Patents

Literature

3922results about "Steam generation using hot heat carriers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

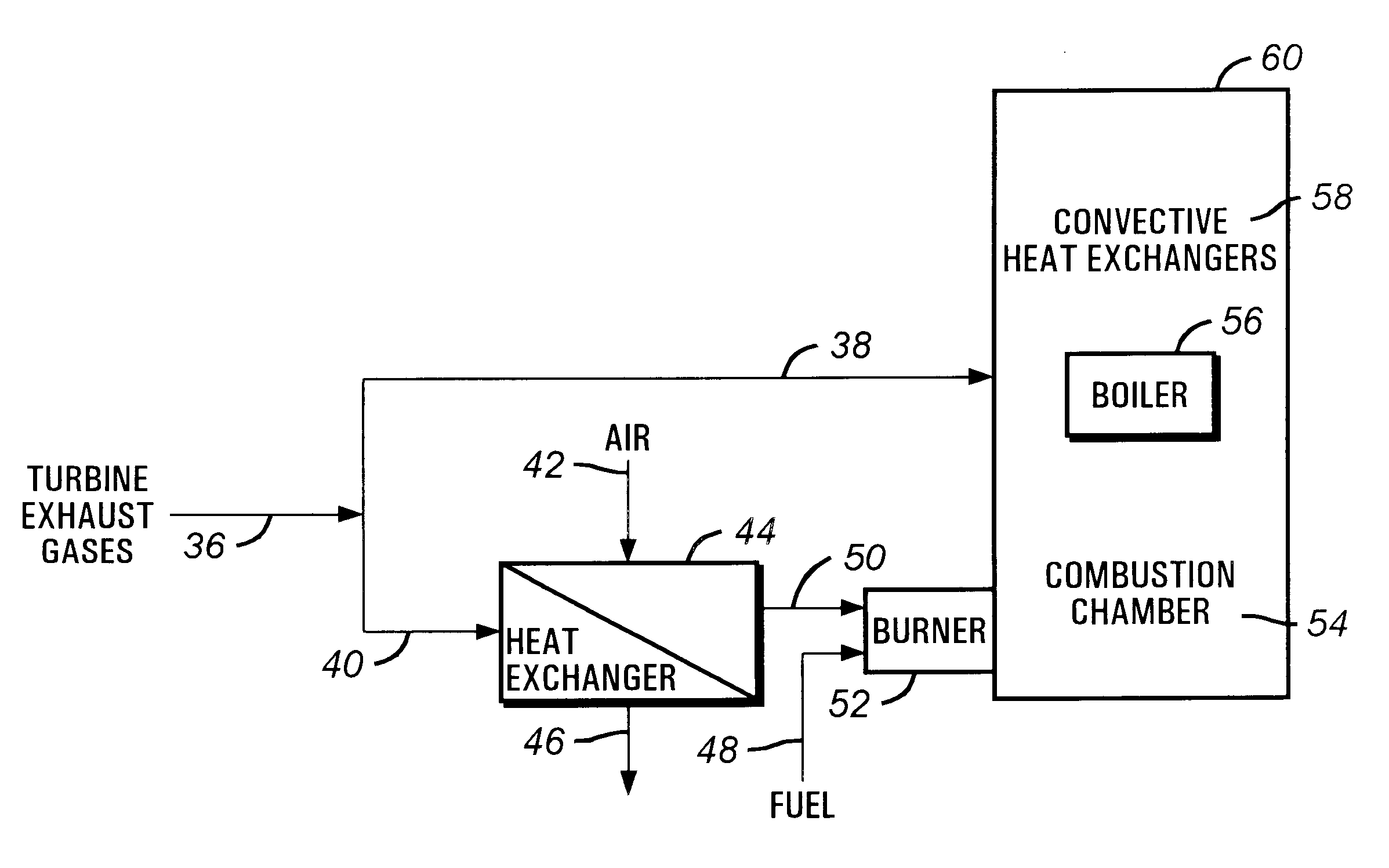

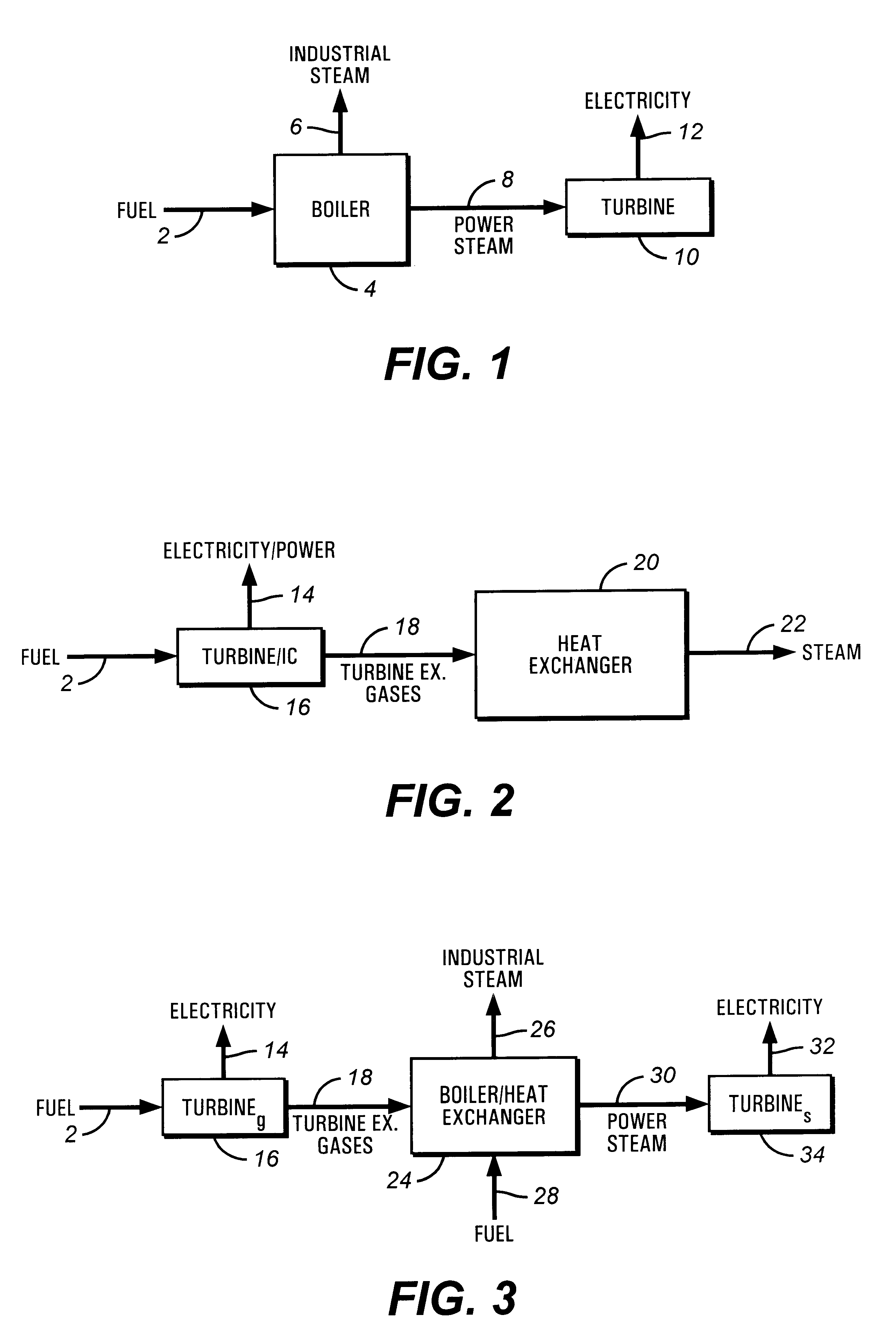

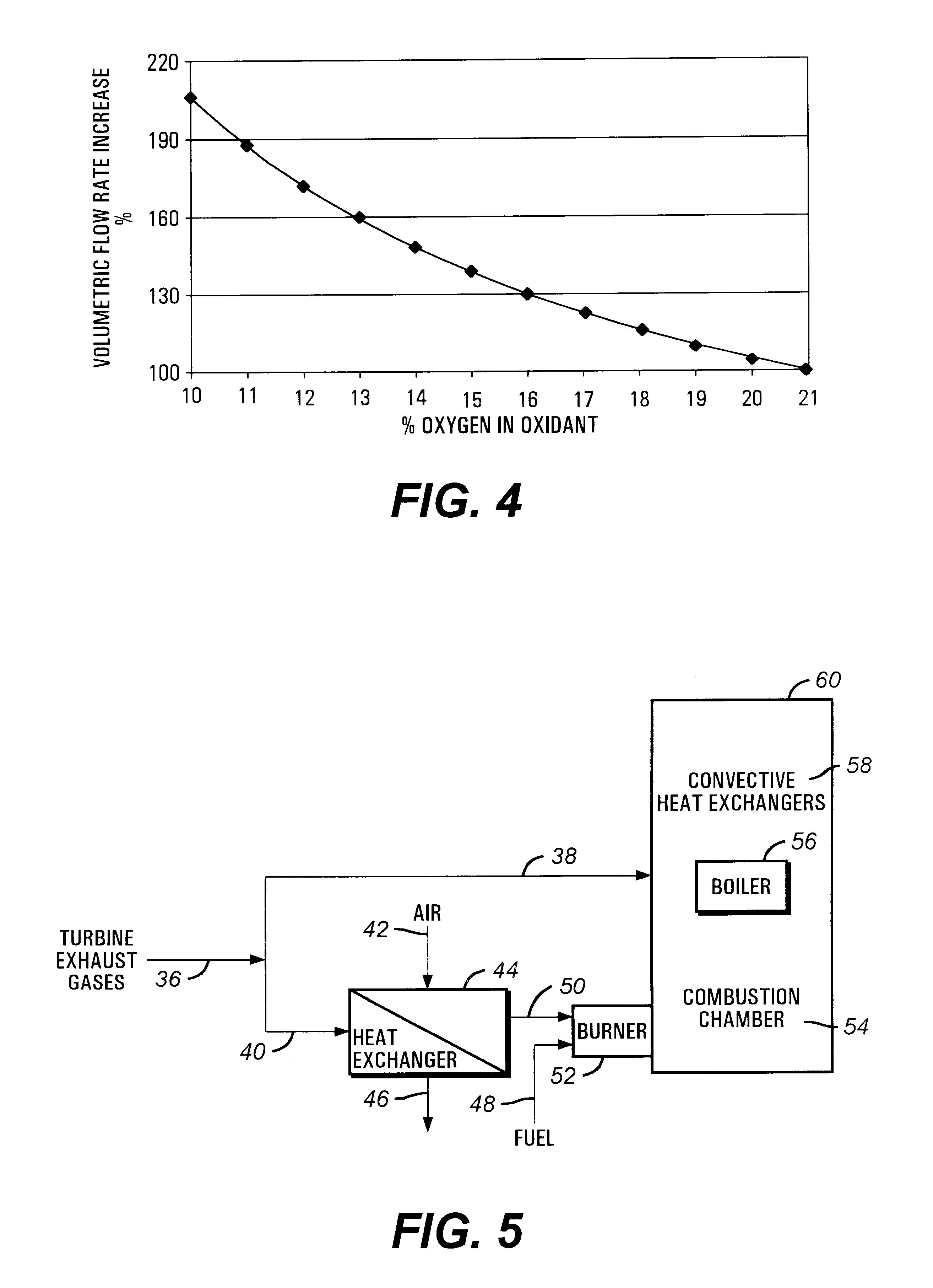

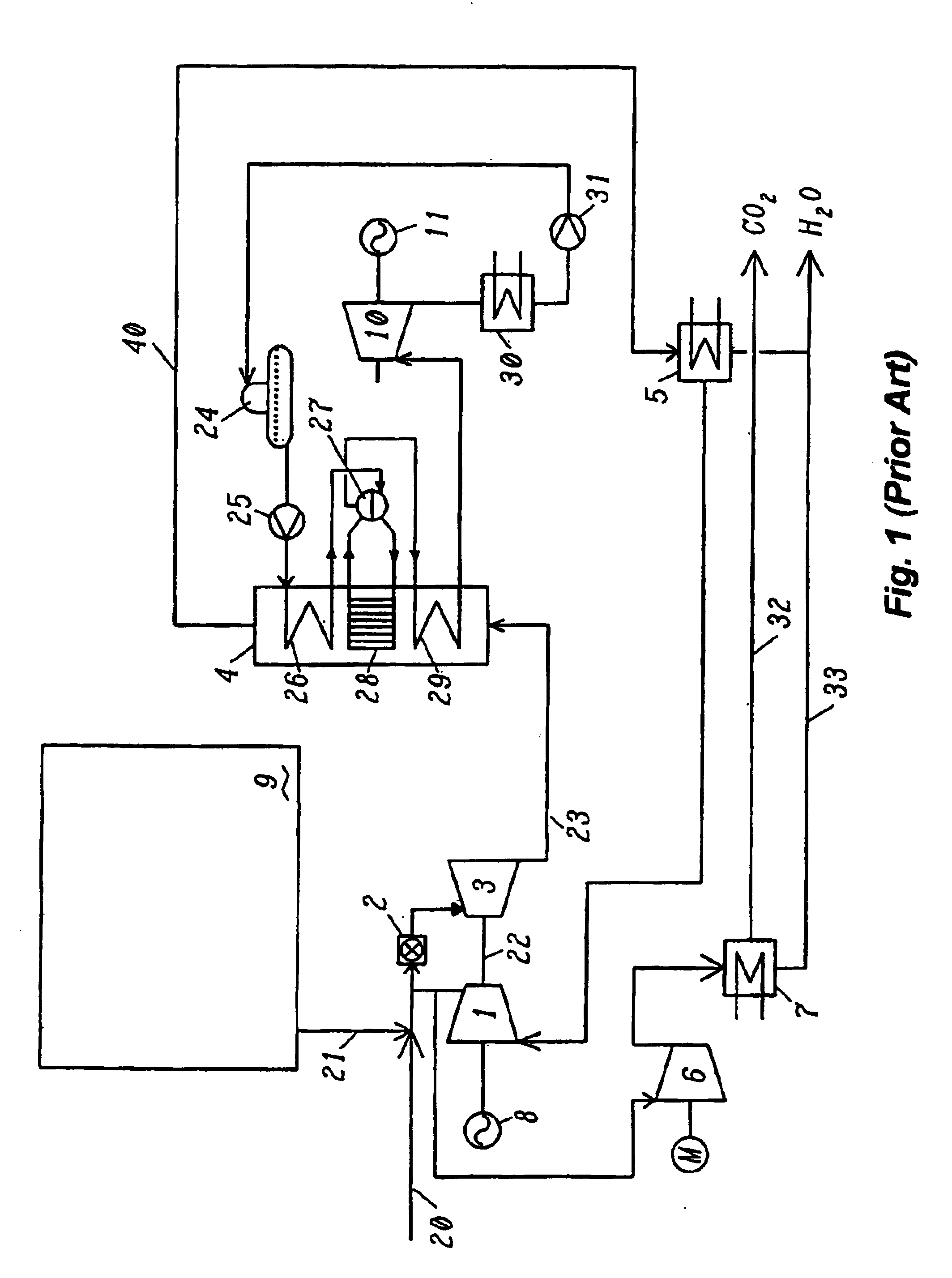

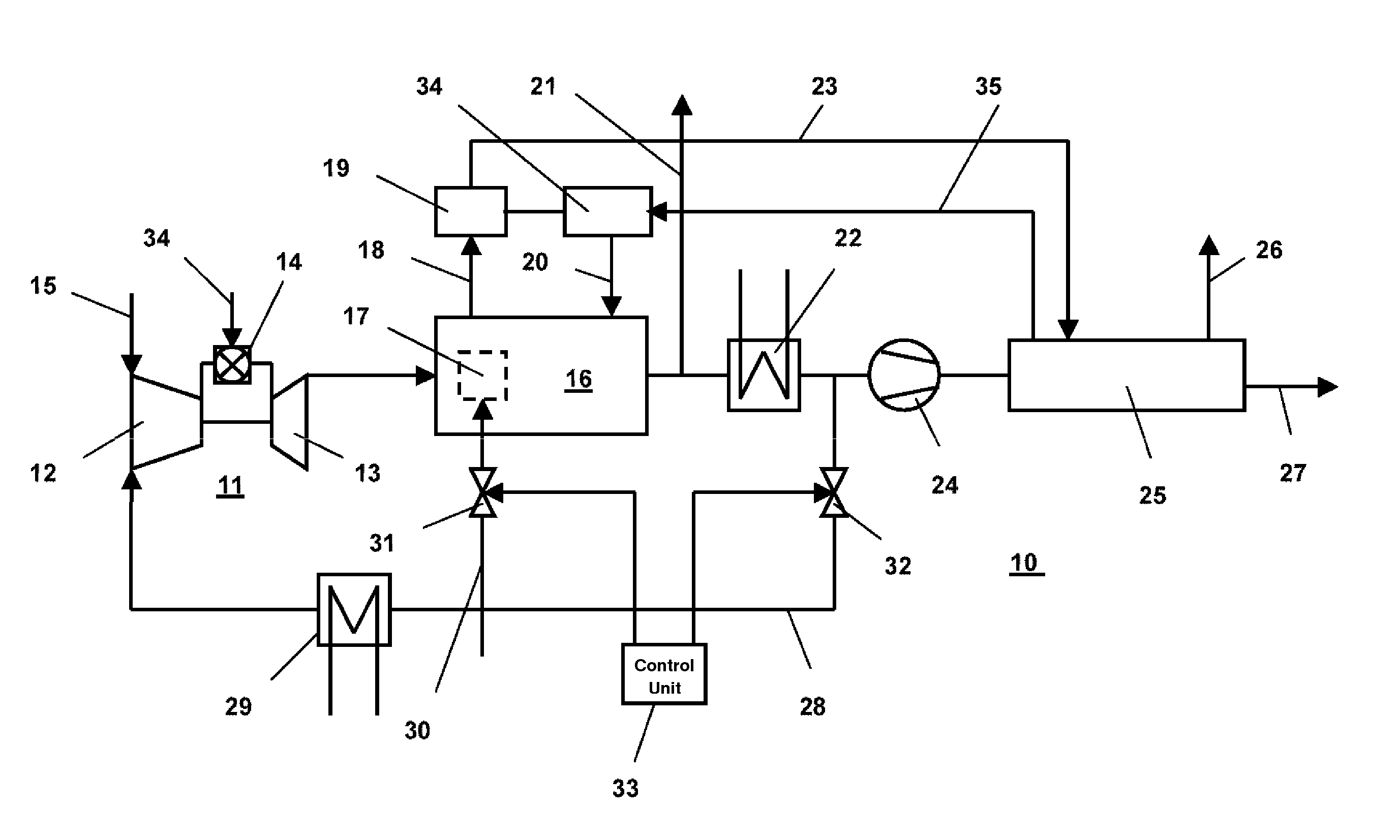

Oxidant control in co-generation installations

InactiveUS6247315B1Steam regenerationIndirect carbon-dioxide mitigationControl system designCogeneration

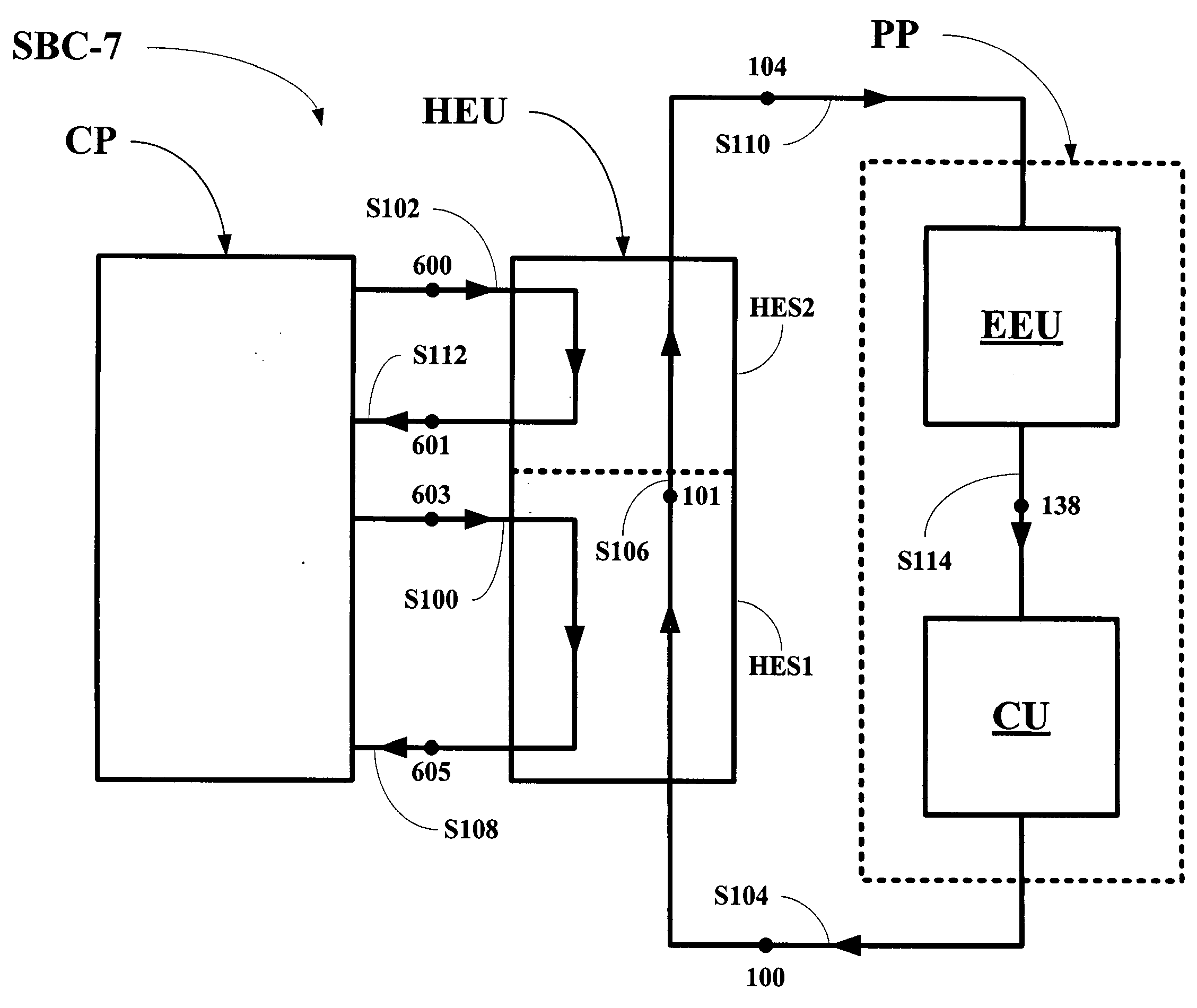

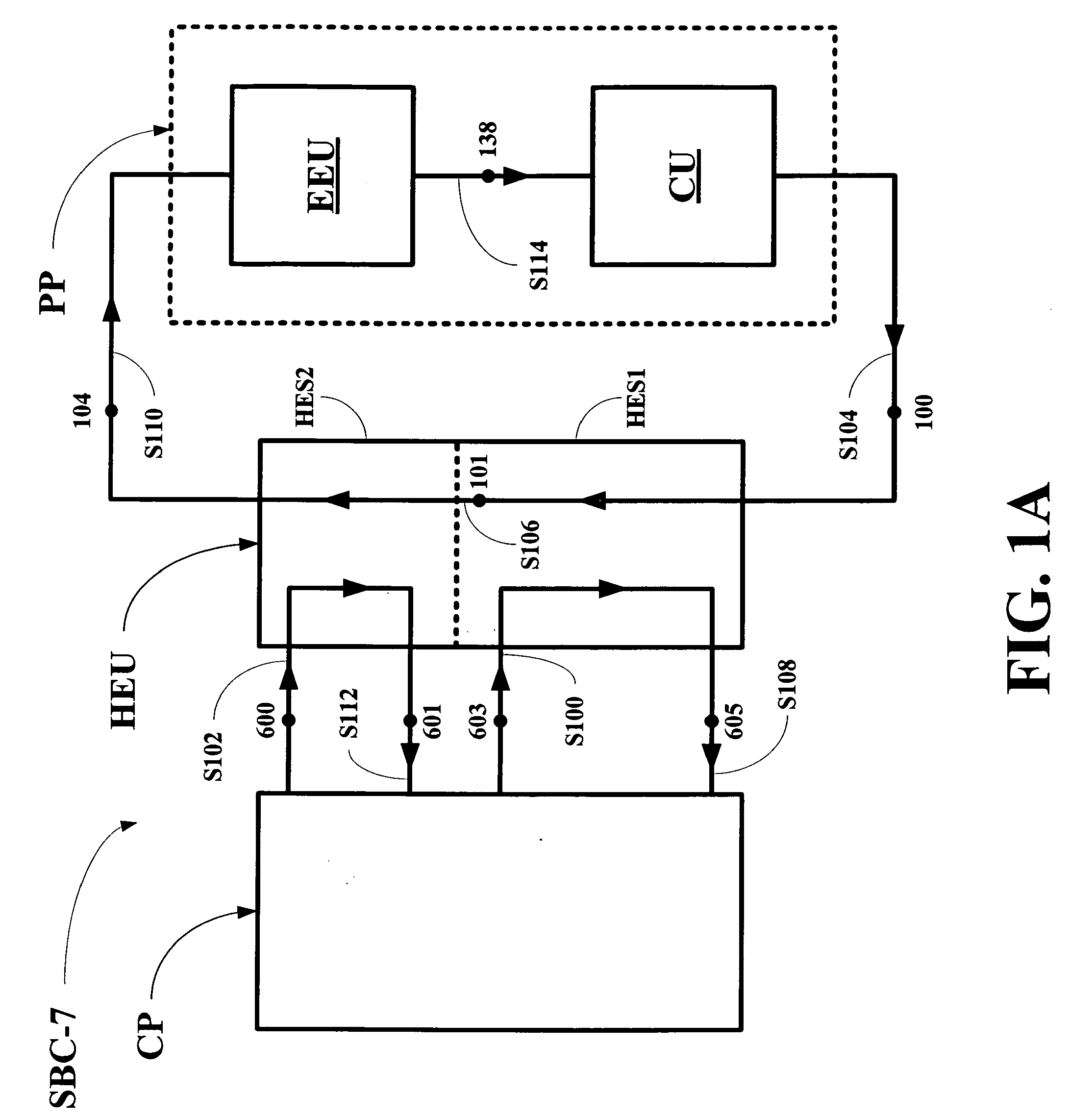

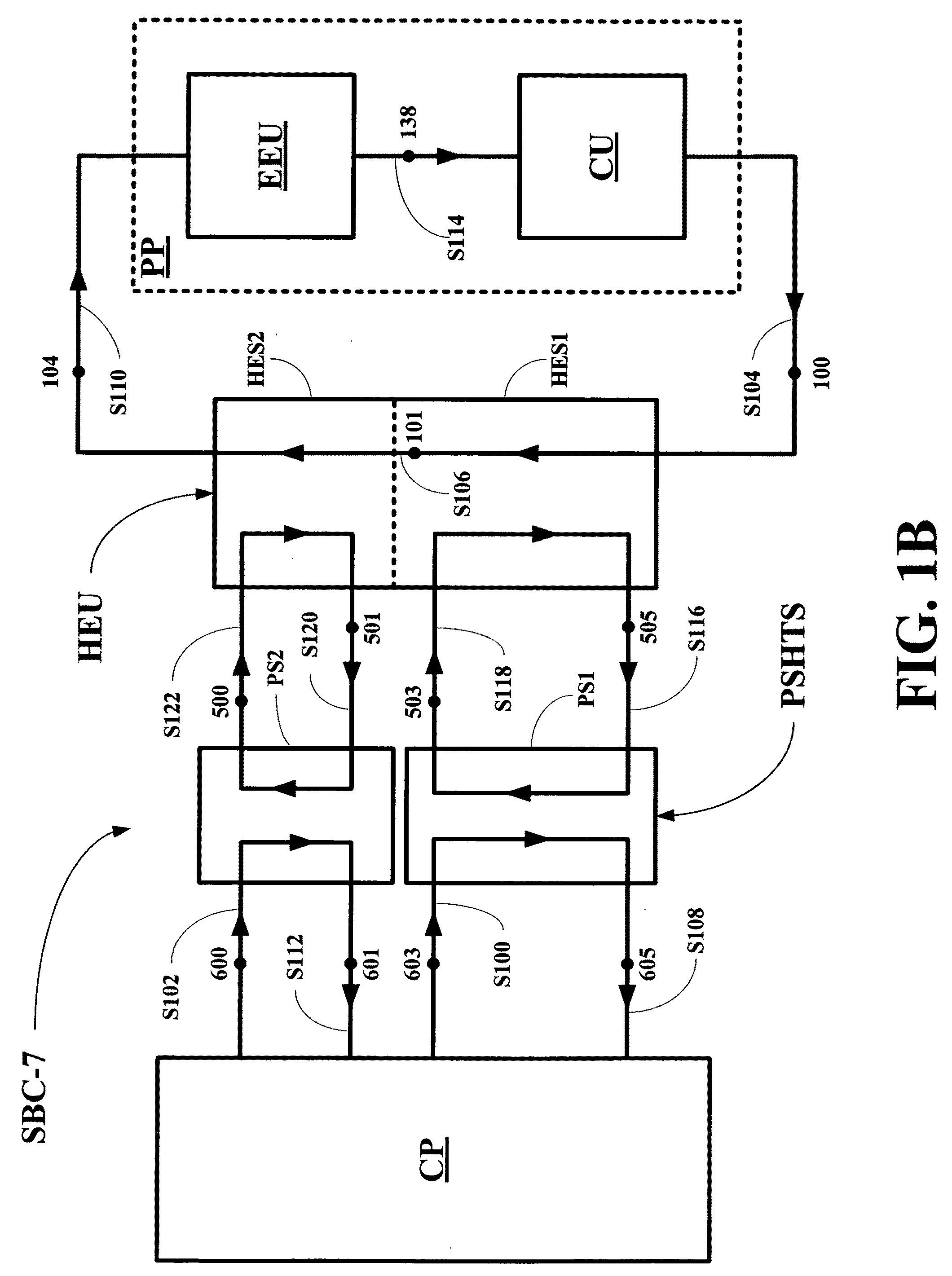

This invention is related to so-called combined cycle co-generation installations, and it addresses present concerns of the industry. Among these, combustion stability, corrosion (due to large water content in the flue gases), large heat transfer areas, and the like. In some embodiments, an additional heat exchanger is added to heat combustion air with a portion of the exhaust gases resulting from an engine, preferably a gas turbine. As a result, the efficiency of the cycle will improve, the oxidant will be enriched by above 50% oxygen, the combustion process will be enhanced, and the dimensions of the boiler may be reduced. It is considered that the combustion air will require between 10% and 80% of the total flue gas volume, more preferably between 20% and 40%. This is the portion of the flue gases sent through the heat exchanger. A control system designed to optimize the flow of the different streams is also presented. Other inventive embodiments forego heat exchanges in lieu of precise control of two flows of exhaust gas, with preferred addition of additional oxidant to the boiler bumers.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

