Patents

Literature

173results about How to "Fully evaporated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric cooker and rice-cooking heating control method

ActiveCN101766439ATransfer of controlEffective control transferBoiling over preventionTemperature control using electric meansThermodynamicsRice dishes

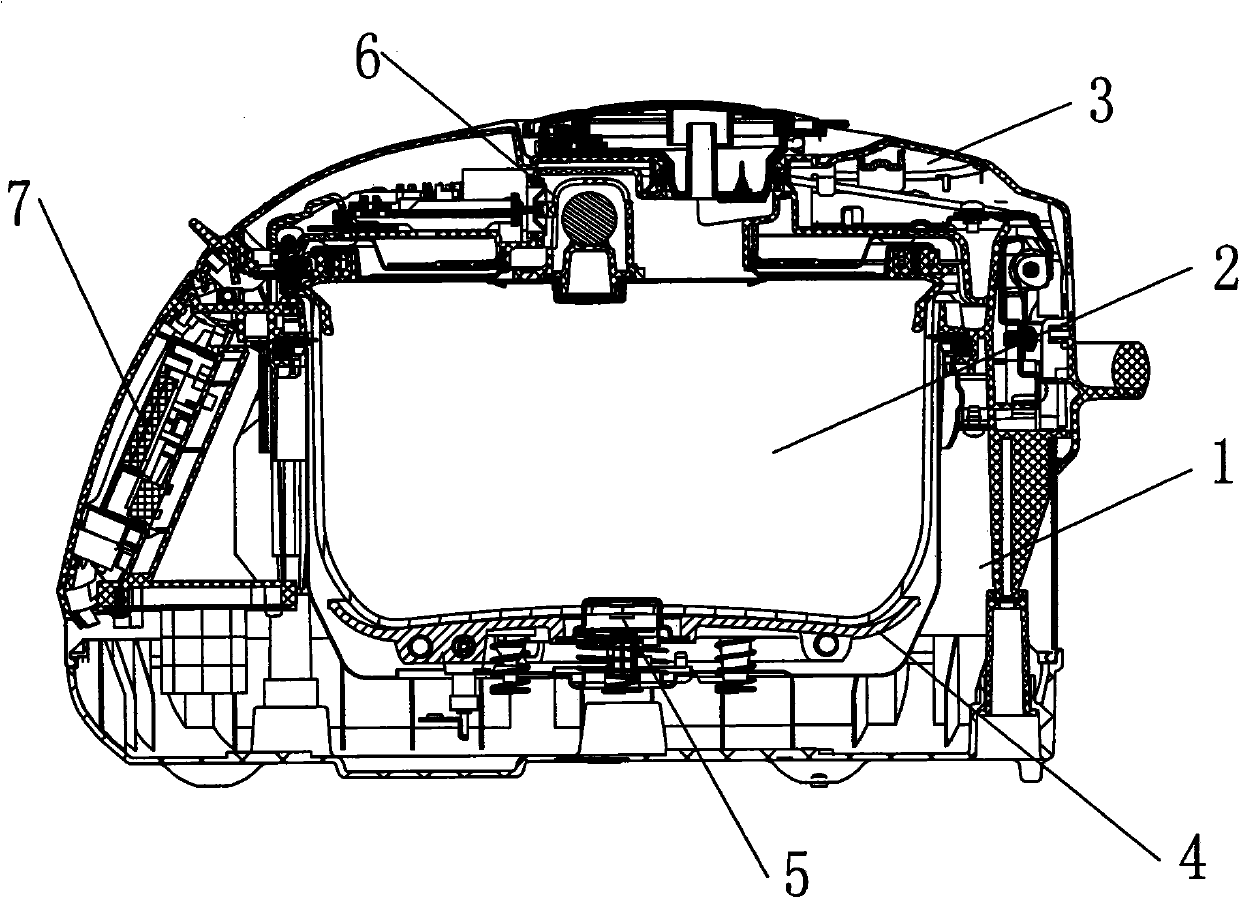

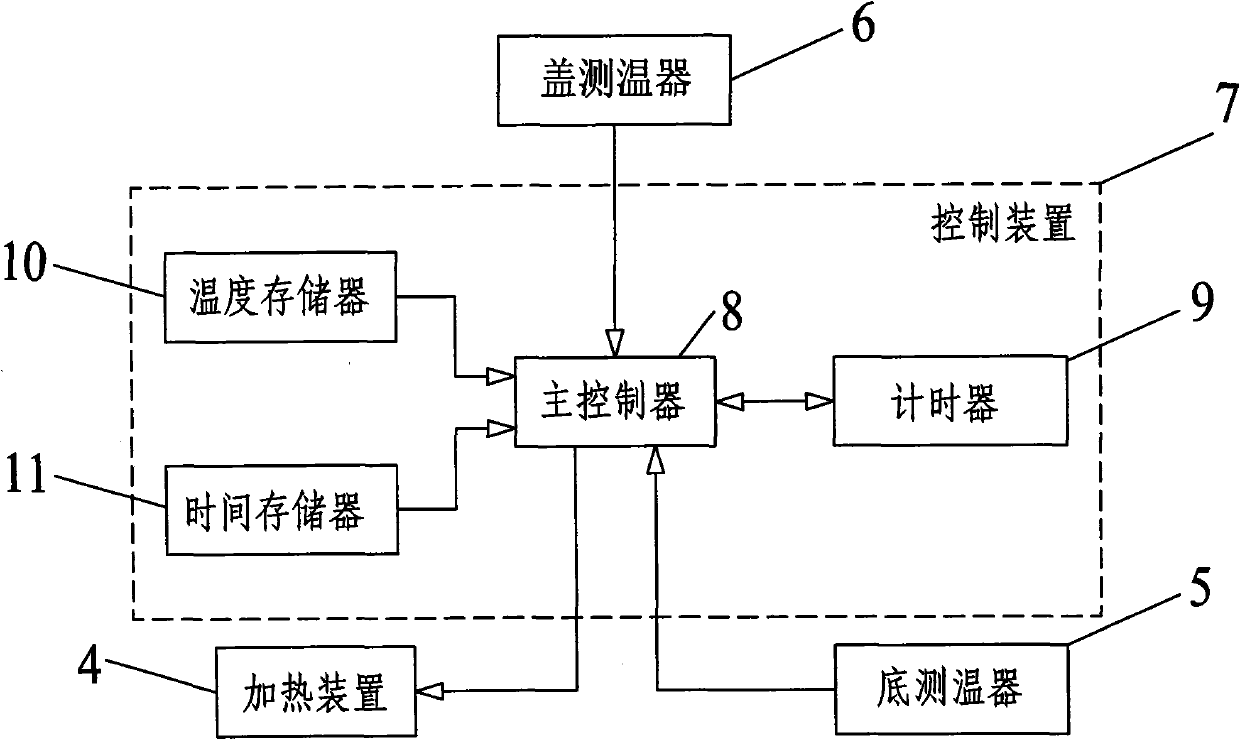

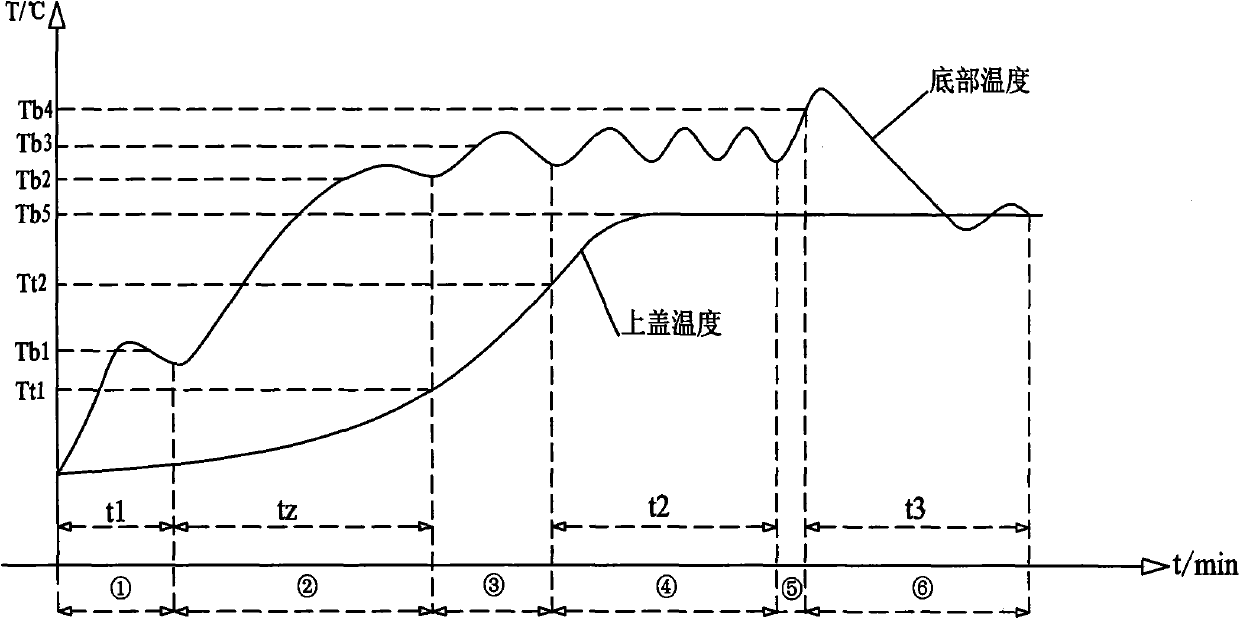

The invention relates to an electric cooker and a rice-cooking heating control method. The electric cooker comprises a cooker body, an inner container, an upper cover device, a heating device for heating the inner container and food; wherein the outside of the bottom of the inner container is provided with a bottom temperature detector for detecting temperature of the inner container, the upper cover device is provided with a cover temperature detector for detecting temperature of the upper cover and a control device for controlling rice cooking; the control device comprises a main controller and a timer and a memory respectively connected with the main controller; the output terminals of the bottom temperature detector and the cover temperature detector are connected with the input terminal of the main controller, the output terminal of the main controller is electrically connected with the heating device. The rice-cooking control method of the invention at least comprises a first heating phase, a second heating phase and a first boiling phase; wherein in the second heating phase, heating temperature and heating time of the first boiling phase is determined by heating time of the first heating phase, so that moisture of small amount of rice can be fully evaporated and overflow can be prevented; in addition, early termination of heating due to abnormal conditions at the bottom of the inner container in the case of large amount of rice can be avoided, thus ensuring enough heating to ripen the rice.

Owner:MIDEA GRP CO LTD

Method for controlling rice steaming and boiling of electric rice cooker

ActiveCN101587330ARaise the temperature gradientFully gelatinizedProgramme control in sequence/logic controllersWarming devicesRice dishesTemperature difference

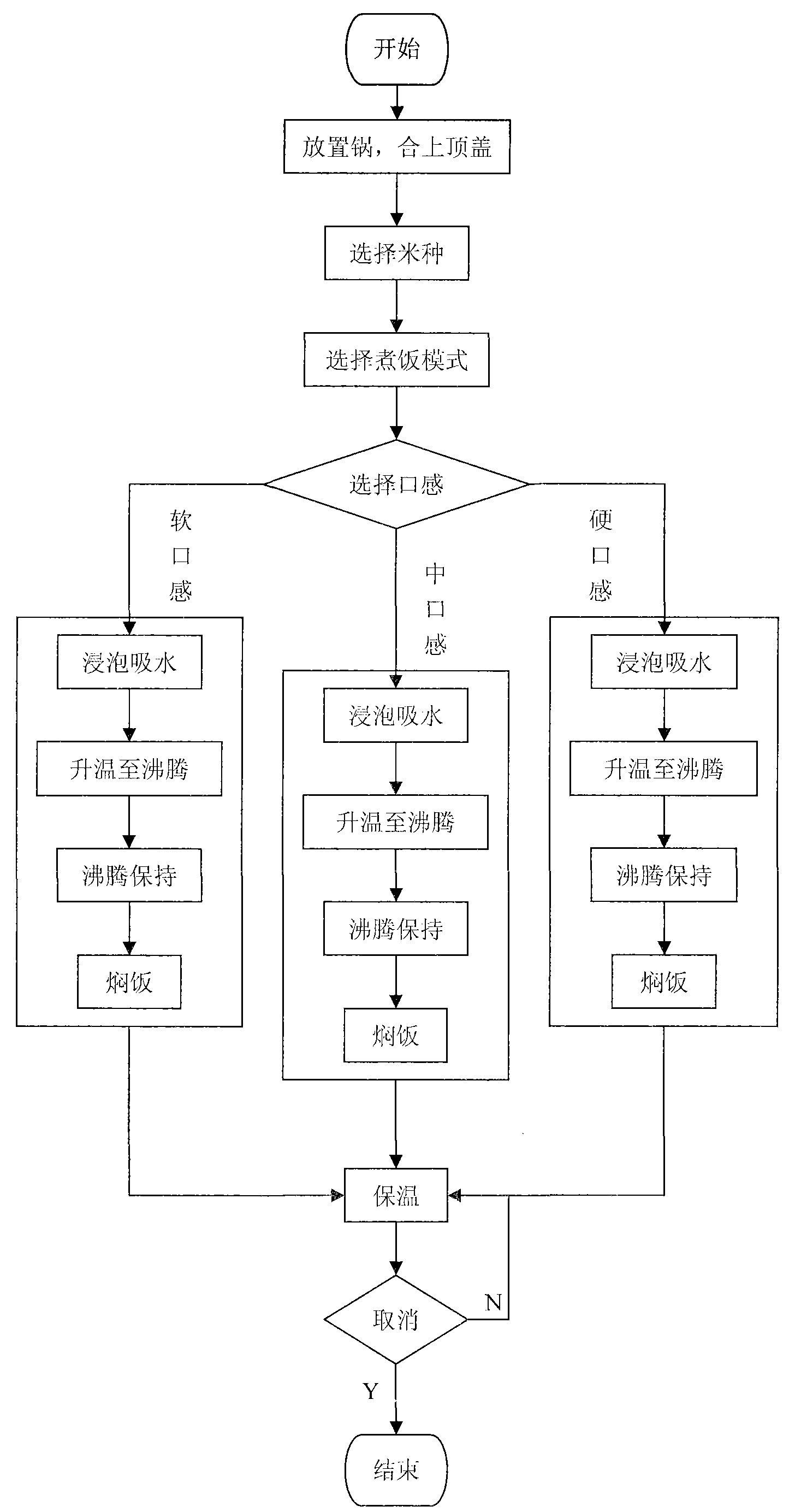

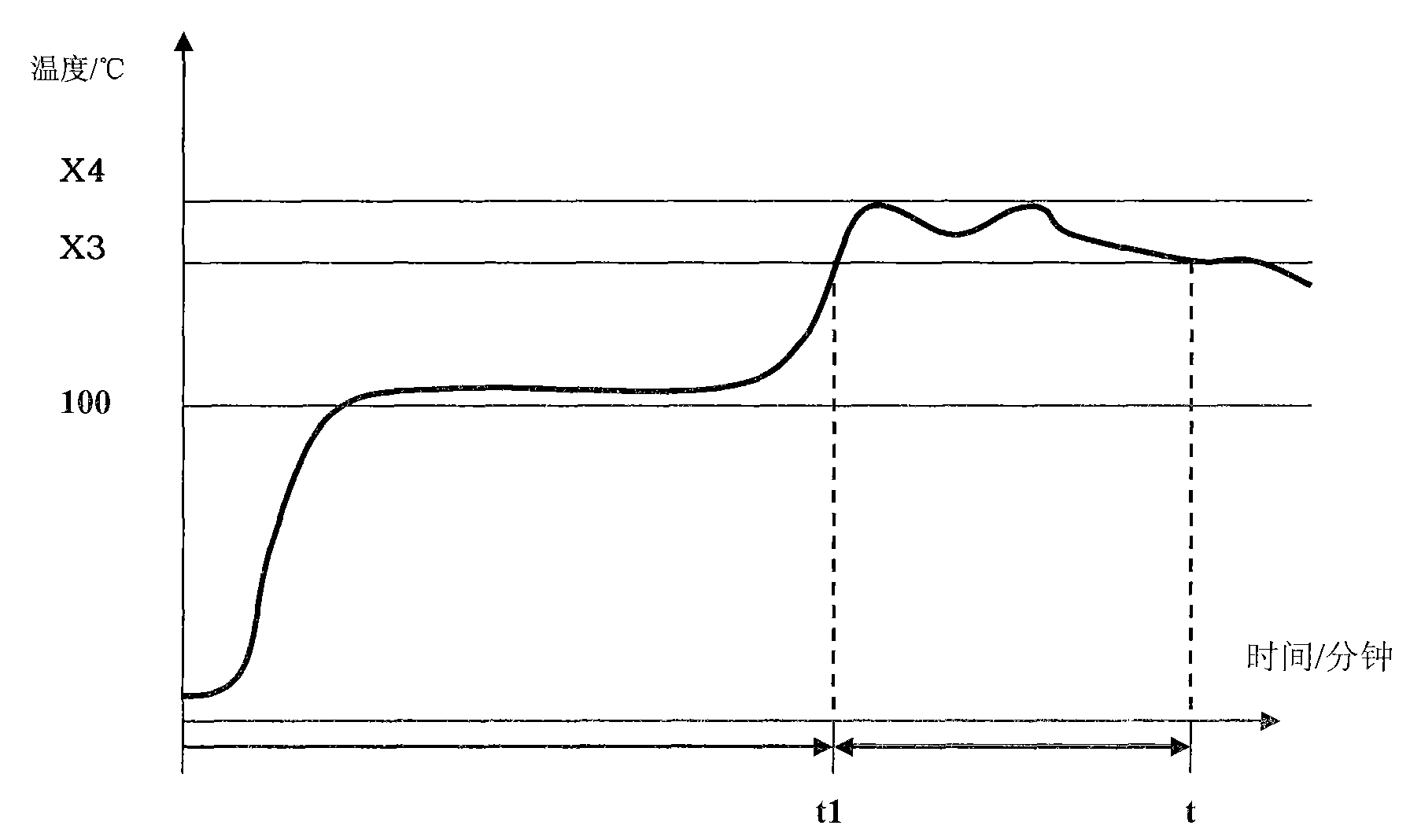

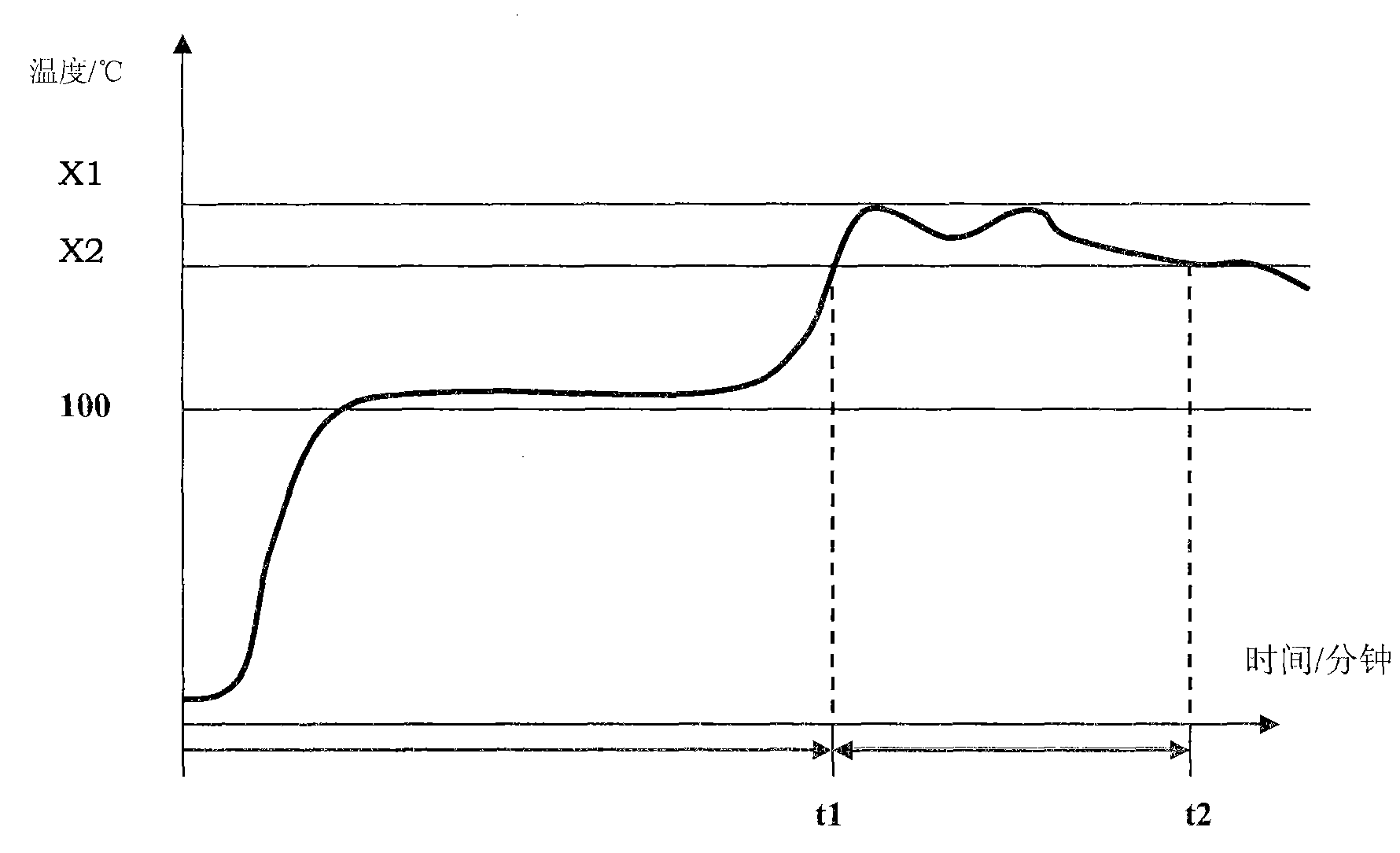

The invention relates to a method for controlling the rice steaming and boiling of an electric rice cooker, which comprises the following steps: (1) confirming the boiling maintenance time t and the boiling maintenance temperature X of the electric rice cooker according to different rice kinds and mouth feeling; (2) starting the electric rice cooker and soaking, dewatering, heating and boiling rice according to a set procedure; (3) achieving the boiling maintenance temperature X= 130-165 DEG C after time t1=15-35 min and maintaining boiling in the electric rice cooker for the maintenance time t=6-10 min; and (4) cooking the rice after achieving the maintenance time t. The invention provides the method for controlling the rice steaming and boiling of the electric rice cooker, which controls the temperature and the time in the process of boiling maintenance, improves a temperature difference between the electric rice cooker and rice boiling, enables the rice to be fully gelatinized and enables water to be fully vaporized and absorbed by rice grains, thereby boiling the rice with high quality.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

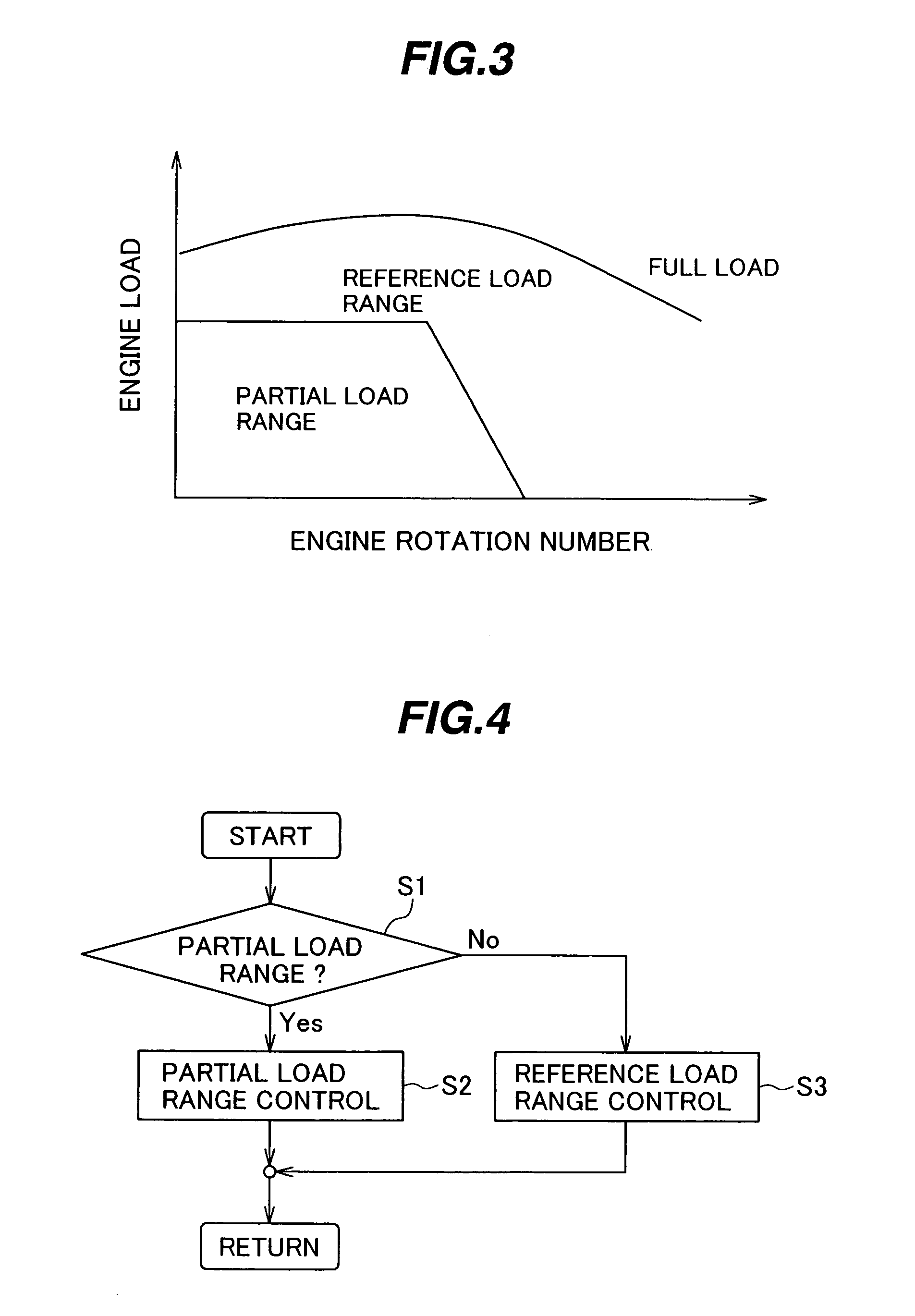

Control device and control method for direct injection engine

ActiveUS7089908B2Sufficiently vaporizedImprove combustion stabilityValve arrangementsElectrical controlCombustion chamberExhaust valve

