Patents

Literature

1555results about How to "Guaranteed insulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

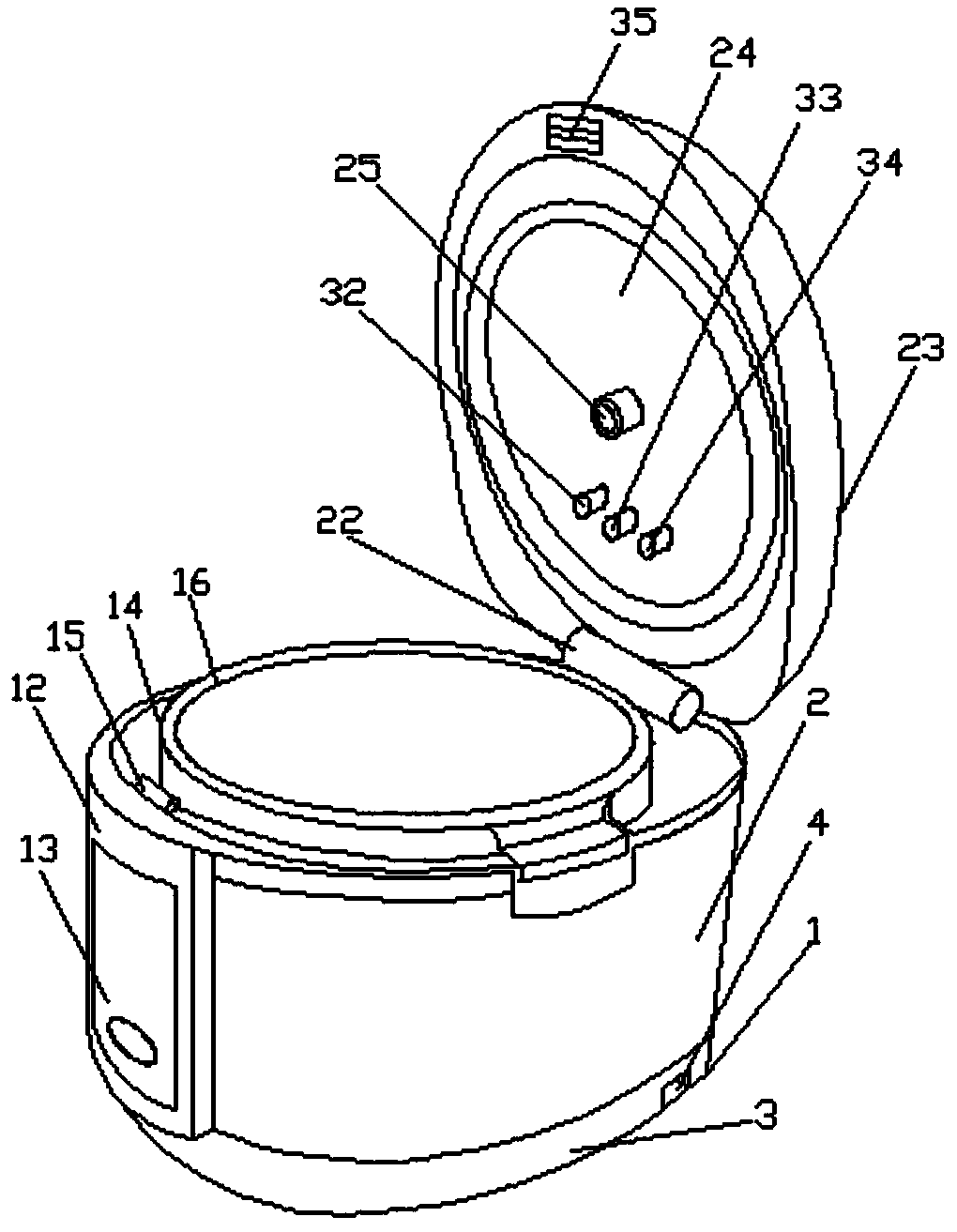

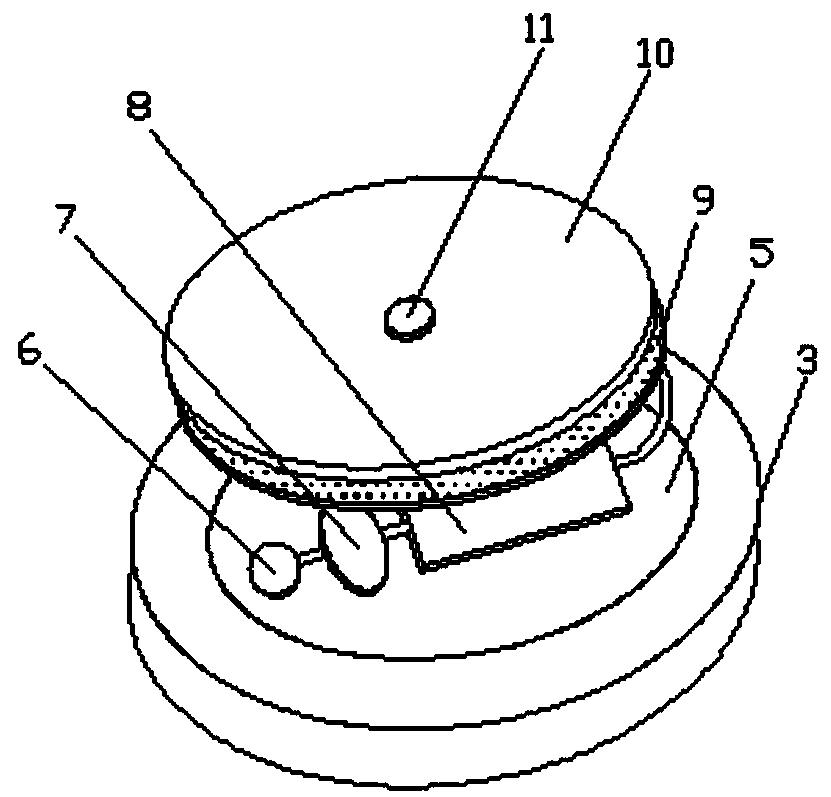

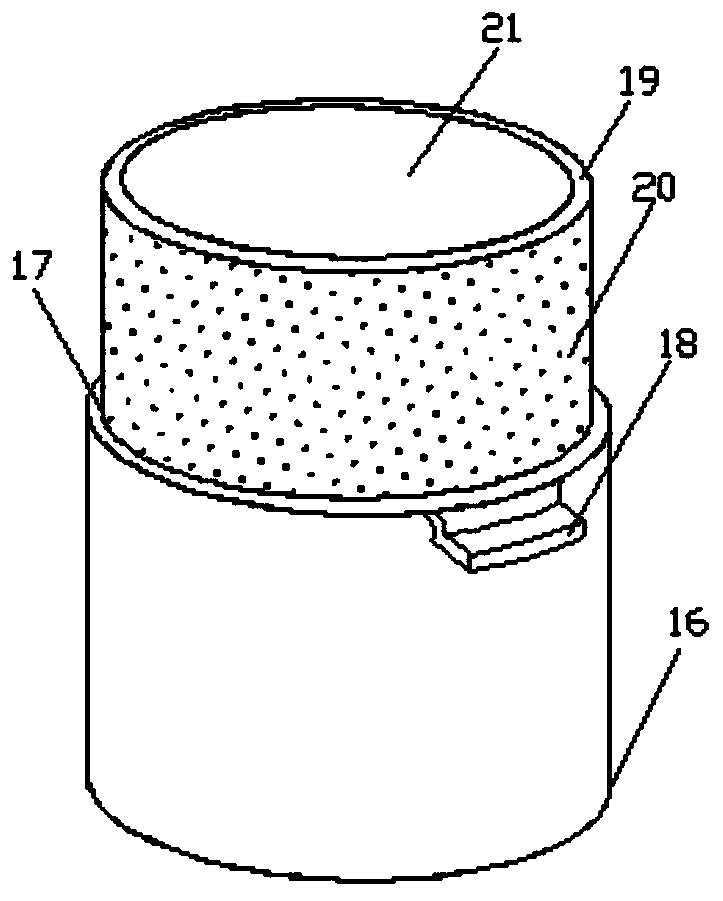

Electric pressure cooker achieving non-self-reset pressure relief

The invention discloses an electric pressure cooker achieving non-self-reset pressure relief. The electric pressure cooker achieving non-self-reset pressure relief structurally comprises an electric pressure cooker body, a housing, a base, an inner groove, a remote wifi receiver, a variable-frequency controller, a battery plate, a heat insulation plate, a heating plate, a temperature sensor, an aluminum alloy panel, an inner container, a protective cover and an air escape valve, wherein the housing is arranged on the electric pressure cooker body, the base is arranged below the housing, the inner groove is formed in the surface of the base, the inner groove is fixedly connected with the housing through the base, and the remote wifi receiver is arranged in the inner groove. By arranging theremote wifi receiver, the variable-frequency controller and the battery plate, the heating plate behind the heat insulation plate can be remotely opened, the movable plate can be opened by utilizingthe impact force of pressure and arranging the movable plate on the surface of the air escape valve under the situation of too high air pressure, the heat insulation effect of an inner container coreis ensured by arranging a vacuum interlayer with medical stones, and the electric pressure cooker is simple in structure and easy to achieve.

Owner:吴振

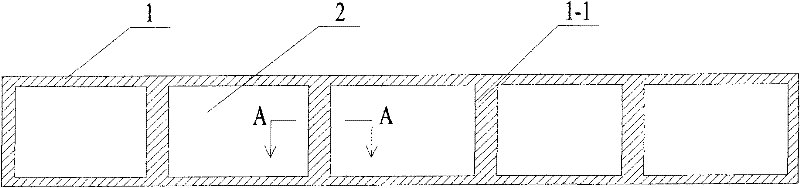

Vacuum glass with mounting holes

ActiveCN102249561AGood brazing performanceEasy to installDoors/windowsClimate change adaptationEngineeringMetal

The invention discloses a vacuum glass with mounting holes, which is compounded from two or multiple glass plates, wherein the peripheries of two or multiple glass plates are mutually sealed hermetically by sealing edges; adjacent glass plates on the inner sides of the sealing edges are vacuumized; the vacuum glass is also provided with mounting holes; and the mounting holes penetrate through thetwo or multiple glass plates and are isolated from vacuum space on the vacuum glass. Since the vacuum glass is provided with the mounting holes, the vacuum glass can be installed and fixed after connecting pieces penetrate through the mounting holes, therefore a high-cost border is not used any more, convenience is brought for the installation of the vacuum glass, and the vacuum glass can be fixed more flexibly. In addition, a plurality of connecting pieces are used for fixing the vacuum glass, so that the section of a metal piece penetrating through the vacuum glass is greatly reduced, heat bridge effect is effectively lowered, and the heat insulation and sound-proof effects of the vacuum glass can be guaranteed. In addition, connecting pieces with the broken bridge heat insulation structure are easy to use, and cost is lower.

Owner:洛阳兰迪真空玻璃科技有限公司

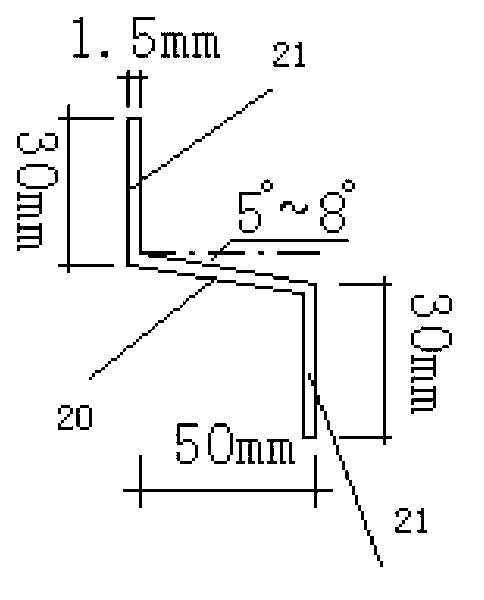

Dried hanging thermal insulation decorative curtain wall and mounting process thereof

InactiveCN101302782AReduce construction costsShorten construction timeCovering/liningsWallsThermal insulationKeel

The invention discloses a dry-hanging curtain wall for thermal insulation and decoration and an installation technique thereof, which essentially comprises a 'duplex F' shape installation hanging part; the radial frameworks and the zonal frameworks of the 'duplex F' shape installation hanging part are vertically arranged; a first layer of the radial frameworks with two or more than two layers is level to the zonal frameworks and the radial framework at the last layer is at a certain distance from the tail end of the zonal framework; the width and thickness of the radial frameworks at every layer can be equal or not. Insulation boards can be fixed in a point-typed installation and location method by the installation hanging part, thus overcoming the defects of the prior art, providing an installation technique of the thermal insulation and decoration curtain wall without installing the horizontal and the vertical joist, simplifying the installation procedure, saving the installation raw materials and cost and overcoming the defect that the rain leakage is easy to happen in the splicing seam of the insulation board adopting the traditional method.

Owner:SHENZHEN MINGYUAN BUILD MATERIALS TECH

Heat-insulation heat-preservation powdered paint, preparation method and coating method of heat-insulation heat-preservation powdered paint, coating formed by using coating method and application of coating

InactiveCN104449200AImprove insulation effectSimplified coating processLiquid surface applicatorsPowdery paintsFoaming agentMetallic materials

The invention discloses a heat-insulation heat-preservation powdered paint, a preparation method and a coating method of the heat-insulation heat-preservation powdered paint, a coating formed by using the coating method and application of the coating. The heat-insulation heat-preservation powdered paint comprises the following components in parts by weight: 90-100 parts of a film-forming agent, 1-10 parts of a curing agent, 0.1-2 parts of a foaming agent and 0.5-5 parts of a flatting agent, wherein the foaming agent is an inorganic component foaming agent or an organic component forming agent of which the decomposition temperature Td is between 120 DEG C and 220 DEG C. Ordinary aluminum alloy sections and aluminum alloy doors / windows using the heat-insulation heat-preservation powder coating have the advantages that no non-metallic material needs to be inserted between two aluminium products, the complexity of a coating process can be reduced and good heat insulation property can be ensured.

Owner:苏州裕丰装饰门窗有限公司 +1

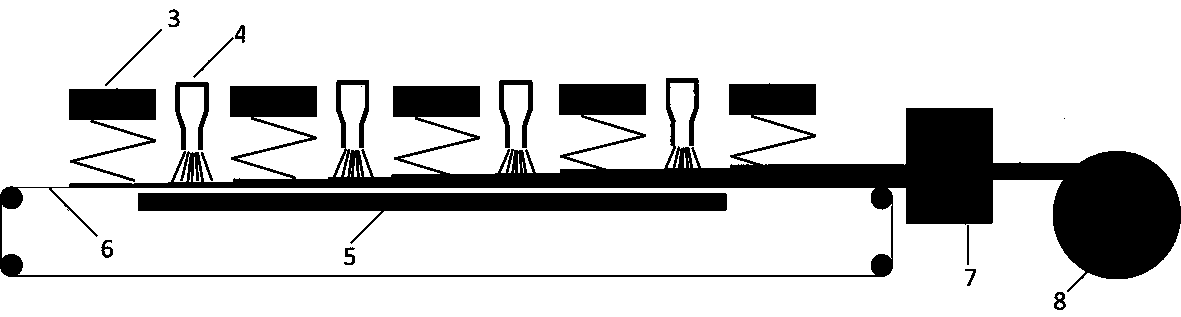

Layered independent heating low-temperature tobacco flake heater

InactiveCN103859606AAvoid it happening againHarm reductionTobacco devicesEngineeringElectric heating

