Patents

Literature

990 results about "Filler particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

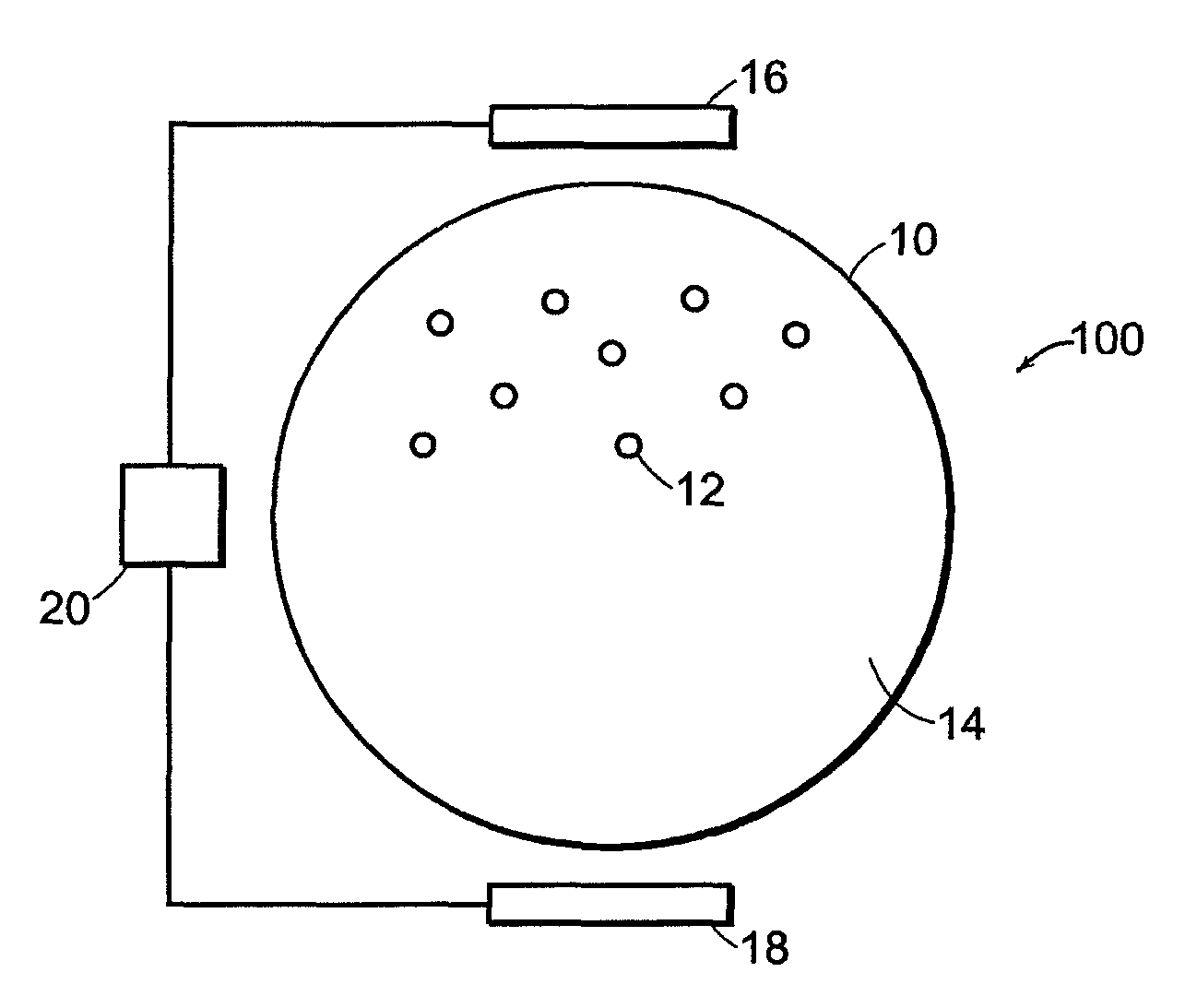

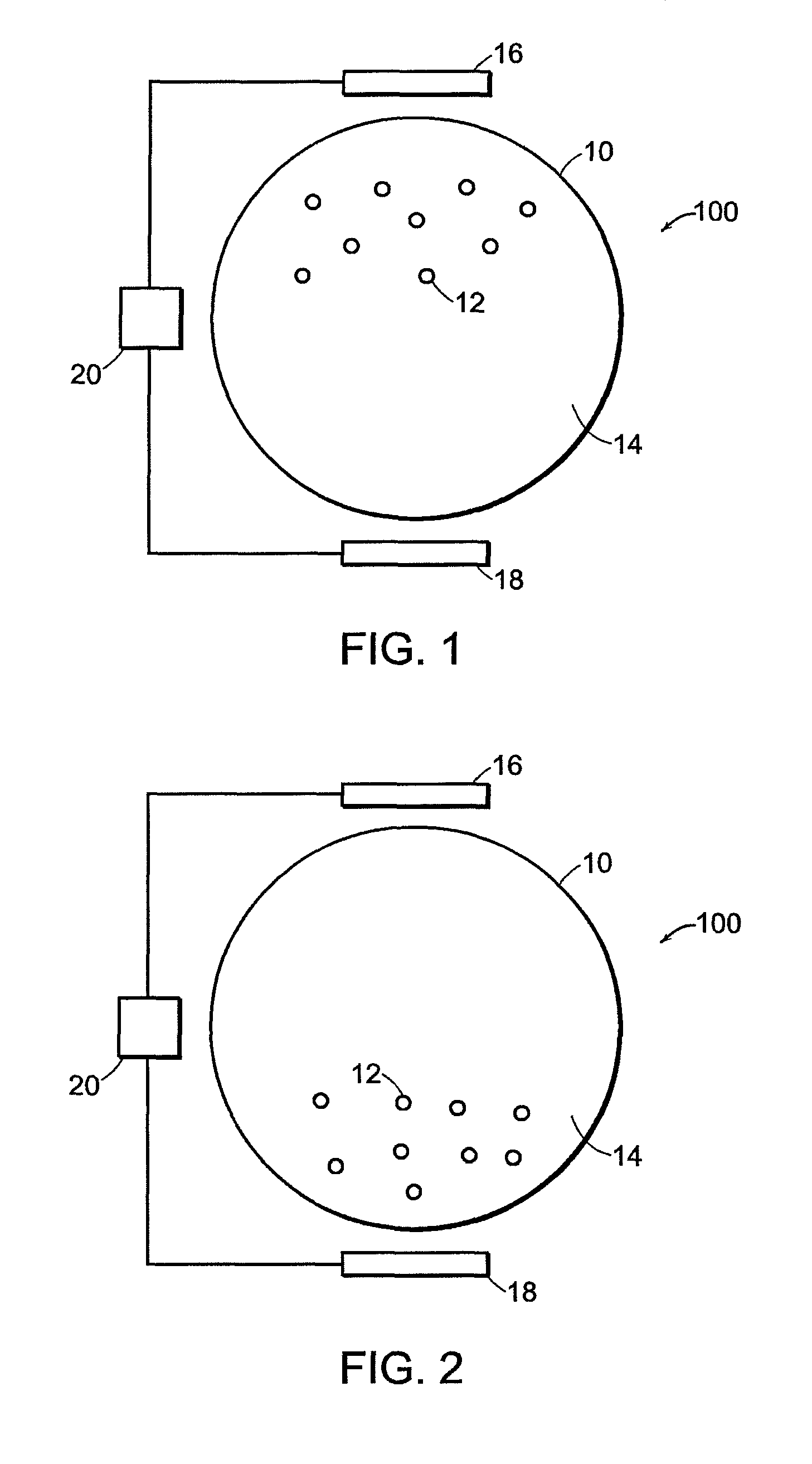

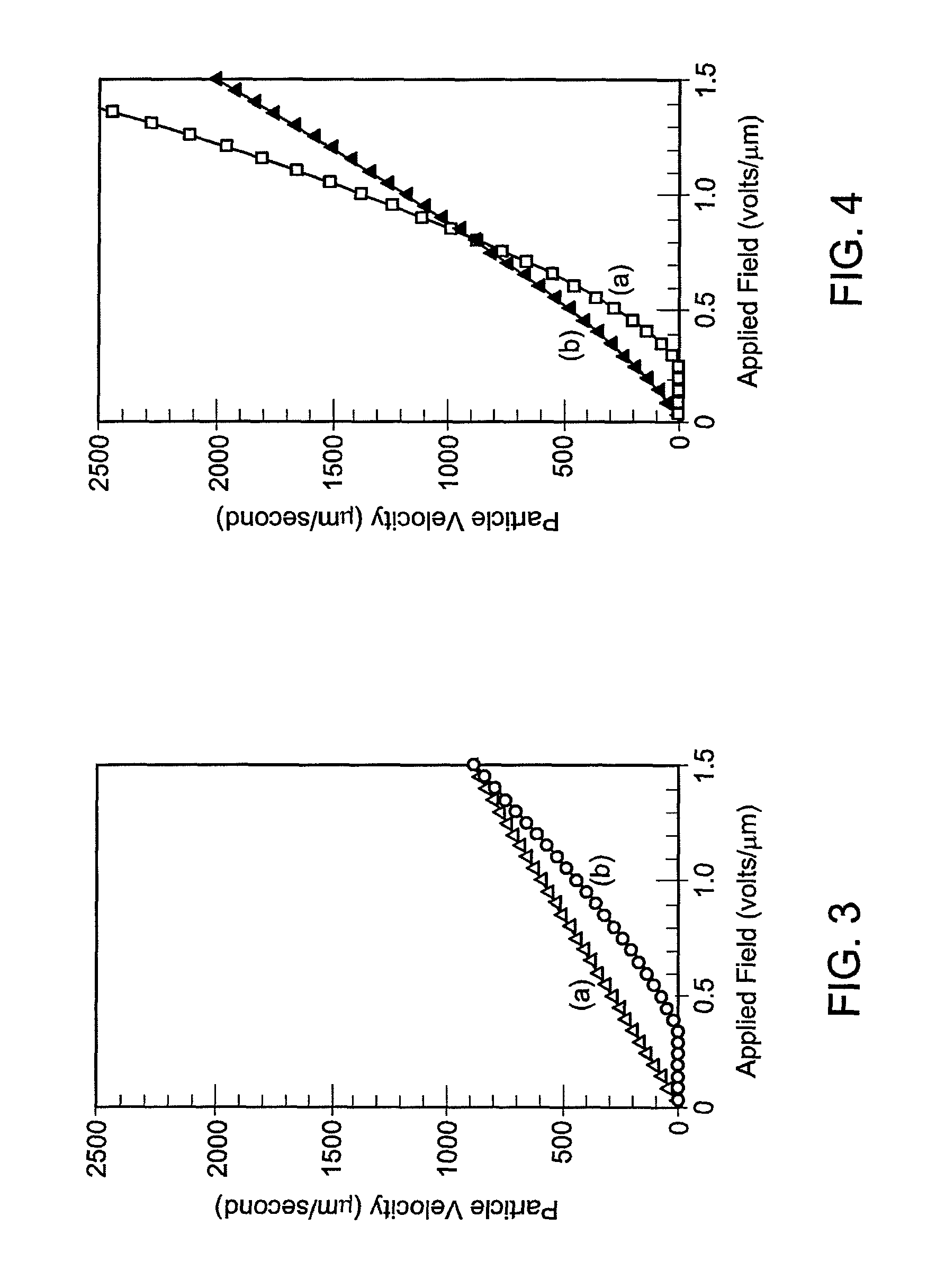

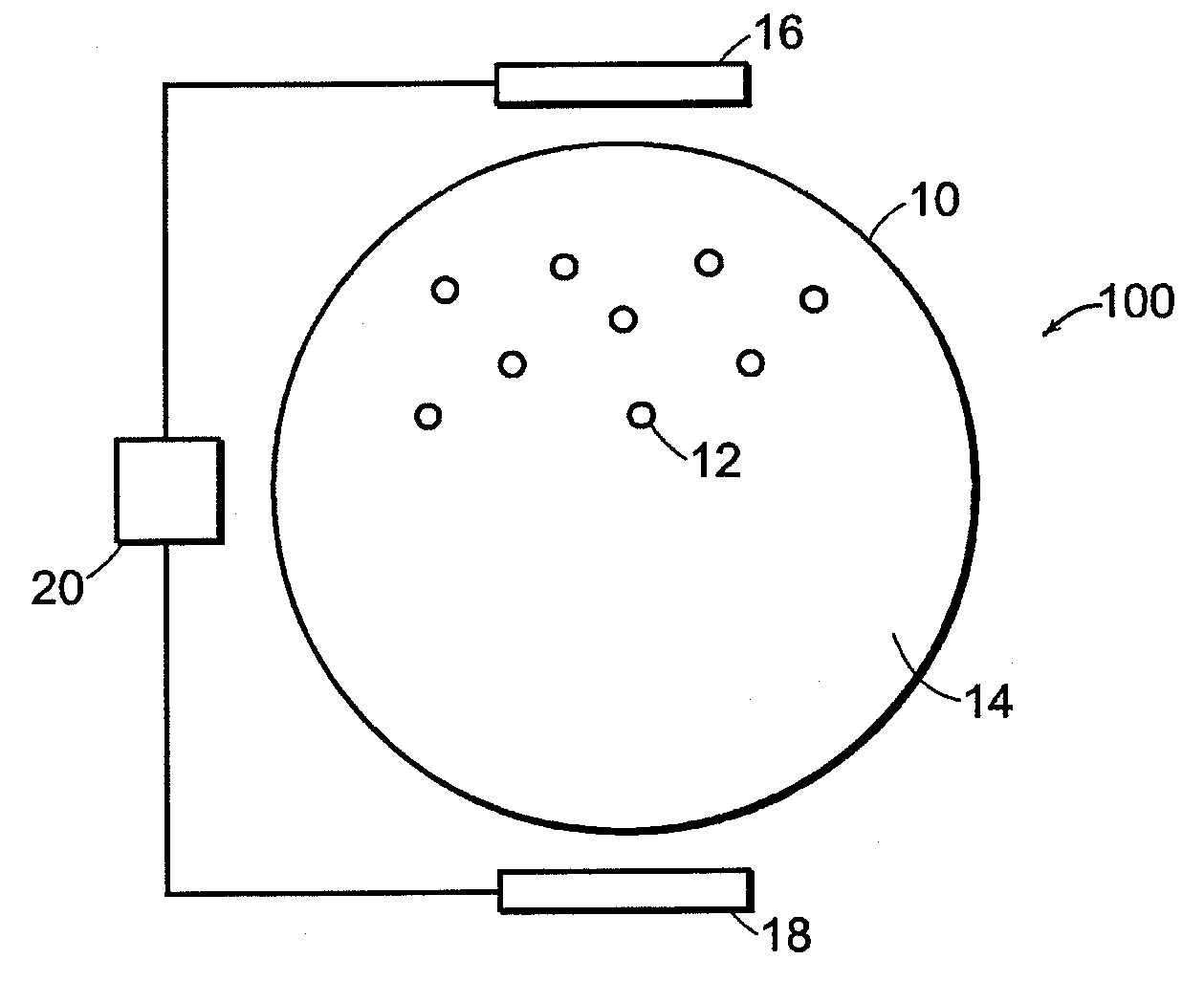

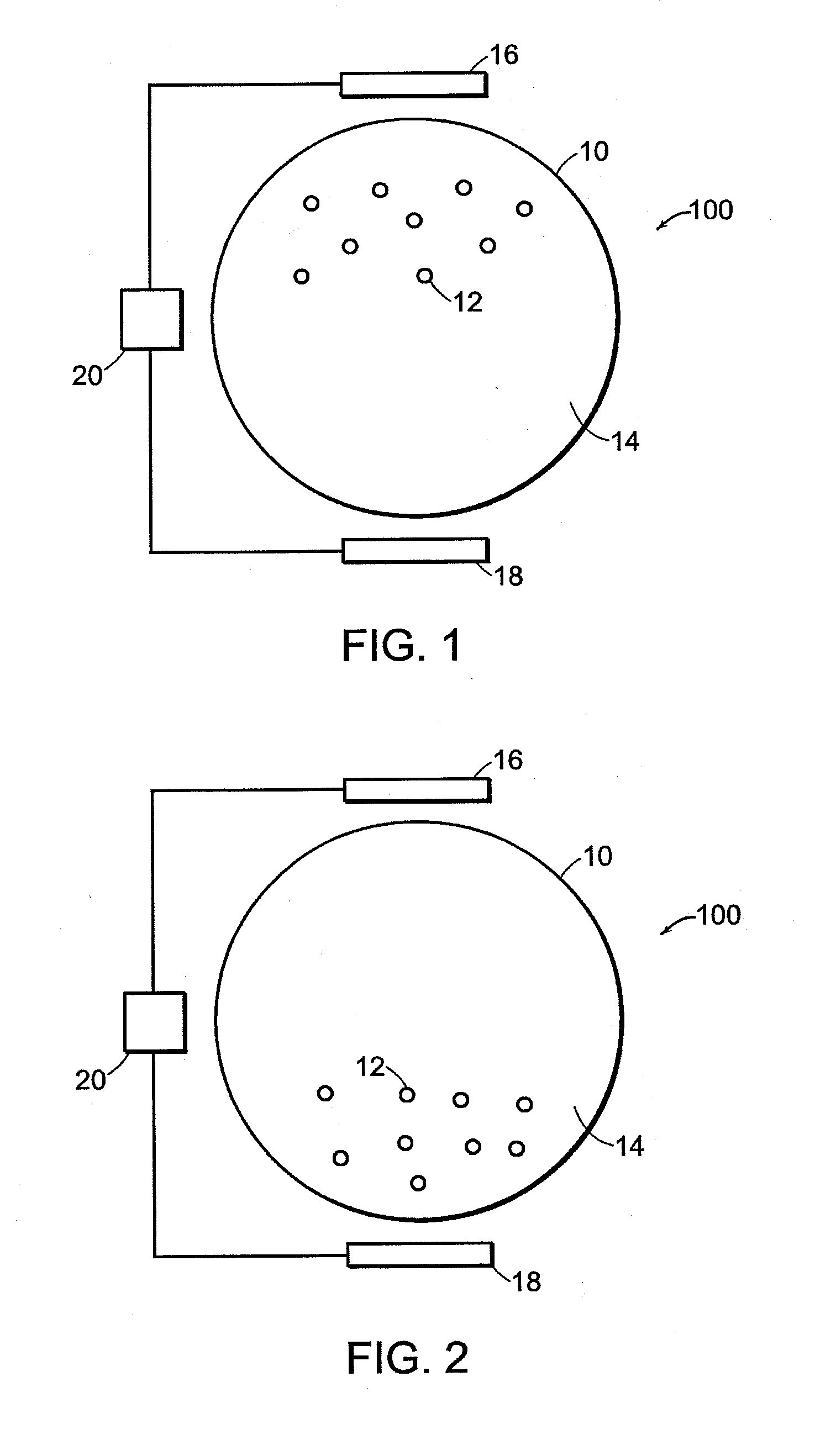

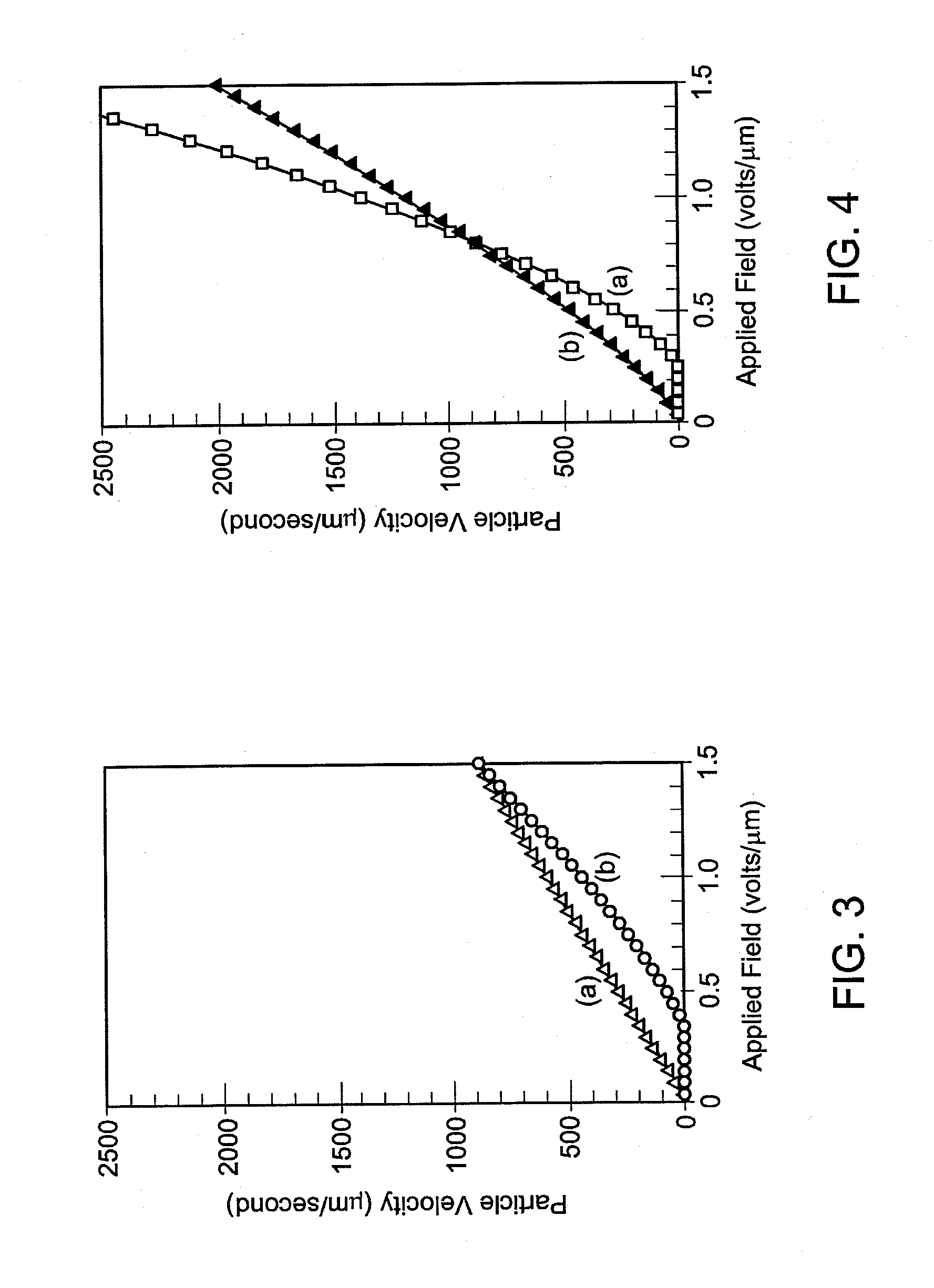

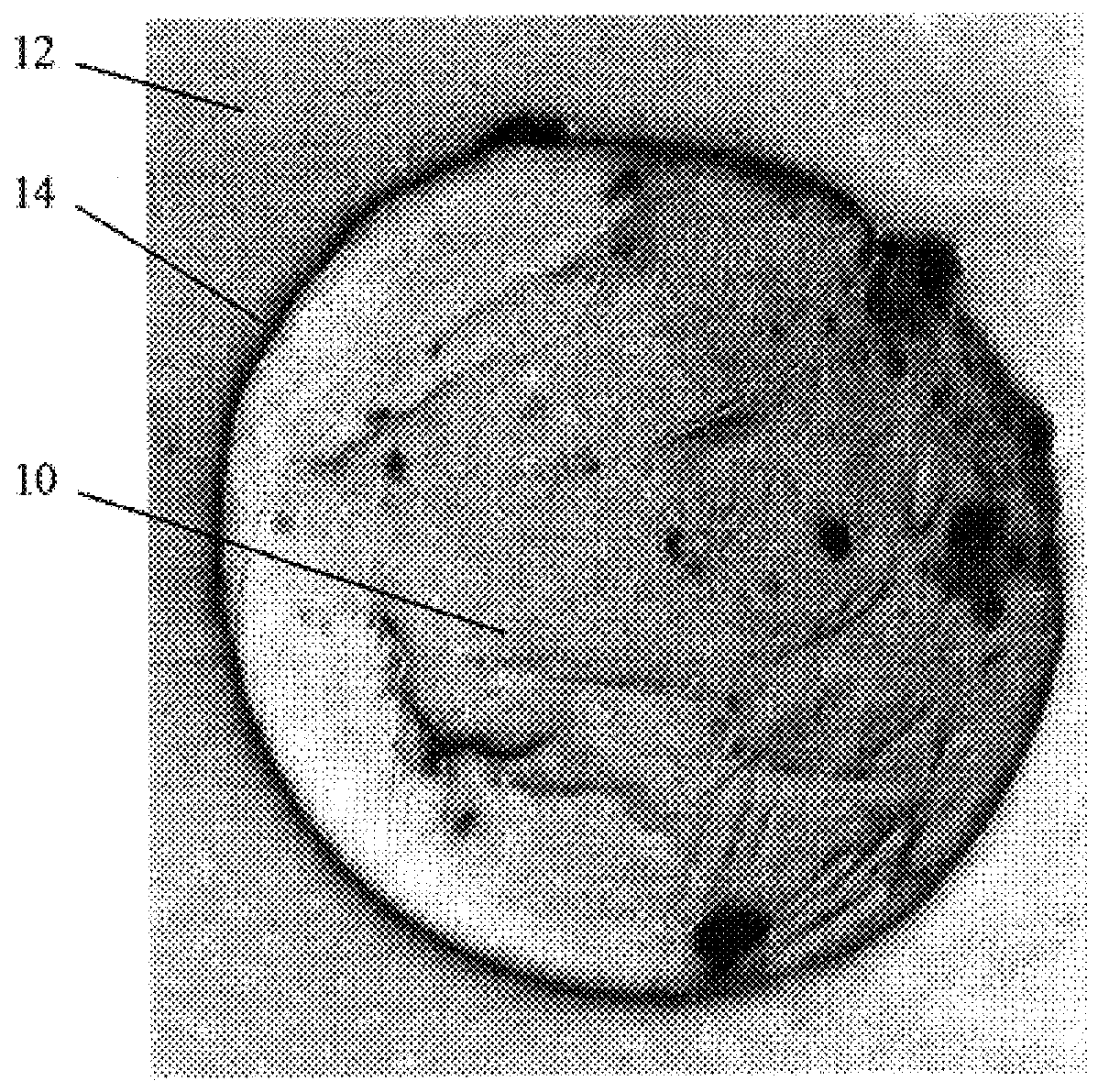

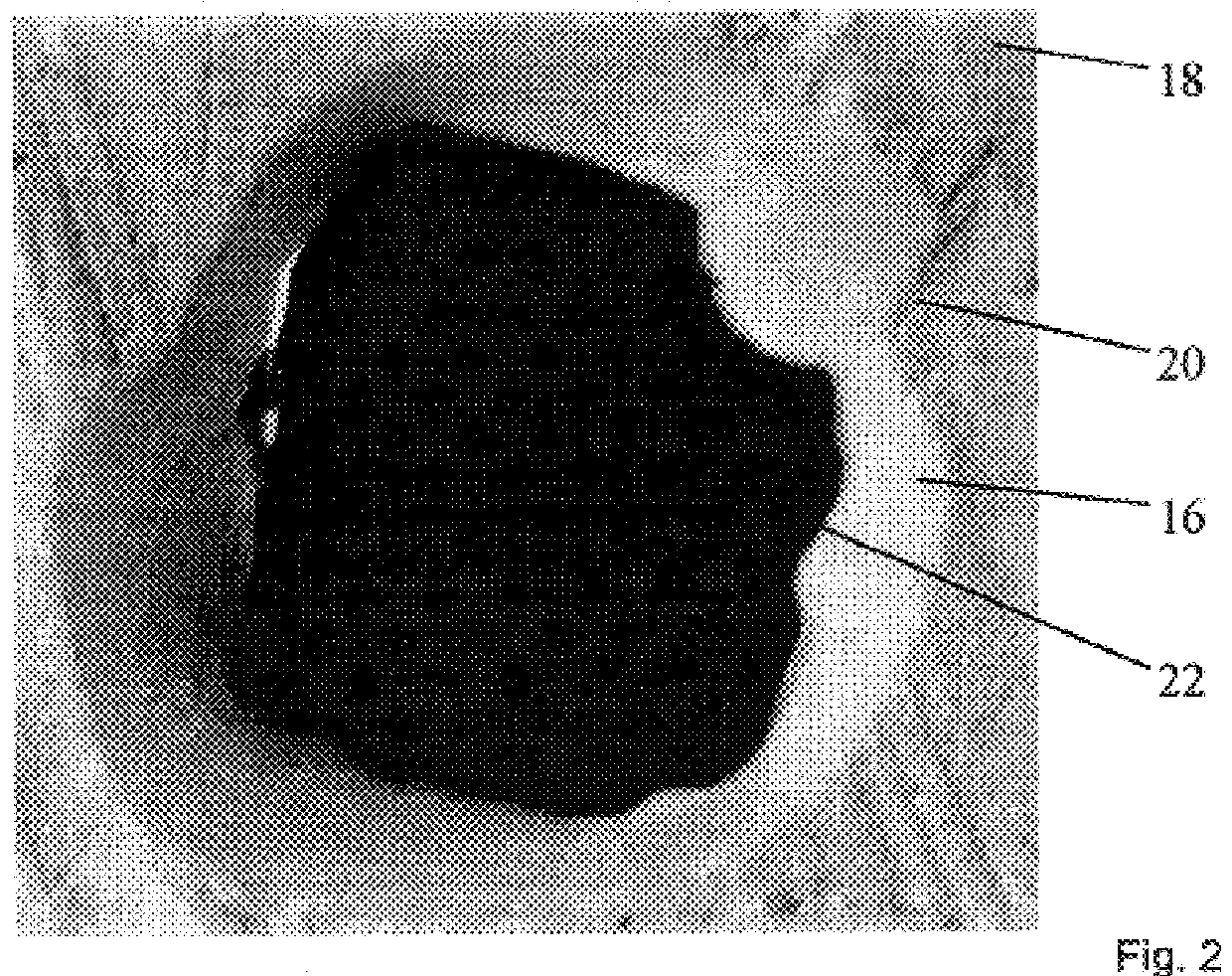

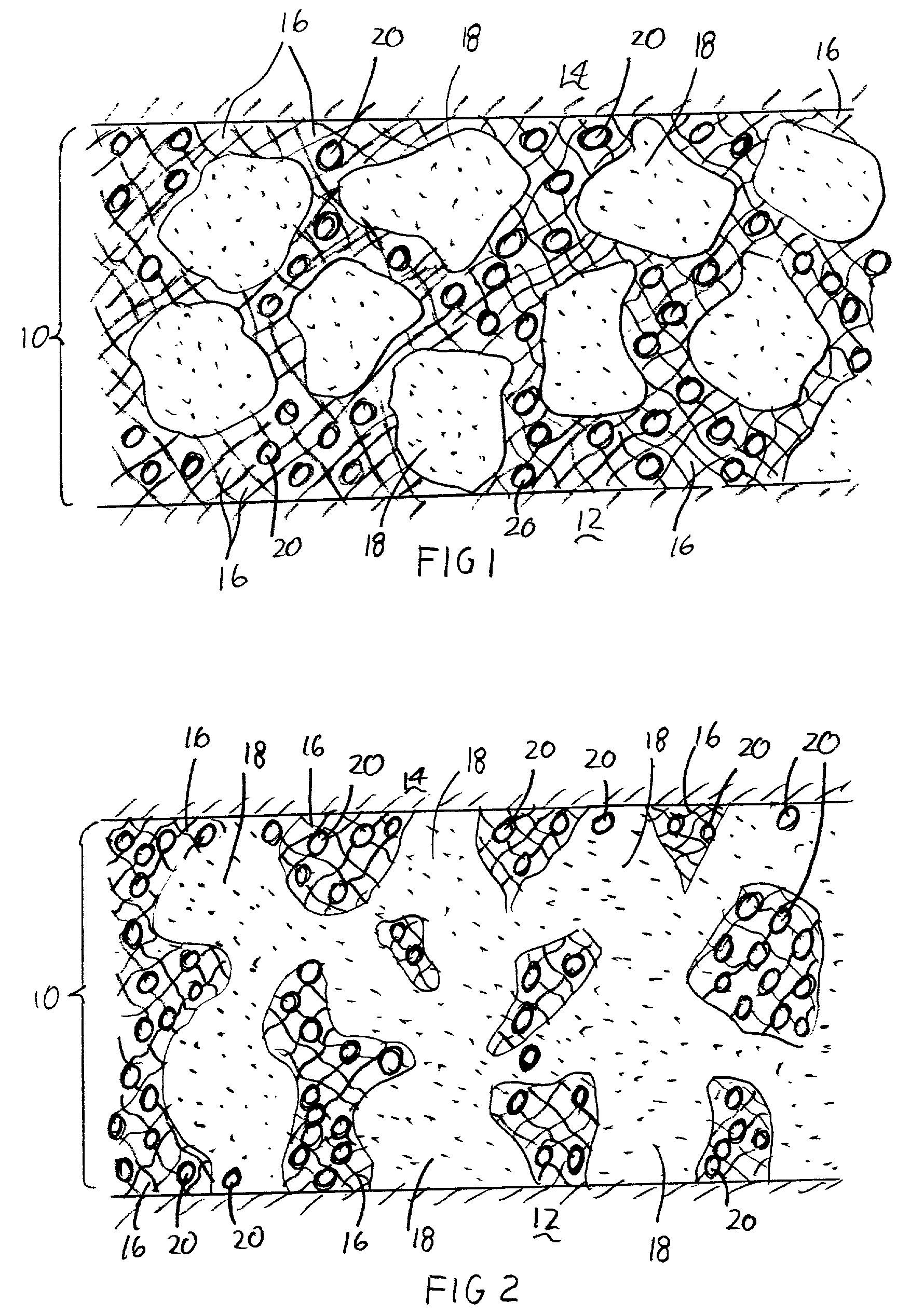

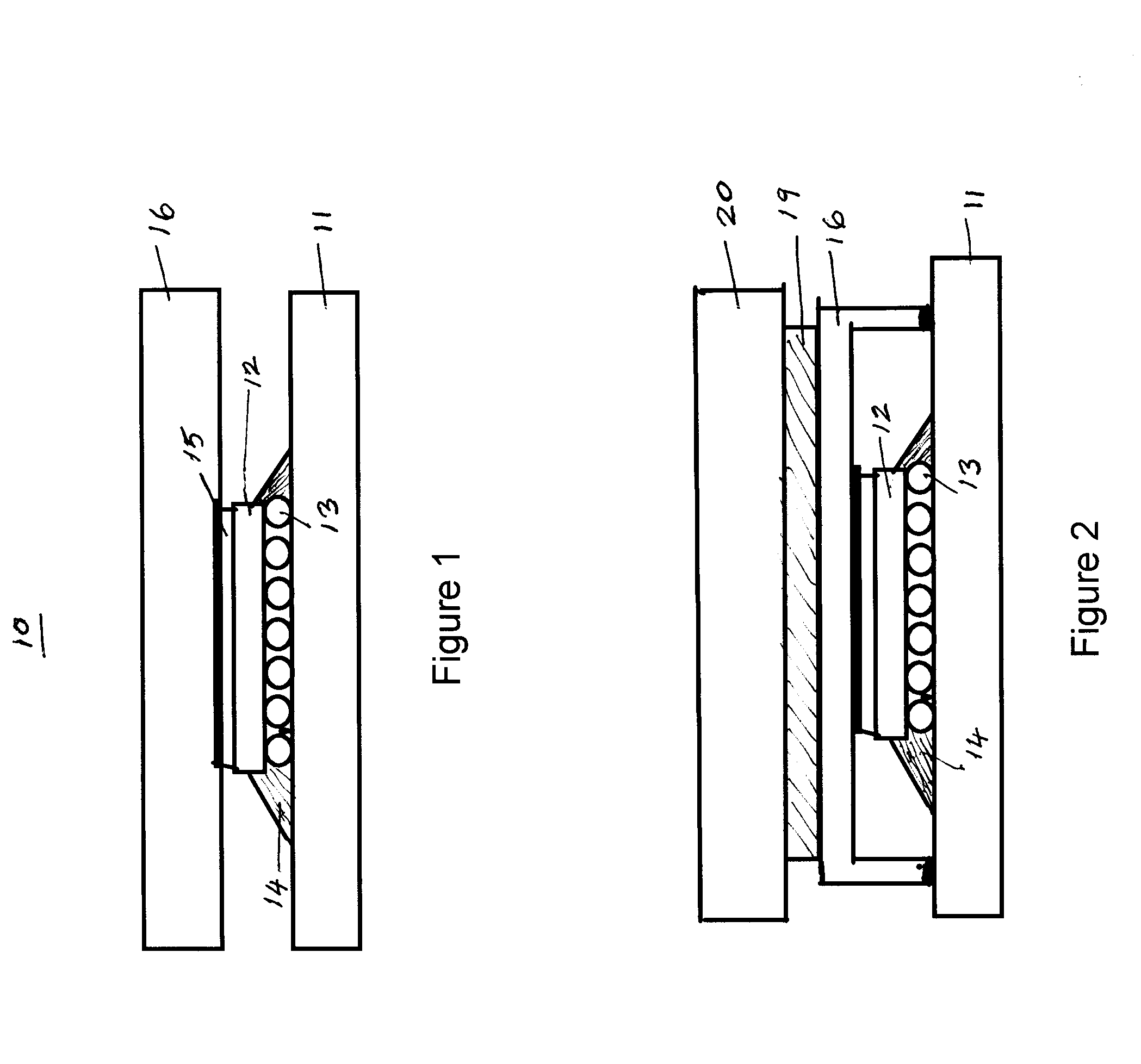

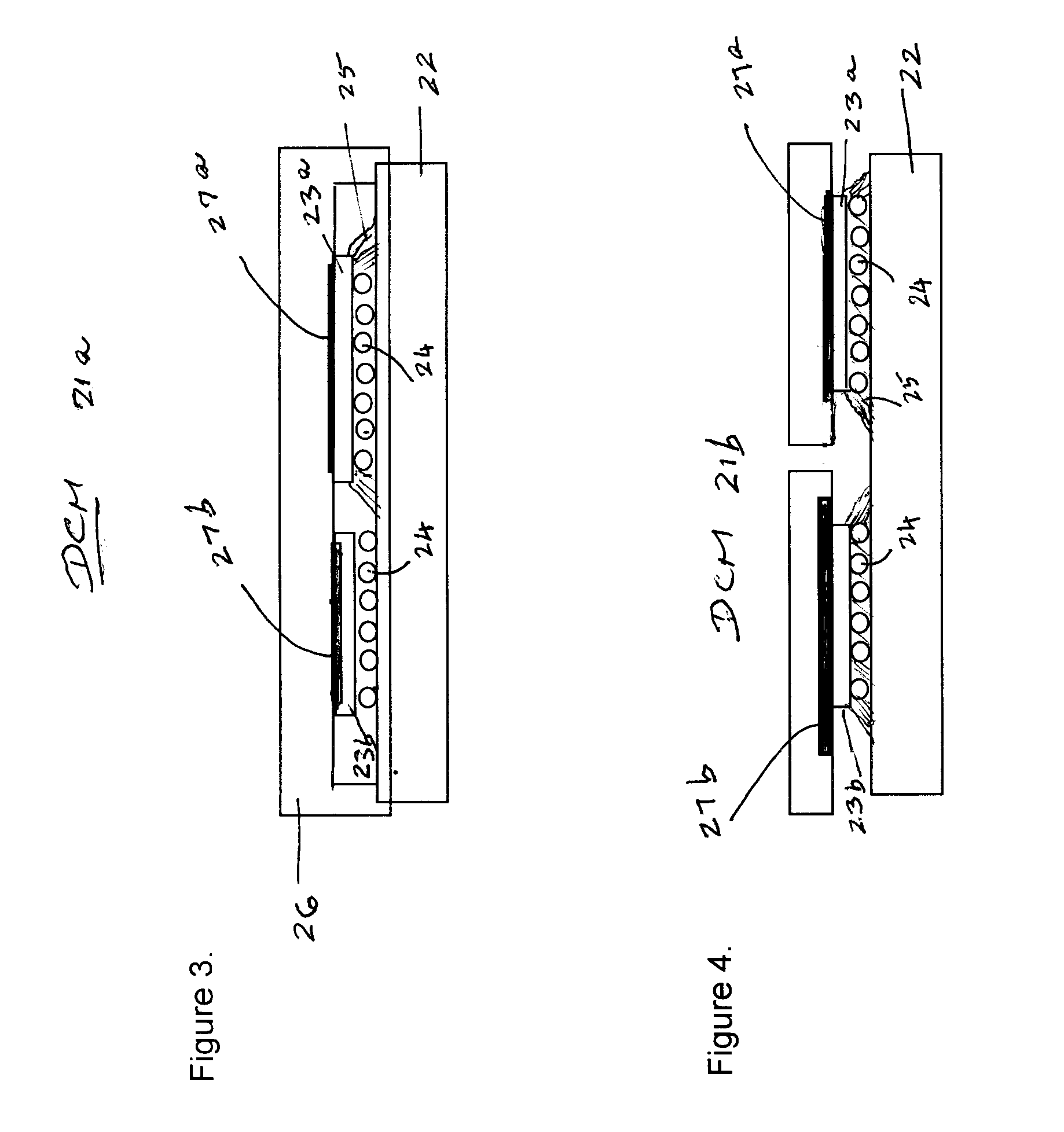

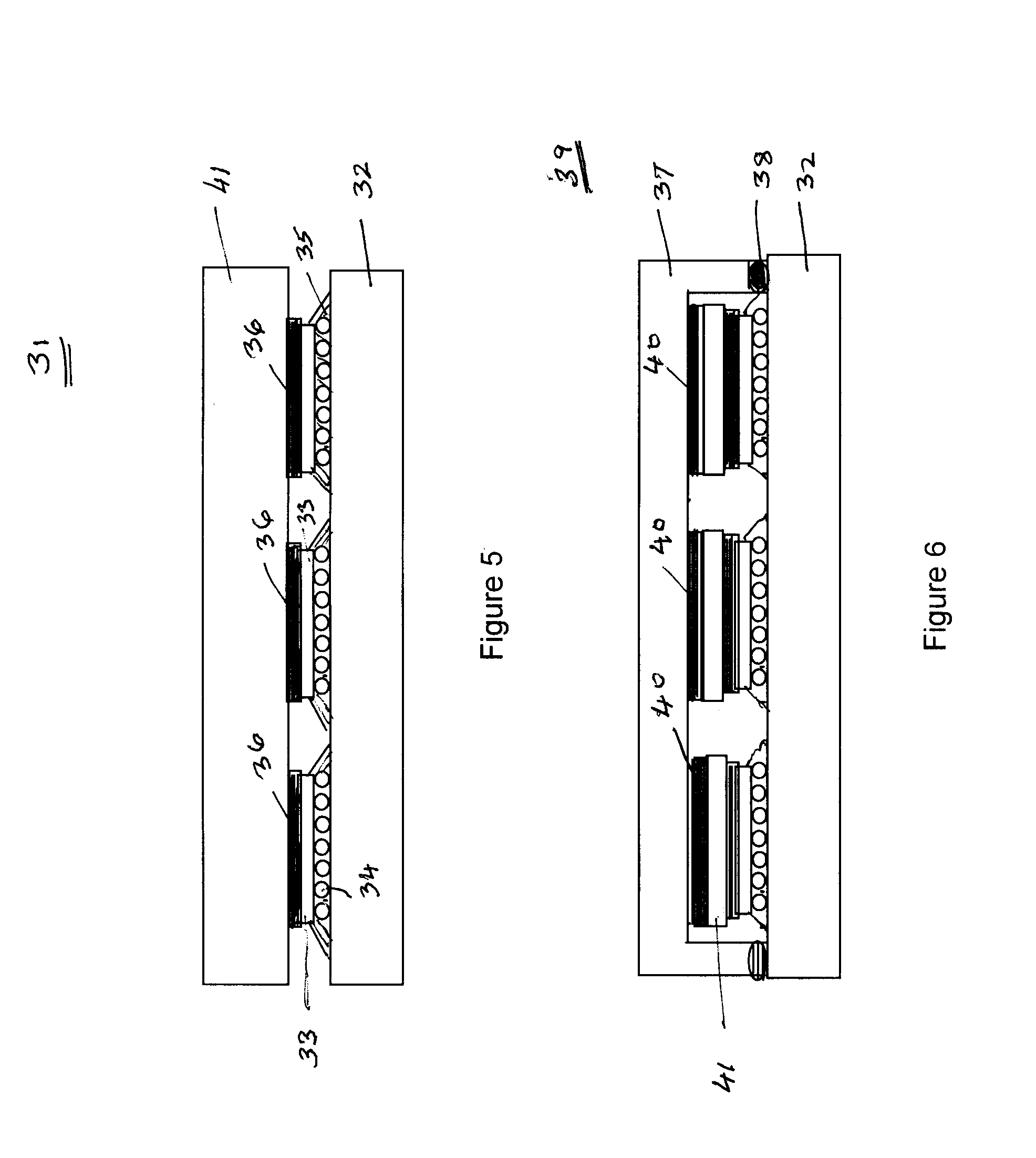

Electrophoretic display element with filler particles

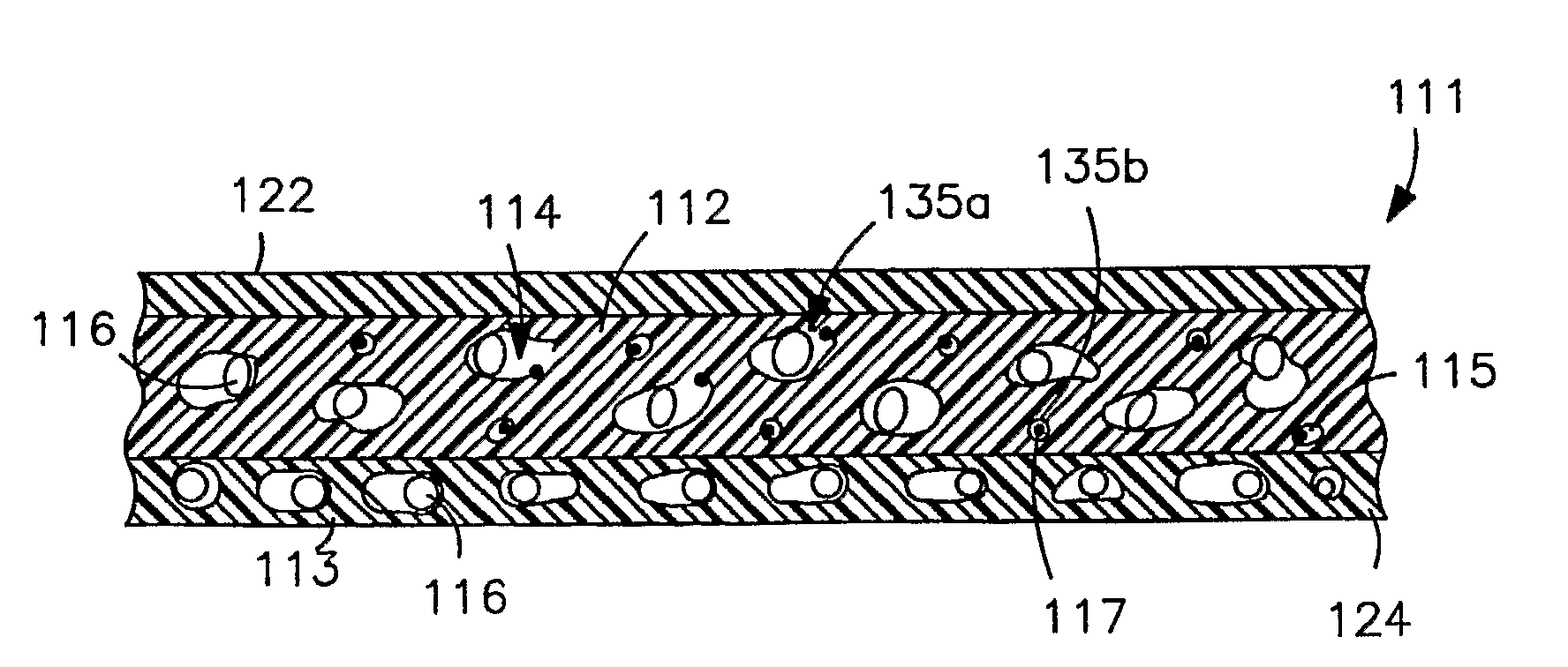

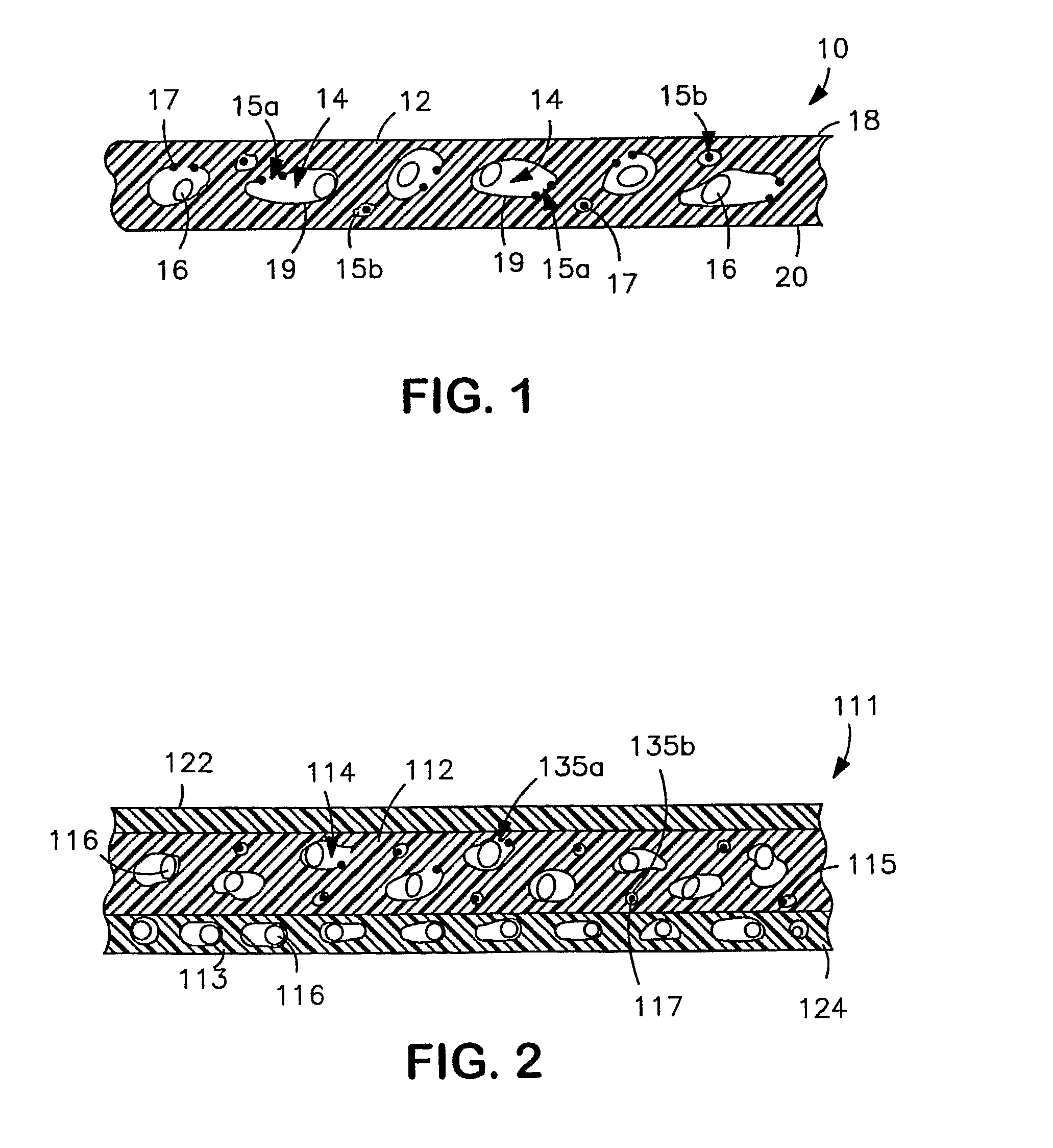

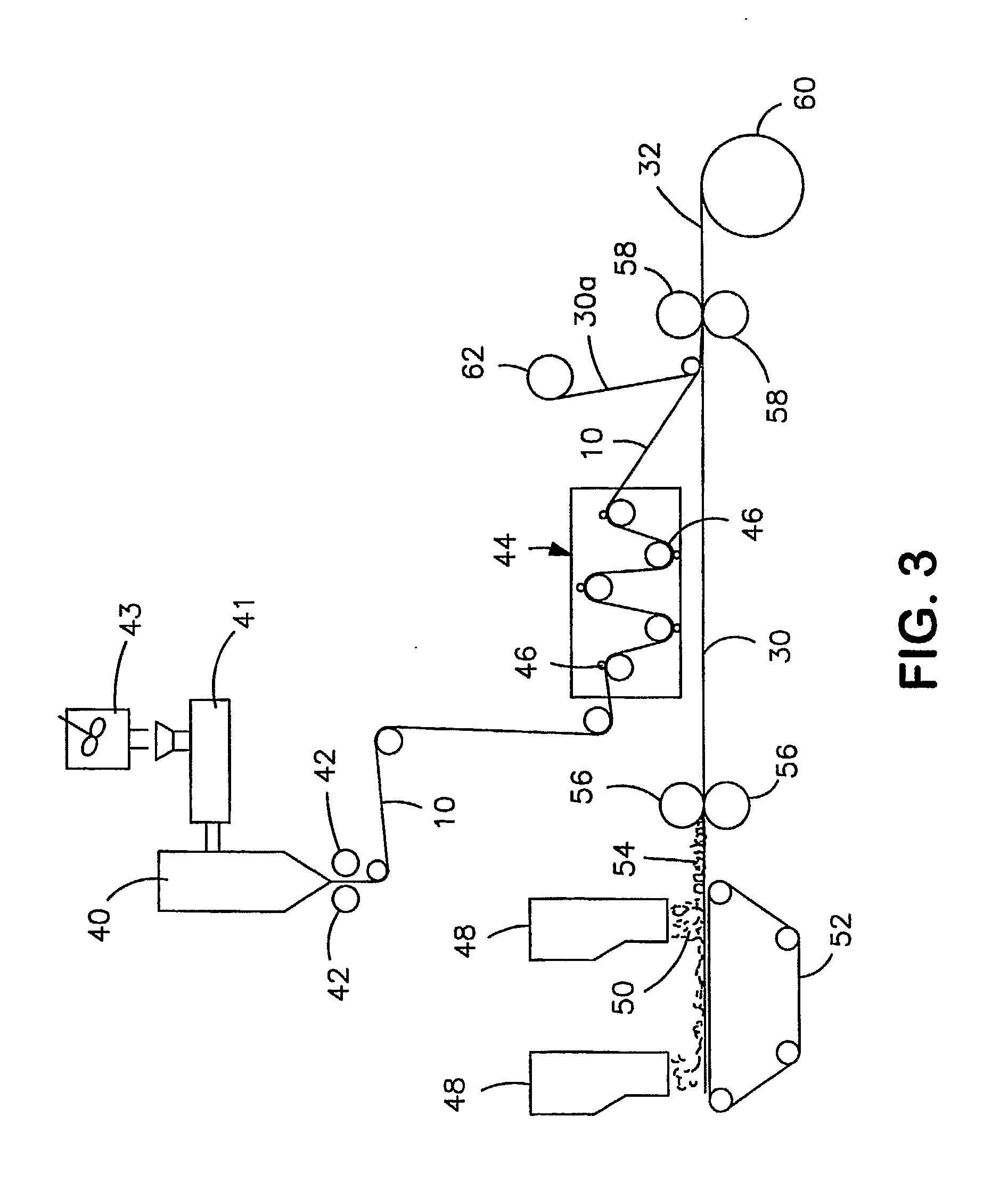

The invention relates to methods and materials for controlling stability and color intensity in an electrophoretic display element. Filler particles in the electrophoretic display element, serves as a medium that the electrophoretic particles must travel through during switching between optical states of the display. The filler particles provide improved control over the color intensity of the electrophoretic display element. In addition, the filler particles create resistance to the migration of the electrophoretic particles, thereby improving the bistability of the electrophoretic displays and inhibiting settling of the electrophoretic particles. Also, migration resistance provided by the filler particles can enable threshold addressing of an electrophoretic display.

Owner:E INK CORPORATION

Electrophoretic display elements

The invention relates to methods and materials for controlling stability and color intensity in an electrophoretic display element. Filler particles in the electrophoretic display element, serves as a medium that the electrophoretic particles must travel through during switching between optical states of the display. The filler particles provide improved control over the color intensity of the electrophoretic display element. In addition, the filler particles create resistance to the migration of the electrophoretic particles, thereby improving the bistability of the electrophoretic displays and inhibiting settling of the electrophoretic particles. Also, migration resistance provided by the filler particles can enable threshold addressing of an electrophoretic display.

