Patents

Literature

1175results about How to "Consistent temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

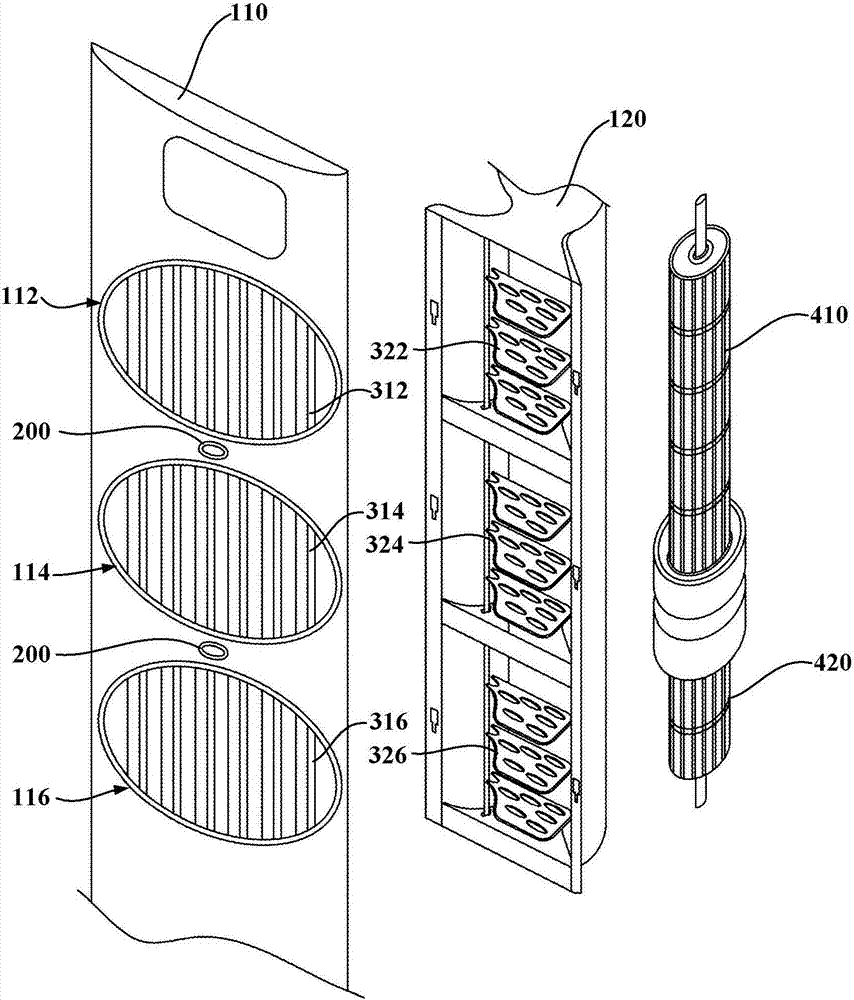

Battery

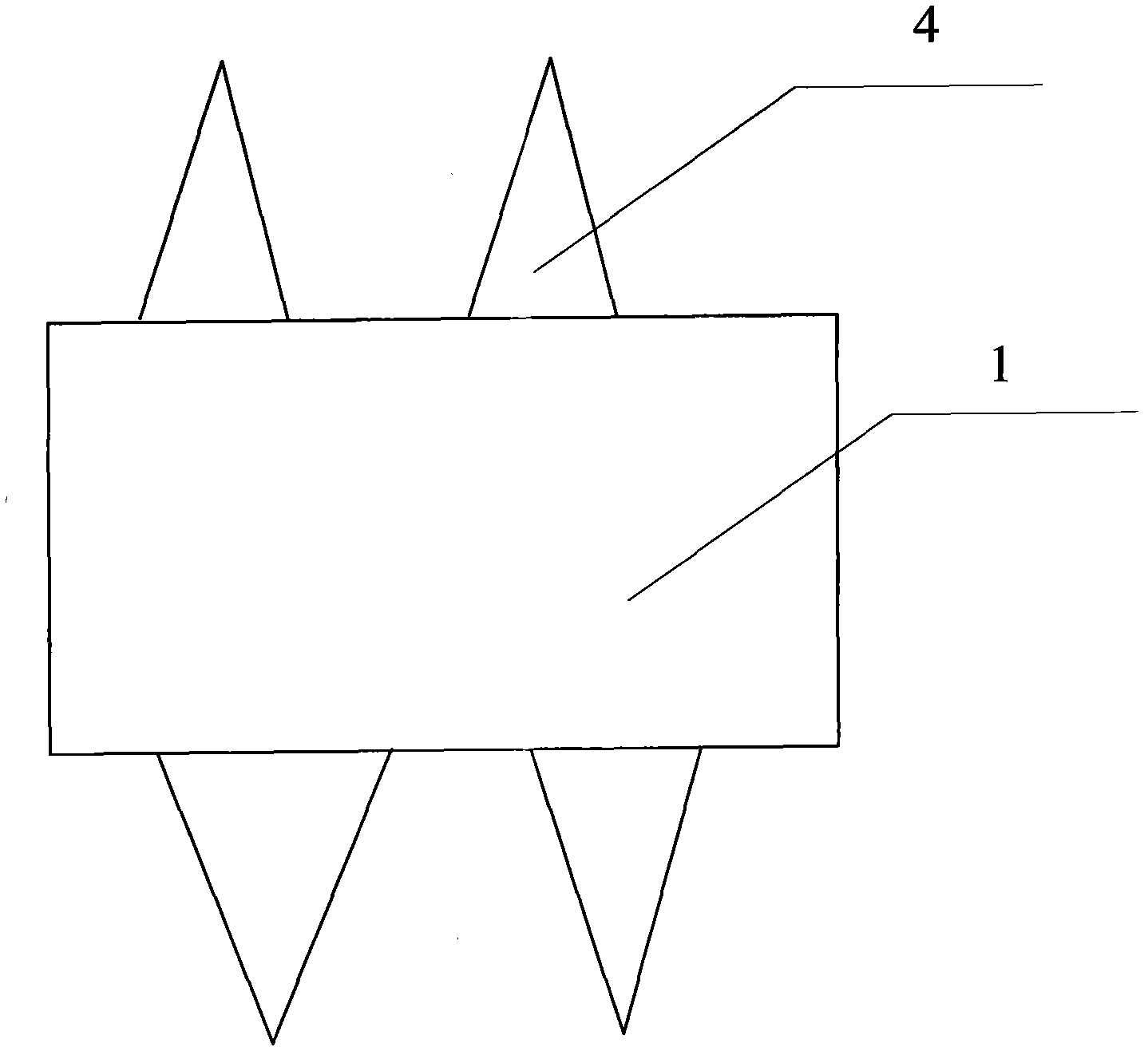

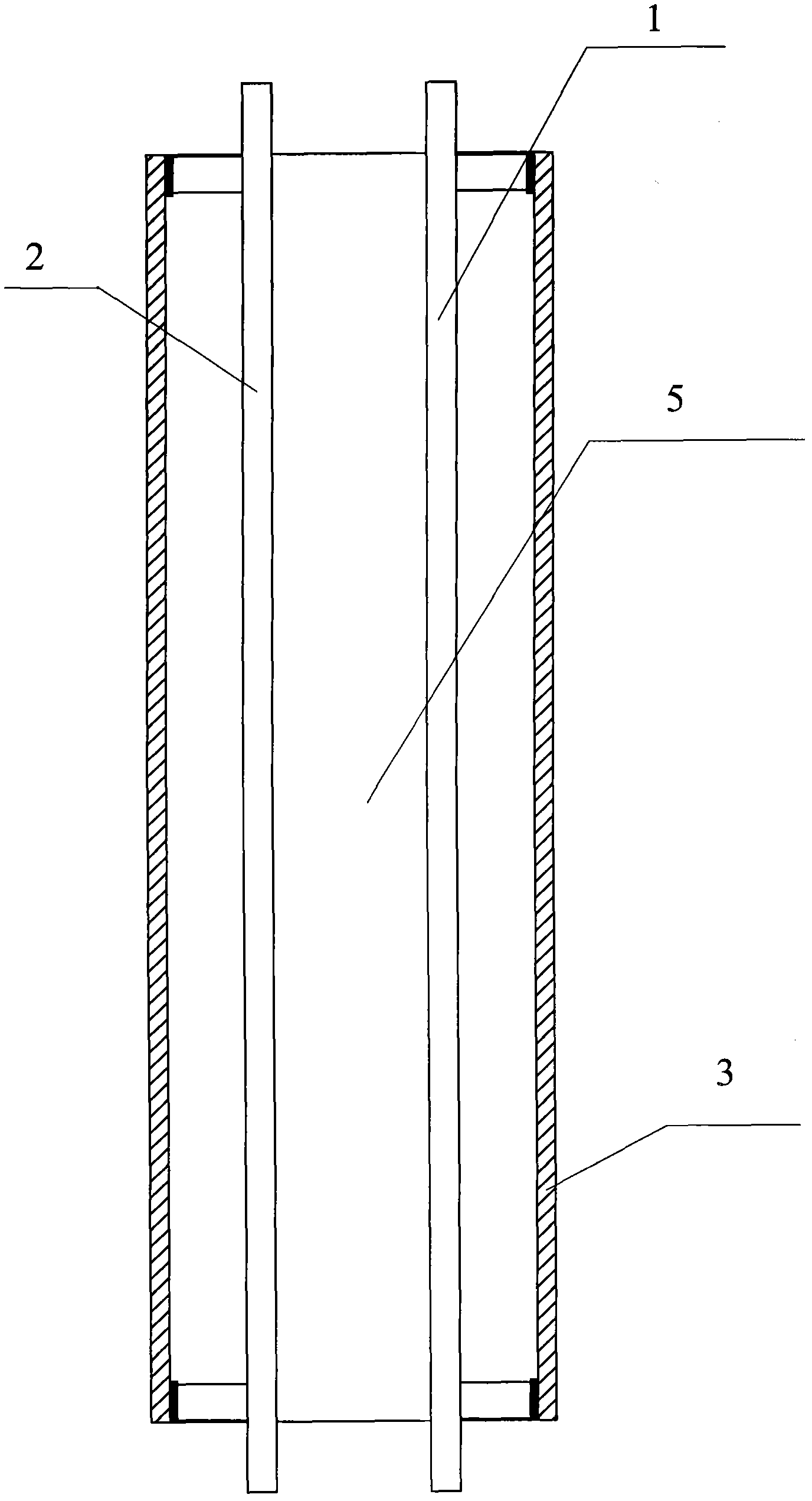

InactiveCN102569866AStable temperatureConsistent temperatureFinal product manufactureCell temperature controlHeat conductingReaction temperature

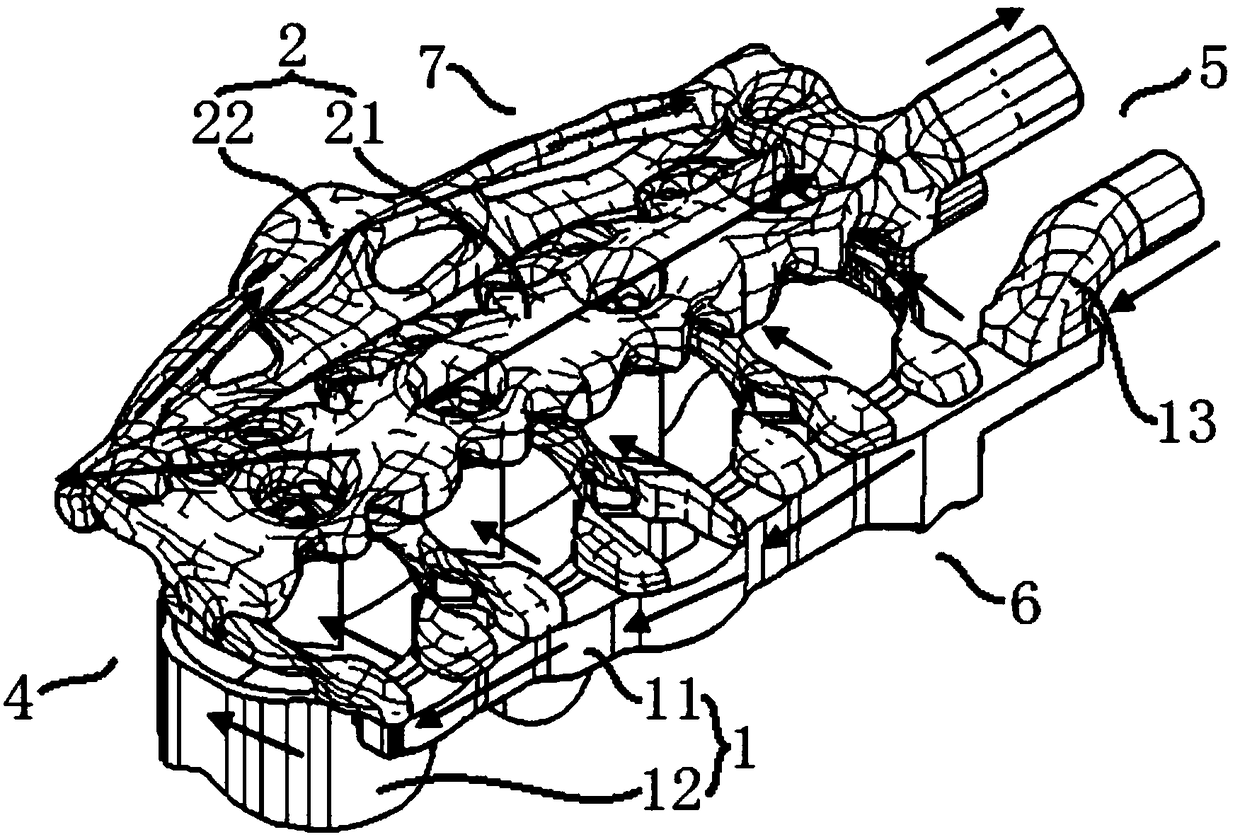

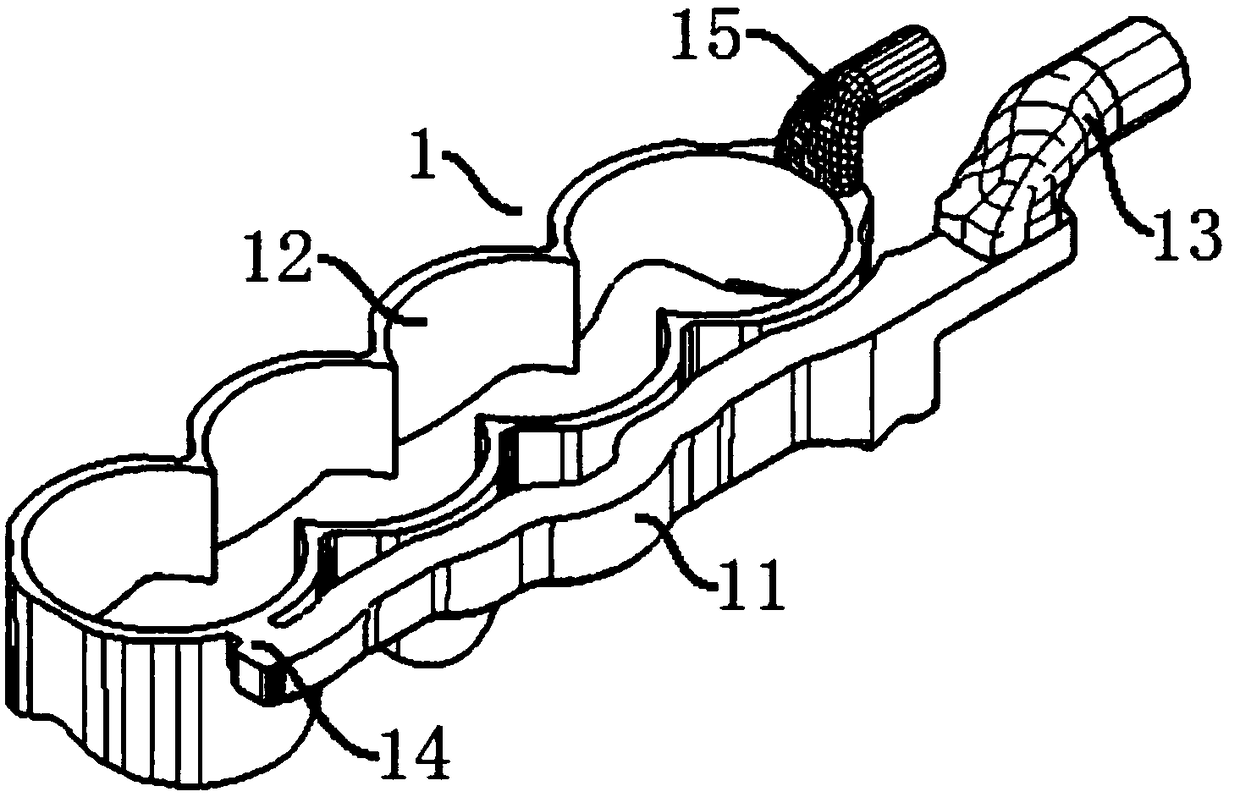

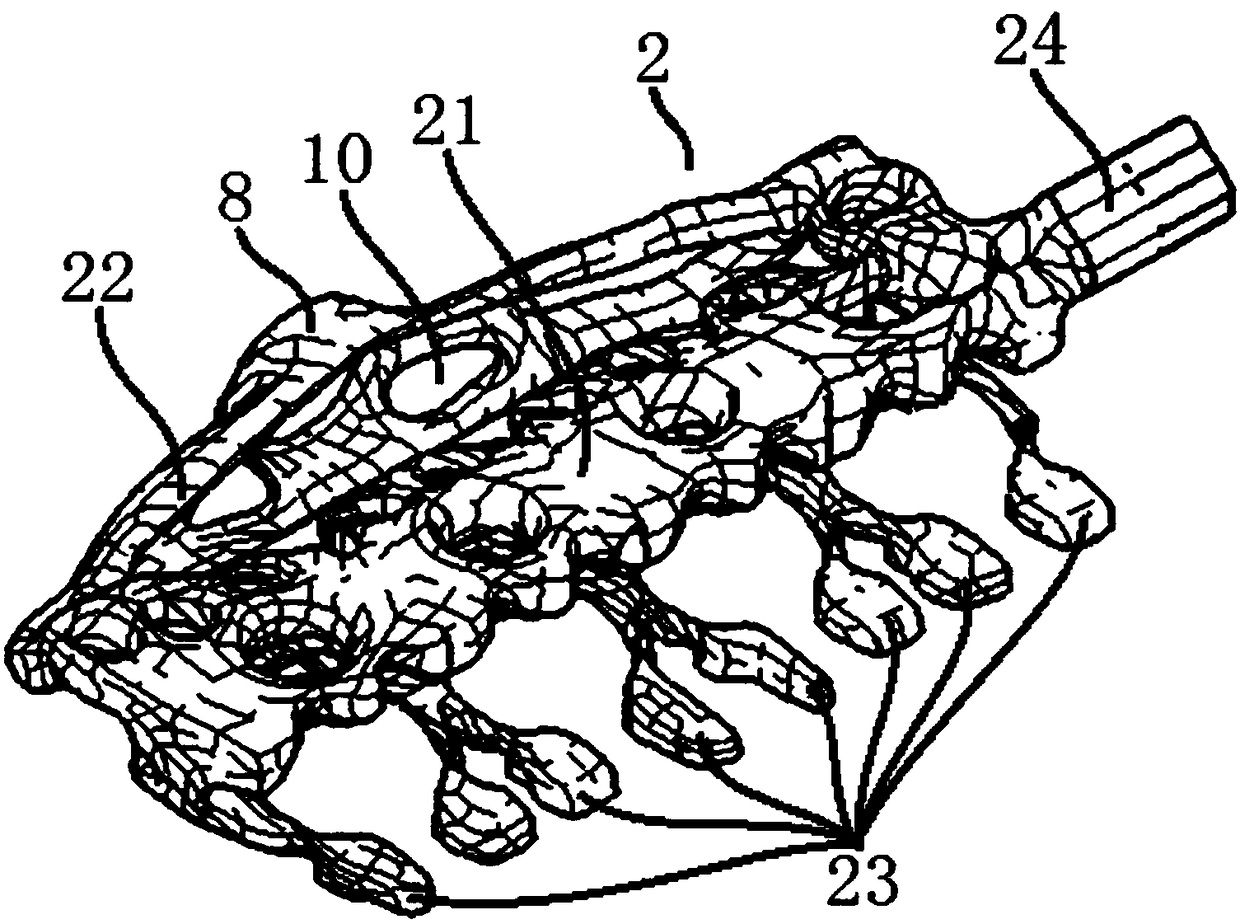

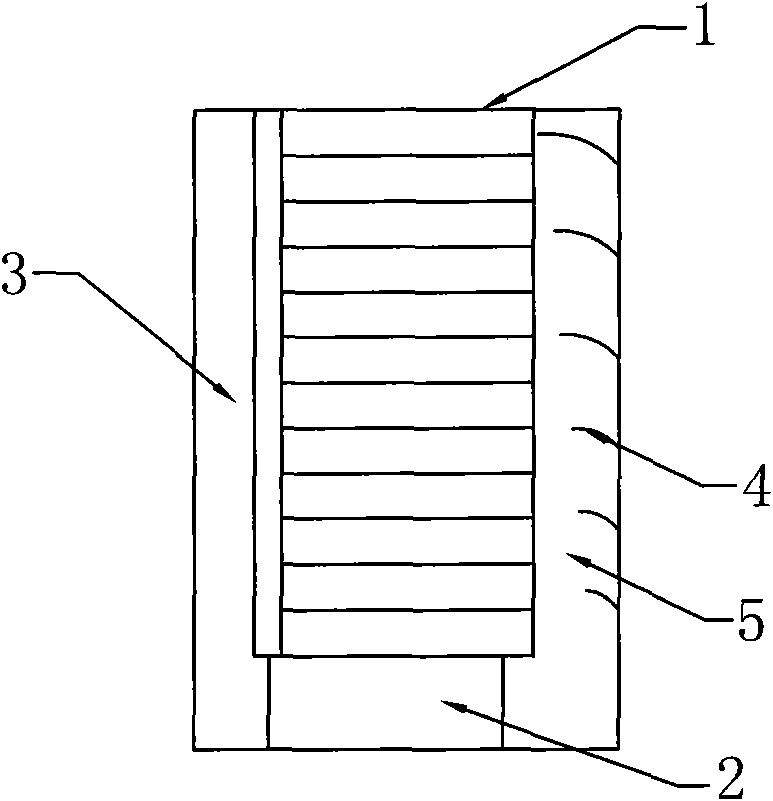

The invention provides a battery, comprising a cover plate, a shell, a battery cell and electrolyte. The battery cell and the electrolyte are sealed in the shell of the battery, and the cover plate is hermetically connected with the shell. The battery cell comprises a positive polar plate, a negative polar plate and a diaphragm arranged between the positive polar plate and the negative polar plate. A positive polar lug is arranged on the positive polar plate, and a negative polar lug is arranged on the negative polar plate. The battery cell is further internally provided with a positive polar current and heat conducting member and a negative polar current and heat conducting member, and the positive polar current and heat conducting member and the negative polar current and heat conducting member are mutually insulated. The positive polar current and heat conducting member and the positive polar lug are conducted; the negative polar current and heat conducting member and the negative polar lug are conducted; the positive polar current and heat conducting member and / or the negative polar current and heat conducting member penetrate(s) through the cover plate to leading out current. According to the invention, the internal heat of the battery cell can be reduced rapidly, substances on the polar plates can be prevented from further thermal reaction, and thus, the safety performance of the battery is increased. Meanwhile, the stability of the internal temperature of the battery cell is guaranteed, the cyclic performance and the like of the battery are improved. In addition, the temperature at all parts in the battery cell can be ensured to be consistent so as to eliminate temperature differences and make the reaction temperature of all parts of the polar plates consistent. Meanwhile, the current and heat conducting members can play roles of backbone and support to support the battery cell, and is beneficial to not only assembly but also winding of the battery cell.

