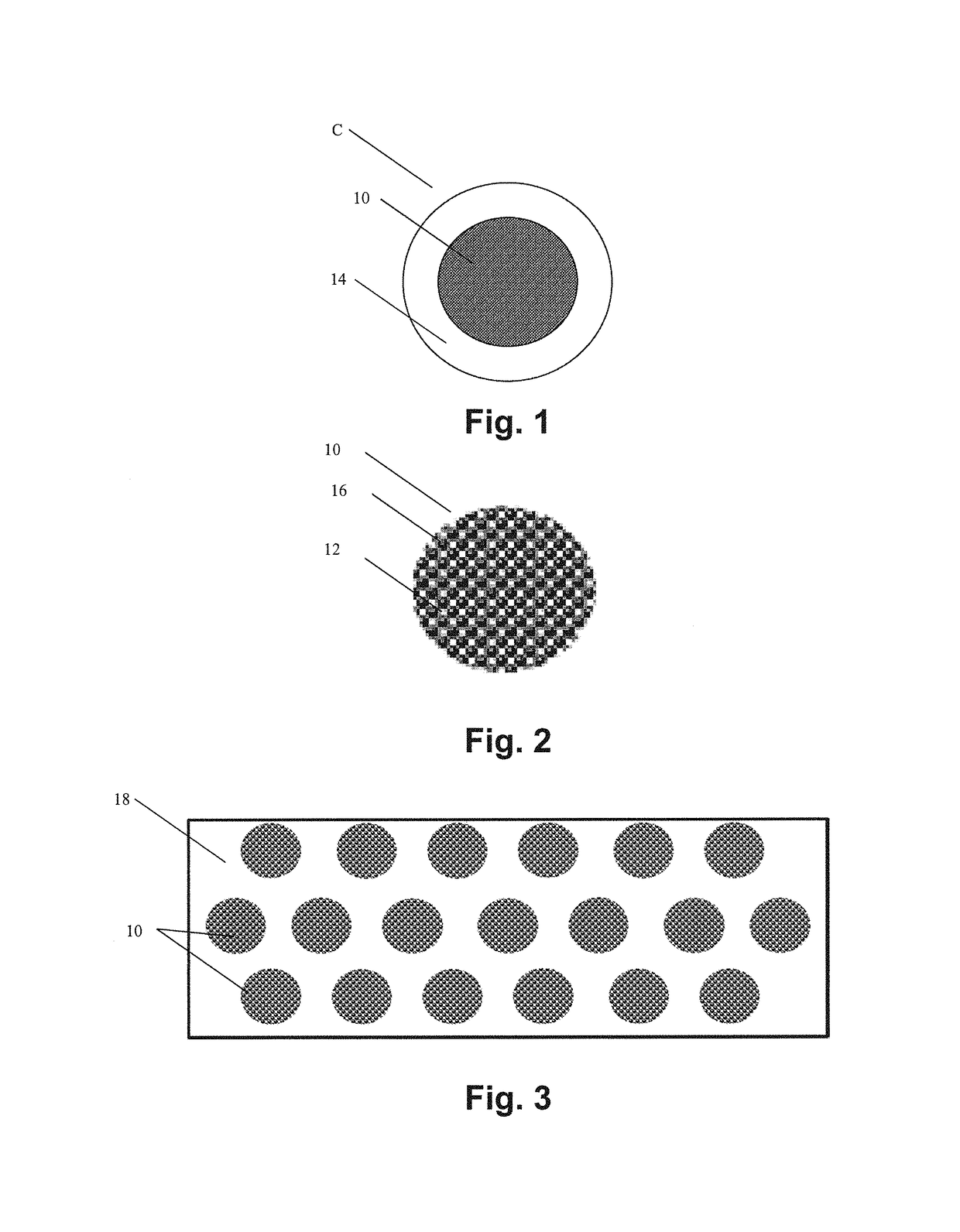

Nano graphene reinforced nanocomposite particles for lithium battery electrodes

ActiveUS20100143798A1Increase stiffnessHigh strengthActive material electrodesSecondary cellsLithium metalNanocomposite

A solid nanocomposite particle composition for lithium metal or lithium ion battery electrode applications. The composition comprises: (A) an electrode active material in a form of fine particles, rods, wires, fibers, or tubes with a dimension smaller than 1 μm; (B) nano graphene platelets (NGPs); and (C) a protective matrix material reinforced by the NGPs; wherein the graphene platelets and the electrode active material are dispersed in the matrix material and the NGPs occupy a weight fraction wg of 1% to 90% of the total nanocomposite weight, the electrode active material occupies a weight fraction wa of 1% to 90% of the total nanocomposite weight, and the matrix material occupies a weight fraction wm of at least 2% of the total nanocomposite weight with wg+wa+wm=1. For a lithium ion battery anode application, the matrix material is preferably amorphous carbon, polymeric carbon, or meso-phase carbon. Such a solid nanocomposite composition provides a high anode capacity and good cycling stability. For a cathode application, the resulting lithium metal or lithium ion battery exhibits an exceptionally high cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

