Patents

Literature

126 results about "Force magnitude" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The magnitude of the force is defined as the sum of all the forces acting on an object. Calculating magnitudes for forces is a vital measurement of physics. The ‘magnitude’ of a force is its ‘size’ or ‘strength’, in spite of the path in which it acts.

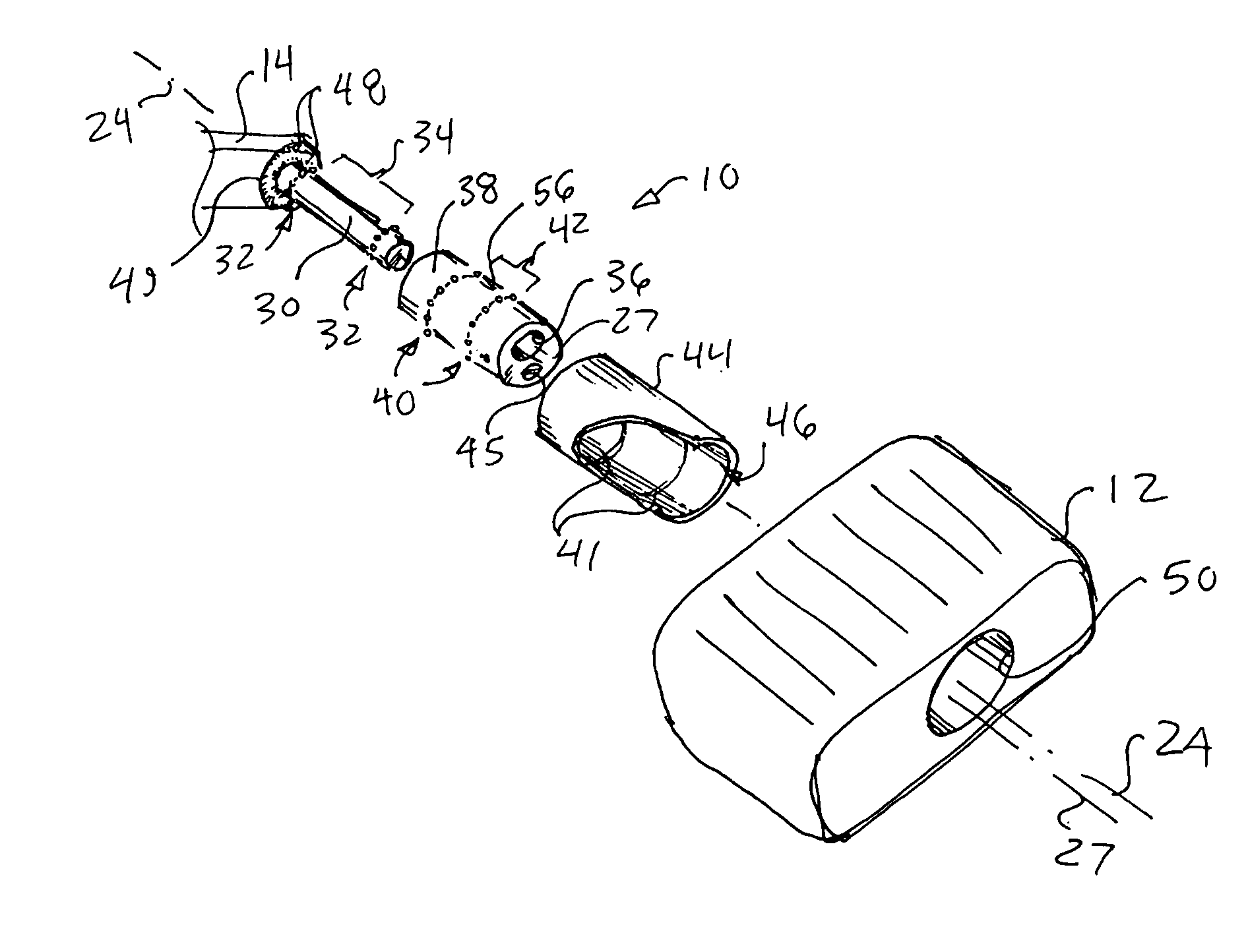

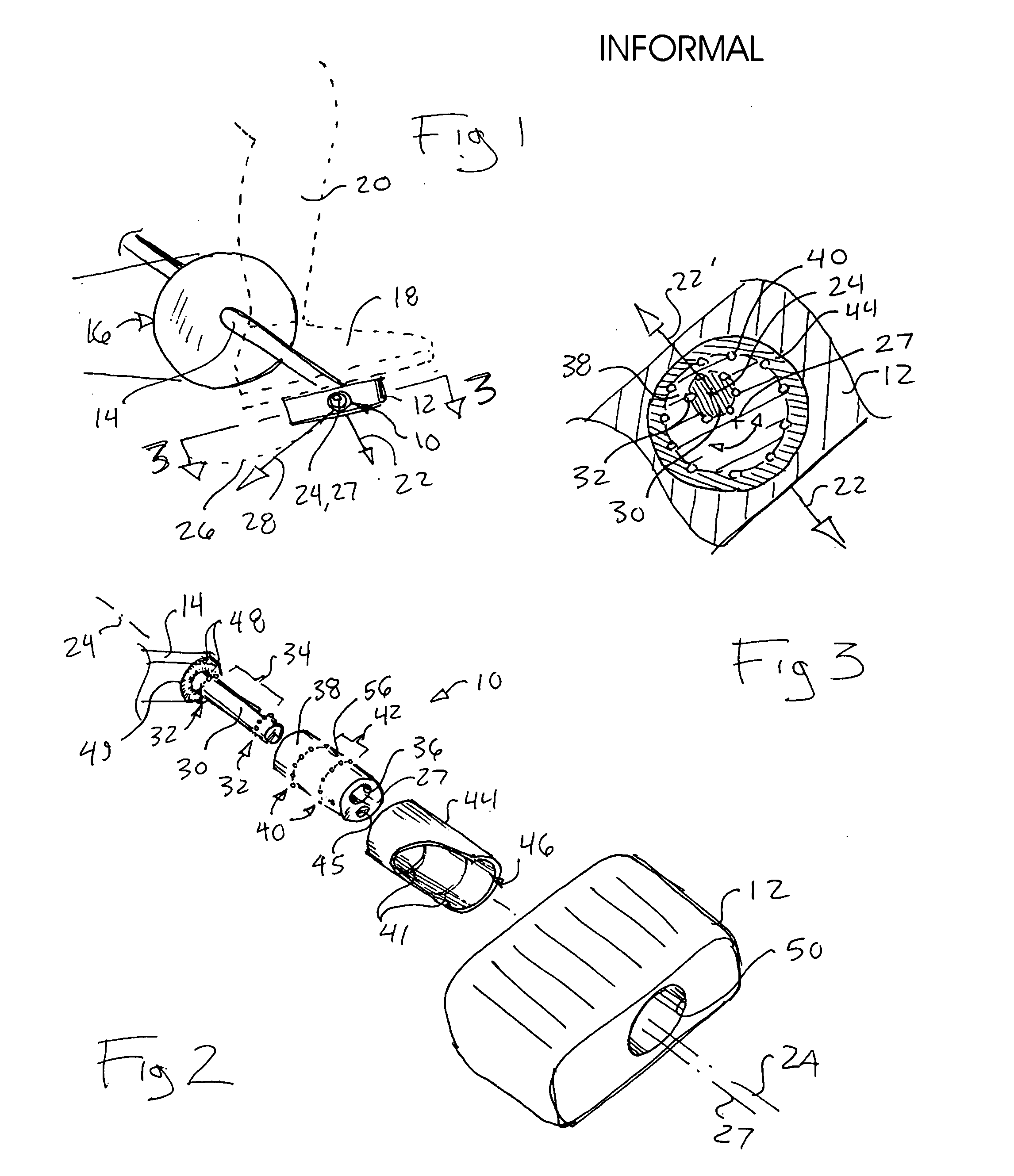

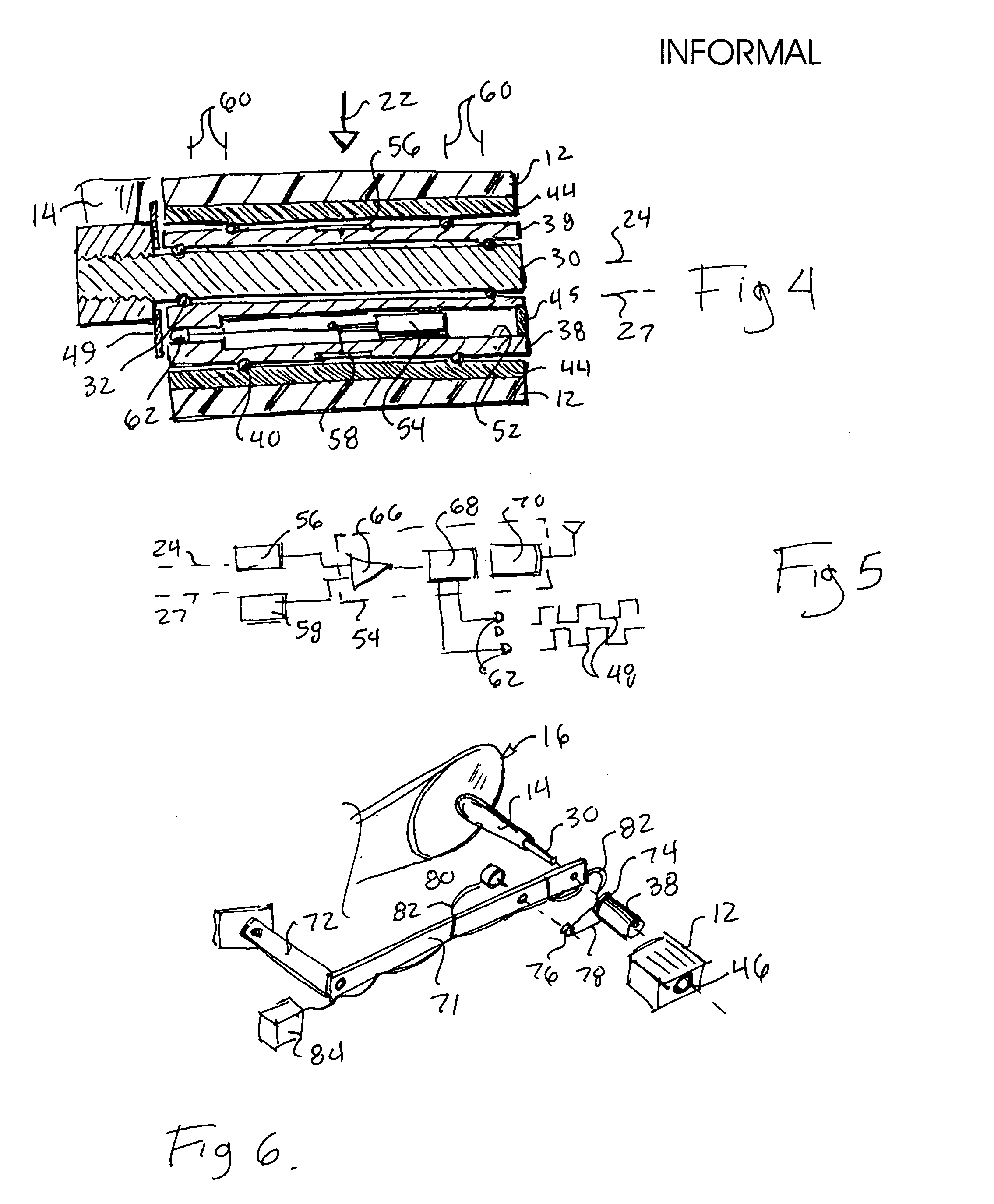

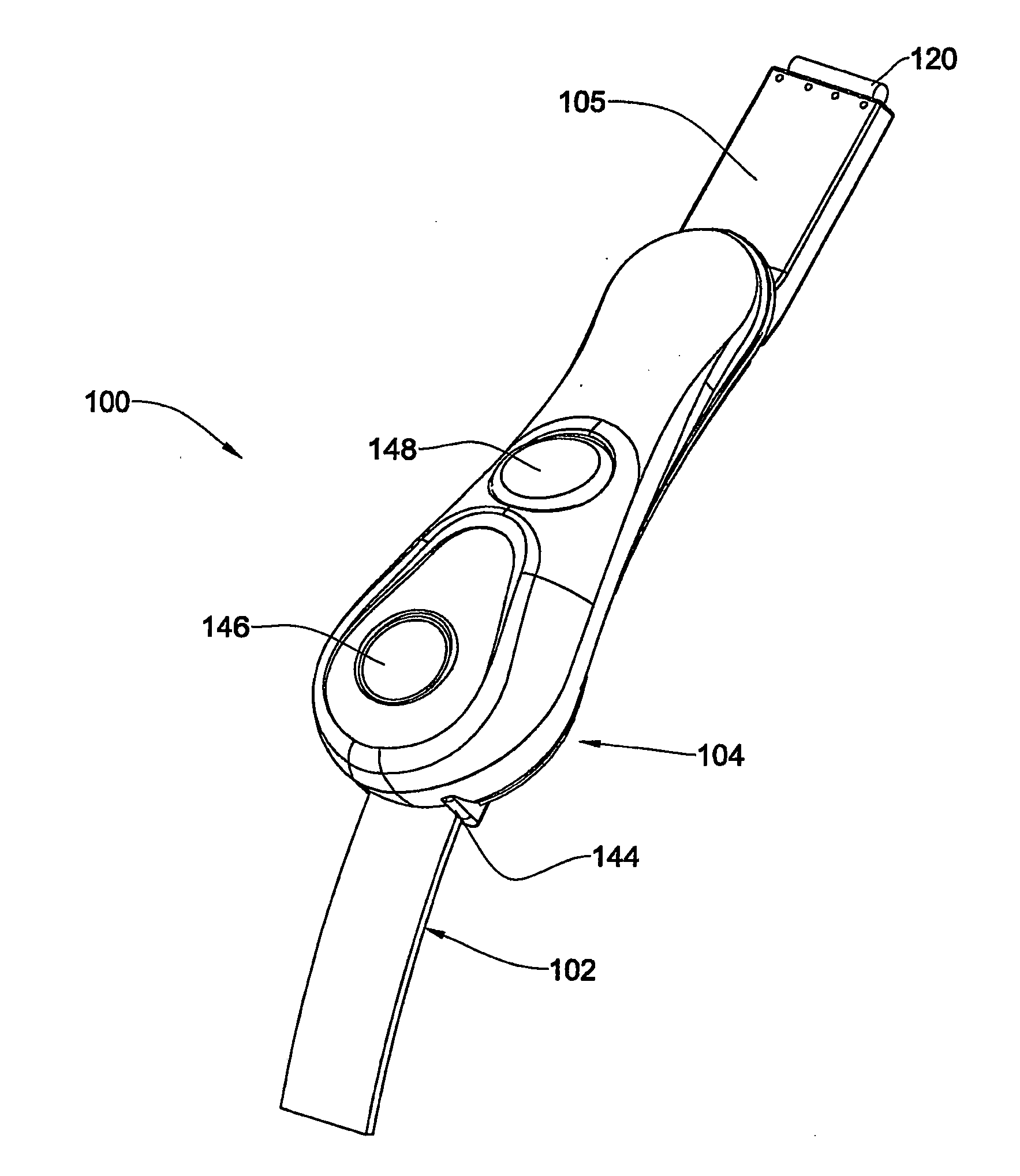

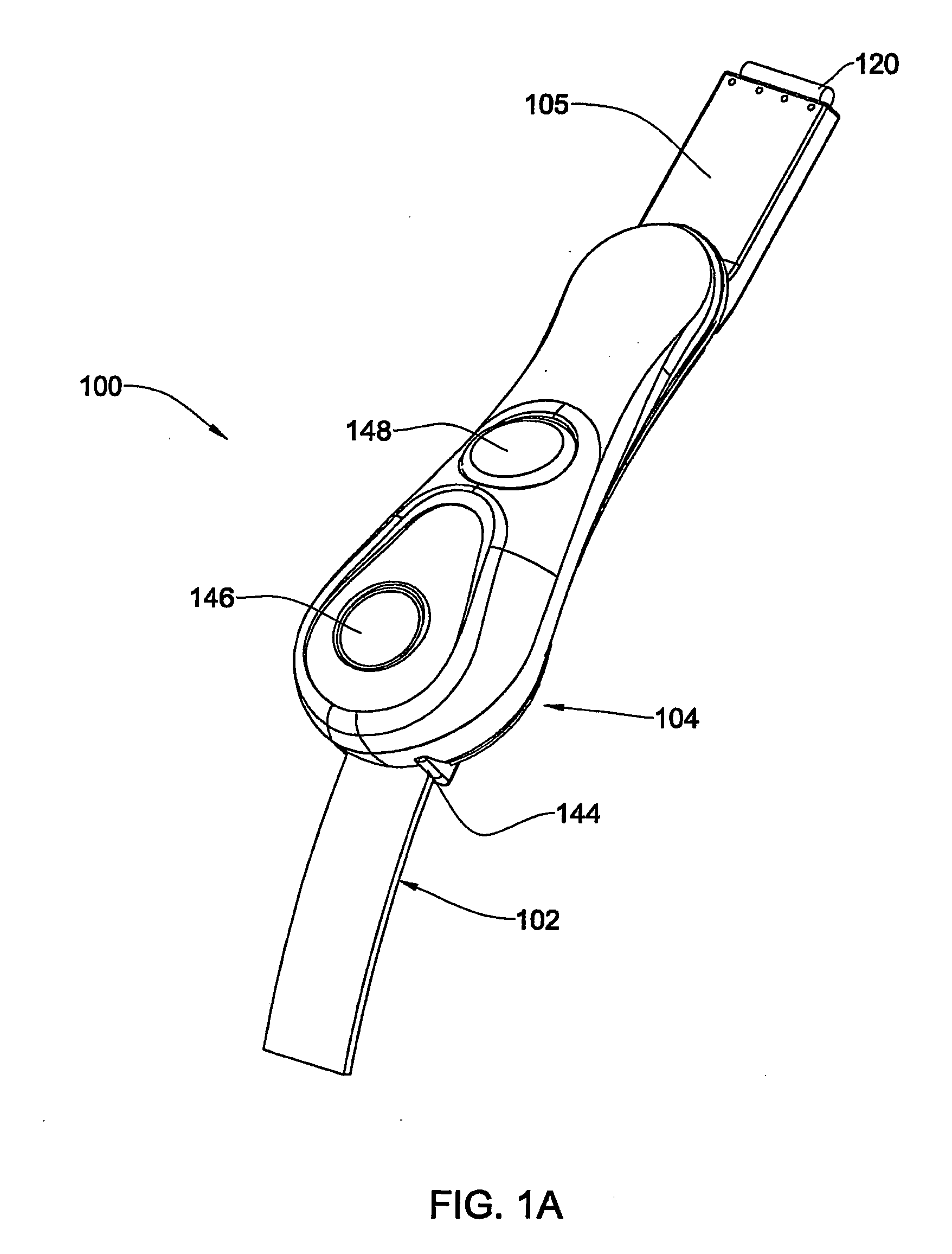

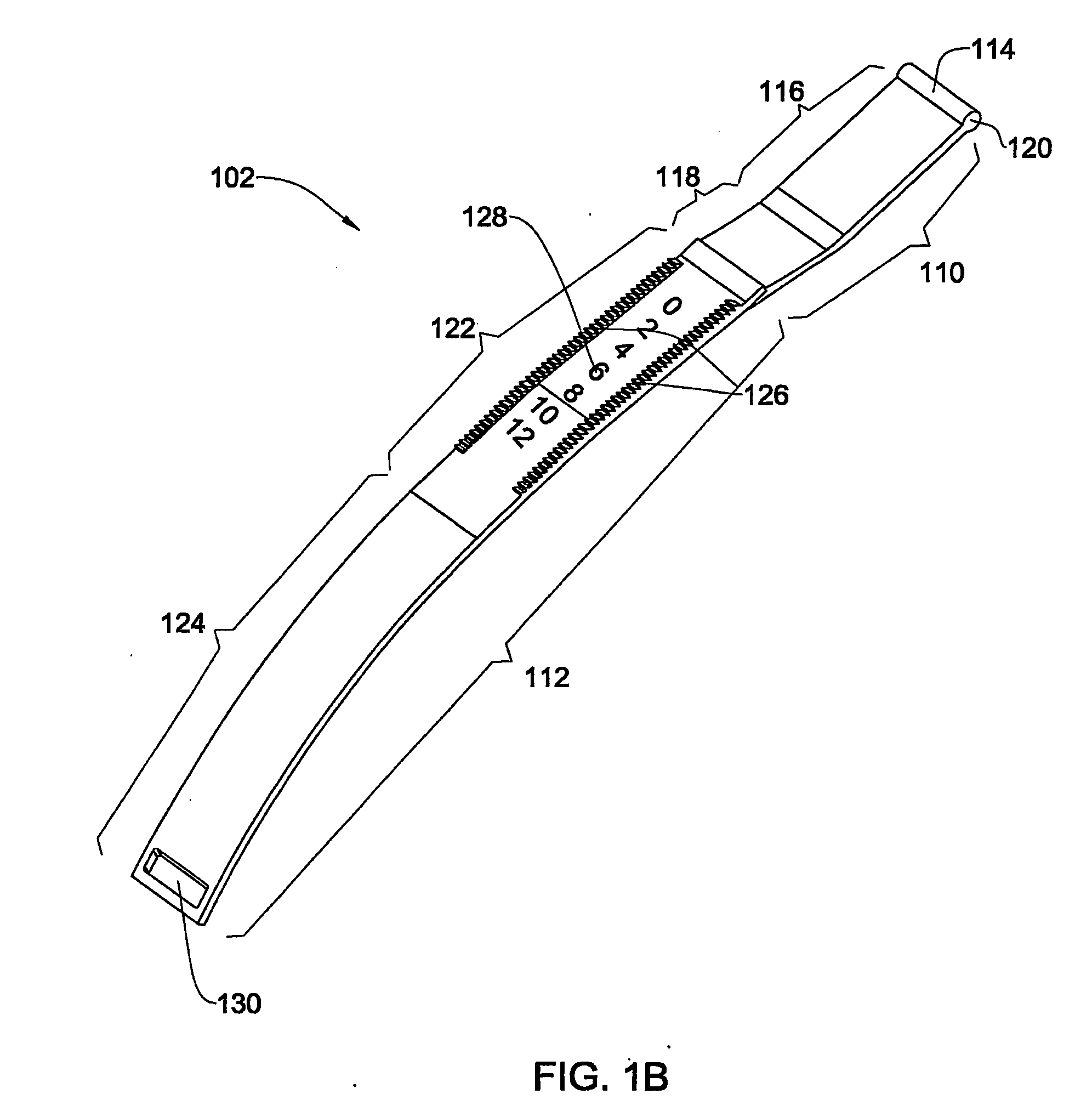

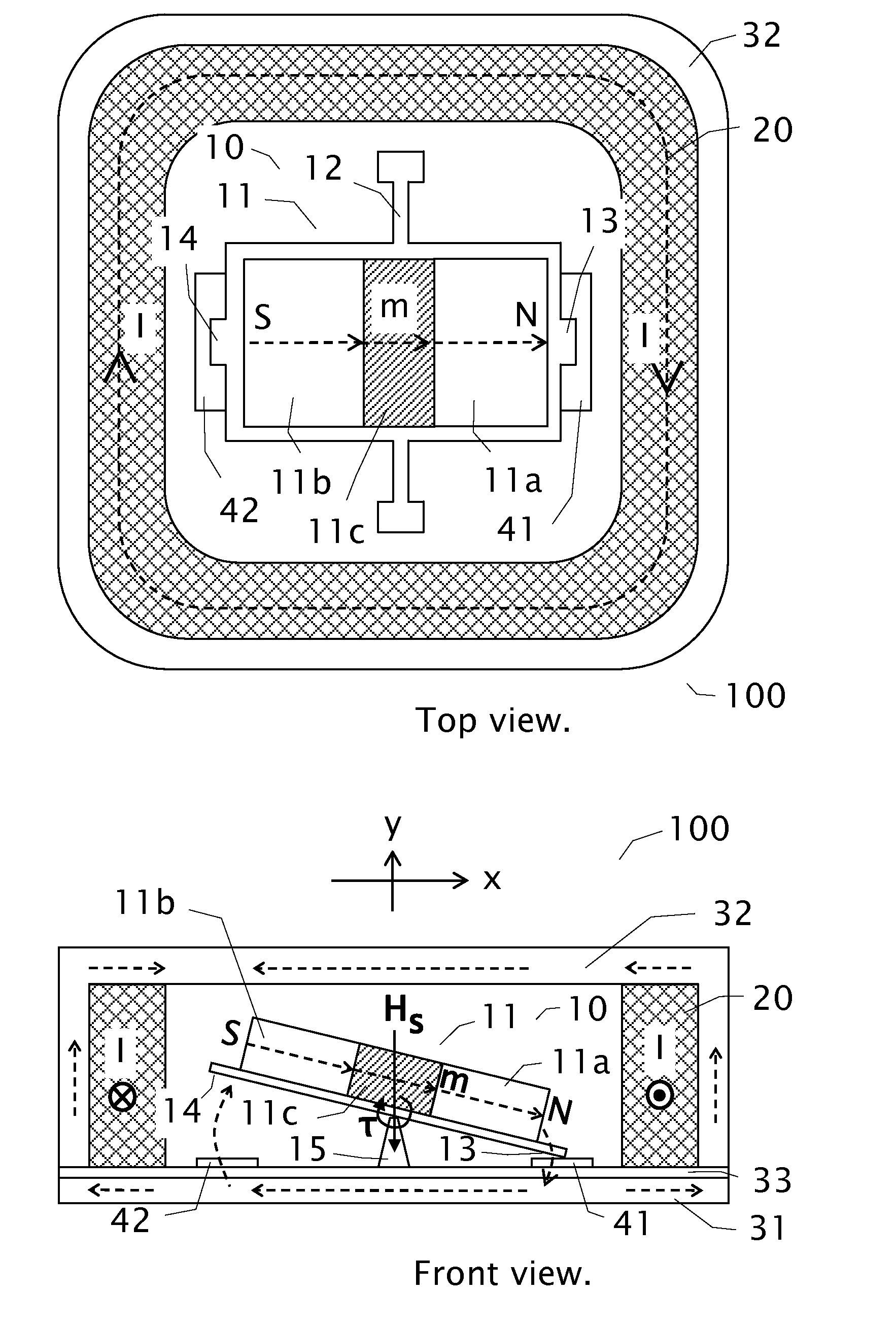

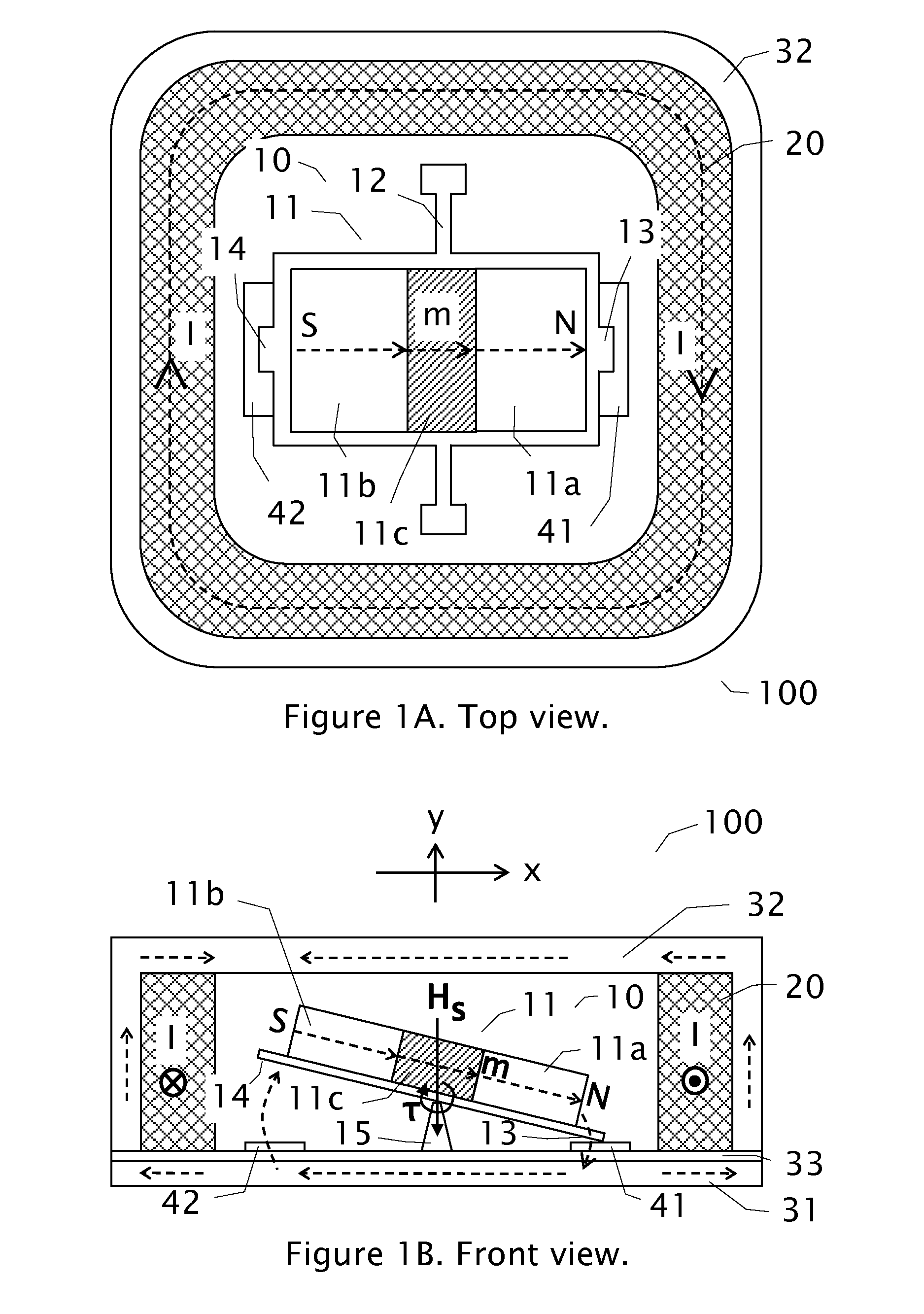

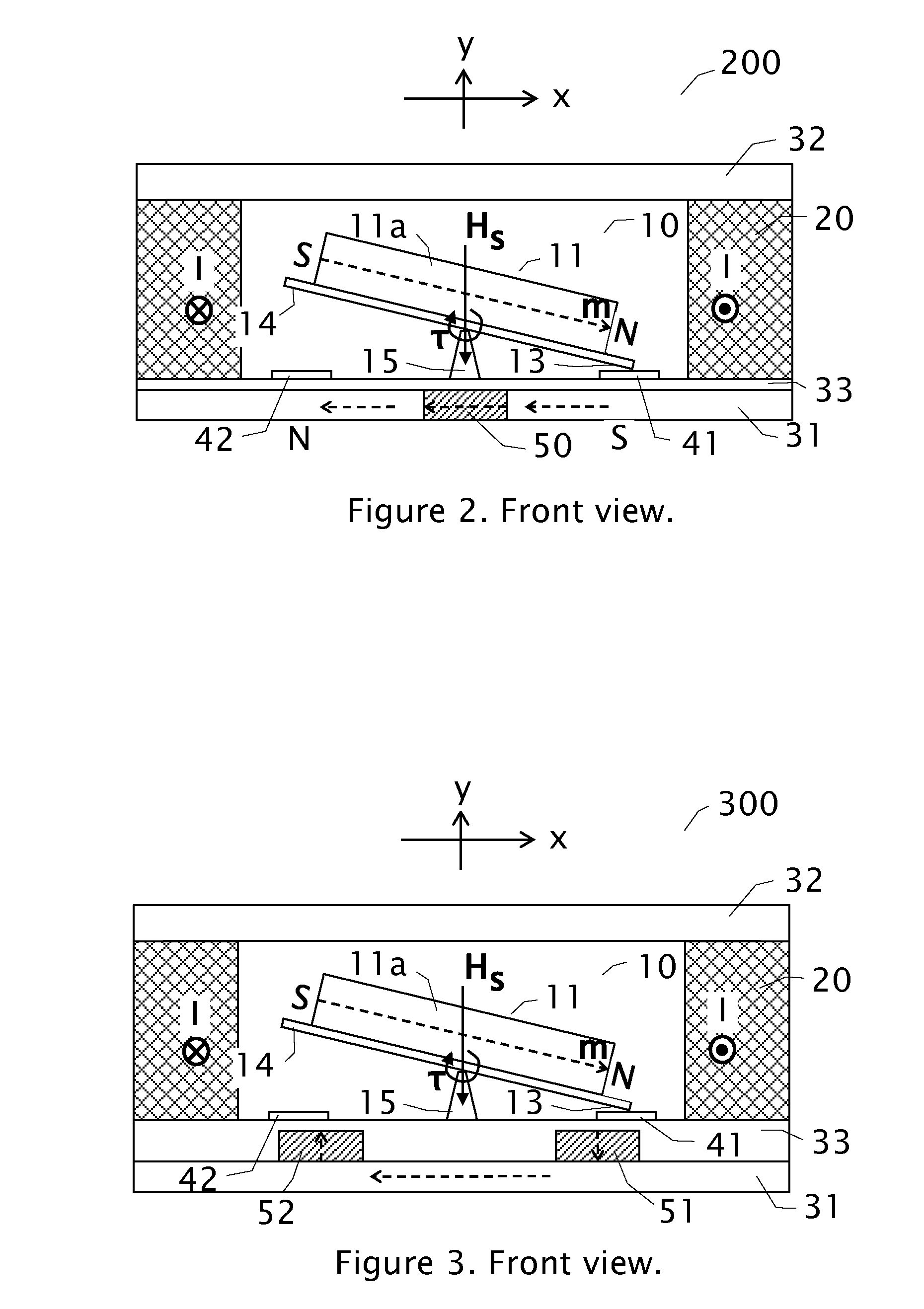

Electromechanical force-magnitude, force-angle sensor

ActiveUS20070137307A1Better user feedbackEasy to FeedbackMechanical apparatusVehicle cranksElectric forceEngineering