Owner:E INK CORPORATION

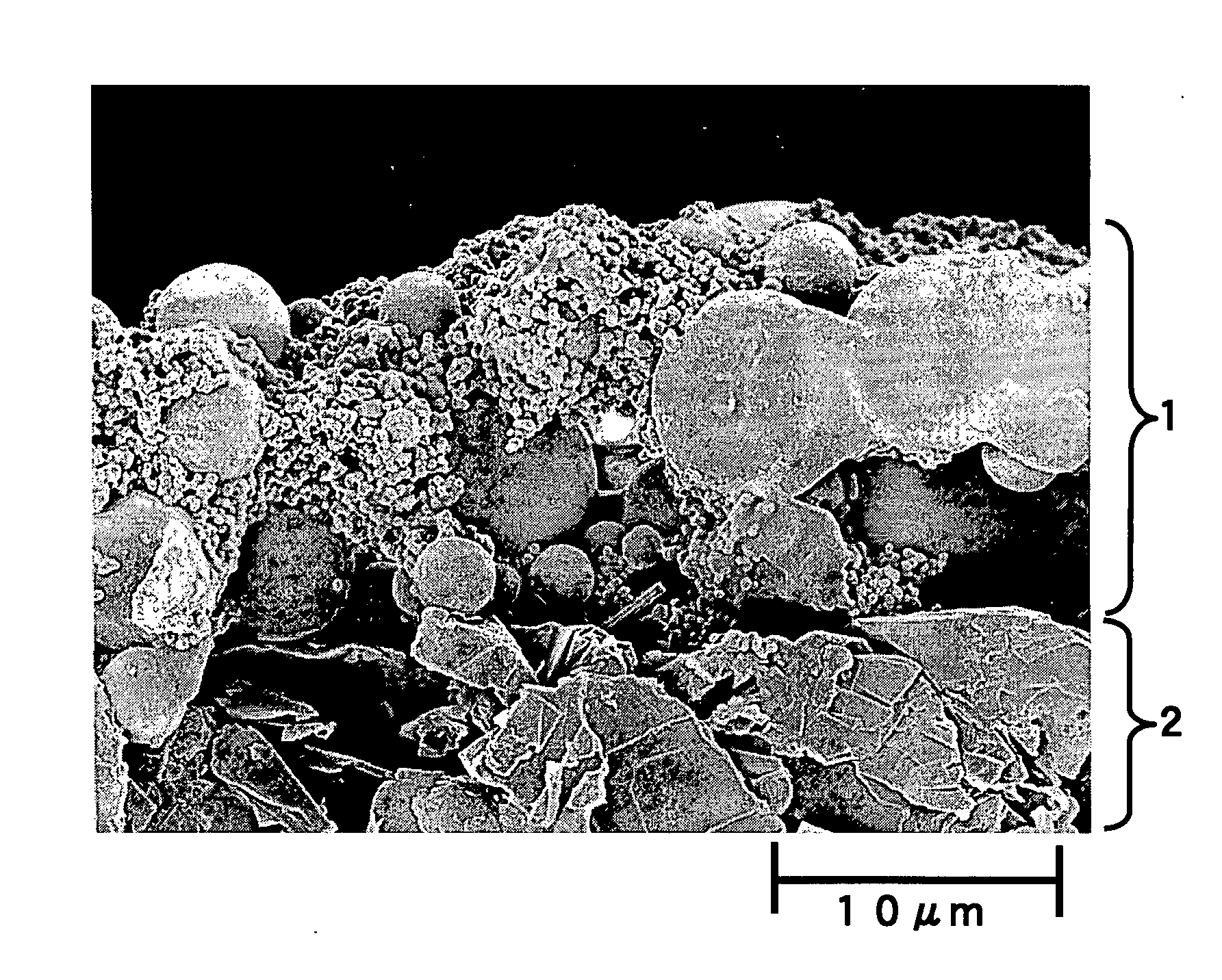

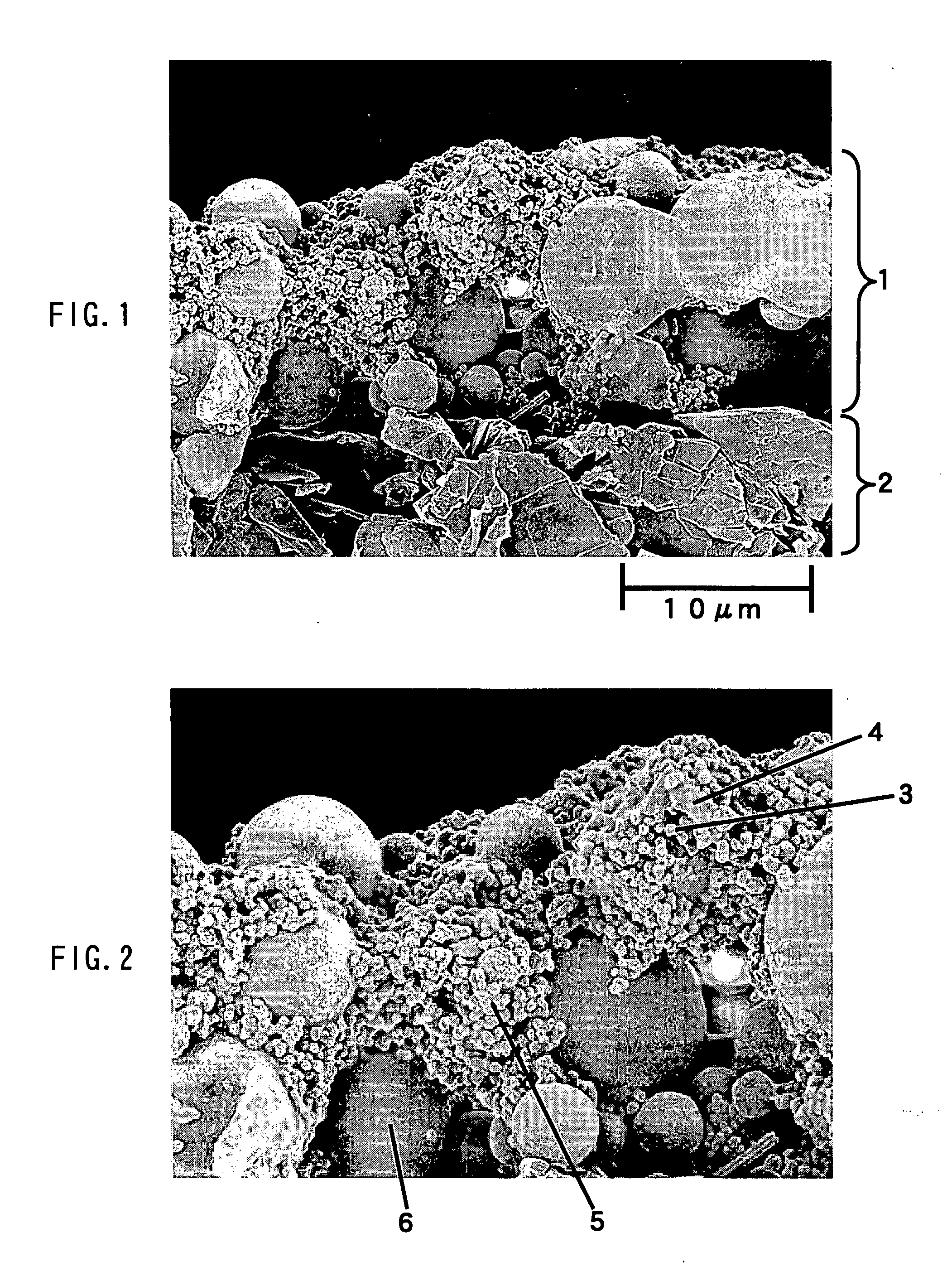

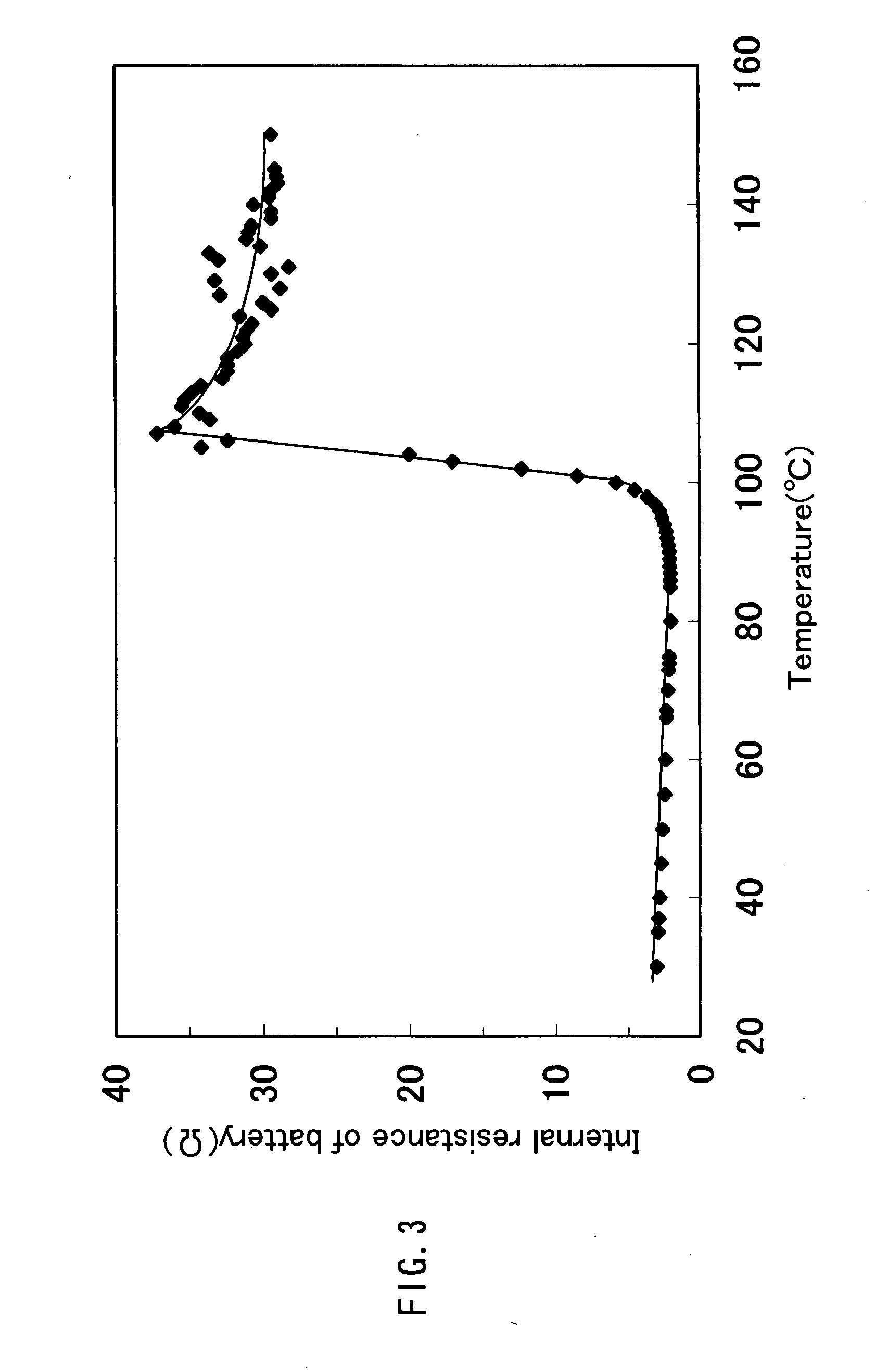

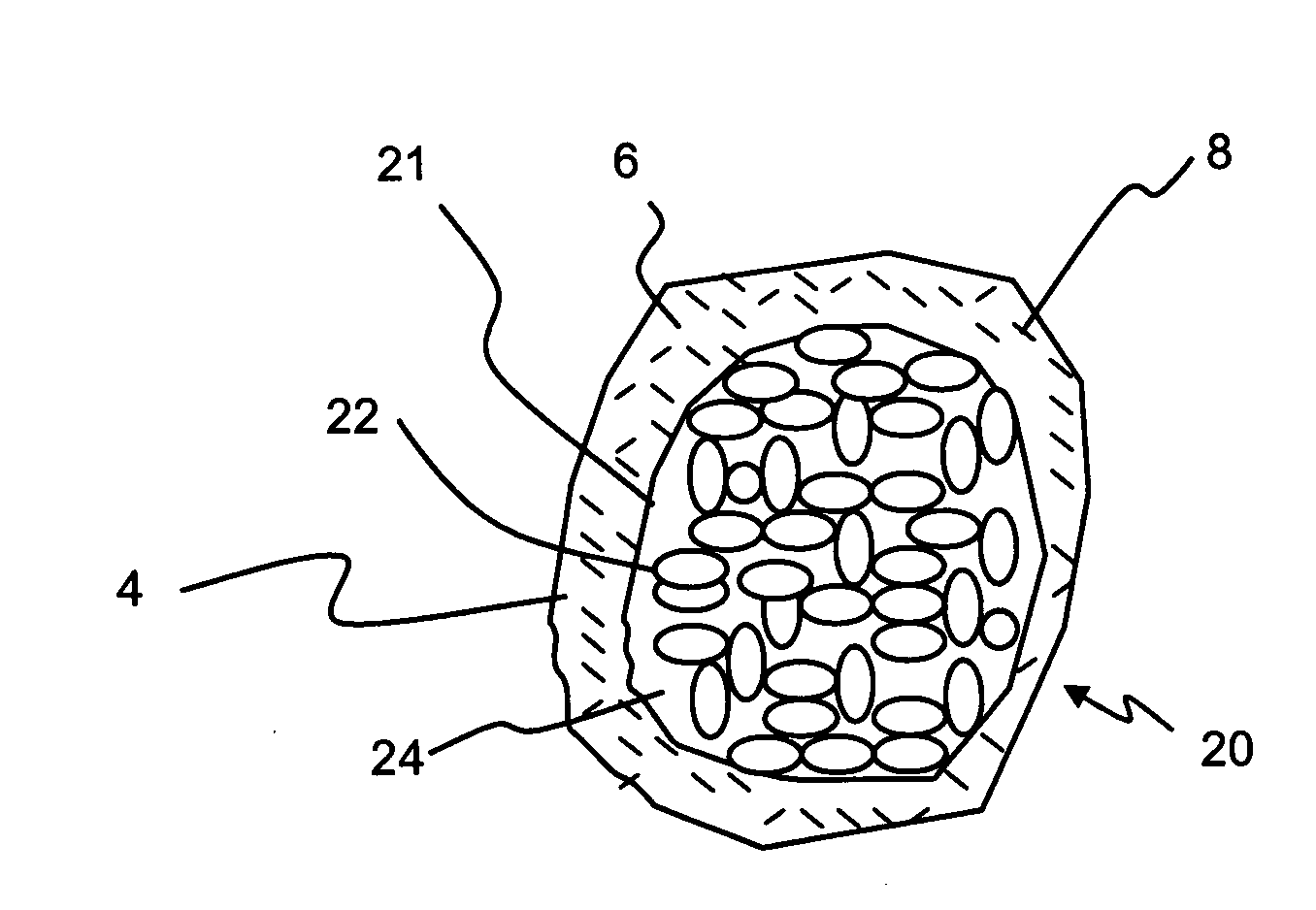

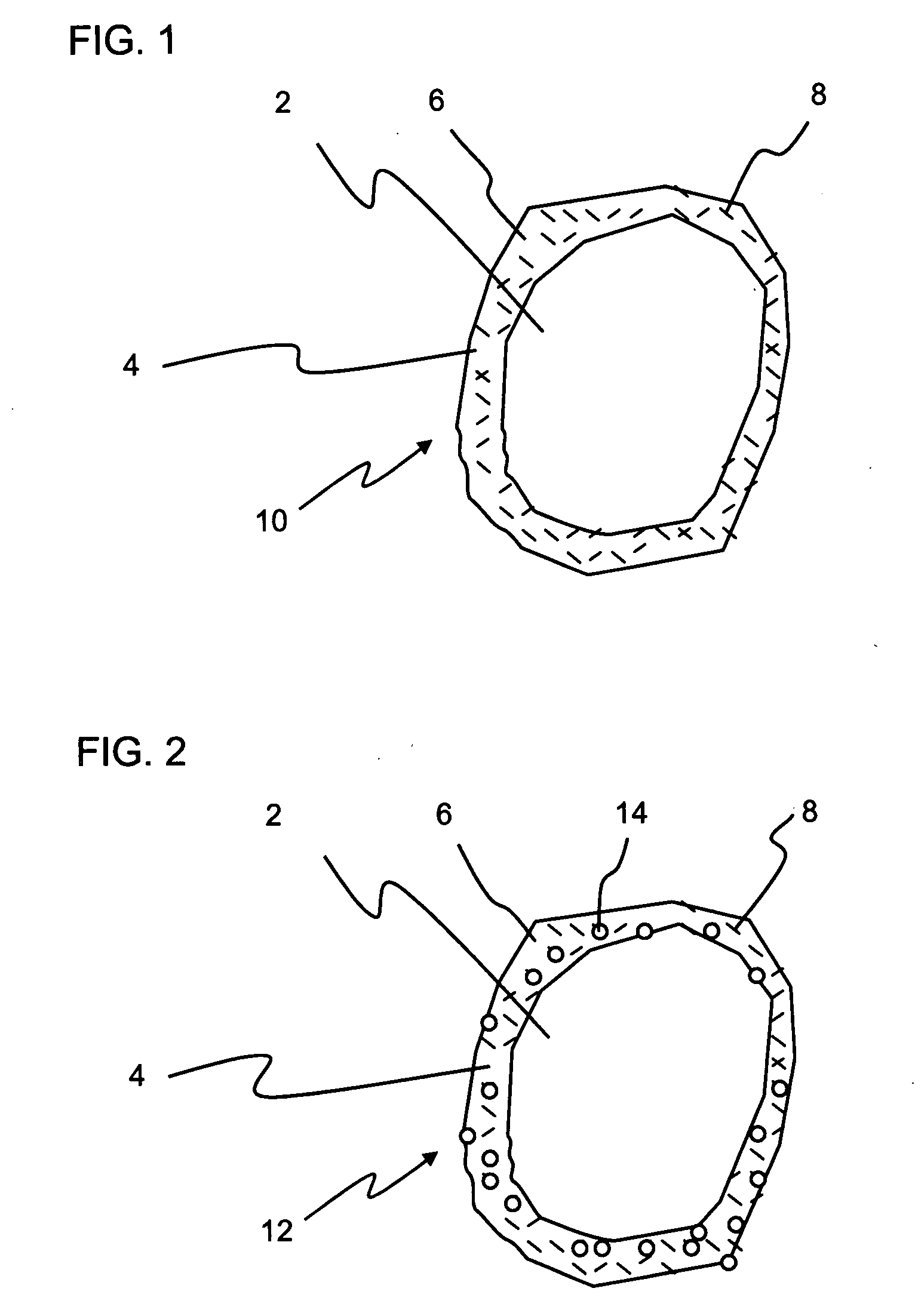

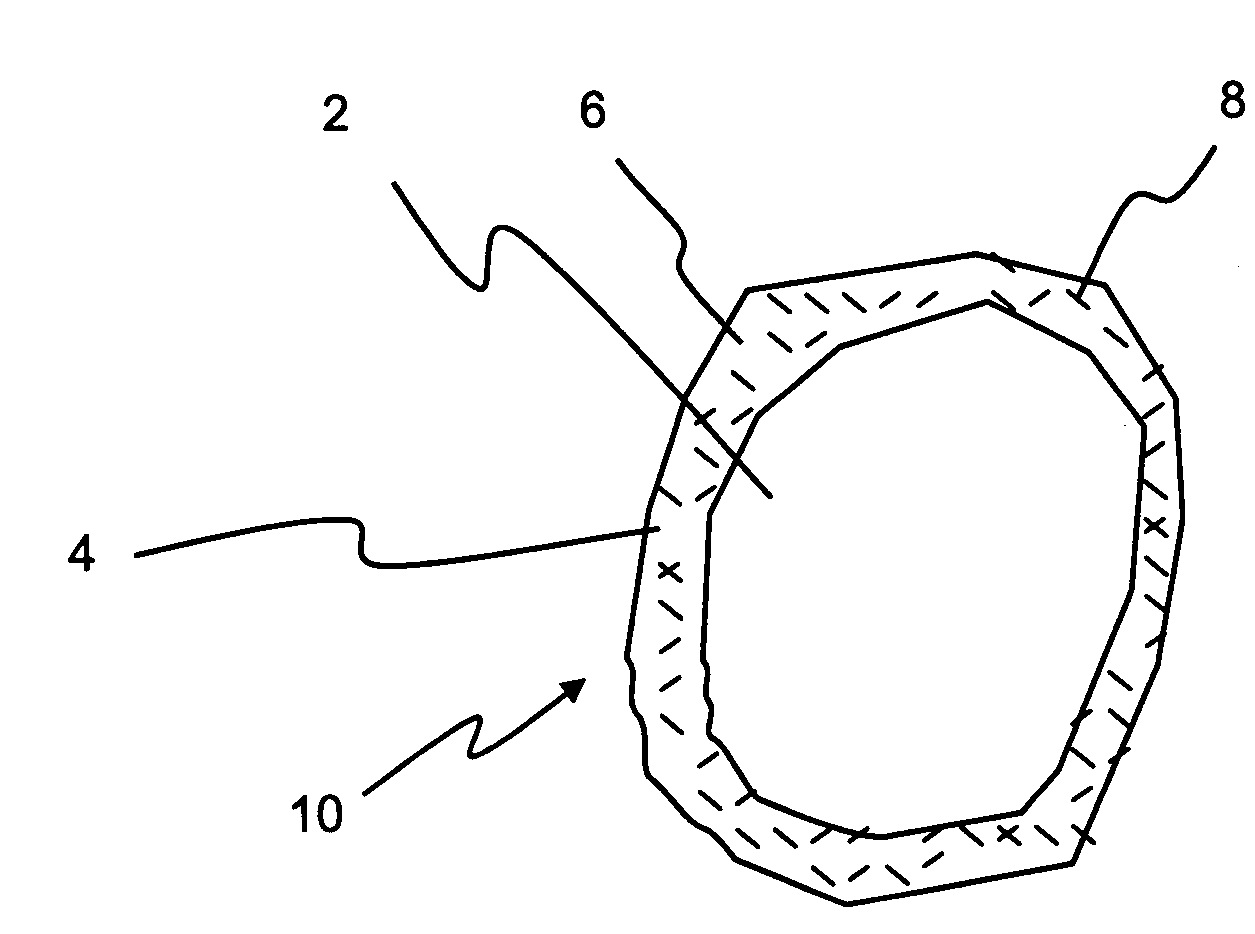

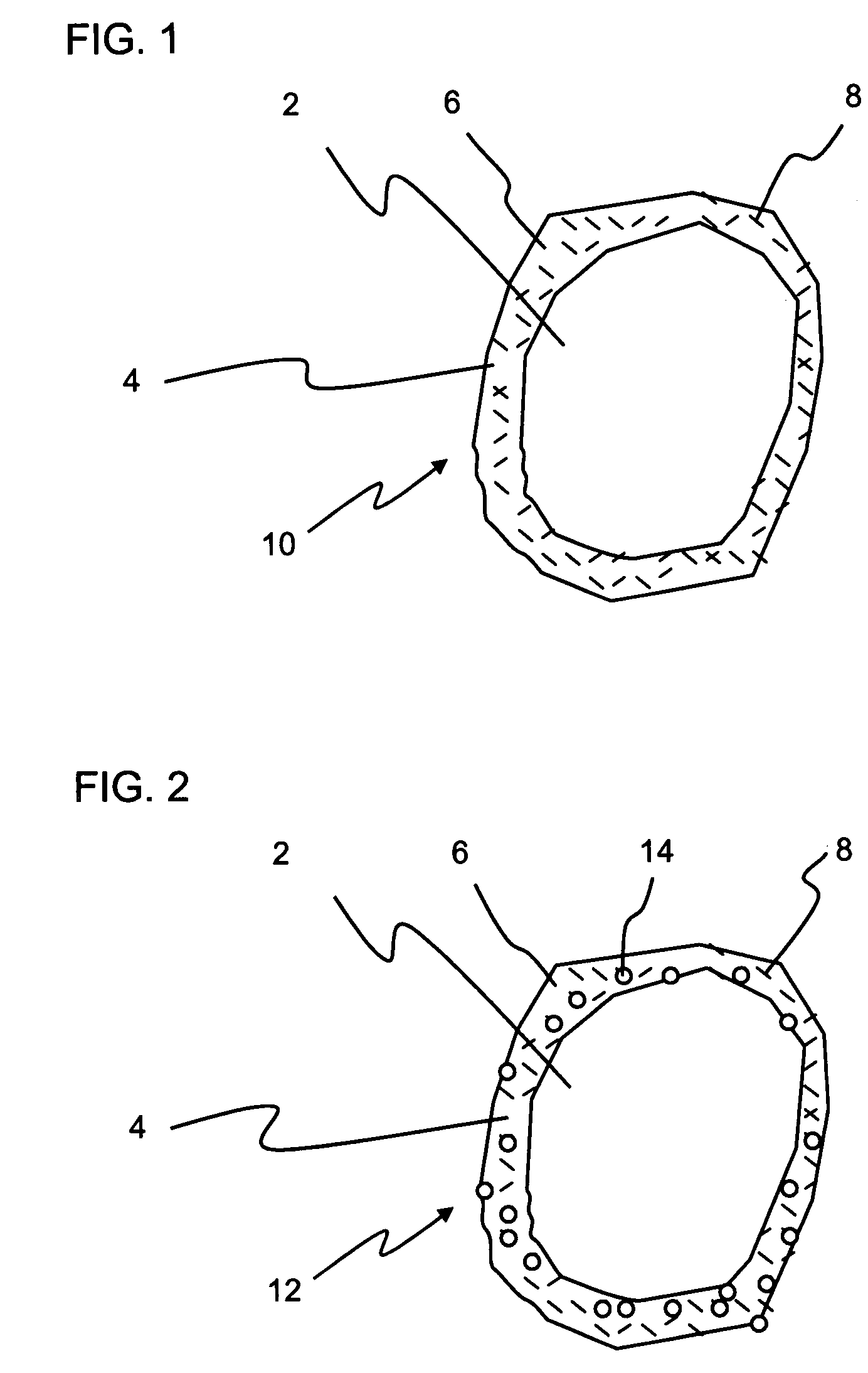

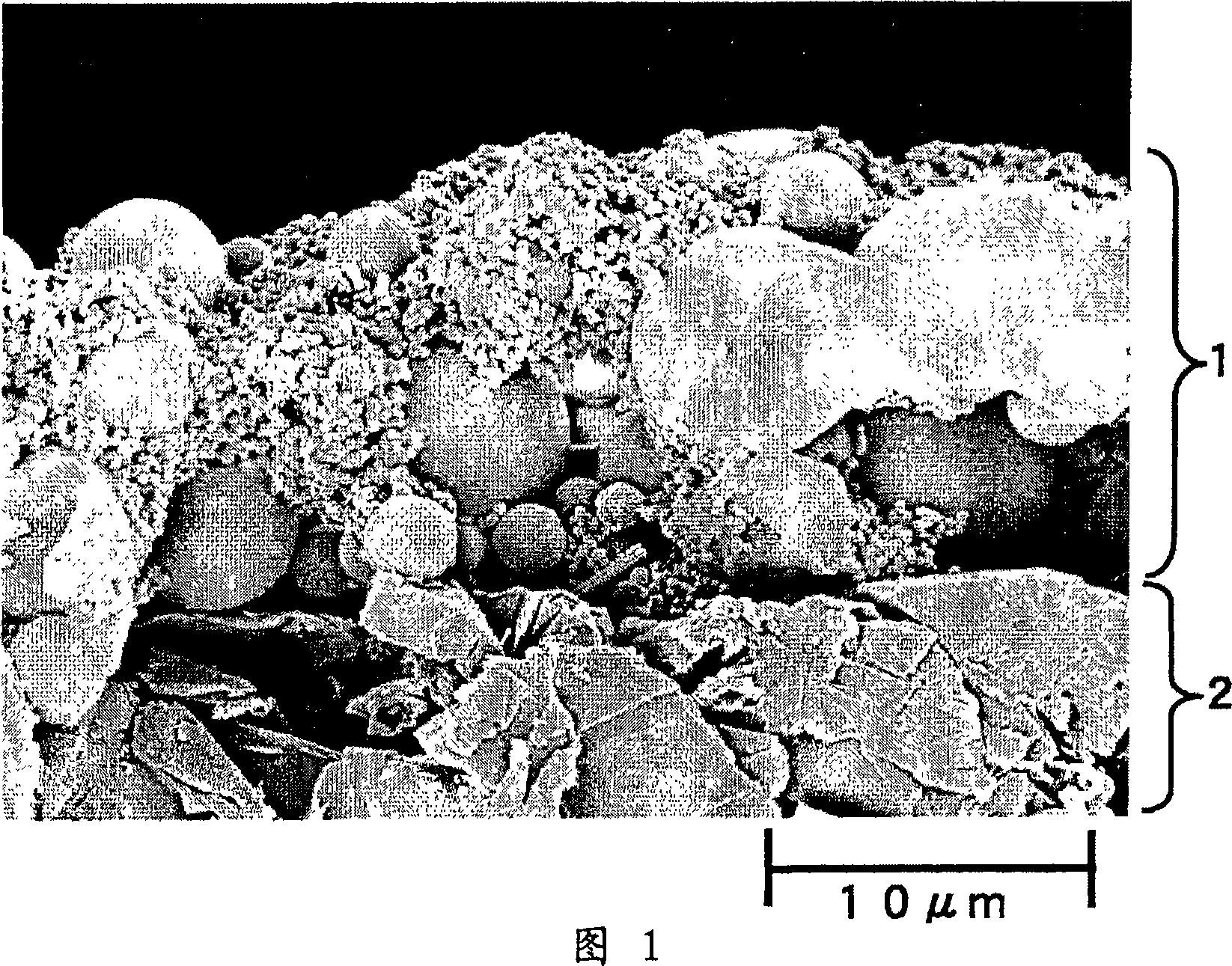

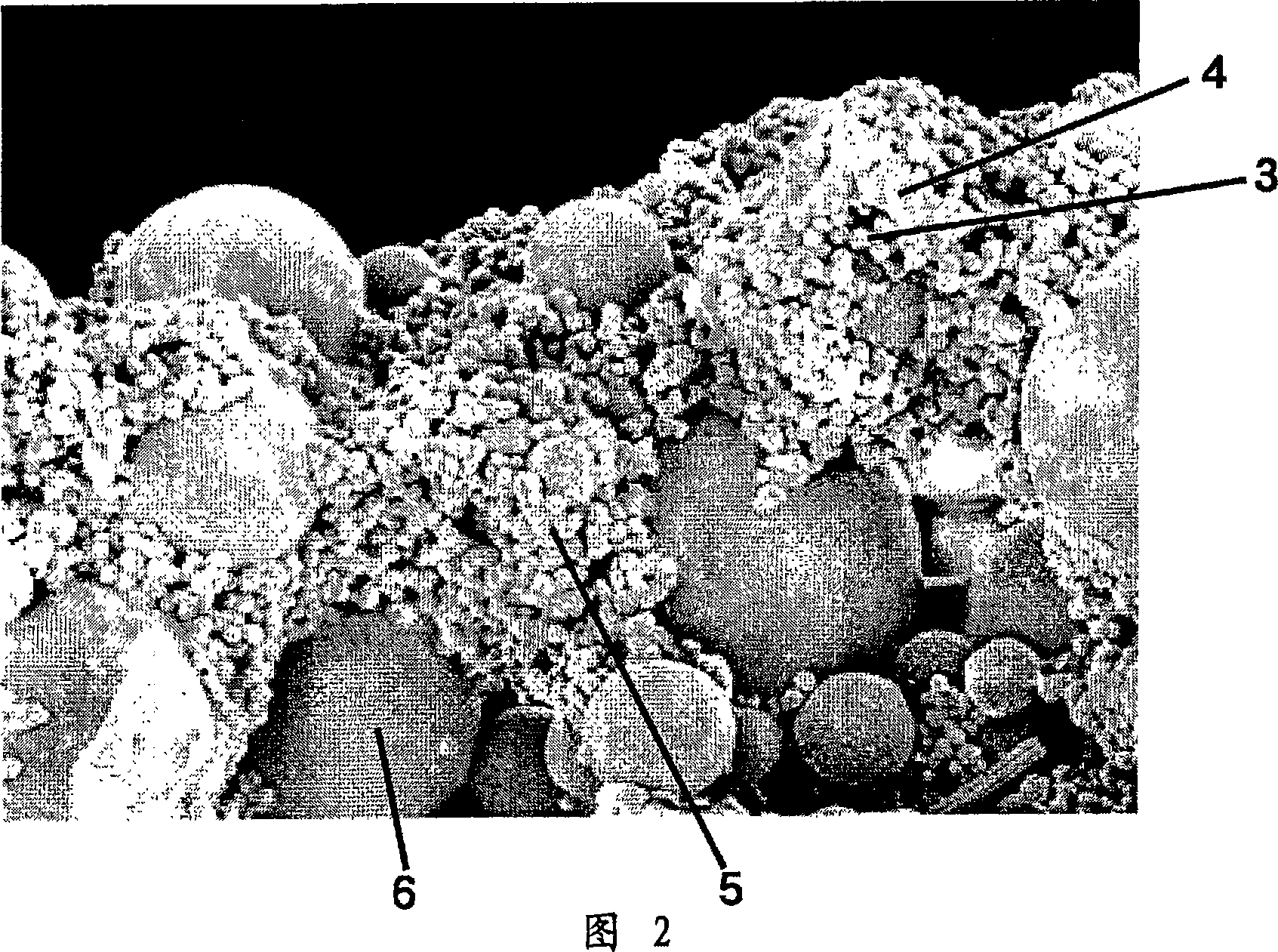

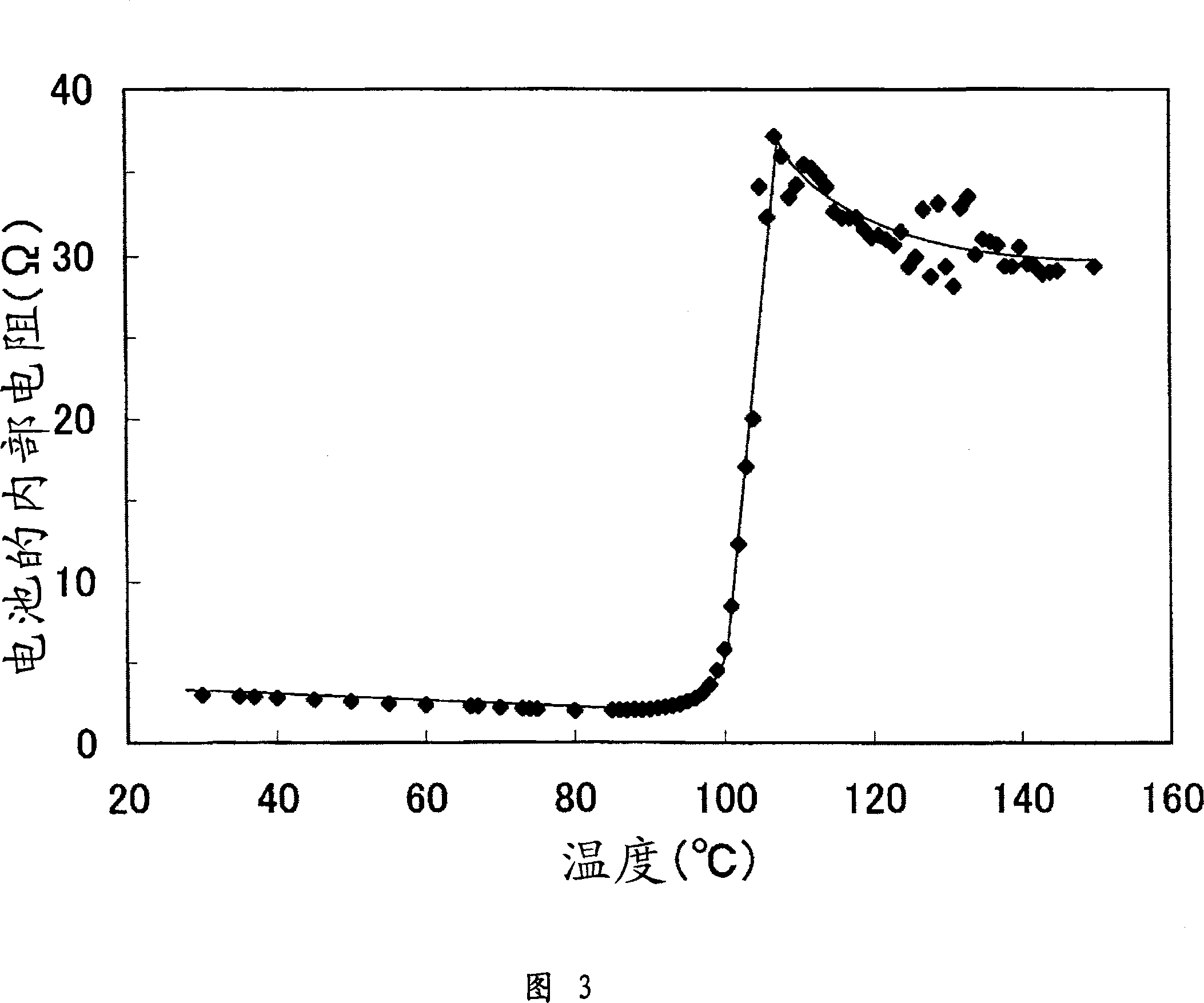

Separator for Electrochemical Device, and Electrochemical Device

ActiveUS20070264577A1Improve securityCell electrodesSecondary cellsPhysical chemistryElectrochemistry

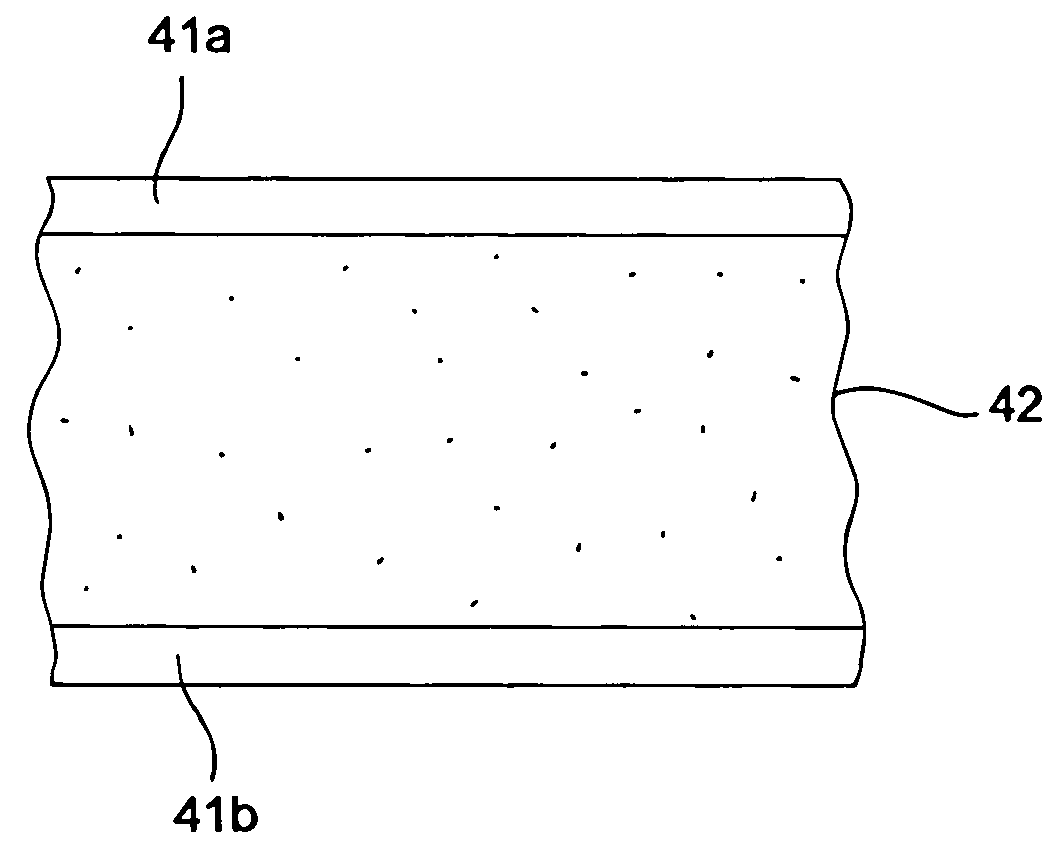

An electrochemical device having excellent safety at high temperature is provided by using a separator for an electrochemical device, which is made of a porous film comprising: a porous base (5) having a heat-resistant temperature of 150° C. or higher and including filler particles (3); at least one kind of shutdown resin (6) selected from the group consisting of resin A that has a melting point in a range of 80° C. to 130° C. and resin B that absorbs an electrolyte and swells due to heating, and the swelling degree is increased as the temperature rises; and a binder (4).

Owner:MAXELL HLDG LTD

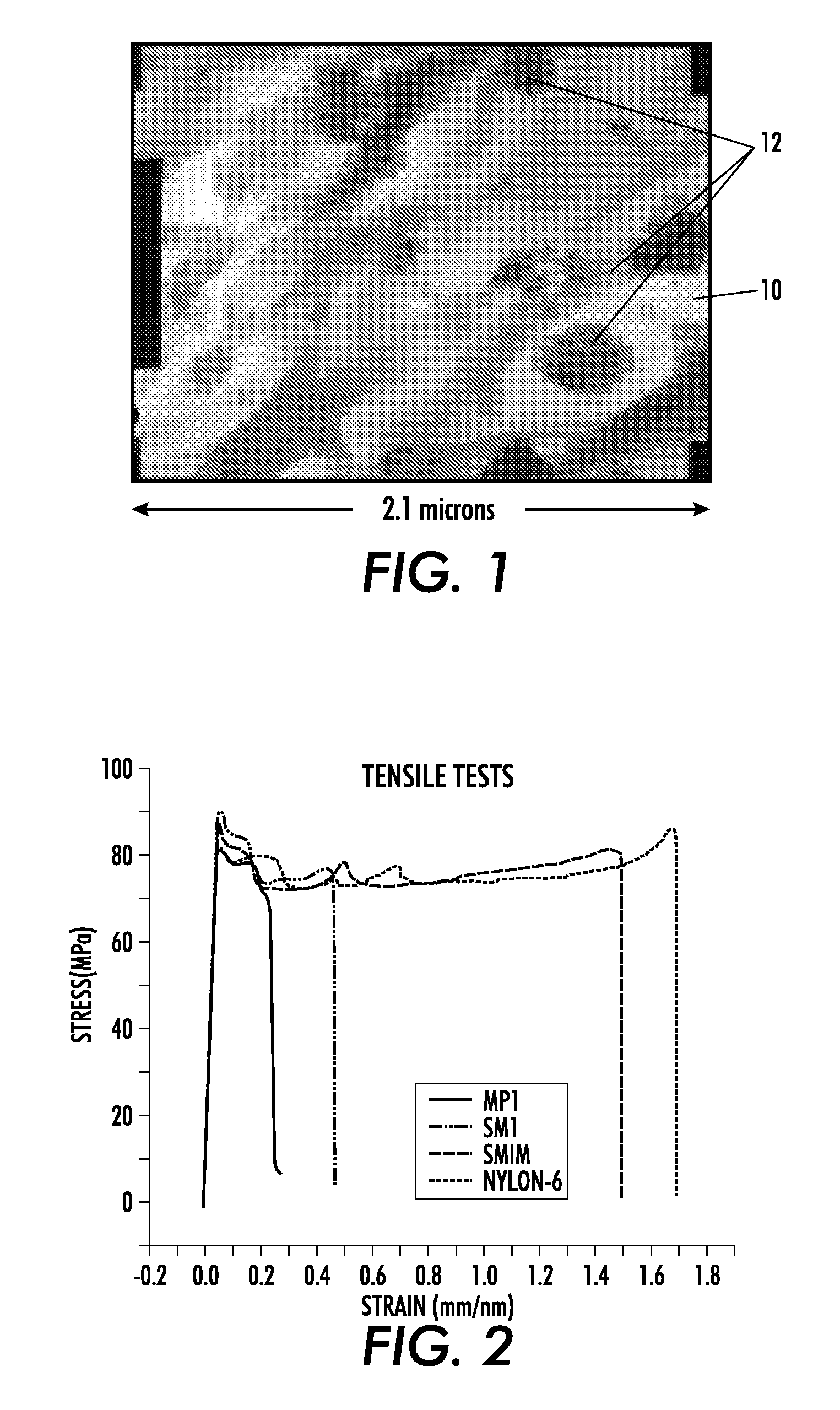

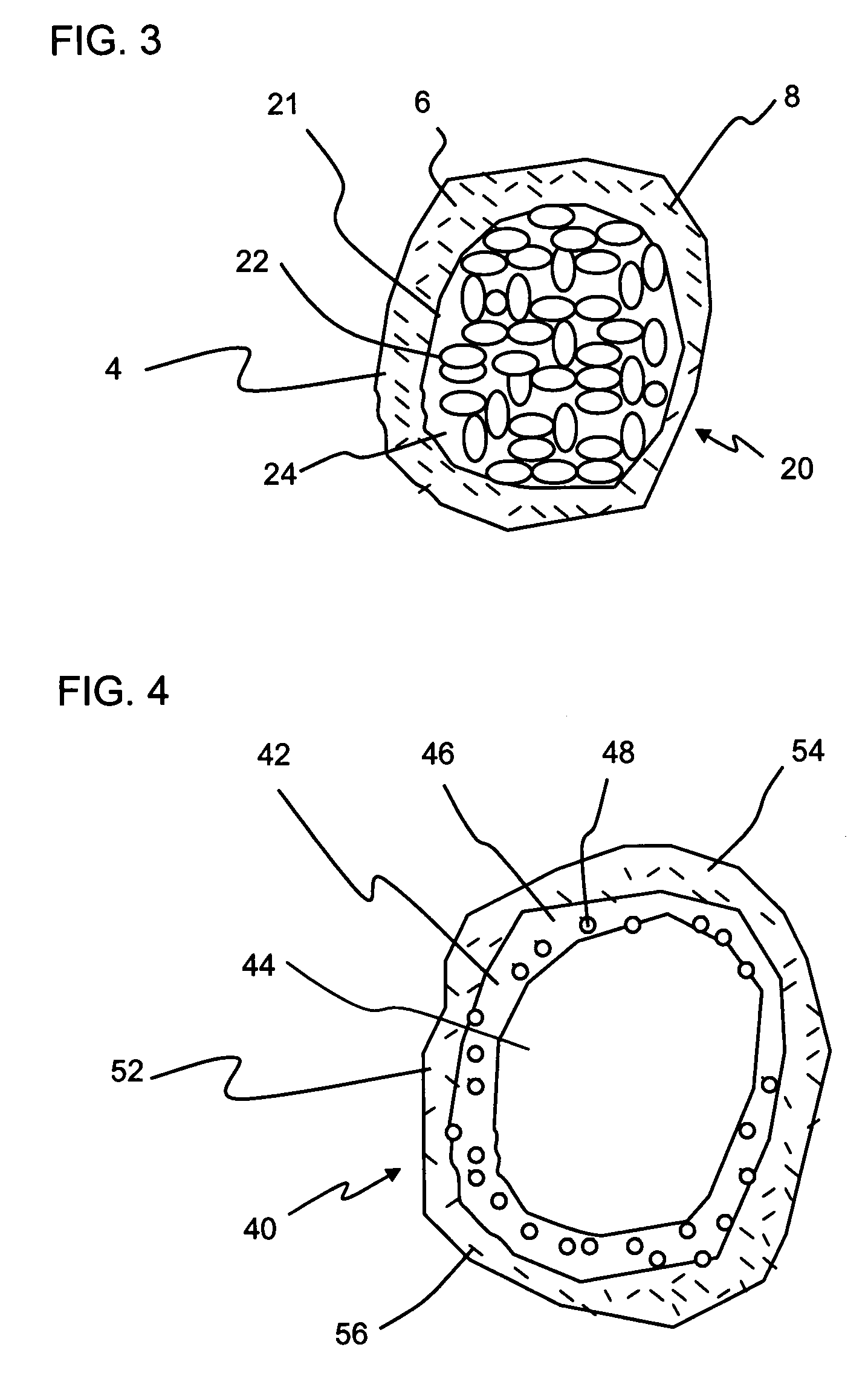

Highly filled polymer composition with improved properties

InactiveUS6362252B1Reduce manufacturing costHigh tensile strengthConductive materialPlastic recyclingPolymer sciencePlasticizer

A highly filled polymer composition with improved properties comprising: a continuous matrix material; a filler material in an amount of 10 to 80 wt. % of said composition; a polymer plasticizer dispersed in said continuous matrix material in an amount of 0.5 to 15 wt. % of said filler; a filler coating material which coats said filler particles in the form of a continuous coating layer