Owner:BYD CO LTD

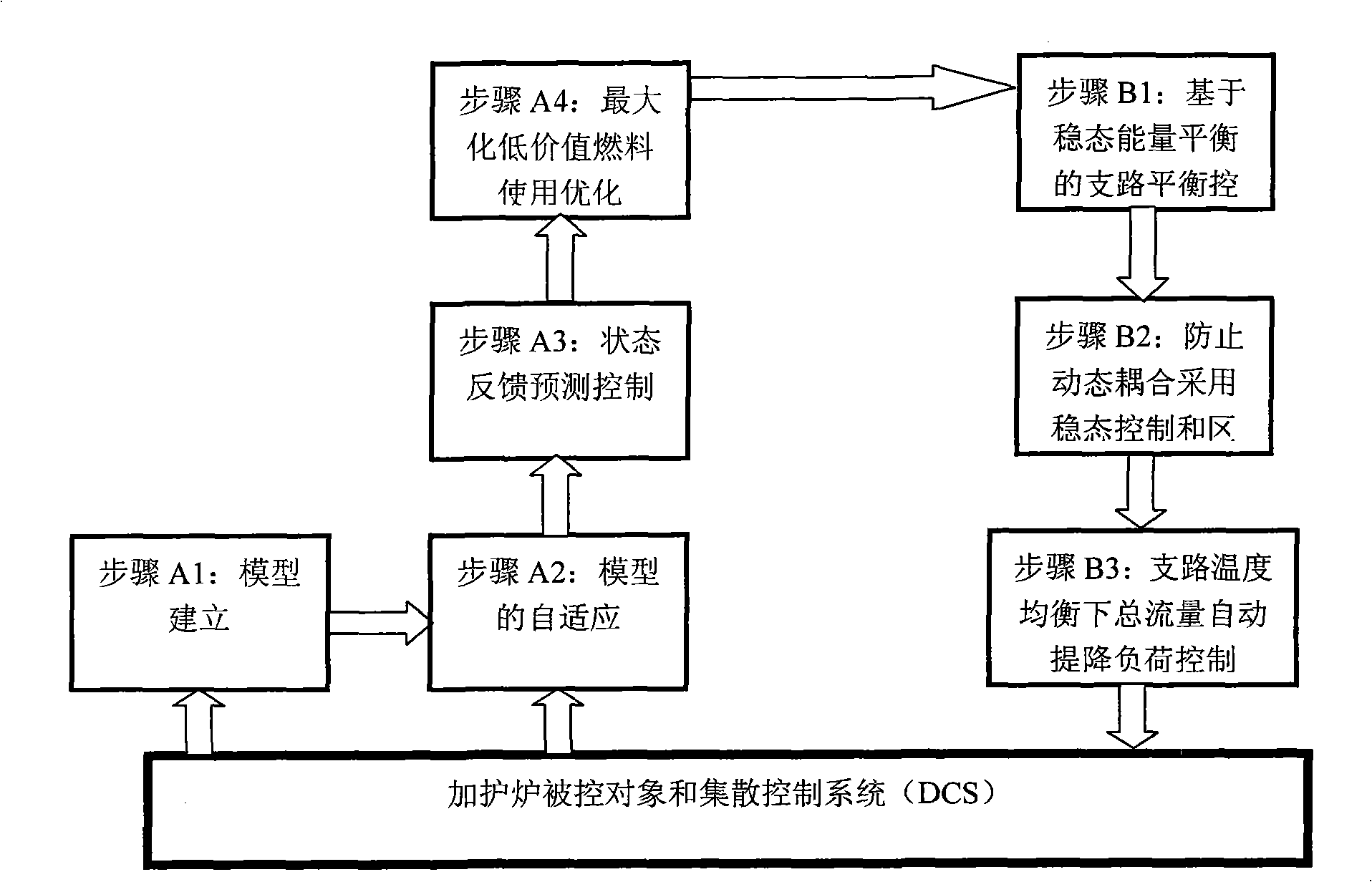

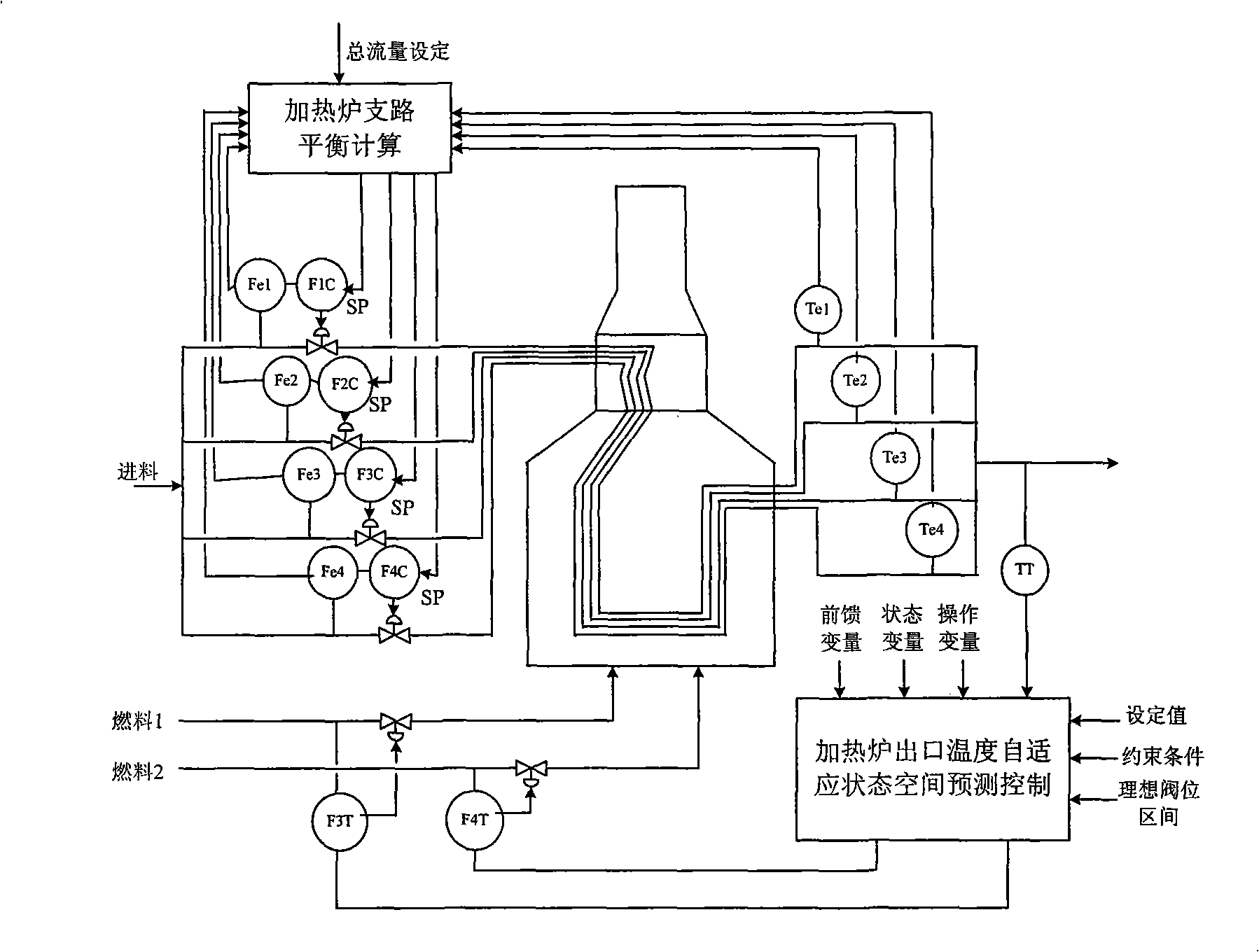

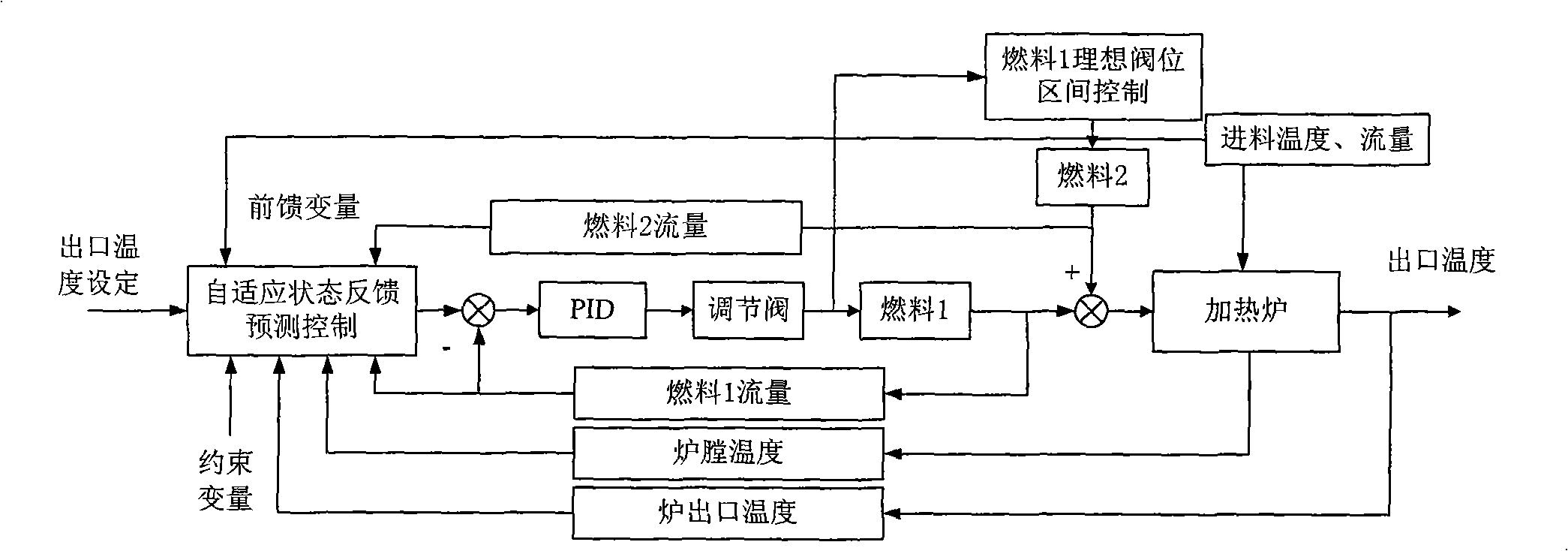

Combination control method for exit temperature of heating furnace

ActiveCN101256418AConsistent temperatureImprove anti-interference abilityFluid heatersTemperature control without auxillary powerFurnace temperatureOnline model

The invention relates to a comprehensive control method for the outlet temperatures of a heating furnace, belonging to the field of furnace temperature control technology. The invention is characterized in that branch balance control makes the outlets temperatures of a multi-branch heating furnace uniform, and automatic load lifting and dropping can be realized. By using state feedback prediction control of measured states and feedforward control, the method effectively improves the anti-interference ability. A state space model of the heating furnace is obtained by mechanism modeling, in no need of testing devices. An on-line model is self-adaptive, which effectively overcomes process characteristic change and improves the rate of putting into operation. Low-value fuel can realize idea valve location interval control, thus saving high-value fuel. The comprehensive control of the outlet temperatures ensures the uniform and stable outlet temperatures of the heating furnace, which is easy to operate and economical.

Owner:TSINGHUA UNIV

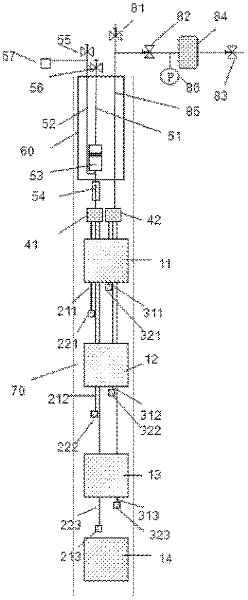

Underground layered gas-liquid two phase fluid pressure and temperature-retaining sampling device

InactiveCN102108861AReduce in quantityStable pressureBorehole/well accessoriesTemperature controlControl system

The invention discloses an underground layered gas-liquid two phase fluid pressure and temperature-retaining sampling device, which is arranged on the inner wall of a drilled hole or a sleeve and consists of a packer system, a liquid sample inlet system, a gas sample inlet system, an automatic multi-way valve, a sampling system, a temperature control system, and an external pressure / flow control system, wherein a thermal-insulation layer or temperature control system covers the outside of the entire sampling device. The device accurately controls the layer under ground fluid sampling positionto realize gas and liquid fluid sampling at different layer positions of a stratum, ensures the temperature and pressure in a sampling process are consistent with those of the underground fluid, and improves the pressure and temperature-retaining degree of the fluid in the sampling process. The principle of the device is simple, the parts are assembled simply and the device is suitable for multilayer sampling in a drilled well and underground gas-liquid two-phase fluid sampling.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

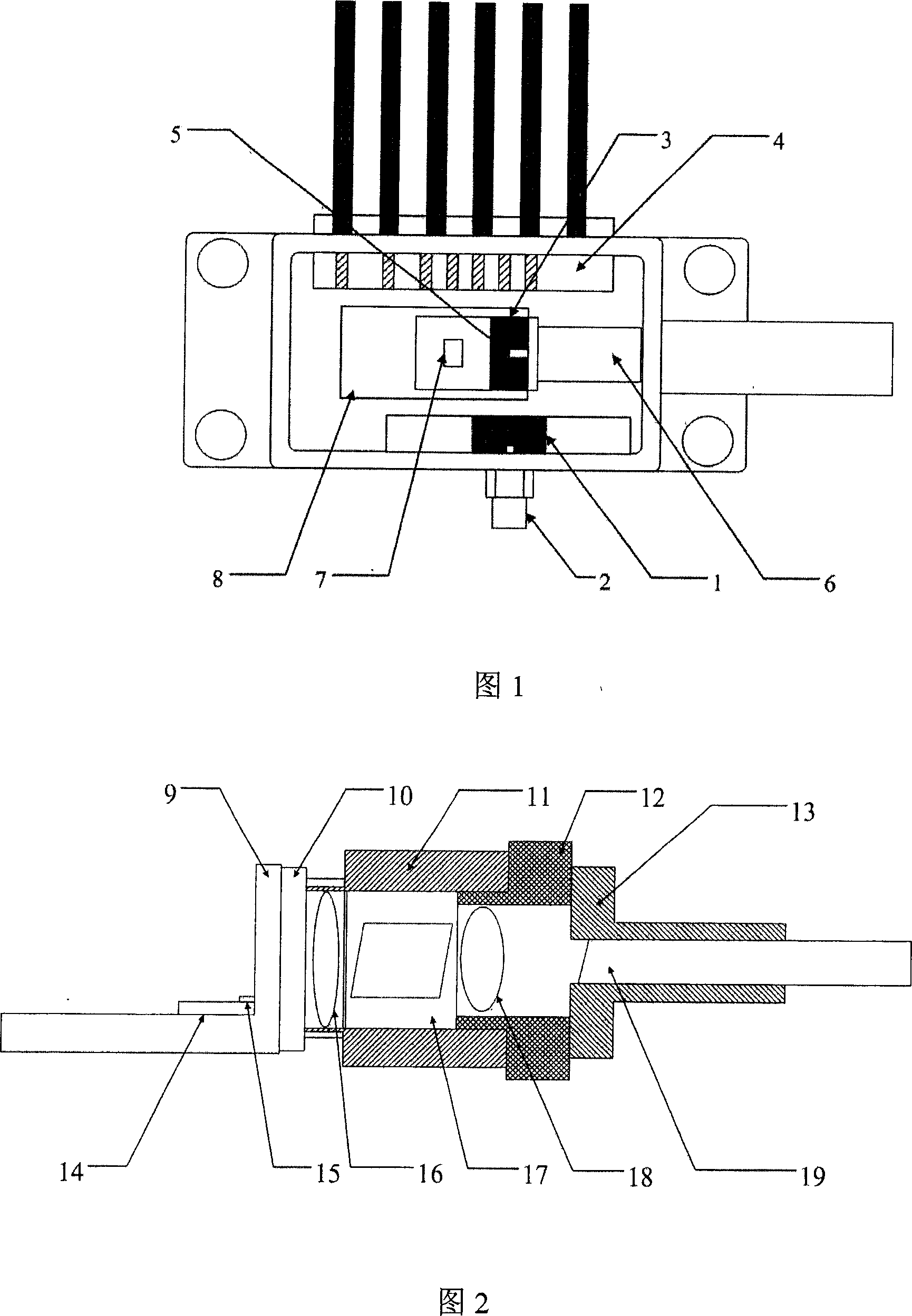

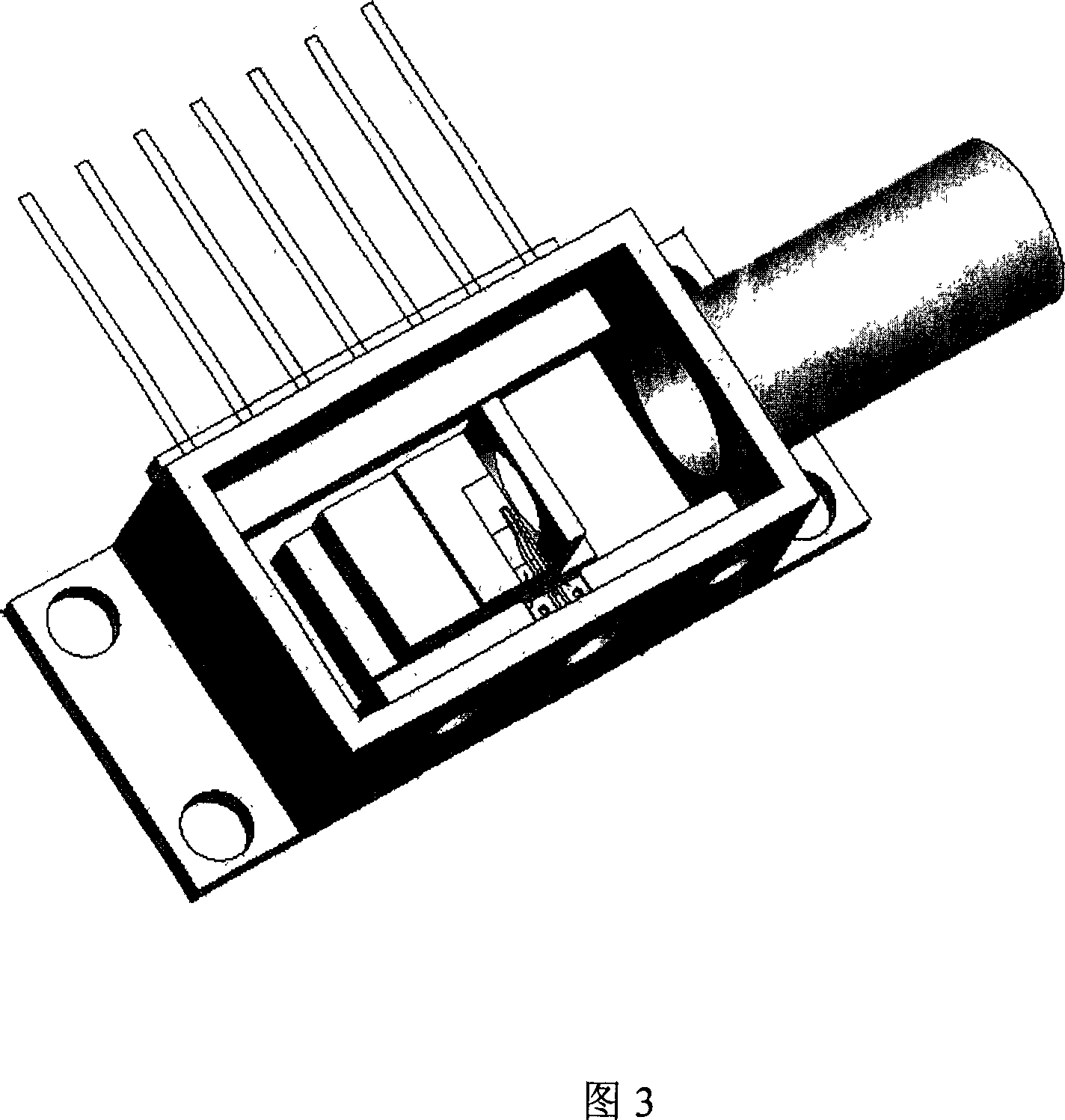

Encapsulation structure and method of the high-speed semiconductor light emission component

InactiveCN101017956AReduce loadEasy to install and debugLaser detailsSemiconductor/solid-state device detailsCoplanar waveguideWorking temperature

The package structure for a high-speed semiconductor light emission assembly comprises: a dish-type case with RF connector, a semiconductor refrigerator to control the work temperature of emission chip, a KOVAR metal heat sink, a medium heat sink substrate, a light emission device, a thermistor, a backlight detector, the metal wire to connect dc connection electrode and case pin, a coplanar waveguide transmission lie on medium substrate, and optical coupling assembly. Wherein, it uses BTF standard package form for dc terminals outside the case.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

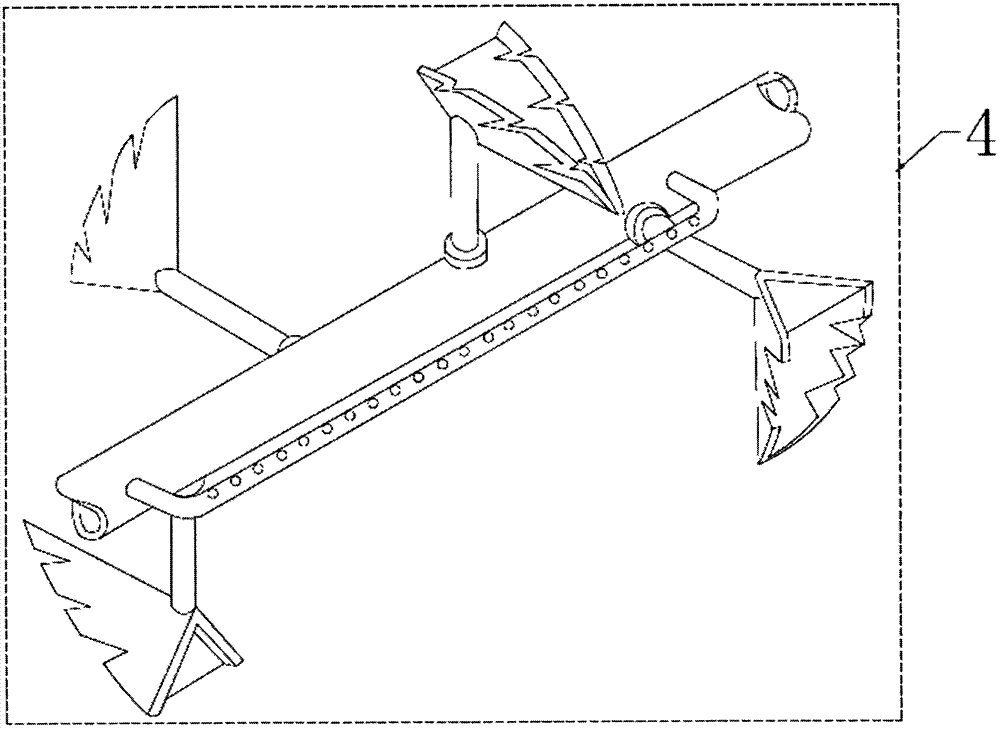

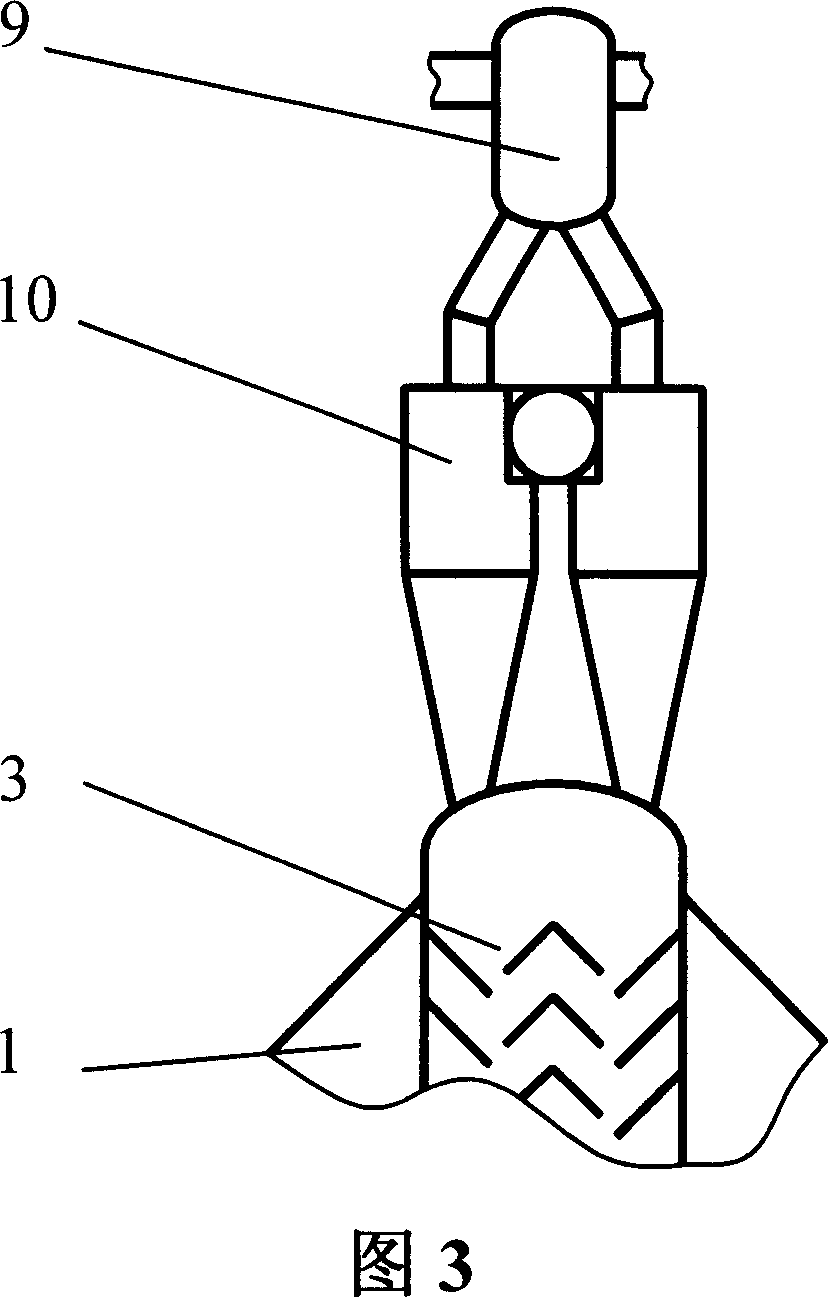

Novel kitchen garbage fermentation device and usage method

InactiveCN102786363AAvoid circulationLow costClimate change adaptationChemical industryMotor driveEngineering

The invention provides a novel kitchen garbage fermentation device and a usage method, which belongs to the environmental protection device field. The device provided by the invention comprises a U-shaped fermenter, a feed inlet, a discharge port, a fragmentation stirrer, a variable frequency motor, a blower, a ventilation duct, an air vent, a microbe inlet pipe, a charging nozzle, an electric heating pipe, a water interlayer, a protection layer, a deodorizing tower, a support and the like. The fragmentation stirrer is composed of a stirring horizontal shaft, a blade support and a triangle cone blade with arc bottom. Several electric heaters are arranged in the interlayer of a double layer U-shaped fermenter. The variable frequency motor drives the fragmentation stirrer to perform fragmentation stirring on the kitchen garbage. The electric heating pipe heats the water interlayer so that the temperature of the fermenter can be kept between 40-60 DEG C, air is introduced in the ventilation duct through the blower, and a microbe liquid bacteria agent is inoculated in the fermenter through a nozzle on the microbe inlet pipe. The product is discharged out of the fermenter through the discharge port, thereby the minimization of the kitchen garbage can be realized, and the product can be used as a soil organic fertilizer conditioning agent.

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION +1

Process for drying fresh momordica grosvenori

InactiveCN102763846ANot easy to regain moisture and deteriorateReduce lossFood preparationPlant ingredientsCuticleMomordica grosvenori

The invention discloses a process for drying fresh momordica grosvenori, comprising the following steps: (1) selecting and cleaning fresh momordica grosvenori without being damaged on skins, and disposing holes on the top stems and the corresponding bottom areolas of the momordica grosvenori; (2) putting the momordica grosvenori with holes in water of 80-100 DEG C, deactivating, boiling for 30-40 seconds, taking out and draining; and (3) putting the deactivated momordica grosvenori into vacuum microwave drying equipment, drying in vacuum at the frequency of 850-900MH and the low temperature of 40-50 DEG C for 5 minutes, starting an infrared heater to heat the skins of the momordica grosvenori for 10-15minutes, and repeating the step (3) for 4-5 times to obtained the dried momordica grosvenori. The detection shows that the momordica grosvenori dried by adopting the process contains water of 1.5% or less, is light yellow, bright and attractive, retains the nutrients of more than 75%, has high content of momordica grosvenori enzyme, tastes good, has no smell of scorching and is not bitter.

