Patents

Literature

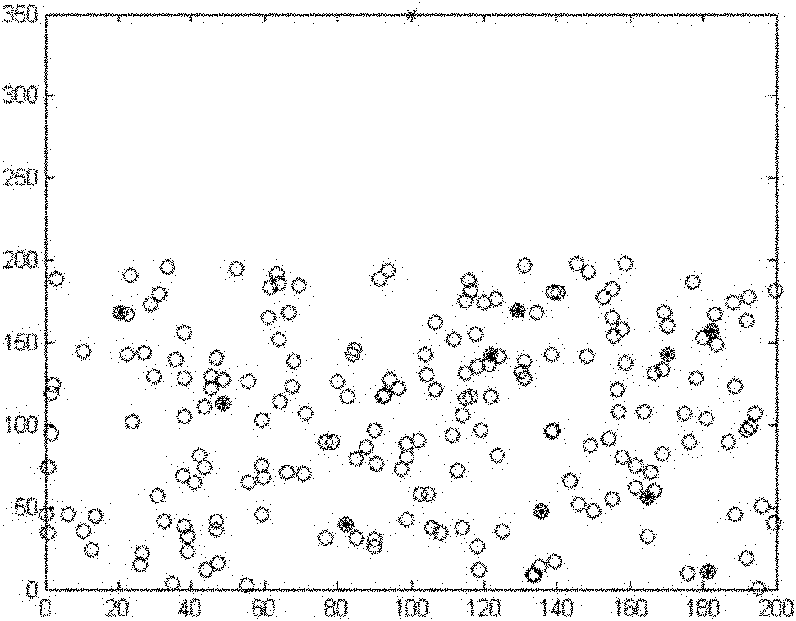

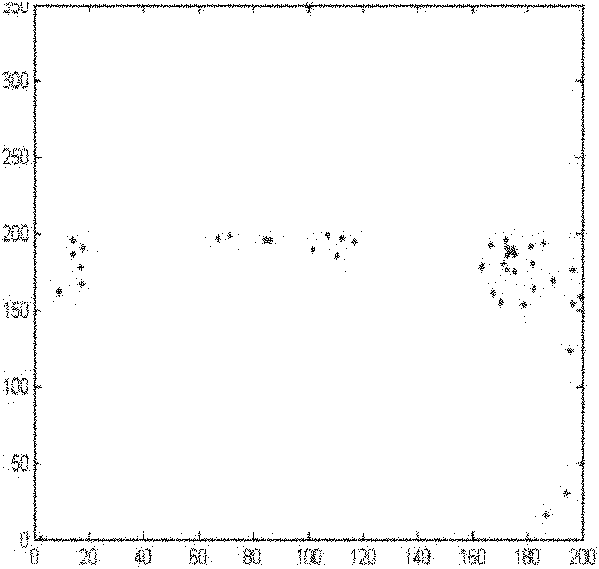

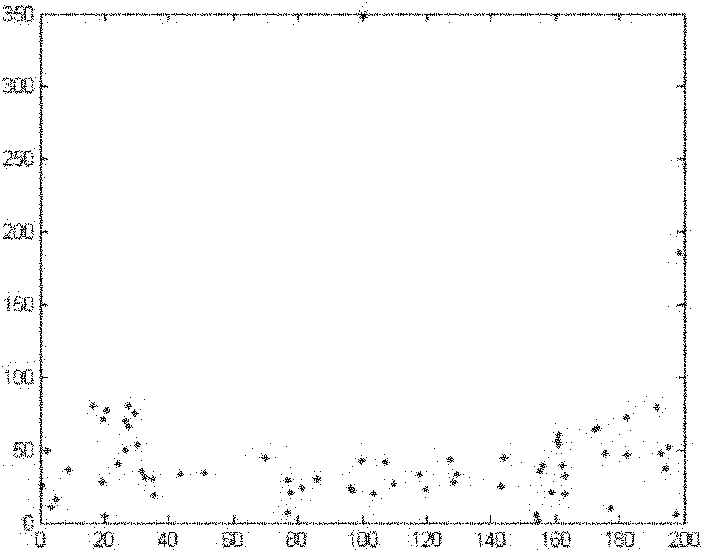

9403results about How to "Improve ductility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bioabsorbable Polymer, Bioabsorbable Composite Stents

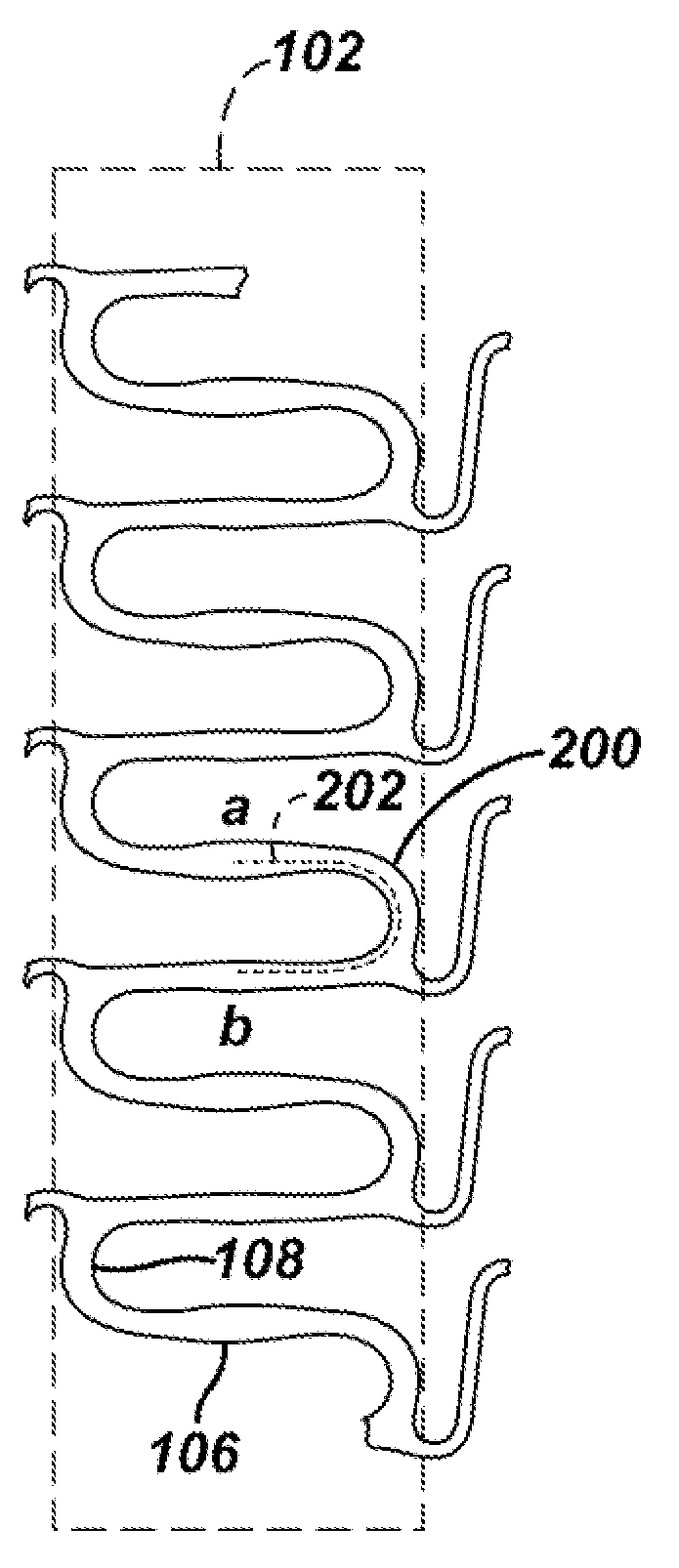

InactiveUS20080249608A1Simple and inexpensive to manufactureVarying of ductilityStentsSurgeryMetallic materialsMedical device

Biocompatible materials may be configured into any number of implantable medical devices including intraluminal stents. The biocompatible material may comprise metallic and non-metallic materials in hybrid structures. In one such structure, a device may be fabricated with one or more elements having an inner metallic core that is biodegradable with an outer shell formed from a polymeric material that is biodegradable. Additionally, therapeutic agents may be incorporated into the microstructure or the bulk material.

Owner:CORDIS CORP

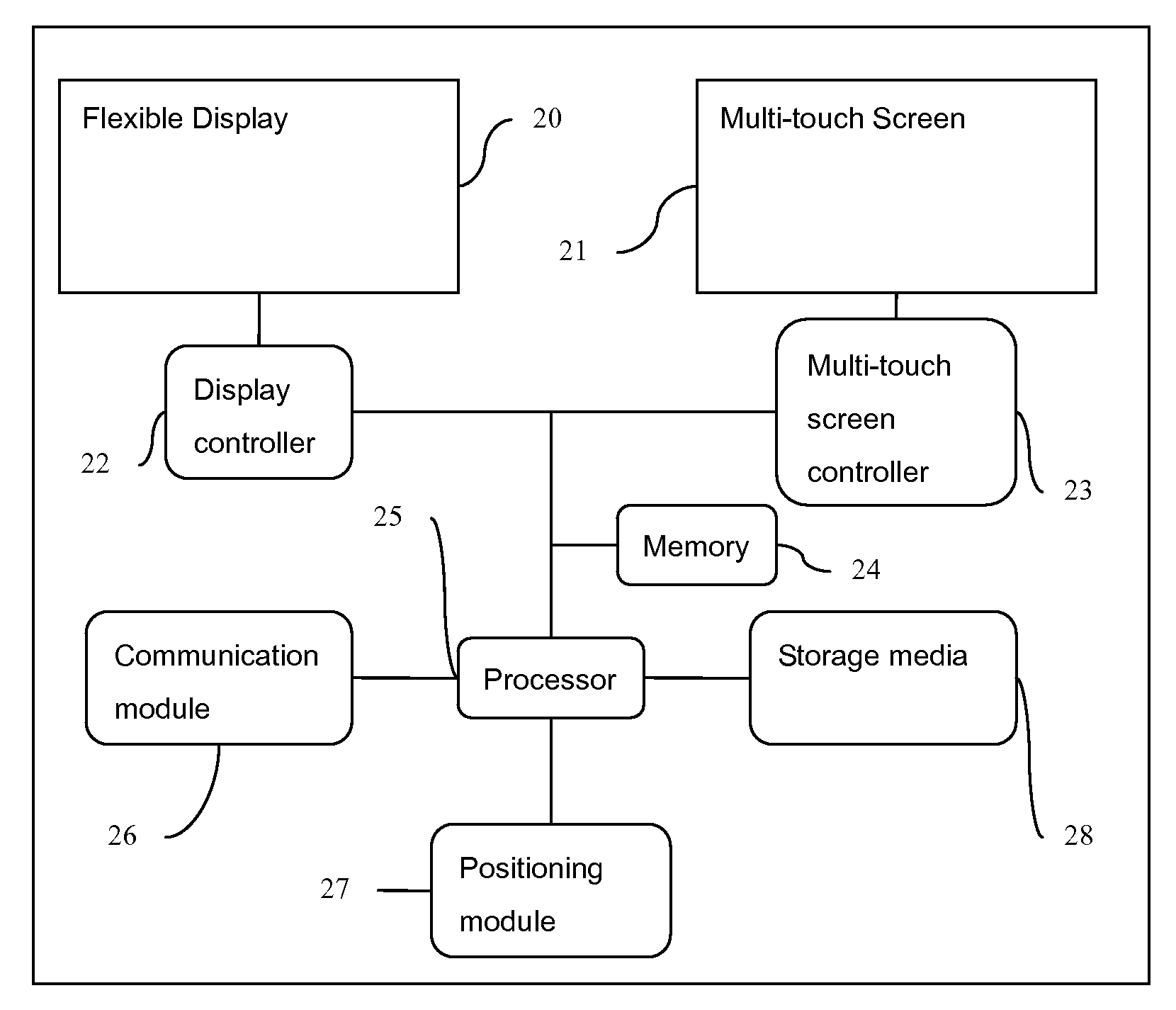

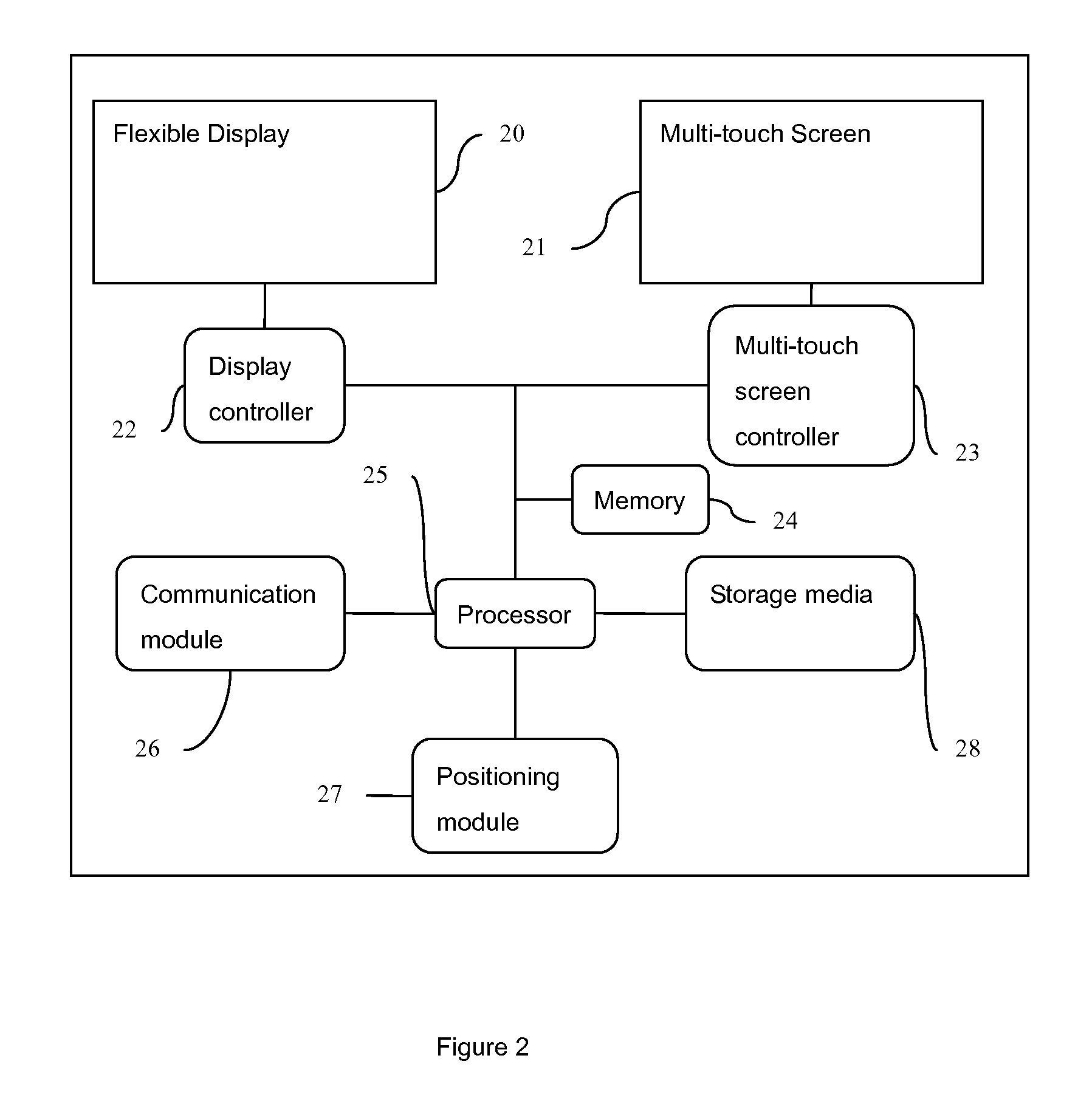

Flexible Multi-touch Screen

InactiveUS20080180399A1Easy to makeLow costInput/output processes for data processingDisplay deviceTouchpad

A method, apparatus, and system of flexible multi-touch touch are provided. The invention comprising: a flexible layer; and one or more sensors configured to detect a plurality of simultaneous touching positions at distinct locations of the layer and to generate distinct signals representative of the locations for each of the touches. And a method for flexible touch panel comprising: driving one or more sensors; and detecting a plurality of simultaneous touching positions at distinct locations of a touch panel, wherein the touch panel comprising a flexible property. The invention is also directed towards a flexible multi-touch screen device, comprising: a display as user interface; and a multi-touch panel with flexible property to combine with the display configured to detect a plurality of simultaneous touching positions at distinct locations of the multi-touch panel.

Owner:CHENG TUNG WAN

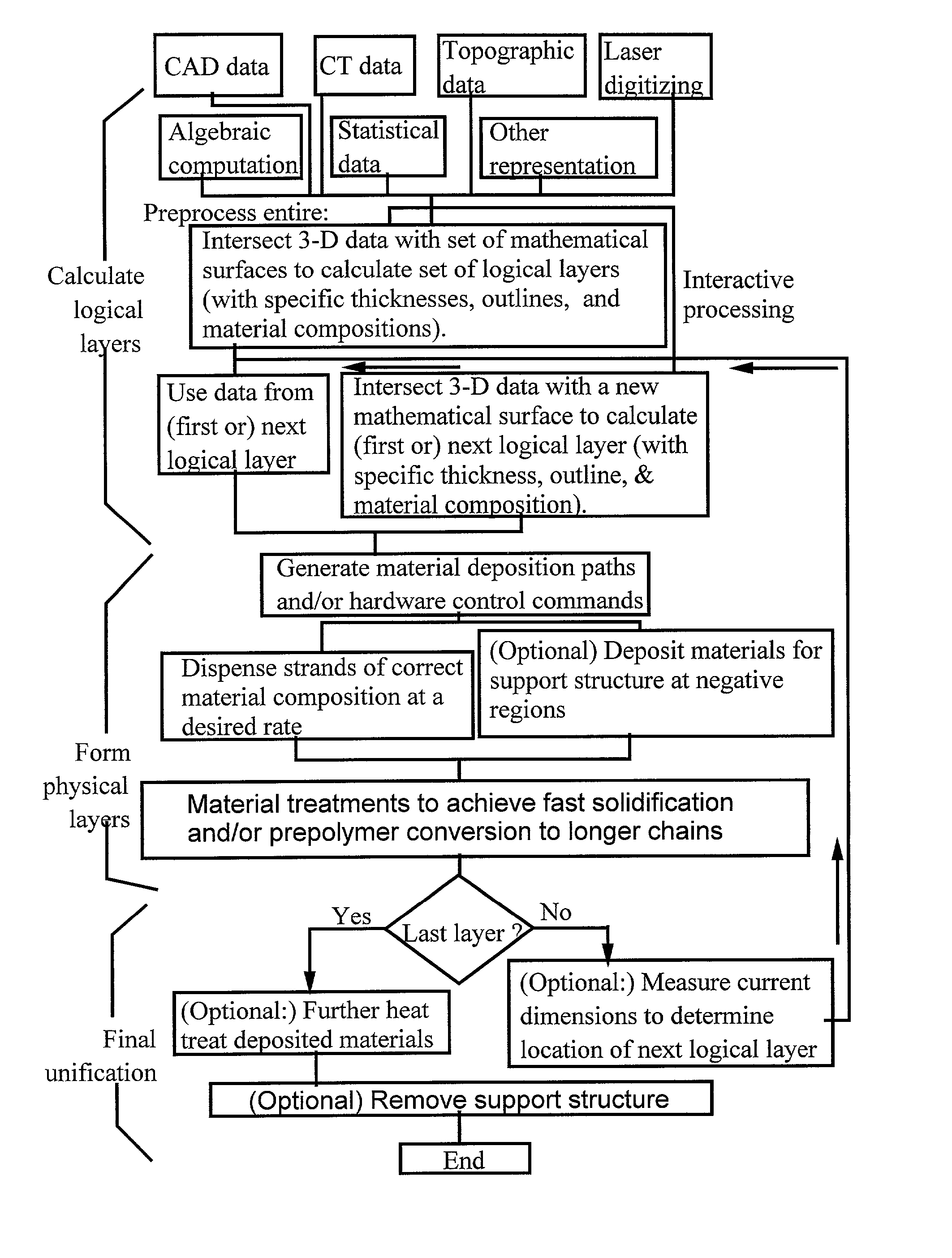

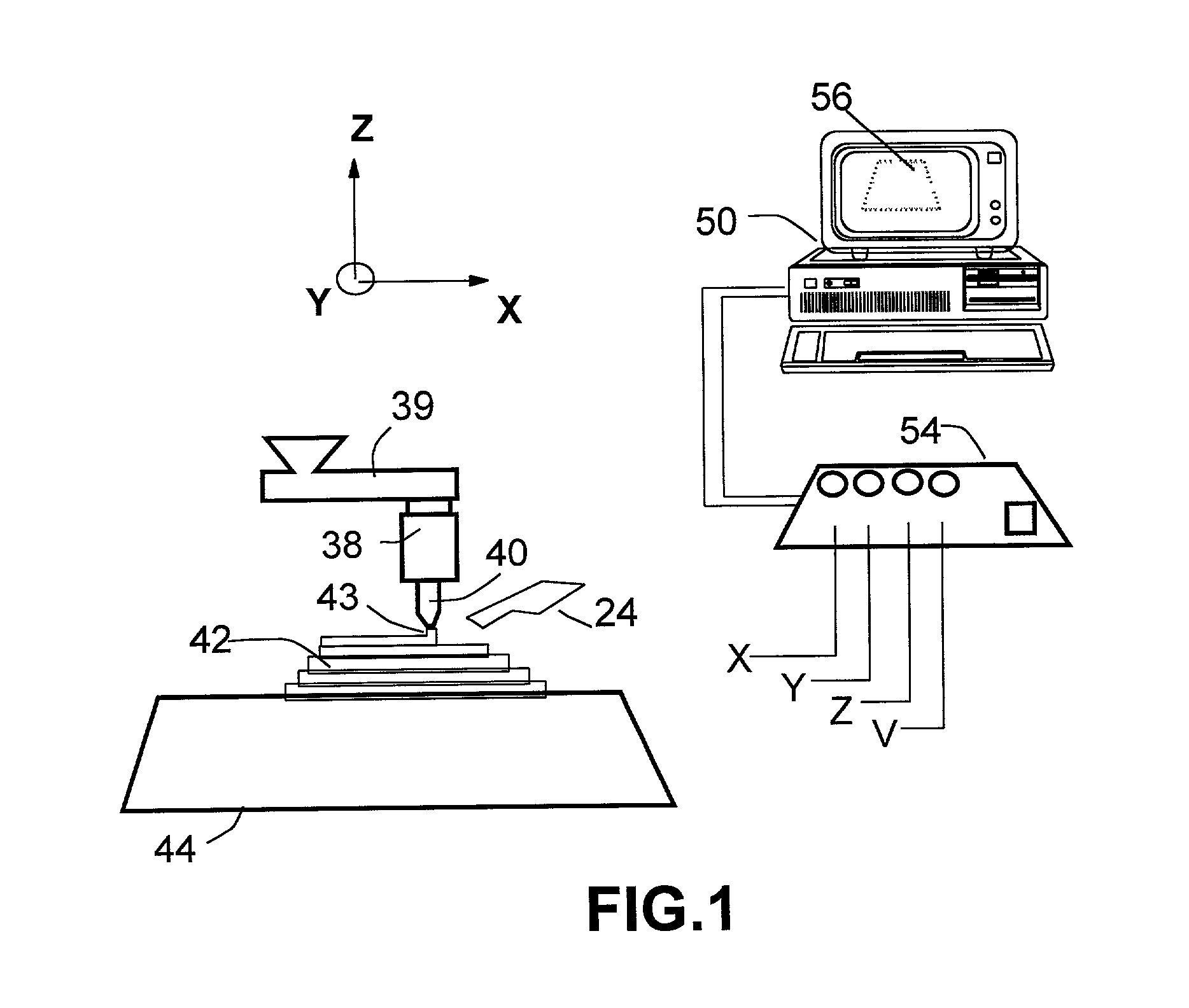

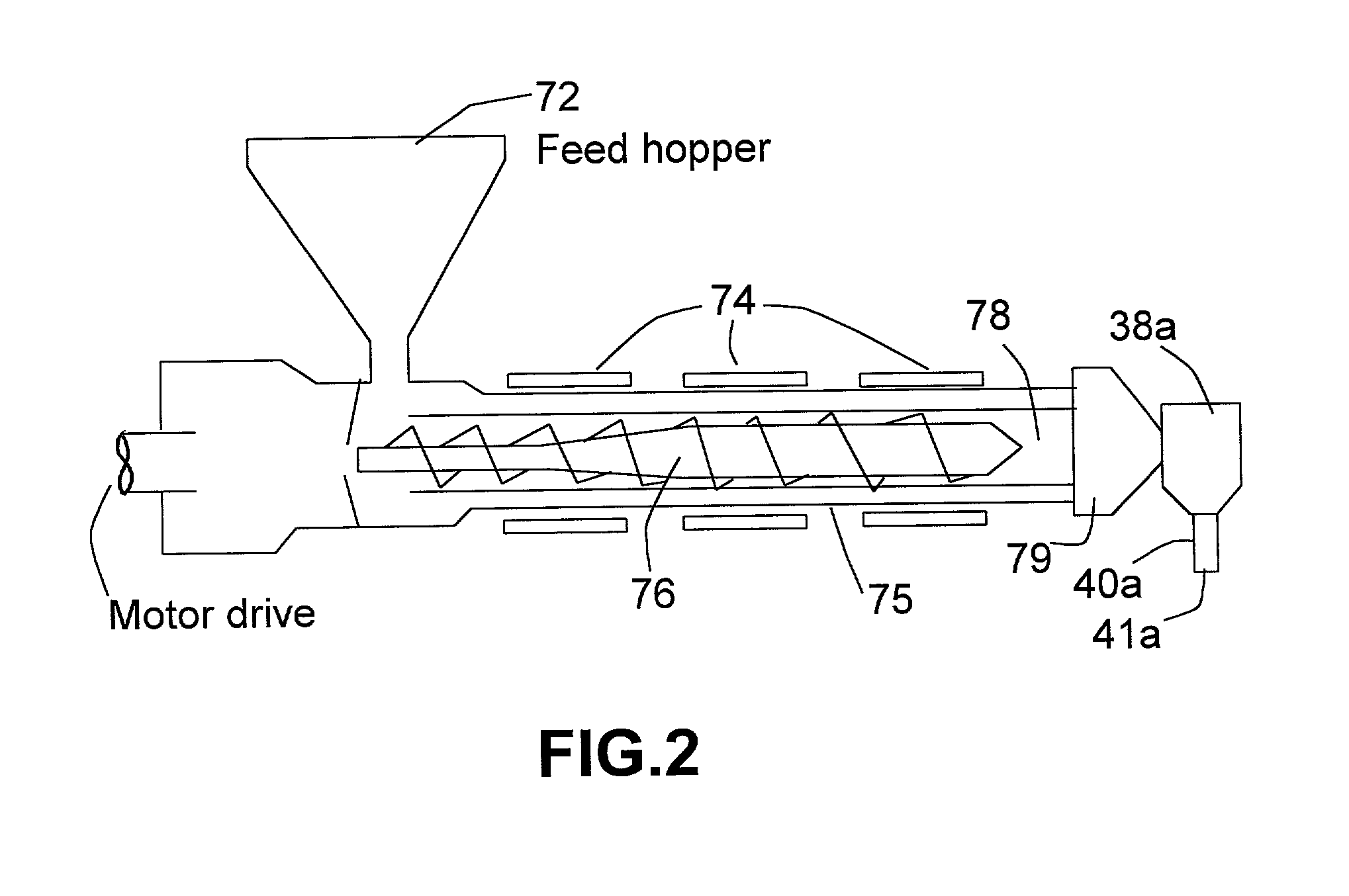

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

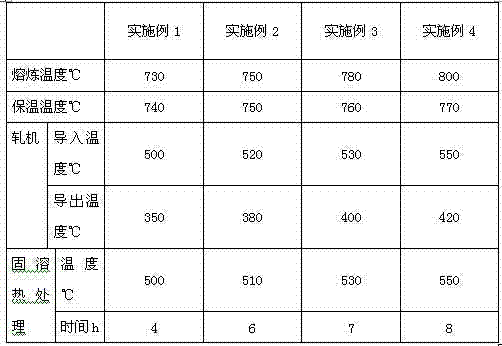

A kind of aluminum alloy material and preparation method thereof

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

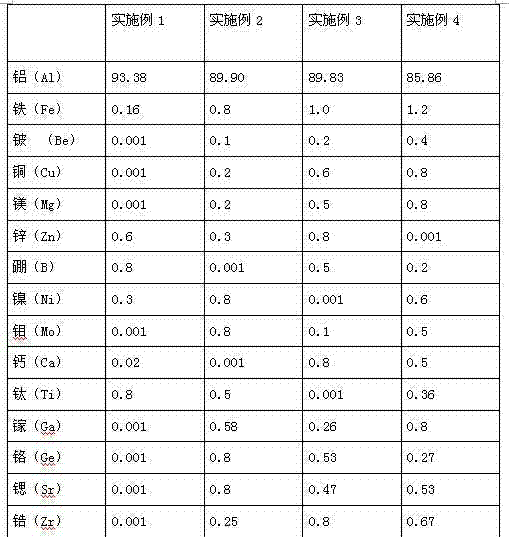

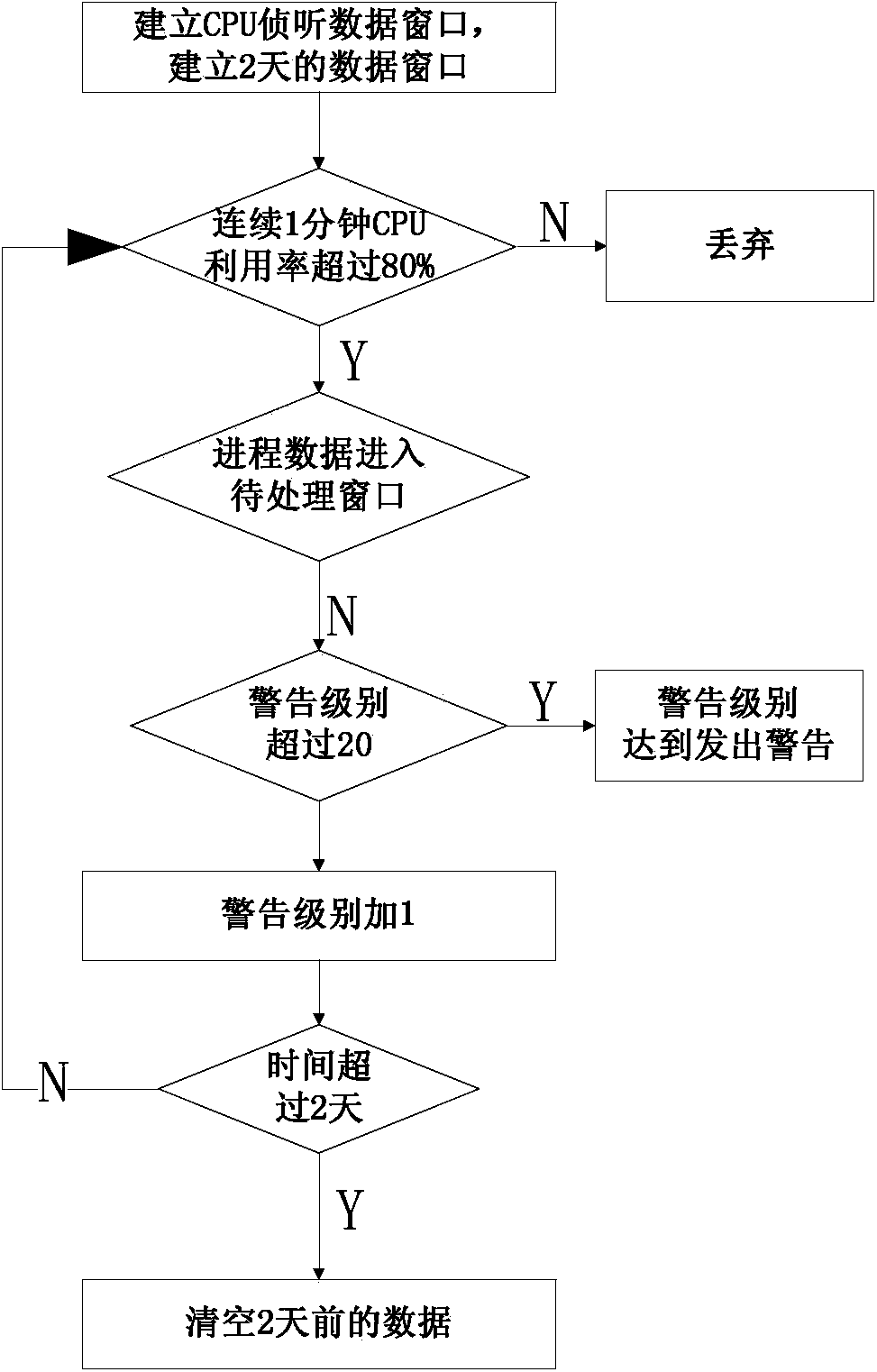

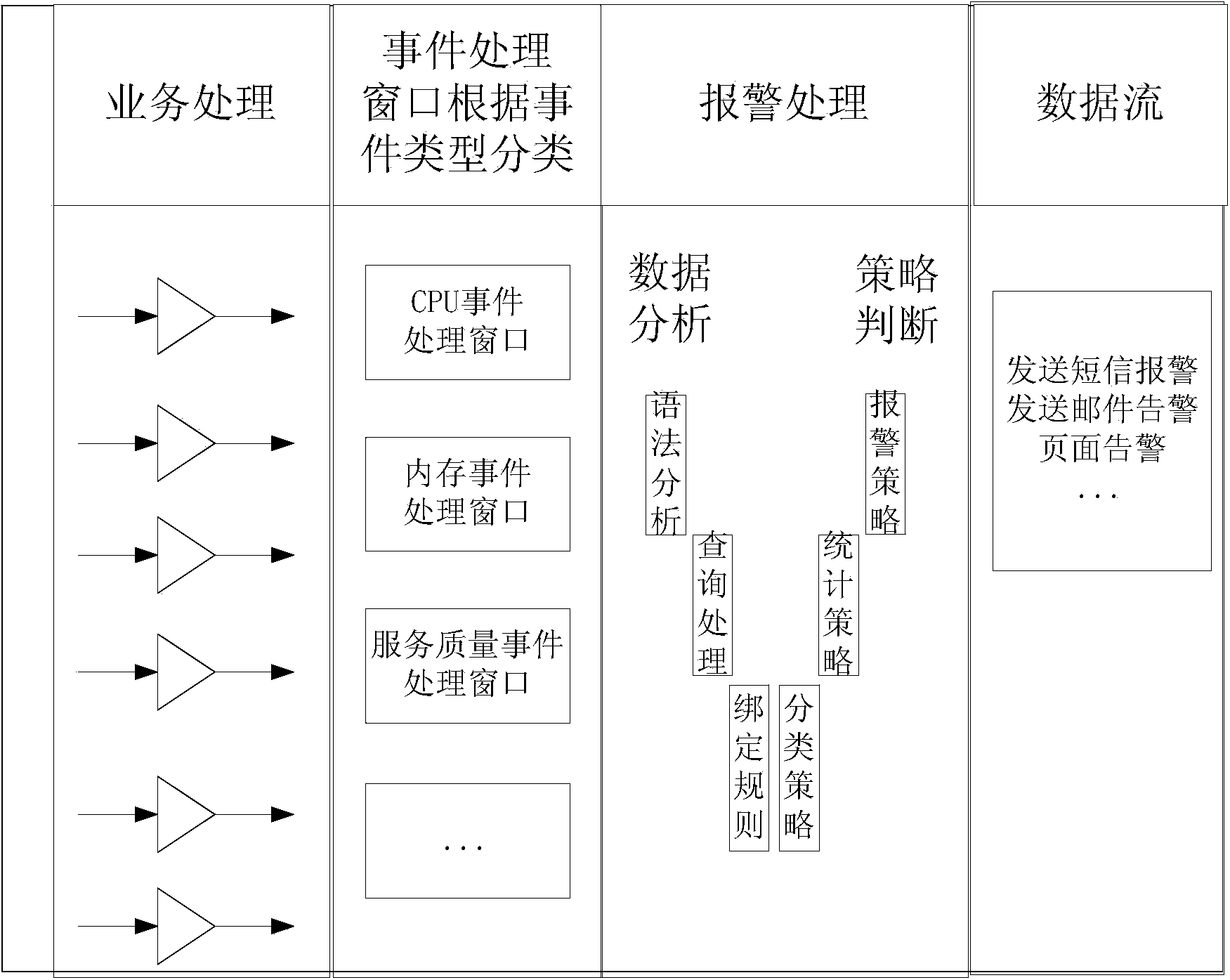

Information system integrated operation and maintenance monitoring service early warning platform and realization method thereof

ActiveCN103888287AImprove operation and maintenance capabilitiesRealize all-round managementMultiprogramming arrangementsResourcesData acquisitionIntegrated operations

The invention relates to the technical field of an IT system, and particularly discloses an information system integrated operation and maintenance monitoring service early warning platform and a realization method thereof. The platform comprises a data acquisition layer which is used for acquiring basic data of the monitored device; a data processing layer which is used for processing the basic data collected by the data acquisition layer; a data presentation layer which is used for displaying the data after being processed by users; and an information system integrated operation and maintenance monitoring service early warning platform management system which is used for managing the platform. The system penetrates through three layers of the data acquisition layer, the data processing layer and the data presentation layer, and configures and manages the three layers of the data acquisition layer, the data processing layer and the data presentation layer in a unified way. The platform has refined, automatic, intelligent and integrated IT operation and maintenance monitoring functions so that information technology operation and maintenance capability of large-scale enterprises is enhanced.

