Patents

Literature

382 results about "Tin chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

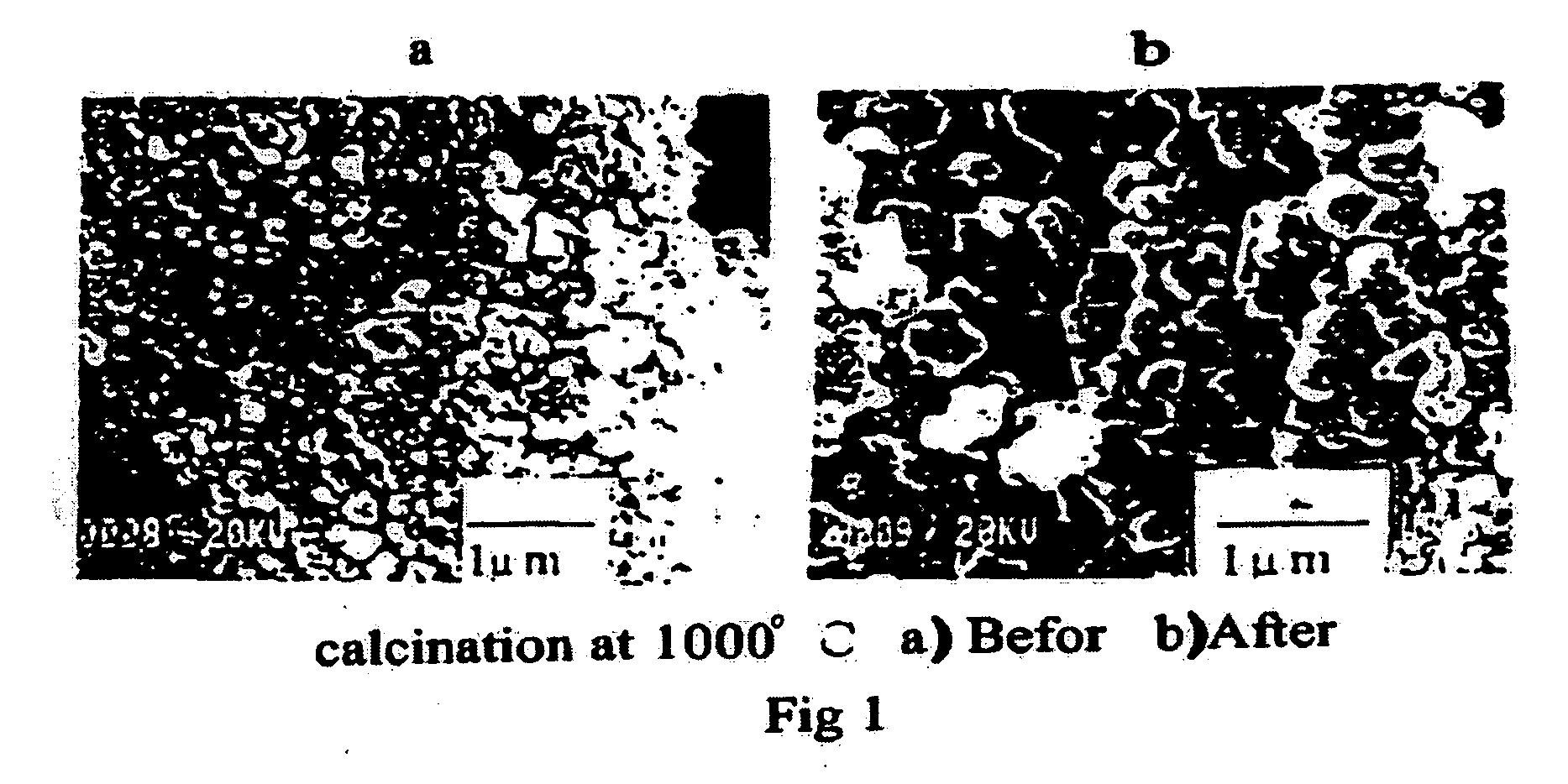

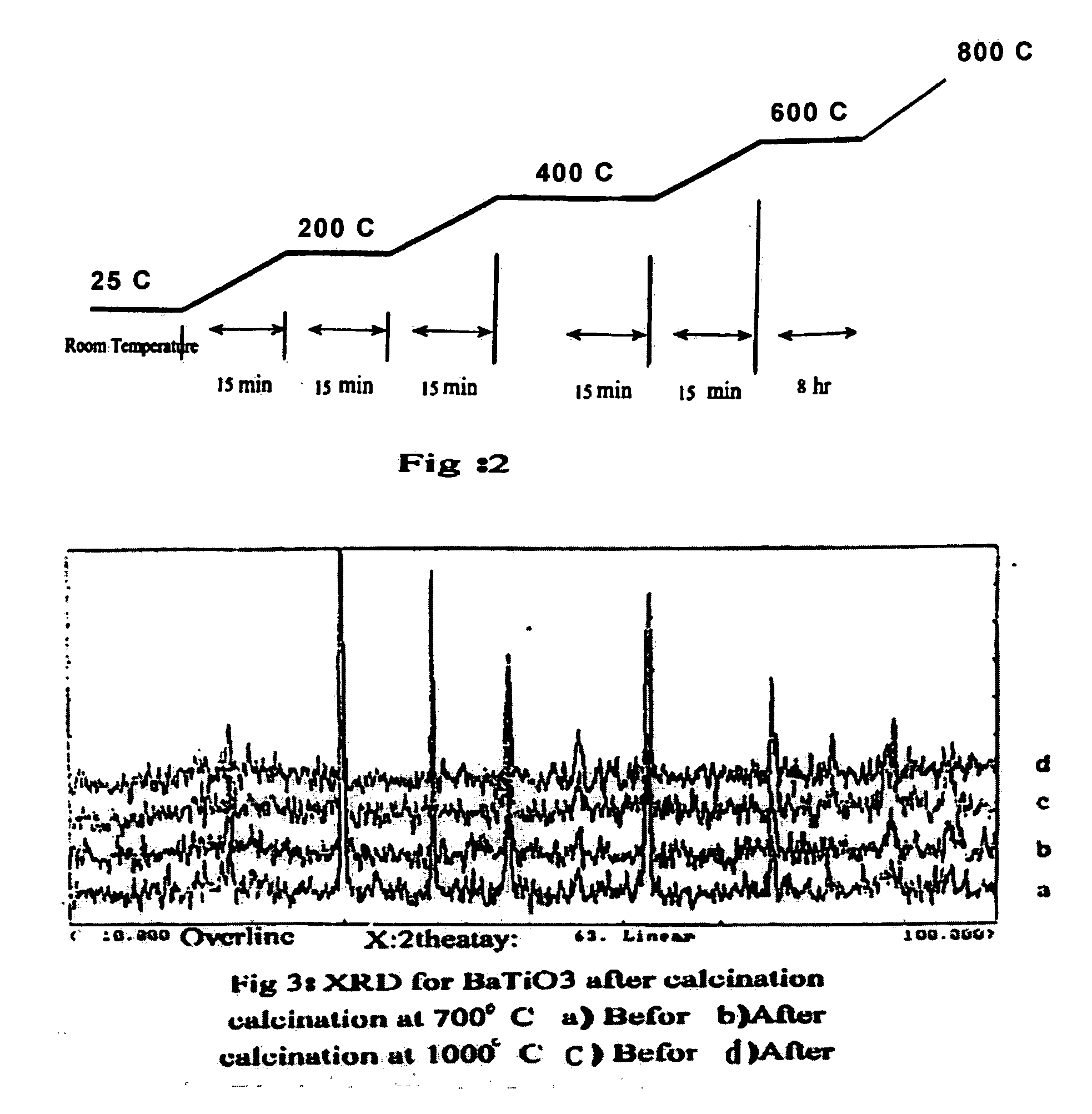

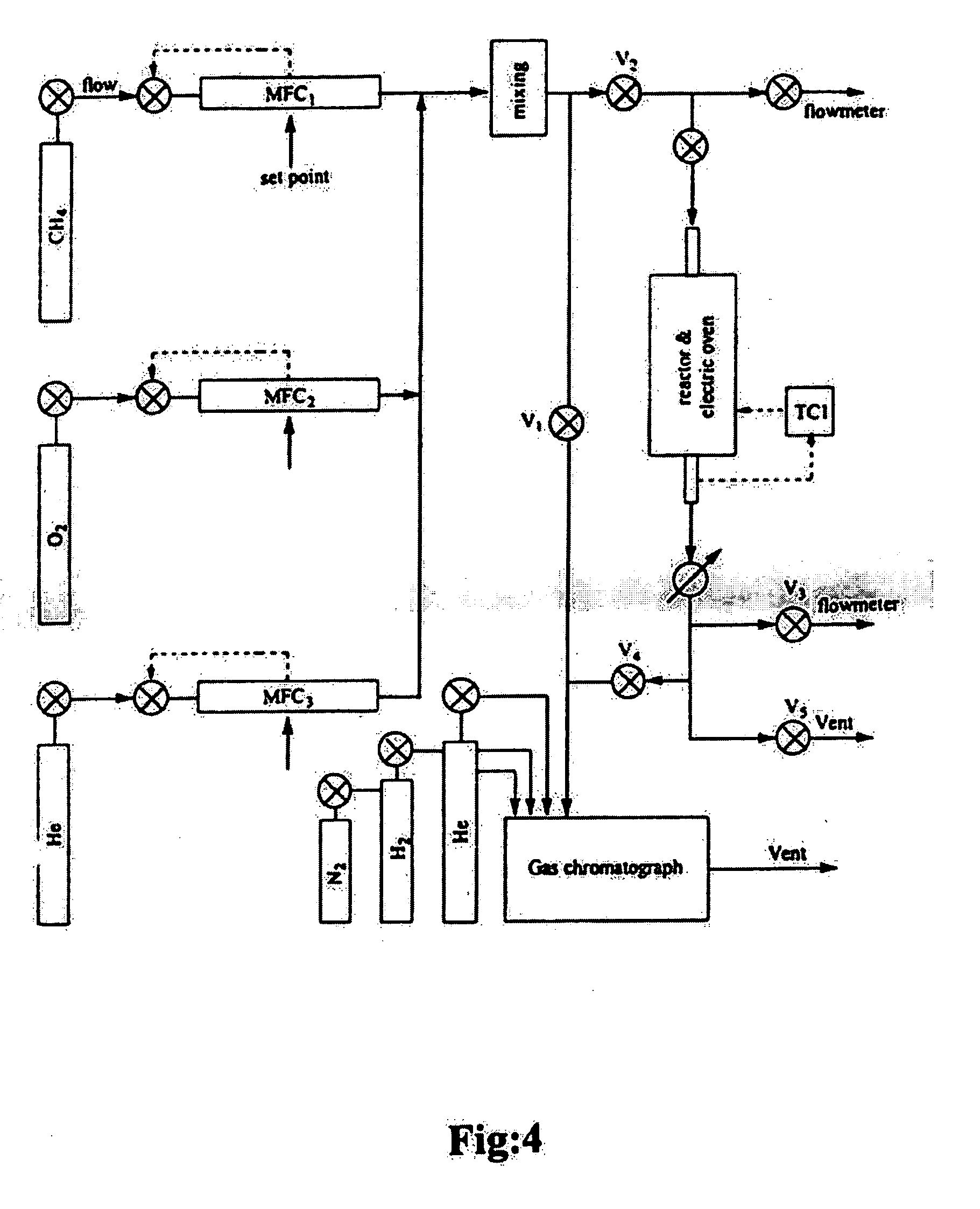

Preparation of catalyst and use for high yield conversion of methane to ethylene

InactiveUS7250543B2Maintain activityAlkaline earth titanatesHydrocarbon by hydrocarbon condensationAlkaline earth metalSlurry