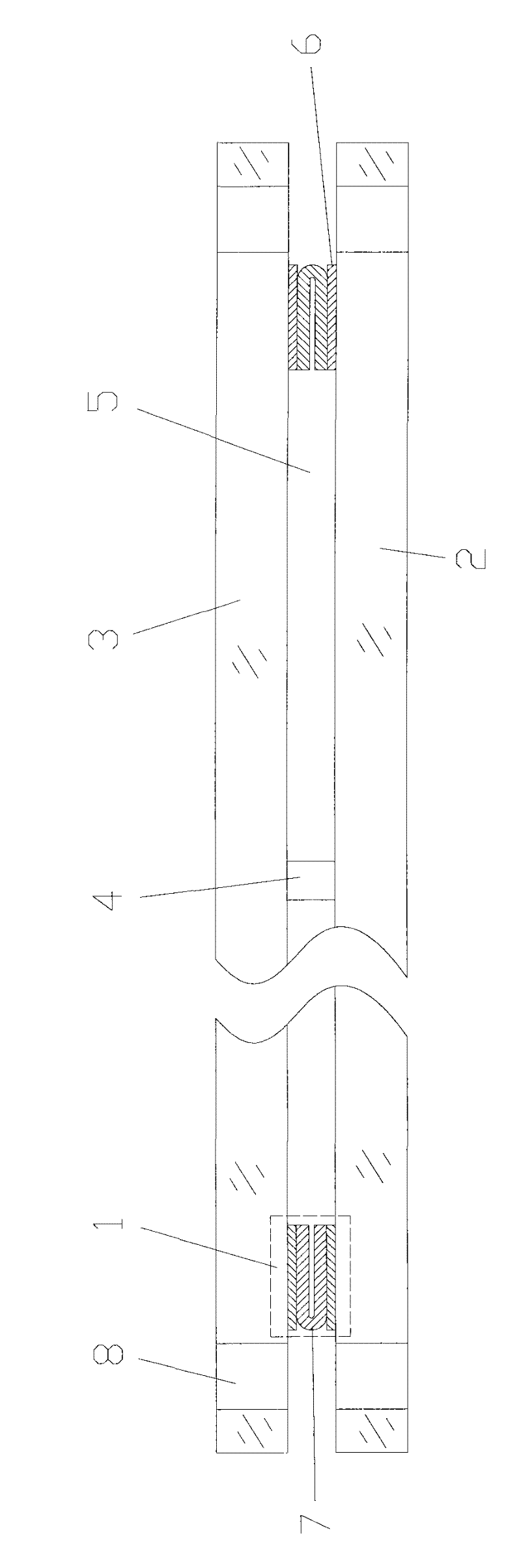

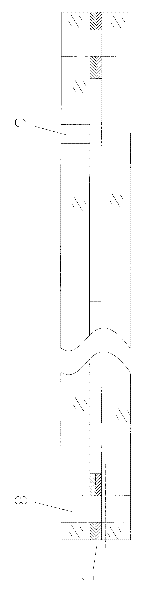

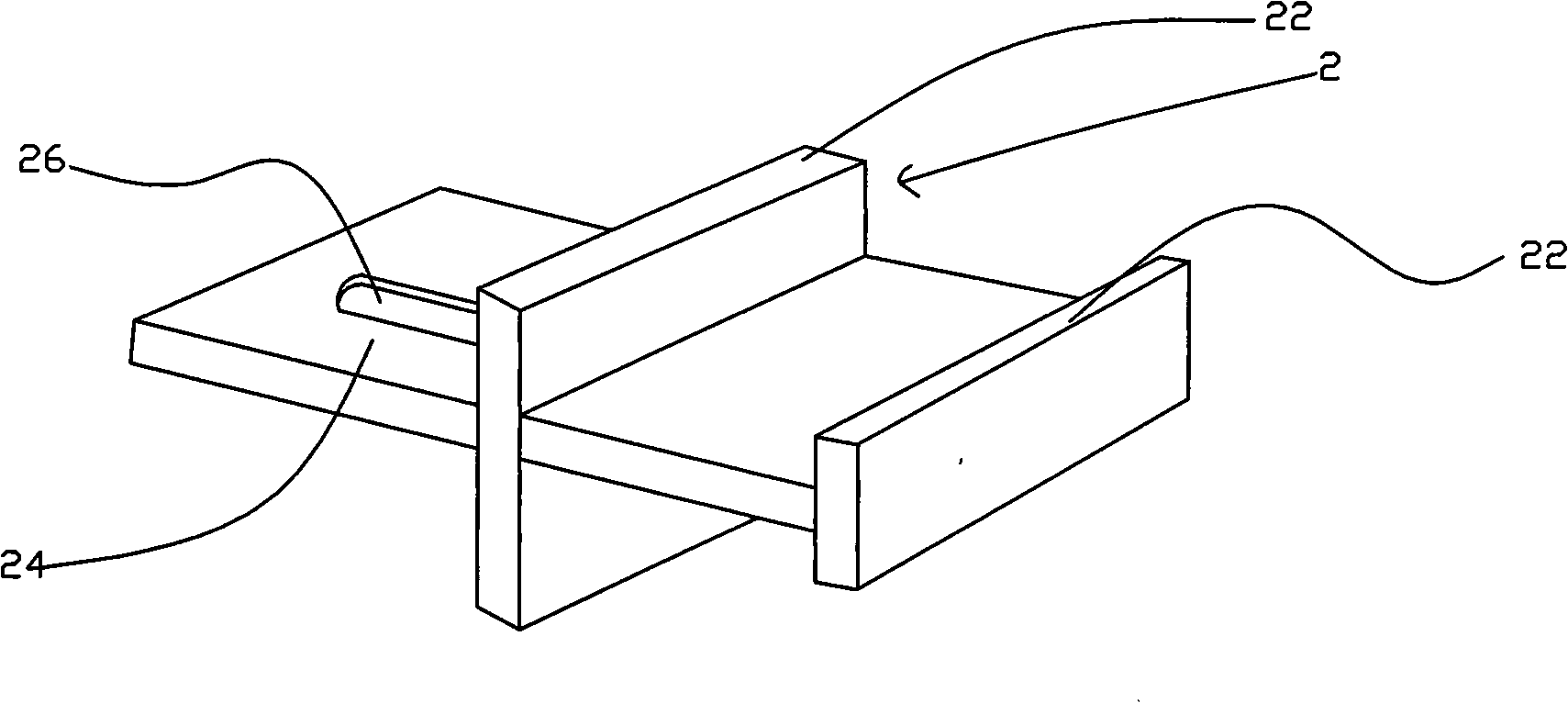

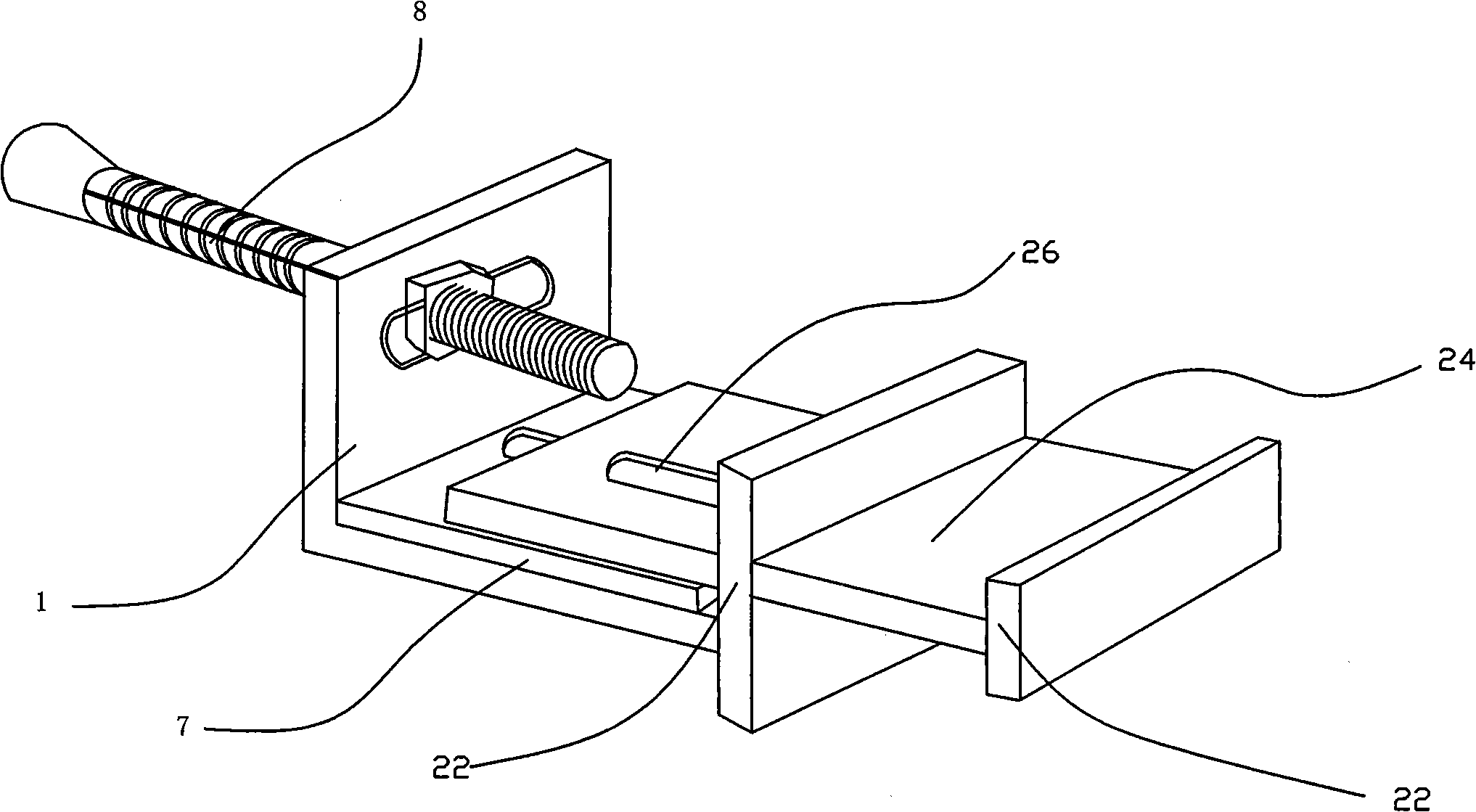

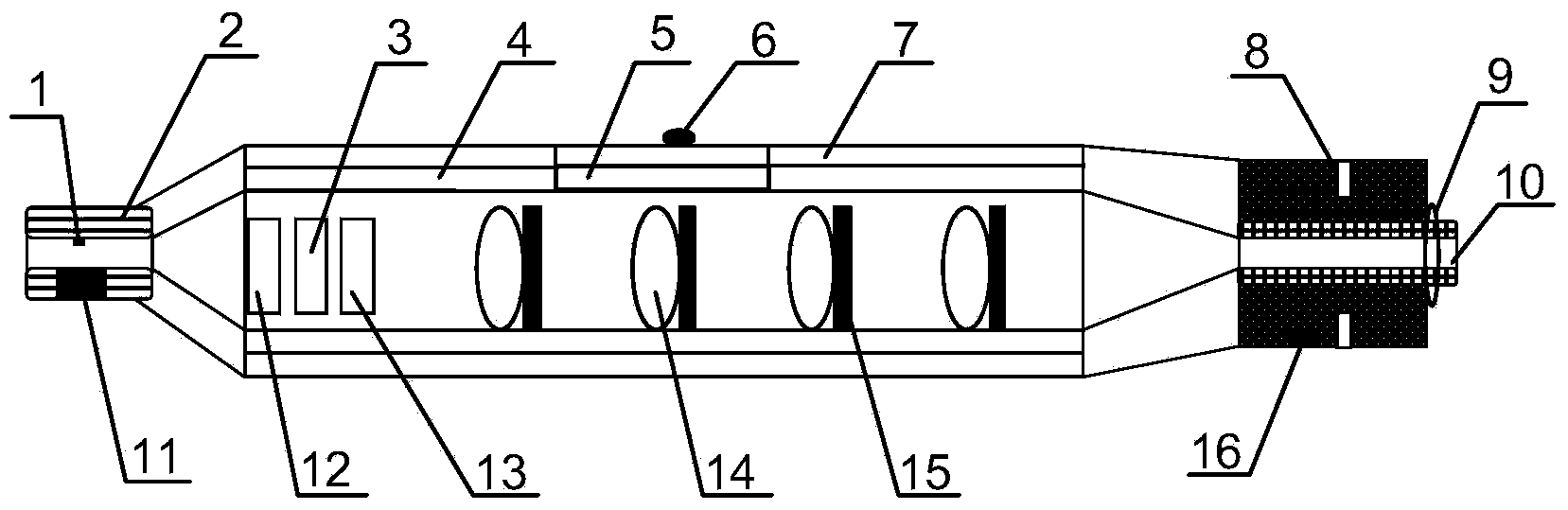

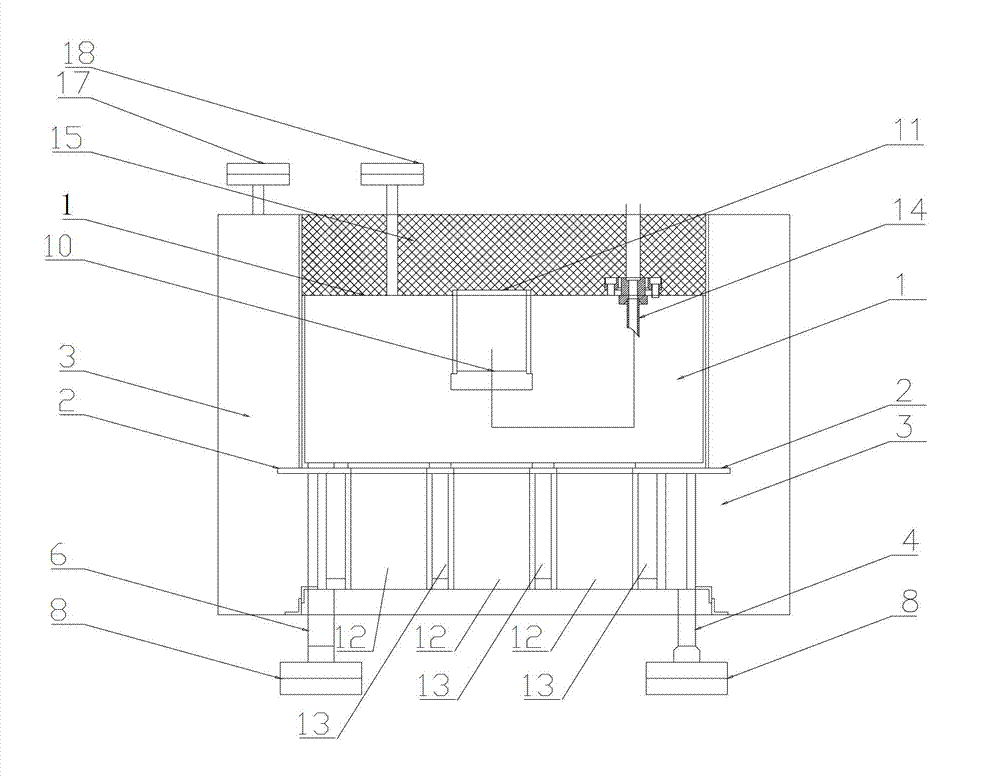

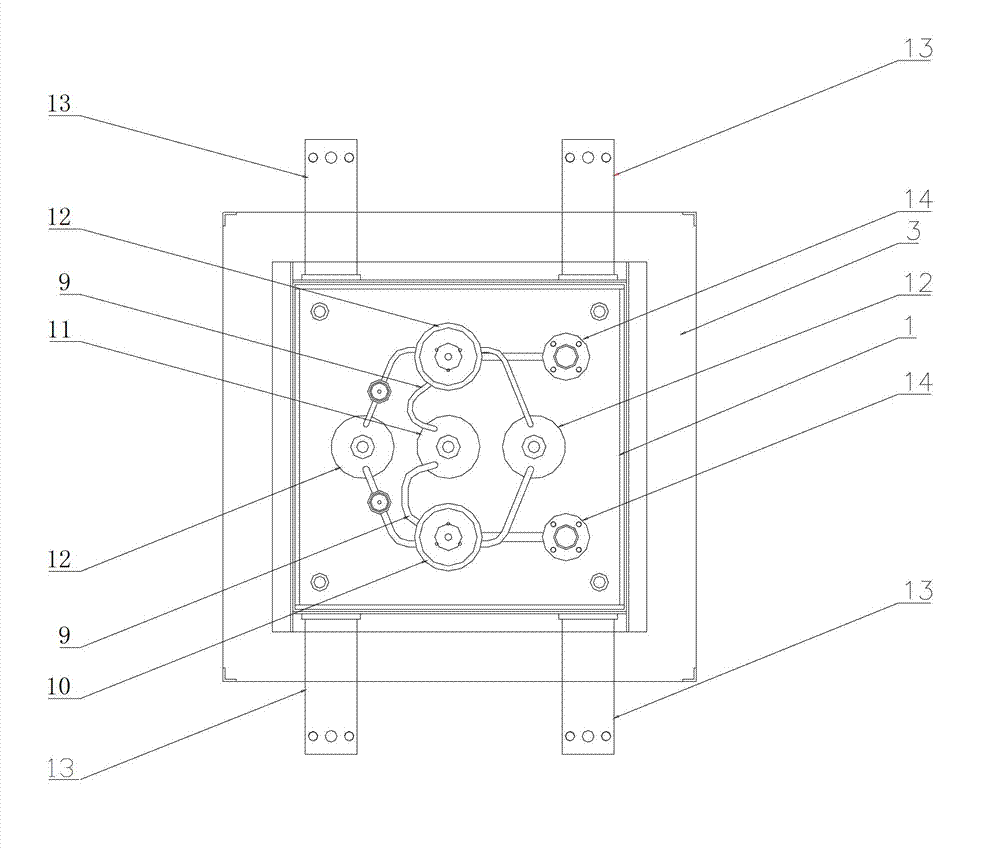

The invention discloses a layered independent heating low-temperature tobacco flake heater. The layered independent heating low-temperature tobacco flake heater is characterized in that the layered independent heating low-temperature tobacco flake heater is mainly formed by an electric heating bin body (4) and a shell (7) arranged on the electric heating bin body (4); an electric heating net (15) placed with a tobacco flake (14) is arranged in the electric heating bin body (4); the shell (7) is provided with a battery (8) for providing energy for the electric heating net (15); the shell (7) is also provided with a door body for opening the electric heating bin body (4); one end of the shell (7) is provided with an air inlet (10) communicated with the electric heating bin body (4); the other end of the shell (7) is provided with a filter nozzle (2) communicated with the electric heating bin body (4). The layered independent heating low-temperature tobacco flake heater is simple in structure and low in cost, the harm to a human body is reduced while a smoker can obtain the satisfaction, the smoke pollution to the environment is reduced and the layered independent heating low-temperature tobacco flake heater is suitable for promotion and use.

Owner:CHINA TOBACCO CHUANYU IND

Colorized reflection heat insulation coating and color card thereof

ActiveCN102181217AModulation shortcutHigh Solar ReflectanceReflecting/signal paintsMulticolor effect coatingsHigh reflectivityMaterials science

The invention discloses a colorized reflection heat insulation coating. Carbon black, iron oxide red, organic yellow, phthalocyanine green, phthalocyanine blue, and other conventional common pigments are replaced by the pigments, namely nickel iron chromite black, nickel iron chromite red, cobalt blue, titanium yellow and cobalt green, so that the colorized reflection heat insulation coating can meet the demand of the external wall decoration on colors and has high reflectivity to solar energy and a good heat insulation effect. The invention also provides a color card by which a colorized coating is formed by mixing the nickel iron chromite black, the nickel iron chromite red, the cobalt blue, the titanium yellow and the cobalt green, a user can quickly mix the coating of the corresponding colors according to the pigment formula corresponding to each color in the color card, and the color card is convenient to use.

Owner:NIPPON PAINT GUANGZHOU

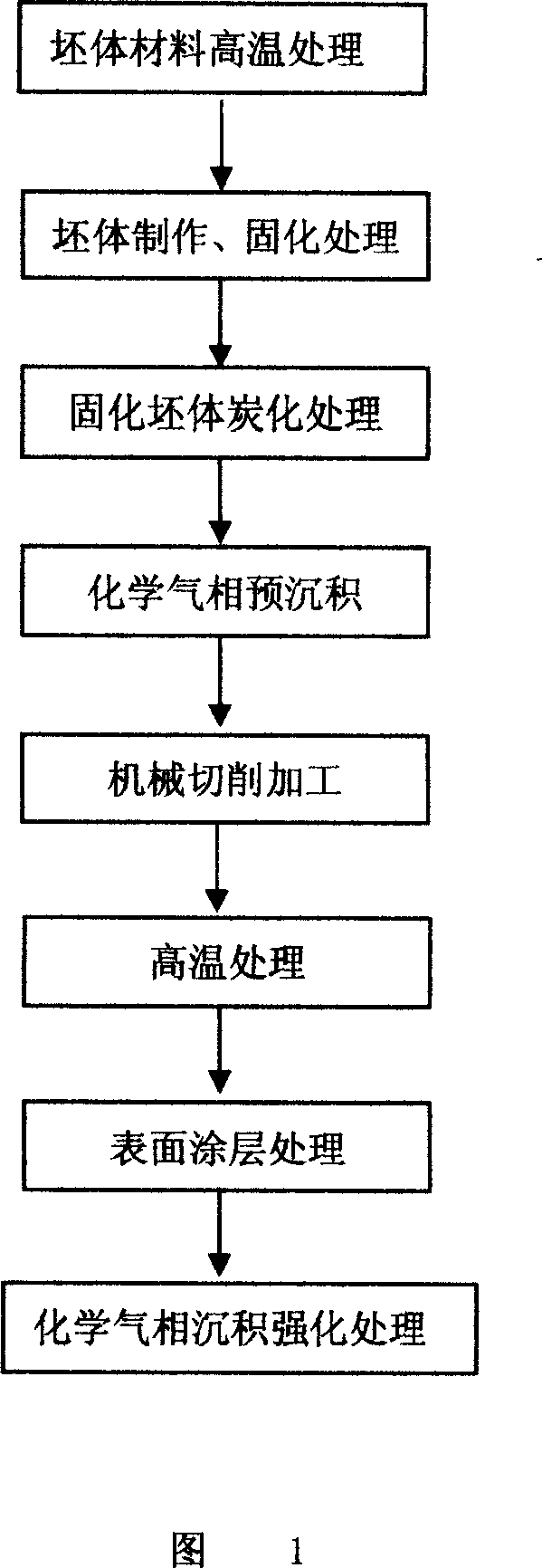

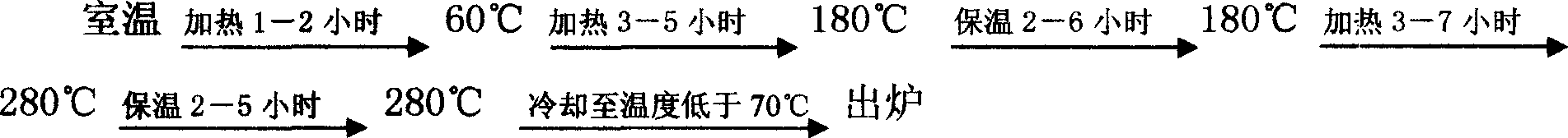

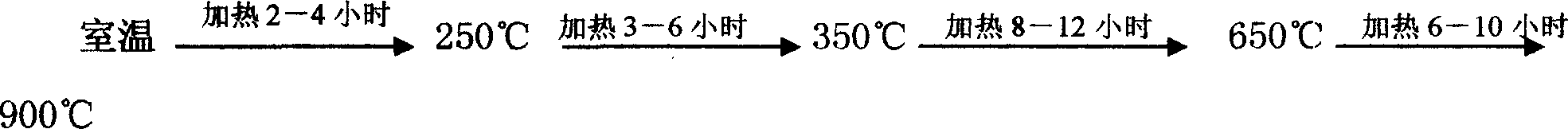

Production method of high purity cured charcoal felt silicon crystal growth oven

InactiveCN1994972AGuaranteed shape retentionMeet the use requirementsAfter-treatment apparatusBy pulling from meltGas phaseMetal impurities

