Patents

Literature

183results about How to "Maximize production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

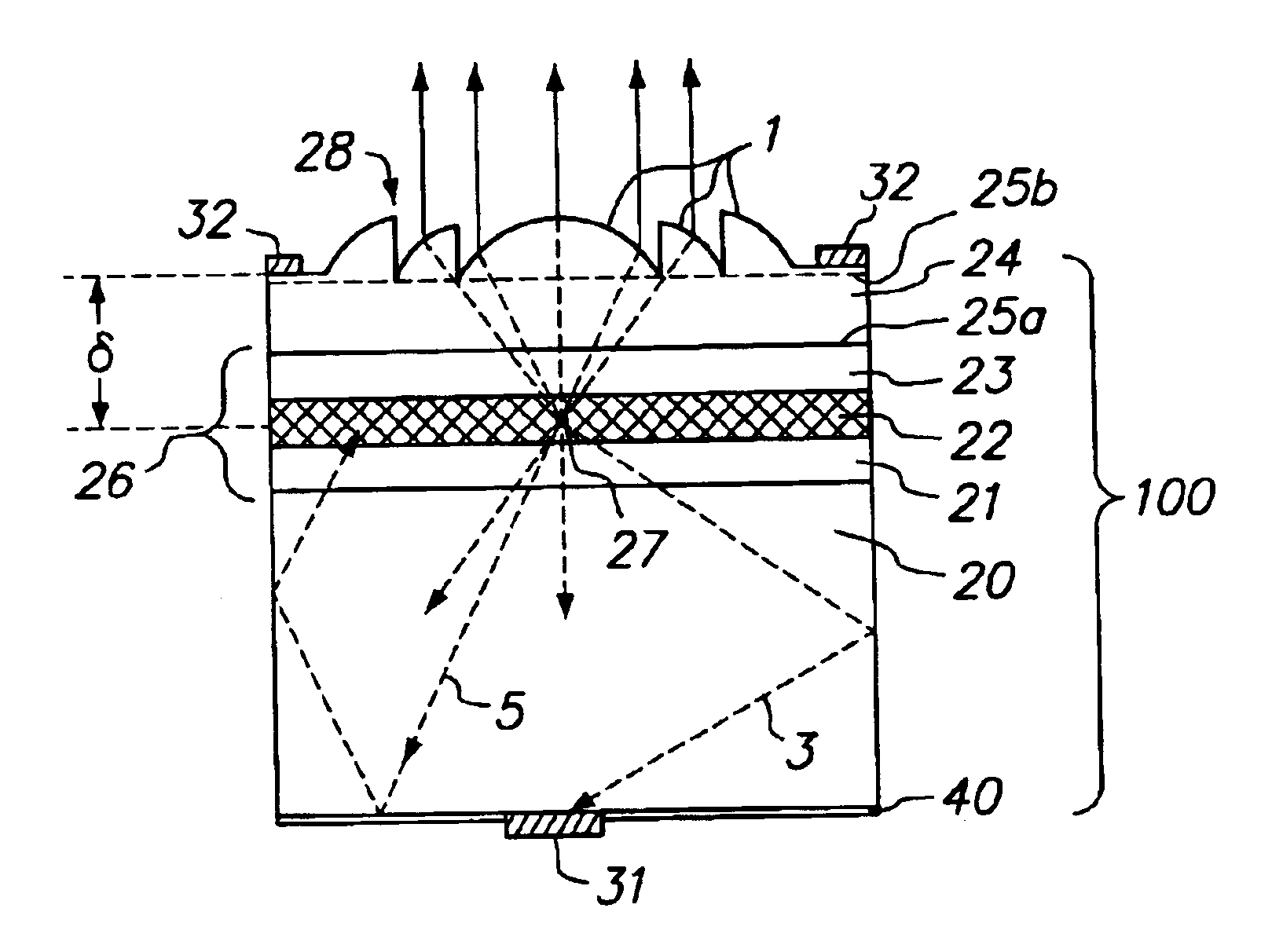

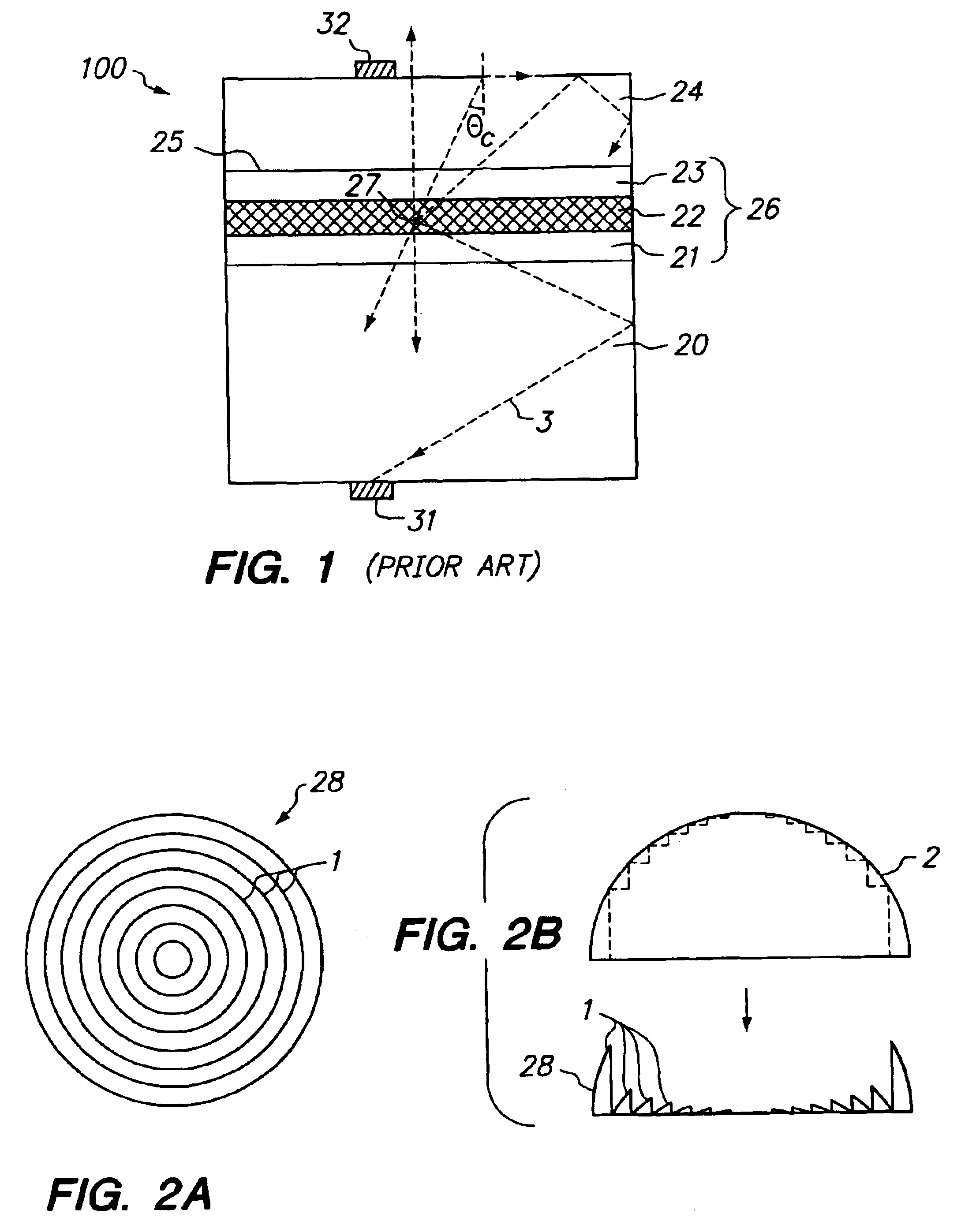

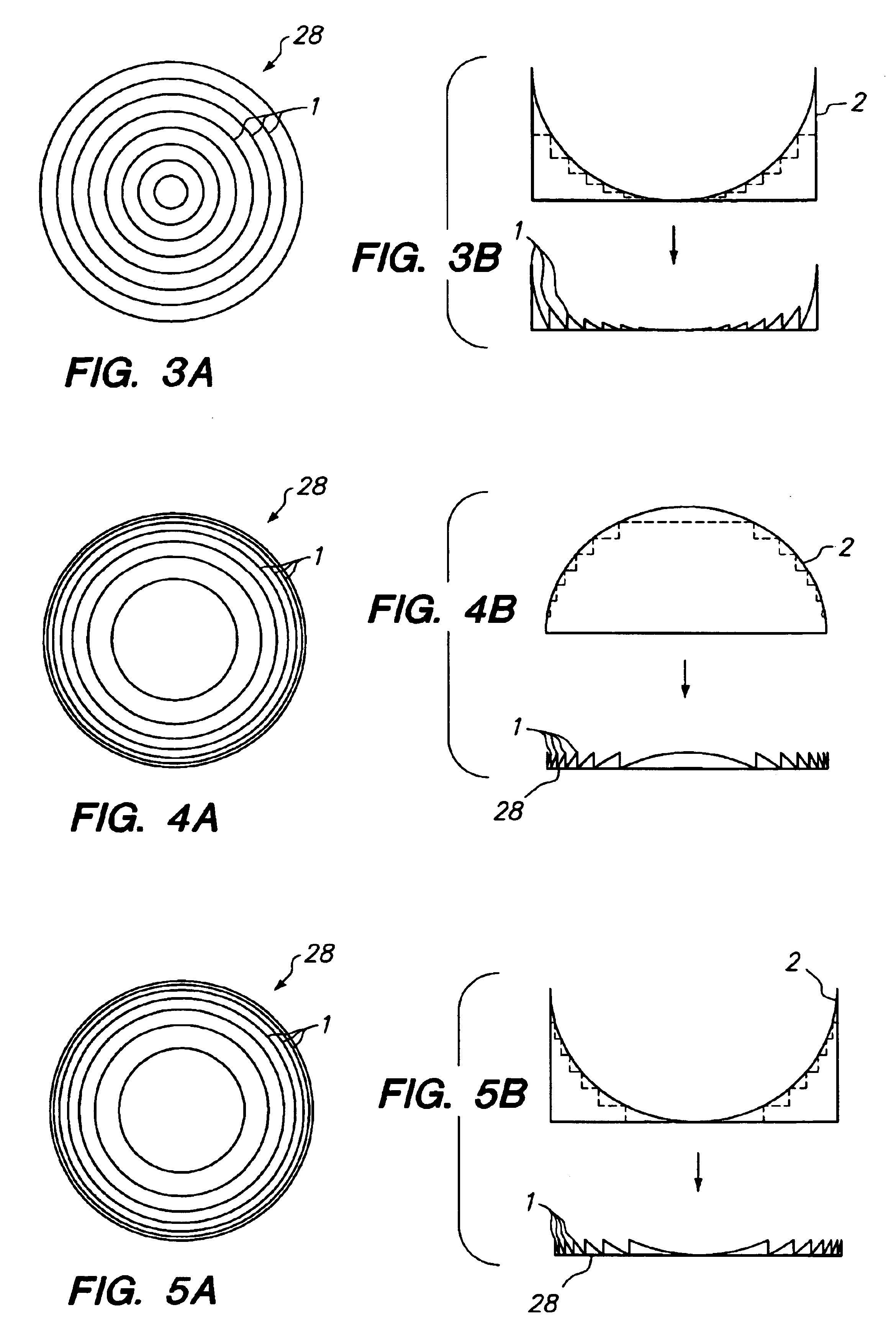

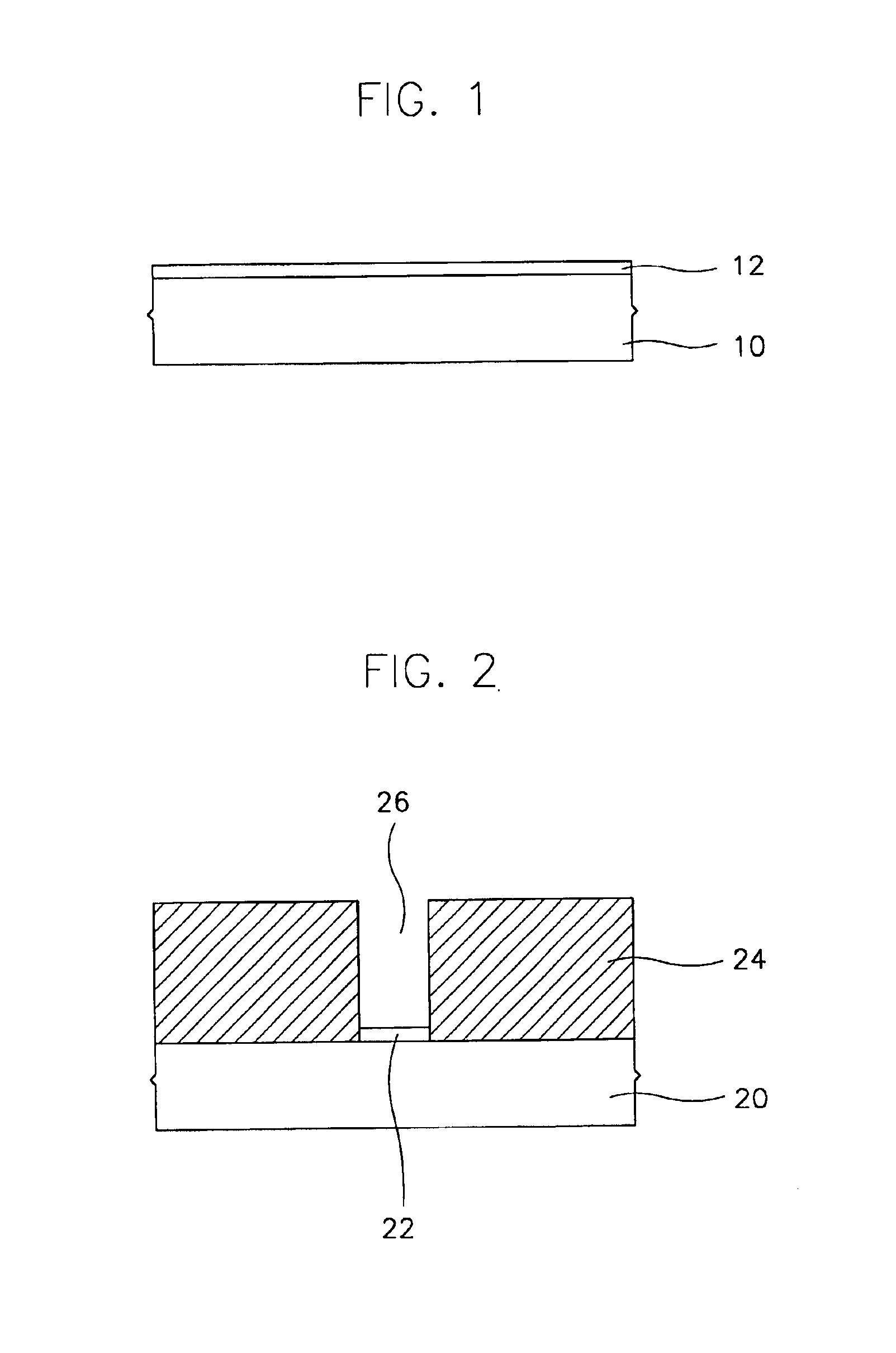

Forming an optical element on the surface of a light emitting device for improved light extraction

InactiveUS6987613B2Easy to integrateMaximize production efficiencyDiffraction gratingsSemiconductor devicesWafer bondingAlternative methods

Provided is a light emitting device including a Fresnel lens and / or a holographic diffuser formed on a surface of a semiconductor light emitter for improved light extraction, and a method for forming such light emitting device. Also provided is a light emitting device including an optical element stamped on a surface for improved light extraction and the stamping method used to form such device. An optical element formed on the surface of a semiconductor light emitter reduces reflective loss and loss due to total internal reflection, thereby improving light extraction efficiency. A Fresnel lens or a holographic diffuser may be formed on a surface by wet chemical etching or dry etching techniques, such as plasma etching, reactive ion etching, and chemically-assisted ion beam etching, optionally in conjunction with a lithographic technique. In addition, a Fresnel lens or a holographic diffuser may be milled, scribed, or ablated into the surface. Stamping, an alternative method for forming an optical element, can also be used to form a Fresnel lens or a holographic diffuser on the surface of a semiconductor light emitter. Stamping includes pressing a stamping block against the surface of a light emitting diode. The stamping block has a shape and pattern that are the inverse of the desired optical element. Optionally, stamping can be done before, after, or concurrently with wafer-bonding. Alternatively, a material can be stamped and later bonded to the semiconductor light emitter.

Owner:LUMILEDS

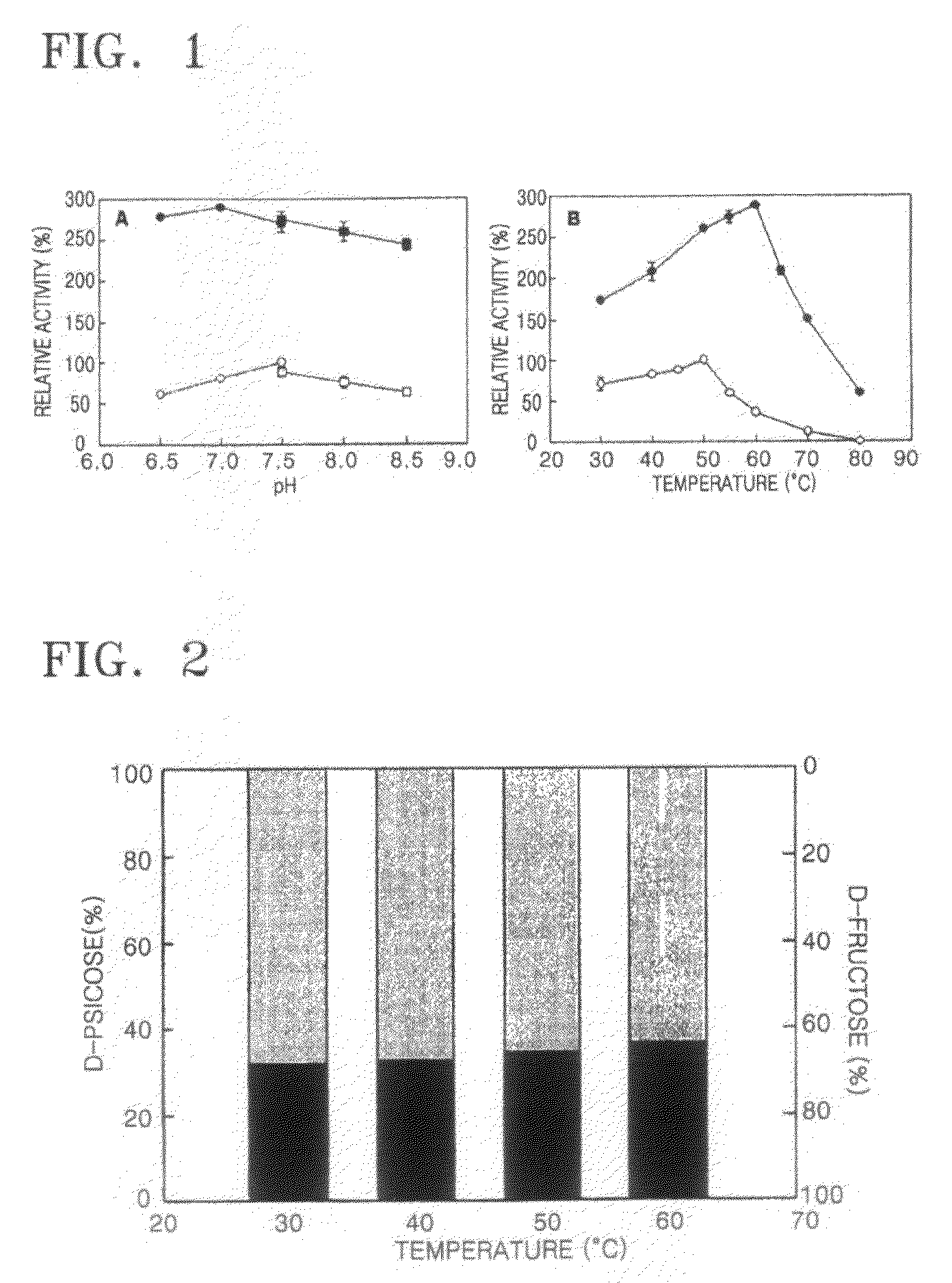

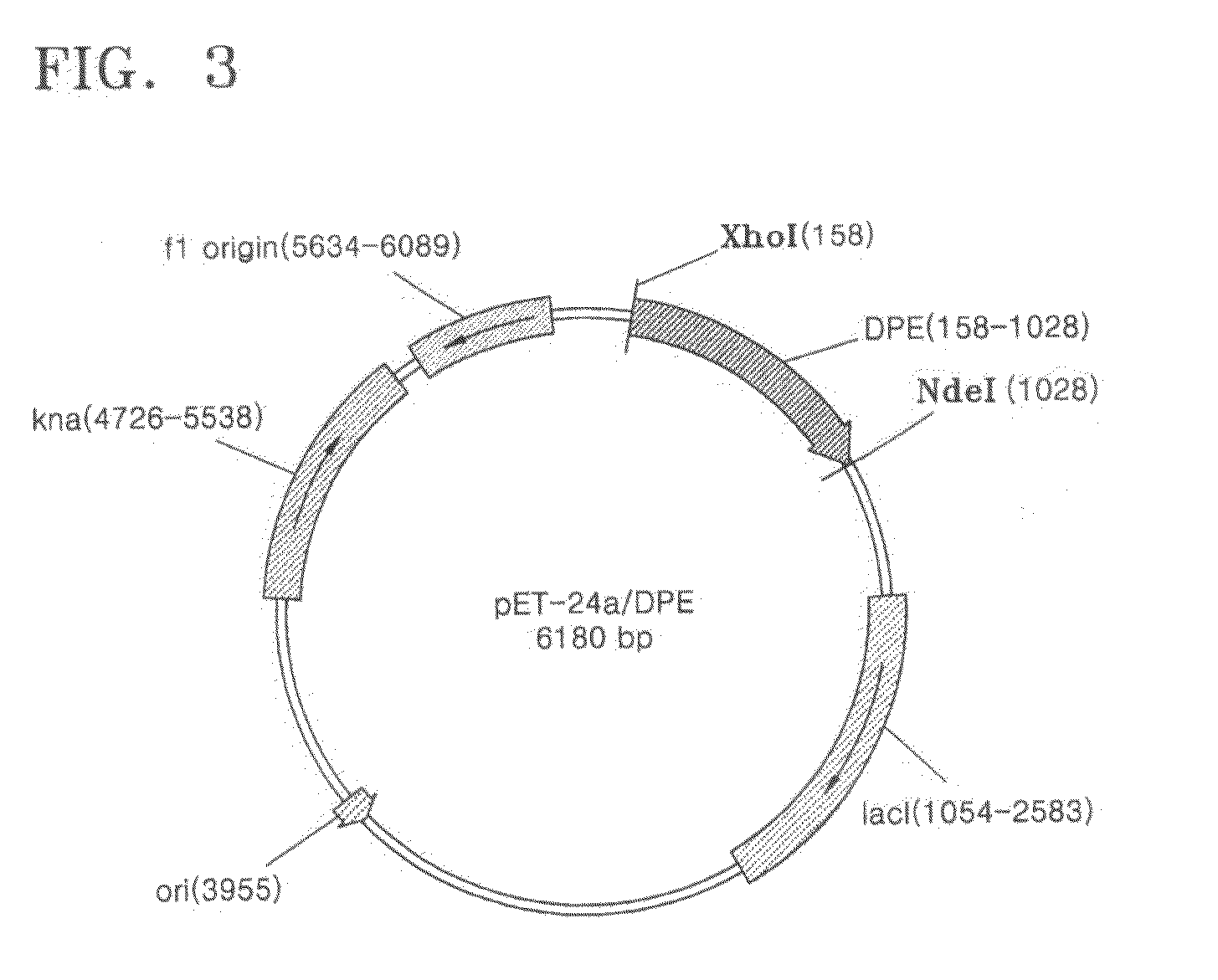

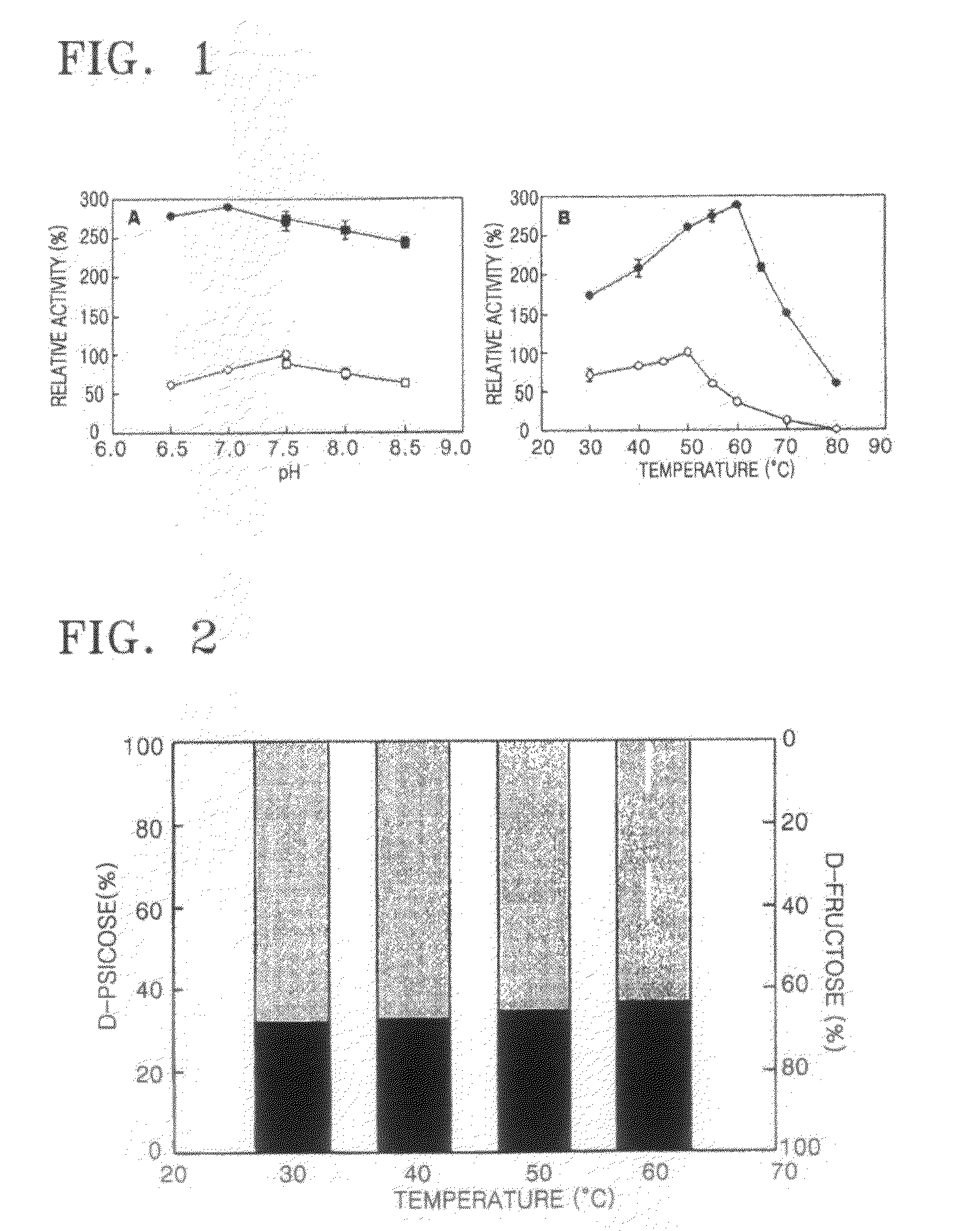

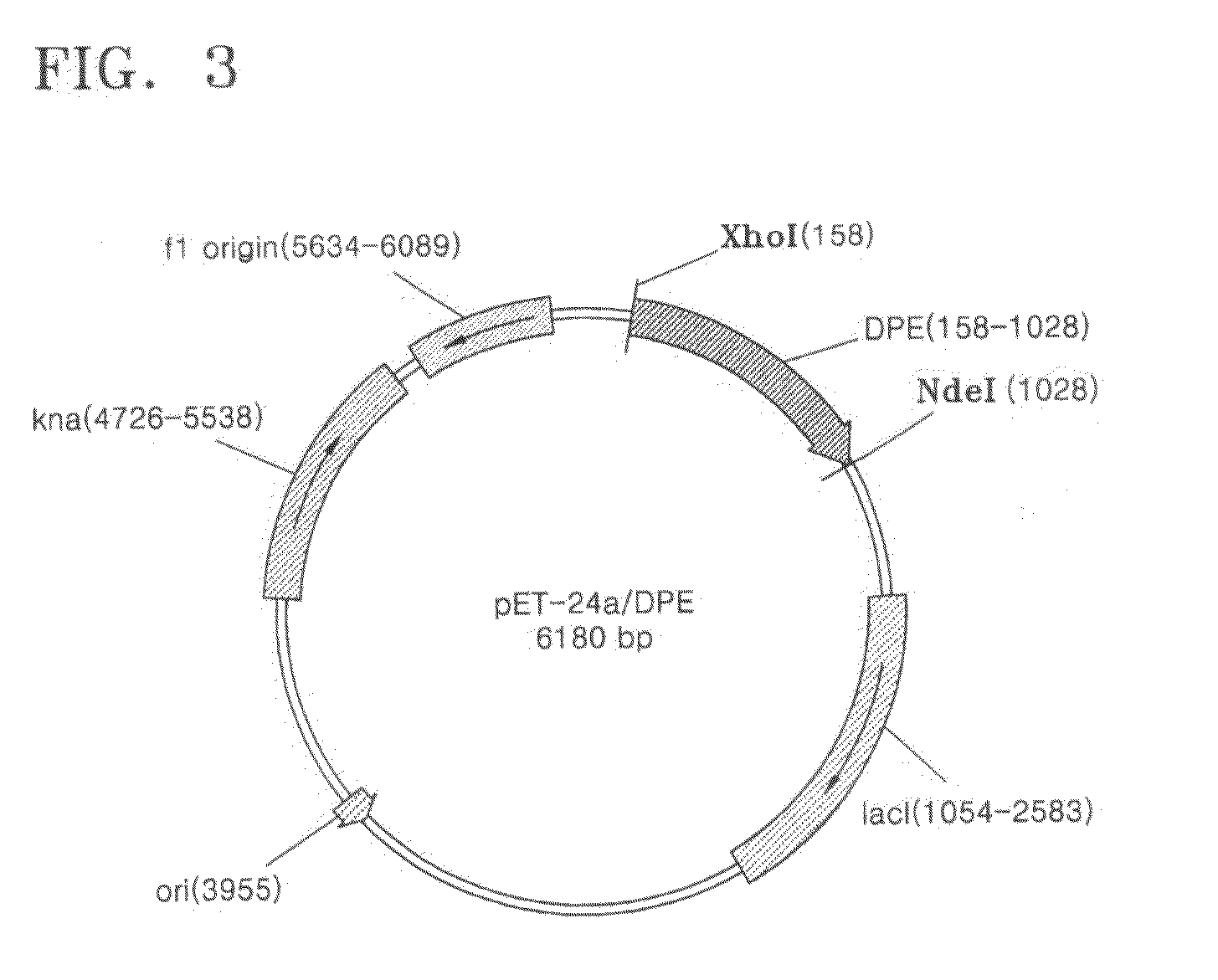

D-psicose production method by D-psicose epimerase

ActiveUS8030035B2Improve production yieldLow production costIsomerasesFermentationIsomerase activityEnzyme

Provided is a method of producing D-psicose using a D-psicose epimerase derived from Agrobacterium tumefaciens. Provided are a protein having an amino acid sequence of SEQ ID NO:1 and having a psicose 3-epimerase activity, a gene encoding the protein, a recombinant expression vector containing the gene, and a method of producing D-psicose by reacting the protein produced on a mass scale with D-fructose. The method of producing D-psicose is an environmentally friendly method using a new enzyme, in which an inexpensive substrate is used, and the activity of the enzyme can be retained for a prolonged time period. Thus, the method can be efficiently used for the mass production of D-psicose.