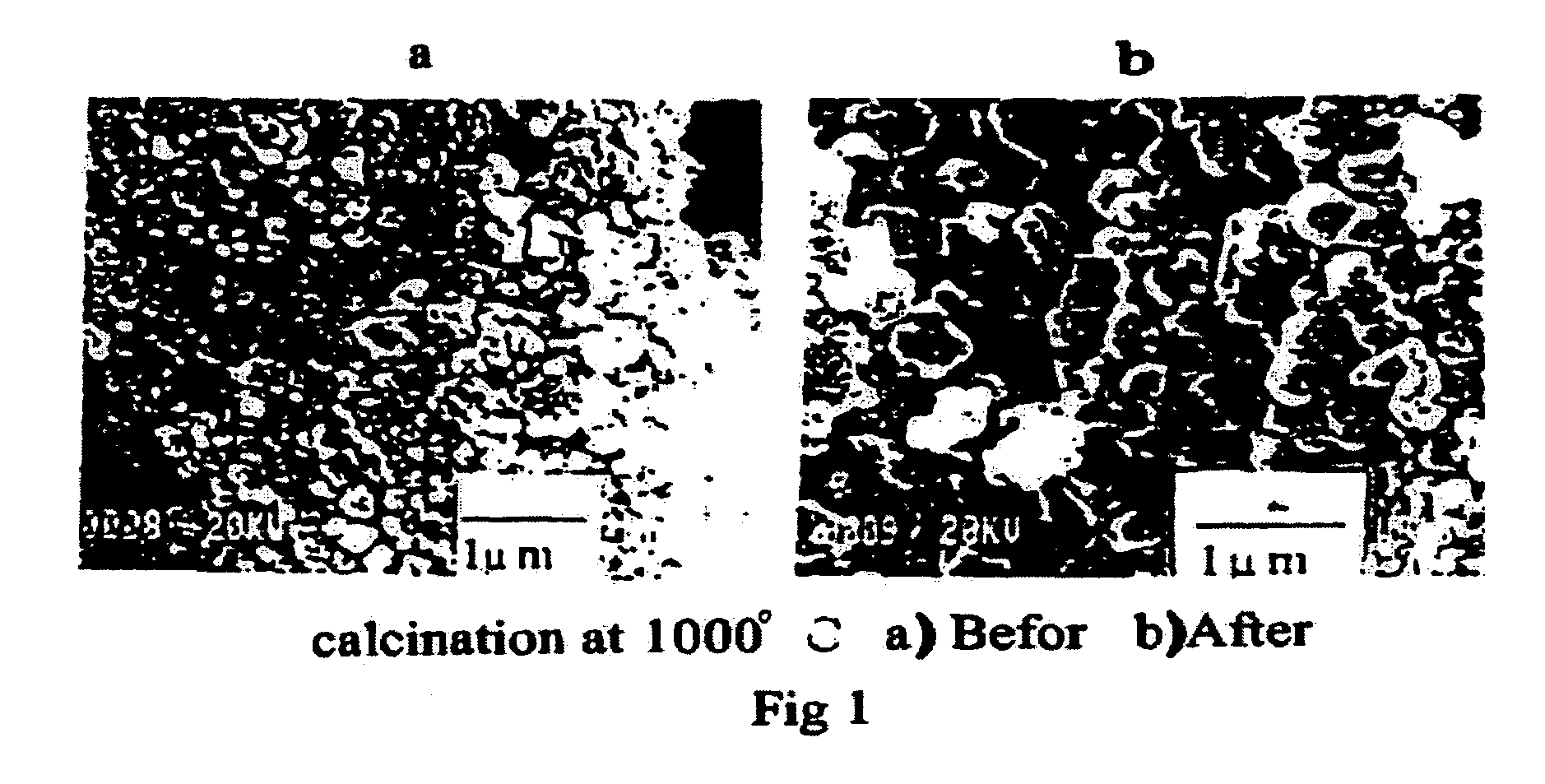

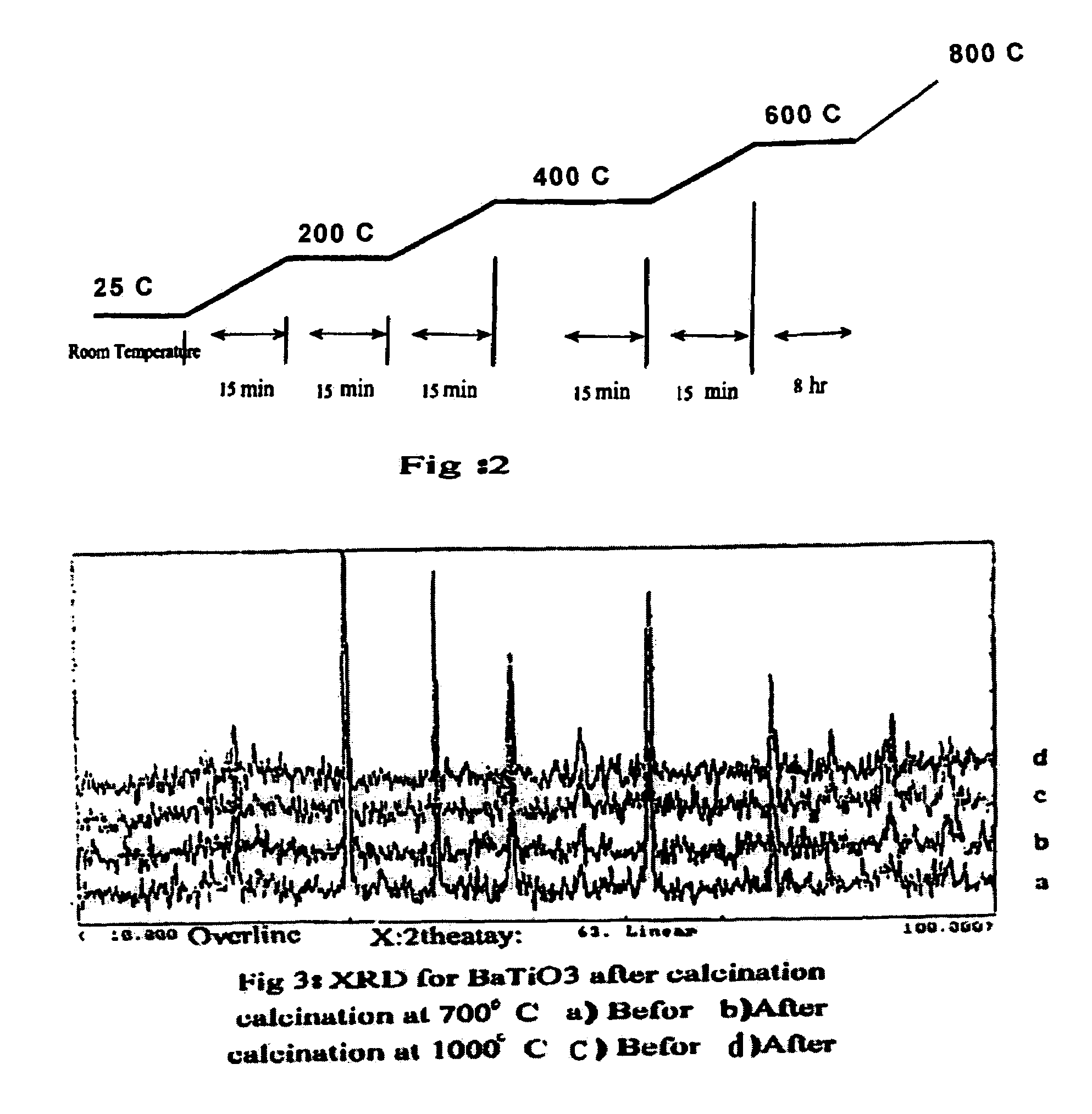

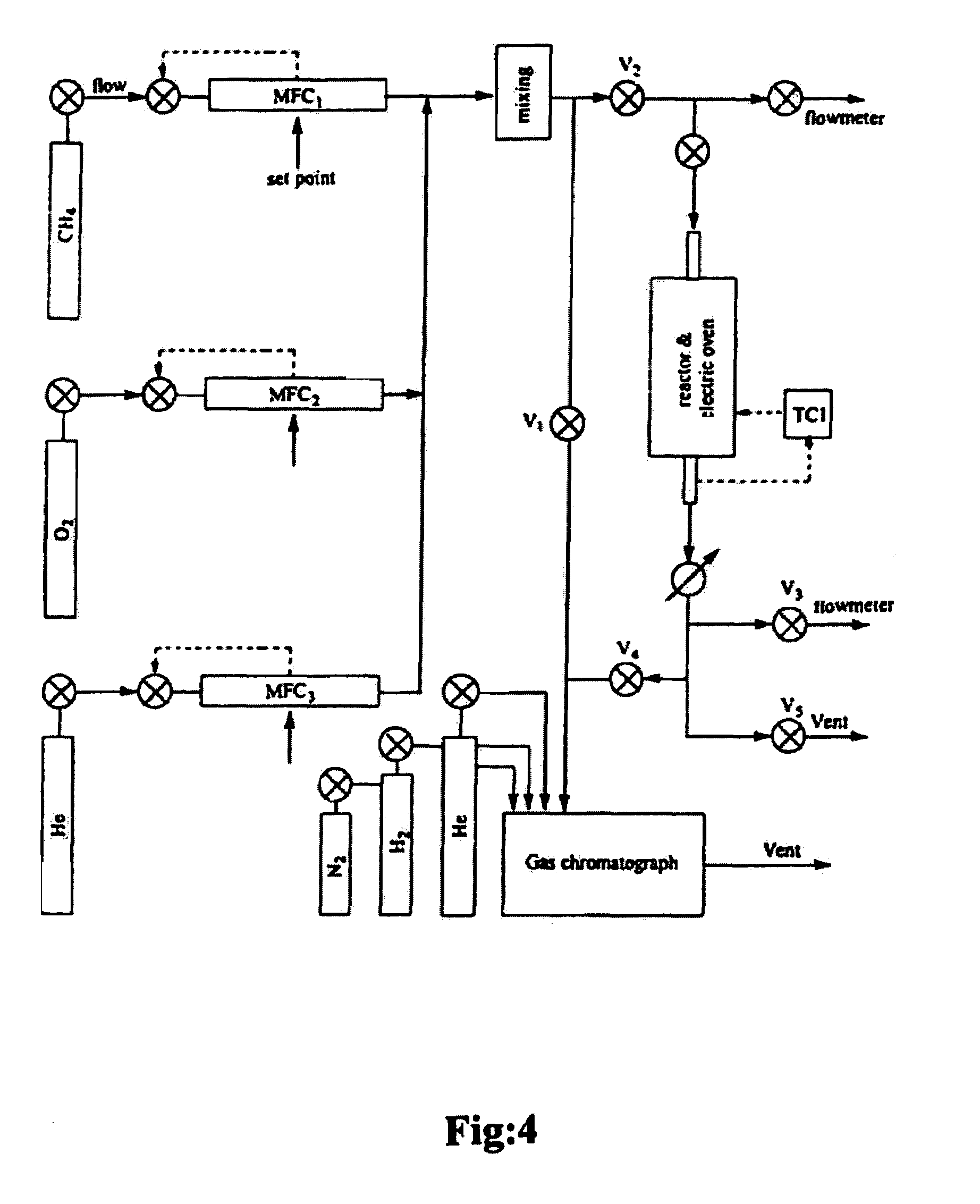

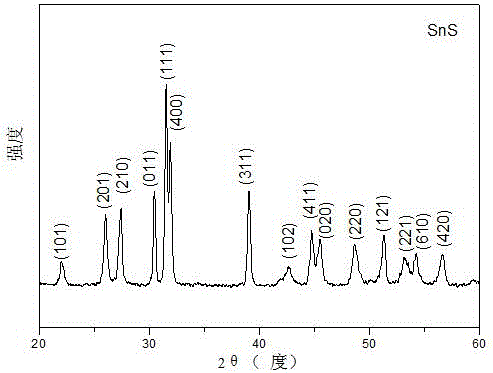

A perovskite catalyst is prepared using a ceramic sol-sol methodology comprising preparing slurry in water of an alkaline earth metal salt, a powdered metal salt and a powdered transition metal oxide, adding a polymeric binder to form a paste, drying and comminuting the paste into a powder and heating the powder with a temperature profile to calcination temperatures. In one embodiment the slurry is formed of titanium oxide with barium carbonate and tin chloride in deionized water, and more specifically by a mixture according to Ba (1-0.05x)+TiO2+SnCl2(0.05x) where x is in moles. The perovskite catalyst is preferably used in a process for oxidative coupling of methane. Catalyst performance is enhanced through the addition of halides to the feed gas in the reaction.

Owner:HRD CORP

Catalyst for preparation of propylene by direct dehydrogenation of propane and preparation method thereof

ActiveCN104248968AHigh activityGood choiceMolecular sieve catalystsHydrocarbonsMolecular sieveAlkaline earth metal

The invention relates to a catalyst for preparation of propylene by direct dehydrogenation of propane; the catalyst comprises a carrier which comprises a mesoporous molecular sieve; an active component supported on the carrier; and an assistant, wherein the active component comprises a platinum group metal, and the assistant comprises a group-IV A metal element and an alkaline earth metal. The invention also provides a preparation method of the catalyst, and the method includes 1) providing the mesoporous molecular sieve as the carrier; 2) impregnating the carrier with ethanol solution of tin chloride to obtain a tin / mesoporous molecular sieve composition; and 3) impregnating the tin / mesoporous molecular sieve composition with a mixed water solution containing platinum and the assistant to obtain the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

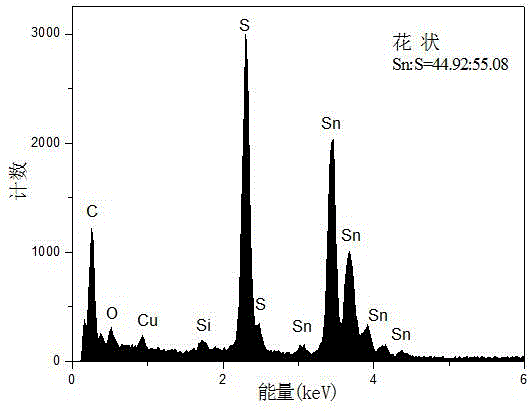

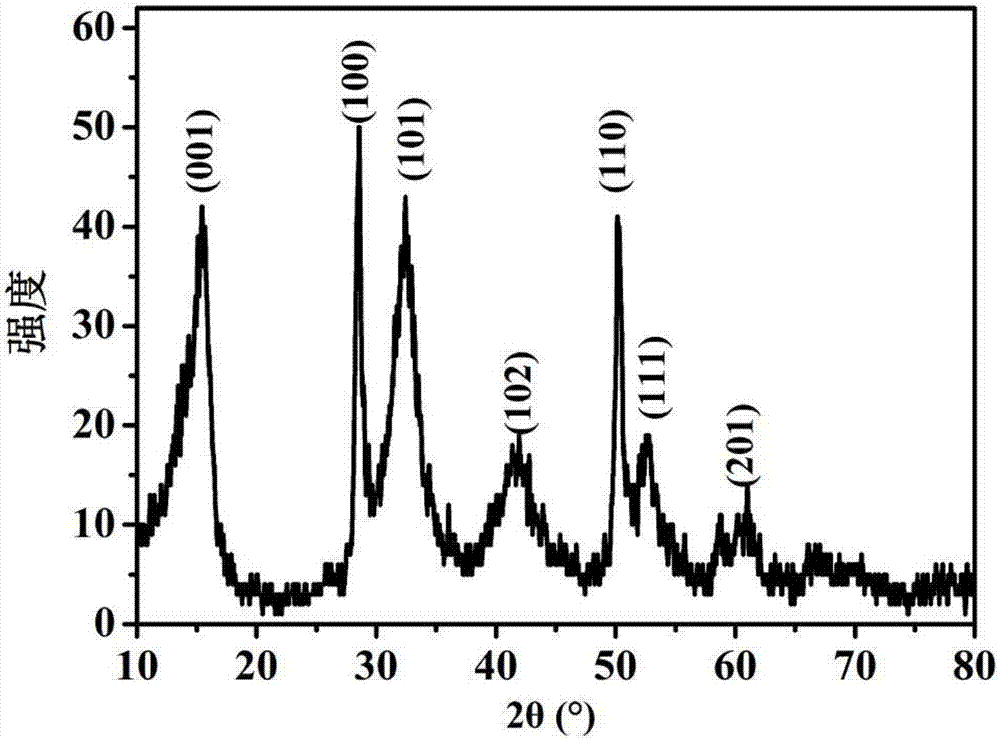

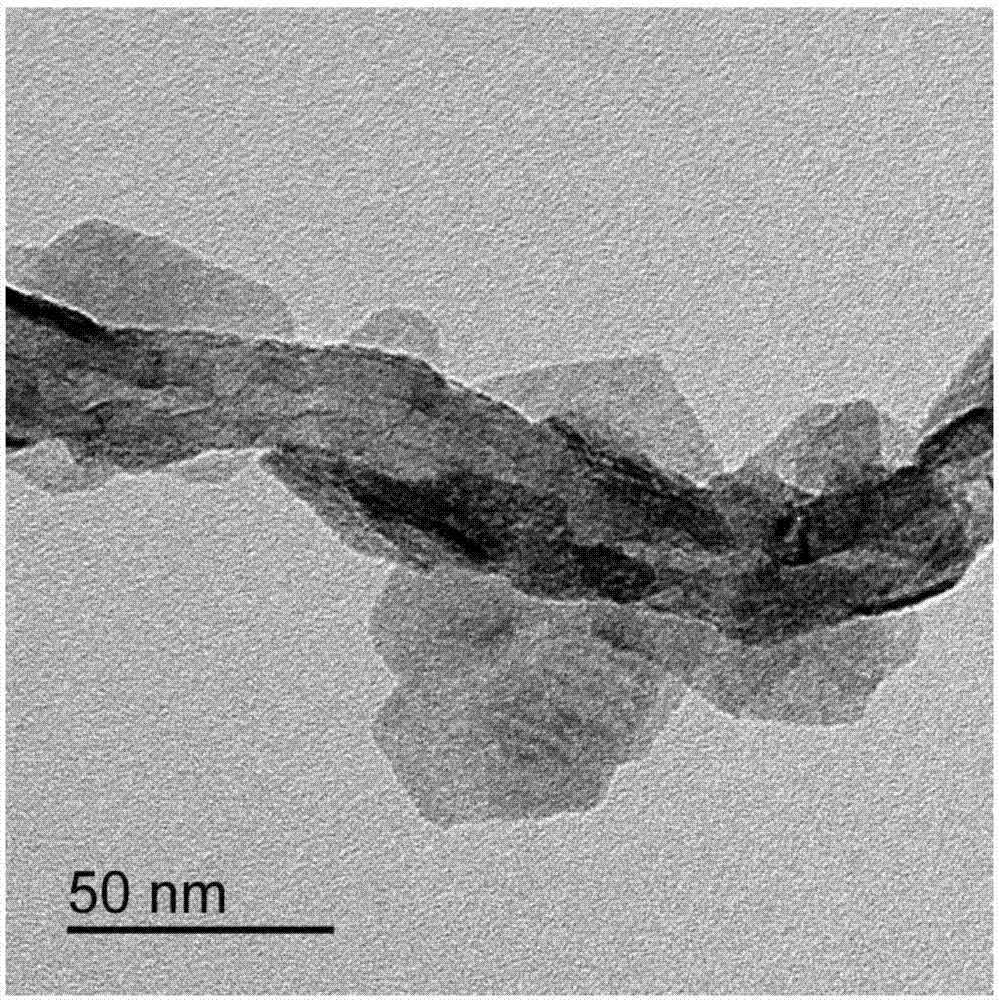

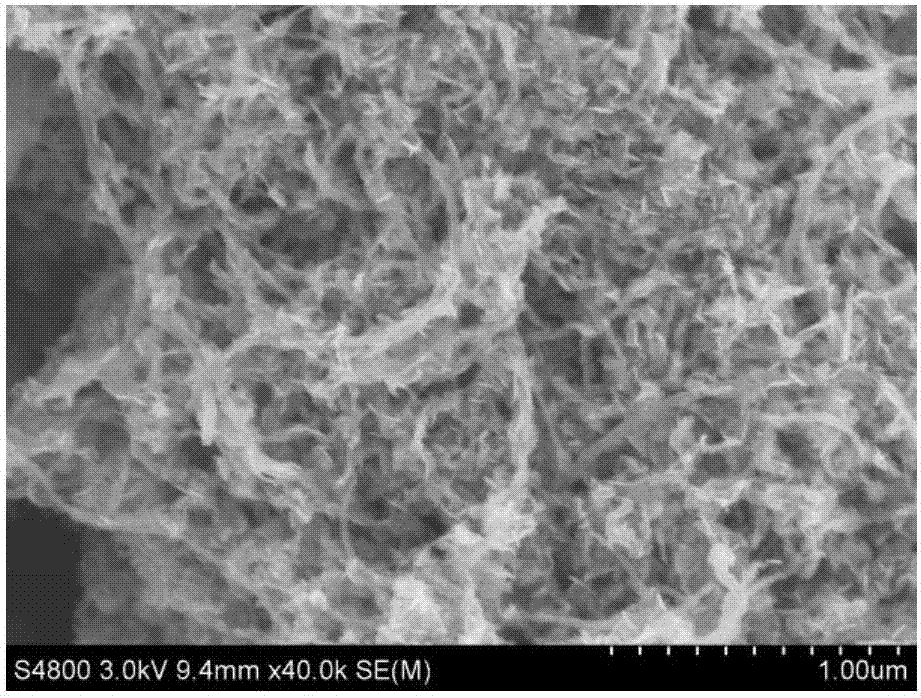

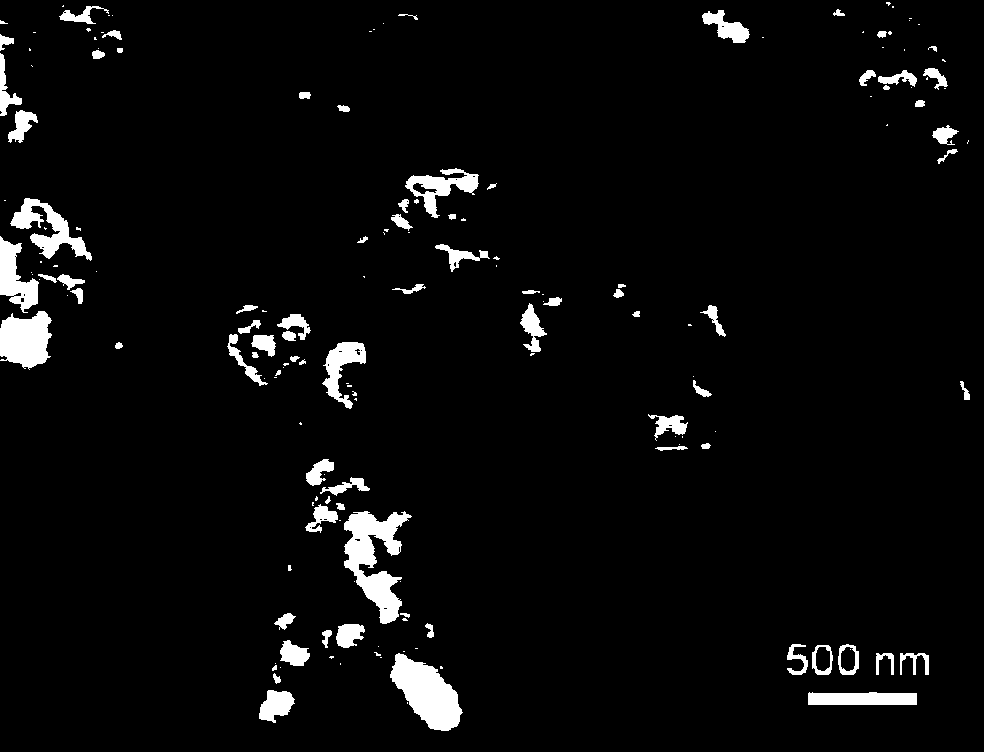

Preparation method and application of tin sulfide material

ActiveCN105800674ASimple methodMild reaction conditionsMaterial nanotechnologyPhysical/chemical process catalystsActive agentReaction temperature

The invention discloses a preparation method of a tin sulfide material. A solvothermal method is adopted, dehydrate-stannous chloride is used as a tin source, the morphology and particle size of the synthetic material are controlled by controlling a sulfur source, the reaction temperature, reaction time, the solvent variety and the surfactant variety, and the SnS photocatalytic material with controllable morphology and high quality is prepared. The method is simple in preparation and easy to carry out, the yield is high, consumed time is short, cost is low, reaction conditions are mild, good development prospects are achieved, industrial production is easy to achieve, and the prepared material has high photocatalytic activity and has good industrial application prospects when serving as the photocatalytic material.

Owner:KUNMING UNIV OF SCI & TECH

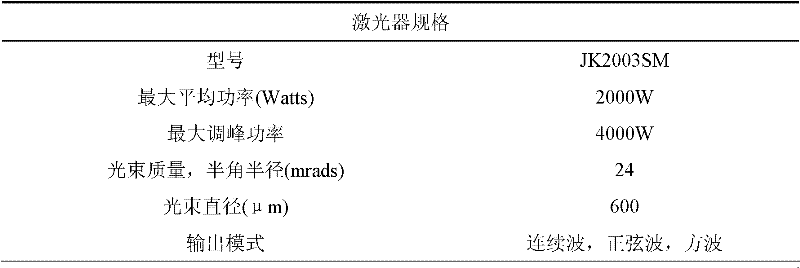

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

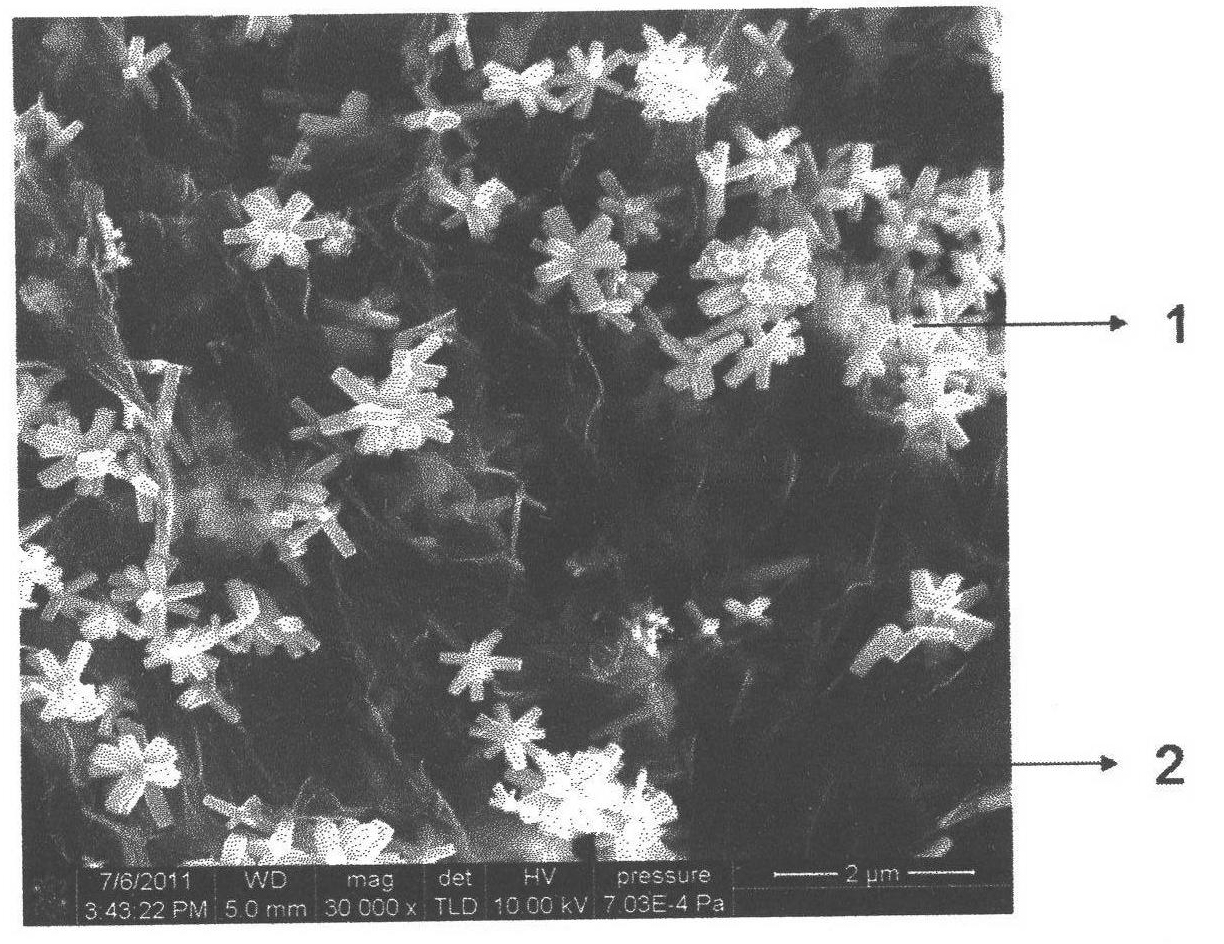

Preparation method of flower-like tin dioxide and graphene composite material

The invention discloses a preparation method of a flower-like tin dioxide and graphene composite material, belonging to the technical field of functional composite materials. According to the preparation method disclosed by the invention, the flower-like tin dioxide and graphene composite material with controllable morphology is prepared from graphene oxide, tin chloride pentahydrate and sodium hydroxide as raw materials by adopting the steps of mixed stirring, hydro-thermal synthesis, solid-liquid separation, cleaning and drying. The method disclosed by the invention has the advantages of simpleness, convenience for operation, lower production cost, no influence on the environment and convenience for popularization and application; and in the method, water is used as solvent and no surfactant is used. The flower-like tin dioxide and graphene composite material prepared by adopting the method can be widely applied to new energy source devices such as a lithium ion battery, a solar cell, a super capacitor and the like, or can be applied to the fields of catalyst carriers, information materials and the like.