Owner:BEIJING CAPITAL INT AIRPORT CO LTD

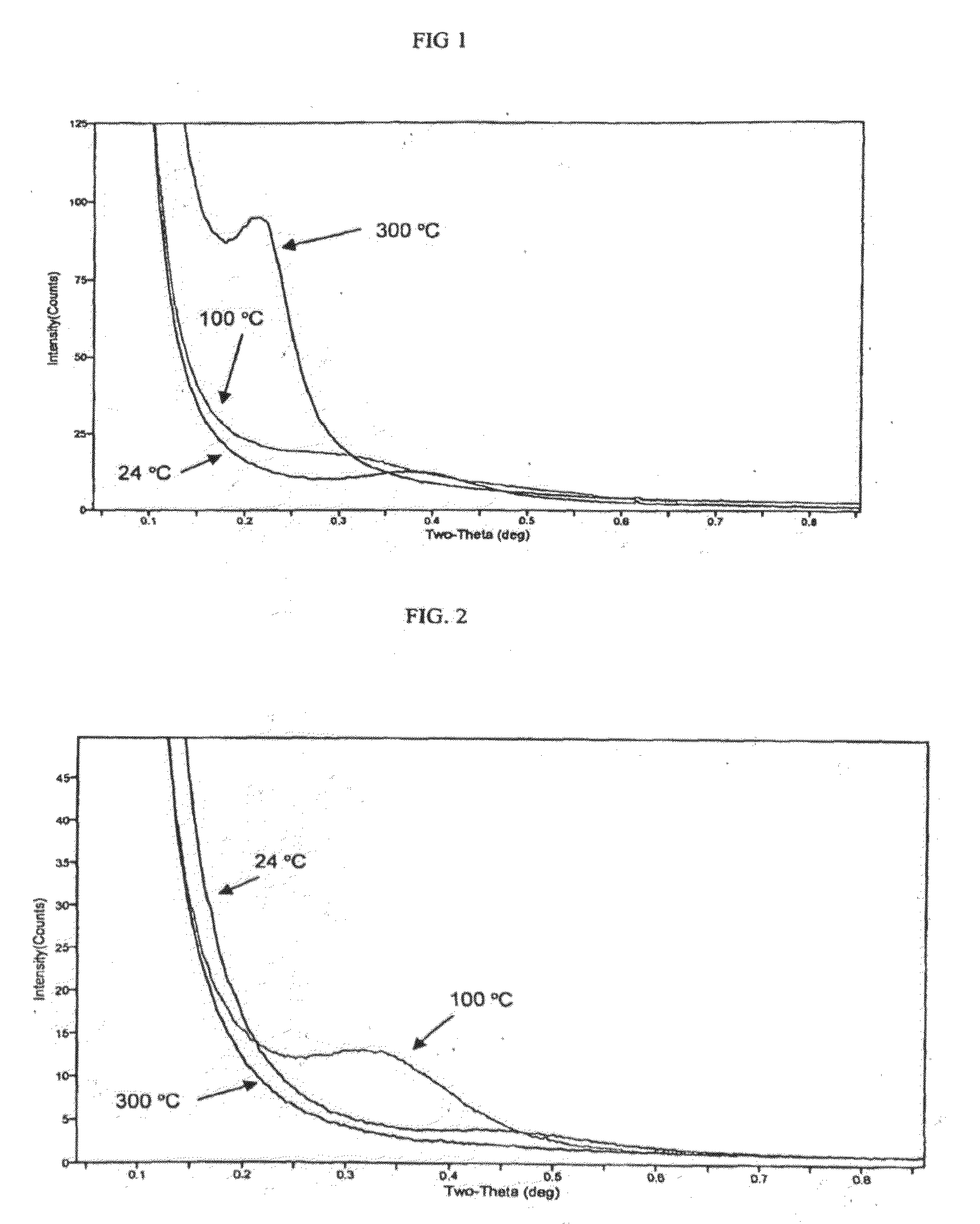

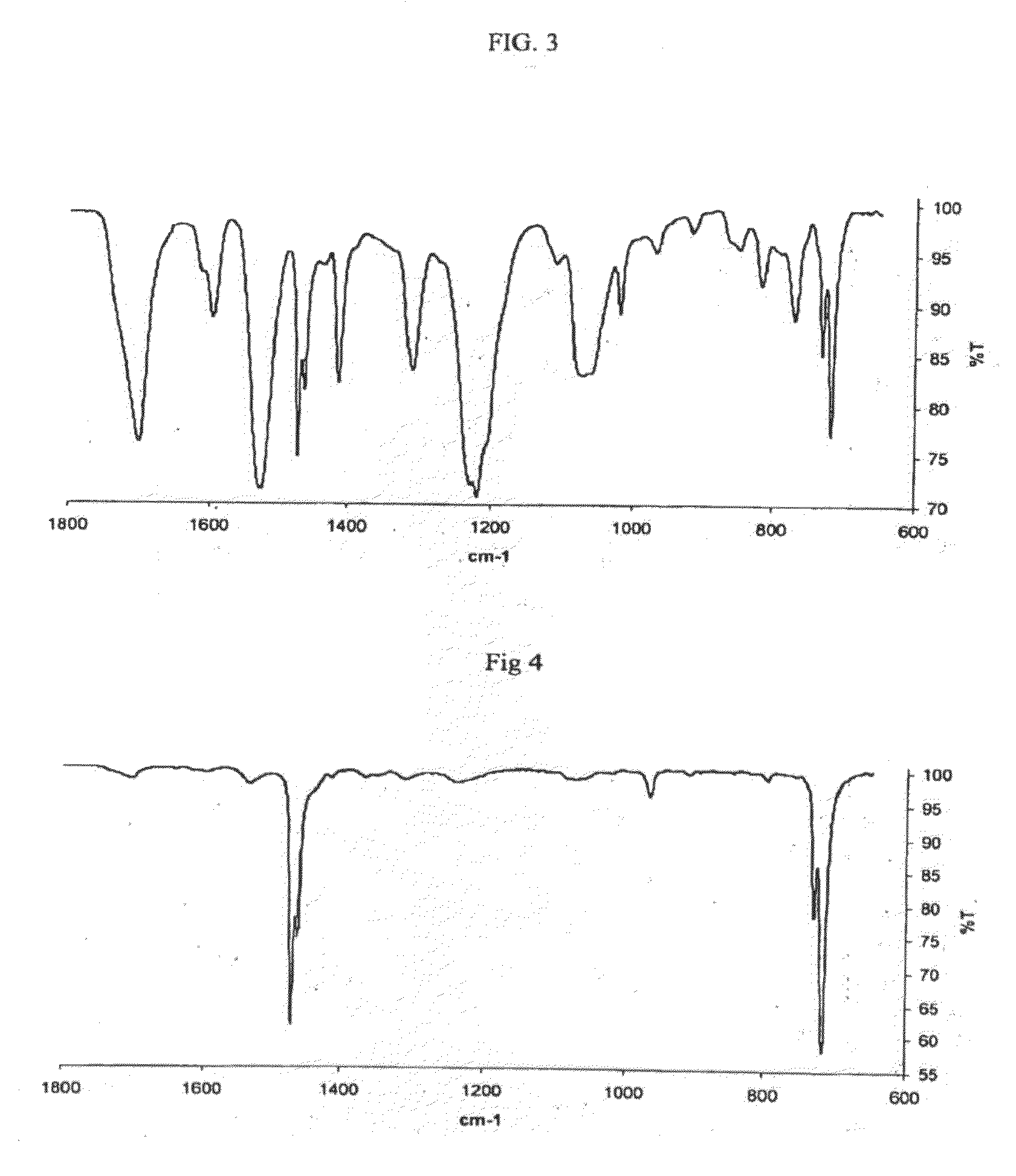

Polymer compositions, method of manufacture, and articles formed therefrom

ActiveUS20060142455A1High tensile modulusImprove ductilityPigmenting treatmentMaterial nanotechnologyPolymer scienceFluoropolymer

A polymer composition is disclosed, which comprises a matrix polymer, a fluoropolymer that may be at least partially encapsulated by an encapsulating polymer, and a filler. Methods for making the polymer compositions and articles made of such compositions are also disclosed. The compositions and article can have improved tensile modulus, ductility, and / or impact properties.

Owner:SABIC INNOVATIVE PLASTICS IP BV

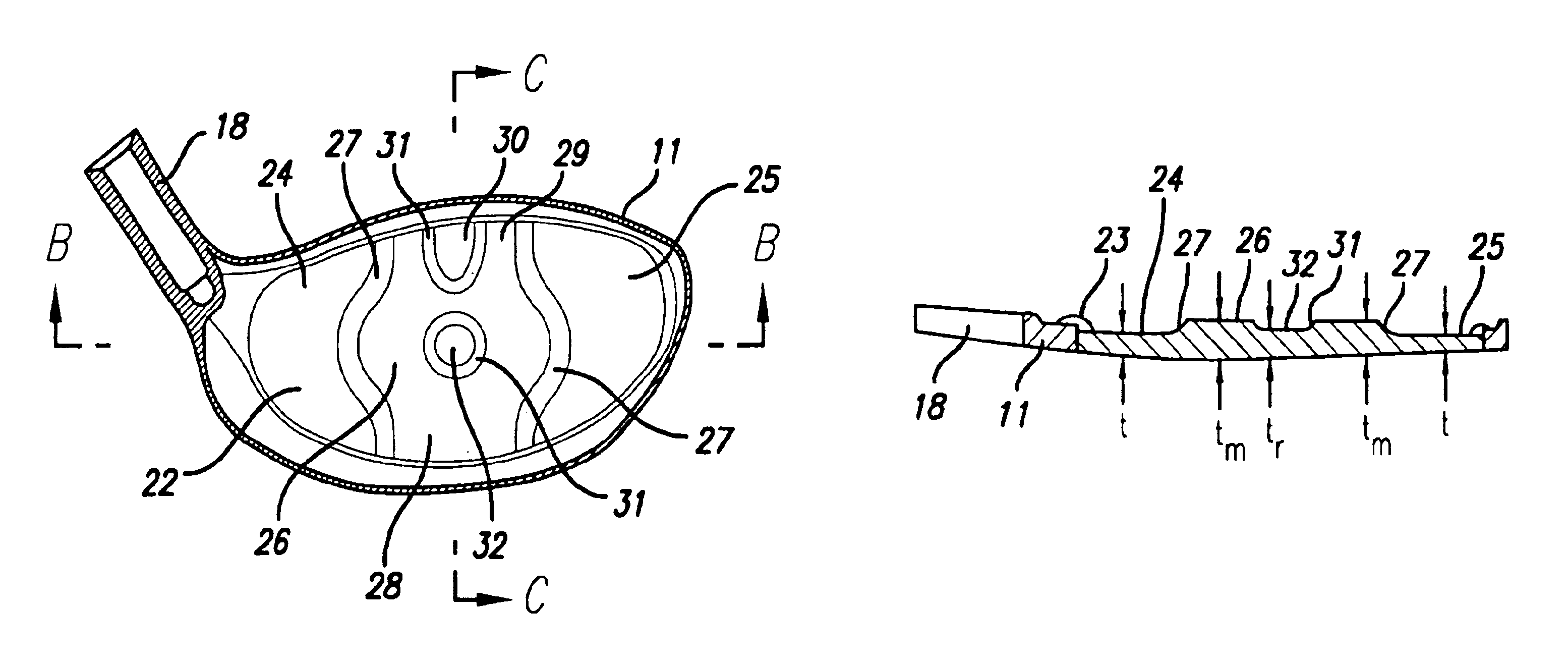

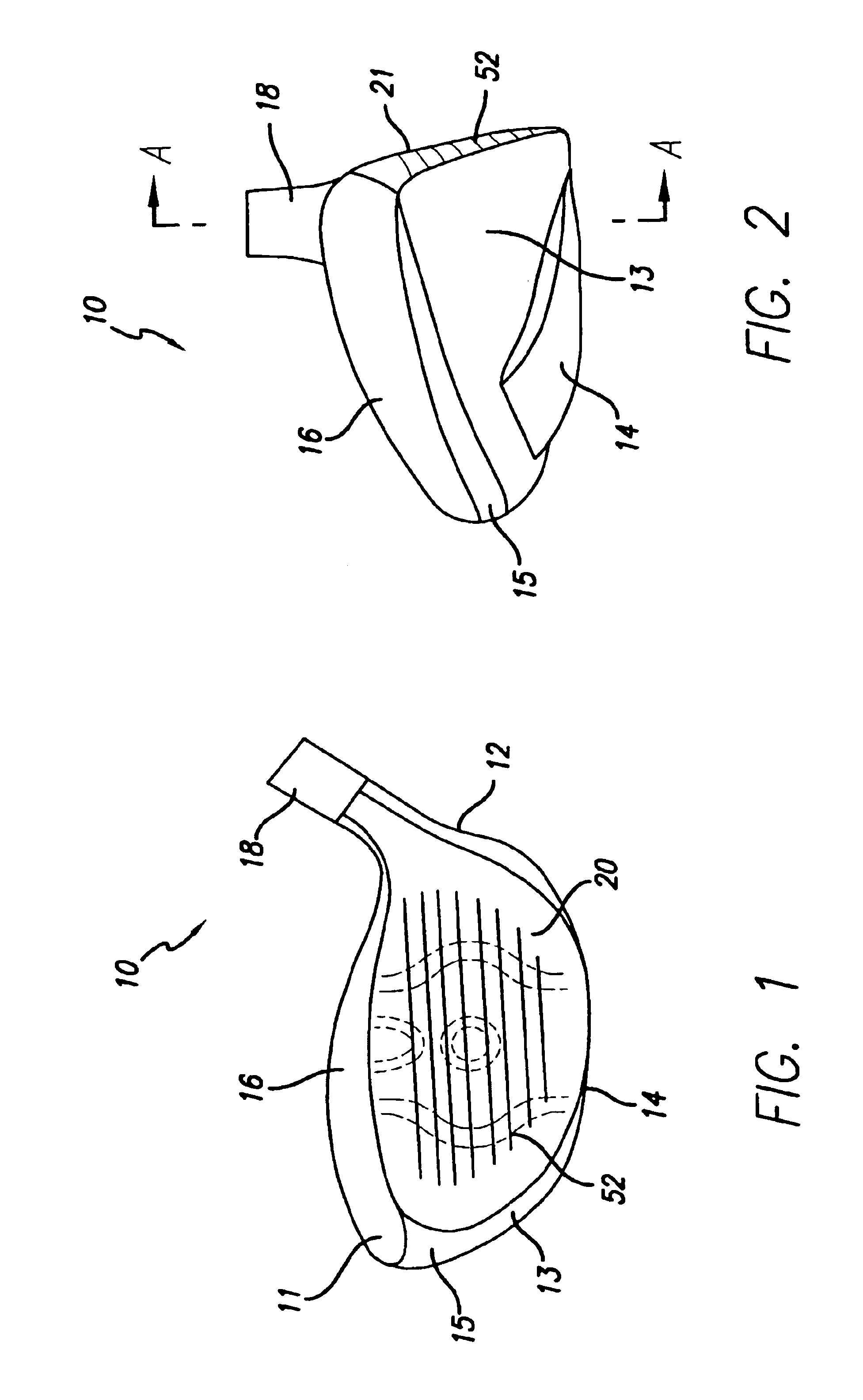

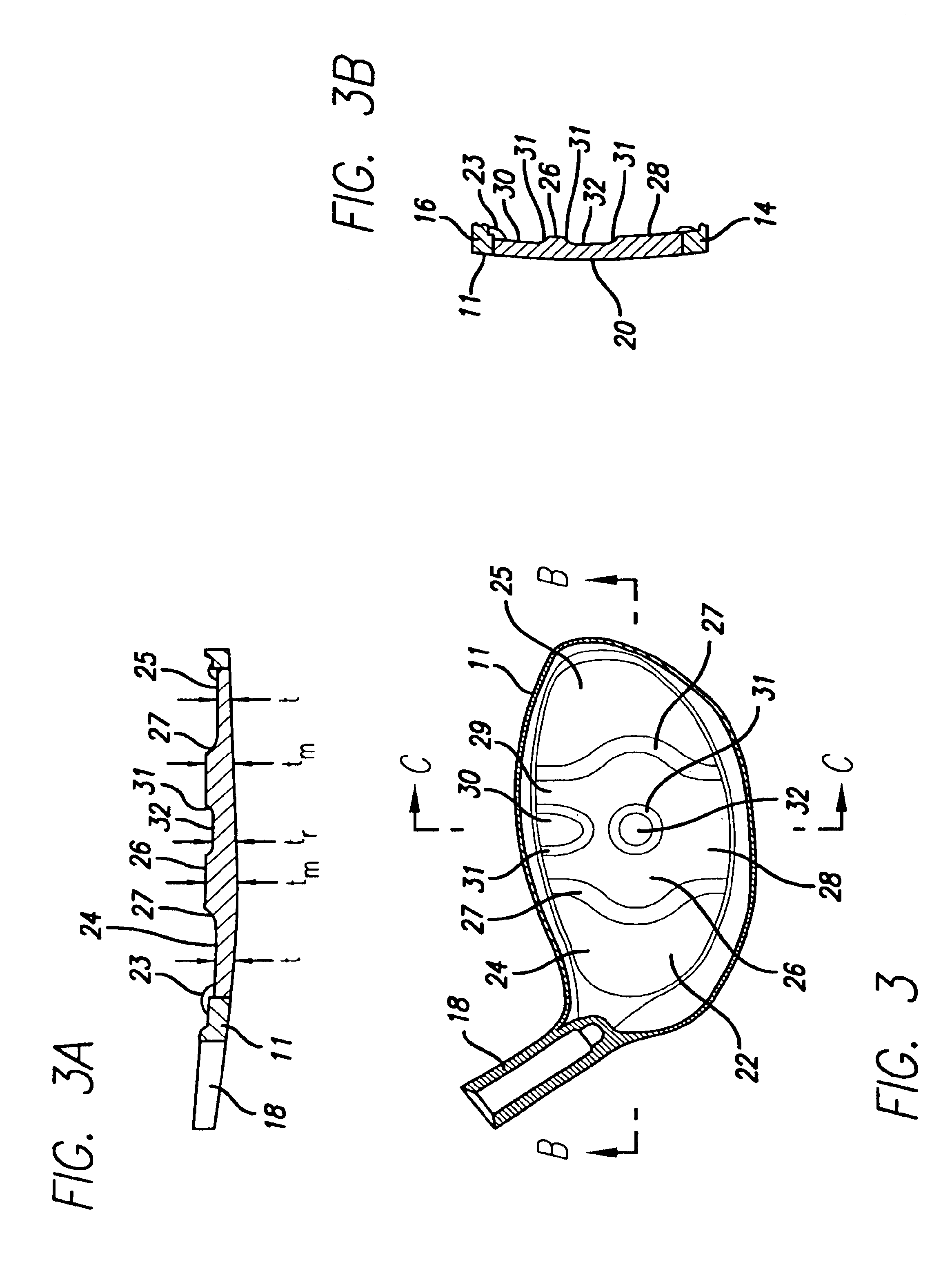

Method for manufacturing a golf club face

InactiveUS6904663B2Large thickness variationImprove performanceGolf clubsRacket sportsVariable thicknessAsymmetric face

A method of manufacturing a face plate for a golf club head is presented to provide face having substantial thickness variation for enhanced performance. The method includes the steps of providing a rolled sheet of metal material having an initial thickness and forming a blank having a prescribed outer shape from the material. The method also includes machining a second side of the blank such that the resulting face plate has a variable thickness. The machining is such that the plate has a first thickness less than or equal to the initial thickness, a second thickness less than the first thickness and a third thickness less than the second thickness. The machining is performed over a substantial portion of the surface area of the second side. Either a CNC lathe or milling machine may be used; however, for an axisymmetric face thickness a CNC lathe is preferred and for an asymmetric face thickness a CNC end mill is preferred. The club head may be a wood-type or iron, and titanium or steel alloys may be used.

Owner:TAYLOR MADE GOLF

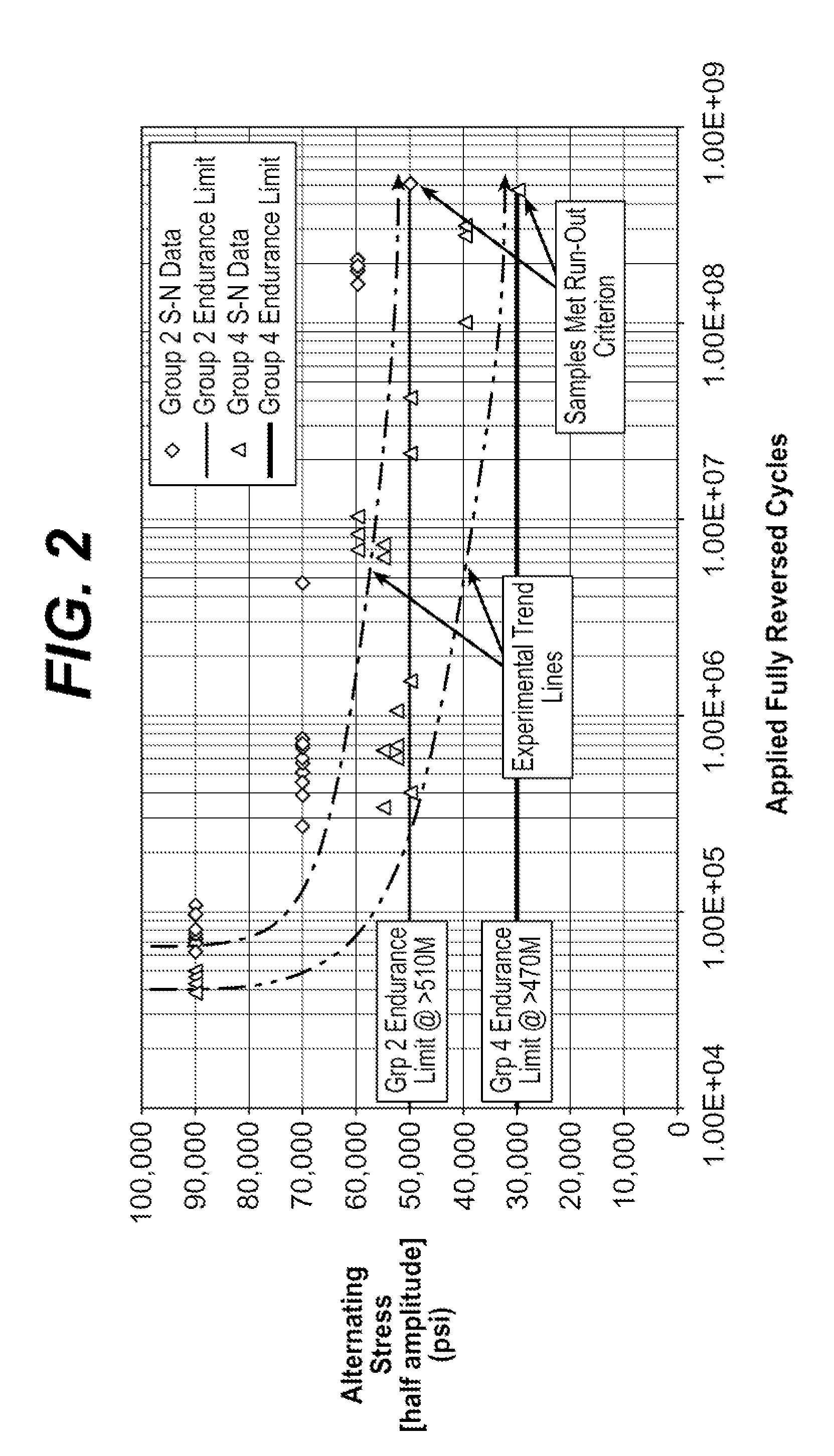

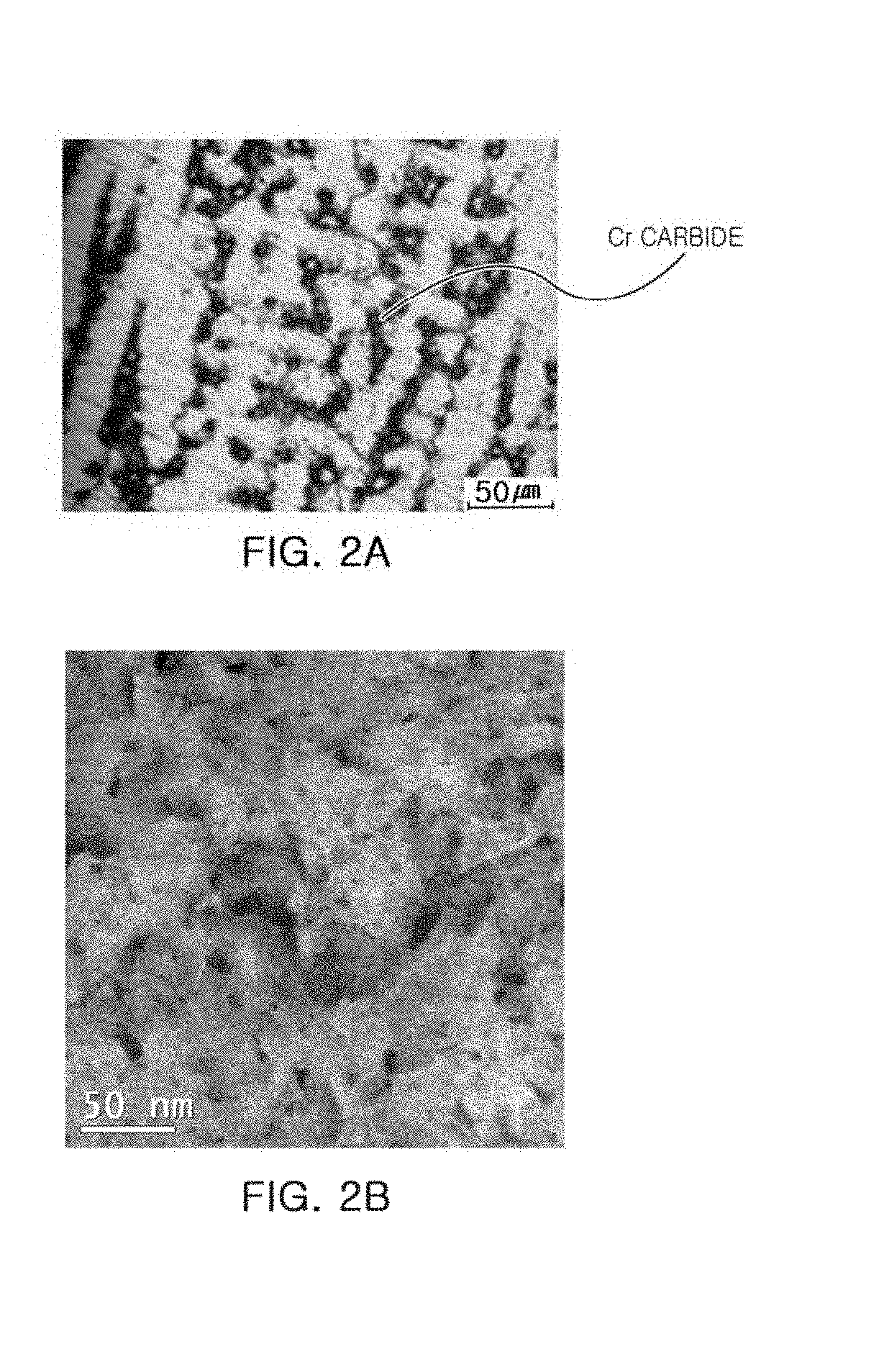

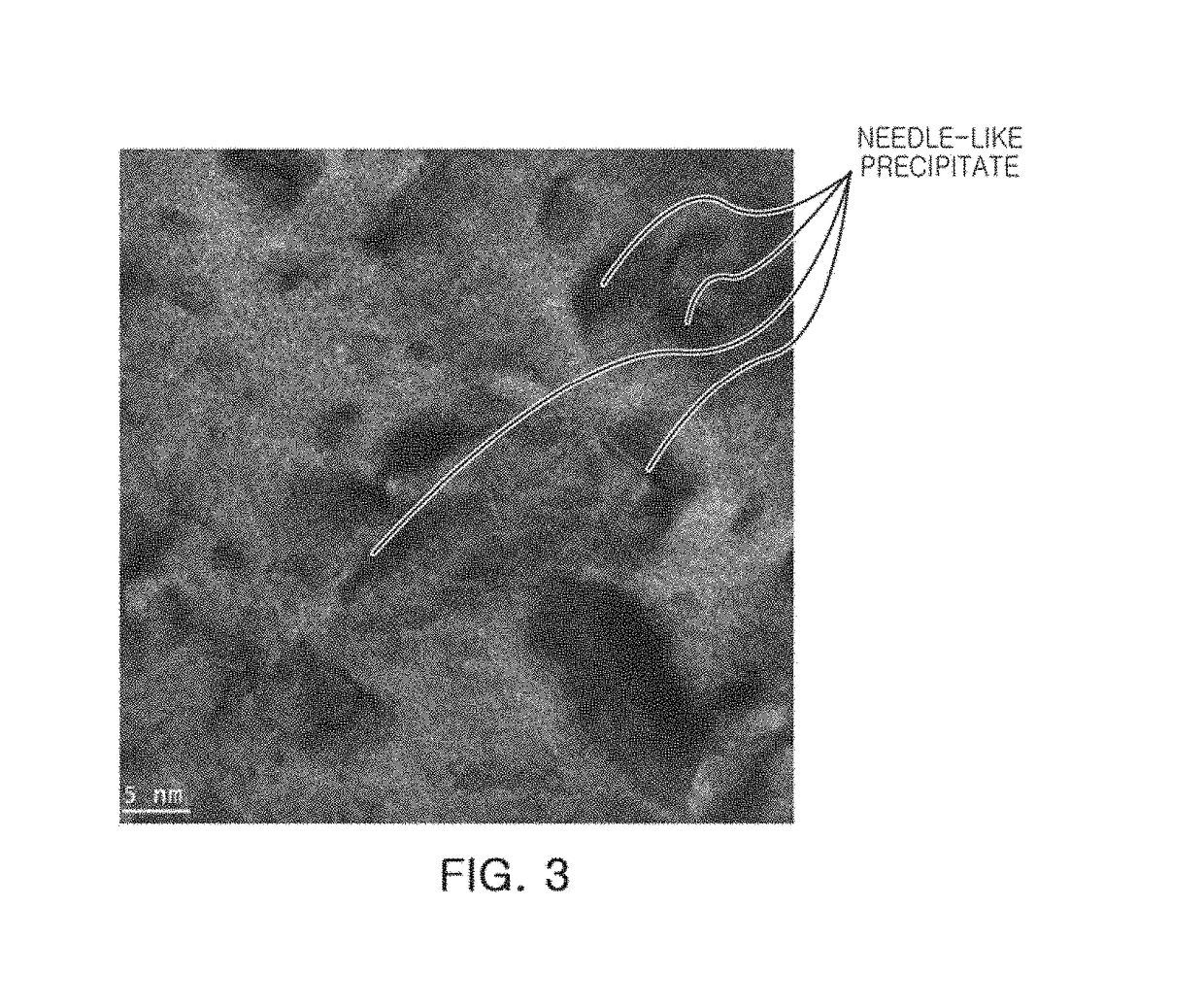

Heat and corrosion resistant cast CF8C stainless steel with improved high temperature strength and ductility

A CF8C type stainless steel alloy and articles formed therefrom containing about 18.0 weight percent to about 22.0 weight percent chromium and 11.0 weight percent to about 14.0 weight percent nickel; from about 0.05 weight percent to about 0.15 weight percent carbon; from about 2.0 weight percent to about 10.0 weight percent manganese; and from about 0.3 weight percent to about 1.5 weight percent niobium. The present alloys further include less than 0.15 weight percent sulfur which provides high temperature strength both in the matrix and at the grain boundaries without reducing ductility due to cracking along boundaries with continuous or nearly-continuous carbides. The disclosed alloys also have increased nitrogen solubility thereby enhancing strength at all temperatures because nitride precipitates or nitrogen porosity during casting are not observed. The solubility of nitrogen is dramatically enhanced by the presence of manganese, which also retains or improves the solubility of carbon thereby providing additional solid solution strengthening due to the presence of manganese and nitrogen, and combined carbon.