Owner:GUILIN PURUI BIOLOGICAL SCI & TECH DEV

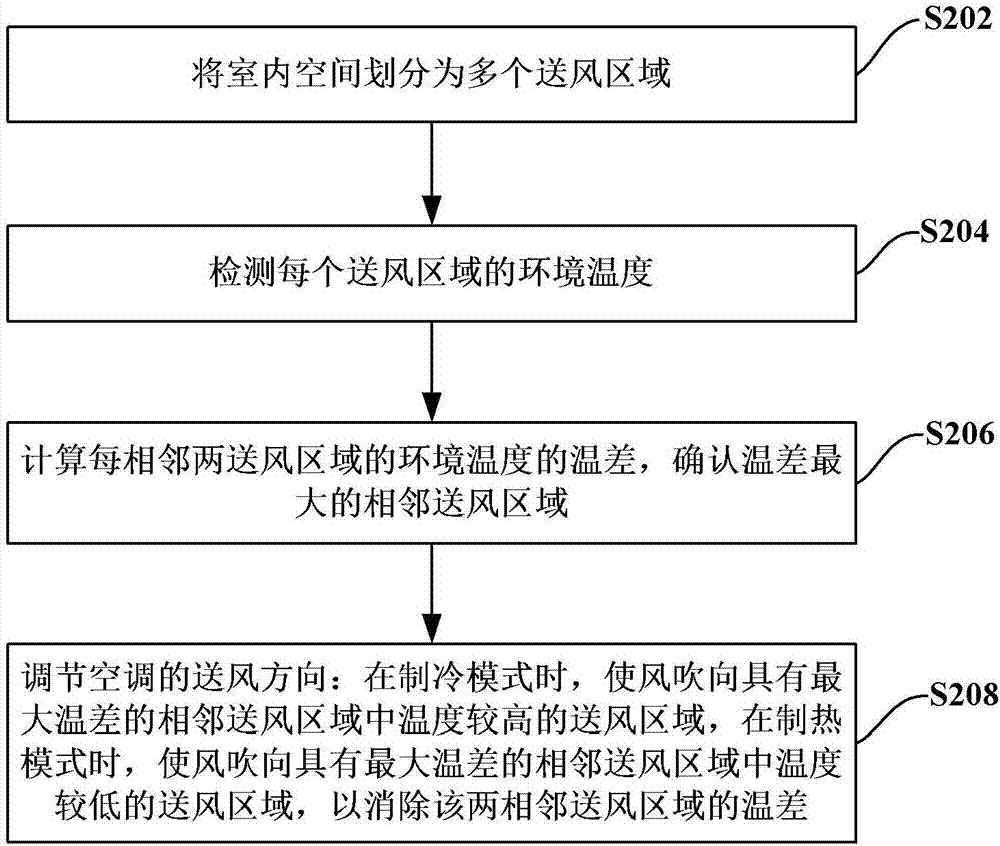

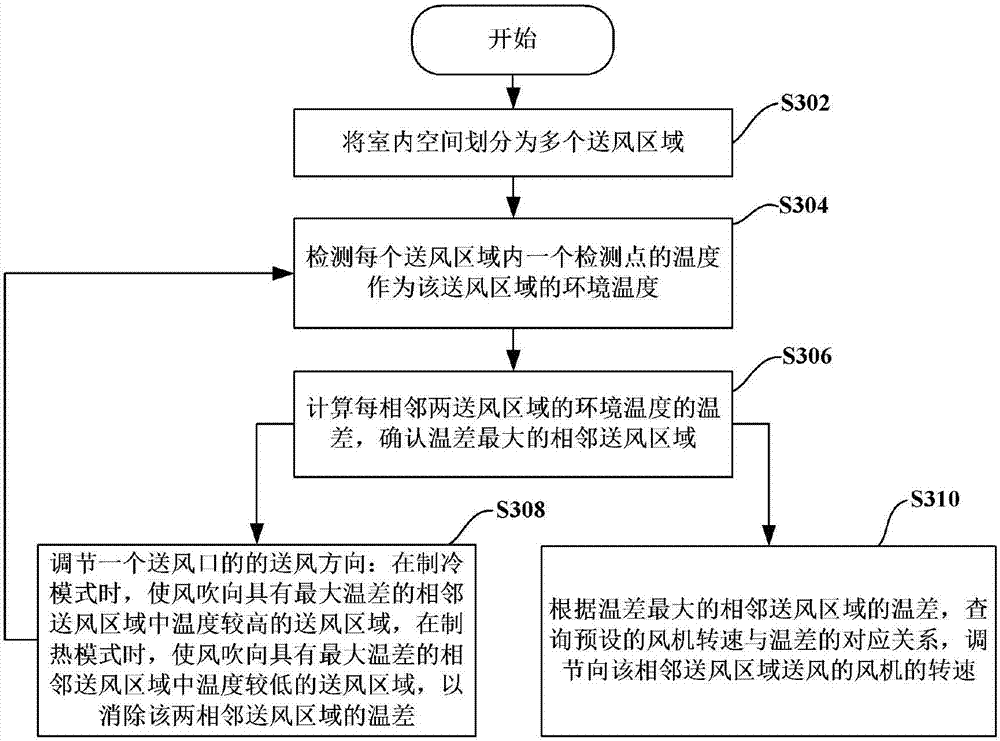

Control method of air conditioner

ActiveCN107120787AConsistent temperatureImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusCold airTemperature difference

The invention provides a control method of an air conditioner. The control method comprises the following steps: dividing an indoor space into a plurality of air supply areas; detecting the environment temperature in each of the air supply areas; calculating the environment temperature difference of every two adjacent air supply areas, and determining the two adjacent air supply areas having the maximum temperature difference; adjusting the air supply direction of the air conditioner; when the air conditioner is in the refrigeration mode, enabling the cold air to be blown to the air supply area with a higher temperature in the two adjacent air supply areas having the maximum temperature difference; when the air conditioner is in the heating mode, enabling the hot air to be blown to the air supply area with a lower temperature in the two adjacent air supply areas having the maximum temperature difference; and therefore the temperature difference of the two adjacent air supply areas is eliminated. According to the control method of the air conditioner provided by the invention, both the temperature uniformity at all places of the indoor space and the comfort level of the indoor environment are improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

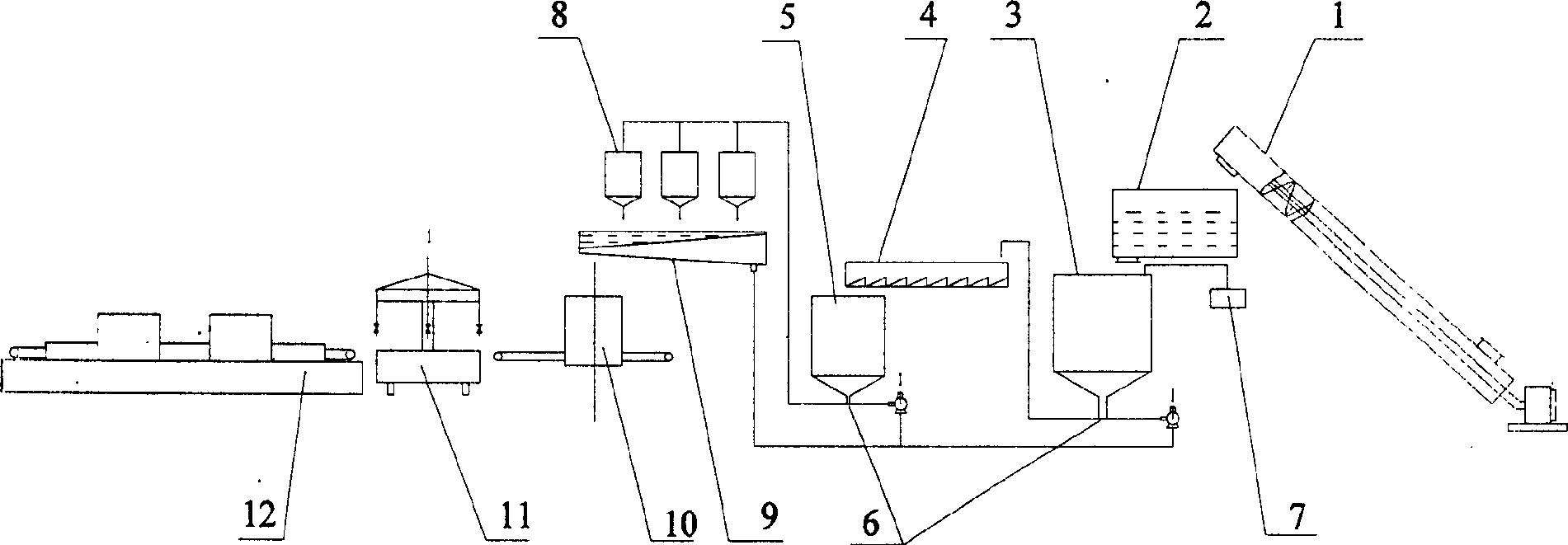

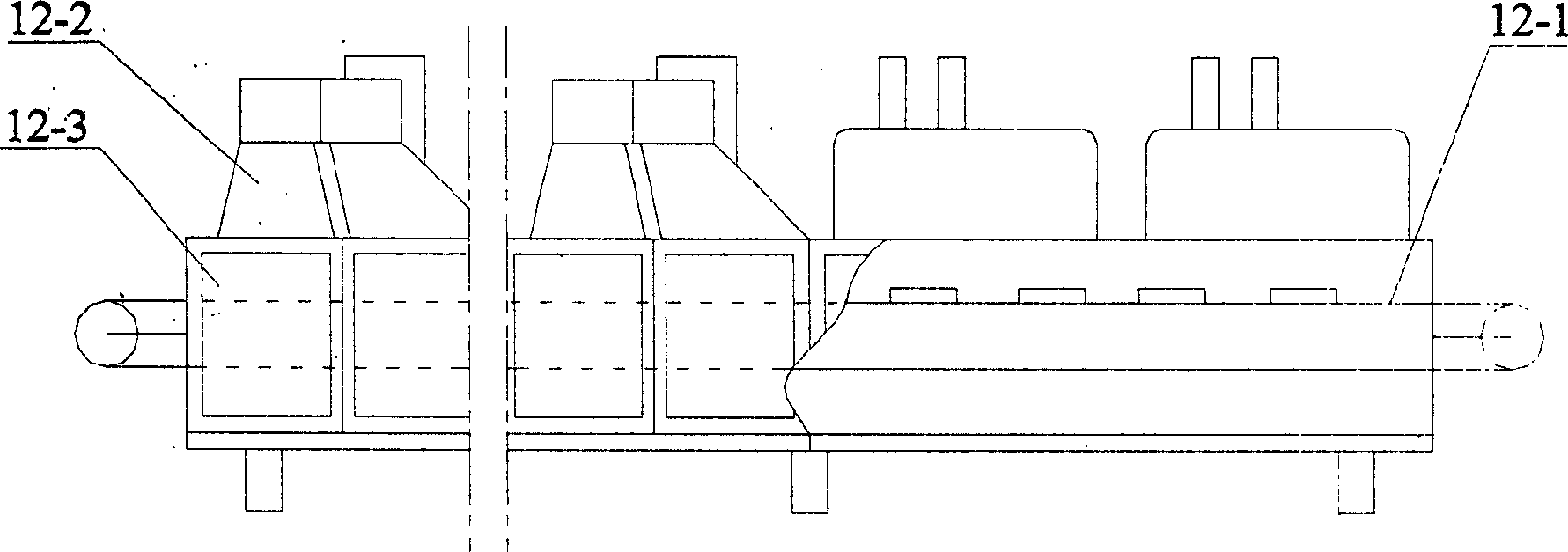

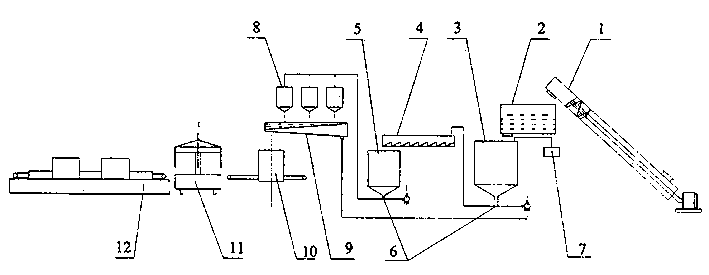

Method and device for continuously cooking rice

A technology for continuously cooking rice includes such steps as washing rice, immersing, quantitatively loading in boxes, microwave cooking and outputting rice in boxes. Its apparatus is composed of screw conveyer, high-position rice tank, rice washer, redox washer, jet-type sprayer, step impurities remover, rice immersing container, oblique rich dropper, quantitative loaders of rice and water, and continuous microwave cooker. Its advantages are high speed, high utilization rate of heat energy, and high productivity.

Owner:SOUTH CHINA UNIV OF TECH

New preparation process of agaricus bisporus culture material

InactiveCN102452853ASave human effortConsistent temperatureBio-organic fraction processingOrganic fertiliser preparationInorganic compoundFermentation rate

The invention discloses a new preparation process of an agaricus bisporus culture material. The product belongs to the field of edible mushroom, and the invention is characterized by relating to the agaricus bisporus culture material. The invention aims at solving the problem that a new tunnel aeration fermentation method is provided to produce the agaricus bisporus culture material. The method has the advantages that: 1, wheat straw and chicken manure are taken as main raw materials, the raw materials are easily available, nitrogen content in the chicken manure is high, and heat productivityis high; 2, automatic mechanical continuous operation is adopted, manpower is saved, and mass production can be realized; 3, heat distribution in the culture material is uniform, fermentation temperature in the material is basically consistent, and quality can be guaranteed; and 4, fermentation speed is high, production efficiency is high, and less sundry bacteria are contained. The raw materialsused for producing the agaricus bisporus culture material comprise the wheat straw, the chicken manure, calcium carbonate, inorganic compound fertilizer, calcium superphosphate, lime powder and gypsum powder, and the product is used for planting agaricus bisporus.

Owner:徐州龙兴农牧科技发展有限公司

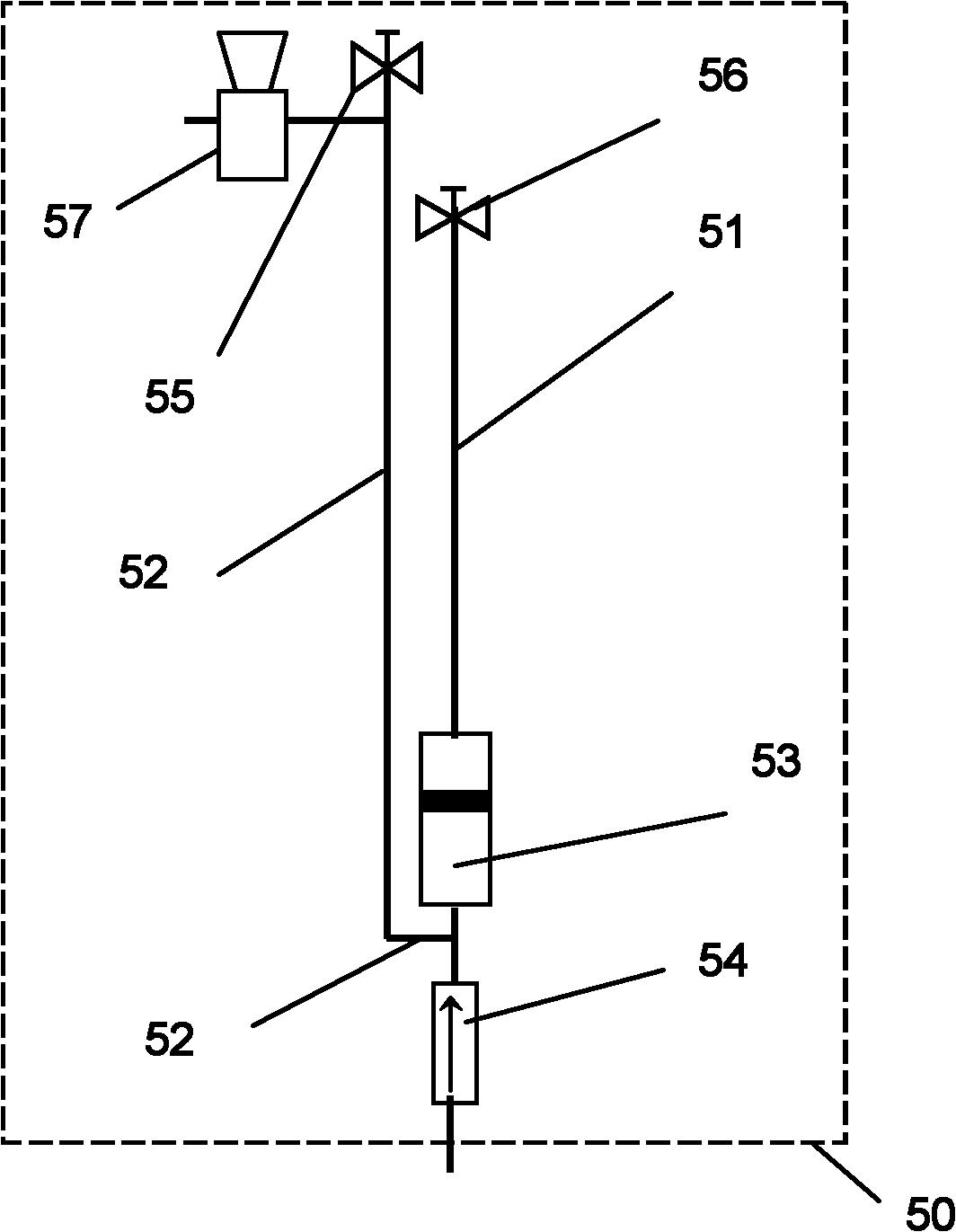

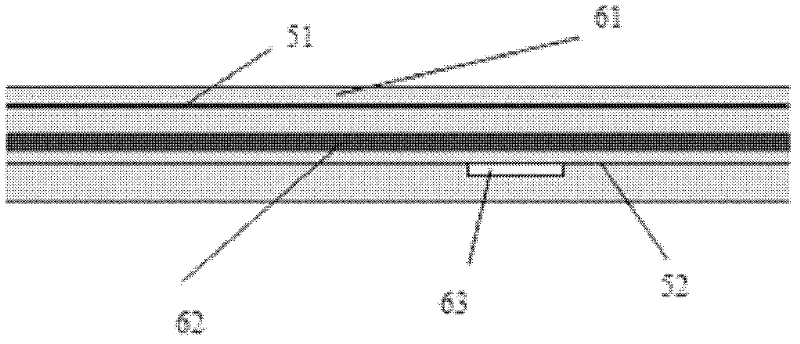

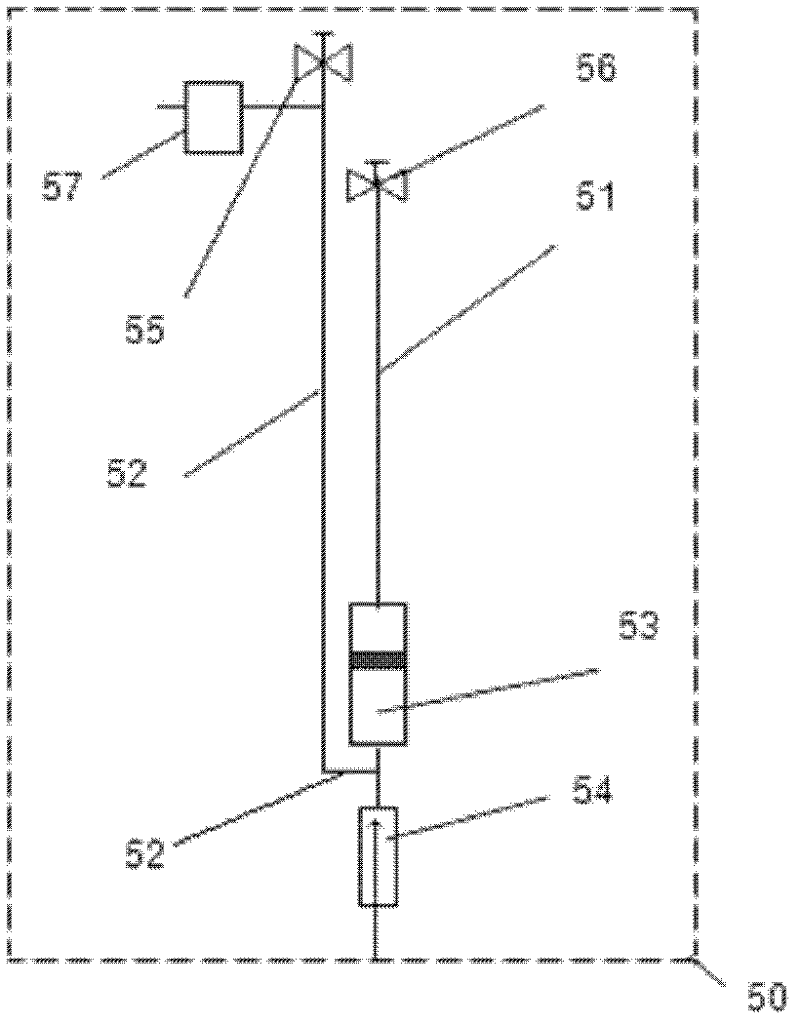

Stratified fluid monitoring and sampling device based on pressure pulse

ActiveCN102505939AComprehensive monitoringComprehensive samplingSurveyConstructionsTemperature controlHorizon

The invention discloses a stratified fluid monitoring and sampling device based on pressure pulse. A sampling device is arranged on the inner wall of a drilled hole or a sleeve and comprises a packer system, a liquid sample injection system, a gas sample injection system, automatic multi-way valves, a sampling system, a temperature control system and the like, wherein a pressure container in a pressure pulse system is connected with the valves and a pressure sensor through a pipeline for forming the pressure pulse system, the pressure pulse system is connected with the underground gas sample injection system through the automatic control multi-way valve, the liquid sample injection system is connected with the liquid automatic multi-way valve, and the gas sample injection system is connected with the gas automatic multi-way valve. The state of fluid in a stratum is judged by the pressure pulse, the underground fluid sampling horizon is simultaneously precisely controlled, respective sampling of gas and liquid fluids in different horizons under constant temperature and pressure conditions can be realized, the response rate of sampling is improved and precise sampling under the low flow rate condition can be particularly realized. The device is simple to assemble all the parts and suitable for monitoring the state of the multi-layer fluid in a bored well and sampling the underground gas and liquid two-phase fluid.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

High temperature-resistant ultralow temperature-cured epoxy polyester powdery coating

InactiveCN103275597AReasonable formulaLow curing temperaturePowdery paintsEpoxy resin coatingsEpoxyLow temperature curing

The invention discloses a high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating solves the problem that the existing low temperature-cured epoxy polyester powdery coating has poor heat resistance and poor thermal conductivity so that in curing, temperatures in a coating film prepared from the existing low temperature-cured epoxy polyester powdery coating are not different and coating curing rates are not different and thus the coating film produces orange peel phenomenon and even crazes and coating film surface-effects are influenced. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating is prepared from 30 to 40wt% of epoxy resin, 15 to 20wt% of polyester resin, 0.5 to 1.5wt% of polyarylene sulfide resin, 10 to 15wt% of titanium dioxide, 2 to 5wt% of nano-metal powder subjected to surface treatment, 0.5 to 1wt% of dibutyltin dilaurate, 1 to 3wt% of an assistant, 1 to 5wt% of sodium fluoride, 15 to 20wt% of a filling material and 10 to 15wt% of a pigment. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating has a low curing temperature, good heat resistance, and physical and mechanical properties and chemical resistance satisfying industrial requirements.