Owner:CJ CHEILJEDANG CORP

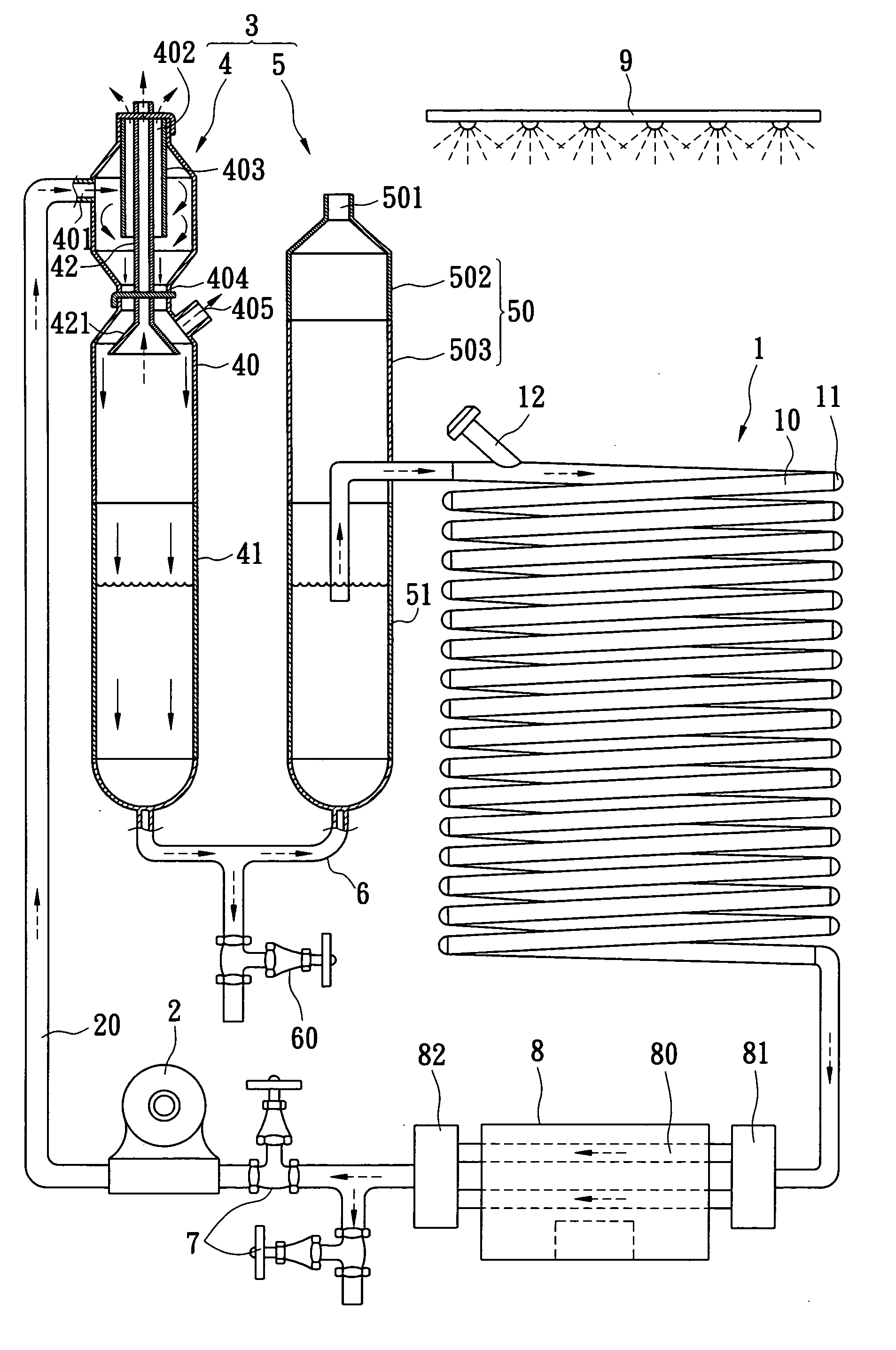

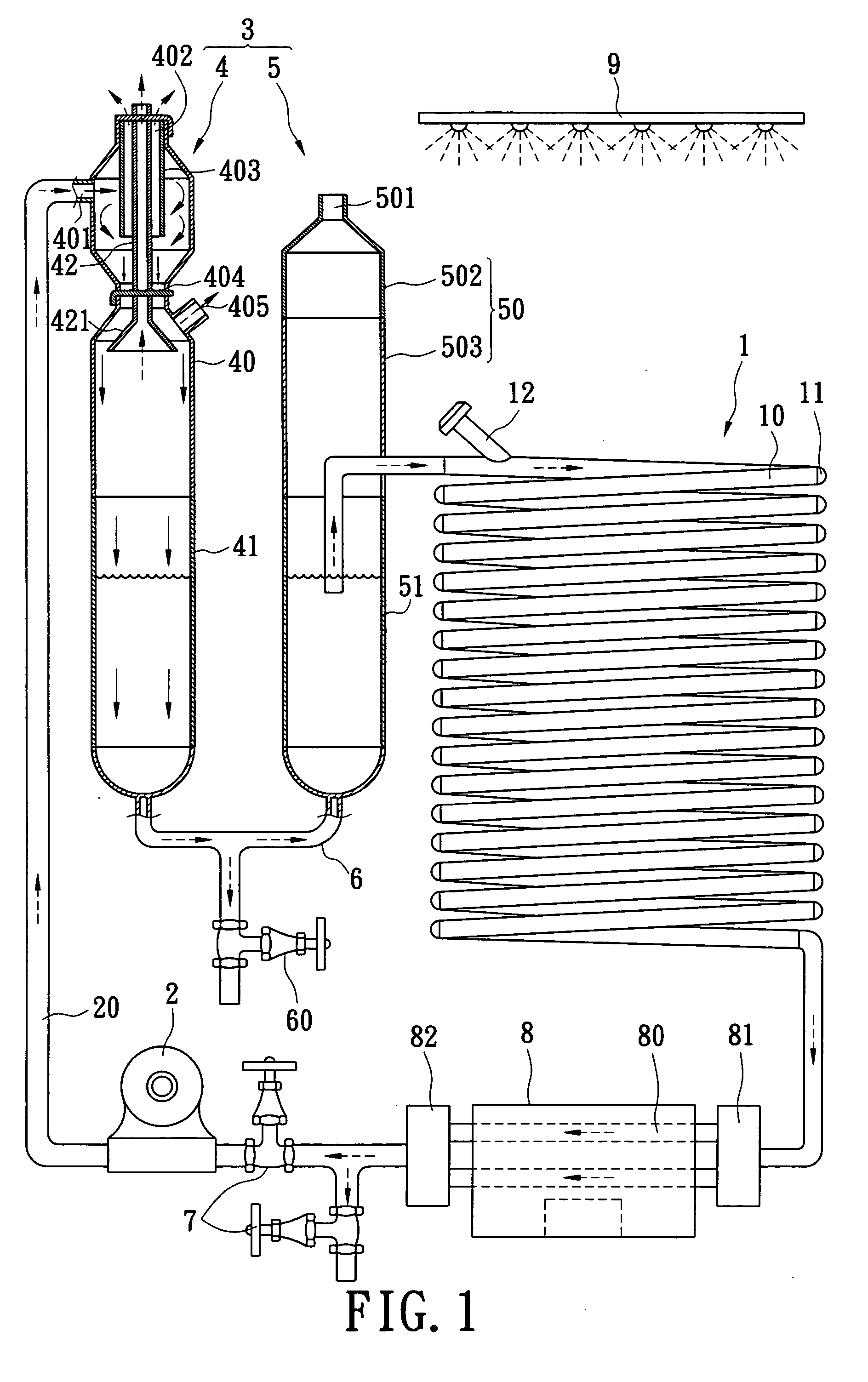

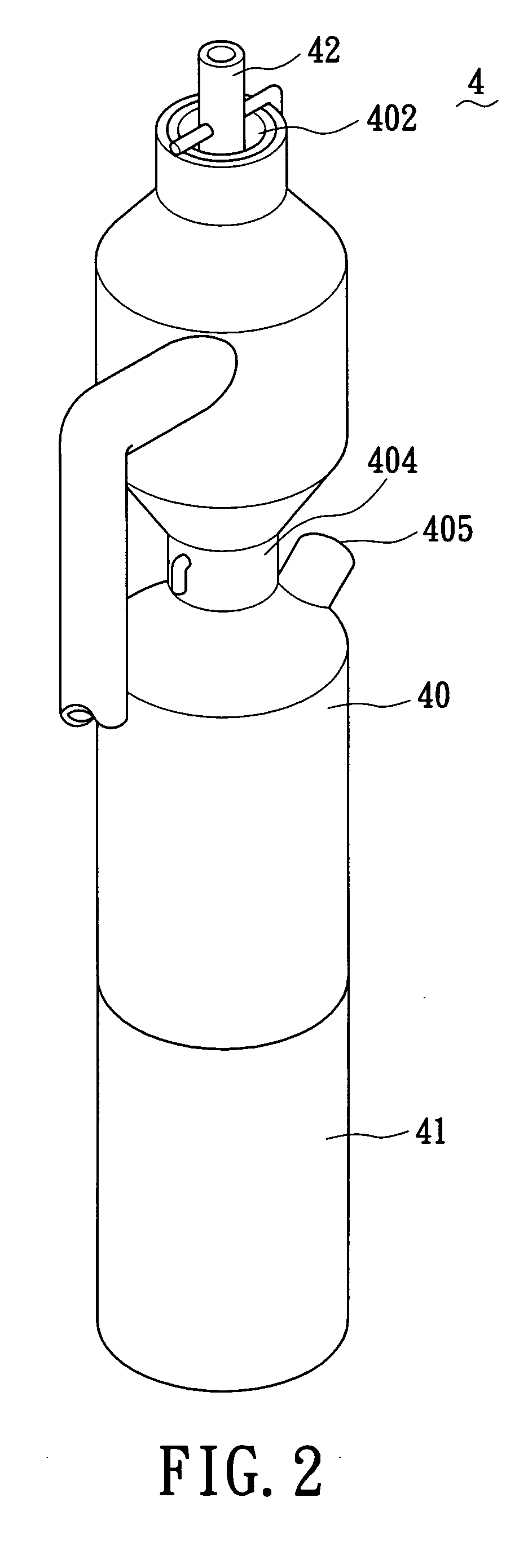

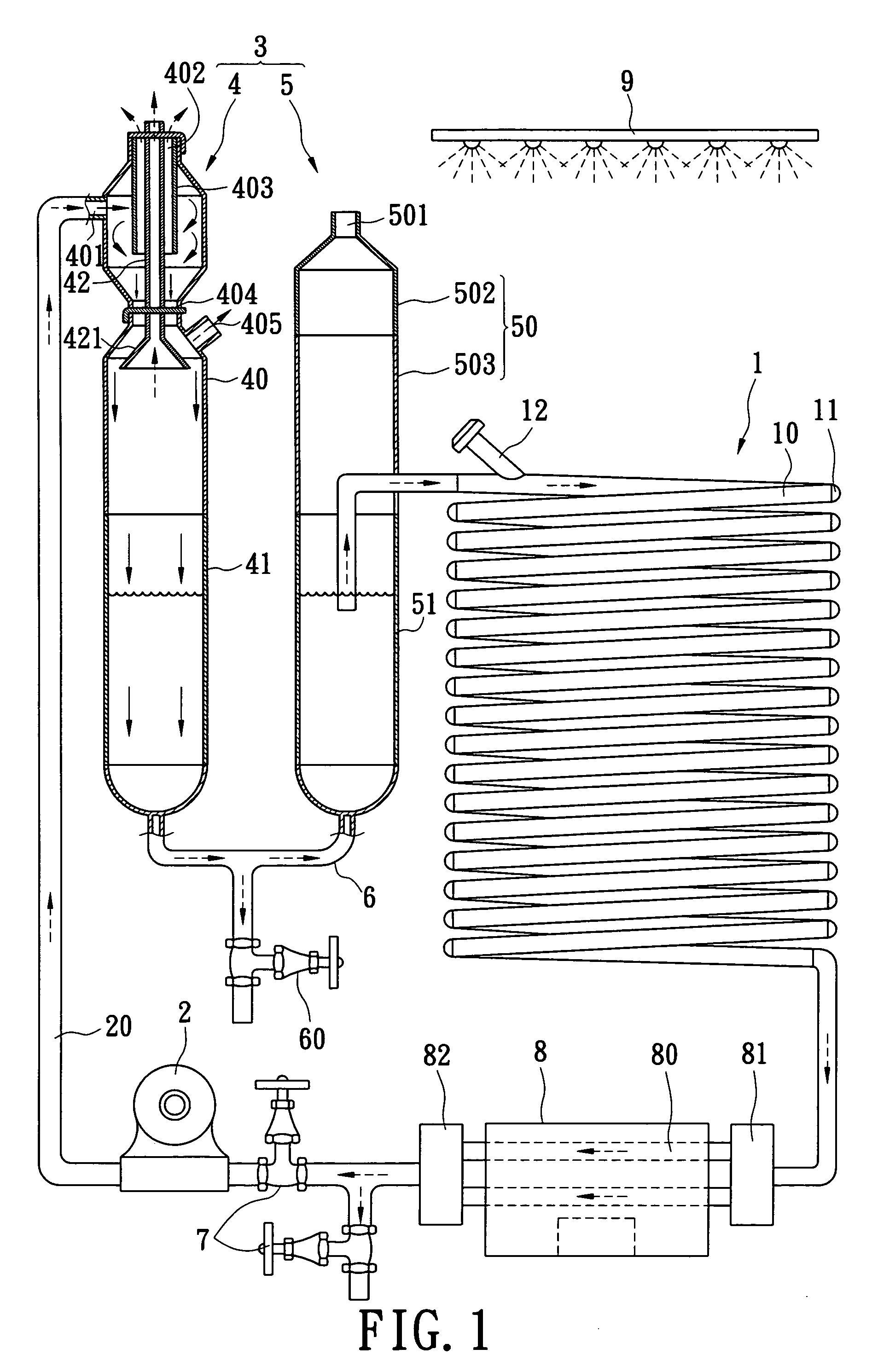

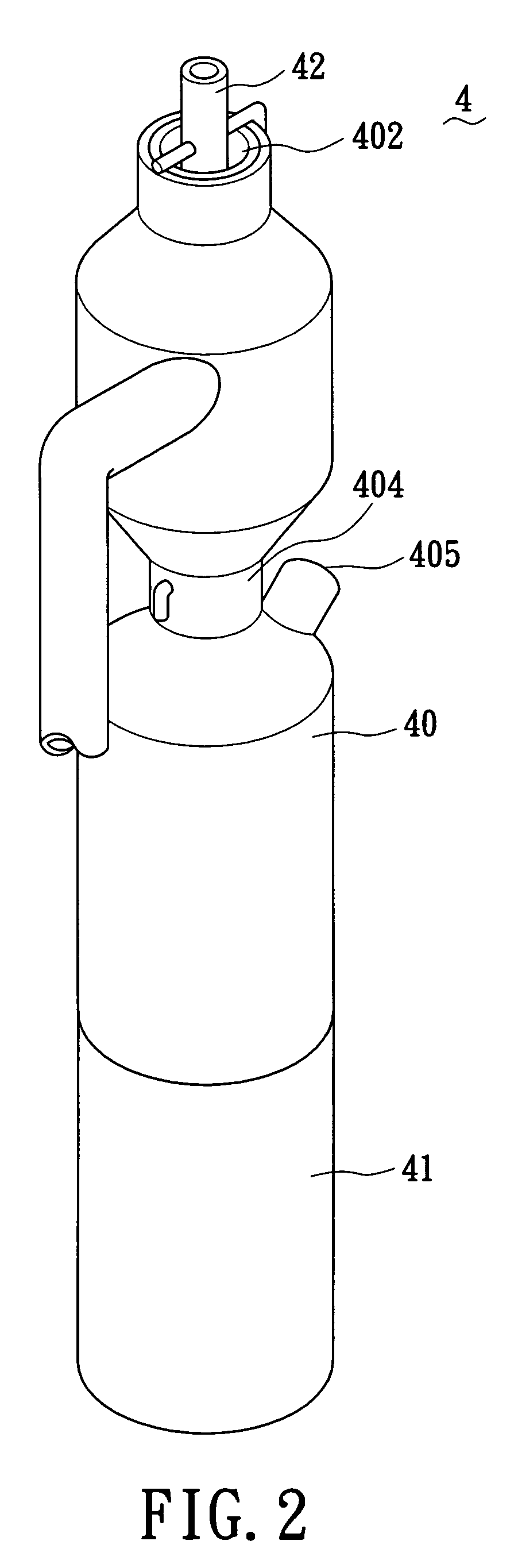

Vegetable alga and microbe photosynthetic reaction system and method for the same

ActiveUS20060141615A1Reduce areaPrevents the alga from being pollutedBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismOxygen

A vegetable alga and microbe photosynthetic reaction system and method for the same is used for vegetable algae and microbe cultivation liquid and algae seeds infused herein to circularly conduct photosynthesis and discharge oxygen; the vegetable alga and microbe photosynthetic reaction system comprises a photosynthetic reaction unit, a pressure liquid infusion unit, and an oxygen discharge and regulation unit; the photosynthetic reaction unit is a light permeable pipeline; the oxygen discharge and regulation unit is assembled with an oxygen discharge can, a liquid collection can, and a regulation can for facilitating production and assembly, and many oxygen discharge points so that oxygen formed in the cultivation liquid can be quickly evaporated.

Owner:LU CHAO HUI

Vegetable alga and microbe photosynthetic reaction system and method for the same

ActiveUS7056725B1Reduce areaPrevents the alga from being pollutedBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismOxygen

A vegetable alga and microbe photosynthetic reaction system and method for the same is used for vegetable algae and microbe cultivation liquid and algae seeds infused herein to circularly conduct photosynthesis and discharge oxygen; the vegetable alga and microbe photosynthetic reaction system comprises a photosynthetic reaction unit, a pressure liquid infusion unit, and an oxygen discharge and regulation unit; the photosynthetic reaction unit is a light permeable pipeline; the oxygen discharge and regulation unit is assembled with an oxygen discharge can, a liquid collection can, and a regulation can for facilitating production and assembly, and many oxygen discharge points so that oxygen formed in the cultivation liquid can be quickly evaporated.

Owner:LU CHAO HUI

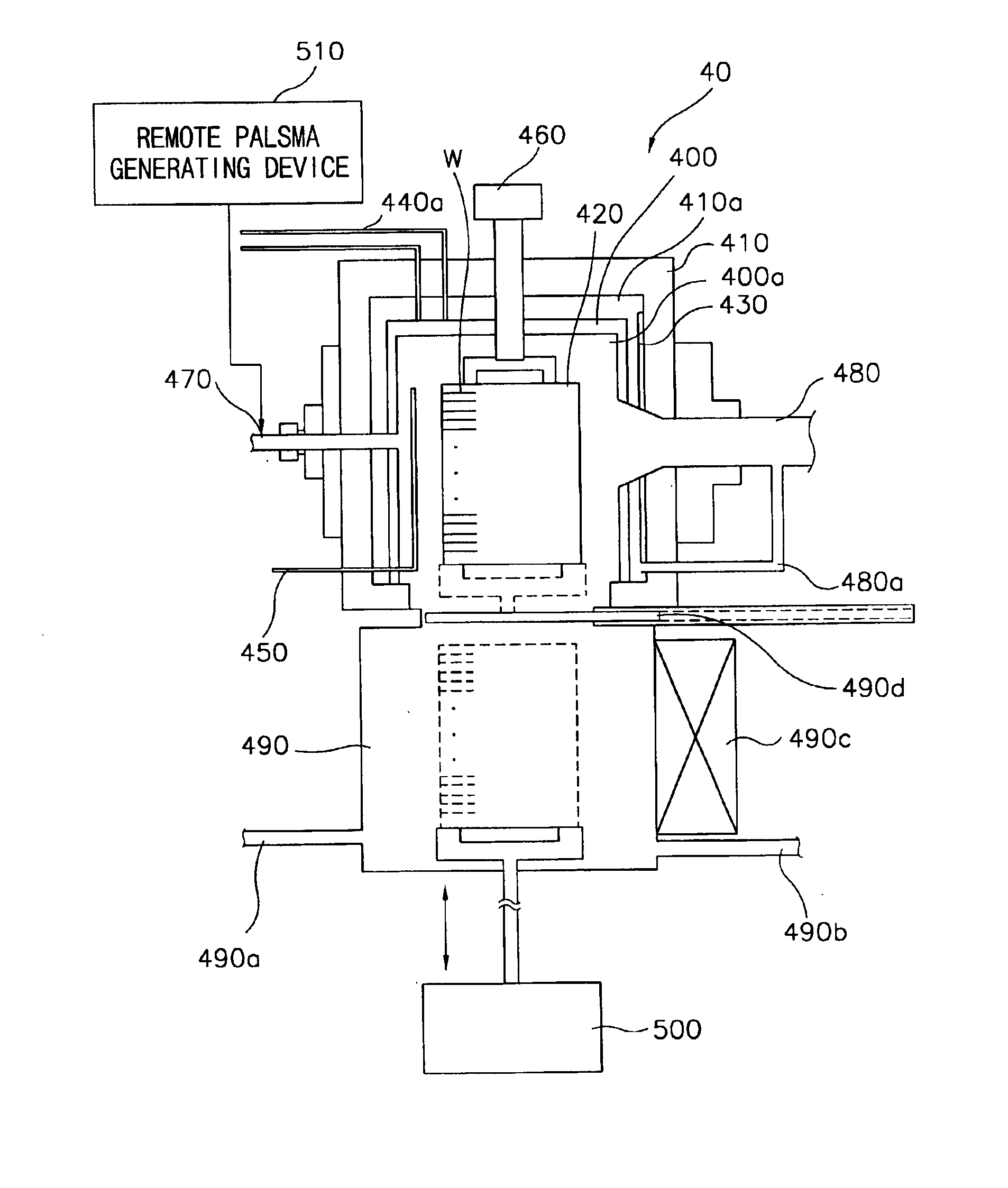

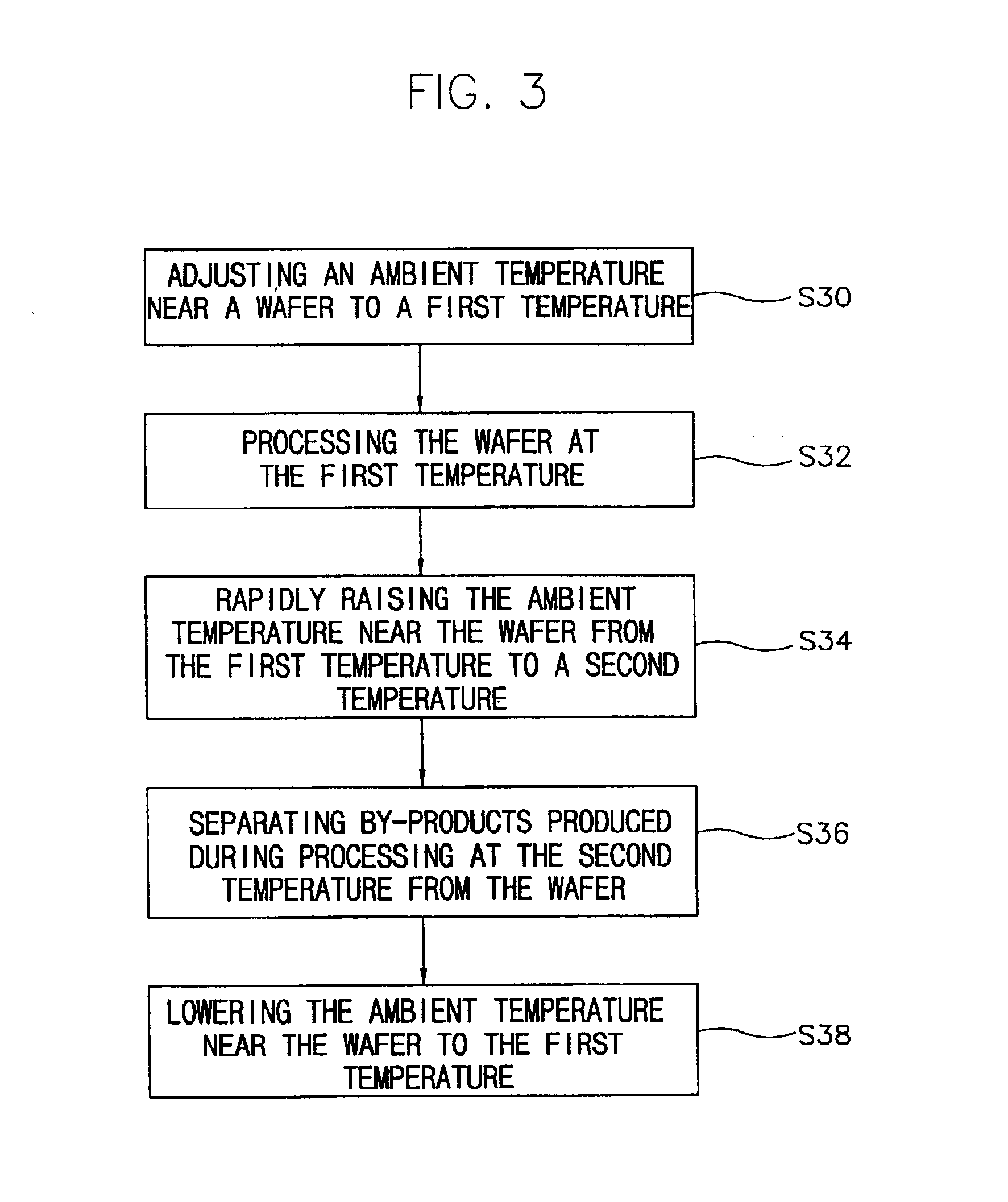

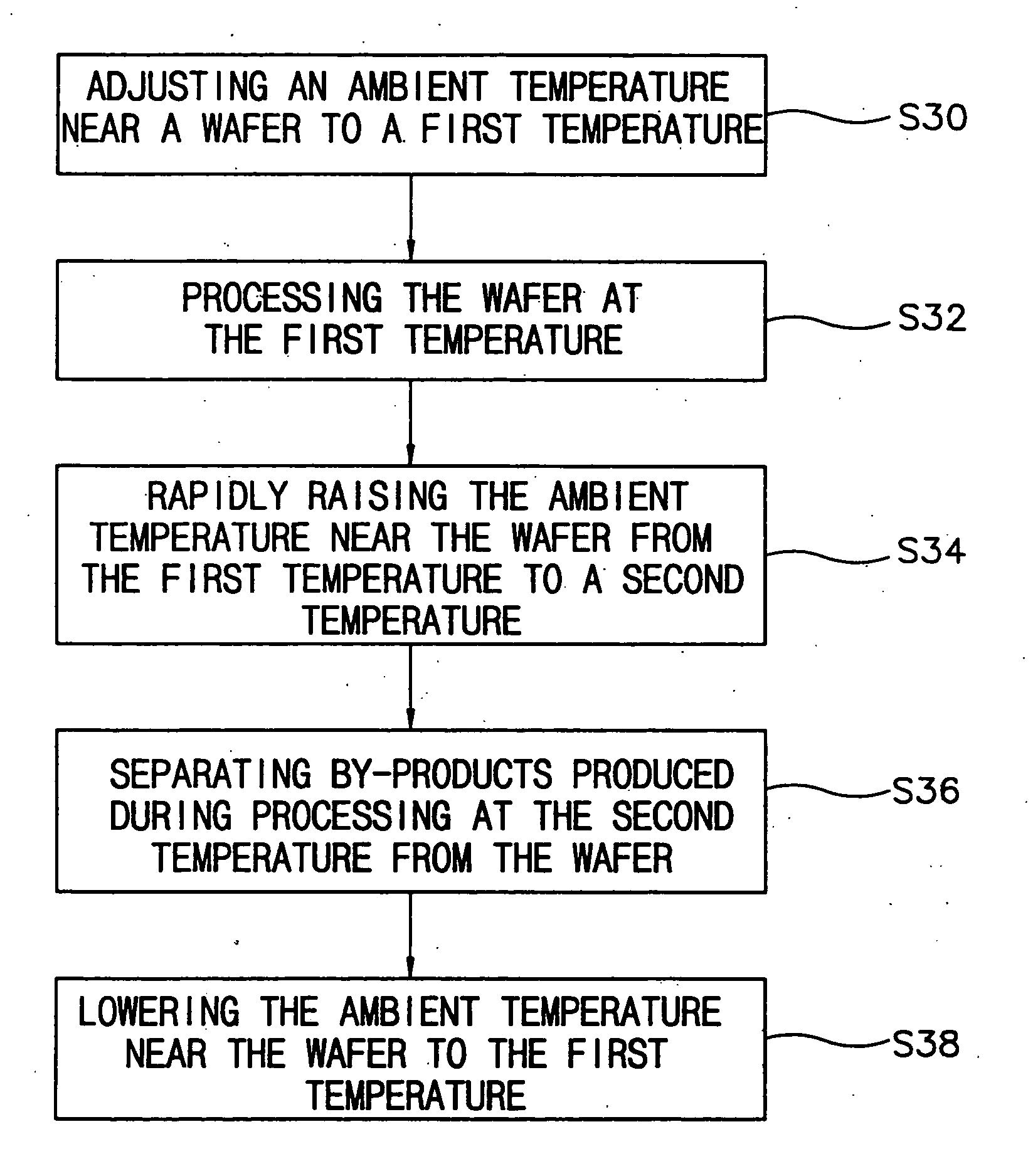

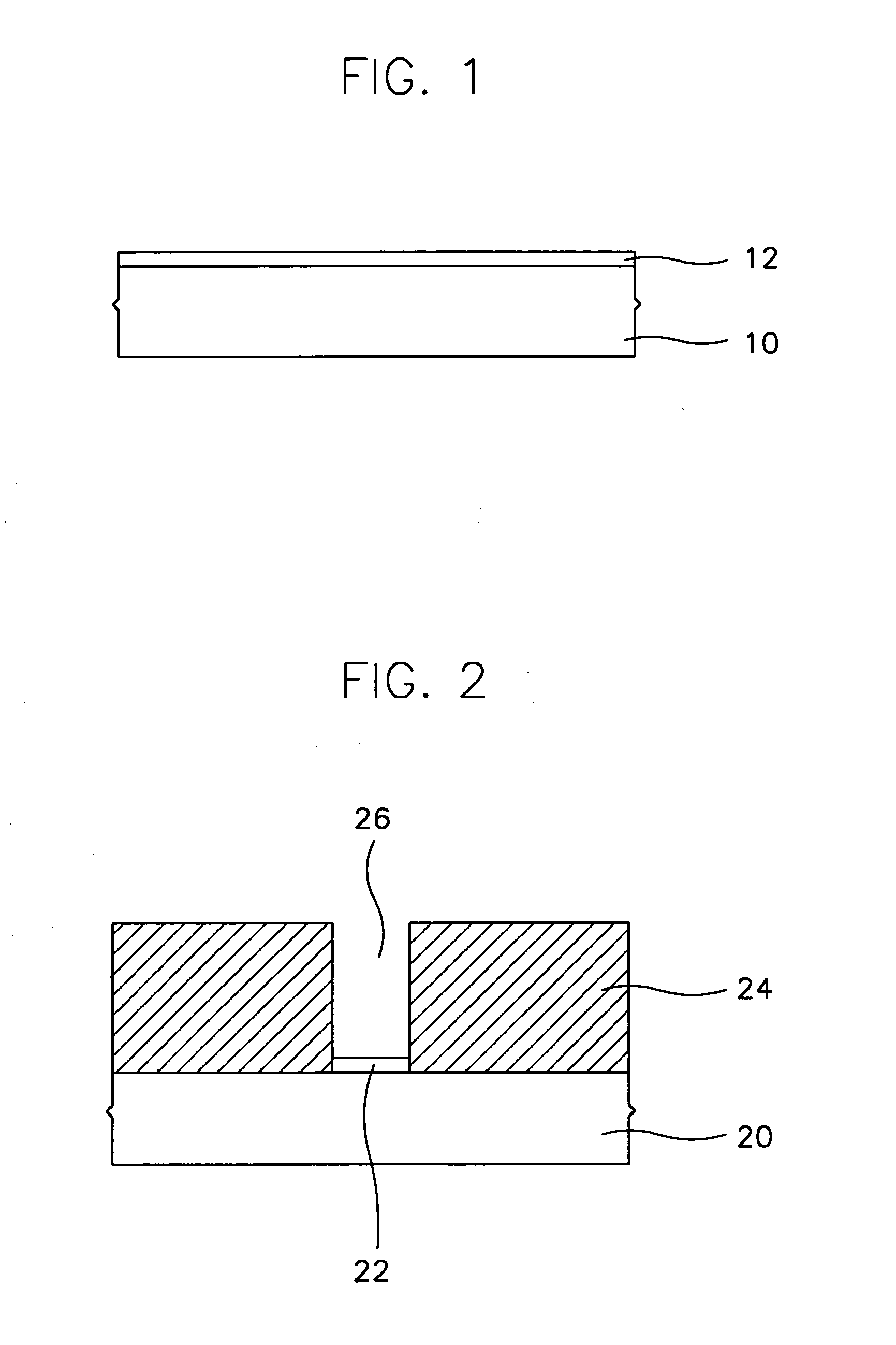

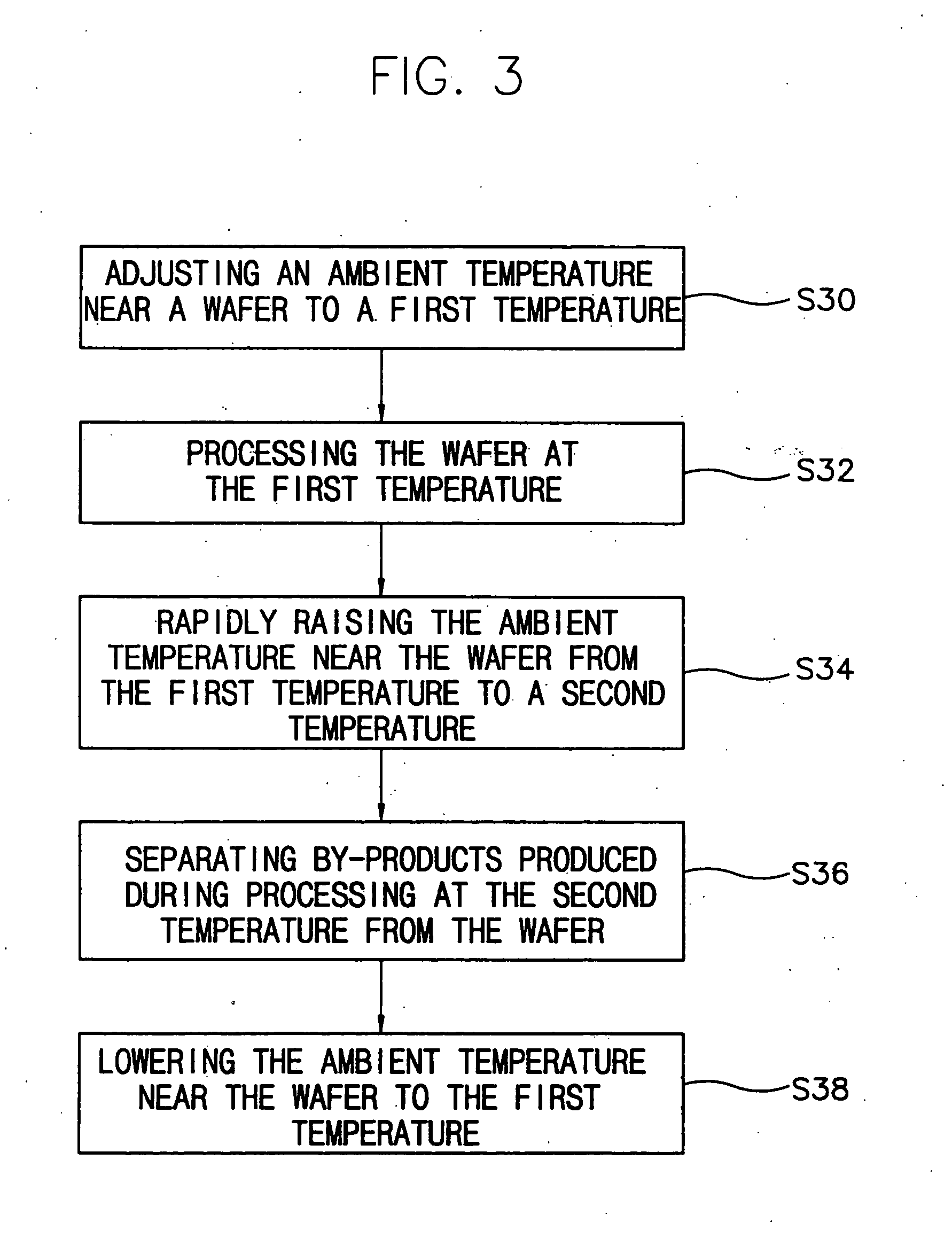

Method for processing a wafer and apparatus for performing the same

InactiveUS6869500B2Producing efficiency can be increasedEasy to etchSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduction rateDevice material

