Electric cooker and rice-cooking heating control method

A technology of heating control and rice cooker, which is applied in the direction of electrical program control, temperature control by electric method, program control in sequence/logic controller, etc. It can solve the problems of rice sandwiching, bubbling, overflowing steam outlet, etc., and achieve control Heat transfer, anti-overflow effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

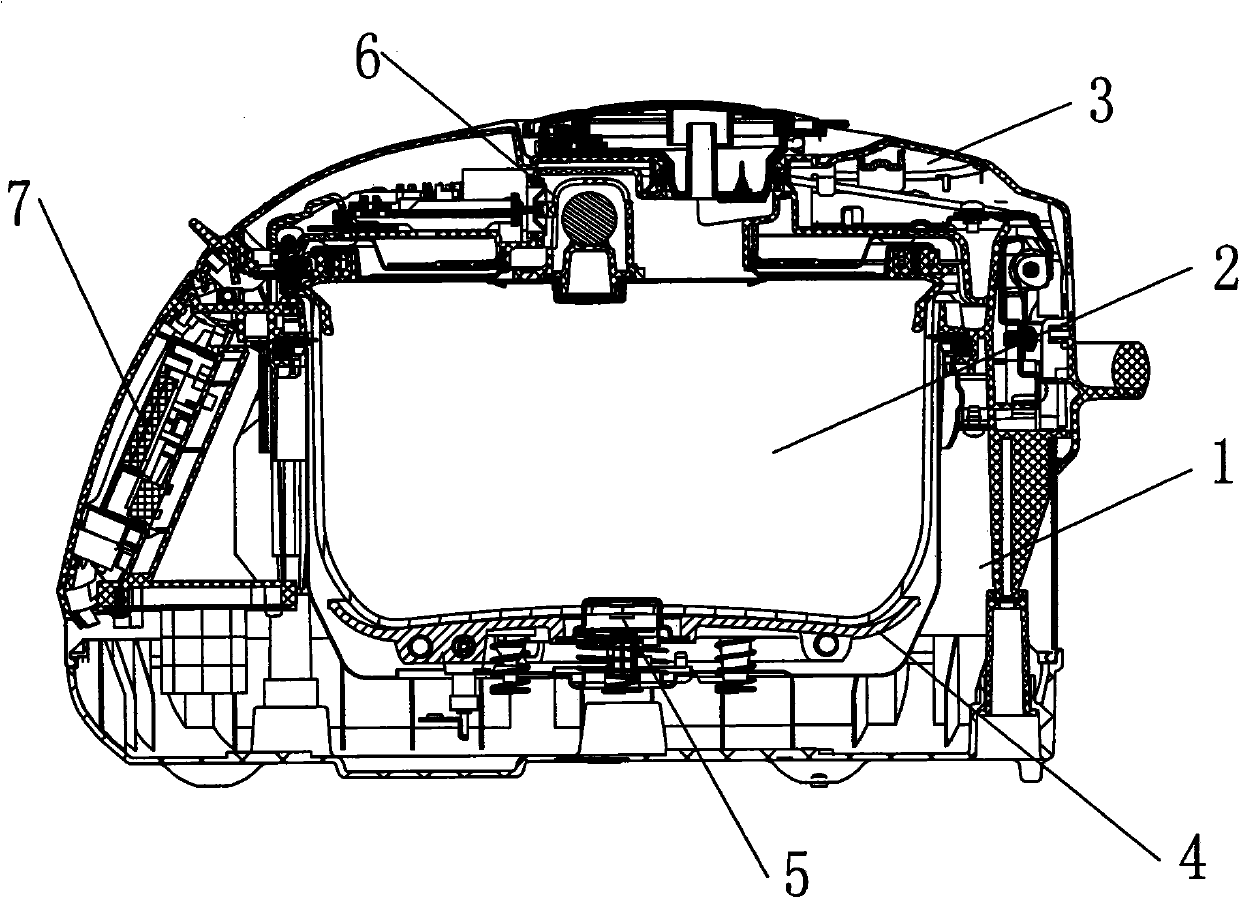

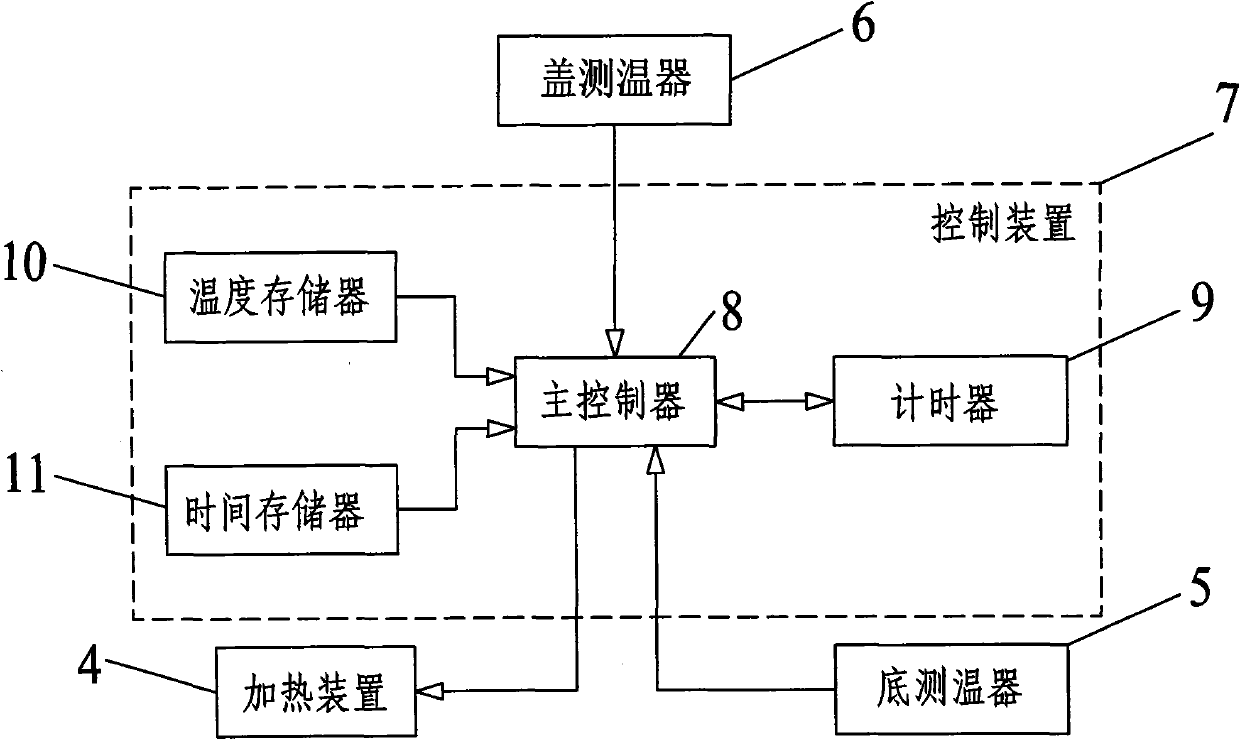

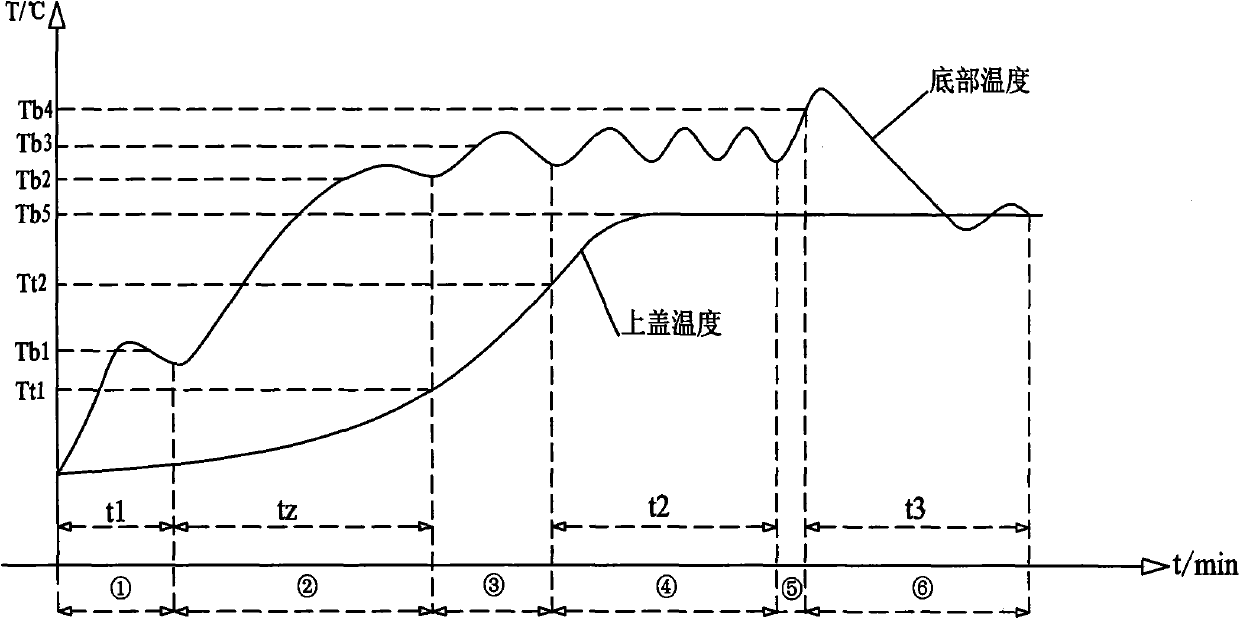

[0027] The structure diagram of the present invention is as figure 1 , figure 2 As shown, it includes a pot body 1, an inner container 2 placed in the pot body 1 for holding food, an upper cover device 3 for sealing the inner container 2, a heating device 4 for heating the inner container and food, The bottom temperature detector 5 arranged outside the bottom of the inner container for detecting the temperature of the inner container, the cover temperature detector 6 arranged in the upper cover device for detecting the temperature of the upper cover, and the control device 7 for controlling the cooking work, the control device 7 It includes an integrated main controller 8, a timer 9, a temperature memory 10 and a time memory 11, the timer 9, temperature memory 10, and time memory 11 are respectively connected to the main controller 8, and the bottom temperature detector 5 and the cover temperature measurement The output terminal of the device 6 is connected with the input te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com