Patents

Literature

190results about How to "Reduce reserves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

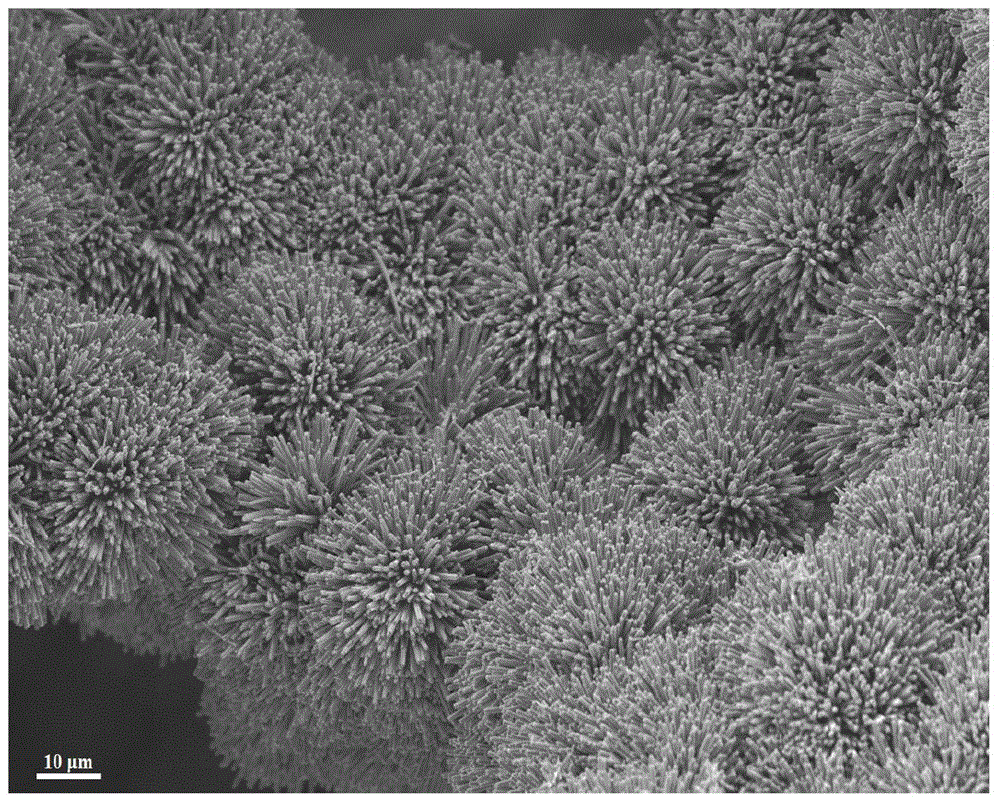

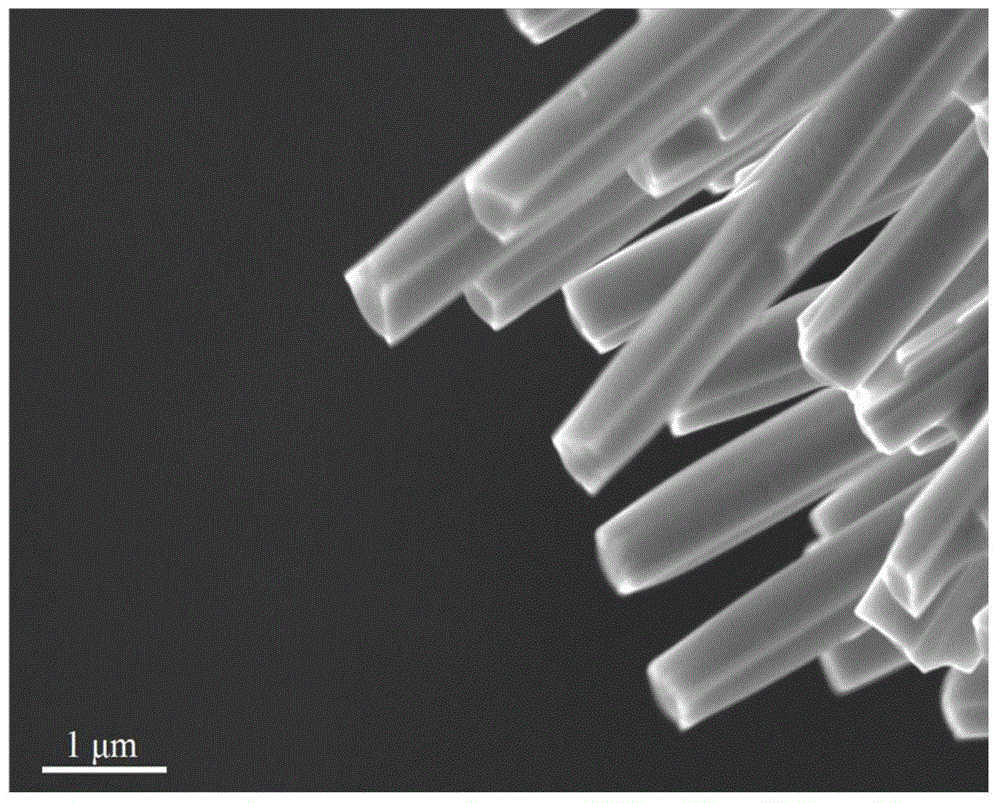

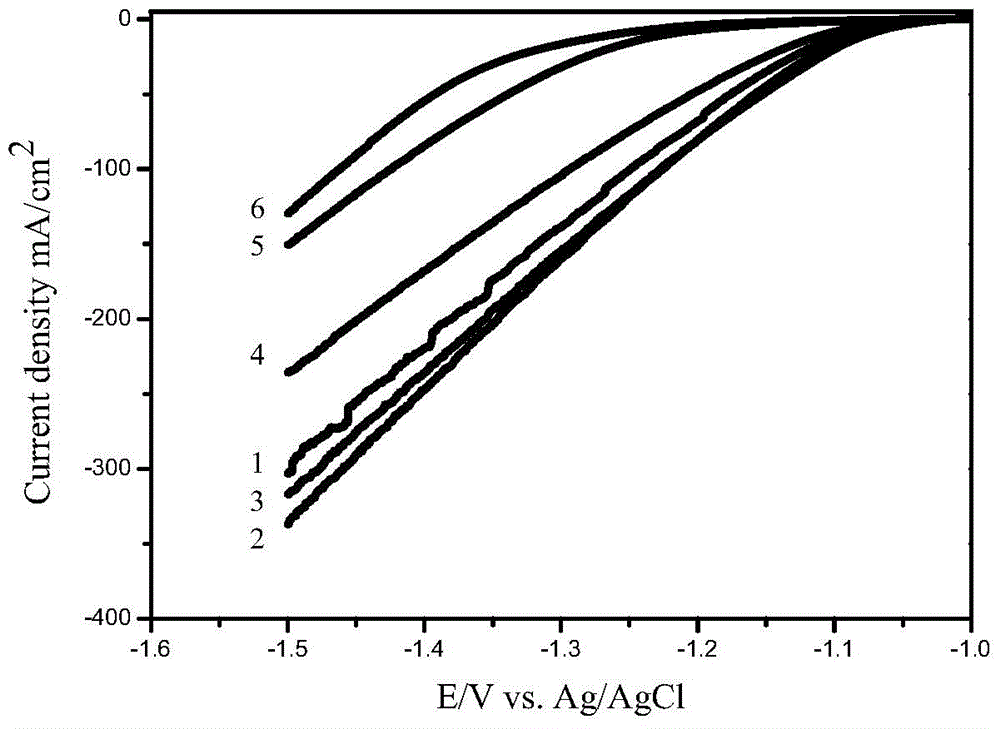

Method for preparing high-performance molybdenum-based hydrogen evolution electrode by phosphatizing molybdate precursor

The invention provides a method for preparing a high-performance molybdenum-based hydrogen evolution electrode by phosphatizing a molybdate precursor and belongs to the fields of water electrolysis and electric catalytic hydrogen evolution in the chlor-alkali industry. The method comprises the steps of pre-processing foamed nickel, growing the molybdate precursor in situ on the surface of a pre-processed foamed nickel base with the hydrothermal synthesis method, and finally placing the prepared precursor and a phosphorus source into a rube furnace together for phosphating of the molybdate precursor so that the high-performance molybdenum-based hydrogen evolution electrode can be prepared. The method is novel, the technology adopted is simple, production cost is low, the requirement for equipment is low, and the method is suitable for industrial production. Furthermore, the electrode is large in specific area, can be combined with the base firmly, has excellent hydrogen evolution activity and stability, and can be widely applied to the fields of water electrolysis and hydrogen evolution in the chlor-alkali industry.

Owner:CHONGQING UNIV

General multifunctional foam fire-extinguishing agent and its preparing method

InactiveCN1820806AEnhanced burn resistanceImprove film formationFire extinguisherChemistryHydrocarbon

The general multifunctional foam fire-extinguishing agent consists of plant protein 0.8-30 wt%, sugar 0.8-30 wt%, hydrocarbon surfactant 1-12 wt%, fluoric surfactant 0.1-5 wt% and additive 5-20 wt%, except water. The general multifunctional foam fire-extinguishing agent may be used to extinguish fire of alcohol and other polar chemical matter and / or light oil, heavy oil and other non-polar chemical matter. The general multifunctional foam fire-extinguishing agent contains no corrosive chemical matter, and has self-cleaning property, capacity of prolonging the service life of the fire-extinguishing equipment, no toxicity and no harm to human body and no environmental pollution.

Owner:北京特威特科技有限公司

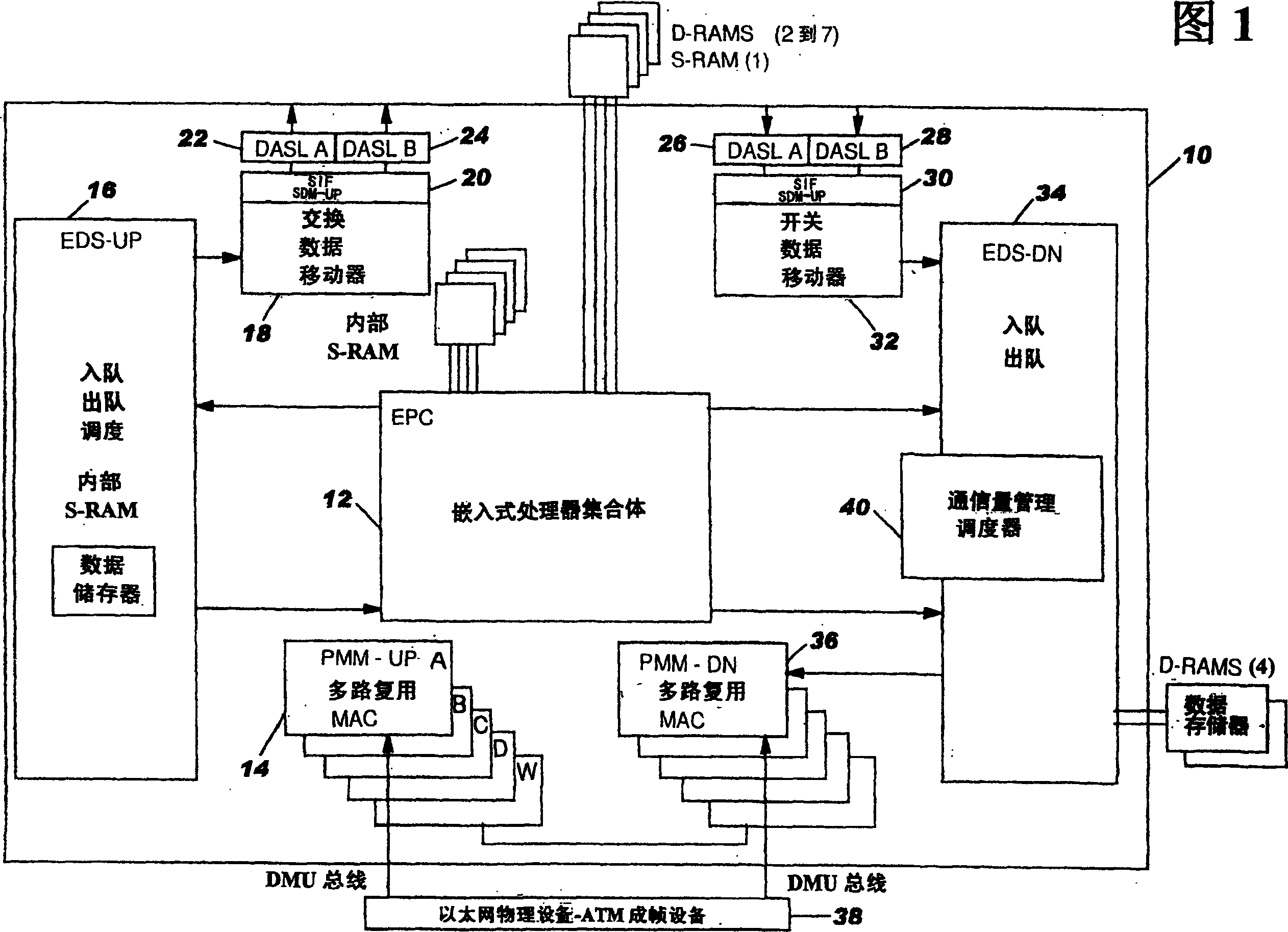

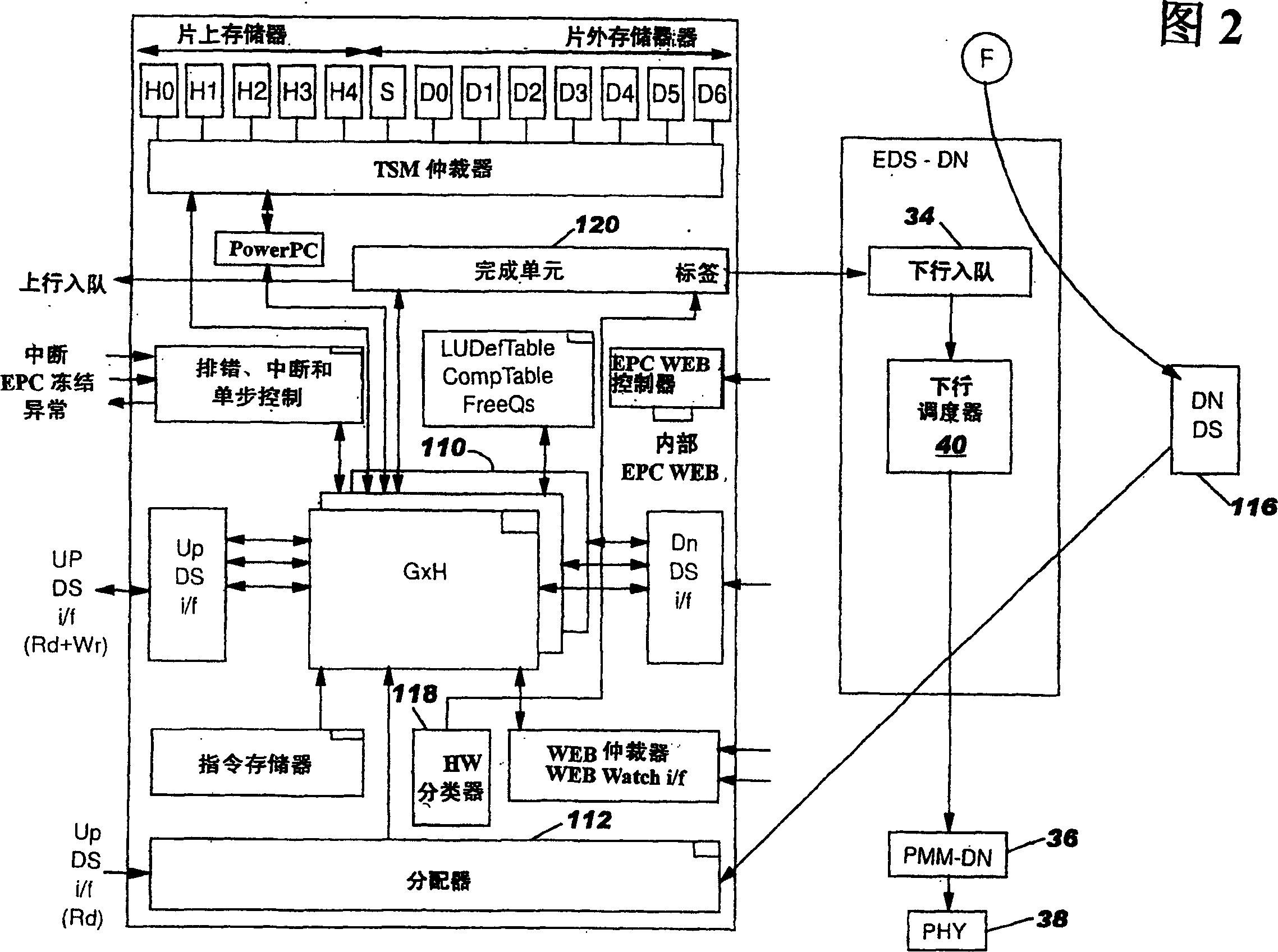

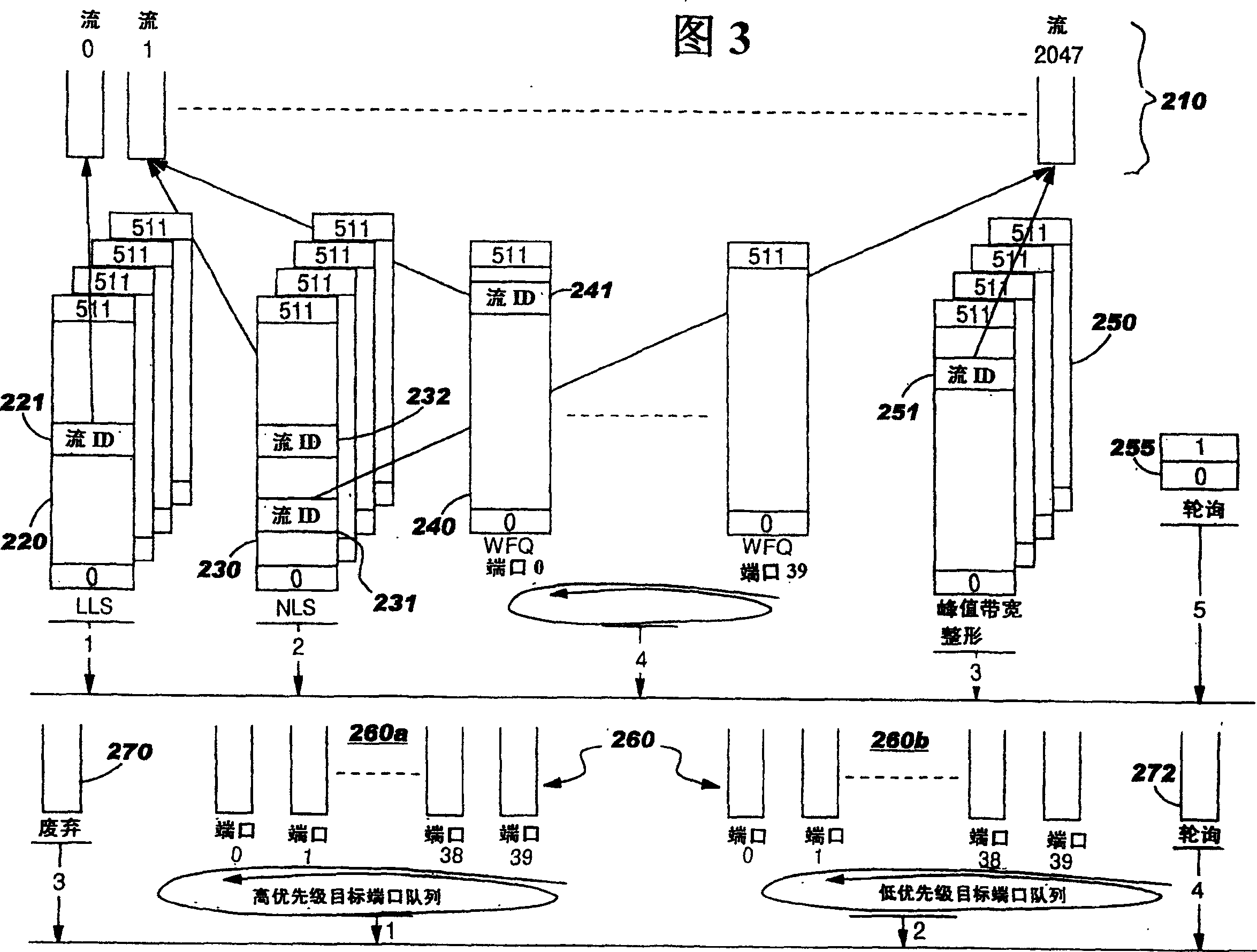

Method and system for network processor scheduling outputs using disconnect/reconnect flow queues

InactiveCN1642143AEfficient use ofFair useStore-and-forward switching systemsTime-division multiplexing selectionHigh bandwidthNetwork processing unit

A system and method of moving information units from a network processor toward a data transmission network in a prioritized sequence which accommodates several different levels of service. The present invention includes a method and system for scheduling the egress of processed information units (or frames) from a network processing unit according to stored priorities associated with the various sources of the information units. The priorities in the preferred embodiment include a low latency service, a minimum bandwidth, a weighted fair queueing and a system for preventing a user from continuing to exceed his service levels over an extended period. The present invention includes a plurality of calendars with different service rates to allow a user to select the service rate which he desires. If a customer has chosen a high bandwidth for service, the customer will be included in a calendar which is serviced more often than if the customer has chosen a lower bandwidth.

