Patents

Literature

35 results about "Gram-force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Similarly, a gram-force is 9.806 65 mN, and a milligram-force is 9.806 65 μN. One kilogram-force is approximately 2.204622 pound-force. Kilogram-force is a non-standard unit and is classified in SI Metric System as a unit that is unacceptable for use with SI.

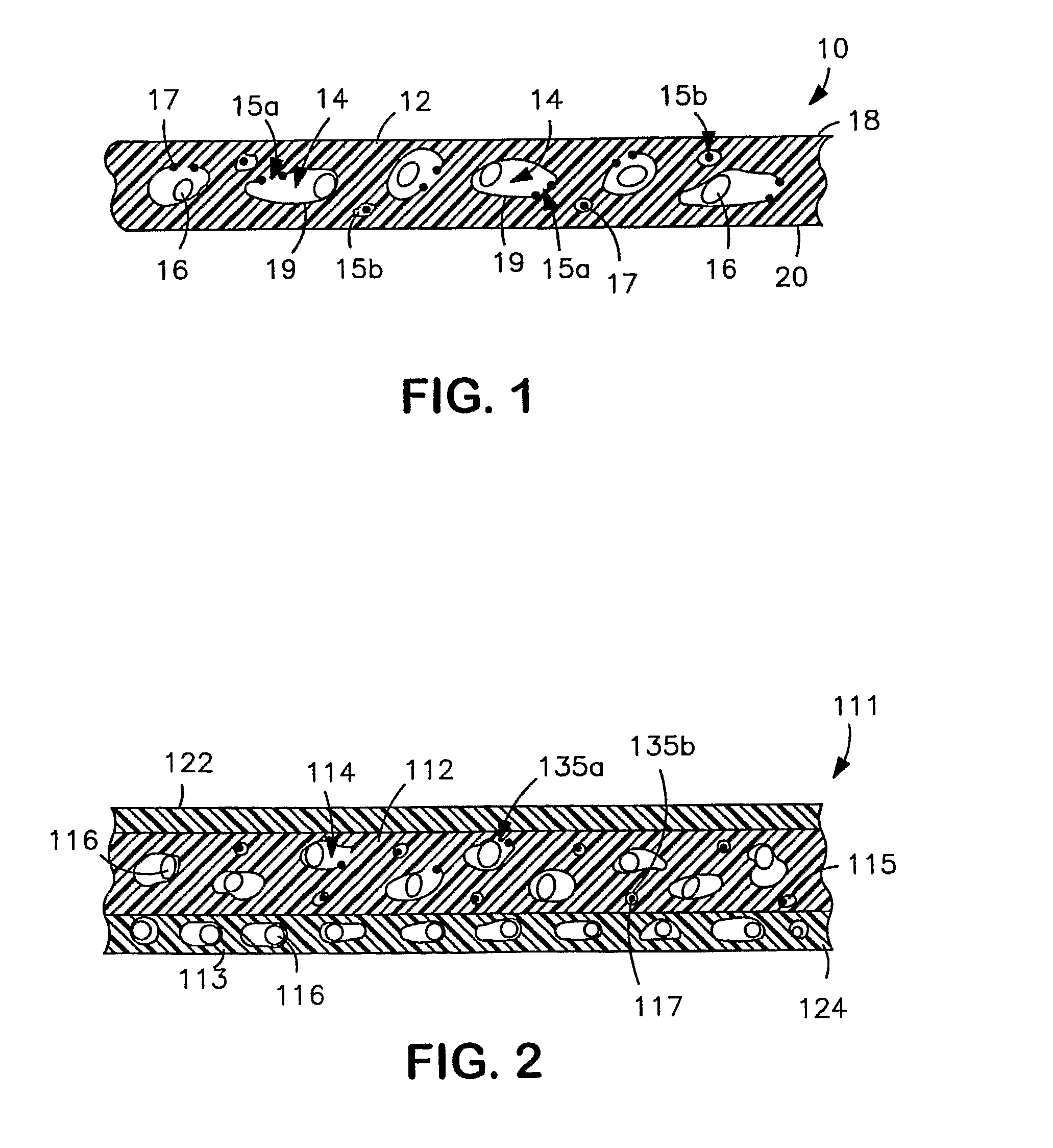

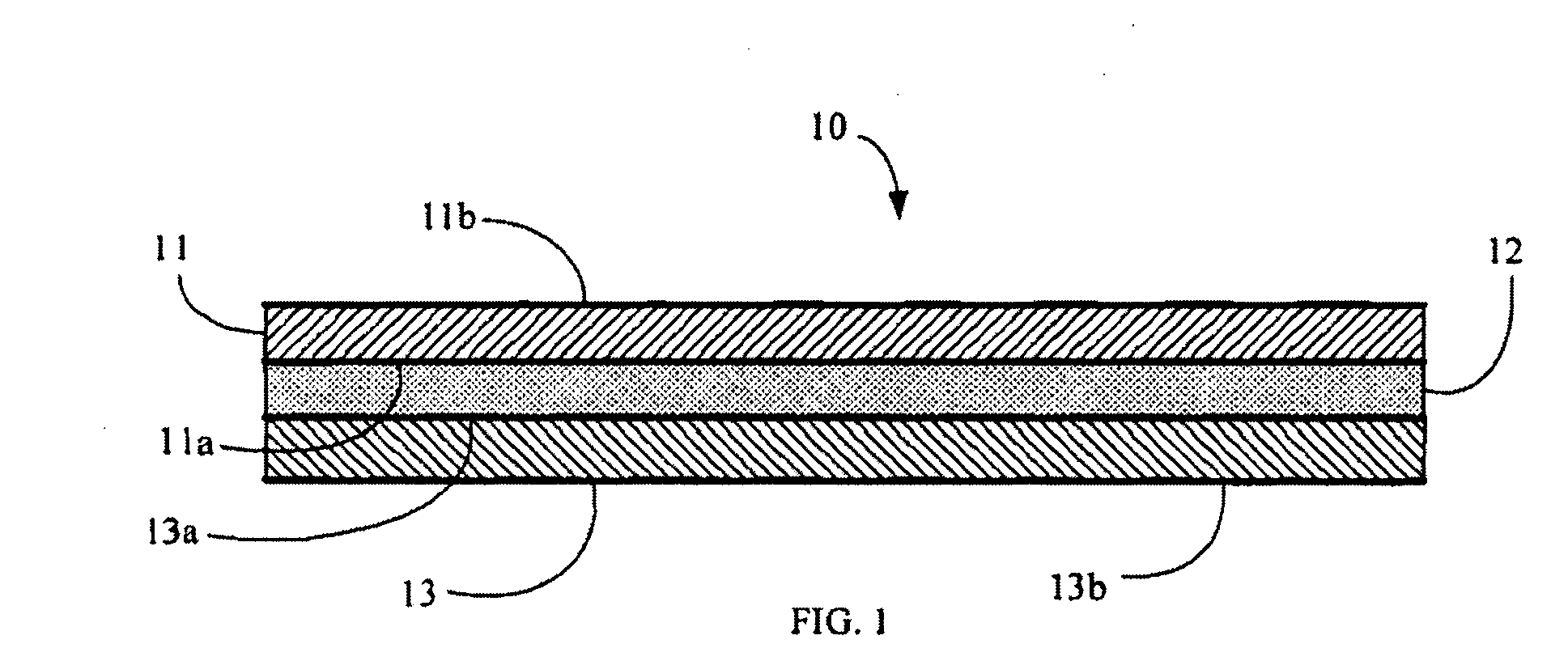

Highly breathable biodegradable films

ActiveUS20100068484A1Lamination ancillary operationsSynthetic resin layered productsWater vaporGram-force

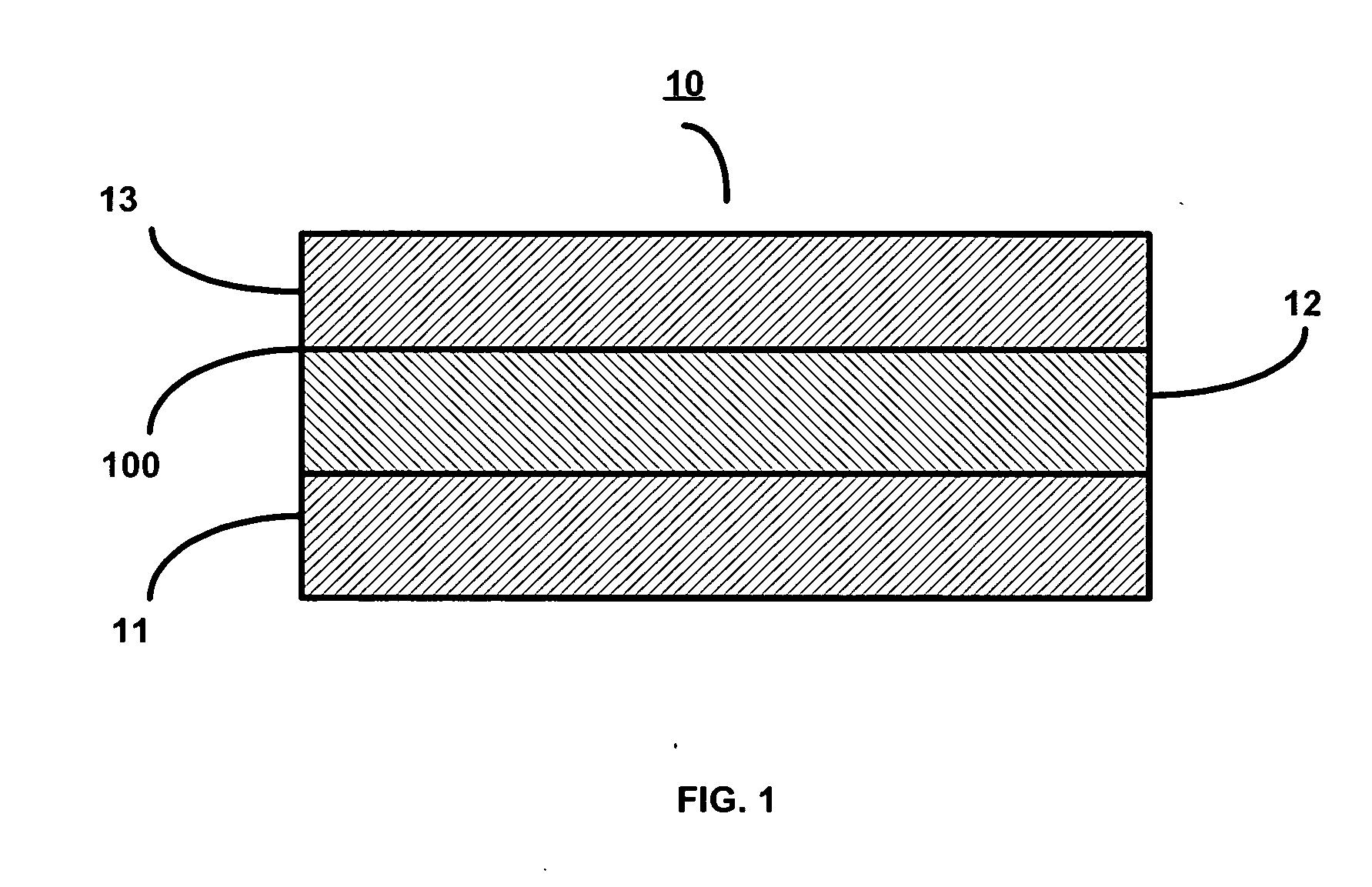

A breathable film having a base layer comprising first filler particles and second filler particles dispersed within a biodegradable polymer matrix is provided. The first filler particles constitute from about 25 wt. % to about 75 wt. % of the base layer and the second filler particles constitute from about 0.1 wt. % to about 10 wt. % of the base layer. The ratio of the average size of the first filler particles to the average size of the second filler particles being from about 2 to about 100. The film exhibits a water vapor transmission rate of about 2,000 g / m2 / 24 hours or more and a peak load in the machine direction of about 800 grams-force per inch or more.

