Patents

Literature

856 results about "High phosphorus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High levels of phosphorus in the blood may be a sign of advancing cancer in some patients. Symptoms of hypothyroidism, a cause of high phosphorus in the blood, may include stomach cramps. Hypothyroidism is a common cause of high phosphorus in the blood.

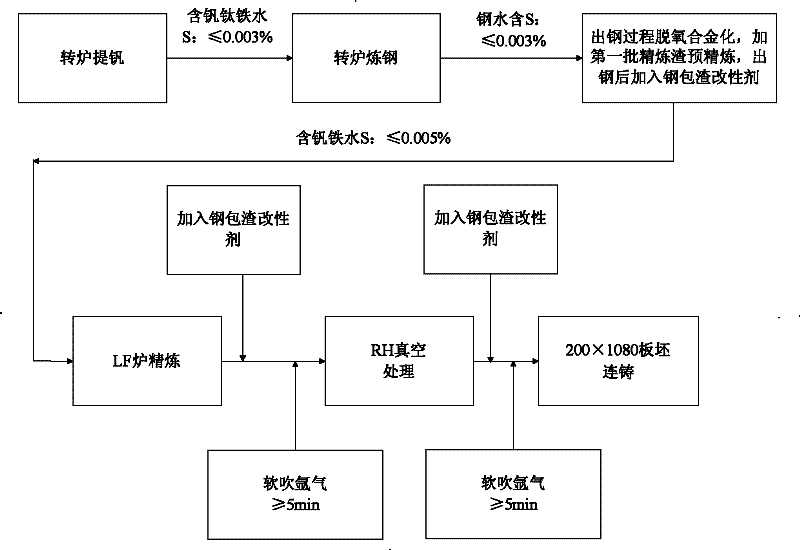

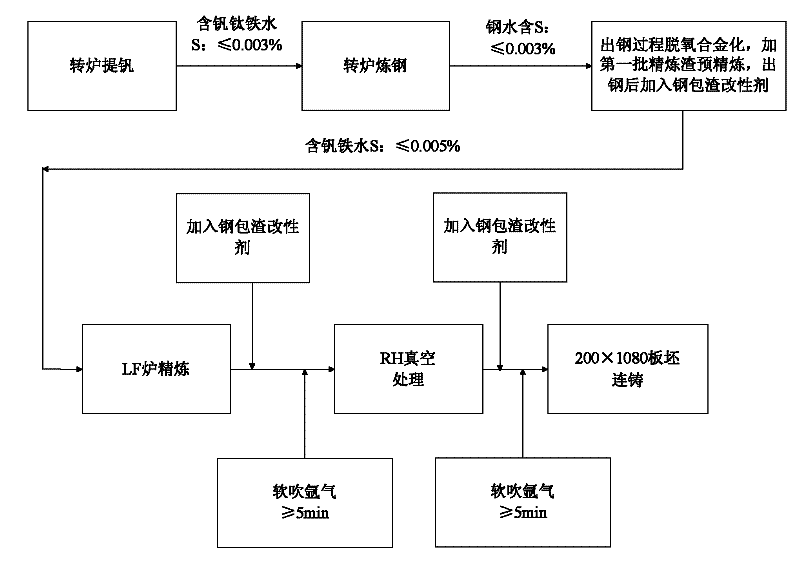

High phosphorus and low sulfur non-oriented electrical steel and its smelting method

ActiveCN102260822AGuaranteed qualifiedSolve the technical difficulties of smeltingElectrical steelSulfur

The invention belongs to the technical field of metallurgy and particularly relates to high-phosphorus low-sulfur non-oriented electrical steel and a smelting method thereof. The technical problem to be solved is to improve resistivity of the electrical steel without influencing the magnetism of the electrical steel. For solving the problem, the invention adopts a technical scheme which is to provide high-phosphorus low-sulfur non-oriented electrical steel. The high-phosphorus low-sulfur non-oriented electrical steel comprises the following ingredients in percentage by weight: 0 to 0.0050 percent of carbon, 0.30 to 1.0 percent of silicon, 0.15 to 0.35 percent of manganese, 0.030 to 0.08 percent of phosphorus, 0 to 0.005 percent of sulfur, less than or equal to 0.0050 percent of aluminum and the balance of ferrum. A production process for the electrical steel is suitable for producing the high-phosphorus low-sulfur non-oriented electrical steel by taking vanadium titanium-containing molten iron as a raw material, and has a good application prospect.

Owner:PANZHIHUA IRON AND STEEL +3

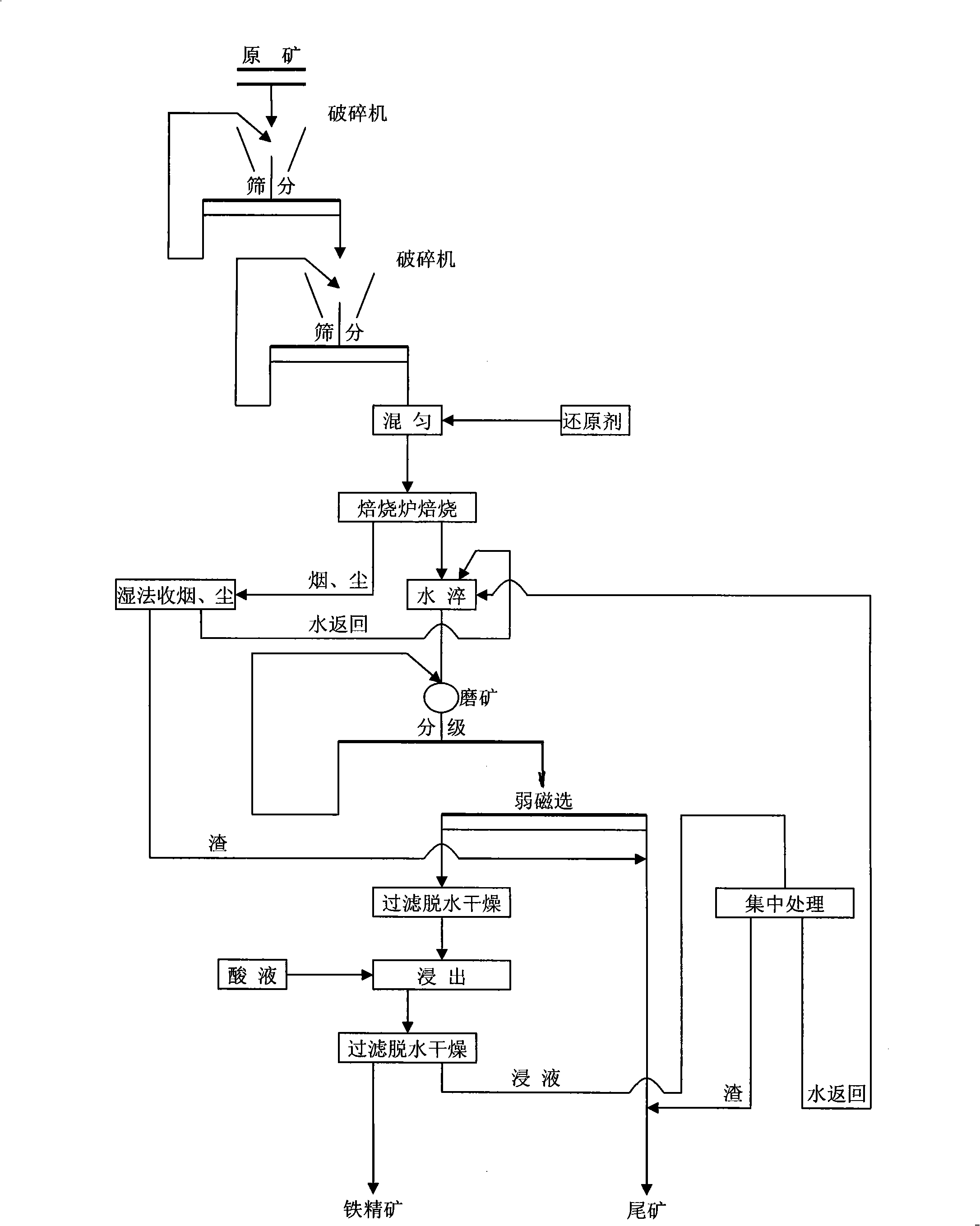

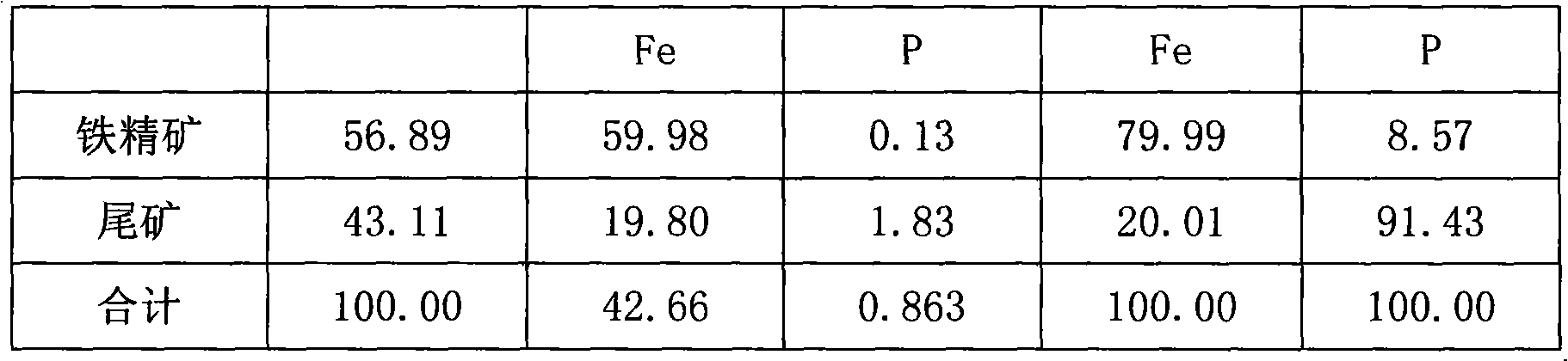

Method for reducing phosphorus in high phosphorus haematite or hematite and limonite ore by magnetization roasting-leaching method

InactiveCN101338361AReduce phosphorus contentProcess efficiency improvementMagnetic separationIronstoneMagnetization

The invention relates to a high phosphorus hematite-hematite-limonite magnetic roasting-extraction phosphorous reduction method, in particular applicable for an extraction phosphorous reduction method for the iron ores which mainly include the hematite-hematite and the limonite and accompany with magnetite, pyrrhotite, iron pyrites, etc. The method of the invention adopts magnetic roasting-wet extraction to reduce phosphorous; after carrying out modifying on high phosphorus iron ore, muriatic acid or vitriol is selected to carry out extraction phosphorous reduction on the iron concentrate obtained by a weak electromagnetic separator which not only can obtain the iron concentrate with an iron grade to be larger than 56 percent; simultaneously the content of the phosphorous in the iron concentrate is lower than 0.30 percent.

Owner:昆明晶石矿冶有限公司

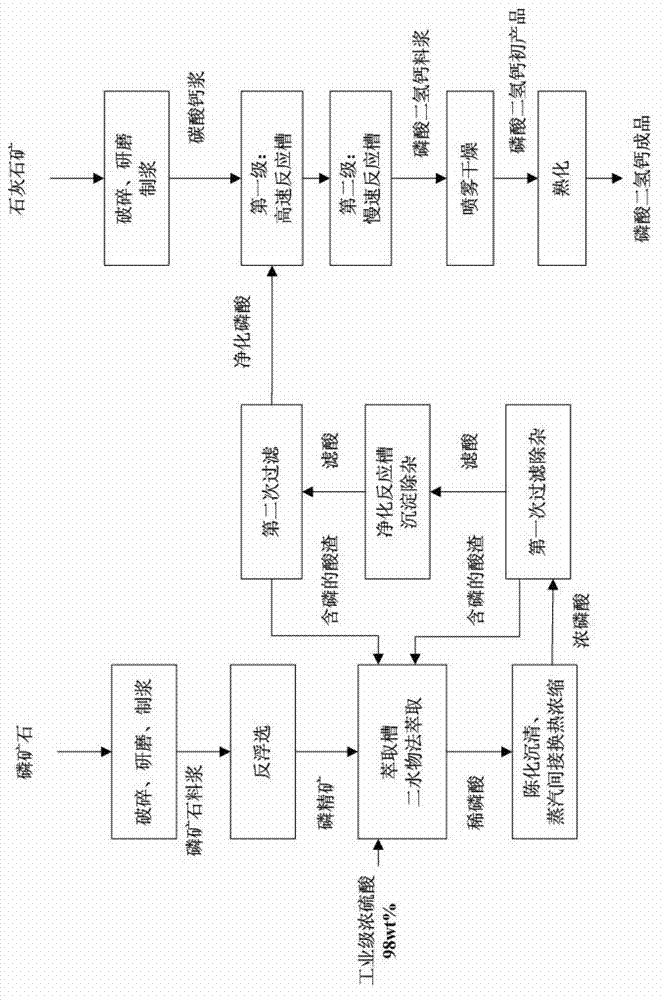

Method for producing feed-grade calcium dihydrogen phosphate from wet-process phosphoric acid

A method for producing feed-grade calcium dihydrogen phosphate from wet-process phosphoric acid comprises the following steps of: pulping by the use of natural phosphate rock and carrying out reverse flotation to obtain phosphate concentrate, extracting for desulphurization by a dihydrate process so as to obtain dilute phosphoric acid, aging, setting and condensing to obtain concentrated phosphoric acid; filtering the concentrated phosphoric acid to remove impurities, extracting acid sludge, filtering acid, setting, removing impurities, carrying out secondary filtration to obtain purified phosphoric acid, and returning filter residue to the extraction step; and grinding limestone mine to obtain a calcium carbonate powder which can pass through a Tyler sieve of -100 meshes and is greater than 95 wt%, adding water to prepare a pulp, performing two stages of high-speed and low-speed reactions between the pulp and the purified phosphoric acid so as to generate a calcium dihydrogen phosphate slurry, and drying and slaking the slurry to obtain a powdered feed-grade calcium dihydrogen phosphate finished product. The method provided by the invention has advantages of high phosphorus yield, good impurity removal effect, low cost, coarse and large crystalllization product and good fluidity. The product is not easy to cake. The method replaces a technological method for producing feed-grade calcium dihydrogen phosphate from hot-process phosphoric acid. The method provided by the invention has advantages of saving energy, reducing emission, decreasing production cost and improving caking property of the calcium dihydrogen phosphate material and material fluidity.

