Patents

Literature

30results about How to "Manufacturing method science" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

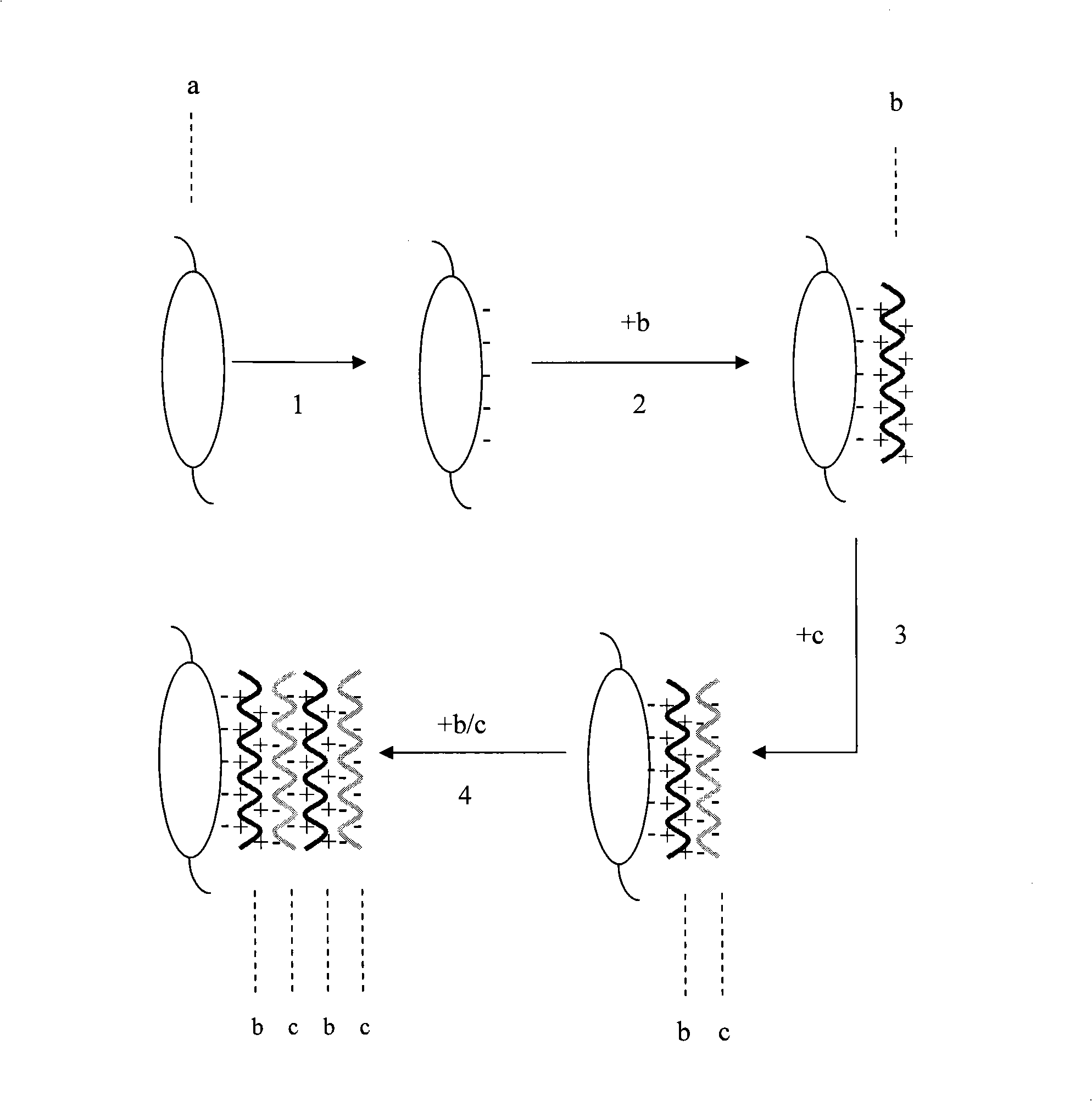

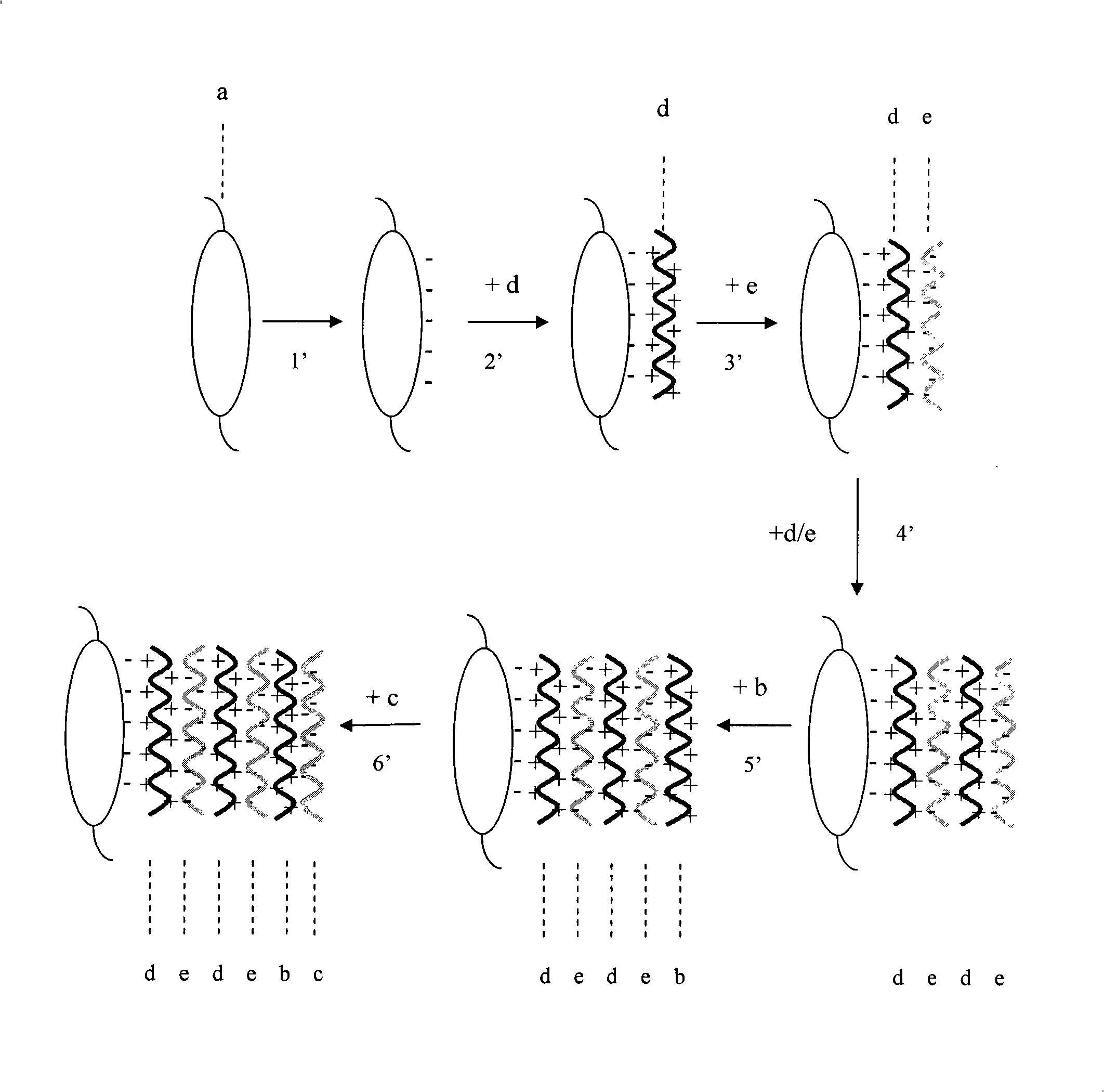

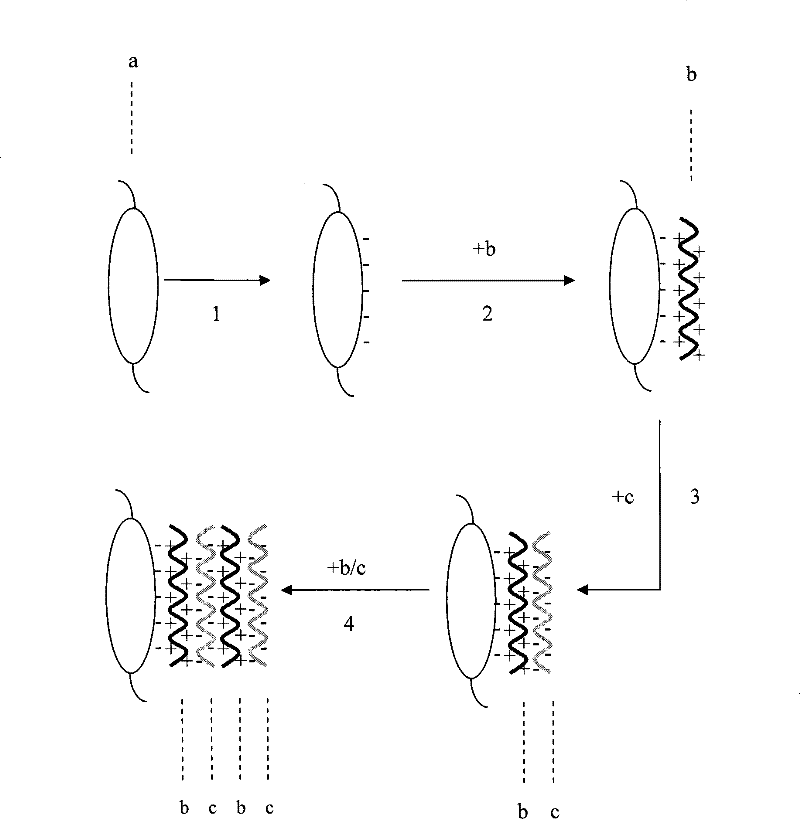

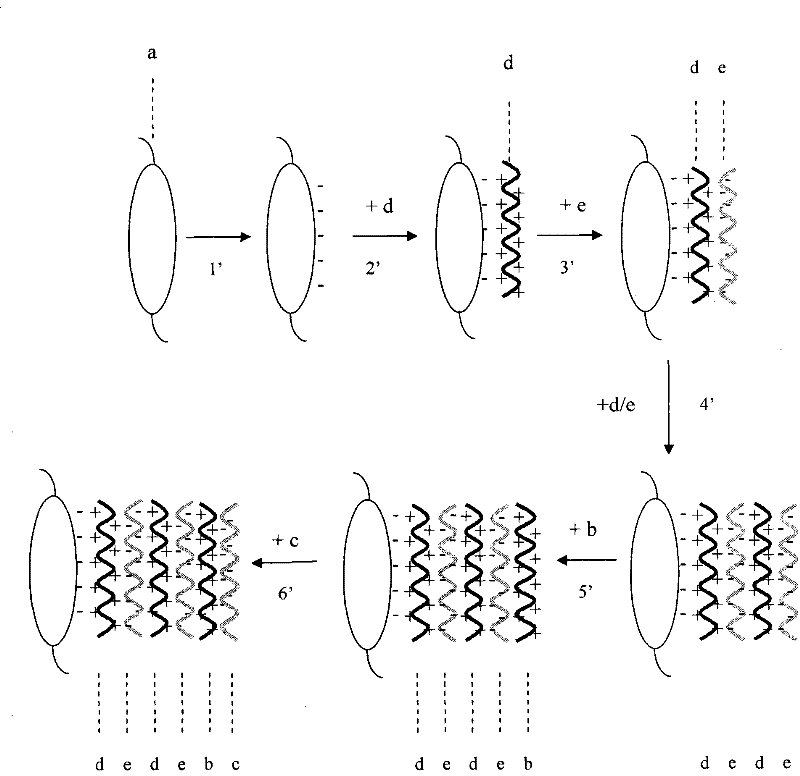

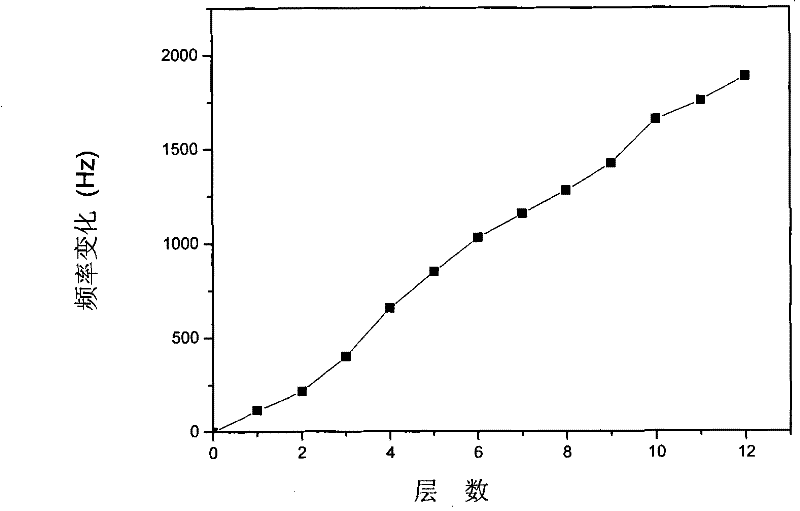

Artificial crystalline len with transforming growth factor resistant beta2 antibody membrane on surface and manufacturing method thereof

The invention provides an artificial lentis, which contains anti-transforming growth factor beta 2 antibody membrane on the surface and can inhibit intercurrent post-cataract after cataract surgery, and also provides a the production method thereof. The production method includes the steps that: the artificial lentis is charged with positive electricity or negative electricity after the artificial lentis is cleaned, dried, and pretreated on the surface; the artificial lentis is soaked in a polyelectrolyte solution the charge of which is opposite to the surface charge of the artificial lentis for adsorbing, and rinsing the artificial lentis by deionized water, and drying the artificial lentis by nitrogen gas; the artificial lentis is soaked in a phosphate buffering solution of anti-transforming growth factor beta 2 antibody, the pH value of which is 4-10, and the carried charge of which is opposite to that of the polyelectrolyte, for adsorption; finally, the artificial lentis is rinsed by phosphate buffering solution, and the artificial lentis is dried by nitrogen gas; the alternating assembly steps are repeated. The artificial lentis of the invention can inhibit the transformation and differentiation as well as cyst membrane shrinkage of the lentis epithelial cells in a target way, and then interdicts the occurrence of the post-cataract, and has excellent biocompatibility. The production method of the invention is scientific and simple, and can ensure the activity under a dry state and the safety and reliability during medical transplantation of the anti-transforming growth factor beta 2.

Owner:SECOND AFFILIATED HOSPITAL ZHEJIANG UNIV COLLEGE OF MEDICINE

Glass fiber reinforcement cement board and production method thereof

InactiveCN101386509AGuaranteed StrengthGuaranteed lifeSolid waste managementCeramicwareExpanded clay aggregateCement board

The invention relates to a building material and a method for preparing the same, in particular to a glass fiber reinforced cement board and a method for preparing the same. The glass fiber reinforced cement board comprises the following components in weight portion: 100 portions of Portland cement, 13.6 to 15 portions of high alumina cement, 3.1 to 3.4 portions of fly ash, 5.7 to 6.3 percent of plaster stone powder, 120 to 132 portions of ceramsite, 6.5 to 7.1 percent of foaming agent, 74.5 to 81.3 percent of dispersing agent, 53 to 58.7 portions of pure water and 3.6 to 4 portions of plastic-coated glass fiber grid cloth. The preparation method sequentially comprises the following steps: mixing weighed-up solid materials, adding weighed-up liquid materials in the previous step, cavity forming, roll extruding, vibration, cutting and curing. The invention has the advantages that: the glass fiber reinforced cement board has advantages of light volume weight, high strength, low dry shrinkage wet swelling coefficient, no after expansion and shrinkage, corrosion resistance, sound insulation, heat insulation, fire resistance and non-combustion; the preparation method has the characteristics of scientific and reasonable method, continuous production, high efficiency and low cost, flat board surface, convenient in-site mounting and the like; the glass fiber reinforced cement board is good in water resistance, and particularly applied to the finishing of internal and external walls and ceilings of various buildings in wet environments; moreover, the glass fiber reinforced cement board and a method for preparing the same have the advantages of ensuring the strength and service life of cement due to the adoption of the plastic-coated anti-alkali glass fiber grid cloth, along with reasonable blending ratio and reduced alkalinity.