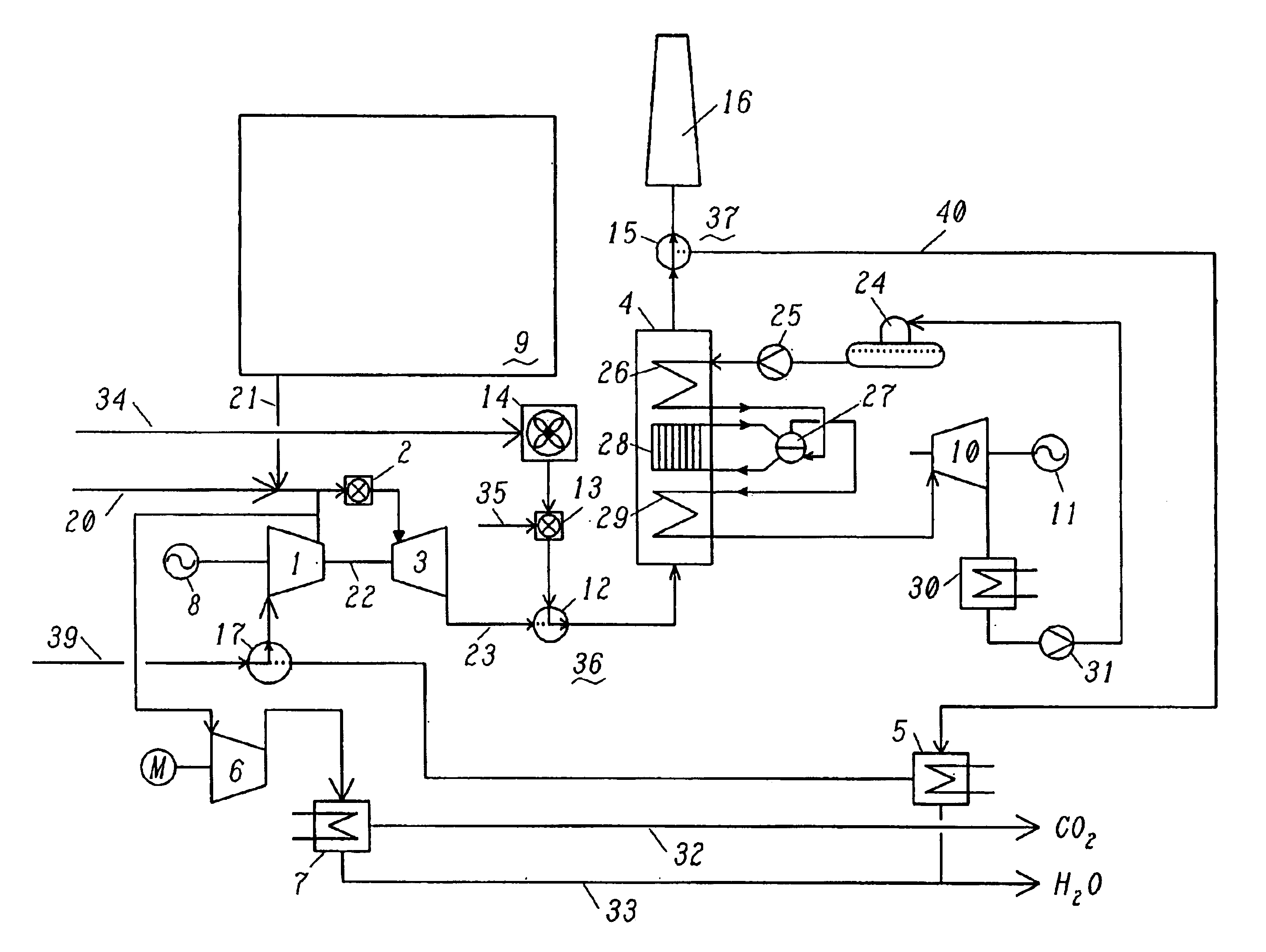

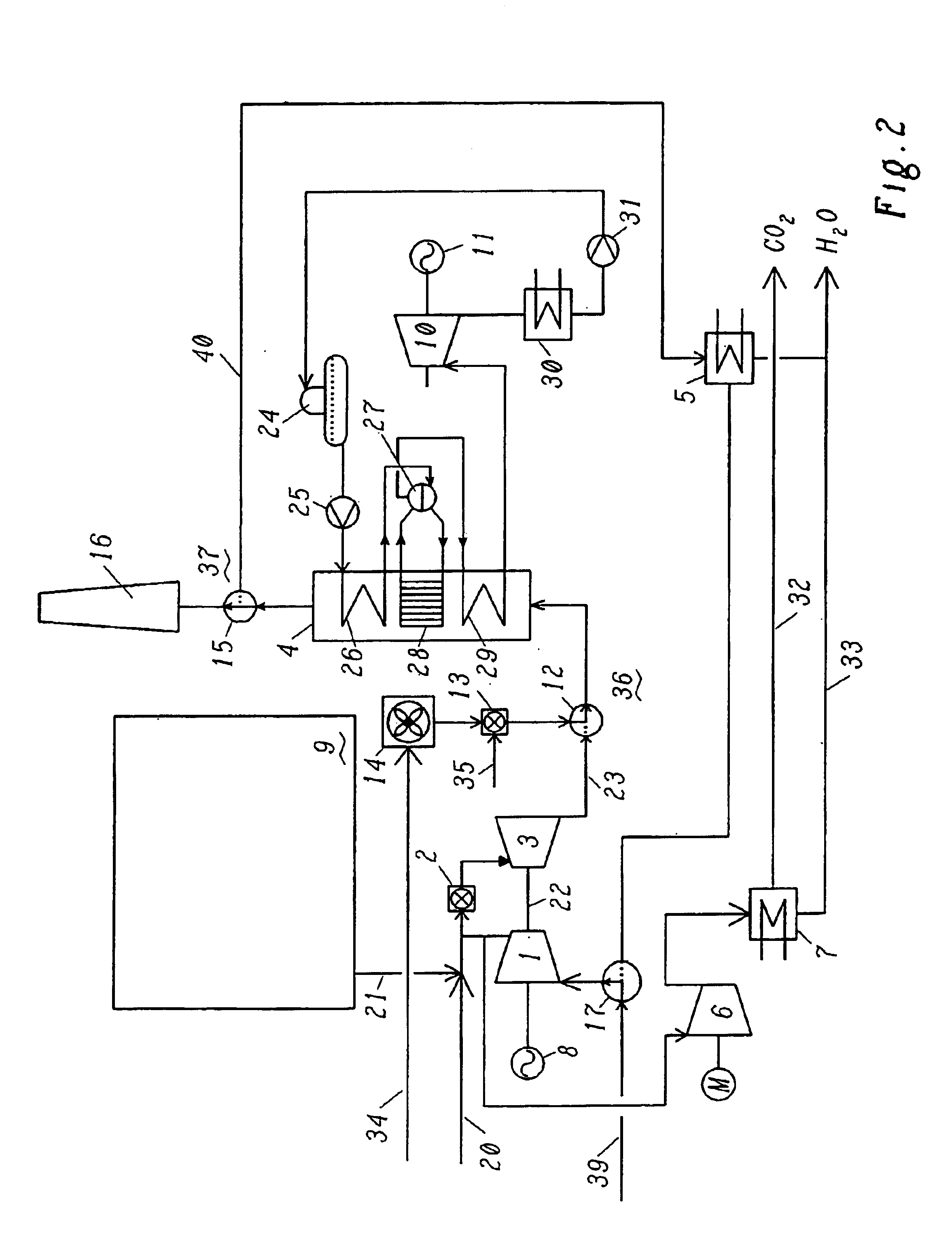

Methods and apparatus for starting up emission-free gas-turbine power stations

InactiveUS6945052B2Large capacityGas turbine plantsIndirect carbon-dioxide mitigationPower stationCombustion chamber

In a power generation plant having at least one gas turbine cycle with heat-recovery boiler (4) and at least one steam turbine cycle operated via the heat-recovery boiler (4), the gas turbine cycle being designed to be semi-closed and essentially free of emissions and essentially comprising a compressor (1), a combustion chamber (2) arranged downstream of the compressor (1), a gas turbine (3) arranged downstream of the combustion chamber (2), a heat-recovery boiler (4) arranged downstream of the gas turbine (3), and at least one generator (8) coupled to the gas turbine (3), modes of operation with the gas turbine cycle stopped and start-up using fresh air are made possible by first means (12) being arranged which alternatively or additionally allow hot gas to be fed into the hot-gas path (23) between gas turbine (3) and heat-recovery boiler (4), and by second means (15) being arranged which alternatively or additionally allow exhaust gas to be expelled from the exhaust-gas path (40) downstream of the heat-recovery boiler (4).