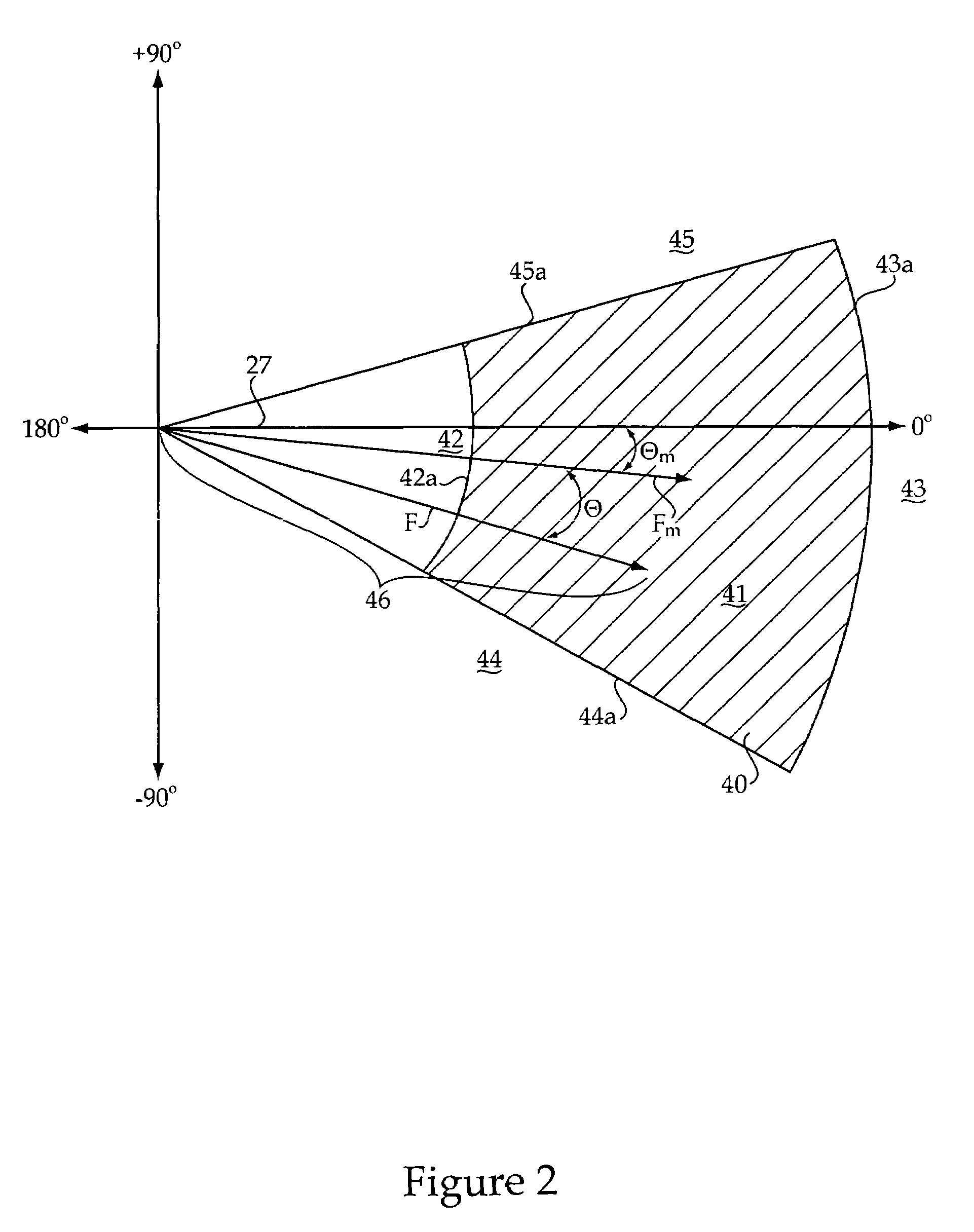

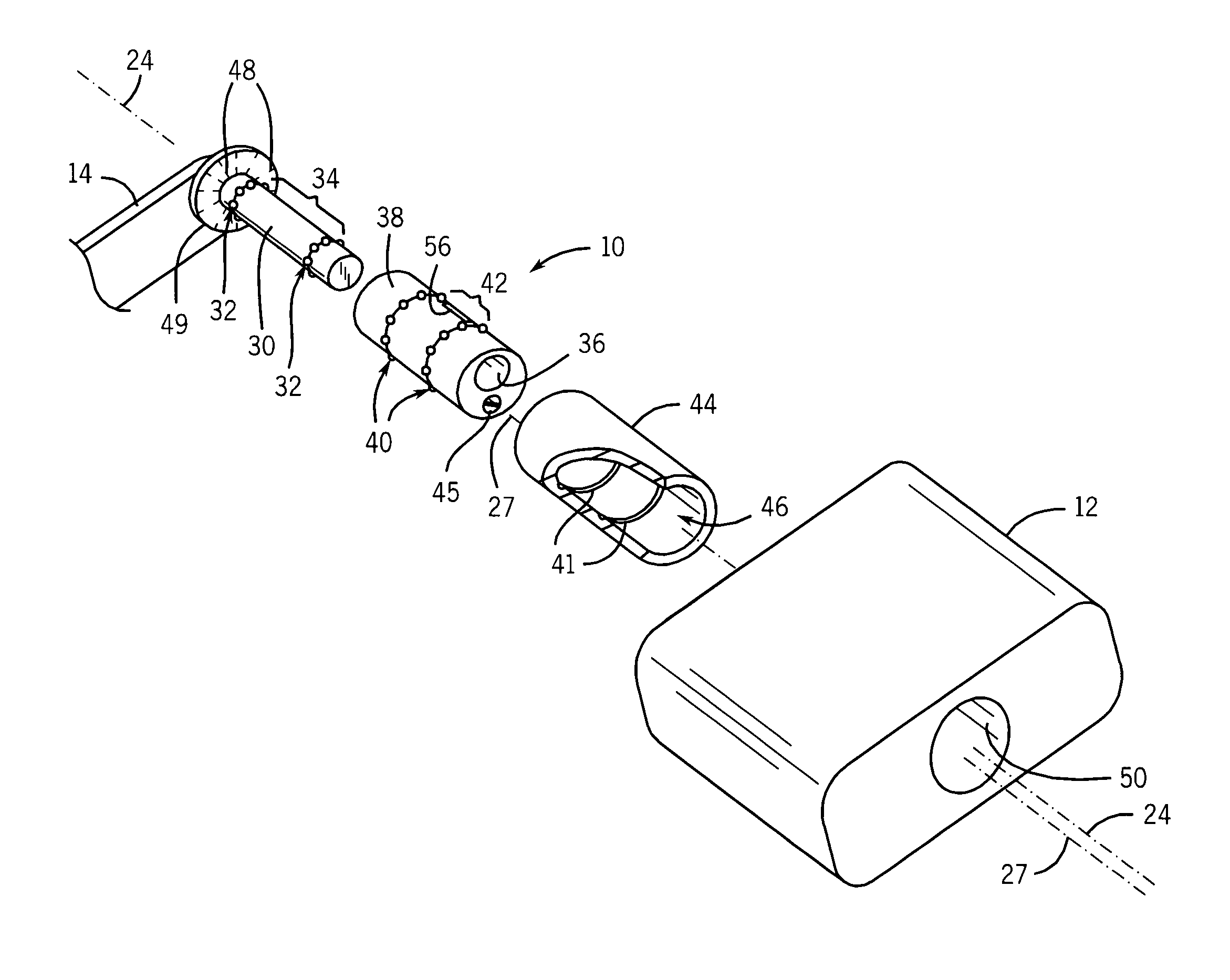

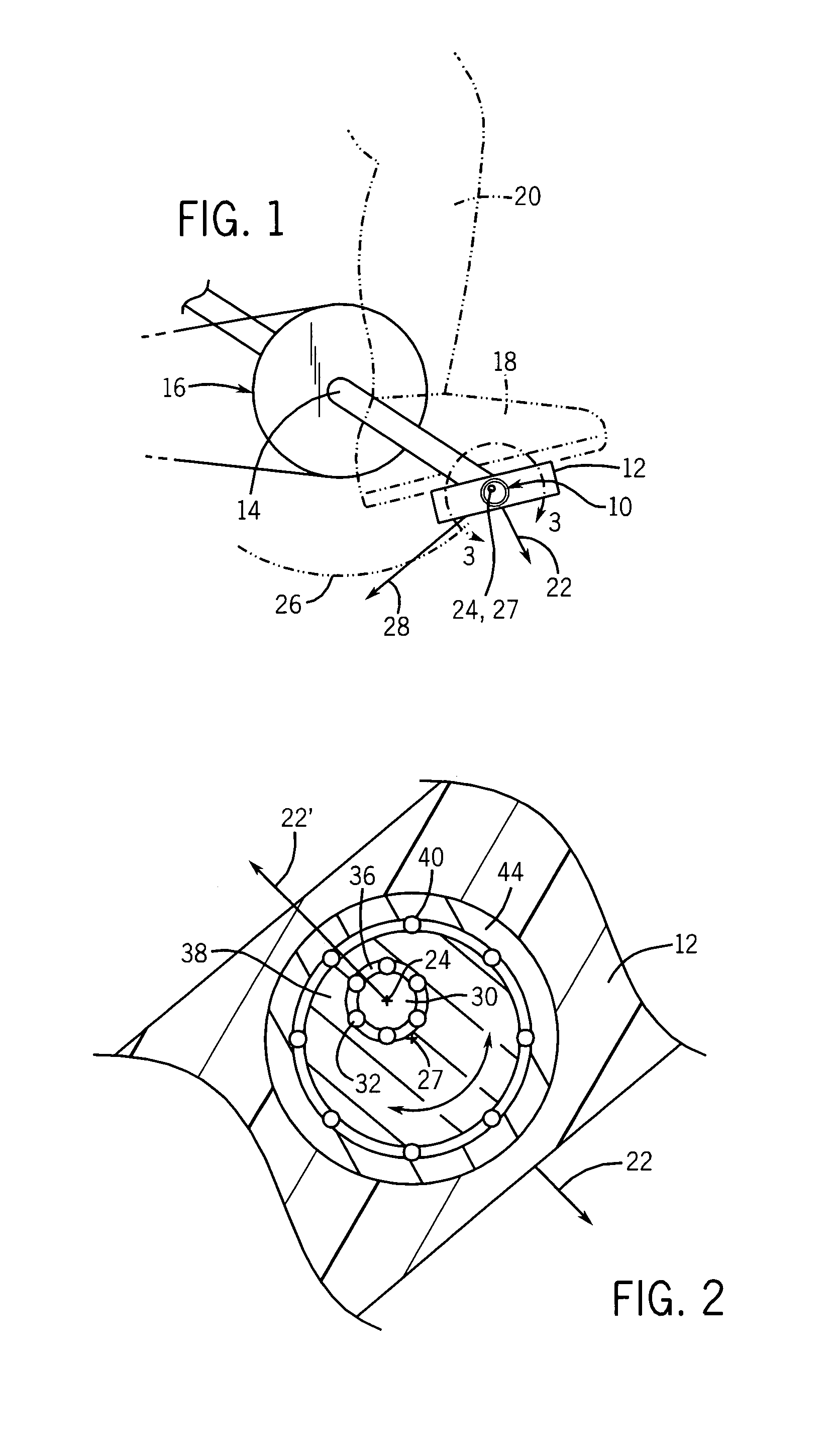

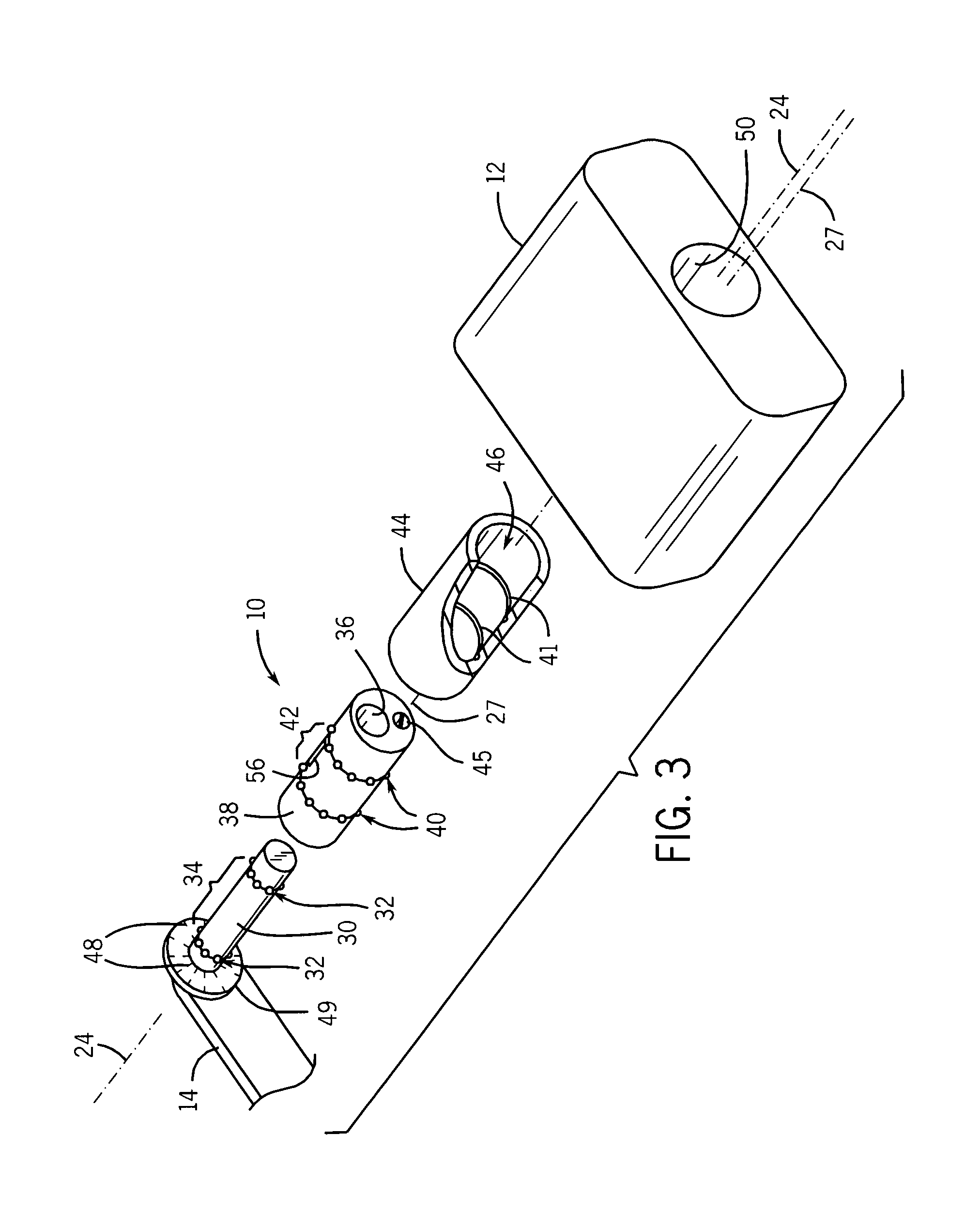

An electromechanical force sensor uses a rotating element that aligns with the force and may carry a force magnitude sensor simplifying and providing more accurate measurement of force-angle and force-magnitude. The ability to detect simply force-angle and force-magnitude enables a variety of training and exercise devices.

Owner:WISCONSIN ALUMNI RES FOUND

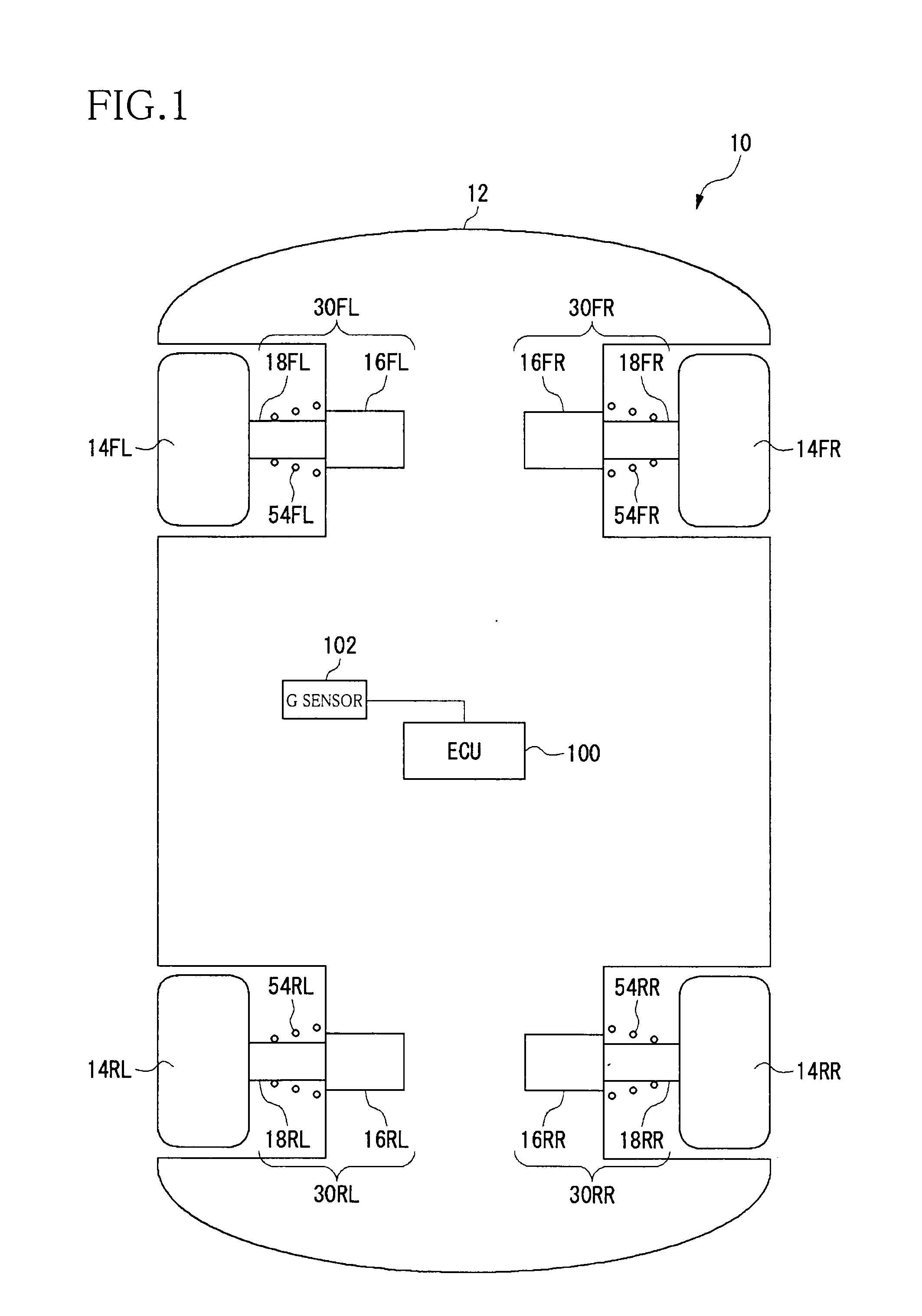

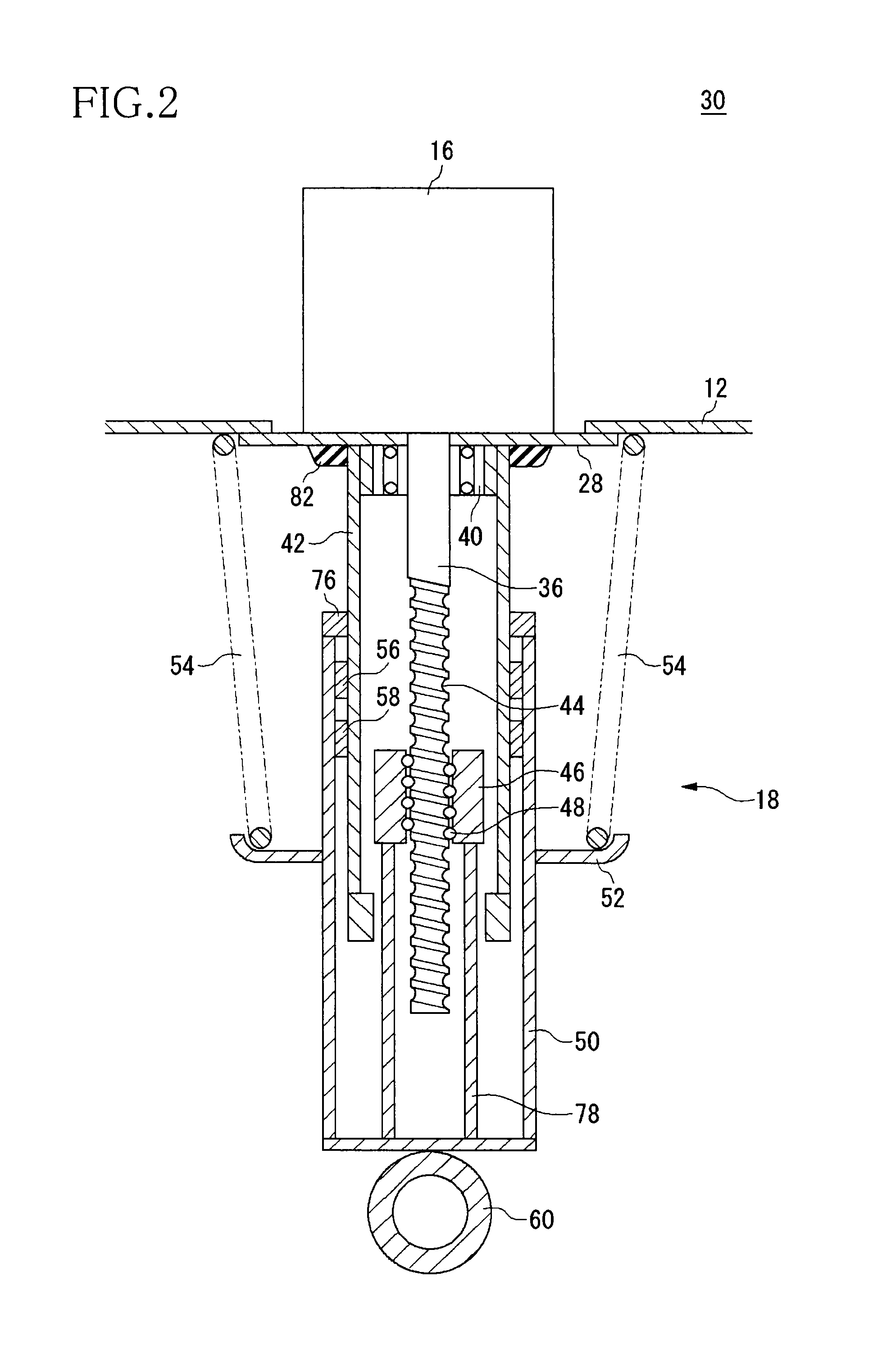

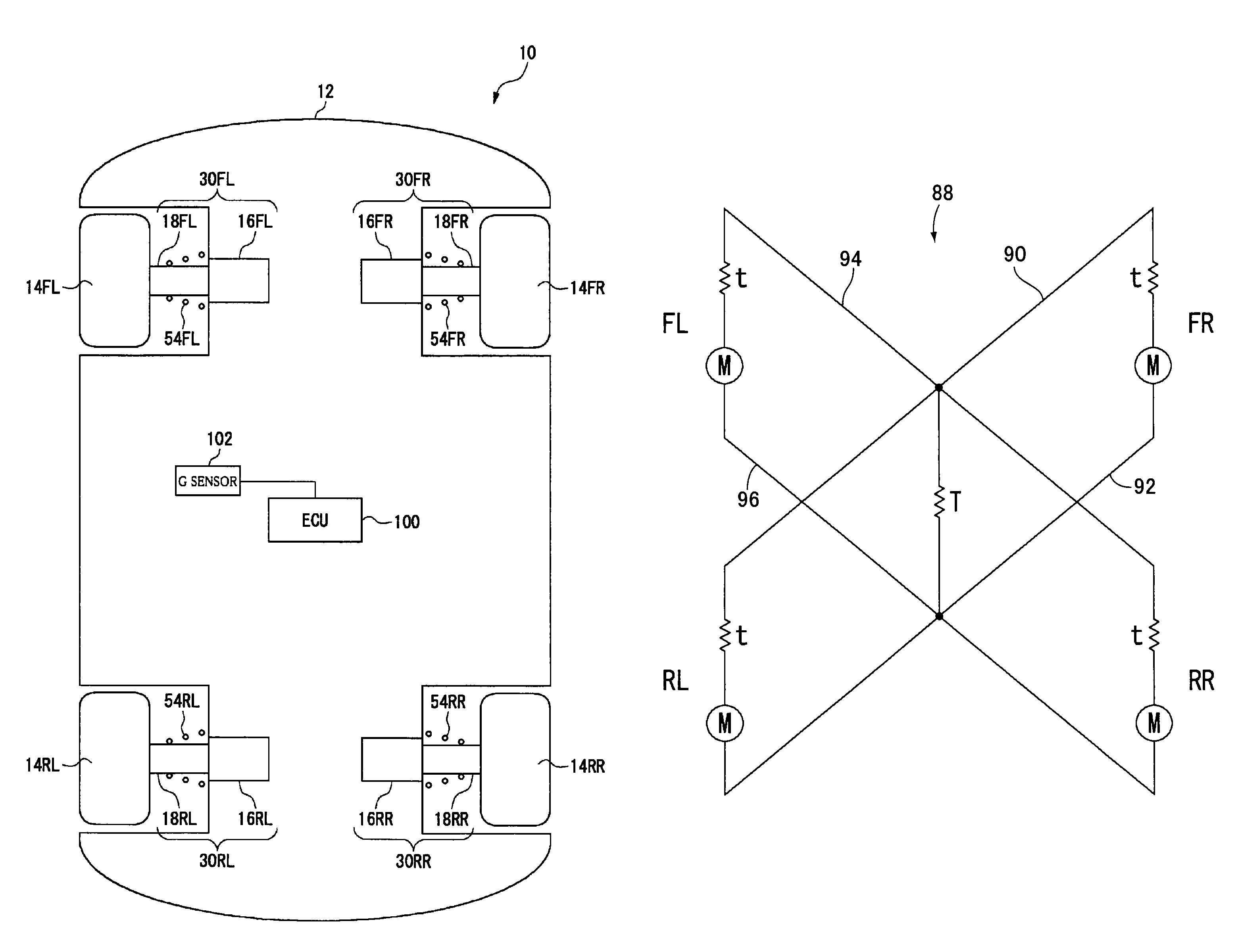

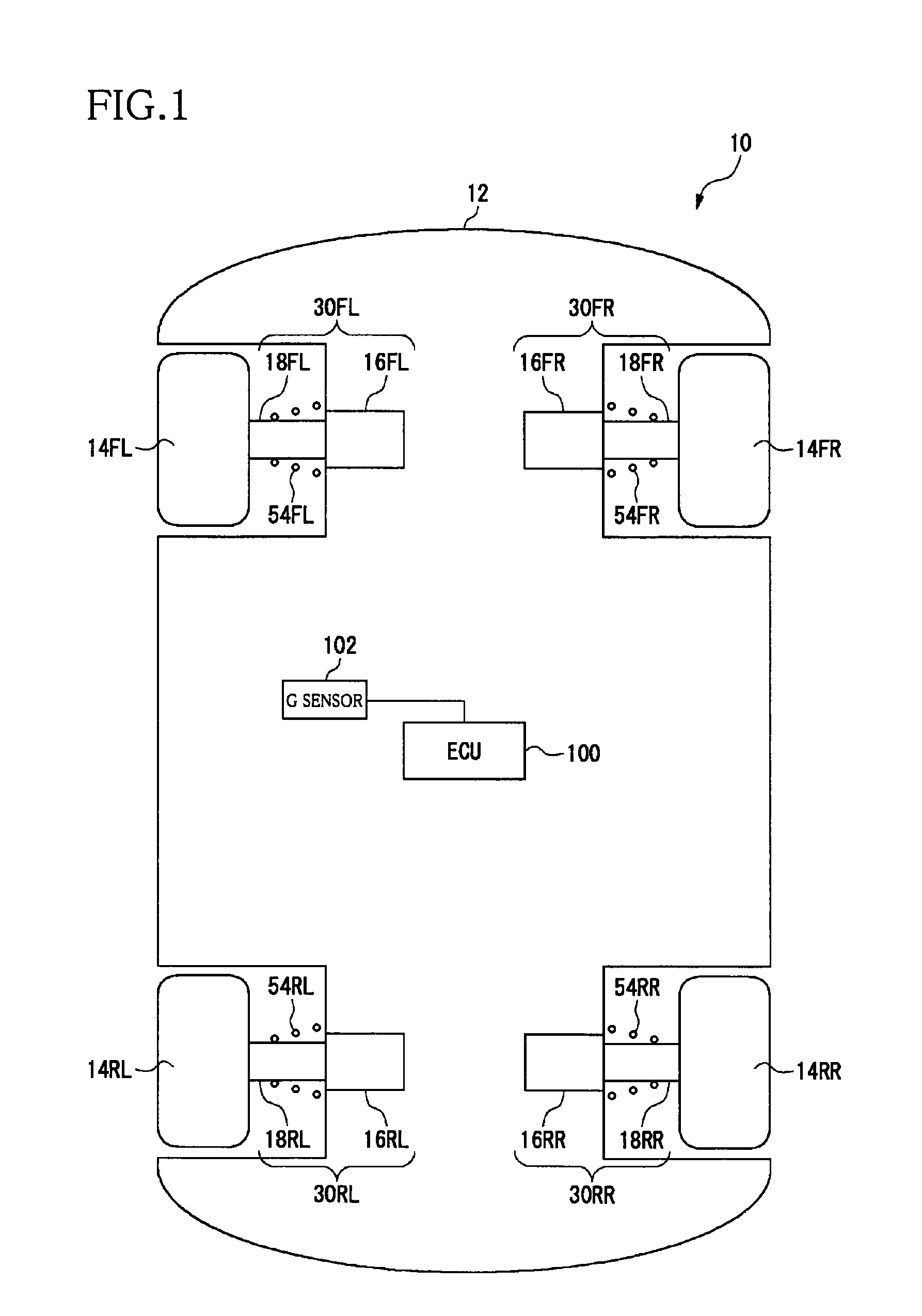

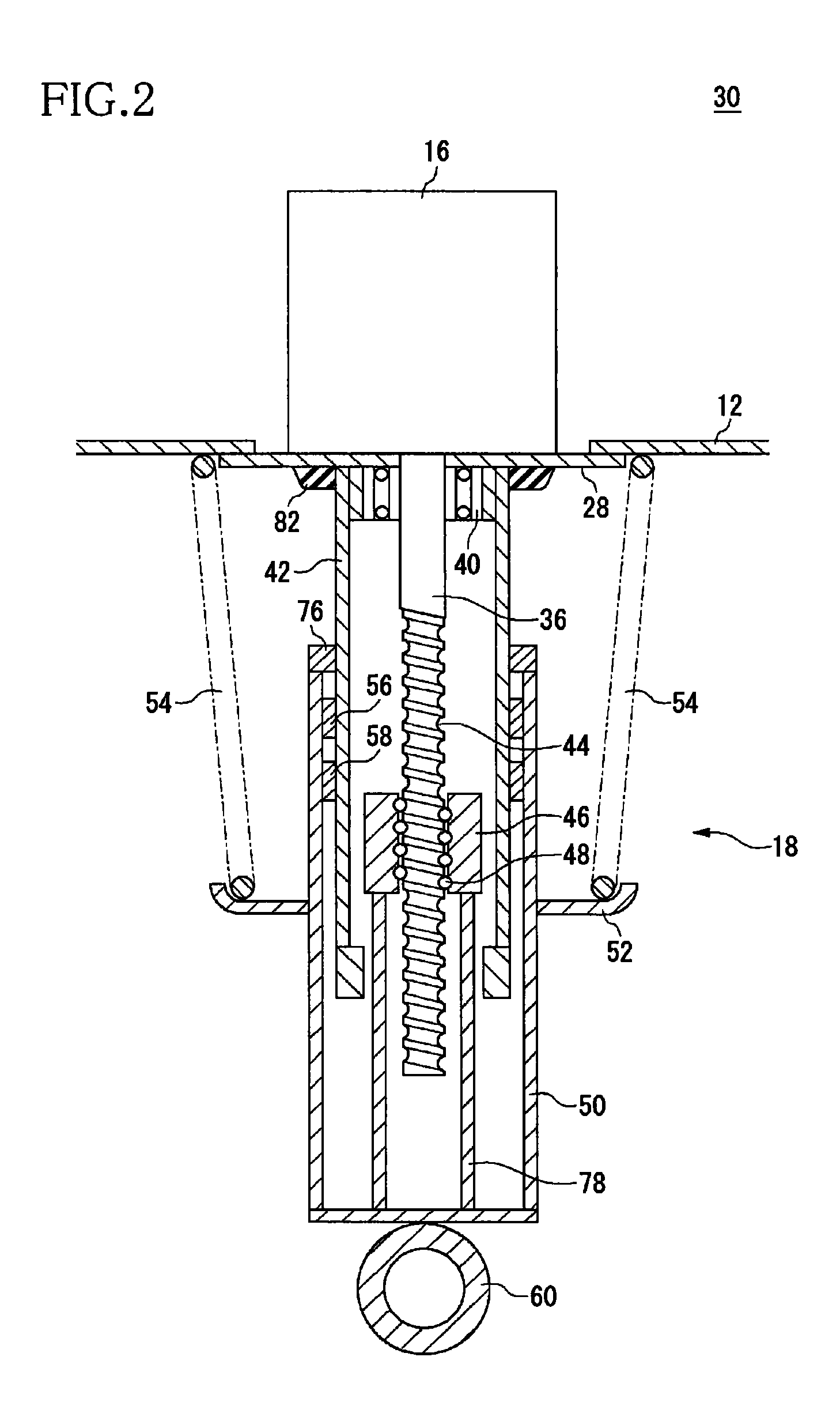

Suspension system for vehicle

ActiveUS20090273147A1Simple structureReduce voltageNon-rotating vibration suppressionDigital data processing detailsElectromagnetic absorbersClosed loop

In a system including four electromagnetic absorbers for respective four vehicle wheels, motor coils of two respective electromagnetic absorbers disposed corresponding to two diagonally located wheels are connected forming a closed loop including the coils. A generated damping force magnitude can be made different between an instance directions of respective movements of the diagonally located two wheels with respect to the vehicle body are the same, and an instance the directions are opposite each other. Each electromagnetic absorber includes a resistor cooperating with the corresponding coil forming a closed loop, and selectively establishes: a connected state in which one of the four coils and any of the other three coils are connected to form a closed loop; and a non-connected state in which the one of the four coils is not connected to any other coil. An appropriate vibration suppressing action is exhibited with respect to a coupled motion.