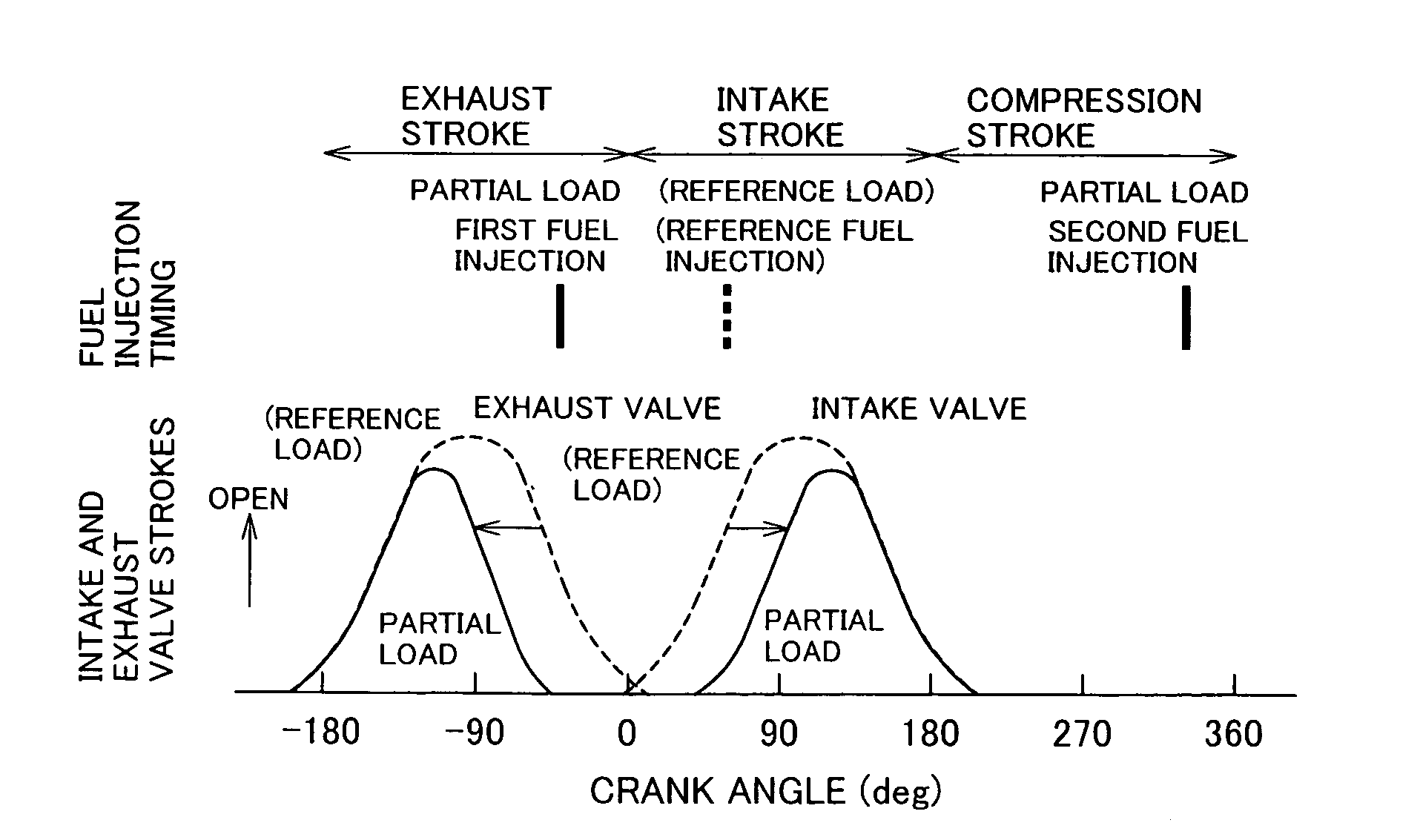

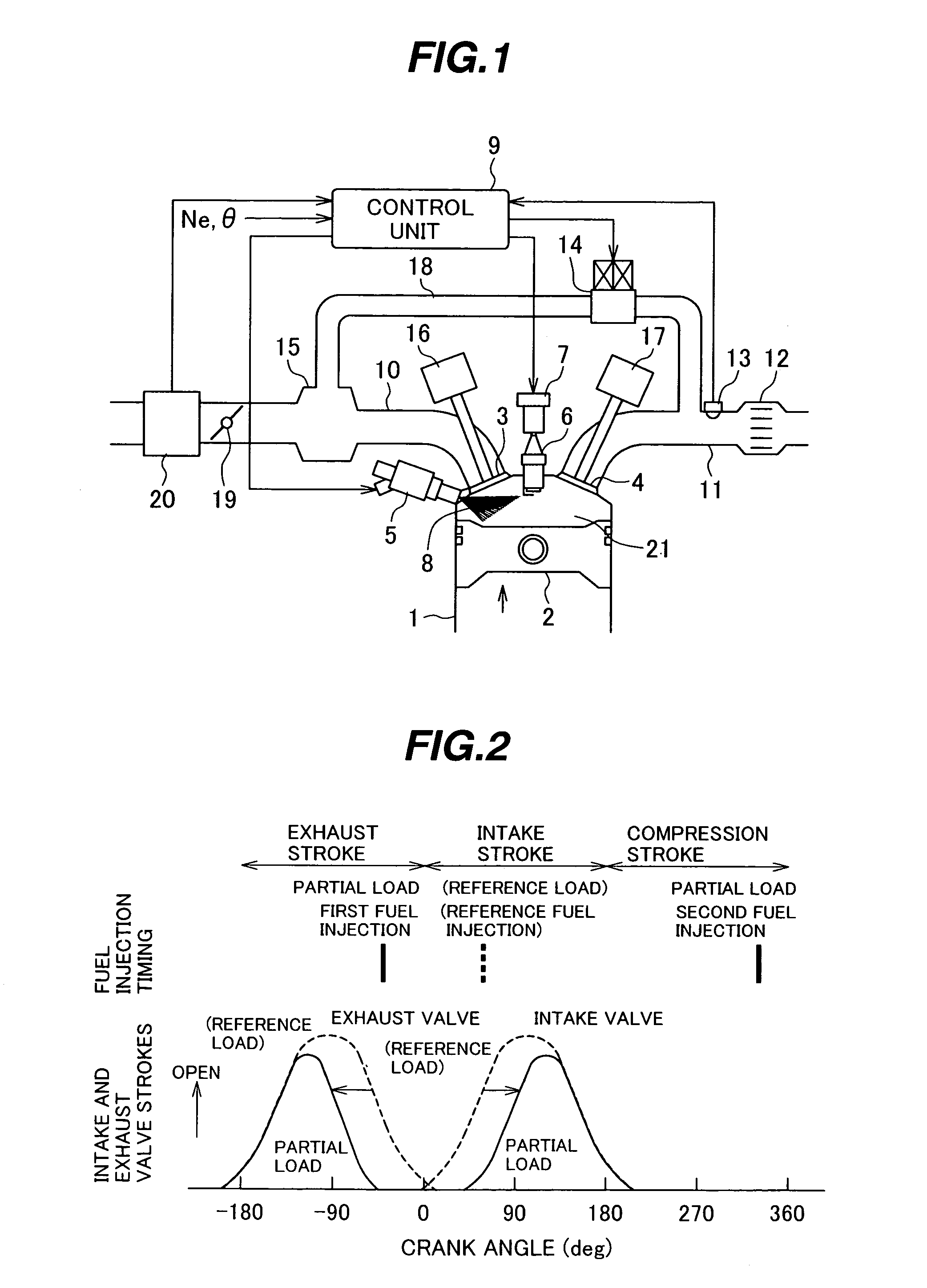

A combustion control device and a method for a direct injection engine are disclosed wherein, when the engine is operating in the partial load range, the valve opening / closing mode of an intake valve and / or an exhaust valve is controlled so that exhaust gases remain in a combustion chamber; and control is performed such that fuel is injected from a fuel injection valve into residual exhaust gases at least once during the time period from the latter half of an exhaust stroke to the first half of an intake stroke in one combustion cycle, and that an air-fuel mixture is ignited in the latter half of a compression stroke thereafter.