Owner:ANSALDO ENERGIA IP UK LTD

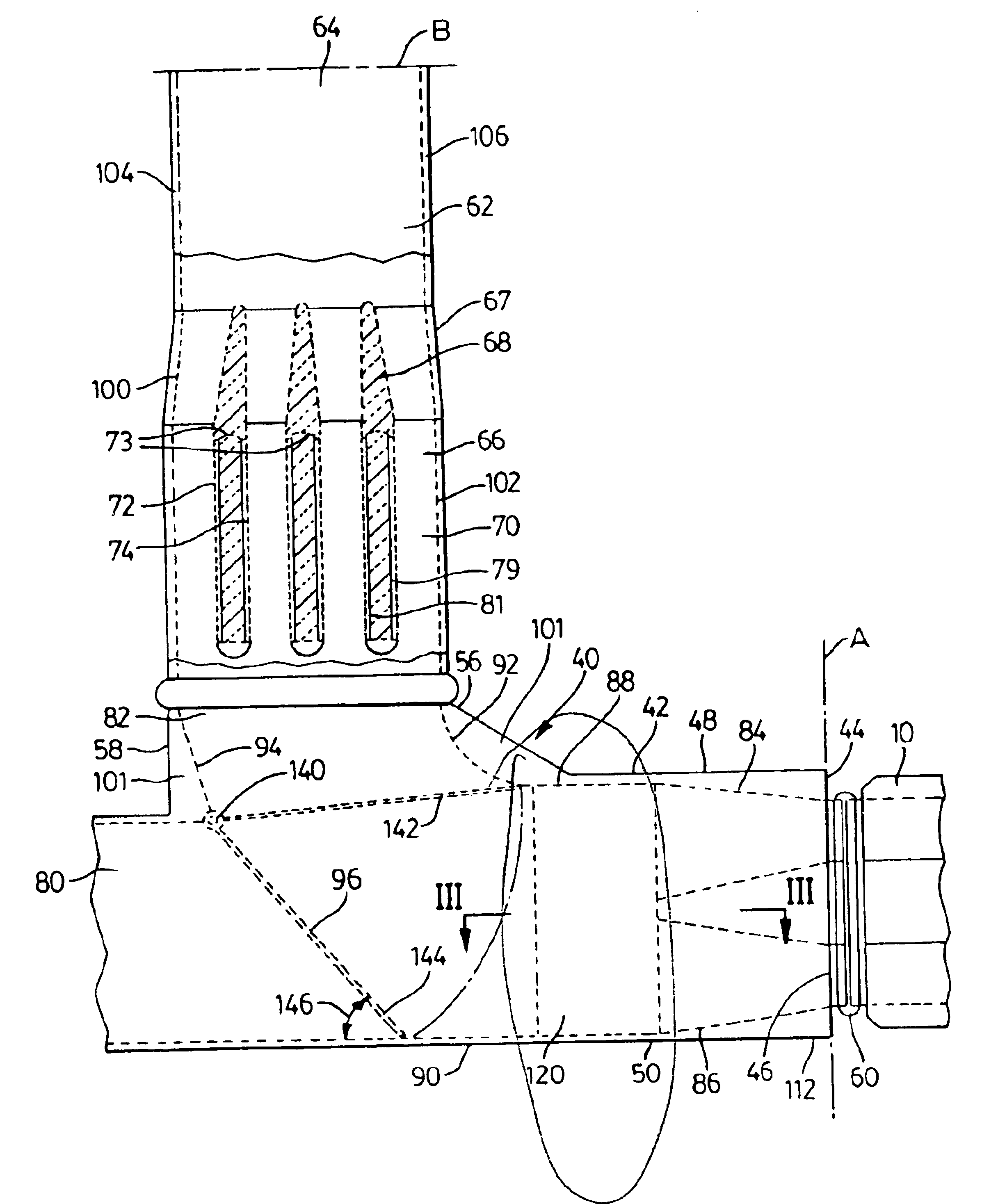

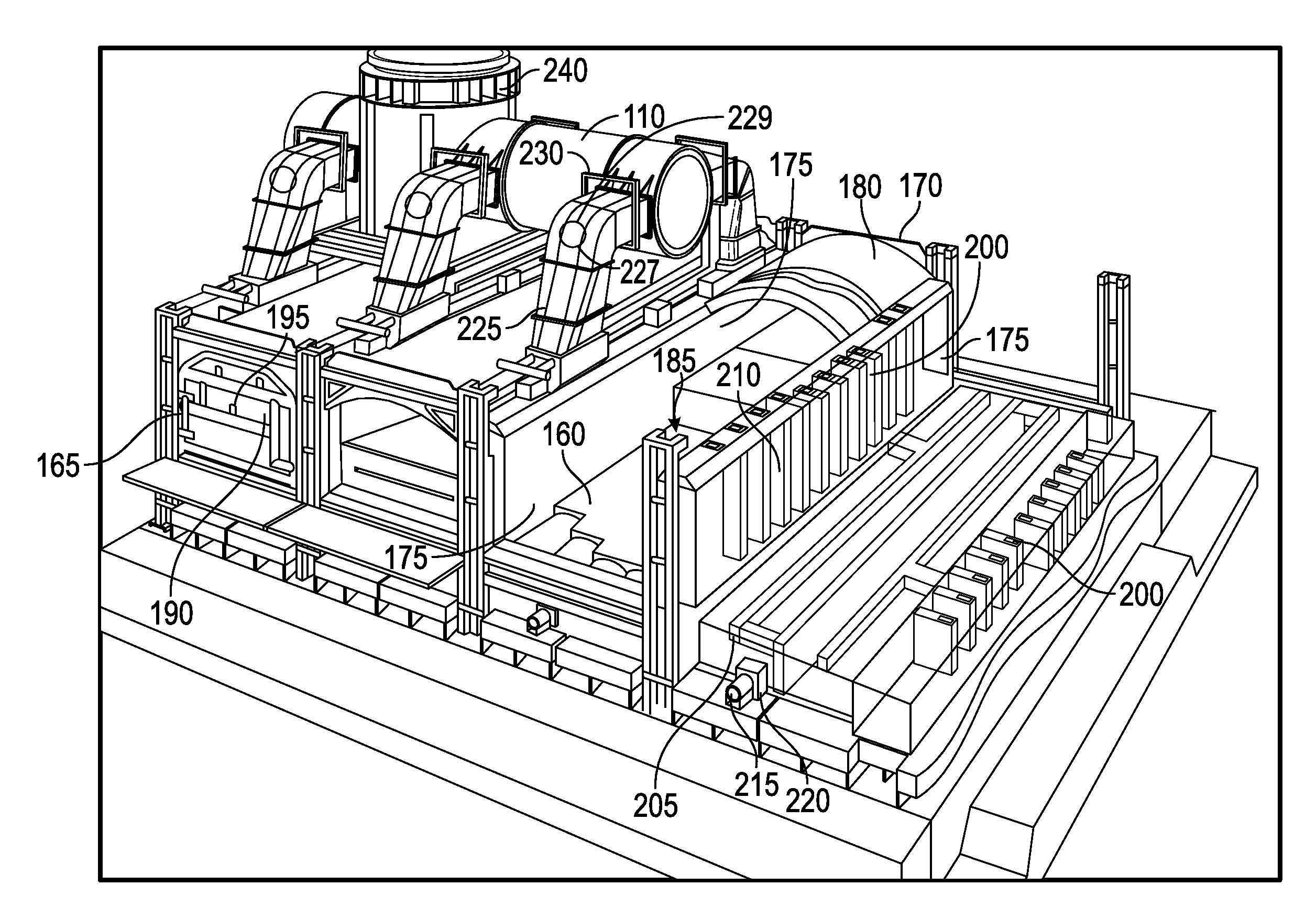

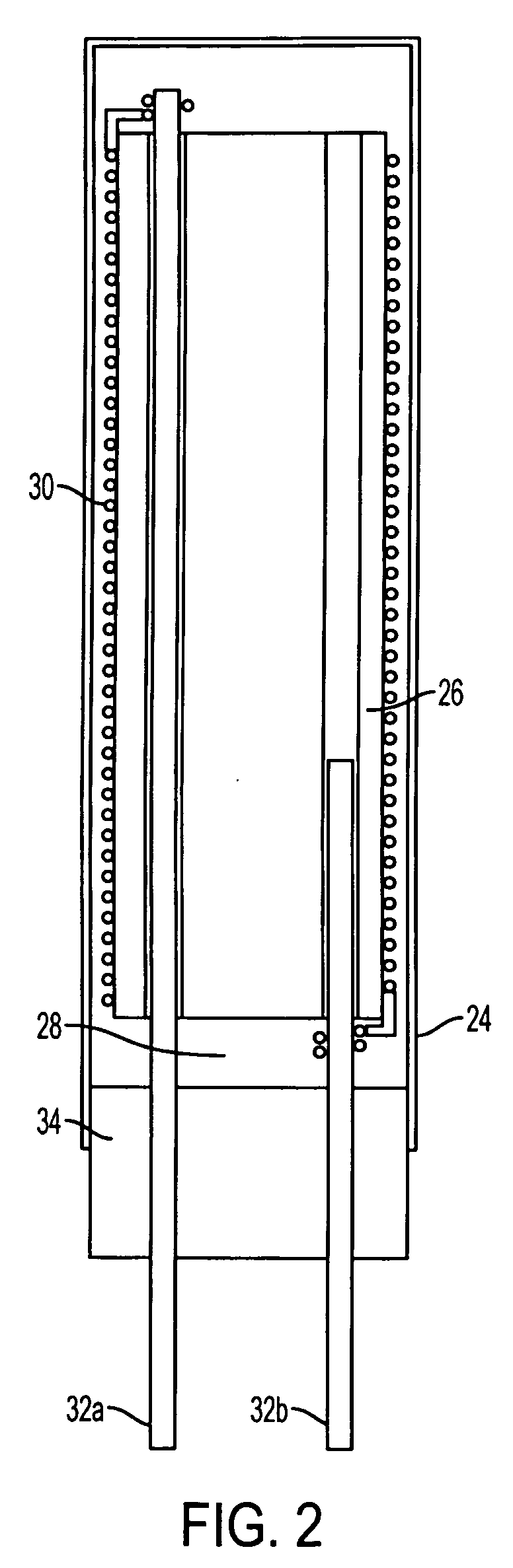

Outlet silencer and heat recovery structures for gas turbine

InactiveUS6851514B2Reduce sound levelPrevent escapeSilencing apparatusGas turbine plantsTurbineMuffler

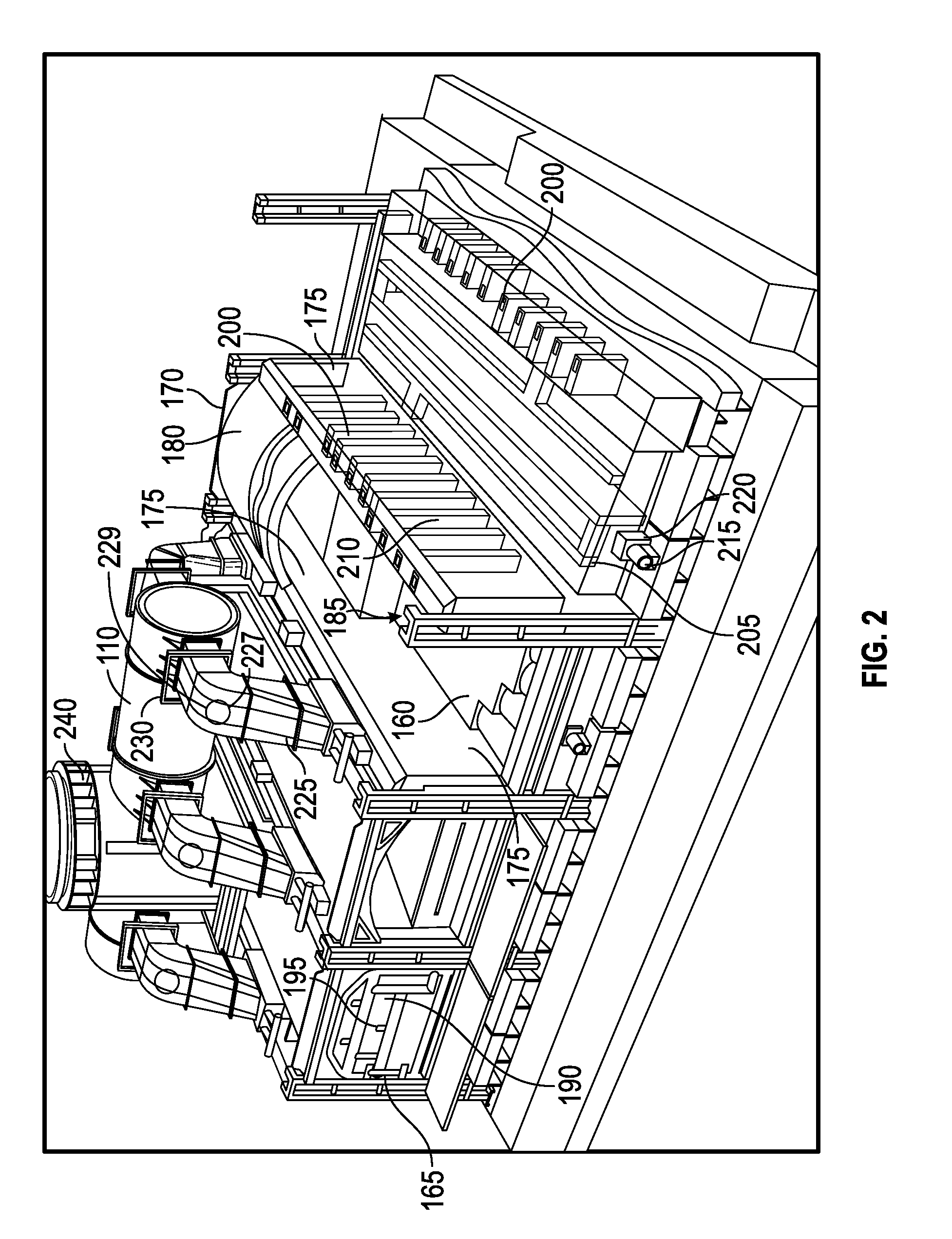

A sound attenuating duct unit suitable for connection to an outlet of a gas turbine and an improved heat recovery apparatus for use with such a turbine are disclosed. The former unit includes a duct housing having exterior sides, an air inlet at one end and first and second air outlets. Interior walls define a main airflow passageway extending from the air inlet to both of the outlets. Sound absorbing and heat insulation material is arranged between these walls and the exterior sides. Sound attenuating members are mounted in the passageway and a diverter damper is mounted in the housing and is able to direct air flow to either one of the air outlets. The sound attenuating members are mounted between the diverter damper and the air inlet. The heat recovery apparatus includes a series of aerodynamic diffusers mounted in a housing adjacent an air flow inlet connectable to the gas turbine.