Owner:YINGCHUANG BUILDING TECH SHANGHAI CO LTD

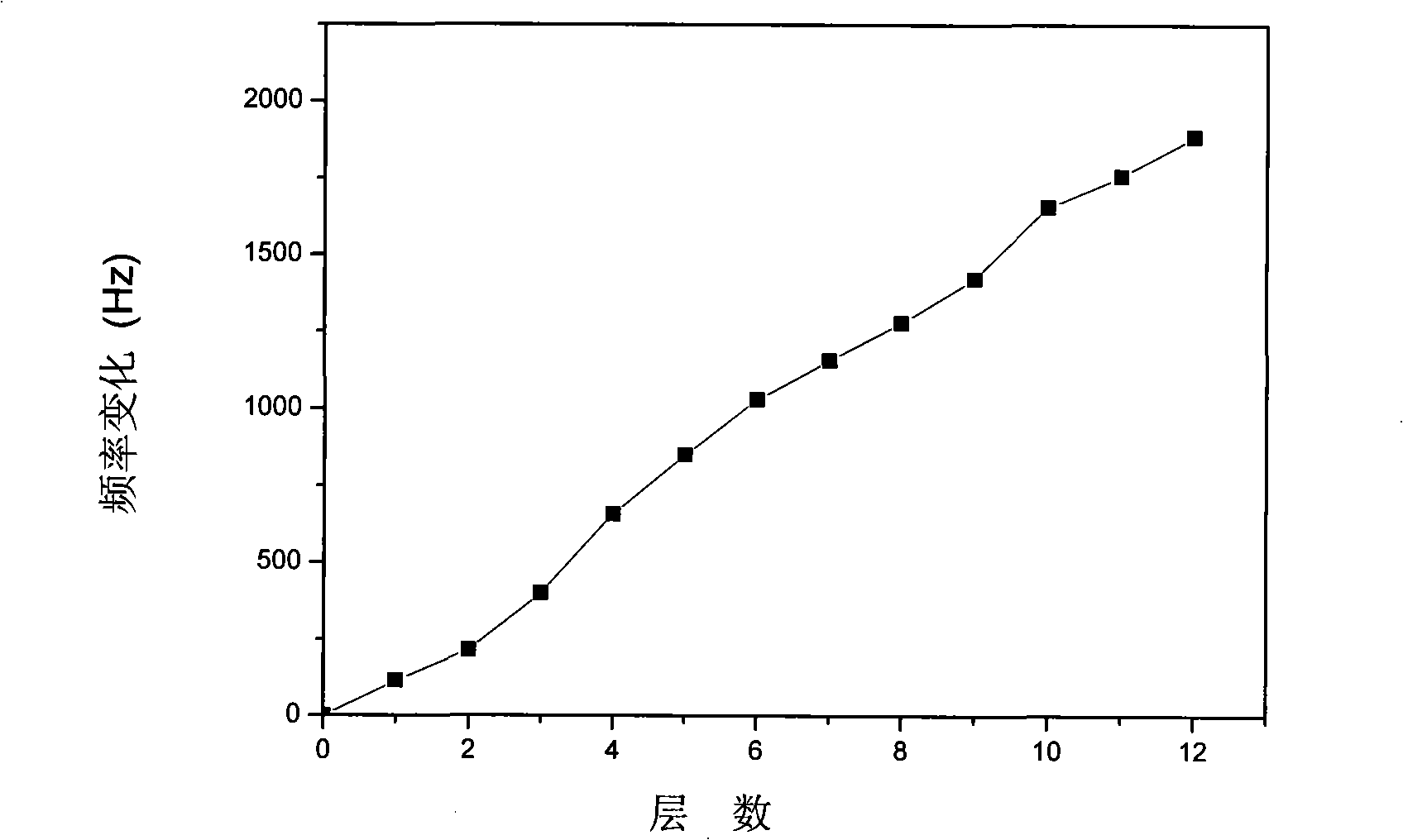

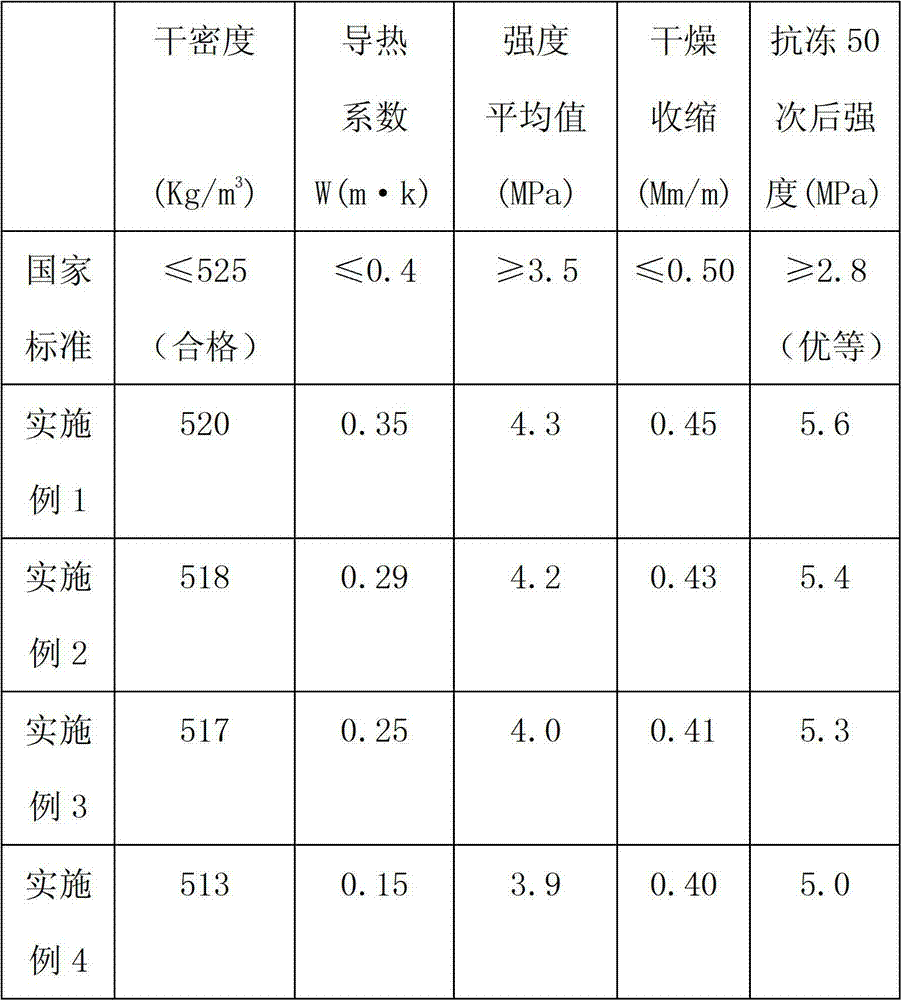

Aerated concrete building block and manufacturing method thereof

InactiveCN102964095AEfficient use ofIncreased durabilitySolid waste managementCeramic shaping apparatusSlurryHigh calcium

The invention discloses an aerated concrete building block and a manufacturing method thereof. According to the aerated concrete building block, fly ash and gypsum are taken as main raw materials. The aerated concrete building block contains the following raw materials in parts by weight: 60-75 parts of high-calcium fly ash, 4-15 parts of ordinary fly ash, 5-8 parts of gypsum, 13-16 parts of lime, 10-13 parts of cement, 0.07-0.10 part of aluminum powder and 43-46 parts of water. The manufacturing method of the aerated concrete building block mainly comprises the following steps of: (1) preparing materials; (2) pouring slurry; (3) standing; (4) cutting; and (5) carrying out autoclaved curing. The aerated concrete building block and the manufacturing method of the aerated concrete building block have the beneficial effects that the quality of the aerated concrete building block meets national standards, and the durability, crack resistance and frost resistance are improved; and the manufacturing method is scientific and reasonable, the effective utilization of the high-calcium and ordinary fly ashes is promoted, the production cost is reduced, and the yield is increased.

Owner:ZUNYI SENTAI ENVIRONMENTAL PROTECTION NEW BUILDING MATERIAL

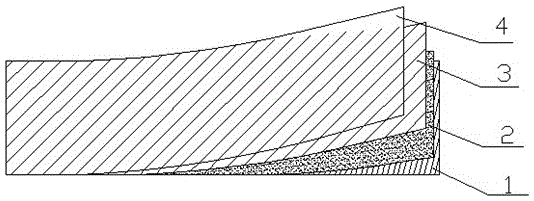

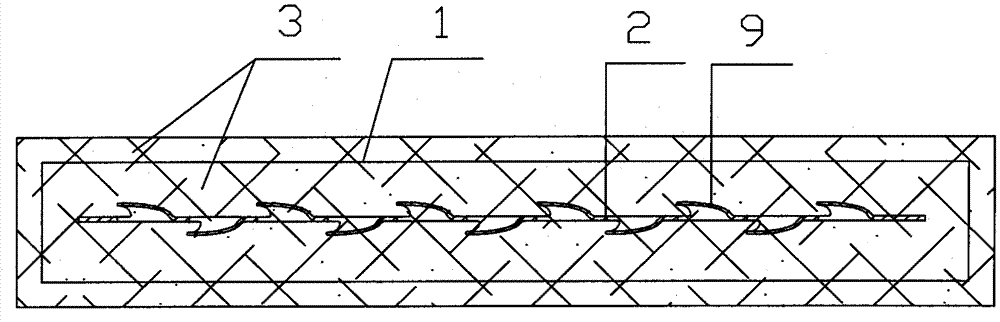

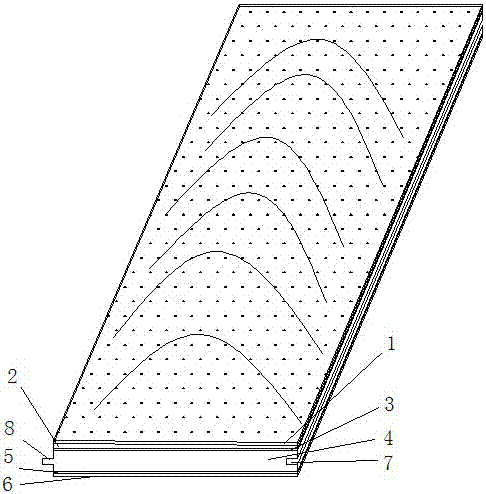

Floor surface board and manufacturing method thereof

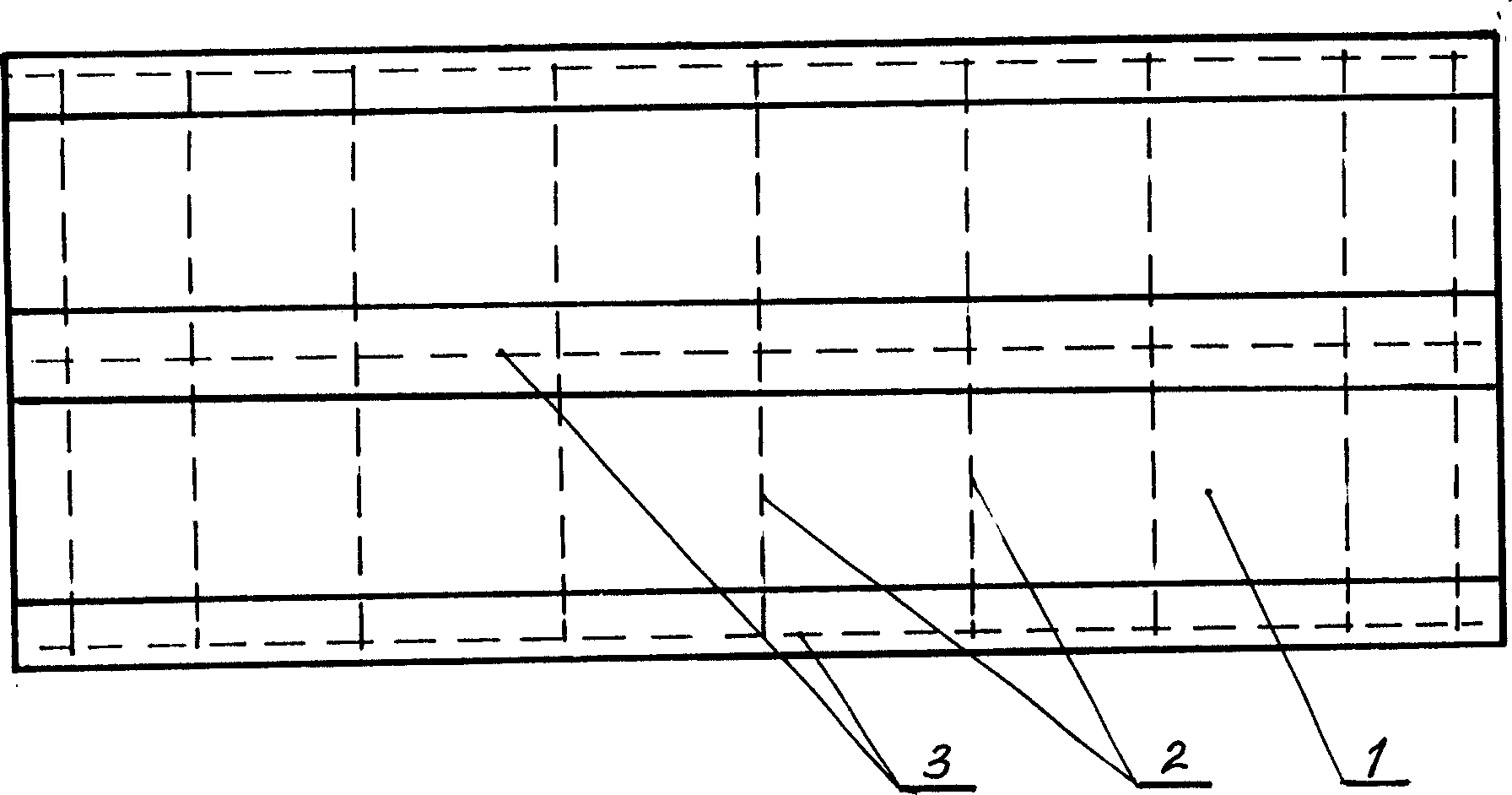

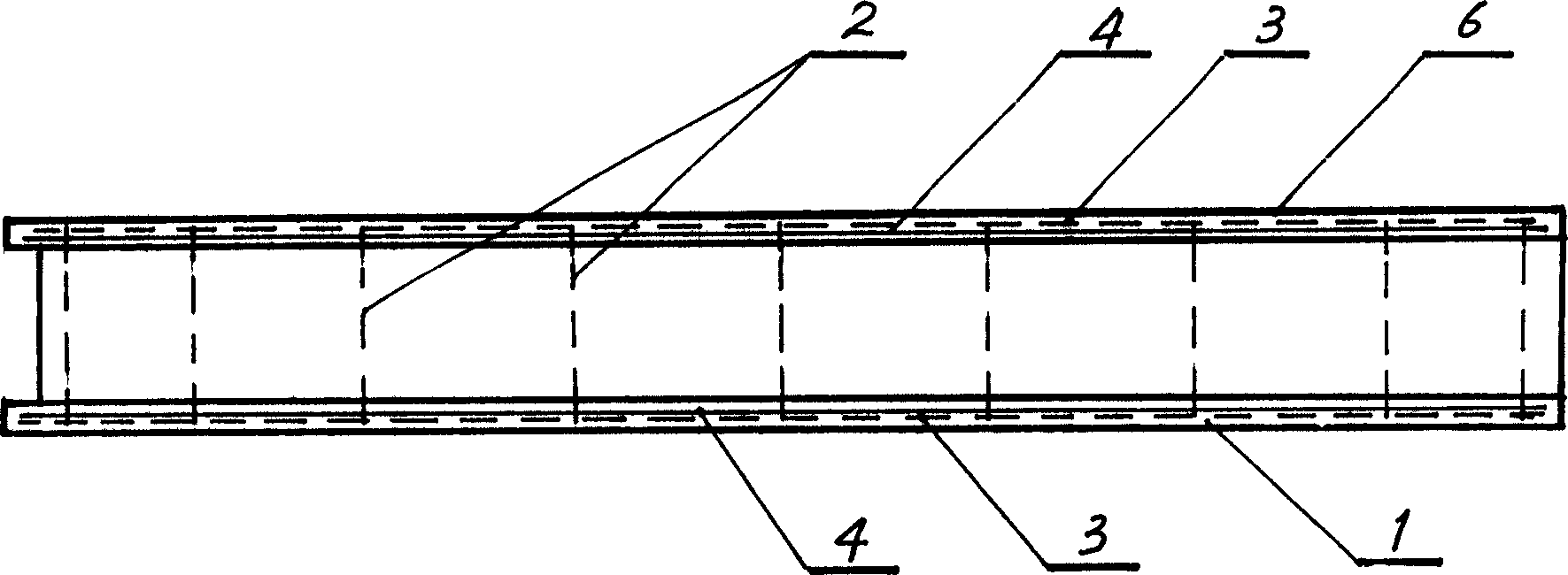

InactiveCN105014766AImprove wear resistanceManufacturing method scienceLaminationLamination apparatusWood veneerCompound a

The invention discloses a floor surface board and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps: taking a fast-growing wood veneer as a substrate; coating the surface of the substrate with a melamine resin adhesive so as to form a substrate gluing layer; compounding a non-woven fabric or paper with a 0.2-0.4mm sliced thin wood, and dipping the wood in a melamine resin so as to form a decoration layer; taking aluminum oxide (Al2O3) wear-resistant paper as a wear-resistant layer; and molding the substrate with a gluing layer, the impregnated decoration layer and the wear-resistant layer at a time by use of a hot pressing forming machine at a temperature of 130-140 DEG C under the pressure of 1.5-2.0 MPa for 3-5 minutes. The manufacturing method is scientific and reasonable, the formation is easy, the quality is good, and the method has disadvantages of both saving wood resources and reinforcing floor surface board performance.