thus forming coated filler particles; a diffusion zone around said coated filler particles where said filler coating and said continuous matrix material are mutually diffused into one another wherein said filler coating material is distributed with concentration decreasing in the direction outward from said continuous coating layer. Provided also is a method of preparing the aforementioned composition which guarantees that during extrusion or similar treatment the filler particles are coated with a continuous layer of the filler coating material and that the aforementioned diffusion zone is formed around the coated filler particles. In the manufacture of various products such as pipes, sheets, profiles, etc., the composition of the invention combines high deformation capacity with sufficient strength. Furthermore, the composition of the invention possesses high anticorrosive properties, has low shrinkage, and has high adhesion to metals, wood, plastics, etc.

Owner:NEXT GENERATIONS TECH

Aerogel/PTFE composite insulating material

ActiveUS20050100728A1Increase flexibilityHigh strengthDigital data processing detailsAdhesive articlesInto-structureMaterials science

A material comprising aerogel particles and a polytetrafluoroethylene (PTFE) binder is formed having a thermal conductivity of less than or equal to 25 mW / m K at atmospheric conditions. The material is moldable or formable, having little or no shedding of filler particles, and may be formed into structures such as tapes or composites, for example, by bonding the material between two outer layers. Advantageously, composites may be flexed, stretched, or bent without significant dusting or loss of insulating properties.

Owner:WL GORE & ASSOC INC

Thermally conductive composition and method for preparing the same

InactiveUS20070241303A1Semiconductor/solid-state device detailsSolid-state devicesBoron nitridePolymer chemistry