Owner:KYB CORP +2

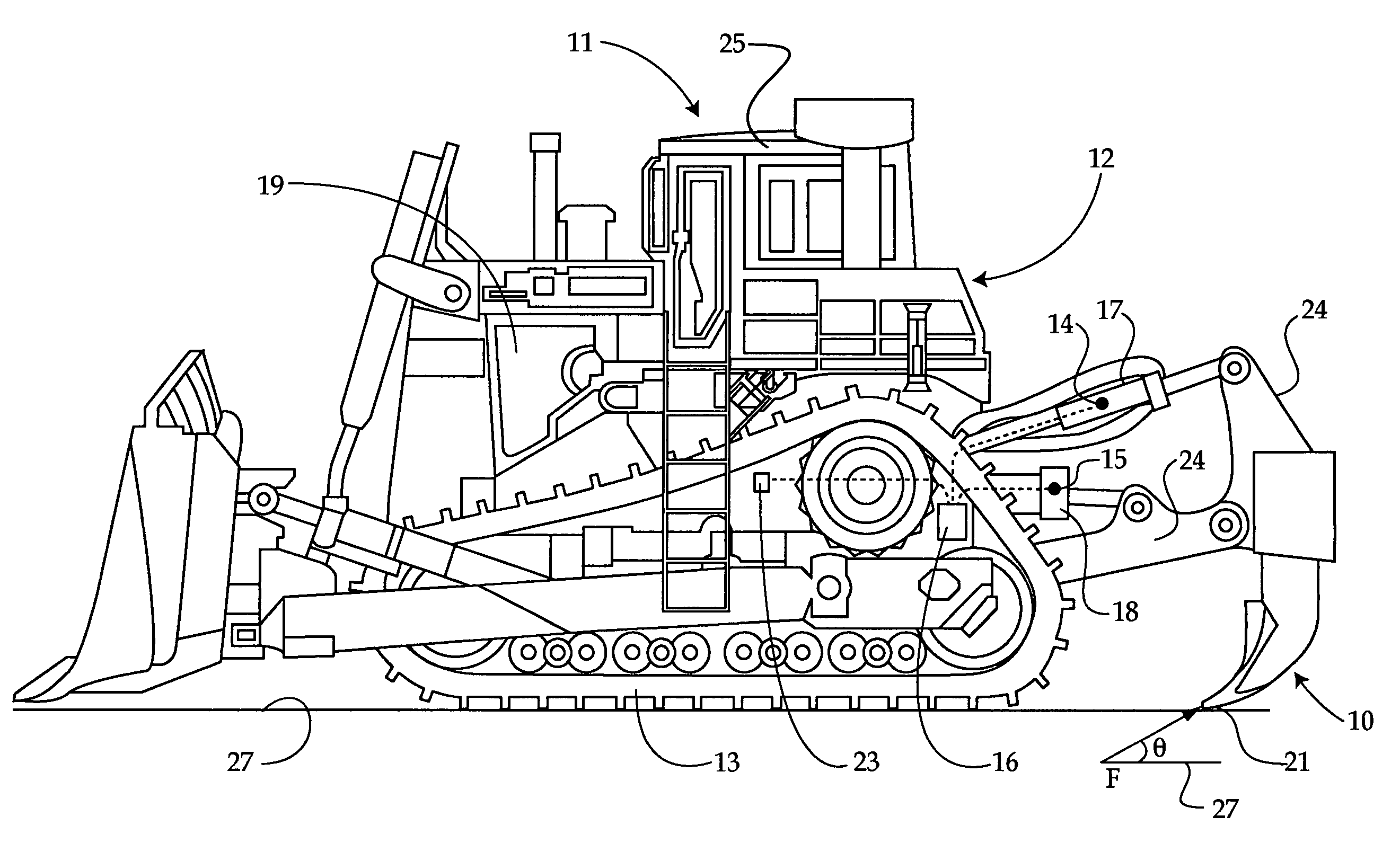

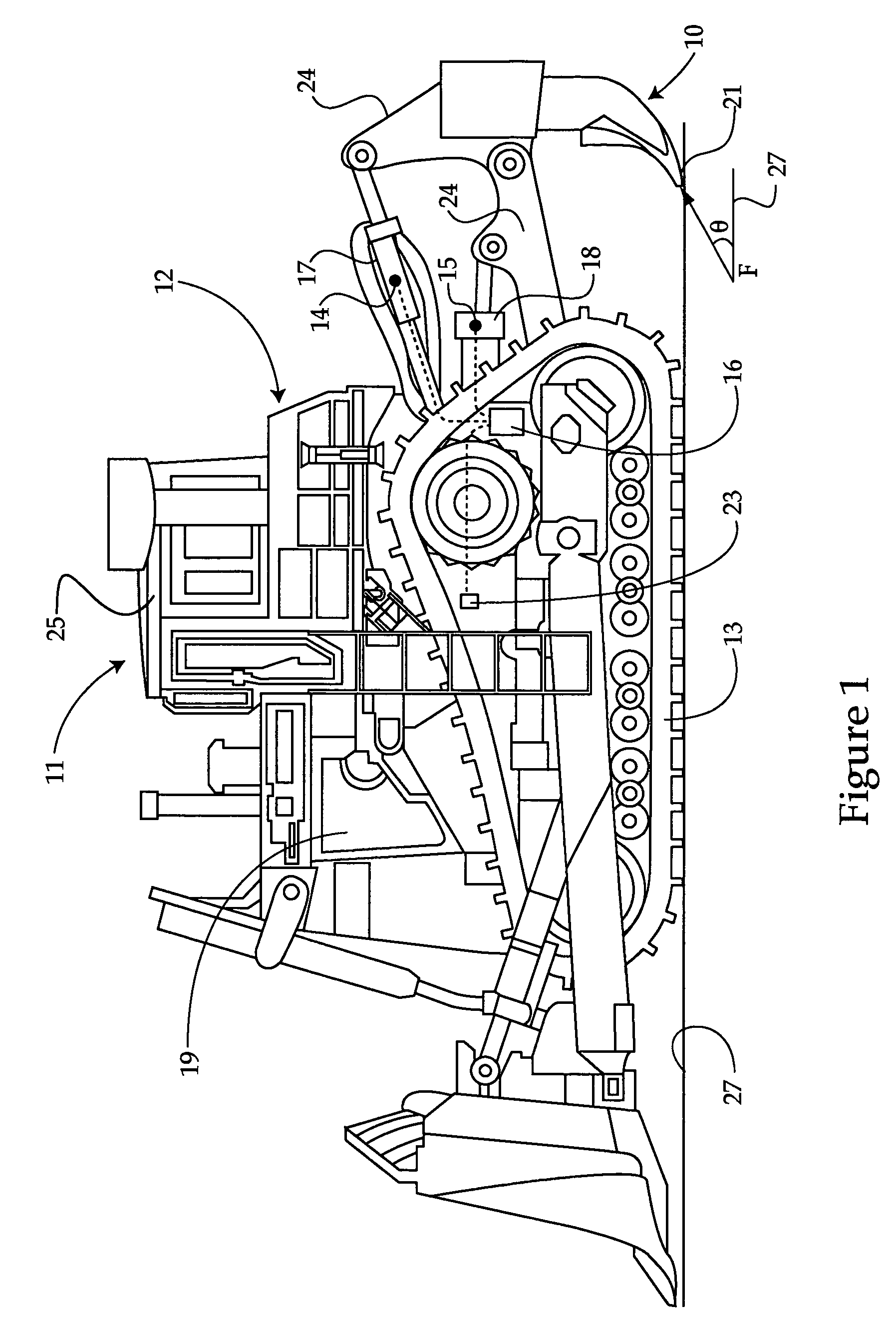

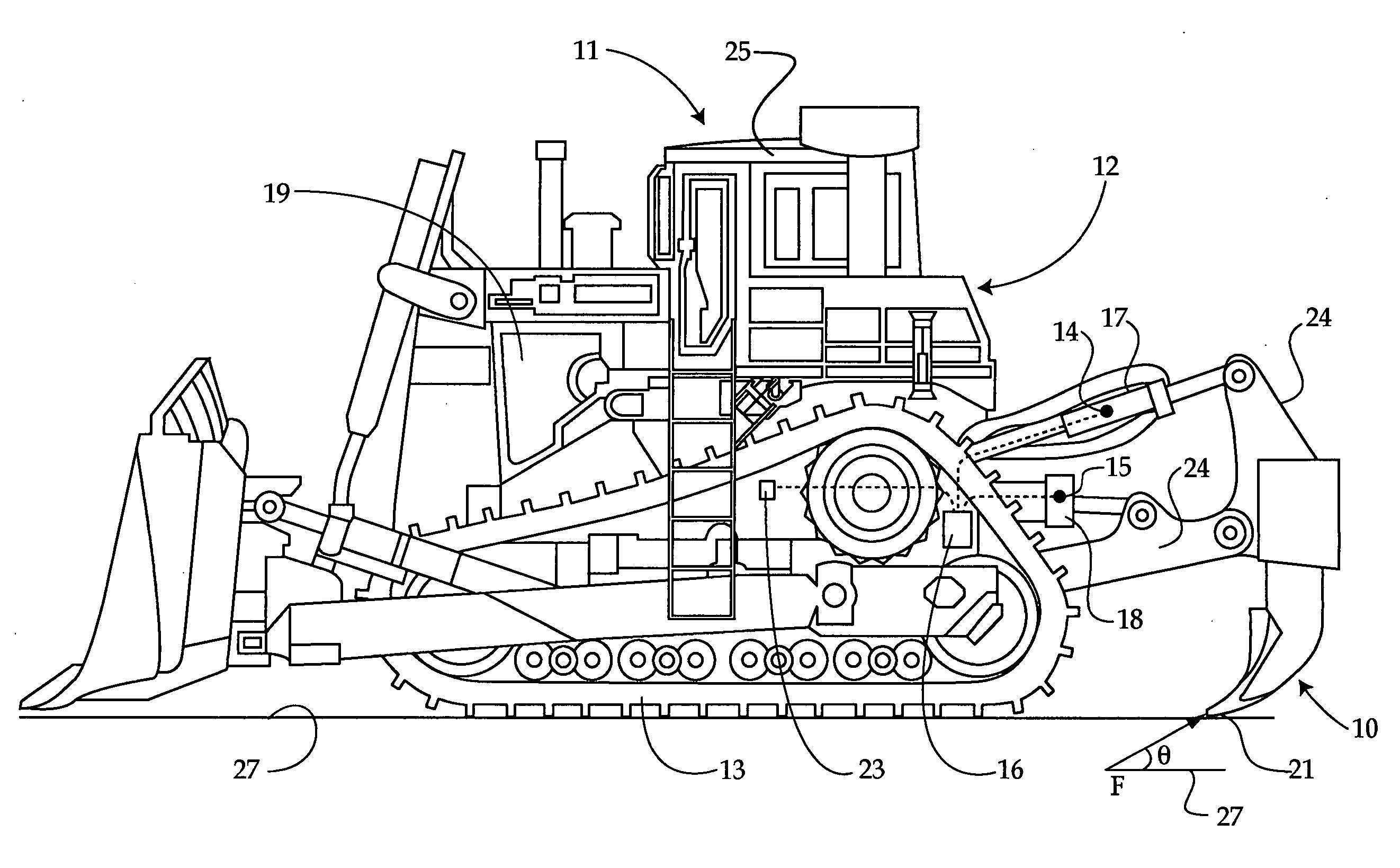

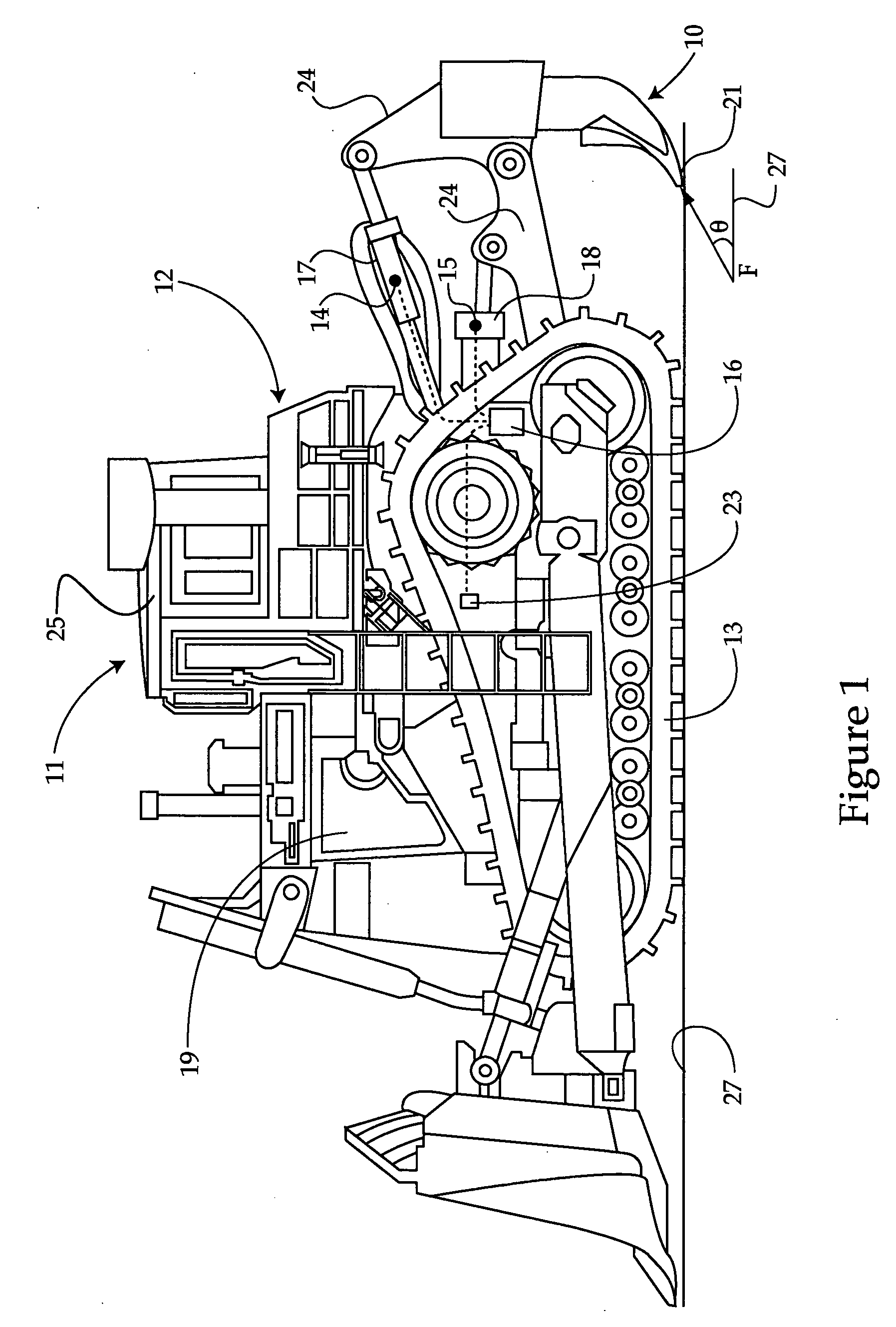

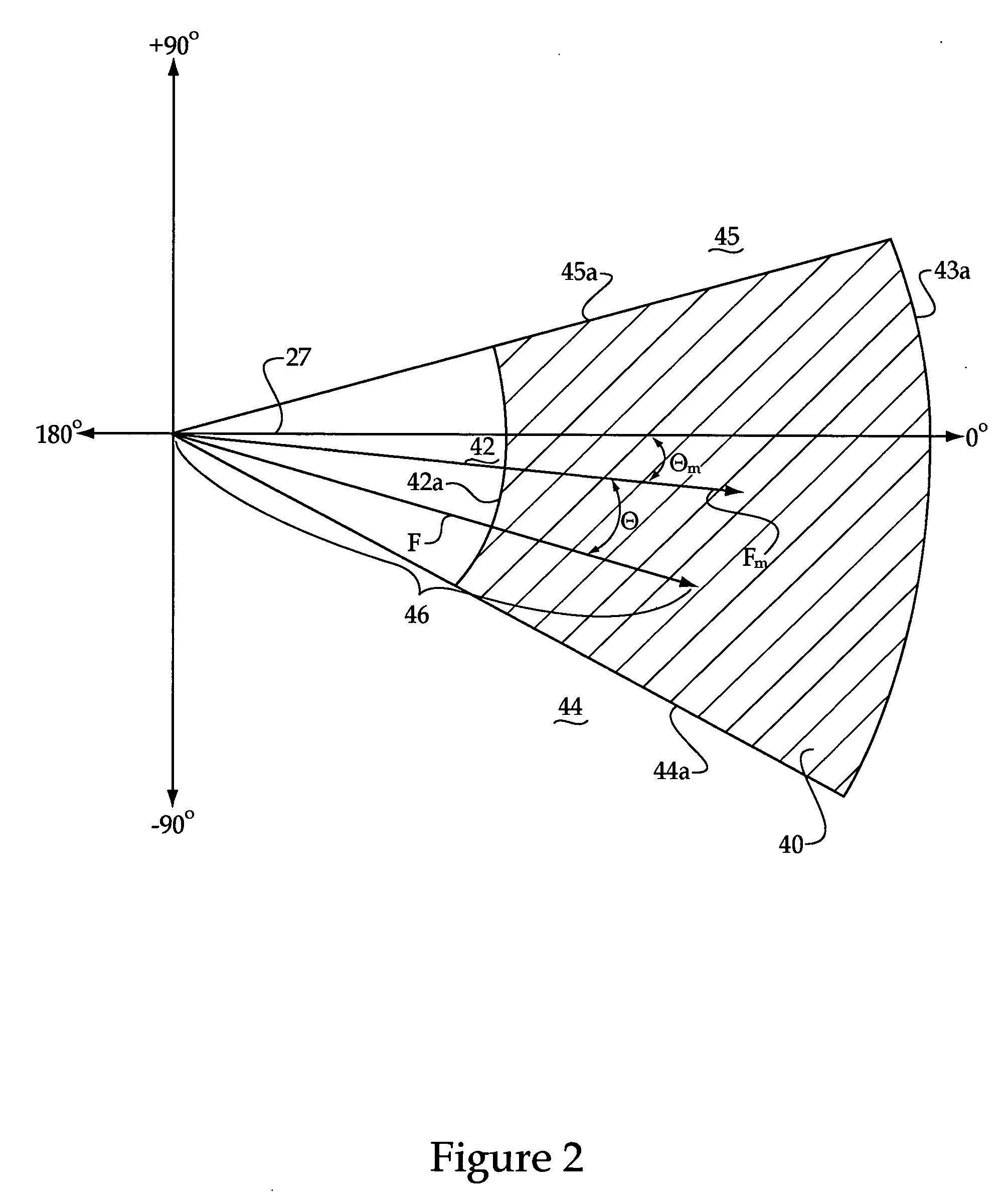

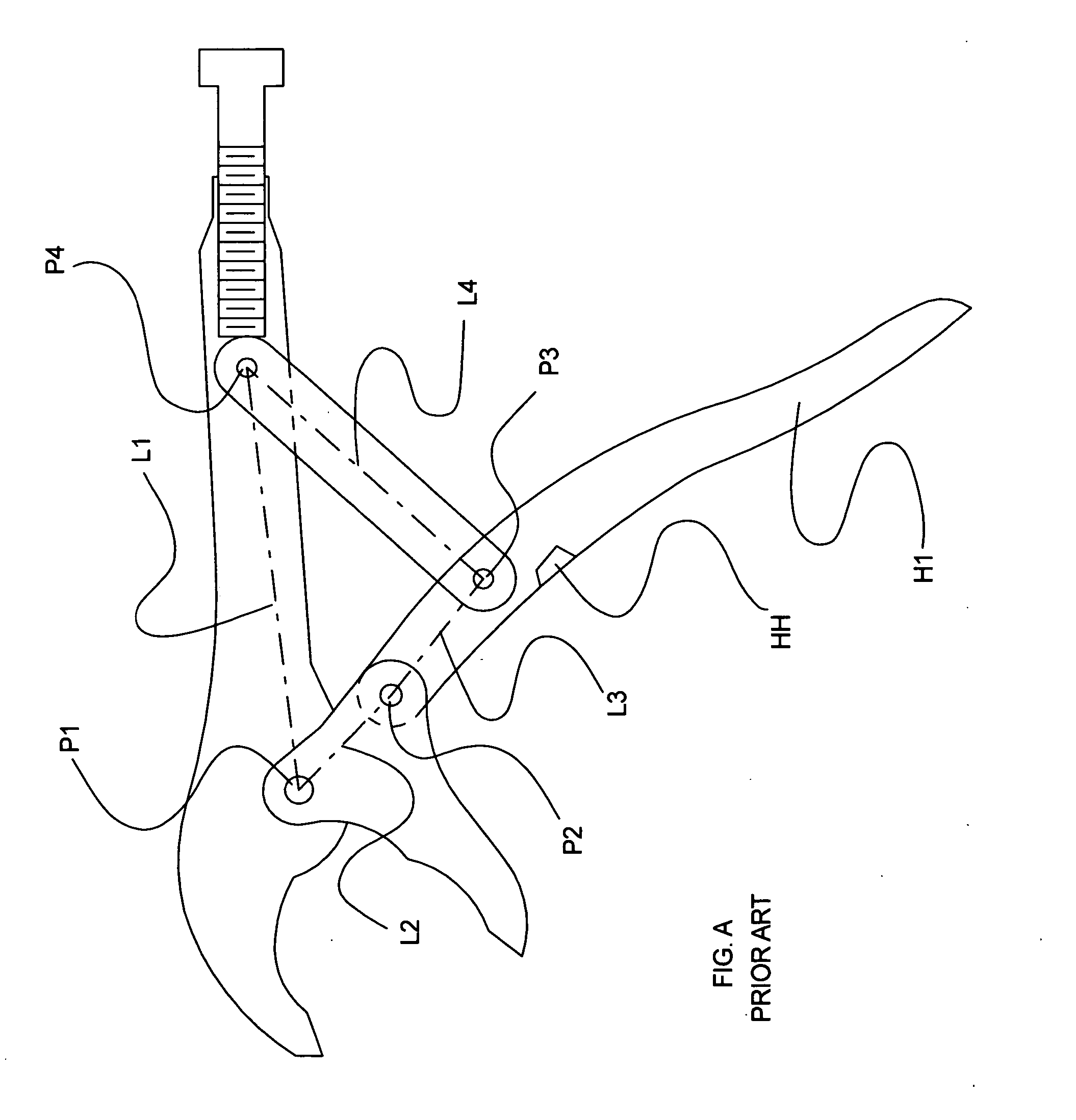

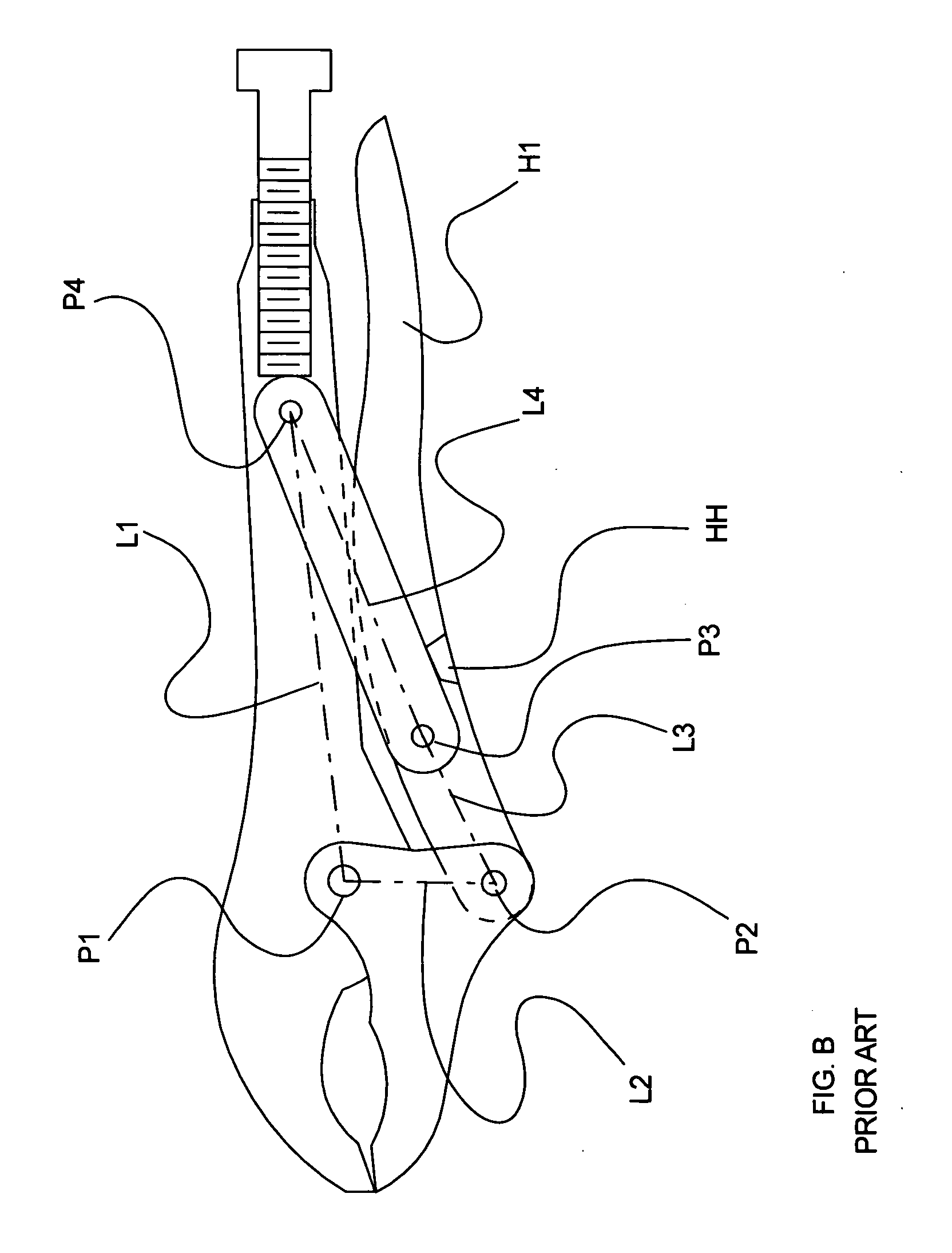

Ripper operation using force vector and track type tractor using same

A method of increasing efficiency and avoiding or reducing potential stall conditions is accomplished by configuring a ripper of a track type tractor responsive to a net force vector acting on the ripper. The net force vector is indicative of the various forces and pressures acting on the ripper, and the values indicative of these forces can be sensed. For instance, the force and value indicative of the force magnitude can be sensed by monitoring driveline torque, whereas the force vector angle can be derived from ripper tilt and lift actuator pressures. The ripper is configured responsive to the force vector magnitude and direction either via a control algorithm, or by inputs generated by an operator.

Owner:CATERPILLAR INC

Electromechanical force-magnitude, force-angle sensor

Owner:WISCONSIN ALUMNI RES FOUND

Ripper operation using force vector and track type tractor using same

A method of increasing efficiency and avoiding or reducing potential stall conditions is accomplished by configuring a ripper of a track type tractor responsive to a net force vector acting on the ripper. The net force vector is indicative of the various forces and pressures acting on the ripper, and the values indicative of these forces can be sensed. For instance, the force and value indicative of the force magnitude can be sensed by monitoring driveline torque, whereas the force vector angle can be derived from ripper tilt and lift actuator pressures. The ripper is configured responsive to the force vector magnitude and direction either via a control algorithm, or by inputs generated by an operator.

Owner:CATERPILLAR INC

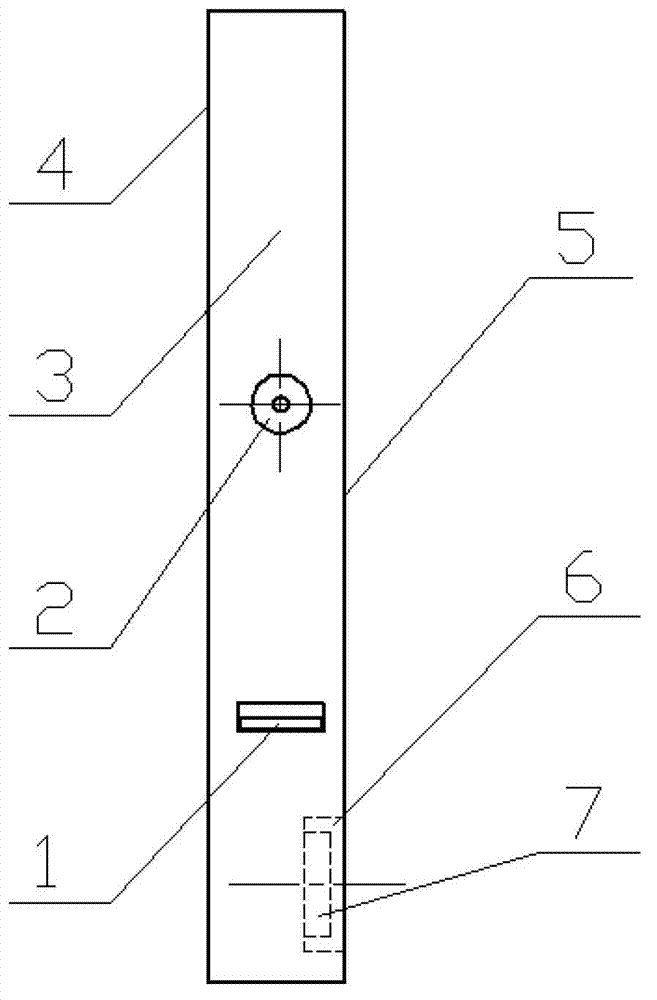

Crane anti-swing system

ActiveCN102120545AReduce swingImprove the anti-shake effectLoad-engaging elementsEngineeringForce magnitude

The invention discloses a crane anti-swing system, which is characterized by comprising a force detection device (20) and a controller (10), wherein the force detection device (20) is used for detecting the force magnitude of an arm support (1); and the controller (10) is used for obtaining the force magnitude from the force detection device (20), judging and detecting whether a crane is in a loading state or unloading state according to the force magnitude, and controlling an amplitude varying mechanism (40) to adjust the included angle between the arm support (1) and the horizontal plane according to the judgment result. The crane anti-swing system provided by the invention performs anti-swing control on the lifting appliance when the crane is in a loading state (namely that the object is just lifted) or in an unloading state (namely that the object is just unloaded) in which the lifting appliance experiences the greatest swing degree, thus the system can minimize swing of the lifting appliance during the entire operation of the crane to realize a perfect anti-swing effect.

Owner:ZOOMLION HEAVY IND CO LTD

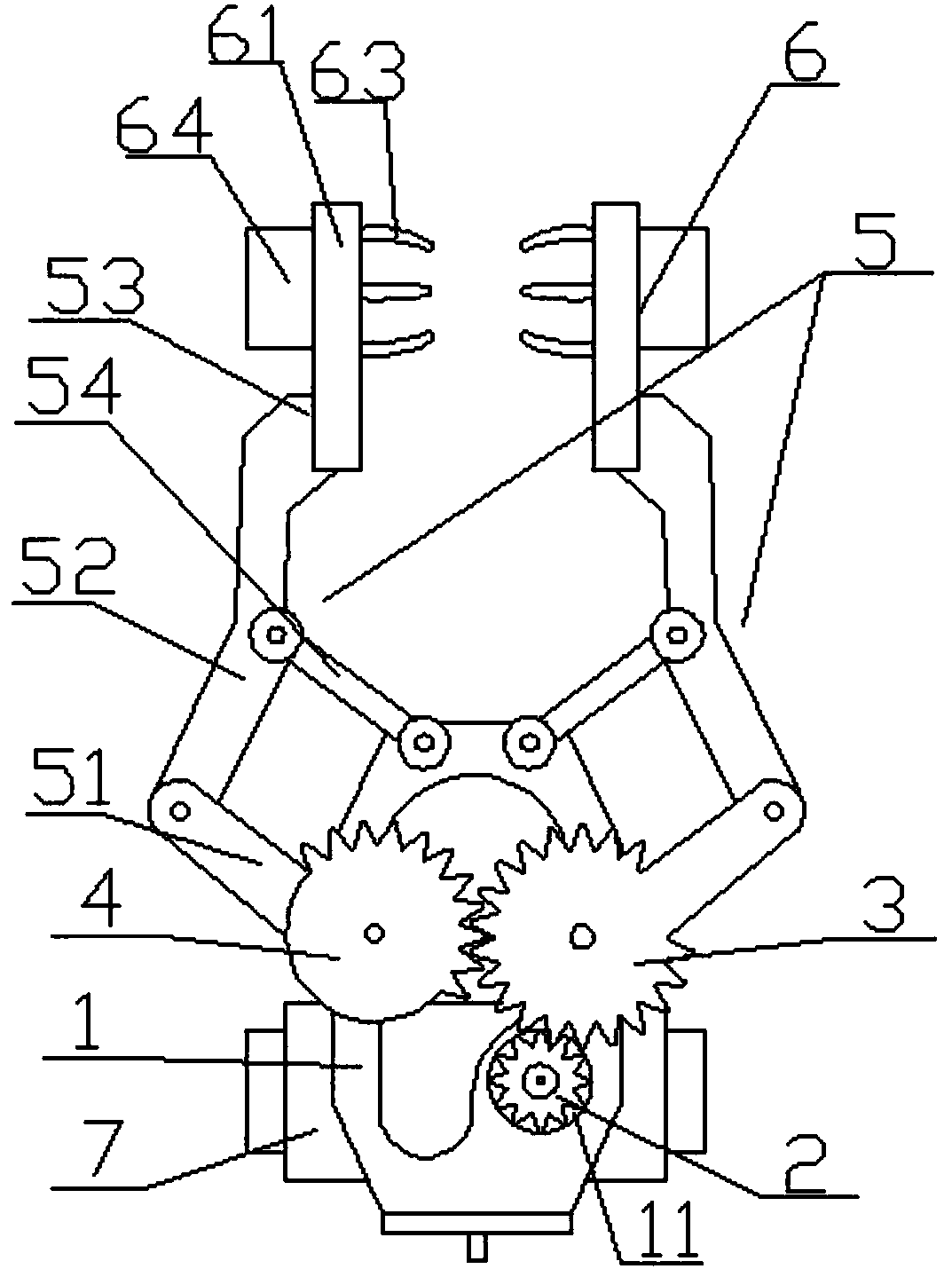

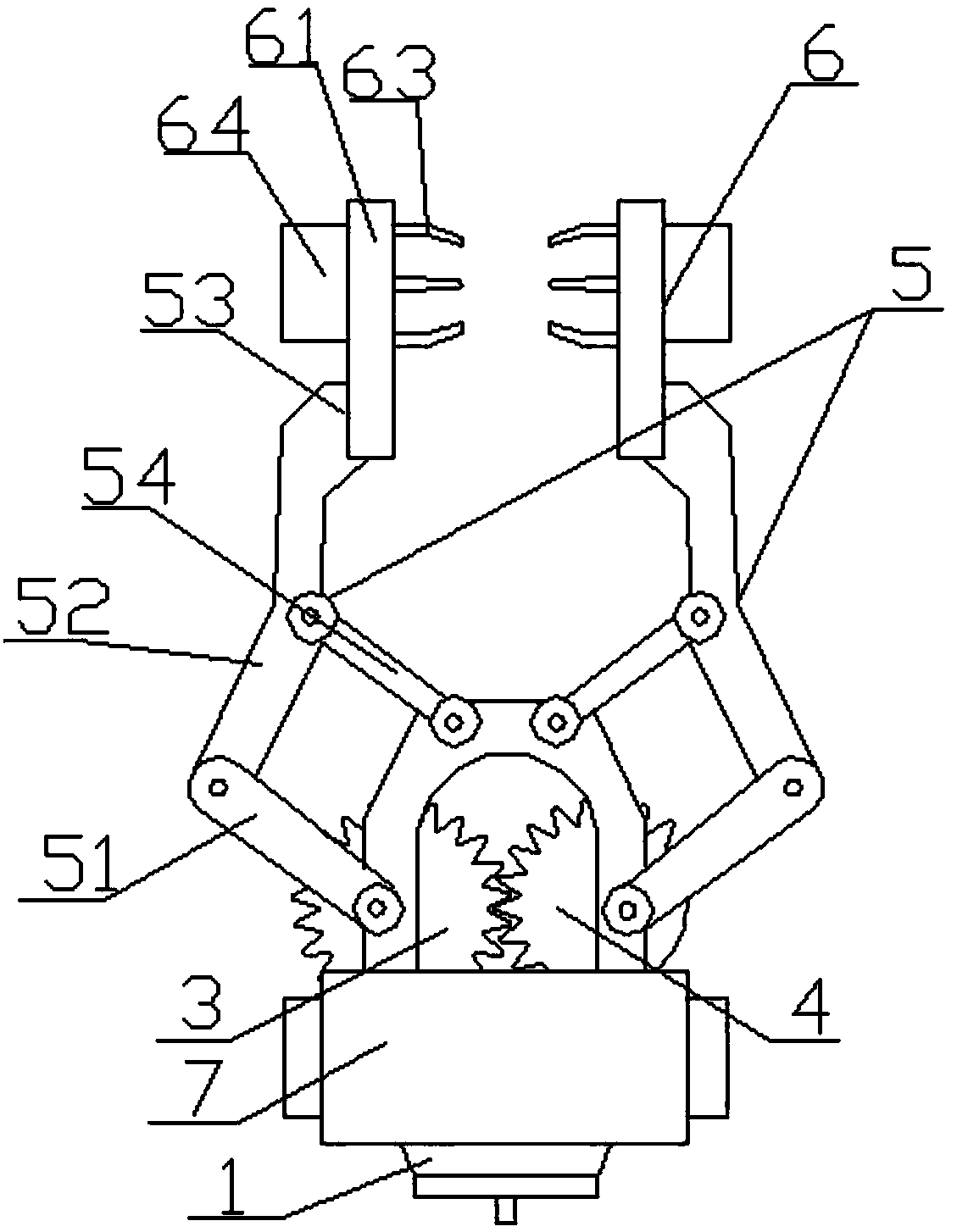

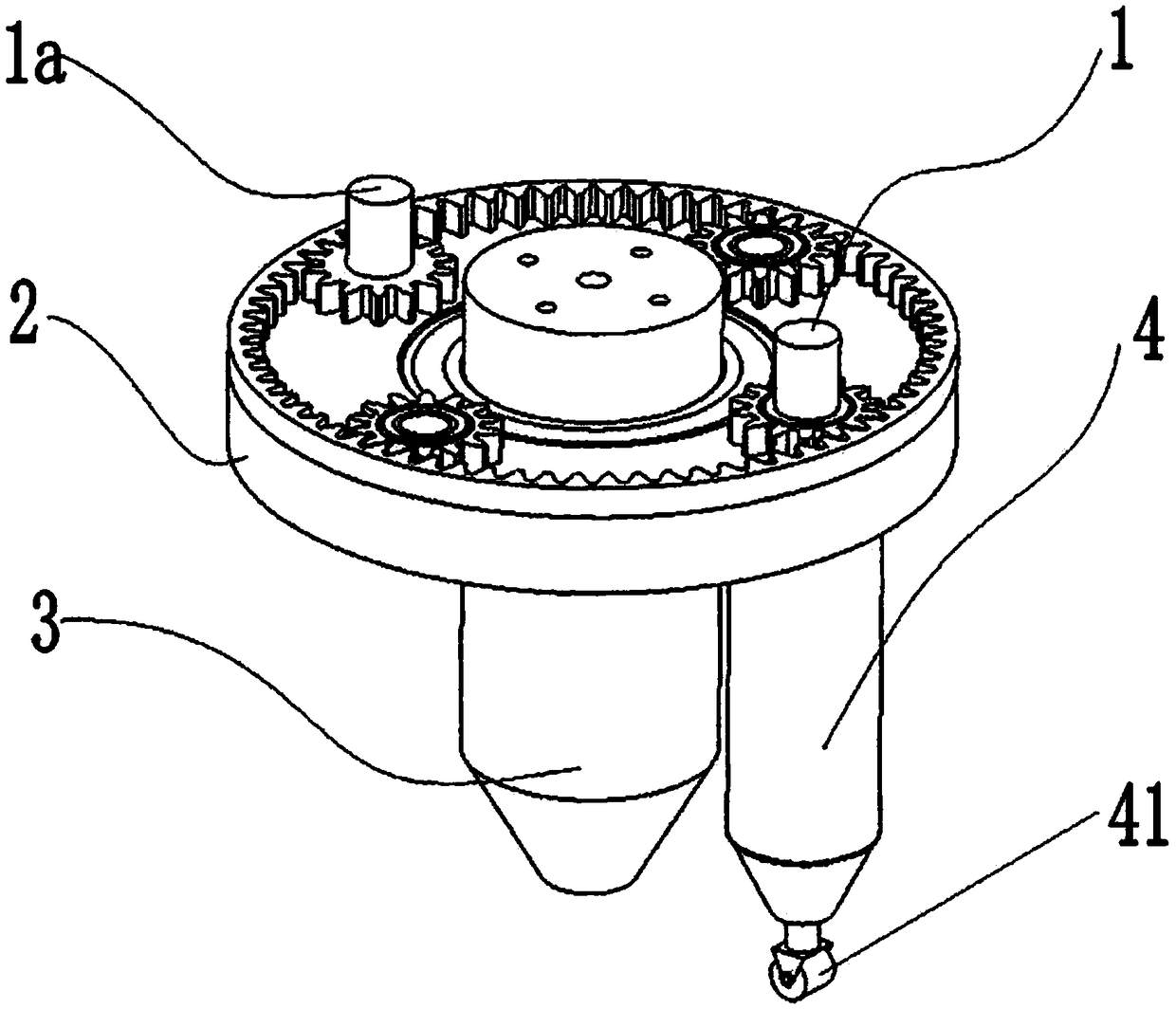

Clamping device having overturning function

InactiveCN107825410AImplement the flip operationControllable gripping forceProgramme-controlled manipulatorGripping headsGear driveGear wheel

