Patents

Literature

39results about How to "Realize extraction and separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting and separating tungsten and molybdenum in high-phosphorus mixed solution containing tungsten and molybdenum

ActiveCN104711422ARealize extraction and separationSimple methodProcess efficiency improvementPhosphomolybdic acidPhosphate

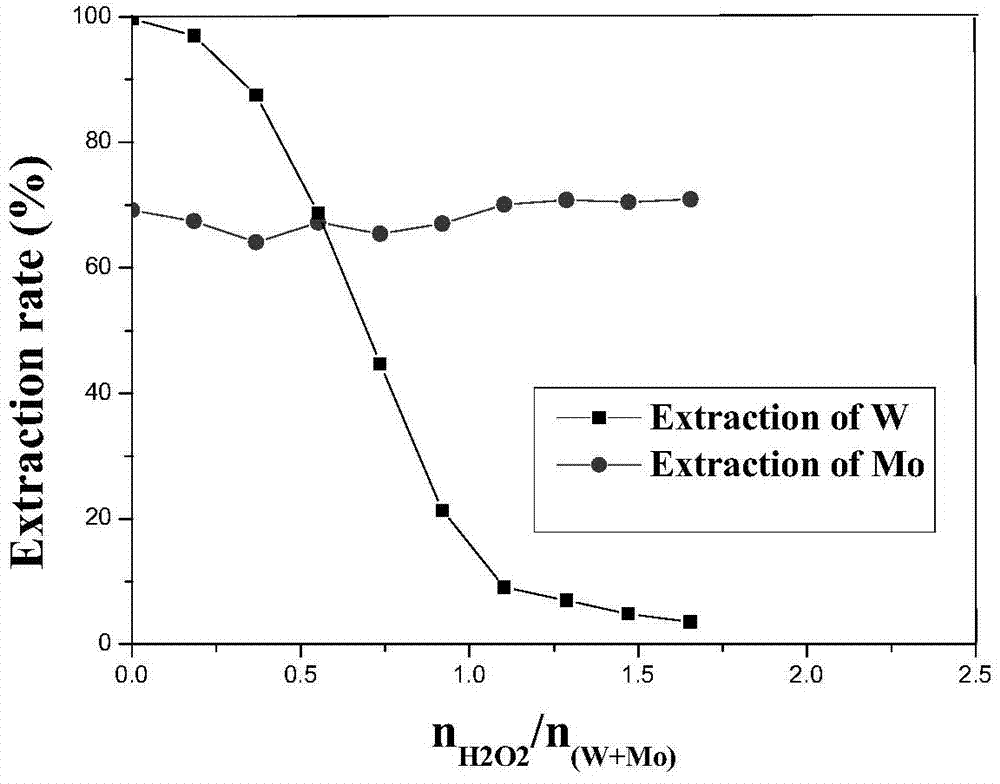

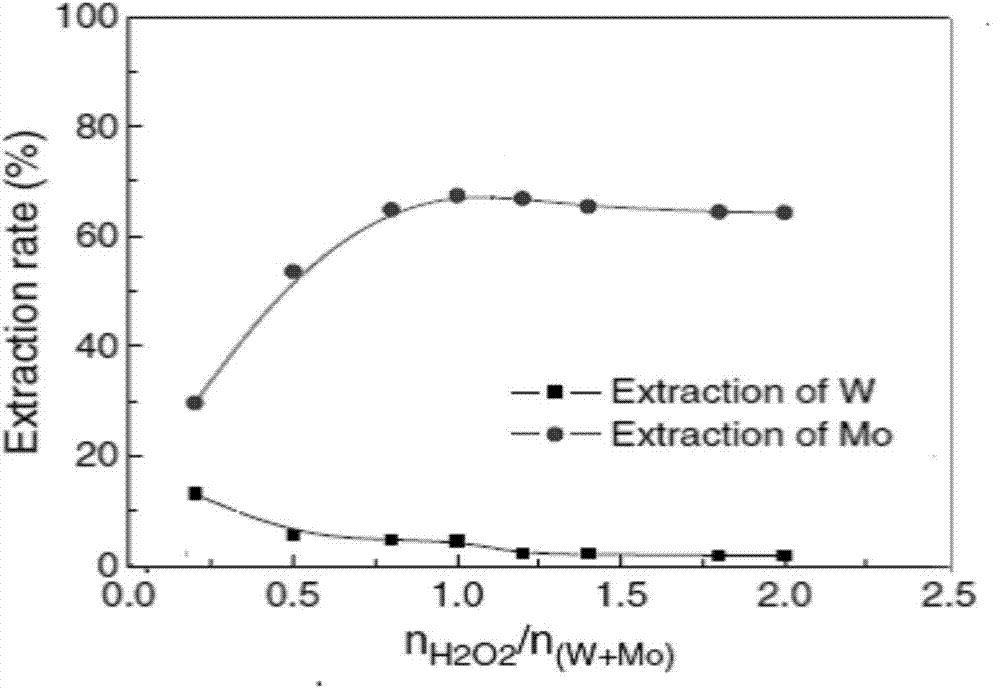

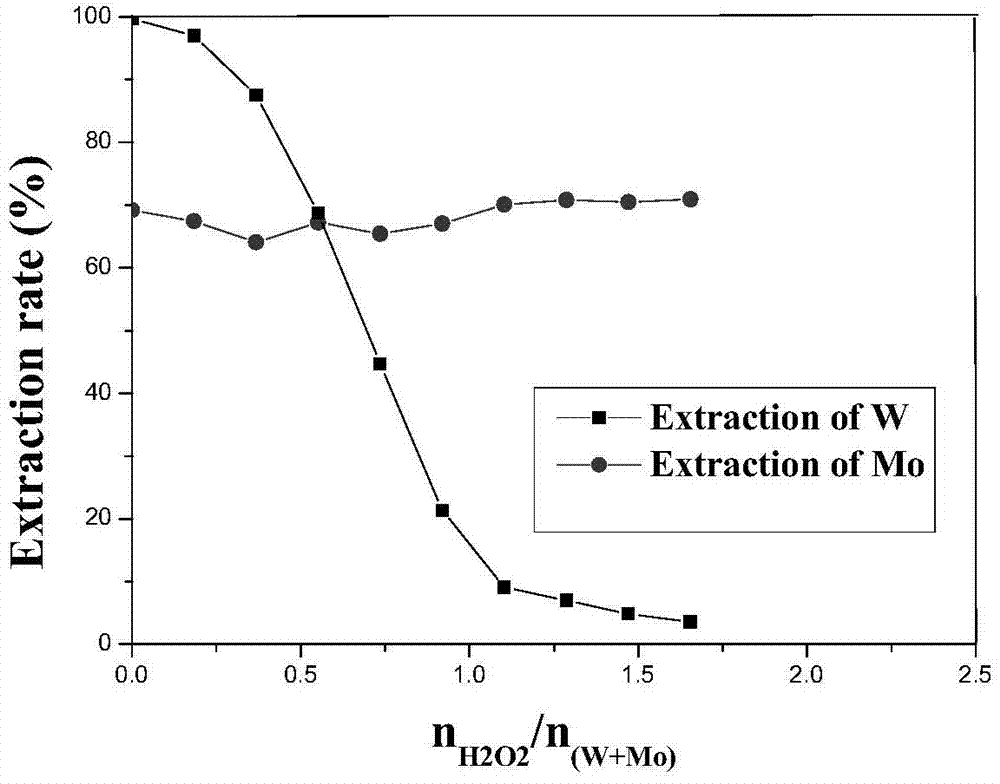

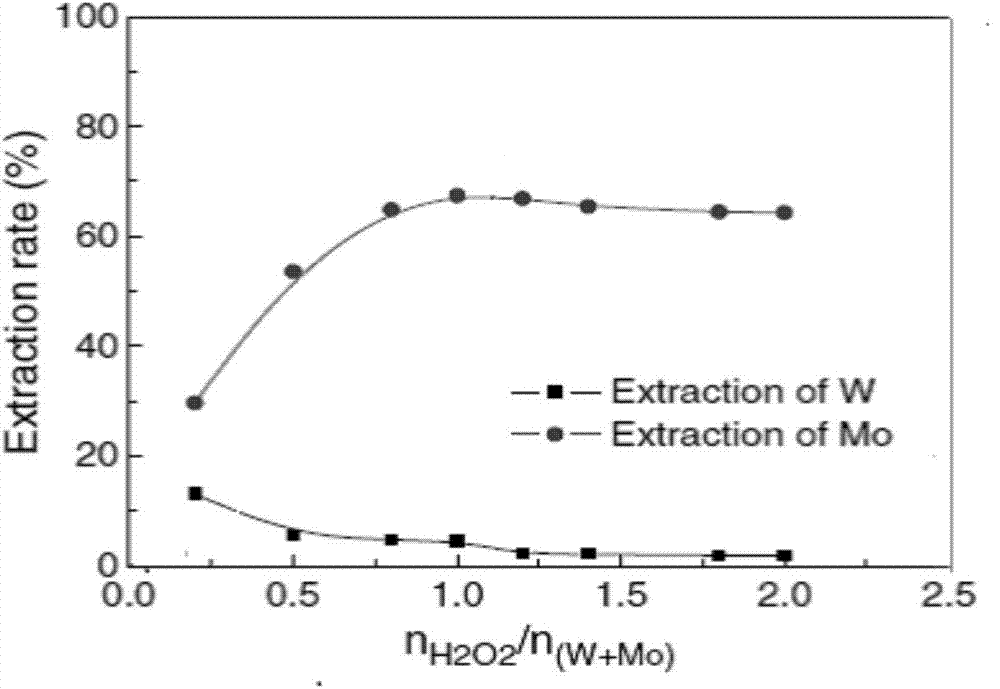

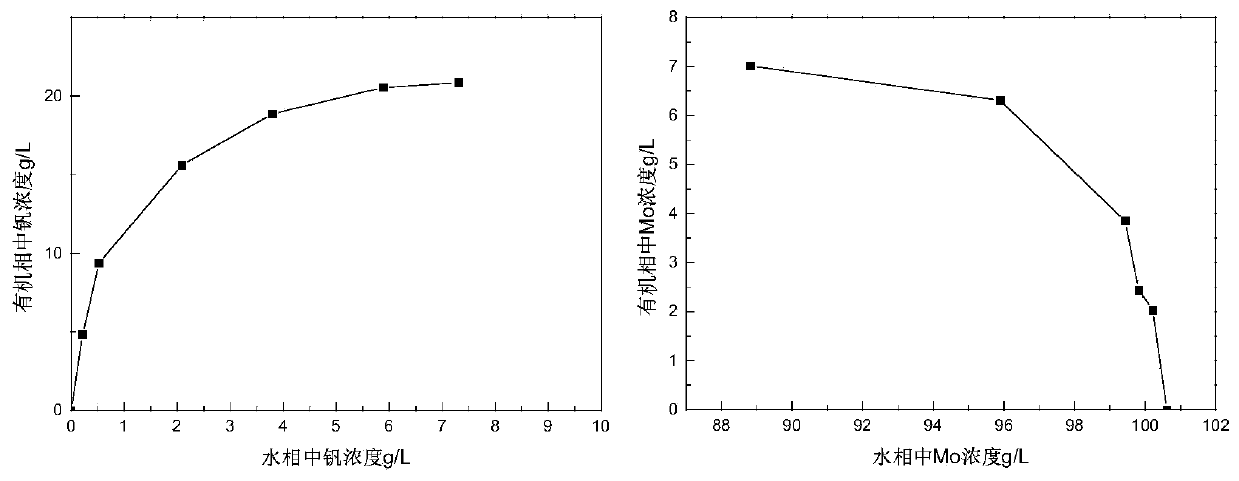

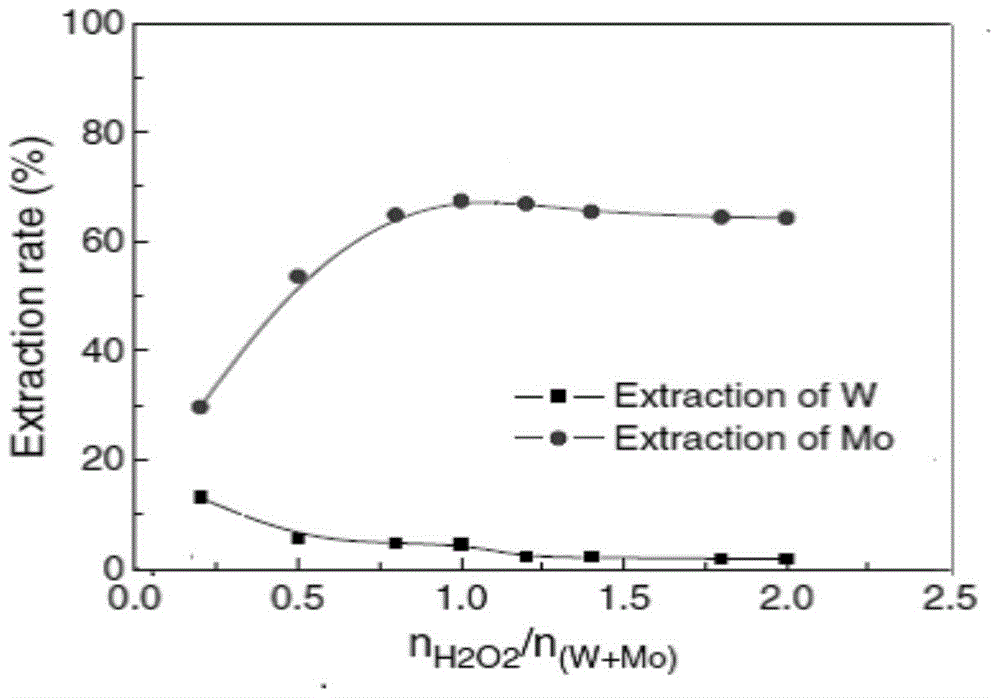

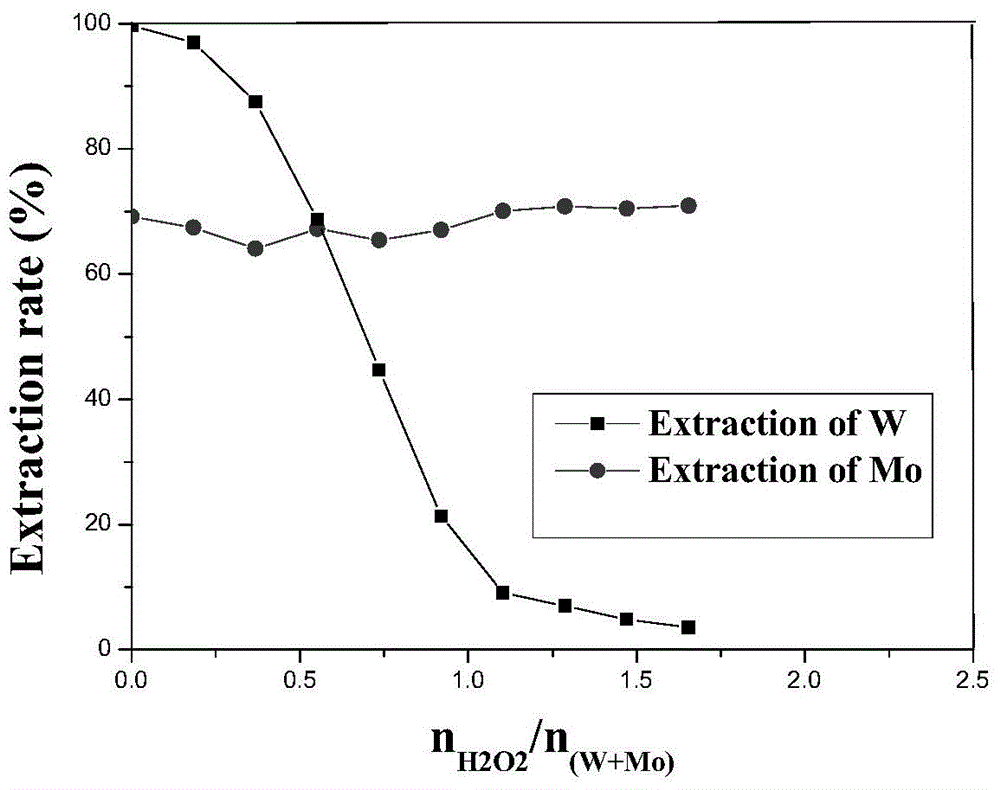

The invention relates to a method for extracting and separating tungsten and molybdenum in a high-phosphorus mixed solution containing tungsten and molybdenum. The method comprises the following steps: adding hydrogen peroxide in the high-phosphorus mixed solution containing tungsten and molybdenum for acidity adjustment and control, and converting phosphotungstic acid and phosphomolybdic acid into peroxy-phosphotungstic acid and peroxy-phosphomolybdic acid; then, taking a mixture of tributyl phosphate (TBP) and methyl phosphate dimethyl heptyl ester (P350) as an extracting agent, extracting the peroxy-phosphomolybdic acid into an organic phase, and leaving the peroxy-phosphotungstic acid in an aqueous phase; from now on, after decomposing the peroxy-phosphotungstic acid in extraction raffinate in the way of heating or ultraviolet irradiation or introduction of sulfur dioxide, extracting tungsten in the solution again with a fresh mixed extracting agent, and finally realizing extraction and separation of tungsten and molybdenum from complex material liquid. The method is small in tungsten co-extraction loss, can effectively solve the extraction and separation problem of tungsten and molybdenum in the high-phosphorus mixed solution containing tungsten and molybdenum, and is easy to realize industrialization.

Owner:CENT SOUTH UNIV

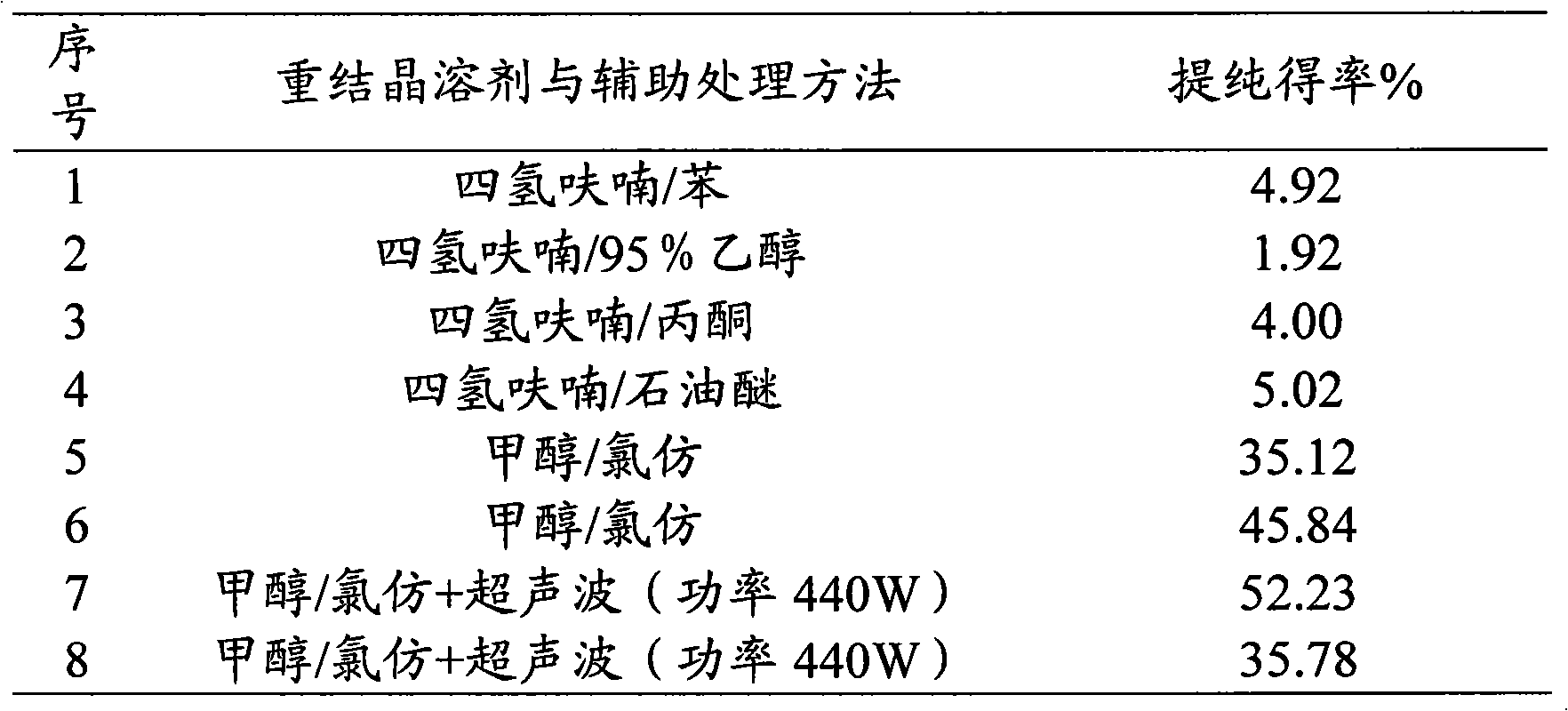

Method for extracting betulin from birch bark

The invention discloses a method for extracting betulin from birch barks, comprising the following steps: firstly, crushed birch barks are added into an ethanol water solution, undergo reflux extraction under auxiliary processing of ultrasonic waves, and then are filtrated for removal of residue, and an extract is obtained; secondly, solid powder is separated out after decompression and concentration of the extract, and then dried to the constant weight so as to obtain betulin coarse products; and thirdly, the betulin coarse products are added into an organic solvent, undergo ultrasonic treatment and then stand, crystals are separated out, and the betulin is obtained after the separated crystals are dried to the constant weight. The method has a simple operation flow, short extraction time, low production cost and high safety, and provides a better method and a better platform for further development and utilization of natural products.

