Patents

Literature

45results about How to "Comprehensive sampling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

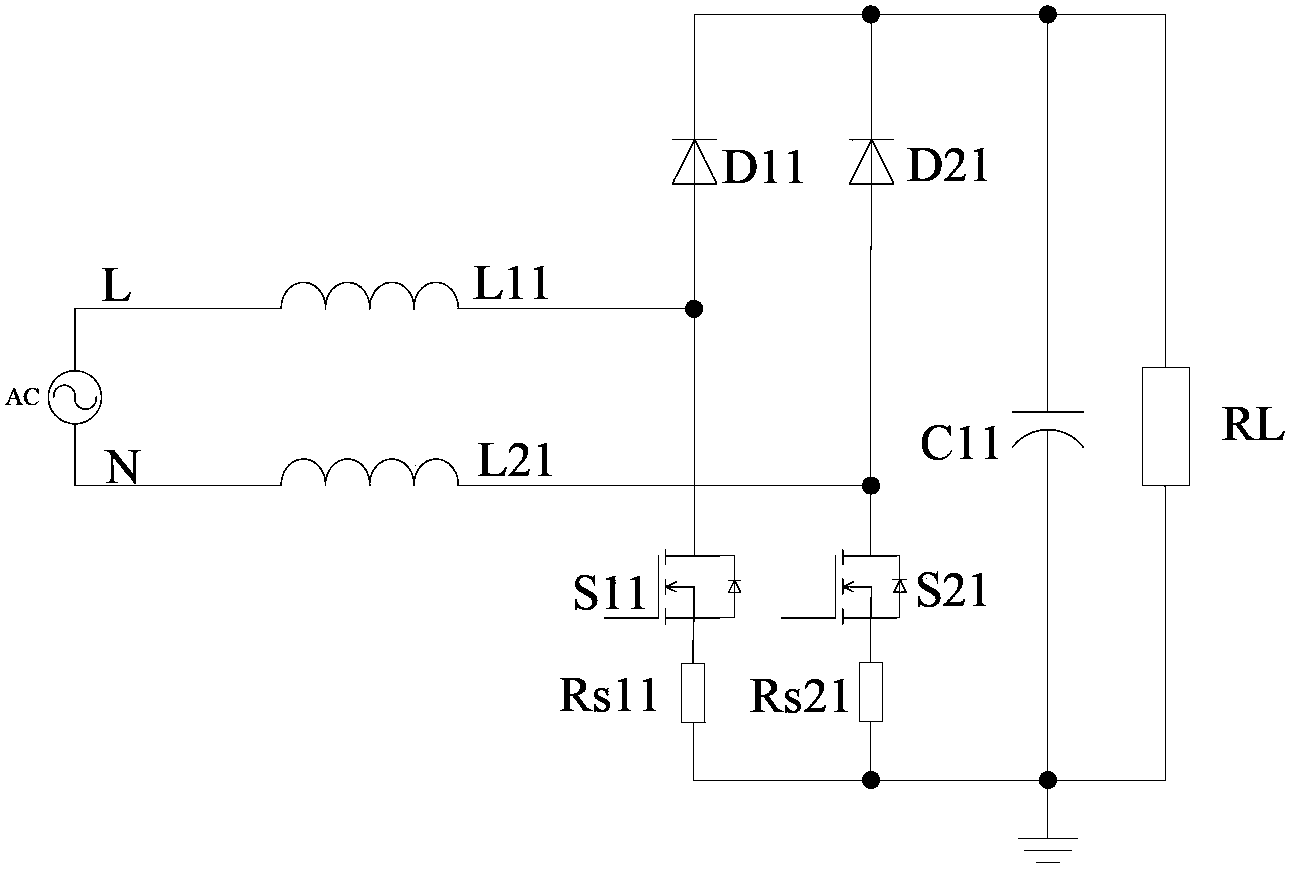

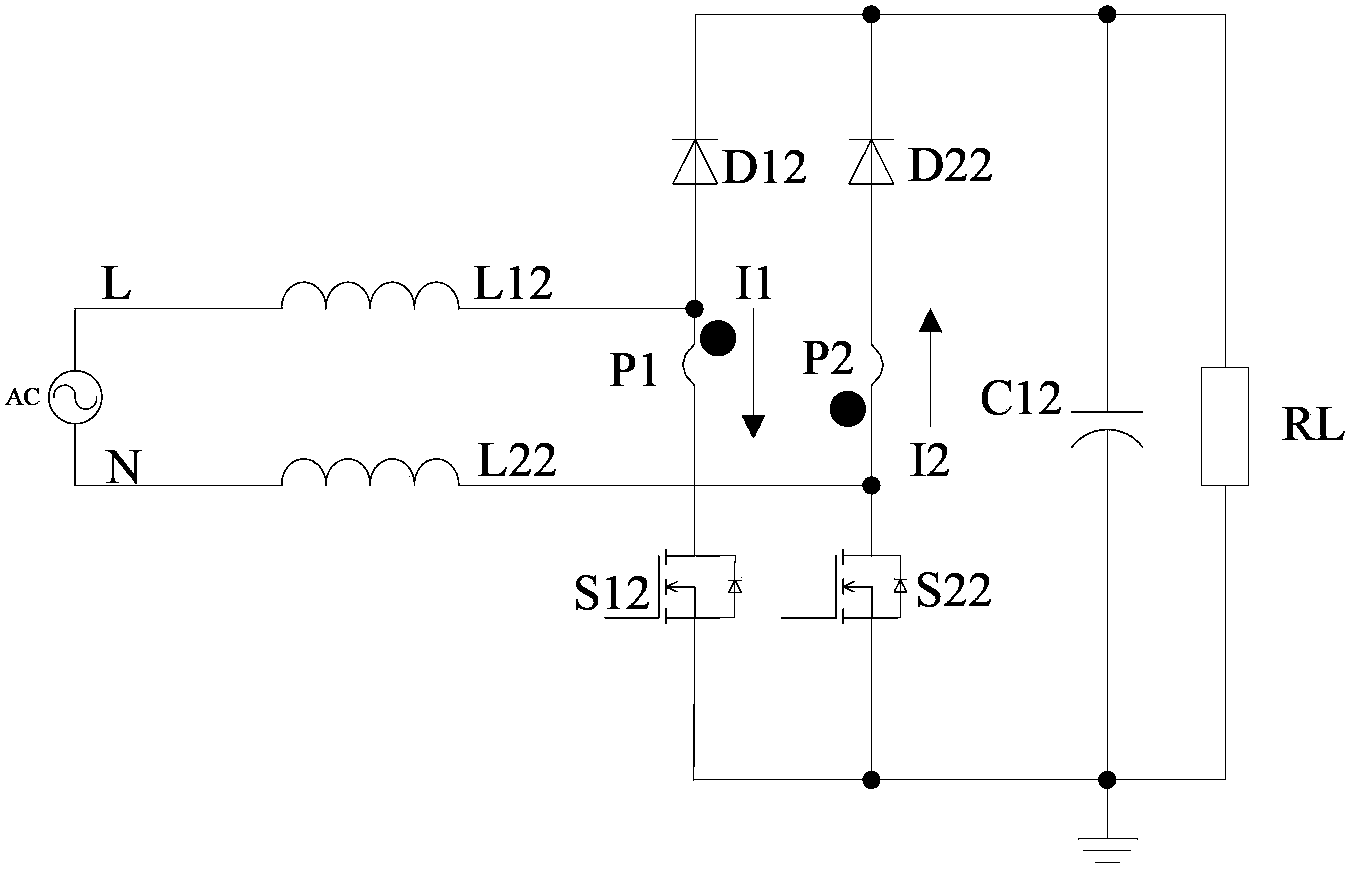

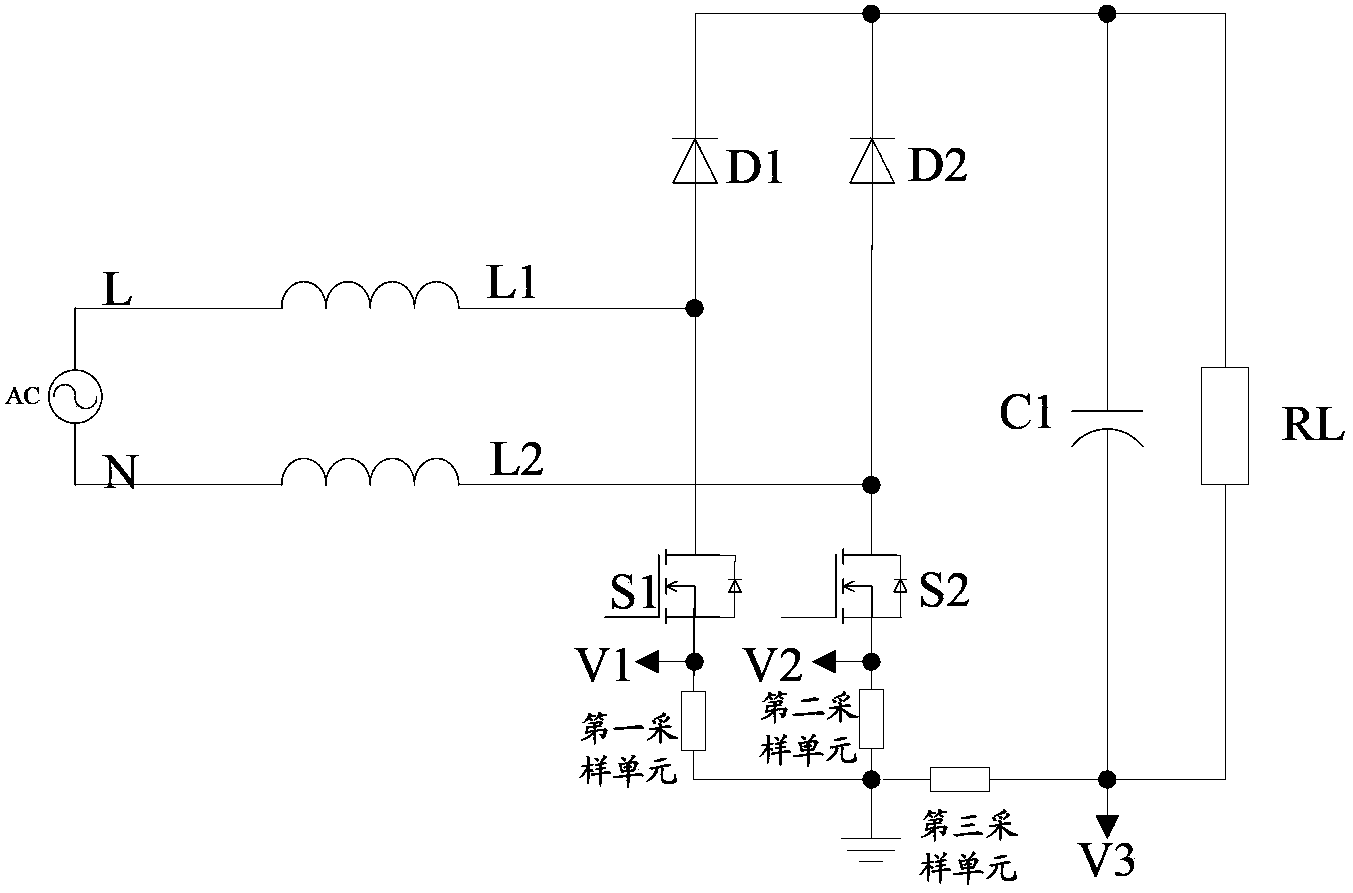

Device and method for inductive current sampling of bridge-free PFC circuit

InactiveCN103809007AReduce difficulty and complexityComprehensive samplingEfficient power electronics conversionAc-dc conversionCapacitanceInductance

The invention discloses a device and method for inductive current sampling of a bridge-free PFC circuit. The device comprises a first sampling unit, a second sampling unit and a third sampling unit. The device for inductive current sampling of the bridge-free PFC circuit is connected with the bridge-free PFC circuit. The first sampling unit is in series connection with a first switch tube of the bridge-free PFC circuit and is used for sampling a current passing through the first switch tube and obtaining first sampling signals V1; the second sampling unit is in series connection with a second switch tube of the bridge-free PFC circuit and is used for sampling a current passing through the second switch tube and obtaining second sampling signals V2; one end of the third sampling unit is connected with the grounding end of the bridge-free PFC circuit, the other end of the third sampling unit is connected with the negative output end of an PFC capacitor of the bridge-free PFC circuit, and the third sampling unit is used for sampling a current passing through a booster diode of the bridge-free PFC circuit and obtaining third sampling signals V3.

Owner:ZTE CORP

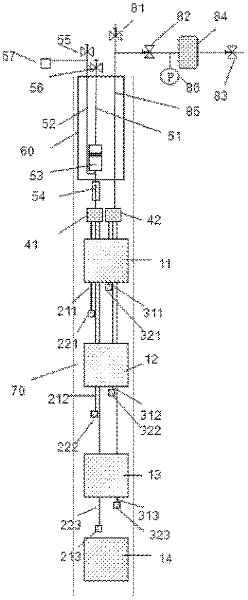

Stratified fluid monitoring and sampling device based on pressure pulse

ActiveCN102505939AComprehensive monitoringComprehensive samplingSurveyConstructionsTemperature controlHorizon

The invention discloses a stratified fluid monitoring and sampling device based on pressure pulse. A sampling device is arranged on the inner wall of a drilled hole or a sleeve and comprises a packer system, a liquid sample injection system, a gas sample injection system, automatic multi-way valves, a sampling system, a temperature control system and the like, wherein a pressure container in a pressure pulse system is connected with the valves and a pressure sensor through a pipeline for forming the pressure pulse system, the pressure pulse system is connected with the underground gas sample injection system through the automatic control multi-way valve, the liquid sample injection system is connected with the liquid automatic multi-way valve, and the gas sample injection system is connected with the gas automatic multi-way valve. The state of fluid in a stratum is judged by the pressure pulse, the underground fluid sampling horizon is simultaneously precisely controlled, respective sampling of gas and liquid fluids in different horizons under constant temperature and pressure conditions can be realized, the response rate of sampling is improved and precise sampling under the low flow rate condition can be particularly realized. The device is simple to assemble all the parts and suitable for monitoring the state of the multi-layer fluid in a bored well and sampling the underground gas and liquid two-phase fluid.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

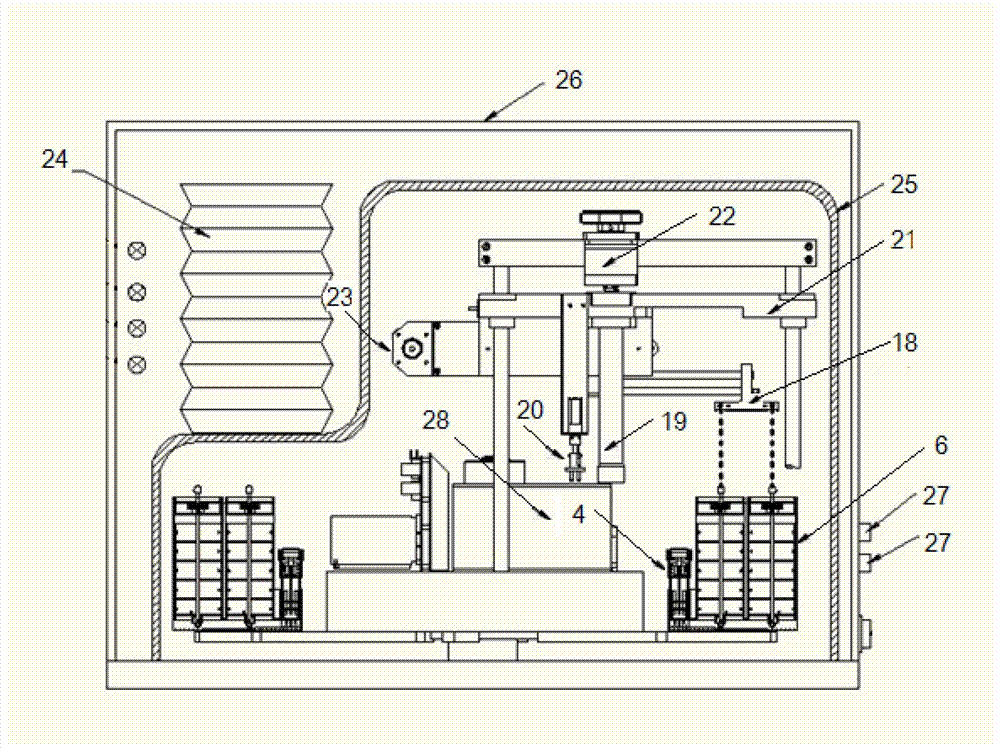

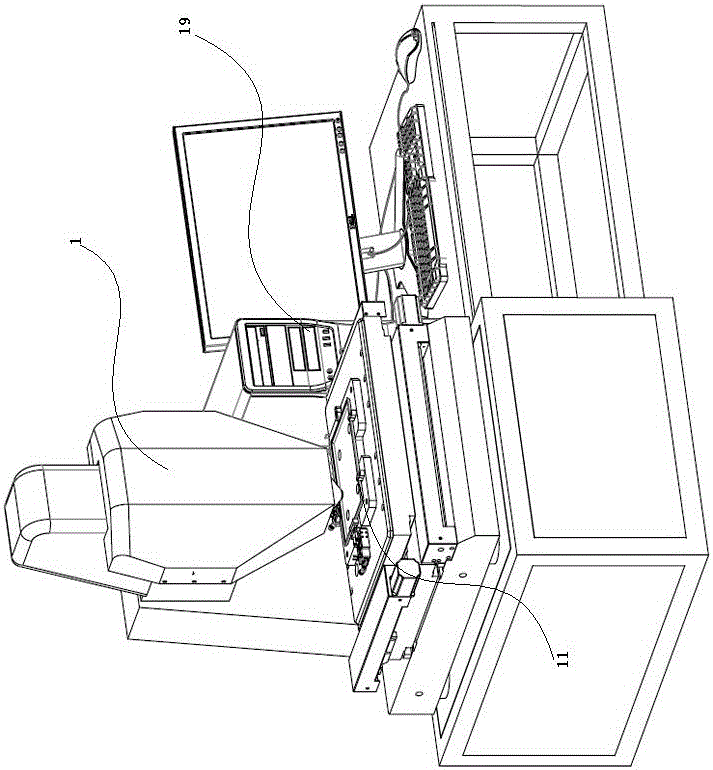

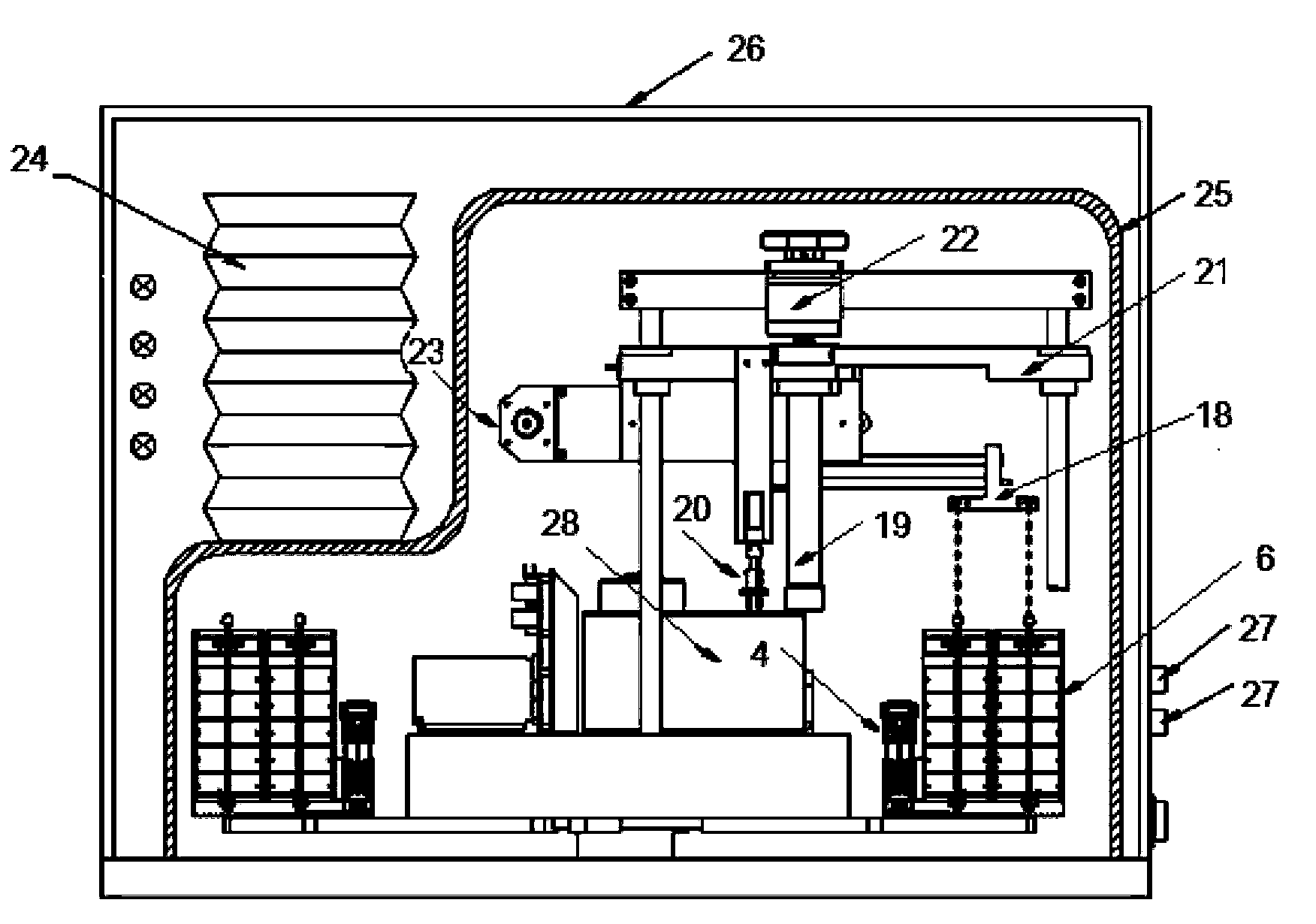

Microbial sample processing system

InactiveCN103194385AEnsure biosecurityImprove airtightnessBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlMicroorganism

The present invention provides a microbial sample processing device, comprising: a machine body provided with a machine chamber and a sealed movable door; and a sealed housing, a stretchable airbag, a sample tray, a mechanical arm, a bar code scanner, a liquefier, culture dishes, a gas-temperature sensor, and a temperature control device which are arranged in the machine chamber, wherein the sample tray is provided with a plurality of sample seats, the sample seats are used for placing the culture dishes, the liquefier is communicated with the culture dishes, each culture dish is provided with culture plates and a streak-inoculation pen used for streak inoculating the sample in the culture dishes from the liquefier on the culture plate. The microbial sample processing device is reasonable in structure, fast and safe, reliable and efficient, can complete the whole process of mixing and liquefying, streak inoculation, dilution and separation, and incubation of microbial community automatically in a one-stop manner, and can replace manual labor and ensure biological safety.