Owner:HANGZHOU GOLDEAGLE PLASTIC POWDER

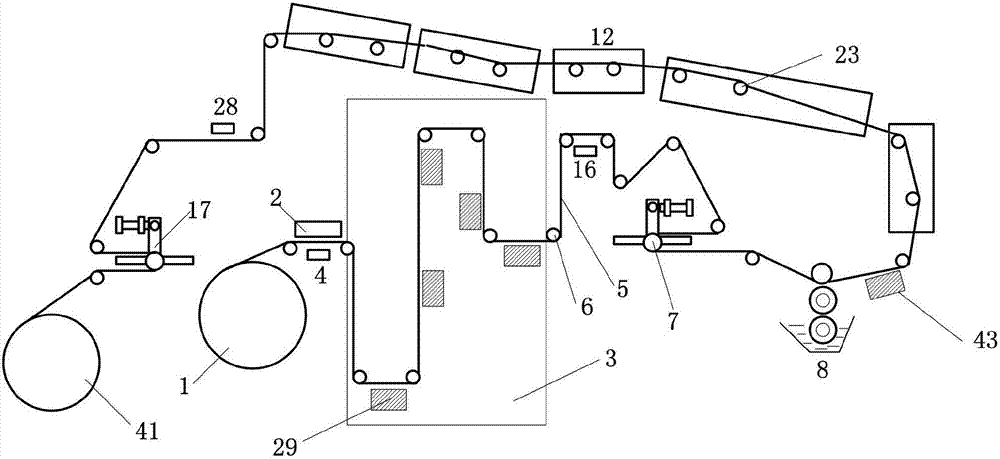

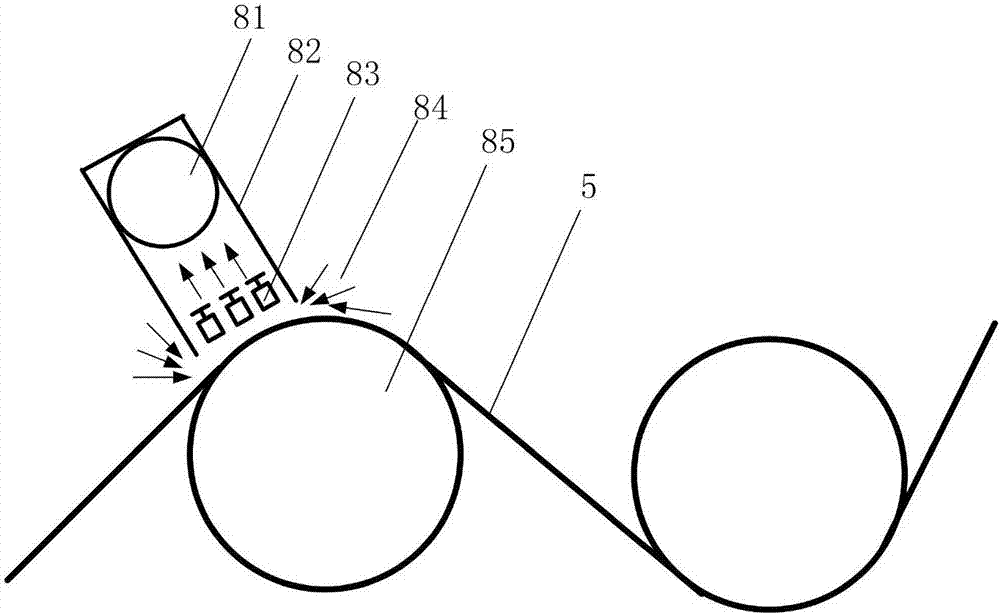

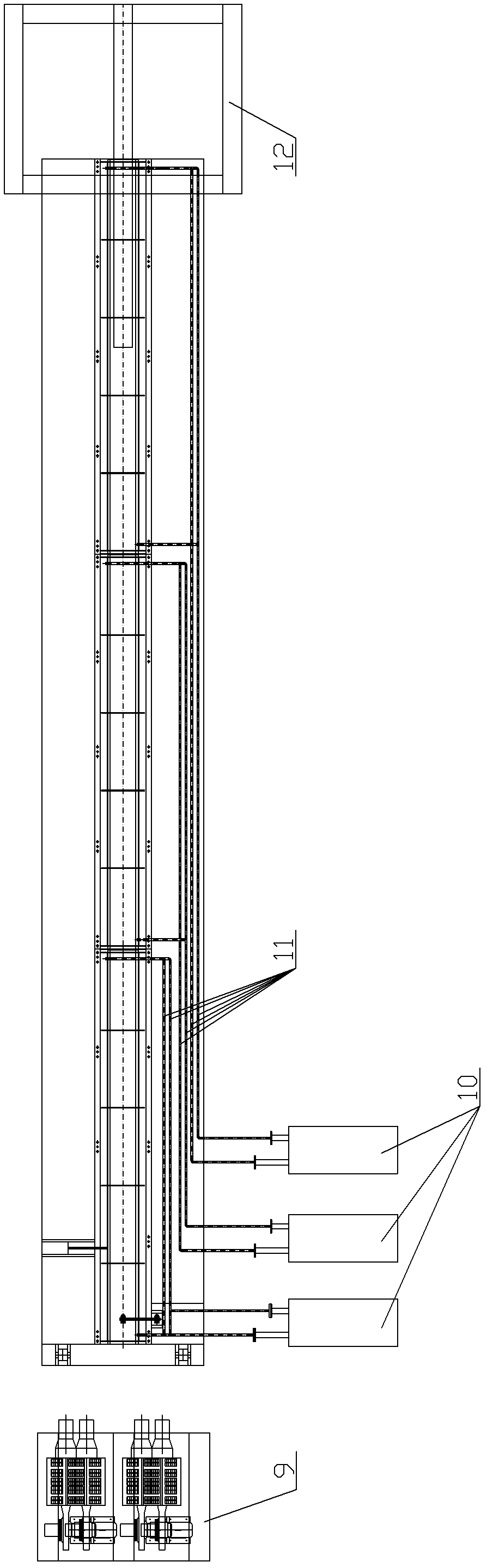

Device for coating graphene on surfaces of metal foils

ActiveCN107457141AThe glue layer is thin and uniformStrong adhesionPretreated surfacesCoatingsMetal foilCopper foil

The invention discloses a device for coating graphene on surfaces of metal foils. The device comprises a control unit, and an unwinding unit, a coating printing device, a baking unit and a winding unit arranged in sequence in a moving direction of the metal foils; the metal foils are aluminum foils or copper foils; the coating printing device comprises a pressing roller, a driving silica gel roller and a driving steel roller laminated from top to bottom; the driving silica gel roller and the driving steel roller are rotated in opposite directions by keeping a micron gap; the driving steel roller is dipped in a colloid pool with viscous materials; and a substrate is arranged between the pressing roller and the driving silica gel roller. The device realizes uniform spraying of materials with submicron thicknesses and thinner layers on the surface of the substrate to meet the thickness requirements of the graphene coated on the metal foils, and achieves excellent adhesion to effectively reduce the contact resistance between carbon particles and the metal foils.

Owner:陕西浩合机械有限责任公司

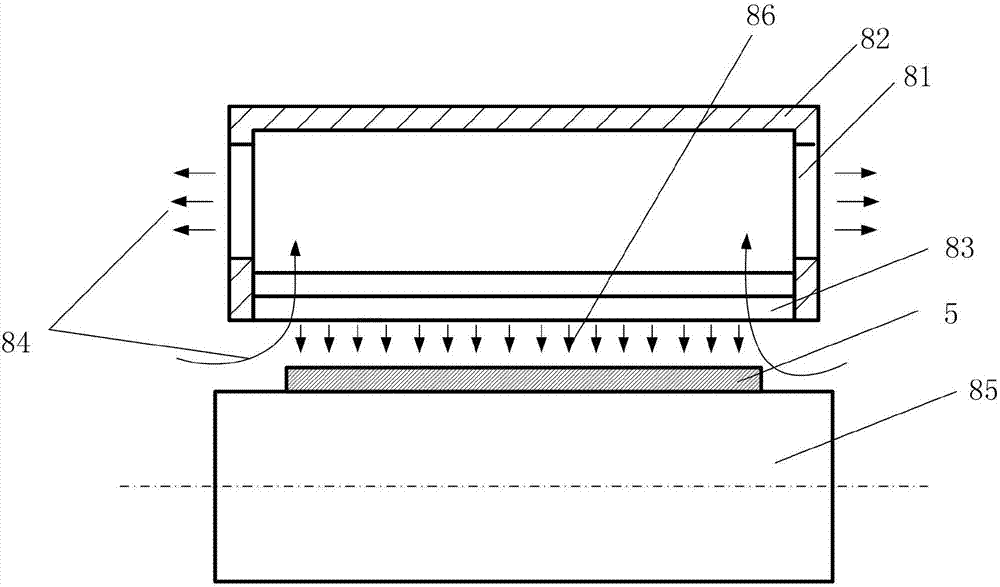

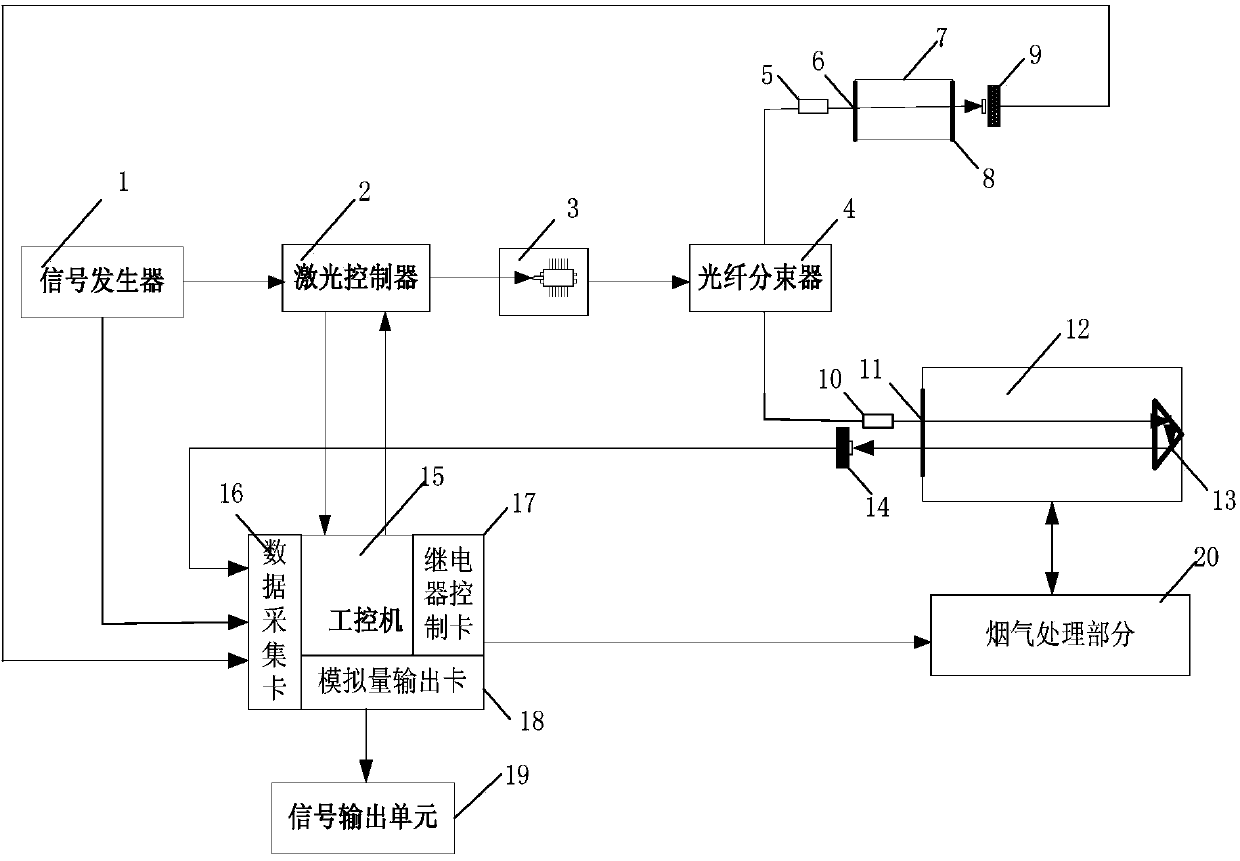

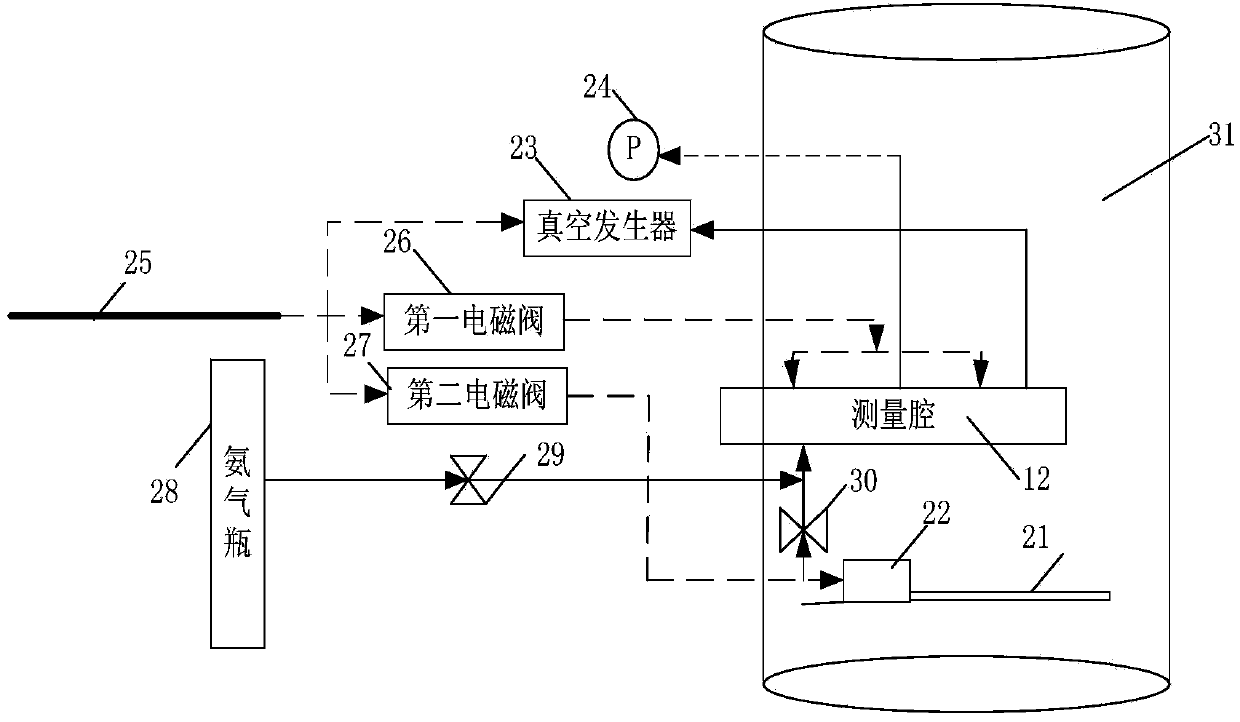

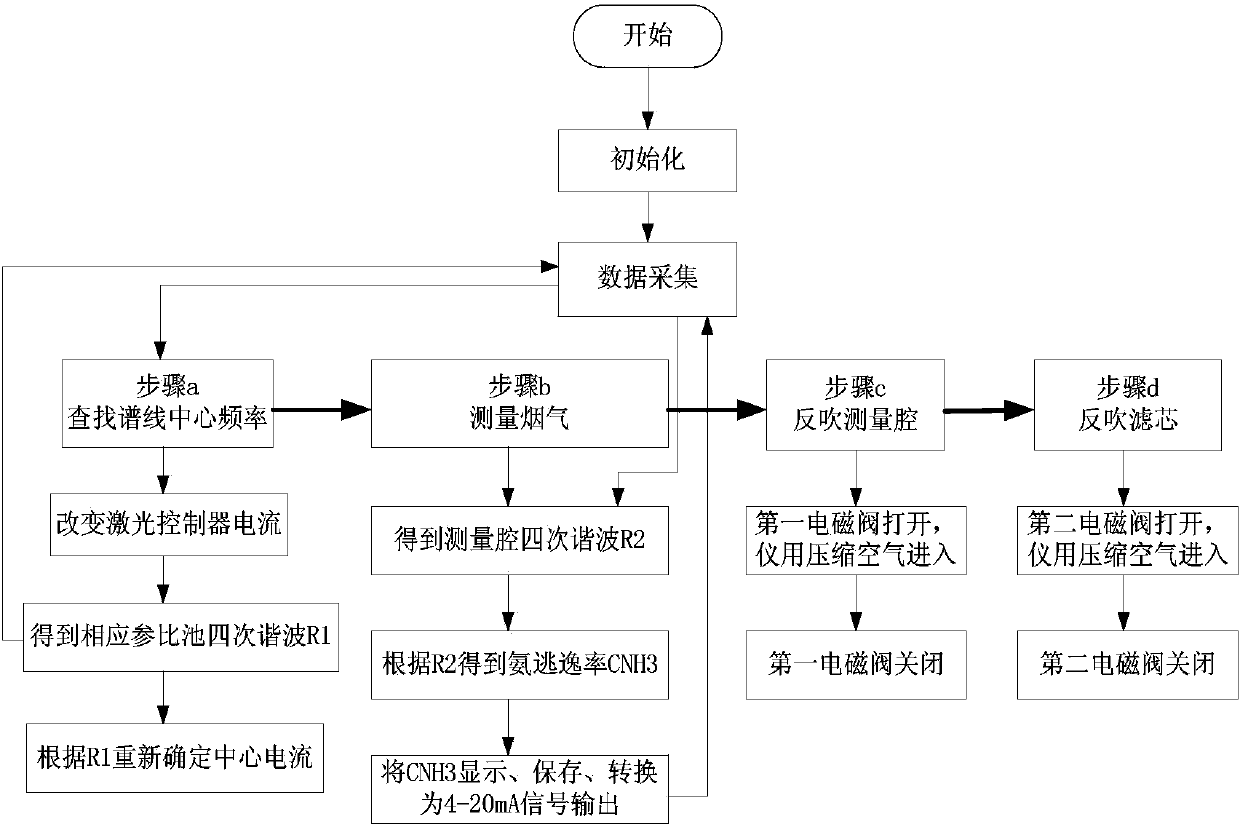

Wavelength modulation spectrum technology-based denitrified ammonia escape rate measurement device and method

ActiveCN104215606AConsistent temperatureAvoid interferenceColor/spectral properties measurementsAir preheaterHigh concentration

The invention relates to a wavelength modulation spectrum technology-based denitrified ammonia escape rate measurement device and method, belonging to the technical field of tunable diode laser absorption spectroscopy. The method is characterized in that laser is split through an optical beam splitter on the basis of quadruple sub-harmonic in the wavelength modulation spectrum technology, a part of laser permeates a high-concentration reference cell to be used for locking a central wavelength and monitoring the zero point of an instrument constantly, and the other part of laser permeates a smoke measurement cavity to be used for obtaining the concentration of an ammonia gas. In an in-situ sampling mode, a sampling rod and the measurement cavity are both arranged in a flue of a denitrified air preheater. The method has the characteristics that with adoption of a low-pressure measurement method, the pressure of the measurement cavity is kept at 0.1atm, a strong absorption spectrum line can be selected and the interference from other gas spectrum lines can be avoided, the sensitivity of the instrument can be improved, and the lower limit of measurement can be lowered. Through the method, a series of problems, caused during application of an existing ammonia escape rate instrument, such as the incapability of laser to permeate dust with high concentration, the deflection of laser resulted from mechanical deformation of a flue wall, the incapability of marking, and blocking of a filtering permeation probe, can be solved.

Owner:TSINGHUA UNIV

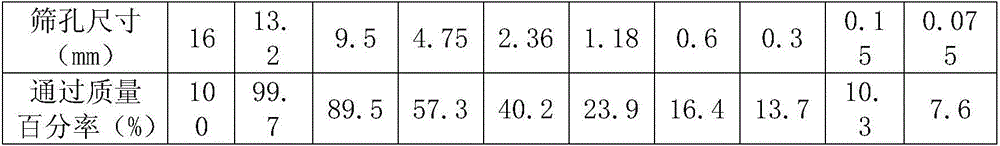

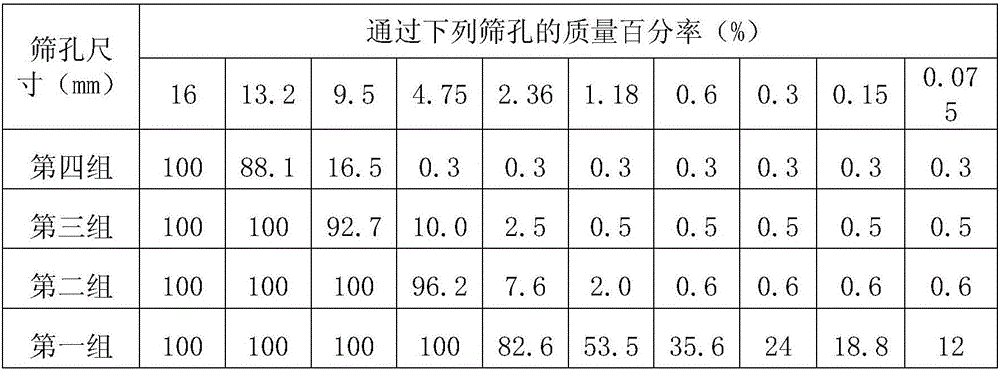

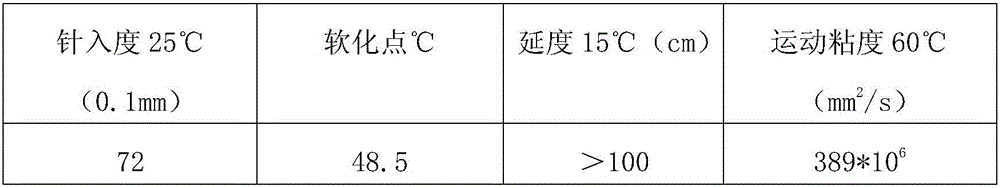

Plant-mixed warm recycled asphalt mixture and preparation method thereof

InactiveCN106009719AAffect low temperature crack resistanceAffects durabilityBuilding insulationsRoad surfaceAsphalt

The invention relates to a road surface construction material, in particular to a plant-mixed warm recycled asphalt mixture and a preparation method thereof. The plant-mixed warm recycled asphalt mixture comprises the following components in percentage by mass: (20-70)% of RAP, (0 to 8)% of new aggregate, (0 to 8)% of limestone mineral powder, (0.5 to 5)% of new asphalt and (0 to 0.5)% of recycling agent, wherein the total mass percentage is 100%, the new asphalt has penetration of less than 75 (0.1mm) and a softening point of more than 48 DEG C, and the recycling agent has kinematic viscosity of (50-60000) mm2 / s at a temperature of 60 DEG C. The plant-mixed warm recycled asphalt mixture provided by the invention has the advantages of simple process, no grey material, good recycling effect, low cost, wide adaptability and good road performance.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

Gum dipping, stentering forming method of earthwork grid cloth

InactiveCN1789540AGuaranteed not to shrinkGuaranteed FounderLiquid surface applicatorsTextile selvedgesMesh gridTowing

The invention relates gumming stretching shaped method, comprising the following steps: accumulating, gumming, stretching and drying, discharging cloth, cooling, towing, accumulating and winding; putting the grid into impregnating groove; before accumulating, carrying out hemming and straightening weft; after accumulating, setting the draught device which is composed at least a drawoff roller, and after stretching and drying, setting cloth discharge and cooling draught device to cool and draw the grid. The method is simple and the grid is not out of shape.

Owner:管昆明

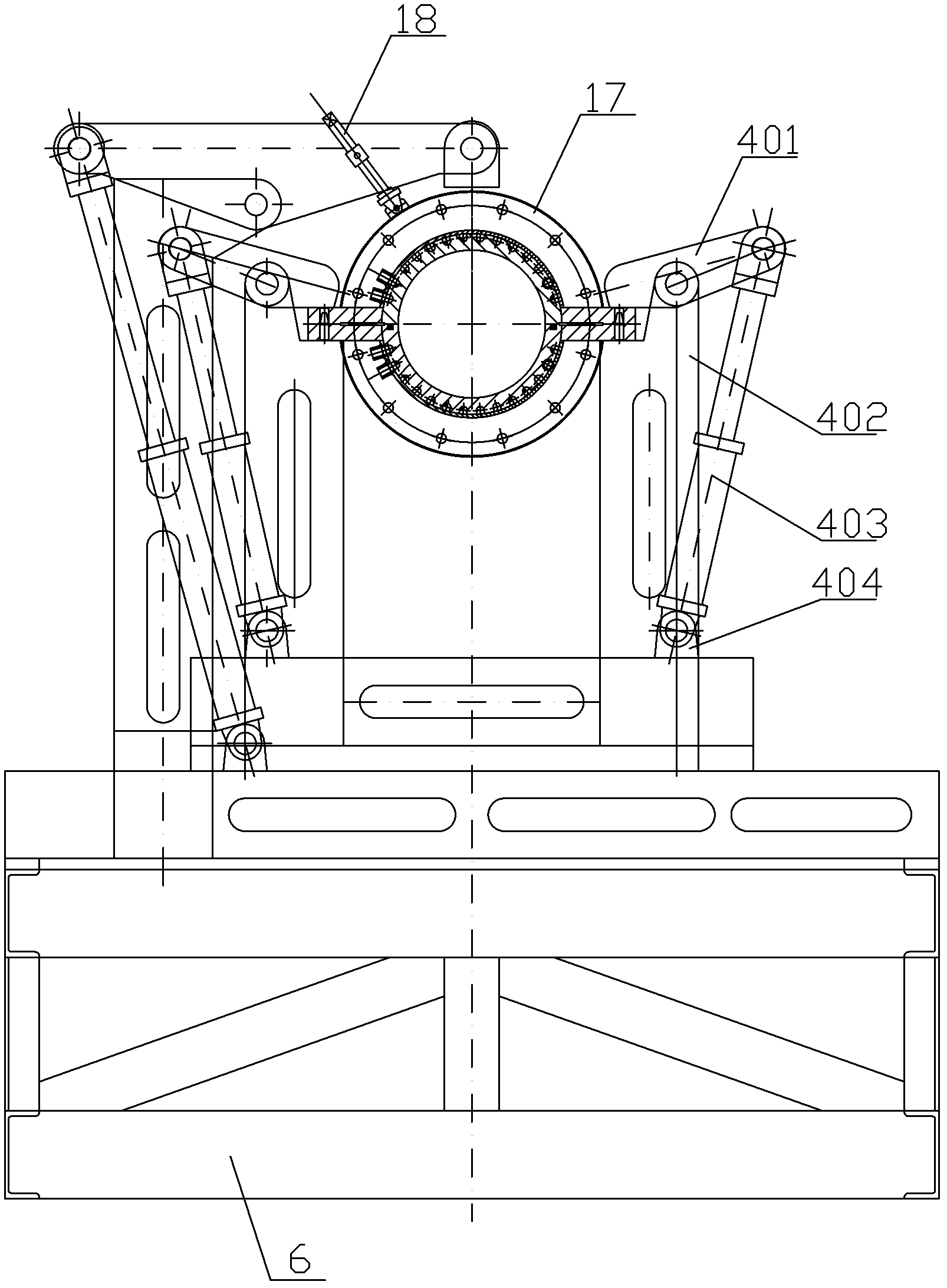

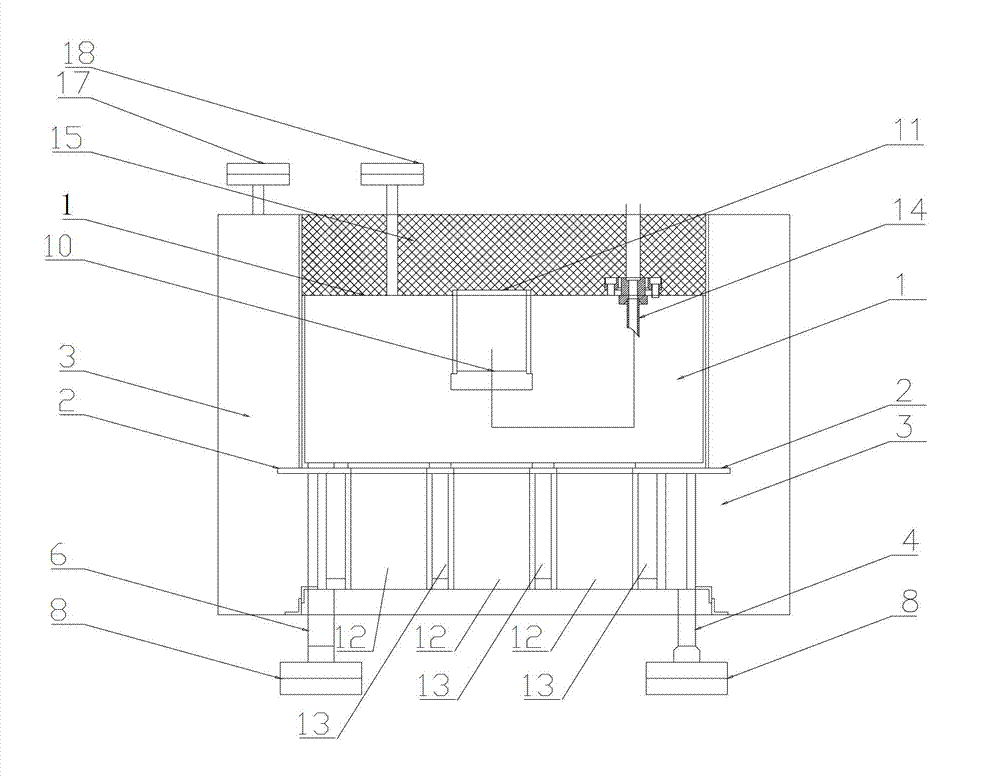

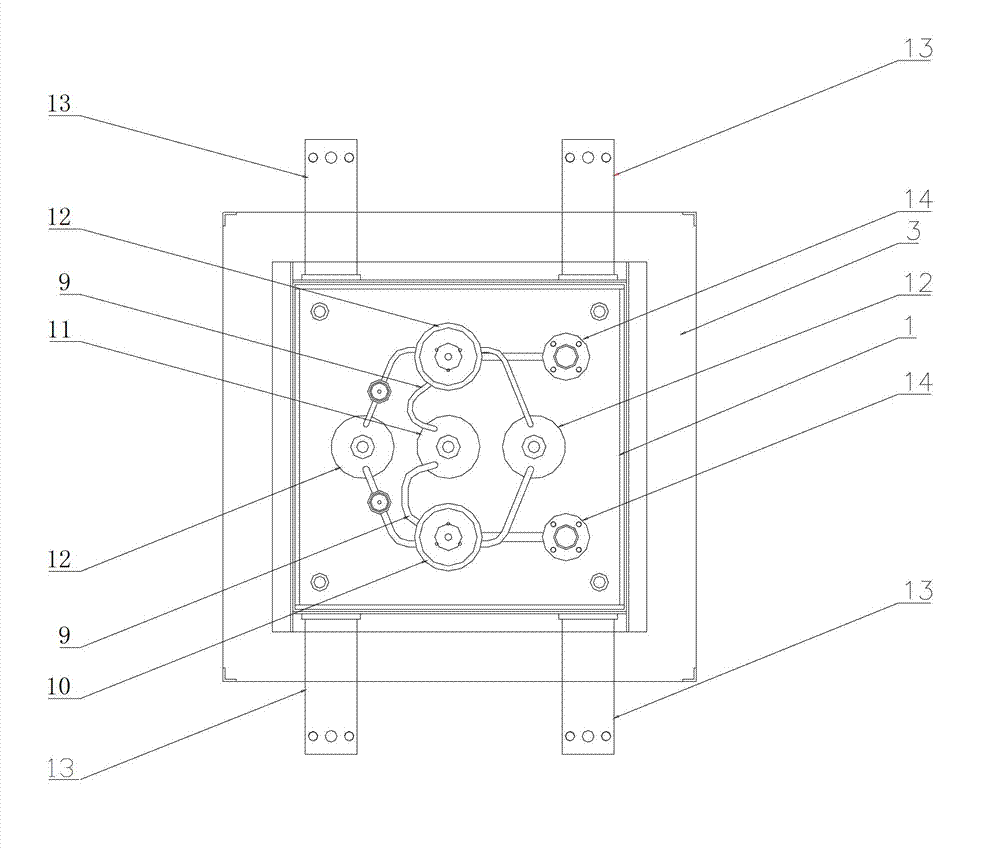

Deep water pipeline composite polyurethane elastomer heat insulation layer casting molding device