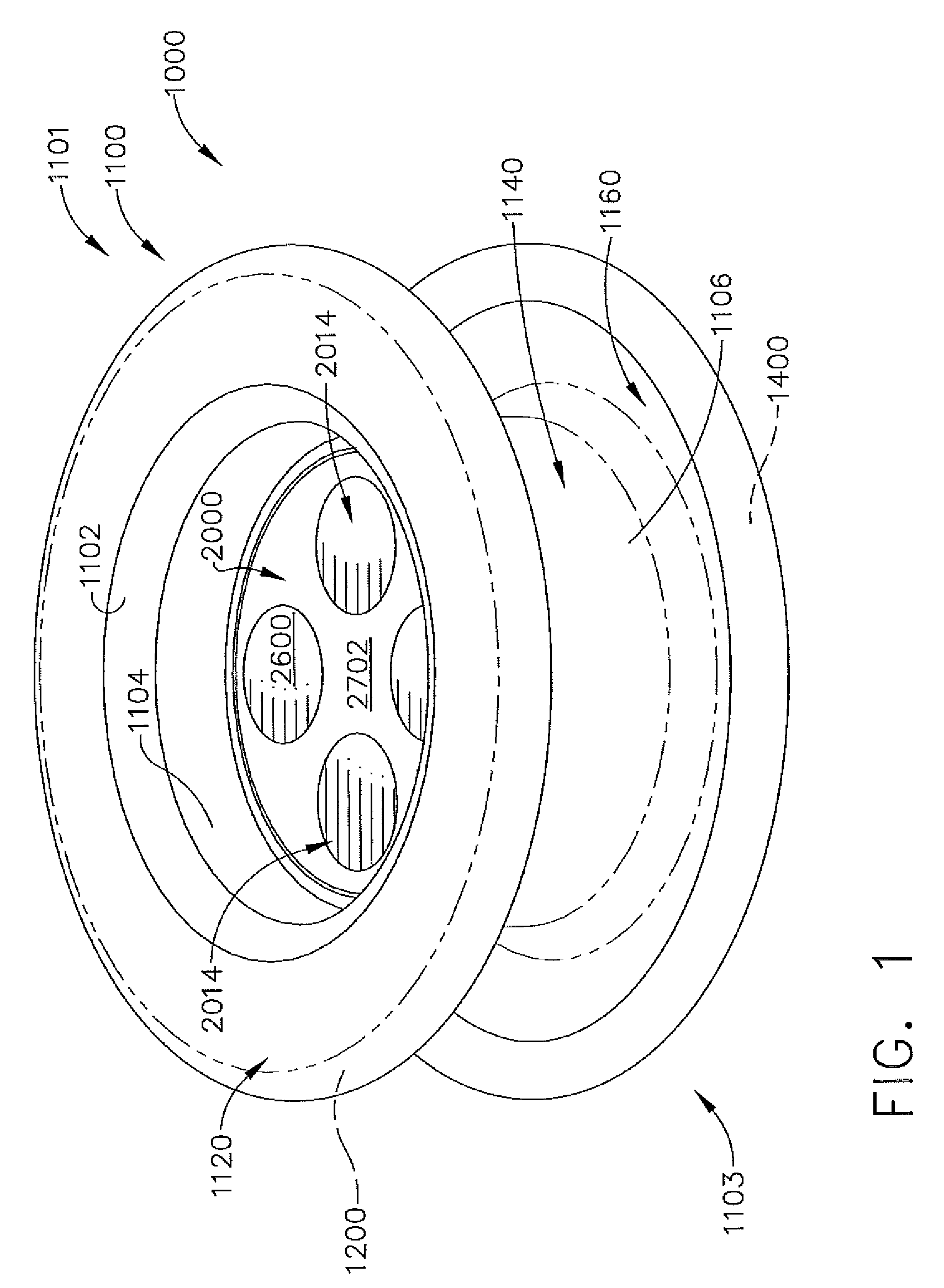

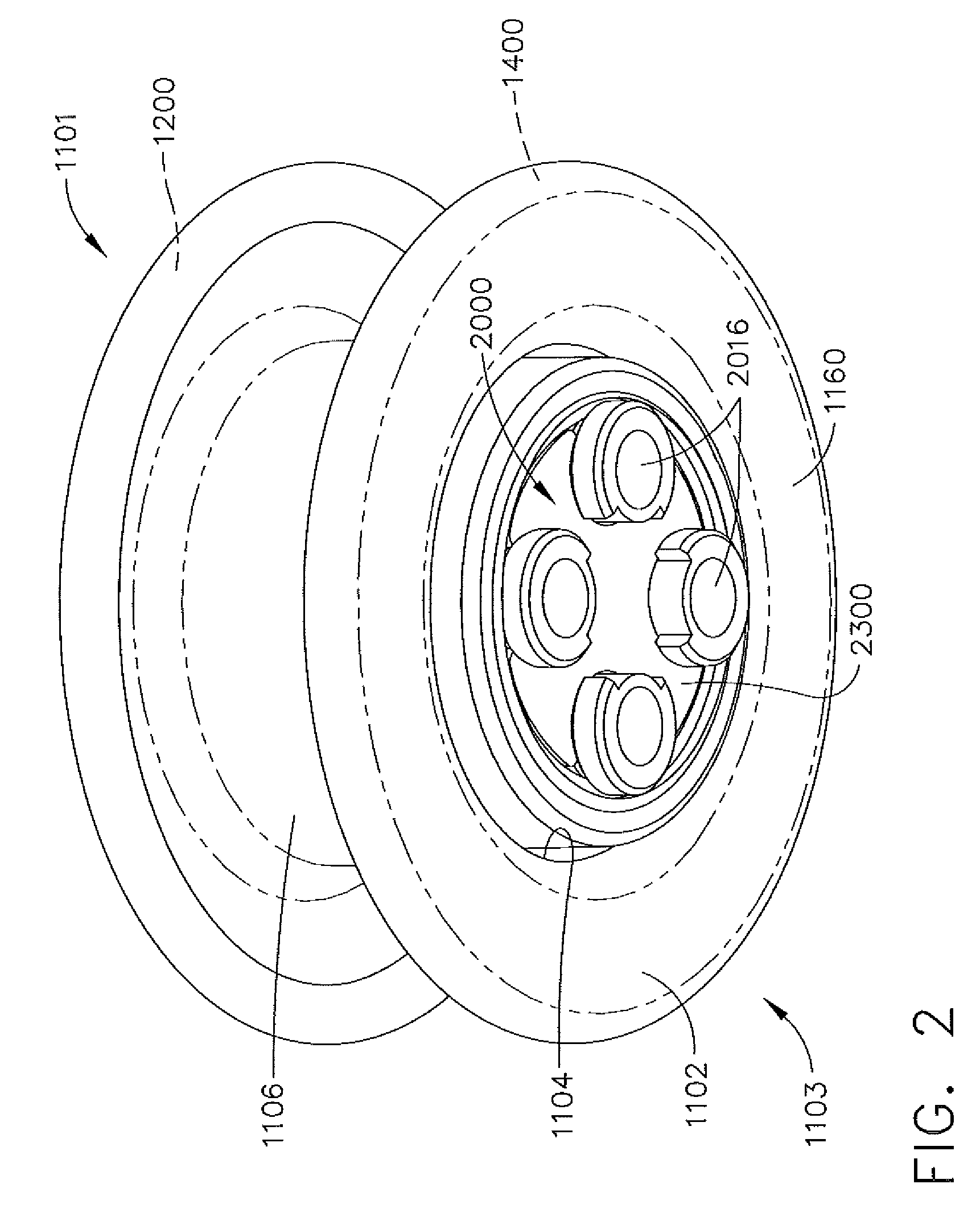

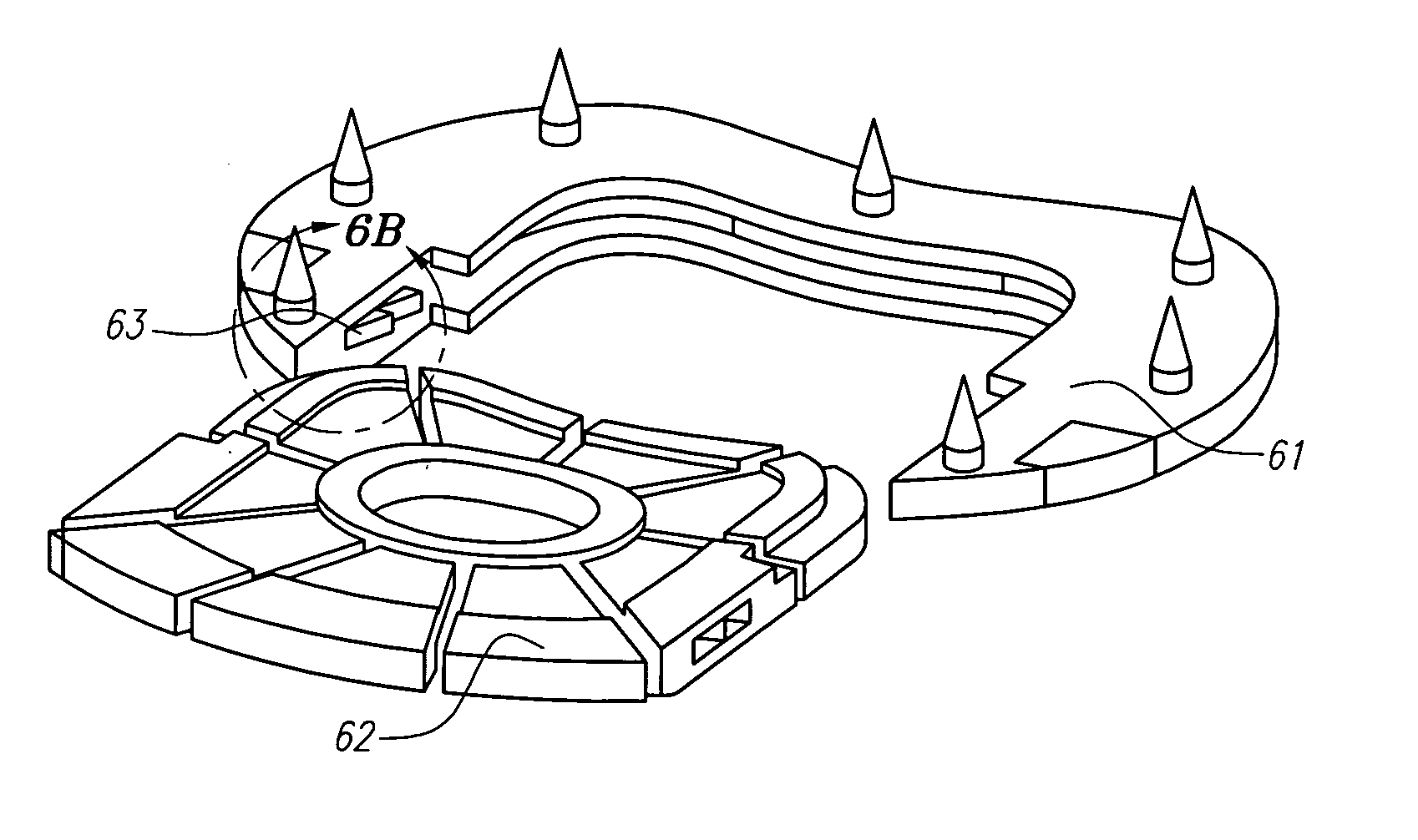

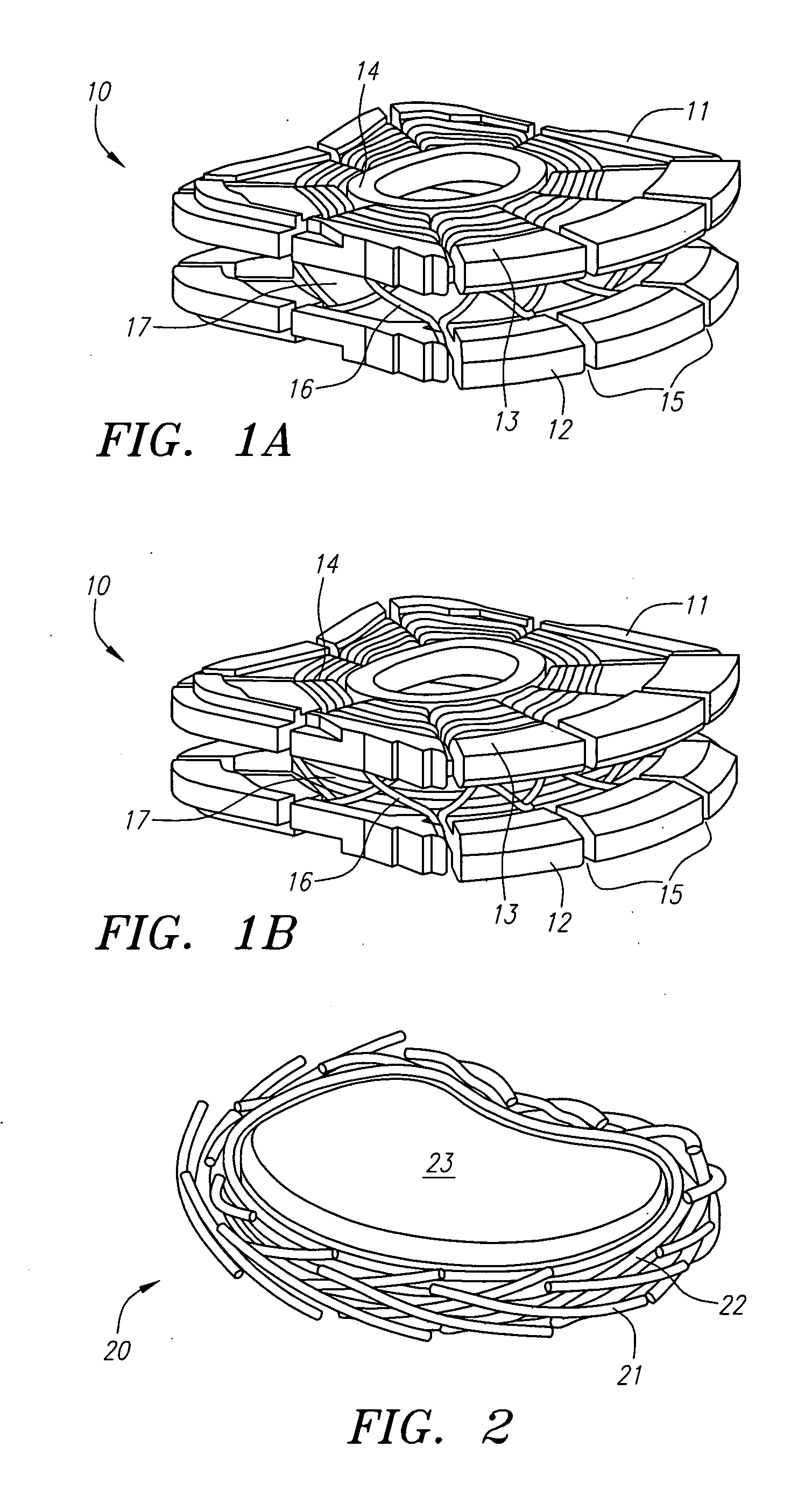

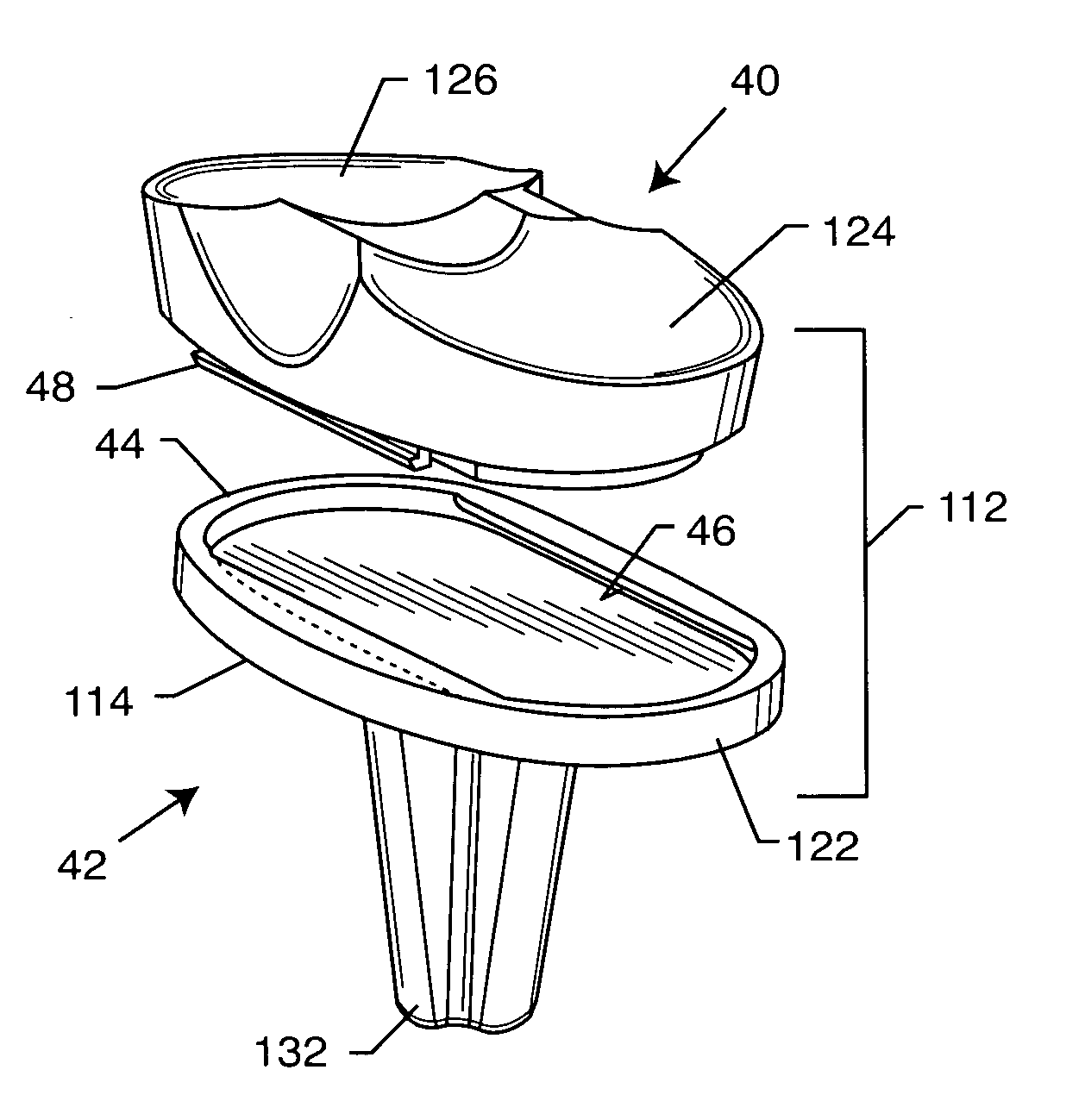

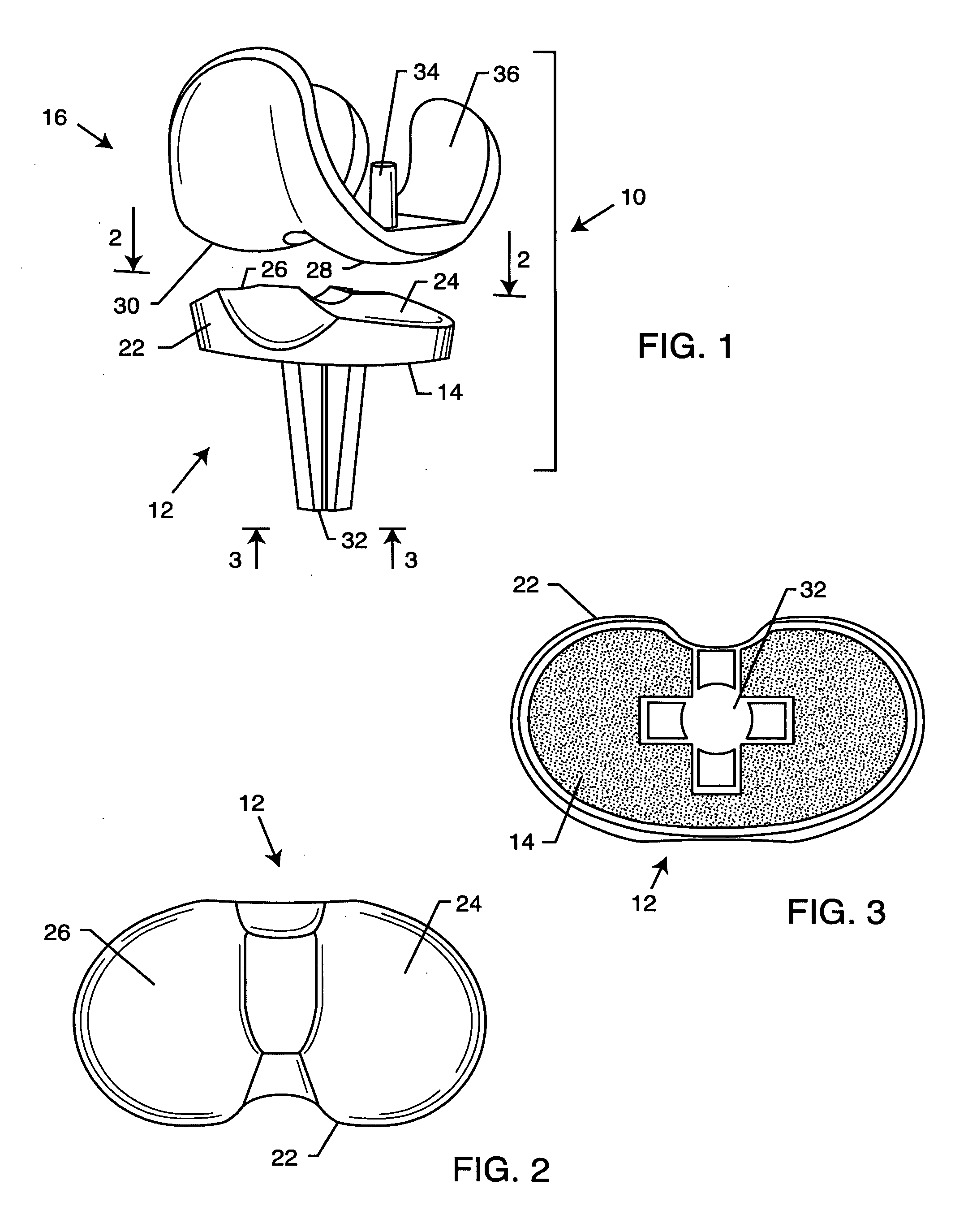

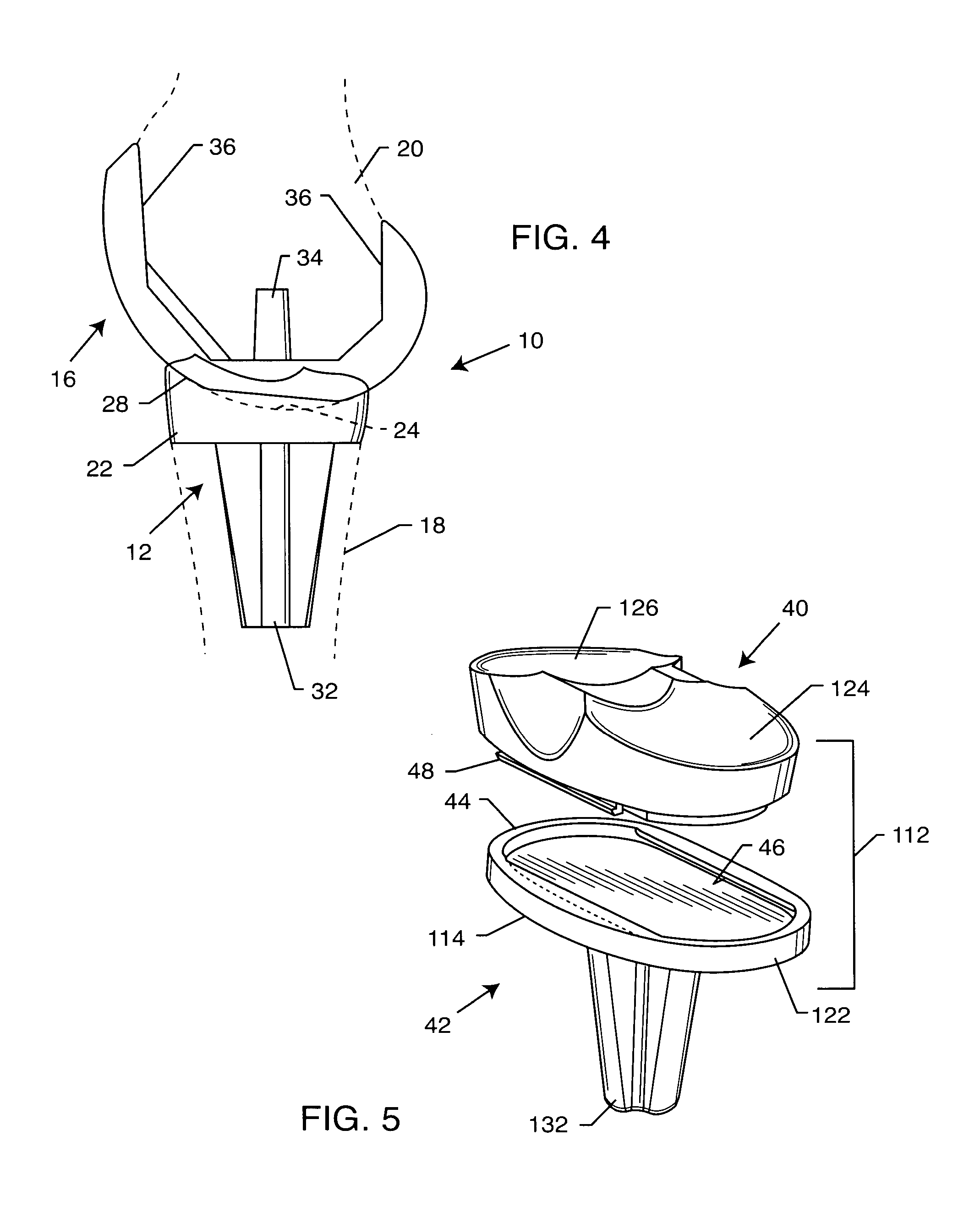

Prosthetic intervertebral disc and methods for using same

InactiveUS20050228500A1Improve toughnessHigh modulusJoint implantsSpinal implantsSurgical operationIntervertebral disc

Prosthetic intervertebral discs and methods for using the same are described. The subject prosthetic discs include upper and lower endplates separated by a compressible core member. The prosthetic discs described herein include one-piece, two-piece, three-piece, and four-piece structures. The subject prosthetic discs exhibit stiffness in the vertical direction, torsional stiffness, bending stiffness in the saggital plane, and bending stiffness in the front plane, where the degree of these features can be controlled independently by adjusting the components of the discs. The interface mechanism between the endplates and the core members of several embodiments of the described prosthetic discs enables a very easy surgical operation for implantation.

Owner:SPINAL KINETICS

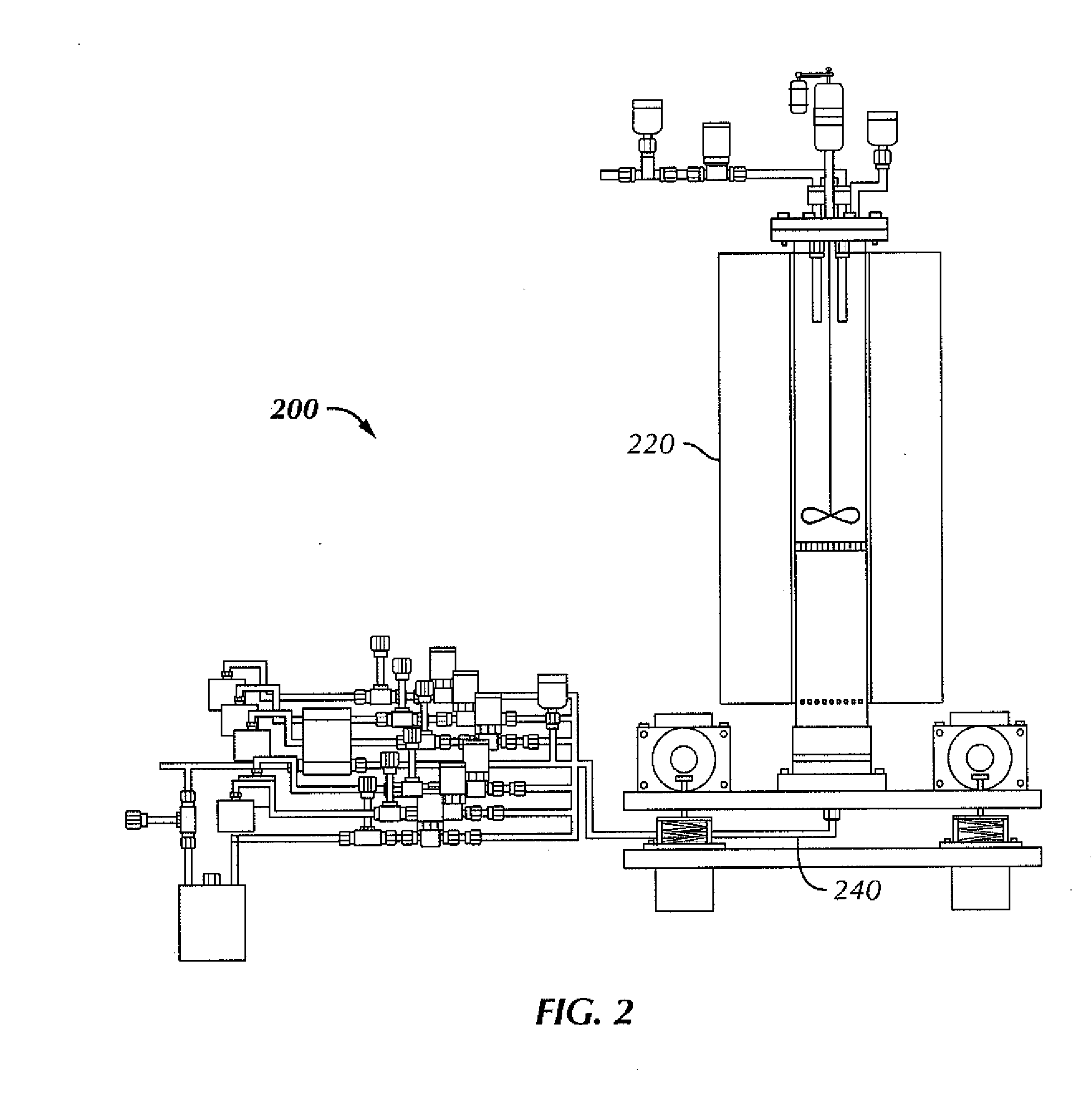

Process for producing nano graphene reinforced composite particles for lithium battery electrodes

ActiveUS20100176337A1Increase stiffnessHigh strengthCell electrodesLi-accumulatorsFiberLithium metal