Owner:湖南千山医疗器械有限公司

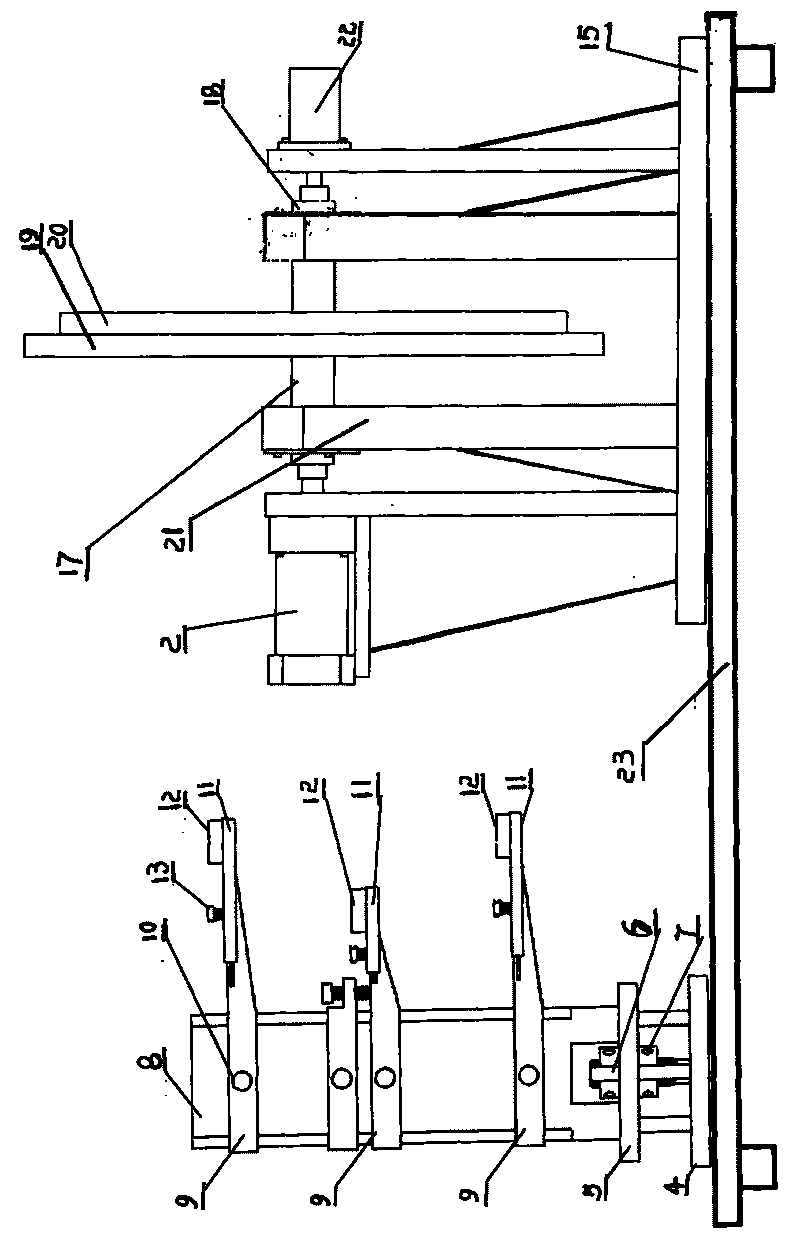

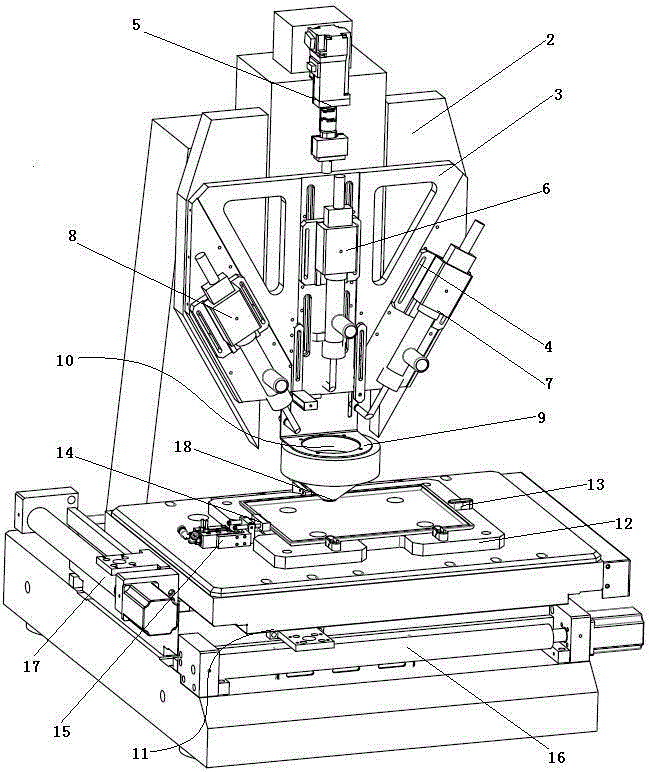

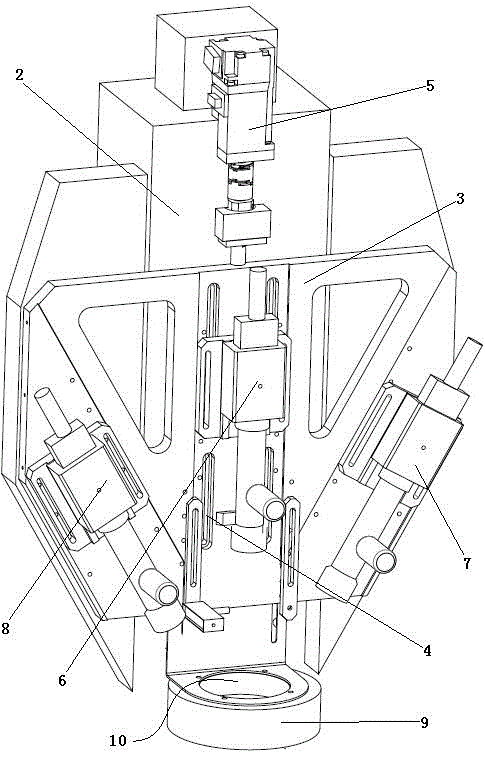

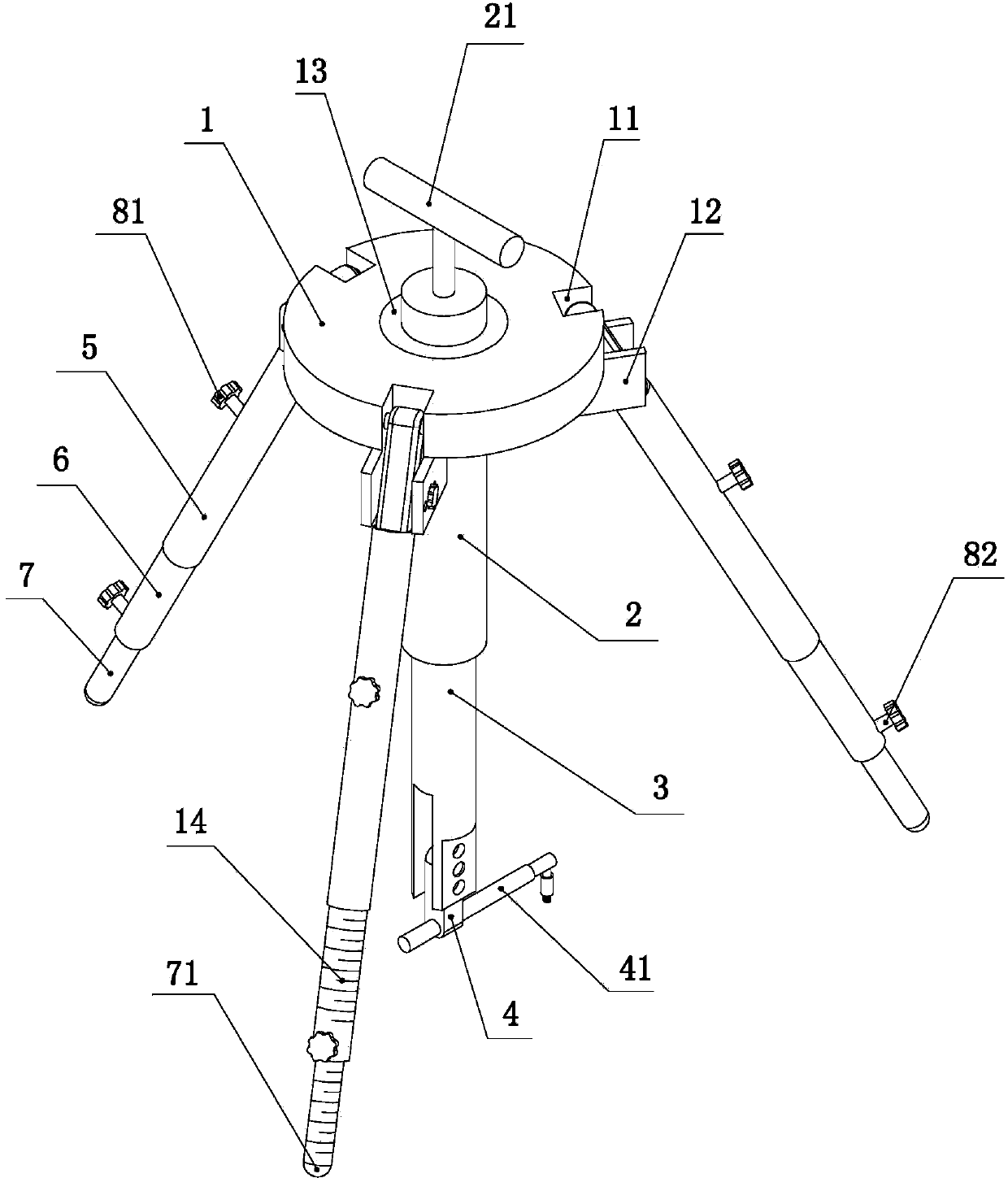

Device for measuring diameter of large shaft working piece by non-contact-type online measurement

InactiveCN101706261ALow positioning accuracy requirementsComprehensive samplingUsing optical meansCircular discElectric machine

The invention relates to a device for measuring the diameter of a large shaft working piece by non-contact-type online measurement, which solves problems of heavy detection tools, inconvenient operation and low measurement precision and measurement efficiency during precisely measuring a machined workpiece with large diameter. Three guide rails are arranged on a tripod head of a measurement base and connected by screws and threads; an upright post is mounted on the base and sleeved with four guide rail sliding blocks and provided with locking screws; sliding plates which are fixed on upper and lower guide rail sliding blocks have same length and provided with respective sensors connected by locking screws; two guide rail sliding blocks sleeved in the middle of the upright post are provided with sliding plates and sensors connected by locking screws; the length of sliding plates of the middle guide rail sliding blocks is smaller than the upper sliding plate and the lower sliding plate; the sensors are connected with a computer by cables; symmetric supporting seats are fixedly mounted on a calibration base, connected with a rotating shaft and provided with bearings; the center of the rotating shaft is provided with a large disc and a small disc the diameters of which are different; an adjustable-speed motor is connected with a bracket and fixed on the calibration base; the shaft of the adjustable-speed motor is connected with one end of the rotating shaft the other end of which is connected with a rotating speed coder fixed on the bracket of the calibration base; and a measurement base and the calibration base are connected by a large platform.

Owner:HUNAN UNIV OF SCI & TECH

Elevator cloud system for achieving lifelong responsibility of manufacturer for elevator and elevator operation control method of elevator cloud system

ActiveCN103964268AReduce maintenance costsImprove maintenance efficiencyElevatorsCloud storageData exchange

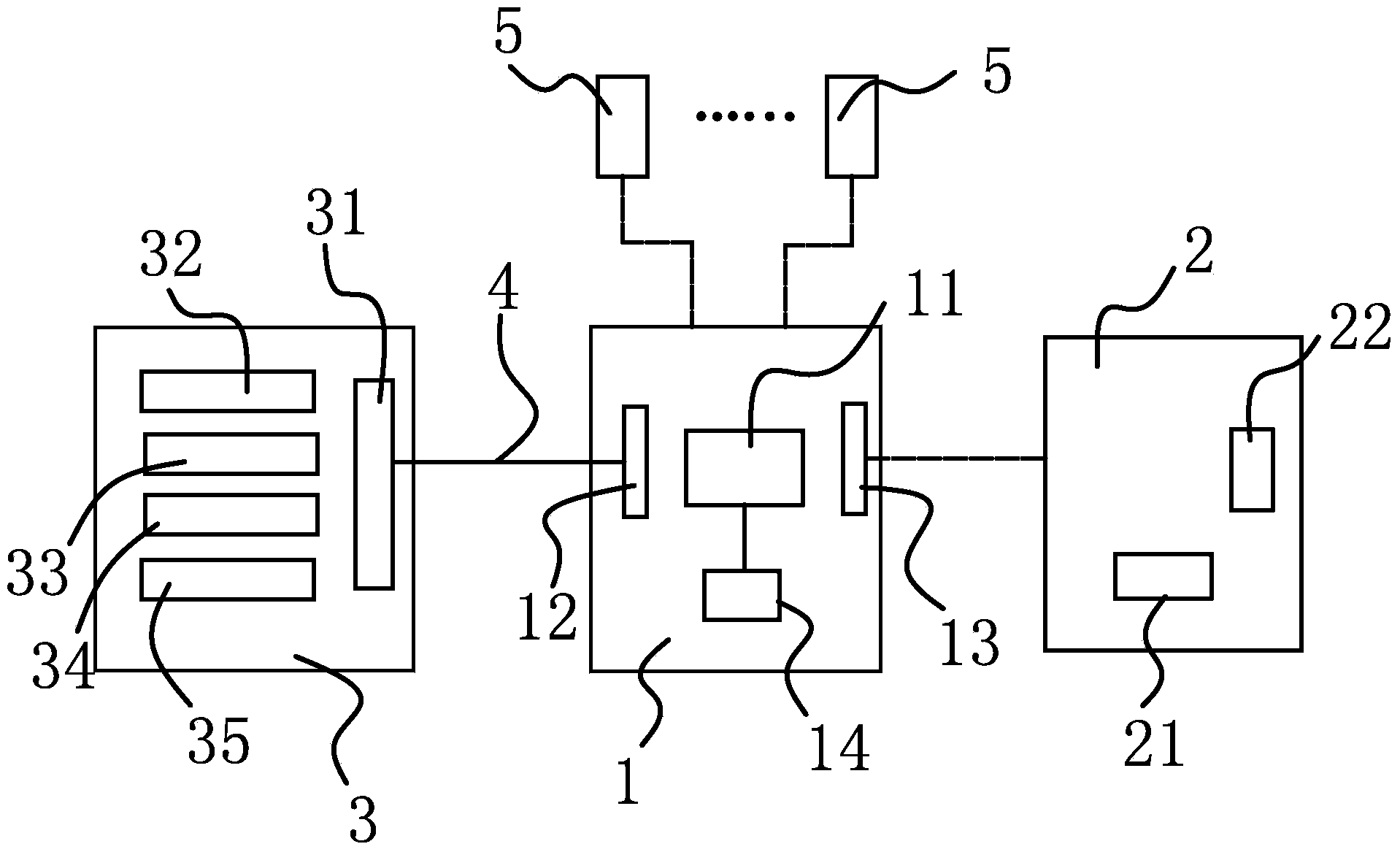

The invention belongs to the technical field of elevator equipment and an intelligent control technology, and relates to an elevator cloud system for achieving lifelong responsibility of a manufacturer for an elevator and an elevator operation control method of the elevator cloud system. The elevator cloud system for achieving lifelong responsibility of the manufacturer for the elevator and the elevator operation control method of the elevator cloud system solve the technical problem that an existing technology is not reasonable enough in design. The system comprises an elevator cloud and a remote monitoring center, the elevator cloud comprises a cloud processing module, the cloud processing module is connected with an elevator communication module and a wireless communication module, the elevator communication module can be connected with an elevator control system and conduct data exchange with the elevator control system, the wireless communication module can be connected with the remote monitoring center through a wireless communication network and conduct data exchange with the remote monitoring center, and the cloud processing module is further connected with a cloud storage. The elevator cloud system and the elevator operation control method have the advantages that effective monitoring and management can be achieved on the elevator, the use safety of the elevator is guaranteed, and the fault maintenance can be conducted in time; the wireless communication module enables information of a broken-down elevator to be fed back to the remote monitoring center in time, the remote monitoring center can assign people to maintain the broken-down elevator in time, the maintenance cost is lowered and the repairing efficiency is increased virtually, and the practicability is high.

Owner:SYNEY ELECTRIC HANGZHOU CO LTD

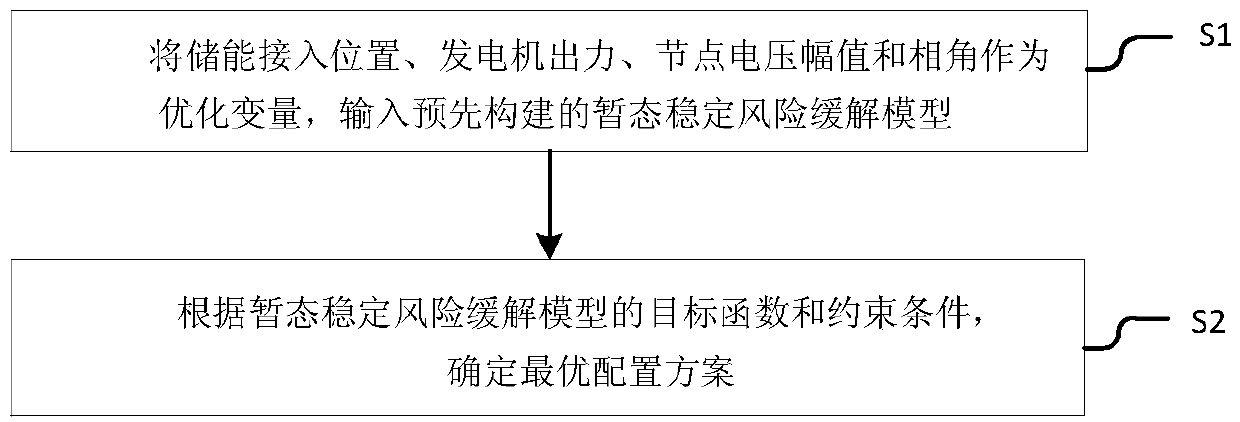

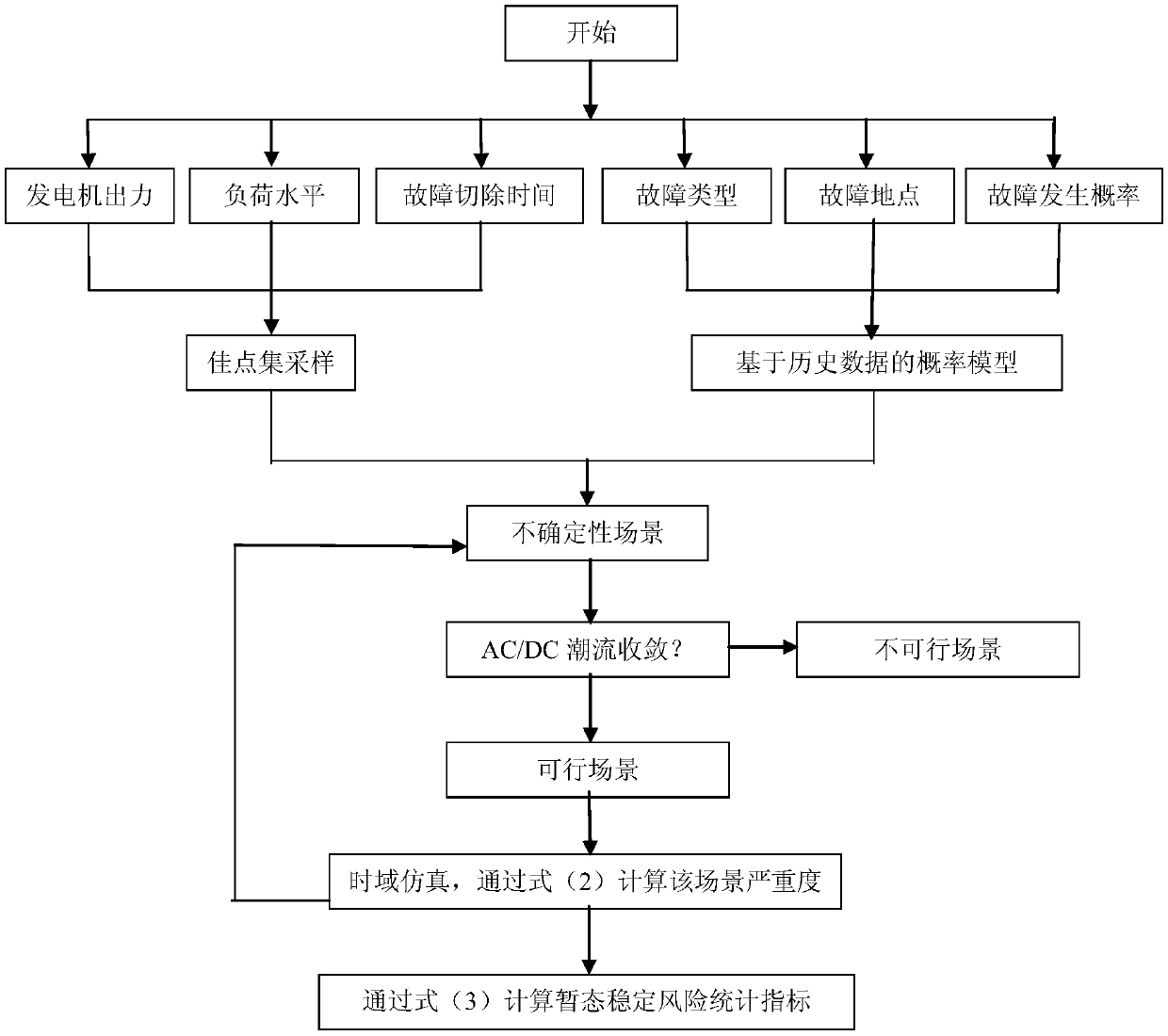

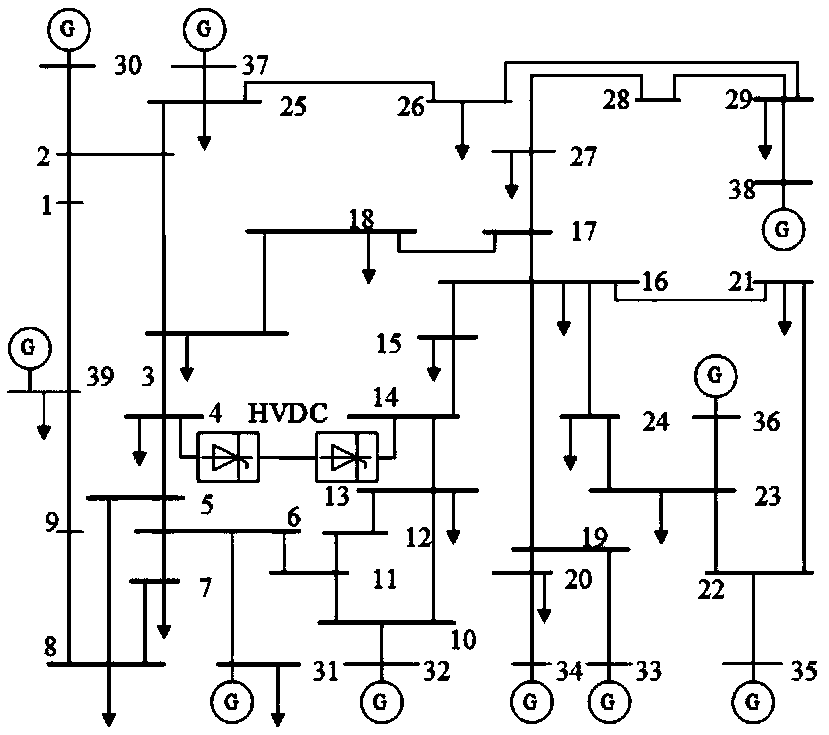

Energy storage planning method based on power system transient stability as well as system

PendingCN109638810ATransient Stability Risk MitigationMitigate the risk of transient instabilityAc network load balancingTransient stateElectric power system

The invention relates to an energy storage planning method based on power system transient stability as well as a system. An energy storage access position, output power of a generator as well as amplitude and a phase angle of a node voltage are taken as optimization variables and are input a transient stability risk mitigation model constructed in advance; and according to an objective function and constraint conditions of the transient stability risk mitigation model, an optimal configuration scheme is determined, wherein the transient stability risk mitigation model is constructed on the basis of minimization of energy storage and generator output power costs as well as predefined transient stability risk indicators, and the transient stability risk indicators are developed according tofault severity and fault occurrence probability of an uncertain scene.

Owner:CHINA ELECTRIC POWER RES INST +2

Threaded hole detection device

InactiveCN105066890AComprehensive samplingReduce missed detection rateUsing optical meansImage detectionCcd camera

The invention relates to a threaded hole detection device, which comprises an image detection mechanism and a carrier table top arranged at one side of the image detection mechanism, wherein the image detection mechanism is provided with at least one image device facing the carrier table top in a forward mode and at least one image device facing the carrier table top in an inclined mode; the image detection mechanism and the carrier table top can move in a relative approaching mode; the carrier table top can move in a plane where the carrier table top is located; the CCD cameras which are arranged in a forward mode and in an inclined mode detect each quality index of the inner thread individually; the CCD cameras with different angles are arranged on a fixing plate, and all quality index items of the same inner thread can be detected; as at least two inclined CCD cameras are arranged, detection and calculation on the inner threaded hole in at least two different angle directions can be realized, sampling is more complete, and the detection omission rate is greatly reduced; and the two inclined CCD cameras are matched for detecting the position and the angle of a screw tooth at the free end of two end parts in the inner thread.

Owner:SUZHOU JQS INFO TECH CO LTD

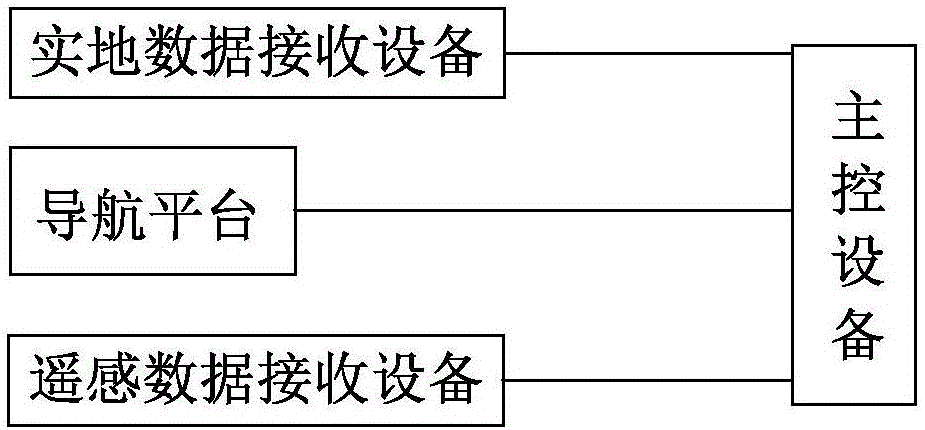

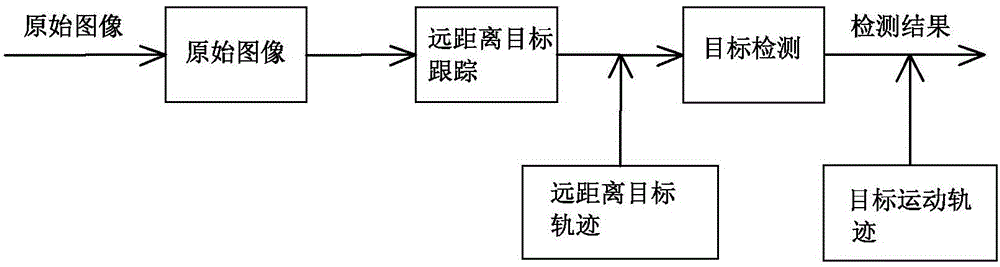

Congestion level analysis platform based on double communication data

InactiveCN106408944AIncrease the lengthImprove accuracyDetection of traffic movementCharacter and pattern recognitionSensing dataField data

The invention discloses a congestion level analysis platform based on double communication data, which belongs to the communication field. The congestion level analysis platform based on double communication data comprises a remote sensing data receiving device, a field data receiving device and a main control device, wherein the remote sensing data receiving device receives a road section remote sensing image of a target road section sent by a remote sensing satellite. The congestion level analysis platform based on double communication data is characterized in that the field data receiving device receives detection information sent by a radar probe in the target road section; moving track images of all vehicles in the target road section are drawn according to the detection information by the main control device; and the main control device determines the congestion level of the target road section according to the remote sensing image of the road section and the moving track images of all vehicles in the road section. In view of the technical problem that the precision of the detection result is not high by the single-factor road section congestion degree detection mode in the prior art, the satellite remote sensing image and the field radar detection are combined through a weighting mode, level judgment is carried out on the congestion degree of each target road section, and more valuable navigation data can be provided.