Owner:CHONGQING UNIV

Composite copper-based catalyst, preparation method and application thereof in the production of vinyl chloride

ActiveCN109821546AHigh activityImprove stabilityPreparation by halogen halide additionCatalyst activation/preparationCeriumPotassium

The invention provides a composite copper-based catalyst, a preparation method and an application thereof in the production of vinyl chloride. The preparation method of the composite copper-based catalyst includes the following steps: soaking acid-treated activated carbon in a solution containing copper salt and an auxiliary agent, and drying and roasting to obtain the composite copper-based catalyst, wherein the auxiliary agent is one or more of ferric chloride, cerium chloride, tin chloride, barium chloride, manganese chloride, zinc chloride, cobalt chloride, lanthanum chloride, nickel chloride, bismuth chloride and potassium chloride; and the mass ratio of the acid-treated activated carbon, the copper salt and the auxiliary agent is 100: 5: 1-100: 10: 5. The catalyst is environment-friendly, low in cost, simple in process and short in production period. The catalyst shows high activity, selectivity and good stability in the reaction of hydrochlorination of acetylene to produce the vinyl chloride, and is expected to be a good substitute for a mercury catalyst.

Owner:鄂尔多斯市瀚博科技有限公司

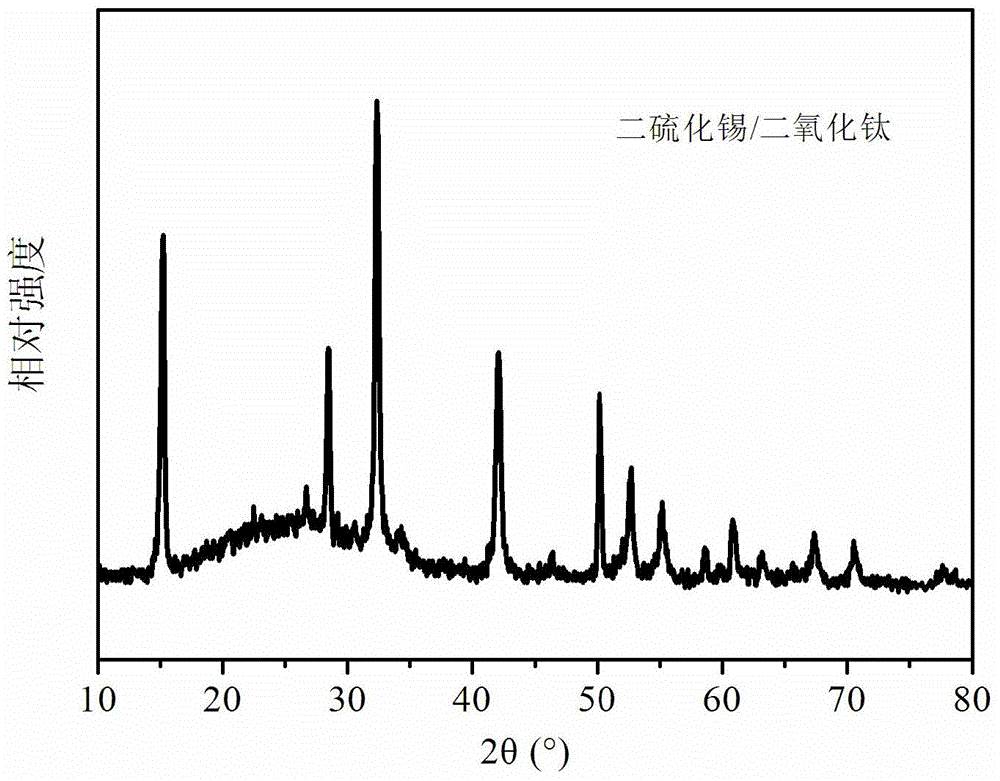

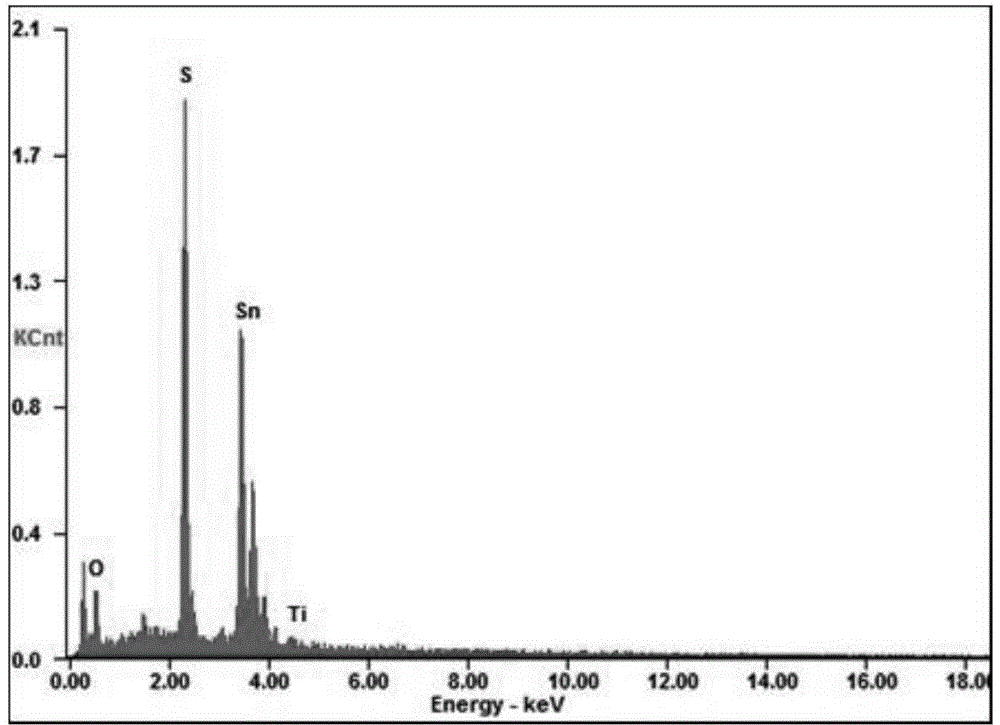

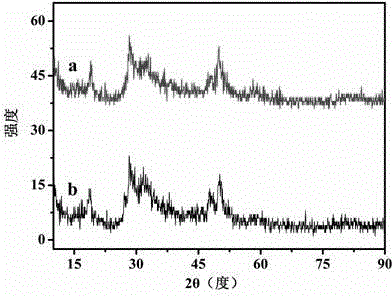

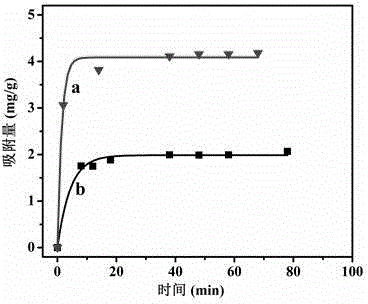

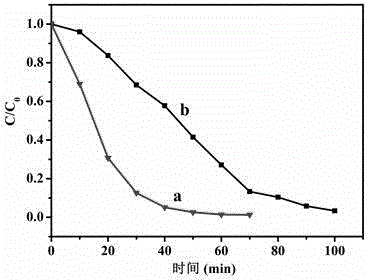

Tin disulfide/titanium dioxide compound photocatalyst and preparation method thereof

ActiveCN104888753AUniform sizeRegular shapeMaterial nanotechnologyWater/sewage treatment by irradiationThioureaPotassium dichromate

The invention discloses a tin disulfide / titanium dioxide compound photocatalyst which is prepared from a precursor solution through hydrothermal reaction, wherein the precursor solution is prepared from tin disulfide powder and butyl titanate in the mass ratio of 1:(20-100). The compound photocatalyst has controllable size, tin disulfide is of a hexagonal nanoscale flake shape, titanium dioxide nano-particles are uniformly loaded on tin disulfide, and the photocatalyst material has high photocatalytic reduction efficiency on potassium dichromate in a water body. The invention also discloses a preparation method of the compound photocatalyst. The preparation method comprises the following steps: a. preparing tin disulfide powder from tin chloride pentahydrate and thiourea; b. mixing the tin disulfide powder and butyl titanate to prepare the precursor solution; and c. hydrothermally heating the prepared precursor solution to prepare the compound photocatalyst. The preparation steps are simplified greatly, the control difficulty of technological parameters is lowered, and the large-scale preparation of the tin disulfide / titanium dioxide compound photocatalyst is realized.

Owner:澄城县海泰电子材料有限责任公司

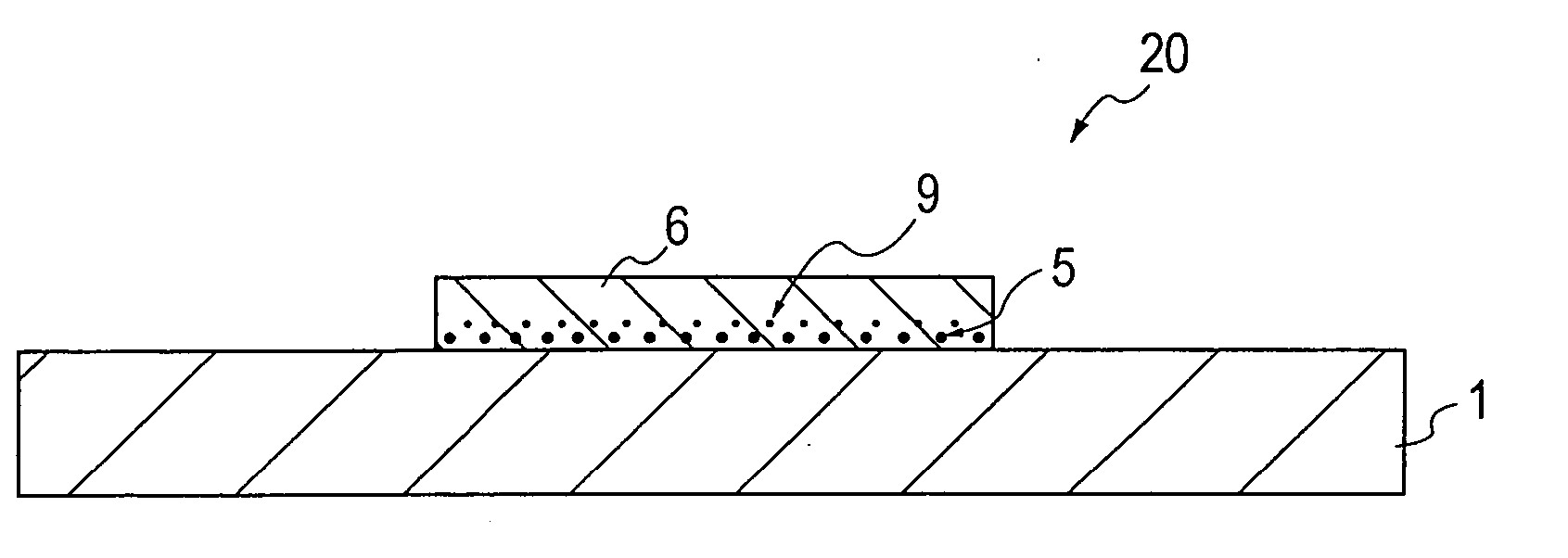

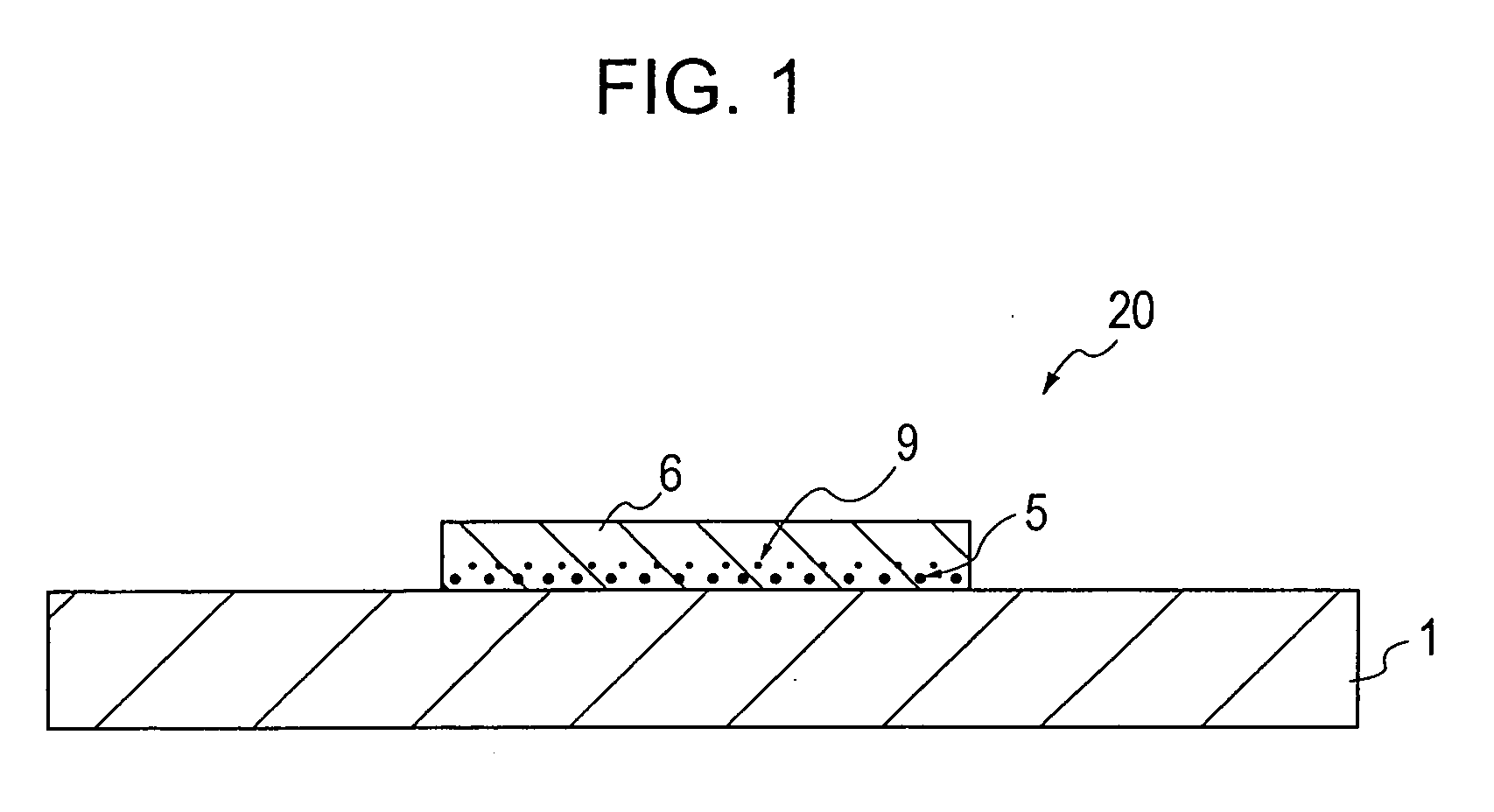

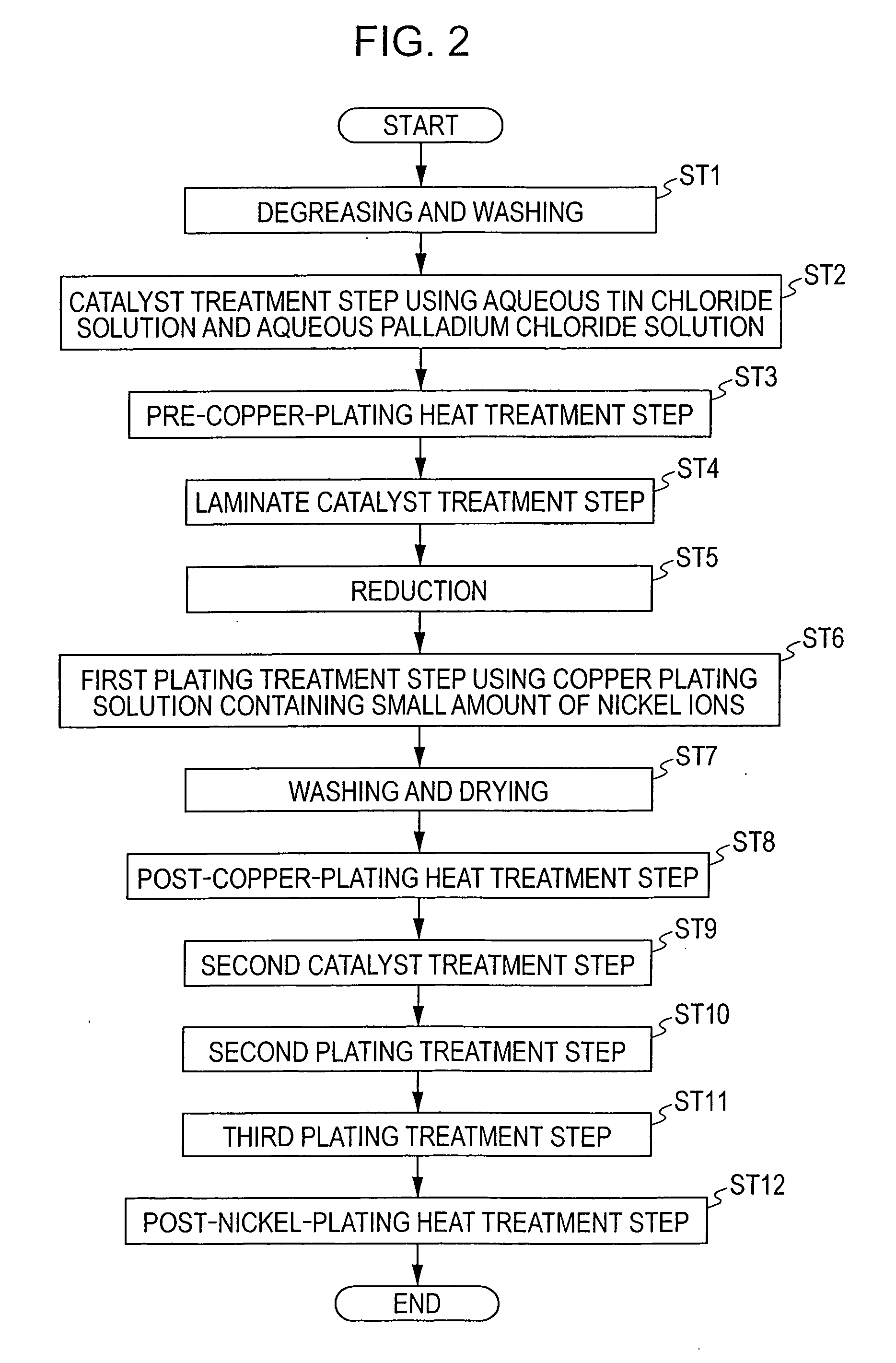

Plating substrate, electroless plating method, and circuit forming method using the same

InactiveUS20060088705A1Maintain good propertiesPretreated surfacesLiquid/solution decomposition chemical coatingVitrificationCopper plating

An electroless copper plating method is provided having a first catalyst step of forming a first catalyst layer on a ceramic base material containing a glass component using a tin chloride solution and a palladium chloride solution; a pre-copper-plating heat treatment step of heating the ceramic base material in an atmosphere containing oxygen; a laminate catalyst treatment step of forming a laminate catalyst layer on the ceramic base material using a tin chloride solution and a palladium chloride solution; a plating treatment step of forming a copper plating film on the ceramic base material using a copper plating solution containing a small amount of nickel ions; and a post-copper-plating heat treatment step of heating the ceramic base material at a heat treatment temperature not more than the glass transition temperature thereof.