The invention discloses a making method of high-purity solidified carbon cushion in the silicon crystal growing stove, which is characterized by the following: selecting flexible cushion with low metal impurity as blank material; disposing under high temperature to form graphite cushion; using graphite cushion as blank; solidifying the blank to shape with evenly permeable hardener; carbonizing the blank; proceeding chemical gas-phase deposition for blank; cutting part of element surface mechanically; disposing blank under high temperature; removing metal impurity and volatile substance; coating the working piece; strengthening the element surface; improving the corrosion resistant of blank surface.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

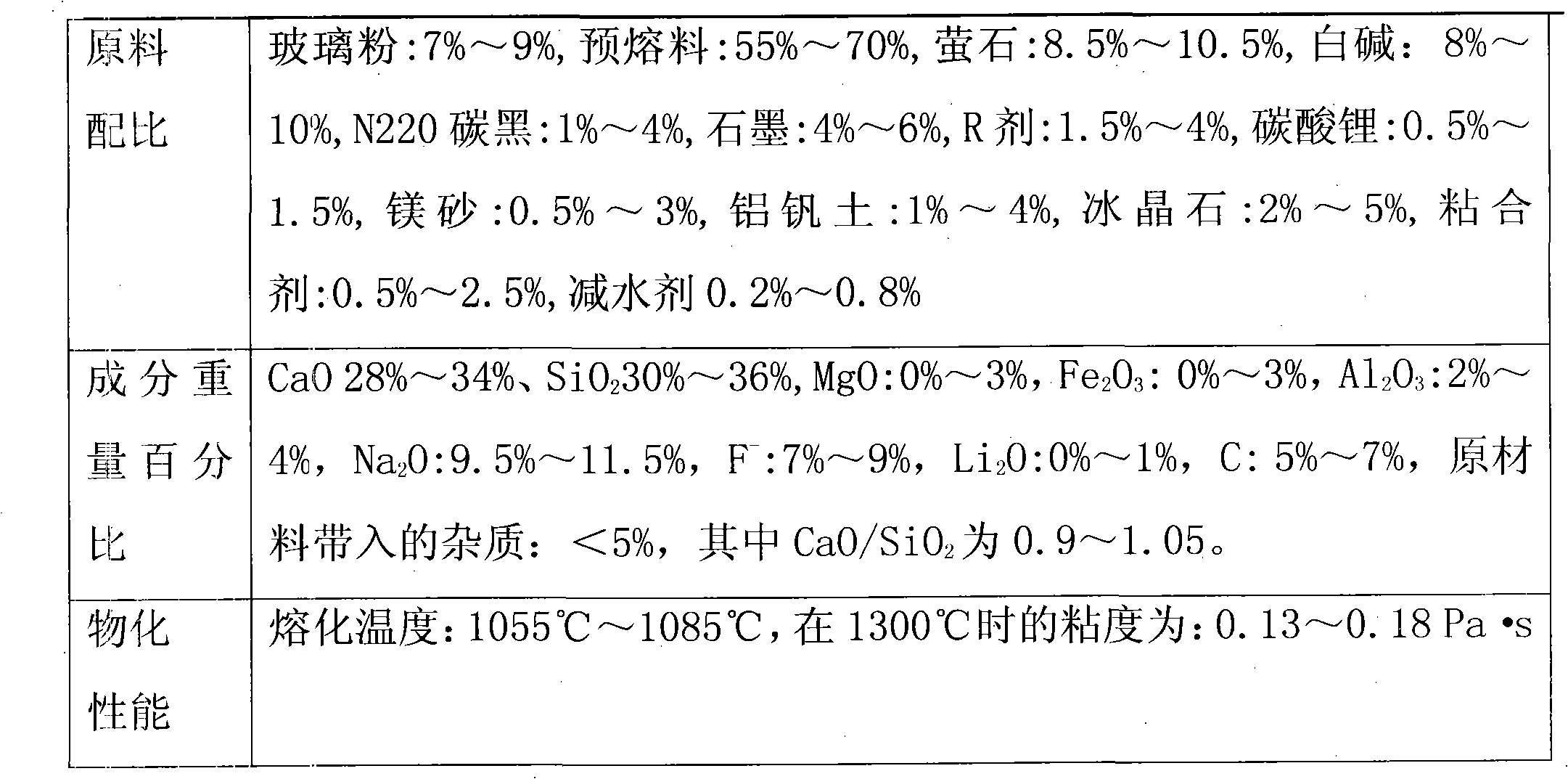

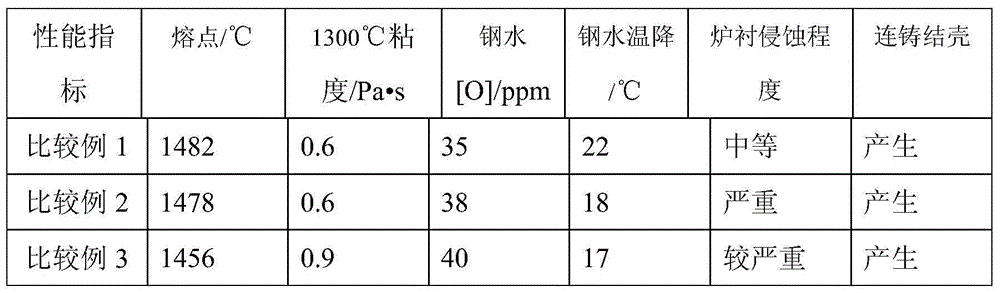

High-viscosity continuous casting protective slag for solving slag inclusion on surface of low-carbon steel

The invention discloses high-viscosity continuous casting protective slag for solving slag inclusion on the surface of low-carbon steel. The protective slag comprises the following raw materials by weight percent: 0%-7% of glass powder, 50%-70% of premelting material, 5.5%-8.5% of fluorite, 4%-8% of dietary alkali, 3% of N330 carbon black, 3.5% of graphite, 0%-3% of R agent, 0.5-2% of lithium carbonate, 2%-5% of manganese carbonate, 2%-5% of magnesite, 3%-7% of bauxite, 1%-3% of cryolite, 1%-3% of adhesive, and 0.3%-1% of water-reducing agent. By utilizing the high-viscosity continuous casting protective slag, mainly on the basis of CaO and SiO2, a certain amount of fluxing agents such as the lithium carbonate, the fluorite, the dietary alkali and the like and a certain amount of carbon materials such as carbon black and graphite are externally added, thus the viscosity is improved and the surface tension is increased; and under the same technique condition, slag inclusion on the surface of a steel billet can be effectively prevented.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

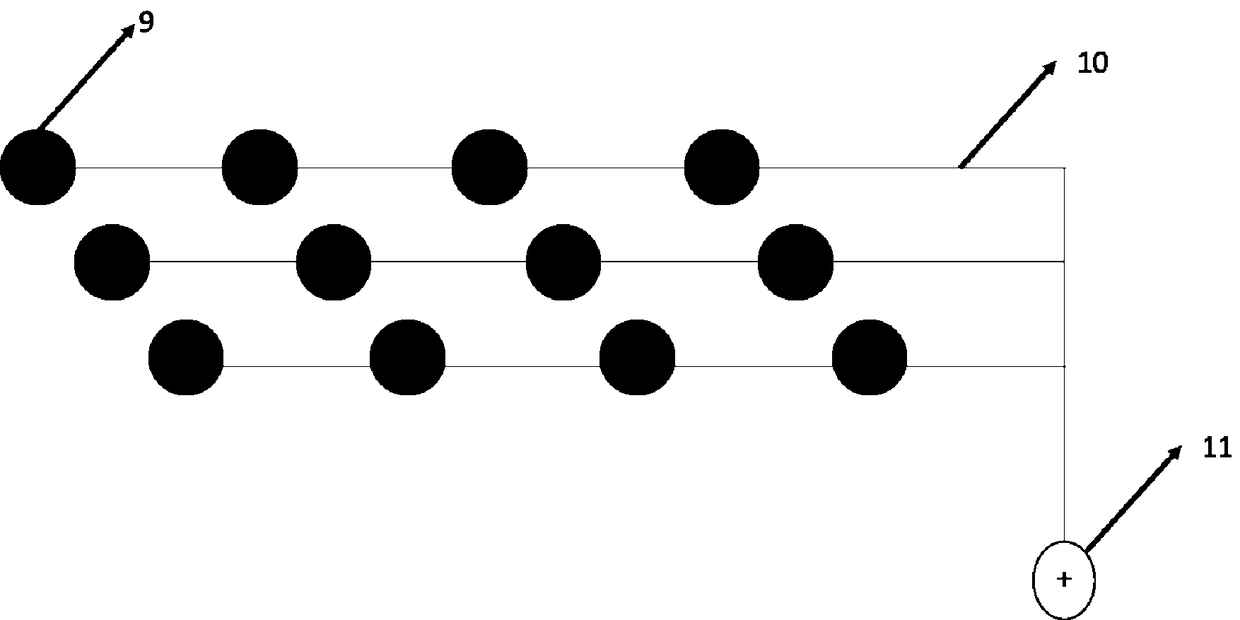

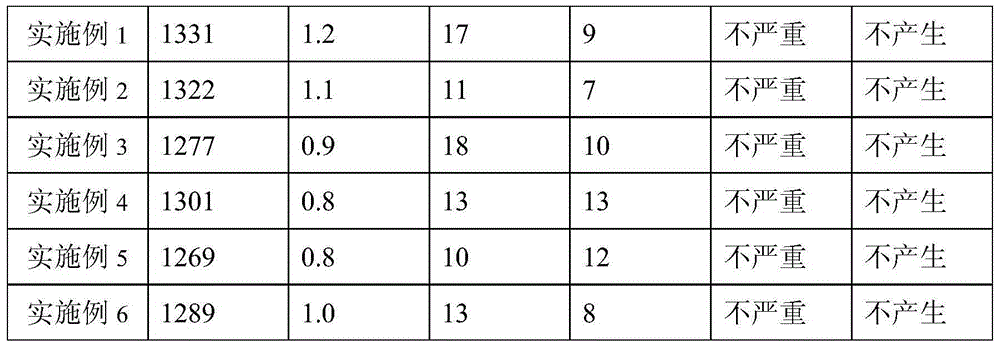

Dacron thin-denier high-hollow short fiber and its production method

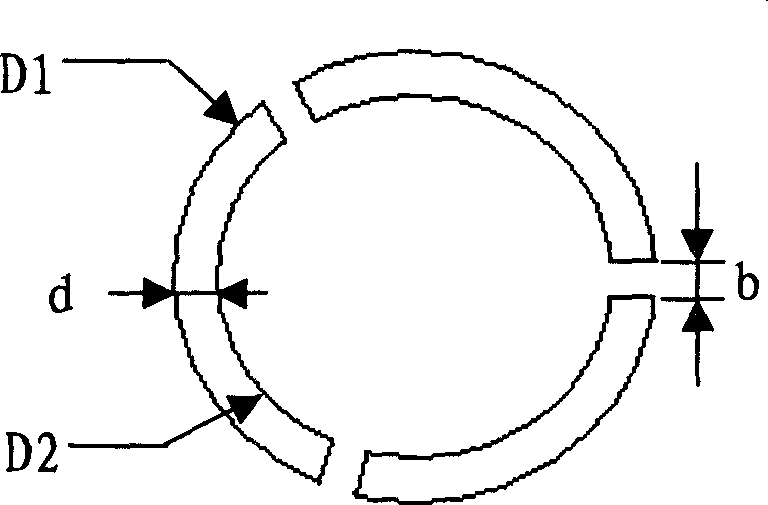

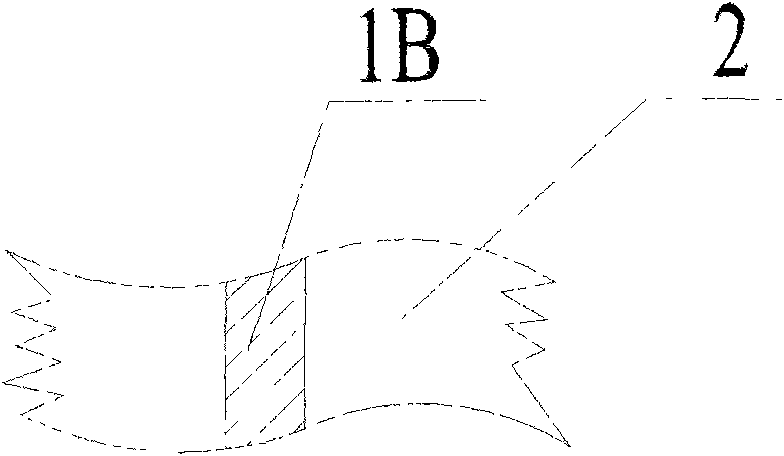

InactiveCN1743515AGuaranteed insulation effectImprove spinnabilityHollow filament manufactureFilament/thread formingFiberEngineering

This invention relates to a terylene fine high hollow short fiber and its production method, which reasonably designs the parameters of three sections of an arc slit nozzle and designs the cooling blow angle of 20 minus or plus 5deg, in which, the section shape of the fiber produced by this method is a triangle-like with three sides convex to an arc, the titer is 1.56~1.67dtex and the hollow degree is 20 minus or plus 3%, which solves the contradiction between the titer and the hollow degree to secure the fine heat-insulating property of the fiber.

