A method for reclaiming anhydrous indium salt and anhydrous tin salt from indium tin oxide

A technology of indium tin oxide and tin salt, applied in the field of alloy waste recycling, can solve the problems of consuming resin, large secondary waste, large energy, etc., and achieve the effects of energy saving, simple operation and high economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

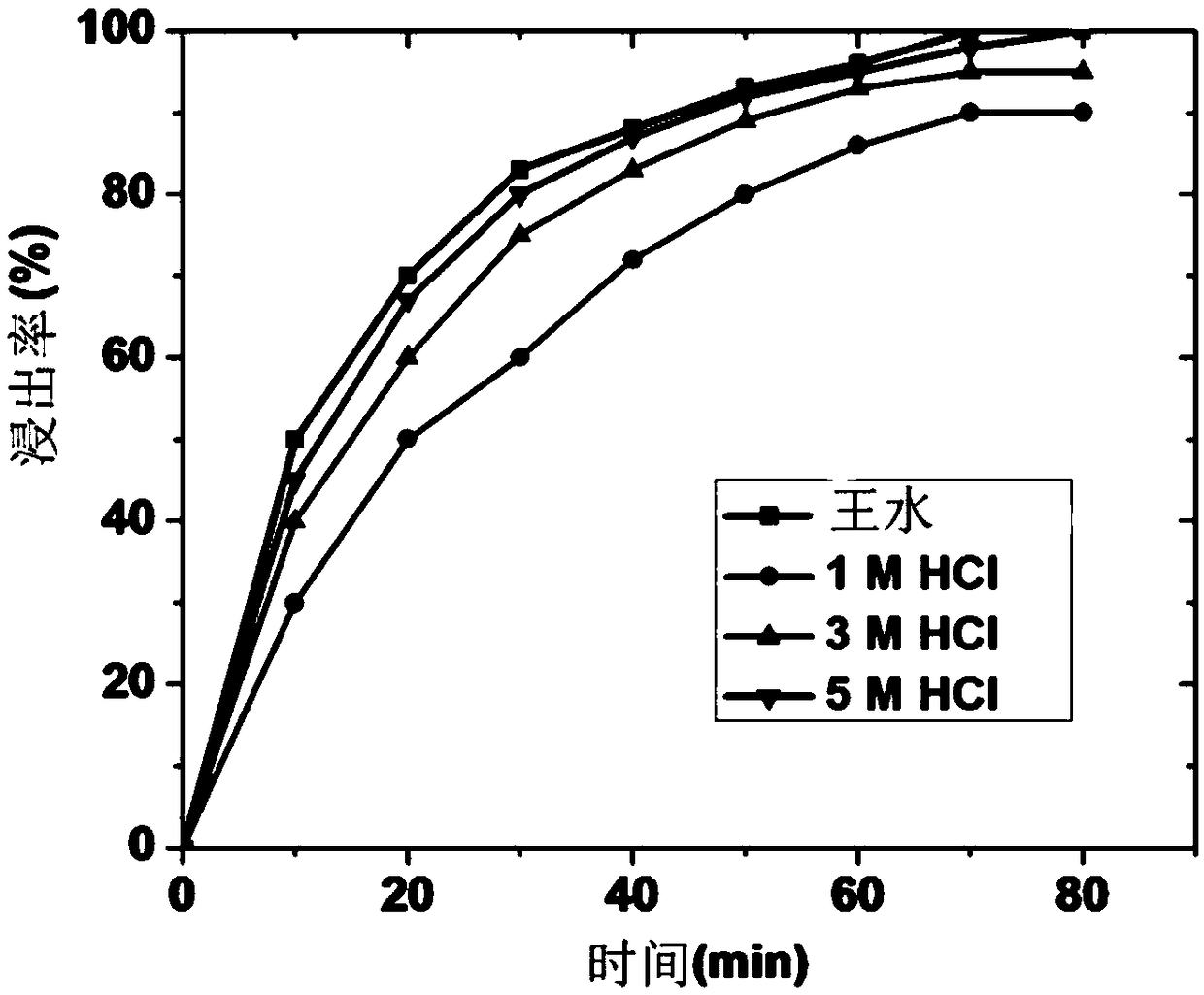

[0040] Firstly, the waste ITO material was pulverized into fine powder for composition analysis, the components of waste ITO were checked by XRF, and the mass fraction of each component in ITO was measured by standard FP quantitative procedure (SQX) analysis. Since SQX is only a semi-quantitative analysis method, after dissolving ITO powder with aqua regia, ICP-OES (Optima 5300DV) was used to determine the actual mass fractions of In and Sn in waste products. Table 1 summarizes the In of three different masses of ITO powder samples determined by ICP-OES 3+ , Sn 4+ and Zn 2+ The average mass fraction of ZnO as the main impurity, In 2 o 3 with SnO 2 The mass ratio is about 95:5.