Owner:BEIHUA UNIV

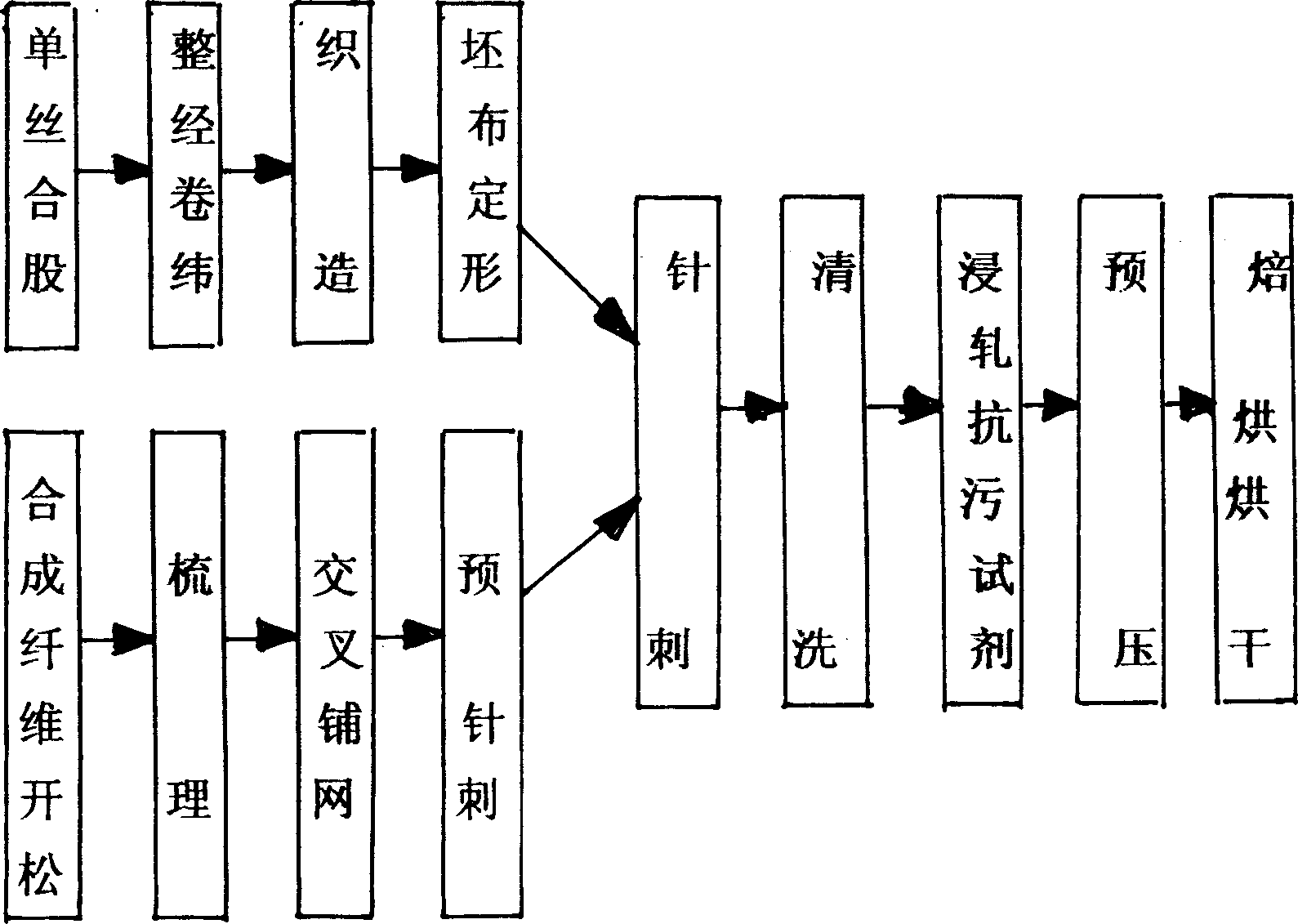

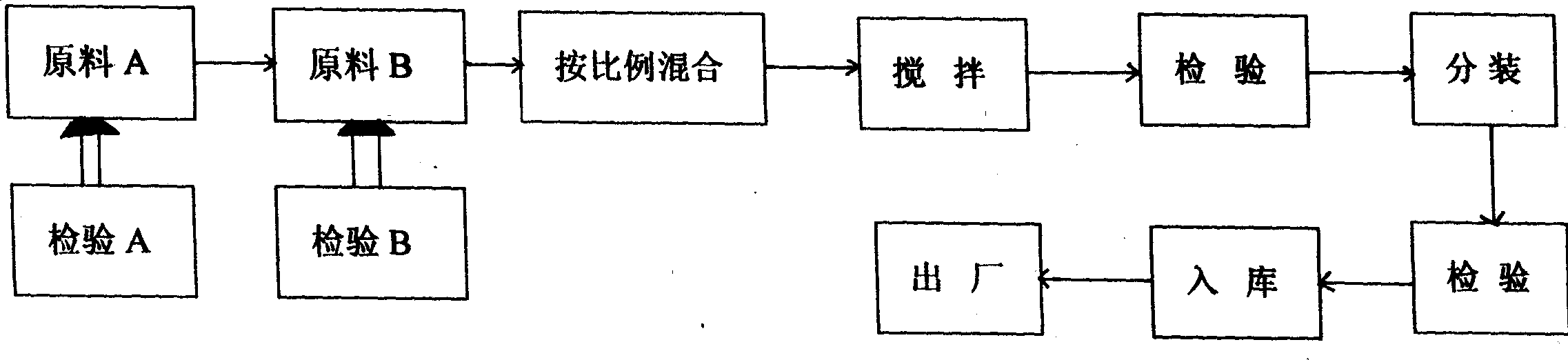

Method for manufacturing antifouling Batt-on-mesh press felt

The invention discloses a pollution-resisting web squeezing paper blanket making method, which is characterized by the following: forming paper-making blanket of weaved bottom web grey cloth through profiling and punching; impregnating the blanket through pollution-resisting agent within fluorine compounds and adhesive after cleaning; precompressing and baking the blanket to generate pollution-resisting web squeezing paper blanket, wherein the pollution-resisting agent formulation is the adhesive of polytef and melamine. The method contains obvious pollution-resisting effect, rational making method and easy operation, which reduces the disposal cost and improves the product added value greatly.

Owner:上海金熊造纸网毯有限公司

Artificial crystalline len with transforming growth factor resistant beta2 antibody membrane on surface and manufacturing method thereof

The invention provides an artificial lentis, which contains anti-transforming growth factor beta 2 antibody membrane on the surface and can inhibit intercurrent post-cataract after cataract surgery, and also provides a the production method thereof. The production method includes the steps that: the artificial lentis is charged with positive electricity or negative electricity after the artificial lentis is cleaned, dried, and pretreated on the surface; the artificial lentis is soaked in a polyelectrolyte solution the charge of which is opposite to the surface charge of the artificial lentis for adsorbing, and rinsing the artificial lentis by deionized water, and drying the artificial lentis by nitrogen gas; the artificial lentis is soaked in a phosphate buffering solution of anti-transforming growth factor beta 2 antibody, the pH value of which is 4-10, and the carried charge of which is opposite to that of the polyelectrolyte, for adsorption; finally, the artificial lentis is rinsedby phosphate buffering solution, and the artificial lentis is dried by nitrogen gas; the alternating assembly steps are repeated. The artificial lentis of the invention can inhibit the transformationand differentiation as well as cyst membrane shrinkage of the lentis epithelial cells in a target way, and then interdicts the occurrence of the post-cataract, and has excellent biocompatibility. Theproduction method of the invention is scientific and simple, and can ensure the activity under a dry state and the safety and reliability during medical transplantation of the anti-transforming growth factor beta 2.

Owner:ZHEJIANG UNIV

Casting material for building material

InactiveCN1616379ALight textureImprove mechanical propertiesSolid waste managementSaw dustBuilding material

The present invention relates to building material, and is especially casting material suitable for producing light wall board and other building material. The casting material of the present invention consists of plant stalk powder, saw dust, magnesia, magnesium chloride aqua, and chemical mother liquid. The casting material of the present invention has the advantages of light weight, high mechanical performance, high mechanical strength, being waterproof, fireproof and aseismic.

Owner:石正

Manufacturing method of inorganic reinforcing agent for gypsum products

The invention provides a manufacturing method of an inorganic reinforcing agent for gypsum products, and belongs to the field of novel building materials. Calcium carbonate, calcium sulfate, potassium sulfate and other common materials are selected and accurately weighed, the materials are ground and sieved by a 250-mesh sieve without processing, the materials are sintered in an intermittent shuttle-type kiln or a continuous rotary kiln, after sufficient cooling, the sintered materials are ground and sieved by a 325-mesh sieve, the ground materials are cooled and homogenized, and the product is checked and packaged if qualified. The strength of a common gypsum product with 1%-5% of the inorganic reinforcing agent doped is increased by 1-2MPa or more, and thus the inorganic reinforcing agent is greatly helpful for upgrading gypsum product industries, and can be widely applied to house decoration or other building products.

Owner:雷志刚

Ecological nutrient soil and preparation method thereof

PendingCN109566341AImprove fertilityPromote rootingExcrement fertilisersBioloigcal waste fertilisersPlant rootsPumpkin seed

The invention discloses ecological nutrient soil and a preparation method thereof. The nutrient soil is prepared from, by weight, 15-20 parts of rabbit dung, 20-25 parts of river sand, 2-4 parts of plant ash, 5-9 parts of a microbial fermentation bacterial agent, 3-5 parts of composite nitrogen-phosphorus-potassium fertilizer, 7-9 parts of aluminium sulfate, 3-5 parts of straw stalk, 4-6 parts ofgarlic, 10-15 parts of coconut residues, 5-10 parts of expanded perlite, 10-15 parts of willow branches, 1-2 parts of bone meal, 2-4 parts of pumpkin seeds, 4-6 parts of vinegar and 5-8 parts of ailanthus altissima leaves. According to the ecological nutrient soil and the preparation method thereof, the preparation method is scientific and reasonable and easy and convenient to operate, the nutrient of the nutrient soil is rich, the rabbit dung is adopted as a raw material, the soil fertility is durable, Chinese herbal medicine nutrient components in the rabbit dung can be decomposed, and the ecological nutrient soil has high permeability, can resist viruses and bacteria, is free of irritating odor or eggs or pollution and also has the function of promoting plant rooting.

Owner:湖南耶啰耶兔业发展有限公司

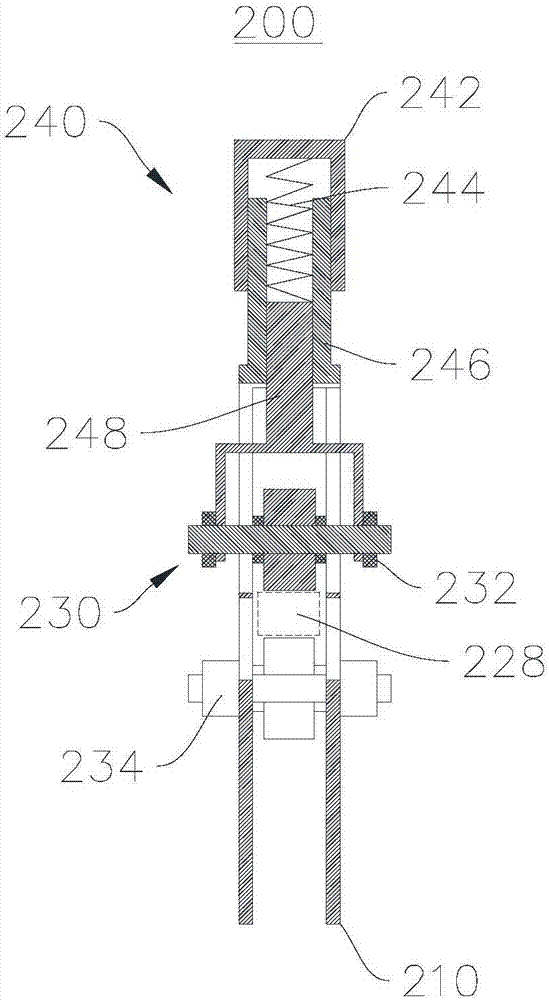

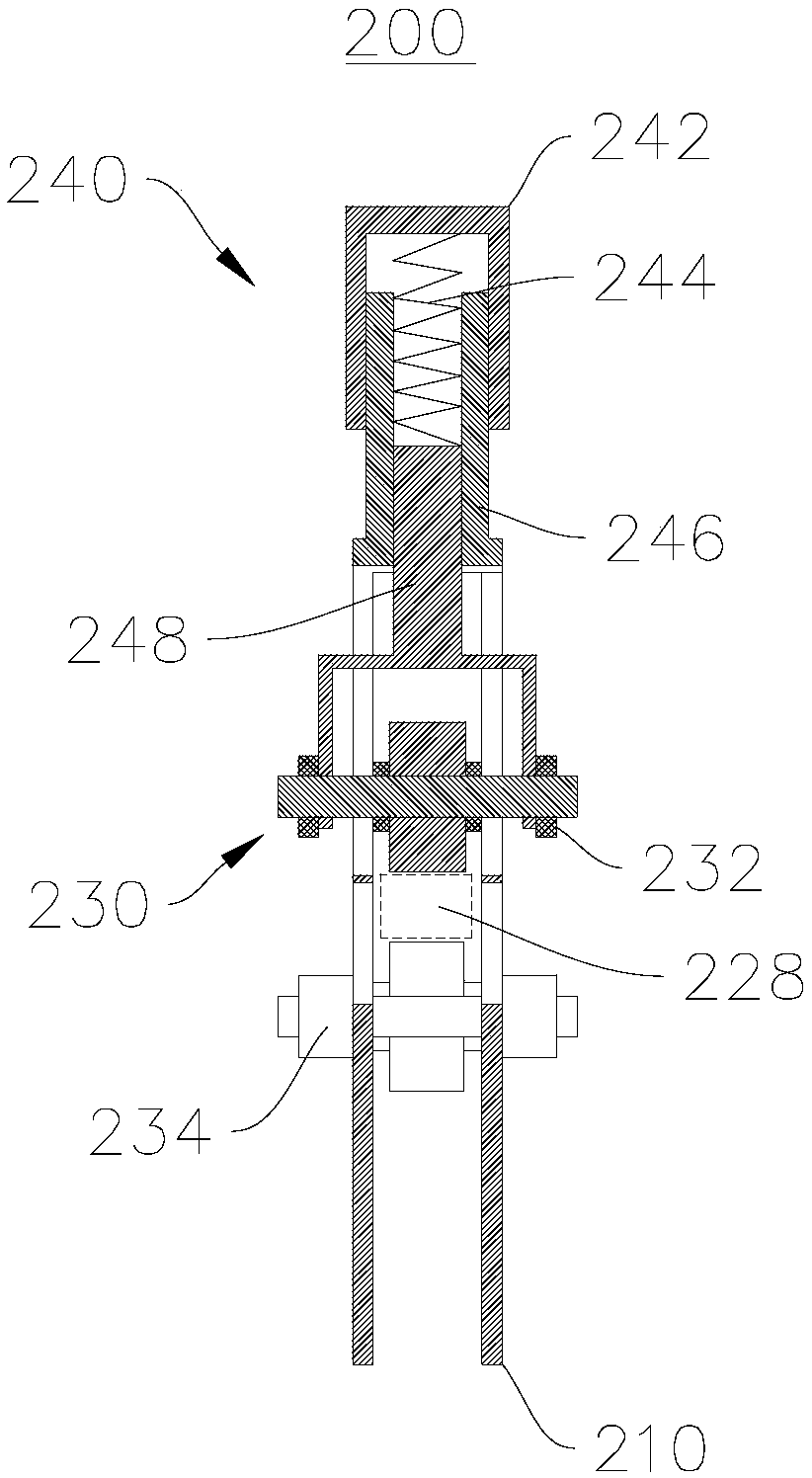

Manufacturing method for zero-length spring and zero-length spring

ActiveCN107502727AManufacturing method systemManufacturing method scienceFurnace typesWire springsGram-forceSolid solution strengthening

The invention provides a manufacturing method for a zero-length spring and the zero-length spring, and relates to the field of sea-air gravity meters. The manufacturing method for the zero-length spring comprises the steps that a microstructure of a wire material is adjusted through a solid solution strengthening treating process, wherein the wire material is a constant elastic wire material; molding treatment is conducted on the solid solution wire material; pretension force is applied to a first spring through a reverse rotation mode; and tempering treating is conducted on a second spring. The manufacturing method for the zero-length spring is more systematic and scientific and high in precise so that the zero length error delta l of the zero-length spring is less than or equal to 1 millimeter, the drifting amount delta is less than or equal to 10<2>[mu] per day, the rigidity error k is less than or equal to 0.01 gram force per millimeter, and the difficult problem of physical zero length which cannot be solved by a traditional process is solved.