The invention discloses a clamping device with flipping function, which comprises a frame, a servo motor is arranged under the frame, a driving gear is arranged on the output shaft of the servo motor, a first driven gear is arranged on one side of the driving gear, and a first driven gear is arranged on the side of the driving gear. The second driven gear on the other side of a driven gear, the first driven gear and the second driven gear are symmetrically provided with the same grabbing assembly, the grabbing assembly includes a first connecting rod assembly, the first connecting rod assembly One end is hinged with a second connecting rod, the other end of the second connecting rod is provided with a clamping part, the clamping part is connected to the clamping assembly, the clamping assembly includes a square base, the center of the square base is provided with a rotating table, and the end of the rotating table is provided with Clamping claws, a vertical rotation device is provided outside the square base, and the vertical rotation device is connected with the center of the rotating table. The invention realizes the controllable grasping force and the overturning operation of the articles, improves the reliability and stability of the overall device, makes the use more convenient, and saves time and effort.

Owner:SICHUAN JUHAI FISHERIES TECH CO LTD

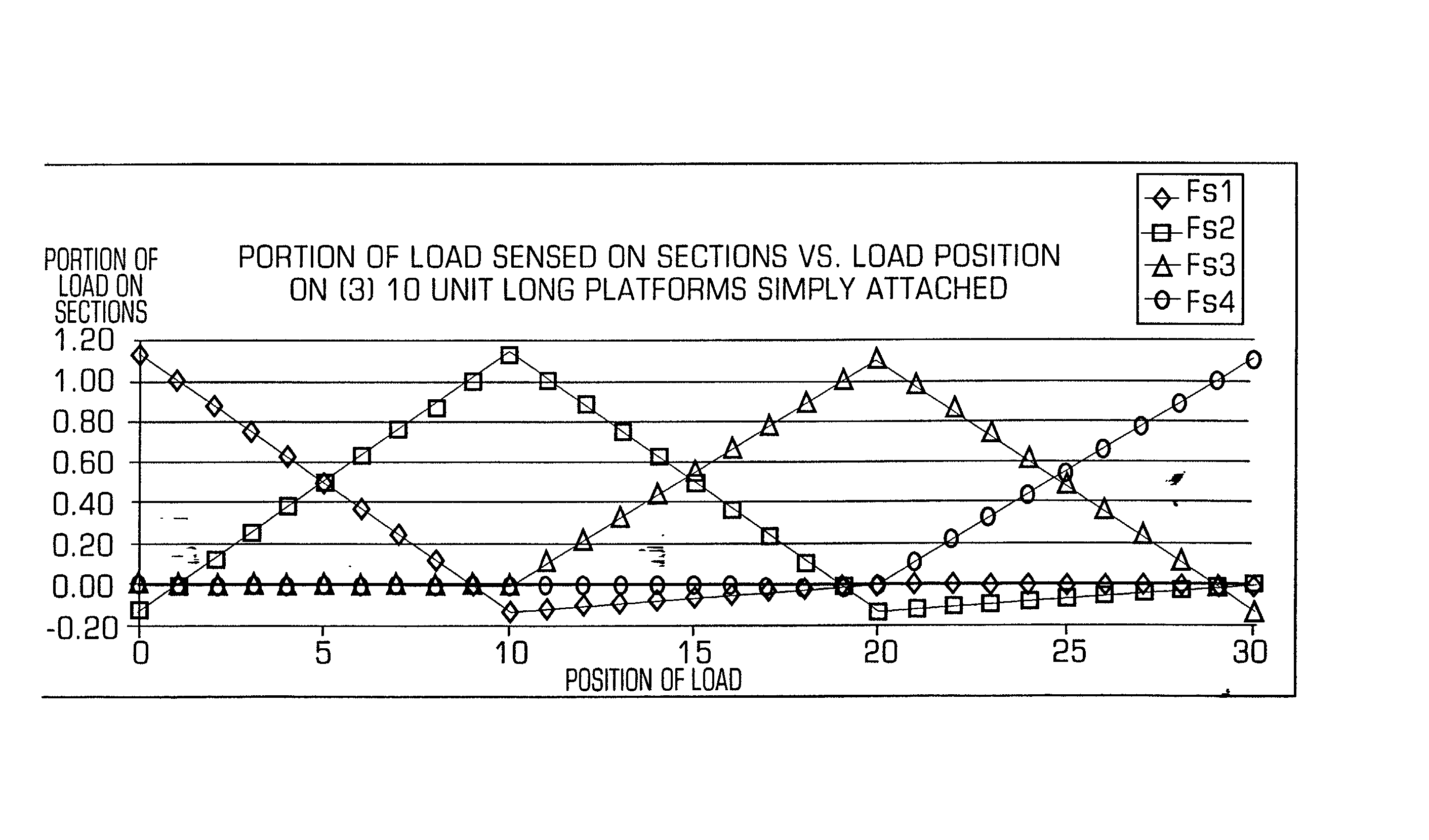

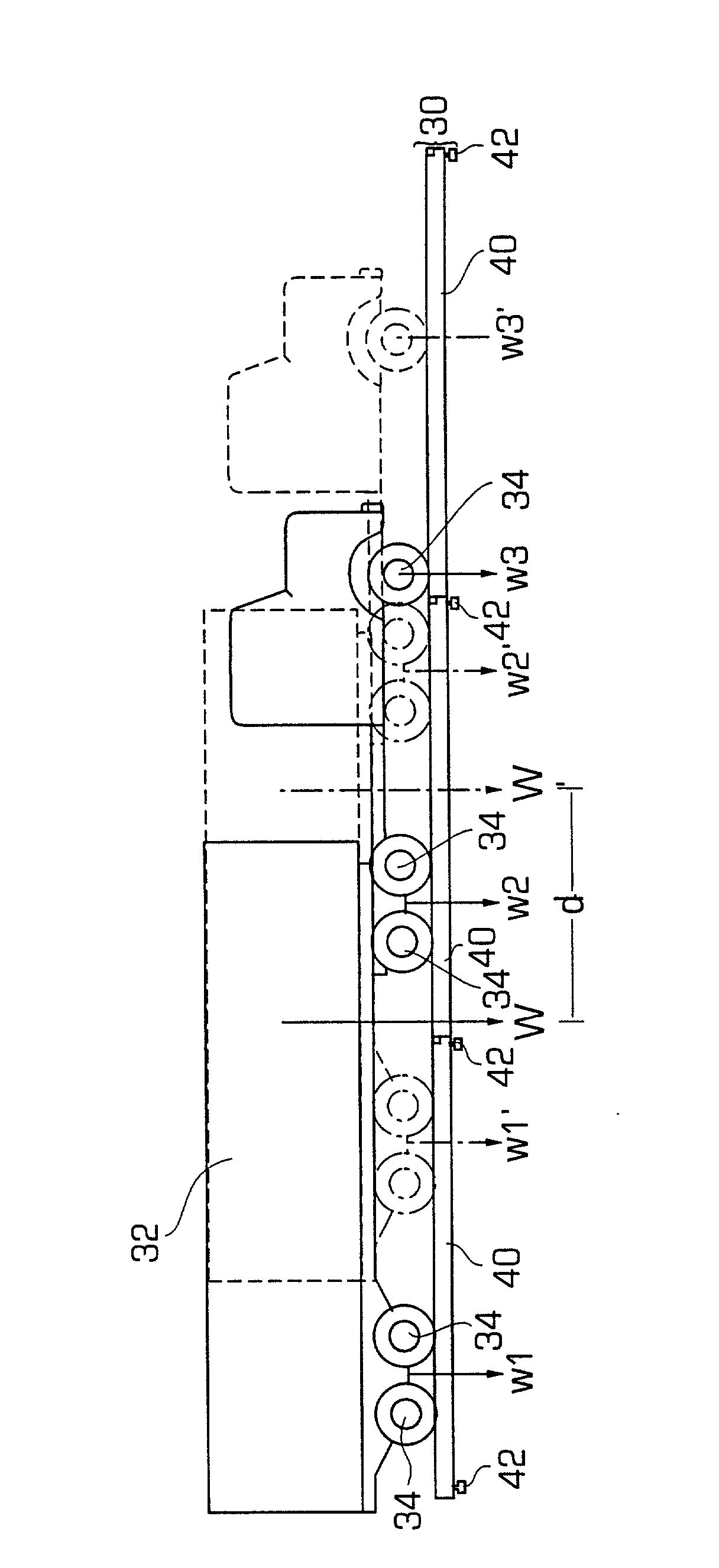

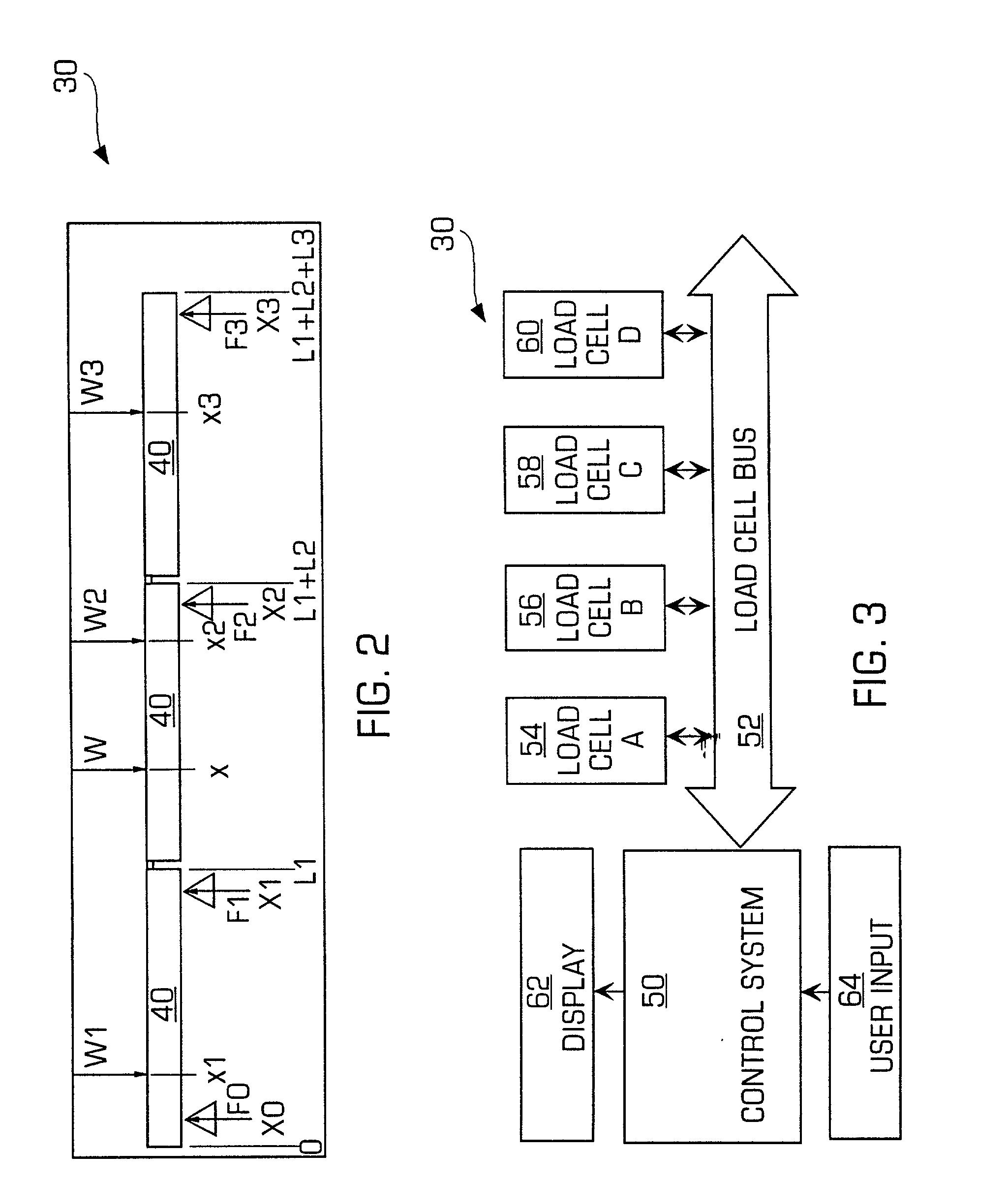

Multiple load sensing multi-load cell scale and method

InactiveUS20030056995A1Increase profitDigital computer detailsWeighing apparatus testing/calibrationLoad sensingLoad cell

Owner:AVERY WEIGH-TRONIX

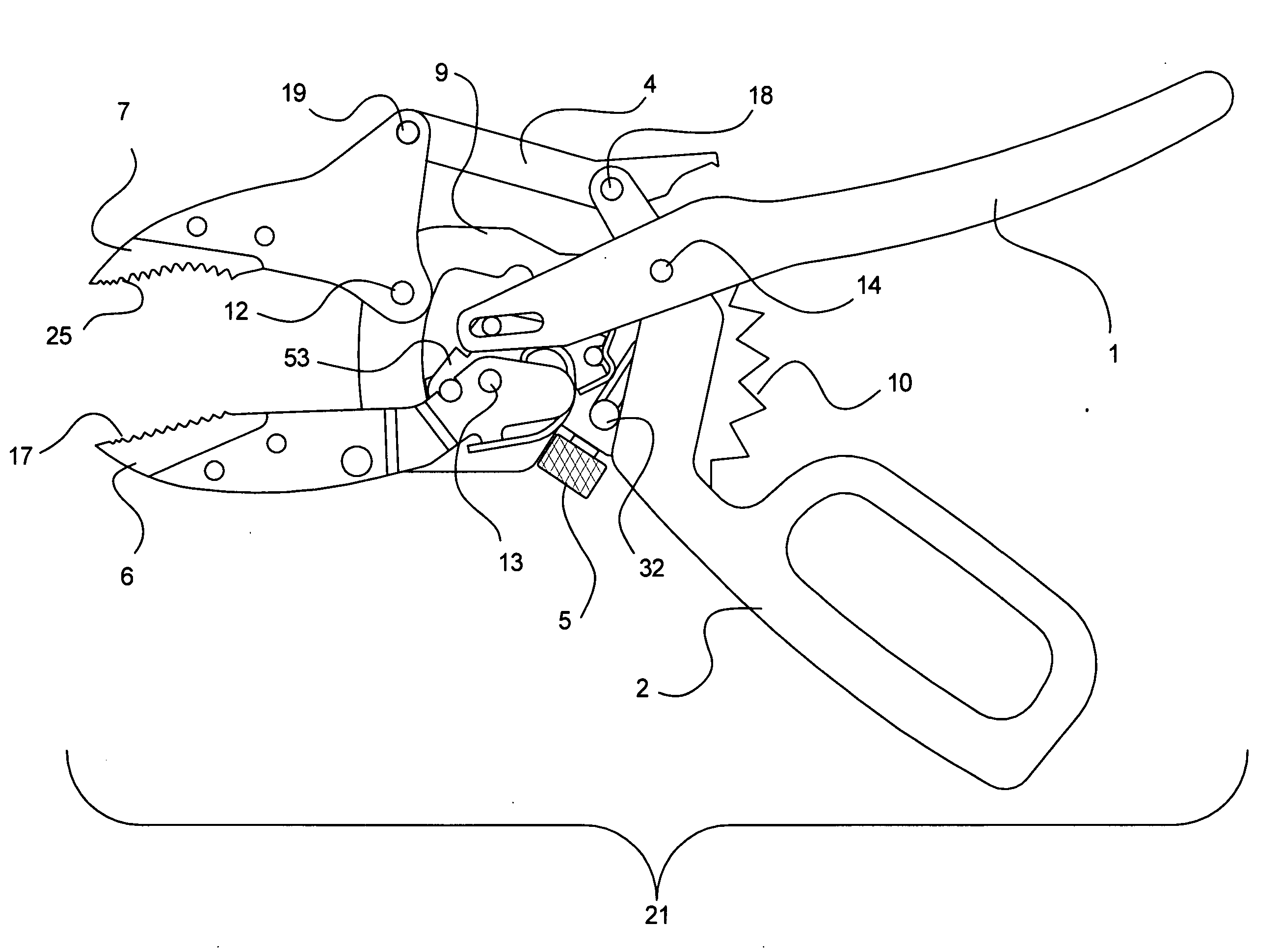

Locking pliers tool with automatic jaw gap adjustment and user-controlled clamping force magnitude

A locking pliers tool which combines a self-locking, frictional brake, gap setting means to set jaw gap size automatically when clamping onto a workpiece, and an over-center linkage clamping means to securely clamp the workpiece in between the opposing tool jaws, and an adjustment means for varying the clamping force to be exerted onto the gripped workpiece.

Owner:WINKLER JOHN ANDREW

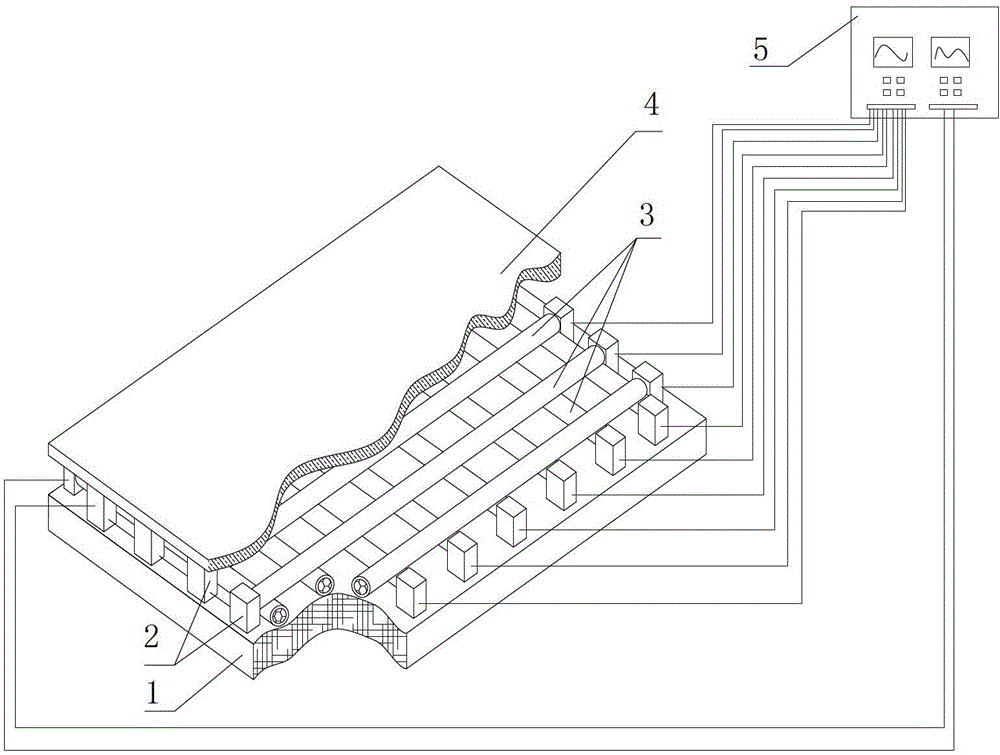

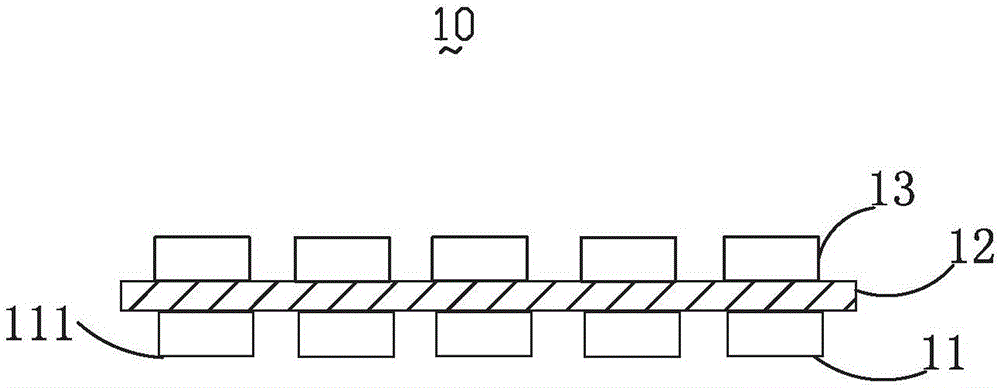

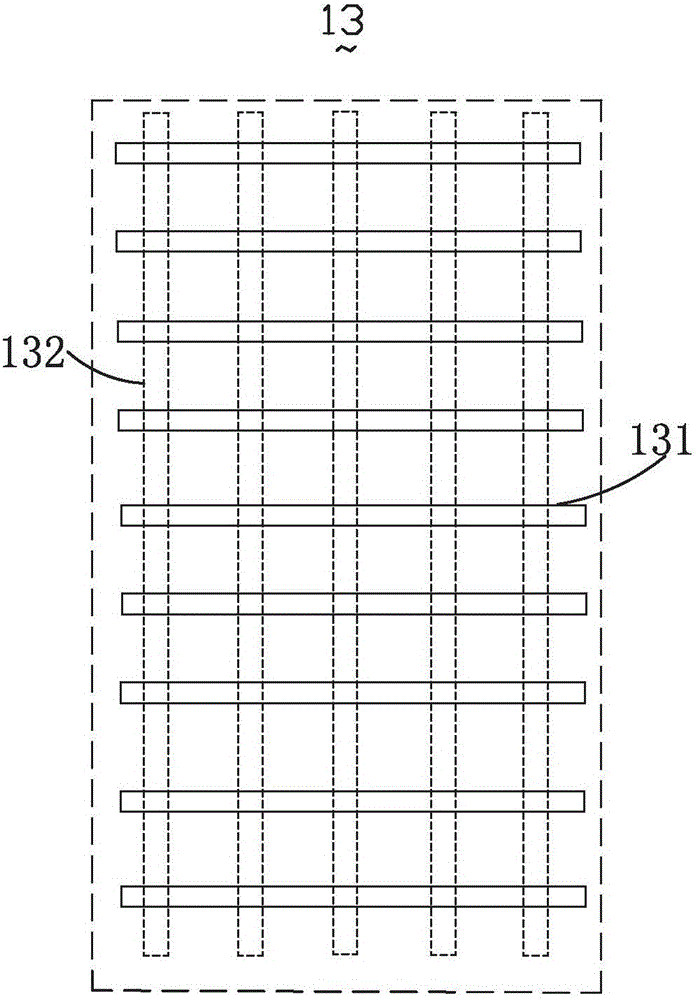

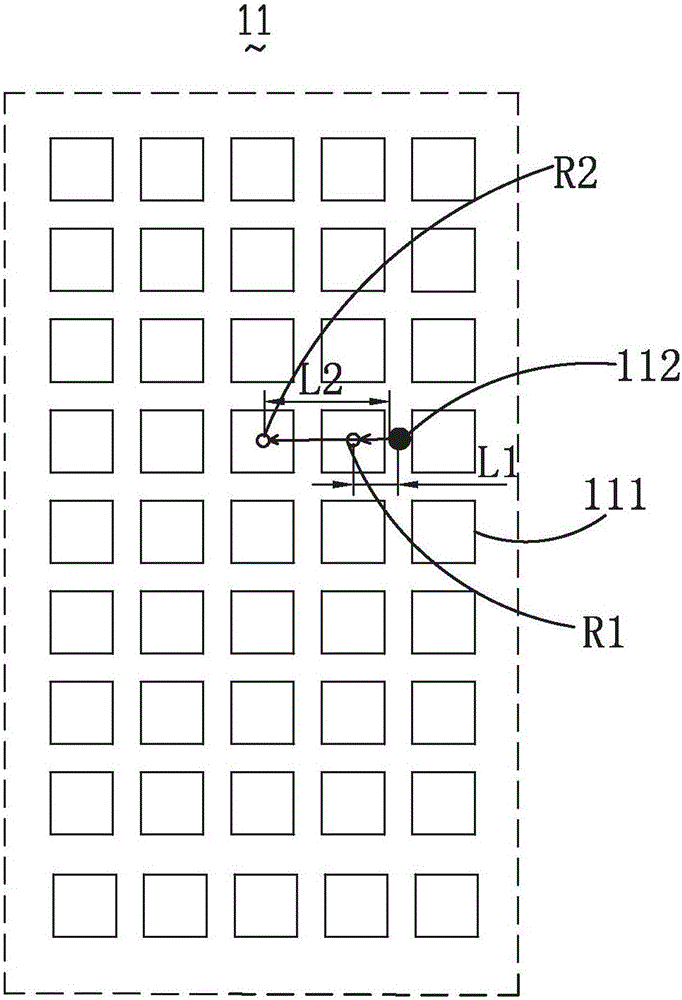

Bionic skin three-dimensional force touch perception device and measuring method thereof

InactiveCN103323152AIntuitively reflect the force distributionHigh precisionForce measurement using piezo-resistive materialsTouch PerceptionElectromagnetic shielding

The invention relates to a bionic skin three-dimensional force touch perception device and a measuring method of the bionic skin three-dimensional force touch perception device. The bionic skin three-dimensional force touch perception device comprises a shell, a unit upper layer, a unit basic level and a circuit module. The measuring method comprises the following steps that dynamic data signals are collected to an MCP3208 chip; analog signals are converted into digital signals after entering the MCP 3208 chip; the digital signals enter an EP10K250A chip and are output after being calculated and analyzed; the output signals enter a CY7C68013 chip and then are sent to an upper PC through a USB interface, and LabView virtual instrument software is operated to calculate the forced magnitude and the forced direction of each sensitive unit; eventually the forced situation is stacked to a skin model. The bionic skin three-dimensional force touch perception device and the measuring method of the bionic skin three-dimensional force touch perception device stimulate the multilayer structure of the real skin, and conducting square blocks are arranged annularly referring to a clock, so that accuracy of direction representation is improved. Besides, an electromagnetic shielding layer is imported, so that electromagnetic insulation protection is formed, and measuring efficiency and accuracy are effectively improved.