Owner:SHANGHAI LIANJI SYNTHETIC FIBRE CO LTD

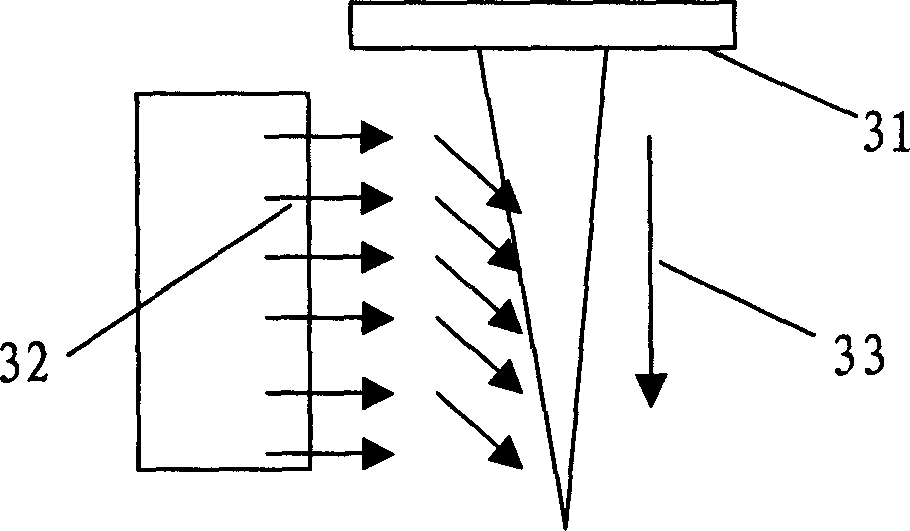

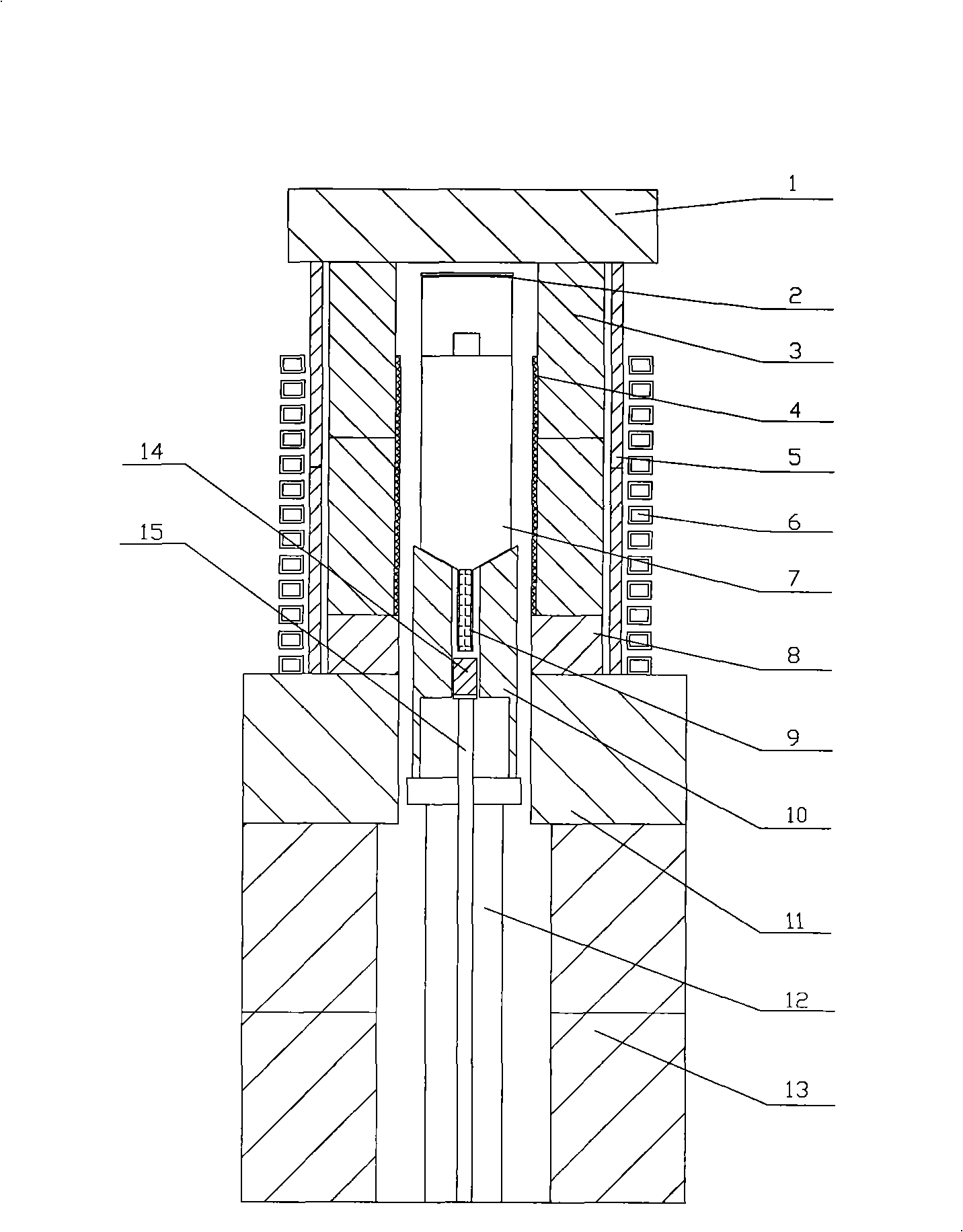

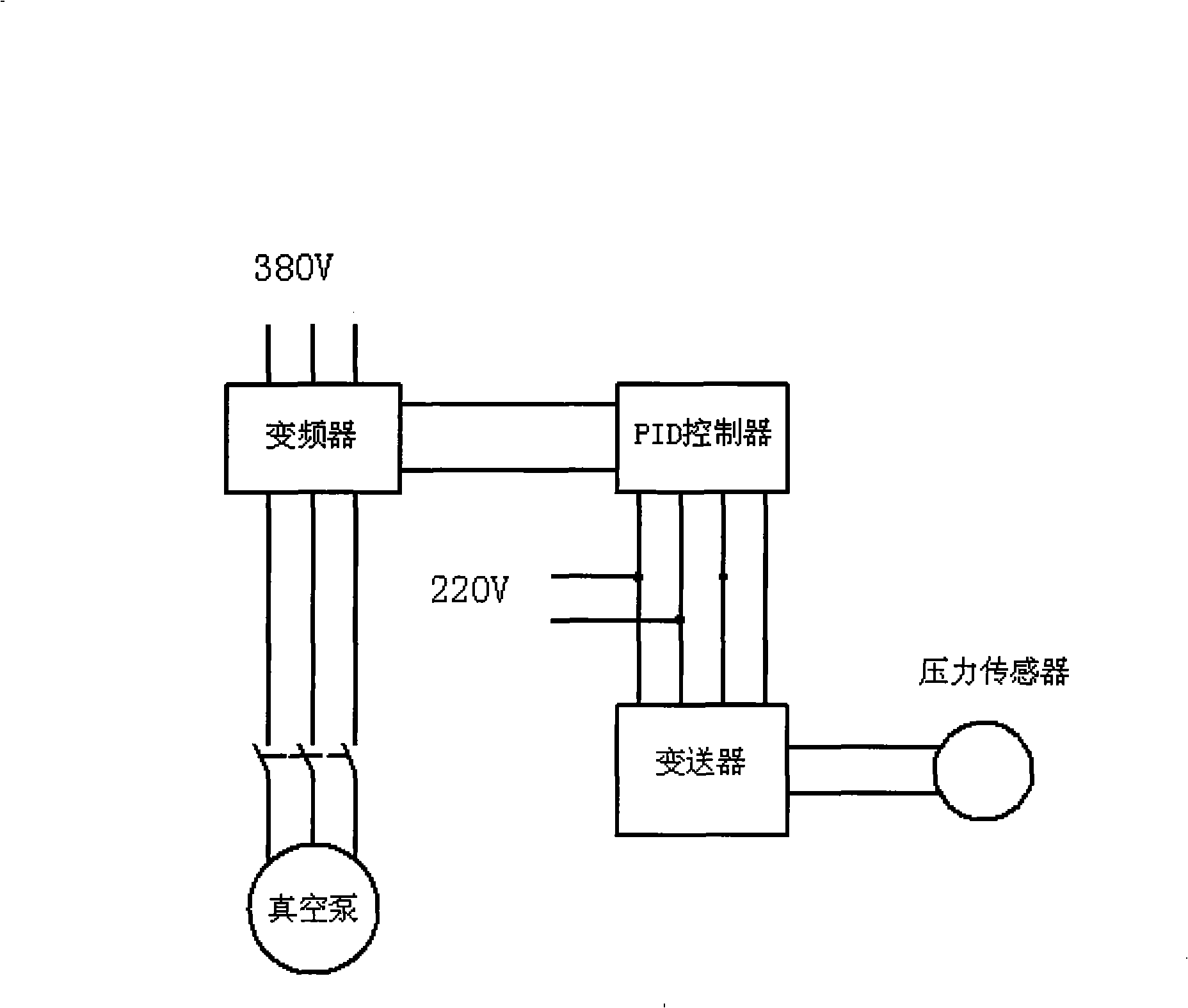

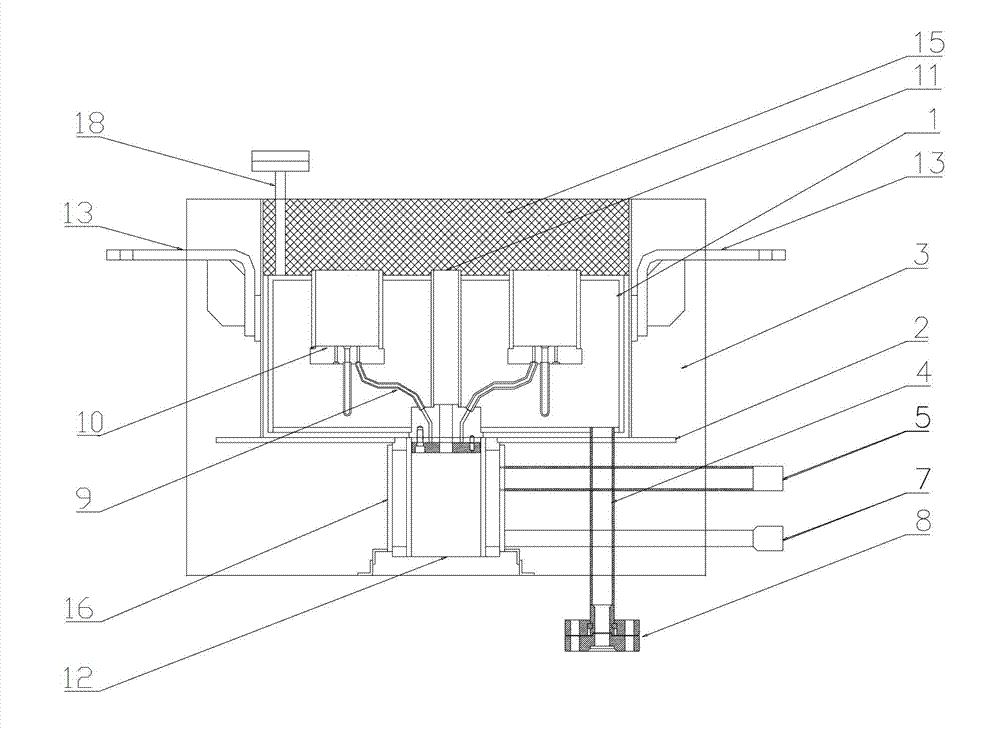

Large size sapphire crystal preparing technology and growing apparatus thereof

ActiveCN101323978AAvoid crackingImprove cleanlinessPolycrystalline material growthFrom frozen solutionsCrucibleSesquioxide

The invention relates to a preparing technique and a growth device of a large-size sapphire crystal, and the preparing technique of the large-size sapphire crystal comprises the following steps: (1) aluminum sesquioxide with high purity that is weighted is filled into a molybdenum crucible pot, a stove is vacuumized until the atmospheric pressure inside the stove is less than 10<-3> Pa, and then protective gases are filled into the stove, and the stove pressure achieves minus 90 to plus 20 KPa; (2) raw materials are heated until complete melting is achieved, and heat is preserved for 3 to 5 hours; (3) seed crystals are lowered by 15 to 120mm under heat preservation, and then the molybdenum crucible pot is lowered by the height of the molybdenum crucible pot; (4) the temperature in the stove is decreased until 1600 to 1750 DEG C; (5) the molybdenum crucible pot is re-raised to a heating region, and heat is preserved for 100 to 150 hours and then the temperature is decreased slowly until room temperature. The preparing technique of the large-size sapphire crystal of the invention is characterized by simple device structure, low production cost, good preparing technique stability, reliable process, easier bubble elimination and high yield, and can cultivate the single sapphire crystal with large size, small dislocation density and high quality.

Owner:成都东骏激光股份有限公司

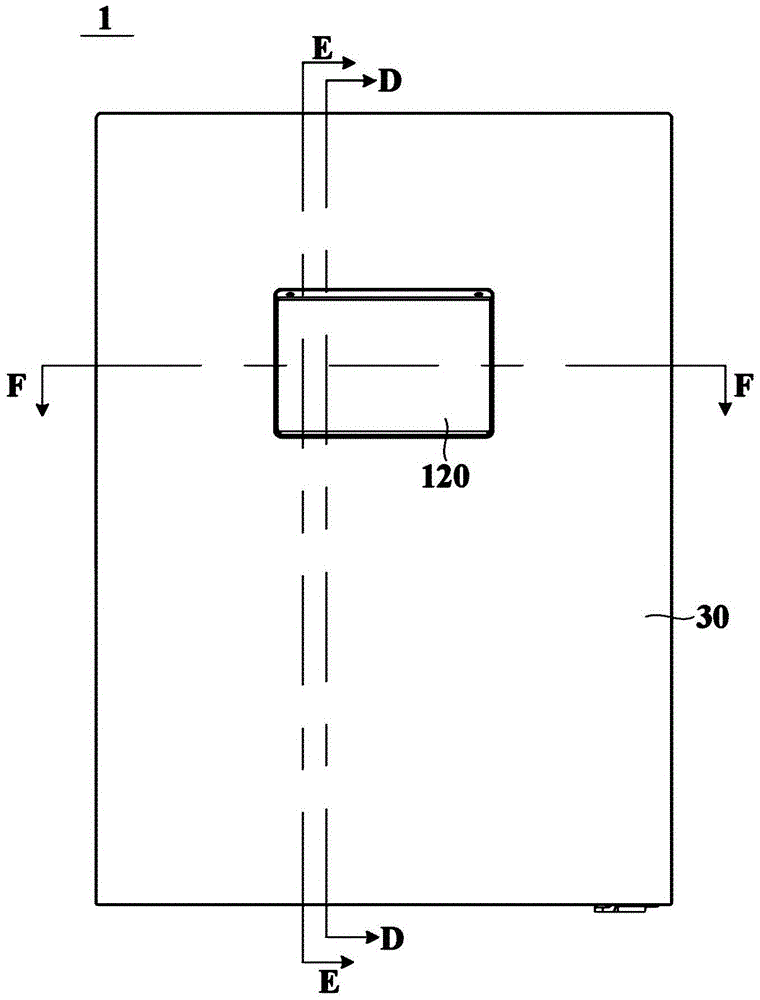

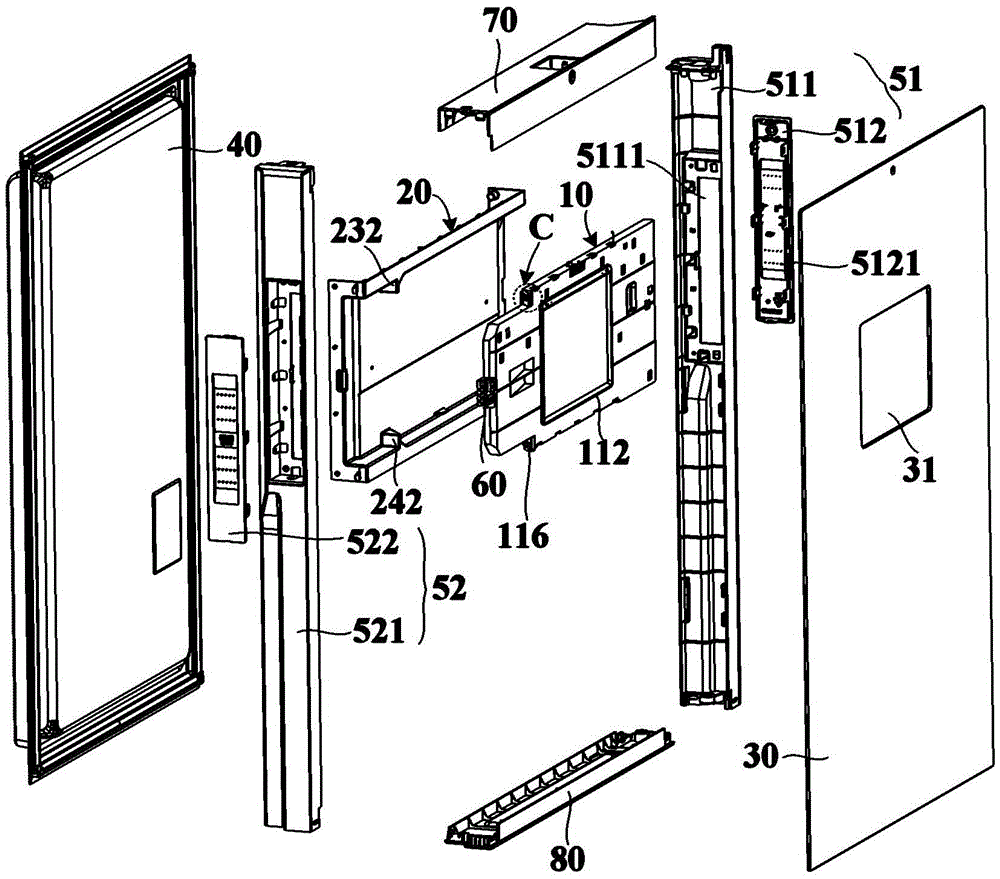

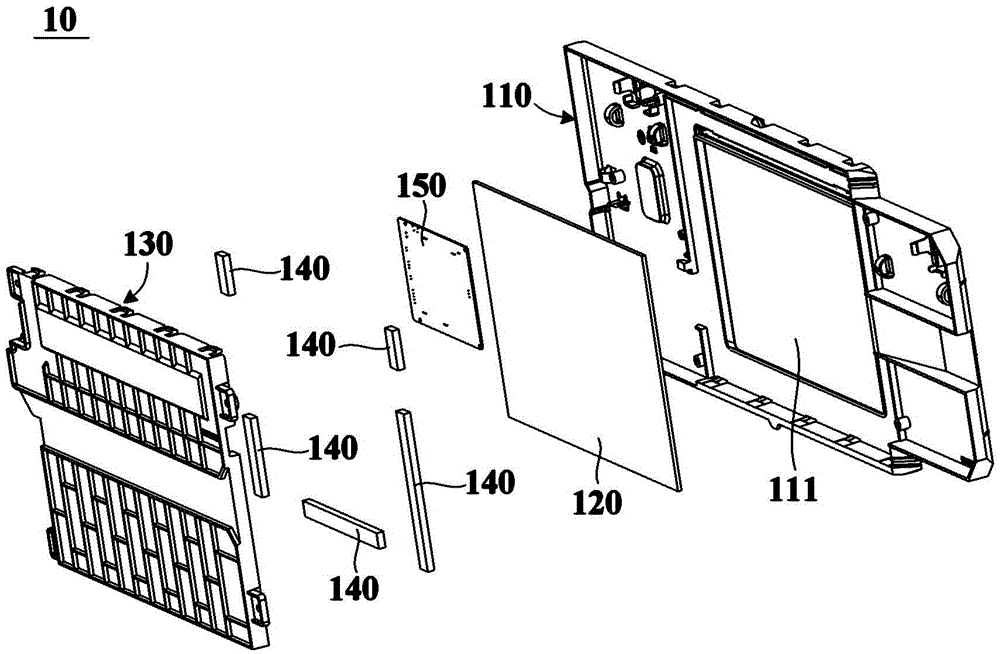

Door body used for cold storage and refrigeration device and cold storage and refrigeration device

InactiveCN105526766AGuaranteed cooling efficiencyGuaranteed cooling effectDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention relates to a door body used for a cold storage and refrigeration device and the cold storage and refrigeration device. Particularly, the door body used for the cold storage and refrigeration device comprises a panel used for forming the front portion of the door body, a door liner used for forming the rear portion of the door body, two side frames used for forming the two side portions of the door body, a rear cover and a display control assembly. The rear cover is arranged between the panel and the door liner, and a containing cavity is defined by the rear cover and the panel. The display control assembly is arranged in the containing cavity. The two side frames are provided with through holes communicating with the containing cavity so as to form a heat dissipation channel transversely penetrating through the door body, air convective circulation is facilitated, heat is dissipated out in time conveniently, and accordingly the heat dissipation efficiency and effect of the display control assembly are ensured. The invention further provides the cold storage and refrigeration device. The cold storage and refrigeration device comprises a refrigerator body with a defined storage space and the door body, and the door body is directly or indirectly connected to the refrigerator body so as to open and / or close at least part of the storage space.

Owner:HAIER SMART HOME CO LTD

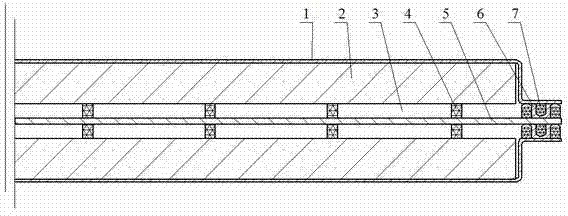

Double-vacuum-layer metal vacuum composite plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746690AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal dilatationComposite plate

A double-vacuum-layer metal vacuum composite plate with the edge sealed by a seal strip comprises a housing, at least two core plates and a vacuum cavity and is characterized in that the housing is a low-carbon steel plate or a low-carbon steel composite plate, the core plates are located in the vacuum cavity formed through seal welding of the housing, the core plates provide additional strength for the housing and ensure the smoothness of the housing under atmospheric pressure, the vacuum cavity is welded and sealed by utilizing a glass solder in a vacuum furnace under high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of the glass solder, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers and are independently manufactured or are directly formed on the core plate or the partition plate. A manufacturing method of the double-vacuum-layer metal vacuum composite plate is simple in process, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

Self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and insulated wallboard

ActiveCN102249641ASolve insulation problemsSolve fire resistanceSolid waste managementCement mortarStearate

A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and an insulated wallboard solve technical problem in a prior art that self-leveling cement mortar with weak waterproofness causes weak insulation effect of an insulated wallboard. A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover is employed as a technique. Ingredients of the self-leveling cement mortar dry powder comprise a compound impervious component; and the impervious component is prepared by mixing a redispersible high-molecular polymer and one of an organosilicon waterproof agent and a stearate, or a mixture of the two, and accounts for 0.6-4.3wt% of the self-leveling cement mortar dry powder. A special impervious ingredient is added to enhance compactness, microdilatancy and low dry shrinkage property of the cement based self-leveling mortar, so as to substantially increase waterproof function and endurance of the cement based self-leveling mortar. Therefore, a problem that a cladded super-light foaming cement sheet material loses insulation function due to water penetration and problems of flame resistance and endurance are solved fundamentally.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

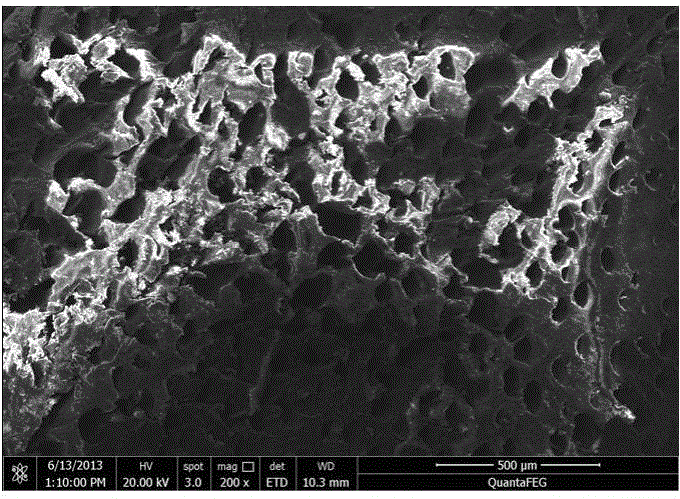

Preparation method of aerogel composite material

InactiveCN103496706AGuaranteed insulation effectEliminate aging stepsSilicaFiberSupercritical drying

The invention relates to a preparation method of an aerogel composite material. The preparation method comprises the following steps: firstly, uniformly mixing a silicon source, a solvent and distilled water in a proportion of (1:4:2)-(1:12:4) and adjusting the pH value to 7-10, and stirring to obtain silicon dioxide sol; and then, dipping fibers in the unaged silicon dioxide sol, and carrying out supercritical drying treatment to obtain the aerogel composite material. According to the method provided by the invention, after the fibers are dipped into the silicon dioxide sol, supercritical drying treatment is directly carried out without gelatinizing and aging the sol at room temperature, so that the prepared aerogel composite material has good flexibility and excellent heat insulating effect. Meanwhile, the method provided by the invention is simple in process flow, the preparation time of the aerogel composite material can be greatly shortened, and the preparation period can be controlled within 4 hours.