Owner:INST OF GEODESY & GEOPHYSICS CHINESE ACADEMY OF SCI

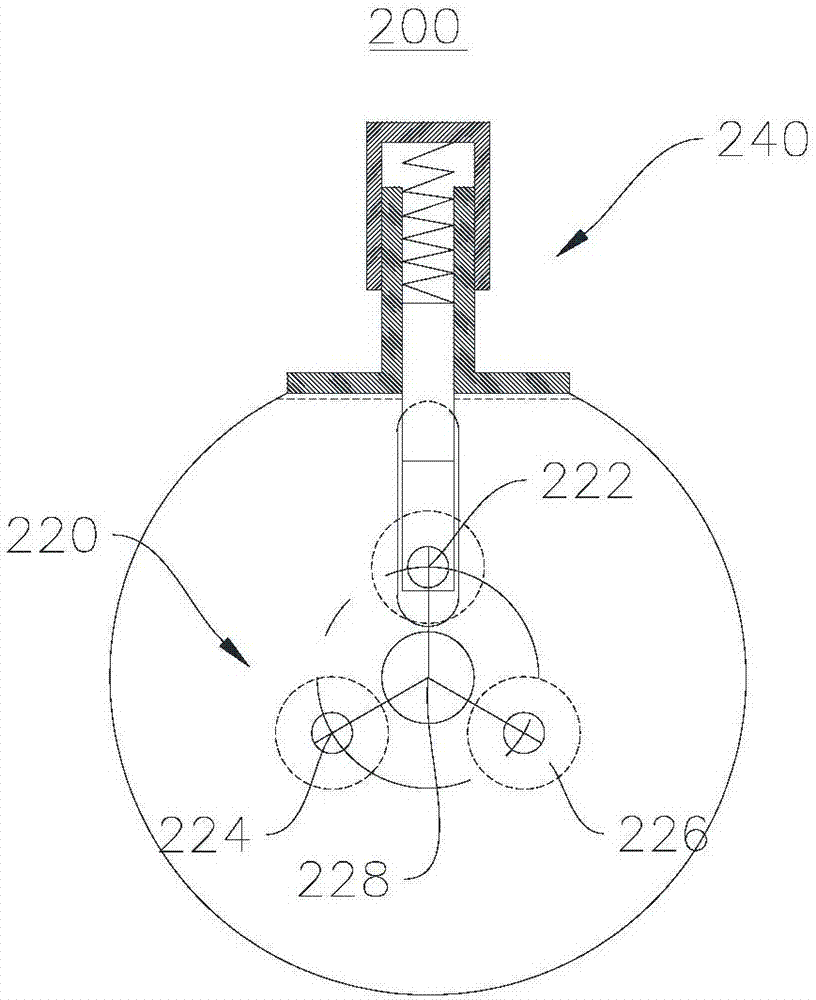

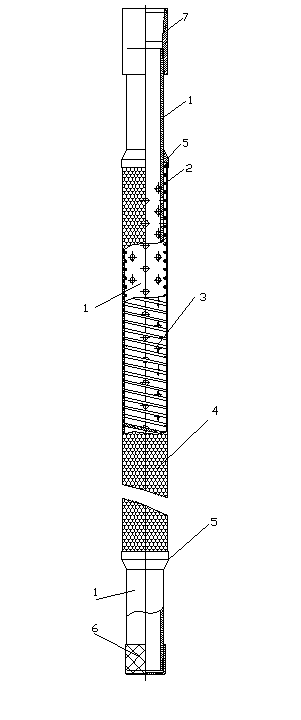

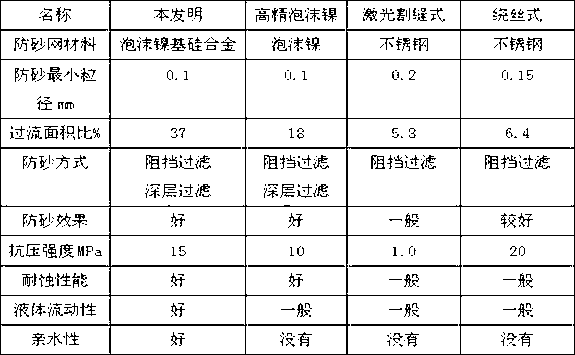

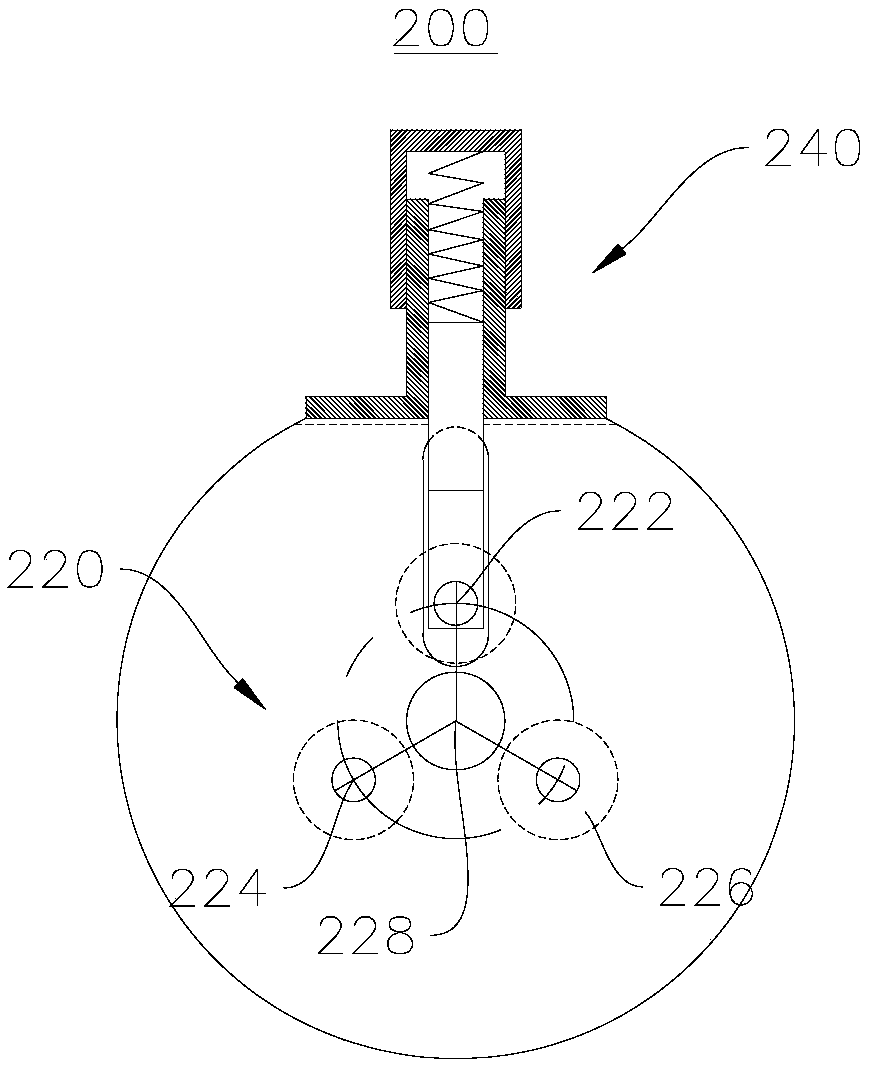

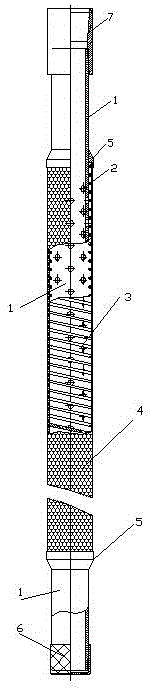

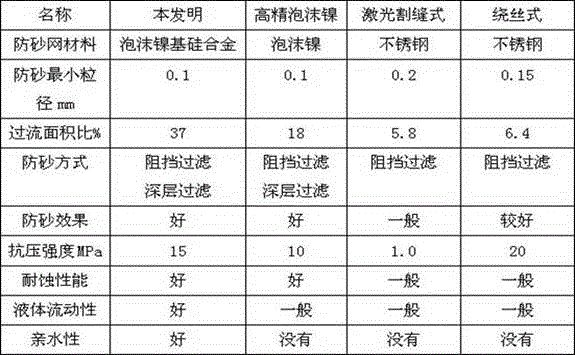

Foamed-nickel-based silicon alloy sand preventing device and manufacturing method thereof

InactiveCN103277074AHigh strengthImprove permeabilityFluid removalSilicon alloyUltimate tensile strength

The invention relates to a foamed-nickel-based silicon alloy sand preventing device. The foamed-nickel-based silicon alloy sand preventing device comprises a base tube, locating hoops, a blocking cap, a pipe joint and a sand preventing sleeve. The pipe joint is fixedly connected to the upper end of the base tube, the blocking cap is fixedly connected to the lower end of the base tube, and a plurality of overflowing holes are formed in the base tube. The foamed-nickel-based silicon alloy sand preventing device is further characterized in that a spiral supporting ring is fixed on the base tube with the overflowing holes, the sand preventing sleeve is a foamed-nickel-based silicon alloy sand preventing sleeve, the foamed-nickel-based silicon alloy sand preventing sleeve is connected to the spiral supporting ring in a sleeved mode, and the upper end and the lower end of the foamed-nickel-based silicon alloy sand preventing sleeve are fixedly connected with the base tube through the locating hoops which are fixedly connected. The foamed-nickel-based silicon alloy sand preventing device has the advantages of being high in strength, large in open area, good in hydrophilia, high in permeability, good in sand preventing effect, long in service life and the like.

Owner:吉林市卓尔新型金属材料有限公司

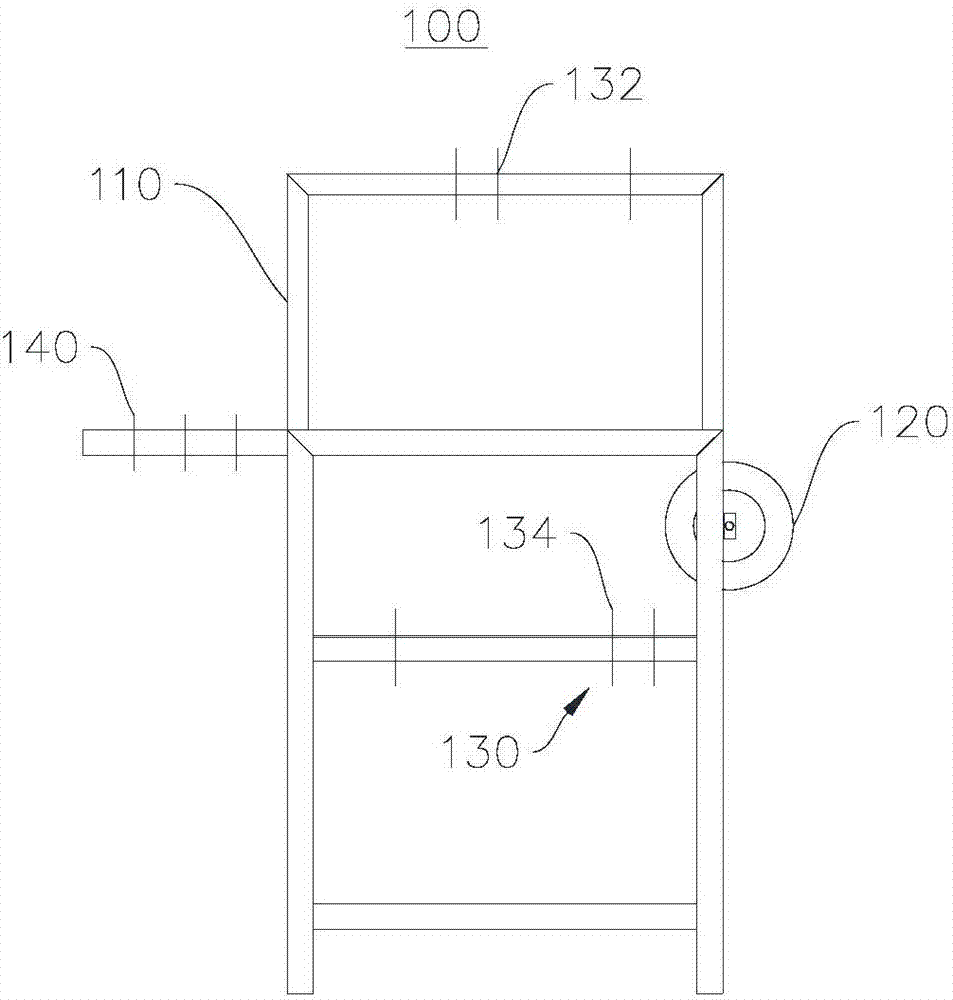

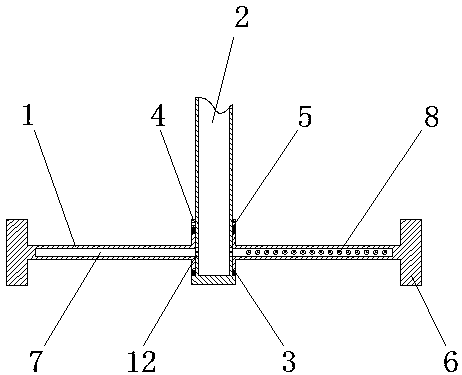

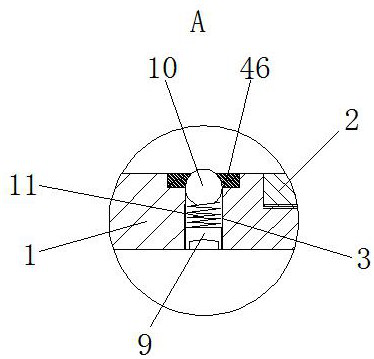

Stirring device with aeration function and manufacturing method thereof

PendingCN111170479AImprove production efficiencyReduce the temperatureWater aerationSustainable biological treatmentMechanical equipmentIndustrial engineering

The invention discloses a stirring device with an aeration function and a manufacturing method thereof. The invention belongs to the technical field of environment-friendly mechanical equipment. On the basis of an impeller-free design, the stirring device is driven to rotate through aerodynamic force, thus stirring materials; an air jet hole has a unique venturi structure, which can effectively reduce the temperature of waste water and waste liquid, so that flocculation and deposition of floccules in waste water and waste liquid are promoted; in order to facilitate smooth processing of the venturi air nozzle structure, the manufacturing method is scientific, not only can the manufacturing efficiency of the stirring device be improved, but also the manufacturing cost is low, and compared with a traditional machining method. The manufacturing method is simple in process, free of rough machining and cutting links, capable of saving a large number of raw materials, capable of achieving batch production and capable of well solving the machining problem of the novel stirring device.