Owner:UT BATTELLE LLC

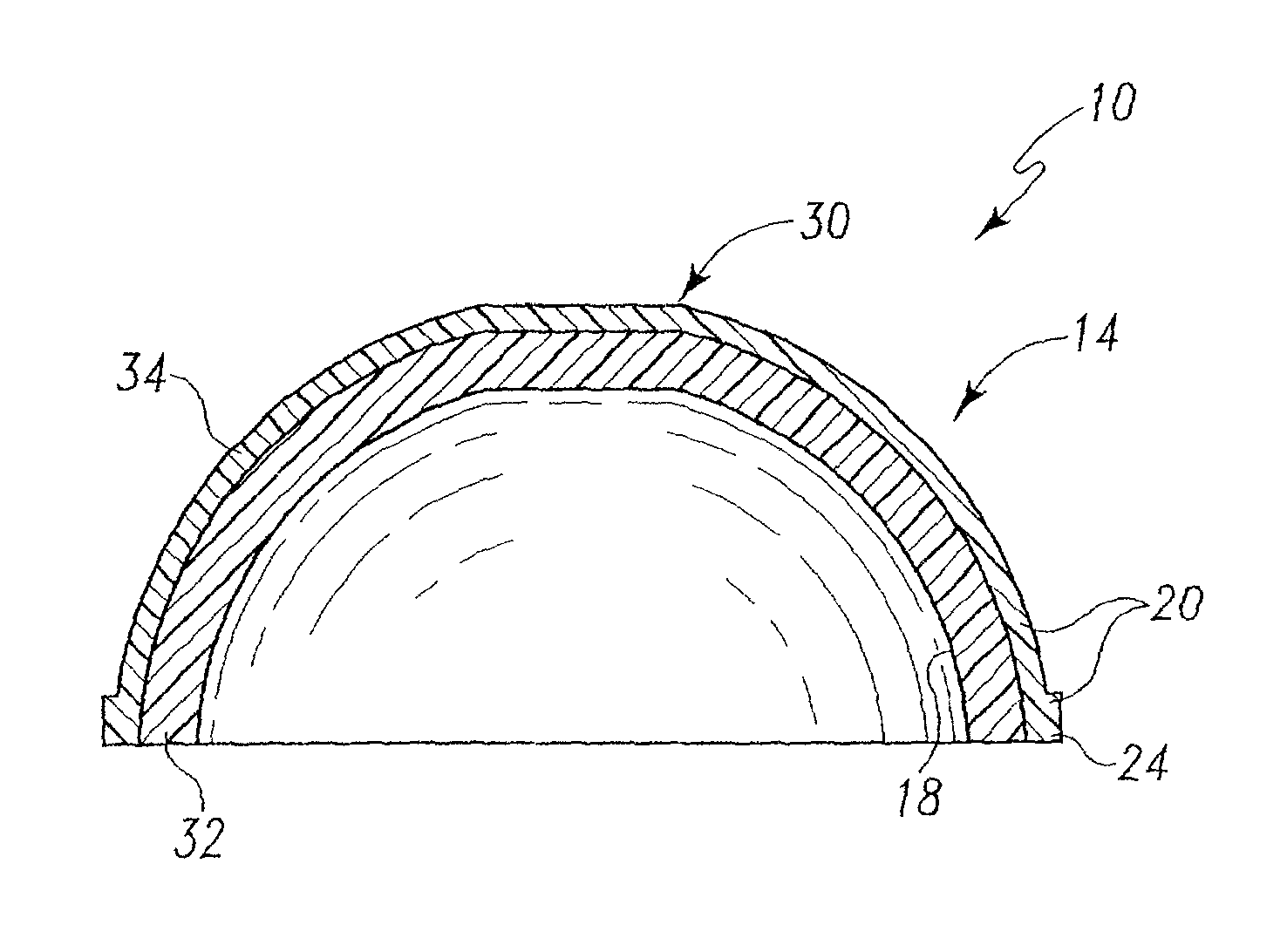

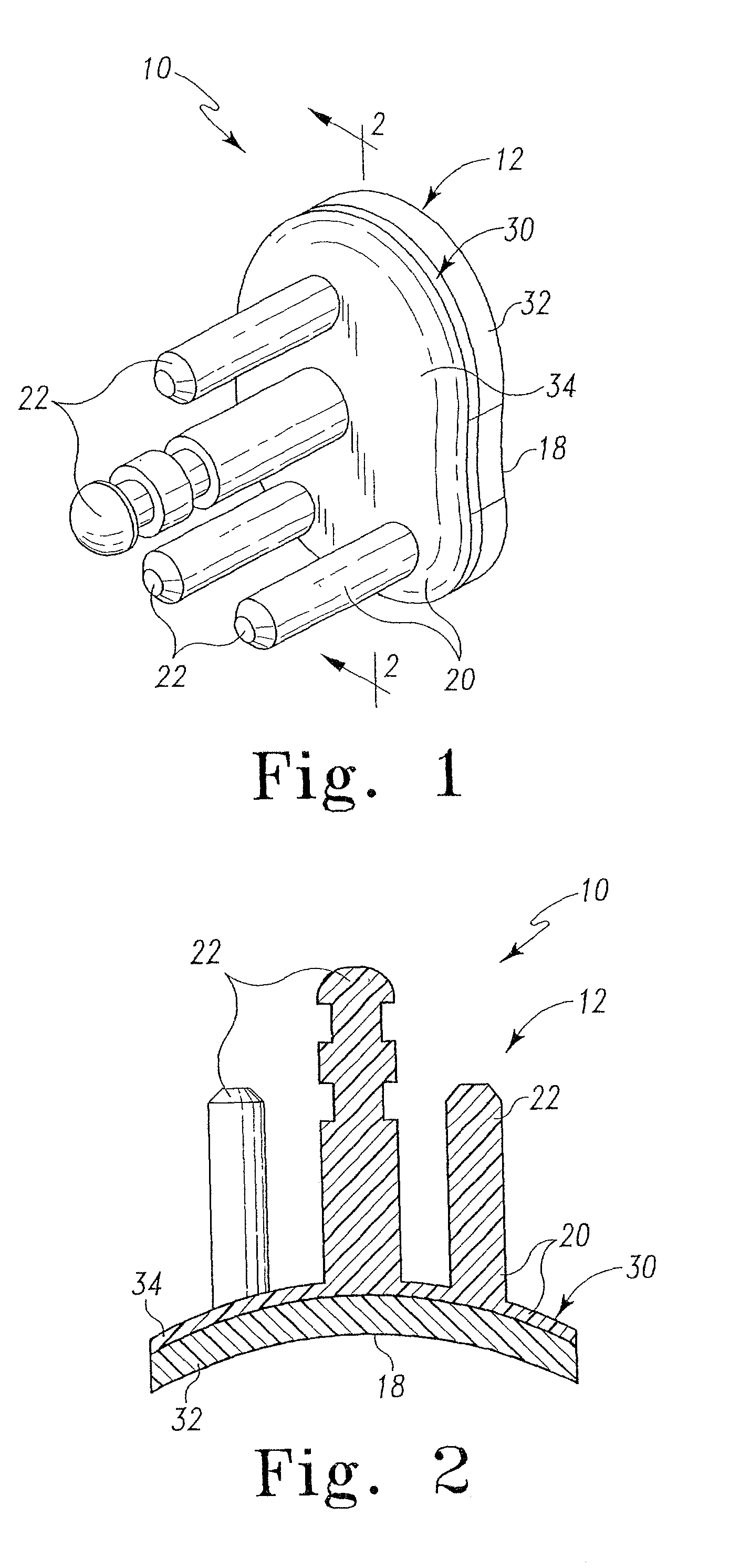

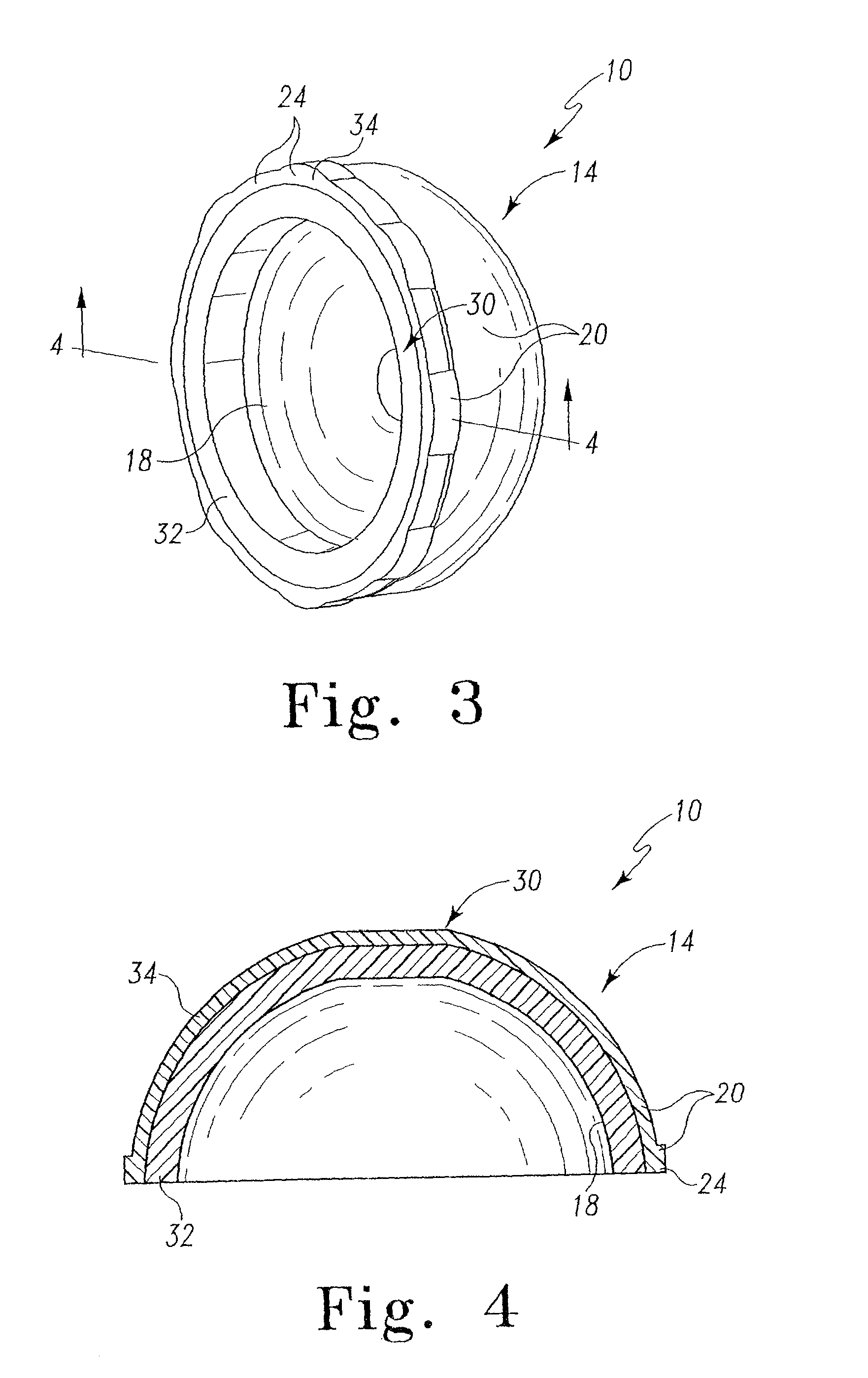

Composite prosthetic bearing having a crosslinked articulating surface and method for making the same

InactiveUS7819925B2Promote oxidationEasy to wearBone implantSynthetic resin layered productsProsthesisCrosslinked polymers

An implantable prosthetic bearing is constructed of a composite material having a first layer and second layer. The first layer has an articulating surface defined therein, whereas the second layer has a engaging surface defined therein for engaging either another prosthetic component or the bone itself The first layer of the implantable prosthetic bearing is constructed of crosslinked polymer such as Ultra-High Molecular Weight Polyethylene, whereas the second layer of the implantable prosthetic bearing is constructed of polymer such as Ultra-High Molecular Weight Polyethylene that is either non-crosslinked or crosslinked to a lesser degree than the first layer. In such a manner, the first layer possesses mechanical properties which are advantageous in regard to the articulating surface (e.g., enhanced wear and oxidation resistance), whereas the second layer possesses mechanical properties which are advantageous in regard to the engaging surface (e.g., high ductility, toughness, and creep resistance). A method of making a prosthetic bearing is also disclosed.

Owner:DEPUY SYNTHES PROD INC

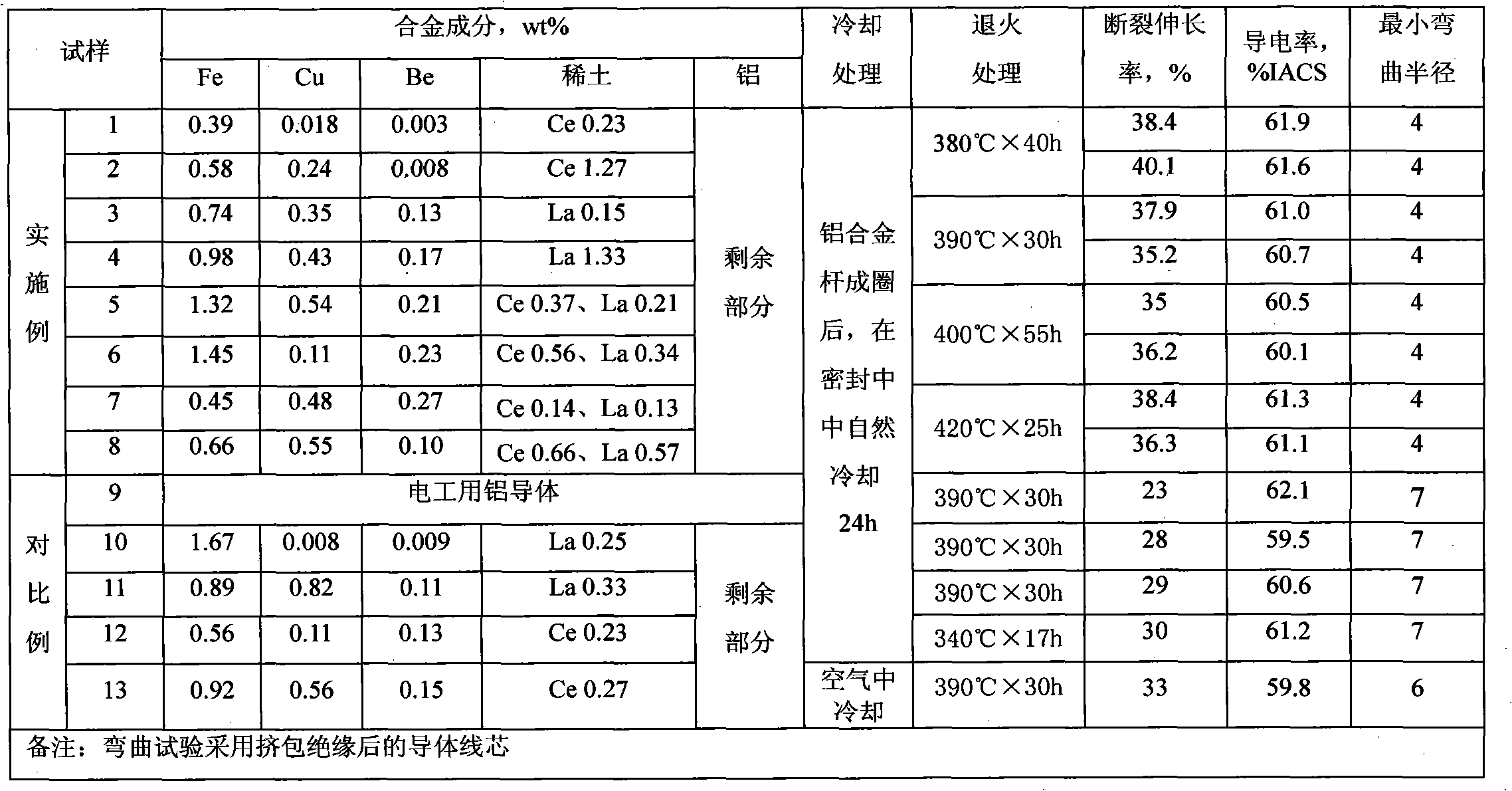

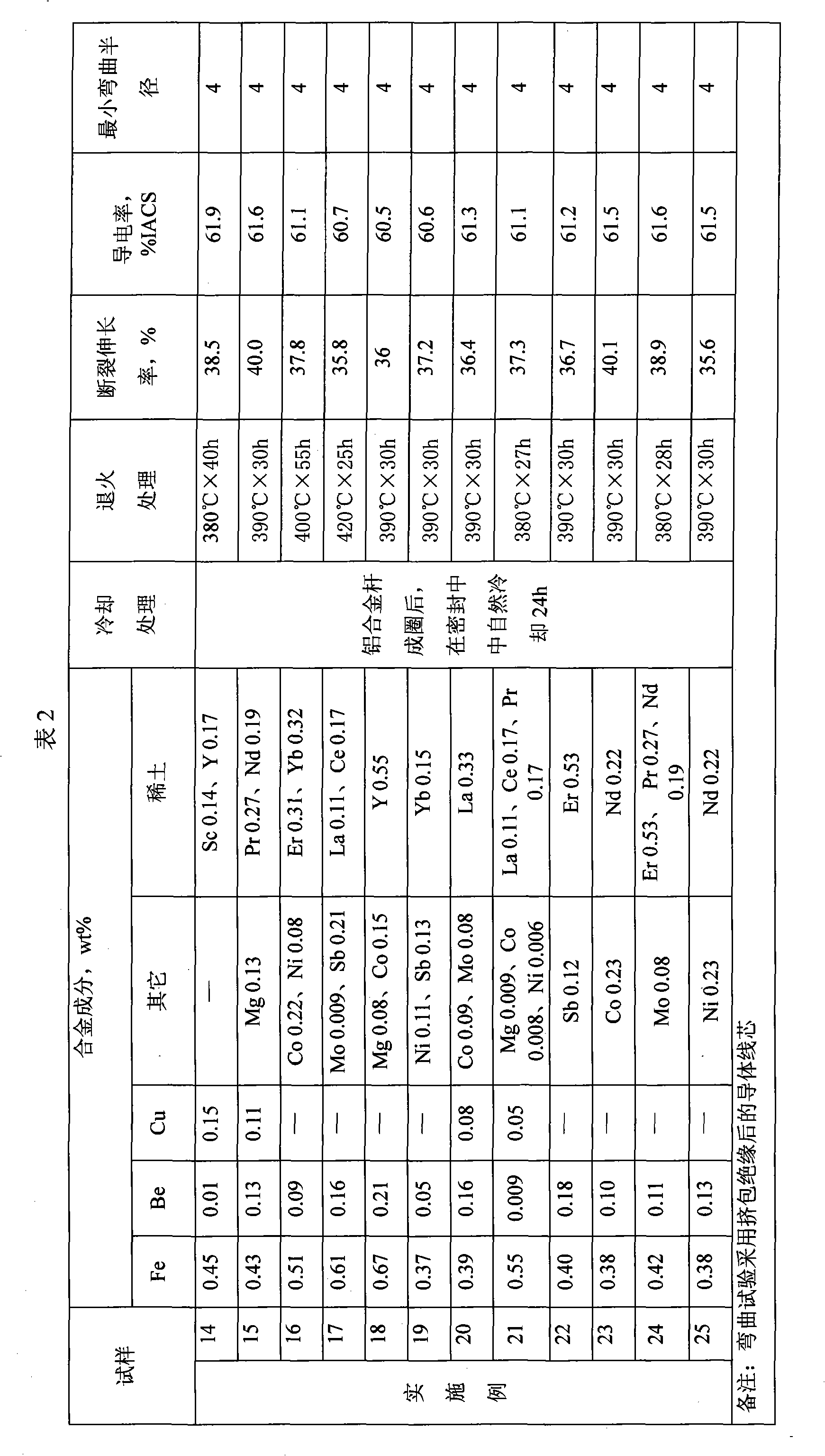

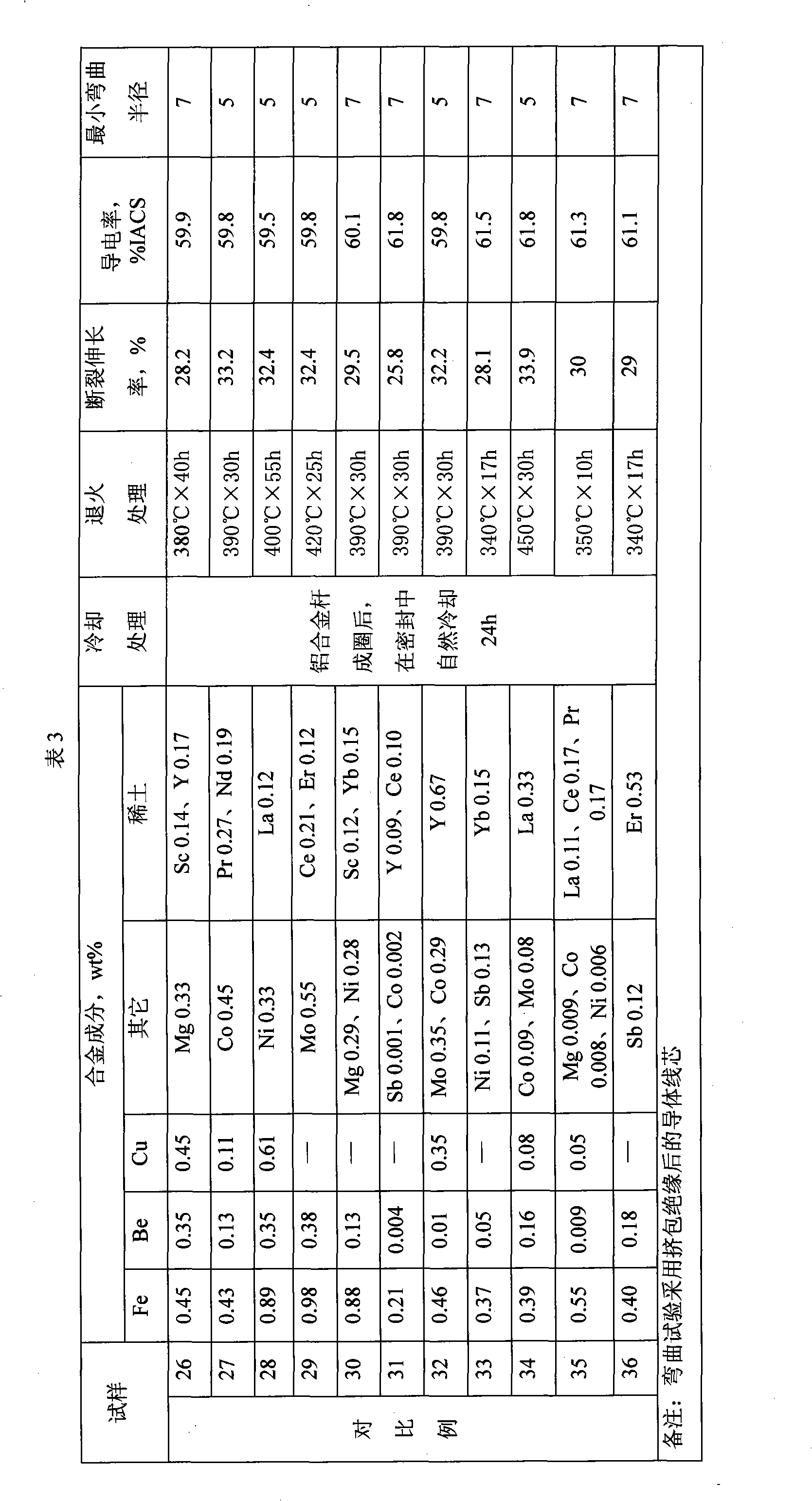

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

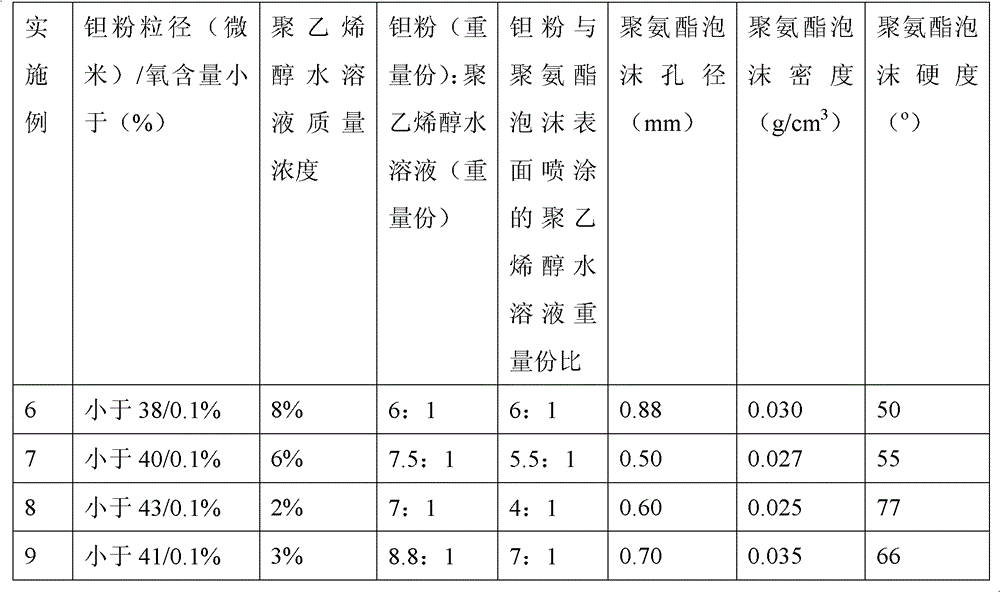

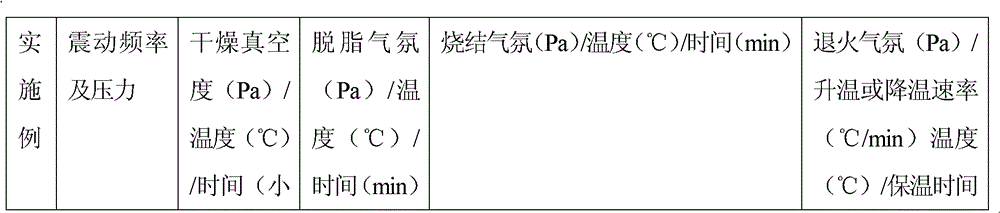

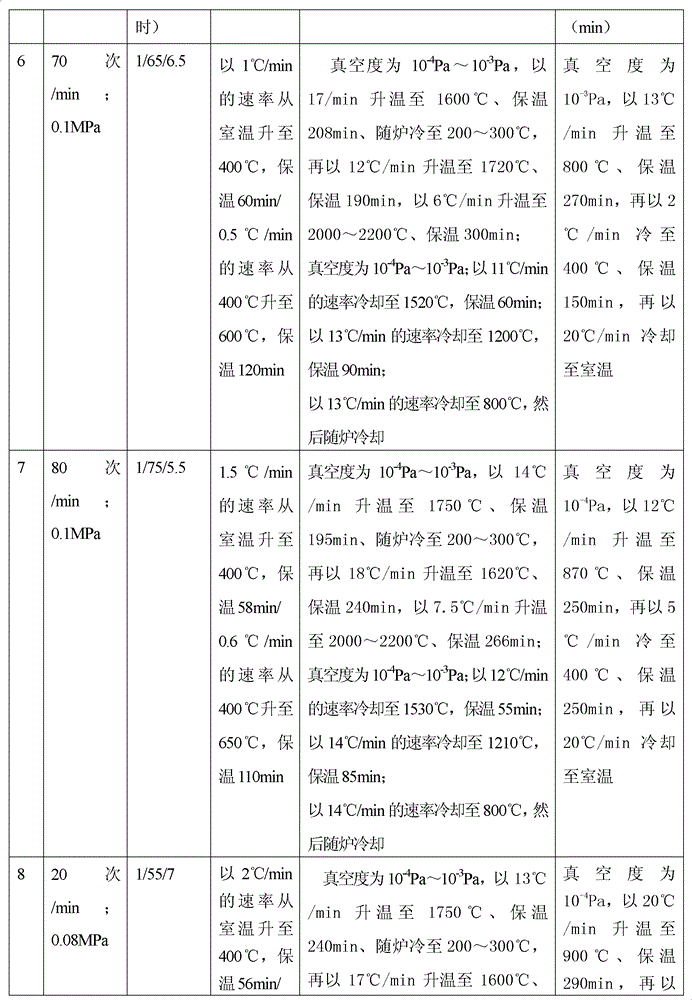

Method for preparing medical porous tantalum implant material

ActiveCN102796894AReduce contentImprove mechanical propertiesProsthesisPolyvinyl alcoholBiocompatibility Testing

The invention discloses a method for preparing a medical porous tantalum material. The method comprises the following steps of: mixing a poly ethanol aqueous solution and tantalum powder to obtain slurry, wherein the mass concentration of the poly ethanol aqueous solution is 2 to 8 percent; injecting the slurry into an organic foam by vibrating and pressurizing, wherein the vibrating frequency is 20 to 80 times / min; drying; degreasing; sintering, namely raising temperature to 1,500 to 1,800 DEG C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3>Pa, preserving heat for 120 to 240 minutes, cooling to 200 to 300 DEG C along with a furnace, raising temperature to 1,500 to 1,800 DEG C at the speed of 10 to 20 DEG C / min again, preserving heat for 180 to 240 minutes, raising temperature to 2,000 to 2,200 DEG C at the speed of 5 to 10 DEG C / min, and preserving heat for 120 to 360 minutes; cooling; and performing thermal treatment, namely raising temperature to 800 to 900 DEG C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3> Pa, preserving heat for 240 to 480 minutes, cooling to 400 DGE C at the speed of 2 to 5 DGE C / min, preserving heat for 120 to 300 minutes, and cooling to room temperature along with the furnace. The porous tantalum prepared by the method is very suitable to be used for the medical implant material for replacing bearing bone tissues, and biocompatibility and the mechanical property can be guaranteed simultaneously.