Owner:SINOCHEM YUNLONG

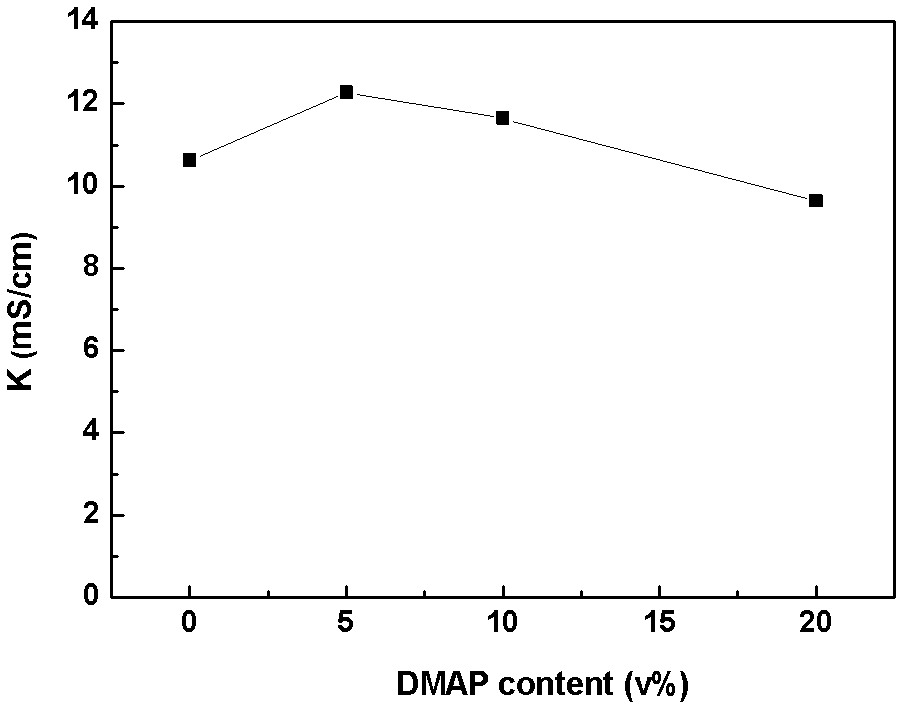

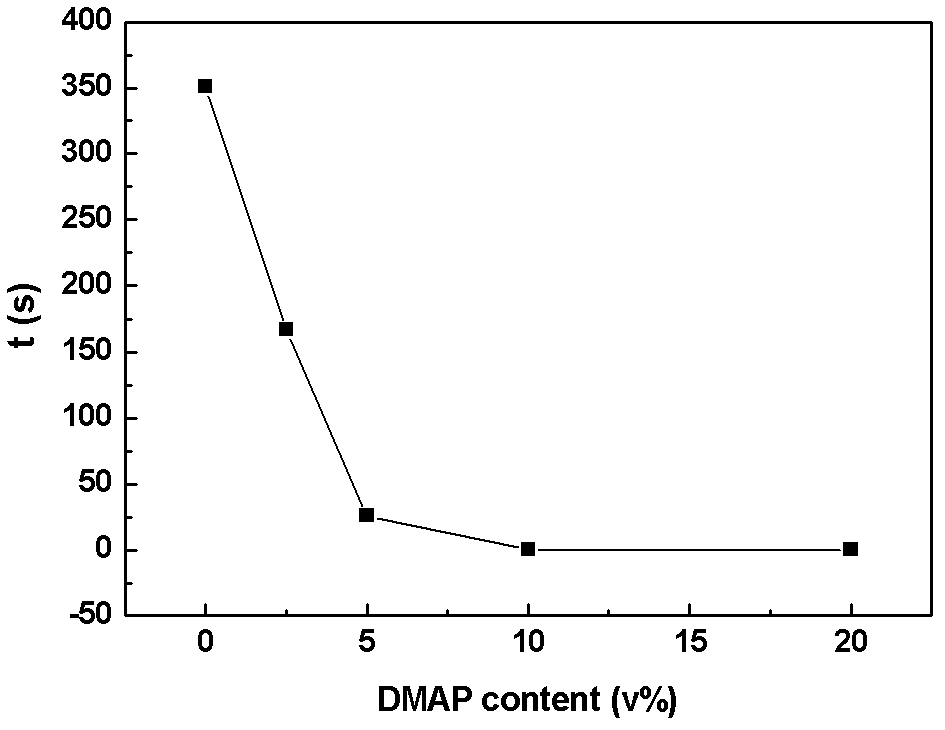

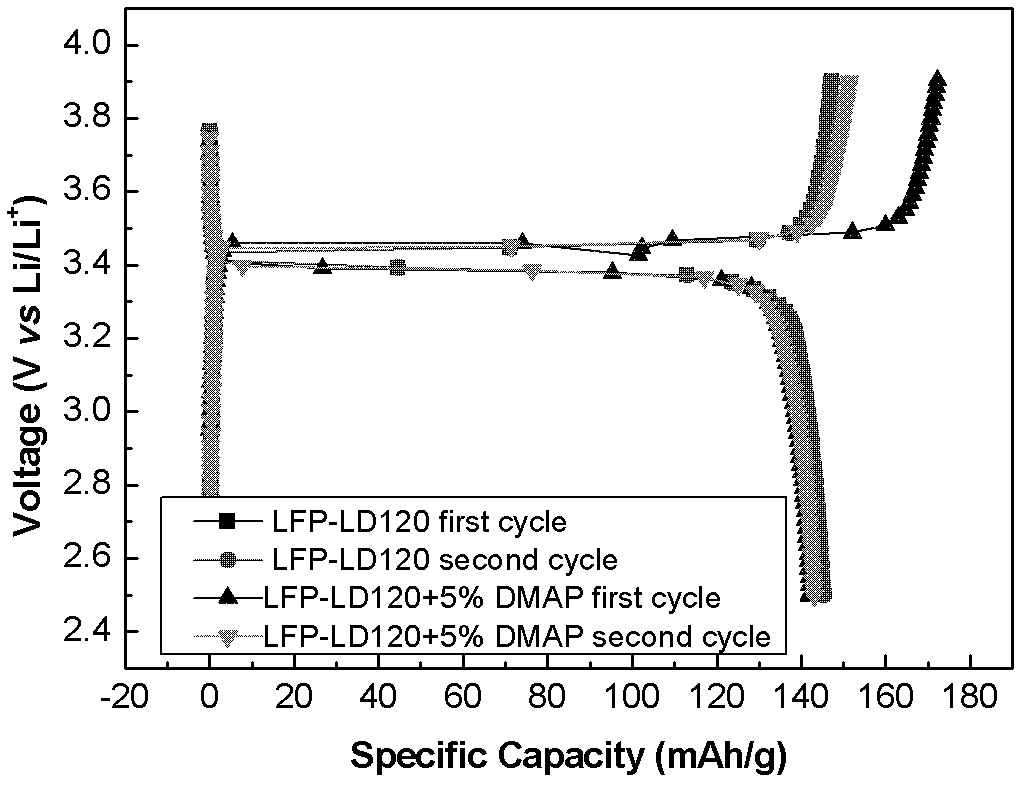

Double-functional lithium battery electrolyte additive and preparation method thereof

InactiveCN102386441AImprove flame retardant performanceGood flame retardancy and even non-combustibilityGroup 5/15 element organic compoundsSecondary cellsOrganic solventPhosphate

The present invention provides a double-functional lithium battery electrolyte additive and a preparation method thereof, and relates to the lithium battery electrolyte. The present invention provides the double-functional lithium battery electrolyte additive and the preparation method thereof, wherein the double-functional lithium battery electrolyte additive has a flame retardant performance, even a totally non-combustible characteristic. The double-functional lithium battery electrolyte additive is alkenyl phosphate. Phosphite trimester and alkenyl alkylogen are used as raw materials and react in organic solvent for preparing the double-functional lithium battery electrolyte additive. The double-functional lithium battery electrolyte additive and the routine lithium ion battery electrolyte can form the lithium ion battery electrolyte with double functions. The double-functional lithium battery electrolyte additive belongs to a double-functional additive and has the advantages of: higher phosphorus content and better flame retardation effect, wherein the existence of double bonds causes prior film forming of the double-functional lithium battery electrolyte additive in a discharging process. Compatibility between the electrolyte and a cathode is improved, and thermal stability of the cathode SEI layer is obtained.

Owner:XIAMEN UNIV

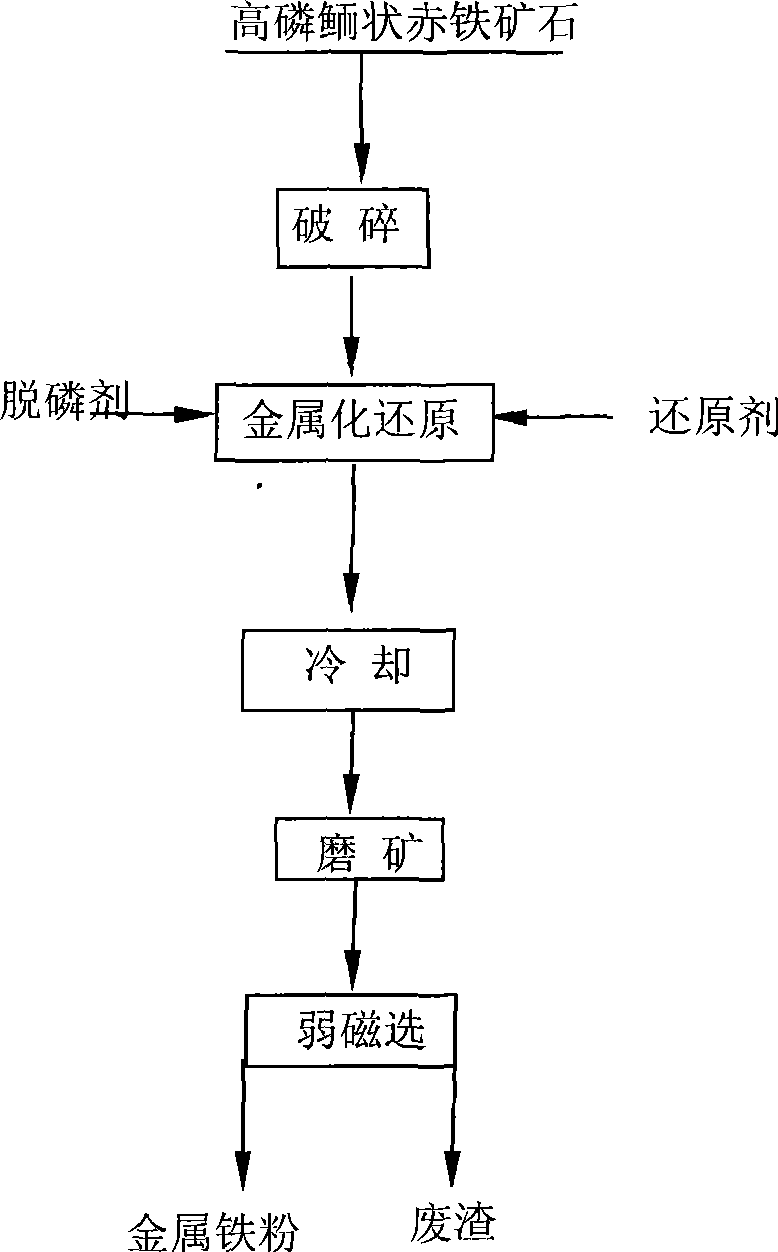

Technological process for directly producing spongy iron from high-phosphor oolitic hematite

InactiveCN101487068AAvoid pollutionEmission reductionProcess efficiency improvementIronstoneResource utilization

A technique method for directly producing spongy iron by using high phosphorus oolitic hematite belongs to the iron making field, and is characterized in that the high phosphorus oolitic hematite is added with a dephosphorizing agent and then is subjected to direct metallization reducing roast by taking coal as a reducing agent, low intensity magnetic separation for raising iron and reducing phosphorus is carried out, thus obtaining the substance with more than 90 percent of iron metal and phosphorus less than 0.08 percent. The invention has the advantages as following: (1) the utilization rate of resource is high, thus shortening the process flow of making raw steel material from iron ore, avoiding from polluting environment in concentrated ore sintering, pelletizing and blast furnace ironmaking in other methods, and having obvious environmental benefits, energy-saving and consumption reduction effects; (2) the technique method is simpler than other methods, the iron raising process and phosphorus reducing process can be completed simultaneously; and (3) coal power with low cost is directly taken as the reducing agent instead of the expensive coke, thus saving the cost in coking process and avoiding from polluting environment; the varieties are simple, the source is rich, the discharging amount of pollutants in the method is less than that in other methods and the pollutants are easy to deal with.

Owner:UNIV OF SCI & TECH BEIJING

Method for comprehensively recovering tungsten and phosphorus from high phosphorus white tungsten ores

ActiveCN102080161ARealize comprehensive utilizationEasy to separate by filtrationProcess efficiency improvementPhosphorus compoundsWater dischargeDecomposition

The invention discloses a method for receiving tungsten and phosphorus from high phosphorus white tungsten ores, which comprises: decomposing the ores by using mixed acid of phosphoric acid and sulfuric acid, wherein phosphorus-containing ore are converted into phosphoric acid, tungsten-containing ore are converted into phosphotungstic acid, and both the phosphorus and the tungsten enter solution; when the total P2O5 mass content in circular leaching filtrate surpasses 30 percent, extracting tungsten from the circular leaching filtrate, extracting phosphoric acid by using a solvent extraction method, reducing P2O5 mass content in the circular leaching filtrate by controlling the extraction rate of phosphoric acid, resupplying sulfuric acid, and returning to newly leached high phosphorus white tungsten ores; and thus, recovering tungsten and phosphoric acid from the leaching filtrate respectively. The method has the advantages of comprehensively recovering tungsten and phosphorus from ores, lowering requirements on tungsten ore raw material, reducing pressure in ore dressing step, ensuring over 98 percent decomposition rate of the white tungsten ore, recycling leaching agent, greatly reducing leaching cost and waste water discharge, along with simple leaching equipment, convenient operation and easy industrialization implementation.