Owner:HITACHI ASTEMO LTD

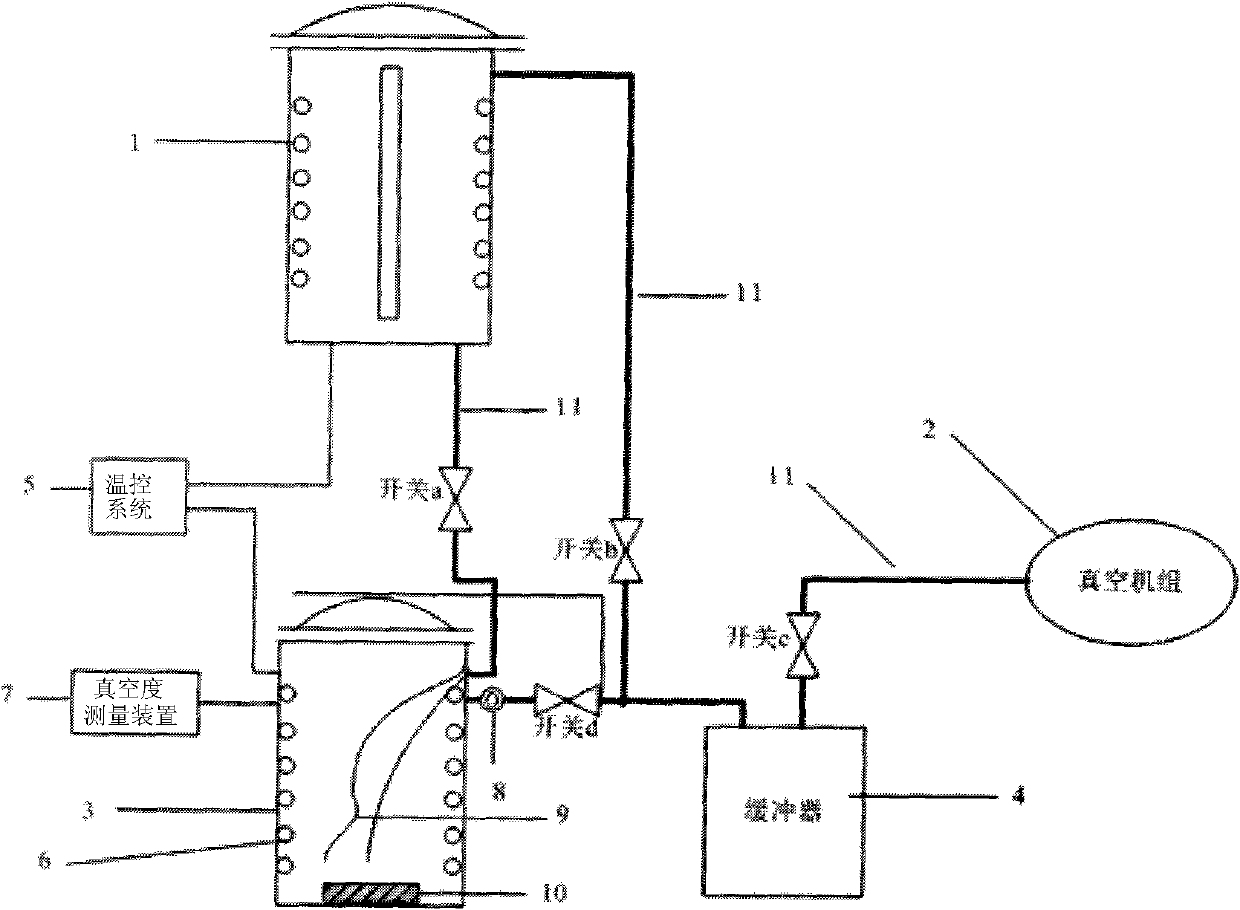

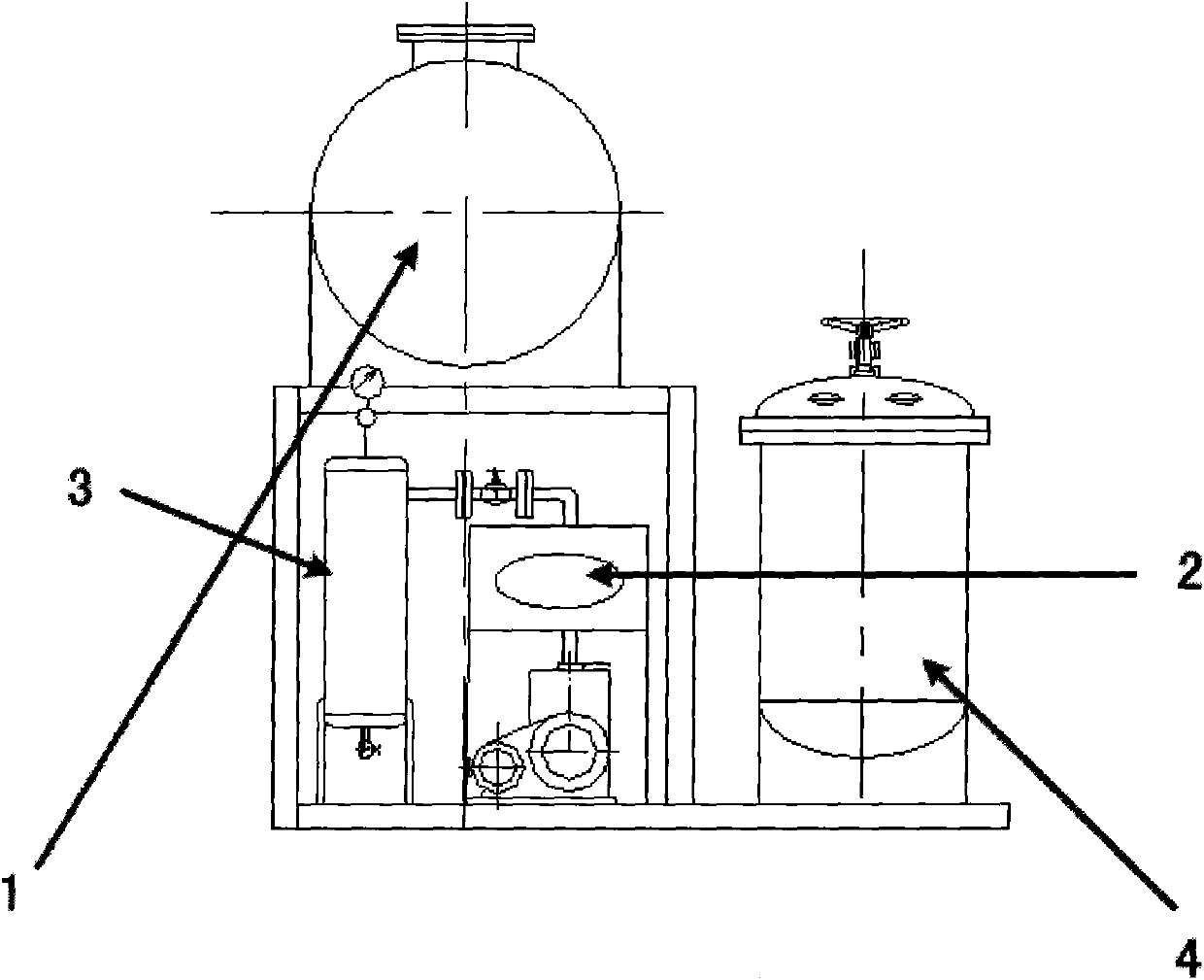

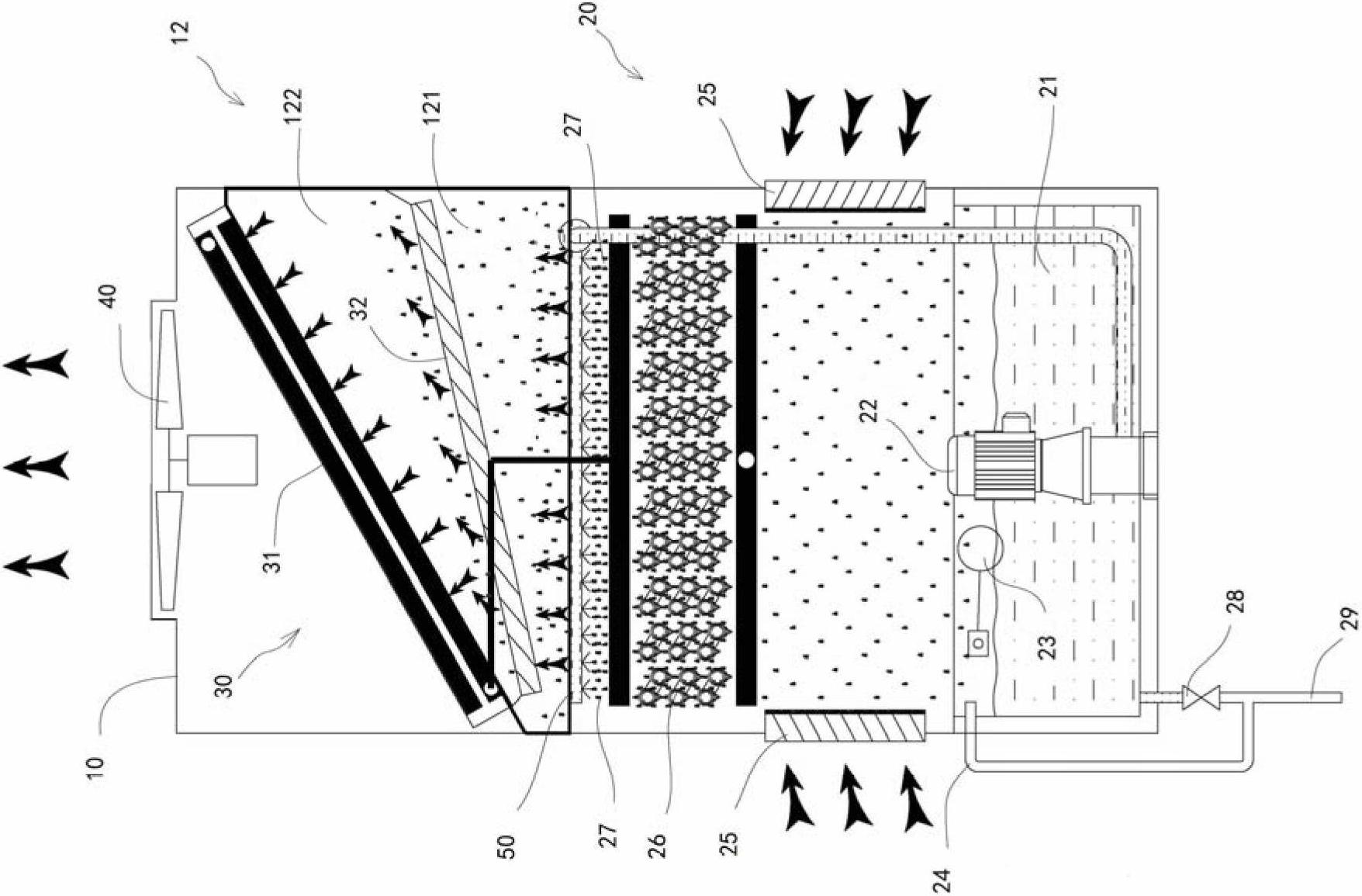

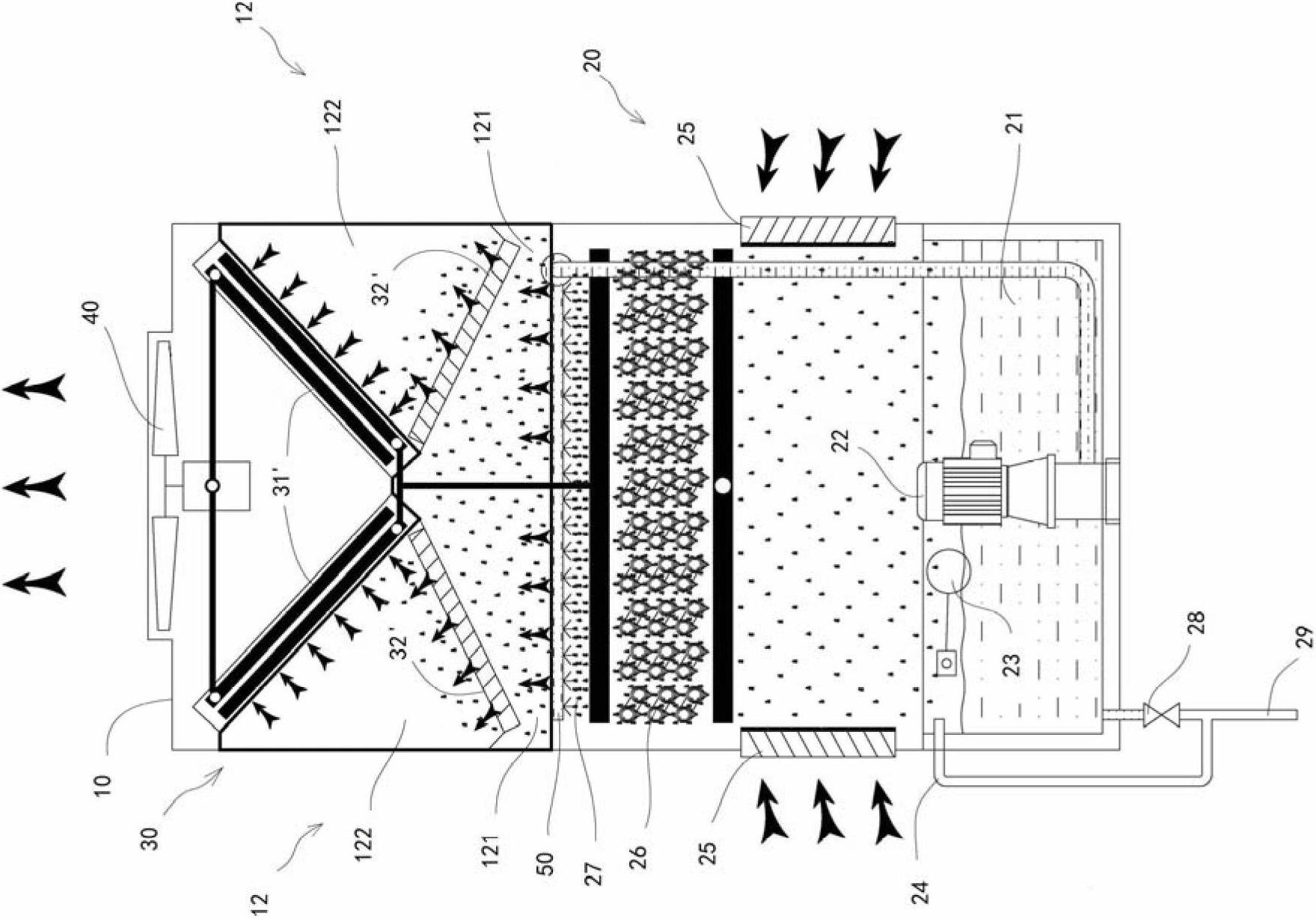

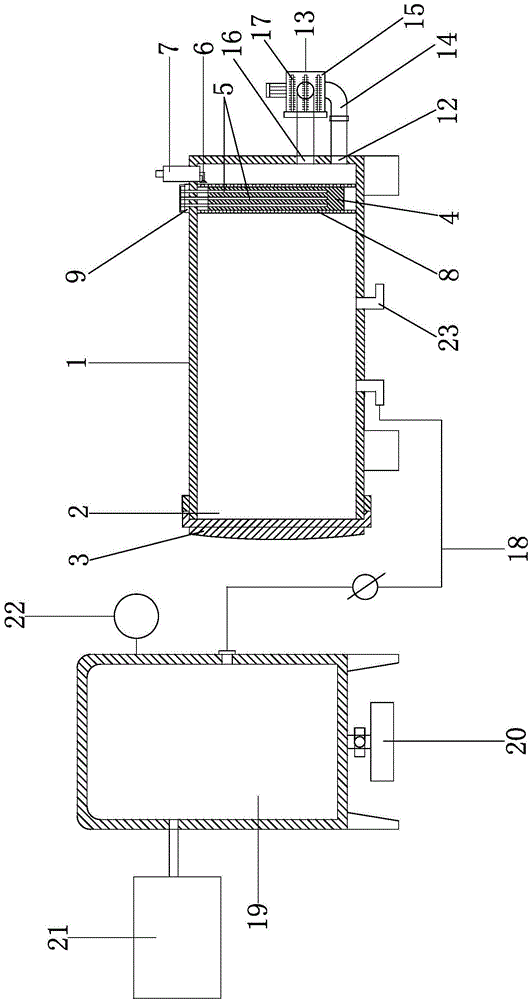

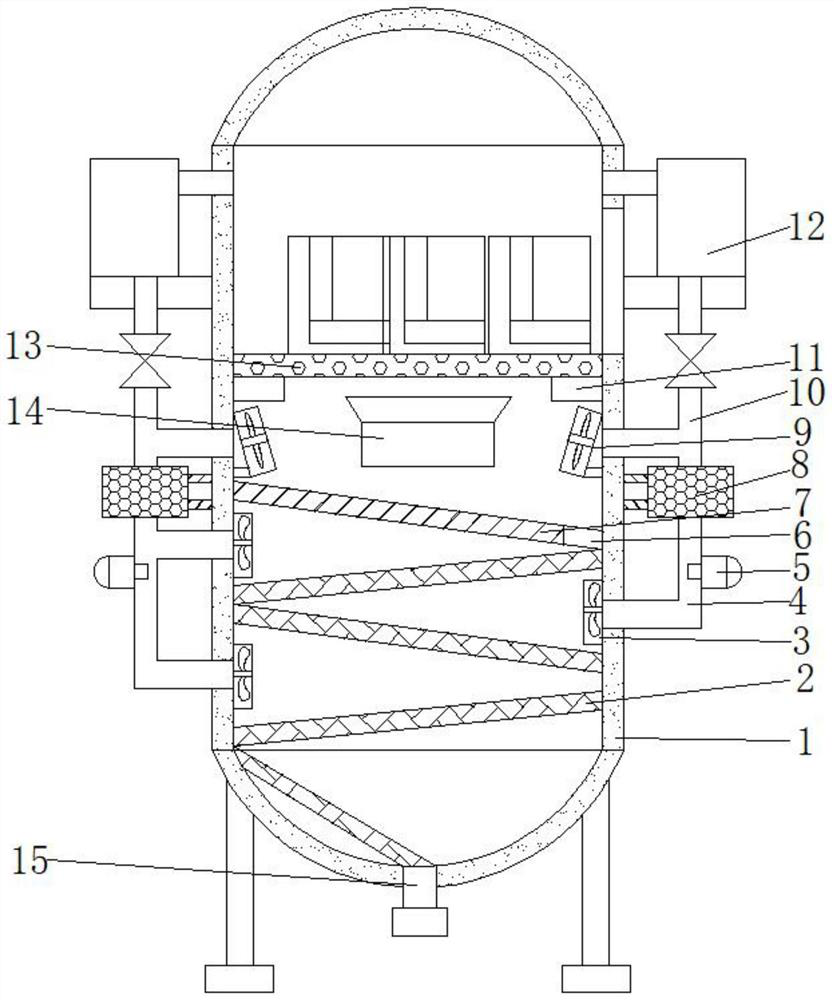

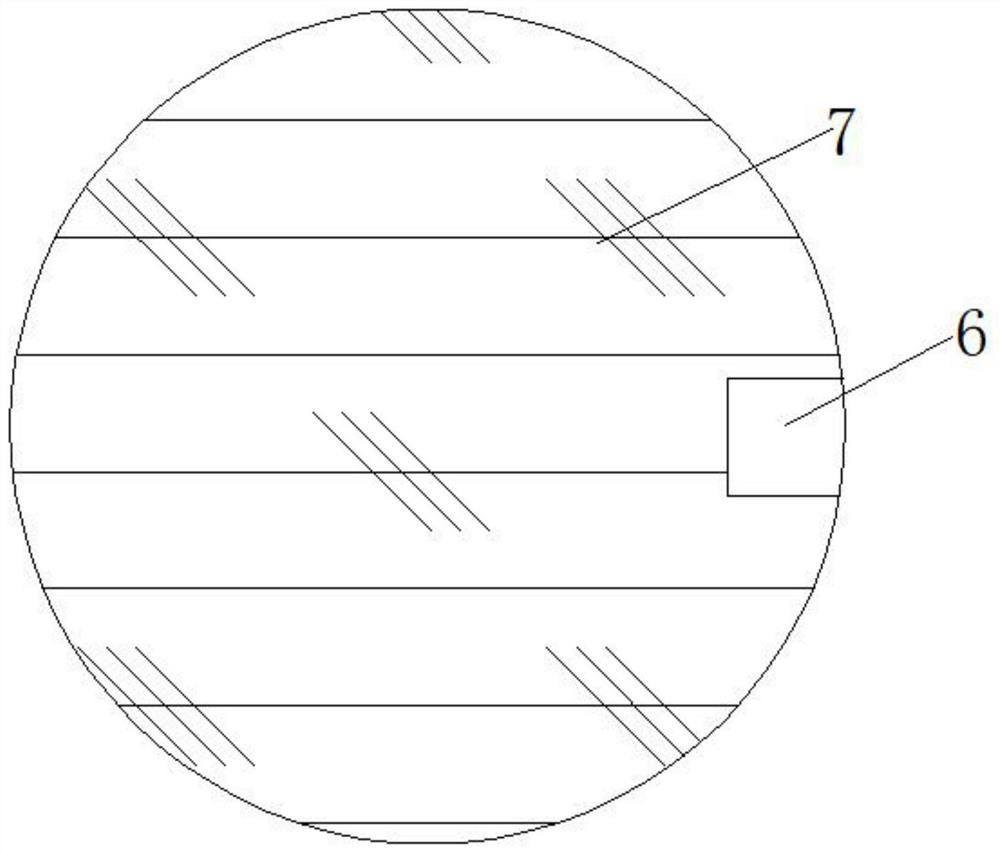

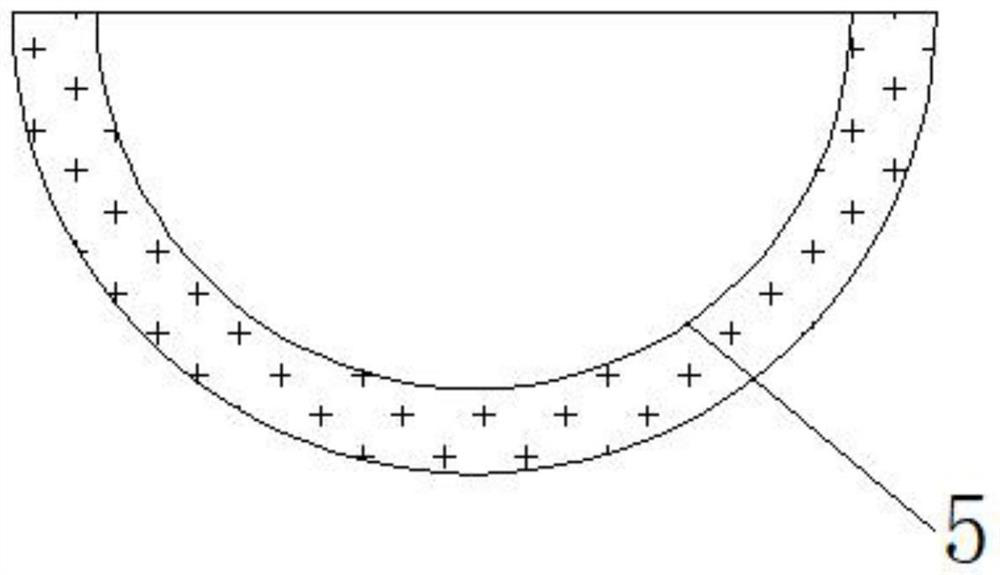

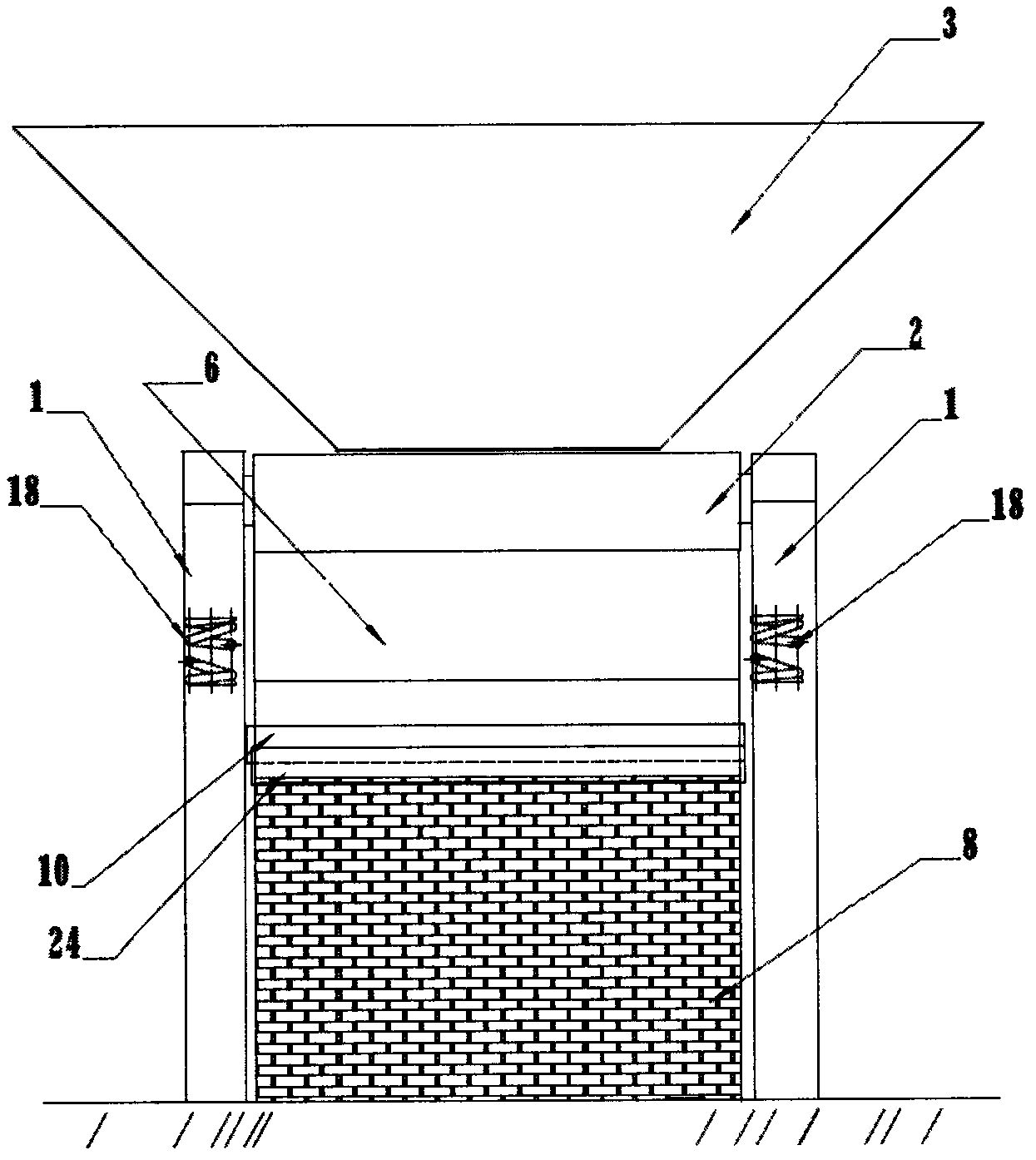

Vacuum insulation oil impregnating device and method thereof

The invention provides a vacuum insulation oil impregnation device and a method thereof. Vacuum oil impregnation is carried out by a liquid level difference method; an oil storage tank is higher than an oil impregnation tank; when the vacuum oil impregnation device works, the vacuum oil impregnation device can fully evaporate the interior of a sample in a high-temperature ultimate vacuum approaching state; after the dryness meets the requirement, a valve for connecting the oil storage tank and the oil impregnation tank is opened; and because the two tanks are all positioned in the ultimate vacuum approaching state, the insulating oil of the oil storage tank automatically flows into the oil impregnation tank under the action of gravity. The device and the method have the advantages that: the defects of the conventional air pressure difference method are avoided, the vacuum degree of the two tanks is kept unchanged, extra gas cannot enter an insulating carton and the transformer oil, oil foam cannot be generated in the oil impregnation process, the moisture inside the solid insulating material is ensured to be fully evaporated, a cavity inside the solid insulating material can be fully filled with a liquid insulating material, the insulating material treatment effect is improved, and the accuracy of the subsequent test conclusion is ensured.

Owner:CHINA ELECTRIC POWER RES INST +1

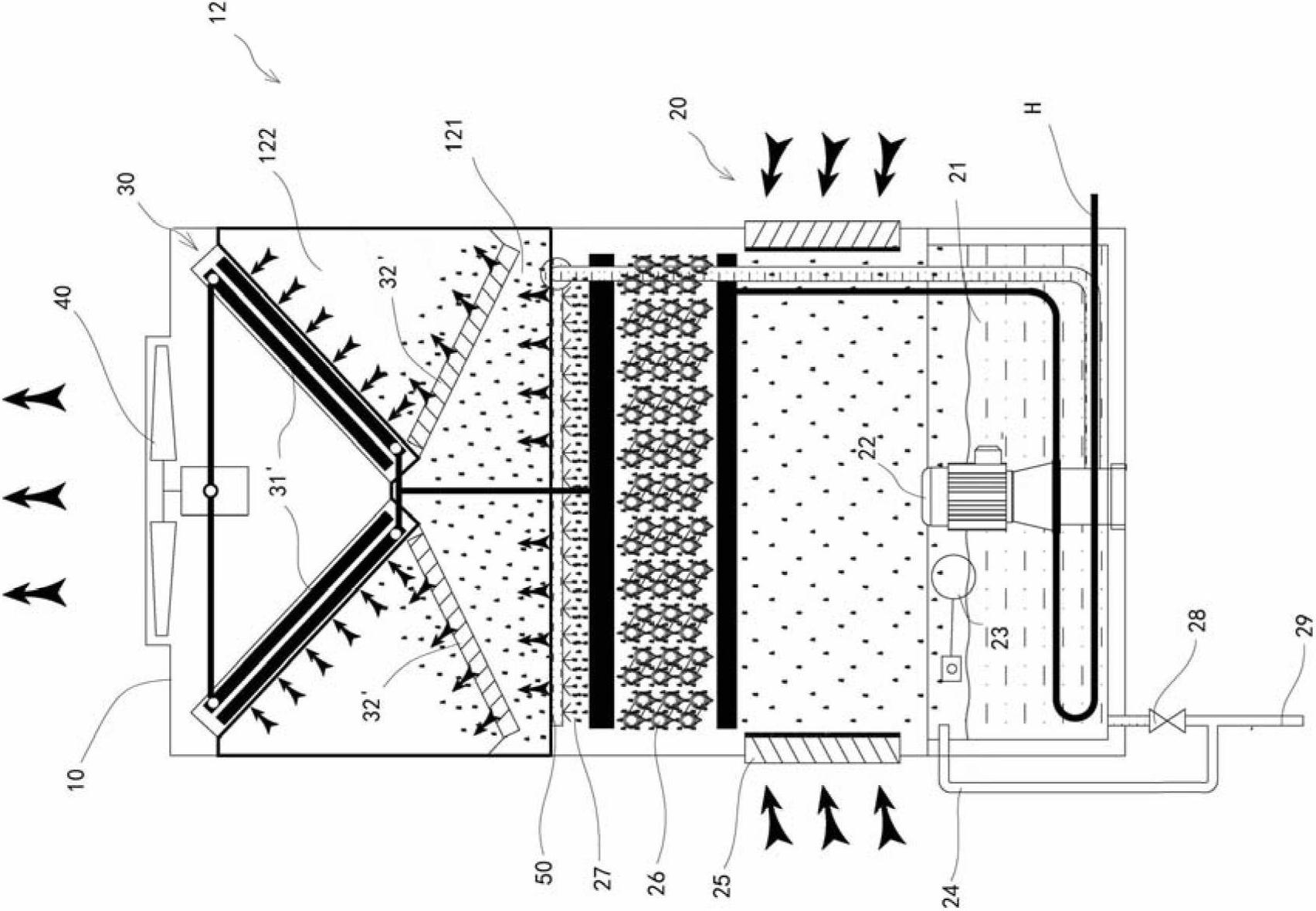

Evaporative condensing and cooling device

ActiveCN102650503AEliminates Legionella GrowthReduce air velocityStationary conduit assembliesEngineeringEnvironmental humidity

The invention relates to an evaporative condensing and cooling device, which comprises a tank body divided into an upper segment and a lower segment, an air inlet and an air outlet, wherein the area of the inner section of the upper segment is larger than the area of the inner section of the lower segment, so as to enable the upper segment of the whole tank body to form a static pressure tank; an evaporative condensing unit formed by a water collecting tank, a first heat exchanger, a spraying device and a water pump is arranged at the inner part of the lower segment of the tank body; a demisting component comprising a second heat exchanger connected in series with an outlet of the first heat exchanger and a wind direction deflecting plate is arranged in the static pressure tank at the upper segment of the tank body; the evaporative condensing and cooling device further comprises a fan arranged in position suitable for providing negative pressure for the evaporative condensing device; air is enabled to enter the tank body from the air inlet at a low first speed, and rises through the first heat exchanger of the evaporative condensing unit, so that saturated water vapor entrained with water drops enters the static pressure tank to be subject to water-vapor separation; and then moisture in the saturated water vapor is evaporated by the second heat exchanger in the demisting component, and the water vapor becomes gas with humidity not higher than the environmental humidity nearby the air outlet and is then discharged from the air outlet, thereby avoiding a water mist problem from occurring around the device.

Owner:上海与进智能科技有限公司

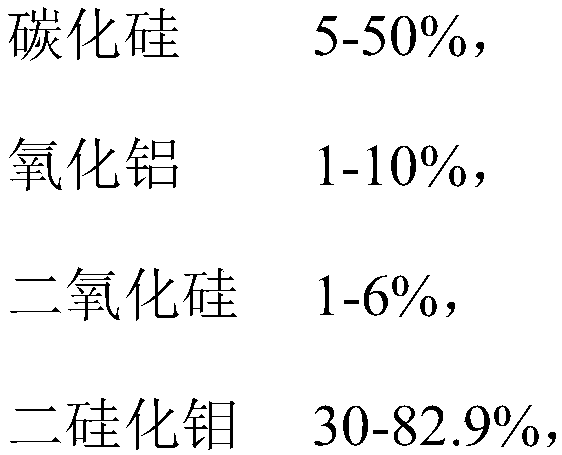

Porous ceramic heating element used for electronic cigarette and preparation method of porous ceramic heating element

The invention discloses a porous ceramic heating element used for an electronic cigarette and a preparation method of the porous ceramic heating element. Electrodes are welded on the two ends of a porous ceramic matrix to obtain the porous ceramic heating element used for the electronic cigarette. The porous ceramic matrix is mainly prepared by preparing silicon carbide, alumina, silicon dioxide,molybdenum disilicide, magnesium oxide and a pore-forming agent in a certain proportion, then forming, sintering and other processes. The electrodes are formed by a metallized layer process. The porous ceramic heating element has a simple process and a stable structure and has no need for burying heating wires. The porous ceramic heating element can generate heat by itself, is uniform in heating and high in thermal conductivity, tobacco tar adsorbed in gaps can be heated evenly, and thus the heating uniformity, the heating efficiency and the taste of the electronic cigarette are all effectively improved.

Owner:广东国研新材料有限公司

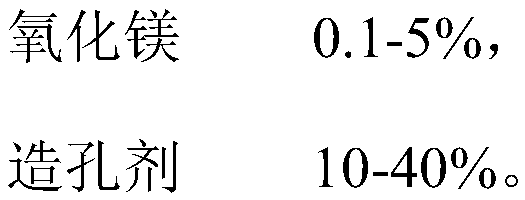

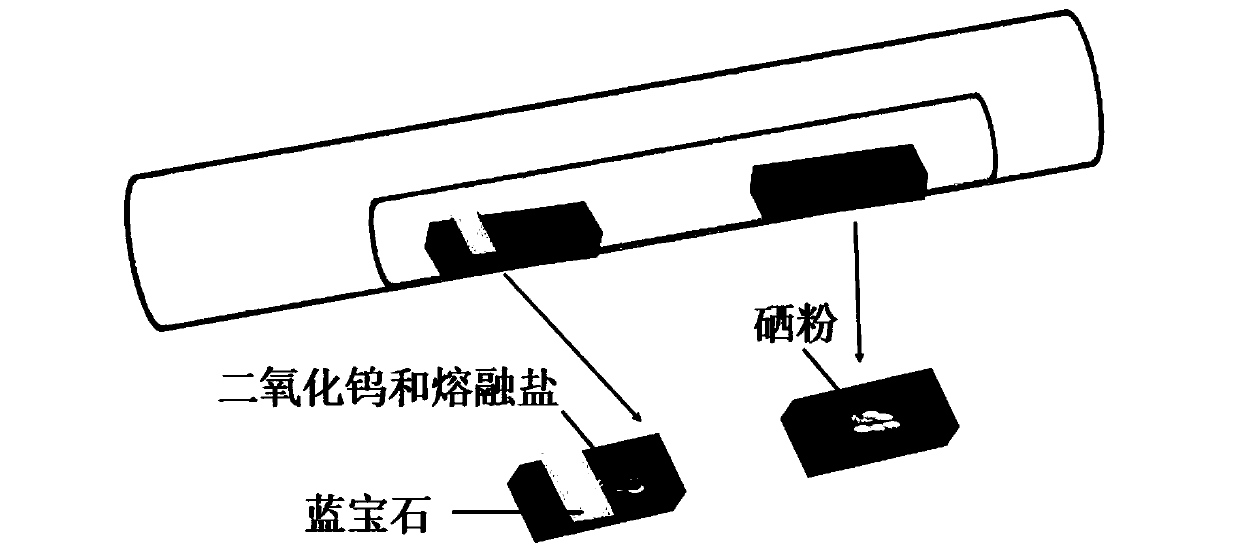

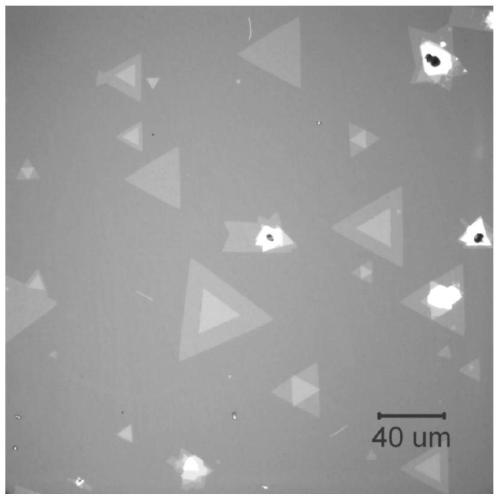

Method for growing multilayer tungsten diselenide single crystal by molten salt assisted chemical vapor deposition

ActiveCN111304738AAchieve single crystal growthEasy to operate and controlPolycrystalline material growthAfter-treatment detailsSource materialPhysical chemistry

The invention belongs to the field of two-dimensional materials. The invention discloses a method for growing a multilayer tungsten diselenide single crystal by molten salt assisted chemical vapor deposition. According to the method, a preset temperature condition is utilized, when a small reaction chamber is under the preset temperature condition, a halide can be molten and react with a tungstensource material to generate an intermediate product with the melting point lower than that of the tungsten source material, and a carrier gas flow can carry gaseous selenium generated by a selenium source material and gaseous tungsten generated by the intermediate product to grow the multi-layer tungsten diselenide single crystal on a substrate based on the chemical vapor deposition principle. According to the invention, key reaction participants and the reaction chamber of the preparation method are improved, halide and a tungsten source material are mixed to participate in reaction, halide molten salt and the tungsten source material react to generate an intermediate product with the melting point lower than that of the tungsten source material, chemical vapor deposition can be effectively controlled to grow the multilayer tungsten diselenide single crystal, the controllability is good, and a multilayer tungsten diselenide single crystal with a large size can be prepared.

