Reproducible phosphorus-uptake ceramsite and preparation method thereof

A technology of ceramsite and particle size, which is applied in the field of renewable phosphorus-absorbing ceramsite and its preparation, can solve the problems of poor phosphorus absorption ability, low cost performance, and poor regeneration, and achieve strong phosphorus absorption ability, high cost performance, and recyclability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A renewable phosphorus-absorbing ceramsite and a preparation method thereof. Its preparation steps are as follows:

[0028] (1) Dry 70~75wt% of fly ash, 13~16wt% of coal powder and 12~14wt% of clay powder at 120~130°C for 2~3 hours respectively, and mix them evenly to prepare a mixture;

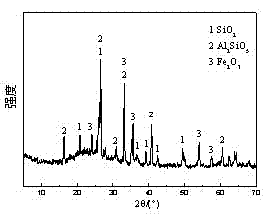

[0029] (2) Add the mixture into the disc pelletizer to form balls. The spray liquid used in the pelletizing process is 0.5~2.0% sodium silicate solution; Dry at ~150°C for 3~4h, then bake at 950~1000°C for 40~50min to obtain fired porous ceramsite;

[0030] (3) Soak the fired porous ceramsite in 0.10~0.20mol / L HCl solution for 20~24h, wash with tap water first, then wash with distilled water or deionized water until the pH value of the washing water is neutral, and then Dry at 100~105°C for 7~8h to obtain dried porous ceramsite;

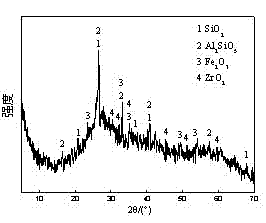

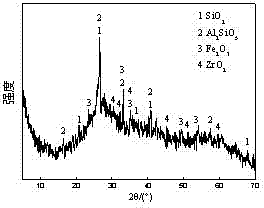

[0031] (4) Add the dried porous ceramsite to ZrOCl with a concentration of 0.5~1.0mol / L 2 solution, the dried porous ceramsite and ZrOCl 2 The volume ra...

Embodiment 2

[0040] A renewable phosphorus-absorbing ceramsite and a preparation method thereof. Its preparation steps are as follows:

[0041] (1) Dry 75~78wt% of fly ash, 10~13wt% of coal powder and 11~14wt% of clay powder at 100~120°C for 3~4 hours, mix them evenly, and prepare the mixture;

[0042] (2) Add the mixture into the disc pelletizer to form balls. The spray liquid used in the pelletizing process is 0.5~2.0% sodium silicate solution; Dry at ~160°C for 2~3h, then bake at 1000~1100°C for 30~40min to obtain fired porous ceramsite;

[0043] (3) Soak the fired porous ceramsite in 0.20~0.30mol / L HCl solution for 16~20h, wash with tap water first, then wash with distilled water or deionized water until the pH value of the washing water is neutral, and then Dry at 105-110°C for 6-7 hours to obtain dried porous ceramsite;

[0044] (4) Add the dried porous ceramsite to ZrOCl with a concentration of 1.0~2.0mol / L 2 solution, the dried porous ceramsite and ZrOCl 2 The volume ratio of ...

Embodiment 3

[0048] A renewable phosphorus-absorbing ceramsite and a preparation method thereof. Its preparation steps are as follows:

[0049] (1) Dry 78~82wt% of fly ash, 12~15wt% of starch and 5~7wt% of clay powder at 110~130°C for 2~3 hours, mix them evenly, and prepare the mixture;

[0050] (2) Add the mixture into the disc pelletizer to form balls. The spray liquid used in the pelletizing process is 0.5~2.0% sodium silicate solution; Dry at ~140°C for 3~4h, then bake at 950~1000°C for 40~50min to obtain fired porous ceramsite;

[0051] (3) Soak the fired porous ceramsite in 0.10~0.20mol / L HCl solution for 16~20h, wash it with tap water first, then wash it with distilled water or deionized water until the pH value of the washing water is neutral, and then wash it in Dry at 100~105°C for 7~8h to obtain dried porous ceramsite;

[0052] (4) Add the dried porous ceramsite to ZrOCl with a concentration of 0.5~1.2mol / L 2 solution, the dried porous ceramsite and ZrOCl 2 The volume ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com