Owner:ALPS ALPINE CO LTD

Environmentally-friendly cable filling material and preparation method thereof

ActiveCN103351548AHigh volume resistivityHigh temperature resistantPlastic/resin/waxes insulatorsLow-density polyethyleneWear resistant

The invention provides an environmentally-friendly cable filling material and a preparation method thereof. The material is characterized by comprising the following raw materials by weight parts: 55-59 parts of SG-4PVC resin, 21-24 parts of metallocene linear low-density polyethylene, 3-4 parts of Mo2B5, 4-5 parts of hafnium diboride, 12-14 parts of polyphenylene thioether, 4-6 parts of poly-4-methyl-1-pentene, 32-36 parts of bentonite, 12-14 parts of alumina, 21-24 parts of barium sulfate, 2-3 parts of zinc oxide, 1-2 parts of an accelerator TMTM, 2-3 parts of bis-tetradecene alcohol ester, 2-3 parts of a silane coupling agent KH 550, 1-2 parts of a cross-linking agent TAC, 4-6 parts of epoxy tetrahydro dicapryl phthalate, 1-2 parts of tributyl tin chloride, 10-12 parts of carbon black N 660, 14-17 parts of precipitated silica, and 6-8 parts of modified diatomite. The cable filling material provided by the invention is high in volume resistivity, high temperature resistant, good in insulating property, relatively good in electrical property and good in wear-resistant property.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

Preparation method of tin dioxide/bismuth tungstate composite photocatalyst

InactiveCN102489293AImprove catalytic performanceEasy to prepareBiocideDisinfectantsTin dioxideTungstate

The invention discloses a preparation method of a tin dioxide / bismuth tungstate composite photocatalyst. The composite photocatalyst is powder containing tin dioxide and bismuth tungstate, wherein the molar ratio of tin dioxide to bismuth tungstate is 1:2-20. The preparation method of the composite photocatalyst comprises the following steps: 1, mixing a nitric acid solution of bismuth nitrate pentahydrate, a sodium hydroxide solution of ammonium tungstate and a tin chloride pentahydrate solution; and 2, preparing the tin dioxide / bismuth tungstate composite photocatalyst by adopting a microwave-assisted heating hydrothermal method. The preparation method of the invention has the advantages of simplicity and low cost; and the prepared composite photocatalyst which has excellent catalytic performances can decompose harmful chemical substances and organic biomasses and has a sterilization effect under the irradiation of visible lights.

Owner:SHAANXI UNIV OF SCI & TECH

Analysis method for phosphor in high temperature alloy

InactiveCN1880946AEliminate the effects ofAnalytical results are reliableMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationDielectricFluohydric acid

The invention discloses a phosphor analyzing method in the high-temperature alloy, which is characterized by the following: heating to dissolve sample through compound acid such as azotic acid and hydrochloric acid or azotic acid, hydrochloric acid and hydrofluoric acid (or microwave sample-fusing furnace); adding perchloric acid to heat until smoke; dripping hydrochloric acid to remove chromium; adding complex citrate in the alkali dielectric; adding complex niobium, tantalum, zirconium, hafnium, titanium, vanadium, tungsten fluohydric acid in the azotic acid dielectric; extracting phosphor through butanol-chloroform composite agent and ammonium molybdate; reextracting organic phase through hydrochloric solution of tin chloride; testing absorbance of water phase at 680nm. The invention eliminates influence of high-content interference element, whose result is accurate and reliable with testing greatest lower limit as 0.0002%(m / m).

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

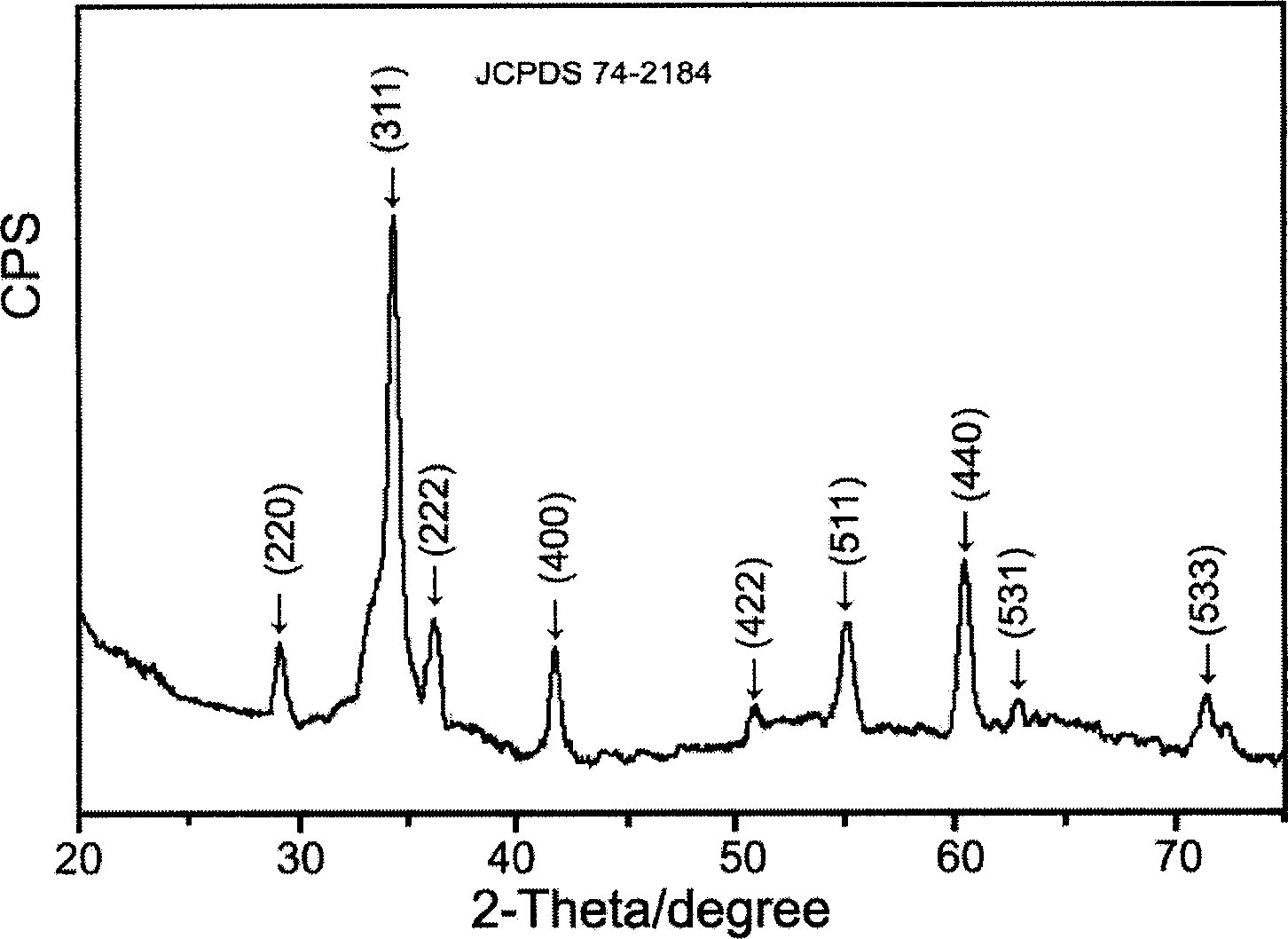

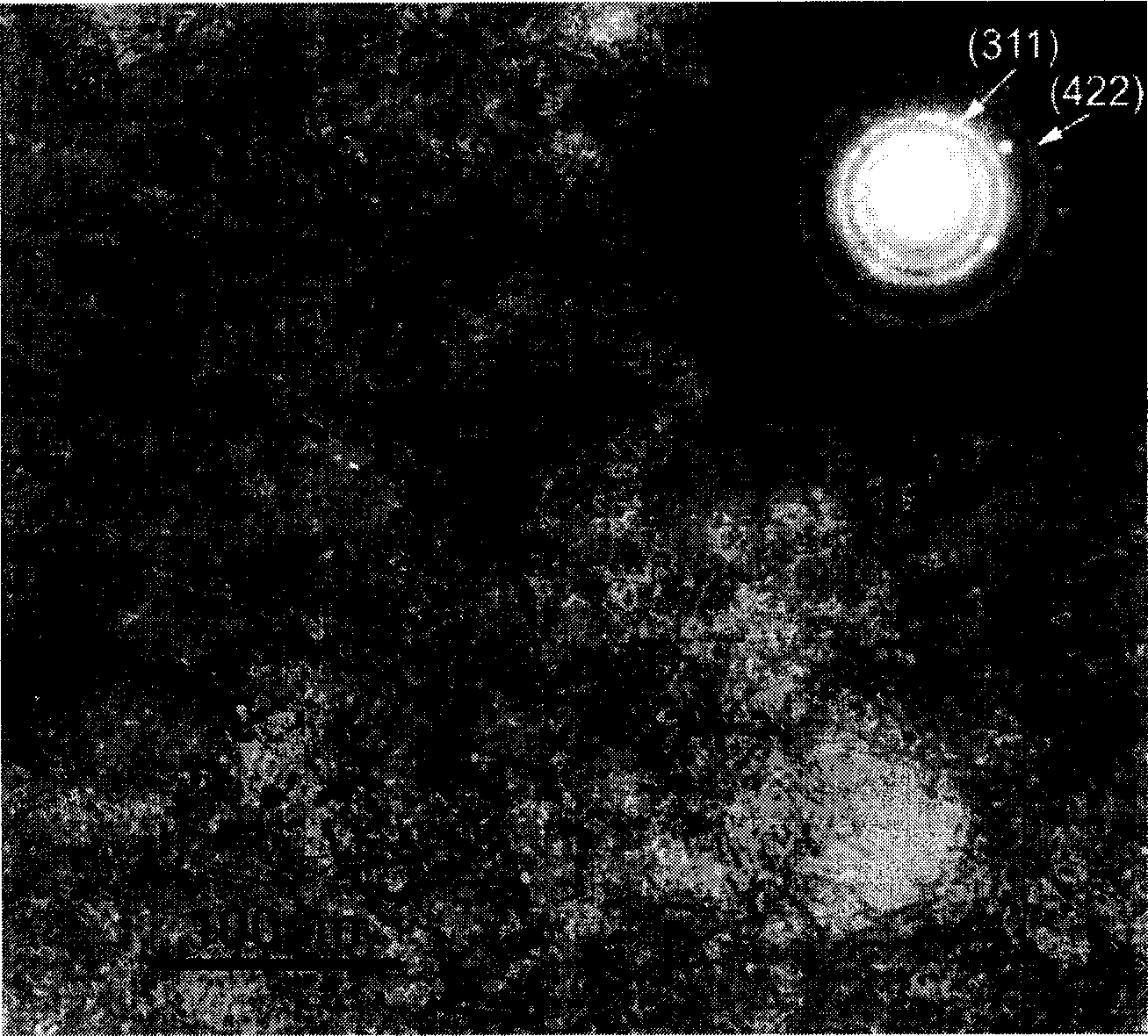

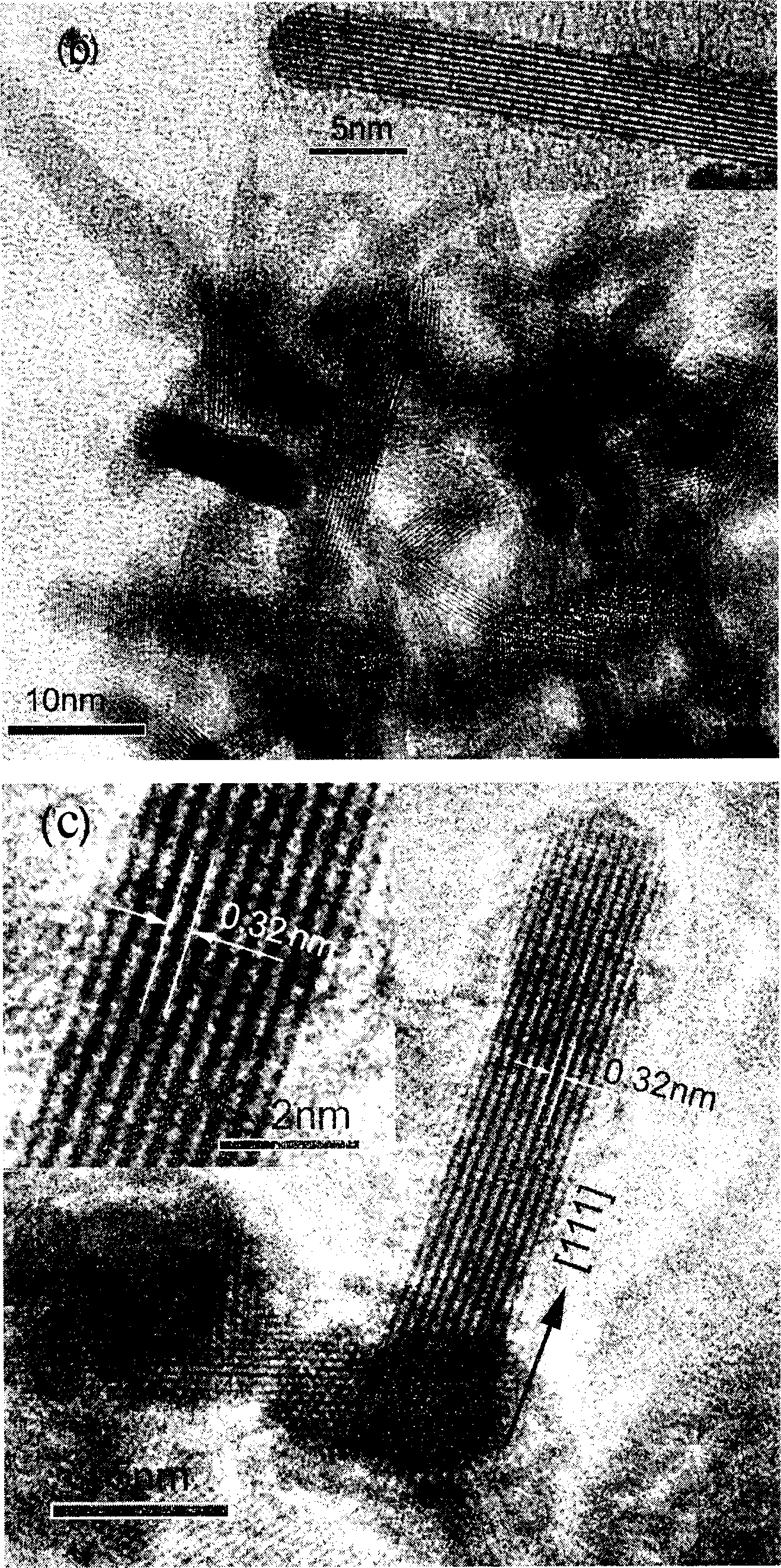

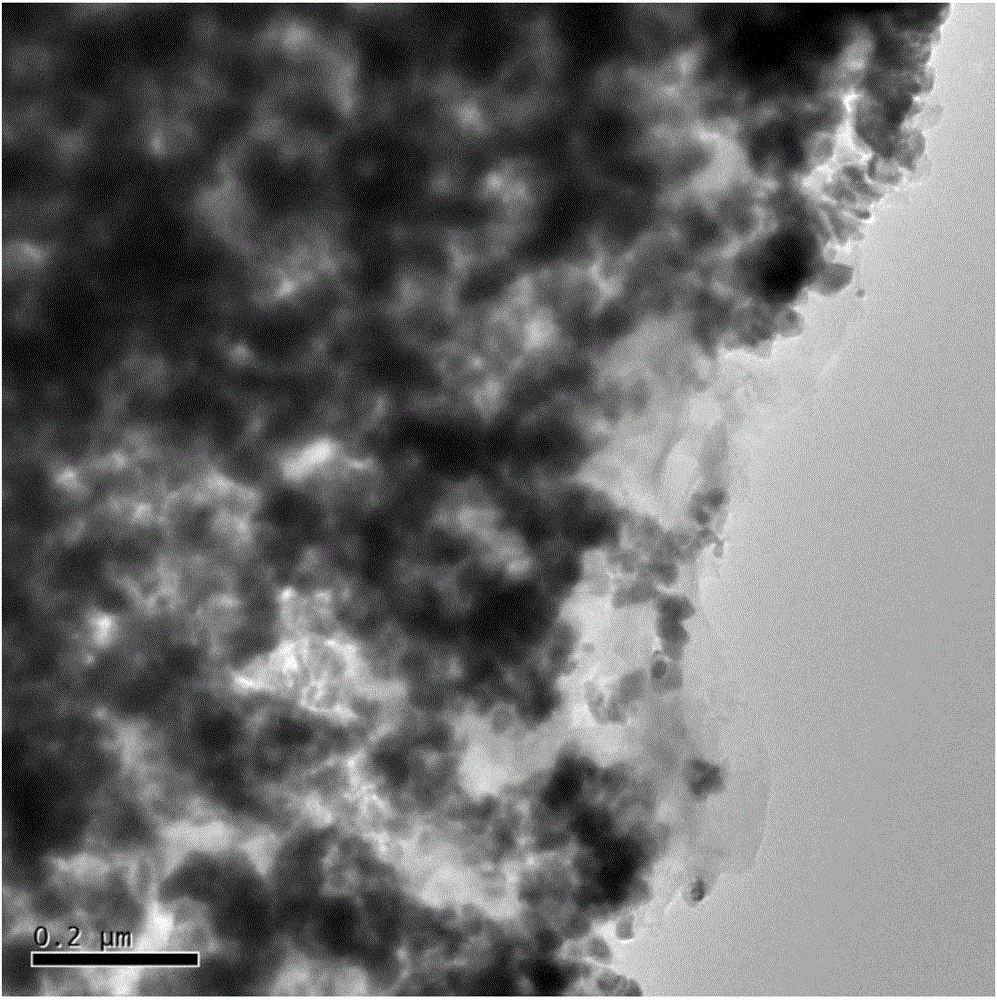

Process for synthesizing spinel zine stannate nano rod

InactiveCN1792812AEasy to controlAchieve synthesisNanostructure manufactureTin compoundsSal ammoniacHydrazine compound