Owner:HUAZHONG UNIV OF SCI & TECH

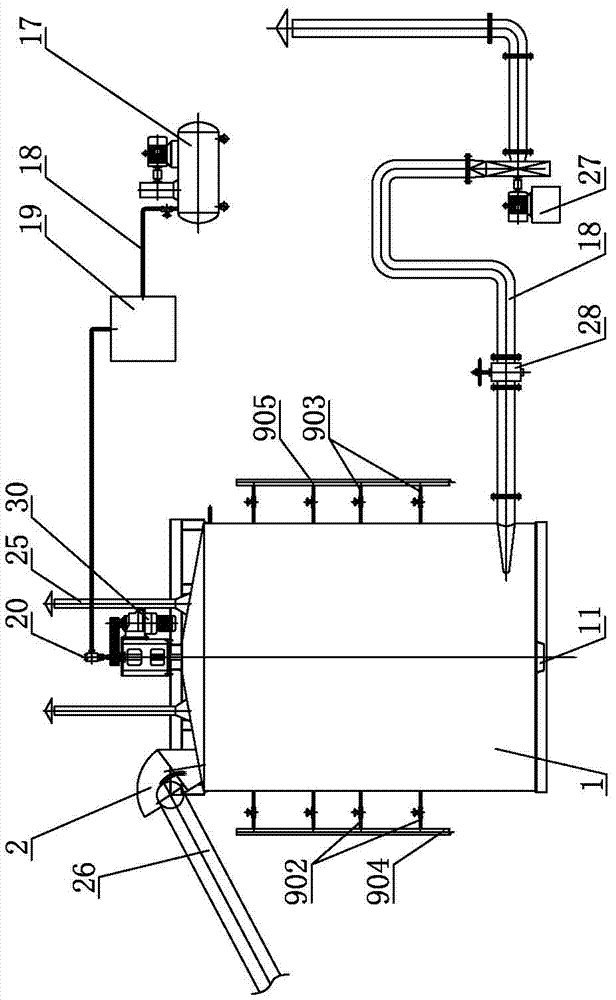

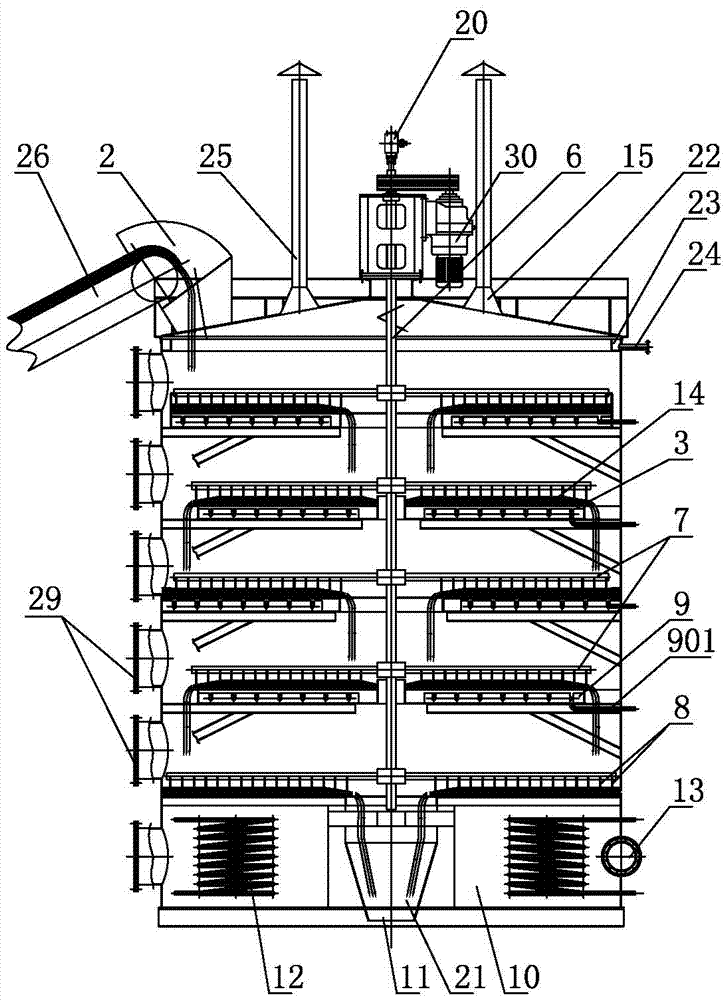

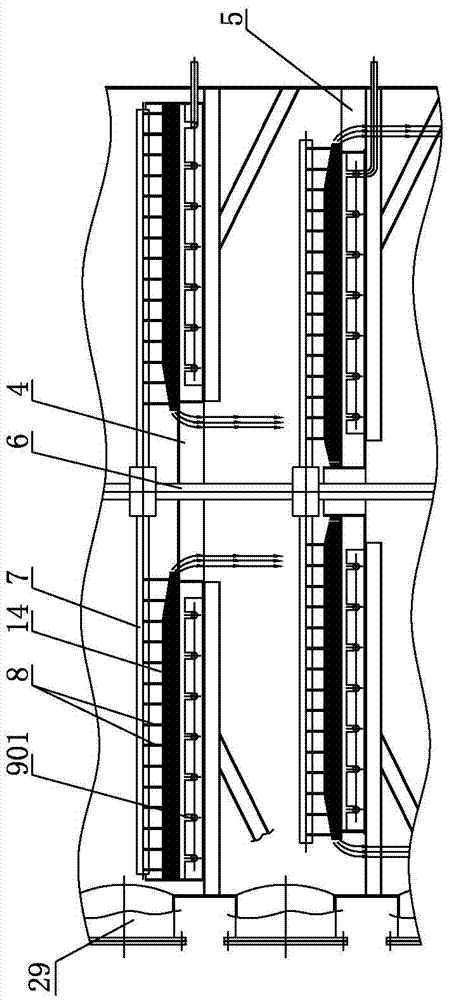

Disc type drying machine

PendingCN107270692ADry evenlyImprove drying effectDrying gas arrangementsDrying solid materialsWater vaporEngineering

The invention discloses a disc type drying machine in the field of conduction heat transfer drying devices. According to the disc type drying machine, a feeding opening is formed in the top of a barrel; multiple layers of material trays are arranged in the barrel; the number of the material trays is an odd number; a falling hole is formed in each of the material trays on the odd layers; a falling channel is arranged between each of the material trays on the even layers and the inner wall of the barrel; a rotary shaft is arranged in the barrel and provided with scraping mechanisms; a first heating device is arranged on the lower portion of each material tray; a heating bin is arranged below the material trays on the bottom layer and provided with a discharging opening; multiple second heating devices are arranged in the heating bin; a hot air inlet is formed in the side face of the barrel and connected with a hot air source; an air distributor is arranged on each swing support, and an air outlet of each air distributor right faces a material on the corresponding material tray; and water vapor outlets are formed in the top of the barrel. According to the disc type drying machine, the materials accumulated inside and outside can be dried uniformly, the contact area of the materials and heat can be increased, water can be fully evaporated, and the material drying effect can be improved.

Owner:杨正清

Parallel flow heat exchanger and use

InactiveCN101419002ASolve the problem of uneven distributionImprove heat exchange efficiencyEvaporators/condensersEngineeringRefrigerant

The invention relates to a parallel flow heat exchanger, which comprises at least two stacked parallel flow heat exchange units, wherein each parallel flow heat exchange unit comprises a top flow collecting pipe, a bottom flow collecting pipe, and a plurality of parallel flat pipes communicating the top flow collecting pipe and the bottom flow collecting pipe; and the axial flowing length of a heat exchange medium on the top flow collecting pipe is larger than that on the bottom flow collecting pipe; and the axial flowing length on the top flow collecting pipe is as long as possible, while the axial flowing length on the bottom flow collecting pipe is as short as possible. The parallel flow heat exchanger improves the heat exchange medium of two-phase flow of gas and liquid remarkably, in particular solves problem of delamination of the gas and the liquid in refrigerant, so as to effectively solve the problem of uneven distribution of the gas and the liquid, improve heat exchange efficiency of the heat exchanger, and fully evaporate the refrigerant. At the same time, the parallel flow heat exchanger saves volume and reduces cost.

Owner:王磊

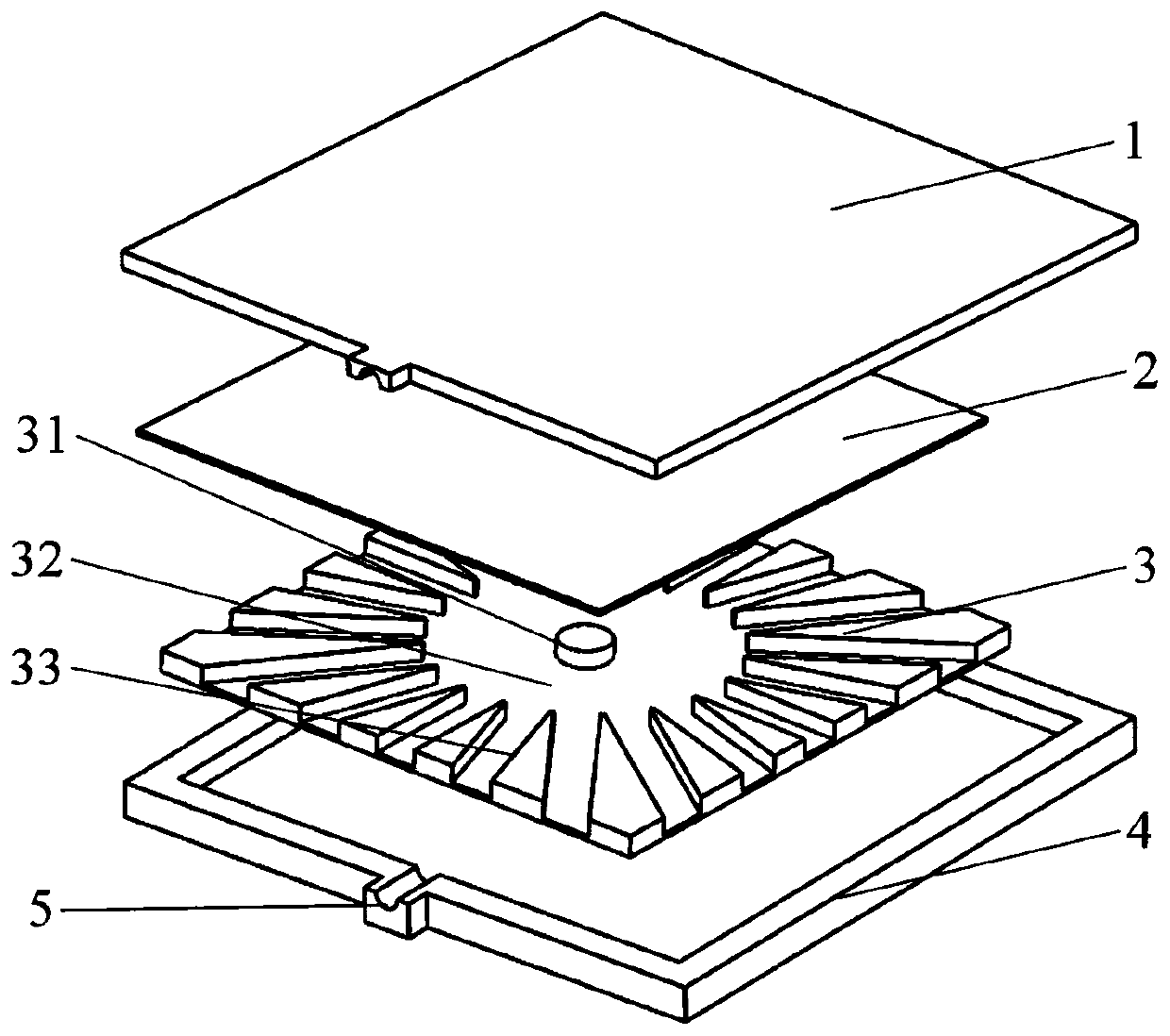

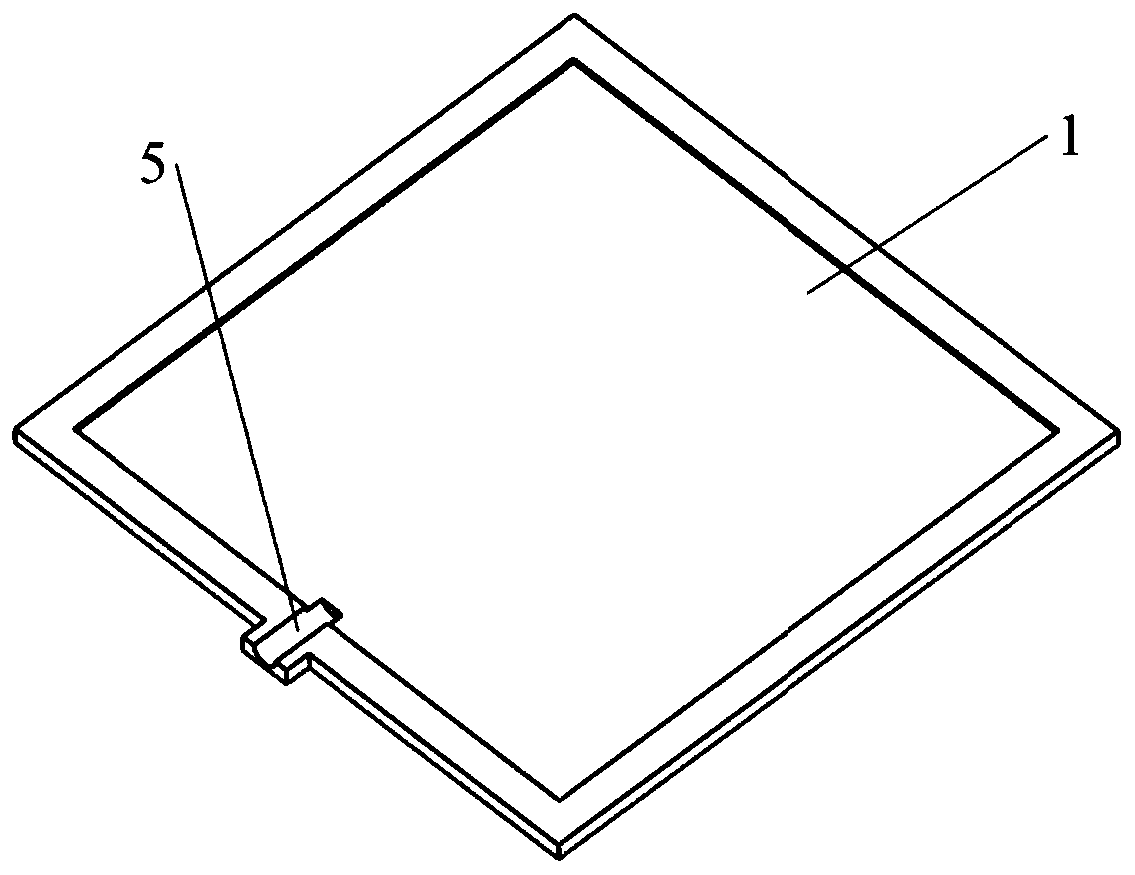

Vapor chamber with supporting pillar and groove composite structure

InactiveCN110108139AAdequate working mediumRealize the collectionIndirect heat exchangersModifications by conduction heat transferThermal deformationEvaporation

The invention discloses a vapor chamber with a supporting pillar and a groove composite structure. The vapor chamber comprises an upper covering plate and a lower covering plate, wherein a condensation end liquid suction core is disposed in a cavity of the upper covering plate; an evaporation end liquid suction core is disposed in a cavity of the lower covering plate; an annular cavity is disposedin the evaporation end liquid suction core; a supporting pillar is disposed at the center of the annular cavity; a groove structure is disposed in peripheries of the annular cavity; both the supporting pillar and the groove structure get contacted with the condensation end liquid suction core; and the upper covering plate and the lower covering plate are sealed, and a liquid filling hole is formed between the upper covering plate and the lower covering plate. Evaporation of a liquid working medium and collection of a condensation liquid are promoted by the cavity of the evaporation end liquidsuction core, and a liquid backflow channel is formed by the supporting pillar to reduce a pressure drop at the center; evaporation of the liquid working medium and backflow of the working medium toa center evaporation area are promoted by the cavity of the groove, so heat transfer performance is improved; a main backflow channel of the condensation liquid is formed by an entity part of the groove, so condensation and backflow are accelerated; and strength of the vapor chamber is ensured by the supporting pillar and the groove structure, so collapse and thermal deformation of the vapor chamber are avoided effectively.

Owner:SOUTH CHINA UNIV OF TECH

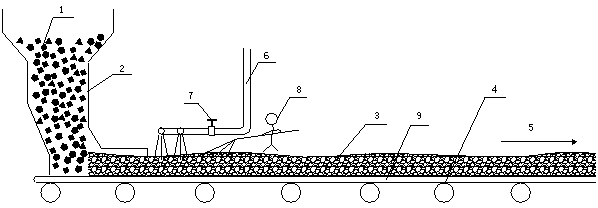

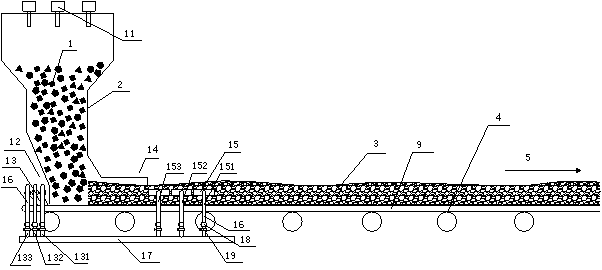

Method for preventing high-temperature fallen material from scalding conveyor belt

ActiveCN104249932AReduce qualityAvoid burnsCharge manipulationConveyor partsControl signalEngineering

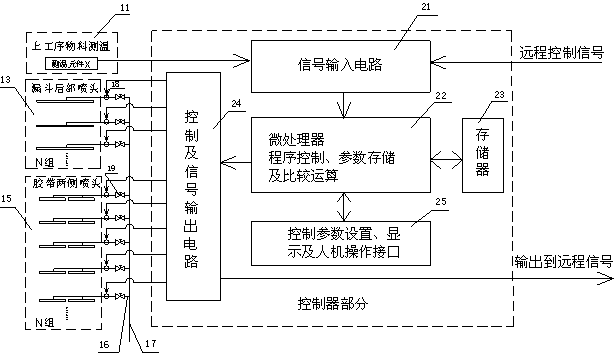

The invention discloses a method for preventing a high-temperature fallen material from scalding a conveyor belt. A temperature detection device (11) is installed between a discharging port of a high-temperature material (1) in the last process and a material receiving hopper (2) of a material receiving conveyor belt machine (4) in the following process; a cooling water nozzle set (13) and a cooling water nozzle set (15) are installed respectively at a material receiving hopper rear portion (12) and a material receiving hopper front portion (14) and above the conveyor belt (9); each cooling water nozzle set is connected with a cooling water branch pipe (16) independently; an electromagnetic valve (18) and a stop valve (19) are installed on each cooling water branch pipe. When heat dissipated from an upper process fallen material is sensed by the temperature detection device, a detected temperature signal is sent to a signal input circuit (21) of a controller by the temperature detection device, after comparison operation is conducted by a microprocessor (22), a water spraying control signal is output to a signal output circuit (24), and therefore the electromagnetic valve of the nozzle set on each branch pipe is controlled to be opened and closed.

Owner:BAOSHAN IRON & STEEL CO LTD

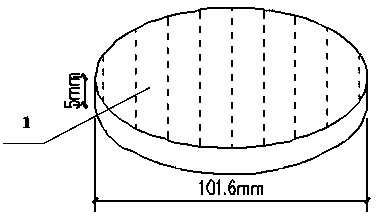

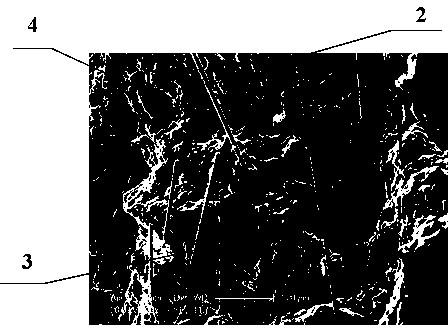

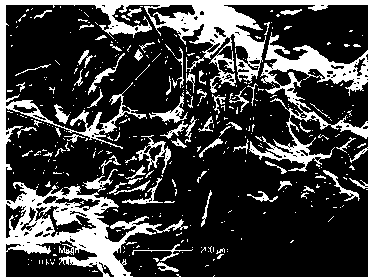

Sample preparation method of scanning electron microscope of basalt fiber and asphalt mixed material fracture

InactiveCN103808549AGood reproducibilityGood for microscopic observationPreparing sample for investigationMaterial analysis by measuring secondary emissionScanning electron microscopeElectron microscope

The invention relates to a sample preparation method of a scanning electron microscope of a basalt fiber and asphalt mixed material fracture, which relates to the technical field of sample preparation of a material for testing of a scanning electron microscope. The method comprises the steps of first preparing an asphalt mixed material Marshall cylindrical test piece doped with basalt fibers by a Marshall standard compaction method, then cutting the cylindrical test piece to obtain bar-shaped test pieces, and cutting each of two opposite edges of each bar-shaped test piece of the mixed material along the height direction to form a small incision; performing water bath on the test pieces to achieve heat balance; and clamping two sides of the incisions of each test piece, fracturing the bar-shaped test piece of the mixed material and air-drying the fractured test piece. The obtained test piece fracture is relatively smooth, thus being favorable for the micro-observation on basalt fibers of the scanning electron microscope, so that the bonding situation between the basalt fibers and the asphalt mixed material and the reinforcement effect of the fibers during fracturing of the asphalt mixed material can be accurately mastered.