Owner:DONGYING POWER SUPPLY COMPANY STATE GRID SHANDONG ELECTRIC POWER +1

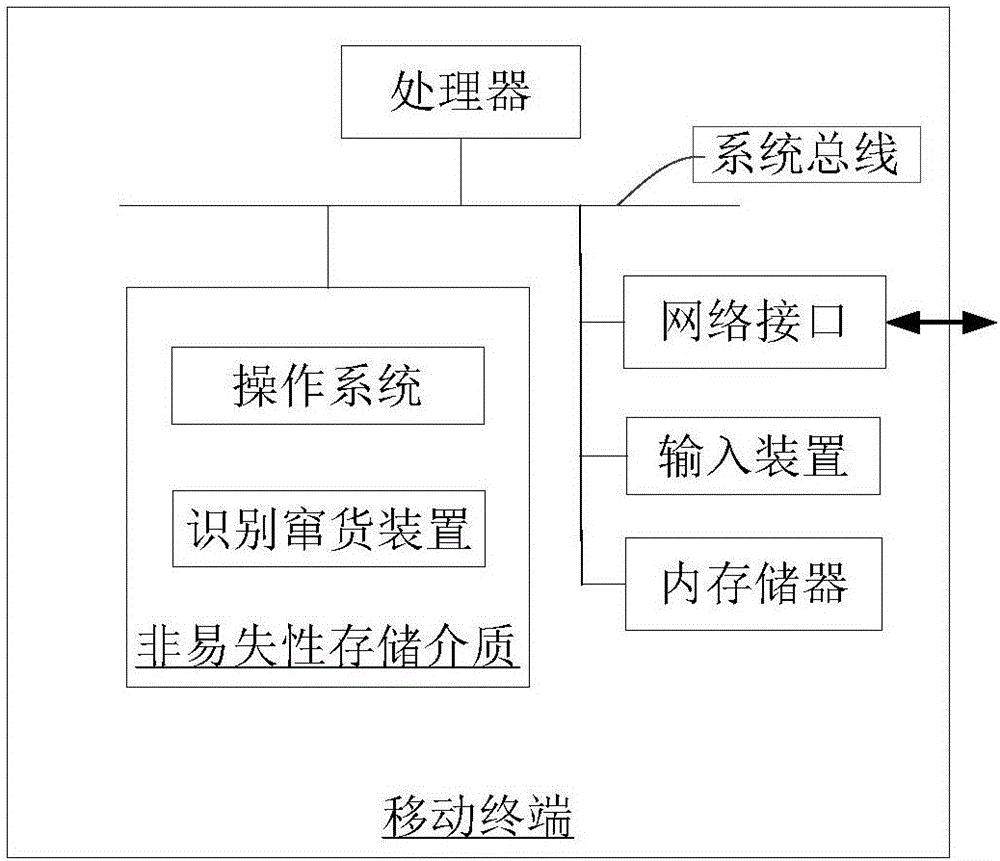

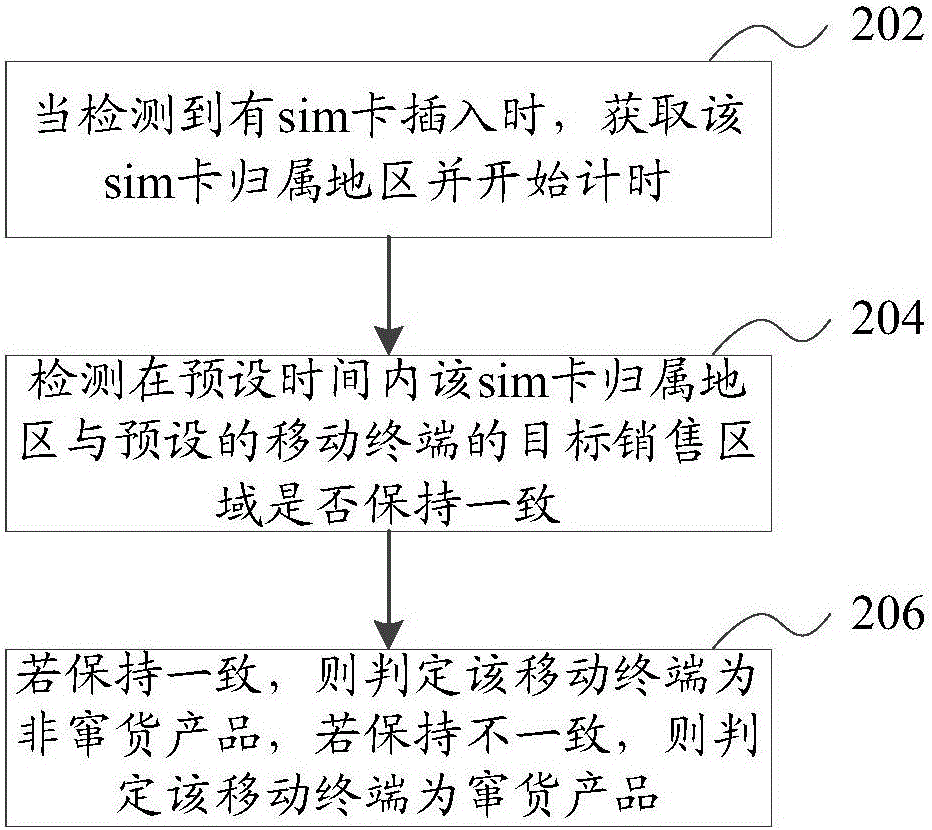

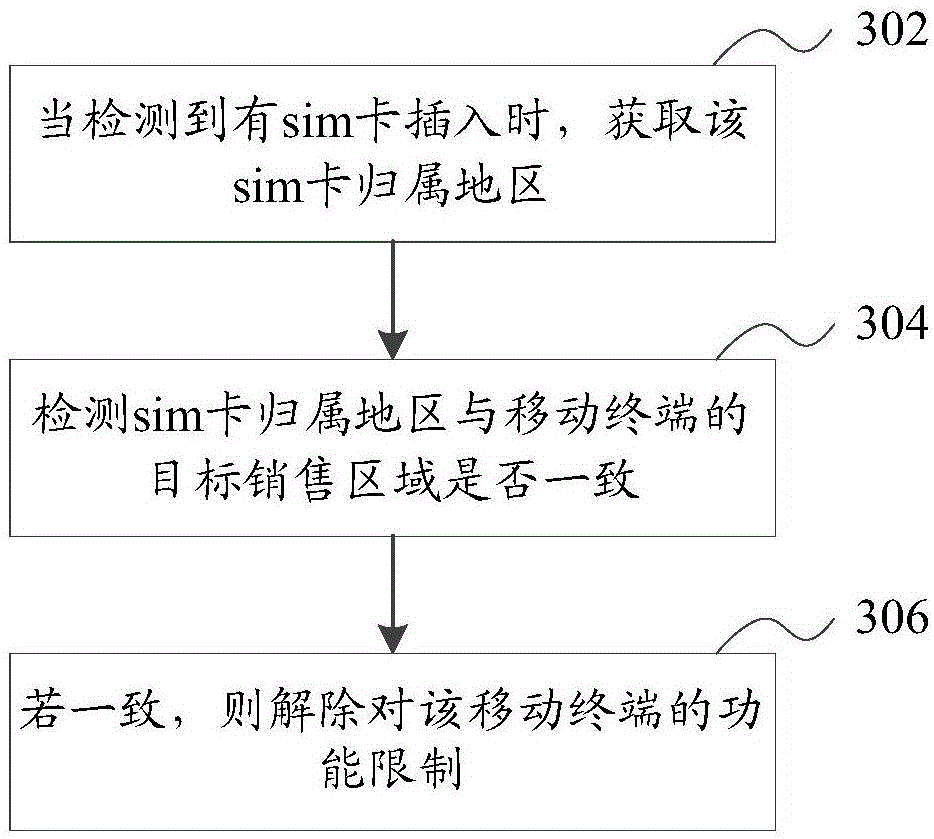

Goods fleeing recognition method and goods fleeing recognition device

The invention relates to a goods fleeing recognition method and a goods fleeing recognition device. The method includes: when insertion of a sim card is detected, acquiring an attribution area of the sim card and starting timing; detecting whether the sim card attribution area is kept uniform with a preset target sales area of a mobile terminal in preset time; if yes, determining that the mobile terminal is not a fleeing product, and if not, determining that the mobile terminal is a fleeing product. By adoption of the method, goods fleeing recognition results are high in reliability.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

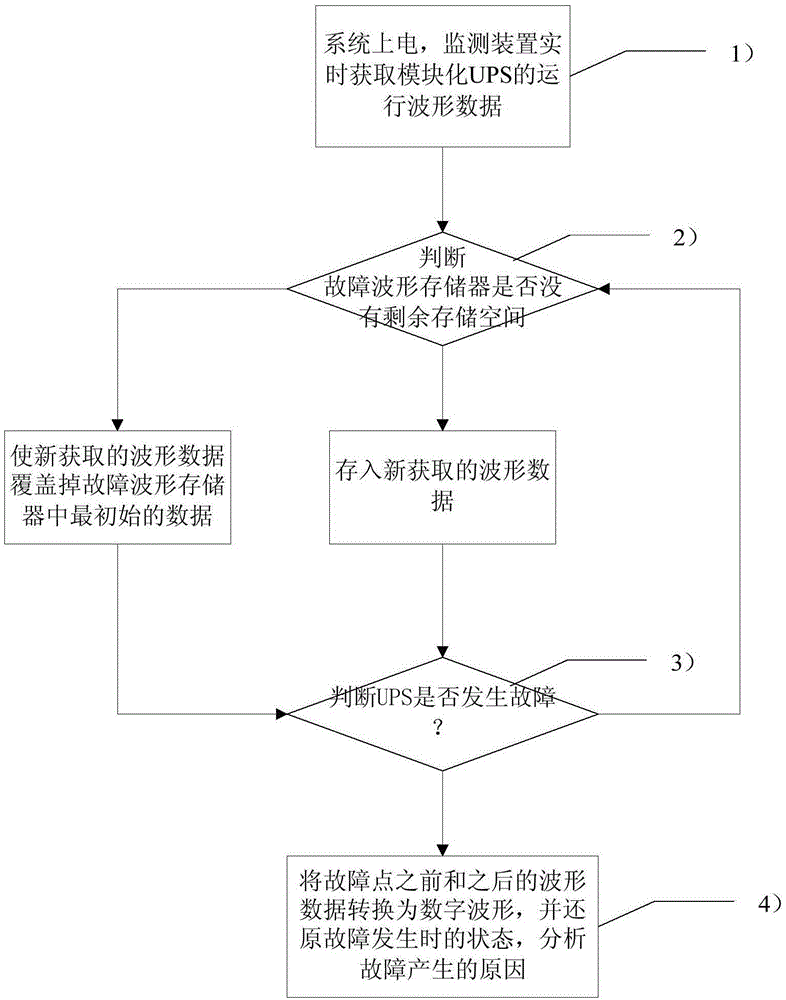

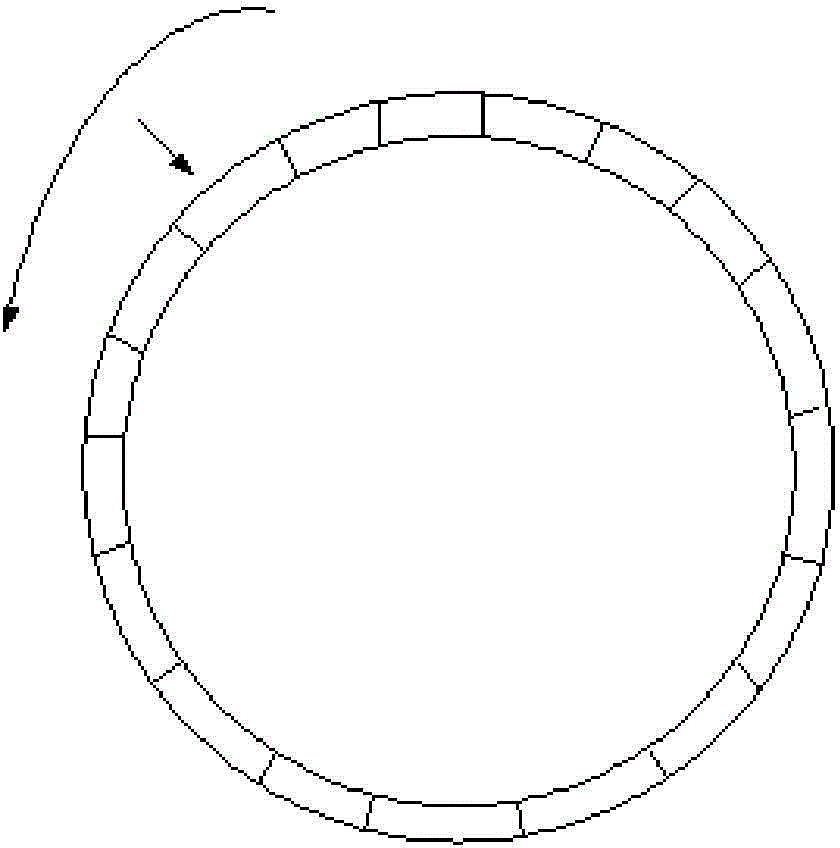

Fault moment real-time recording method and system of modular UPS

The invention relates to a fault moment real-time recording method and system of a modular UPS. The method includes steps: 1) the system is powered on, and a monitoring device acquires operation waveform data of the modular UPS in real time; 2) whether there is remaining storage space in a fault waveform memory is checked, if not, new acquired waveform data covers original data in the fault waveform memory, and if yes, new obtained waveform data is stored; 3) according to the operation waveform data of the modular UPS, whether a fault occurs is determined; if yes, the waveform data before and after a fault point in the fault waveform memory is stored in an EEPROM, and step 4) is executed; and if not, step 2) is returned to; and 4) the waveform data before and after the fault point is converted to digital waveforms, the state during occurrence of the fault is restored, and the reason of fault occurrence is analyzed. Compared with the prior art, the method and system is advantaged by visuality and accuracy, data acquisition diversity, and real-time monitoring.

Owner:上海航天智能装备有限公司

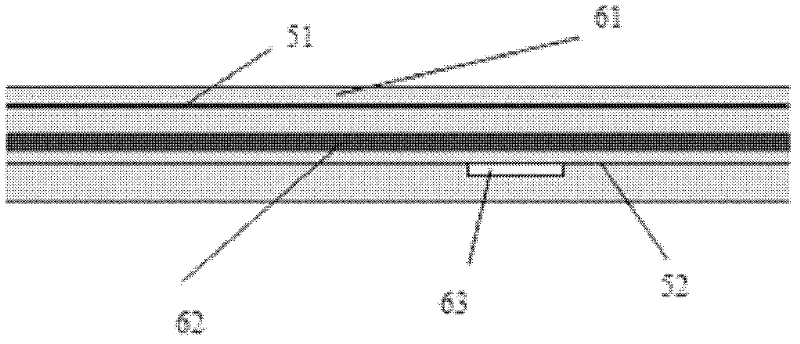

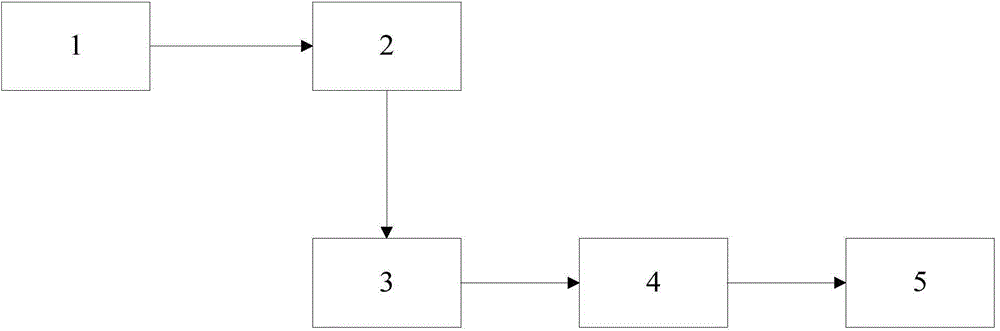

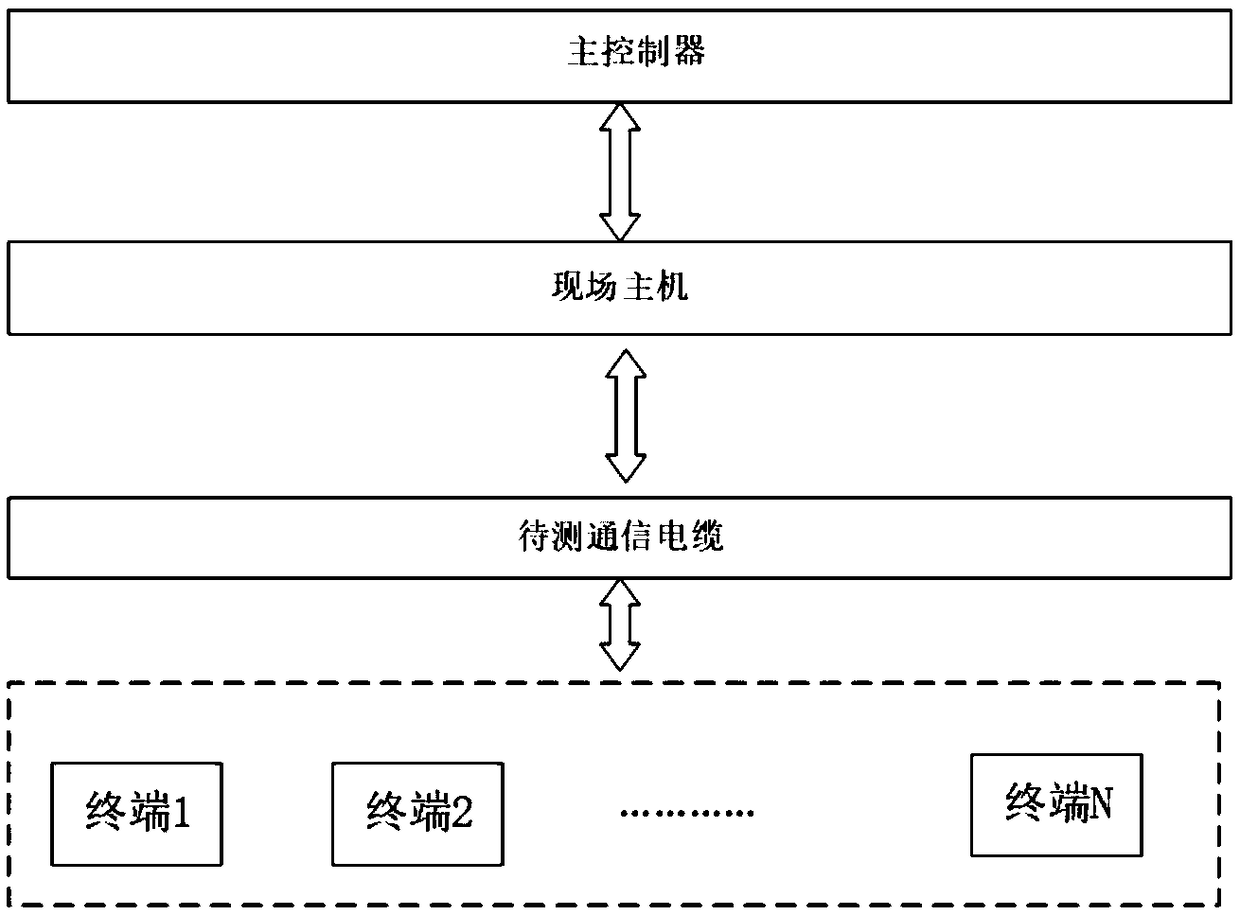

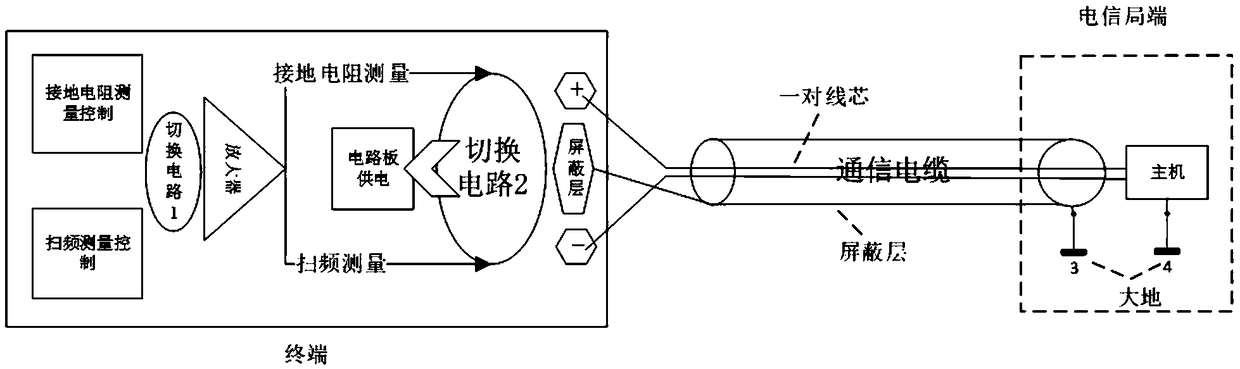

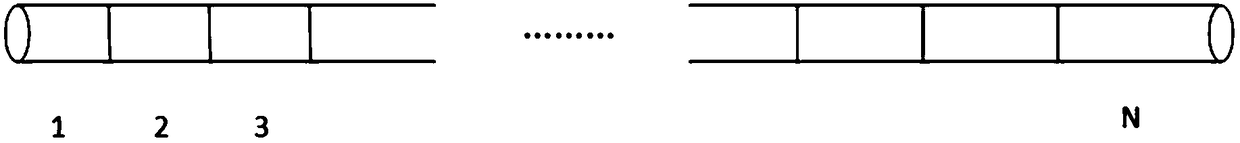

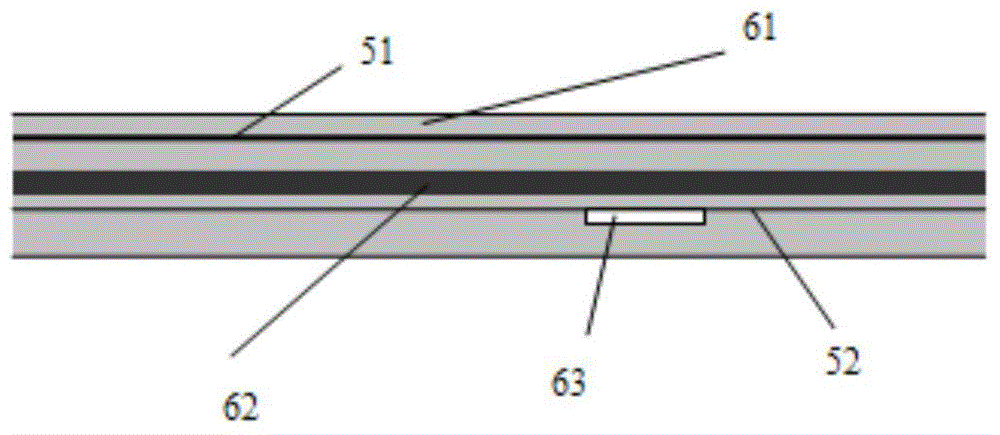

Online monitoring and evaluation method and system for shielding effectiveness of shielding layer of communication cable

ActiveCN109116126ASolving one of the biggest challenges in shielded securityAchieving system performanceElectromagentic field characteristicsElectrical resistance and conductanceGrounding resistance

The invention discloses an online monitoring and evaluation method and system for the shielding effectiveness of a shielding layer of a communication cable. The method comprises: on the basis of a cable segmented frequency sweeping measuring method, fault identification and positioning of a cable shielding layer are carried out; with a loop impedance measurement method, the state of a grounding resistor of the cable shielding layer is determined; comprehensive analysis and reverse evaluation of the shielding effectiveness of the cable are carried out by using an algorithm. According to the invention, reasonable quantitative evaluation of the shielding effectiveness, which can not be evaluated easily in the prior art, of the shielding layer of the communication cable is realized; and a problem of the safety field of the communication cable shielding is solved. Meanwhile, with measurement of various cable physical parameters, systematic, holistic and complementary evaluation of the cableshielding layer is realized.