Owner:ZHEJIANG UNIV

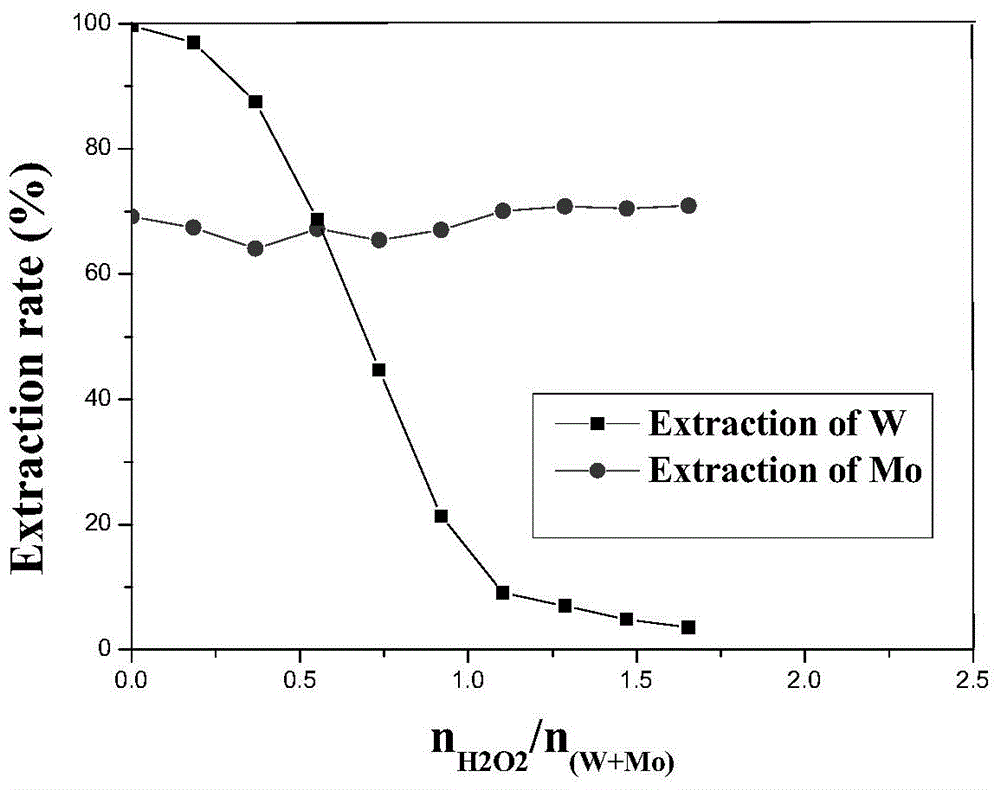

Method of selectively extracting and separating molybdenum from high-phosphorus tungsten- and molybdenum-containing mixed solution

ActiveCN104762476ASimple methodRealize extraction and separationProcess efficiency improvementCo extractionTungsten

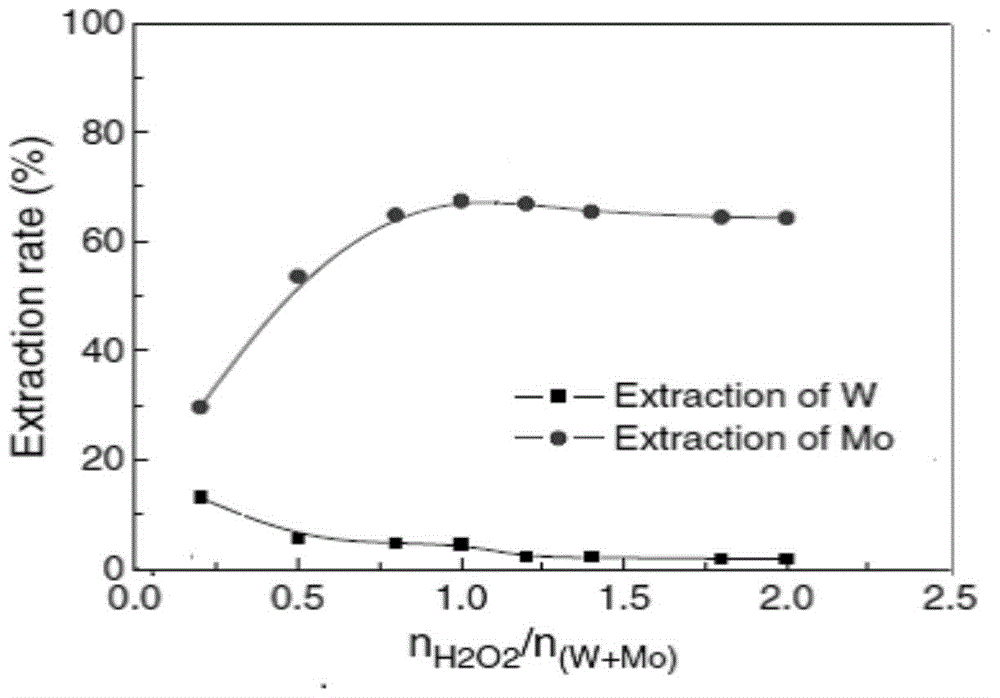

The invention relates to a method of selectively extracting and separating molybdenum from a high-phosphorus tungsten- and molybdenum-containing mixed solution. In the prior art, according to the process of extraction and separation of tungsten and molybdenum through complexation of hydrogen peroxide, when the content of phosphorus in the solution is higher than 0.005 mol / L, the extraction efficiency of the tungsten and the molybdenum is greatly reduced, so that the conventional process of extraction and separation of the tungsten and the molybdenum through complexation of the hydrogen peroxide cannot be used for directly treating the tungsten- and molybdenum-containing mixed solution being higher than 0.005 mol / L in the content of the phosphorus. According to the invention, by means of adjustment and control of the content of acid in the high-phosprous mixed solution, the tungsten and the molybdenum in the mixed solution can be reacted with the phosphorus completely to form tungstomolybdophosphate acid. By means of addition of a proper amount of the hydrogen peroxide, the phosphor-tungstic heteropoly acid and phospho-molybdic heteropoly acid are depolymerized to generate peroxy phosphotungstic acid and peroxy phospho-molybdic acid. By means of TBP as an extraction agent, the peroxy phospho-molybdic acid is extracted into an organic phase and then the loaded organic phase is subjected to reverse-extraction by an alkaline reverse-extraction agent. The method can treat the high-phosphorus tungsten- and molybdenum-containing mixed solution, is low in co-extraction of tungsten, can reach 70% in molybdenum extraction rate in a single stage, is low in the cost of the employed extraction agent and is easy to industrialize.

Owner:CENT SOUTH UNIV

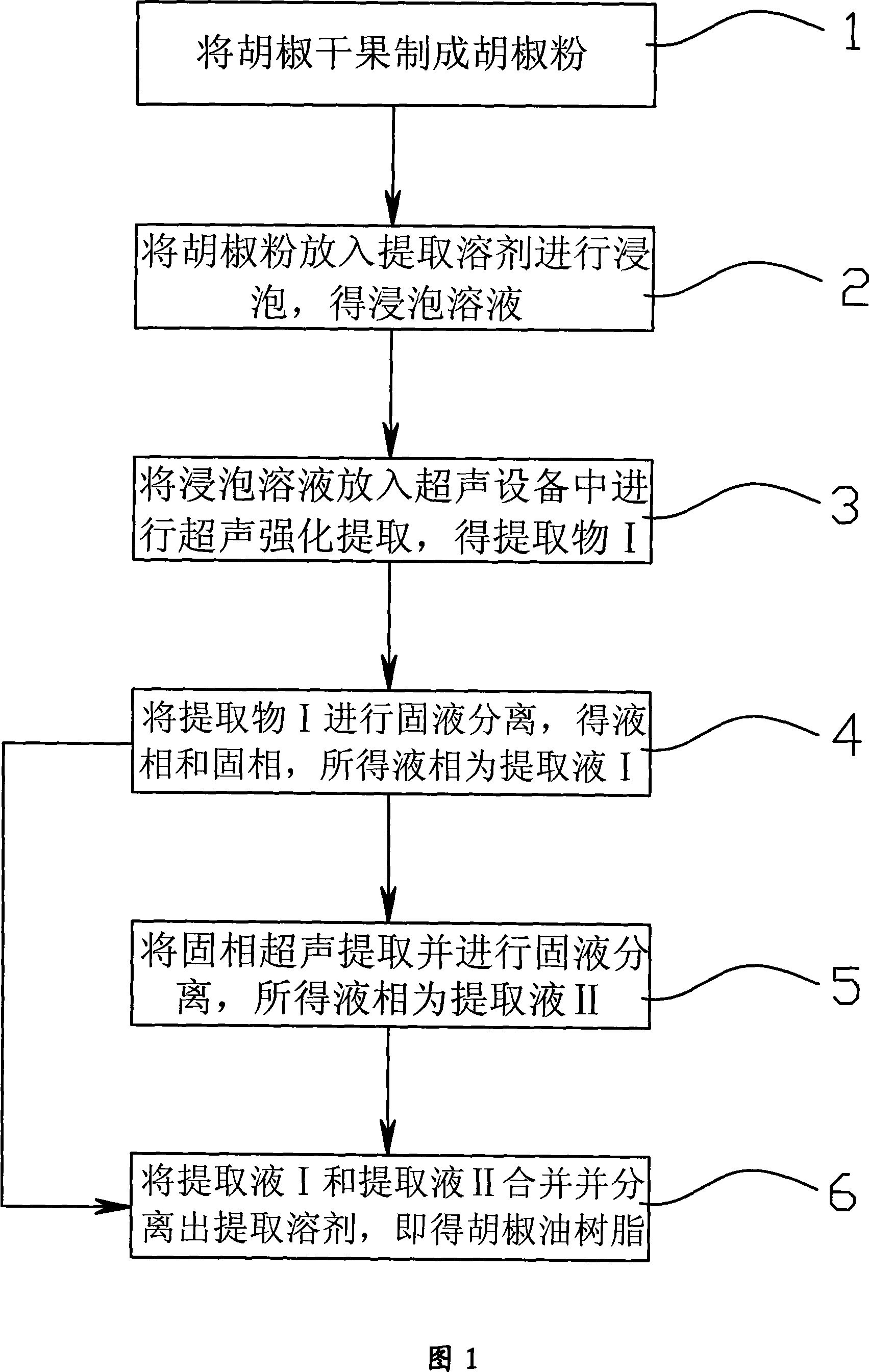

Ultrasonic-assisted method for extracting pepper oleoresin

InactiveCN101205502AActive ingredients are not destroyedFresh and pure oilFatty-oils/fats productionUltrasonic assistedDistillation

The invention provides a method for ultrasonic-assisted extraction of pepper oil resin which comprises the following procedures: peppers are cleaned, sundried or oven-dried, and pulverized into pepper powder; the pepper powder is put into the extraction solvent for dipping treatment to obtain the dipping solution; the dipping solution is put into ultrasonic equipment for ultrasonic enhanced extraction to obtain an extract I; the extract I is made a solid-liquid separation to obtain a liquid phase and a solid phase, and the liquid phase is the extract liquid I; the solid phase is put into the ultrasonic equipment for second ultrasonic enhanced extraction to obtain an extract II, then the extract II is made the solid-liquid separation, the obtained liquid phase is the extract liquid II; the extract liquid I and the extract liquid II are merged, then are made a pressure-reducing distillation, the extraction solvent is separated, and the brown pasty fluid, namely pepper oil resin, can be obtained. The method has simple operation, strong practicability, short time used to extract the pepper oil resin, convenience and quickness, high extraction yield, short production cycle and low cost.

Owner:郑州雪麦龙食品香料有限公司

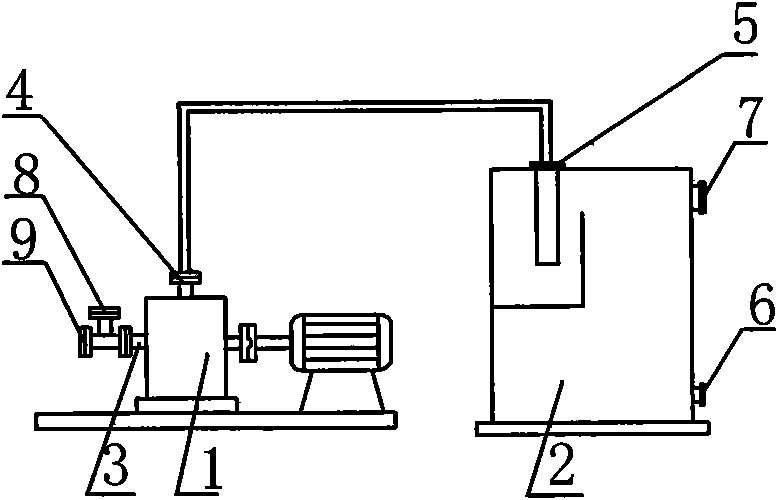

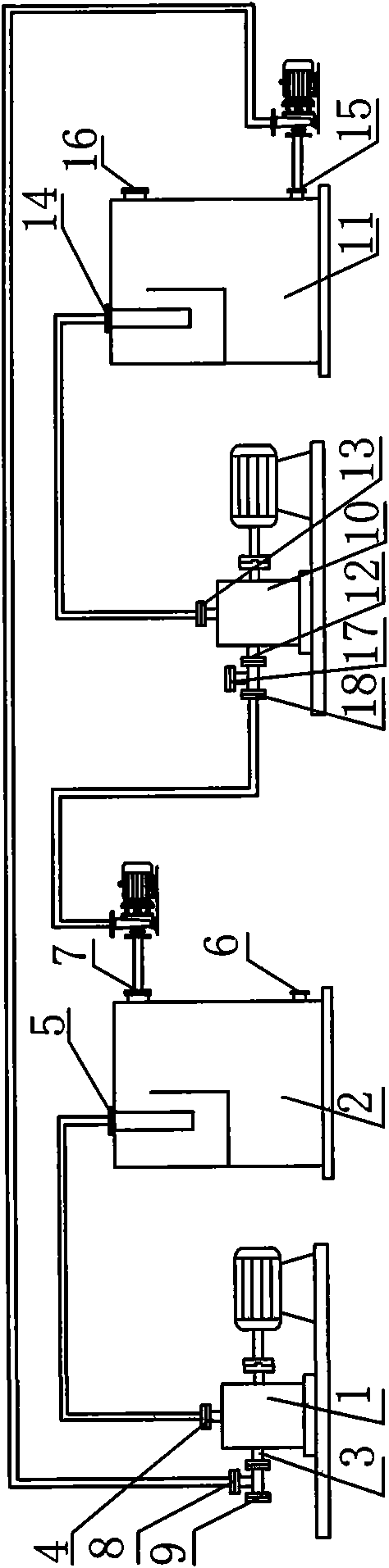

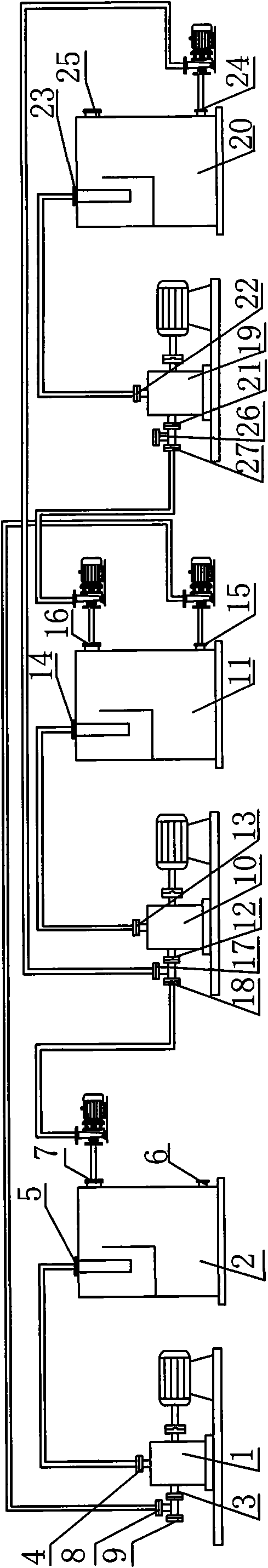

Extraction device

InactiveCN101898048ALarge mass transfer areaEasy to phaseLiquid solutions solvent extractionPhase splittingEngineering

The invention discloses an extraction device comprising an emulsifying machine (1) and a phase-splitting apparatus (2). The emulsifying machine (1) is provided with an emulsifying machine inlet (3) and an emulsifying machine outlet (4), the phase-splitting apparatus (2) is provided with a mixed phase inlet (5), a heavy phase outlet (6) and a light phase outlet (7), the emulsifying machine inlet (3) is connected with an extracted object inlet (8) and a solvent inlet (9), and the emulsifying machine outlet (4) is connected with the mixed phase inlet (5) of the phase-splitting apparatus. When multistage extraction devices are combined, the light phase outlet of the phase-splitting apparatus in the extraction device at the current level is connected with the solvent inlet of the extraction device at the next level through a pipeline provided with a pump, and the heavy phase outlet of the phase-splitting apparatus in the extraction device at the next level is connected with the extracted object inlet of the extraction device at the current level through the pipeline provided with the pump. The invention has high extraction efficiency, small size, less occupied area, simple operation and capability of saving apparatus investment and running cost.