Owner:KIMBERLY-CLARK WORLDWIDE INC

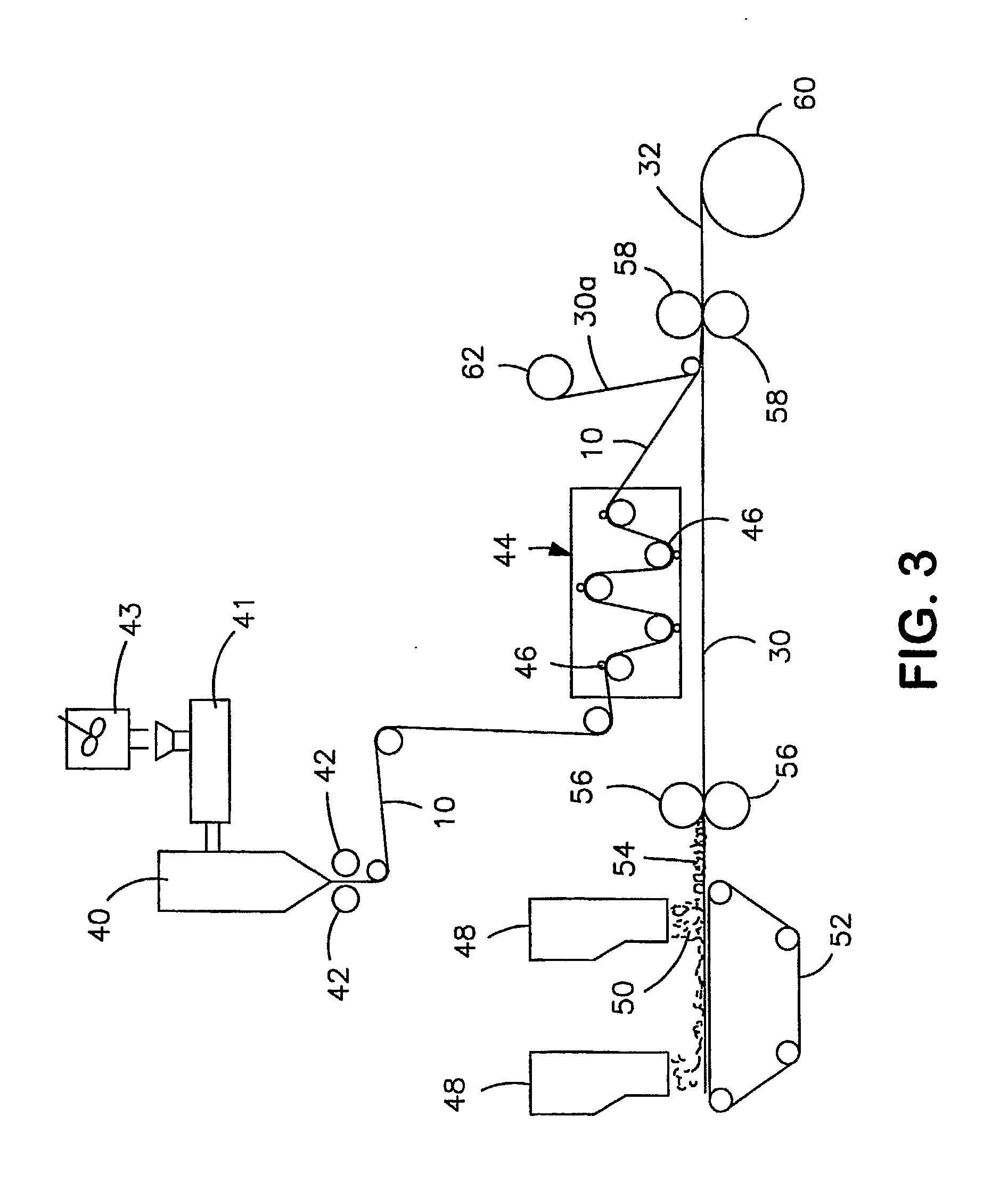

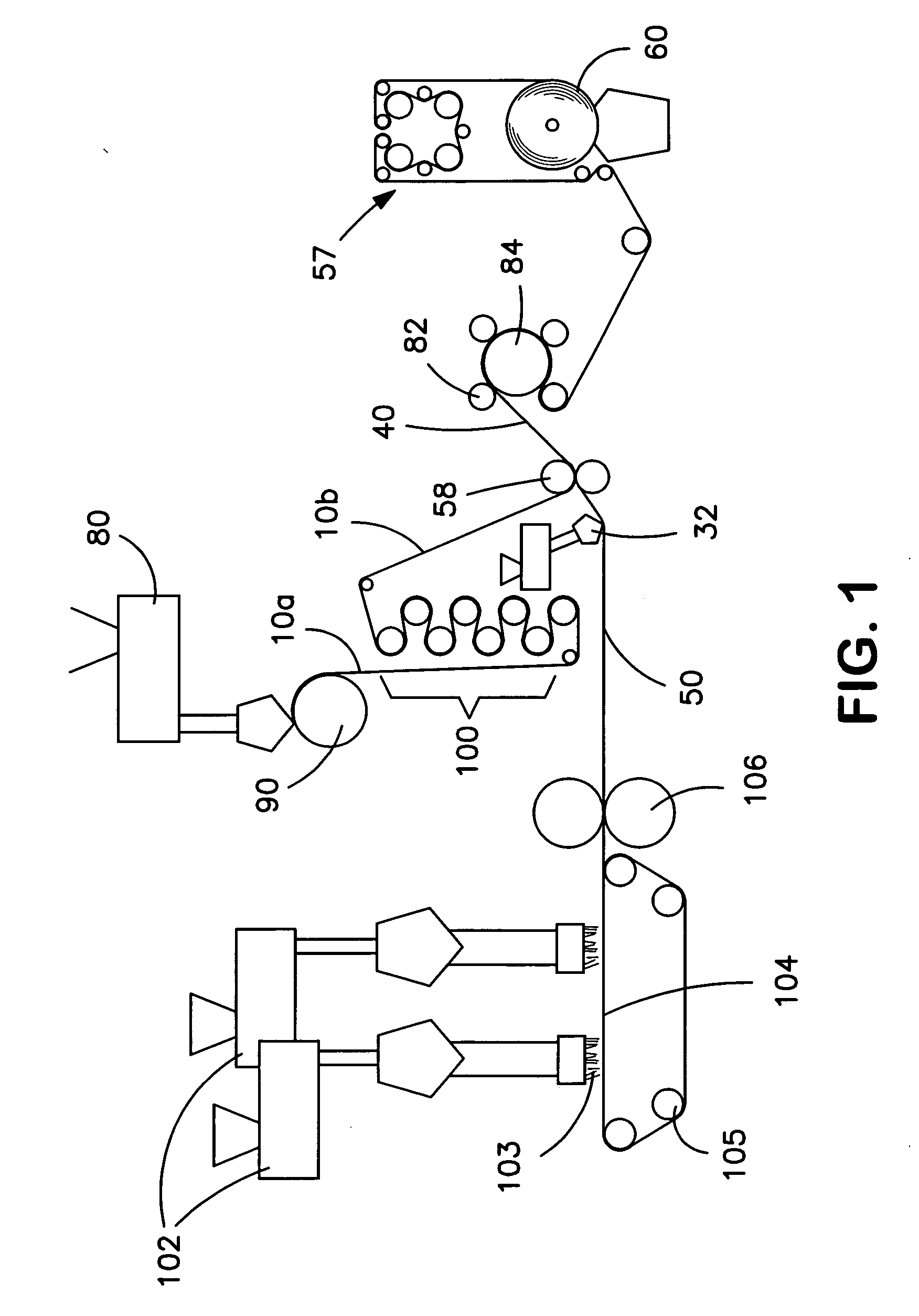

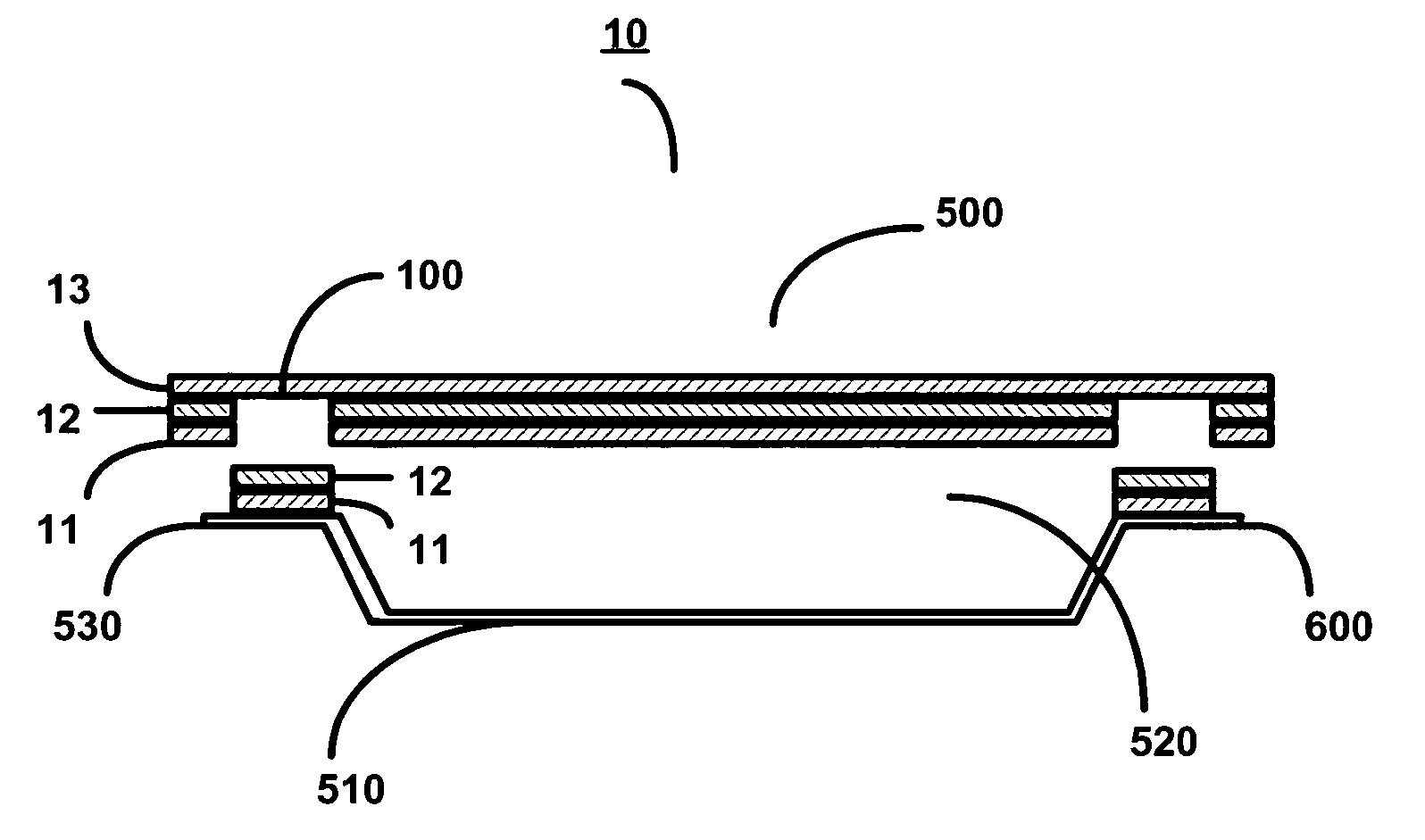

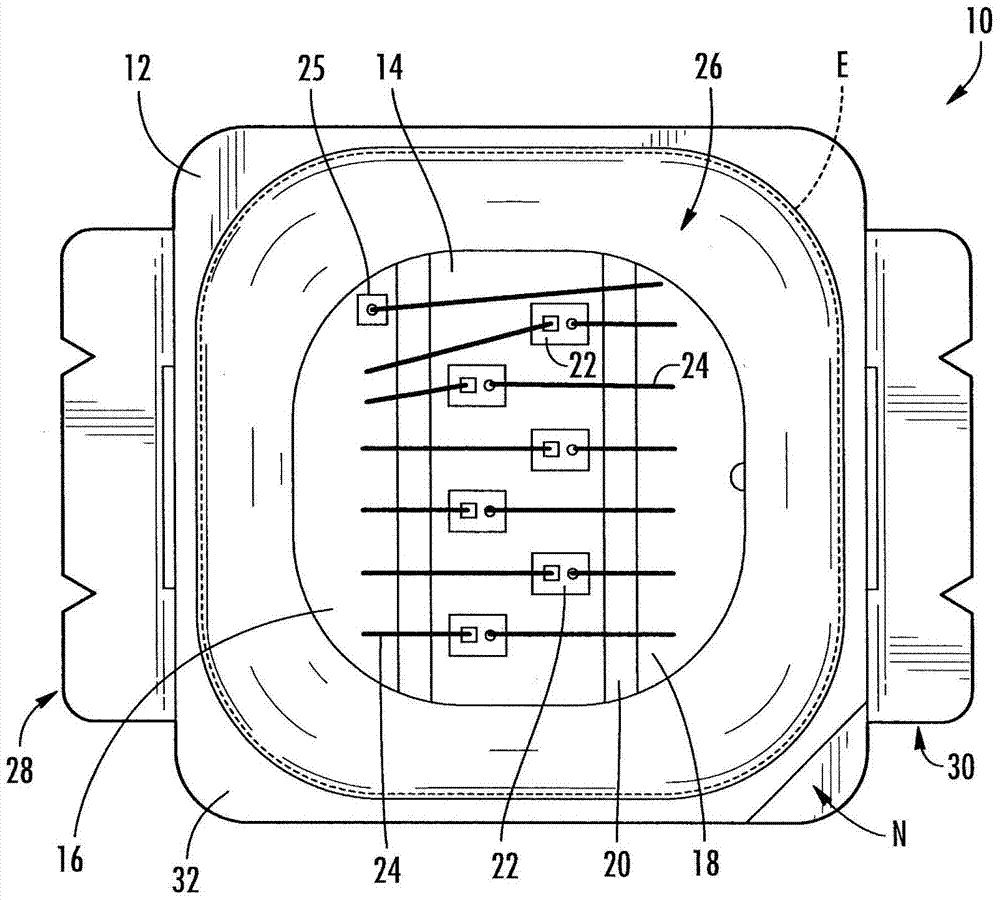

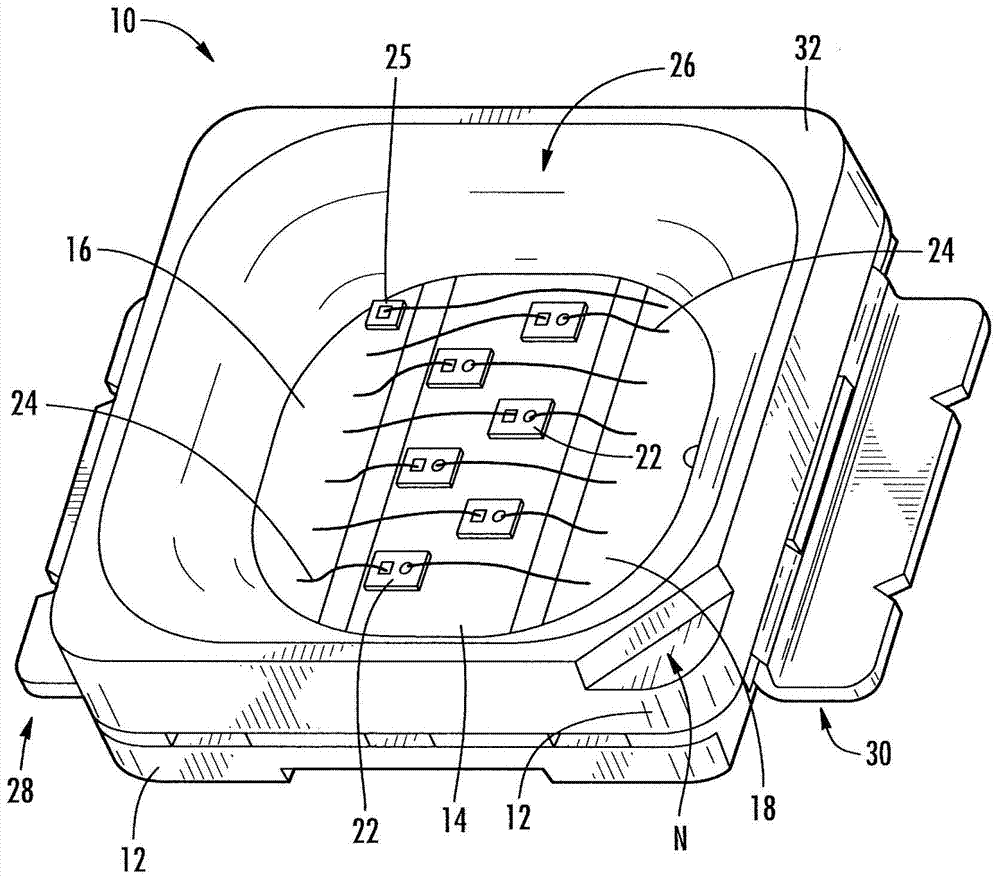

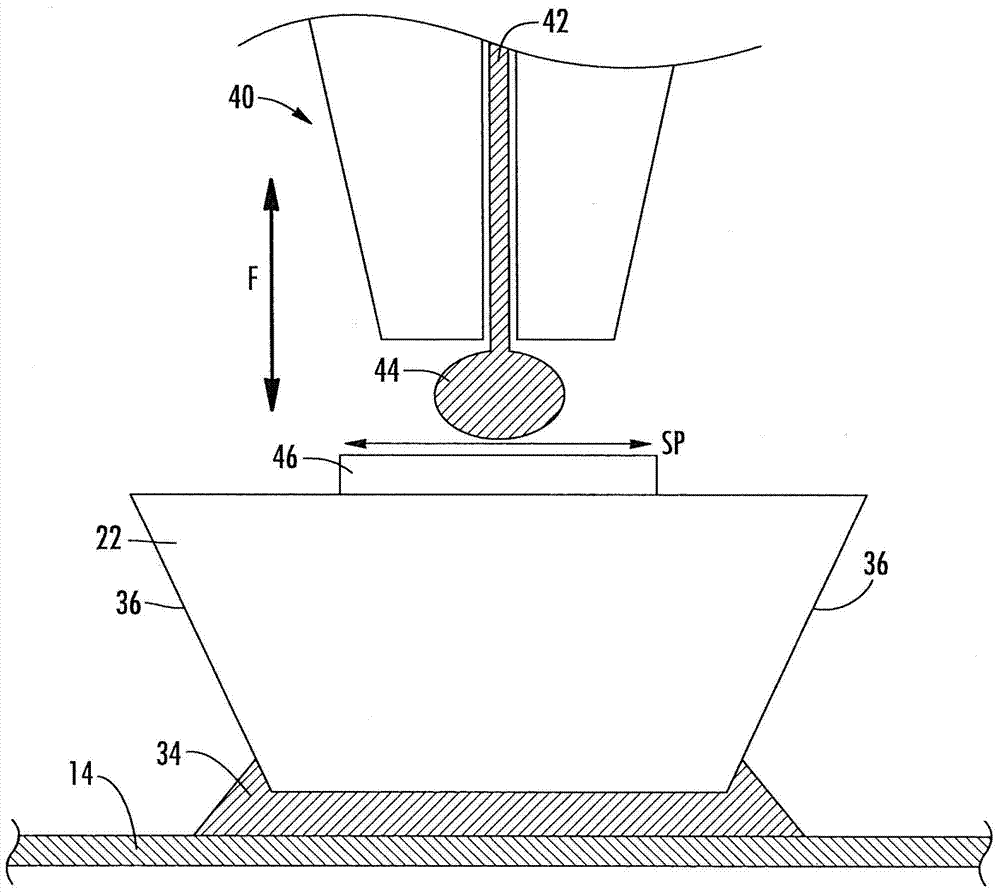

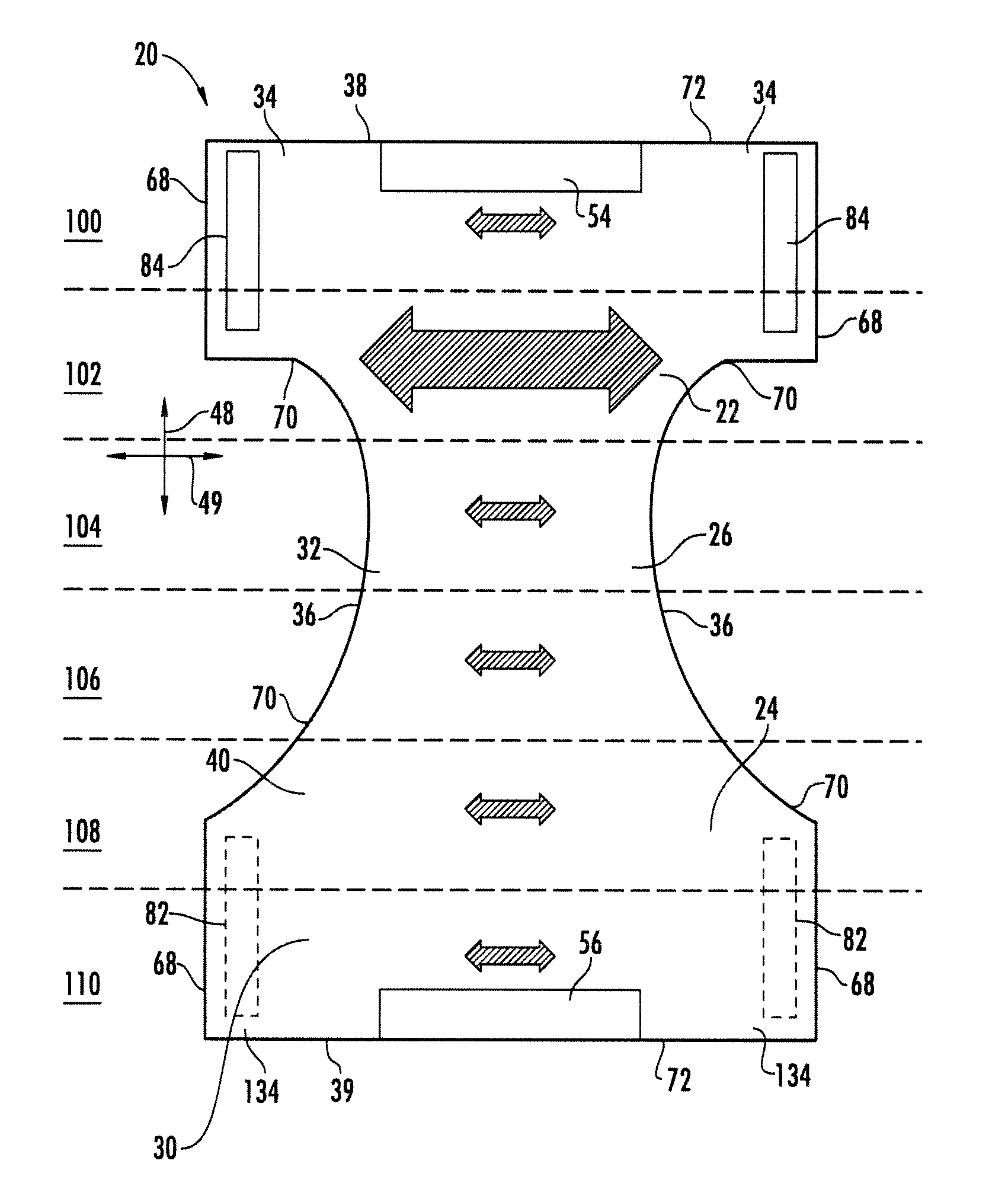

Method for forming an elastic laminate

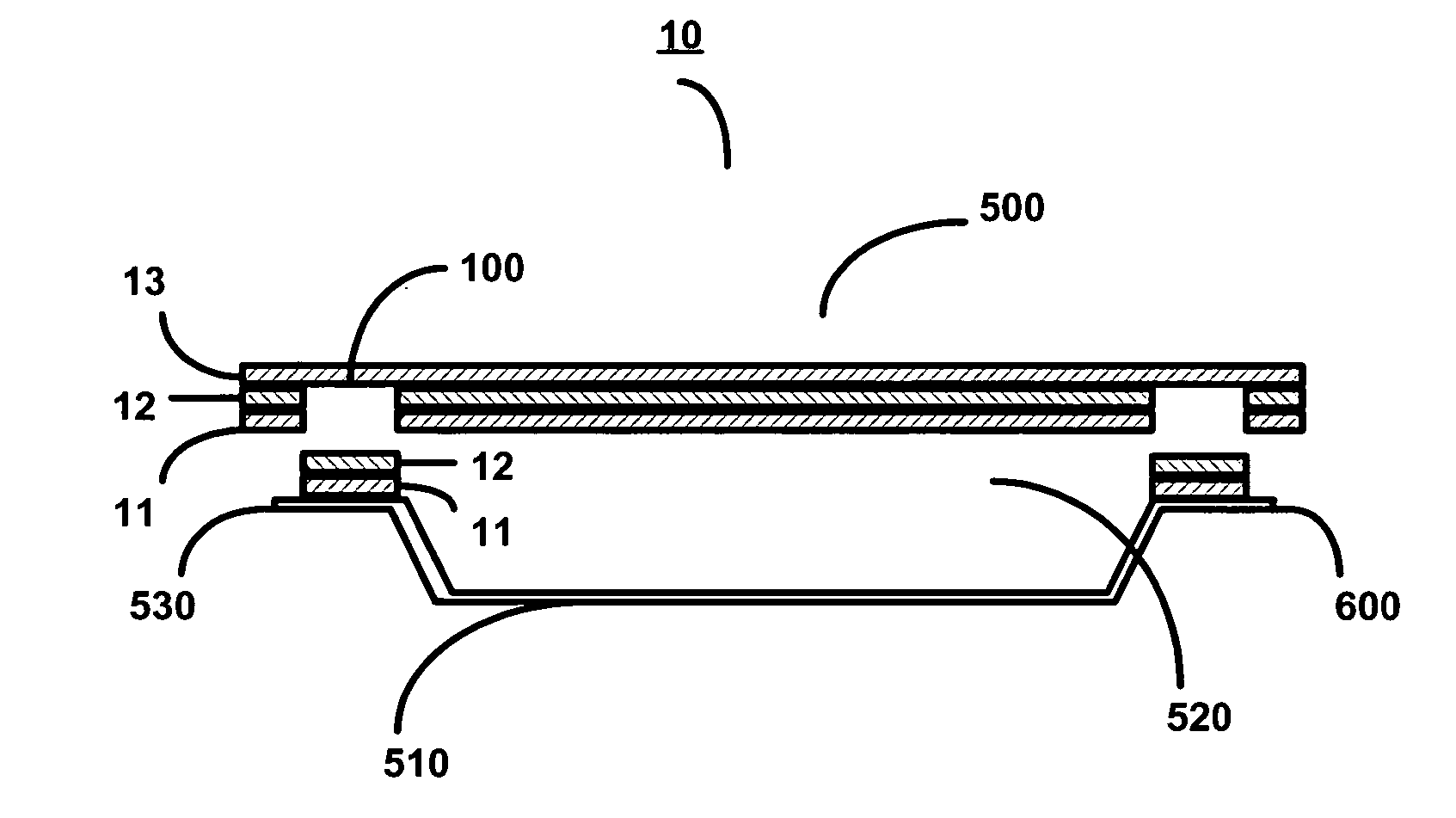

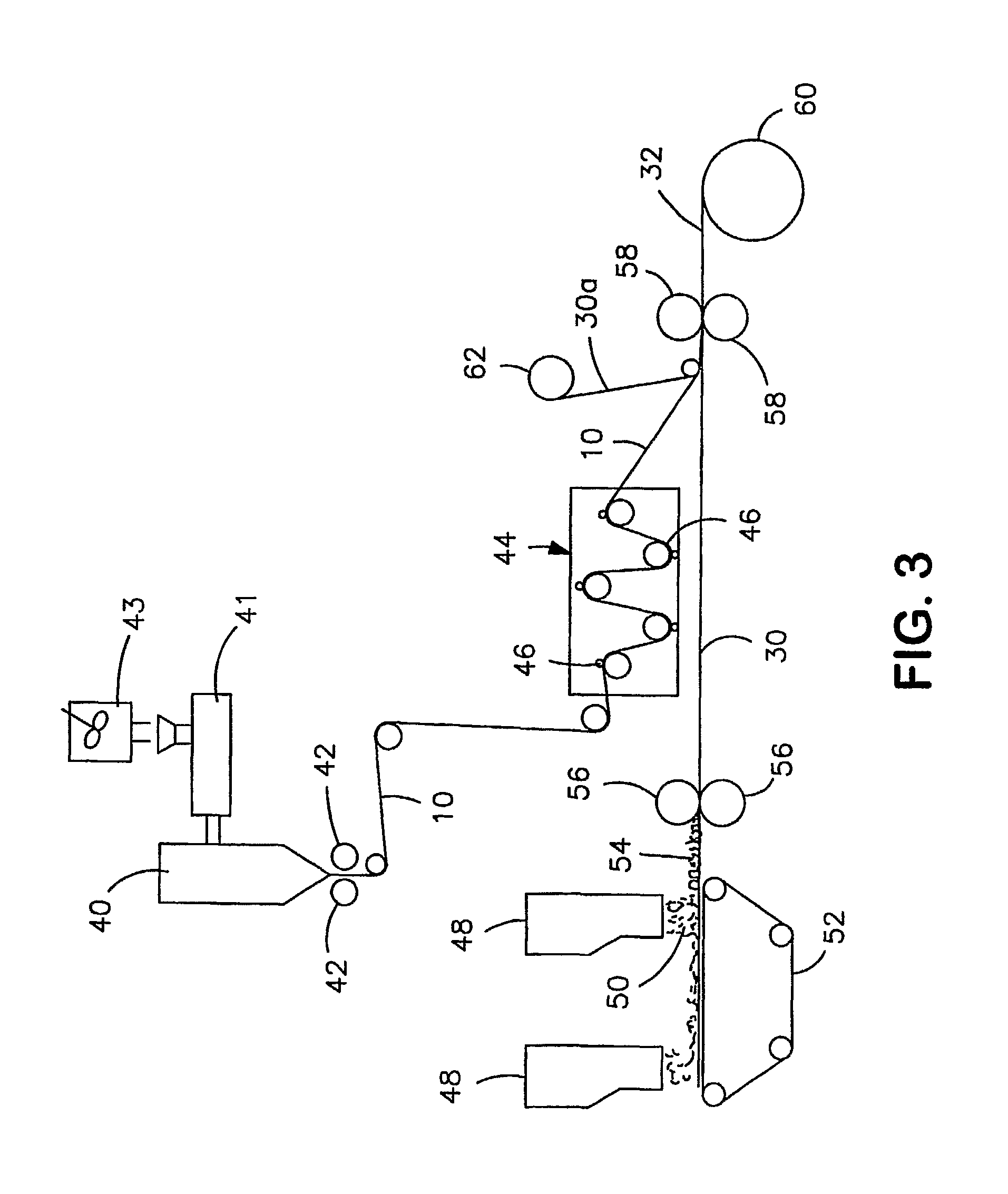

An efficient, in-line method for forming an elastic laminate is provided. To form the laminate, a polymer composition containing an elastomeric polymer is extruded as a film. In one embodiment, the film is uniaxially oriented in the machine direction (“MD”), or optionally, biaxially oriented in the machine direction and the cross-machine direction (“CD”). Regardless, the elastic film is then laminated to a nonwoven web material. Prior to lamination, the percent stretch of the nonwoven web material is generally no more than 25% when 500 grams-force is applied per 3 inches of the material in either the cross-machine or machine direction. Such a relatively inextensible nonwoven web material may restrict the overall extensibility of the laminate. Thus, to improve extensibility, the resulting laminate is mechanically stretched in the cross-machine and / or machine directions. Extensibility may also be improved by allowing the laminate to relax and retract prior to winding so that the nonwoven web material gathers or forms buckles.

Owner:KIMBERLY-CLARK WORLDWIDE INC

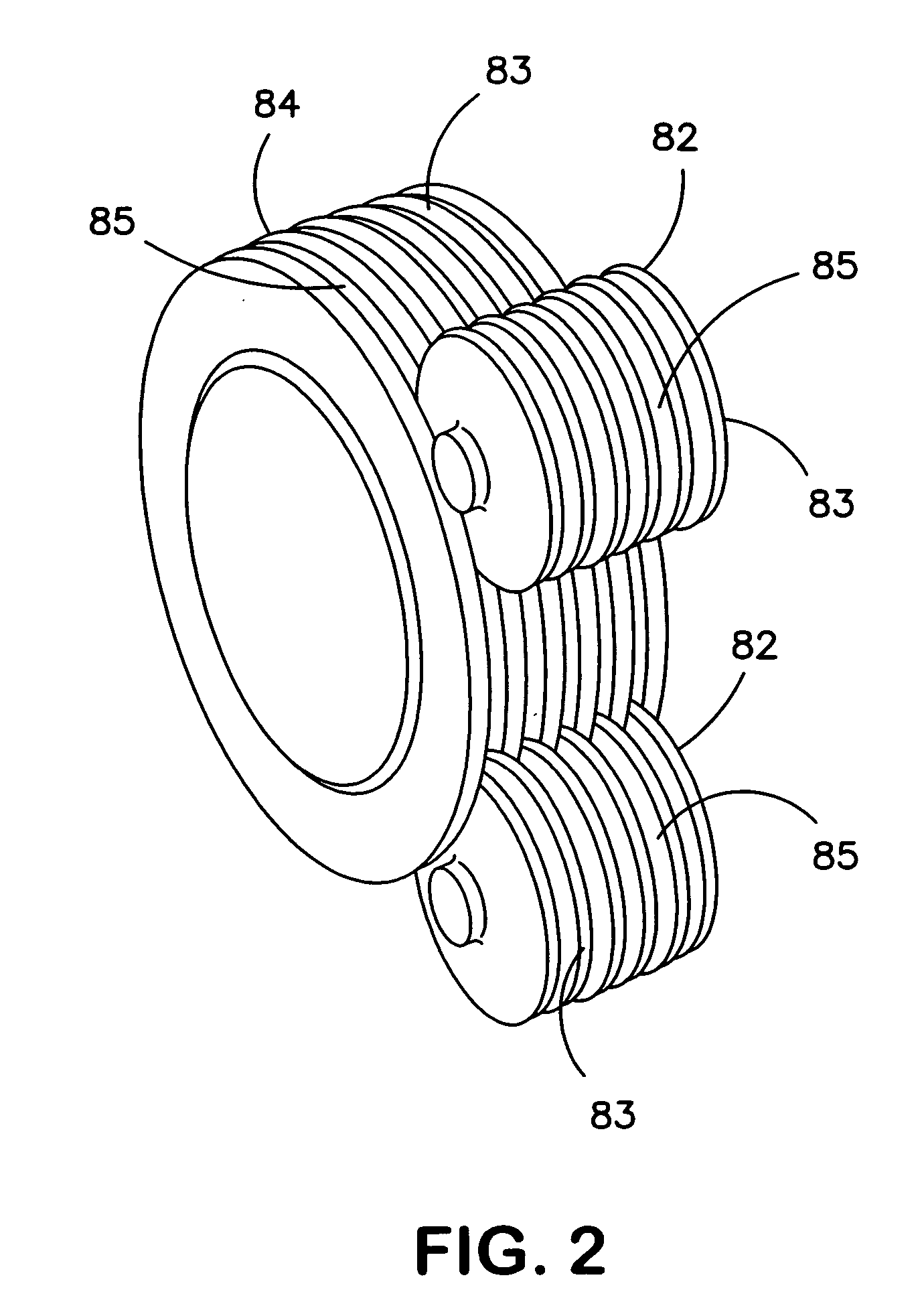

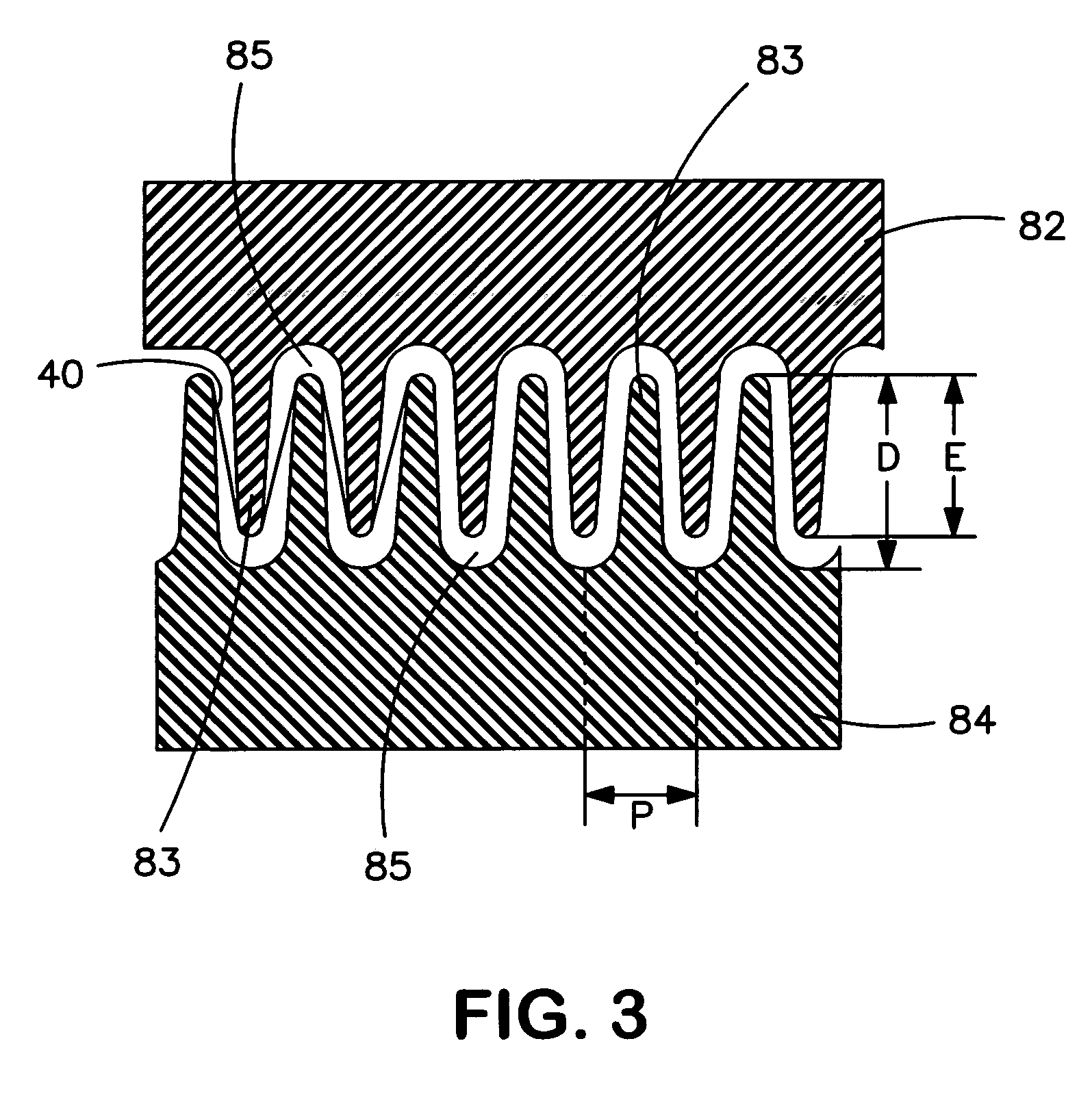

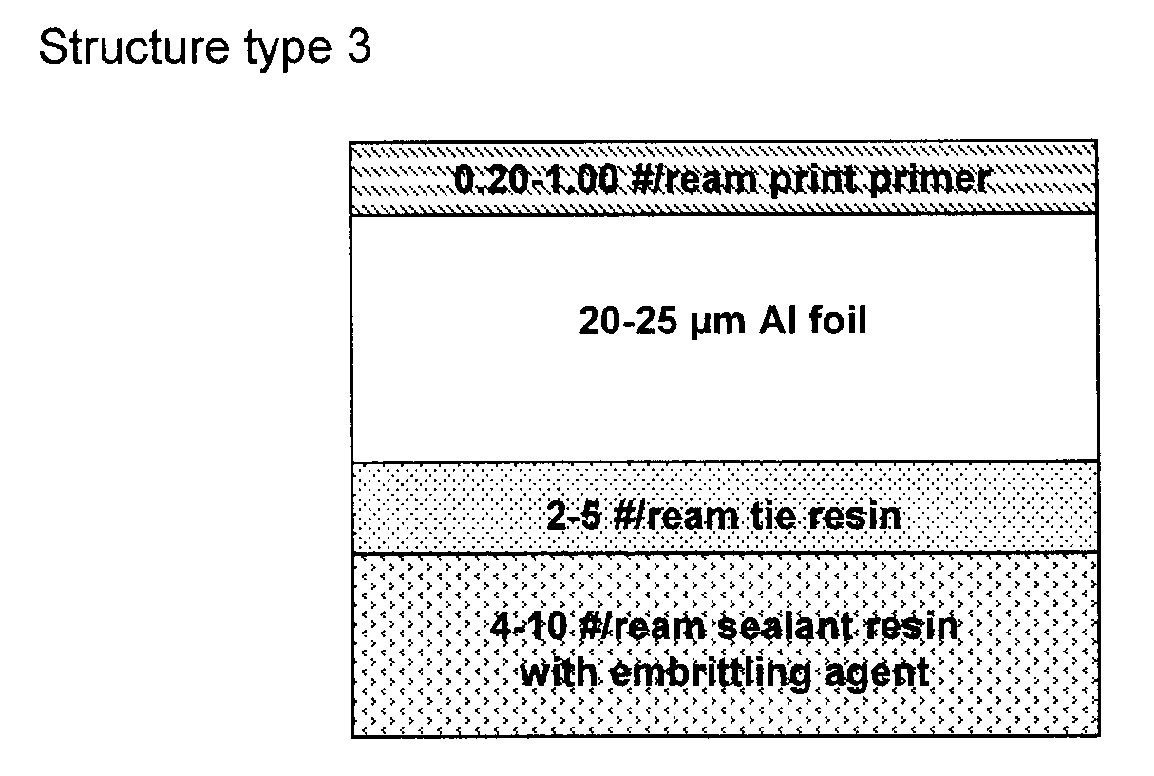

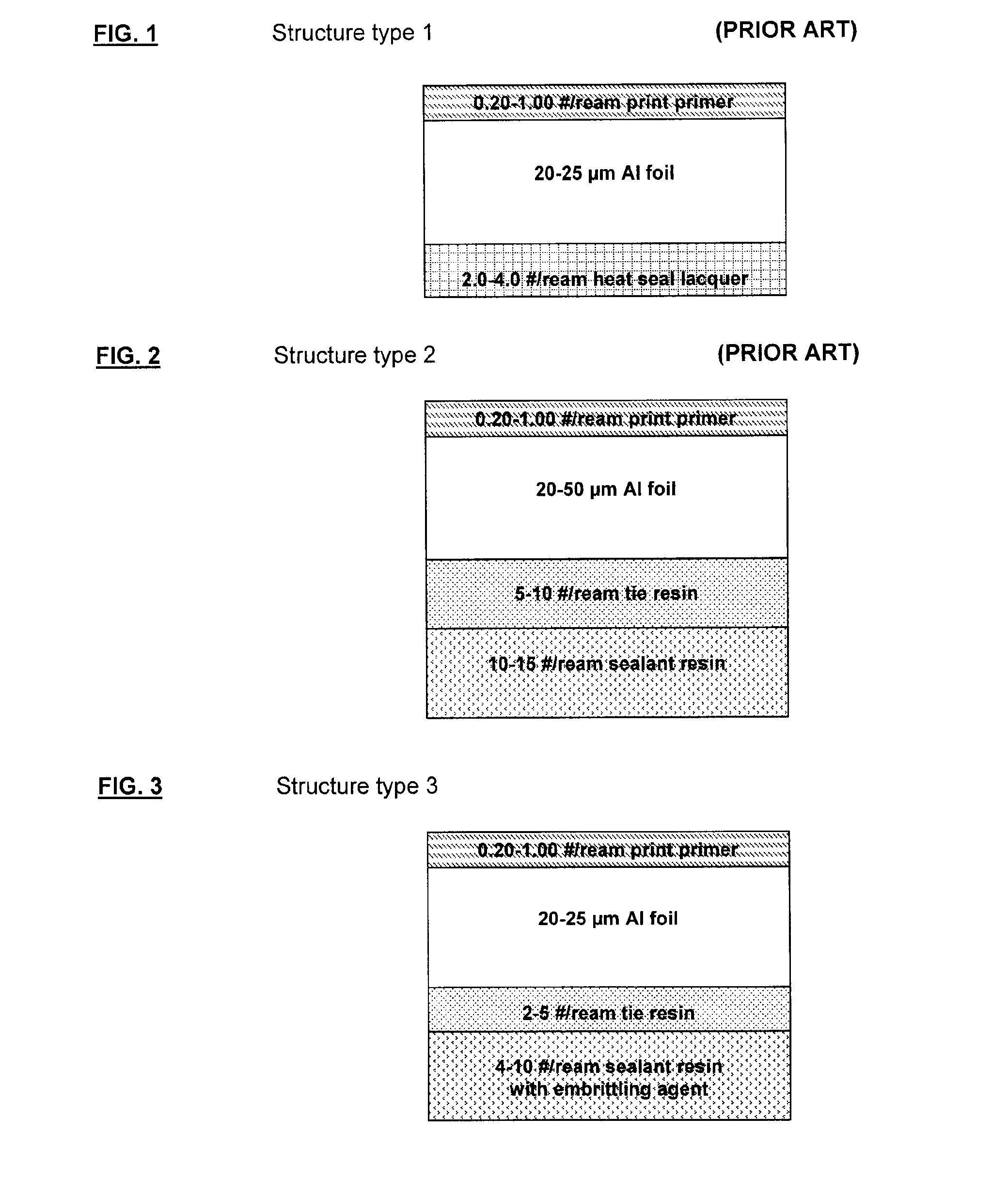

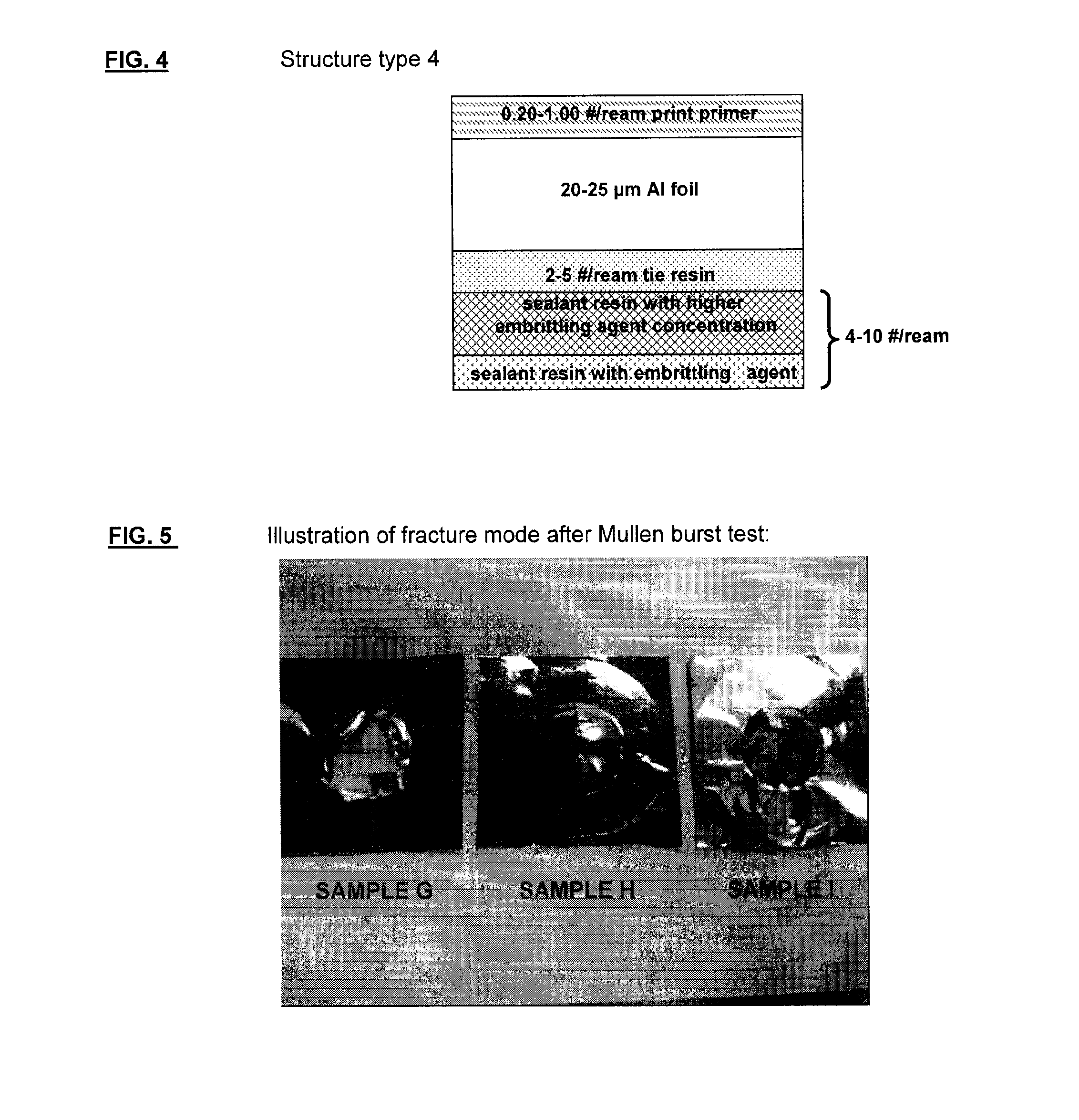

Extrusion-Coated Lidding Foil For Push-Through Blister Packaging

InactiveUS20110005961A1Small article dispensingContainer/bottle contructionBursting strengthGram-force

An extrusion-coated lidding foil for blister packaging particularly suitable for push-through pharmaceutical and food blister packaging. The lidding foil includes a foil layer on which one or more tie layer and one or more sealant layer, one or both of which include an embrittling agent mixed therein, are extrusion coated resulting in a lidding foil having push-through ability. The push-through ability of the lidding foil is characterized by a Mullen burst strength of about 10 psi to about 30 psi and an MD tear strength of about 30 to about 100 grams-force.

