Gasification method of shock chilling type pulp or powder carbonaceous material

A slurry state, chilling technology, applied in the gasification of granular/powdered fuel, chemical industry, and the manufacture of combustible gas, etc., can solve the problems of gray water entrainment, affecting catalyst life, easy scaling, etc., to reduce water consumption and Effects of energy consumption, good recycling and utilization, and flexible load regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

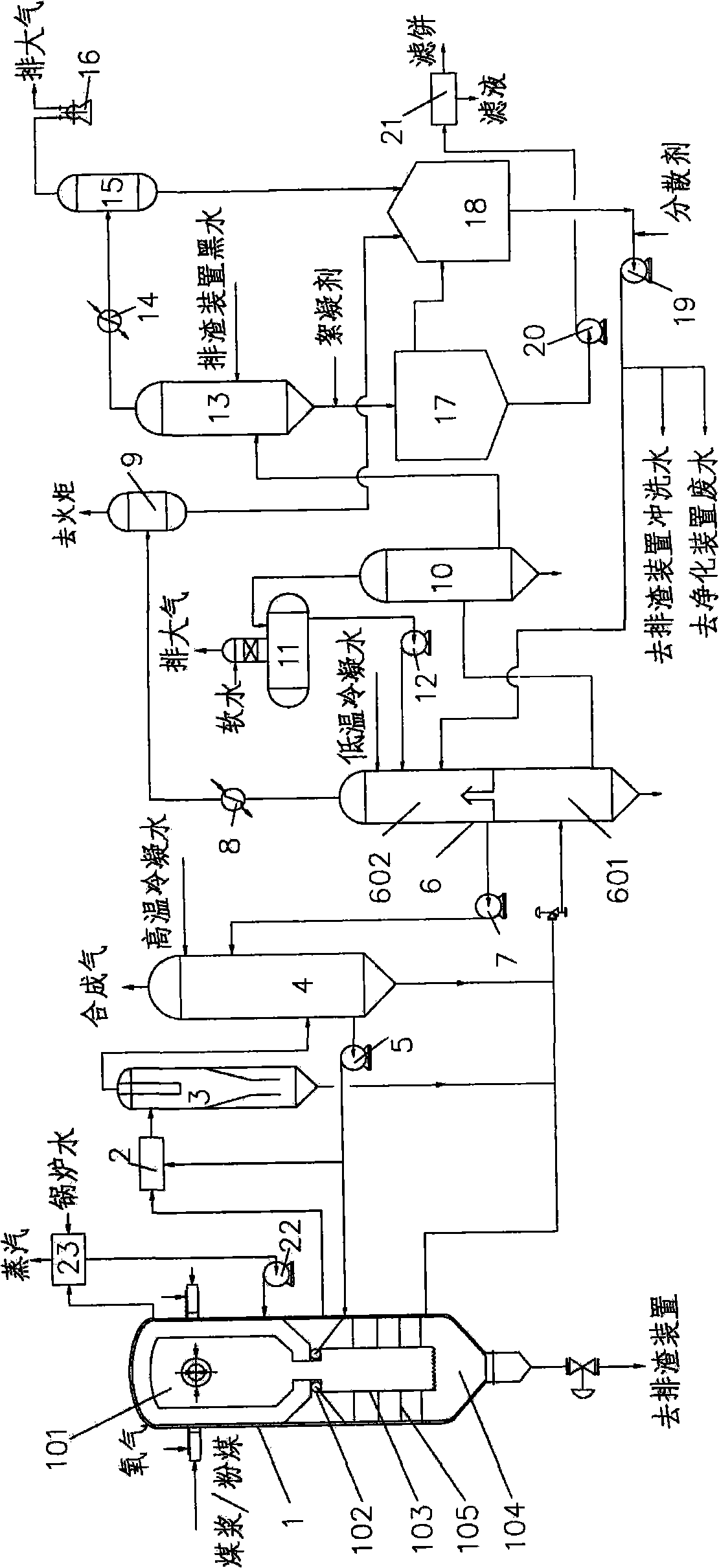

[0089] Using coal water slurry as raw material, according to figure 1 The gasification process shown in the figure realizes the gasification method of coal-water slurry.