Owner:CHONGQING RUNZE PHARM CO LTD

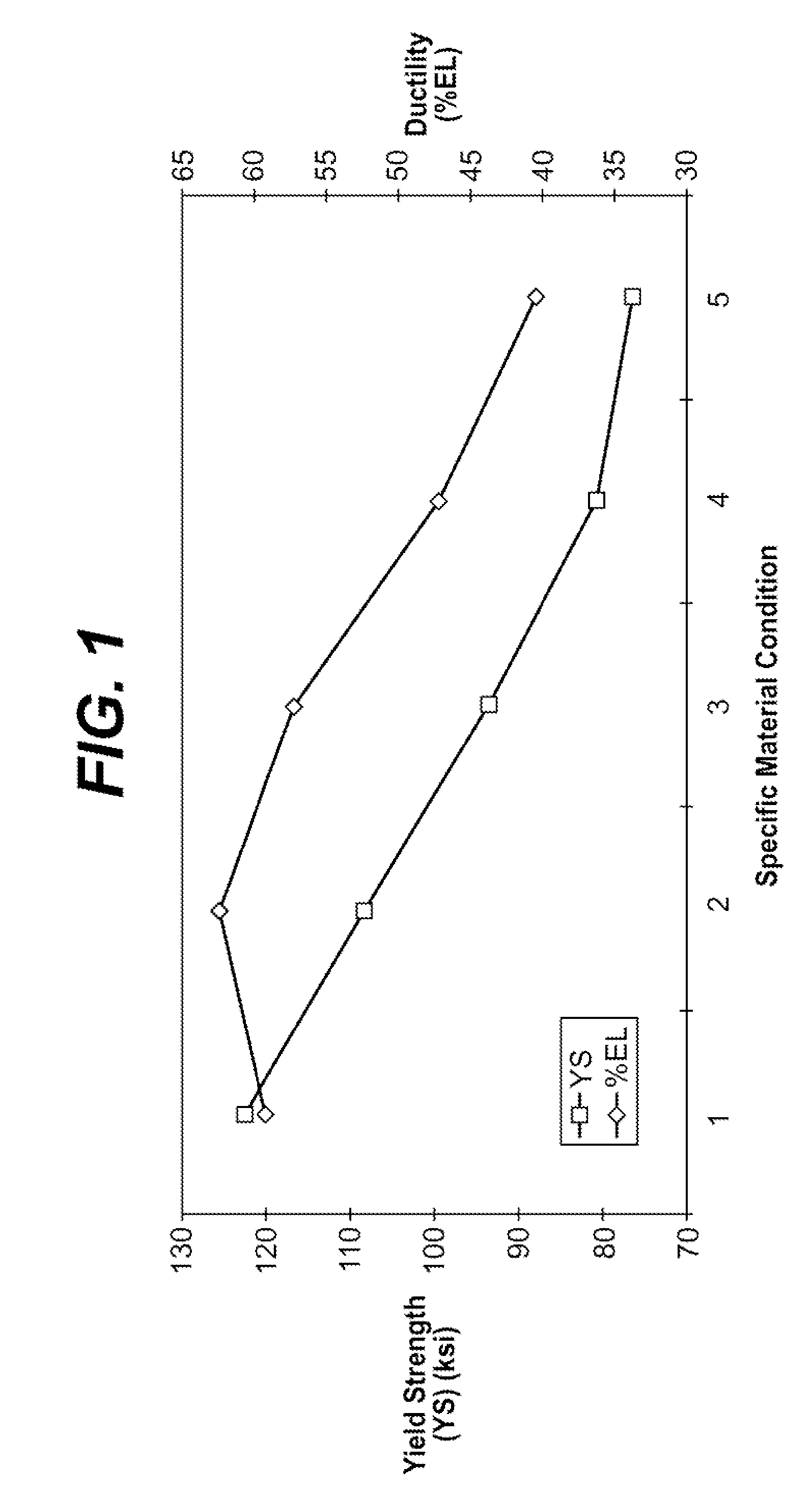

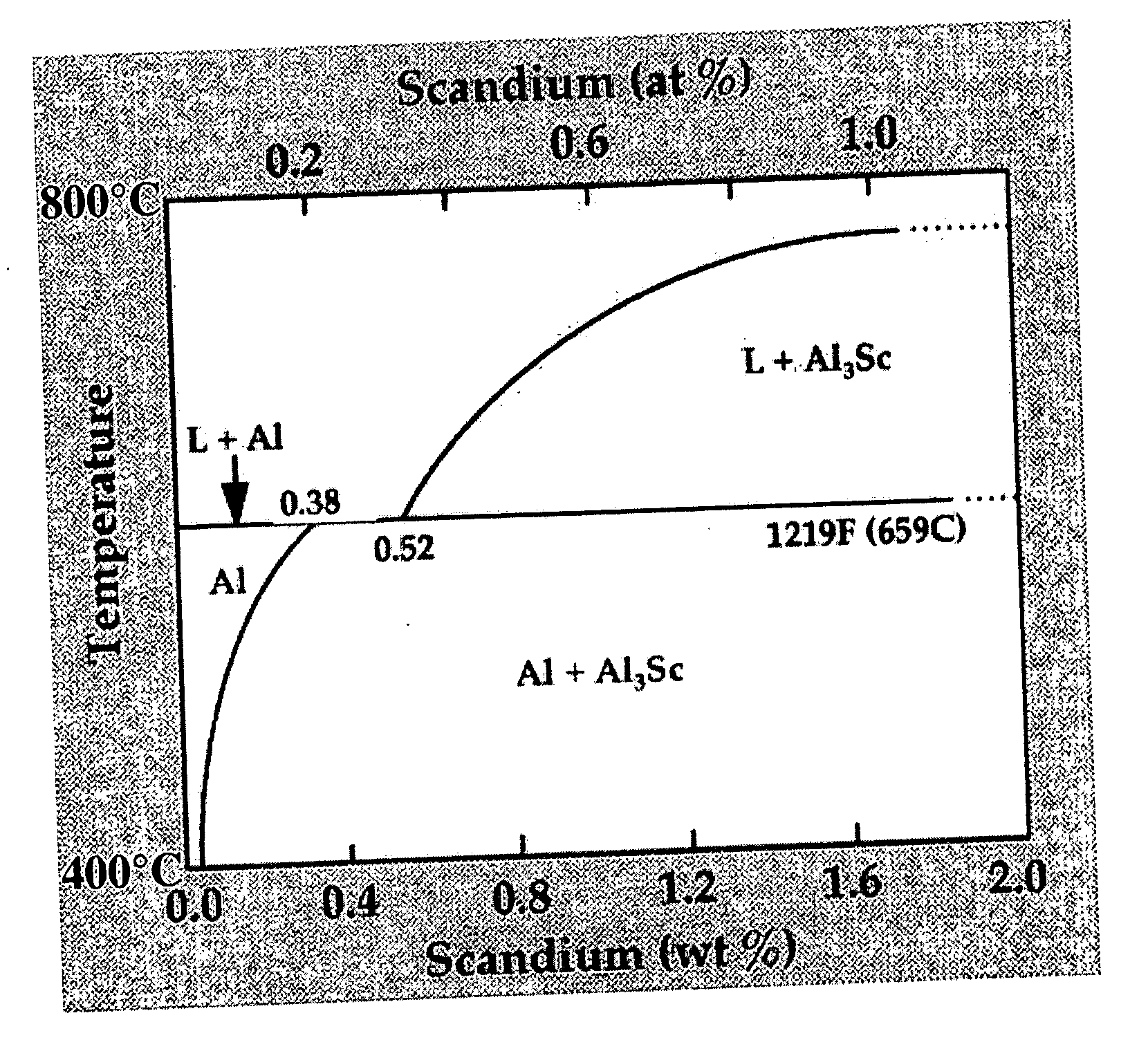

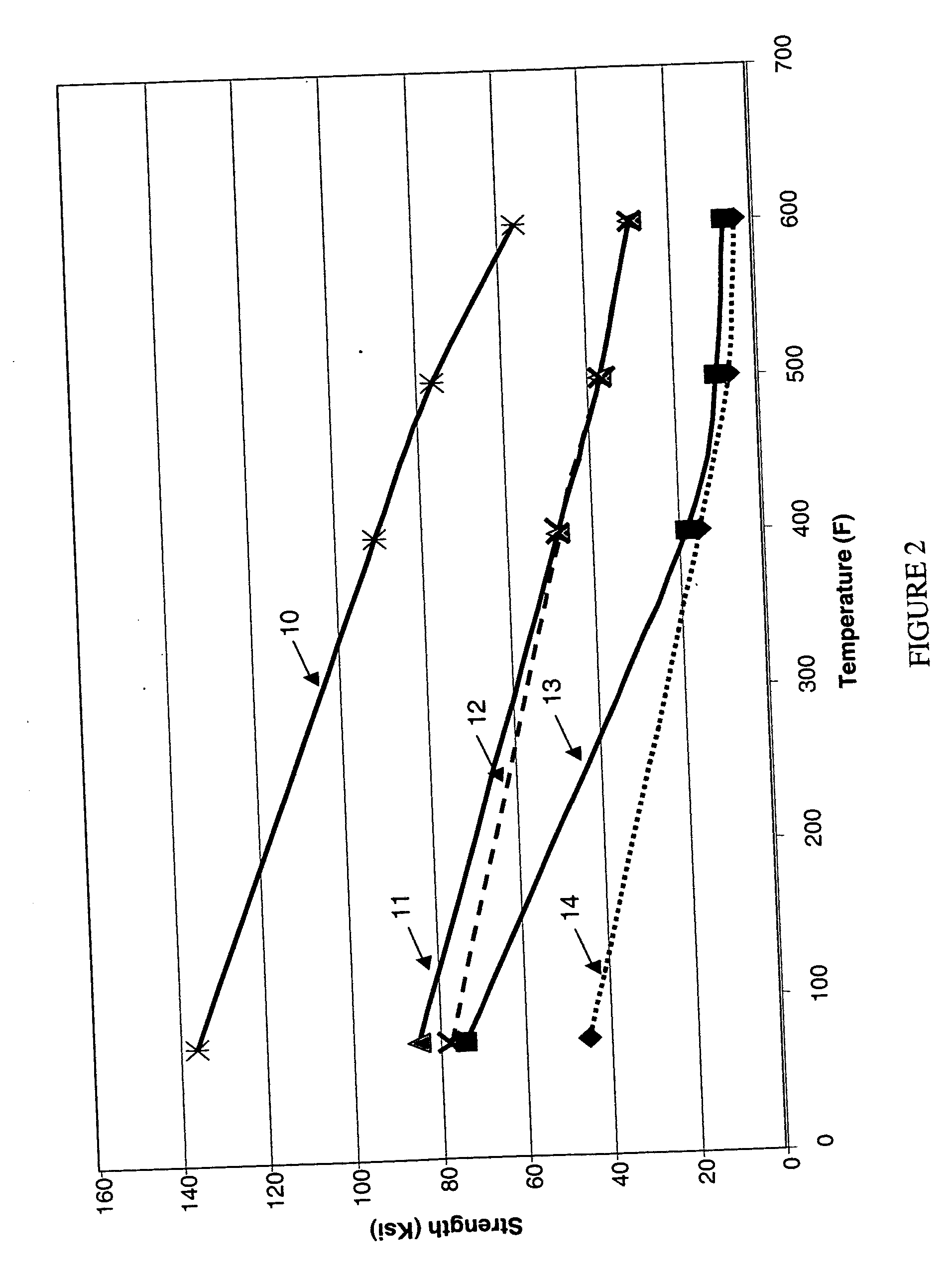

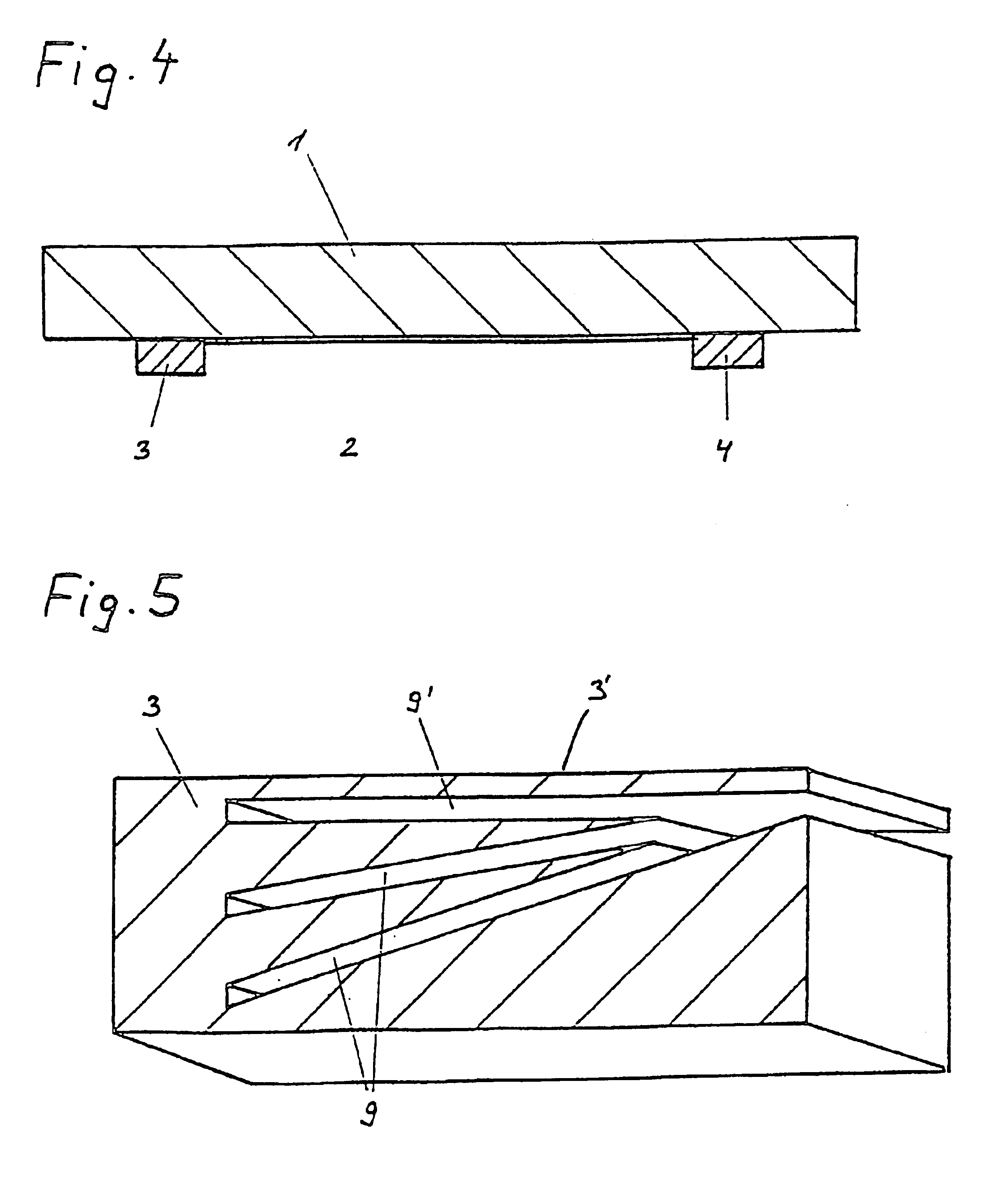

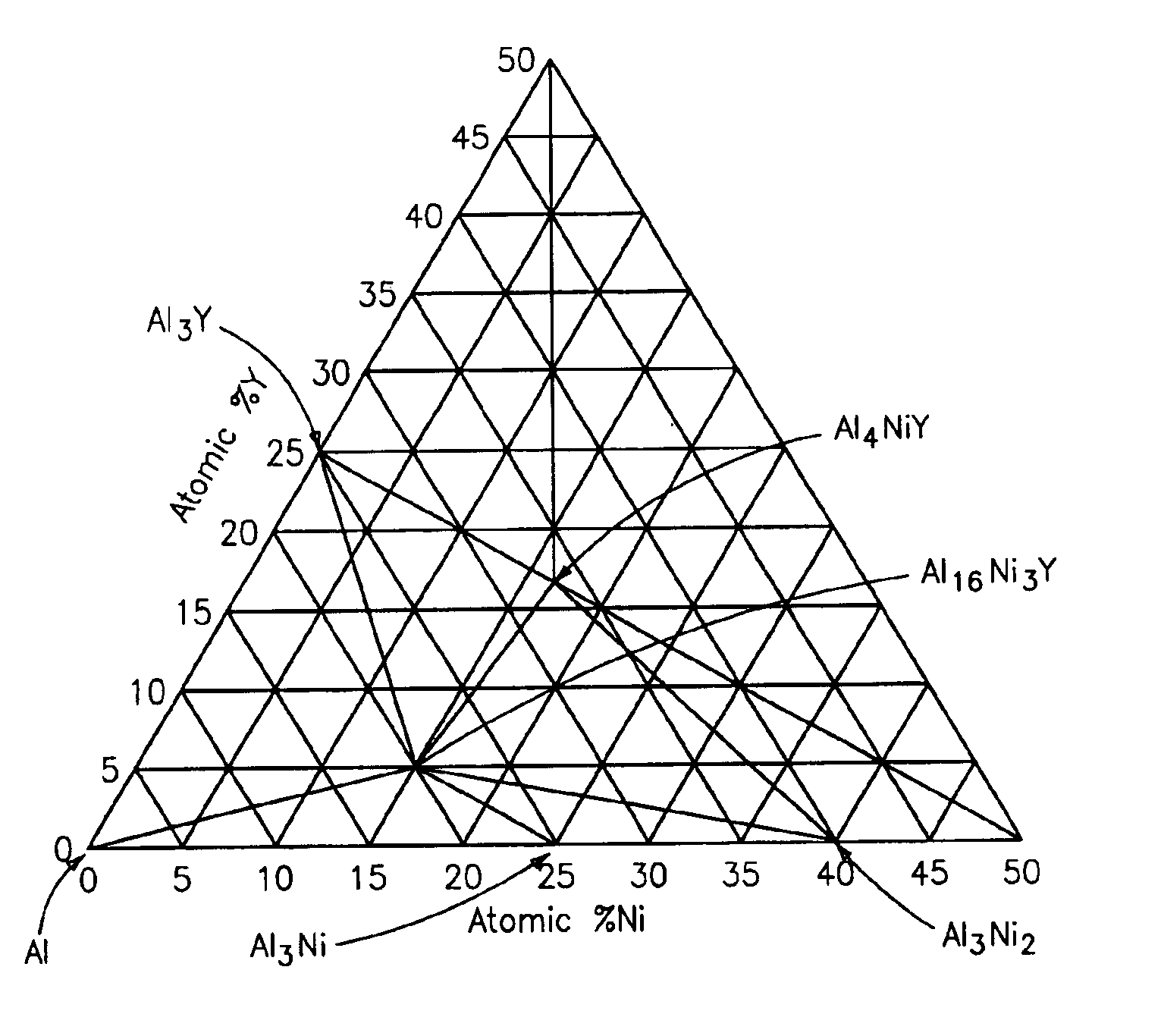

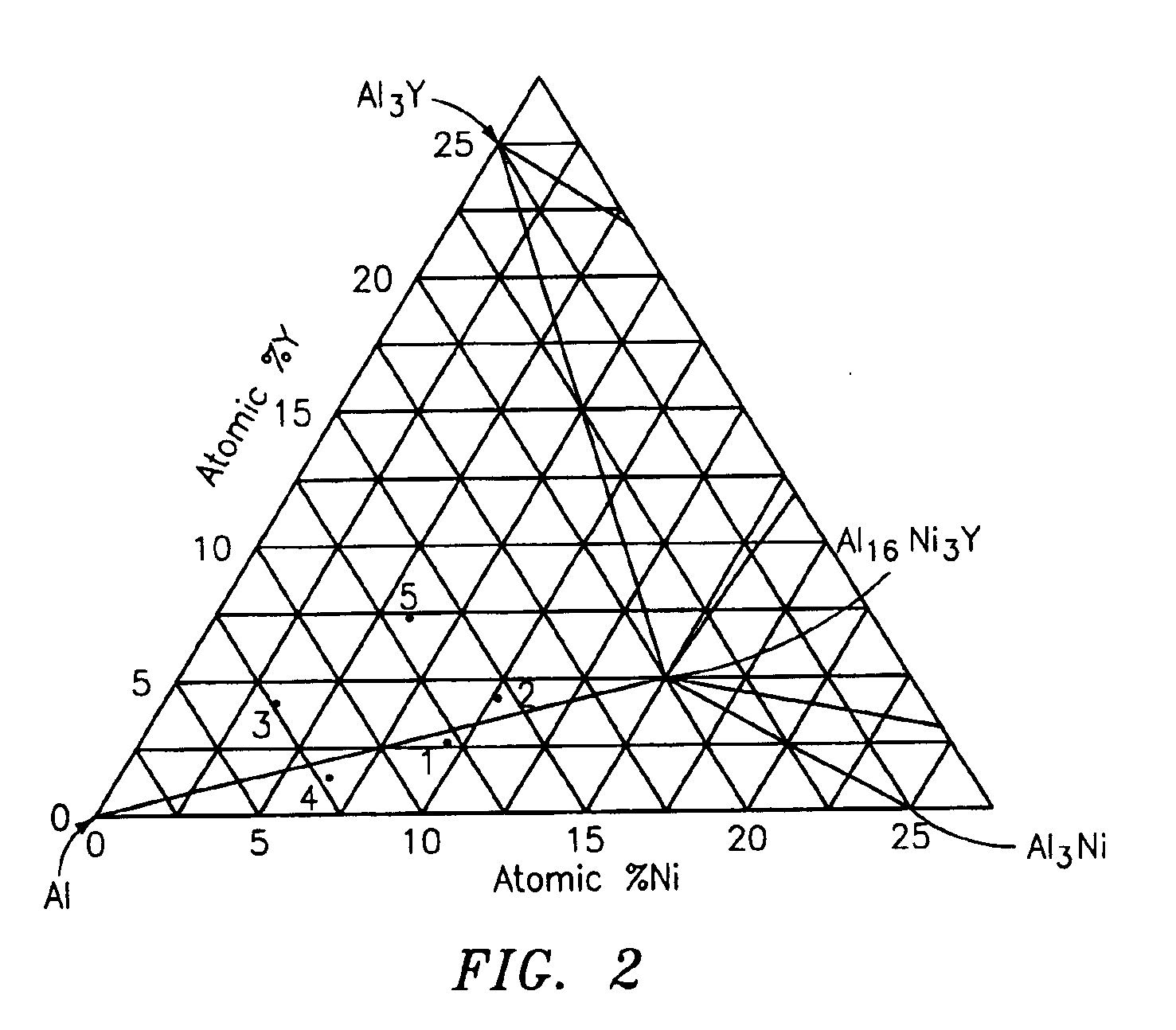

High temperature aluminum alloys

High temperature aluminum alloys that can be used at temperatures from about −420° F. (−251° C.) up to about 650° F. (343° C.) are described herein. These alloys comprise aluminum; scandium; at least one of nickel, iron, chromium, manganese and cobalt; and at least one of zirconium, gadolinium, hafnium, yttrium, niobium and vanadiuim. These alloys comprise an aluminum solid solution matrix and a mixture of various dispersoids. These alloys are substantially free of magnesium.