Owner:WINPAK HEAT SEAL PACKAGING

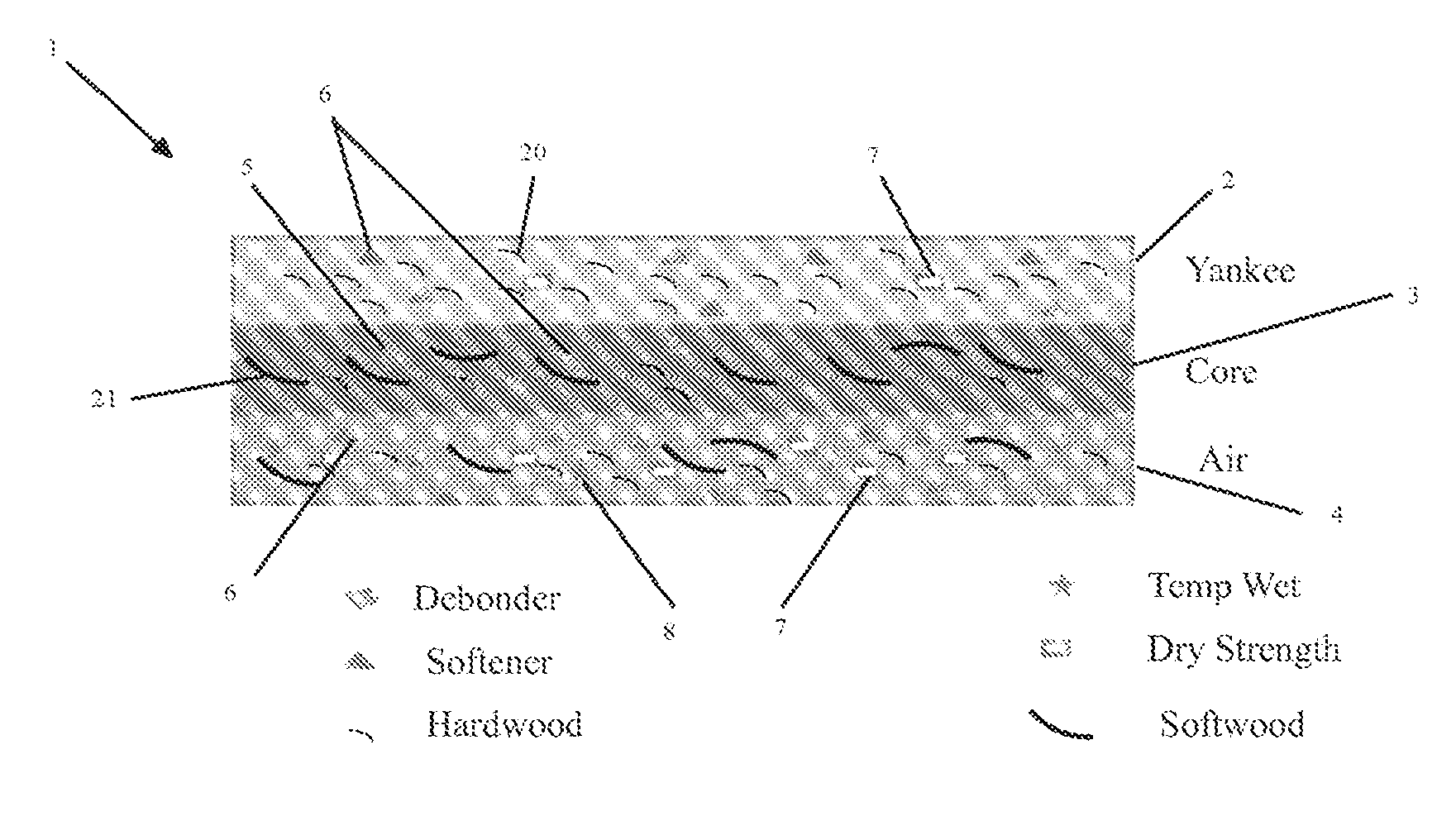

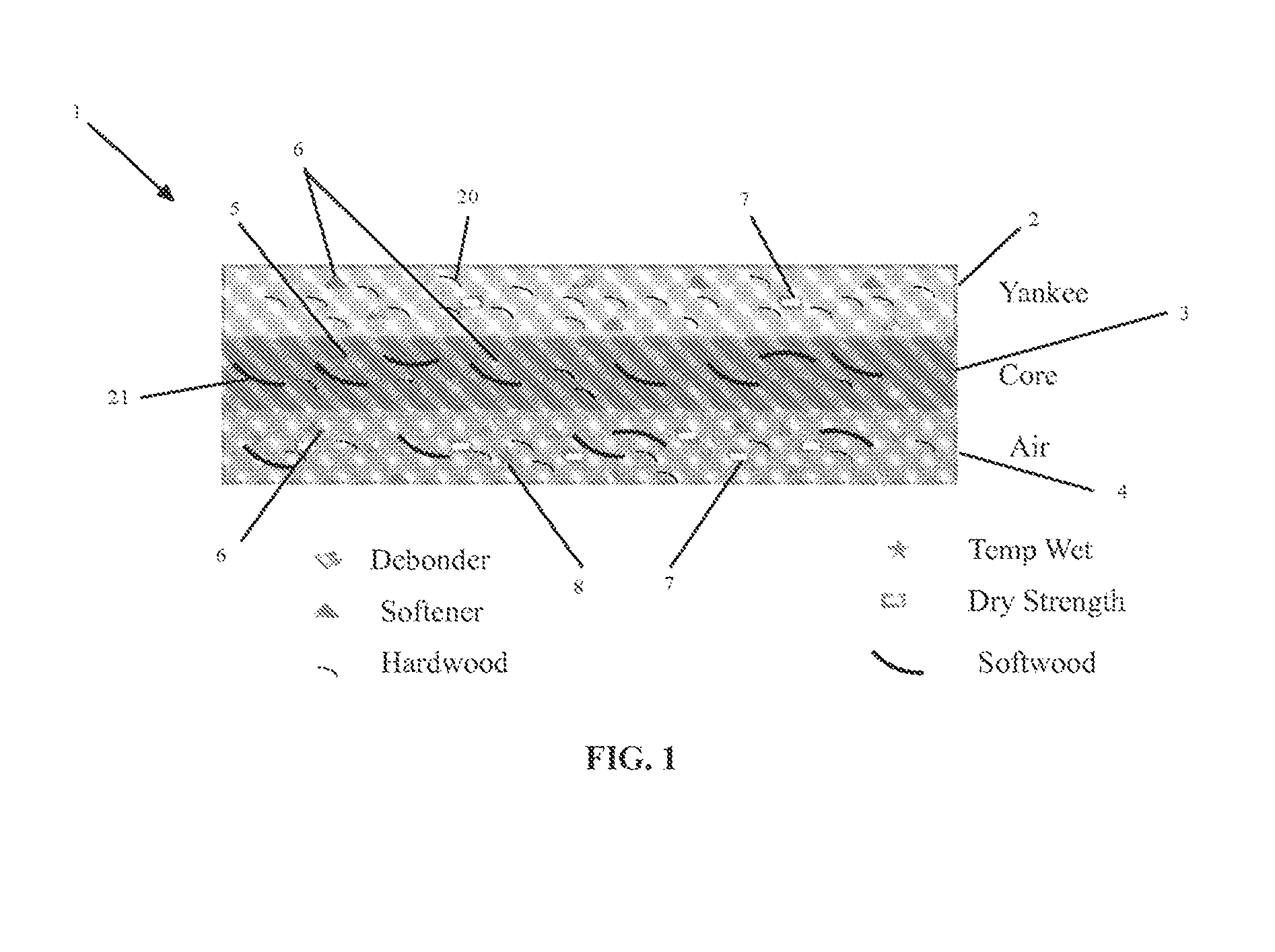

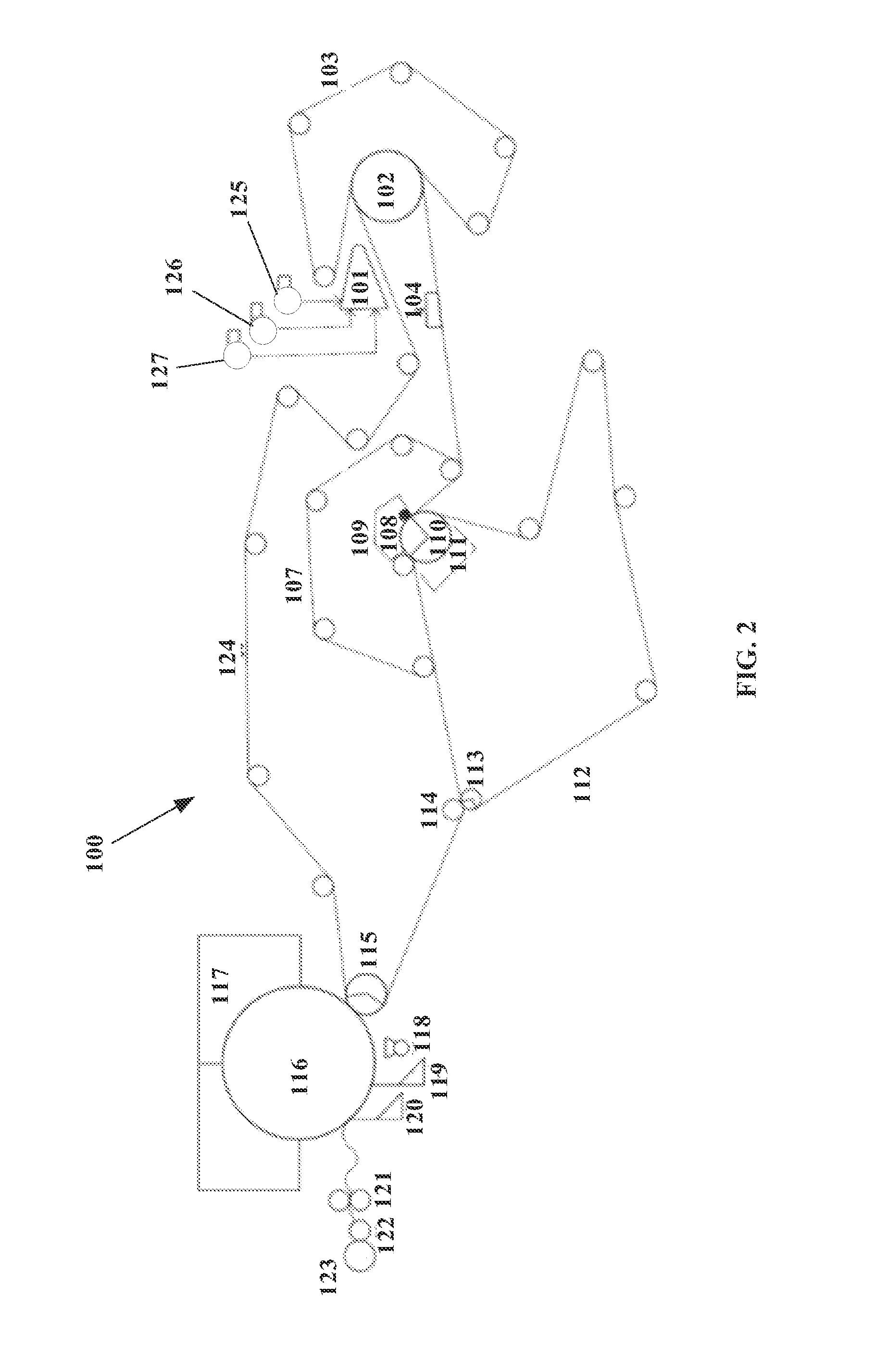

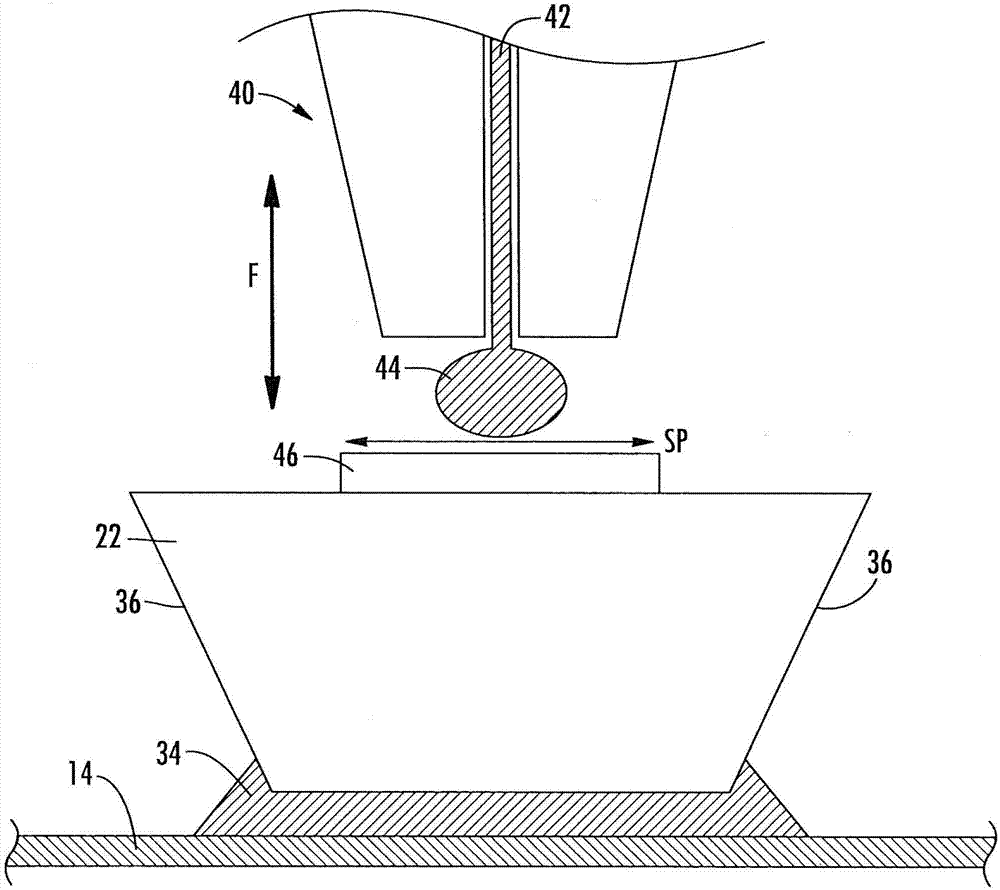

Soft tissue produced using a structured fabric and energy efficient pressing

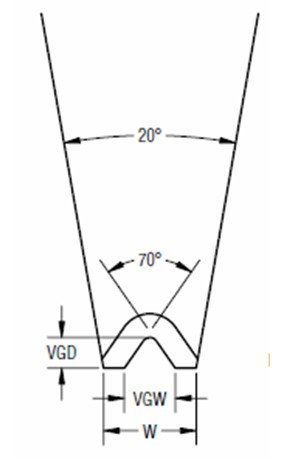

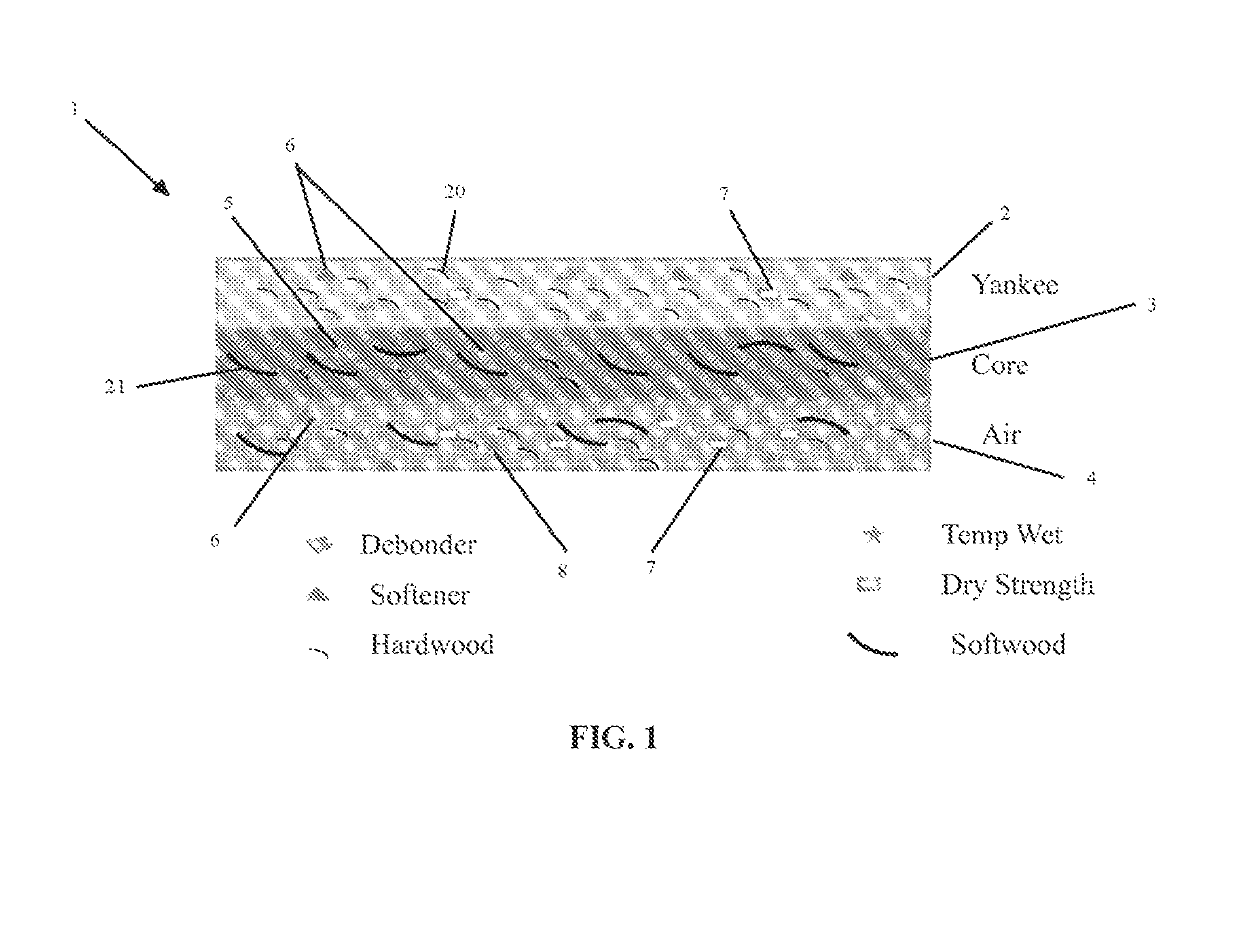

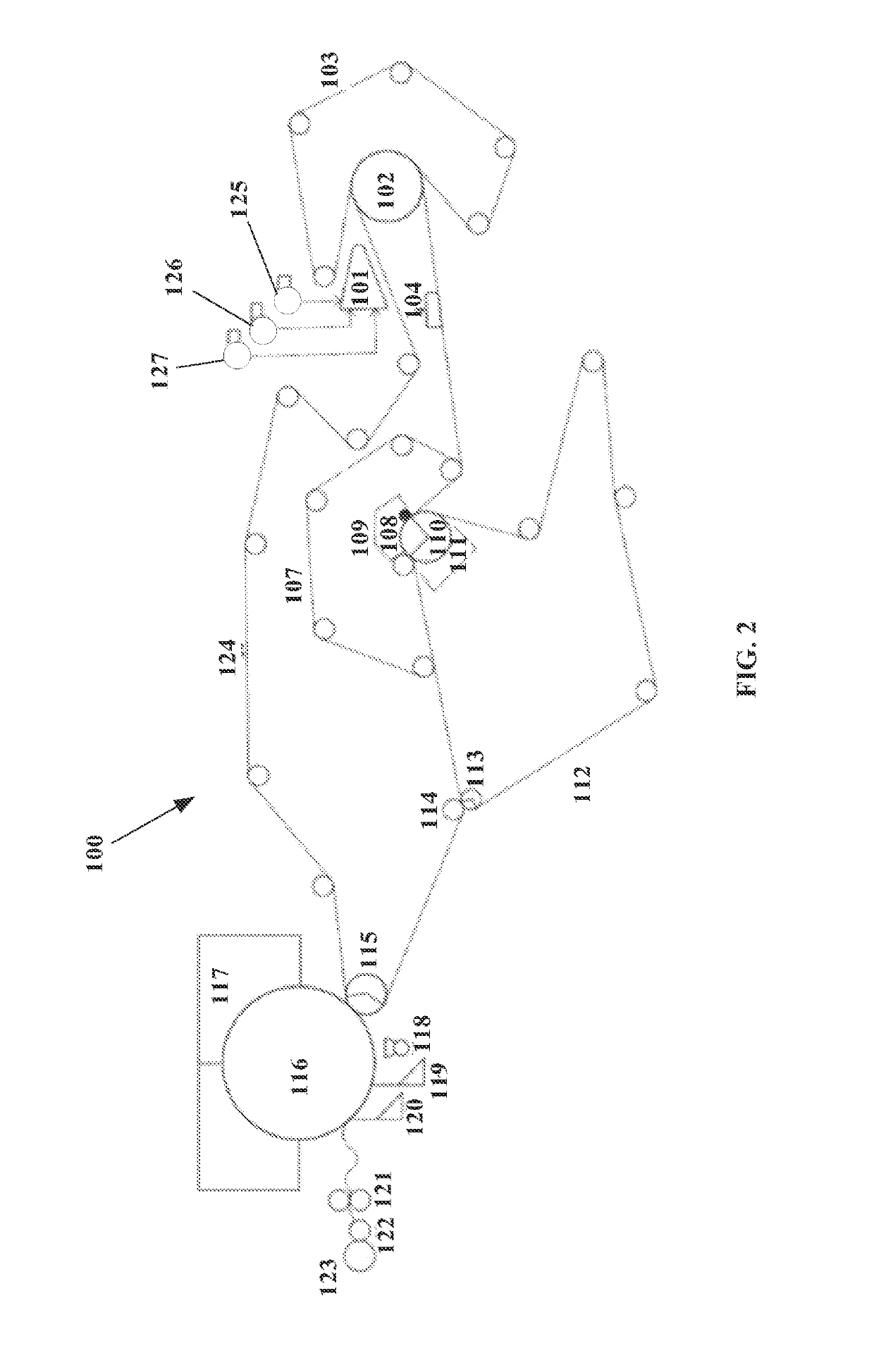

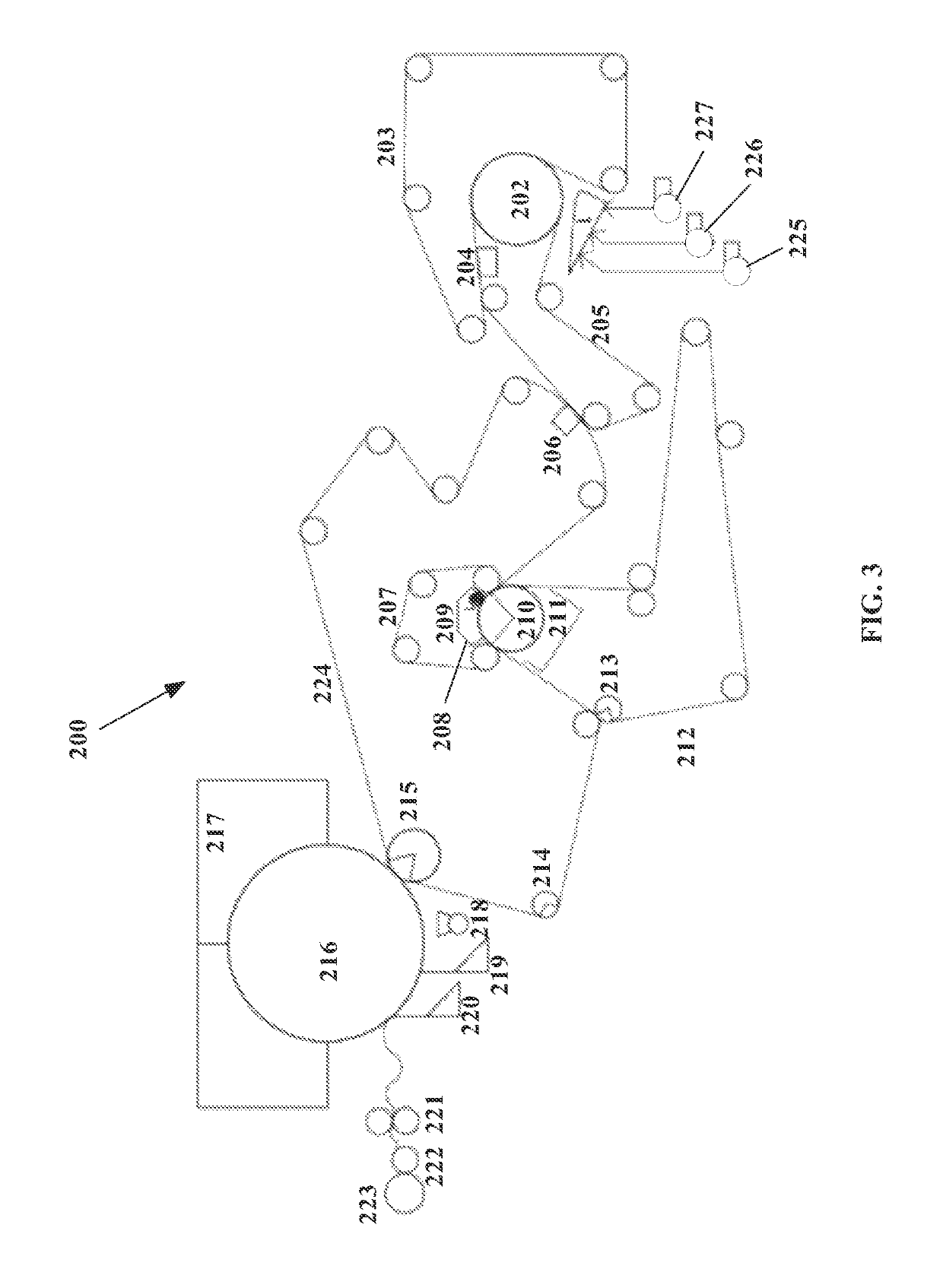

ActiveUS20160145810A1Avoid disadvantagesLarge structureMechanical working/deformationPaper after-treatmentGram-forceEngineering

Owner:FIRST QUALITY TISSUE

Hydrocolloid adhesive compositions

InactiveUS6825246B1Easy to processCost efficientCosmetic preparationsOrganic detergent compounding agentsGram-forceGram

The present invention is directed to pressure sensitive hydrocolloid adhesive compositions having probe tack of about 300-750 grams force, tensile strength of about 500-3500 grams / cm<2 >and saline absorbency of about 500-5000 grams / m<2> / 24 hours.