Owner:WENGFU (GRP) CO LTD

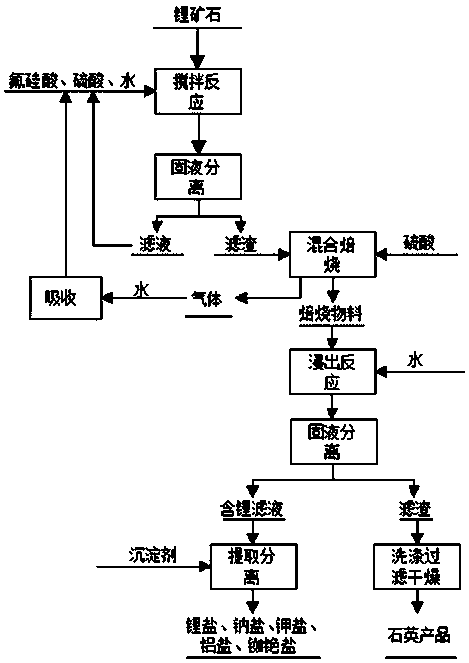

Comprehensive utilization method for directly extracting lithium by silicate-based lithium-containing ore acid process

The invention discloses a method for extracting lithium by using silicate lithium-containing ore as a raw material through an acid process. The method comprises the following steps: the lithium-containing silicate ore such as natural alpha-spodumene and lepidolite is crushed and ground, sieving is performed, the obtained lithium ore powder, fluorosilicic acid, sulfuric acid and water are used to prepare slurry, reaction is performed at a certain temperature, filtration is performed, the filtrate is recycled for preparation of slurry from lithium ore, the filter cake and concentrated sulfuric acid are mixed, the mixture is put into a roaster for a reaction, the roasted product is extracted by using water to extract a lithium salt, an alkali metal salt and an aluminum salt, and the extraction slag is quartz slag. The invention provides a general method suitable for extraction of the lithium, other alkali metals, aluminum and silicon from various silicate-based lithium-containing ore, andthe method can realize maximum utilization of resources and fluorine cycle, reduce energy consumption, and realize green and environment-friendly production of extraction of the lithium from the ore.

Owner:FUZHOU UNIV

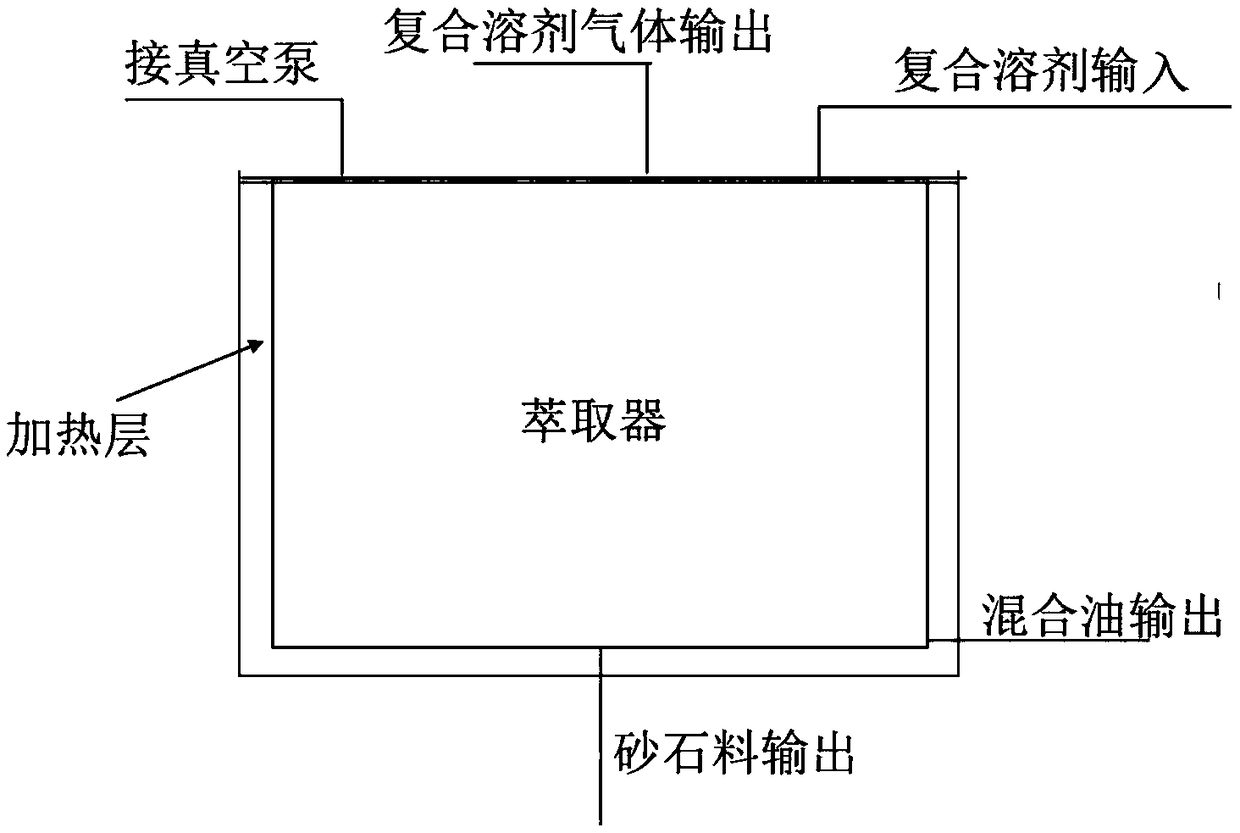

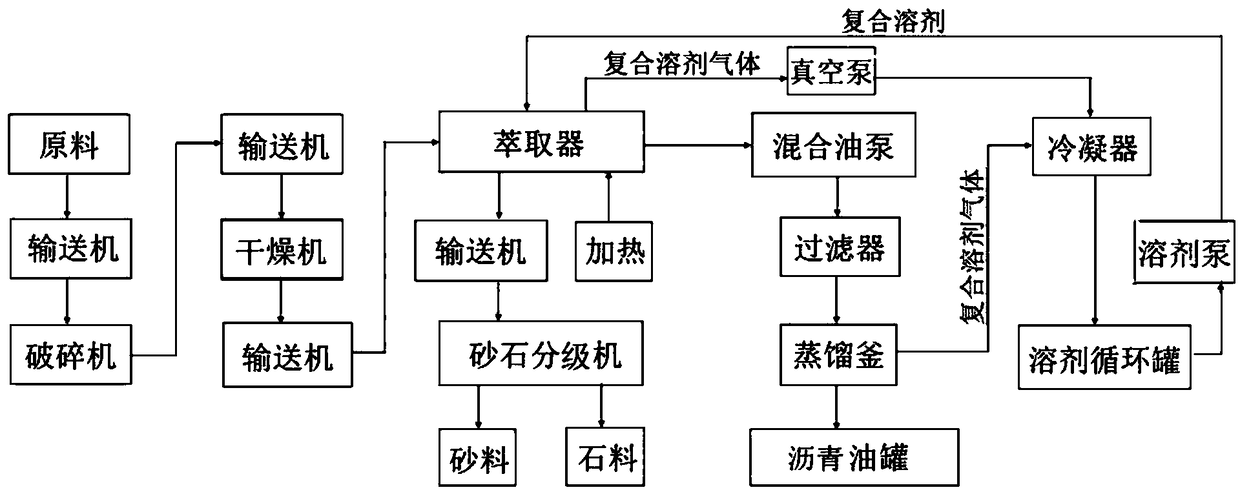

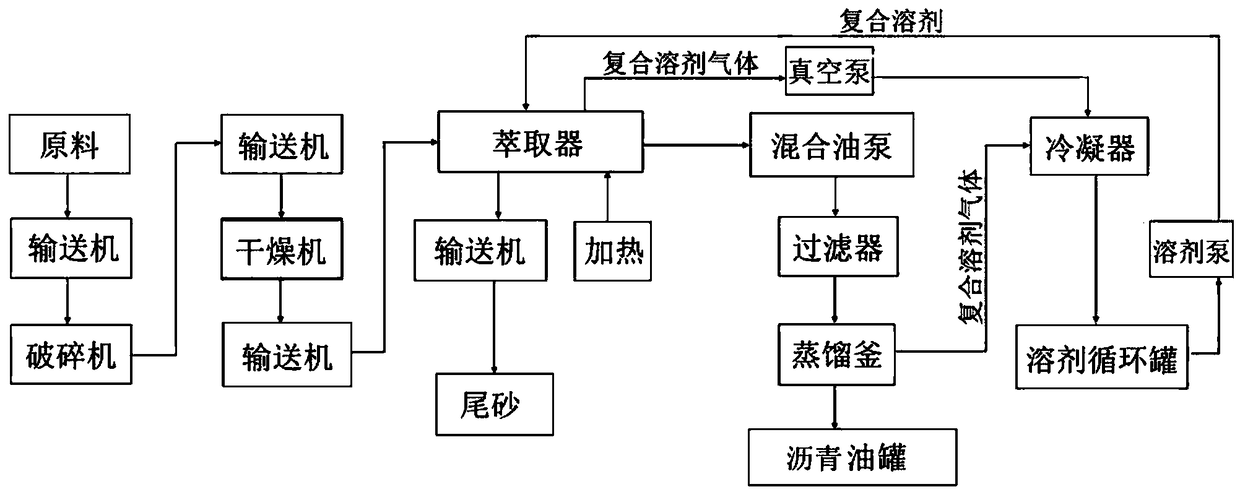

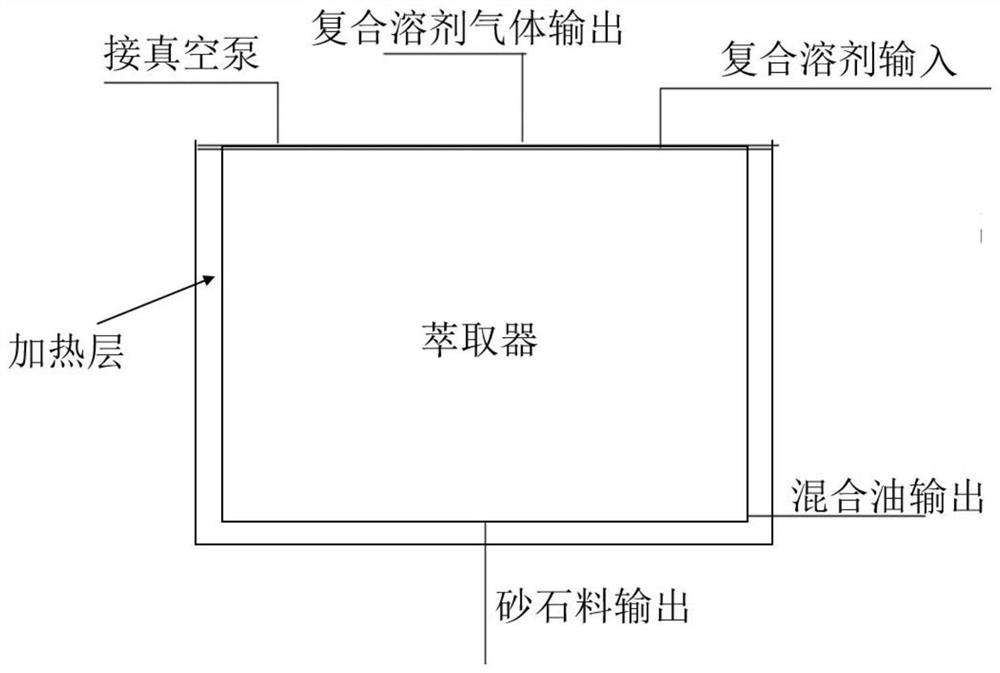

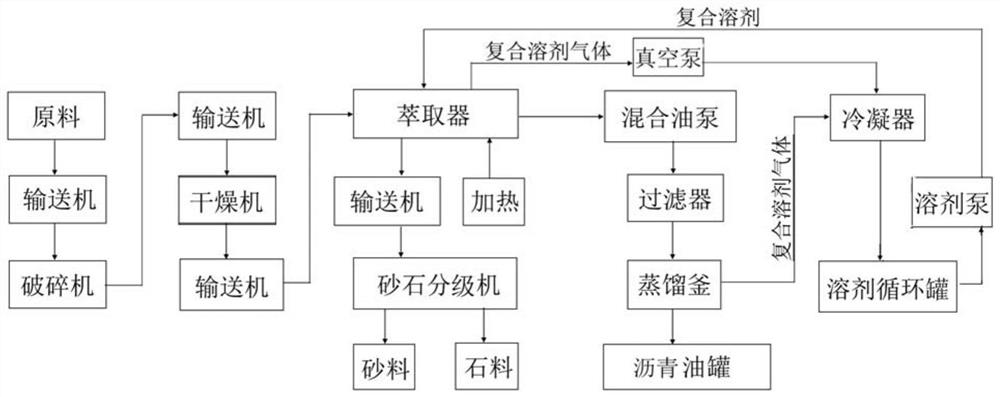

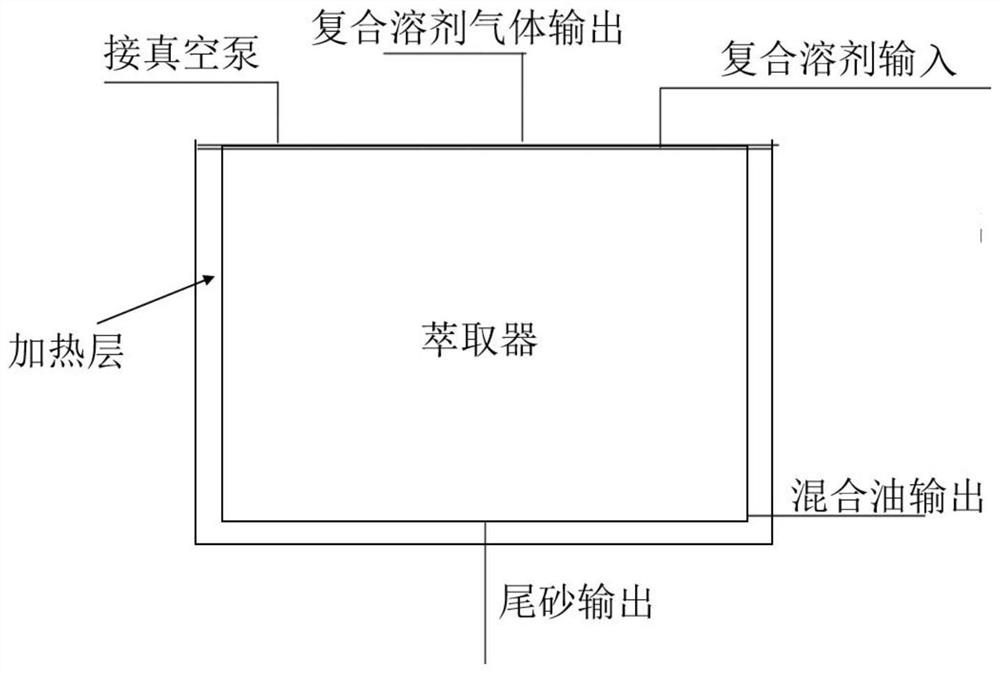

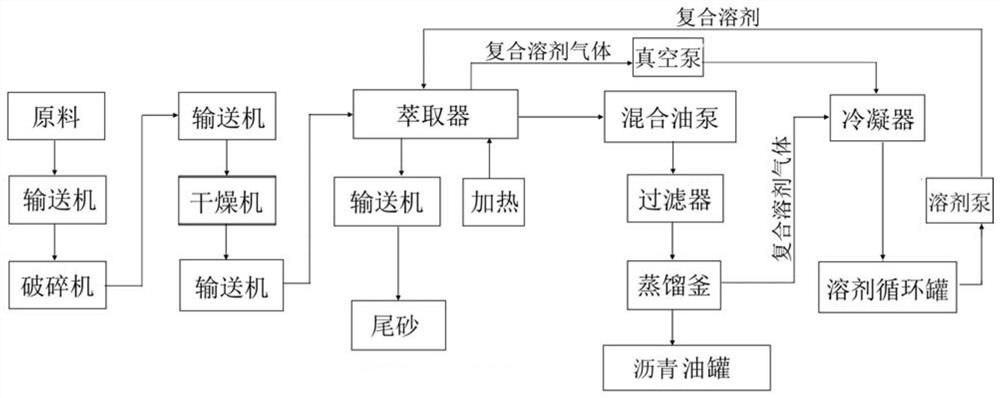

Separation method of highway RAP (Reclaimed Asphalt Pavement) material

ActiveCN109260755AResource SustainabilitySolve the problem of adding new stoneLiquid hydrocarbon mixture productionSolid solvent extractionDistillationEngineering

The invention discloses a separation method of a highway RAP (Reclaimed Asphalt Pavement) material, and belongs to the technical field of separation of the highway RAP material. The method comprises:firstly, after grinding and drying the highway RAP material, inputting the ground and dried highway RAP material into an extractor; after carrying out extraction processing by a composite solvent, separating out asphalt oil and a sand and gravel material; after evaporating mixed oil formed by the asphalt oil and the composite solvent by a distillation still, pumping the obtained asphalt oil into an asphalt oil tank; condensing evaporated composite solvent gas into liquid for recycling; heating residual materials in the extractor to a temperature of 90 to 130 DEG C, controlling a vacuum degreeto be within a range of 1.5 to 3KPa, and after converting the residual composite solvent in the sand and gravel material into gas for output, outputting the sand and gravel material. In the separationprocess, the highway RAP material is processed by the specific composite solvent and process parameters, an extraction rate of the asphalt oil is 94% or more, and less asphalt is left in the separated sand and gravel material.

Owner:凌港

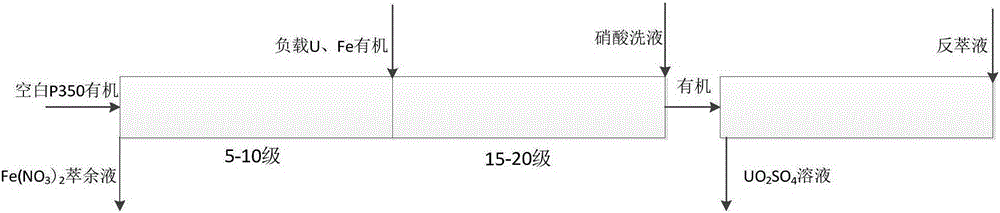

Uranium, iron, thorium and rare earth extraction and separation process

The invention relates to a uranium, iron, thorium and rare earth extraction and separation process, wherein a UFe / ThRE-containing solution is subjected to extraction and separation with P350 in a hydrochloric acid system, a reducing substance is added to the obtained U-Fe-supported organic phase, the organic phase is subjected to washing-iron with a nitric acid solution to obtain the pure-U-supported organic phase and the raffinate containing bivalent iron, and the pure-U-supported organic phase is subjected to back extraction with a Na2SO4-containing H2SO4 solution so as to obtain the UO2SO4 solution. According to the present invention, with the introduction of the reducing substance into the process, the difficultly-separated trivalent iron and the hexavalent uranium can be effectively separated; and the whole process achieves the comprehensive utilization of the whole element.