Owner:CHINA UNIV OF MINING & TECH

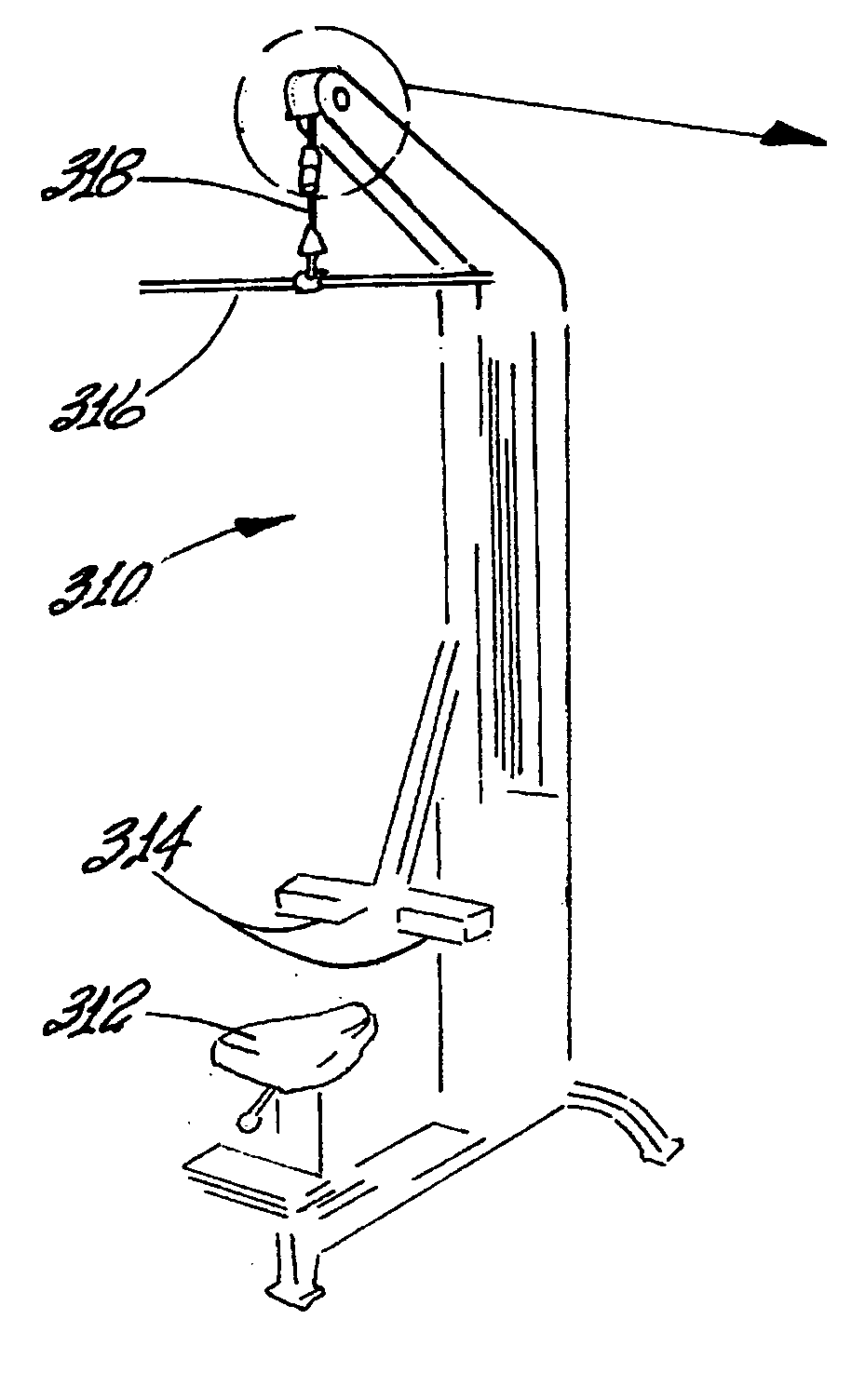

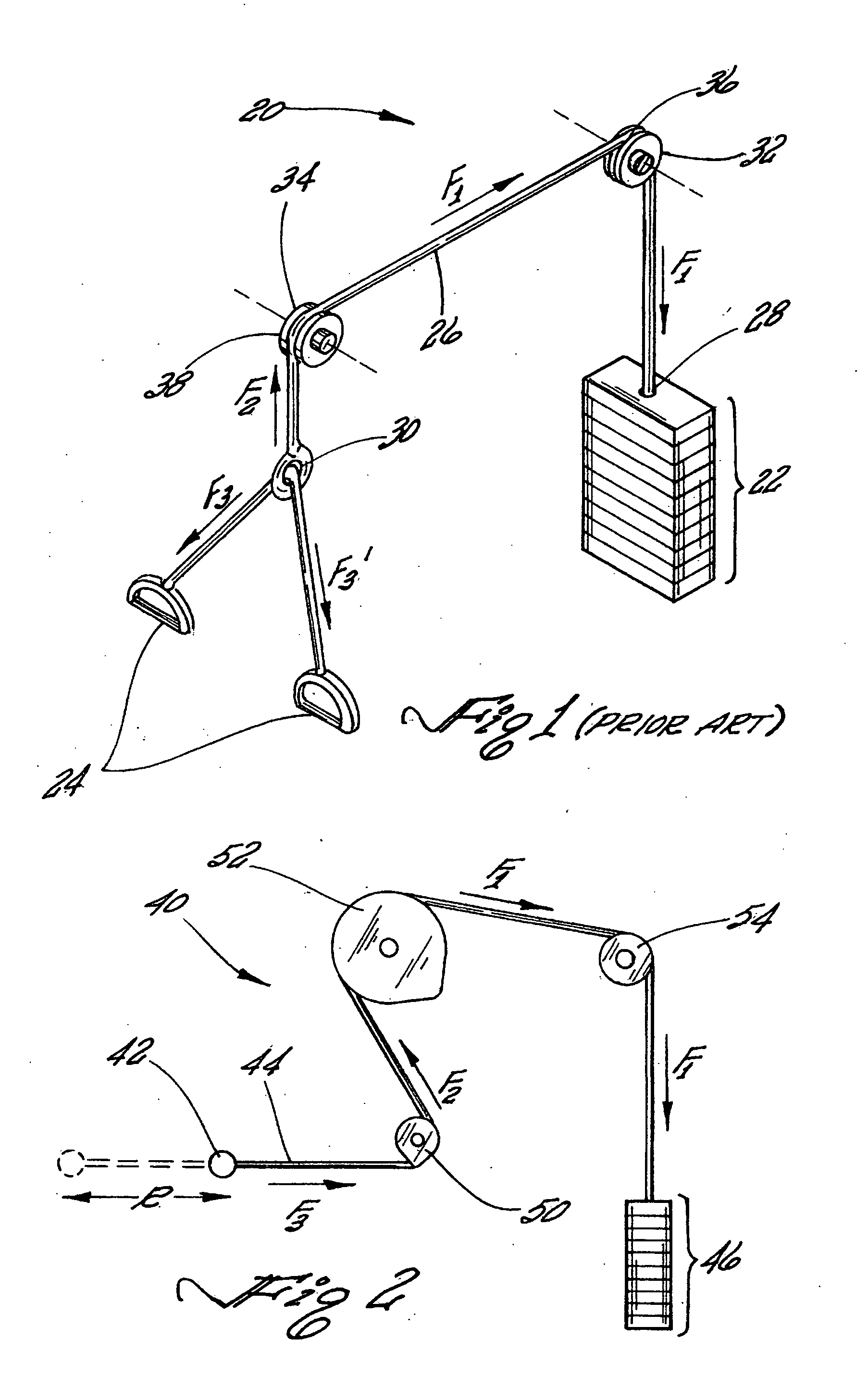

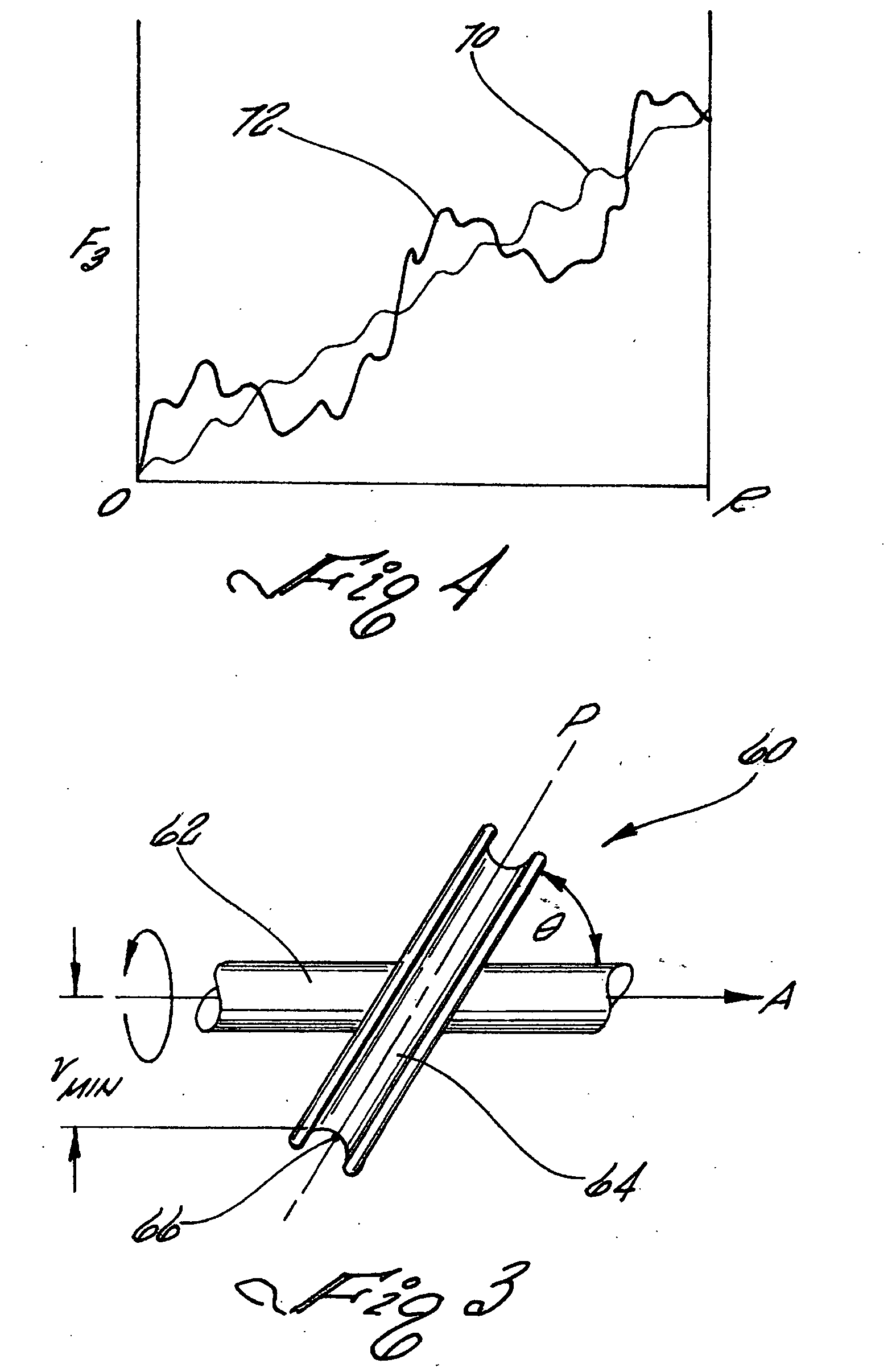

Oscillatory resistance exercise device and method

InactiveUS20070207902A1Increase the itineraryIncrease the number ofMuscle exercising devicesSpherical bearingMuscle contraction

A method for exercising one or more muscles of the body wherein one or more muscle(s) are contracted to move a limb through a range of motion in opposition to an oscillating resistive force. During a muscular contraction, the direction and / or the magnitude of the resistive force changes in an oscillatory fashion thereby inducing perturbations in the musculature. The oscillations in the magnitude and / or the direction of the resistive force include a plurality of cycles during a single repetition of muscular contraction. The waveform and frequency of the oscillations may vary during a repetition or remain constant. Embodiments of devices providing an oscillatory resistive force are presented. The embodiments provide means for enabling an exerciser to perform resistance-type exercises in accordance with the method. A guided spherical bearing may be used for rotating a lead pulley or a rigid arm to create lateral resistive force oscillations. Non-circular lead pulleys may be used to fluctuate the resistive force magnitude. The oscillations in magnitude and / or direction of the resistive force may be periodic or randomized such that during subsequent repetitions the oscillations occur at differing points.

Owner:TIAHRT LEIF K

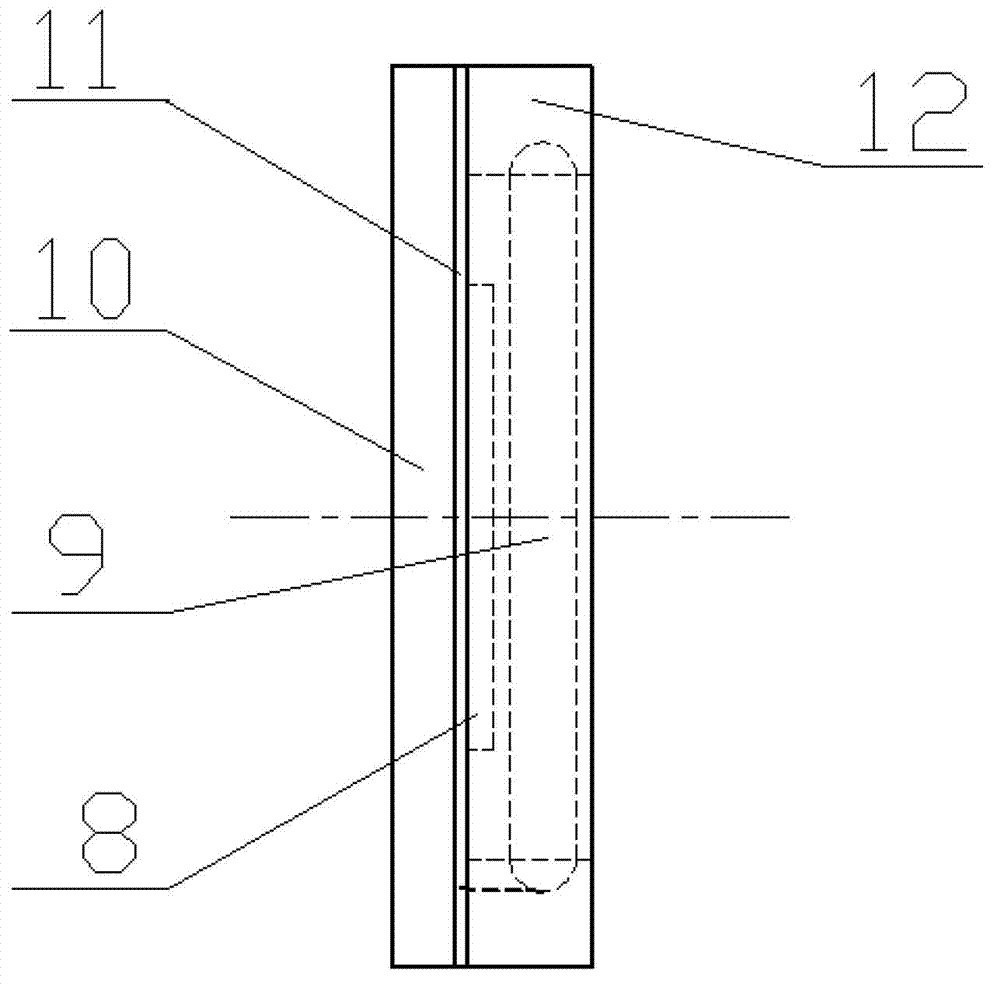

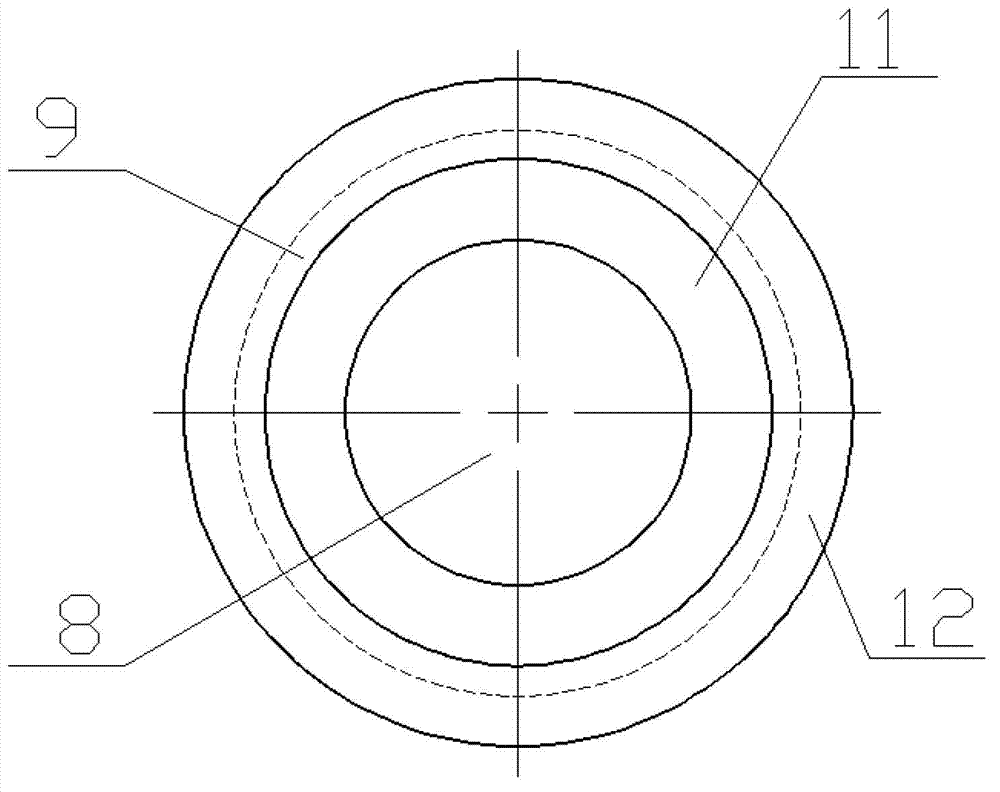

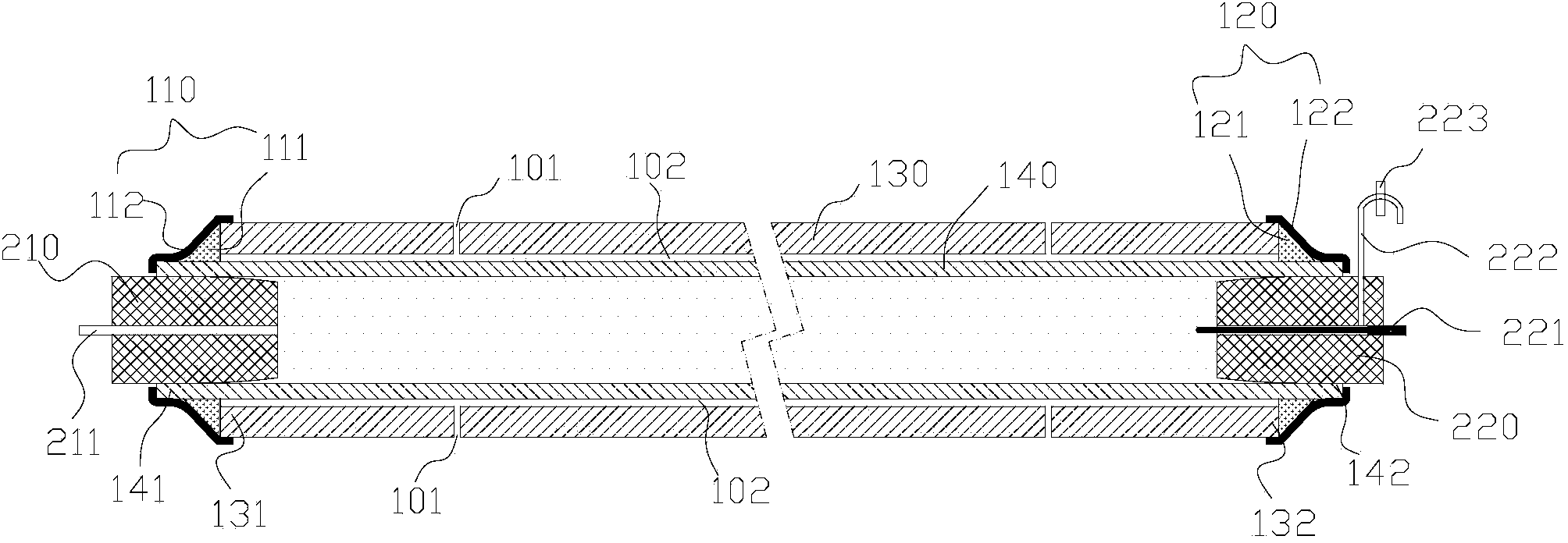

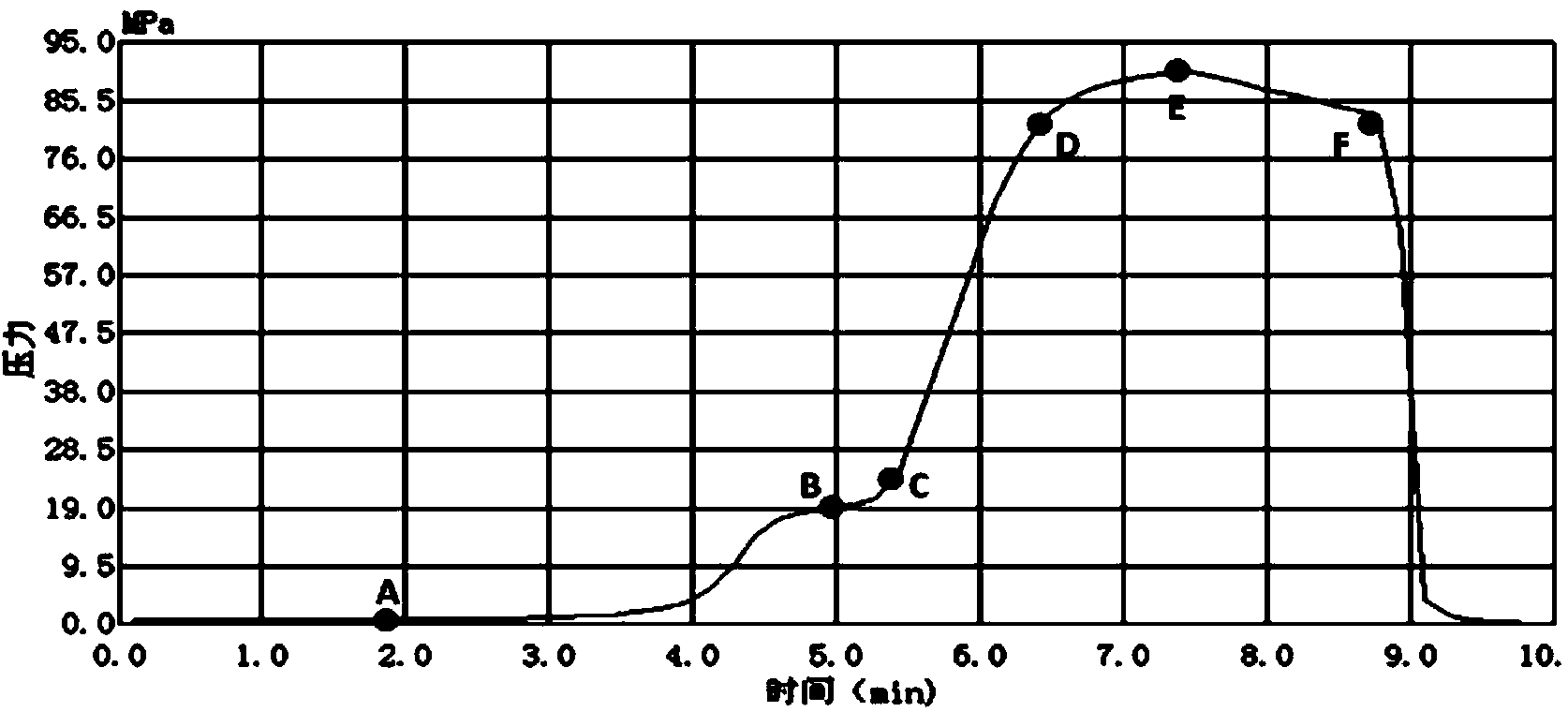

Bimetal composite pipe semi-finished product and machining method thereof

The invention discloses a bimetal composite pipe semi-finished product and a machining method thereof. The bimetal composite pipe semi-finished product comprises an outer metal pipe and an inner metal pipe. The outer metal pipe and the inner metal pipe are respectively provided with a first end opening and a second end opening. The inner metal pipe is arranged in the outer metal pipe in a sleeved mode. A clearance area is arranged between the inner wall of the outer metal pipe and the outer wall of the inner metal pipe. A vent hole is formed in the outer metal pipe, a first sealing device and a second sealing device are arranged at the two end openings of the bimetal pipe respectively, a first plug is arranged at the first end opening of the inner metal pipe, a guide pipe is arranged in the first plug, an inner cavity of the inner metal pipe is communicated with the outside through the guide pipe, a second plug is arranged at the second end opening of the inner metal pipe, a hydraulic sensor and a vent pipe are arranged in the second plug, the hydraulic sensor penetrates through the second plug and extends into the cavity of the inner metal pipe, and the inner cavity of the inner metal pipe is communicated with the outside through the vent pipe. According to the bimetal composite pipe semi-finished product and the machining method thereof, sticking force magnitude between composite pipe layers can be controlled, and bimetal composite pipes meeting the standard requirement can be manufactured.

Owner:番禺珠江钢管(珠海)有限公司

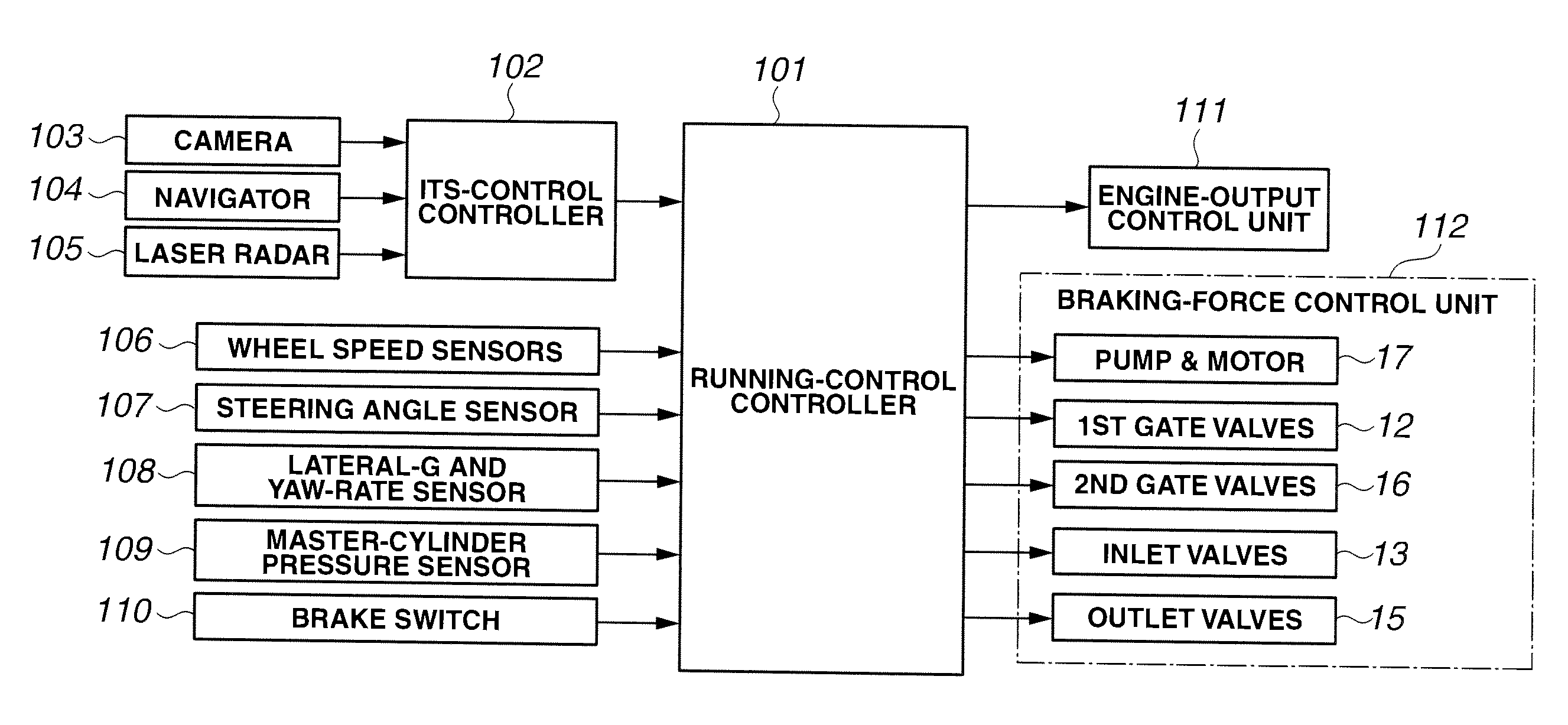

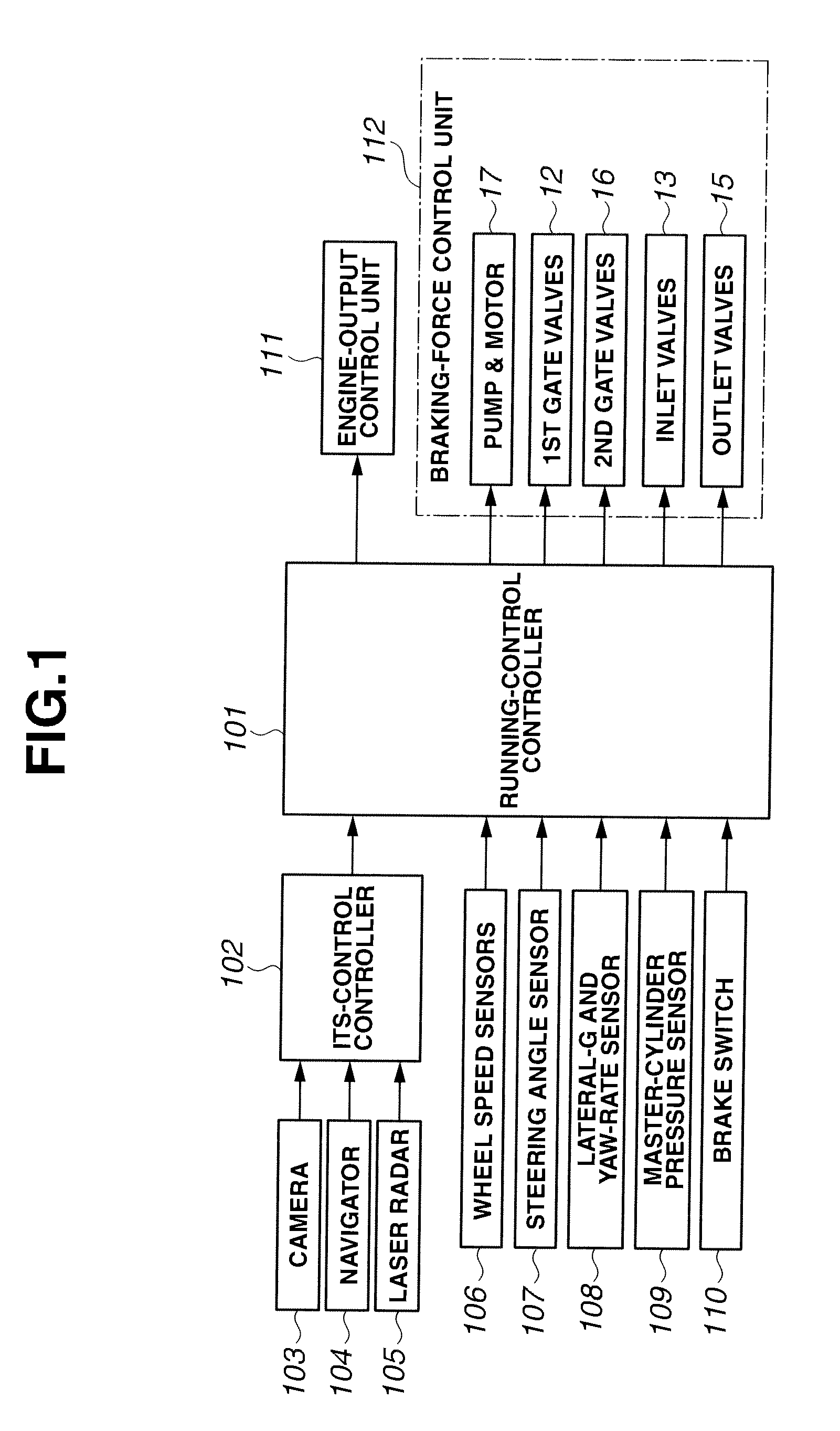

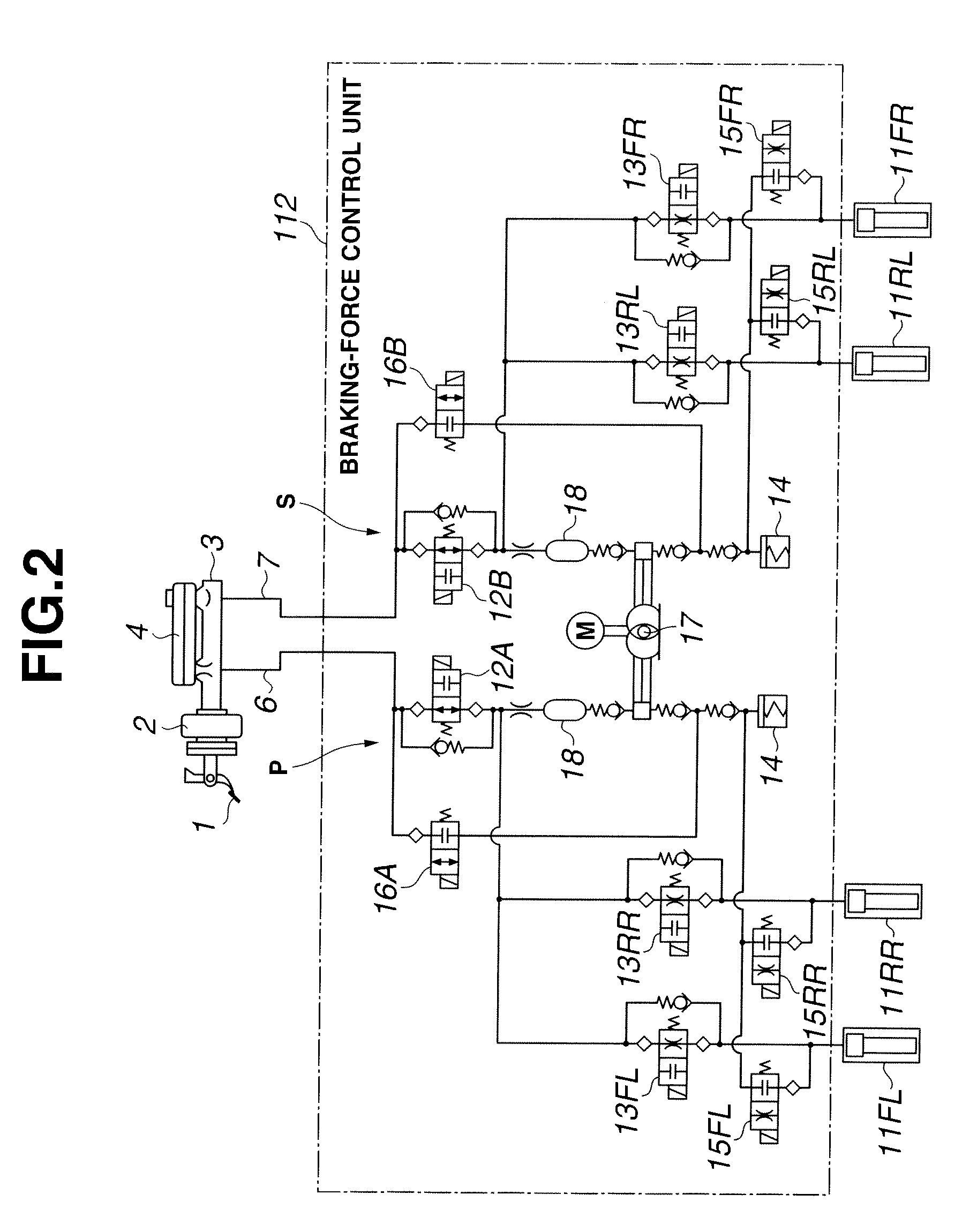

Braking force control device for vehicles

ActiveUS20110004385A1High deceleration control responsivenessAvoid poor deceleration feelAnalogue computers for trafficAutomatic initiationsAutomatic brakingForce magnitude

A controller of a braking force control device for vehicles is characterized by comprising an automatic-brake selective-actuation section configured to compare a braking force created by a manual brake device with a required braking force for an automatic brake device and to selectively actuate the automatic brake device when the required braking force exceeds in braking-force magnitude, a braking-force-difference time-rate-of-change calculation section configured to calculate a braking-force-difference time rate of change corresponding to a rate of change per unit time in a difference, which difference is obtained by subtracting the required braking force for the automatic brake device from the braking force created by the manual brake device, and a required braking force control section configured to correct the required braking force for the automatic brake device in a manner so as to reduce the required braking force when selectively actuating the automatic brake device. Also, a reducing amount of the required braking force is corrected to decrease, as the calculated braking-force-difference time rate of change increases.

Owner:NISSAN MOTOR CO LTD

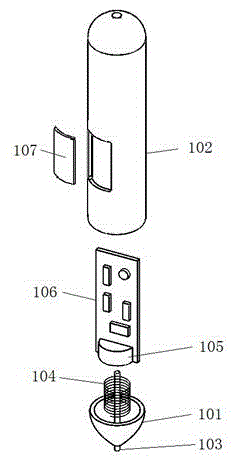

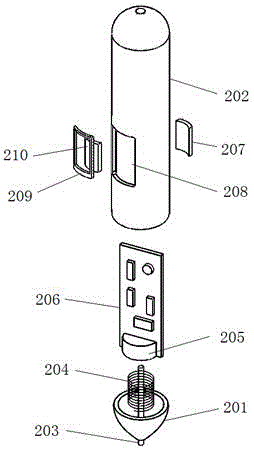

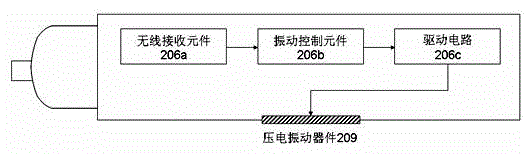

Touch pen with touch vibration function

InactiveCN105068680ADetection impactUndisturbedInput/output for user-computer interactionGraph readingEngineeringPiezoelectric sensor

The invention provides a touch pen with a touch vibration function. The touch pen comprises a pen point (201), a shell (202), a pen point rod (203), a coil (204), a pressure sensor (205), an integrated circuit board (206), an operation switch plate (207), a piezoelectric vibration device (209) and a piezoelectric sensing device (210). By enabling the touch pen to generate touch vibration feedback, no matter whether the touch pen is used in non-contact or contact with a screen, a user can obtain the touch vibration experience. The piezoelectric sensing device is arranged on the outer surface of the touch pen, so that force applied by fingers of the user when the user holds the touch pen can be sensed, and a response is given. In the non-contact using process, the function similar to piezoelectric sensing can also be achieved, and the touch vibration intensity can be adjusted based on the holding force magnitude. The touch vibration of the touch pen does not interfere with the effects of the piezoelectric sensing function and the holding force detection function.