Owner:RTX CORP

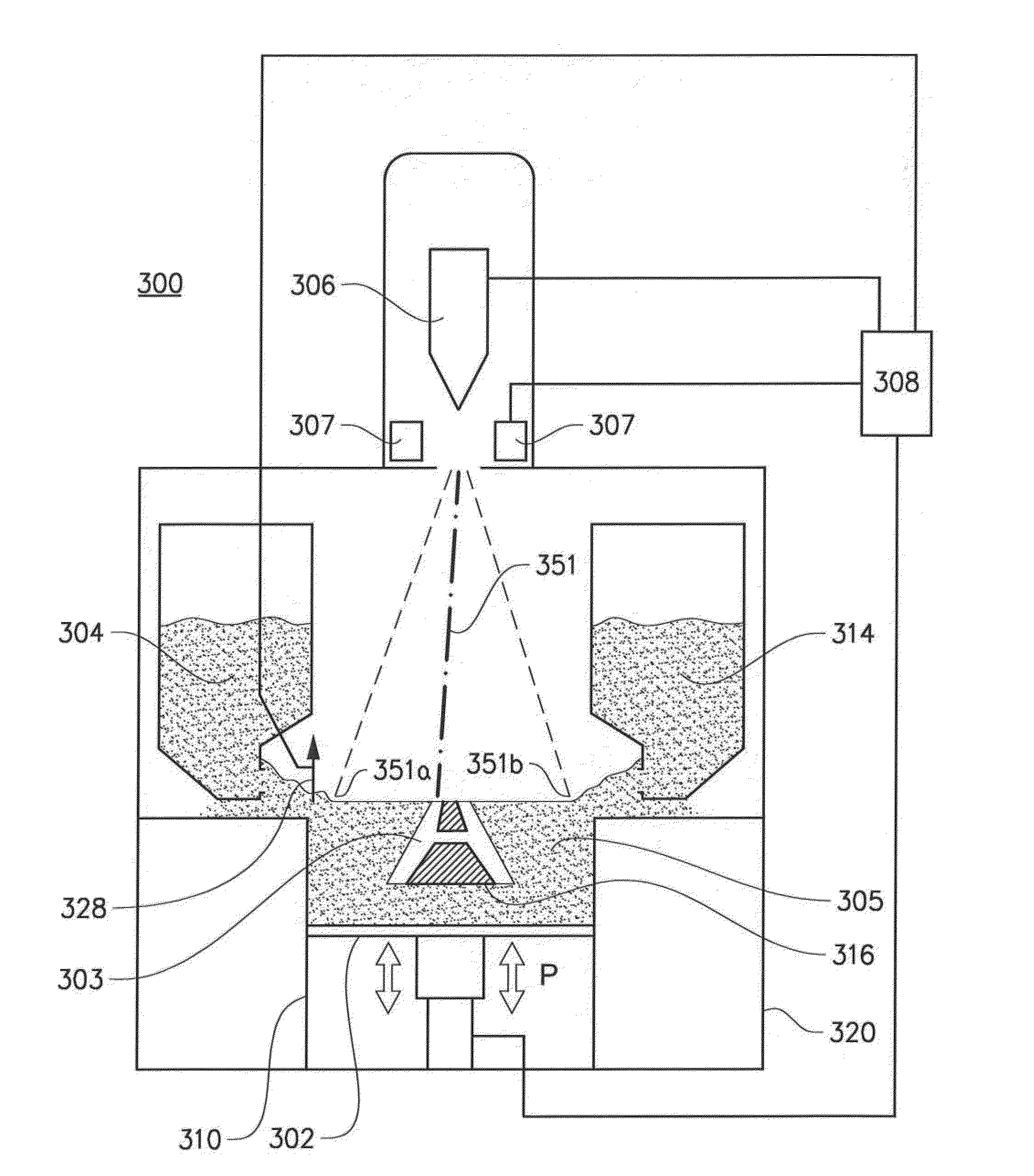

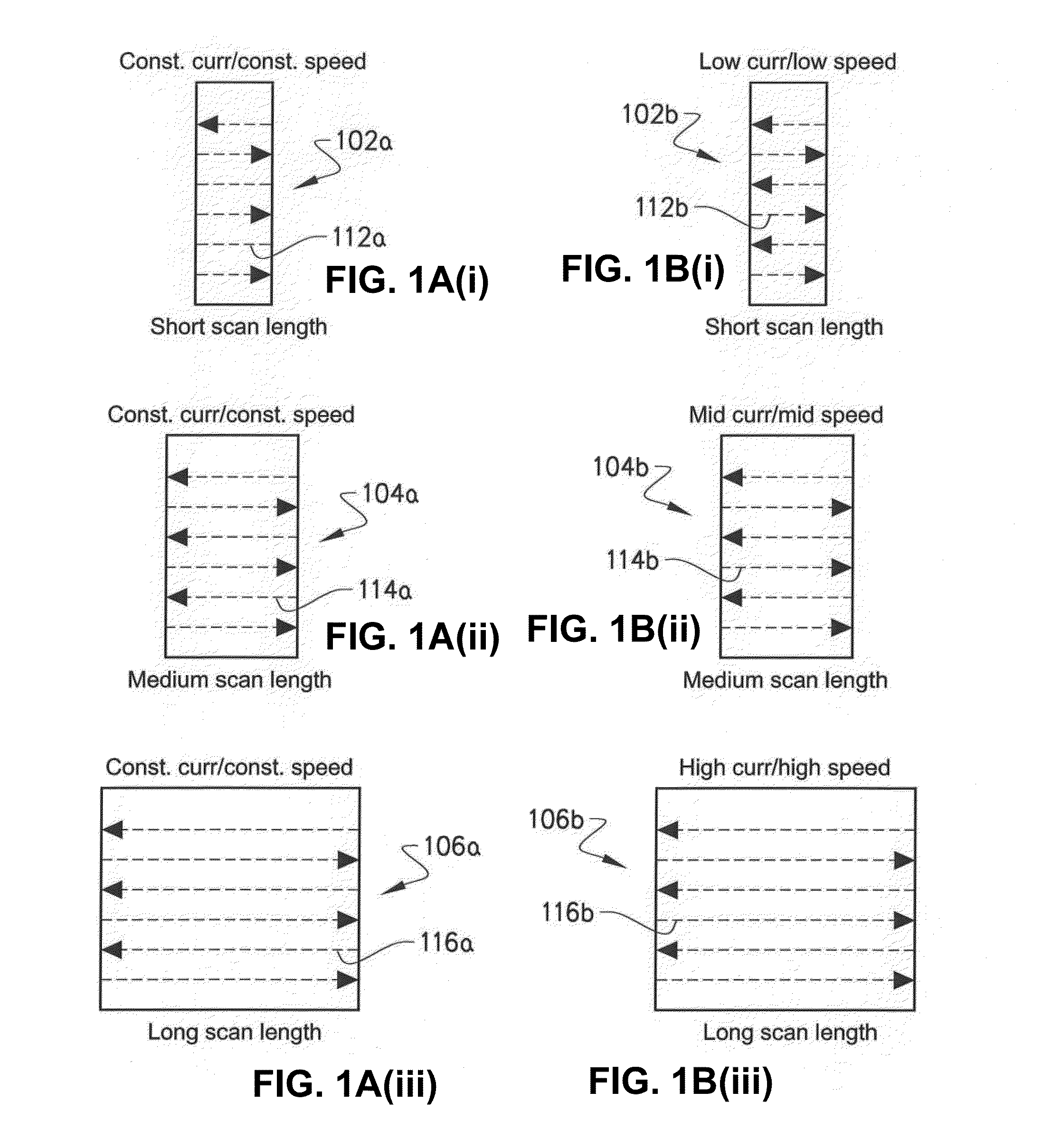

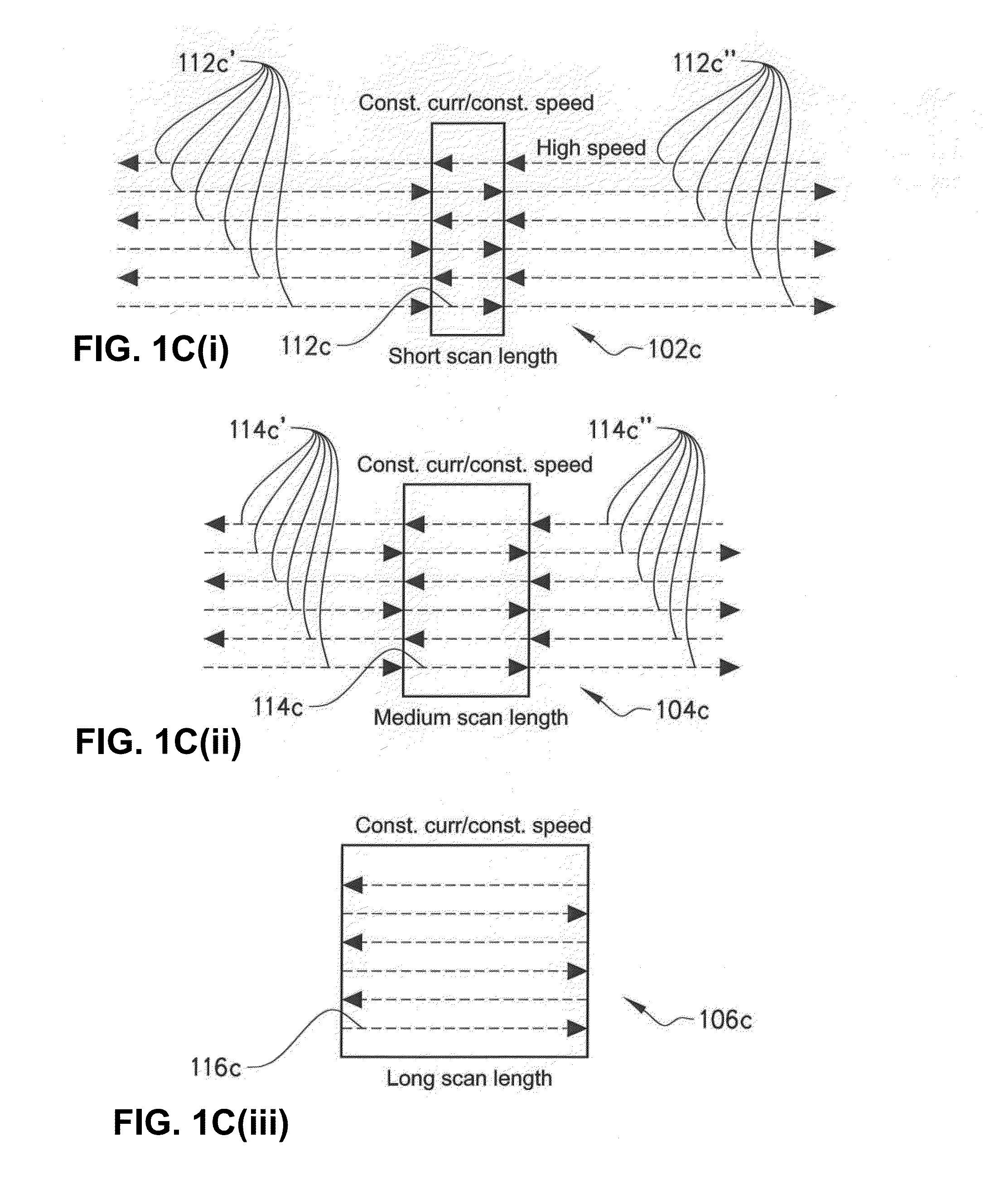

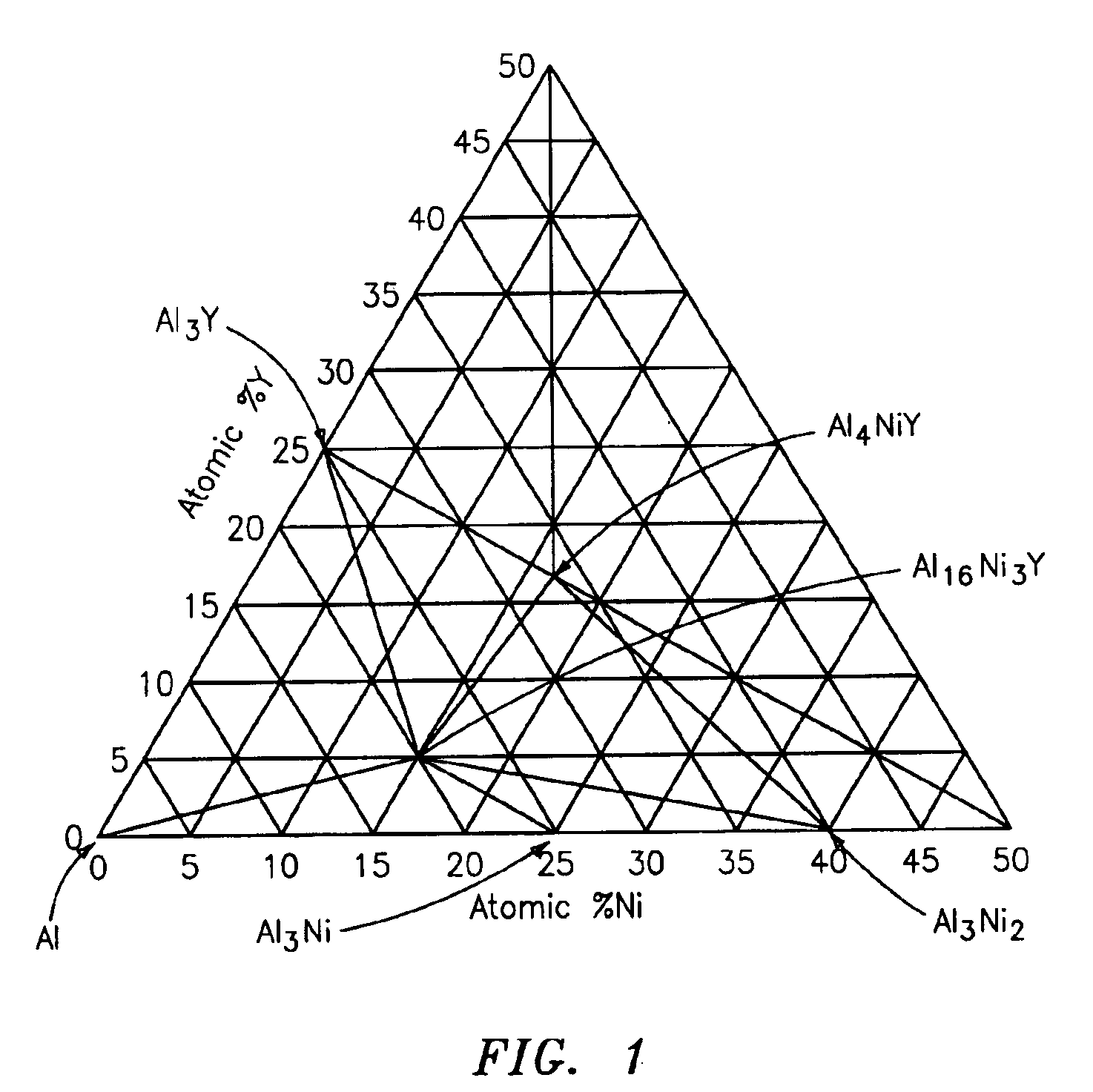

Method for additive manufacturing

ActiveUS20150174695A1Easy to controlImprove ductilityAdditive manufacturing apparatusIncreasing energy efficiencyScan lineBeam source

The invention relates to a method for forming a three-dimensional article through successive fusion of locations of a powder bed. The method comprising: providing a model of said three-dimensional article; applying a powder layer on a work table; determining a maximum scan length of an energy beam; directing said energy beam from a first energy beam source over said work table with constant energy causing said first powder layer to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, wherein locations with a shorter scan length than said maximum scan length is provided with a time sink before and / or after said scan line so that the time period between each two adjacent scan lines is constant throughout the manufacture of said three-dimensional article.

Owner:ARCAM AB

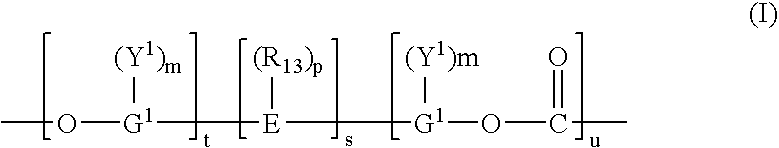

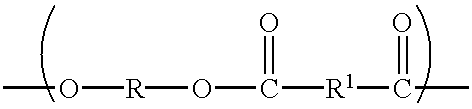

Resin compositions with fluoropolymer filler combinations

InactiveUS20050143508A1Improve propertiesImprove mechanical propertiesSpecial tyresOrganic dyesDuctilityPolymer chemistry

A thermoplastic resin composition is disclosed which comprises a matrix polymer, and a combination of a fluoropolymer that can be at least partially encapsulated by an encapsulating polymer, and a filler. Methods for making the thermoplastic resin composition and articles made of such compositions are also disclosed. The composition and article can have improved tensile modulus, ductility and impact properties.

Owner:GENERAL ELECTRIC CO

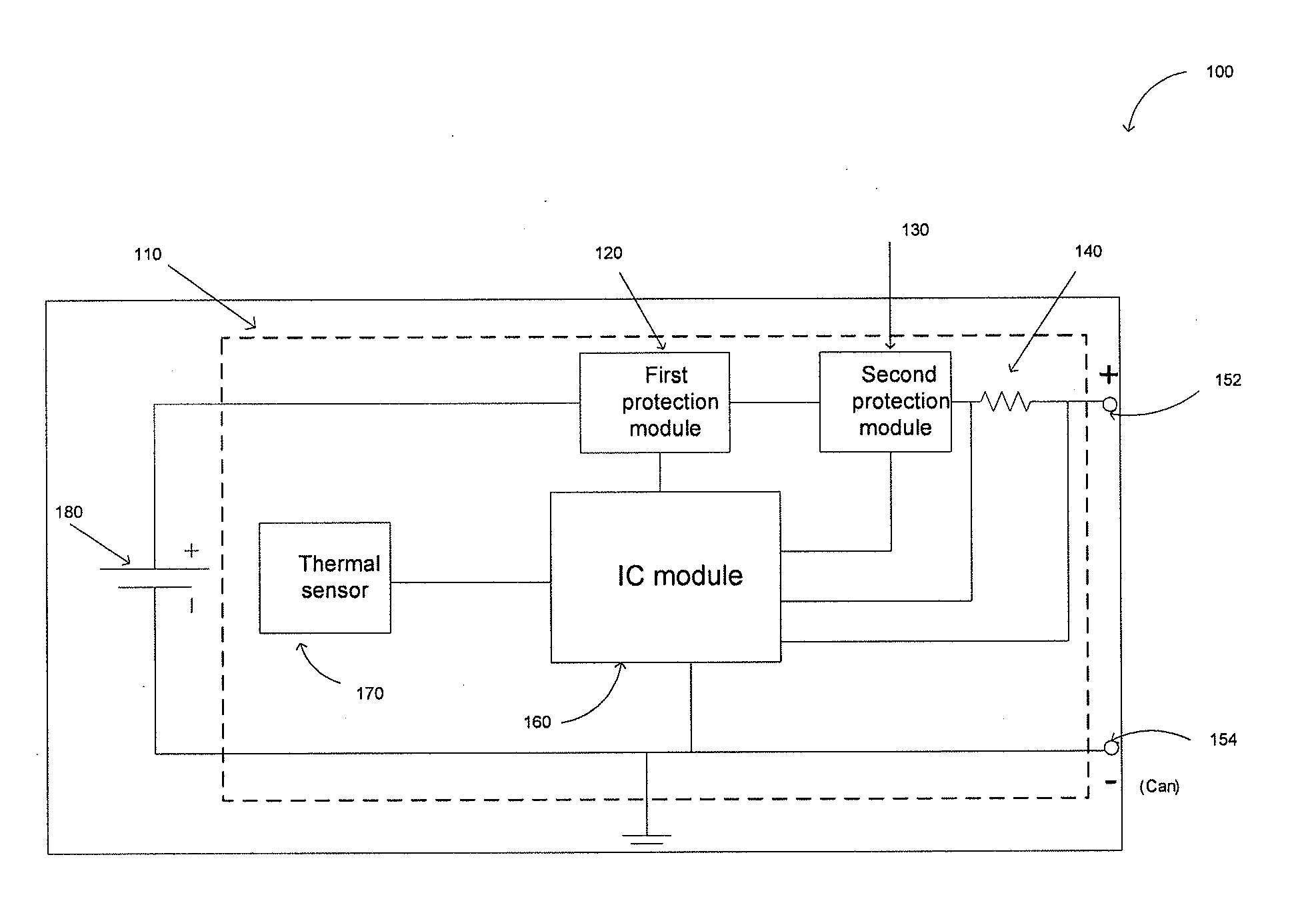

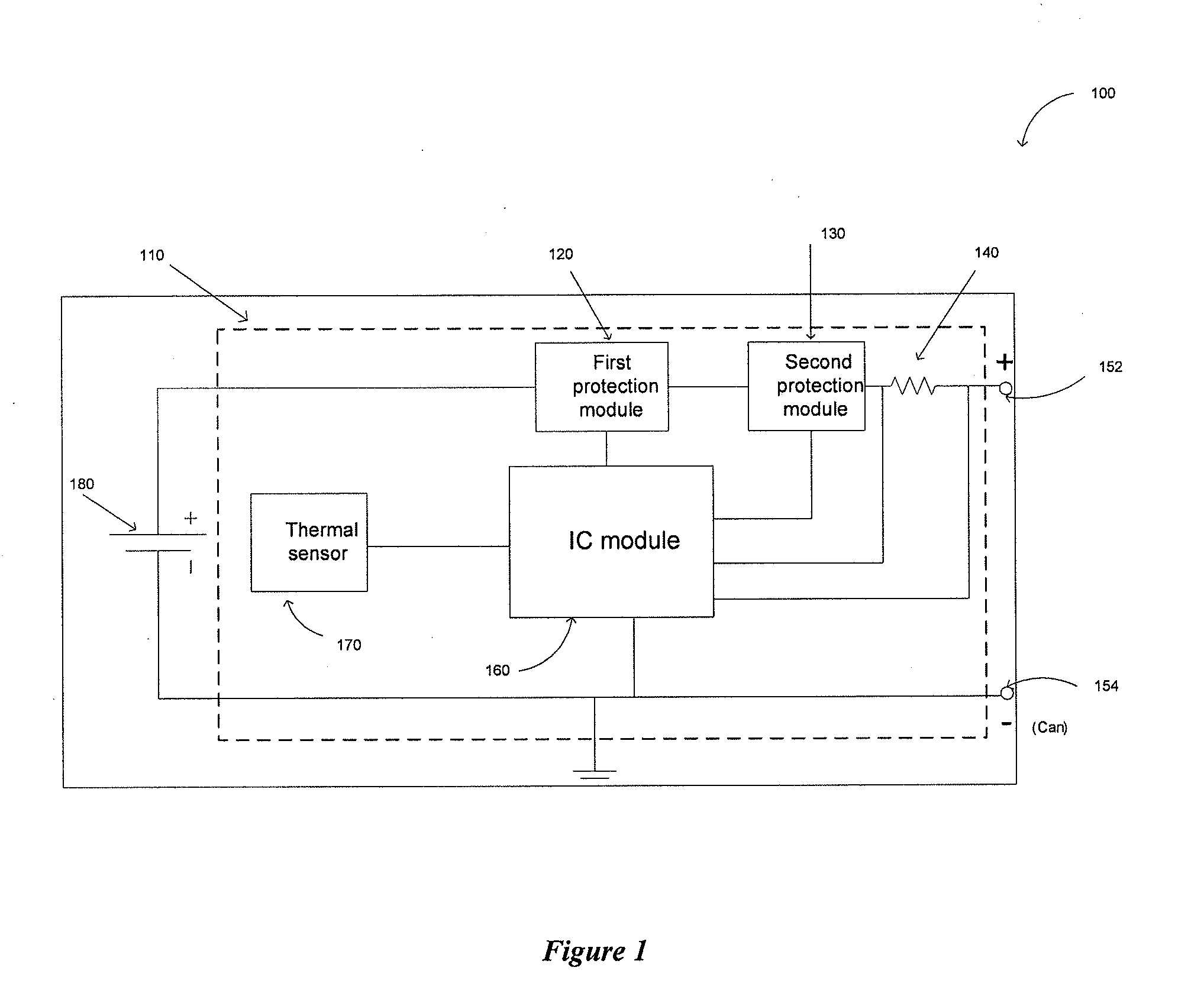

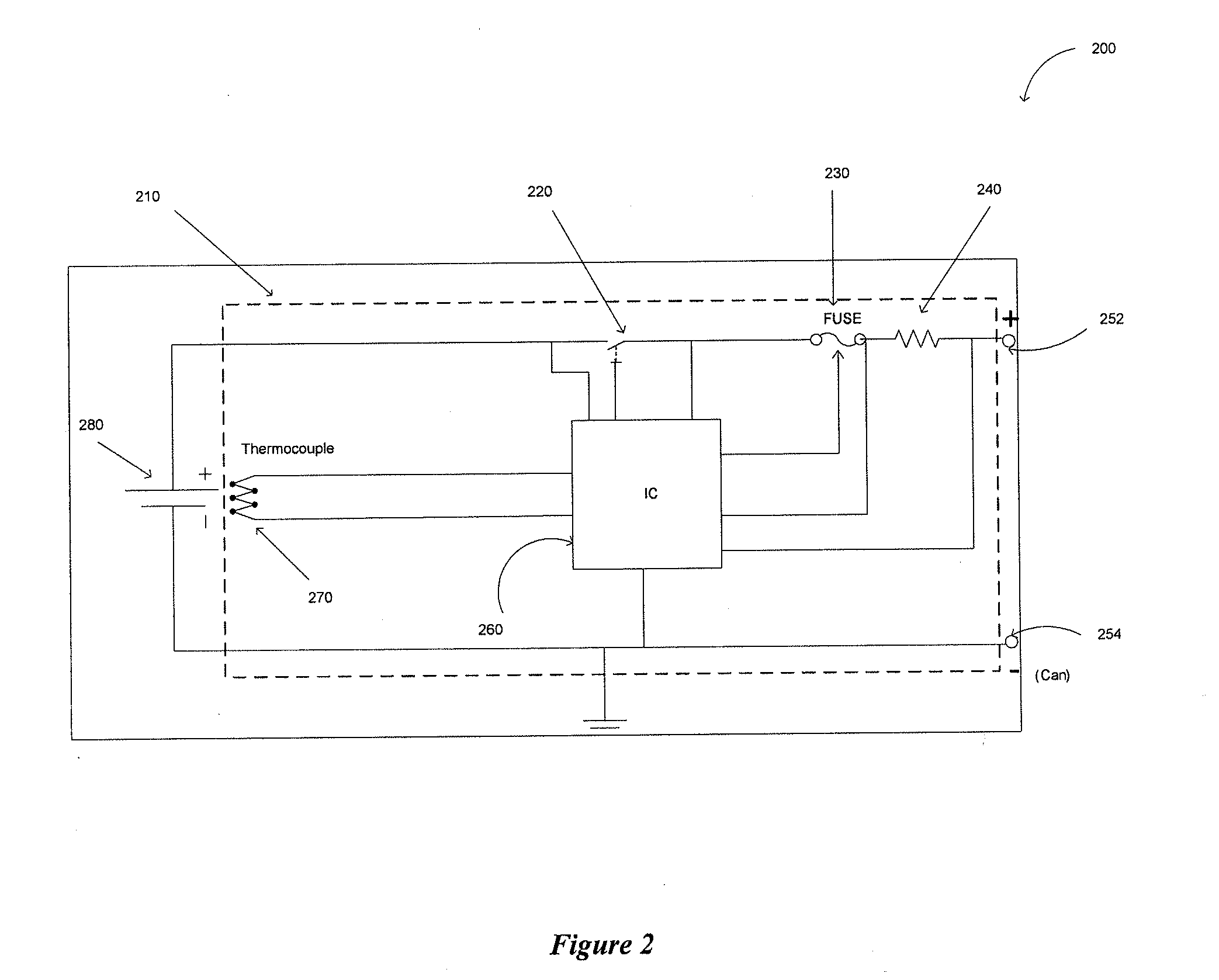

Electronic current interrupt device for battery

InactiveUS20100119881A1Low resistance contactReduce contact resistanceEmergency protective circuit arrangementsElectrical testingLithiumThermocouple

The present invention provides a protection circuit disposed in a lithium-ion cell for protection of the lithium-ion cell. The protection circuit includes a first protection module, a second protection module, an integrated circuit module, a thermal sensor or thermocouple, a switch, a fuse and / or a resistor.

Owner:LEYDEN ENERGY

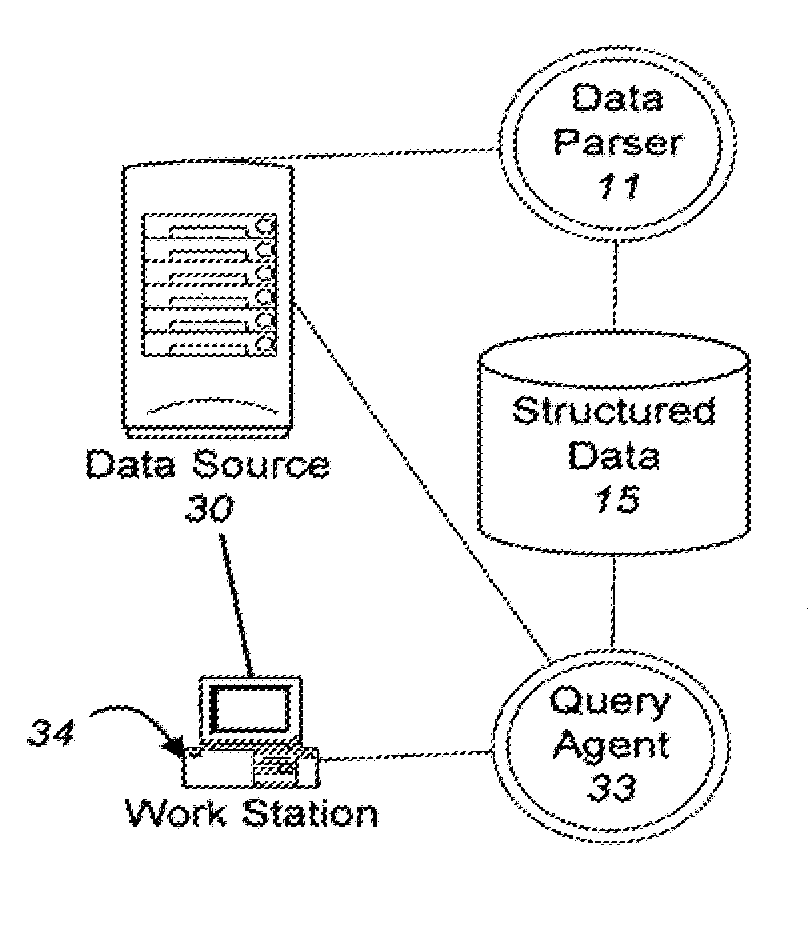

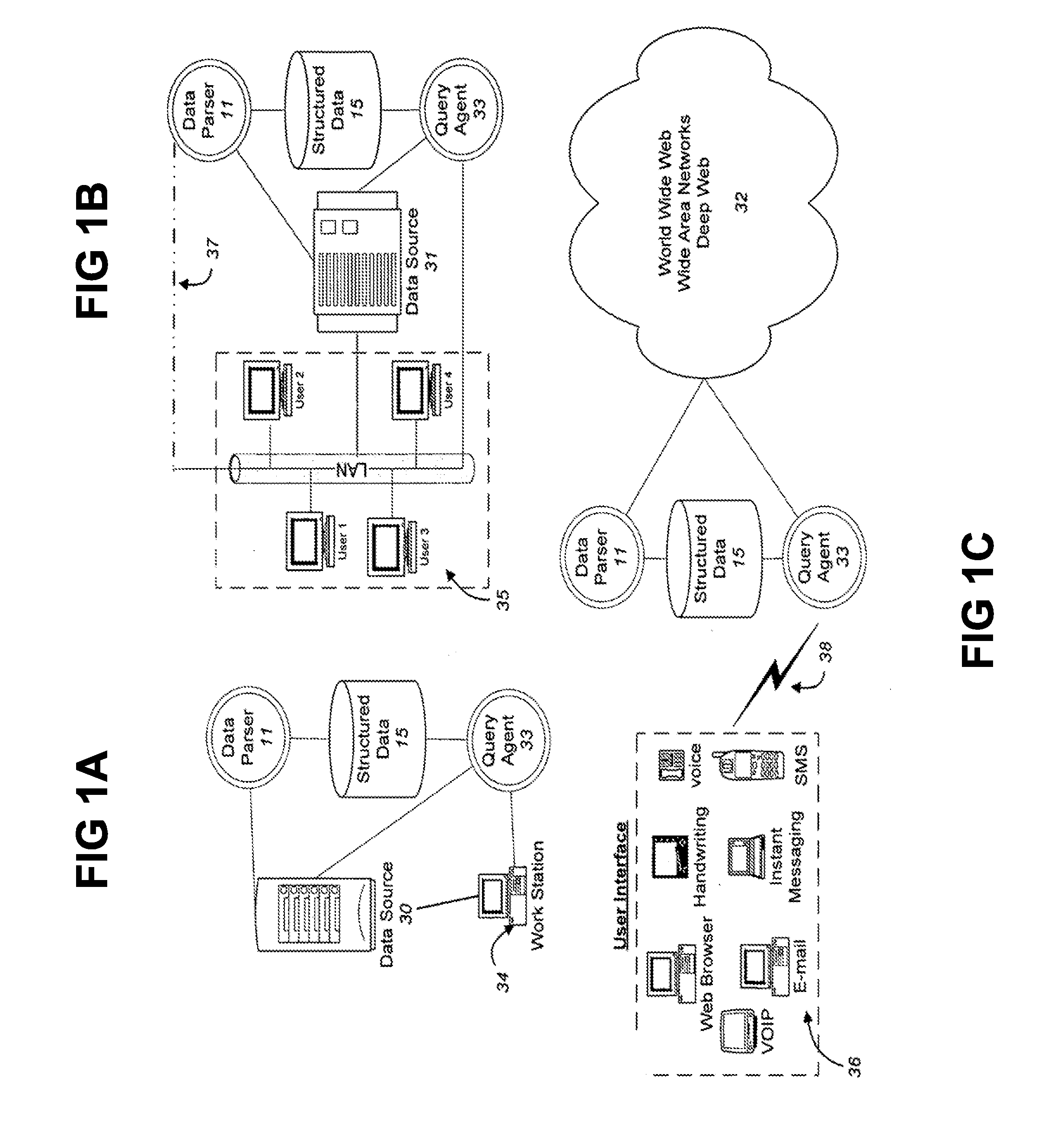

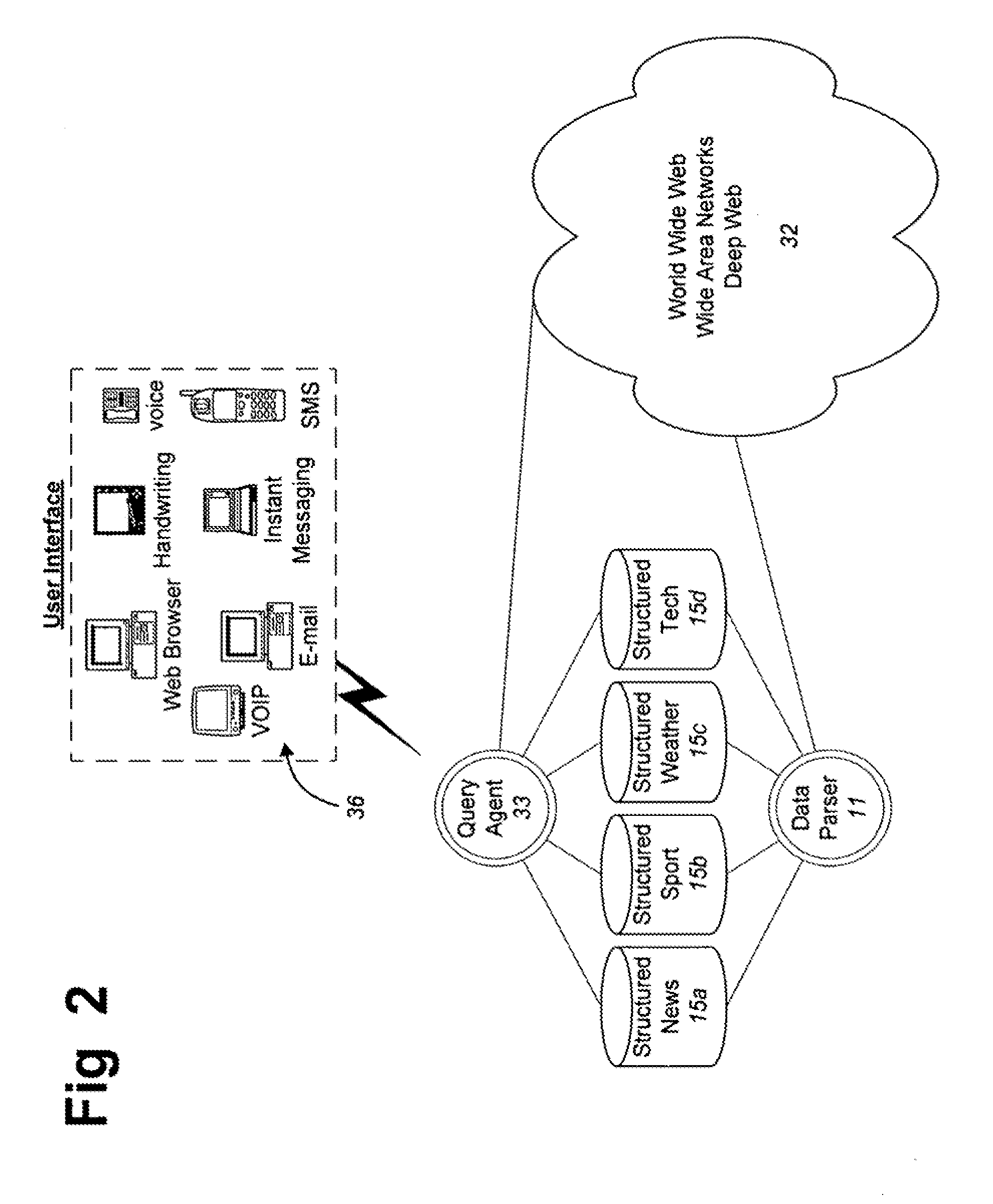

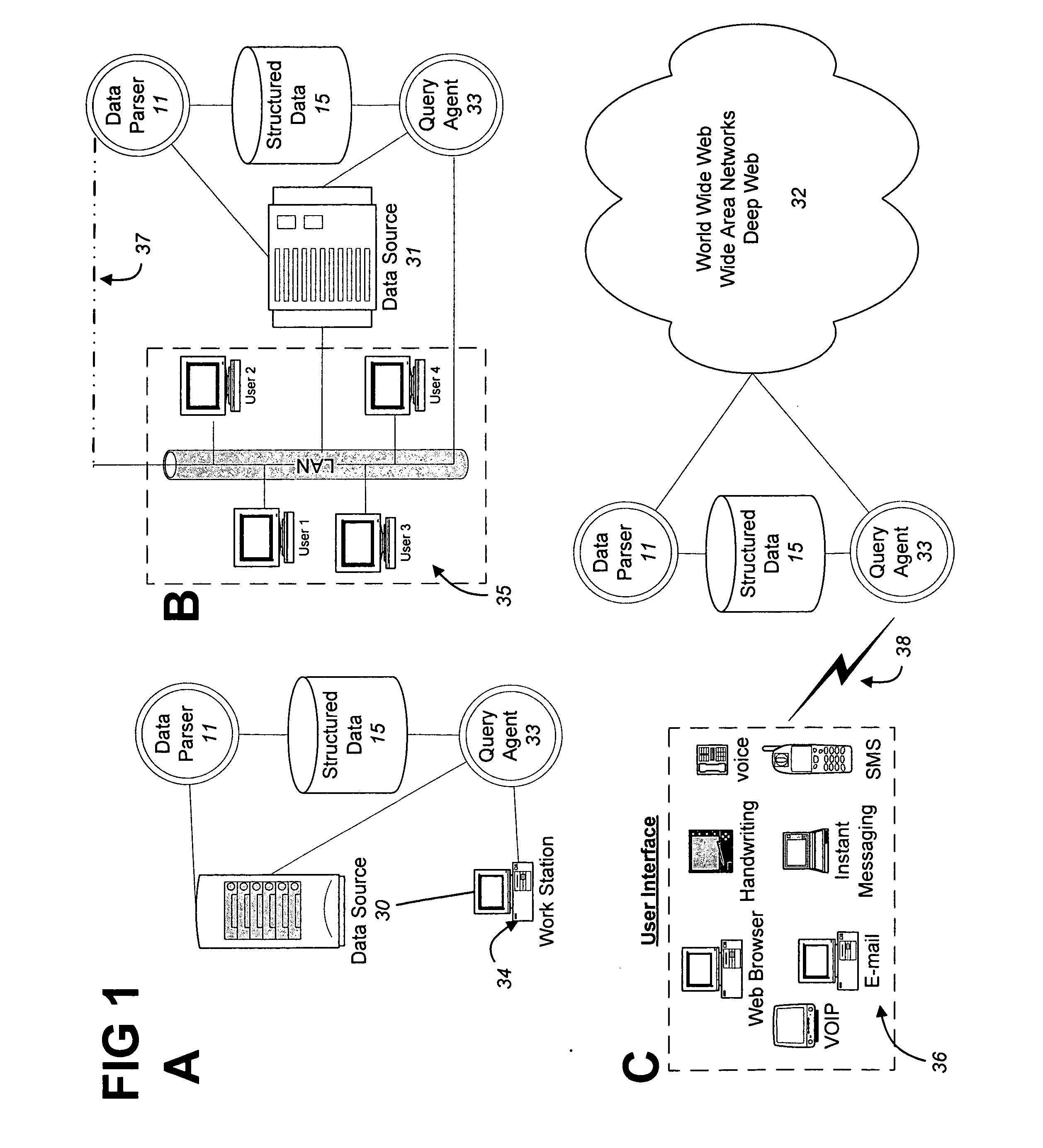

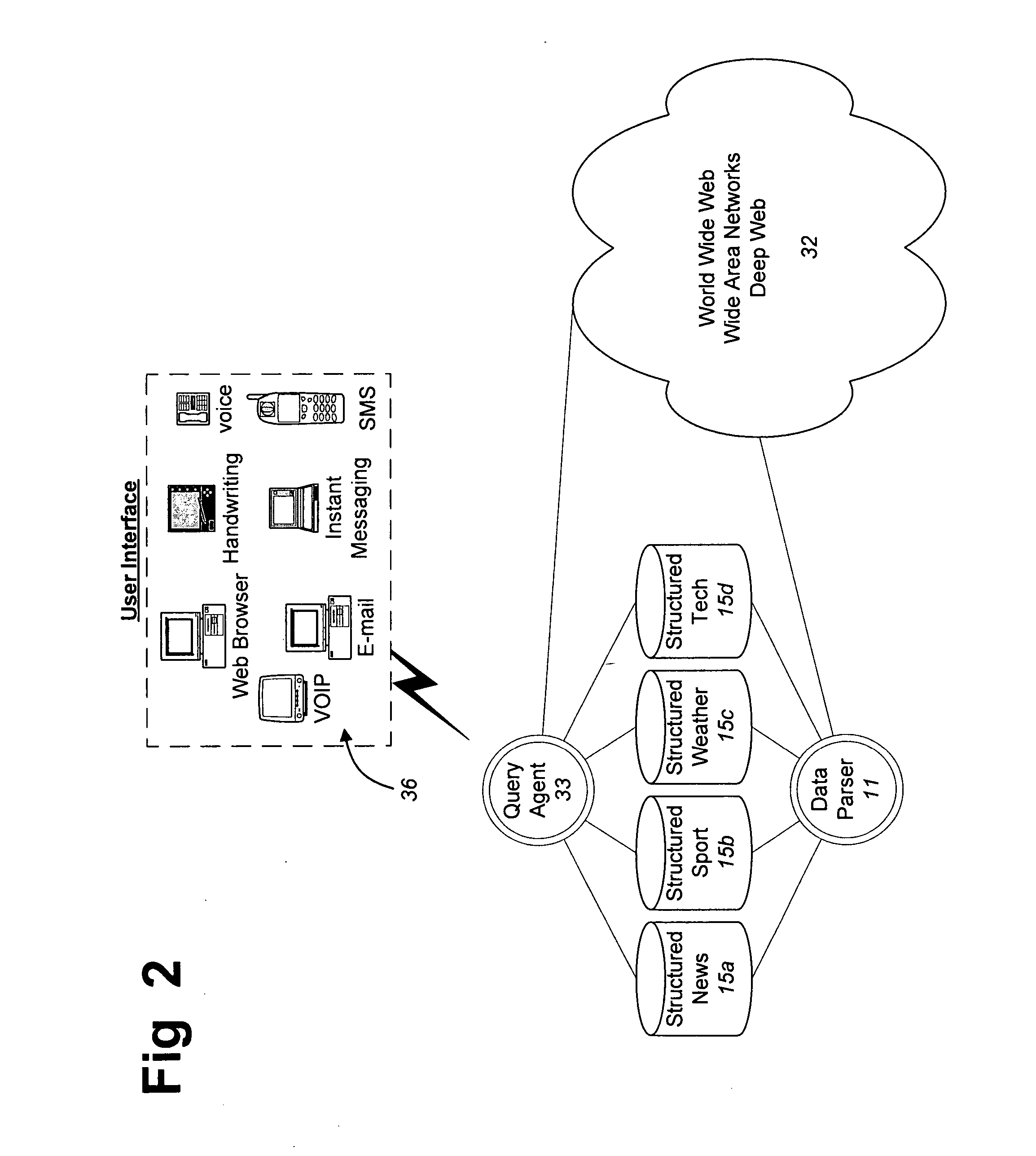

Telephonic information retrieval systems and methods

InactiveUS20070208732A1Efficient storageEffectively storing informationDigital data information retrievalSpecial data processing applicationsWalkie-talkieInformation retrieval

The present invention is directed to systems and methods for encoding and retrieving information from a variety of sources using novel search techniques. The systems and methods of the invention are capable of extracting all types of structural and relational information from a query or a source data allowing for the recognition of subtle differences in meaning. The capability of discerning subtle differences in meaning that are beyond the search systems and methods presently available, the invention described herein is capable of repeatedly providing accurate and meaningful responses to a diverse set of queries. Particular embodiments of the present invention include walkie-talkie-type telephone interfaces where the user may speak directly to the present invention and receive a spoken response relevant to any provided enquiry.