Owner:康威通信技术股份有限公司

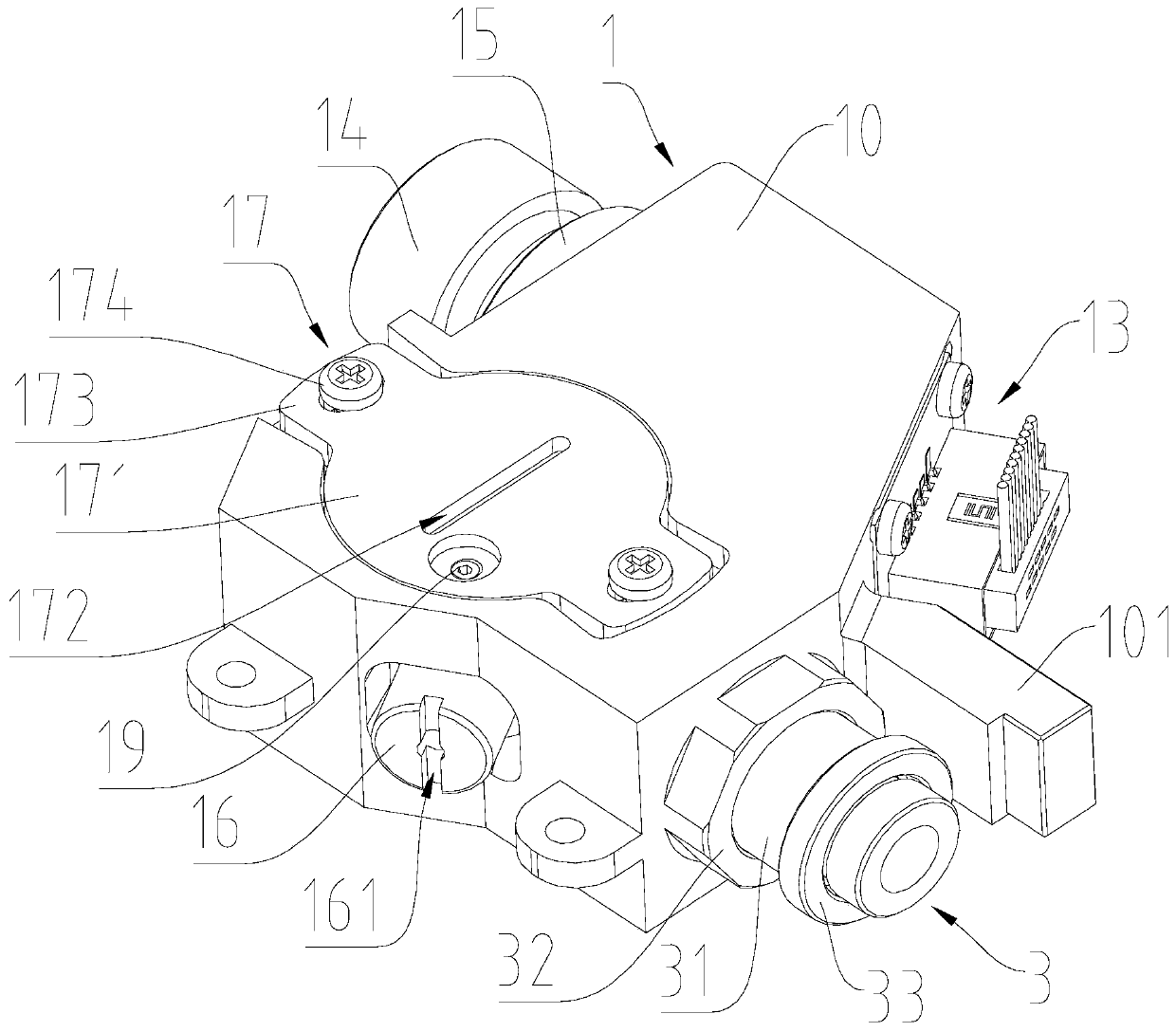

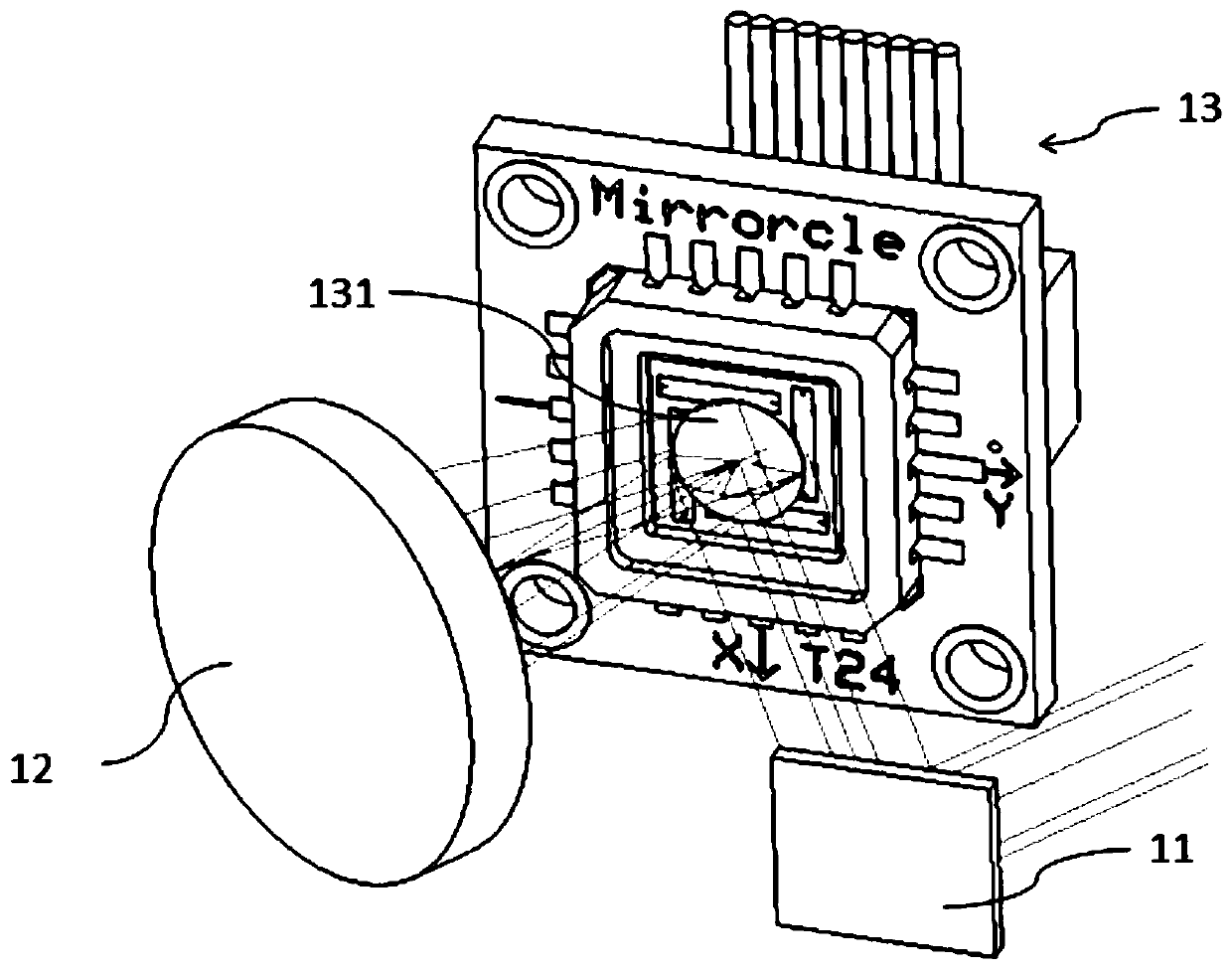

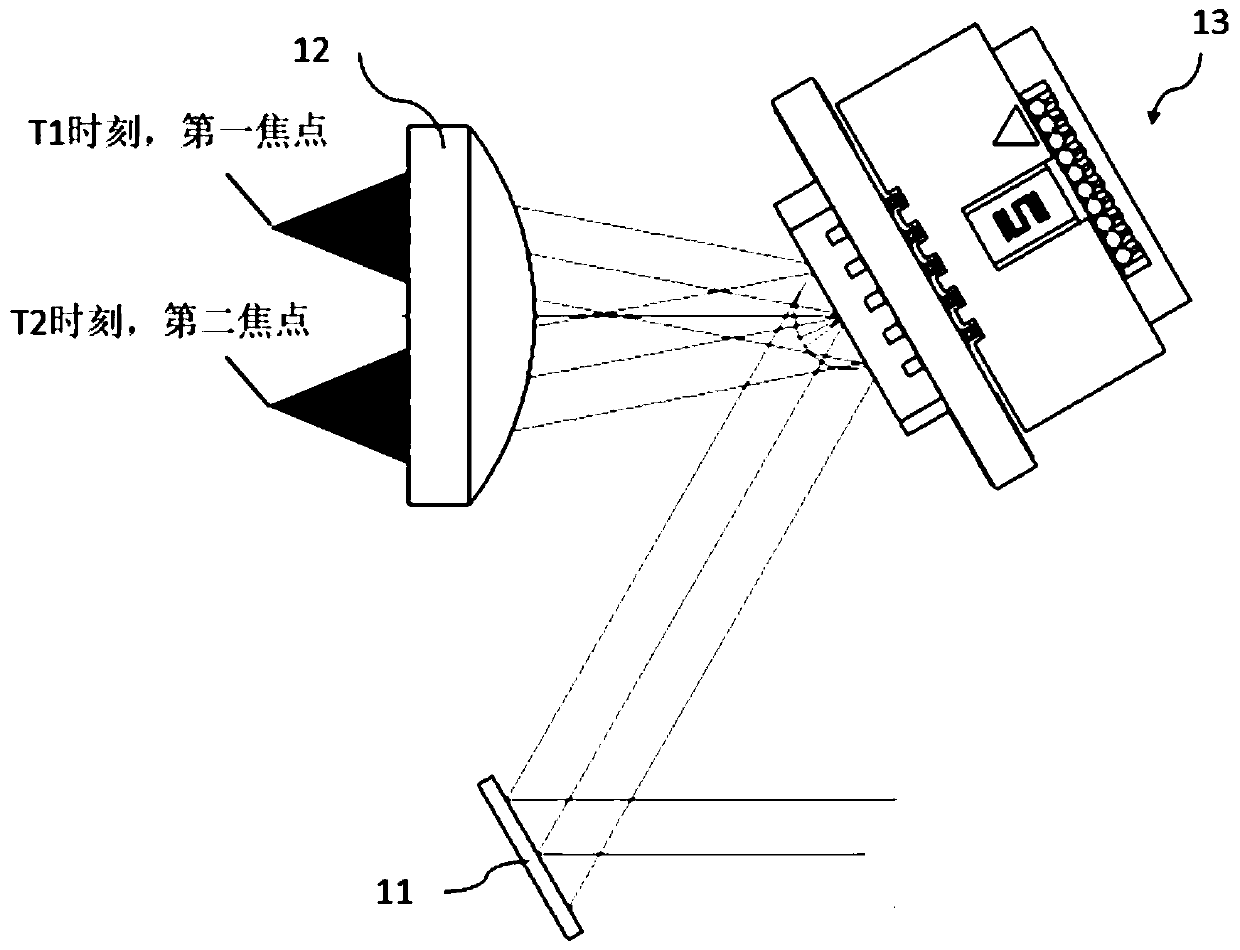

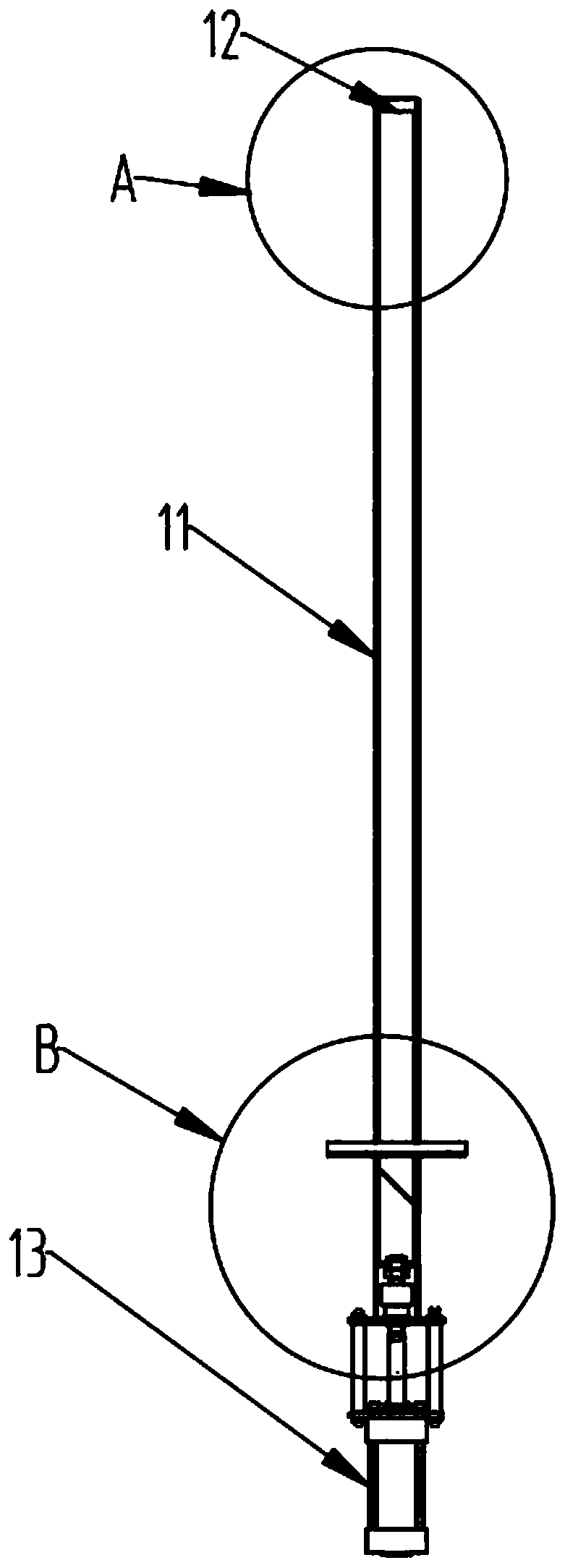

Surface scanning probe system and spectrometer

PendingCN111077130AAvoid ignitionImprove operational safetyRaman scatteringExcitation beamOptical Module

The invention relates to a surface scanning probe system and a spectrometer. The surface scanning probe system comprises a first shell, a surface scanning optical module, a MEMS module, and an objective lens module, wherein the shell is provided with a light guide hole so as to enable an excitation light beam to irradiate into the first shell, and the excitation light beam comes from a light passing hole of a Raman detection system of the spectrometer; the surface scanning optical module is mounted to the first shell and includes a reflection element; the MEMS module is fixed to the first shell and includes an MEMS driver and an MEMS reflector, and the MEMS driver drives the MEMS reflector to move; and the objective lens module is fixed to the first shell and includes a collimating lens, and the excitation light beam entering from the light guide hole is reflected by the reflecting element, then irradiates towards the MEMS reflector and is reflected by the MEMS reflector into a plurality of parallel light beams which irradiate towards an image side surface of the collimating lens at different angles. Through the technical scheme, the surface scanning probe system provided by the invention can realize multi-point detection scanning, and is beneficial to improving operation safety and detection precision of the spectrometer.

Owner:BEIJING CLOUDOPTEK TECH CO LTD

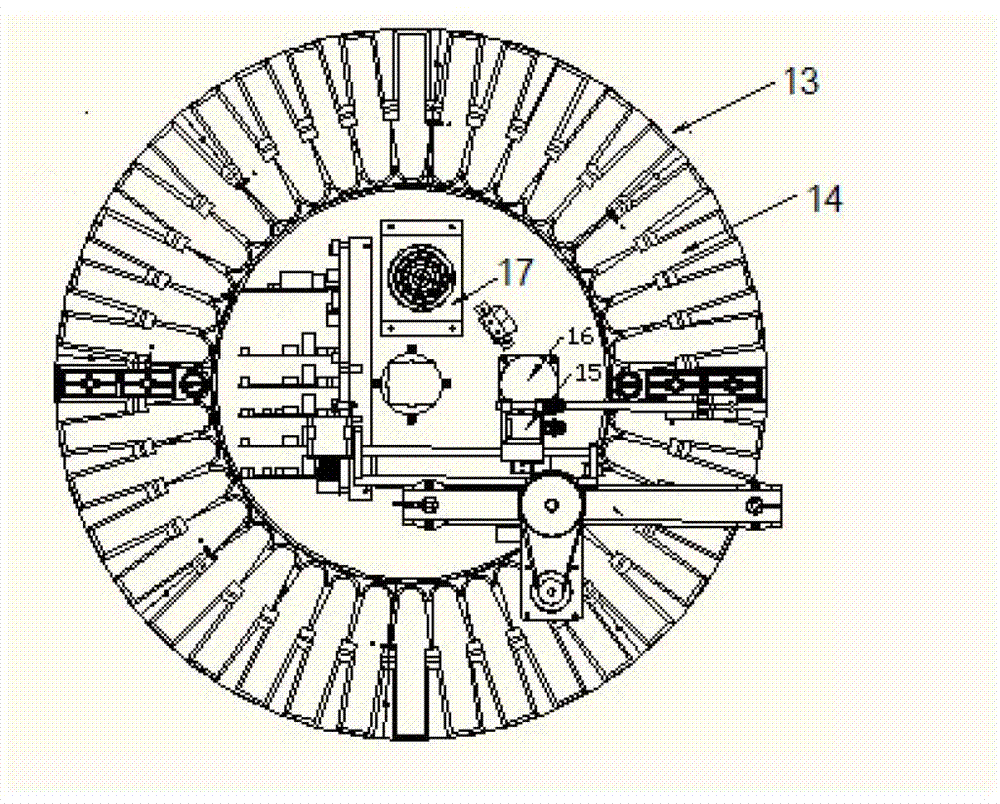

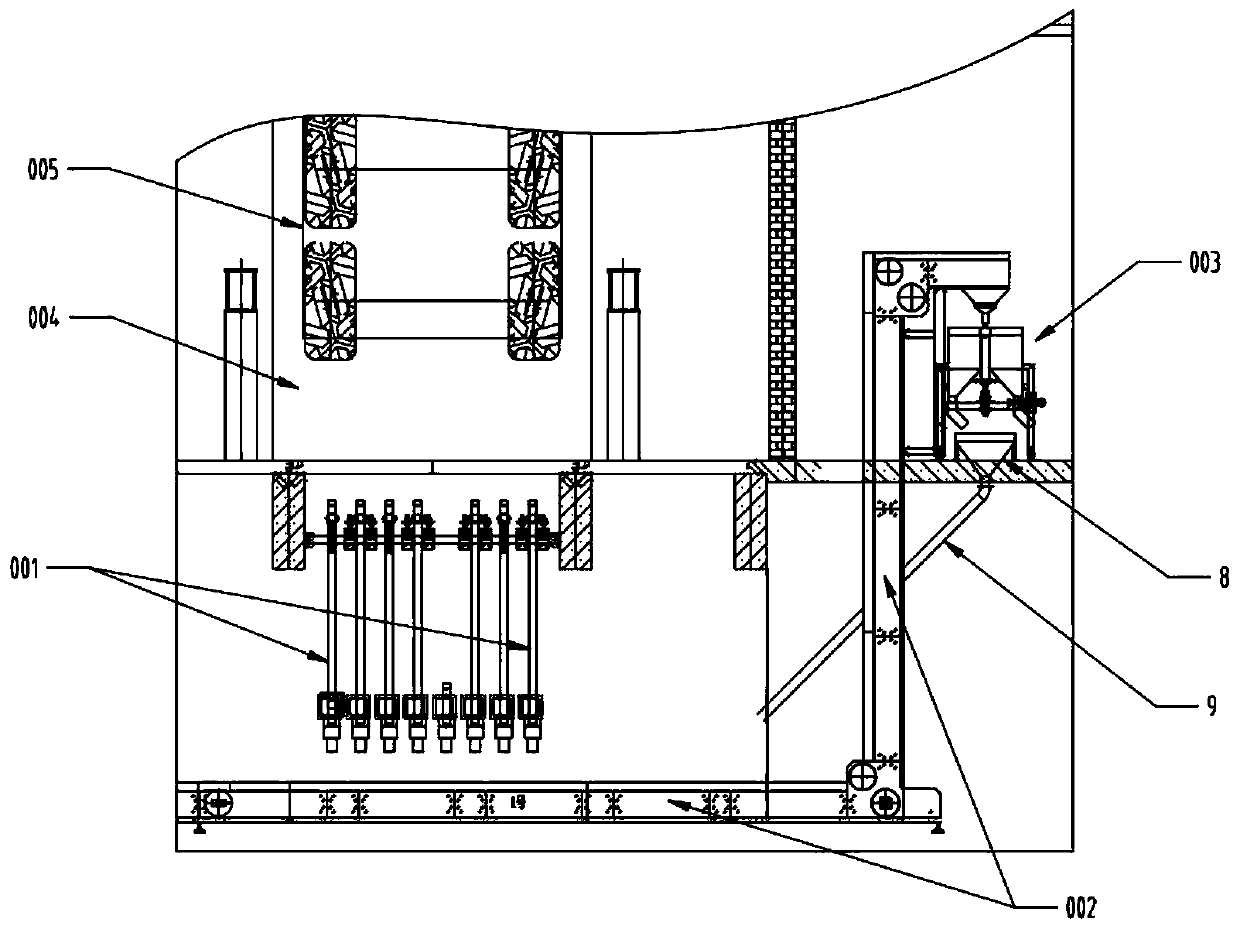

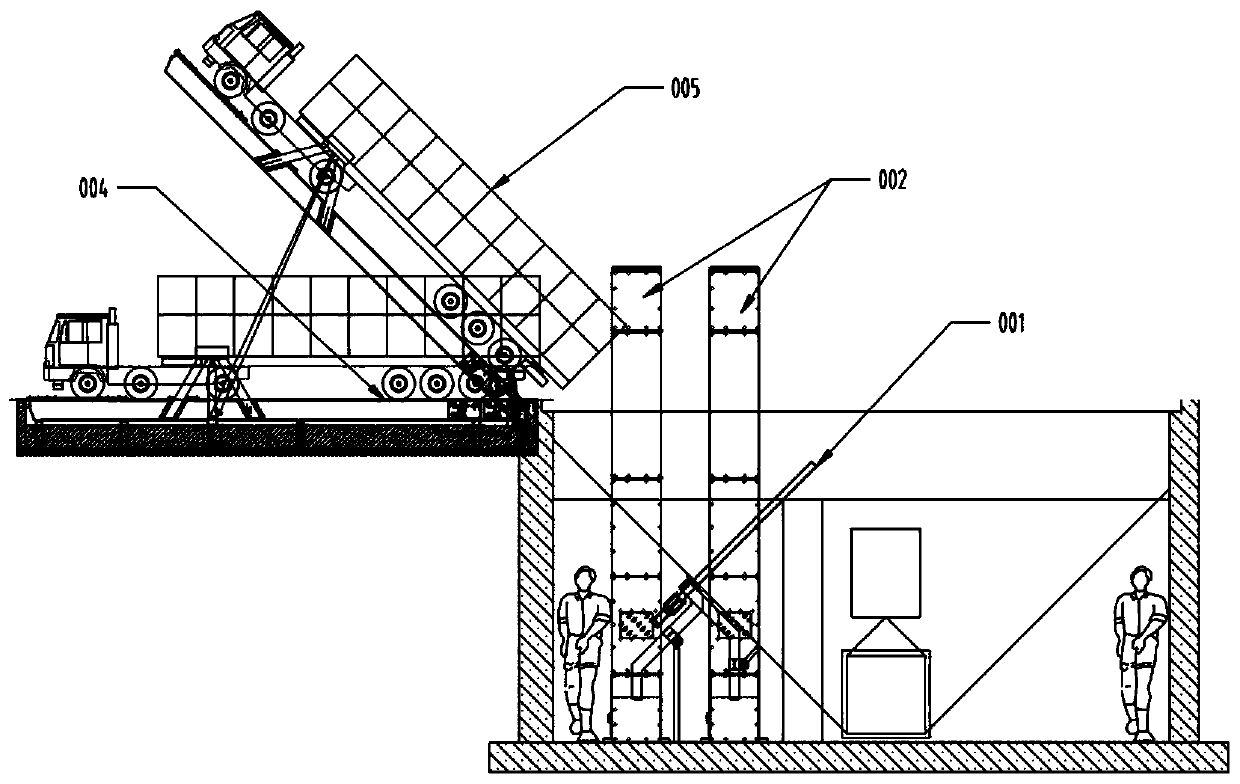

Random sampling system for granular materials

PendingCN110987531AEliminate uneven samplingSampling is reasonableWithdrawing sample devicesMechanical engineeringMechanics

The invention discloses a random sampling system for granular materials. The random sampling system comprises a random sampler, a sample conveying device and an equant sample divider, wherein the random sampler is arranged on a necessary channel for a material during unloading and is used for quantitatively extracting a sample according to a set frequency in the unloading process of a whole vehicle; the sample conveying device is used for conveying samples collected by the random sampler to the equant sample divider; the equant sample divider is used for further equally dividing the collectedsamples into a plurality of parts, and one part is taken as an inspection sample. Therefore, the random sampling system for granular materials can be used for random sampling continuously in the wholematerial unloading process, and the sample is equally divided again at the tail end, so that the consistency of the obtained sample and the whole material is improved, the condition of the whole material can be better represented, the phenomena of non-uniform sampling quantity, poor representativeness and artificial counterfeiting are avoided, and the material sampling is more reasonable, more comprehensive and more scientific.

Owner:莱阳鲁花智能科技有限公司

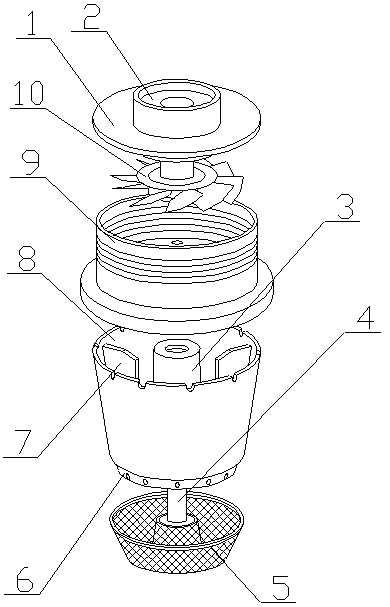

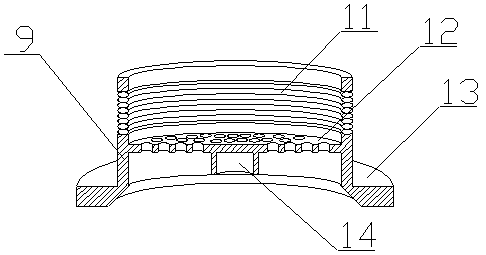

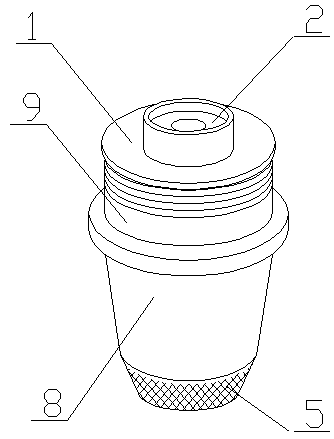

Air flow type spore trapper

ActiveCN109385368AEasy to take outReduce volumeBiological material testing proceduresSporeRound table

The invention discloses an air flow type spore trapper which has the advantages that the area is adjustable, spores and pollen are comprehensively collected in the circumferential direction, and the taking out of the collected spores and pollen is facilitated. The trapper is small in volume and can adapt to different environments. The trapper is characterized in that a middle casing pipe is placedin a caching case and located in the middle of the caching case; one end of the middle casing pipe is placed in the middle of the bottom of the caching case; a communication hole is formed in the middle of the bottom of the caching case and is communicated with the middle casing pipe; the diameter of the middle casing pipe is gradually decreased from bottom to top; the diameter of the caching case is gradually increased from bottom to top; a plurality of through holes are formed in the bottom of the caching case; the diameter of each of the through holes is gradually decreased from bottom totop; a dustproof mesh enclosure is sleeved on the bottom of the caching case; a round table is placed in the middle of the dustproof mesh enclosure; one end of a connecting rod is placed on the roundtable; the other end of the connecting rod penetrates through the communication hole and is placed into the hollow casing pipe.