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

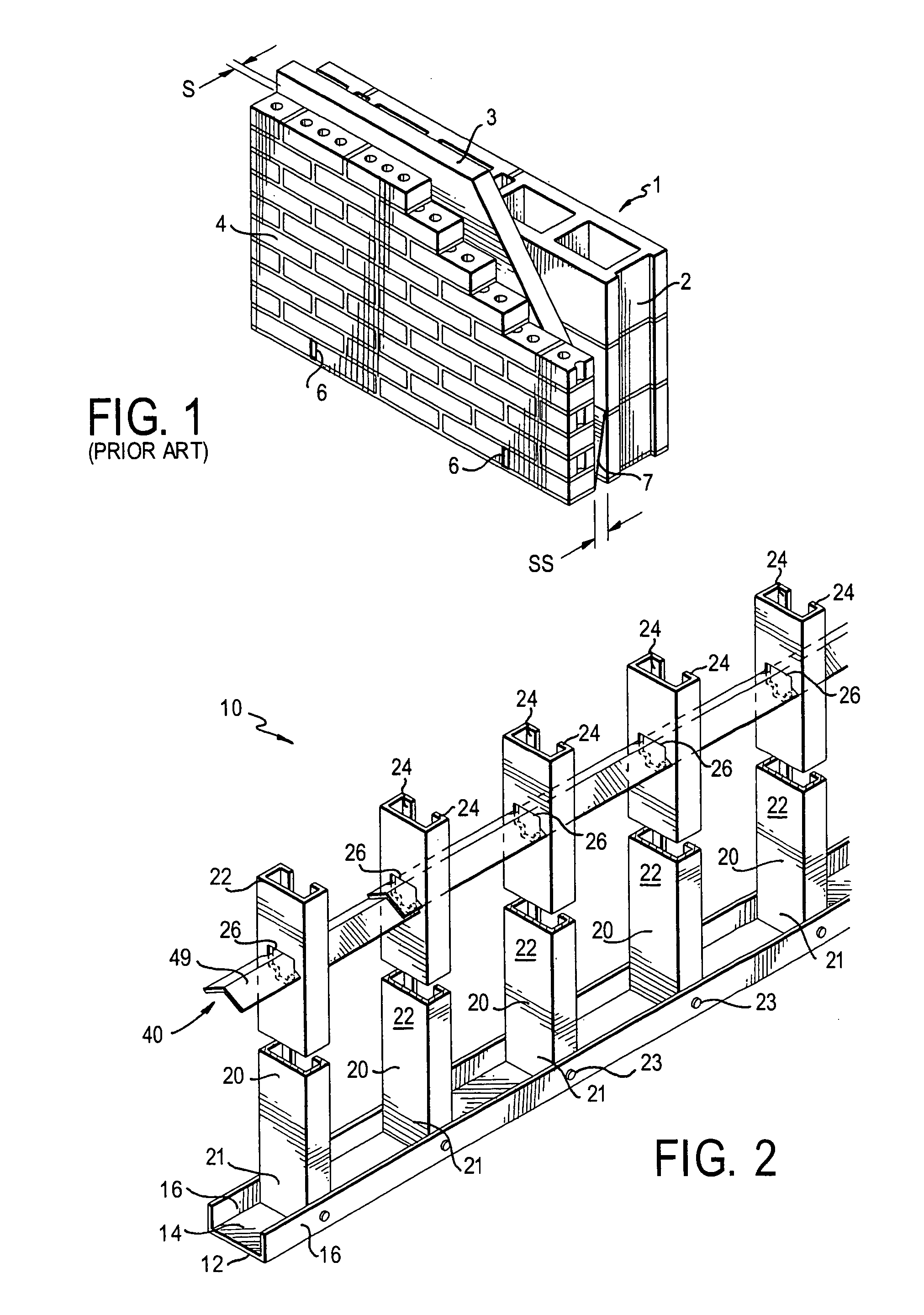

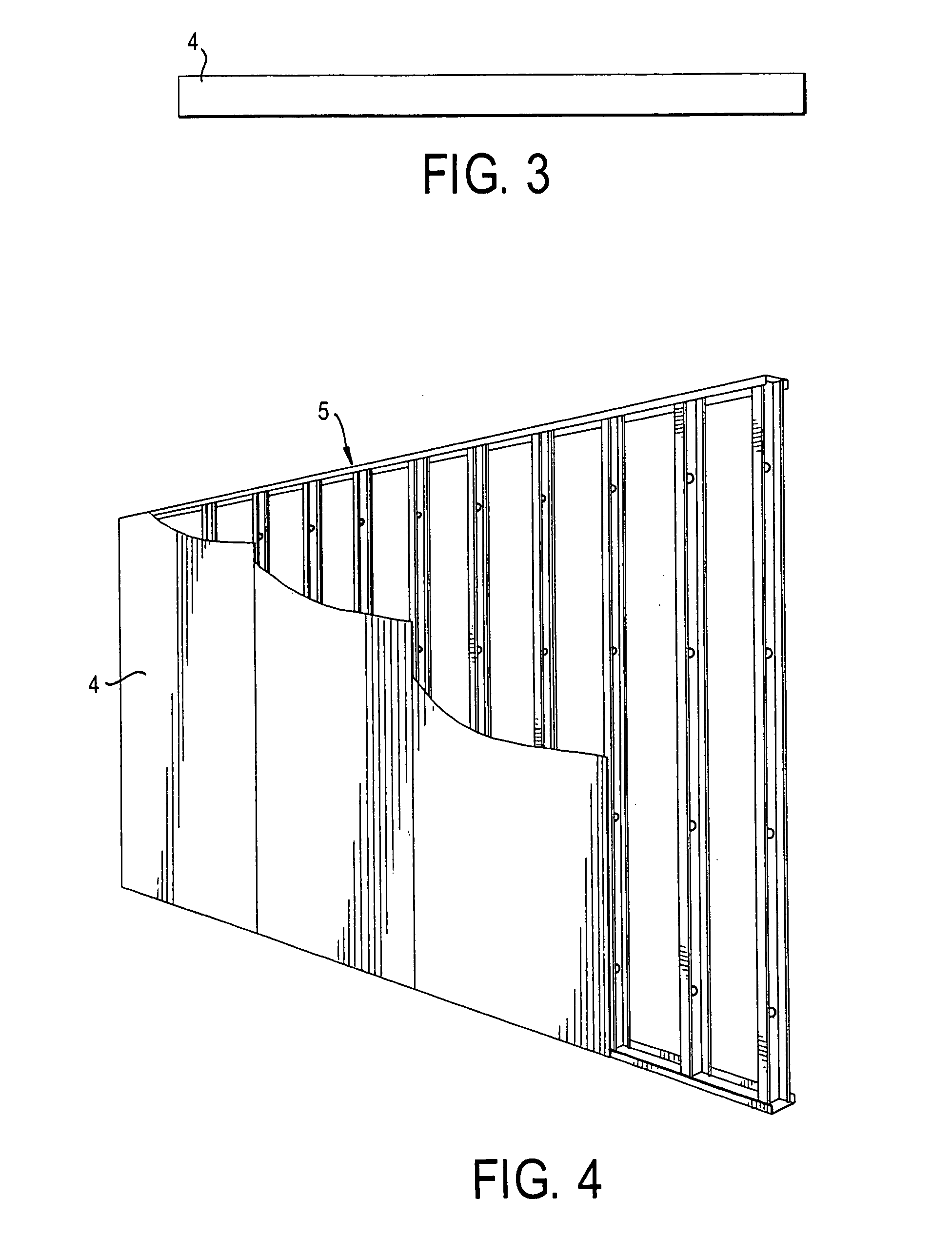

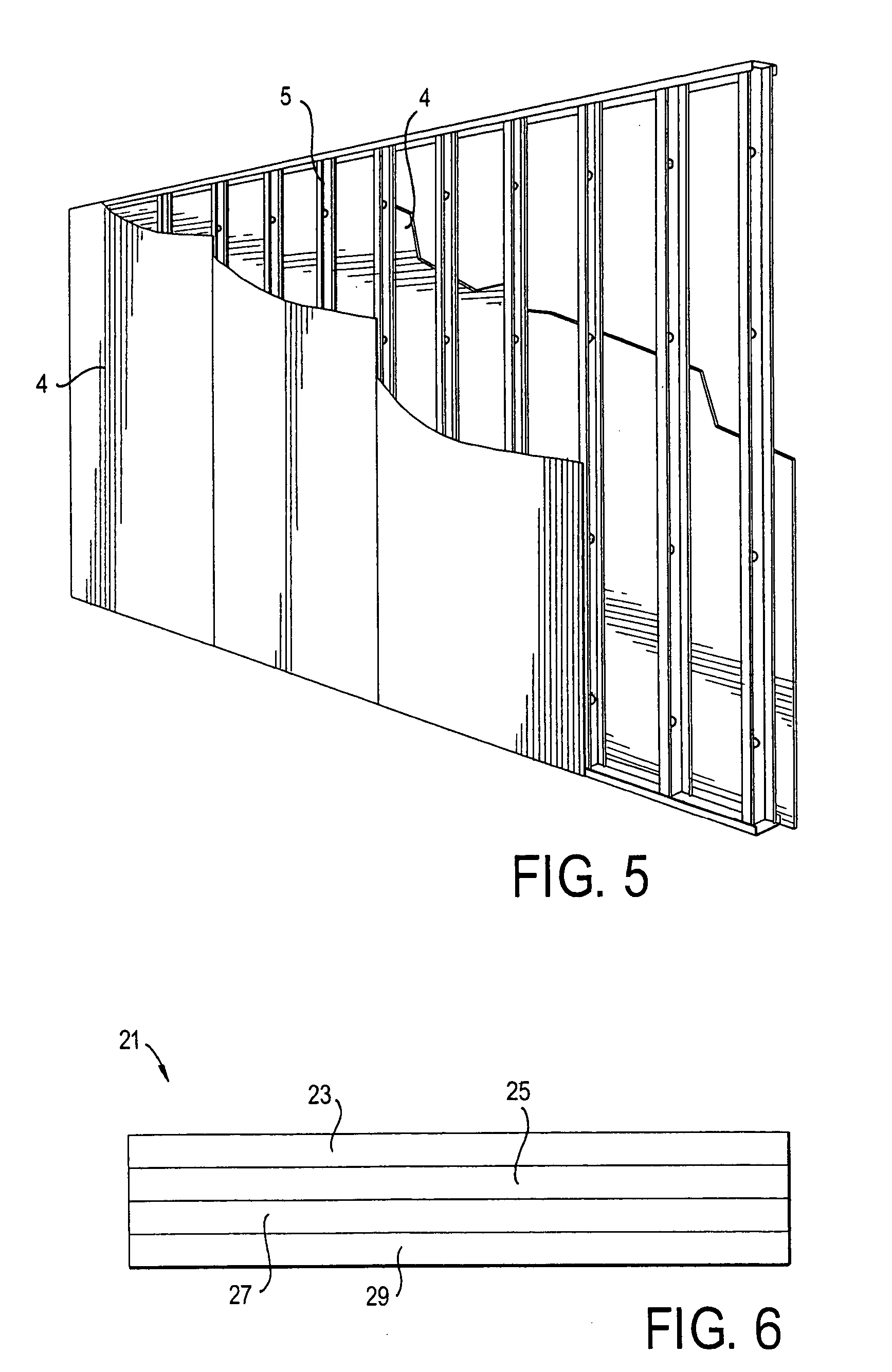

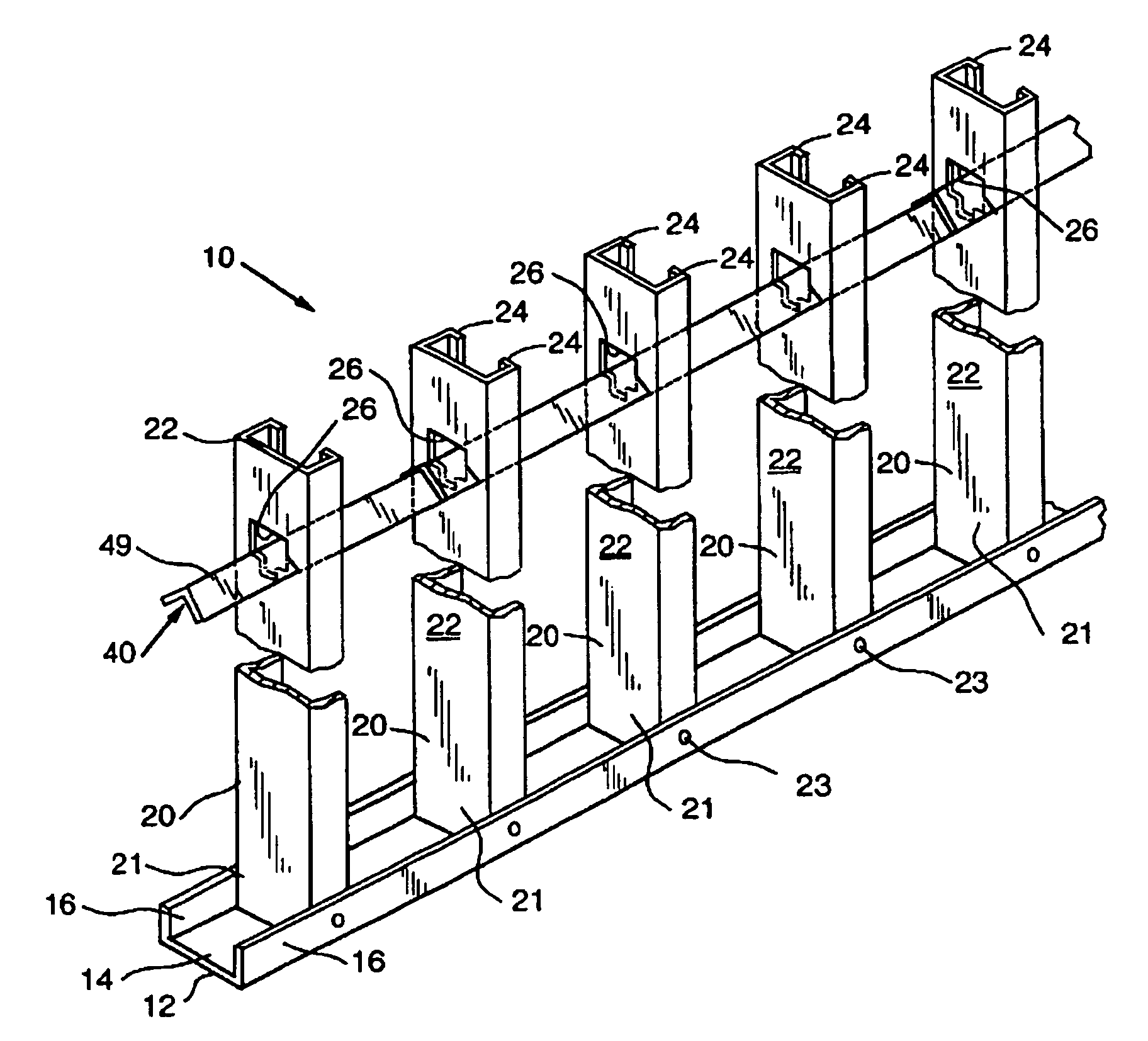

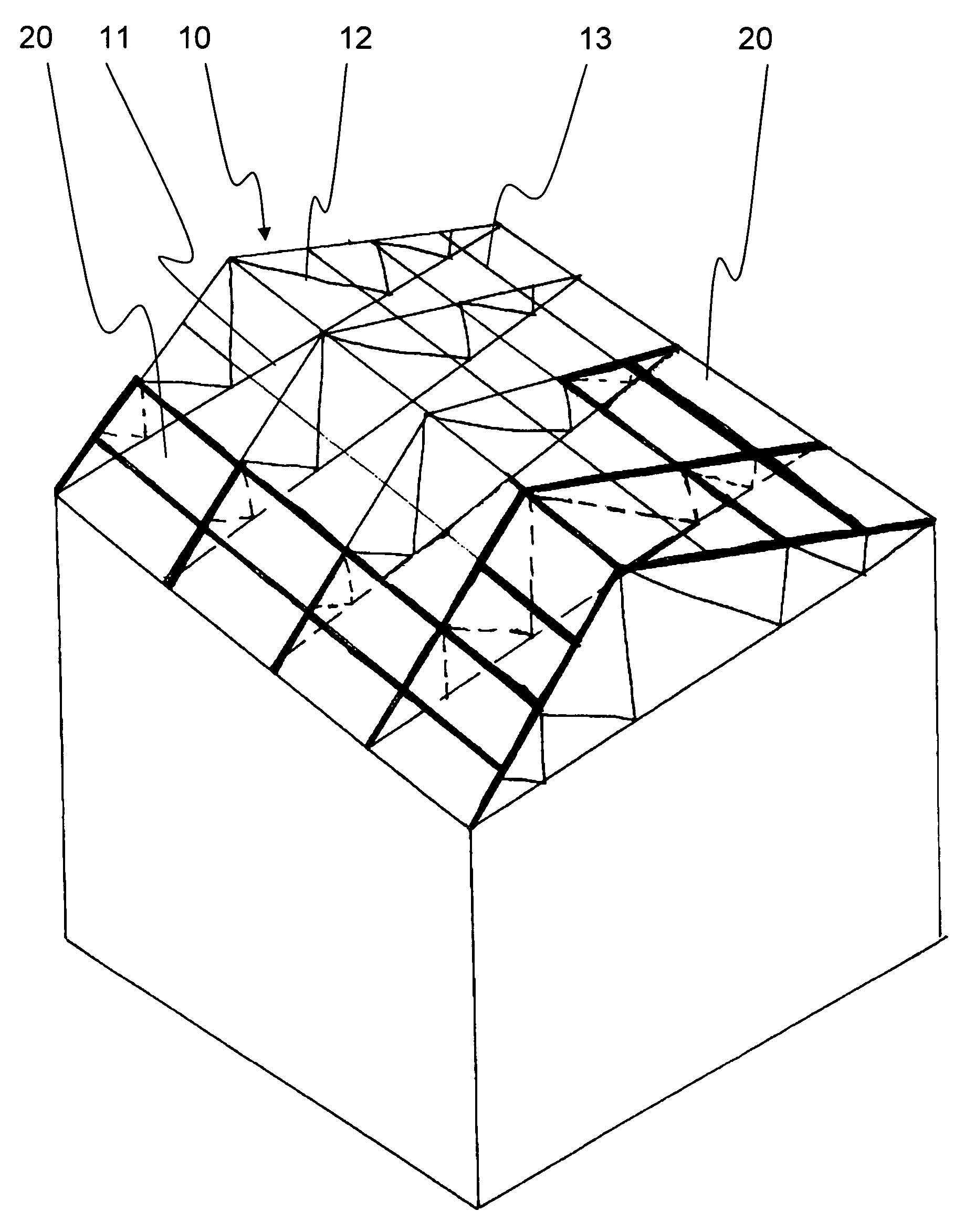

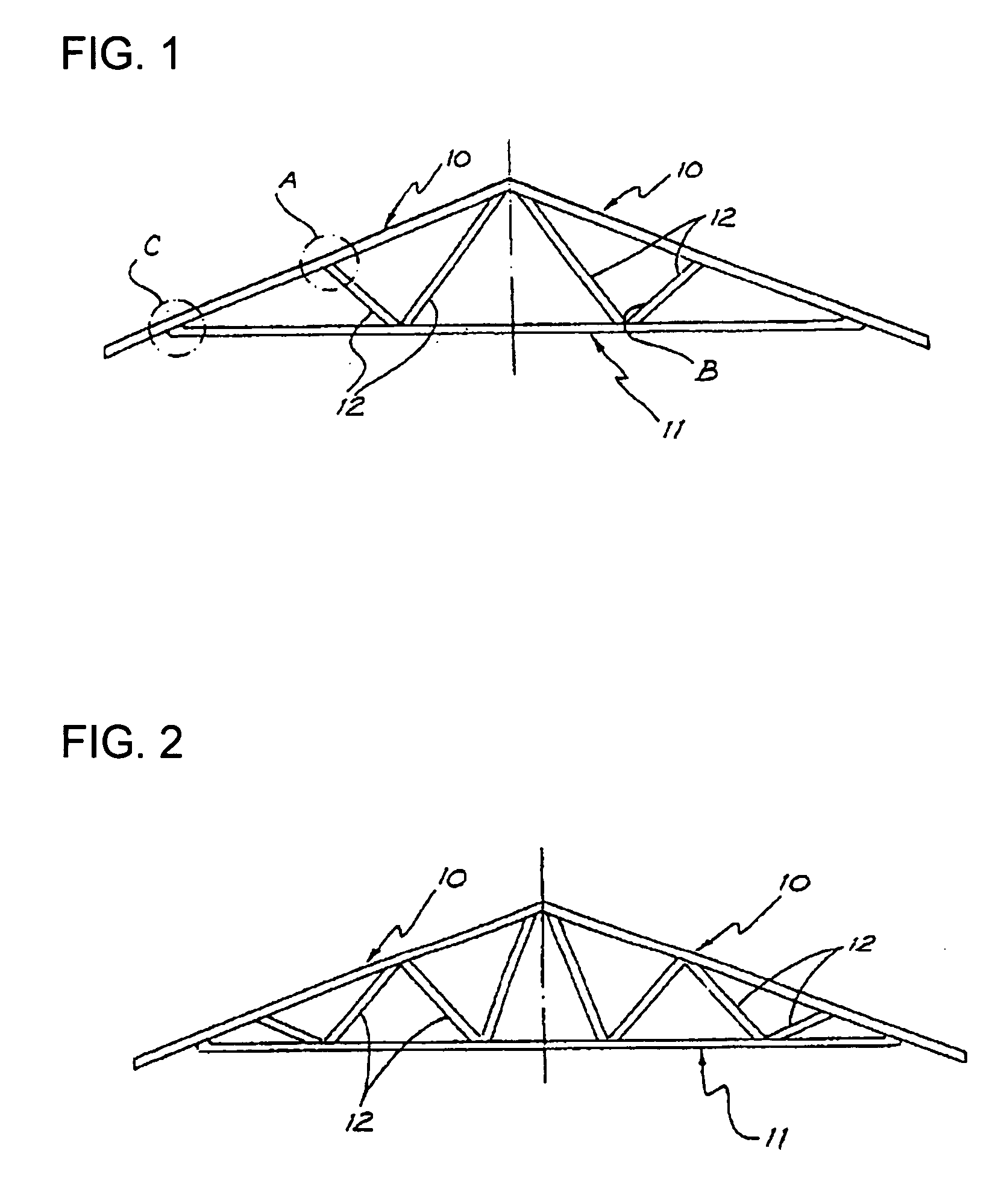

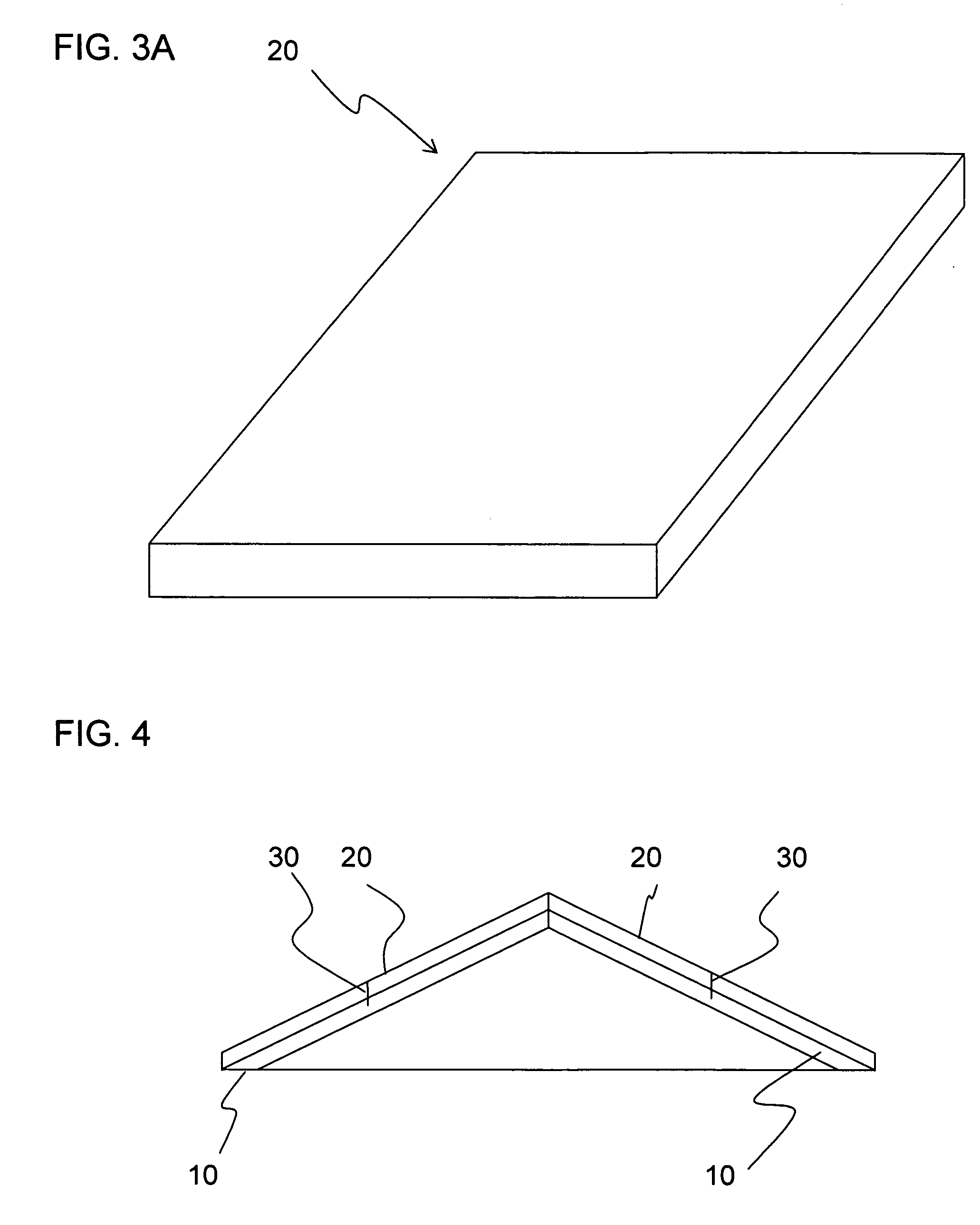

Non-combustible reinforced cementitious lighweight panels and metal frame system for a fire wall and other fire resistive assemblies

ActiveUS20060168906A1Reduce buildReduce capacityBuilding roofsSolid waste managementMicrosphereMetal framework

A fire resistive assembly including metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The assembly is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Low temperature coated particles for use as proppants or in gravel packs, methods for making and using the same

ActiveUS20080230223A1Improves unconfined compressive strength propertyImprove performanceLiquid surface applicatorsSynthetic resin layered productsPolyesterParticulates

Disclosed herein are free flowing coated particles and low temperature methods of making same. Each particle has a curable coating disposed upon a substrate. The substrate is a particulate substrate including an inorganic material, a particulate substrate including an organic material, a composite substantially homogeneous formed particle including a first portion of an at least partly cured binder and filler particles, or a hybrid particle having an inorganic particle as a core and a composite coating including at least partially cured resin and filler. The curable coating includes a continuous phase including resole resin and reactive powder particles embedded or adhered to the continuous phase. The reactive powder particles typically include resole resin, novolak resin, polyester, acrylic and / or urethane. A method including applying a coating including the continuous phase including resole resin and reactive or non-reactive powder particles embedded or adhered to the continuous phase.

Owner:HEXION INC

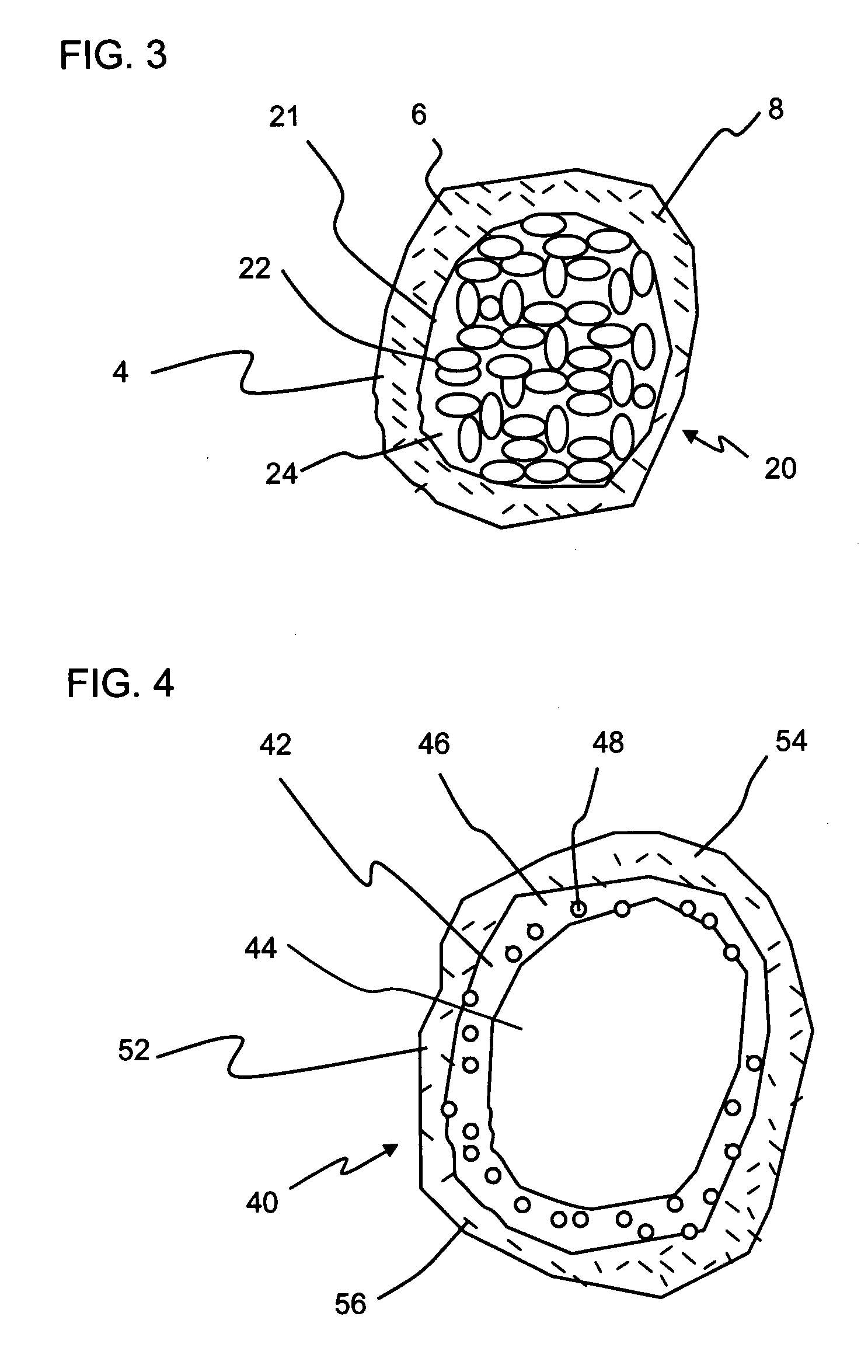

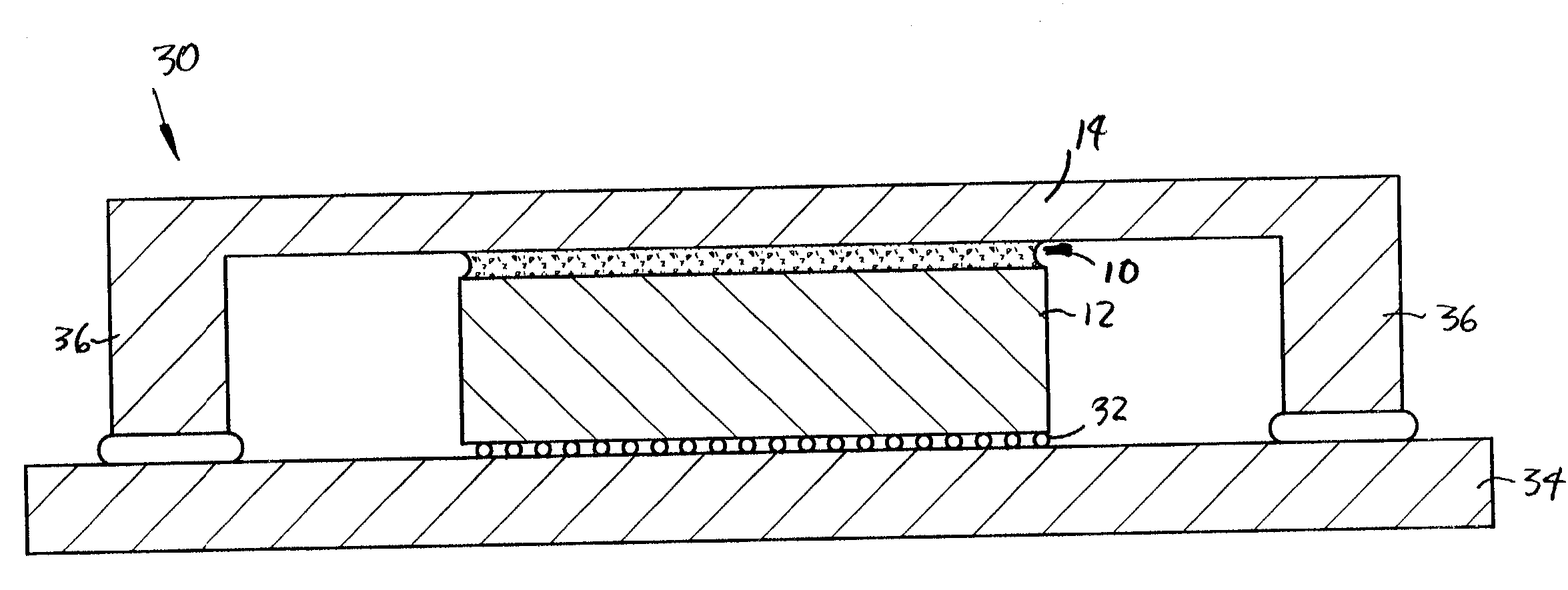

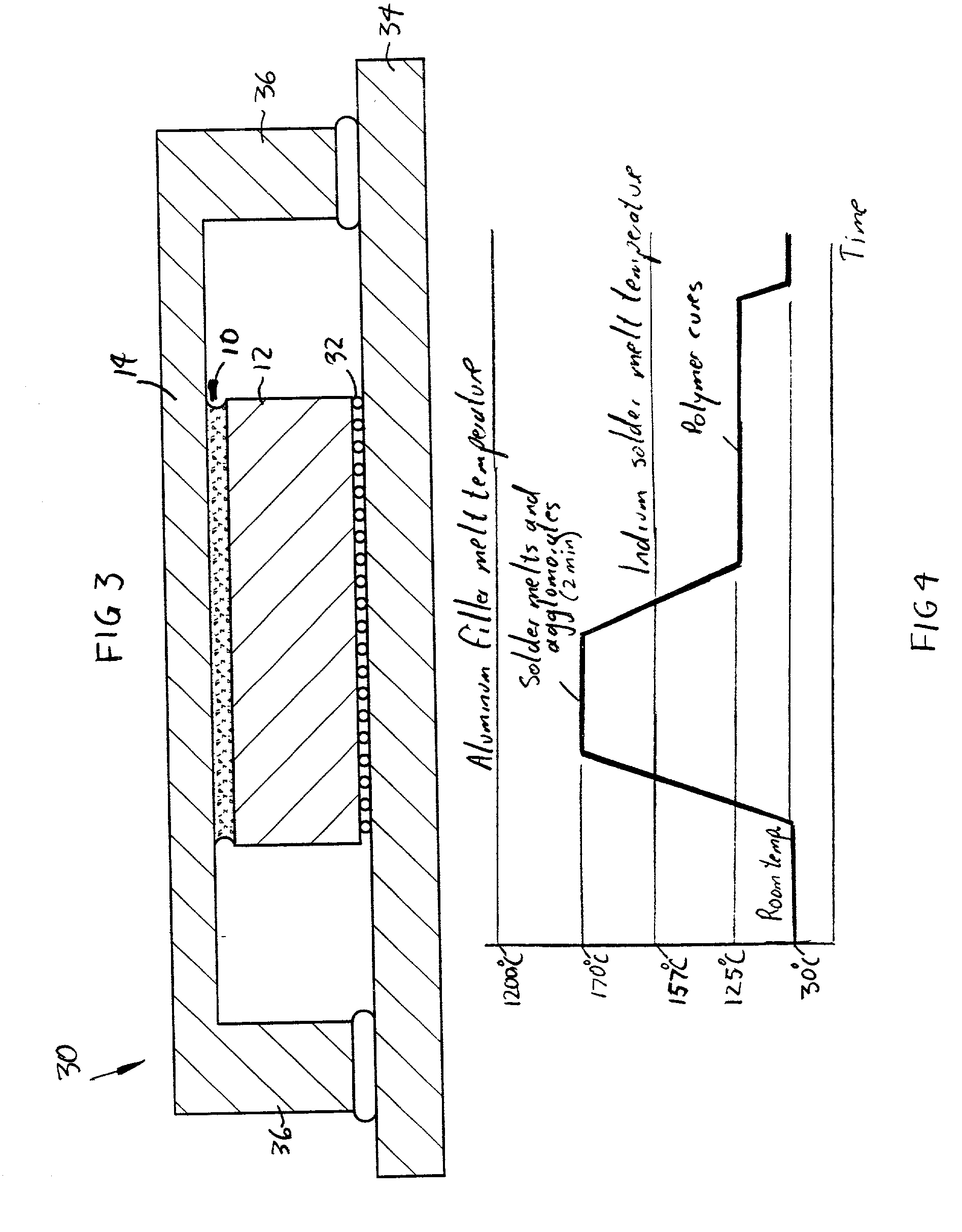

Thermal interface material and electronic assembly having such a thermal interface material

InactiveUS20030077478A1Artificial flowers and garlandsSemiconductor/solid-state device detailsStress conditionsIndium

A thermal interface material is described for thermal coupling of an electronic component to a thermally conductive member. The thermal interface material includes a viscoelastic polymer matrix material, fusible solder particles in the matrix material, and filler particles in the matrix material. The solder particles have a melting temperature below a selected temperature (e.g. 157° C. for indium) and the filler particles have a melting temperature substantially above the selected temperature (e.g. 961° C. for silver). The filler particles keep the thermal interface material intact under adverse thermal and stress conditions.

Owner:INTEL CORP

Highly breathable biodegradable films

ActiveUS20100068484A1Lamination ancillary operationsSynthetic resin layered productsWater vaporGram-force

A breathable film having a base layer comprising first filler particles and second filler particles dispersed within a biodegradable polymer matrix is provided. The first filler particles constitute from about 25 wt. % to about 75 wt. % of the base layer and the second filler particles constitute from about 0.1 wt. % to about 10 wt. % of the base layer. The ratio of the average size of the first filler particles to the average size of the second filler particles being from about 2 to about 100. The film exhibits a water vapor transmission rate of about 2,000 g / m2 / 24 hours or more and a peak load in the machine direction of about 800 grams-force per inch or more.