Owner:CENT SOUTH UNIV

Ore dressing process of oolitic high phosphorus hematite

The ore dressing process of oolitic high phosphorus hematite includes the following steps: roasting crushed oolitic high phosphorus hematite in 80-99 wt% with coal powder as reductant in 1-20 wt% inside a shaft furnace or rotary kiln at 700-1050 deg.c for 0.5-2.5 hr and sealed cooling to room temperature; crushing the roasted hematite, grinding and weak magnetic separation; regulating pH value of the coarse concentrate to 8-12, adding iron ore inhibitor sulfonated starch in 0.5-3.0 kg / ton, activator in 0.2-2.0kg / ton and collecting agent in 0.2-3.0kg / ton and final reverse floatation. The process converts the weak magnetic hematite into strong magnetic mineral, concentrates iron mineral via weak magnetic separation and eliminate P, Si and other impurities in reverse floatation, and can obtain iron concentrate with iron grade higher than 63 %, P content less than 0.15 %, and iron recovering rate over 75 %.

Owner:WUHAN UNIV OF SCI & TECH

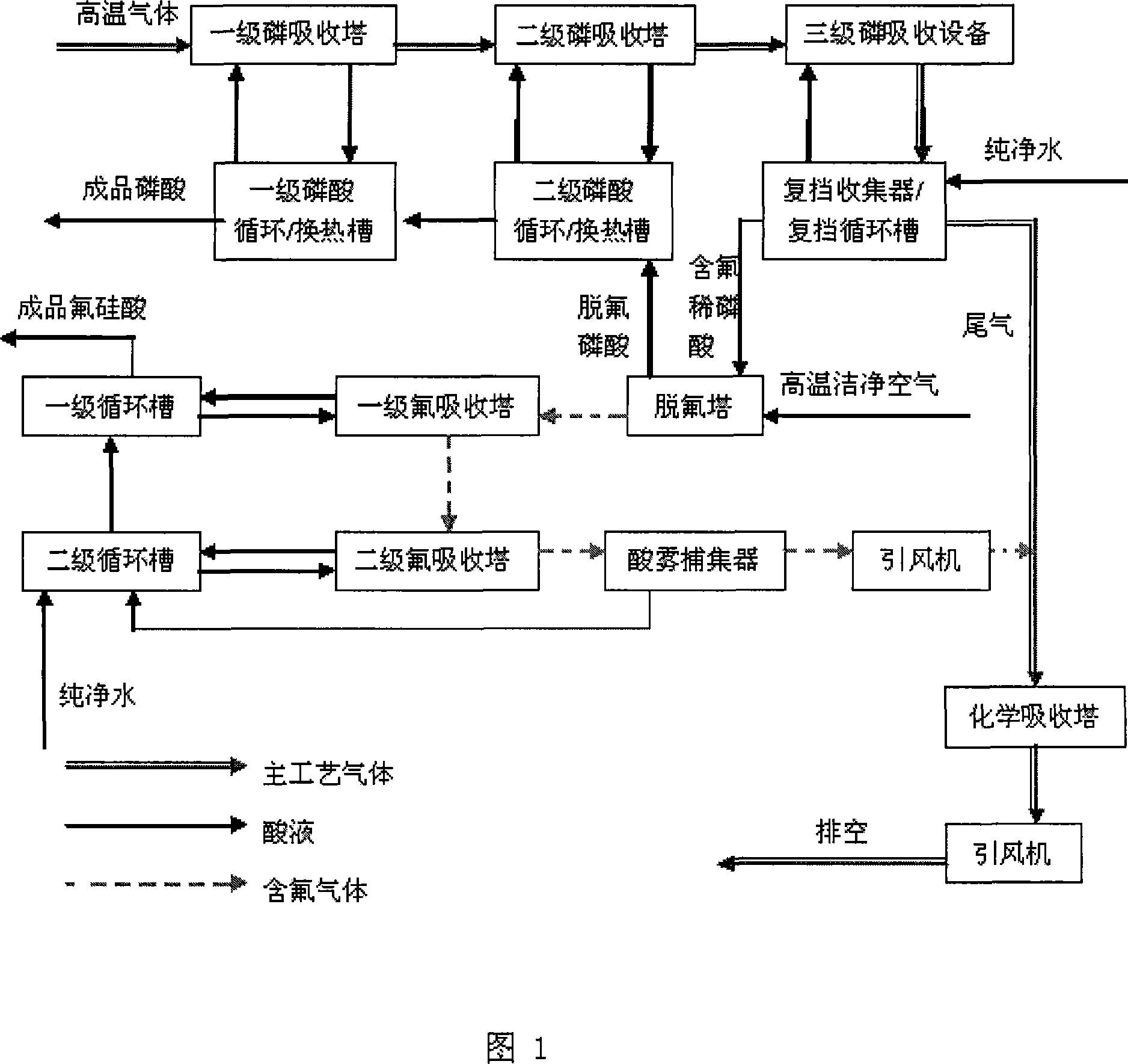

Method for absorbing and extracting phosphor and fluorin from phosphoric acid produced in kiln method

InactiveCN101049920AImprove separation rateHigh puritySilicon halogen compoundsPhosphoric acidHigh concentrationAbsorption column

This invention discloses a method for separating phosphorus and fluorine of kiln process phosphoric acid by absorption. The method comprises: sending relatively high temperature phosphoric acid after hydration in primary and secondary hydration columns to a circulation tank for cooling, pumping into the hydration columns for circulation, sending gases after primary and secondary absorption to a Venturi absorber for re-absorption, collecting the residual acid mist by a collector, sending the absorbed gas and tail gas after fluorine absorption together to a chemical absorption column, and exhausting the tail gas. Besides, qualified fluosilicic acid can be obtained from the fluorine-containing diluted H3PO4 in the collector. The method utilizes the air with residual heat in the kiln, and has such advantages as no extra energy consumption, high phosphorus and fluorine separation efficiency, high concentration and low fluorine content in obtained H3PO4, and low P2O5 content in obtained fluosilicic acid. The obtained fluosilicic acid has a wide concentration range and a high purity, and is easy to utilize.

Owner:HUBEI SANXIN PHOSPHORIC ACID

Dephosphorus iron extraction production method of oolitic high phosphorus red iron ore

The present invention relates to a production method for dephosphorization and extracting iron from oolitic high-phosphorus haematite. Said method includes the following steps: uniformly mixing (by wt%) 60%-90% of oolitic high-phosphorus haematite powder, 8%-20% of coke powder or coal powder and 0-20% of lime hydrate, briquetting or balling, drying, making reduction at 1100 deg.C-1450 deg.C in high-temperature furnace, reduction time is 10-30 min, cooling reduced product, grinding and making magnetic separation, finally making the metal iron granules be separated from phosphorus-rich ganque or slag.

Owner:WUHAN UNIV OF SCI & TECH

Electroless nickel-phosphorus plating process for Nd-Fe-Bo permanent magnet material

InactiveCN1807682AAvoid bulgingPrevent peelingLiquid/solution decomposition chemical coatingCleaning using liquidsElectroless nickelPhosphor

The invention discloses a chemical plating nickel plating method of neodymium-iron- boron permanent magnet material, which is characterized by the following: adopting plugging chemical plating to plug neodymium-iron-boron and thick and block-up neutral chemical plating; carrying on chemical plating nickel phosphor method of acidic high-phosphorus chemical plating, wherein the method comprises the following steps: tumbling; chamfering; degreasing; derusting; activating; plugging chemical plating; neutering chemical plating; acidifying high-phosphorus chemical plating; inactivating. The invention simplifies the application of industry, which reduces cost of production.