[0041] Table 1 Chemical composition of spent ITO materials determined by SQX analysis of XRF and ICP-OES

[0042] Composition determined by XRF

In 2 o 3

SnO 2

ZnO

other

Quality score (%)

94.92

4.94

0.12

0.02

Components determined by ICP

...

Embodiment 2

[0070] Follow the steps below to recover anhydrous indium chloride, anhydrous indium nitrate and anhydrous tin chloride:

[0071] 1. Dissolving: the waste ITO material (In 2 o 3 and SnO 2 The mass ratio is 90:10) and crushed into fine powder, using aqua regia to completely dissolve the waste indium tin oxide powder, the ratio of ITO to solvent is 1g:8mL, the leaching temperature is 70°C, the stirring speed is 500rpm, and the time is 1.5h. Indium and tin then exist in aqua regia in the form of indium ions and tin ions, respectively.

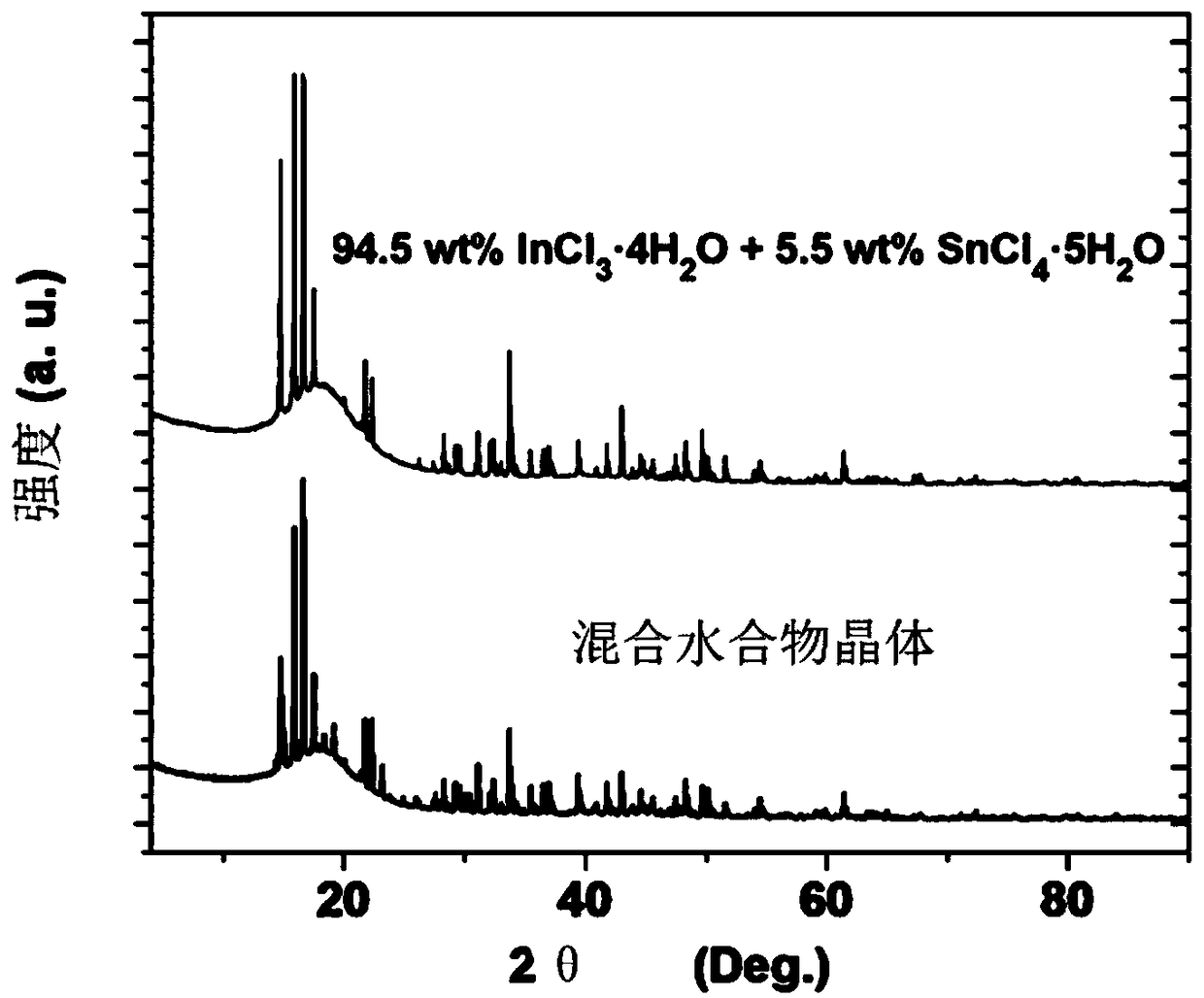

[0072] 2. Distillation: The leaching solution is then distilled under reduced pressure, and the residue after distillation is a mixture of indium nitrate trihydrate, indium chloride tetrahydrate and tin chloride pentahydrate.

[0073] 3. Dehydration: Then grind the crystal mixture, add benzene to the crystal mixture, add 5mL of benzene per gram of crystal mixture, heat the flask, reflux the benzene for 3 hours, and fully remove the water in the...