Owner:INT BUSINESS MASCH CORP

Forging process of bearing ring

ActiveCN104827245AEliminate Inherent DefectsIncrease tightnessBearing componentsEngine componentsPunchingMedium frequency

The invention relates to a forging process of a bearing ring. The process includes following steps that: 1) in first firing, a medium-frequency induction heating furnace is adopted to heat an ingot to 1200 DEG C, dead head pressing, chamfering and sprue filing are performed; 2) in second firing, re-heating, upsetting and drawing out are performed on the machined ingot; 3) in third firing, re-heating, upsetting, rotary flattening, punching and reaming are performed on the machined ingot; 4) in fourth firing, the machined ingot is re-heated, and upsetting is performed on the machined ingot in a mold ring, so that the machined ingot can be in a technique size, the mold is removed, and reaming is performed on the machined ingot, so that the machined ingot can be in a technique size, and total forging ratio is controlled to be larger than 5; 5) groove turning is performed, the machined ingot is subjected to cold rolling and reeling on a closed shaping and reaming machine, and rolling paths and chamfered angles are molded with one step, truing is performed, and two end surfaces are subjected to soft grinding; 6) the machined ingot is pre-heated to 800 DEG C to 850 DEG C, after crack detection is performed, when the temperature of the machined ingot is lower than 450 DEG C, the machined ingot is put into the furnace so as to pre-heated to 600 DEG C to 650 DEG C, and heat preservation is performed on the machined ingot, and the machined ingot is put in to the furnace of which the temperature ranges from 950 DEC C to 1000 DEC and is rapidly heated to 1140 DEC C to 1200 DEC C, and water quenching is performed, and instantly, tempering from 550 DEC C to 600 DEC C is performed on the machined ingot, and the machined ingot is cooled to 400 DEC C to 450 DEC C in the furnace, and the machined ingot is taken out from the furnace and cooled. With the forging process adopted, inherent defects of metal can be eliminated, and the service life of a bearing can be prolonged.

Owner:JIANGSU JINYUAN FORGE

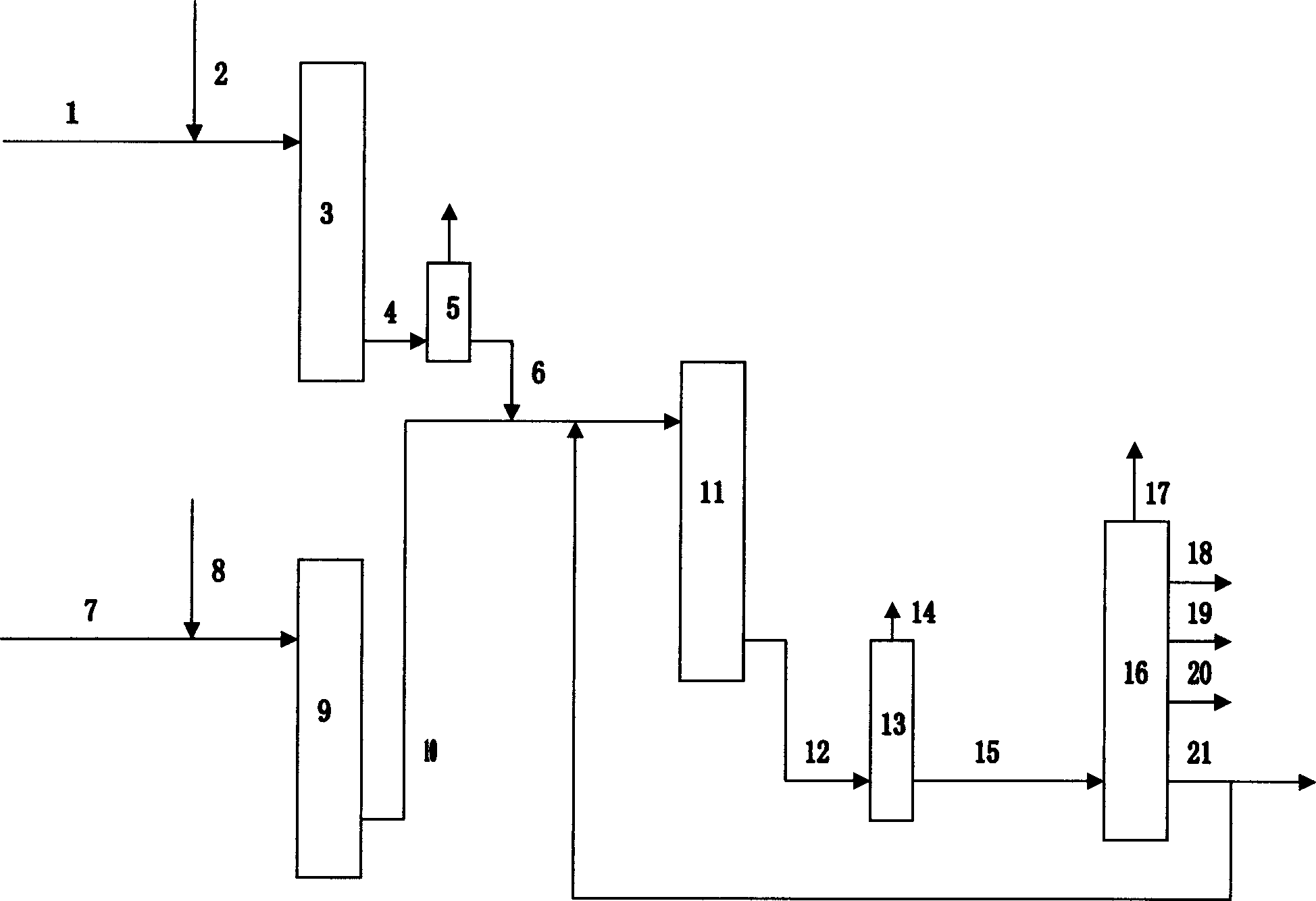

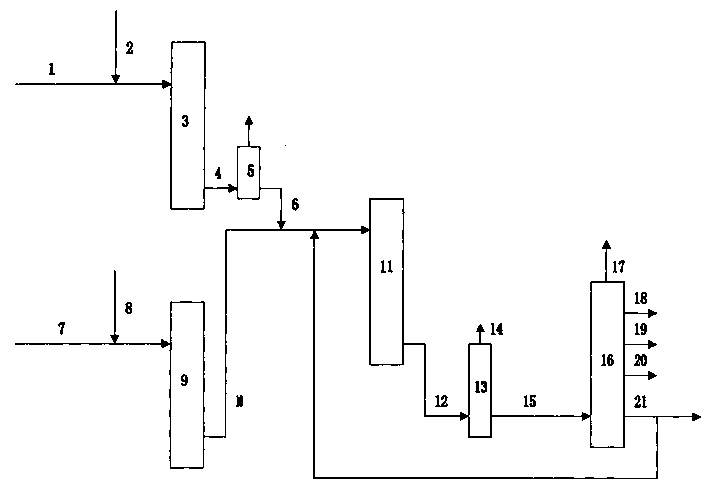

Hydrocracking method for increasing quality of refined diesel oil

InactiveCN1488731AIncrease the volume ratioReduced inlet temperature requirementsTreatment with hydrotreatment processesSulfurHydrodesulfurization

The present invention discloses a hydrocracking process for raising refined diesel oil quality, and is mainly characterized by that the poor diesel oil is undergone the process of hydrodesulfurization treatment, then the desulfurized refined diesel oil is mixed with the refined hydrocracked raw material oil, and fed into the hydrocracking reactor, and the sulfur and nitrogen contents in the mixed oil of the refined diesel oil and refined hydrocracked raw material oil must meet the feeding requirements of hydrocracking reactor. As compared with existent technology said invention can utilize hydrocracking equipment to raise the quality of refined poor diesel oil and can obtain high-quality clean fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

