Patents

Literature

398results about How to "Improve light extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

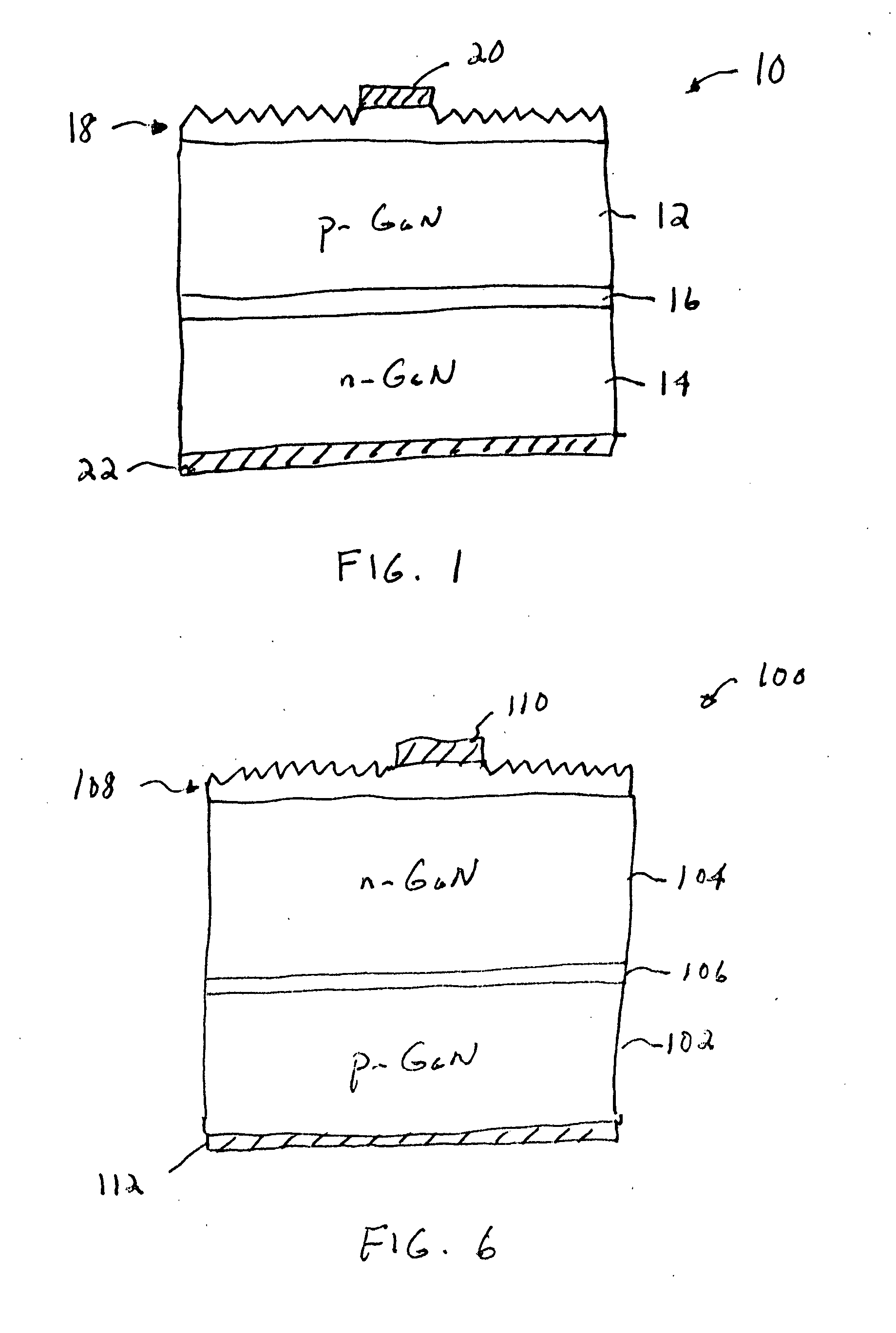

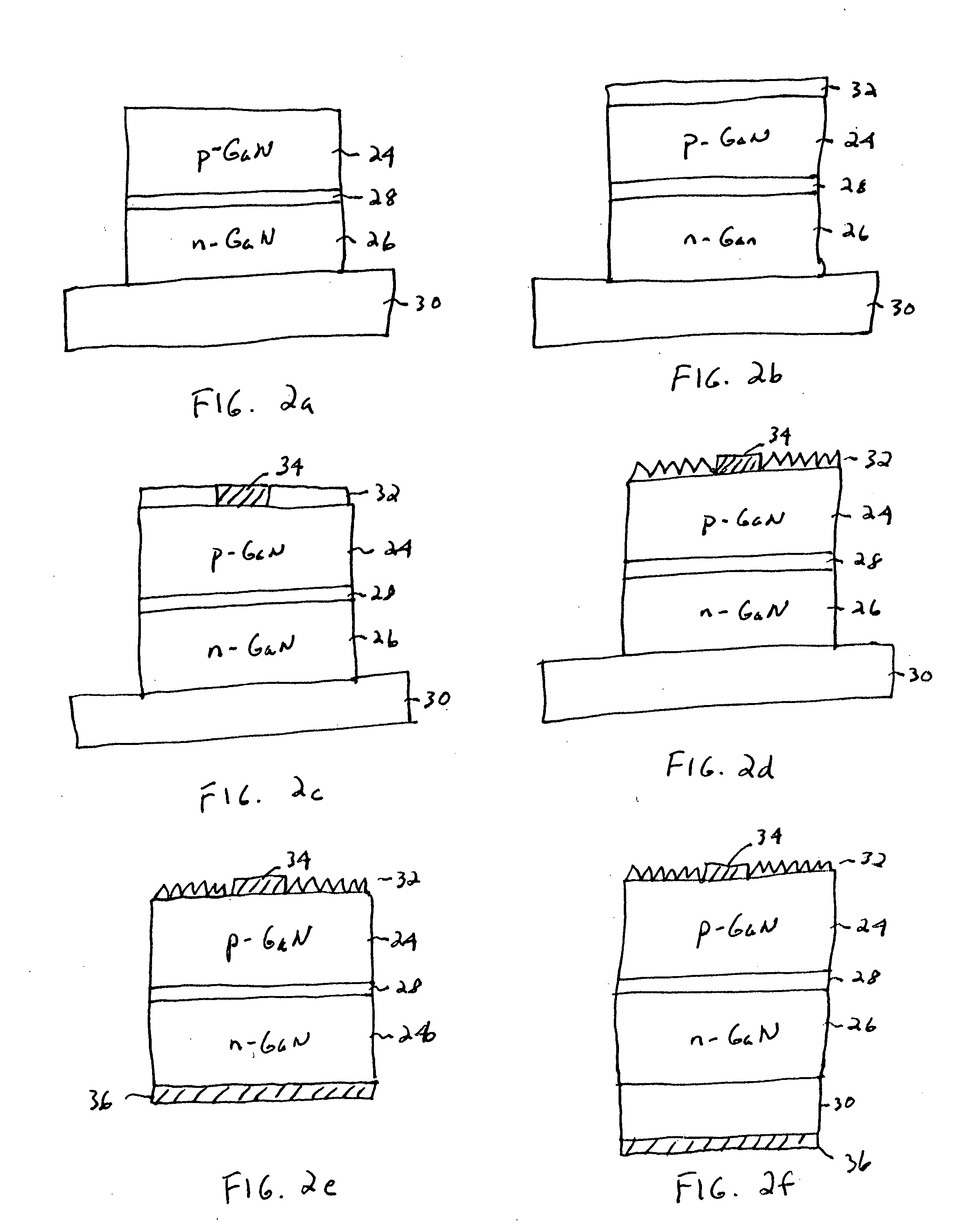

Substrate removal process for high light extraction LEDs

ActiveUS20060189098A1Index matchingImprove light extractionSemiconductor/solid-state device manufacturingSemiconductor devicesNitrideLight-emitting diode

A method for fabricating light emitting diode (LEDs) comprises providing a plurality of LEDs on a substrate wafer, each of which has an n-type and p-type layer of Group-III nitride material formed on a SiC substrate with the n-type layer sandwiched between the substrate and p-type layer. A conductive carrier is provided having a lateral surface to hold the LEDs. The LEDs are flip-chip mounted on the lateral surface of the conductive carrier. The SiC substrate is removed from the LEDs such that the n-type layer is the top-most layer. A respective contact is deposited on the n-type layer of each of the LEDs and the carrier is separated into portions such that each of the LEDs is separated from the others, with each of the LEDs mounted to a respective portion of said carrier.

Owner:CREELED INC

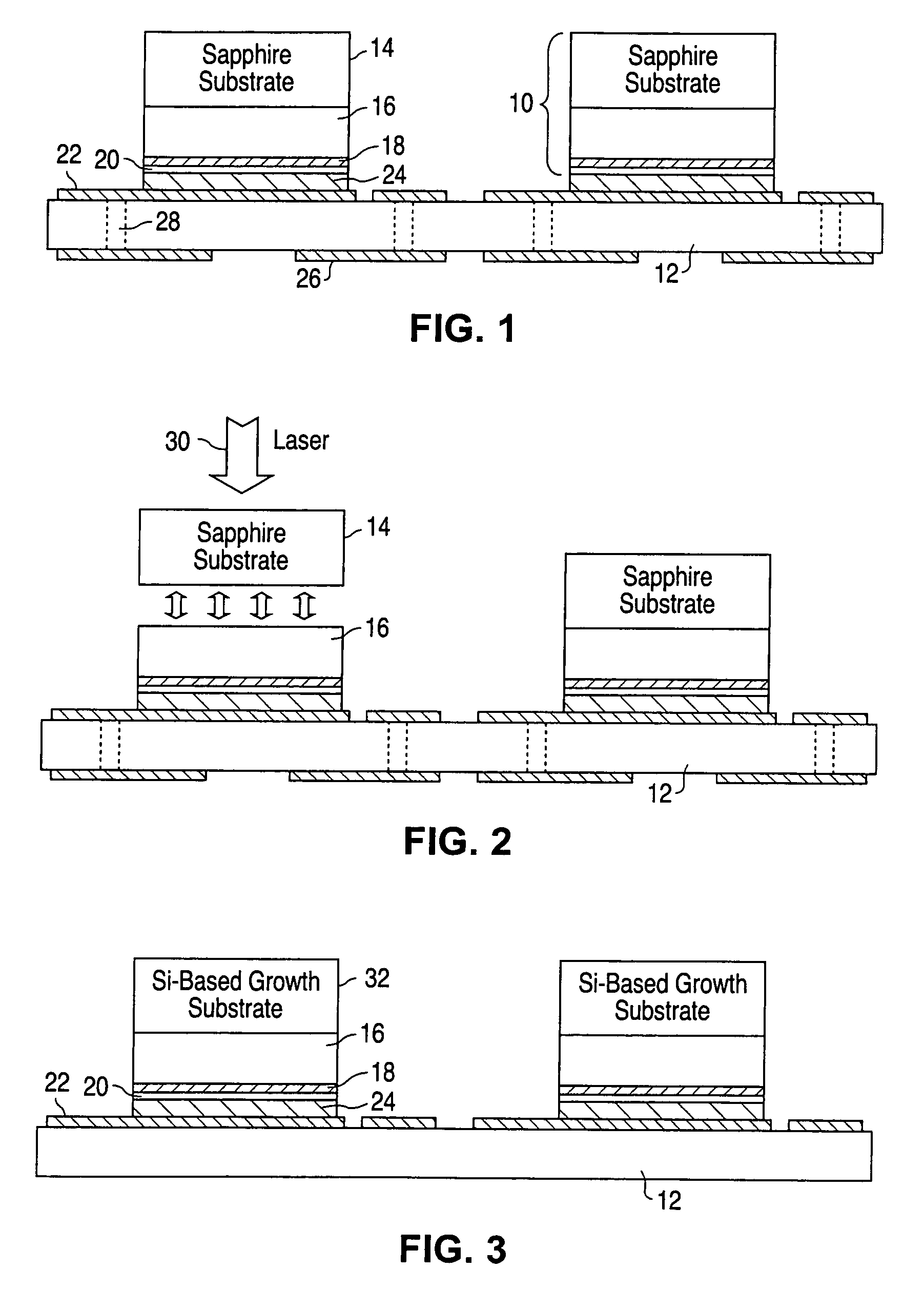

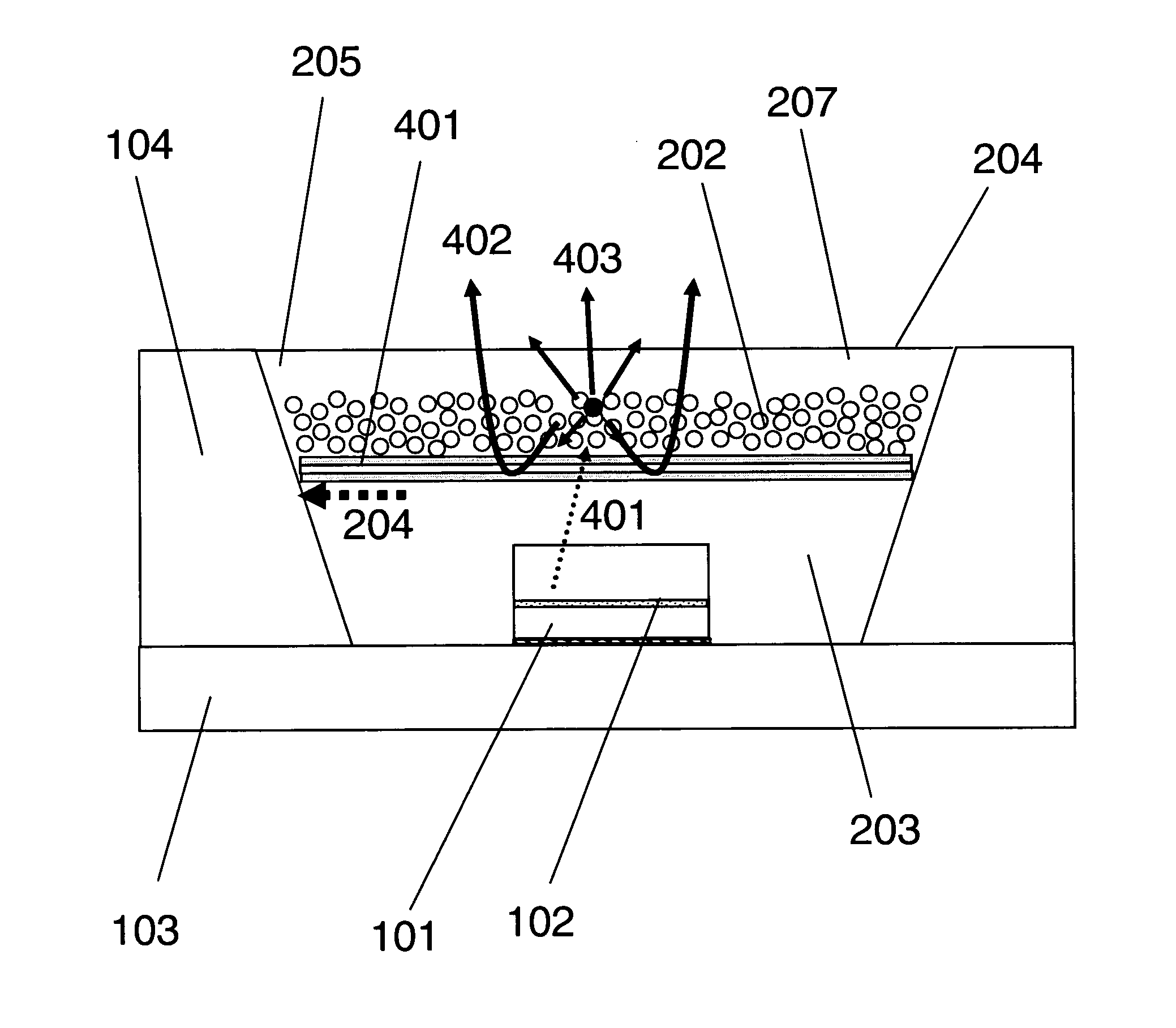

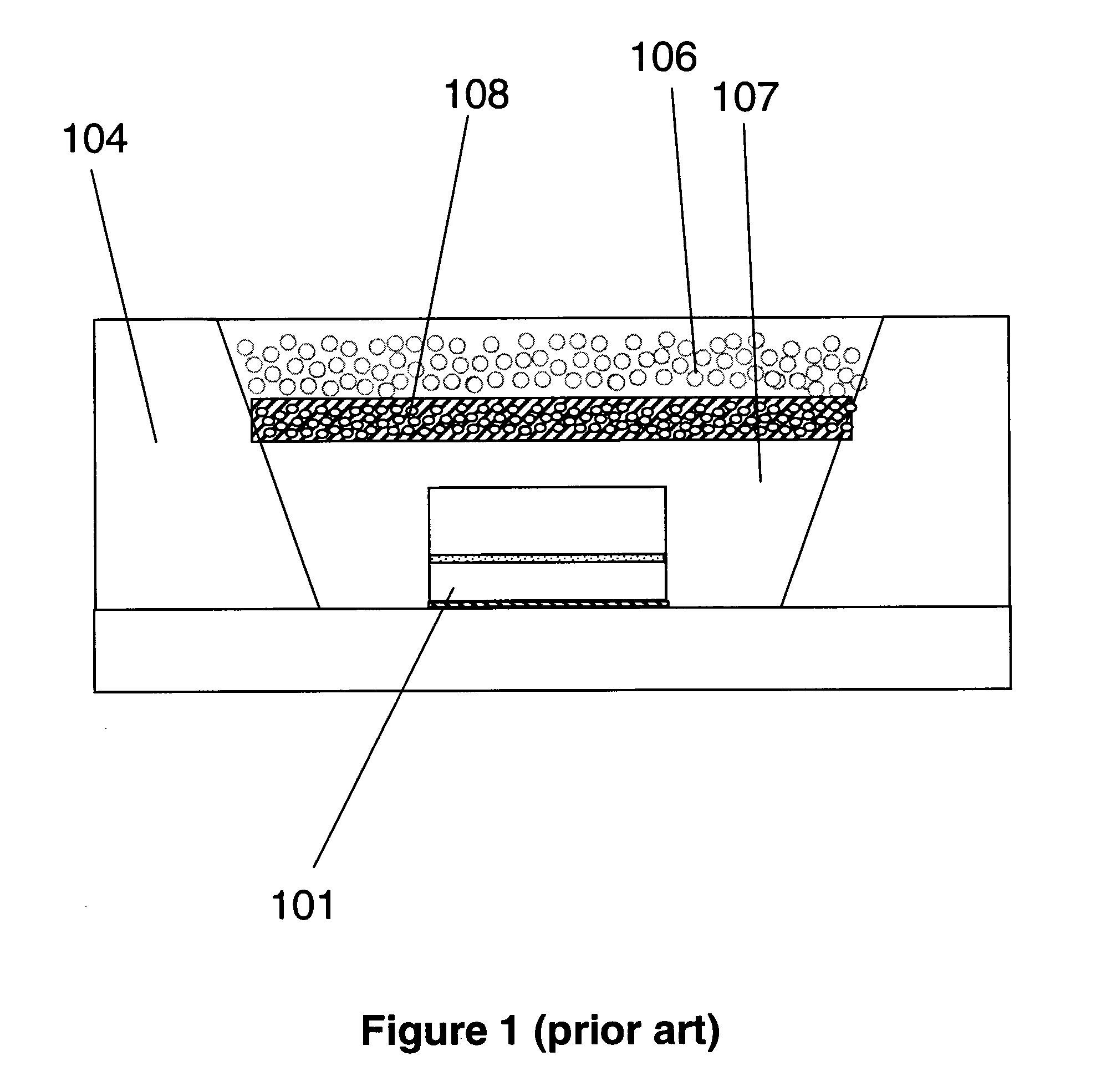

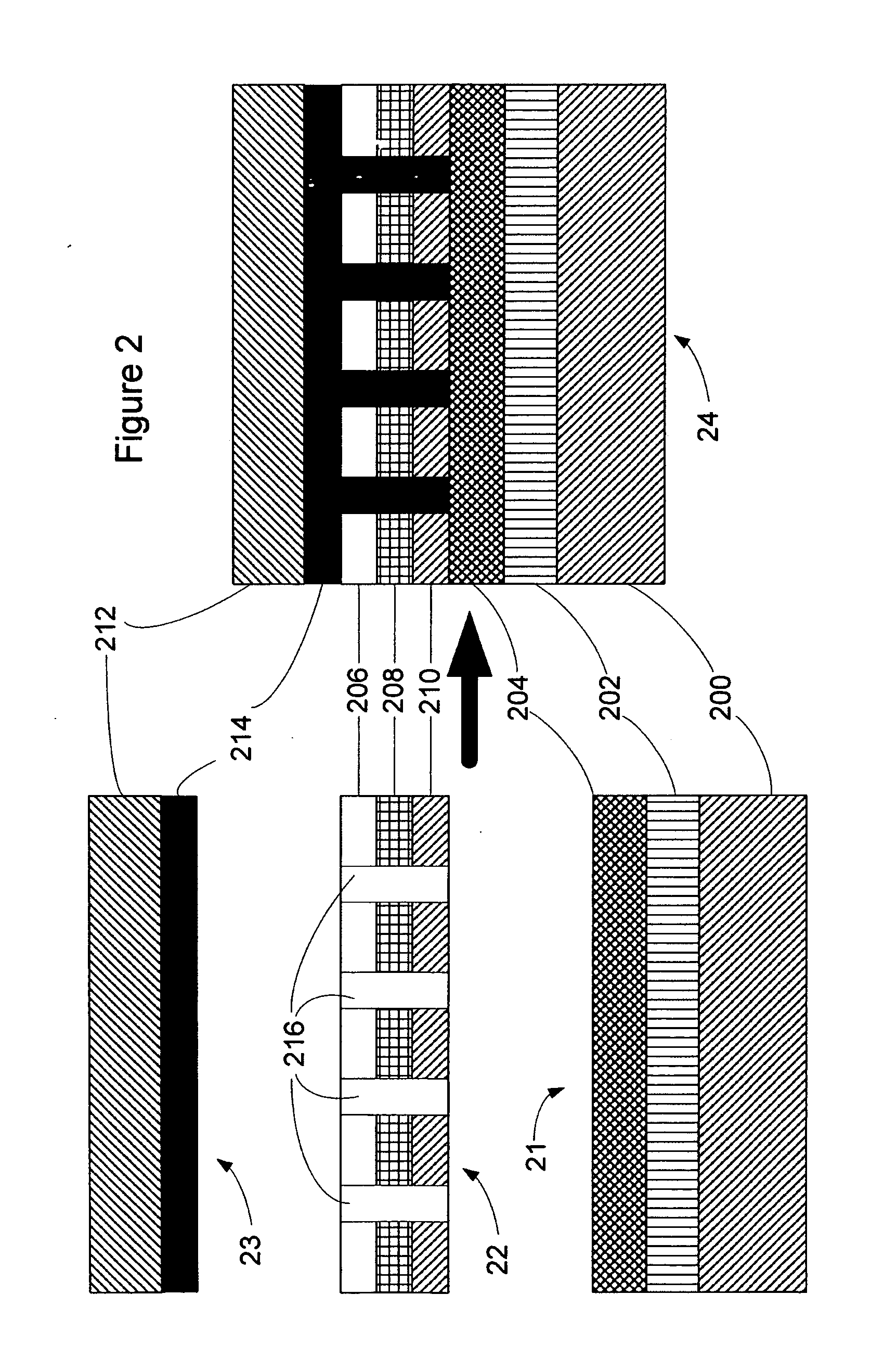

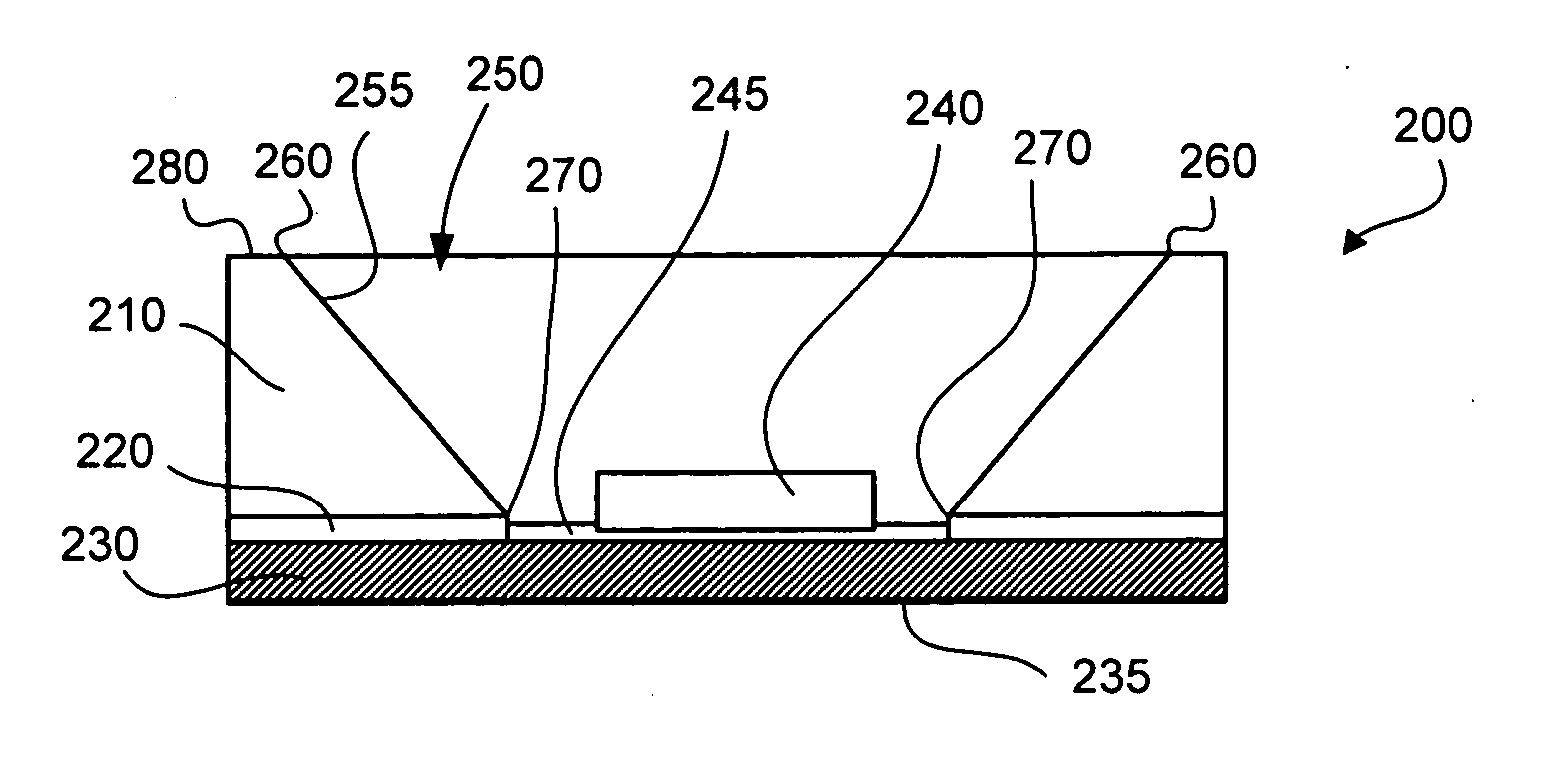

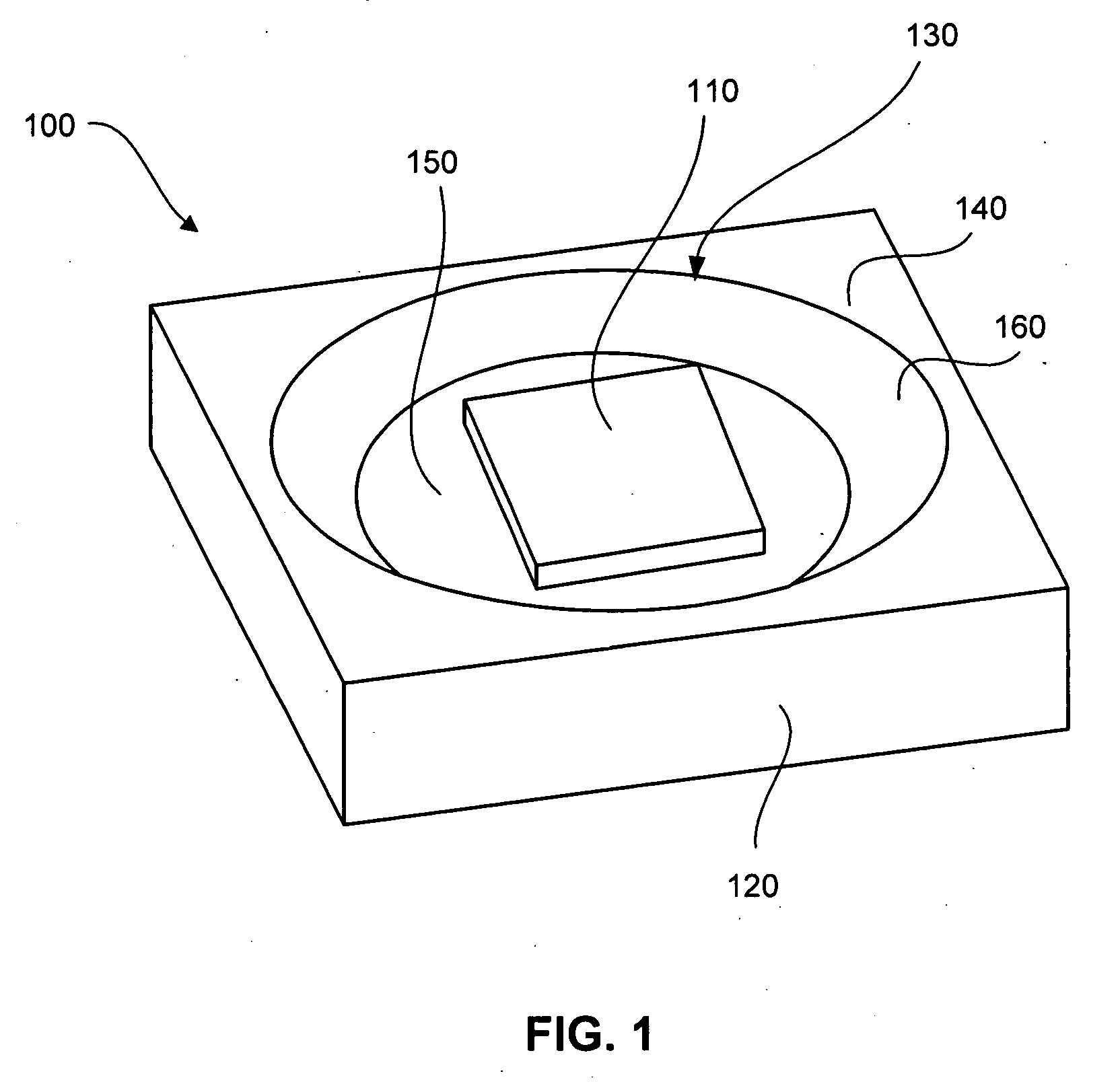

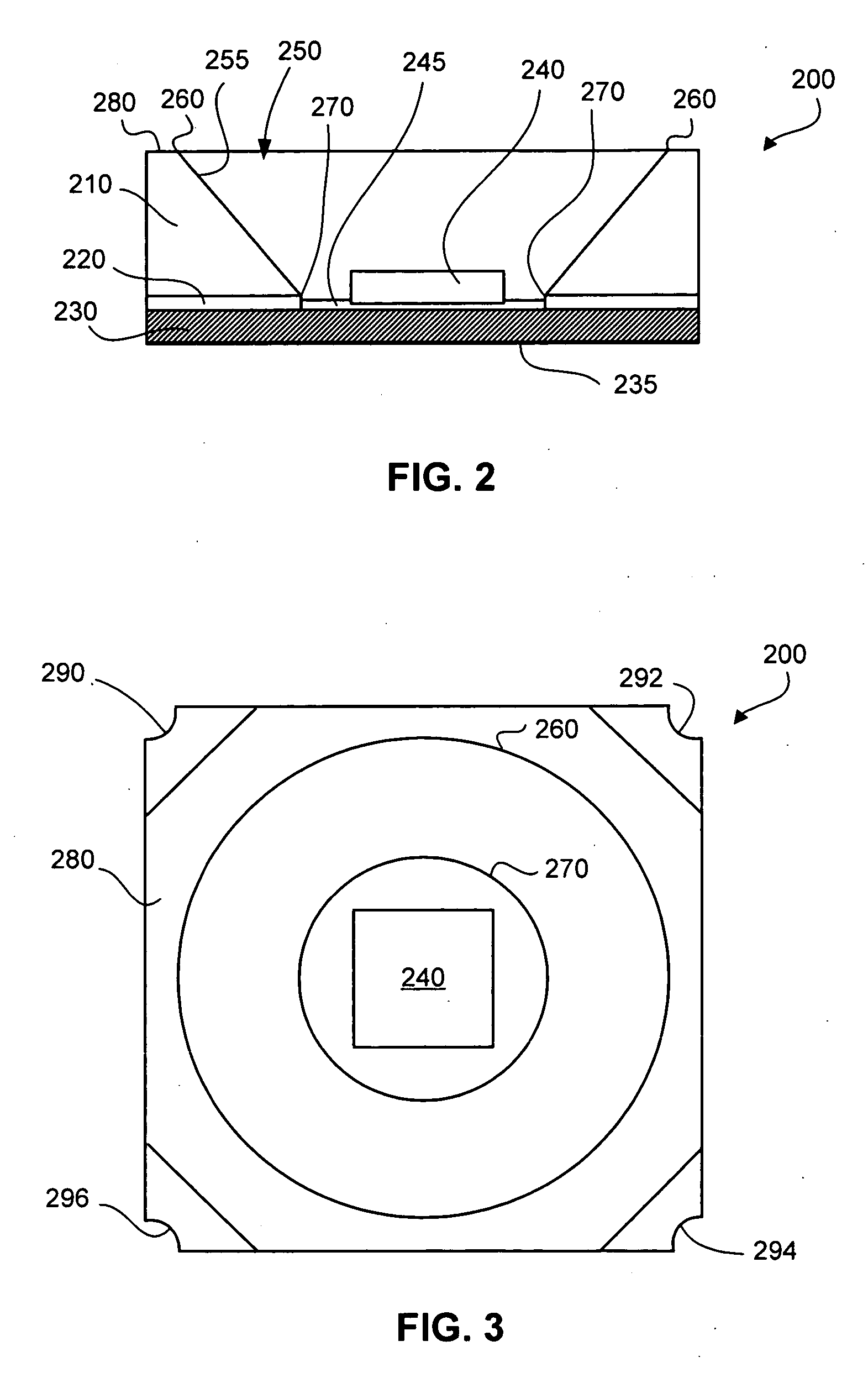

Package-integrated thin film LED

ActiveUS7256483B2Little absorption of lightHigh thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesThermal conductivityEngineering

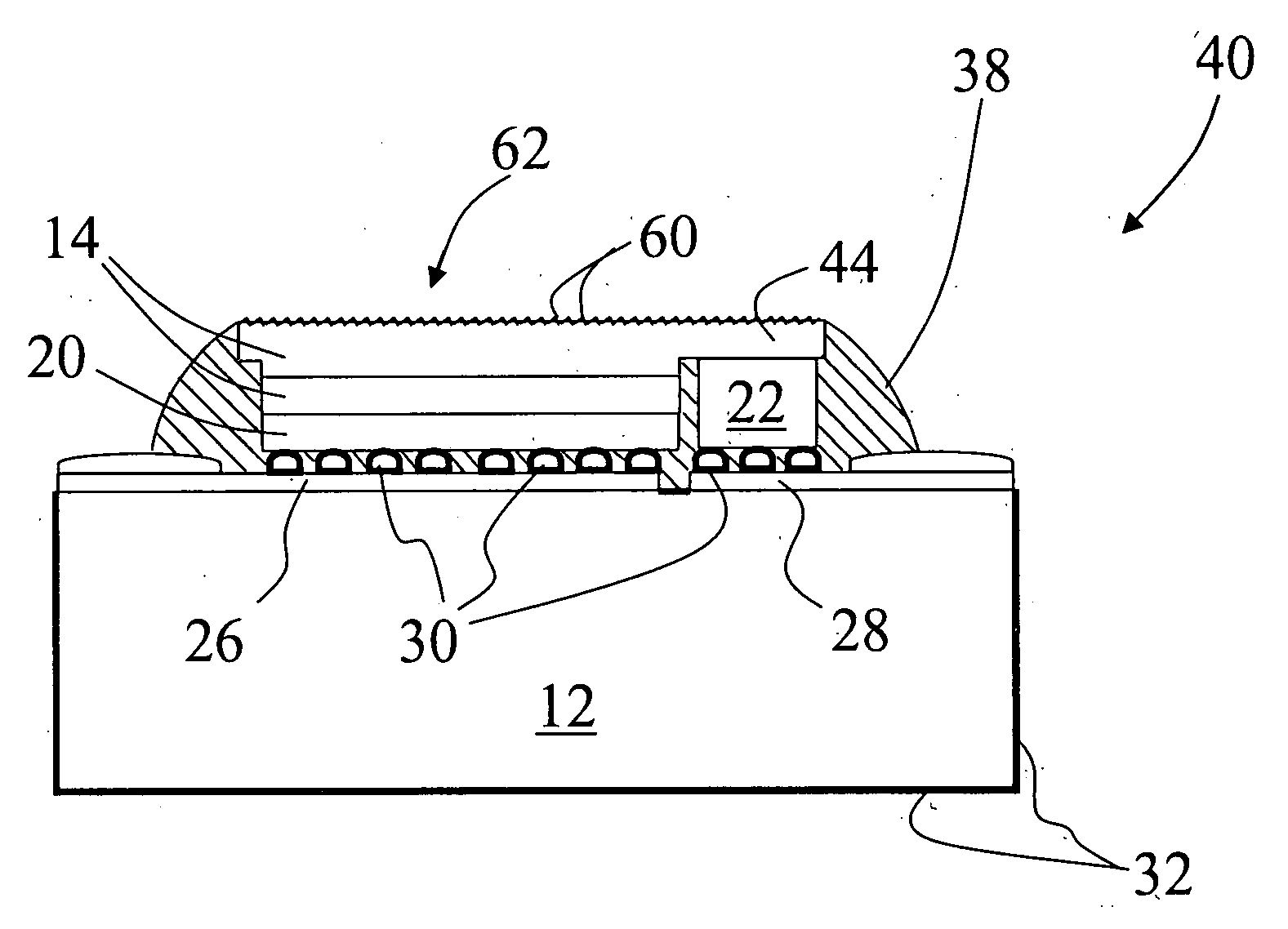

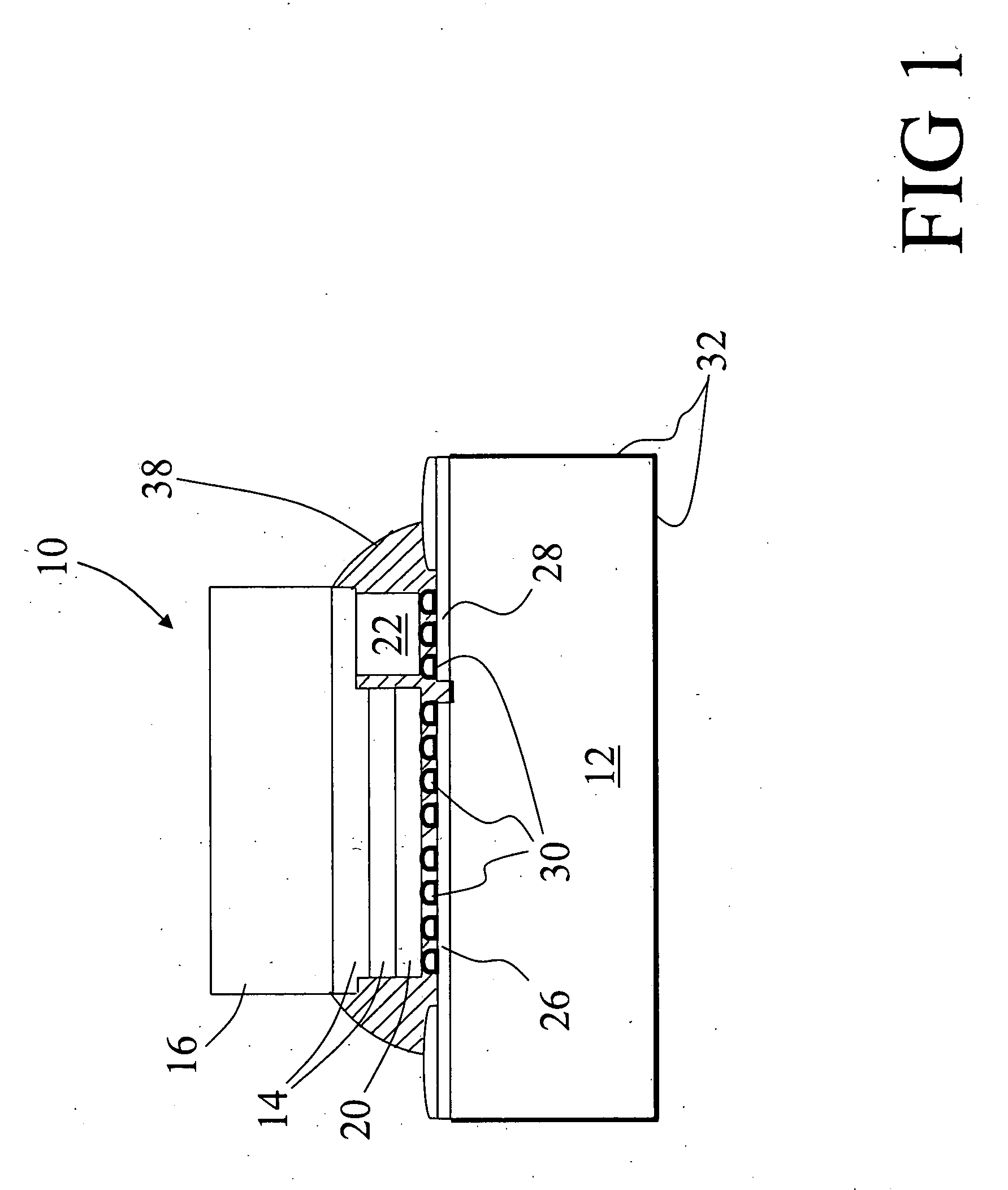

LED epitaxial layers (n-type, p-type, and active layers) are grown on a substrate. For each die, the n and p layers are electrically bonded to a package substrate that extends beyond the boundaries of the LED die such that the LED layers are between the package substrate and the growth substrate. The package substrate provides electrical contacts and conductors leading to solderable package connections. The growth substrate is then removed. Because the delicate LED layers were bonded to the package substrate while attached to the growth substrate, no intermediate support substrate for the LED layers is needed. The relatively thick LED epitaxial layer that was adjacent the removed growth substrate is then thinned and its top surface processed to incorporate light extraction features. There is very little absorption of light by the thinned epitaxial layer, there is high thermal conductivity to the package because the LED layers are directly bonded to the package substrate without any support substrate therebetween, and there is little electrical resistance between the package and the LED layers so efficiency (light output vs. power input) is high. The light extraction features of the LED layer further improves efficiency.