Owner:YANGZHOU UNIV

Tobacco filler for non-combustion type heat smoking article

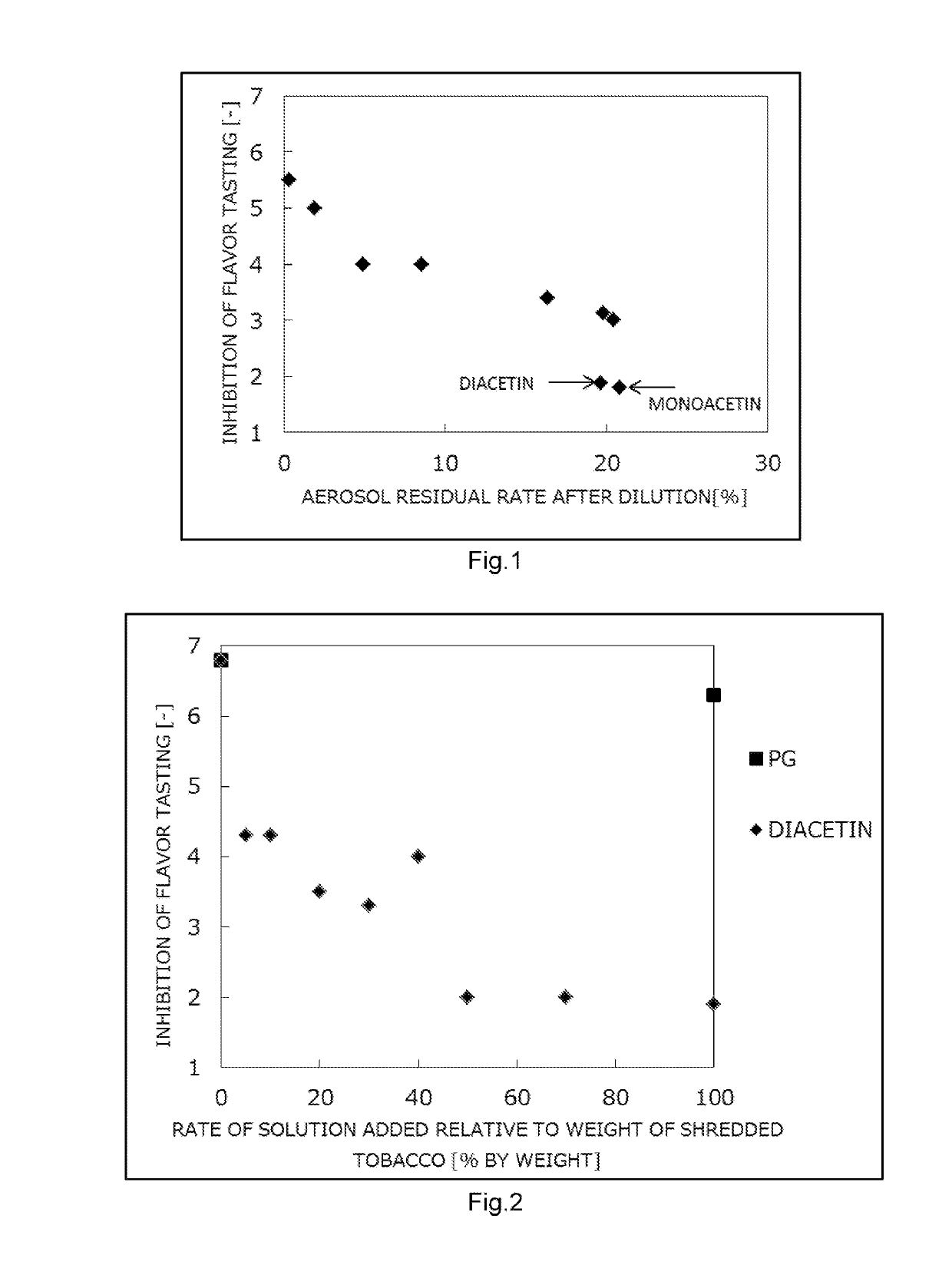

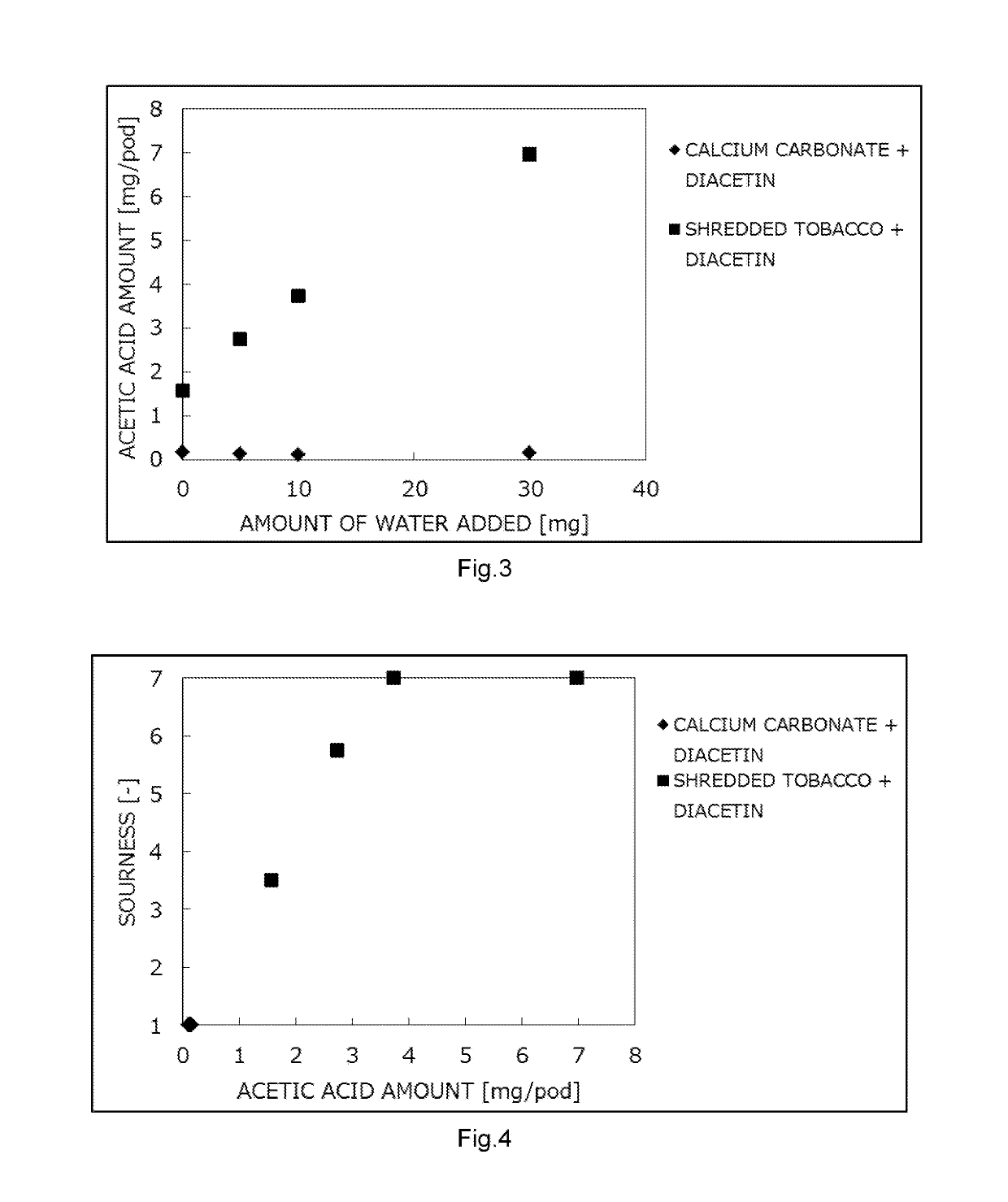

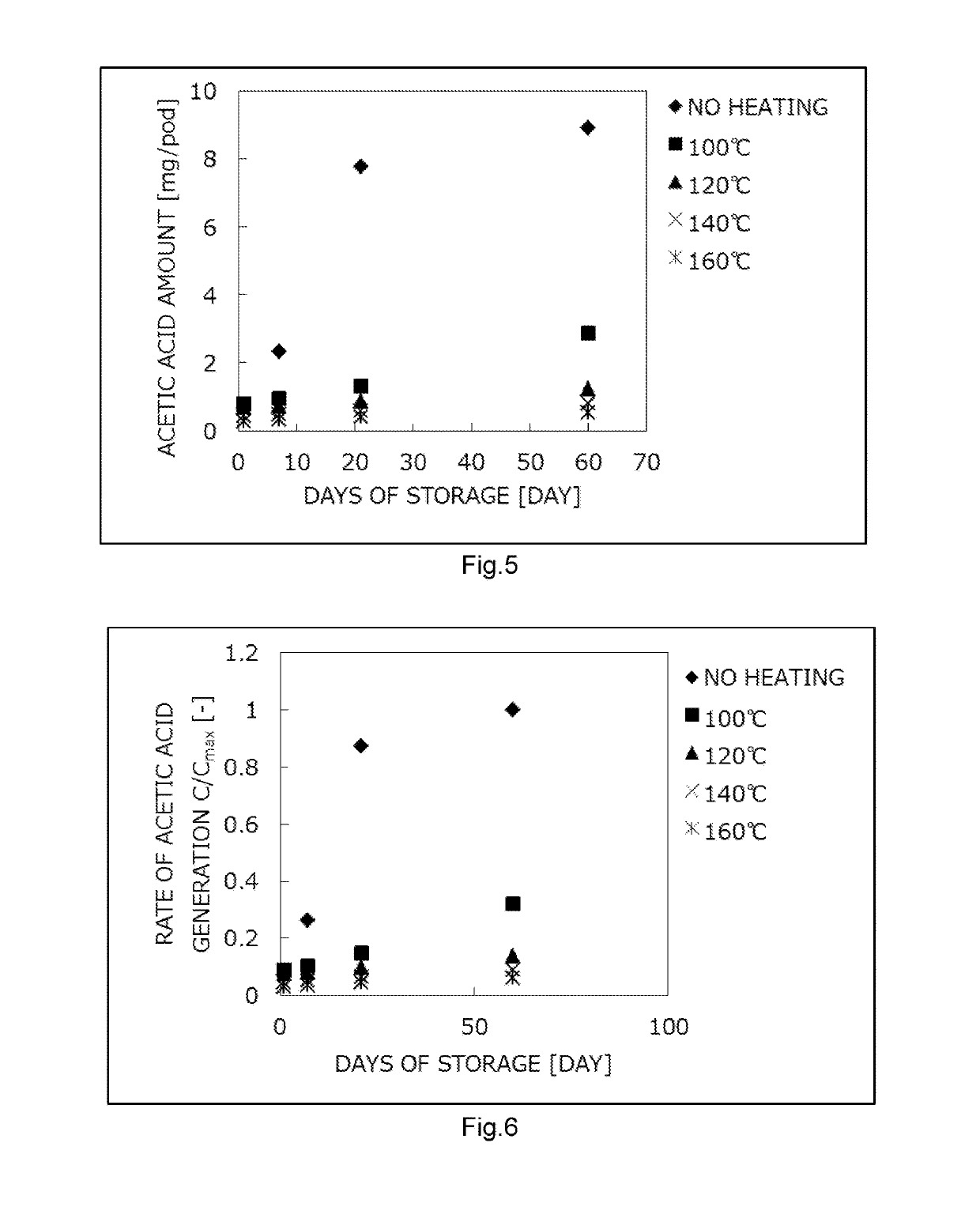

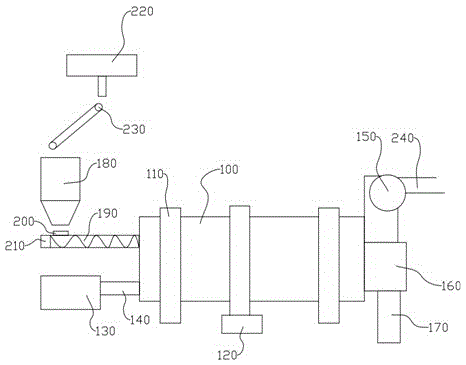

InactiveUS20190142072A1Fully evaporatedReduce inhibitionTobacco treatmentCigar manufactureFlavorProduction rate

The purpose of the present invention is to provide a tobacco filler that can maintain a good smoking flavor and yet reduce “a feeling of lessened smoking flavor” in a non-combustion type heat smoking article served in the form of a tobacco material-containing filler to be heated. Provided is a tobacco filler for a non-combustion type heat smoking article, said tobacco filler containing a tobacco material and an aerosol-forming liquid, wherein the aerosol-forming liquid contains diacetin and / or monoacetin and the acetic acid production rate constant of the tobacco material is 1.25×10−8 s−1 or less.

Owner:JAPAN TOBACCO INC

Lightweight grain dryer

InactiveCN105091524AQuality improvementEfficient use ofSeed preservation by dryingDrying machines with non-progressive movementsHeat conductingEngineering

The invention discloses a lightweight grain dryer. The lightweight grain dryer comprises a feeding hopper and a rotary drum. The feeding hopper is connected with the rotary drum through a grain inlet of a spiral rotating shaft. Supporting rotating shafts are arranged on the two sides of the rotary drum. The hollow part inside the rotary drum is arranged to be a drying area. A stirring disc is installed inside the drying area. A rotating motor is arranged on the outer side of the rotary drum. A heat inlet of the rotary drum is connected with a heater through a heat-conducting pipe. A cooling hole of the rotary drum is connected with a cyclone discharger. One side of the cyclone discharger is connected with a dampness outlet through a draught fan, and the other side of the cyclone discharger is connected with a discharging hopper. Fresh grains are filtered to enter the rotary drum directly, are stirred in the rotary drum to be dried and turn over when stirred, heat can be effectively utilized, moisture in the grains can be sufficiently evaporated, dampness in the grains can be conveniently discharged, and the grain drying quality can be improved. Thus, the lightweight grain dryer is an excellent innovation scheme and has broad market promotion prospects.

Owner:WUXI HAI CHANG MACHINERY

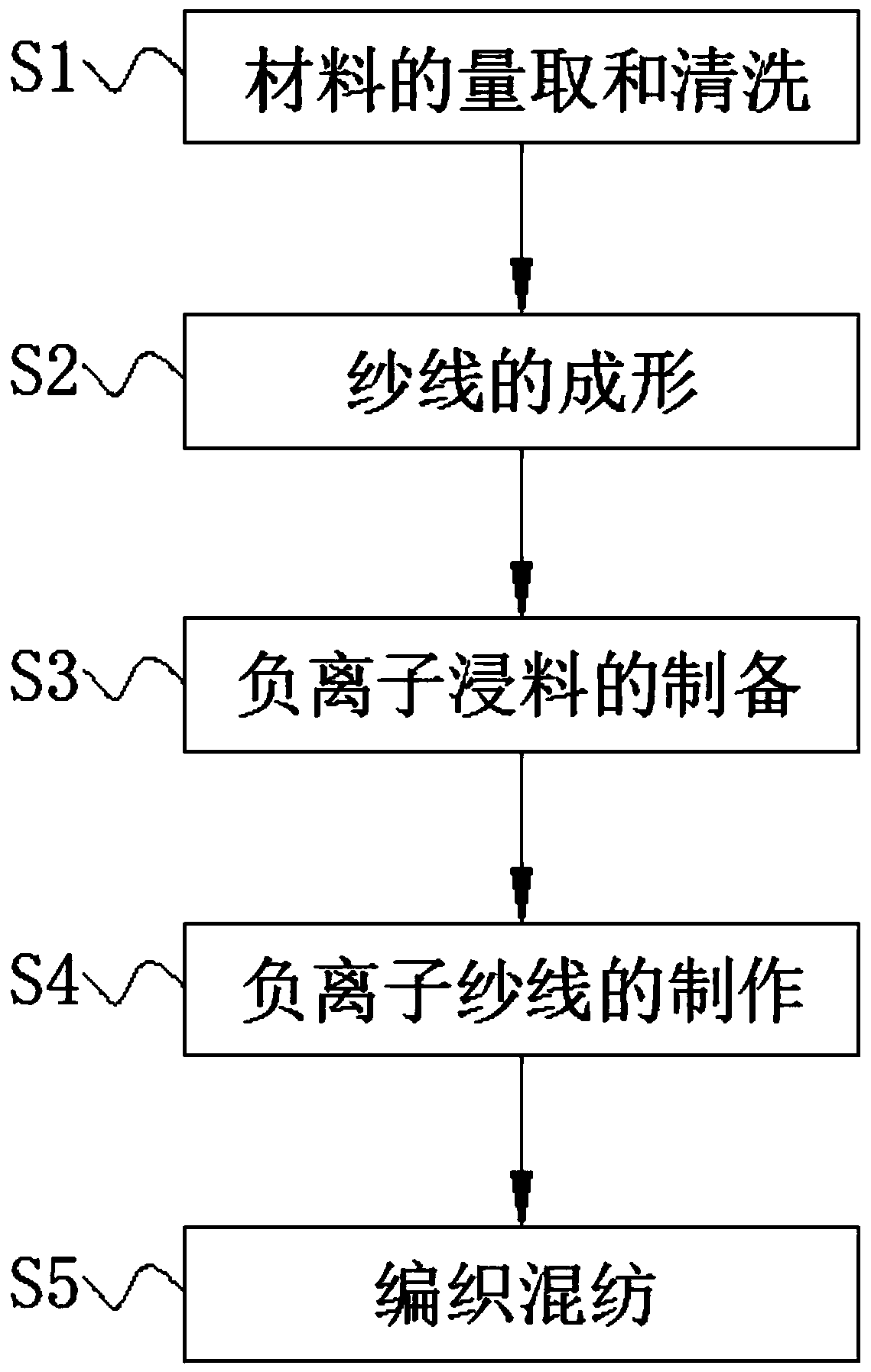

Preparation method of negative ion health-care fabric

The invention discloses a preparation method of a negative ion health-care fabric. The preparation method specifically comprises the following steps: S1, measuring and washing materials, S2, forming yarns, S3, preparing a negative ion immersion material, S4, manufacturing negative ion yarns, and S5, carrying out weaving and blending. The invention relates to the technical field of textile materialprocessing. According to the preparation method of the negative ion health-care fabric, negative ion treatment can be carried out on the weaving yarns before fabric forming, the surfaces of the treated yarns are coated with protective coatings, so that the yarns in the fabric are fully combined with negative ion treatment liquid, the purposes that by coating the protective coatings, negative ionsubstance on the surfaces of the yarns does not fall off during the weaving process, and meanwhile, the protective capability of the woven fabric is promoted are well achieved, therefore, the health-care effect of the fabric is guaranteed, the duration of the health-care effect of the negative ion fabric is greatly prolonged, and finally, people can use the negative ion fabric for health care conveniently.

Owner:广东蓝墨科技有限公司

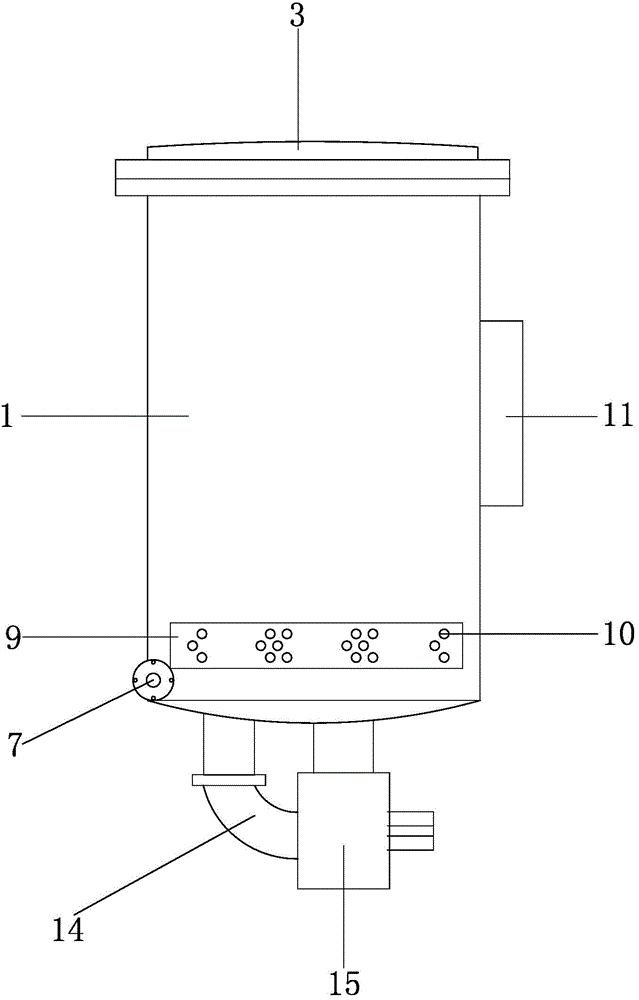

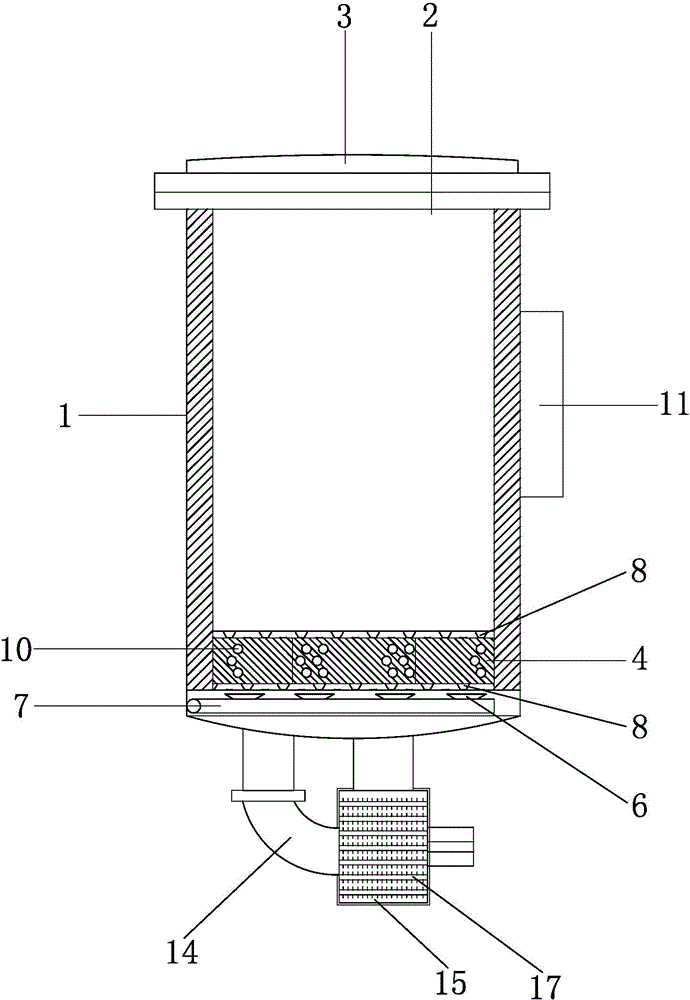

Stream setting machine

ActiveCN104593979AEfficient conversionImprove evaporation efficiencyTextile treatment containersHeating/cooling textile fabricsEngineeringVacuum pump

The invention provides a stream setting machine, and belongs to the technical field of a setting machine. The stream setting machine solves the problems that the heating speed of the existing structure is slow, the steam quantity cannot be easily controlled, the whole machine size is bulky and the existing structure does not have heat storage function, and the like. The stream setting machine is characterized in that a sealed cap is arranged at the open end of the front side of a tank body, a high temperature heat storage plate is arranged in the tank body, a heating pipe is detachably arranged in the high temperature heat storage plate, a plurality of spray headers that can spray water to the high temperature heat storage plate are arranged on one side of the high temperature heat storage plate, spray headers are all connected to a water inlet pipeline; a circulating heating mechanism is arranged at the rear end of the tank body, a vacuum tank that the interior is in a negative pressure condition is connected with the tank body by a pressure relief control pipeline, a condensate water collecting tank is arranged on the bottom of the vacuum tank, a vacuum pump is connected with the vacuum tank, and a pressure gauge is installed on the vacuum pump. The stream setting machine has the advantages that the steam can be effectively converted, the heat in the tank body is uniform, the setted objects can be dried fast, and the usage of power shortage areas can be met.

Owner:TIANTAI COUNTY MINGTONG MACHINERY

Vermiculite fireproof thermal-insulation sound-insulation sheet material and preparation method thereof

InactiveCN103496938AExcellent fire insulation and sound insulation performanceEfficient synthesisPolymer scienceThermal insulation

The invention relates to a vermiculite fireproof thermal-insulation sound-insulation sheet material and a preparation method thereof. The vermiculite fireproof thermal-insulation sound-insulation sheet material is prepared by compacting the raw materials: in percents by weight, 50-70% of expanded vermiculite, 10-15% of expanded vitrified vermiculite powder, 5-15% of expanded vitrified pitchstone,5-15% of fly ash floating bead and 5-10% of an aqueous binder. The vermiculite fireproof thermal-insulation sound-insulation sheet material has excellent fireproof thermal-insulation sound-insulation performance, and makes up the disadvantages that lightweight aggregate prepared from an organic material is bad in fireproofness, is easy to deform severely at a high temperature and causes shedding and melt dropping and causes injuries on people, and generates harmful gas at a high temperature and causes environmental pollution. The vermiculite fireproof thermal-insulation sound-insulation sheet material is good in fireproof thermal-insulation sound-insulation effect, stable in structure, has a same service life with buildings, and also has the advantages of being energy-saving, none in pollution and economical.

Owner:逄红国

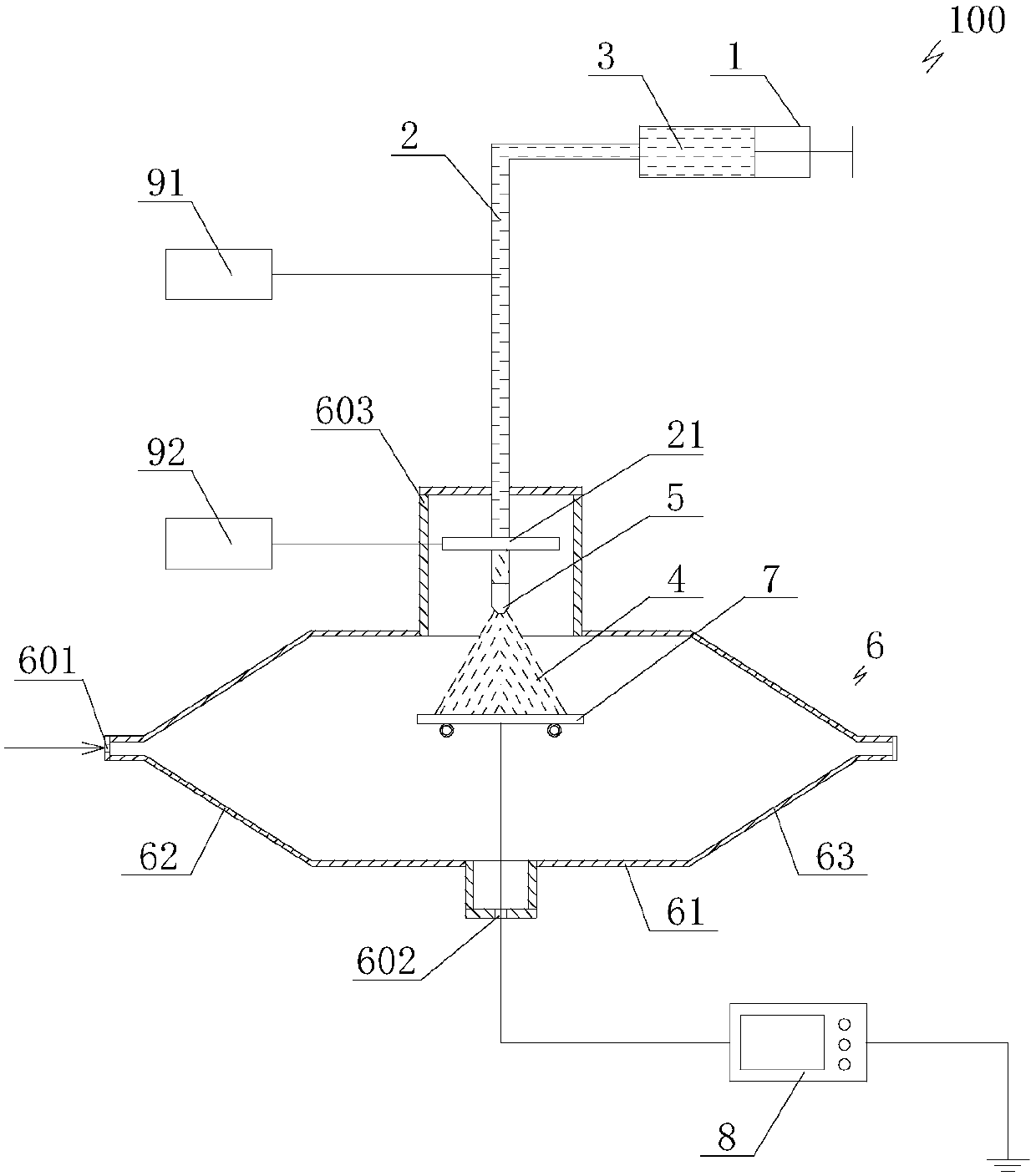

Novel method and device for preparing polymer particles

ActiveCN107715789AAvoid the influence of the preparation processOvercome surface tensionGranulation by liquid drop formationEnergy based chemical/physical/physico-chemical processesPolymer scienceOrganic solvent

The invention relates to a novel method and device for preparing polymer particles. The method includes the following steps that, a conductive organic solvent is pumped into an insulated capillary tube through an injection pump, the capillary tube is sealed and penetrate through a shuttle-shaped pneumatic conveying container which can be sealed, the outlet end of the capillary tube is communicatedwith a nozzle, under the strong electric field effect generated by a high voltage source, the organic solvent is dispersed to form charged droplets, under the traction force effect of electric fieldforce, gravity and flowing gas in the container, the charged droplets are uniformly spread on a grounded collection plate in the shuttle-shaped pneumatic conveying container, and the charged dropletsare grounded through the collection plate so as to remove static electricity, and solid polymer particles are formed. The novel method for preparing the polymer particles is convenient to operate, thedevice for preparing the polymer particles is simple in structure, and the particle size and shape of the obtained products, namely the polymer particles, are uniform, the performance is stable, andthe method and the device are conducive to application and popularization.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