Owner:徐州华显凯星信息科技有限公司

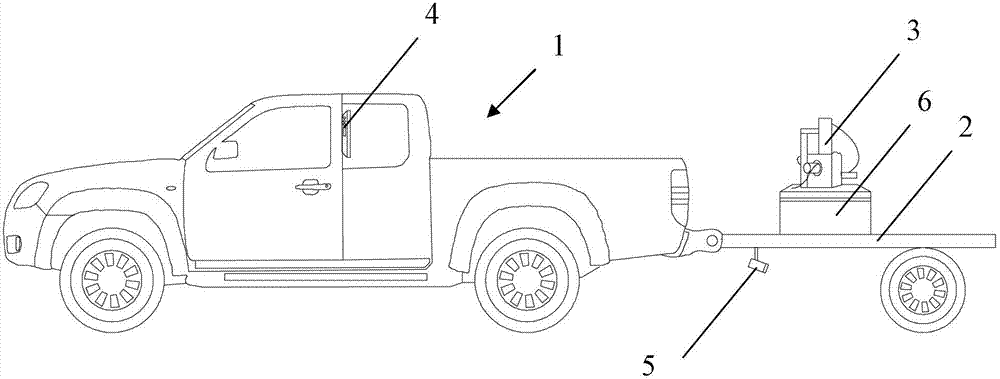

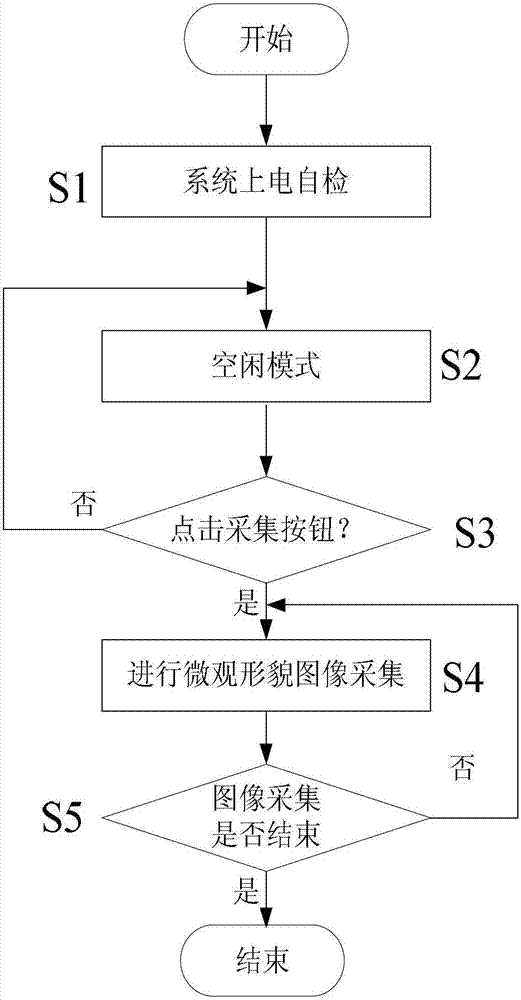

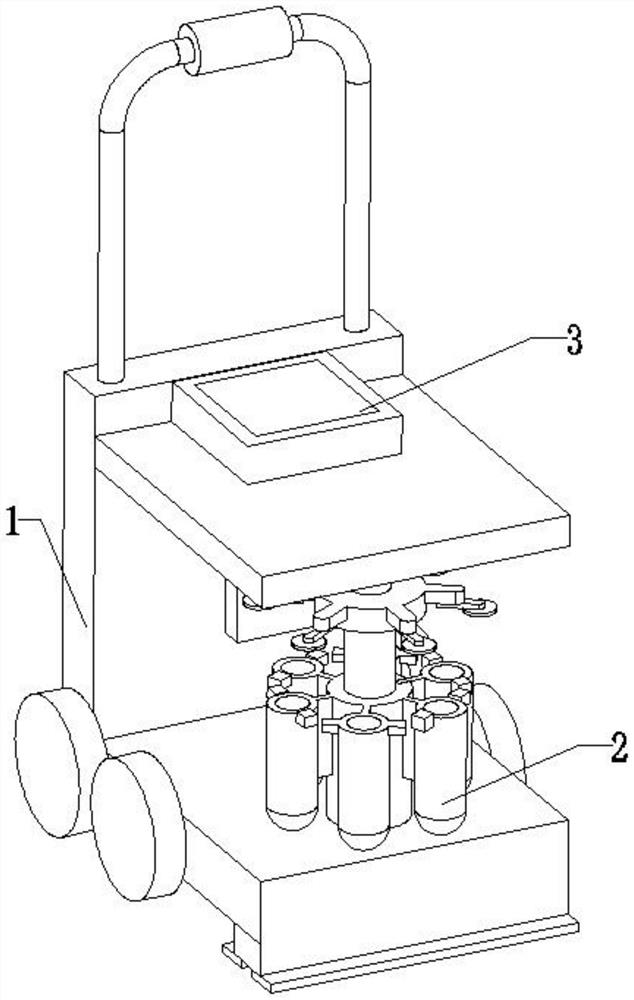

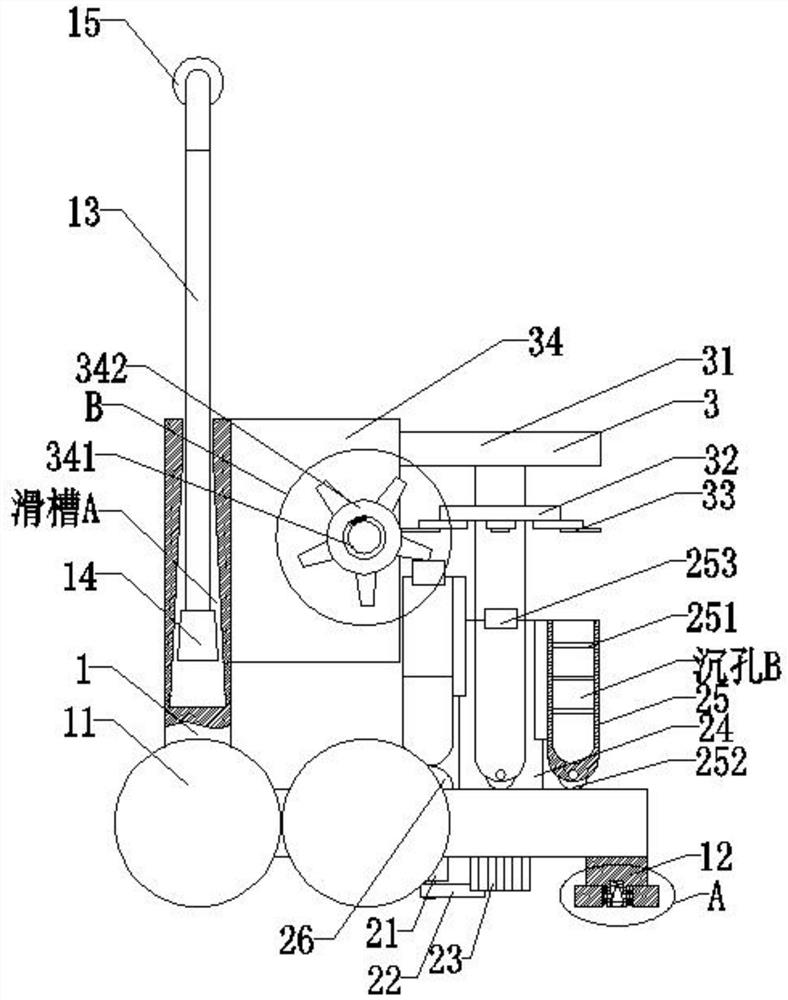

Vehicle-mounted airport pavement damage microtopography image acquisition system and control evaluation method

InactiveCN103196921BNon-invasiveAcquisition speed is fastOptically investigating flaws/contaminationRoads maintainenceScanning electron microscopeEngineering

The invention discloses a vehicle-mounted airport pavement damage microtopography image acquisition system and a control evaluation method. The acquisition system is installed on an acquisition vehicle, and comprises a pull-type flat vehicle, a scanning electron microscope, a sealing chamber, a surface metal spraying instrument, a main control computer and a camera, wherein the pull-type flat vehicle is connected to the tail part of the acquisition vehicle, and the lower part of the acquisition vehicle is provided with the camera; and the scanning electron microscope is installed on the pull-type flat vehicle in a lifting mode and is connected with the main control computer. The vehicle-mounted airport pavement damage microtopography image acquisition system provided by the invention has the advantages that an airport pavement is not damaged, and the defect that the pavement is required to be sampled by a traditional method is overcome; the acquisition speed is high, and is not restricted by the time of suspending of air service; and a whole flight zone can be covered, so that the data sampling is more comprehensive, and the conclusion is more reliable.

Owner:CIVIL AVIATION UNIV OF CHINA

Movable metering, detecting and processing equipment

InactiveCN113310898AEasy to operateReduce detection stepsMaterial analysis by observing effect on chemical indicatorProcess engineeringEnvironmental geology

The invention relates to movable metering, detecting and processing equipment. The equipment comprises a movable frame, a loading assembly and a detection assembly; the loading assembly is installed on the movable frame; and the detection assembly is installed above the loading assembly. When PH detection is performed on afield unfamiliar water area, the following problems appear:a, when sampling detection is carried out on the field water area, after water source sampling is carried out manually, PH test paper needs to be sheared manually to monitor the acidity and alkalinity of the water source, as a result, the number of operation steps of staff is increased, and manpower is wasted; and b when the field water area is detected, a portable device is light in weight, as a result, the portable device is prone to toppling over on the uneven ground, and the device is prone to damage, and experimental materials are prone to damage. With the movable metering, detecting and processing equipment adopted, the above problems can be solved.

Owner:王军

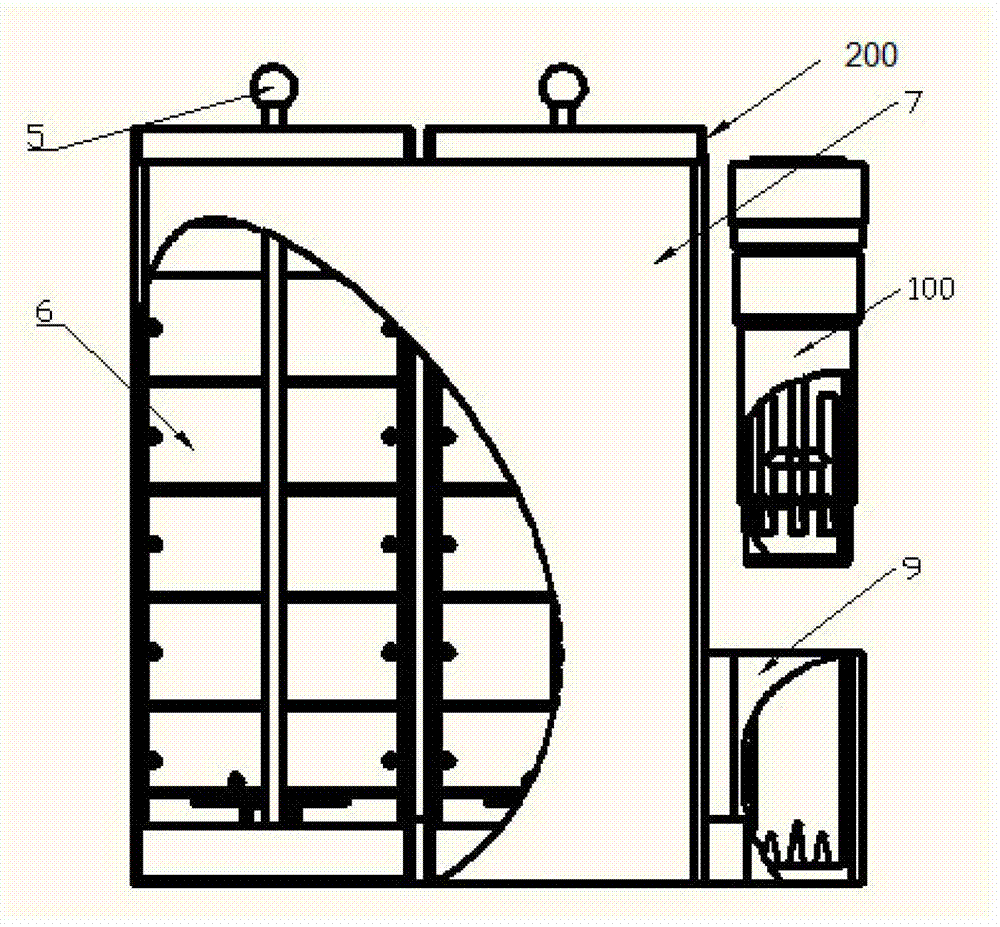

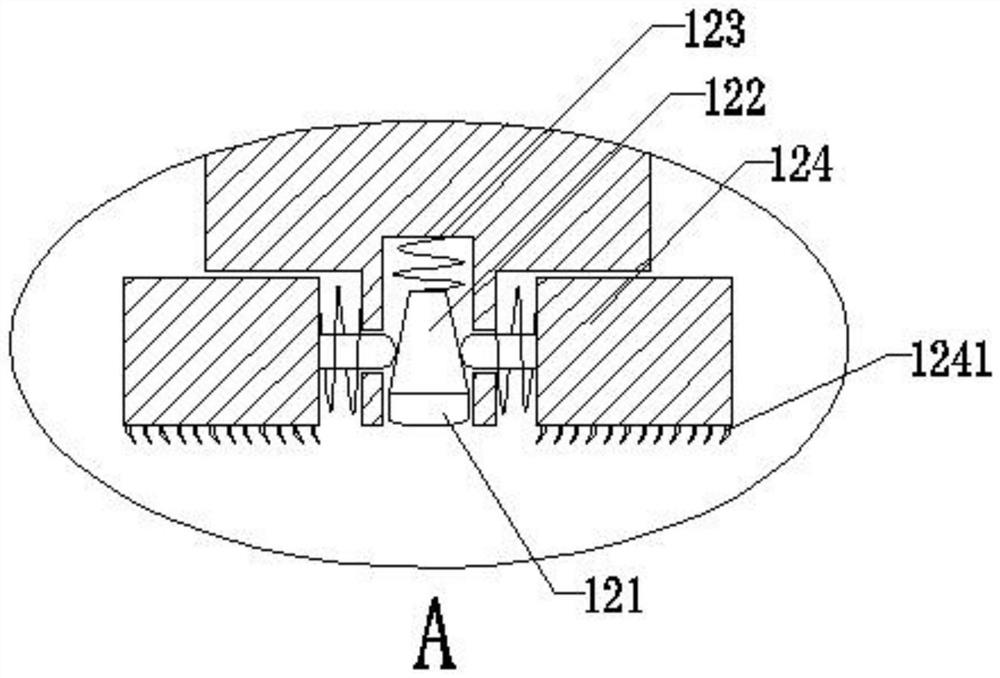

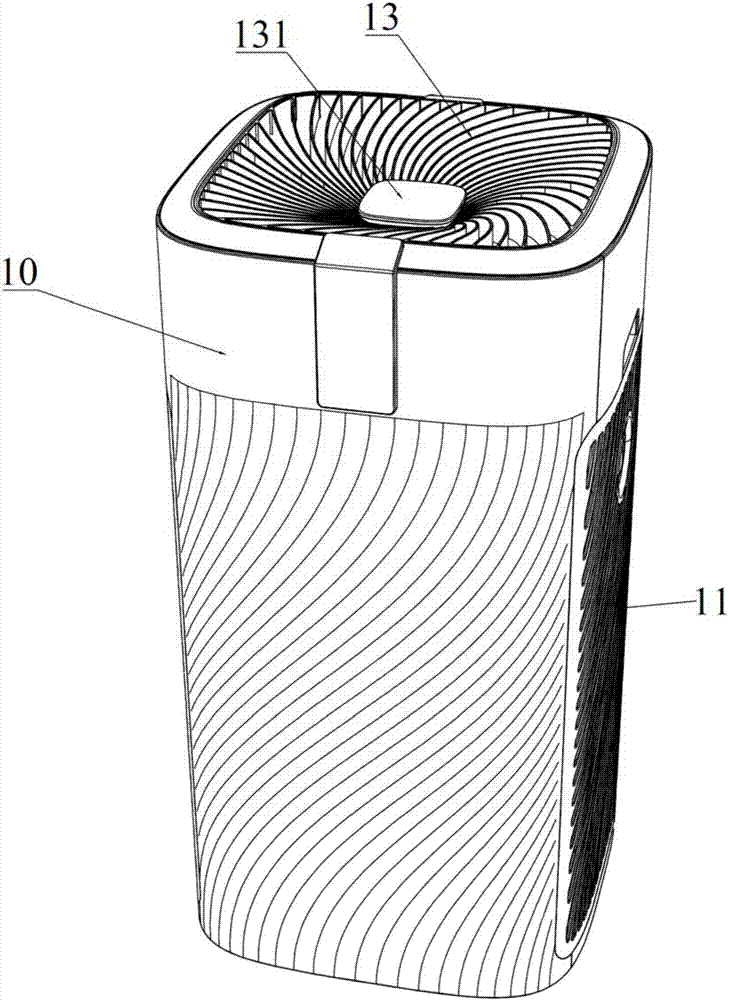

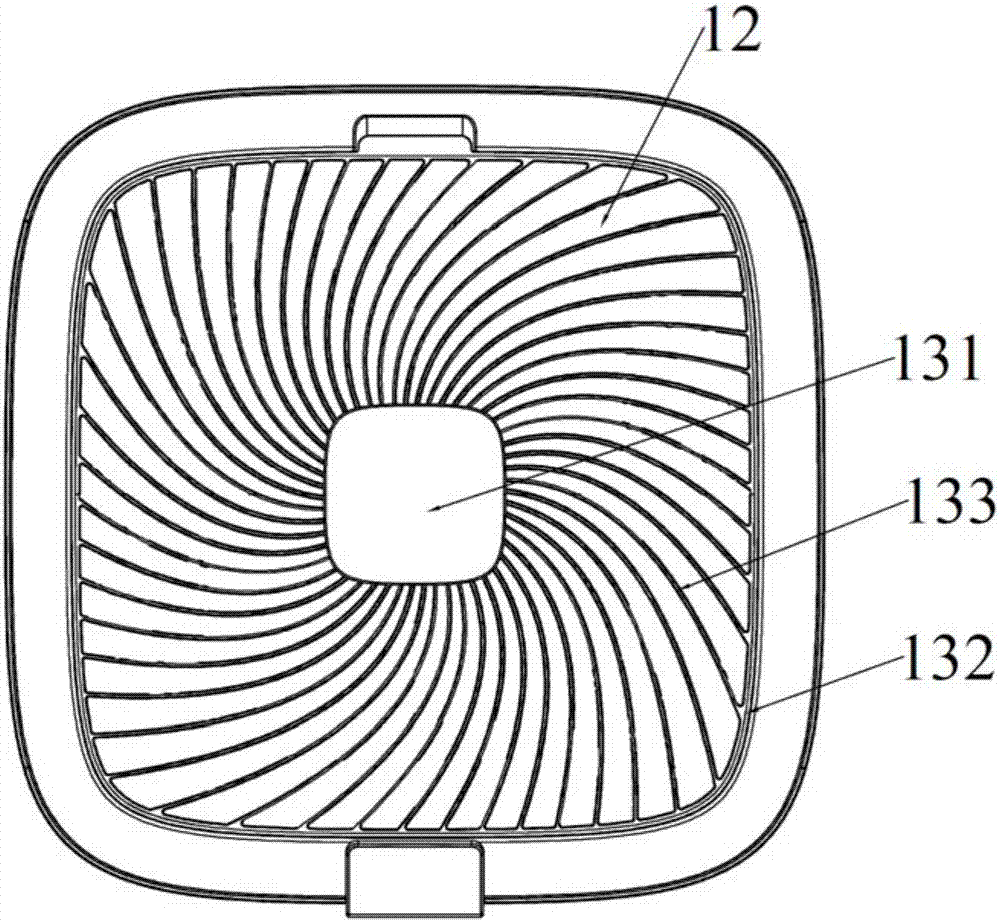

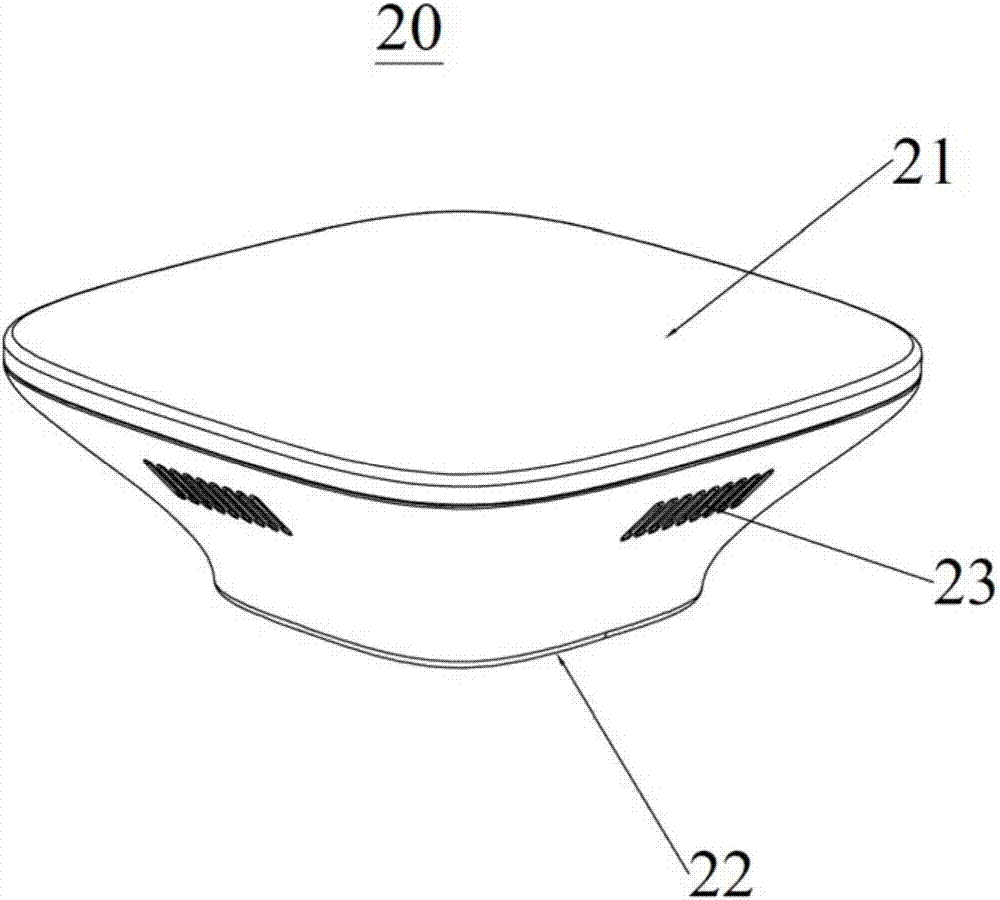

Air purifier

InactiveCN107013995AEasy to sampleComprehensive samplingMechanical apparatusSpace heating and ventilation safety systemsAir purifiersComputer engineering

The invention discloses an air purifier. The air purifier comprises a host machine and an air detector; the host machine is provided with an intake port and an exhaust port; a mounting table is arranged in the exhaust port; the air detector comprises a shell provided with multiple sampling ports, a detecting unit arranged in the shell for detecting air collected by the sampling ports, and a power storage unit for supplying power to the detecting unit; the shell is detachably mounted on the mounting table; and the host machine charges the power storage unit. In the air purifier, the shell of the air detector is detachably mounted on the mounting table, so that the air detector and the host machine can be used in a separation or combination manner, and one machine achieves more purposes. In addition, the power storage unit is charged through the host machine, so that the air detector can be charged when being placed on the mounting table of the host machine, the use is convenient and simple, and the use experiences of users are improved.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

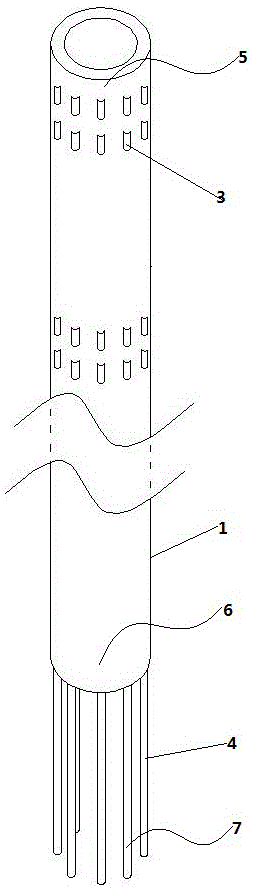

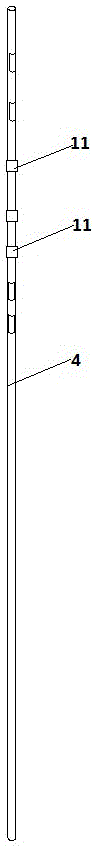

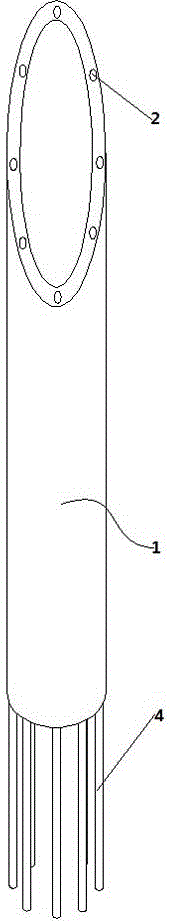

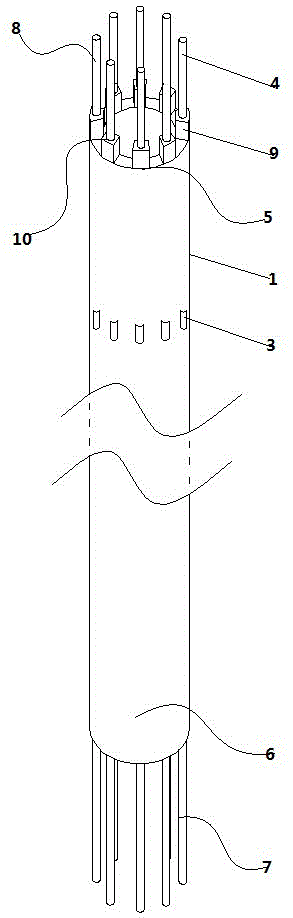

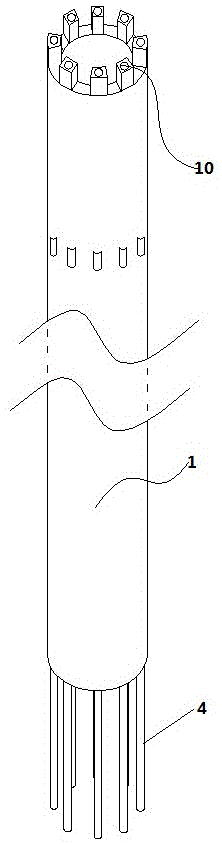

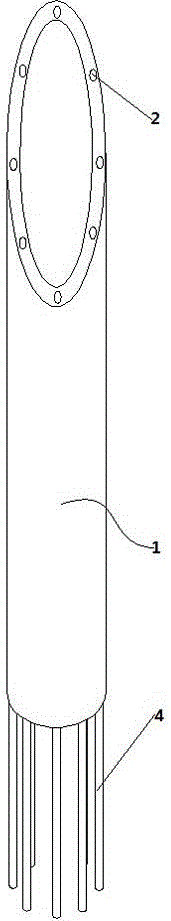

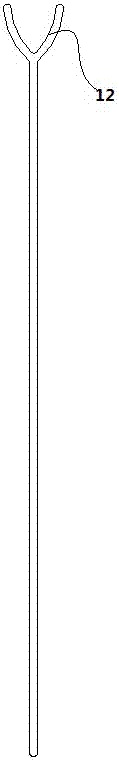

Medical multi-point implantable sampling tube

InactiveCN105125239ASimple structureCause secondary damageSurgeryVaccination/ovulation diagnosticsBiomedical engineeringMulti point

The invention relates to a medical multi-point implantable sampling tube. The medical multi-point implantable sampling tube comprises an implantation hose, wherein a plurality of sampling holes are formed in the wall of the implantation hose. The medical multi-point implantable sampling tube is characterized in that the extension direction of the sampling holes is consistent with the extension direction of the sampling tube, a sampling line is arranged in each sampling hole, one end of each sampling line extends out of the sampling hole for certain length, two ends of the implantation hose are respectively an implantation end and an exposure end, the opening of the sampling hole is positioned on the exposure end, the extension part of each sampling line is an extraction end, a plurality of sampling windows are arranged on the outer wall of the implantation hose and are communicated with the sampling holes, and the sampling lines are exposed out through the sampling windows. The plurality of sampling lines are arranged in the wall of the implantation hose in a penetration manner, after the implantation hose is implanted into the human body at once, the implantation hose does not need to be moved, the wounded parts inside the human body can be sampled only by extracting the sampling lines, then testing and measuring are carried out, and no secondary harm is caused to the wounded parts.