Owner:ZHEJIANG RIBON INTELLIGENT EQUIP CO LTD

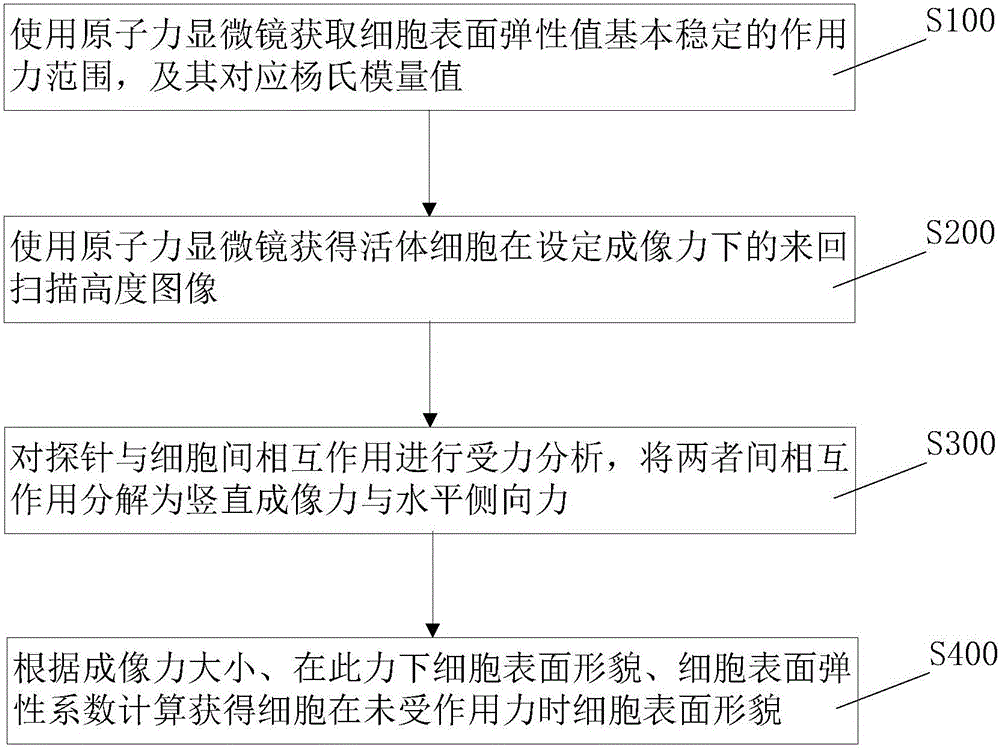

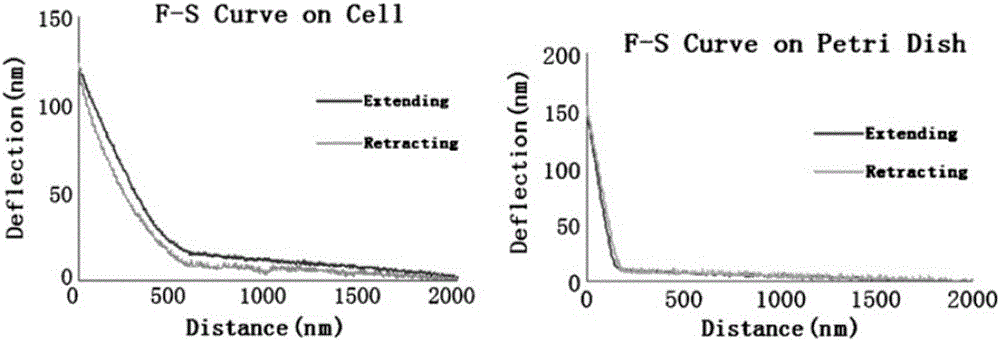

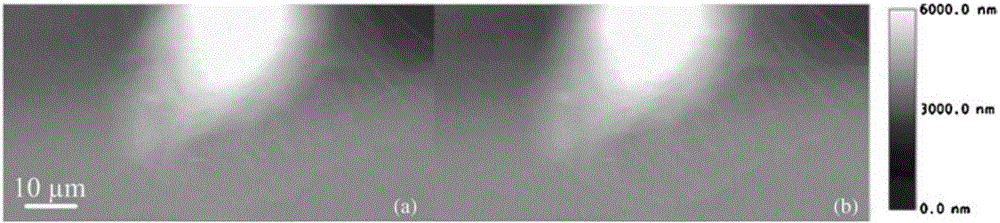

Fast and accurate characterization method for living cell surface morphology atomic force microscope

ActiveCN106199078AHigh precisionImprove time resolutionScanning probe microscopyAtomic force microscopyCell–cell interaction

The invention provides a fast and accurate characterization method for a living cell atomic force microscope. The method comprises the steps that the atomic force microscope is used to acquire the substantially stable applied force range of the cell surface elasticity value and the corresponding Young's modulus value; the atomic force microscope is used to acquire the back-and-forth scanning height image of a living cell under a set imaging force; force analysis is carried out on the interaction between a probe and the cell, and the interaction between the probe and the cell is decomposed into a vertical imaging force and a horizontal lateral force; and according to the imaging force magnitude, the cell surface topography under the force and the cell surface elasticity coefficient, the cell surface morphology of the cell without applied force is calculated. The fast and accurate characterization method for the living cell atomic force microscope has the advantages of high precision, high time resolution and the like.

Owner:SHANGHAI JIAO TONG UNIV

Weight-Measuring Device

InactiveUS20100181354A1Easy to controlEasy to provideTravelling sacksWeighing apparatus using elastically-deformable membersMeasurement deviceEngineering

A weight-measuring device is described that is adapted to be attached between two objects, and to be brought to a stretched state and to an unstretched state. The device may be attachable to a harness of the type which comprises a pair of shoulder strap assemblies, for example of the type used with backpacks, parachute units or similar constructed systems for holding or carrying an object or load to a person's body. The weight-measuring device comprises a force resistance element altered by the application of force thereto, and a weight indicator providing an indication of the force magnitude applied thereto.

Owner:LANIADO SHLOMO

Impact sensor capable of positioning

InactiveCN103335764AImprove flexibilityEasy to make and mountApparatus for force/torque/work measurementMicro nanoFiber

An impact sensor capable of positioning relates to a sensor. The impact sensor capable of positioning is provided with flexibility, an impact force magnitude detection function and an impact force positioning function. The impact sensor is provided with a base layer, a piezo-sensitive film, a protective layer, an electrode assembly and a signal processor. The base layer is made from an insulating flexible material; the piezo-sensitive film is an orthogonal grid-type array film formed by a high-molecular polymer micro nano fiber in a criss-cross manner; the piezo-sensitive film is arranged on the upper surface of the base layer and is covered by the protective layer; each polymer micro nano fiber forming the piezo-sensitive film is provided with a core and a shell which are coaxial; the core is made from high-molecular polymer equally-piezoelectric material; the shell is made from high-molecular polymer insulation material; the electrode assembly has a plurality of pairs of electrodes; two ends of each polymer micro nano fiber are provided with a pair of electrodes; and each pair of electrodes is electrically connected with the signal processor. The impact sensor of the invention can be mounted on a large flexible object surface to detect the impact; and the production and mounting are easy and low-cost.

Owner:XIAMEN UNIV

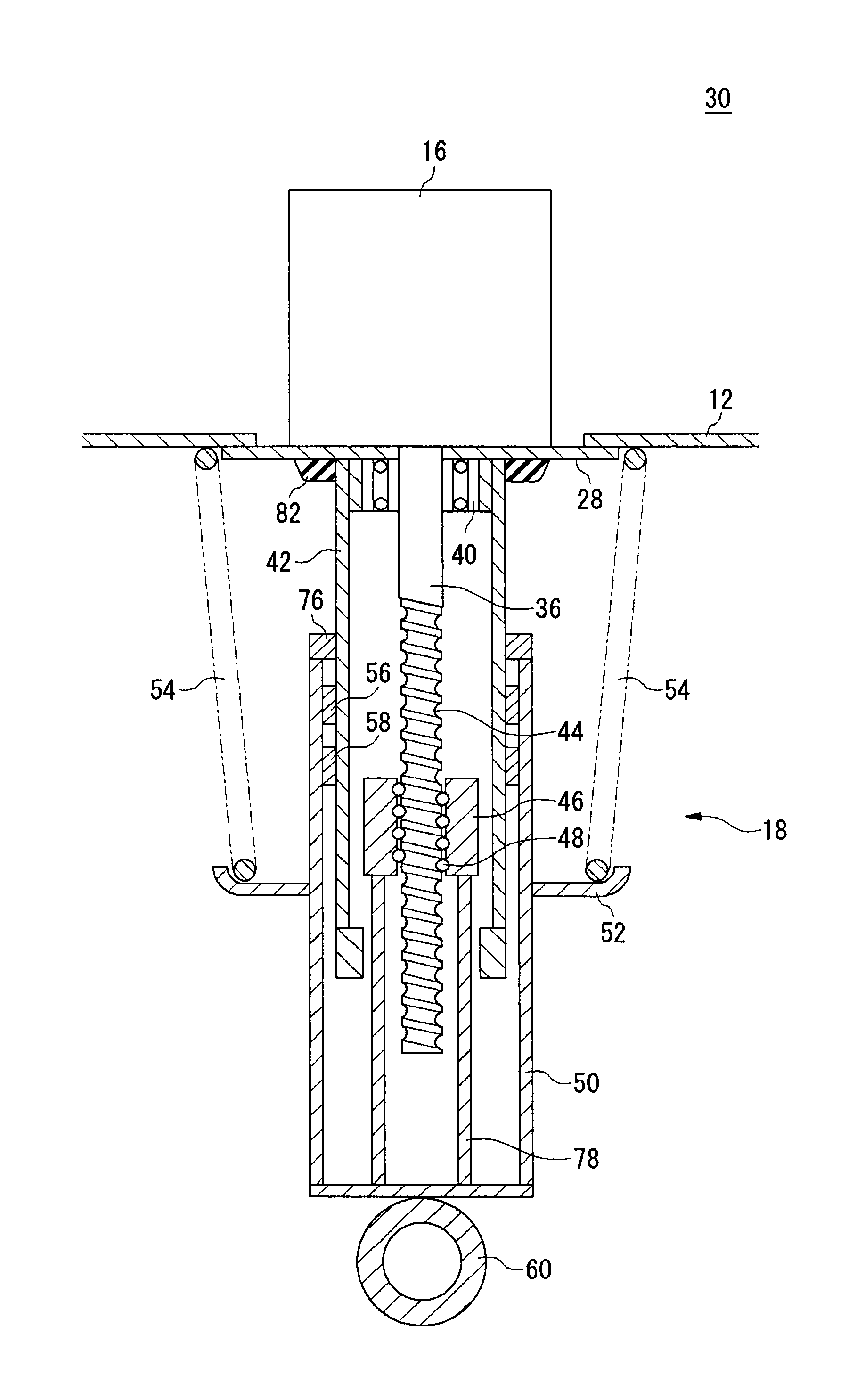

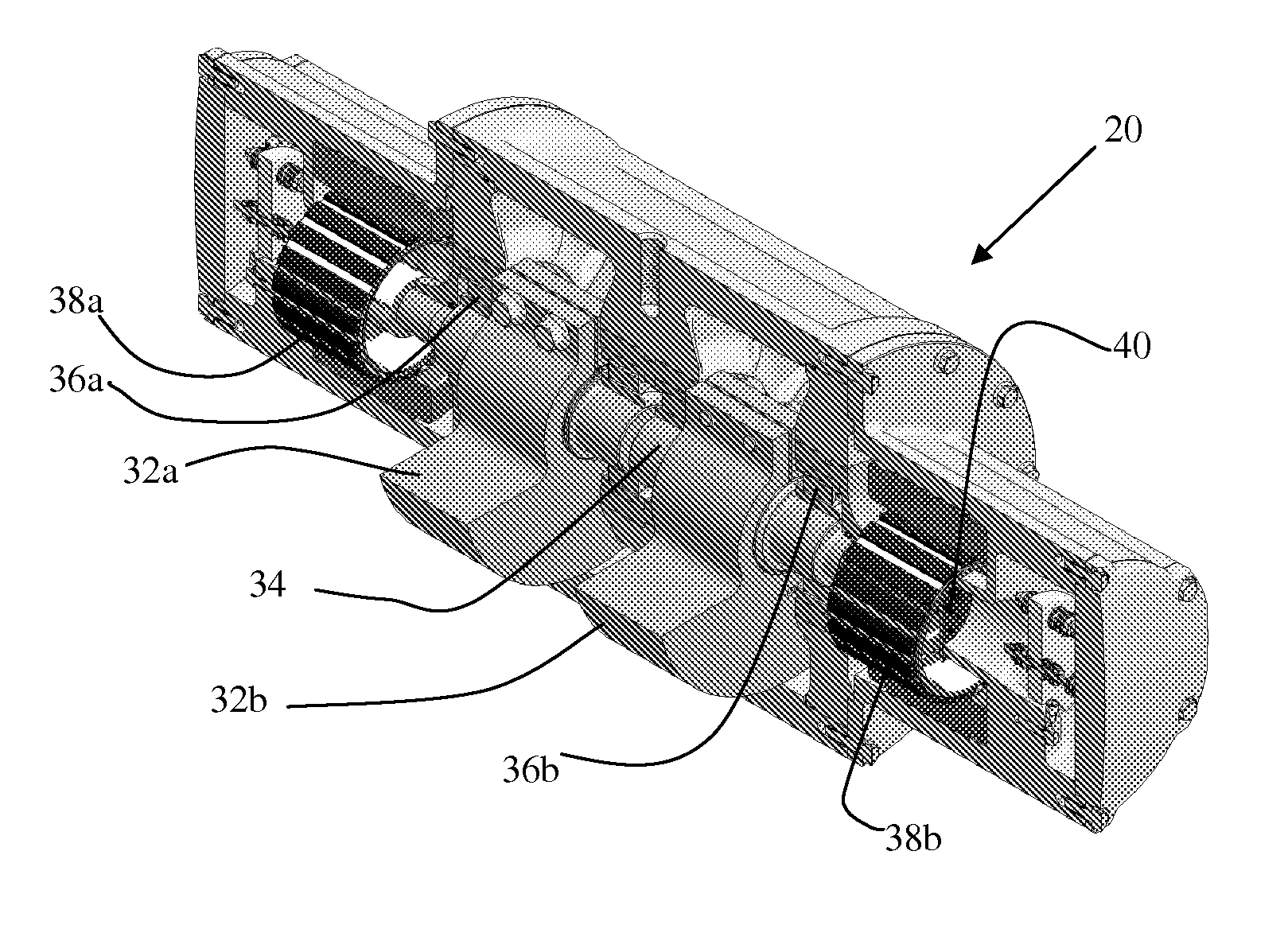

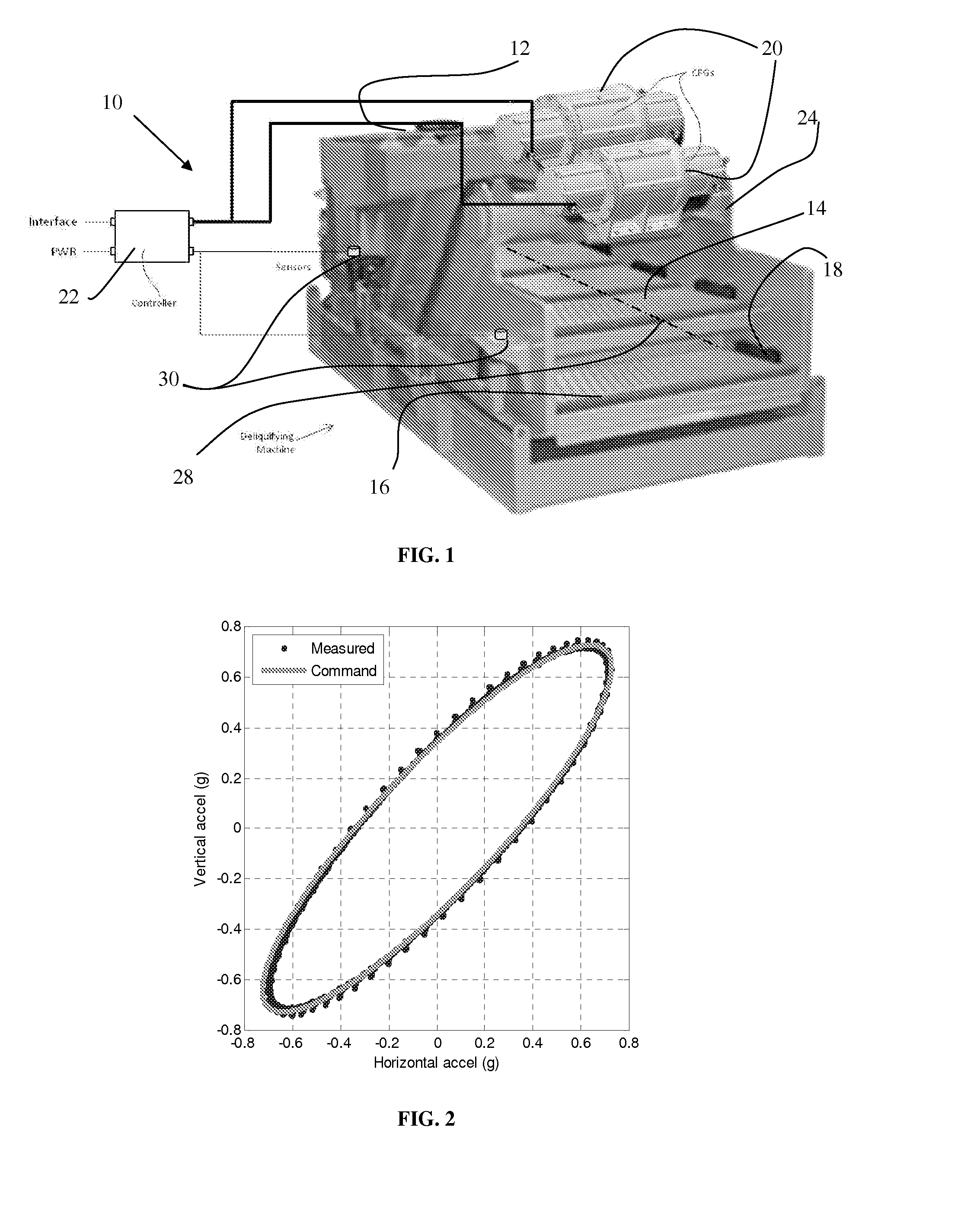

Mechanical devices and method of creating prescribed vibration

InactiveUS20150340981A1Motor/generator/converter stoppersAC motor controlForce frequencyElectronic communication

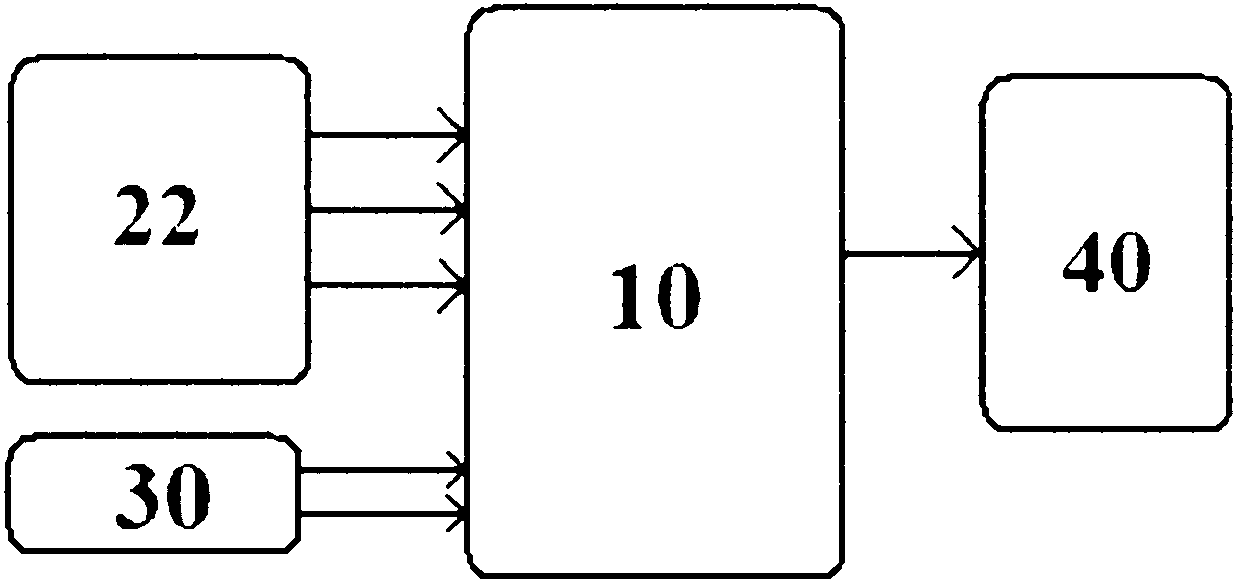

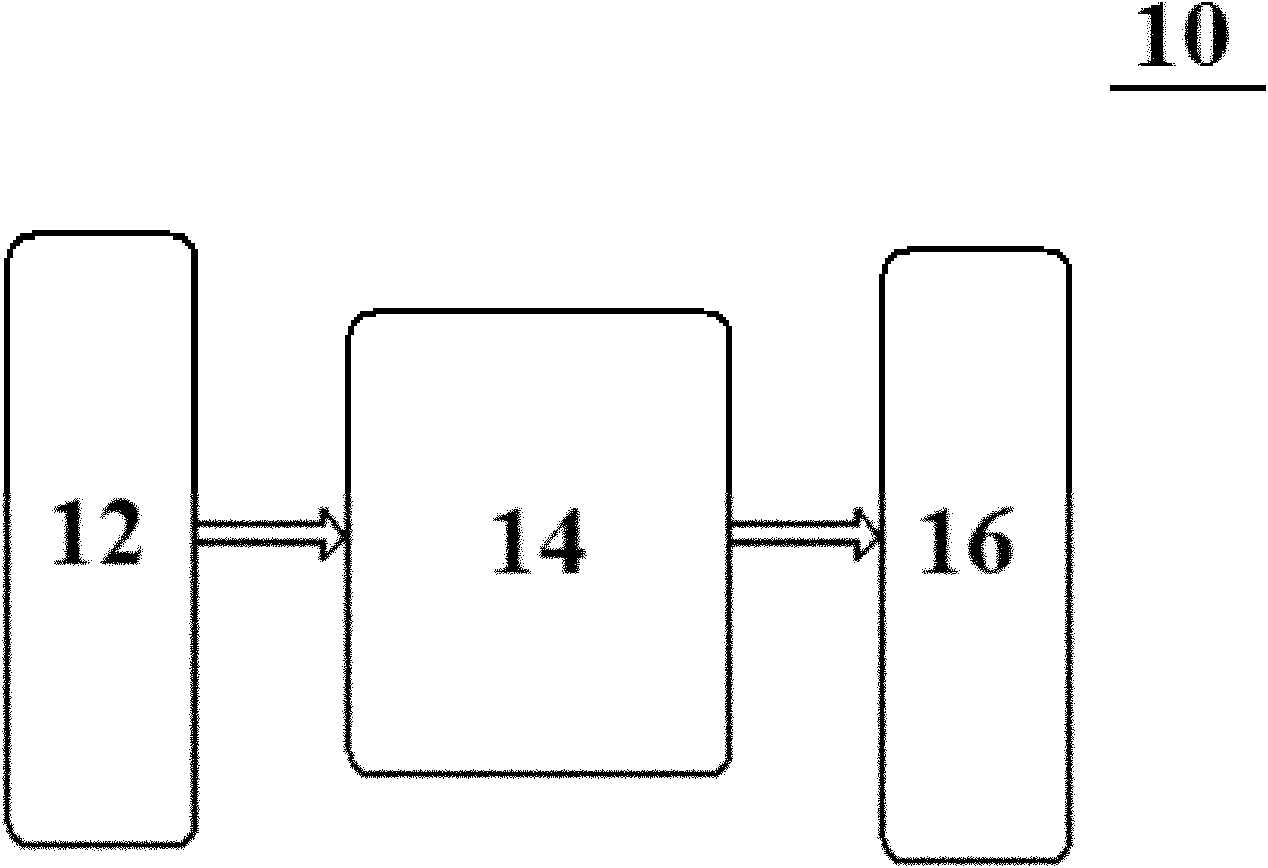

The invention provides a system for creating a prescribed vibration profile on a mechanical device comprising a sensor (30) for measuring an operating condition of the mechanical device, a circular force generator CFG (20) for creating a controllable rotating force vector comprising a controllable force magnitude, a controllable force phase and a controllable force frequency, a controller (22) in electronic communication with said sensor and said circular force generator, the controller operably controlling the controllable rotating force vector, wherein the difference between the measured operating condition and a desired operating condition is minimized.

Owner:LORD CORP

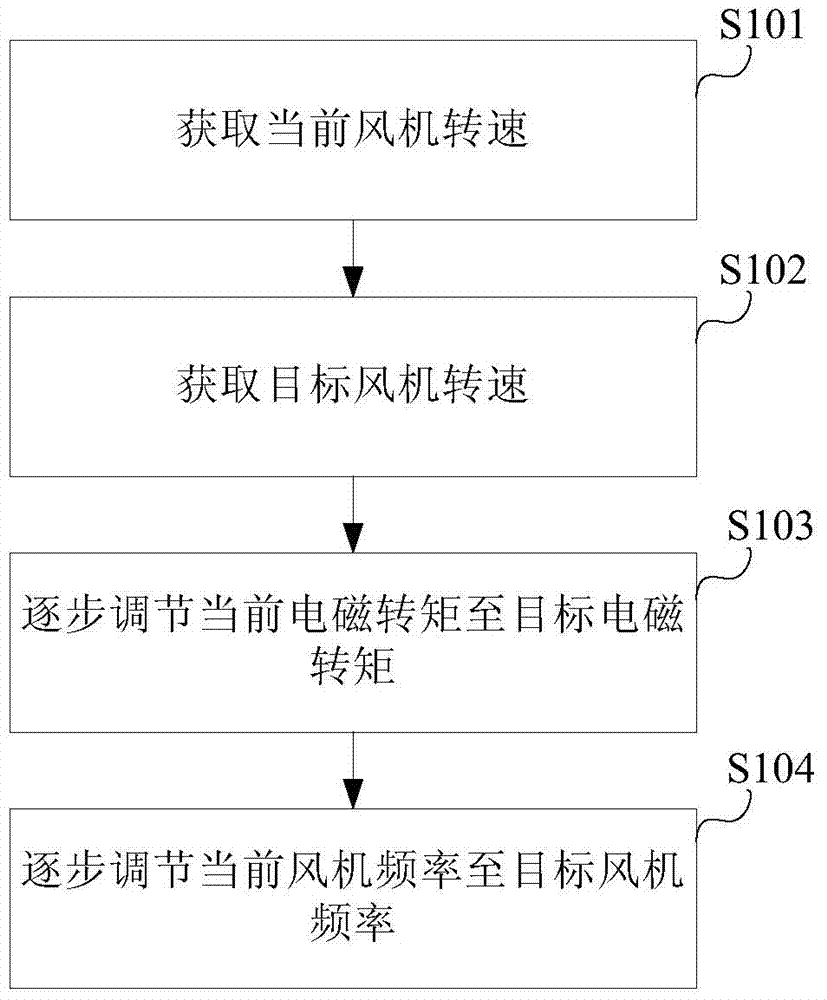

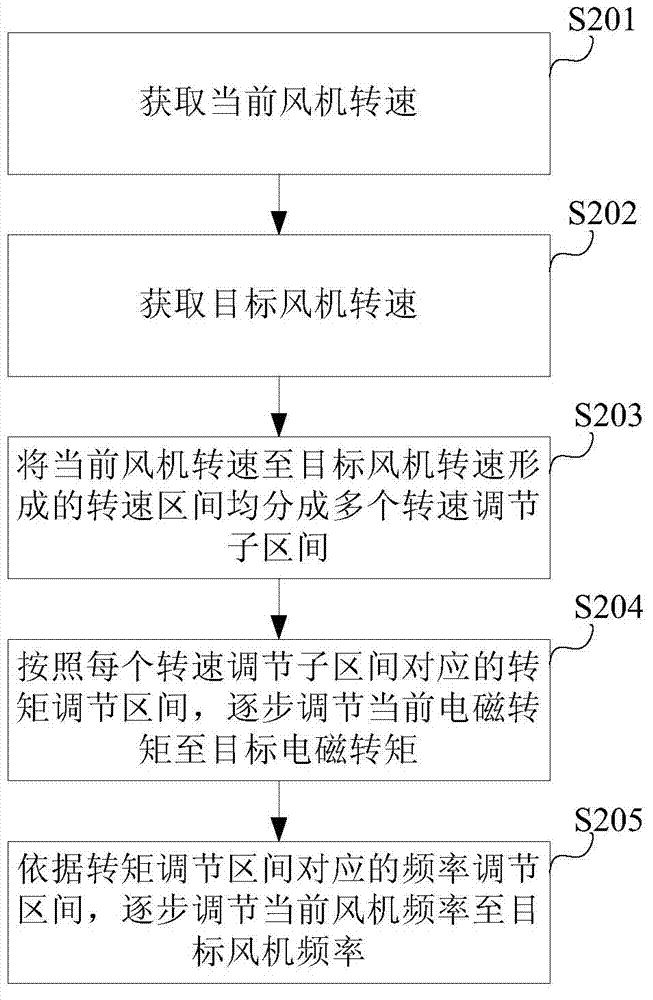

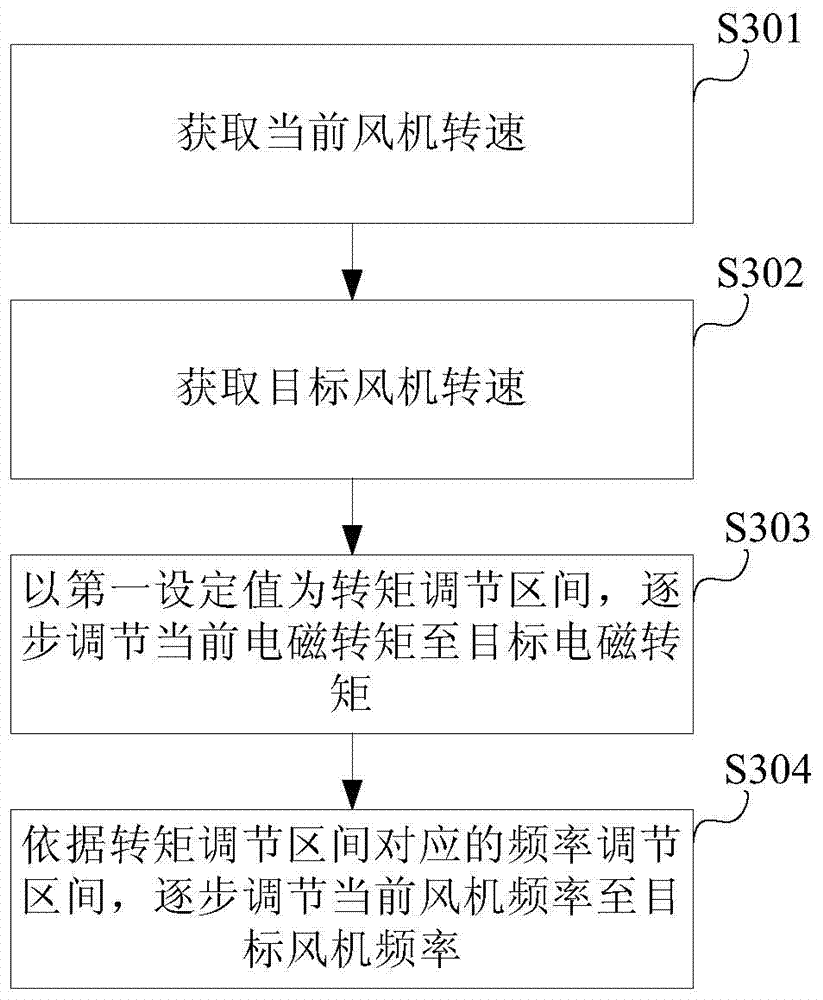

Frequency conversion speed regulation method and system for draught fans

ActiveCN103671199AGuaranteed uptimeExtended service lifePump controlNon-positive displacement fluid enginesElectric machineFrequency conversion

The invention discloses a frequency conversion speed regulation method for draught fans. The method includes the following steps that (1) the rotating speed of the current draught fan and the rotating speed of a target draught fan are obtained; (2) current electromagnetic torque corresponding to the rotating speed of the current draught fan is gradually regulated to target electromagnetic torque corresponding to the rotating speed of the target draught fan, and frequency, corresponding to the rotating speed of the current draught fan, of the current draught fan is gradually regulated to frequency, corresponding to the rotating speed of the target draught fan, of the target draught fan according to frequency regulation amplitudes corresponding to electromagnetic torque regulation amplitudes in various steps. The invention further discloses a frequency conversion speed regulation system for the draught fans. According to the method and system, the alternating force magnitude can be reduced to relieve influences of negative factors such as partial sudden changes of wind pressure and sudden changes of electromagnetic torque output by motors of the draught fans, the draught fans can operate more safely, and the service life of the draught fans can be prolonged.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

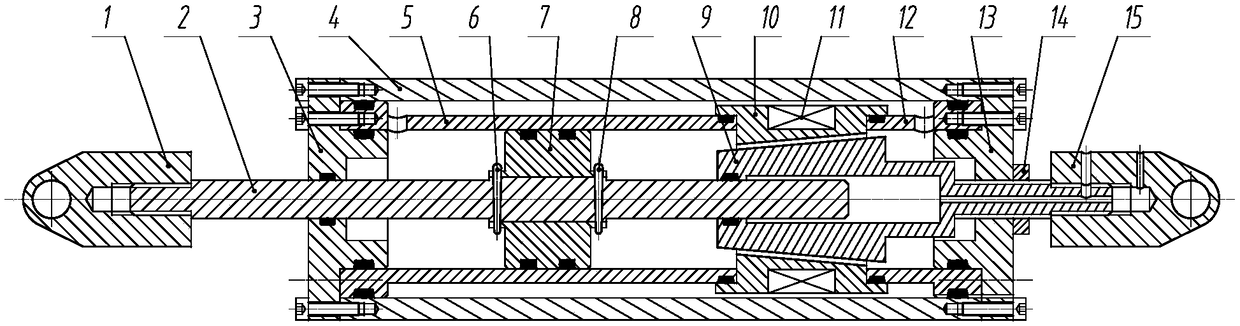

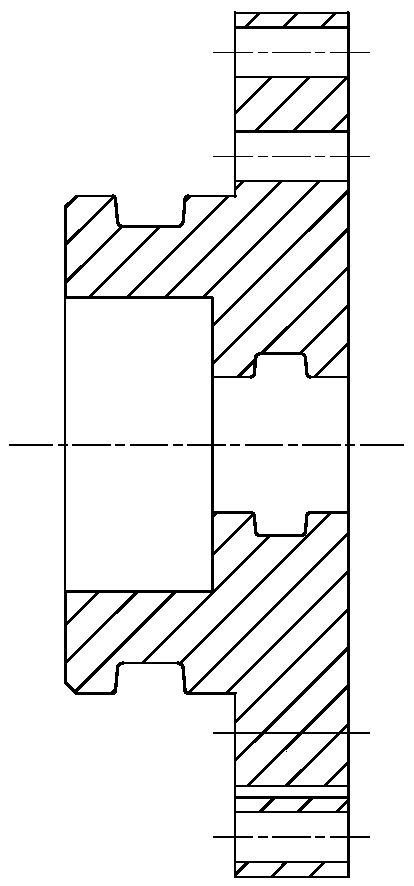

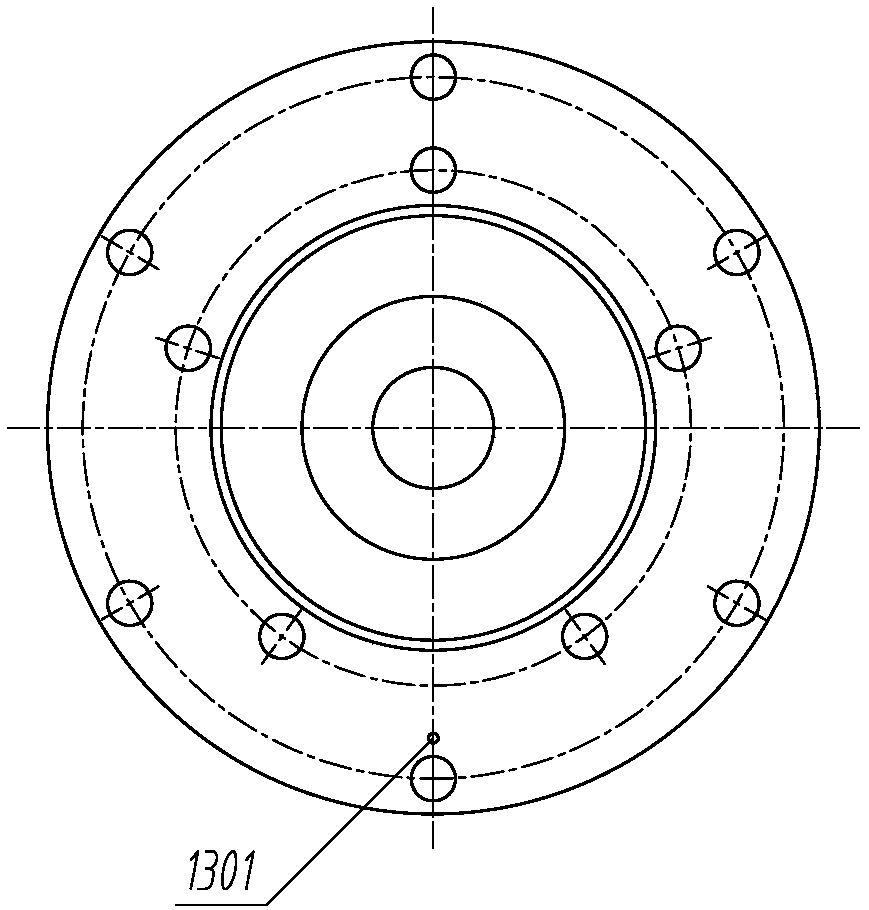

Damping gap adjustable magnetorheological damper with series liquid flow channels