Owner:CONVATEC TECH INC

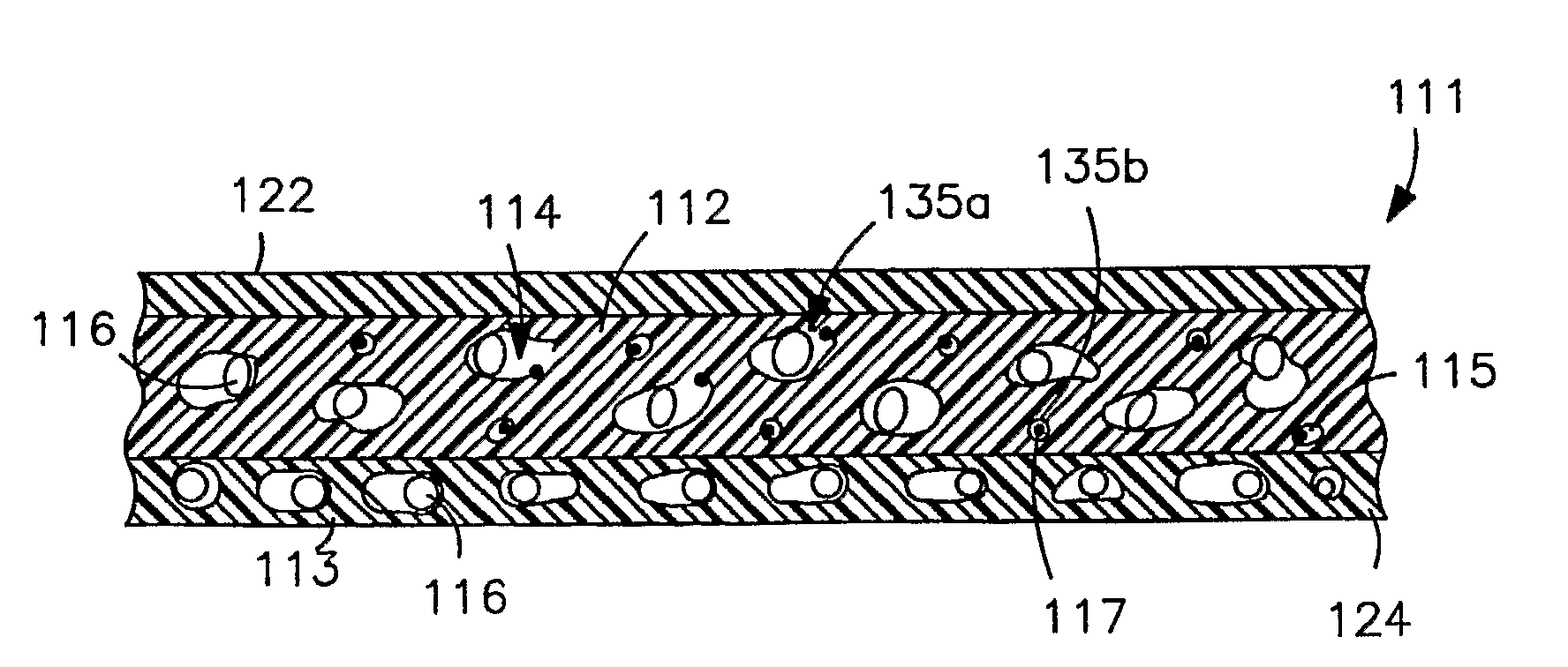

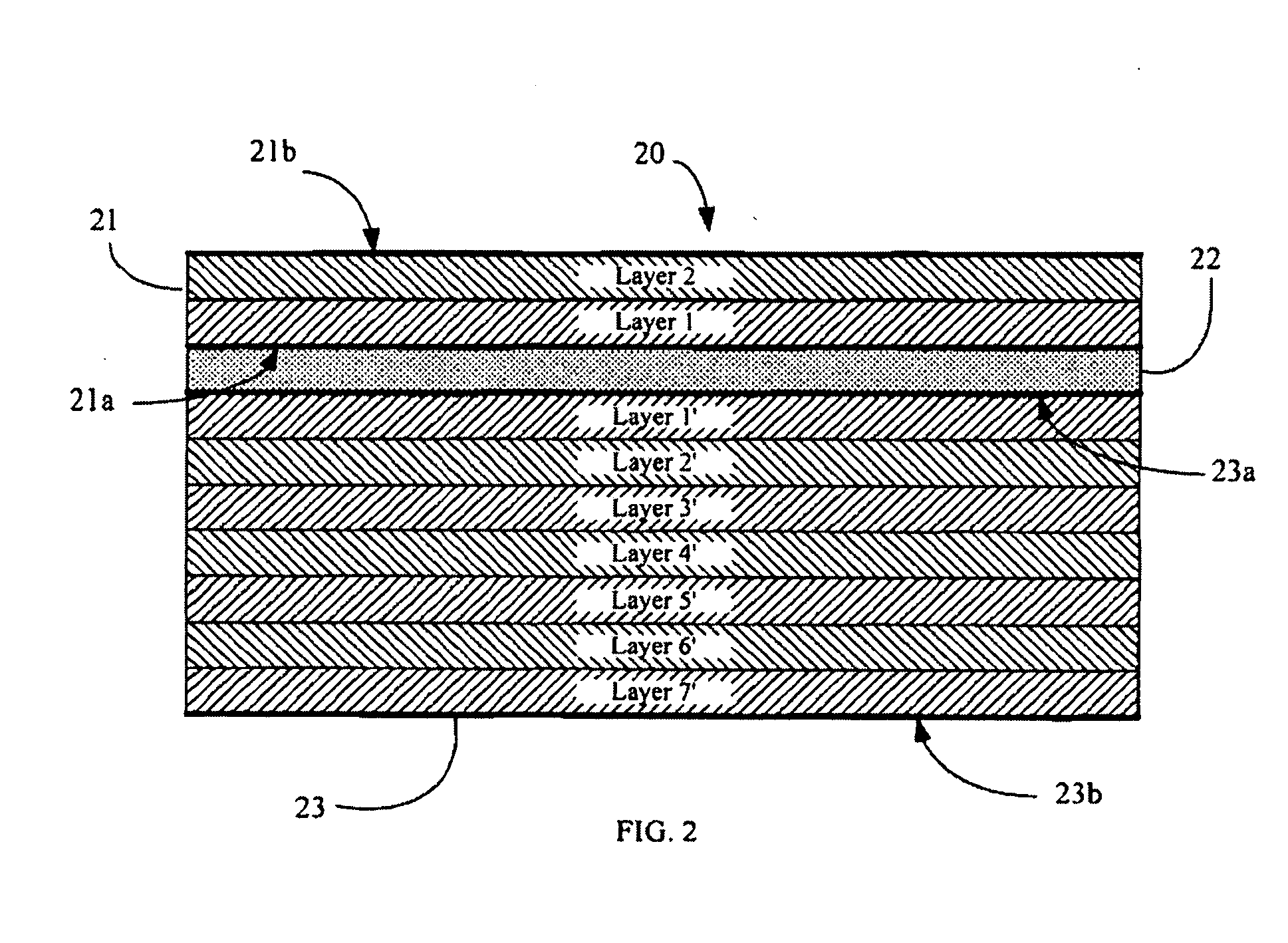

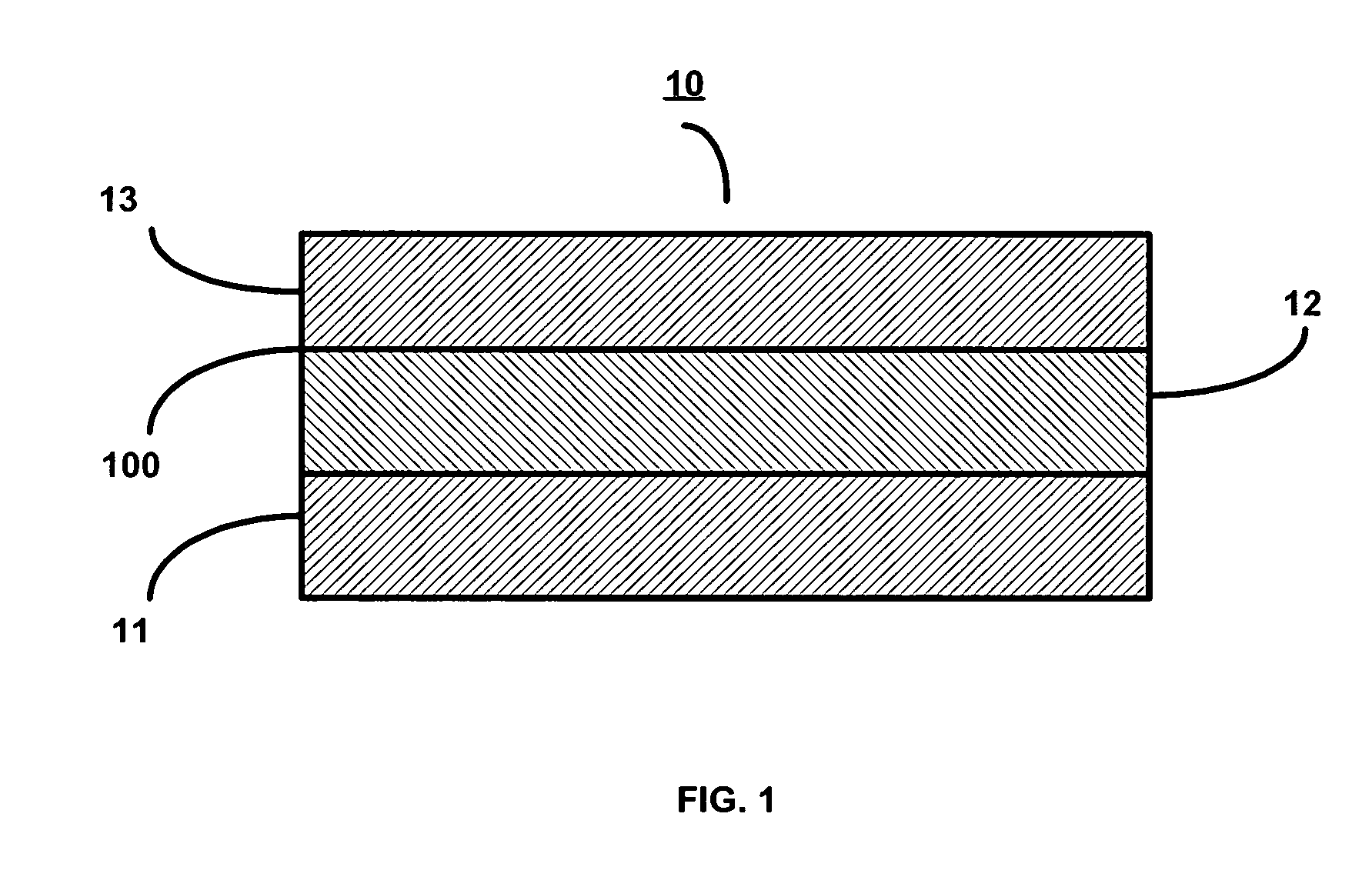

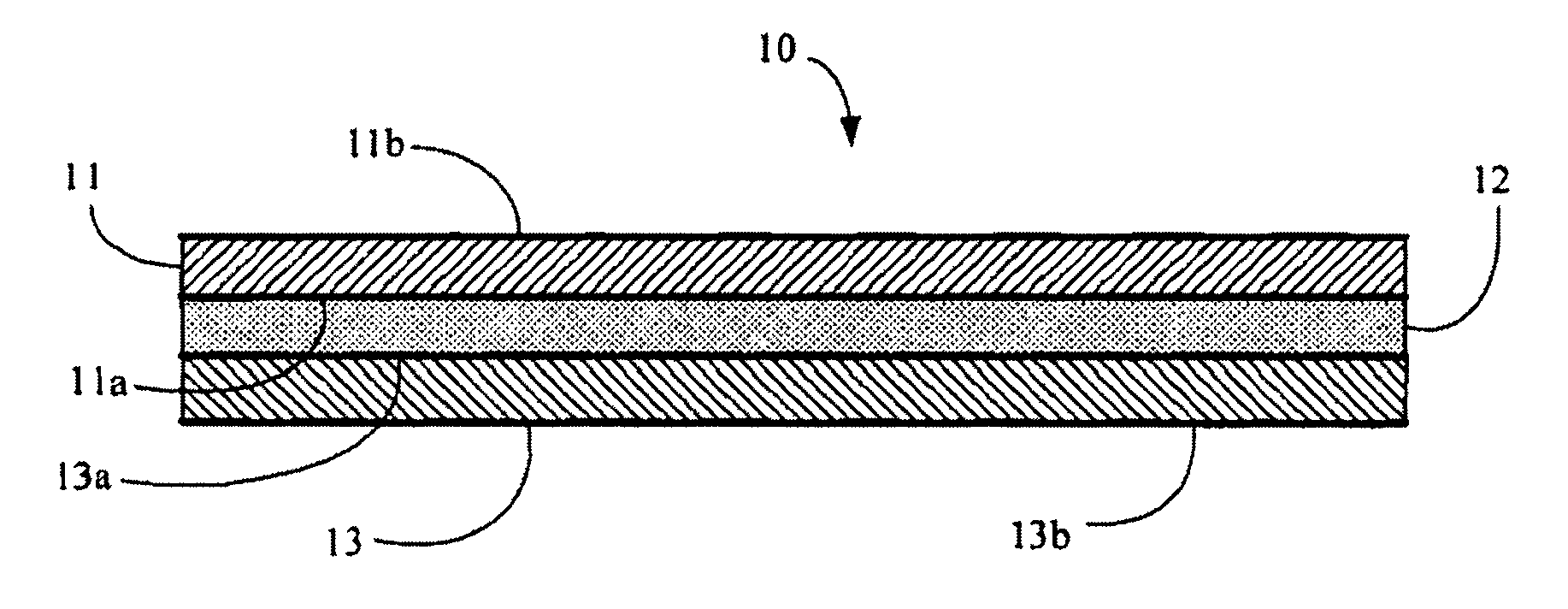

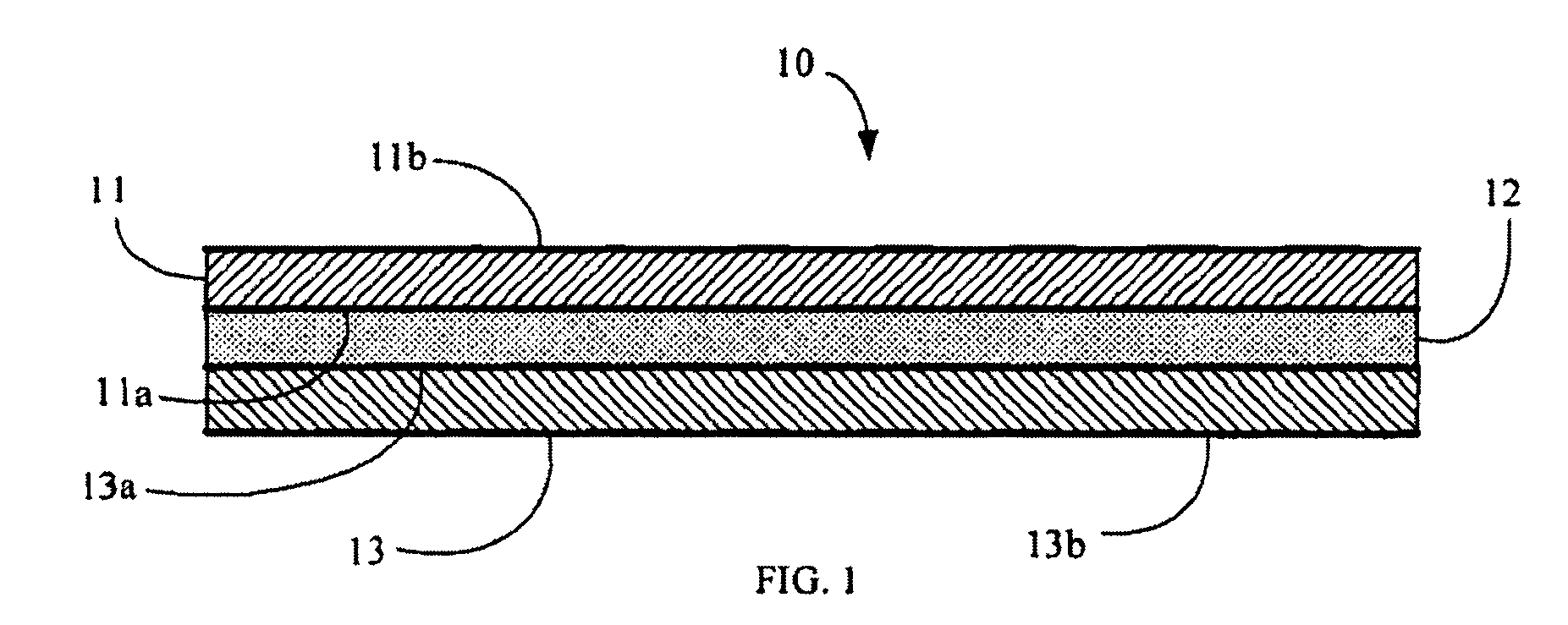

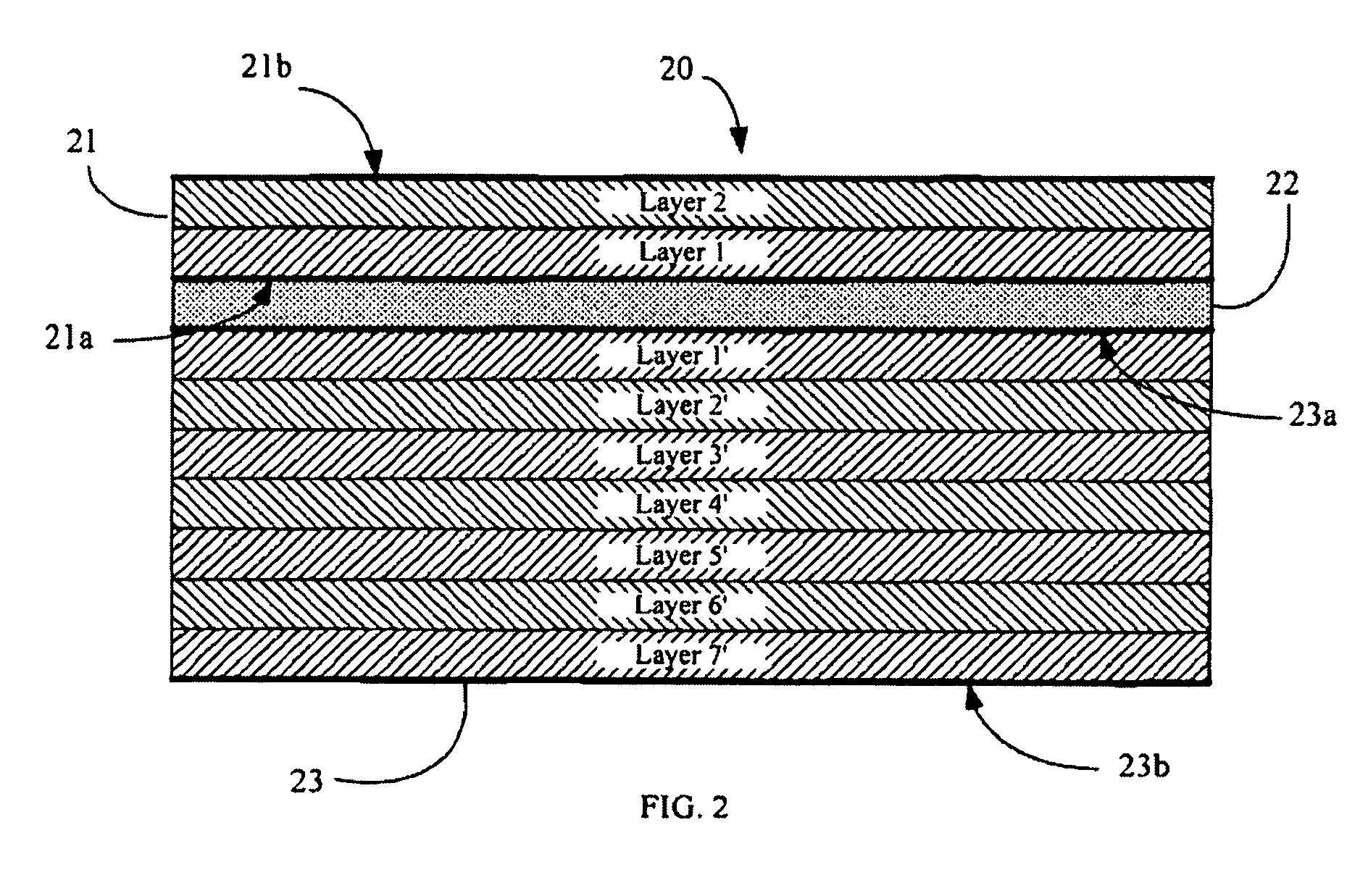

Easy-open reclosable films having an interior frangible interface and articles made therefrom

ActiveUS20070082161A1Easily and repeatedly separated and rejoinedSynthetic resin layered productsDomestic containersPolymer scienceGram-force

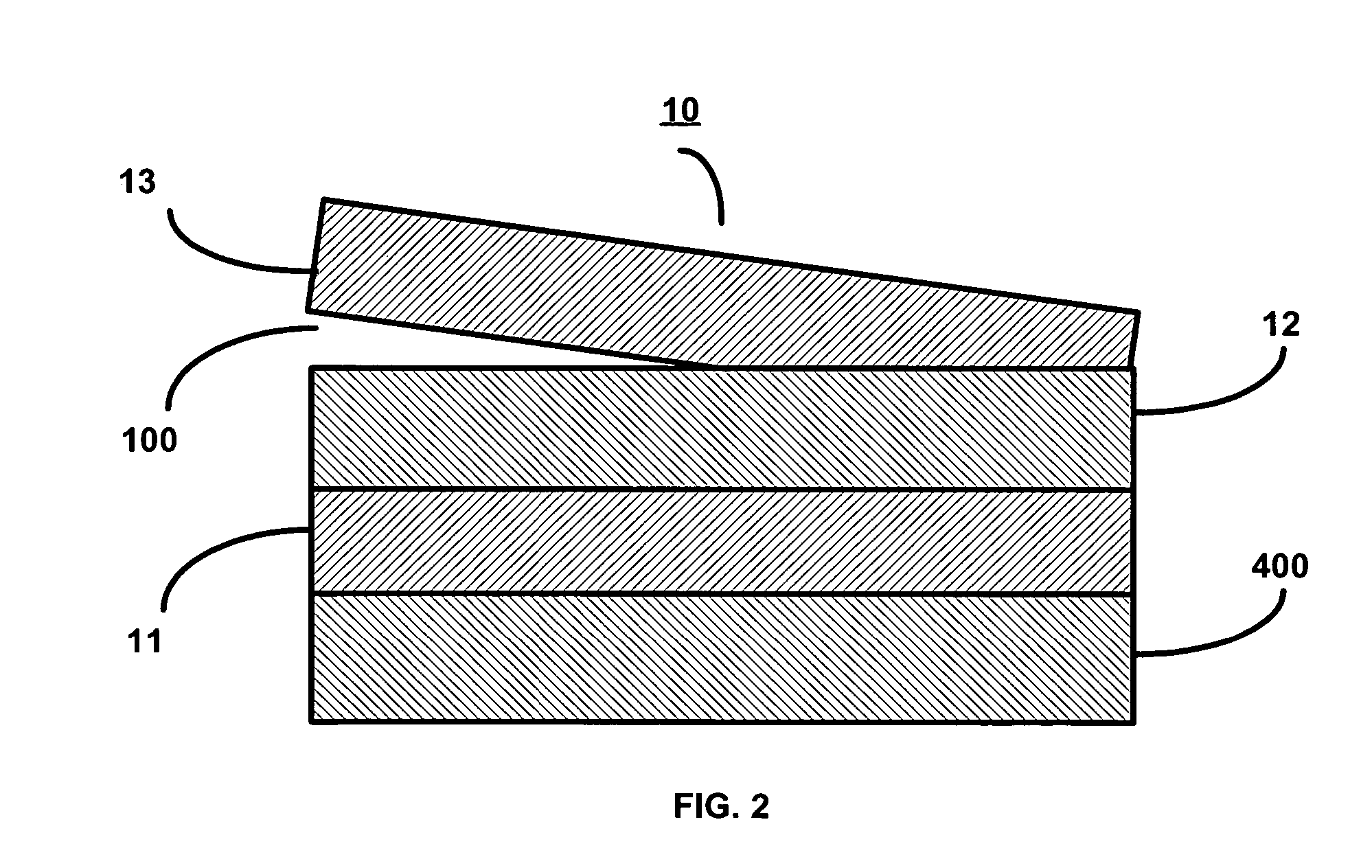

The present invention relates to peelable resealable multilayer films which include at least a first polymer layer, a second polymer layer of pressure-sensitive adhesive in direct contact with and bonded to both the first and third layers. The bond formed between the second and third layers includes a peelable resealable interface having a first interfacial peel strength, A, and a second interfacial peel strength, B. The peelable resealable interface includes a first interfacial peel strength, A, having a value of less than 3500 gram-force / inch (1350 newton / meter) as measured in accordance with ASTM F-904-98 test method when the films of the present invention are peeled from a second thermoplastic film to which the film has been heat-sealed. The second interfacial peel strength, B, has a value of at least 400 gram-force / inch (154 newton / meter) as measured in accordance with ASTM F-904-98 test method when the films are peeled from and re-adhered to a second film.

Owner:BEMIS COMPANY INC

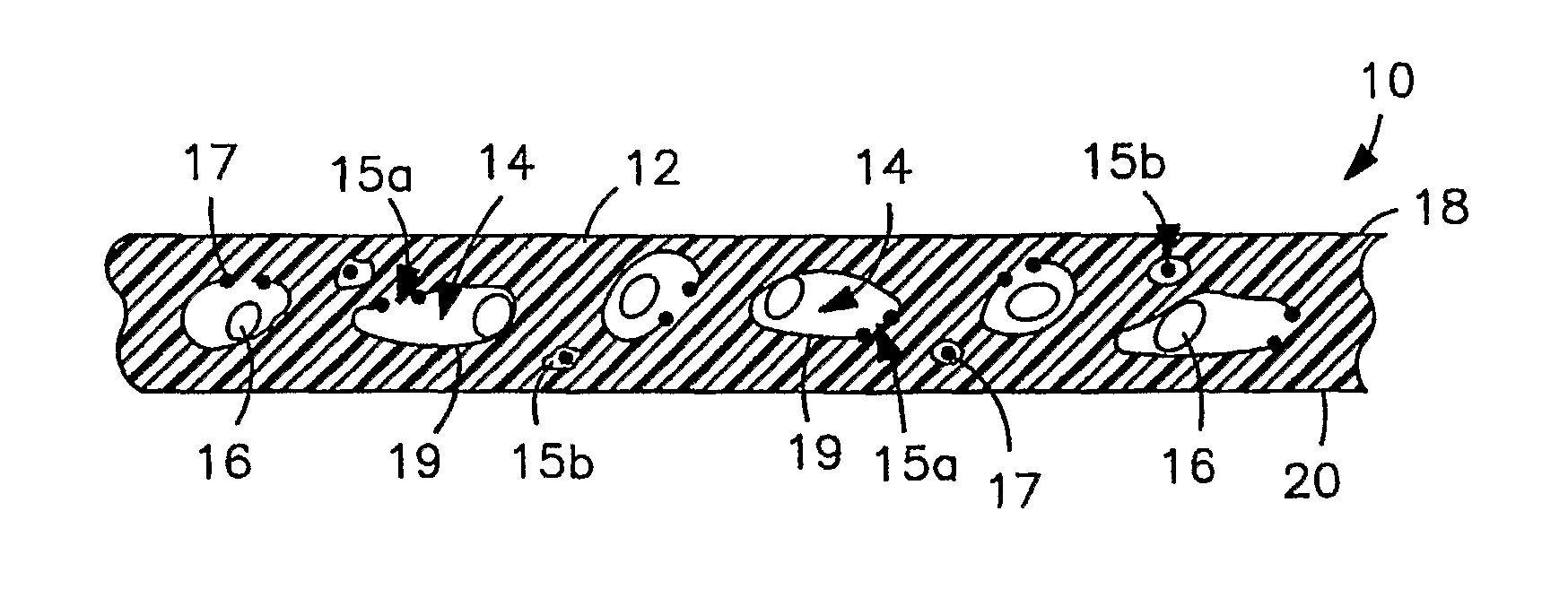

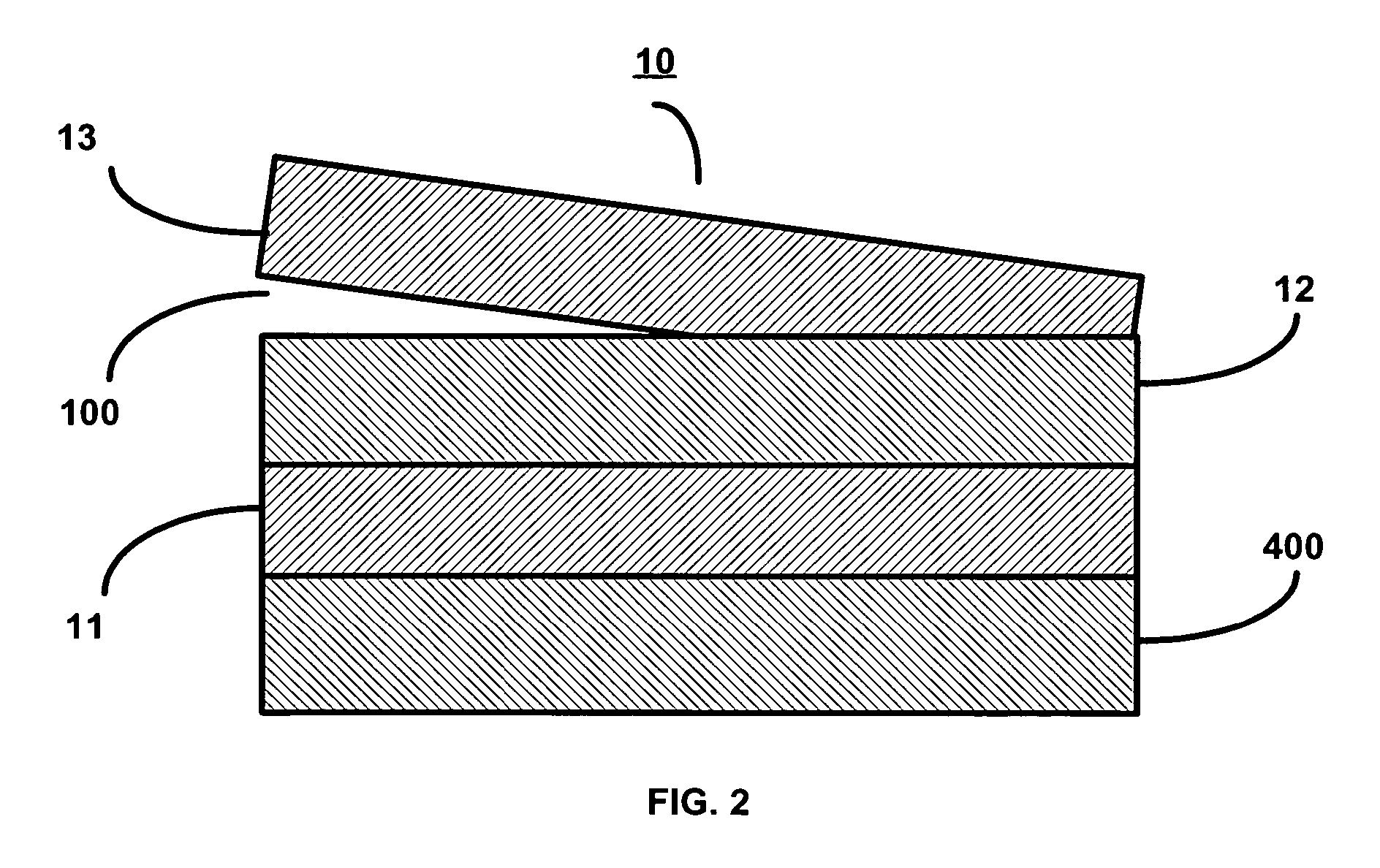

Peelable Film and Package Using Same

ActiveUS20100181370A1High Slow Rate Penetration Resistance valueMore puncture resistantFlexible coversWrappersPolyolefinGram-force

The present invention is directed to a peelable packaging film comprising a first thermoplastic substrate and a second thermoplastic substrate wherein the packaging film has a Heat Shrinkage value between 0 and 10% at 102° C. in either the machine or transverse directions. The first and second substrates each have a first surface and a second surface. Each of the first surfaces comprises a polyolefin and has a surface energy of at least 36 dynes / cm2. At least one first surface is oriented, preferably biaxially oriented, and at least one first surface is non-heat shrinkable. In contact with both first surfaces is a contiguous adhesive layer. A peelable interface is provided between the adhesive layer and at least one the first surfaces of the substrates. The peelable interface is adapted to have a peelable seal strength of between 60 and 2,500 grams-force / in.