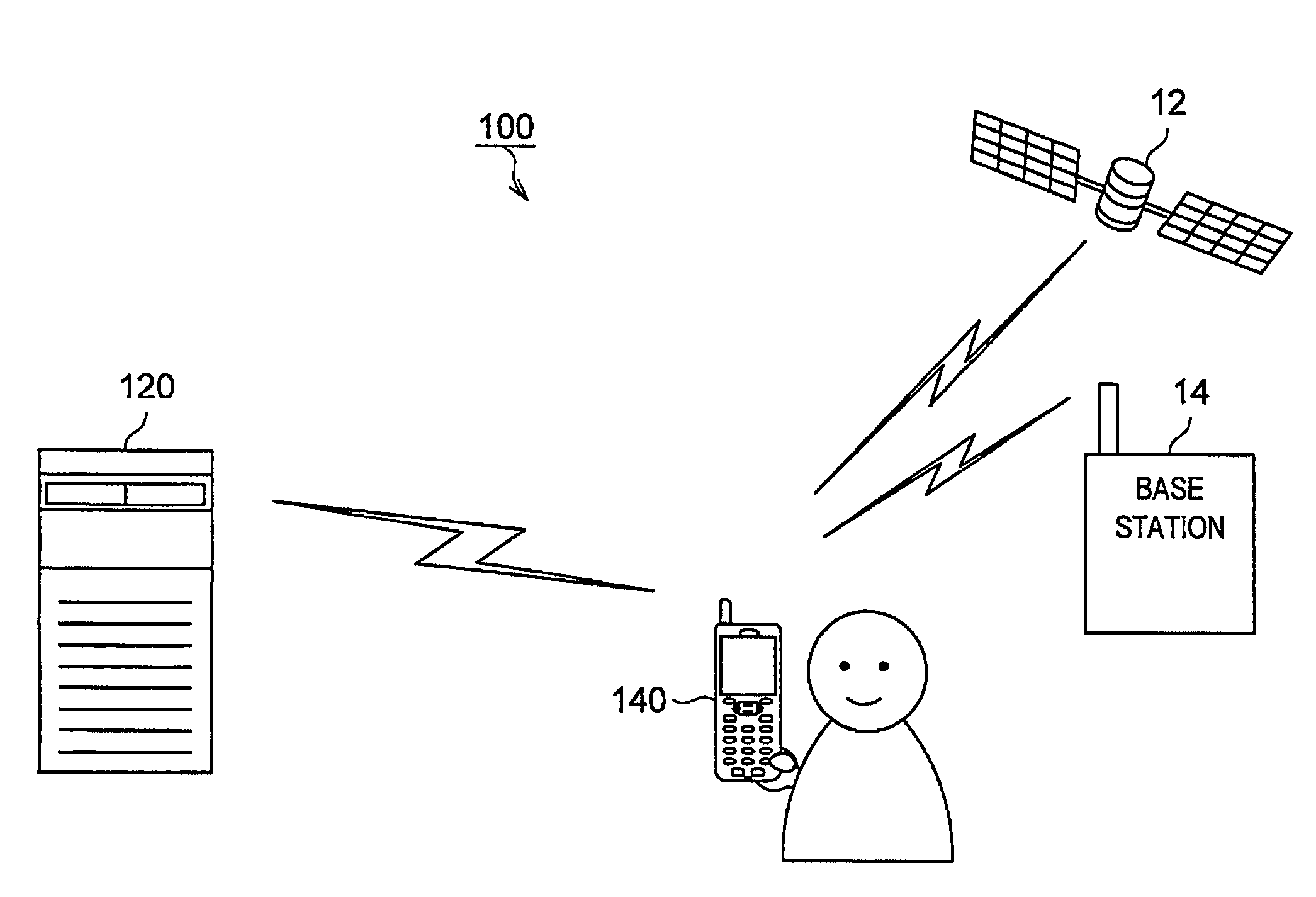

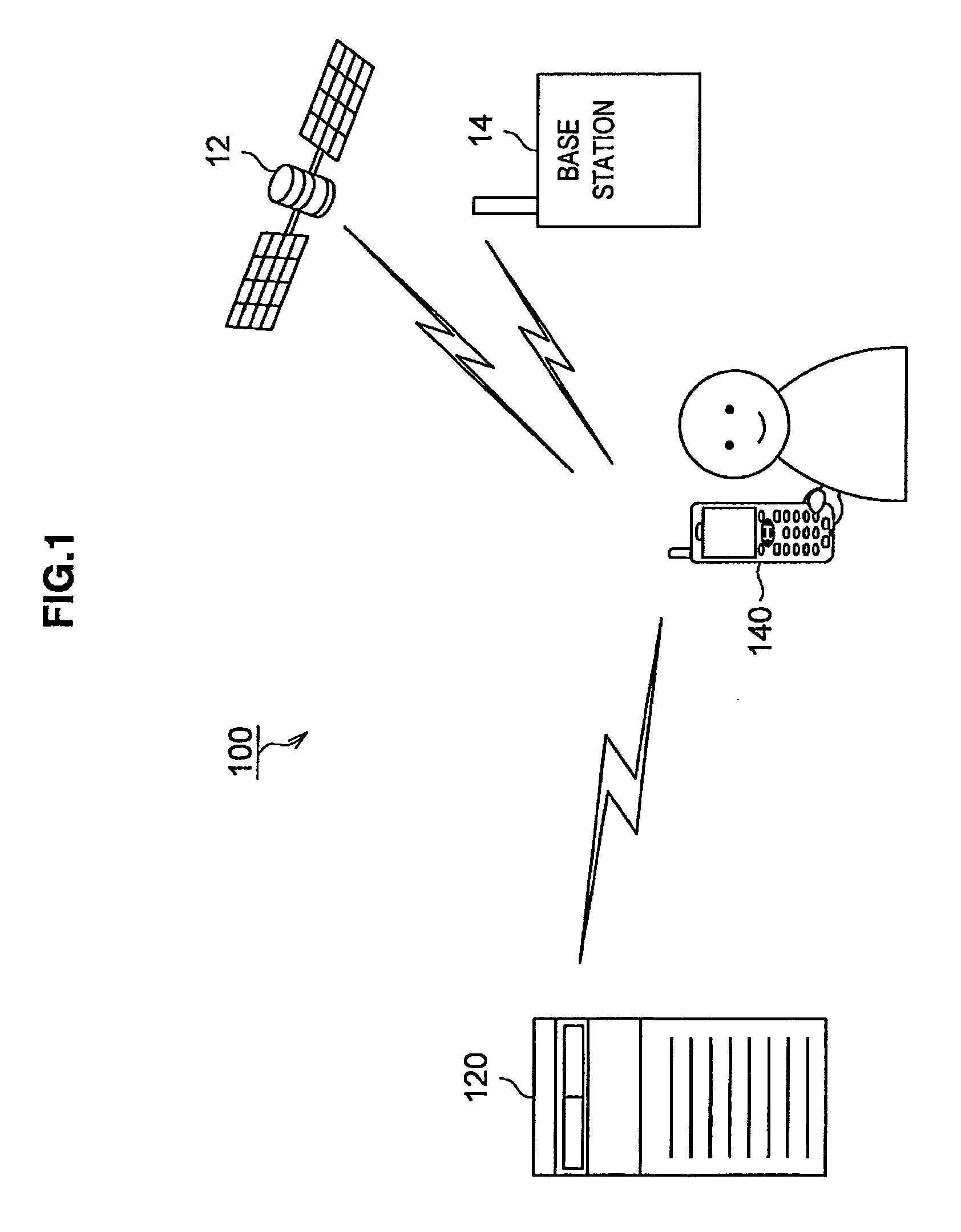

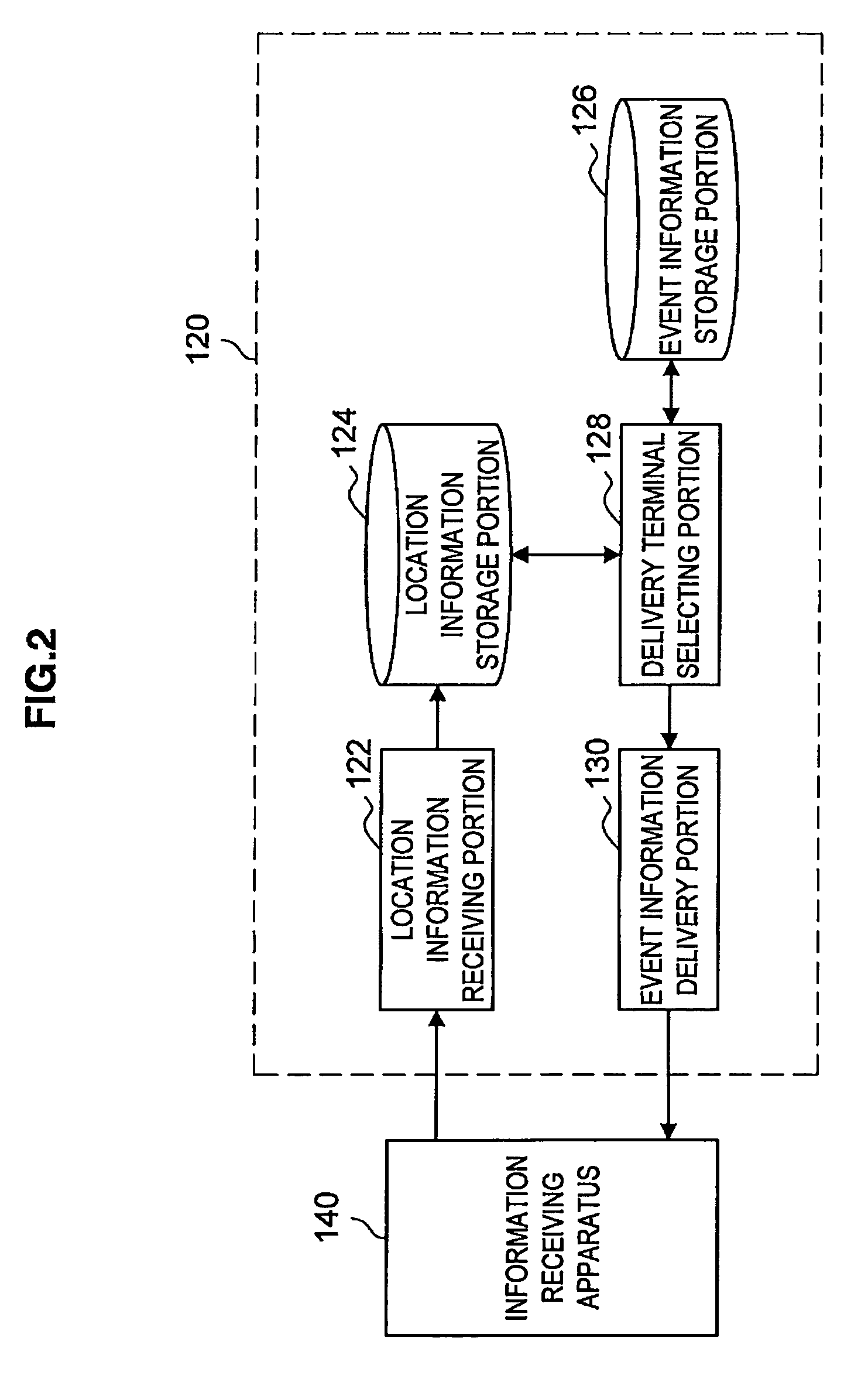

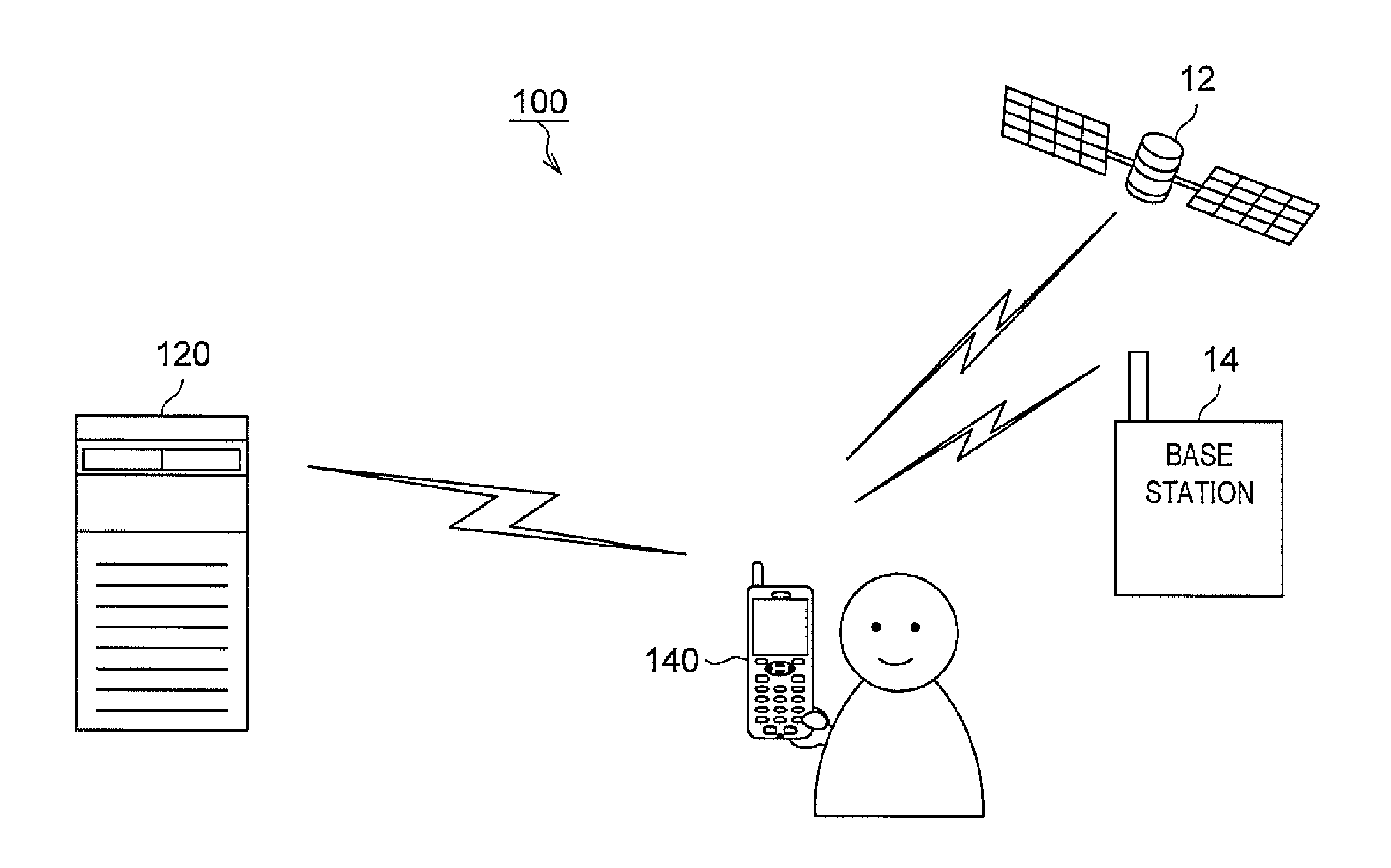

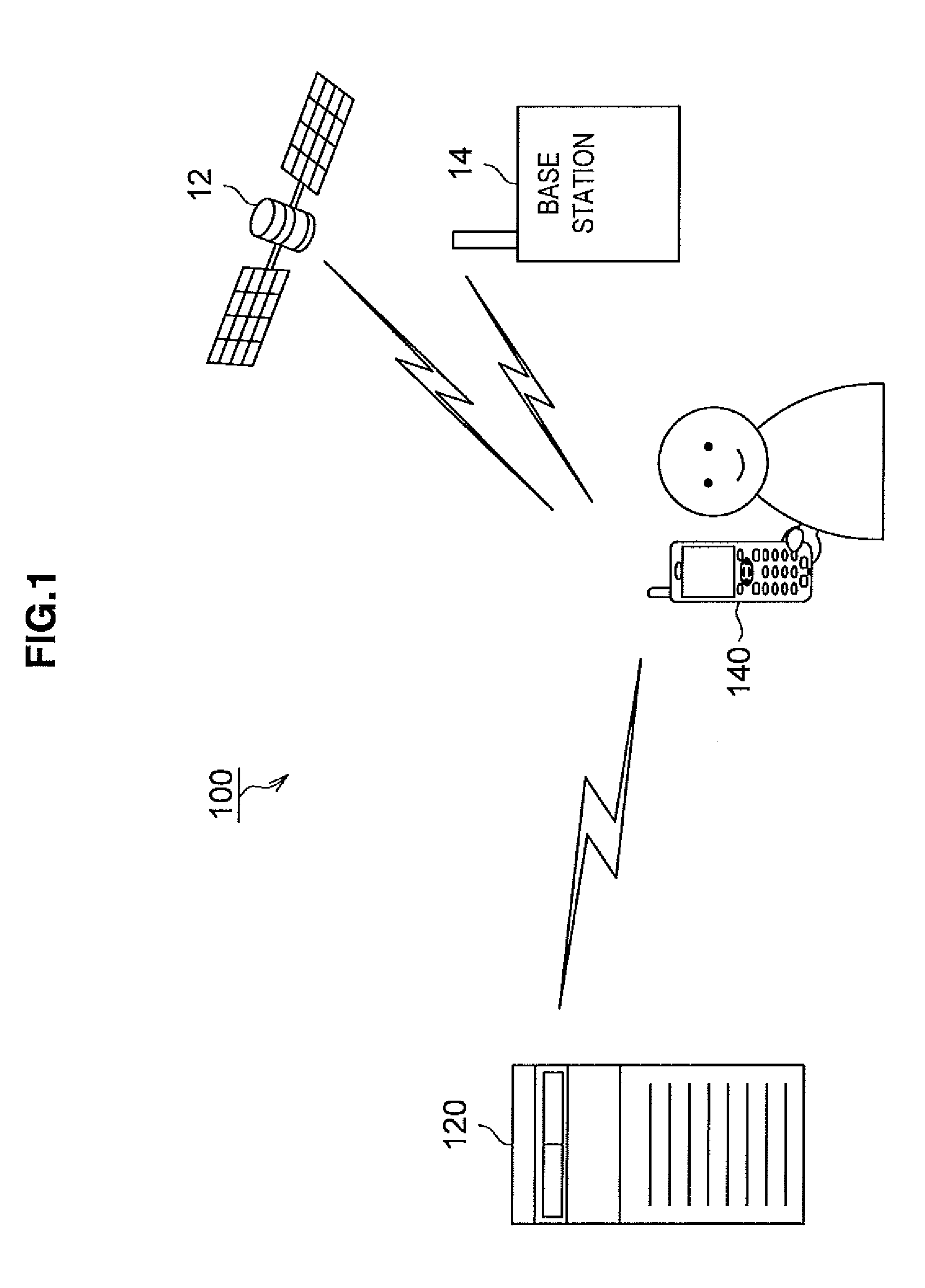

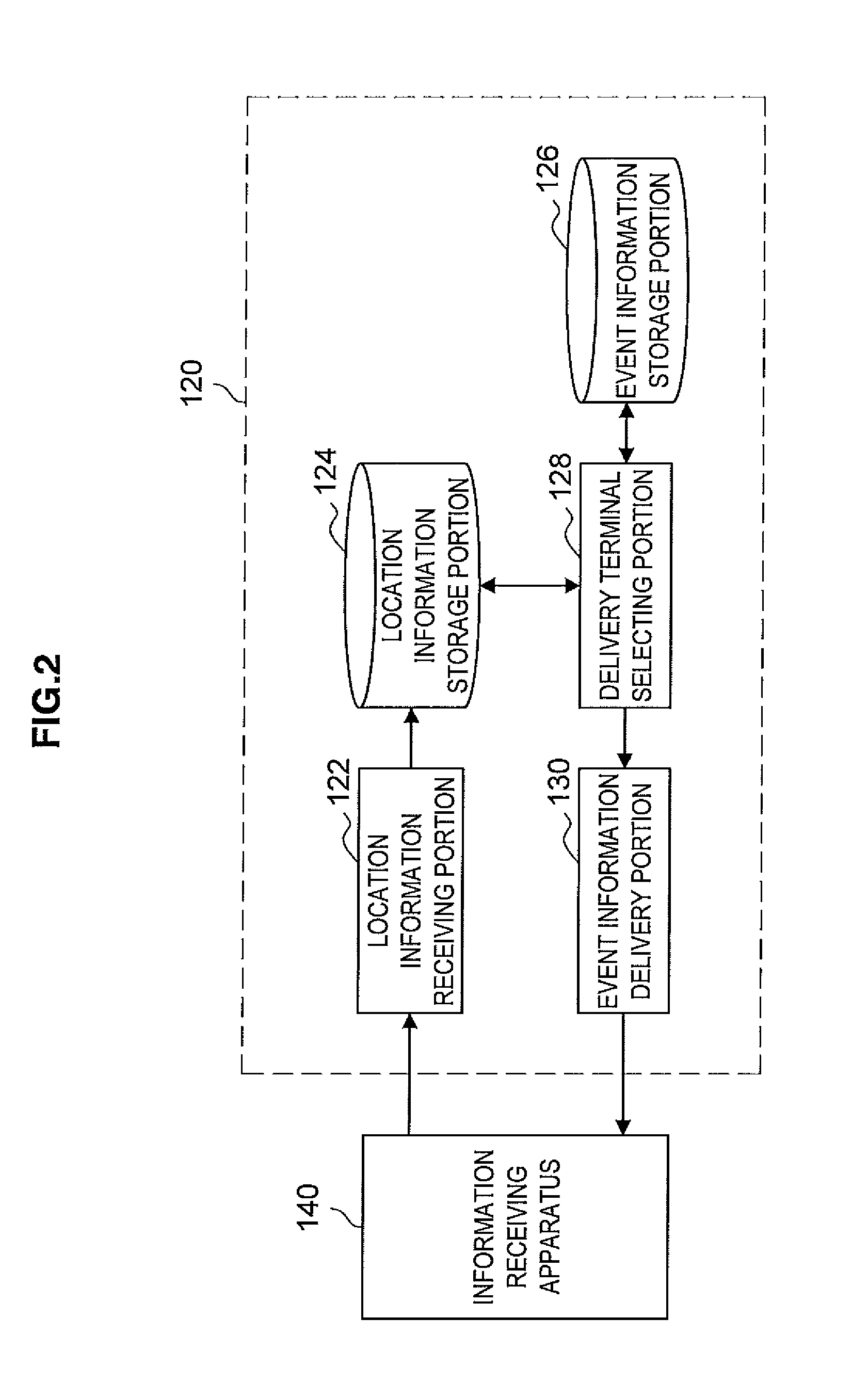

Information delivery apparatus, information receiving apparatus, information delivery method, information receiving method and information delivery system

ActiveUS20090068992A1Improve advertising effectImprove advertising effectivenessInformation formatContent conversionInformation deliveryReal-time computing

There is provided an information delivery apparatus including a receiving portion to receive location information of a mobile communication terminal at a given time and acquired date and time of the location information from the terminal, an event information storage portion to store event information including an event place, date and time, a delivery terminal selecting portion to select the mobile communication terminal to which the event information is to be delivered based on the location information and the acquired date and time of the location information and on the event place, date and time, and an event information delivery portion to deliver the event information to the selected mobile communication terminal. The delivery terminal selecting portion selects the mobile communication terminal whose location indicated by location information is within a predetermined range and whose acquired date and time of the location information are before the event date and time.

Owner:SONY CORP

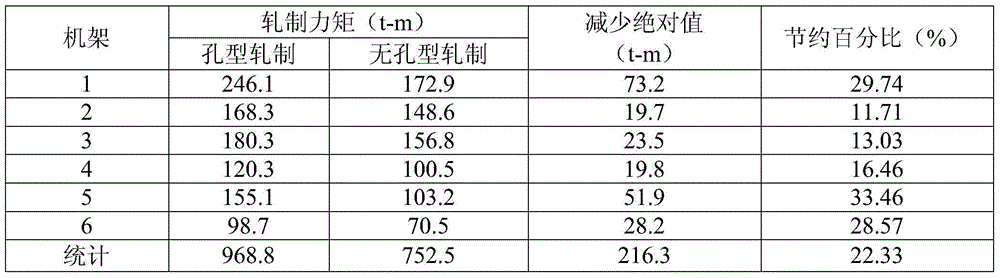

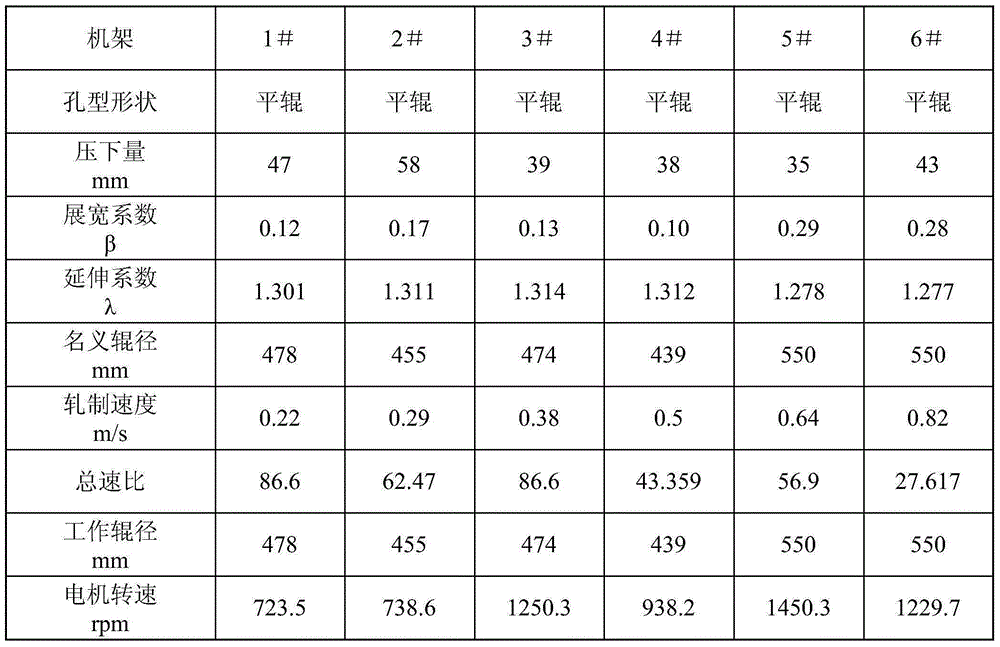

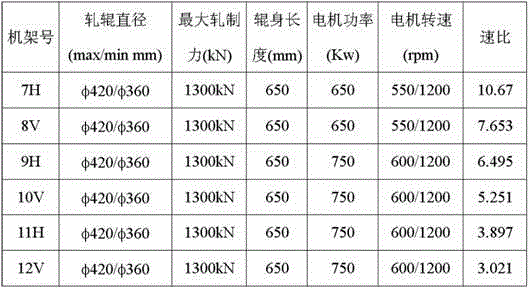

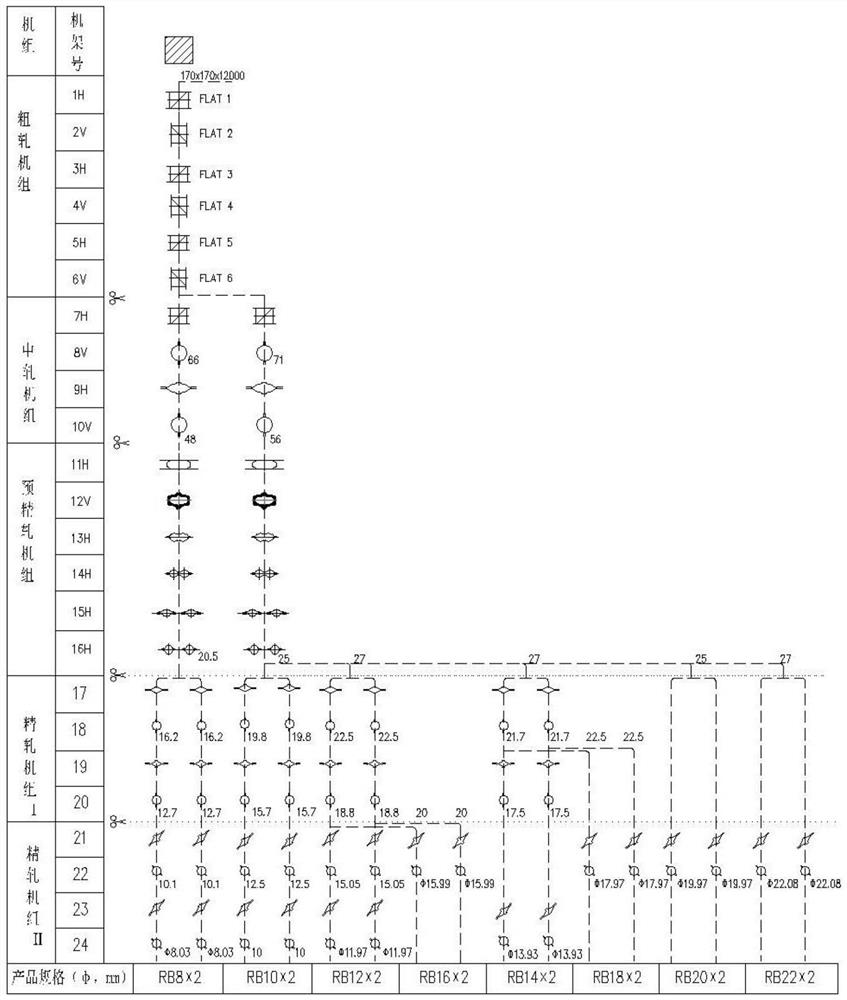

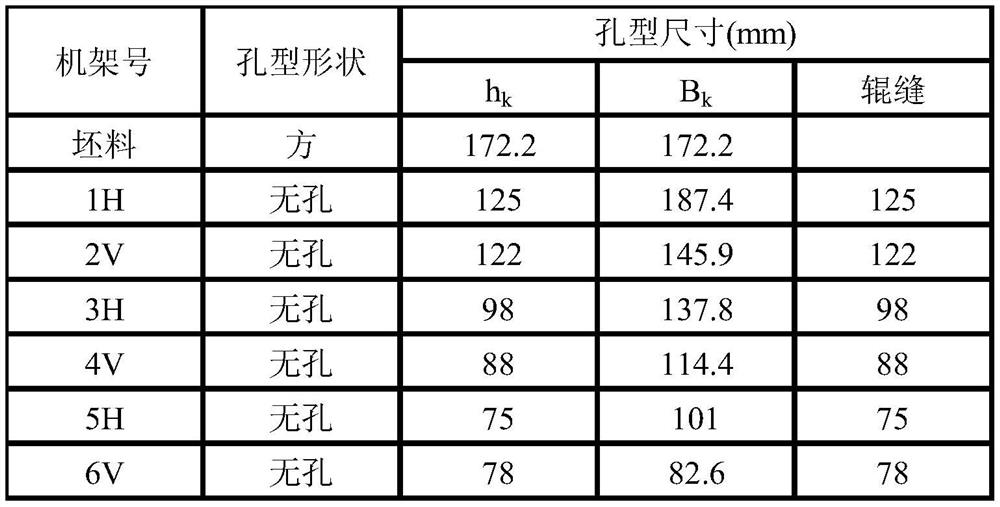

Production process for grooveless rolling of 82B wire rod by high-speed wire mill

ActiveCN104084421ASharedReduce reservesWork treatment devicesMetal rolling arrangementsWire rodEconomic benefits

The invention belongs to the technical field of rod wire deformation processes in metallurgical industry and particularly relates to a production process for grooveless rolling of an 82B wire rod by a high-speed wire mill. The production process aims that special equipment is not required, the processing cost is low, industrialized production is easy to realize, the steel off-square problem of a grooveless rolling production process is solved, the production accident rate is greatly reduced, the product quality is improved, and the economic benefit is increased. The production process adopts the technical scheme as follows: the production process comprises the following steps: (1) heating a 82B steel billet; (2) rolling by a grooveless flat-roll rough rolling unit, wherein in the rolling process, the extension coefficient of each pass is controlled from 1.20 to 1.45, the broadening coefficient ranges from 0.10 to 0.65, and the running speed of the steel billet ranges from 0.20 m / s to 1.04 m / s; (3) entering an intermediate rolling unit and a pre-finishing unit in sequence for rolling; (4) rolling by a finishing unit; (5) cooling by water and entering a wire-feeding machine to obtain the wire rod; (6) cooling by air, winding and transporting, and finally packaging and warehousing to obtain the finished high-speed 82B wire rod.