Owner:SAMSUNG ELECTRONICS CO LTD

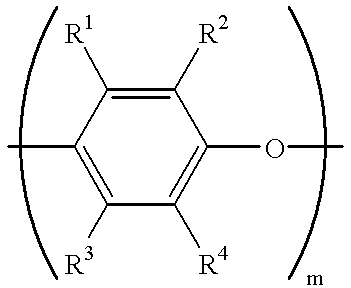

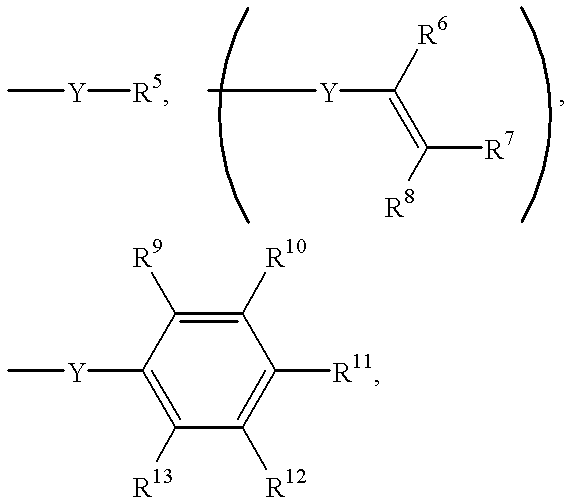

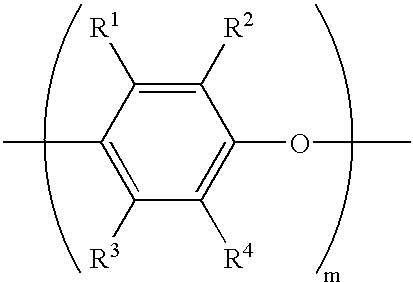

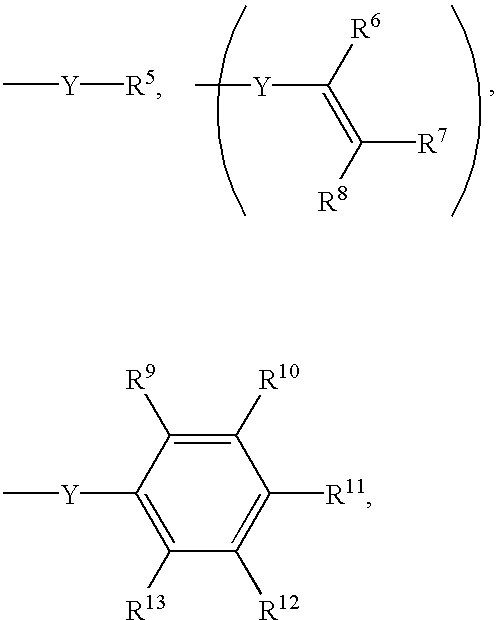

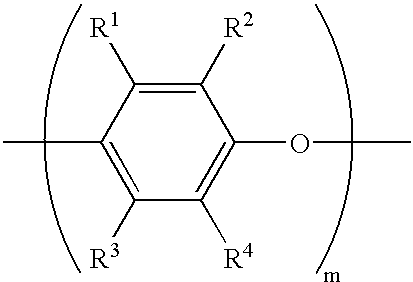

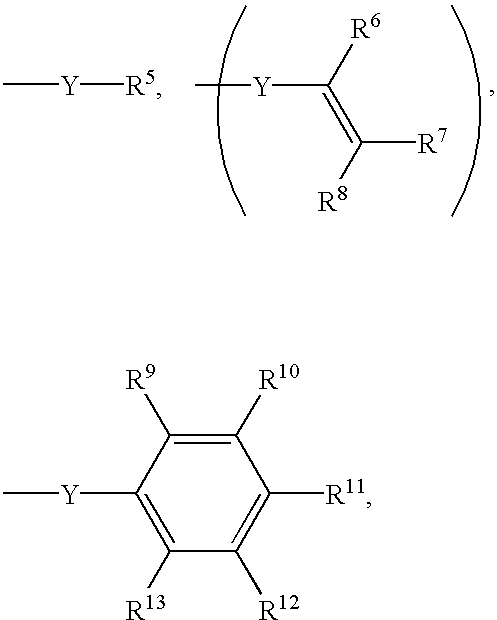

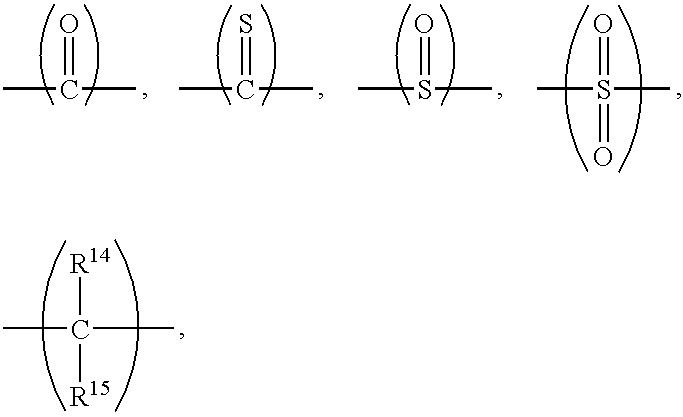

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS6627704B2Fast curingReduce sensitivitySynthetic resin layered productsPolyether coatingsHeat resistanceEther

Owner:SABIC INNOVATIVE PLASTICS IP BV

Structural modified epoxy adhesive compositions

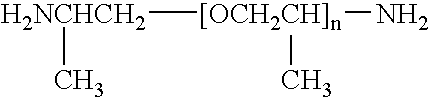

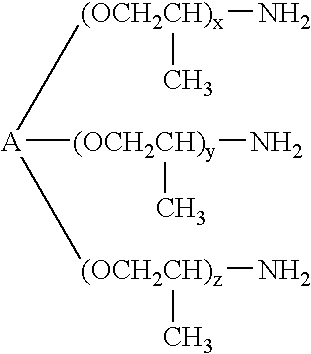

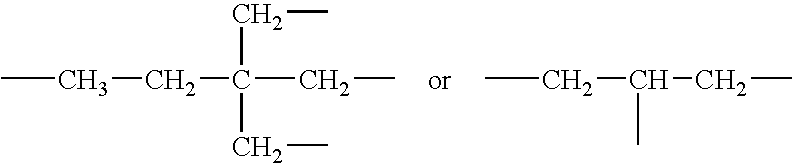

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

Knee prosthesis with ceramic tibial component

InactiveUS20060052875A1Reduce wearHigh strengthHeart valvesJoint implantsArticular surfacesTibial bone

An improved knee prosthesis includes a ceramic tibial component for articulation with natural or prosthetic (re-surfaced) femoral surfaces. The ceramic tibial component is provided in the form of a ceramic monoblock adapted for fixation relative to the patient's tibial bone, or alternately in the form of a ceramic bearing insert component carried by a tibial baseplate member which is adapted in turn for fixation relative to tibial bone. In either form, the ceramic tibial component includes at least one upwardly concave articulation surface for movable bearing engagement by a generally convex or condylar shaped femoral articulation surface. The ceramic tibial component provides improved wear characteristics with extended service life.

Owner:AMEDICA A DELAWARE

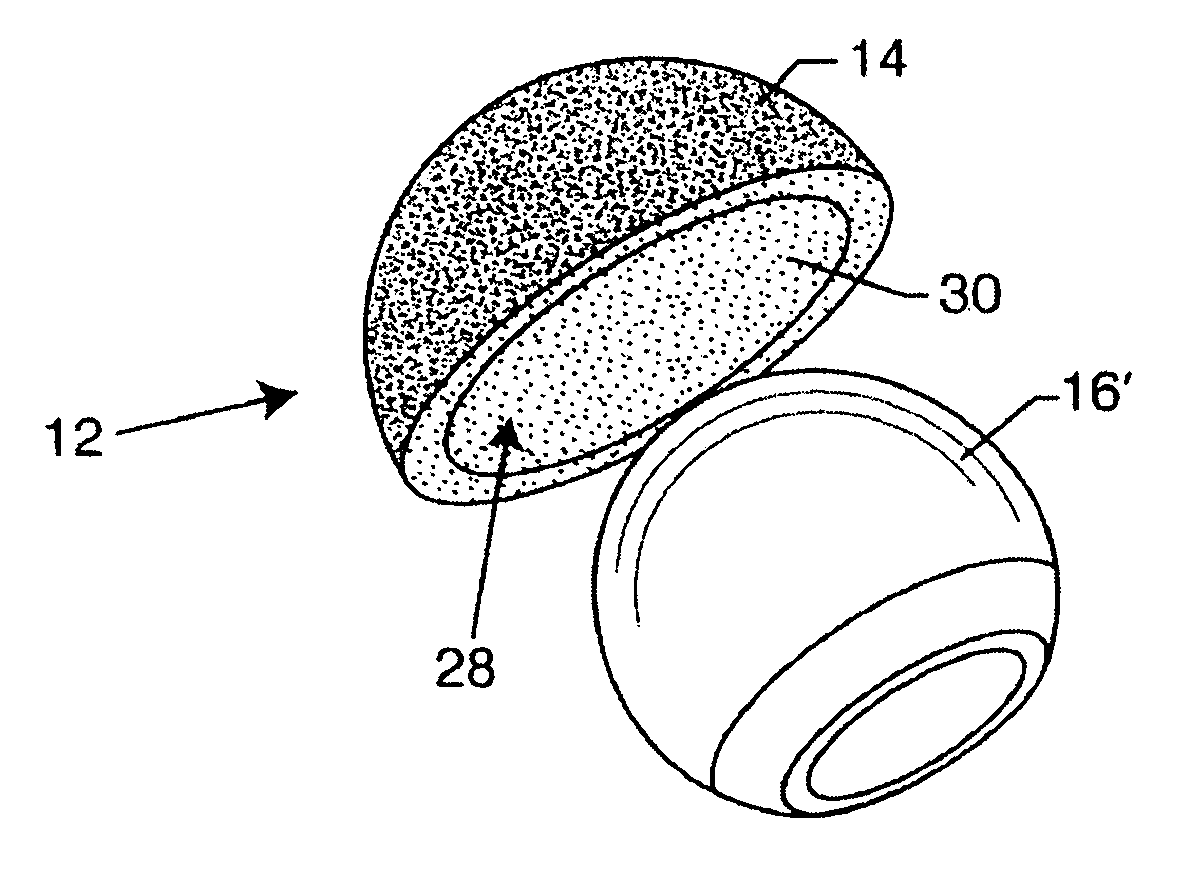

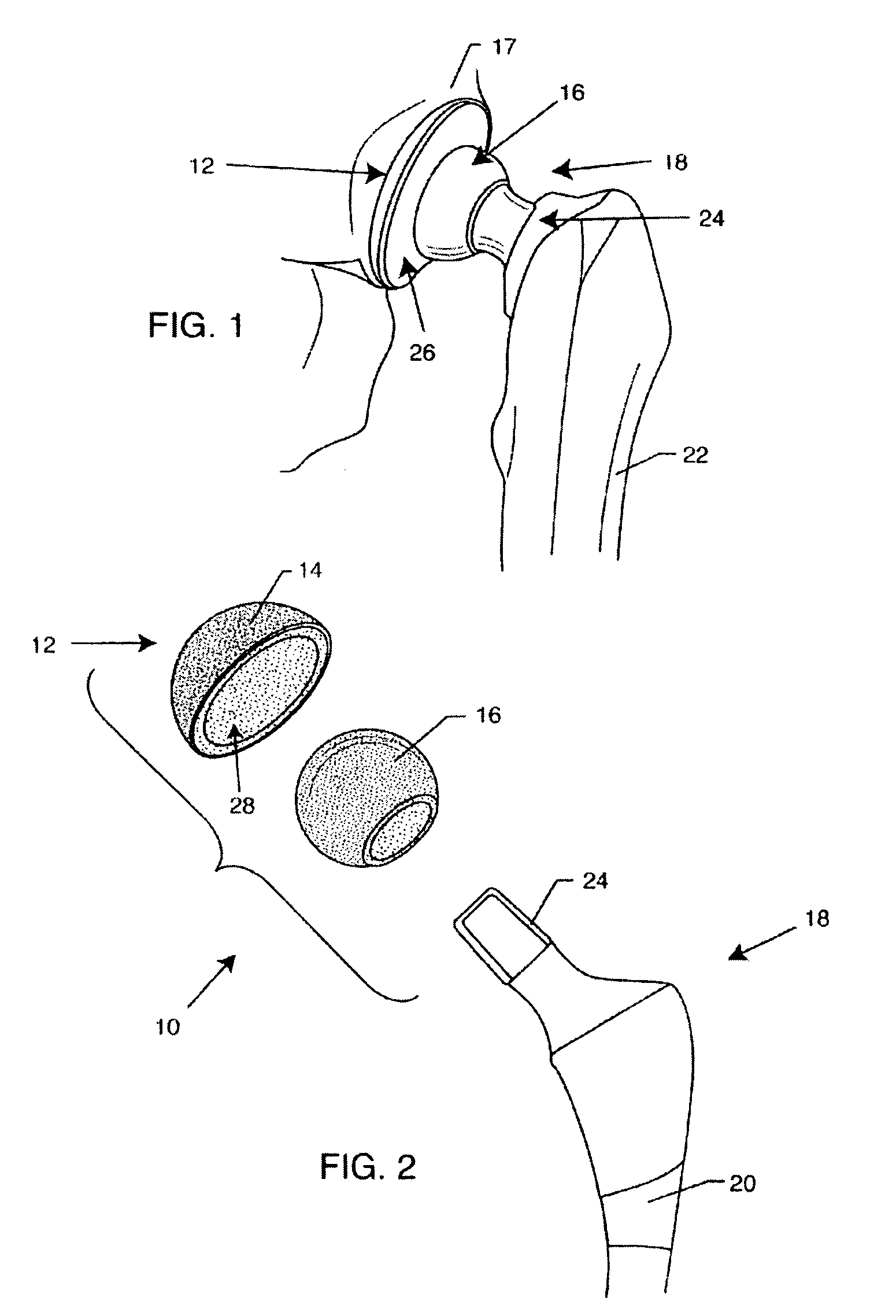

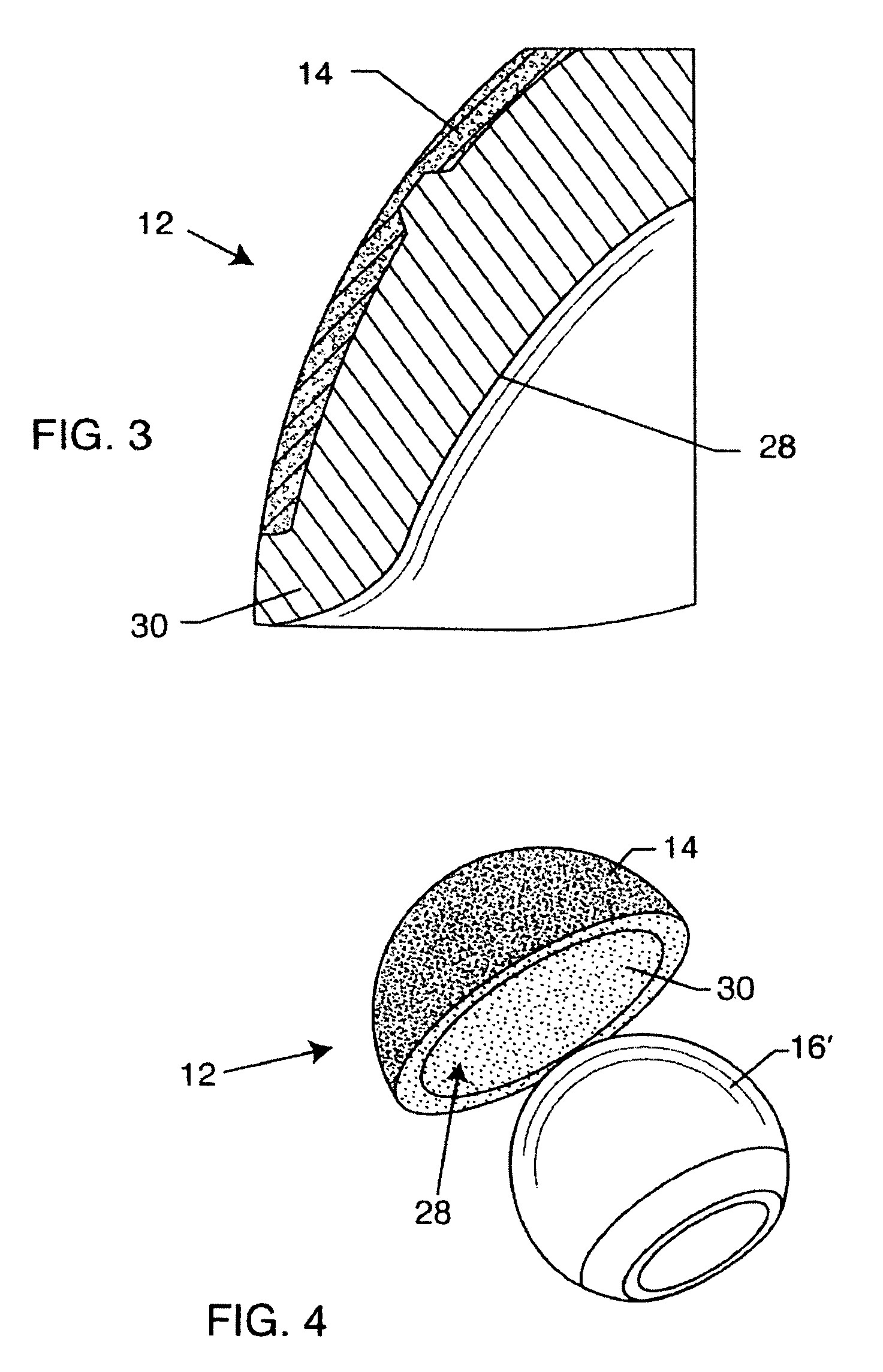

Hip prosthesis with monoblock ceramic acetabular cup

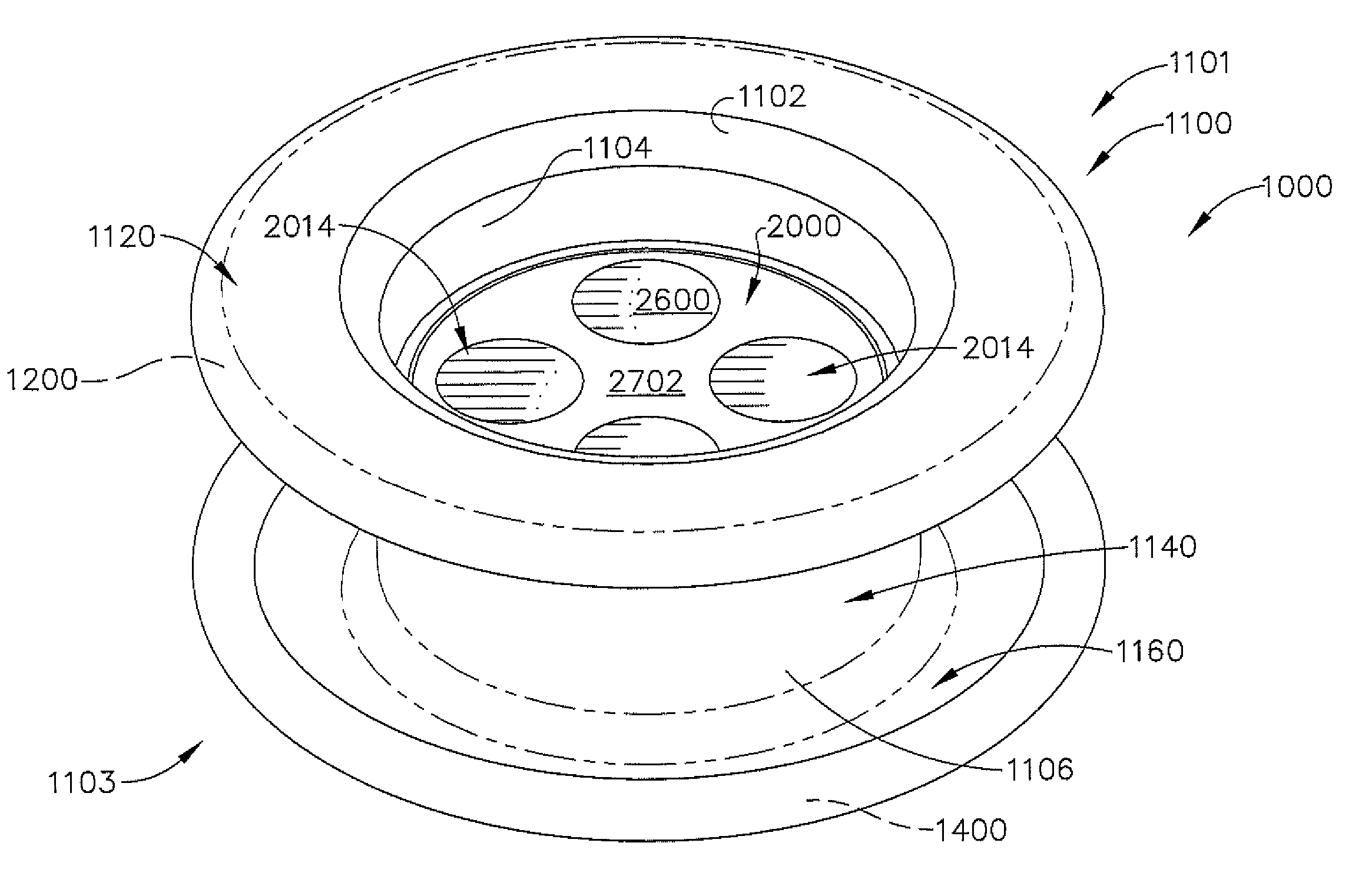

InactiveUS7695521B2High strengthImprove toughnessBone implantJoint implantsRight femoral headMetallic materials

An improved hip prosthesis includes an acetabular cup bearing component constructed from a relatively hard and high strength ceramic material for articulation with a ball-shaped femoral head component which may be constructed from a compatible ceramic or metal material. In one form, the acetabular cup further includes a ceramic porous bone ingrowth surface adhered thereto for secure ingrowth attachment to natural patient bone.