Disclosed are a method and an apparatus for processing a wafer in manufacturing a semiconductor device and a method and an apparatus for etching a material formed on the wafer, wherein first and second cooling parts adjust an ambient temperature near a plurality of wafers to a first temperature, the wafers are processed by introducing a reaction gas at the first temperature, then, a heating part rapidly raises the temperature of the atmosphere near the wafers from the first temperature to the second temperature to partially separate by-products produced during the processing, the second temperature is maintained to separate most of the by-products from the wafers, and the processing steps are implemented in-situ within the same space. Accordingly, a native oxide layer formed on several wafers can be etched and the reaction by-products can be removed in-situ in the same chamber so productivity is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

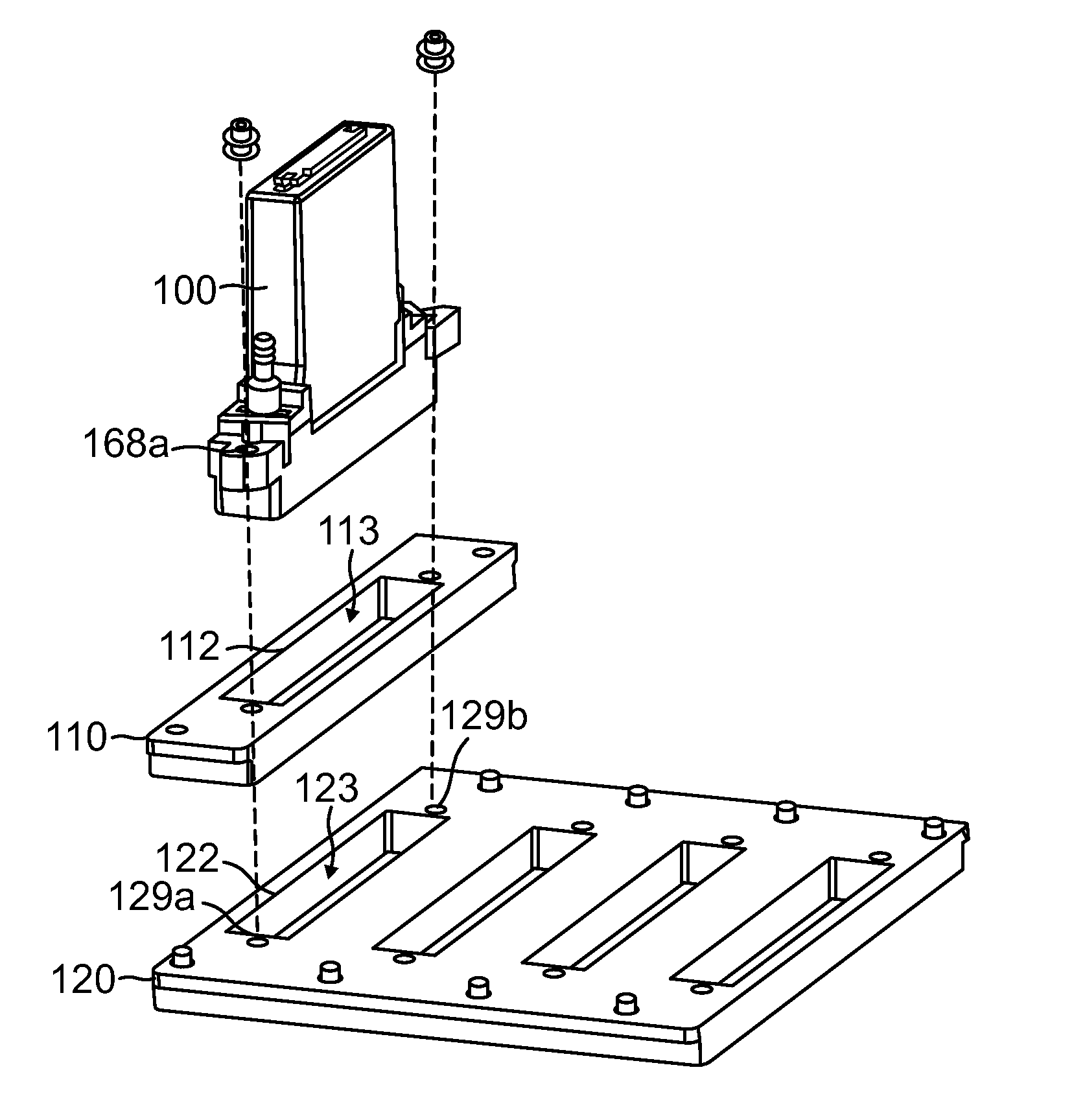

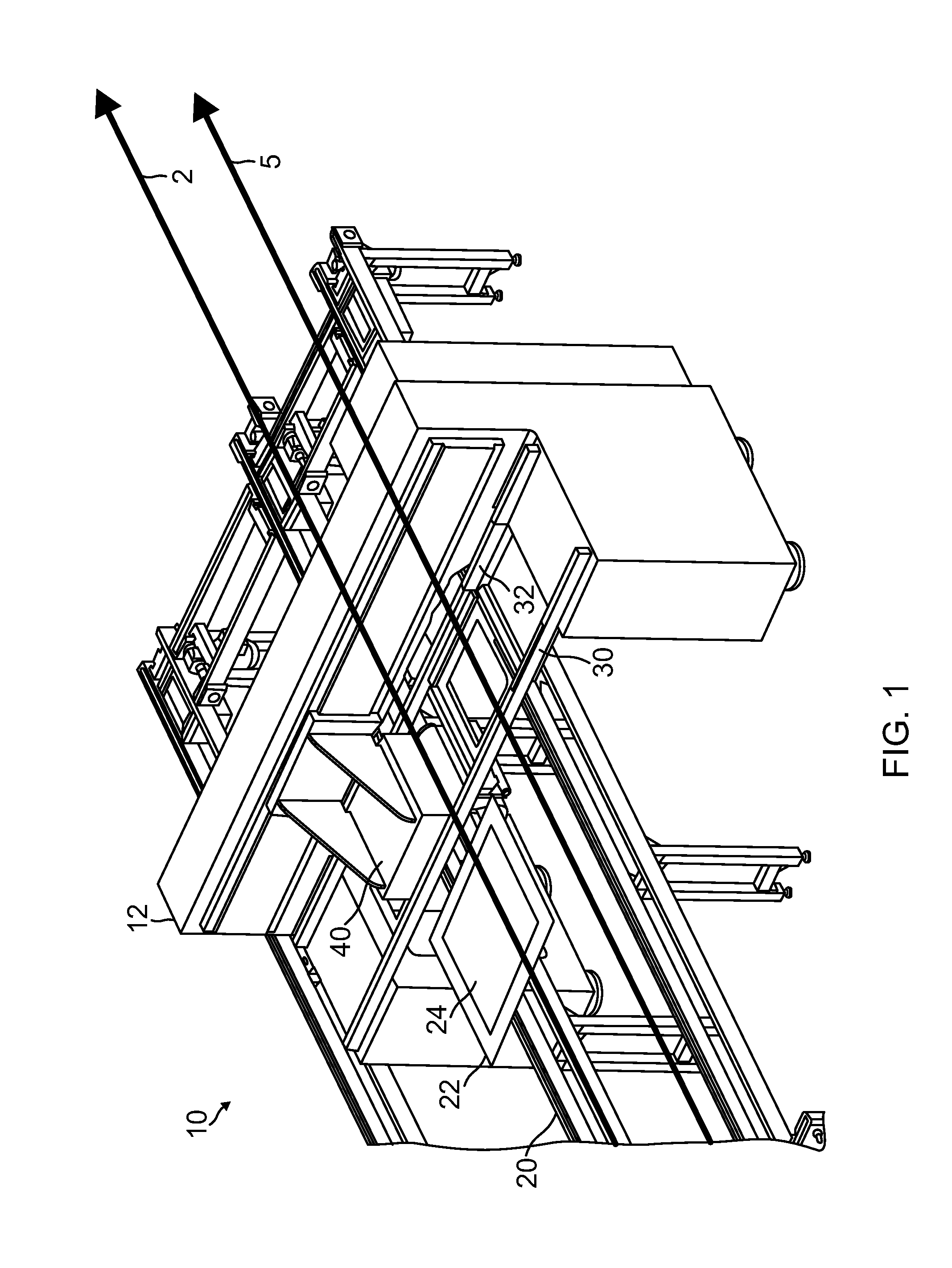

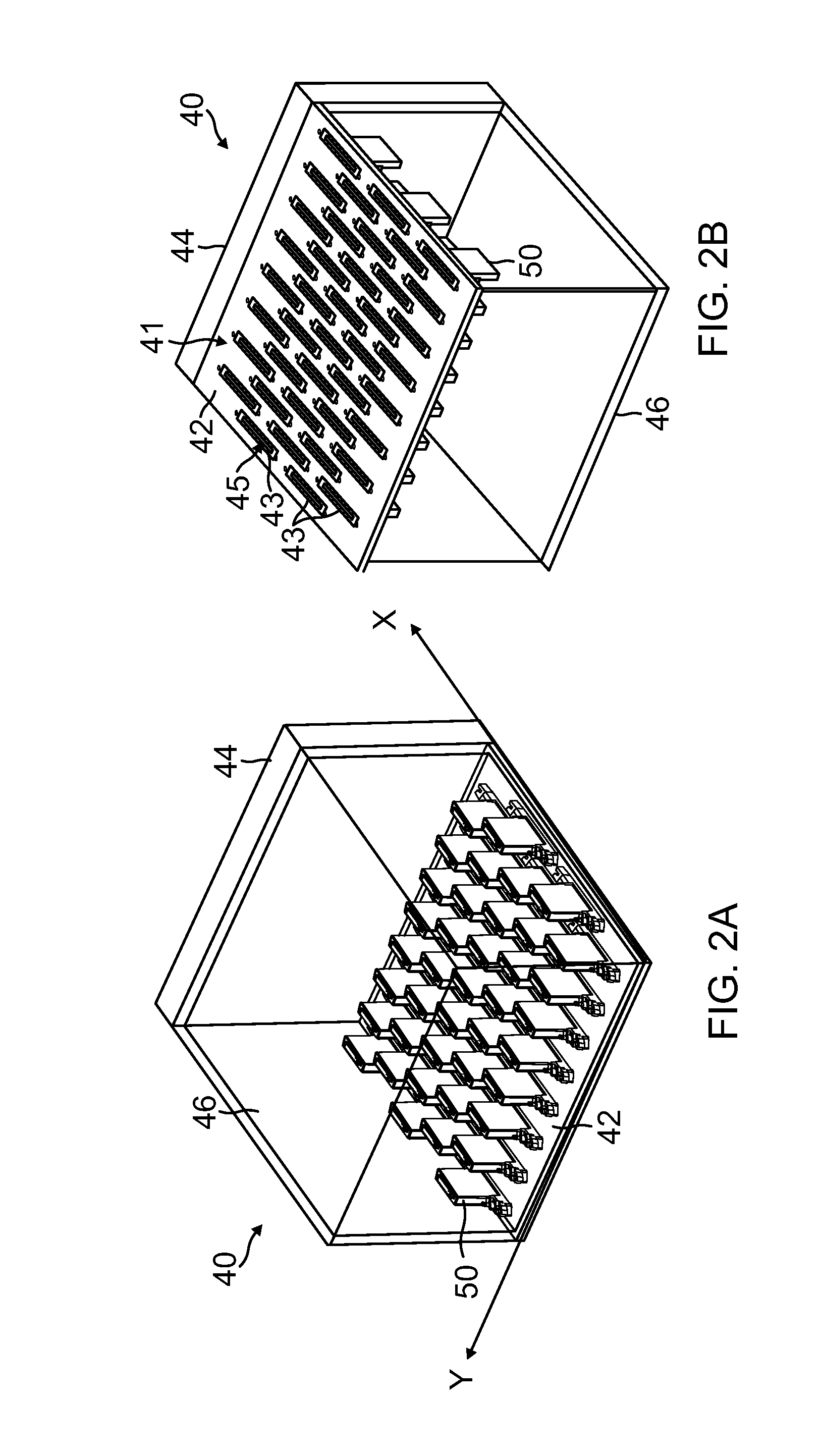

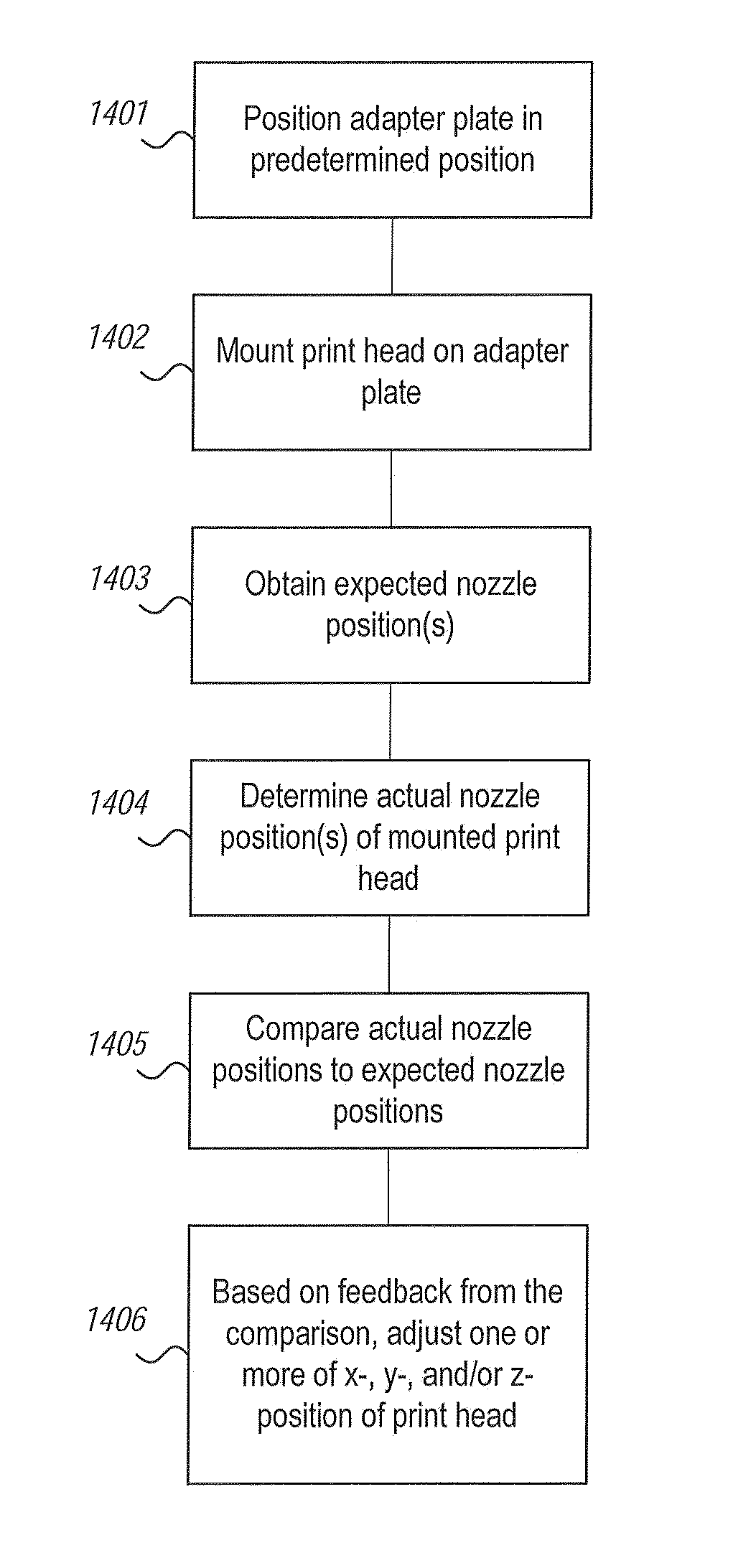

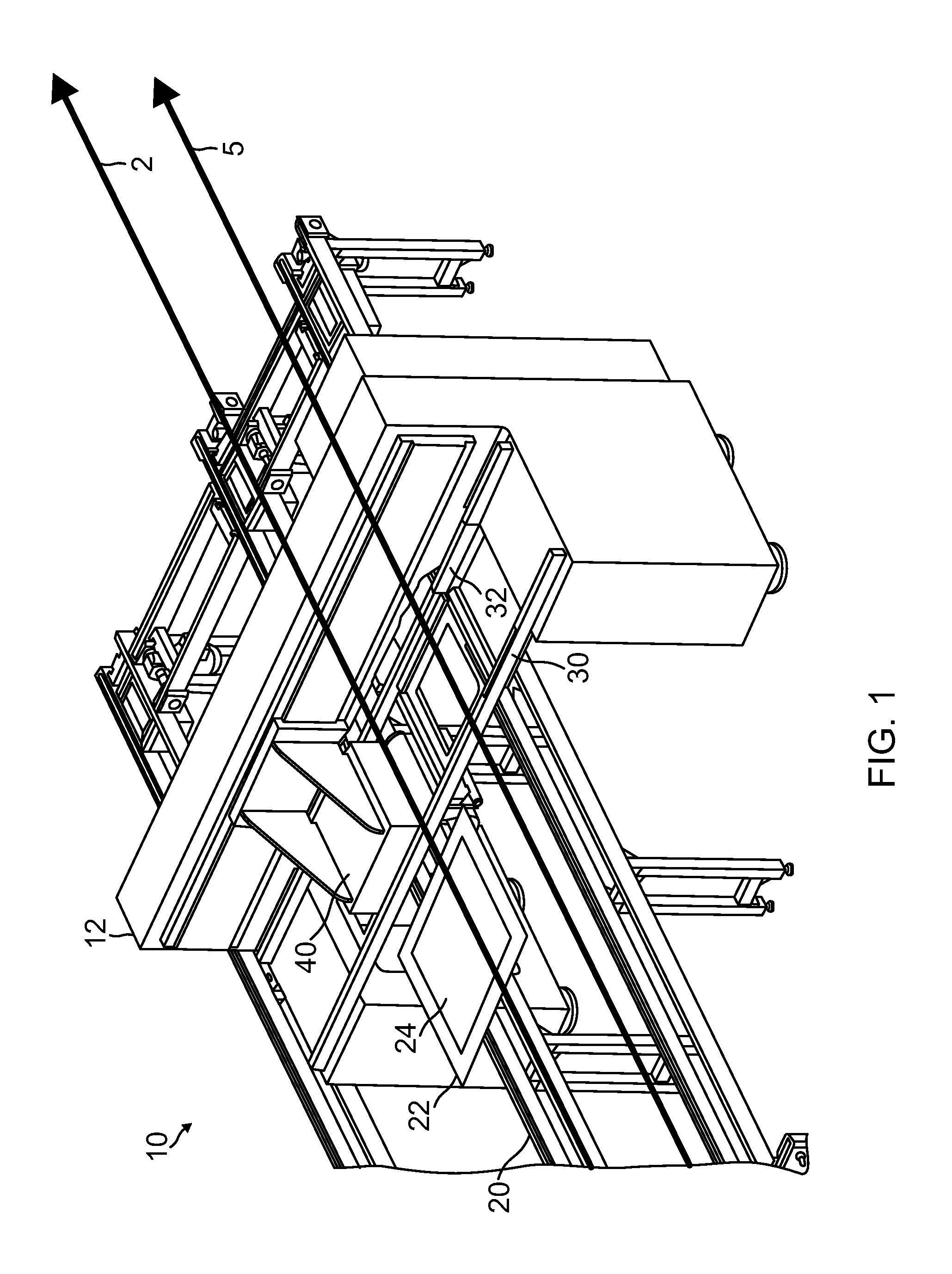

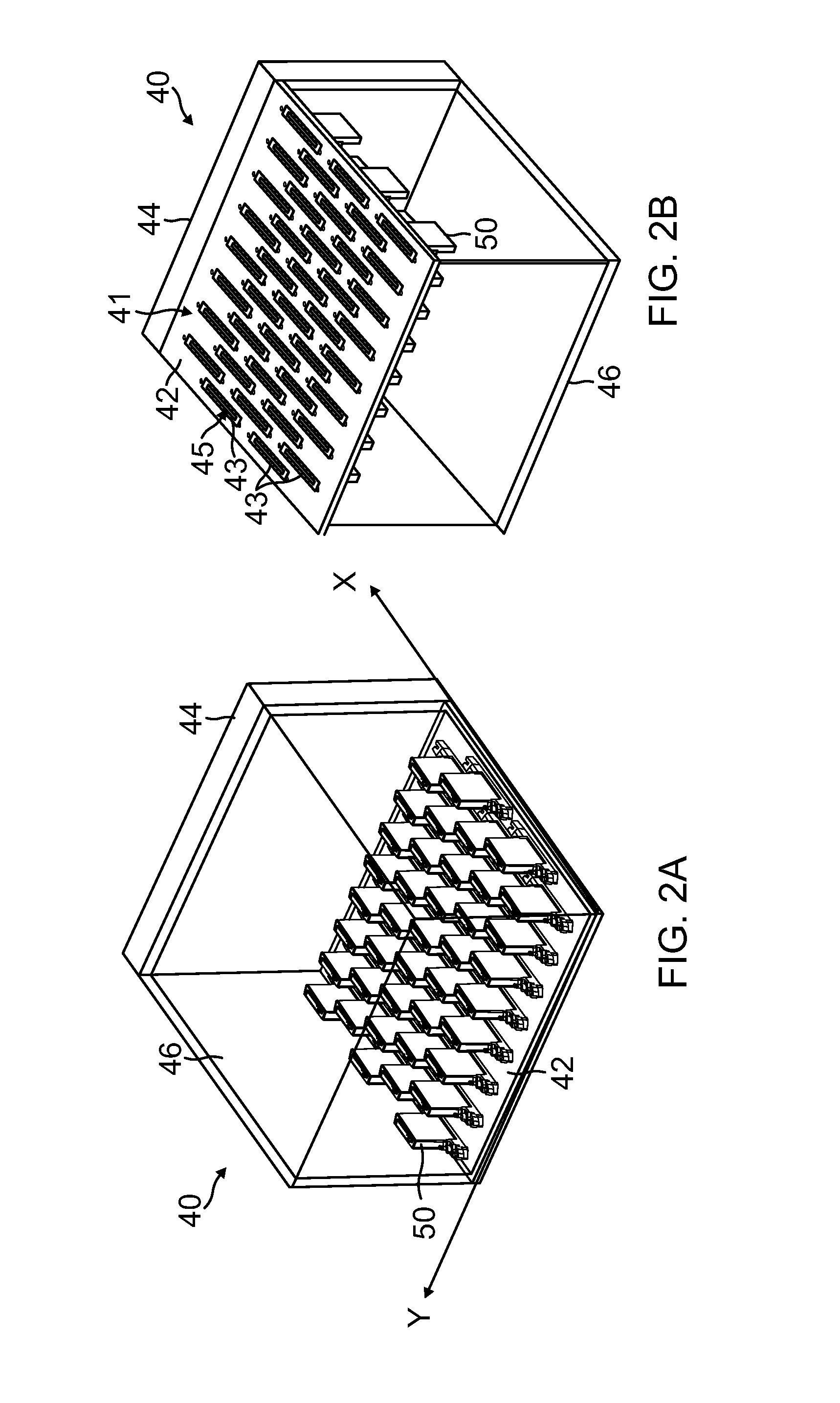

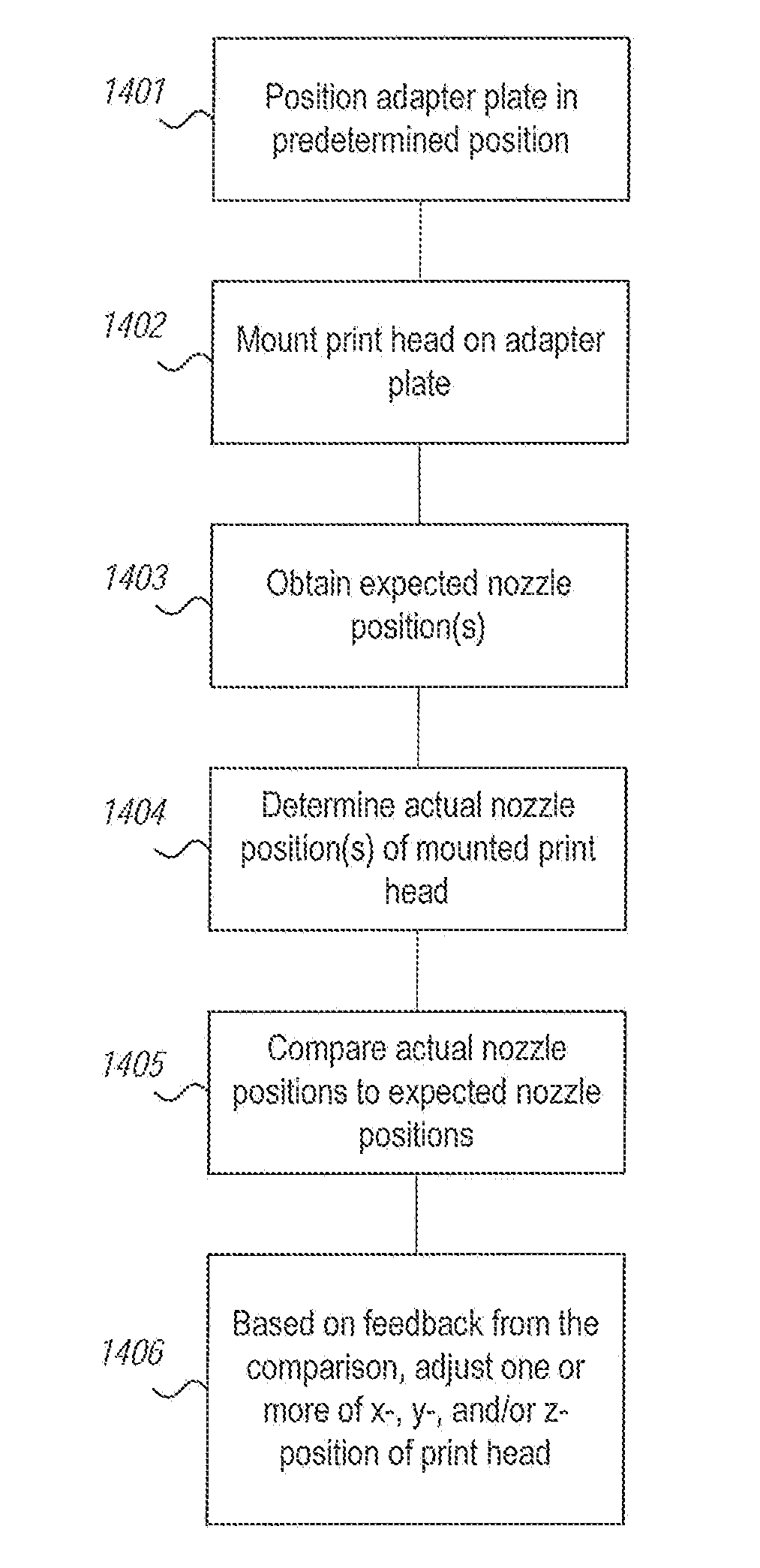

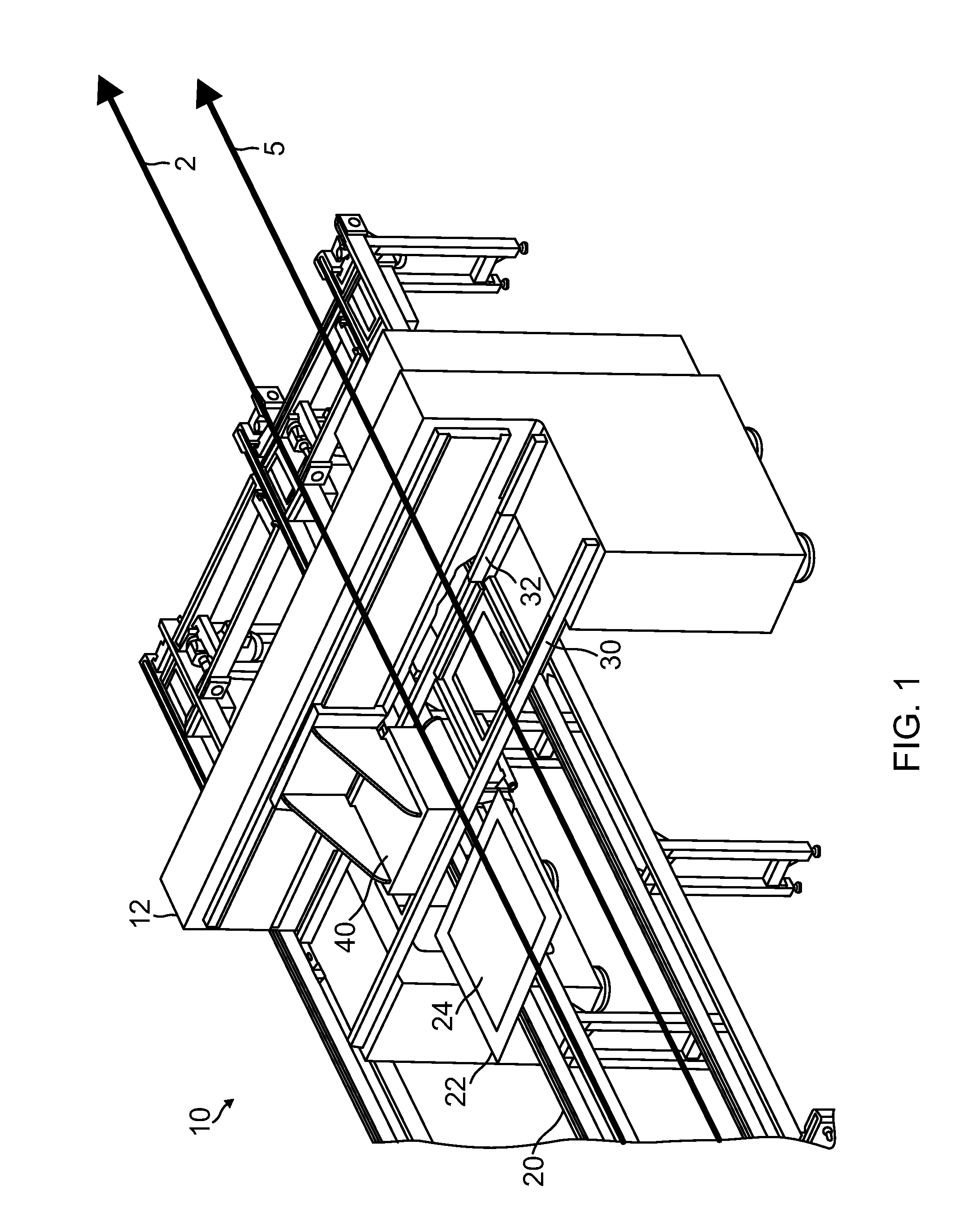

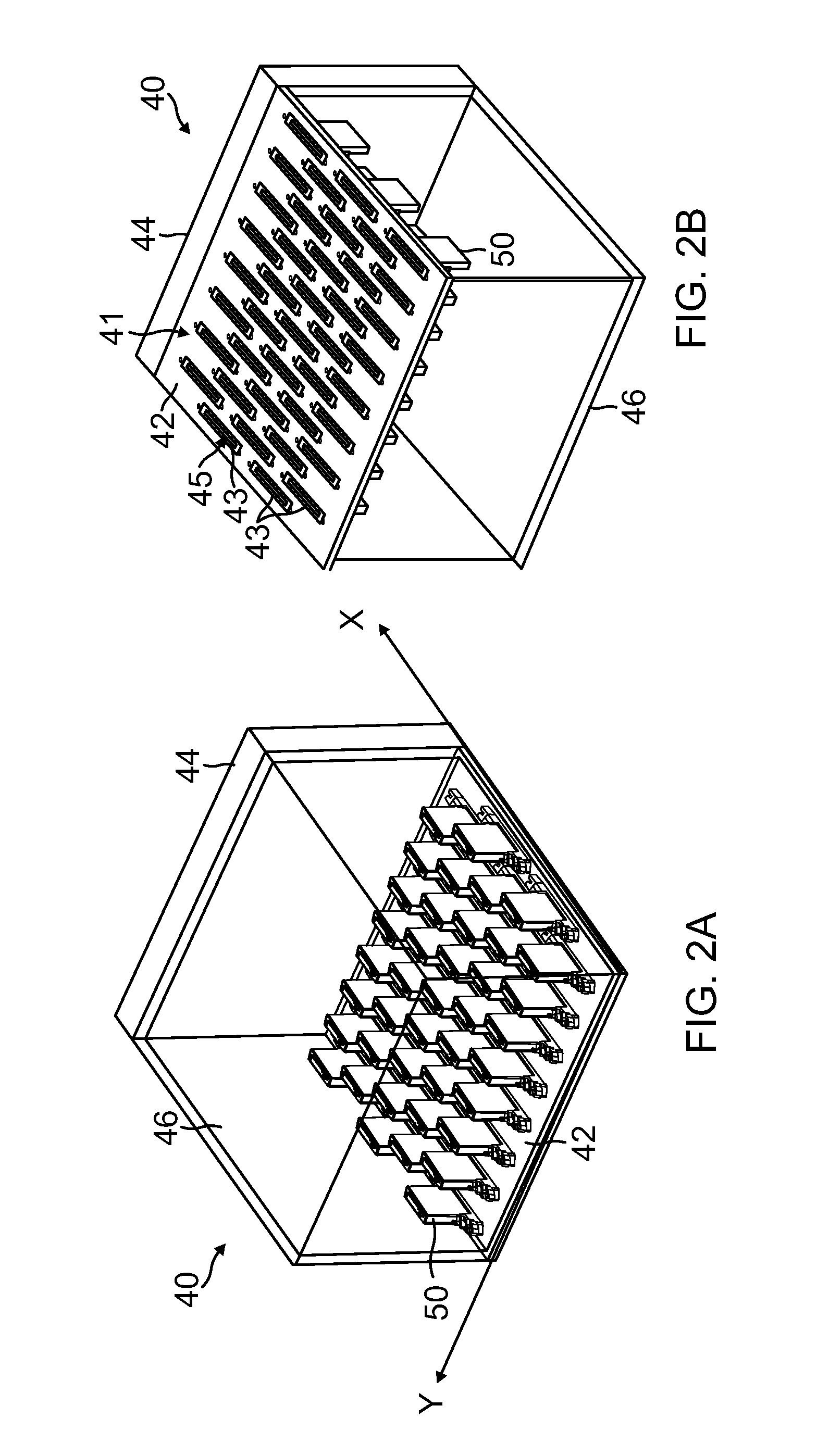

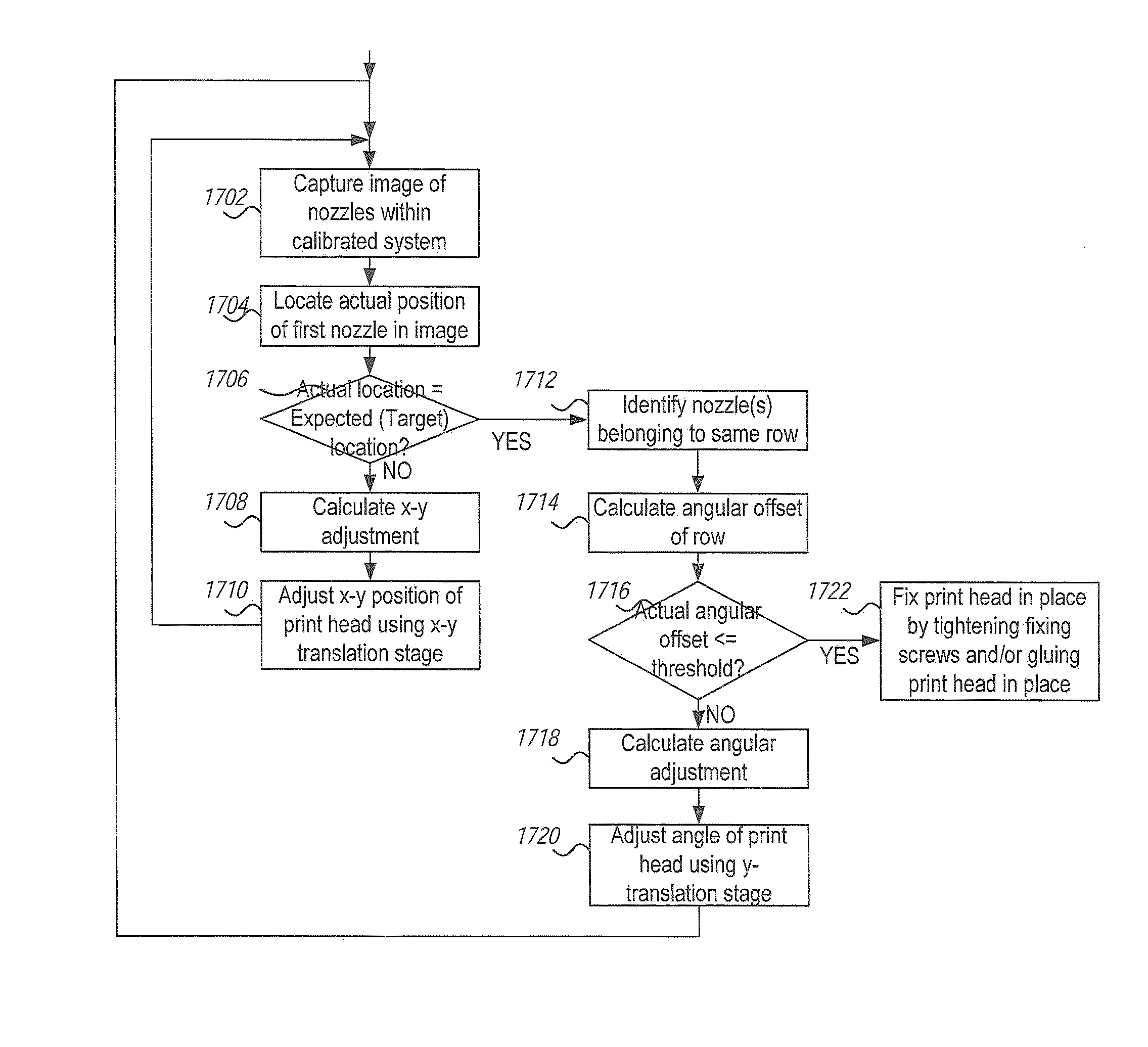

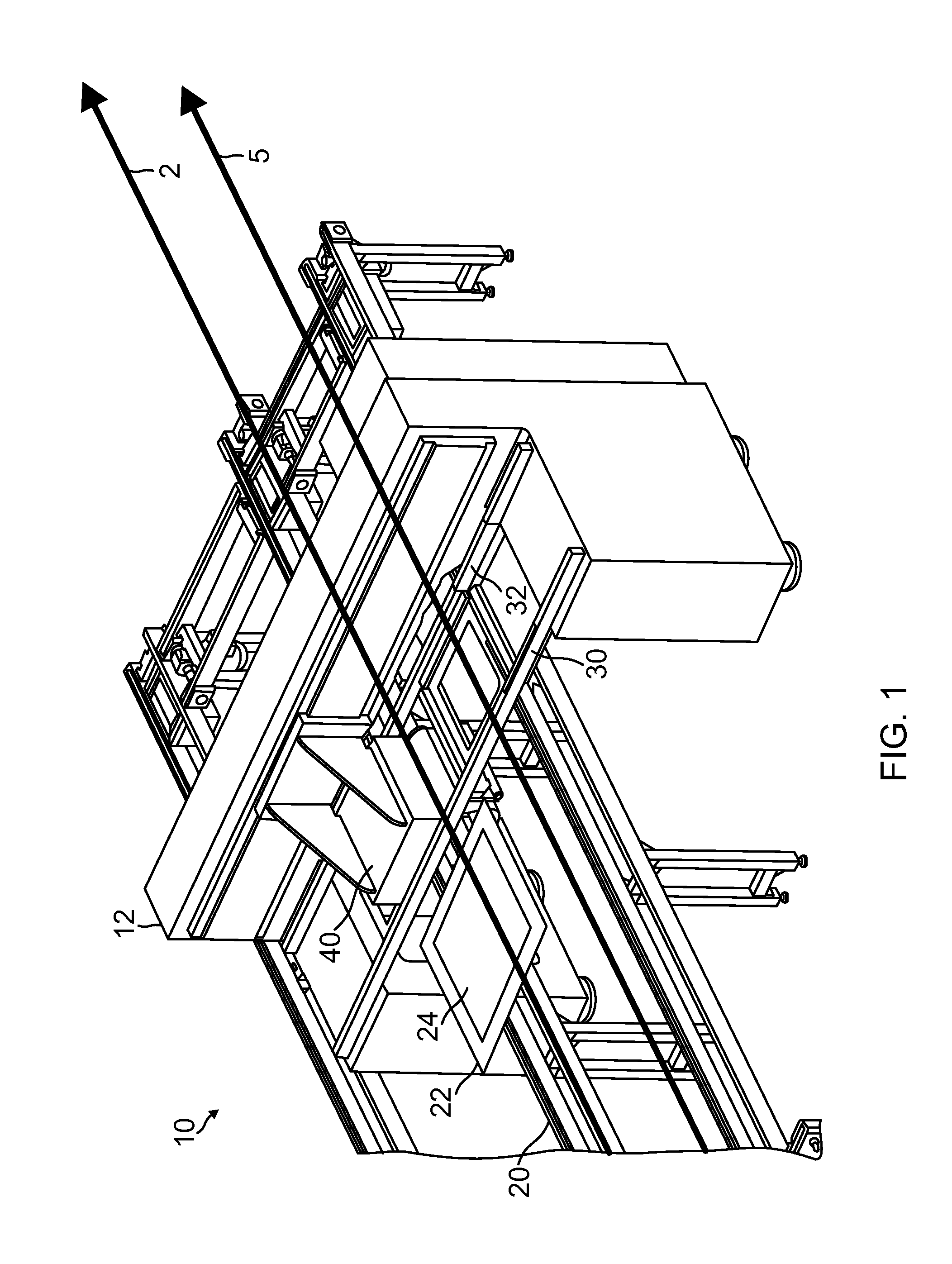

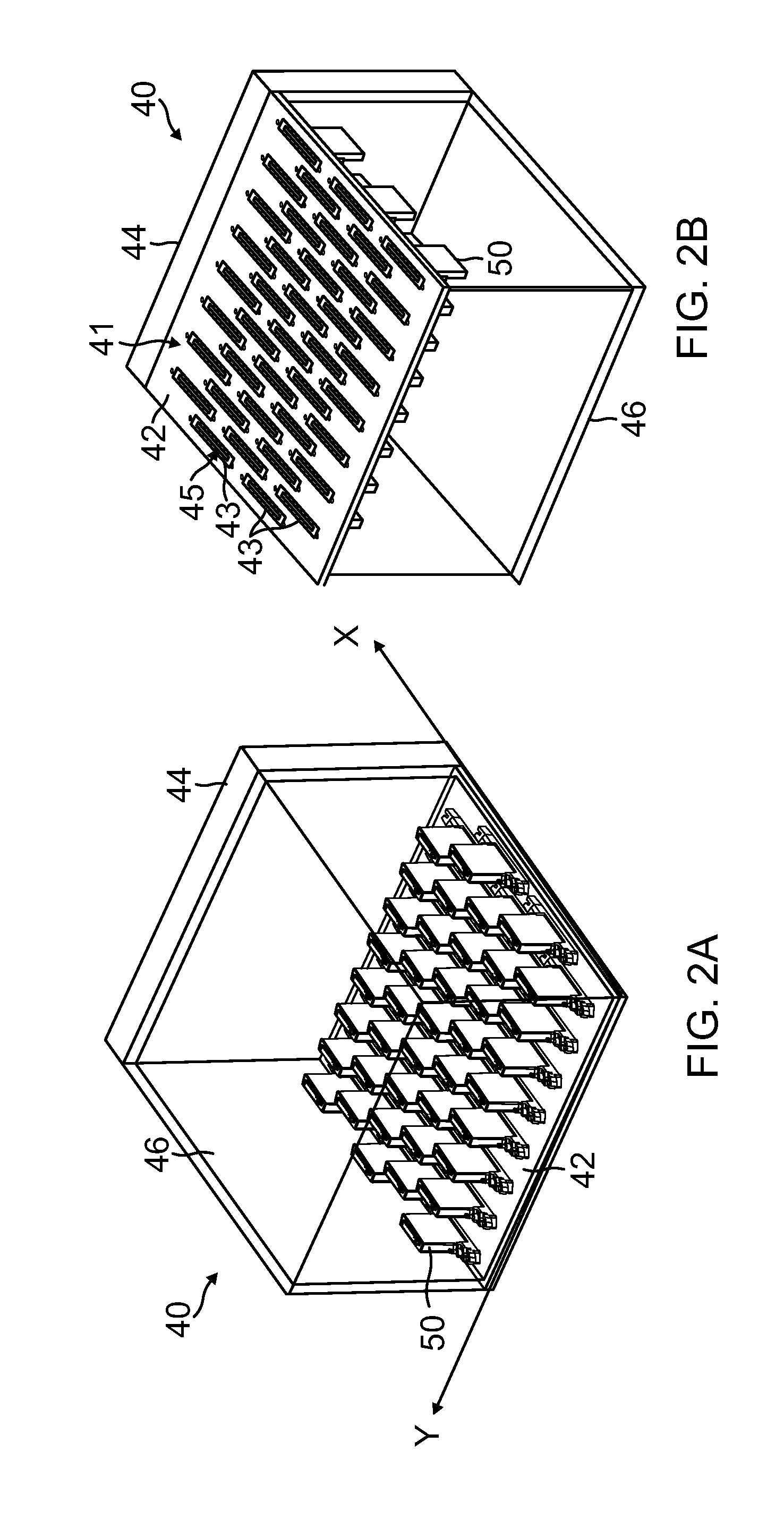

System and method for print head alignment using alignment adapter

InactiveUS20140168319A1Facilitate efficiency in print head alignmentShorter printing system downtimeInking apparatusPower drive mechanismsImage resolutionIndustrial engineering

Systems and methods for pre-aligning print head(s) to alignment adapter(s) to increase print resolution of printed matter, and to reduce offline time of a printing system due to print head alignment, include the use of an alignment adapter to which a print head is pre-aligned and which includes precision alignment features which precisely engage cooperating precision alignment features on the print head carriage mounting plate of the print head carriage. Print head(s) can be pre-aligned and fine-tuned to alignment adapter(s) even while the printing system is still in print production. Pre-aligned print head / alignment adapter assemblies can then be quickly mounted on the print head carriage using the cooperating precision alignment features of the adapter and print head carriage mounting plate. Duplicate sets of print head mounting sockets can include print heads aligned at different relative offsets (e.g., half a pixel) to increase the print resolution.

Owner:CIMPRESS SCHWEIZ

Print head alignment systems and methods for increasing print resolution

InactiveUS20140168303A1Effective alignmentShorter printing system downtimeInking apparatusPower drive mechanismsComputer hardwareComputer graphics (images)

Systems and methods for pre-aligning print head(s) to alignment adapter(s) to increase print resolution of printed matter, and to reduce offline time of a printing system due to print head alignment, include the use of an alignment adapter to which a print head is pre-aligned and which includes precision alignment features which precisely engage cooperating precision alignment features on the print head carriage mounting plate of the print head carriage. Print head(s) can be pre-aligned and fine-tuned to alignment adapter(s) even while the printing system is still in print production. Pre-aligned print head / alignment adapter assemblies can then be quickly mounted on the print head carriage using the cooperating precision alignment features of the adapter and print head carriage mounting plate. Duplicate sets of print head mounting sockets can include print heads aligned at different relative offsets (e.g., half a pixel) to increase the print resolution.

Owner:CIMPRESS SCHWEIZ

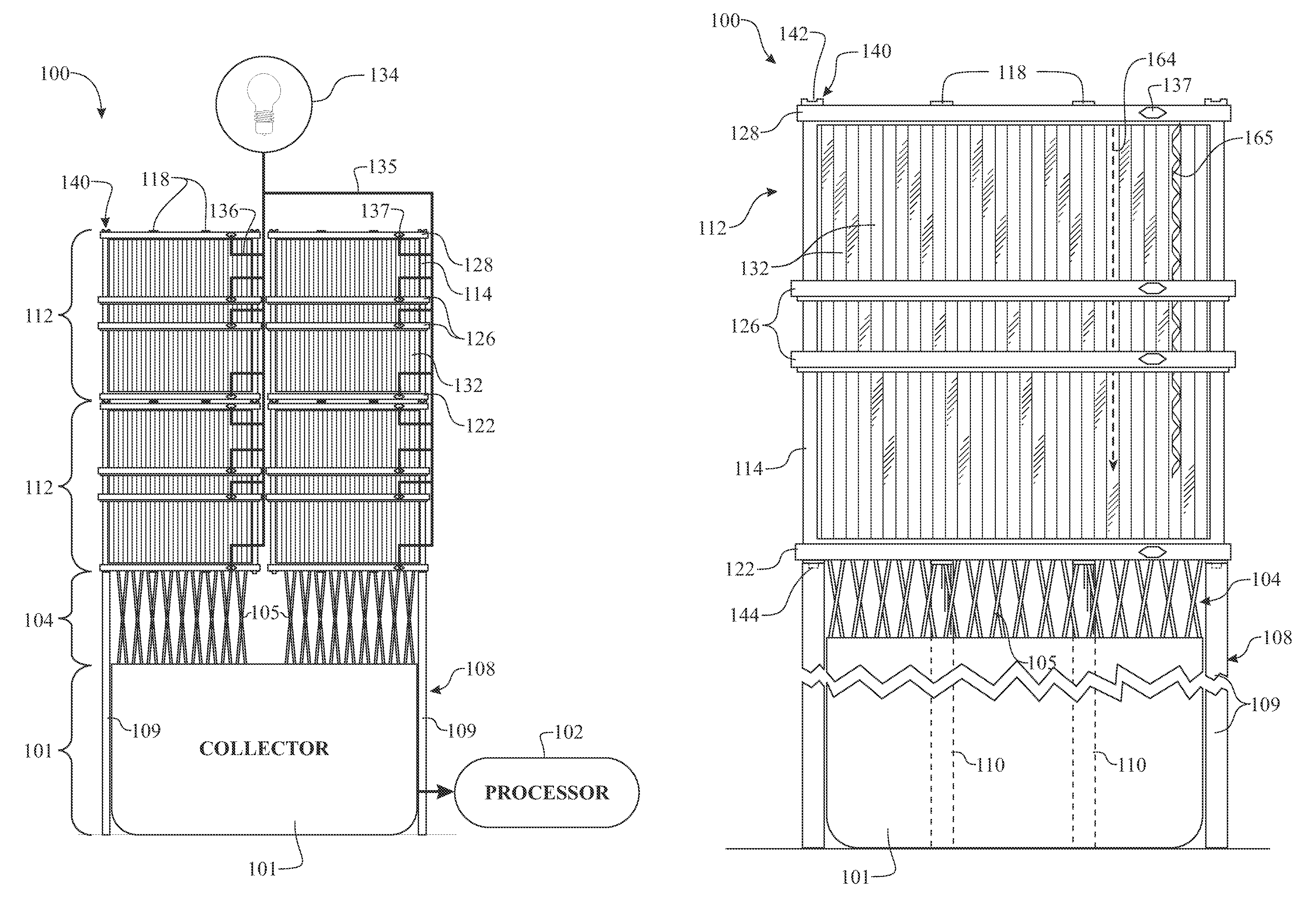

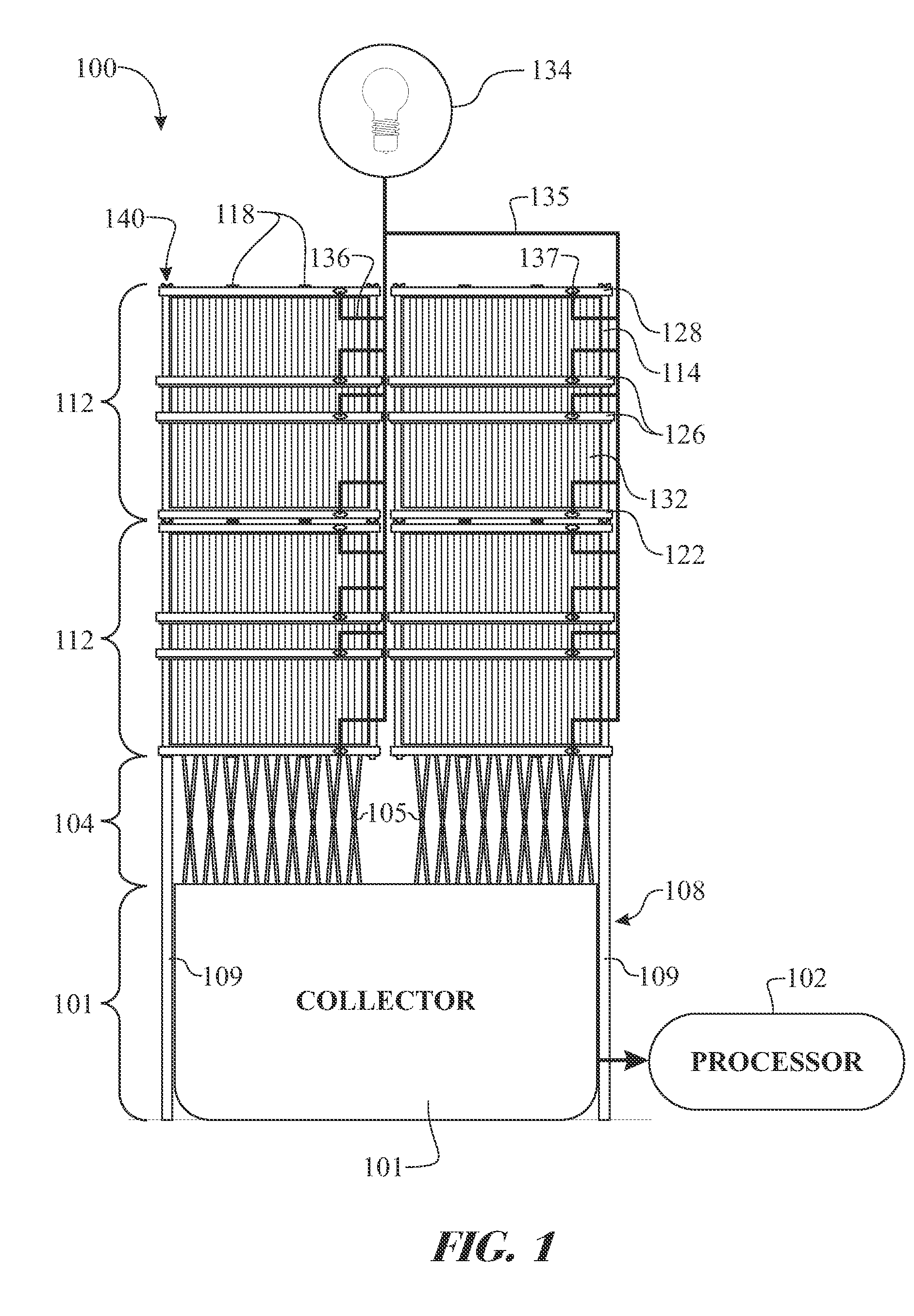

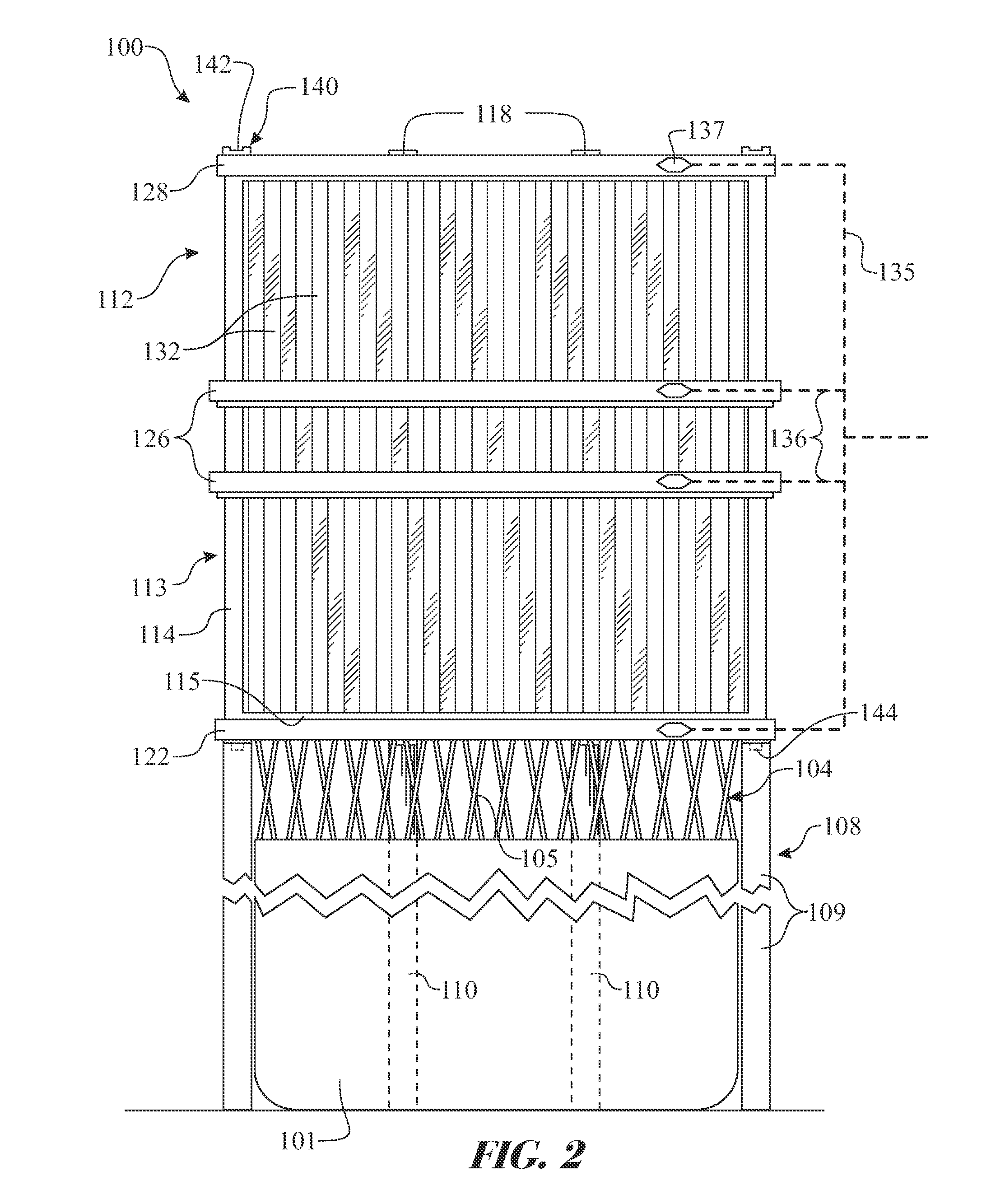

Algae production and harvesting apparatus

InactiveUS7997025B1Maximize production efficiencyFacilitates efficient deploymentAlgae productsPhotobioreactorsInterior spaceBioproducts