Owner:鲁国强

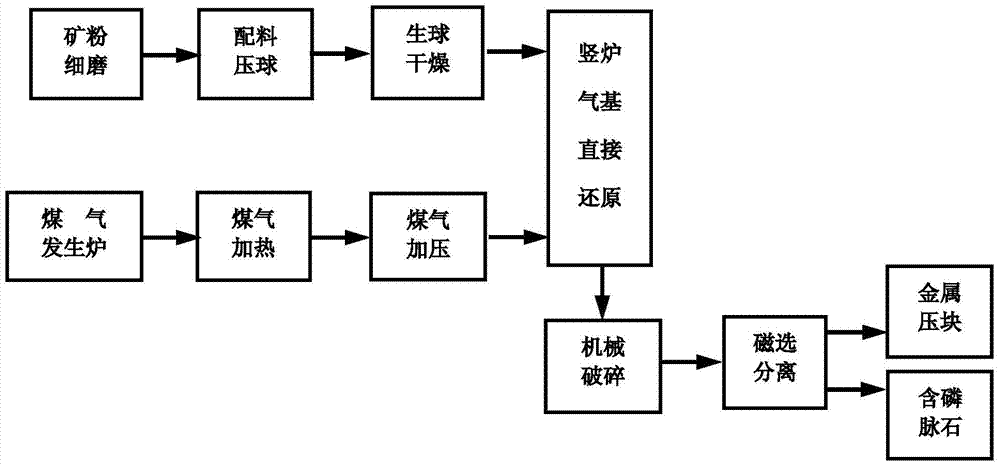

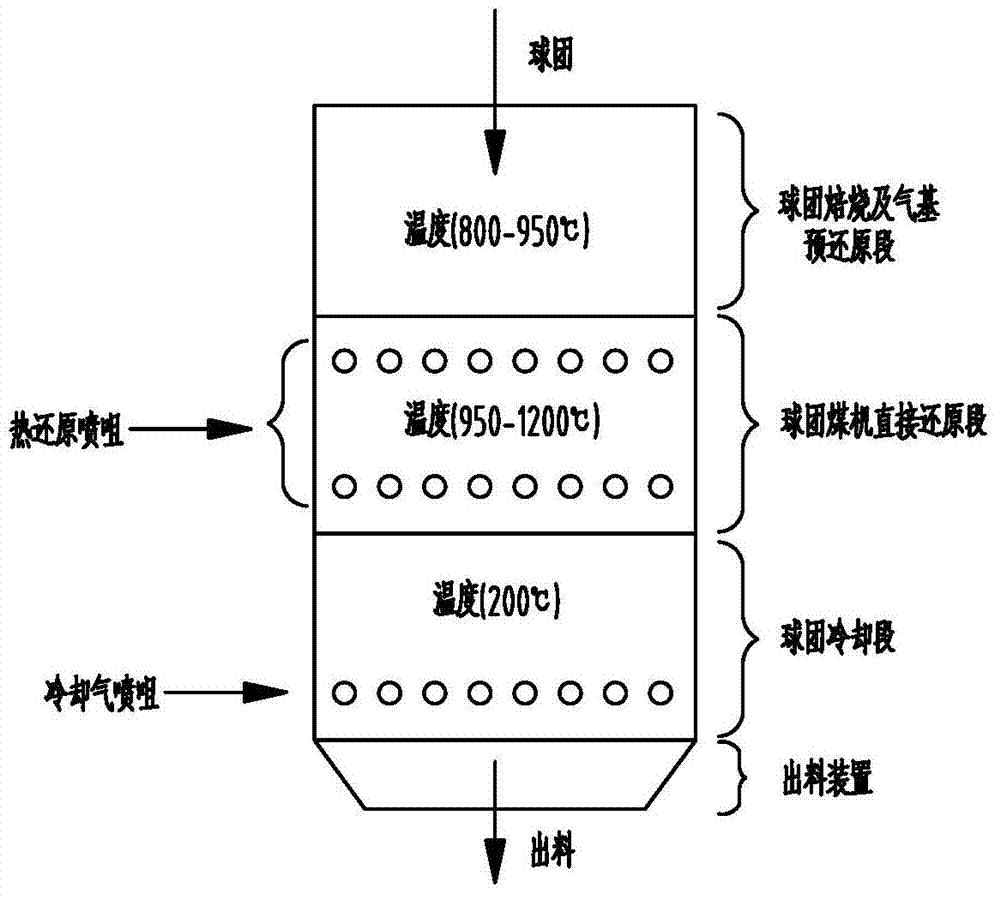

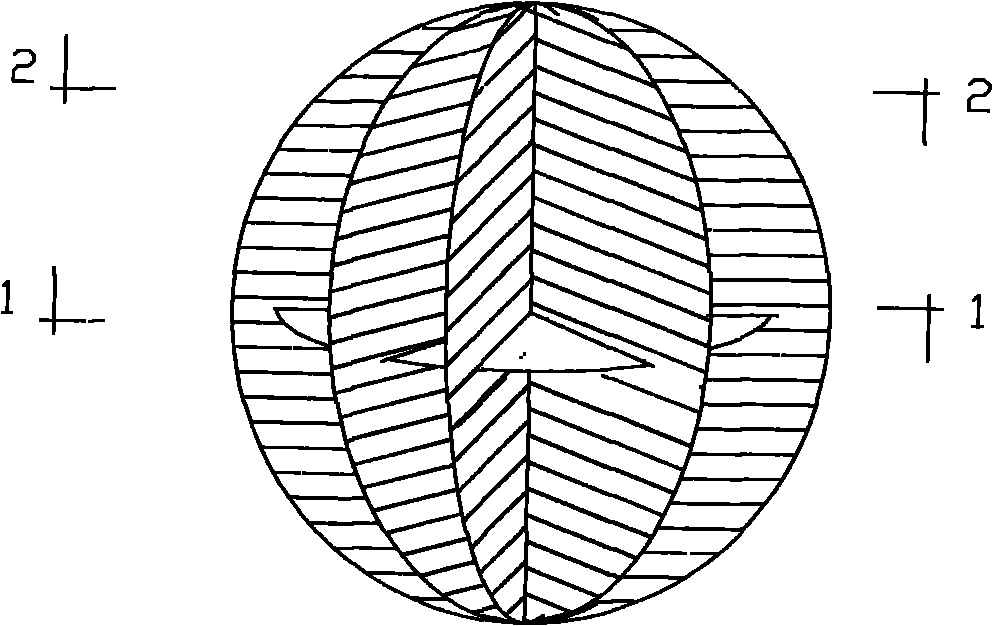

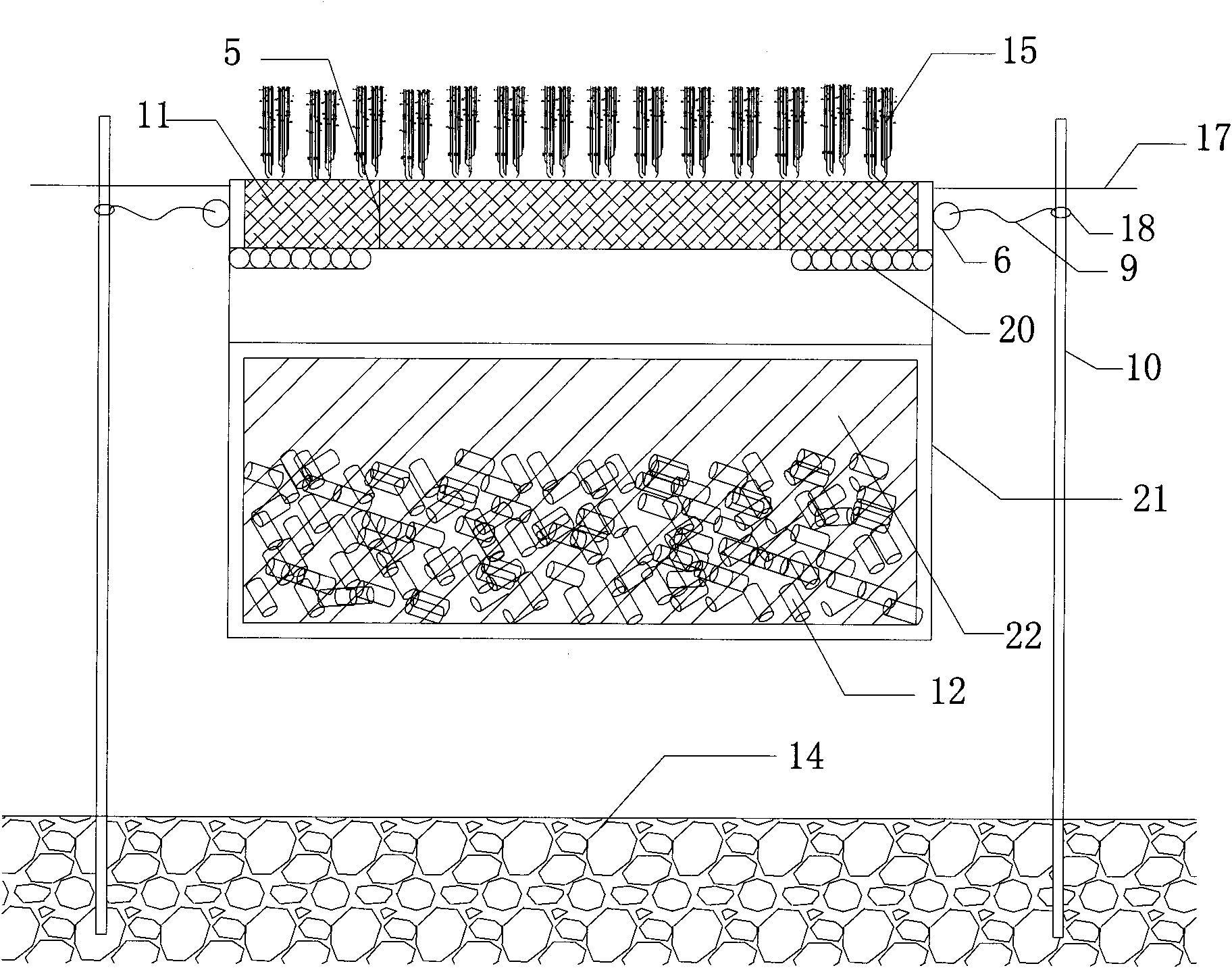

Method for preventing pellets from high temperature reduction bonding in high phosphorus oolitic hematite treatment shaft furnace

ActiveCN103667687ARelieve stickingGood for magnetic separationShaft furnaceDecreased energyShaft furnace

The invention discloses a method for preventing pellets from high temperature reduction bonding in a high phosphorus oolitic hematite treatment shaft furnace, belonging to the technical field of direct-reduction ironmaking. High phosphorus oolitic hematite powder, pulverized coal, a dephosphorization agent and a bonding agent are mixed together according to a proper ratio, the mixture is milled and pressed into balls so as to prepare cold bound pellets, and the bound pellets are dried or maintained and are further conveyed into a direct-reduction shaft furnace; in the direct-reduction shaft furnace, the pellets are subjected to hot coal gas roasting, gas-based prereduction, coal-based direct reduction and cooling process from top to bottom, temperature range of gas-based prereduction and coal-based direct reduction for the bound pellets is 850-1200 DEG C, and standing time in the shaft furnace is 1-5 hours; the reduction gas comprises H2 and CO in a ratio of 1.2-4; the reduced pellets are sealed and cooled, at the outlet of a cooling section, temperature of the bound pellets is controlled to be 100-200 DEG C, and the bound pellets are further smashed, magnetically separated and briquetted, wherein TFe in the obtained iron product is not less than 88%, and phosphorus content is less than 0.3%. The method has the advantages of decreasing energy consumption of reduction process of the shaft furnace.

Owner:韩其平

Degumming process for edible vegetable oil and application thereof

ActiveCN102533441AImprove degumming effectHigh yieldFatty-oils/fats refiningOil processingOil and grease

The invention relates to a degumming process for edible vegetable oil and the application thereof. The degumming process for edible vegetable oil comprises the following steps: reacting raw oil with an acid to convert non-hydrated phospholipids in the raw oil into hydrated phospholipids, agglomerating micelles by hydration, and performing centrifugal separation to obtain degummed oil. The degumming process for edible vegetable oil can be applied to refining of edible vegetable oil. The invention further discloses a process of refining edible vegetable oil, which can produce RBD oil products by performing the following steps in sequence: degumming process mentioned above, decoloring treatment, deacidifying treatment and deodorizing treatment. The degumming process for edible vegetable oil is suitable for degumming of various edible vegetable oil, particularly seed oil with high phosphorus content (more particularly seed oil with high non-hydrated phospholipids content), and has excellent degumming effect. The degumming process is an innovation in oil and fat degumming aspect, and besides, the improvement on the degumming process promotes the generation of novel physical refining techniques in oil processing.

Owner:SHANGHAI HAOYOU IND EQUIP

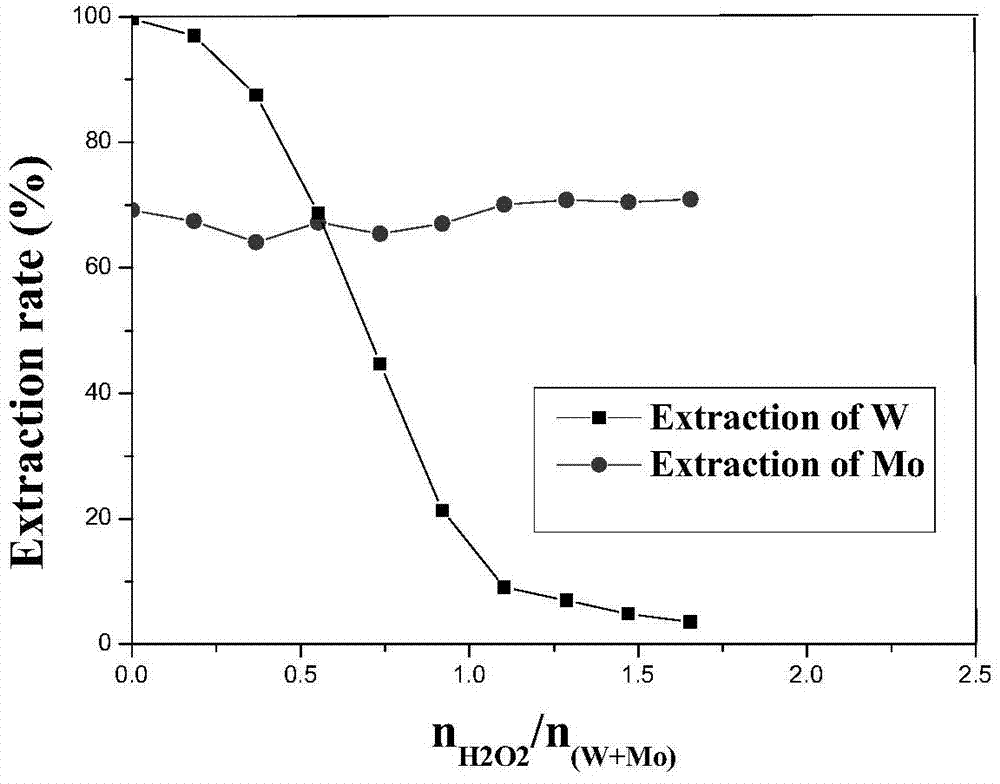

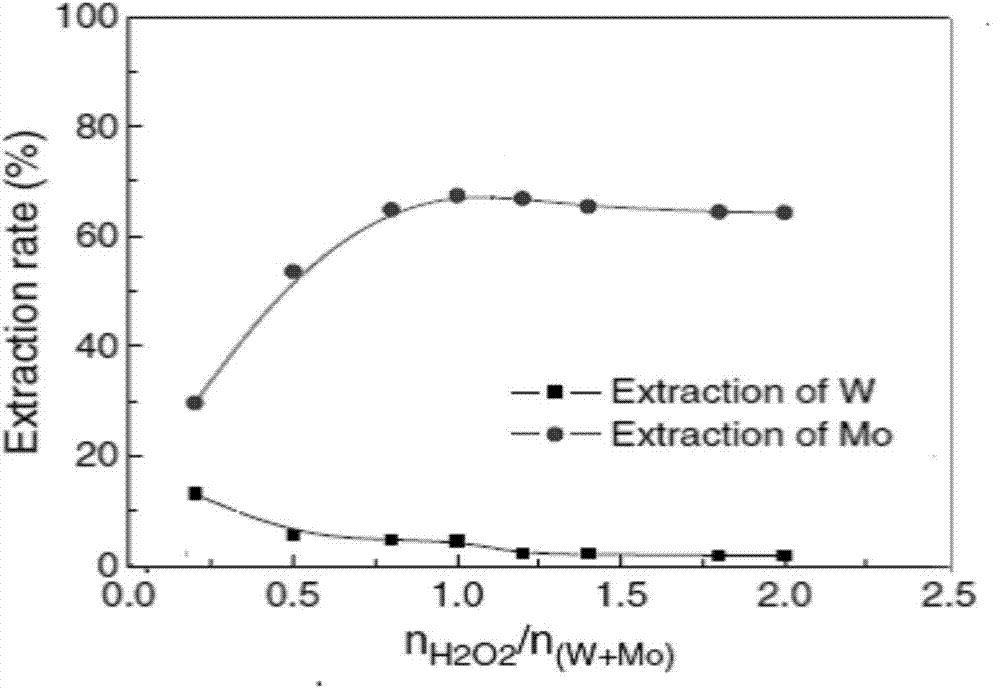

Method for extracting and separating tungsten and molybdenum in high-phosphorus mixed solution containing tungsten and molybdenum

ActiveCN104711422ARealize extraction and separationSimple methodProcess efficiency improvementPhosphomolybdic acidPhosphate

The invention relates to a method for extracting and separating tungsten and molybdenum in a high-phosphorus mixed solution containing tungsten and molybdenum. The method comprises the following steps: adding hydrogen peroxide in the high-phosphorus mixed solution containing tungsten and molybdenum for acidity adjustment and control, and converting phosphotungstic acid and phosphomolybdic acid into peroxy-phosphotungstic acid and peroxy-phosphomolybdic acid; then, taking a mixture of tributyl phosphate (TBP) and methyl phosphate dimethyl heptyl ester (P350) as an extracting agent, extracting the peroxy-phosphomolybdic acid into an organic phase, and leaving the peroxy-phosphotungstic acid in an aqueous phase; from now on, after decomposing the peroxy-phosphotungstic acid in extraction raffinate in the way of heating or ultraviolet irradiation or introduction of sulfur dioxide, extracting tungsten in the solution again with a fresh mixed extracting agent, and finally realizing extraction and separation of tungsten and molybdenum from complex material liquid. The method is small in tungsten co-extraction loss, can effectively solve the extraction and separation problem of tungsten and molybdenum in the high-phosphorus mixed solution containing tungsten and molybdenum, and is easy to realize industrialization.