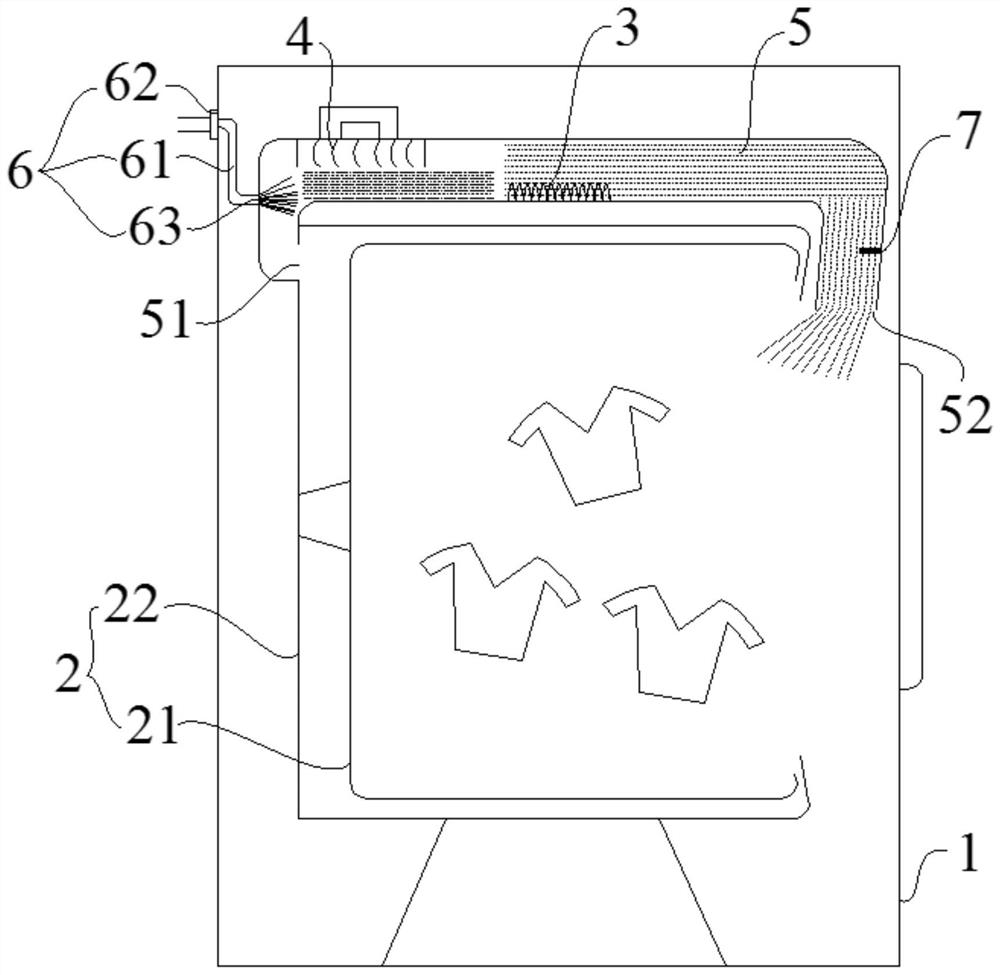

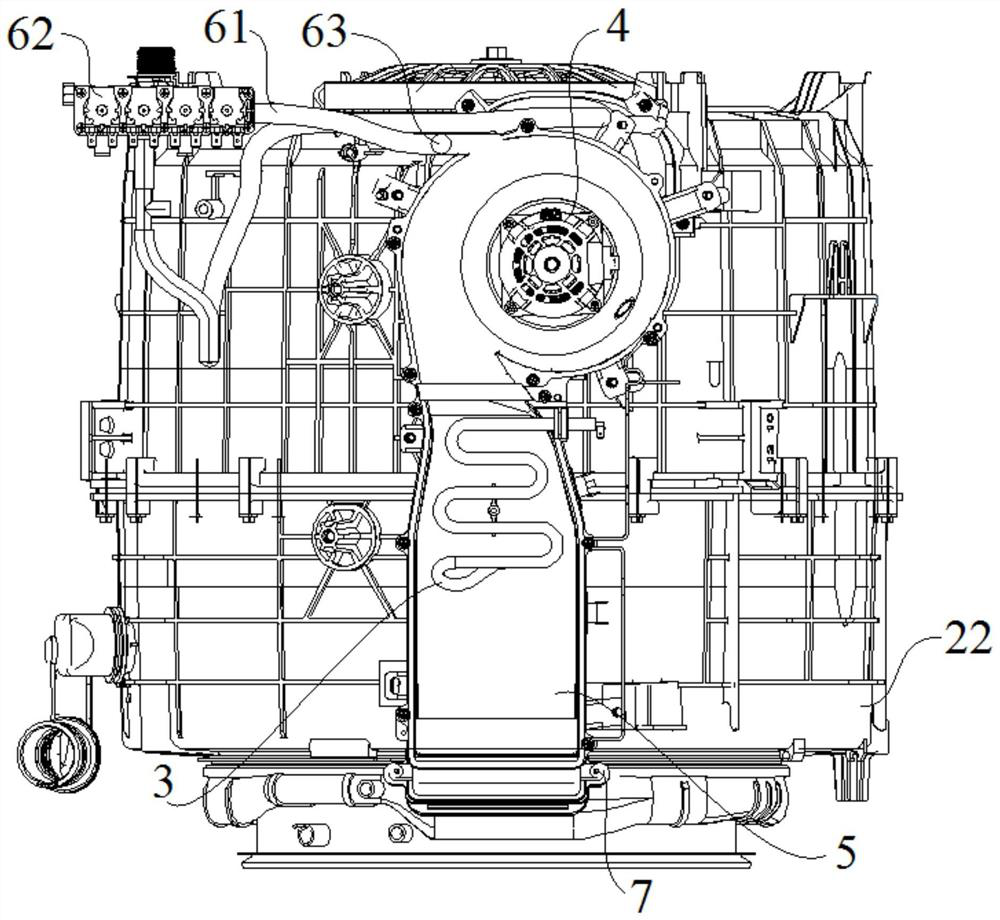

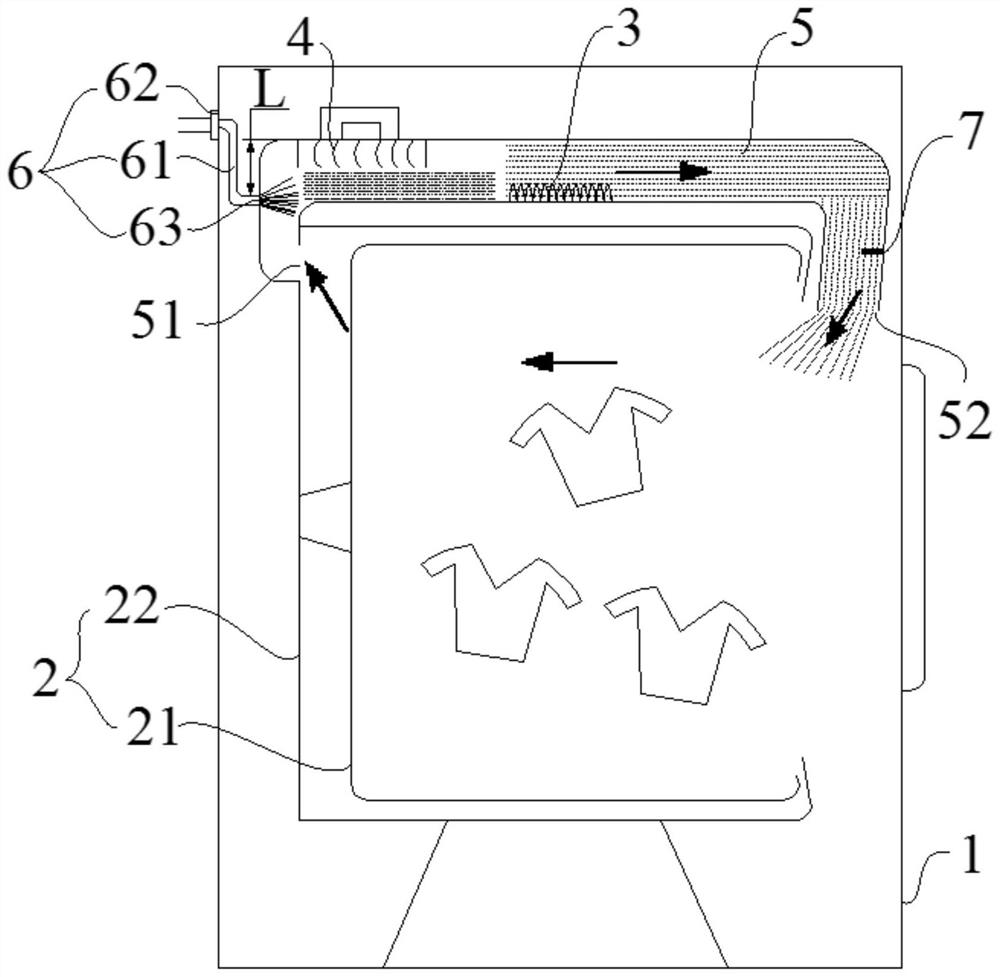

Control method of washing machine

PendingCN112160119AWith steaming and scalding functionLow costControl devices for washing apparatusTextiles and paperLaundry washing machineElectric machinery

The invention discloses a control method of a washing machine, and relates to the technical field of washing machine control. The control method is used for solving the problem of high cost of a washing machine with a wrinkle removing function. The washing machine comprises a spraying device, a motor and a drying air duct between a shell and a washing drum, the drying air duct communicates with different positions of the washing drum, and a heating device and a fan are installed in the drying air duct. The spraying device comprises a spray head mounted in the drying air duct, the spraying direction of the spray head is consistent with the air guide direction of the drying air duct, and the fan is used for guiding water sprayed out by the spray head to the heating device. The control methodcomprises the steps that after a steaming washing operation signal is received, the motor is controlled to drive the washing drum to rotate to a preset rotating speed, and the current weight value ofthe washing drum is obtained; according to the current weight value, the total number of times of the steaming washing process needing to be carried out is determined; the heating device is controlled to be started, the fan and the spraying device are controlled to circularly execute the steaming washing process, and the number of times of executing the steaming washing process is counted; and after the number of times of counting reaches the total number of times, the washing machine exits from the steaming washing process.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

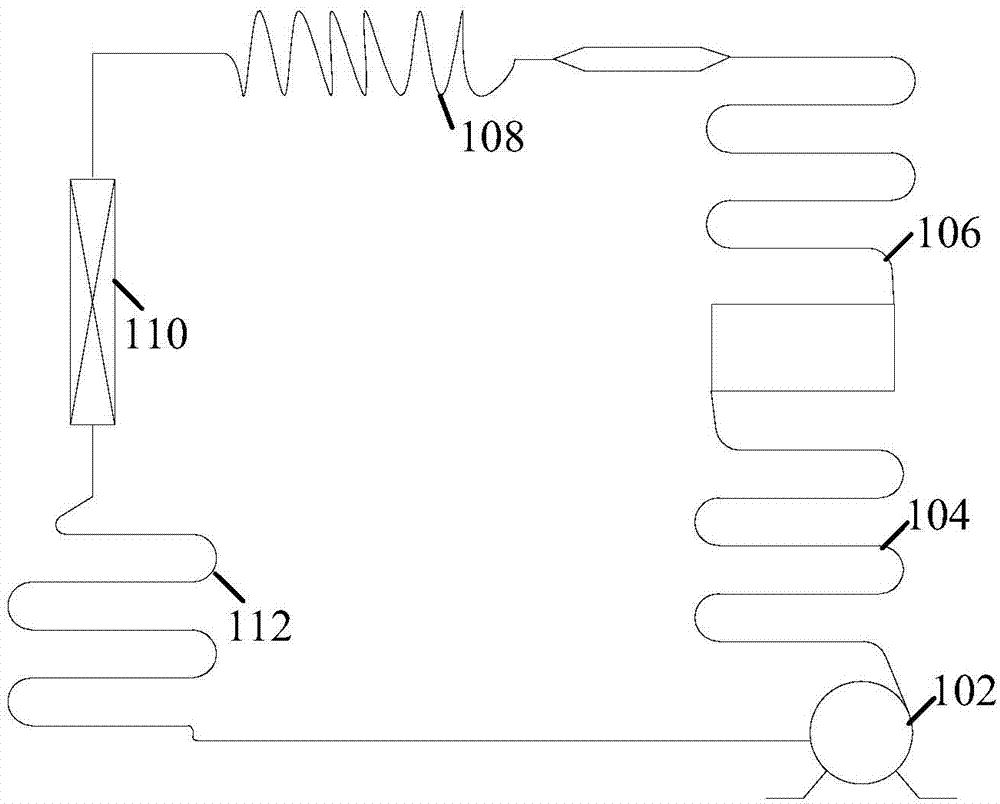

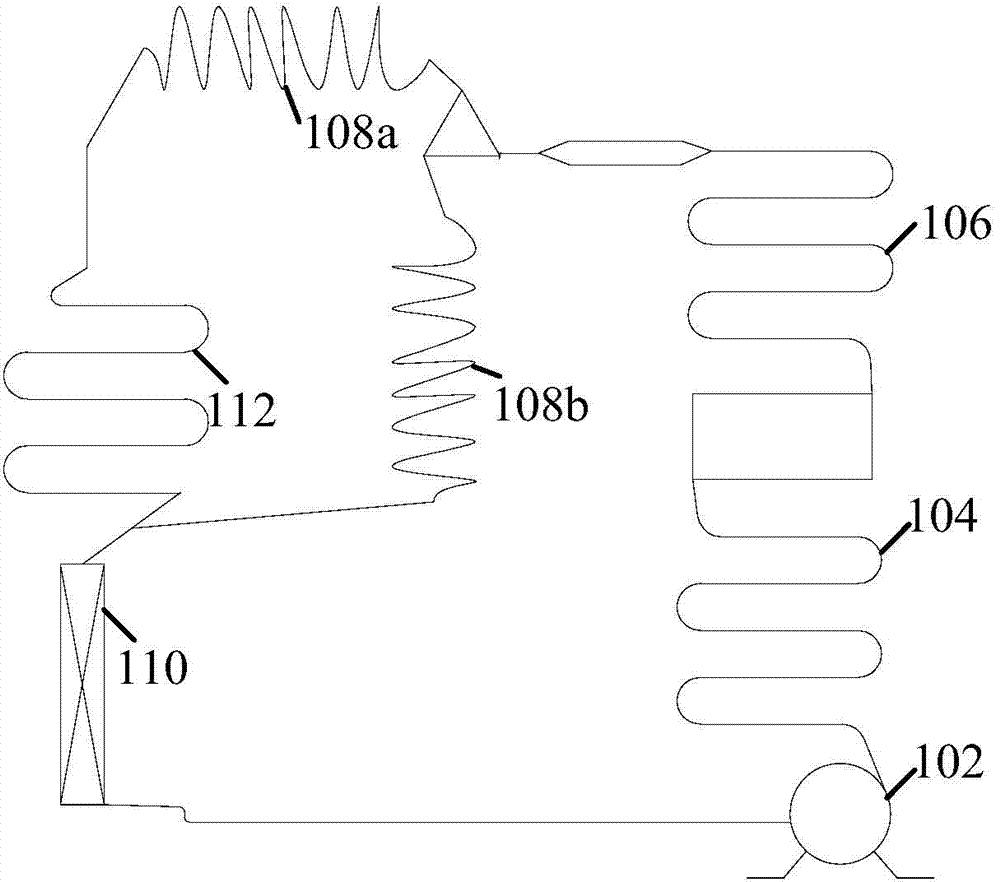

Refrigerating system for refrigerator and refrigerator

InactiveCN104501439AIncrease power consumptionImprove cooling effectMechanical apparatusCompression machines with non-reversible cycleRefrigerationRefrigerated temperature

The invention provides a refrigerating system for a refrigerator and the refrigerator. The refrigerating system for the refrigerator comprises a first evaporator, a first throttling device, a second throttling device and an electromagnetic reversing valve, wherein the first evaporator is arranged in the freezing chamber of the refrigerator; the first throttling device is connected to an inlet of the first evaporator to be used for controlling the amount of a refrigerant flowing into the first evaporator; the second throttling device is connected in parallel with the first throttling device, and the unit flowing amount of the second throttling device is less than that of the first throttling device; the electromagnetic reversing valve is connected to the first throttling device and the second throttling device to be used for preventing the first throttling device or the second throttling device from being switched in a refrigerating circuit. According to the technical scheme, rapid refrigeration for the freezing chamber of the refrigerator can be effectively realized, and the problem that food is frozen off due to an over-low temperature in the freezing chamber, which is caused by the continuous running of the compressor, can be solved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

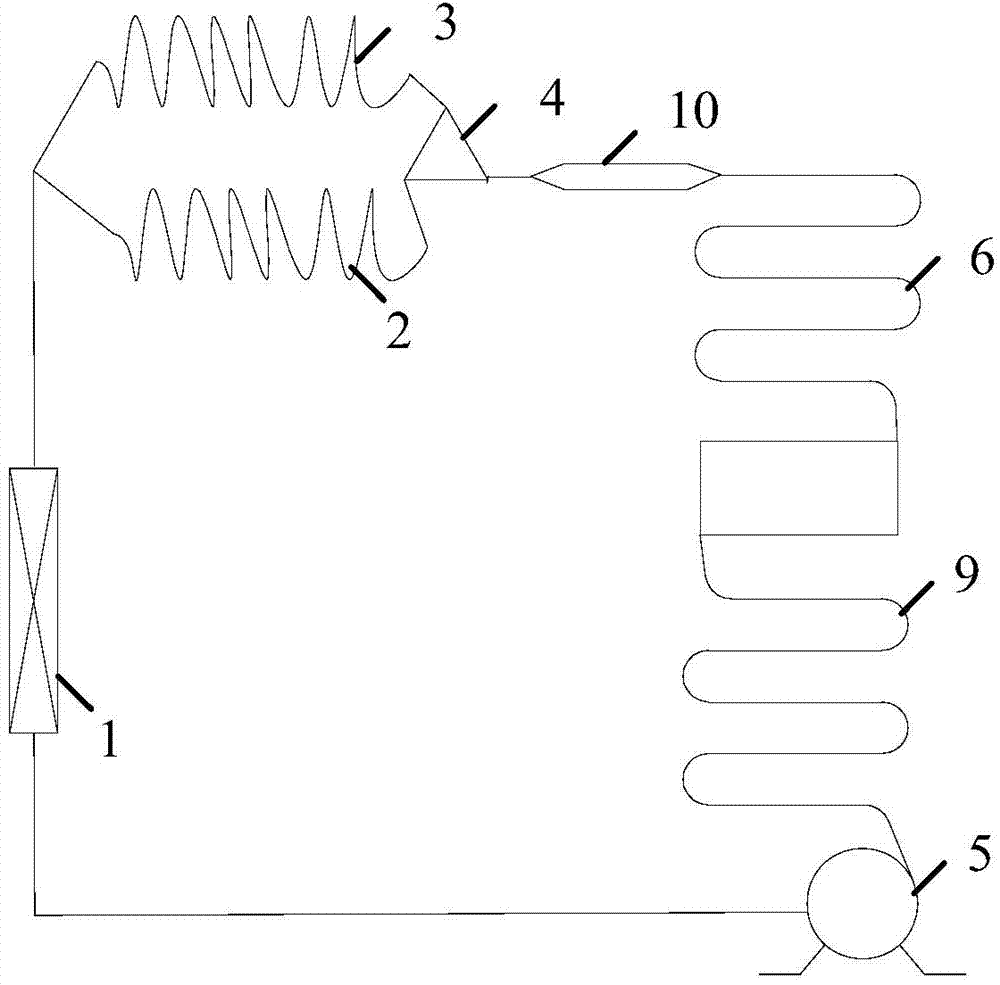

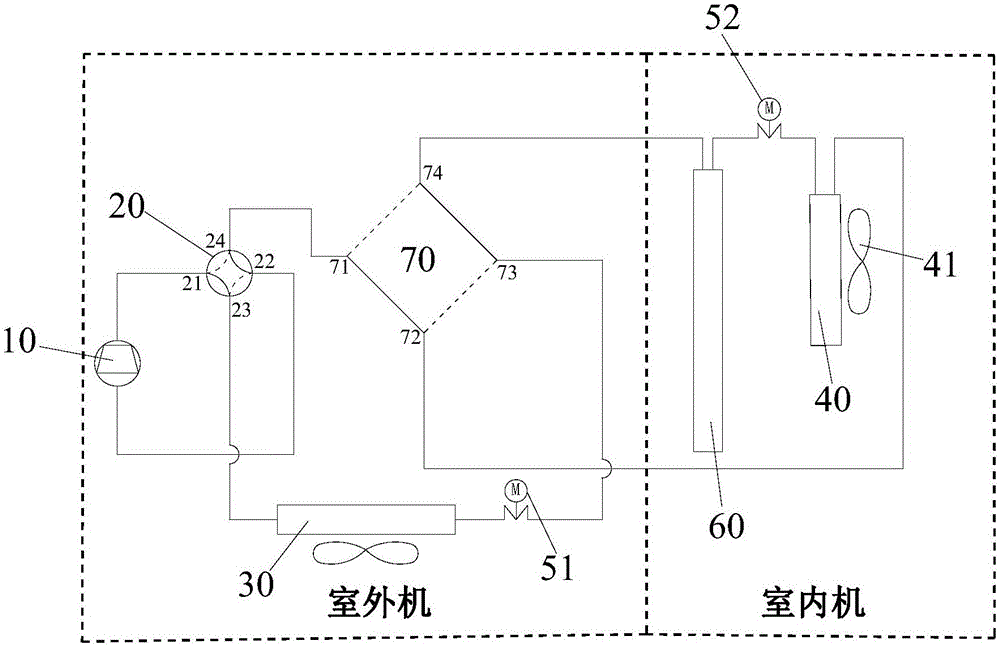

Air conditioner system and control method of air conditioner system

ActiveCN106440454AImprove comfortImprove heat transfer efficiencyMechanical apparatusEfficient regulation technologiesFour-way valveEngineering

The invention discloses an air conditioner system and a control method of the air conditioner system. The air conditioner system comprises a compressor, a four-way valve, an outdoor side heat exchanger, an indoor heat exchanger, a first electronic expansion valve, a second electronic expansion valve, an indoor radiant plate and a control part; the control part comprises a first pipeline opening, a second pipeline opening, a third pipeline opening and a fourth pipeline opening; the first pipeline opening of the control part can be switched to be communicated with the second pipeline opening or the fourth pipeline opening; the third pipeline opening of the control part can be switched to be communicated with the fourth pipeline opening or the second pipeline opening; the second pipeline opening of the control part is communicated with the first end of the indoor heat exchanger; the third pipeline opening of the control part is communicated with the second end of the outdoor side heat exchanger through a pipeline; and the fourth pipeline opening of the control part is communicated with the second end of the indoor heat exchanger through a pipeline. By means of the air conditioner system and the control method of the air conditioner system, the problems that an air conditioner system in the prior art is poor in heat exchange effect and low in comfort degree are effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

