Manufacturing method for zero-length spring and zero-length spring

A zero-length spring and manufacturing method technology, applied in the field of manufacturing zero-length springs and zero-length springs, can solve the problems of narrow elastic modulus temperature coefficient, gravity measurement error, and inability to overcome lateral disturbance, etc., to achieve a more efficient manufacturing method The effect of the manufacturing method system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

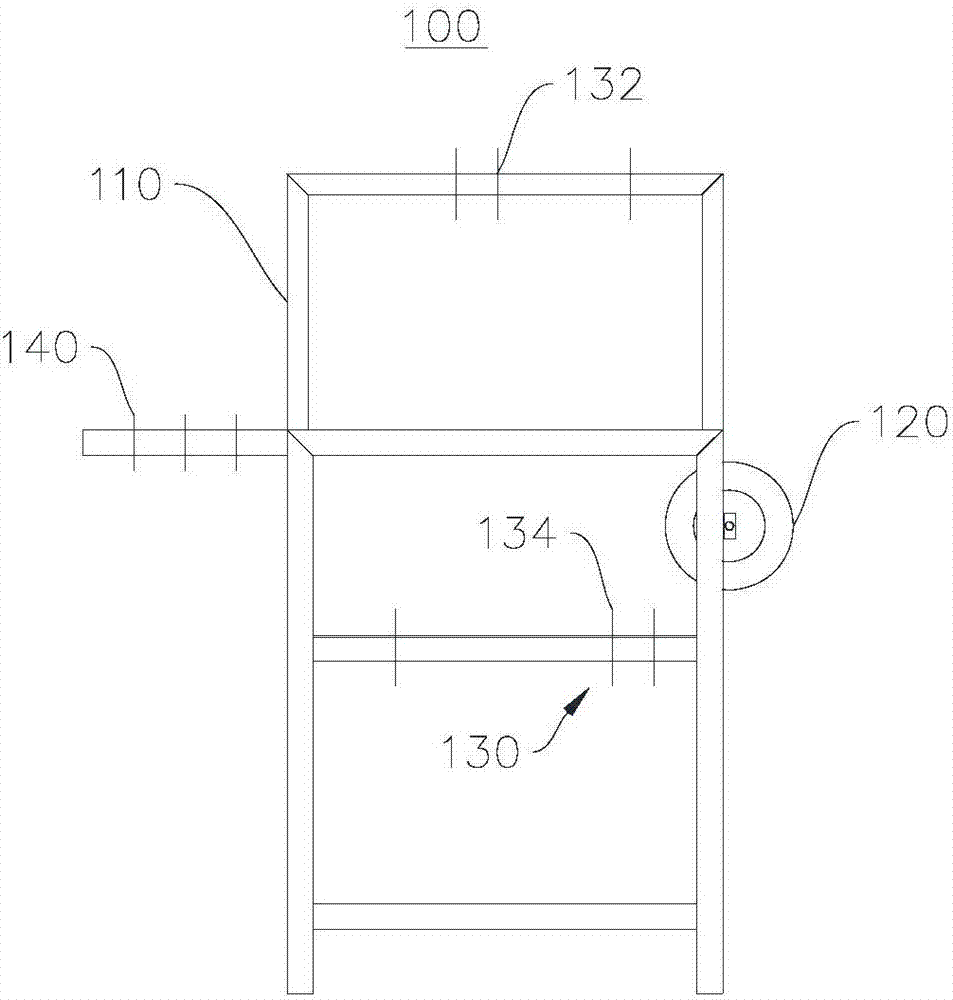

[0057] see figure 1 , this embodiment provides a method for manufacturing a zero-length spring. The method for manufacturing a zero-length spring provided by this embodiment is more systematic, scientific, and high-precision, and can make the zero-length error of the zero-length spring: Δl≤1 mm, Daily drift: δ≤10 -2 μ / day, stiffness error: K≤0.01 gf / mm, overcoming the problem of physical zero length that cannot be solved by traditional techniques.

