Phosphorus-removing filling and preparation method thereof

A technology of raw material and bentonite, which is applied in the field of phosphorus removal filler and its preparation, can solve the problems of unstable raw material composition, unstable adsorption performance, low adsorption efficiency, etc., and achieves the effects of strong porosity, high efficiency and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

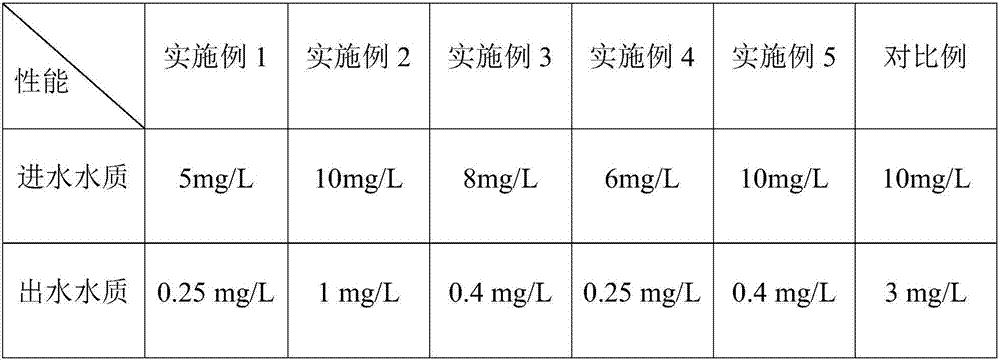

Examples

preparation example Construction

[0039] The present invention also provides a preparation method for phosphorus removal filler, comprising the following steps:

[0040] Add bentonite, activated alumina, and adhesive to the acidic solution for activation;

[0041] and baking and cooling to obtain the modified bentonite phosphorus removal filler.

[0042] The volume fraction of the above acid solution is 3-7%, such as 3%, 4%, 5%, 6% or 7%.

[0043] The above-mentioned acidic solution can be exemplified by sulfuric acid solution or hydrochloric acid solution, etc., preferably sulfuric acid solution. The role of acidity is to provide an acidic reaction environment by decomposing hydrogen ions, which is more conducive to the mixing and activation of modified activated alumina, natural bentonite and adhesive to obtain modified bentonite with better adsorption.

[0044] Preferably, the activated alumina is modified activated alumina; the modification step is specifically:

[0045]Take the activated alumina, wash ...

Embodiment 1

[0055] A preparation method for phosphorus removal filler, comprising the following steps:

[0056] (1) Preparation of modified activated alumina: take activated alumina and wash it with deionized water until there is no inorganic impurities on the surface, filter the cleaned activated alumina and dry at 100°C. Add the dried activated alumina to the aluminum sulfate solution with a concentration of 0.025mol / L, shake at 21°C at a vibration speed of 110r / min, take it out after shaking for 3 hours, wash it with deionized water for several times, and filter it at 100 °C drying; then baked at 500 °C for 4 hours to obtain modified activated alumina, grind the modified activated alumina and pass through a 100-mesh sieve to obtain modified activated alumina with a particle size of 100 mesh.

[0057] (2) Get natural bentonite and pass through a 200 mesh sieve to obtain bentonite with a particle size of 200 mesh.

[0058] (3) 200 mesh bentonite, 100 mesh modified activated alumina, adh...

Embodiment 2

[0061] A preparation method for phosphorus removal filler, comprising the following steps:

[0062] (1) Preparation of modified activated alumina: take activated alumina and clean it with deionized water until there is no inorganic impurities on the surface, filter the cleaned activated alumina and dry at 110°C. Add the dried activated alumina to the aluminum sulfate solution with a concentration of 0.026mol / L, shake at 23°C at a vibration speed of 120r / min, take it out after shaking for 3.2h, wash it with deionized water for several times, and filter it in Dry at 110°C; then bake at 540°C for 4.2 hours to obtain modified activated alumina, grind the modified activated alumina and pass through a 150-mesh sieve to obtain modified activated alumina with a particle size of 150 mesh.

[0063] (2) Get natural bentonite and pass through a 250-mesh sieve to obtain bentonite with a 250-mesh specification.

[0064] (3) 250 mesh bentonite, 150 mesh modified activated alumina, adhesive,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com