Owner:BEMIS COMPANY INC

Highly breathable biodegradable films

A breathable film having a base layer comprising first filler particles and second filler particles dispersed within a biodegradable polymer matrix is provided. The first filler particles constitute from about 25 wt. % to about 75 wt. % of the base layer and the second filler particles constitute from about 0.1 wt. % to about 10 wt. % of the base layer. The ratio of the average size of the first filler particles to the average size of the second filler particles being from about 2 to about 100. The film exhibits a water vapor transmission rate of about 2,000 g / m2 / 24 hours or more and a peak load in the machine direction of about 800 grams-force per inch or more.

Owner:KIMBERLY-CLARK WORLDWIDE INC

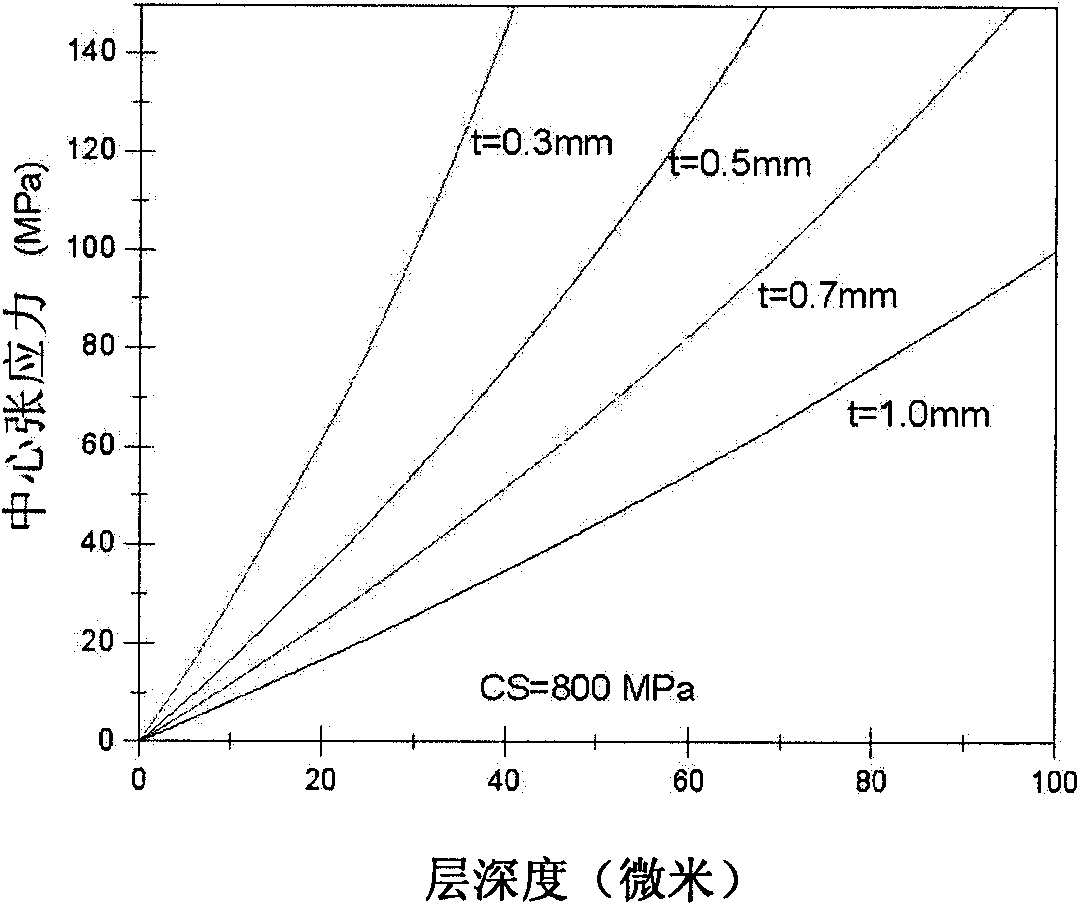

Chemical toughened glass capable of carrying out subsequent cutting

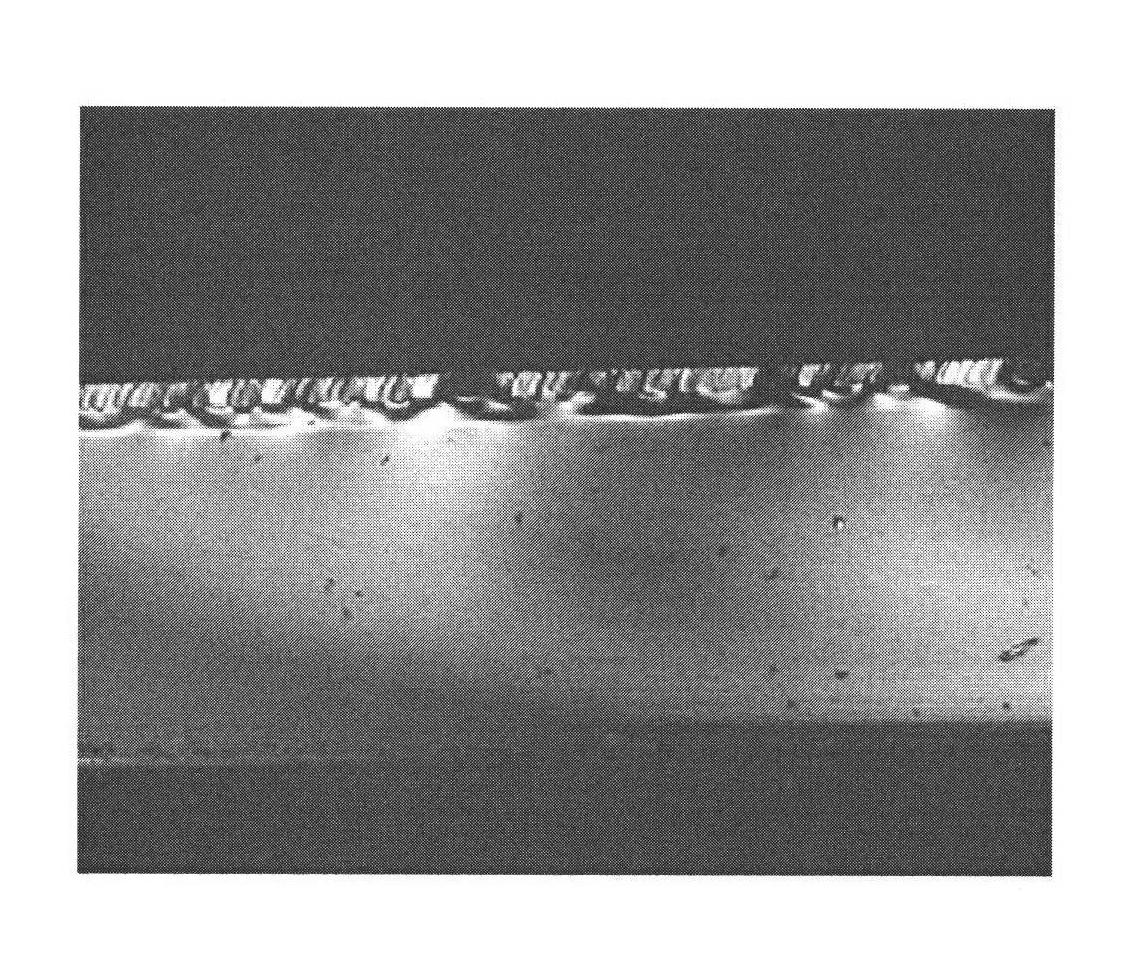

The invention discloses chemical toughened glass capable of carrying out subsequent cutting, which is characterized in that the Young modulus of the glass is 70-100MPa, the Knoop hardness (0.1 / 20, 100 gram force, 20s) of the glass is 500-800Kg / mm<2>, and the CTE (Coefficient of Thermal Expansion) of the glass is 5.0-11.0*10<-6> / DEG C.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

Easy-open reclosable films having an interior frangible interface and articles made therefrom

ActiveUS7927679B2Easily and repeatedly separated and rejoinedSynthetic resin layered productsDomestic containersPolymer scienceGram-force

The present invention relates to peelable resealable multilayer films which include at least a first polymer layer, a second polymer layer of pressure-sensitive adhesive in direct contact with and bonded to both the first and third layers. The bond formed between the second and third layers includes a peelable resealable interface having a first interfacial peel strength, A, and a second interfacial peel strength, B. The peelable resealable interface includes a first interfacial peel strength, A, having a value of less than 3500 gram-force / inch (1350 newton / meter) as measured in accordance with ASTM F-904-98 test method when the films of the present invention are peeled from a second thermoplastic film to which the film has been heat-sealed. The second interfacial peel strength, B, has a value of at least 400 gram-force / inch (154 newton / meter) as measured in accordance with ASTM F-904-98 test method when the films are peeled from and re-adhered to a second film.

Owner:BEMIS COMPANY INC

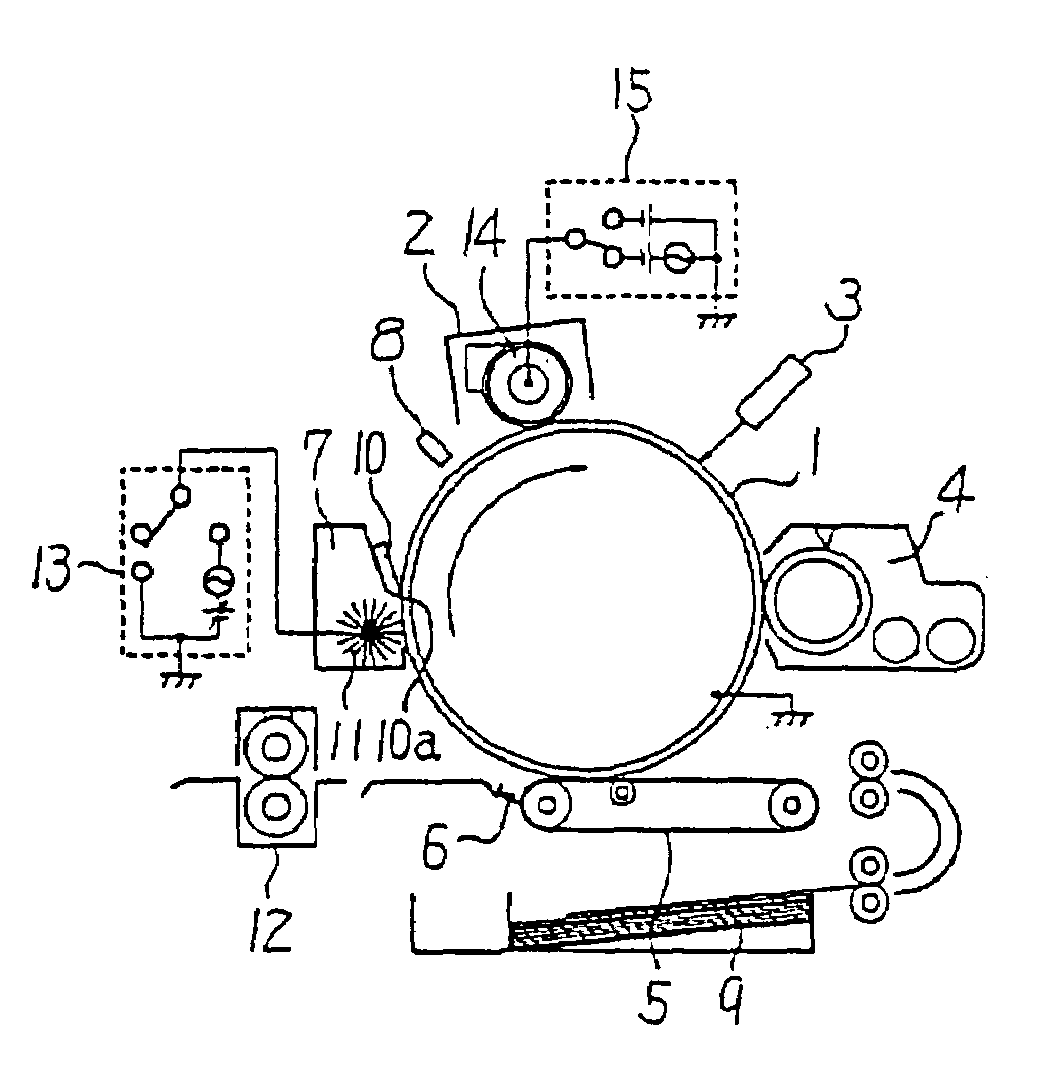

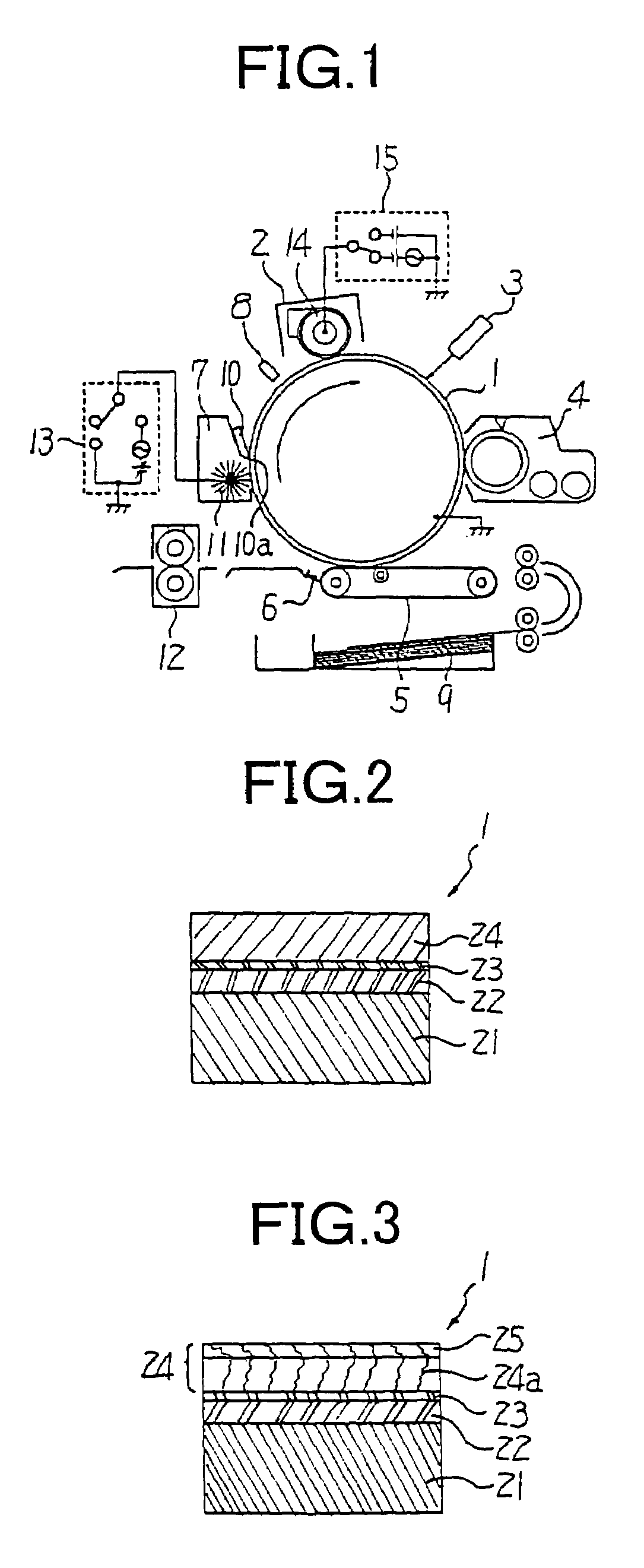

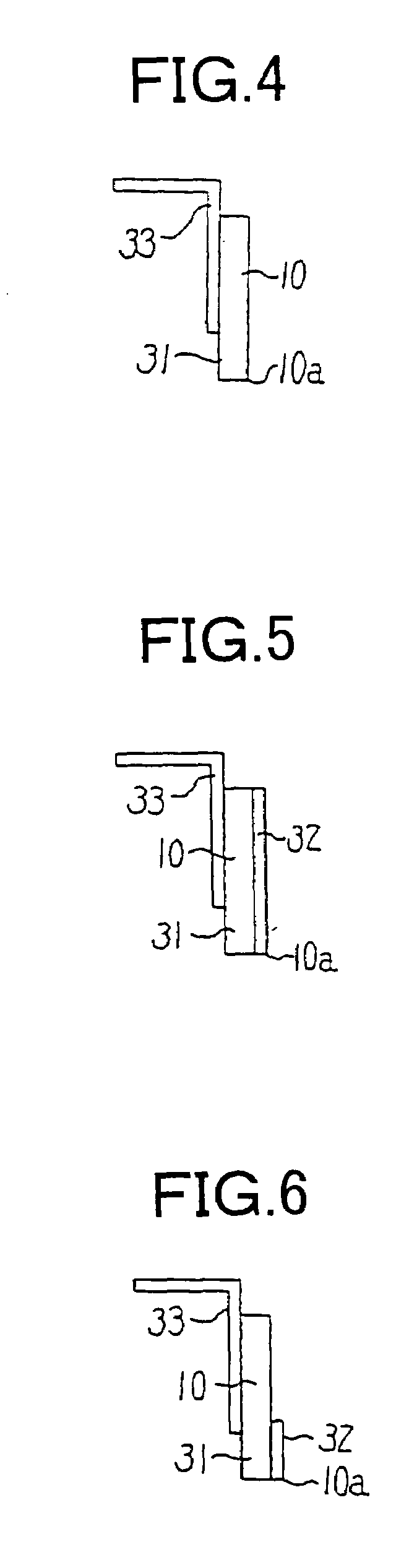

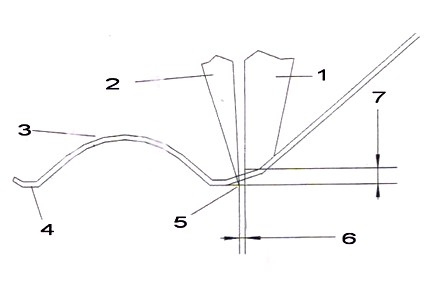

Measurement of frictional resistance of photoconductor against belt in image forming apparatus, process cartridge, and image forming method

An image forming apparatus includes a photoconductor having a surface with a frictional resistance ranging from 45 gram-force to 200 gram-force, a 10-point average roughness RzJIS ranging from 0.1 mm to 1.5 mm or a maximum height Rz of 2.5 mm. Image formation is performed by the image forming apparatus to allow irregular-shaped toner or spherical toner to be cleaned off efficiently and any background stain on a copied sheet to be prevented. A lubricant is applied to the photoconductor so as to form a nonuniform film thereon, which prevents the frictional resistance from abnormally lowering, thus suppressing image degradation.

Owner:RICOH KK

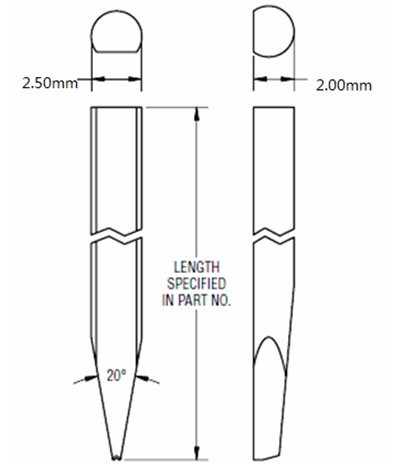

Realization method for lead bonding thick aluminum wire

ActiveCN102637613ANot easily oxidizedSimple production processSemiconductor/solid-state device testing/measurementSolid-state devicesGram-forceLead bonding

The invention relates to the technical field of the semiconductor packaging, in particular to a realization method for lead bonding a thick aluminum wire. The method comprises the following four important operation key points of designing and optimizing a chopper, detecting chip surface aluminum layer thickness, optimizing and matching a bonding technical parameter, and detecting the bonding strength. As the thick aluminum wire is unlikely to oxidize, the production technology is simplified, and the cost can be obviously lowered. Meanwhile, the thick aluminum wire has the advantages of small contact resistance, low device power consumption, high bonding strength and the like. The chip aluminum layer thickness is detected by 85% phosphoric acid solution so as to ensure that the aluminum layer thickness is more than 5.0mum when the thick aluminum wire is lead bonded, and craters can be prevented from generating in the operation process. The technical parameter adopts initial power pressure, and the craters can be prevented by regulating the initial power pressure according to the practical situation. Whether the welding strength reaches the standard is judged by measuring the breaking force of the bonding wire by a gram force meter. According to the realization method for lead bonding the thick aluminum wire, the cost can be obviously lowered, the device power consumption is lowered, and the product reliability can be improved.

Owner:SICHUAN LIPTAI ELECTRONICS

Soft tissue produced using a structured fabric and energy efficient pressing

ActiveUS10273635B2Avoid disadvantagesLarge structureSurfactants additionReinforcing agents additionGram-forceEngineering