Owner:CENT SOUTH UNIV

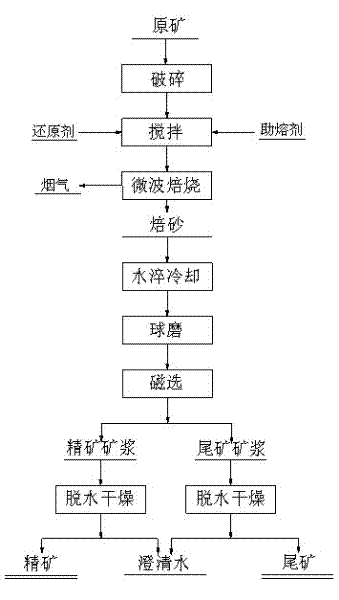

Method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation

InactiveCN102212677AReduce grinding energy consumptionShorten milling timeMagnetic separationMixed materialsQuenching

The invention relates to a method for refining iron and removing phosphorus from complex refractory high-phosphorus iron ore, in particular to a method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation, and belongs to the technical field of mineral processing, particularly iron ore beneficiation. The method comprises the following steps: crushing refractory high-phosphorus iron ore used as raw material into granules with granularity of less than 2mm; mixing the crushed raw ore with a fluxing agent and a reducing agent in a certain proportion; transferring the obtained mixed material into a microwave reaction furnace for reduction roasting; and carrying out water-quenching, cooling, ball-milling and wet-magnetic-separating on the obtained roasted ore to finally obtain iron ore concentrate. In the method, the ore is reduced by utilizing a microwave roasting technology, wherein microwave reduction roasting time is short, and the temperature of the ore is raised quickly; and meanwhile the fluxing agent is added so as to promote gangue softening and improve refractory ore structure together with microwave roasting reaction. By utilizing the method for sorting the high-phosphorus iron ore, the iron ore concentrate with grade of more than 58.39% can be obtained, and phosphorus removal rate reaches over 70.44%, thus a new technique is provided for sorting the high-phosphorus iron ore.

Owner:KUNMING UNIV OF SCI & TECH

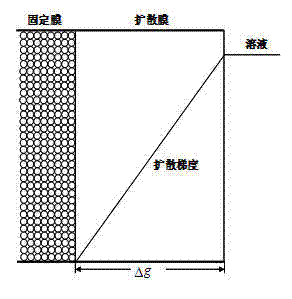

Improved phosphorus fixing film used in DGT (diffusive gradients in thin films) measurement and preparation method thereof

InactiveCN102507388AImprove physical strengthLittle flexibilitySurface/boundary effectMoisturePolyacrylamide

The invention provides an improved phosphorus fixing film used in DGT (diffusive gradients in thin films) measurement. The improved phosphorus fixing film is a polyacrylamide gel film containing zirconium dioxide (ZrO2) and is characterized in that ZrO2 particles of which the particle size is less than or equal to 5mu m are uniformly distributed on the surface of the phosphorus fixing film. A preparation method of the improved phosphorus fixing film comprises the following steps: uniformly mixing ZrO2 powder with the moisture content of 45-55% with an acrylamide solution at the weightmeasurement ratio of (1:3)-(1:6); grinding and then carrying out ultrasonication; standing for removing precipitates, adding tetramethylethylenediamine of which the volume is (1:1600)- (1:1400) of that of acrylamide and a 10% ammonium persulfate solution of which the volume is (1:60)-(1:40) of that of acrylamide, uniformly mixing and injecting into a glass mold; horizontally placing the glass mold at room temperature; After the zirconium powder is freely precipitated, raising the temperature to 40-60DEG C until the mixed solution forms a gel film; and soaking in de-ionized water for more than 12 hours, thus obtaining the phosphorus fixing film. The phosphorus fixing film provided by the invention can be used for maintaining high phosphorus ion adsorption capacity and simultaneously improving the resolution ratio of DGT in phosphorus analysis.

Owner:HOHAI UNIV

Filler special for artificial wetland and preparation method thereof

InactiveCN101863646AImprove adsorption capacityHigh adsorption rateSustainable biological treatmentCeramicwareConstructed wetlandFoaming agent

The invention aims to improve the phosphorus removal rate of an artificial wetland and provides a filler special for the artificial wetland and a preparation method thereof. The preparation method comprises the following steps of: after mixing cement and fly ash by using water, adding an aluminum powder foaming agent, and uniformly stirring and mixing, wherein the mass ratio of the cement to the fly ash to the aluminum powder to the water is 50-100:10-30:0.1-0.5:25-50; and pouring the stirred slurry into a mold for molding, foaming at the temperature of between 20 and 50 DEG C for 20 to 60 minutes, and curing to prepare the filler special for the artificial wetland. The method has the characteristics of simple production method, low cost, and the like. The filler has the advantages of high phosphorus adsorption efficiency, high intensity, light mass, large specific surface area, and the like.

Owner:NANJING UNIV OF TECH

Process and electrolytes for deposition of metal layers

ActiveUS7846503B2Constant layer propertyHigh in phosphorusPretreated surfacesAnti-corrosive paintsFormateElectroless deposition

The invention concerns an electrolyte for electroless deposition of metal layers with internal compressive stresses containing a metal base salt, a reducing agent, a complexing agent, an accelerator and a stabilizer. In order to make available an electrolyte of the said kind, from which uniform pore-free and crack-free metal-phosphorus coatings can be deposited with constant layers properties and high phosphorus contents at an elevated deposition rate over a long period of time, it is proposed by means of the invention that the electrolyte contain as metal base salt a metal salt whose anions contain at least one carbon atom and that is present in a starting concentration from 0.01 to 0.3 mol / L. At least one salt consisting of metal acetate, metal formate, metal oxalate, metal propionate, metal citrate and metal ascorbate, especially preferably metal acetate, is used as the metal salt whose anion contains at least one carbon atom. In addition, a method that is especially suitable for the use of the said electrolyte is proposed, where this method advantageously has a closed material circulation. Through the use of the invention especially pore-free and crack-free metal coatings with constant layer properties are uniformly deposited over a long time of use of the bath of at least 14-22 MTO.

Owner:MACDERMID ENTHONE INC

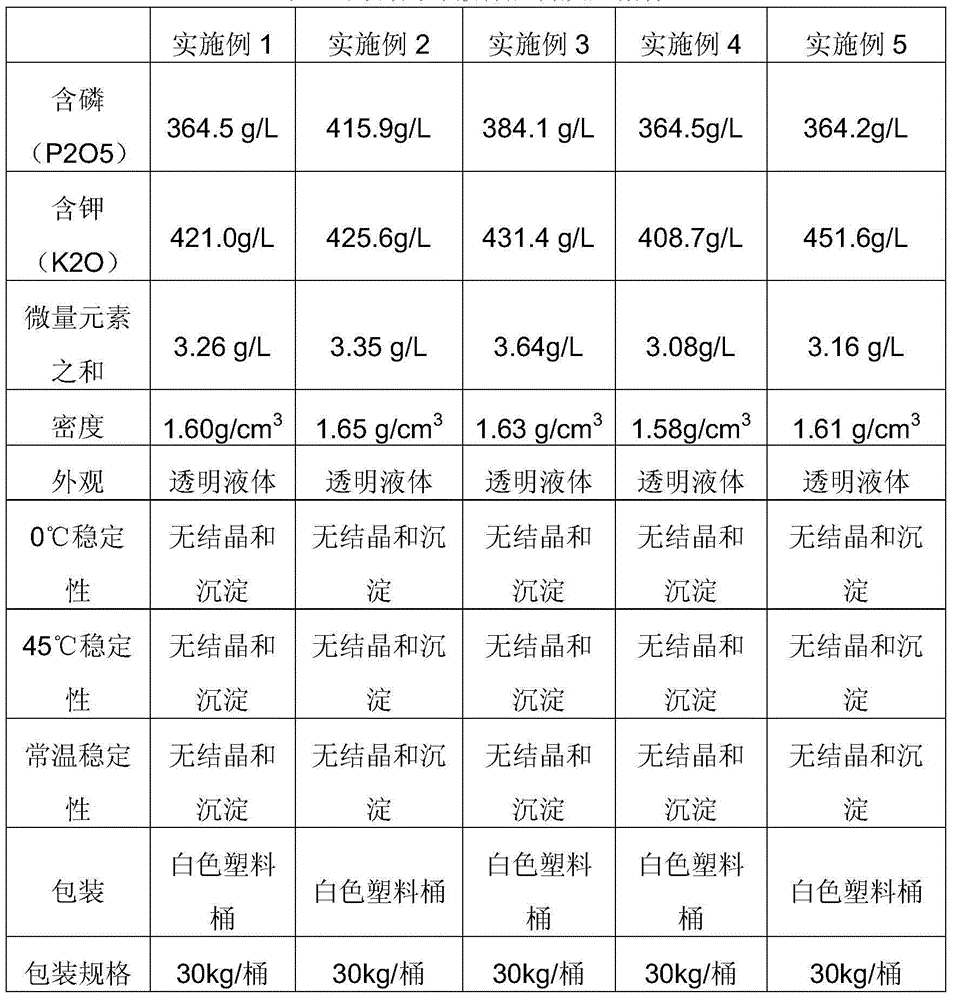

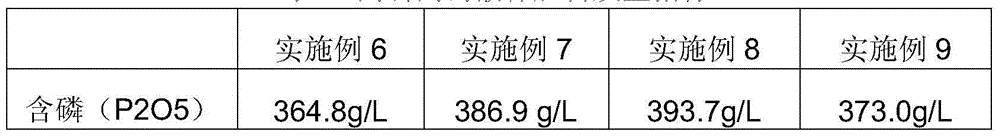

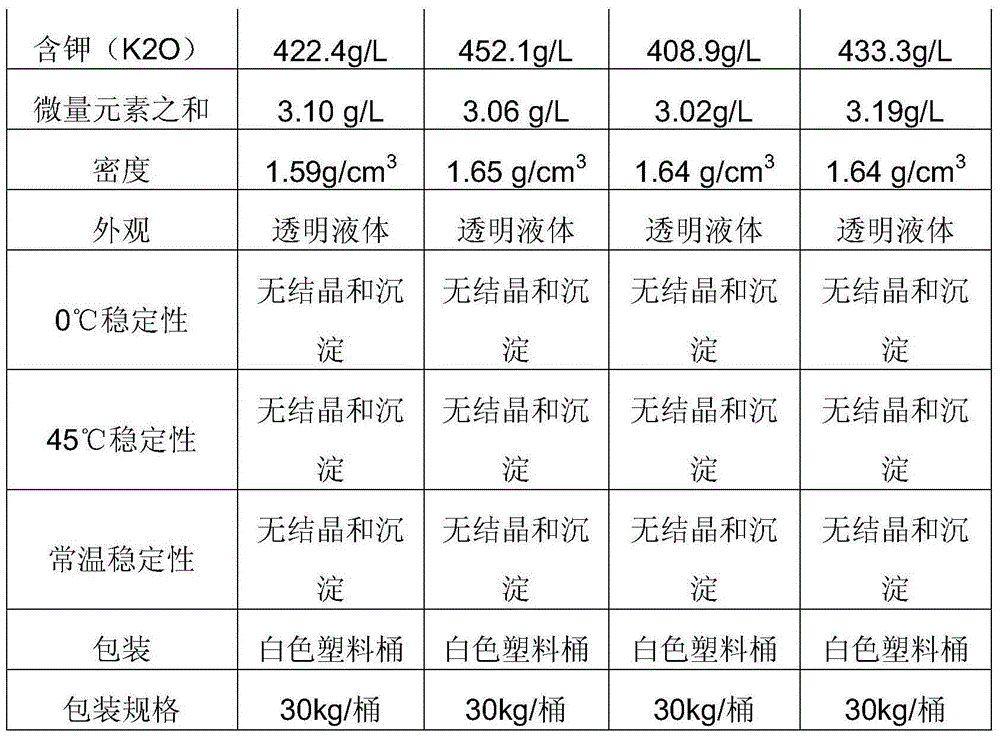

High-phosphorus high-potassium liquid compound fertilizer as well as preparation method and application method thereof

InactiveCN104446761AHigh nutrient contentPhysical stabilityFertilizer mixturesHigh concentrationSolvent

The invention provides a high-phosphorus high-potassium liquid compound fertilizer. The liquid compound fertilizer comprises the following components: 20-120 parts of a phosphorus fertilizer, 15-60 parts of a potassium fertilizer, 0.1-12 parts of a microelement fertilizer, 0.5-5 parts of a co-solvent and 10-50 parts of water, wherein the microelement fertilizer is one or more of a boron fertilizer, a manganese fertilizer, a zinc fertilizer and an iron fertilizer and is a water-soluble fertilizer. The invention also provides a preparation method and an application method of the high-phosphorus high-potassium liquid compound fertilizer. The contents of phosphorus and potassium in the high-phosphorus high-potassium liquid compound fertilizer are higher, the phosphate radicals and potassium ions stably coexist in a liquid phase so that the generation of insoluble precipitates such as potassium phosphate is avoided, the high-phosphorus high-potassium liquid compound fertilizer has the advantages of high content of the total nutrient, stable physical and chemical shapes, no phenomena such as crystallization, precipitation and layering under high temperature, low temperature and room temperature conditions, good fluidity, high-concentration nutrients, time conservation, labor conservation, fertilizer conservation, high fertilizer efficiency and the like, the high-phosphorus high-potassium liquid compound fertilizer is suitable for larger-area automatic fertilizer-applying operation and the fertilizer-applying efficiency can be significantly increased.

Owner:GUANGZHOU YIXIANG AGRI TECH

Low-cost slagging and dephosphorizing technique for high-phosphorus molten iron through converter smelting

ActiveCN105671237ALow costIncreased (MgO) contentManufacturing convertersProcess efficiency improvementAlkalinitySlag

The invention discloses a low-cost slagging and dephosphorizing technique for high-phosphorus molten iron through converter smelting. The slagging and dephosphorizing technique comprises the steps of slag remaining and splashing, primary charging, primary blowing, turning down and deslagging, secondary feeding, secondary blowing, and terminal control and steel tapping, all final slag is reserved for slag splashing after steel tapping, and the steps are repeated circularly. The obtained final slag comprises, 35-48% of CaO, 8-14% of MgO, 8-13% of SiO2, 10.20-18.50% of TFe, and 2.50-5.60% of P2O5, and the alkalinity is 2.5-6. By the adoption of the slagging and dephosphorizing technique, smelting of the high-phosphorus molten iron is integrally optimized; materials, such as high-cost slagging agents, magnesite pellets and light-burned magnesian limestone, are partially or completely replaced by low-cost and environment-friendly sintered and returned mines and raw magnesian limestone, and a corresponding technological system is set; and the extra heat is balanced while smooth dephosphorizing is guaranteed, the slag oxidation, the P2O5 content and the final slag MgO content are improved, the slagging cost is reduced by over 8 yuan / t while a furnace lining is protected and the dephosphorizing effect is achieved, the furnace age is prolonged from 12000 times to 15000 times, and the application value and popularization value are high.