Owner:ZHEJIANG SCI-TECH UNIV

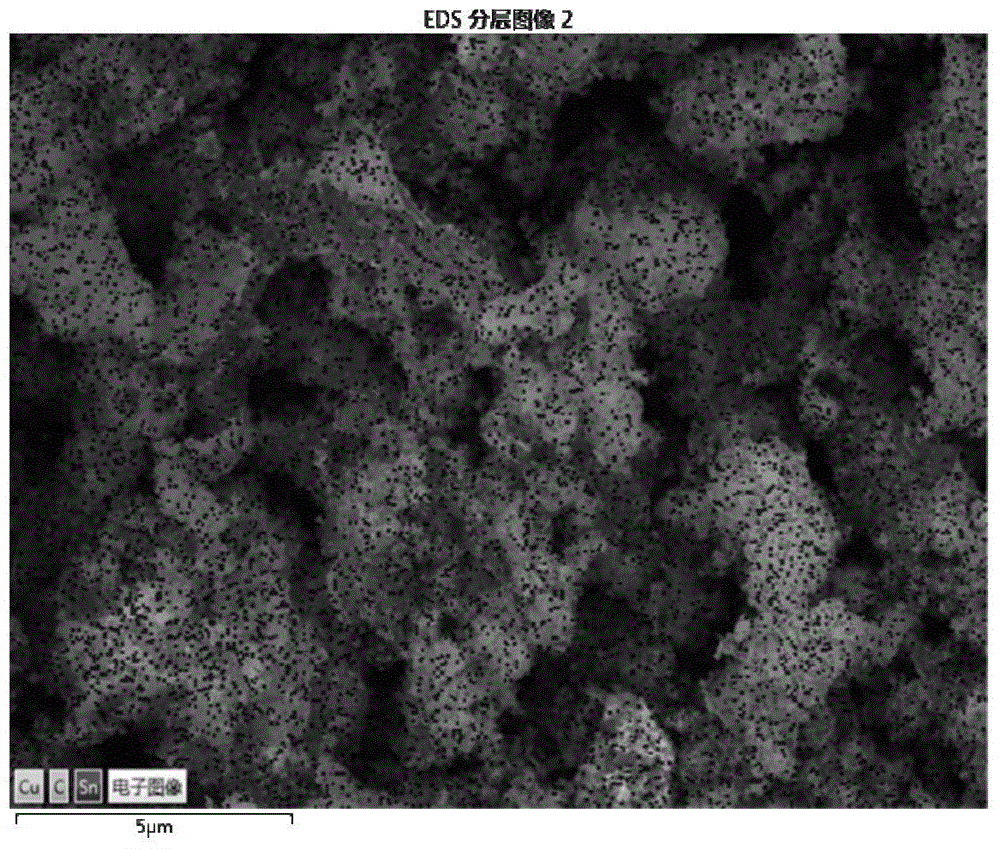

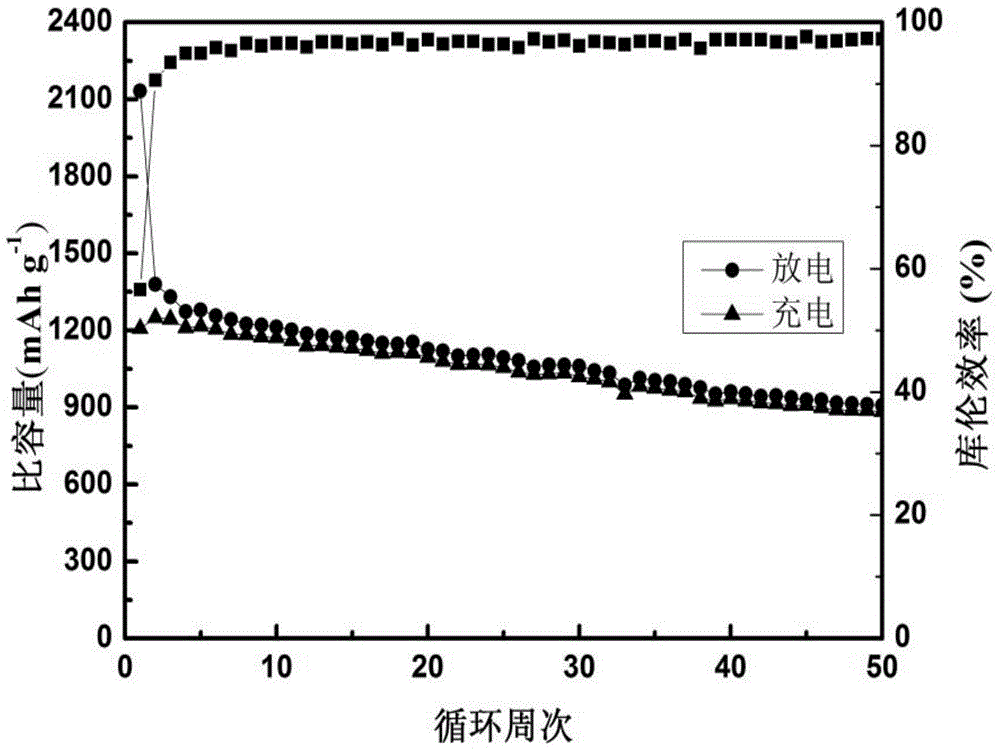

Tin oxide and porous carbon composite lithium ion battery anode materials

Disclosed is a production method of tin oxide and porous carbon composite lithium ion battery anode materials. The production method comprises the following steps of step 1, producing HKUST-1; step 2, activating HKUST-1, removing an organic solvent, adding a tin chloride solution by an injection method under the condition that the air is isolated and fully impregnating a pore passage, wherein the pore passage is occupied by the organic solvent; step 3, removing the solvent to obtain a precursor, performing 600 DEG C of firing of a muffle furnace under the protection of the argon gas, performing trimesic acid ligand carbonization, performing copper and tin reduction and alloying and obtaining a high dispersion of copper and tin alloy and carbon compound; step 4, selectively removing copper through nitric acid, converting tin oxide into tin dioxide to be stored in the pore passage in the form of nanocrystallization and obtaining the high performance composite materials. The tin oxide and porous carbon composite materials produced by the production method are firm in compositing, simple in operation and uniform in product; the tin oxide and porous carbon composite materials are large in capacity, high in current density, high in coulomb efficiency and high in rate performance current density when being applied to the lithium ion battery anode materials; the mass production can be achieved and the production cost is low.

Owner:NANKAI UNIV

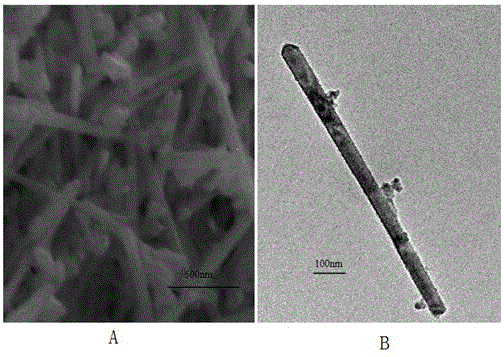

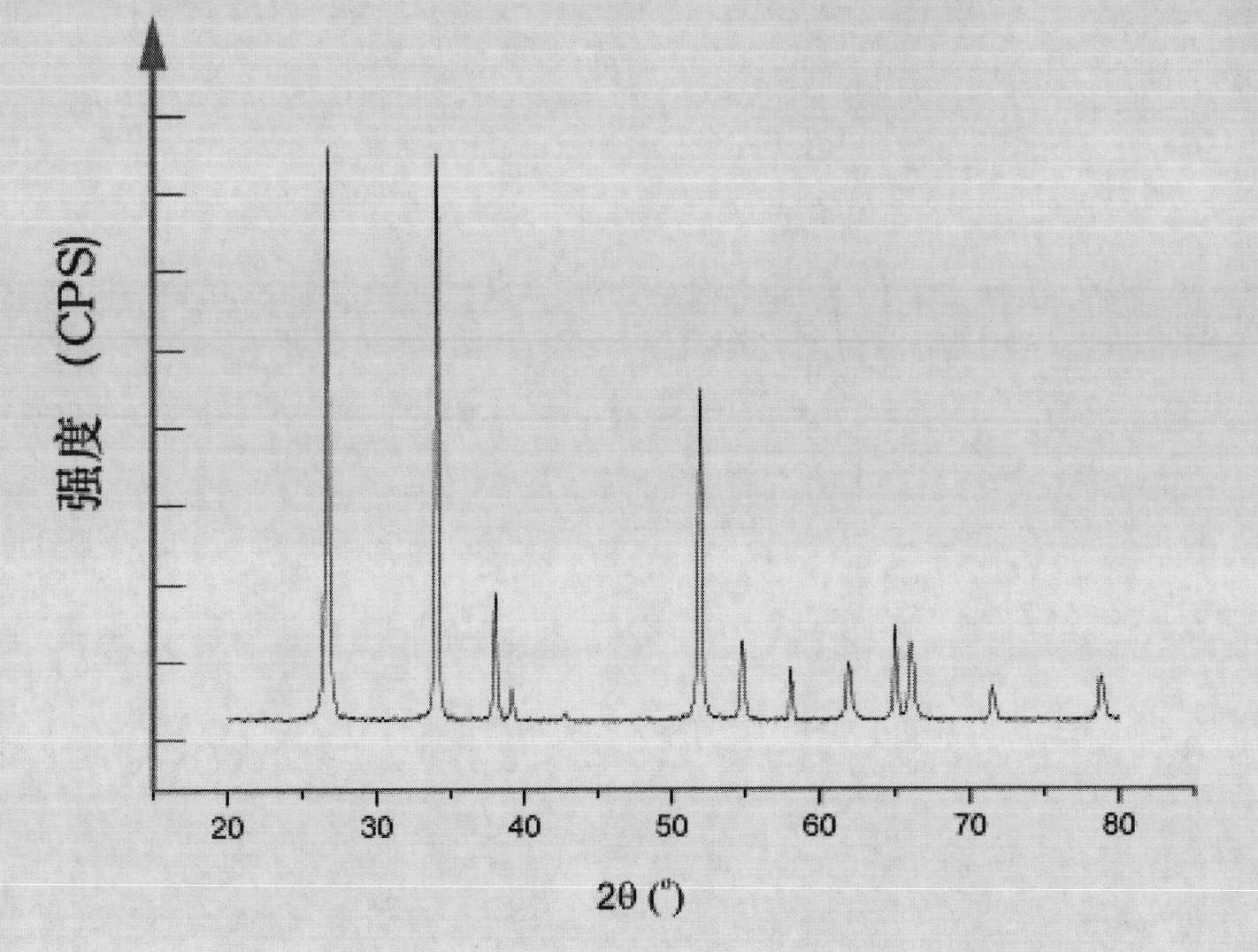

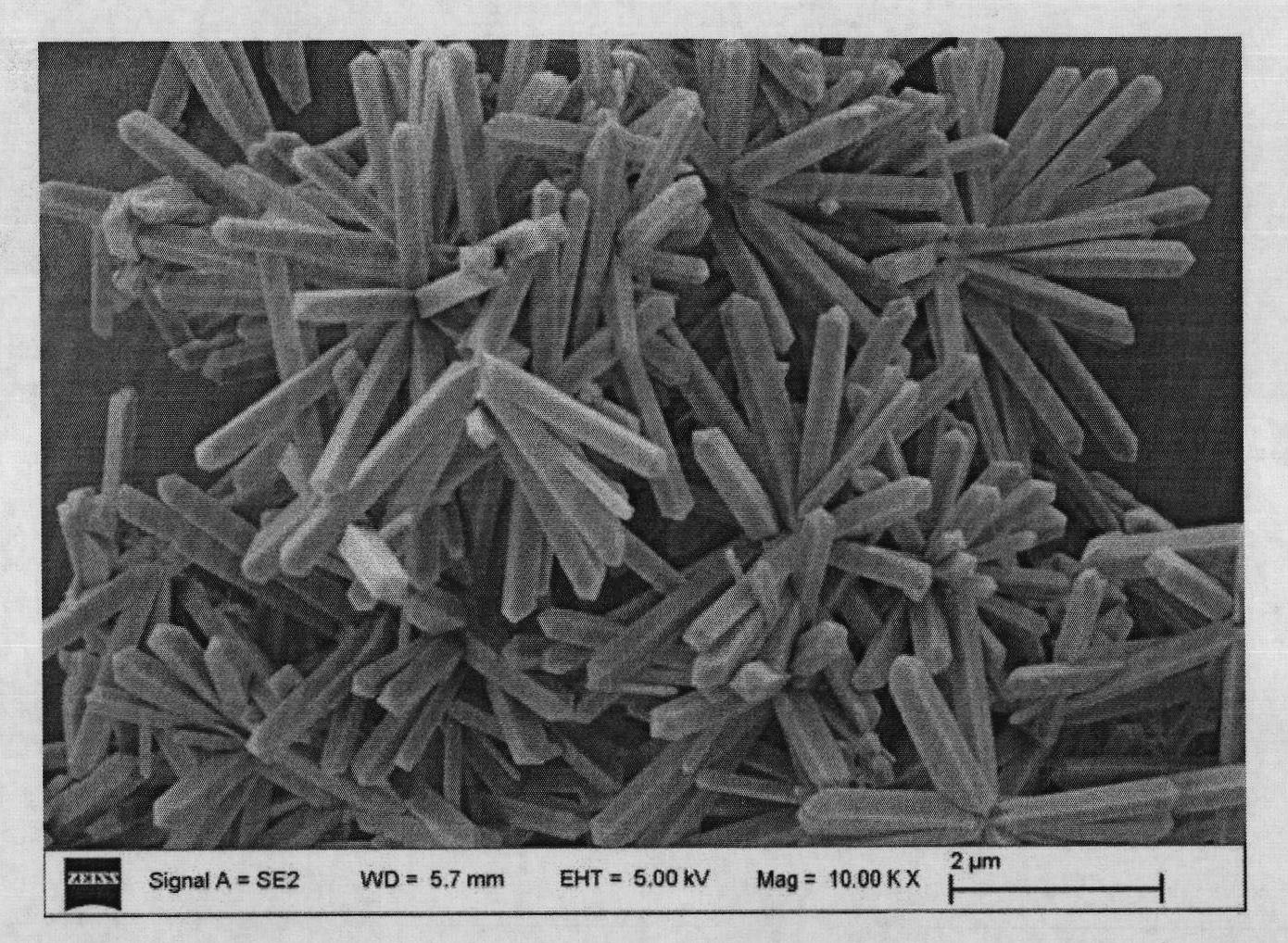

Tin oxide nanomaterial and preparation method thereof

The invention provides a tin oxide nanomaterial and a preparation method thereof. One-dimensional tin oxide nanomaterial with high crystallization degree and good appearance is successfully prepared by performing solvothermal synthesis on tin chloride and alkali serving as raw materials in solution of ethanol, wherein the diameter of the one-dimensional tin oxide nanomaterial is 50 to 300nm and the length is 1 to 8 mu m. Compared with the conventional method for preparing the one-dimensional tin oxide nanomaterial, the method adopted by the invention has the advantages of good appearance of the product, high crystallization degree of crystals, low industrialization cost, simple operation and high product yield. The prepared tin oxide nanomaterial has high gas sensitivity to carbon monoxide gas and is a good gas-sensitive material.

Owner:BEIJING UNIV OF CHEM TECH

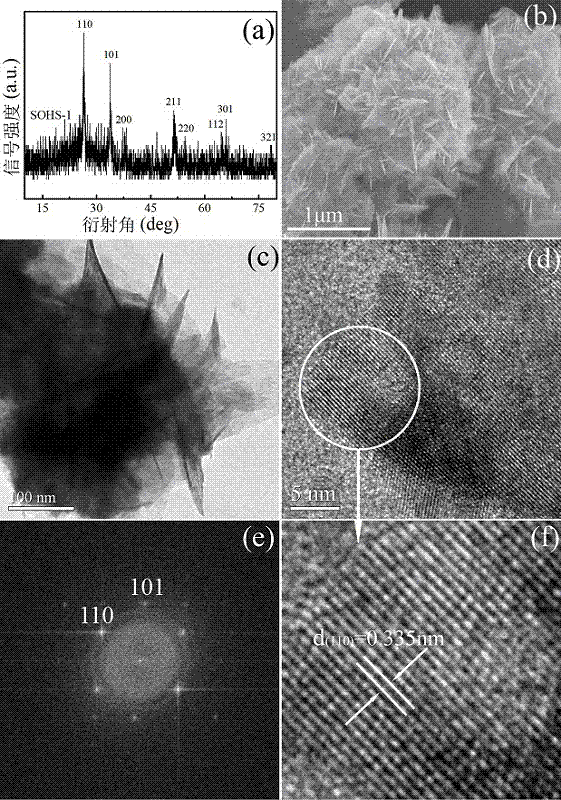

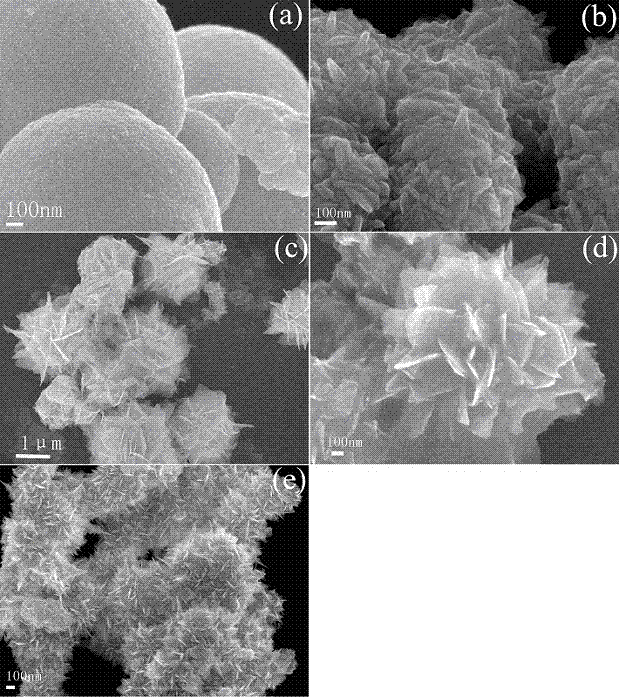

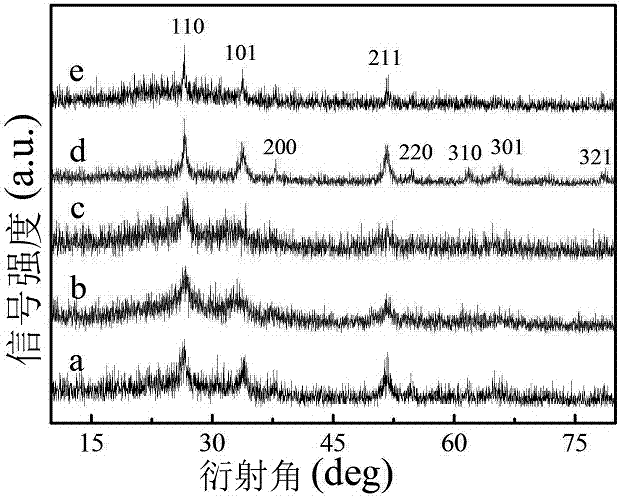

Preparation method of three-dimensional layered multilevel flower-shaped stannic oxide microsphere

The invention discloses a preparation method of a three-dimensional layered multilevel flower-shaped stannic oxide microsphere, belonging to the field of material preparation processes. The preparation method comprises the steps: adding tin dichloride dihydrate powder in a mixed solution of alcohol and water (volume ratio of 1:1), through controlling a concentration and a temperature of tin ions and an amount of urea, and preparing stannic oxide materials of different morphologies, with a three-dimensional multilevel layered structure, under a hydrothermal condition. Researches on the prepared materials prove that the urea is an important influence factor of controlling the three-dimensional multilevel layered structure of stannic oxide, and an oxidation function is a key factor of forming a nanometer sheet. According to the preparation method, the reaction cost can be reduced, the production efficiency of the stannic oxide nano material is increased; and the prepared nano material is controllable in morphology, and has the advantages of high purity, high performance, large specific surface area, and the like, and can be widely applied to new energy devices such as a lithium ion battery, a solar energy battery, a supercapacitor, and can also be applicable to the fields of a catalyst carrier and an information material. Any surfactant or template is needed for assistance, no toxic and harmful organic solvent is used, and used raw materials are low in price and easy to obtain, thus the preparation method is an environment-friendly preparation method.