Owner:SUZHOU BAILI MEDICAL PROD

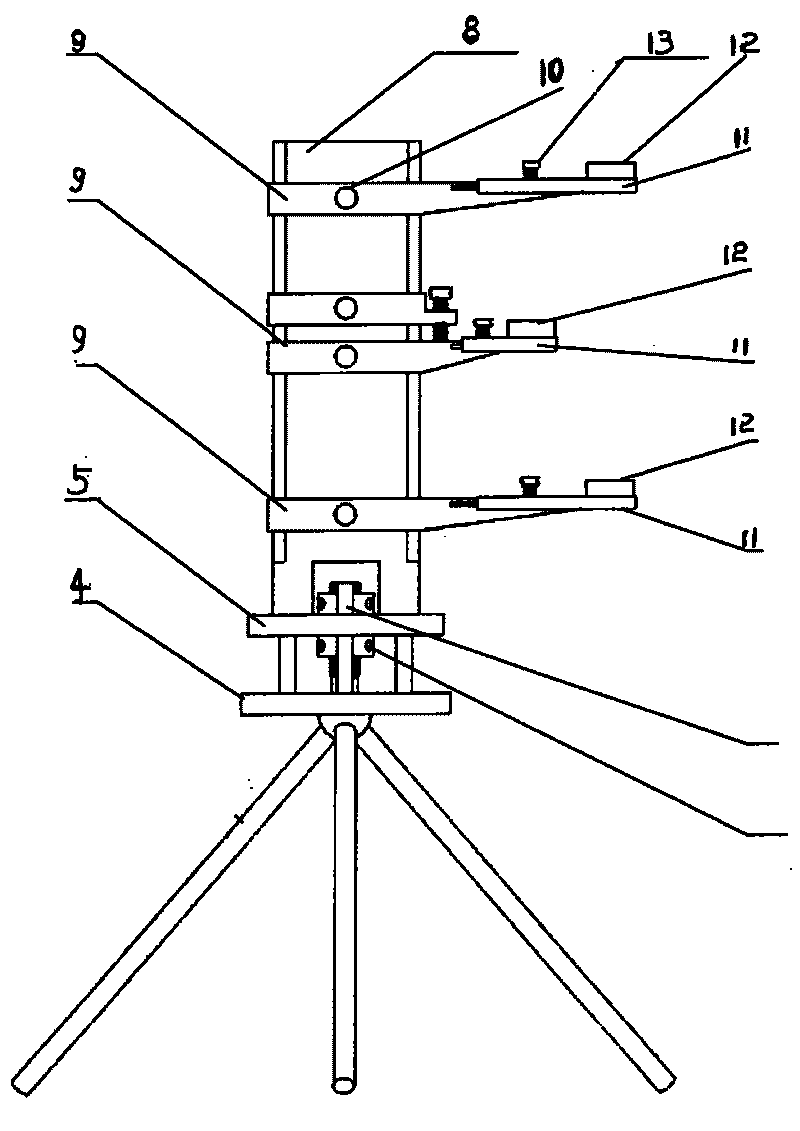

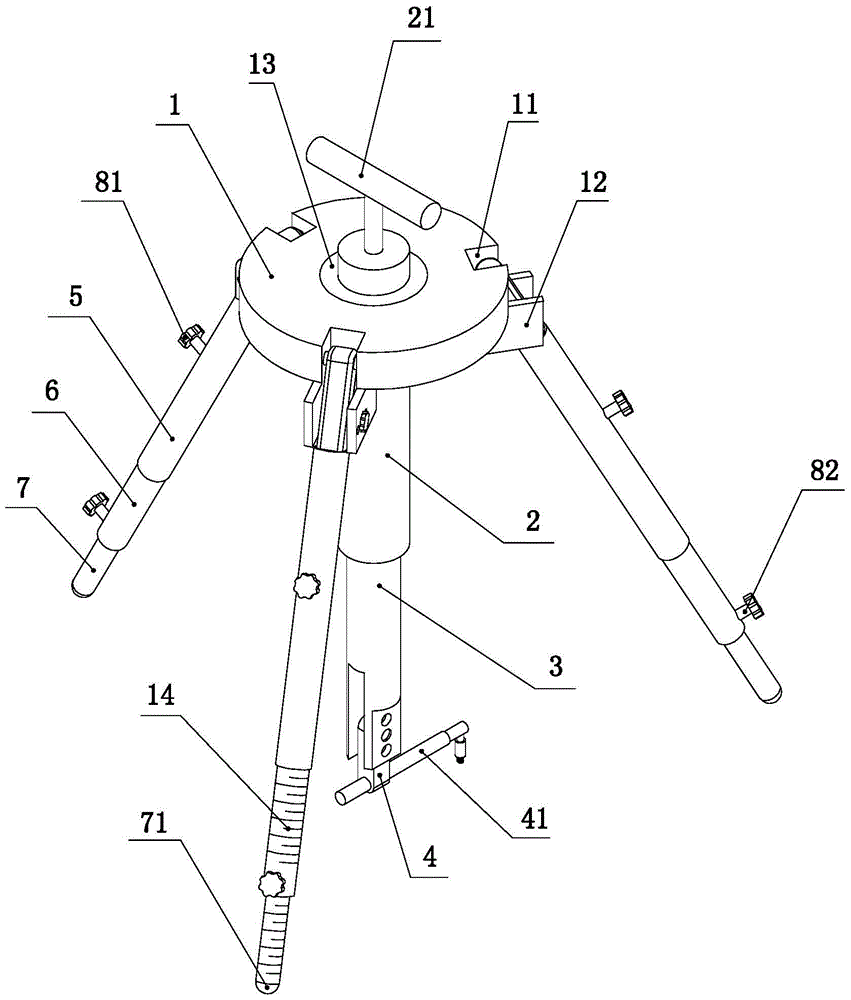

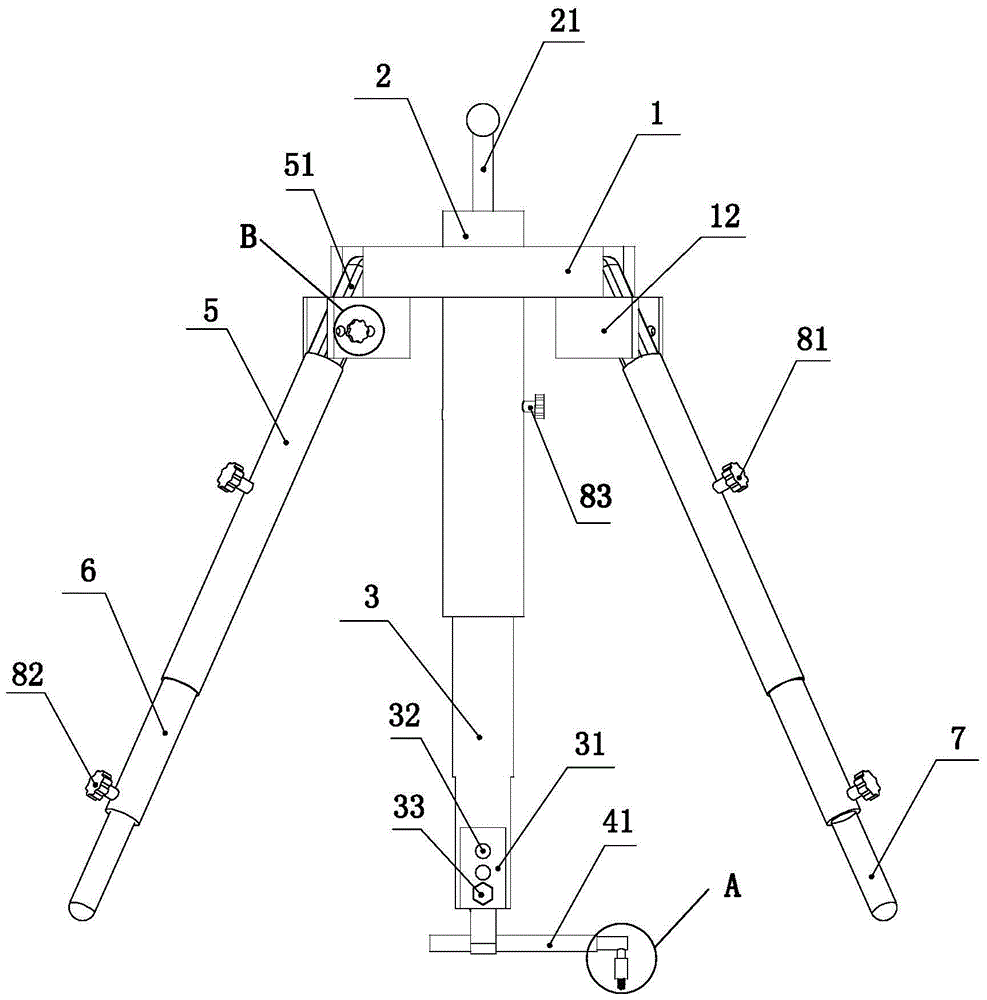

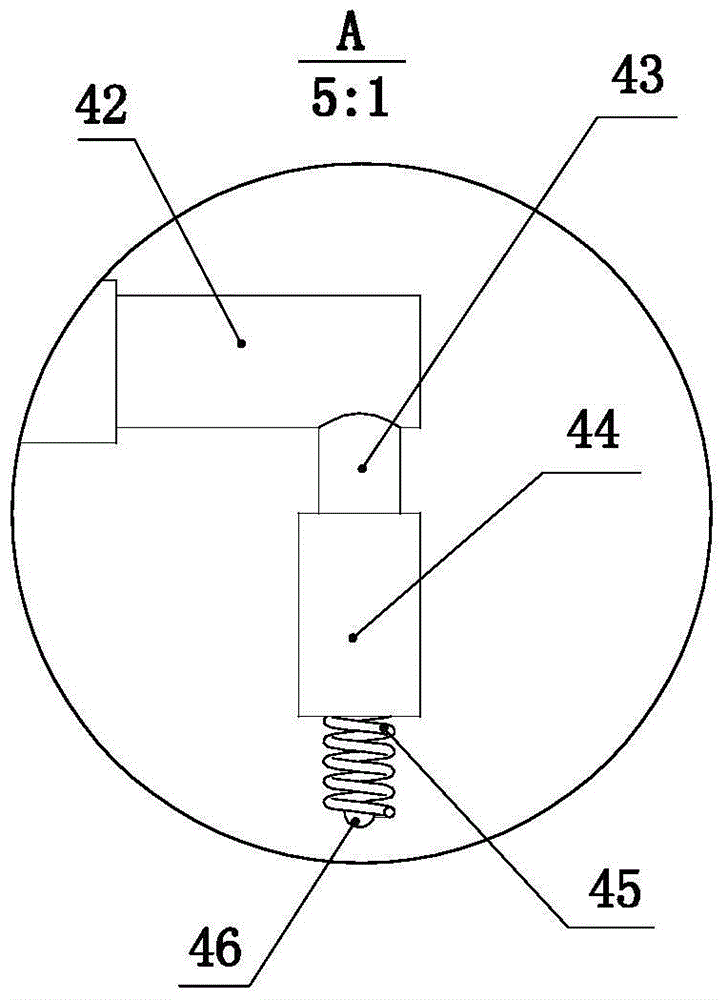

Wall flatness detection device

ActiveCN104197889ALearn about flatnessAdjustable turning radiusMeasurement devicesEngineeringSteel ball

The invention discloses a wall flatness detection device and relates to the technical field of wall flatness detection; the device is used for detecting the wall flatness accurately and is convenient to carry and flexible in structure. A device body is pressed onto a wall through three support legs, a first and second rotary barrels are rotationally mounted on a base, a spring, a steel ball and a force sensor are arranged on the second rotary barrel, the steel ball and the wall to be detected is pressed mutually, the stress is transmitted to the force sensor through the spring, and the flatness of the wall can be known clearly by the force sensor sensing the force magnitude and value distribution. More samples can be obtained by adjusting the rotating radius of the spring and steel ball. The supporting legs are telescopic and can be folded corresponded to the base, and carrying is facilitated.