Owner:WUKUN STEEL

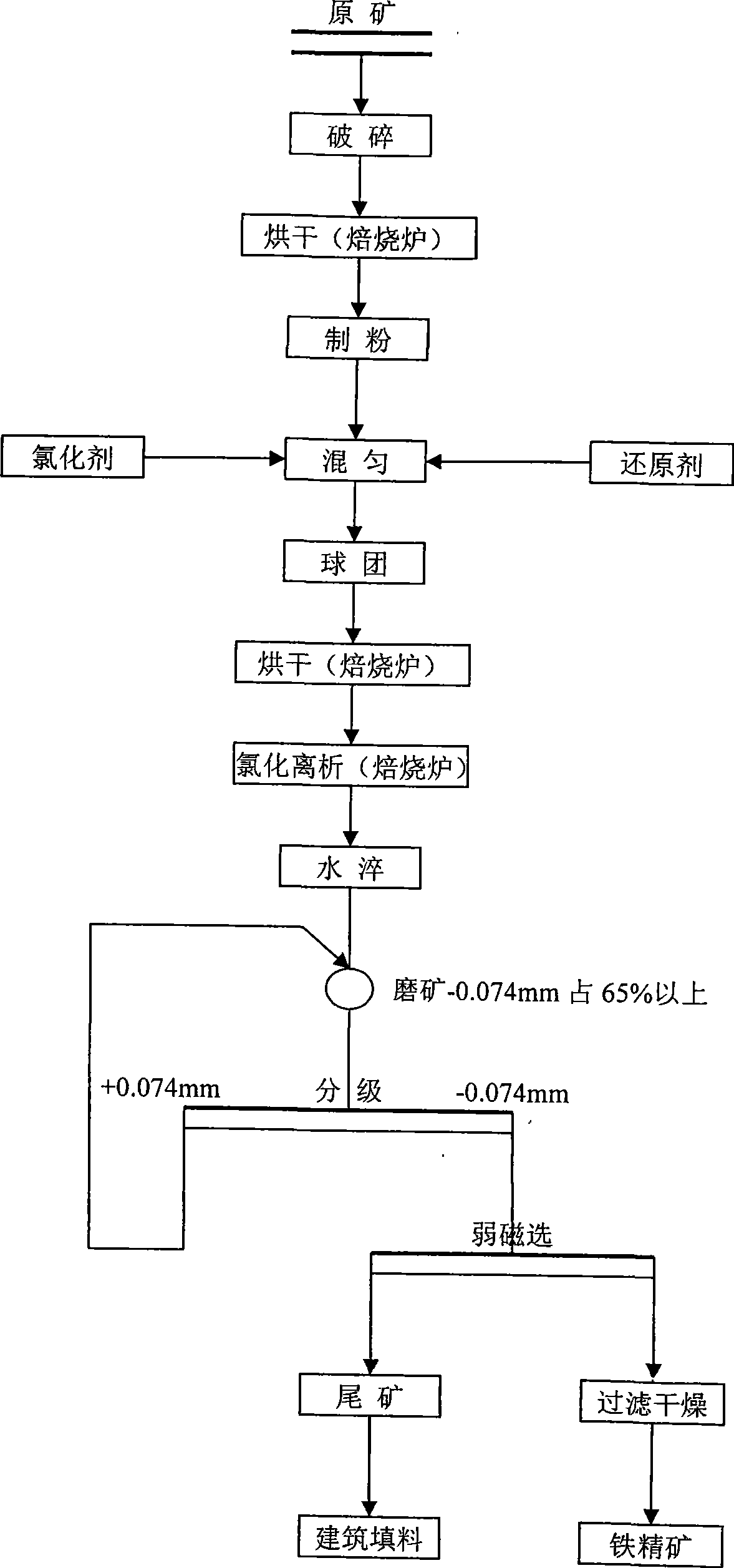

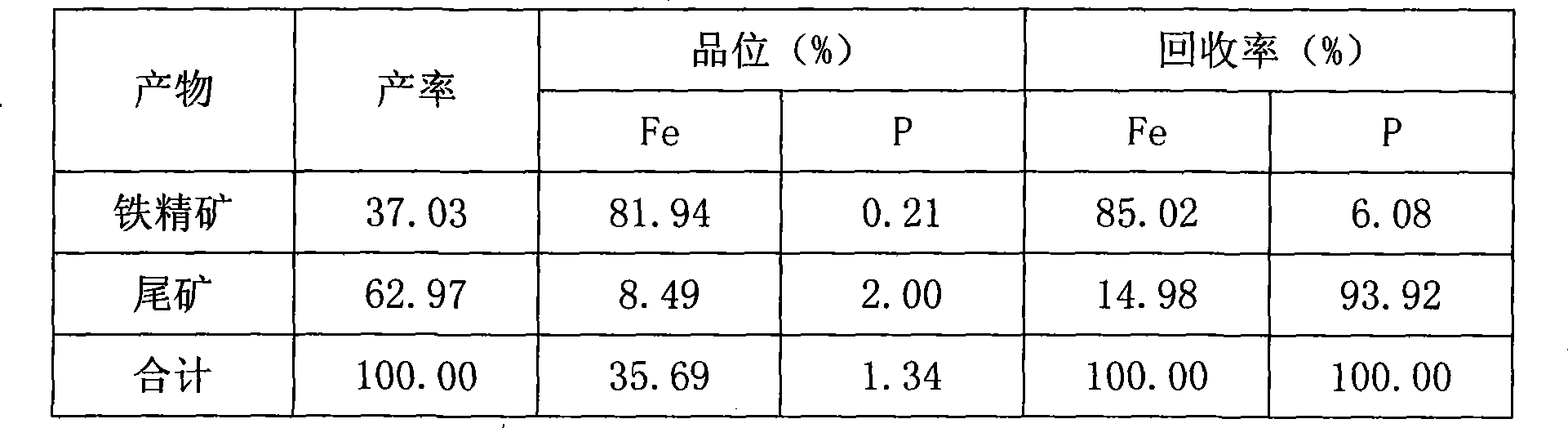

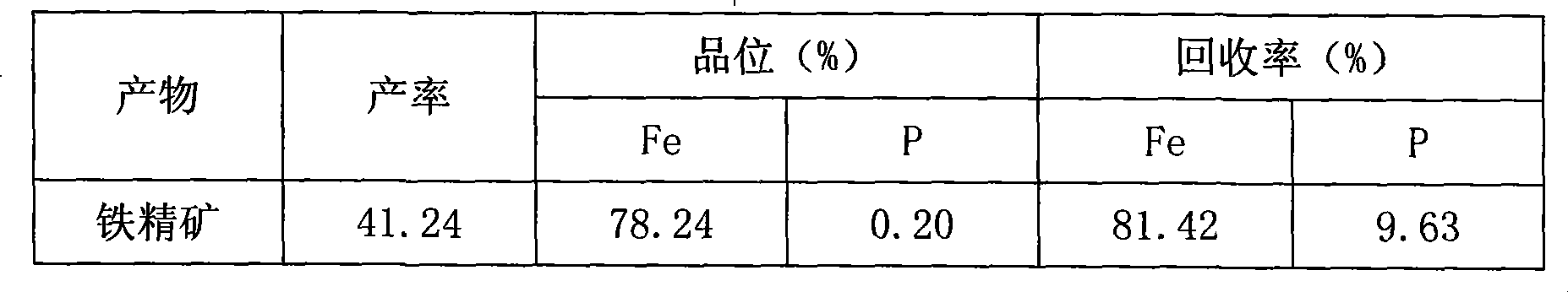

Method for reducing phosphorus by chloridization separation-weak of high phosphor iron ore

InactiveCN101457288AReduce phosphorus contentGood beneficiation indexMagnetic separationWet separationIronstoneIron increased

The invention relates to a chloridizing segregation-low-intensity magnetic separation method for reducing phosphorus of a high phosphorus iron ore. A chloridizing segregation-low intensity magnetic separation process is adopted to realize iron increase and phosphorous reduction in the method. A chlorinating agent and a reducing agent coke are added to the high phosphorus iron ore and mixed evenly, then chloridizing segregation roasting is carried out in a roasting furnace; the roasted product is water quenched and ball milled, and then separated by a low-intensity magnetic field magnetic separator, thus being capable of obtaining an iron ore concentrate with the iron grade more than 80%, the iron recovery rate more than 85% and the phosphorous content less than 0.20%. The iron ore concentrate powder can be taken as a raw material for smelting pig iron after being pelletized. Additionally, with regard to high phosphorus iron ores which contain sulfur or contain sulfur and arsenic at the same time, such as hematite, hematite-limonite ore, oolitic hematite-limonite ore, hematite, siderite and the like, the product iron ore concentrate with the sulfur content less than 0.20% and the arsenic content less than 0.04% can also be obtained.

Owner:昆明晶石矿冶有限公司

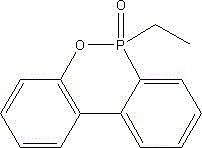

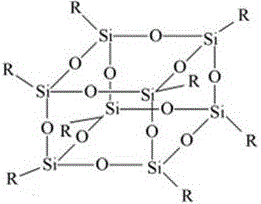

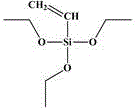

Phosphorus-containing flame retardant based on polyhedral oligomeric silsesquioxane (POSS) and preparation method of phosphorus-containing flame retardant

The invention discloses a phosphorus-containing flame retardant based on polyhedral oligomeric silsesquioxane (POSS) and a preparation method of the phosphorus-containing flame retardant. The flame retardant is prepared by carrying out hydrogenated addition and acid-catalyzed hydrolysis condensation reaction on 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and DOPO derivatives thereof and vinyltriethoxysilane (VTES); the flame retardant has the advantages of high phosphorus content, high flame-retardant efficiency, good heat resistance and little influence on mechanical property of a material; the flame retardant is used for products such as high temperature vulcanized silicone rubber and room temperature vulcanized silicone rubber, and also can be used as a temperature-resistant flame retardant of a thermoplastic polymer material; meanwhile, the flame retardant is high in phosphorus content; by adding a small amount of flame retardant, an excellent flame-retardant effect can be realized; a unique POSS structure belongs to a semi-inorganic organosilicone material, so the heat resistance of the flame retardant is improved.

Owner:SHANDONG SHIP TECH RES INST

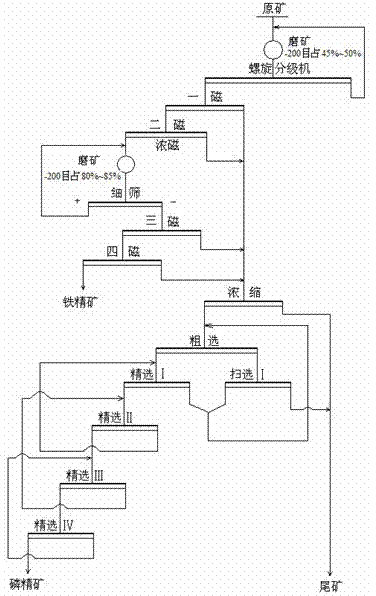

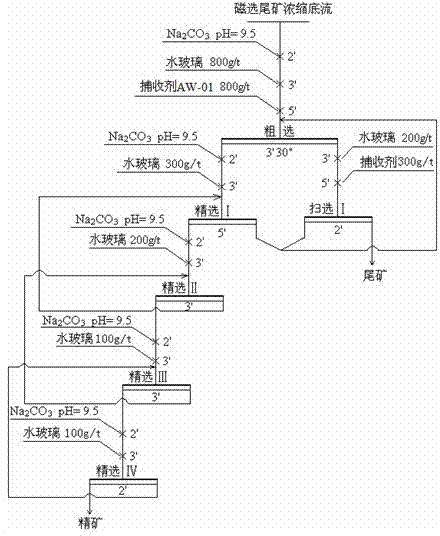

Mineral processing technology for comprehensively recycling iron phosphate from low-grade high phosphorus vanadium titanium magnetite

InactiveCN102728477AEfficient use ofIncrease the economic benefits of the dressing plantFlotationMagnetic separationPhosphateMagnetite

The invention discloses a mineral processing technology for comprehensively recycling iron phosphorus from low-grade high phosphorus vanadium titanium magnetite. The low-grade high phosphorus vanadium titanium magnetite is subjected to stage grinding and low intensity magnetic separation processes to obtain iron ore concentrate and magnetic separation tailings; the magnetic separation tailings uses low temperature flotation to recycle phosphorus after concentration, wherein the low temperature flotation is as follow: adding a slurry pH adjusting agent, an inhibitor and a collecting agent to the slurry of magnetic separation tailings, adjusting the pH of the slurry to 9-10, and performing flotation under 15-20 DEG C. The technology provided by the invention puts forward a mineral processing technology for comprehensively recycling iron phosphorus aiming at the low-grade high phosphorus vanadium titanium magnetite, which firstly adopts the low intensity magnetic separation method to recycle iron from ores and then adopts the low temperature flotation method to recycle phosphorus from tailings, thus realizing efficient utilization of such kind of mineral resources and increasing the economic benefits of concentrators. The low temperature flotation of the technology can reduce the subsequent costs of processing phosphate ores, improve the benefit of the comprehensive utilization of resources, reduce the production cost and achieve low cost and efficient recycling of phosphorus.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