The invention discloses a deep water pipeline composite polyurethane elastomer heat insulation layer casting molding device. A subsection machining and integral assembly mode is adopted in a die, heating temperature control devices are arranged corresponding to subsection assemblies in subsections, and heating oil passages are arranged opposite; a positioning structure and a sealing structure arearranged in the parting surface of the die; and the die is provided with a die opening device, a die closing and an inclination device controlled by a hydraulic system. The device realizes mechanicaloperation of casting molding of a product, and has practical structure and strong operability; by adopting subsection machining in the die, the machining difficulty and the machining cost are reduced, and the machining precision and the machining quality are improved; and meanwhile, three sets of heating devices are used corresponding to three sections of assemblies, so that the heating temperature difference is reduced, the quality of the cast product is improved, automatic control of the temperature of the casting die can be realized, the heat insulation time of the polyurethane heat insulation layer in the die is shortened, and the service efficiency of the casting die is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Control method for bearing steel network carbides and banded carbides and bearing steel

ActiveCN105648170AReduce formation effectReduce the formation effect of bearing steel network carbides and banded carbides Significant formation effectTemperature controlCarbide

The invention discloses a control method for bearing steel network carbides and banded carbides and bearing steel. The temperature of a finishing pass during hot rolling of the bearing steel is controlled to be within the range of 830 to 870 DEG C, and a large number of carbides are prevented from being separated out; then cooling equipment is utilized for performing water cooling on eventually rolled bar materials, the temperature of the bar materials is made to rapidly pass through the temperature range being 700 to 850 DEG C, the carbides are forcefully inhibited from being separated out, and the proportion of cementite in pearlite is increased; and meanwhile, the temperature of the bar materials after water cooling is controlled to be 600 DEG C to 650 DEG C, and a bainite or martensite structure is prevented from being generated. Production proves that the effect on reducing formation of the bearing steel network carbides and banded carbides is remarkable through the method, the grade of the network carbides in the bearing steel is decreased to the second grade or third grade from above third grade in GB / T18254 and the metallographic phase form of the carbides is a semi-net shape or a mass point shape, and the grade of the banded carbides in the bearing steel reaches the first grade in GB / T18254.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

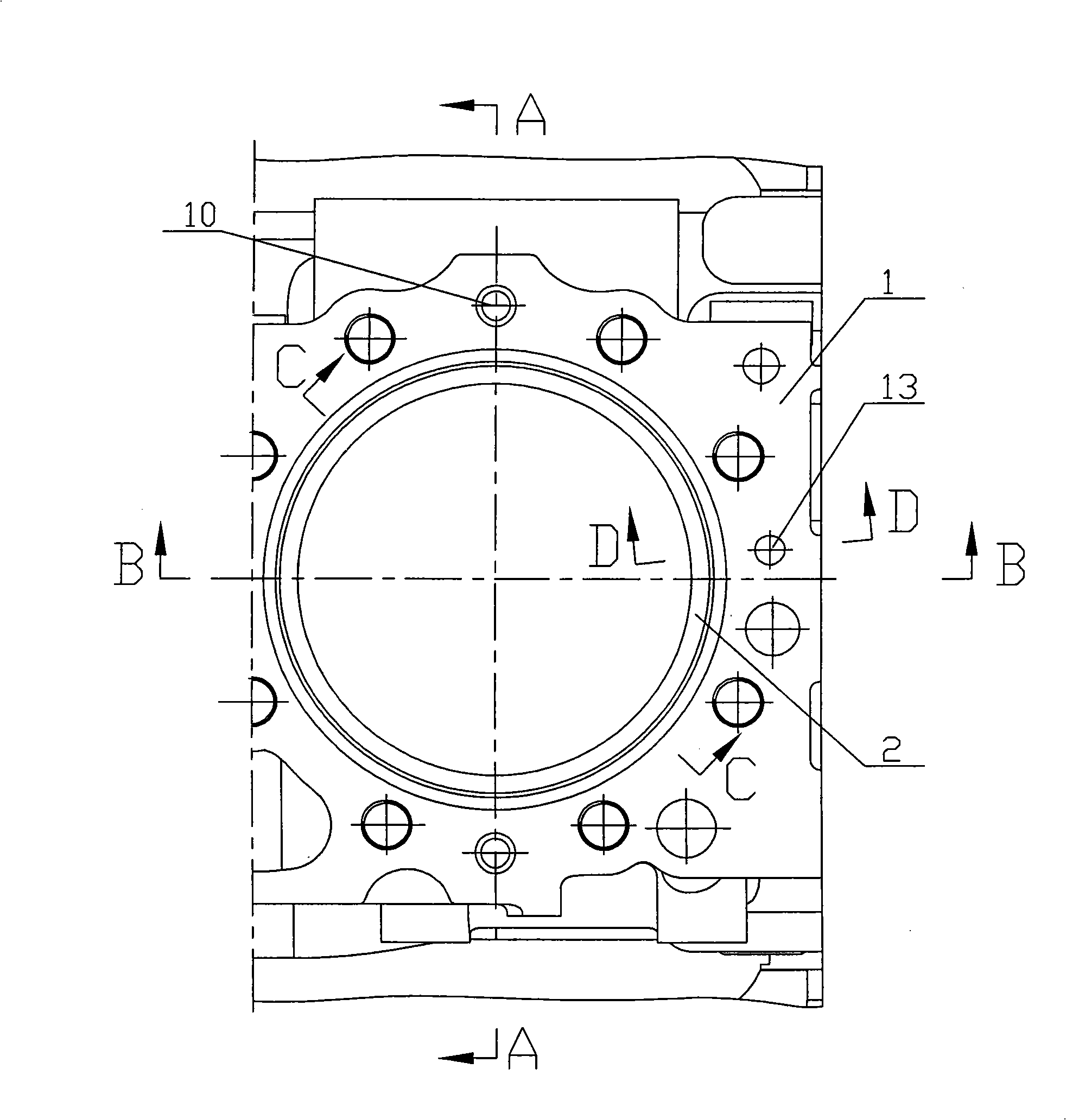

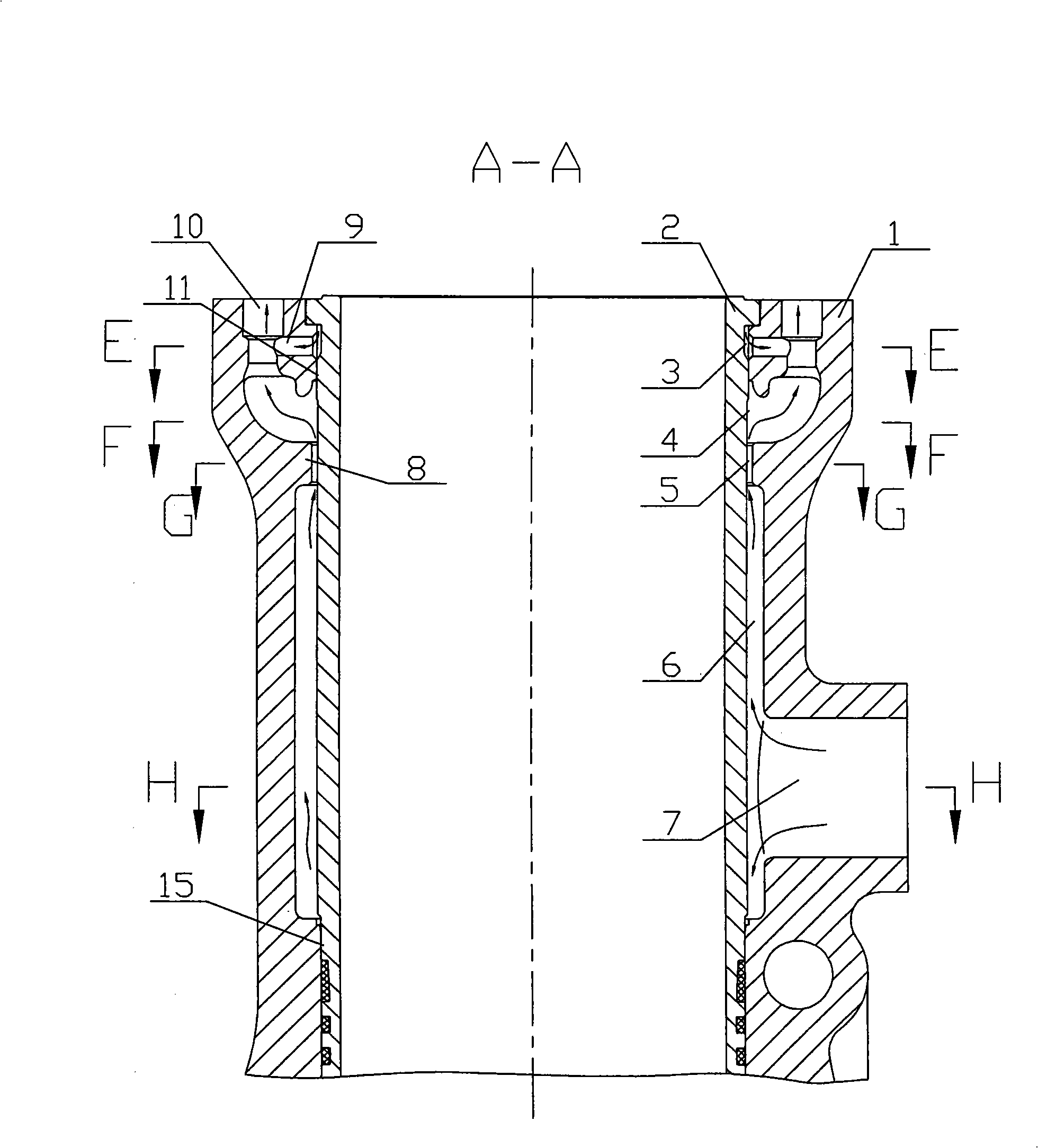

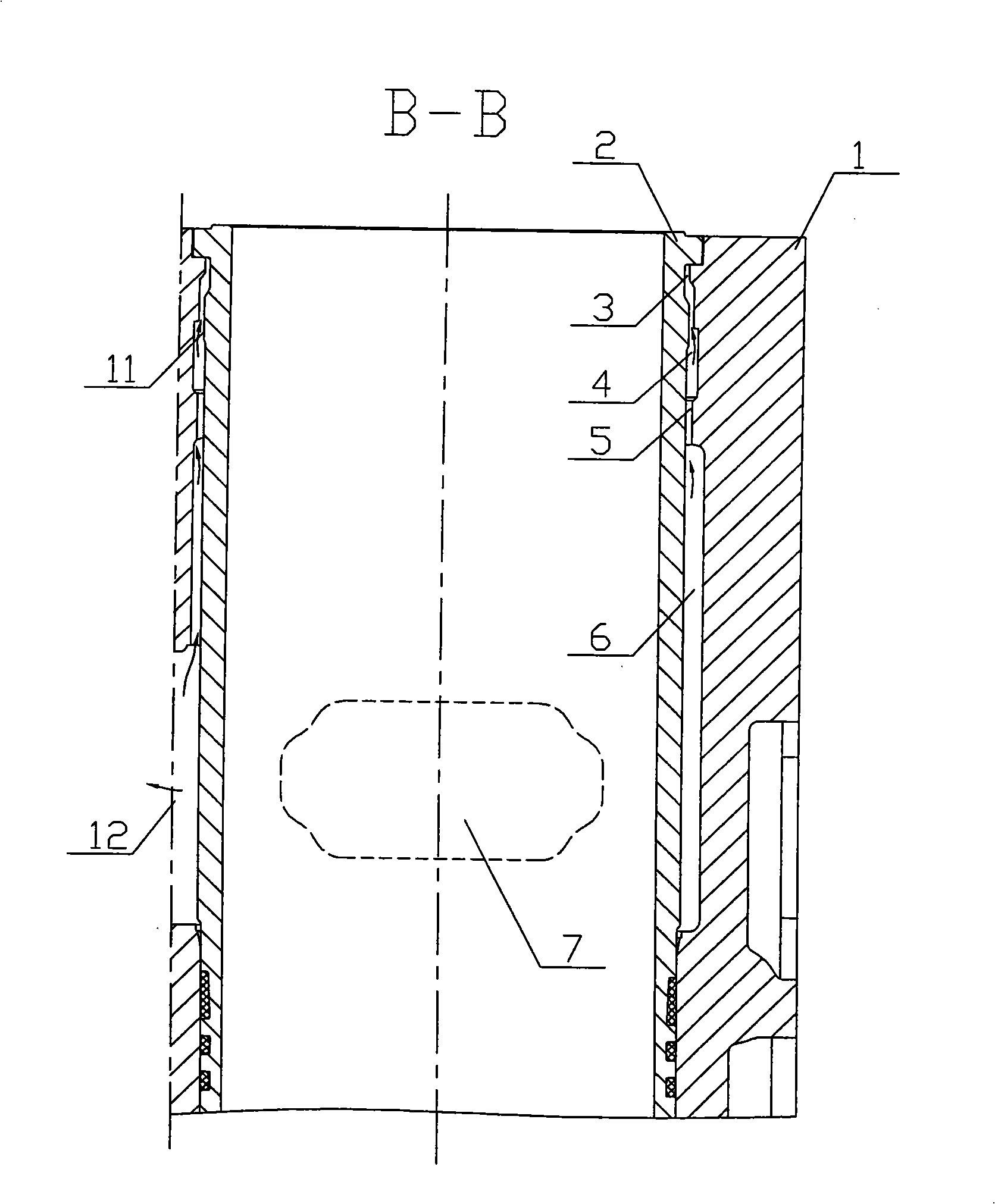

Water-cooled engine body

InactiveCN101349213AIncrease flow rateHigh trafficLiquid coolingCylinder headsCooling chamberEngineering

The invention relates to a water-cooled engine body, in particular to an air cylinder body of a wet-type cylinder liner engine. The air cylinder body comprises a cylinder body and a cylinder liner, and is characterized in that an upper positioning belt and a lower positioning belt are arranged on the cylinder liner; the inner surface of the cylinder body is provided with a convex ring; a cooling water channel formed between the lower positioning belt and the convex ring is used as a first cooling chamber; the cooling water channel formed between the convex ring and the upper positioning belt is used as a second cooling chamber; the cooling water channel formed over the upper positioning belt is used as a third cooling chamber; the cross-sectional area of the second cooling chamber is less than that of the first cooling chamber; and the cross-sectional area of the third cooling chamber is less than that of the second cooling chamber. The invention has the advantages that the air cylinder body can raise the flow velocity of cooling liquid, increase the flow rate of the cooling liquid, raise the heat dissipation rate of a high-temperature area, ensure that the whole cylinder liner is uniform in temperature, guarantee normal fit clearances among parts of the cylinder body and guarantee the normal work of the engine.

Owner:WUXI KIPOR POWER CO LTD

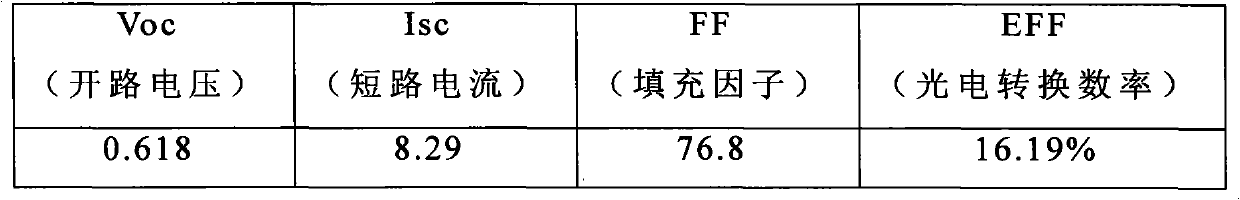

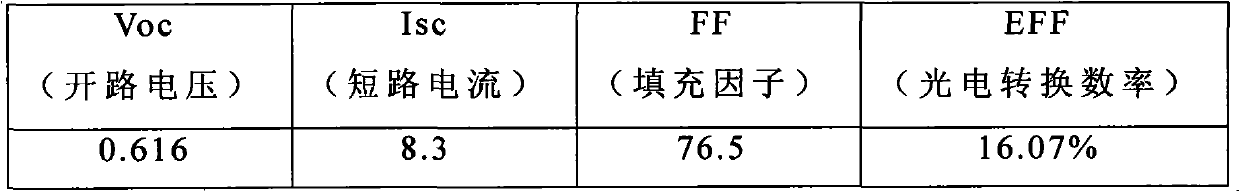

Method for improving phosphorus diffusion uniformity of solar cell

ActiveCN102005502AAvoid uneven diffusionReduce uneven diffusionFinal product manufactureSemiconductor devicesNitrogen atmosphereNitrogen gas

The invention discloses a method for improving phosphorus diffusion uniformity of a solar cell. The method comprises the following steps of: (1) placing a silicon slice in a diffusion furnace and raising the temperature of each region in the furnace to 700 to 780 DEG C, wherein the environment in the furnace is uniform nitrogen atmosphere, and the flow rate of the nitrogen gas is 8 to 30L / minute; (2) simultaneously introducing phosphorus-carrying source gas at the speed of 0.8 to 2L / minute and dry oxygen at the speed of 0.4 to 2.5L / minute after the temperature is stable, ensuring that the gas environment in the furnace is uniform, and diffusing for 10 to 40 minutes; (3) stopping introduction of the phosphorus-carrying source gas source and the dry oxygen, synchronously and uniformly raising the temperature of each region in the furnace at the rate of below 5 DEG C / minute, raising temperature to 810 to 900 DEG C and diffusing for 10 to 40 minutes; and (4) reducing temperature and discharging out of a boat. Through uniform gas and consistent temperature in the furnace, the phosphorus diffusion uniformity during preparation of the battery plate is improved, and the conversion efficiency of the solar cell is improved to a certain extent.