Owner:西安盛日机电科技有限公司

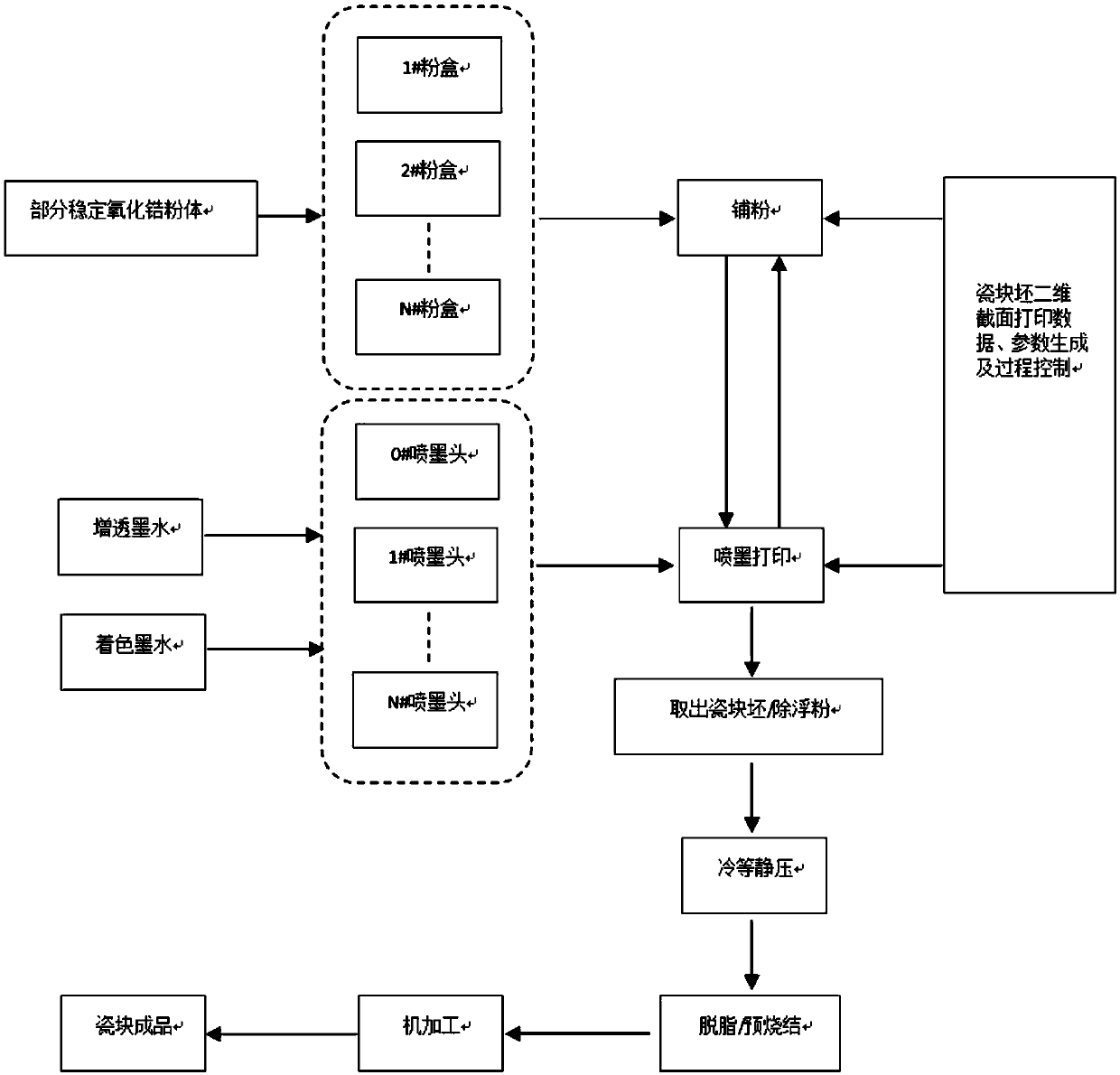

Zirconia porcelain block for all-porcelain denture, and preparation process thereof

ActiveCN111072382AEasy to processReduce reservesAdditive manufacturing apparatusLight transmissionBatch manufacturing

The invention provides a zirconia porcelain block for all-porcelain denture, and a preparation process thereof, and belongs to the technical field of dental ceramic materials. According to the invention, the color and / or the light transmittance of the zirconia porcelain block are / is in multilayer quasi-continuous gradient change from one side to the other side in a determined direction; the zirconia porcelain block is prepared by adopting an ink-jet additive printing technology, and is formed by periodically laying powder layer by layer along a determined direction and selectively printing andsuperposing blank ink and / or coloring ink with different solute concentrations and / or anti-reflection ink layer by layer in an ink-jet printing manner by taking partially stabilized zirconia powder as a raw material; the adopted ink-jet additive printing technology is high in forming speed, large-batch production can be achieved, and personalized customization can be achieved; and the produced product is stable in performance, can completely avoid the defects that the existing zirconia porcelain block for the all-porcelain denture is hard in color and / or light transmittance change, unnatural,vivid and the like, and meets the aesthetic repair requirement of the all-porcelain denture .

Owner:SUZHOU DINGAN ELECTRONICS TECH

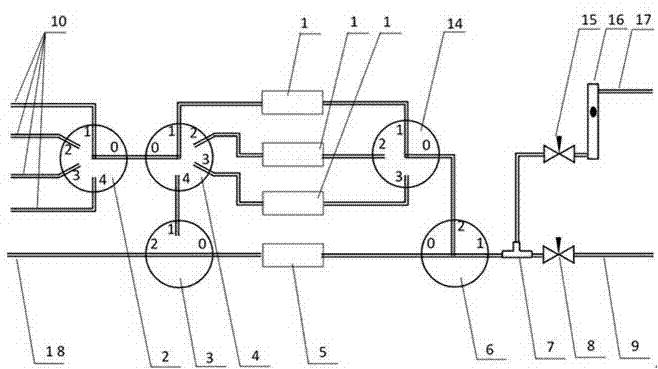

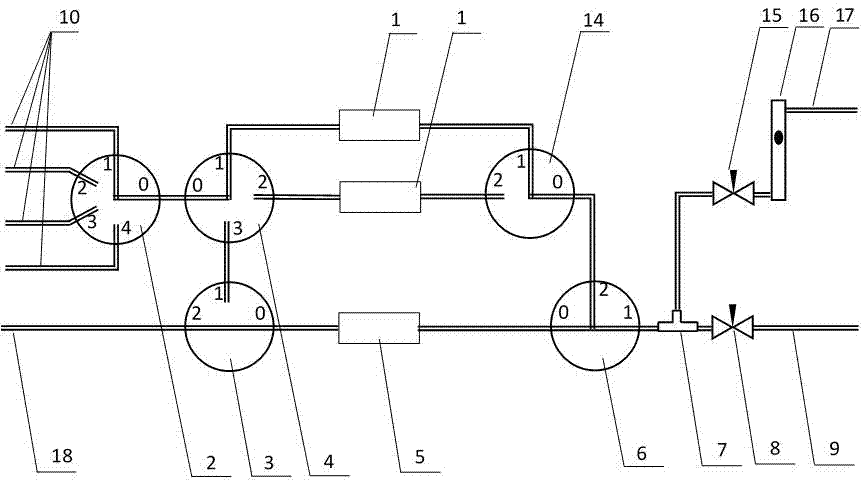

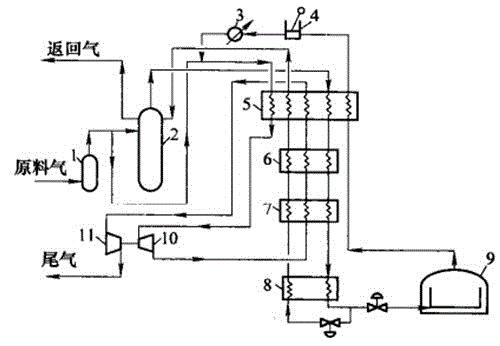

Single-package dynamic air distributing device

ActiveCN103528878AGuaranteed accuracyReduce reservesPreparing sample for investigationDiffusionProcess engineering

The invention discloses a single-package dynamic air distributing device which comprises feed gas mass flow controllers, a diluent gas mass flow controller and a mixer. An outlet of the diluent gas mass flow controller is connected with an inlet of the mixer, and the single-package dynamic air distributing device further comprises a feed gas input ball valve and a feed gas output ball valve. The feed gas input ball valve and the feed gas output ball valve both are multi-way ball valves, the number of the feed gas mass flow controllers is at least two, the measuring ranges of the feed gas mass flow controllers increase in equal ratio, the common ratio of equal ratio is not smaller than 5, feed gas is input to the feed gas mass flow controllers through the feed gas input ball valve, and the feed gas mass flow controllers are connected with the inlet of the mixer through the feed gas output ball valve. According to the single-package dynamic air distributing device, a wide dilution ratio range is provided, feed gas of one concentration can be used for preparing standard gas meeting requirements of most instruments to be detected, storage and use of the feed gas are reduced, a connector does not need to be mounted and dismounted, airflow leakage and diffusion interference can be avoided, and the single-package dynamic air distributing device has the advantages of being convenient to use, flexible in allocation, and the like.

Owner:STATE GRID CORP OF CHINA +1

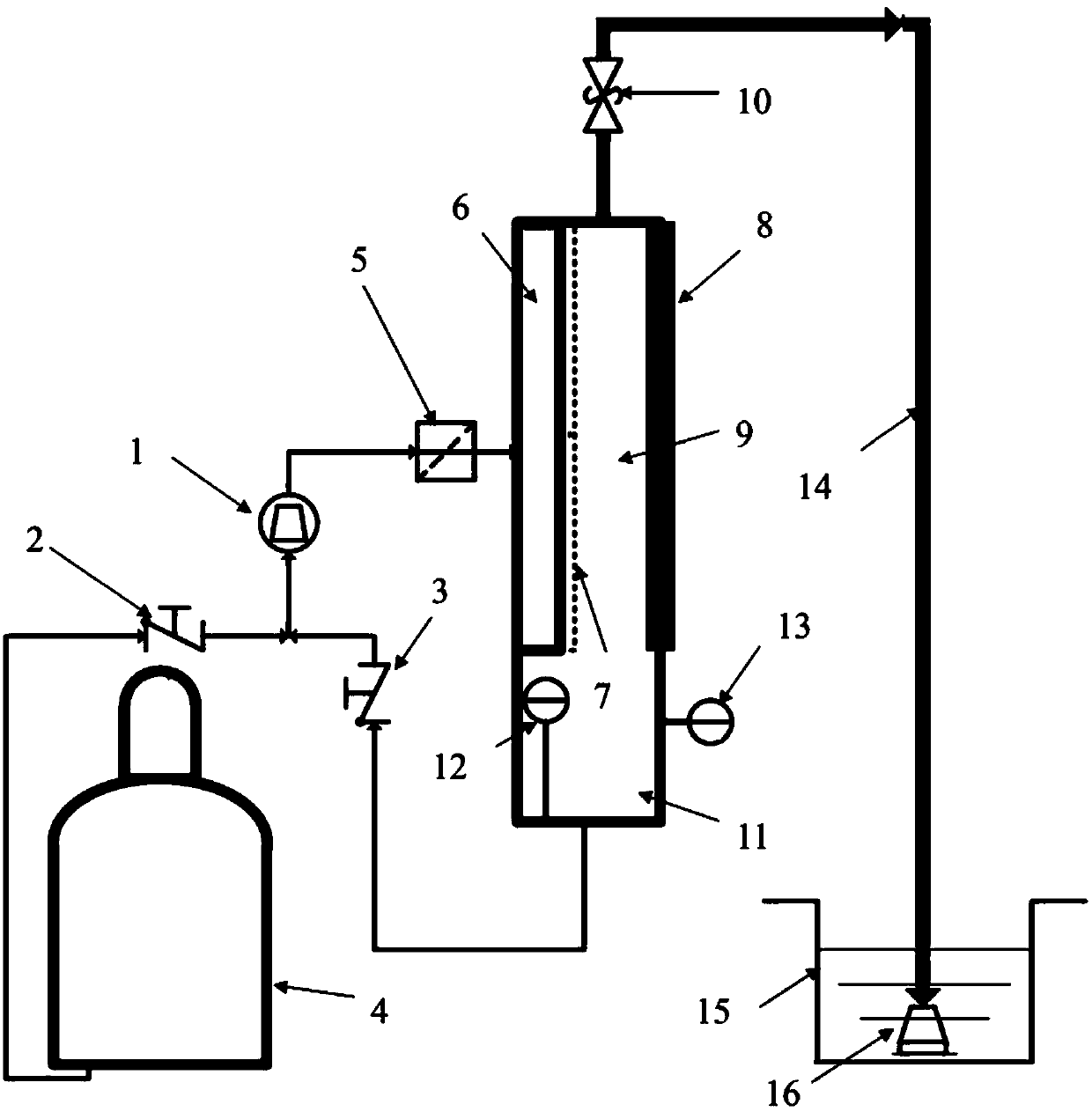

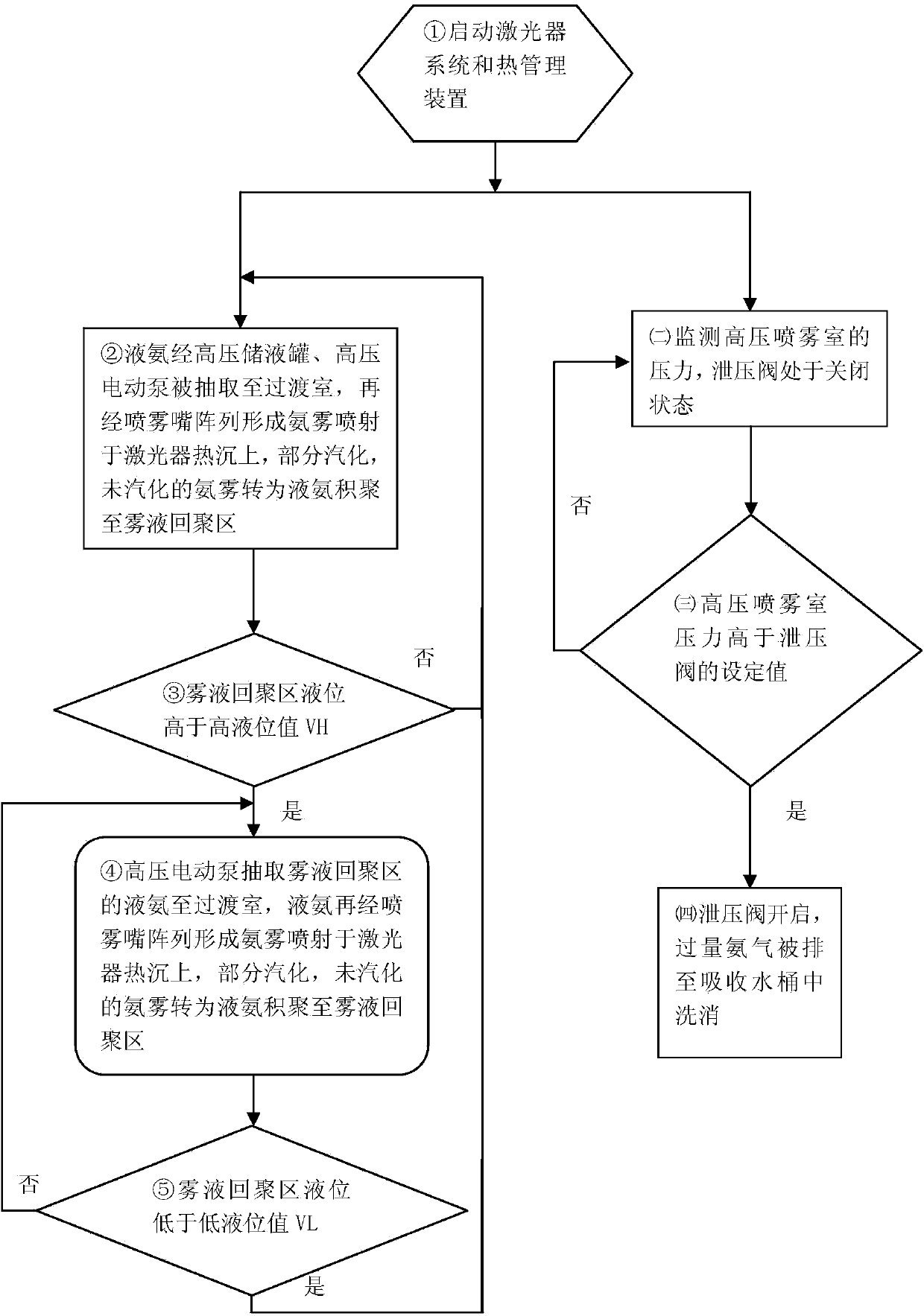

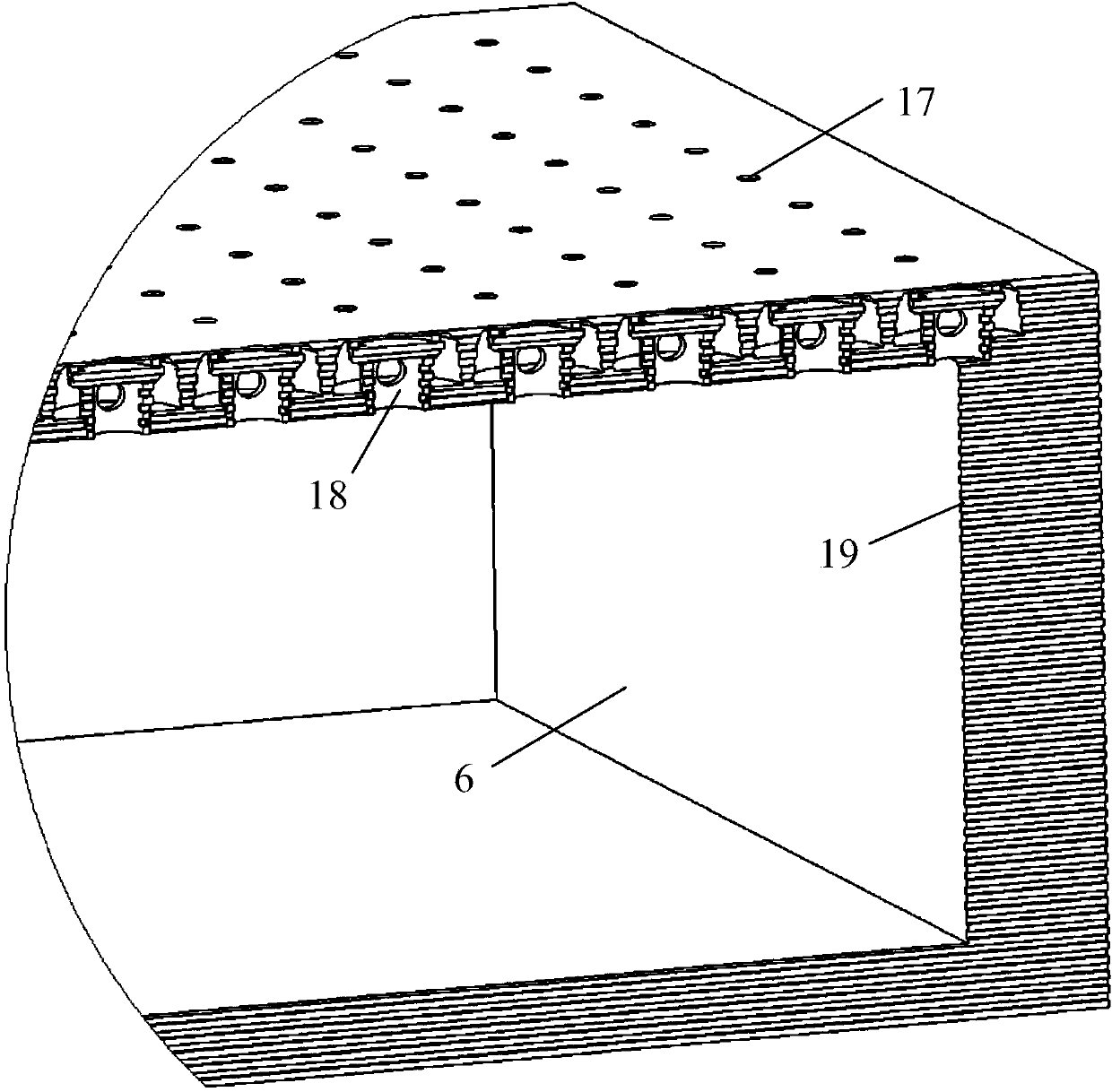

Device and method for high-power laser heat management based on spray evaporation