Owner:LUMILEDS

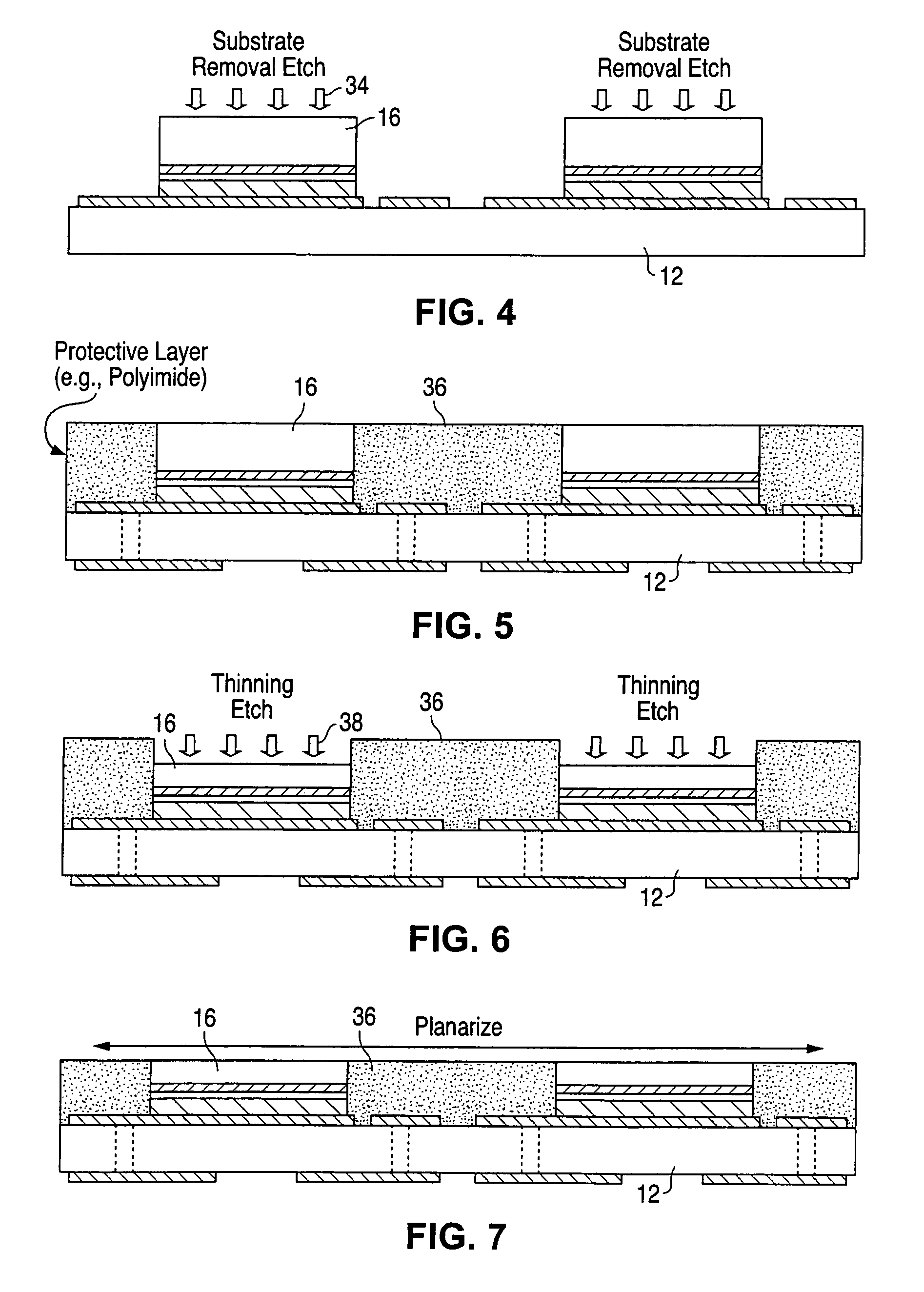

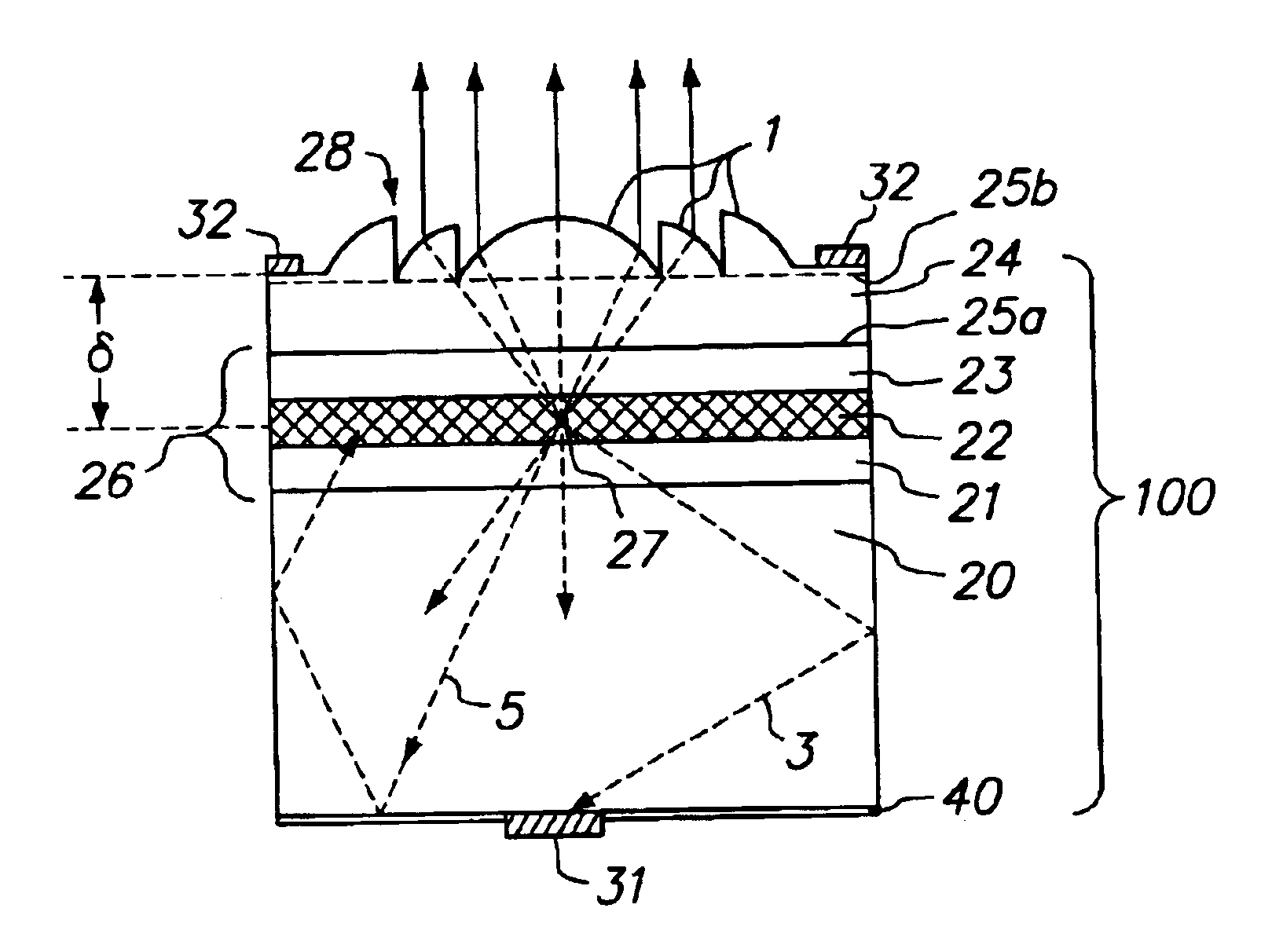

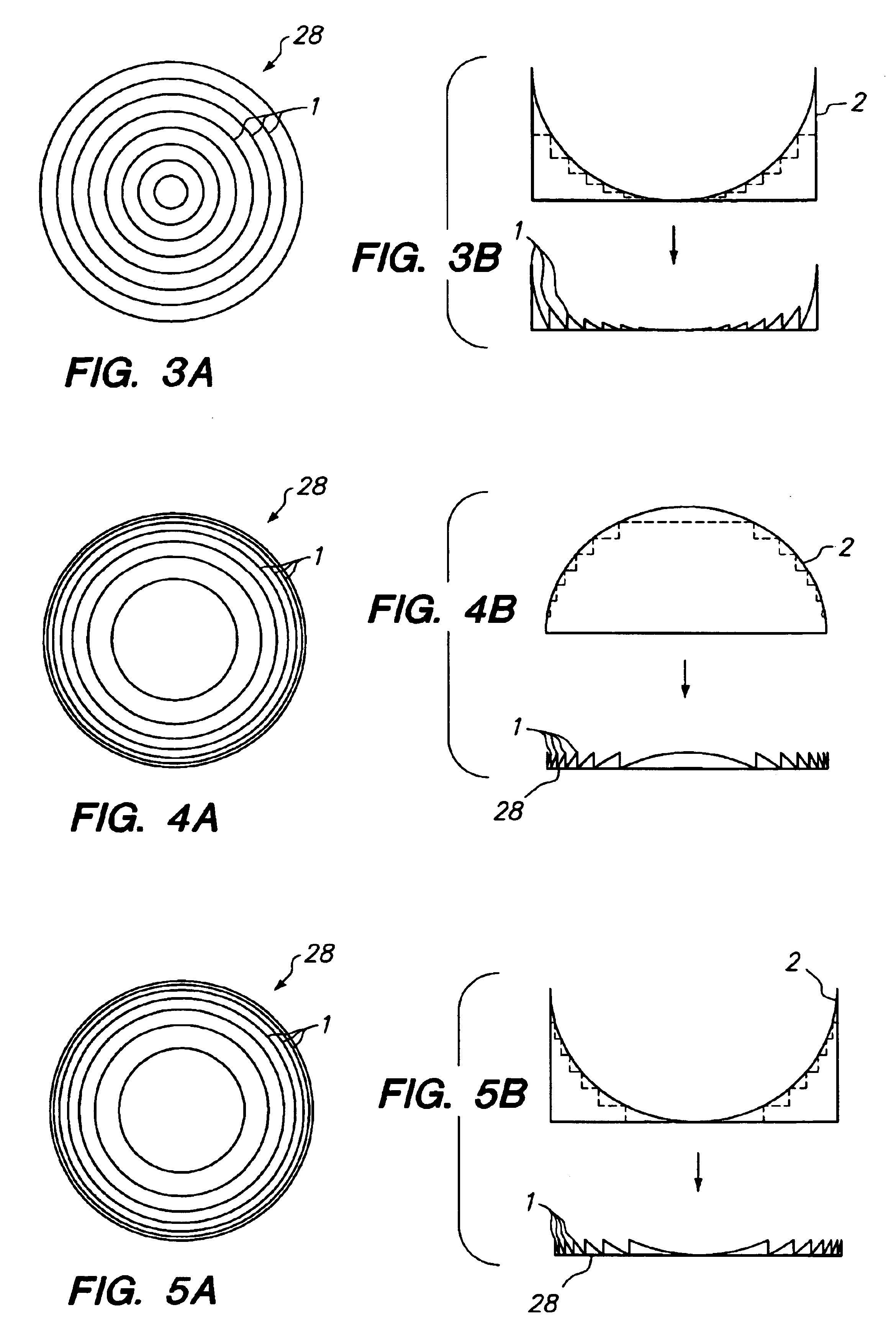

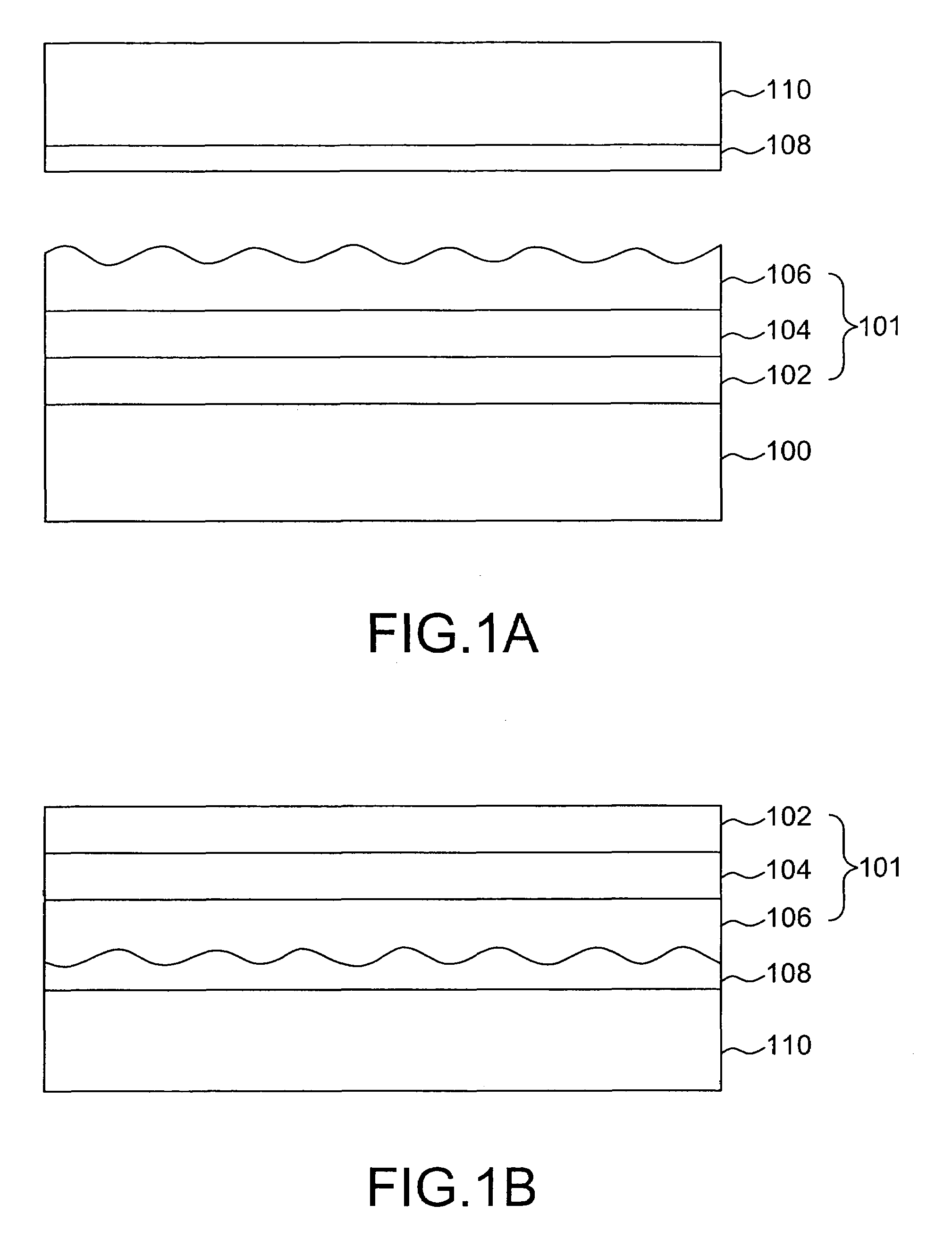

Forming an optical element on the surface of a light emitting device for improved light extraction

InactiveUS6987613B2Easy to integrateMaximize production efficiencyDiffraction gratingsSemiconductor devicesWafer bondingAlternative methods

Provided is a light emitting device including a Fresnel lens and / or a holographic diffuser formed on a surface of a semiconductor light emitter for improved light extraction, and a method for forming such light emitting device. Also provided is a light emitting device including an optical element stamped on a surface for improved light extraction and the stamping method used to form such device. An optical element formed on the surface of a semiconductor light emitter reduces reflective loss and loss due to total internal reflection, thereby improving light extraction efficiency. A Fresnel lens or a holographic diffuser may be formed on a surface by wet chemical etching or dry etching techniques, such as plasma etching, reactive ion etching, and chemically-assisted ion beam etching, optionally in conjunction with a lithographic technique. In addition, a Fresnel lens or a holographic diffuser may be milled, scribed, or ablated into the surface. Stamping, an alternative method for forming an optical element, can also be used to form a Fresnel lens or a holographic diffuser on the surface of a semiconductor light emitter. Stamping includes pressing a stamping block against the surface of a light emitting diode. The stamping block has a shape and pattern that are the inverse of the desired optical element. Optionally, stamping can be done before, after, or concurrently with wafer-bonding. Alternatively, a material can be stamped and later bonded to the semiconductor light emitter.

Owner:LUMILEDS

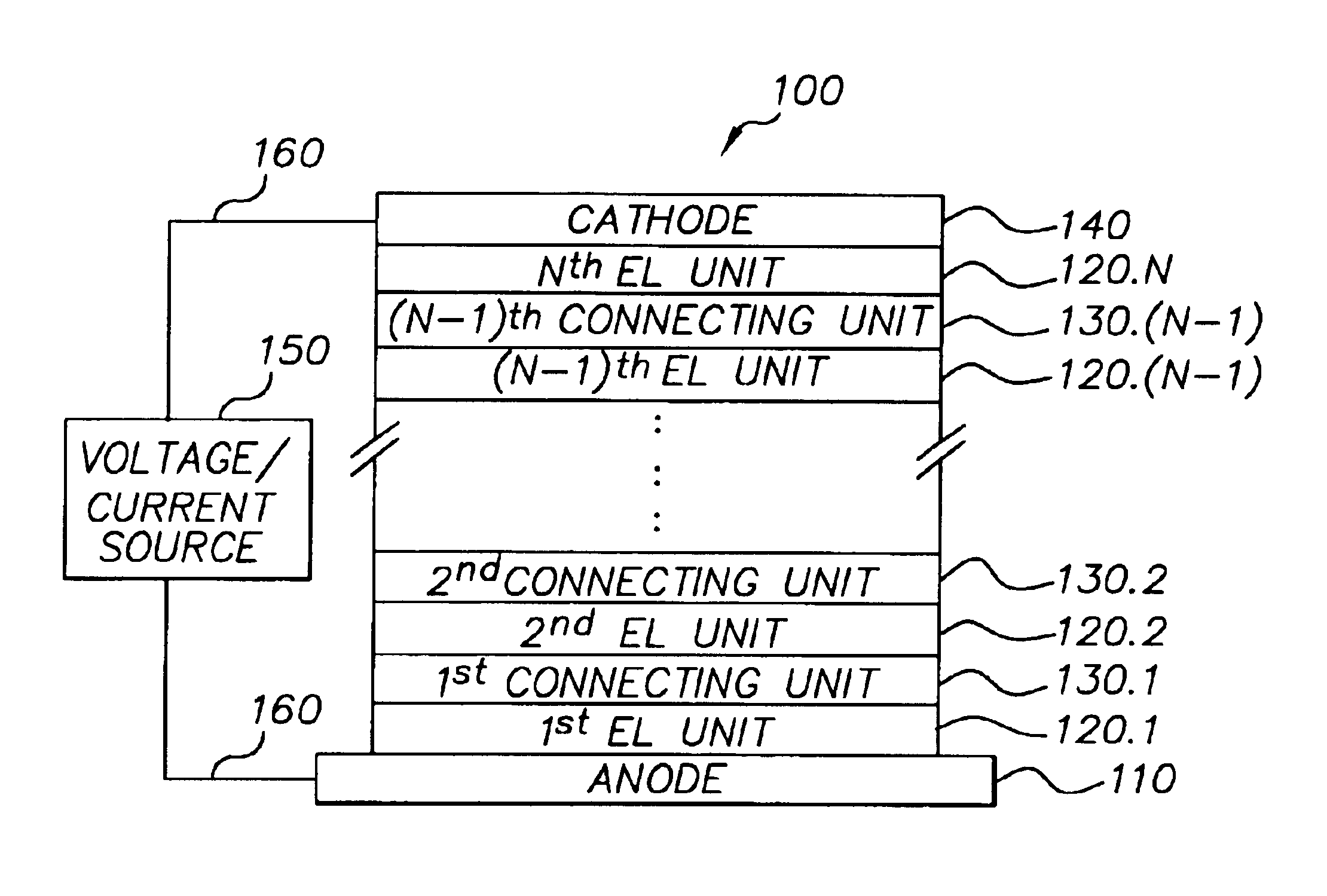

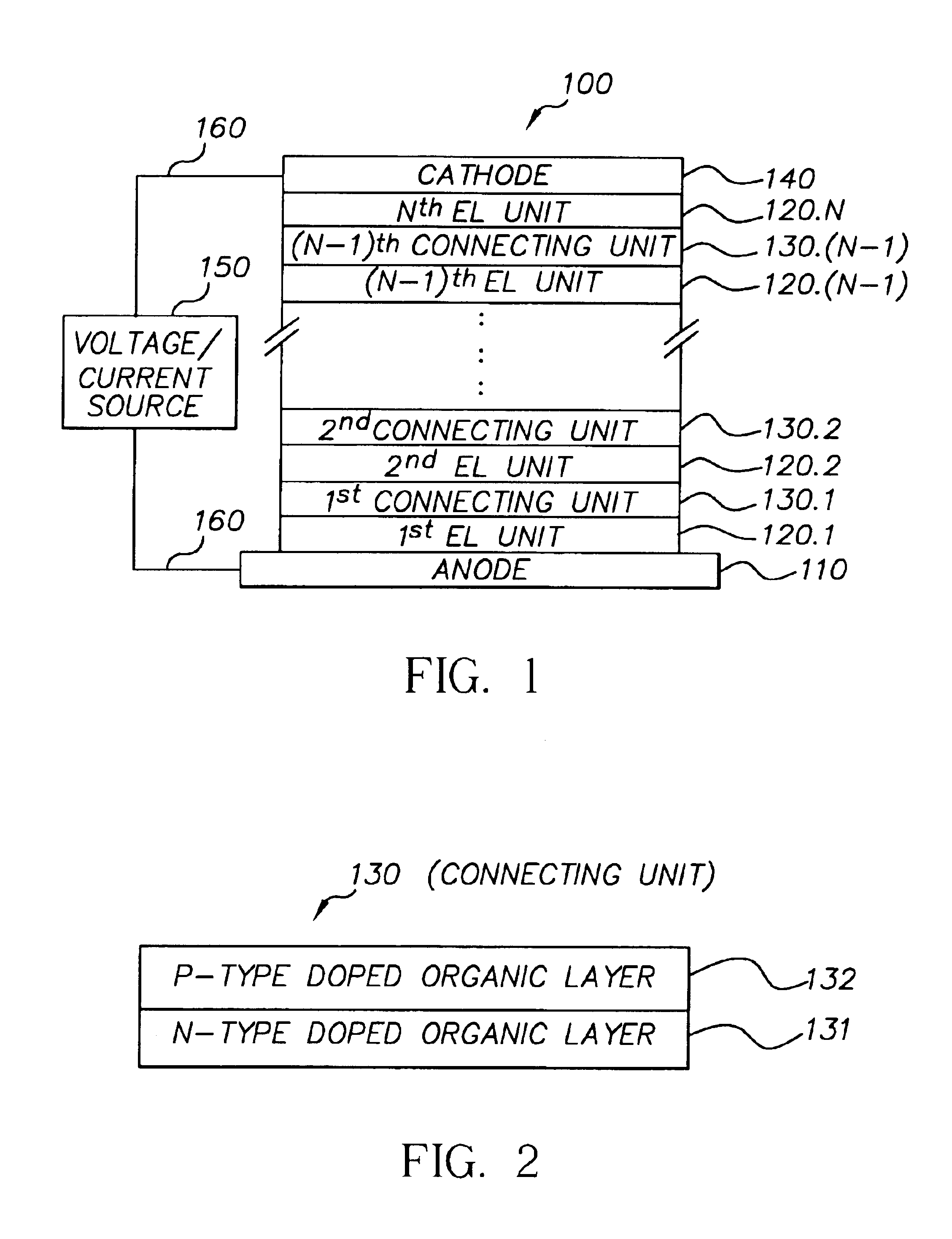

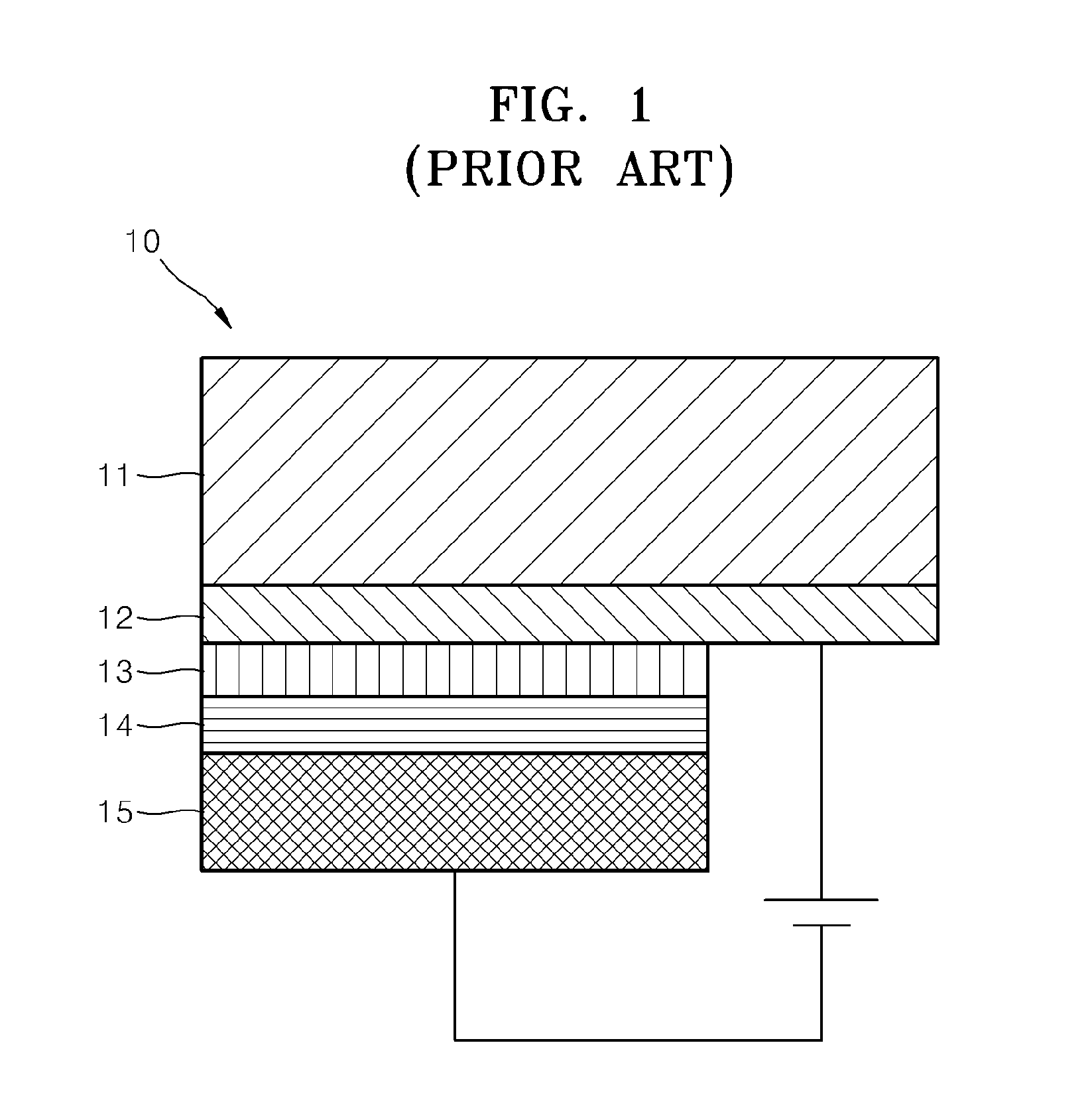

Cascaded organic electroluminescent device having connecting units with N-type and P-type organic layers

ActiveUS6936961B2Improve light extractionSimplify fabrication stepDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceP type doping

A cascaded organic electroluminescent device includes an anode and a cathode. The device also includes a plurality of organic electroluminescent units disposed between the anode and the cathode, wherein the organic electroluminescent units comprise at least a hole-transporting layer, an electron-transporting layer, and an electroluminescent zone formed between the hole-transporting layer and the electron-transporting layer wherein the physical spacing between adjacent electroluminescent zones is more than 90 nm; and a connecting unit disposed between each adjacent organic electroluminescent unit, wherein the connecting unit comprises, in sequence, an n-type doped organic layer and a p-type doped organic layer forming a transparent p-n junction structure wherein the resistivity of each of the doped layers is higher than 10 Ω-cm.

Owner:GLOBAL OLED TECH

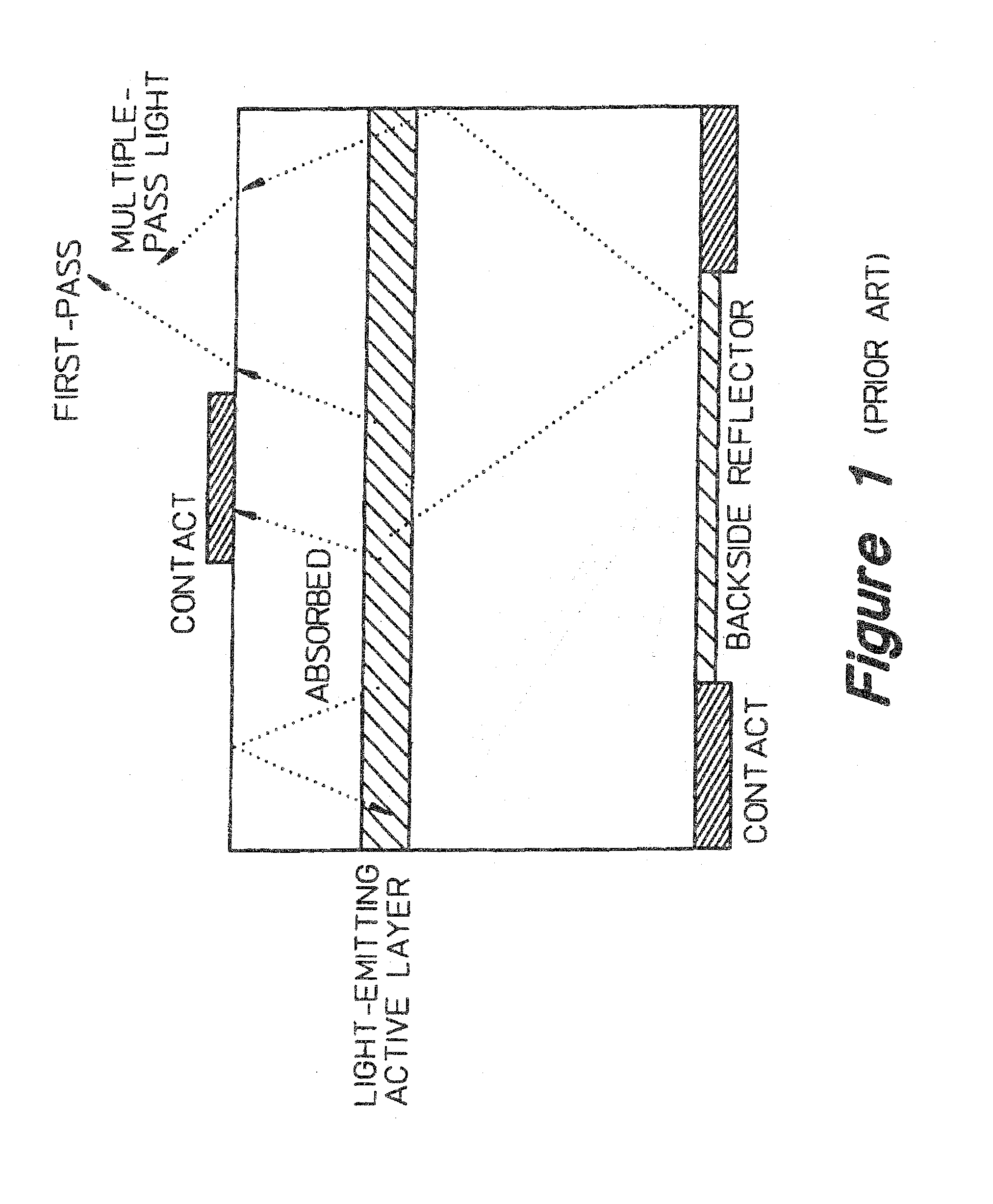

High light extraction efficiency light emitting diode (LED)

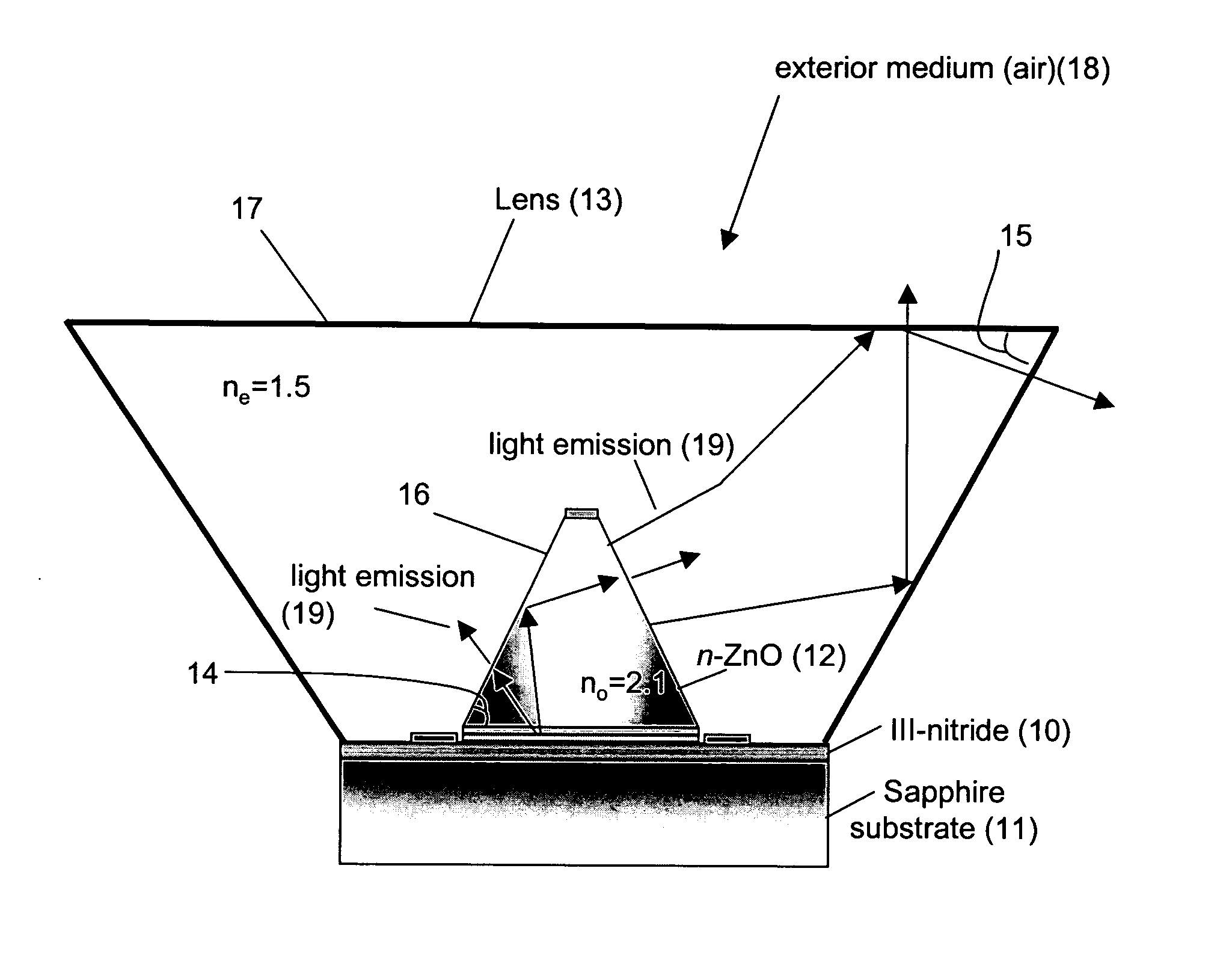

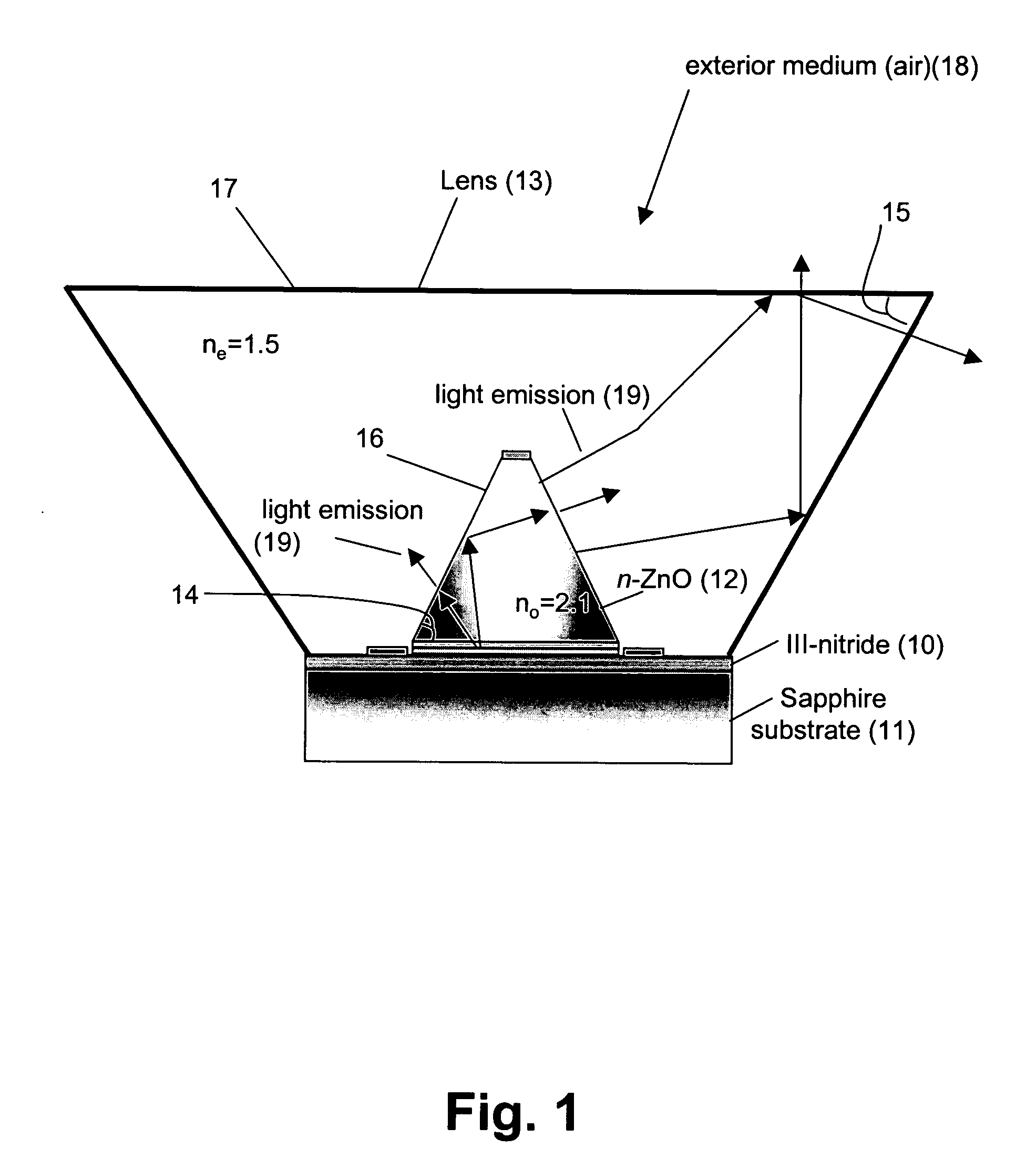

InactiveUS20070102721A1Maximize refraction of lightHigh extraction efficiencySemiconductor/solid-state device manufacturingRefractorsPhysicsRefractive index

An (Al, Ga, In)N and ZnO direct wafer bonded light emitting diode (LED) combined with a shaped plastic optical element, in which the directional light from the ZnO cone, or from any high refractive index material in contact with the LED surface, entering the shaped plastic optical element is extracted to air.

