Method for disposing household refuse in cooperation with cement kiln with partial waste heat recovery function and system

A waste heat recovery and co-processing technology, applied in the field of energy conservation and environmental protection, can solve the problems of unrecognized economic benefits, secondary pollution, large investment, etc., and achieve the effect of realizing enterprise production efficiency, saving investment and space, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

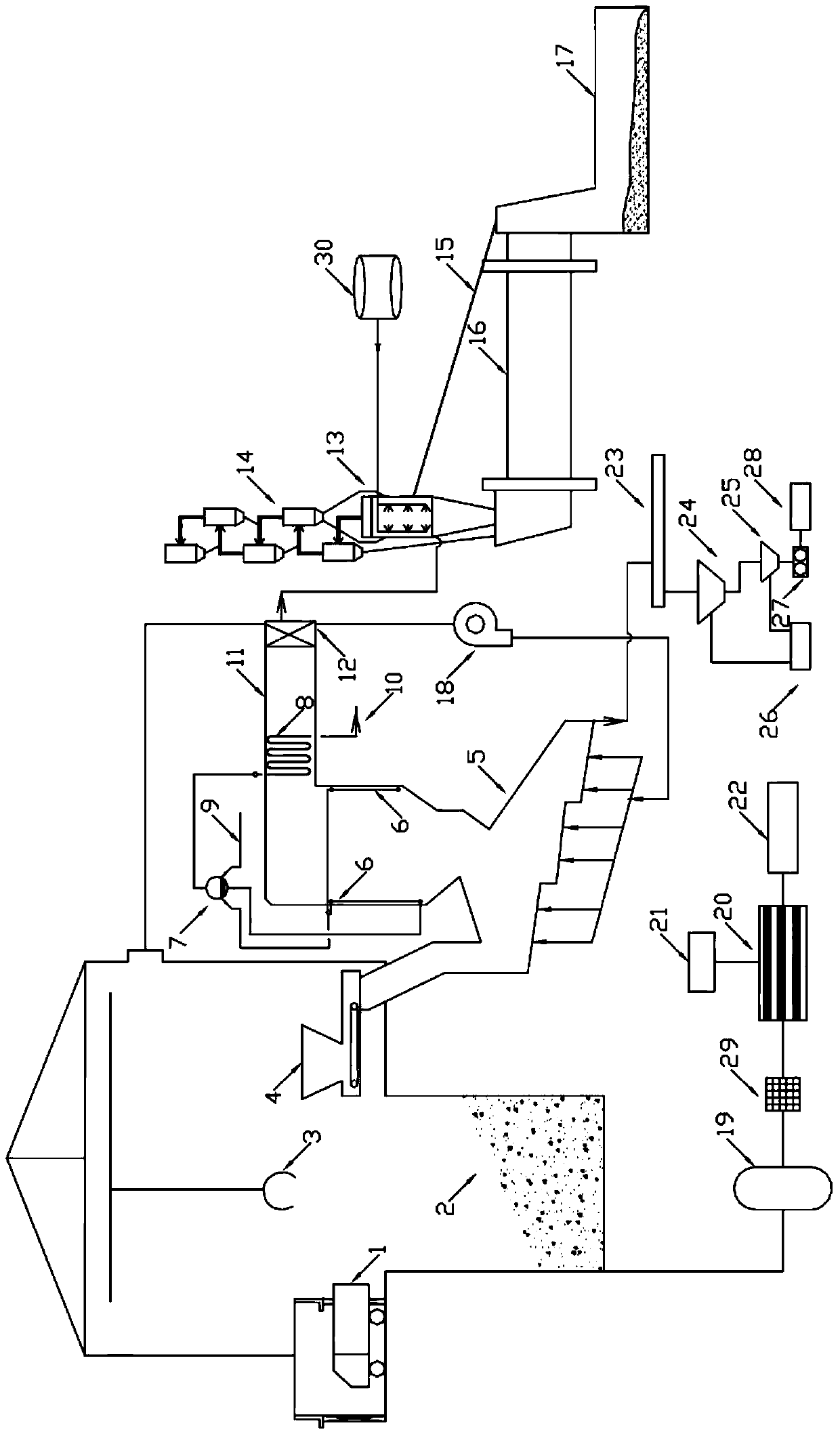

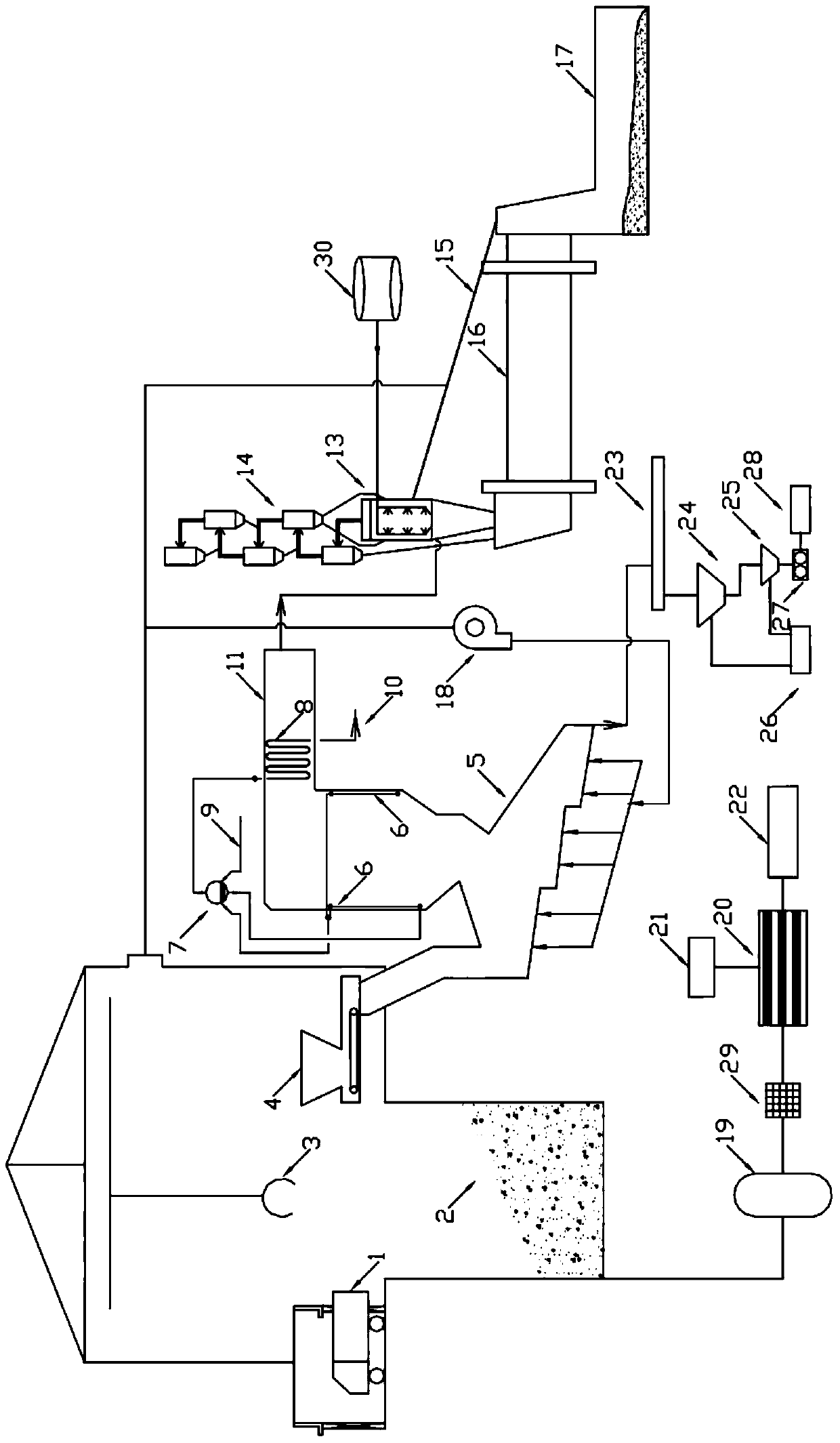

[0031] The method steps of the present invention are partly the same as those of the above-mentioned technical solution, and will not be described again. Such as figure 1 As shown, the cement kiln co-processing domestic waste system with partial waste heat recovery, the municipal solid waste is transported by the transport vehicle 1 to the garbage warehouse 2, and the whole garbage warehouse adopts a closed negative pressure structure, and the garbage storage is considered as 5 to 7 days. Generated by the fan 18, the discharged odorous air is preheated to 200-220°C by the air preheater 12, and then introduced into the mechanical grate incinerator 5 as combustion-supporting air, while maintaining a negative pressure environment in the garbage store 2 to prevent odor from fermentation of garbage Interfere with the normal production of cement. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com