Owner:BEIJING AIRUOGE SCI & TECH DEV

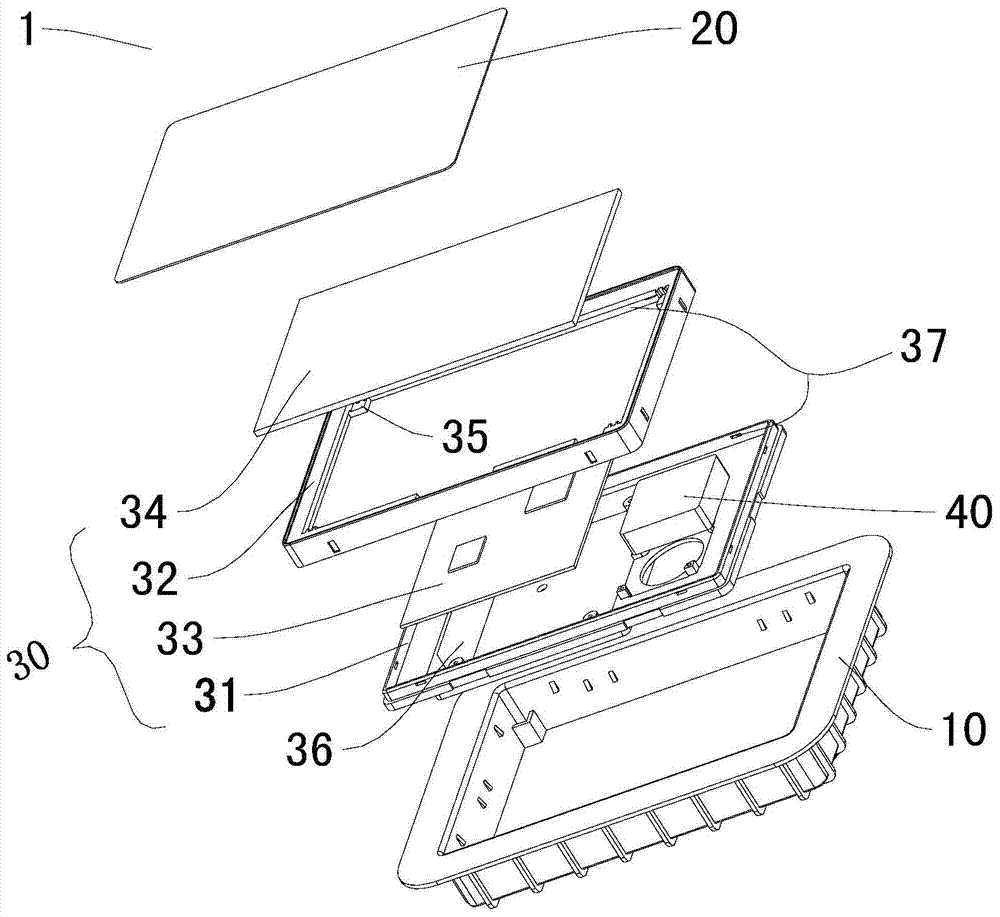

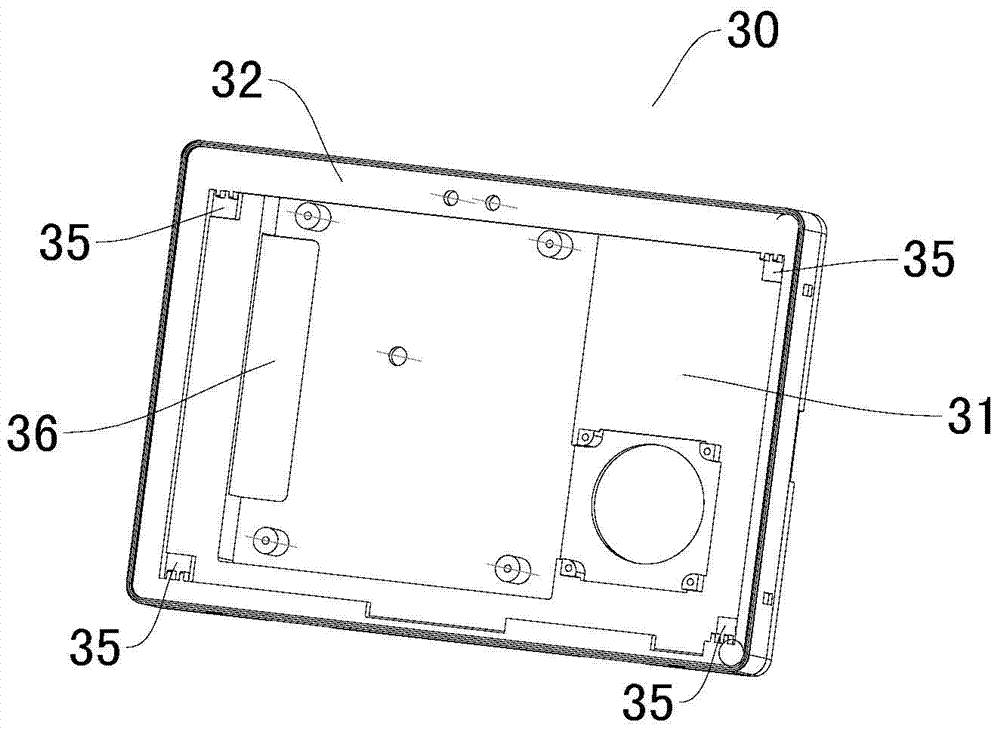

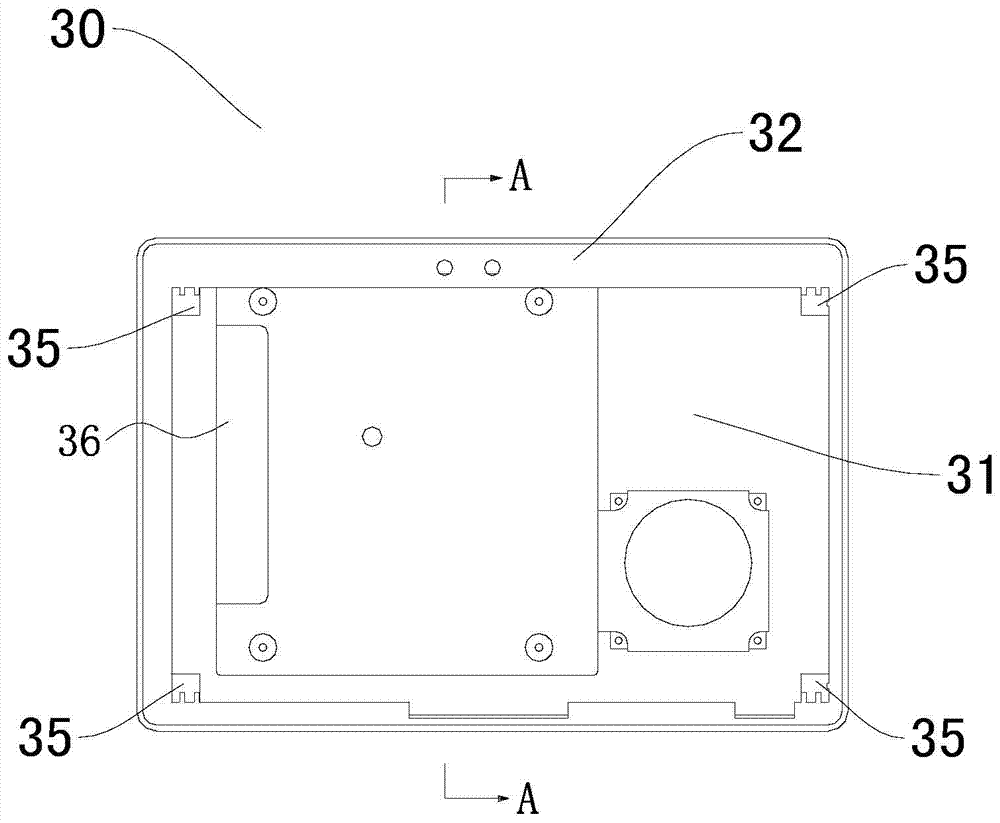

Door body for refrigeration equipment and refrigeration equipment provided with same

ActiveCN103512302AGuaranteed insulation effectImprove cooling effectDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention discloses a door body for refrigeration equipment and refrigeration equipment provided with the same. The door body for the refrigeration equipment comprises a main body, a pre-buried box, a touch screen, a display control assembly, and an air circulation device, wherein the main body is provided with an opening; the pre-buried box is pre-buried in the opening before being foamed, and the front side of the pre-buried box is opened; the touch screen is used for sealing the front side of the pre-buried box, and an accommodating cavity is defined between the touch screen and the pre-buried box; the display control assembly is arranged in the accommodating cavity; the air circulation device is arranged in the accommodating cavity to perform heat dissipation on the display control assembly. According to the door body for the refrigeration equipment, provided by the embodiment of the invention, the display control assembly and the air circulation device are arranged in the accommodating cavity formed between the pre-buried box and the touch screen, and the air circulation device can facilitate the air circulation flow in the accommodating cavity, so that the display control assembly can be subjected to heat dissipation; the internal circulated heat dissipation structure guarantees the heat preservation performance of the door body, besides, the heat dissipation performance is better, and the integral door body is more attractive in appearance.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

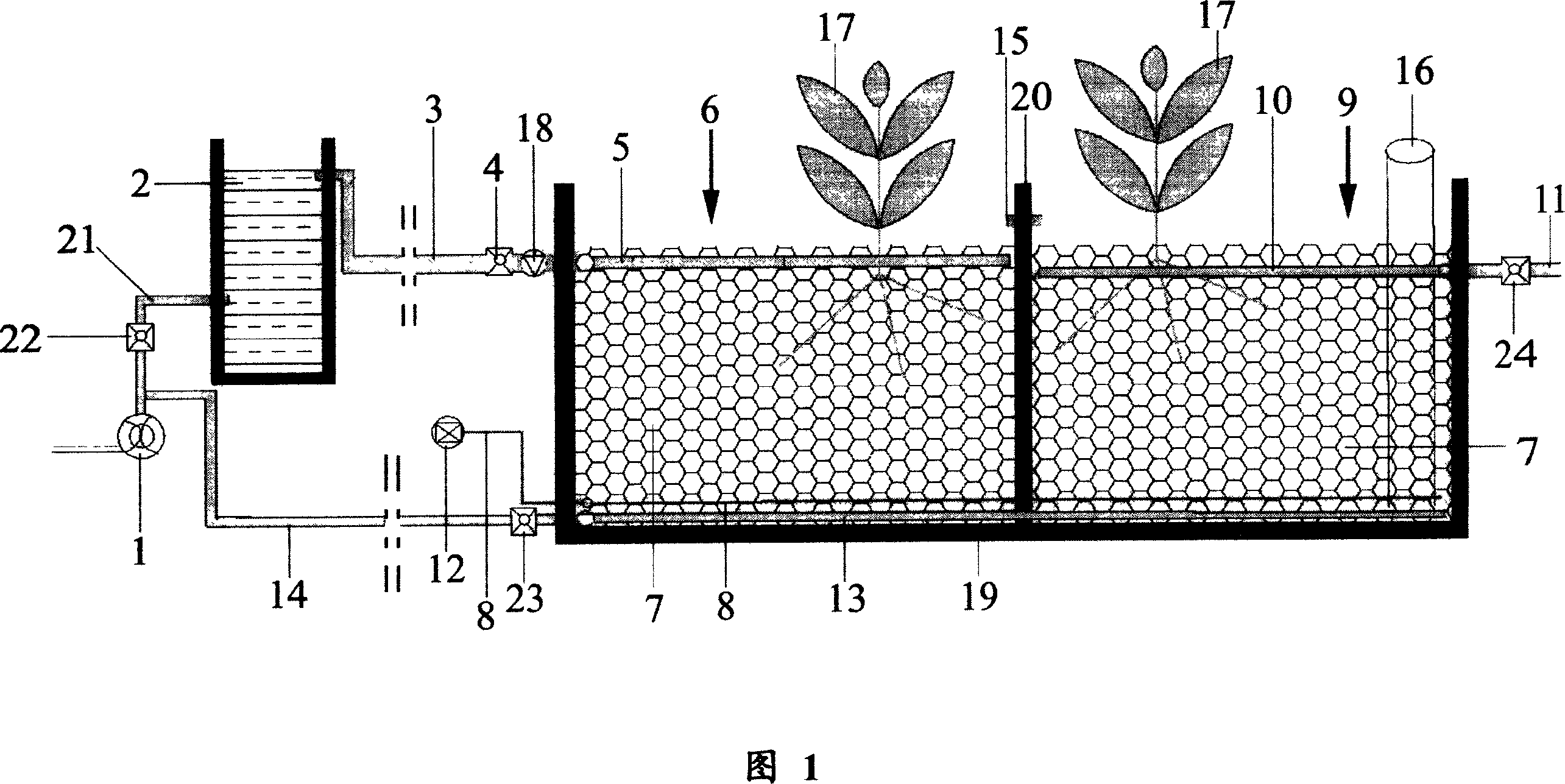

Backwash, aeration type undercurrent wetland water body purification apparatus and water body purification method

InactiveCN101007687AImprove water purification abilityAvoid cloggingTreatment using aerobic processesTreatment with aerobic and anaerobic processesWater pipeSmall footprint

The invention discloses a purifying device of backwash, aeration type hidden flow marshland water body and a method of purifying water body, wherein the whole purified pool display cube box; the separating pool separate the pool as downward pool and upper pool; the filling base material pack evenly in the pool; planting amphibious plant on the upper; setting cloth water pipe on the upper of the upper pool; making the upper of adjusting pool higher than purifying pool; setting inlet pipe and water-feed pump on the one side of the adjusting pool; setting admitting pipe and admitting pipe on the upper of the upper pool; setting aeration machine on one side of the purifying pool. The invention possesses high load factor, small plot area and good treatment effect, which can improve treatment effect.

Owner:TIANJIN WATER CONSERVANCY INST

Energy-efficient priming paint

The invention belongs to constructional wall-facing material technical field, especially relating to energy-efficient priming paint which has decoration and thermal insulation effects to inner and exterior walls of a building. The energy-efficient priming paint of the invention comprises the following components by weight: 15%-25% of mixed emulsion, 1%-3% of film forming auxiliary agents, 5%-15% of silica sol, 0.1%-0.2% of antifoaming agents, 0.1-0.2% of mildew-resistant bactericides, 5%-20% of hollow glass beads, 10%-30% of heavy calcium carbonate and 0.2%-1.5% of thickening agents, and rest is water, wherein the hollow glass beads have a granularity range of is 10 microns-180 microns, a bulk density of 0.10-0.50g / cm<3> and a floating rate more than 90%. The energy-efficient priming paint in the invention has functions of waterproof and thermal insulation. Painting the paint on the inner and exterior walls of the building has a great meaning for maintaining indoor temperature and saving energy. The energy-efficient priming paint is especially suitable for matching usage with synthetic resin thick slurry paint and synthetic resin sand textured paint.

Owner:陈轶 +2

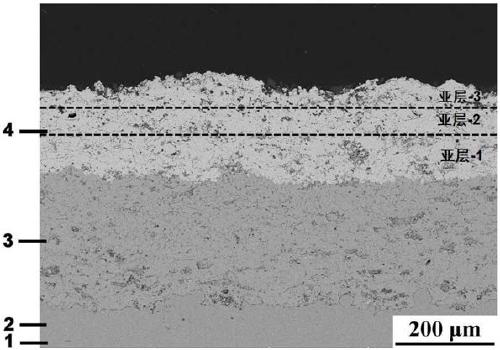

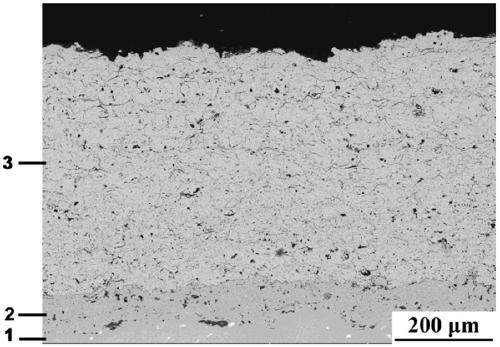

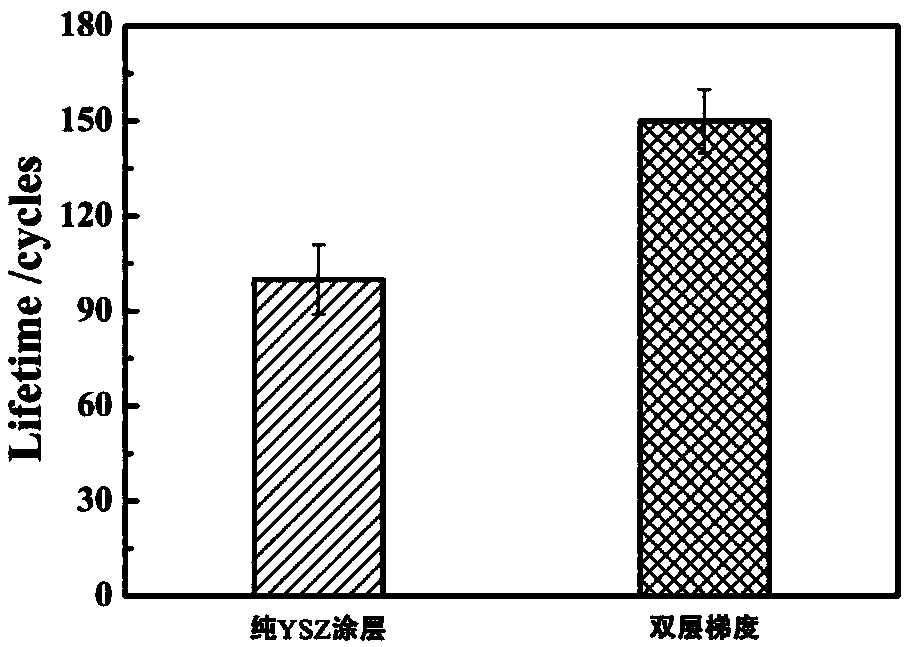

Thermal barrier coating with double-layer gradient structure and preparation technology thereof

ActiveCN109023201AImprove heat insulationImprove insulation performanceMolten spray coatingSuperimposed coating processThermal insulationPhase change

The invention discloses a thermal barrier coating with a double-layer gradient structure. The thermal barrier coating with the double-layer gradient structure comprises a first layered thermal insulation layer positioned inside and a second layered thermal insulation layer positioned outside. The second layered thermal insulation layer is formed by stacking N sublayers, the thermal insulation temperature of each sublayer is equal, and the thermal conductivity of the sublayers of the second layered thermal insulation layer decreases from inside to outside. The first layer thermal insulation layer accounts for 20%-60% of the total thickness of the thermal barrier coating with the double-layer gradient structure, and the fracture toughness of the materials used is greater than or equal to 2.5MPa.m<1 / 2>. The second layer thermal insulation layer accounts for 40%-80% of the total thickness of the thermal barrier coating with the double-layer gradient structure, and the used materials have no phase change at 1200-1600 DEG C, and the thermal conductivity is lower than 1.8W / m.K at 1000-1600 DEG C. The double-layer gradient structure realizes the combination of new materials / new structures,breaks through the reverse restriction relation of the thickness of a single material coating on the thermal insulation capability and the service life, and so that the cooperative design of high thermal insulation, long service life and high temperature resistance of the new structure is achieved.