Owner:YANCHENG CANADIAN SOLAR INC

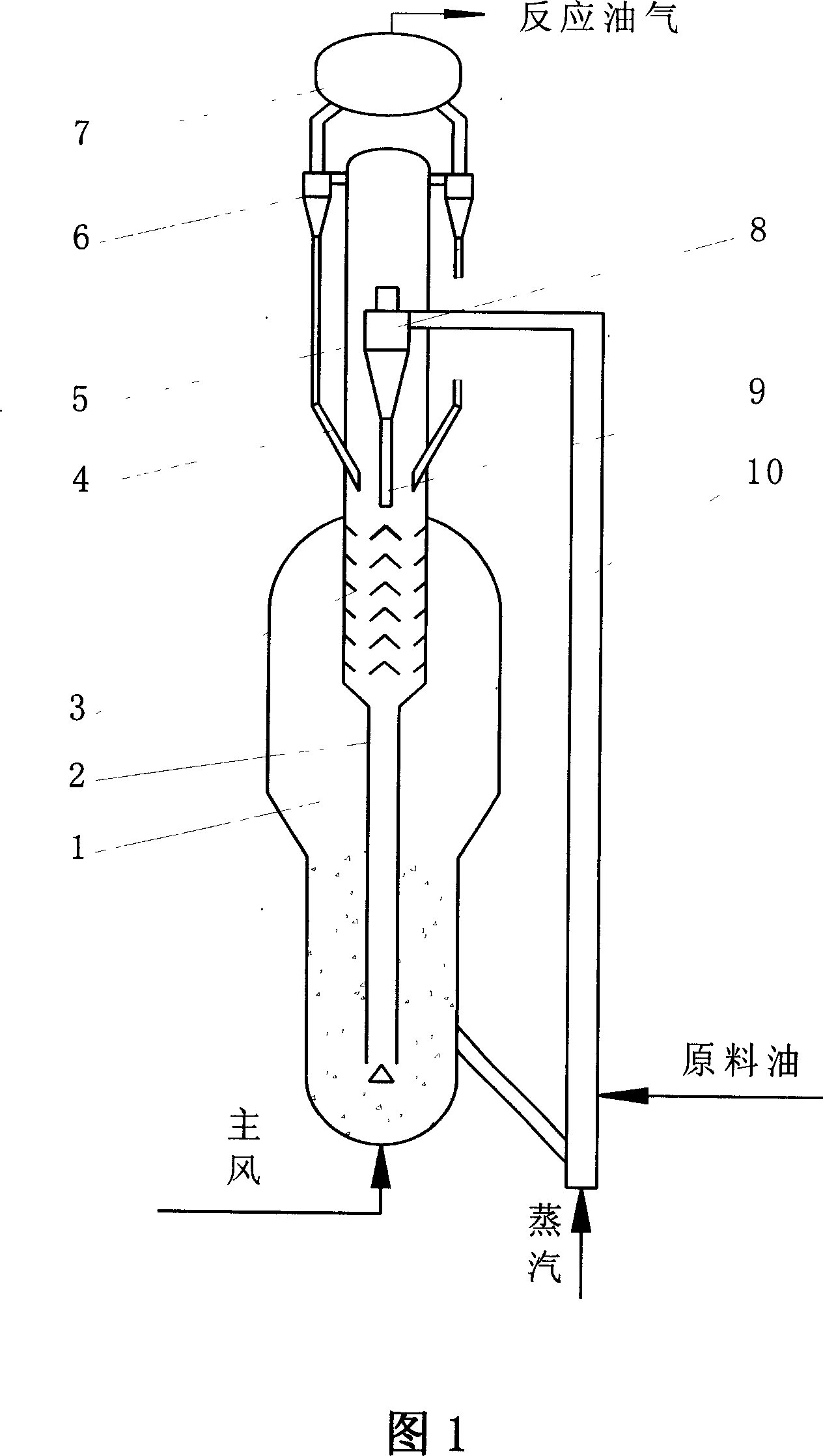

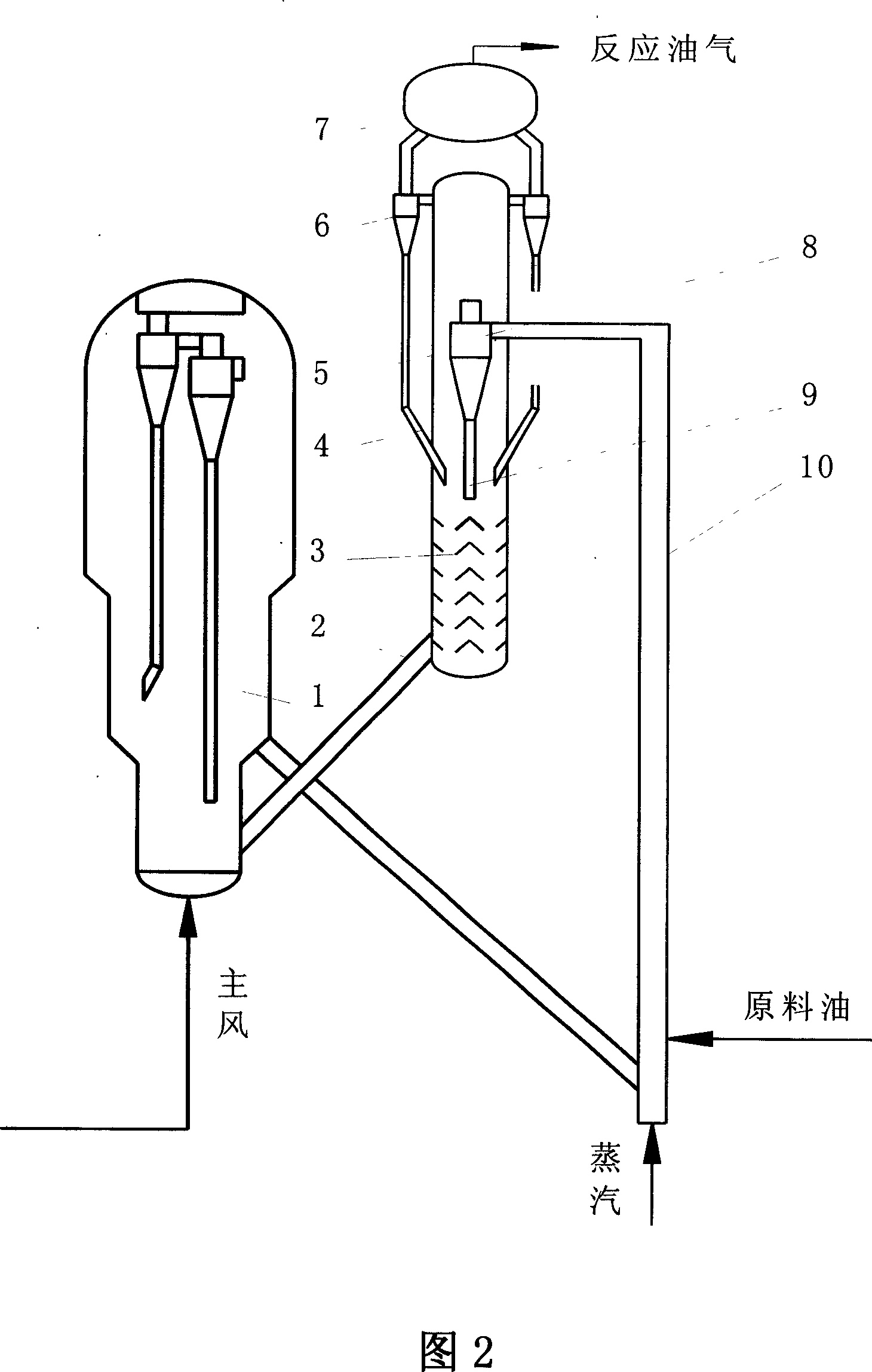

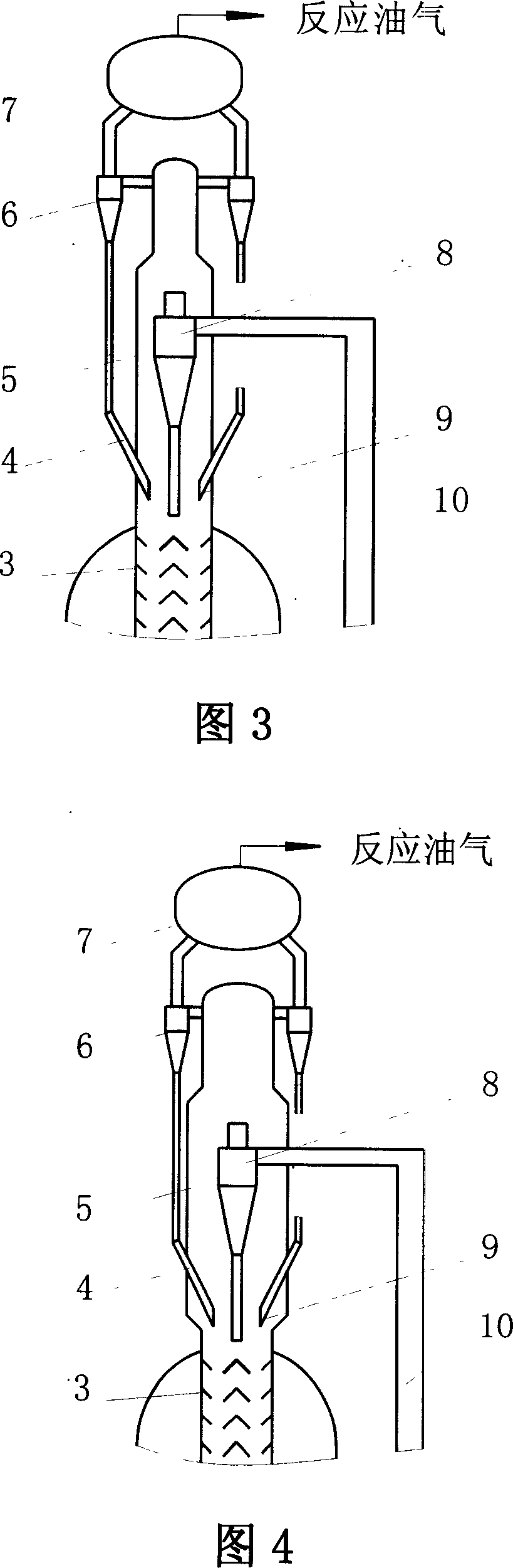

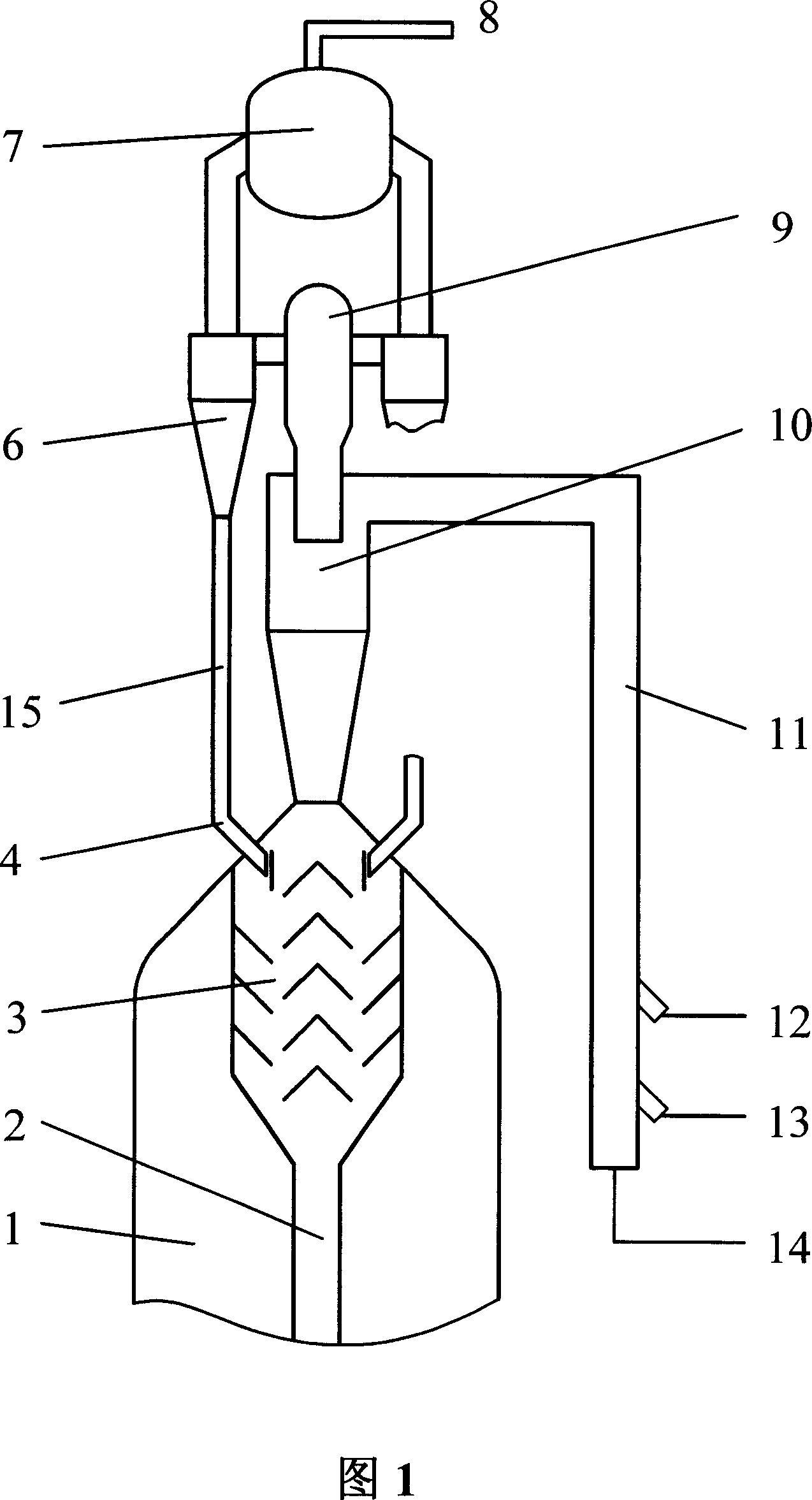

Catalytic cracker with internal tubular settler

The present invention is fluid catalytic cracker with fast separation of oil gas from catalyst. The fluid catalytic cracker has a riser with outlet connected to thick coiled pipe inside the tube settler, a stripping device below the tube settler, a catalyst regenerator connected through pipe tot lower end of the stripping device, and a top coiled pipe outside the tube settler. The fluid catalytic cracker can realize the efficient and fast gas-solid separation in the separation efficiency as high as 99.99 %, reduce average oil gas residence time to less than 2-3 sec and decrease scaling, and has compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Automobile engine cooling water jacket structure integrating exhaust manifold

ActiveCN108547703AImprove cooling effectUniform temperatureExhaust apparatusCylinder headsCombustion chamberCylinder block

The invention relates to an automobile engine cooling water jacket structure integrating an exhaust manifold. The automobile engine cooling water jacket structure comprises a cylinder body water jacket, a cylinder cover water jacket and an air cylinder mat; the automobile engine cooling water jacket structure is characterized in that the cylinder body water jacket comprises a water passing way arranged on the air inlet side of an engine and a cylinder body water jacket body wrapping the air cylinder and communicating with the water passing way; and the cylinder cover water jacket comprises a burning chamber water jacket wrapping a burning chamber and communicating with the water passing way and an exhaust manifold water jacket wrapping the exhaust manifold and communicating with the burning chamber water jacket. By means of the automobile engine cooling water jacket structure, an air cylinder cover and an air cylinder body are better cooled, the cooling water distribution ratio of thecylinder body water jacket to the cylinder cover water jacket can be adjusted to enable the cooling effect on the air cylinder cover and the air cylinder body to be better, the more even air cylindertemperature can be guaranteed, the cooling strength of the burning chamber and the exhaust way zone can be adjusted, and the temperature of the burning chamber and the temperature of the exhaust way zone can keep coincident; and the cooling capacity of the exhaust manifold can be improved, and the reliability and the economical efficiency of the engine are improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

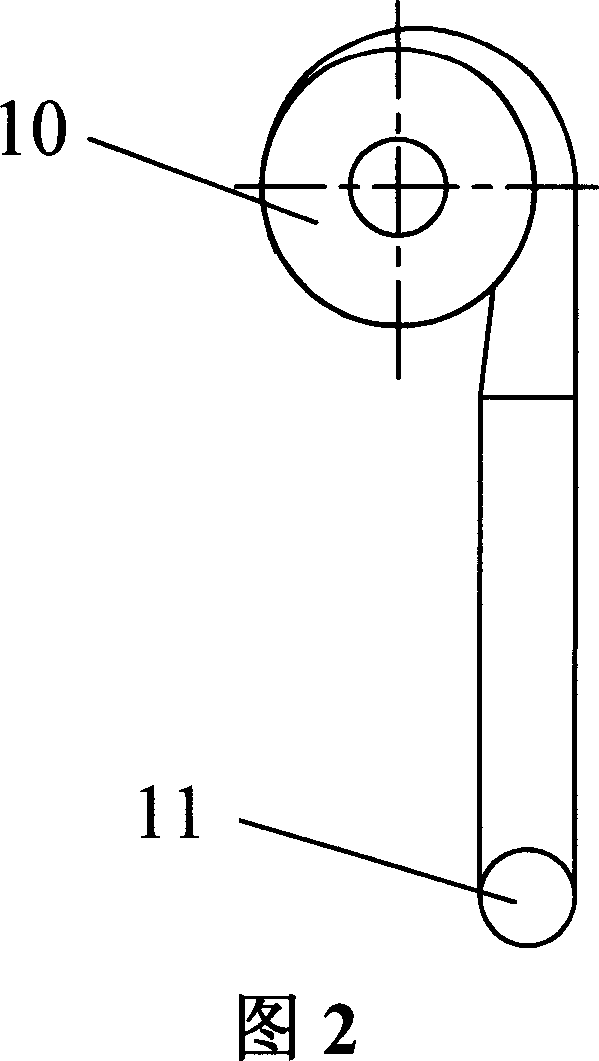

Detachable spinning manifold heated by biphenyl steam which is heating medium

ActiveCN103205819AEasy to disengageUniform temperatureArtificial thread manufacturing machinesMelt spinning methodsRefluxInsulation layer

The invention discloses a detachable spinning manifold heated by biphenyl steam which is a heating medium. The detachable spinning manifold comprises an upper manifold and a lower manifold. The detachable spinning manifold has the advantages that components such as metering pumps and melt pipelines which can be blocked easily are arranged in the upper manifold, a replaceable spinning assembly and a fixed heat-insulation structure are disposed in the lower manifold, the upper manifold and the lower manifold are respectively provided with biphenyl steam inlets and biphenyl condensate reflux inlets which are of straight pipe structures with loose flanges, and a detachable filled heat-insulation layer is arranged on the surface of the upper manifold, so that the upper manifold can be easily separated from a biphenyl steam circulating system or connected with the biphenyl steam circulating system and can be perpendicularly hoisted out or assembled; and the upper manifold and the lower manifold are connected into the same biphenyl steam generator by parallel biphenyl circulating pipelines, so that the temperature of the inside of the upper manifold and the temperature of the inside of the lower manifold keep uniform and consistent.

Owner:CTA HIGH TECH FIBER

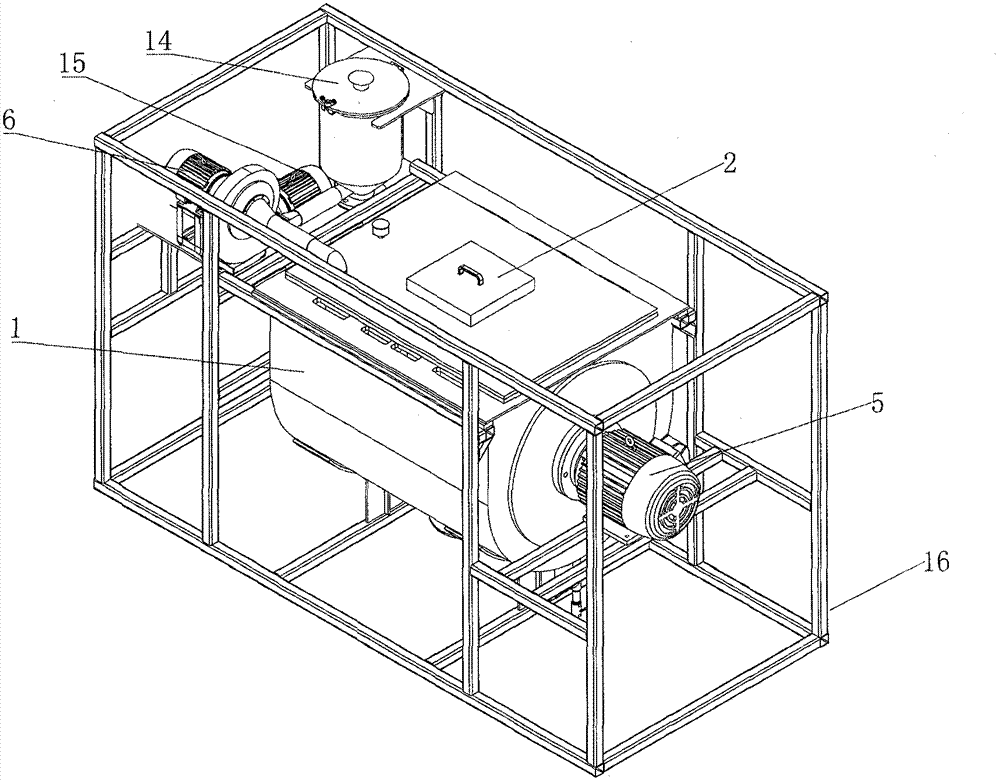

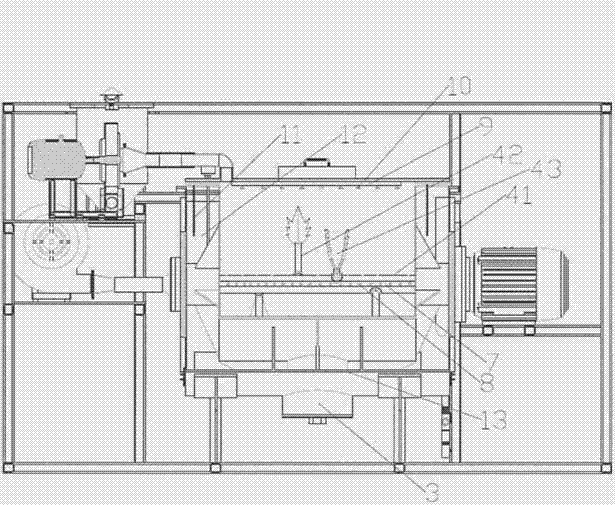

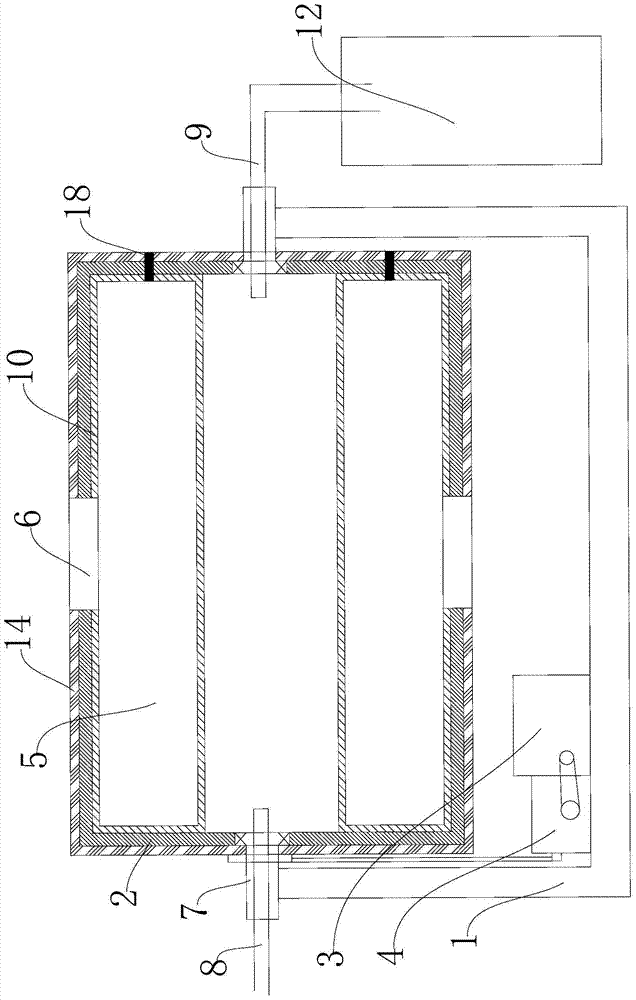

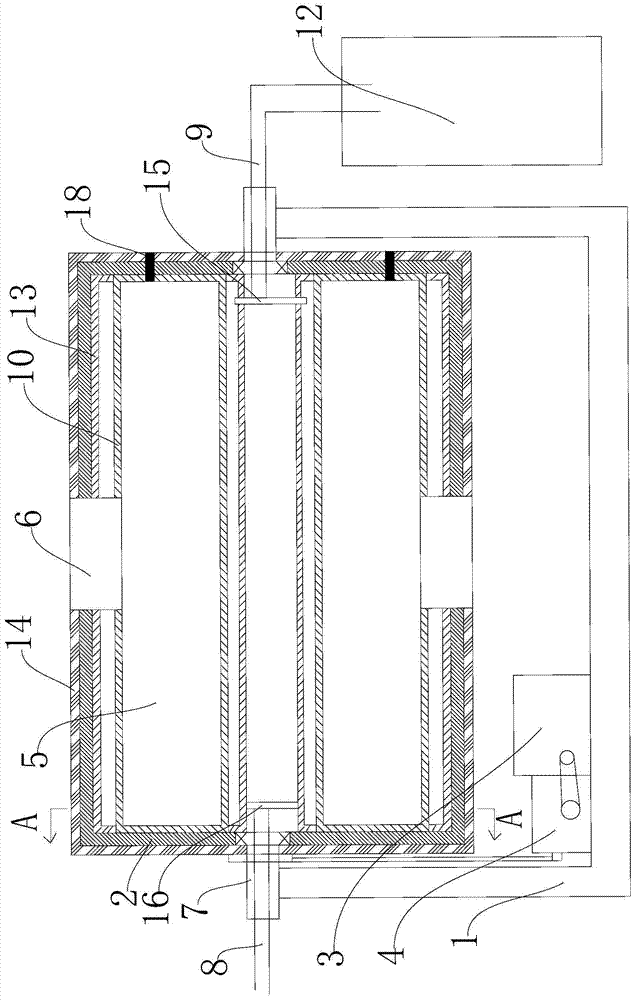

Efficient, energy-saving and low-emission fur polychromatic dyeing all-in-one machine and fur dyeing method

InactiveCN103938383AConsistent temperatureAvoid wastingTextile treatment containersLiquid/gas/vapor treatment machines driving mechanismsMotor driveEngineering

The invention relates to the field of fur dyeing devices, in particular to an efficient, energy-saving and low-emission fur polychromatic dyeing all-in-one machine which can simultaneously conduct dyeing of different colors on fur. The efficient, energy-saving and low-emission fur polychromatic dyeing all-in-one machine comprises a machine frame, an outer cavity, a motor, a gearbox and dyeing cylinders, wherein the motor drives the outer cavity to rotate through the gearbox, the outer cavity is connected with the machine frame through shafts at the two ends, the dyeing cylinders are fixed inside the outer cavity and make contact with the inner wall of the outer cavity, feeding doors are formed in the positions where the dyeing cylinders make contact with the inner wall of the outer cavity, and a plurality of partition plates are arranged in the annular wall in each dyeing cylinder at equal intervals. Fur raw materials, corresponding dye and corresponding additives can be added to different dyeing cylinders, and therefore dyeing of different colors can be simultaneously conducted on fur, production efficiency is improved, and meanwhile energy waste can be avoided; by means of heating conducted through steam, the temperature inside the whole outer cavity can be kept uniform, and therefore the temperatures of the dyeing cylinders are kept the same, and the dyeing effect is improved.