Owner:AMEDICA A DELAWARE

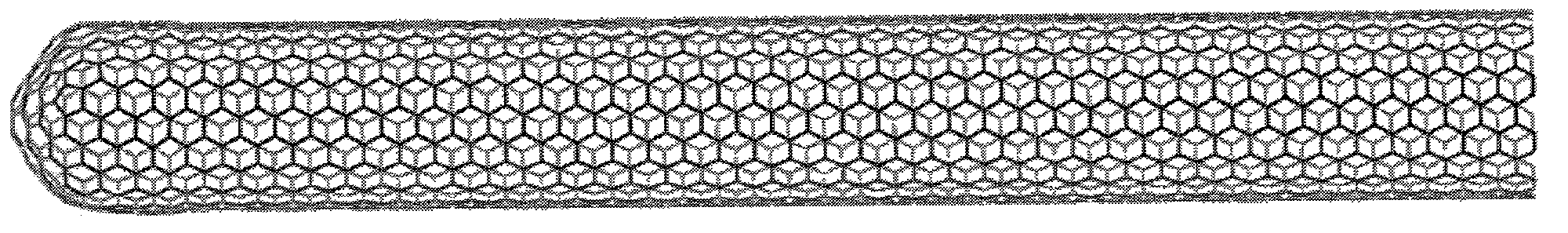

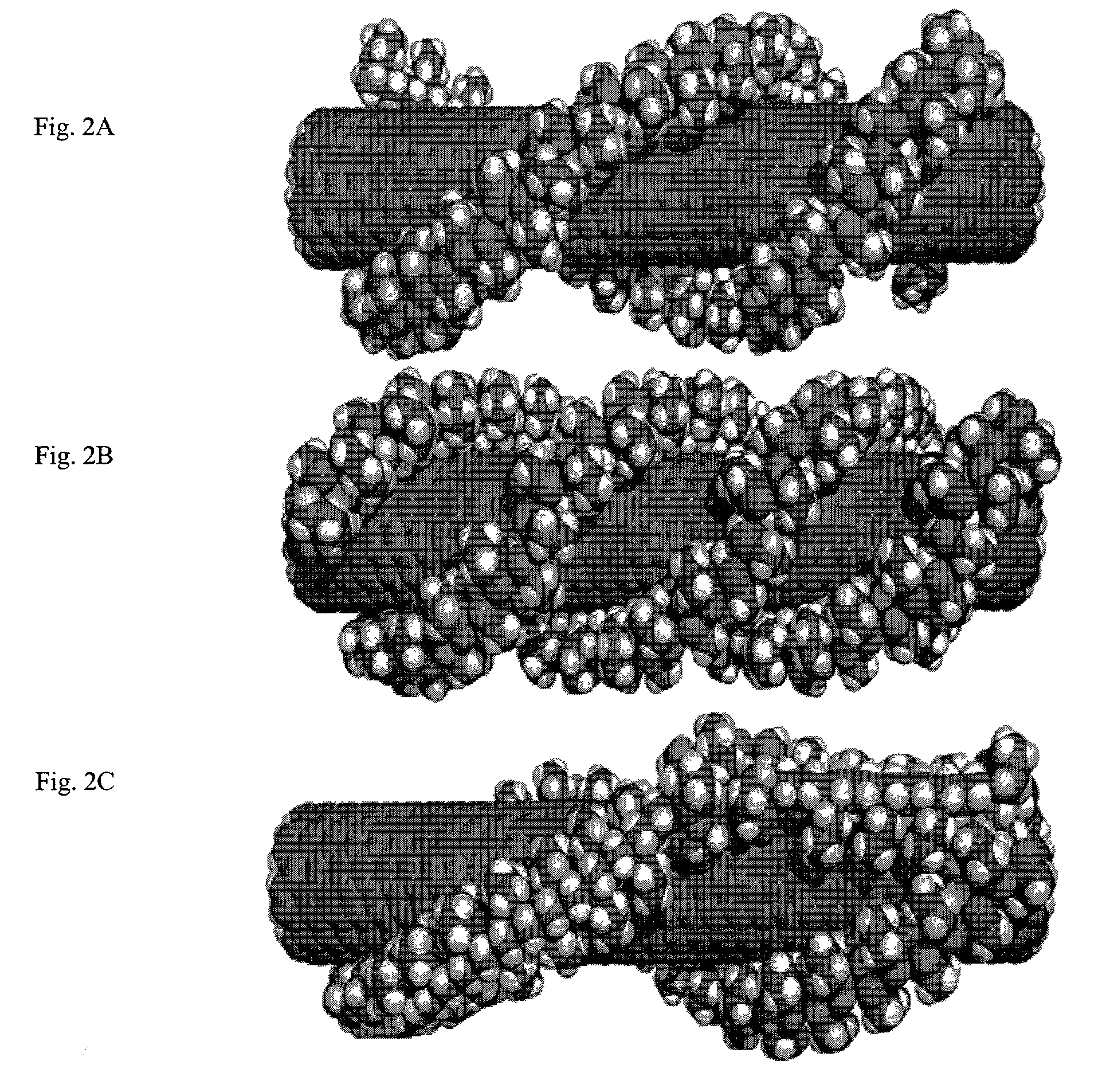

Polymer-wrapped single wall carbon nanotubes

InactiveUS7008563B2Novel behaviorHigh absorptivityMaterial nanotechnologyNanoinformaticsAmount of substanceSingle-Walled Nanotube

The present invention relates to new compositions of matter and articles of manufacture comprising SWNTs as nanometer scale conducting rods dispersed in an electrically-insulating matrix. These compositions of matter have novel and useful electrical, mechanical, and chemical properties including applications in antennas, electromagnetic and electro-optic devices, and high-toughness materials. Other compositions of matter and articles of manufacture are disclosed, including polymer-coated and polymer wrapped single-wall nanotubes (SWNTs), small ropes of polymer-coated and polymer-wrapped SWNTs and materials comprising same. This composition provides one embodiment of the SWNT conducting-rod composite mentioned above, and also enables creation of high-concentration suspensions of SWNTs and compatibilization of SWNTs with polymeric matrices in composite materials. This solubilization and compatibilization, in turn, enables chemical manipulation of SWNT and production of composite fibers, films, and solids comprising SWNTs.

Owner:RICE UNIV

Heterogeneous composite bodies with isolated cermet regions formed by high temperature, rapid consolidation

ActiveUS9943918B2Increase spacingUniform compositionRolling contact bearingsTransportation and packagingNanoparticleNanometre

A heterogeneous composite consisting of near-nano ceramic clusters dispersed within a ductile matrix. The composite is formed through the high temperature compaction of a starting powder consisting of a core of ceramic nanoparticles held together with metallic binder. This core is clad with a ductile metal such that when the final powder is consolidated, the ductile metal forms a tough, near-zero contiguity matrix. The material is consolidated using any means that will maintain its heterogeneous structure.

Owner:POWDERMET

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS20010053820A1Fast curingReduce sensitivitySynthetic resin layered productsThin material handlingHeat resistanceEther

A thermosetting composition comprises a capped poly(arylene ether), an alkenyl aromatic monomer, and an acryloyl monomer. The composition provides good flow properties and fast curing rates. After curing, the composition exhibits good stiffness, toughness, heat resistance, and dielectric properties.

Owner:SABIC INNOVATIVE PLASTICS IP BV

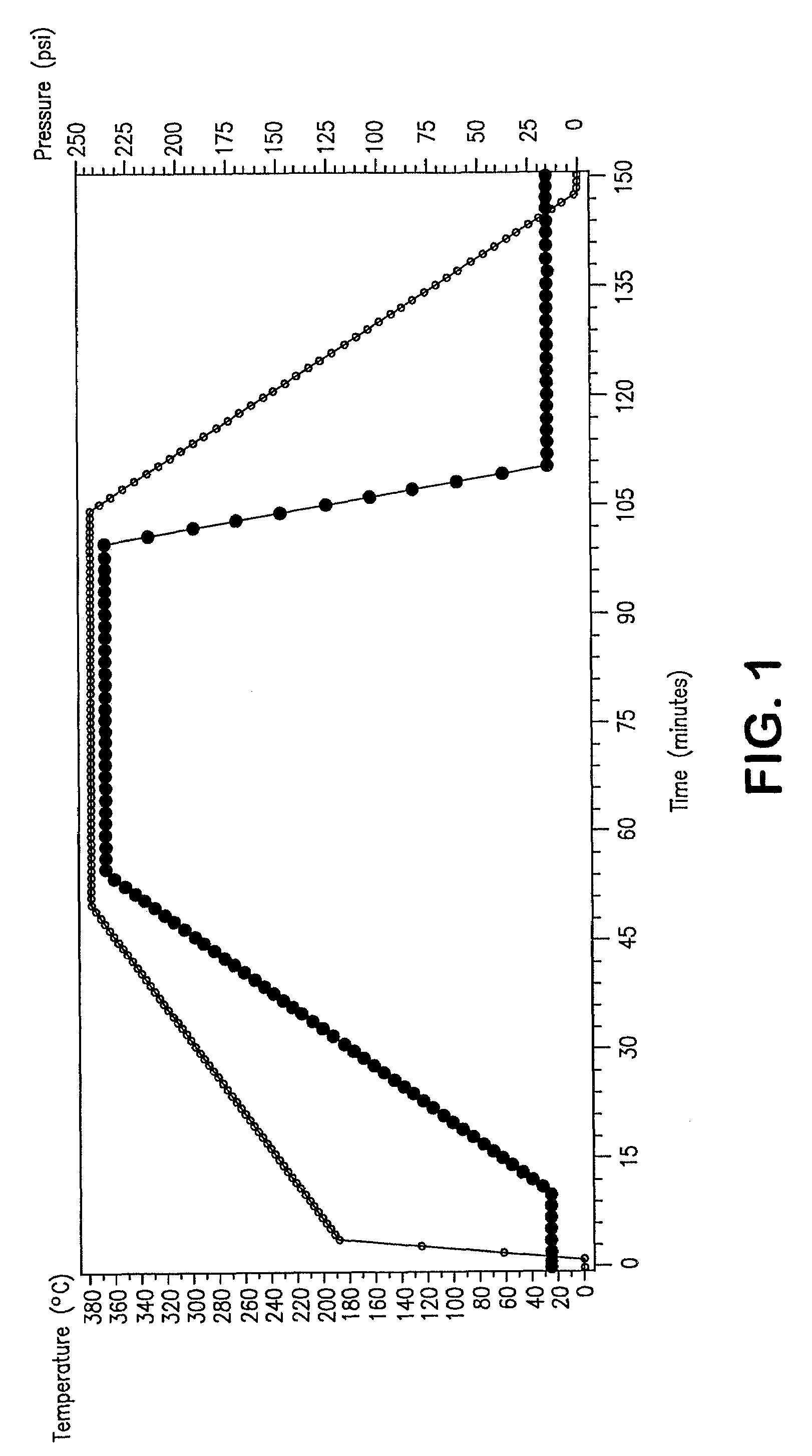

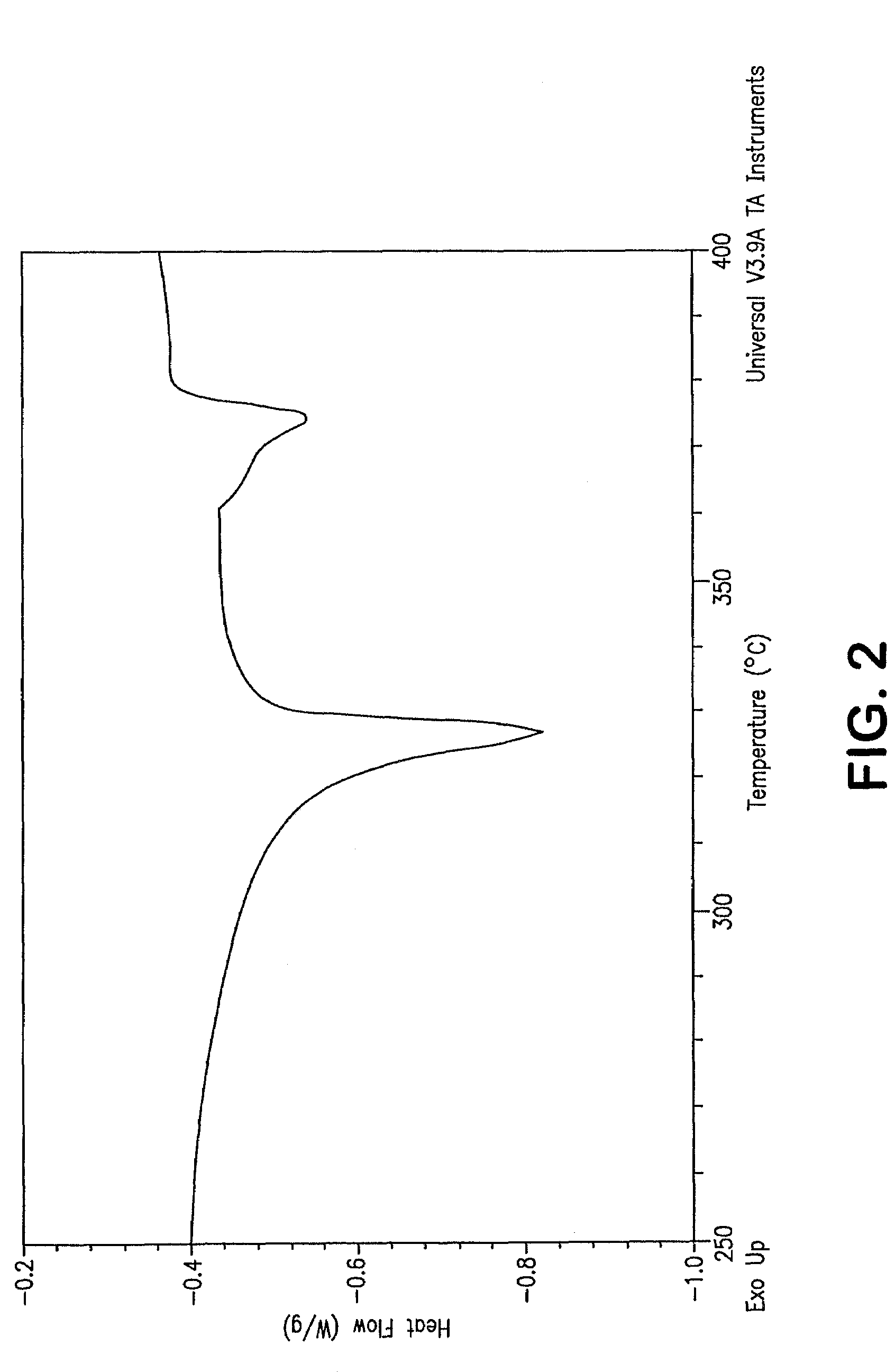

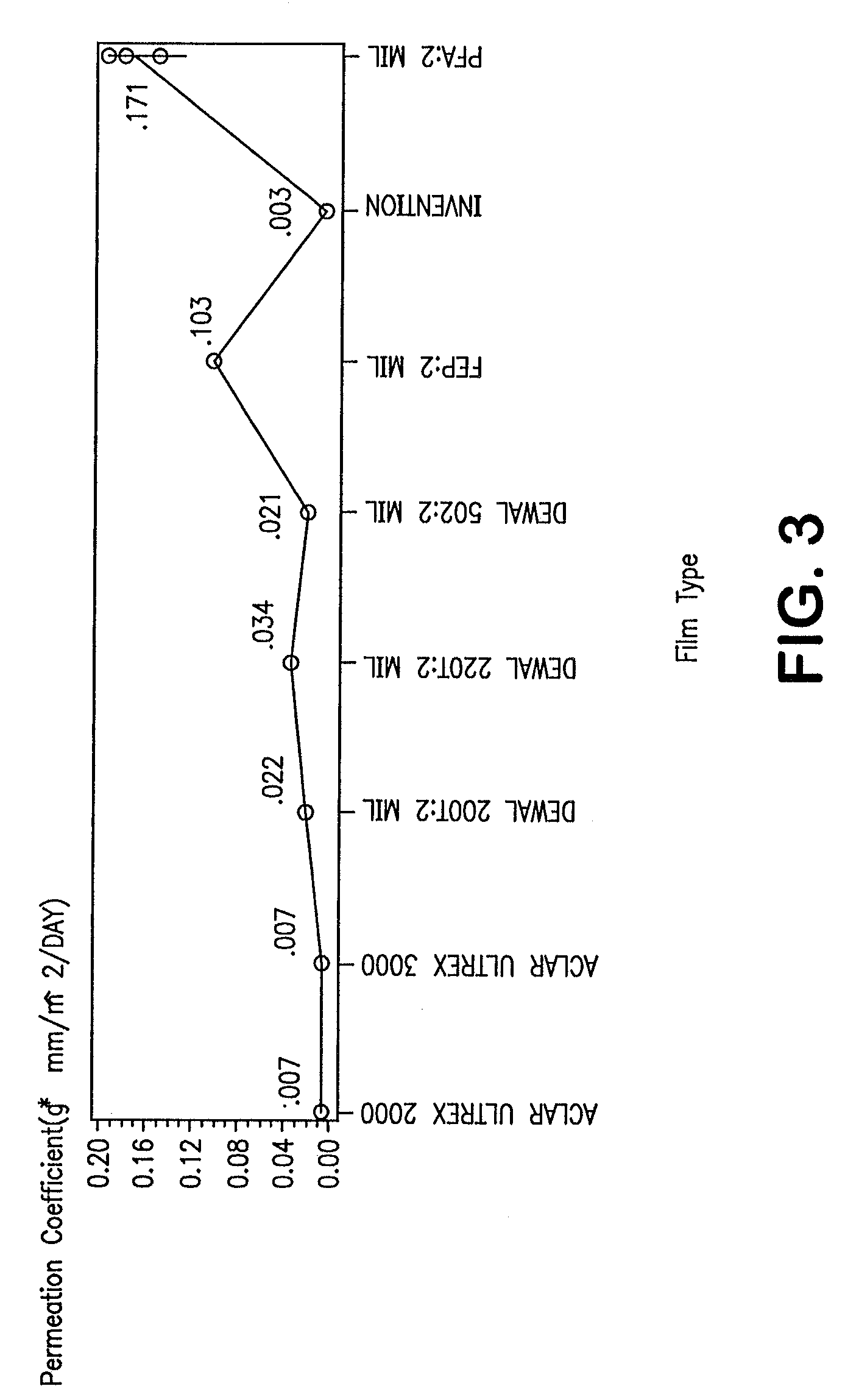

Fluoropolymer barrier material

InactiveUS7521010B2Improve barrier propertiesImprove permeabilitySynthetic resin layered productsCeramic shaping apparatusPolymer scienceWater vapor permeability

A novel densified fluoropolymer article is described which has a water vapor permeation of about 0.015 g-mm / m2 / day or less, and preferably has a matrix tensile strength of at least 10,000 psi in two orthogonal directions. The articles are made by compressing expanded porous PTFE at pressures, temperatures and times which result in elimination of the pores, and subsequent stretching above the crystalline melt temperature.