Owner:咸阳瞪羚谷新材料科技有限公司

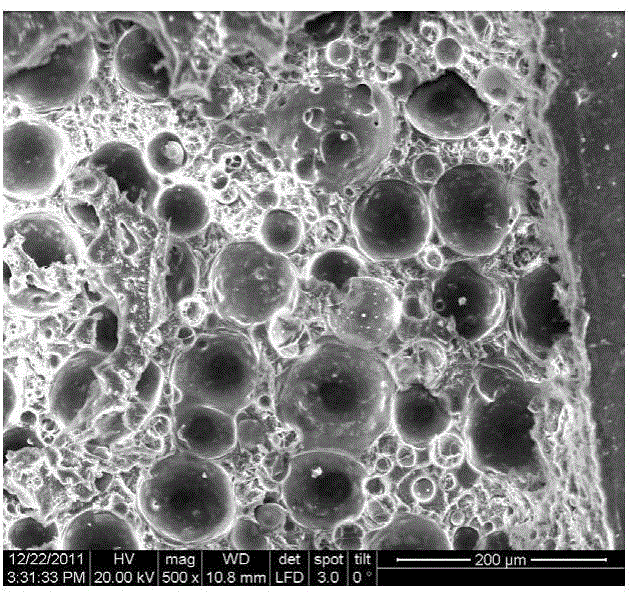

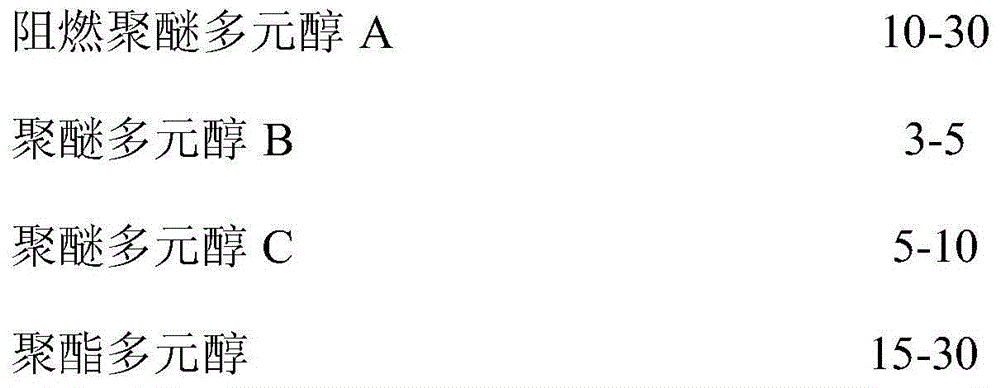

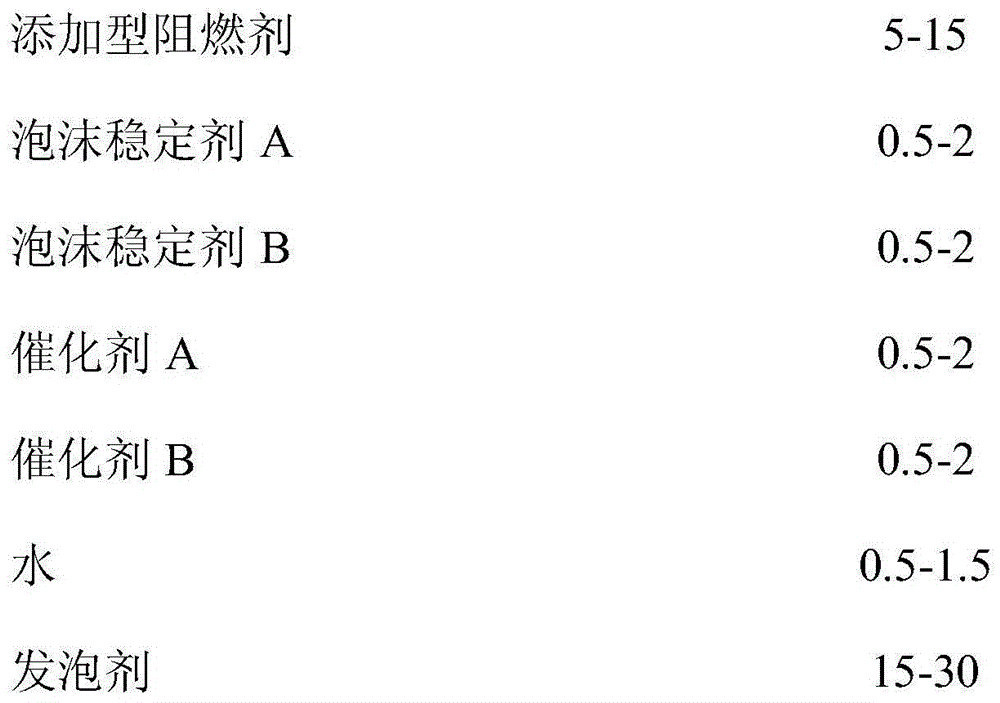

B1-grade flame-retardant polyurethane rigid foam used for continuous line production as well as preparation method and usage thereof

ActiveCN104628979ALittle impact on mechanical propertiesImprove physical performancePolyesterCollocation

The invention discloses a B1-grade flame-retardant polyurethane rigid foam used for continuous line production and a preparation method thereof. According to the invention, a new polyester polyol comprising high temperature-resistant rigid groups with benzoylimino heterocyclic structures and a flame-retardant polyether polyol are used as principal raw materials; relevant flame-retardant silicone oil, a catalyst with a special structure, a liquid flame retardant, a foaming agent and the like are added therein to prepare a compound polyol; and the compound polyol is then reacted with polyisocyanate to generate a polyisocyanurate (PIR) foam with high index. The B1-grade flame-retardant polyurethane rigid foam disclosed by the invention is applicable to continuous line producing processes. Compared with traditional PIR sheet foams, the B1-grade flame-retardant polyurethane rigid foam has the advantages of stable foaming and durable flame-retardant performance. By introducing a reasonable collocation of new rigid polyesters and other accessory ingredients, less flame retardant addition is required in the formula to make the polyurethane foam reach a B1 level while excellent performances such as low feeding density, high strength, stable size and the like are endowed to the foam.

Owner:WANHUA CHEM NINGBO RONGWEI POLYURETHANE

Lightweight high-strength heat-insulation refractory castable

InactiveCN103396141AMake up for the lack of performance degradationAvoid missing gradesFiberDefoaming Agents

The invention discloses a lightweight high-strength heat-insulation refractory castable. The castable comprises the following raw materials by weight: 30 to 40% of lightweight mullite aggregate, 5 to 10% of an aluminum-rich spinel hollow sphere, 5 to 8% of andalusite, 6 to 9% of aluminum-rich spinel powder, 5 to 7% of kyanite powder, 5 to 8% of silicon powder, 5 to 10% of rho-Al2O3 micro powder, 12 to 18% of calcium aluminate cement, 3 to 6% of a refractory fiber, 0.05 to 0.15% of sodium hexametaphosphate, 0.05 to 0.15% of an organic water reducing agent, 0.04 to 0.07% of an organosilicon coupling agent and 0.01 to 0.02% of a defoaming agent. According to the invention, the heat insulation performance of the lightweight refractory castable is guaranteed, close bonding between aggregate and powder in the refractory castable is improved, mechanical strength, capacity of resisting mechanical and thermal shock damage, anti-permeability and comprehensive usage performance at high temperature of the refractory castable are enhanced, and cost for the refractory castable is reduced, thereby finally achieving the comprehensive targets of reduction of heat loss in cooling of furnace beams and columns, prolongation of the service life of a heat insulation lining, improvement of heating quality in a furnace, reduction of energy consumption and maintenance cost, etc.

Owner:武汉钢铁有限公司

One-way moisture permeable and heat preservation composite material and preparation method thereof

ActiveCN108486769AGuaranteed insulation effectHydrophilic effect is easy to controlSynthetic resin layered productsElectro-spinningTextile technologyNanofiber

The invention belongs to the technical field of textiles, relates to a preparation method of composite materials, in particular to a one-way moisture permeable and heat preservation composite materialand a preparation method thereof. The one-way moisture permeable and heat preservation composite material comprises a fluffy layer and an air-tight sealing layer, the fluffy layer is formed by the arrangement of nano fiber layers and coarse denier fiber layers at intervals, the air-tight sealing layer is PET-PA6 double-component ultrafine fiber non-woven fabric, the nano fiber layers are PVA nanofiber layers, and the coarse denier layers are fiber layers blended and carded by PE / PP sheath-core double-component fiber, three-dimensional curved terylene and hydrophilic fiber. The fiber composite material prepared by means of the method has ideal one-way moisture permeable and heat preservation effects and is suitable for liners of cold-proof garments and blankets, building heat preservationmaterials, high fluffiness heat-preserving layers for heat preservation of pipelines and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

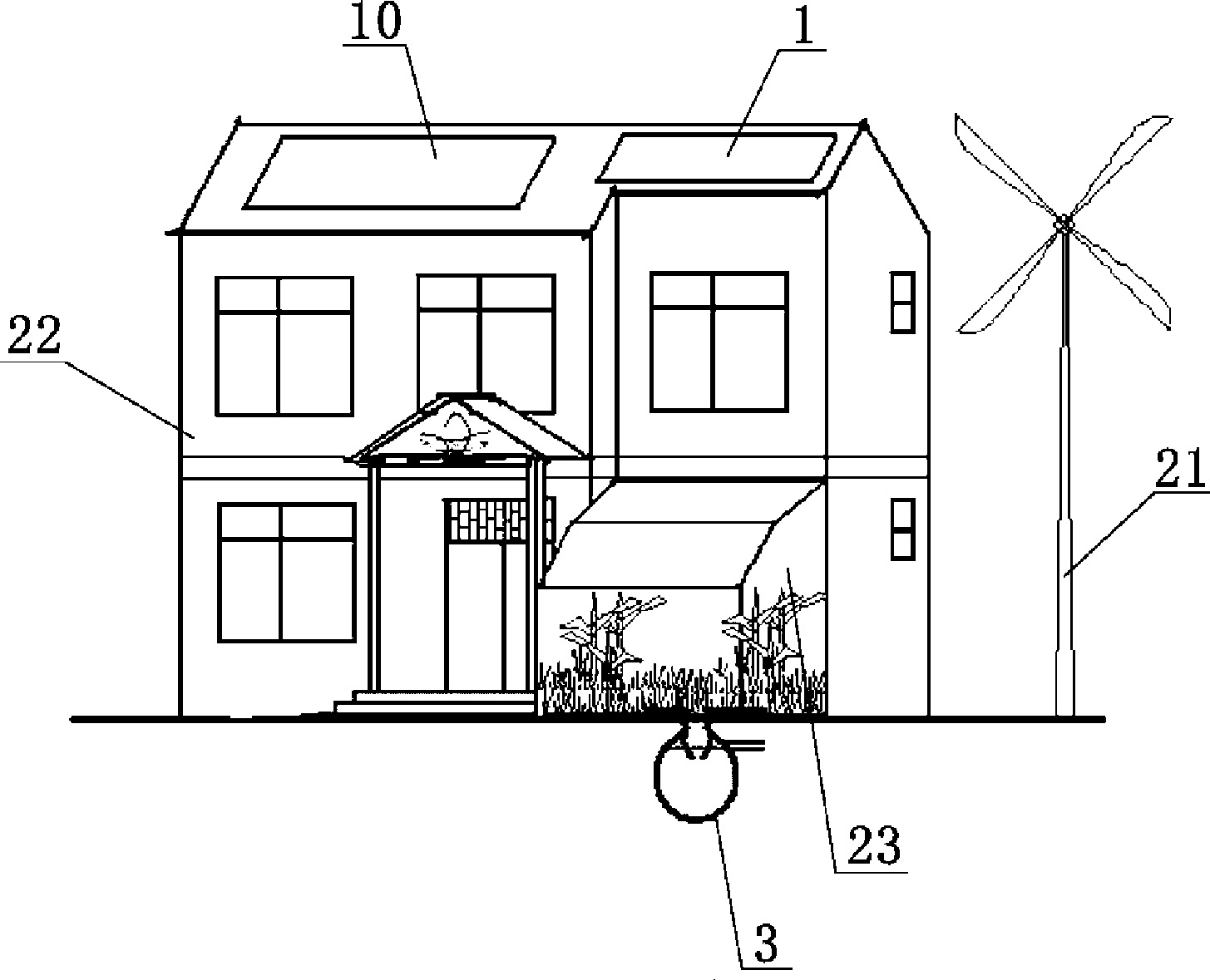

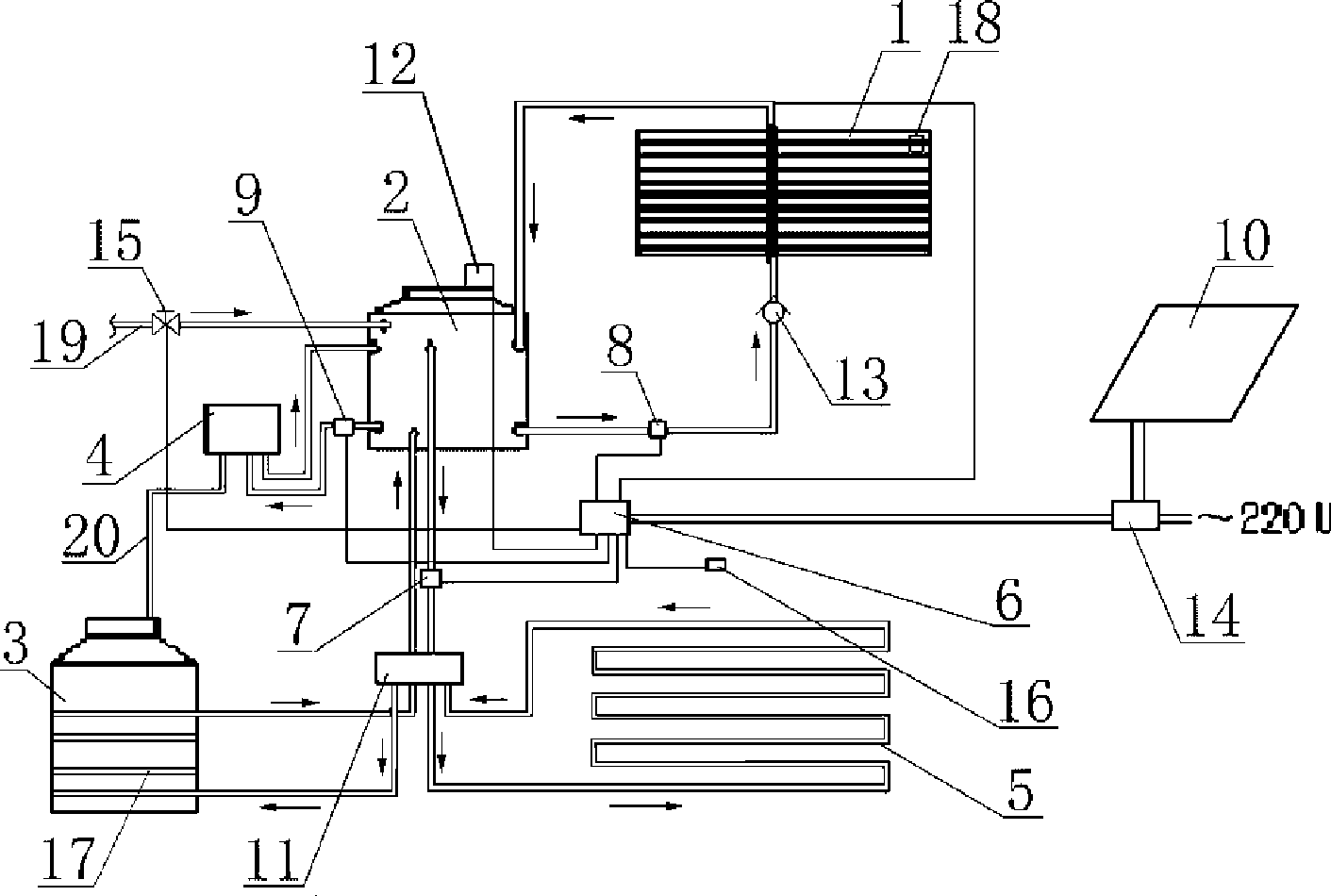

Green ecological zero energy consumption integration house

InactiveCN101457594AIncrease heatIncrease gas productionWallsSolar heat devicesLiving roomCollector device

The invention relates to a green ecological zero energy integrated building, a first floor of the building is provided with a living room, a bedroom, a dinning room, a kitchen, a toilet; a second floor of the building is provided with a bedroom and a toilet; a heat supply system is arranged inside the room, the building is connected with a heliogreenhouse on the ground and is connected with a methane tank under the ground. A solar thermal collector arranged at the top of the building is communicated with a temperature-holder box arranged inside the rooms of the building by a circulating pipe of the first line, the temperature-holder box is communicated with a water heating pipe of a gas-fuel heater by the circulating pipe, a gas line of the gas-fuel heater is communicated with the methane tank by a methane pipe. A hot water outlet of the temperature-holder box is respectively communicated with a PE-RT pipe and a heating pipe of the methane tank which is buried near the methane tank. A water tank temperature sensor, a room temperature sensor and a collector temperature sensor are connected with an intelligent controller. With the solar energy, bioenergy and wind energy complementing each other, the building has the characteristics of comfort, environmental protection, energy saving and zero-pollution.

Owner:赵民忠

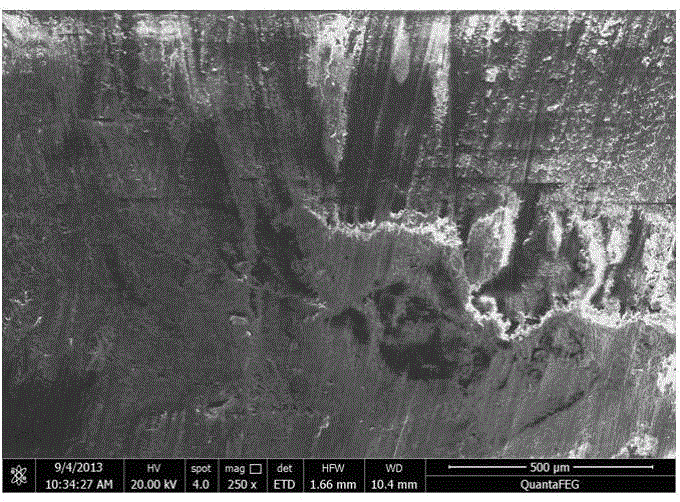

Preparation and application methods of carbon fiber mat surface antioxidation coating

InactiveCN103774435ARaw materials are easy to getWide range of optionsFibre treatmentHeating/cooling textile fabricsFiberCarbon fibers

The present invention provides preparation and application methods of a carbon fiber mat surface antioxidation coating; after chemical modification of matrix resin by use of an inorganic acid salt, the matrix resin is used as a precursor for blending with inorganic powder, and then coats the surface of a carbon fiber mat thermal insulation material by a brush, and then a high temperature coating with antioxidation and thermal erosion resistance is prepared by curing, carbonization, high temperature and other processes. The raw materials are easy to get, the optional range is wide, the preparation process is simple, the cost is low, the prepared coating structure reduces the specific surface area of the carbon fiber mat thermal insulation material, and further suppresses the aerobic oxidation phenomenon of the carbon fiber mat thermal insulation material at a low temperature, in the environment of high temperature and inert atmosphere, the material surface has a certain of thermal erosion resistance, the service life and long-acting thermal insulation ability of a carbon fiber mat can be prolonged, in addition, the slag-off phenomenon of the coated carbon fiber mat in the use process is suppressed, and the application scope of the carbon fiber mate is broaden.