Owner:RGT UNIV OF CALIFORNIA +1

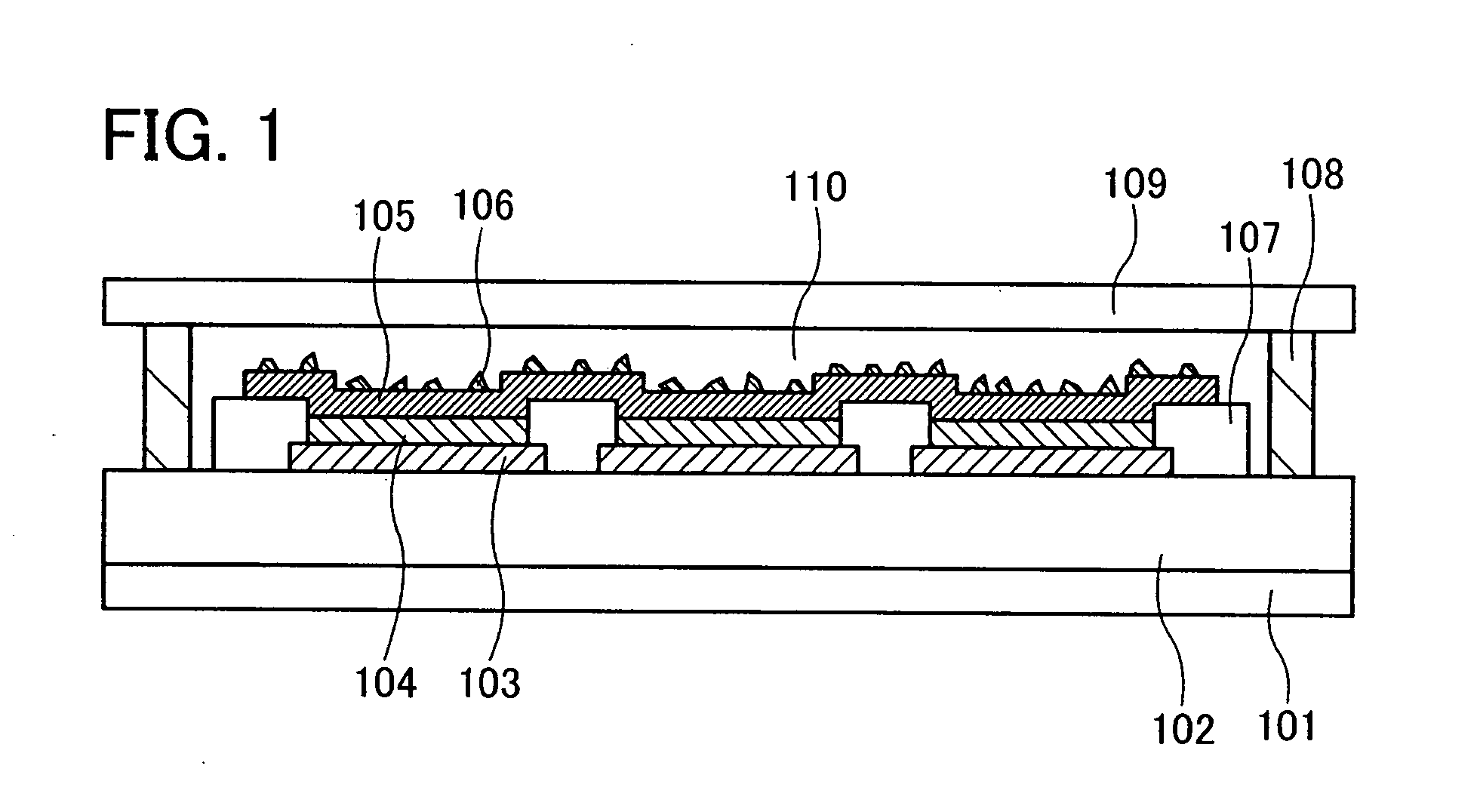

Wedge light extractor with risers

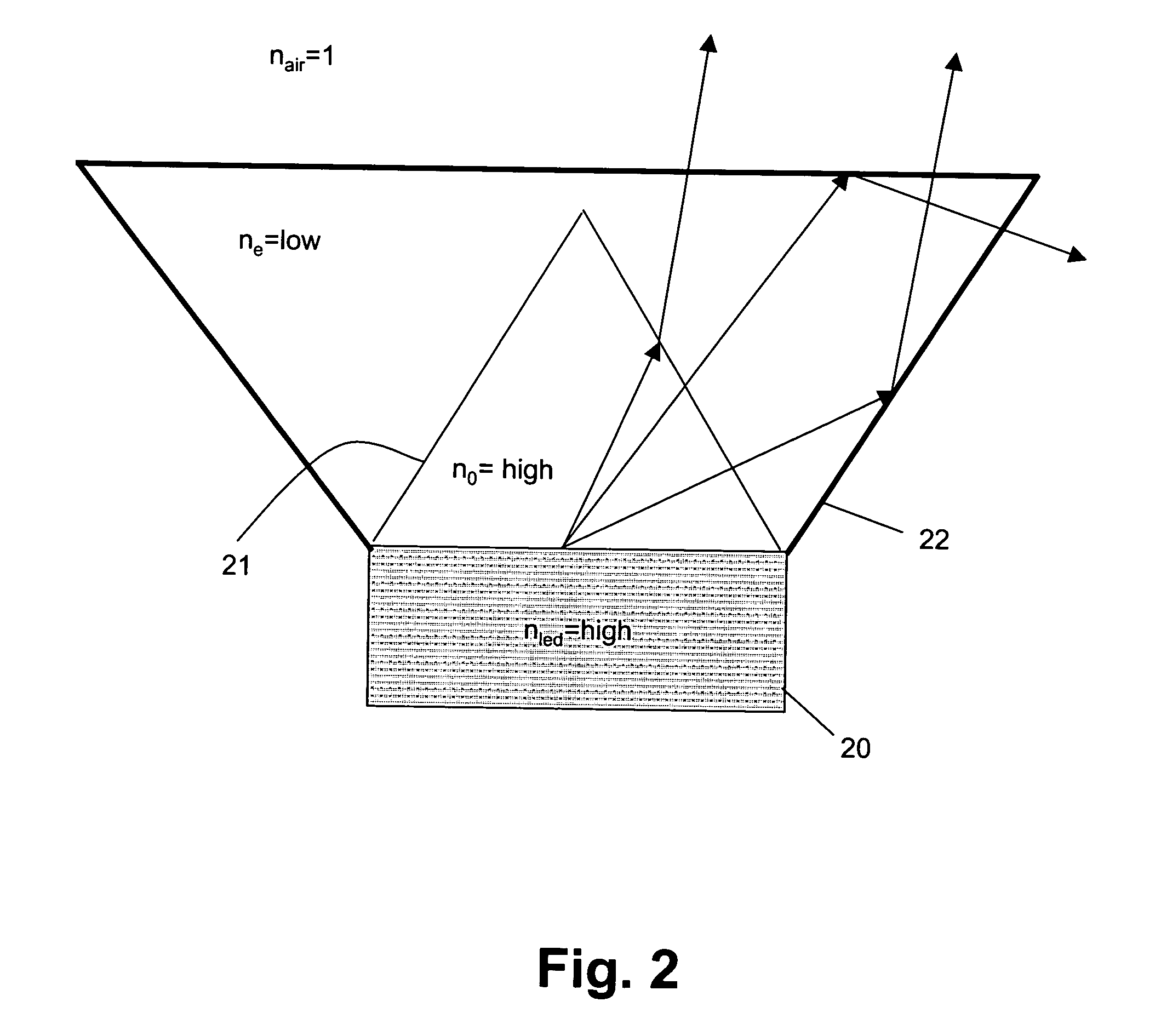

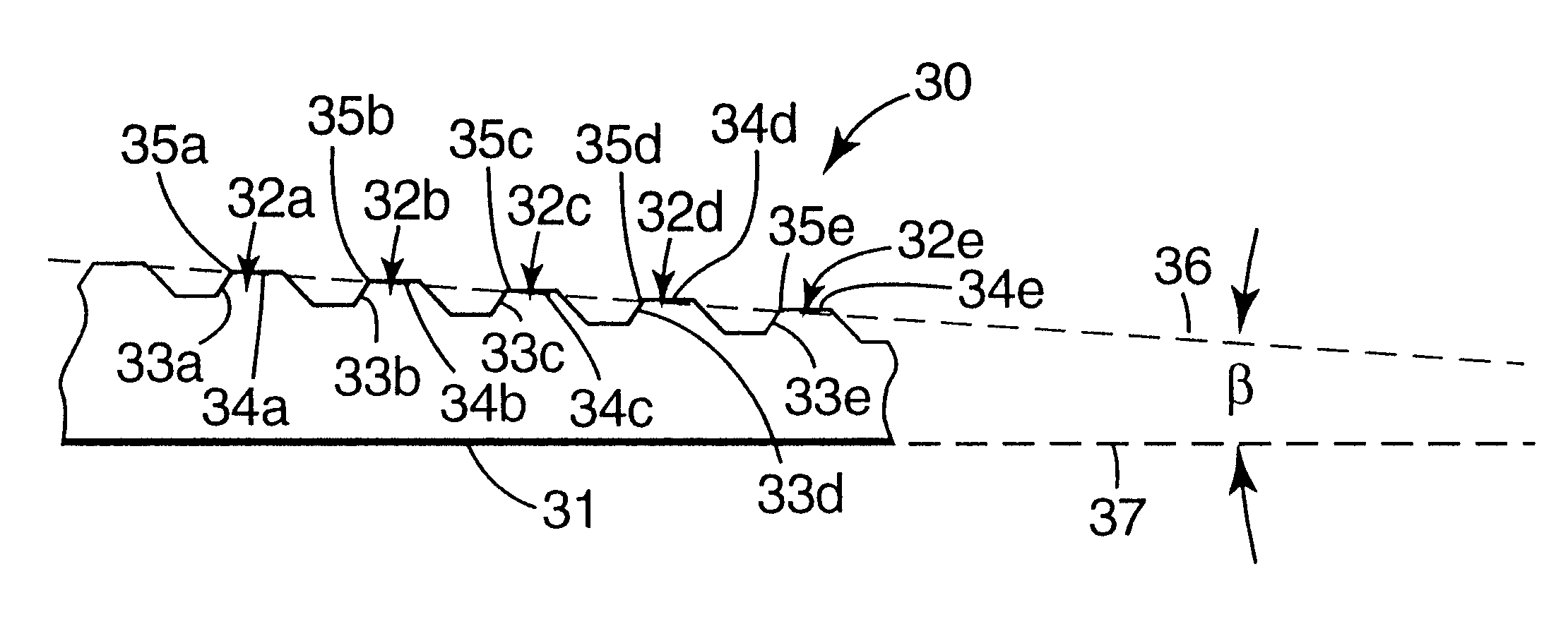

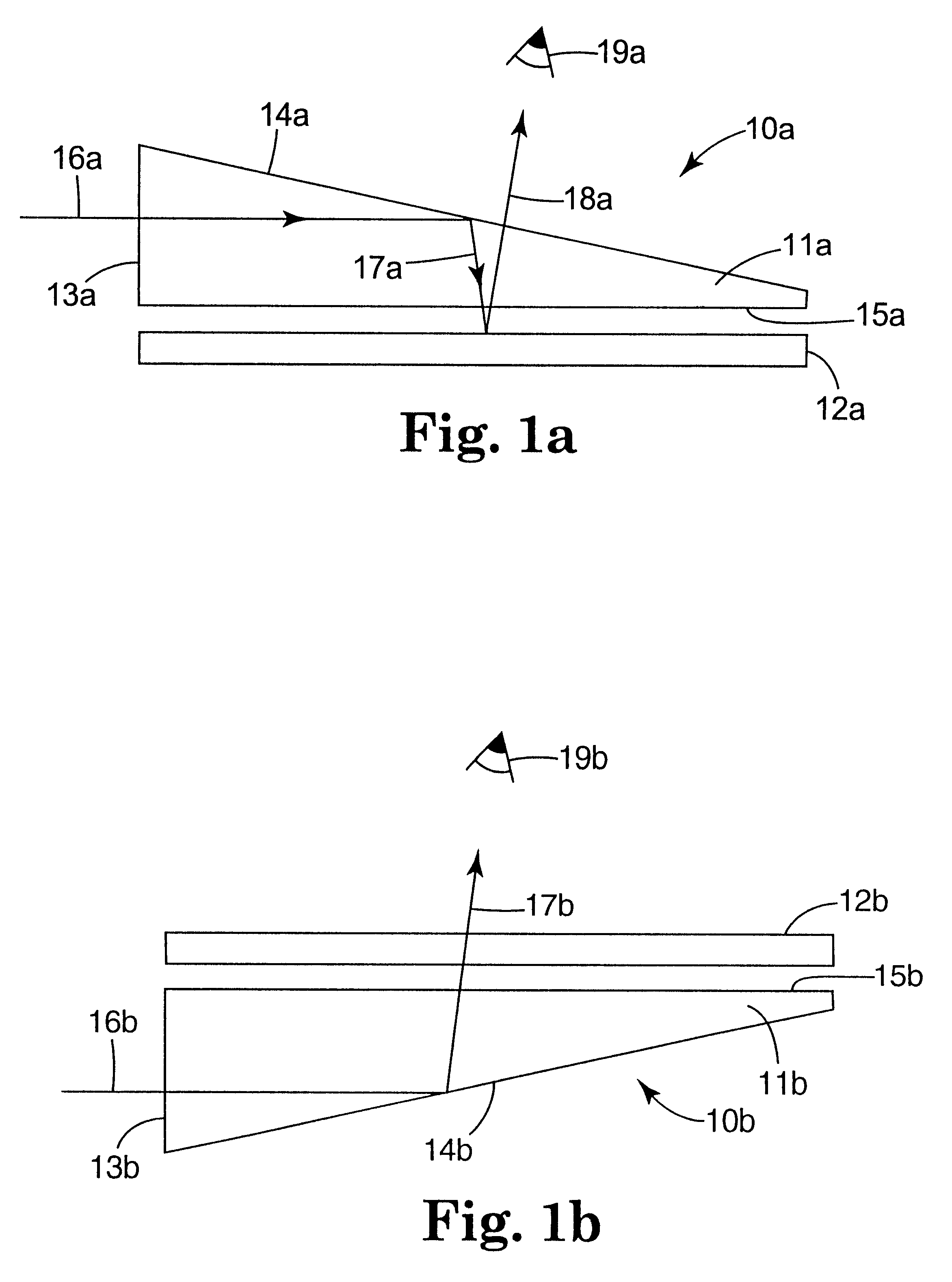

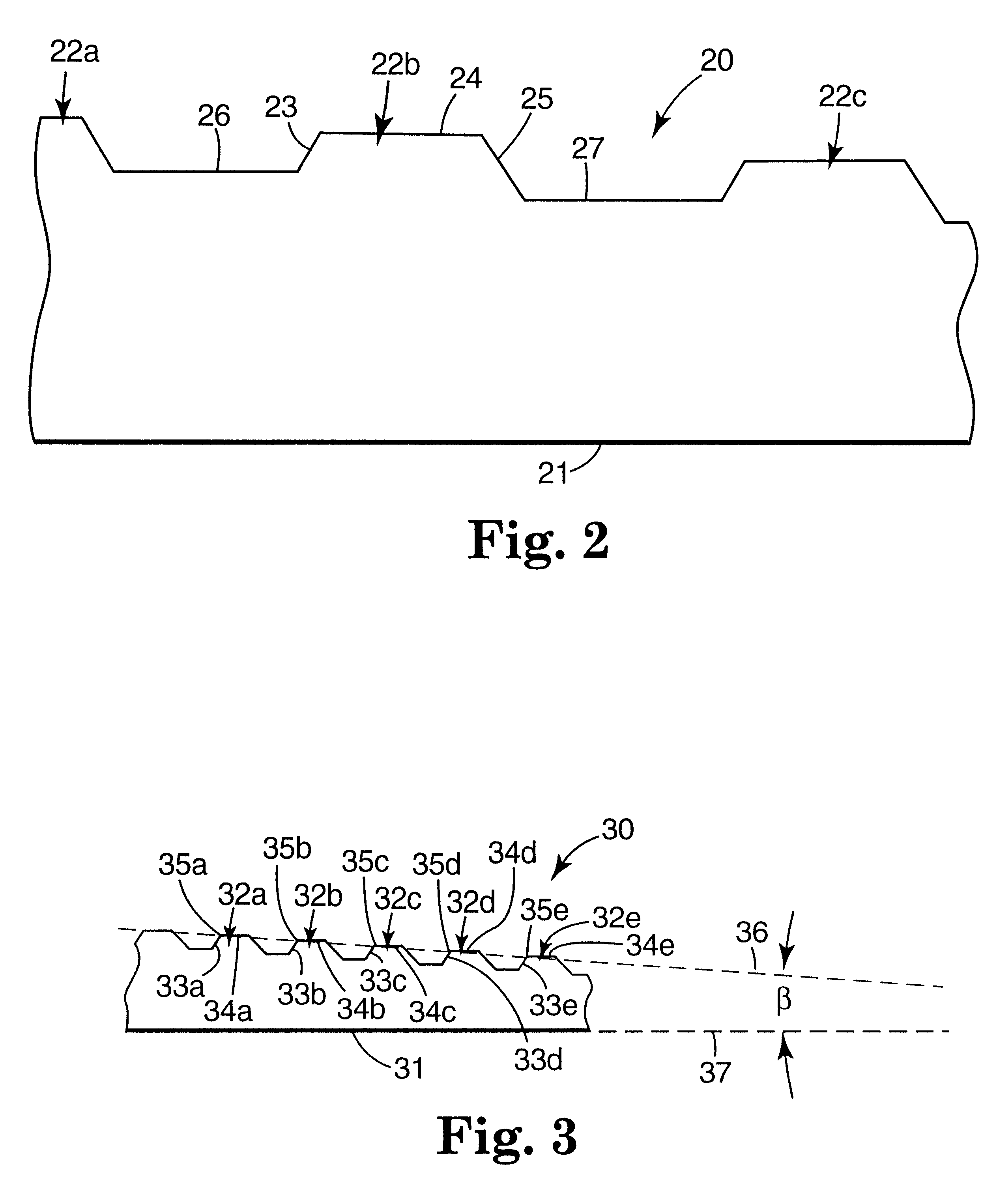

InactiveUS6347874B1Reduce power consumptionEfficient designMechanical apparatusPoint-like light sourceOptoelectronicsAvailable light

A wedge-shaped light extractor having a light-redirecting surface with a plurality of projections having a riser segment, a plateau segment, and a facet segment, with land segments flanking the projections. The projections improve extraction efficiency, thereby facilitating use of available light from a light source.

