Detachable spinning manifold heated by biphenyl steam which is heating medium

A spinning box and box technology, applied in the field of detachable spinning box, can solve the problems of poor spinning temperature stability and uniformity, complicated disassembly and installation operations, and reduced workload, so as to ensure the heat preservation effect , Solve the effect of disassembly and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

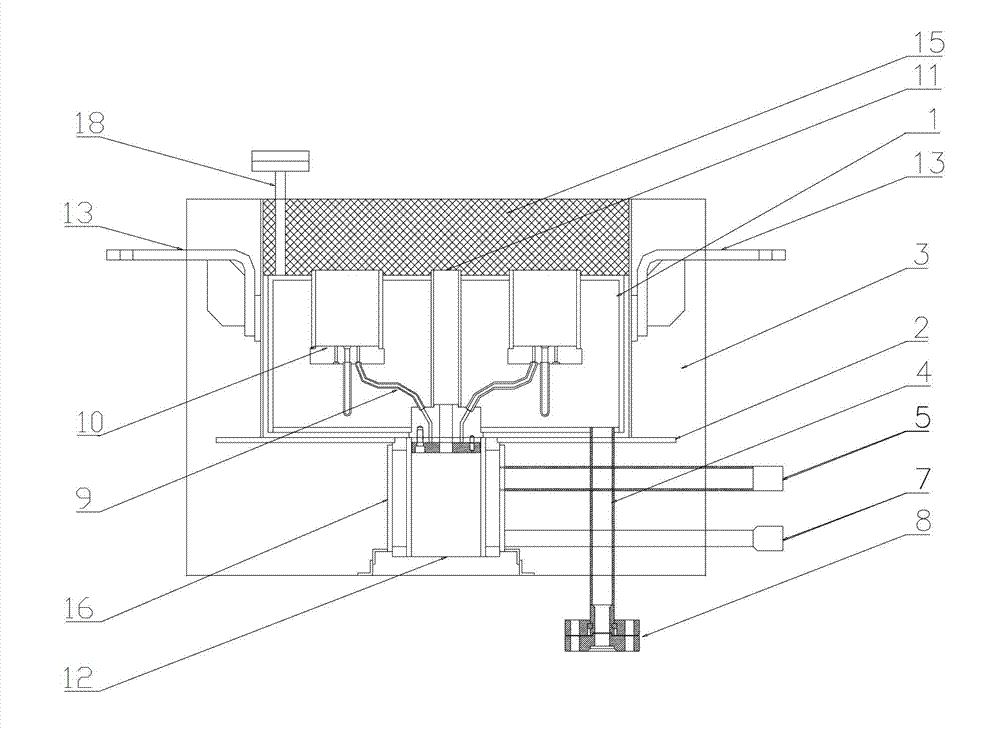

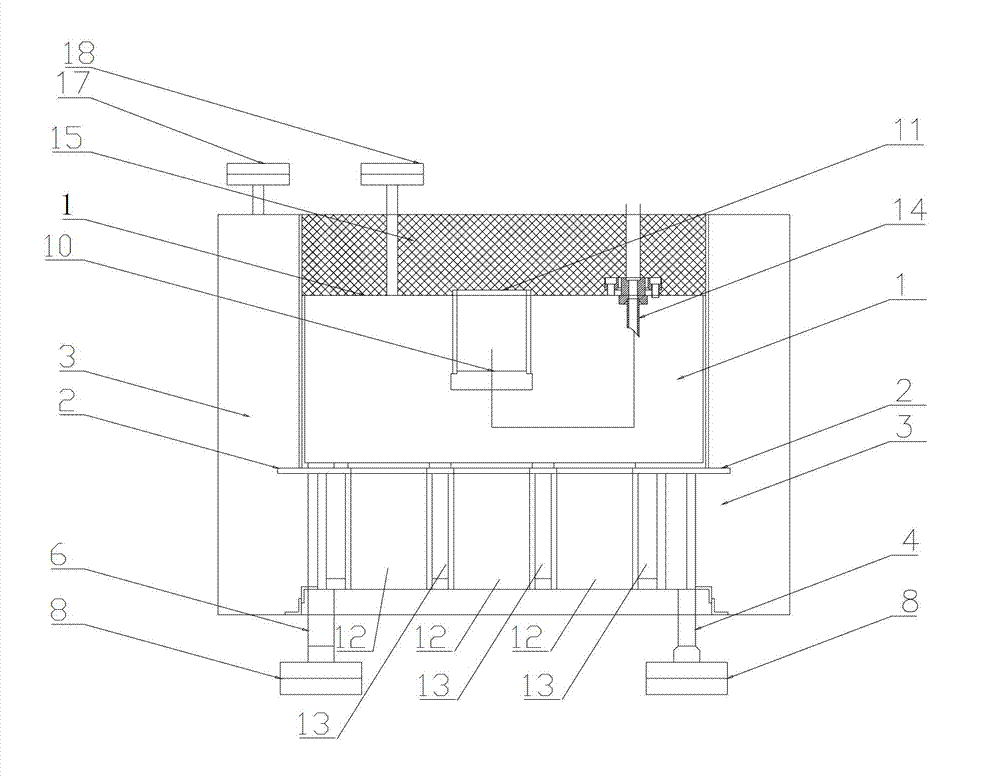

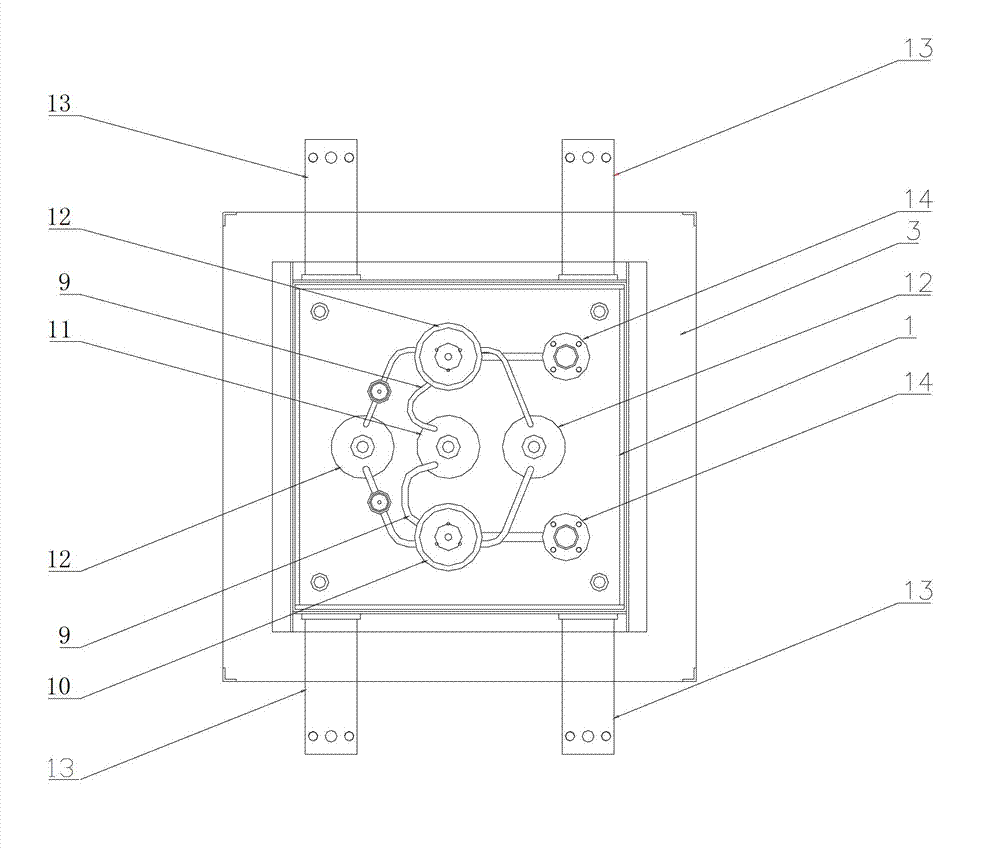

[0031] see figure 1 , figure 2 and image 3 as shown,

[0032] In this specific embodiment, a detachable spinning box heated by biphenyl heat medium steam is introduced, which includes two parts, the upper box 1 and the lower box 3, and the upper surface of the lower box 3 is set There is an inward pit, and the upper box 1 is detachably arranged in the pit of the lower box 3. In this specific embodiment, it is preferable that the upper box 1 is integrally arranged in the pit, so The above-mentioned upper box body can also be partially arranged in the pit. The upper box body 1 can be a structure of any shape. In this specific embodiment, it is preferable to set the shape of the upper box body 1 to match the shape of the pit, and the shape of the pit and the upper box body 1 is set to cooperate with each other. of rectangular shape.

[0033] In this specific embodiment, a metering pump groove is arranged in the upper box body 1, a melt inlet 14 is arranged on the upper sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com