Owner:YANGZHOU UNIV

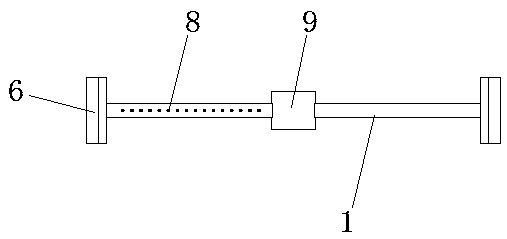

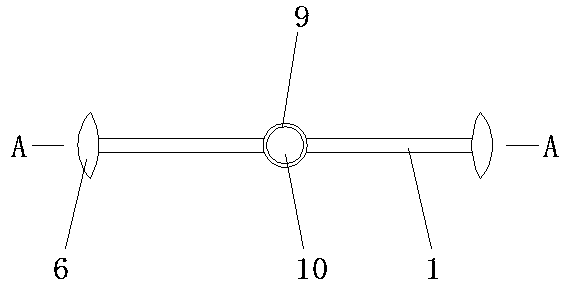

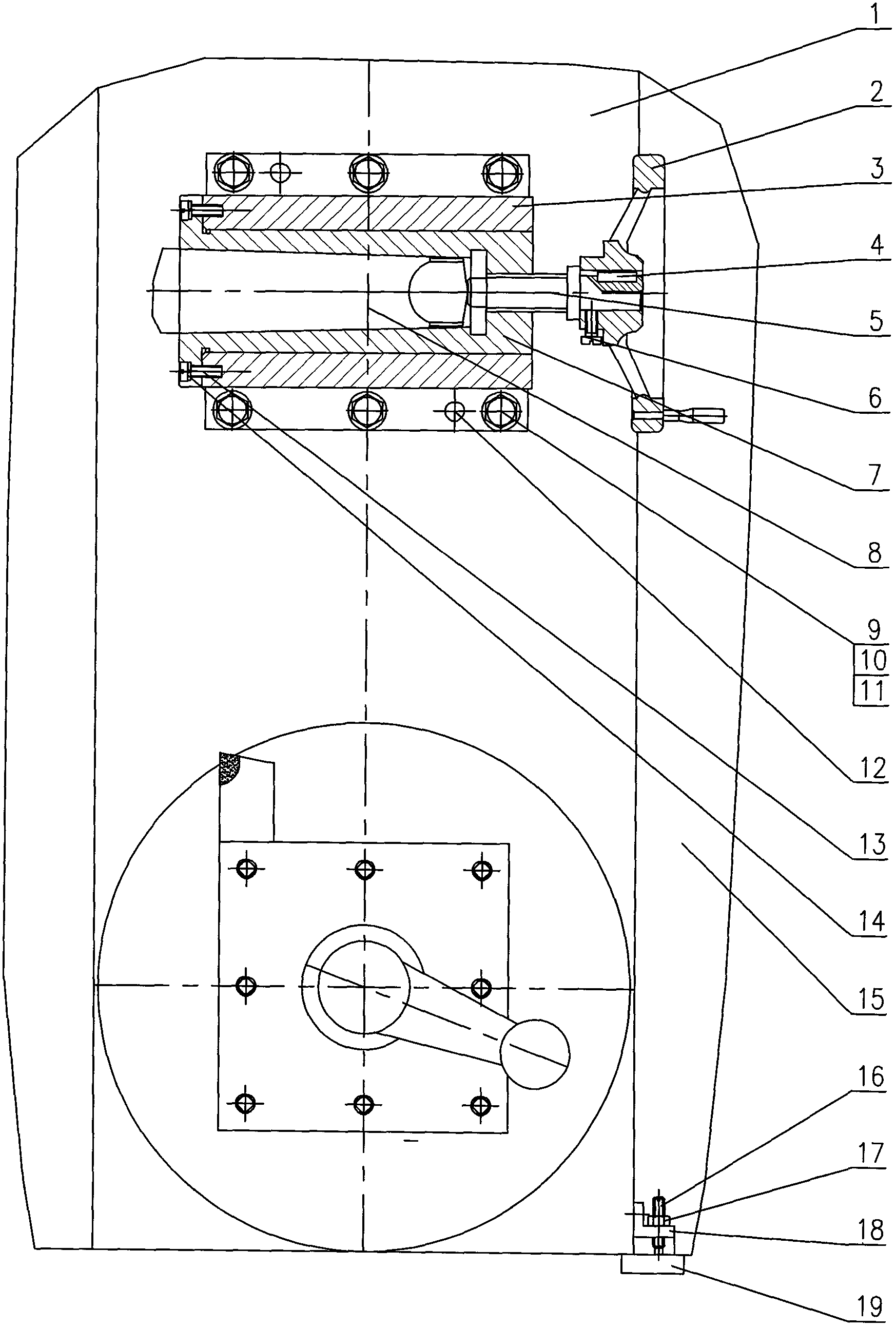

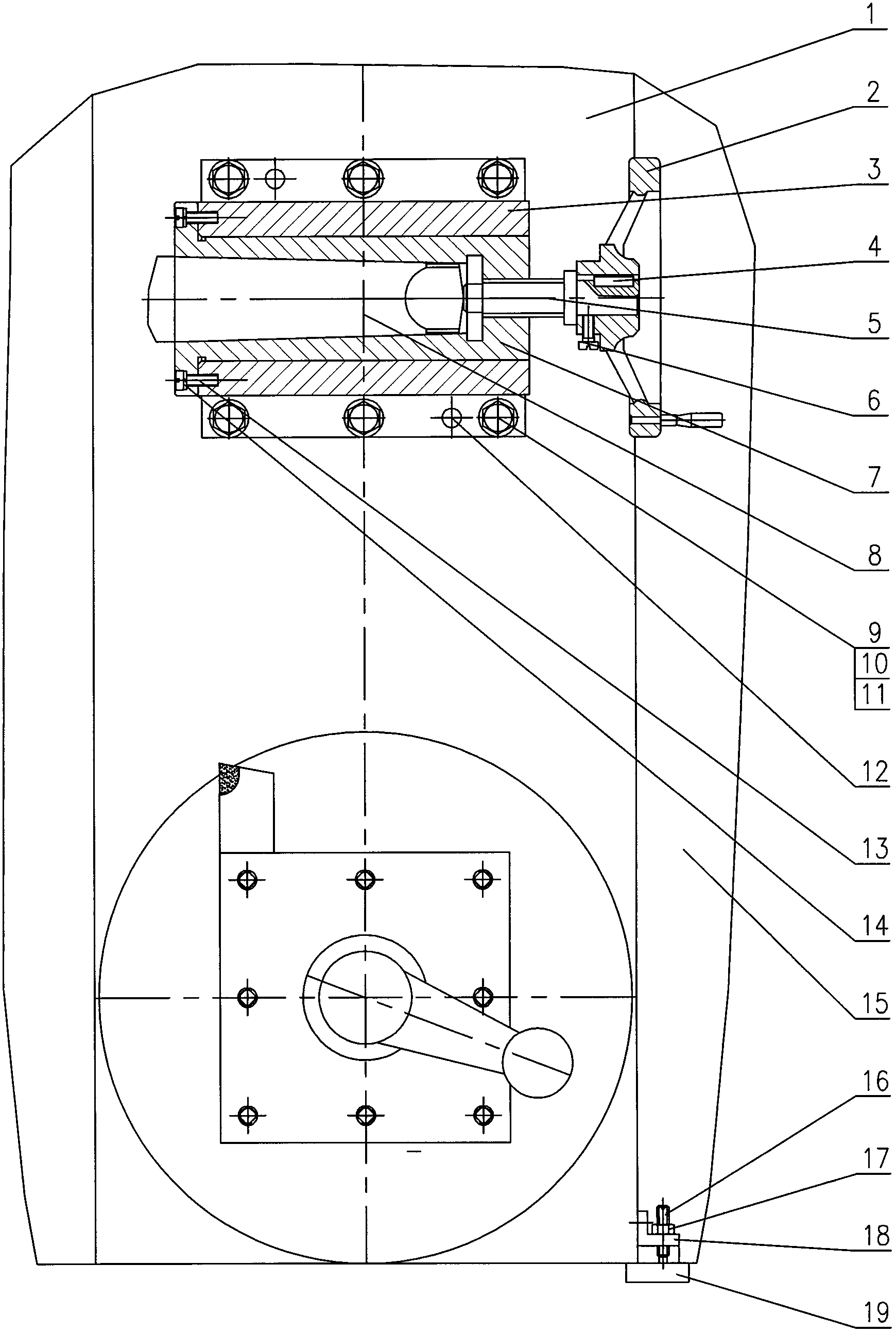

Manufacturing method for sleeve pipe mounted on middle planker

A manufacturing method for a sleeve pipe mounted on a middle planker comprises the following steps: 1, cylinder processing: blanking, large end cutting and small end cutting, small end excircle gear grinding allowance and inner hole cutting, and taper hole gear grinding, bolt hole drilling, heat treatment and fine inner hole grinding; 2, seat processing: casting, scribing, bottom surface peeling, inner hole cutting and fine boring, and threaded hole drilling and tapping; 3, drilling and tapping on the large slide carriage of a lathe by using a motor drill, and fixing a positioning plate; 4, fixing a support in a proper position of the middle planker of the lathe; 5, mounting a set screw at the slotted long cylindrical post end on the support by using a nut for locking, and propping the cylindrical end of the bolt on the positioning plate; 6, fixing the seat onto the middle planker of the lathe so as to enable the axial line of the inner hole of the seat to be basically coaxial with the rotation axis of the main shaft of the lathe; 7, clamping a boring bar onto the main shaft of the lathe, the feeding a cutter into the middle planker and finely boring the inner hole of the seat; 8, grinding the excircle of the small end of the cylinder according to the dimension of the finely bored seat so as to enable the match of the cylinder and the inner hole of the seat to be H7 / h6; 9, fixing the cylinder into the inner hole; and 10, fixing a hand wheel onto a lead screw and mounting the lead screw into the screw hole of the cylinder. The manufacturing method is simple, scientific and low in cost, and has high economic benefits.

Owner:孙效

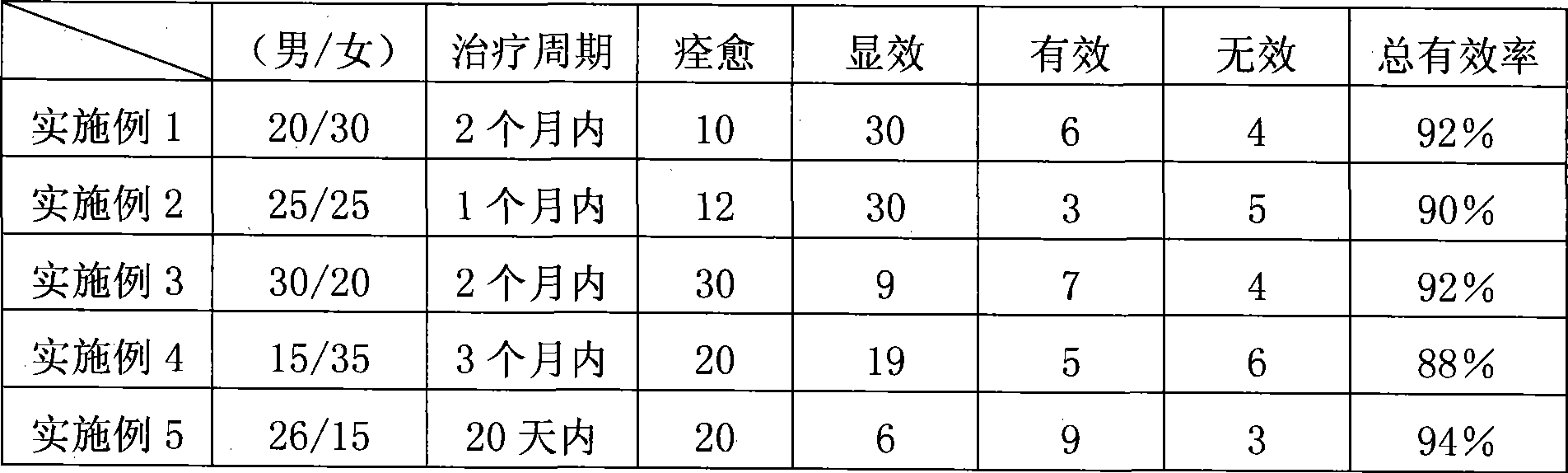

Pure Chinese herbal medicine gargle water for treating oral inflammation

InactiveCN101391011BInhibition formationProlong the action timeHydroxy compound active ingredientsDigestive systemMedicinal herbsSide effect

The invention provides a pure Chinese medicinal herb gargle for curing stomatitis, and the gargle is composed of following Chinese medicinal herbs: 20 to 40 parts of aloe leave, 10 to 25 parts of ginkgo, 10 to 25 parts of ginkgo leave, 10 to 25 parts of mint leave, 10 to 20 parts of honeysuckle, 10 to 20 parts of wind chrysanthemum, 3 to 5 parts of tuckahoe, 5 to 10 parts of fruit of glossy privet, 5 to 8 parts of liquorice and 5 to 10 parts of balloon flower root. The medical gargle prepared by the invention can resist bacterium, diminish inflammation, release pain and promote muscle; the medicine has long effect in the oral cavity, the curative effect is fine without side effect; through resisting bacterium and diminishing inflammation, repairing and acting the cells damaged in the oralcavity so as to reduce the bacterium quantity in the oral cavity, the Chinese traditional herbal medicine gargle can reach the effect of curing both symptoms and root cause at the same time, and is aideal medicine for curing the stomatitis, ulcerative stomatitis, pharyngitis, laryngitis, oral aphthae, oral peculiar smell, periodontitis and ngivitis.

Owner:朱惠芬

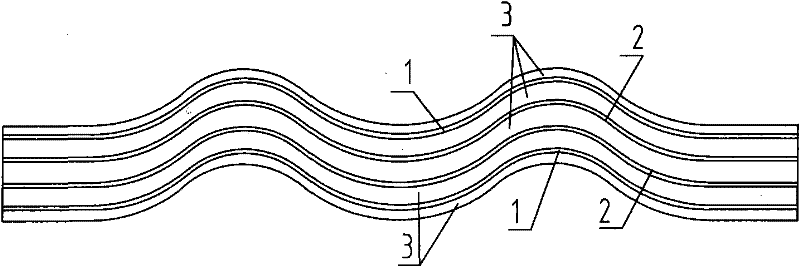

High density glass fiber reinforced cement curved plate and manufacturing method thereof

ActiveCN101985849BImprove performanceNo manual carving requiredConstruction materialFiberglass meshGlass fiber

The invention relates to a high density glass fiber reinforced cement curved plate and a manufacturing method thereof. The curved plate comprises curve-shaped frames which have constant section and are made of fiberglass meshes, each frame is internally provided with two layers of glass long fibers with same curve shape, and coagulated layers which are composed of cement paste and glass fiber chopped strands and have same curve shape are respectively arranged between the two layers of curve-shaped glass long fibers, between the layers of curve-shaped glass long fibers and the upper and lower curve-shaped fiberglass meshes as well as the outer layers of the upper and lower curve-shaped fiberglass meshes. The manufacturing method has the following important steps: constructing a forming cavity prototype which is composed of a bottom prototype, a middle prototype and a top prototype, sizing and curing in a curve-shaped die cavity after semi-solidification, and completing the curve forming. The invention has the advantages of 1) breaking through the traditional view that cement products are necessary to combine with steel bars to constitute products, 2) breaking through the traditional view that the cement products are only flat-shaped, and 3) breaking through the traditional view that the prepared cement products only can be provided with straight surfaces.

Owner:盈创建筑工业化襄阳有限公司

Penicillin plant bactericide, its preparation method and application in agriculture

The present invention relates to a penicillin plant germicide for preventing and curing plant crop diseases, its preparation method and application. Its formula is scientific and reasonable. It is a preparation made up by using penicilling sodium as main raw material, and adding trace elements of zinc and copper, etc. and adjuvant as carrier, not only possesses the strong power for killing bacteria, fungi and virus, but also has the actions of impellieng crops to absorb nutrients, promoting growth of crops and obviously raising yield.