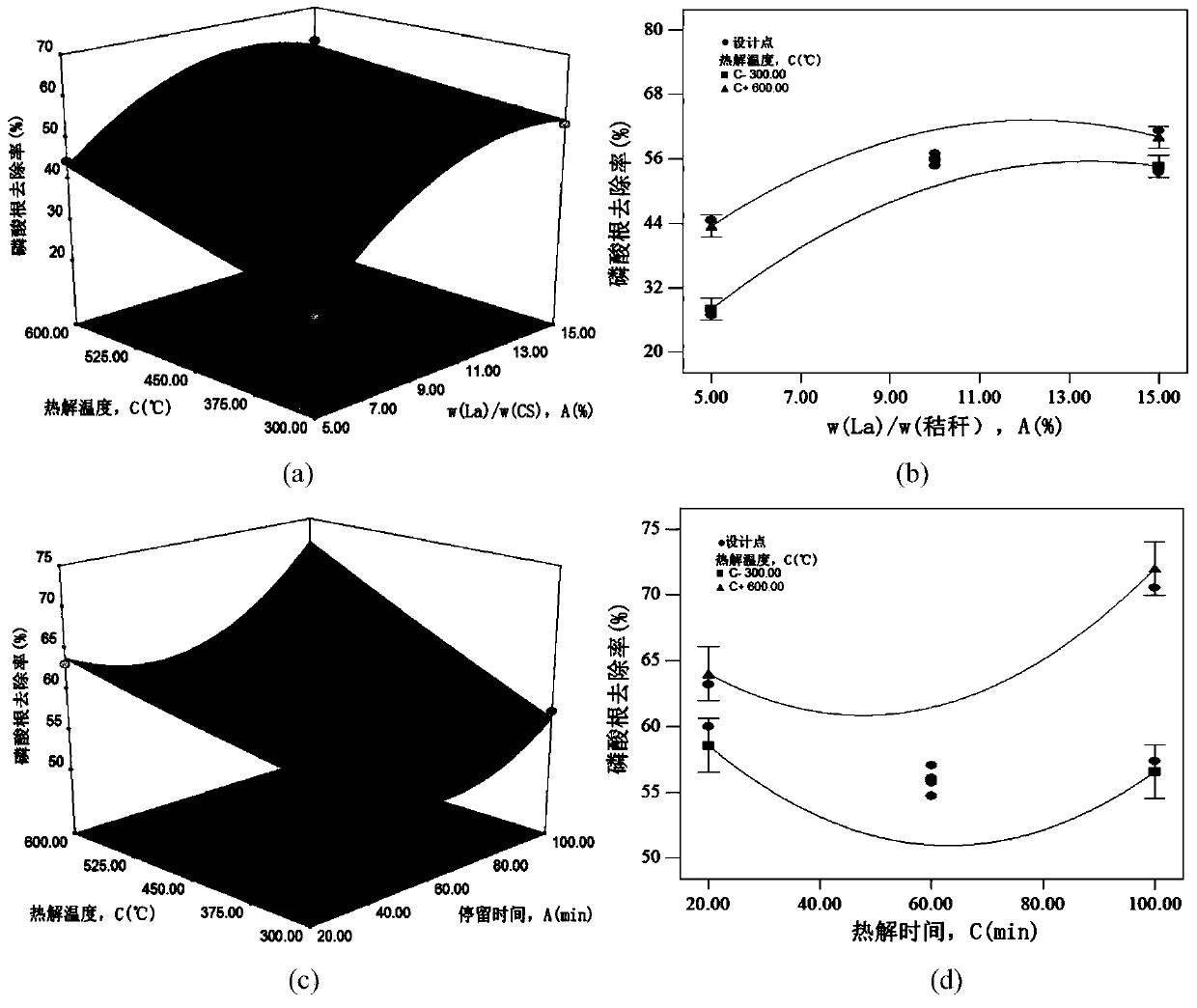

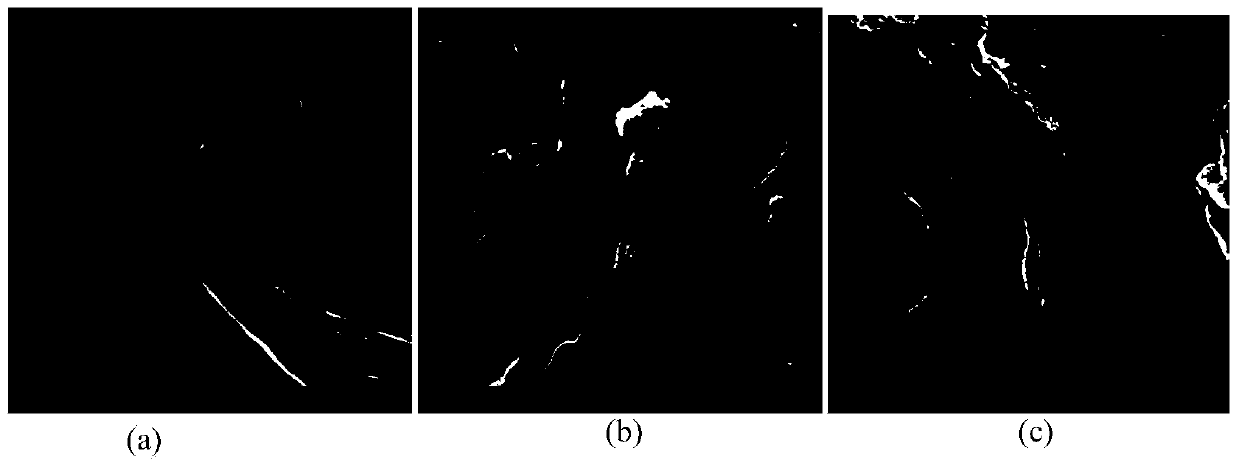

Method for preparing lanthanum-loaded charcoal used for purifying phosphorus polluted water

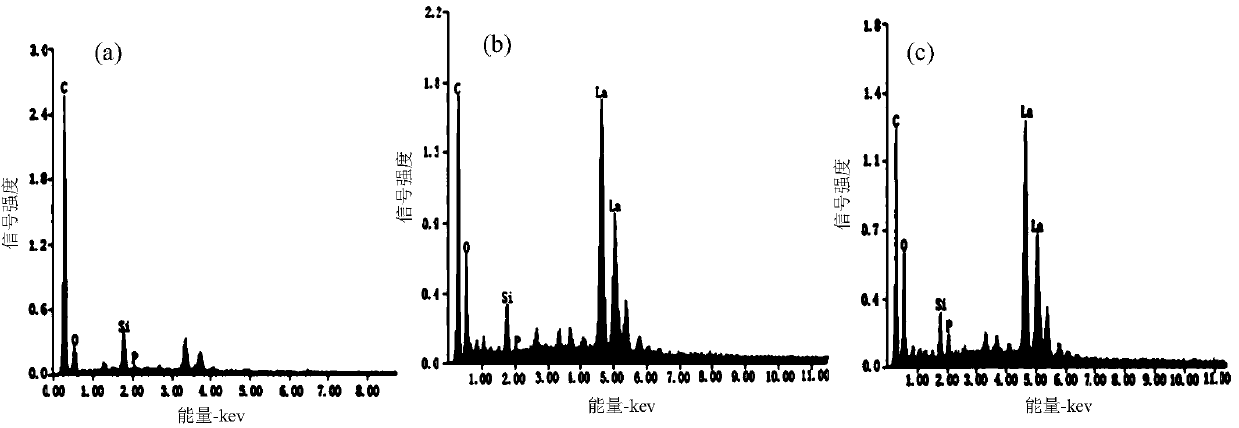

InactiveCN103785357AReduce the risk of eutrophicationStrong phosphorus removal capacityOther chemical processesWater/sewage treatment by sorptionLanthanumMuffle furnace

The invention discloses a method for preparing lanthanum-loaded charcoal used for purifying phosphorus polluted water. The method comprises the following steps: adding maize straws which pass through a 60-100-mesh sieve into a lanthanum solution, regulating the pH of the solution to be not less than 10 by using 4-6M of NaOH or ammonium hydroxide, centrifuging, removing supernatant, and cleaning by using 95% ethanol; drying and mashing cleaned solids, and performing pyrolysis in a muffle furnace; cooling a pyrolysis product to room temperature, grinding the materials which pass through the 60-100-mesh sieve, repeatedly cleaning the materials to be pH of below 8 by using distilled water, and drying to obtain products, wherein the product which passes through the 60-100-mesh sieve is the lanthanum-loaded charcoal. The prepared lanthanum-loaded charcoal has the high phosphorus removal efficiency, the preparation process is simple and feasible, the preparation cost is low, straw wastes are fully utilized, the environmental pollution caused by straw incineration is reduced, the lanthanum-loaded charcoal is reutilized for returning to field, and the carbon pool and the phosphorus pool of soil are increased.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

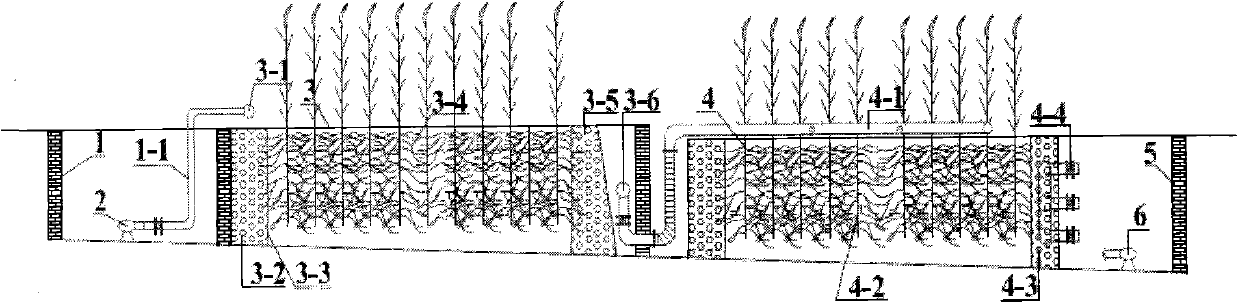

An/O type composite artificial wetland system for enhanced treatment of low-C/N ratio wastewater

InactiveCN102557330AHigh removal rateReduce consumptionMultistage water/sewage treatmentPorosityConstructed wetland

The invention relates to an An / O type composite artificial wetland system for the enhanced treatment of low-C / N ratio wastewater. The invention relates to a wastewater treatment apparatus, which is a land treatment apparatus suitable for treating low-C / N ratio wastewater and recycling treated water. According to the An / O type composite artificial wetland system, wastewater sequentially flows through a horizontal subsurface flow wetland and a vertical subsurface flow wetland, effluent water part then flows back into the horizontal subsurface flow wetland, and a dissolved oxygen (DO) gradient is utilized to couple aerobic ammonia-oxidizing bacteria (AOB), nitrite-oxidizing bacteria (NOB) and anammox in the vertical subsurface flow wetland by means of effluent water level regulation in order to enhance the low-C / N ratio wastewater denitrification efficiency of the An / O type composite artificial wetland system. Broken bricks, oyster shells and other packing with large specific surface area, high porosity and good adsorbability are filled in the composite artificial wetland system, consequently, the amount of organisms held by the system is greatly increased, and high phosphorus-and-nitrogen-removing efficiency is guaranteed. The An / O type composite artificial wetland system has the advantages of simple structure, multiple functions, high efficiency, low cost and the like, is easy to operate and manage, can stably operate, and can synchronously remove carbon, nitrogen and phosphorus, the treated effluent water can be directly recycled, landscape plants can be planted on the ground surface, and the An / O type composite artificial wetland system can be combined with ecological construction and city and town greening functions.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Phosphorus removal adsorbent for modifying oyster shell with iron salt and preparation method as well as application thereof

InactiveCN102500337AWide variety of sourcesImprove energy savingOther chemical processesWater/sewage treatment by sorptionIron saltsSorbent

The invention discloses a composition of a phosphorus removal adsorbent for modifying oyster shell with iron salt and a preparation method as well as application thereof in the aspect of sewage treatment. The adsorbent is prepared by the following steps of: mixing 30-mesh to 100-mesh oyster shell powder and iron salt solution according to a certain mass ratio; and stirring at the room temperature, adjusting pH value, filtering, collecting precipitate and drying, wherein the adsorbent main body in a product is the oyster shell; the iron salt is used as a modifier; the removal effect of phosphorus by the product is measured through molybdenum stibium anti-spectrophotometer; and results prove that the adsorbent has higher phosphorus removal rate under the condition of pH of 5-9, the adsorption is balanced, and the required time is short. Simulated wastewater test shows that the removal rate of the phosphorus in a water body is over 95 percent after the solution with phosphorus content of 100 mg / l is adsorbed for 2 hours. The product has the advantages of simple production process, readily available raw materials, obvious energy-saving effect, low production cost, easiness in promotion and application and more contribution to realizing double purposes of environmental protection and waste control by waste.

Owner:DALIAN UNIV OF TECH

Environmental protection and high efficiency corrosion inhibitor for inhibiting salt water corrosion on carbon steel, preparation method and use method thereof

ActiveCN103508570AEffective corrosion inhibitionAvoid corrosionScale removal and water softeningPhosphomolybdic acidBenzoic acid

The present invention provides an environmental protection and high efficiency corrosion inhibitor for inhibiting salt water corrosion on carbon steel, a preparation method and a use method thereof, and relates to the field of chemistry. The corrosion inhibitor has characteristics of high efficiency, low cost, low toxicity and environmental protection, and is prepared through carrying out mixing stirring dissolving on 5-50% of a benzotriazole substance, 1-10% of benzoic acid and a salt thereof, 1-10% of molybdate, tungstate, phosphomolybdic acid and a salt thereof, and phosphotungstic acid and a salt thereof, 2-20% of an alcohol amine substance, 1-10% of an acid phosphate, 1-10% of a gluconate, 1-10% of an alkaline regulator, 1-10% of an oxygen scavenging agent and the balance of water. According to the present invention, the potassium dichromate or the sodium nitrite with high toxicity, and the non-environmental protection high phosphorus and high zinc can be replaced, and corrosion of calcium chloride salt water on carbon steel and copper can be significantly inhibited when the concentration of the corrosion inhibitor is 0.3-0.5%.