Owner:M & I POWER TECH

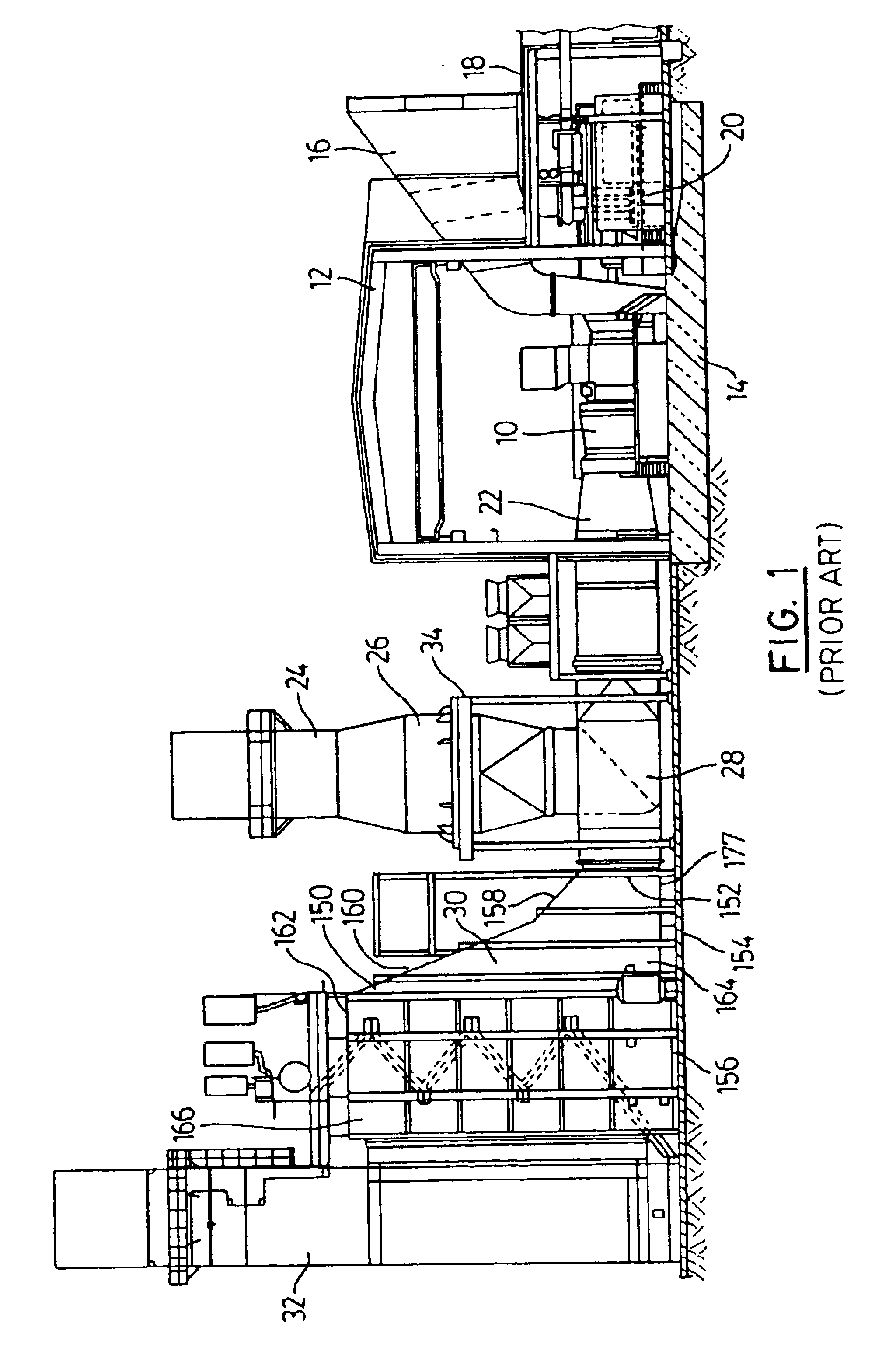

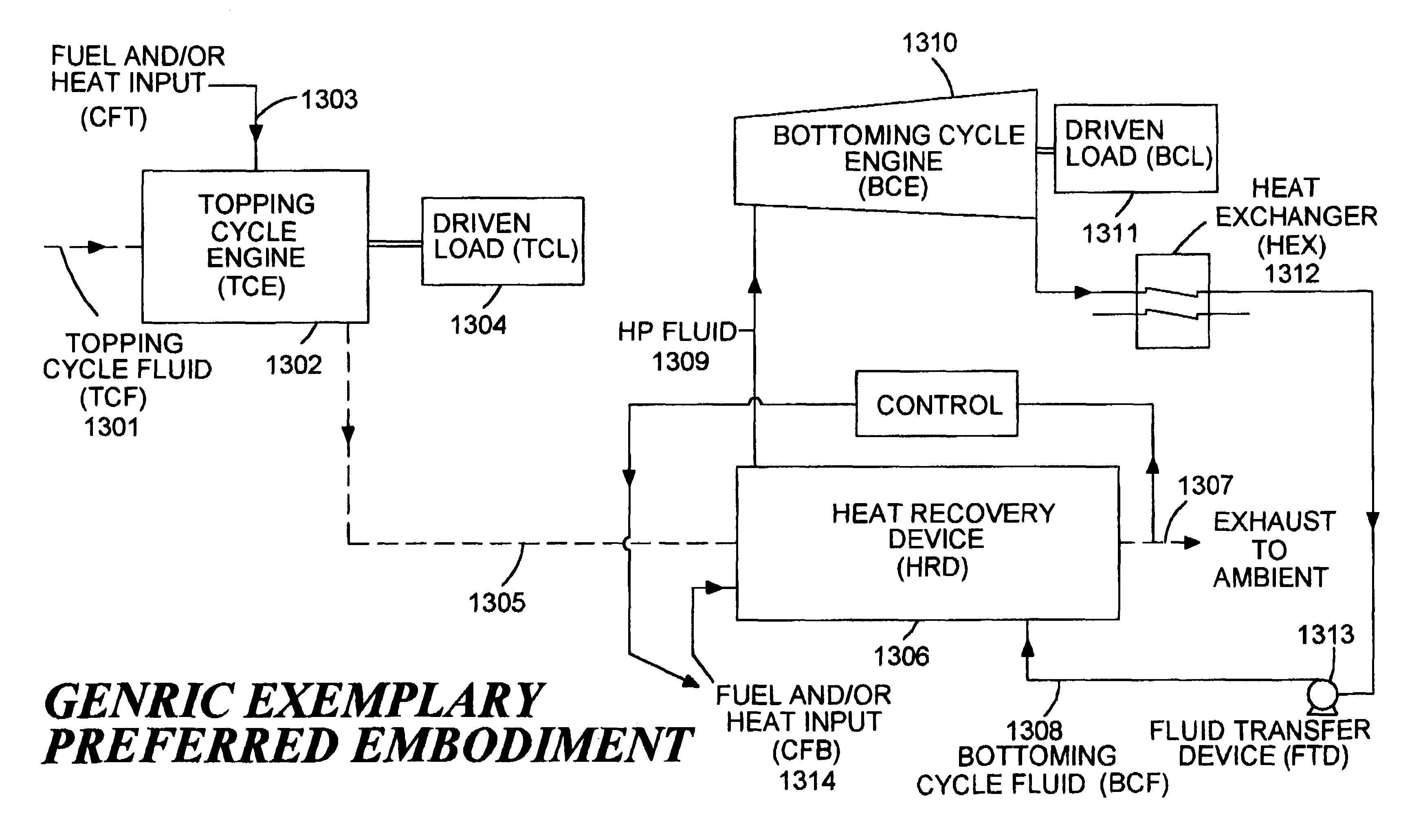

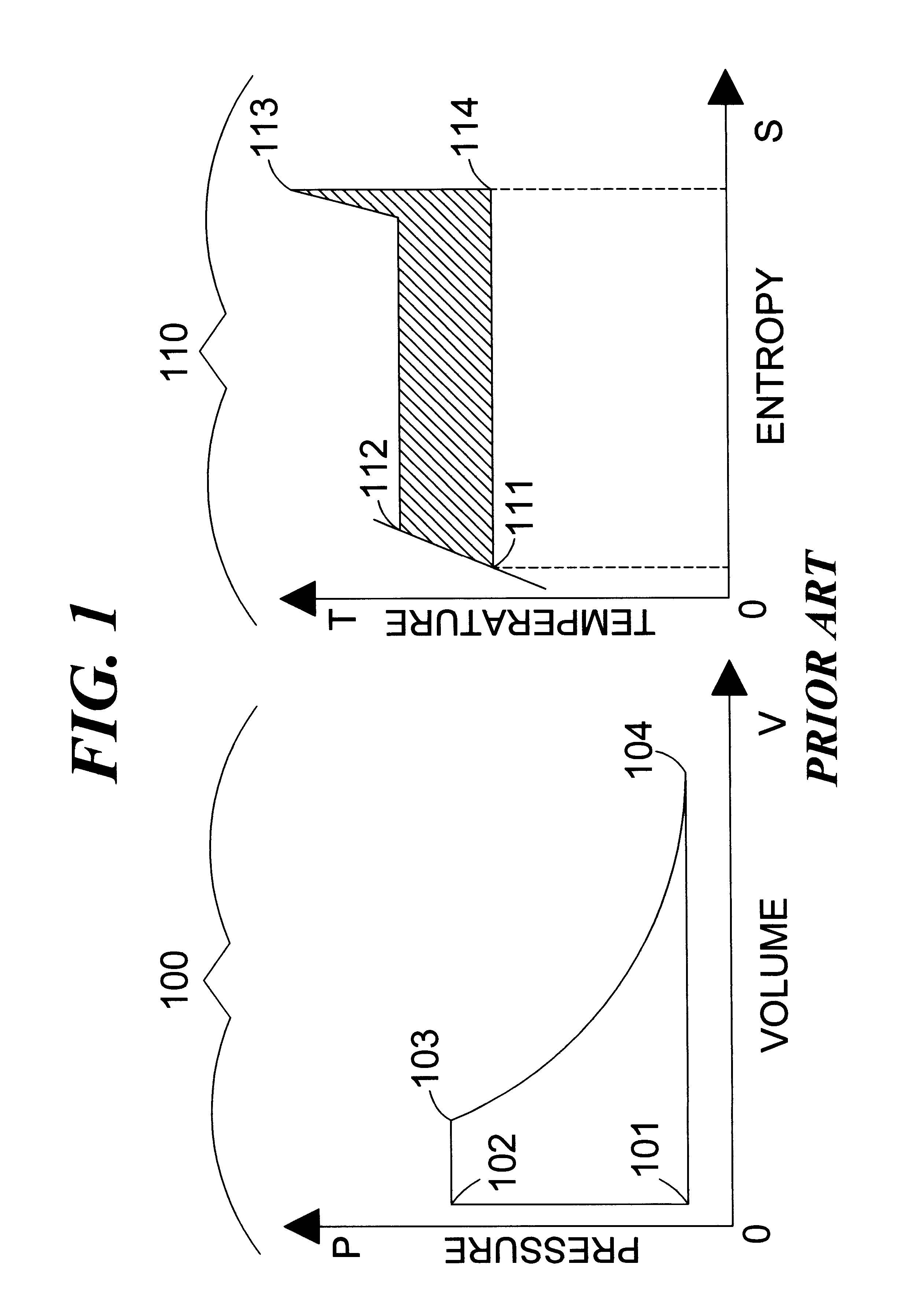

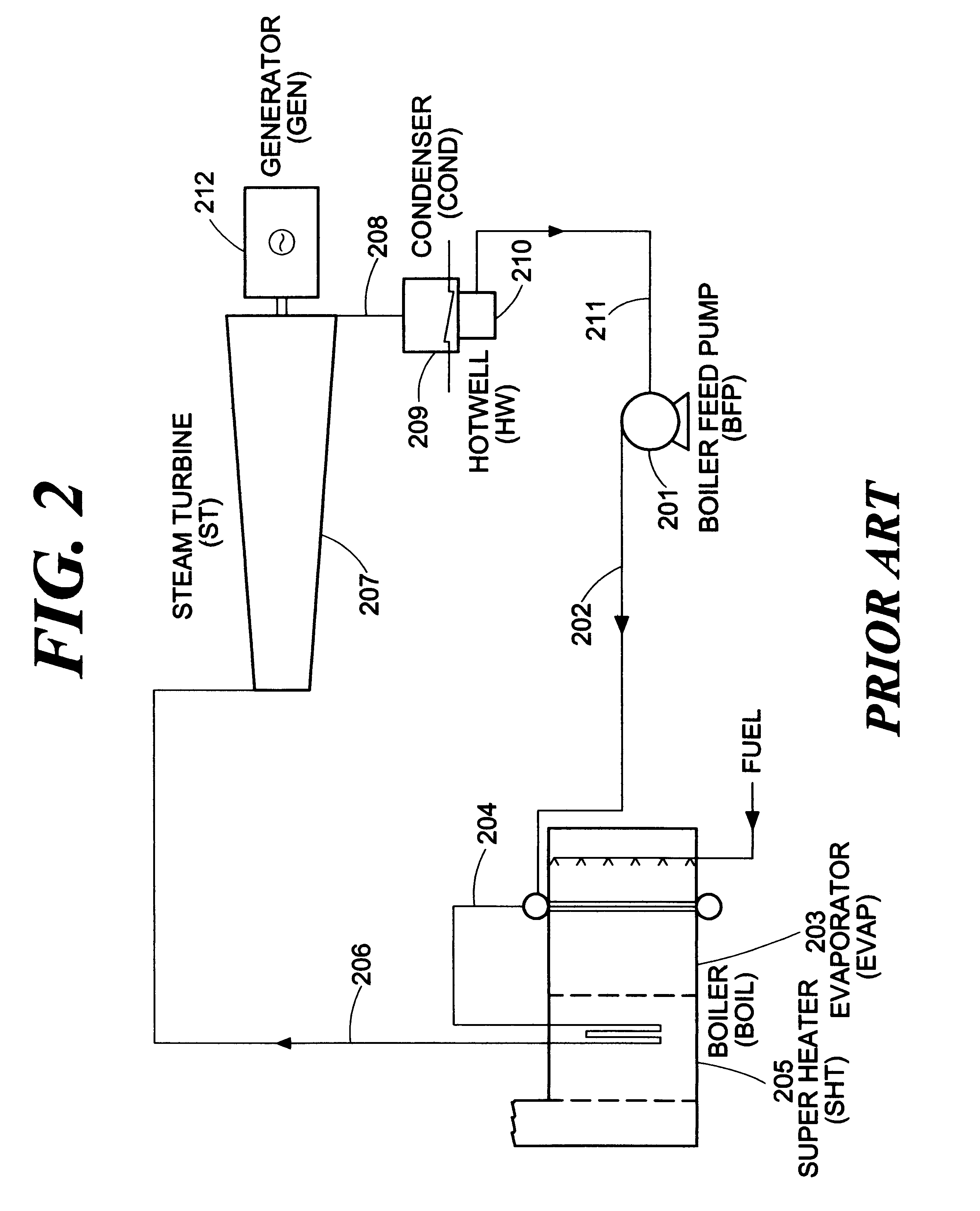

High power density combined cycle power plant

InactiveUS6230480B1Reduce installation costsService degradationEnergy industryGas turbine plantsPower stationCogeneration

A system and method for increasing the specific output of a combined cycle power plant and providing flexibility in the power plant rating, both without a commensurate increase in the plant heat rate, is disclosed. The present invention demonstrates that the process of upgrading thermal efficiencies of combined cycles can often be accomplished through the strategic use of additional fuel and / or heat input. In particular, gas turbines that exhaust into HRSGs, can be supplemental fired to obtain much higher steam turbine outputs and greater overall plant ratings, but without a penalty on efficiency. This system and method by in large defines a high efficiency combined cycle power plant that is predominantly a Rankine (bottoming) cycle. Exemplary embodiments of the present invention include a load driven by a topping cycle engine (TCE), powered by a topping cycle fluid (TCF) which exhausts into a heat recovery device (HRD). The HRD is fired with a supplementary fuel or provided an additional heat source to produce more energetic and / or a larger quantity of the bottoming cycle fluid (BCF) which is used to power a bottoming cycle engine, (BCE) which drives a load (potentially the same load as the topping cycle engine). Energy contained in either the TCF or BCF is used to power the TCE and BCE respectively, but these fluids, and / or their respective engine exhausts, may also be used to support a wide variety of cogeneration applications.