Owner:WL GORE & ASSOC INC

Polymer-bioceramic composite for orthopaedic applications and method of manufacture thereof

InactiveUS20040002770A1Promote ingrowthImprove toughnessBone implantJoint implantsCompression moldingPolymer science

Polymer-bioceramic structures are described for use in the repair of bone defects. The composites of the present disclosure are characterized by a polymer disposed in a porous bioceramic matrix. Processes for preparing the composites of the present invention by compression molding are described, including compression molding to induce orientation of the polymer is multiple directions. The composites of the present invention are also useful as drug delivery vehicles to facilitate the repair of bone defects.

Owner:DEPUY SYNTHES PROD INC

Reinforced polymers

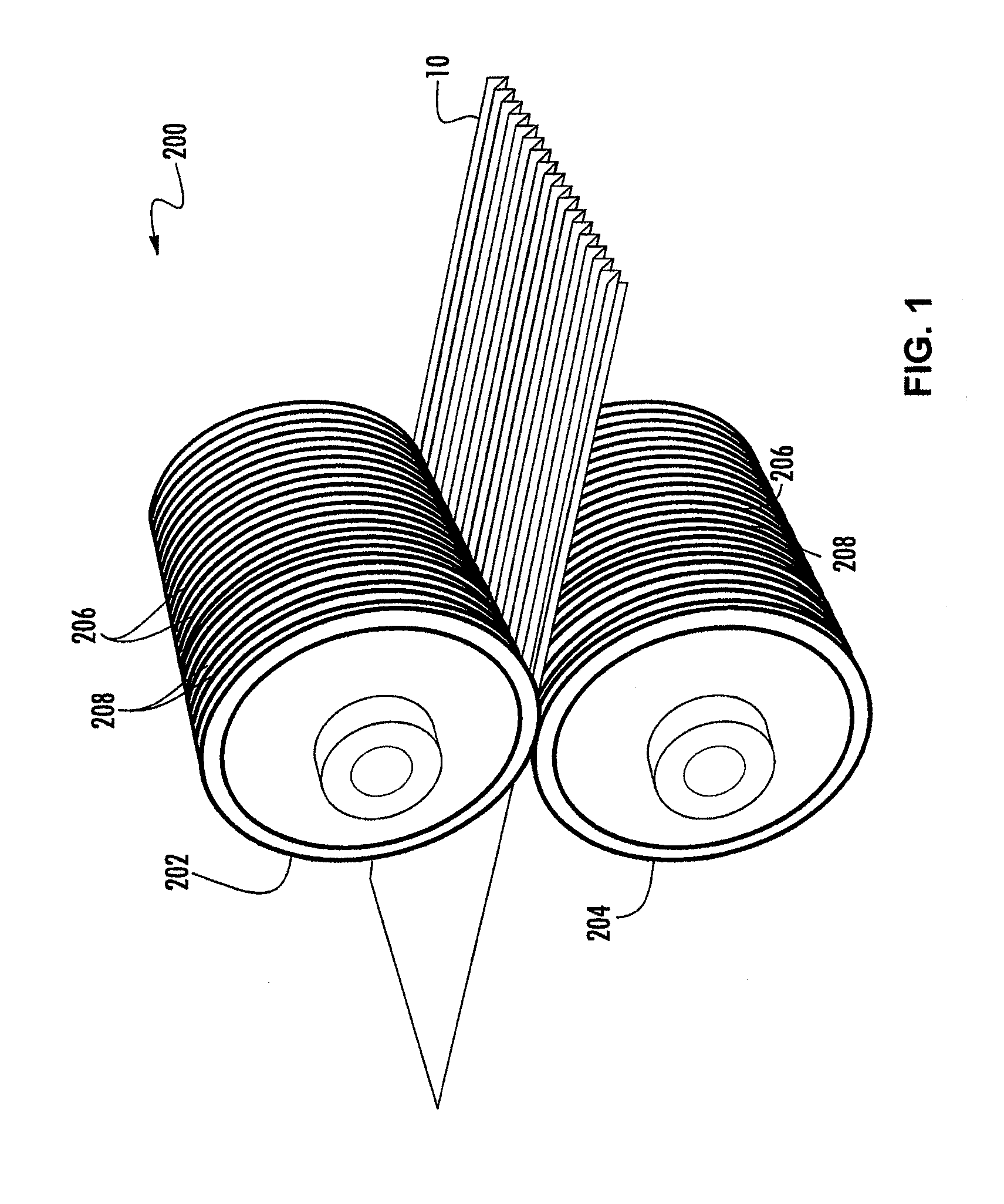

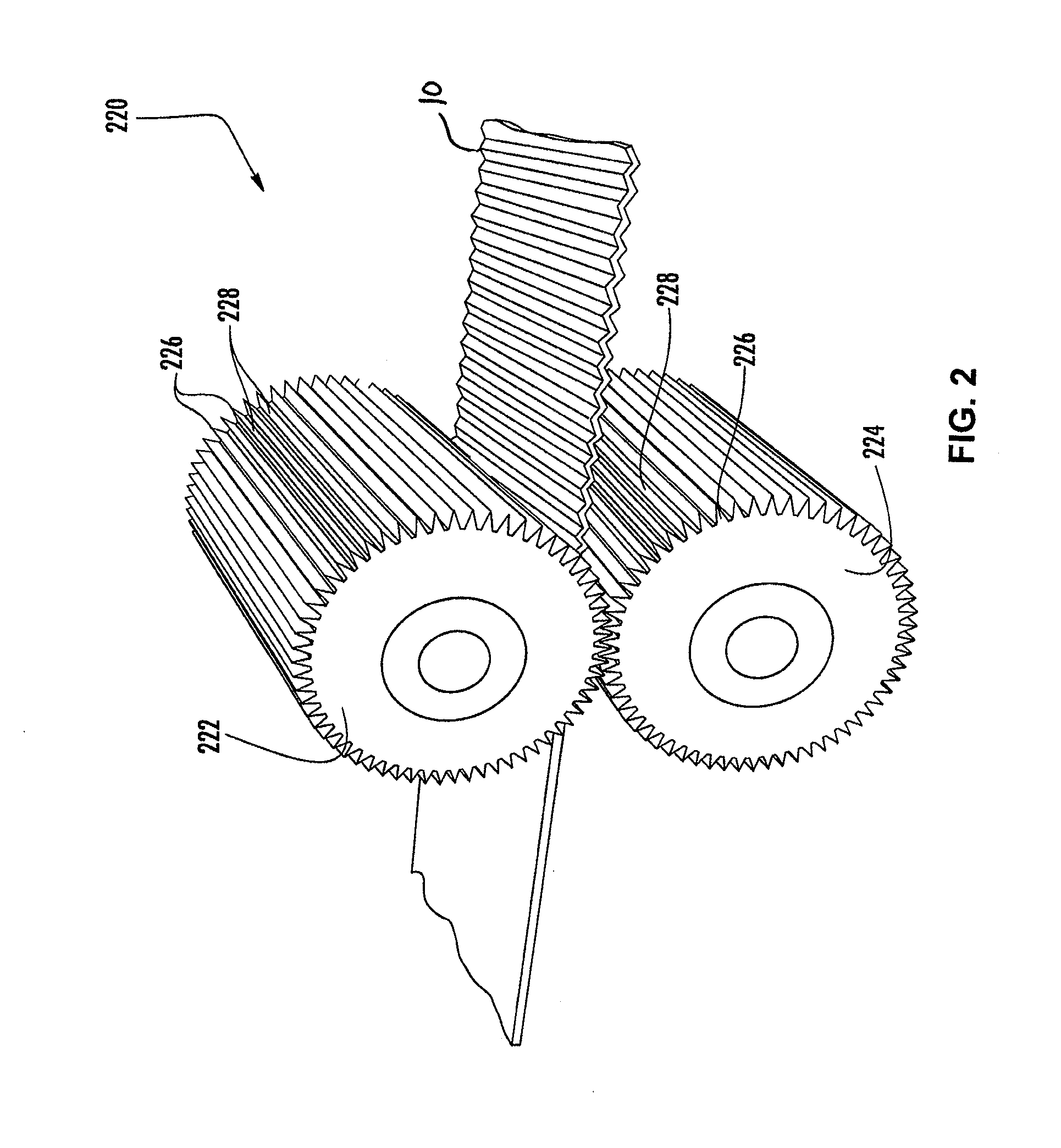

InactiveUS6331265B1Less tangleImprove mechanical propertiesMaterial nanotechnologyWood working apparatusPolymer scienceNanotube

Provided is a method for the production of a reinforced polymer, which method comprises:(a) introducing carbon nanotubes into a polymer to provide a mixture of the polymer and the nanotubes;(b) stretching the mixture at or above the melting temperature (Tm) of the polymer to orient the carbon nanotubes; and(c) stretching the mixture in the solid state to further orient the carbon nanotubes.