Owner:SHANGHAI UNIV

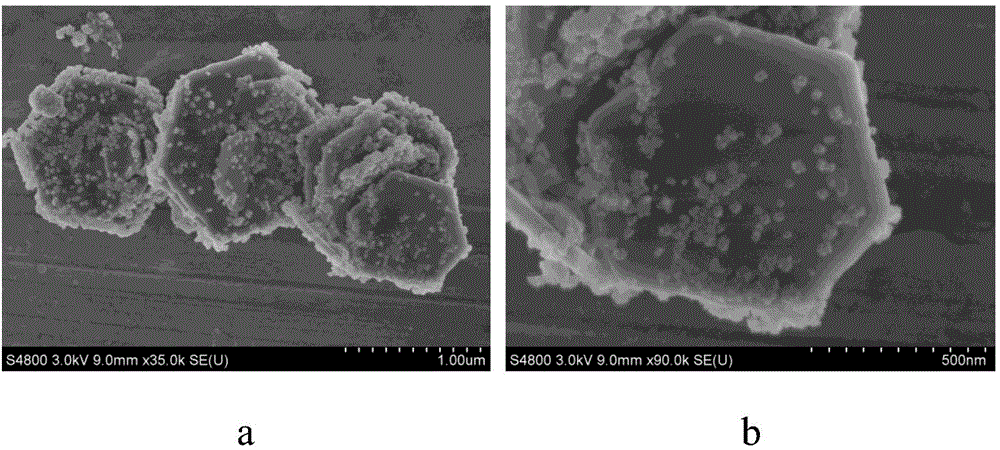

Antimony-doped tin oxide cladding titanium dioxide composite conductive material and preparation method

InactiveCN103985430AUniform compositionHigh purityConductive layers on insulating-supportsOxide conductorsTin dioxideDispersity

The invention discloses an antimony-doped tin oxide cladding titanium dioxide composite conductive material and a preparation method of the antimony-doped tin oxide cladding titanium dioxide composite conductive material. The antimony-doped tin oxide cladding titanium dioxide composite conductive material is composed of antimony-doped tin oxide cladding and titanium dioxide, wherein the percentage composition ratio of the molar content of the antimony-doped tin oxide in the cladding to the molar content of the titanium dioxide is 0.3-0.9:1. The preparation method comprises the following steps that the titanium dioxide is added into deionized water, so that suspension liquid 1 with the molar concentration of 10-20% is prepared; crystal tin chloride and antimony butter are added into a hydrochloric acid solution, so that a solution 2 is prepared; sodium hydroxide is added into deionized water, so that a solution 3 is prepared; the suspension liquid 1, the solution 2 and the solution 3 are mixed, centrifugation, washing, drying and calcinations are conducted on the mixed solution after aging, and the composite conductive material is obtained. The antimony-doped tin oxide cladding titanium dioxide composite conductive material and the preparation method of the antimony-doped tin oxide cladding titanium dioxide composite conductive material have the advantages that the composite conductive material prepared through a coprecipitation method is simple in synthetic process, the prepared powder is uniform in composition, high in purity and controllable in stoichiometric ratio, and prepared conduvtive power materials are high in purity, light in color, small in grain size and good in dispersity.

Owner:TIANJIN UNIV

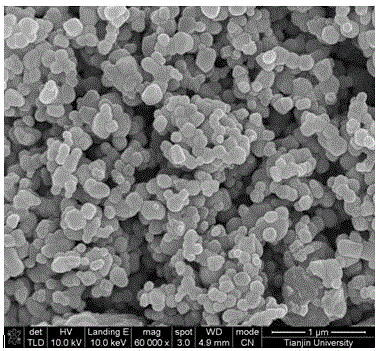

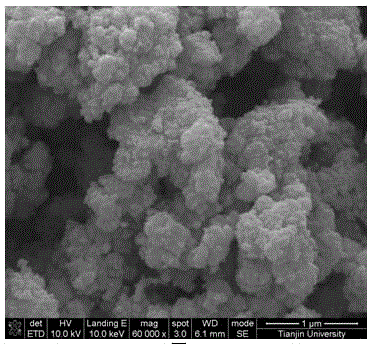

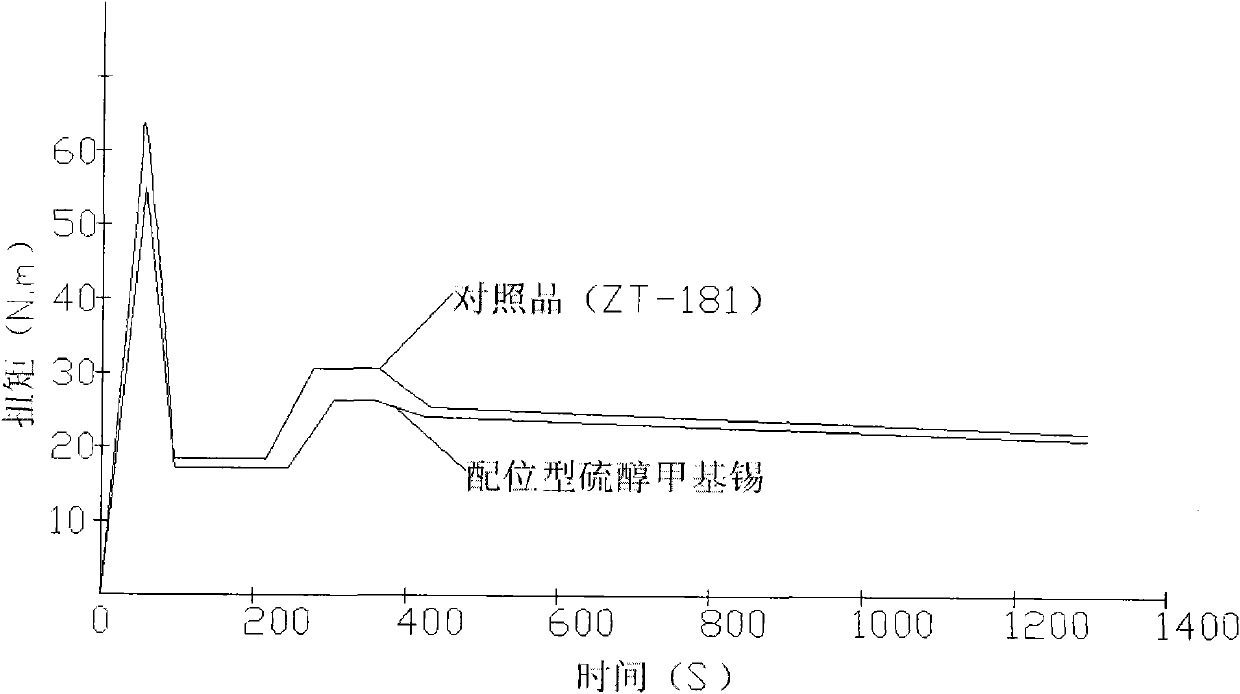

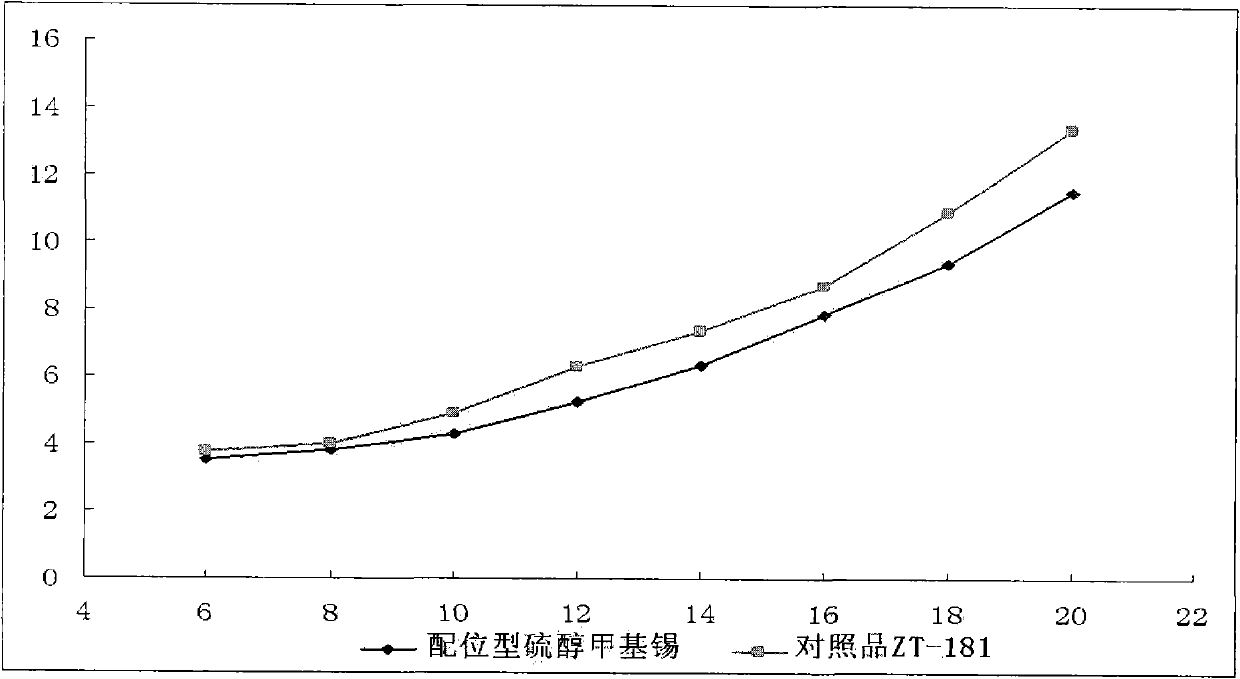

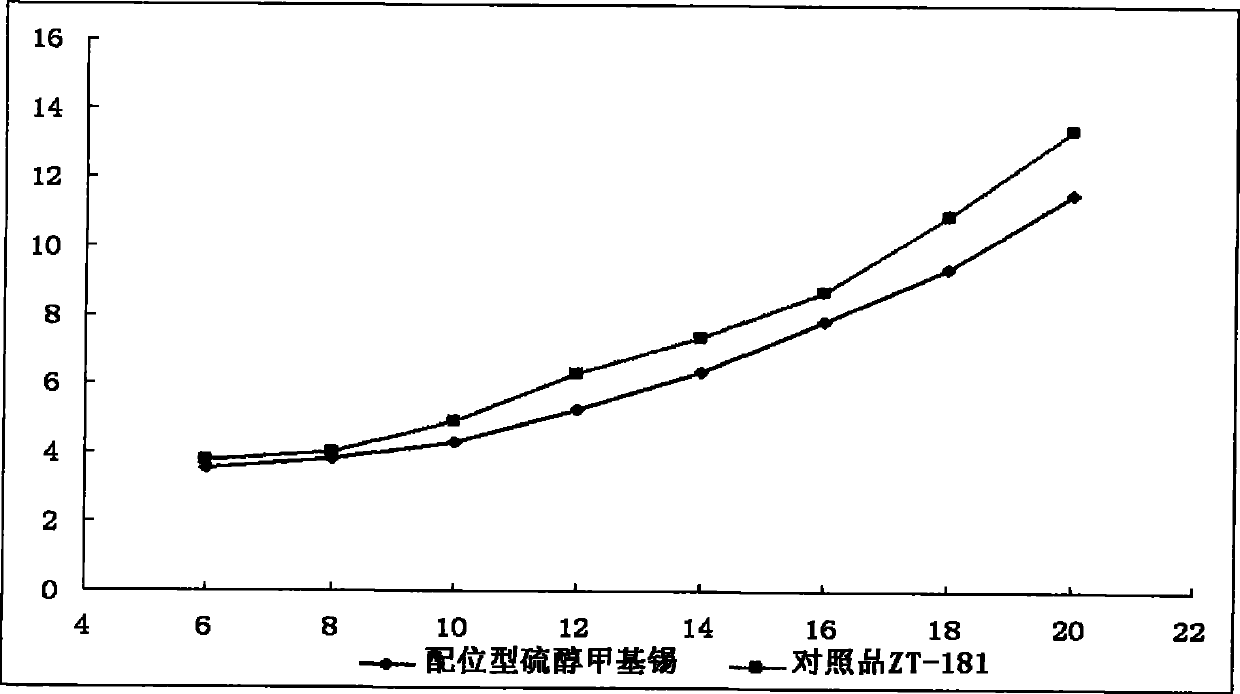

Coordination methyl tin mercaptide compound, preparation method and application thereof

ActiveCN101768184ANot easy to volatile precipitationHigh molecular weightTin organic compoundsThiolThermal stability

The invention provides a coordination methyl tin mercaptide compound, a preparation method and application thereof. The coordination methyl tin mercaptide compound is prepared by adopting one-step process catalysis to synthesize an intermediate and condensation reacting with isooctyl thioglycolate, and the intermediate is an aqueous solution of the methyl tin chloride and has a molar ratio of 1:5 with the isooctyl thioglycolate. The preparation method of the coordination methyl tin mercaptide compound comprises steps of preparing the methyl tin chloride and preparing the methyl tin mercaptide. The product provided in the invention is used as a heat stabilizer in the PVC processing and has the advantages of high molecular weight, difficult volatilization and precipitation in the processing and excellent heat stability compared with the traditional methyl tin mercaptide mixture.

Owner:湖北犇星新材料股份有限公司

Preparation method of glass glaze surface winebottle

The invention relates to a preparation method of a glass glaze surface winebottle. The preparation method is characterized in that a glaze material is prepared from the following raw materials in parts by weight: 12-14 parts of talcum, 4-5 parts of limestone, 3-4 parts of calcium phosphate, 4-5 parts of B2O3, 1-2 parts of potassium chloride, 3-4 parts of tin chloride, 1-2 parts of boracic acid, 1-2 parts of chromium trioxide, 1-2 parts of Nb2O5, 13-14 parts of adhesives and a right amount of water. The glass winebottle prepared through the method disclosed by the invention is smooth and lustrous in glaze surface without cracks and can be used for achieving the sintering finished product ratio of 99% without damage.

Owner:安徽鑫民玻璃股份有限公司

Preparation of catalyst and use for high yield conversion of methane to ethylene

InactiveUS20070055083A1Maintain activityAlkaline earth titanatesHydrocarbon by hydrocarbon condensationAlkaline earth metalSlurry

A perovskite catalyst is prepared using a ceramic sol-sol methodology comprising preparing slurry in water of an alkaline earth metal salt, a powdered metal salt and a powdered transition metal oxide, adding a polymeric binder to form a paste, drying and comminuting the paste into a powder and heating the powder with a temperature profile to calcination temperatures. In one embodiment the slurry is formed of titanium oxide with barium carbonate and tin chloride in deionized water, and more specifically by a mixture according to Ba (1−0.05x)+TiO2+SnCl2(0.05x) where x is in moles. The perovskite catalyst is preferably used in a process for oxidative coupling of methane. Catalyst performance is enhanced through the addition of halides to the feed gas in the reaction.

Owner:HRD CORP

Electroplating method for flowers and tree leaves

InactiveCN1524978AGood conductive surface layerDoes not damage surface tissueElectrolytic organic material coatingChemical platingPalladium chloride

The invention provides a plating method for flowers and leaves comprising the steps of, cleaning with water to remove dirt in the gas cavity, immersing the pretreated flowers and leaves into solution containing tin chloride 8-12 g / l and chlorhydric acid 8-12 ml / l, for chemical plating, cleaning with water, immersing into water solution containing palladium chloride 0.15-0.25 g / l and chlorhydric acid 2-3 ml / l for surface activating treatment, then placing into solution containing nickel sulfate 25-0.25 g / l, sodium citrate 25-35 g / l, and ammonium chloride 45-55 / l, regulating pH to 10-11 of chemical nickel plating solution through ammonia for chemical plating of nickel, rhodium and other noble metal to obtain the final ornament.

Owner:夏红元

Preparation method of tin sulfide-carbon nanotube composite electrode material

InactiveCN107394129ARaw materials are easy to getImprove conductivityCell electrodesSecondary cellsUltrasonic dispersionVacuum drying

The invention discloses a preparation method of a tin sulfide-carbon nanotube composite electrode material. The preparation method comprises the steps of 1, adding a certain amount of a carboxylation multiwalled carbon nanotube into a certain amount of absolute ethyl alcohol, and performing ultrasonic dispersion for 2.5-3.5 hours to obtain a dispersion liquid A; 2, weighing a certain amount of tin chloride pentahydrate into the dispersion liquid A in the step 1, performing stirring for 10-30 minutes, adding a certain amount of thioacetamide under a stirring state, and performing stirring for 30-40 minutes to obtain a solution B; 3, transferring the solution B obtained in the step 2 to a reaction kettle with a polytetrafluoroethylene lining, performing hydrothermal reaction under a certain temperature, naturally cooling to a room temperature after reaction is completed to obtain a deep green precipitant; and 4, collecting the deep green precipitant obtained in the step 3, sequentially and centrifugally washing the deep green precipitant with deionized water and the absolute ethyl alcohol, and placing the deep green precipitant in a vacuum drying box for drying to obtain the tin sulfide-carbon nanotube composite electrode material. The tin sulfide-carbon nanotube composite electrode material is simple in preparation process.

