Plug brick and plug wall

A technology of corner insertion and convex card, which is applied in the field of building bricks and building wall technology, can solve the problems of complex technology, high cost of building walls, easy cracking, etc., and achieve the effect of simplifying the process and reducing the cost of building walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

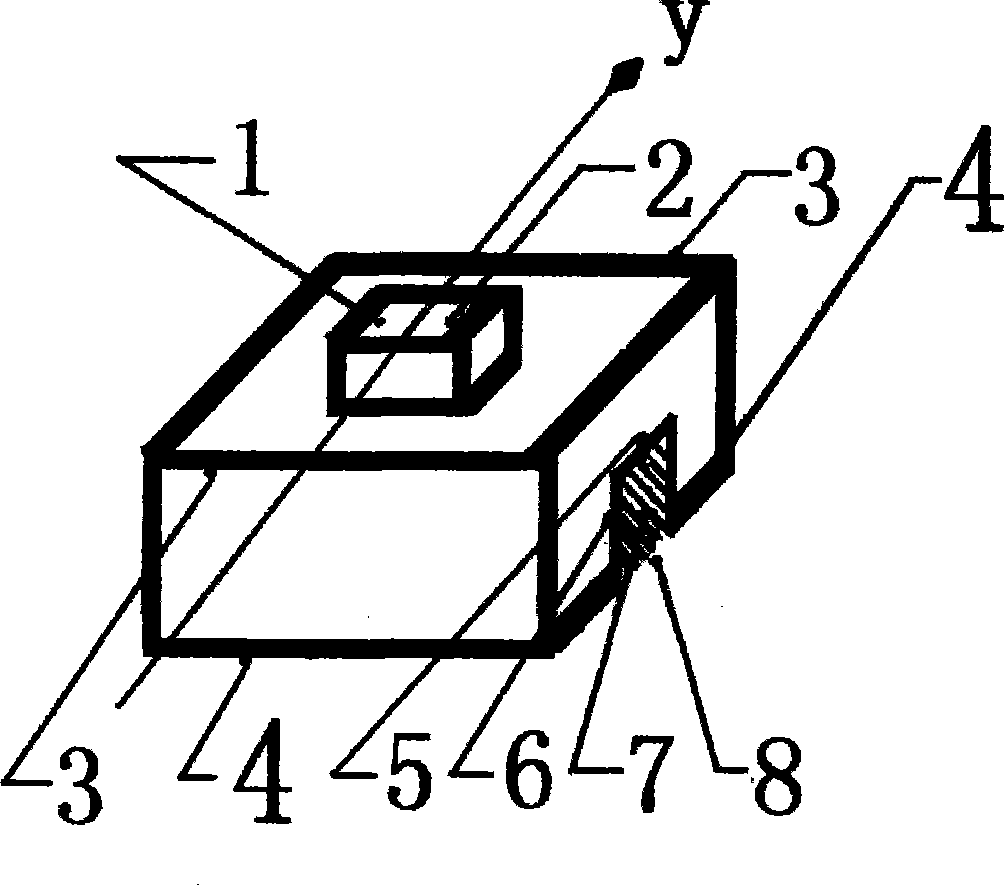

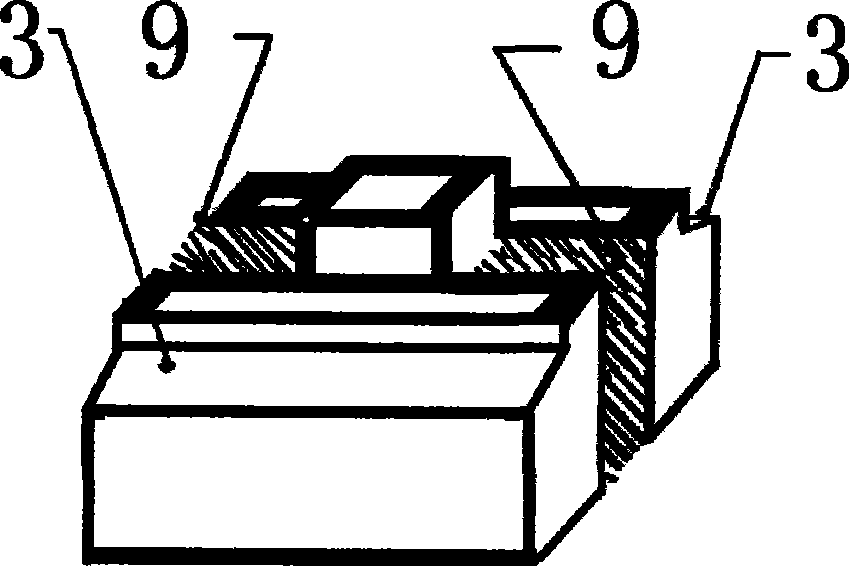

[0009] 1. The Y axis is a symmetrical axis, and the convex card A (1) and the convex card B (2) are distributed on both sides of the Y axis. They are collectively called convex cards, they can be one body, and there can be gaps between them. For clamping any configuration of the side walls (6) of the two concave grooves, the total length of the convex card is less than or equal to the length of the concave groove.

[0010] 2. The groove (7) includes: the bottom opening of the groove (8), the side wall of the groove (6), and the top wall of the groove (5). The groove top wall (5) may or may not contain the groove top opening (9). The best embodiment of the width from the concave groove cross section of the convex card height to the bottom of the concave groove cross section is to gradually expand by a small amount.

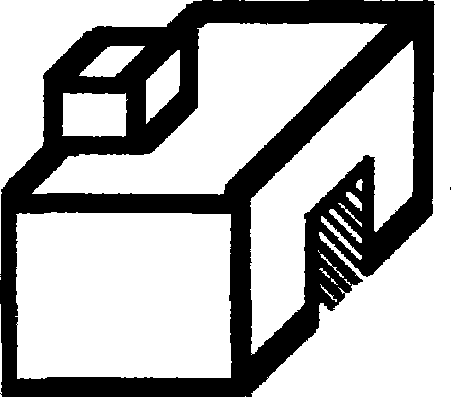

[0011] 3. When the plug-in bricks are staggeredly plugged into the plug-in wall upwards, the upper corner (3) of the lower plug-in brick and the lower corner (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com