Owner:永州市湘江稀土有限责任公司

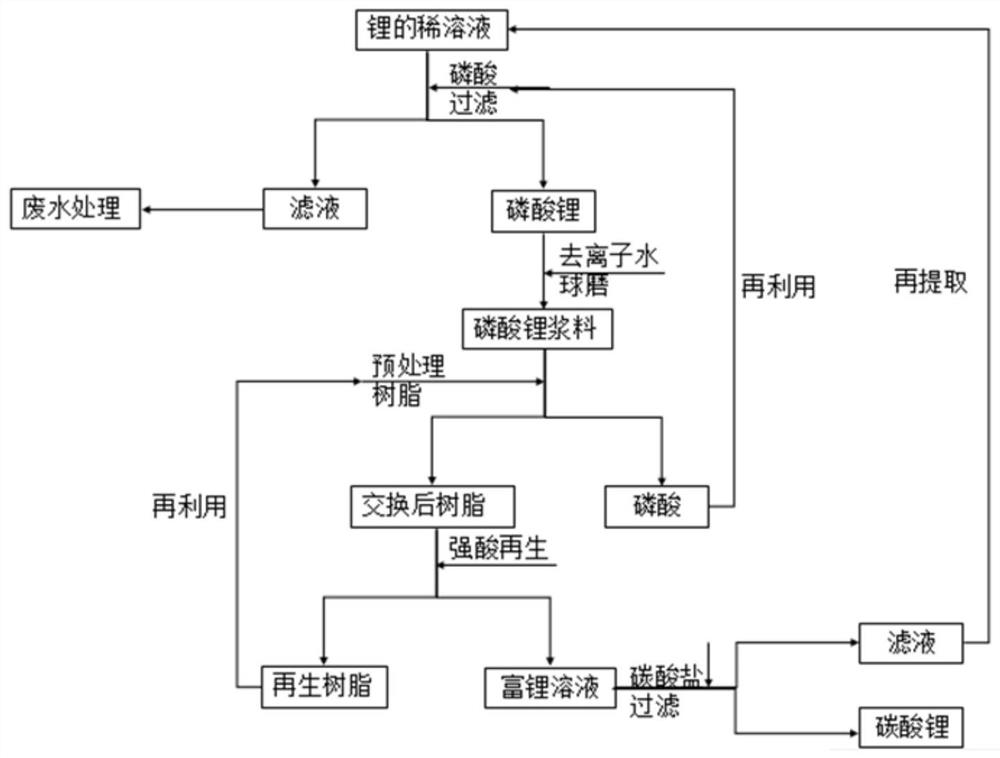

Method for extracting lithium from waste battery cathode material recovery dilute solution

ActiveCN111697282ARealize extraction and separationHigh recovery rateCation exchanger materialsWaste accumulators reclaimingIon exchangePhosphoric acid

The invention provides a method for extracting lithium from a waste battery positive electrode material recovery dilute solution. The method comprises the following steps of recovering lithium ion precipitation in the dilute solution from a lithium-containing positive electrode material to obtain lithium salt precipitation, preparing the lithium salt precipitate into lithium salt slurry, carryingout ion exchange with strong acid type cation exchange resin, then replacing lithium ions in the resin subjected to ion exchange into a lithium-containing solution, and finally precipitating the lithium ions in the lithium-containing solution to obtain the lithium salt. The method is advantaged in that the phosphoric acid solution obtained by exchanging the lithium phosphate slurry with the resincan be continuously used as a raw material, the exchanged resin is regenerated by strong acid to obtain recyclable regenerated resin and a lithium-rich solution, and a lithium carbonate product with awider application range is further obtained, the solution for preparing the lithium salt can continuously return to the system to continuously extract lithium, therefore, the whole process forms a closed-loop lithium dilute solution treatment system which is pollution-free, low in energy consumption, low in cost and high in lithium recovery rate.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

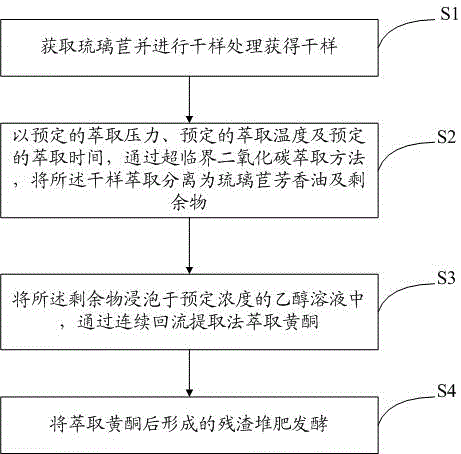

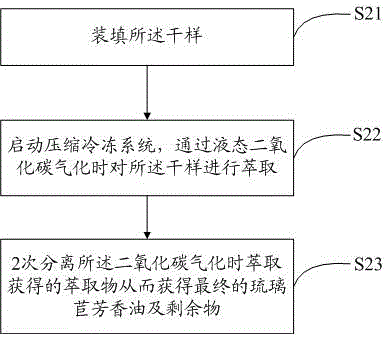

Borage deeply processing method and deeply processed products thereof

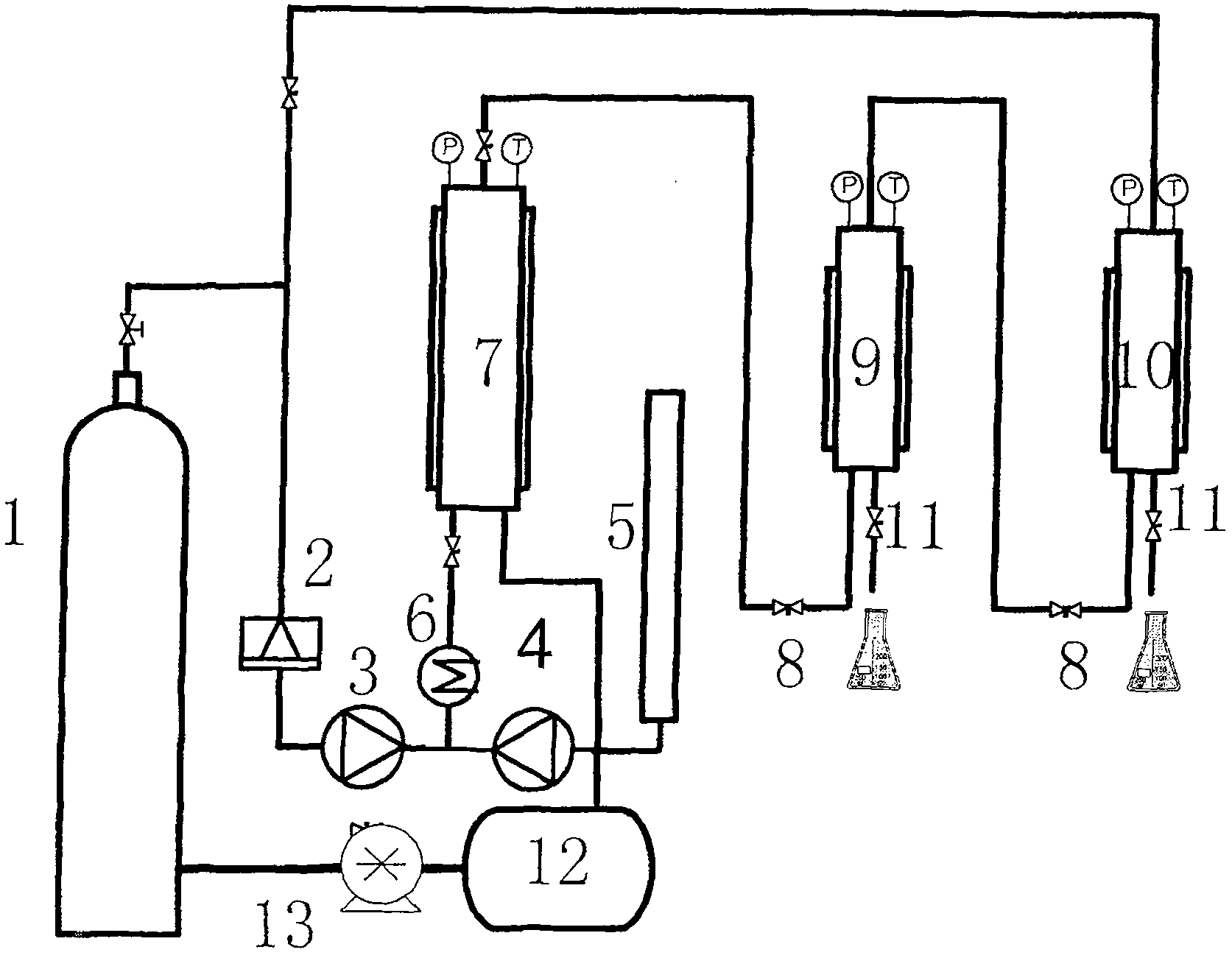

InactiveCN105535064ARealize extraction and separationImprove utilization efficiencyBio-organic fraction processingClimate change adaptationChemistryFlavones

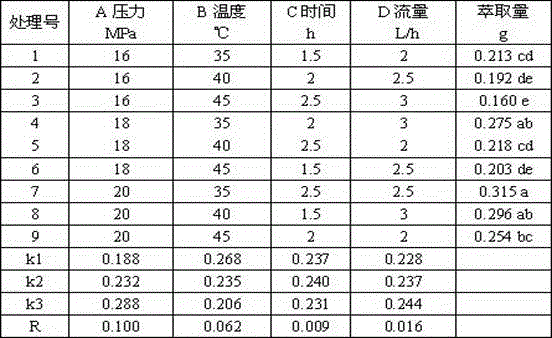

The invention provides a borage deeply processing method and deeply processed products thereof. The method comprises the following steps: A, obtaining borage, and performing dry sample treatment so as to obtain dry samples; B, performing extraction and separation on the dry samples so as to obtain borage aromatic oil and remnants at preset extraction pressure and preset extraction temperature for preset extraction time according to a supercritical carbon dioxide extraction method; C, soaking the remnants or the dry samples in an alcohol solution with a preset concentration, and performing extracting flavone according to a continuous regurgitation extraction method. In the processing technology course, the extraction and the separation of the aromatic oil and flavone active substances are realized, and the utilization efficiency of the borage can be effectively improved; besides, the overground parts of the borage of which the seeds are collected can be used, so that the utilization of resources is facilitated.

Owner:FOSHAN UNIVERSITY

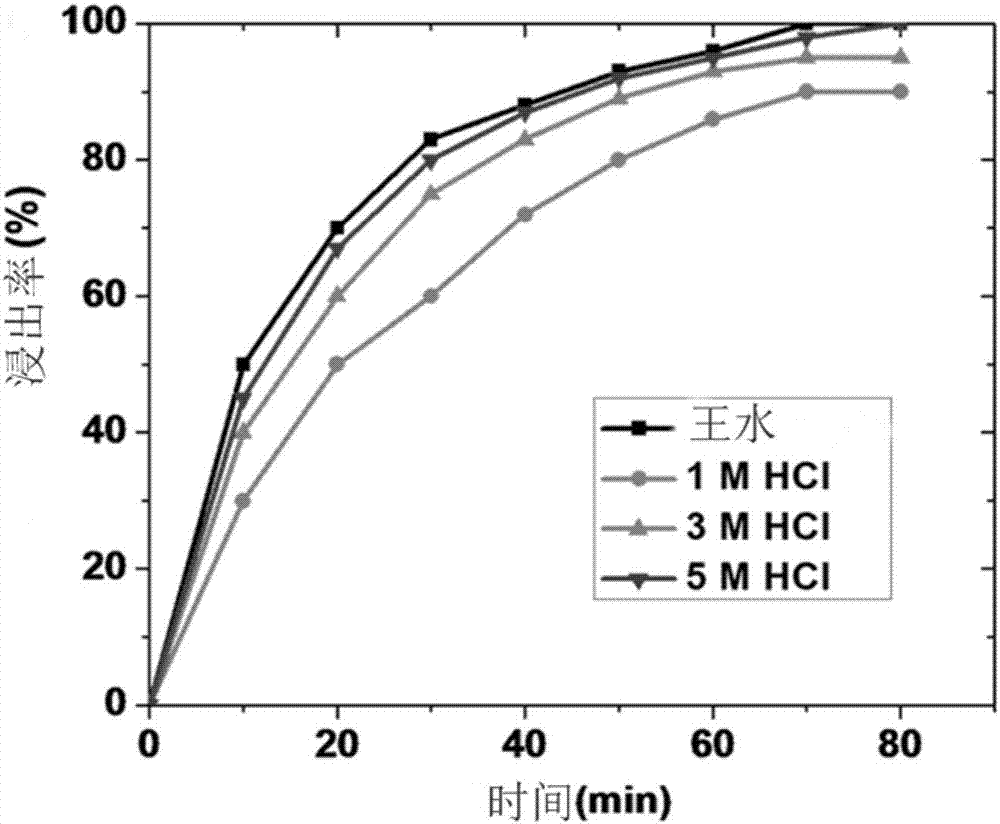

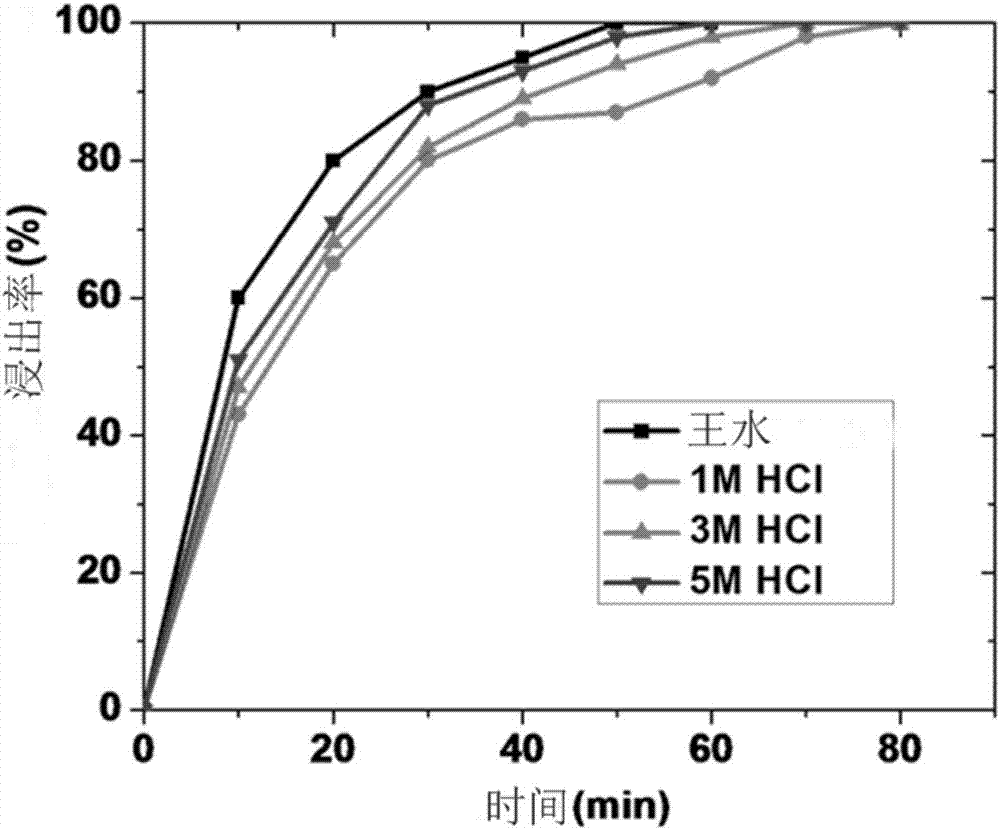

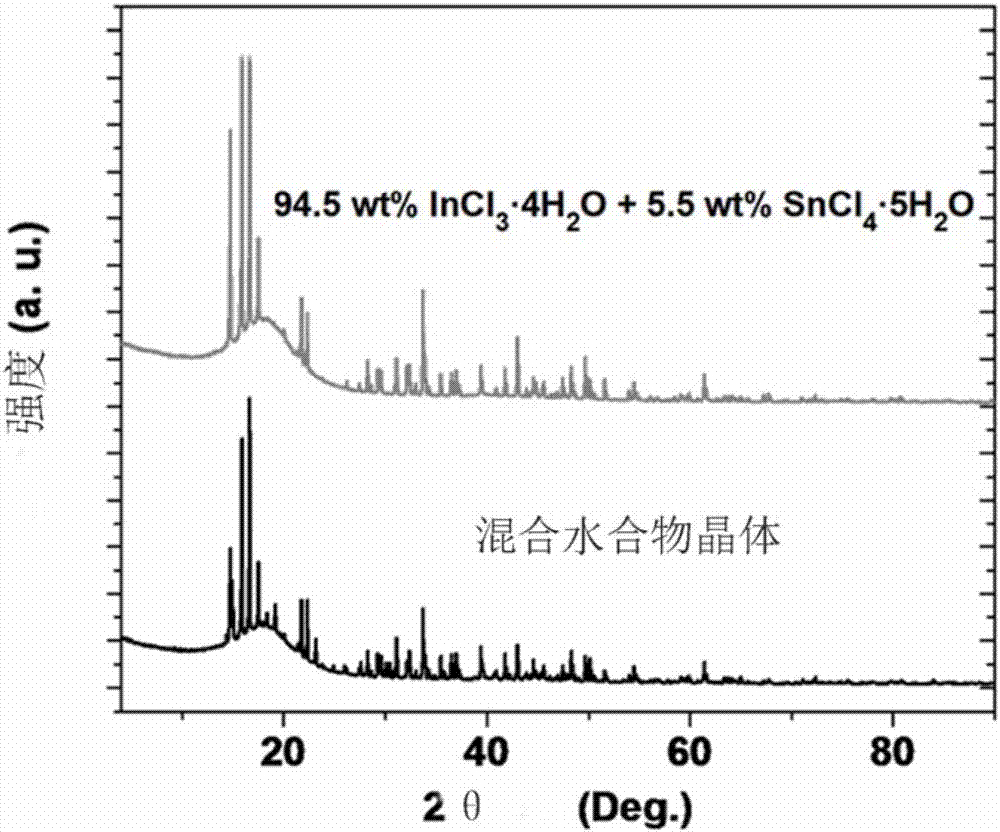

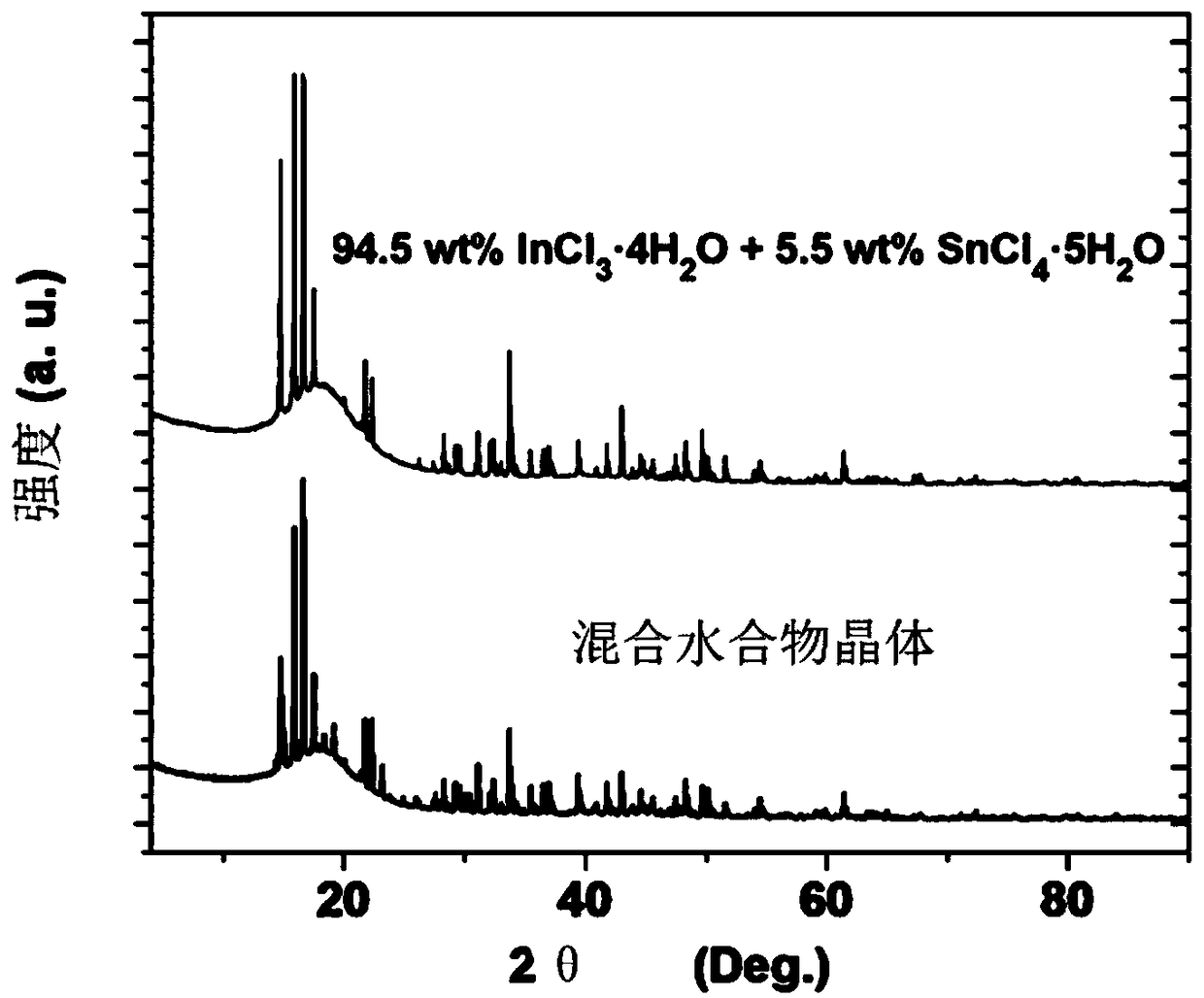

Method for recovering anhydrous indium salt and anhydrous tin salt from indium tin oxide

ActiveCN107226480AHigh purityHigh recovery rateGallium/indium/thallium compoundsTin halidesIndiumDistillation

The invention belongs to the technical field of alloy waste material recovery and utilization, and discloses a method for recovering anhydrous indium salt and anhydrous tin salt from indium tin oxide. The method comprises the following steps that S1, the indium tin oxide is dissolved by acid; indium and tin exist in the acid in an ion form; S2, the acid is removed through distillation; an indium salt hydrate and a tin salt hydrate are left; S3, a dehydrating agent is added into the hydrates in the S2; heating reflux is performed to obtain the anhydrous indium salt and the anhydrous tin salt; S4, the anhydrous indium salt and the anhydrous tin salt are separated. The method disclosed by the invention has the advantages that the product with extremely high purity can be obtained; all used reagents can be almost cyclically used; no pollution is generated on the environment; less energy and fewer reagents are consumed by the method; the method can be stably used for large-scale industrial practice; a large amount of energy can be saved; the operation is simple and convenient; the extremely high economic performance is realized.