Owner:ROLLINS III WILLIAM SCOTT

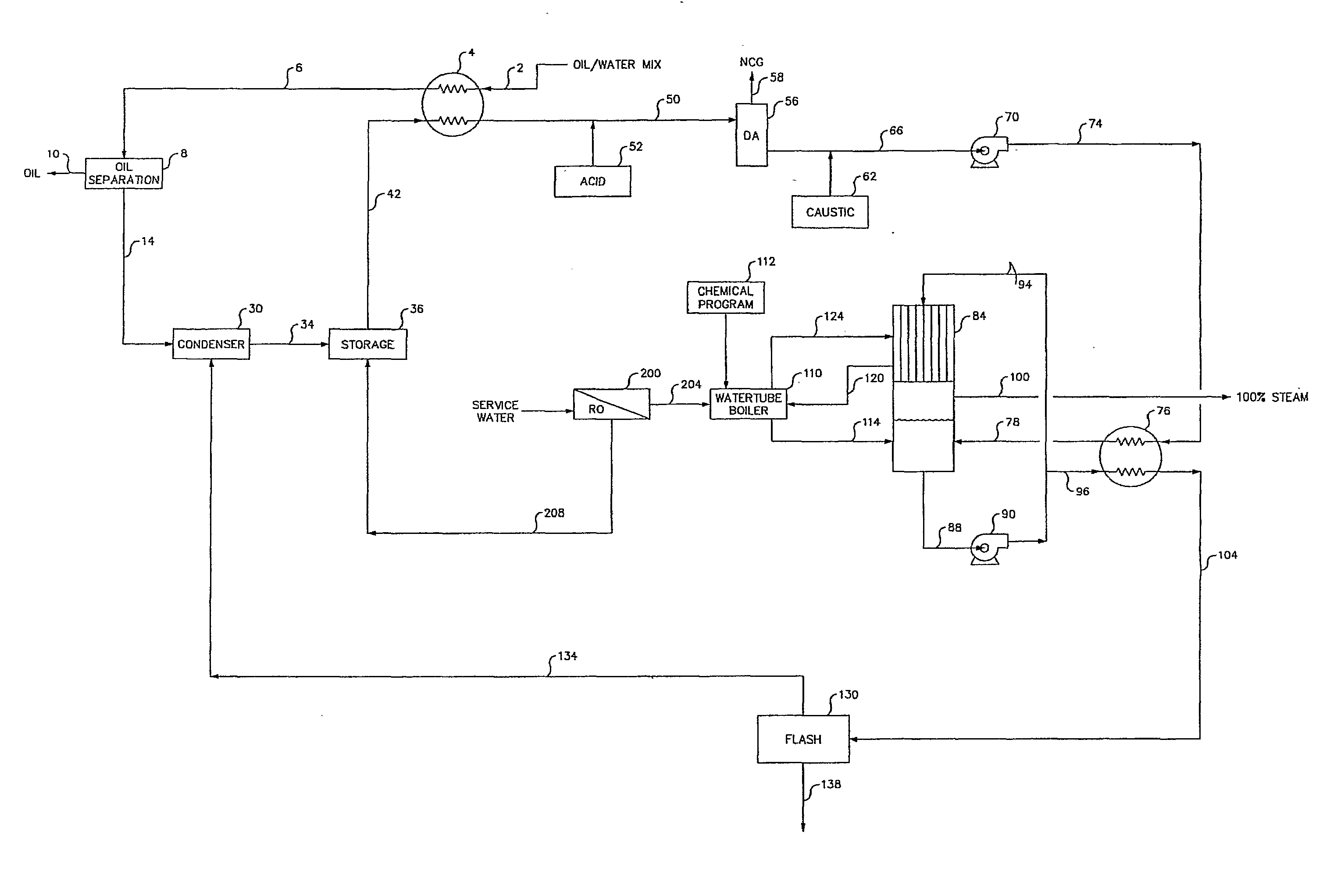

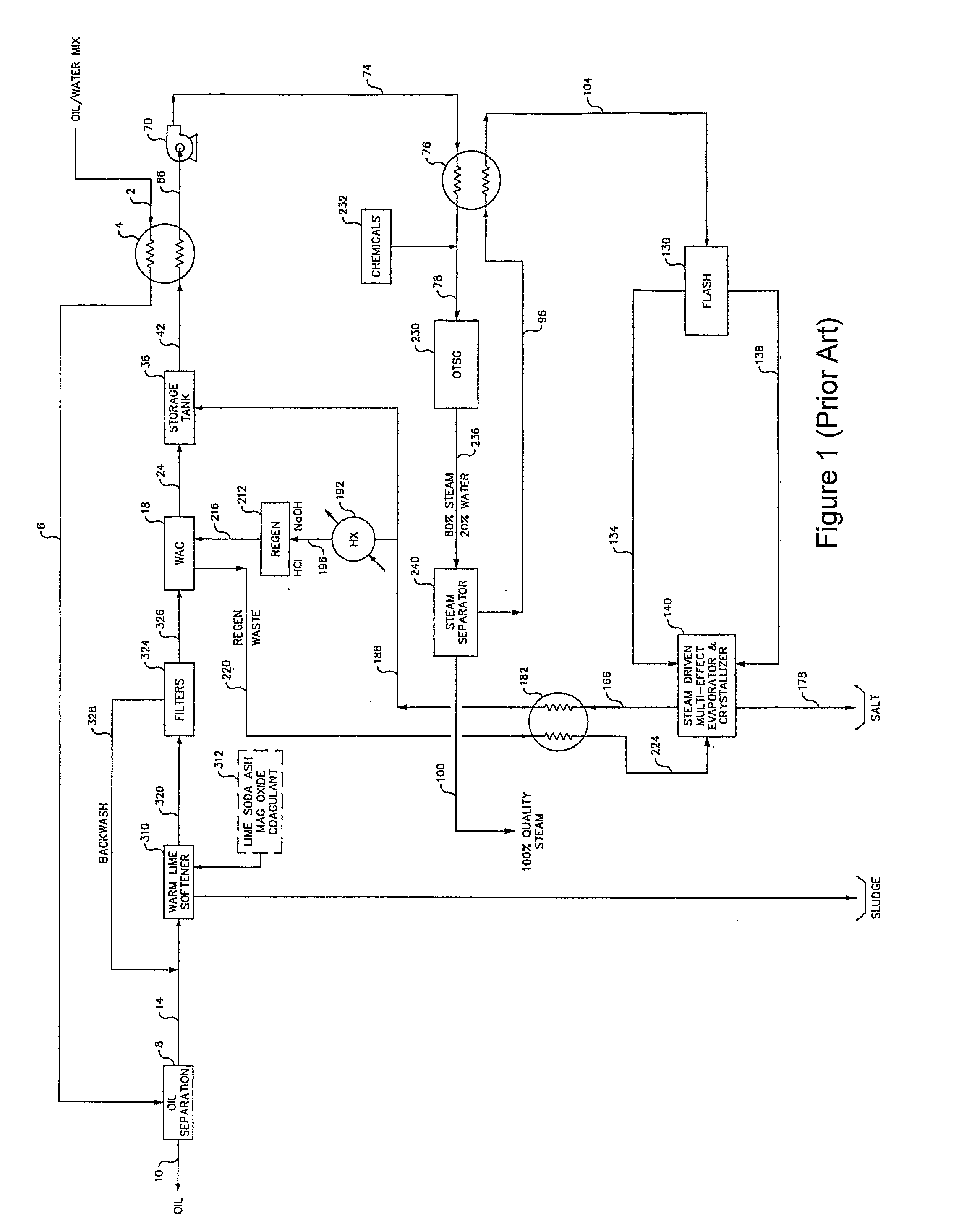

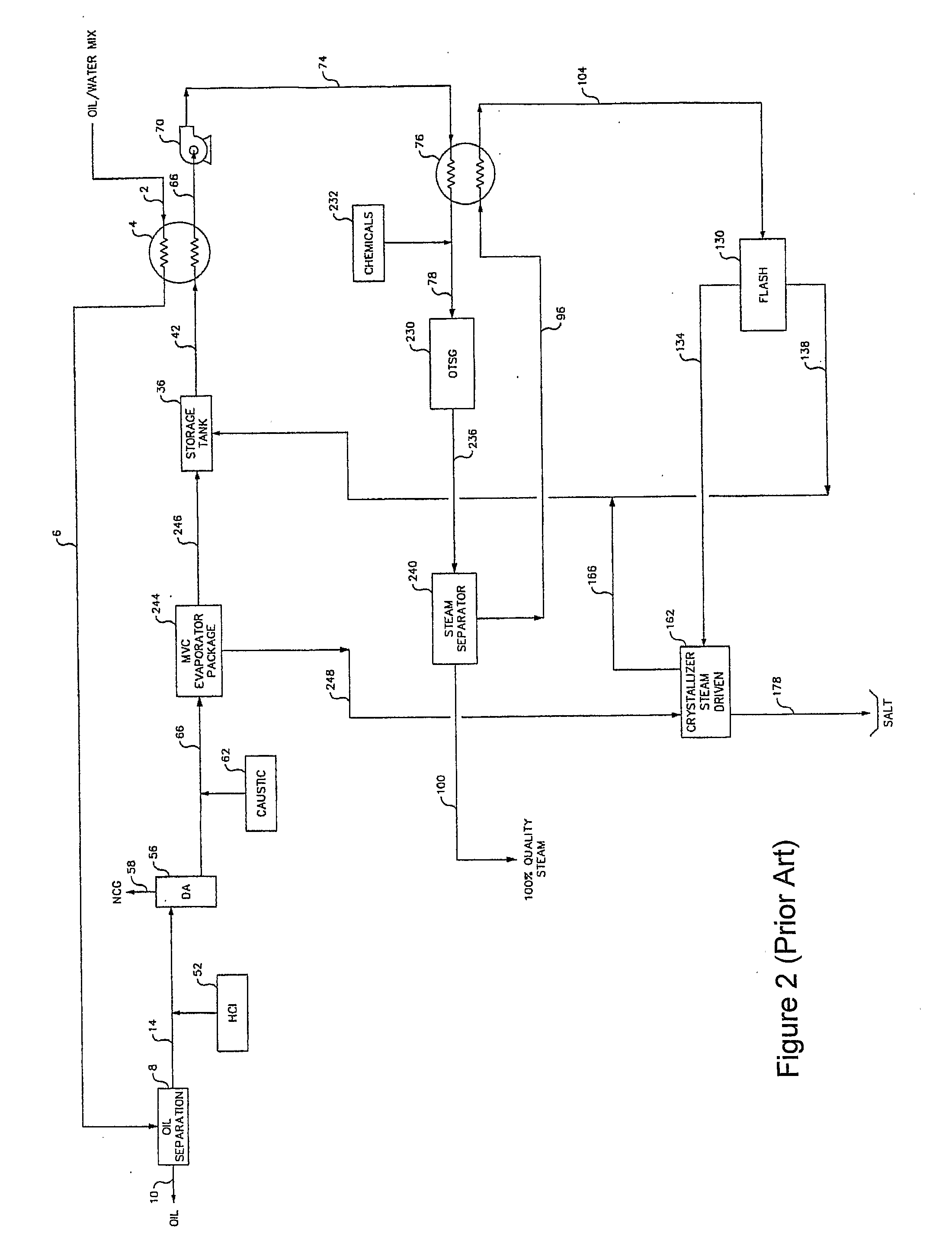

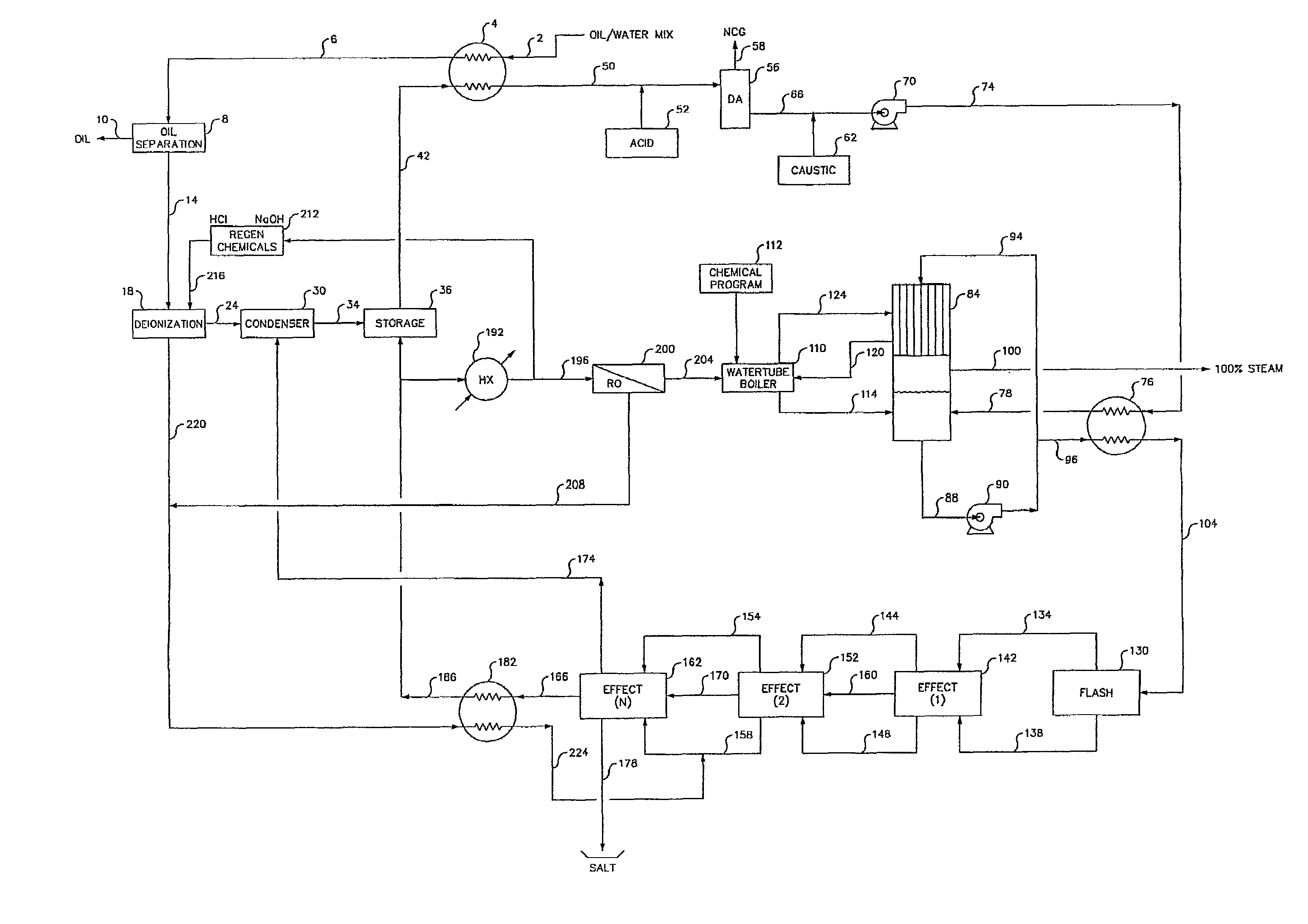

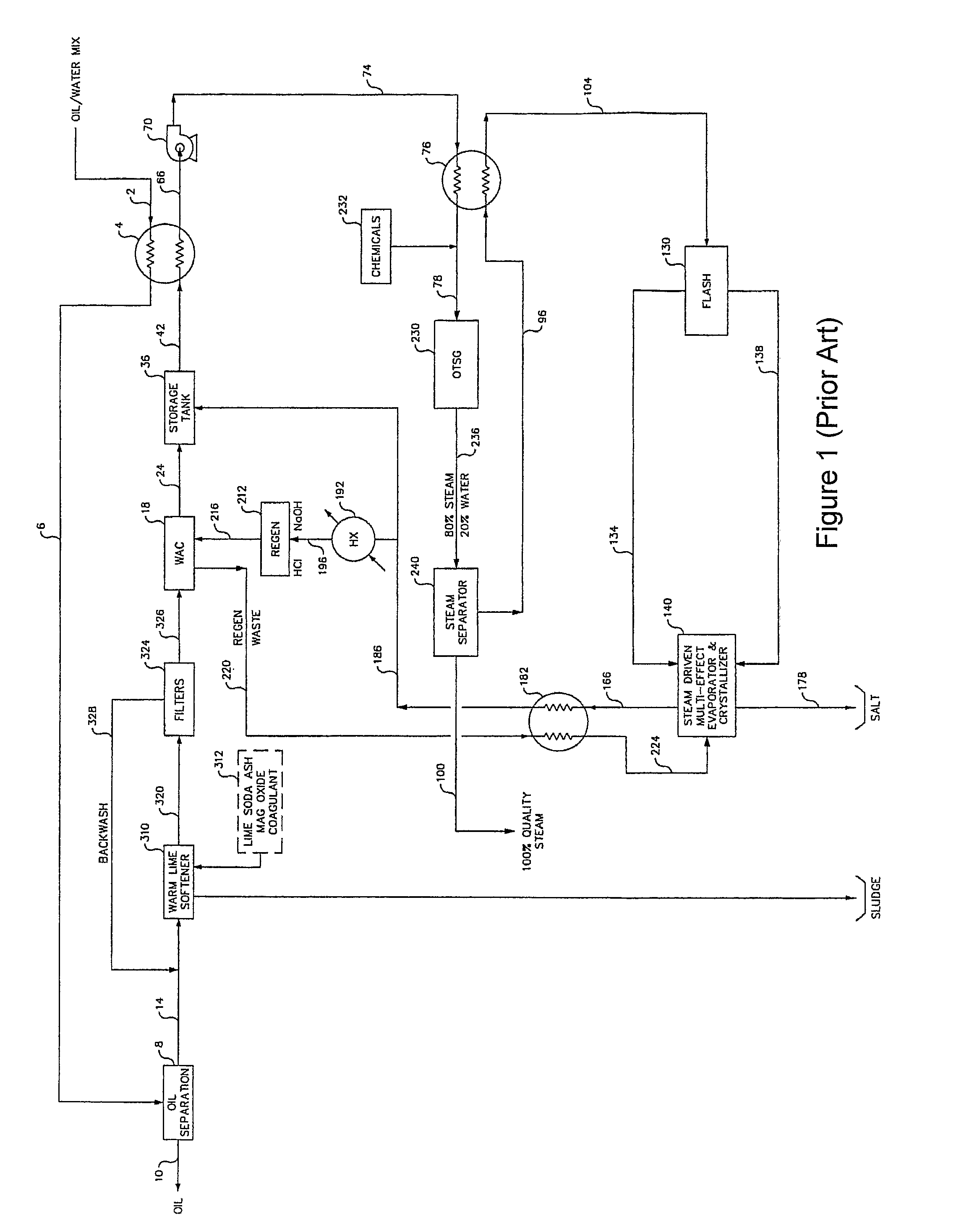

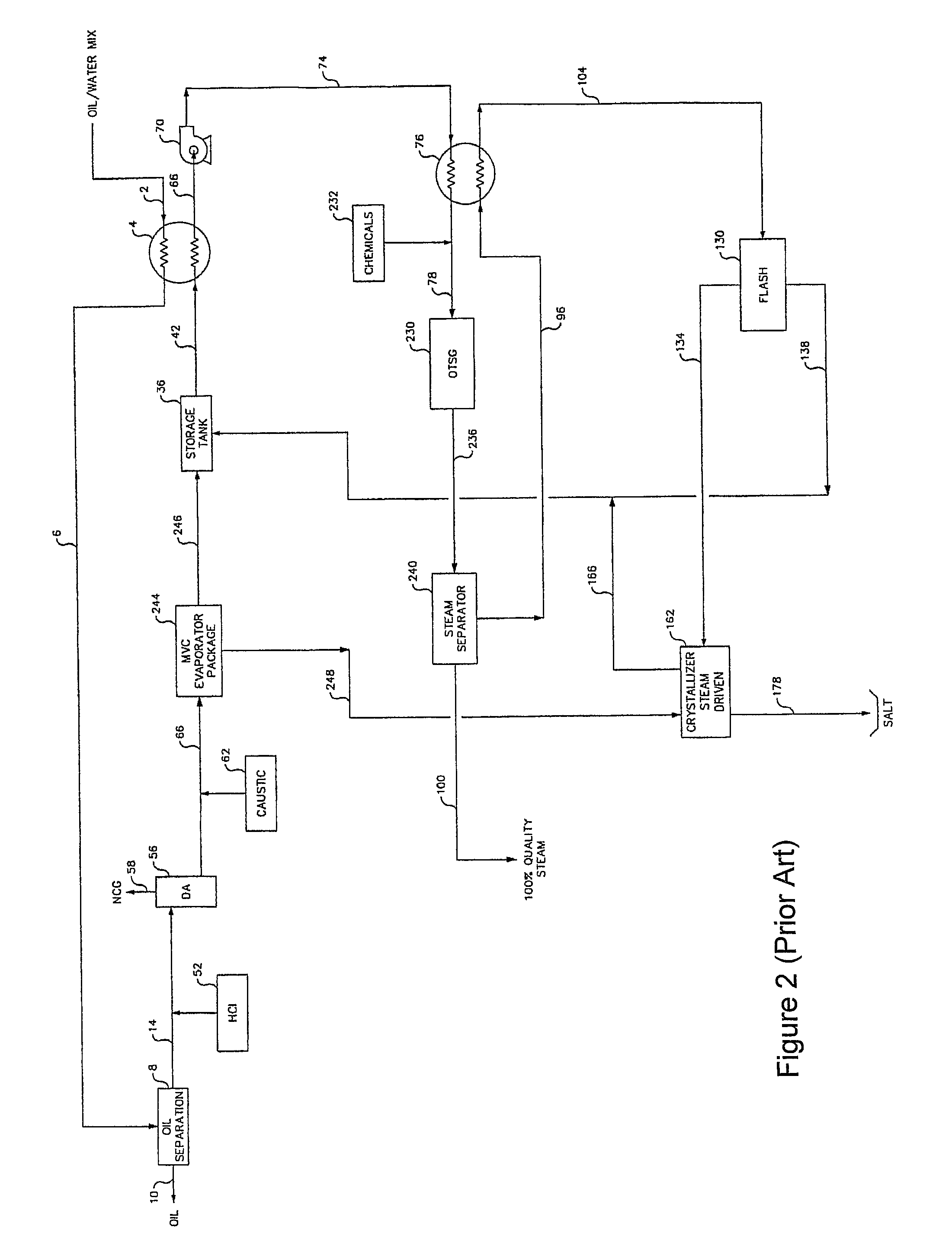

Method for Production of High Pressure Steam from Produced Water

InactiveUS20080110630A1Average power consumptionMinimize waste generationDrying using combination processesSolid sorbent liquid separationChemical treatmentDistillation

