Wastewater treatment process and device of sulfonic dye and dye intermediate

A technology for dye intermediates and waste water treatment, which is applied in neutralizing water/sewage treatment, water/sewage treatment, heating water/sewage treatment, etc. It can solve problems such as high salt content and high concentration of organic matter in waste water, and improve the recovery rate , the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

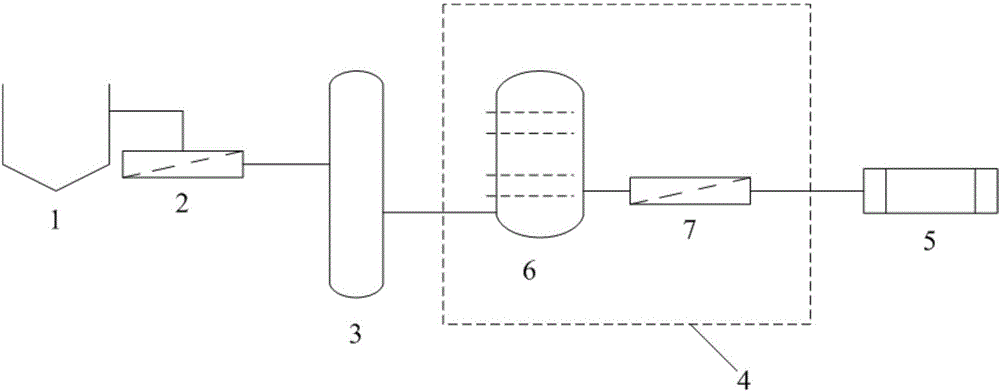

Method used

Image

Examples

Embodiment 1

[0044] 100L of sulfonic acid dye intermediate waste water was added with medium flocculant polyaluminum chloride (PAC) and polyacrylamide (PAM), the amount of PAC added was 1500ppm, the amount of PAM added was 30ppm, coagulated and settled for 0.5h to filter, and the effluent COD was 48370mg / L, the filtered clear liquid is adjusted to pH 2 with sulfuric acid, and then enters the heavy phase inlet of the centrifugal extractor, and the light phase inlet enters the extractant, which is composed of 20% N235, 70% kerosene and 10% isotetradecyl alcohol by volume , control the oil-water flow ratio of the centrifugal extractor to 8:1, adopt the three-stage countercurrent extraction method, the extracted oil phase enters the subsequent centrifugal stripping unit, the stripping agent is 10% hydroxide solution, and the COD of the extracted water phase is 15630mg / L, Enter the ceramic ultrafiltration membrane for filtration treatment, the average pore size of the membrane is 50nm, and filt...

Embodiment 2

[0047] 100L of sulfonic acid dye intermediate waste water was added with medium flocculant polyaluminum chloride (PAC) and polyacrylamide (PAM), the amount of PAC added was 1500ppm, the amount of PAM added was 30ppm, coagulated and settled for 0.5h to filter, and the effluent COD was 48370mg / L, the filtered clear liquid is adjusted to pH 2 with sulfuric acid, and then enters the heavy phase inlet of the centrifugal extractor, and the light phase inlet enters the extractant, which is composed of 20% N235, 70% kerosene and 10% isotetradecyl alcohol by volume , control the oil-water flow ratio of the centrifugal extractor to 8:1, adopt the three-stage countercurrent extraction method, the extracted oil phase enters the subsequent centrifugal stripping unit, the stripping agent is 10% hydroxide solution, and the COD of the extracted water phase is 15630mg / L, Enter the ceramic ultrafiltration membrane for filtration treatment. The average pore size of the membrane is 20nm. Filtrati...

Embodiment 3

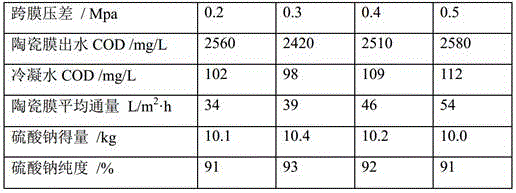

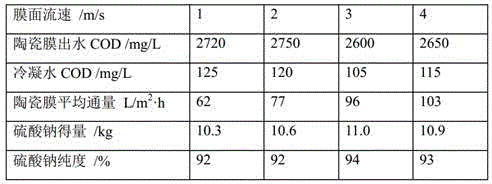

[0050] 100L of sulfonic acid dye intermediate waste water was added with coagulants polyaluminum chloride (PAC) and polyacrylamide (PAM), the amount of PAC added was 2000ppm, the amount of PAM added was 100ppm, coagulated and settled for 0.5h to filter, and the effluent COD was 48370mg / L, the filtered clear liquid is adjusted to pH 1 with sulfuric acid, and then enters the heavy phase inlet of the centrifugal extractor, and the light phase inlet enters the extractant, which is composed of 15% N235, 75% kerosene and 10% isotetradecyl alcohol by volume , control the oil-water flow ratio of the centrifugal extractor to 8:1, adopt the three-stage countercurrent extraction method, the extracted oil phase enters the subsequent centrifugal stripping unit, the stripping agent is 10% hydroxide solution, and the COD of the extracted water phase is 14960mg / L, Enter the ceramic ultrafiltration membrane for filtration treatment. Ceramic membranes with different average pore diameters are u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com