Owner:顾帅

Method for enriching scandium from titanium white wastewater

ActiveCN106636684AAddress scandium lossReduce consumption and pollutant emissionsProcess efficiency improvementTitaniumScandium

The invention discloses a method for enriching scandium from titanium white wastewater. The method comprises the six steps of primary extraction, primary reverse extraction, acid dissolution for impurity removal, secondary extraction, washing for titanium removal and secondary reverse extraction. The method for enriching the scandium from the titanium white wastewater achieves comprehensive scandium recycle, the scandium recovery rate is improved from below 50% to 83% or above, extraction and separation of scandium target element and impurities are achieved, the problems of scandium loss, entrainment, emulsification and the like of a traditional process are effectively solved, the coarse scandium purity is above 36%, organic phase, alkaline liquor and acid liquor can be recycled, chemical raw material consumption and pollutant discharge are reduced, and the production cost is reduced.

Owner:CHINALCO GUANGXI NONFERROUS RARE EARTH DEV CO LTD

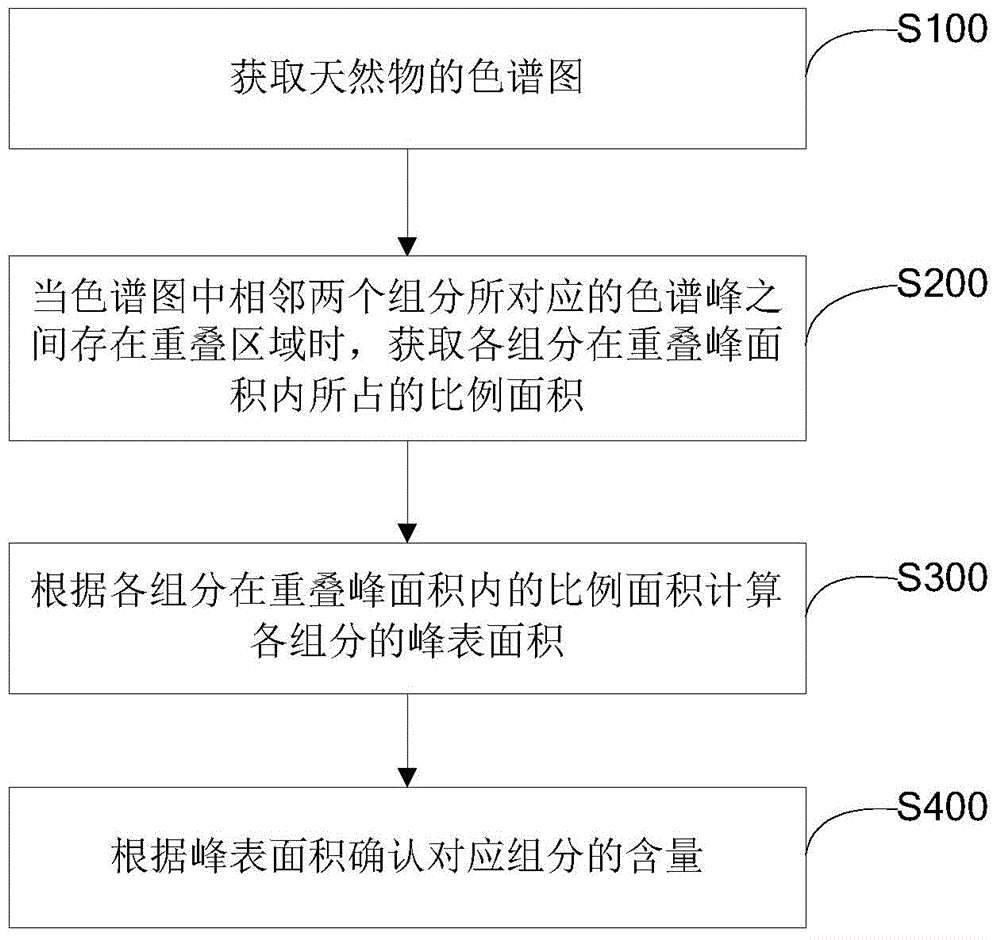

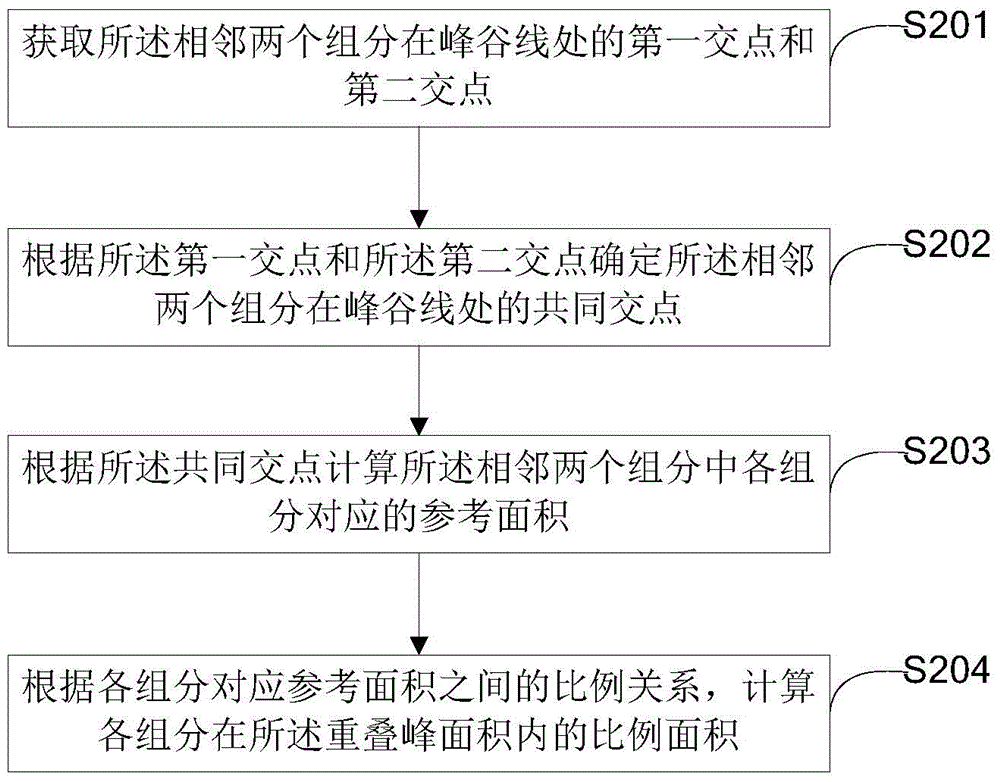

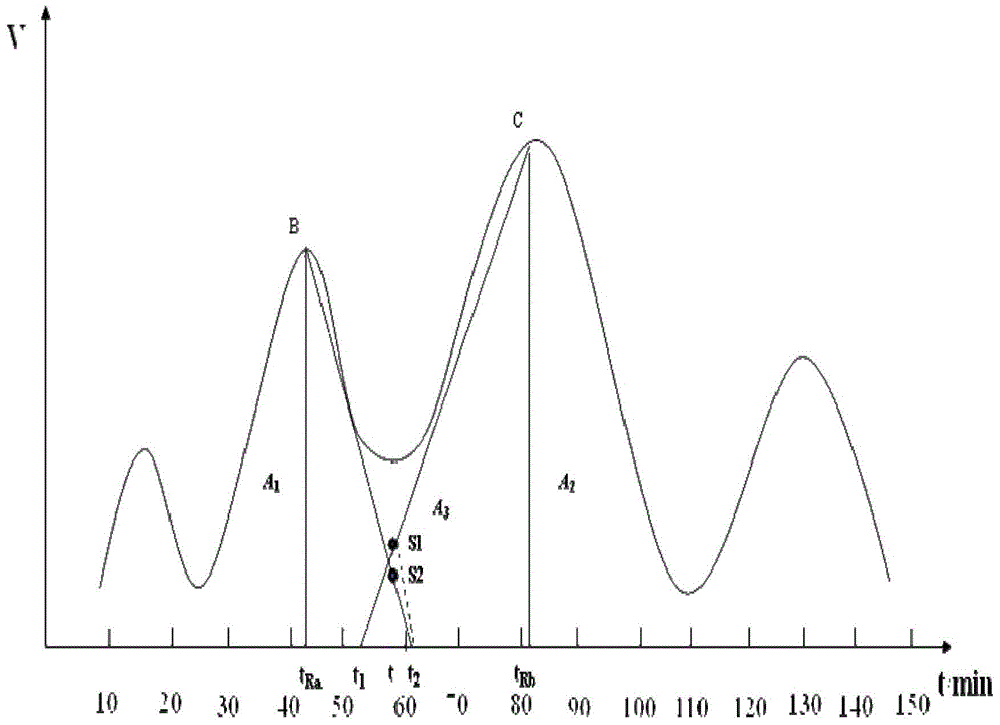

Method and system for confirming contents of components in natural material

InactiveCN104655770AHigh purityRealize extraction and separationComponent separationPeak areaNatural material

The invention provides a method and a system for confirming the contents of components in a natural material. The method for confirming the contents of the components in the natural material comprises the steps of acquiring the chromatogram of the natural material; when an overlapping region exits between chromatographic peaks of two adjacent components in the chromatogram, acquiring the proportion areas of all the components within the overlapping peak area; calculating the peak surface areas of all the components according to the proportion areas of all the components within the overlapping peak area; confirming the contents of the corresponding components according to the peak surface areas. The method and the system can be used for accurately measuring the contents of all the components in the natural material, thus providing an accurate data support for the qualitative and quantitative analysis of the natural material.

Owner:ANKE SMART CITY TECH PRC

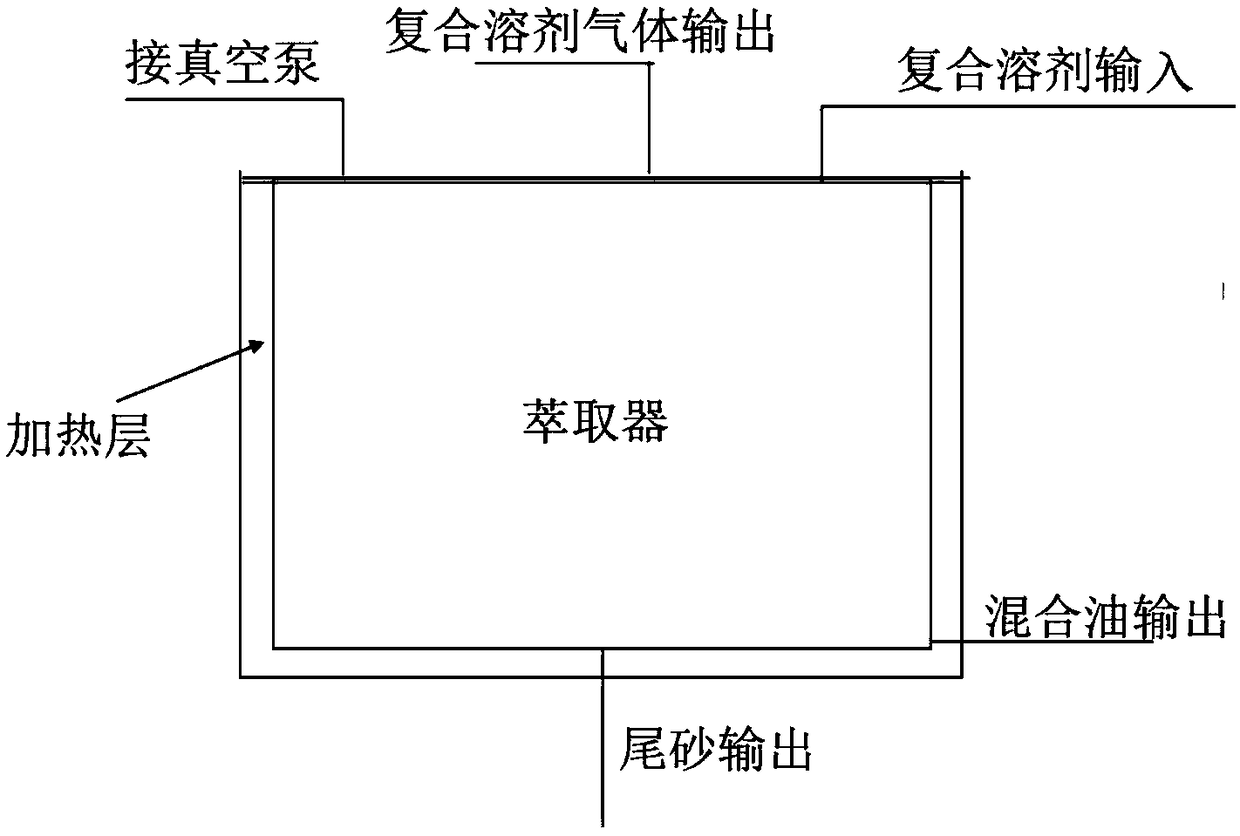

Oil sand separation method

ActiveCN109181739ASolve the problem of insufficient supply in the marketRealize extraction and separationLiquid hydrocarbon mixture productionDistillationEvaporation

The invention discloses an oil sand separation method, and belongs to the technical field of oil sand separation. The oil sand separation method comprises following steps: an oil sand raw material issubjected to crushing and drying, and is introduced into an extractor; the oil sand raw material is subjected to extraction using a composite solvent in the extractor so as to obtain an asphalt and composite solvent mixed oil through separation; the asphalt and composite solvent mixed oil is pumped into a filter, impurities are removed, and the asphalt and composite solvent mixed oil is pumped into a distillation still for evaporation so as to obtain asphalt oil, and the asphalt oil is pumped into an asphalt tank; the composite solvent gas is converted into liquid through condensation for recycling; a mixed material obtained in the extractor is heated to 90 to 130 DEG C, the vacuum degree is controlled to be 2 to 3KPa, stirring is carried out, the composite solvent in tailings is convertedinto gas state for discharging, the composite solvent gas is subjected to condensation so as to obtain a liquid for recycling, and tailings output is carried out. According to the oil sand separationprocess, the specific composite solvent and technological parameters are adopted for processing of oil sand, the asphalt extraction rate in oil sand is 97% or higher, and asphalt left in the tailingsis low.

Owner:凌港

Supercritical safflower extracting process

ActiveCN101019909BHigh yieldRealize extraction and separationAntibacterial agentsMetabolism disorderHigh concentrationWax

The supercritical safflower extracting process includes the following steps: the first extraction of the safflower material with supercritical CO2 as extractant, two-stage of decompression separation to obtain vegetable wax and volatile safflower oil, the second extraction of the safflower residue to obtain macromolecular non-polar matter, the third extraction of the safflower residue in the presence of entrainer and CO2 and decompression separation to obtain polar matter and entrainer. The present invention has high volatile safflower oil yield, realizes the extraction and separation of volatile oil and wax in one step and utilizes the non-polar matter in safflower effectively. The present invention has the advantages of high product concentration and capacity of producing high concentration medicine preparation easily.