Owner:SHAANXI UNIV OF SCI & TECH

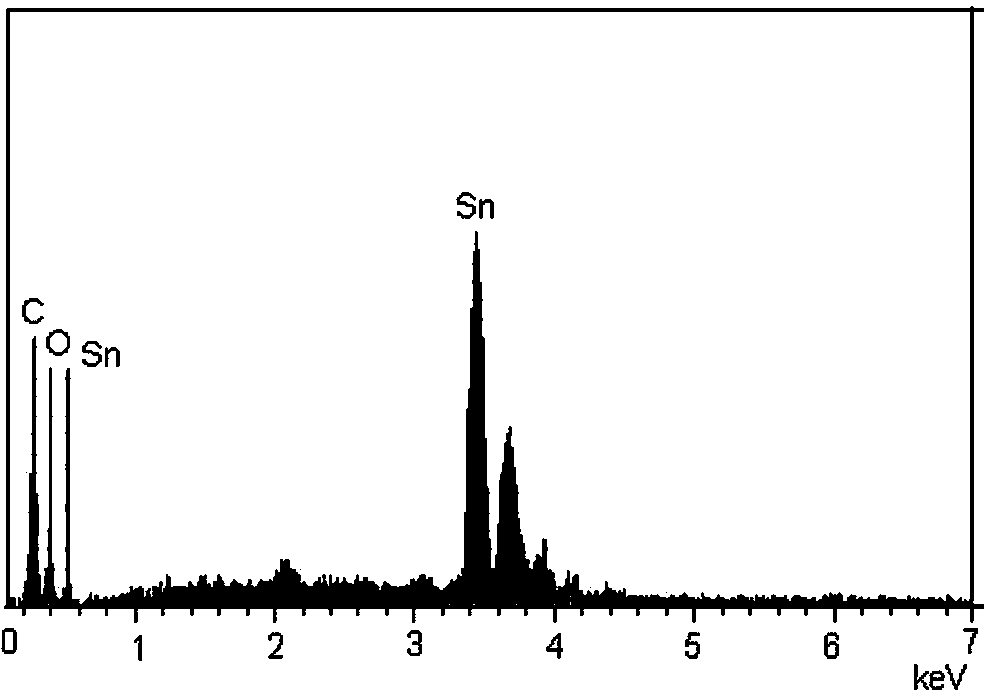

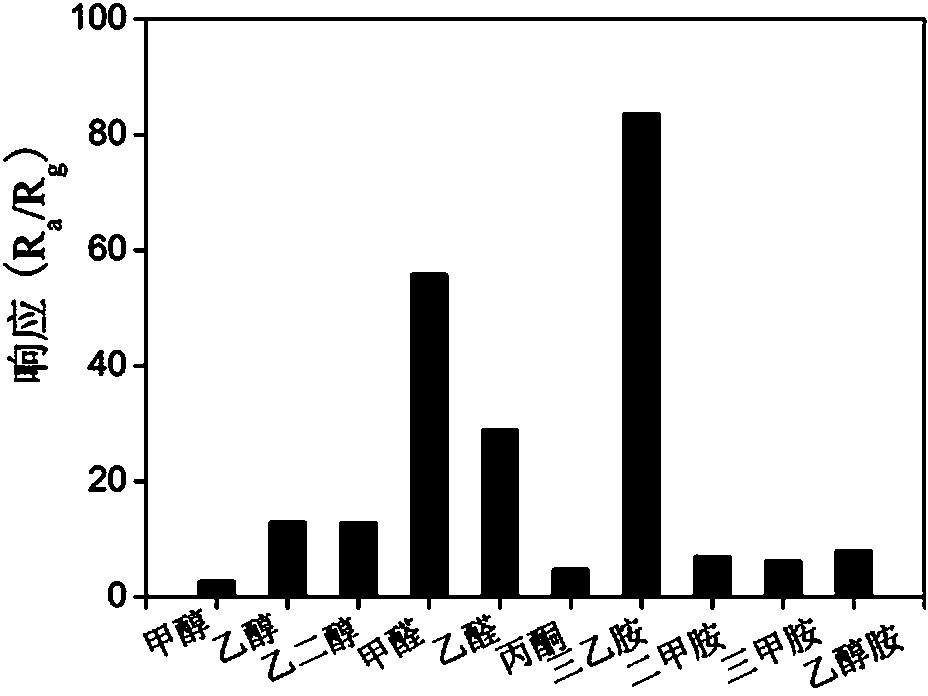

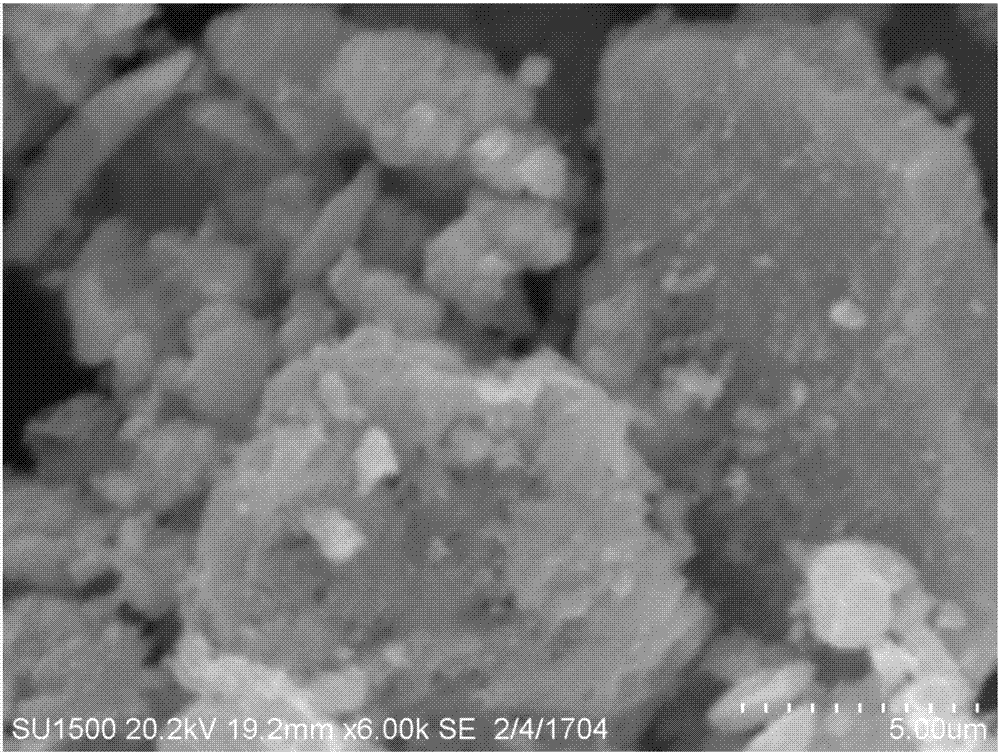

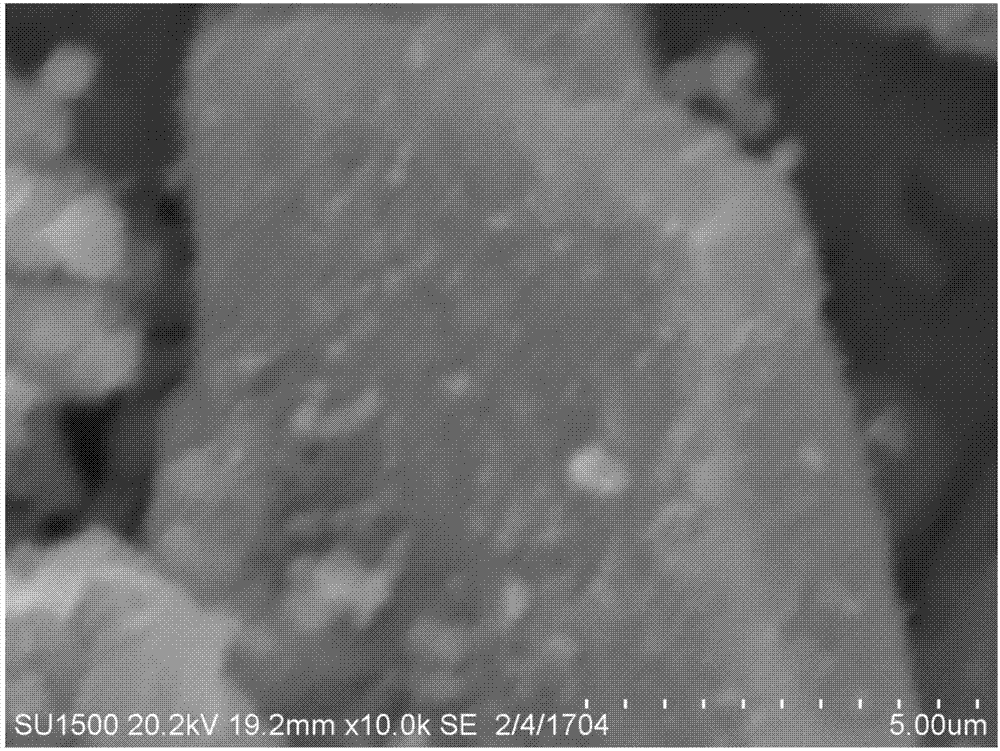

Preparation method and application of graphene/tin oxide nano composite material

ActiveCN103995088AHigh sensitivityQuick responseMaterial nanotechnologyMaterial analysisMeth-Tetrachloride

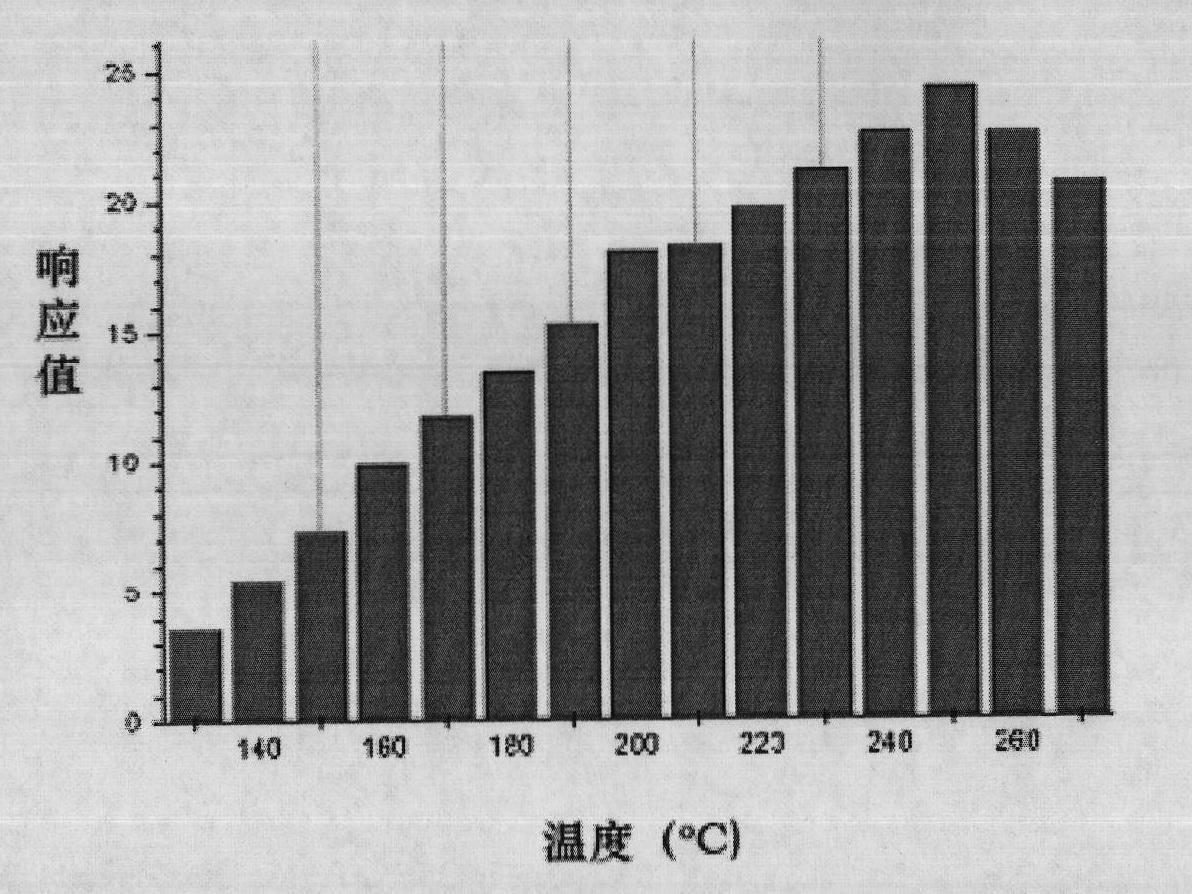

The invention relates to the field of preparation and application of a nano composite material and particularly relates to a preparation method and an application of a graphene / tin oxide nano composite material. The preparation method comprises the following steps: (1) dissolving 2-2.5 parts of tin tetrachloride or tin dichloride into methanol and carrying out ultrasonic assistance to sufficiently dissolve; then adding 0.0005-0.001 part of graphene oxide; carrying out ultrasonic treatment for 30-45 minutes and adding 0.05-0.06 part of cetyl trimethyl ammonium bromide to be mixed sufficiently; adjusting the pH (Potential of Hydrogen) of a solution to 9 by using ammonia water; continuing to carry out the ultrasonic treatment for 30-45 minutes, wherein the mass / volume ratio of the tin tetrachloride or the tin dichloride to the methanol is 5% (w / v); (2) putting a mixed solution obtained by the step (1) into a reaction kettle and carrying out a constant-temperature reaction at 140-150 DEG C for 18-20 hours; after cooling the reaction kettle to room temperature, taking out reactants; centrifuging, washing and drying to obtain the graphene / tin oxide nano composite material.

Owner:TAIYUAN UNIV OF TECH

Preparation method of tin-dioxide-supported carbon nanorod material

ActiveCN106711409AVolume change controllableGood conductivity and stabilityMaterial nanotechnologyCell electrodesTin dioxideCarbonization

The invention discloses a preparation method of a tin-dioxide-supported carbon nanorod material. The method comprises the following steps: by using a cellulose raw material as the substrate, treating cellulose by an acid catalysis process to remove amorphous regions and impurity components in the cellulose, extracting a cellulose nanocrystal suspension, carrying out chemical supporting on the cellulose nanocrystals by using tin chloride to prepare tin-containing cellulose nanocrystals, and carrying out high-temperature oxidation-carbonization treatment to prepare the high-length-diameter-ratio tin-dioxide-supported carbon nanorod material of which the diameter is 10-30nm and the length is 150-350nm. By effectively utilizing the biomass material cellulose, the method has the characteristics of wide raw material sources, renewable raw material and no pollution. The carbon nanorods have the advantage of excellent electric conductivity and have the size which is not possessed by the past carbon material, and have favorable effects of relieving the volume change and improving the cycle performance of batteries.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of composite core-shell-structure nano powder

ActiveCN107162044AGood dispersionThe experimental equipment is simpleSilicaCoatingsWater bathsTin dioxide

The invention discloses a preparation method of a composite core-shell-structure nano powder. The preparation method includes the steps of: 1) dissolving tin chloride pentahydrate and antimony trichloride in a hydrochloric acid solution, and adding ammonia water to obtain a first solution; 2) performing a reaction to the first solution in constant-temperature water bath to form a first precipitate, and calcining the first precipitate to prepare an antimony-doped tin dioxide nano-powder; 3) dispersing the antimony-doped tin dioxide nano-powder in anhydrous ethanol, and adding ammonia water to obtain a second solution; 4) adding tetraethyl orthosilicate to the second solution and performing a reaction to form a second precipitate, and calcining the second precipitate to prepare an intermediate powder; 5) dissolving tin chloride pentahydrate and antimony trichloride in anhydrous ethanol containing acetylacetone, stirring the mixture and performing a reaction to obtain a third solution, dropwise adding distilled water with stirring and aging the solution to prepare antimony-doped tin hydroxide sol; and 6) adding the intermediate powder to the antimony-doped tin hydroxide sol with dispersion, sealing the mixture, allowing the mixture to stand to obtain a third precipitate, and calcining the third precipitate to obtain the composite core-shell-structure nano powder.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST +1

Method for preparing graphene-SnIn4S8 nano composite photocatalyst at low temperature by adopting coprecipitation method

InactiveCN104667950AReduce the temperatureShort preparation timeMaterial nanotechnologyPhysical/chemical process catalystsReaction temperatureElectron

The invention relates to a method for preparing a graphene-SnIn4S8 nano composite photocatalyst at low temperature by adopting a coprecipitation method. The method is characterized by comprising the following steps: preparing graphene oxide by utilizing a modified Hummers method, and reducing the graphene oxide by utilizing 80% hydrazine hydrate to obtain reduced graphene oxide; dissolving raw materials such as tin chloride, indium chloride and thioacetamide in an organic alcohol solution, mixing the reduced graphene oxide which is prepared in advance, and preparing the graphene-SnIn4S8 nano composite photocatalyst bonded in chemical bonds by utilizing a low-temperature co-precipitation method. The method has characteristics that the reaction temperature is low, the reaction time is short, the prepared graphene-SnIn4S8 nano composite photocatalyst is relatively large in specific surface area and narrow in energy gap, photo-generated electrons can be effectively separated from electron holes, the stability is high, the regeneration performance is good, and the light absorption activity and the light catalytic activity are relatively strong under the visible light.

Owner:NANCHANG HANGKONG UNIVERSITY

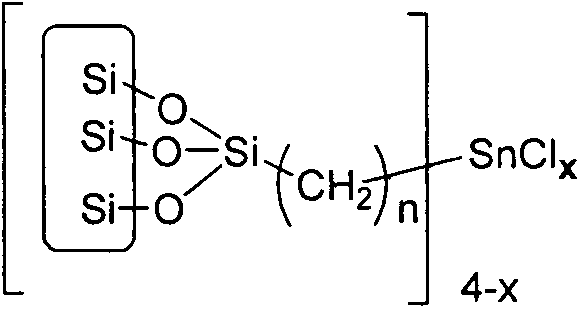

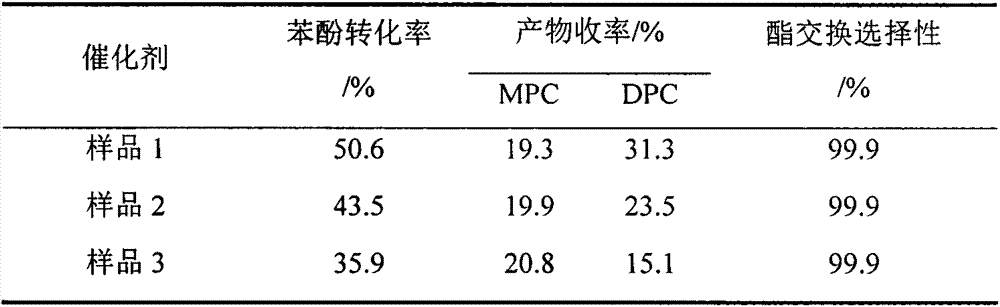

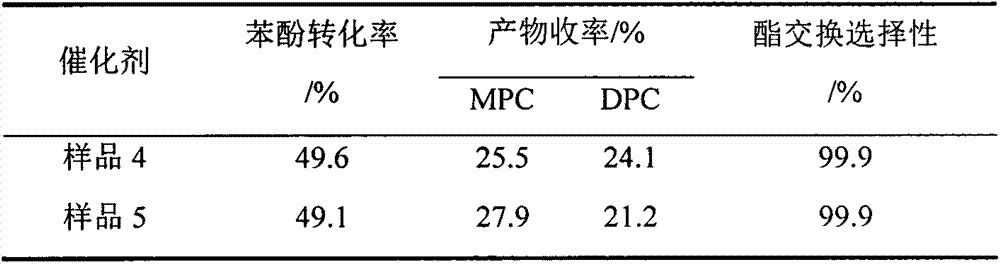

Silicon oxide-immobilized organic tin catalyst for transesterification of dimethyl carbonate and phenol ester, and preparation method thereof

InactiveCN107308984AEasy to prepareImprove catalytic performanceOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsMethyl carbonateSilanes

The present invention is a silicon oxide-immobilized organic tin catalyst for transesterification of dimethyl carbonate and phenol ester, and a preparation method thereof, wherein the silicon oxide-immobilized organic tin catalyst is prepared by using the silane reagent of alkyl tin chloride as an organotin precursor, the basic composition comprises alkyl tin chloride and silicon oxide, alkyl tin chloride is used as an active component, and silicon oxide is used as a carrier. According to the present invention, the silicon oxide-immobilized organic tin catalyst shows excellent catalytic performance in the dimethyl carbonate and phenol ester transesterification reaction for synthesis of diphenyl carbonate, wherein the phenol conversion rate is 50.6%, the transesterification selectivity is more than 99.9%, and the catalyst is a heterogeneous catalyst, can reduce the toxicity of organotin, is easily separated and recovered from the reaction system after the reaction, and can be reused.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