Owner:JILES

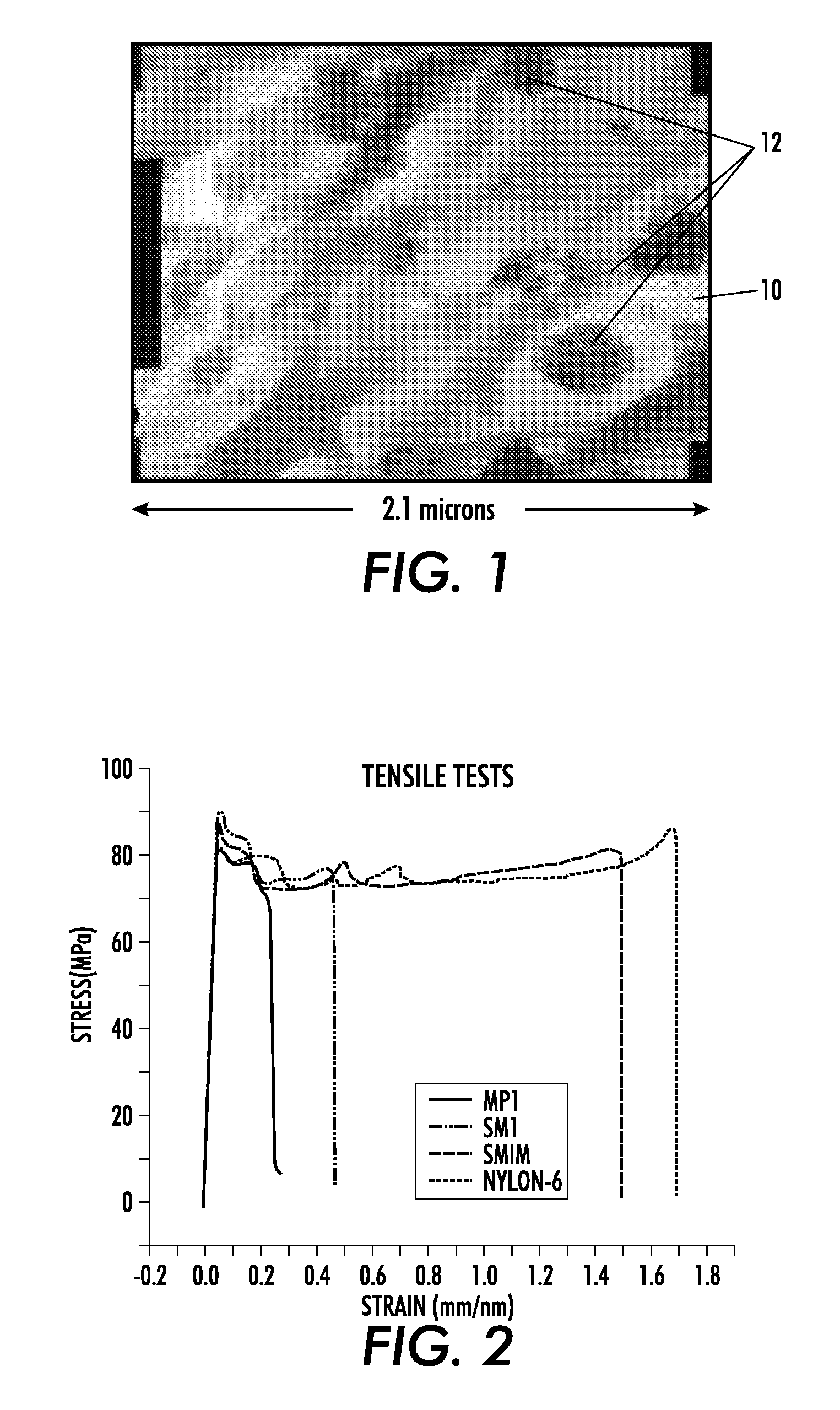

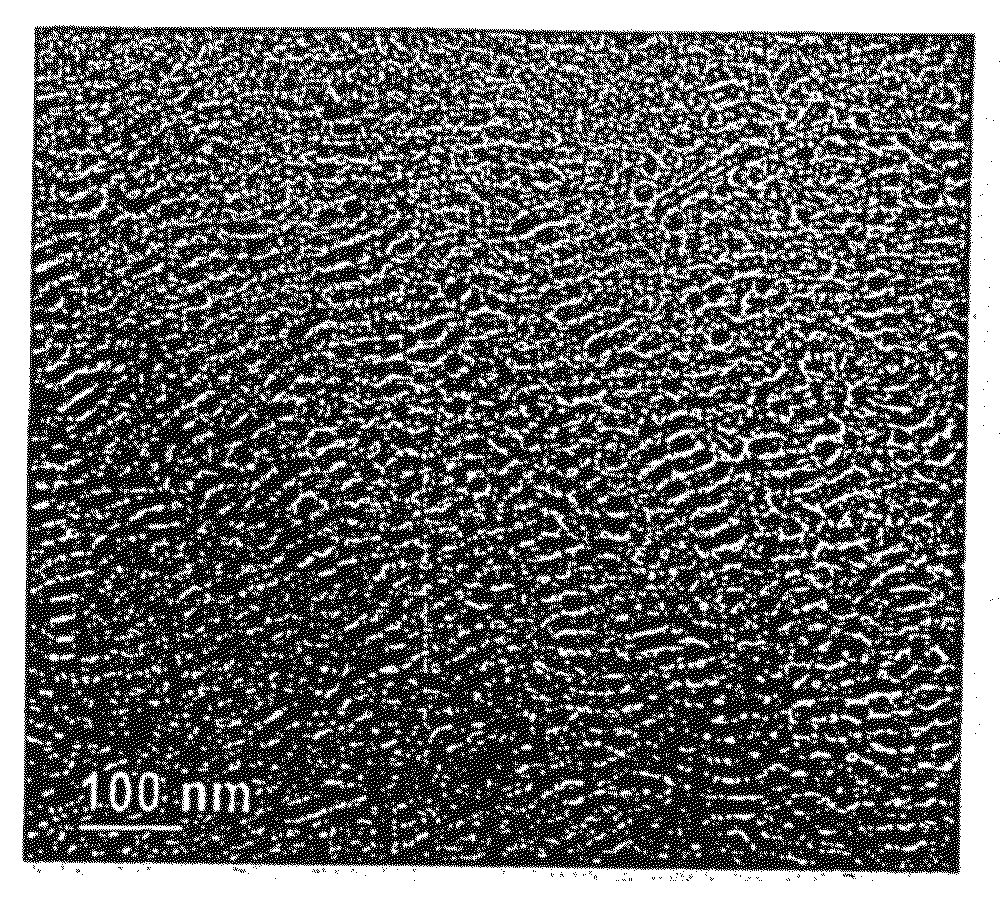

Polymeric composite including nanoparticle filler

InactiveUS20070106006A1Increase potential environmental impactReduce load levelHalloysiteNanoparticle

Disclosed is a novel polymeric composite including a nanoparticle filler and method for the production thereof. More particularly, the present invention provides a novel halloysite nanoparticle filler which has the generally cylindrical or tubular (e.g. rolled scroll-like shape), in which the mean outer diameter of the filler particle is typically less than about 500 nm. The filler is effectively employed in a polymer composite in which the advantages of the tubular nanoparticle filler are provided (e.g., reinforcement, flame retardant, chemical agent elution, etc.) with improved or equivalent mechanical performance of the composite (e.g., strength and ductility).

Owner:NATURALNANO CORP

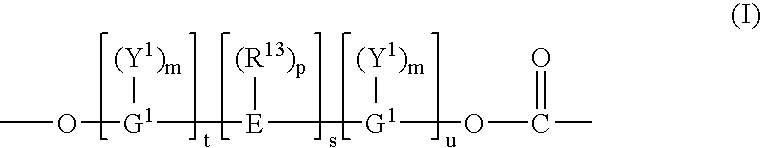

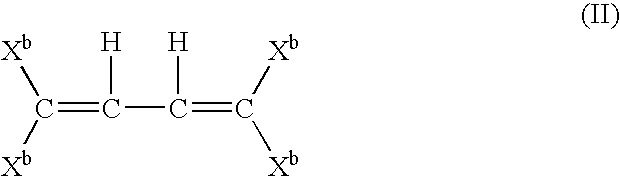

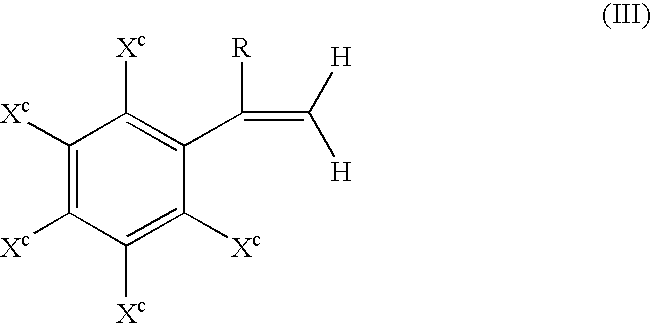

Production of meta-block copolymers by polymer segment interchange

Meta-block copolymers and a process for preparing a product mixture comprising meta-block copolymers by contacting a metathesis catalyst under metathesis conditions with a composition comprising two or more ethylenically unsaturated polymers, said unsaturation defining one or more polymer segments in each ethylenically unsaturated polymer, at least one polymer segment in at least one ethylenically unsaturated polymer being chemically distinguishable from at least one polymer segment in at least one other ethylenically unsaturated polymer, characterized in that each meta-block copolymer in the product mixture comprises a random distribution of said chemically distinguishable polymer blocks.

Owner:DOW GLOBAL TECH LLC +1

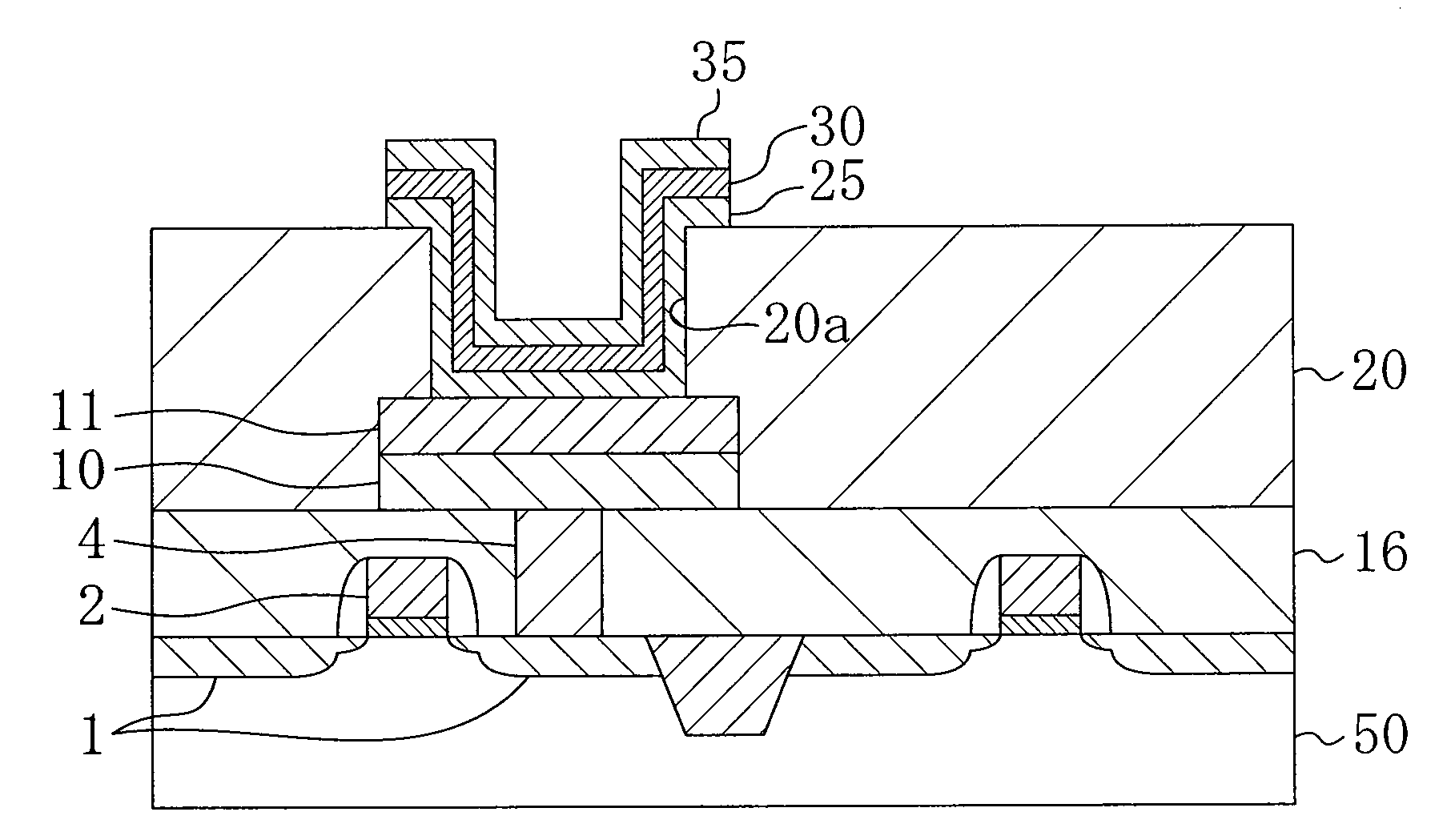

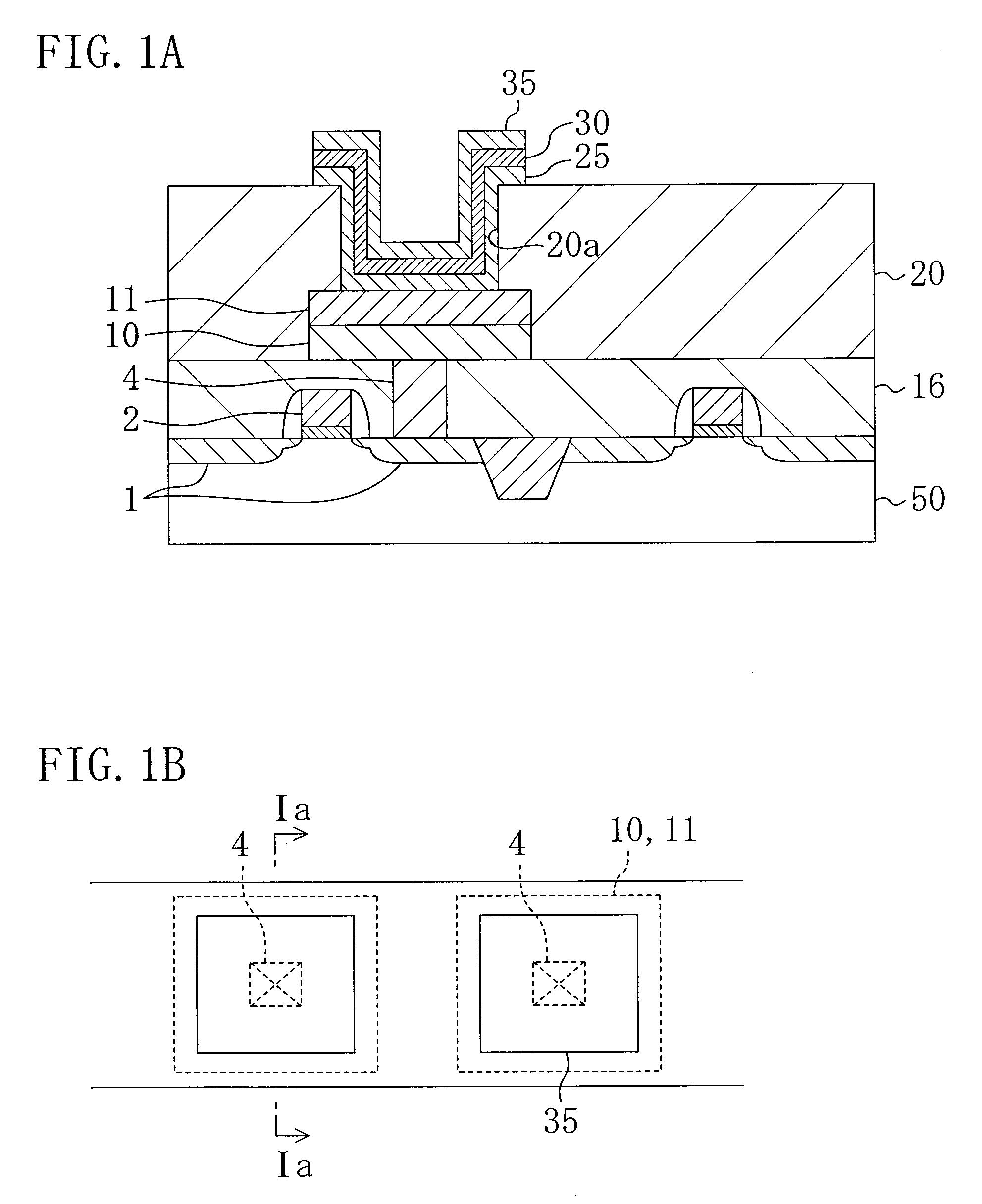

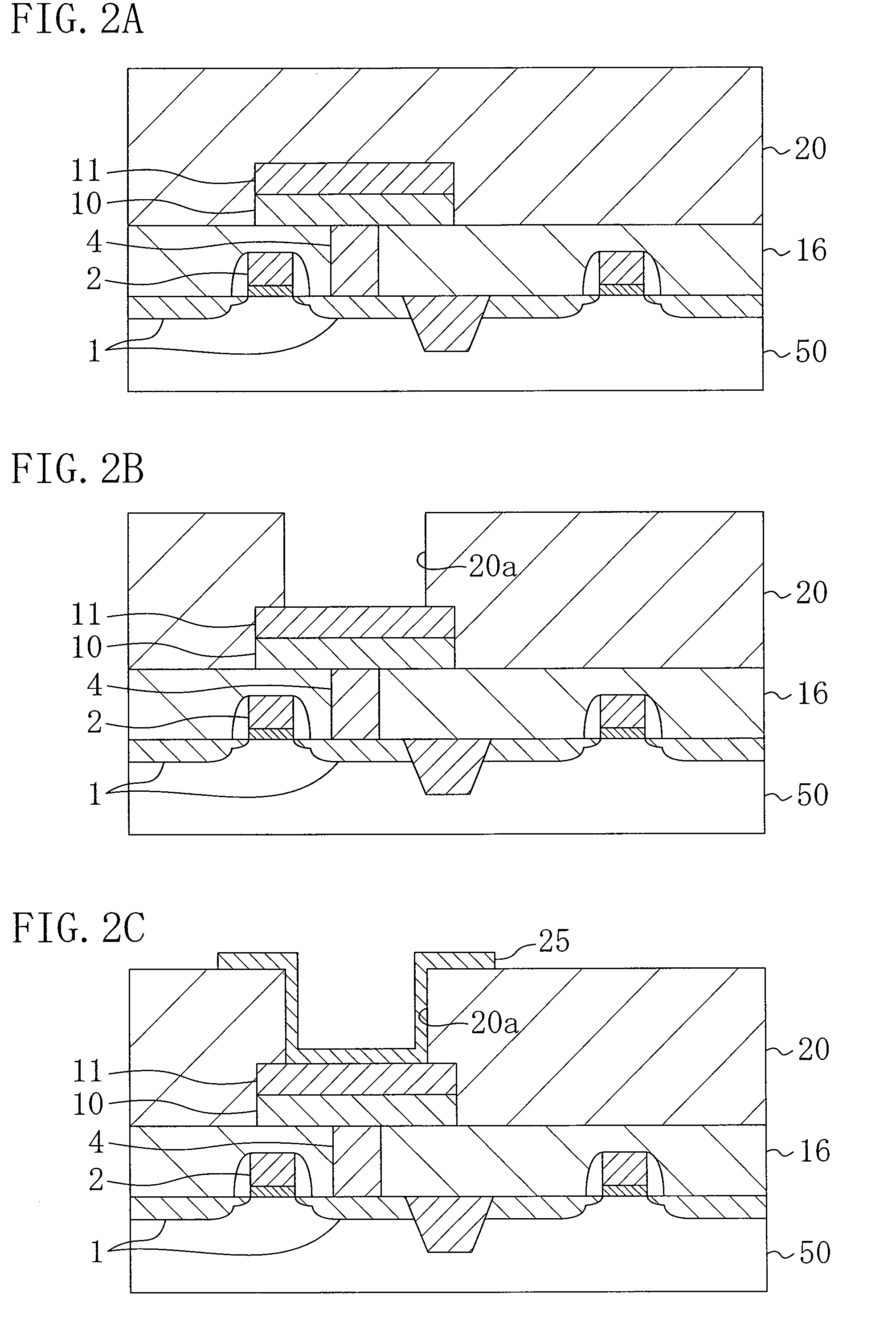

Semiconductor storage device and manufacturing method of the same

InactiveUS20090250787A1Decrease in remanent polarization can be preventedAvoid breakingTransistorSolid-state devicesCapacitanceAdhesive

A semiconductor storage device includes: a first conductive adhesive layer selectively formed over a semiconductor substrate; an insulating film formed on the semiconductor substrate to cover the first conductive adhesive layer and having an opening exposing a central part of the first conductive adhesive layer; and a capacitive element including a bottom electrode formed along a bottom surface and a wall surface of the opening, a capacitive insulating film formed on the bottom electrode, and a top electrode formed on the capacitive insulating film. The first conductive adhesive layer is in contact with the bottom electrode only at a bottom surface part of the opening which includes a corner where the bottom surface of the opening meets the wall surface thereof.

Owner:PANASONIC CORP

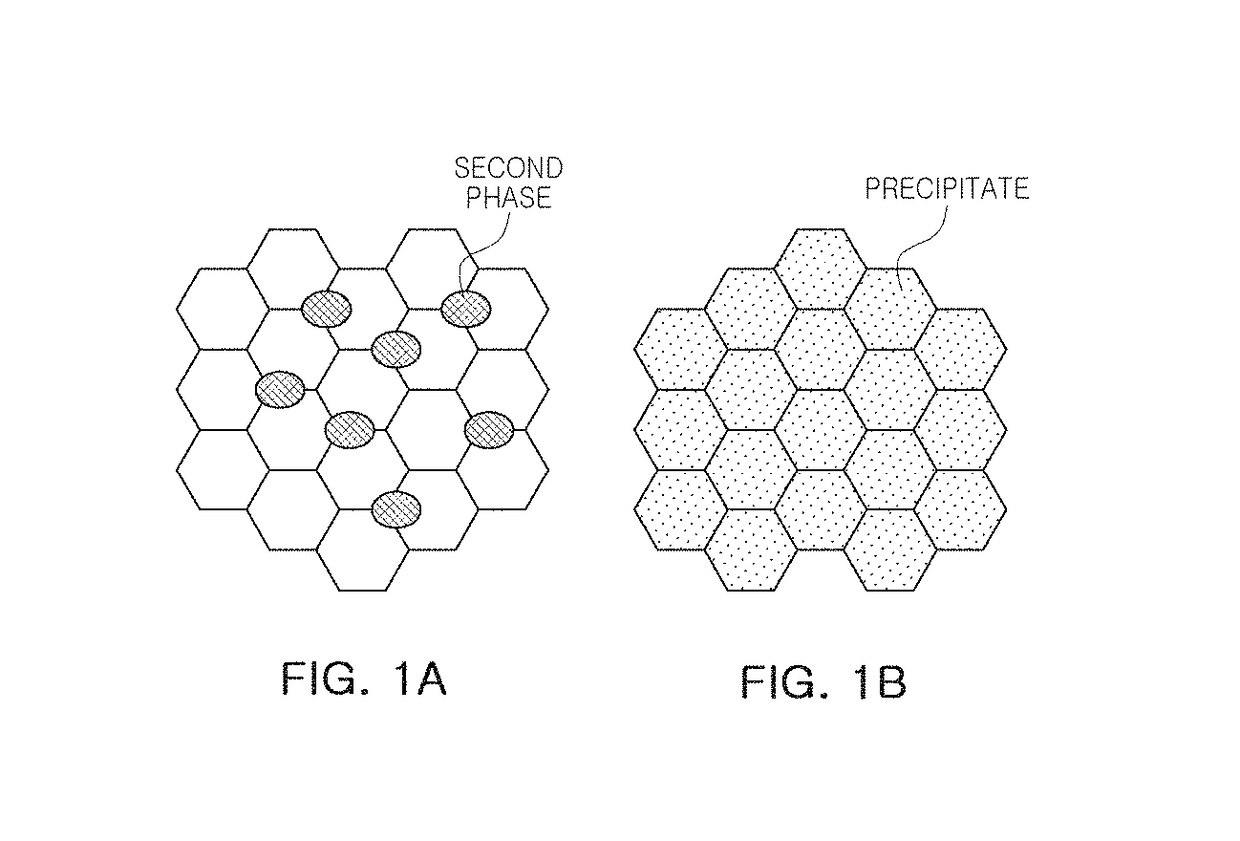

Precipitation Hardening High Entropy Alloy and Method of Manufacturing the Same

High-entropy alloy, particularly a precipitation hardening high entropy alloy, is provided as a component material used in electromagnetic, chemical, shipbuilding, mechanical, and other applications, a component material used in extreme environments requiring high strength and good corrosion resistance, and the like.