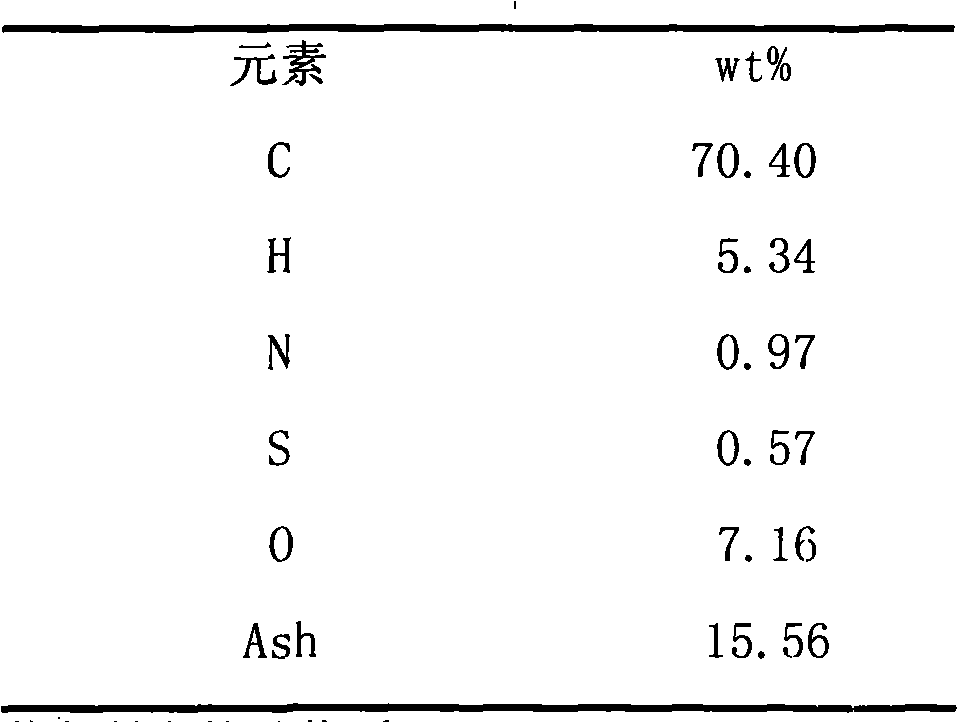

[0090] The gasification raw material is coal water slurry in slurry state, the flow rate is 105 tons / hour, the corresponding coal processing capacity (dry basis) is 62.5 tons / hour (1500 tons / day), the gasification pressure is 6.5MPaG, and the gasification temperature is Gasification is carried out at 1350°C. Among them: 4 (two groups) opposed nozzles are set in the gasification chamber of the gasification furnace and a hot wall type refractory lining is used. The coal quality analysis of raw coal is listed in the table below:

[0091] Coal Composition

[0092]

[0093] Where Ash represents the minerals contained in the coal.

[0094] 105 tons / hour of coal slurry with a coal particle diameter of 30-100 microns, 97000Nm 3 The pure oxygen with an oxygen content of 99% (V / V) per hour is evenly divided in...

Embodiment 2

[0103] With coal powder as raw material, according to figure 1 The gasification process flow shown is a method for realizing the gasification of coal materials.

[0104] In the gasification furnace with water wall refractory lining, the pulverized coal processing capacity is 100 tons / hour (2400 tons / day), the gasification pressure is 4.0MPaG, and the gasification temperature is 1600℃. For (4) opposed nozzles, the elemental analysis of coal quality is as follows:

[0105] Coal Composition

[0106]

[0107] Where Ash represents the minerals contained in the coal.

[0108] 100 tons / hour pulverized coal with an average particle diameter of 30-100 microns, 60000Nm 3 Pure oxygen with an oxygen content of 99% (V / V) per hour and superheated steam with a temperature of 430°C at 8 tons per hour are equally divided into 4 parts and sprayed into the gasification chamber of the gasification furnace through 4 nozzles Among them, the combustion and gasification reactions are carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com