Embodiment 3

[0077] Follow the steps below to recover anhydrous indium chloride and anhydrous tin chloride:

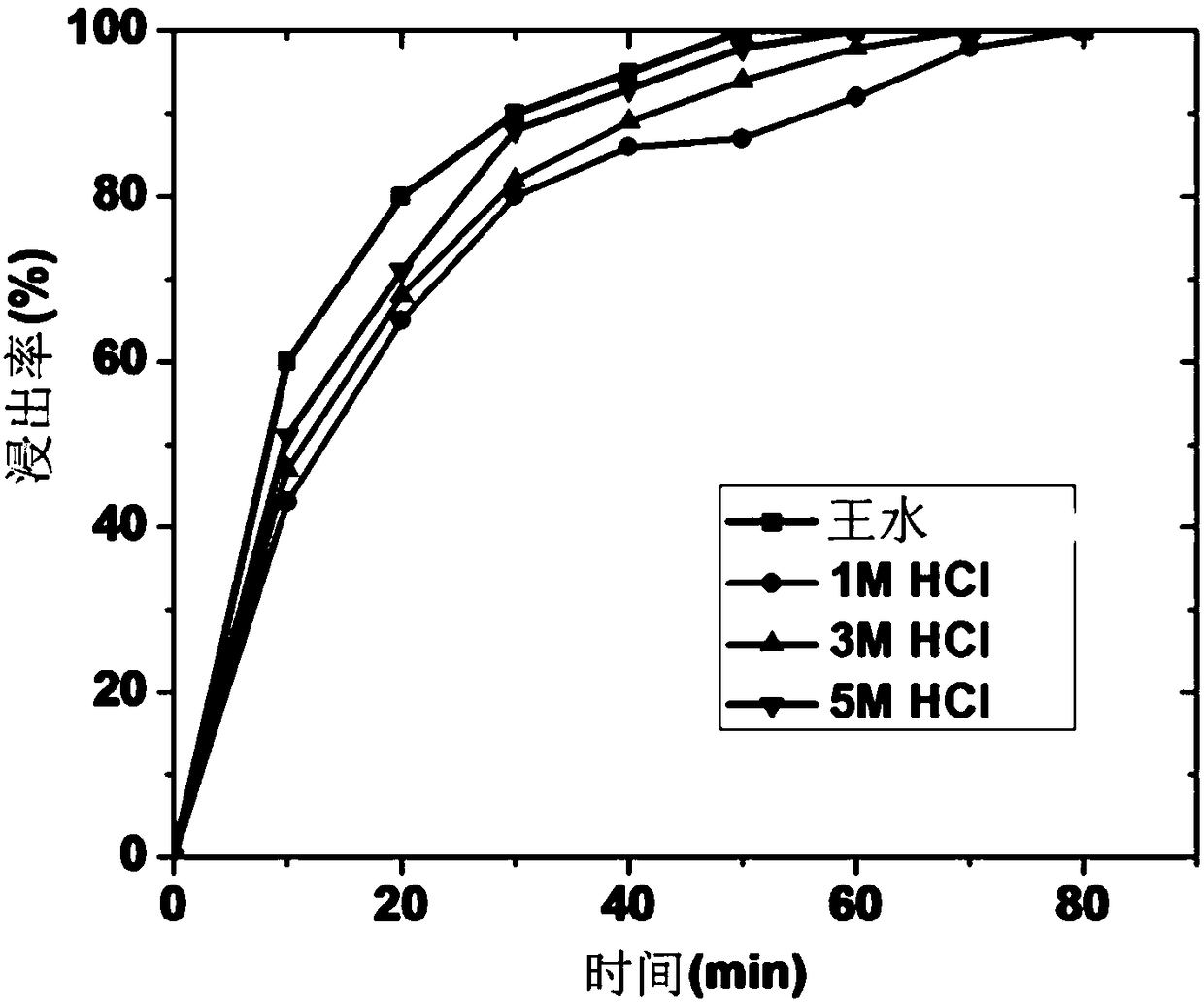

[0078] 1. Dissolving: the waste ITO material (In 2 o 3 and SnO 2 The mass ratio of 96:4) was crushed into fine powder, and the waste indium tin oxide powder was completely dissolved with hydrochloric acid. The ratio of ITO to solvent was 1g:40mL, the concentration of hydrochloric acid was 1M, the leaching temperature was 100°C, and the stirring speed was 500rpm. The time is 1 h, after which indium and tin exist in the hydrochloric acid solution in the form of indium ions and tin ions, respectively.

[0079] 2. Distillation: The leaching solution is then distilled under reduced pressure to recycle hydrochloric acid, and the residue after distillation is a mixture of indium chloride tetrahydrate and tin chloride pentahydrate.

[0080] 3. Dehydration: Then grind the crystal mixture, add n-butanol to the crystal mixture, add 6 mL of n-butanol per gram of crystal mixture, heat the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com