Owner:蒋长宁

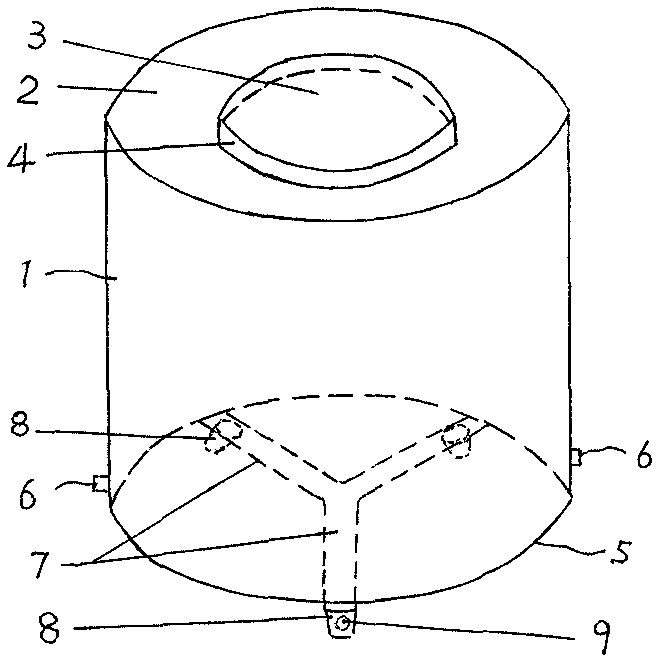

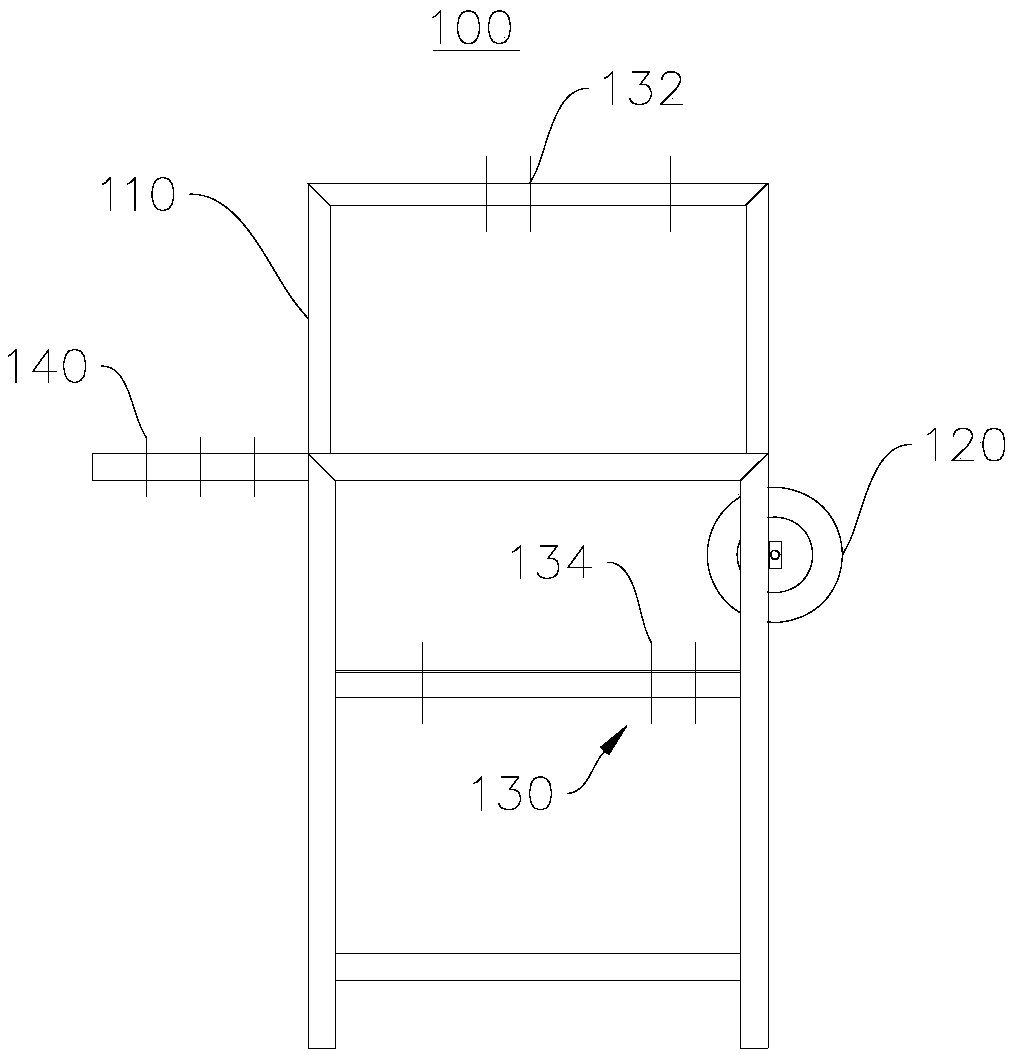

Barrel-shaped integral concrete water storage tower tank and preparation method thereof

InactiveCN102561779BHigh strengthEasy to useMixing operation control apparatusCeramic shaping apparatusMaterials preparationWater storage

Disclosed are a barrel-shaped integral concrete water storage tower tank and a preparation method thereof. The barrel-shaped integral concrete water storage tower tank is characterized in that a tank body, a tank top cover and a tank base are barrel-shaped semi-closed structures which are manufactured integrally, reinforcing ribs are arranged on the tank base, and a supporting base is integrally fixedly connected with or movably embedded at the bottoms of the reinforcing ribs. An integral precast method includes steps of material preparation, mold manufacture preparation and mold assembly, uniform concrete stirring, casting molding and curing and demoulding of finished products. The barrel-shaped integral concrete water storage tower tank and the preparation method thereof have the advantages that the integral strength of the tank body is high, service performances are excellent, processing is convenient, carrying and hoisting are easy, a manufacturing method is scientific, energy conservation and environmental protection are realized, labor and materials are saved, cost is low (the quantity of reinforced concrete is saved by about 30%), the barrel-shaped integral concrete water storage tower tank can be placed on a roof of the top of a building to be used as a domestic water reservoir or water storage tower tank and the like, and market competitiveness further can be strengthened.

Owner:陈生金

Preparation method of environment-friendly adhesive for board

InactiveCN107987765AGood weather resistanceImprove permeabilityMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesEnvironmental resistanceAdhesive

The invention discloses a preparation method of an environment-friendly adhesive for a board, and belongs to the technical field of building materials. The preparation method comprises the following preparation steps of weighing the following components in parts by weight: 90 parts of formaldehyde aqueous solution with a mass concentration of 15wt% to 25wt%, 0.3 to 0.5 part of alkaline matter solution with a mass concentration of 20wt% to 30wt% and 0.3 to 0.5 part of amino-terminated hyperbranched polymer PAMAM (Polyamidoamine) and agitating to obtain an initial mixture; adding 2 to 6 parts byweight of hexachlorocyclotriphosphazene into the initial mixture, raising a temperature to 80 DEG C, adding 20 to 30 parts by weight of melamine when the temperature is raised to 85 DEG C, continuously raising the temperature to 90 DEG C and reacting to obtain a primary condensation polymer; adding 30 to 40 parts by weight of melamine into the primary condensation polymer and adding 0.8 to 1.5 parts by weight of para toluene sulfonamide, so as to obtain a second condensation polymer; adding 20 to 35 parts by weight of urea when the temperature of the second condensation polymer is decreased to 60 DEG C, continuously reacting for 15min to 20min and discharging the adhesive when the temperature is decreased to 50 DEG C. The environment-friendly adhesive not only retains a better flame-retarding effect and has a small formaldehyde emission amount, but also has more stable product quality.

Owner:安徽信耀玻璃有限公司

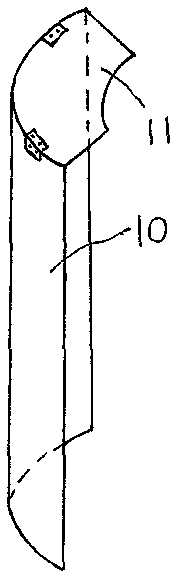

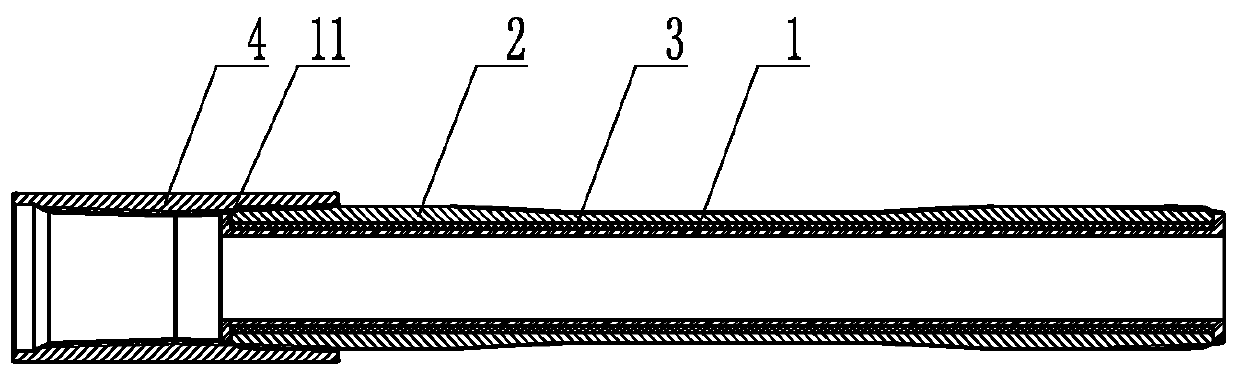

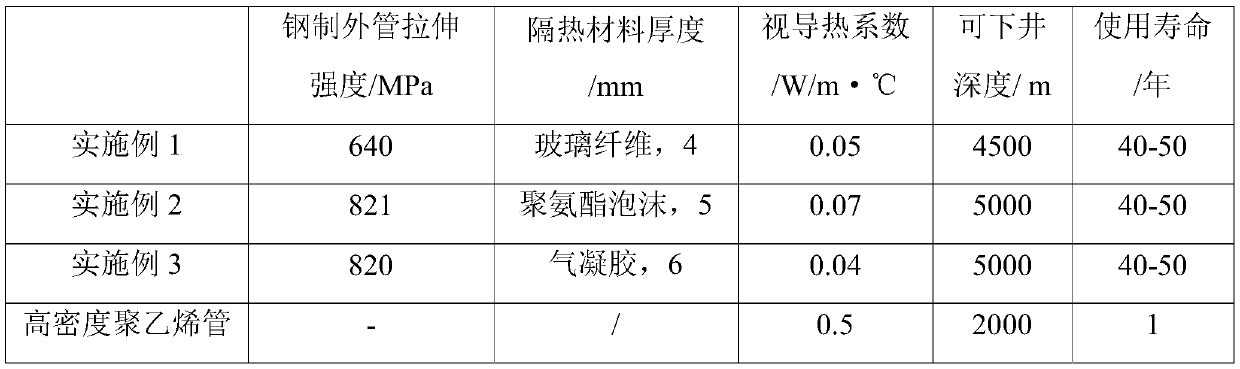

Heat insulation pipe for geothermal exploitation and manufacturing method thereof

InactiveCN111043451AGood heat insulationHigh utilization rate of geothermalThermal insulationPipe protection by thermal insulationCorrosion resistantMechanical engineering

The invention relates to a heat insulation pipe for geothermal exploitation and a manufacturing method thereof, and belongs to the technical field of geothermal exploitation and utilization. The heatinsulation pipe for geothermal exploitation comprises a lining pipe, an outer pipe and a heat insulation material, the two ends of the lining pipe are bent to form outer flanges, the lining pipe is sleeved with the outer pipe, the two ends of the outer pipe abut against the outer flanges at the two ends of the lining pipe respectively, and a cavity between the lining pipe and the outer pipe is filled with the heat insulation material. The heat insulation pipe for geothermal exploitation has the advantages of being good in heat insulation performance, high in threaded connection strength, resistant to corrosion, self-lubricating, resistant to scaling, deep in the depth of entering a well and long in service life; and the manufacturing method of the heat insulation pipe is scientific, reasonable, simple and feasible.