A photo-bioreactor module adapted for stacking a plurality of such modules for producing algal bioproducts includes at least an upper and a lower light-transmitting member each having a plurality of openings. The upper and lower light-transmitting members are spaced apart from one another and at least one of the upper and lower light-transmitting members includes at least one light connection terminal for coupling in light from a light source and transmitting the light laterally. A plurality of photobioreactor conduits each extending from respective openings in the upper and lower light-transmitting member define algae containment interior spaces, wherein the plurality of photobioreactor conduits contact the upper and a lower light-transmitting members along areas of contact. The light transmitted laterally by the upper and lower light-transmitting members couples into the plurality of photobioreactor conduits along the areas of contact.

Owner:TRINITAS LLC

D-psicose production method by d-psicose epimerase

ActiveUS20100190225A1Increase product yieldProduction cost be reduceSugar derivativesIsomerasesEnzymeProtein formation

Provided is a method of producing D-psicose using a D-psicose epimerase derived from Agrobacterium tumefaciens. Provided are a protein having an amino acid sequence of SEQ ID NO:1 and having a psicose 3-epimerase activity, a gene encoding the protein, a recombinant expression vector containing the gene, and a method of producing D-psicose by reacting the protein produced on a mass scale with D-fructose. The method of producing D-psicose is an environmentally friendly method using a new enzyme, in which an inexpensive substrate is used, and the activity of the enzyme can be retained for a prolonged time period. Thus, the method can be efficiently used for the mass production of D-psicose.

Owner:CJ CHEILJEDANG CORP

System and method for offline print head alignment

InactiveUS20140168302A1Facilitate efficiency in print head alignmentShorter printing system downtimeInking apparatusPower drive mechanismsImage resolutionEngineering

Systems and methods for pre-aligning print head(s) to alignment adapter(s) to increase print resolution of printed matter, and to reduce offline time of a printing system due to print head alignment, include the use of an alignment adapter to which a print head is pre-aligned and which includes precision alignment features which precisely engage cooperating precision alignment features on the print head carriage mounting plate of the print head carriage. Print head(s) can be pre-aligned and fine-tuned to alignment adapter(s) even while the printing system is still in print production. Pre-aligned print head / alignment adapter assemblies can then be quickly mounted on the print head carriage using the cooperating precision alignment features of the adapter and print head carriage mounting plate. Duplicate sets of print head mounting sockets can include print heads aligned at different relative offsets (e.g., half a pixel) to increase the print resolution.

Owner:CIMPRESS SCHWEIZ

Print head pre-alignment systems and methods

InactiveUS20140168293A1Facilitate efficiency in print head alignmentShorter printing system downtimeInking apparatusTypewritersImage resolutionEngineering

Systems and methods for pre-aligning print head(s) to alignment adapter(s) to increase print resolution of printed matter, and to reduce offline time of a printing system due to print head alignment, include the use of an alignment adapter to which a print head is pre-aligned and which includes precision alignment features which precisely engage cooperating precision alignment features on the print head carriage mounting plate of the print head carriage. Print head(s) can be pre-aligned and fine-tuned to alignment adapter(s) even while the printing system is still in print production. Pre-aligned print head / alignment adapter assemblies can then be quickly mounted on the print head carriage using the cooperating precision alignment features of the adapter and print head carriage mounting plate. Duplicate sets of print head mounting sockets can include print heads aligned at different relative offsets (e.g., half a pixel) to increase the print resolution.