Owner:山西华卫药业有限公司

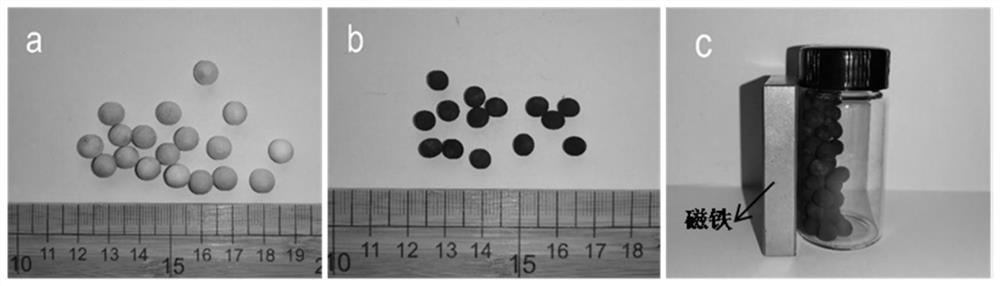

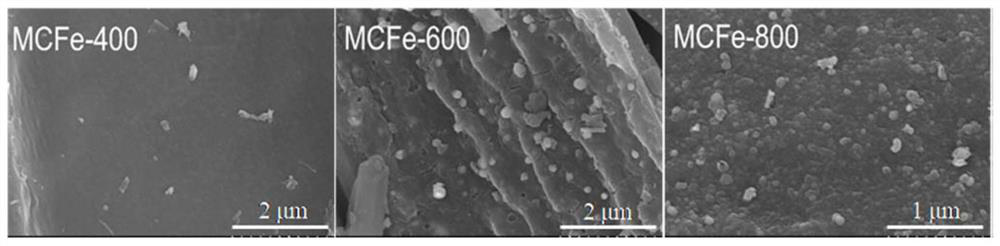

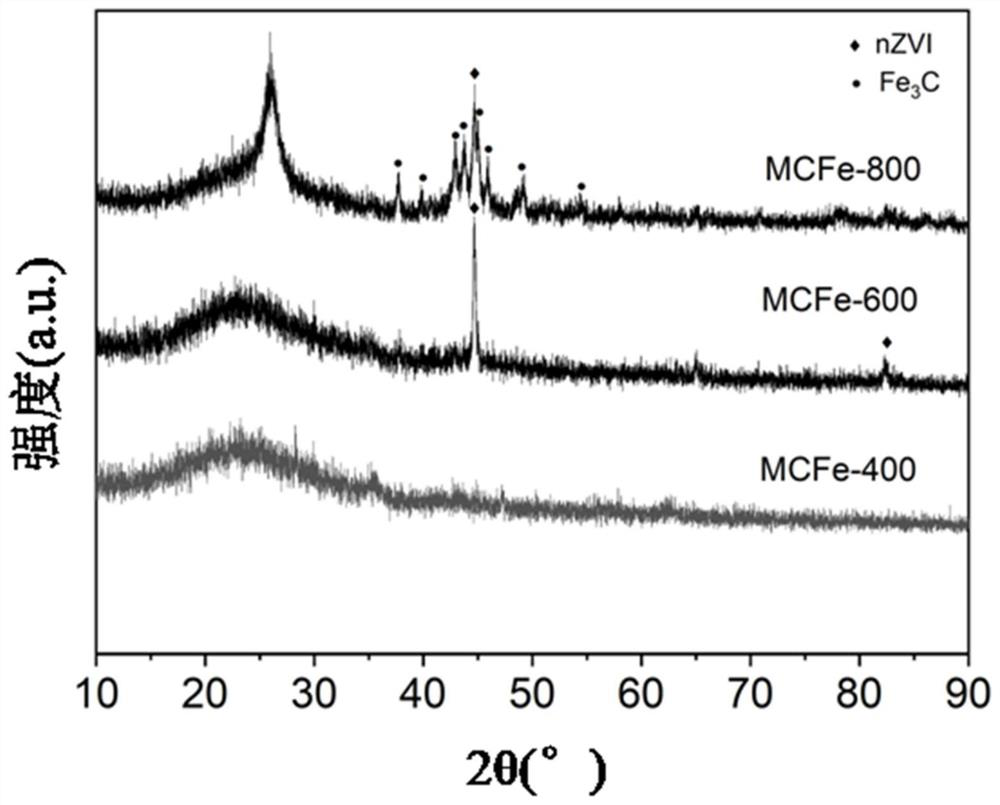

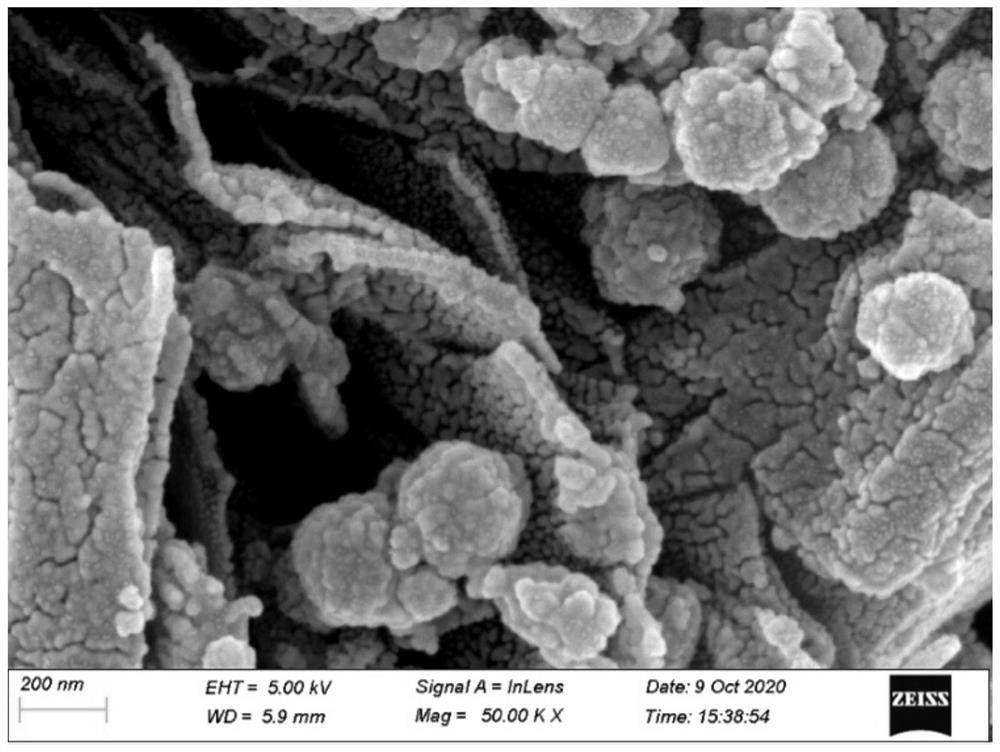

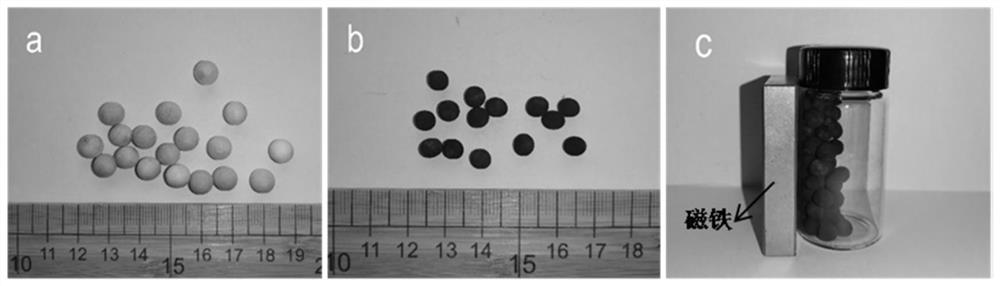

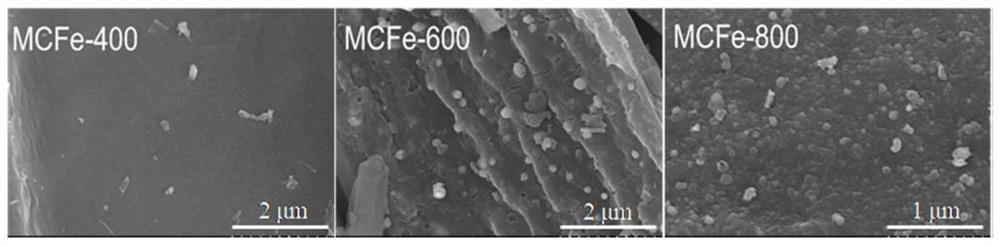

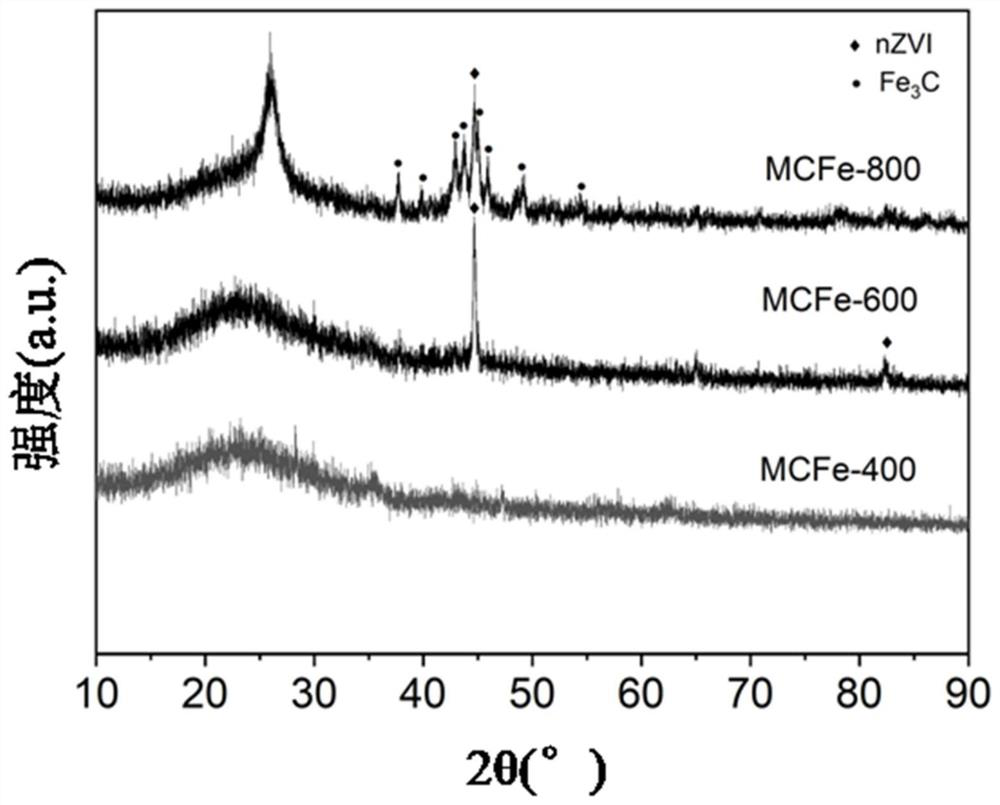

Magnetic porous carbon material as well as preparation method and application thereof

ActiveCN113070029ARich surface functional groupsIncrease the areaOther chemical processesWater contaminantsPorous carbonZerovalent iron

The invention discloses a magnetic porous carbon material and a preparation method and application thereof. The magnetic porous carbon material comprises porous carbon and nanoscale zero-valent iron, the diameter of the porous carbon is 6-10 mm, and the nanoscale zero-valent iron is loaded in the porous carbon. The millimeter-scale porous carbon is adopted to load the active substance nano zero-valent iron, so that the interference of soil particles or colloidal particles on the porous carbon can be effectively reduced, the adsorption and fixation effects on heavy metals are effectively improved, and the service life of the material is prolonged. Meanwhile, the millimeter-scale porous carbon is easy to recycle, so that the heavy metal can be extracted and separated from the polluted water body or soil, the content of the heavy metal in the water body or soil is reduced, and the recycling of the material is realized.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

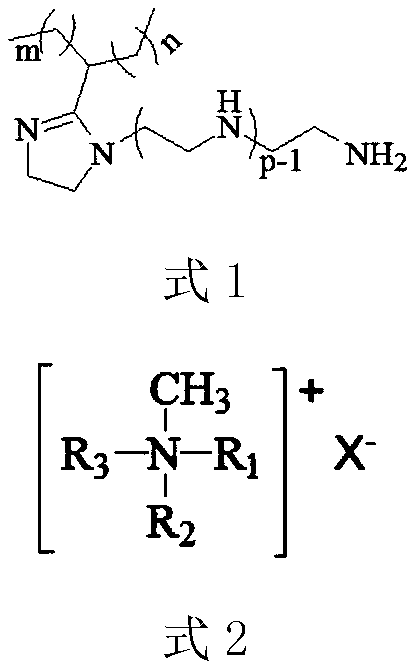

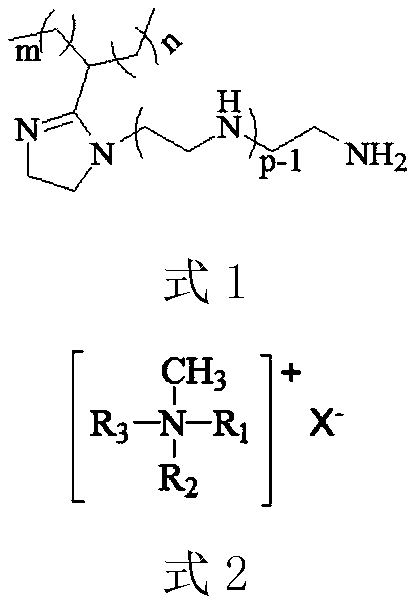

A mixed amine extractant for the separation of molybdenum and vanadium and a method for separating and recovering molybdenum and vanadium from spent catalysts

ActiveCN109022797BLarge saturated capacityShort split timeProcess efficiency improvementPtru catalystPhysical chemistry

The invention relates to a mixed amine extractant for the separation of molybdenum and vanadium and a method for separating and recovering molybdenum and vanadium from waste catalysts. The mixed amine extractant includes imidazole compounds and quaternary ammonium salt compounds, which are separated from waste catalysts. The method for recovering molybdenum and vanadium is as follows: the waste catalyst containing molybdenum and vanadium is leached with alkali to obtain a leach solution containing molybdenum and vanadium, and the leach solution containing molybdenum and vanadium is extracted and separated by an organic phase containing a mixed amine extractant, and the raffinate The solution is a molybdenum-containing solution, and the loaded organic phase is washed and stripped to obtain a vanadium-containing solution; the mixed amine extractant has the characteristics of large saturation capacity, short phase separation time, excellent extraction and stripping performance, and high separation coefficient of molybdenum and vanadium. The method can realize high-efficiency separation of vanadium and molybdenum in the alkaline solution system, and has good industrial application prospects.

Owner:肇庆市珈旺环境技术研究院

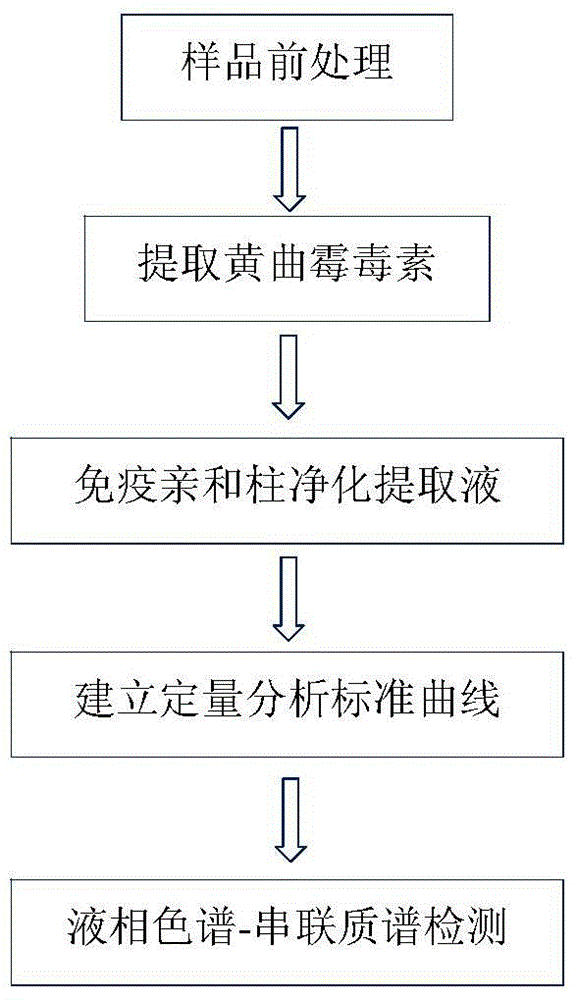

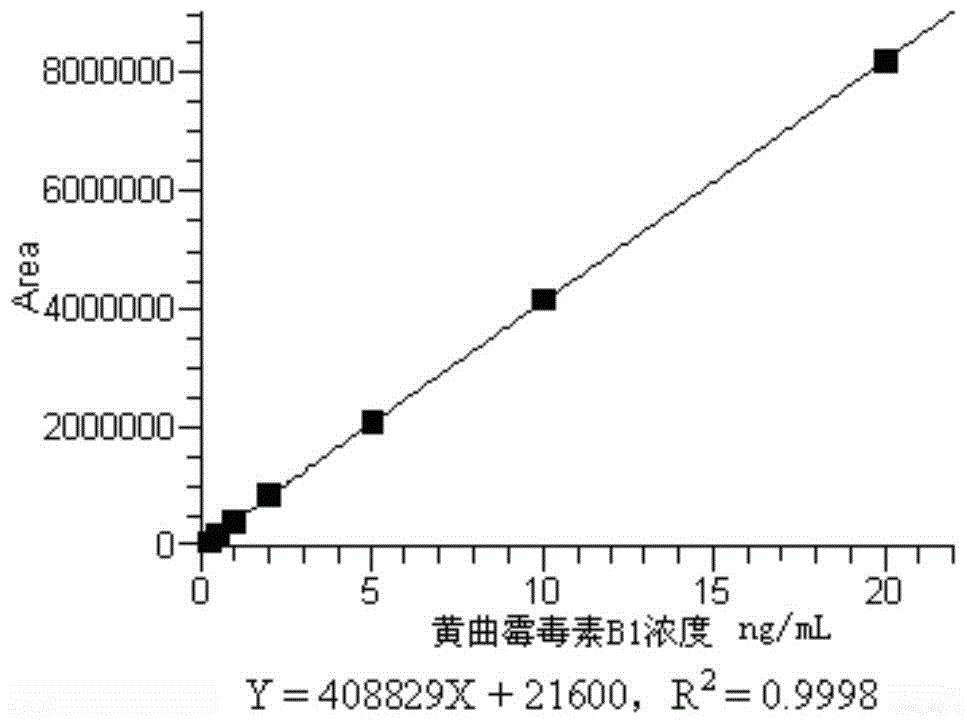

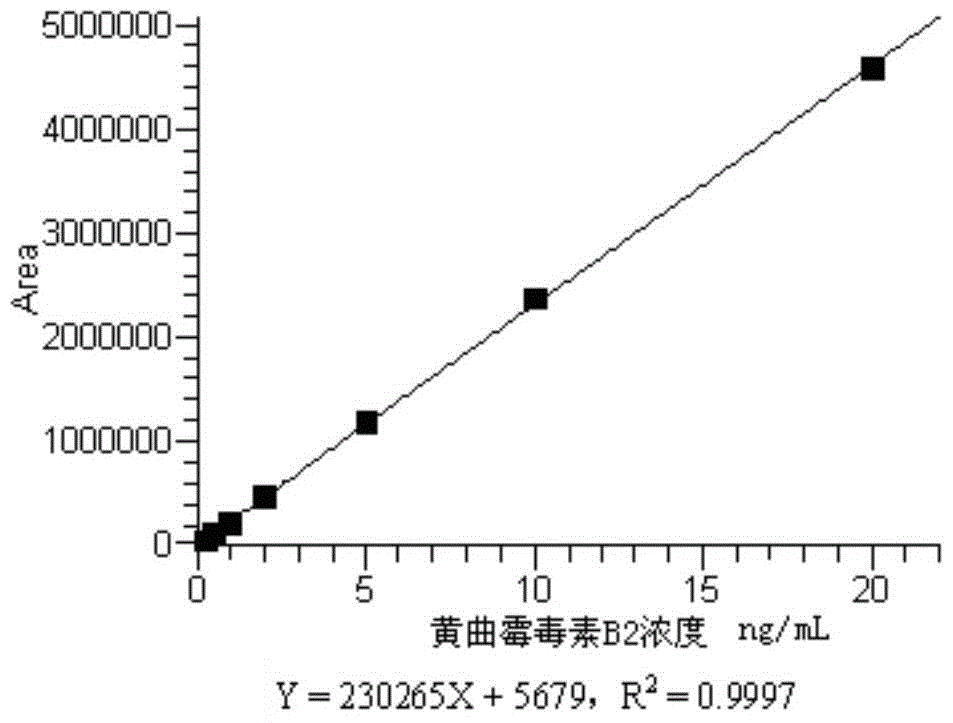

A method for the simultaneous determination of four aflatoxins in tobacco and tobacco products based on liquid chromatography-tandem mass spectrometry

ActiveCN104678039BRealize extraction and separationEliminate distractionsComponent separationRepeatabilityTobacco product

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

A method for enriching scandium from titanium dioxide wastewater

ActiveCN106636684BAchieve recyclingHigh recovery rateProcess efficiency improvementAcid dissolutionStrontium

The invention discloses a method for enriching scandium from titanium white wastewater. The method comprises the six steps of primary extraction, primary reverse extraction, acid dissolution for impurity removal, secondary extraction, washing for titanium removal and secondary reverse extraction. The method for enriching the scandium from the titanium white wastewater achieves comprehensive scandium recycle, the scandium recovery rate is improved from below 50% to 83% or above, extraction and separation of scandium target element and impurities are achieved, the problems of scandium loss, entrainment, emulsification and the like of a traditional process are effectively solved, the coarse scandium purity is above 36%, organic phase, alkaline liquor and acid liquor can be recycled, chemical raw material consumption and pollutant discharge are reduced, and the production cost is reduced.

Owner:CHINALCO GUANGXI NONFERROUS RARE EARTH DEV CO LTD

Separation method of highway waste asphalt pavement materials

ActiveCN109260755BResource SustainabilitySolve the problem of adding new stoneLiquid hydrocarbon mixture productionSolid solvent extractionSolvent extractionPetroleum engineering

The invention discloses a method for separating waste and old asphalt pavement materials of highways, and belongs to the technical field of separation of waste and old asphalt pavement materials (RAP). In this method, the waste road asphalt pavement material is first pulverized and dried, and then input into the extractor. After the compound solvent extraction treatment, the asphalt oil and sand and gravel are separated, and the mixed oil formed by the asphalt oil and the compound solvent is evaporated in a distillation pot. Asphalt oil is pumped into the asphalt tank. The evaporated composite solvent gas is condensed and turned into a liquid for recycling. Heat the remaining material in the extractor to 90-130°C, control the vacuum degree to 1.5-3KPa, convert the residual composite solvent in the sand and gravel into gaseous output, and then output the sand and gravel. During the separation process, the road waste asphalt pavement (RAP) is treated with a specific composite solvent and process parameters, the extraction rate of asphalt oil is over 94%, and the asphalt residue in the separated sand and gravel is less.

