Water source heat pump unit system for low temperature water source

A water source heat pump unit and water source technology, applied in heat pumps, refrigerators, refrigeration components, etc., can solve the problems of difficult discharge, freeze cracking, and large amount of refrigerant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

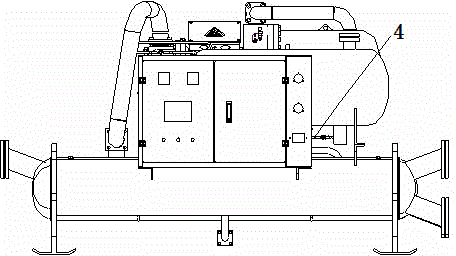

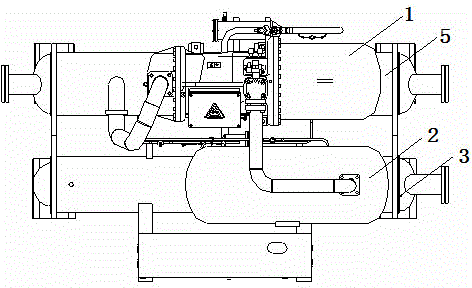

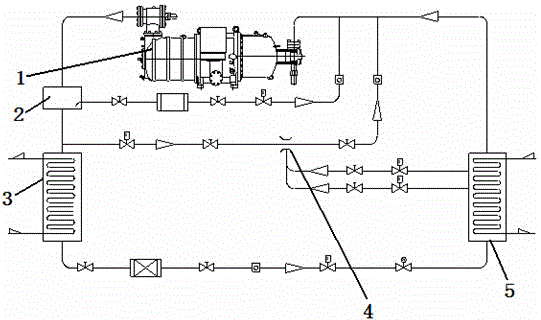

[0019] For the water source heat pump unit system applicable to low temperature water sources in this embodiment, refer to Figure 1-5 , including compressor 1, oil separator 2, condenser 3, oil return injection device 4, evaporator 5, and also includes dry filter, filter, hand valve, solenoid valve, regulating valve, expansion valve, sight glass and so on to connect the adjustment parts.

[0020] Among them, the evaporator 5 adopts a falling film structure, and a liquid distributor 6 is installed on the top of the evaporator. The liquid inlet pipe 7-1 is provided on the top of the evaporator, and its nozzle is in contact with the surface of the liquid distributor 6, and the liquid distributor 6 6 below is provided with heat exchange tube bundle 8. The mixture of refrigerant and lubricating oil enters the evaporator through the liquid inlet pipe 7-1, and is evenly distributed to the surface of the heat exchange tubes through the liquid distributor to fully evaporate the refri...

Embodiment 2

[0028] In order to achieve a better liquid distribution effect, the water source heat pump unit system of this embodiment is suitable for low-temperature water sources, so further improvements are made on the basis of the structure of Embodiment 1, that is, the heat exchange tubes in the heat exchange tube bundle 8 are in the shape of an equilateral triangle The arranged single-process shell-and-tube structure and the single-process circulation of refrigerant water avoid the risk of freezing and cracking of heat exchange tubes caused by multi-process heat exchange and lower water temperature.

Embodiment 3

[0030] The water source heat pump unit system suitable for low-temperature water sources in this implementation is based on Embodiments 1 and 2, and the liquid distributor is limited to a spray structure, and the refrigerant is sprayed through the spray liquid distributor. On the heat transfer surface of the heat exchange tube, the surface of the heat exchange tube is better wetted and has a better heat exchange effect.

[0031] The water source heat pump unit system suitable for low temperature water sources of the present invention has the following advantages:

[0032] 1. The evaporator adopts a falling film structure and the water system in the heat exchange tube bundle is a single-flow cycle. The refrigerant is evenly distributed to the heat exchange tubes through the liquid distributor above the evaporator to increase the heat exchange effect and fully evaporate the refrigerant. In turn, less refrigerant is stored at the bottom of the evaporator, which prevents too much ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com