Owner:TONGXIANG NEW ERA FUR

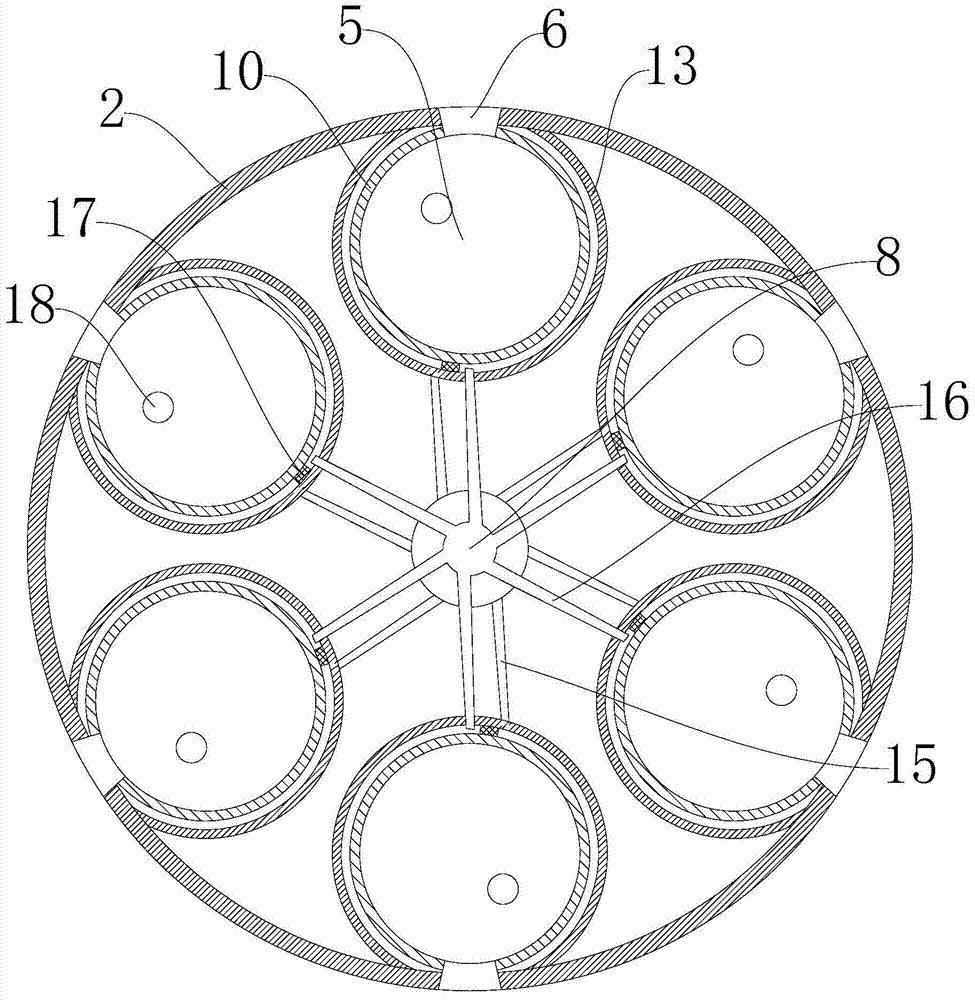

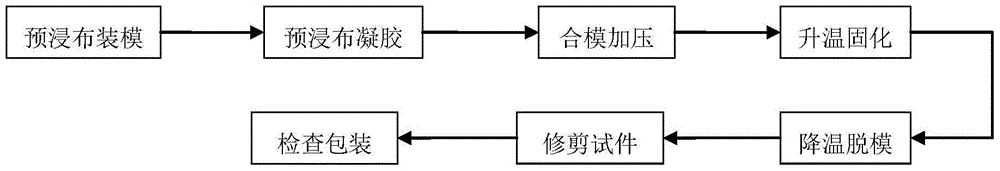

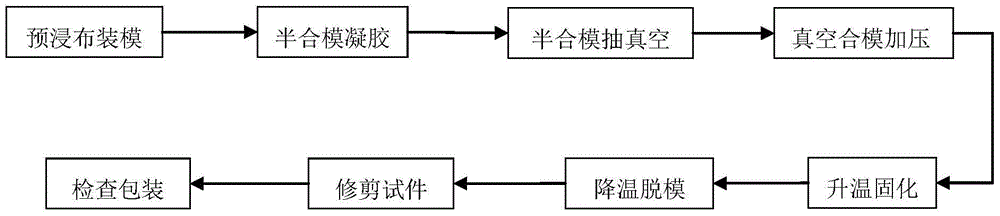

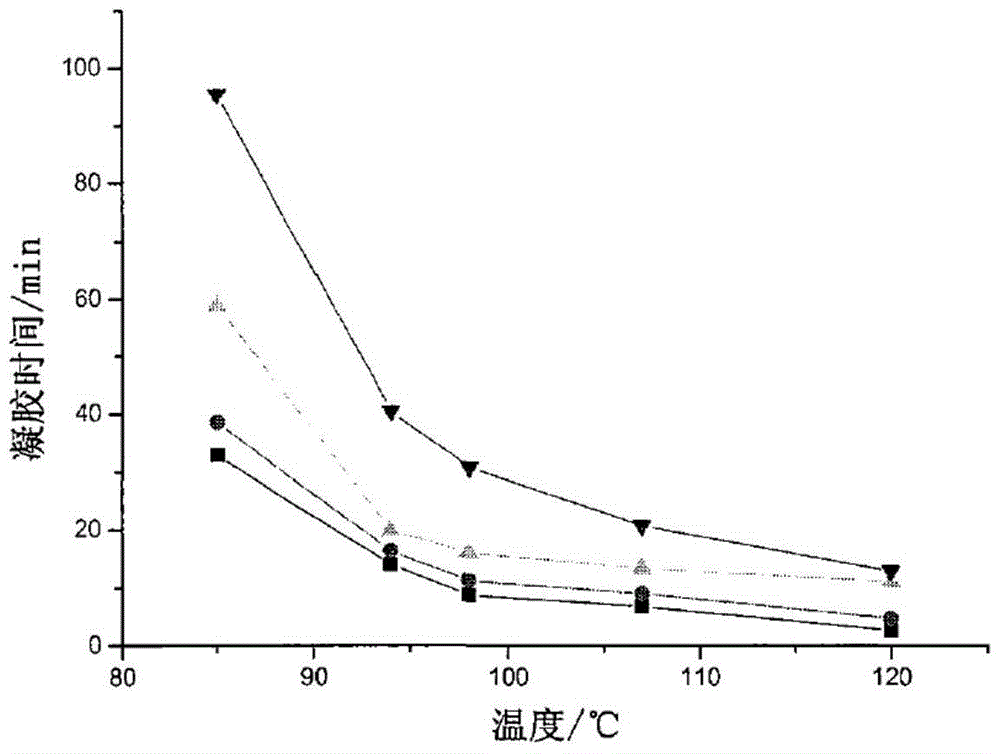

Vacuum compression molding device for carbon fiber composite

InactiveCN105034410AImprove mechanical propertiesImprove the finishCompression moldingNumerical control

The invention discloses a vacuum compression molding device for a carbon fiber composite. The vacuum compression molding device for the carbon fiber composite solves the problem that the performance of a carbon fiber composite molded test piece is poor and comprises an upper mechanism, a lower mechanism, a vacuumizing device, a temperature control device, a pressure control device and a numerical control operation platform. The upper mechanism is installed at the top end of guide posts installed in the lower mechanism through an upper heat conducting plate. Top-pasted type pressure sensors of the pressure control device adhere to the bottom face of the upper heat conducting plate and are connected with the numerical control operation platform through wires. Bottom-pasted type pressure sensors of the pressure control device adhere to a lower heat conducting plate and are connected with the numerical control operation platform through wires. Upper temperature sensors of the temperature control device adhere to the two sides of an upper male die of the upper mechanism and are connected with the numerical control operation platform through wires. Lower temperature sensors of the temperature control device adhere to the two sides of the upper surface of a lower female die and are connected with the numerical control operation platform through wires. The vacuumizing device is installed on a vacuum compression molding device base on the left side of the lower mechanism, and a one-way valve of the vacuumizing device is installed on the lower female die. The numerical control operation platform is installed on the right side of the lower mechanism.

Owner:JILIN UNIV

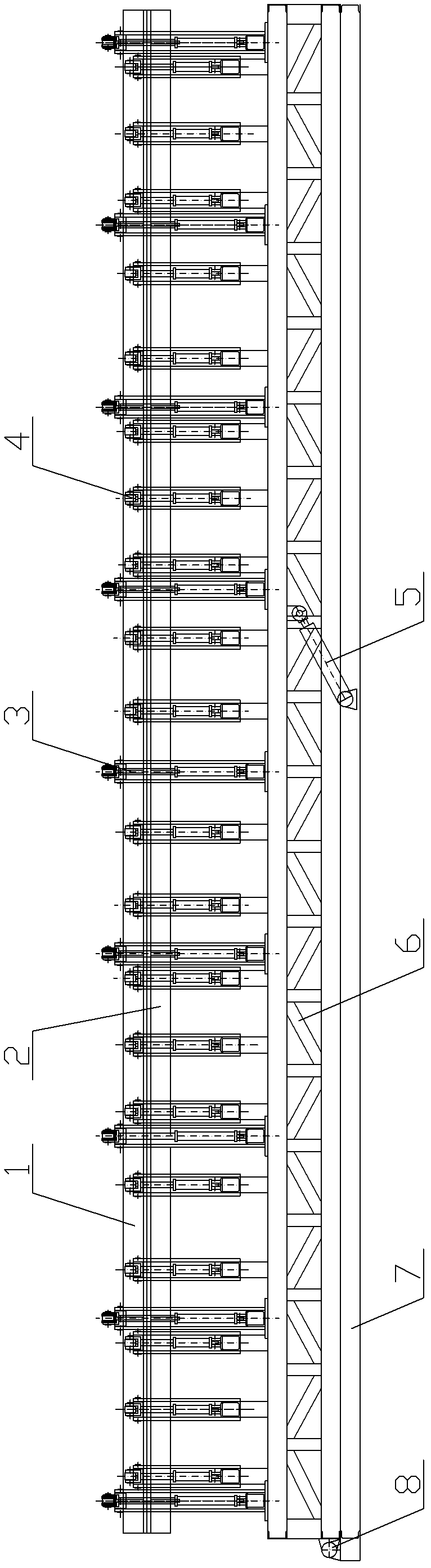

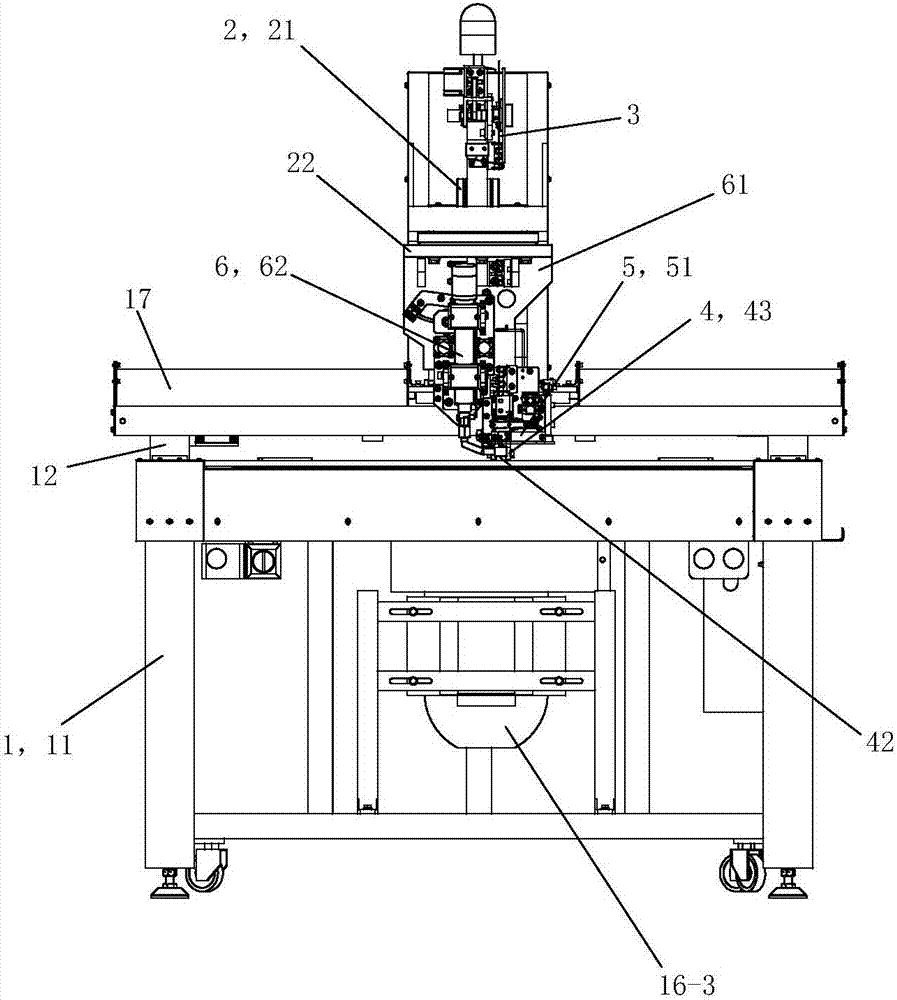

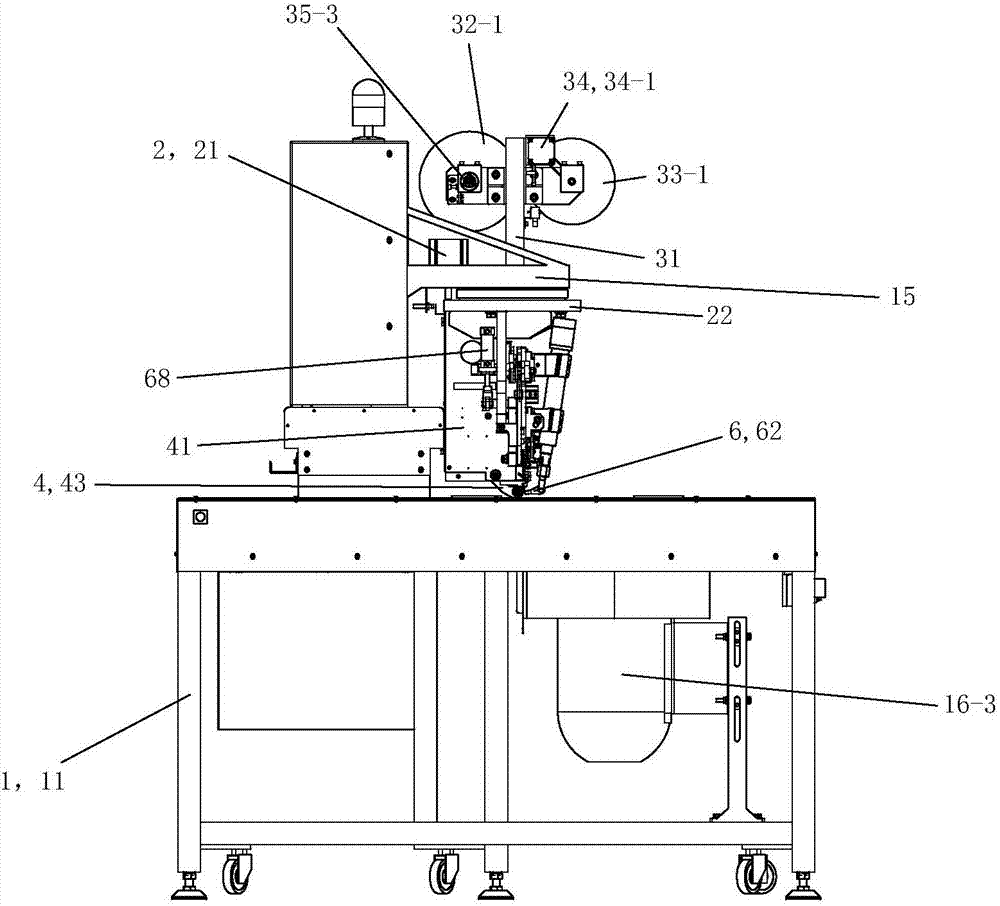

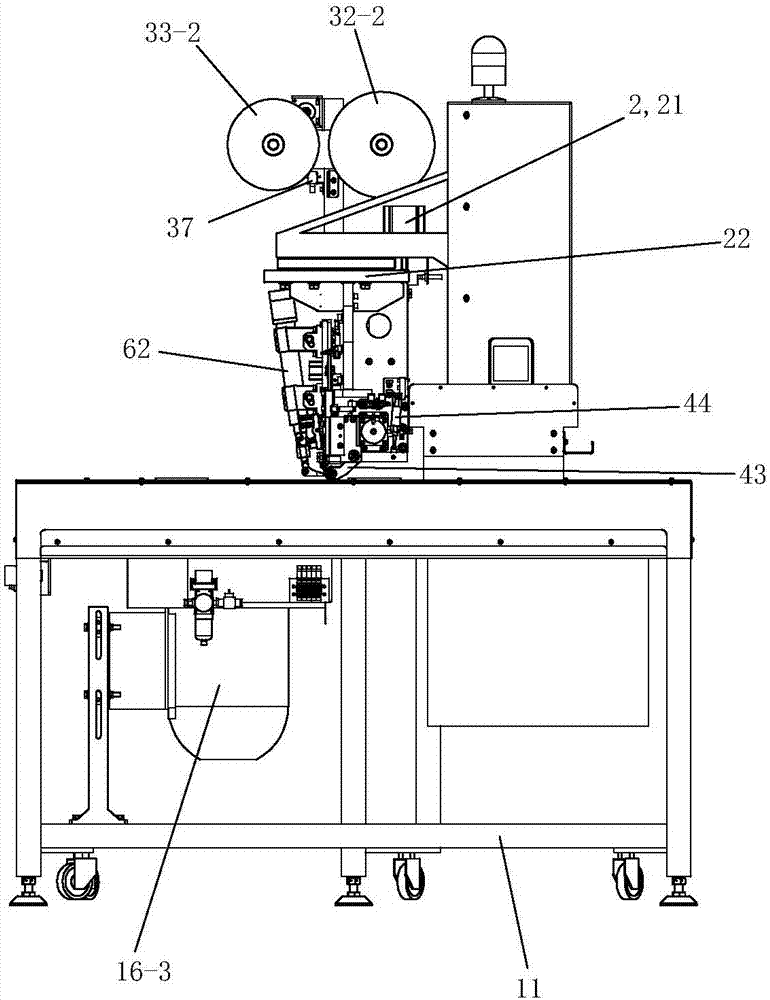

Hot-melting strip pasting machine

The invention discloses a hot-melting strip pasting machine which is characterized by comprising a working table, an adjustment assembly, a conveying device, a pressing roller device, a shearing device and a hot wind device, wherein the working table comprises a rack, a first movable portal frame, a front-rear walking mechanism, a left-right walking mechanism and a second installation hanging bracket; the first movable portal frame is disposed on the rack by the front-rear walking mechanism and can be moved back and forth; the second installation hanging bracket is disposed on the first movable portal frame by the left-right walking mechanism and can be moved horizontally; the conveying device, the pressing roller device and the hot wind device are disposed on the second installation hanging bracket of the working table in a rotatable manner by the adjustment assembly; the conveying device is used to install corresponding hot-melting adhesive films and recycle corresponding release paper; the pressing roller device is used to press and paste the hot-melting adhesive films on corresponding fabrics; the shear device is disposed on the pressing roller device and used to cut off the hot-melting adhesive films; and the hot wind device is used to heat the holt-melting films.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Network equipment cabinet with cooling system

ActiveCN101640992AReduce energy consumptionReduce noiseCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersAir convectionEngineering

The invention relates to a network equipment cabinet with a cooling system, in particular to a network server cabinet for keeping temperature by using cold-hot air convection. The cabinet of the technical scheme comprises side walls, a cabinet body and an equipment frame, wherein a cold-hot exchanger is arranged at the lower part of the cabinet body and forms a cold air supplying duct and a hot air draining channel in the cabinet body; the side wall of the cabinet body through which the cold air supplying duct passes is provided with a deflector which adopts an arc plate to drain the cold airto heating equipment, and then adopts an air guide pipe arranged on the hot air draining channel to carry out targeted absorption on local heat of the equipment. The cabinet in the scheme can cool theinner temperature thereof to the set temperature, can realize local temperature reduction, lead the temperature of all the parts in the cabinet to be uniform, reduce energy consumption and noise, issimple and reliable, and achieve the purpose of drainage of local high temperature in the cabinet body, thus realizing the effect of leading the temperature of the whole cabinet to keep balance.