Owner:3M INNOVATIVE PROPERTIES CO

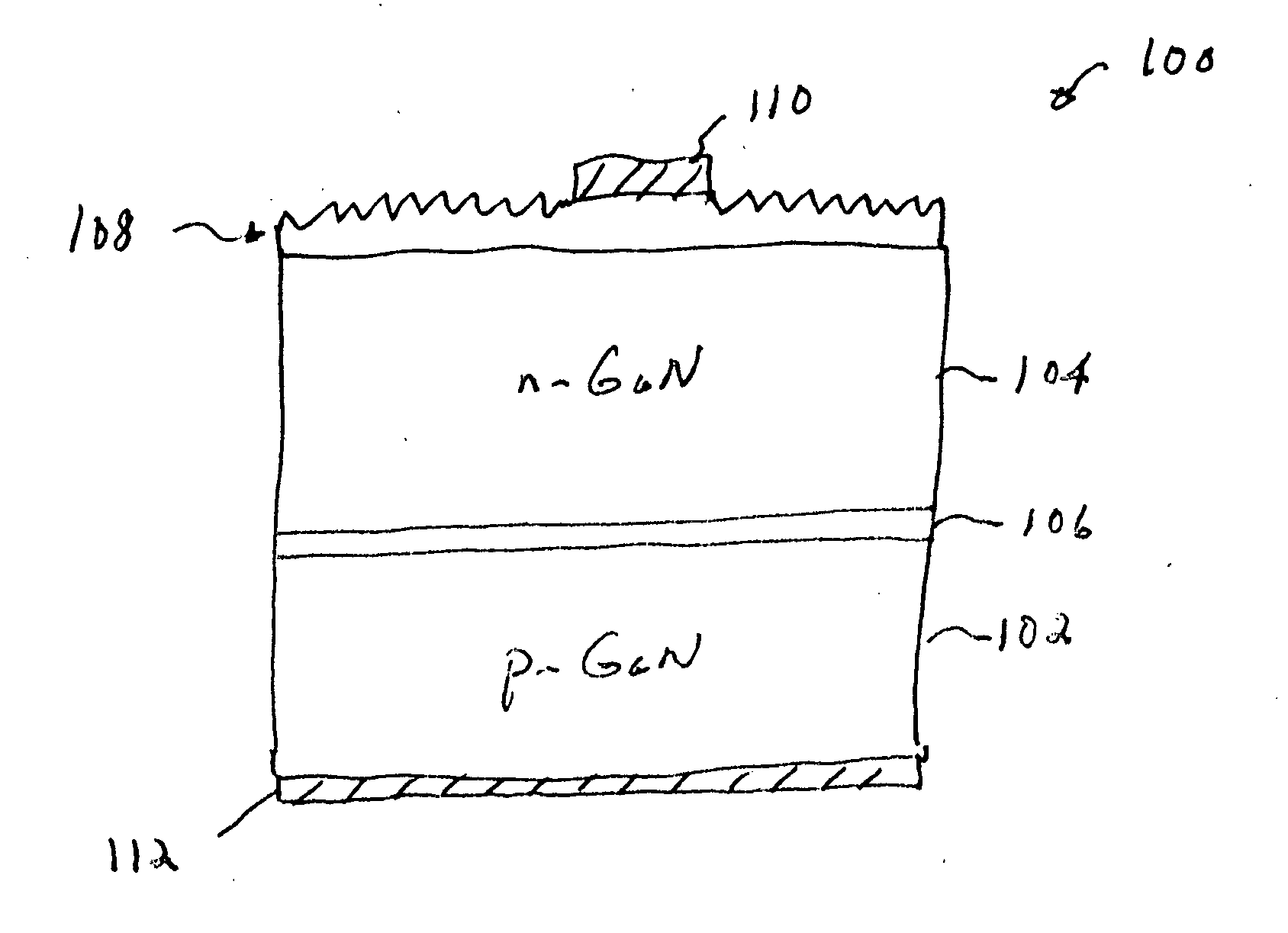

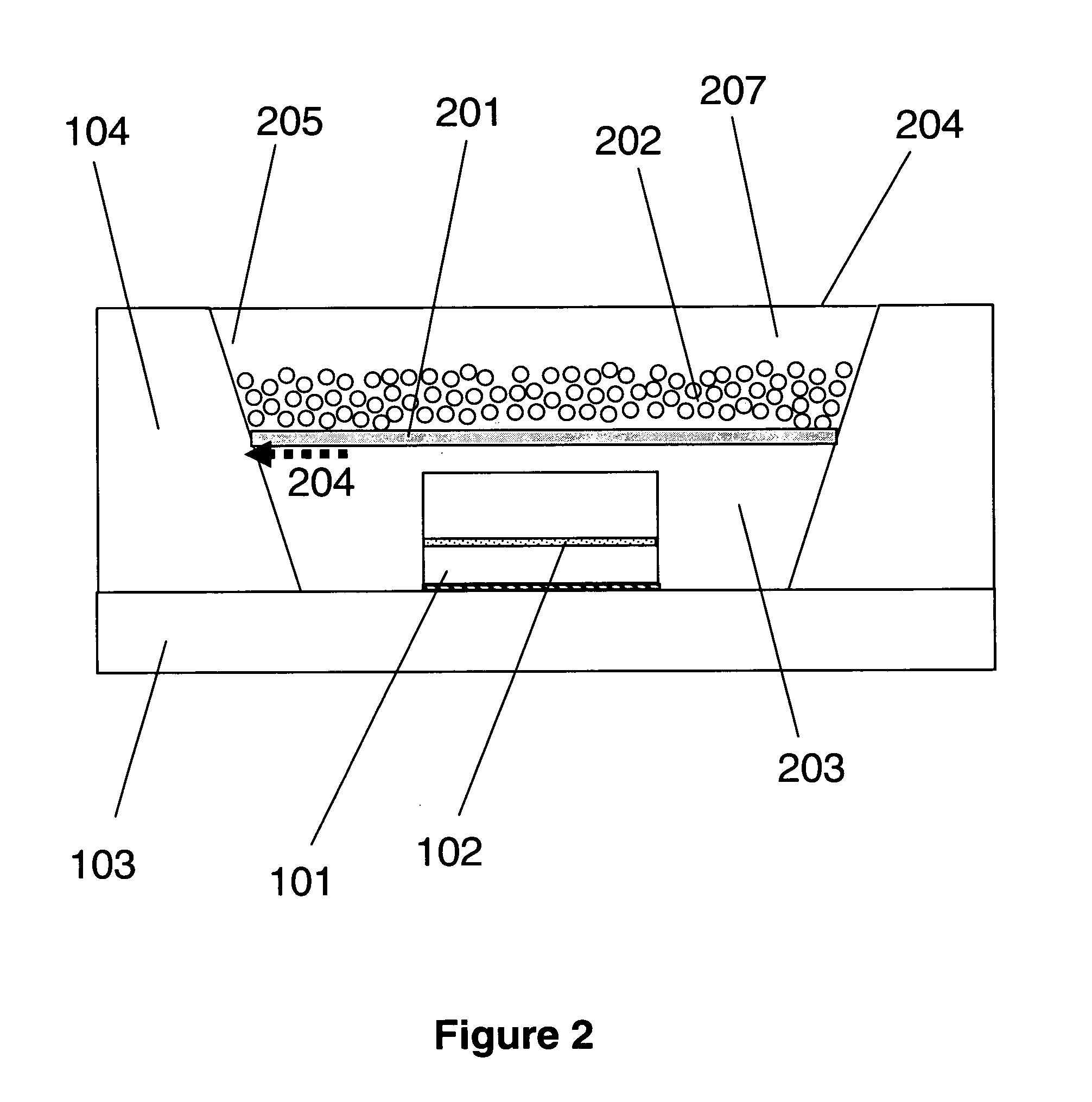

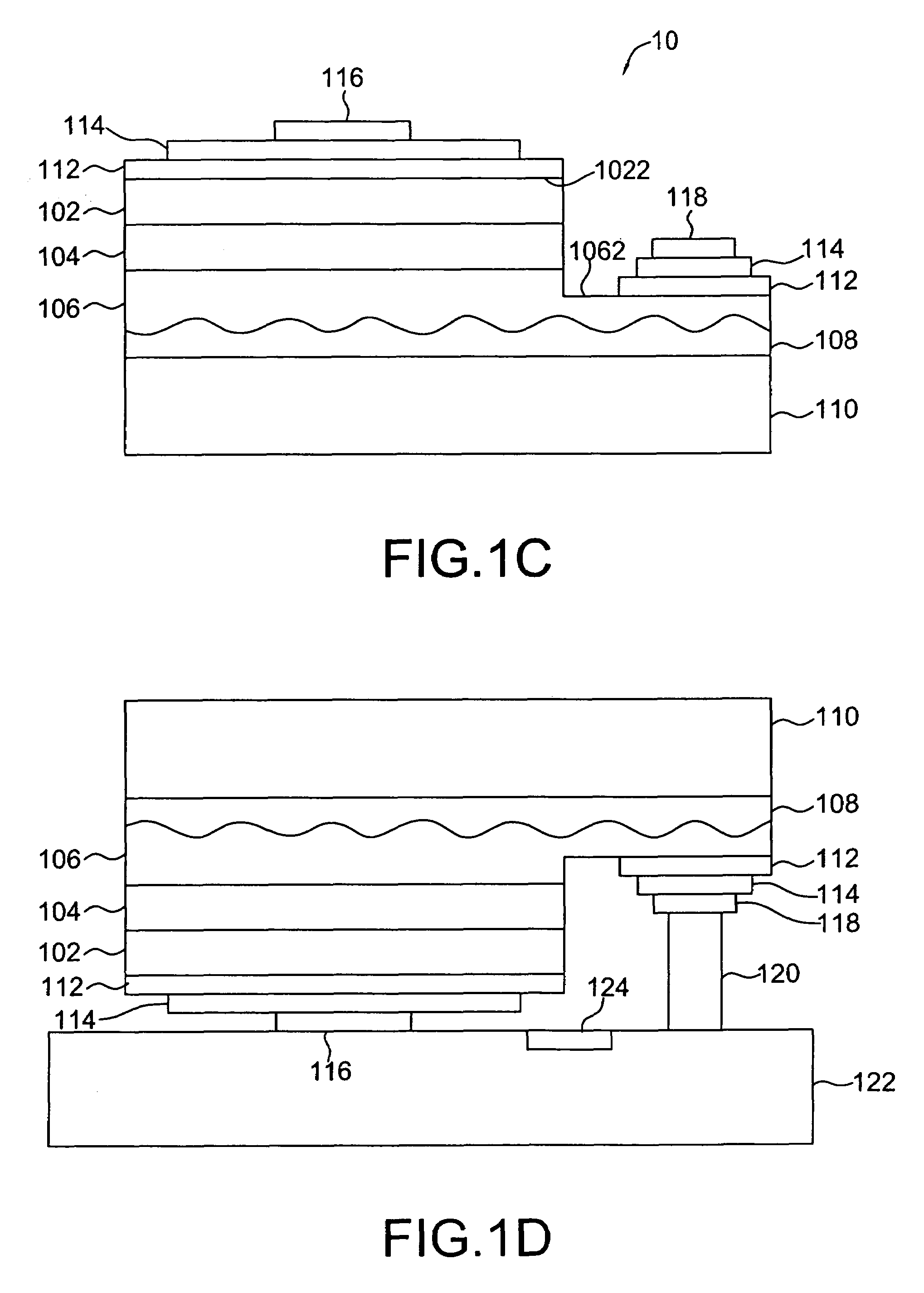

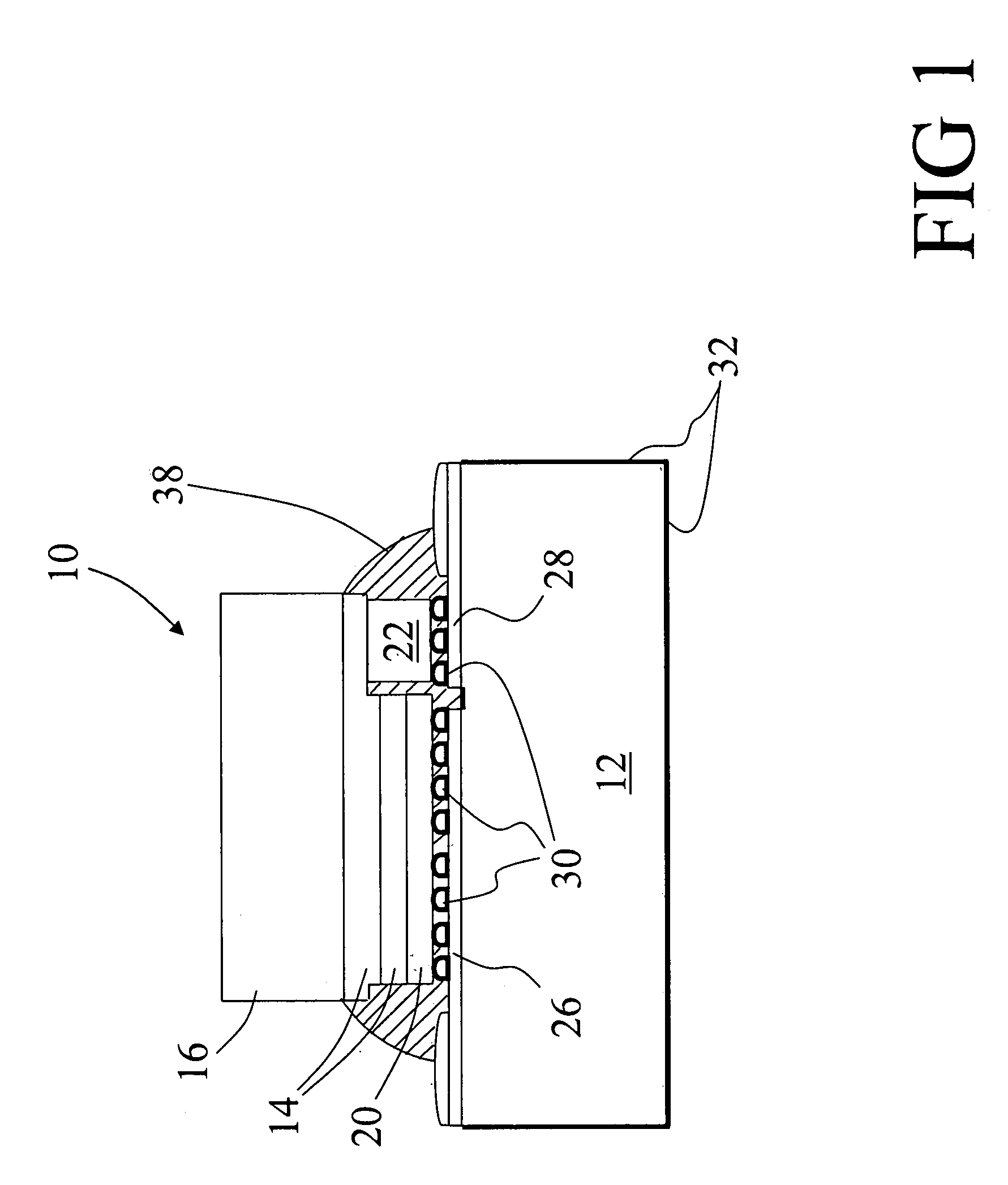

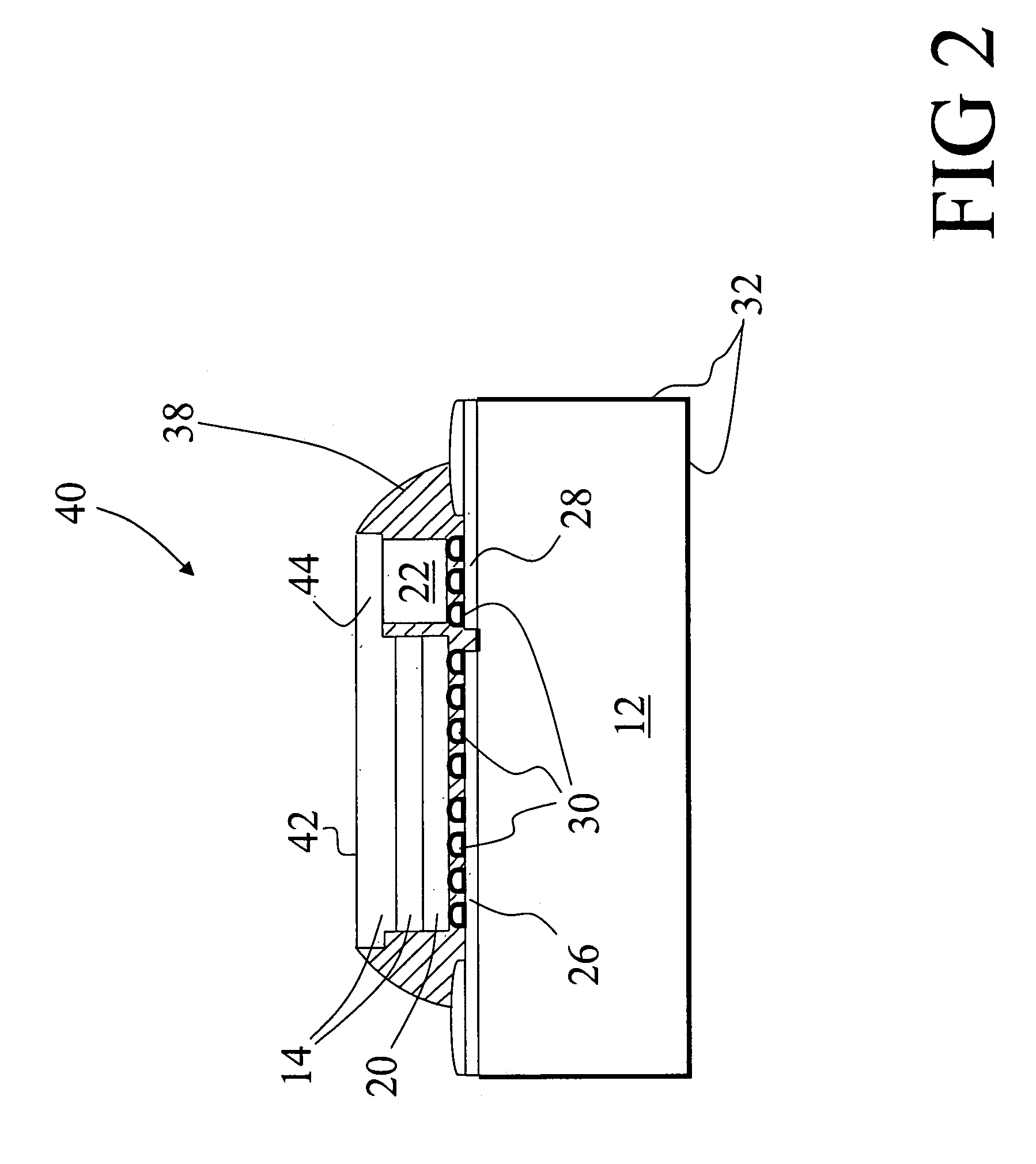

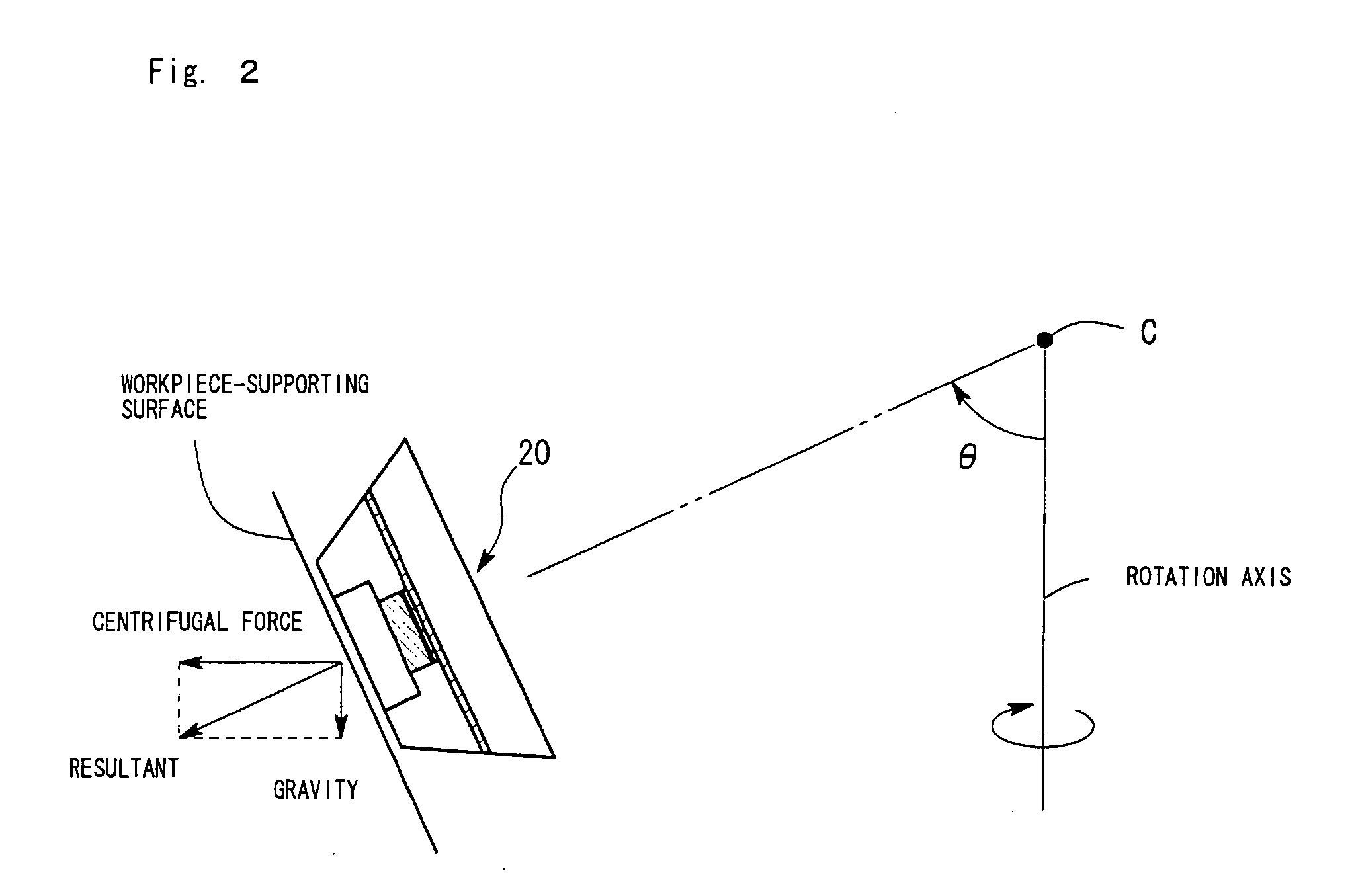

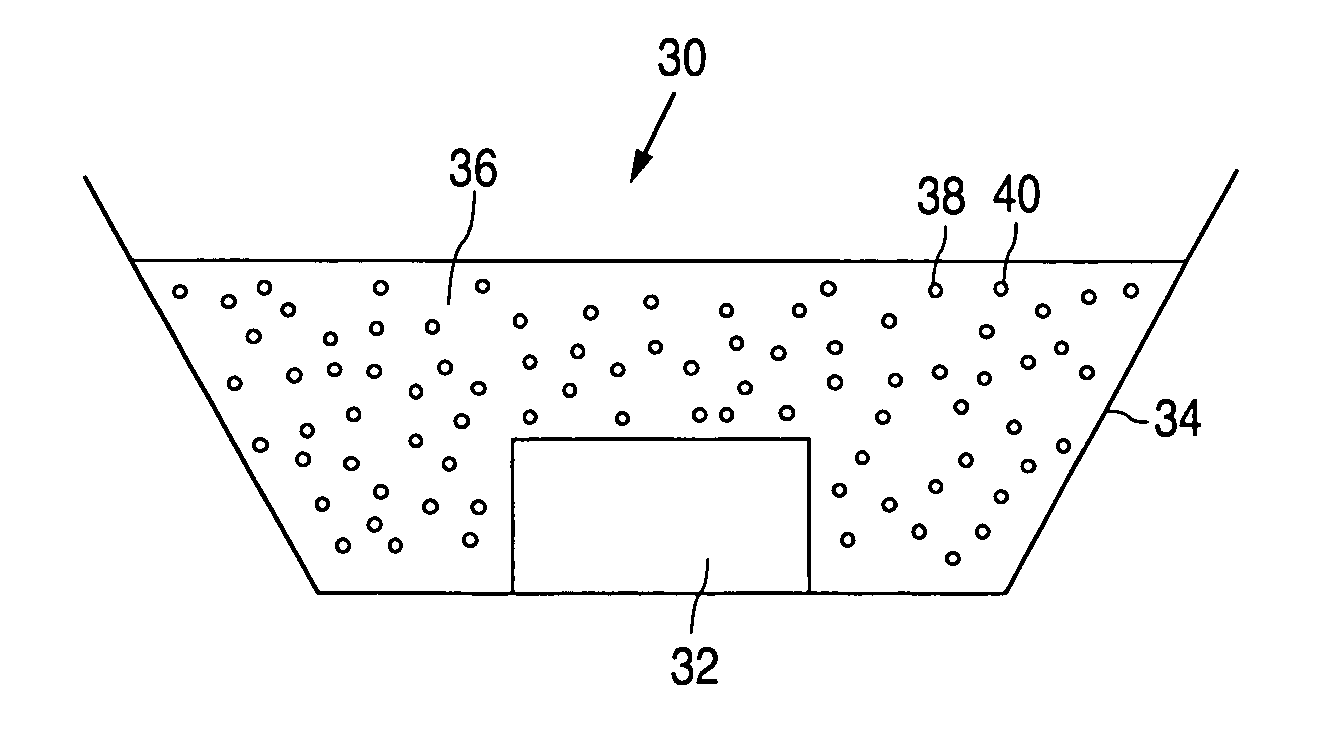

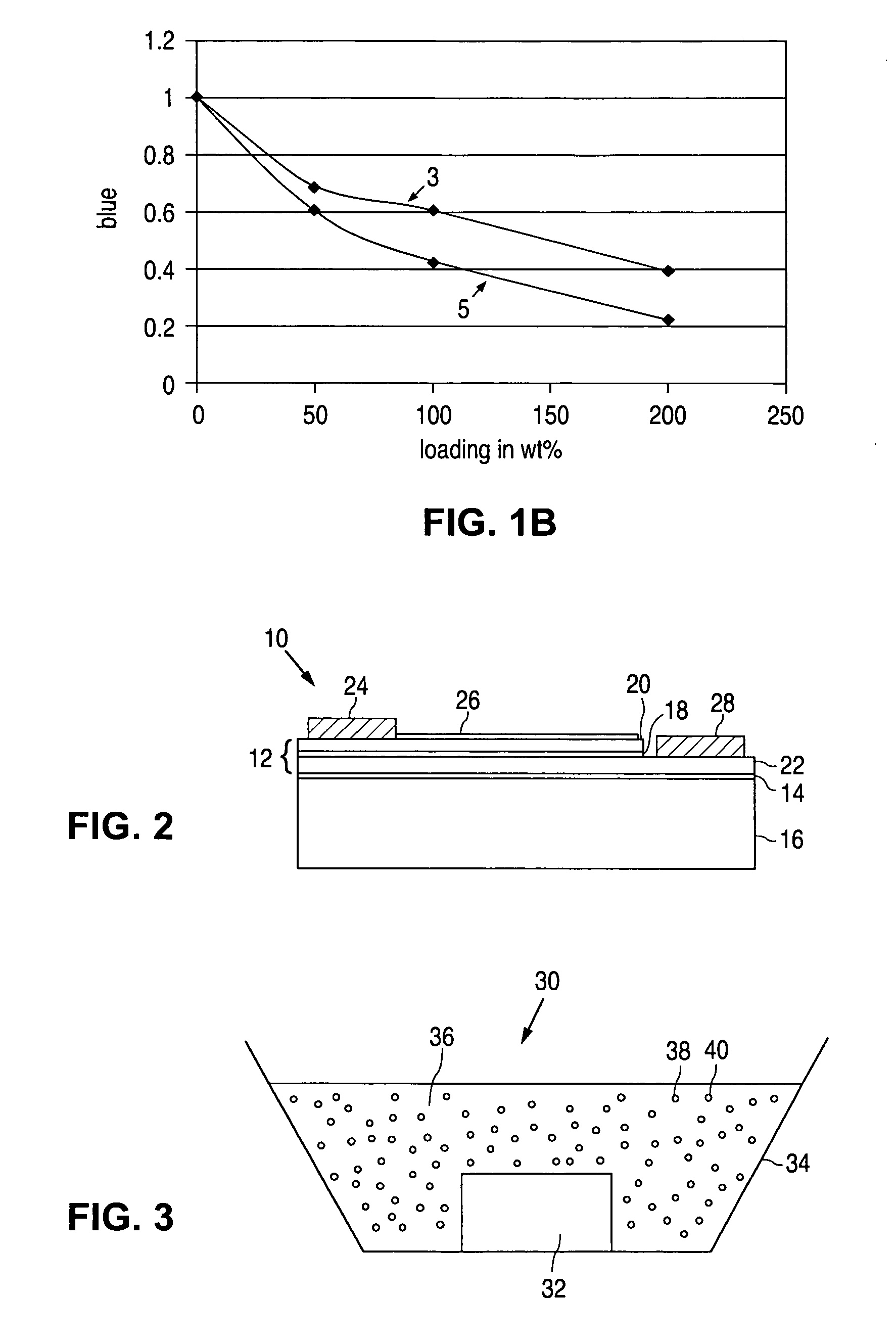

Increased light extraction from a nitride LED

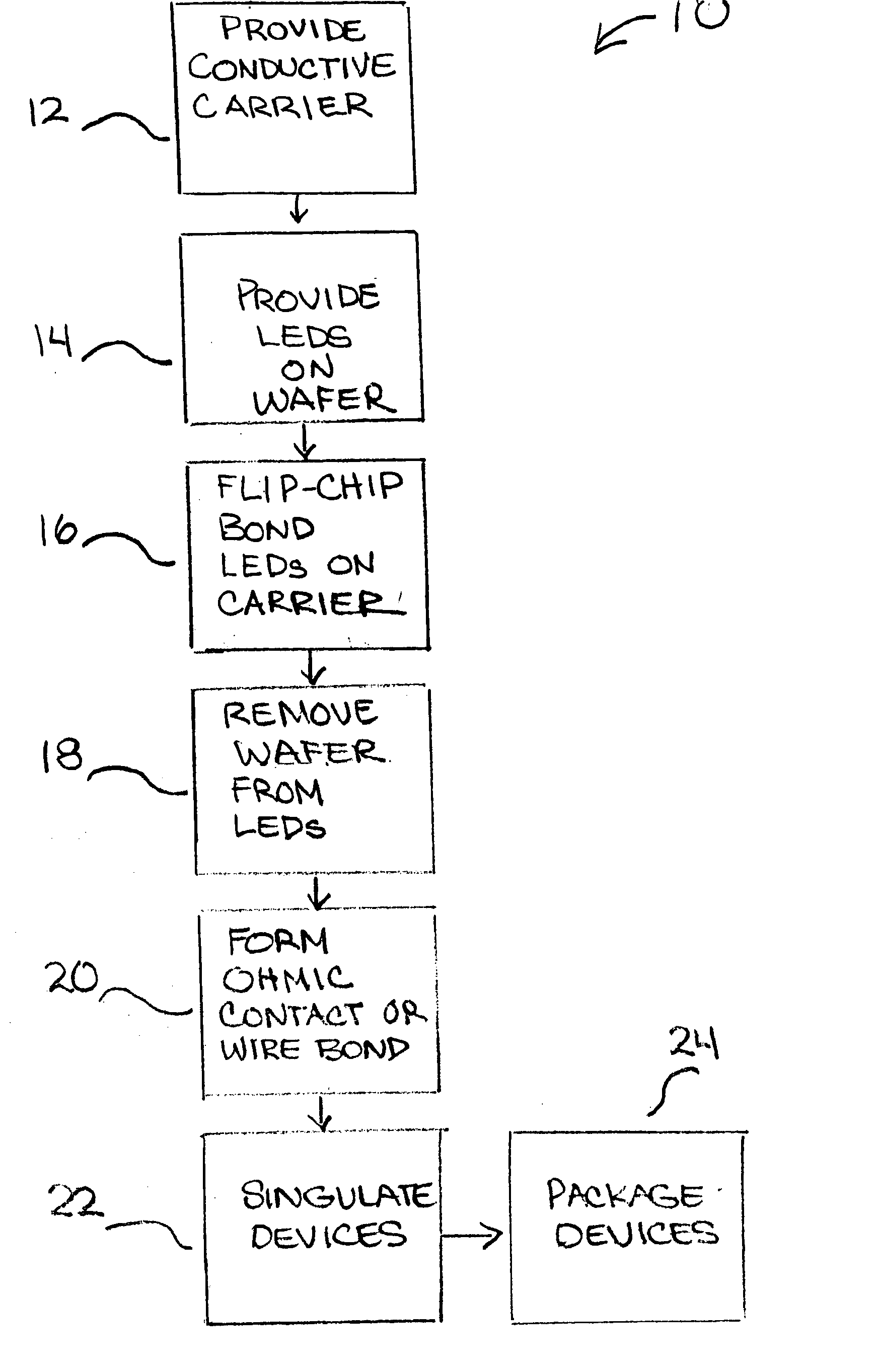

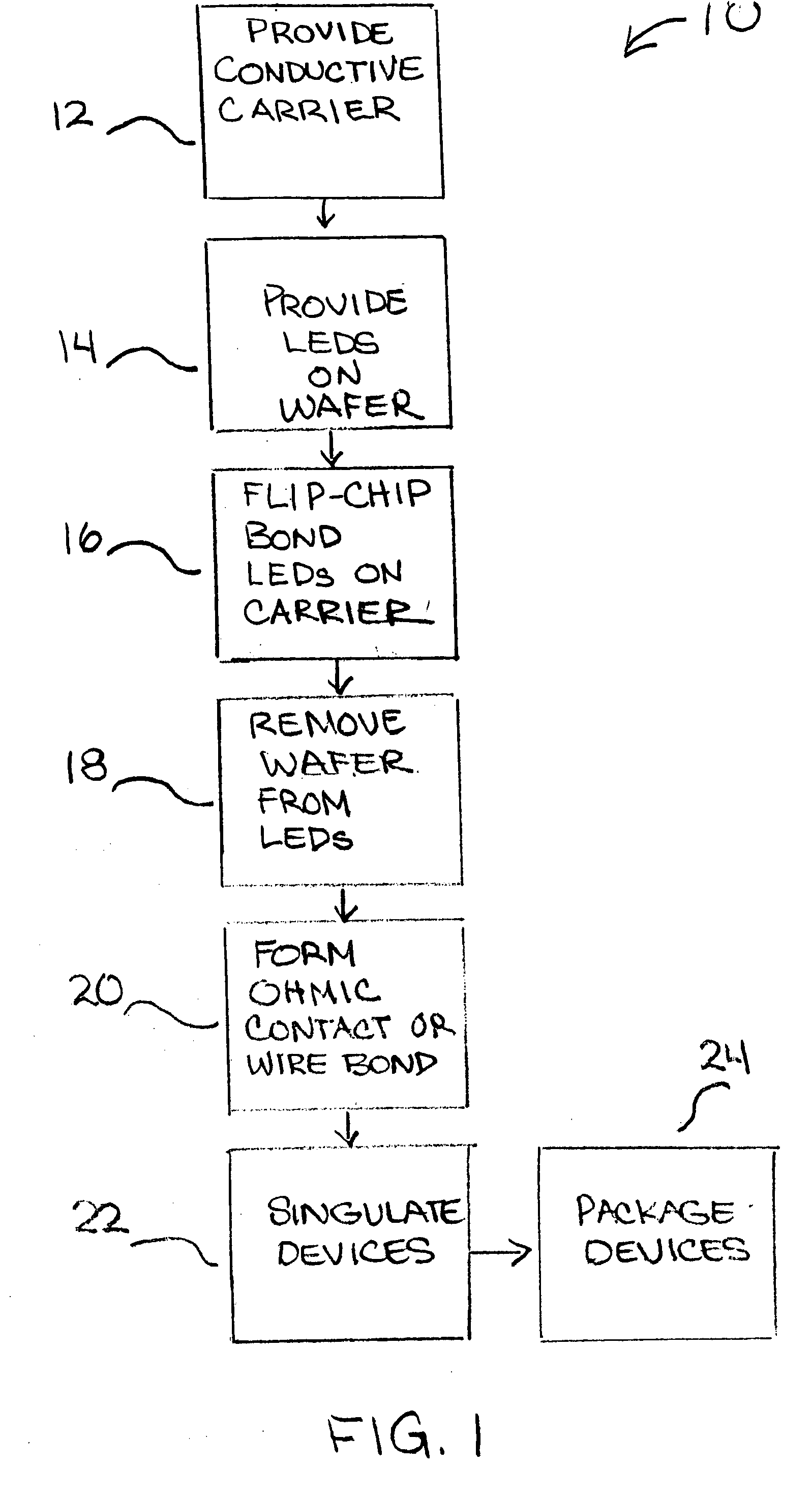

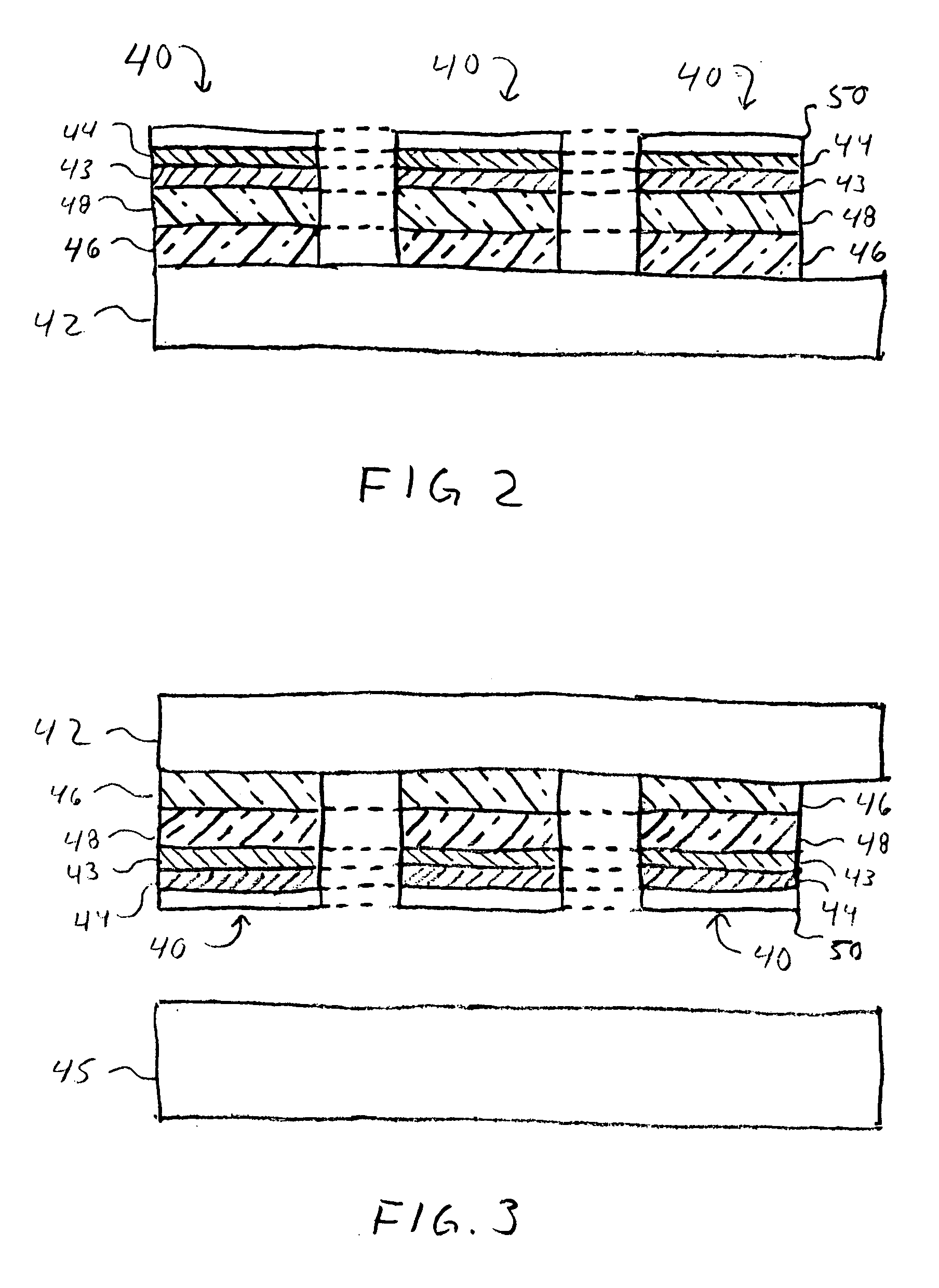

InactiveUS20060202223A1Improve light extractionEasy to fixSemiconductor/solid-state device detailsSolid-state devicesWaferingFlip chip

In a method for fabricating a flip-chip light emitting diode device, a submount wafer is populated with a plurality of the light emitting diode dies. Each device die is flip-chip bonded to the submount. Subsequent to the flip-chip bonding, a growth substrate is removed. The entire submount is immersed in the etchant solution, exposed to the light for a prespecified period of time, removed from the solution, dried and diced into a plurality of LEDs., The LEDs are immediately packaged without any further processing.

Owner:GELCORE LLC (US)

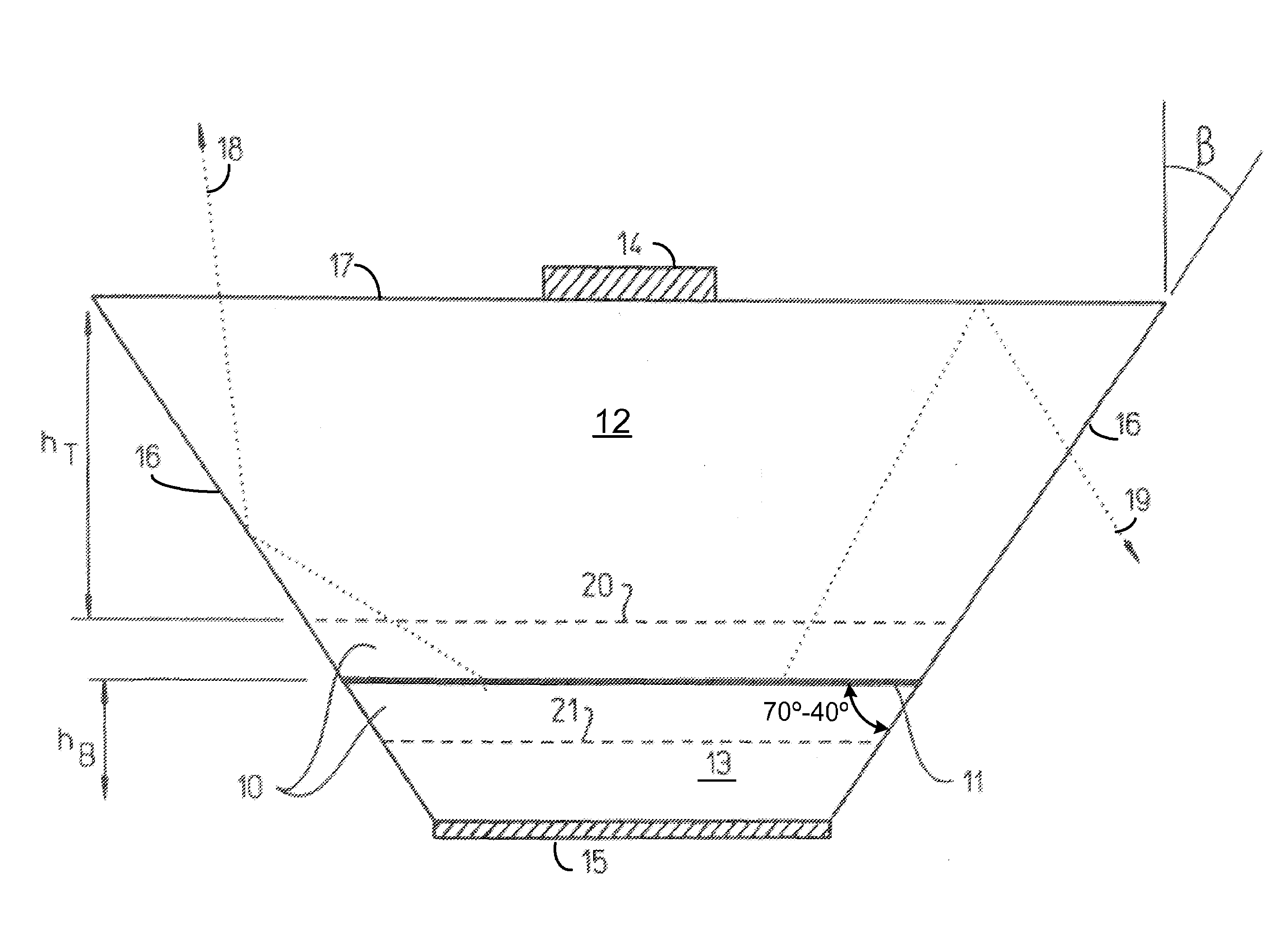

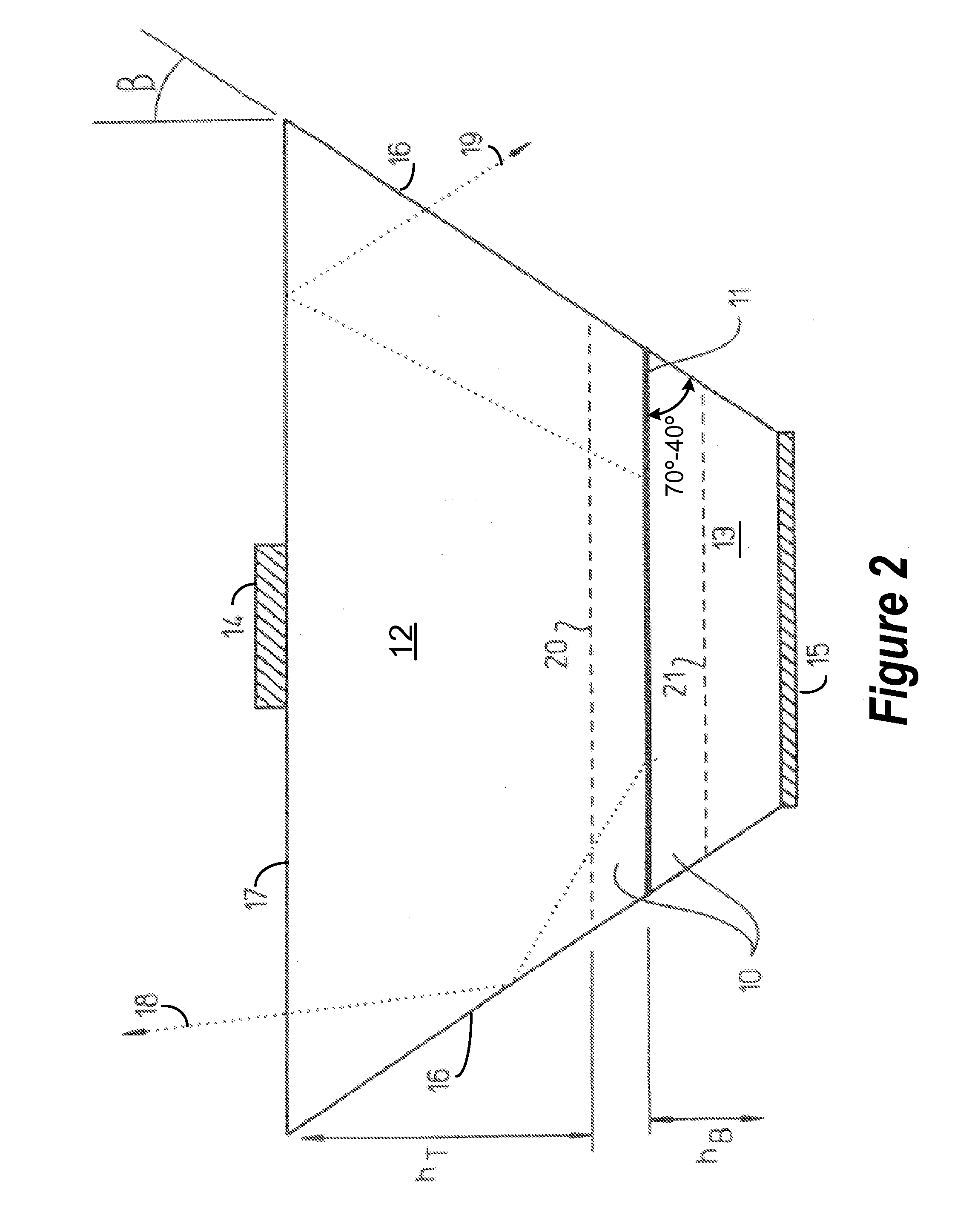

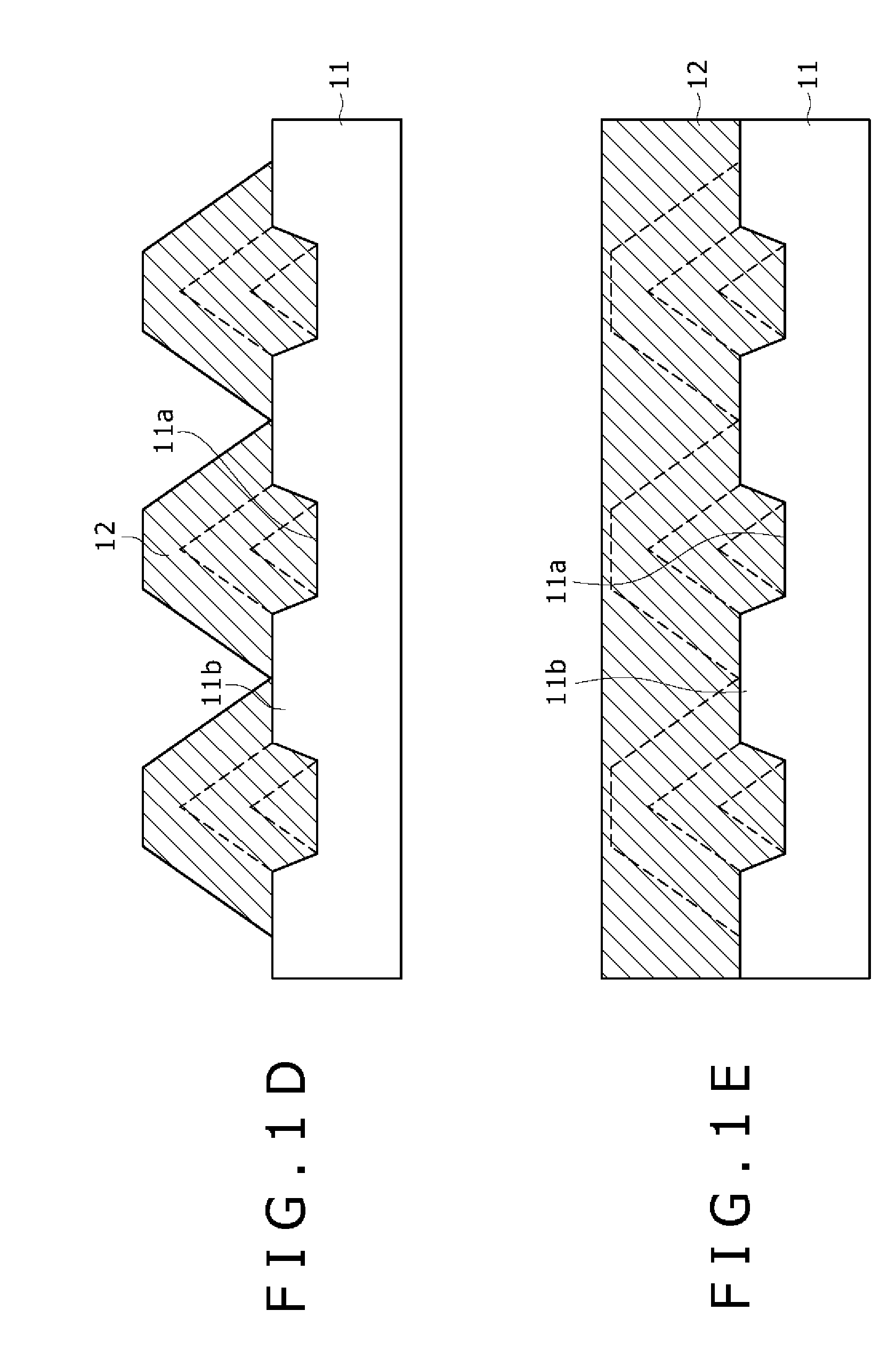

Light extraction from a semiconductor light emitting device via chip shaping

InactiveUS7268371B2Precise positioningReasonable degreeSolid-state devicesSemiconductor devicesHigh volume manufacturingActive layer

A method for designing semiconductor light emitting devices is disclosed wherein the side surfaces (surfaces not parallel to the epitaxial layers) are formed at preferred angles relative to vertical (normal to the plane of the light-emitting active layer) to improve light extraction efficiency and increase total light output efficiency. Device designs are chosen to improve efficiency without resorting to excessive active area-yield loss due to shaping. As such, these designs are suitable for low-cost, high-volume manufacturing of semiconductor light-emitting devices with improved characteristics.