Owner:凌港

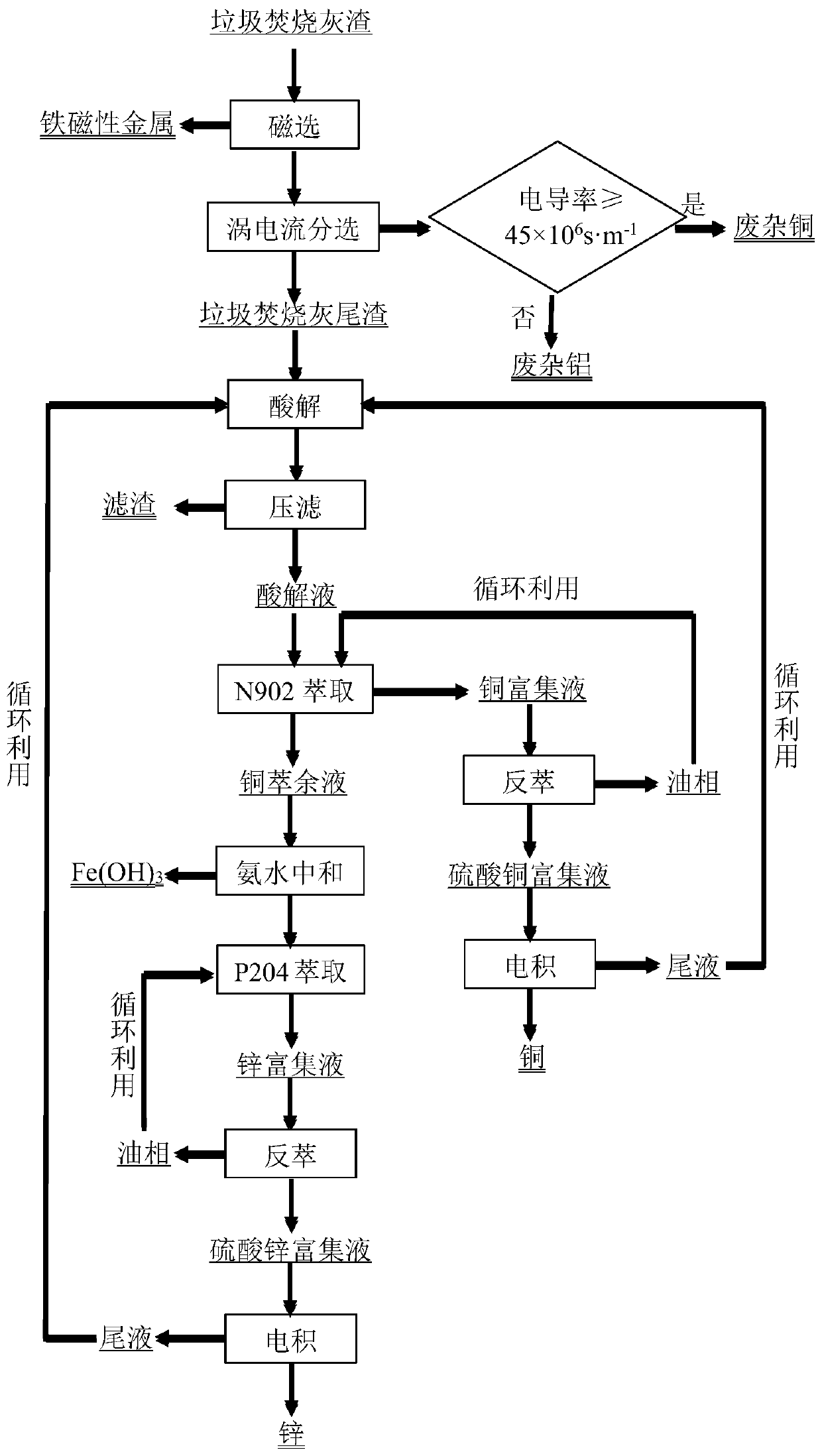

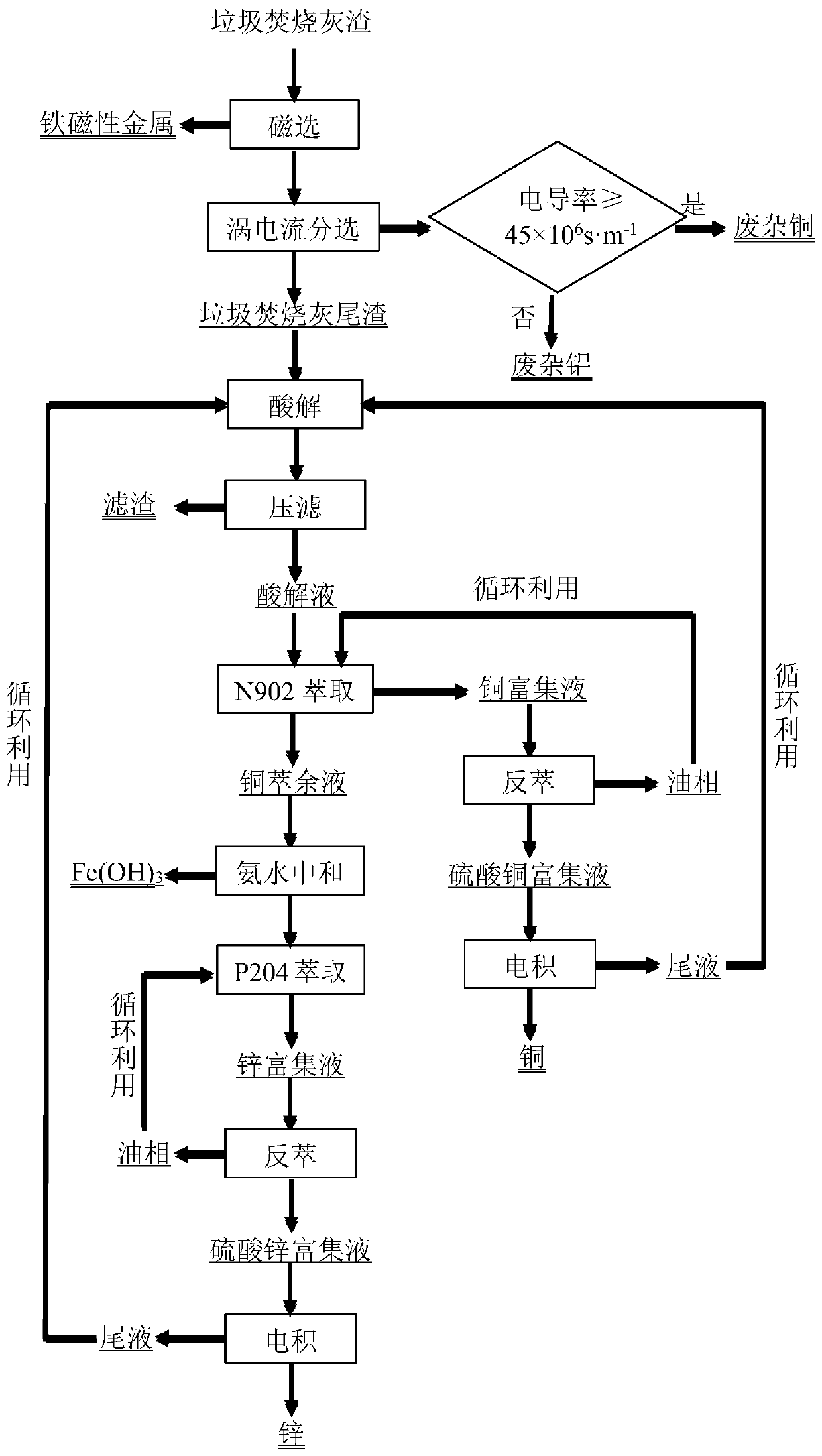

A method for extracting valuable metals from waste incineration ash

ActiveCN109402404BAchieve recyclingNo pollution in the processPhotography auxillary processesMagnetic separationSlagZinc ion

The invention provides a method for extracting valuable metals from garbage incineration ash, which belongs to the technical field of comprehensive utilization of resources. The method adopts physical separation-hydrometallurgy to extract and separate the valuable metals in the waste incineration ash, specifically: the waste incineration ash is magnetically separated to recover ferromagnetic metals, and then eddy current separation is used to recover non-ferrous metals; The tailings after current separation are subjected to acidolysis and pressure filtration to obtain an acidolysis solution, and the acidolysis solution is sequentially extracted with copper ions, and copper is extracted by electrowinning; the copper raffinate after the extraction of copper ions is sequentially neutralized to remove iron, Extraction of zinc ions, zinc electrowinning. The method of the invention realizes the recovery of ferromagnetic metals and non-ferrous metals such as copper, aluminum and zinc from garbage incineration ash, has the advantages of high efficiency, precision, no pollution and low cost, and is suitable for industrial application.

Owner:UNIV OF SCI & TECH BEIJING

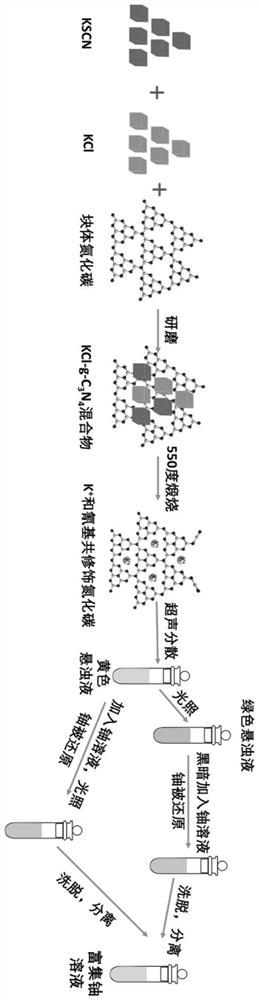

Catalyst for extracting and separating uranium in uranium-containing wastewater or seawater and application of catalyst

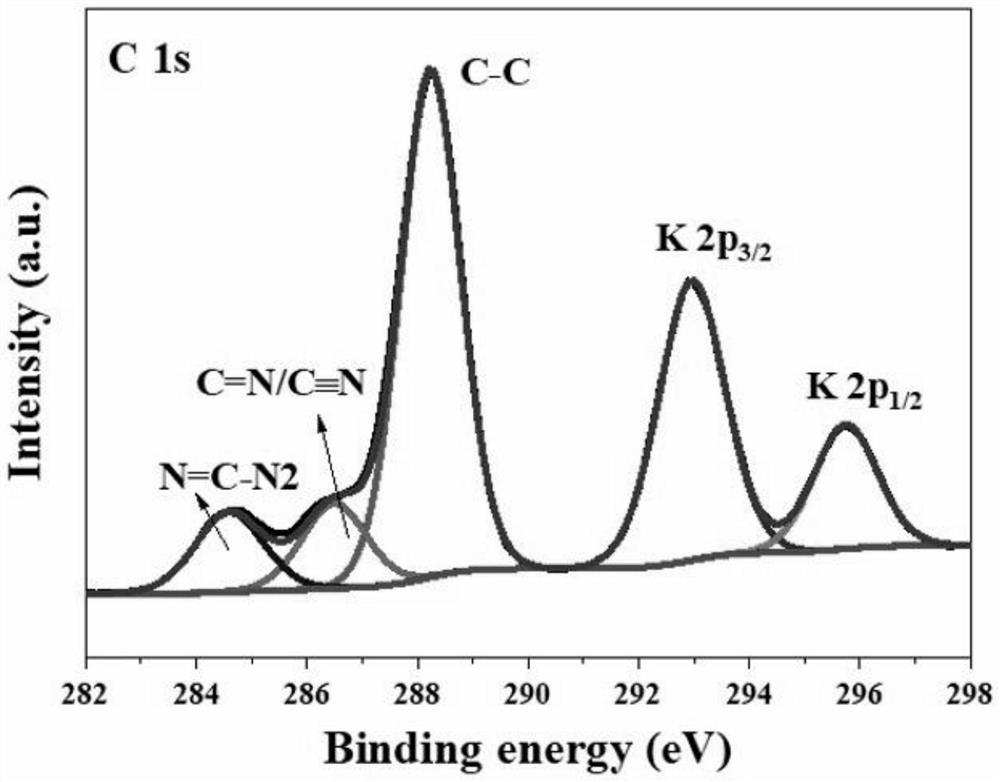

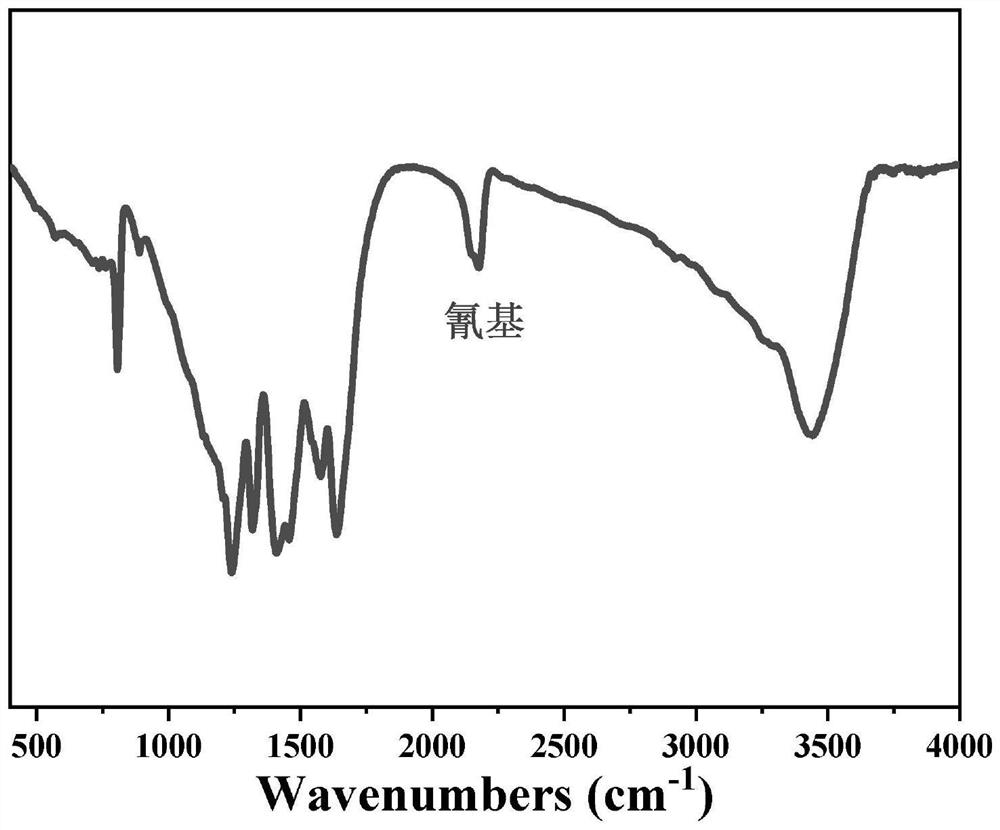

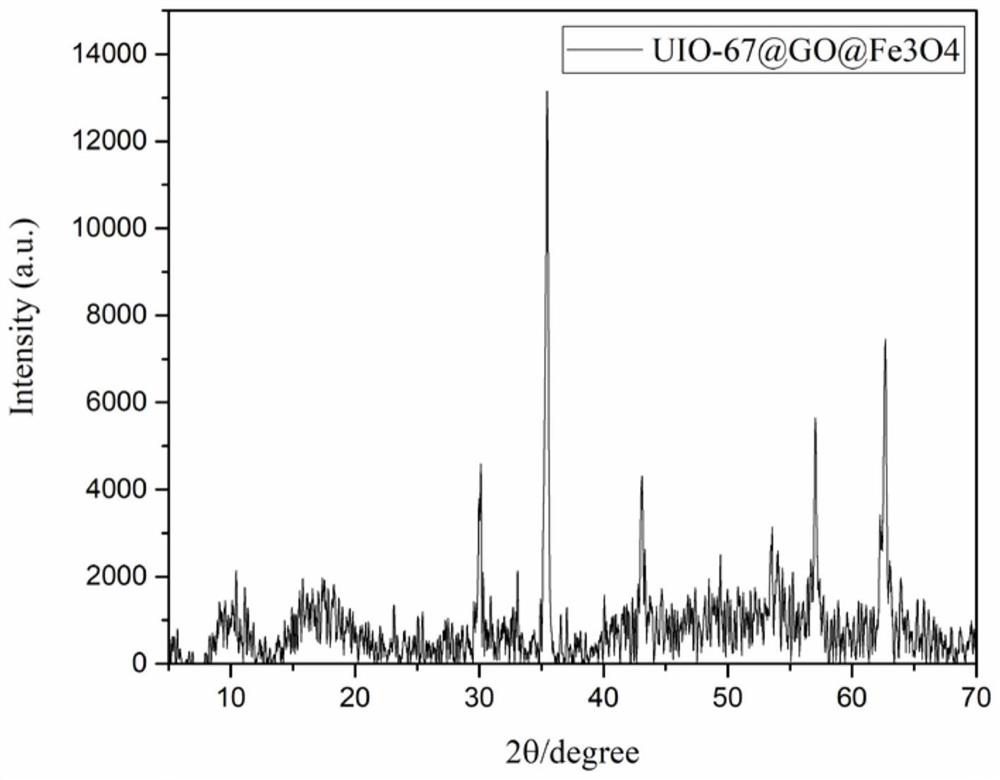

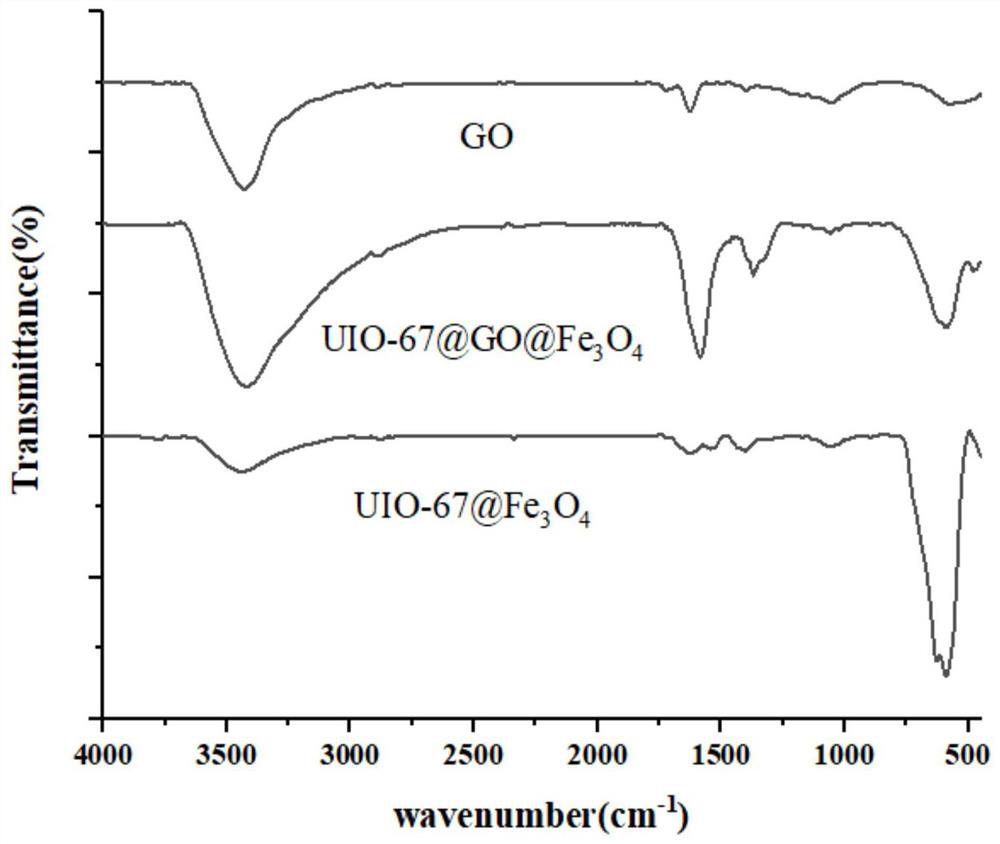

ActiveCN114558606APerformance impactInhibition of dissolutionCatalyst activation/preparationProcess efficiency improvementPtru catalystPotassium thiocyanate