Owner:THE IND & ACADEMIC COOPERATION & CHUNGNAM NAT UNIV

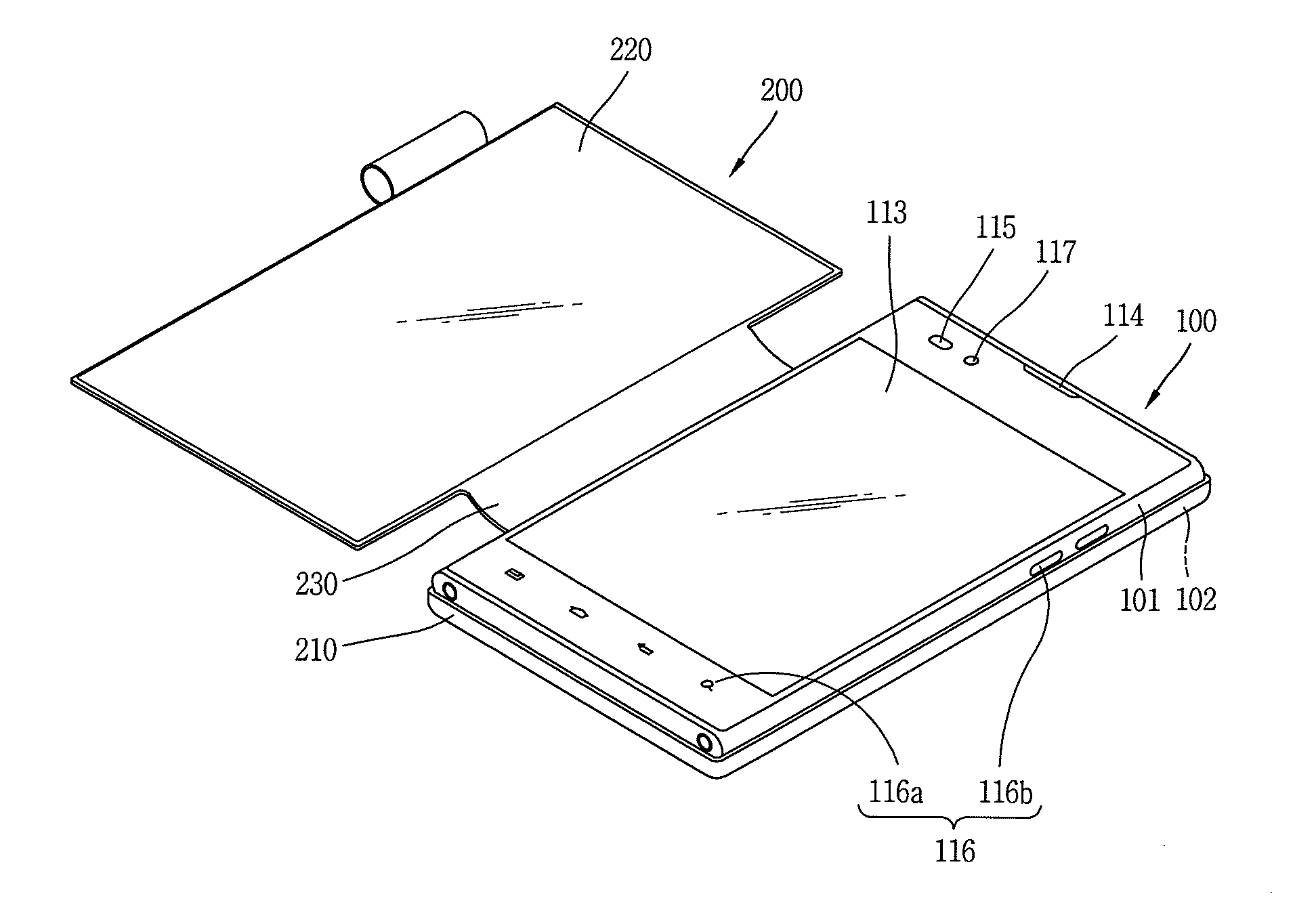

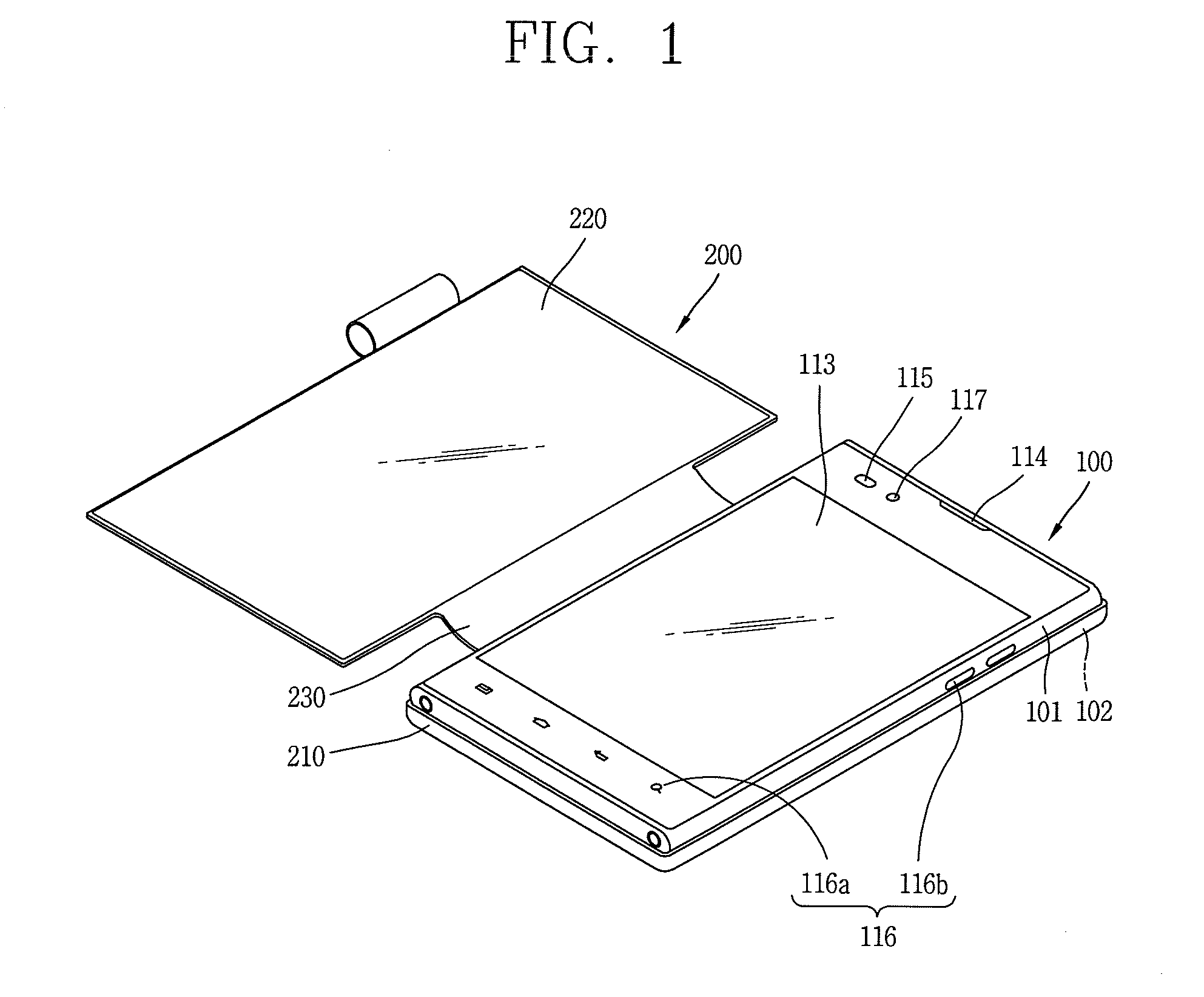

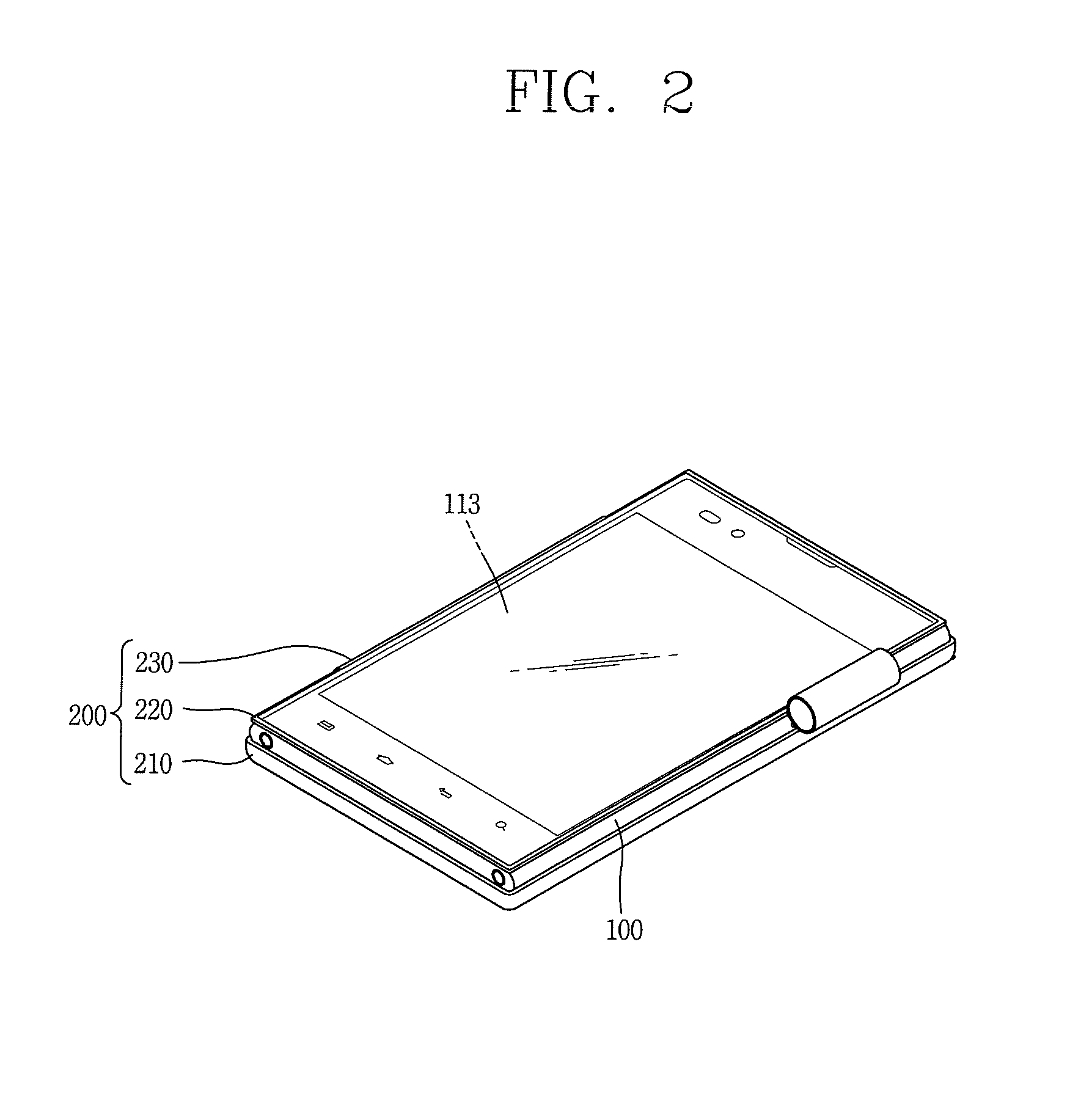

Pouch and portable electronic device received therein

ActiveUS20130300679A1Improve tightnessEasy to transformDigital data processing detailsOther accessoriesHuman–computer interactionClosed state

A pouch for receiving a main body of a portable electronic device having a touch screen provided on a front surface thereof includes: a first part for receiving a rear surface of the main body; and a second part rotatably connected to the first part to close or open the touch screen, wherein the second part is formed to expose visual information of the touch screen to the outside in a state in which the touch screen is covered, and has conductivity allowing the touch screen to sense a touch input applied thereto in the closed state.

Owner:LG ELECTRONICS INC

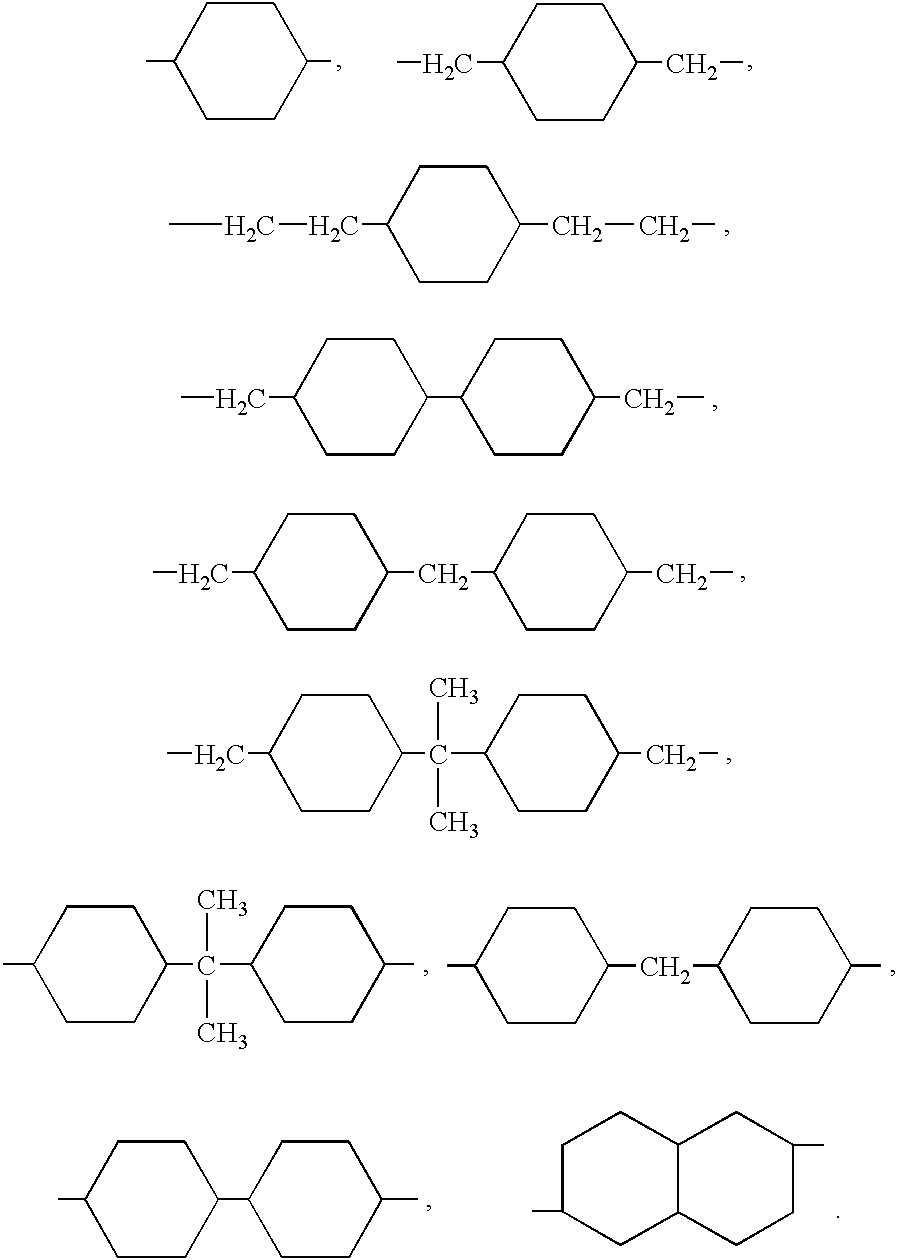

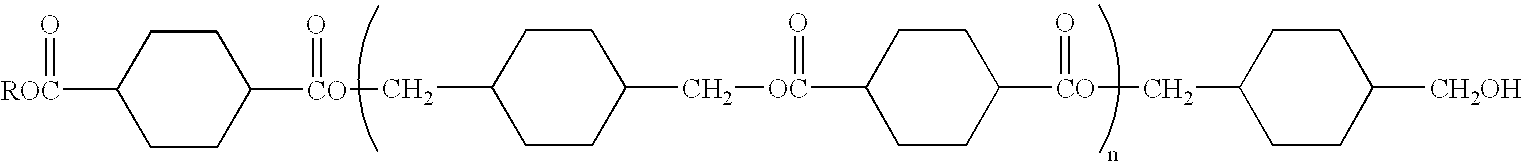

Insert molded article

InactiveUS6458913B1Prevent substrate deformationLow process temperatureSynthetic resin layered productsCeramic shaping apparatusPolymer substrateShell molding

A molded structure comprises a decorative film or substrate, and an adjacent injection molded polymeric base comprising a substantially transparent cycloaliphatic polyester resin which may have an opening for exposing the transparent polymeric base resin to the exterior of the molded article, and a process for making the molded structure is described.

Owner:SABIC GLOBAL TECH BV

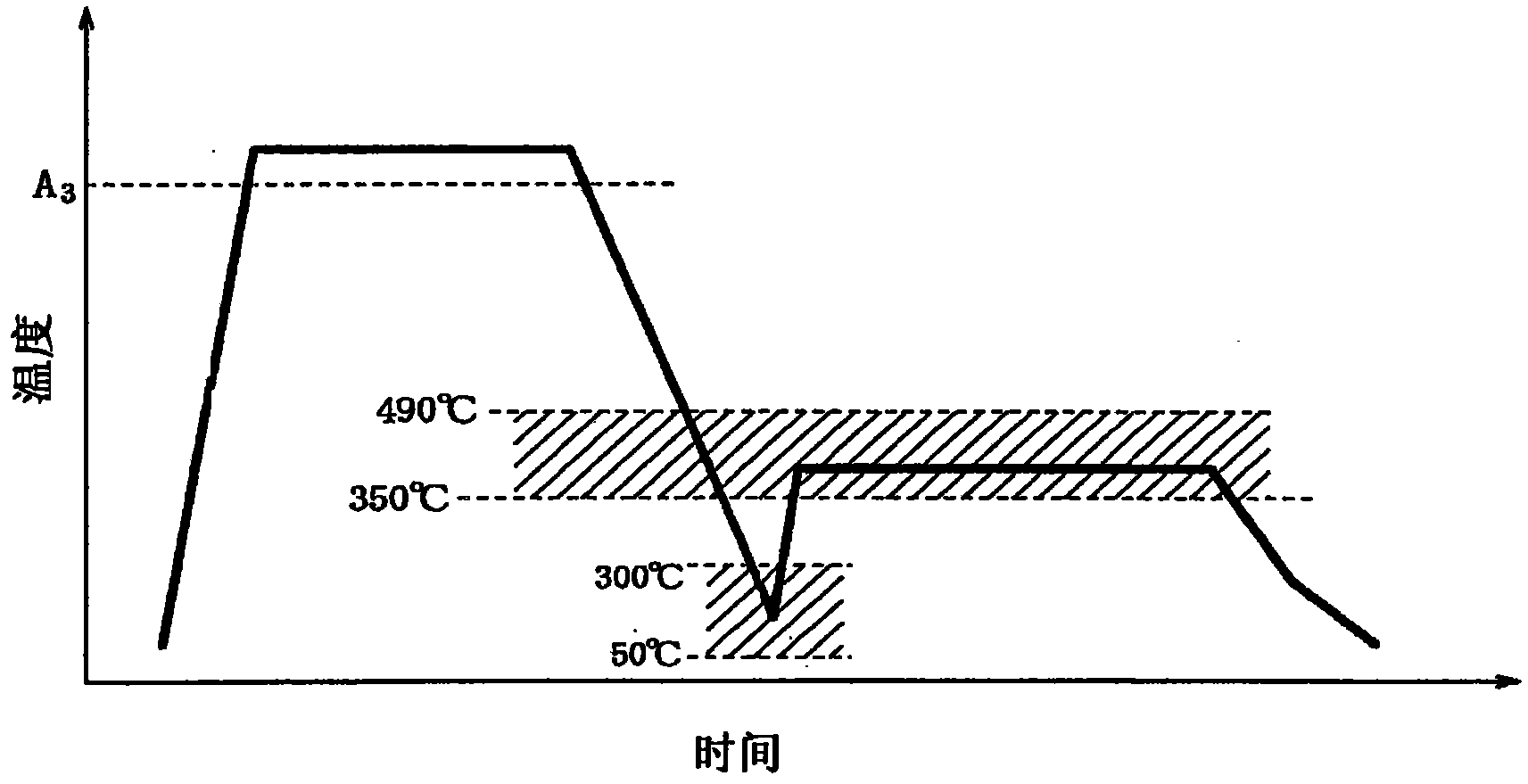

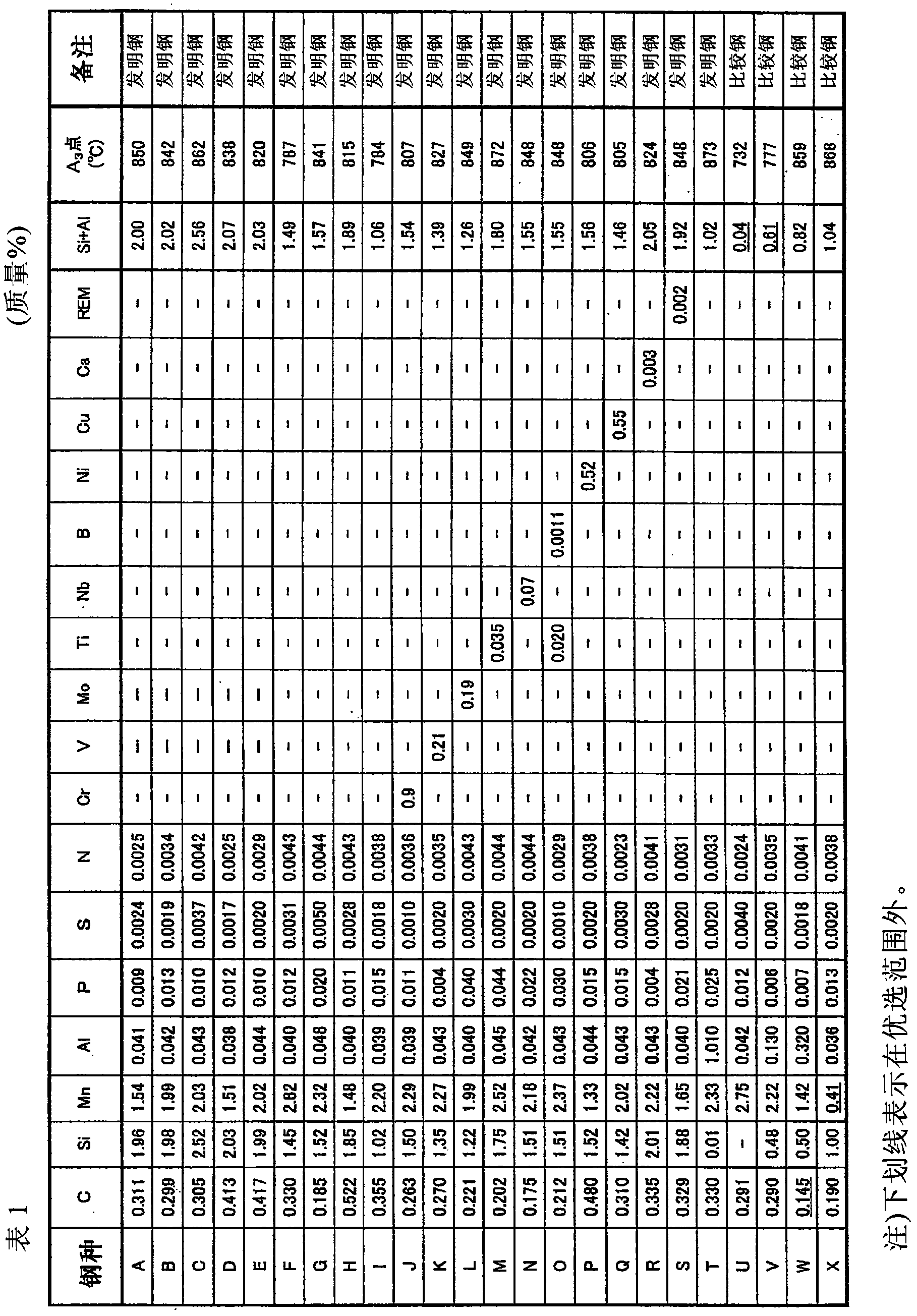

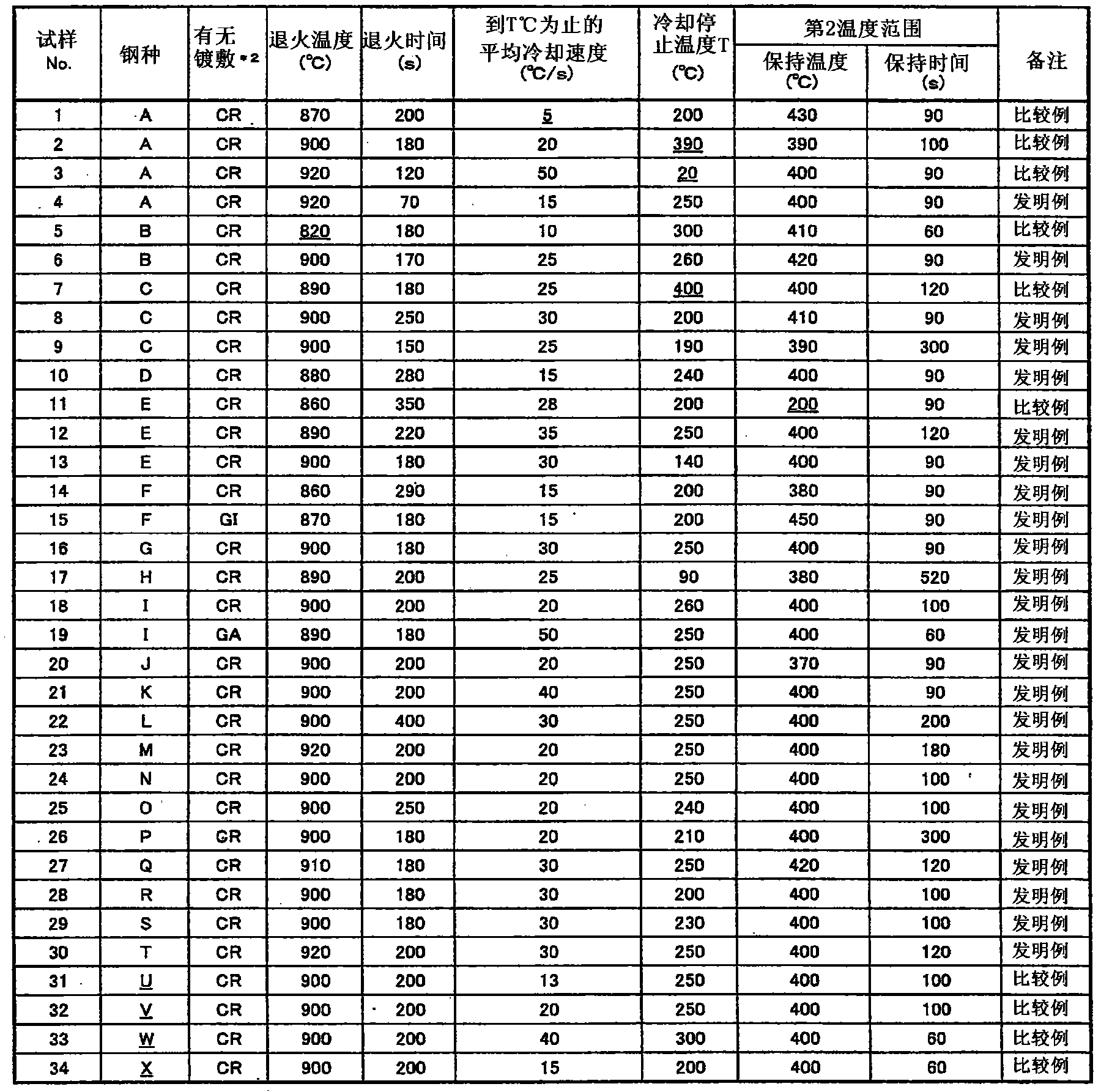

High-strength steel plate and manufacturing method thereof

ActiveCN102149840AGood ductilityExcellent stretch flangeabilityHot-dipping/immersion processesFurnace typesSteel platesDuctility

Disclosed is a high-strength steel plate having superior ductility and stretch flangeability and a tensile strength (TS) of 980 MPa or higher, and having 0.17-0.73% C, 3.0% or less Si, 0.5-3.0 or less Mn, 0.1% or less P, 0.07% S, 3.0% or less Al, 0.010% or less N, and 0.7% or more Si + Al, an area ratio of martensite of 10-90% with respect to the entire steel plate composition, a residual austenite amount of 5-50%, and an area ratio of bainitic ferrite in the upper bainite of 5% or less with respect to the entire steel plate composition. Twenty-five percent or more of the aforementioned martensite is tempered martensite, and the total of the area ratio of the aforementioned martensite with respect to the entire steel plate composition, the aforementioned residual austenite amount and the area ratio of the aforementioned bainitic ferrite in the upper bainite with respect to the entire steel plate composition is 65% or more. The area ratio of polygonal ferrite with respect to the entire steel plate composition is 10% or less (including 0%), and the average amount of C in the aforementioned residual austenite is 0.70% or more.

Owner:JFE STEEL CORP

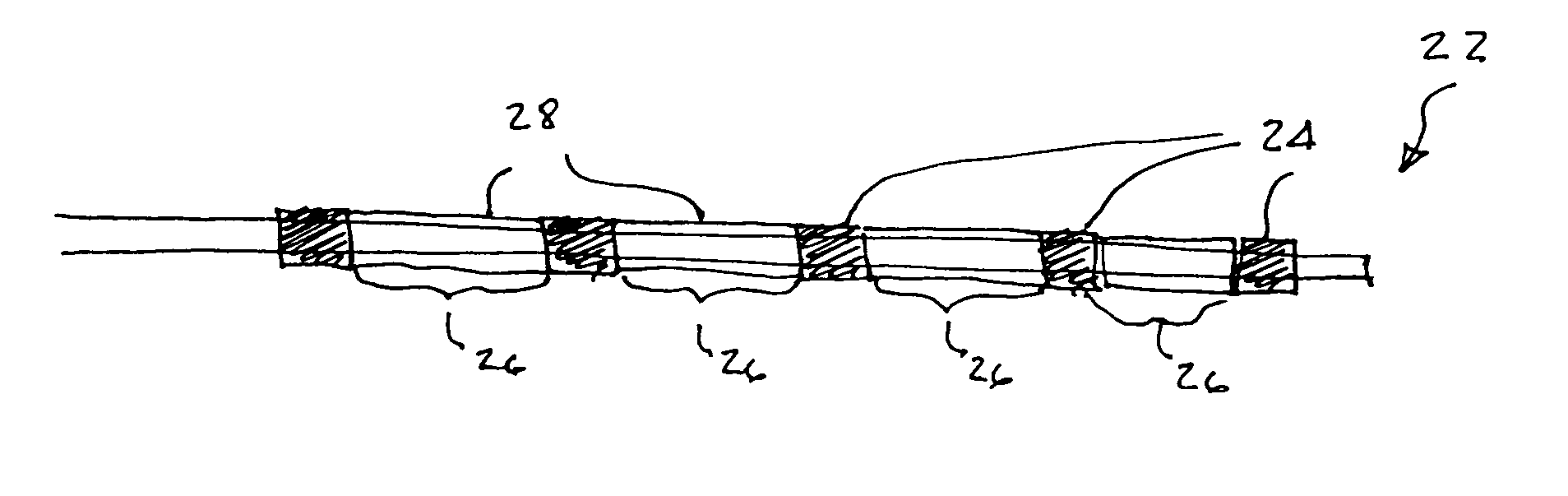

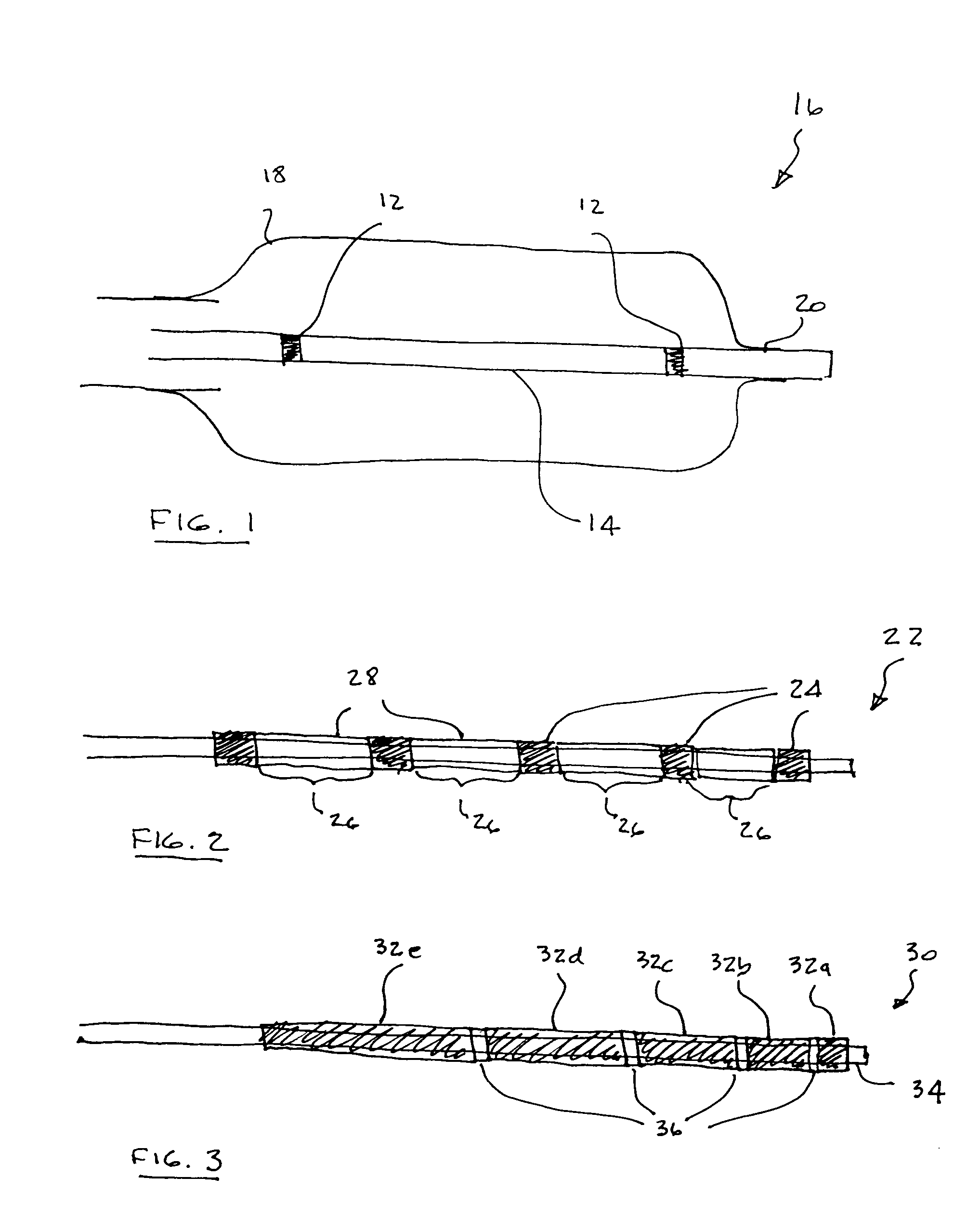

Polymeric marker with high radiopacity

InactiveUS20050064223A1Overcomes shortcomingImprove fill rateSurgeryConductive materialPolymer resinRadiopaque agent

High radiopacity is achieved in a polymeric marker by combining a polymeric resin, a powdered radiopaque agent having uniformly shaped particles of a specific particle size distribution and a vetting agent. The method to produce the marker calls for the blending and pelletization of these materials followed by extrusion onto support beading. The resulting supported tubing is subsequently cut to length with the beading still in place. After ejection of the beading remnant the marker is slipped into place on the device to be marked and attached by melt bonding. Marking of a guidewire allows lesions to be measured while the marking of balloon catheters allow the balloon to be properly positioned relative to a lesion.