Owner:PHILIPS LUMILEDS LIGHTING CO LLC

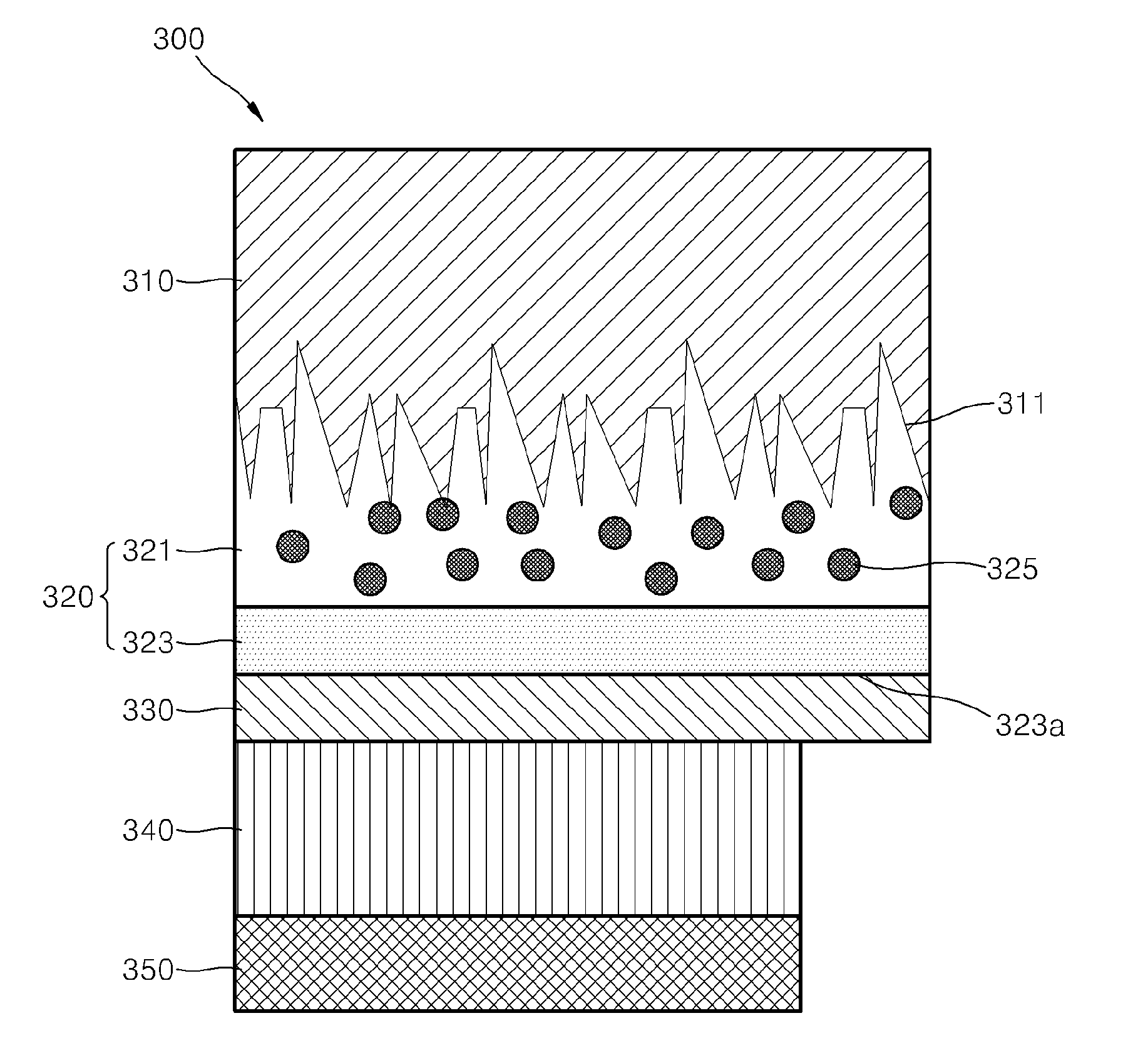

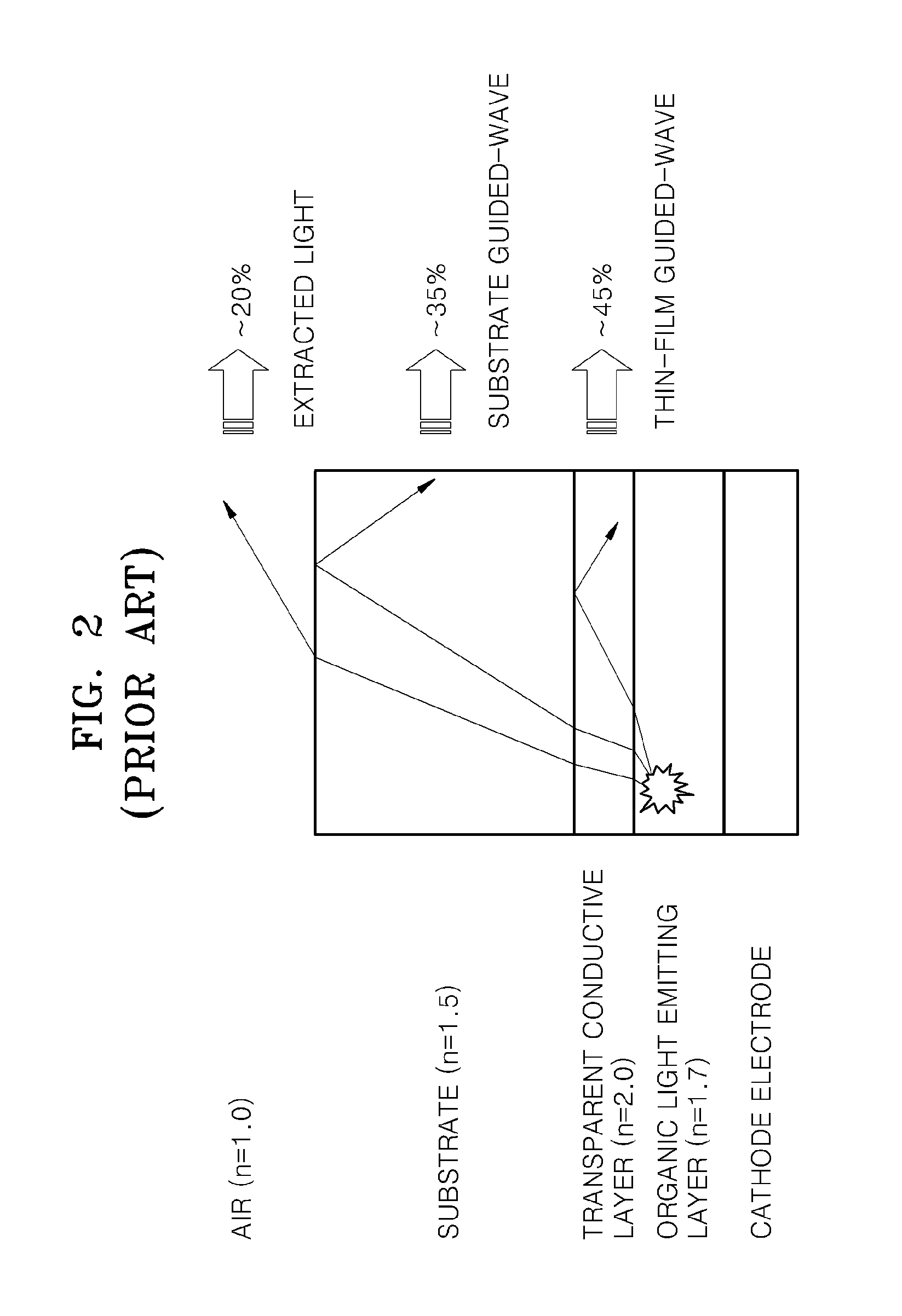

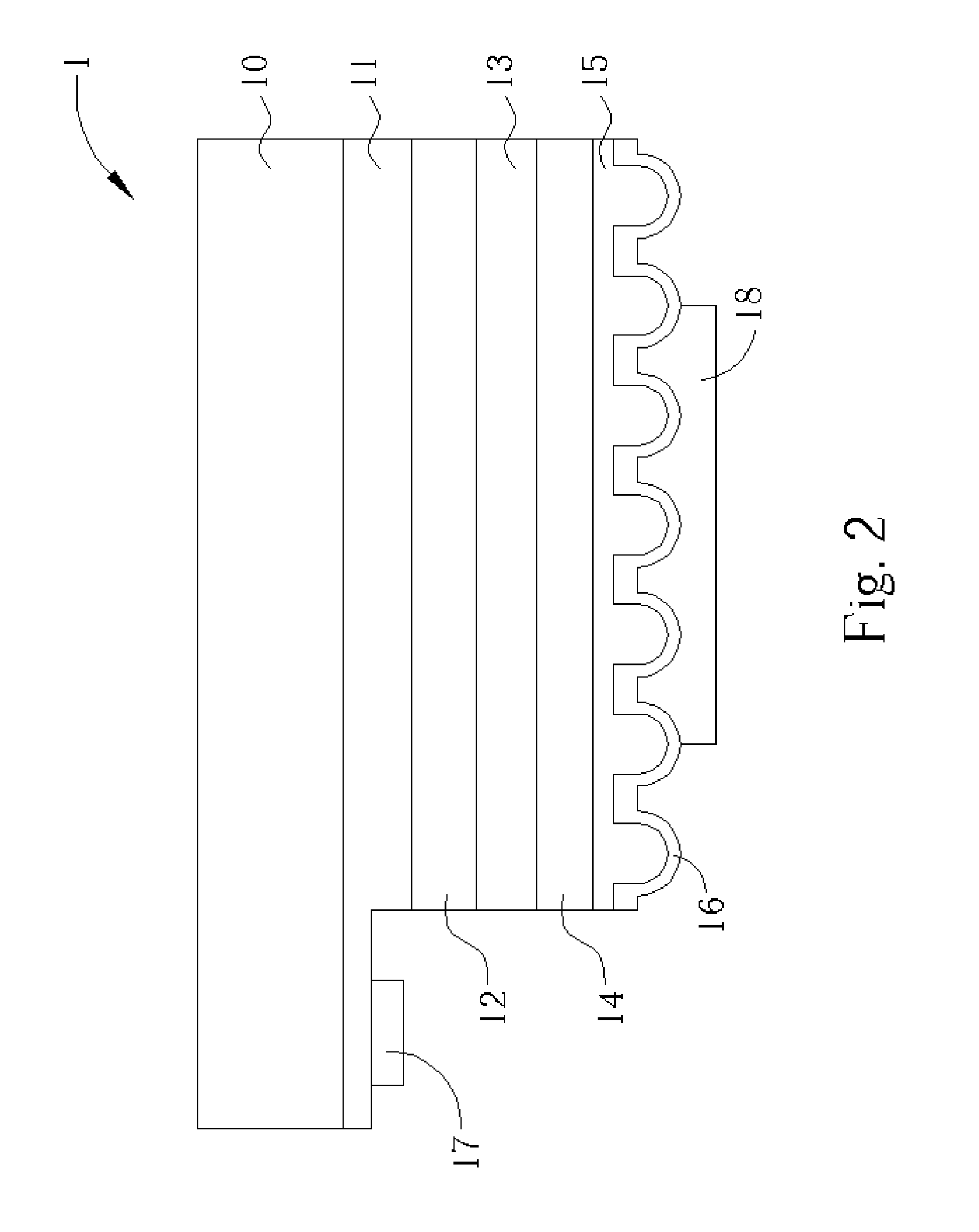

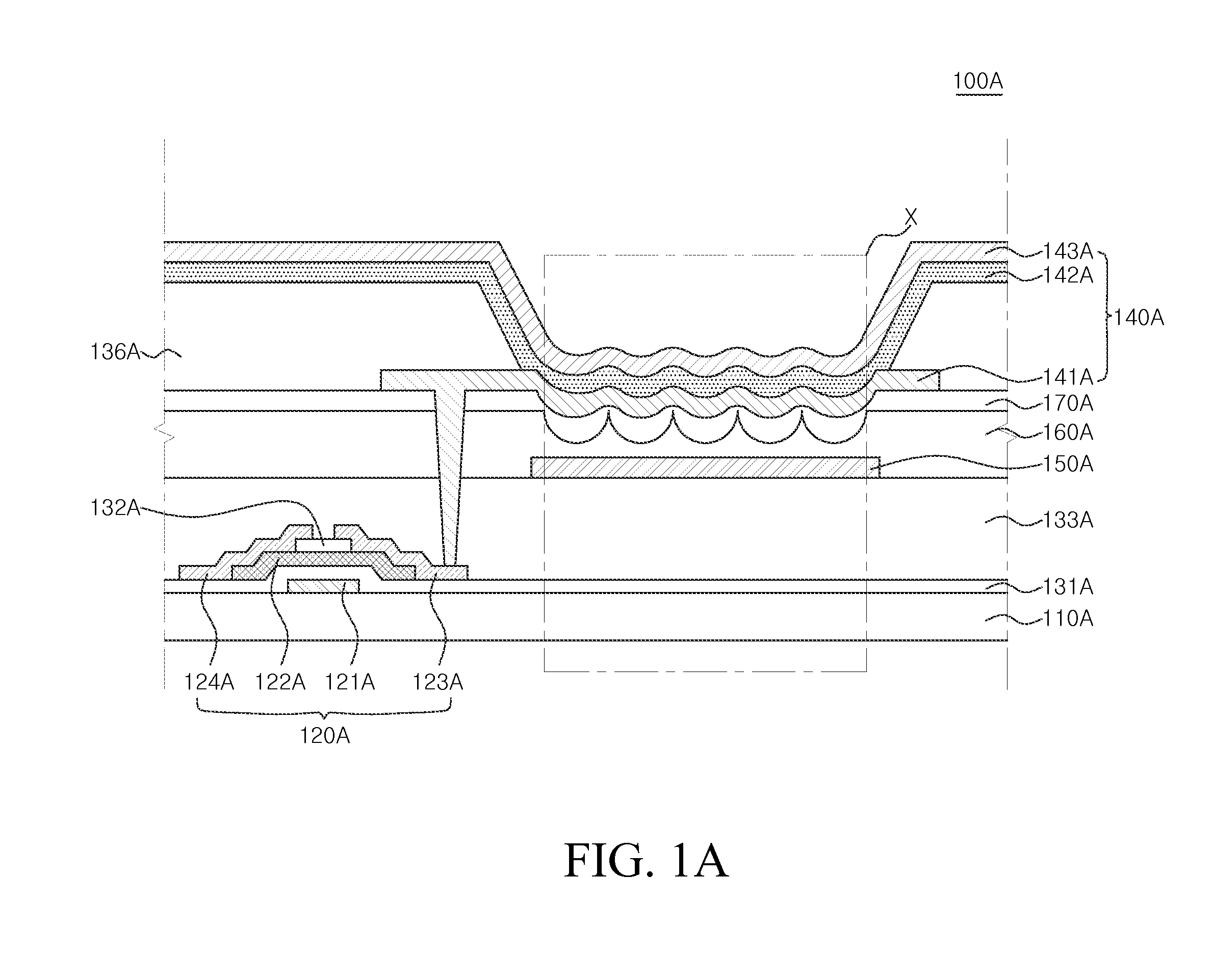

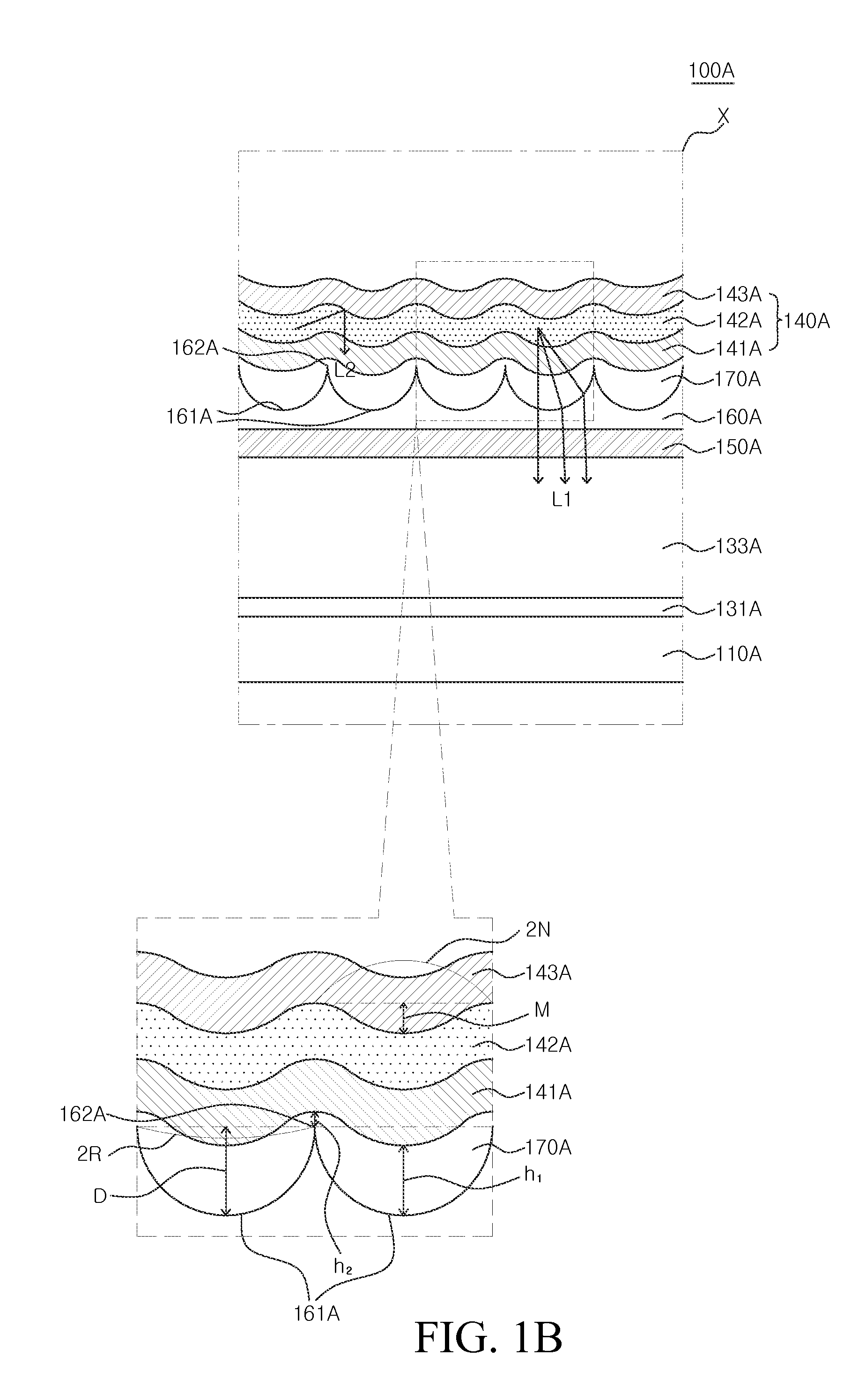

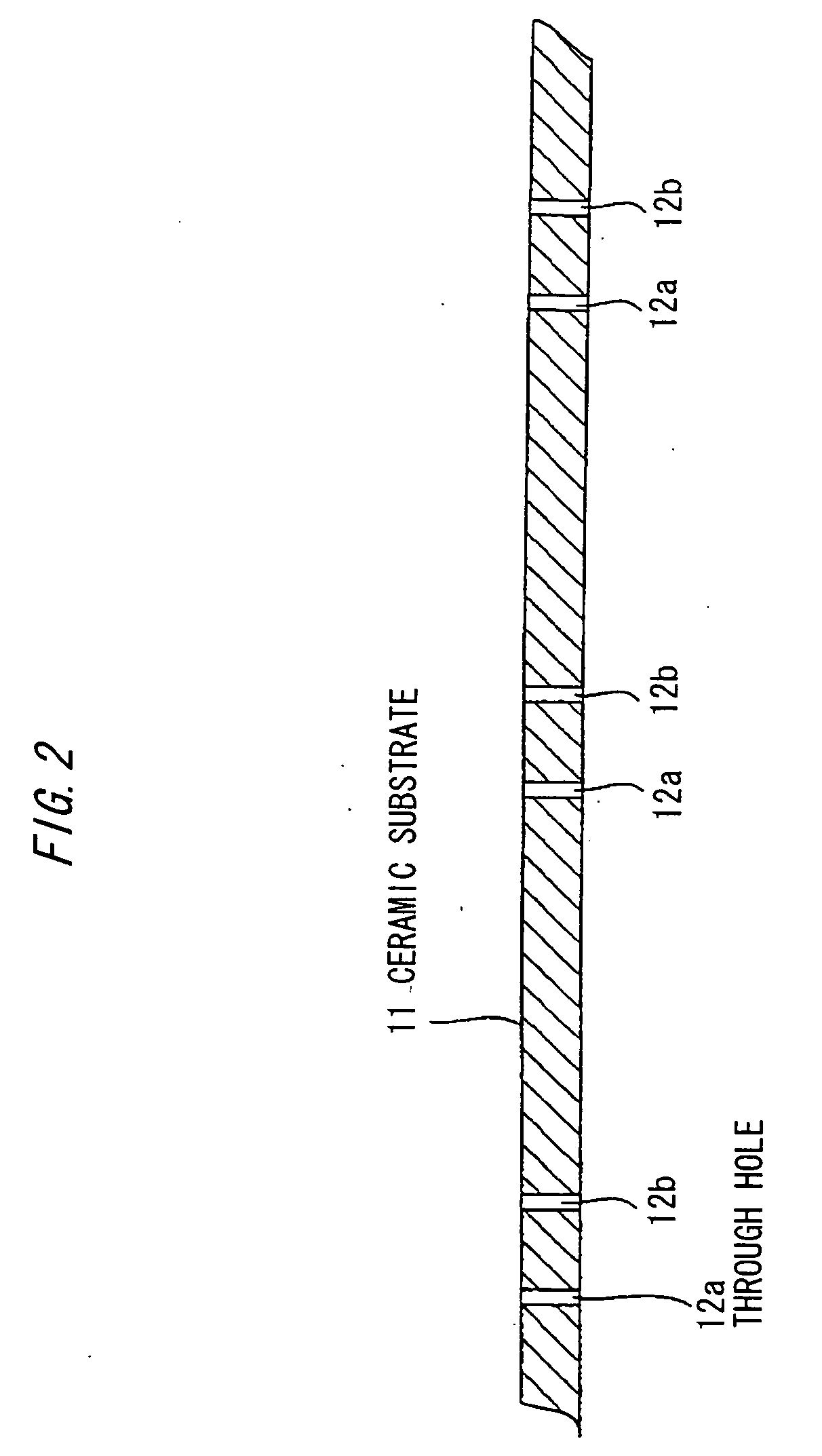

Substrate for surface light emitting device and method of manufacturing the substrate, surface light emitting device, lighting apparatus, and backlight including the same

ActiveUS20120155093A1Not be reduceLower manufacturing requirementsSolid-state devicesOptical articlesThin membraneEngineering

A substrate for a surface light emitting device in which a transparent electrode, an organic thin film layer, and a cathode electrode are sequentially stacked, the substrate including: a transparent support substrate; and a highly refractive layer that is disposed between the support substrate and the transparent electrode and comprises at least one layer having a refractive index that is equal to or greater than a refractive index of the support substrate, wherein the highly refractive layer comprises a light diffusion unit that diffuses light incident from the transparent electrode and a planarized surface that contacts the transparent electrode. Accordingly, a Haze value of the highly refractive layer is set to be 5% or less, and a diameter of bubbles existing in the highly refractive layer is set to be 1 / 10th or less of a thickness of the highly refractive layer.

Owner:SAMSUNG ELECTRONICS CO LTD

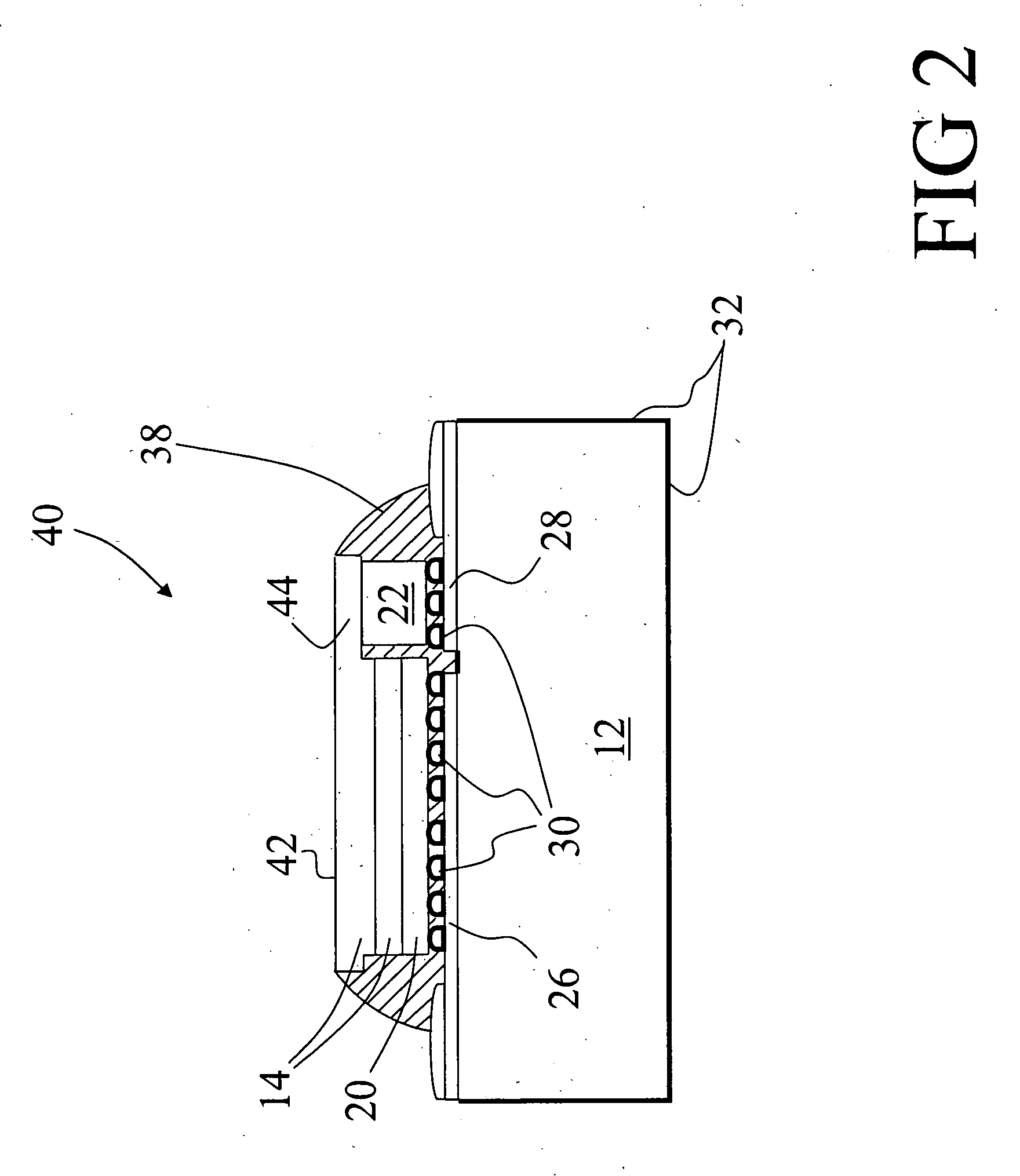

Flip-chip light-emitting device with micro-reflector

ActiveUS7294866B2Improve light extractionSolid-state devicesSemiconductor devicesEngineeringLight emitting device

A Flip-chip light-emitting device with integral micro-reflector. The flip-chip light-emitting device emits reflected light provided by a light-emitting layer. The micro-reflector reflects light that might otherwise be lost to internal refraction and absorption, so as to increase light-emitting efficiency.

Owner:FORMOSA EPITAXY INCORPORATION

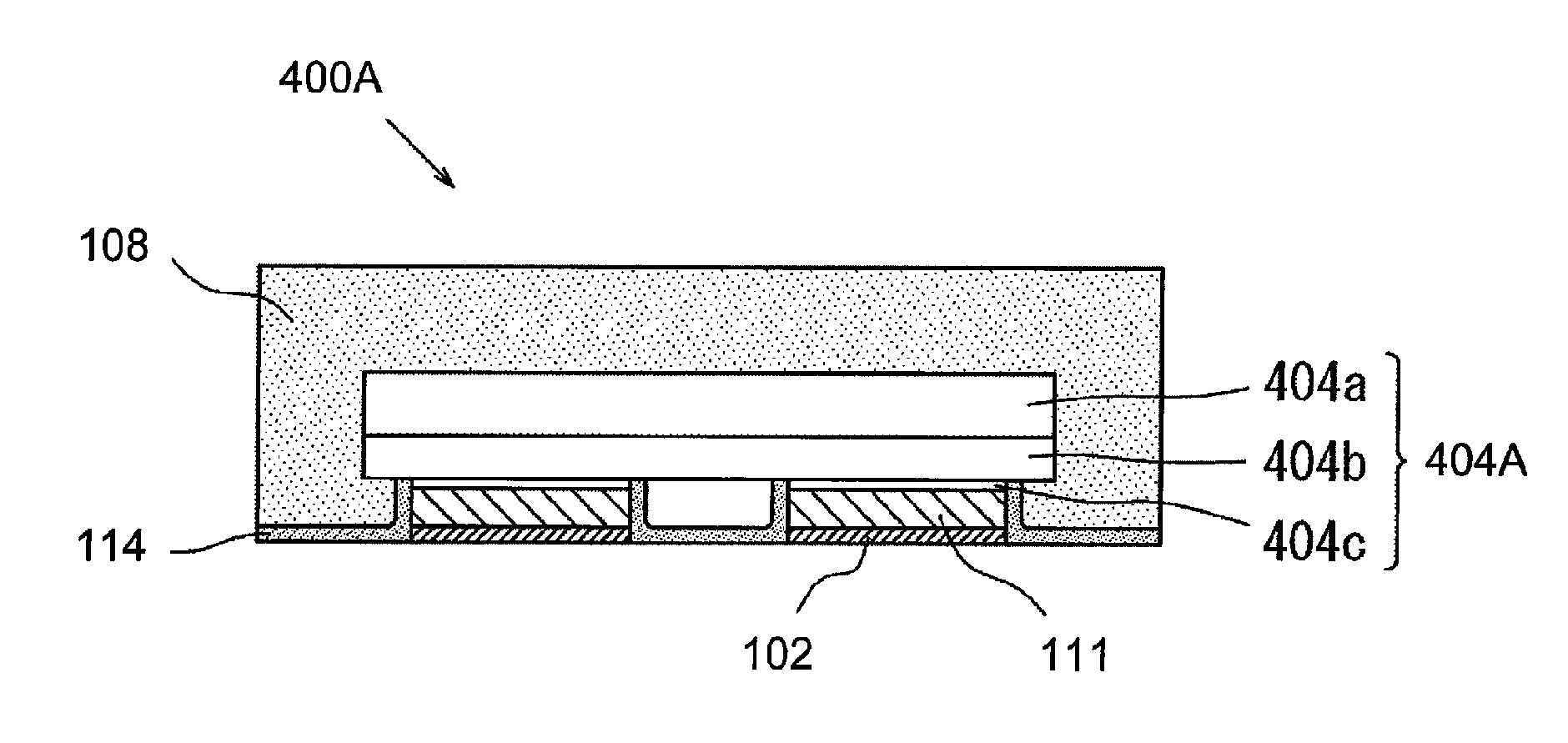

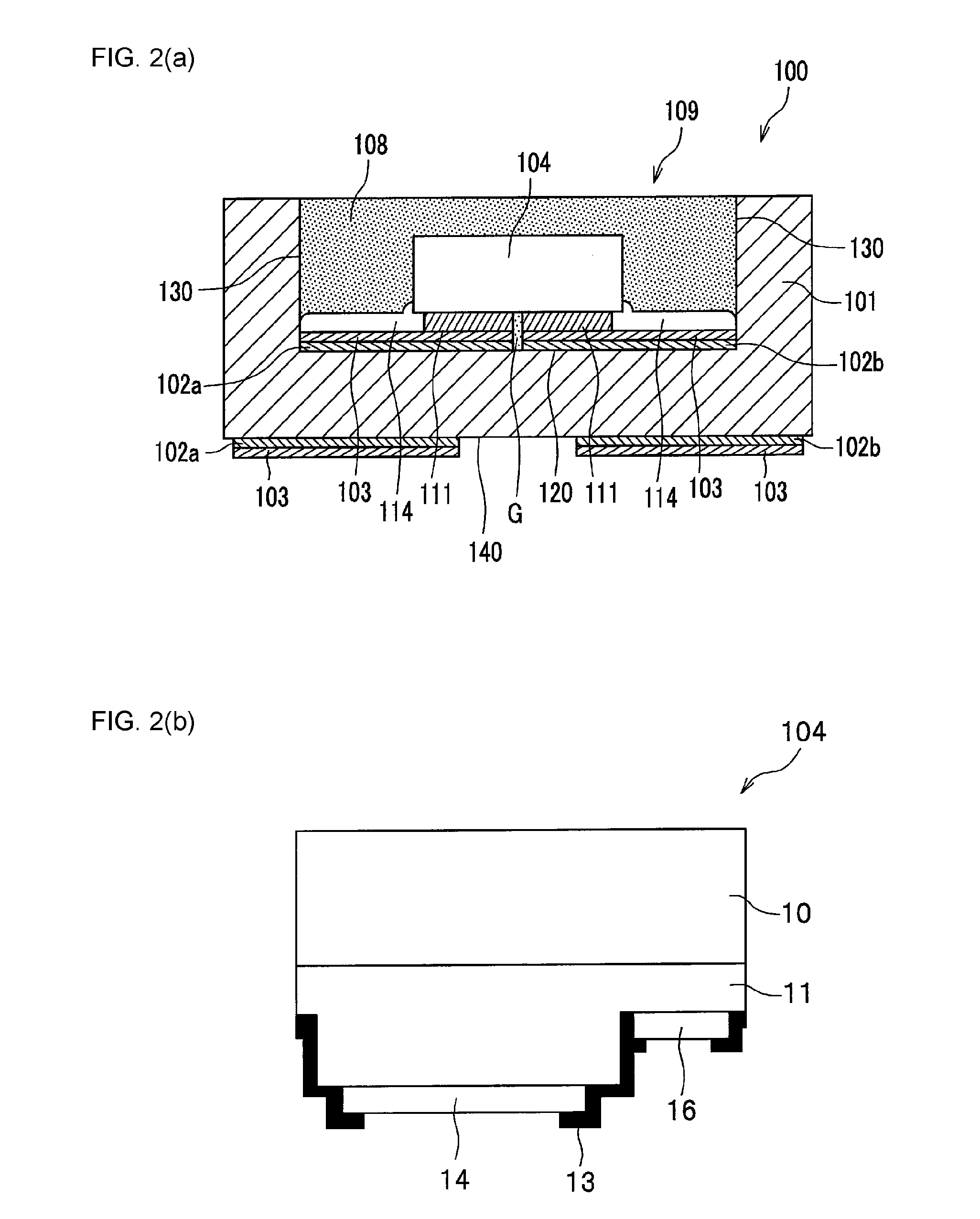

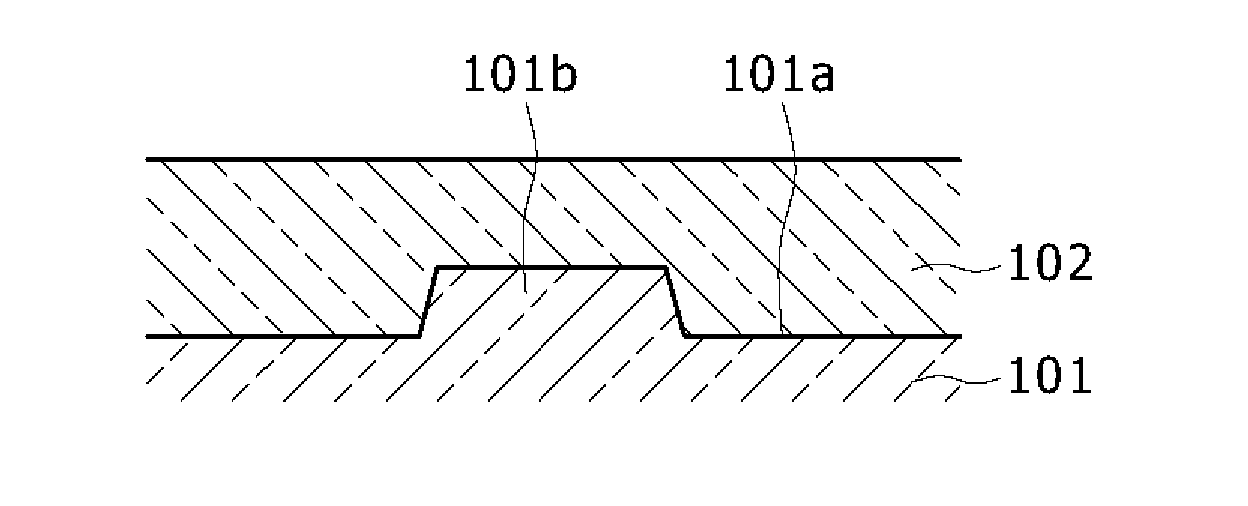

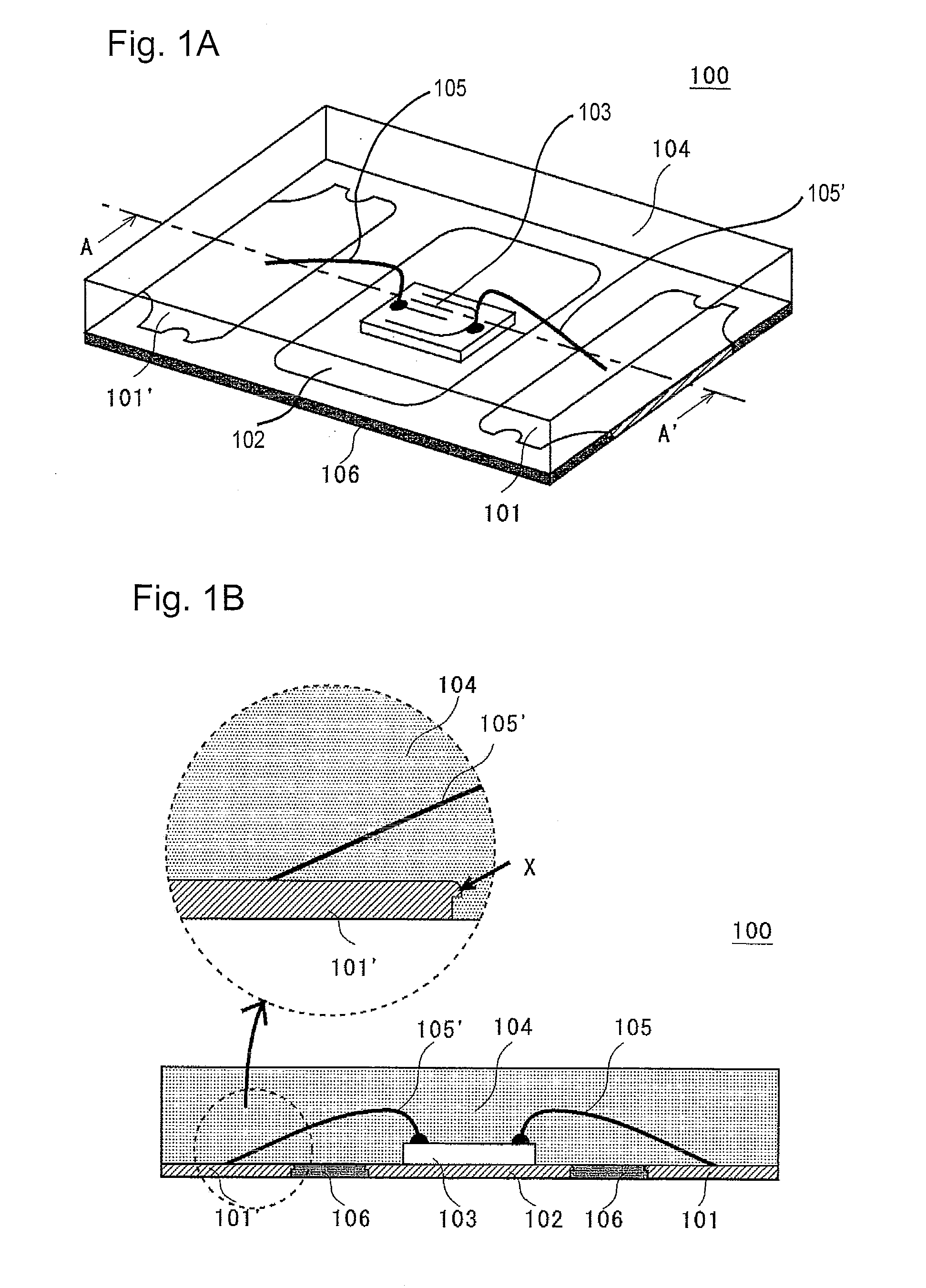

Light emitting device and method for manufacturing light emitting device

ActiveUS20130037842A1Increase productionAvoid light leakageSolid-state devicesSemiconductor devicesLight emitting deviceLight-emitting diode

A light emitting device (100) includes a base member (101), electrically conductive members (102a, 102b) disposed on the base member (101), a light emitting element (104) mounted on the electrically conductive members (102a, 102b), an insulating filler (114) covering at least a portion of surfaces of the electrically conductive members (102a, 102b) where the light emitting element (104) is not mounted, and a light transmissive member (108) covering the light emitting element (104).

Owner:NICHIA CORP

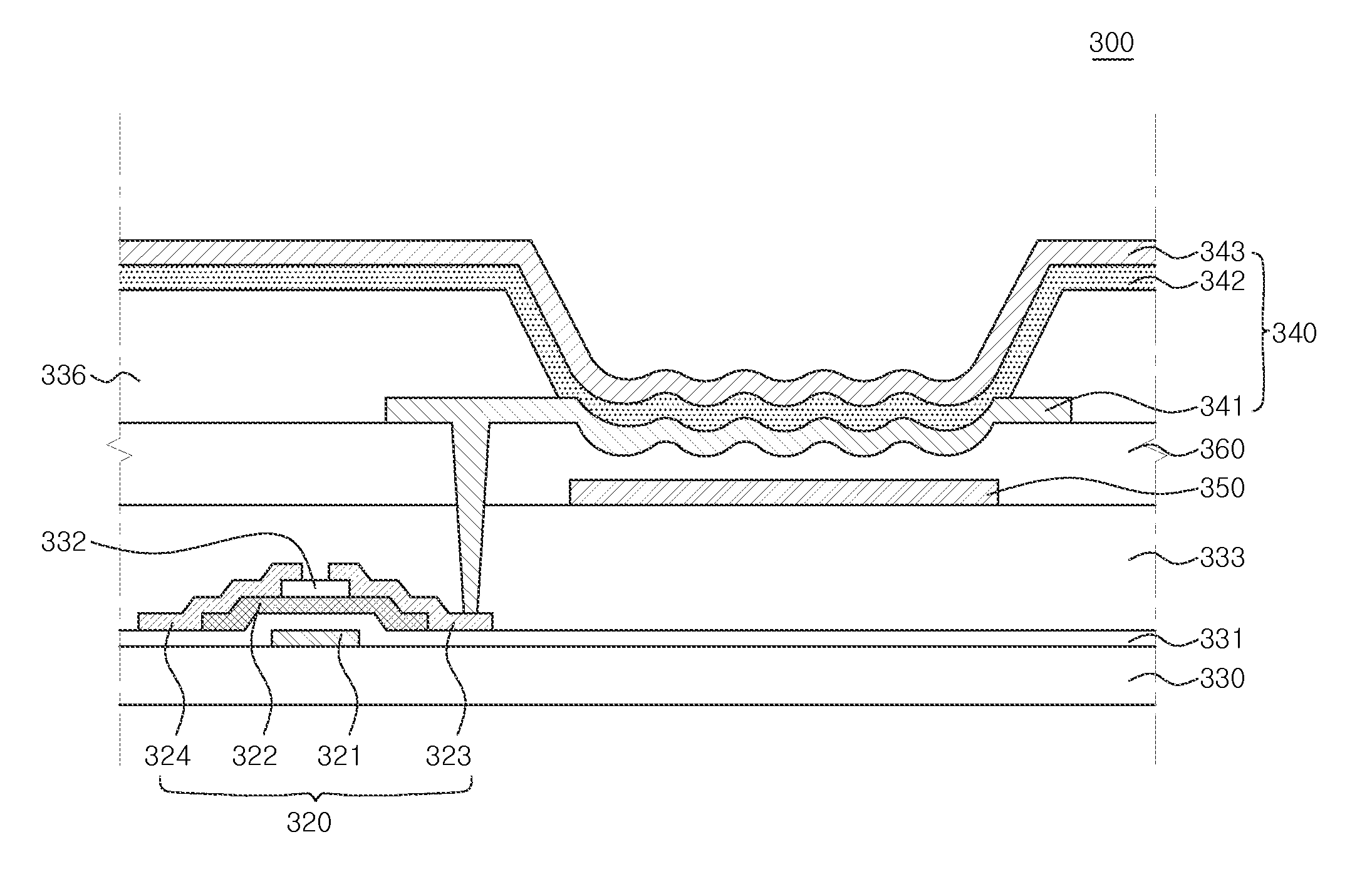

Organic light emitting display device and method for manufacturing the same

ActiveUS20150380466A1Reduce step differenceHigh refractive indexSolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexDisplay device

Provided are an organic light emitting display device and a method for manufacturing the same. A color filter is disposed on a substrate. An overcoating layer is disposed on the color filter and includes a plurality of protrusions or a plurality of recesses. The plurality of protrusions and the plurality of recesses are disposed on the color filter to be overlapped with the color filter. A buffer layer for reducing step difference is disposed on the overcoating layer. The buffer layer has a higher refractive index than the overcoating layer and reduces a step difference caused by the plurality of protrusions and the plurality of recesses. An organic light emitting element including an anode, an organic light emitting layer, and a cathode is disposed on the buffer layer. Since the buffer layer has a higher refractive index than the overcoating layer, light extraction efficiency can be increased.

Owner:LG DISPLAY CO LTD

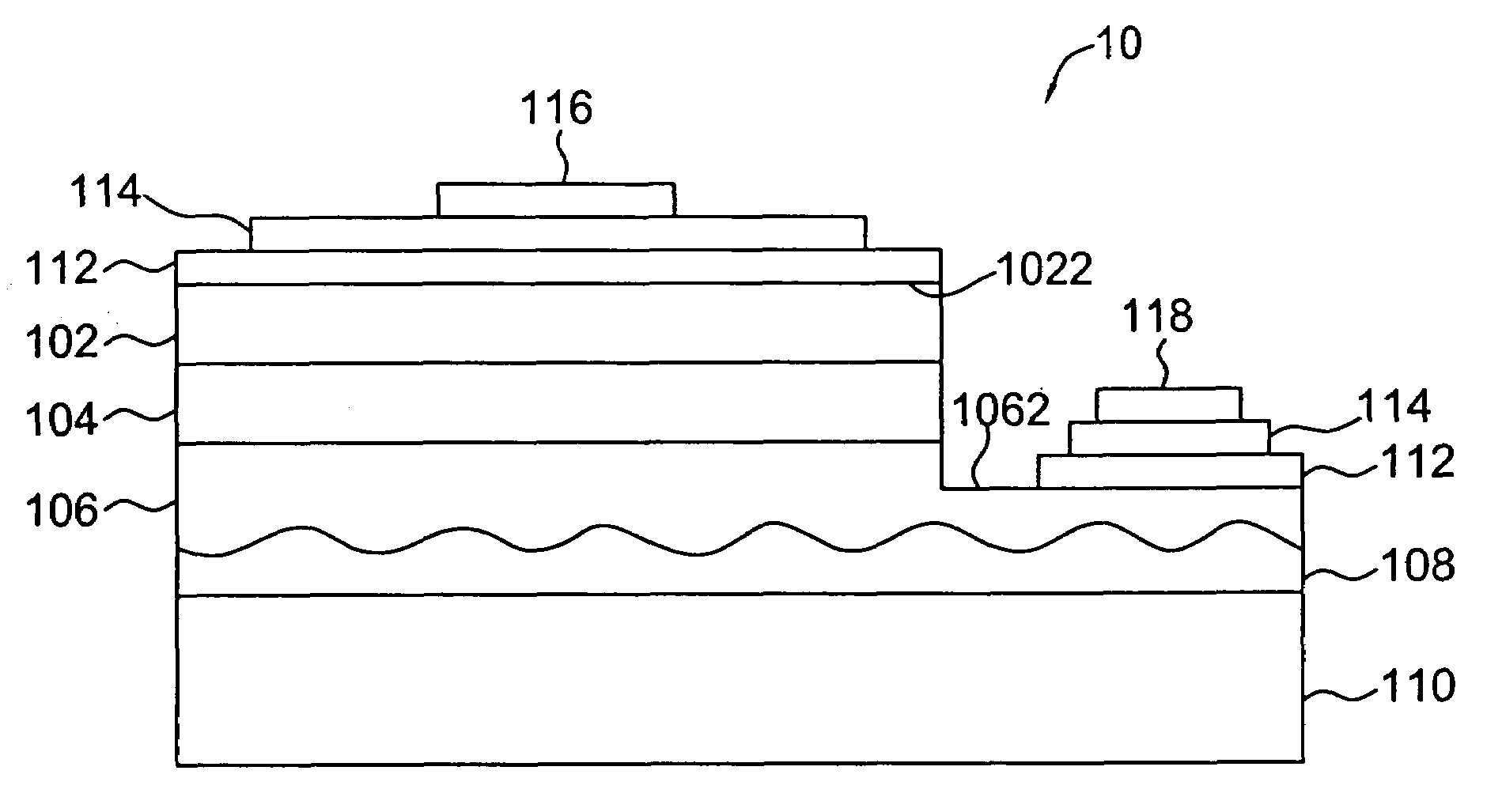

Roughened high refractive index layer/LED for high light extraction

ActiveUS20070018183A1Improve light extractionSemiconductor devicesRefractive indexConductive materials

A light emitting diode (LED) includes a p-type layer of material, an n-type layer of material and an active layer between the p-type layer and the n-type layer. A roughened layer of transparent material is adjacent one of the p-type layer of material and the n-type layer of material. The roughened layer of transparent material has a refractive index close to or substantially the same as the refractive index of the material adjacent the layer of transparent material, and may be a transparent oxide material or a transparent conducting material. An additional layer of conductive material may be between the roughened layer and the n-type or p-type layer.

Owner:CREELED INC

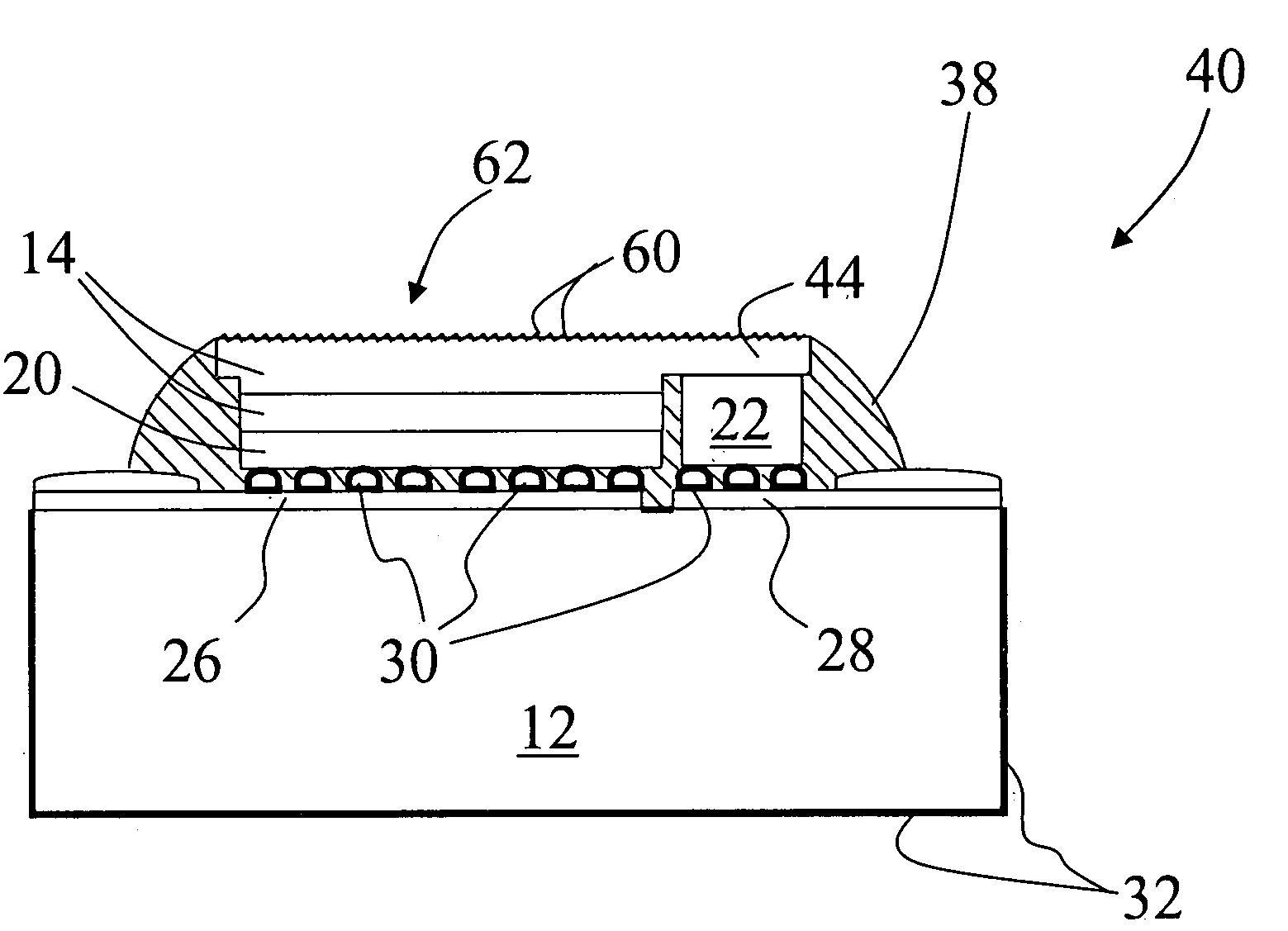

Light emitting module with optically-transparent thermally-conductive element

ActiveUS20110001157A1Extended service lifeThe process is compact and efficientSolid-state devicesSemiconductor/solid-state device manufacturingLength waveInorganic materials

A light emitting module with improved optical functionality and reduced thermal resistance is described, which comprises a light emitting device (LED), a wavelength converting (WC) element and an inorganic optically-transmissive thermally-conductive (OTTC) element. The WC element is capable of absorbing light generated from the LED at a specific wavelength and re-emitting light having a different wavelength. The re-emitted light and any unabsorbed light exits through at least one surface of the module. The OTTC is in physical contact with the WC element and at least partially located in the optical path of the light. The OTTC comprises one or more layers of inorganic material having a thermal conductivity greater than that of the WC element. As such, a compact unitary integrated module is provided with excellent thermal characteristics, which may be further enhanced when the OTTC provides a thermal barrier for vertical heat propagation through the module but not lateral propagation.