Owner:山东美生热能科技有限公司

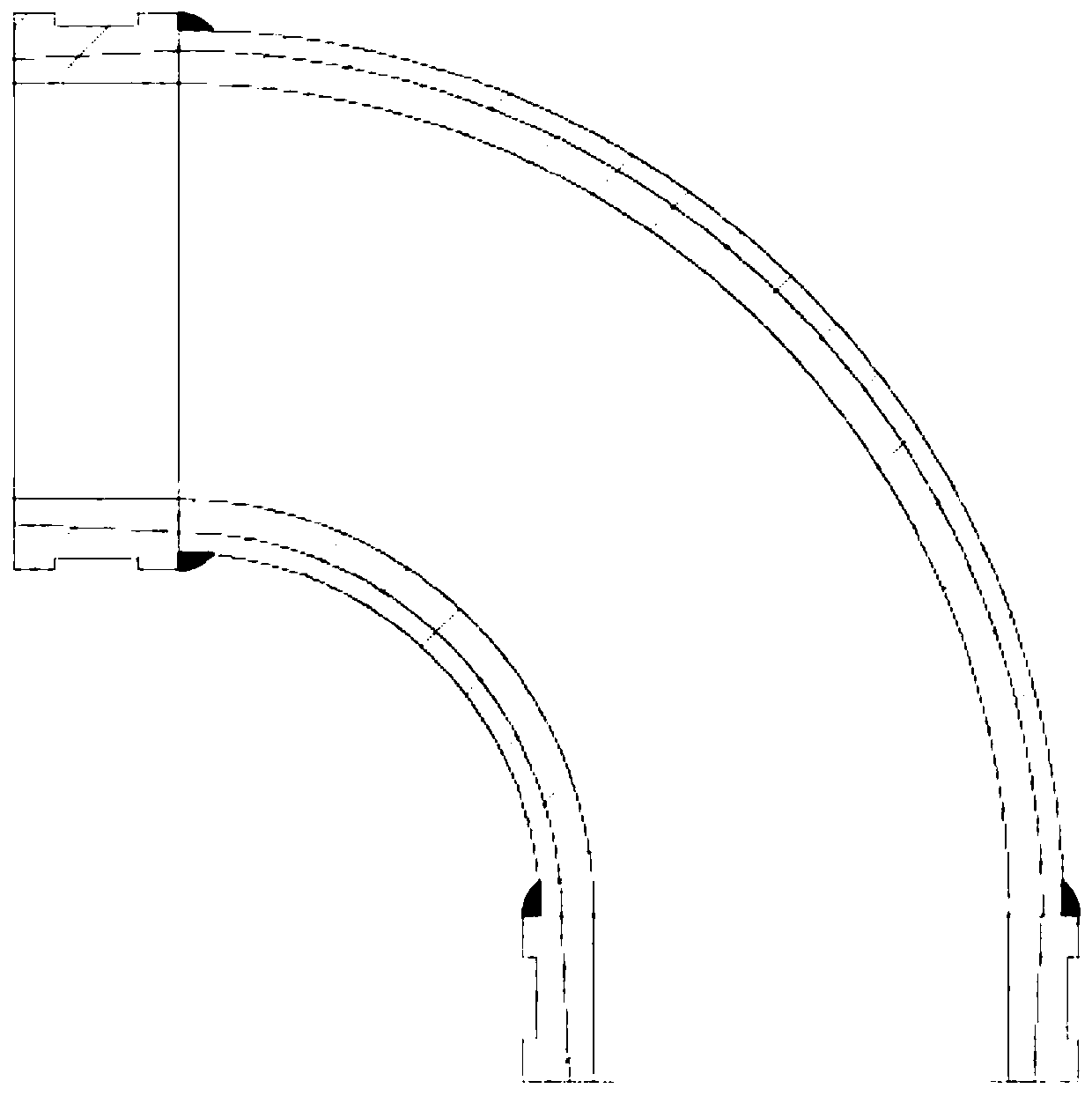

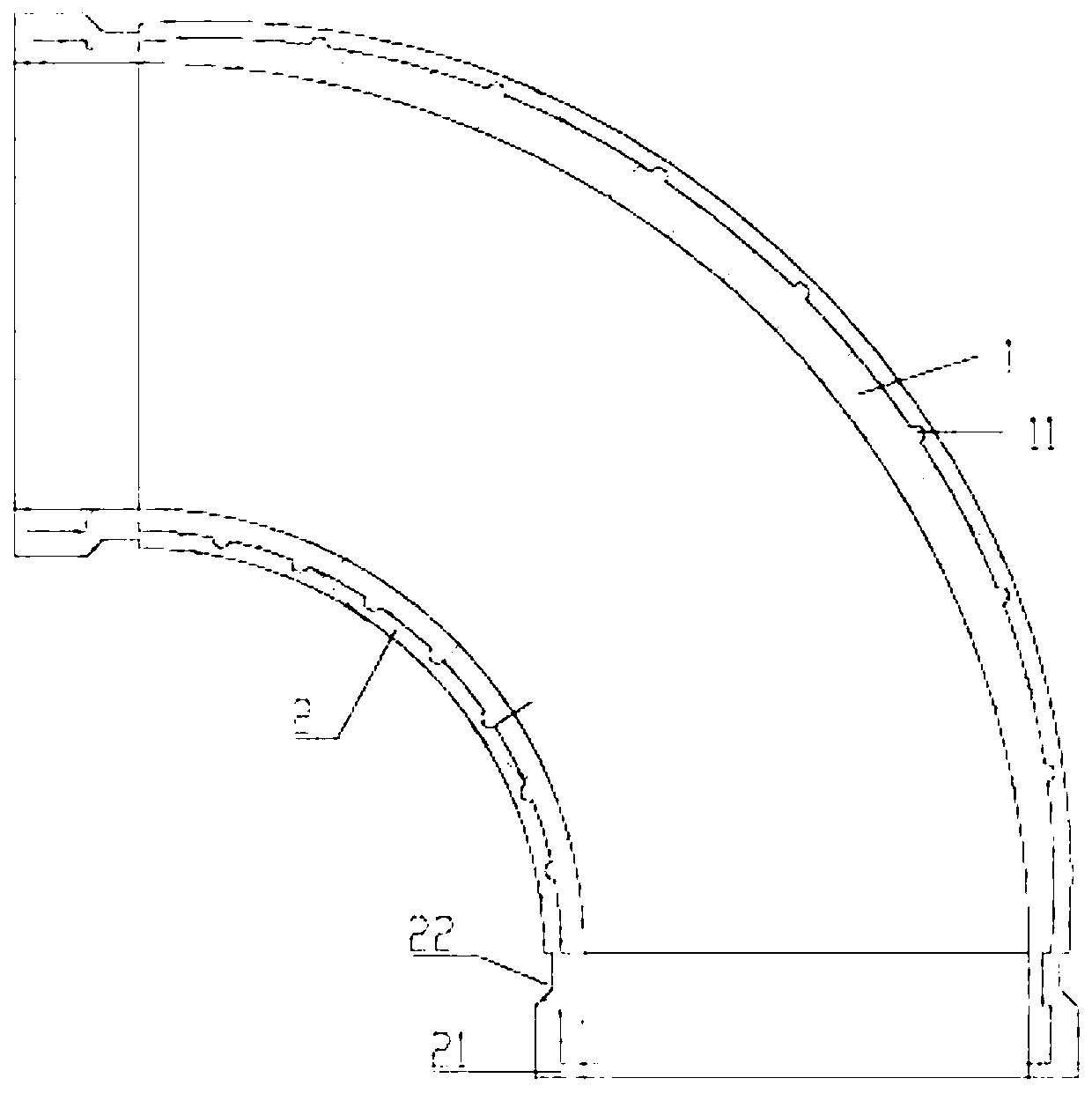

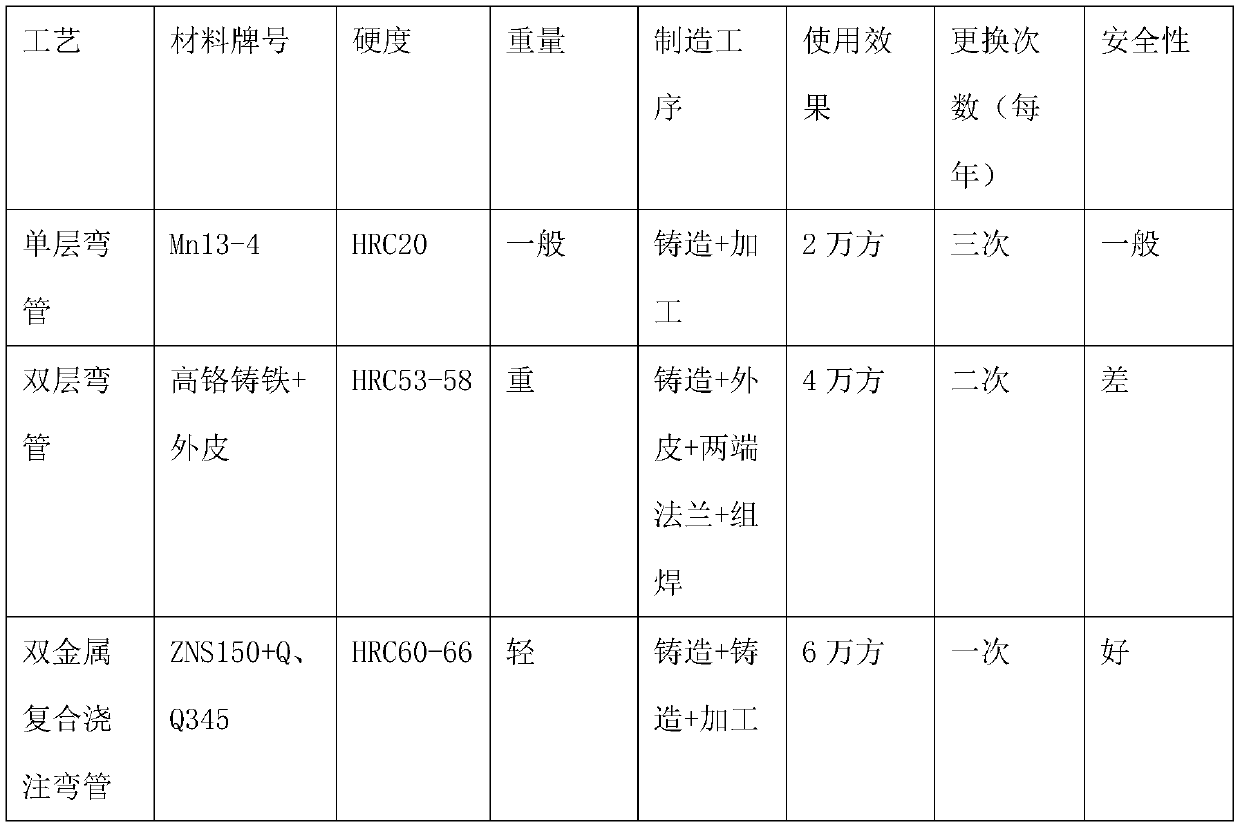

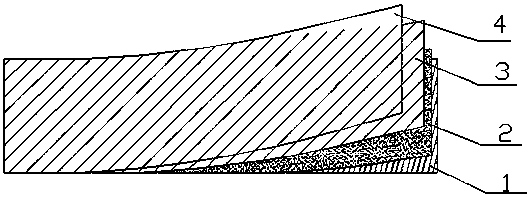

Bi-metal composite pouring bent pipe used for concrete conveying and manufacturing method

InactiveCN110640117AReduce weightManufacturing method scienceCorrosion preventionPipe protection against corrosion/incrustationPipeMechanical engineering

The invention relates to the technical field of concrete conveying pipe manufacturing, in particular to a bi-metal composite pouring bent pipe used for concrete conveying and a manufacturing method. The dual-metal bent pipe comprises an inner container with a wear-resisting corrosion-resisting property and a shell welded with the inner container. The wear-resisting corrosion-resisting inner container is poured, the cooled inner container serves as a mold core for pouring of the shell, and high-temperature metal is used for welding the inner and outer dual-metal bent pipe. The bent pipe is simple in structure, separation falling of the inner and outer bent pipe can be thoroughly eradicated, the use failure rate is reduced, the adopted manufacturing method is simple and practical, productiondifficulty is greatly reduced, production efficiency is improved, the inner container is formed through casting of a high-strength wear-resisting corrosion-resisting material, the quality need is achieved under the condition that the whole bent pipe is thinner, the weight of the bent pipe is reduced, finally, the weight of equipment using the bent pipe is reduced, and safety and stability are improved.

Owner:谷城大成机械有限公司

Floor surface board and its manufacturing method

InactiveCN105014766BImprove wear resistanceManufacturing method scienceLaminationLamination apparatusWood veneerWear resistant

The present invention relates to a floor panel and a manufacturing method thereof, which is characterized in that the steps include: a substrate of a fast-growing wood veneer; a substrate coating layer coated with a melamine resin adhesive on the surface of the substrate; using non-woven fabric or paper with 0.2 The decorative layer impregnated with melamine resin composited with sliced veneer of ~0.4 mm; the wear-resistant layer is made of aluminum oxide wear-resistant paper; the base plate with glued layer, the decorative layer impregnated with glue, and the wear-resistant layer are made of a hot press molding machine. At a temperature of 130~140°C and a pressure of 1.5~2.0MPa, it takes 3~5 minutes to form at one time. The manufacturing method is scientific and reasonable, easy to form, and of good quality, and can simultaneously take into account the advantages of saving wood resources and having the performance of a reinforced floor surface board.

Owner:BEIHUA UNIV

Sleeve installed on medium carriage

InactiveCN103170848AEasy to prepareManufacturing method sciencePositioning apparatusMetal-working holdersSet screwArchitectural engineering

The invention discloses a sleeve installed on a medium carriage. According to the sleeve installed on the medium carriage, a base is fixed on the medium carriage of a lathe, a cutter barrel is fixed in an inner hole in the base, the axis of a taper hole of the cutter barrel is coaxial with the rotation axis of a lathe main shaft, a hand wheel is fixed on a cylinder on the left side of a lead screw, the right side of the lead screw is arranged in a screw hole of the cutter barrel, a fixing plate is fixed on a large slide carriage of the lathe, a support frame is fixed on the medium carriage of the lathe, a groove long cylindrical end set screw is arranged in a screw hole of the support frame and is locked by a nut, and the cylindrical end of the groove long cylindrical end set screw abuts against the fixing plate. A groove cylindrical head screw and a spring washer used by the cutter barrel are fixed in the inner hole of the base in a mode that the matching is H7 / h6 and hot processing of the cutter barrel is 48-52 HRC. Cutters required by machining can be fast replaced and installed in the cutter barrel on the medium carriage of the lather, machining of a hole can be achieved with a corresponding cutter by means of the function of mechanical cutter feeding function of the lathe, machining is fast, and labor is saved. A lathe fast cutter dismantling device is low in manufacturing cost and high in economic benefit.

Owner:孙效

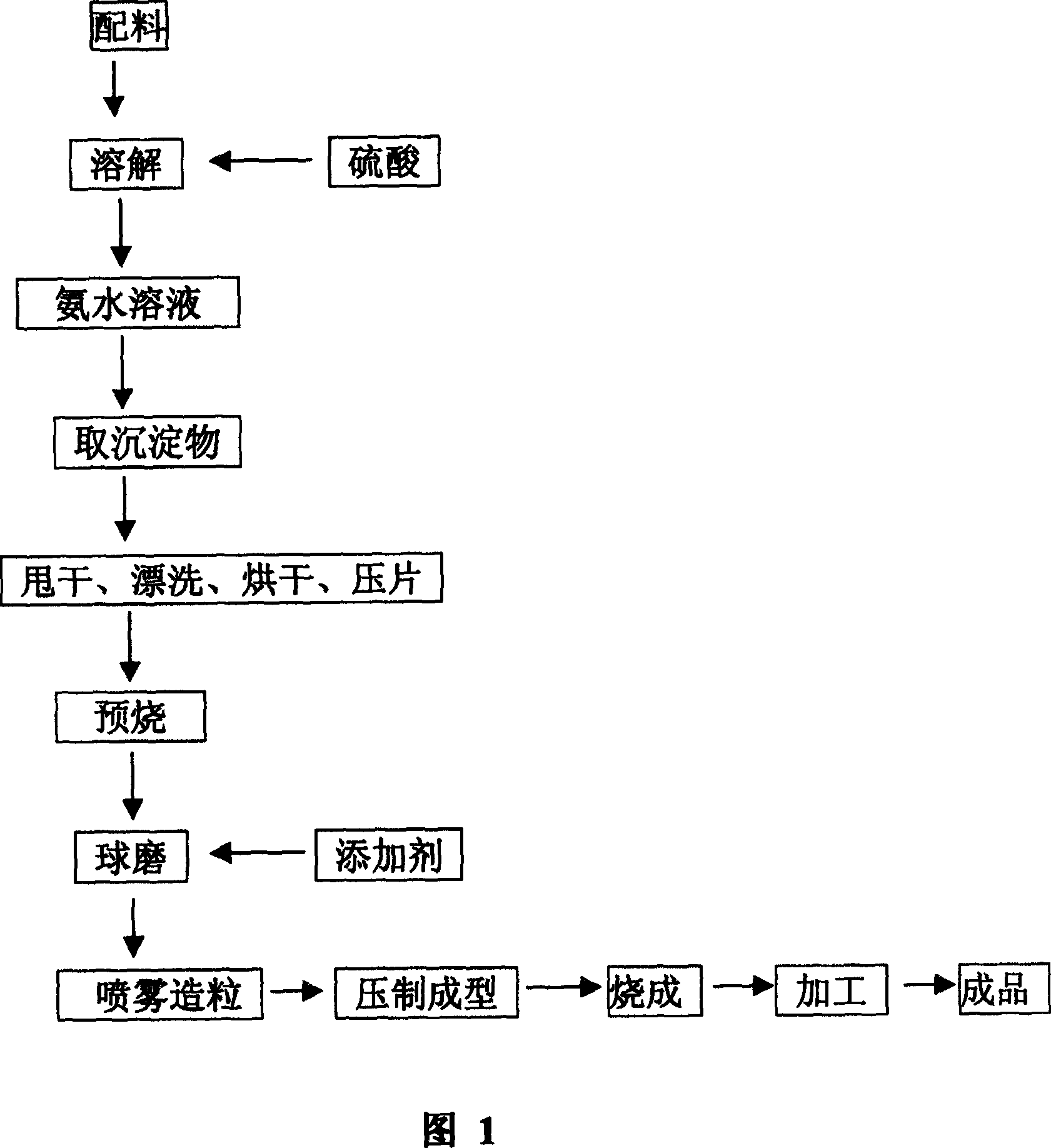

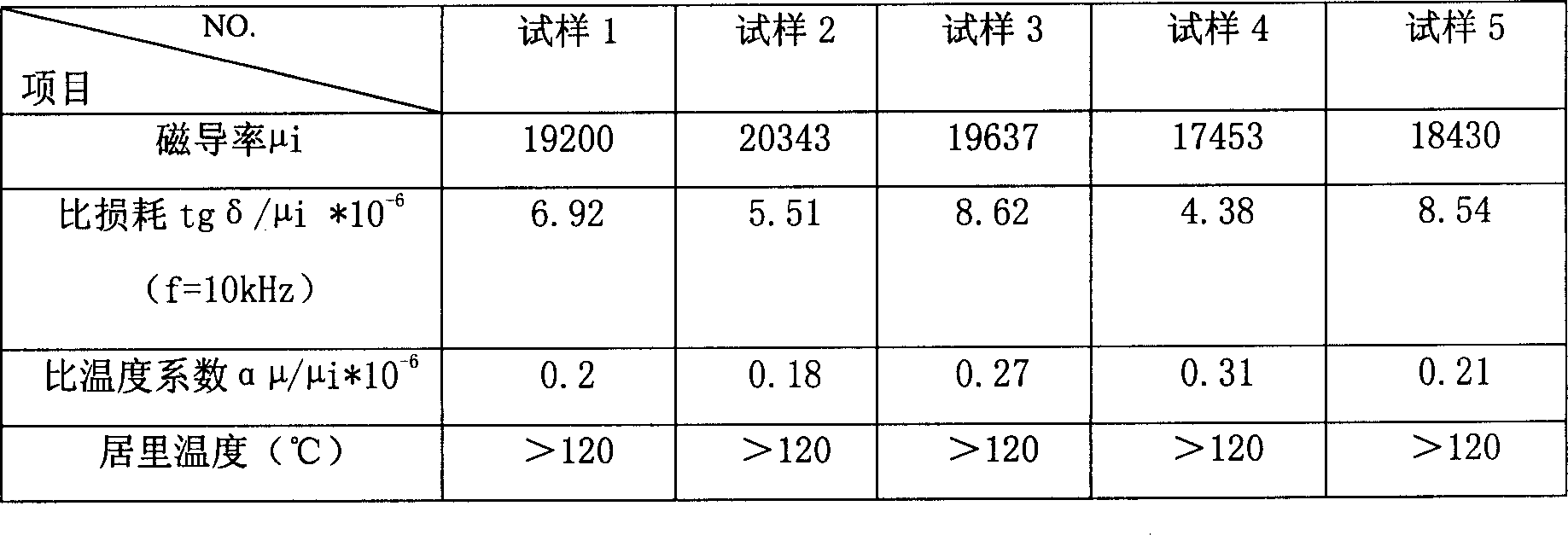

Process for mfg, 18k manganese zine iron oxygen body magnetic powder magnetic core

InactiveCN1333411CImprove frequency characteristicsImproved loss characteristicsInorganic material magnetismElectrolysisManganese

The invention relates to manufacture method for 18k manganese-zinc ferrite magnetic powder magnetic core that includes the steps of mixing, solving, depositing, pre-firing, crushing, molding, and sintering. The manganese-zinc ferrite magnetic powder magnetic core has the feathers that magnetic permeability could reach to 18K, Curie temperature could reach to 120 degree centigrade, and the frequency could reach 100KHz. It could satisfy the request on communication, digital technology or network technology.

