Control system for adjusting push-pull speed and push-pull force of horizontal directional drilling machine

A technology for directional drilling and level adjustment, which is applied in directional drilling, fluid pressure actuation system safety, fluid pressure actuation system components, etc., and can solve problems such as breaking or breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

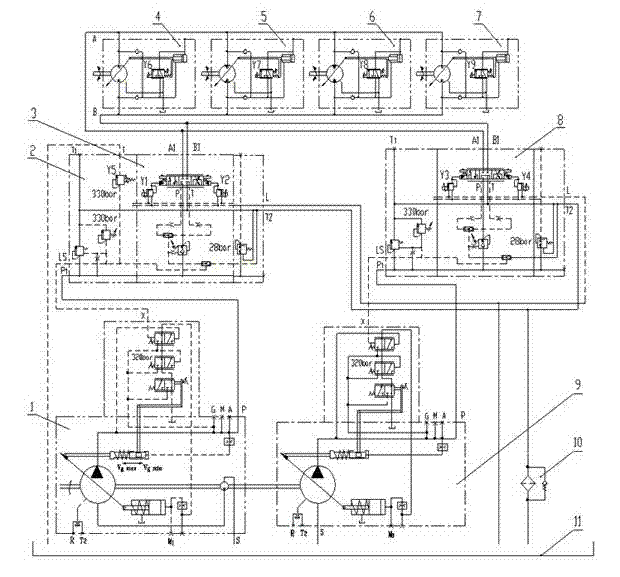

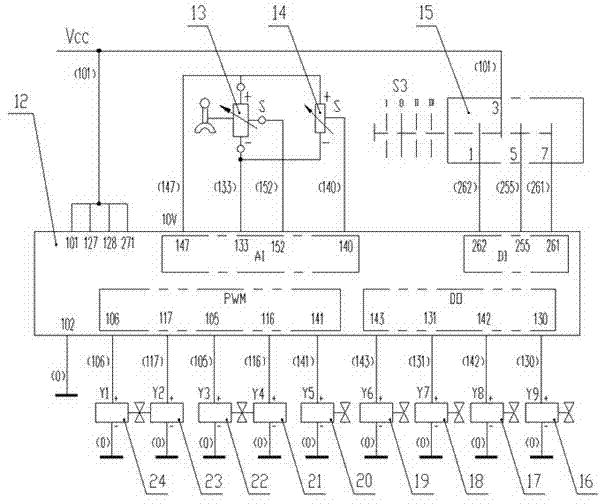

[0017] Such as Figure 1 to Figure 2 As shown, a control system for adjusting the push-pull speed and push-pull force of a horizontal directional drilling rig includes a hydraulic control part and an electrical control part. The hydraulic control part includes a first push-pull pump 1, a first push-pull main valve 3, a second Push-pull pump 9, push-pull pressure regulating valve 2, the first push-pull pump 1 is fixed on the engine through the connection plate, the second push-pull pump 9 is fixed on the rear end of the first push-pull pump 1 through the flange, the first push-pull pump 1 The P port of the push-pull pump 1 is connected with the P1 port of the push-pull pressure regulating valve 2 and the P1 port of the first push-pull main valve 3 through the pipeline, and the X port of the first push-pull pump 1 is connected with the LS port of the push-pull pressure regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com