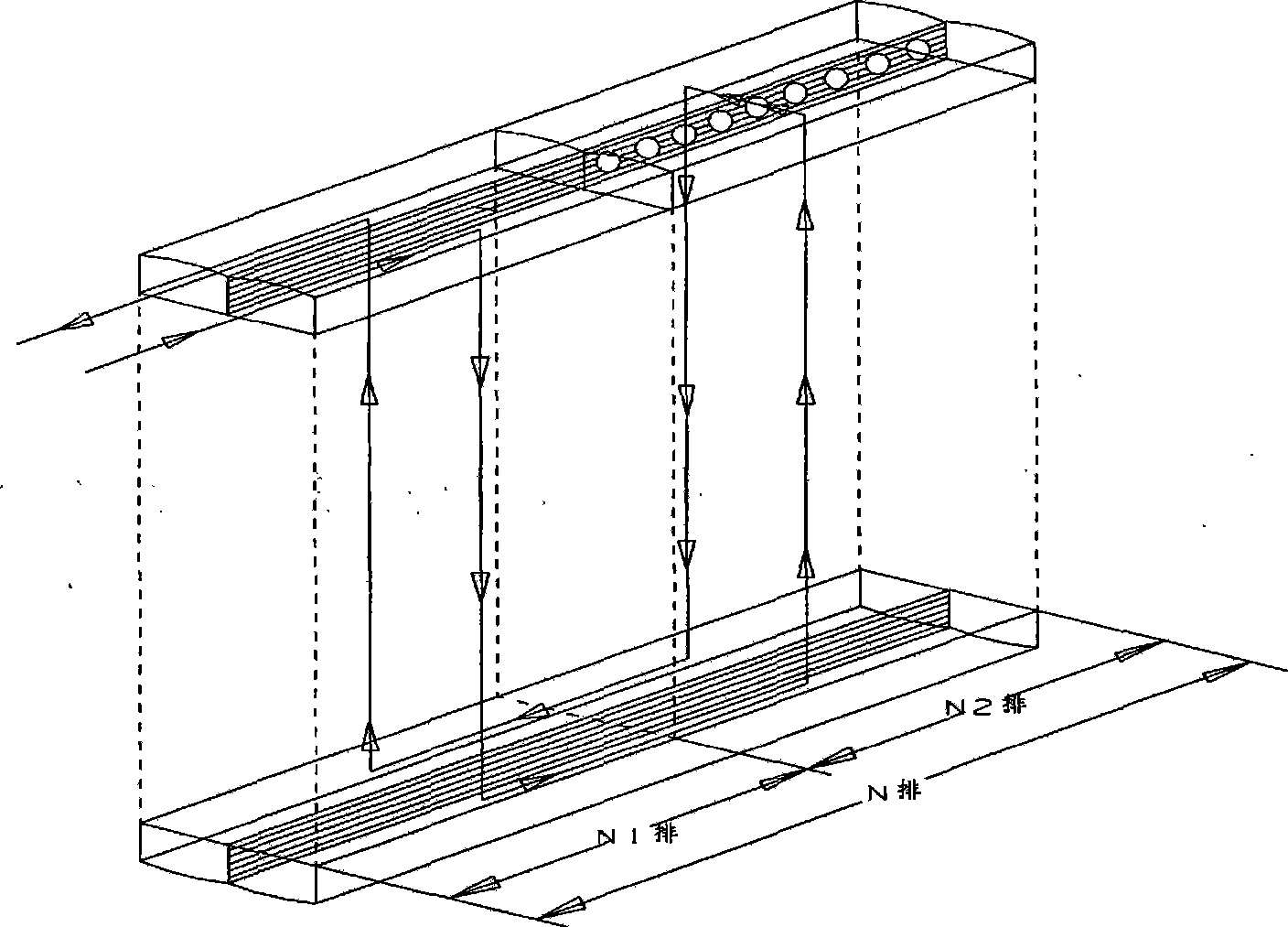

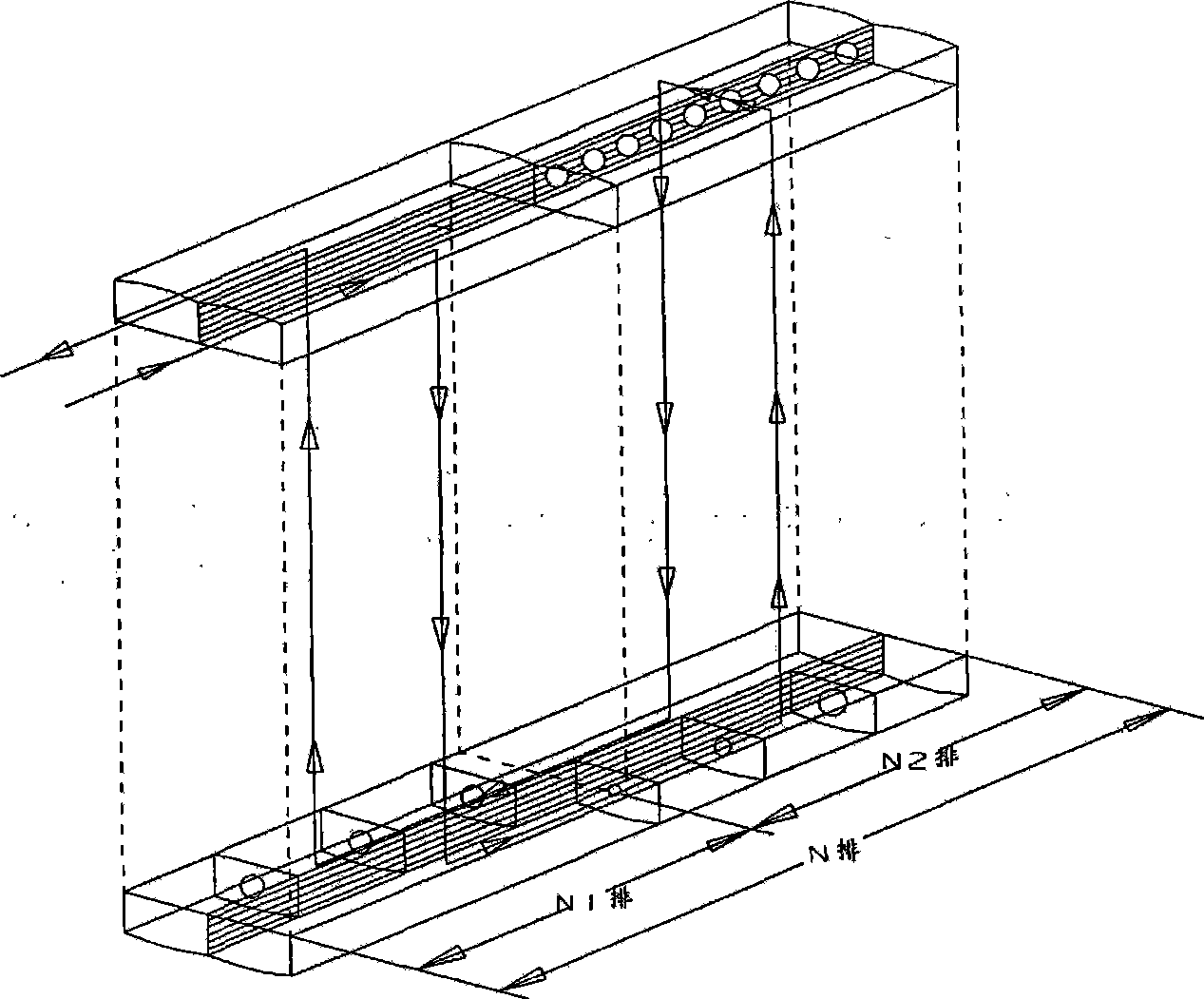

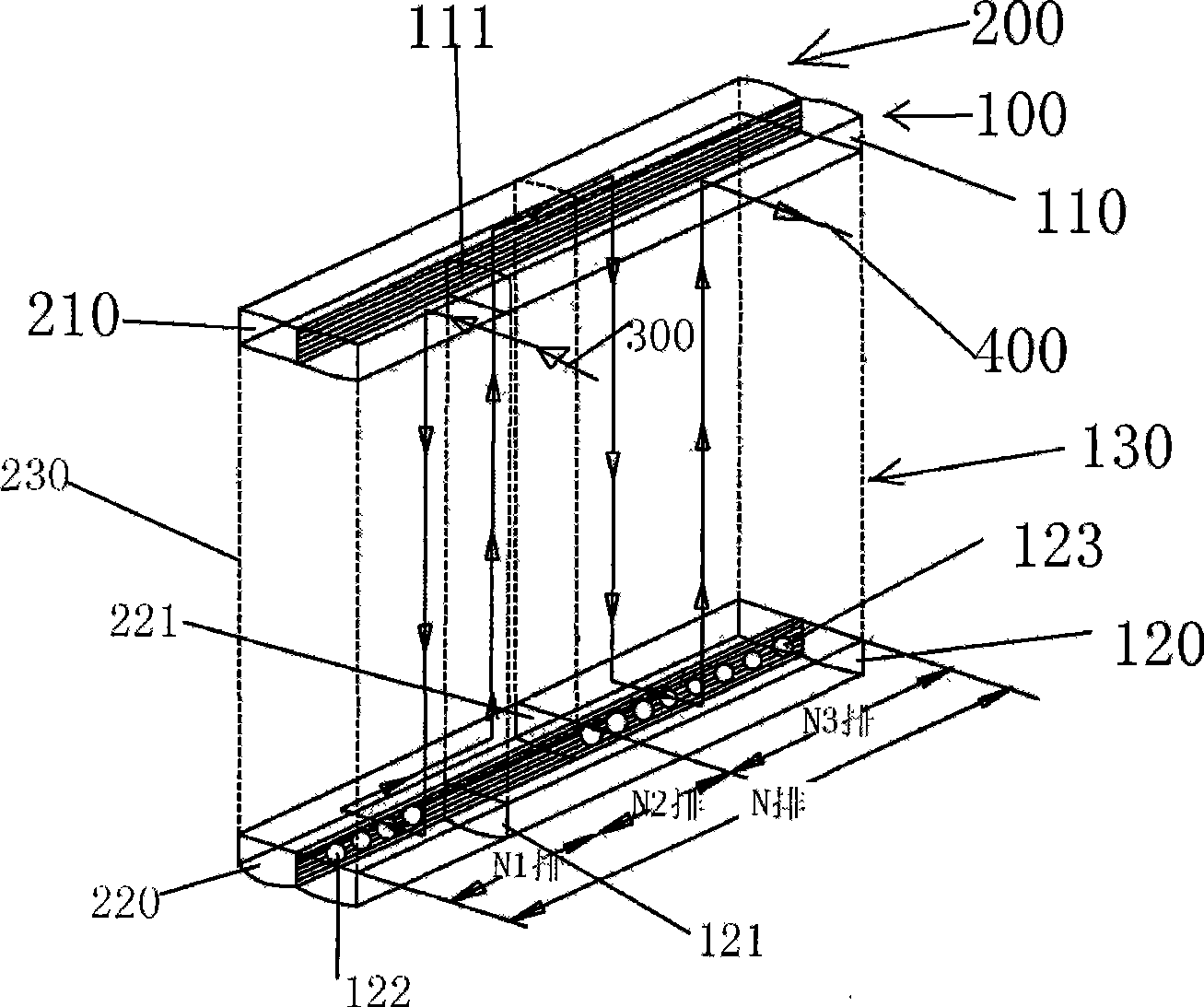

Drying method of ultrahigh molecular weight polyethylene (UHMWPE) fibers

InactiveCN102115964BAvoid localized heatStable mechanical propertiesArtificial filament washing/dryingNon-woven fabricsFiberYarn

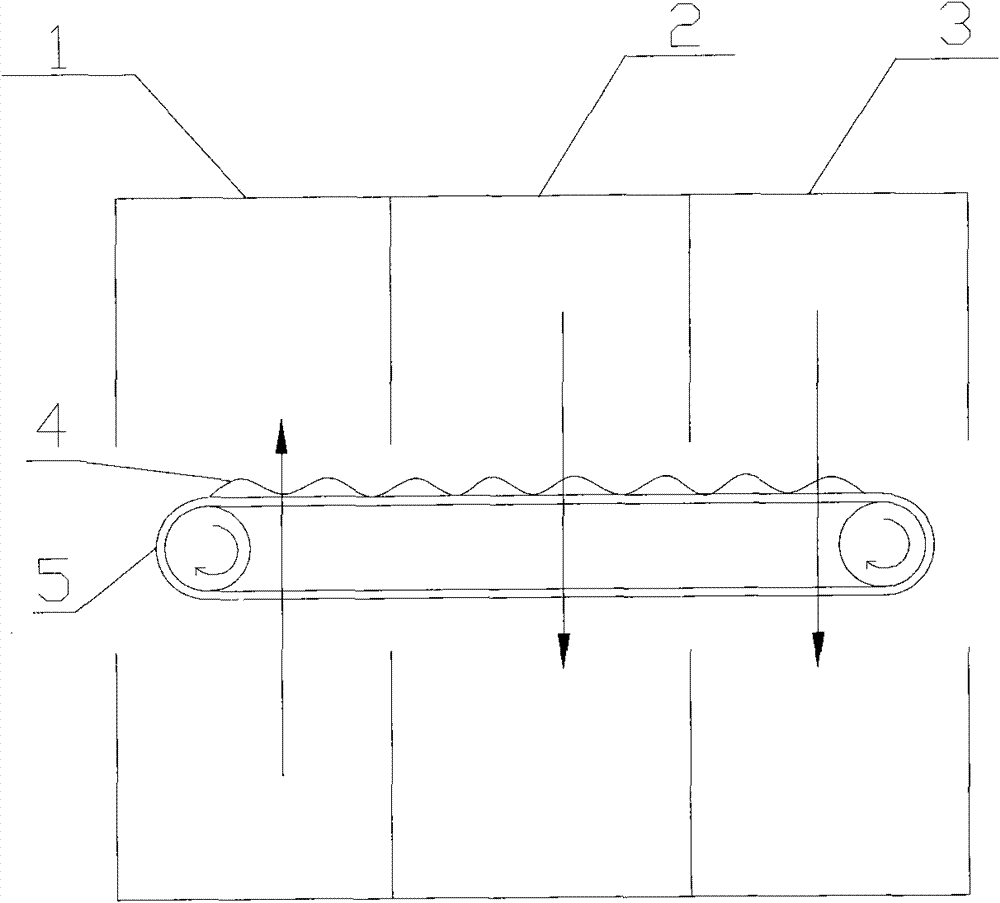

The invention provides a drying method of ultrahigh molecular weight polyethylene (UHMWPE) fibers. The method comprises the following steps: coiled UHMWPE fiber yarns are fed into a dryer to go through first-stage drying, second-stage drying and third-stage drying in sequence; during the first-stage drying process, hot air blows from the lower parts of the UHMWPE fibers to the upper parts of the UHMWPE fibers; during the second-stage drying process, hot air blows from the upper parts of the UHMWPE fibers to the lower parts of the UHMWPE fibers; and during the third-stage drying process, hot air blows from the upper parts of the UHMWPE fibers to the lower parts of the UHMWPE fibers. Through the drying method provided by the invention, partial heating of the UHMWPE fibers in the drying processes caused by over-high temperature of a conveyor belt is avoided, and the mechanical performance of the UHMWPE fibers is stabilized, so that a finally manufactured anti-puncture fabric has even mechanical performance and high puncture resistance.

Owner:杨珍芬

Intelligent dewaxing and dewatering purification device

InactiveCN112823872AAffects water removal and purificationImprove water purification efficiencyFoundry moulding apparatusEvaporator accessoriesStructural engineeringProcess engineering

The invention discloses an intelligent dewaxing and dewatering purification device which comprises a reaction kettle body, a horizontally-arranged net plate is welded to the inner wall of the reaction kettle body, protection plates distributed at equal intervals are welded to the bottom end of the net plate, and second fans distributed at equal intervals are welded to the inner wall of the reaction kettle body. Two steam heaters are welded to the inner wall of the reaction kettle body, the height of the top ends of the steam heaters is larger than that of the top end of the second fan, an obliquely-arranged flow guide plate is welded to the inner wall of the reaction kettle body, a flow guide hole is formed in one side of the outer wall of the top of the flow guide plate, and the flow guide plate is located at the bottom of the second fan. Flow guide pipes which are distributed in a zigzag manner are welded on the inner wall of the reaction kettle body. According to the invention, wax can be fully heated, so that water in the wax is fully evaporated, the water removal efficiency is improved, hot air in the reaction kettle body can be recycled, heat loss is reduced, and the device is energy-saving, environment-friendly and high in intelligent degree.

Owner:王政清

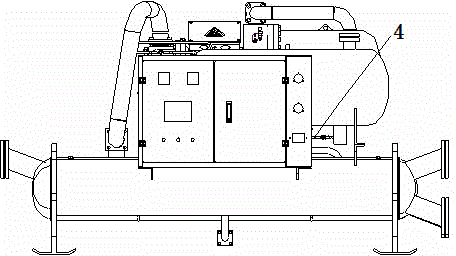

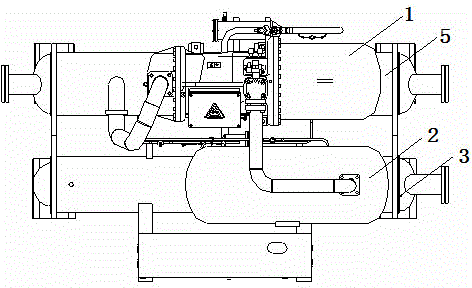

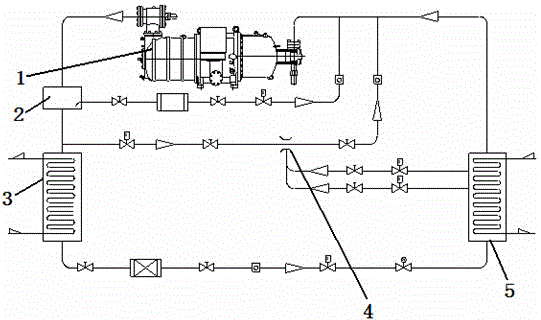

Water source heat pump unit system for low temperature water source

InactiveCN104676978AReduce freezingPrevent freezingHeat pumpsEvaporators/condensersWater source heat pumpWater source

The invention relates to an air conditioning unit device, in particular to a water source heat pump unit system for a low temperature water source. The system comprises a compressor, an oil separator, a condenser, a oil return injecting device and an evaporator; the evaporator is in a falling film type structure, a liquid distributor is arranged in the upper portion of the evaporator, the top of the evaporator is provided with a liquid incoming pipe, the port of the liquid incoming pipe contacts with the surface of the liquid distributor, the top of the evaporator is provided with an exhaust pipe, the bottom of the evaporator is provided with a discharge pipe, and heat exchange pipe beams are arranged below the liquid distributor. According to the system, water is distributed to the surface of the heat exchange pipes evenly through the liquid distributor, the heat exchange effect is fine, the refrigerant can be evaporated fully, the refrigerant storage amount is reduced, and the heat exchange pipes are prevented from freezing; meanwhile, since the level of the evaporator is low, the mixing ratio of lubrication oil is decreased, the lubrication oil can be injected to the compressor through the oil return injecting device, and the fine oil returning effect is achieved.

Owner:SHANDONG YUGIA FUERDA AIR CONDITIONER EQUIP

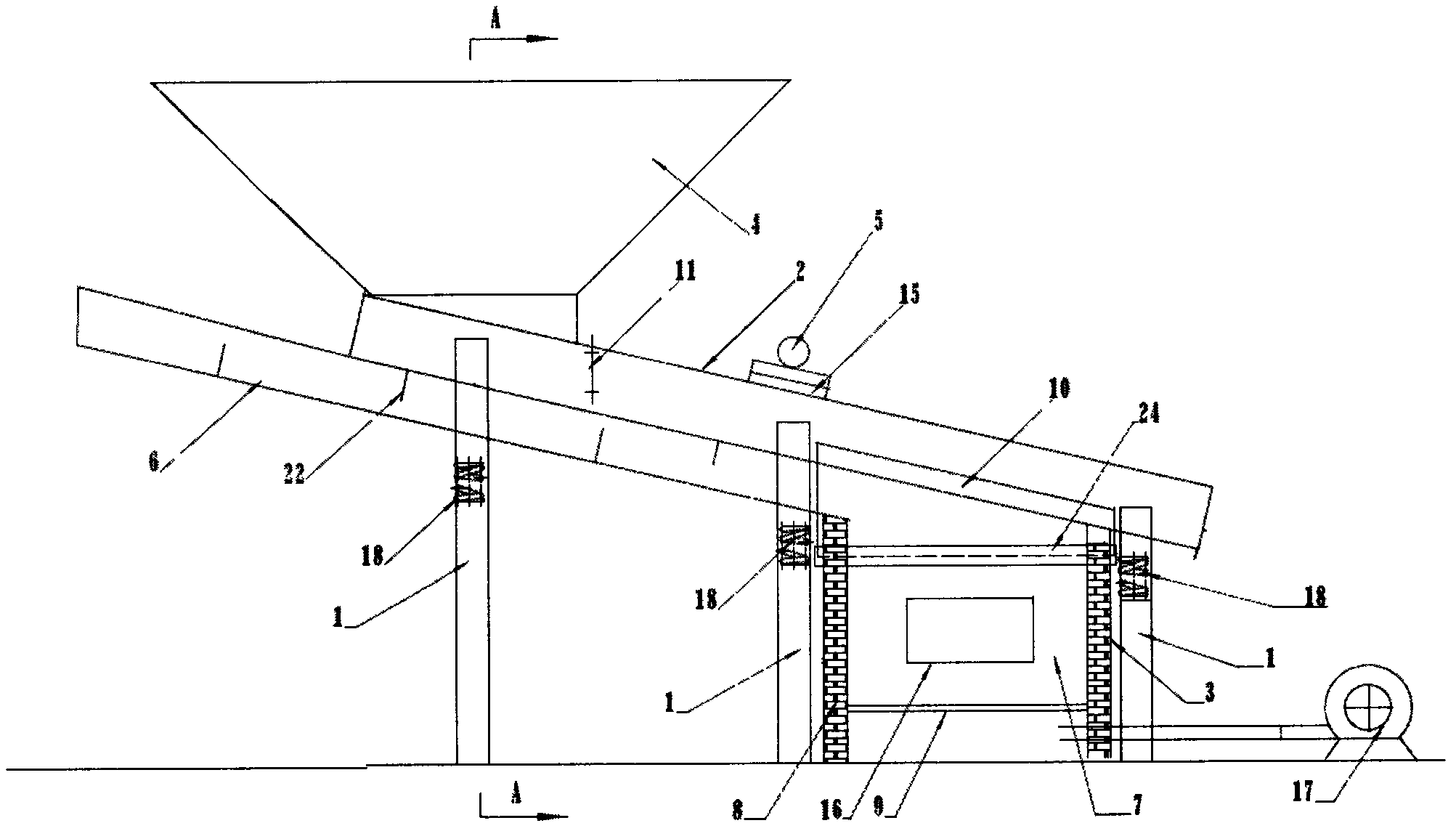

Efficient direct-heating dryer for powdery materials

ActiveCN103234338ASimple structureFully evaporatedDrying solid materialsHeating arrangementEngineeringRadiant heat

A dryer for powdery materials is particularly suitable for drying moisture-containing mineral aggregates after mineral dressing. The dryer comprises a bearing column, a groove-shaped inclined chute is arranged on a column support, and an included angle formed by the inclined chute and the horizontal line is in a range of 7-30 degrees; a heating cavity is positioned below the inclined chute and capable of providing heat to heat the inclined chute, and the heated inclined chute dries mineral aggregates; and the heating cavity is provided with a chimney, and the top of the inclined chute is connected with a feeding hopper. The dryer is simple in structure and can be disassembled easily, the heat source is fully utilized, and radiant heat can be fully utilized when combustible substances are used for heating the inclined chute.

Owner:滨州市科创孵化器有限公司

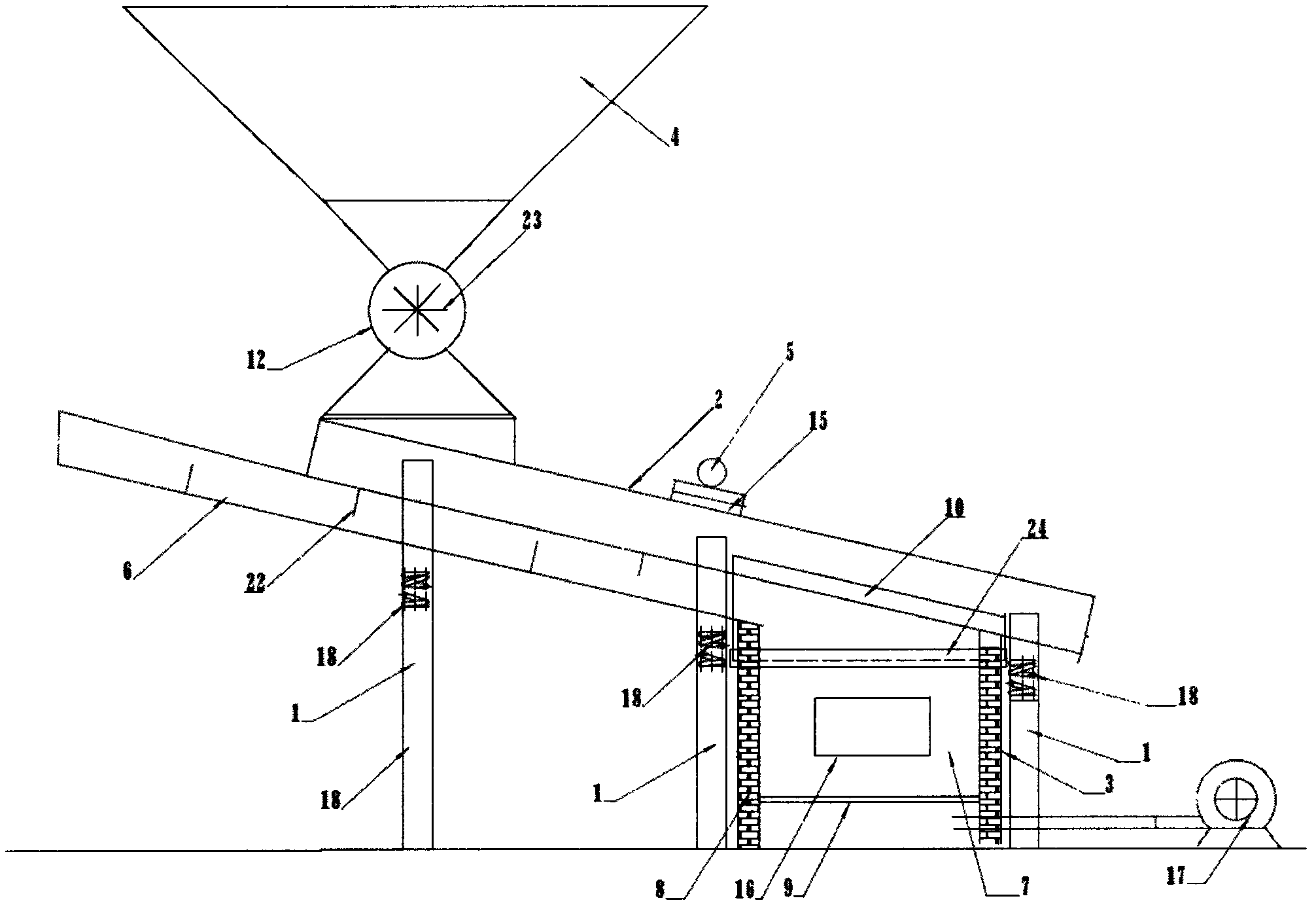

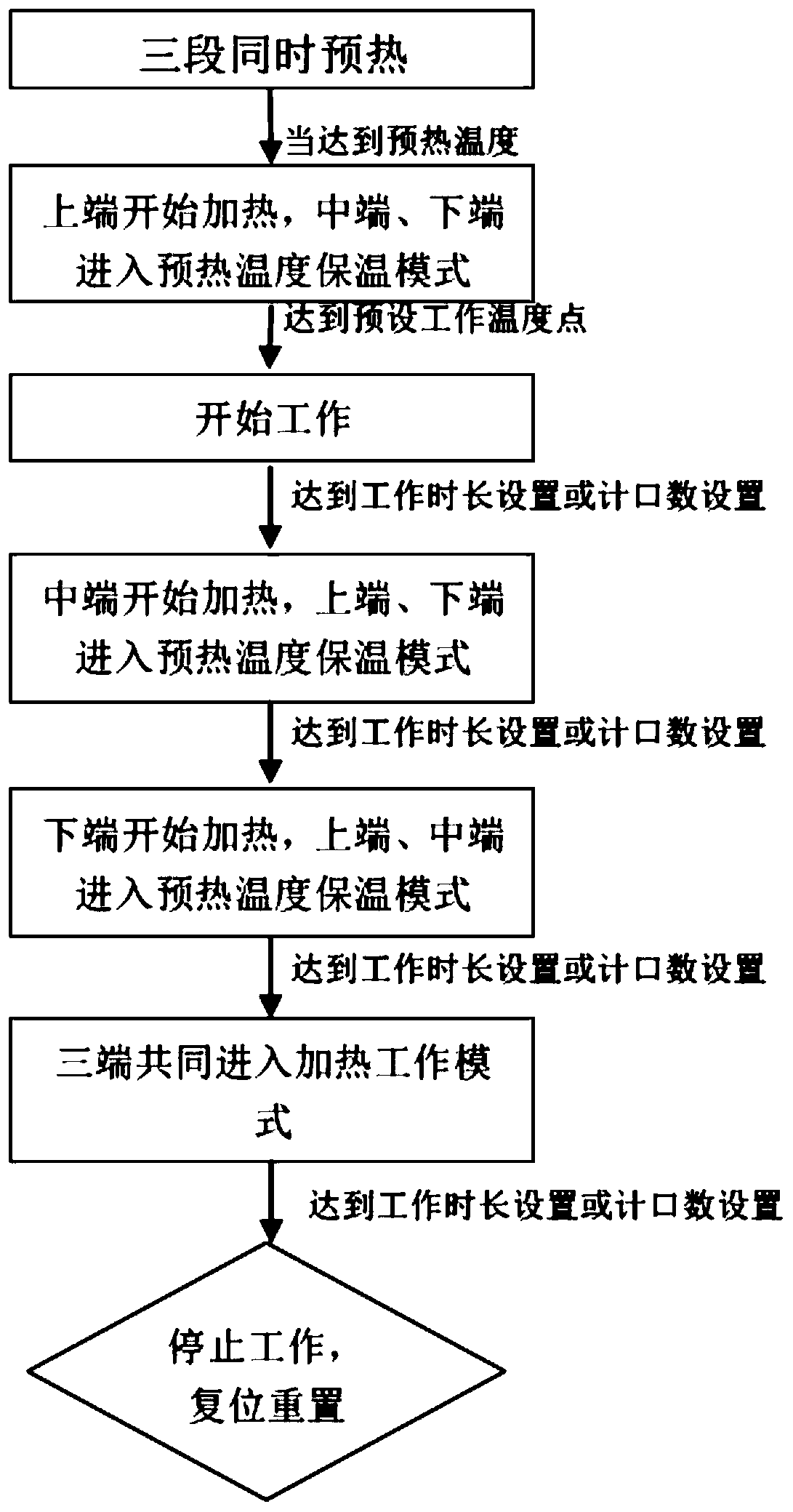

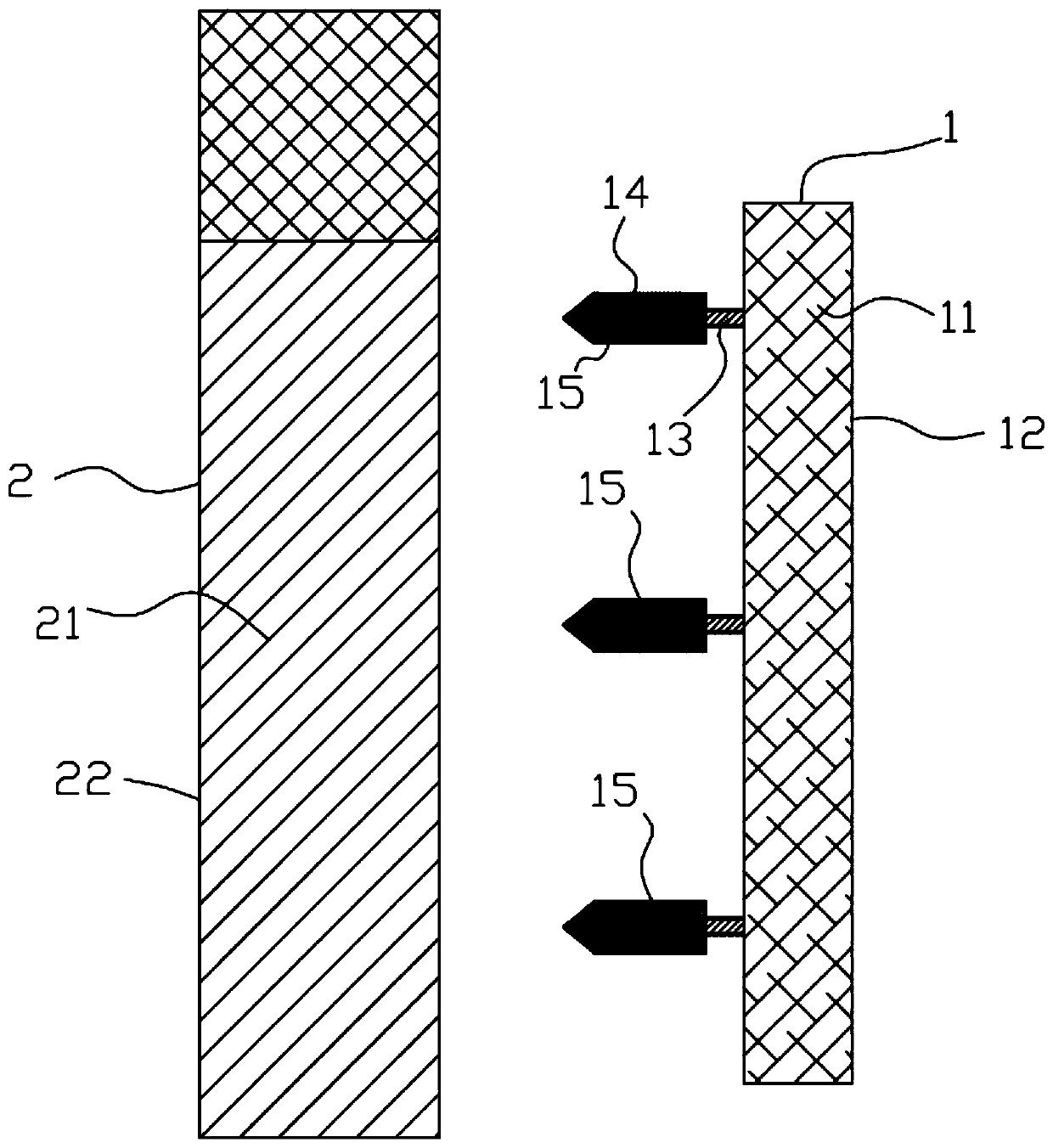

Multi-stage temperature control method of heat-not-burn system

The invention provides a multi-stage temperature control method for a heat-not-burn system. According to the method, a base plate is included, a third heating needle is arranged on the base plate, andheating modes of a first heating needle, a second heating needle and the third heating needle are controlled by a circuit board respectively; the first heating needle, the second heating needle, andthe third heating needle are inserted into a first section, a second section and a third section of a cigarette, and the first heating needle, the second heating needle, and the third heating needle heat the first section, the second section and the third section respectively and sequentially and then heat the cigarette together. The inside of the cigarette can be heated uniformly, the heat transfer is uniform, heat in the cigarette is in a balance state, and the defect is overcome that the local temperature is extremely high. The aromas from the cigarette can be fully volatilized, and the taste of smoking can be kept consistent and full with the fresh aromas at a time.