Owner:CIMPRESS SCHWEIZ

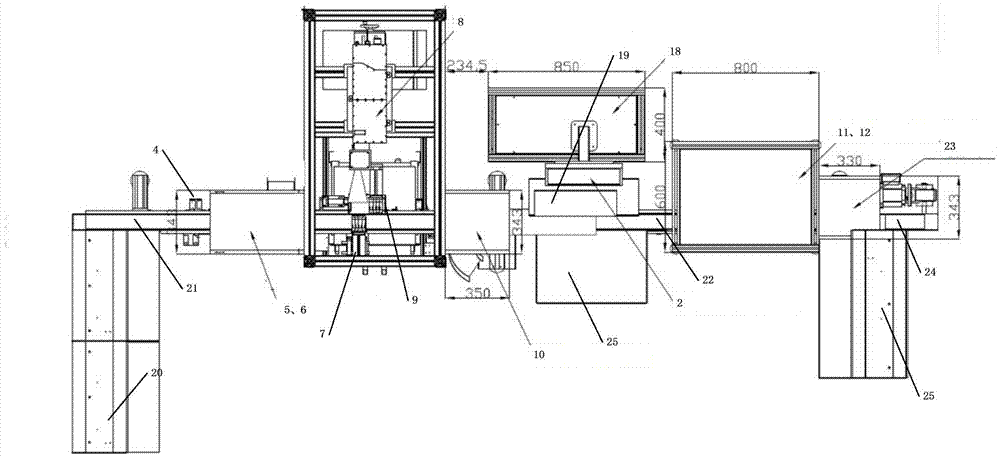

Production line device used for similar multistage assembly product code assigning and tracing

ActiveCN104494985AVersatilityLow costPackaging automatic controlSensing by electromagnetic radiationProduction lineAutomatic control

The invention is suitable for the technical field of automatic control, and provides a production line device used for similar multistage assembly product code assigning and tracing. A first bar code reader 5 is used for reading EAN-13 codes of single stage products after separation, a first rejection device 6 is used for rejecting the single stage products with the reading EAN-13 codes, not involved in current work order information, a first obstruction cylinder 7 is used for obstructing the single stage products under a laser coding machine 8, the laser coding machine 8 is used for printing two-dimensional codes on the upward sides of the single stage products, a first pushing cylinder 9 is used for pushing the obstructed single stage products periodically, an interval separation device 10 is used for separating the single stage products moving again at equal intervals according to a setup parameter, a two-dimensional code collector 11 is used for reading the two-dimensional codes of the single stage products, and a second rejection device 12 is used for rejecting the single stage products with the two-dimensional codes which cannot be read successfully. Through operations of an IPC and a PLC device, the parameter setting is finished, so that the production line device can produce special-type or special-stage finished products as required, and has the universality, and the cost is reduced.

Owner:武汉华工赛百数据系统有限公司

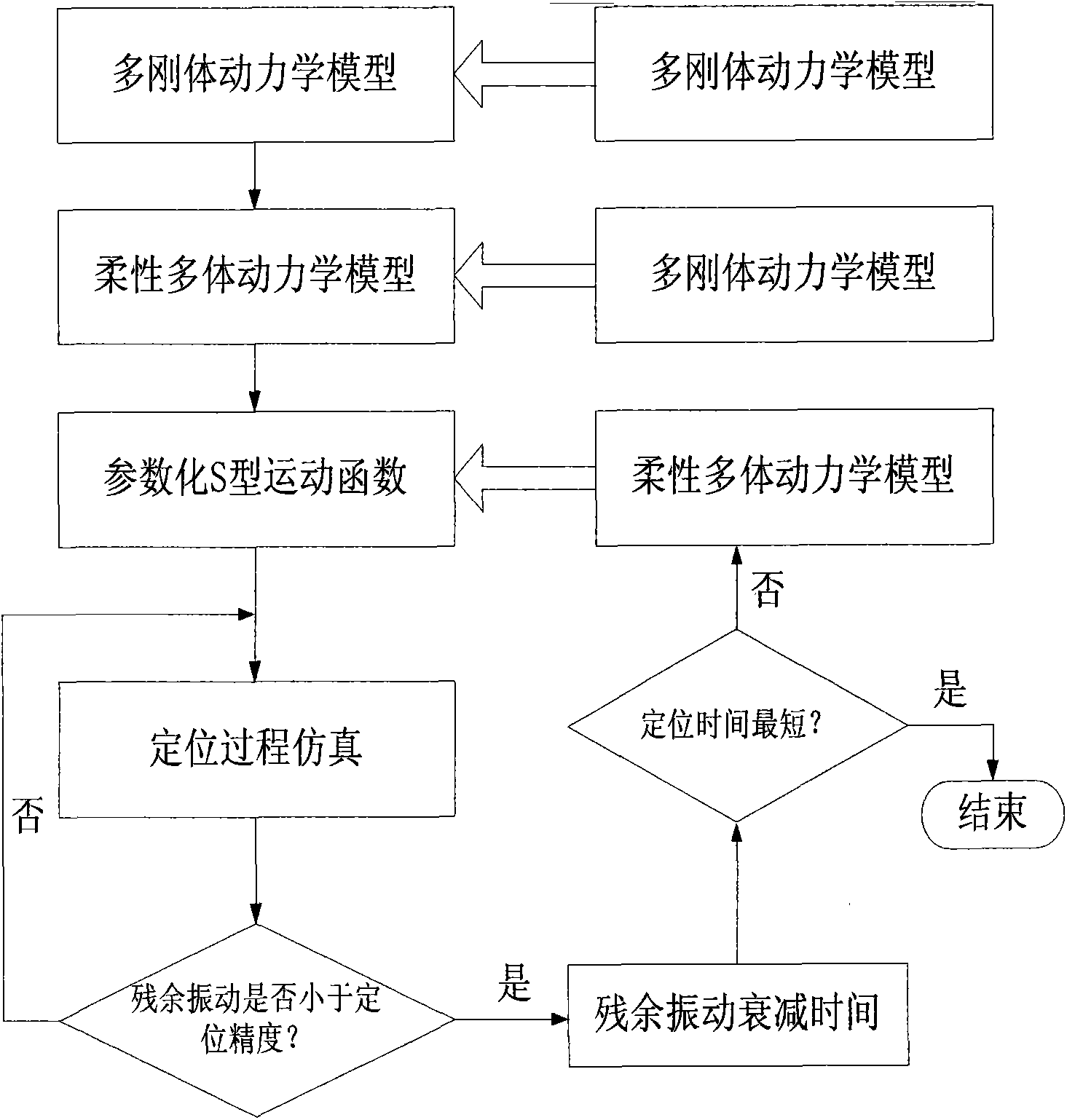

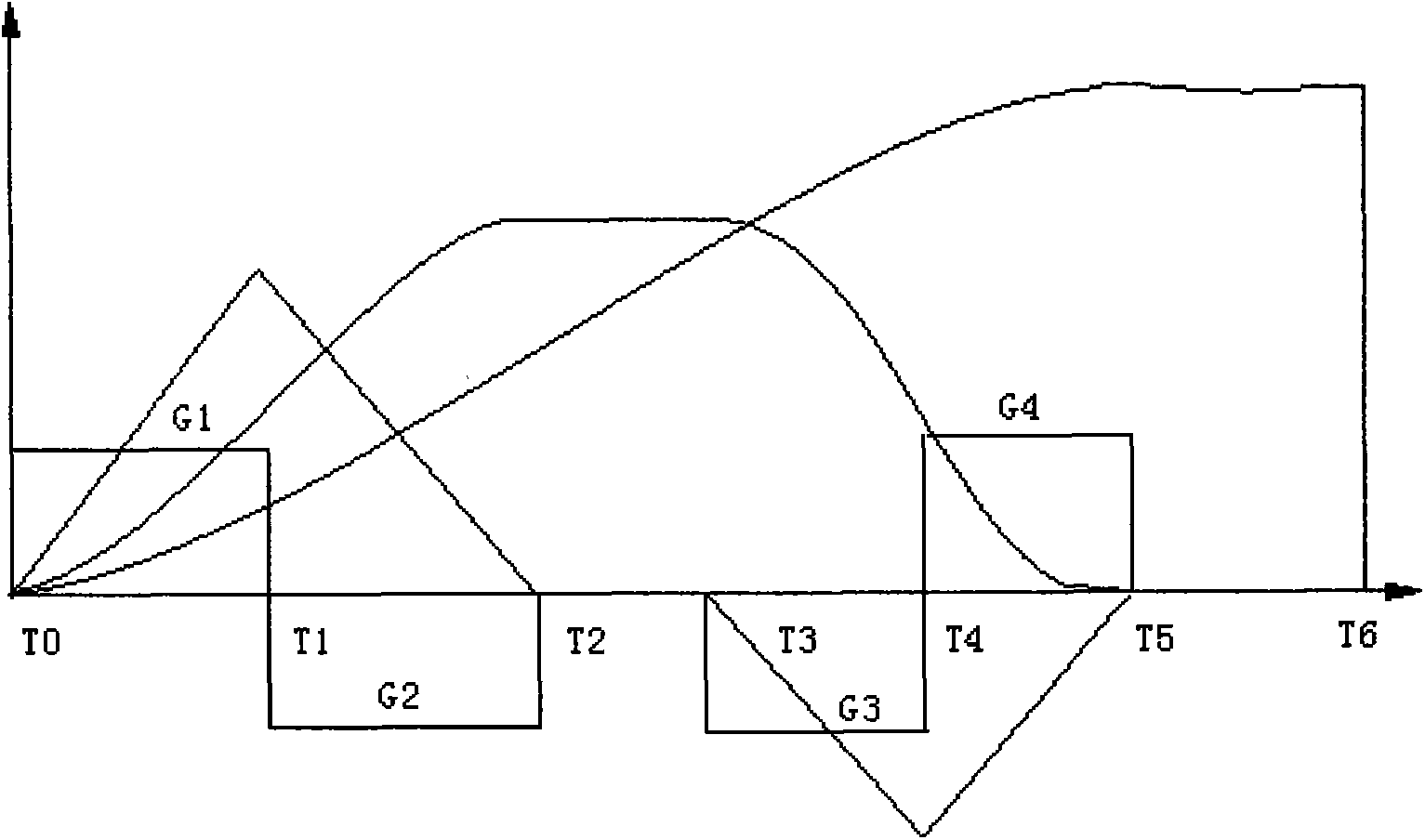

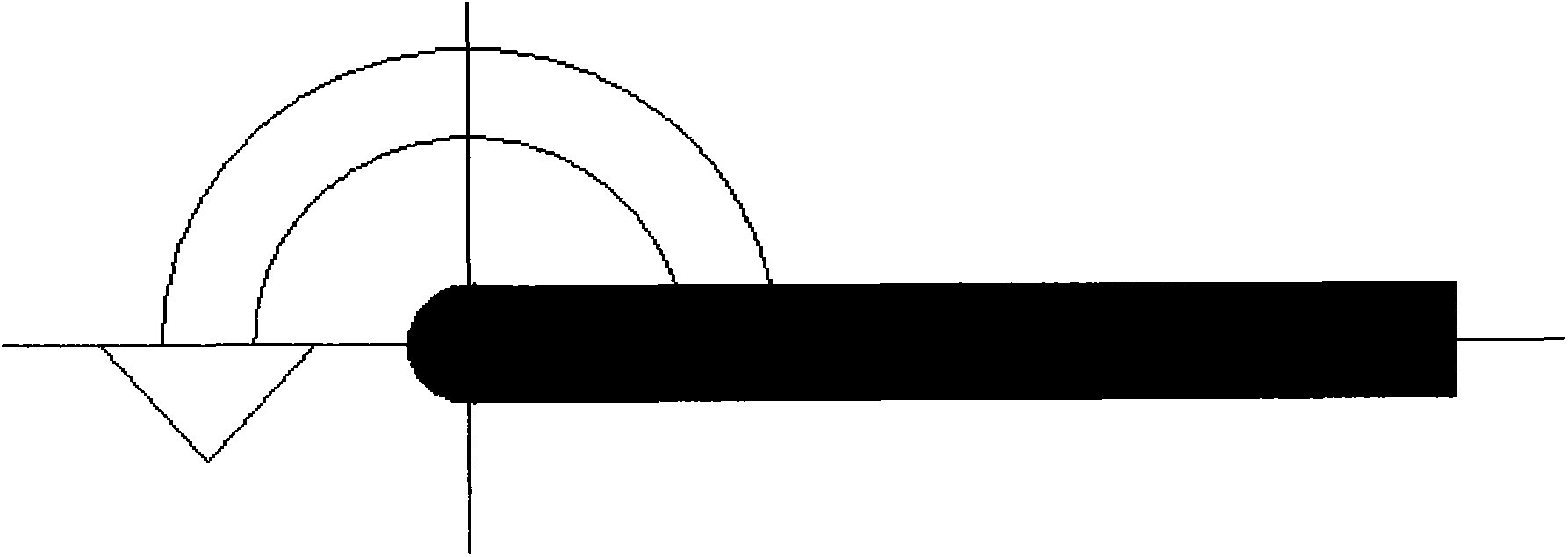

S-shaped movement curve planning method for reducing residual oscillation of high-speed mechanism

ActiveCN103513575AAchieve smoothness and productivityImprove stabilityAdaptive controlEngineeringPlanning method

The invention discloses an S-shaped movement curve planning method for reducing residual oscillation of a high-speed mechanism. The method comprises the following steps that according to the definition of an S-shaped movement curve, movement is divided into an add-add movement speed section (T1) with jerk G1, a minus-add movement speed section (T2) with jerk G2, a uniform movement section (T3), a minus-add movement speed section (T4) with jerk G3, a minus-minus movement speed section (T5) with jerk G5, and a minus-minus movement speed section (T6) with jerk G5. The damping time T6 for considering the residual oscillation is added, so influence of the residual oscillation is reduced. Influence of dynamics residual oscillation caused by systematic movement of the mechanism on actual movement locating time is considered, and stability of actual movement and maximization of production efficiency are achieved.

Owner:GUANGDONG UNIV OF TECH

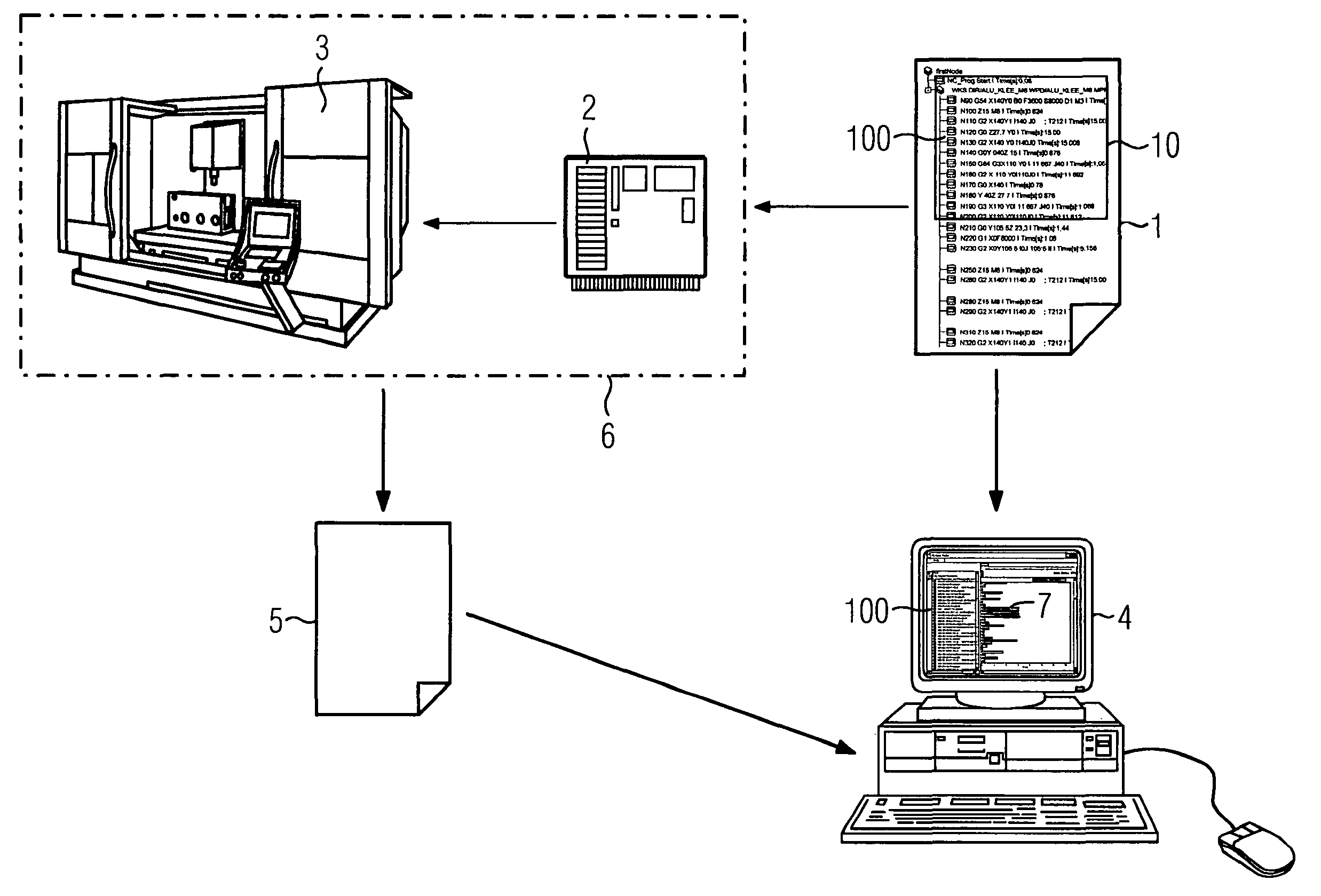

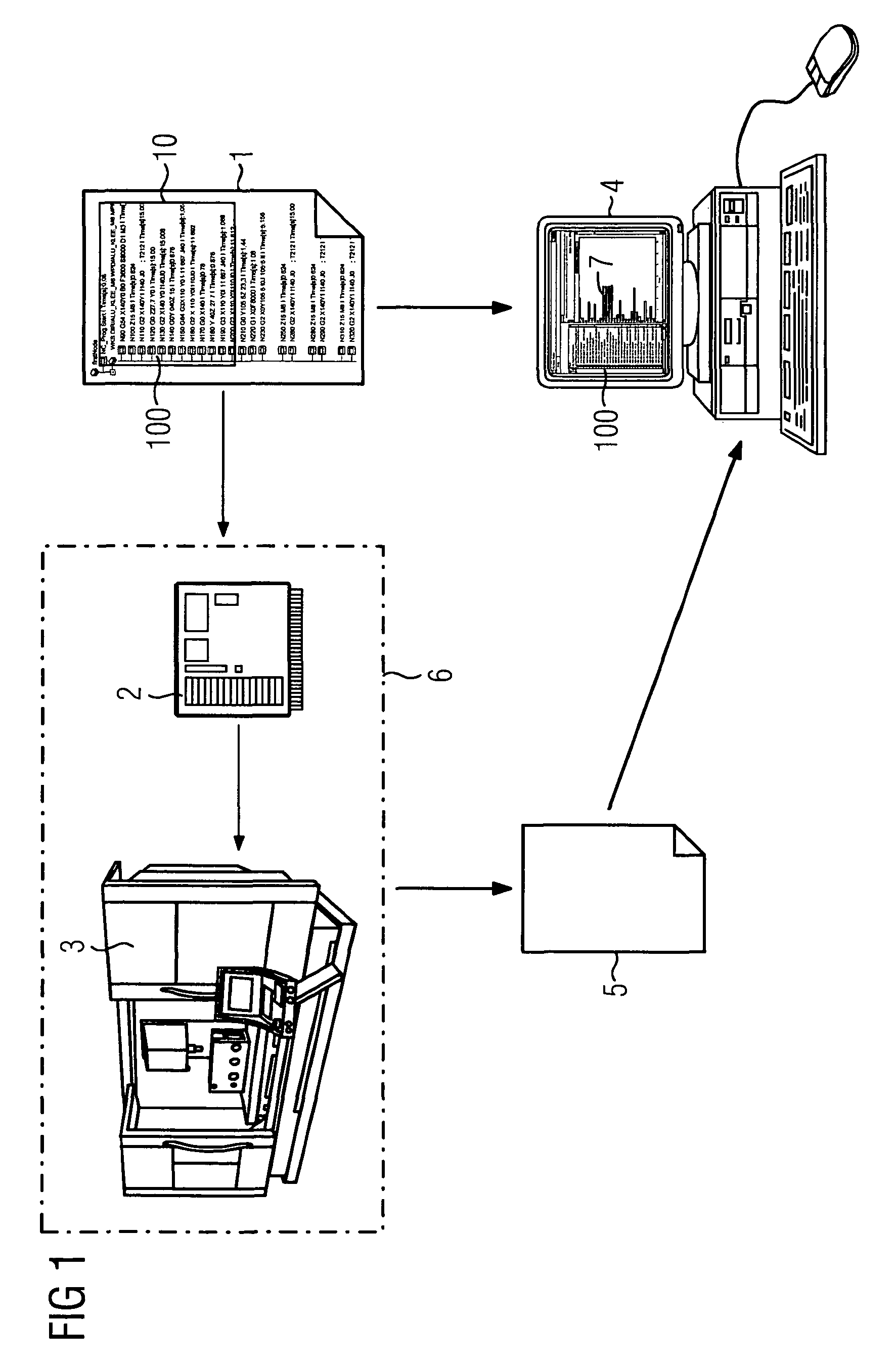

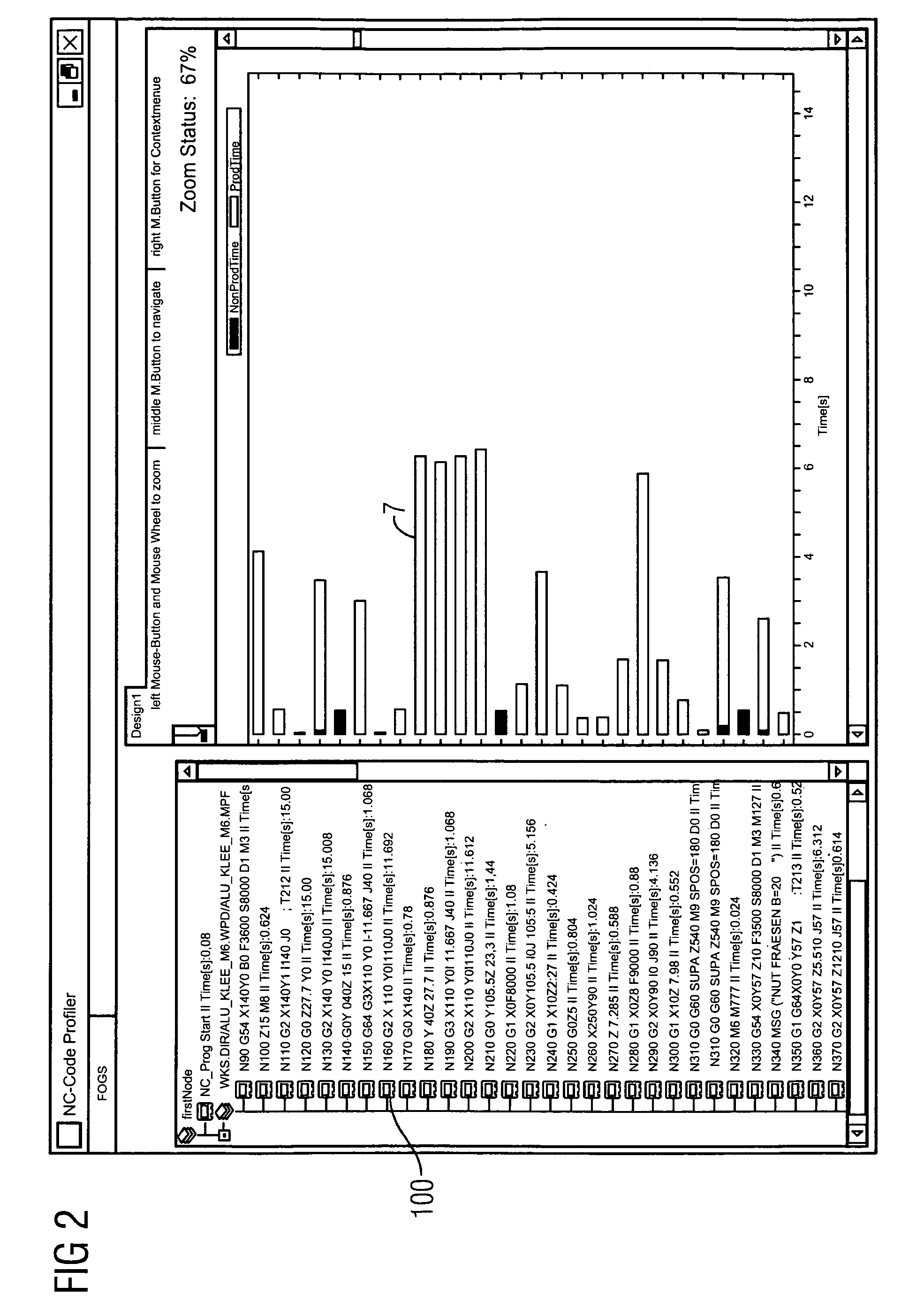

System and method for analyzing a production process

InactiveUS7933678B2Improve utilizationMaximize production efficiencyProgramme controlAnalogue computers for electric apparatusComputer scienceData records

Owner:SIEMENS AG

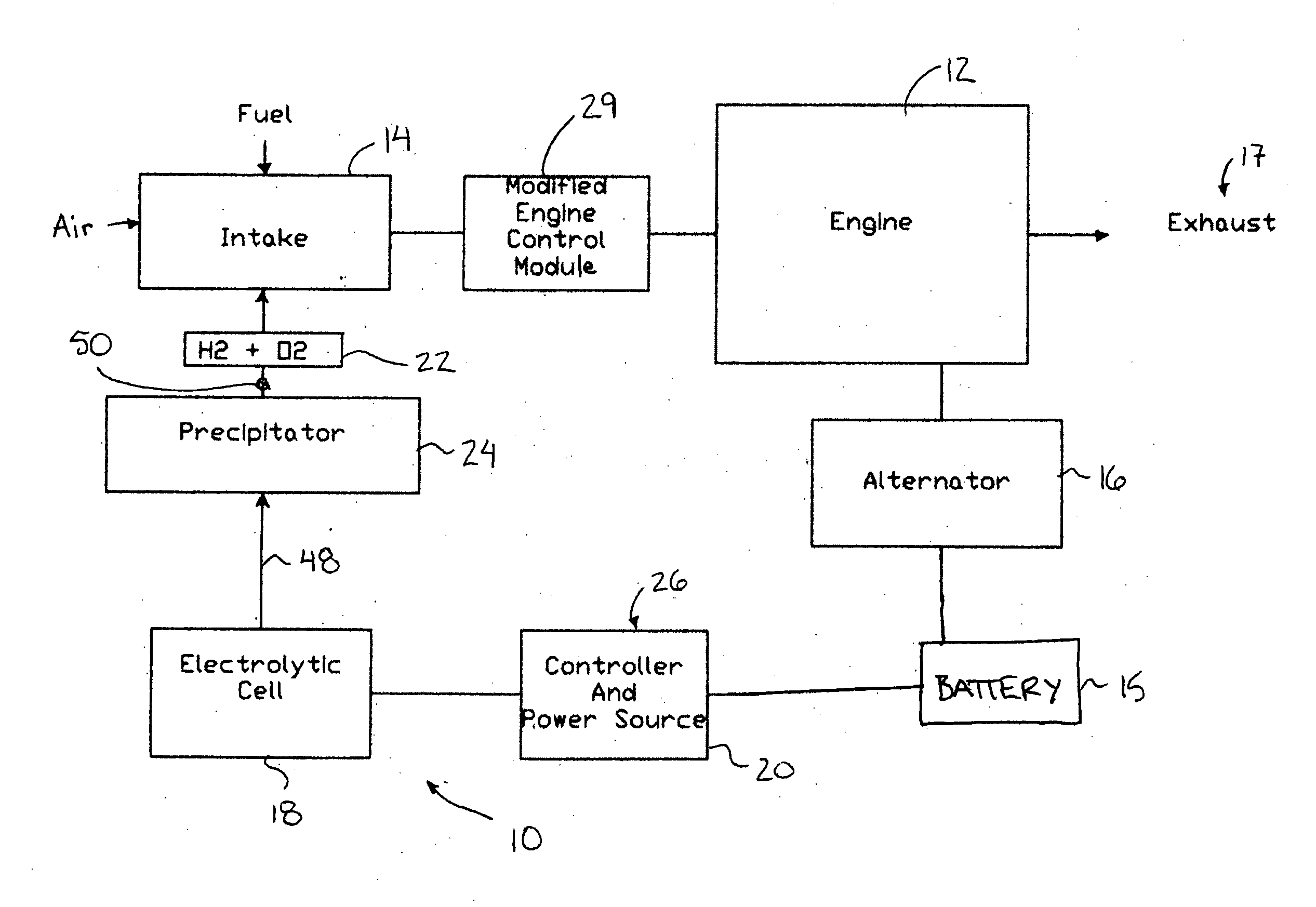

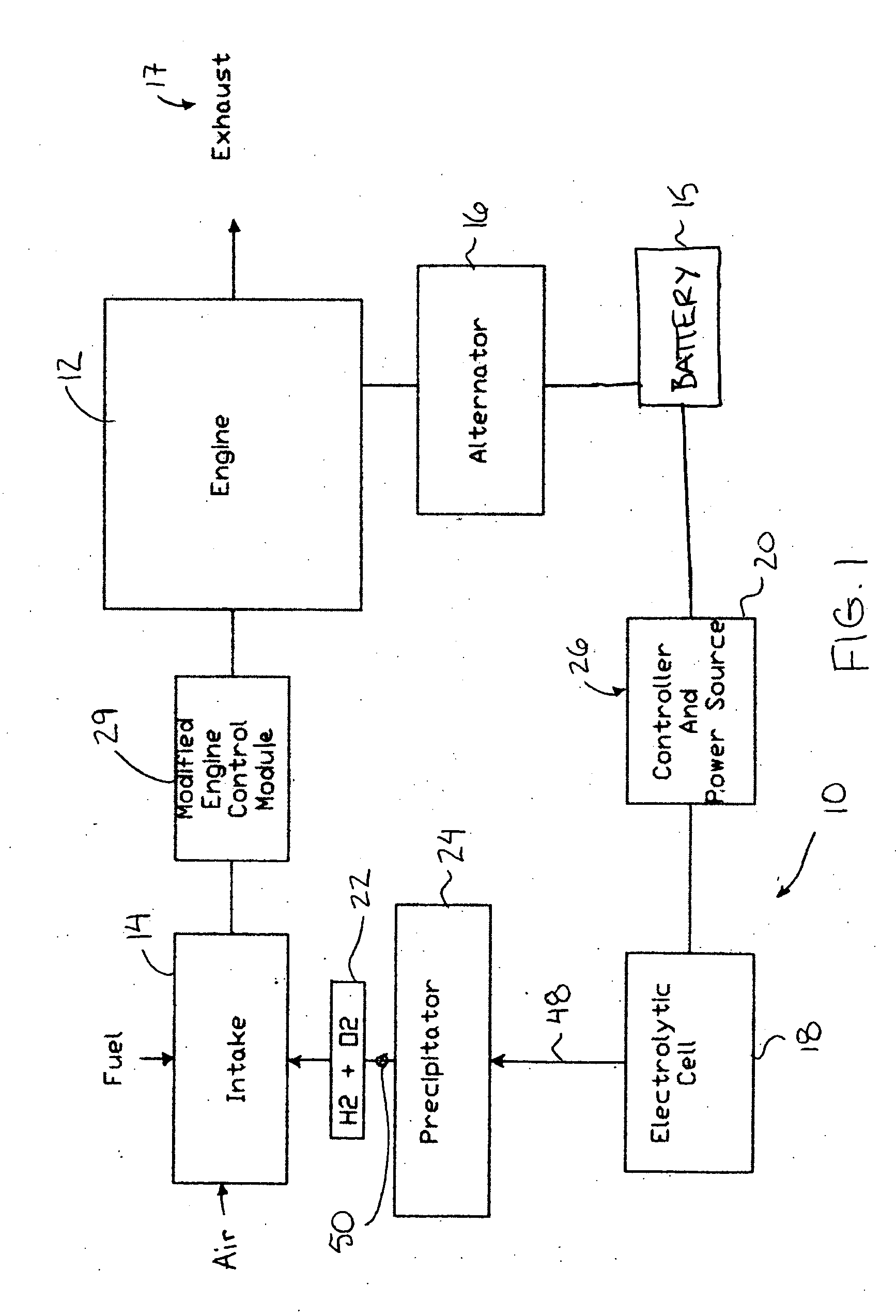

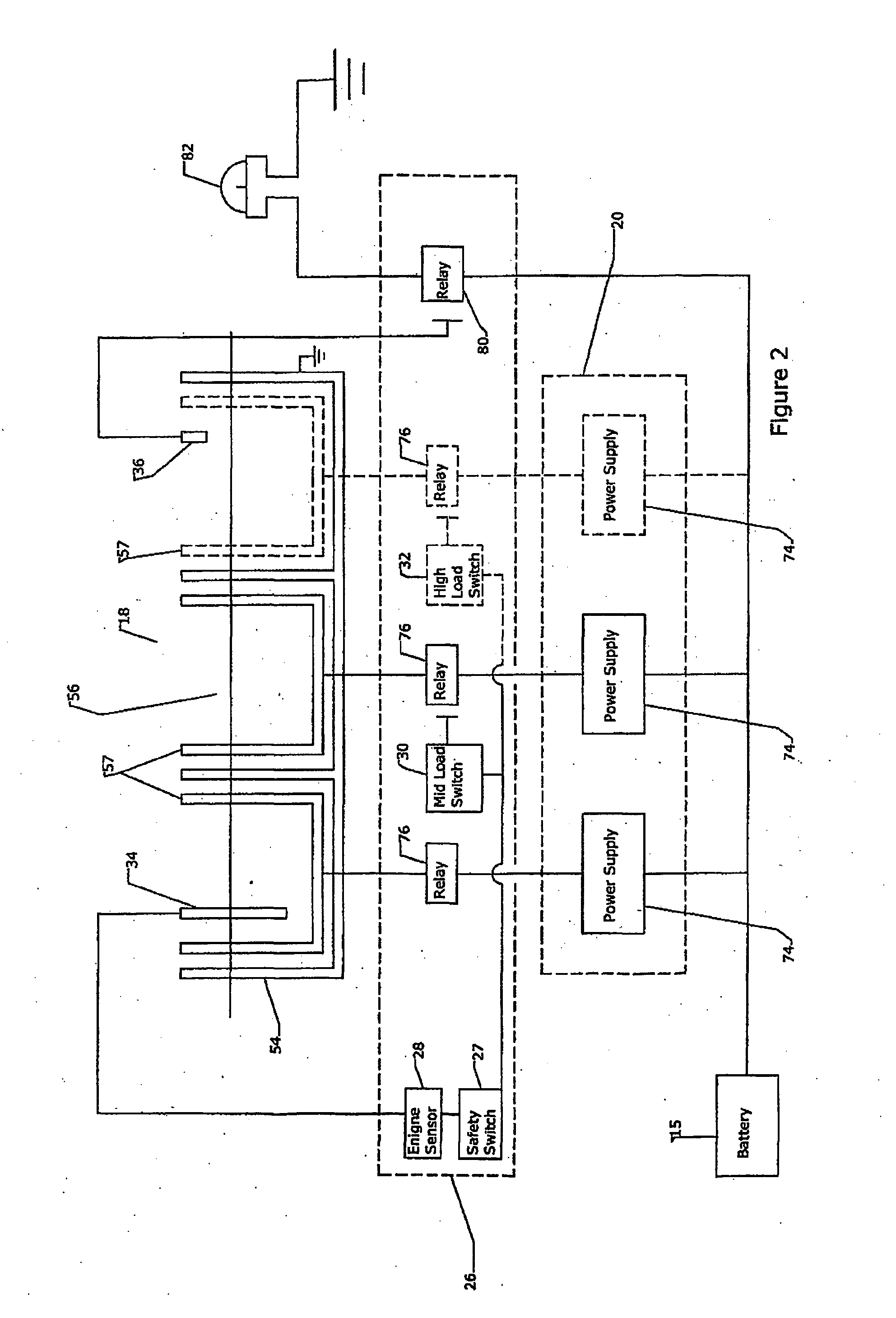

Electrolytic Cell for an Internal Combustion Engine

InactiveUS20100147231A1Improve efficiencyImprove reliabilityCellsCombustion enginesProduction rateCombustion

An electrolyser system produces combustion enhancing gas for communication with the intake of an internal combustion engine. An anode and a cathode are supported spaced apart from one another in a chamber filled with electrolytic solution with the cathode and the anode being nearest one another adjacent a bottom end of the chamber to concentrate the electrolysis activity adjacent the bottom end of the chamber. The electrolysis activity is therefore not significantly affected by varying levels of solution in the chamber. The anode comprises a plurality of independent units with respective independent power supplies. An amperage control selectively connects and disconnects the power supplies with the respective independent units of the anode for adjusting applied amperage across the solution and accordingly for varying the production rate of combustion enhancing gas responsive to engine demands.

