Preparation method of three-dimensional layered multilevel flower-shaped stannic oxide microsphere

A tin dioxide, three-dimensional layering technology, applied in the direction of tin oxide, etc., can solve the problems of easy cracking of products, long processing time, expensive instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

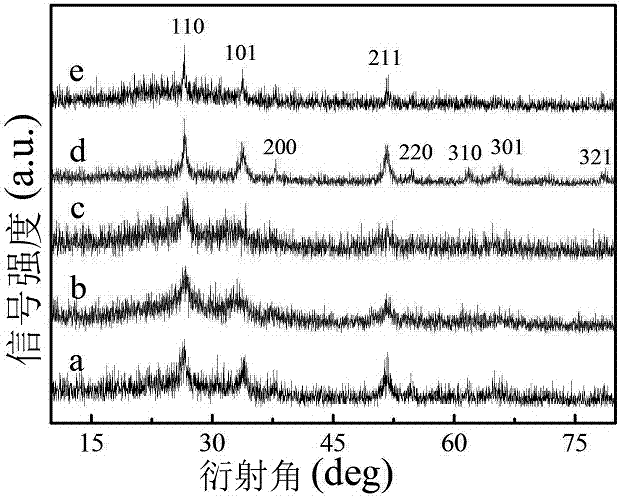

Embodiment 1

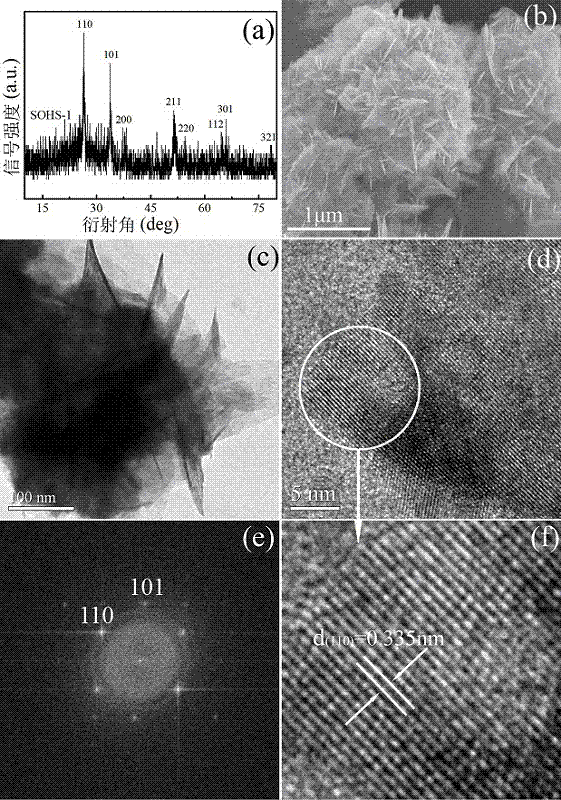

[0023] A method for preparing three-dimensional layered multi-level flower-like tin dioxide microspheres, comprising the following steps:

[0024] 1) Dissolve 0.2g urea in a mixed solution of 35ml deionized water and 15ml ethanol, then add SnCl with a mass fraction of 98% 2 2H 2 O reaches Sn 2+ Concentration 10 mM / L, shake gently to form a suspension, and add 1.0 ml of 6 M / L NaOH solution dropwise under microwave-assisted conditions.

[0025] 2) Transfer the solution to a 60 ml polytetrafluoro autoclave, and keep the temperature in an oven at 160°C for 18 hours. The resulting product was washed 3 times with deionized water to obtain the primary product.

[0026] 3) Disperse the primary product in deionized water again, let it stand for 30 minutes, remove the gray precipitate, and centrifuge again. Dry in a vacuum oven at 60°C for more than 8 hours to obtain a three-dimensional layered multi-level flower-like tin dioxide microsphere sample 1.

Embodiment 2

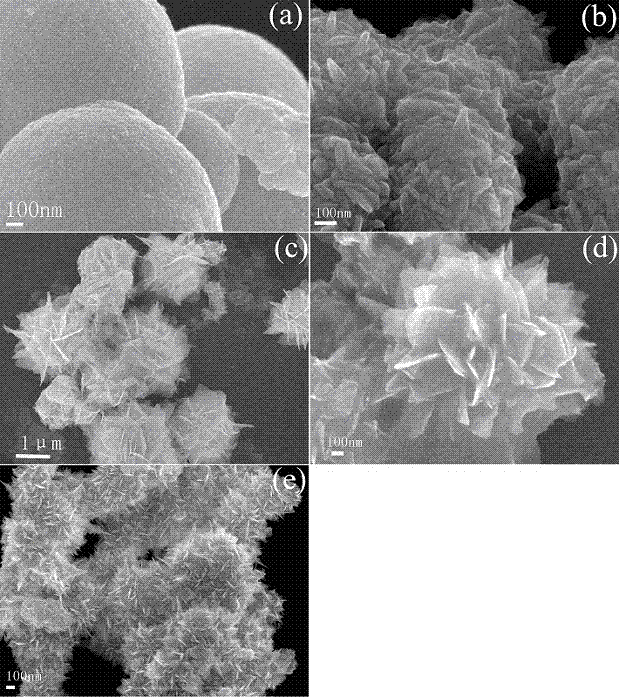

[0028] This example is basically the same as Example 1, except that the reaction temperature in step 2) is 150° C., and sample 2 of three-dimensional layered multi-level flower-shaped tin dioxide microspheres is obtained.

Embodiment 3

[0030] This embodiment is basically the same as Embodiment 1, the difference is that the Sn in step 1) 2+ When the concentration reaches 15 mM, a three-dimensional layered multi-level flower-like tin dioxide microsphere sample 3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com