Owner:郭强

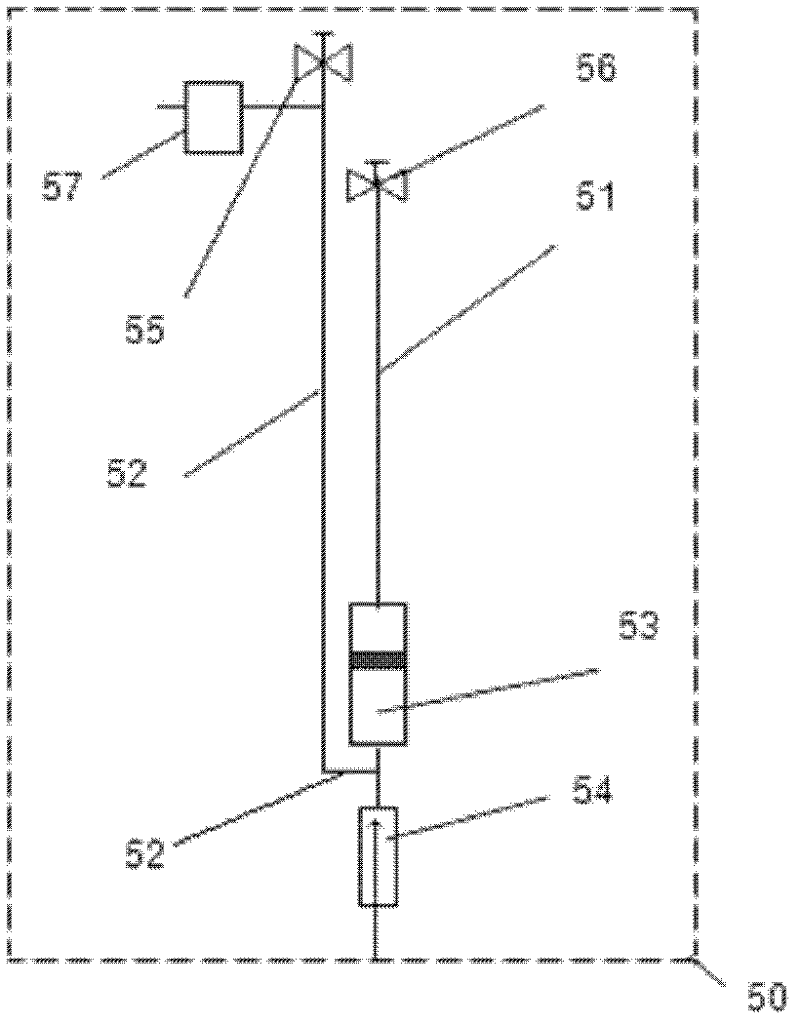

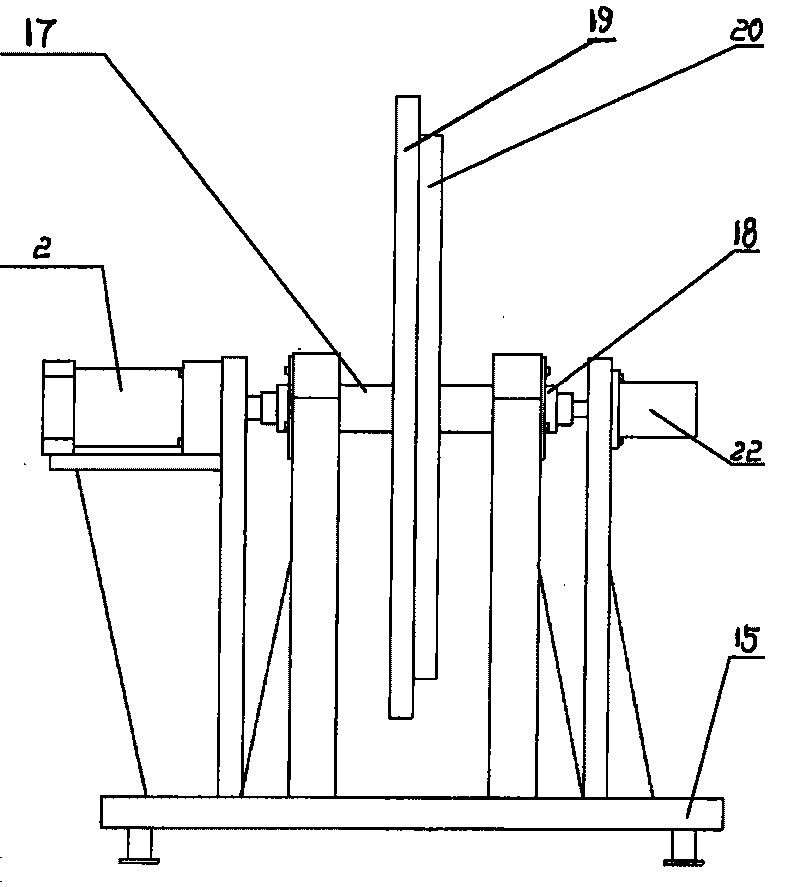

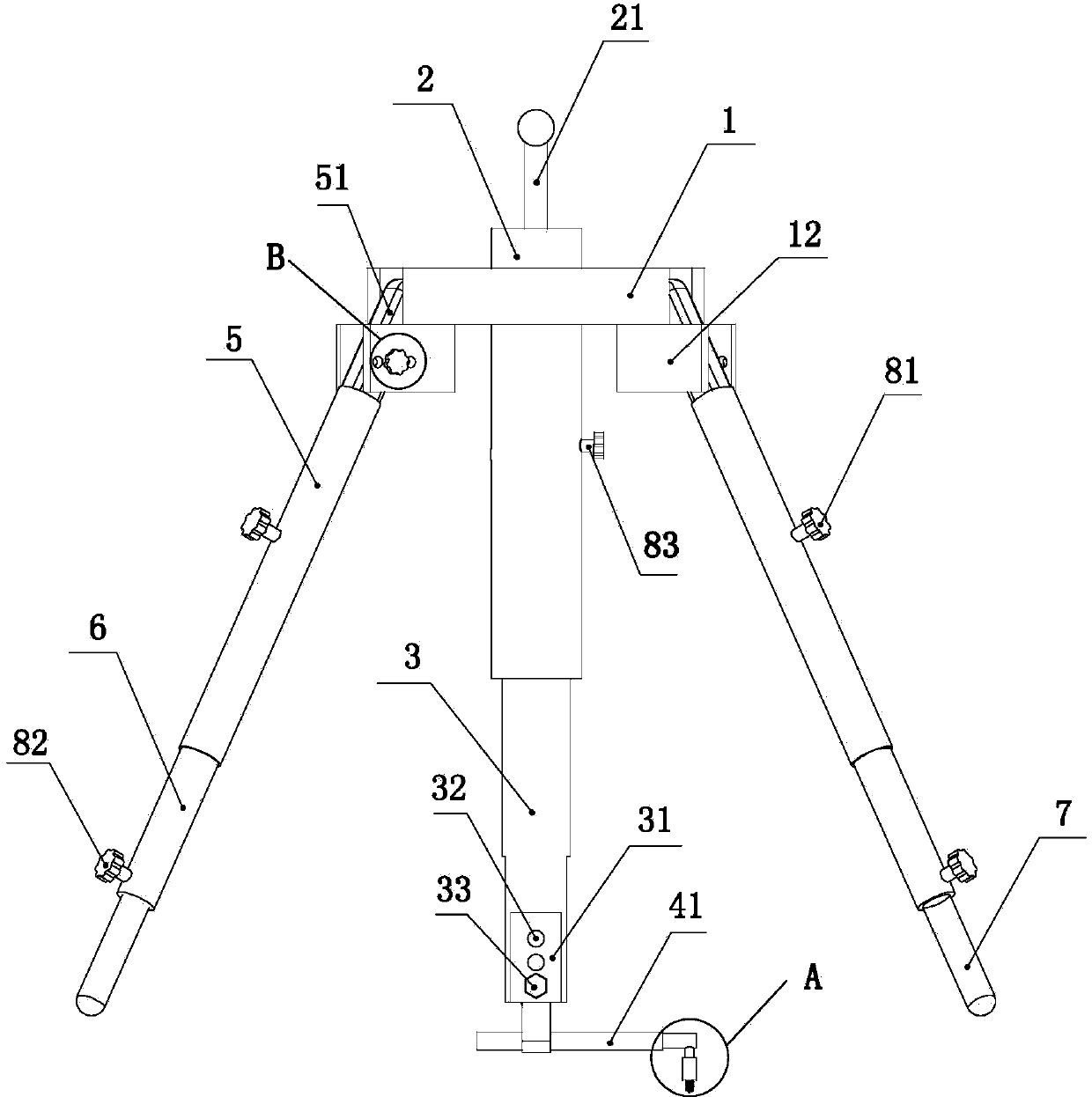

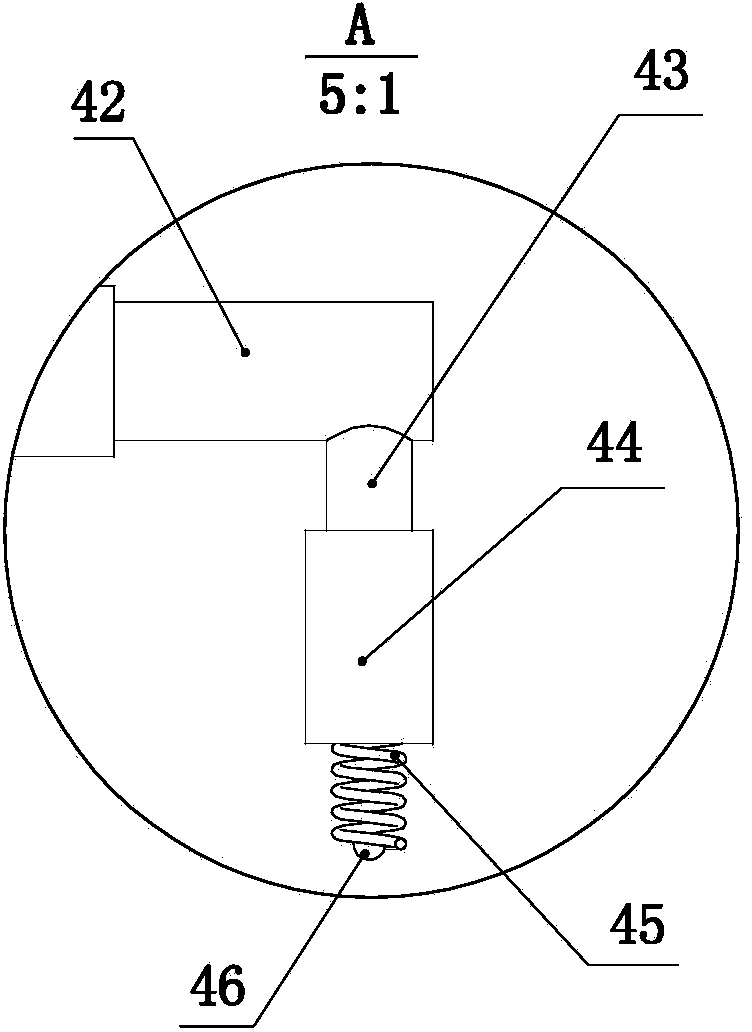

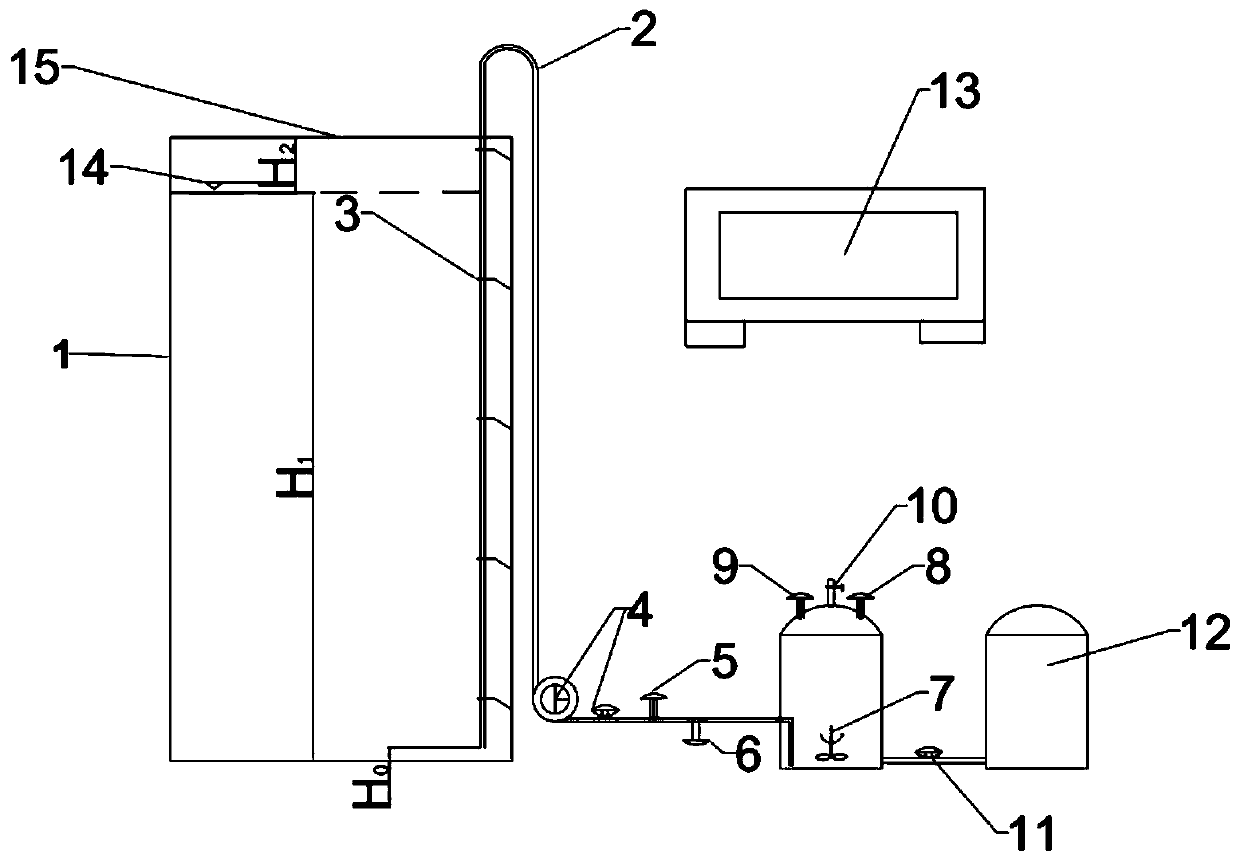

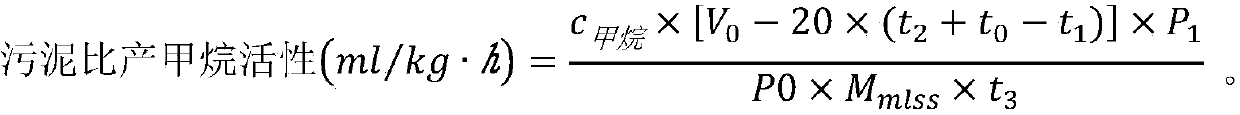

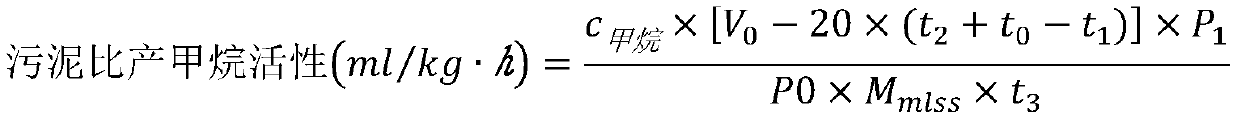

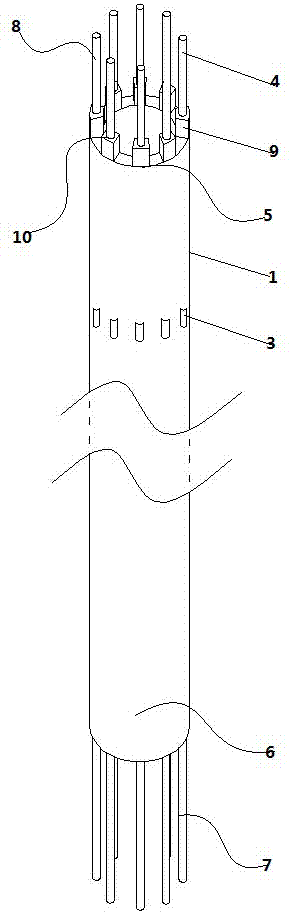

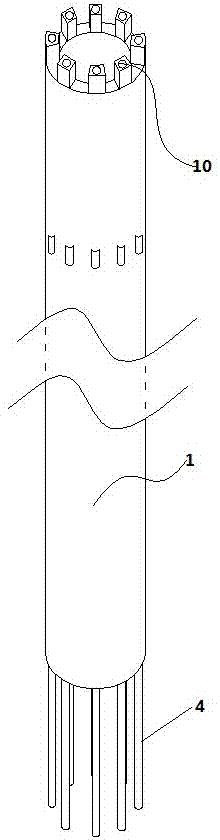

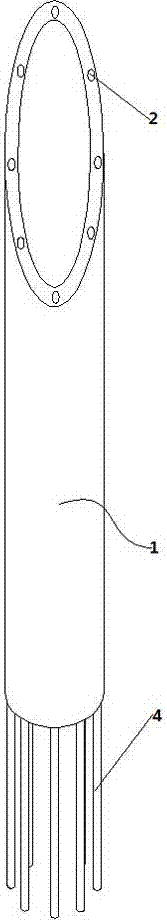

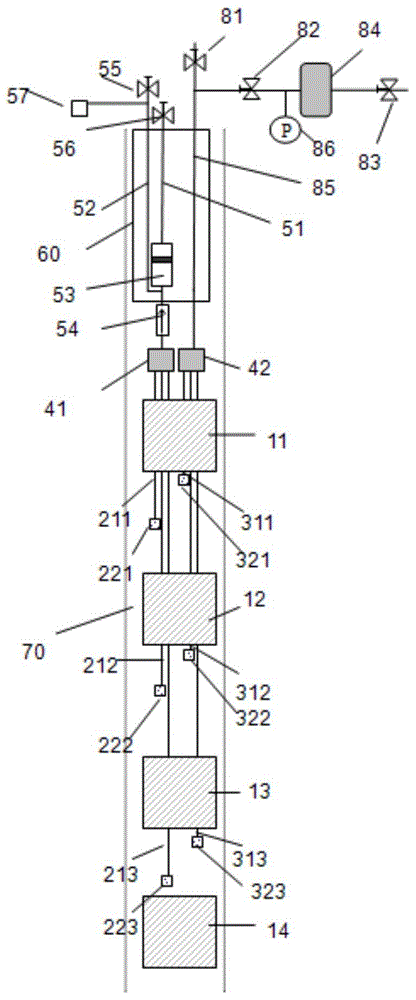

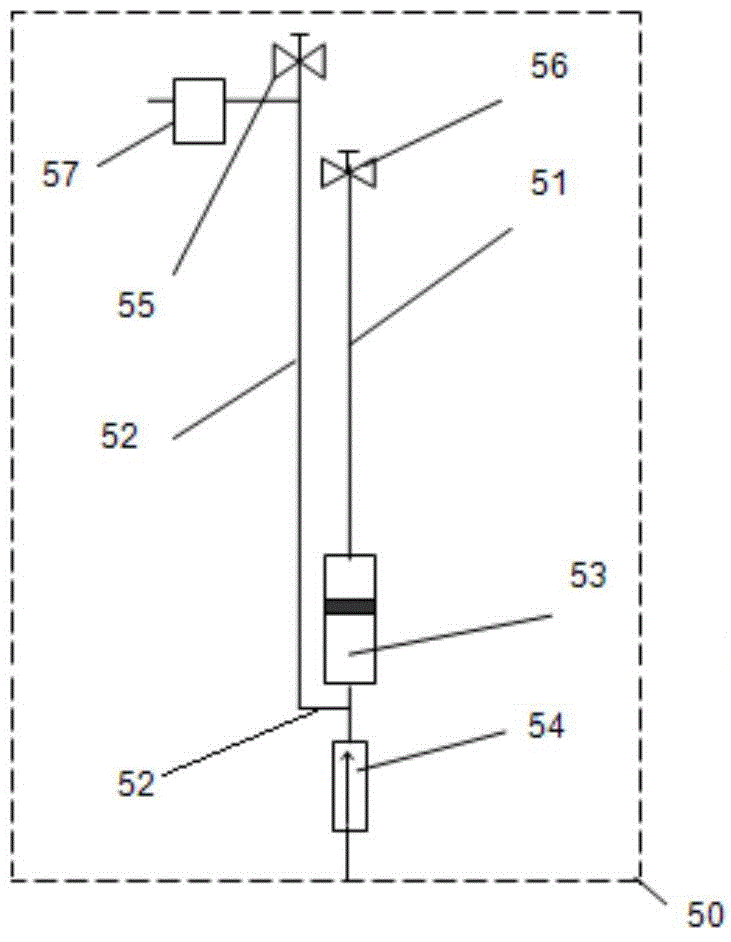

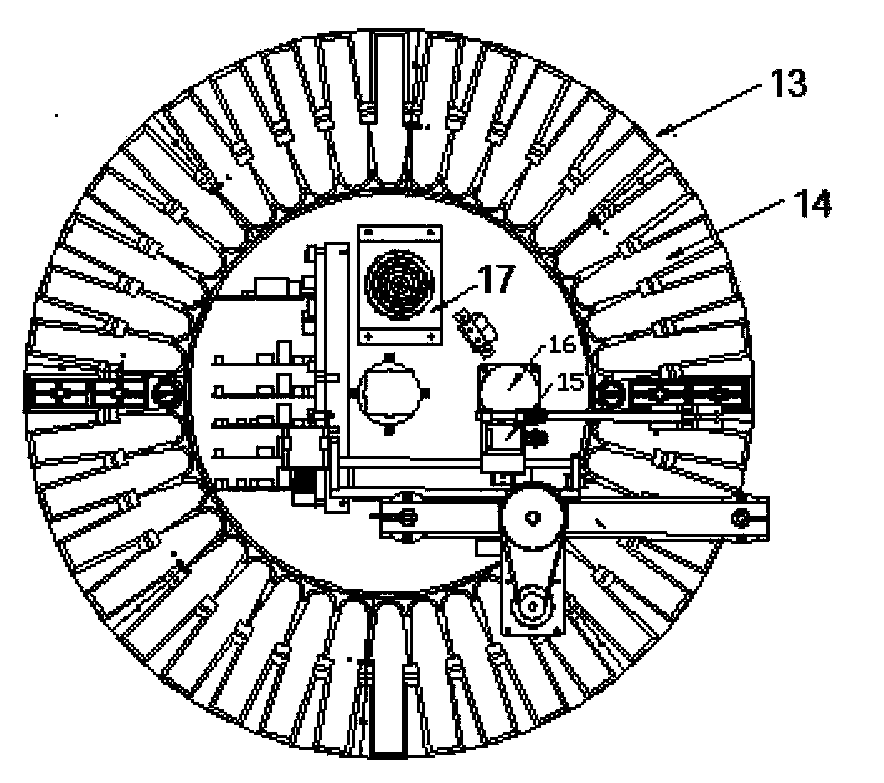

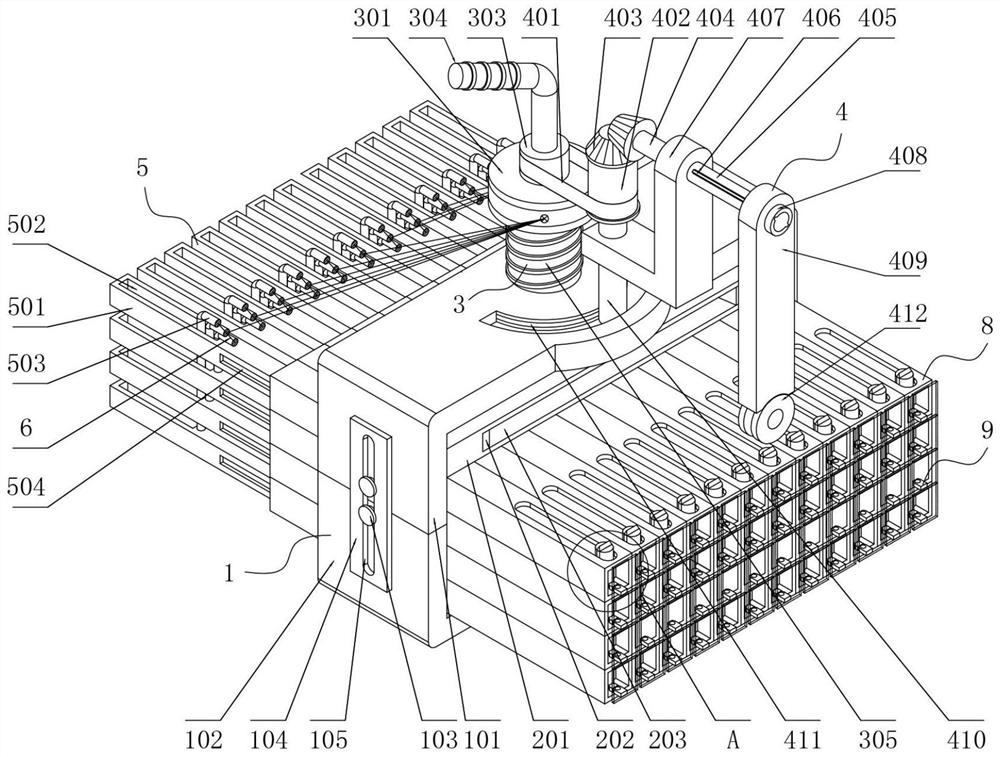

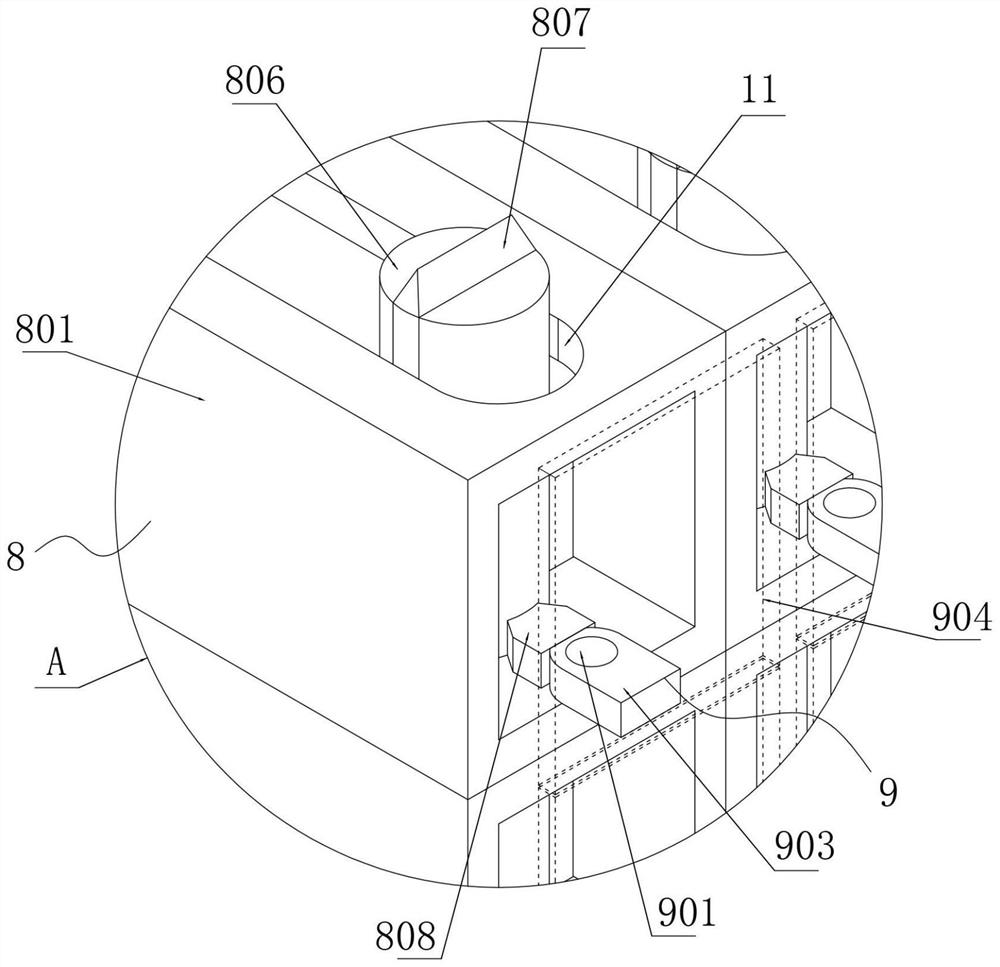

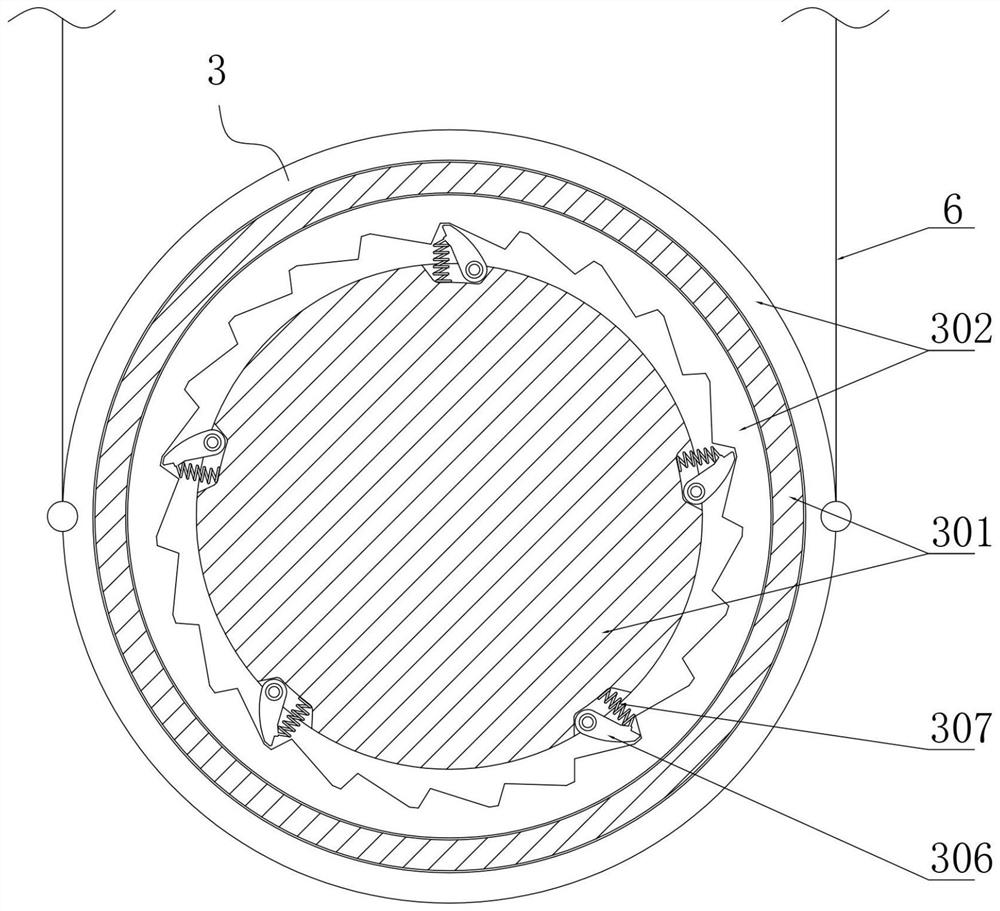

Coil type sludge sampling and activity evaluation device for anaerobic reactor and working method thereof

ActiveCN110668565AComprehensive samplingHigh degree of self-controlWithdrawing sample devicesTreatment with anaerobic digestion processesControl systemLiquid storage tank

The invention relates to a coiled tube type sludge sampling and activity evaluation device for an anaerobic reactor and a working method thereof. The device comprises a coiled tube sampling system, asludge testing system and a PLC control system. The coil sampling system comprises the anaerobic reactor, a stainless steel hose, a support frame and a positive and negative constant-speed coil-metering pump. The sludge testing system comprises a densimeter, a pH / T tester, a storage reaction tank with a stirrer, a pressure gauge, a methane / carbon dioxide concentration tester, a methane emptying pipe with a control valve, a metering pump and a detection liquid storage tank. The PLC control system includes a PLC central controller. The whole sampling period comprises two times of full-height sampling of the anaerobic reactor from bottom to top and from top to bottom, thus ensuring the representativeness, comprehensiveness and data accuracy of the sampled sludge.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

A wall flatness detection device

ActiveCN104197889BLearn about flatnessAdjustable turning radiusMeasurement devicesSpring forceEngineering

A kind of wall flatness detection device involves the field of wall flatness detection technology, which is used to achieve precise detection of wall flatness, and the detection device is convenient for carrying and flexible structure.A kind of wall flat degree detection device provided by the present invention, press the detection device on the wall through three support legs, rotate the first and second cylinders on the base, and there is a spring on the second turret., Steel ball and force sensor, squeeze between steel balls and to be measured to measure the wall, and pass the force to the force sensor through the spring. Through the size and value distribution of the perception of the force sensor, you can clearly understand the wall surface of the wall surface.Flatness.And adjust the rotation radius of spring and steel balls to get more sampling.The support legs can be retracted and can be folded relative to the base, which is easy to carry.

Owner:郭强

Medical Implantable Tip Sampling Tube

InactiveCN105147338BCause secondary damageReal-time detection and judgmentSurgeryMedical devicesBody fluidBiomedical engineering

The invention relates to an implantable end sampling tube for medical use, which comprises an implanted hose, wherein a plurality of sampling holes are formed in the wall of the implanted hose; the extension direction of the sampling holes are consistent with the extension direction of the sampling tube; a sampling thread is arranged in each sampling hole; both ends of the sampling threads extend out of the sampling holes by certain lengths; two ends of the implanted hose are respectively an implanted end and an exposed end; and the extension parts of the sampling threads, located at the implanted end, are sampling ends, and the extension parts, located at the exposed end, are drawing ends. The sampling tube disclosed by the invention, by inserting multiple sampling threads in the tube wall of the implanted hose, can sample affected parts inside a human body just by drawing the sampling threads without moving the implanted hose which is implanted into the human body in one time, and then the sampling tube can implement test and detection, so as to avoid secondary hurt to the affected parts; and by virtue of tube holes formed in the inner wall of the implanted hose, liquid is guided into the human body, so that drugs can be conveyed into the human body and body liquid and the like can be discharged out of the human body.

Owner:SUZHOU BAILI MEDICAL PROD

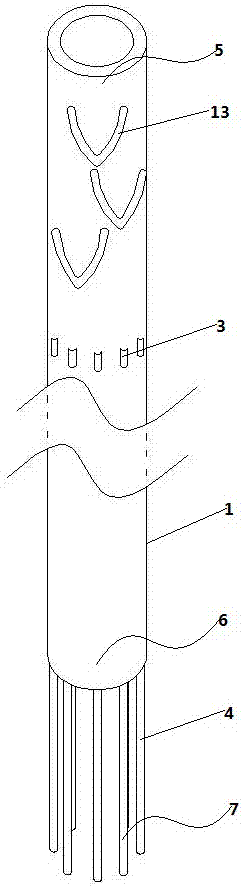

Stratified fluid monitoring and sampling device based on pressure pulse

ActiveCN102505939BComprehensive monitoringComprehensive samplingSurveyConstructionsTemperature controlHorizon

The invention discloses a stratified fluid monitoring and sampling device based on pressure pulse. A sampling device is arranged on the inner wall of a drilled hole or a sleeve and comprises a packer system, a liquid sample injection system, a gas sample injection system, automatic multi-way valves, a sampling system, a temperature control system and the like, wherein a pressure container in a pressure pulse system is connected with the valves and a pressure sensor through a pipeline for forming the pressure pulse system, the pressure pulse system is connected with the underground gas sample injection system through the automatic control multi-way valve, the liquid sample injection system is connected with the liquid automatic multi-way valve, and the gas sample injection system is connected with the gas automatic multi-way valve. The state of fluid in a stratum is judged by the pressure pulse, the underground fluid sampling horizon is simultaneously precisely controlled, respective sampling of gas and liquid fluids in different horizons under constant temperature and pressure conditions can be realized, the response rate of sampling is improved and precise sampling under the low flow rate condition can be particularly realized. The device is simple to assemble all the parts and suitable for monitoring the state of the multi-layer fluid in a bored well and sampling the underground gas and liquid two-phase fluid.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

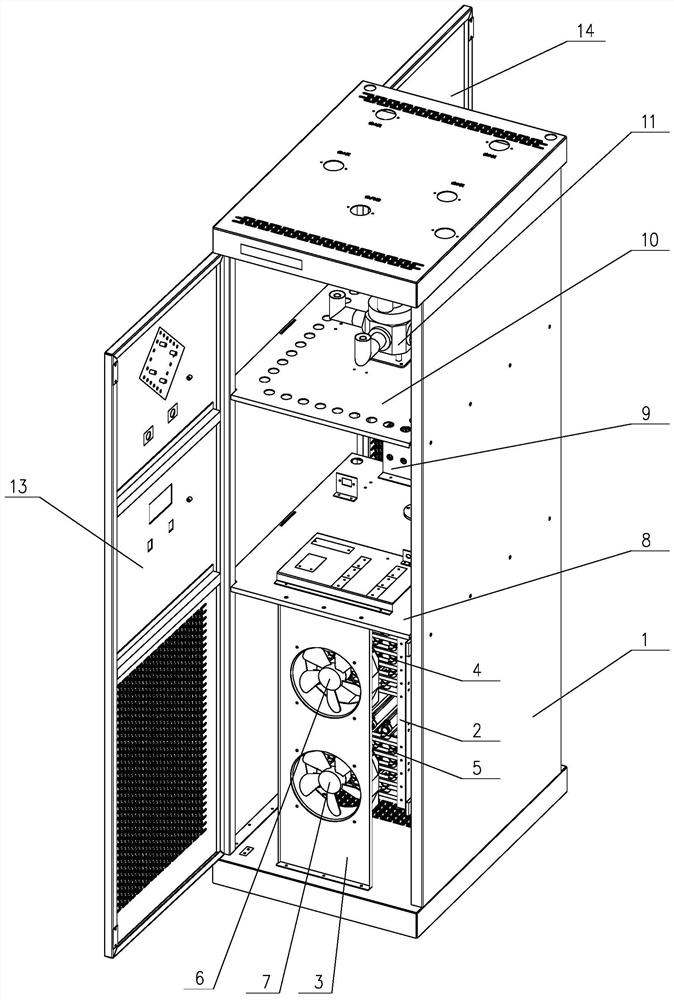

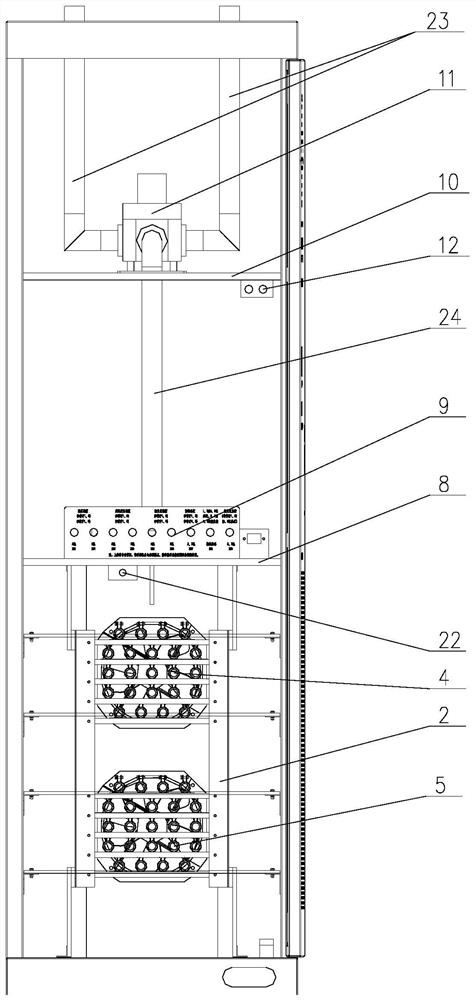

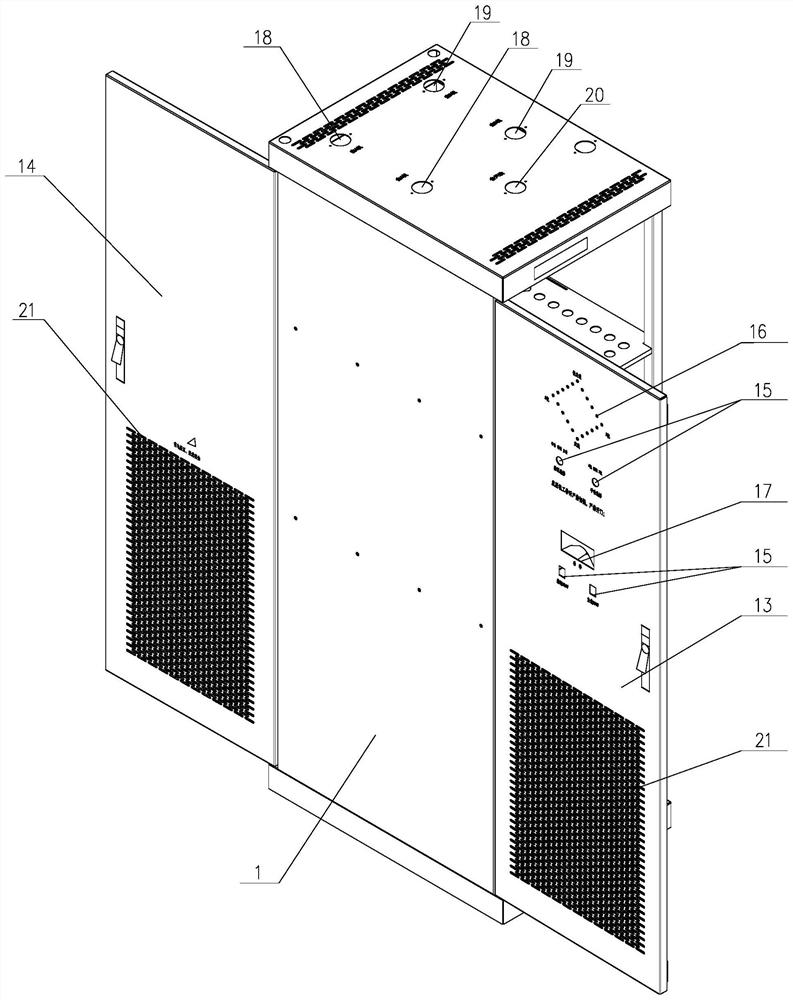

Broadcast transmitter switching device and switching method thereof

PendingCN113922902AReasonable layoutNeat layoutTransmitter side switchingConvertersHigh frequency power

The invention discloses a broadcast transmitter switching device and a switching method thereof. The switching device comprises a mechanical carrier and a control unit, the mechanical carrier comprises a cabinet body, a resistor body framework and a fan support are arranged on the lower portion in the cabinet body, a first resistor body and a second resistor body are arranged on the resistor body framework, a first fan and a second fan are arranged on the fan support, a first partition plate is arranged on the upper portion of the resistor body framework, and an external interface board is arranged on the first partition plate. The upper part of the cabinet body is provided with a second separator plate, the upper part of the second separator plate is provided with a coaxial converter, the lower part of the second separator plate is provided with an emergency support, the cabinet body is provided with a front door and a rear door, a front door panel is provided with a switch, an indicating lamp and a high-frequency power meter, and an external interface board and the emergency support are arranged at the inner side of the rear door. The method can be effectively applied to switching of broadcast transmitters, stable and efficient switching among the host, the standby, the transmitting antenna and the dummy load can be realized, and the method is stable and reliable in performance, wide in market prospect and convenient to popularize and use.