Owner:FINA RES SA

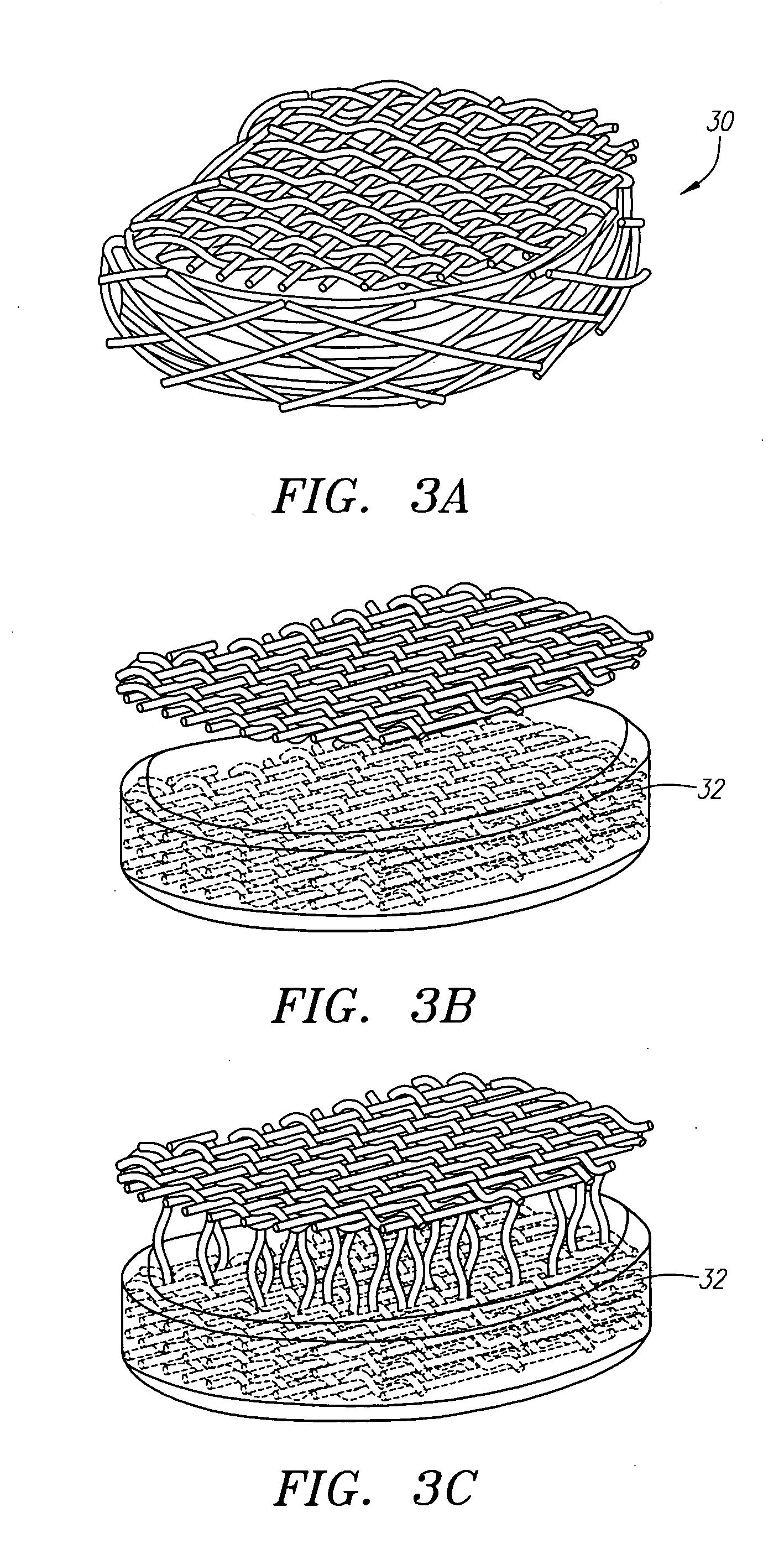

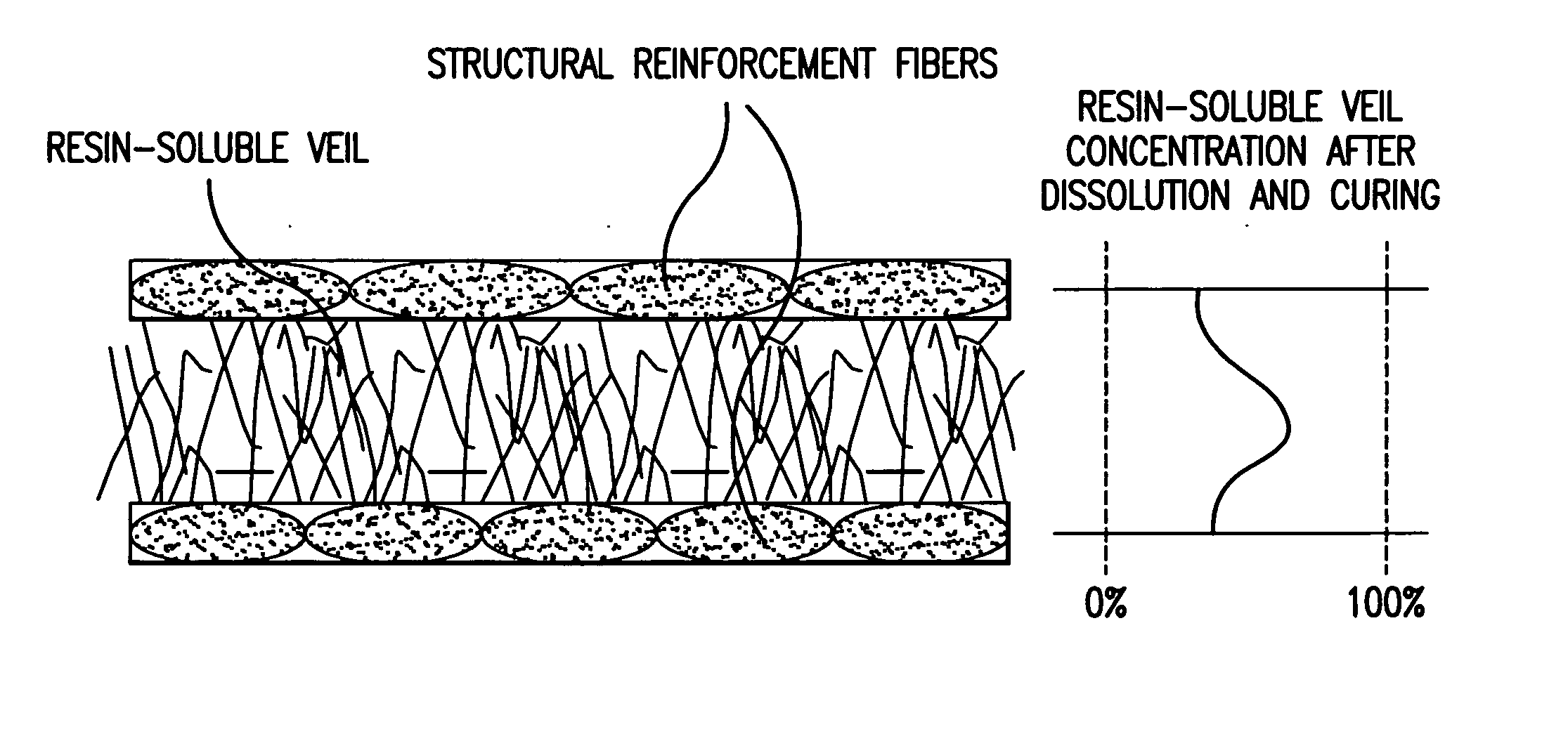

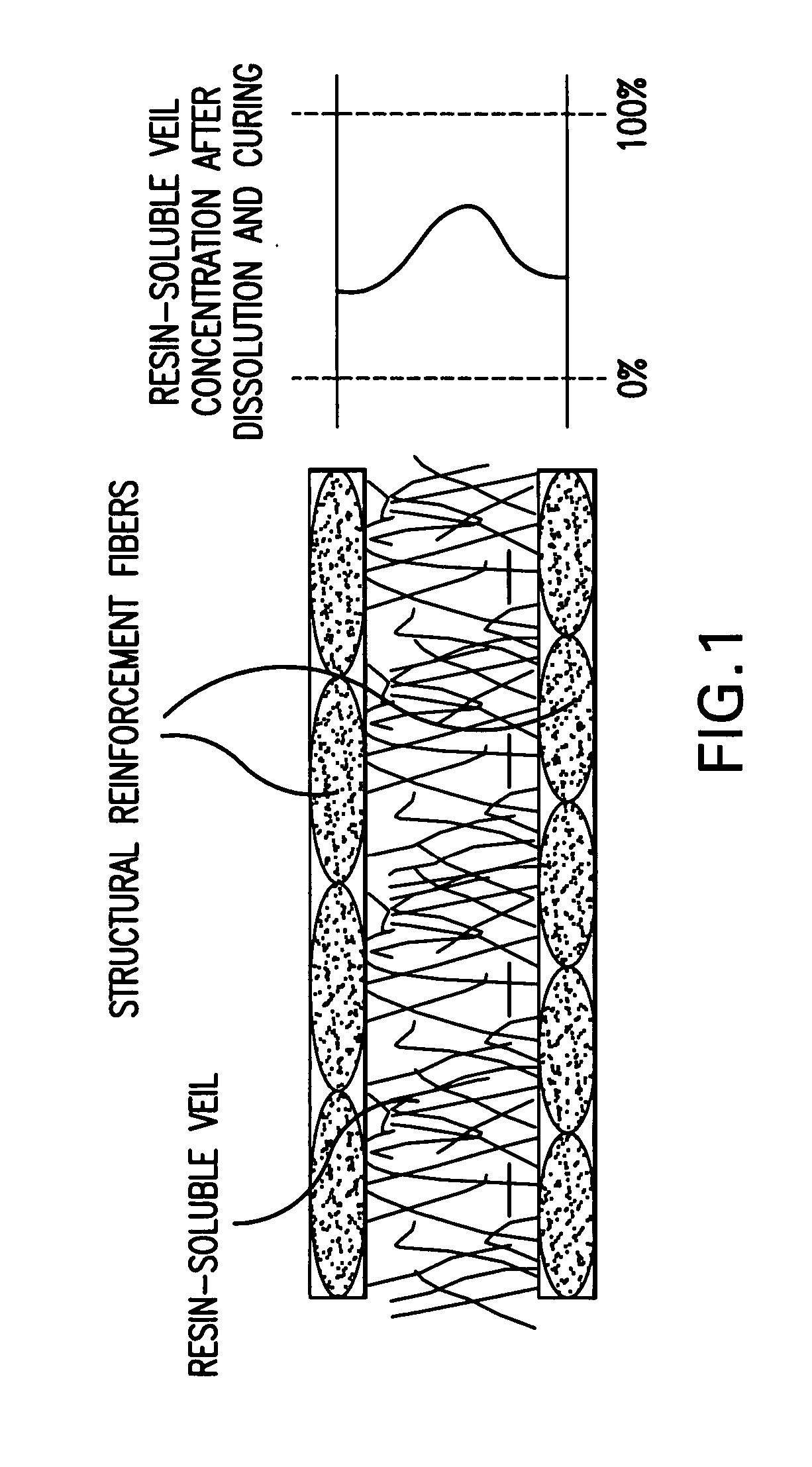

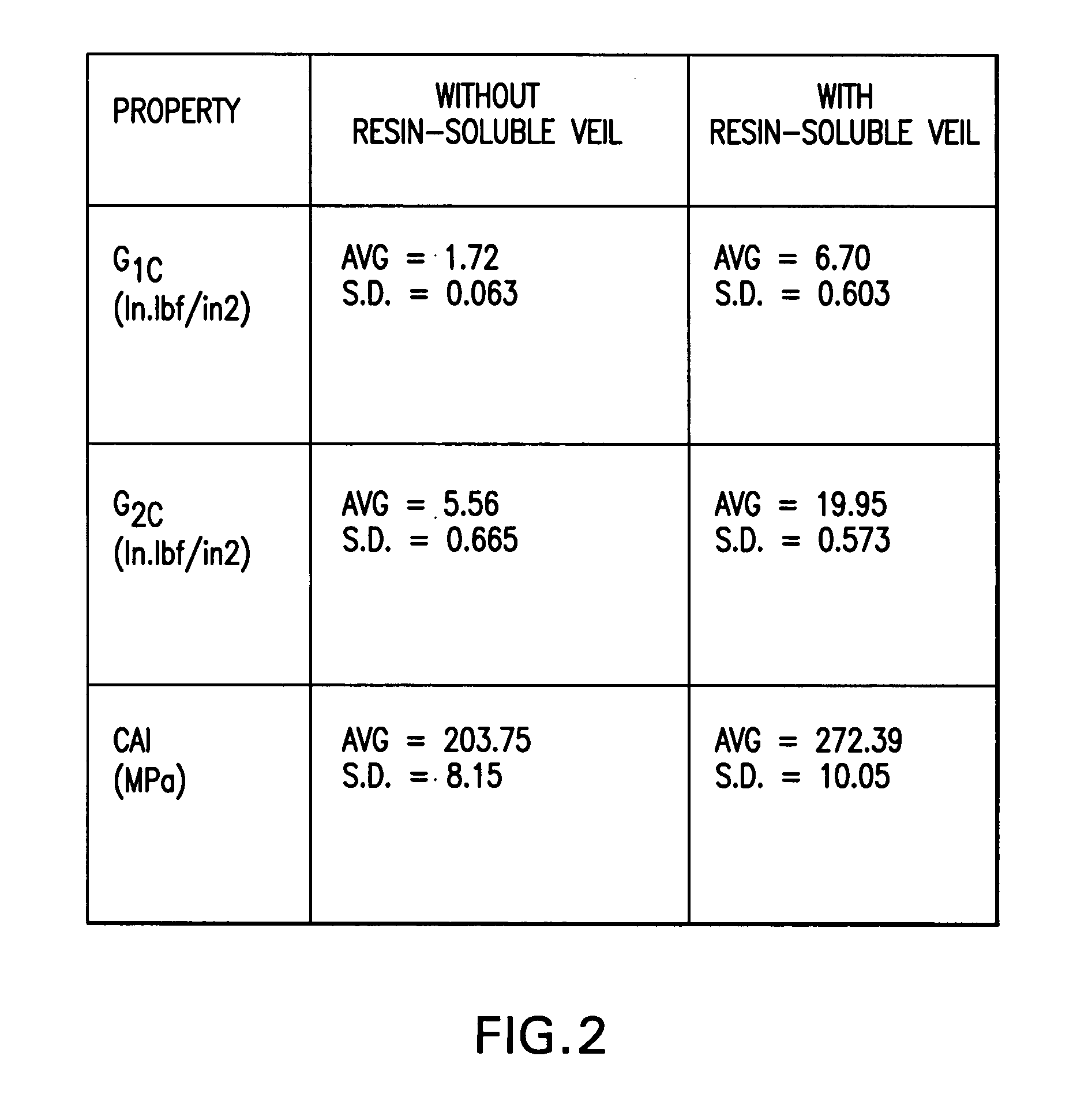

Resin-soluble thermoplastic veil for composite materials

ActiveUS20060252334A1Improve the level ofImprove toughnessWood working apparatusVehicle componentsFiberResin matrix

A resin-soluble thermoplastic polymer veil toughening element for a curable composition wherein the polymer element is a non-woven veil in solid phase adapted to undergo at least partial phase transition to fluid phase on contact with a component of the curable resin matrix composition in which it is soluble at a temperature which is less than the temperature for substantial onset of gelling and / or curing of the curable composition and which temperature is less than the polymer elements melt temperature; a method for the preparation thereof, a preform support structure for a curable composition comprising the at least one thermoplastic veil element together with structural reinforcement fibers, methods for preparation thereof, a curable composition comprising the at least one thermoplastic veil element or the support structure and a curable resin matrix composition, a method for preparation and curing thereof, and a cured composite or resin body obtained thereby, and known and novel uses thereof.

Owner:CYTEC TECH CORP

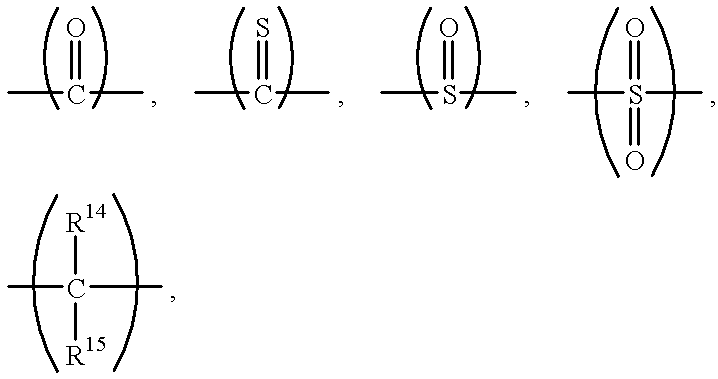

Implantable biomedical devices including biocompatible polyurethanes

Disclosed are implantable devices that include biocompatible polyurethane materials. In particular, the disclosed polyurethane materials can maintain desired elastomeric characteristics while exhibiting thermoset-like behavior and can exhibit improved characteristics so as to be suitable in load-bearing applications. For example, the disclosed polyurethane materials can be suitable for use in artificial joints, including total joint replacement applications. The disclosed polyurethane materials include biocompatible cross-linking agents as chain extenders, more particularly chain extenders comprising a terminal group capable of side reactions and further comprising an electron withdrawing group immediately adjacent the terminal group. In addition, the reaction materials and conditions can be selected to encourage intermediate levels of cross-linking without the use of traditional cross-linking trifunctional reagents. In addition, the chain extenders can also include substantially inflexible moieties so as to increase the rigidity of the product polyurethanes.

Owner:CLEMSON UNIVERSITY +1

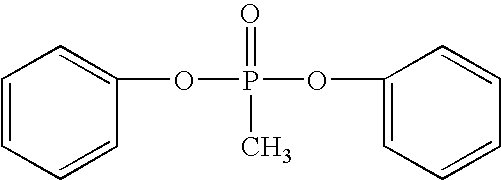

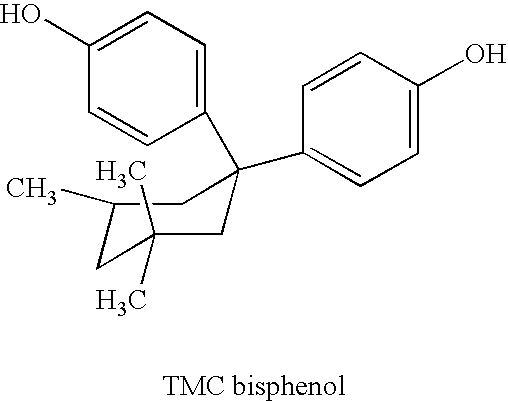

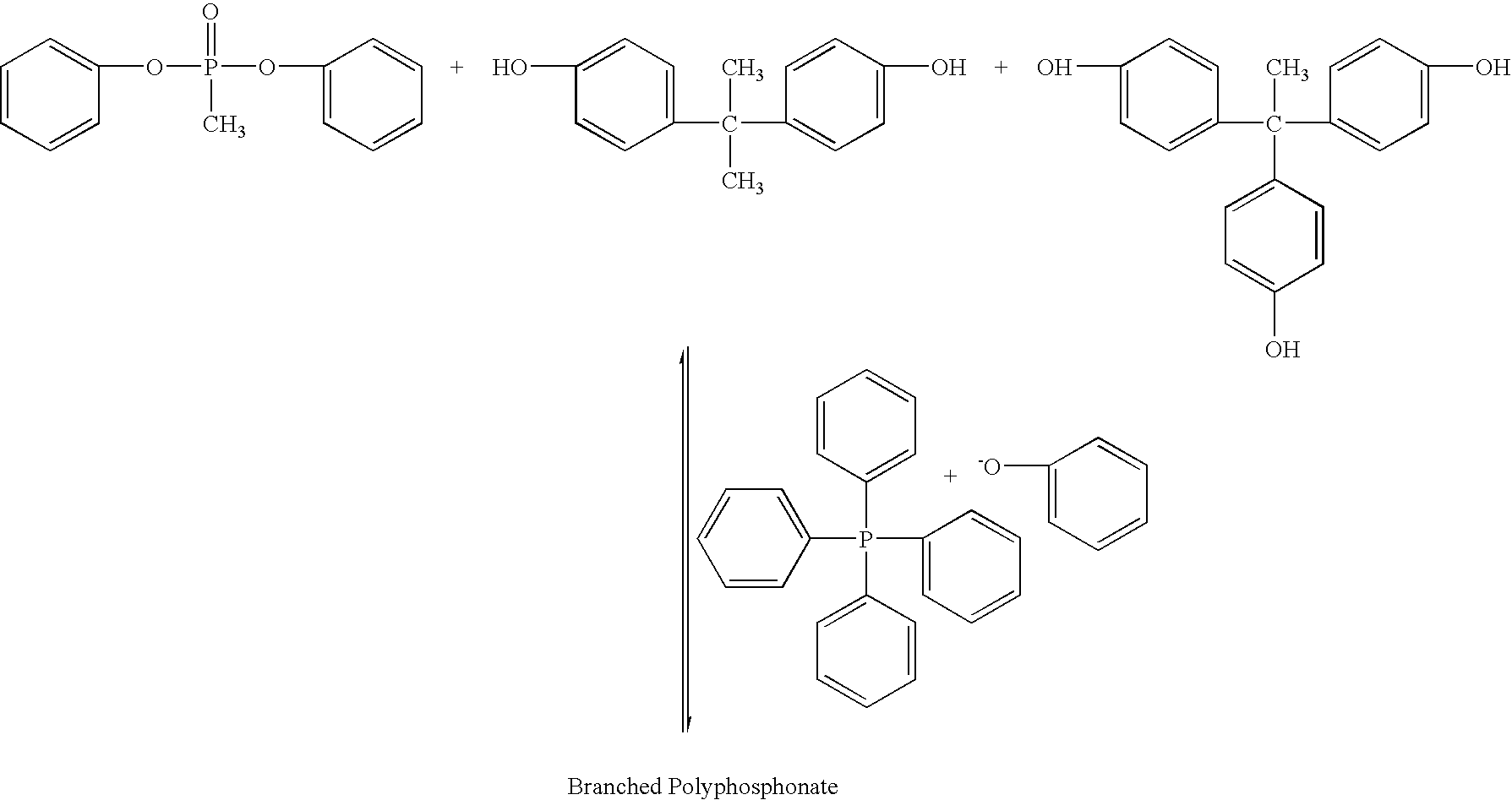

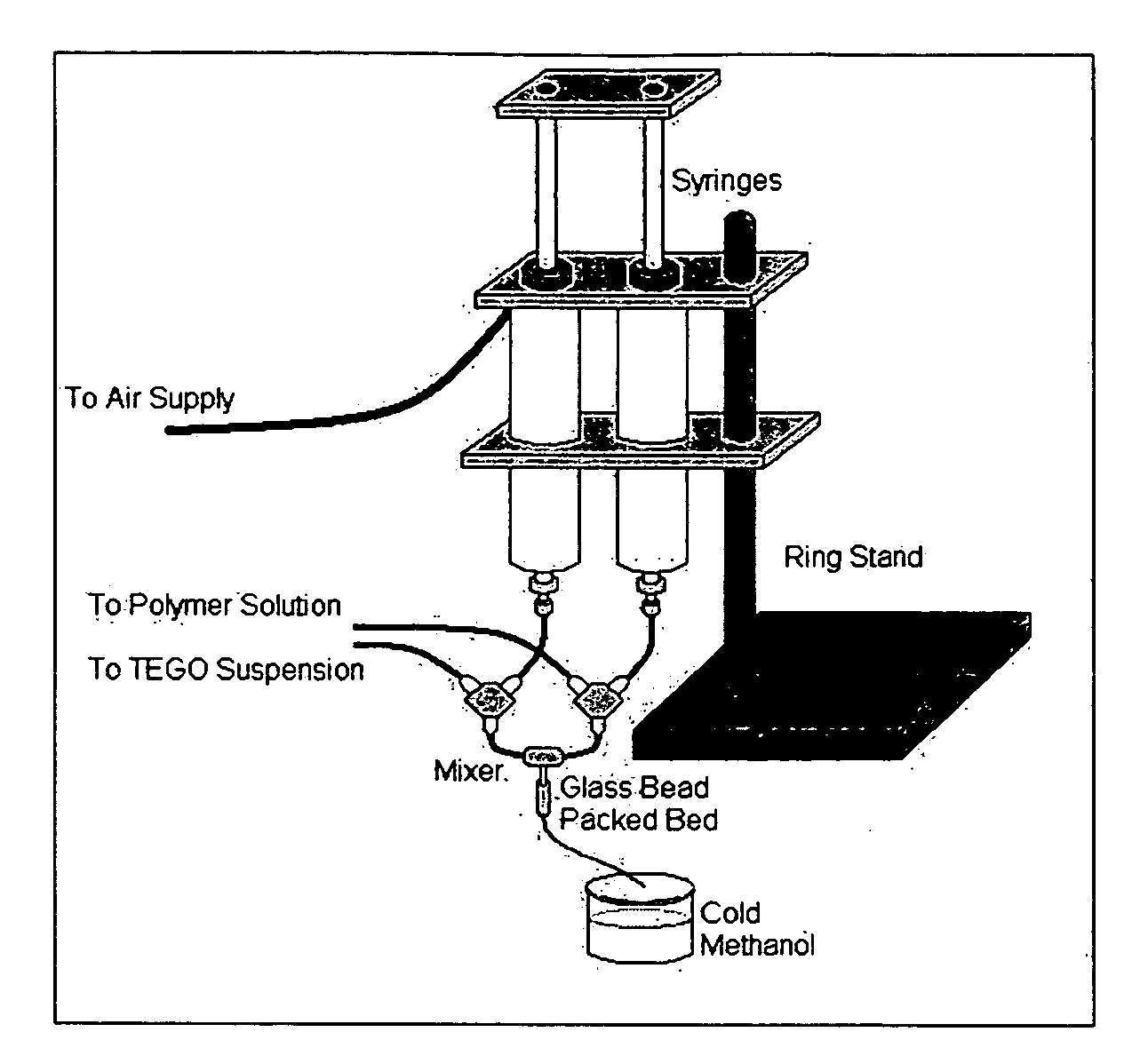

Branched polyphosphonates that exhibit an advantageous combination of properties, and methods related thereto

Disclosed are branched polyphosphonates produced via a superior transesterification process, and methods related thereto. These branched polyphosphonates exhibit a unique and advantageous combination of properties, such as outstanding fire resistance, improved heat stability, improved toughness, and superior processing characteristics. Also disclosed are polymer compositions that comprise these branched polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these polymers, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof; these articles may be coated with a moisture barrier to enhance their moisture resistance properties.