ActiveCN108953467AWide dynamic adjustment rangeLarge controllable damping forceSpringsNon-rotating vibration suppressionPower flowEngineering

The invention discloses a damping gap adjustable magnetorheological damper with series liquid flow channels. The damper is mainly composed of a piston rod, an end cover, cylinder bodies, a piston head, a valve element, an excitation coil, a winding frame and the like. The conical liquid flow channel is formed in a gap between the valve element and the winding frame, the circular liquid flow channel is formed in a gap between the outer cylinder body and the winding frame, the conical liquid flow channel and the circular liquid flow channel make up a series liquid flow channel structure, and four effective damping gaps can be formed under action of a magnetic field, wherein the liquid flow channel formed between the winding frame and the valve element can form two conical effective damping gaps, the thickness of the damping gaps can be changed through adjusting the valve element position, so that the effect of adjusting damping force magnitude is achieved. When the excitation coil is powered on to work, effective control of the damping force can be realized through controlling the magnitude of current. According to the damper, liquid flow damping length is effectively increased through the series liquid flow channels, it is guaranteed that the damper can output the damping force which is strong enough and wide in adjustable range, and is particularly suitable for vibration damping systems in industries of railway, traffic and the like.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Pressure sensing method and system thereof

ActiveCN105912159AInput/output processes for data processingElectrical resistance and conductancePressure sense

The invention provides a pressure sensing method and system thereof. The method comprises following steps: solving an equation of a function relationship in order to obtain variations in resistance value induced by pressure at a compression position and obtaining compression magnitude at the compression position based on variations in resistance value. The function relationship is formed among resistance variations induced by pressure of a finger compression position, resistance variations induced by temperature, resistance variations induced by compression force of at least two sensing electrodes adjacent to the compression position. The pressure sensing method and system thereof have following beneficial effects: based on a function relationship, pressure-induced variations in resistance value at the compression position and variations in resistance value induced by temperature variations are obtained by solving the equation; and based on variations in resistance value, real compression force magnitude and real temperature at the compression position can be detected.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

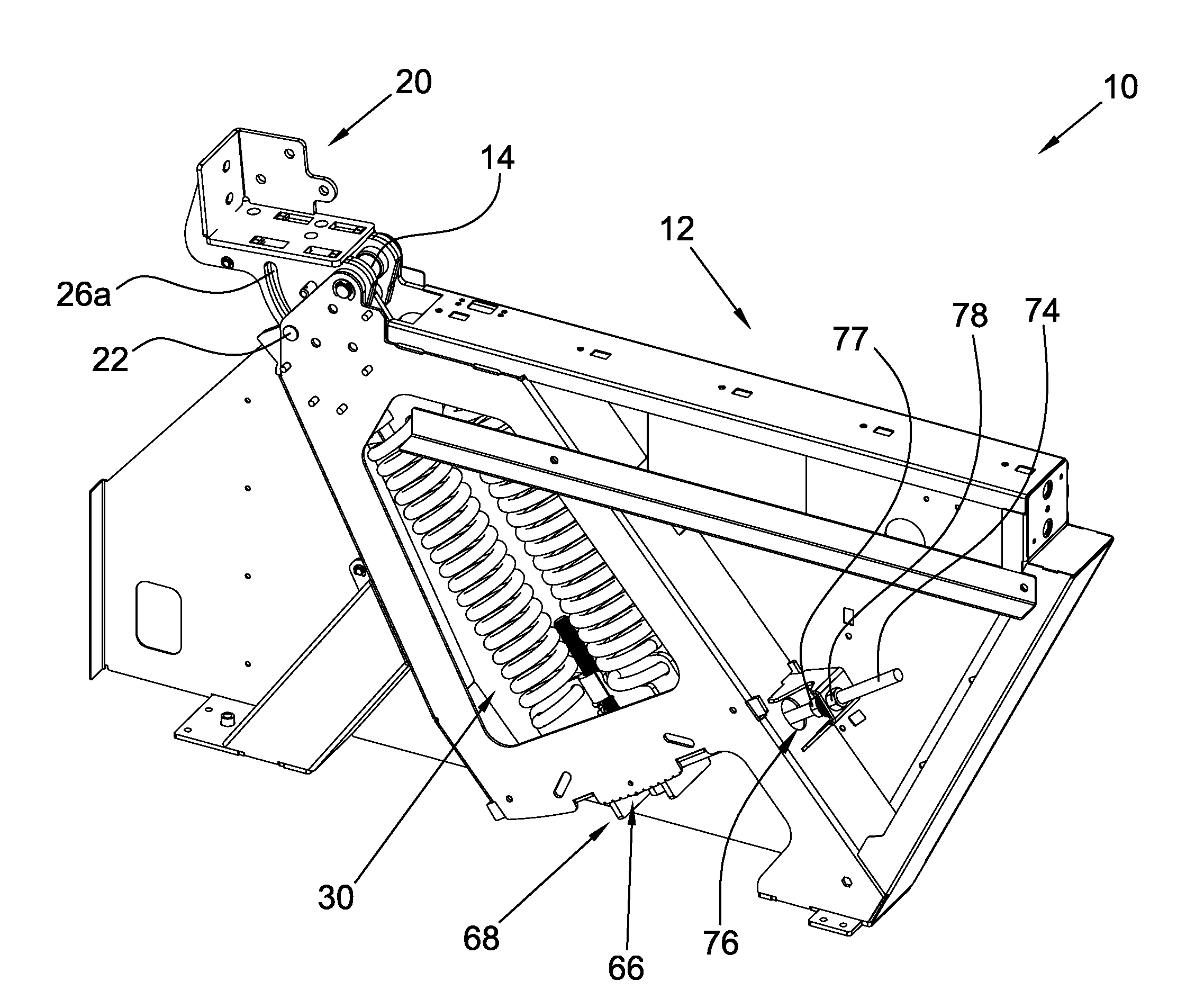

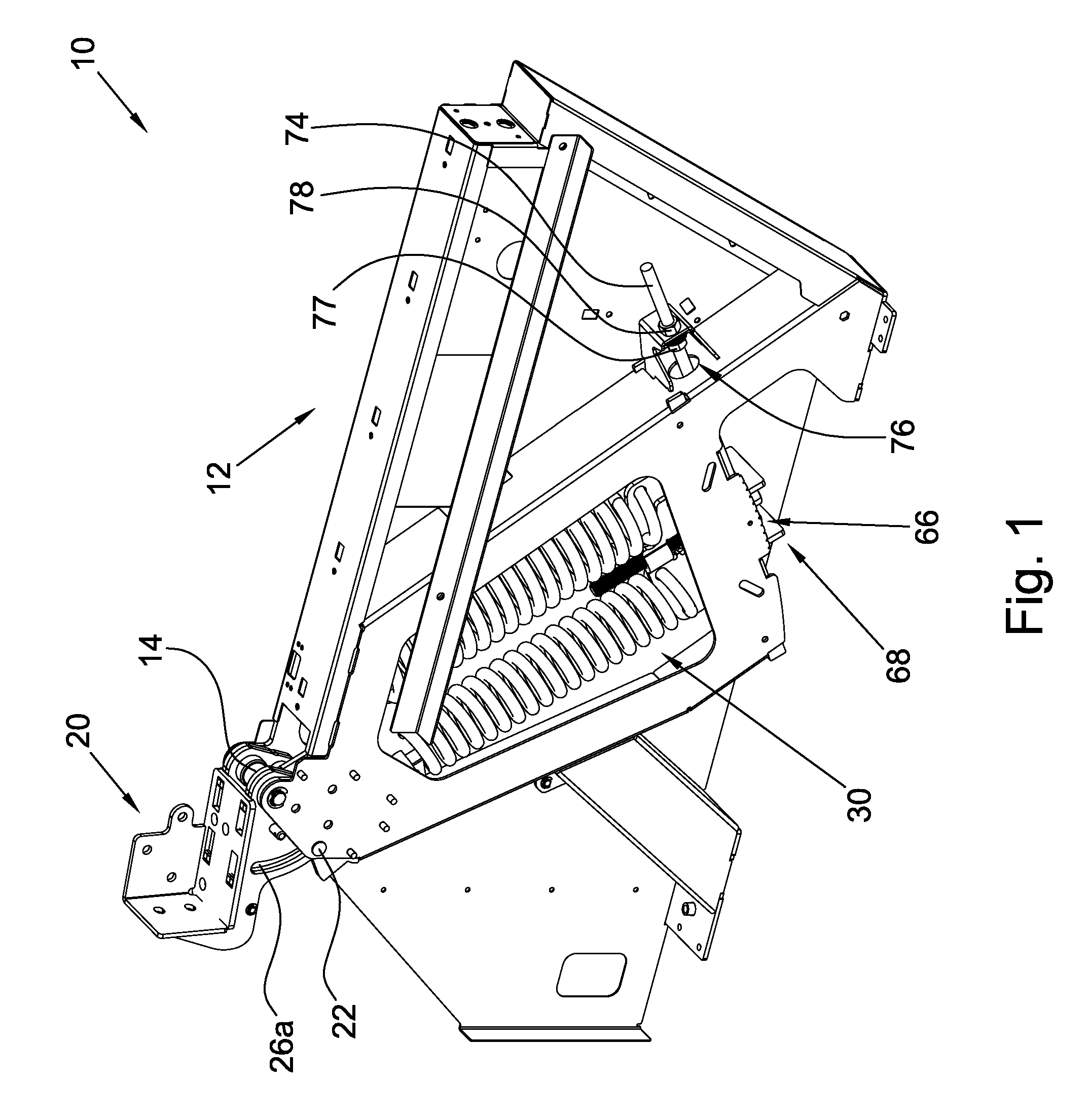

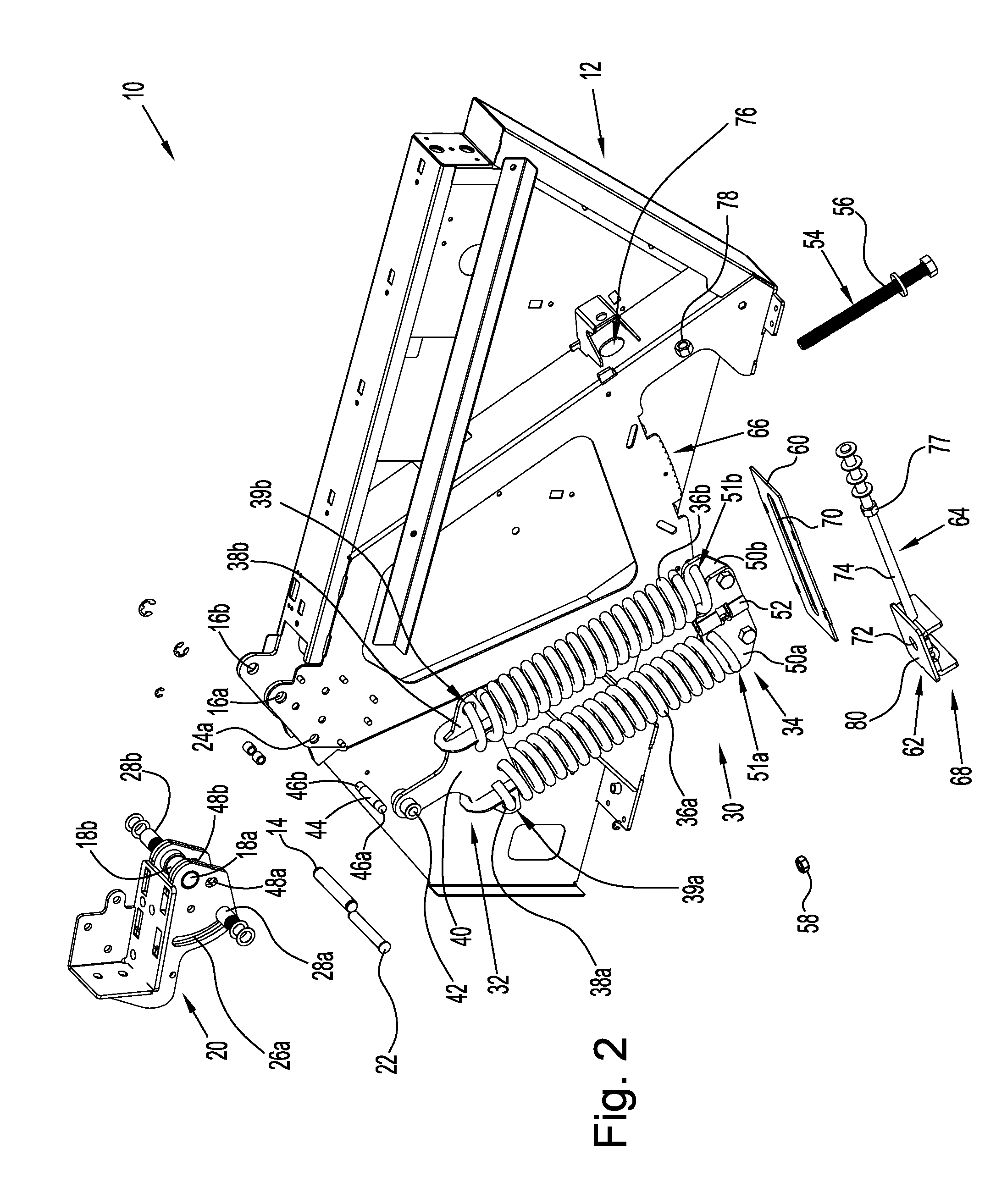

Counterbalance mechanism

A counterbalance mechanism including: a housing having a first aligned pair of through holes and a second aligned pair of through holes; a pivot nose having a third aligned pair of through holes, a fourth aligned pair of through holes and an aligned pair of arcuate slots; an energy storage device having first and second spring mounts and at least one spring, the first spring mount having at least one first flange and a pivot flange having a fifth through hole, the second spring mount having at least one second flange and a sixth through hole and the at least one spring includes first and second ends, the first end is secured to the at least one first flange and the second end is secured to the at least one second flange; a first pivot pin disposed in the first aligned pair of through holes and the third aligned pair of through holes; a stop member disposed in the second aligned pair of through holes and the aligned pair of arcuate slots; a second pivot pin disposed in the fourth aligned pair of through holes and the fifth through hole; a force magnitude adjuster arranged to control a force of the at least one spring; and, a force angle adjuster arranged to control a force direction of the at least one spring.

Owner:WEBER KNAPP

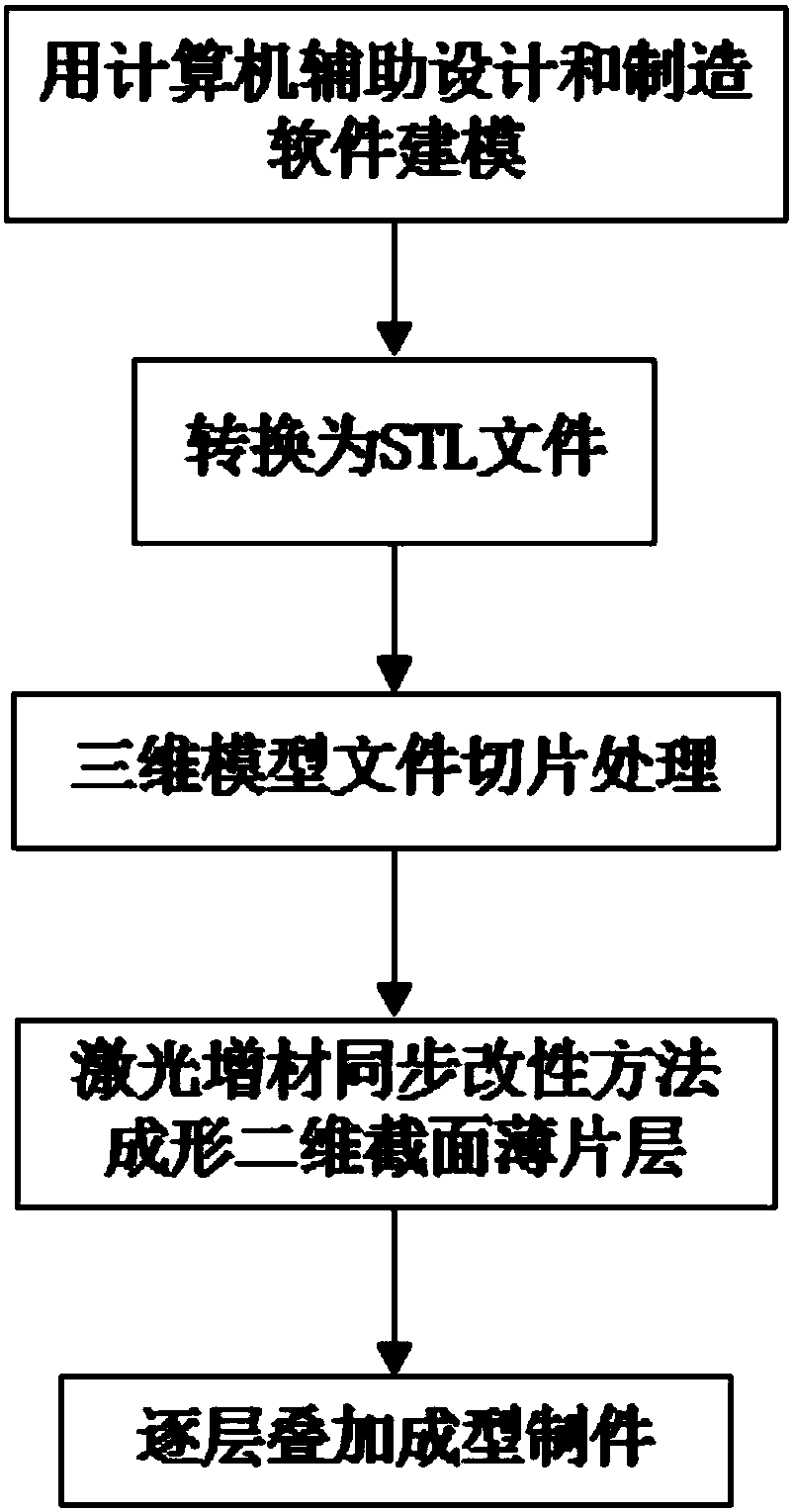

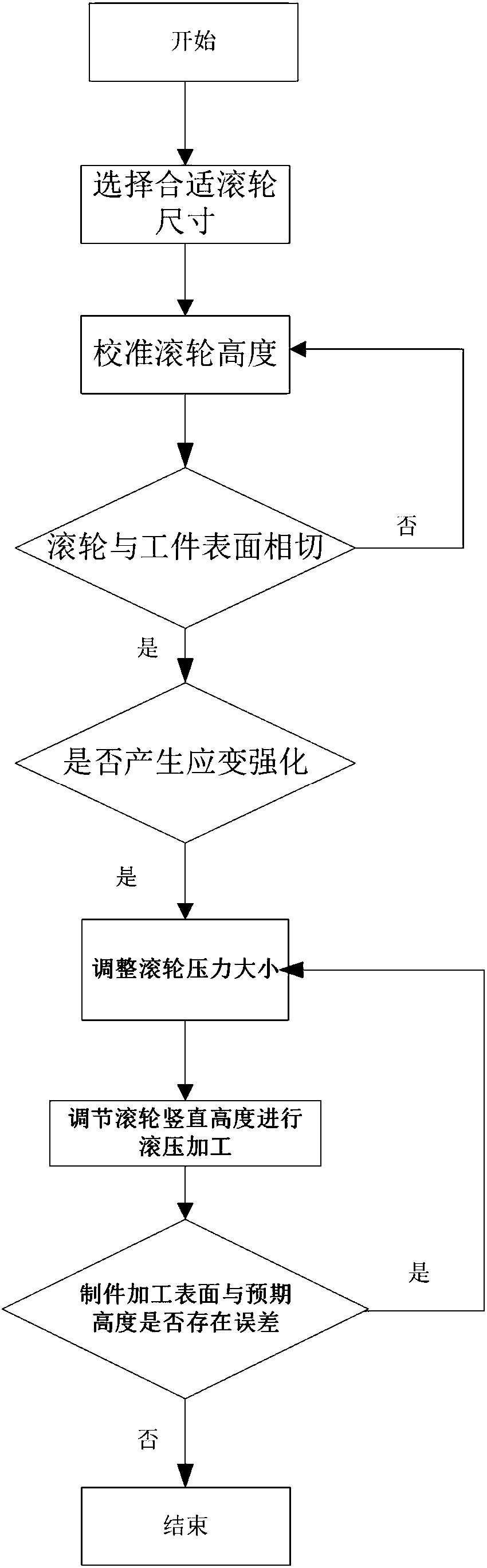

Method for conducting synchronous modification on powder-feeding type laser additive manufacturing manufactured workpiece

ActiveCN108247056AReduce surface roughnessHigh surface hardnessAdditive manufacturing apparatusIncreasing energy efficiencyLaser additive manufacturingMachining process

The invention discloses a method for conducting synchronous modification on a powder-feeding type laser additive manufacturing manufactured workpiece. A synchronous following rolling process is addedin the machining process of the laser additive manufacturing manufactured workpiece, the method comprises the steps that a suitable rolling wheel size is selected; the height of a rolling wheel for achieving the rolling function is calibrated; as for the rolling wheel with the height being calibrated, the rolling force magnitude range is judged according to the rolling machining effect to be reached by the manufactured workpiece, and the feed amount of the rolling wheel is adjusted accordingly; a 3D print nozzle runs on a printed substrate according to the printing path; the rolling force magnitude can be adjusted according the relative height of current manufactured workpiece machining in the printing process; the rolling wheel with adjusting of the rolling force magnitude being finishedis subjected to synchronous following rolling work; and the printing layers are stacked layer by layer, and the metal manufactured workpiece is formed after cooling. The method for conducting synchronous modification on the powder-feeding type laser additive manufacturing manufactured workpiece can improve the inner quality and internal structure of the metal manufactured workpiece without changing the shape of the workpiece, the compactness of the manufactured workpiece is increased, and the strength of the manufactured workpiece is improved.

Owner:JILIN UNIV

Electromechanical relay and method of operating same

Owner:MAGVENTION (SUZHOU) LTD

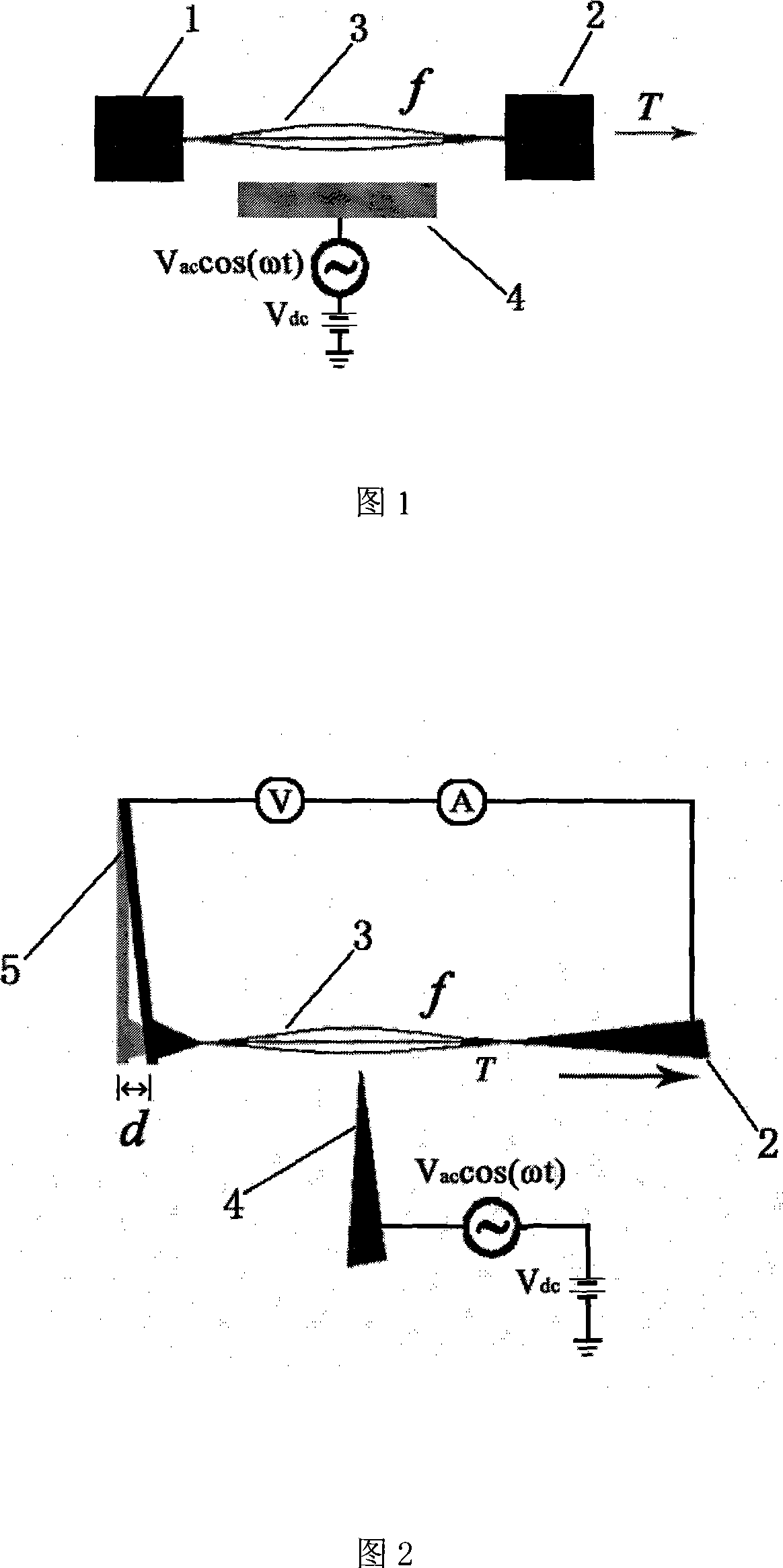

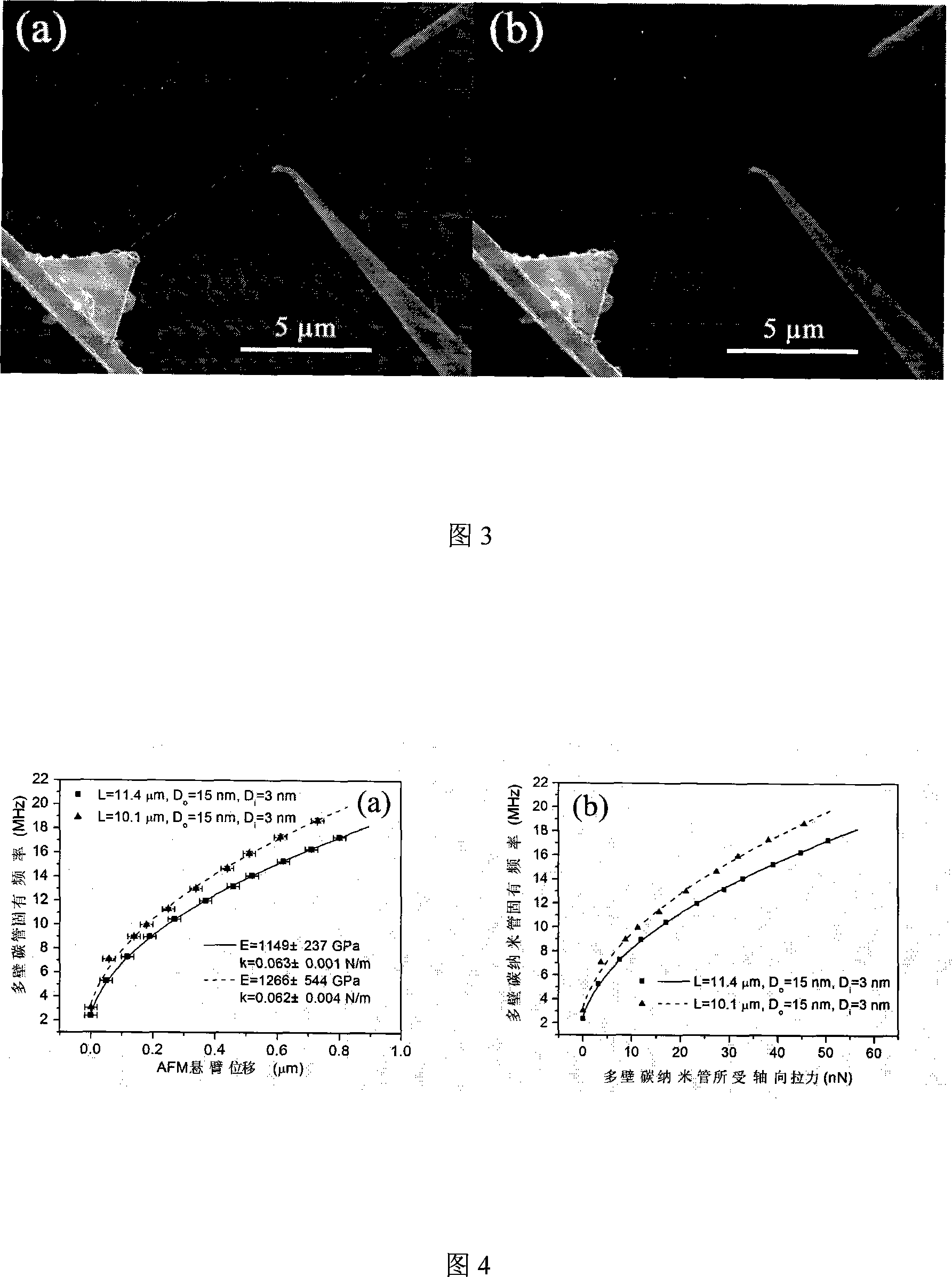

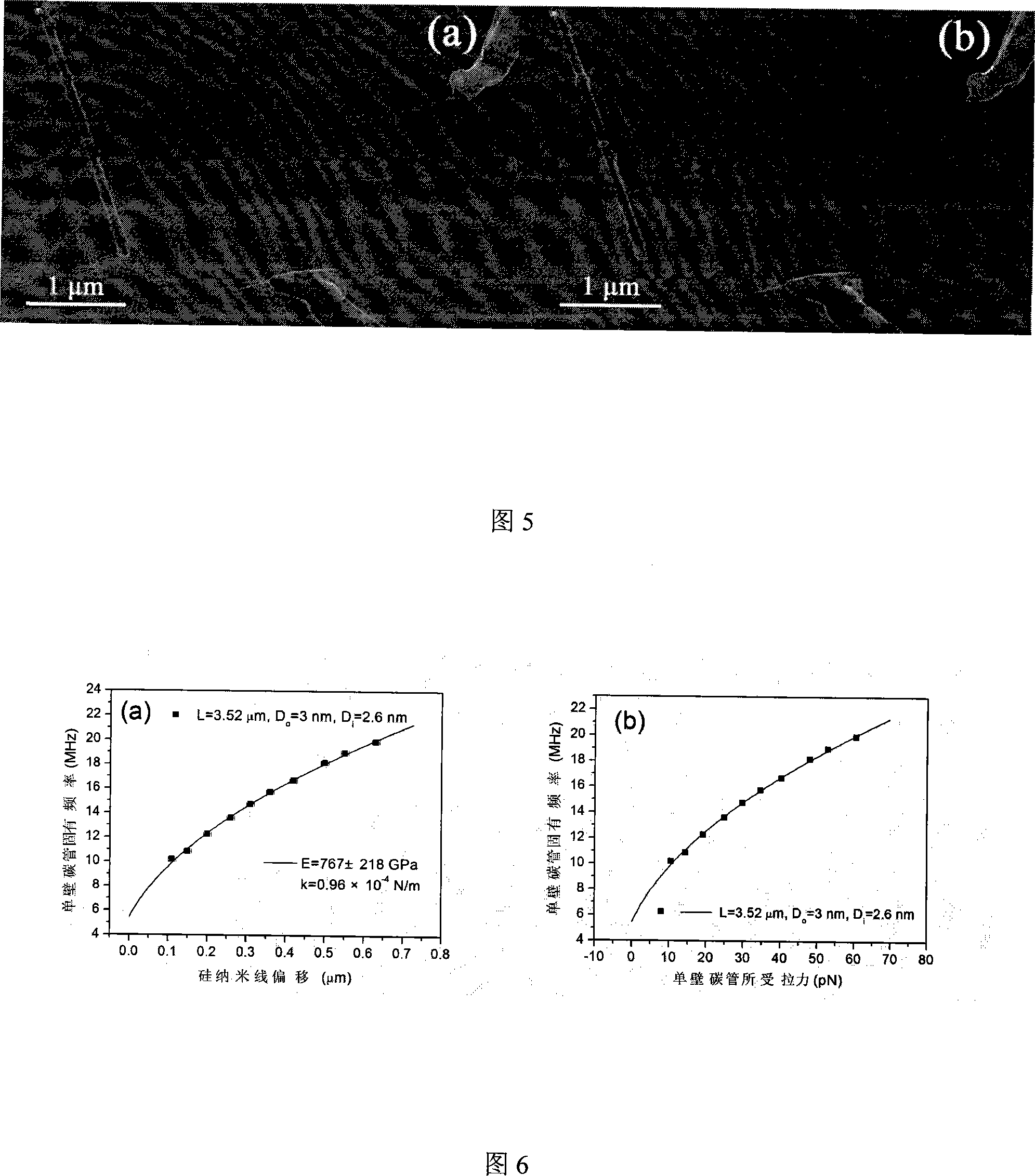

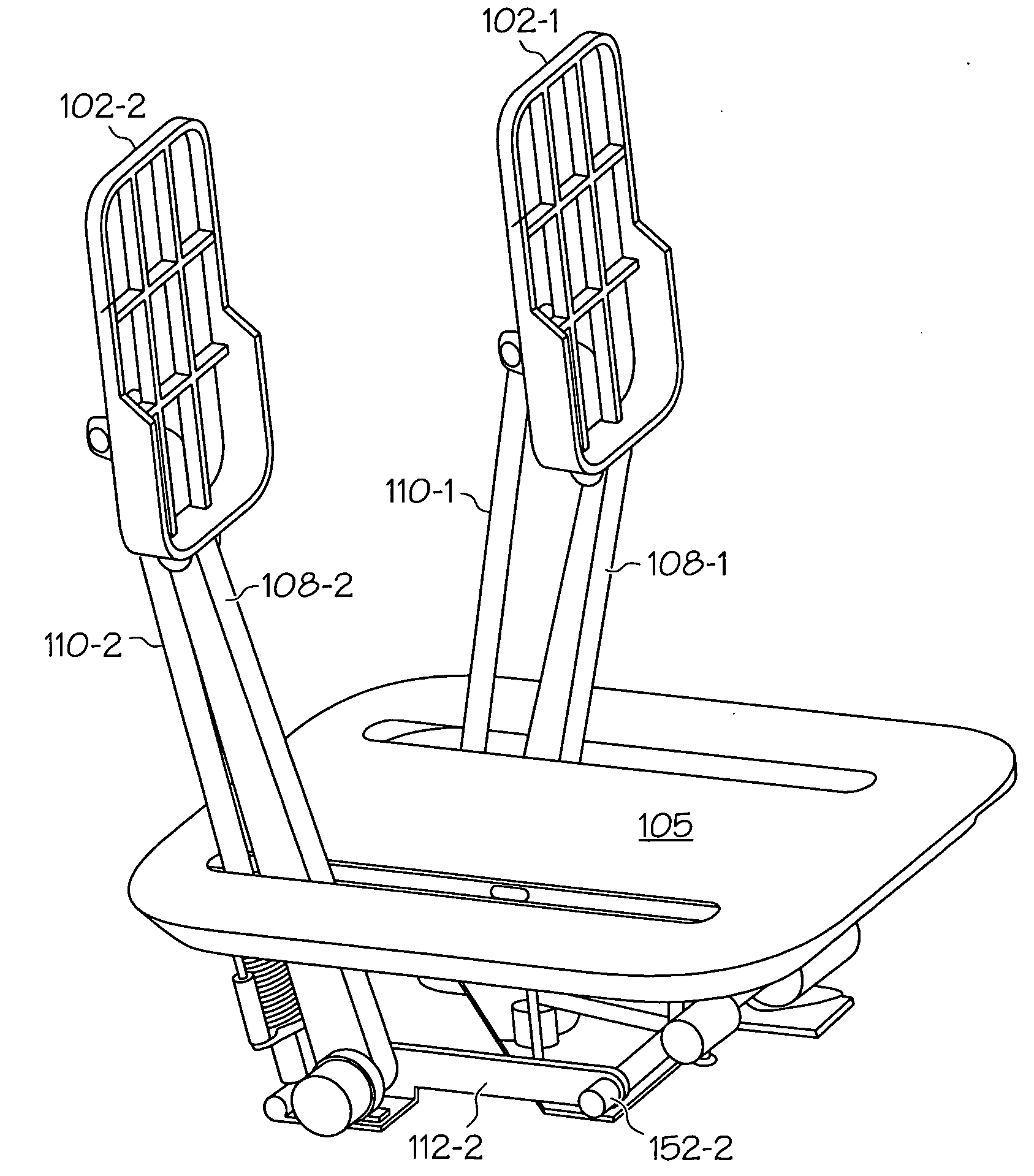

Method for accurately measuring micro-force and measuring micro-cantilever force constant

InactiveCN101183033AAccurate measurementForce measurement by measuring frquency variationsPull forceResonance

The invention provides a method for accurately measuring a tiny force and a force constant of a micro-cantilever, belonging to the field of nanometer measurement. In this method, the two ends of a nanomaterial are fixed on two fulcrums, and a small axial pulling force T is applied to the nanomaterial; on the side of the nanomaterial, an electrode is placed in the middle of the nanomaterial, and a The alternating voltage excites the nanomaterial to make it resonate, and the natural frequency f of the nanomaterial is measured; according to the material characteristics and geometric characteristics of the nanomaterial and the boundary conditions of the nanomaterial, the natural frequency of the nanomaterial is calculated from the vibration equation. The relationship between the axial tensile force received, that is, the f-T curve of the nanomaterial; according to the natural frequency f measured above, the magnitude of the micro tensile force T is obtained. The method is further used to measure the micro-deflection force of the micro-cantilever when it is deflected, and the force constant of the micro-cantilever is measured in combination with the measurement of the deflection displacement. The invention can be used to develop an instrument for accurately measuring tiny forces of the order of pico-newtons or even flying newtons.