The invention belongs to the technical field of new energy development, and discloses a catalyst for extracting and separating uranium in uranium-containing wastewater or seawater and application thereof.The catalyst is prepared through the following steps that after carbon nitride, potassium chloride and potassium thiocyanate are ground and mixed to be uniform, heat preservation is conducted for 3-5 h at the temperature of 500-600 DEG C, and a catalyst precursor is obtained; washing the catalyst precursor with clear water and an alcohol solution in sequence to wash salt and impurities on the surface of the catalyst precursor to obtain a washed catalyst precursor; and carrying out freeze drying treatment on the catalyst precursor to obtain the catalyst. The catalyst is good in cycle performance, uranium can be continuously separated from the water body through the separation method, only sunlight is needed in the whole process, and the method is environmentally friendly, sustainable and free of pollution.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

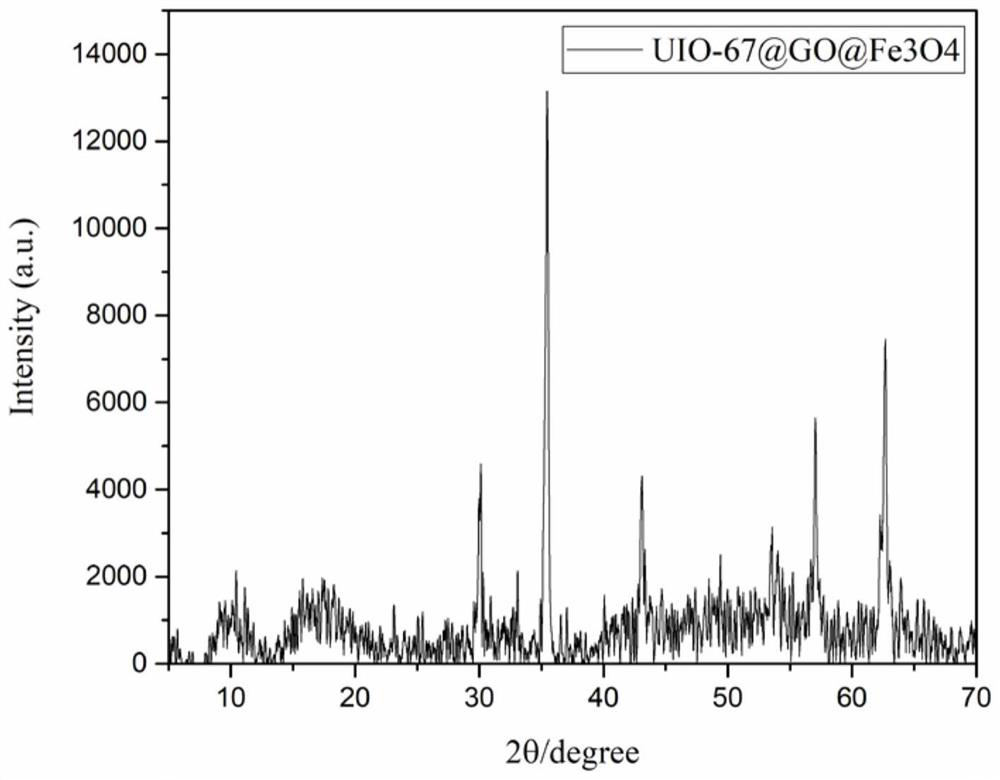

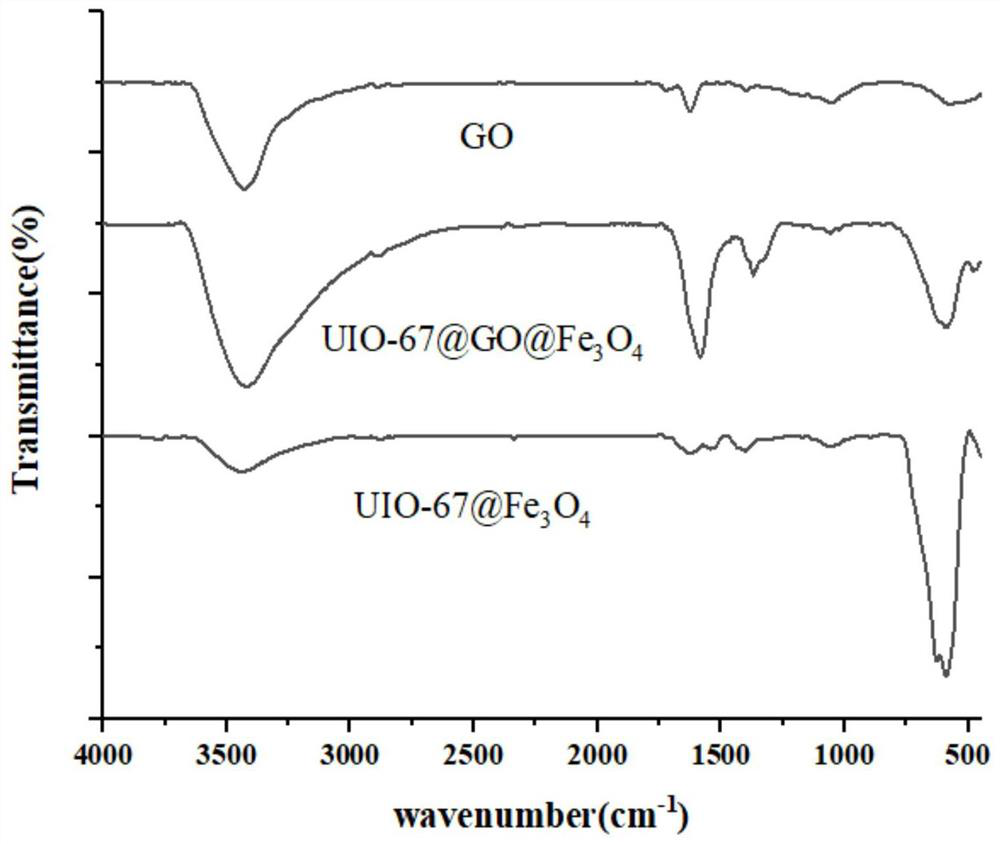

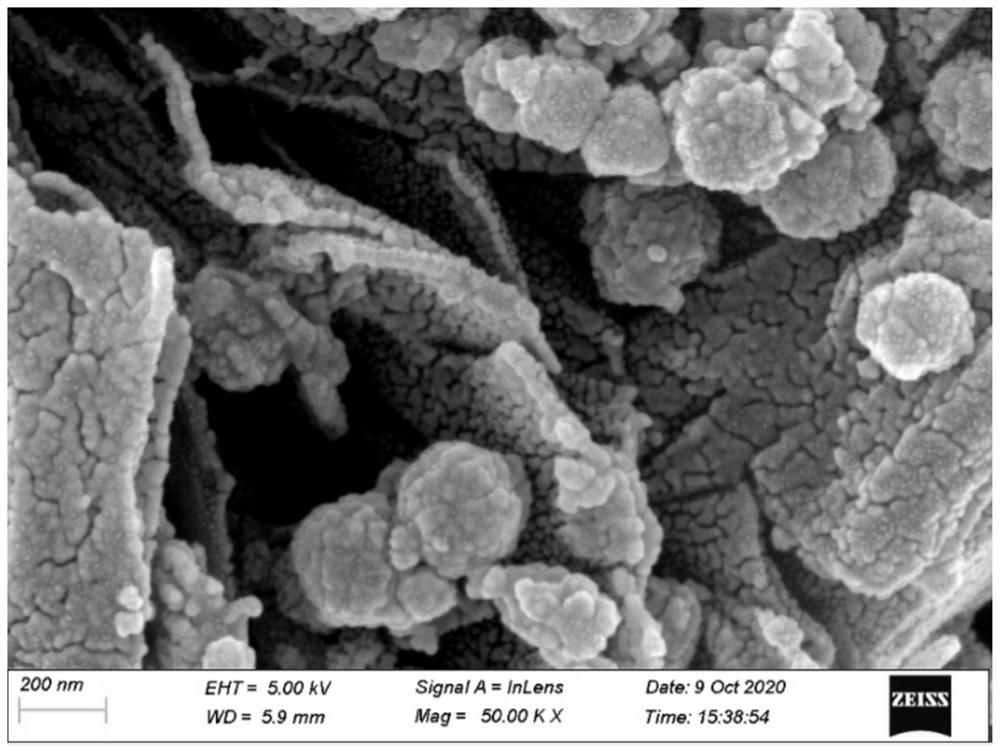

Method for detecting sulfonamide antibiotics in biogas slurry and sample treatment method

ActiveCN113030308AImprove adsorption capacitySignificant specific adsorptionComponent separationPhysical chemistrySolid phase extraction

The invention discloses a method for detecting sulfonamide antibiotics in biogas slurry and a sample treatment method. The sample treatment method comprises the following steps of: taking UIO-67@GO@Fe3O4 powder obtained by synthesizing graphene oxide, ferroferric oxide, zirconium tetrachloride and 4, 4'-diphenyldicarboxylic acid as an adsorption material; and adjusting the pH value of a biogas slurry sample to 3-7, carrying out magnetic solid-phase extraction by using UIO-67@GO@Fe3O4 powder, and blow-drying desorbed eluent to obtain a treated biogas slurry sample. The treated biogas slurry sample is directly determined by one or more of the existing sulfonamide antibiotic determination methods. The method is simple and convenient to operate, time-saving and rapid, the adsorption material can be recycled, the detection result is accurate, and the method can be widely popularized and applied.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Oil sand separation method

ActiveCN109181739BSolve the problem of insufficient supply in the marketRealize extraction and separationLiquid hydrocarbon mixture productionMixed materialsOil sands

The invention discloses an oil sand separation method, and belongs to the technical field of oil sand separation. The oil sand separation method comprises following steps: an oil sand raw material issubjected to crushing and drying, and is introduced into an extractor; the oil sand raw material is subjected to extraction using a composite solvent in the extractor so as to obtain an asphalt and composite solvent mixed oil through separation; the asphalt and composite solvent mixed oil is pumped into a filter, impurities are removed, and the asphalt and composite solvent mixed oil is pumped into a distillation still for evaporation so as to obtain asphalt oil, and the asphalt oil is pumped into an asphalt tank; the composite solvent gas is converted into liquid through condensation for recycling; a mixed material obtained in the extractor is heated to 90 to 130 DEG C, the vacuum degree is controlled to be 2 to 3KPa, stirring is carried out, the composite solvent in tailings is convertedinto gas state for discharging, the composite solvent gas is subjected to condensation so as to obtain a liquid for recycling, and tailings output is carried out. According to the oil sand separationprocess, the specific composite solvent and technological parameters are adopted for processing of oil sand, the asphalt extraction rate in oil sand is 97% or higher, and asphalt left in the tailingsis low.

Owner:凌港

A method for selective extraction and separation of molybdenum from high-phosphorus tungsten-molybdenum mixed solution

ActiveCN104762476BRealize extraction and separationSimple methodProcess efficiency improvementHigh phosphateSingle stage

The invention relates to a method of selectively extracting and separating molybdenum from a high-phosphorus tungsten- and molybdenum-containing mixed solution. In the prior art, according to the process of extraction and separation of tungsten and molybdenum through complexation of hydrogen peroxide, when the content of phosphorus in the solution is higher than 0.005 mol / L, the extraction efficiency of the tungsten and the molybdenum is greatly reduced, so that the conventional process of extraction and separation of the tungsten and the molybdenum through complexation of the hydrogen peroxide cannot be used for directly treating the tungsten- and molybdenum-containing mixed solution being higher than 0.005 mol / L in the content of the phosphorus. According to the invention, by means of adjustment and control of the content of acid in the high-phosprous mixed solution, the tungsten and the molybdenum in the mixed solution can be reacted with the phosphorus completely to form tungstomolybdophosphate acid. By means of addition of a proper amount of the hydrogen peroxide, the phosphor-tungstic heteropoly acid and phospho-molybdic heteropoly acid are depolymerized to generate peroxy phosphotungstic acid and peroxy phospho-molybdic acid. By means of TBP as an extraction agent, the peroxy phospho-molybdic acid is extracted into an organic phase and then the loaded organic phase is subjected to reverse-extraction by an alkaline reverse-extraction agent. The method can treat the high-phosphorus tungsten- and molybdenum-containing mixed solution, is low in co-extraction of tungsten, can reach 70% in molybdenum extraction rate in a single stage, is low in the cost of the employed extraction agent and is easy to industrialize.

Owner:CENT SOUTH UNIV

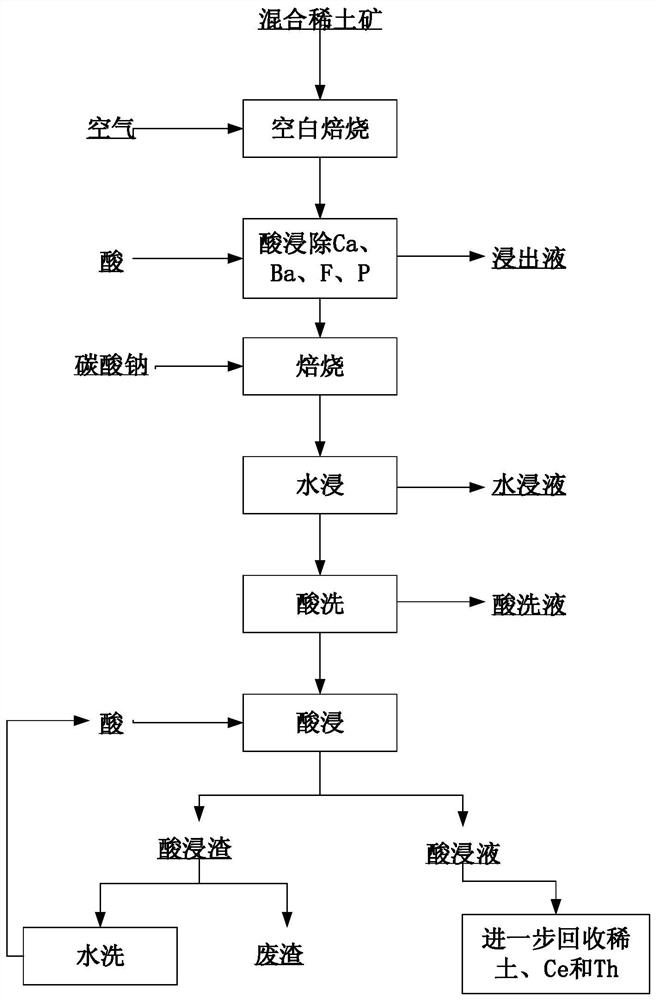

A kind of roasting decomposition method of mixed rare earth ore

ActiveCN109022834BReduce dosageSolve agglomerationProcess efficiency improvementPhosphoric acidPregnant leach solutionSlag

The invention relates to a roasting decomposition method for mixed rare earth ore. The roasting decomposition method for the mixed rare earth ore comprises the steps that the mixed rare earth ore is blankly roasted in air, a product obtained through blank roasting is mixed with acid liquor and is then leached, and leachate and slag are obtained after solid-liquid separation; and the slag and sodium carbonate are mixed and then roasted, a roasted product is leached with water, and aqueous leaching liquor and aqueous leaching residues are obtained after solid-liquid separation. According to theroasting decomposition method for the mixed rare earth ore, bastnaesite in the mixed rare earth ore is decomposed through blank roasting first, and then the acid liquor is added for optimized leachingto remove calcium, barium, fluorine and phosphorus before the sodium carbonate in the mixed rare earth ore is roasted, so that consumption of the sodium carbonate is reduced, the problem of caking inthe roasting process is solved, and the production cost is greatly reduced. By adoption of the roasting decomposition method for the mixed rare earth ore, the technological process is shortened, energy consumption is reduced, no waste gas is exhausted in the whole technological process, and the radioactivity of the slag reaches the standard; and meanwhile, comprehensive step-by-step recycling ofrare earth, thorium, fluorine and phosphorus is achieved, and the roasting decomposition method has good economic benefits and application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A method for extracting and separating tungsten and molybdenum in a high-phosphorus tungsten-molybdenum mixed solution

ActiveCN104711422BRealize extraction and separationSimple methodProcess efficiency improvementPhosphomolybdic acidPhosphate

The invention relates to a method for extracting and separating tungsten and molybdenum in a high-phosphorus mixed solution containing tungsten and molybdenum. The method comprises the following steps: adding hydrogen peroxide in the high-phosphorus mixed solution containing tungsten and molybdenum for acidity adjustment and control, and converting phosphotungstic acid and phosphomolybdic acid into peroxy-phosphotungstic acid and peroxy-phosphomolybdic acid; then, taking a mixture of tributyl phosphate (TBP) and methyl phosphate dimethyl heptyl ester (P350) as an extracting agent, extracting the peroxy-phosphomolybdic acid into an organic phase, and leaving the peroxy-phosphotungstic acid in an aqueous phase; from now on, after decomposing the peroxy-phosphotungstic acid in extraction raffinate in the way of heating or ultraviolet irradiation or introduction of sulfur dioxide, extracting tungsten in the solution again with a fresh mixed extracting agent, and finally realizing extraction and separation of tungsten and molybdenum from complex material liquid. The method is small in tungsten co-extraction loss, can effectively solve the extraction and separation problem of tungsten and molybdenum in the high-phosphorus mixed solution containing tungsten and molybdenum, and is easy to realize industrialization.

Owner:CENT SOUTH UNIV

A method for reclaiming anhydrous indium salt and anhydrous tin salt from indium tin oxide

ActiveCN107226480BHigh purityHigh recovery rateGallium/indium/thallium compoundsTin halidesIndiumDistillation

The invention belongs to the technical field of alloy waste material recovery and utilization, and discloses a method for recovering anhydrous indium salt and anhydrous tin salt from indium tin oxide. The method comprises the following steps that S1, the indium tin oxide is dissolved by acid; indium and tin exist in the acid in an ion form; S2, the acid is removed through distillation; an indium salt hydrate and a tin salt hydrate are left; S3, a dehydrating agent is added into the hydrates in the S2; heating reflux is performed to obtain the anhydrous indium salt and the anhydrous tin salt; S4, the anhydrous indium salt and the anhydrous tin salt are separated. The method disclosed by the invention has the advantages that the product with extremely high purity can be obtained; all used reagents can be almost cyclically used; no pollution is generated on the environment; less energy and fewer reagents are consumed by the method; the method can be stably used for large-scale industrial practice; a large amount of energy can be saved; the operation is simple and convenient; the extremely high economic performance is realized.

Owner:顾帅

Method for detecting nitroimidazole antibiotics in honey and sample treatment method

ActiveCN113030309ASignificant specific adsorptionCompact distributionComponent separationNitroimidazoleHoney samples

The invention discloses a method for detecting nitroimidazole antibiotics in honey and a sample treatment method. The sample treatment method comprises the following steps of: taking UIO-67@GO@Fe3O4 powder obtained by synthesizing graphene oxide, ferroferric oxide, zirconium tetrachloride and 4, 4'-diphenyldicarboxylic acid as an adsorption material; and adjusting the pH value of a honey sample to 3-7, carrying out magnetic solid-phase extraction by using the UIO-67@GO@Fe3O4 powder, and blow-drying desorbed eluent to obtain a treated honey sample. The treated honey sample is directly determined by adopting one or more of the existing nitroimidazole antibiotic determination methods. The method is simple and convenient to operate, time-saving and rapid, the adsorption material can be recycled, the detection result is accurate, and the method can be widely popularized and applied.

Owner:ZHEJIANG UNIV OF TECH +1

A kind of magnetic porous carbon material and its preparation method and application

ActiveCN113070029BRich surface functional groupsIncrease the areaOther chemical processesWater contaminantsPorous carbonZerovalent iron

The invention discloses a magnetic porous carbon material and a preparation method and application thereof. The magnetic porous carbon material includes porous carbon and nano zero-valent iron, the diameter of the porous carbon is 6-10 mm, and the nano zero-valent iron supports in the porous carbon. The invention can effectively reduce the interference of the porous carbon by soil particles or colloidal particles by using the millimeter-scale porous carbon to load the active material nano-zero-valent iron, effectively improve the adsorption and fixation of heavy metals, and prolong the life of the material; Millimeter-sized porous carbon is easy to recycle, which can realize the extraction and separation of heavy metals from polluted water or soil, reduce the content of heavy metals in water or soil, and realize the recycling of materials.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com