Owner:GANSU HAOSHI CARBON FIBER

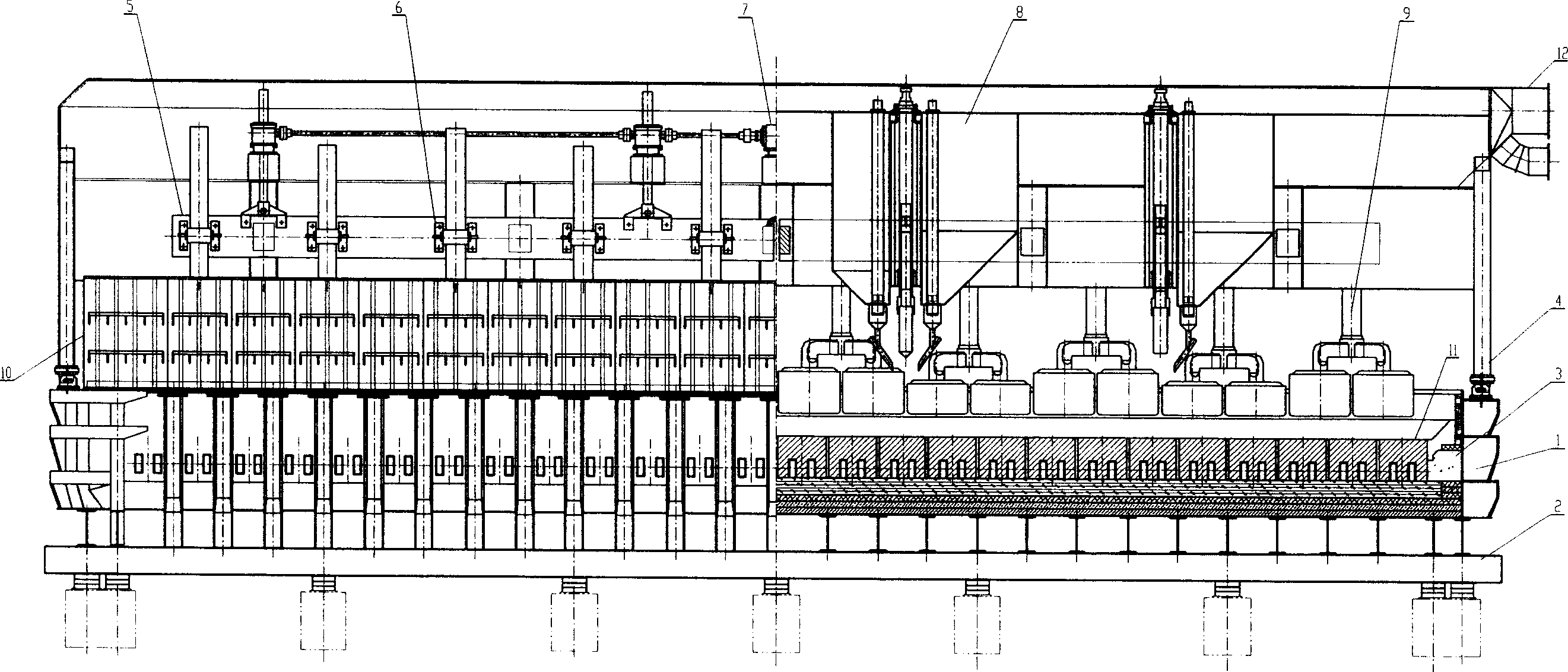

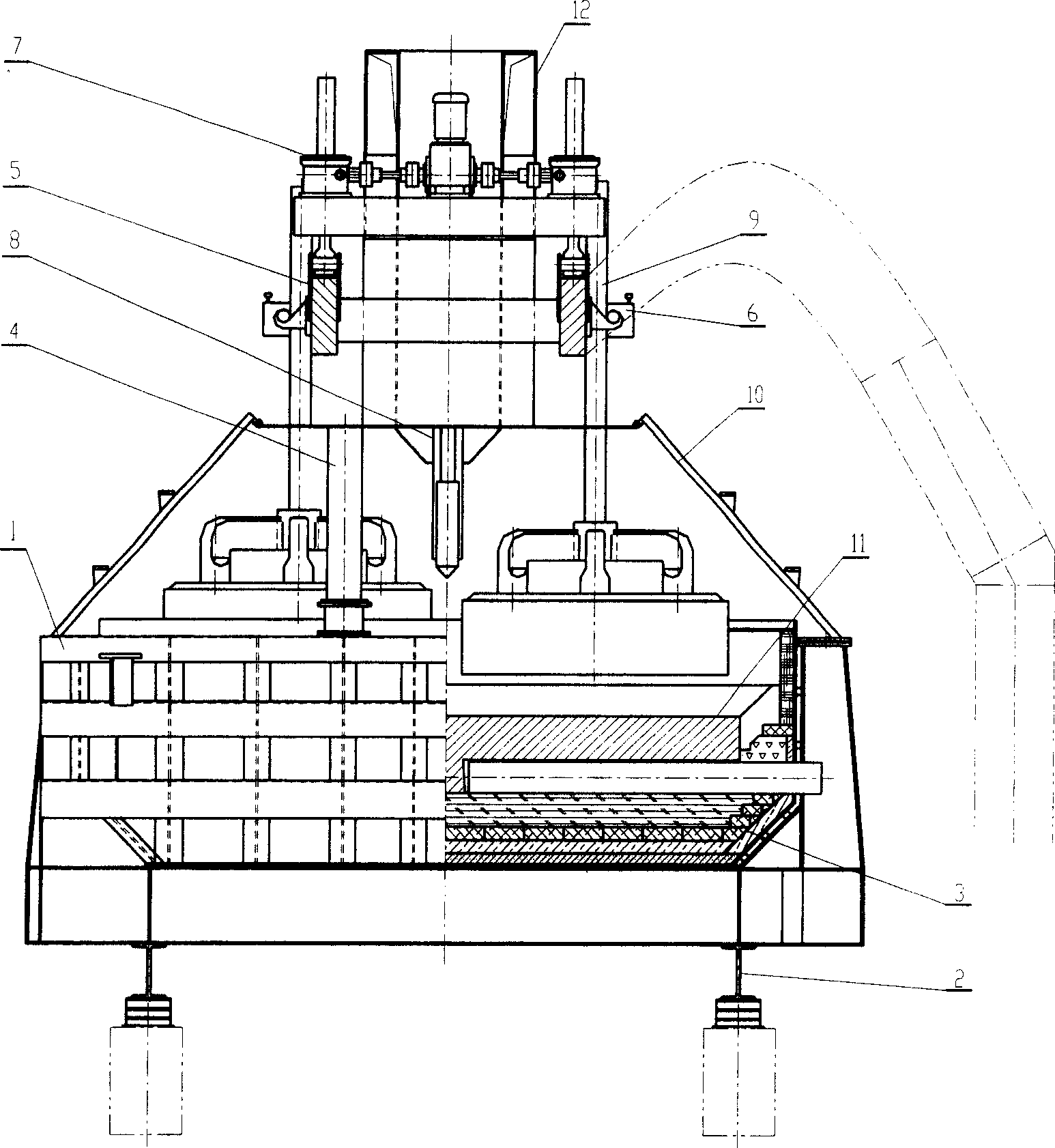

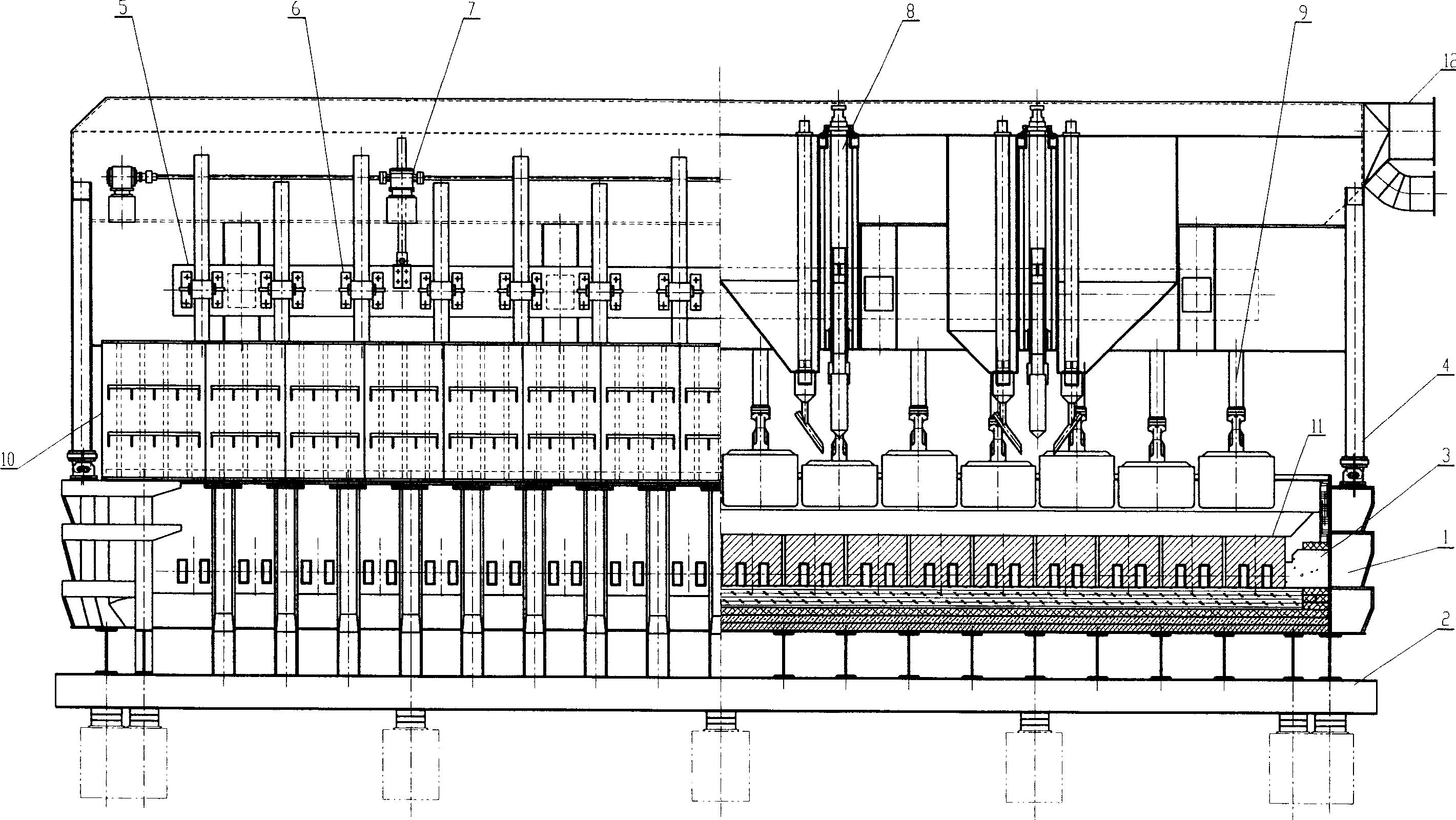

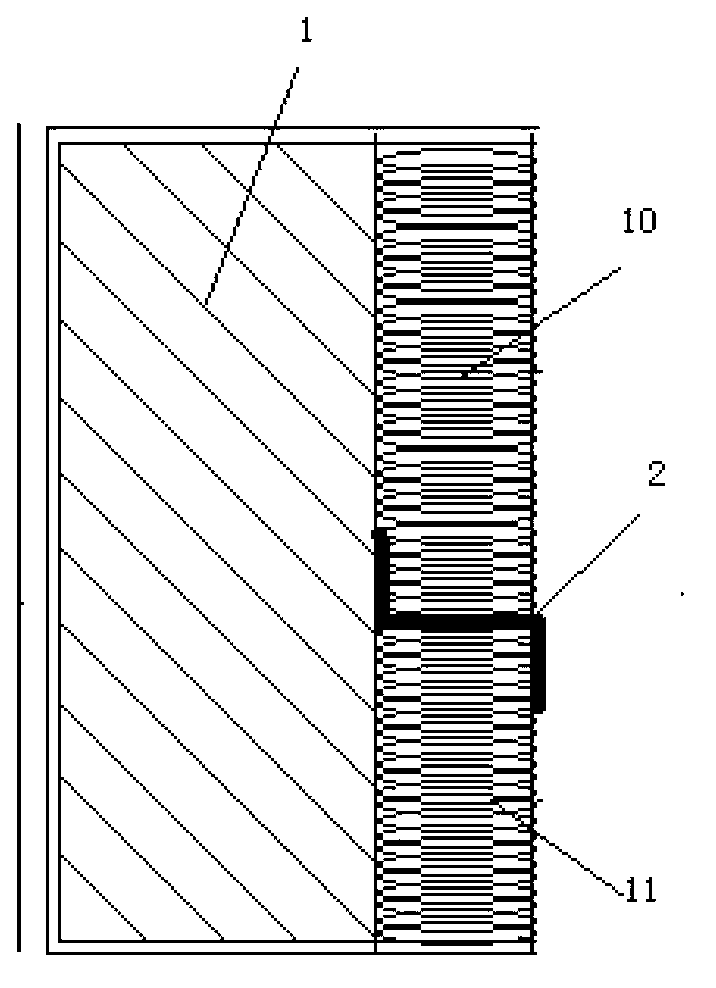

Large-scale aluminium electrolysis pre-baking tank

The large aluminum electrolyzing pre-roasting tank includes anode carbon block combination, anode bus, breaking and feeding unit, anode elevating mechanism, crossbeam and portal upright, tank sealing air exhaust system, tank casing, cathode structure and bottom heat insulating structure. It features the double anode structure comprising two anode carbon blocks assembled through aluminum rod and steel pawl; the elevator installed below the top surface of the crossbeam; the tank sealing air exhaust system set inside the crossbeam; and the cathode with surround casing, carbon block with bottom composite heat insulating layer, side silicon nitride to combine silicon carbide blocks and surrounding cast material. The present invention has improved structure resulting in raised fume collecting efficiency, reasonable gas flow distribution and smooth aluminum electrolyzing process.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Nanometer thermal insulation material of automobile glass and manufacturing method thereof

InactiveCN102153948AStrong absorption capacityFacilitate throughRadiation-absorbing paintsReflecting/signal paintsInfraredIndium

The invention discloses a manufacturing method of a nanometer thermal insulation material of automobile glass. The nanometer material mainly comprises the following components according to content percentage: 50-70% of nanometer modified organic silica solution, 5-10% of nanometer oxidized silica solution, 5-15% of nanometer indium tin oxide size, 10-20% of organic solvent and 1-5% of film forming substances, and the total percentage of all the components is 100%. By adopting the method, the nanometer size with the function of thermal insulation forms a film on the inner surface of the automobile glass through an organic silicon carrier, so that the glass has the function of thermal insulation, as well as very high visible light transmission, an excellent infrared rejection rate, an excellent ultraviolet absorption rate, prominent adhesion and ultrahigh film hardness.

Owner:李海洋

Treatment structure of heat insulation cotton seam

InactiveCN103266669AGuaranteed insulation effectLong-term insulation effectHeat proofingBuilding insulationsArchitectural engineeringBuilding construction

The invention discloses a treatment structure of a heat insulation cotton seam. A connecting member is arranged between upper heat insulation cotton and lower heat insulation cotton of an outer wall, the connecting member is a Z-shaped galvanized iron sheet, and an angle between the connecting side of the Z-shaped galvanized iron sheet and a horizontal plane is from 5 DEG to 8 DEG. According to the treatment structure, the Z-shaped connecting member is adopted as the connecting member for treating the details of the heat insulation cotton seam, reasonable construction steps are combined, the phenomenon that water enters the heat insulation cotton because rain invades during outdoor construction is avoided, thereby guaranteeing the long-time heat insulation effect of the heat insulation cotton and prolonging the service life of an energy saving system of a building, the smoothness of the heat insulation cotton seam is good, and the division engineering quality of energy saving construction of the building is guaranteed.

Owner:ZHONGTIAN CONSTR GROUP

Tundish covering agent and application thereof

The invention relates to a tundish covering agent and application thereof and belongs to the technical field of tundishes in the continuous casting process. The tundish covering agent is mainly prepared from, by percentage content, 35-45% of CaO, 8-15% of SiO2, 25-30% of Al2O3, 5-15% of MgO, 5-12% of (Na2O+Li2O), 1-5% of B2O3 and 0.5-1% of TiO2. The tundish covering agent has the advantages that the melting point is low and is 1250-1350 DEG C, the viscosity is high and is 0.8-1.2 Pa*s at the temperature of 1300 DEG C, and the basicity is high and is 3-6. The tundish covering agent is applicable to the continuous casting production process, for producing the tundishes, of titanium-added steel. When the tundish covering agent is applied to the continuous casting production process of the titanium-added steel, produced TiO2, produced TiN and other produced inclusion can be effectively dissolved. The inclusion is prevented from entering a crystallizer, the cleanness degree of molten steel is improved, and therefore the quality of cast blanks is improved.

Owner:CENT SOUTH UNIV

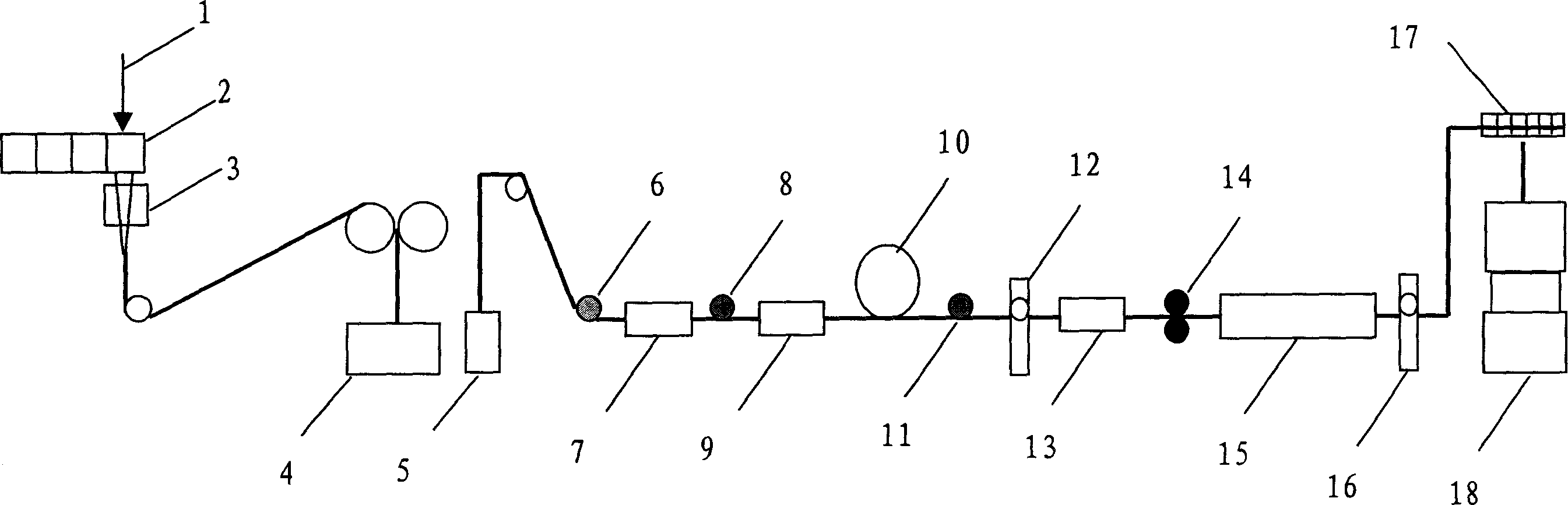

Detachable spinning manifold heated by biphenyl steam which is heating medium

ActiveCN103205819AEasy to disengageUniform temperatureArtificial thread manufacturing machinesMelt spinning methodsRefluxInsulation layer

The invention discloses a detachable spinning manifold heated by biphenyl steam which is a heating medium. The detachable spinning manifold comprises an upper manifold and a lower manifold. The detachable spinning manifold has the advantages that components such as metering pumps and melt pipelines which can be blocked easily are arranged in the upper manifold, a replaceable spinning assembly and a fixed heat-insulation structure are disposed in the lower manifold, the upper manifold and the lower manifold are respectively provided with biphenyl steam inlets and biphenyl condensate reflux inlets which are of straight pipe structures with loose flanges, and a detachable filled heat-insulation layer is arranged on the surface of the upper manifold, so that the upper manifold can be easily separated from a biphenyl steam circulating system or connected with the biphenyl steam circulating system and can be perpendicularly hoisted out or assembled; and the upper manifold and the lower manifold are connected into the same biphenyl steam generator by parallel biphenyl circulating pipelines, so that the temperature of the inside of the upper manifold and the temperature of the inside of the lower manifold keep uniform and consistent.