Owner:FIRST QUALITY TISSUE

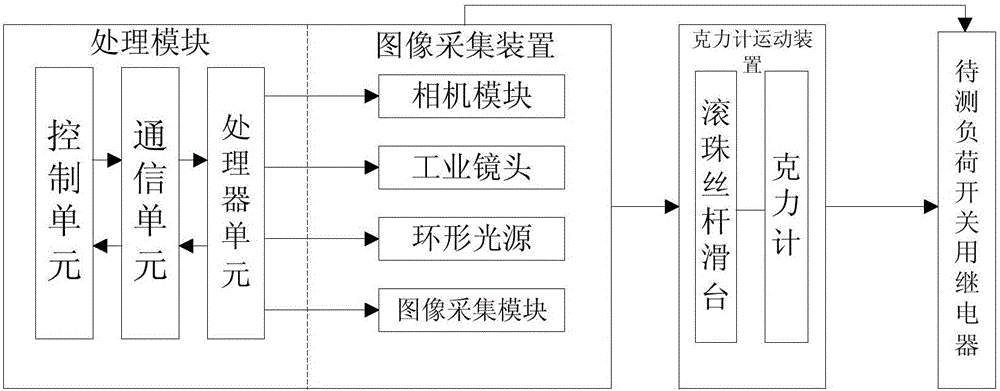

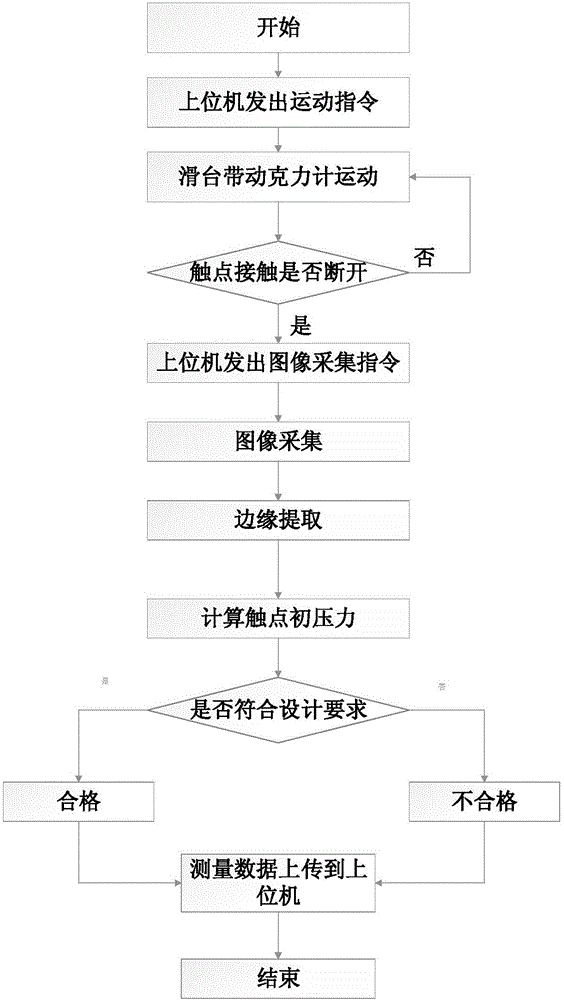

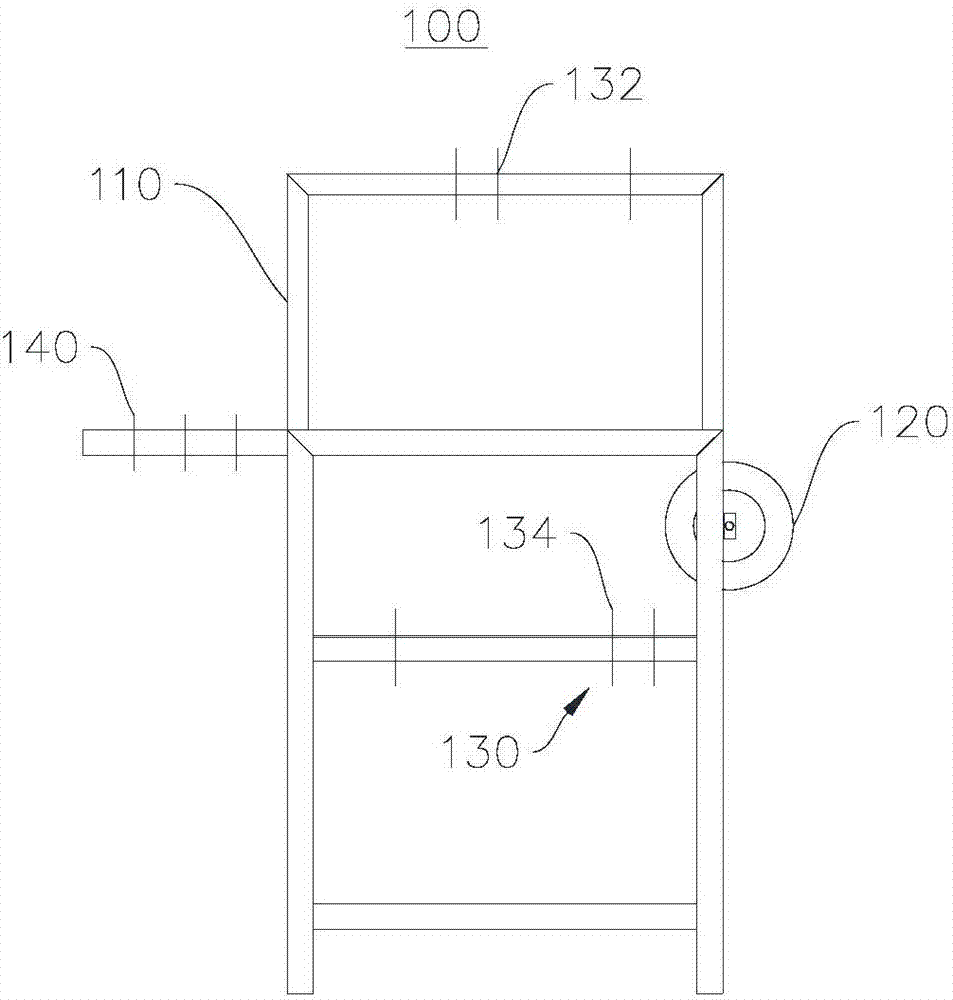

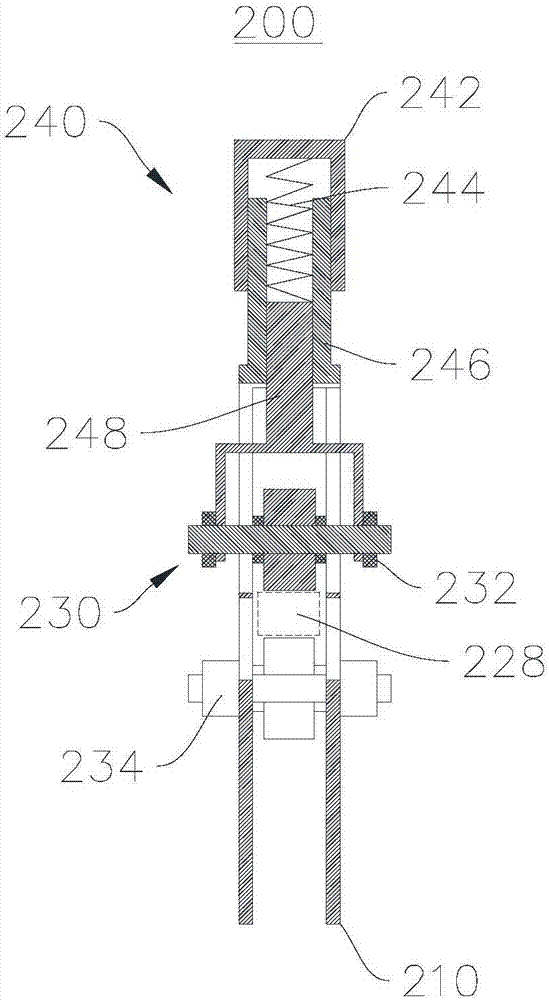

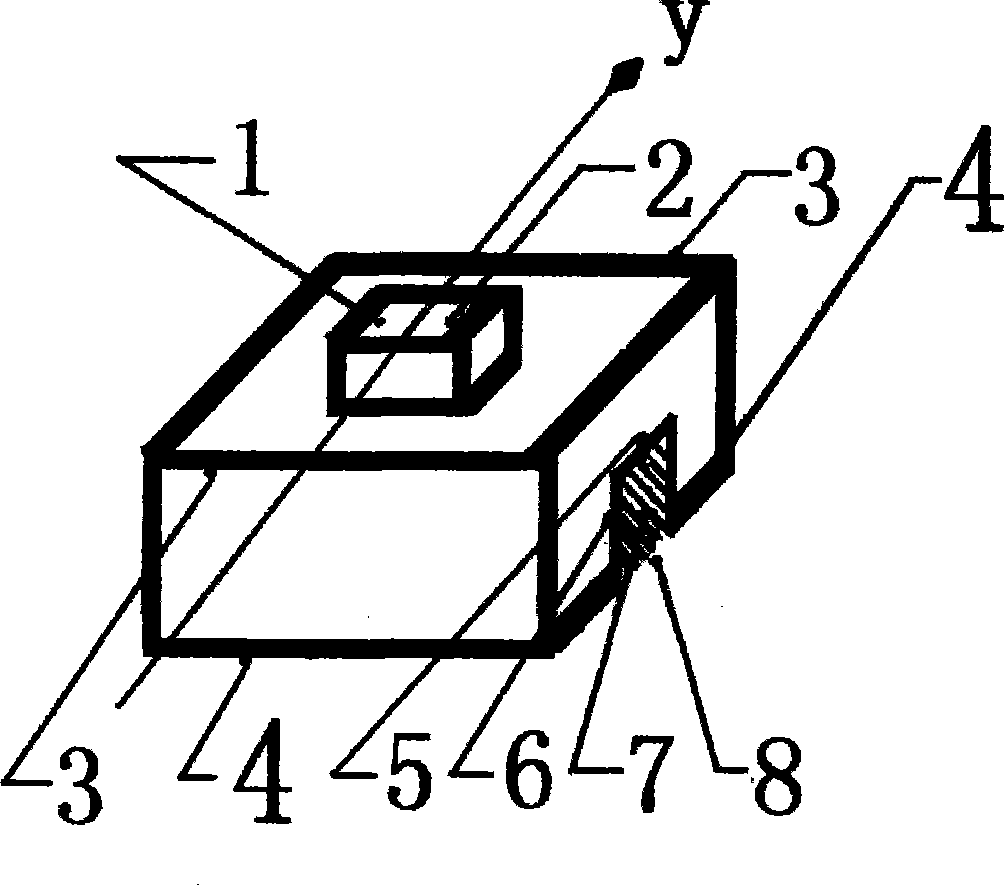

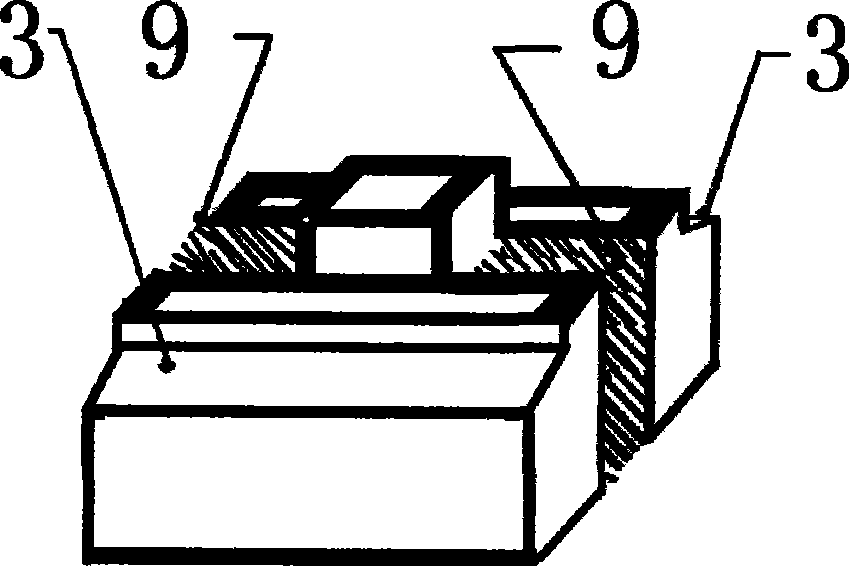

System and method for measuring primary pressure of contact of load switch spring system

PendingCN106441678AFulfilling Automated Measurement RequirementsSimple structureApparatus for force/torque/work measurementGram-forceQuality control

The invention provides a system and a method for measuring primary pressure of a contact of a load switch spring system. The system comprises a gram force meter movement device and an image acquisition device, wherein the gram force meter movement device is used for pulling a static stationary spring leaf of a relay to be separated from a dynamic spring leaf through a gram force meter, and used for transmitting an image acquisition instrument when the static stationary spring leaf of a relay is separated from the dynamic spring leaf; the image acquisition device is connected with the ram force meter movement device, and is used for acquiring gram force meter reads according to the image acquisition instruction. By adopting the system and the method, an automatic measurement requirement of the primary pressure of the contact in an ammeter mounting load switch contact spring system can be achieved, measurement on primary pressure of one or more groups of ammeter load switch contacts can be automatically and independently controlled, and thus convenience in quality control and checking of operators can be brought.

Owner:ELECTRIC POWER RES INST STATE GRID JIBEI ELECTRIC POWER COMPANY +6

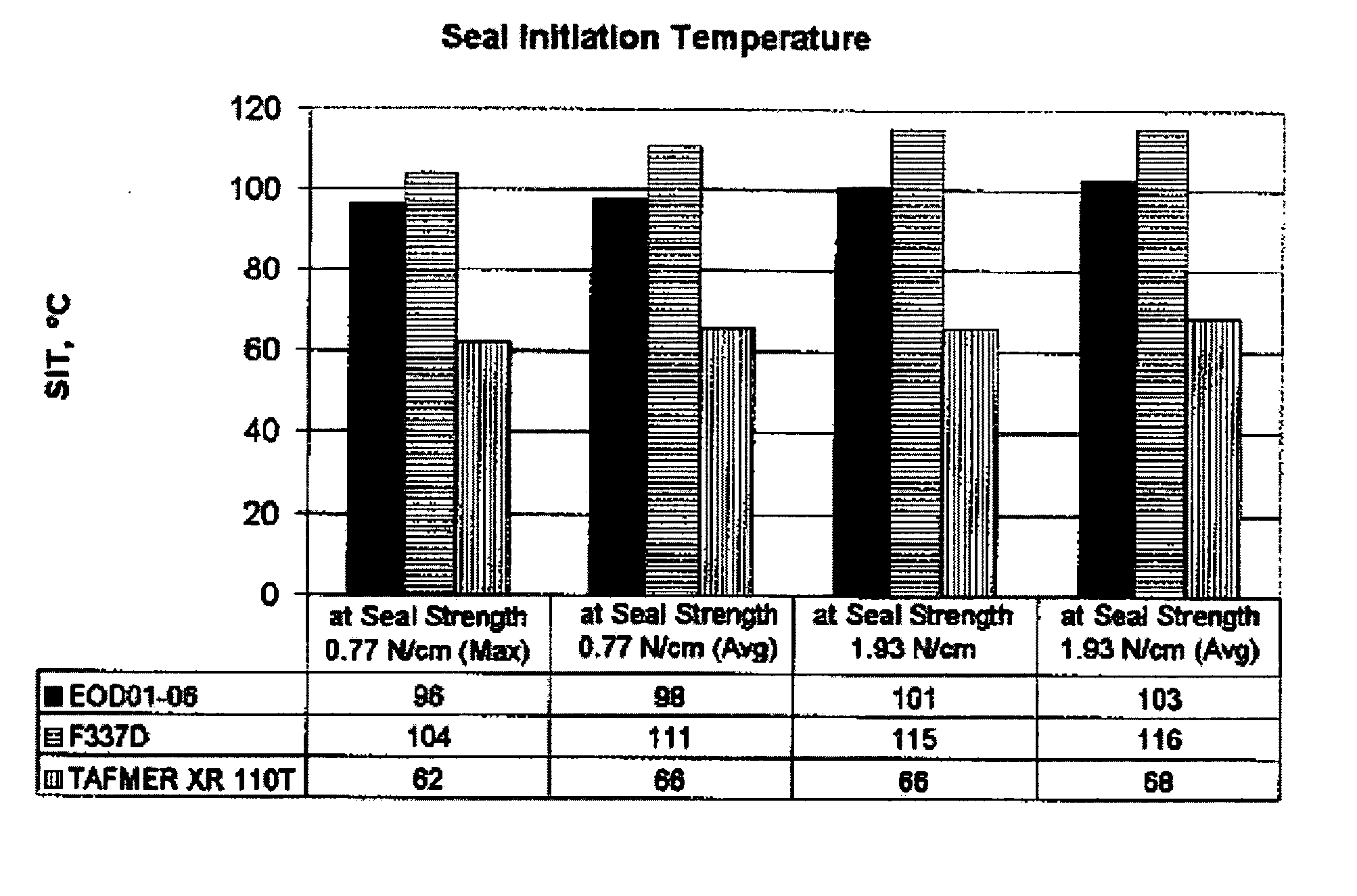

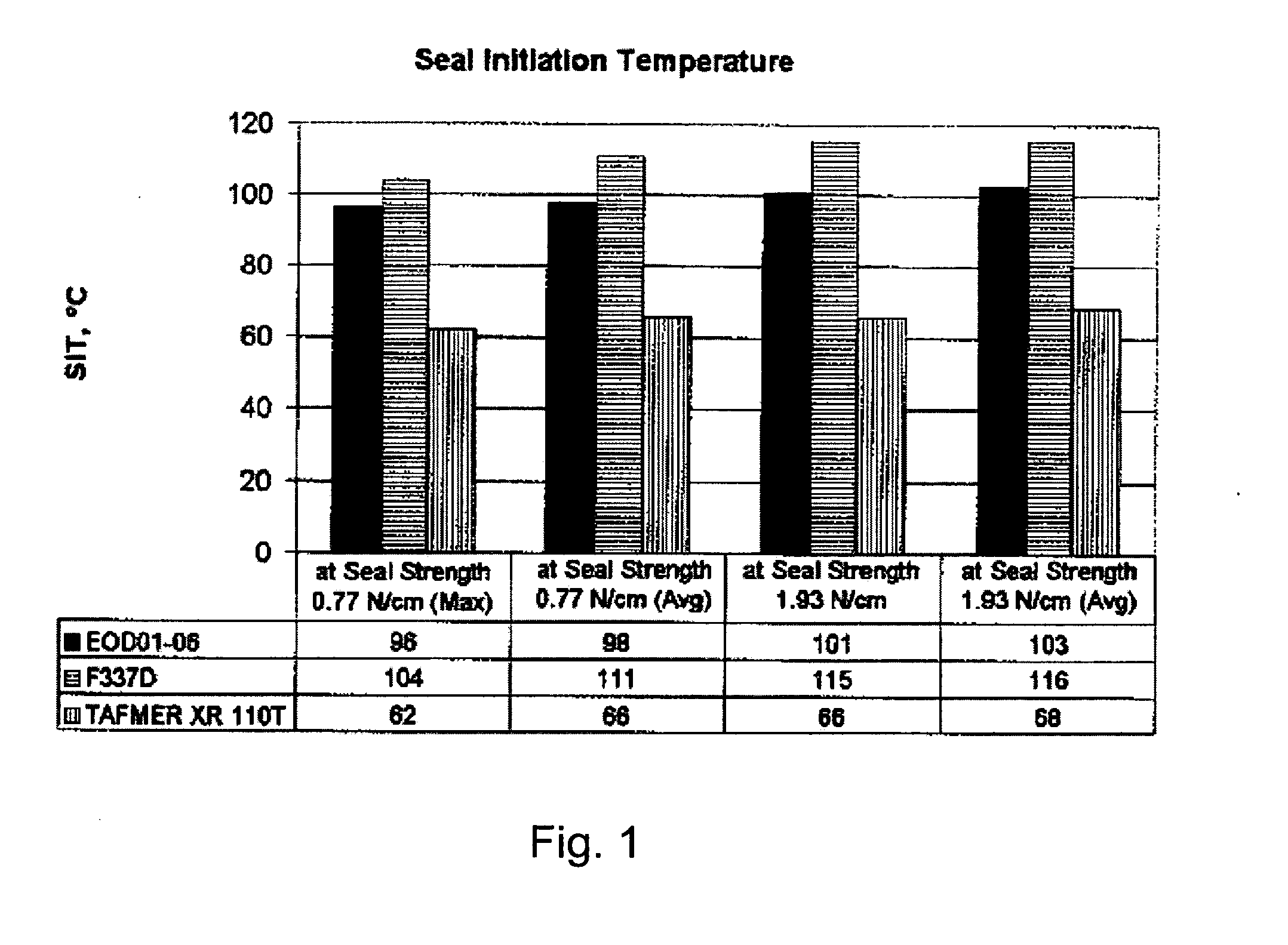

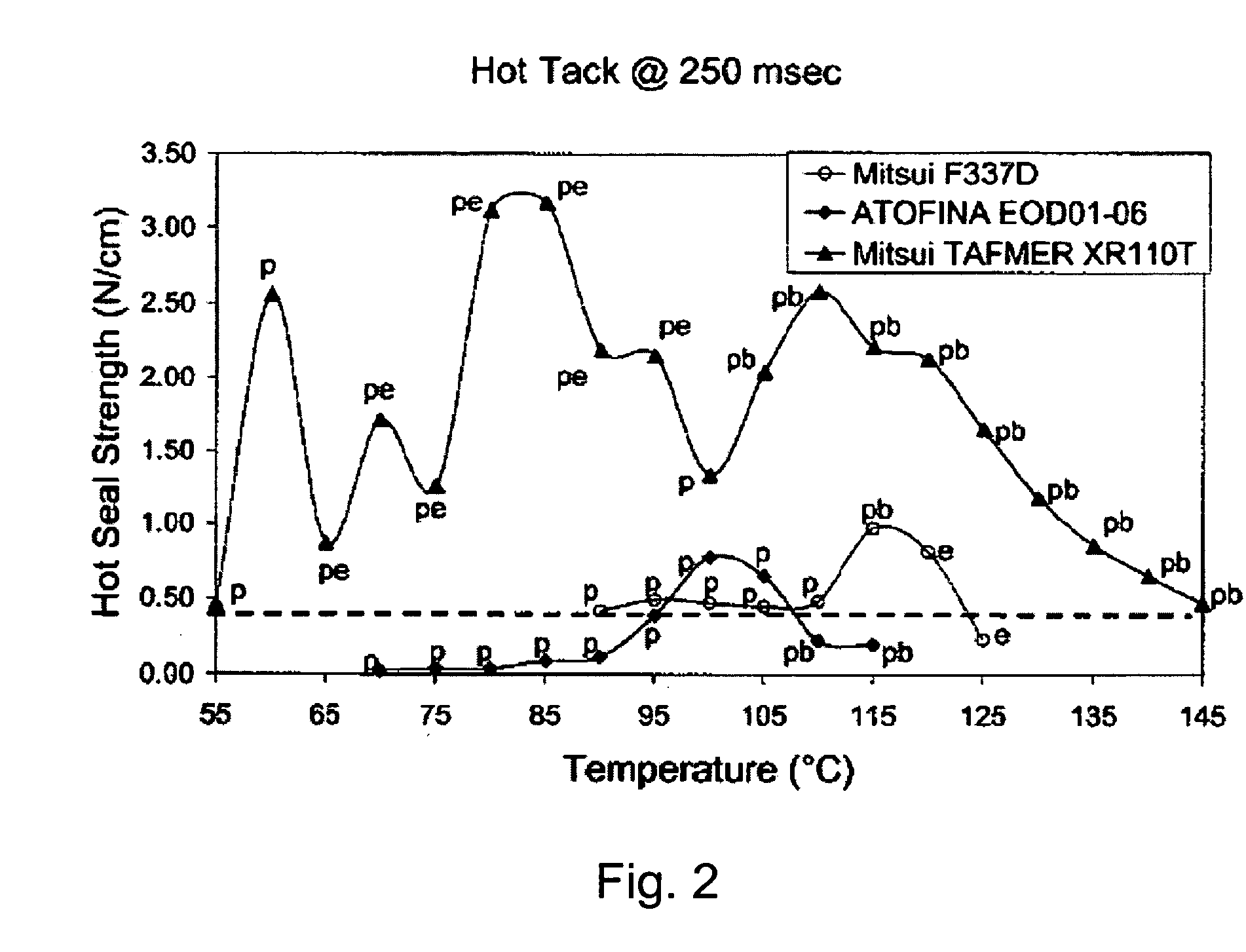

Hot seal resins

A film having a seal strength of at least 100 grams force / inch and a seal initiation temperature of less than about 100 ° C. A polymeric composition comprising a metallocene catalyzed random ethylene-propylene copolymer and a propylene / alpha olefin copolymer or ethylene / alpha olefin copolymer. An article comprised of a film having a seal strength of at least 100 grams force / inch and a seal initiation temperature of less than about 100 ° C.