ActiveCN103441422AOverall small sizeSmall weightLaser detailsSemiconductor lasersHigh power lasersLiquid storage tank

The invention discloses a device and method for high-power laser heat management based on spray evaporation. The device for the high-power laser heat management comprises a high-pressure spray chamber arranged on a laser heat sink, a spray nozzle array and an air pressure sensor are arranged in the high-pressure spray chamber, the high-pressure spray chamber is adjacent to a transitional chamber, the transitional chamber is connected with a high-pressure liquid storage tank through a high-pressure electric pump, a spray liquid returning and accumulating area on the bottom portion of the high-pressure spray chamber is connected with the transitional chamber through the high-pressure electric pump, the high-pressure spray chamber is further connected with an exhaust pipe, and a decompression valve is arranged on the exhaust pipe. The method for the high-power laser heat management is achieved through the device for the high-power laser heat management, and the method is used for maintaining the pressure of gas refrigerants in the high-pressure spray chamber to be constant, and therefore temperature is maintained to be constant to achieve constant temperature control over the laser heat sink. The device is simple and reliable in structure, high in compactness, accurate in temperature control and stable in operation, and the method is simple and easy to implement, high in efficiency and environmentally friendly.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of mulberry leaf sugar-free walnut cake

InactiveCN103503958AReduce wet glutenImprove plasticityDough treatmentBakery productsCooking & bakingVegetable oil

The invention discloses a preparation method of a mulberry leaf sugar-free walnut cake. Steaming, high-temperature aroma bettering, smashing and other steps are carried out on mulberry leaves to obtain mulberry leaf powder, weak strength flour, corn modified starch, the mulberry leaf powder, xylitol, vegetable oil, egg liquid, zymin activated through warm water and baking soda are blended according to weight ratios to be fed into a walnut cake forming machine to be shaped up, and the mulberry leaf sugar-free walnut cake is obtained after baking and cooling. According to the preparation method, a traditional formula of the walnut cake is improved, the amount of oil and fats in the walnut cake is reduced, the modified starch, the mulberry leaf powder and the zymin which are of reasonable proportions are added, the problems that a common low-fat sugar-free walnut cake is dry, hard and coarse and the like are resolved, and damage of excessive chemical raising agents is avoided; the prepared mulberry leaf sugar-free walnut cake has the clean aroma and the green color of the mulberry leaves, is crispy and tasty, has the health care functions of lipid-decreasing, blood pressure reduction, diabetes resistance and the like, and is delicious, healthy and suitable for being eaten by various crowds.

Owner:JIANGXI SERICULTURE & TEA RES INST

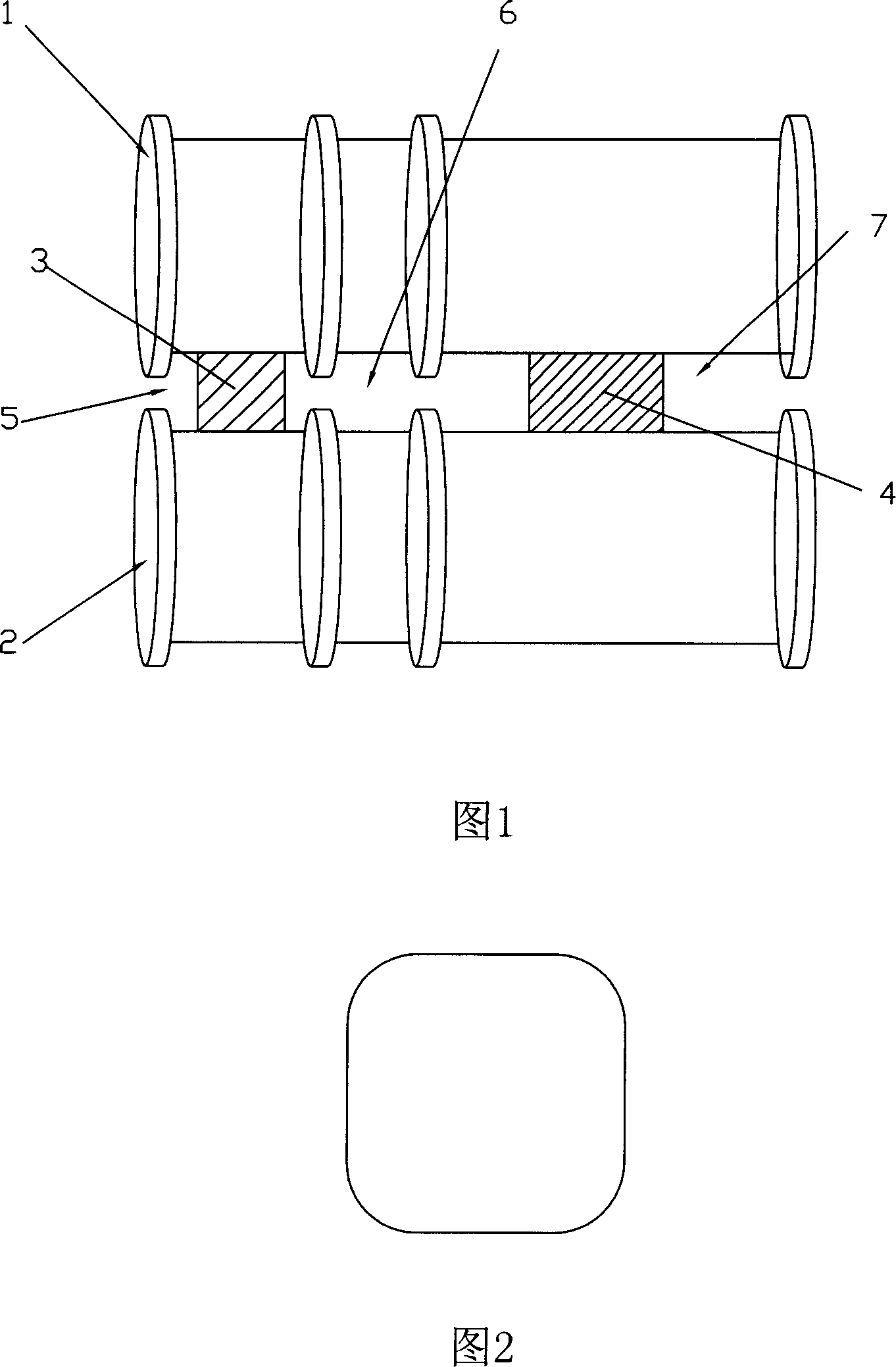

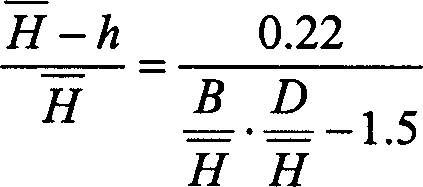

A method of preparing a color-mixed colorized pattern-carrying fabric based on color matching of primary color fibers

A method of preparing a color-mixed colorized pattern-carrying fabric based on color matching of primary color fibers is disclosed. The method includes: forming four fiber primary colors by adopting yellow, pinkish red, green, black and white fibers as raw materials, and blending and weaving fibers having at least three colors from the yellow, pinkish red, green, black and white fibers of the same kind, or fibers having at least three colors from yellow, pinkish red, green, black and white fibers of the different kinds. The color-mixed colorized pattern-carrying fabric shows randomness and irregularity in appearance and styles to a larger degree, and is enhanced in color layering sense and novel in style. The method can reduce reserves of dye varieties and color fiber varieties, thus reducing overstocked funds, and facilitating management.

Owner:泰州吉泰毛纺织染厂 +2

Method for rolling large-size square steel by single machine frame without groove

ActiveCN101024227AIncrease profitReduce manufacturing costMetal rolling arrangementsEngineeringLarge size

The invention discloses single frame non slot rolling large size square steel method. It adopts big delivery head two-high reversing blooming mill system. Each of blank side is repeatedly made into roller pressing underside and free spread side, processed reciprocating many passes non slot rolling by the horizontal mill to form finished product. It uses critical percent of reduction control method to control the size of the single and double drum ratio in the approved range, control width to height ratio to remove rolling off square. Thus the invention can reduce pass positioning, produce the large square steel product with high quality and flexible size by using non slot rolling technique.

Owner:BAOSHAN IRON & STEEL CO LTD

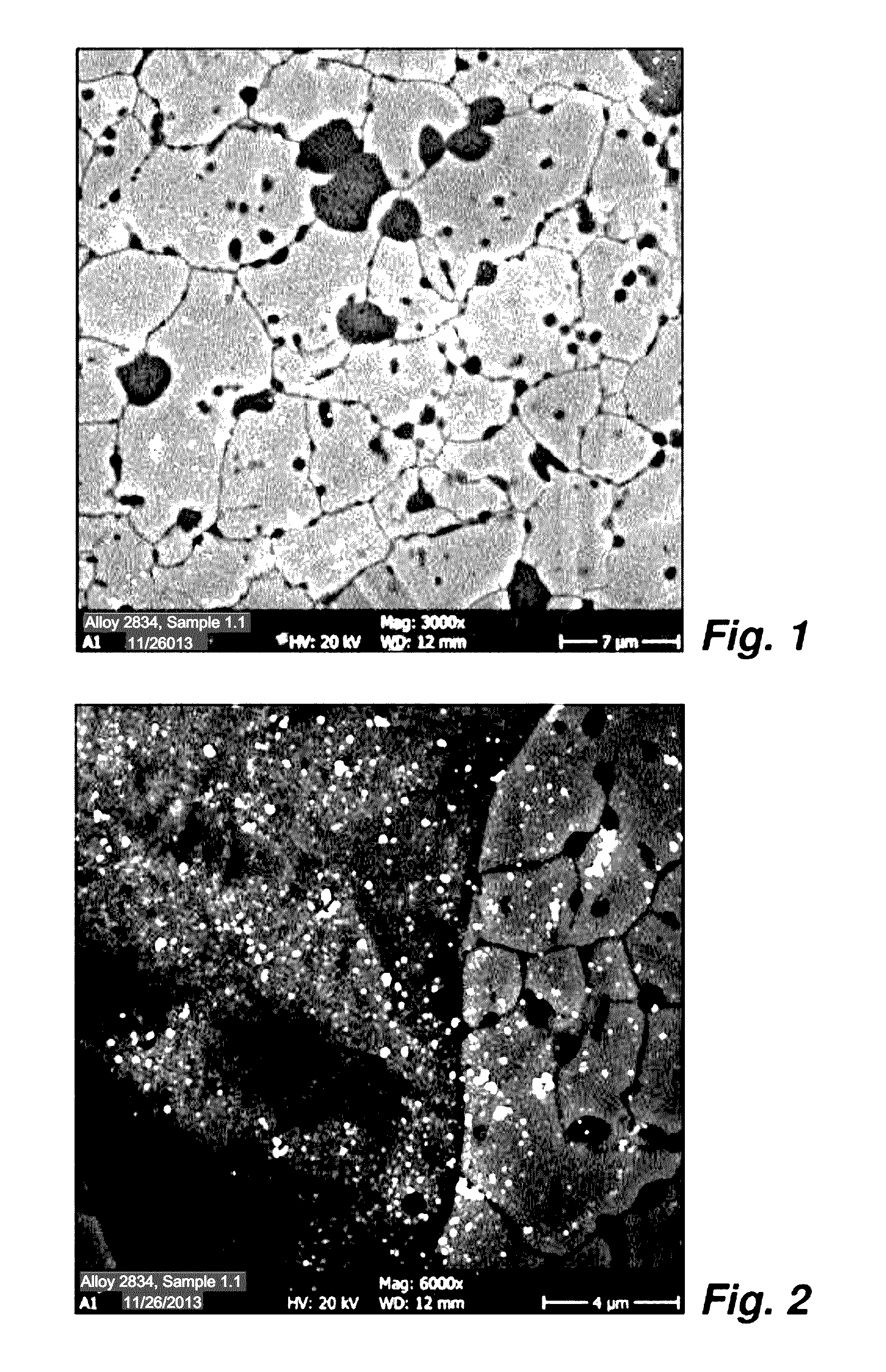

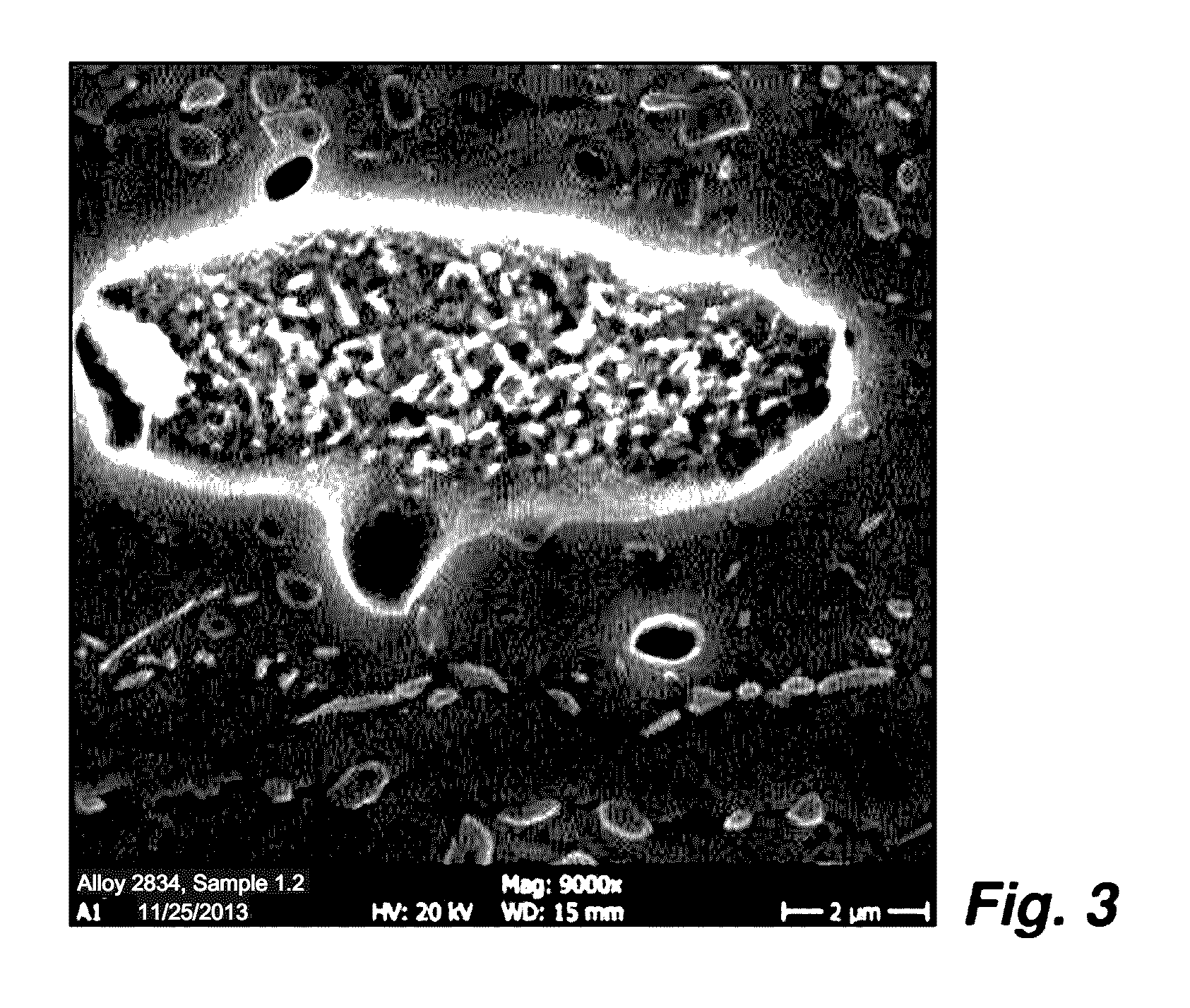

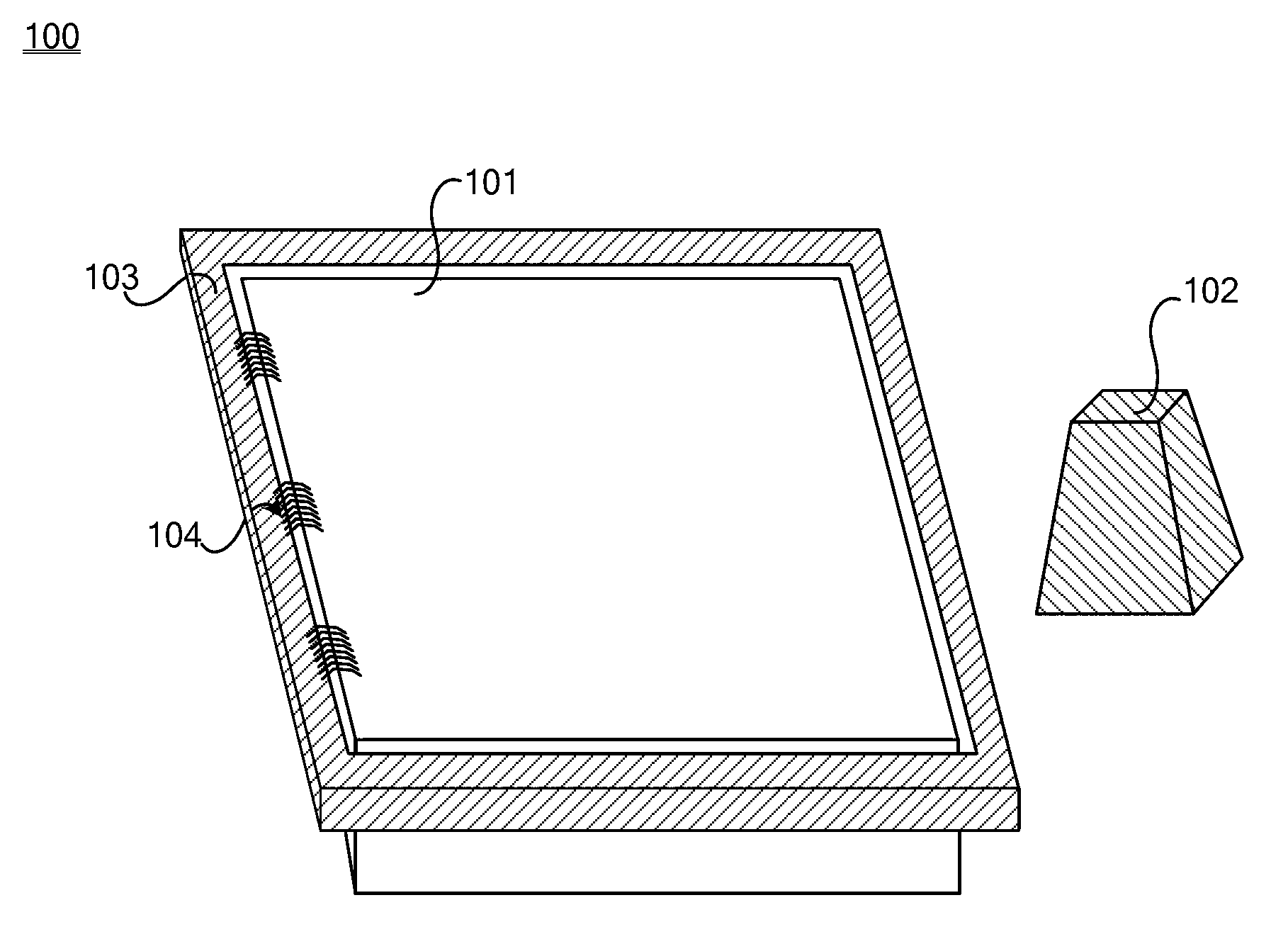

Aluminium Bronze Alloy, Method for the Production Thereof and Product Made from Aluminium Bronze

An aluminum bronze alloy containing 7.0-10.0% by weight Al; 3.0-6.0% by weight Fe; 3.0-5.0% by weight Zn; 3.0-5.0% by weight Ni; 0.5-1.5% by weight Sn; ≦0.2% by weight Si; ≦0.1% by weight Pb; and the remainder Cu in addition to unavoidable impurities. Also described is an aluminum bronze product having such an alloy composition, and a method for producing such a product from an aluminum bronze alloy.