Owner:CTA HIGH TECH FIBER

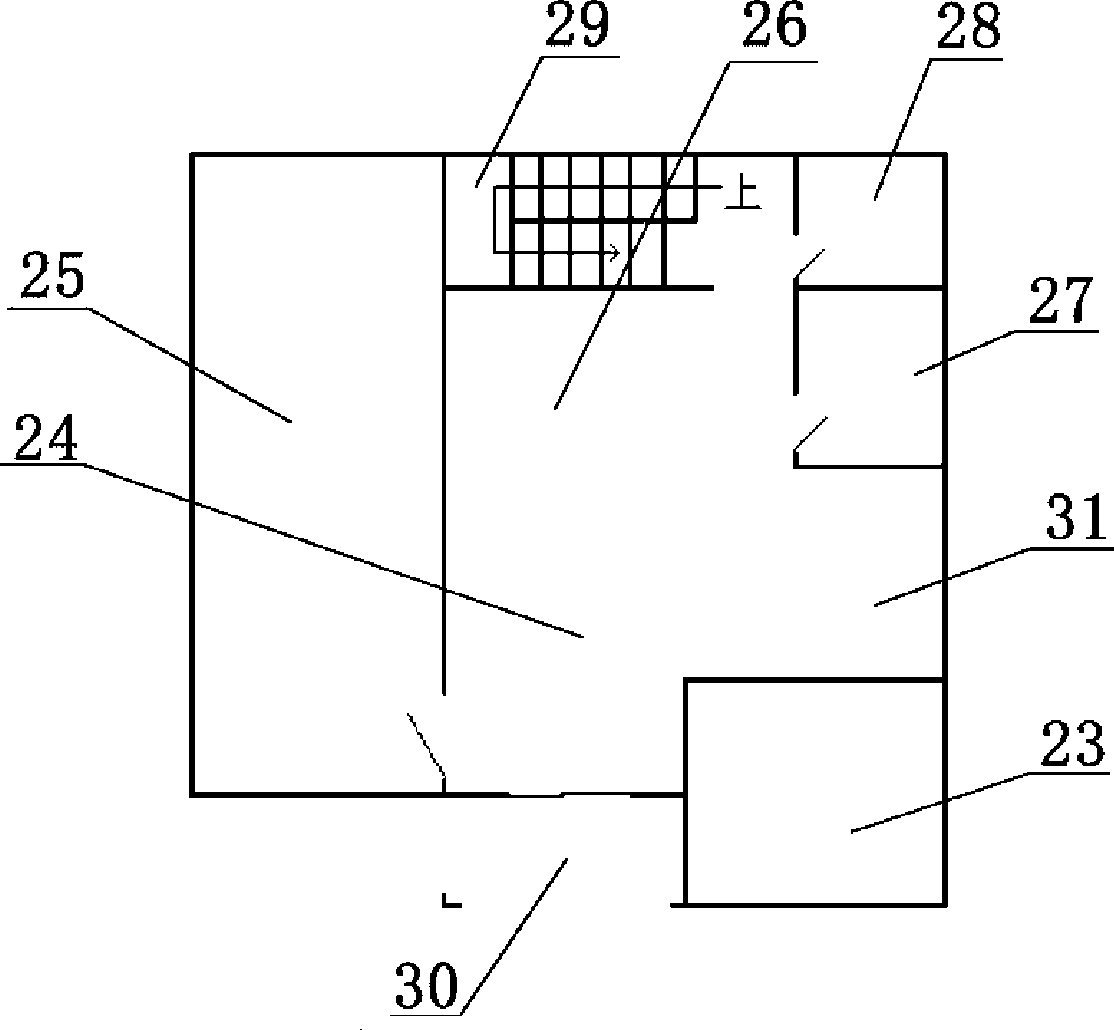

Double-layer roller-way kiln provided with lifting device

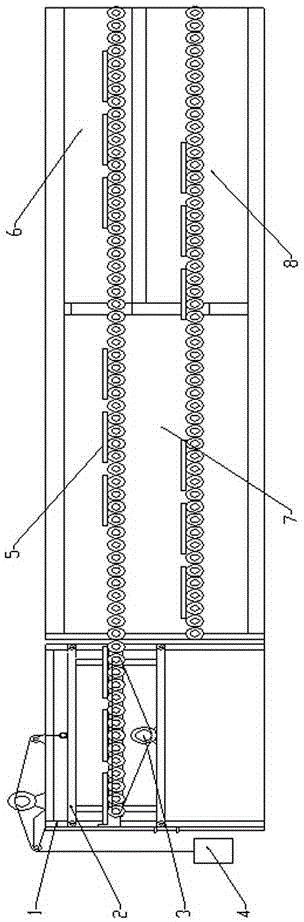

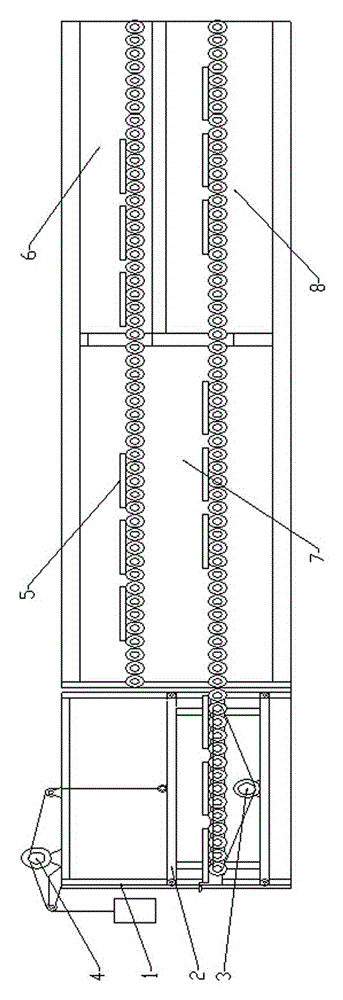

InactiveCN104880062AIncrease the areaLong construction periodFurnace typesFixed frameSmall footprint

The invention discloses a double-layer roller-way kiln provided with a lifting device. The double-layer roller kiln comprises a double-layer roller-way device and the lifting device, the double-layer roller-way device comprises an upper layer kiln way and a lower layer kiln way, the upper layer kiln way is provided with a preheating chamber and a firing chamber, the lower layer kiln way is provided with a firing chamber and a cooling chamber, and the lifting device is arranged beside the firing chambers; the lifting platform comprises a fixing frame, a lifting platform, a roller platform located in the lifting platform and a lifting mechanism which drives the lifting platform to ascend and descend; the lifting platform comprises a lifting plate, a load-bearing plate and support plates which are located between the lifting plate and the load-bearing plate, and the roller platform comprises a rack, a chain wheel transmission device and roller rods; the lifting mechanism comprises a motor, a hauling cable and a balance weight. According to the double-layer roller-way kiln, the structure is simple, the operation is convenient, the manufacture and use can be conducted, the occupied area is small, and the management and maintenance are facilitated; meanwhile, the energy utilization ratio is high, the cost is saved, and the kiln is suitable for being used and popularized.

Owner:绥阳县华夏陶瓷有限责任公司

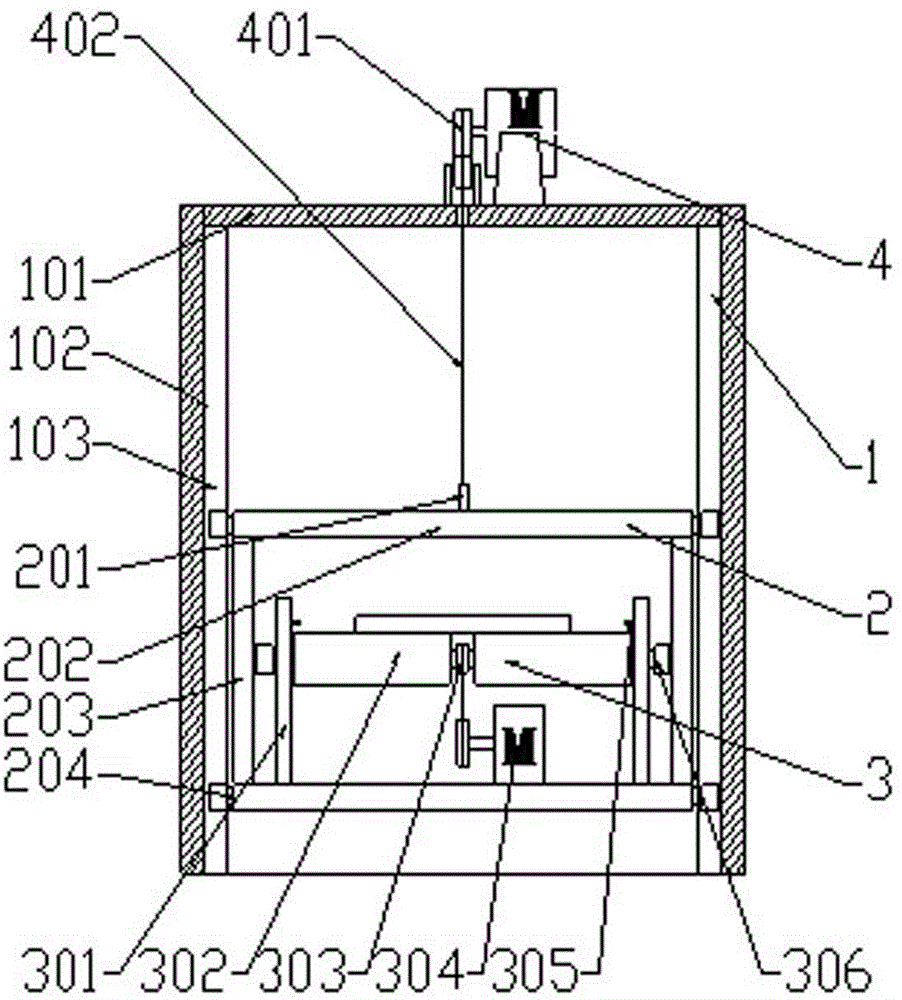

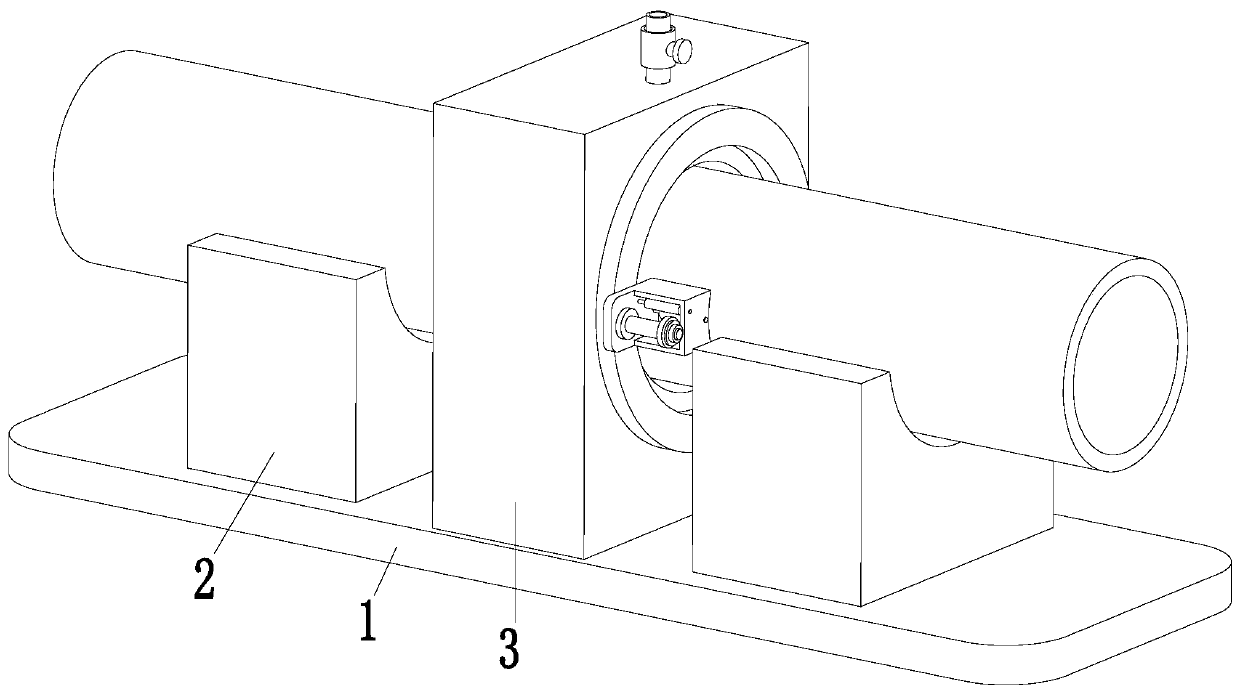

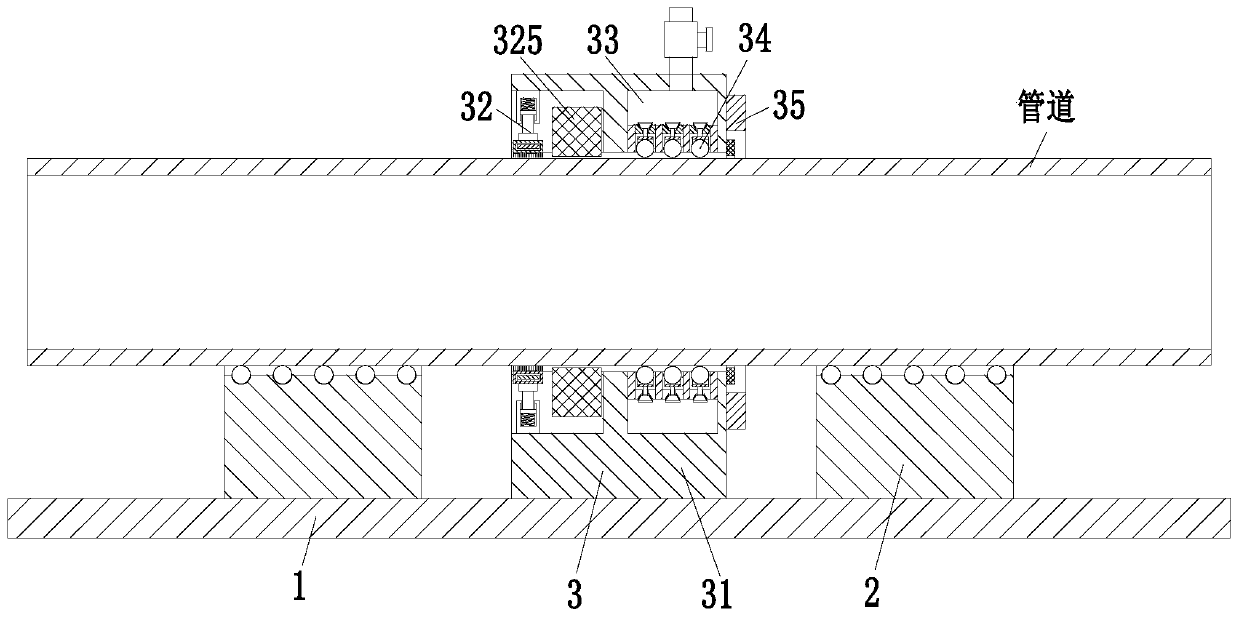

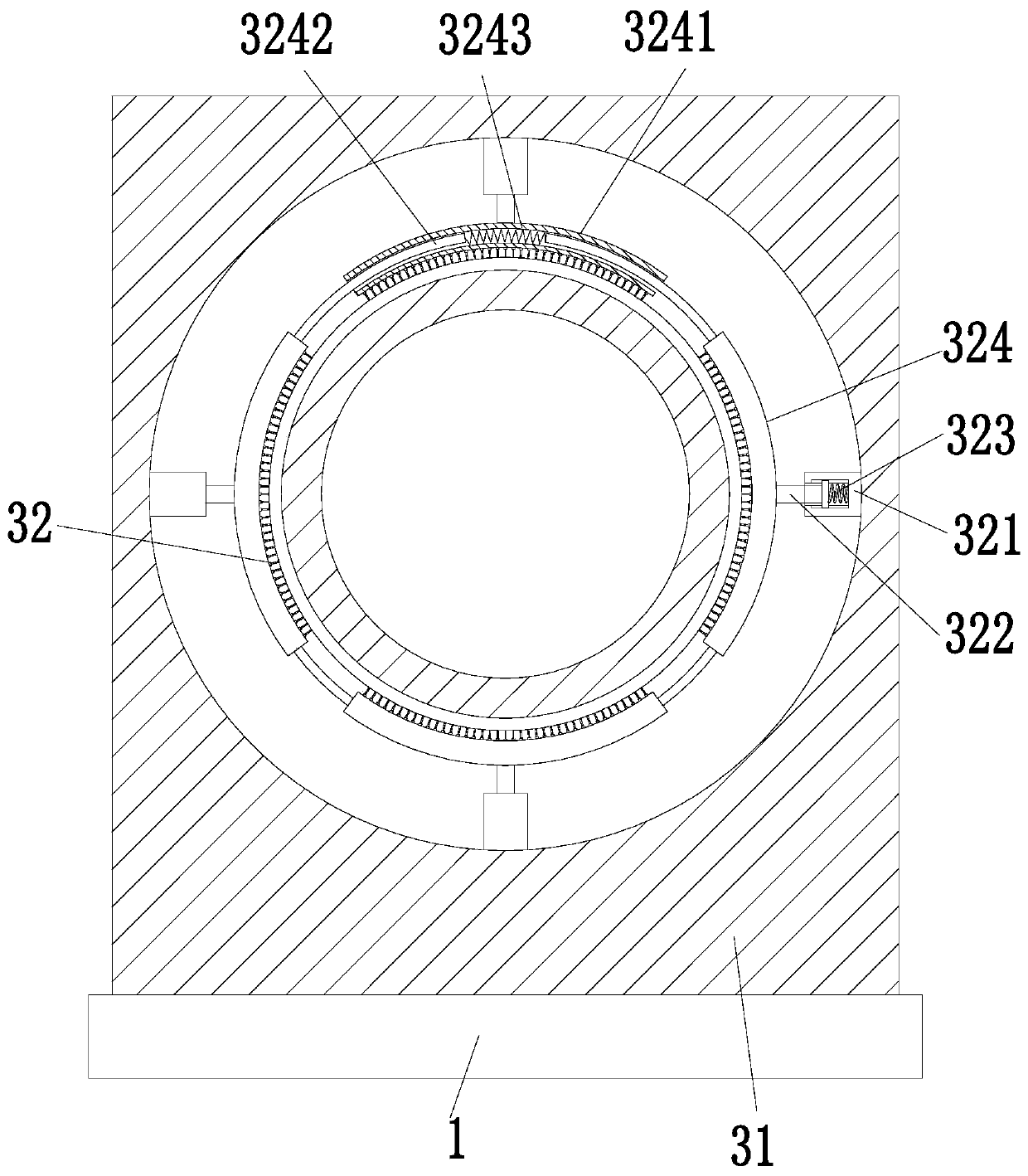

Insulation processing equipment of petroleum conveying pipeline and pipeline insulation processing technology

ActiveCN111318410AFacilitate subsequent processingEfficient removalLiquid surface applicatorsThermal insulationProcess engineeringPipe insulation

The invention relates to insulation processing equipment of a petroleum conveying pipeline and a pipeline insulation processing technology. The equipment comprises a bottom plate, locating frames anda processing device. The locating frames are symmetrically mounted at the upper end of the bottom plate. The processing device is arranged between the locating frames and is mounted in the middle of the upper end of the bottom plate. The problems that when existing equipment carries out gluing processing on the pipeline, generally, impurities adhering to the surface of the pipeline cannot be removed, the adhesion result of glue is influenced, meanwhile, generally, the glue smearing effect is poor, the glue is not smeared evenly, a gap is prone to being generated between an insulation band andthe pipeline, when the existing equipment winds the insulation band on the outer surface of the pipeline, the winding effect is poor, efficiency is low, the attachment result between the insulation band and the pipeline is poor, and the insulation effect of the pipeline is influenced can be solved.

Owner:荆州市恒基石油机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com