Heat insulation pipe for geothermal exploitation and manufacturing method thereof

A technology of thermal insulation and manufacturing method, which is applied in the direction of protecting pipelines by thermal insulation, thermal insulation, pipeline protection, etc., can solve the problems of easy aging, poor resistance to internal pressure and external extrusion, well falling, etc., and achieves high thread connection strength, The effect of improving the utilization rate of geothermal heat and obvious thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

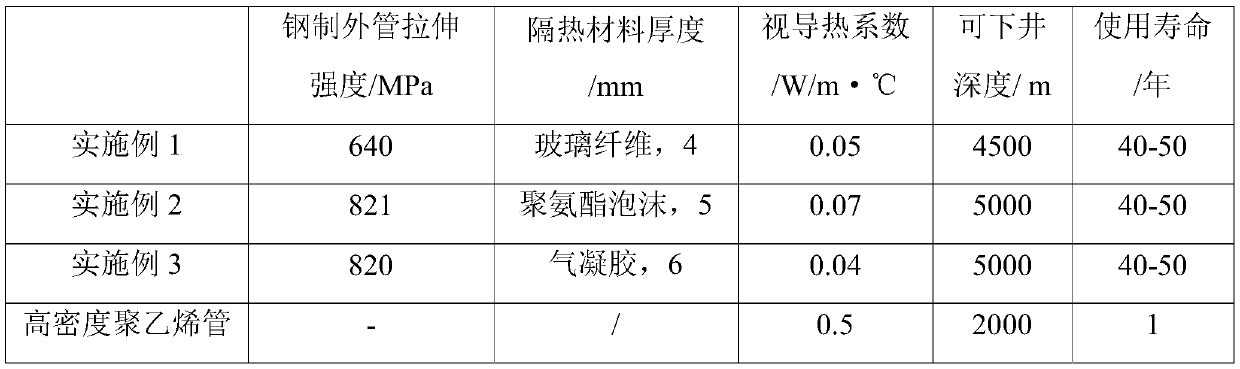

Embodiment 1

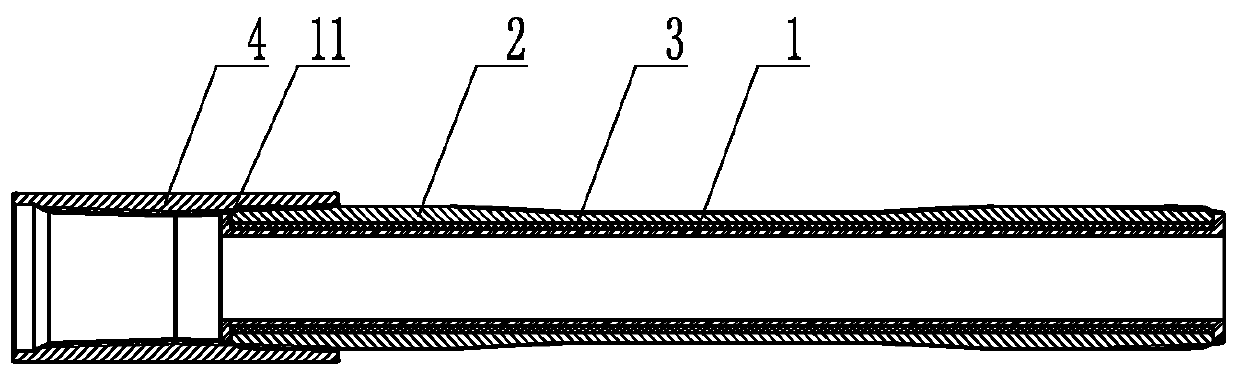

[0035] Such as figure 1 As shown, the above-mentioned geothermal heating adopts heat-insulating and heat-preserving pipes, including an inner lining pipe 1, an outer pipe 2 and a heat insulating material 3. Outside the inner liner 1 , the two ends of the outer tube 2 are respectively pressed against the outer flanges 11 at both ends of the inner liner 1 , and the cavity between the inner liner 1 and the outer tube 2 is filled with heat insulating material 3 .

[0036] The heat insulating material 3 is glass fiber.

[0037] The two ends of the outer pipe 2 are provided with external threads, and the different outer pipes 2 are connected by couplings 4, and the single geothermal heaters are connected into a whole with heat-insulating pipes, that is, the geothermal heaters use heat-insulated pipe strings.

[0038] The lining pipe 1 is a high-density polyethylene pipe, and the outer pipe 2 is a steel pipe.

[0039] The difference between the inner diameter of the outer tube 2 an...

Embodiment 2

[0047] The structure of the thermal insulation pipe used for geothermal development is shown in Example 1.

[0048] The difference is that the heat insulating material 3 is foamed polyurethane.

[0049] The difference between the inner diameter of the outer tube 2 and the outer diameter of the inner liner 1 is 5 mm.

[0050] Its manufacturing method consists of the following steps:

[0051] 1) Process the outer tube 2 according to the size, and process external threads at both ends of the outer tube 2;

[0052] 2) Cut out the high-density polyethylene lining pipe 1 according to the size;

[0053] 3) Put the high-density polyethylene lining pipe 1 into the steel outer pipe 2, and fill the cavity between the high-density polyethylene lining pipe 1 and the steel outer pipe 2 with foaming polyurethane to obtain Combined pipe body;

[0054] 4) Heat the combined pipe body to 90° C. and keep it for 30 minutes. The inner liner 1 expands and combines tightly with the outer pipe 2 ....

Embodiment 3

[0057] The structure of the thermal insulation pipe used for geothermal development is shown in Example 1.

[0058] The difference is that the heat insulating material 3 is aerogel.

[0059] The difference between the inner diameter of the outer tube 2 and the outer diameter of the inner liner 1 is 4 mm.

[0060] Its manufacturing method consists of the following steps:

[0061] 1) Process the outer tube 2 according to the size, and process external threads at both ends of the outer tube 2;

[0062] 2) Cut out the high-density polyethylene lining pipe 1 according to the size;

[0063] 3) Airgel with a thickness of 6mm is wrapped on the outside of the inner liner 1, and the high-density polyethylene liner 1 wrapped with the airgel is mechanically reduced in diameter, and then pulled into the steel outer pipe 2 to obtain a combined pipe body ;

[0064] 4) Heat the combined pipe body to 70°C and keep it for 60 minutes, the inner liner 1 expands and combines tightly with the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com