Owner:INNOVATIVE HYDROGEN SOLUTIONS

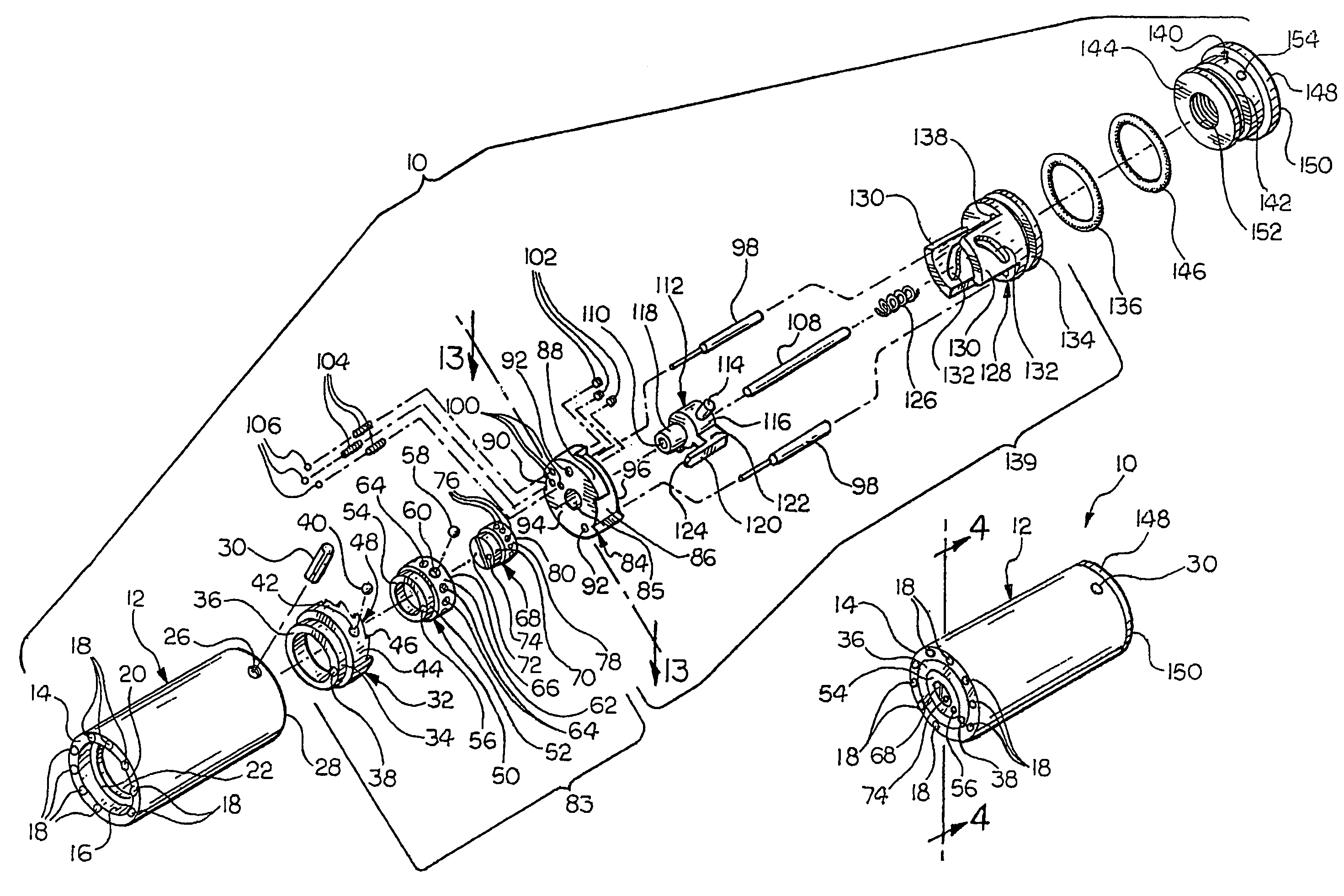

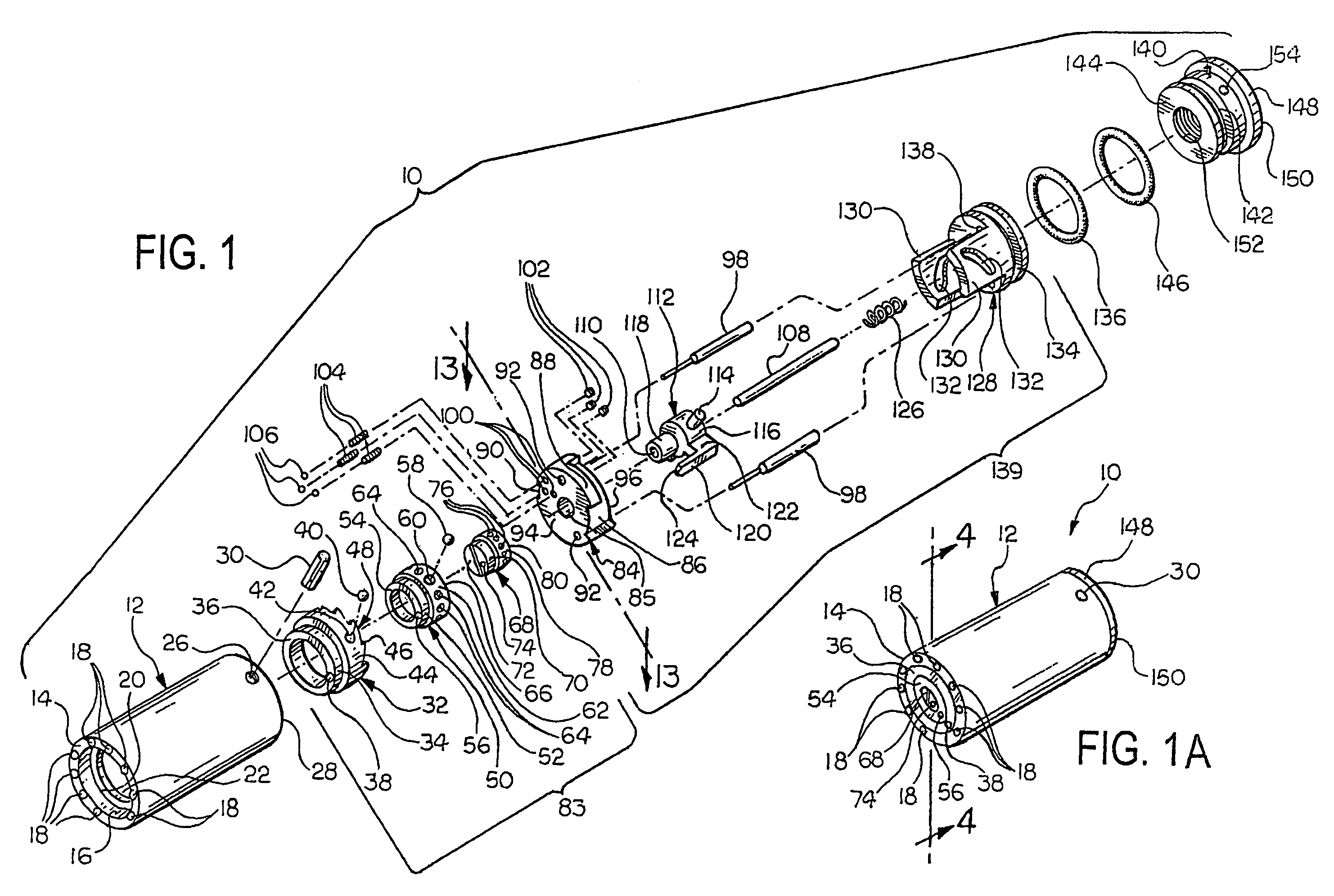

Numbering device for molded or cast parts

InactiveUS7252136B2Easy to changeMaximize production efficiencyMoulding toolsMoulding machinesShell moldingConcentric cylinder

A numbering device is disclosed for marking molded cast parts, the device including a plurality of concentric cylinders having indicia disposed on an end thereof, the cylinders being rotatingly indexable to cause the indicia to move as desired to form the desired mark, the mark is then impressed into a sand mold and subsequently reproduced on the cast part.

Owner:GM GLOBAL TECH OPERATIONS LLC

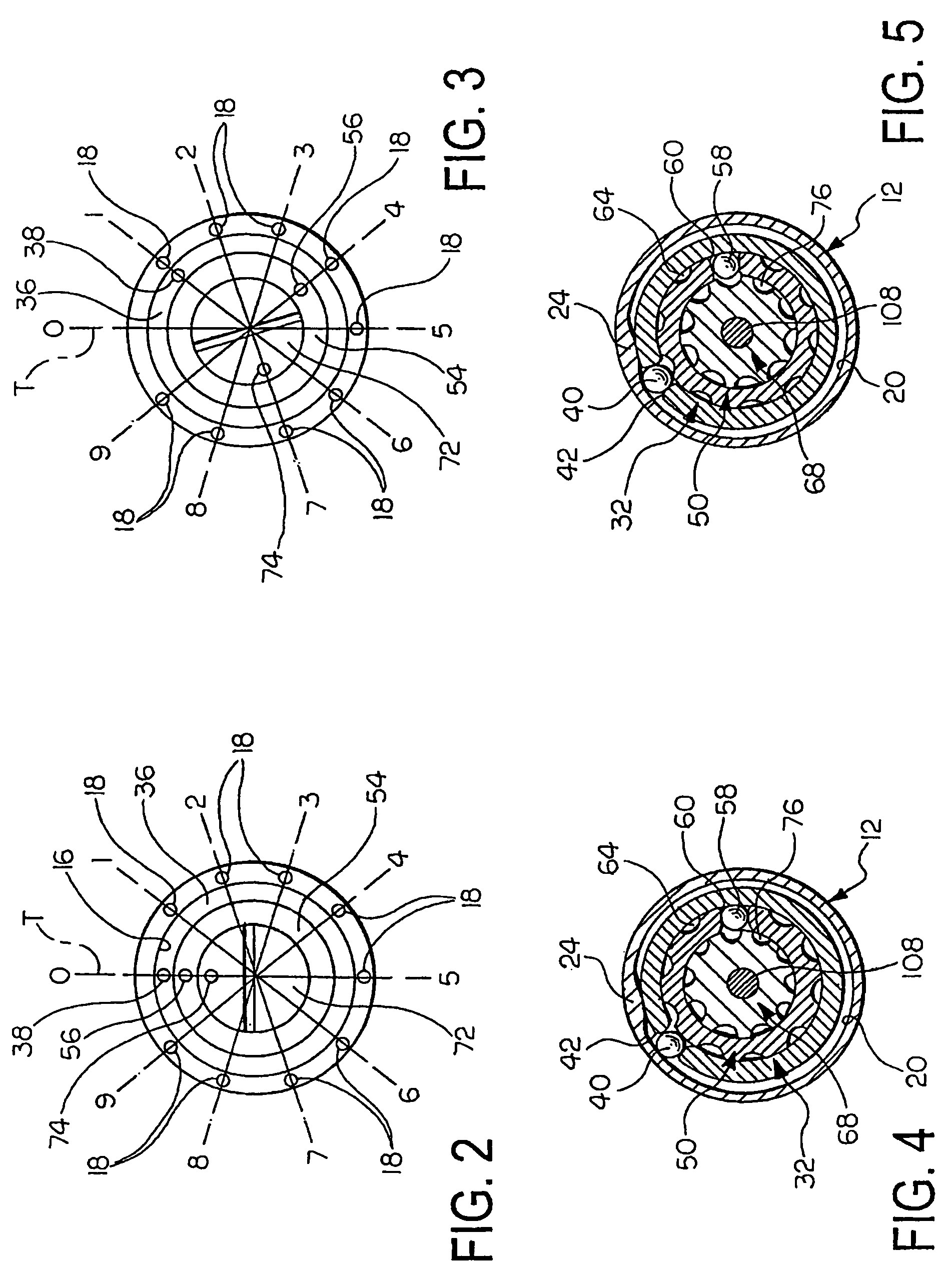

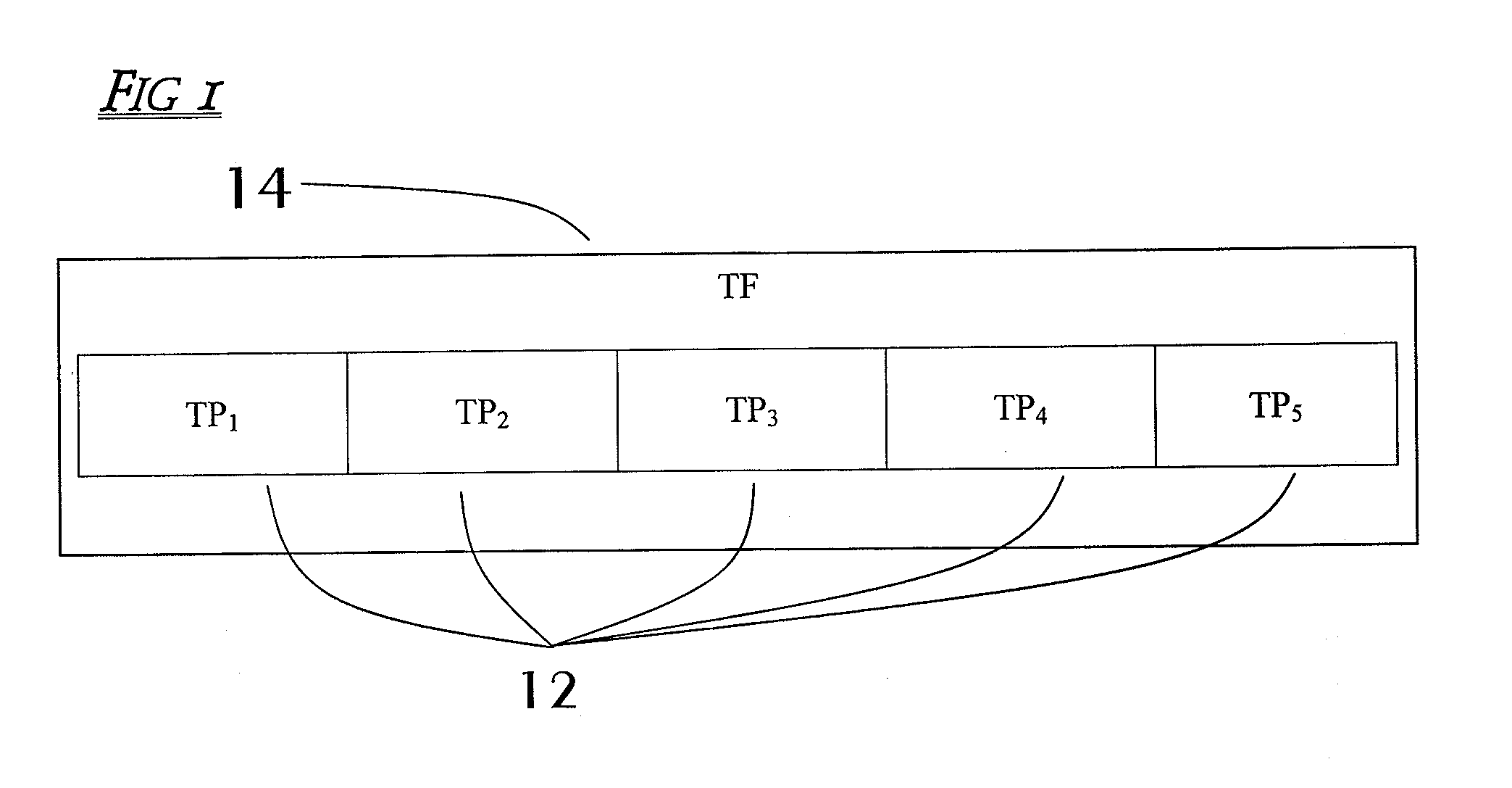

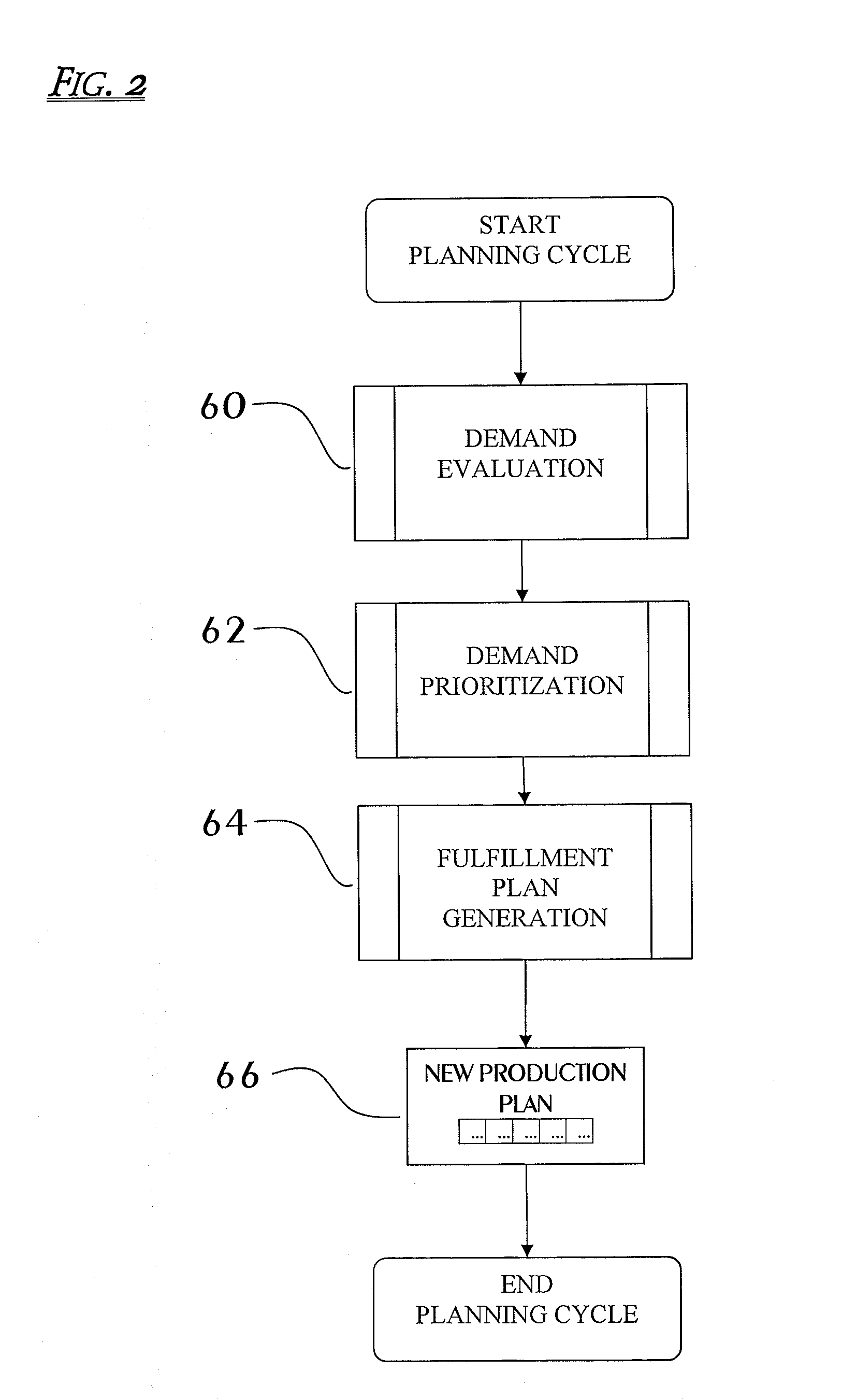

Dynamic fulfillment planning method and apparatus

InactiveUS20100042240A1Good flexibilityMaximize production efficiencyNuclear monitoringDigital computer detailsProgram planningEngineering

This invention relates to a method for production planning in which changing demands and current demands are combined and separated into fixed demands, time-flexible demands, and quantity-flexible demands before being prioritized according to a set of rules that optimize efficient handling of changing demands while minimizing changes in and maximizing flexibility of a production schedule.

Owner:ICON-SCM

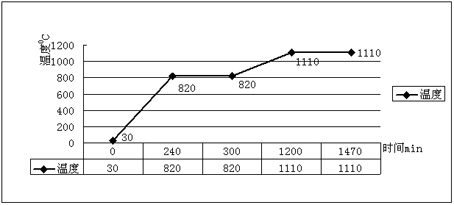

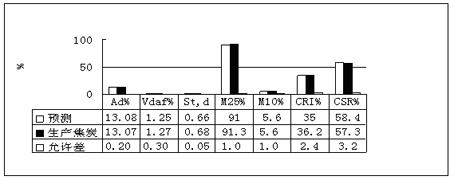

Method for predicting quality of industrially produced coke by using 40kg test coke oven

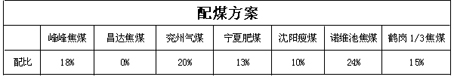

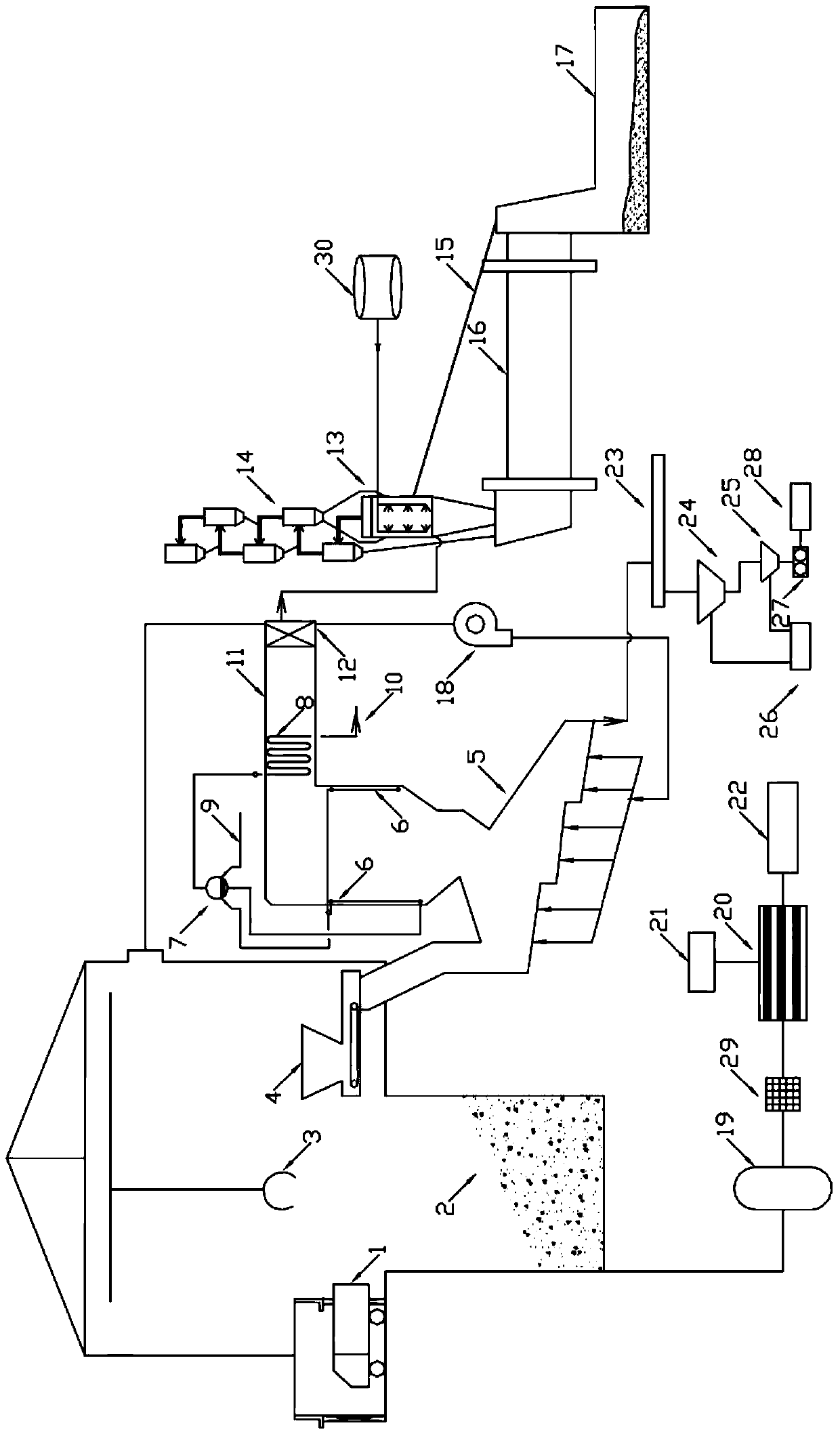

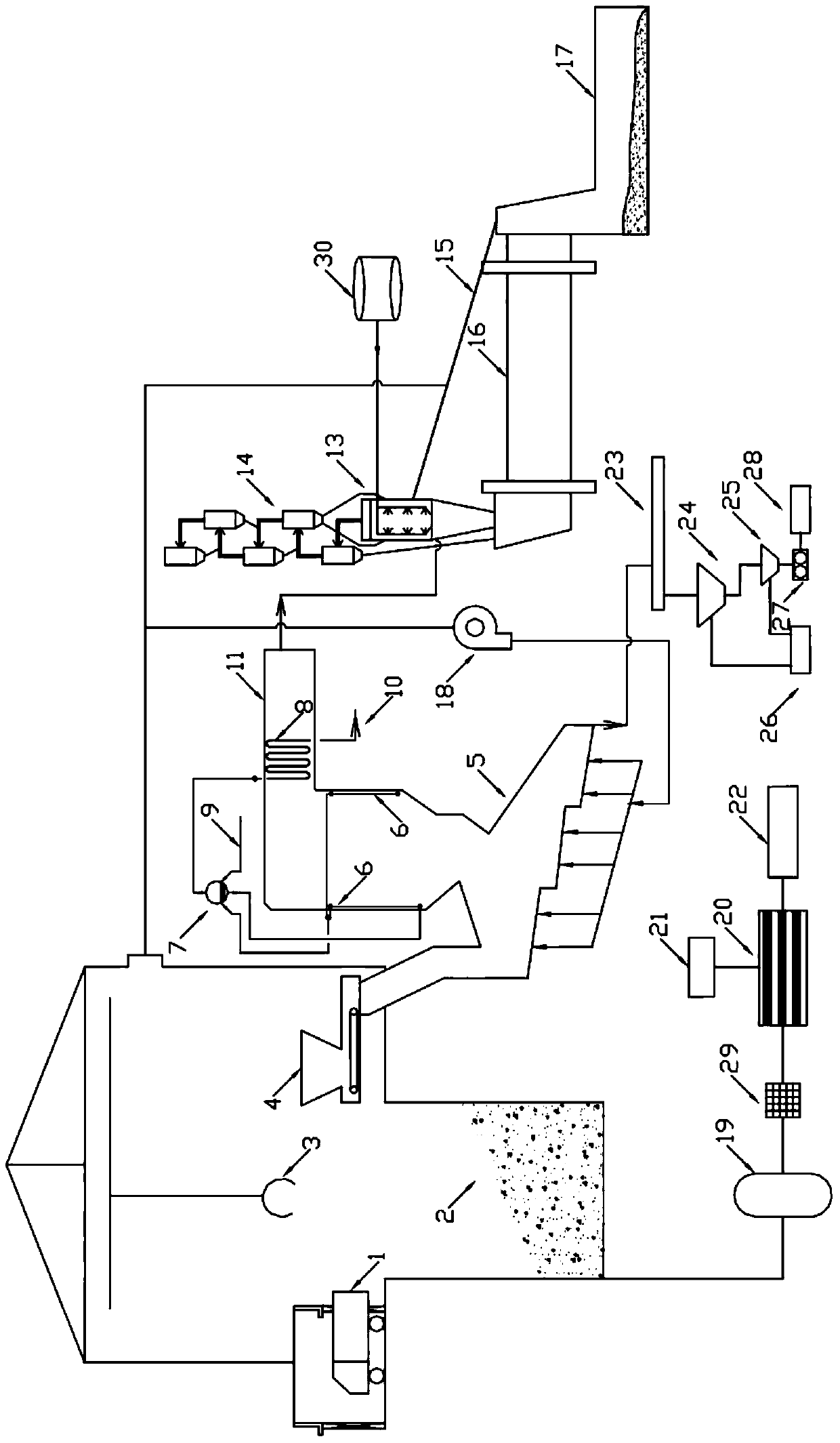

ActiveCN101957359AReduce production riskRealize production benefitsCoke ovensFuel testingEngineeringProduction risk

The invention relates to a method for predicting quality of industrially produced coke by using a 40kg test coke oven and belongs to the technical field of metallurgical test. The technical scheme comprises the following steps of: firstly, taking test coal according to the ratio of industrial production, mixing, crushing and producing coke in the 40kg test coke oven; secondly, making an industrial analysis sample and a terminal performance sample to obtain corresponding technical indexes; and finally, predicting the quality of the industrially produced coke according to the technical index test result of the test coke. The method has the advantages that the 40kg small coke oven test coke is used for predicting the industrially mass produced coke. Through the small coke oven test, an optimal coal blending scheme can be found according to the conditions of coal source, the coke with high quality can be produced, the production risks can be reduced and the production benefit can be maximized.