Owner:KIMBERLY-CLARK WORLDWIDE INC

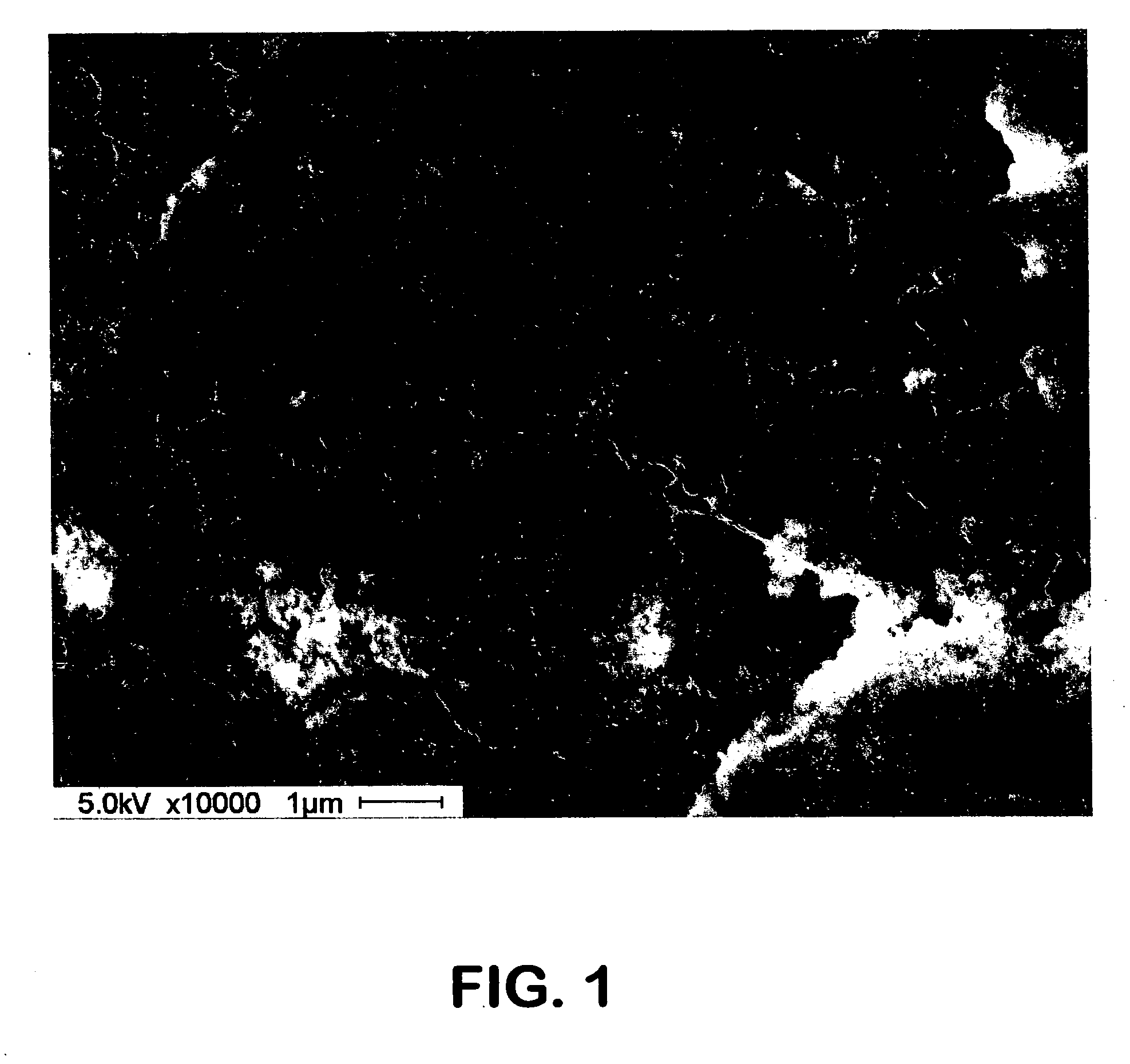

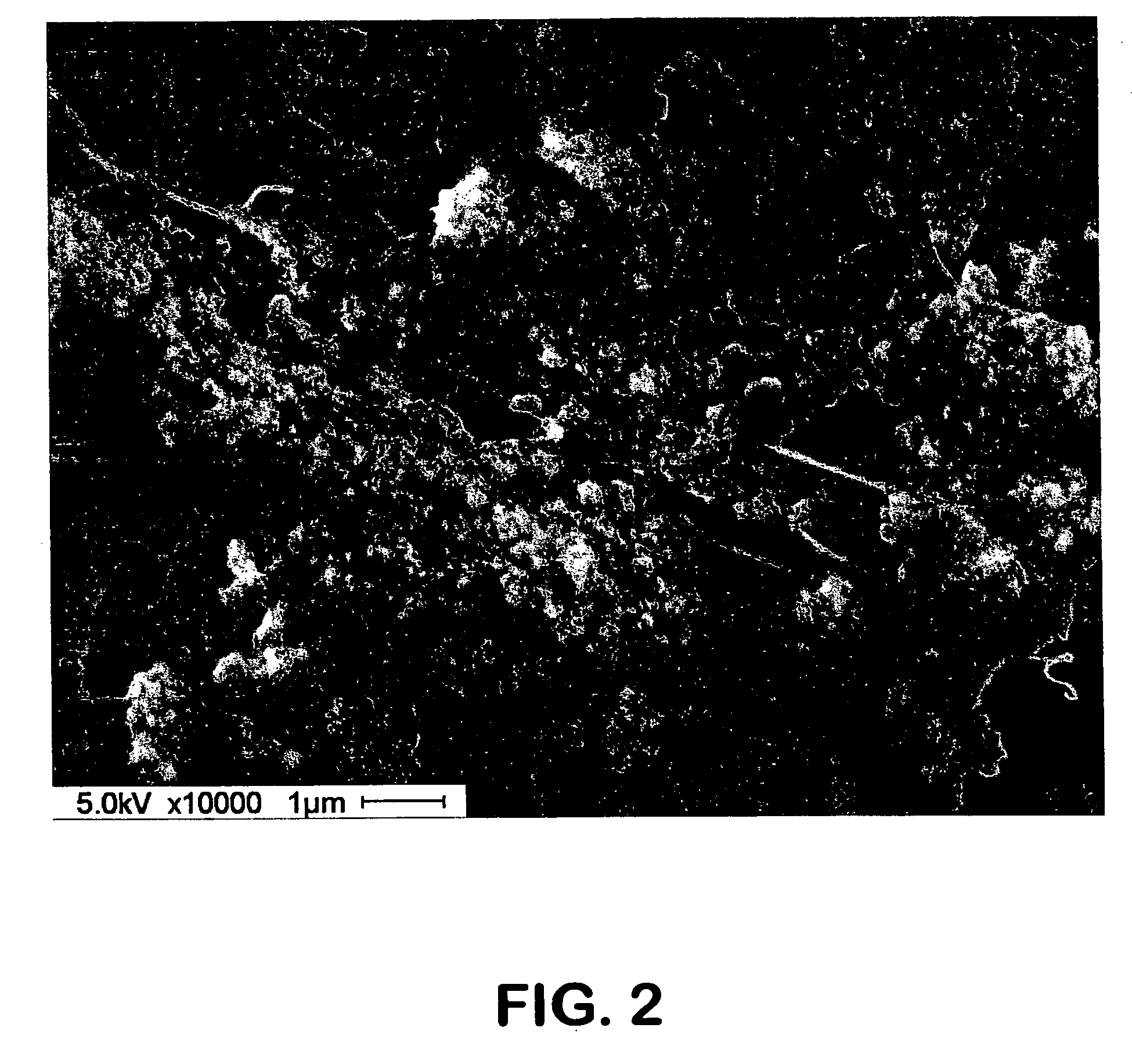

Polymeric composite including nanoparticle filler

InactiveUS20070106006A1Increase potential environmental impactReduce load levelHalloysiteNanoparticle

Disclosed is a novel polymeric composite including a nanoparticle filler and method for the production thereof. More particularly, the present invention provides a novel halloysite nanoparticle filler which has the generally cylindrical or tubular (e.g. rolled scroll-like shape), in which the mean outer diameter of the filler particle is typically less than about 500 nm. The filler is effectively employed in a polymer composite in which the advantages of the tubular nanoparticle filler are provided (e.g., reinforcement, flame retardant, chemical agent elution, etc.) with improved or equivalent mechanical performance of the composite (e.g., strength and ductility).

Owner:NATURALNANO CORP

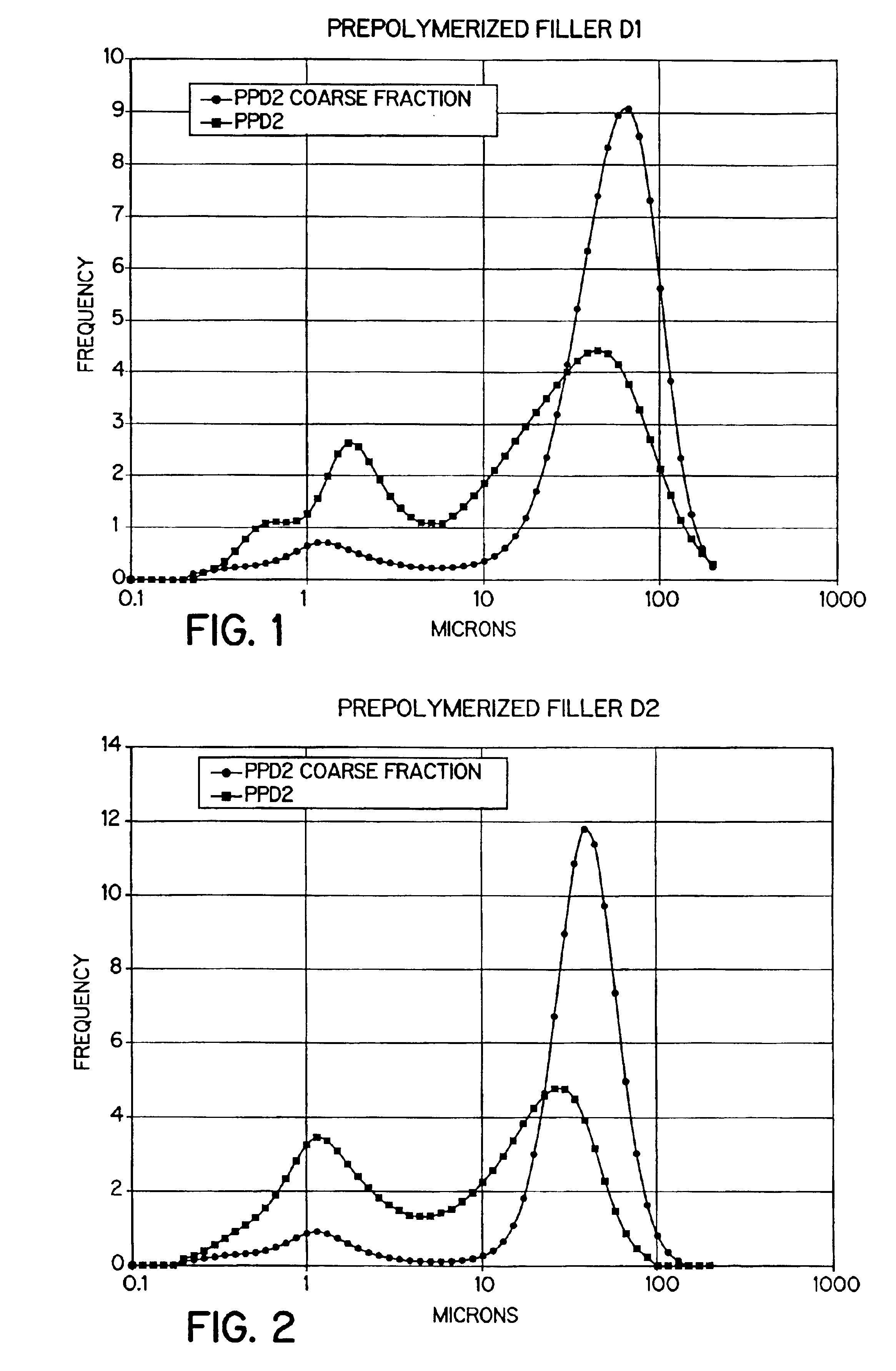

Prepolymerized filler in dental restorative composite

InactiveUS6890968B2High filler loadingReduce Shrinkage ProblemsImpression capsSurgical adhesivesDental compositeUltimate tensile strength

A dental composite having high filler loading and low shrinkage thereby providing good strength and marginal integrity. Through the use of prepolymerized filler particles in combination with a structural filler and a nanofiller, the composite exhibits very low shrinkage and is useful in stress bearing restorations and in cosmetic restorations. The structural filler used is ground to a mean particle size of less than 0.5 μm and the nanofiller has discrete particles of a mean particle size less than 100 nm to improve handling and mechanical characteristics. The prepolymerized filler particles also allow for less viscosity and better handling characteristics of the composite.

Owner:THE KERR

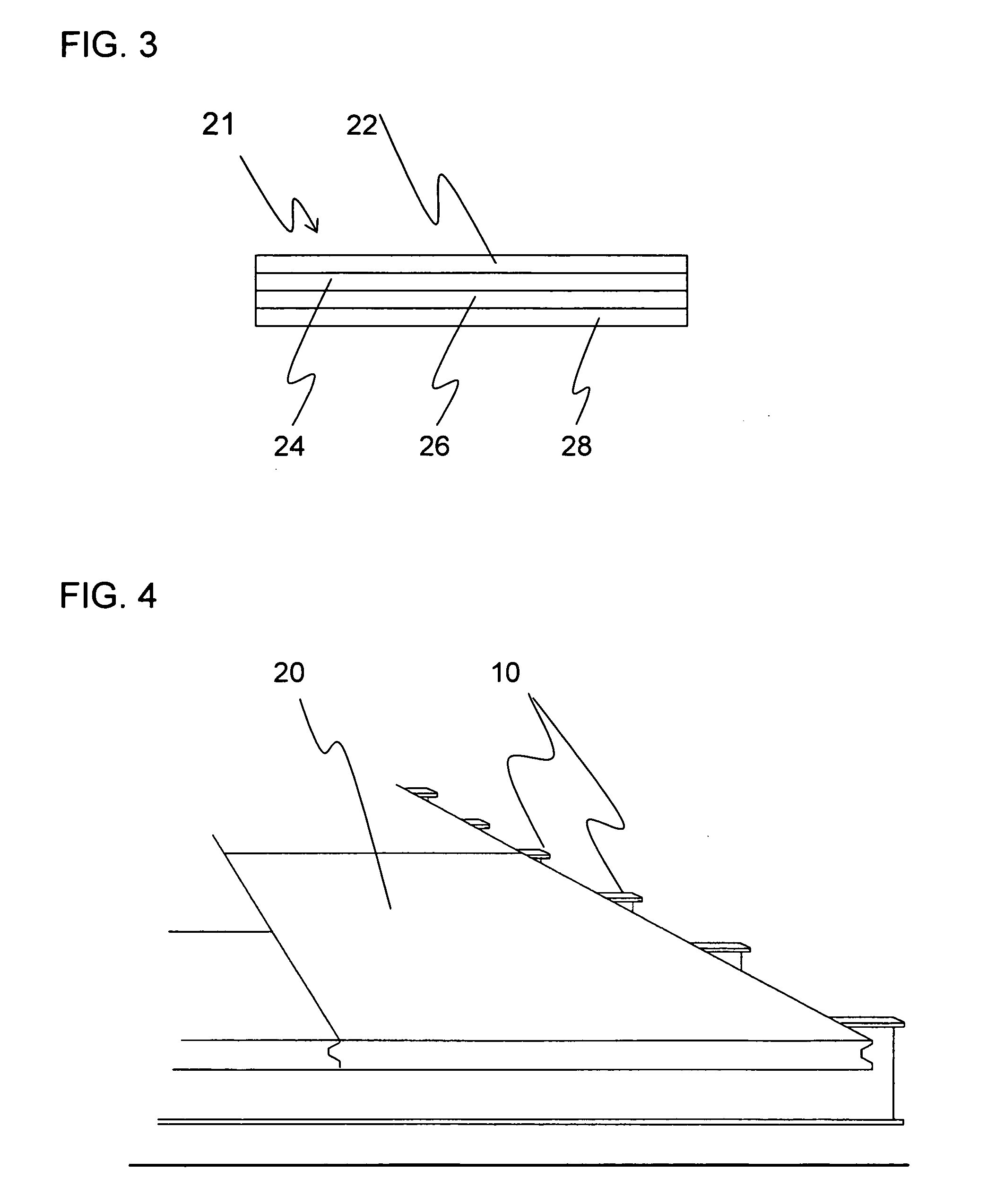

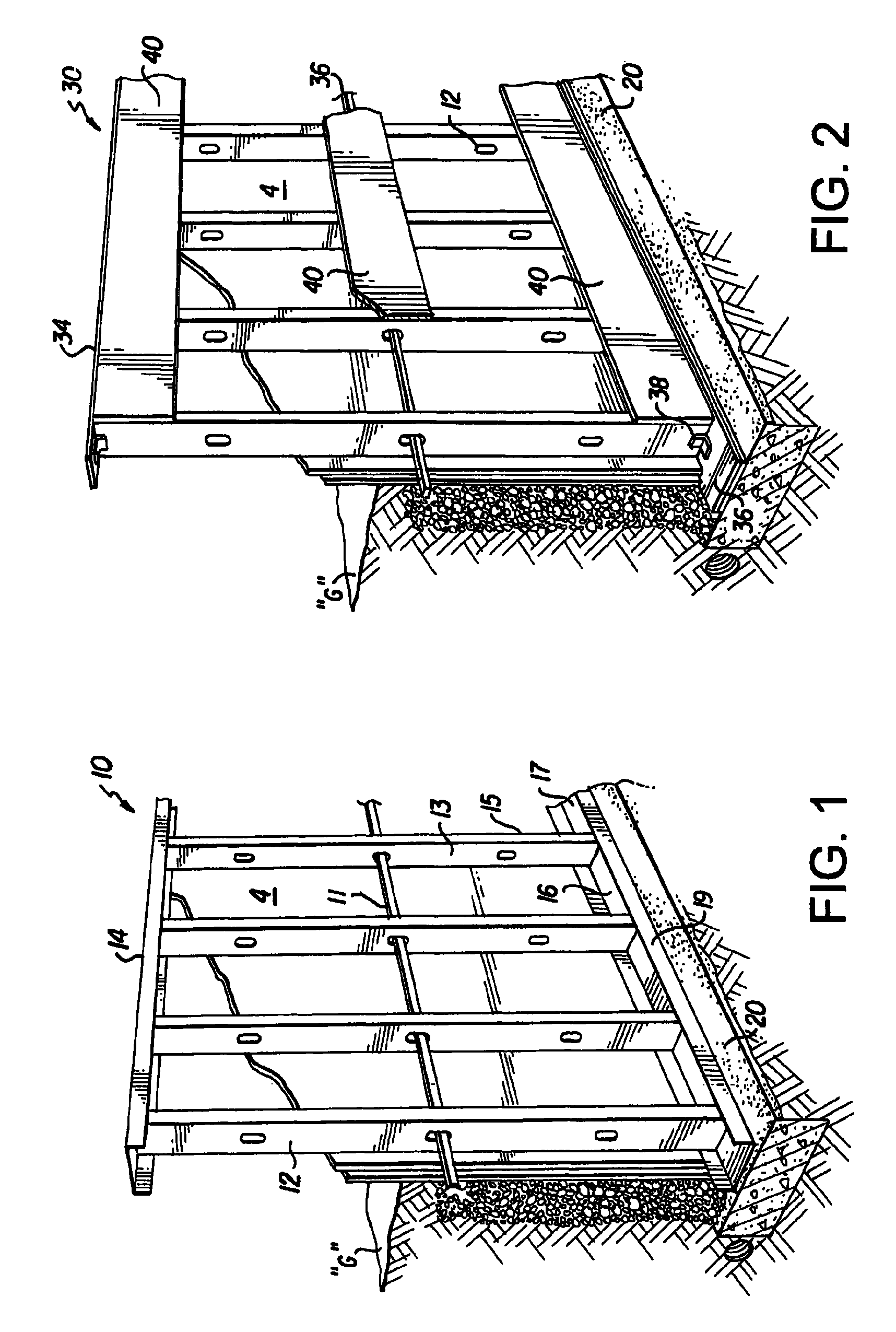

Non-combustible reinforced cementitious lightweight panels and metal frame system for flooring

ActiveUS20060144005A1Easy constructionIncreasing builder productivitySolid waste managementFloorsMicrosphereEngineering

A flooring system including horizontal metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The flooring system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Cellulose-reinforced high mineral content products and methods of making the same

ActiveUS20120080156A1Great filler fixationStrengthen and consolidateSpecial paperPaper after-treatmentCelluloseFiber

A method to prepare aqueous furnishes useful as feedstock in the manufacture of very high-mineral content products, particularly paper sheets having mineral filler content up to 90% that display the required physical properties for the intended applications; the furnishes comprise fibrillated long fibres / mineral fillers mixed with anionic acrylic binders and co-additives, in presence or absence of cellulose fibrils; the fibrillated long fibres and cellulose fibrils provide high surface area for greater filler fixation and the reinforcement backbone network that ties all of the product components together; the anionic binders allow rapid and strong fixation of filler particles onto the surfaces of fibrils when mixing is conducted at temperatures higher than the glass transition temperature (Tg) of the binder. The aqueous furnish provides excellent filler retention and drainage during product fabrication.

Owner:FPINNOVATIONS INC

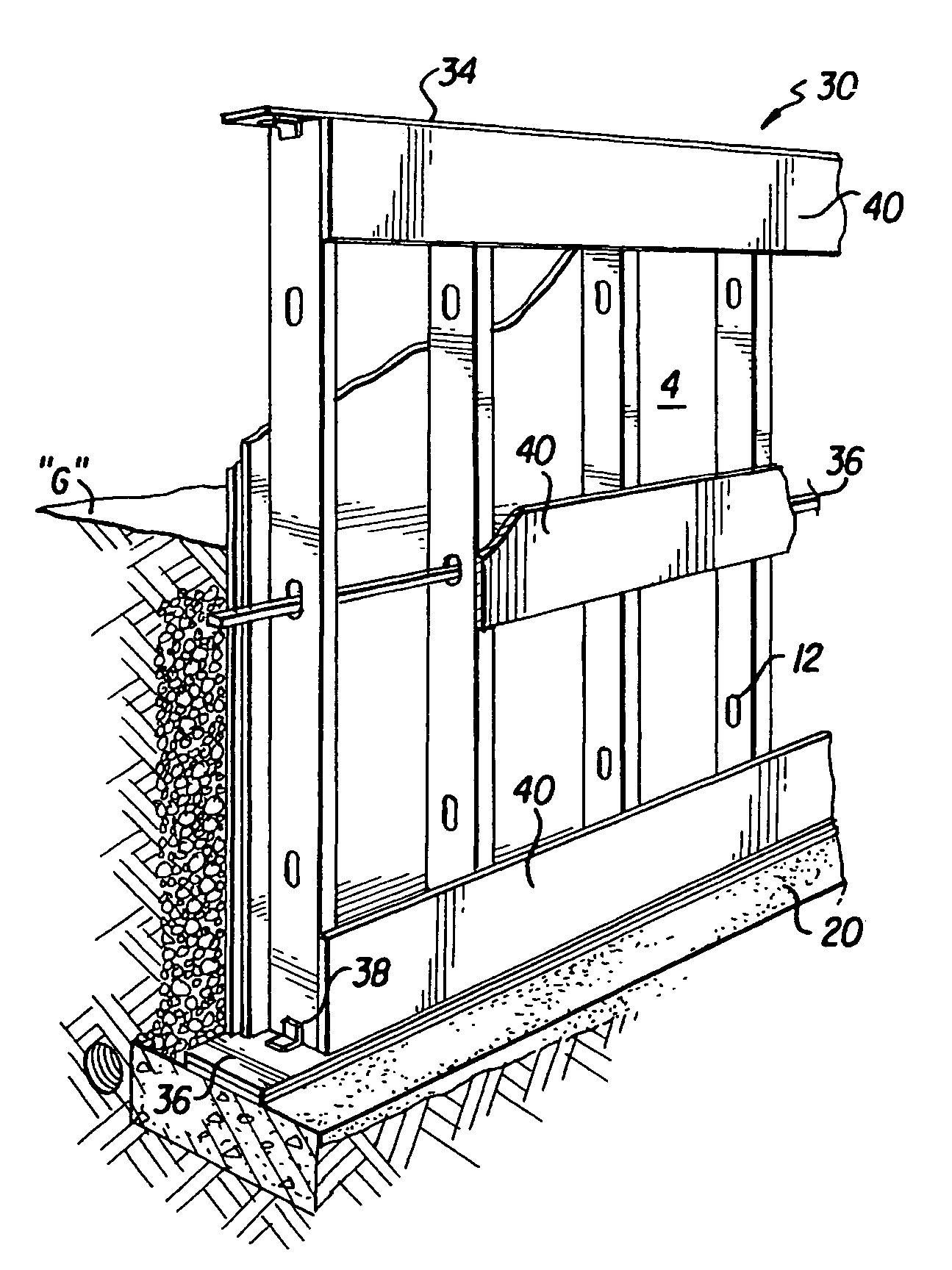

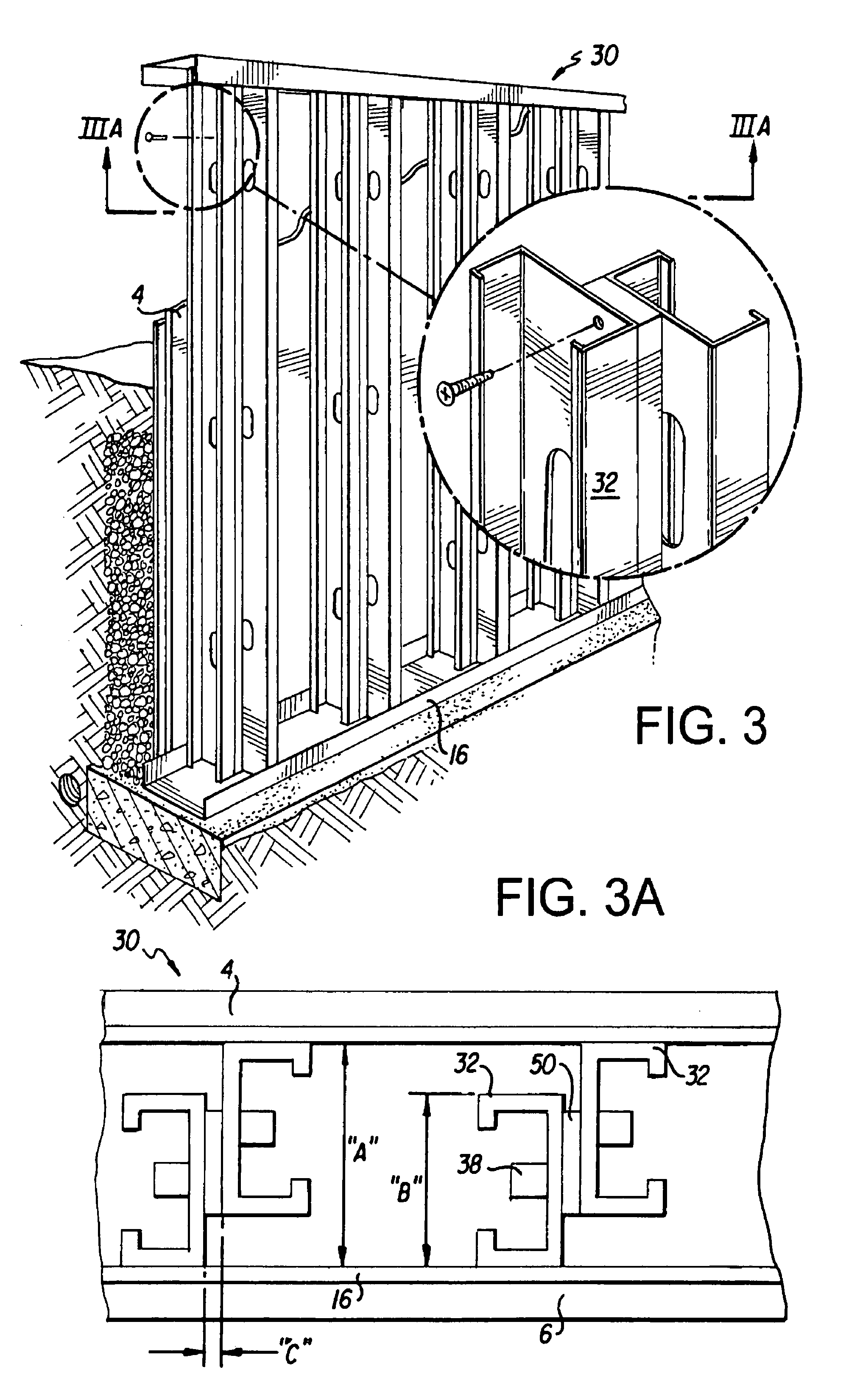

Non-combustible reinforced cementitious lightweight panels and metal frame system for shear walls

ActiveUS20060174572A1Heavy loadMaximization of building volumeSolid waste managementWallsMicrosphereVertical shear

A vertical shear wall system including vertical metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The shear wall system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

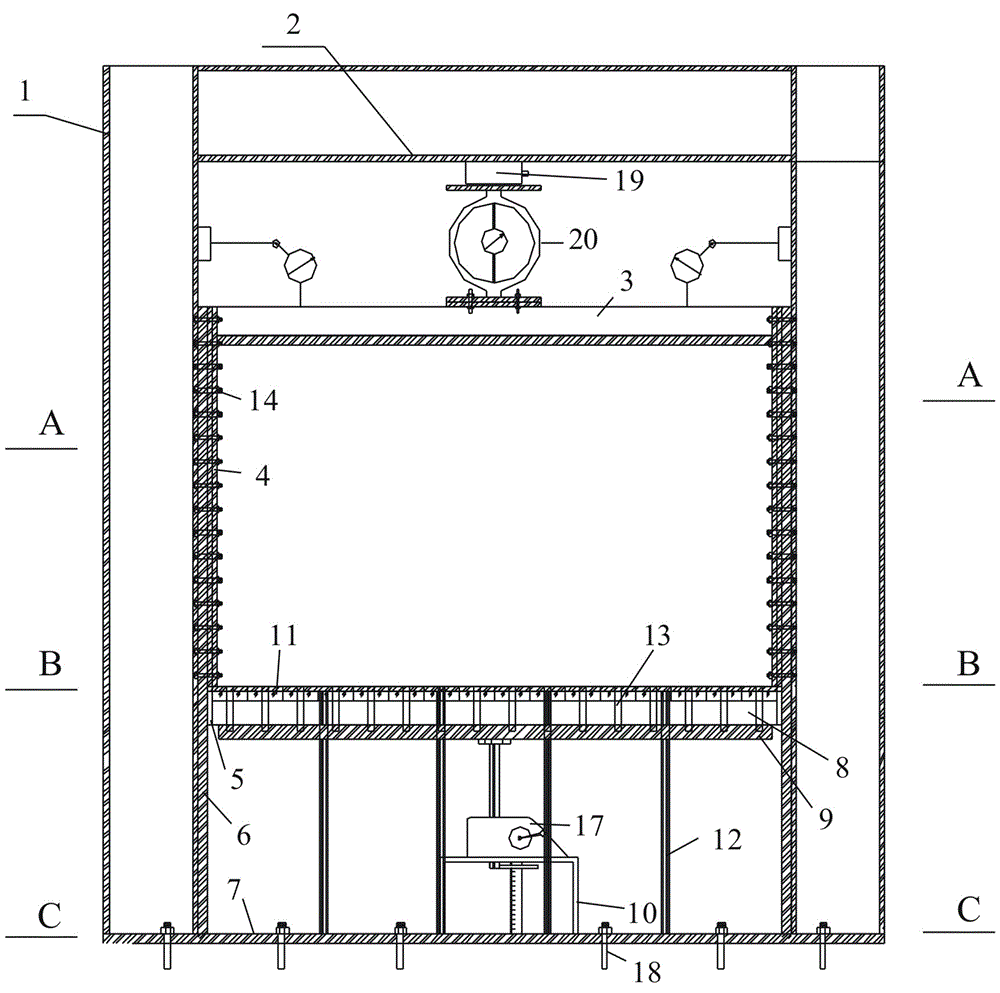

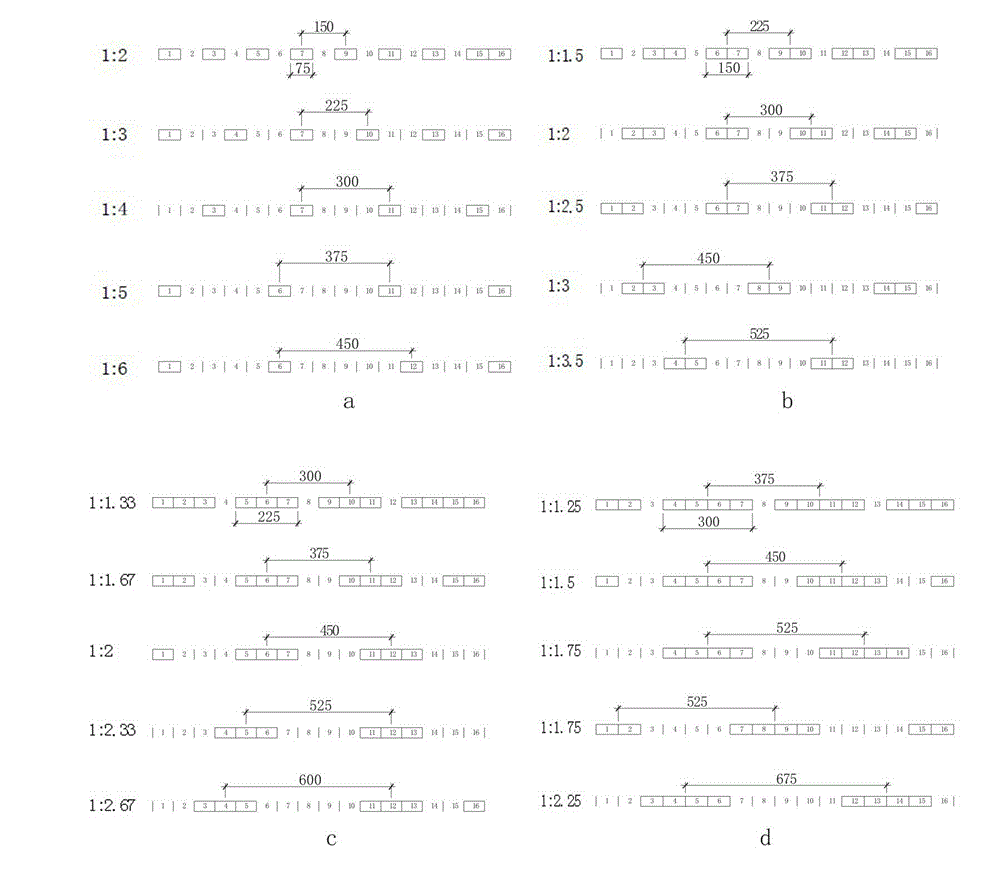

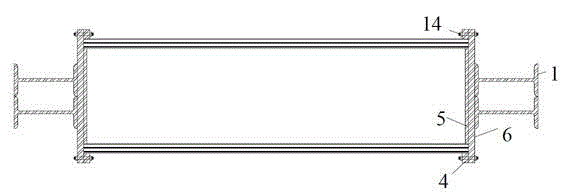

Multifunctional geotechnical model test chamber

InactiveCN102914632AExtensive simulationRealize the move down control functionEarth material testingTest chamberModel test

The invention discloses a multifunctional geotechnical model test chamber device adopting photogrammetric technology. The multifunctional geotechnical model test chamber device comprises a model test chamber body, a loading and testing part, a movable pile baffle, a downward-moving control part, a displacement testing system and the like. The whole-filed displacement is measured by using the photogrammetric technology. The soil arch effect demonstration of 20 different pile spacing ratios, the pile-supported embankment filler particle soil arch effect and a compound foundation cushion layer effect simulation test under the rigid foundation can be realized. Meanwhile, the geotechnical model test chamber device can also carry out simulation such as stress and deformation simulation of buried pipes, slope deformation, excavation of foundation pits, stress and deformation of an enclosing structure and the like by using the test chamber.