Owner:FRX POLYMERS LLC

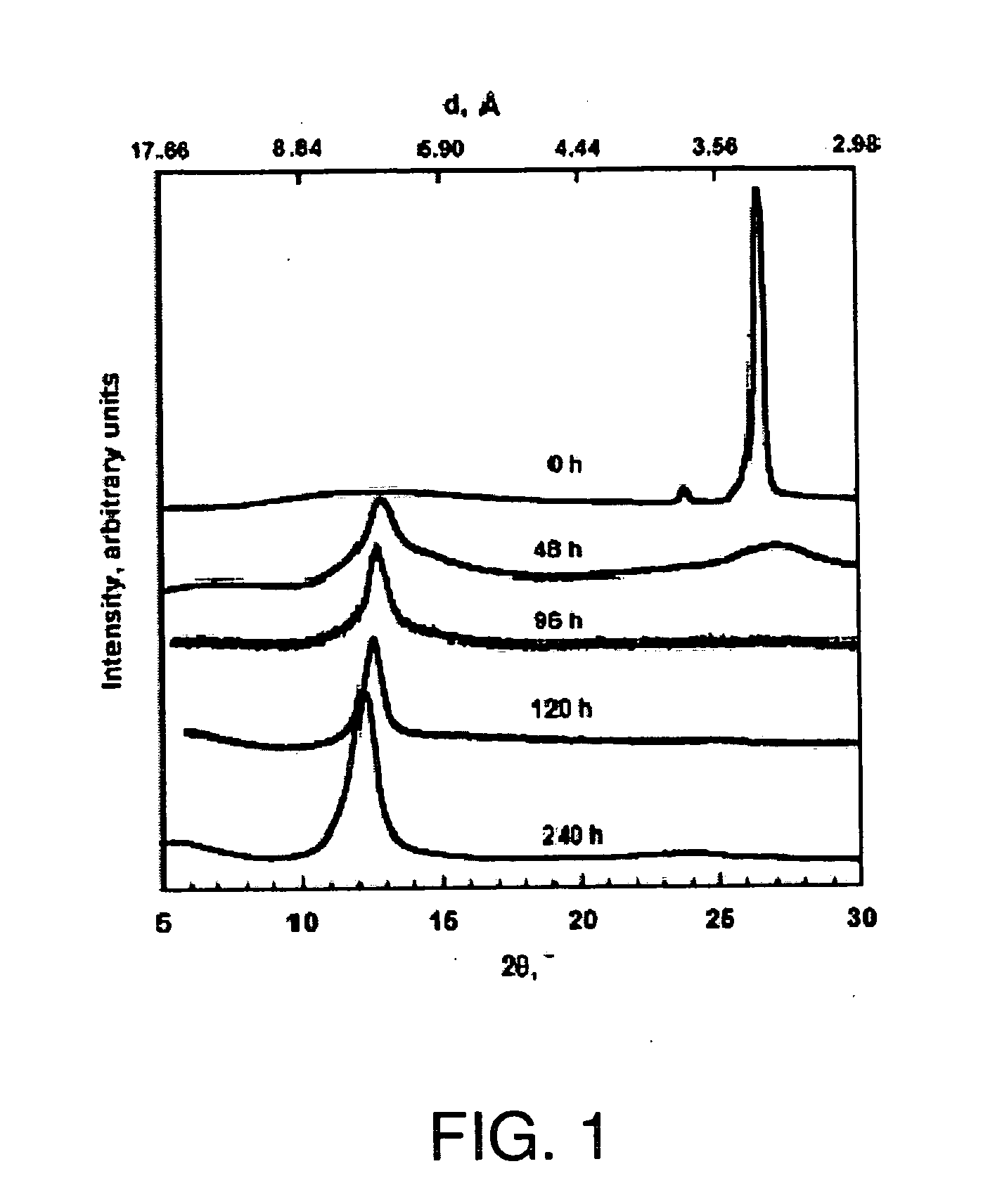

Functional graphene-polymer nanocomposites for gas barrier applications

InactiveUS20100096595A1Excellent gas barrier performanceImprove suppression propertiesMaterial nanotechnologyNanostructure manufactureNano compositesX-ray

Owner:THE TRUSTEES FOR PRINCETON UNIV

Shaped articles from cycloaliphatic polyester compositions

ActiveUS20050124779A1Improve melt processing characteristicIncrease stiffnessEnvelopes/bags making machinerySynthetic resin layered productsFiberPolyester

Disclosed are oriented, shaped articles such as, for example, film, fibers, bottles, and tubes, with excellent strength, toughness, clarity, chemical resistance, and UV resistance. The articles can be prepared from cycloaliphatic polyesters and from compositions comprising cycloaliphatic polyesters and cycloaliphatic polyester elastomers. The articles may be oriented by stretching in at least one direction and have a modulus which results in a soft feel. Also disclosed are polyester compositions comprising cycloaliphatic polyesters and polyester elastomers.

Owner:EASTMAN CHEM CO

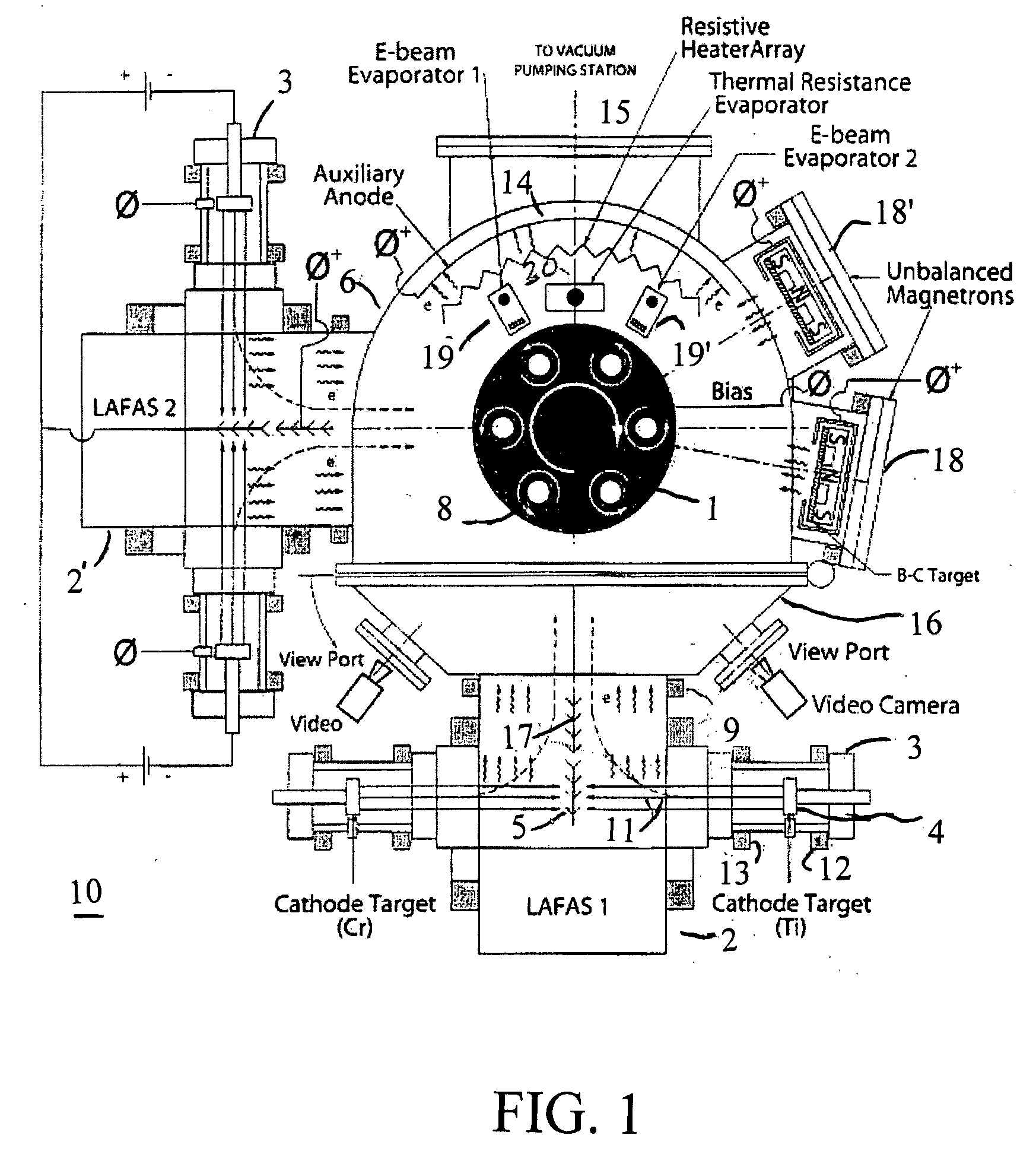

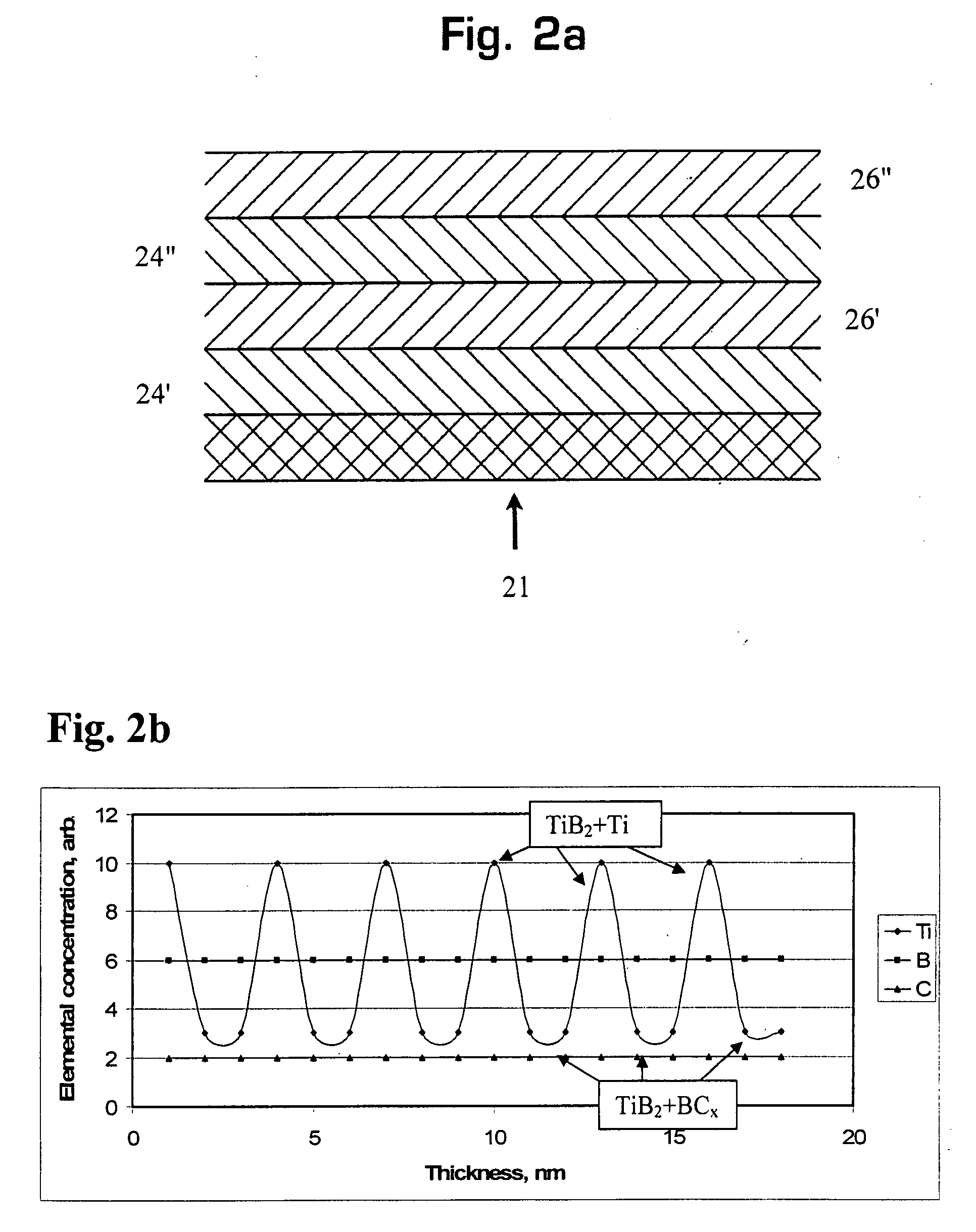

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS6812276B2Fast curingReduce sensitivitySynthetic resin layered productsSpecial tyresEndcappingHeat resistance

Owner:SABIC GLOBAL TECH BV

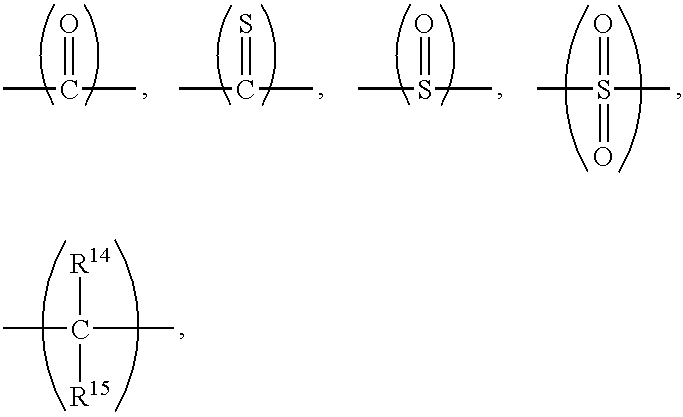

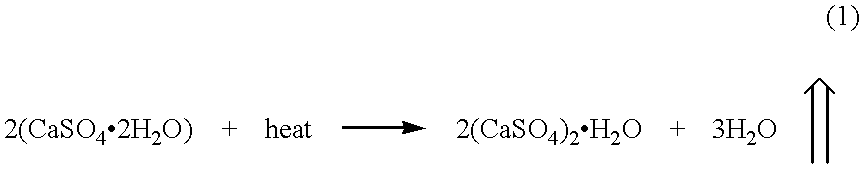

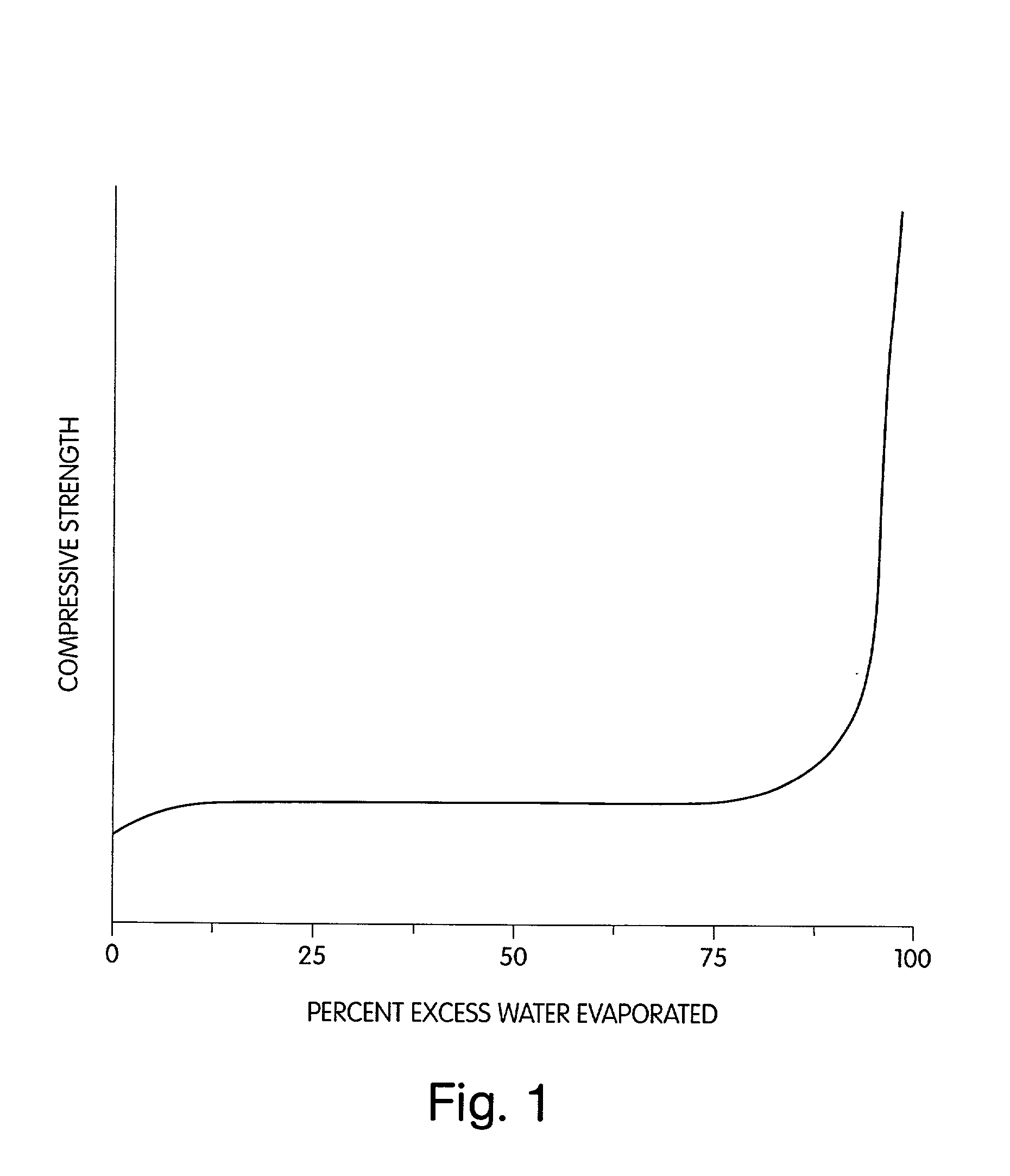

Three dimensional printing material system and method

InactiveUS20020026982A1High strengthReduce the amount of solutionSolid waste managementCeramic shaping apparatusEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

Polymeric/ceramic composite materials for use in medical devices

ActiveUS20060230476A1Improve featuresEnhanced abrasionStentsBalloon catheterCeramic compositeMedical device

Owner:BOSTON SCI SCIMED INC

Poly (arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS20030096123A1Fast curingReduced curing rate oxygen sensitivitySynthetic resin layered productsSpecial tyresHeat resistanceEther

Owner:SABIC GLOBAL TECH BV

Extensible Nonwoven Fabric

ActiveUS20140276517A1High elongationImprovement in one or moreBaby linensWoven fabricsExtensibilityNonwoven fabric

Extensible nonwoven fabrics having improved elongation, extensibility, abrasion resistance and toughness. In particular, embodiments of the invention are directed to extensible spunbond fabrics comprising a polymeric blend of a metallocene catalyzed polypropylene, polyethylene, and a third polymer component.