Owner:LUMILEDS HLDG BV

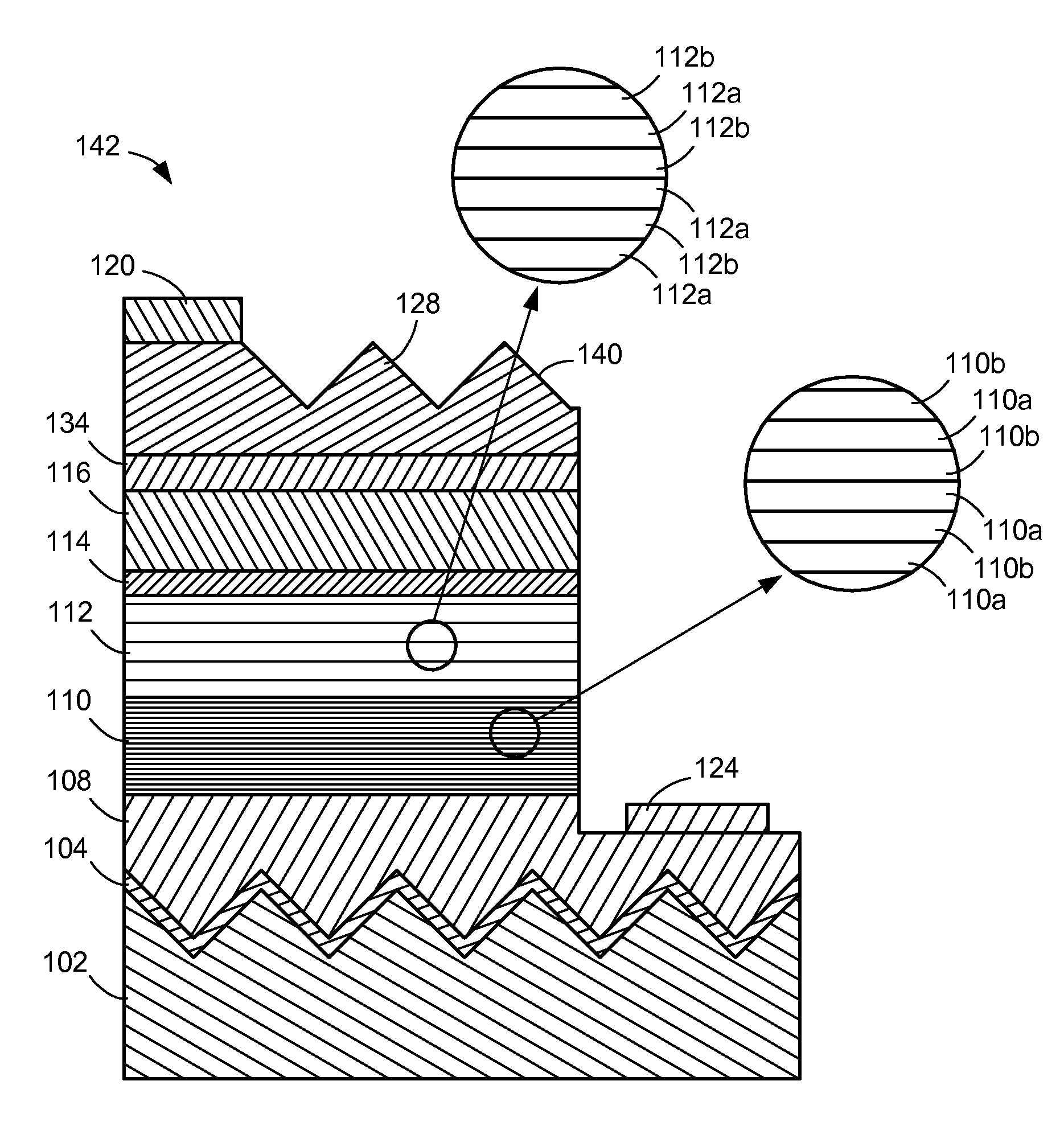

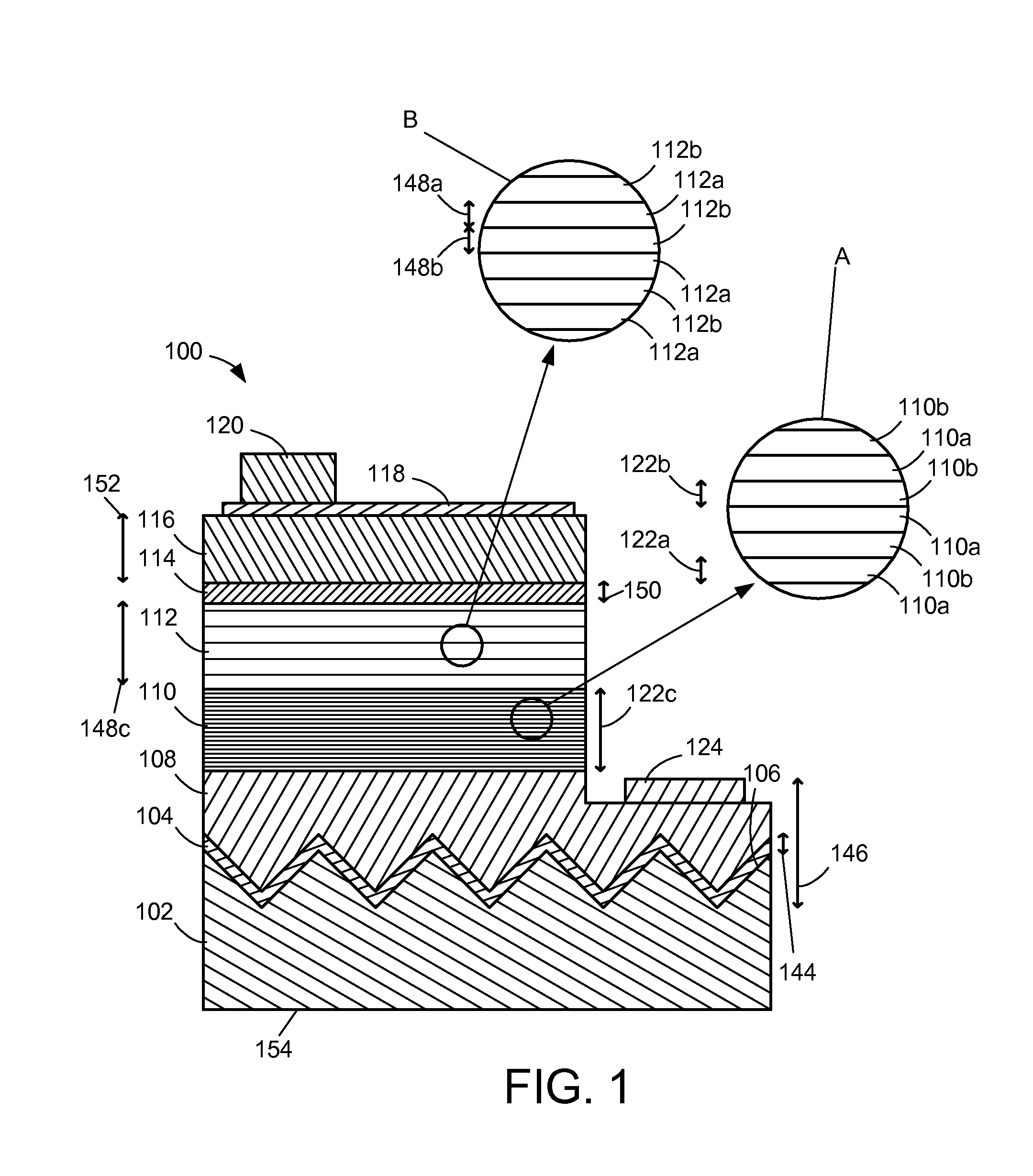

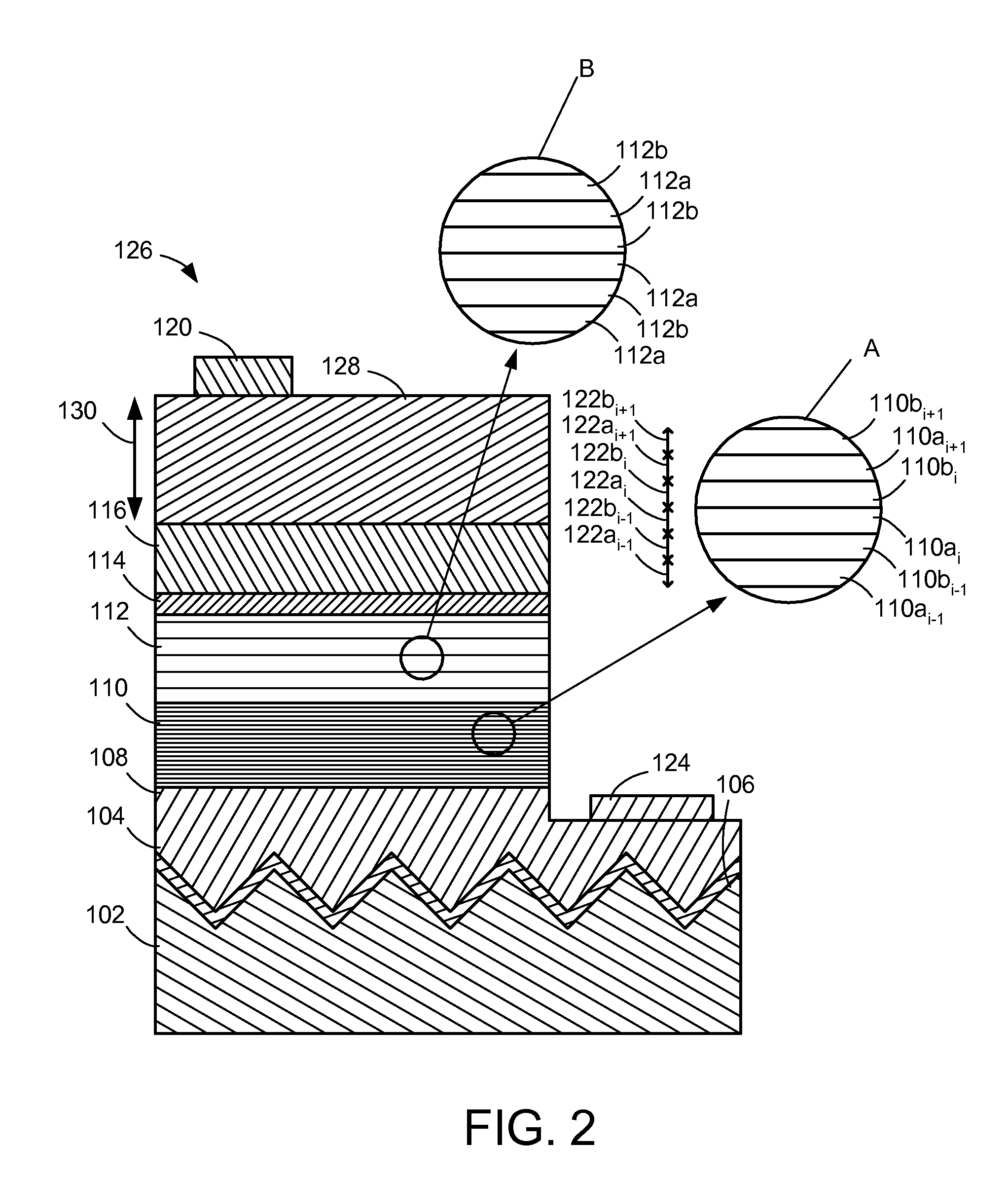

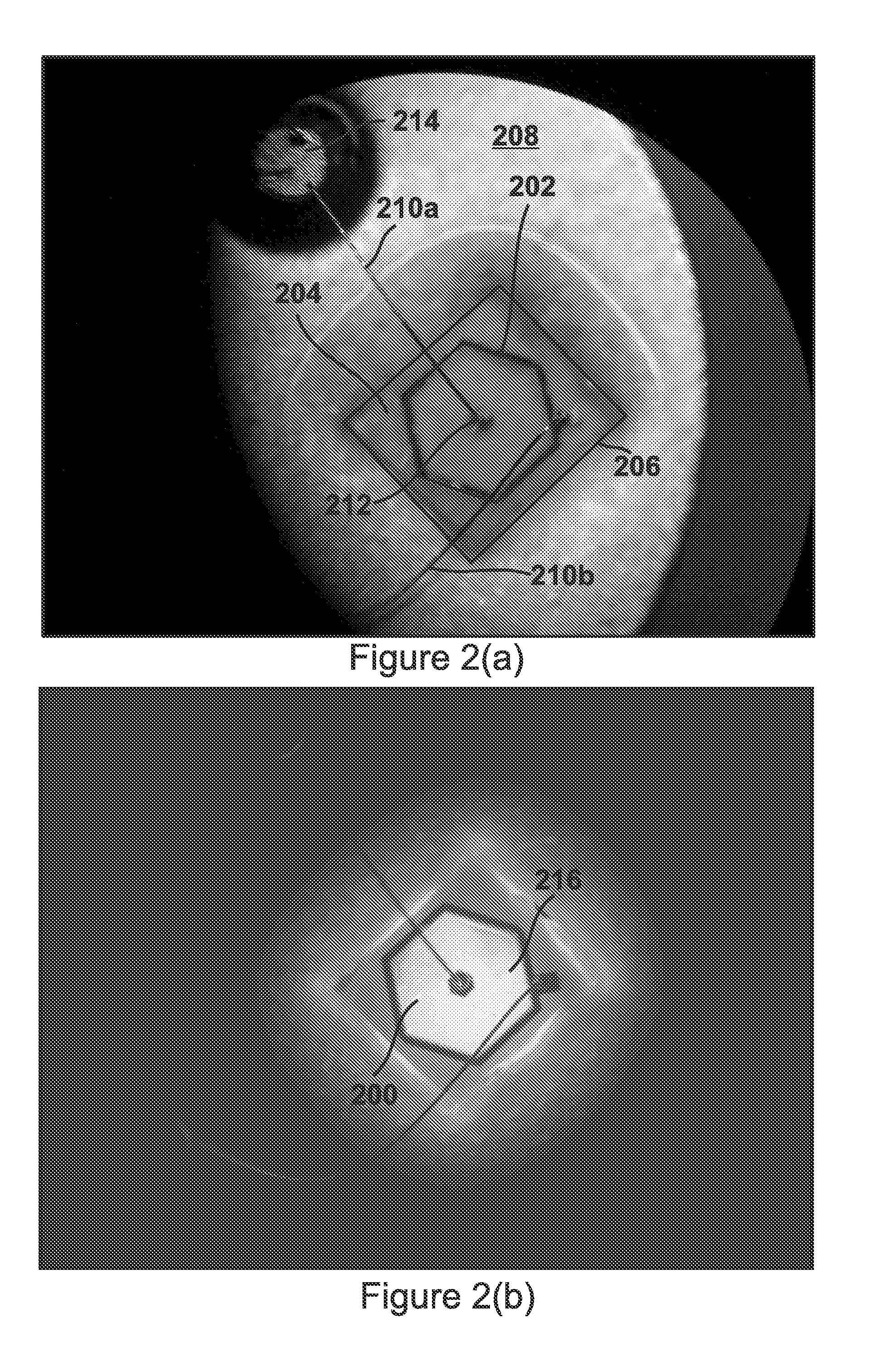

(Al,In,Ga,B)N DEVICE STRUCTURES ON A PATTERNED SUBSTRATE

ActiveUS20090072262A1High luminous output powerLight emission efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesQuantum wellPatterned substrate

A nitride light emitting diode, on a patterned substrate, comprising a nitride interlayer having at least two periods of alternating layers of InxGa1-xN and InyGa1-yN where 0<x<1 and 0≦y<1, and a nitride based active region having at least one quantum well structure on the nitride interlayer.

Owner:RGT UNIV OF CALIFORNIA

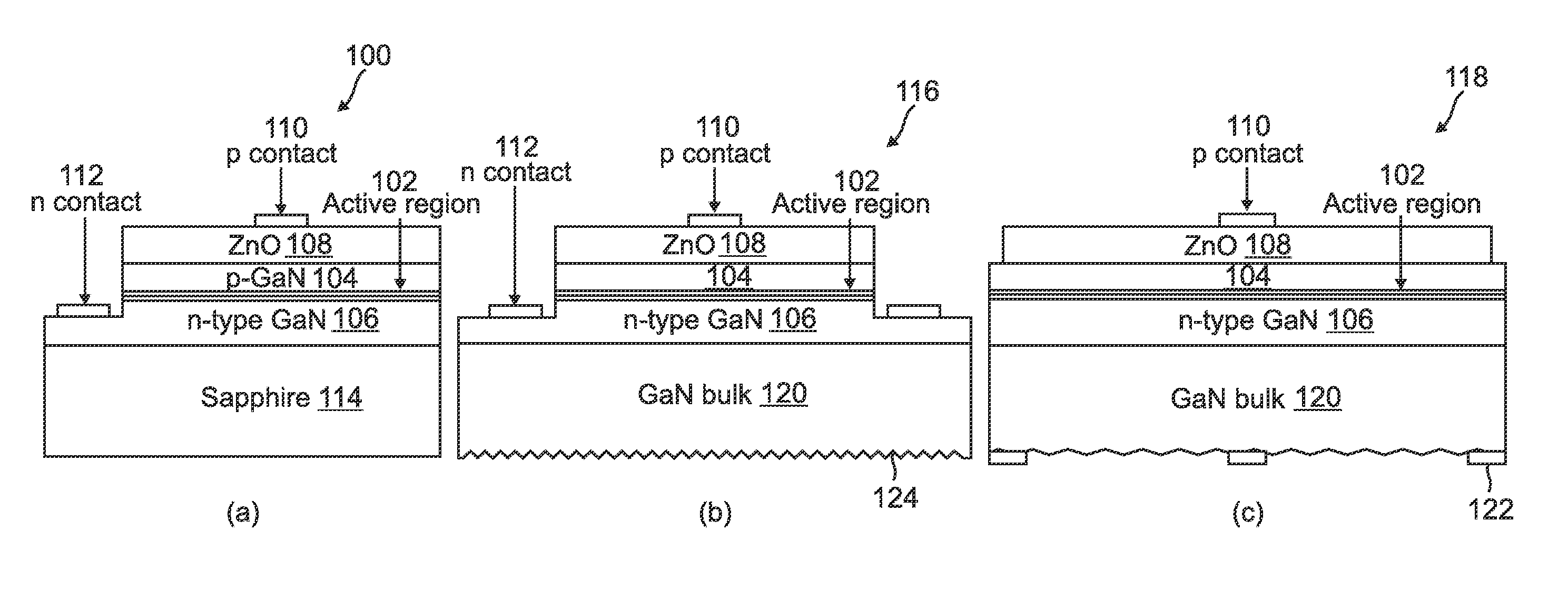

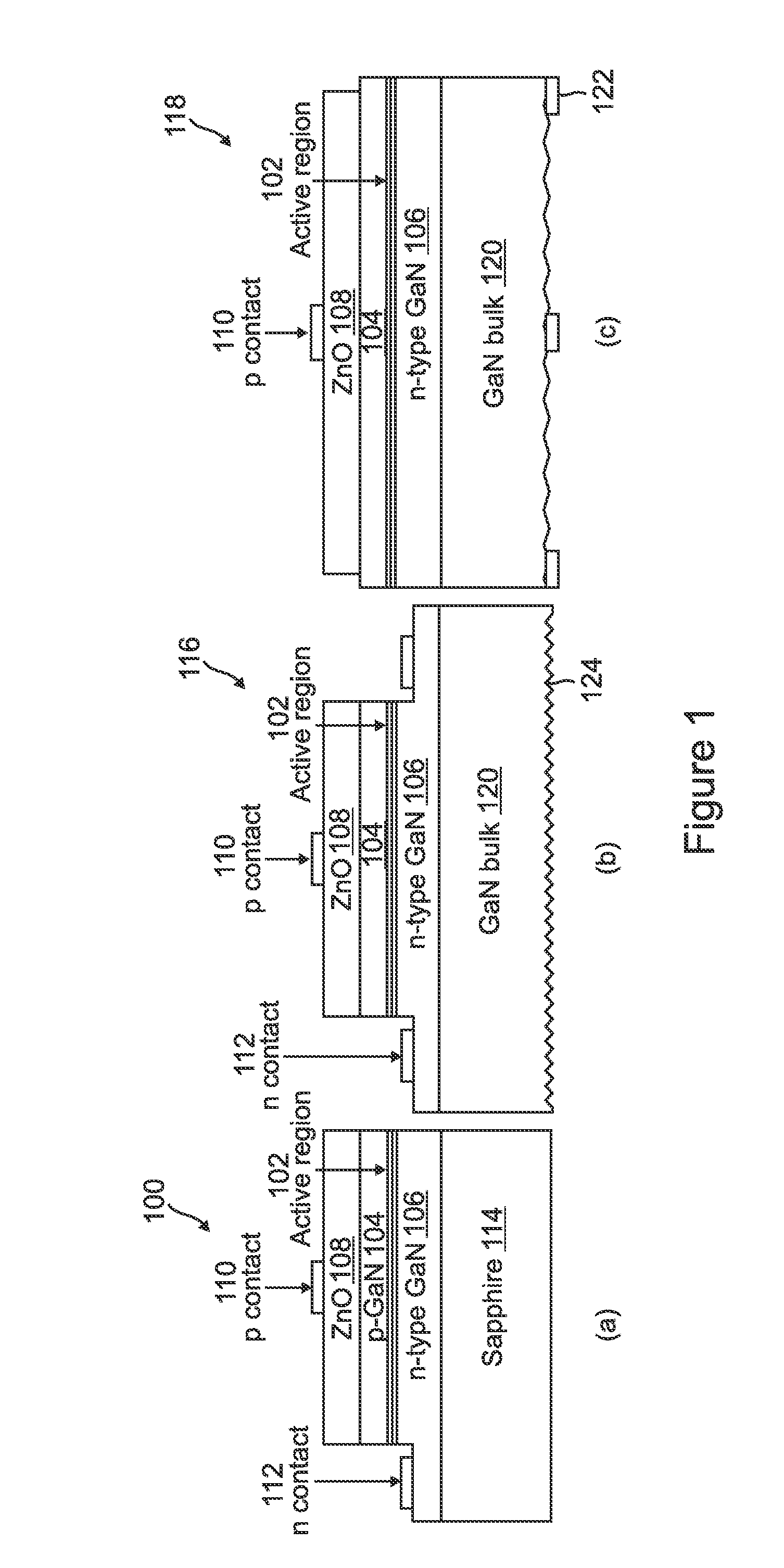

Light emitting diodes with zinc oxide current spreading and light extraction layers deposited from low temperature aqueous solution

ActiveUS20110101414A1Accelerated dissipationEasy extractionLiquid-phase epitaxial-layer growthZinc oxides/hydroxidesPower flowAqueous solution

A method for fabricating a Light Emitting Diode (LED) with increased light extraction efficiency, comprising providing a III-Nitride based LED structure comprising a light emitting active layer between a p-type layer and an n-type layer; growing a Zinc Oxide (ZnO) layer epitaxially on the p-type layer by submerging a surface of the p-type layer in a low temperature aqueous solution, wherein the ZnO layer is a transparent current spreading layer; and depositing a p-type contact on the ZnO layer. The increase in efficiency may be more than 93% with very little or no increase in cost.

Owner:RGT UNIV OF CALIFORNIA

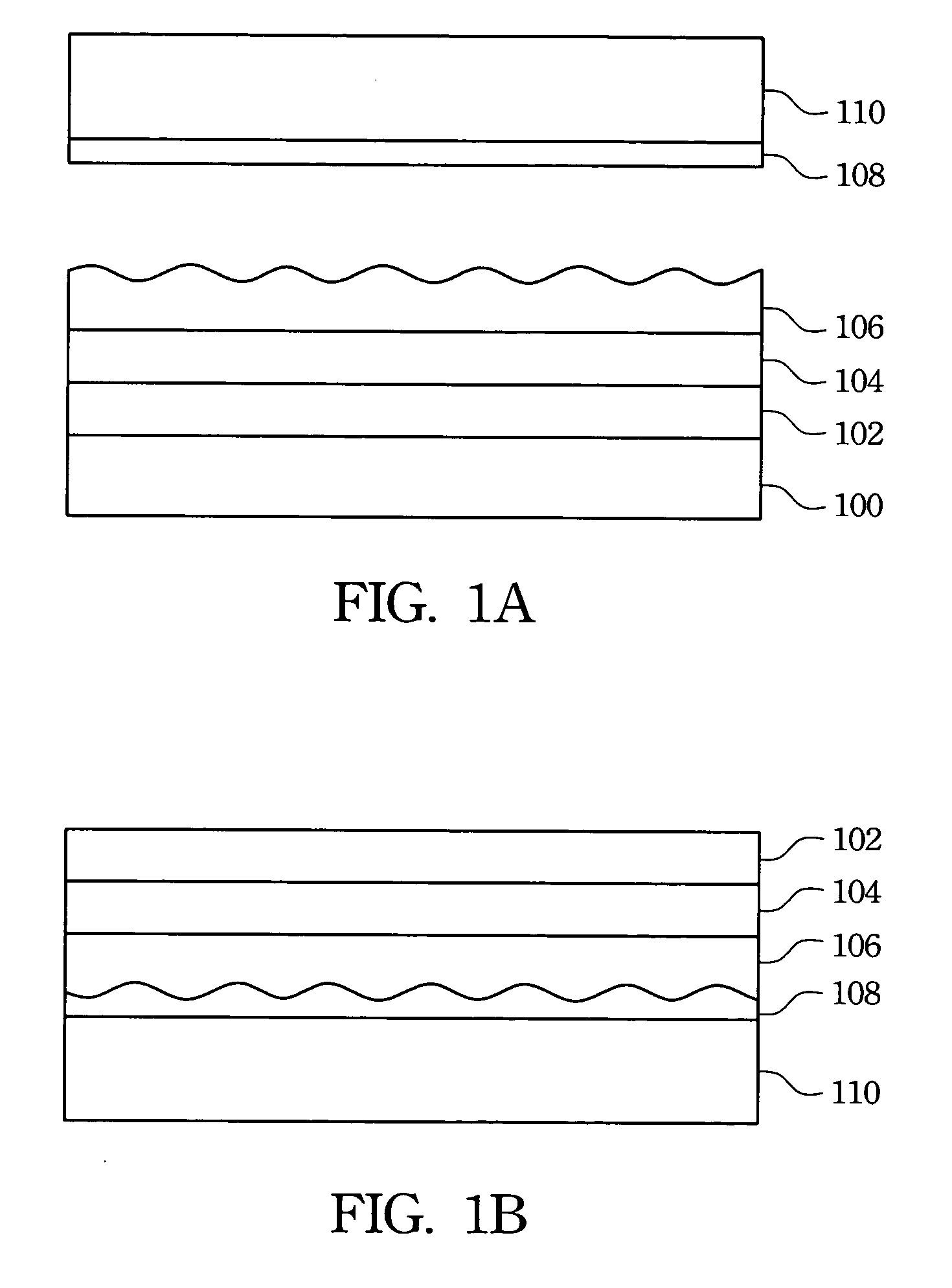

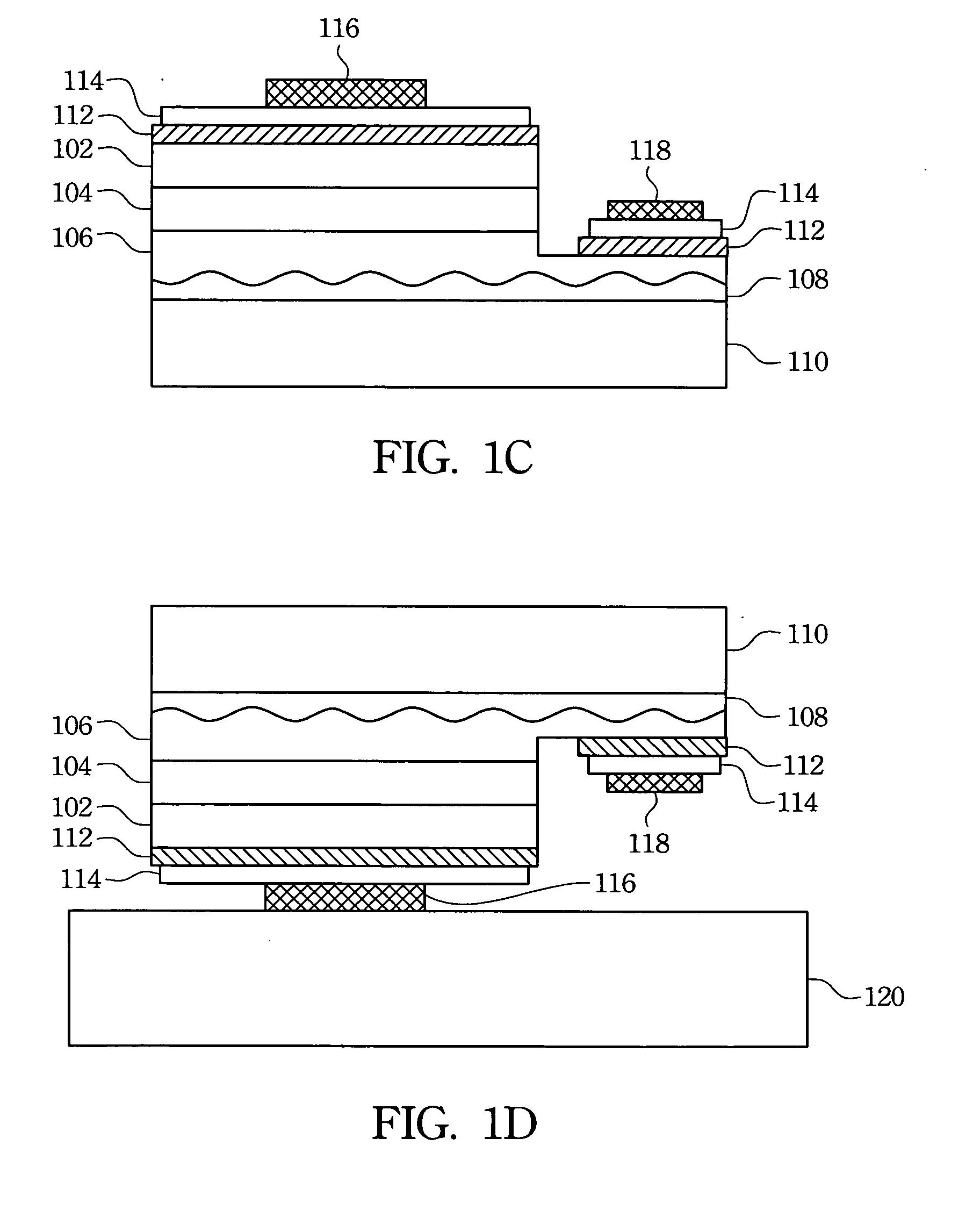

Method of fabricating algainp light-emitting diode and structure thereof

ActiveUS20050287687A1Increased light output intensityReduce reflectionSolid-state devicesSemiconductor/solid-state device manufacturingReflective layerLight-emitting diode

A soft transparent adhesive layer is utilized to bond a transparent substrate material onto an AlGaInP light-emitting diode epitaxy on a GaAs substrate, and the GaAs substrate is next removed entirely. Then, a mesa etching process is performed to form a first top surface and a second top surface on the AlGaInP light-emitting diode epitaxy for respectively exposing an n-type layer and a p-type layer in the AlGaInP light-emitting diode epitaxy. Next, a metal reflective layer and a barrier layer are formed on the AlGaInP light-emitting diode epitaxy in turn, and electrodes are finally fabricated on the barrier layer.

Owner:EPISTAR CORP

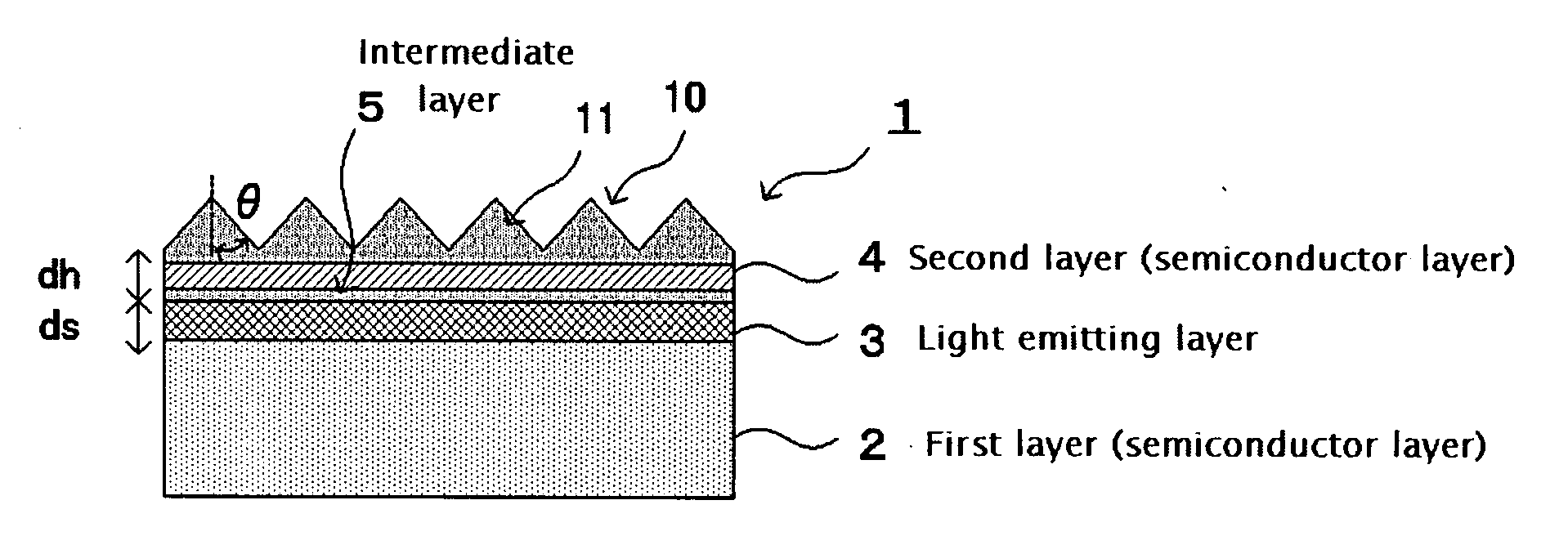

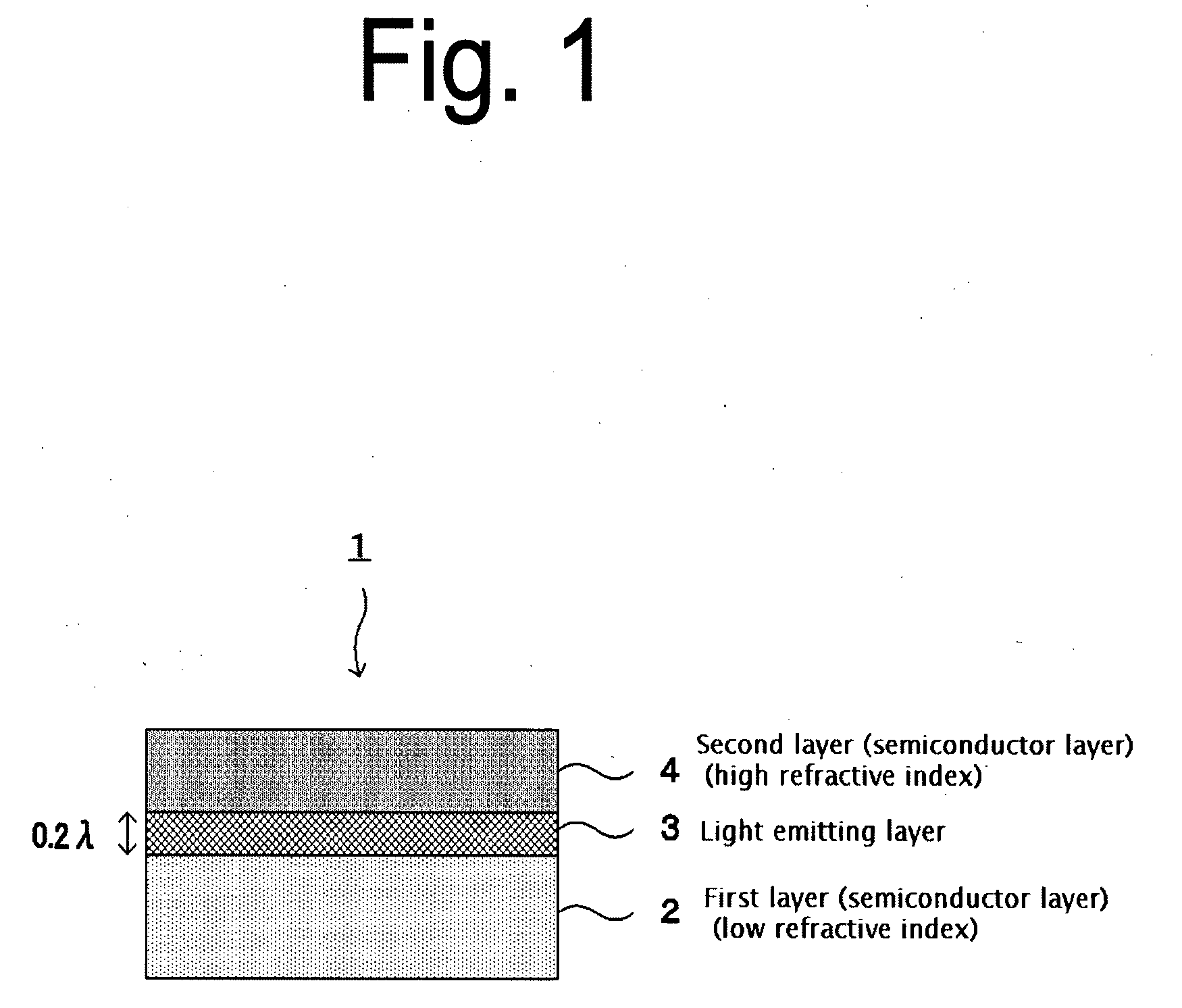

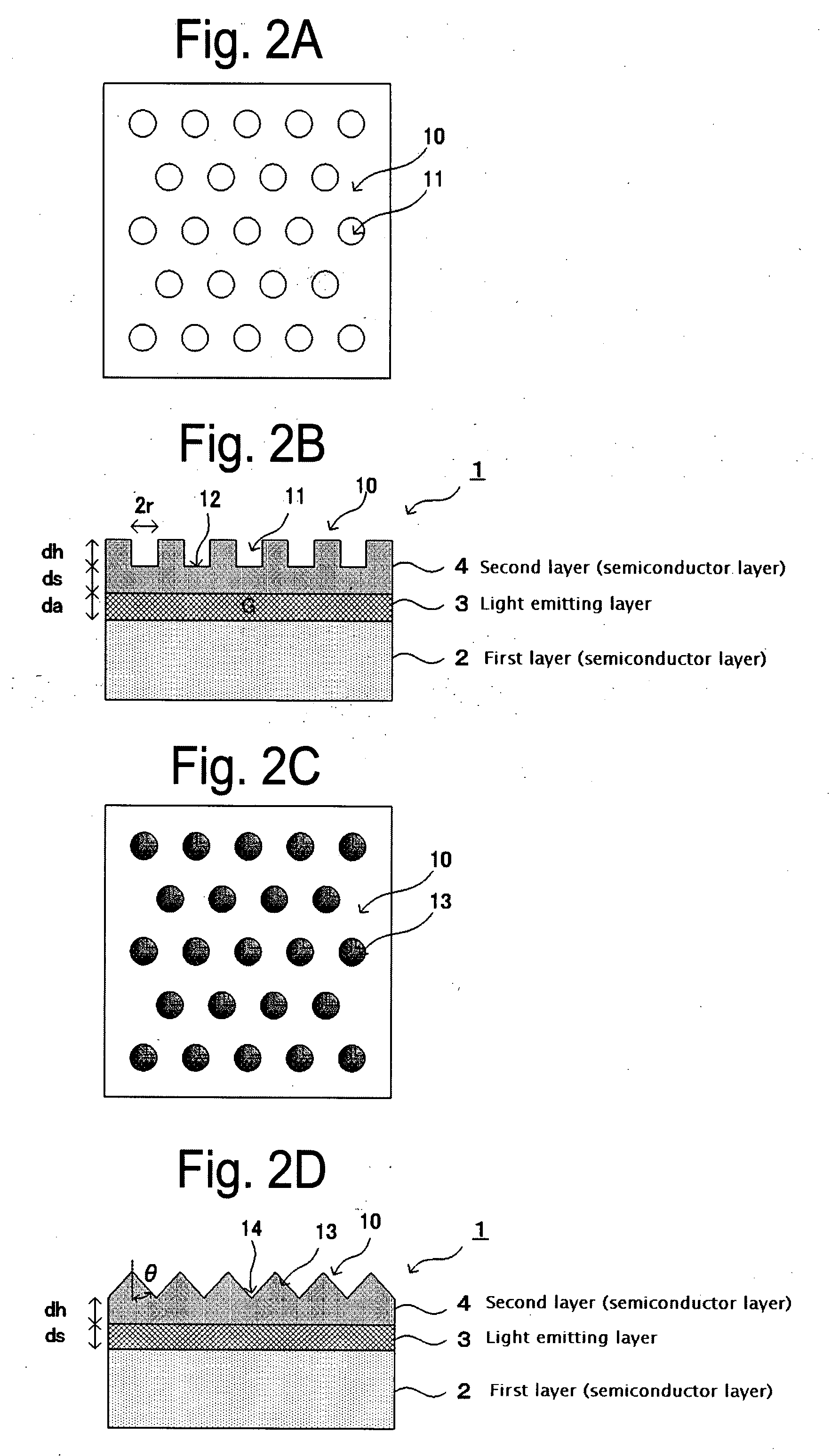

Self-luminous device

InactiveUS20080173887A1Improve light extractionHigh light extractionSemiconductor devicesComputational physicsSecondary layer

A self-luminous device 1 is one embodiment which has an increased light extraction efficiency by optimizing the distribution of refractive index in semiconductor layers. The self-luminous device 1 includes a first layer (semiconductor layer 2), a light emitting layer 3 overlaying the first layer (semiconductor layer 2), and a second layer (semiconductor layer 4) overlaying the light emitting layer 3. The first layer (semiconductor layer 2) and the second layer (semiconductor layer 4) have different refractive indices so that the refractive indices of the two layers (semiconductor layers 2 and 4) are asymmetric with respect to the light emitting layer interposed therebetween. In the refractive index distribution of asymmetric layers (semiconductor layers), the refractive index of the second layer (semiconductor layer 4) is higher than that of the first layer (semiconductor layer 2).