Owner:WUHAN UNIV OF TECH

Methods and compositions for enhancing proppant pack conductivity and strength

InactiveUS20080006405A1Enhancing proppant pack conductivityHigh strengthFluid removalFlushingParticulatesUltimate tensile strength

Methods comprising providing a curable resin composition that comprises a curable resin and at least a plurality of filler particles; and coating at least a plurality of particulates with the curable resin composition on-the-fly to form curable resin coated particulates. The curable resin coated particulates may be suspended in a treatment fluid and placed into at least a portion of a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Low temperature coated particles for use as proppants or in gravel packs, methods for making and using the same

ActiveUS7624802B2Improves unconfined compressive strength propertyImprove performanceLiquid surface applicatorsSynthetic resin layered productsPolyesterParticulates

Disclosed herein are free flowing coated particles and low temperature methods of making same. Each particle has a curable coating disposed upon a substrate. The substrate is a particulate substrate including an inorganic material, a particulate substrate including an organic material, a composite substantially homogeneous formed particle including a first portion of an at least partly cured binder and filler particles, or a hybrid particle having an inorganic particle as a core and a composite coating including at least partially cured resin and filler. The curable coating includes a continuous phase including resole resin and reactive powder particles embedded or adhered to the continuous phase. The reactive powder particles typically include resole resin, novolak resin, polyester, acrylic and / or urethane. A method including applying a coating including the continuous phase including resole resin and reactive or non-reactive powder particles embedded or adhered to the continuous phase.

Owner:HEXION INC

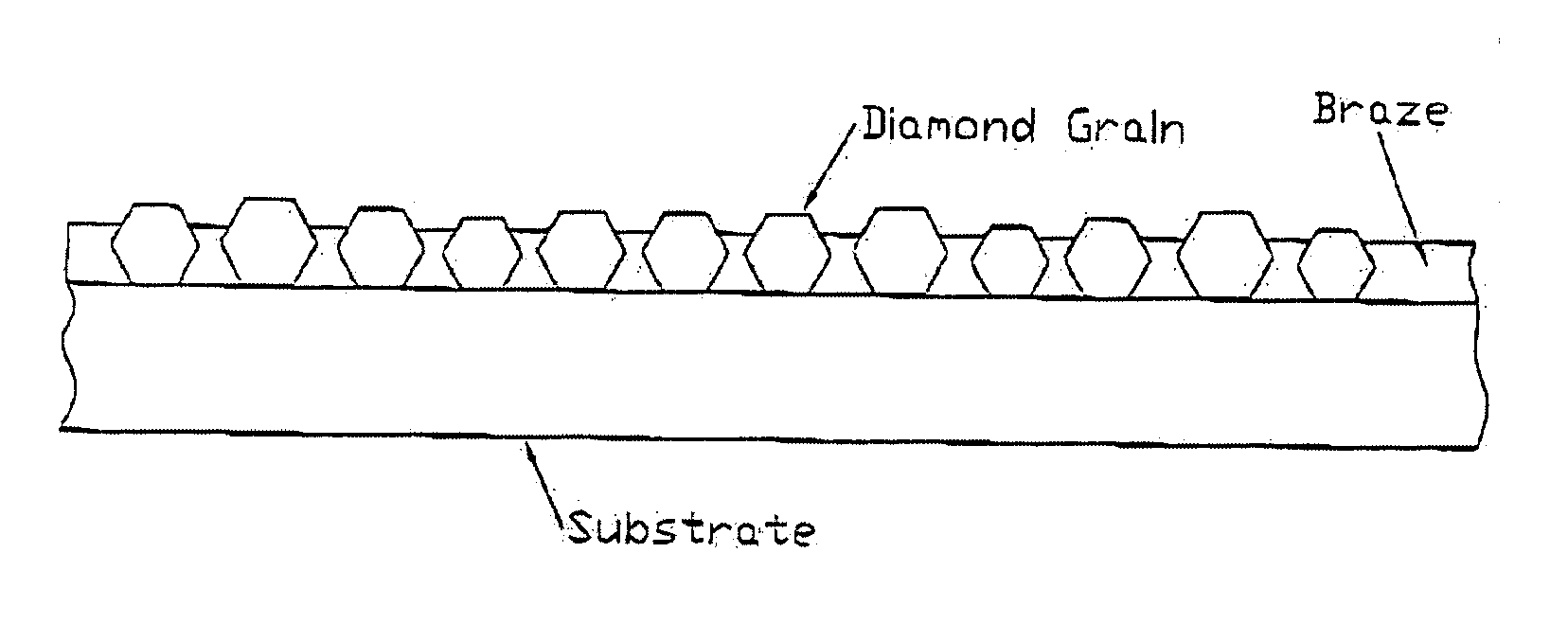

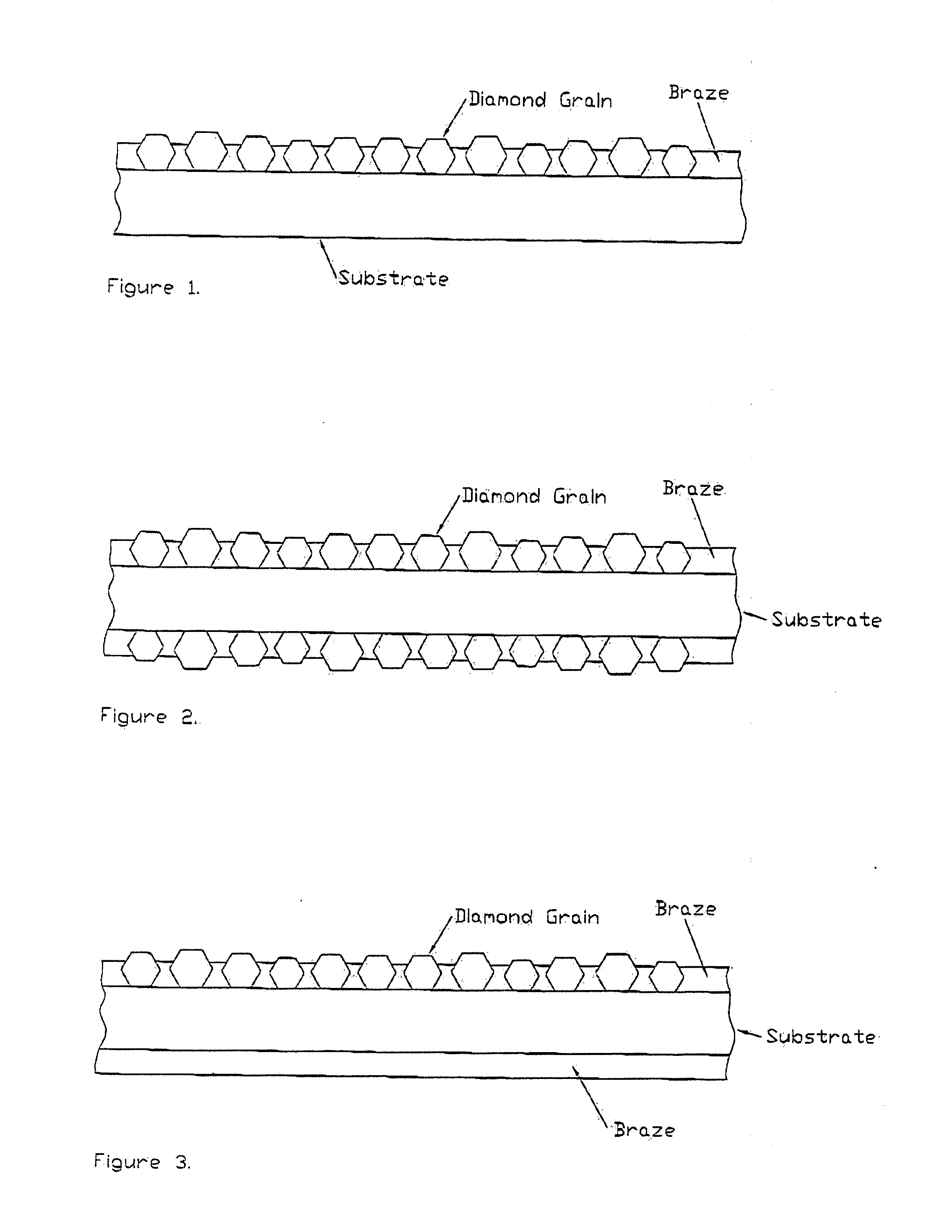

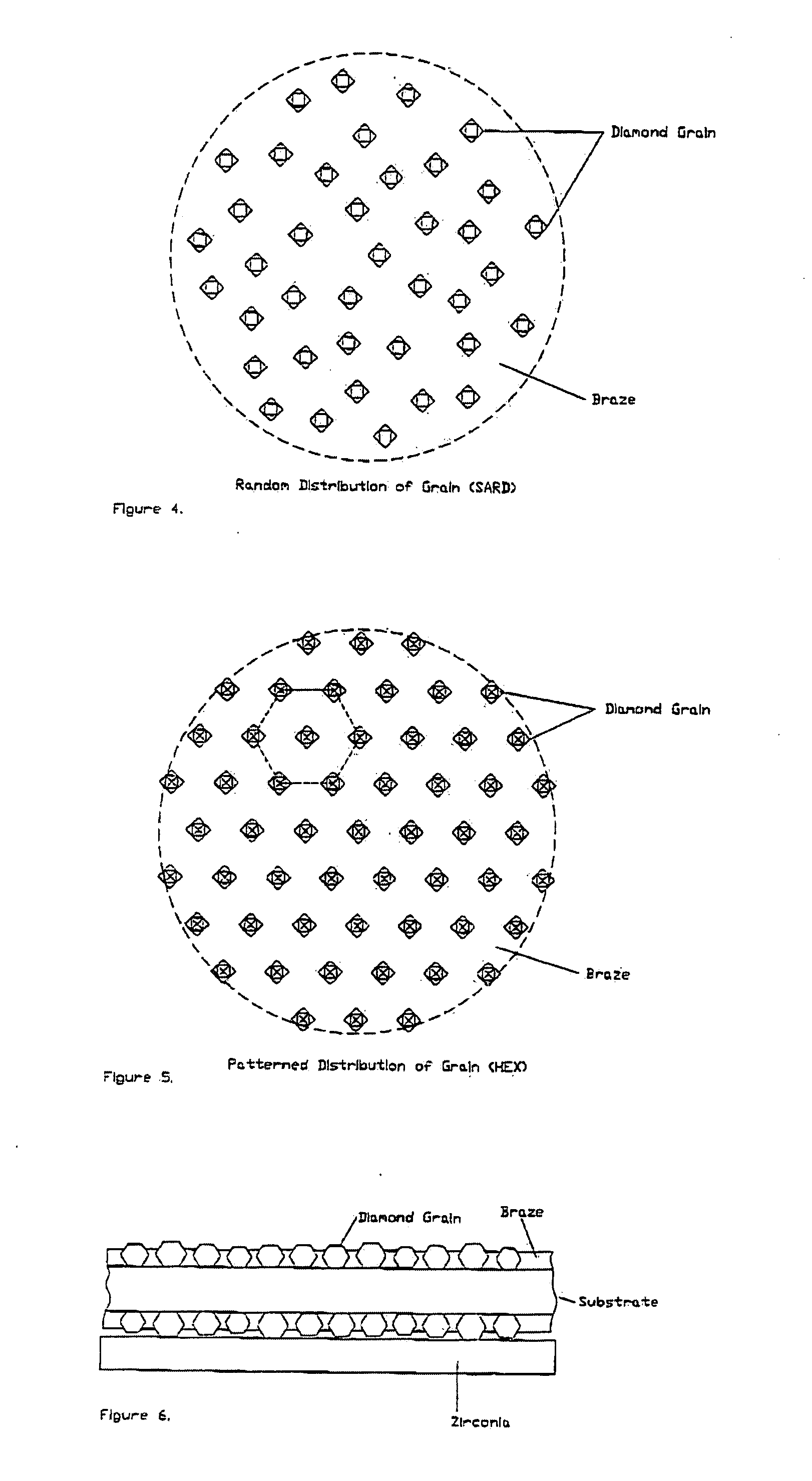

Conditioning tools and techniques for chemical mechanical planarization

InactiveUS20080271384A1Reduce the overall heightPigmenting treatmentOther chemical processesCopperMetal

Tools for conditioning chemical mechanical planarization (CMP) pads comprise a substrate with abrasive particles coupled to at least one surface. The tools can have various particle and bond configurations. For instance, abrasive particles may be bonded (e.g., brazed or other metal bond technique) to one side, or to front and back sides. Alternatively, abrasive particles are bonded to a front side, and filler particles coupled to a back side. The abrasive particles can form a pattern (e.g., hexagonal) and have particle sizes that are sufficiently small to penetrate pores of a CMP pad during conditioning, leading to fewer defects on wafers polished with the conditioned CMP pad. Grain bonding can be accomplished using brazing films, although other metal bonds may be used as well. Also, balanced bond material (e.g., braze on both sides) allows for low out-of-flatness value.

Owner:SAINT GOBAIN ABRASIFS INC +1

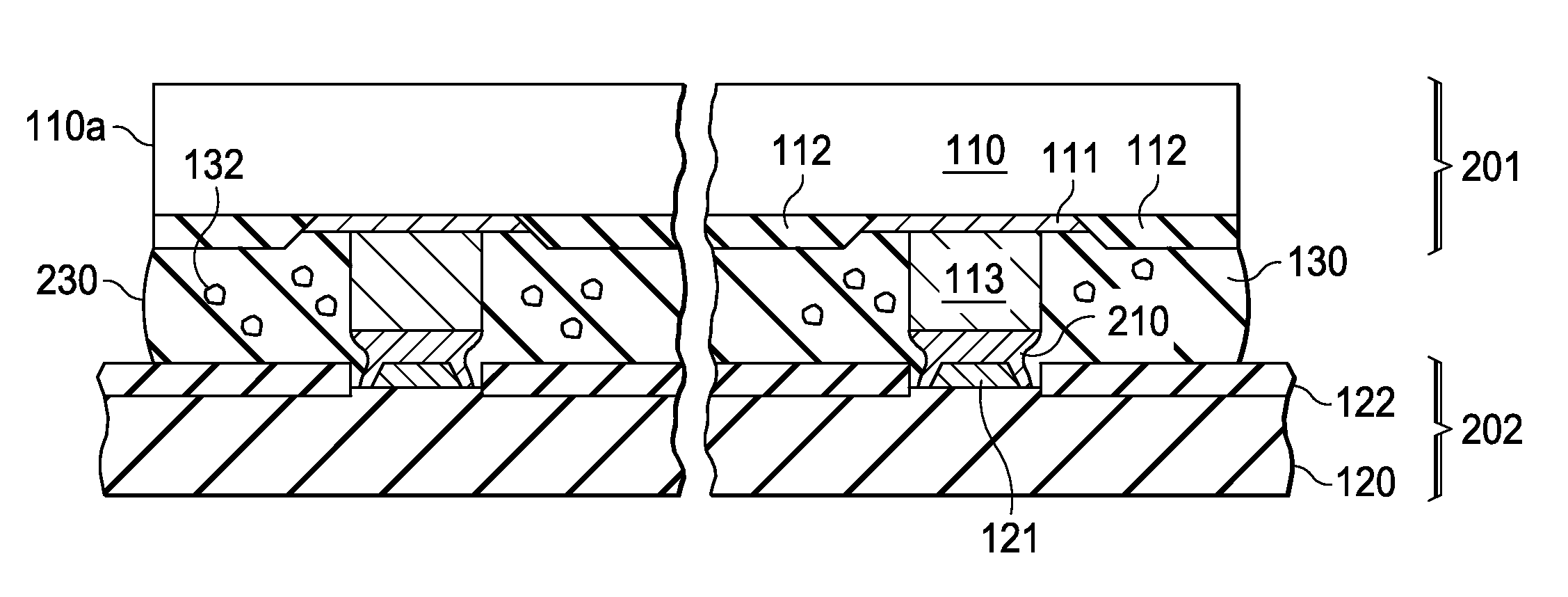

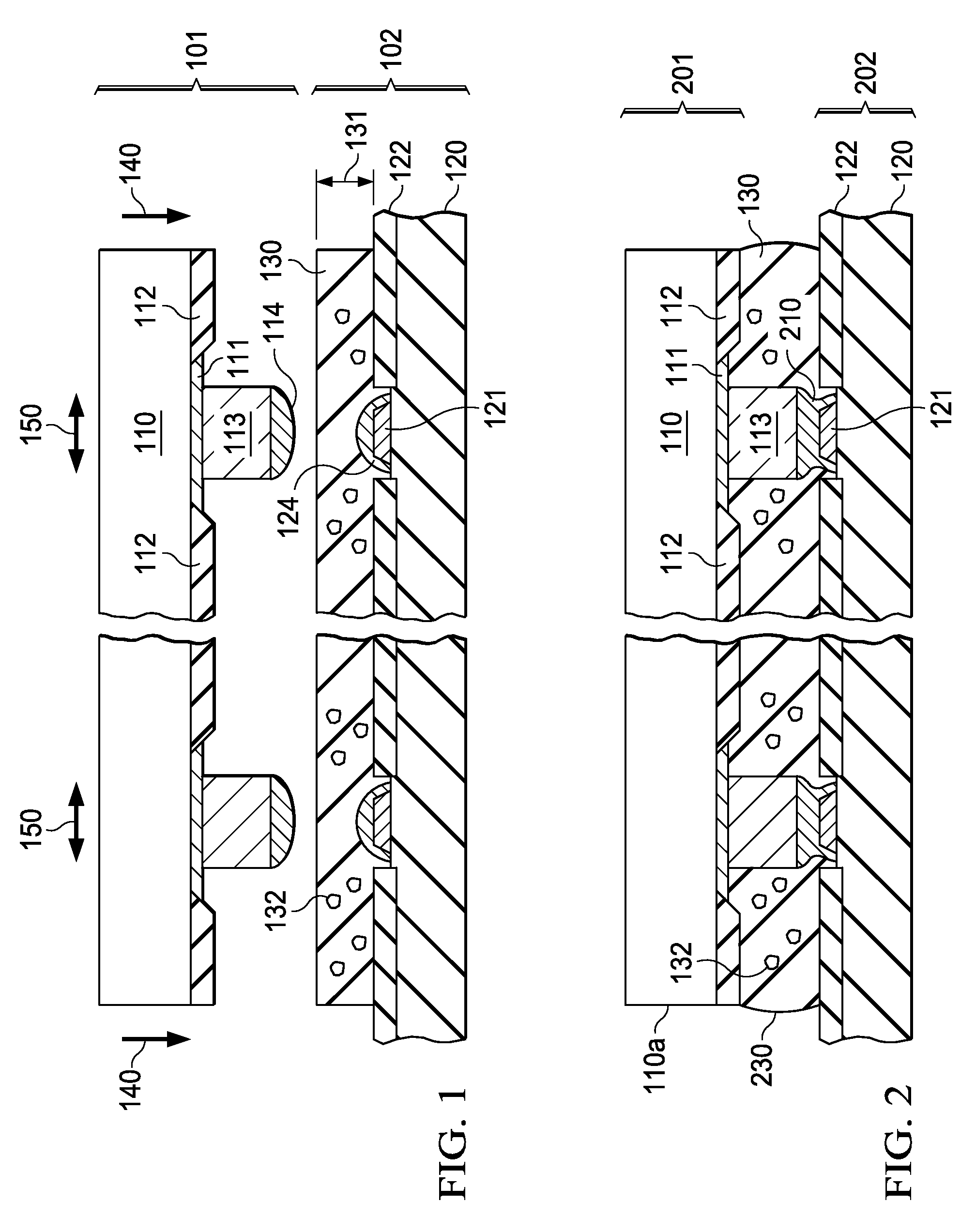

Method for fine-pitch, low stress flip-chip interconnect

ActiveUS7790509B2Easy to separateSolid-state devicesSemiconductor/solid-state device manufacturingFlip chip interconnectSemiconductor chip

Attaching a semiconductor chip to a substrate by applying mechanical vibrations (150) to a polymeric compound (130) and the contacting areas (114, 124) of a first (113) and a second (121) metallic member immersed in the compound, while the two metallic members approach (140) each other until they touch. The mechanical vibration causes displacements of the first member relative to the second member, and the vibration includes displacements (150) oriented at right angles to the direction (140) of the approach. The polymeric compound (130) includes a non-conductive adhesive resin paste (NCP) and filler particles; the paste is deposited before the attaching step. The first member (113) is affixed to the chip and the second member (121) to the substrate.

Owner:TEXAS INSTR INC

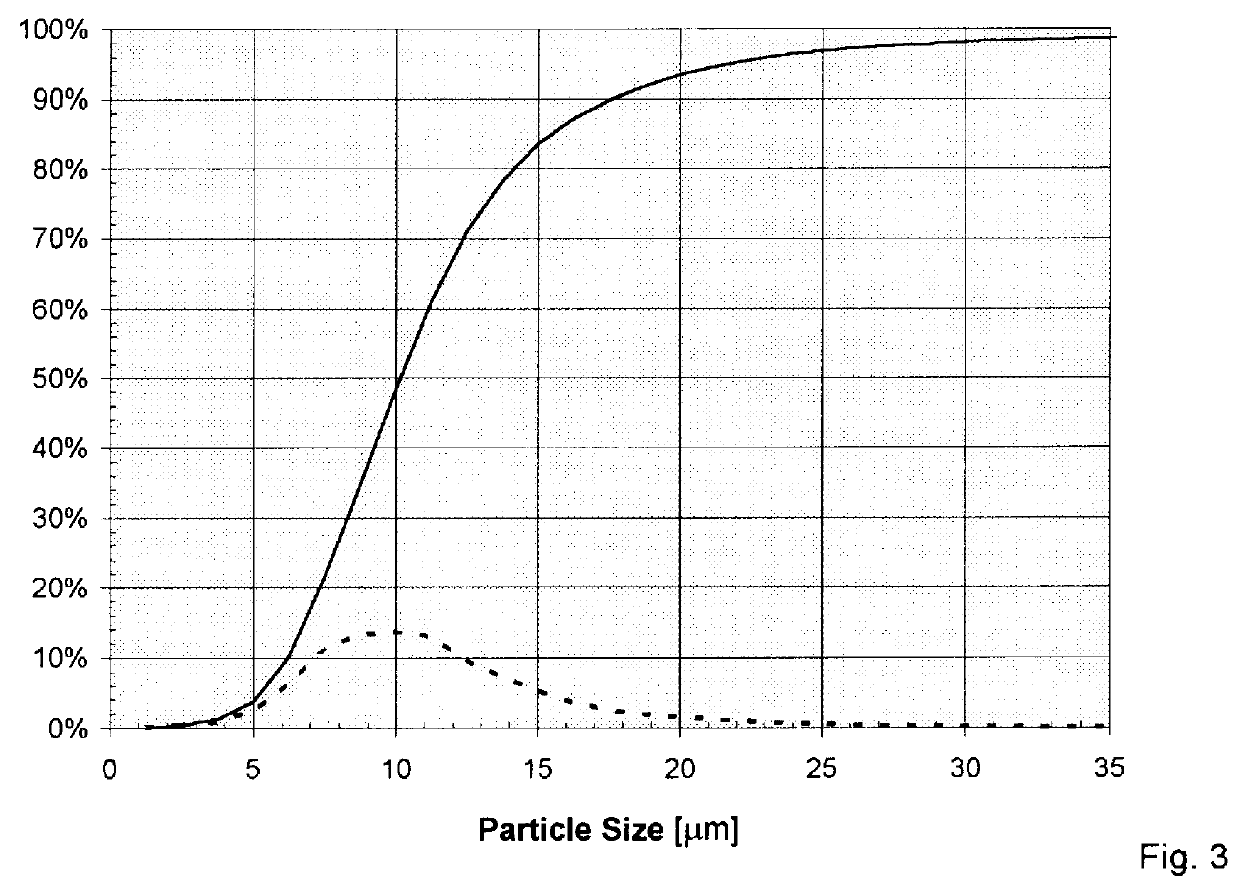

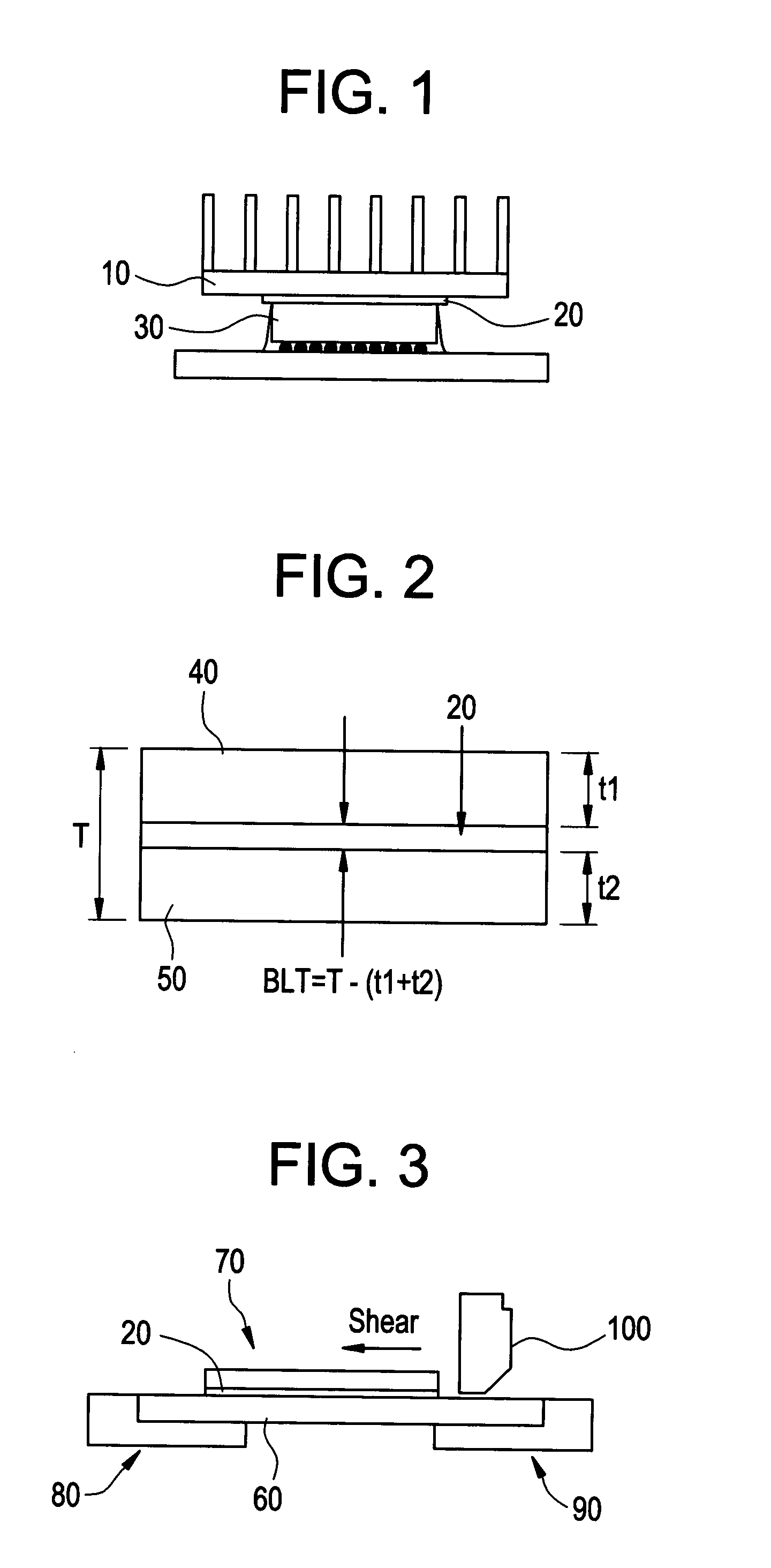

Thin bond-line silicone adhesive composition and method for preparing the same

InactiveUS20050049350A1Low viscosityImprove wettabilitySemiconductor/solid-state device detailsSolid-state devicesPolymer scienceBond line

Thermal interface compositions contain filler particles possessing a maximum particle size less than 25 microns in diameter blended with a polymer matrix. Such compositions enable lower attainable bond line thickness, which decreases in-situ thermal resistances that exist between thermal interface materials and the corresponding mating surfaces.