Owner:FINA TECH

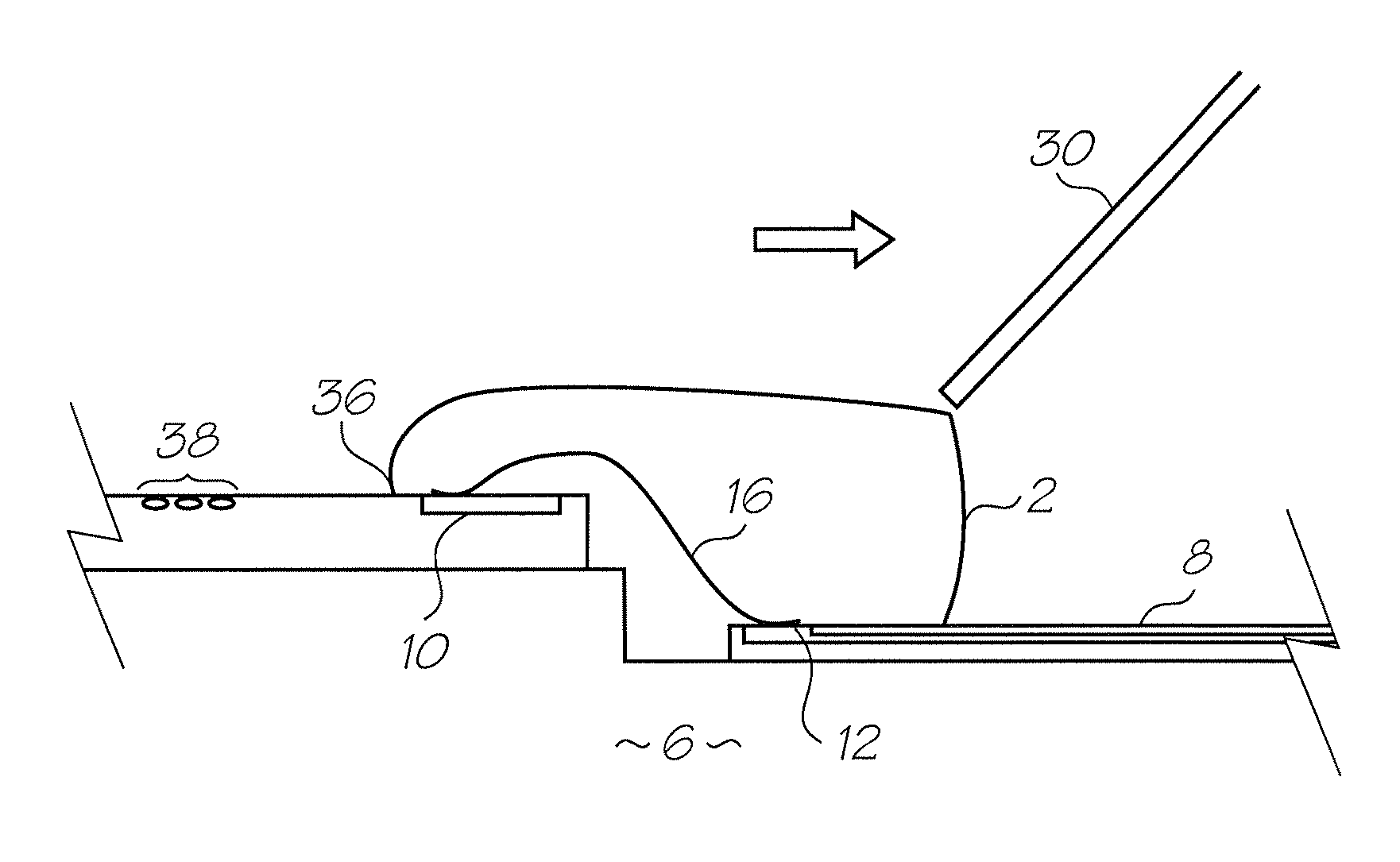

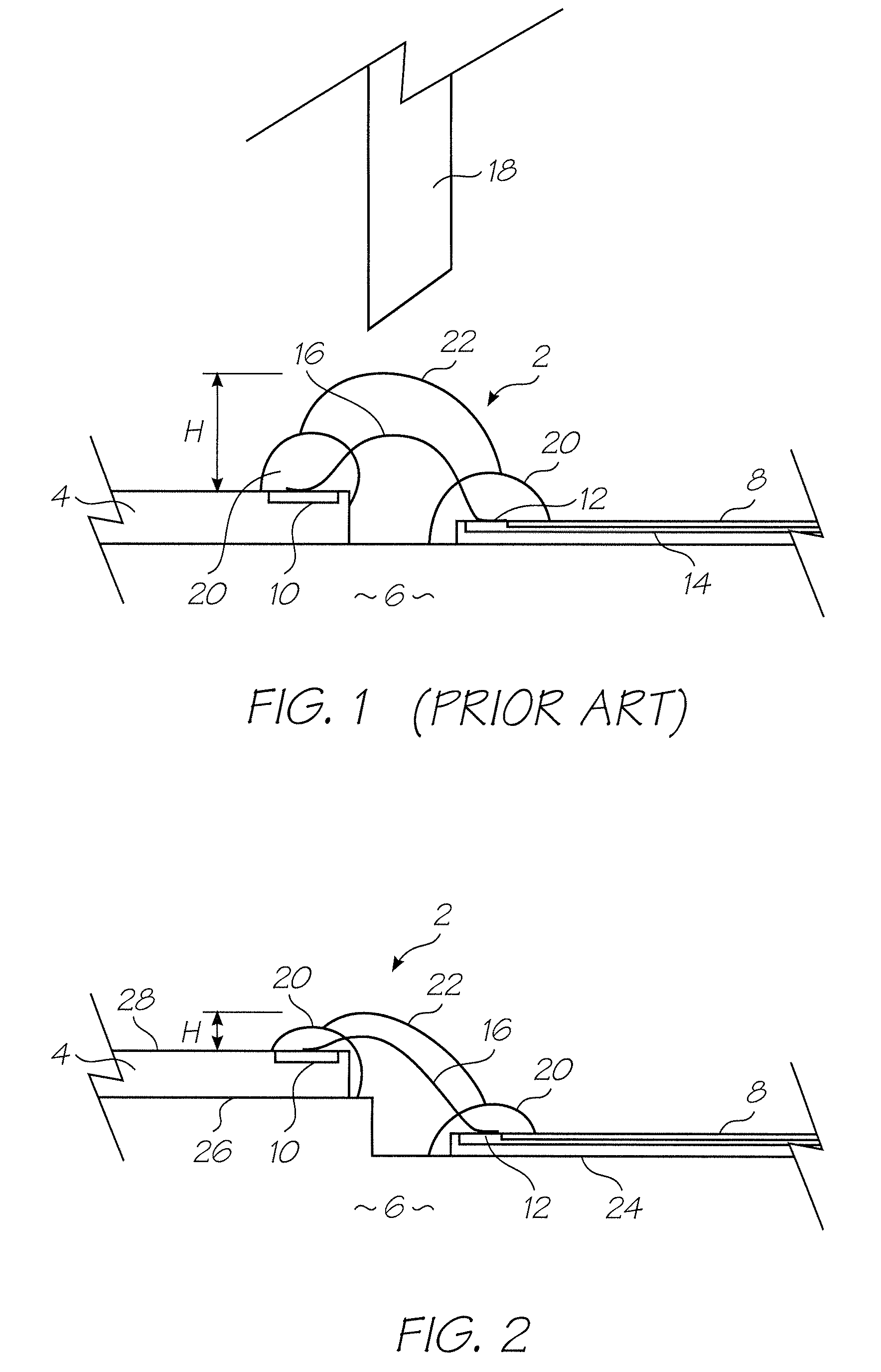

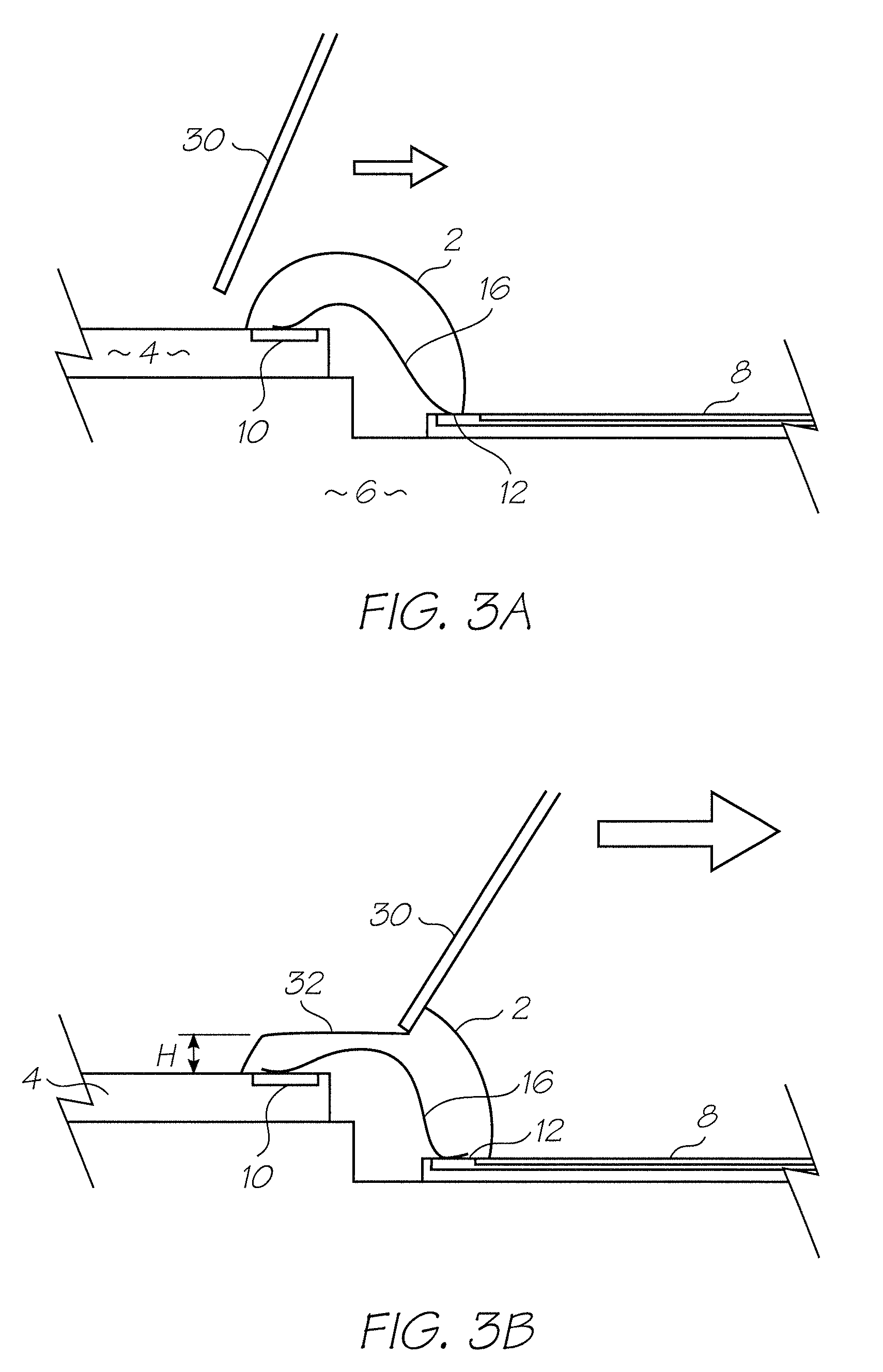

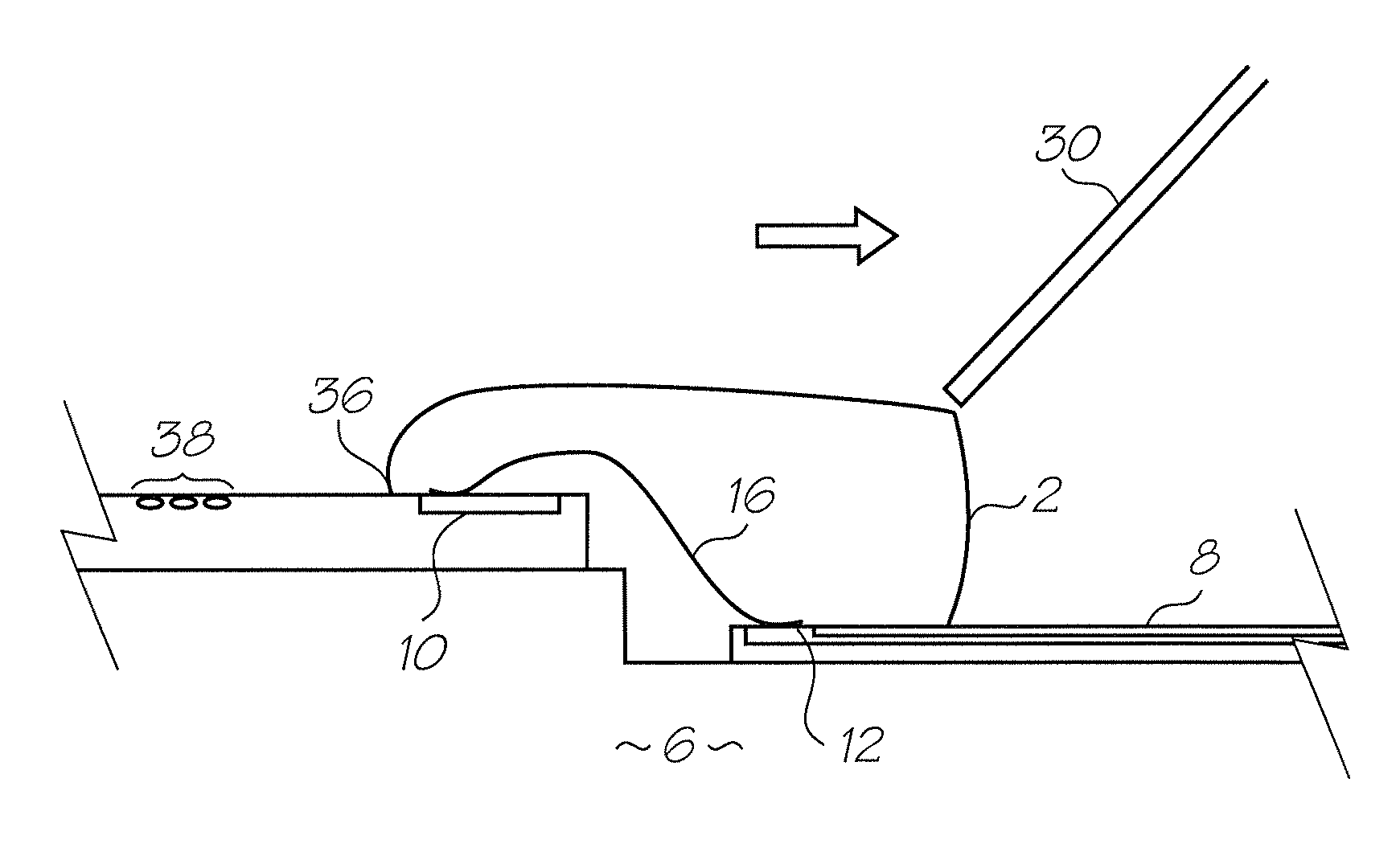

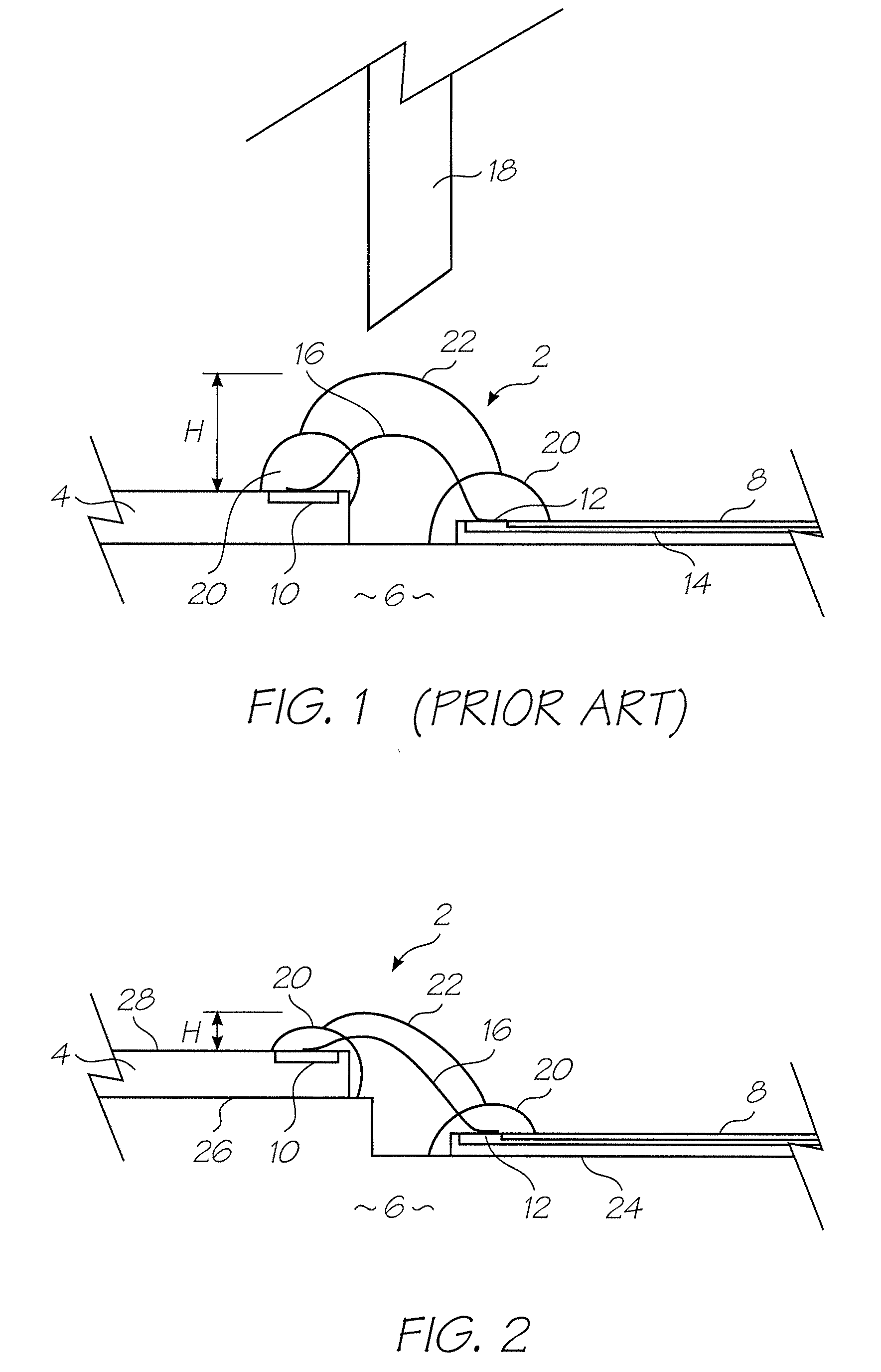

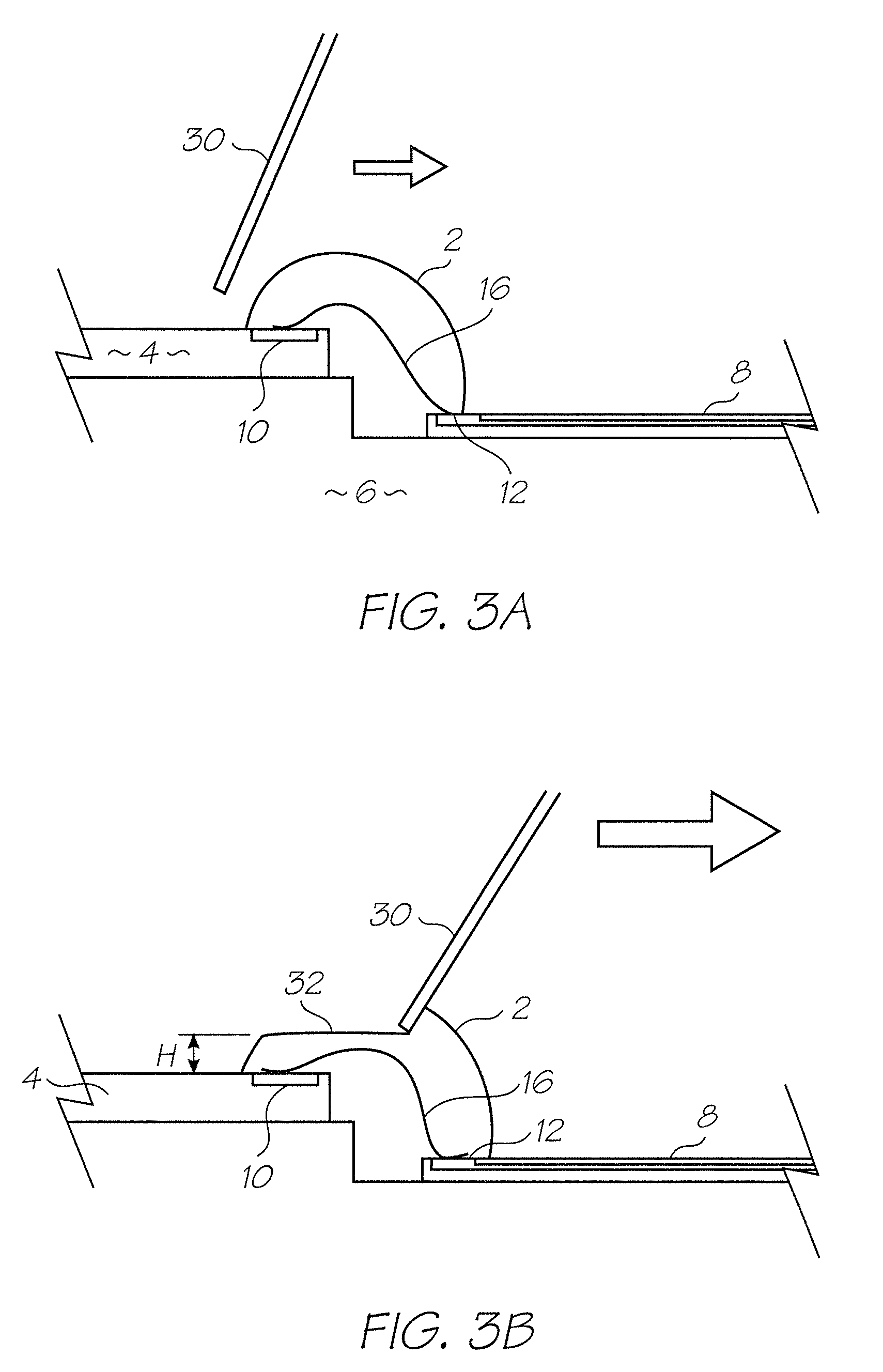

Method of reducing wire bond profile height in integrated circuits mounted to circuit boards

InactiveUS7988033B2Reduced strengthEasy to controlSemiconductor/solid-state device detailsSolid-state devicesElectricityContact pad

A method of profiling a wire bond between a contact pad on a die, and a conductor on a supporting structure, by electrically connecting the contact pad on the die to the conductor on the supporting structure with a wire bond, the wire bond extending in an arc from the contact pad to the conductor, pushing on the wire bond to collapse the arc and plastically deform the wire bond, and then releasing the wire bonds such that the plastic deformation maintains the wire bond in a flatter profile shape. The strength of the wire bond is known to be relatively small; of the order of 3 to 5 grams force. However, the Applicant's work has found that the wire bond structure is robust enough to withstand a certain degree of work hardening from plastic deformation. The arc of the wire bond can be deformed into a flatter profile without compromising the electrical connection with the PCB.

Owner:SILVERBROOK RES PTY LTD +1

Spun-laid webs with at least one of lofty, elastic and high strength characteristics

A continuous filament spun-laid web includes a plurality of polymer fibers within the web, the web having a first thickness and the web being free of any thermal or mechanical bonding treatment. Activation of the web results in at least one of an increase from the first thickness prior to activation to a second thickness post activation in which the second thickness is at least about two times greater than the first thickness, a decrease in density of the web post activation in relation to a density of the web prior to activation, the web being configured to withstand an elastic elongation from about 10% to about 350% in at least one of a machine direction (MD) of the web and a cross-direction (CD) of the web, and the web having a tensile strength from about 50 gram-force / cm2 to about 5000 gram-force / cm2.

Owner:希尔斯公司

Manufacturing method for zero-length spring and zero-length spring

ActiveCN107502727AManufacturing method systemManufacturing method scienceFurnace typesWire springsGram-forceSolid solution strengthening

The invention provides a manufacturing method for a zero-length spring and the zero-length spring, and relates to the field of sea-air gravity meters. The manufacturing method for the zero-length spring comprises the steps that a microstructure of a wire material is adjusted through a solid solution strengthening treating process, wherein the wire material is a constant elastic wire material; molding treatment is conducted on the solid solution wire material; pretension force is applied to a first spring through a reverse rotation mode; and tempering treating is conducted on a second spring. The manufacturing method for the zero-length spring is more systematic and scientific and high in precise so that the zero length error delta l of the zero-length spring is less than or equal to 1 millimeter, the drifting amount delta is less than or equal to 10<2>[mu] per day, the rigidity error k is less than or equal to 0.01 gram force per millimeter, and the difficult problem of physical zero length which cannot be solved by a traditional process is solved.

Owner:INST OF GEODESY & GEOPHYSICS CHINESE ACADEMY OF SCI

Anhydrous antiperspirant cream compositions having improved perfume longevity

The present invention discloses anhydrous antiperspirant cream compositions having improved fragrance persistence. These compositions have a penetration force value of from about 75 gram force to about 500 gram force and comprise (a) an antiperspirant active, and (b) a perfume / cyclodextrin inclusion complex. The present invention also discloses a packaged anhydrous antiperspirant cream composition comprising (a) an antiperspirant active; (b) a fragrance / cyclodextrin inclusion complex; and (c) a dispensing package containing the composition, Wherein the dispensing package comprises (i) a container body having an inner chamber and a dispensing end, and (ii) a porous top cover connected to the dispensing end of the container body, the porous top cover has a plurality of holes penetrating through the thickness of the porous top cover, and the holes The area accounts for about 15% to about 80% of the total surface area of the porous mantle.

Owner:THE PROCTER & GAMBLE COMPANY

Liquid crystal ultrahigh molecular polyethylene composite material

The invention relates to a liquid crystal ultrahigh molecular polyethylene composite material, and belongs to the technical field of high molecular materials. The liquid crystal ultrahigh molecular polyethylene composite material is prepared from 70.5-88.5wt% of ultrahigh molecular weight polyethylene, 8-26wt% of liquid crystal high-molecular polymer, 2.5wt% of superfine graphite and 1wt% of calcium stearate at a mass ratio. The raw materials in the proportions are input into a blending machine to stir for 50-60 minutes; and a powder material is put into a mould for mould pressing and sintering at 280-300 DEG C to prepare the liquid crystal ultrahigh molecular polyethylene modified composite material. By using the liquid crystal ultrahigh molecular polyethylene modified composite material prepared from the formulas, under the condition of keeping the original high performance of the ultrahigh molecular polyethylene product, the comprehensive performance is improved, the softening temperature reaches 110 DEG C, the tensile strength is 35 MPa, the abrasion loss is 0.08mg, and the shore hardness is 68-72 gram force.

Owner:周恒勇

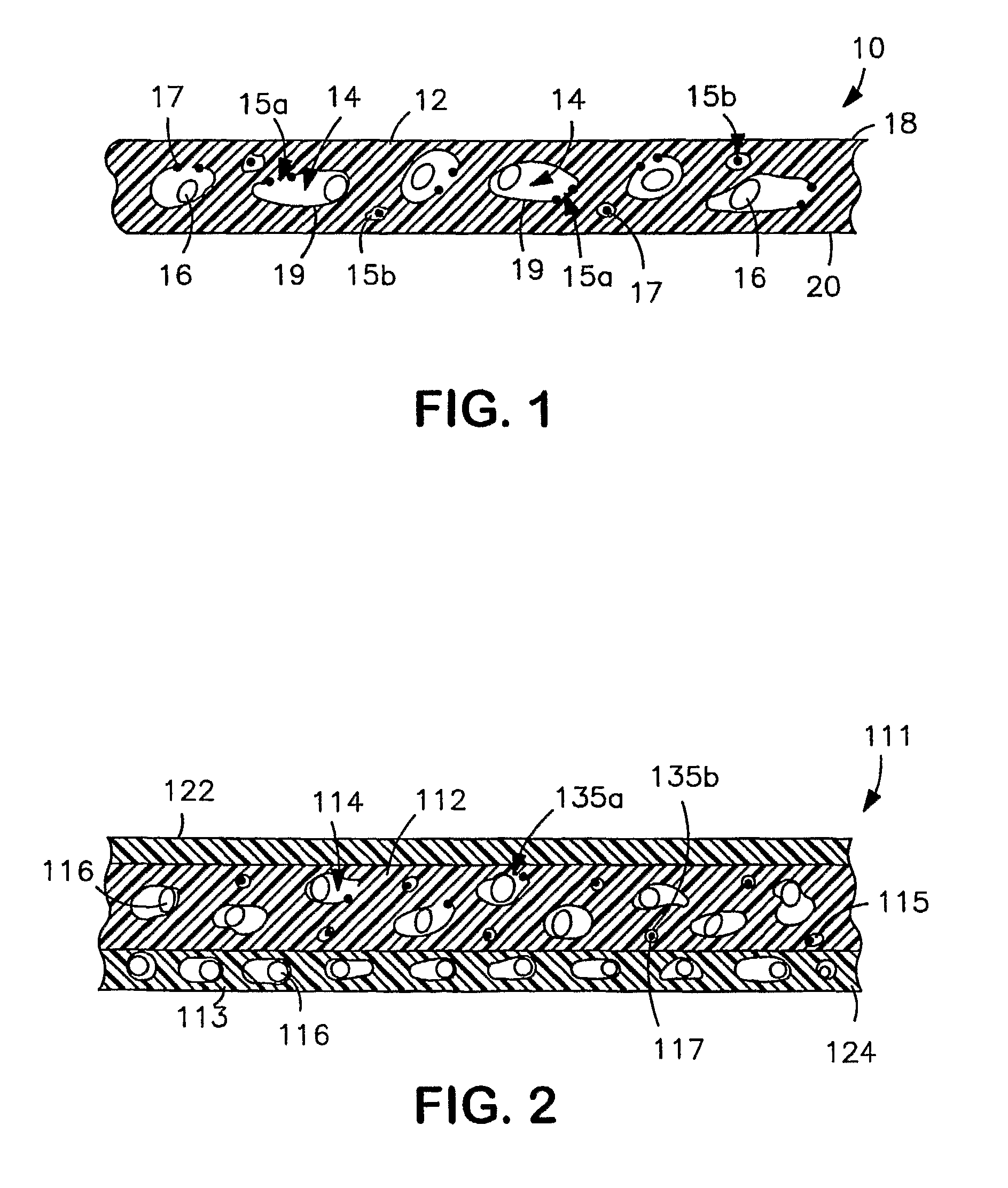

Flame and particulate resistant knit article

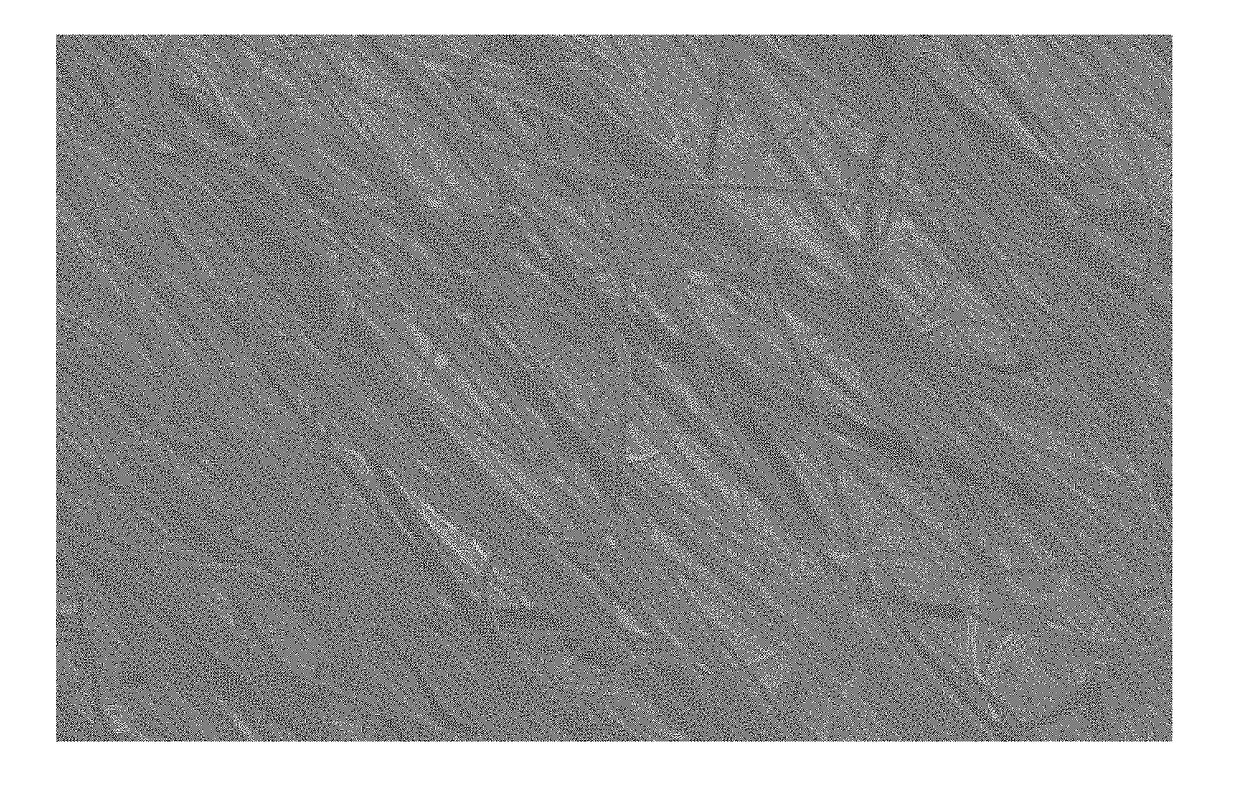

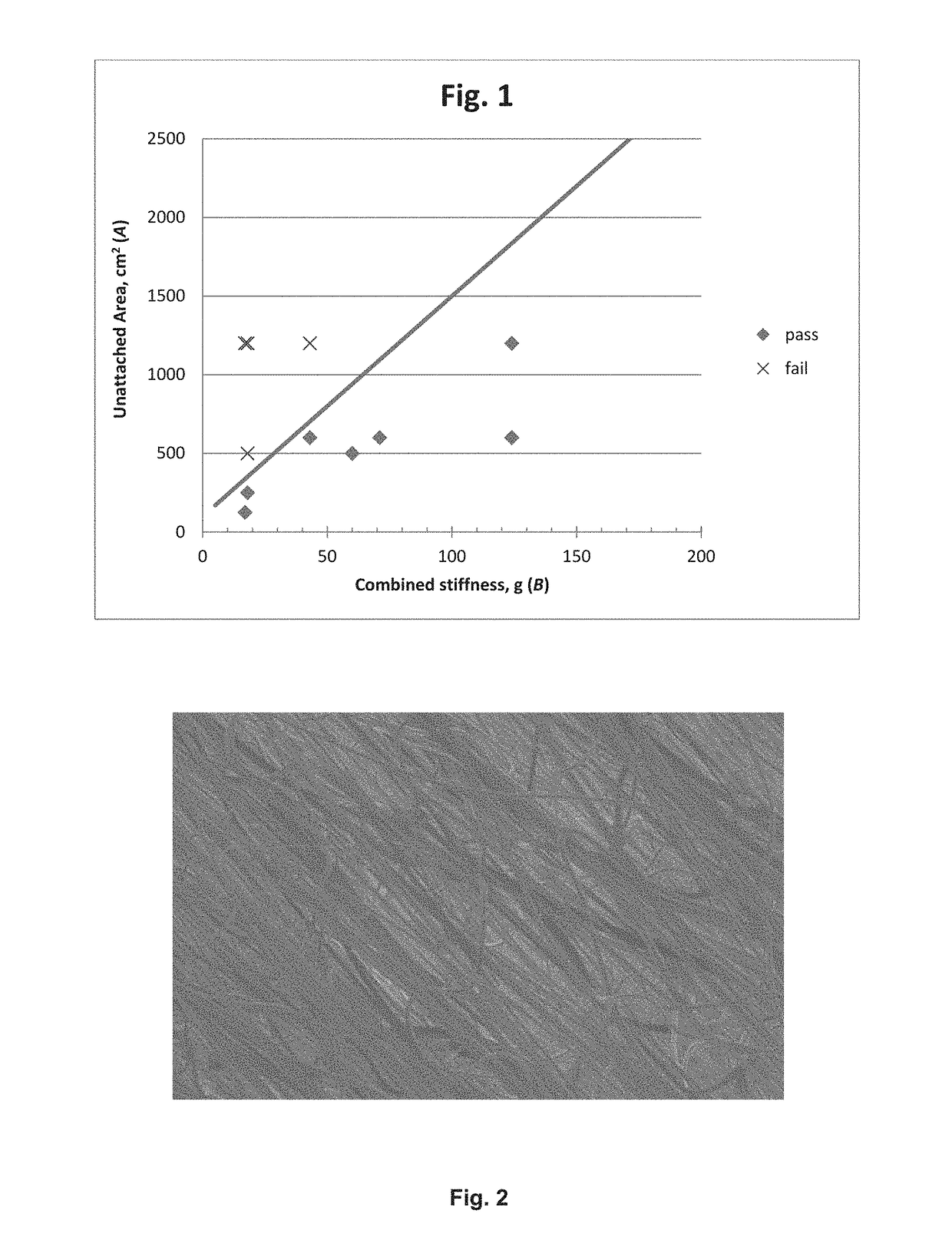

An article of protective clothing comprising a durable multilayer fabric laminate formed fromi) a first flame resistant knitted fabric made from yarns, the fabric having an average fabric modulus of 8 grams-force of greater;ii) a flame-resistant nonwoven fabric having a machine direction and a cross direction, and consisting of a plurality of continuous filaments having a diameter of less than 1000 nm, the filaments in the fabric being substantially oriented parallel with the machine direction and having stretch and recovery in the cross direction; andiii) a second flame resistant knitted fabric made from yarns, the fabric having an average fabric modulus of 8 grams-force of greater;wherein the nonwoven fabric is positioned between and coextensive with the first and second flame-resistant knitted fabrics; the nonwoven fabric being attached to the first knitted fabric by a set of first attachment points, the attachment points defining a first unattached area having a first effective diameter; the nonwoven fabric also being attached to the second knitted fabric by a set of second attachment points, the attachment points defining a second unattached area having a second effective diameter; wherein both the first unattached area and the second unattached area each have a value A, in square centimeters, according to the formula:C<A< / =(14*B)+100the value B being the sum of the average fabric modulus of the first knitted fabric and the average fabric modulus of the second knitted fabric, in grams-force; and the value C being 5 square centimeters.

Owner:DUPONT SAFETY & CONSTR INC

Peelable film and package using same

ActiveUS8679604B2High Slow Rate Penetration Resistance valueMore puncture resistantSynthetic resin layered productsCellulosic plastic layered productsPolyolefinGram-force

The present invention is directed to a peelable packaging film comprising a first thermoplastic substrate and a second thermoplastic substrate wherein the packaging film has a Heat Shrinkage value between 0 and 10% at 102° C. in either the machine or transverse directions. The first and second substrates each have a first surface and a second surface. Each of the first surfaces comprises a polyolefin and has a surface energy of at least 36 dynes / cm. At least one first surface is oriented, preferably biaxially oriented, and at least one first surface is non-heat shrinkable. In contact with both first surfaces is a contiguous adhesive layer. A peelable interface is provided between the adhesive layer and at least one the first surfaces of the substrates. The peelable interface is adapted to have a peelable seal strength of between 60 and 2,500 grams-force / in.