Owner:唐山建龙简舟钢铁有限公司

Method for disposing household refuse in cooperation with cement kiln with partial waste heat recovery function and system

InactiveCN104048298AIncrease power generationRealize enterprise production efficiencySolid waste managementRotary drum furnacesDecompositionHeavy metals

The invention discloses a method for disposing household refuse in cooperation with a cement kiln with a partial waste heat recovery function and a system for implementing the method, and relates to the field of energy conservation and environment protection. The method includes the steps that household refuse is sent into a sealed negative-pressure refuse room to be stored and fermented for five days to seven days, air in the refuse room is extracted and sent into a mechanical fire grate refuse combustion furnace to be used as primary air and secondary air, hot smoke enters a waste heat furnace for heat exchange after drying, thermal decomposition, combustion and after-combustion are conducted on the refuse in the combustion furnace, produced low-pressure steam is sent to a cement kiln waste heat power generation system, the smoke is sent to a decomposition furnace after heat exchange is conducted on the smoke in the waste heat furnace, dioxin and other harmful gas produced by the refuse are absorbed and disposed through the high-temperature alkaline negative-pressure condition in a decomposition furnace, and combustion slag serves as a cement raw material. According to the method and the system, through combination with the existing waste heat power generation system of the cement kiln, dioxin exhaust and heavy metal solidification during refuse combustion can be effectively controlled, waste heat power generation capacity of the cement kiln can be improved, waste heat power generation investment and tail gas clean-up investment are saved, and good environment protection characteristics and economical efficiency are achieved.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Out-of-season breeding method for gladiolus hybridus hort seed bulbs

InactiveCN101766088AMaximize production efficiencySeed immunisationHorticultureRoom temperatureDormancy

The invention provides an out-of-season breeding method for gladiolus hybridus hort seed bulbs and belongs to the technical field of flower planting. To solve the problems of long storage period and great nutrient loss of the gladiolus hybridus hort seed bulbs in the conventional summer flowering system, the invention provides the out-of-season breeding method for the gladiolus hybridus hort seed bulbs, which comprises the following steps of: (1) selecting the seed bulbs; (2) using a bactericide and an insecticide to sterilize the seed bulbs after immersion; (3) planting the seed bulbs during the period from September to November; (4) performing managements such as watering, weeding and the like on the seed bulbs after planting; and (5) collecting the planted seed bulbs in six months, wherein dormancy of the seed bulbs can be broken and the seed bulbs can be planted as soon as the seed bulbs are stored for 60 days at the storage room temperature of between 2 and 5 DEG C. The gladiolus hybridus hort seed bulbs bred by using the method has high quality and short storage period, so the aim of flowering in winter is fulfilled, and the production gain is maximized.

Owner:元江县臧健花卉科技开发有限公司

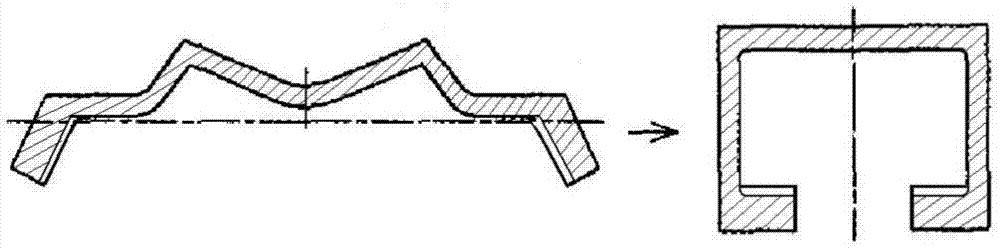

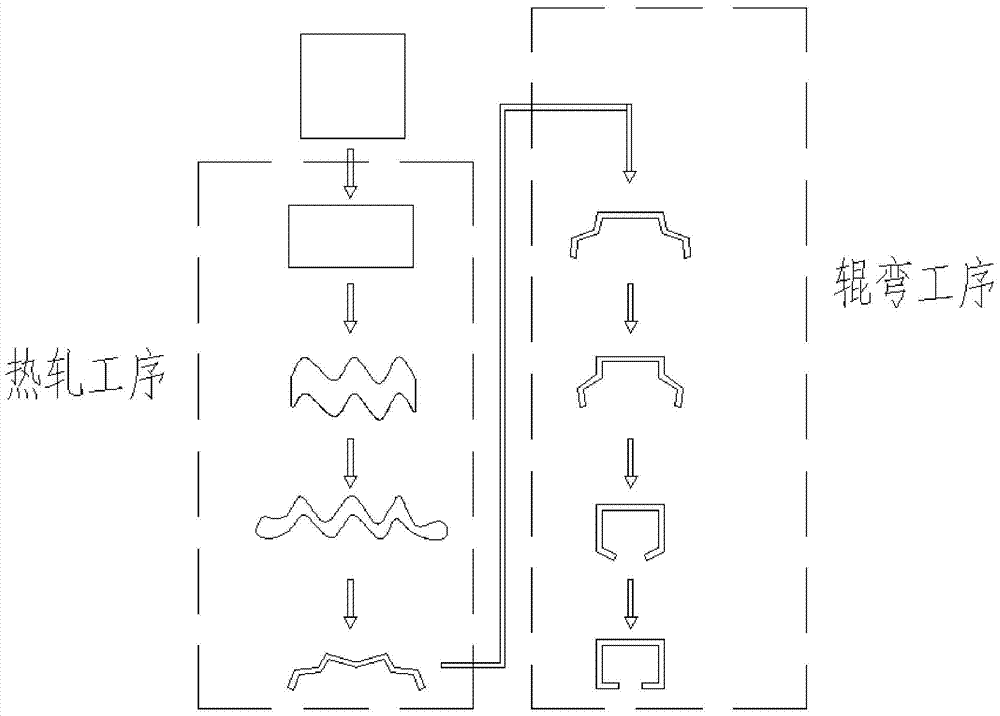

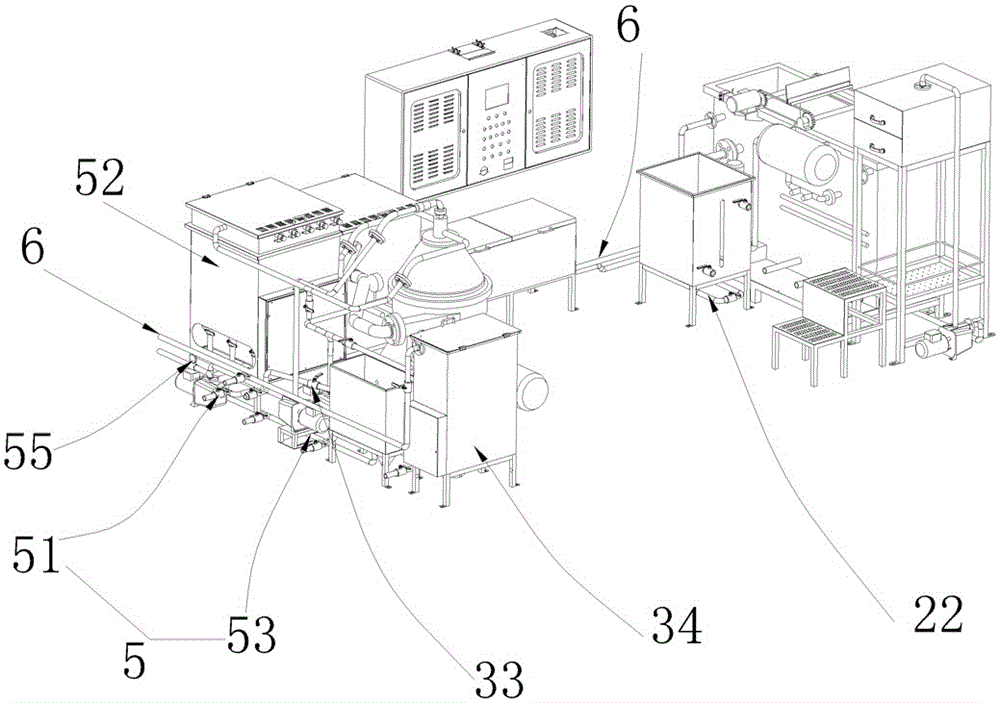

Channel section steel production system and production method thereof

ActiveCN104759892ASimple production processSimplified pass rolling passesOther manufacturing equipments/toolsProduction lineMethods of production

The invention provides a channel section steel production system and a production method thereof. The channel section steel production system comprises a feeding device, a heating device, a hot-rolling unit, a roll-bending unit and a fixed-length cutting device which are sequentially arranged. Flat steel blank raw materials are selected, heated through an electric induction heating device and then are fed into rolling mills of two machine frames to be subjected to rolling deformation, a first pass is used for thickness decrease, a second pass is used for plate shape forming of cross sections of rolled pieces before hot bending, and the two machine frames conducts deformation rolling on the raw materials simultaneously in a continuous-rolling state. By the adoption of simplified two-pass hot rolling, the thickness and plate shapes all cross section of flattened and spread channel section steel are rolled, waste heat is utilized to conduct hot bending forming on the continuous roll-bending unit, and fixed-length sawing, cooling and finishing are performed to obtain channel section steel products. The production method is simplified, hole type rolling pass is simplified, production difficulty is reduced, and the production success rate and finished material rate are improved. The number of the rolling mills is decreased, a production line is shortened, short-process production is achieved, and investment and follow-up maintenance cost are reduced.

Owner:CISDI ENG CO LTD +1

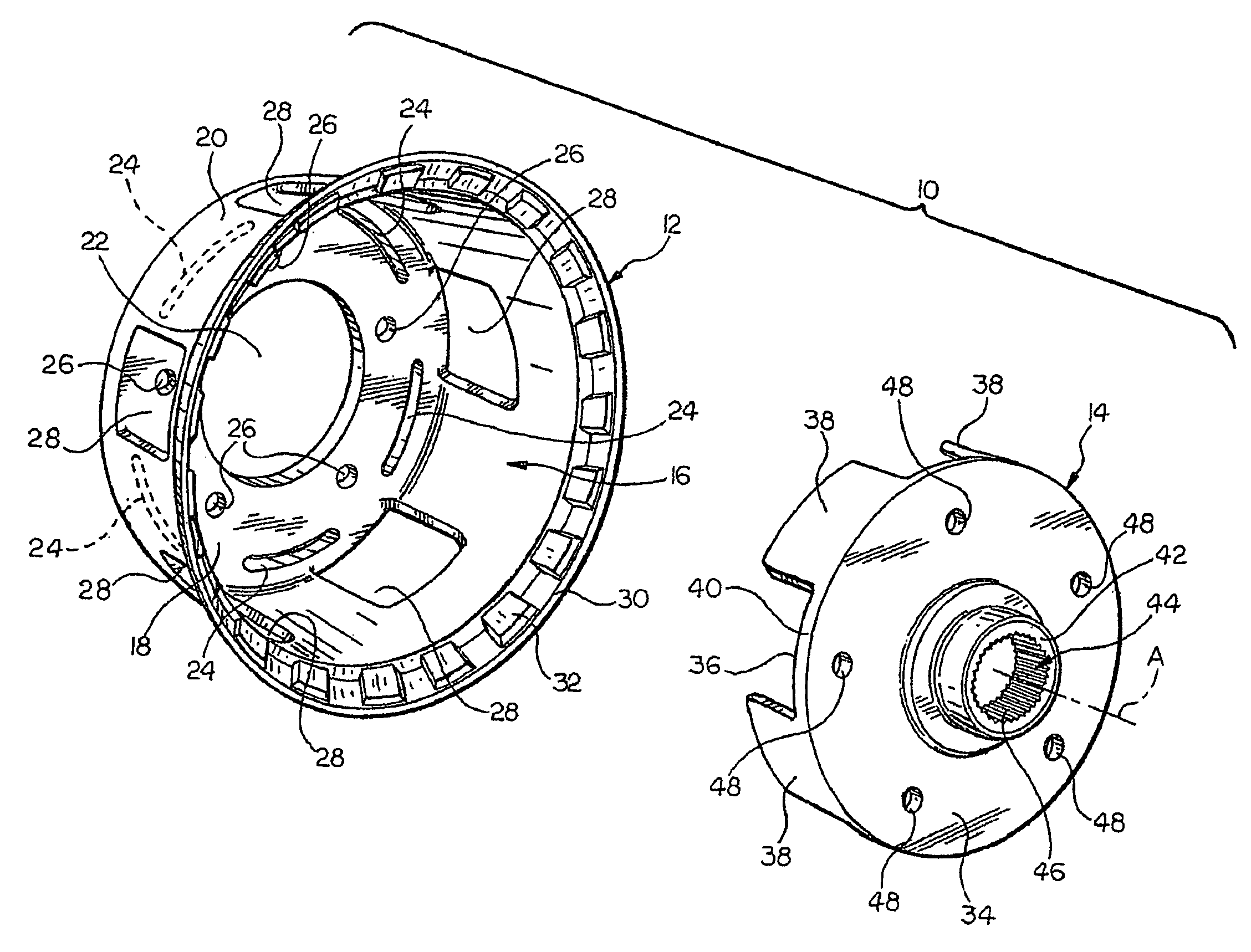

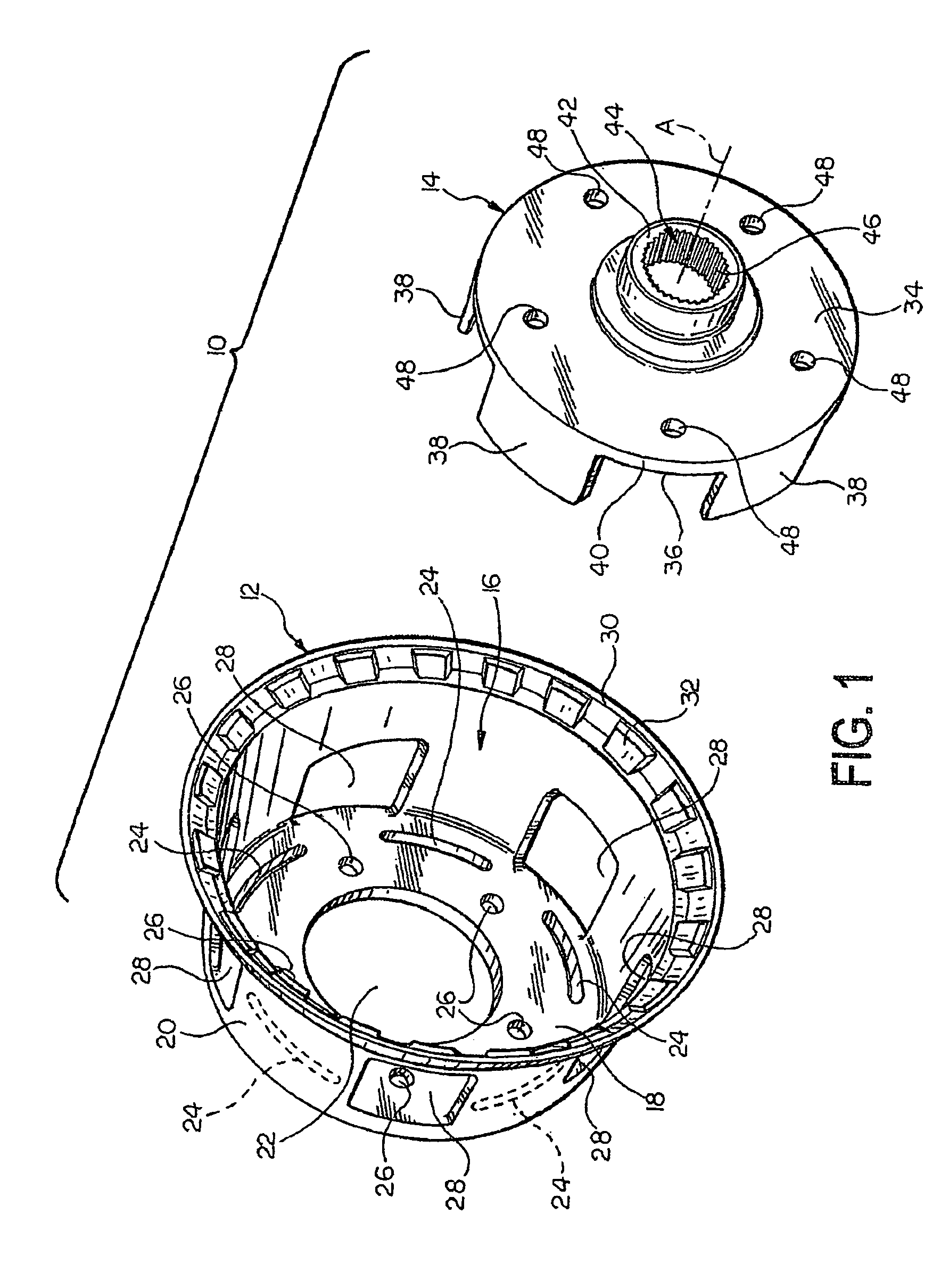

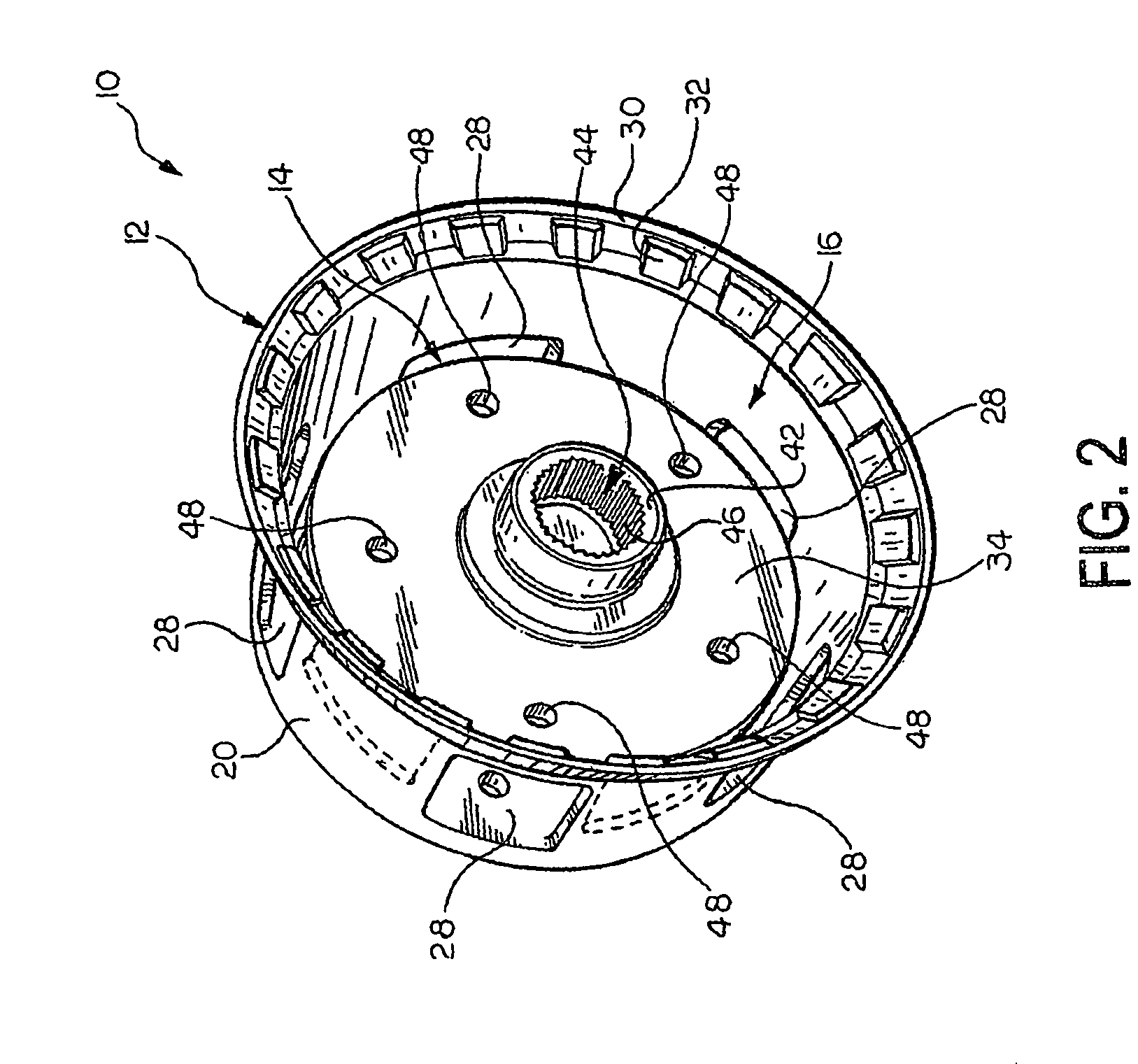

Torque transmitting assembly and method of producing

ActiveUS7341539B2Easy transferMaximize production efficiencyGearboxesToothed gearingsMechanical engineeringEngineering

An improvement in manufacturing and resulting structure of a torque transmitting assembly for use in a vehicle transmission which transmits torque from a first rotating member to a second rotating member wherein production efficiency is maximized and production costs are minimized.

Owner:METAL FORMING & COINING

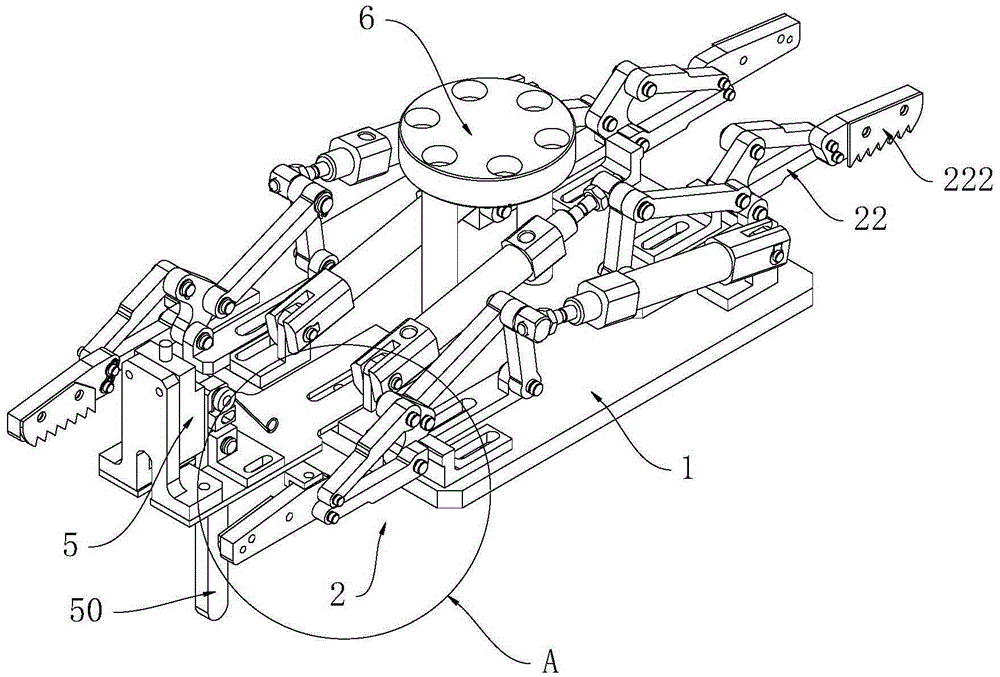

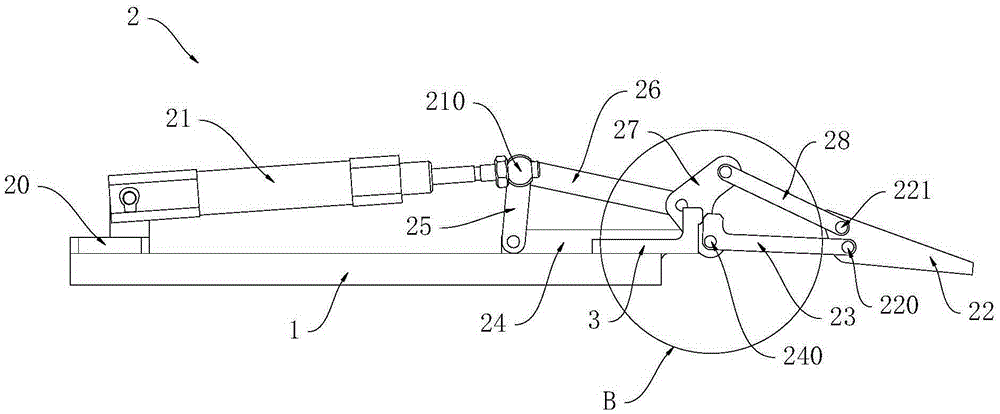

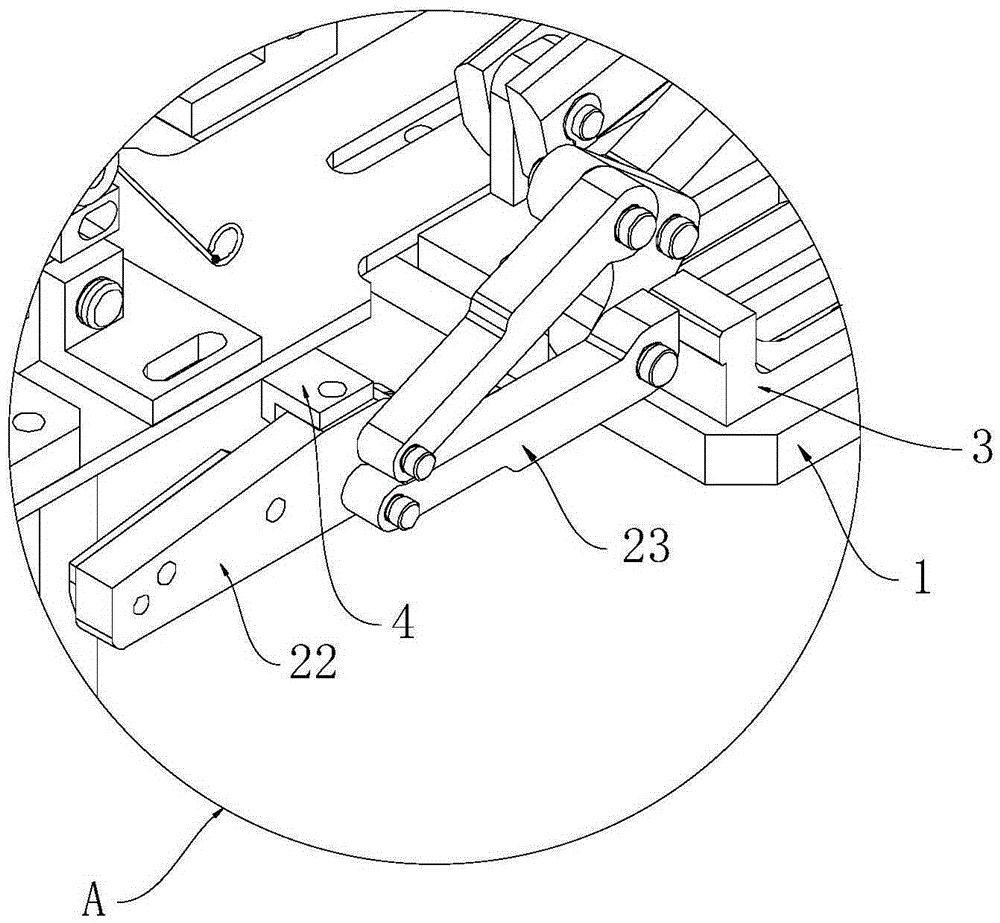

Wide-range grabbing under-actuated multi-adaptive manipulator

InactiveCN105415392ARapid responseReduce unreliabilityGripping headsArchitectural engineeringManipulator

The invention discloses a wide-range grabbing under-actuated multi-adaptive manipulator. The wide-range grabbing under-actuated multi-adaptive manipulator comprises a support frame and a single-finger mechanism; the single-finger mechanism includes a cylinder base, a cylinder, a front knuckle, a middle knuckle, a terminal knuckle, a first connecting rod, a second connecting rod, a V-shaped connecting rod and a third connecting rod; when the cylinder drives and pushes joints to move forwards, the second connecting rod is used for urging the V-shaped connecting rod to overturn forwards, and the third connecting rod is used for applying thrust to the front knuckle to enable the single-finger mechanism to locate in a folding state; and when the cylinder drives and pushes the joints to move backwards, the second connecting rod is used for urging the V-shaped connecting rod to overturn backwards, and the third connecting rod is used for applying tension to the front knuckle to enable the single-finger mechanism to locate in an opening state. The wide-range grabbing under-actuated multi-adaptive manipulator can realize wide-range grabbing, and has such beneficial effects as simple structure, good reliability, easiness in popularization and application and convenience for maintenance and replacement.

Owner:SHENZHEN HIKER TECH CO LTD

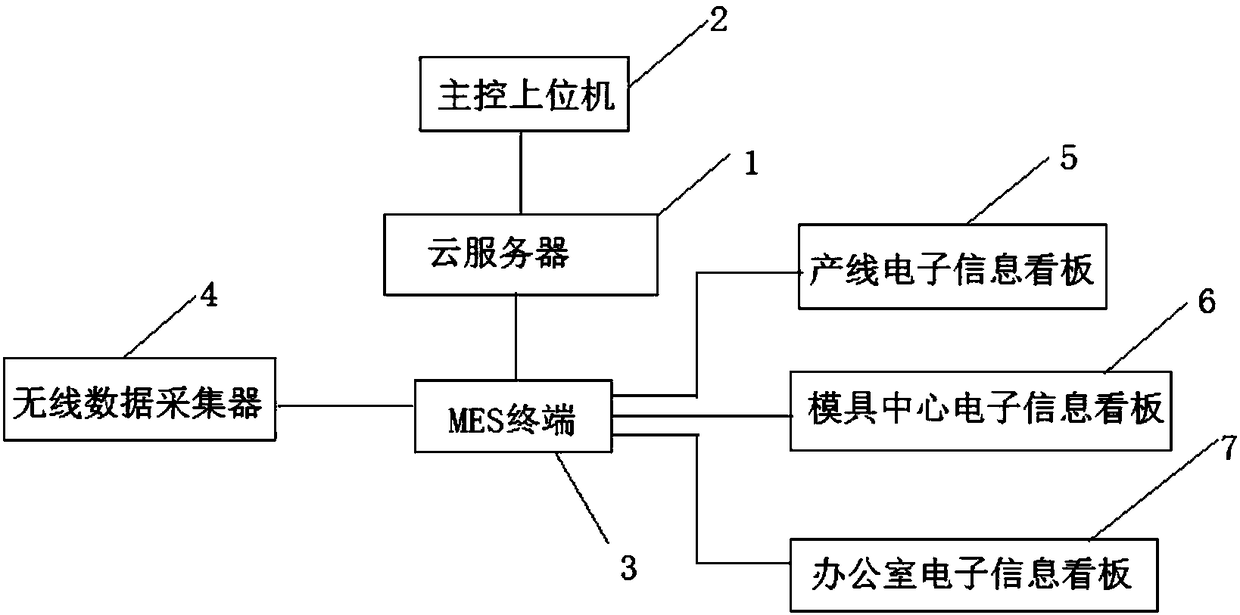

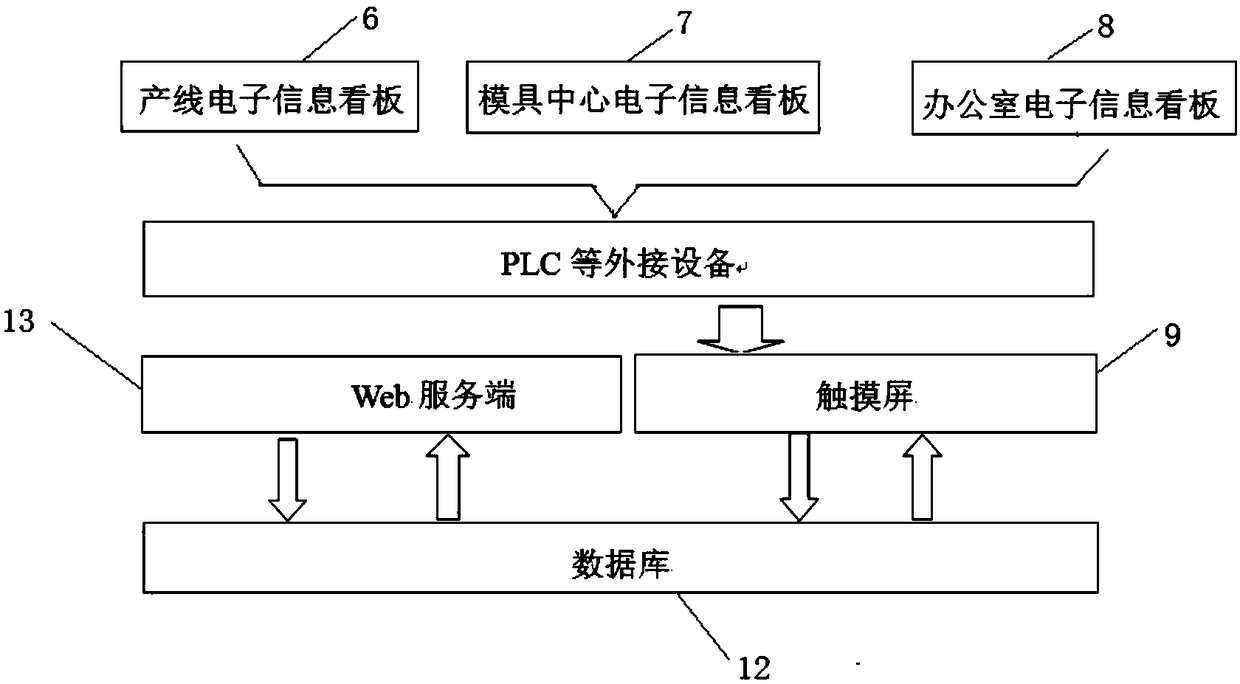

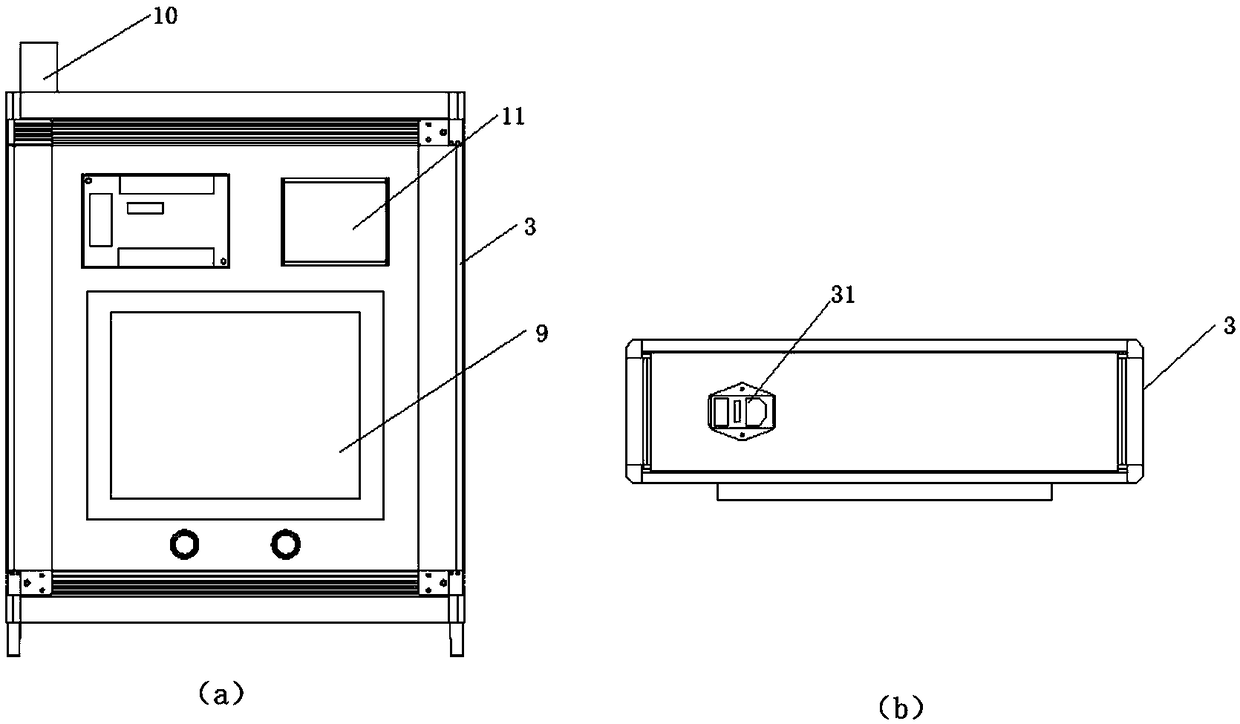

Intelligent MES terminal work station production monitoring system

InactiveCN108536100AEasy to manageSave human effortTotal factory controlProgramme total factory controlElectronic informationWireless data

The invention discloses an intelligent MES terminal work station production monitoring system comprising a cloud server, a main control upper computer, an MES terminal, a wireless data collector, a production line electronic information billboard, a mold center electronic information billboard, an office room electronic information billboard and an Andon press button box, wherein the mold center electronic information billboard, the Andon press button box, the mold center electronic information billboard, the office room electronic information billboard and the production line electronic information billboard are in wireless connection with the MES terminal via a wireless gateway; the wireless data collector is connected with the MES terminal, the MES terminal is connected with the cloud server via the wireless gateway, and the cloud server is connected with the main control upper computer in a wired or wireless manner. In production management, the system disclosed in the invention can be used for real-time production volume monitoring, working efficiency of works in workshops can be improved, cost reduction can be realized, and management of management staff can be provided.