Owner:陕西如意广播电视设备有限公司

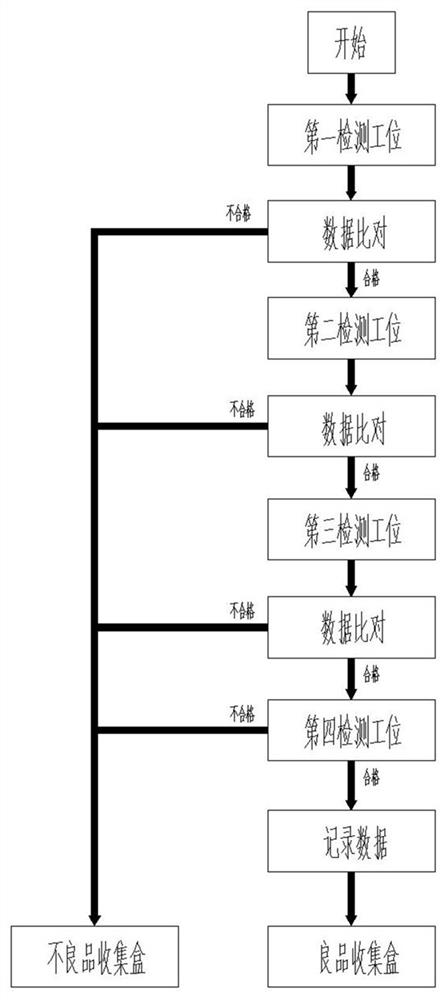

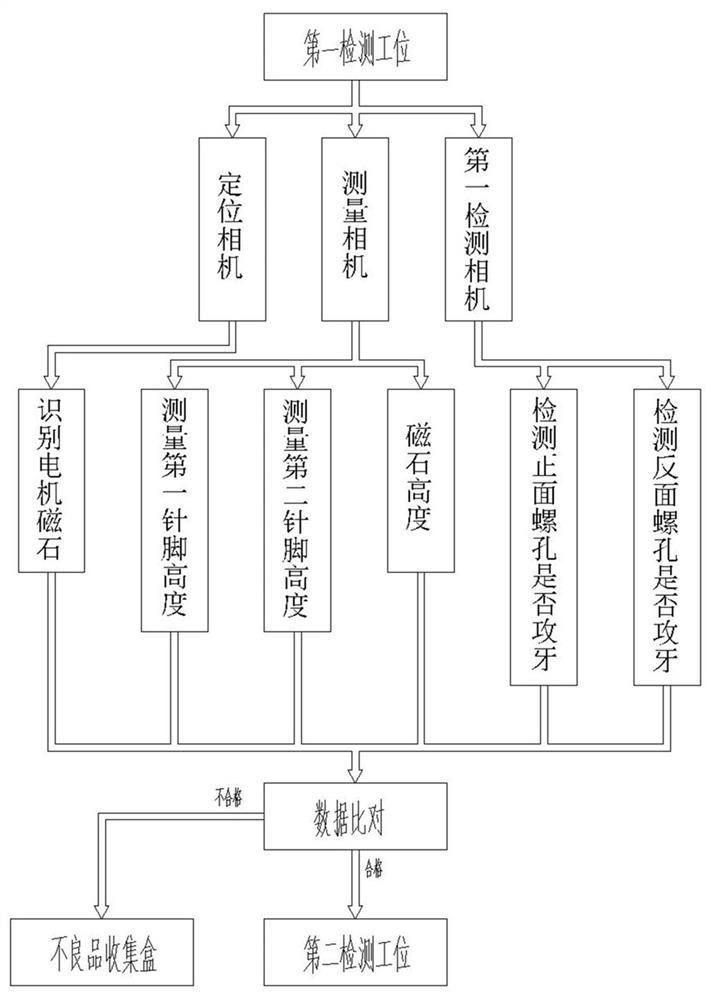

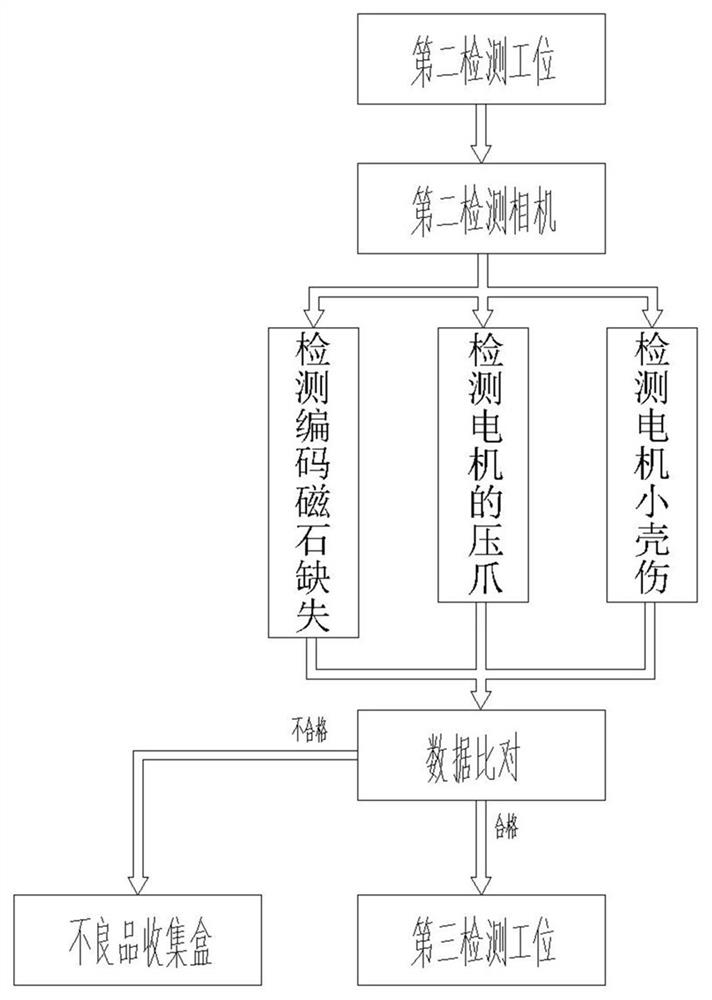

Visual detection method for motor

PendingCN114062375AHigh precisionAccelerateOptically investigating flaws/contaminationUsing optical meansInductorMagnet

The invention aims to provide a visual detection method for the motor, which can realize full-automatic appearance detection and greatly improve the appearance detection effect and efficiency of the motor. Four detection stations are adopted, and the motor is sequentially conveyed into the four detection stations through a conveying mechanism. The detection of small shell damage, terminal deformation, reverse installation of a coding magnet, poor terminal height, unbuckled small shell of the pressing claw of the motor, missing of a pressing claw of the motor, missing of the coding magnet, poor height of the coding magnet, omission of the coding magnet, reverse pasting of a label, missing or smudginess of a label two-dimensional code, no size of the two-dimensional code and the edge of the label in a specification range, repeated labeling, wrong labeling positions, inclined labeling, labeling omission, writing of a large shell, screw hole damage, shaft damage, gear oxidation, tapping omission of a large shell, foreign matters in screw holes, gear damage and other defects can be carried out. The method can be applied to the field of appearance detection of products such as motors and inductors.

Owner:珠海高纳智能科技有限公司

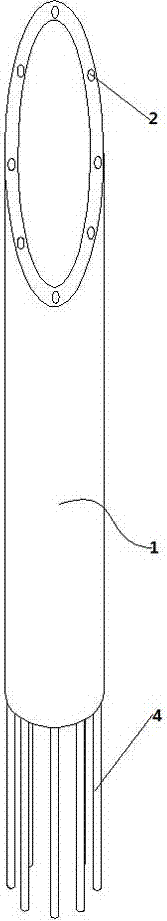

Implantable end sampling tube for medical use

InactiveCN105147338ASimple structureCause secondary damageSurgeryMedical devicesBody fluidBiomedical engineering

The invention relates to an implantable end sampling tube for medical use, which comprises an implanted hose, wherein a plurality of sampling holes are formed in the wall of the implanted hose; the extension direction of the sampling holes are consistent with the extension direction of the sampling tube; a sampling thread is arranged in each sampling hole; both ends of the sampling threads extend out of the sampling holes by certain lengths; two ends of the implanted hose are respectively an implanted end and an exposed end; and the extension parts of the sampling threads, located at the implanted end, are sampling ends, and the extension parts, located at the exposed end, are drawing ends. The sampling tube disclosed by the invention, by inserting multiple sampling threads in the tube wall of the implanted hose, can sample affected parts inside a human body just by drawing the sampling threads without moving the implanted hose which is implanted into the human body in one time, and then the sampling tube can implement test and detection, so as to avoid secondary hurt to the affected parts; and by virtue of tube holes formed in the inner wall of the implanted hose, liquid is guided into the human body, so that drugs can be conveyed into the human body and body liquid and the like can be discharged out of the human body.

Owner:SUZHOU BAILI MEDICAL PROD

Microbial sample processing system

InactiveCN103194385BEnsure biosecurityImprove airtightnessBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlMicroorganism

The present invention provides a microbial sample processing device, comprising: a machine body provided with a machine chamber and a sealed movable door; and a sealed housing, a stretchable airbag, a sample tray, a mechanical arm, a bar code scanner, a liquefier, culture dishes, a gas-temperature sensor, and a temperature control device which are arranged in the machine chamber, wherein the sample tray is provided with a plurality of sample seats, the sample seats are used for placing the culture dishes, the liquefier is communicated with the culture dishes, each culture dish is provided with culture plates and a streak-inoculation pen used for streak inoculating the sample in the culture dishes from the liquefier on the culture plate. The microbial sample processing device is reasonable in structure, fast and safe, reliable and efficient, can complete the whole process of mixing and liquefying, streak inoculation, dilution and separation, and incubation of microbial community automatically in a one-stop manner, and can replace manual labor and ensure biological safety.

Owner:湖南千山医疗器械有限公司

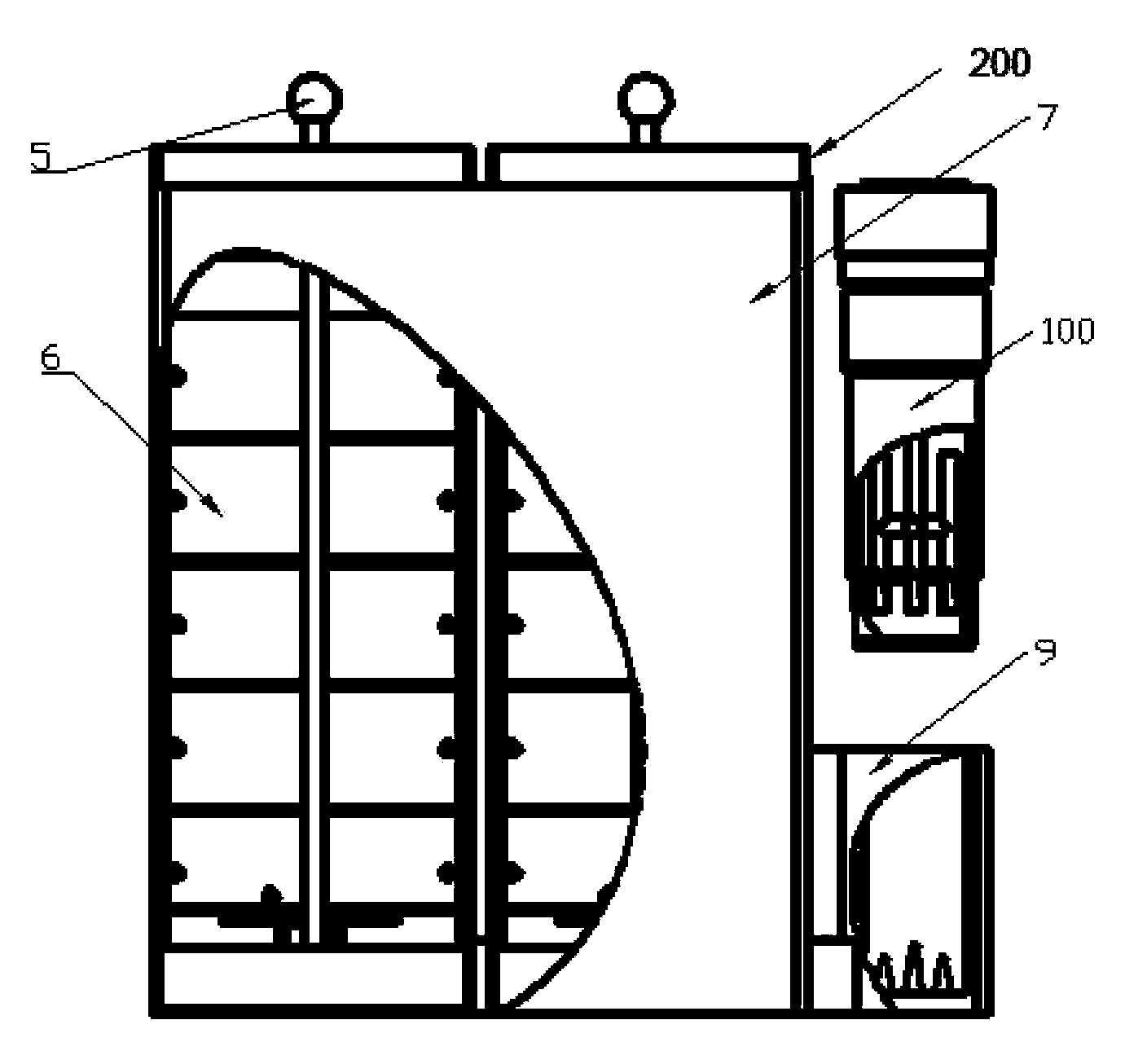

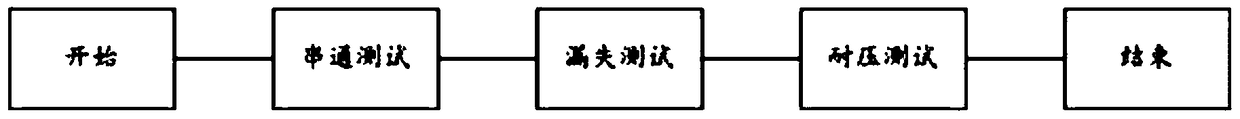

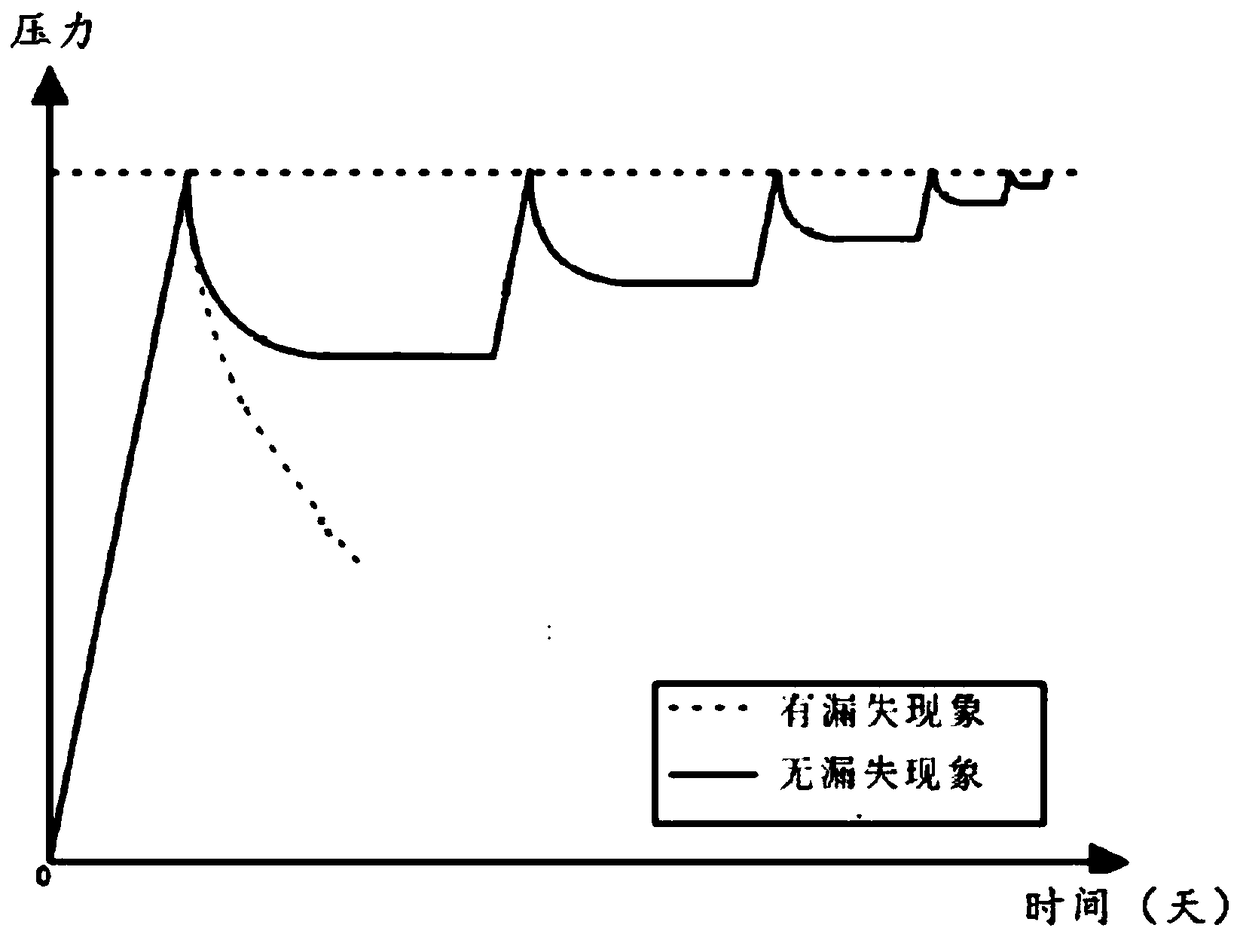

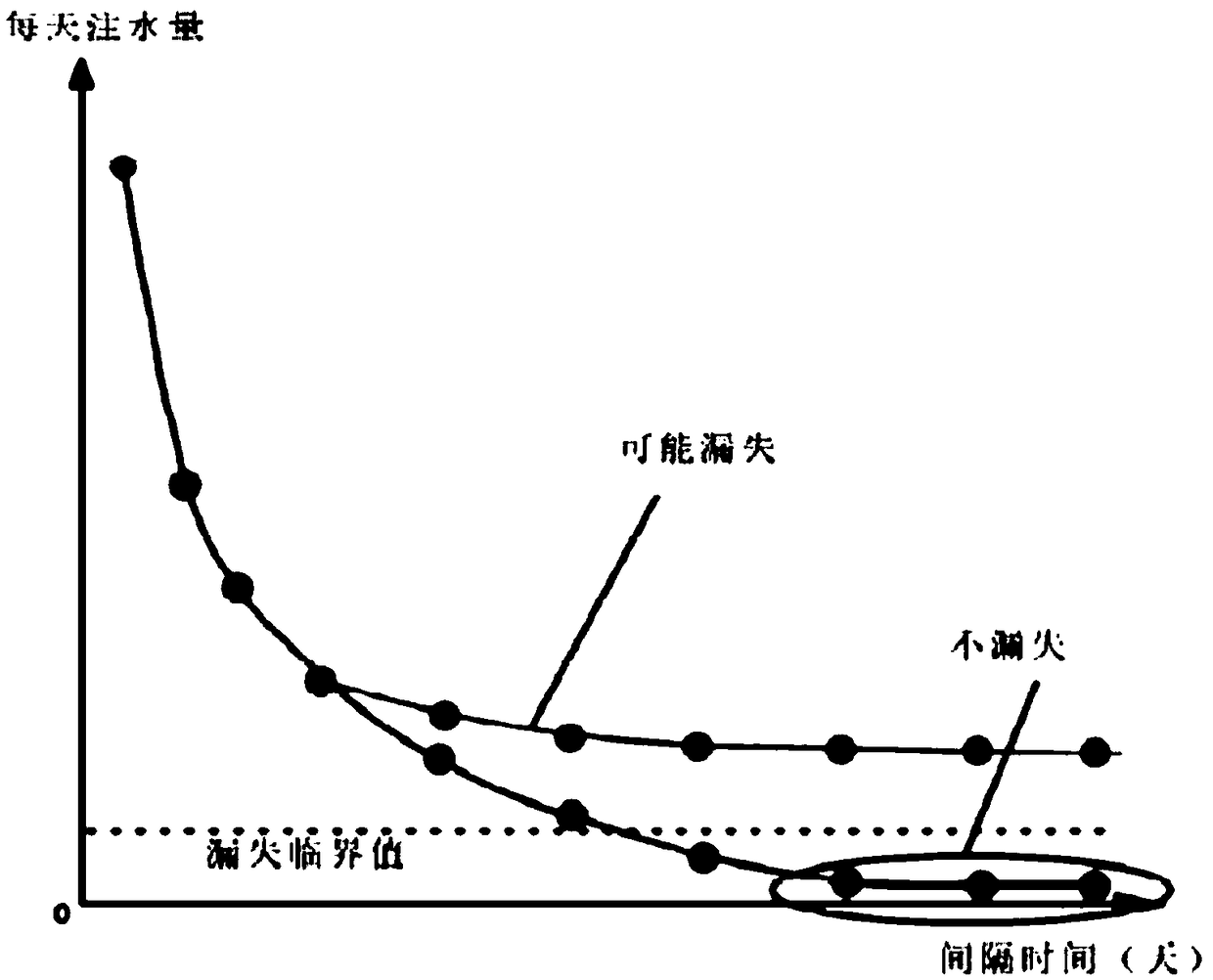

Method for testing seal performance of salt wells

InactiveCN109506850AComprehensive samplingPay attention to heat balanceMeasurement of fluid loss/gain rateEngineeringHeat balance

The invention belongs to the technical field of old and abandoned salt well recycling, and discloses a method for testing the seal performance of salt wells. The method includes steps of 1 well groupcollaboration tests, 2 well group leakage tests and 3 well group pressure-tight tests. The method has the advantages that the collaboration tests, the leakage tests and the pressure-tight tests are successively carried out, and accordingly the method is reasonable; large quantities of test data are sampled, sampling points are scientific, and test and evaluation bases are effective; attention is paid to heat balance of salt caverns in test procedures, rock salt corrosion, plastic deformation of the salt wells and the like are prevented in the test procedures, and accordingly test results are accurate.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD

Medical non-disassembly sampling tube

InactiveCN105125240BCause secondary damageReal-time detection and judgmentSurgeryVaccination/ovulation diagnosticsBiomedical engineeringLaboratory testing

The invention relates to a medical non-detachable sampling tube, which comprises: an implanted hose, a plurality of sampling holes are arranged on the tube wall of the implanted hose, and the extending direction of the sampling holes is the same as the extending direction of the sampling tube. Consistent, each of the sampling holes is provided with a sampling line, one end of the sampling line protrudes from the orifice of the sampling hole for a certain length, and the two ends of the implanted hose are the implanted end and the exposed end respectively, The opening of the sampling hole is located at the exposed end, the protruding part of the sampling line is the extraction end, the sampling line is located near the implanted end with a bifurcation, and the implanted soft end near the implanted end A bifurcation window is provided on the outer wall of the tube, and the bifurcation is exposed through the bifurcation window. There are multiple sampling lines running through the wall of the implanted hose. After the implanted hose is implanted into the human body at one time, the implanted hose does not need to be moved, and the sampling lines in the human body can be detected by simply extracting the sampling line. The affected area is sampled and then tested for laboratory testing, which will not cause secondary damage to the affected area.

Owner:SUZHOU BAILI MEDICAL PROD

A metering device for irregular surfaces or contours with adjustable precision

ActiveCN113203344BRealize regulationGuaranteed accuracyMechanical counters/curvatures measurementsWork holdersClassical mechanicsEngineering

The application provides a metering device with adjustable precision for irregular surfaces or contours, which includes a housing and an electric heating wire. The inside of the housing is fitted with a clamping assembly, and an adjustment assembly is arranged above the housing. The adjustment assembly The front end of the housing is provided with a transmission assembly; the rear end of the housing is provided with a calibration assembly, the front end of the calibration assembly is provided with a pressing assembly, and the front end of the pressing assembly is connected with a contour fitting assembly; the housing includes a top shell, a bottom shell, a fixed shaft , a movable plate, a card slot, an inner groove and a limiting plate; a bottom case is movably installed below the top case, and fixed shafts are fixedly connected to the left and right sides of the top case and the bottom case. The present application improves on the existing basis, and through the linkage structure among the adjustment assembly, the transmission assembly, the pressing assembly and the contour fitting assembly, the device can adapt to objects of different sizes for more comprehensive contour sampling, and The overall shape of the profile can be displayed in time after sampling.

Owner:成都辰迈科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com