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

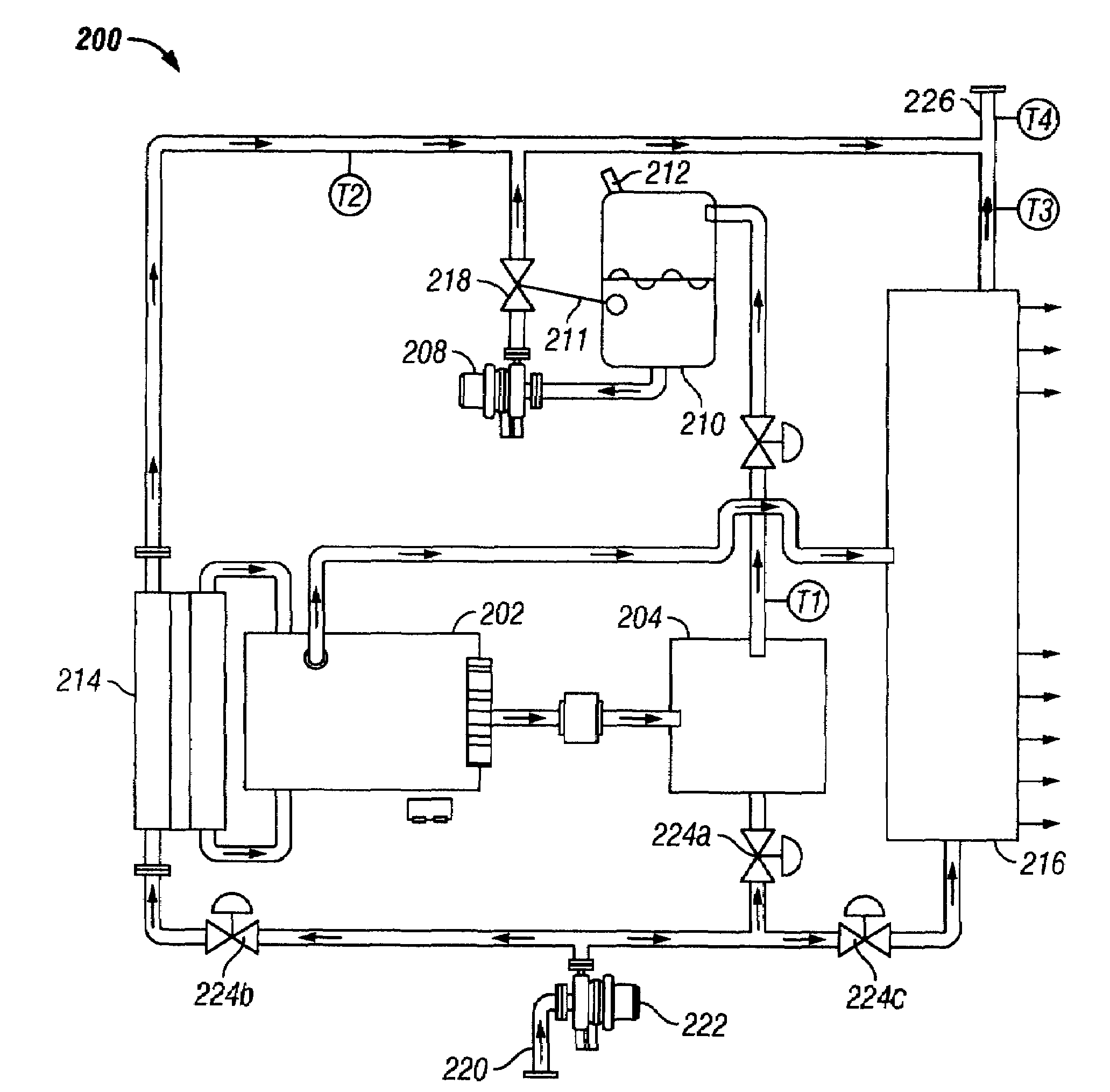

Method and apparatus for heating, concentrating and evaporating fluid

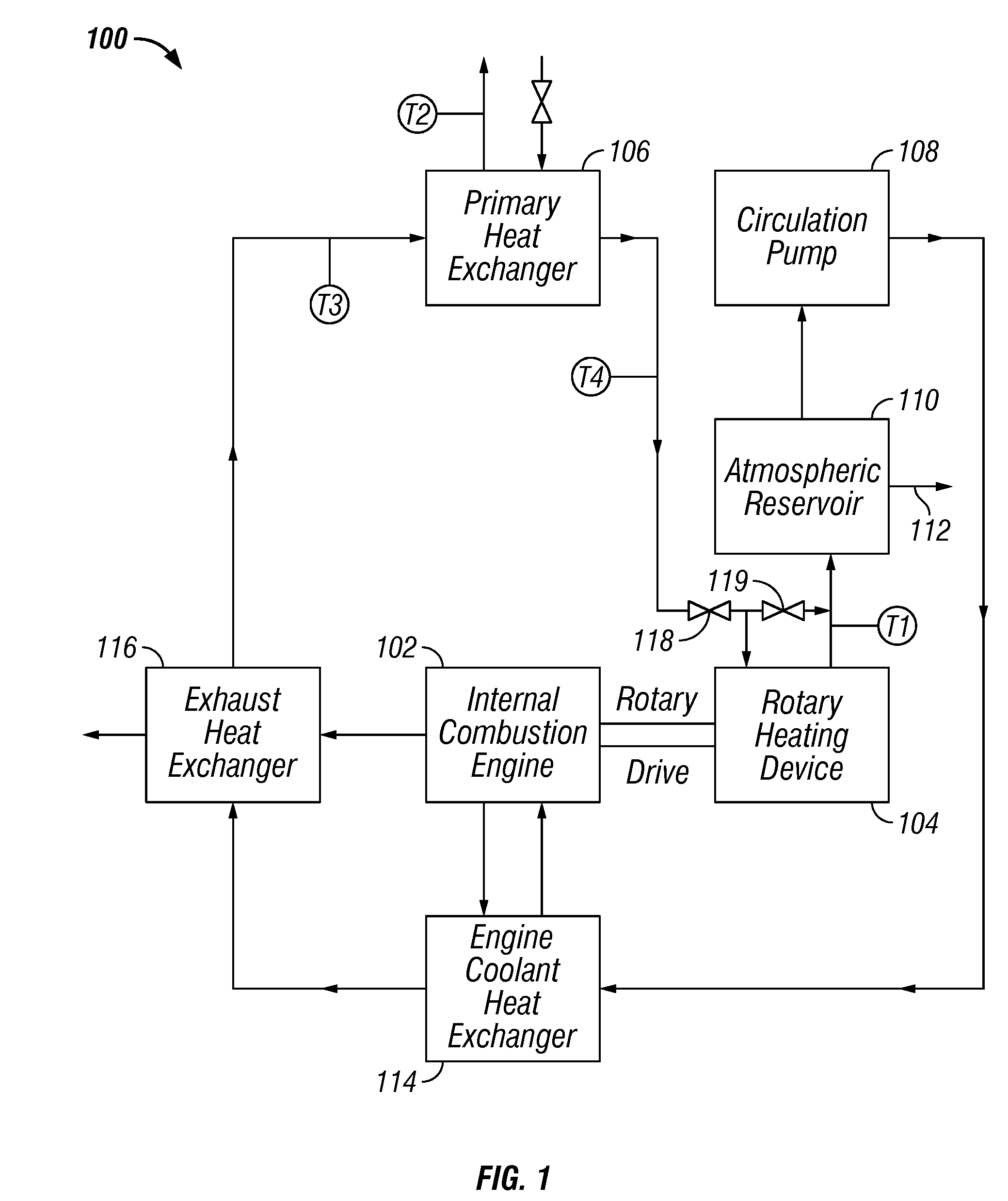

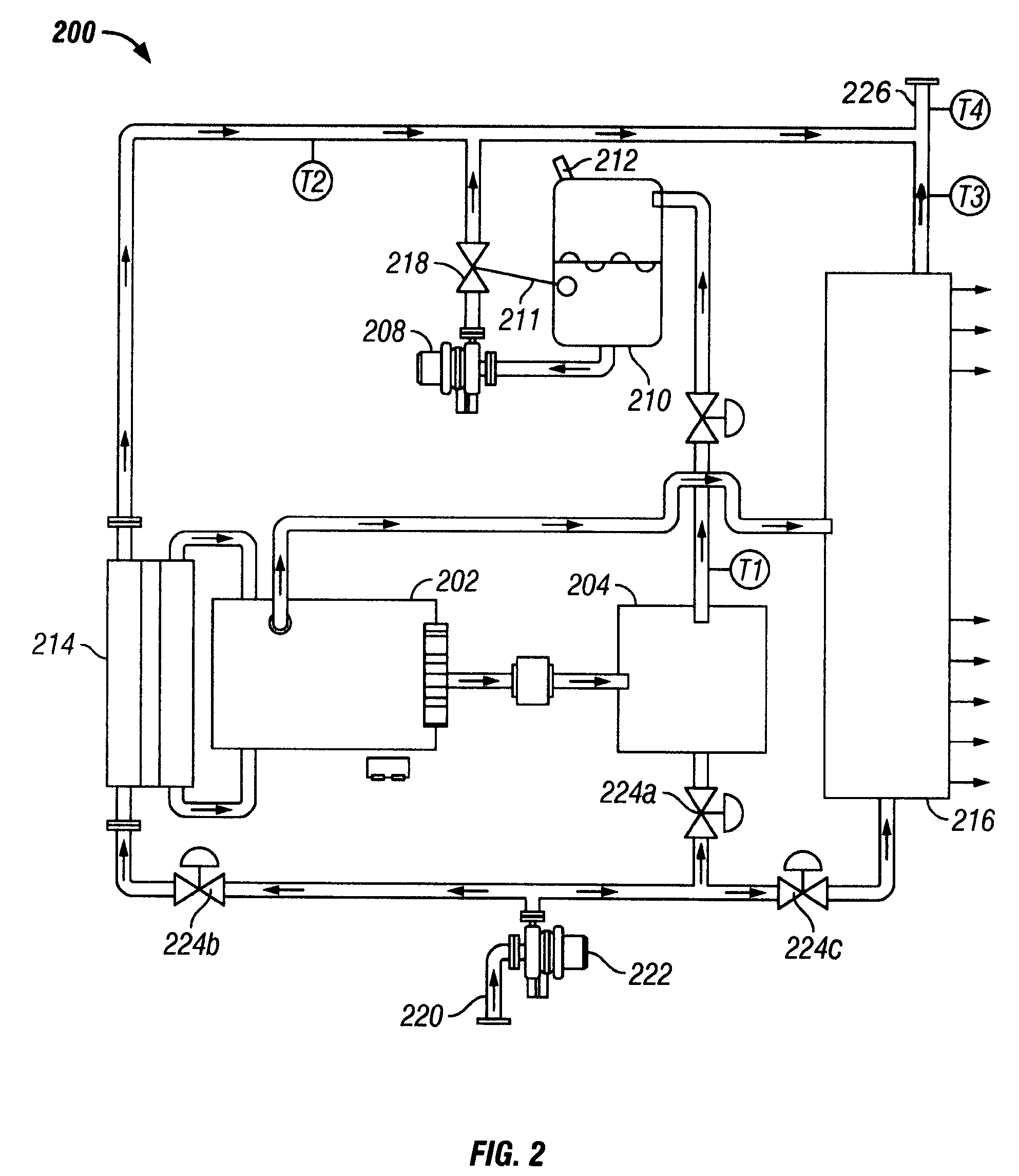

InactiveUS7614367B1Steam generation using mechanical energyAir-treating devicesWater brakeEvaporation

A system and method are provided for heating, concentrating and / or