Owner:INNOKIN TECH

Leather hide powder implanting processing technology

ActiveCN109701827AFully distributedCompletely curedPretreated surfacesCoatingsMaterials scienceSpray drying

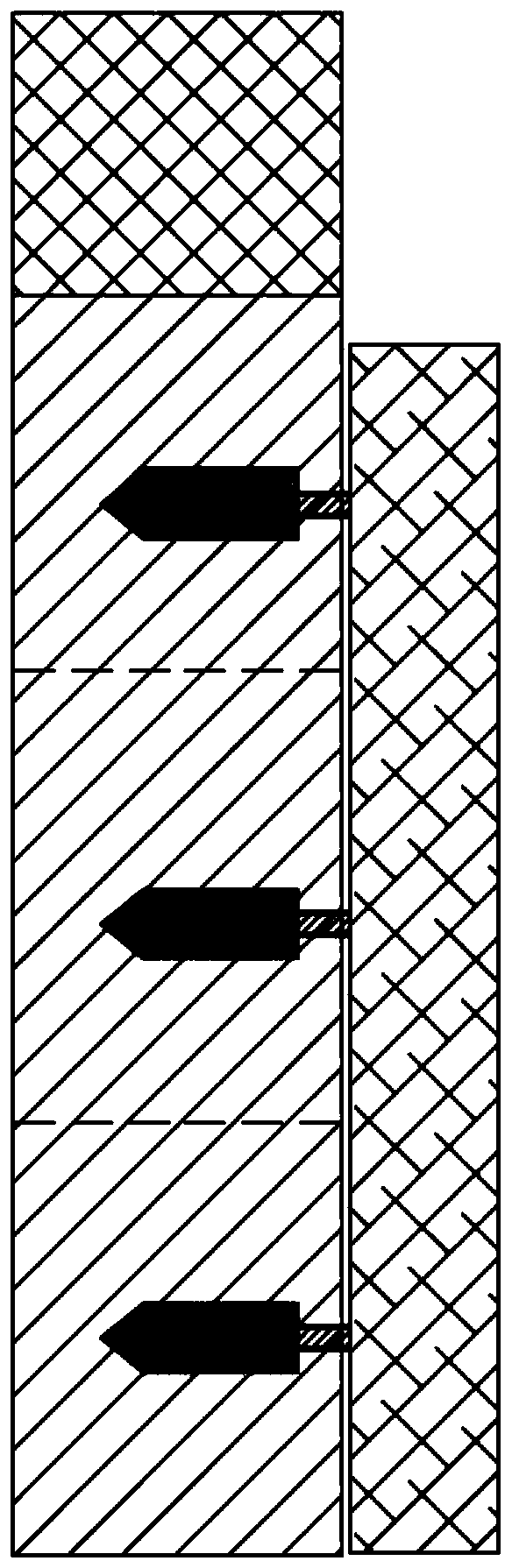

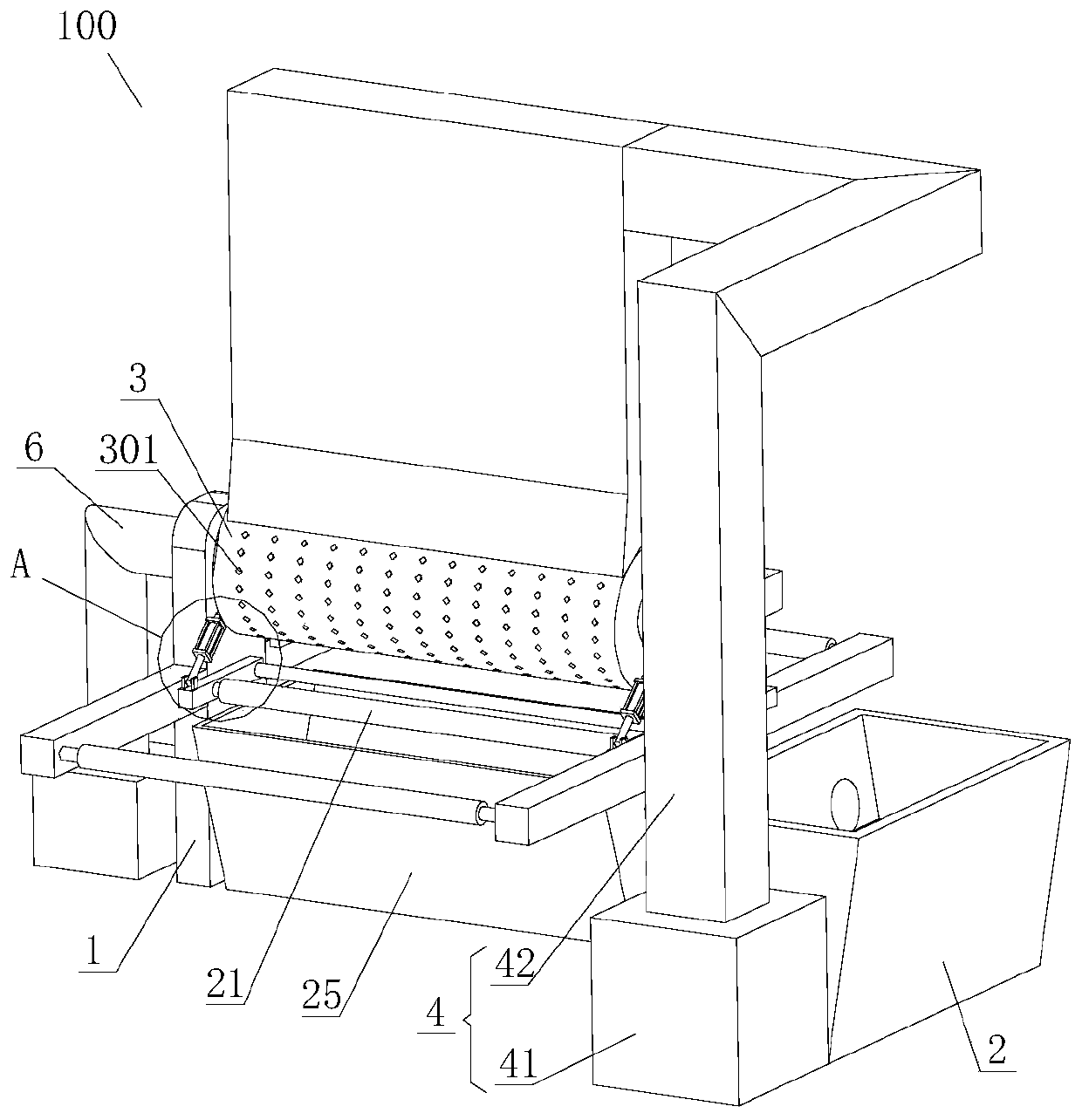

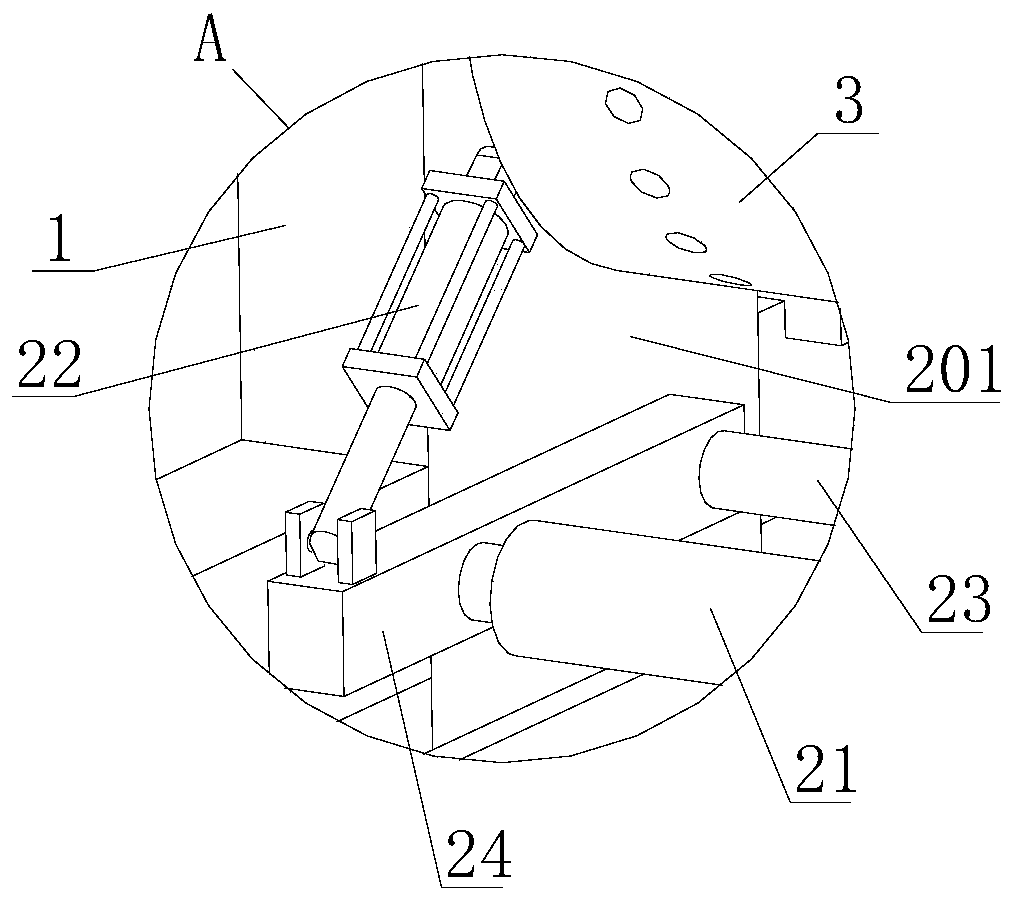

The invention relates to the technical field of hide powder implanting processing of leather, in particular to a leather hide powder implanting processing technology. According to the key point of thescheme, the leather hide powder implanting processing technology comprises the following working procedures: S1, coating the hide powder implanting surface of leather substrate with glue; S2, implanting the hide powder onto the hide powder implanting surface of the leather substrate; S3, feeding the leather substrate after hide powder implanting into drying equipment, wherein the drying equipmentcomprises a first drying box for carrying out primary drying on the leather substrate and a second drying box for carrying out secondary drying on the leather substrate, and an interval is arranged between the first drying box and the second drying box, so that when the leather substrate passes through the interval, the leather substrate is exposed to the external air; and the drying temperaturein the first drying box is lower than that in the second drying box; S4, brushing the hide powder implanting surface of the leather substrate; S5, polishing the hide powder implanting surface of the leather substrate; and S6, rolling the polished leather substrate. According to the scheme, the hide powder is unlikely to fall off the leather substrate.

Owner:东莞市亿兆布料制品有限公司

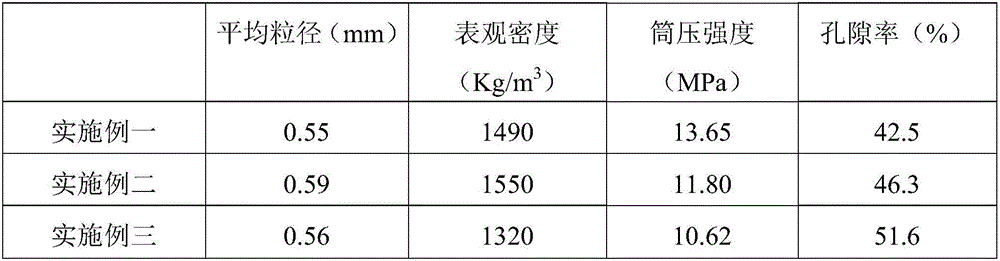

Diatomite-based ceramsite and preparation method thereof

The invention relates to a diatomite-based ceramsite and a preparation method thereof, and belongs to the field of ceramic materials. Raw materials used in the preparation method of the diatomite-based ceramsite comprise a solid raw material and an additive, wherein the solid raw material comprises, by mass, 50-60% of low grade diatomite, 15-20% of dolomite, 5-10% of glass powder and 10-20% of borax, the additive is a sodium silicate solution with the concentration of 13% or 26%, and the use amount of the sodium silicate is 8% of the total weight of the solid raw material. Compared with the prior art, the method disclosed in the invention has the advantages of sintering temperature reduction and small particle size. The method reduces the sintering temperature under the increasing short circumference of energy, so energy is saved, the produced ceramsite is environmentally-friendly, and the application range of the ceramsite is enlarged.

Owner:DALIAN POLYTECHNIC UNIVERSITY

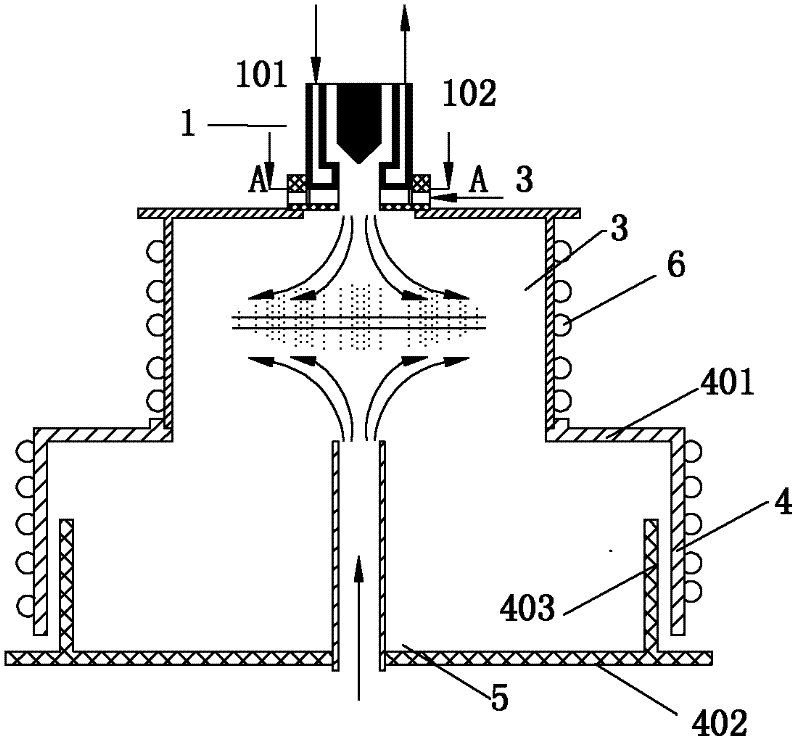

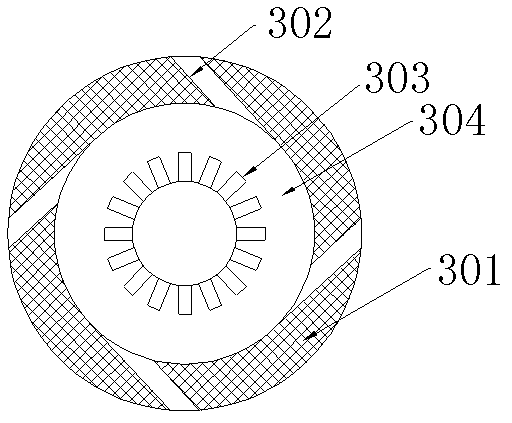

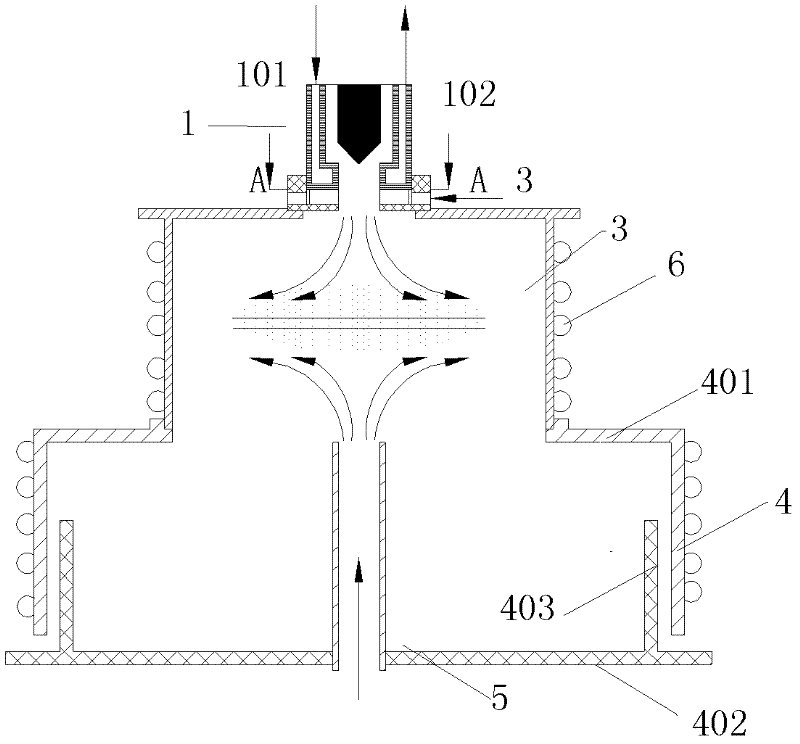

Annular uniform airflow power supplying device

InactiveCN102378461AEven powder supplyExtended stayNanotechnologyPlasma techniquePlasma jetPlasma generator

The invention discloses an annular uniform airflow power supplying device, belonging to the technical field of the preparation of a nanometer material by using direct-current arc plasma. The device comprises a plasma generator, a raw material injection ring, a quenching chamber, a collection chamber, a reverse quenching injection pipe and a cooling water pipe, wherein the plasma generator is provided with a cooling water inlet and a cooling water outlet, and is embedded in a notch of an annular fence frame of the raw material injection ring; the raw material injection ring comprises an outer ring, tangential inlets, the annular fence frame and a power supply mixing cavity; the outer ring is uniformly provided with tangential inlets; the center of the outer ring is provided with the hollowannular fence frame; the raw material injection ring is fixedly connected with the quenching chamber; and the collection chamber comprises an upper end of the collection chamber and a lower end of the collection chamber. According to the invention, raw material particles are injected into high-temperature plasma jet by the annular fence frame; therefore the distribution of the raw material is more uniform, and the melting and evaporation are more sufficient; and thus nanometer powder materials with higher quality are obtained.

Owner:BEIHANG UNIV

SiO2 aerogel and preparation method thereof

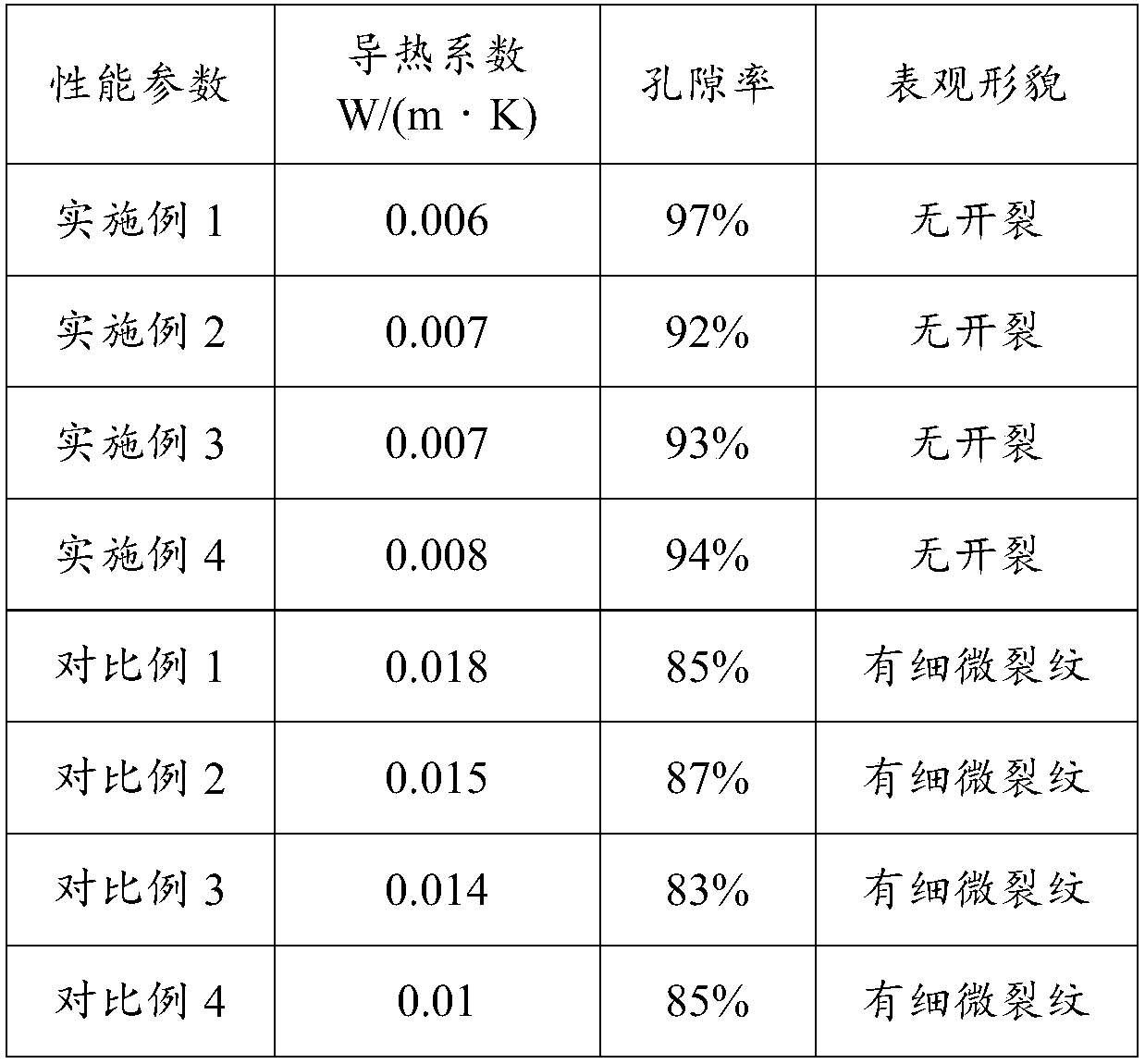

The invention provides SiO2 aerogel and a preparation method thereof and relates to the field of aerogel. The preparation method of the SiO2 aerogel comprises the step: drying wet SiO2 gel prepared byadopting a sol-gel method by utilizing a supercritical drying method, thereby obtaining the SiO2 aerogel. The supercritical drying comprises sub-steps: gradually boosting the pressure in an inert atmosphere and in a pressure range of 2-7MPa so as to perform gradient stage drying, raising the pressure to 11-12MPa, and performing constant pressure drying, wherein the constant pressure drying temperature is 270-280 DEG C. According to the preparation method, the technical problem that aerogel skeleton shrinkage crack and hole collapse is easily caused in the conventional preparation method can be solved, and the aims of improving the porosity and preventing the aerogel from cracking are achieved.

Owner:TIANJIN MROGAN KUNDOM HI TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com