Owner:CHAOYANG GUANGDA CHEM

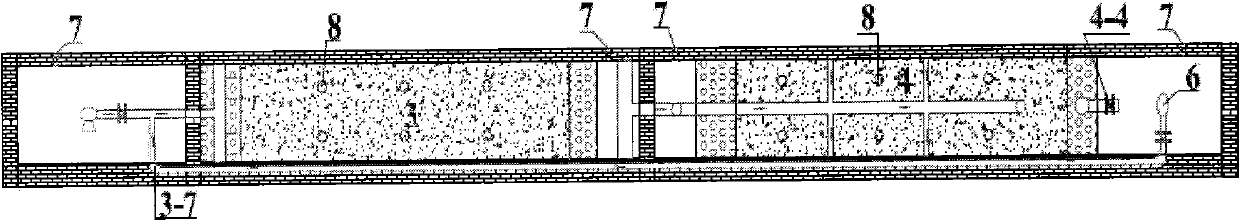

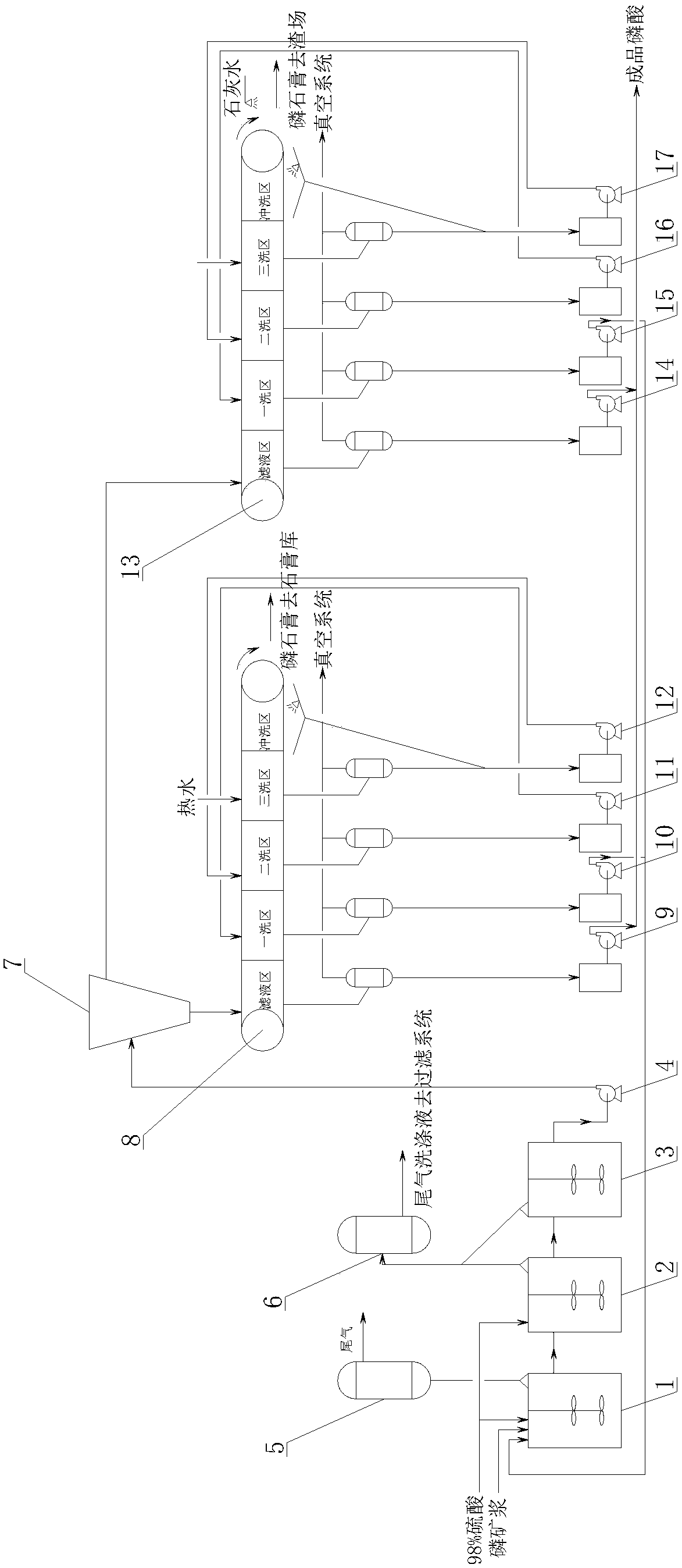

One-step method dihydrate-semi-hydrated wet production process for phosphoric acid

ActiveCN107840317AAvoid concentrated inputsGood energy saving effectPhosphorus compoundsHigh concentrationWash water

The invention relates to a one-step method dihydrate-semi-hydrated wet production process for phosphoric acid. The one-step method dihydrate-semi-hydrated wet production process comprises the following steps: carrying out leaching reaction and dehydrate-semi-hydrated conversion; growing grains; separating, filtering and washing; by controlling technological indicators of all the steps, finished product phosphoric acid filtrate with high concentration and by-product phosphogypsum with high quality are obtained. The finished product phosphoric acid filtrate obtained by production of the one-stepmethod dihydrate-semi-hydrated wet production process disclosed by the invention has the advantages that the concentration of P2O5 is about 35 percent, concentration input of the phosphoric acid canbe avoided and an energy-saving effect is good. In addition, the phosphorus conversion rate and the washing rate are high; the final by-product phosphogypsum has the characteristics that the total content of the P2O5 is smaller than or equal to 0.5 percent, the content of water-soluble P2O5 is smaller than or equal to 0.15 percent and the yield of the P2O5 reaches 98 percent. The one-step method dihydrate-semi-hydrated wet production process disclosed by the invention retains the characteristics of good energy-saving effect, high phosphorus yield and high quality of byproduct alpha-semi-hydrated gypsum of a traditional two-step method dehydrate-semi-hydrated technology; meanwhile, a dihydrate filtration procedure is omitted, the process flow is shortened and the operation rate of a deviceis improved, so that the problem that water balance of a system cannot be realized due to overhigh content of wash water for filter cloth is solved.

Owner:ANHUI LIUGUO CHEM CO LTD

Method for chemically plating double-layer Ni-P plating layer

InactiveCN102644067ASmooth appearanceBright appearanceLiquid/solution decomposition chemical coatingChemical platingVolumetric Mass Density

The invention relates to a method for chemically plating a double-layer Ni-P plating layer on different matrixes. The method comprises the following steps of: (1) chemical oil removal: removing oil of a workpiece in oil removal liquid; (2) first activation: activating in sulfuric acid with volume fraction of 5-10%; (3) chemically plating an acid high-phosphorus Ni-P layer; (4) second activation: activating in sulfuric acid with volume fraction of 10%; (5) chemically plating an acid low-phosphorus Ni-P layer; and (6) carrying out treatment after plating. In the invention, the workpiece is chemically plated with the acid high-phosphorus Ni-P layer which is then plated with the acid low-phosphorus Ni-P layer; the plating layer has the advantages of good binding force, good uniformity and density, high hardness, corrosion resistance and strong wear resistance; the low-phosphorus and high-phosphorus chemical plating Ni-P liquid does not contain toxic heavy metal elements such as lead, cadmium, hexavalent chromium and the like, thus the harm to the environment and human bodies is reduced, and the liquid is environment-friendly plating liquid; and meanwhile, the wastewater is easy to treat at low cost, and the life cycle of the plating liquid is long.

Owner:GUANGZHOU HONWAY TECH CORP +1

Method for smelting high-phosphorus steel by low-temperature low-silicon molten iron in converter

InactiveCN102776313AReduce usageReduce the burden onManufacturing convertersProcess efficiency improvementAlloyOxygen

The invention discloses a method for smelting high-phosphorus steel by low-temperature low-silicon molten iron in a converter. The method comprises the following steps that: scrap steel is added into the converter; active lime is added in the converter for the first time, and an oxygen lance, the position of which is lower than the normal position for 10-20 centimeters, blows oxygen; after the oxygen blowing is performed for 50-60 seconds, dolomite is added into the converter at one time; when the oxygen blowing is performed for 90-110 seconds, the oxygen lance is lifted to the normal oxygen blowing position, and active lime is added into the converter again; and tapping is carried out. The method fully utilizes the conditions of the low-temperature low-silicon molten iron in reducing a phosphorus removal rate to smelt the high-phosphorus steel, the phosphorus removal rate can be reduced to 40%-50% from the above 85% of the current conventional smelting, and thus the phosphorus content of the smelting at the end point is effectively improved; the lime addition amount is reduced to be not over 25Kg / ton of steel from 40Kg-60Kg / ton of steel, and the usage amount of phosphorus alloy can also be reduced; the waste residue discharge can be reduced; and moreover, a fluorite slagging agent is not used, and thus the environmental burden can be relieved.

Owner:武汉钢铁有限公司

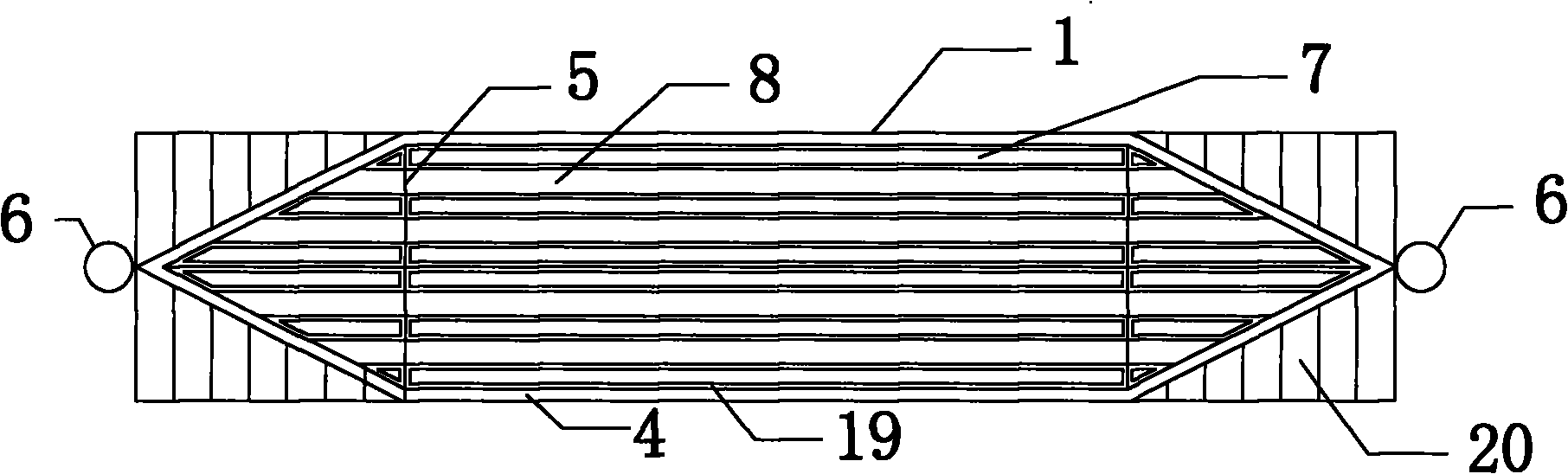

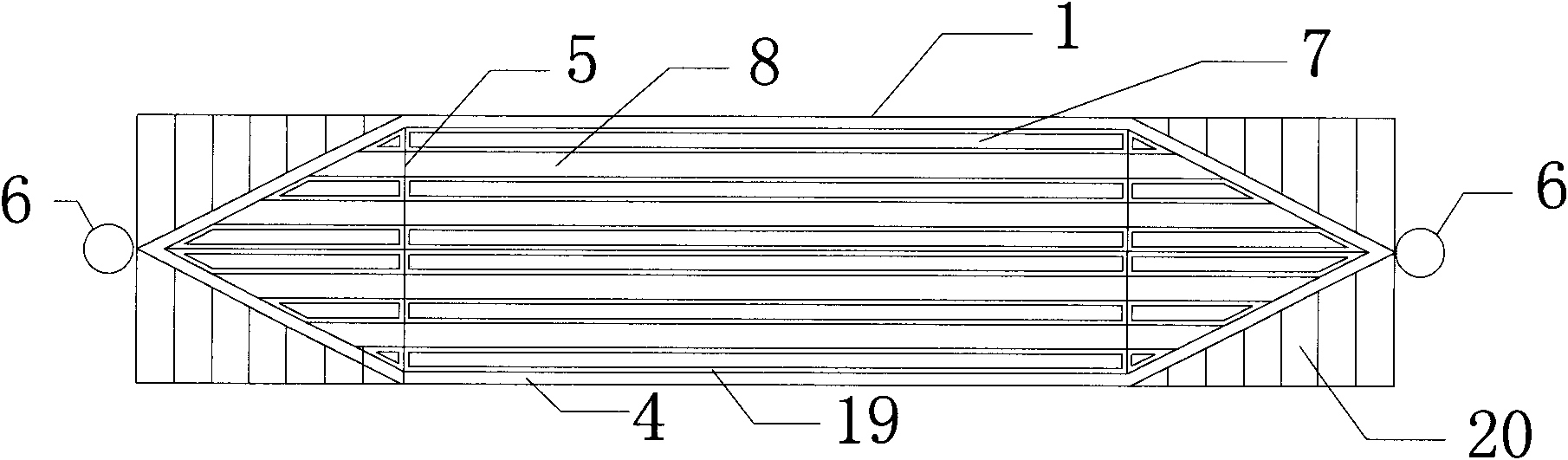

Ecological floating bed suitable for high-sediment large-flow rate water body

InactiveCN101811778AScour stableExtended service lifeBiological water/sewage treatmentPolyvinyl chlorideEconomic benefits

The invention discloses an ecological floating bed suitable for a high-sediment large-flow rate water body. The ecological floating bed is formed by interconnecting two floating bed units, wherein each floating bed unit comprises floating bed fixing rods, hollow PVC tubes, wave eliminating rafts and a gauze; a plurality of hollow PVC tubes are horizontally arranged and fixed by the floating bed fixing rods so as to form a floating raft; the wave eliminating rafts are arranged below the two ends of the floating raft respectively; the gauze in which hollow columnar polyvinyl chloride short corrugated tube packing is packed is hung below the floating raft; and the gauze is positioned below the wave eliminating rafts. The ecological floating bed can treat the water body which contains high sediment and high phosphorus and nitrogen concentration, is suitable for a river with large flow rate, can build a landscape effect without influencing shipping, and can produce part of economic benefits.

Owner:HOHAI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com