Owner:ABBOTT CARDIOVASCULAR

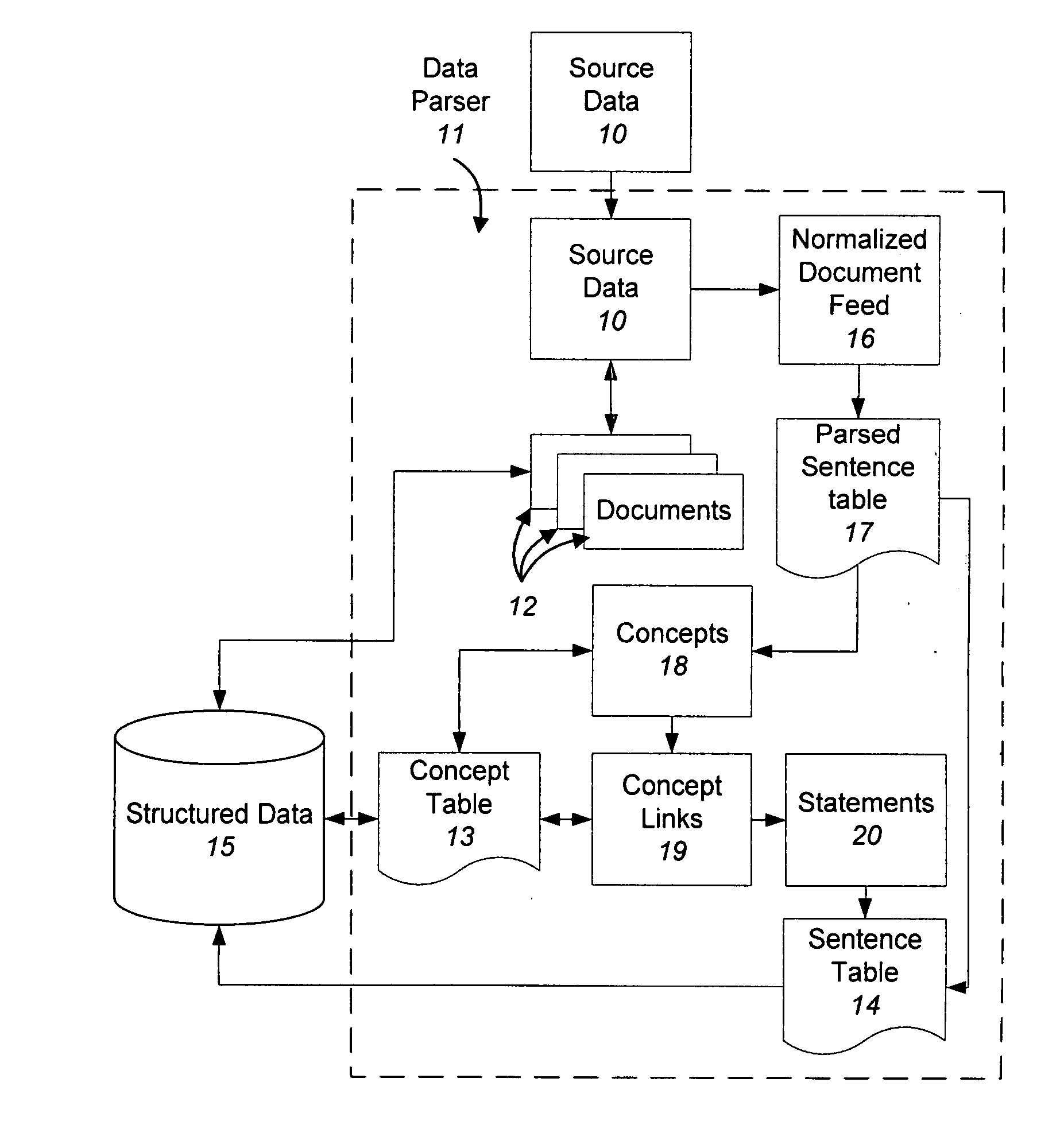

Novel information retrieval systems and methods

InactiveUS20070078814A1Efficient storageEffectively storing informationDigital data information retrievalSpecial data processing applicationsData miningSource data

The present invention is directed to systems and methods for encoding and retrieving information from a variety of sources using novel search techniques. The systems and methods of the invention are capable of extracting all types of structural and relational information from a query or a source data allowing for the recognition of subtle differences in meaning. The capability of discerning subtle differences in meaning that are beyond the search systems and methods presently available, the invention described herein is capable of repeatedly providing accurate and meaningful responses to a diverse set of queries.

Owner:JILES

Electrochemical cells with tabs

InactiveUS20100285352A1Stable metallic tabReduce contact resistanceFinal product manufacturePrimary cellsEngineeringElectrochemical cell

The present invention provides electrochemical cells and batteries having one or more electrically conductive tabs and carbon sheet current collectors, where the tabs are connected to the carbon sheet current collectors; and methods of connecting the tabs to the carbon based current collectors. In one embodiment, the electrically conductive tabs are metallic tabs.

Owner:LEYDEN ENERGY

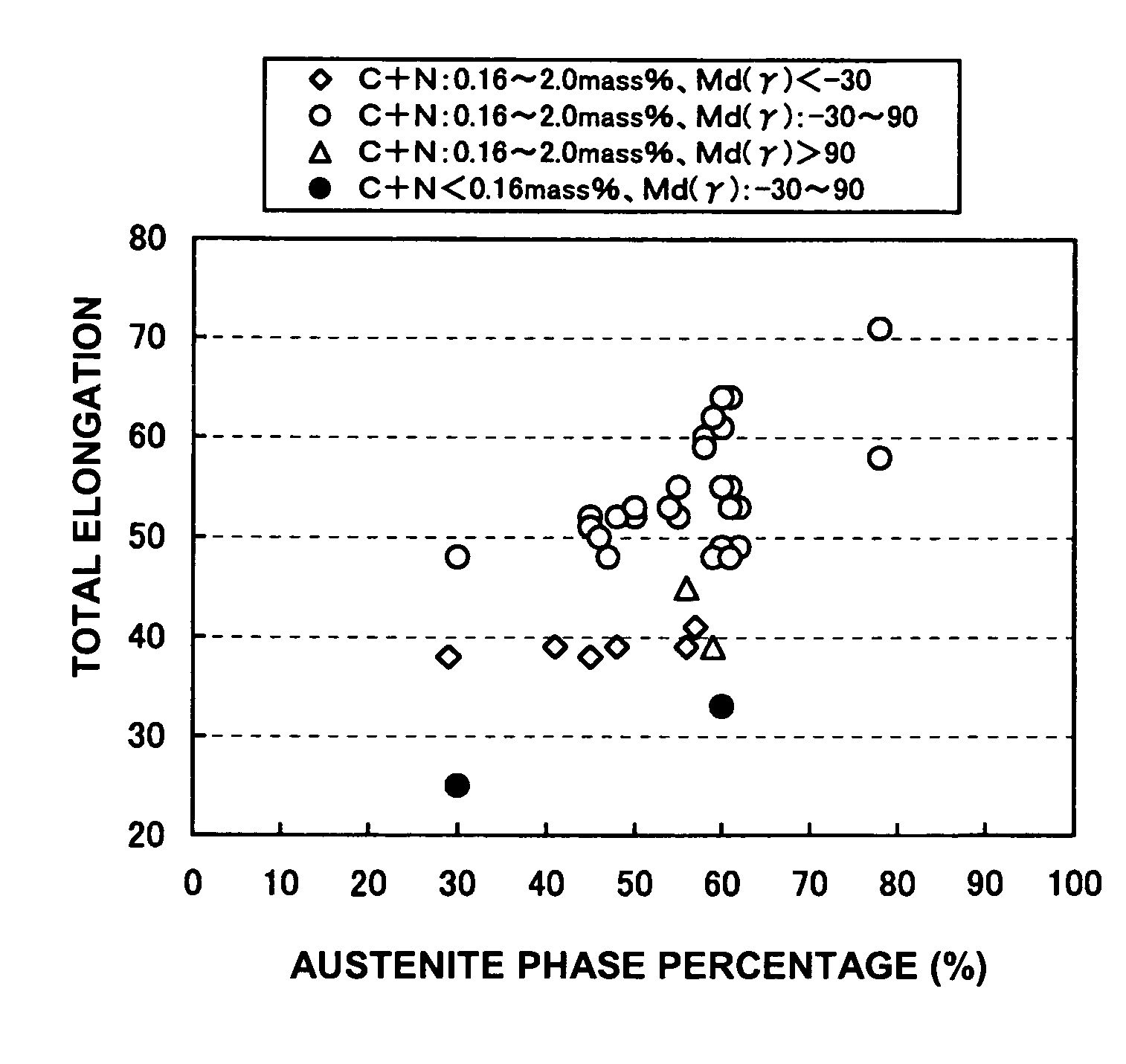

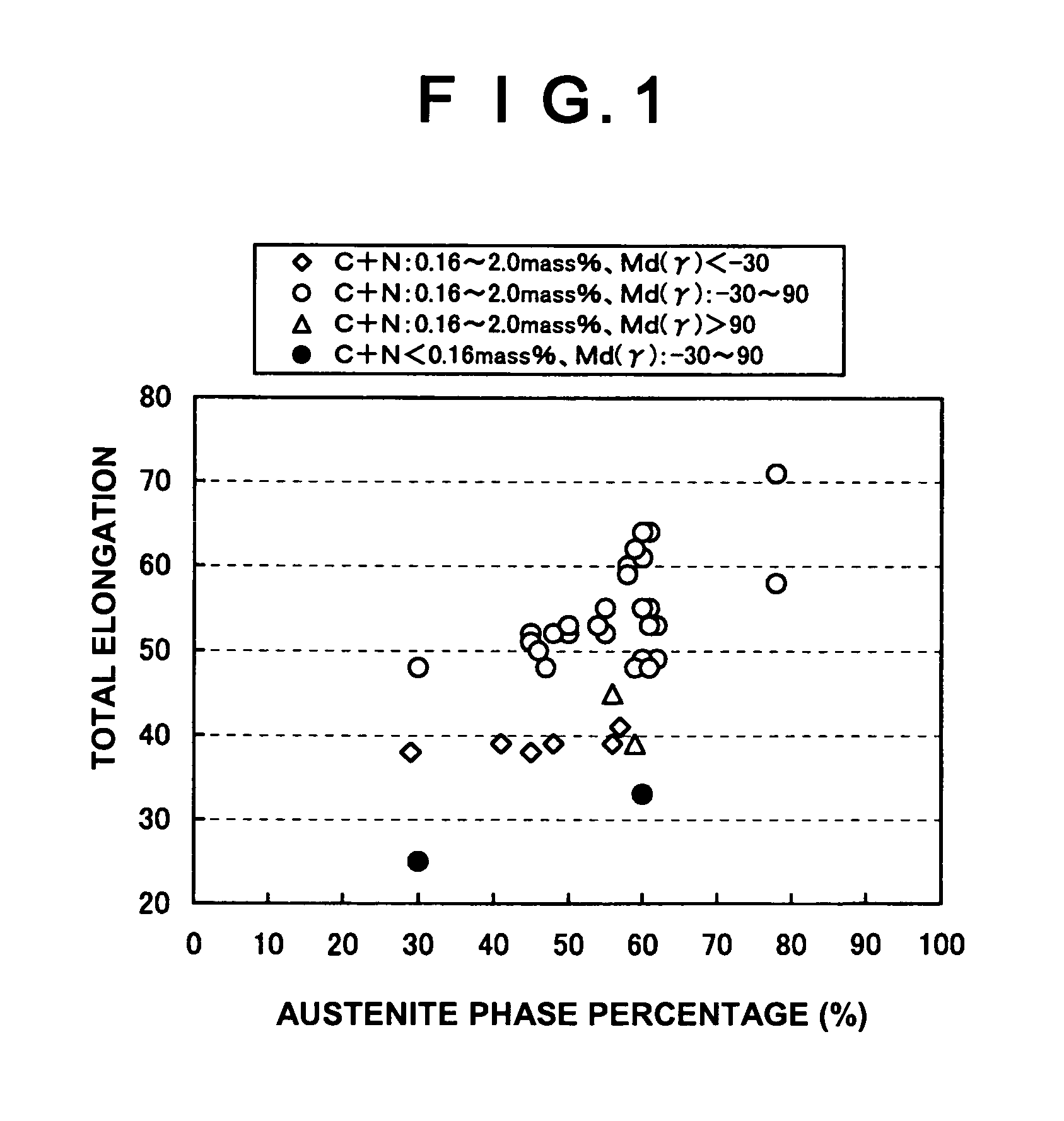

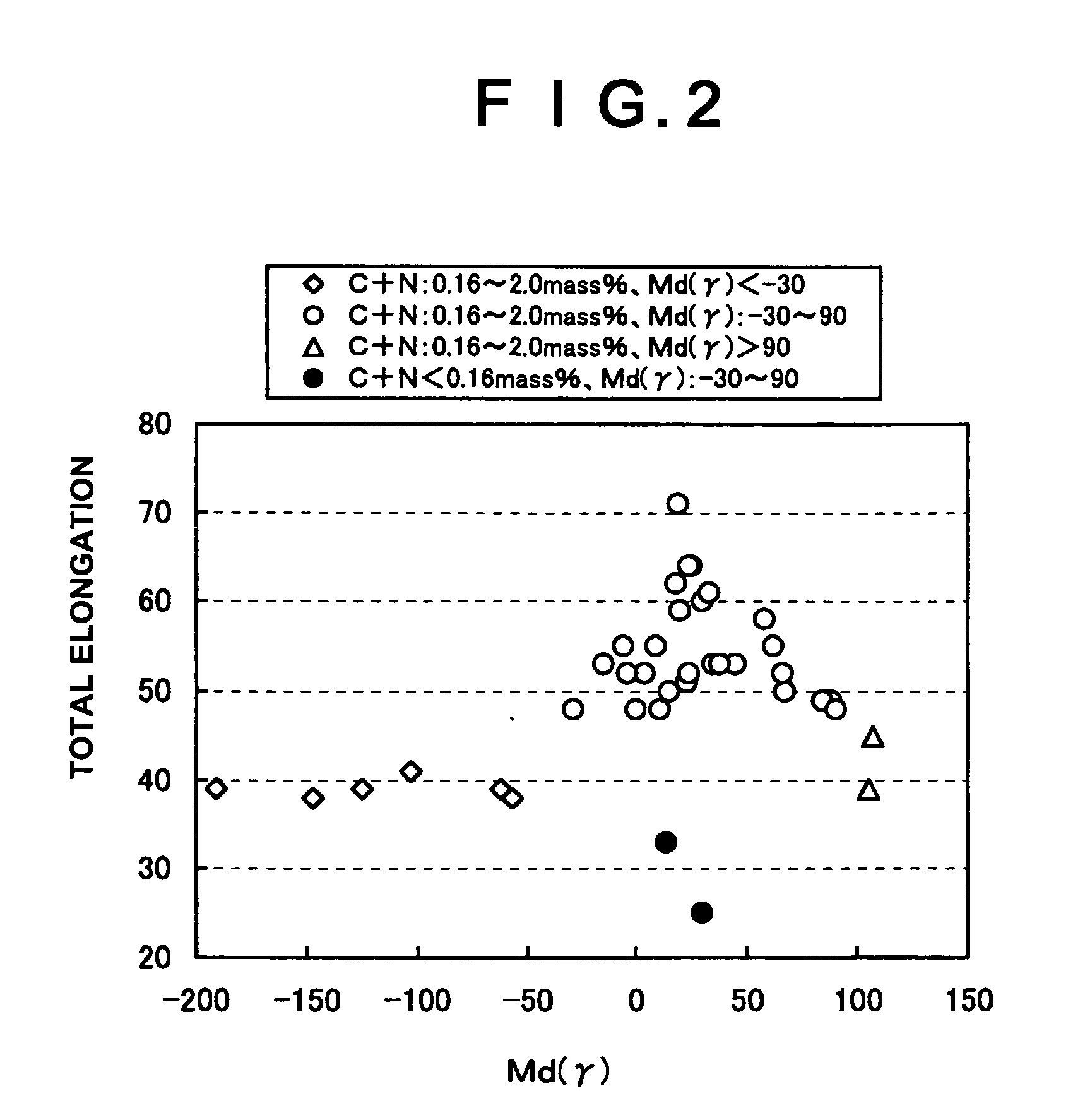

Austenitic-ferritic stainless steel

A low Ni and high N austenitic-ferritic stainless steel is disclosed. It includes an austenitic-ferritic stainless steel having high formability and punch stretchability, crevice corrosion resistance, corrosion resistance at welded part, or excellent intergranular corrosion resistance, from a stainless steel structured by mainly austenite phase and ferrite phase, and consisting essentially of 0.2% or less C, 4% or less Si, 12% or less Mn, 0.1% or less P, 0.03% or less S, 15 to 35% Cr, 3% or less Ni, and 0.05 to 0.6% N, by mass, by adjusting the percentage of the austenite phase in a range from 10 to 85%, by volume. Furthermore, it includes an austenitic-ferritic stainless steel having higher formability by adjusting the amount of (C+N) in the austenite phase to a range from 0.16 to 2% by mass.

Owner:JFE STEEL CORP

Energy balancing wireless sensor network clustering method

ActiveCN102036308AEvenly distributedShorten the timePower managementEnergy efficient ICTEnergy balancingExtensibility

The invention relates to an energy balancing wireless sensor network clustering method, which comprises the following three steps of: selecting cluster heads, building a cluster and transmitting data, wherein in the process of selecting the cluster heads, the priorities of nodes to be selected as the cluster heads are set by parameters such as the energy of the nodes, the number of neighboring nodes and the like, so that the cluster heads are more uniformly distributed; in the process of building the cluster, an energy threshold is set as the rebuilding condition of the cluster, so that the aim of reducing the rebuilding frequency of the cluster is fulfilled; meanwhile, a single-hop and multi-hop combined data transmission model is adopted, so that hot problems in a network are solved. Bythe method, the energy can be effectively utilized, the stability of the network is improved, the energy consumption of the network can be balanced, the service life of the network is effectively prolonged, and the network has higher extensibility and safety.

Owner:JIANGSU HILLSUN INFORMATION IND

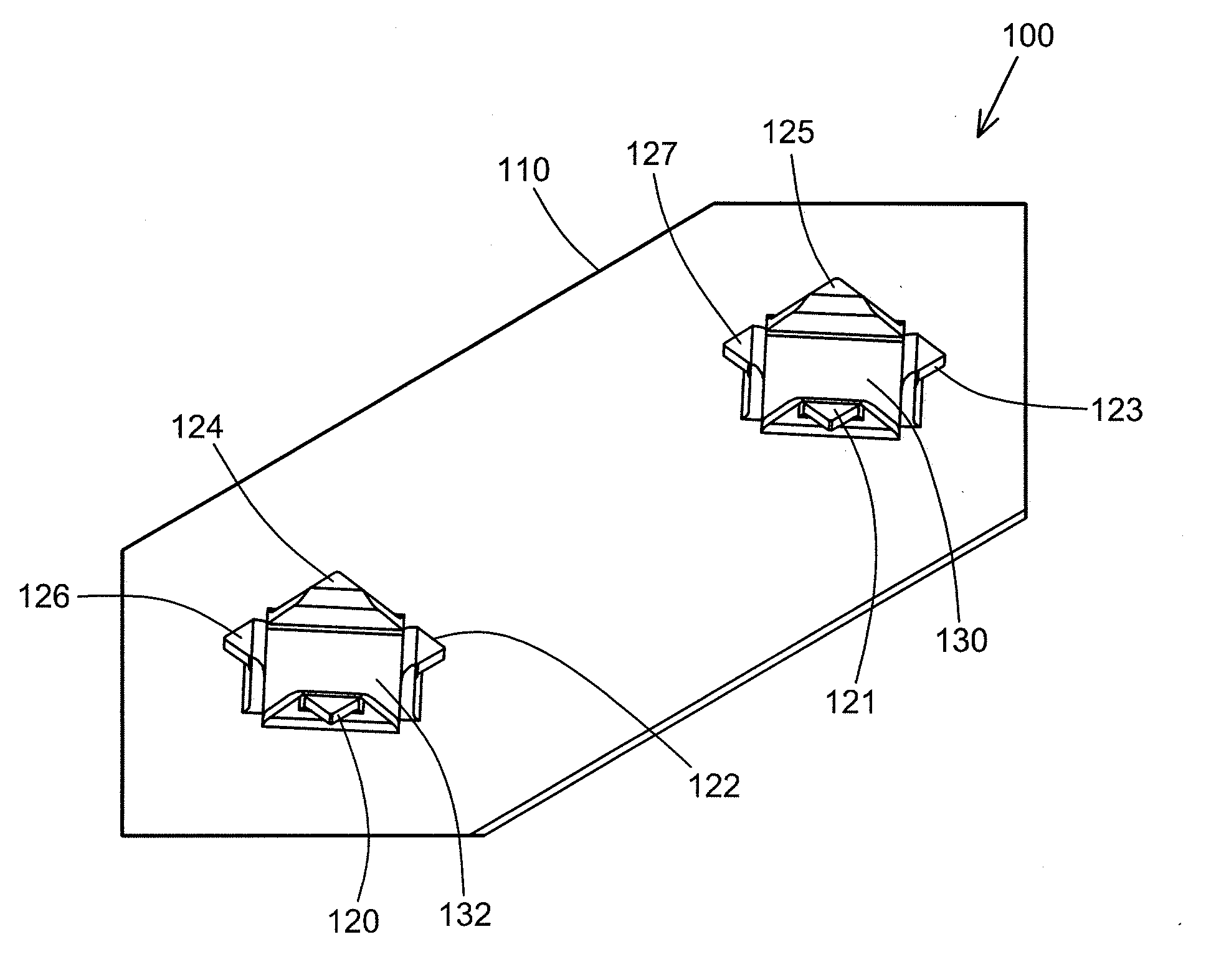

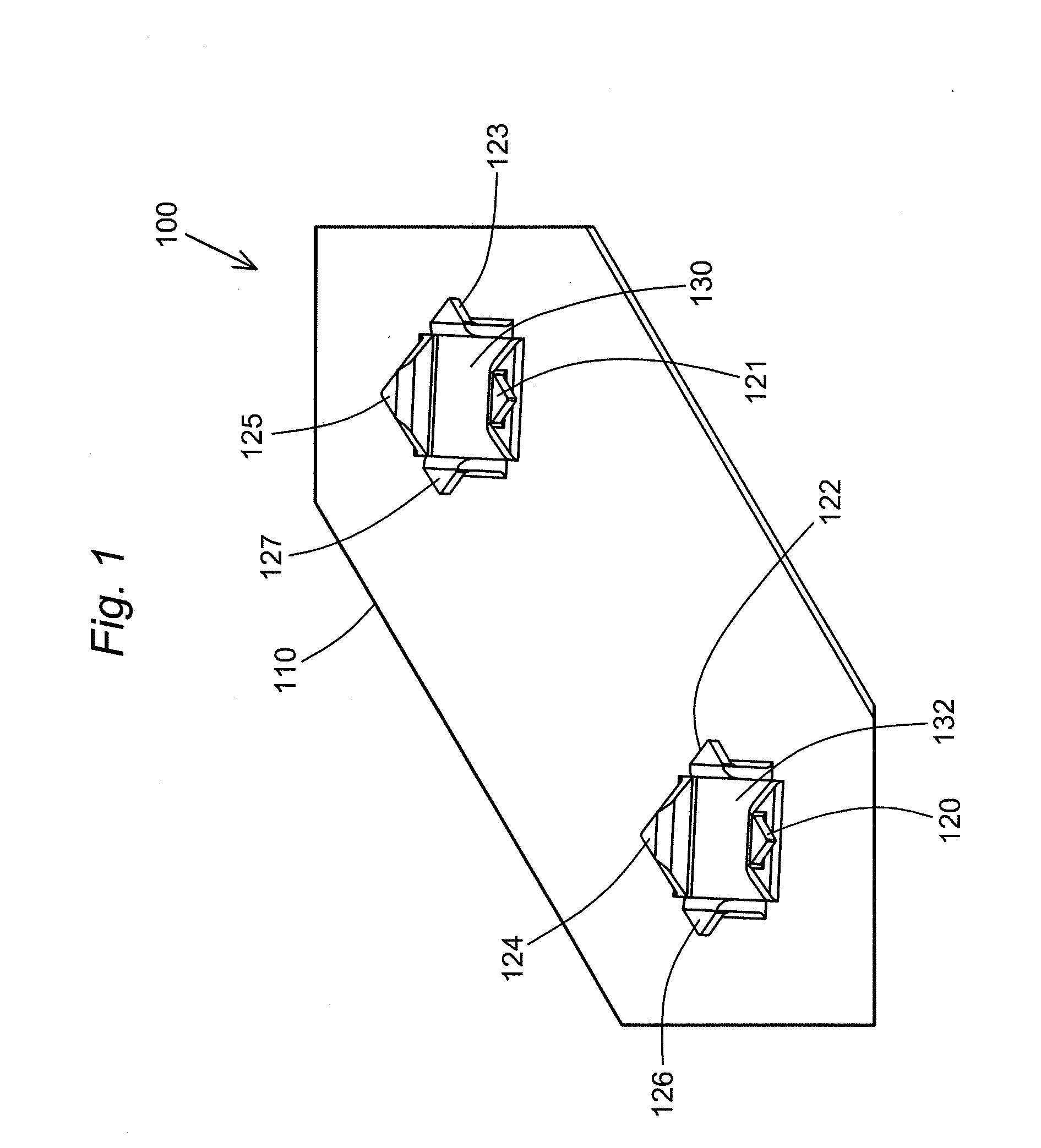

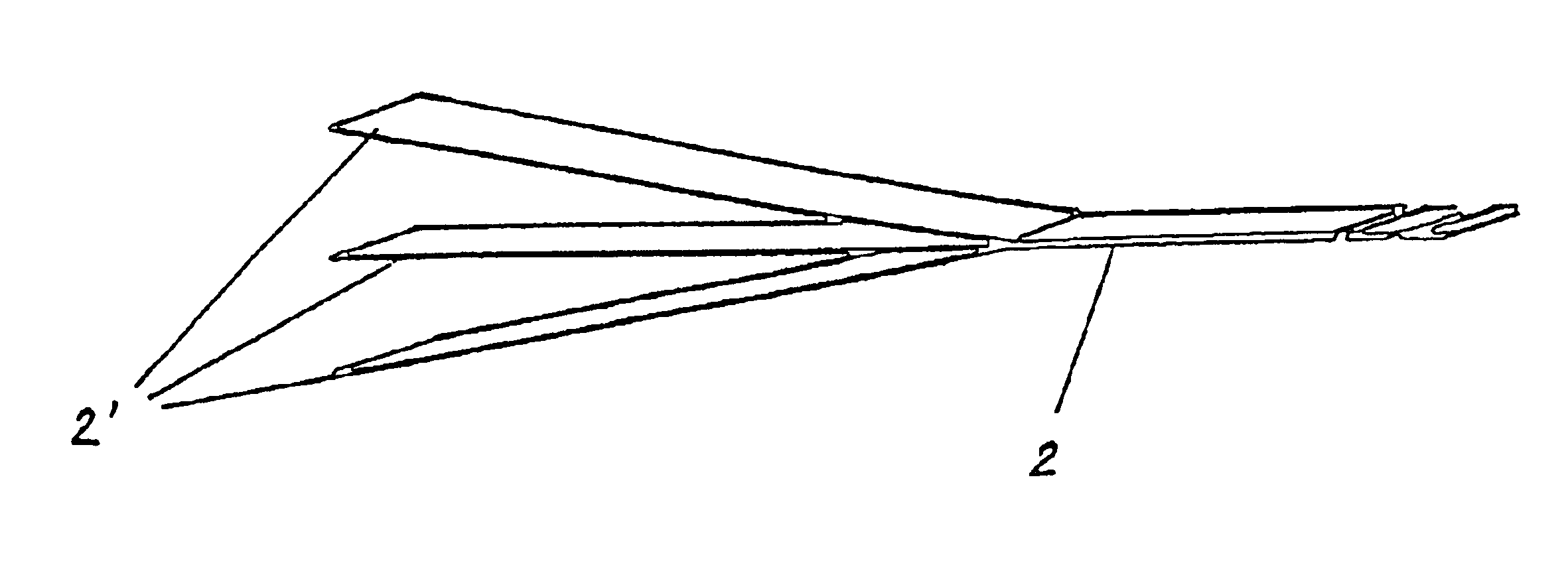

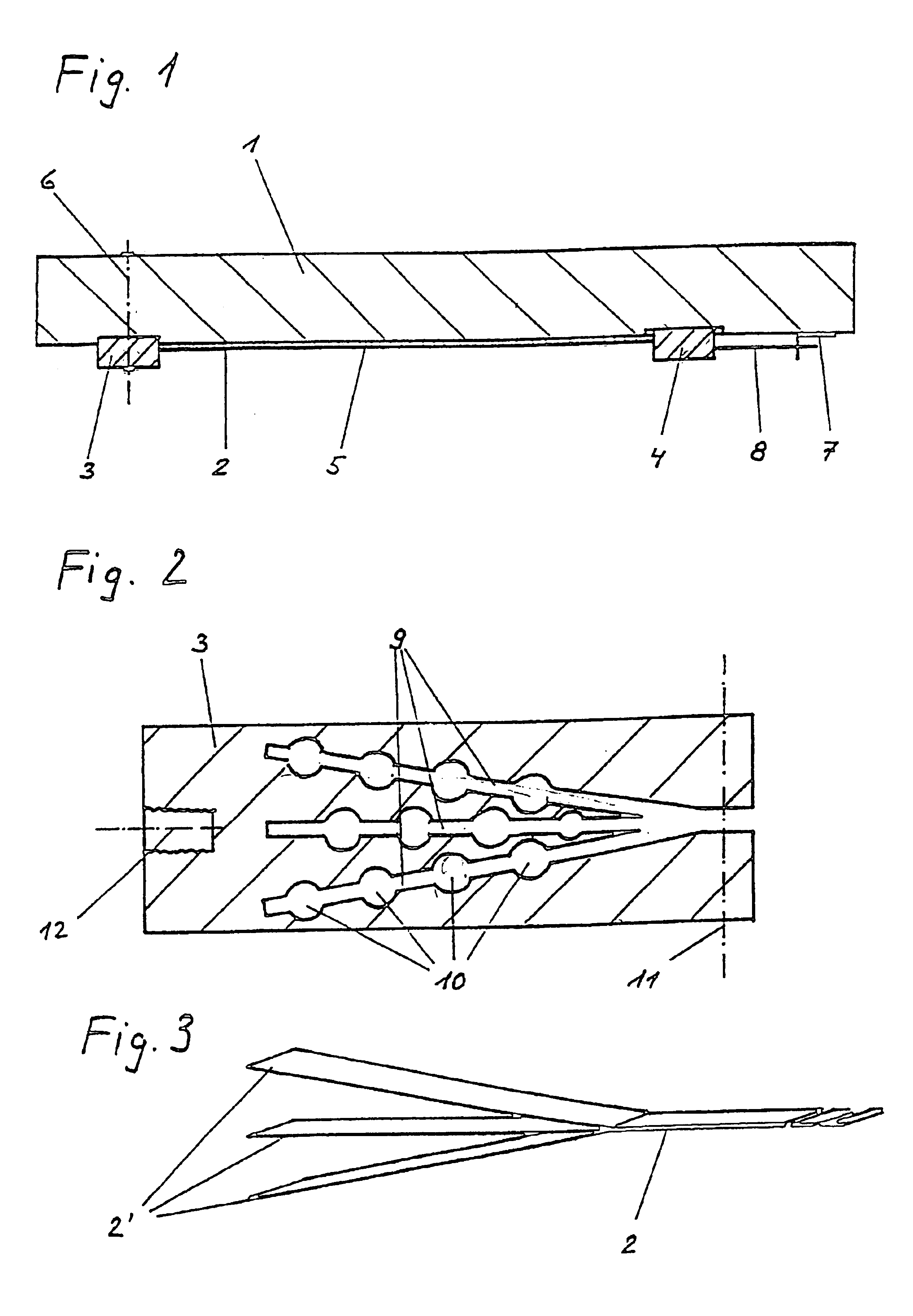

Reinforcement device for supporting structures

InactiveUS6851232B1Smooth connectionGood initiativeLamination ancillary operationsCovering/liningsConcrete beamsStructural engineering

The ends of carbon plates reinforcing supporting elements, such as concrete beams, are divided into at least two splines having approximately the same thickness and are glued in the appropriate retaining slots of a terminal element. The splines form an angle in relation to each other. This assembly is then glued to the traction side of the supporting element, whereby the carbon plates are directly prestressed by the terminal elements in relation to the supporting element. The terminal element can be inserted into an appropriate groove in the supporting element or glued directly on the surface of the supporting element and / or doweled, optionally by using a transverse tensioning device.

Owner:SIKA SCHWEIZ AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com