Owner:江苏麦酷博信息科技有限公司

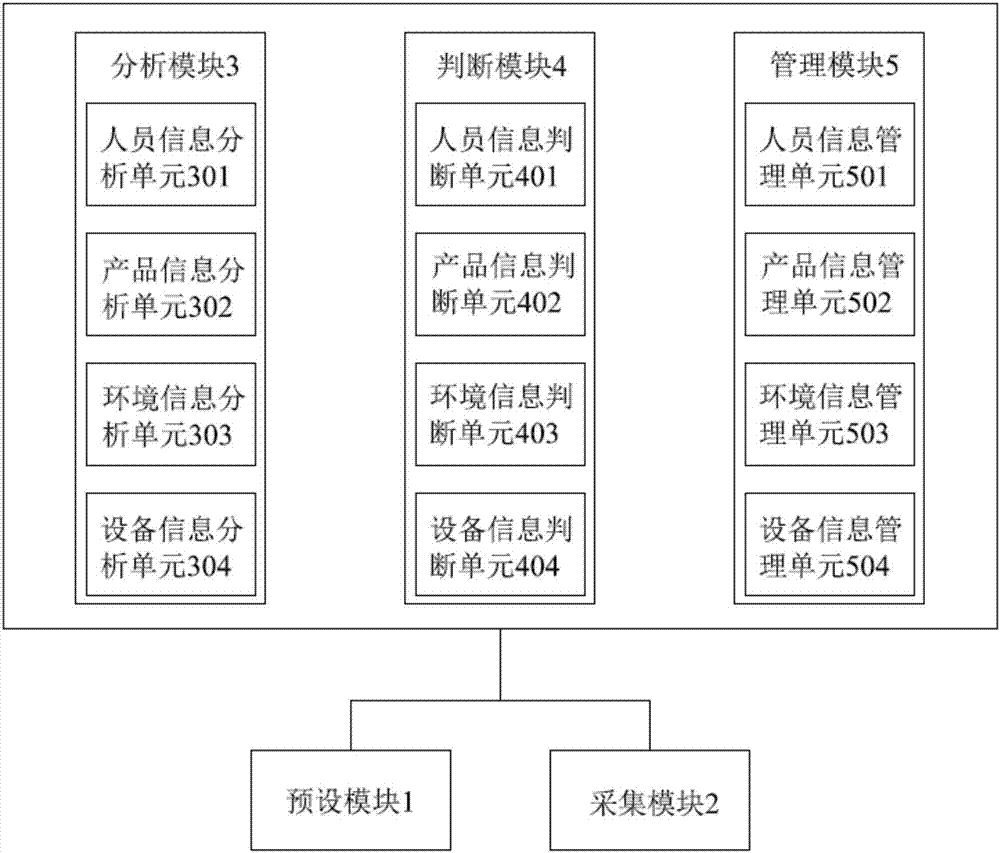

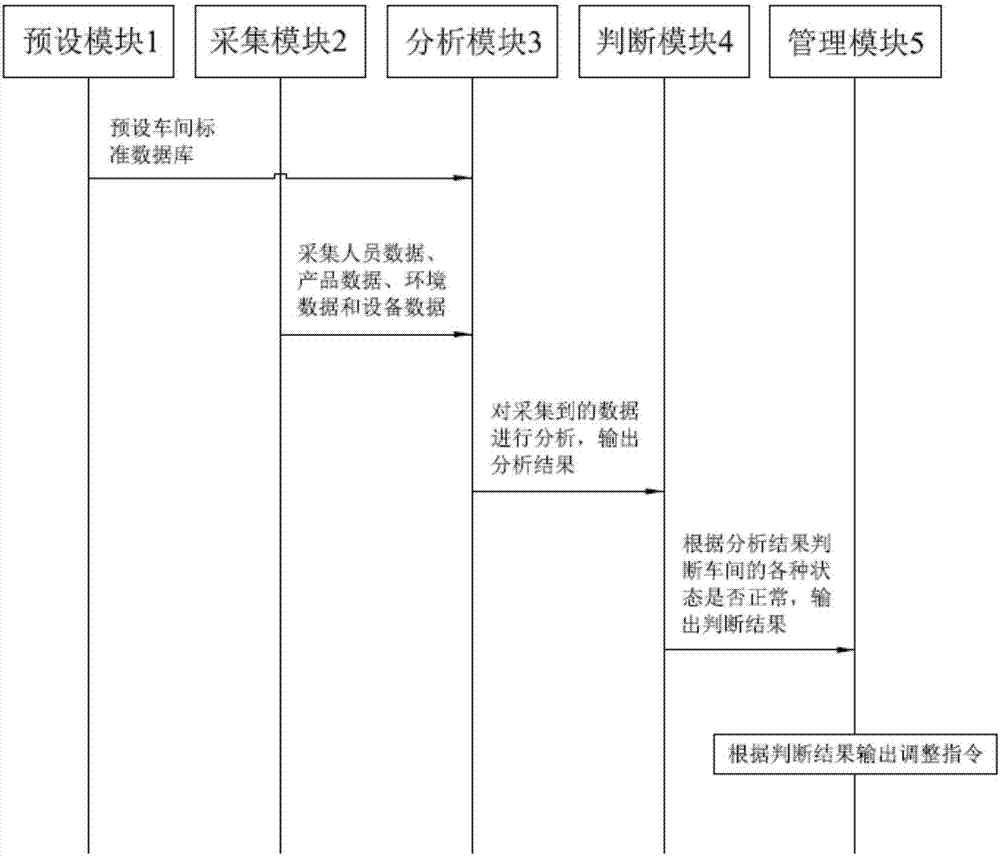

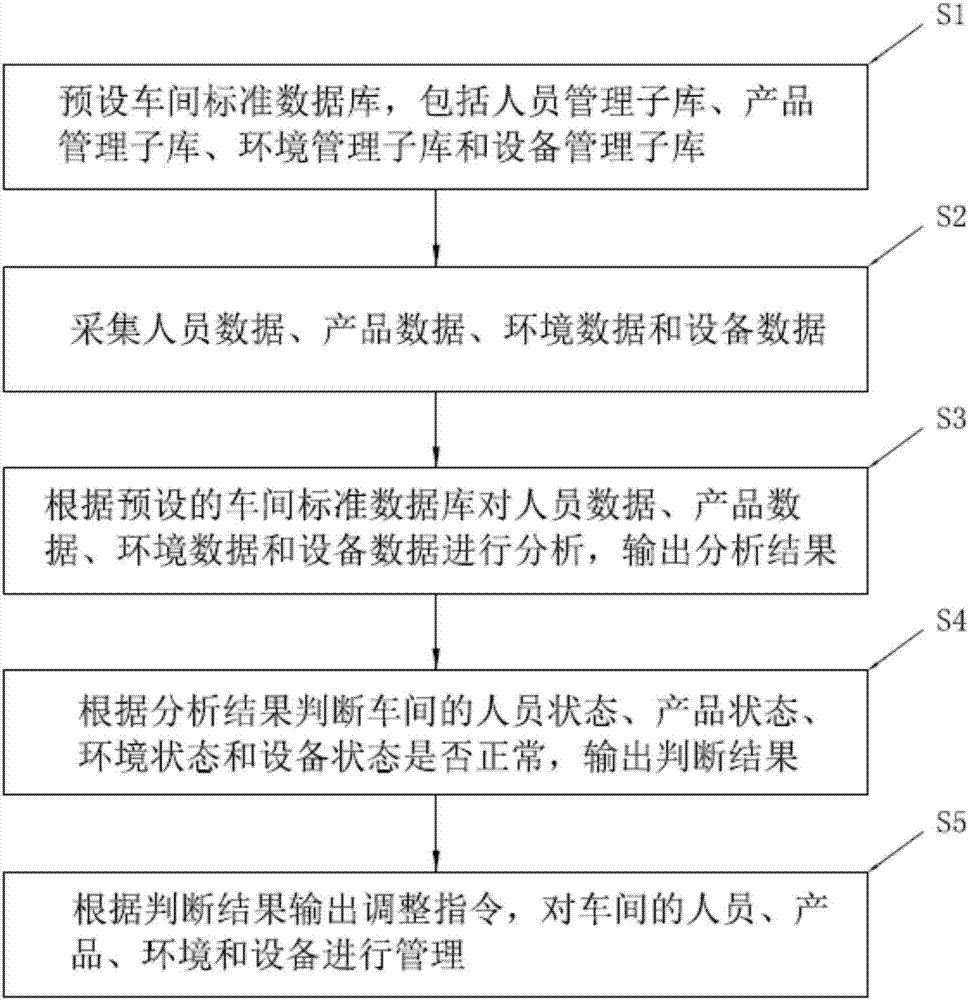

Intelligent workshop management method and system

InactiveCN107272621AEliminate exceptionsSave human effortTotal factory controlProgramme total factory controlApproaches of managementComputer module

The invention relates to an intelligent workshop management method and system, and the method comprises the steps: presetting a workshop standard database; collecting the personnel data, product data, environment data and equipment data; carrying out the analysis of the personnel data, product data, environment data and equipment data; judging whether each state of a workshop is normal or not; outputting an adjustment instruction, and carrying out the management of the personnel, products, environment and equipment of the workshop. The system comprises a presetting module which is used for presetting the workshop standard database; a collection module which is used for collecting the personnel data, product data, environment data and equipment data; an analysis module which is used for the analysis of the personnel data, product data, environment data and equipment data; a judgment module which is used for judging whether each state of the workshop is normal or not; and a management module which is used for outputting the adjustment instruction and carrying out the management of the personnel, products, environment and equipment of the workshop. The method and system achieve the comprehensive management of the personnel, products, environment and equipment of the workshop.

Owner:SHENZHEN SHENGLU IOT COMM TECH CO LTD

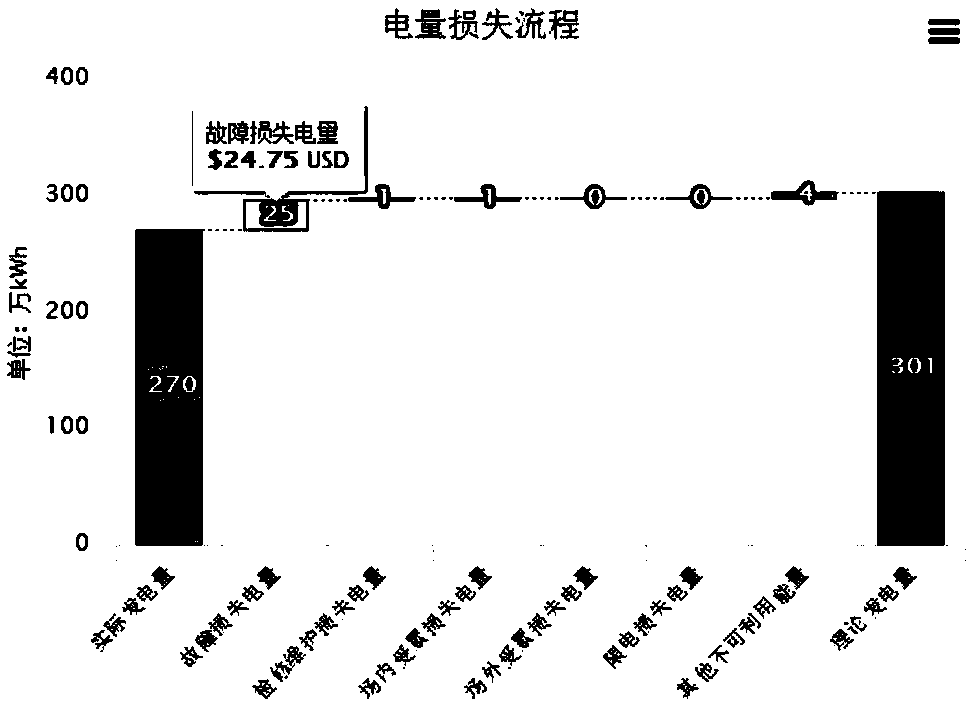

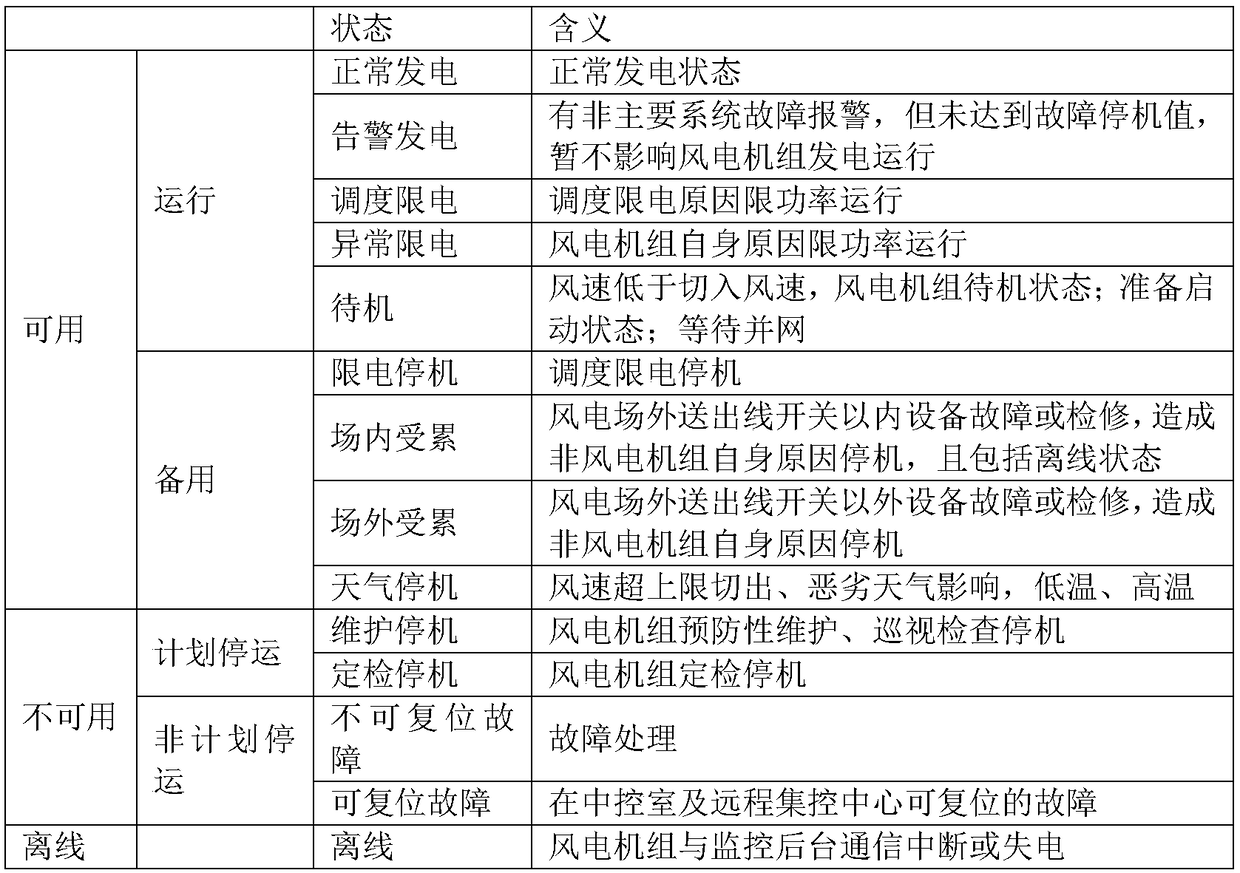

A method for calculating the power loss of wind turbine generator system based on reliability dimension

InactiveCN109086253AAnalysis flowMaximize production efficiencyData processing applicationsComplex mathematical operationsElectricityReal-time data

The invention discloses a method for calculating the power loss of a wind turbine generator system based on a reliability dimension, which comprises the following steps: 1) dividing the state of the wind turbine generator system into 14 kinds based on the reliability dimension; 2) collecting that historical data of the actual wind speed and the actual power of the unit in a preset period of time,filter the collected historical data and obtaining an average value; 3) fitting the filtered and averaged historical data with the least square method to obtain the wind speed; Power curve as reference curve; 4) through that real-time data of the reliability state of the wind turbine generator set, the time period in which the wind turbine generator set is in the non-resettable fault, the scheduled inspection, the maintenance, the dispatch power restriction, the power restriction shutdown, the on-site and off-site affected state being found out in the calculation time period; 5) the actual wind speed corresponding to the time period of each state being taken as a variable and substituted into a reference curve to obtain the correspond theoretical power po; 6) the calculated theoretical power po being subjected to statistical integral to obtain the corresponding power loss under each state of the wind turbine generator system.

Owner:西安西热电站信息技术有限公司

Method for processing a wafer and apparatus for performing the same

InactiveUS20050130451A1Producing efficiency can be increasedEasy to etchSemiconductor/solid-state device manufacturingProduction rateDevice material

Owner:SAMSUNG ELECTRONICS CO LTD

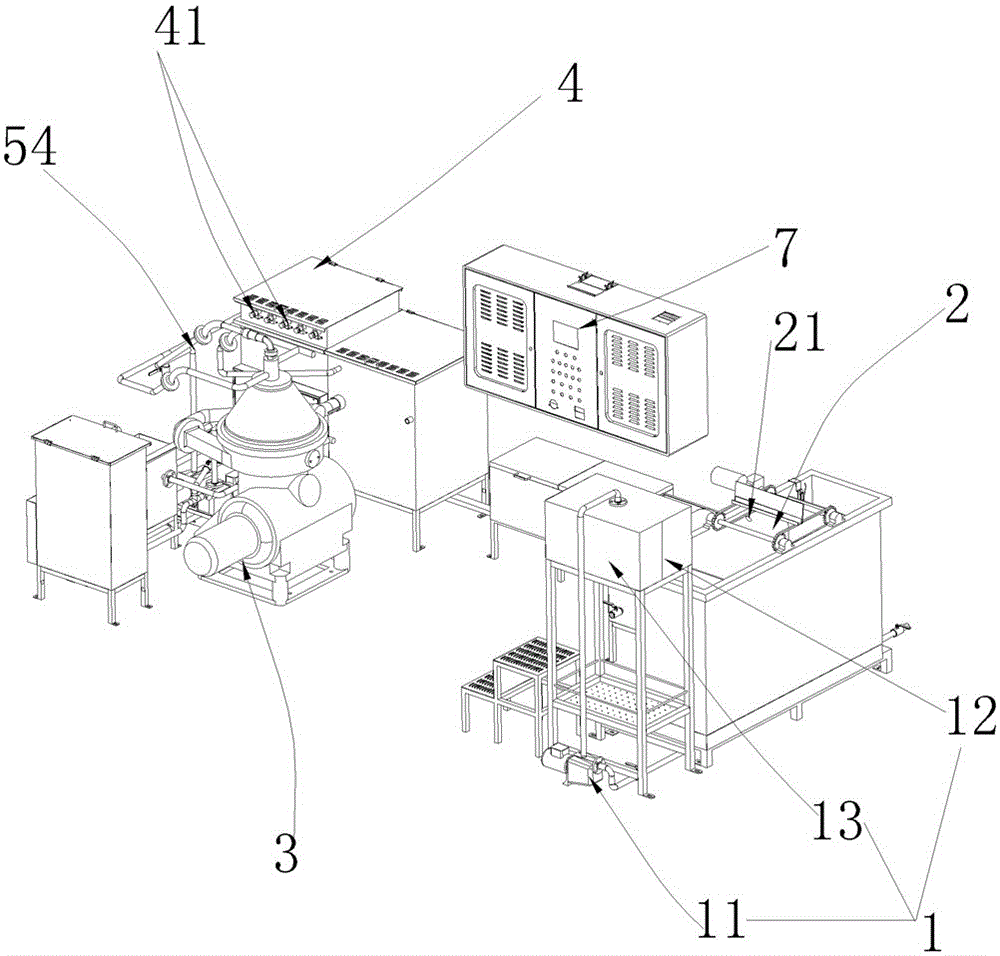

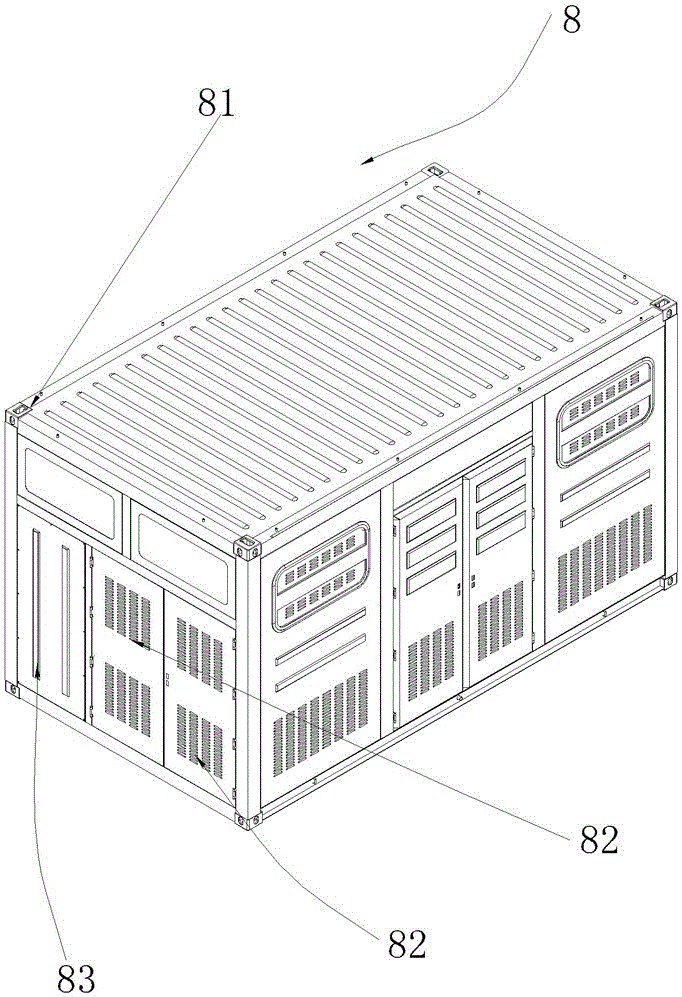

Cutting liquid recycling equipment and recycling method thereof

InactiveCN105081868AAdvantage equipmentAdvantage Recycling MethodFiltration circuitsMaintainance and safety accessoriesRecovery methodSlag

The invention discloses cutting liquid recycling equipment and a recycling method thereof. The equipment comprises an automatic loading device, a dissolved air flotation machine, a high-speed centrifuge, a UV photolytic sterilization device, an automatic discharge device and a PLC, wherein the automatic loading device is provided with a feed pump and a feed transfer box having a filter screen inside; a discharge pump and a discharge box are arranged on the automatic discharge device; and the feed pump and the discharge pump are respectively in electric connection with the output end of the PLC. The equipment can reduce the manpower resource and the labor intensity while improving the treatment efficiency, reduces the industrial sewage emission, and can clearly distinguish cutting liquid, waste oil and waste slag; and recovered materials are free of bacteria and stink, so that the production efficiency and data and the production environment and the treatment clearness are maximal, and users clearly master the operation conditions of the equipment.

Owner:SHENZHEN TIANDEYI ENVIRONMENT TECH

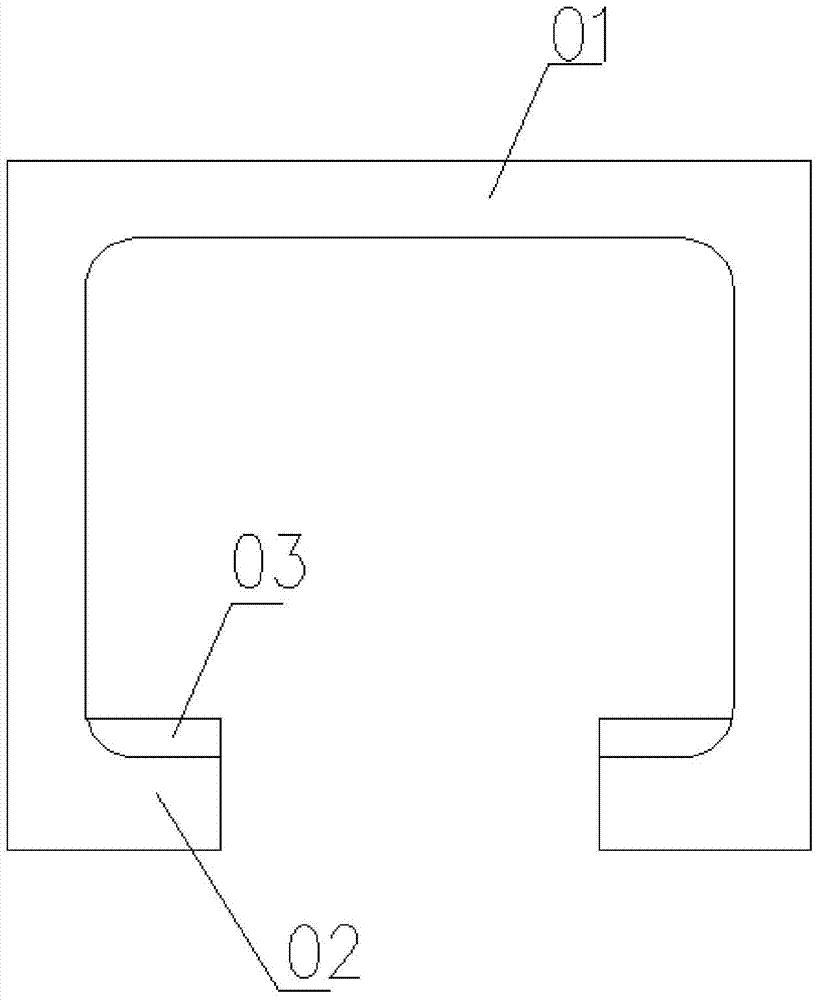

Process for preparing of [gamma]-butyrolactone and n-methyl pyrrolidone from 1,4-butanediol

ActiveCN102029156APromote degradationStable manufacturingOrganic chemistryMetal/metal-oxides/metal-hydroxide catalysts1,4-ButanediolCost effectiveness

The invention provides a process for preparing of [gamma]-butyrolactone (GBL) and n-methyl pyrrolidone (NMP) from 1,4-butanediol with the existence of a non-chromium catalyst. More specifically, the invention provides a method for preparing GBL with the existence of a non-chromium catalyst in an environmental friendly manner. The preparing process has high cost efficiency and high yield and selectivity. The process can be used for preparing NMP in a highly productive and stable manner. No catalyst is used in the process under a mild condition, and the obtained GBL and methylamine (MMA) aqueous solution are feed to a reactor so that the GBL and MMA aqueous solution are interreacting with each other.

Owner:SK INNOVATION CO LTD +1

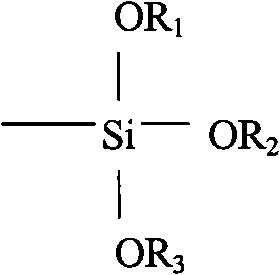

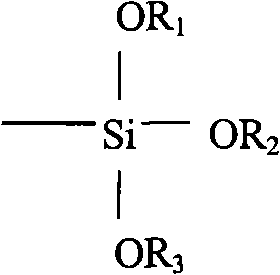

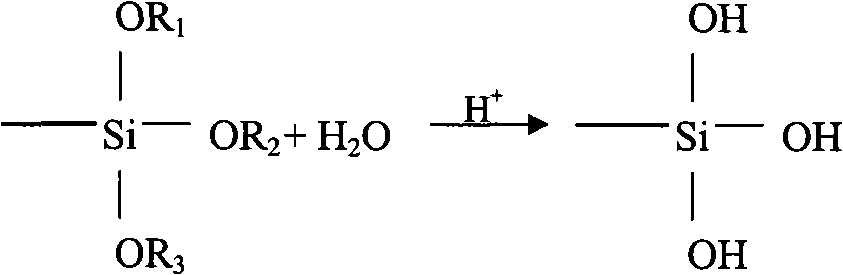

UV B-stageable, moisture curable composition useful for rapid electronic device assembly

InactiveCN101405360AQuick assemblyPrevent slumpEster polymer adhesivesOrganic non-macromolecular adhesiveAcrylic resinAdhesive

The invention provides an adhesive composition which is useful for electronic assembly comprising a photopolymerizable acrylic resin containing polymerizable acrylate, a moisture-curable resin including an alkoxy or acyloxy silane terminated polymer, a photoinitiator for initiating polymerization of the acrylate, and a photoacid generator for catalyzing a moisture curing reaction of the alkoxy or acyloxy silane terminated polymer. Also provided are assemblies including such adhesives, such as electronic assemblies and radio frequency identification tags.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Process for preparing of [gamma]-butyrolactone and n-methyl pyrrolidone from 1,4-butanediol Process for preparing of [gamma]-butyrolactone and n-methyl pyrrolidone from 1,4-butanediol](https://images-eureka.patsnap.com/patent_img/ed3f2eb6-35a2-4a1e-9ecc-58f80c53a1c6/HSA00000289326400011.png)

![Process for preparing of [gamma]-butyrolactone and n-methyl pyrrolidone from 1,4-butanediol Process for preparing of [gamma]-butyrolactone and n-methyl pyrrolidone from 1,4-butanediol](https://images-eureka.patsnap.com/patent_img/ed3f2eb6-35a2-4a1e-9ecc-58f80c53a1c6/HSA00000289326400012.png)

![Process for preparing of [gamma]-butyrolactone and n-methyl pyrrolidone from 1,4-butanediol Process for preparing of [gamma]-butyrolactone and n-methyl pyrrolidone from 1,4-butanediol](https://images-eureka.patsnap.com/patent_img/ed3f2eb6-35a2-4a1e-9ecc-58f80c53a1c6/ESA00000289326100011.png)