Owner:OTTO FUCHS

Process for extracting theaflavin product

The invention discloses a process for extracting a theaflavin product, and relates to the technical field of the deep processing of tea products. In order to solve the problems of excessive oxidization and low yield caused by the uncontrolled consecutive reaction in traditional in-vitro enzymatic oxidization process for the preparation of theaflavin, the invention provides the process for extracting the theaflavin product, which comprises the following steps of: (a) the preparation of a substrate solution; (b) the preparation of an enzymatic catalyst; (c) the preparation of fermentation; (d) the separation of an ester phase; (e) the concentration and phase inversion; and (f) drying. When the process is adopted, the process control of the fermentation process is realized, the conversion rate and specification of the theaflavin product are improved, and the process cost for the follow-up refining and purification is reduced.

Owner:HANGZHOU TEA RES INST CHINA COOP

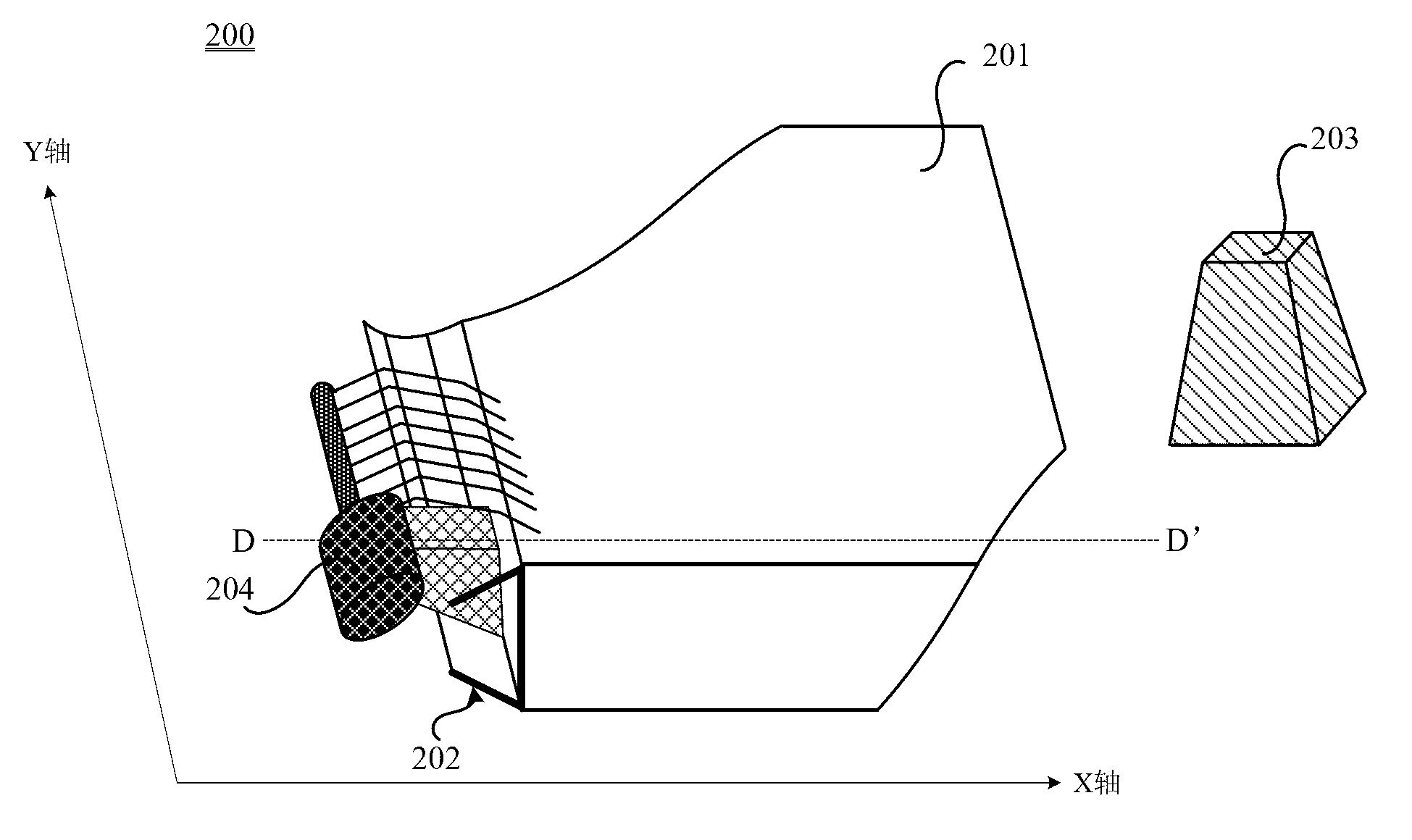

Testing device and testing method of TFT (Thin Film Transistor) base plate

ActiveCN103268027AReduce reservesAvoid possessionElectrical testingNon-linear opticsEngineeringMicroscope

The invention discloses a testing device and a testing method of a TFT (Thin Film Transistor) base plate. The testing device comprises a microscope stage, a detection unit and at least one probe unit, wherein a sliding structure is arranged on at least one side of the microscope stage; the detection unit is positioned above the microscope stage; the probe unit comprises at least one probe and a sliding component; and the probe unit slides along the sliding structure along with the sliding component. By adopting the testing device of the TFT base plate, the testing specification can be quickly changed, additionally, the reserve of a testing framework is reduced, and occupation of space and funds for reserving the testing framework is avoided.

Owner:CHENGDU TIANMA MICROELECTRONICS

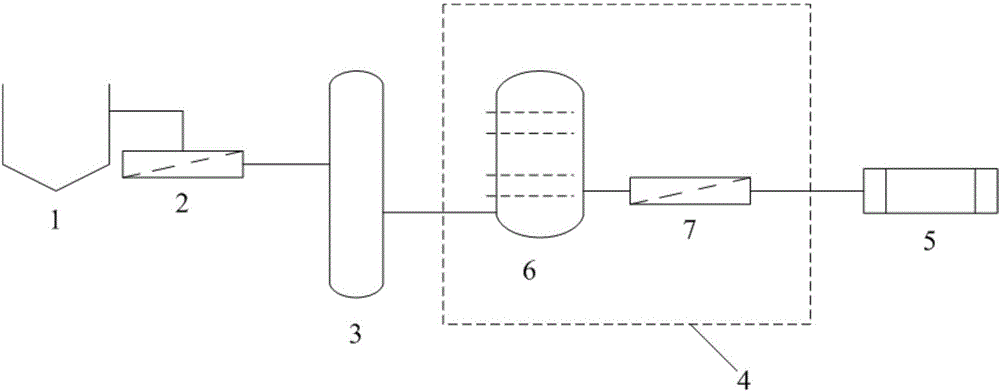

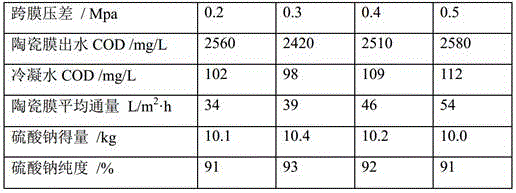

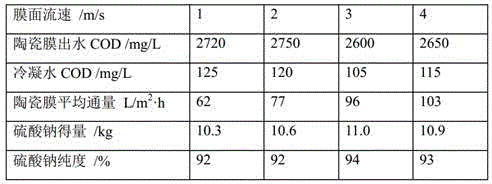

Wastewater treatment process and device of sulfonic dye and dye intermediate

InactiveCN105800849AImprove water qualityEasy to handleWater/sewage treatment by irradiationWater contaminantsHigh concentrationUltrafiltration

The invention relates to a wastewater treatment process and a device of a sulfonic dye and a dye intermediate. The process comprises the following steps: separating wastewater produced by the sulfonic dye and a sulfonyl-containing intermediate by using an extraction method to obtain an organic phase and an aqueous phase; oxidizing and / or ultrafiltrating the aqueous phase, and concentrating and crystallizing to obtain sodium sulfate. Through the technology, the problems that the wastewater from sulfonic dye and the dye intermediate has high concentration of organic matter and high salinity are solved, and the water quality index meets the inflow index of entering a sewage treatment plant after the wastewater is treated.

Owner:JIANGSU JIUWU HITECH

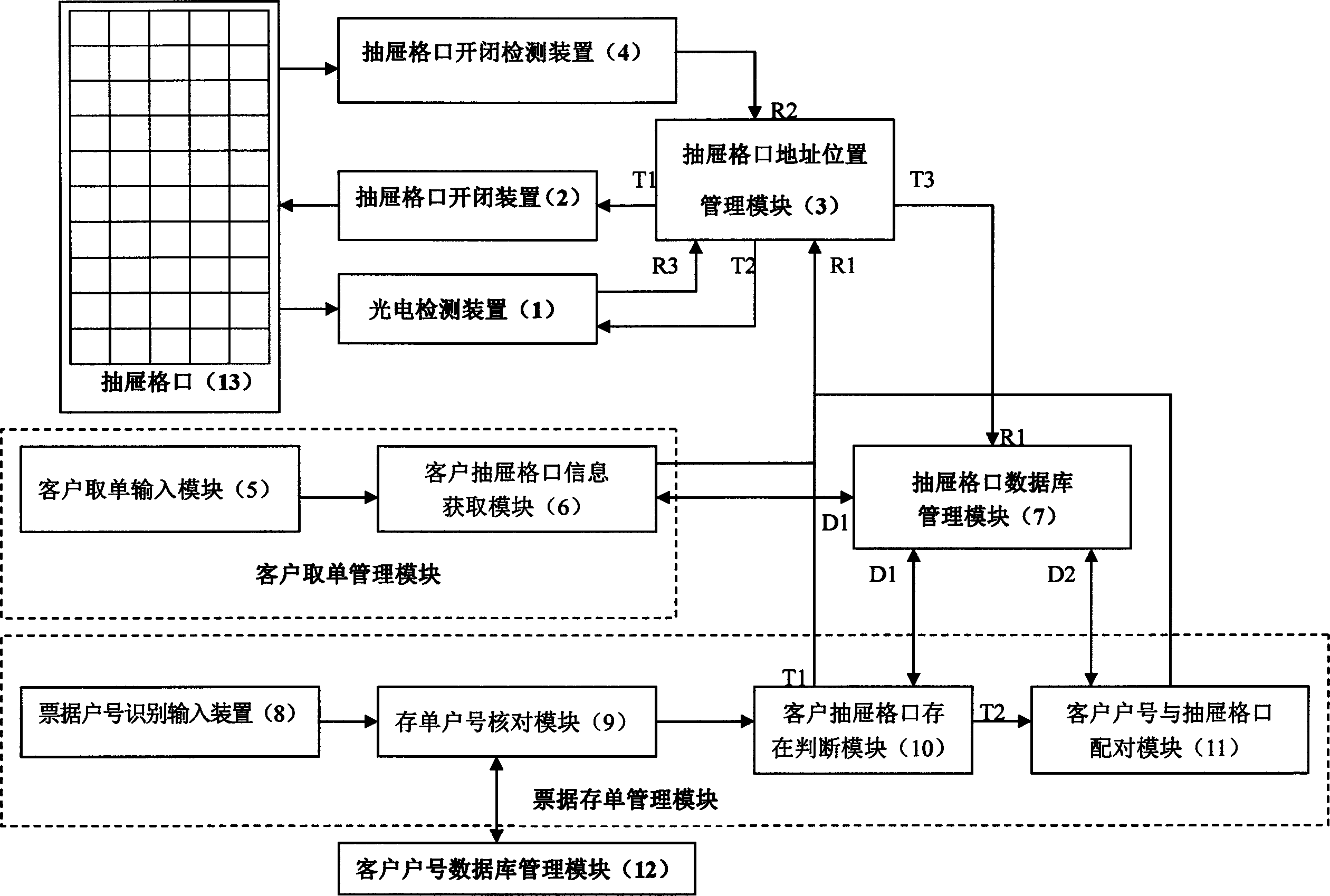

Intelligent bill access management system

ActiveCN104240400AReduce reservesSave storage spaceApparatus for meter-controlled dispensingResourcesEngineeringAccess management

The invention relates to an original certificate access management technology, in particular to an intelligent bill access management system which comprises drawer grid holes, a photoelectric detection device, a drawer grid hole opening and closing device, a drawer grid hole opening and closing detection device, a drawer grid hole address location management module, a drawer grid hole database management module, a client bill taking management module, a bill and deposit receipt management module and a client account number database management module, wherein the bill and deposit receipt management module also comprises a bill account number identification input module, a deposit receipt account number checking module, a client drawer grid hole existence judgment module and a module for paring client account numbers and the drawer grid holes. The invention aims at designing an intelligent bill access management system which is high in utilization rate of the drawer grid holes and intelligent in access management. Compared with the prior art, the intelligent bill access management system has the advantages that the system is high in intelligence and is conveniently operated by a manager, the error rate is reduced, the storage in the drawer grid holes can be reduced, the drawer storage space is reduced, the resource of the drawer grid holes occupied by an enterprise can be reduced, and the like.

Owner:WENZHOU HUAYIN ELECTRIC EQUIP DEV

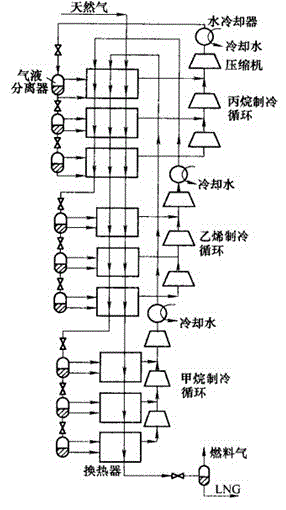

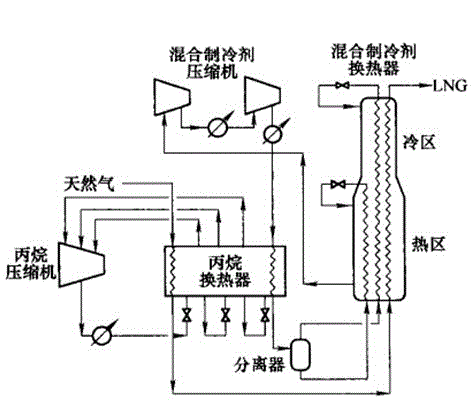

Natural gas isobaric liquefaction device

ActiveCN103148673ARealize isobaric liquefactionImprove energy savingSolidificationLiquefactionPower cycleMotive power

The invention relates to a natural gas isobaric liquefaction device. A Rankine cycle system of similar heat energy power cycle devices at a low temperature end is adopted, a cryogenic liquid pump is adopted to input power, and cold is compensated for the natural gas liquefaction device through refrigerant so as to realize the isobaric liquefaction of natural gas. On the premise of the same refrigerating capacity, compared with the conventional advanced unit, the natural gas liquefaction device disclosed by the invention can save energy by more than 30%, breaks through the conventional natural gas liquefaction technology, and has obvious economical, social and environment-friendly benefits.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

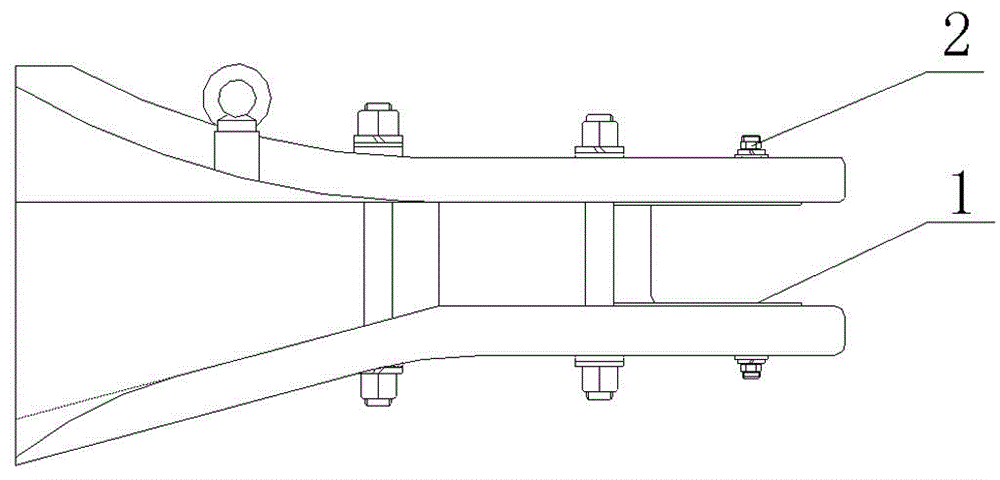

Method for rolling rods with 150 square blanks and 165 square blanks through both rough rolling and intermediate rolling

ActiveCN104148380AAchieve sharingReduce reservesGuiding/positioning/aligning arrangementsMetal rolling arrangementsReduction ratioStructural engineering

The invention discloses a method for rolling rods with 150 square blanks and 165 square blanks through both rough rolling and intermediate rolling. According to the method, six rough rolling mills and four to six intermediate rolling mills are used, wherein no-groove rolling is adopted by the rough rolling mills from t1# to 5#, round hole rolling is adopted by the 6# rough rolling mill, round-oval hole rolling is adopted by the intermediate rolling mills, when five intermediate rolling mills are adopted, the 7# intermediate rolling mill idles, and when six intermediate rolling mills are adopted, the 7# intermediate rolling mill and the 8# intermediate rolling mill idle. According to the method, no-groove rolling is adopted by the racks from 1# to 5#, and the rough rolling hole type and the intermediate rolling hole type are combined into one series; original 12 hole type passes are reduced to 10 passes by changing extending coefficients, the intermediate rolling speed is increased through the speed reduction ratio advantage of the racks from 9# to 12#, and the rotating speed limitation problem is solved; matched rollers of the rolling mills from 1# to 5# are rationalized, and common use of both rough rolling and intermediate rolling is achieved; by adjusting the size and the structure of a sliding guiding and guarding device, all the specifications are in common use. The method has the advantages of being simple, efficient and capable of making replacement easy to perform.