Owner:YUXING ELECTRONICS MATERIAL ZIBO

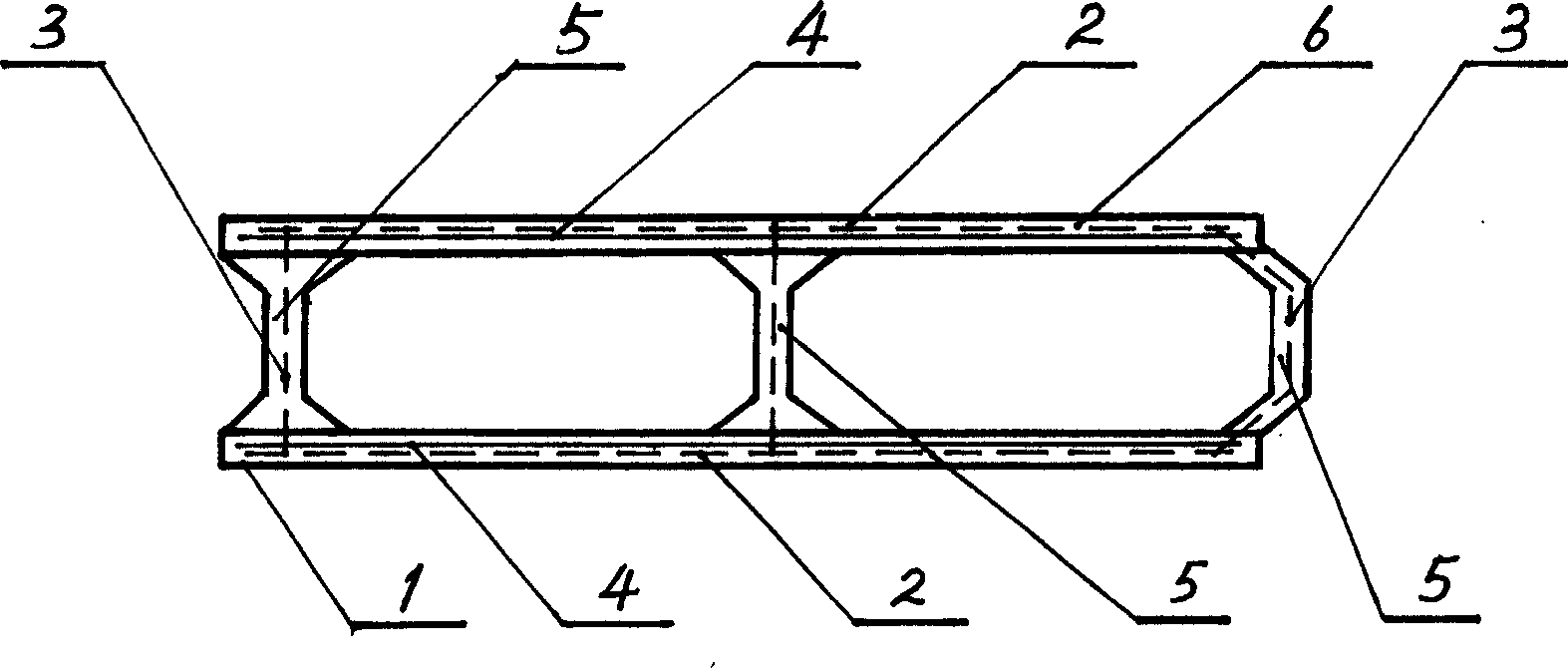

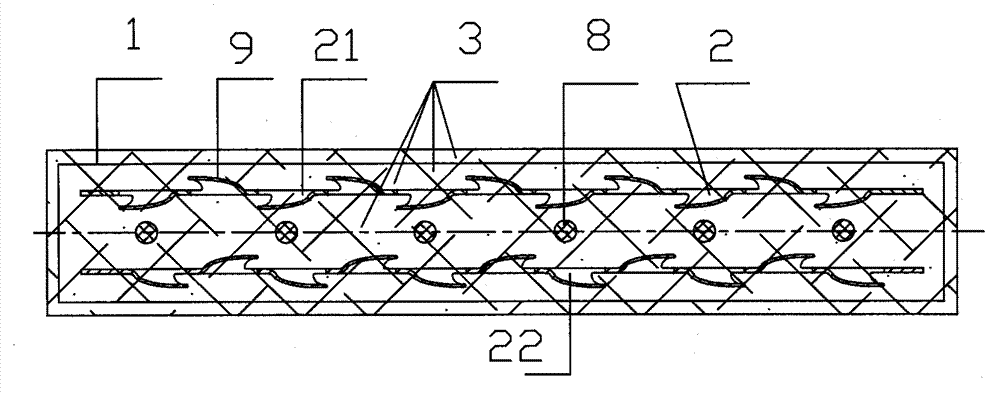

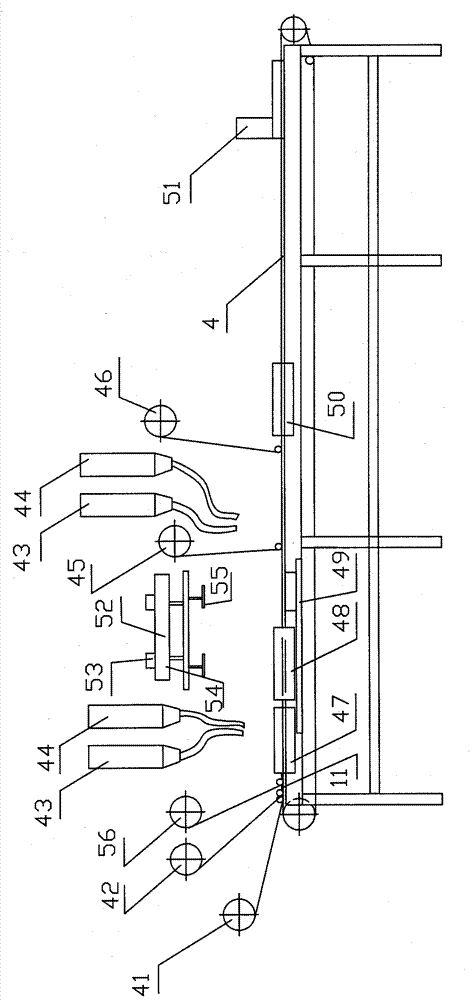

Composite high-strength glass fiber reinforced cement decoration, fireproof and explosion-proof board and its production line

ActiveCN102839801BTake advantage of flexibilityImprove impact resistanceCovering/liningsCeramic shaping plantsYarnFiberglass mesh

The invention relates to a composite high strength glass fiber reinforcing cement decorative, a fireproof and anti-explosive plate and a production line of the composite high strength glass fiber reinforcing cement decorative, waterproof and anti-explosive plate. The decorative, fireproof and anti-explosive plate comprises a chamber body structure formed by the enclosing of glass fiber gridding meshes, a metal layer, and a concrete layer with short glass fiber yarn embedded into the cement paste body, wherein a plurality of fins which are transversely arranged at a certain spacing and outwards punched to form outward openings are arranged on the metal layer plate body; and the metal layer is placed into the chamber body structure formed by the enclosing of the glass fiber gridding meshes. The invention also provides a production line of the decorative, fireproof and anti-explosive plate. The decorative, fireproof and anti-explosive plate and the production line have the following advantages: 1) an upper concrete layer and a lower concrete layer are organically combined through a plurality of fins which are transversely arranged at a certain spacing and outwards punched to form outward openings on the metal layer plate body, so that the impacting resistance is improved; and the combined part can be directly arranged on the external wall of a building structure as a fireproof and anti-explosive external wall decorative plate; and 2) a product is scientific and reasonable in manufacture method, continuous in production, high in efficiency and low in cost; and the plane of the product is varied along with the variation of a forming formwork; and the surface of the product is smooth, the deformation does not exist, and additional decoration is not required.

Owner:YINGCHUANG BUILDING TECH SHANGHAI CO LTD

A kind of manufacturing method of zero-length spring and zero-length spring

ActiveCN107502727BManufacturing method systemManufacturing method scienceFurnace typesWire springsGram-forceEngineering

The invention provides a manufacturing method for a zero-length spring and the zero-length spring, and relates to the field of sea-air gravity meters. The manufacturing method for the zero-length spring comprises the steps that a microstructure of a wire material is adjusted through a solid solution strengthening treating process, wherein the wire material is a constant elastic wire material; molding treatment is conducted on the solid solution wire material; pretension force is applied to a first spring through a reverse rotation mode; and tempering treating is conducted on a second spring. The manufacturing method for the zero-length spring is more systematic and scientific and high in precise so that the zero length error delta l of the zero-length spring is less than or equal to 1 millimeter, the drifting amount delta is less than or equal to 10<2>[mu] per day, the rigidity error k is less than or equal to 0.01 gram force per millimeter, and the difficult problem of physical zero length which cannot be solved by a traditional process is solved.

Owner:INST OF GEODESY & GEOPHYSICS CHINESE ACADEMY OF SCI

A foam nickel-based silicon alloy sand control device and its manufacturing method

InactiveCN103277074BHigh strengthImprove permeabilityFluid removalSilicon alloyUltimate tensile strength

The invention relates to a foamed-nickel-based silicon alloy sand preventing device. The foamed-nickel-based silicon alloy sand preventing device comprises a base tube, locating hoops, a blocking cap, a pipe joint and a sand preventing sleeve. The pipe joint is fixedly connected to the upper end of the base tube, the blocking cap is fixedly connected to the lower end of the base tube, and a plurality of overflowing holes are formed in the base tube. The foamed-nickel-based silicon alloy sand preventing device is further characterized in that a spiral supporting ring is fixed on the base tube with the overflowing holes, the sand preventing sleeve is a foamed-nickel-based silicon alloy sand preventing sleeve, the foamed-nickel-based silicon alloy sand preventing sleeve is connected to the spiral supporting ring in a sleeved mode, and the upper end and the lower end of the foamed-nickel-based silicon alloy sand preventing sleeve are fixedly connected with the base tube through the locating hoops which are fixedly connected. The foamed-nickel-based silicon alloy sand preventing device has the advantages of being high in strength, large in open area, good in hydrophilia, high in permeability, good in sand preventing effect, long in service life and the like.

Owner:吉林市卓尔新型金属材料有限公司

Sound-insulation floor and manufacturing method thereof

InactiveCN108104406AMeet the decoration design specification requirementsImprove sound insulationFlooring insulationsInsulation layerAdhesive

The invention discloses a sound-insulation floor and a manufacturing method thereof, and belongs to the technical field of building materials. The sound-insulation floor comprises a decorative layer and a veneer layer and is characterized in that the sound-insulation floor is further constituted by a sound-insulation layer; the sound-insulation layer is constituted by a sound-insulation plate, a honeycomb plate and a filling material; the sound-insulation floor sequentially comprises the sound-insulation plate, the honeycomb plate, the veneer layer and the decorative layer from the back surface to the top surface; the filling material is arranged in the honeycomb plate in a filled mode; and all the layers are mutually connected through adhesives. The preparation method is scientific, compared with a traditional manufacturing method of the sound-insulation floor, cost performance is high, sound-insulation performance is good, the flame-retardant level is high, the code requirement of decoration design in buildings is met, and the sound-insulation performance of the composite floor is greatly improved.

Owner:安徽信耀玻璃有限公司

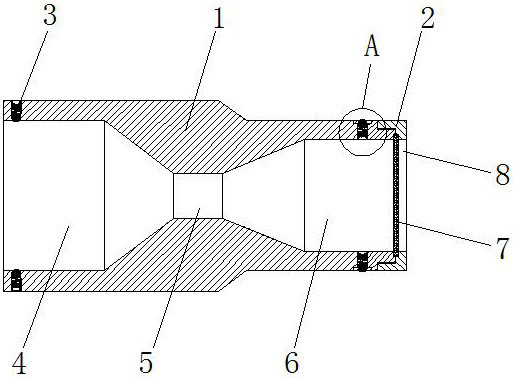

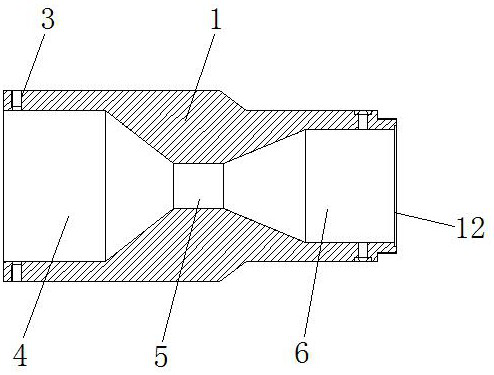

Venturi exhaust air adapter device for purifying oil fume and manufacturing method thereof

ActiveCN110285460BGreat suctionQuick assemblySleeve/socket jointsDomestic stoves or rangesAir velocityElectric machine

A Venturi exhaust air transfer device for purifying oil fume and a manufacturing method thereof belong to the technical field of machining. All parts are processed by casting molding, the manufacturing method is scientific and reasonable, and the manufacturing speed is fast. Compared with traditional milling, it can not only save processing materials, but also realize large-scale processing in the same process, reducing manufacturing costs. The components in the device are easy to assemble and disassemble quickly. The air inlet, throat and air outlet in the main structure of the device form a Venturi effect structure. The air speed of the air outlet is greater than the air speed of the air inlet, and negative pressure is generated through the venturi throat, and the fume is generated. Under the condition that the power of the machine suction motor is constant, the suction force of the oil fume is increased, and the energy saving effect is improved. In addition, the setting of the activated carbon cake further achieves the purpose of protecting the environment.

Owner:YANGZHOU UNIV

Wood-plastic composite floor and preparation method thereof

ActiveCN104989065BIncrease profitSave resourcesWood layered productsFlooringFreeze-dryingHazardous substance

The invention relates to a wood-plastic composite floor and a manufacturing method thereof. The wood-plastic composite floor manufactured by the method comprises: from top to bottom, a surface coating layer, an upper surface board layer, an upper surface board modified layer, an intermediate layer, The lower panel modified layer and the lower panel layer are compositely composed. It can further alleviate the shortage of precious wood, and the surface of the carbonized surface is modified and then compounded with the intermediate layer, which improves the decoration of the surface of the wood-plastic composite material, and the veneer after carbonization treatment has good dimensional stability, small color difference, and wood. High utilization rate. The 18mm-thick wood-plastic composite floor of the present invention has a bending load of 1240N after being boiled (immersed)-freeze-dried, a dipping peeling rate of 0, and a wet friction coefficient of 0.7; it can save wood resources and have solid wood floors at the same time. Surface effect and other advantages, no harmful substances are released, and can be widely used indoors and outdoors. The manufacturing method is scientific and reasonable and easy to form.

Owner:BEIHUA UNIV

Manufacturing method of environment-friendly nontoxic decorating plate

InactiveCN108058241AImprove environmental performanceManufacturing method scienceNon-macromolecular adhesive additivesProtein adhesivesHindered amine light stabilizersPulp and paper industry

The invention discloses a manufacturing method of an environment-friendly nontoxic decorating plate, and belongs to the technical field of building materials. The method comprises the steps that a hindered amine light stabilizer is dispersed in melamine modified resin, and woodgrained paper is sequentially subjected to first-time immersion treatment, first-time drying, second-time immersion treatment and second-time drying in the melamine modified resin to prepare a high-color-fastness facing layer; the melamine modified resin is prepared, particularly, thee times of melamine addition polycondensation are carried out, one time of urea polycondensation is carried out, and the mole ratio of HCHO to NH2 is 0.5; second-time immersion treatment is carried out, particularly, nanosilicon dioxideis added successively, wherein the adding amount of the nanosilicon dioxide is 8% of the mass of the melamine modified resin; the upper surface and the lower surface of a substrate layer are coated with environment-friendly glue, wherein the substrate layer is multiply plywood; the upper surface and the lower surface of a substrate are prepressed, wherein prepressing unit pressure is 0.8 MPa, andtime is 30 min; a prepressing plate is subjected to hot pressing, wherein hot pressing unit pressure is 1.2 MPa, time is 15 min, the temperature is not lower than 120 DEG C, and finally the decoratingplate with high environmental protection performance is obtained.

Owner:安徽信耀玻璃有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com