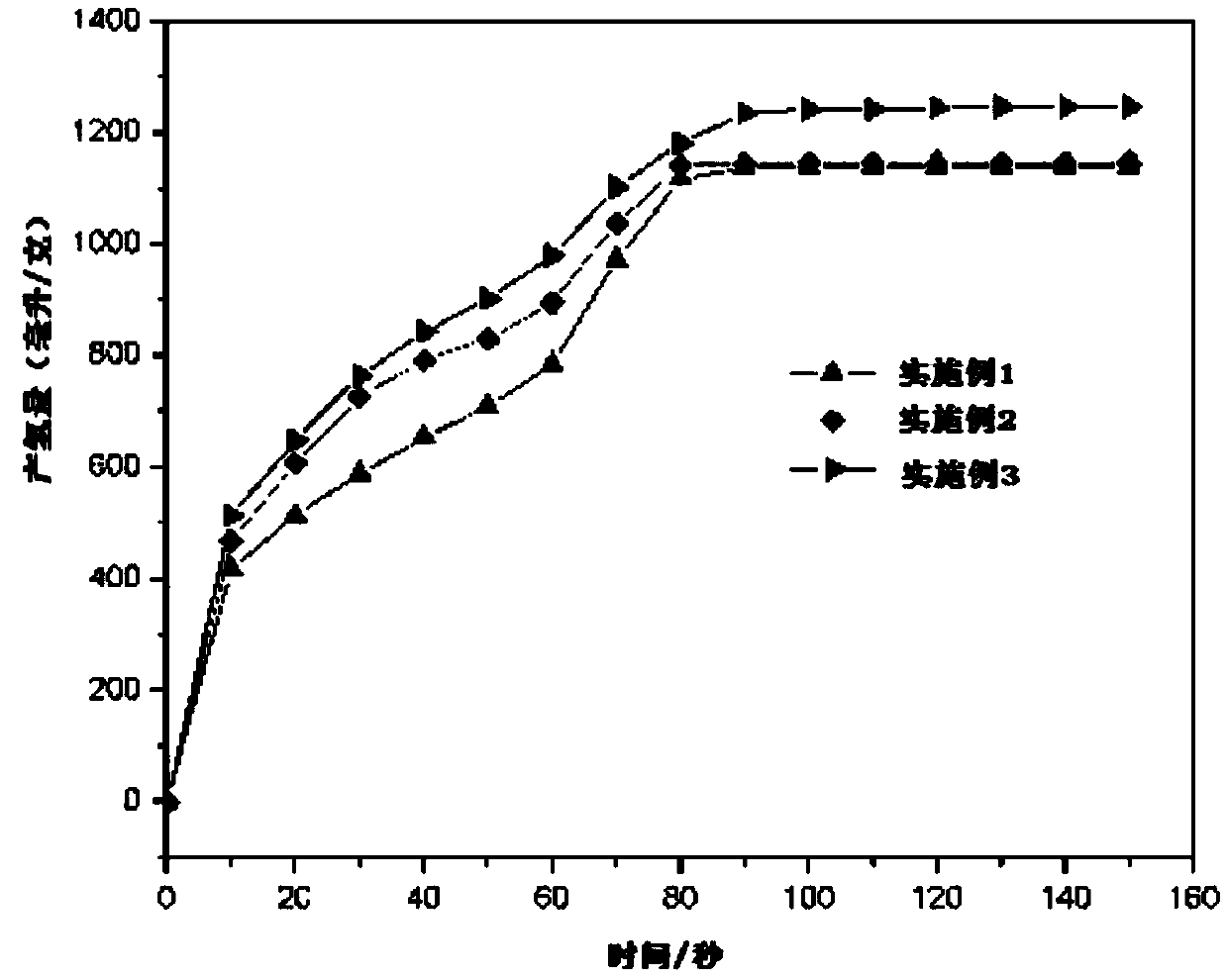

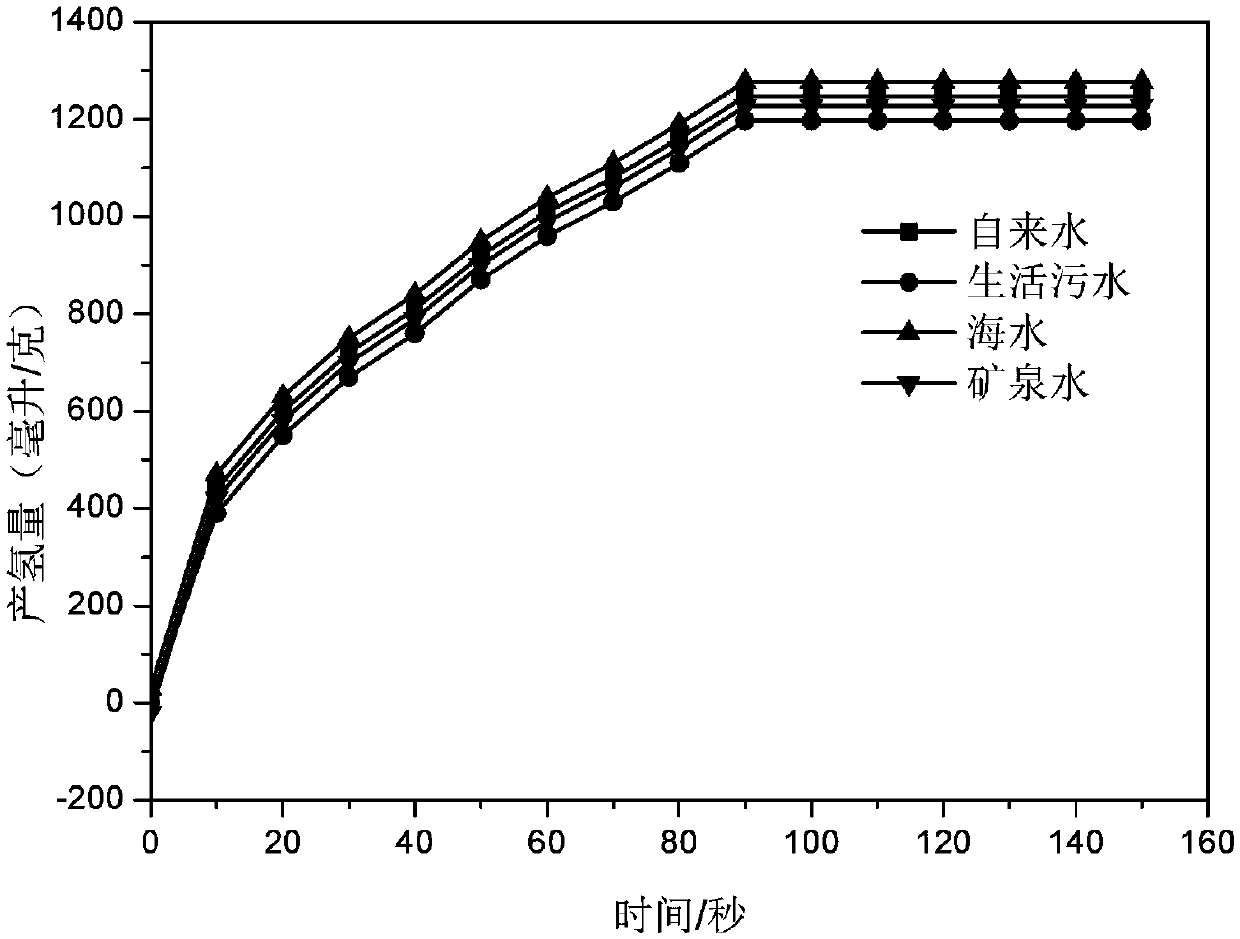

Hydrolysis hydrogen production aluminum alloy, preparing method thereof and application

InactiveCN109652684AHigh activityImprove the performance of hydrogen production by hydrolysisHydrogen productionPotassiumCadmium Cation

The invention discloses a hydrolysis hydrogen production aluminum alloy. The hydrolysis hydrogen production aluminum alloy comprises raw materials including, by mass percent, 90 to 95% of Al and 5 to10% of an additive. The additive is one or multiple of a metal element, metallic oxide and metal chloride, the metal element comprises one or multiple of magnesium, antimony, zinc, lead, cadmium, bismuth, tin, potassium and sodium, the metallic oxide comprises one or multiple of magnesium oxide, antimony oxide, zinc oxide, lead oxide, cadmium oxide, bismuth oxide, tin oxide, potassium oxide and sodium oxide, and the metal chloride comprises one or multiple of magnesium chloride, antimony chloride, zinc chloride, lead chloride, cadmium chloride, bismuth chloride, tin chloride, potassium chloride and sodium chloride. In the hydrolysis hydrogen production aluminum alloy, the cost of hydrolysis hydrogen production aluminum alloy is greatly reduced while hydrogen production is ensured. The invention further provides a preparing method of the hydrolysis hydrogen production aluminum alloy and application.

Owner:HUBEI UNIV OF TECH

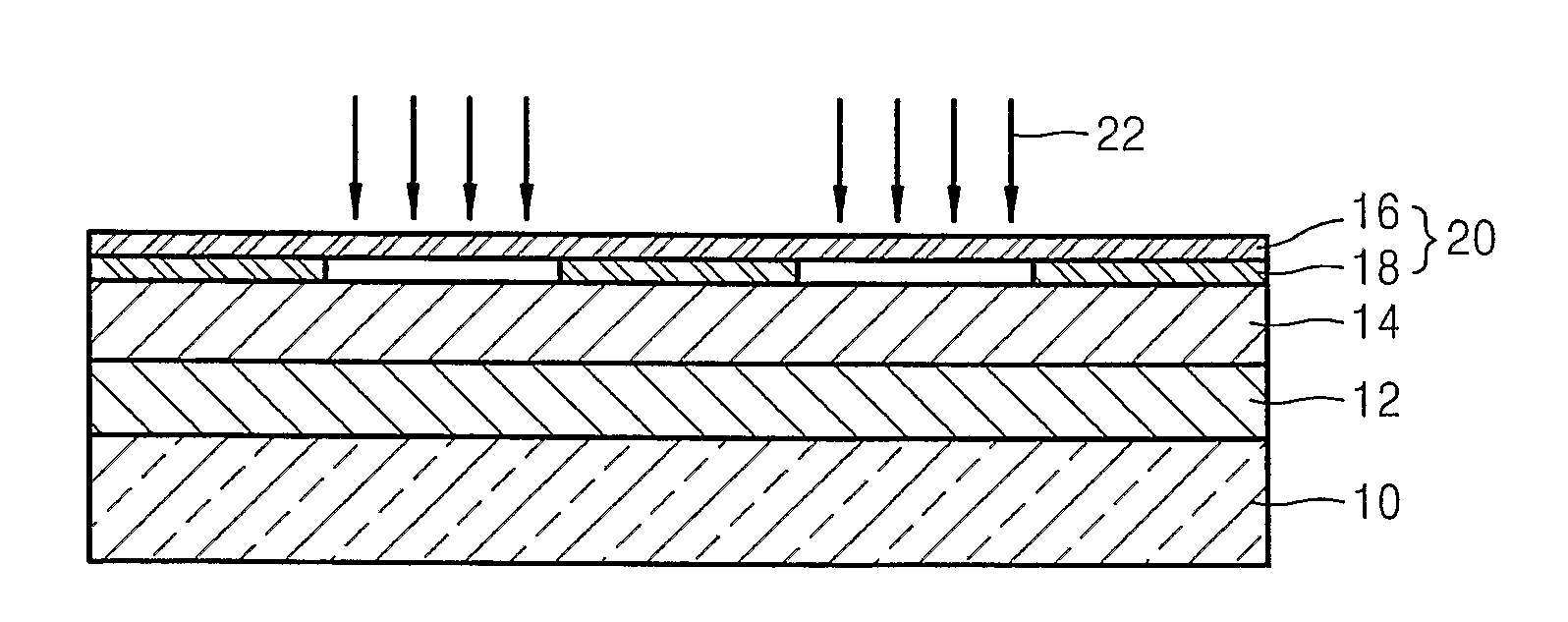

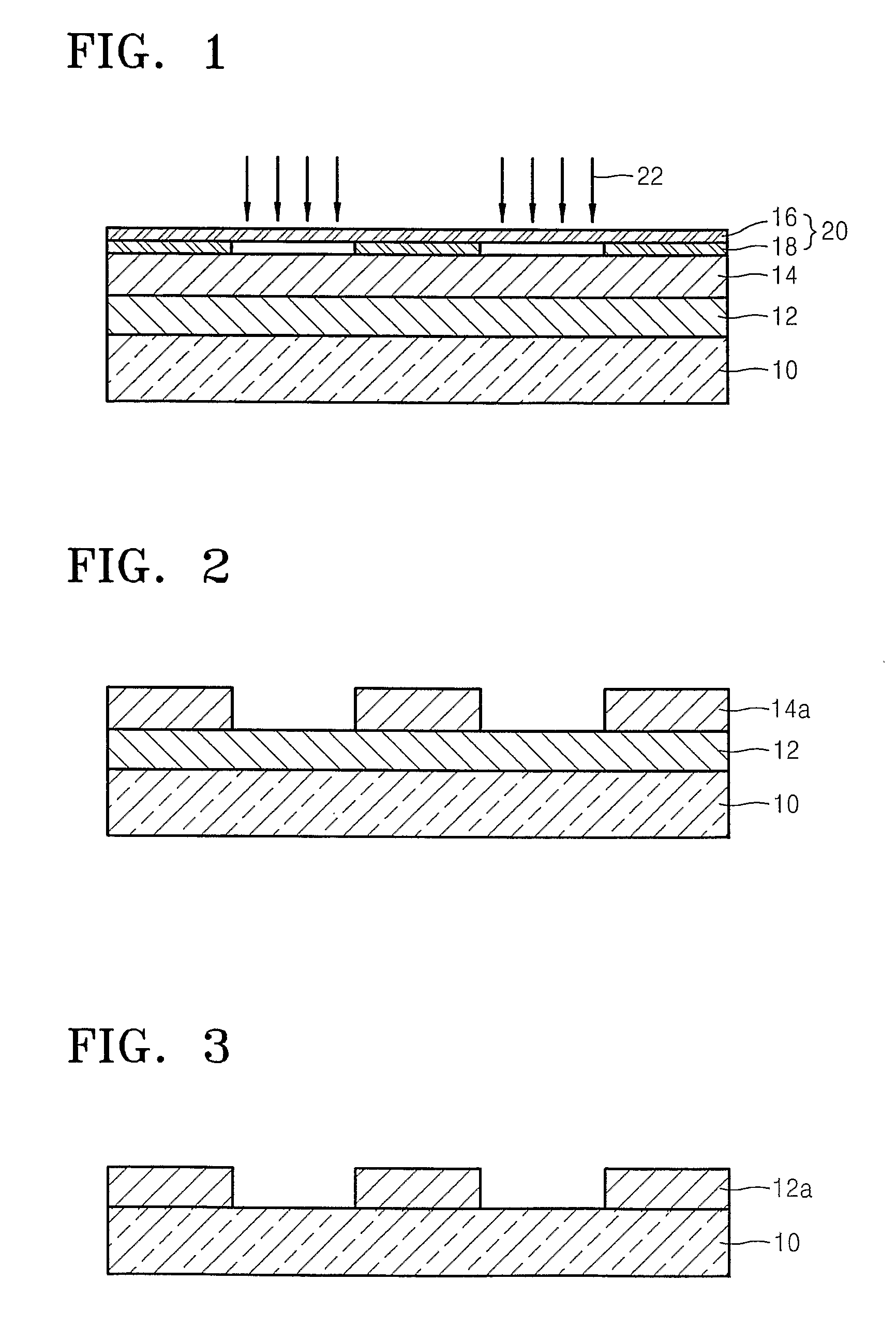

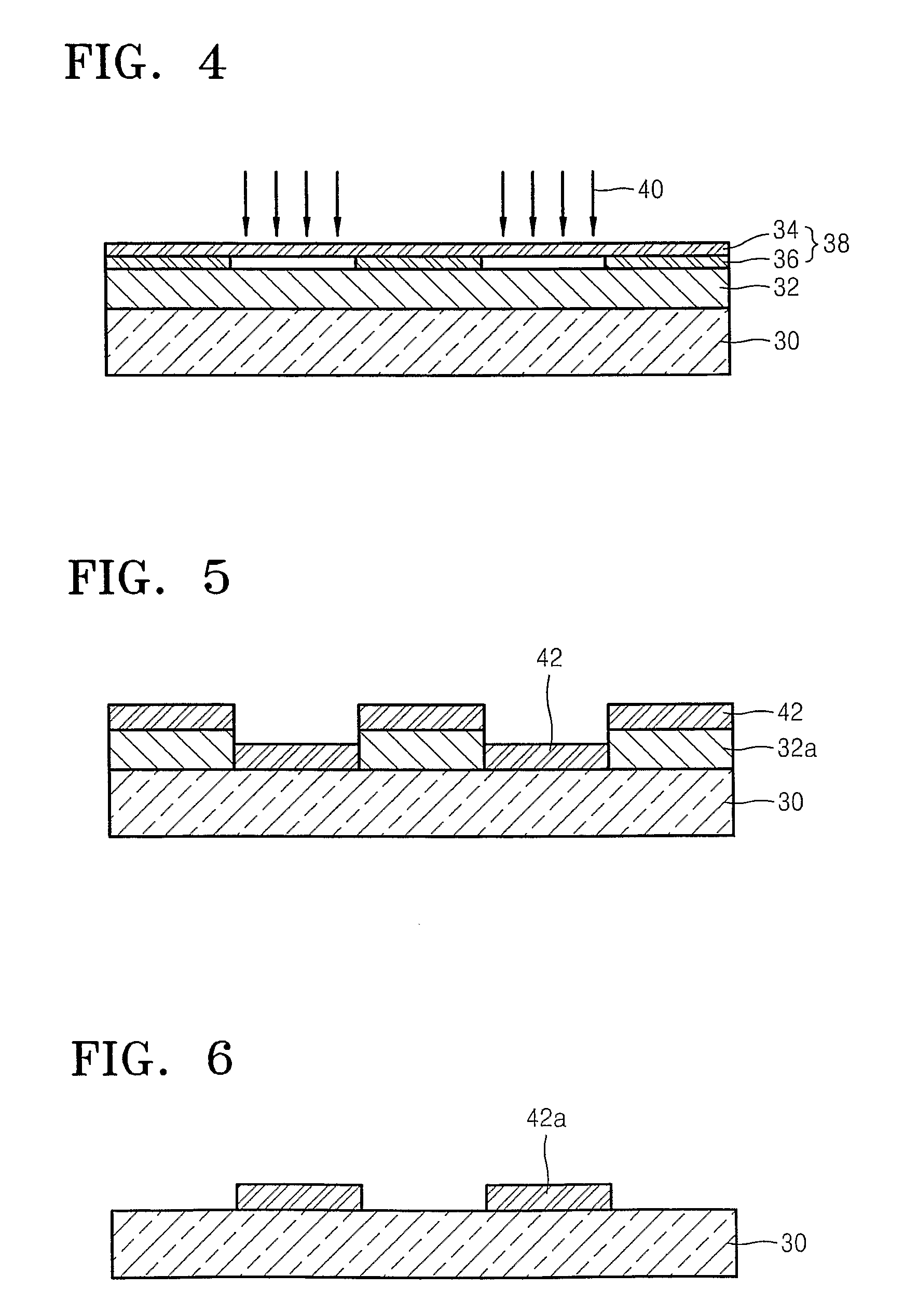

Method of synthesizing ITO electron-beam resist and method of forming ITO pattern using the same

ActiveUS20100035179A1Eliminate the problemHigh light transmittanceTin compoundsPhotosensitive materialsAtomic physicsElectron beam resist

Provided is a method of synthesizing an ITO electron beam resist and a method of forming an ITO pattern. The ITO electron beam resist is synthesized by dissolving indium chloride tetrahydrate and tin chloride dihydrate in 2-ethoxy ethanol. The method of forming an ITO pattern includes: forming an ITO electron beam resist film on a substrate, forming an ITO electron beam resist pattern by patterning the ITO electron beam resist film, and forming an ITO pattern by annealing the ITO electron beam resist pattern.

Owner:ELECTRONICS & TELECOMM RES INST

Production process for 18k gold titanium crystal pearlescent pigment

ActiveCN102250495AHigh chromaIncrease coverageInorganic pigment treatmentAluminium chlorideTitanium chloride

The invention discloses a production process for pure golden 18k gold titanium crystal pearlescent pigment which adopts mica film as a substrate and is subjected to multilayer coating. The production process is characterized by: sequentially coating the surface of the plate-like substrate of the mica film with a mixture of tin chloride pentahydrate and crystal aluminum trichloride, titanium tetrachloride, sodium metasilicate pentahydrate, a mixture of trichloride ferric and ammonium metavanadate, titanium tetrachloridethe; carrying out sucking filtration, washing, drying and annealing to formthe 18k gold titanium crystal pearlescent pigment. Compared to the prior art, the prepared 18k gold titanium crystal pearlescent pigment through the production process provided by the present invention has characteristics of high chromaticity, good covering power and strong weathering resistance. With the present invention, although the production process does not contain the gold element, the prepared 18k gold titanium crystal pearlescent pigment has the effect of the 18k gold, and has cheap price. In addition, the 18k gold titanium crystal pearlescent pigment has great economic value; the production process is simple and easy to be controlled, and is applicable for producing the 18k gold titanium crystal pearlescent pigment on a large scale.

Owner:河南凌宝新材料科技有限公司

Molybdenum disulfide/tin disulfide/graphene composite and preparation method thereof

InactiveCN108539175AInhibition of agglomerationImprove conductivityCell electrodesGrapheneSulfurCvd graphene

The invention discloses a molybdenum disulfide / tin disulfide / graphene composite and a preparation method thereof. Molybdenum disulfide / tin disulfide grows on the surface of graphene in a manner of horizontal interface contact growth; with graphene oxide as a carbon source, tin chloride pentahydrate as a tin source, sodium molybdate dihydrate as a molybdenum source and thioacetamide as a sulfur source, the carbon source, tin source, molybdenum source and sulfur source are added sequentially into deionized water and heated at 200 DEG C for 16h to synthesize the molybdenum disulfide / tin disulfide / graphene composite. The molybdenum disulfide / tin disulfide / graphene composite has a stable structure and high electrical conductivity, and has the advantages of large specific surface area and excellent electrochemical performance; the preparation method has low requirements on reaction conditions, simple operation, high yield and good repeatability.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com