Owner:WUKUN STEEL

Two-in-one technic of Morgan '8+4'high-line mill milling round steel and ribbed steel bars

InactiveCN101081404AReduce reservesShorten the timeRoll force/gap control deviceMetal rolling arrangementsProduction rateRound bar

The present invention relates to metallurgic technology, and is especially two-in-one pass schedule technology of rolling round bar and ribbed steel bar in an Morgan '8+4' rolling machine. According to plastic deformation theory of metal and through combining with technological practice, ribbed steel bar are rolled via allocating lengthening coefficient reasonably and enlarging the roll gap of pass schedule for rolling round bar, i. e., ribbed steel bars of 6 mm, 8 mm and 10 mm diameter are produced separately in a pass schedule of 5.5 mm, 6.5 mm and 8 mm diameter for producing round bar. The present invention has the features of saving in pass schedule replacing time, reduced faults, raised production efficiency and production stability, decreased technological spares, reduced production cost, etc.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

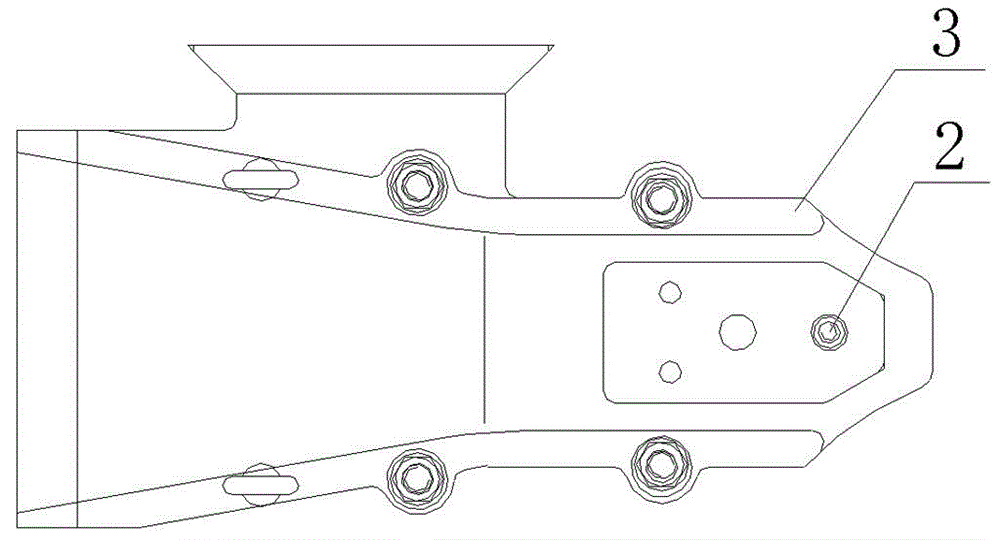

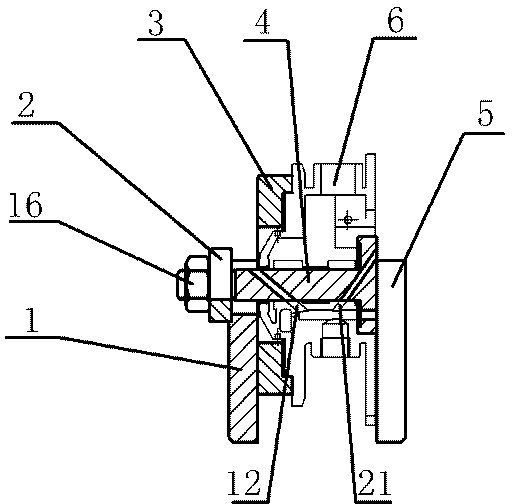

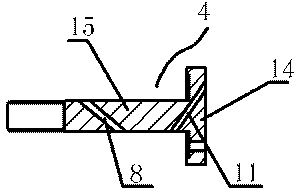

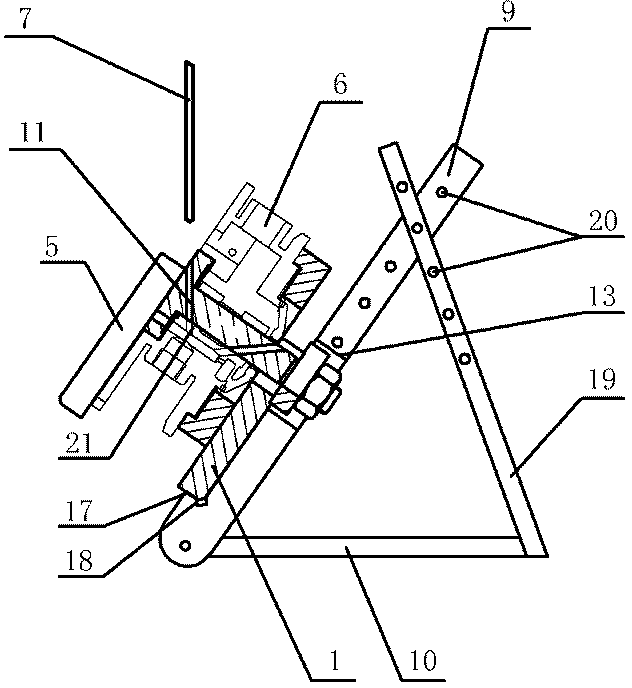

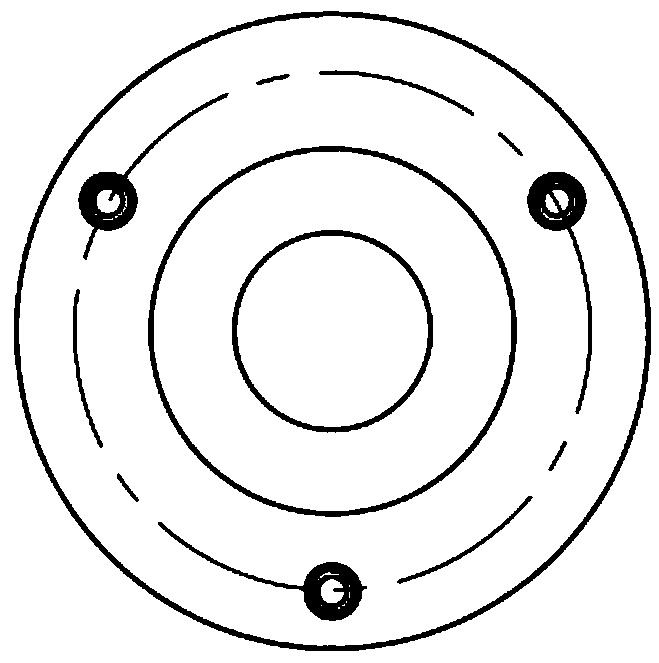

Drilling mold for intermediate body inclined hole

InactiveCN102990128AAvoid secondary disassemblyReduce reservesPositioning apparatusDrill jigsOptoelectronicsMachining

The invention provides a drilling mold for an intermediate body inclined hole. By using the drilling mold, the continuous machining of two inclined holes in a supercharger volute casting can be realized, the drilling mold is unnecessary to be changed, the production efficiency is improved, the reserve quantity of the drilling molds is reduced, and the production cost is reduced. The drilling mold comprises a drilling mold structure and an inclined surface fixing structure. The drilling mold is characterized in that the inclined surface fixing structure comprises a fixed bracket and an inclined plate; the inclined plate is arranged on the fixed bracket in an inclined manner; the drilling mold structure is arranged on the surface of the inclined surface; and the angle between the inclined plate and the horizontal surface is equal to the angle between a drilling mold through hole and the horizontal surface.

Owner:WUXI MINGZHU TURBOCHARGER MFG

Information delivery apparatus, information receiving apparatus, information delivery method, information receiving method and information delivery system

ActiveUS20120094641A1Improve advertising effectivenessEliminate needInformation formatSpecial service for subscribersComputer scienceReal-time computing

An information delivery apparatus is provided, including a receiving portion to receive location information of a mobile communication terminal at a given time and acquired date and time of the location information from the terminal, an event information storage portion to store event information including an event place, date and time, a delivery terminal selecting portion to select the mobile communication terminal to which the event information is to be delivered based on the location information and the acquired date and time of the location information and on the event place, date and time, and an event information delivery portion to deliver the event information to the selected mobile communication terminal. The delivery terminal selecting portion selects the mobile communication terminal whose location indicated by location information is within a predetermined range and whose acquired date and time of the location information are before the event date and time.

Owner:SONY GRP CORP

Preparation method of cellulose ultra-strong water-absorbent resin

The invention discloses a preparation method of cellulose ultra-strong water-absorbent resin, which comprises the following steps of: adding deionized water into cellulose; stirring, adding Al(OH)3 and heating; adding (NH4)2S2O8 and sodium acrylate aqueous solution, stirring and heating for reaction; after colloidal dope appears during the reaction, stopping the heating and cooling to room temperature; and washing the product with deionized water and drying to obtain the ultra-strong water-absorbent resin. The method disclosed by the invention adopts cellulose and Al(OH)3 to synthesize resin, and has abundant resources and low price; the reaction does not need a protective gas, the conditions are moderate, and the use value of cellulose is greatly increased; and the prepared resin is particularly suitable for the water retention and water conservation in an arid region in heavy demand and can be used as a medical water-absorbent material.

Owner:TAIYUAN UNIV OF TECH

Method for determining and maintaining defect of servo valve

ActiveCN102108992AExtended service lifeImprove the accuracy of useFluid-pressure actuator testingRolling millSpare part

The invention relates to a method for determining and maintaining the defect of a servo valve. In the method, the defect type is determined according to the static characteristic curve test result of the servo valve or the roller gap change condition of a rolling mill; the displacement of a valve plug is determined according to the hydraulic output power change of the servo valve, and the abrasion loss of a valve sleeve and the valve plug is determined according to the numerical value fluctuation degree of an internal leakage curve; fit clearance is reduced by improving the assembly accuracy of the valve plug and the valve sleeve; and the electrical zero of the servo valve is adjusted, and the relative position of a valve core and the valve sleeve is adjusted, so that the internal leakageof the servo valve and the abrasion of the valve core and the valve sleeve are reduced, the service life of the servo valve is prolonged, the reserve of spare parts and cost are reduced, and the thickness control accuracy of a steel plate and the qualification rate of a product are improved.

Owner:ANGANG STEEL CO LTD

Double-high-bar rolling system suitable for multi-specification and multi-size production

PendingCN111618091AReduce reservesReduce occupancyMetal rolling stand detailsMetal rolling arrangementsEngineeringMechanical engineering

The invention provides a double-high-bar hole pattern rolling system suitable for multi-specification and multi-size production. The double-high-bar hole pattern rolling system is used for solving theproblem that in the prior art, multiple hole pattern systems are needed for production of double high bars of different specifications. The double-high-bar hole pattern rolling system sequentially comprises a roughing mill unit, an intermediate rolling unit, a pre-finishing mill unit and a finishing mill unit in the rolling direction; the roughing mill unit is of a flat-roller hole-free pattern rolling structure; the intermediate rolling unit comprises a hole-free pattern rolling structure and a hole pattern rolling structure, and the bar is sequentially subjected to hole-free pattern rollingand hole pattern rolling in the intermediate rolling unit; the pre-finishing mill unit adopts the same hole pattern rolling structure; and the finishing mill unit adopts the same hole pattern rollingstructure, more than one rack is arranged in the finishing mill unit, and the roll gap of each rack in the finishing mill unit is adjustable. The double-high-bar hole pattern rolling system can adaptto a wider size rolling range, the spare amount of dies such as rollers, roll collars and guides can be greatly reduced, and the capital occupation of enterprises is reduced.

Owner:CHONGQING IRON & STEEL CO LTD

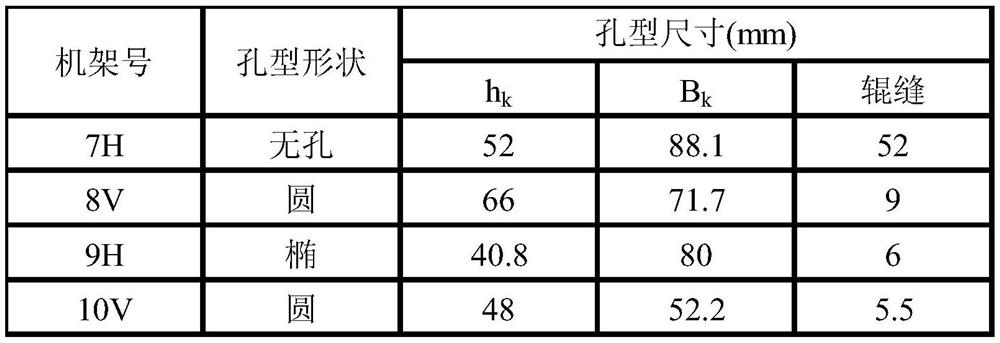

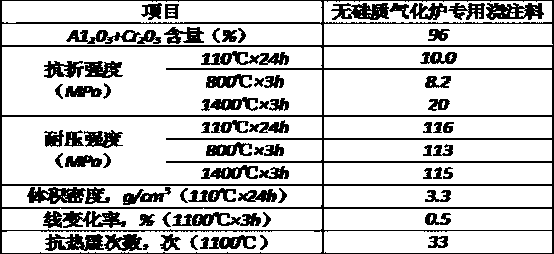

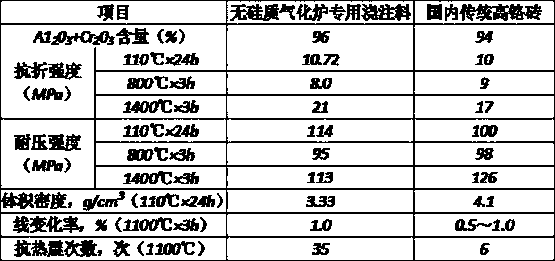

Special castable for silicon-free gasifying furnace and preparation method of castable

The invention particularly relates to a special castable for a silicon-free gasifying furnace and a preparation method of the castable, belongs to the technical field of refractory castables, and aimsto provide the special castable for the silicon-free gasifying furnace which has the resistance to the corrosion and penetration of molten slag and strong erosive wear resistance and the preparationmethod of the castable. According to the technical scheme, the special castable for the silicon-free gasifying furnace is prepared from the following raw materials in parts by weight: 30 to 50 parts of electric-smelting corundum aggregate, 15 to 40 parts of chrome corundum aggregate, 5 to 25 parts of electric-smelting corundum powder, 3 to 20 parts of chrome corundum powder, 2 to 18 parts of activated alumina micro-powder, 2 to 12 parts of pure calcium aluminate cement CA-70, 0.1 to 2 parts of a compound alumina micro-powder dispersant and 2 to 8 parts of water. The invention discloses the preparation method of the special castable for the silicon-free gasifying furnace. By adopting the special castable for the silicon-free gasifying furnace prepared with the preparation method, the masonry construction efficiency can be improved, the using cost can be reduced, and the service life of the castable can be ensured.

Owner:中国有色集团晋铝耐材有限公司

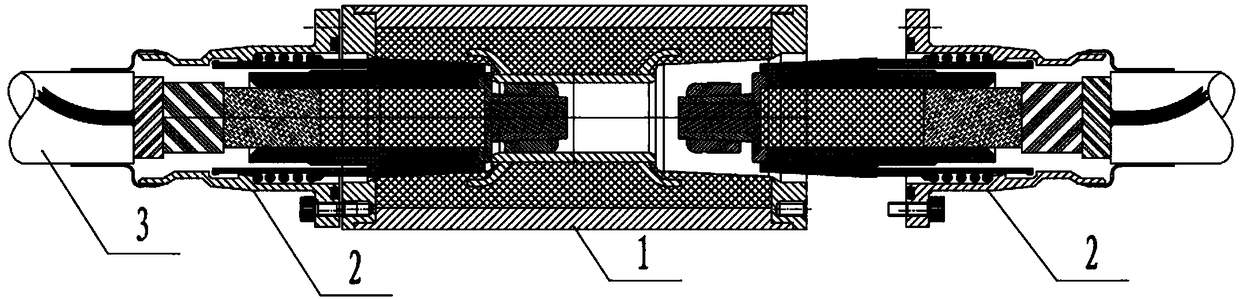

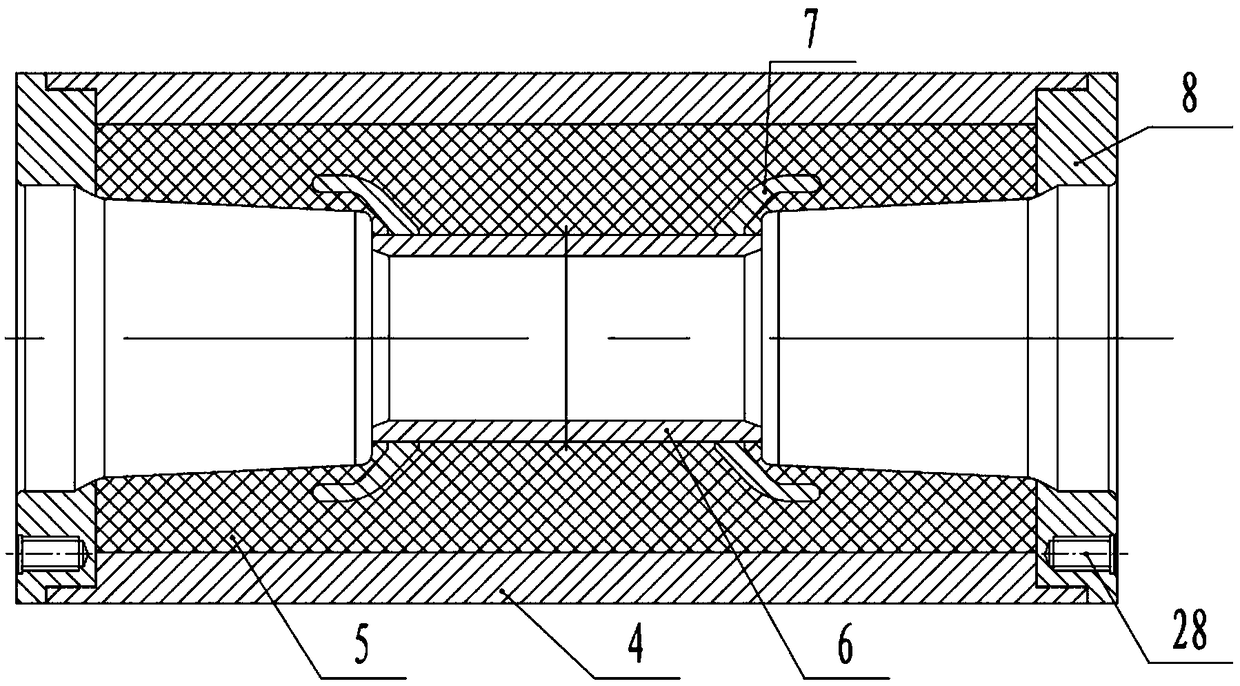

Quick connector device for flexible medium-voltage cable

PendingCN108649353AFirmly connectedFast connectionSecuring/insulating coupling contact membersCoupling contact membersWorking environmentPigtail

The invention discloses a quick connector device for a flexible medium-voltage cable. The device comprises a middle socket and two cable terminal plugs, wherein one ends of the two cable terminal plugs are respectively connected to the ends of the two cables, and the other ends of the two cable terminal plugs are detachably connected to the two ends of the middle socket respectively. According tothe quick connector device, through the two cable terminal sockets and the middle socket, a standardized cable connector is achieved, and a connection between a ring main unit and the cable becomes very convenient and efficient; compared with a traditional copper pigtail connection mode, the connection speed of the connector device is increased by tens of times, a problem that the connection efficiency is low in the traditional mode is effectively solved, the on-site rapid connection is realized, the all-weather working environment is adapted, the efficiency of installation and power transmission can be effectively improved, a user complaint rate can be reduced, the connector is normalized, and the device adapts to connections of the cables of different manufacturers and is easy to installand convenient to match.