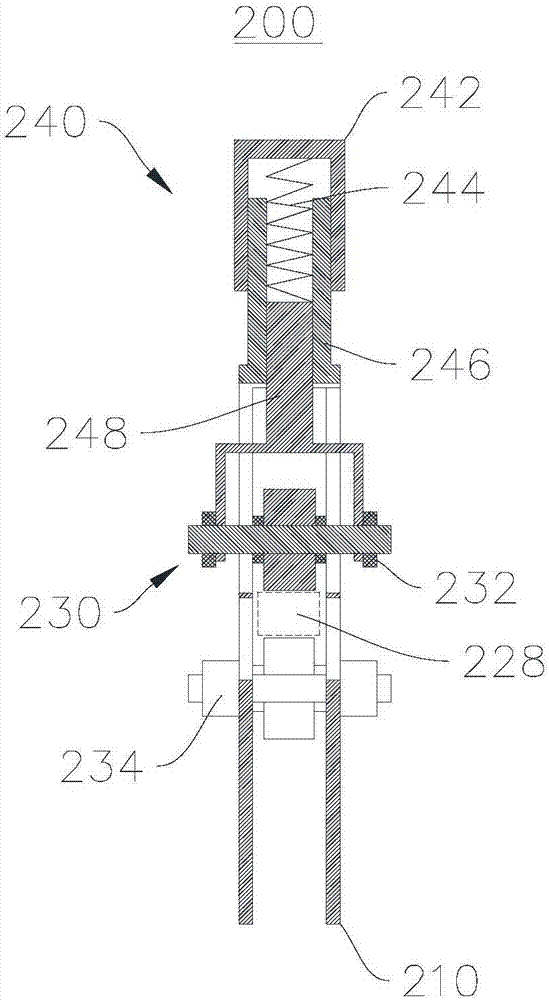

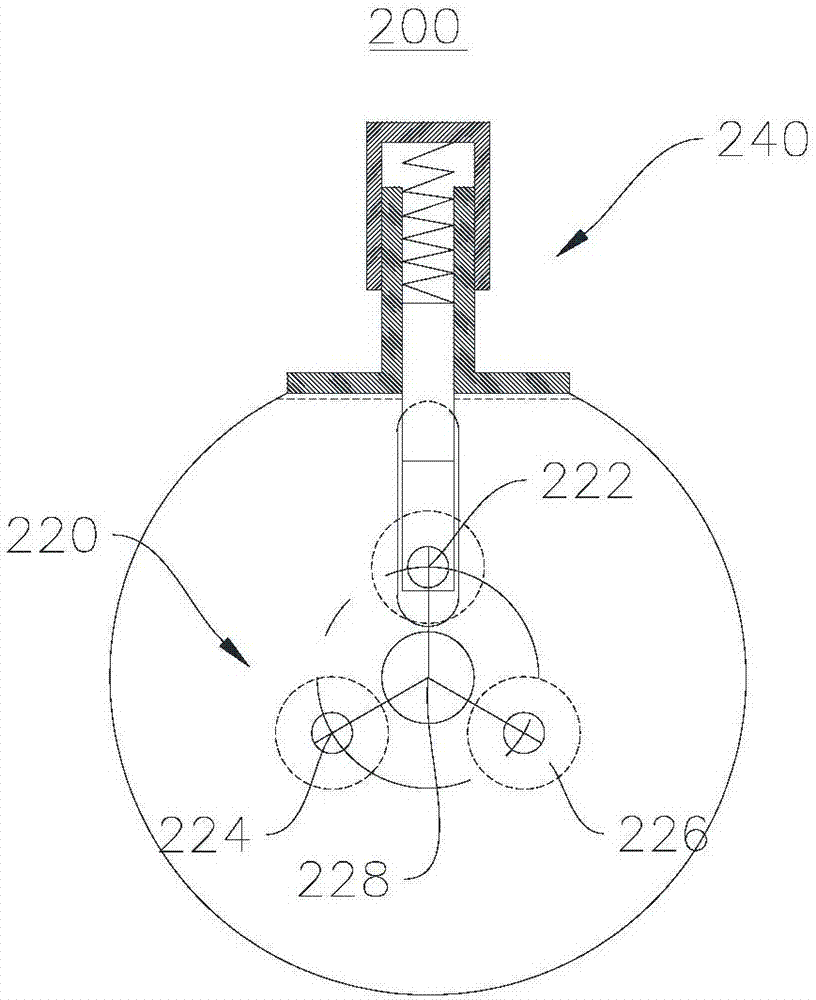

[0058] The manufacturing method of the zero-length spring includes adjusting the microstructure of the wire material through a solid solution strengthening treatment process, wherein the wire material is a constant elastic wire material; the solid solution wire material is formed; and the first spring is applied in a reverse rotation manner. Pretension; temper the second spring.

[0059] In this embodiment, firstly, the constant elastic wire is Fe-Ni alloy (Ni44CrTiAl) wire, which has good processability and can be made into elas...

Embodiment 2

[0103] A zero-length spring provided in this embodiment, the zero-length spring provided in this embodiment is more systematic, more scientific, and high-precision, and can make the zero-length error of the zero-length spring: Δl≤1 mm, and the daily drift: δ≤10 -2 μ / day, stiffness error: K≤0.01 gf / mm, overcoming the problem of physical zero length that cannot be solved by traditional technology.

[0104] The zero-length spring provided in this embodiment is made by the manufacturing method of the zero-length spring provided in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com