Owner:BEMIS COMPANY INC

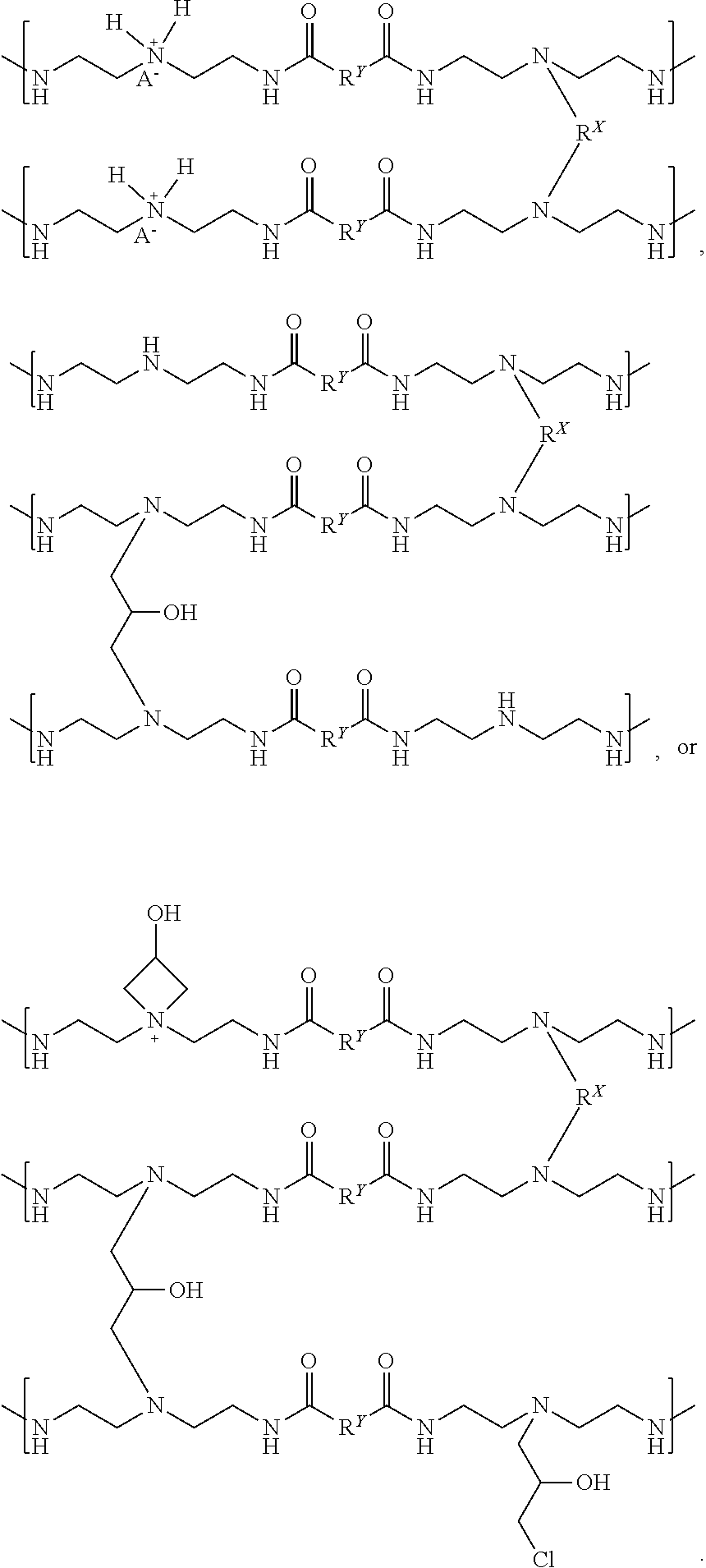

Creping adhesives containing functionalized crosslinked resins

Owner:ECOLAB USA INC

Light emitter packages and devices having improved wire bonding and related methods

Light emitter packages and devices having improved wire bonding and related methods are disclosed. In one embodiment, a light emitter package can include at least one light emitting diode (LED) chip electrically connected to an electrical element via a wire bond. The wire bond can be provided at improved wire bonding parameters such as a temperature of approximately 150 DEG C or less, a bonding time of approximately 100 ms or less, a power of approximately 1,700 mW or less, and a force of approximately 100 grams force (gf) or less, or combinations thereof.

Owner:CREELED INC (N D GES D STAATES DELAWARE NEWARK)

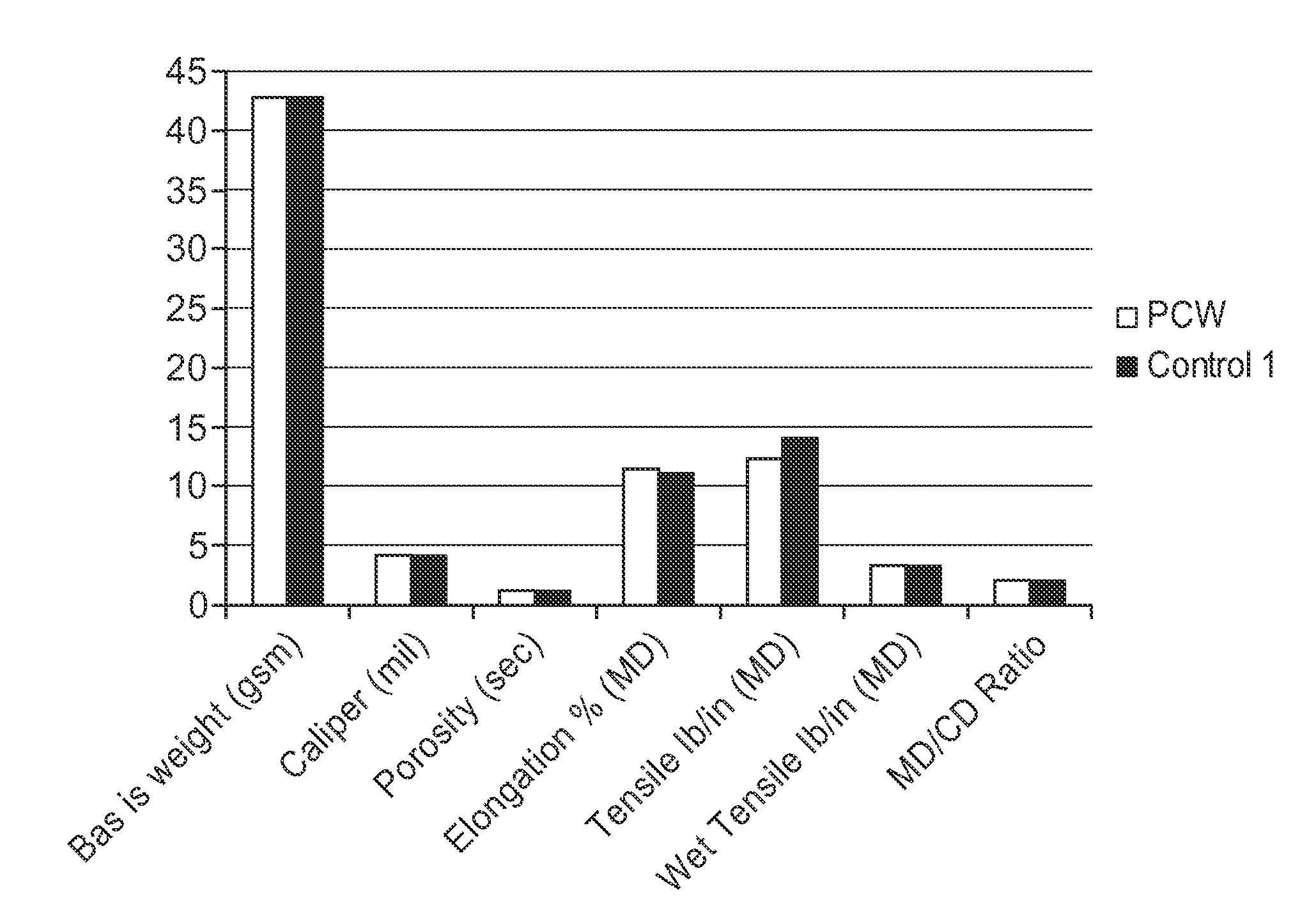

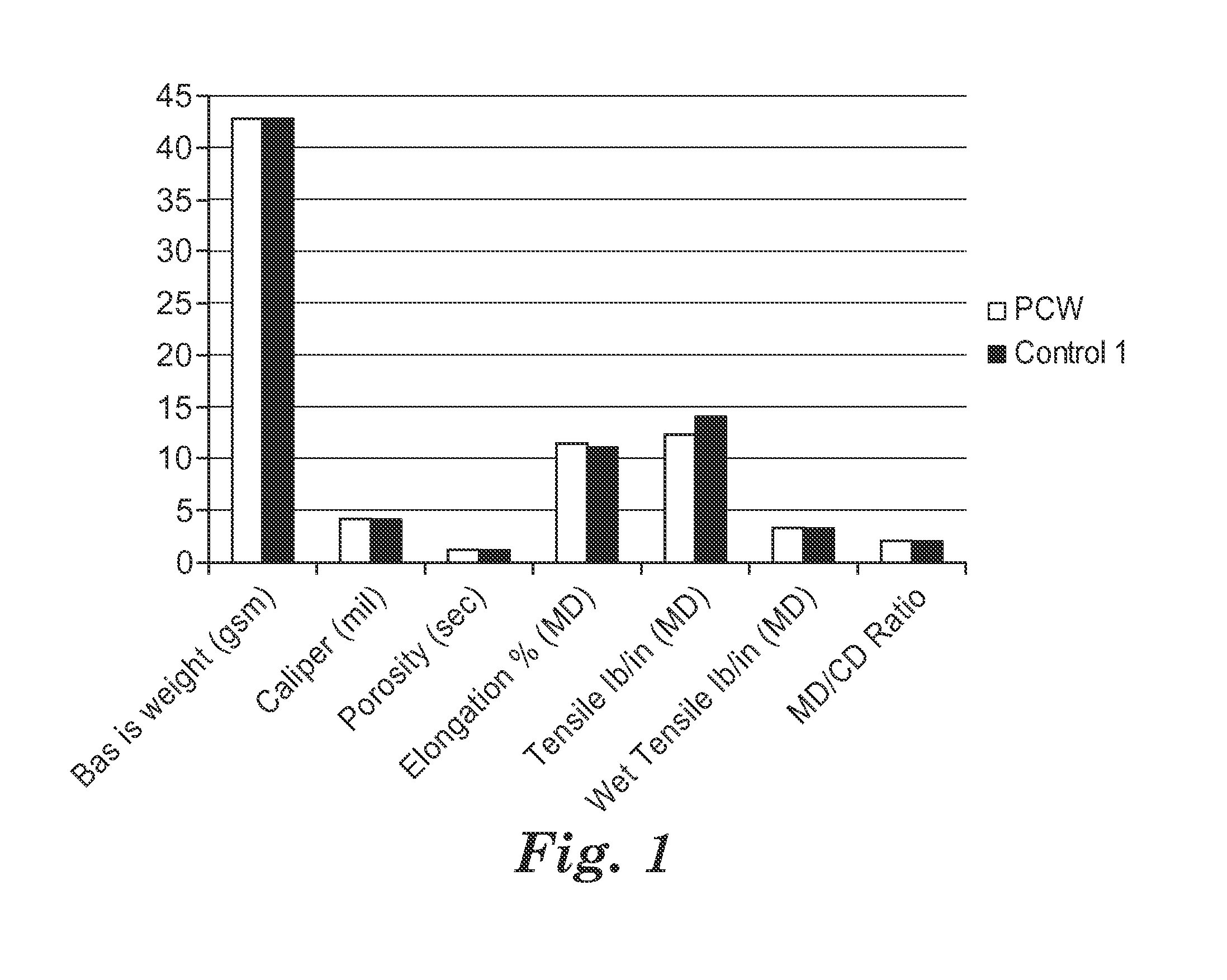

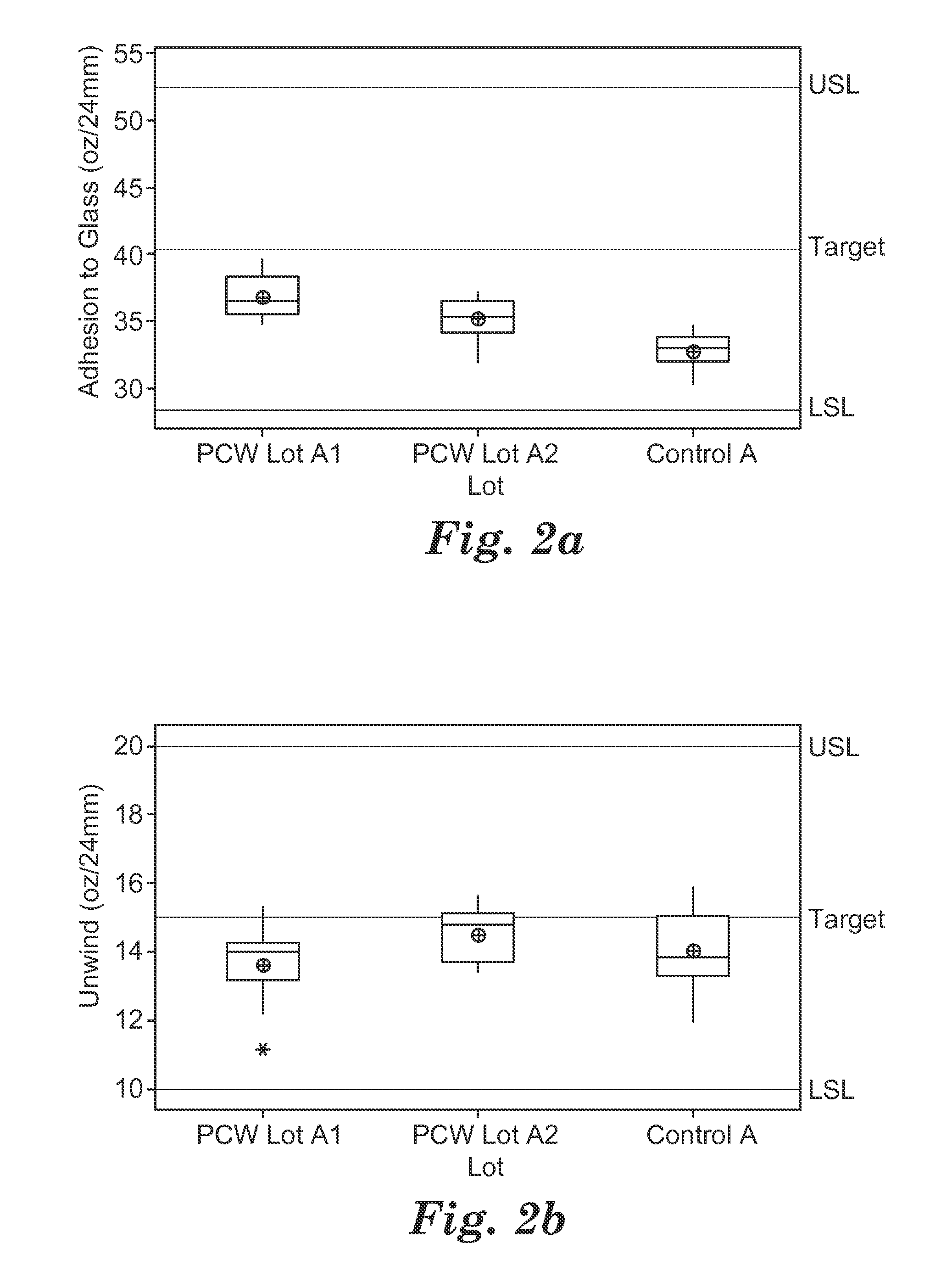

Tape comprising recycled paper

InactiveUS20110274920A1Easy to drawReduce in quantityNon-fibrous pulp additionFilm/foil adhesivesMasking tapeGram-force

A masking tape having a crepe paper backing comprising recycled post-consumer waste (PCW) paper. The paper backing comprises at least about 30 wt % PCW paper and retains the desirable resistance to slivering of non-PCW containing masking tapes through selection of an increased dry saturant loading rate of at least 40 wt %. This results in cross-directional (CD) tear values of at least 40 grams-force (gf).

Owner:3M INNOVATIVE PROPERTIES CO

Method of reducing wire bond profile height in integrated circuits mounted to circuit boards

InactiveUS20090081832A1Reduce gapEasy to controlSemiconductor/solid-state device detailsSolid-state devicesContact padGram-force

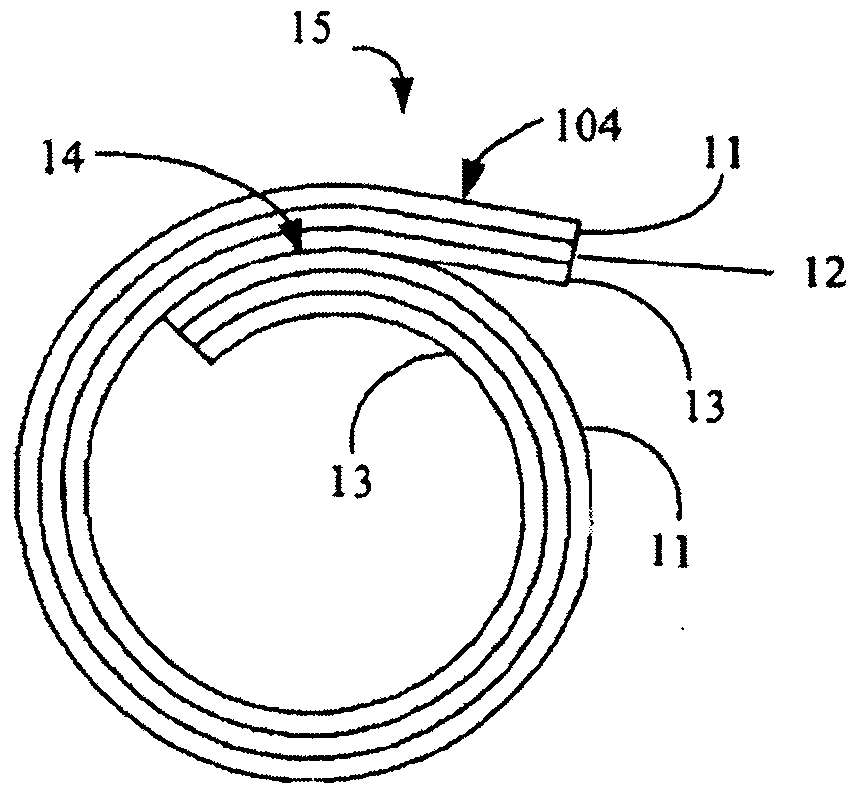

A method of profiling a wire bond between a contact pad on a die, and a conductor on a supporting structure, by electrically connecting the contact pad on the die to the conductor on the supporting structure with a wire bond, the wire bond extending in an arc from the contact pad to the conductor, pushing on the wire bond to collapse the arc and plastically deform the wire bond, and then releasing the wire bonds such that the plastic deformation maintains the wire bond in a flatter profile shape. The strength of the wire bond is known to be relatively small; of the order of 3 to 5 grams force. However, the Applicant's work has found that the wire bond structure is robust enough to withstand a certain degree of work hardening from plastic deformation. The arc of the wire bond can be deformed into a flatter profile without compromising the electrical connection with the PCB.

Owner:SILVERBROOK RES PTY LTD +1

Anhydrous antiperspirant cream compositions having improved perfume longevity

Disclosed are anhydrous antiperspirant cream compositions that have improved fragrance longevity. These compositions have a penetration force value of from about 75 gram-force to about 500 gram-force and comprise (a) antiperspirant active, and (b) a perfume / cyclodextrin inclusion complex. Also disclosed are packaged anhydrous antiperspirant cream compositions which comprise (a) antiperspirant active; (b) a perfume / cyclodextrin inclusion complex; and (c) a dispensing package containing the composition, wherein the dispensing package comprises (i) a container body having an interior chamber and a dispensing end, and (ii) a perforated dome attached to the dispensing end of the container body and having a plurality of openings extending through the thickness of the perforated dome and covering from about 15% to about 80% of the total surface area of the perforated dome.

Owner:THE PROCTER & GAMBLE COMPANY

Plug brick and plug wall

The invention relates to an inserting brick and an inserting wall, and belongs to the field of building brick and wall building technology. The inserting brick comprises a convex clip, a concave ditch, an upper corner and a lower corner. The inserting wall is formed by combining the inserting bricks, semi-inserting bricks, tee-joint inserting bricks and corner inserting bricks and inserting the bricks upwards in a staggered form. The inserting wall is characterized in that the convex clips can clamp the concave ditches when the inserting bricks insert upwards into the inserting wall in the staggered form, so that the horizontal swinging range of the inserting bricks is small; and the convex clips and the concave ditches have the autocorrection function. When the inserting bricks insert upwards into the inserting wall in the staggered form, upper corners of lower inserting bricks and lower corners of upper inserting bricks can be manufactured into a clamping type and can also be manufactured into being clamped into the shape of trough lines which can be filled by concrete. An inserted and integrated D-shaped wall body is hollow, can be filled by direct casting and does not need a gram force baffle plate. The inserting brick and the inserting wall greatly simplify the wall building technology, and greatly reduce the cost of the wall body of a building, and the wall body of the inserting wall is not cracked.

Owner:徐伟善

Light emitter package and device with improved wire bonding and related methods

Light emitter packages and devices with improved wire bonding and related methods are disclosed. In one embodiment, the light emitter package may include at least one light emitting diode (LED) chip electrically connected to an electrical component by wire bonds. The wire bond can be passed through improved wire bonding parameters, such as a temperature of about 150° C. or less, a bonding time of about 100 ms or less, a power of about 1700 mW or less, and a force of about 100 grams force (gf) or less. force or a combination thereof.

Owner:CREELED INC (N D GES D STAATES DELAWARE NEWARK)

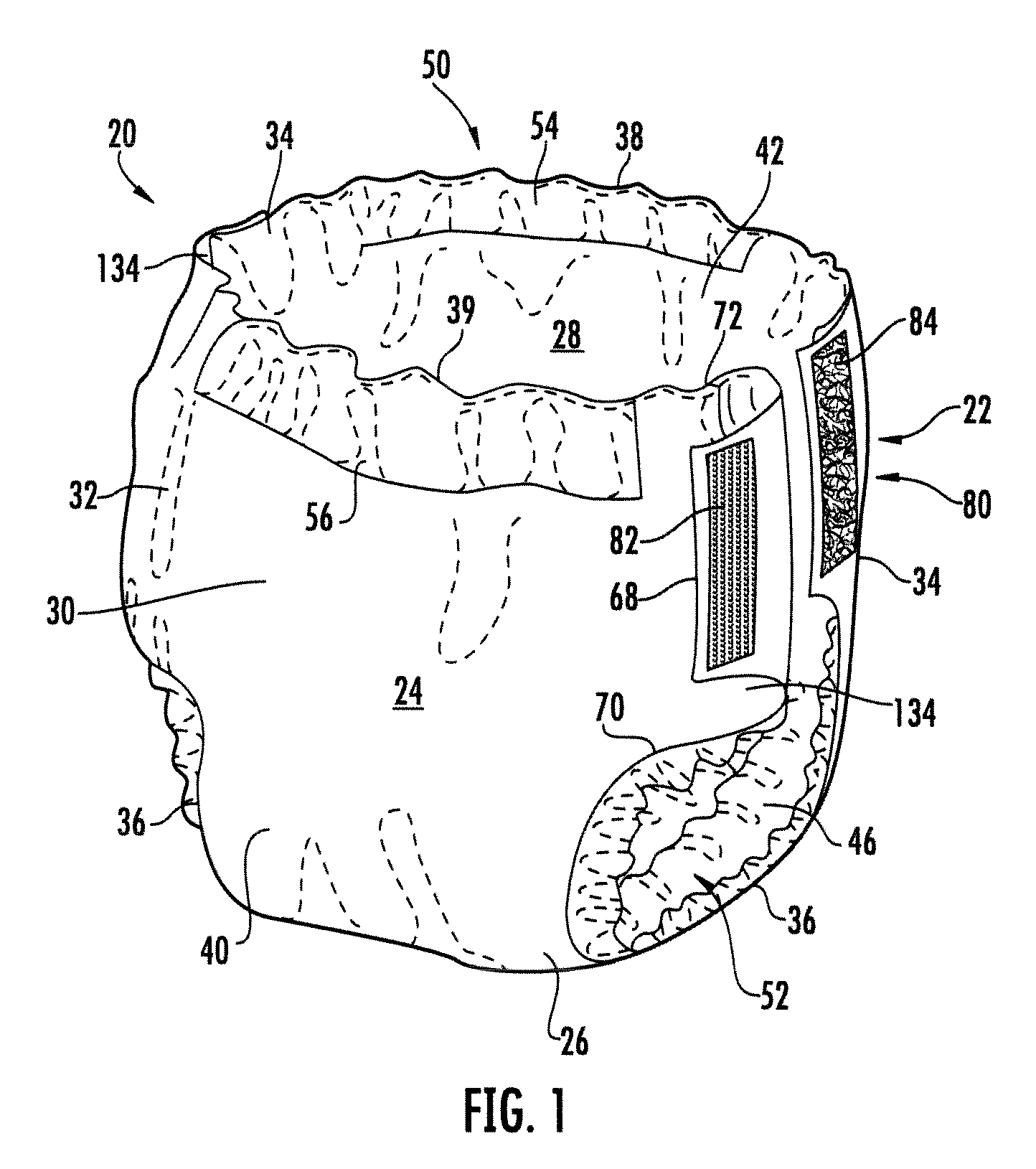

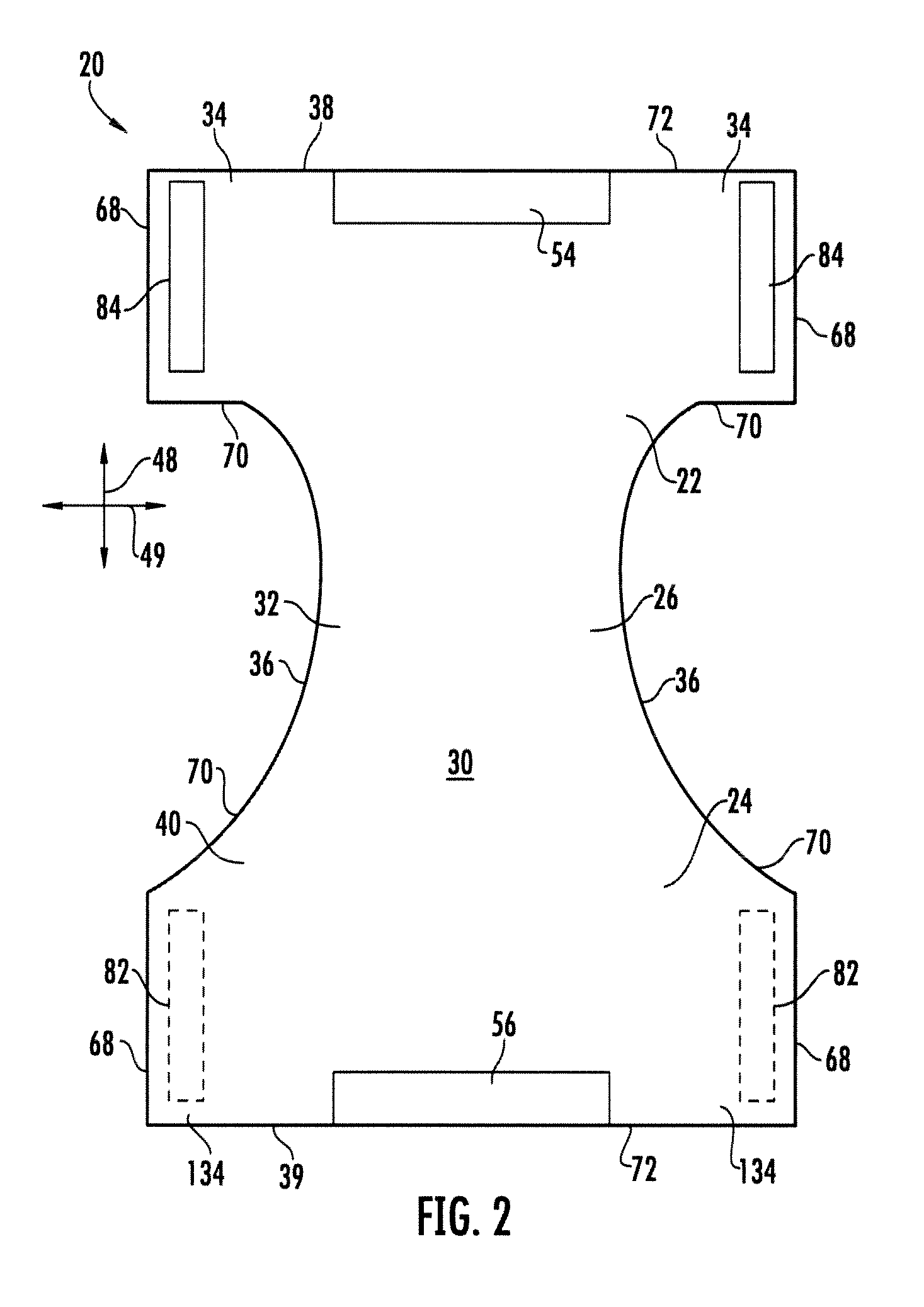

Absorbent garments with improved fit in the front leg area

Absorbent articles with carefully controlled stretch properties are provided. Of particular advantage, the carefully controlled stretch properties can prevent too much tension in the front leg area of the garment. The outer cover is constructed such that the front leg zone has a tension of less than about 1200 grams-force at about 160% to about 175% stretch in the lateral direction, and each of the front waist zone, the front crotch zone, the back crotch zone, the back leg zone, and the back waist zone of the outer cover has a tension of greater than about 1500 grams-force at about 160% to about 175% stretch in the lateral direction. Methods of making such an absorbent article are also provided.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com