Owner:GUIZHOU POWER GRID CO LTD

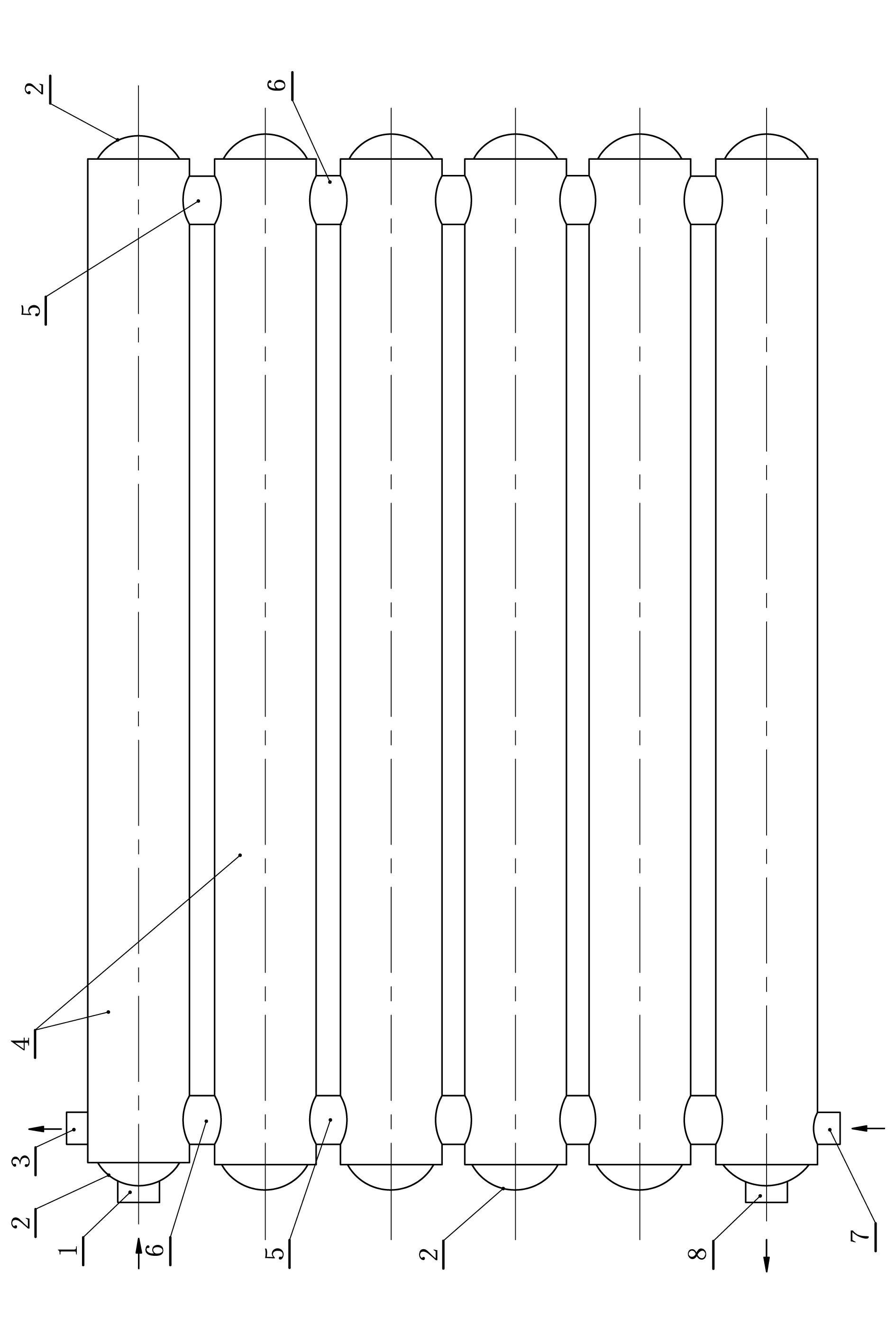

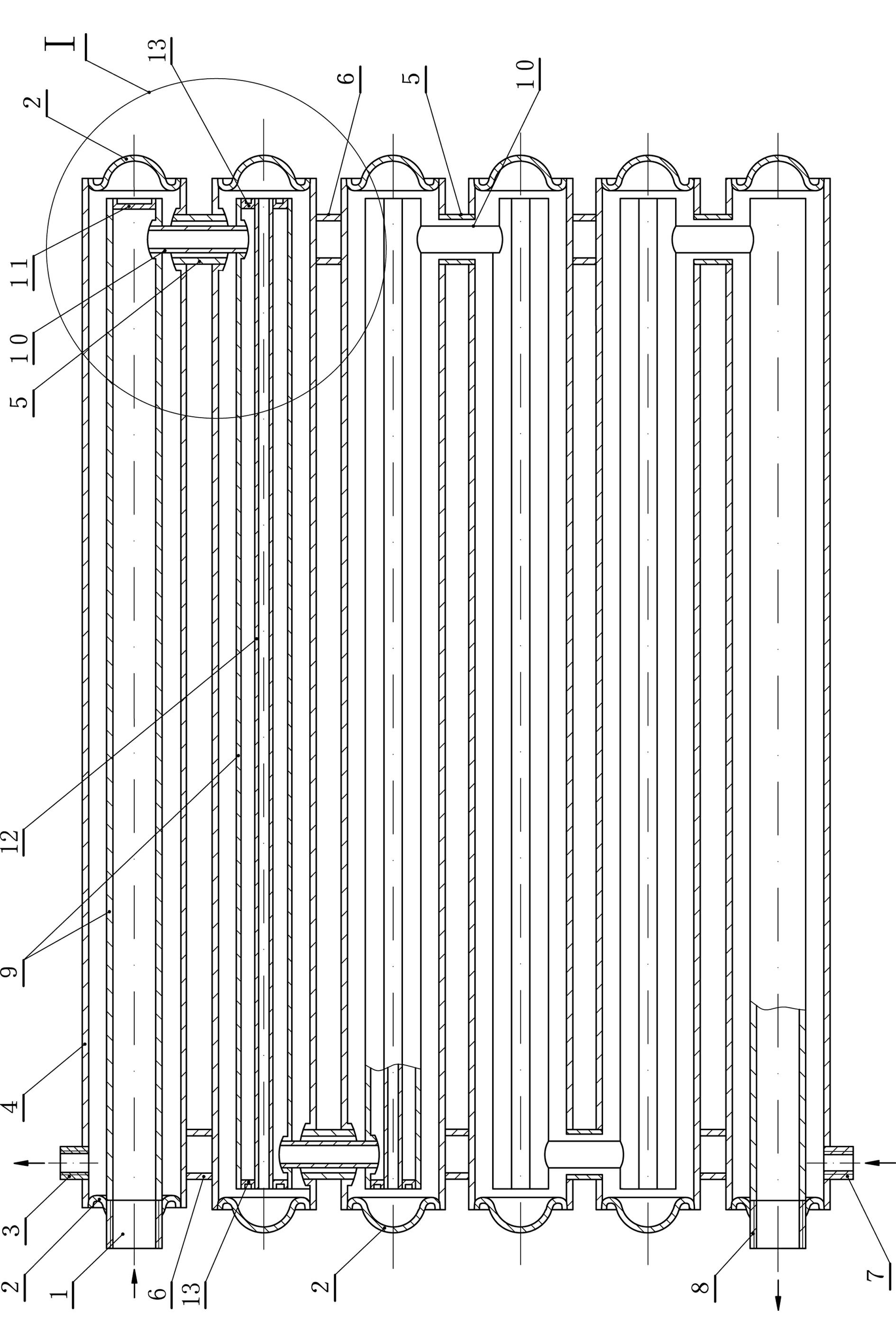

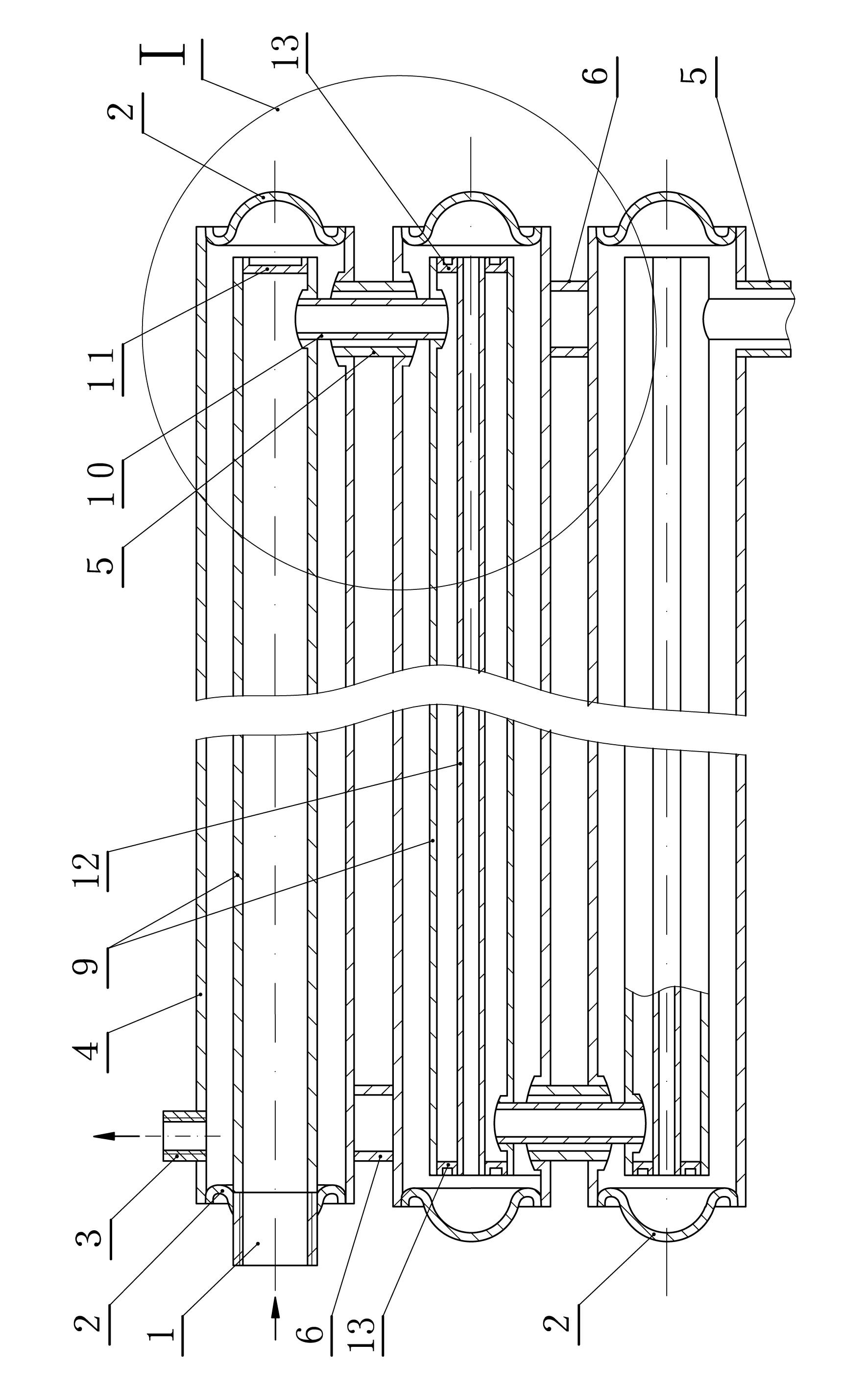

Pipe-communicated double-partition-wall heat transfer heat exchanger and manufacturing process thereof

ActiveCN102538513AImprove thermal efficiencyIncrease heat transfer areaStationary tubular conduit assembliesTap waterEngineering

The invention discloses a pipe-communicated double-partition-wall heat transfer heat exchanger and a manufacturing process thereof. The heat exchanger comprises two or more tap water heat absorbing outer pipes, wherein the tips of the tap water heat absorbing outer pipes are fixedly connected with tap water heat absorbing outer pipe sealing heads; heat supply pipes are arranged in the tap water heat absorbing outer pipes; the tap water heat absorbing outer pipes are communicated with each other through a tap water communicating pipe; the heat supply pipes are communicated with each other through a heat supply pipe communicating pipe; a hot air inlet and a hot air outlet are fixedly communicated with the inlet ends and the outer ends of the heat supply pipes respectively; and a tap water inlet and a tap water outlet are fixedly communicated with the inlet ends and the outlet ends of the tap water heat absorbing outer pipes respectively. The heat exchanger is characterized in that: tap water heat absorbing inner pipes are arranged in a part of or all of the heat supply pipes, and are communicated with the cavities of the tap water heat absorbing outer pipes. The heat exchanger has the advantages of simple structure, easiness for welding kneading edges, high pressure bearing, no water leakage and high heat exchange efficiency.

Owner:张伟

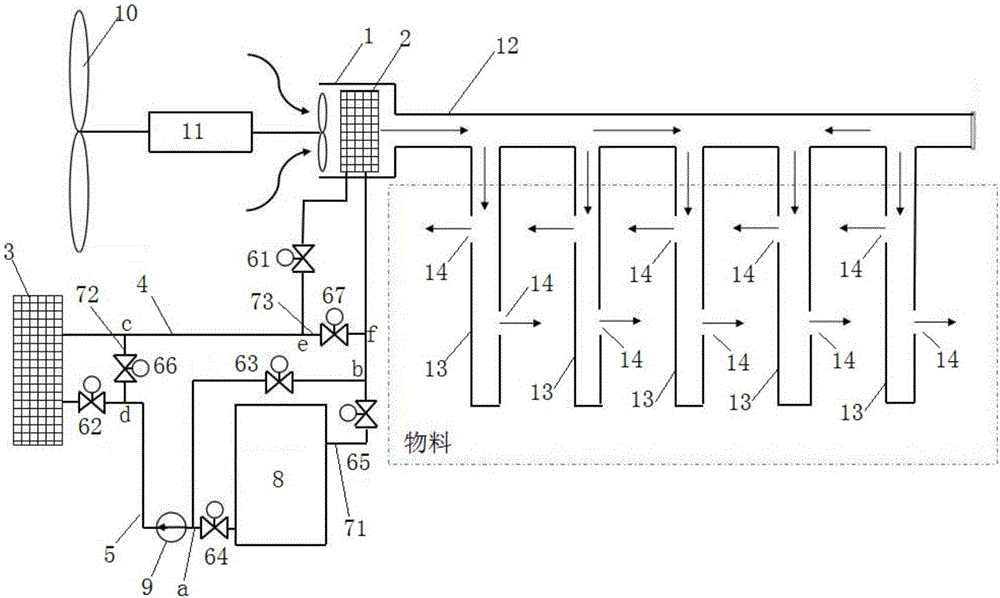

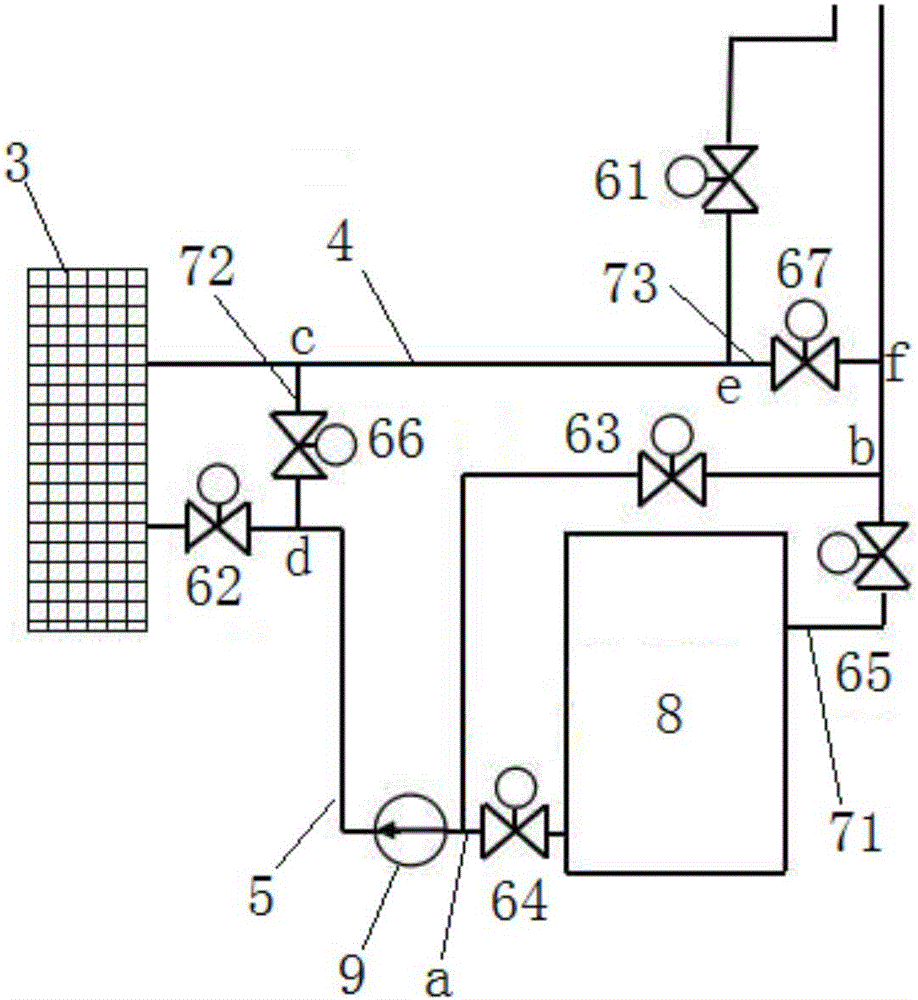

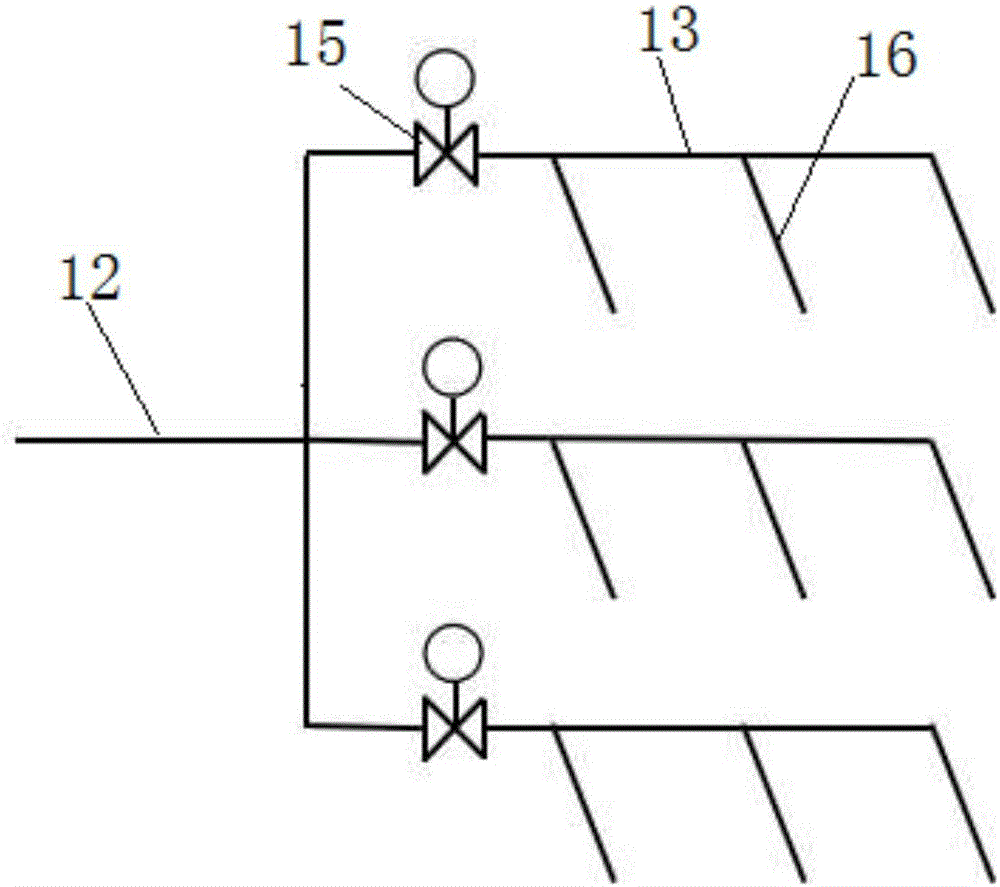

Solar heat collection type drying device and control method thereof

ActiveCN107178989AEfficient use ofEfficient heatingDrying gas arrangementsWind motor combinationsEngineeringTransferring (function)

The invention discloses a solar heat collection type drying device and a control method thereof. The solar heat collection type drying device comprises an air supply device, a heat exchange device (2) and a solar heat collection device. The air supply device comprises a fan (1) capable of rotationally absorb outside airflow and conducting acceleration and pressurization on the airflow, so that materials are dried through the accelerated and pressurized airflow. The heat exchange device (2) is arranged in the fan so as to conduct heat exchange on the airflow entering the fan. The solar heat collection device is used for obtaining solar energy and for transferring the obtained energy to the airflow in the fan through the heat exchange device so as to achieve an airflow heating function. According to the solar heat collection type drying device and the control method thereof, the solar energy can be obtained through the solar heat collection device, the obtained energy is transferred to the airflow in the fan through the heat exchange device, so that the airflow heating function is achieved, heating and heat transferring functions can be achieved on the materials effectively, the drying rate is increased, the drying efficiency is improved, the solar energy is effectively used under the circumstance of the same dry degree, and less energy is consumed.

Owner:乐陵市福惠圆农副产品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com