Owner:STANLEY ELECTRIC CO LTD

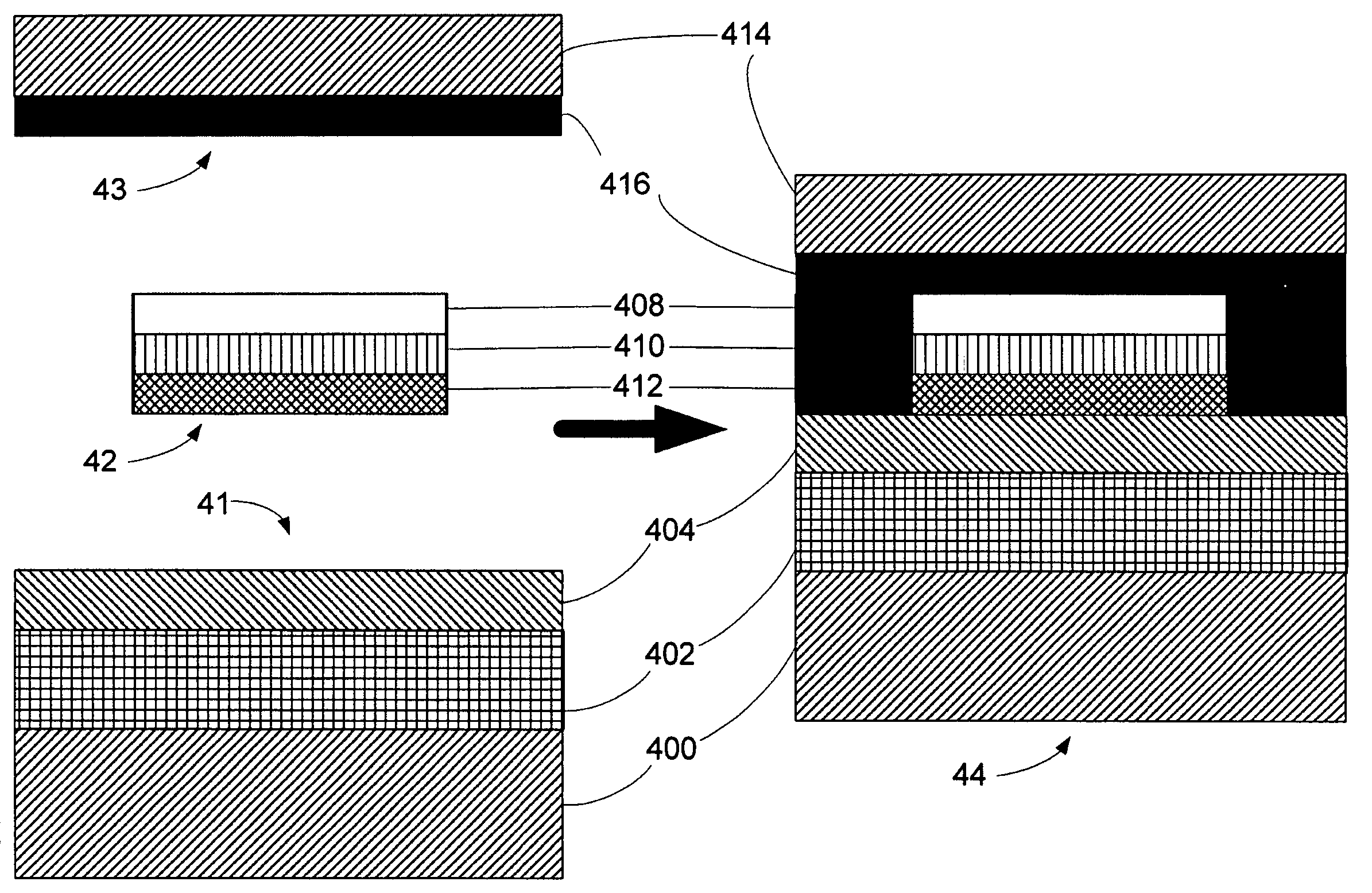

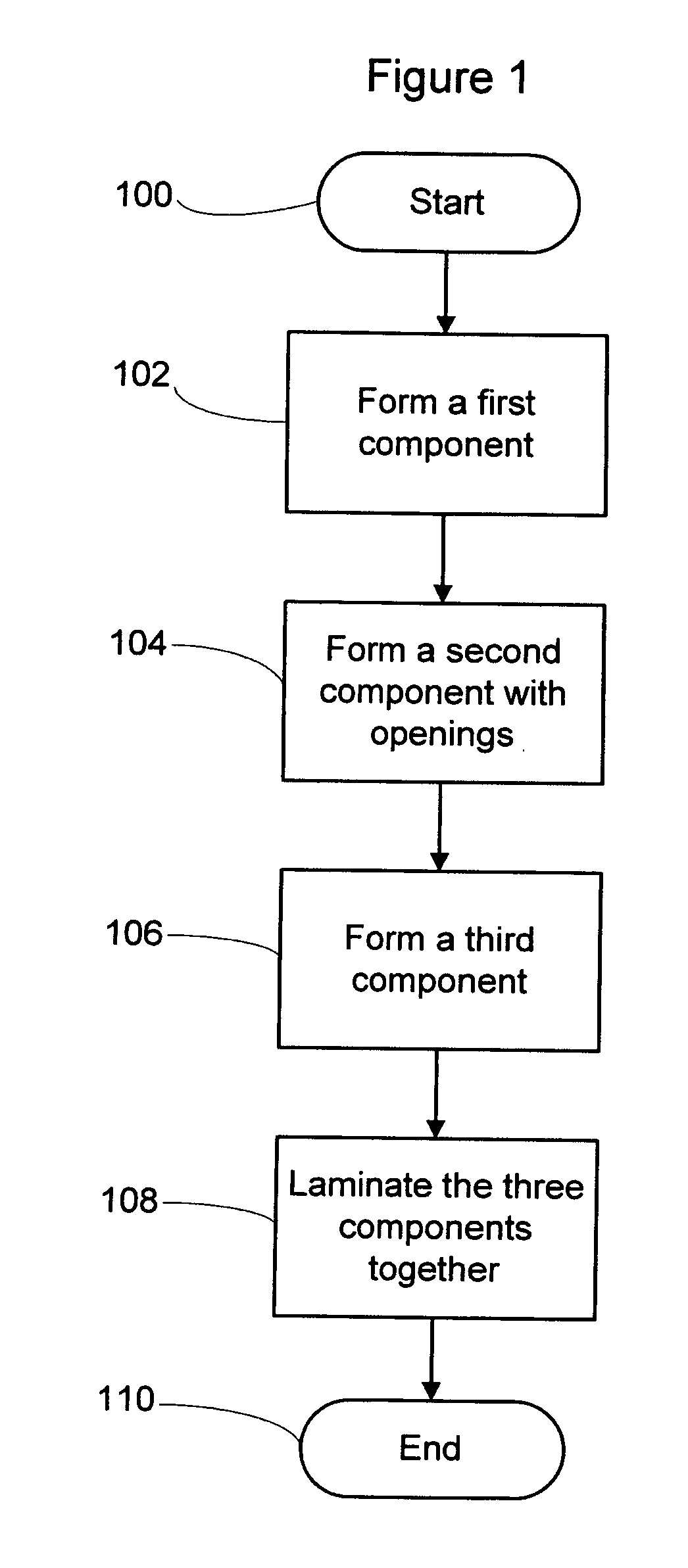

Organic electro-optic device and method for making the same

ActiveUS20050093001A1Reduce the possibilityEfficient manufacturingFinal product manufactureElectroluminescent light sourcesElectro-opticsMaterials science

The present invention directed to an organic light emitting device and method for making the same. The method comprises the steps of: forming a first component comprising at least one first material on a first substrate; forming a second component comprising at least one second material on a second substrate, wherein at least one opening is formed through the second component; forming a third component; and laminating the first component, the second component and the third component together such that the second component is located between the first component and the third component, the at least one first material and the at least one second material form at least part of an organic electro-optic device located between the first substrate and the second substrate, the third component is bonded to the second component, and the third component is bonded to the first component through the at least one opening.

Owner:BOE TECH GRP CO LTD

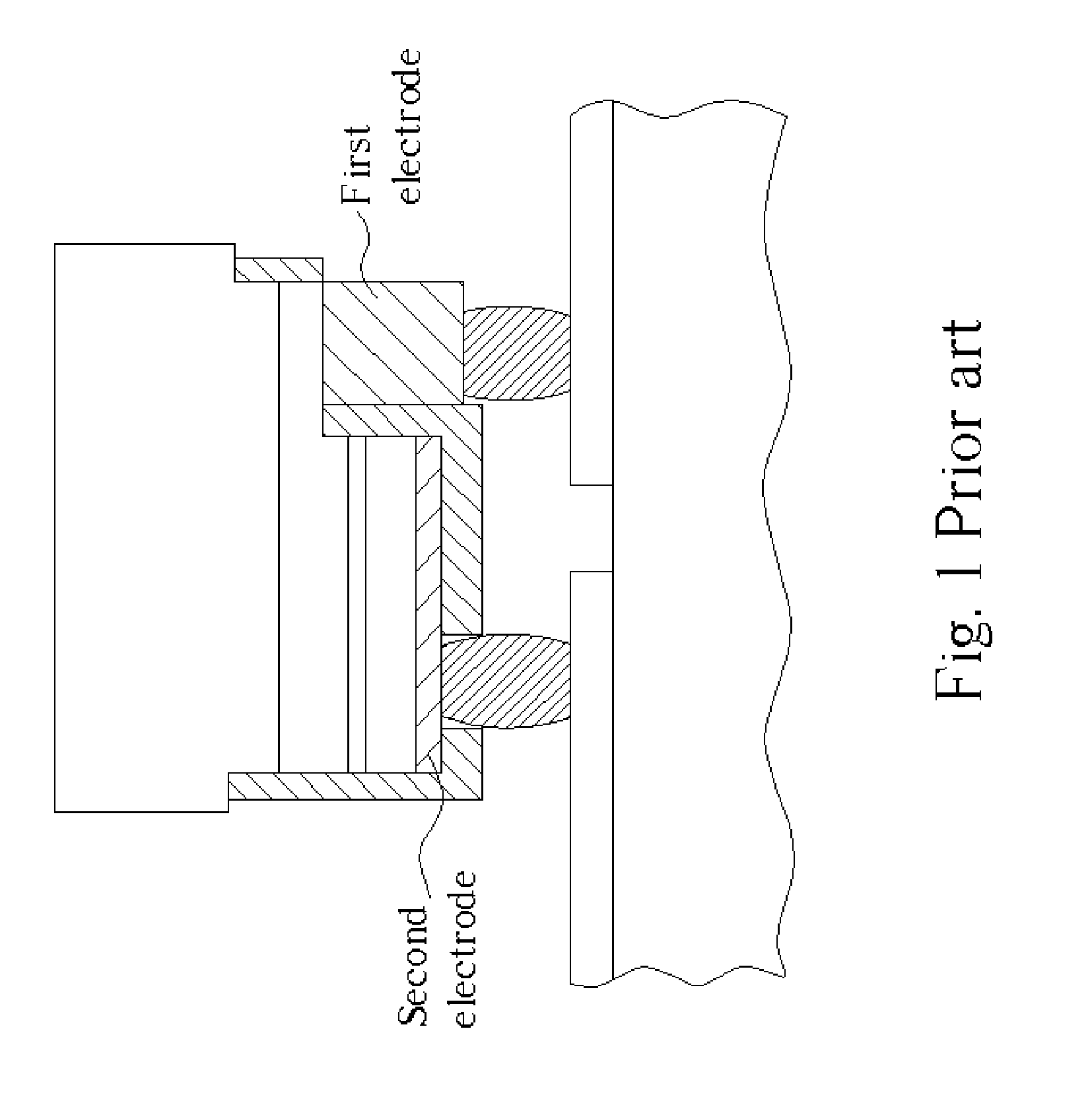

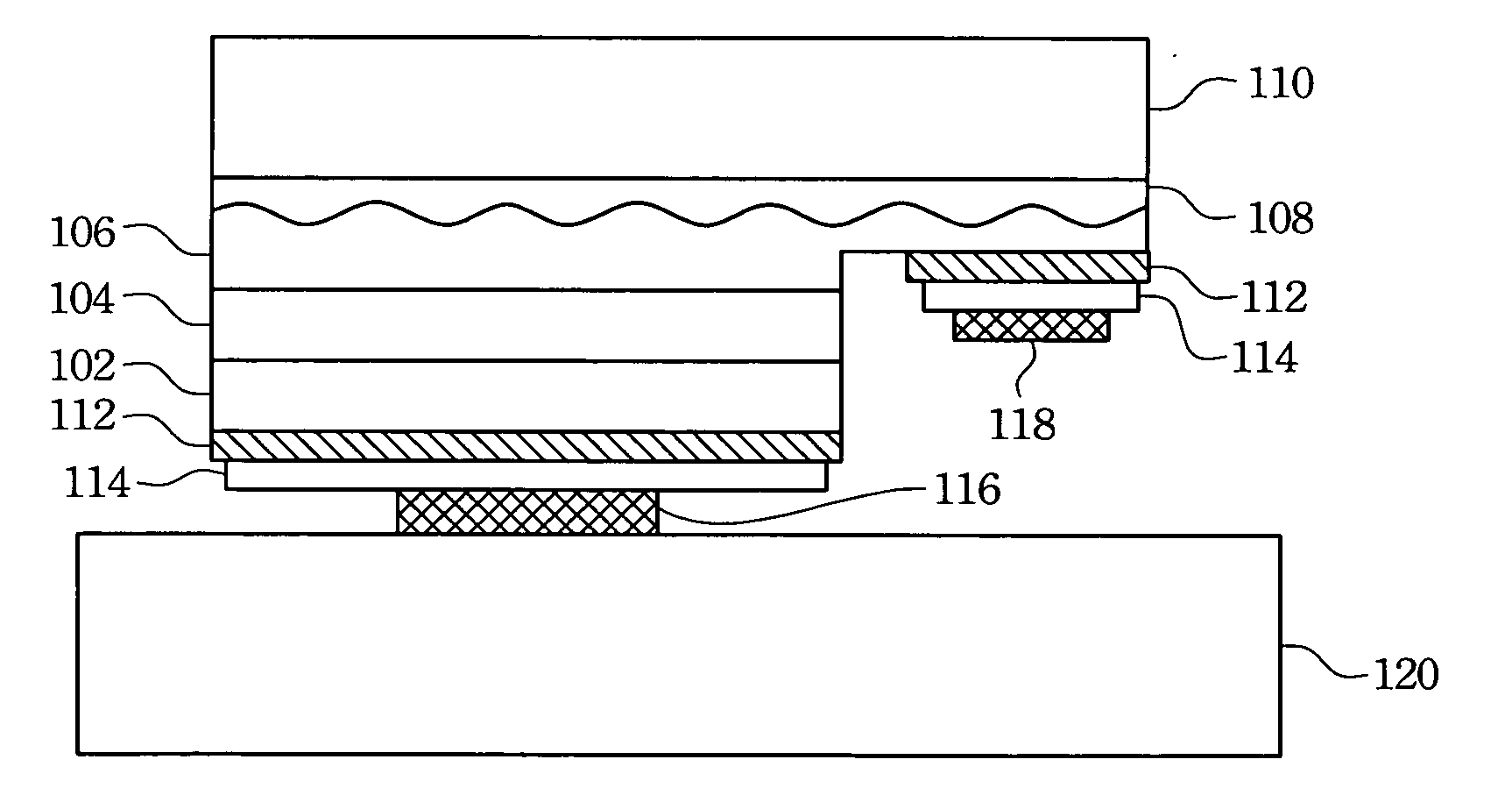

Flip-chip light emitting diode and fabricating method thereof

ActiveUS7067340B1Improve light outputIncrease brightnessSemiconductor/solid-state device testing/measurementSolid-state devicesReflective layerLight-emitting diode

A flip-chip light emitting diode and fabricating methods are disclosed. A soft transparent adhesive layer is utilized to past a transparent conductive substrate onto a light emitting diode epitaxy structure on a substrate, and the substrate is next removed entirely. Then, a mesa-etching process is performed to form a first top surface and a second top surface on the light emitting diode epitaxy structure for respectively exposing an n-type layer and a p-type layer in the light emitting diode epitaxy structure. Next, a metal reflective layer and a barrier layer are formed on the light emitting diode epitaxy structure in turn, and electrodes are finally fabricated on the barrier layer.

Owner:UNITED EPITAXY +1

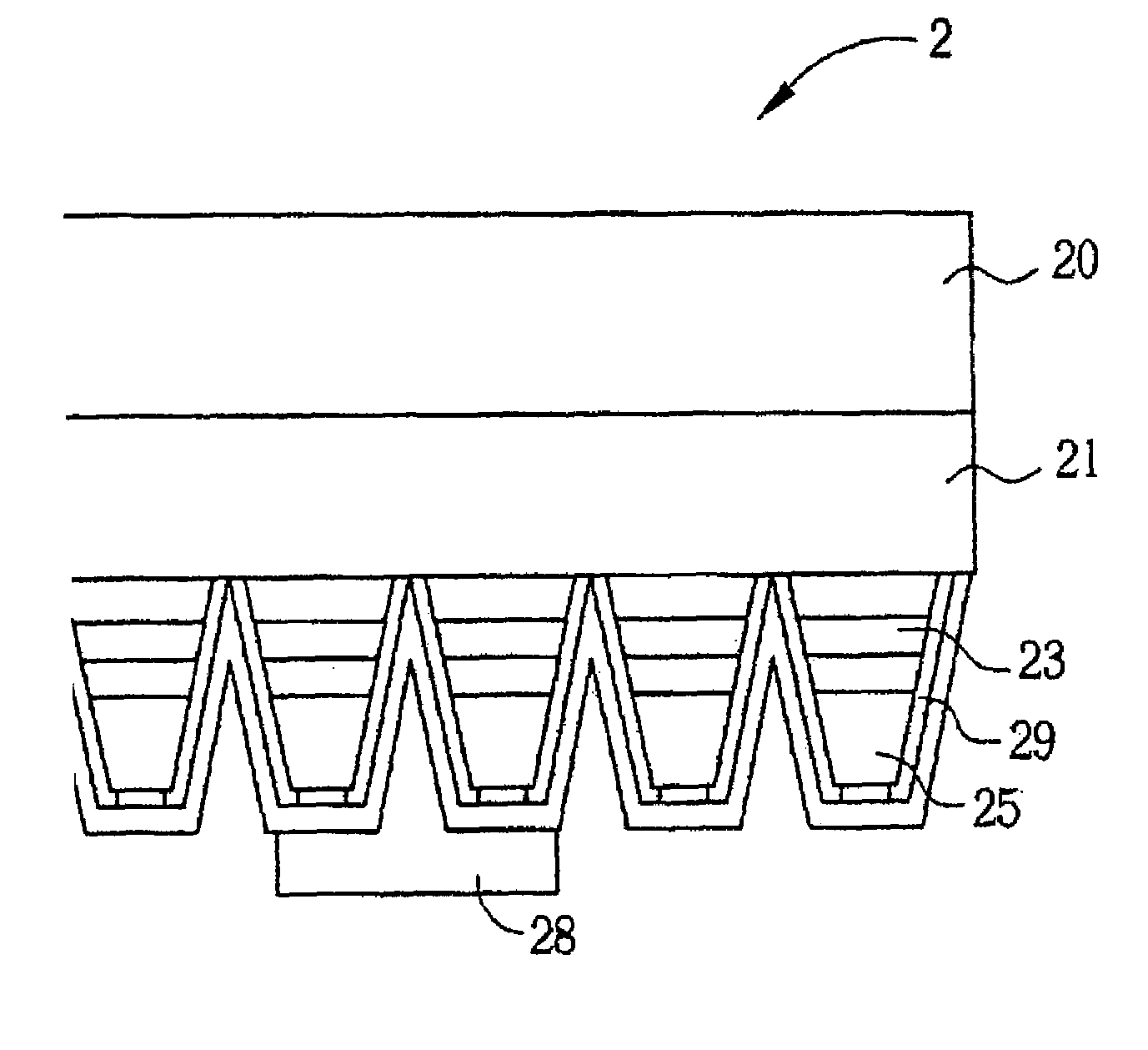

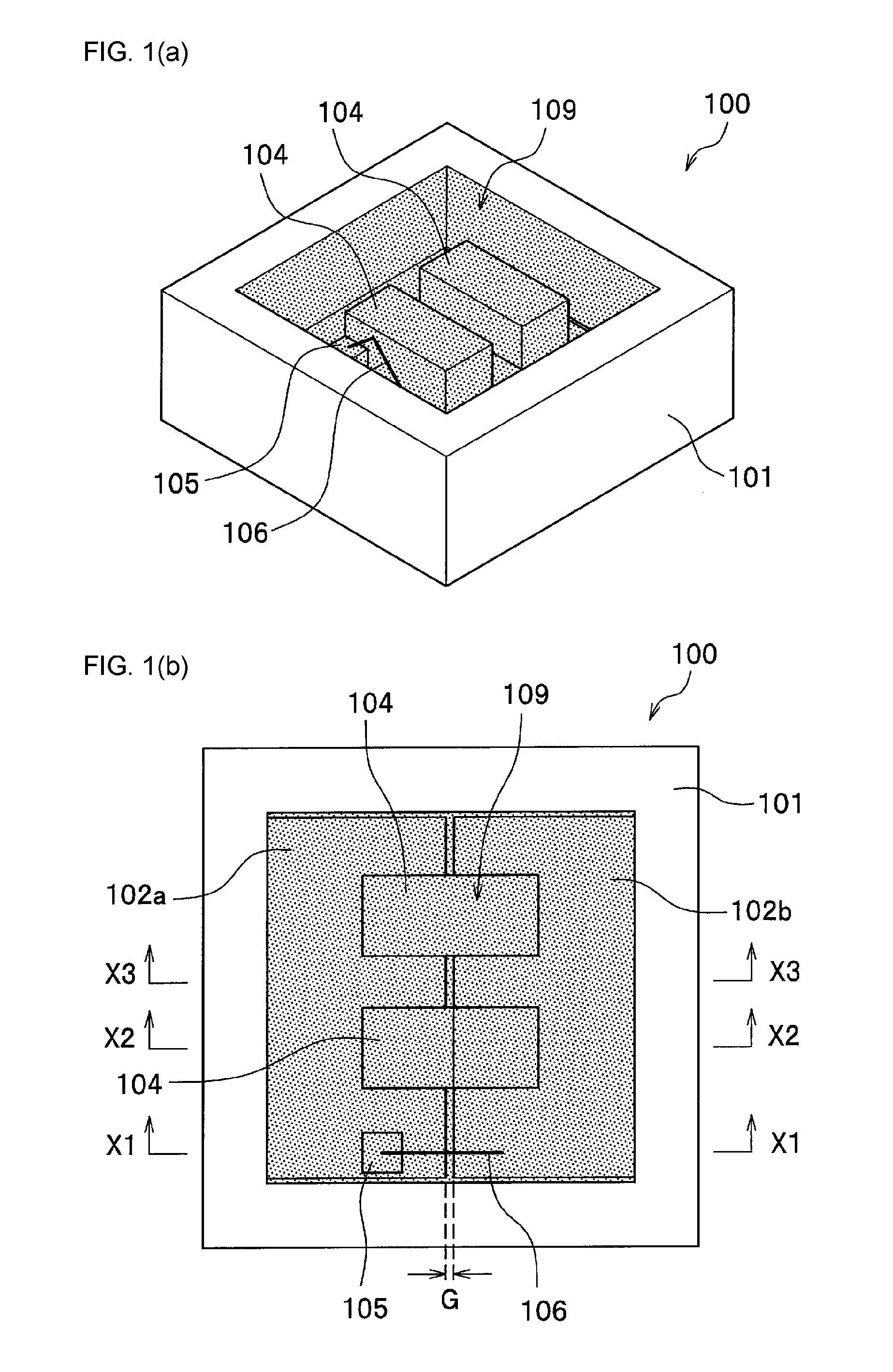

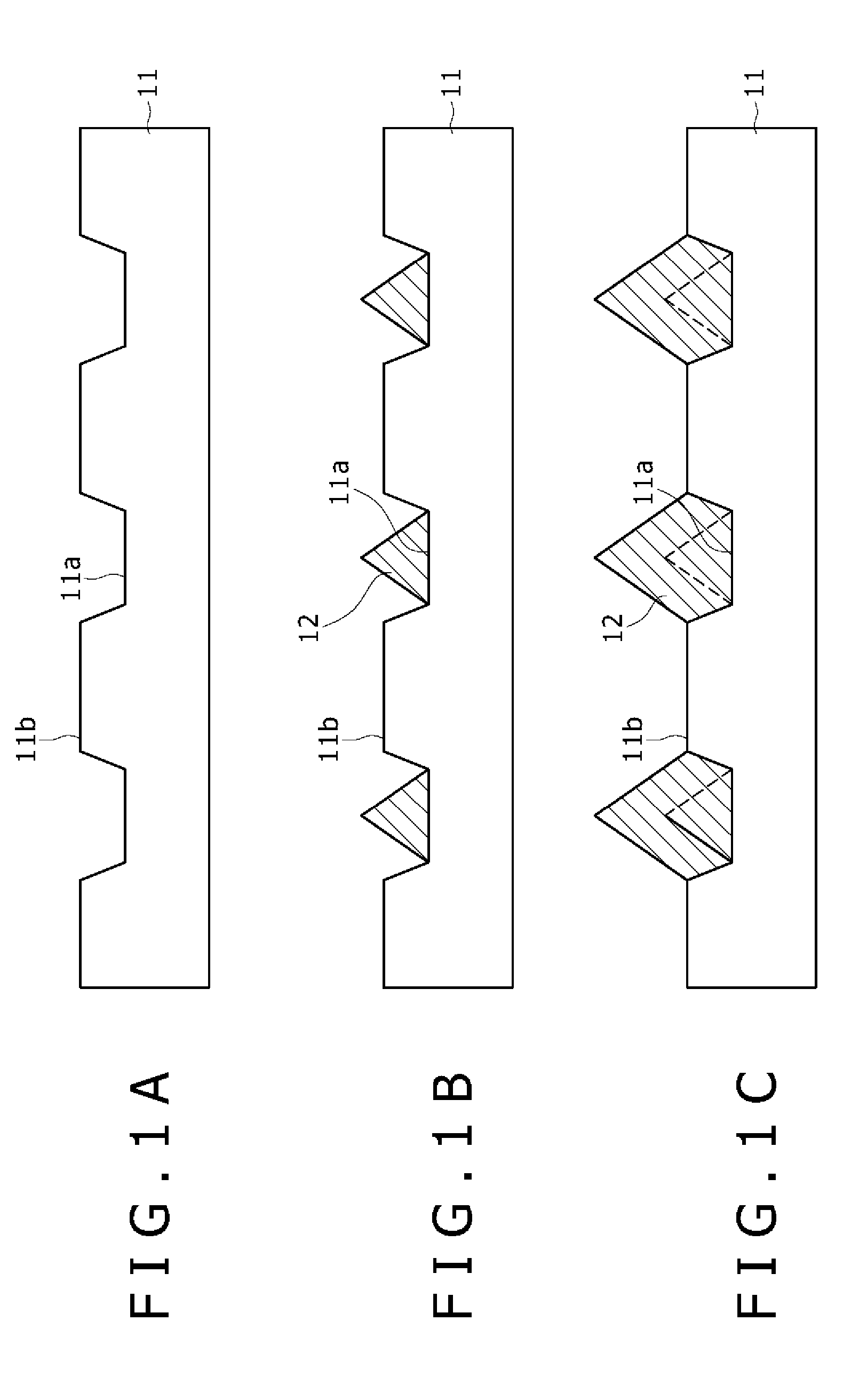

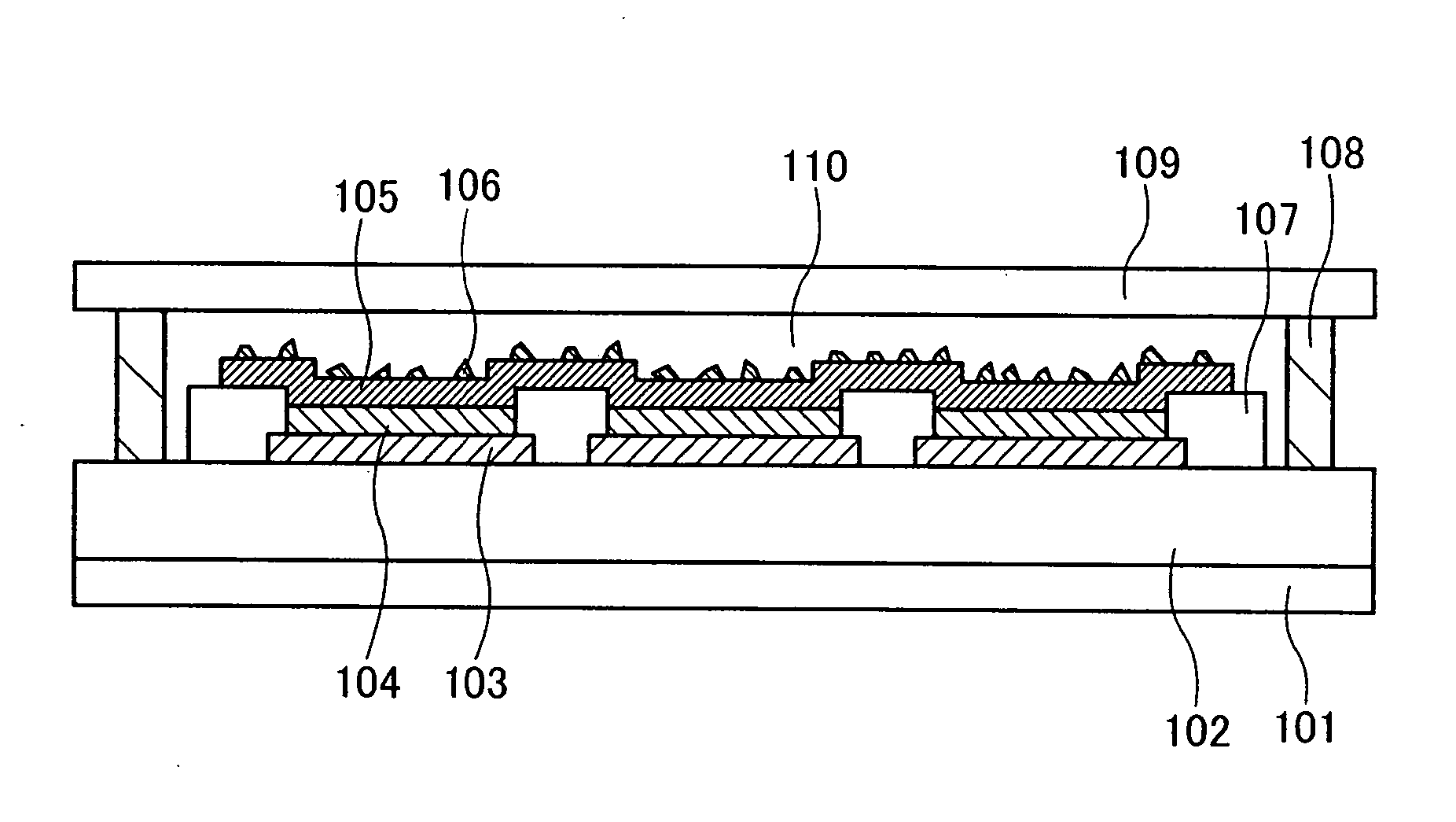

Light-emitting diode, method for making light-emitting diode, integrated light-emitting diode and method for making integrated light-emitting diode, method for growing a nitride-based iii-v group compound semiconductor, light source cell unit, light-emitting diode backlight, and light-emitting diode display and electronic device

InactiveUS20060258027A1Light emission efficiency is reducedImprove light emission efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

A method for making a light-emitting diode, which including the steps of: providing a substrate having at least one recessed portion on one main surface and growing a first nitride-based III-V group compound semiconductor layer through a state of making a triangle in section having a bottom surface of the recessed portion as a base thereby burying the recessed portion; laterally growing a second nitride-based III-V group compound semiconductor layer from the first nitride-based III-V group compound semiconductor layer over the substrate; and successively growing a third nitride-based III-V group compound semiconductor layer of a first conduction type, an active layer and a fourth nitride-based III-V group compound semiconductor layer of a second conduction type on the second nitride-based III-V group compound semiconductor layer.

Owner:SONY CORP

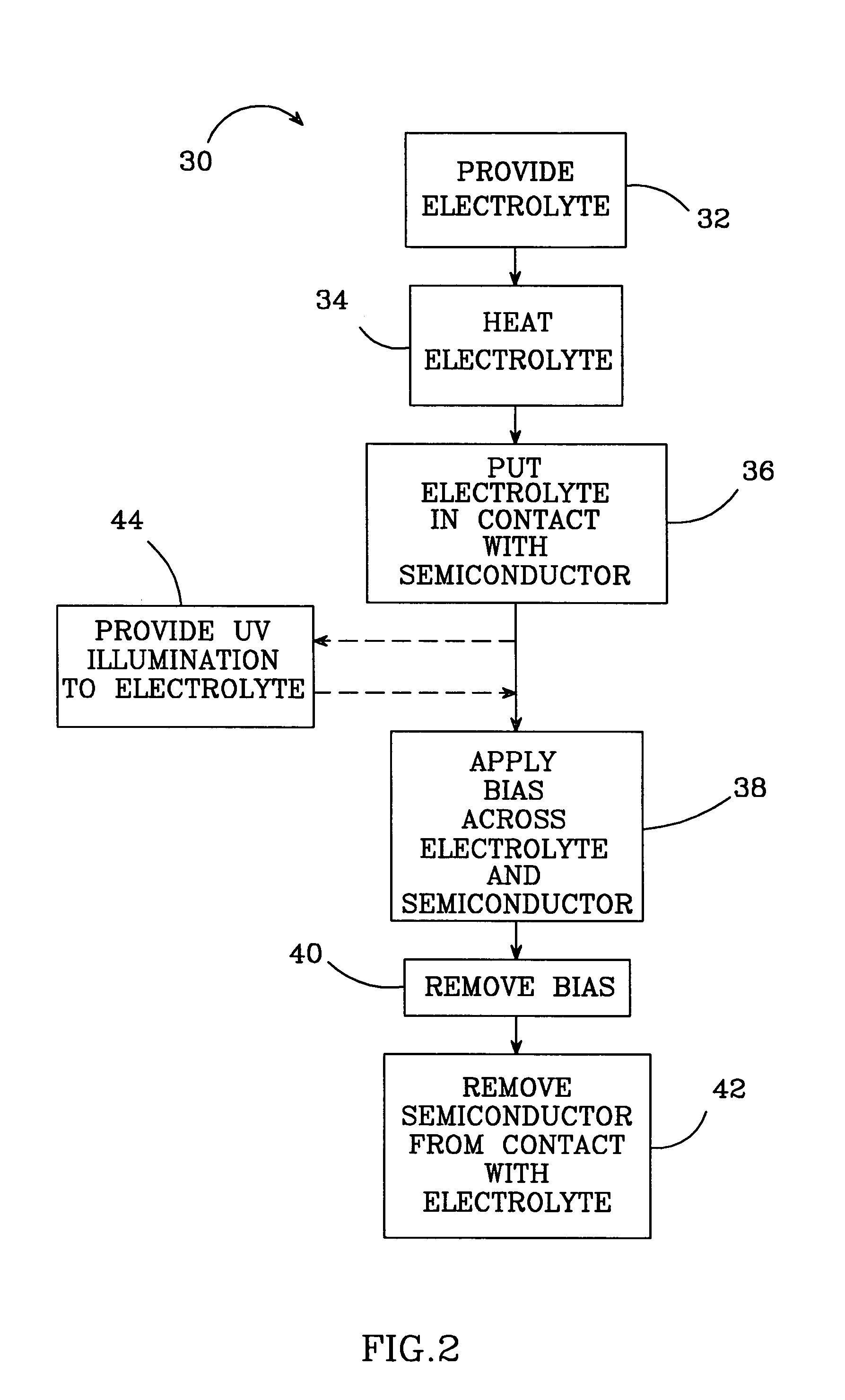

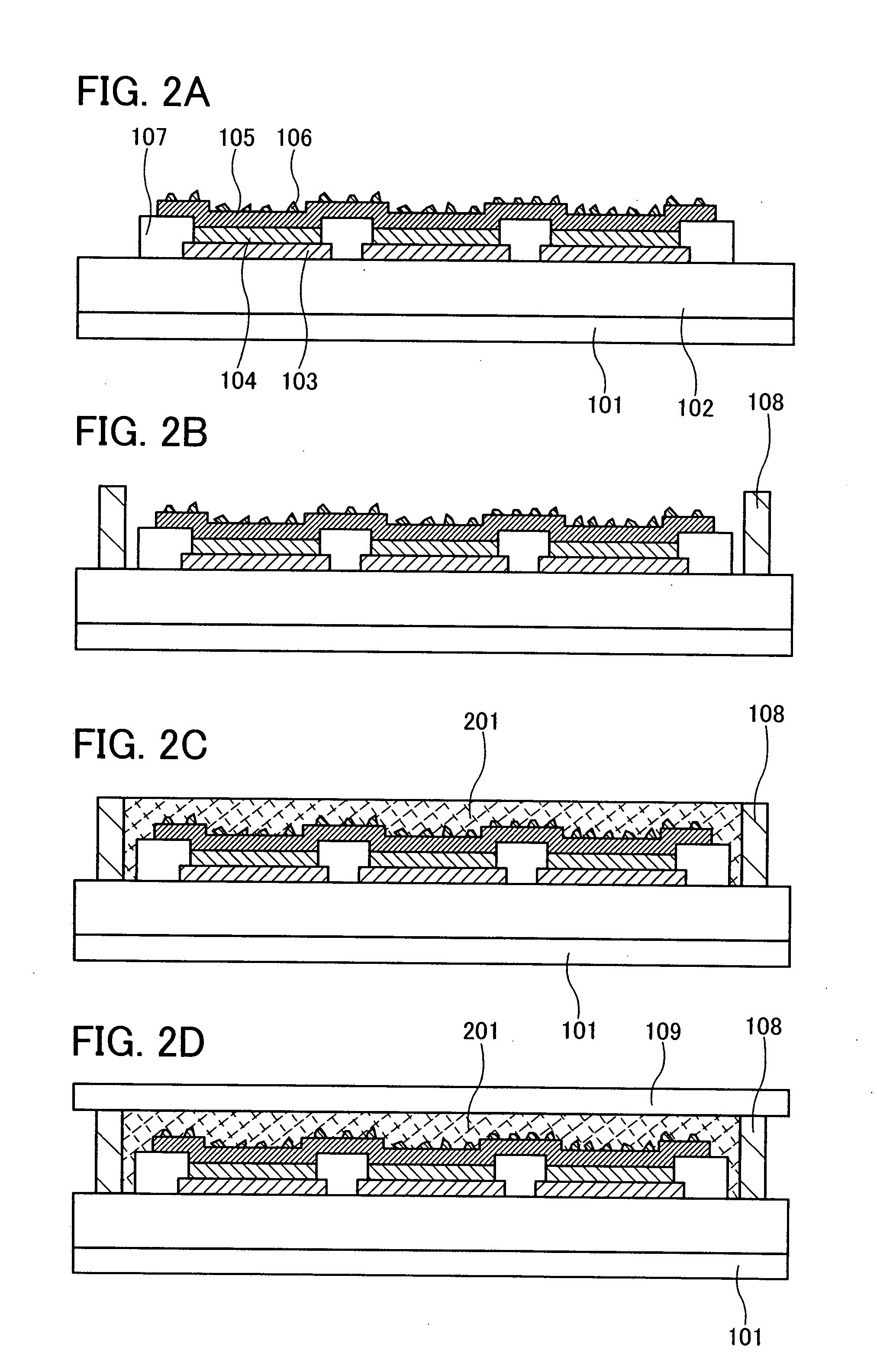

Increased light extraction from a nitride LED

InactiveUS7125734B2Improve light extractionEasy to fixSemiconductor/solid-state device detailsSolid-state devicesWaferingLight-emitting diode

In a method for fabricating a flip-chip light emitting diode device, a submount wafer is populated with a plurality of the light emitting diode dies. Each device die is flip-chip bonded to the submount. Subsequent to the flip-chip bonding, a growth substrate is removed. The entire submount is immersed in the etchant solution, exposed to the light for a prespecified period of time, removed from the solution, dried and diced into a plurality of LEDs. The LEDs are immediately packaged without any further processing.