Owner:广西中科曙光云计算有限公司

High-efficiency and energy-saving intensive tobacco flue-curing house

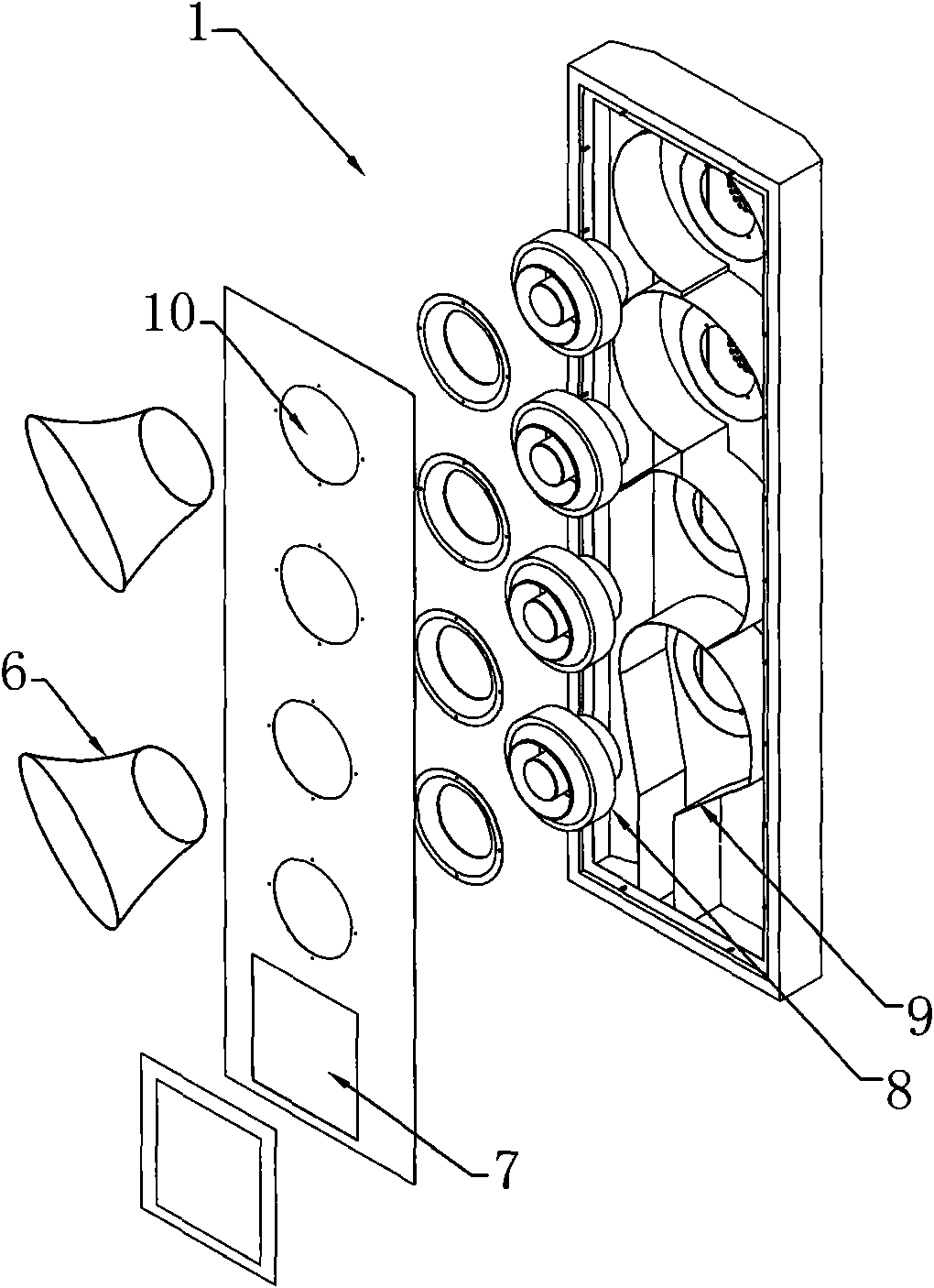

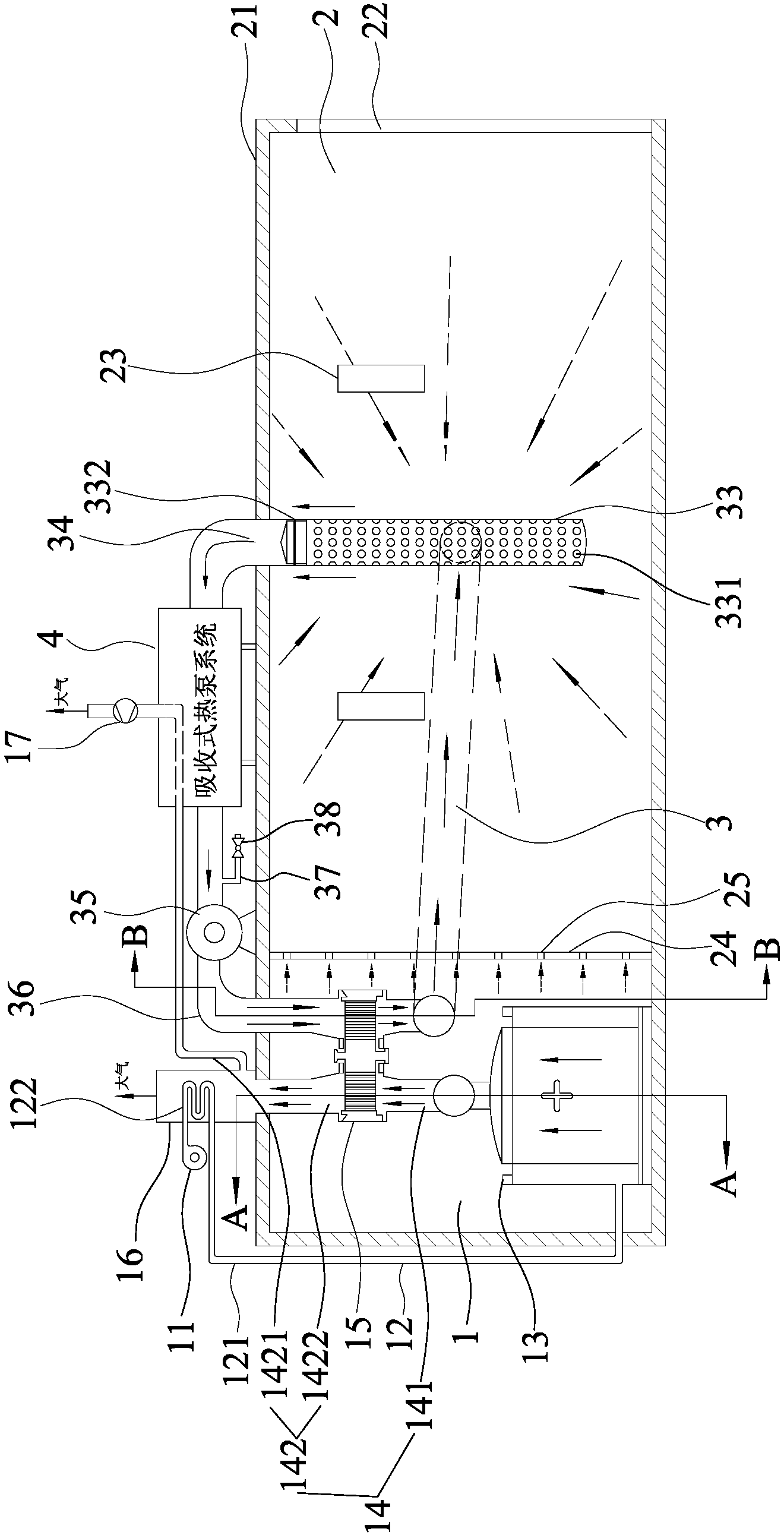

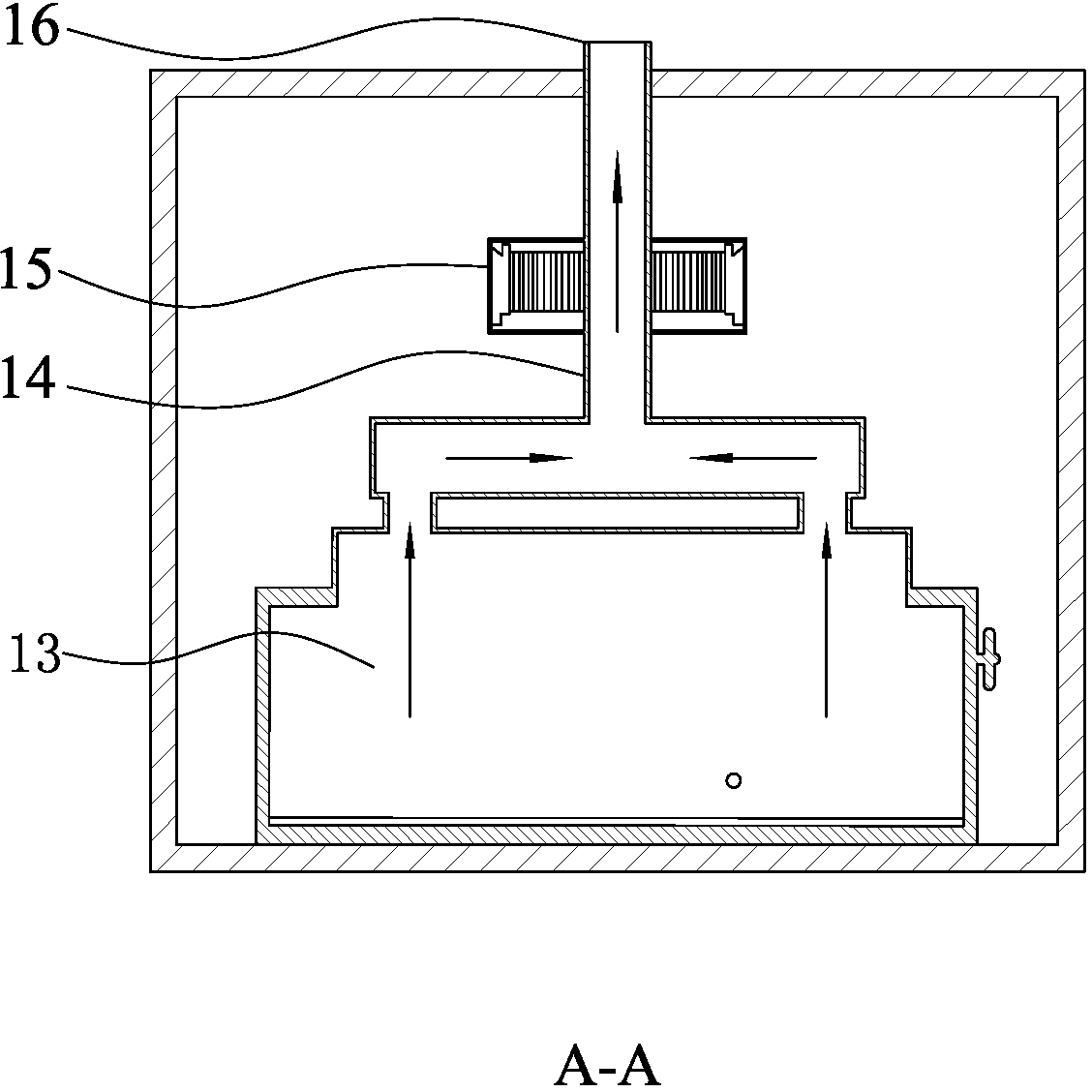

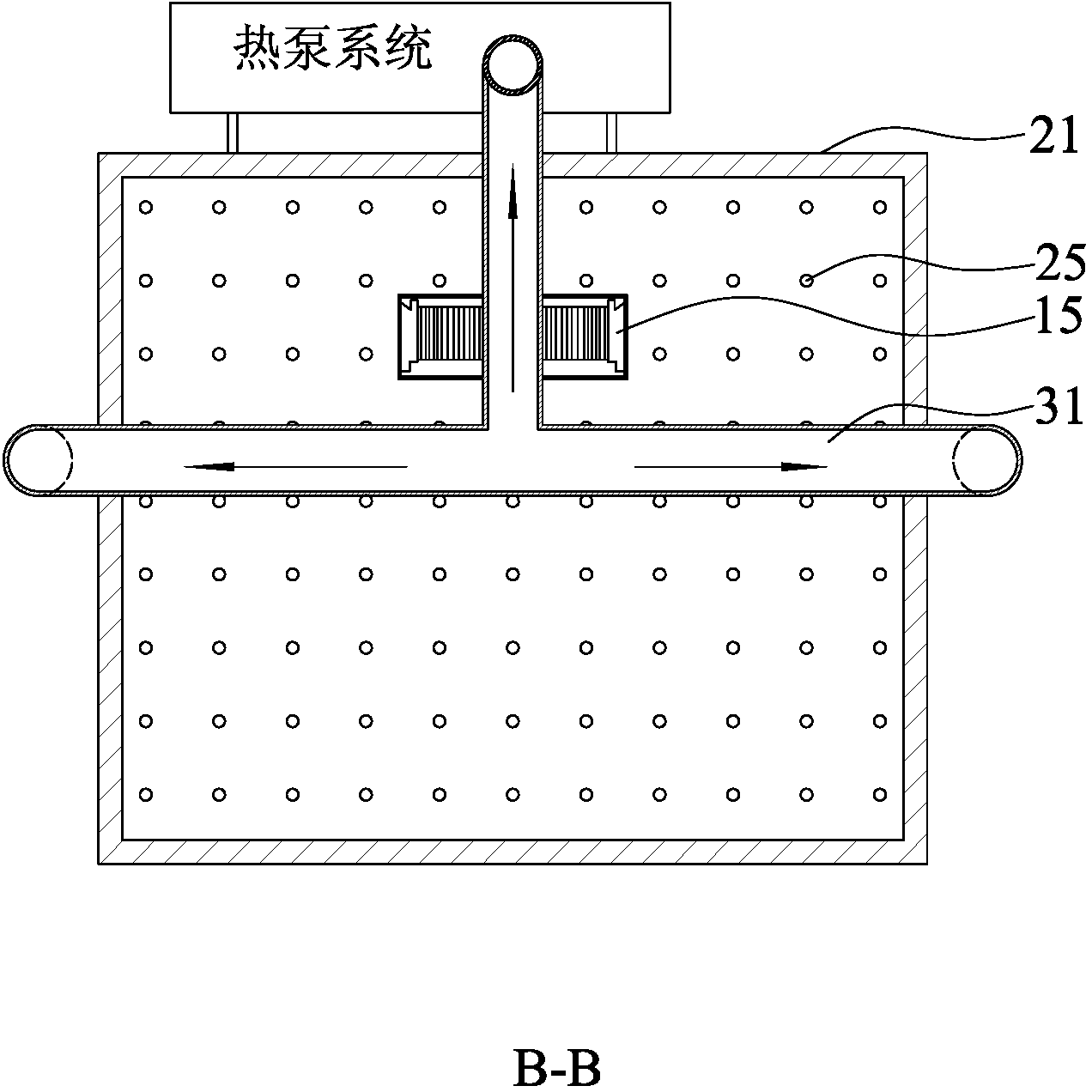

ActiveCN102697157AImprove combustion efficiencyImprove energy utilizationTobacco preparationFinal product manufactureHigh energyAbsorption heat pump

The invention discloses a high-efficiency and energy-saving intensive tobacco flue-curing house, which comprises a heat supply chamber, a baking chamber, a hot air circulating system and an absorption type heat pump system, wherein the hot air circulating system is connected with the heat supply chamber, the baking chamber and the absorption type heat pump system sequentially by a pipeline; and the absorption type heat pump system is arranged on the top of the baking chamber. According to the high-efficiency and energy-saving intensive tobacco flue-curing house, the heat exchange efficiency and energy utilization rate are improved by utilizing a technology of performing heat exchange by a rotary air heat exchanger, a technology of preheating air required by the combustion of a hearth by recovered smoke waste heat, a technology that the recycled smoke waste heat is used as a heat source of the absorption type heat pump system and the like; a baking effect of the tobacco flue-curing house is improved by utilizing technologies of supplying air from two sides of a side wall air distribution board and exhausting the air from the center of a central air draft pipe; and a humidity-discharging effect and an energy-saving effect are improved by utilizing a technology of performing deep dehumidification and recovering humidity-discharging waste heat by the heat pump system. Therefore, the high-efficiency and energy-saving intensive tobacco flue-curing house has the characteristics of high heat exchange efficiency, high energy utilization rate, good baking effect and good humidity-discharging effect, is particularly suitable for low-cost and large-scale production, and can be widely applied to the technical field of tobacco flue-curing.

Owner:JIMEI UNIV

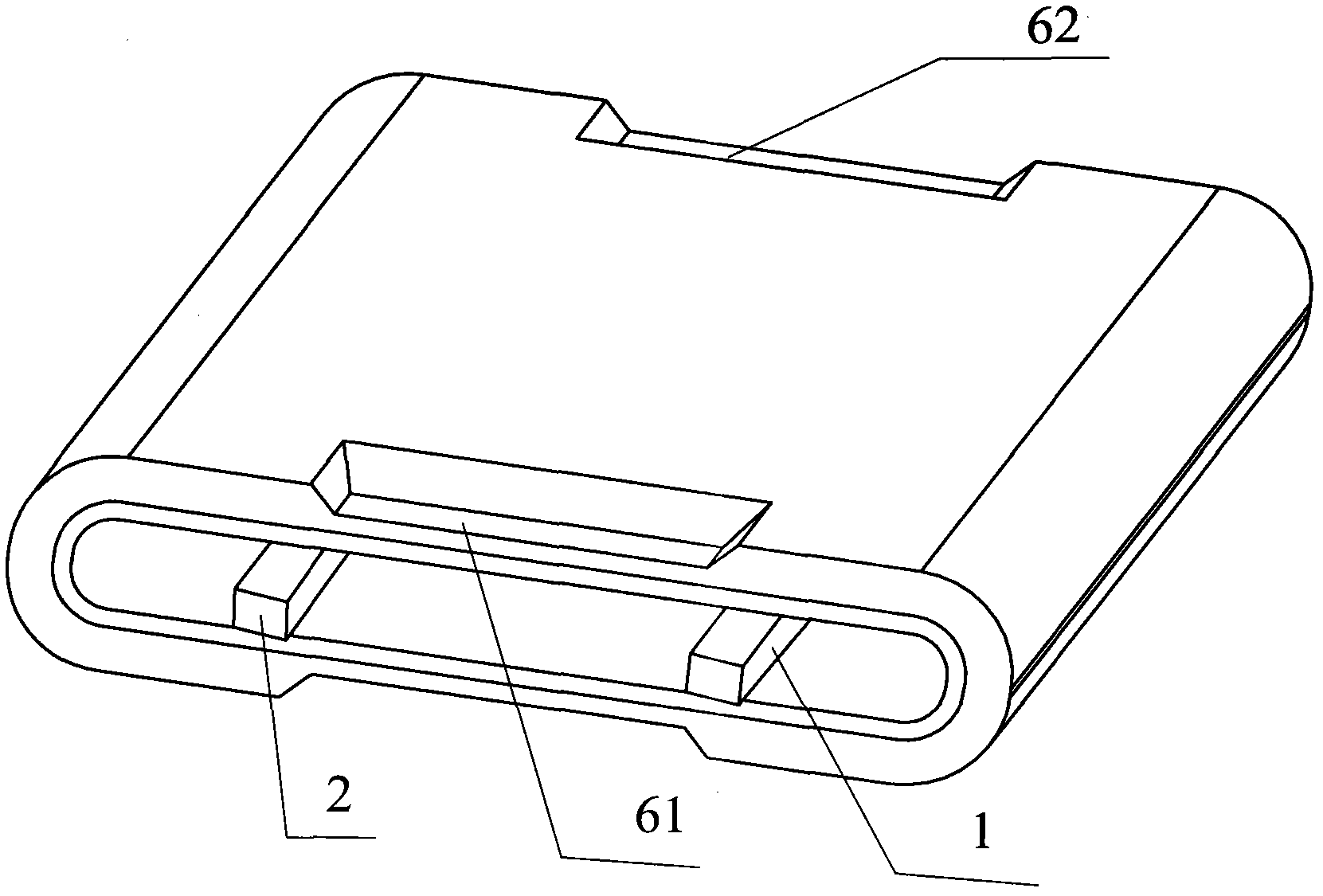

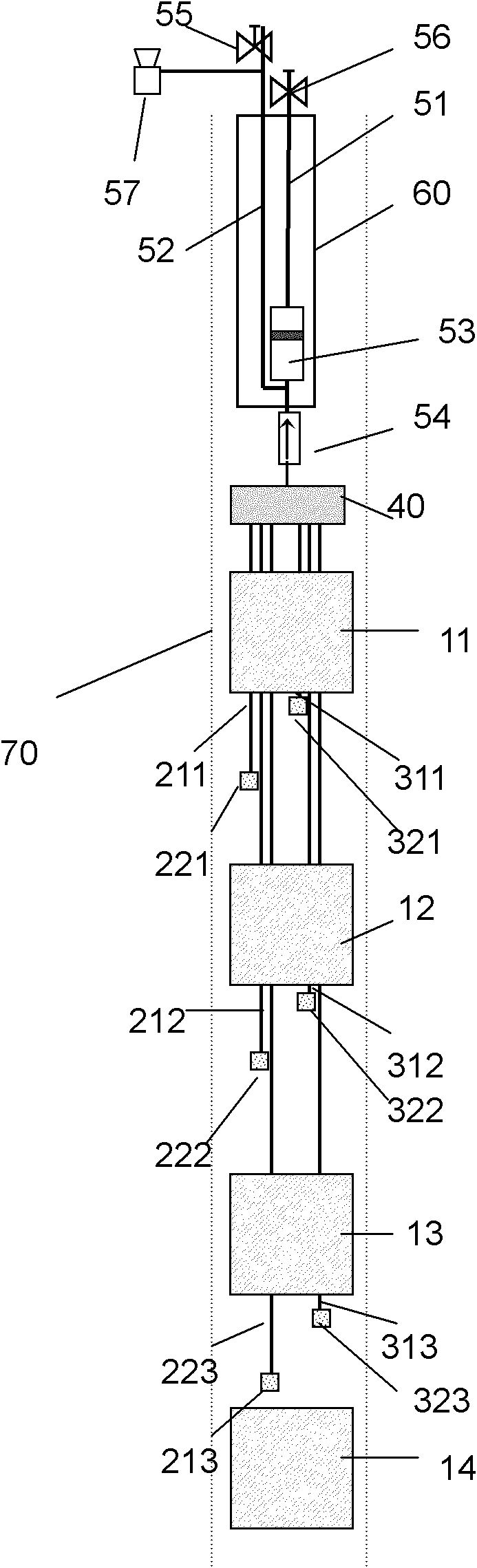

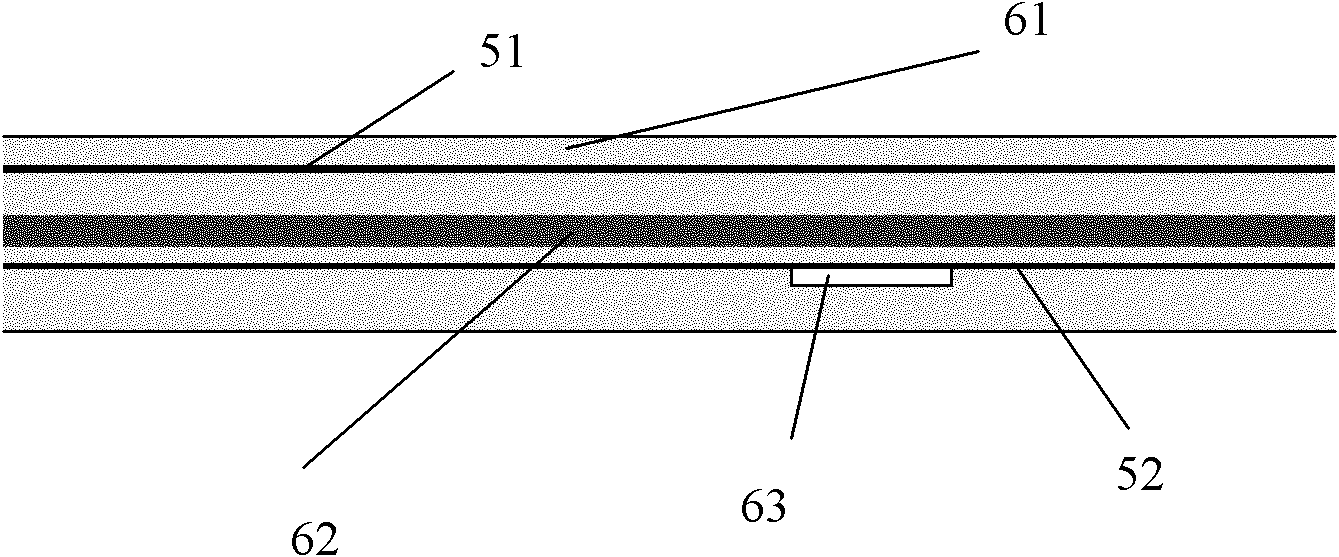

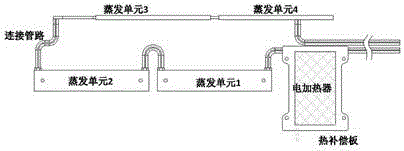

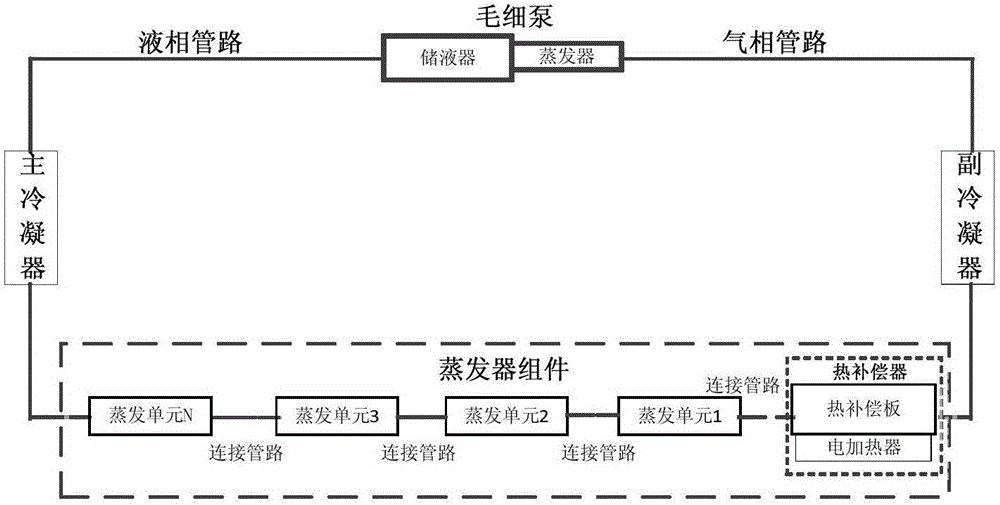

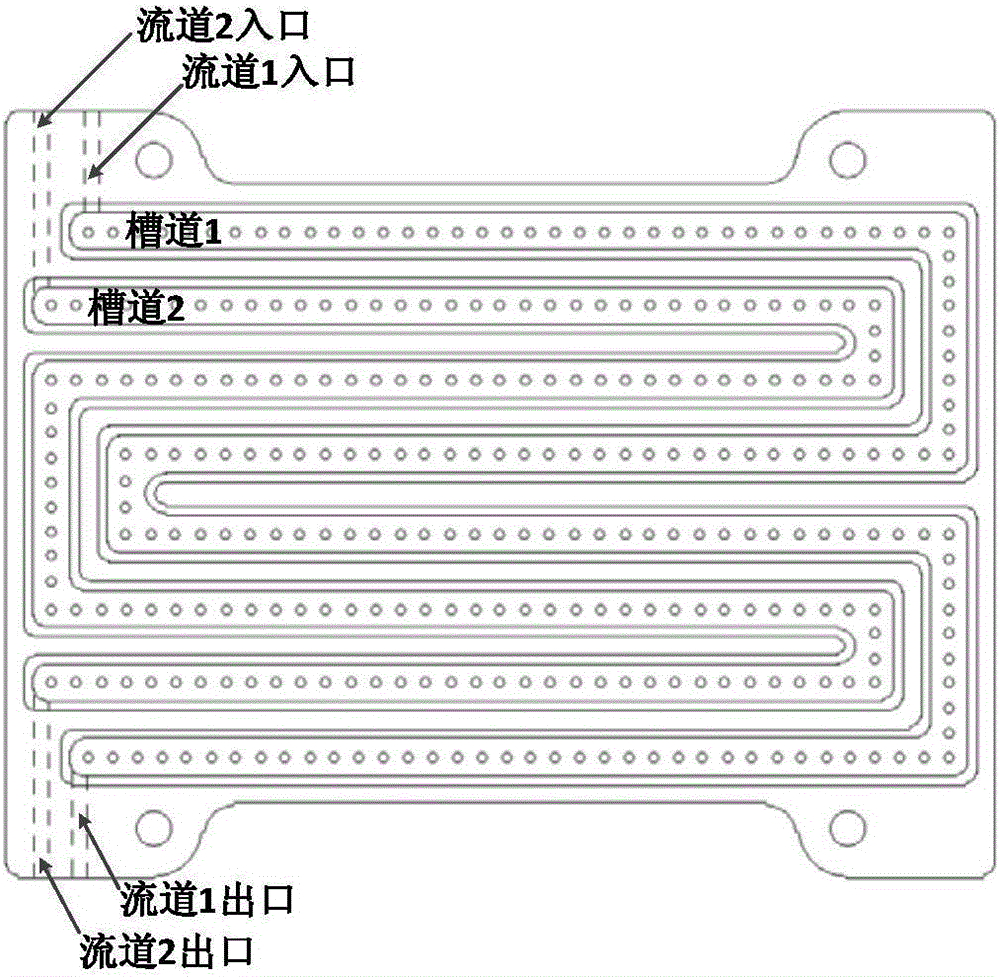

Temperature control type loop heat pipe evaporator assembly

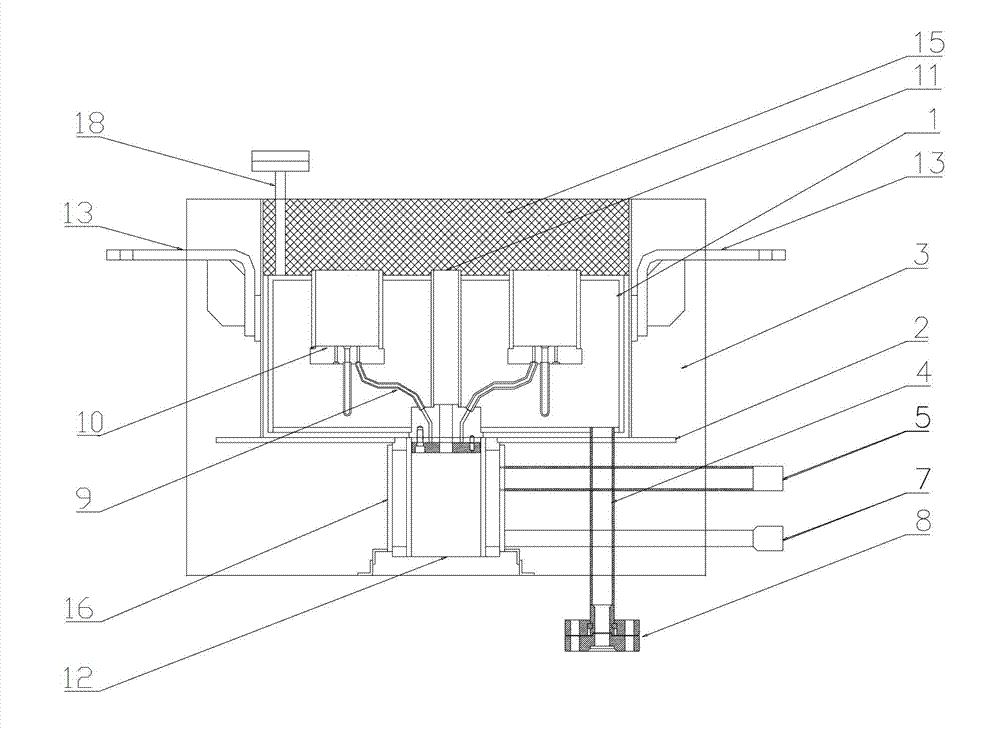

ActiveCN105910479AStable temperatureConsistent temperatureIndirect heat exchangersTemperature controlMicro-loop heat pipe

A temperature control type loop heat pipe evaporator assembly comprises a heat compensator, N evaporation units and a connecting pipeline, wherein the N is a positive integer bigger than or equal to 1; the heat compensator is arranged in the input end so as to heat up the liquid working medium in the loop heat pipe into gas-liquid two-phase state; the N evaporation units are connected by the connecting pipeline so as to form an evaporation network; the input end of the evaporation network is connected with the output end of the heat compensator through the connecting pipeline; the output end of the evaporation network serves as the output end of the evaporator assembly. The evaporator assembly can ensure the working medium entering each evaporation unit in the loop heat pipe operation to be two-phase working medium, thus ensuring constant and consistent temperature of the heat source in working / non working state, and accurately controlling the temperature in the complete cycle.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Catalytic cracker without settler

InactiveCN1974728AGood effectEasy to separateCatalytic crackingChemical/physical processesResidence timeHydrocarbon

The present invention relates to fast oil gas and catalyst separation in hydrocarbon material fluid catalytic cracking, and is especially one catalytic cracker without settler. The catalytic cracker without settler features the stripping unit with lower end connected via a vertical pipe to one regenerator, the first cyclone separator connected to the upper end of the stripping unit, the riser tube with outlet connected to the first cyclone separator via pipeline, and the second cyclone separator connected serially to the upper end of the first cyclone separator and with material feeding structure communicated to the stripping unit. The catalytic cracker can realize the efficient fast gas-solid separation in the separating efficiency up to 99.99 % and average oil gas residence time shortened to 2-3 sec, and has less scaling, compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

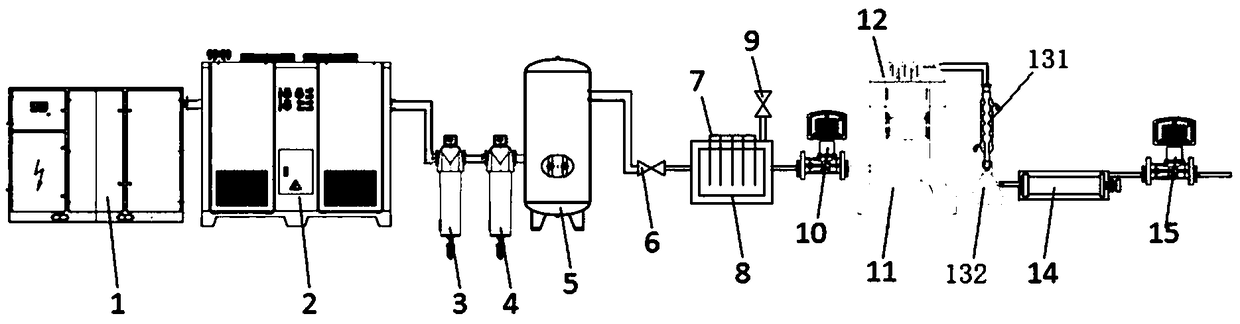

Engine oil-gas separation test evaluation device and method

PendingCN109060361AImprove test accuracyIncrease success rateEngine testingPressure stabilizationAir filter

The invention provides an engine oil-gas separation test evaluation device and method. The device comprises a gas pretreatment device, an engine simulation device and a gas detection device, wherein the gas pretreatment device comprises an air compressor, a dryer, an air filter, an oil removal filter and a storage tank; the air compressor is connected to the storage tank through the dryer, the airfilter and the oil removal filter in sequence; the engine simulation device comprises a heatable pressure stabilization box, a front-end gas flowmeter and an engine; the gas detection device comprises an oil-gas condenser, a collecting bottle, an oil-gas filter and a rear-end gas flowmeter; and the oil-gas condenser is connected to the rear-end gas flowmeter through the collecting bottle and theoil-gas filter in sequence. According to the engine oil-gas separation test evaluation device and method, the flow, temperature and pressure generated by an oil-gas mixture can be controlled, the testmethod is closer to a real working condition of the engine, and a test result is more accurate and reliable.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com