Owner:FITESA GERMANY +1

Preparation method of high-strength hydrogel

InactiveCN103739861AThe preparation process takes a short timeReduce energy consumptionPolymer chemistryDouble network

The invention relates to a high-strength hydrogel and a preparation method thereof. The preparation method comprises the steps of directly mixing a polymer, a monomer, an initiator, a cross-linking agent and water once, dissolving all the substances to form a homogeneous solution under a certain simulation condition, and then initiating and polymerizing by using heat or light to obtain the high-strength hydrogel, wherein the polymer is needed for preparation of the hydrogel and used for forming a first double network of a dual-network hydrogel; the monomer is used for polymerizing and forming a second double network of the dual-network hydrogel; the initiator is used for initiating the monomer to be polymerized; the cross-linking agent is used for performing cross-linking reaction in a monomer polymerizing process so as to form the second double network. According to the preparation method, a one-pot method is used for preparing the high-strength hydrogel, so that the method is simple and practicable; the prepared high-strength hydrogel has the characteristics of high strength and high toughness; a tensile strength of the gel is 0.6-1.2MPa, a tensile modulus is 100-200 KPa and a tensile strain reaches 1000-2680%; the prepared high-strength hydrogel can be widely applied to the fields of tissue repair, artificial organ, drug sustained release, sensors and the like.

Owner:HENAN POLYTECHNIC UNIV

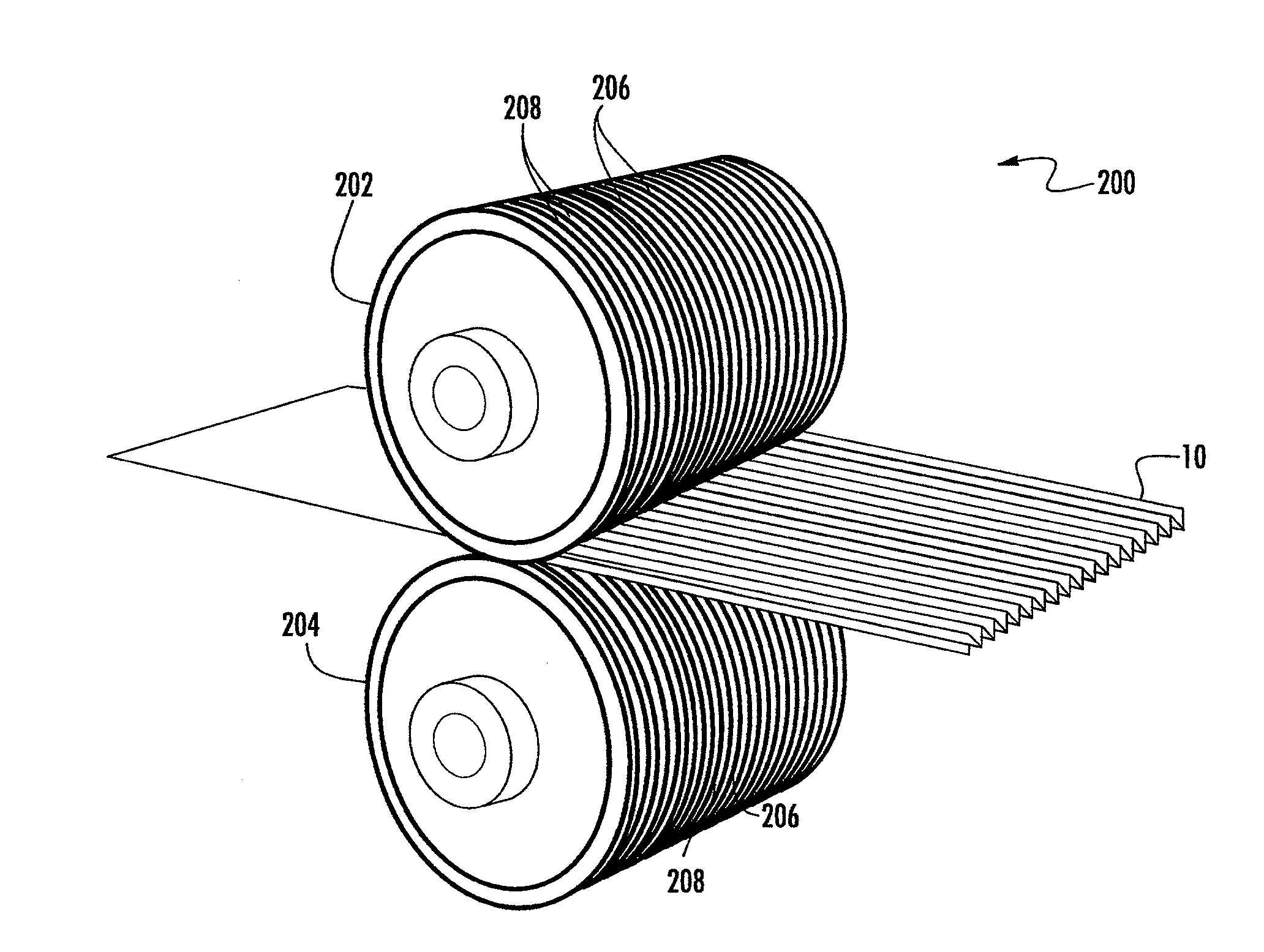

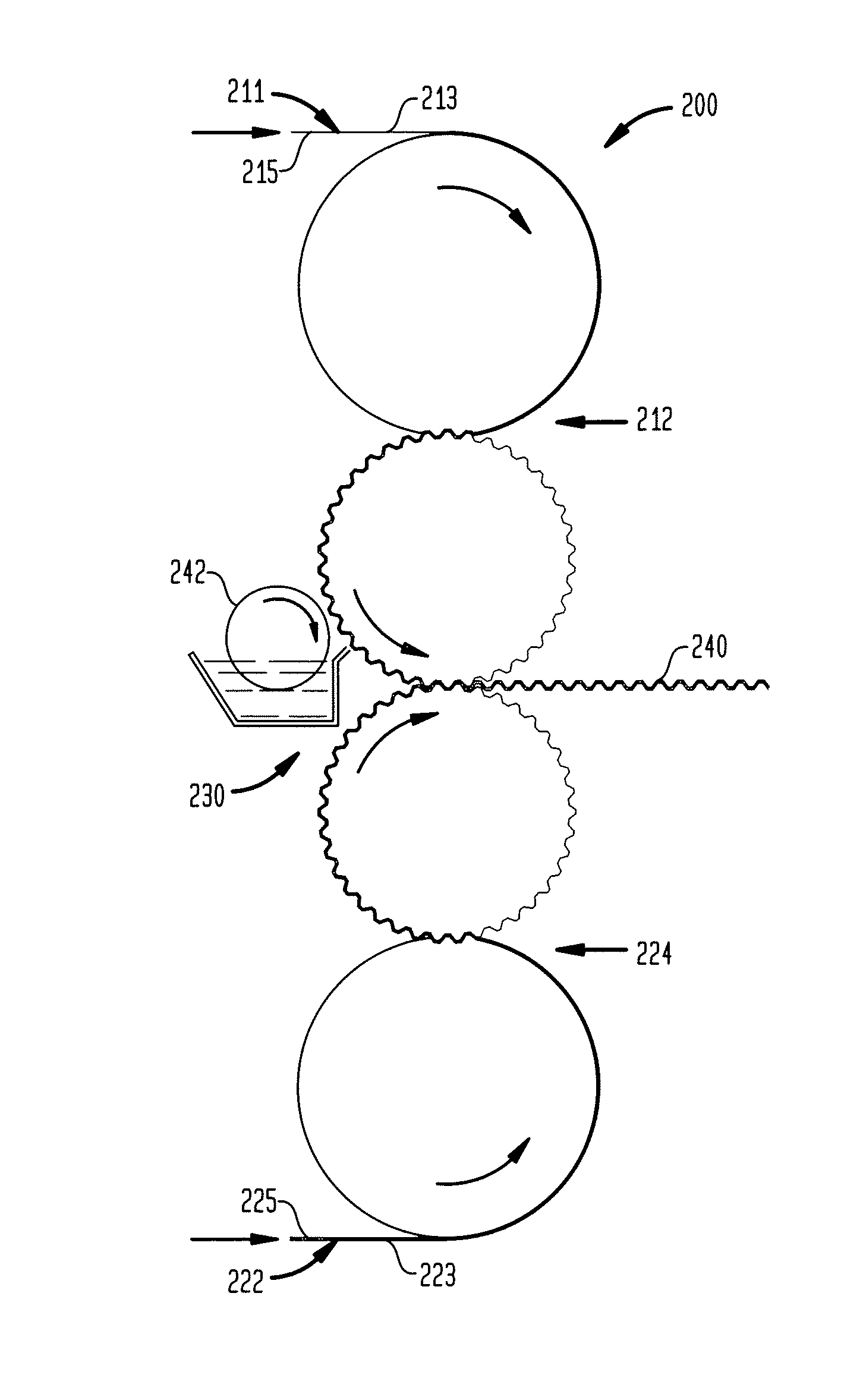

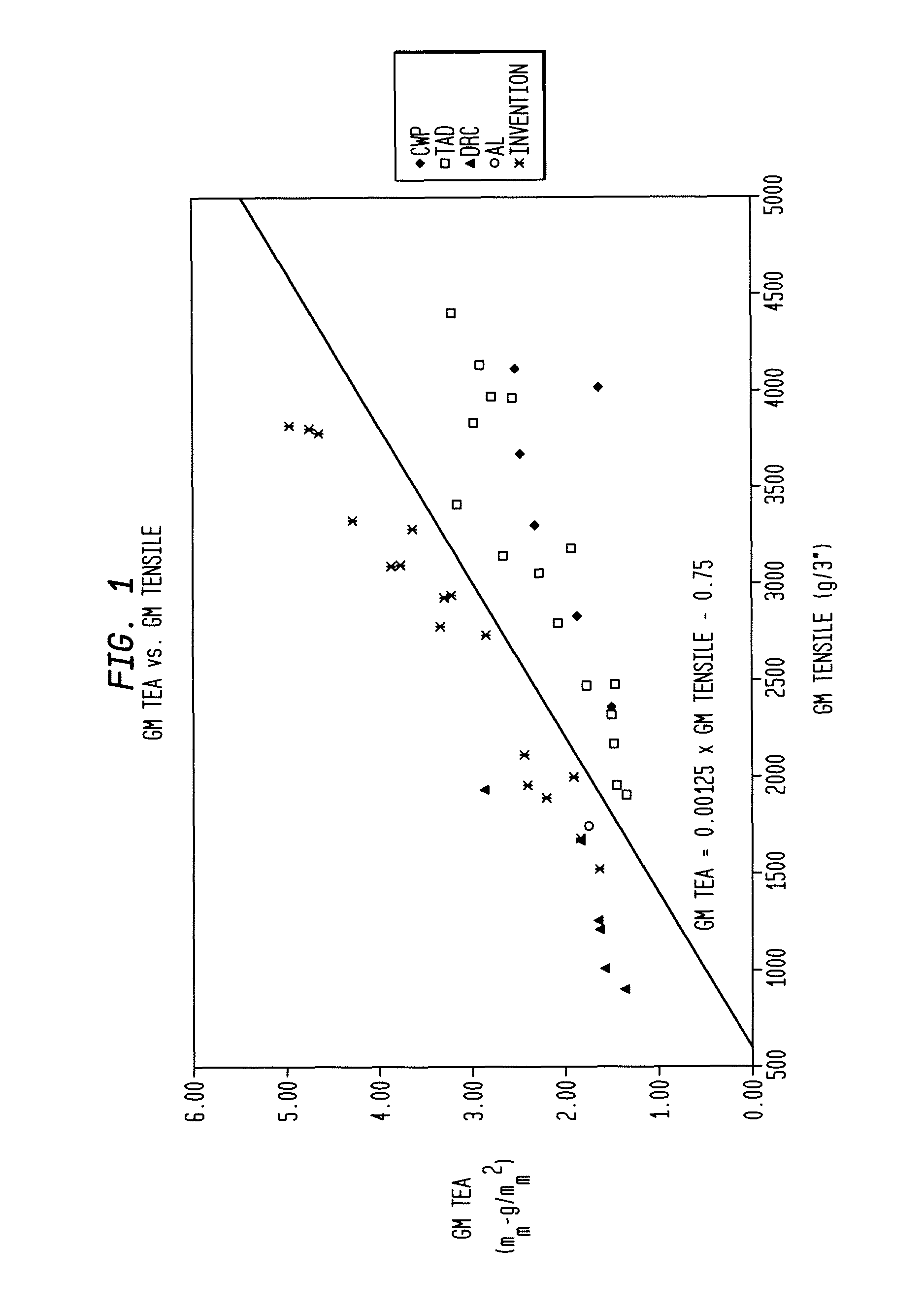

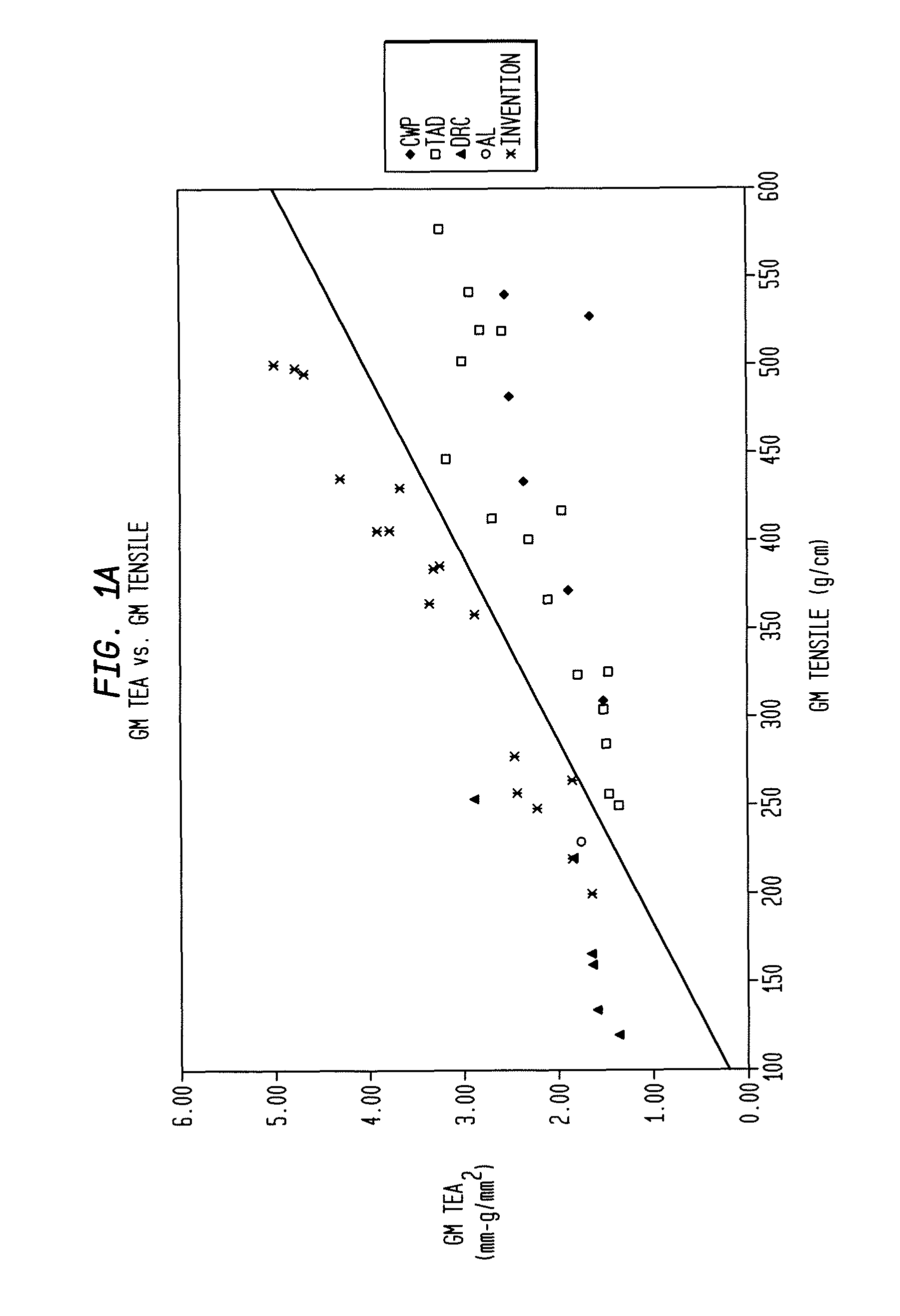

Multi-ply paper towel with creped plies

ActiveUS8409404B2Improve toughnessHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaper towel

A multi-ply absorbent towel made from papermaking fiber comprising at least a first ply and a second ply bonded together, the towel having a basis weight of greater than 30 lbs per 3000 ft2 ream (48.8 gsm) and less than 50 lbs per 3000 ft2 ream (81.4 gsm), wherein the plies are selected and adhered together such that the towel typically exhibits (i) a GM TEA, mm-g / mm2 of greater than [0.00125 (GM Tensile, g / 3″)−0.75] and (ii) a GM Tensile Modulus, g / in / %, less than [0.0083 (GM Tensile Strength, g / 3″)+15.4] {(i) a GM TEA, mm g / mm2, of greater than [0.00952 (GM Tensile, g / cm)−0.75] and (ii) a GM Tensile Modulus, g / cm / %, less than [0.0249 (GM Tensile Strength, g / cm)+6.06}.

Owner:GPCP IP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com