Owner:PEKING UNIV

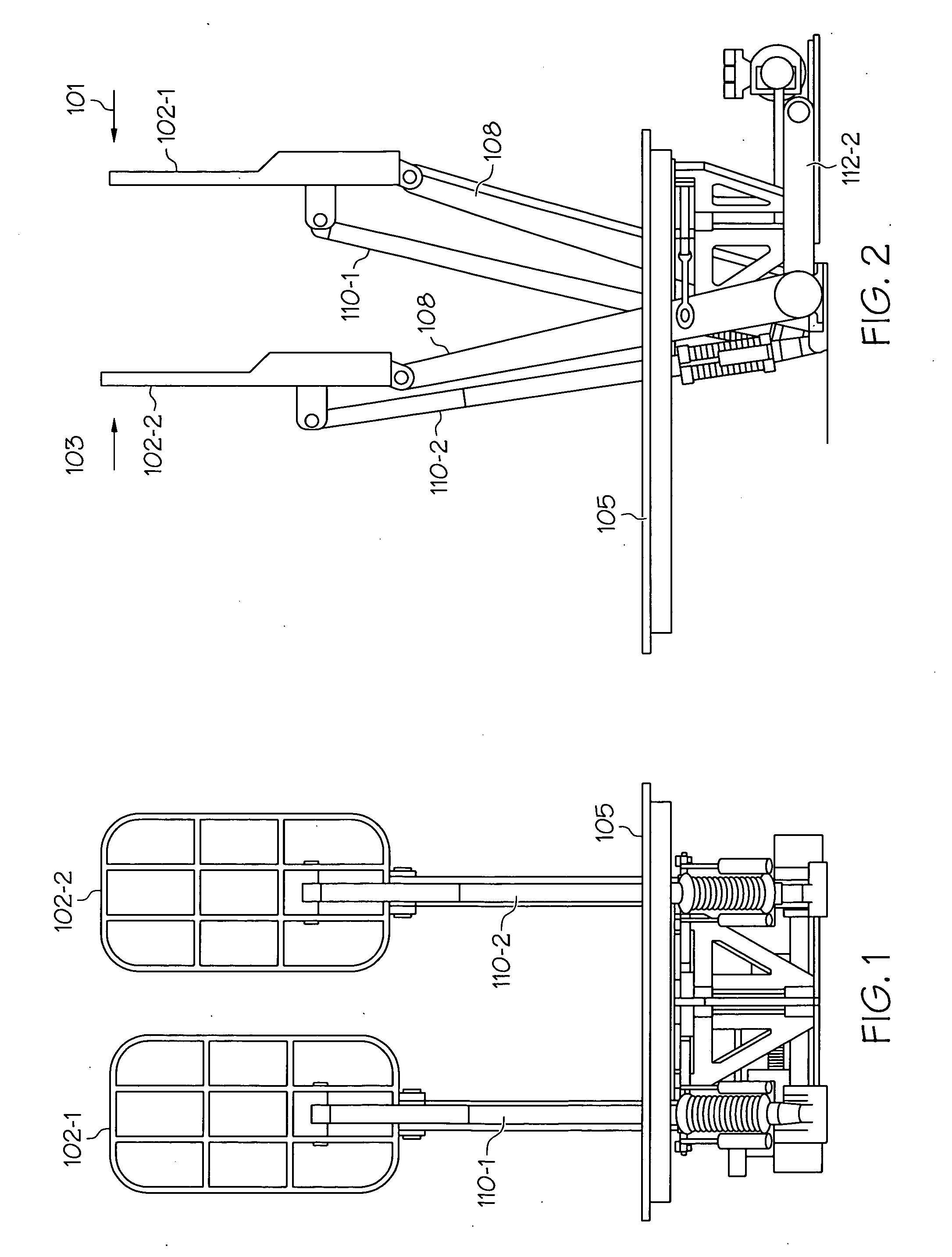

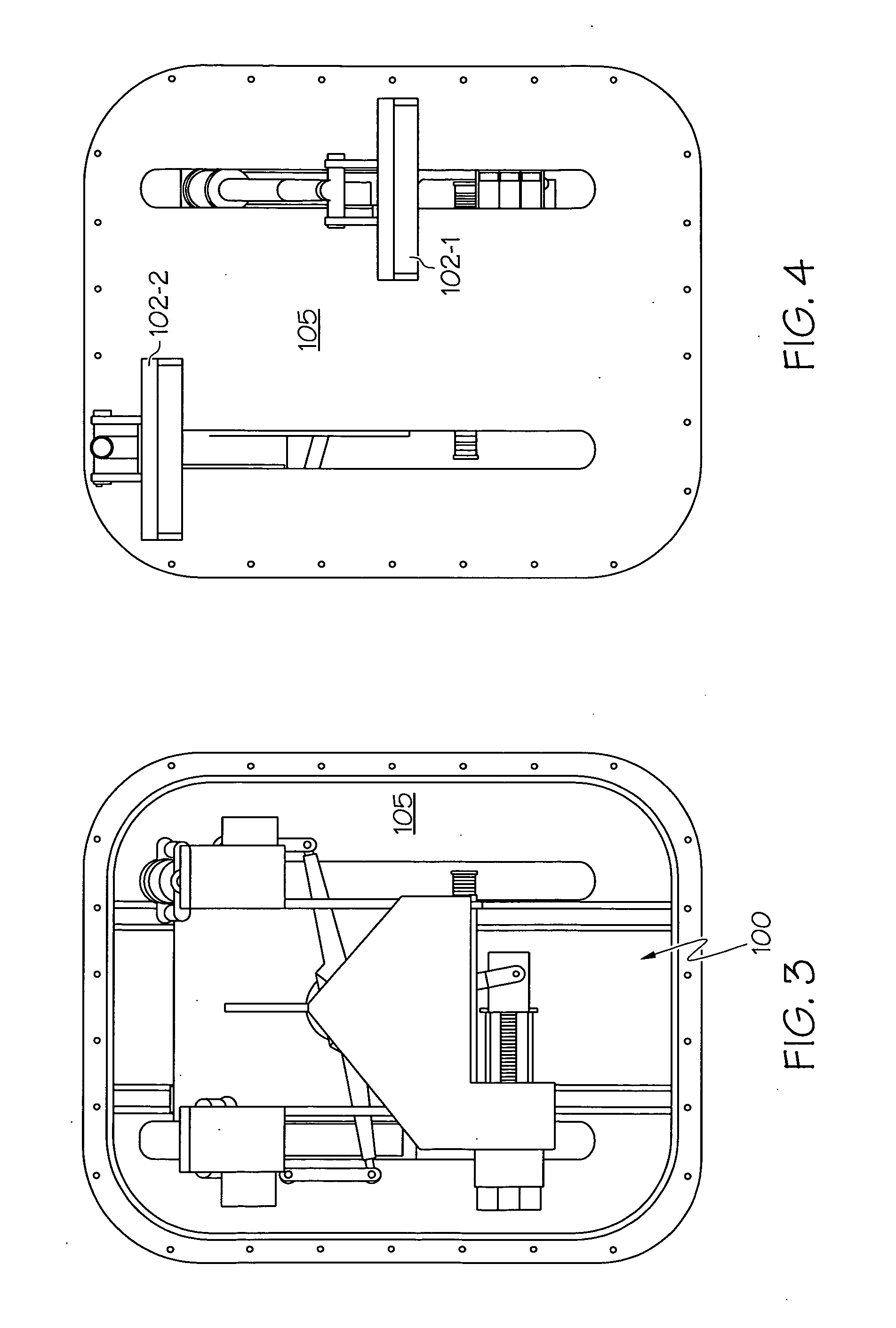

Active rudder pedal mechanism with foreign object strike tolerance and articulating brake

A rudder pedal mechanism is configured with foreign object strike tolerance and / or with an articulating brake. The foreign object strike tolerance is implemented via a force transfer mechanism that is responsive to an input force supplied to the rudder pedal. The force transfer mechanism is configured to supply a transfer force to a rudder position command unit when the input force is supplied in a first direction, and to not supply the transfer force to the rudder position command unit when the input force is supplied in the second direction and exceeds at least a predetermined force magnitude. The articulating brake is implemented via a brake rod assembly that is rotationally coupled to the rudder pedal, and includes a first rod that is rotationally coupled to the rudder pedal, and a second rod that surrounds at least a portion of the first rod.

Owner:HONEYWELL INT INC

Suspension system for vehicle

ActiveUS8103408B2Simple structureReduce voltageNon-rotating vibration suppressionDigital data processing detailsElectromagnetic absorbersClosed loop

In a system including four electromagnetic absorbers for respective four vehicle wheels, motor coils of two respective electromagnetic absorbers disposed corresponding to two diagonally located wheels are connected forming a closed loop including the coils. A generated damping force magnitude can be made different between an instance directions of respective movements of the diagonally located two wheels with respect to the vehicle body are the same, and an instance the directions are opposite each other. Each electromagnetic absorber includes a resistor cooperating with the corresponding coil forming a closed loop, and selectively establishes: a connected state in which one of the four coils and any of the other three coils are connected to form a closed loop; and a non-connected state in which the one of the four coils is not connected to any other coil. An appropriate vibration suppressing action is exhibited with respect to a coupled motion.

Owner:KYB CORP +2

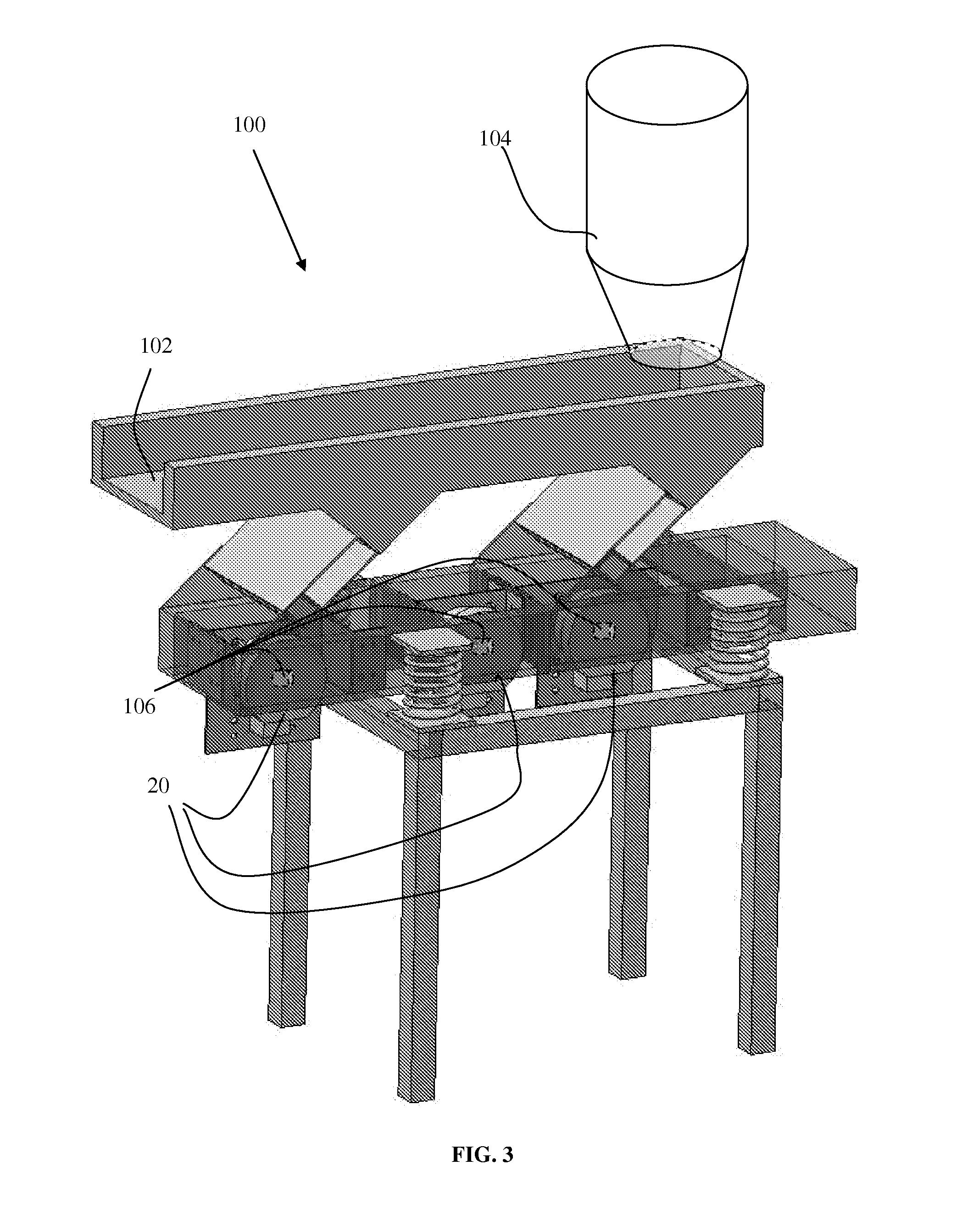

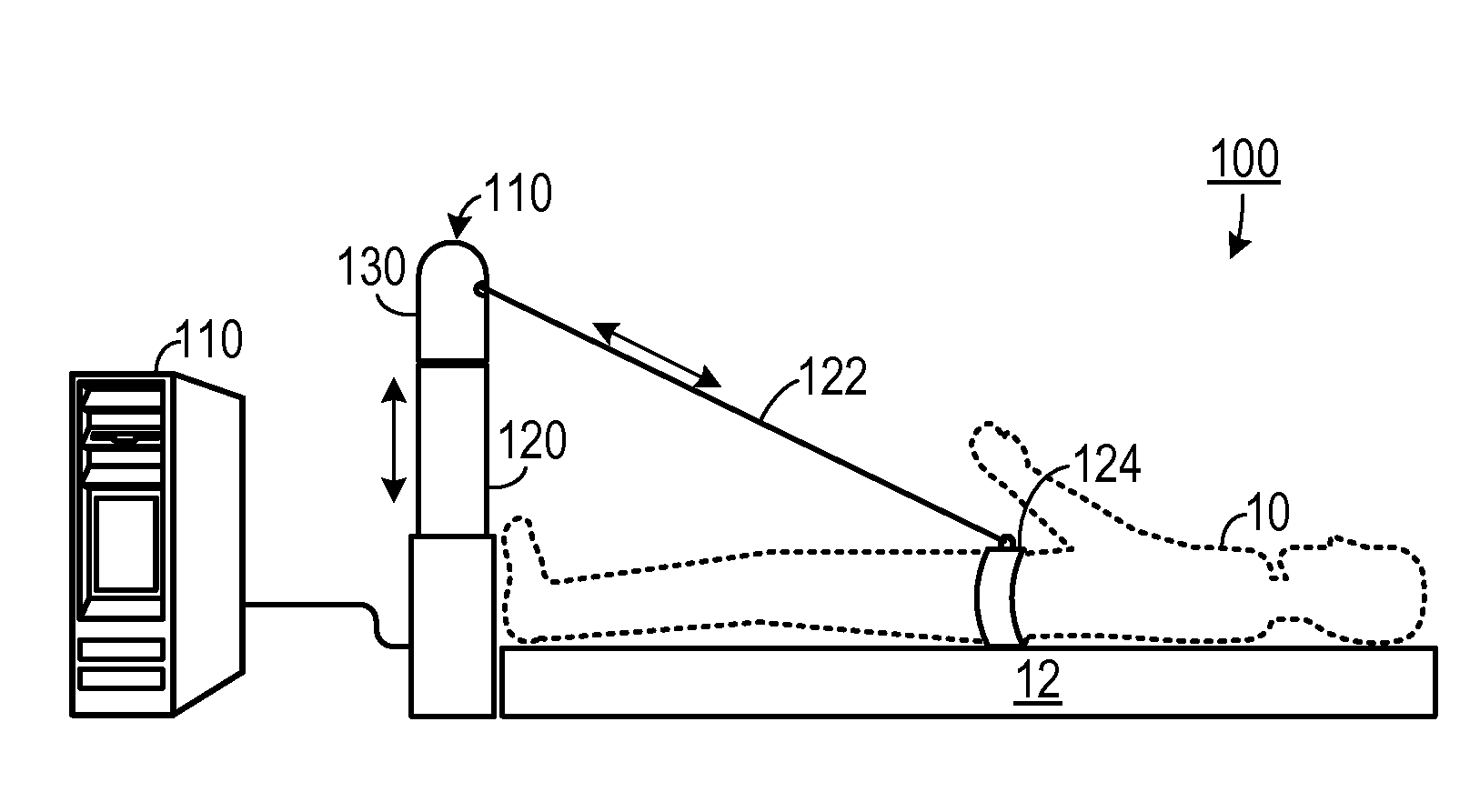

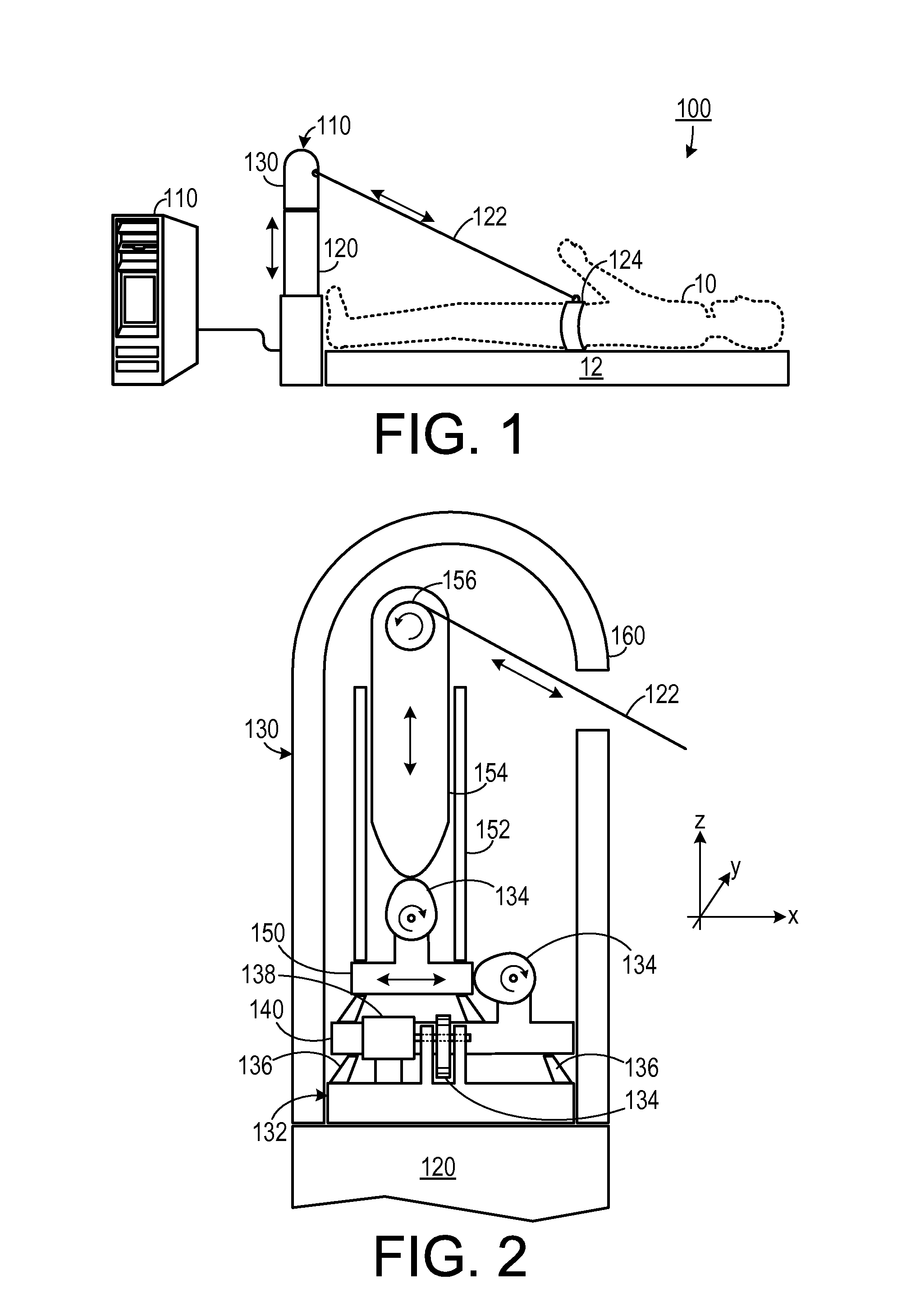

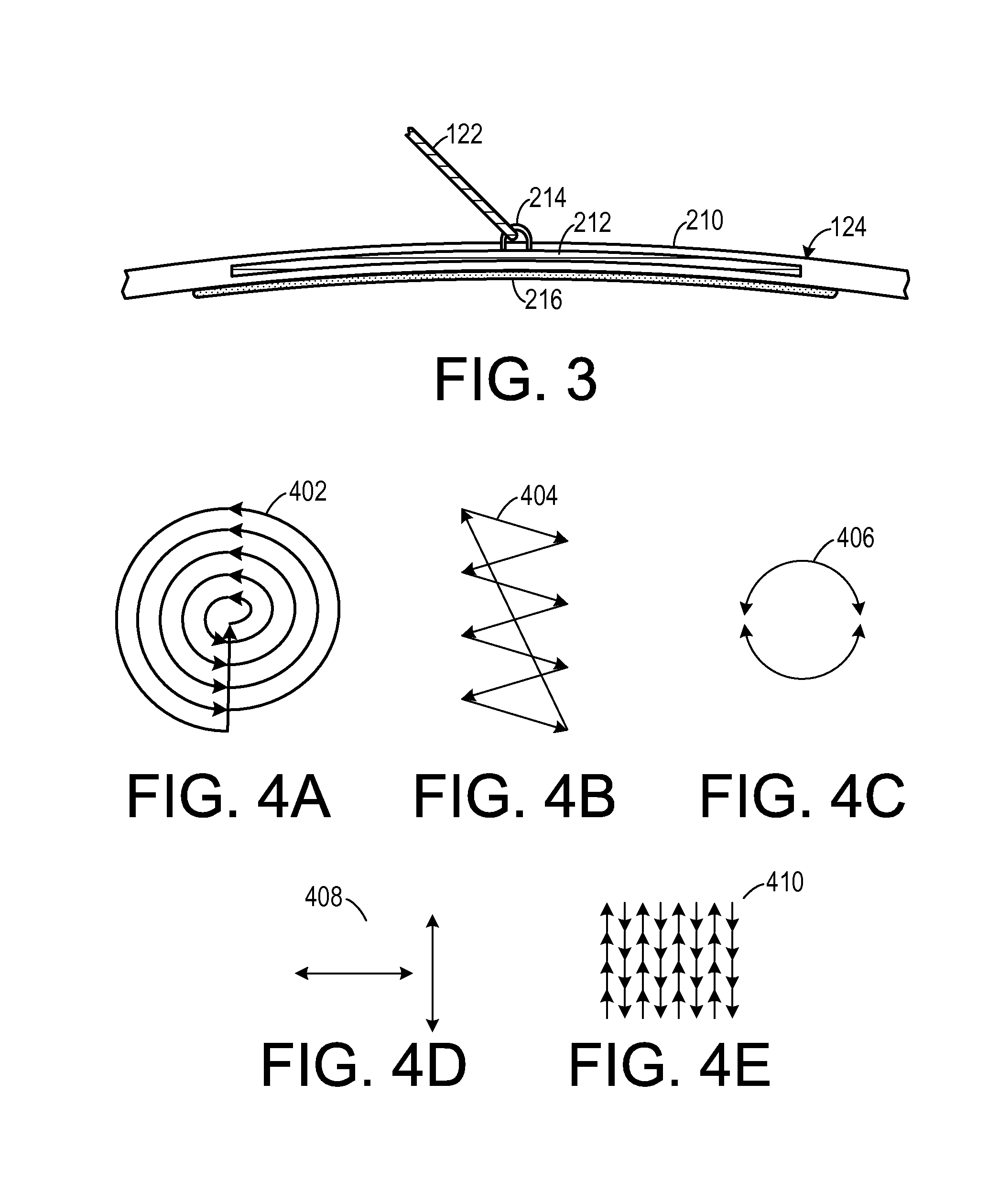

Spinal distraction device with three dimensionally vibrating matrix head

InactiveUS20080188780A1Overcome disadvantagesChiropractic devicesVibration massageDistractionEngineering

A spinal treatment system for applying a preselected force regimen to a spine of a patient includes a treatment bed, having a head end and a foot end, is configured to support the patient. A harness is configured to transmit force to a portion of the spine of the patient. A cable having a first end is coupled to the harness and is configured to apply force to the harness. A matrix head is coupled to the cable and is configured to apply a force, having a force magnitude and a force direction, to the cable, so that the force direction varies along more than one axis. A vertical displacement drive is disposed adjacent to the foot end of the treatment bed and is configured to support the matrix head and to displace the matrix head along a vertical axis. A computer is programmed to drive the vertical displacement drive and the matrix head.

Owner:NORTH AMERICAN MEDICAL CORPORTAION

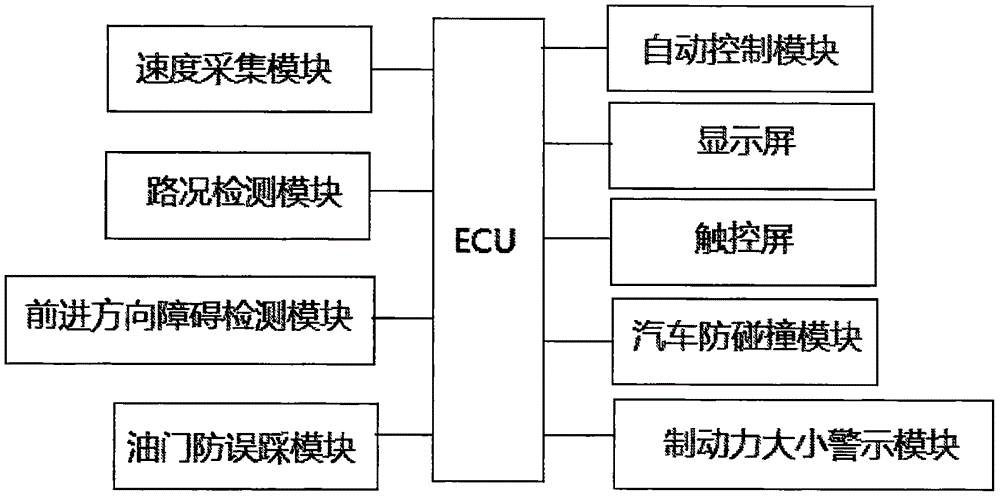

Automobile deceleration safety system

InactiveCN106080482AAdd to securityRealize automatic controlPedestrian/occupant safety arrangementAutomatic initiationsAutomatic controlRoad surface

The invention discloses an automobile deceleration safety system. The automobile deceleration safety system comprises a speed acquisition module, an automobile anti-collision module, an advancing direction obstacle detection module, a road condition detection module, an accelerator anti-mistaken-treading module, a braking force magnitude alarming module, an ECU and an automobile control module. The situations of an automobile, an obstacle and a road surface are comprehensively considered, the anti-collision function and the anti-mistaken-treading function are achieved, the safety of the automobile in the deceleration operating process is greatly improved, automatic control can be achieved, and use is convenient.

Owner:HENAN POLYTECHNIC

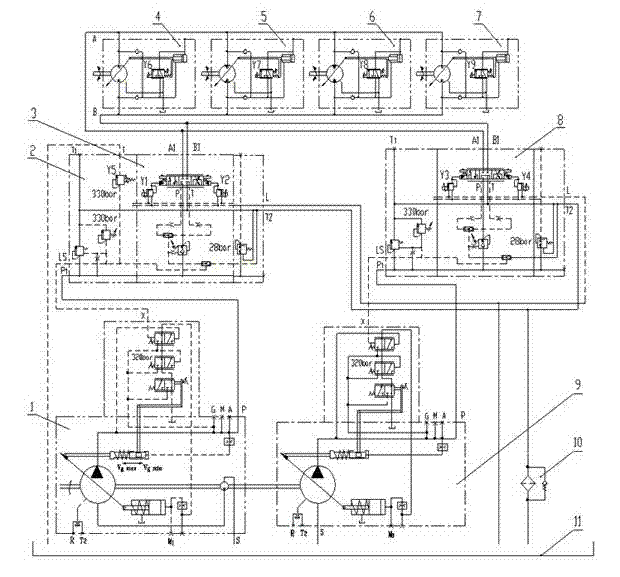

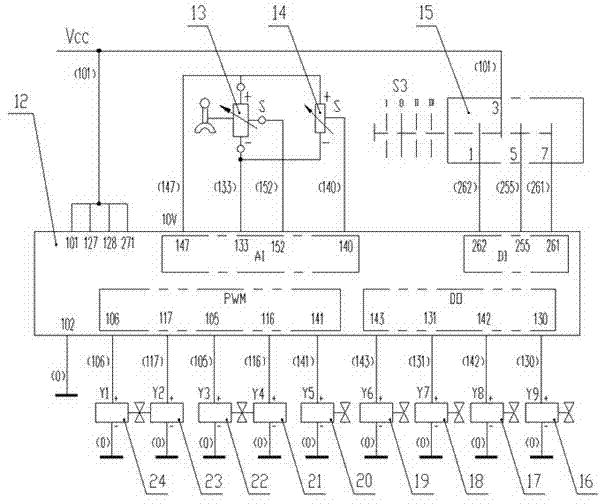

Control system for adjusting push-pull speed and push-pull force of horizontal directional drilling machine

ActiveCN104265705APrevent overflowAvoid breakingFluid-pressure actuator safetyServomotorsPull forceSolenoid valve

The invention provides a control system for adjusting push-pull speed and push-pull force of a horizontal directional drilling machine. A first push-pull pump (1) is in pipeline connection with a first push-pull main valve (3) through a push-pull pressure adjusting valve (2); a second push-pull pump (2) is in pipeline connection with a second push-pull main valve (8); the first push-pull main valve (3) and the second push-pull main valve (8) are respectively in pipeline connection with four push-pull motors; the four push-pull motors are all provided with electromagnetic valves; a push-pull handle (13), a push-pull pressure adjusting knob (14) and a push-pull speed selecting switch (15) are all connected with a controller (12) through circuits; and the controller (12) is connected with a push-pull pressure adjusting electromagnetic valve (20) on the push-pull pressure adjusting valve (2) and the electromagnetic valves on the four push-pull motors through circuits. The control system effectively guarantees multiple gears of selection speed for the pushing and pulling of a power head in the operation of the horizontal directional drilling machine, and can adjust the push-pull force magnitude of the power head according to the project scale.

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com