Owner:GENERAL ELECTRIC CO

Thermally conductive polyimide film composites having high thermal conductivity useful in an electronic device

InactiveUS20060127686A1Excellent dielectric propertiesImprove thermal conductivityPrinted circuit aspectsConductive materialUltimate tensile strengthDielectric layer

In electronic devices, heat removal is an important consideration of any device designer. Thermally conductive, high-temperature polyimide composites are disclosed herein which are generally useful as a dielectric layer in an electronic device, or a precursor metal-laminate, where the dielectric is layered on one side (or on both sides) with a metal. The polyimide composites of the present invention contain dispersed therein thermally conductive filler particles at a weight percent between 40 and 85 % weight percent. These film composites have good dielectric strength, good thermal conductivity, and optionally good adhesivity.

Owner:EI DU PONT DE NEMOURS & CO

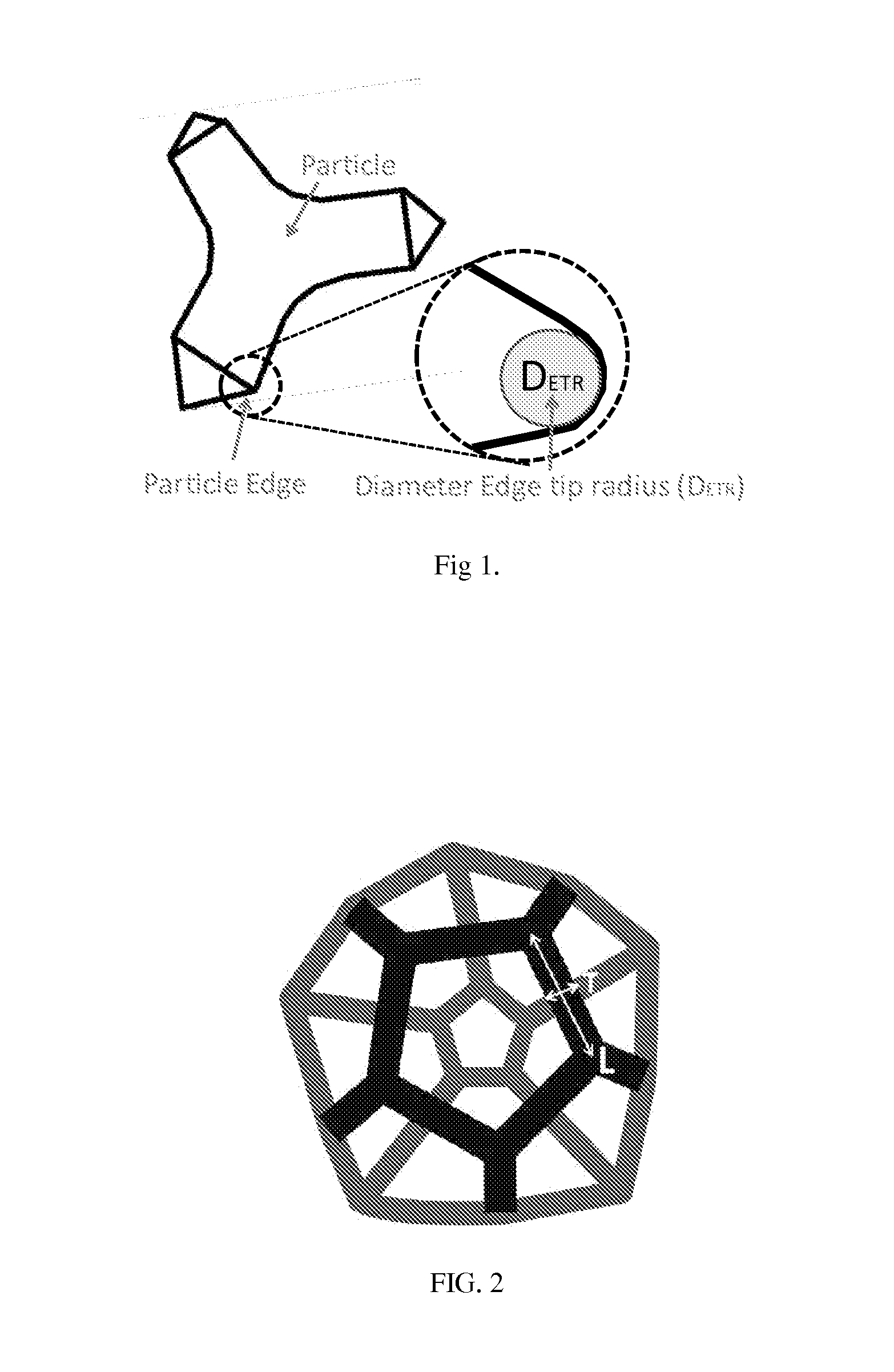

Liquid cleaning and/or cleansing composition

InactiveUS20140357544A1Lower levelProvide benefitsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPolymer chemistryFiller particle

A liquid cleaning and / or cleansing composition comprising non-spherical and / or non-rolling abrasive cleaning particles derived from a foam structure comprising a plurality of struts, wherein the abrasive cleaning particles comprise a plurality of filler particles at least partly incorporated therein, wherein the particle size of the abrasive cleaning particles is greater than the particle size of the filler particles and wherein the ratio of the mean area-equivalent diameter of the filler particles to the abrasive cleaning particles is from 0.01 to 0.2, the area-equivalent diameter being measured according to ISO 9276-6.

Owner:THE PROCTER & GAMBLE COMPANY

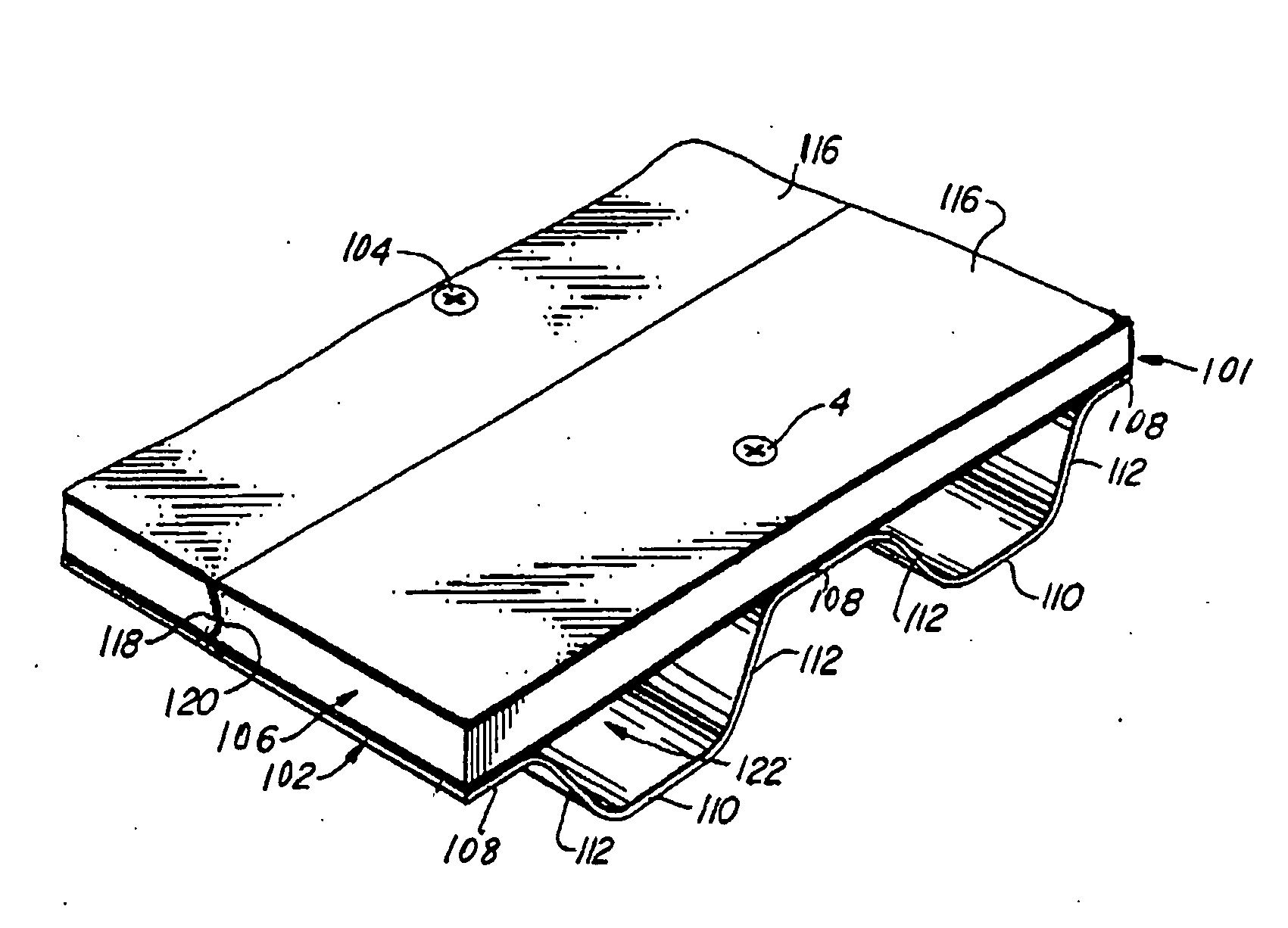

Non-combustible reinforced cementitious lightweight panels and metal frame system for roofing

A roofing system including horizontal or sloped metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The roofing system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

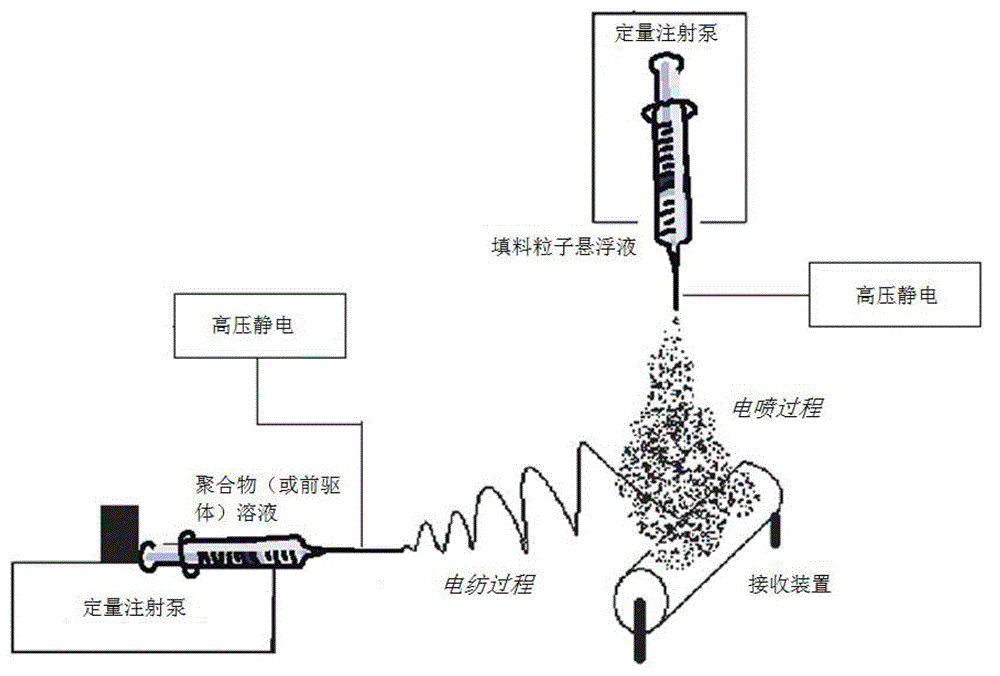

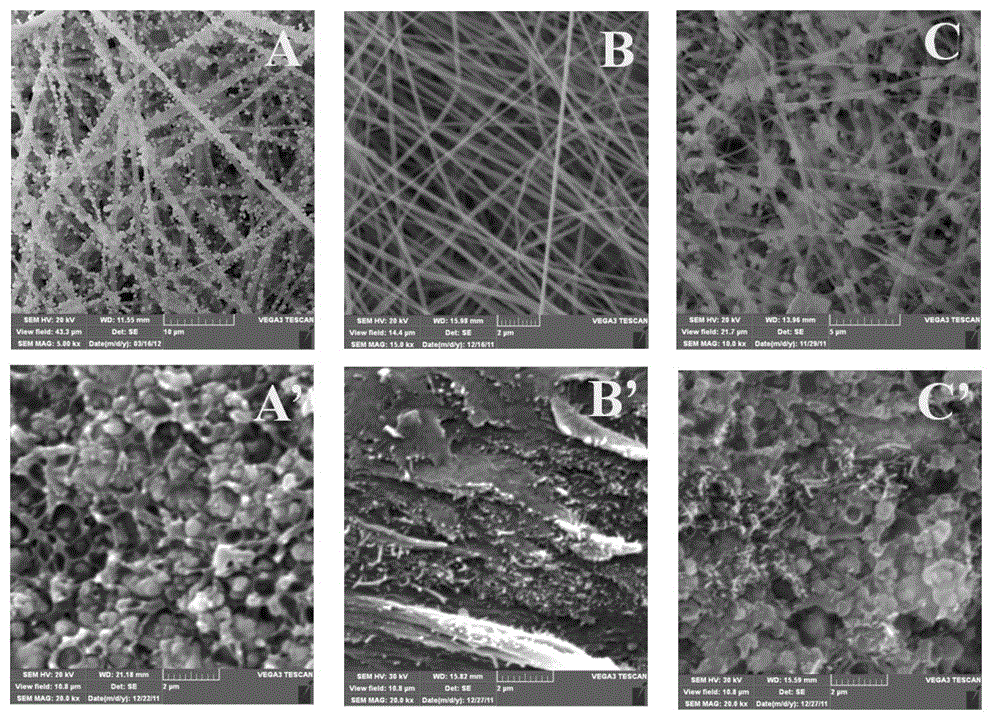

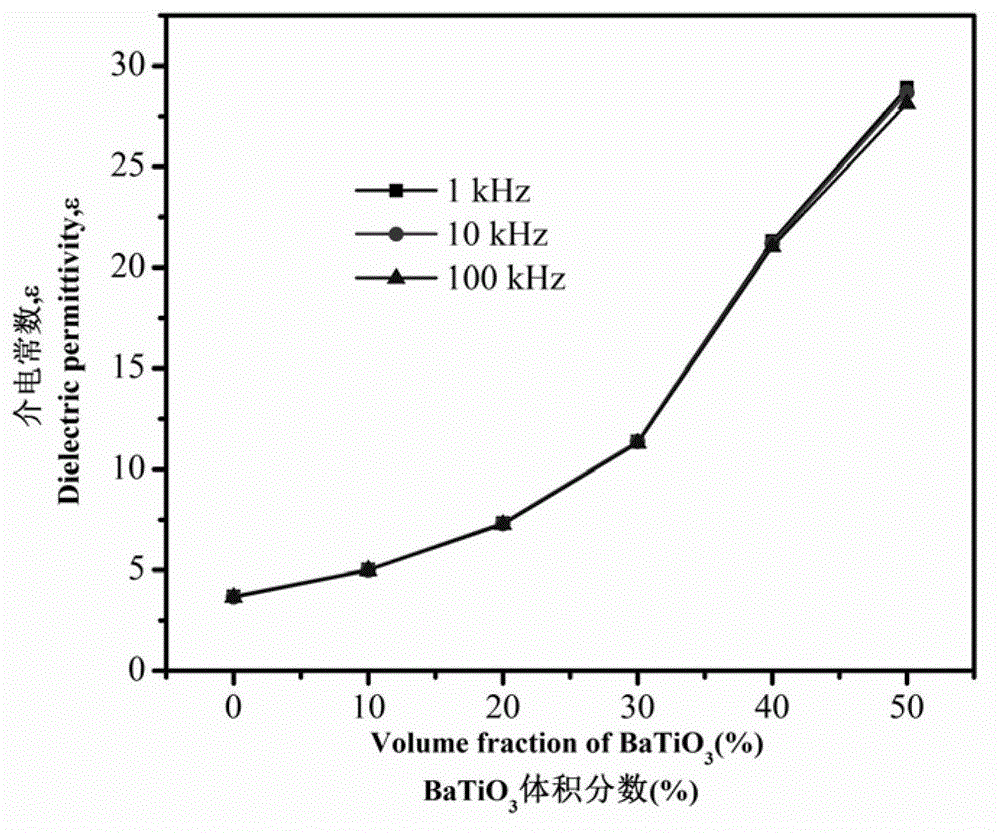

Method for preparing high dielectric constant polymer-based nano composite material

InactiveCN103147226AHigh dielectric constantControllable dielectric constantNon-woven fabricsFiberMatrix solution

The invention provides a method for preparing high dielectric constant polymer-based nano composite material. The method comprises the following steps: performing electrostatic spinning on a polymer matrix solution and simultaneously performing electrostatic spraying on a filler particle suspension; simultaneously receiving the products of the electrostatic spinning and the electrostatic spraying through a common receiving device to obtain a composite fiber membrane; and finally obtaining the high dielectric constant polymer-based nano composite material with filler particles uniformly dispersed after the composite fiber membrane is processed through a hot-pressing processing technique. The composite material prepared by the invention has the characteristics of high dielectric constant, low dielectric loss and the like; and at the same time the dielectric constant of the composite material can be adjusted through adjusting the content of the filler particles in the polymer matrix. The invention has the advantages of simple process, convenient operation and little environment pollution, can well solve the problem that the filler particles is uniformly dispersed in the polymer matrix, and is expected to the microelectronic industry as dielectric material and the like for preparing embedded capacitors.

Owner:JIANGXI NORMAL UNIV

Non-combustible reinforced cementitious lightweight panels and metal frame system for building foundations

ActiveUS7870698B2Stiffen and strengthen and toughen panelSolid waste managementWallsGlass fiberMicrosphere

A foundation system includes metal framing members that support a reinforced, lightweight, dimensionally stable cementitious panel. The foundation system is non-combustible, water durable, mold and rot resistant, and termite resistant. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

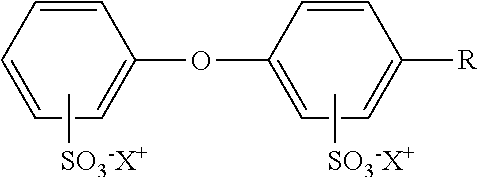

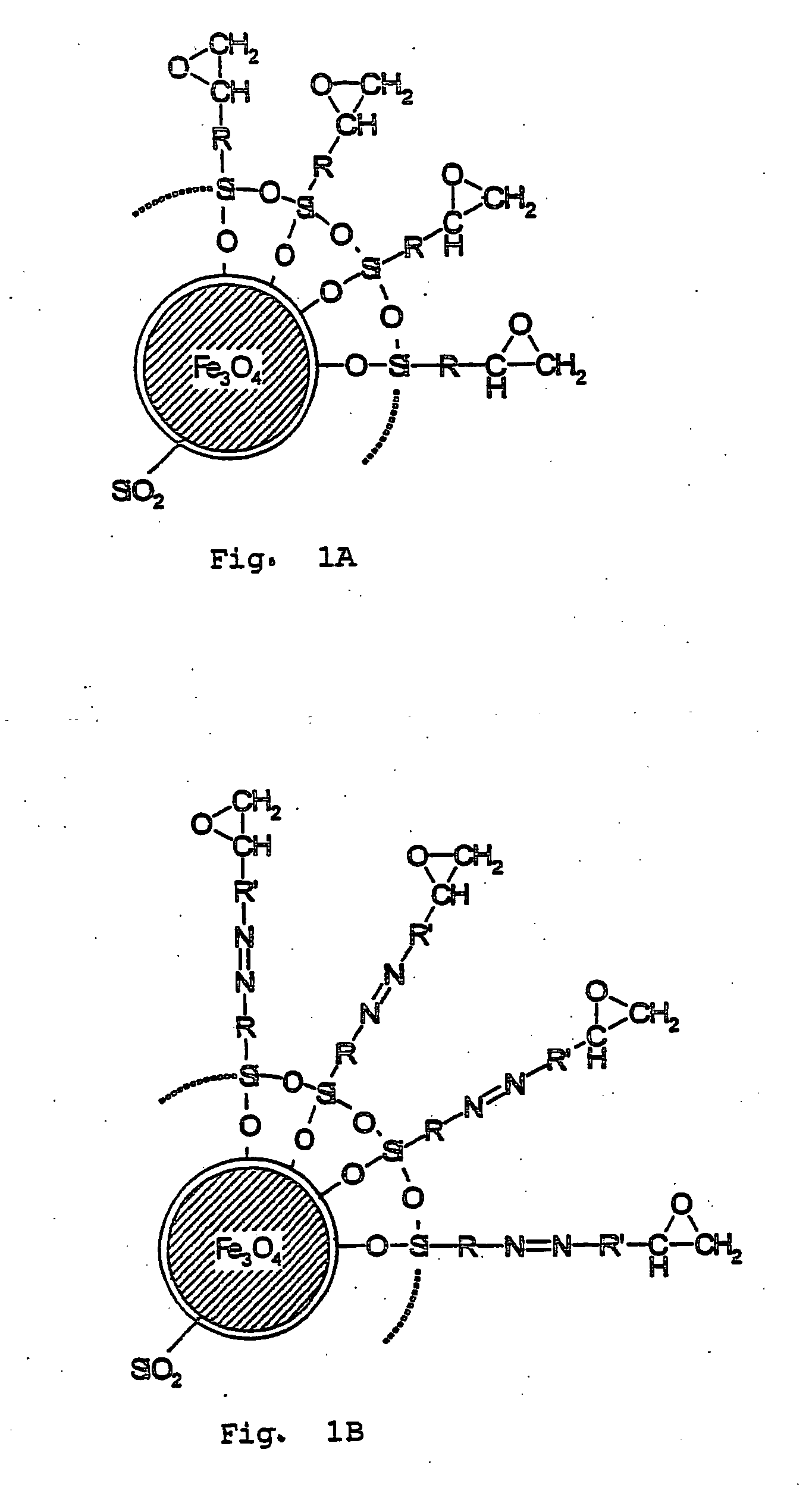

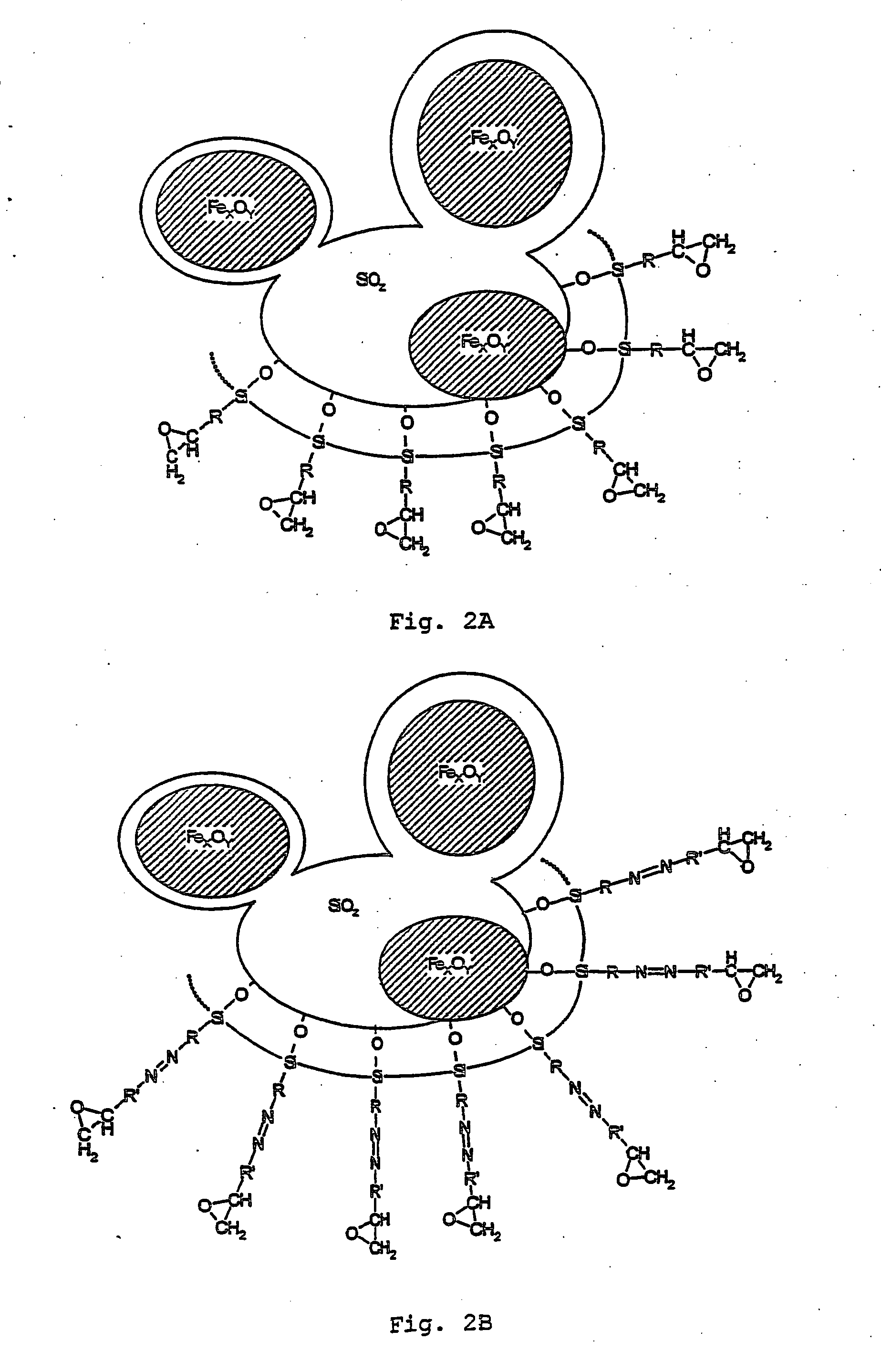

Curable bonded assemblies capable of being dissociated

InactiveUS20040249037A1Without the long-term resistance of the adhesive joint inevitably suffering therebyNon-macromolecular adhesive additivesConductive materialElectrical resistance and conductanceHigh resistance

The invention concerns an adhesive composition for producing thermoset products, capable of being heated by means of an electric field, a magnetic field, an electromagnetic field or an alternating electromagnetic field, and containing filler particles which are metallic, ferromagnetic, ferrimagnetic, superparamagnetic or paramagnetic. Said adhesive composition can be hardened under the action of heat to form a high-resistance stable adhesive assembly, said resulting adhesive assemblies capable of being likewise dissociated under the action of heat.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Thermal interface adhesive and rework

InactiveUS20050256241A1Printed circuit assemblingNon-macromolecular adhesive additivesEpoxyDevice material

A reworkable conductive adhesive composition, and method of making such, comprising an epoxy based conductive adhesive containing conductive metal filler particles dispersed in a solvent-free hybrid epoxy polymer matrix. In an additional embodiment an improved method of removing cured conductive polymer adhesives, disclosed here as thermal interface materials, from electronic components for reclamation or recovery of usable parts of module assemblies, particularly high cost semiconductor devices, heat sinks and other module components.

Owner:IBM CORP

Separator for electrochemical device, and electrochemical device

ActiveCN101048892AImprove securityLi-accumulatorsCell component detailsPhysical chemistryElectrochemistry

An electrochemical device having excellent safety at high temperature is provided by using a separator for an electrochemical device, which is made of a porous film comprising: a porous base ( 5 ) having a heat-resistant temperature of 150 DEG C. or higher and including filler particles ( 3 ); at least one kind of shutdown resin ( 6 ) selected from the group consisting of resin A that has a melting point in a range of 80 DEG C. to 130 DEG C. and resin B that absorbs an electrolyte and swells due to heating, and the swelling degree is increased as the temperature rises; and a binder ( 4 ).

Owner:MAXELL HLDG LTD

Waterborne external thermal insulation coating and preparation method thereof

InactiveCN102329545AImprove waterproof and anti-corrosion performanceEasy constructionPolyurea/polyurethane coatingsReflecting/signal paintsThermal insulationDefoaming Agents

The invention provides a waterborne external thermal insulation coating. The coating consists of the following components in part by weight: 25 to 50 parts of functional filler, 30 to 50 parts of emulsion, 20 to 35 parts of filler, 8 to 20 parts of film-forming aid, 1 to 3 parts of wetting dispersant, 1 to 2 parts of propylene glycol, 1 to 2 parts of defoaming agent, 0.5 to 1.5 parts of mildew preventive, 1 to 5 parts of thickening agent and 10 to 20 parts of water. The invention is characterized in that: the coating is safe and environment-friendly, has excellent waterproof and anticorrosive properties, high thermal resistance and reflectivity, excellent thermal insulation property, and good weather resistance, is convenient to construct, and can be well adhered to various base materials, and the density of a dry film is low; an extremely thin hollow cavity layer is formed after the coating is coated on the surface of a base material and then is dried, so that an effective thermal barrier is formed; functional filler particles have large heated cathodes, low coefficient of thermal conductivity, and high heat reflectivity; the consumption of energy sources is remarkably reduced; the coating can reflect, refract and scatter thermal radiation and stop heat conduction; and the energy is saved.

Owner:QINGDAO AIR NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com