Owner:GELCORE LLC (US)

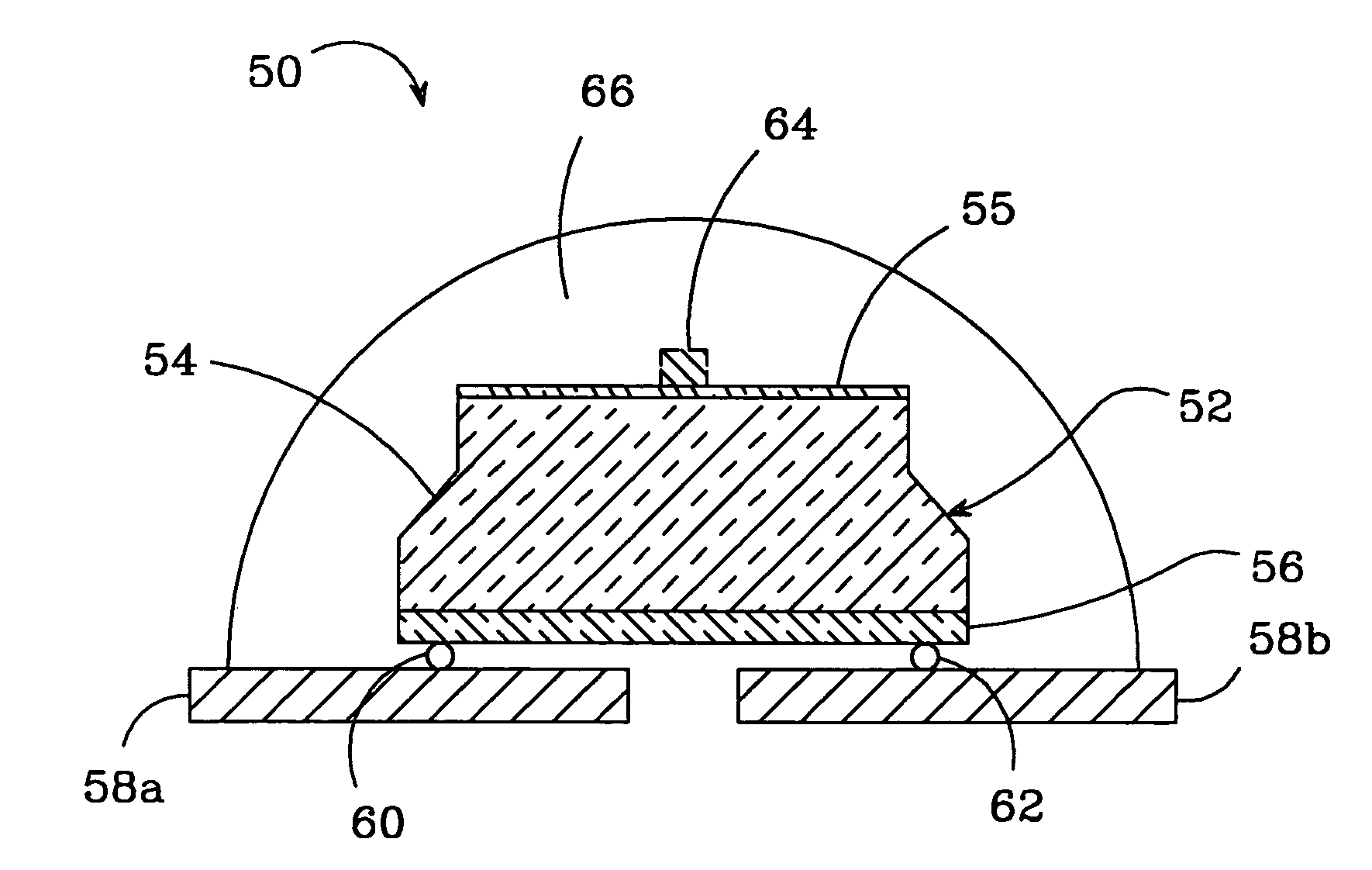

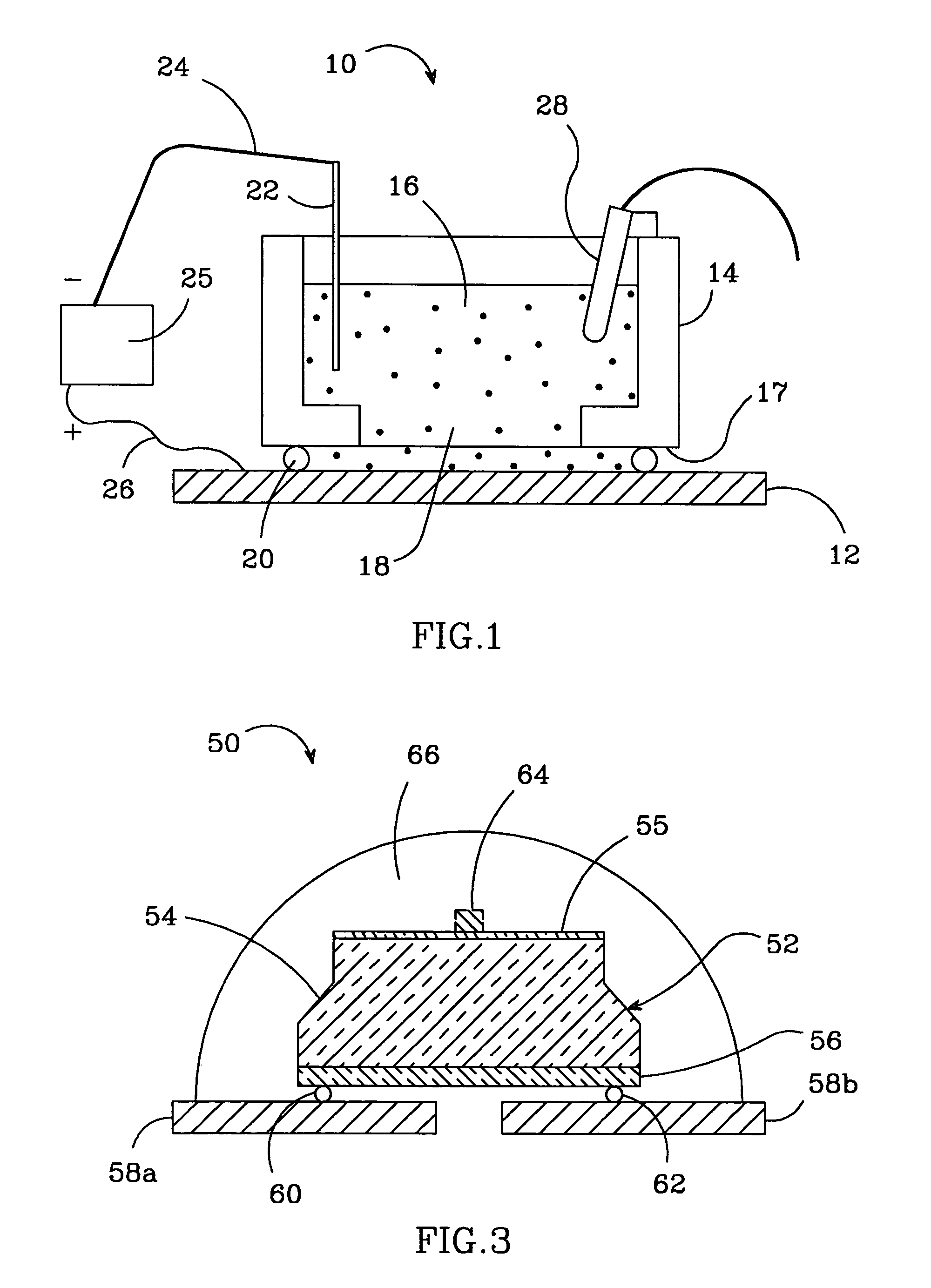

Light emitting diode with porous SiC substrate and method for fabricating

InactiveUS6972438B2Speed up the extraction processImprove light extractionSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsPorous layer

A method and apparatus for forming a porous layer on the surface of a semiconductor material wherein an electrolyte is provided and is placed in contact with one or more surfaces of a layer of semiconductor material. The electrolyte is heated and a bias is introduced across said electrolyte and the semiconductor material causing a current to flow between the electrolyte and the semiconductor material. The current forms a porous layer on the one or more surfaces of the semiconductor material in contact with the electrolyte. The semiconductor material with its porous layer can serve as a substrate for a light emitter. A semiconductor emission region can be formed on the substrate. The emission region is capable of emitting light omnidirectionally in response to a bias, with the porous layer enhancing extraction of the emitting region light passing through the substrate.

Owner:CREELED INC

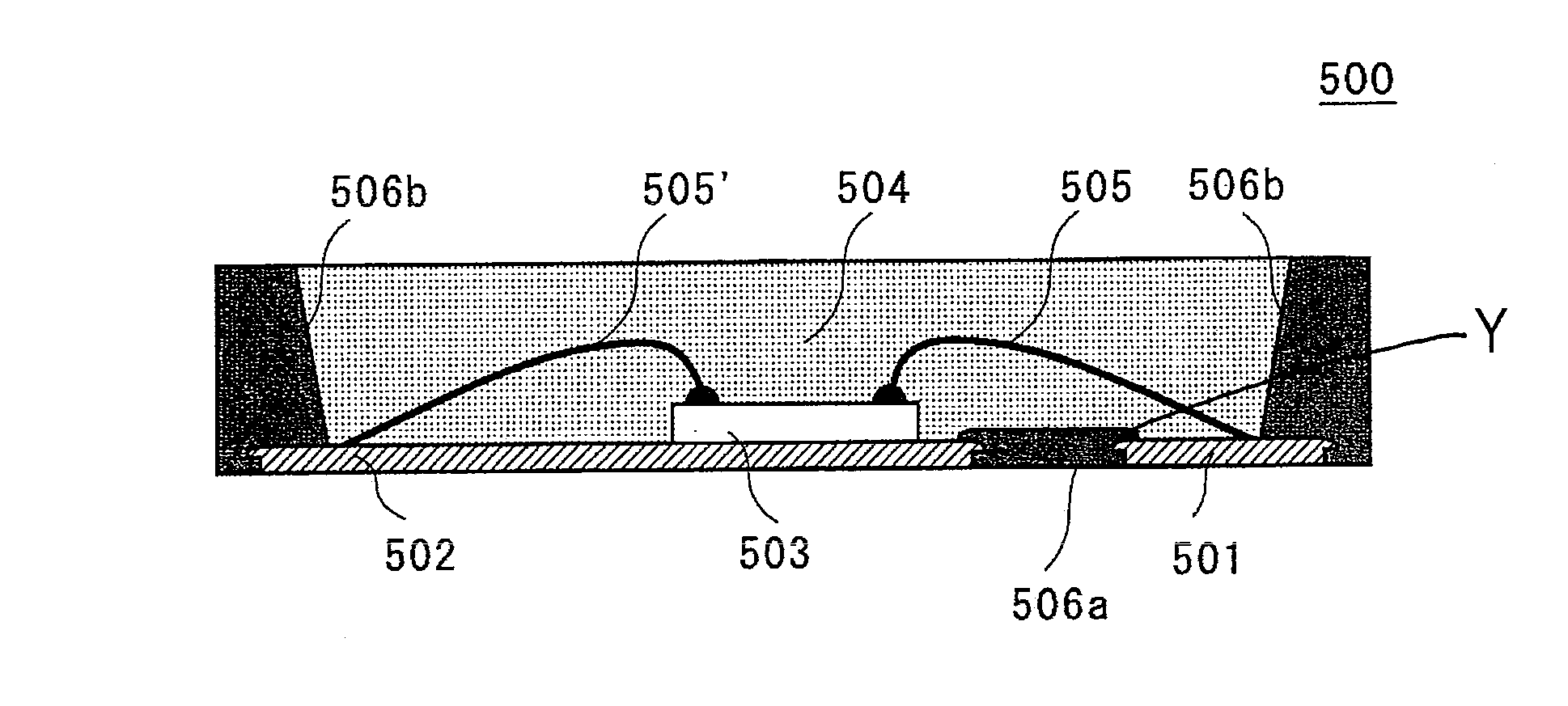

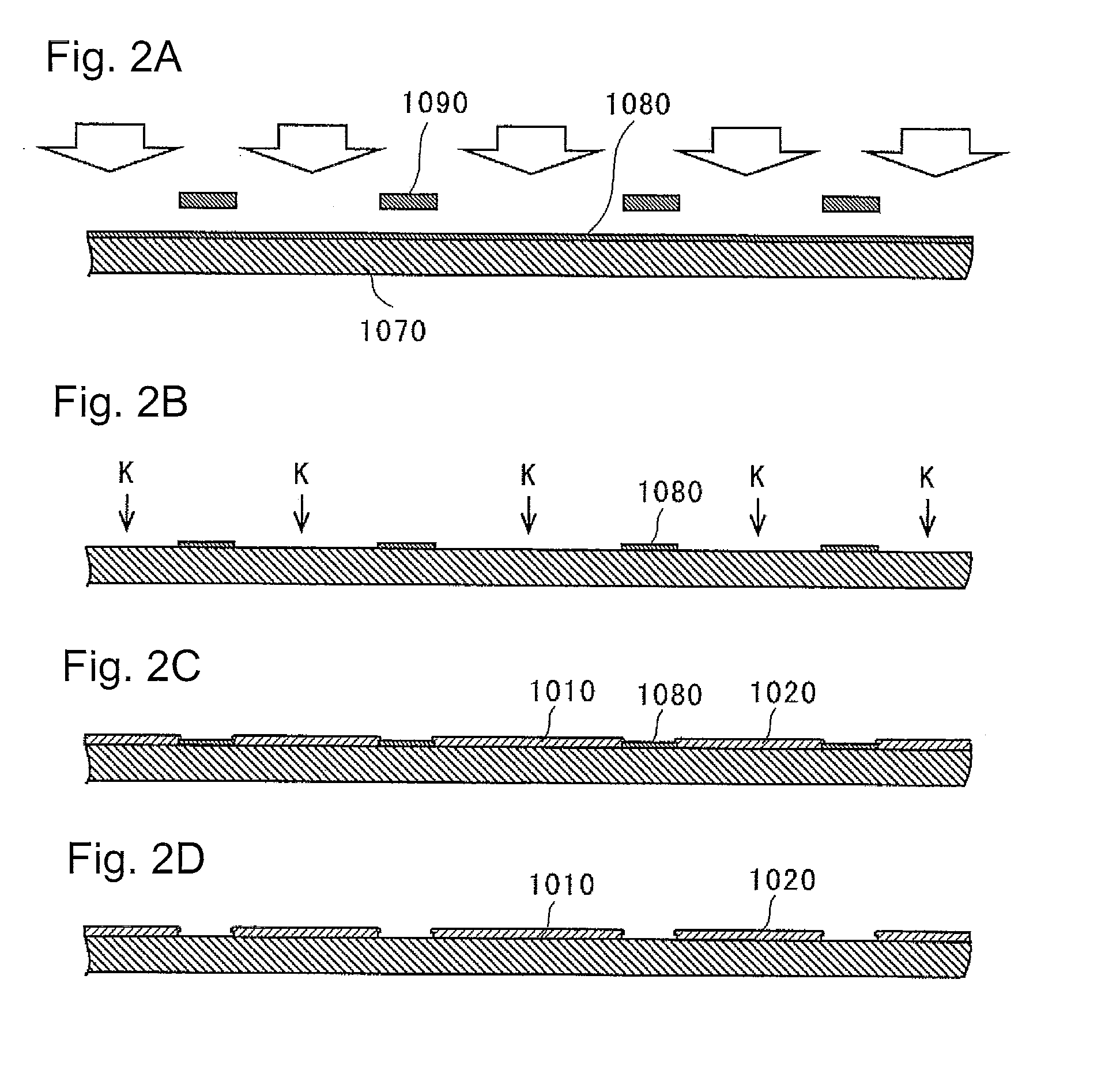

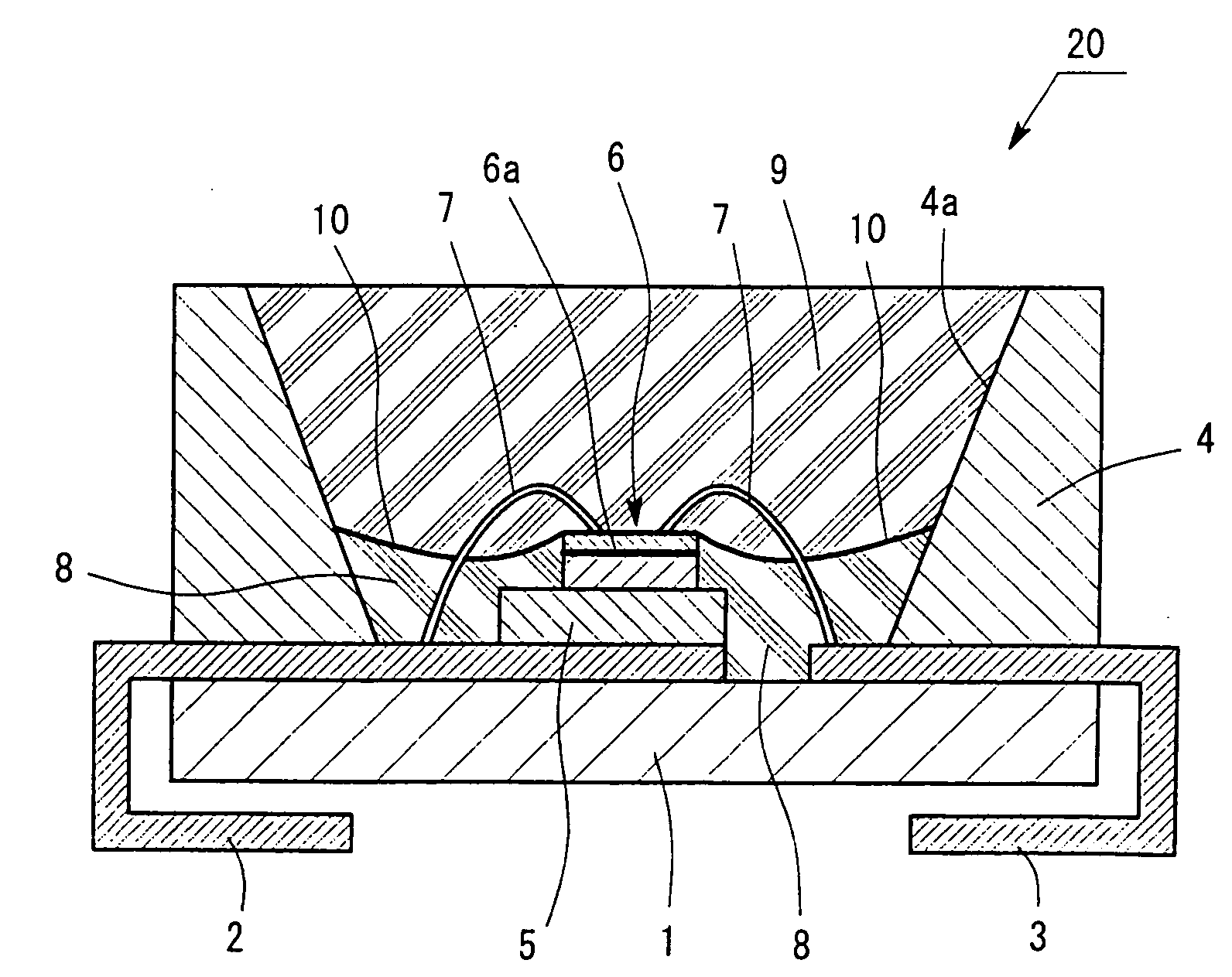

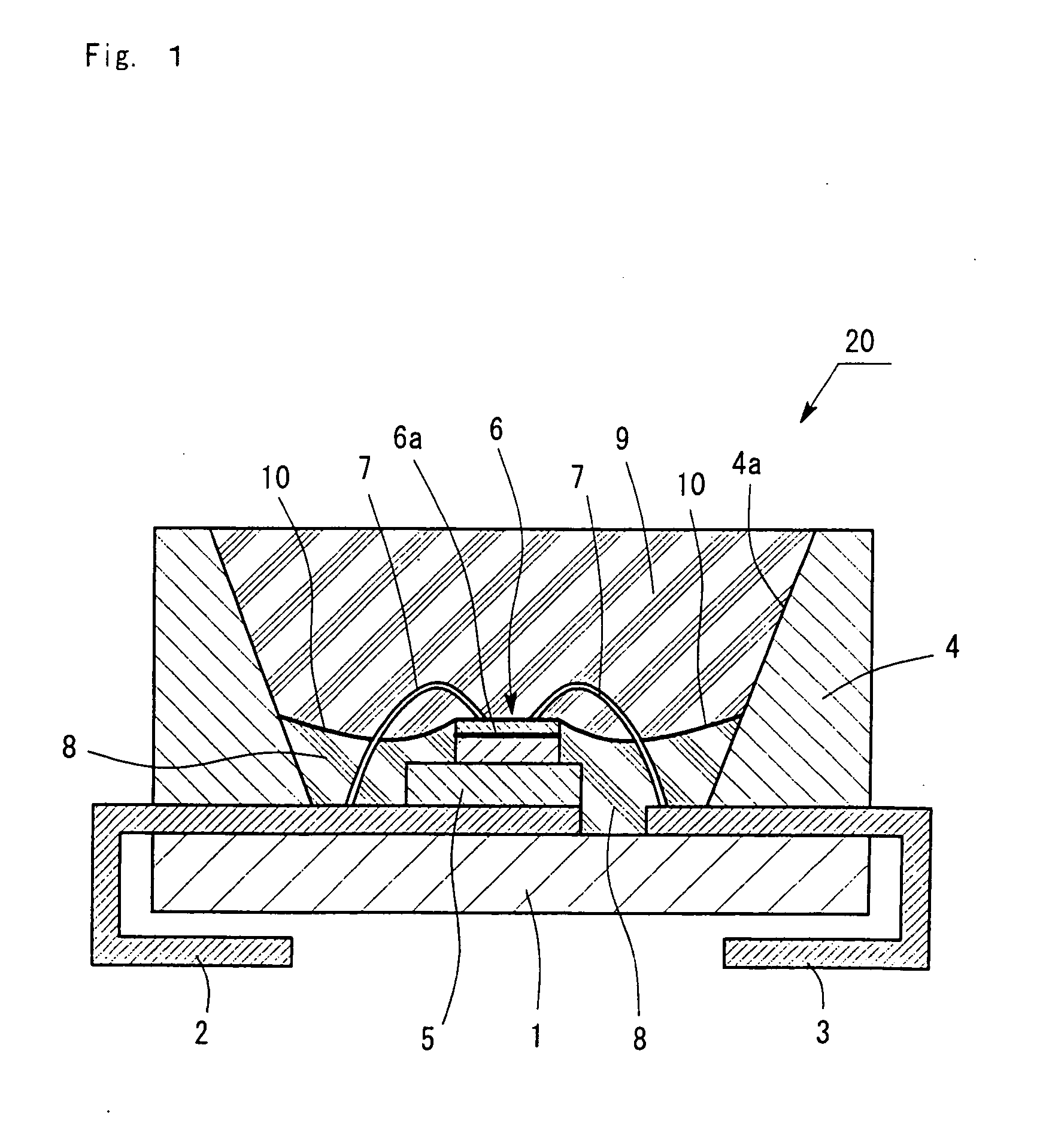

Optical-semiconductor device and method for manufactruing the same

ActiveUS20100059782A1Easy to manufactureImprove light extractionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor device

A method for manufacturing an optical-semiconductor device, including forming a plurality of first and second electrically conductive members that are disposed separately from each other on a support substrate; providing a base member formed from a light blocking resin between the first and second electrically conductive members; mounting an optical-semiconductor element on the first and / or second electrically conductive member; covering the optical-semiconductor element by a sealing member formed from a translucent resin; and obtaining individual optical-semiconductor devices after removing the support substrate.

Owner:NICHIA CORP

LED package with structure and materials for high heat dissipation

ActiveUS20060091415A1Improve cooling effectLow fracture toughnessSemiconductor/solid-state device detailsSolid-state devicesConductive materialsThermal expansion

LED packages are provided that include a material that is both thermally conductive and has a coefficient of thermal expansion that is matched to that of an LED. The material can be a ceramic such as aluminum nitride. The package has a body that includes a bottom surface and a cavity disposed into the body. The cavity has a floor for bonding to the LED so that the LED sits within the cavity. The thermally conductive material is disposed between the floor of the cavity and the bottom surface of the package. The body can be fabricated from a number of layers where the thermally conductive material is in a layer disposed between the floor and the bottom surface. The other layers of the body can also be fabricated from the thermally conductive material. A light emitting device is made by attaching the LED to the LED package.

Owner:LED ENGIN

Light emitting element, light emitting device, manufacturing method of light emitting device, and sheet-like sealing material

ActiveUS20080018231A1Reduce the amount of reflectionImprove lighting efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesRefractive indexLight emitting device

A method to improve light extraction efficiency of a light emitting element such as an electroluminescent element is disclosed. Over a substrate, a first electrode, a light emitting layer, and a second electrode are sequentially stacked. The first electrode is a reflective electrode. The second electrode is an electrode which transmits visible light, and light emitted from the light emitting layer is extracted from the second electrode. In contact with a surface of the second electrode, many fine particles are provided. The fine particles have a refractive index which is equal to or higher than that of the second electrode. Light which passes through the second electrode is scattered and refracted by the fine particles. Accordingly, the amount of light which is totally reflected at an interface between the second electrode and a gas is reduced, and light extraction efficiency is improved.

Owner:SEMICON ENERGY LAB CO LTD

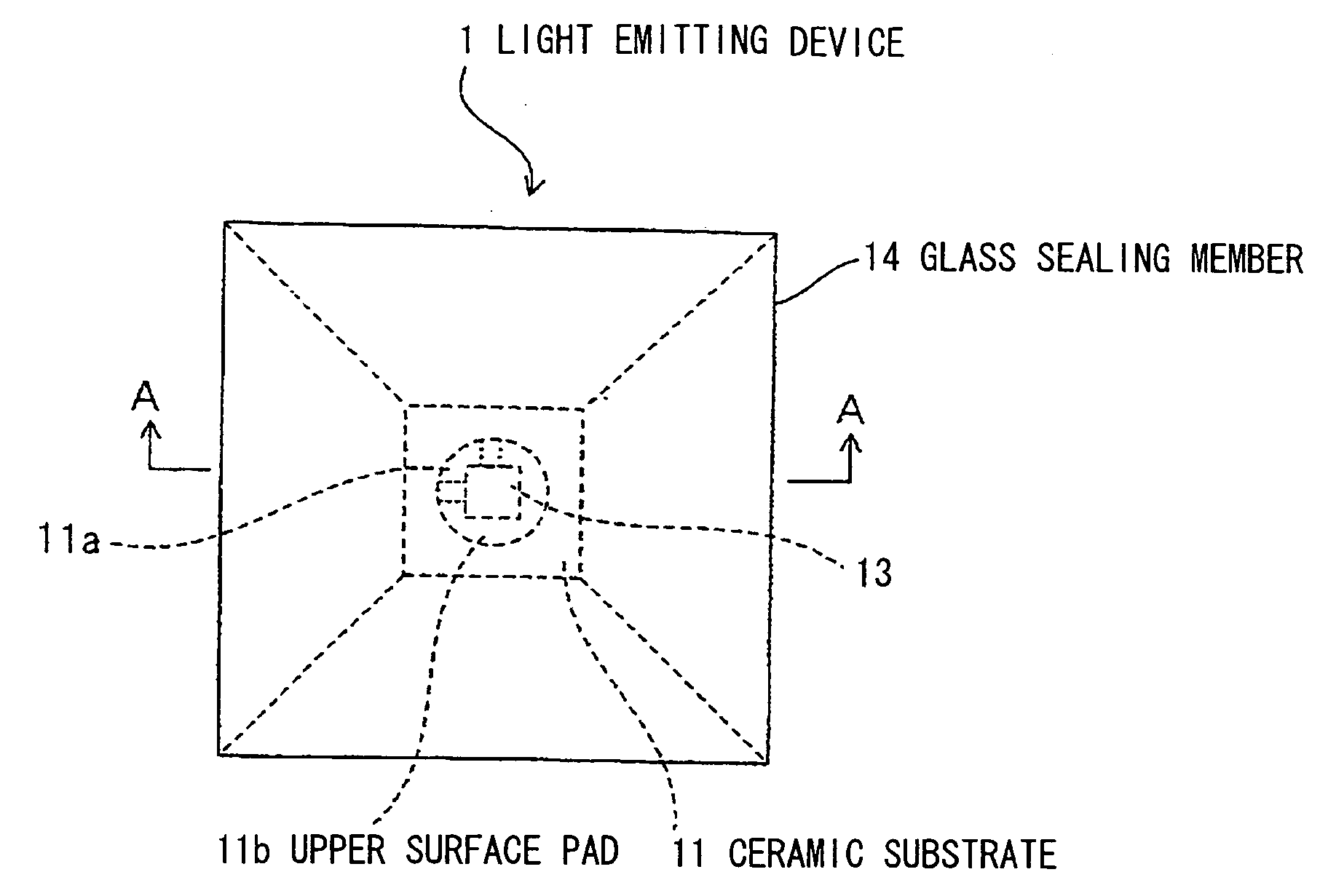

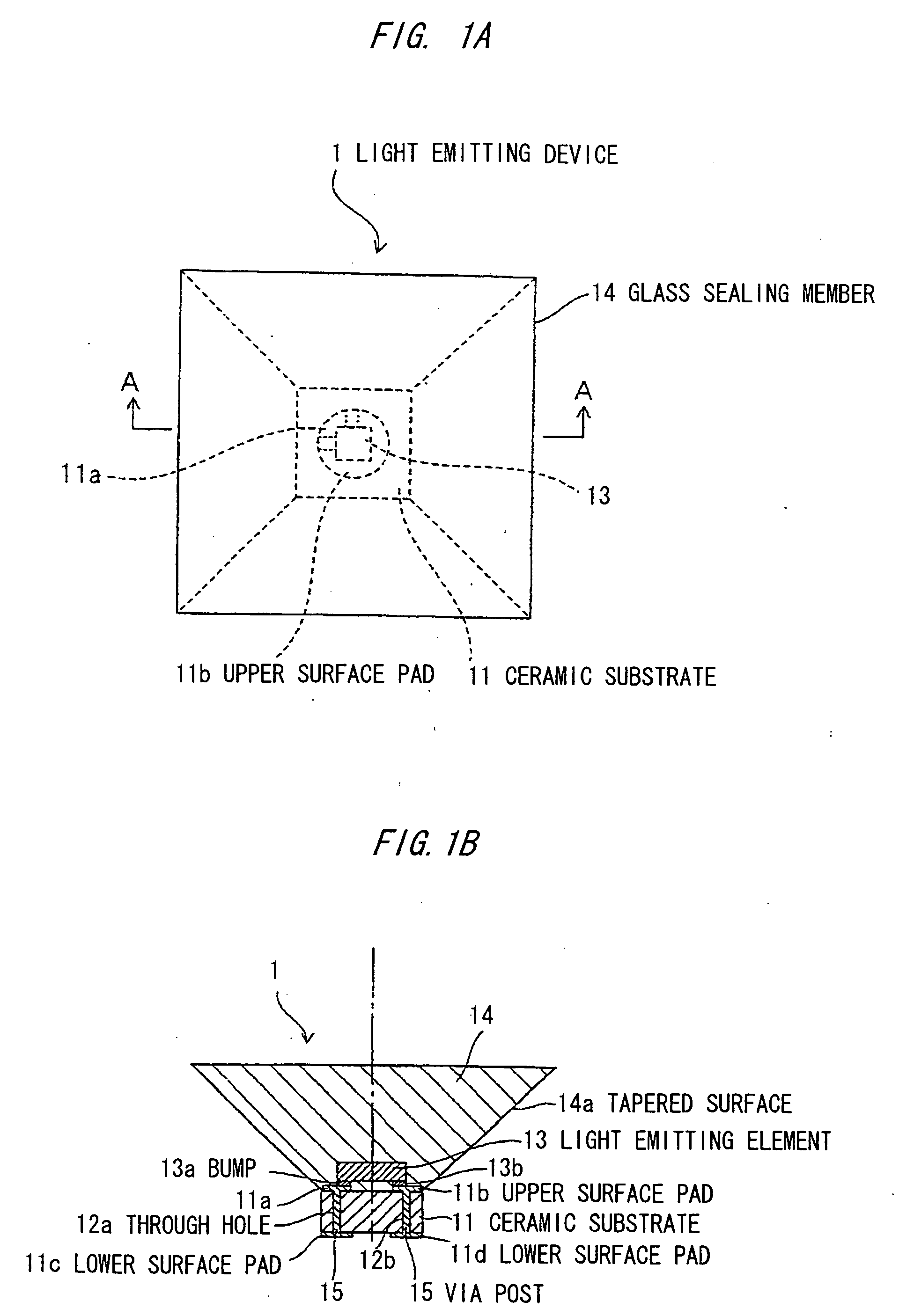

Light emitting device and method of producing same

InactiveUS20060054913A1Avoid high temperatureLight extraction efficiency can be improvedSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting device

A light emitting device having: a light emitting element; an electricity supply portion on which the light emitting element is mounted and which supplies electricity; and an inorganic sealing material for sealing the light emitting element. The inorganic sealing material has a tapered surface which becomes wider outward in a side surface direction with respect to a center axis of the light emitting element.

Owner:TOYODA GOSEI CO LTD

Semiconductor light-emitting device and method for manufacturing semiconductor light-emitting device

InactiveUS20080218072A1Improve light extraction efficiencyInhibit coloringDischarge tube luminescnet screensLamp detailsPhosphorEngineering

A semiconductor light-emitting device in which a light-emitting diode including a light-emitting layer is placed directly on the bottom of a cup-shaped case or placed above the case bottom with a submount disposed therebetween includes a transparent primary sealing member that seals a side region, located under the light-emitting layer, surrounding the light-emitting diode that is fixed in the case; a transparent secondary sealing member disposed on the primary sealing member; and a uniform deposition layer formed by depositing phosphor particles or light diffuser particles contained in a material for forming the secondary sealing member. The phosphor particles or the light diffuser particles are deposited on the upper surface of the light-emitting diode and the upper surface of the primary sealing member to form a uniform layer that is as thin as a one-particle to five-particle layer.

Owner:TOYODA GOSEI CO LTD

Light-emitting devices utilizing nanoparticles

InactiveUS20050215164A1Improve light extractionReduce light scatterDischarge tube luminescnet screensElectroluminescent light sourcesNanoparticleRefractive index

Light-emitting devices are disclosed that comprise a light source emitting first light, a first material substantially transparent to and located to receive at least a portion of the first light, and particles of a second material dispersed in the first material. The second material has an index of refraction greater than an index of refraction of the first material at a wavelength of the first light. The particles of the second material have diameters less than about this wavelength. Particles of a third material may also be dispersed in the first material.

Owner:LUMILEDS

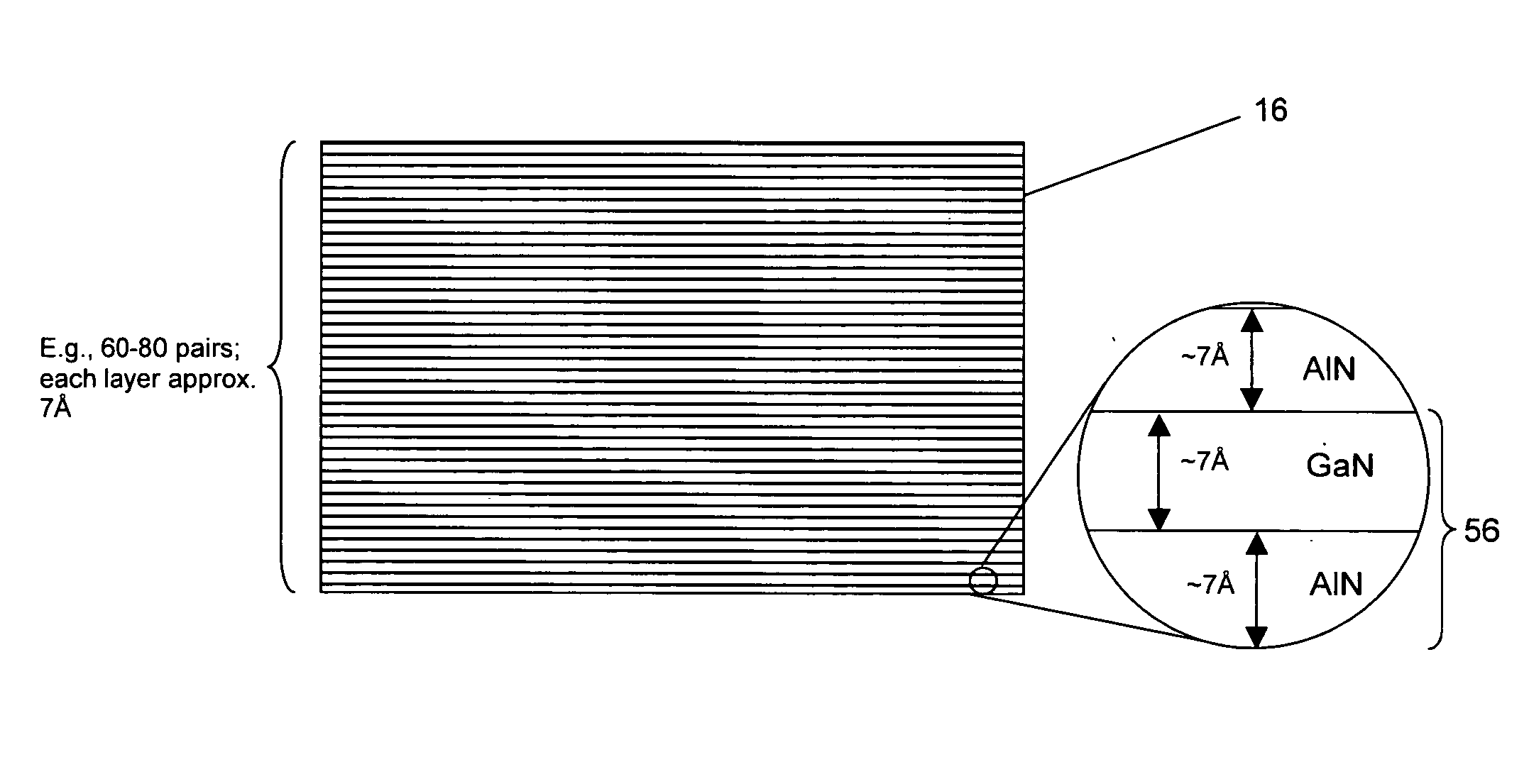

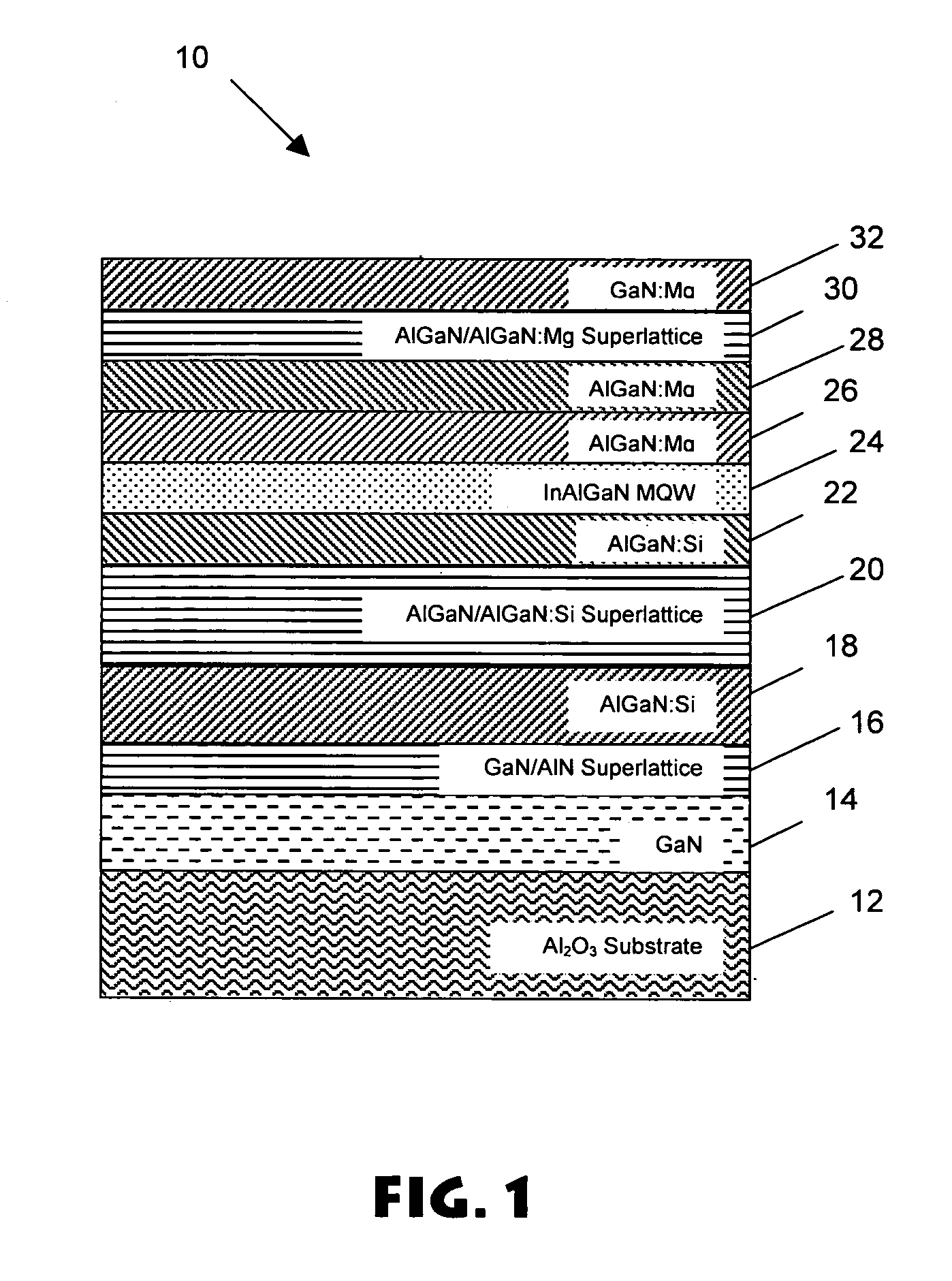

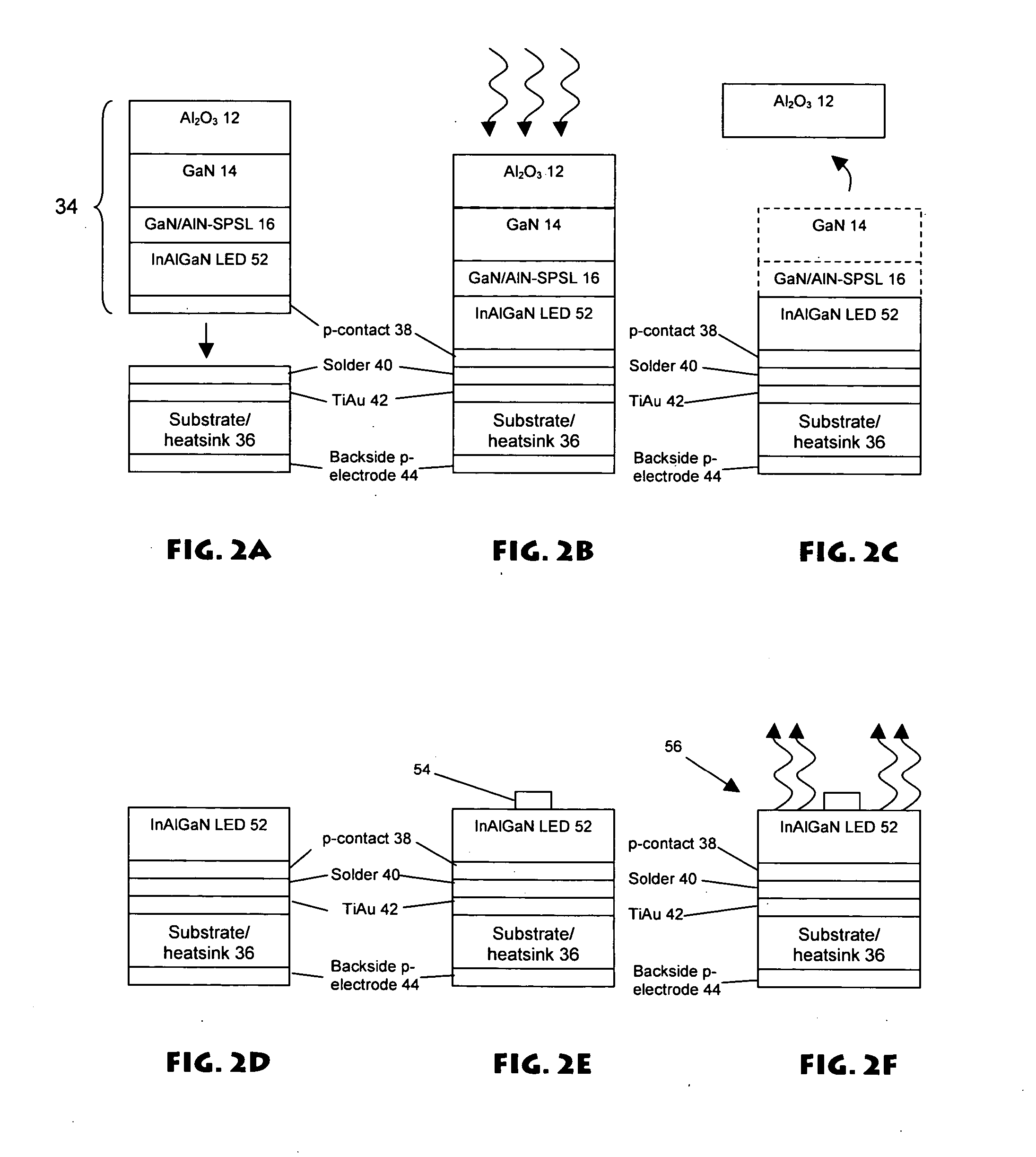

Superlattice strain relief layer for semiconductor devices

ActiveUS20070108456A1High aluminum contentEfficient productionSolid-state devicesNanoopticsLength waveLight-emitting diode

A GaN / AlN superlattice is formed over a GaN / sapphire template structure, serving in part as a strain relief layer for growth of subsequent layers (e.g., deep UV light emitting diodes). The GaN / AlN superlattice mitigates the strain between a GaN / sapphire template and a multiple quantum well heterostructure active region, allowing the use of high Al mole fraction in the active region, and therefore emission in the deep UV wavelengths.

Owner:XEROX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com