evaporating a fluid by heating the fluid in a heating subsystem comprising a rotary heating device, such as a water brake dynamometer, and then evaporating all or a portion of the fluid in an evaporation subsystem and / or concentrating the fluid in a concentration subsystem.

Owner:PHOENIX CALIENTE INC

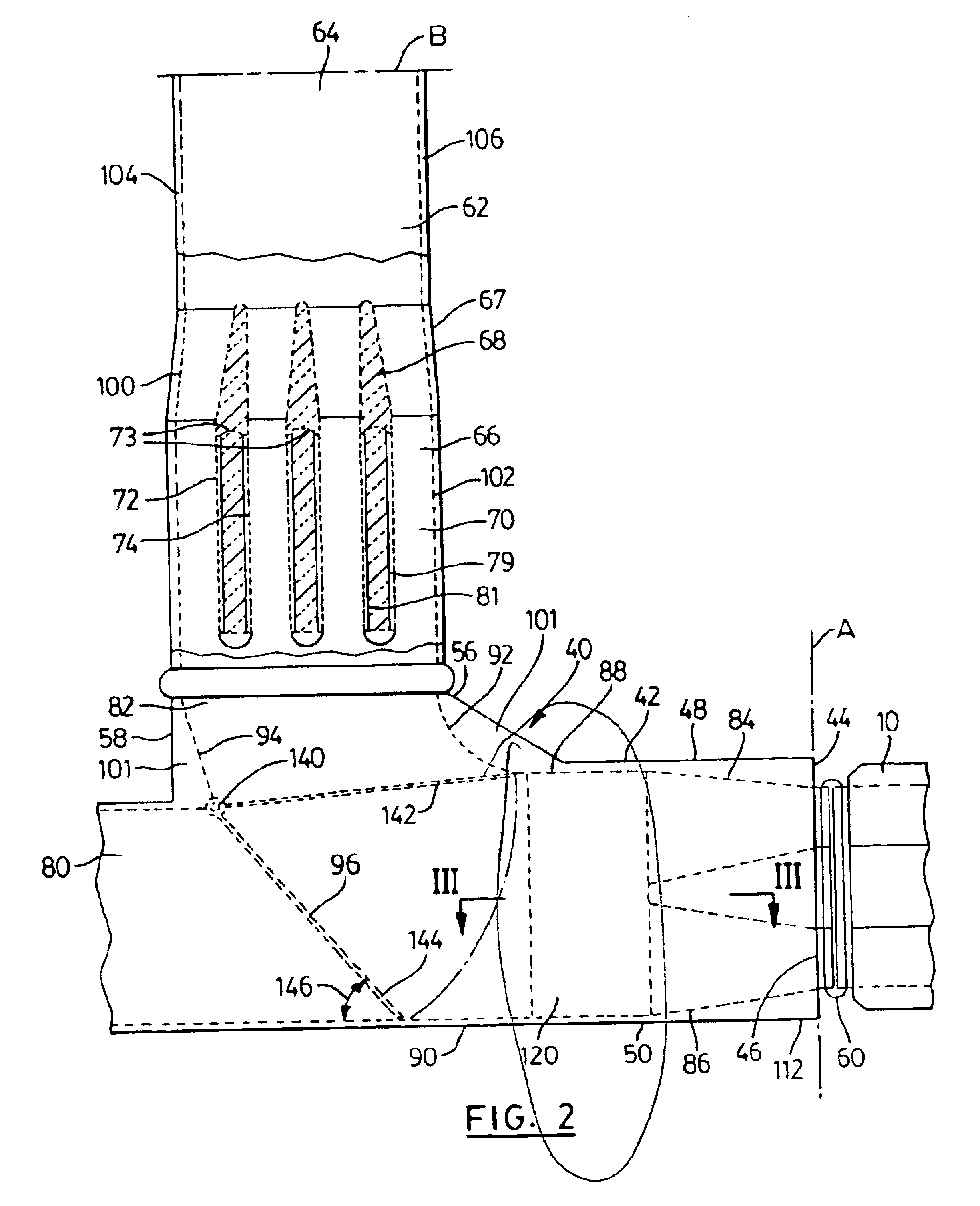

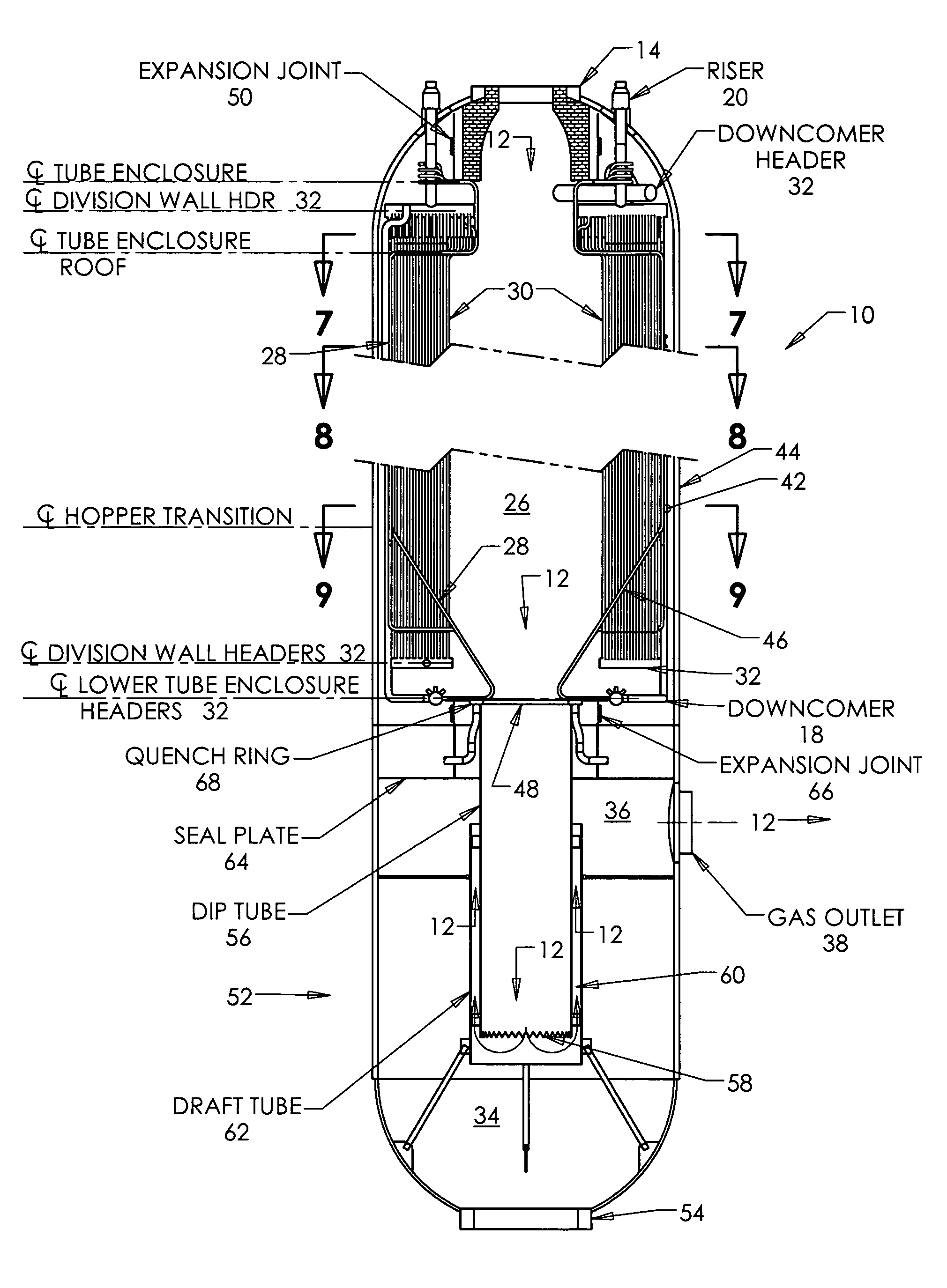

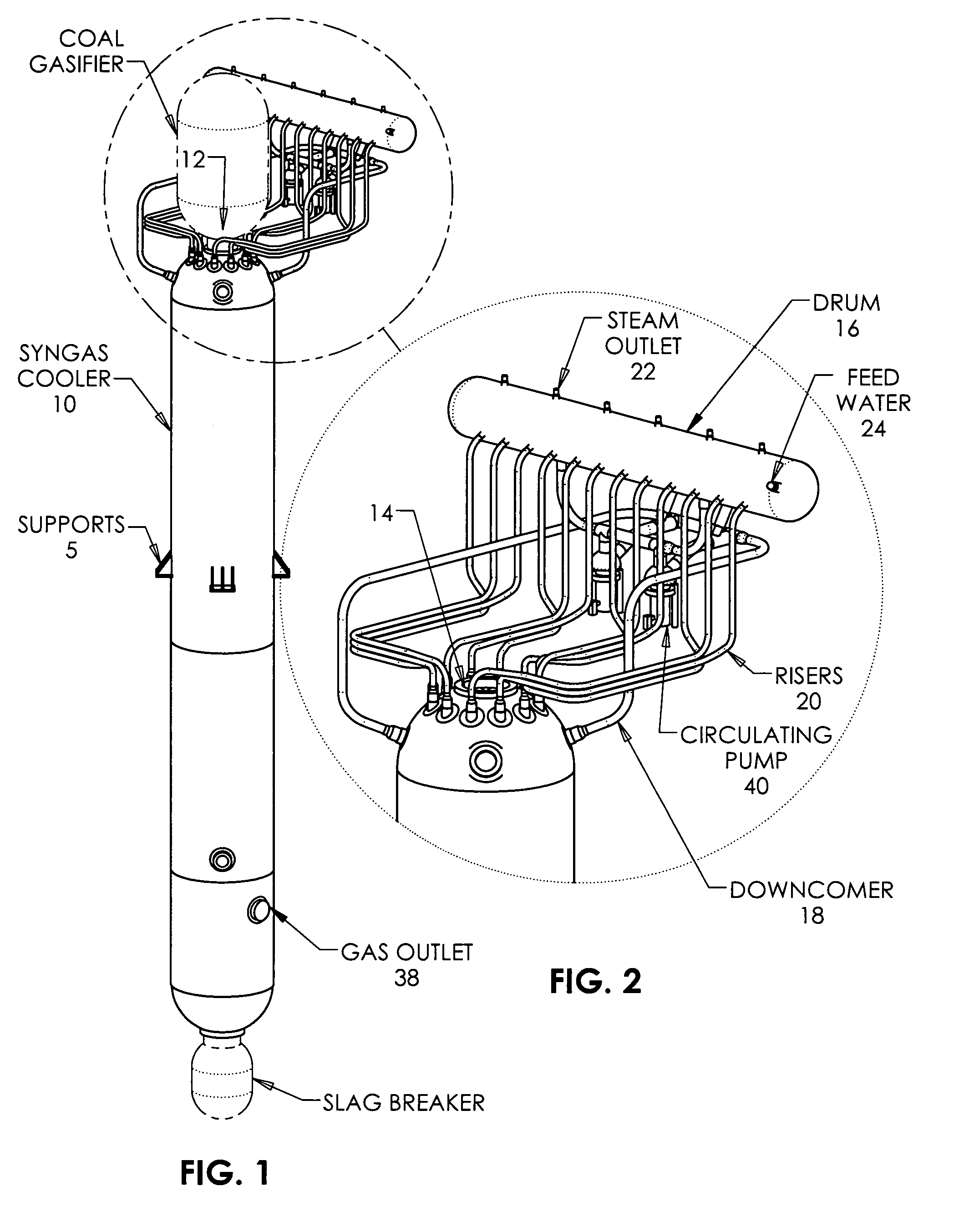

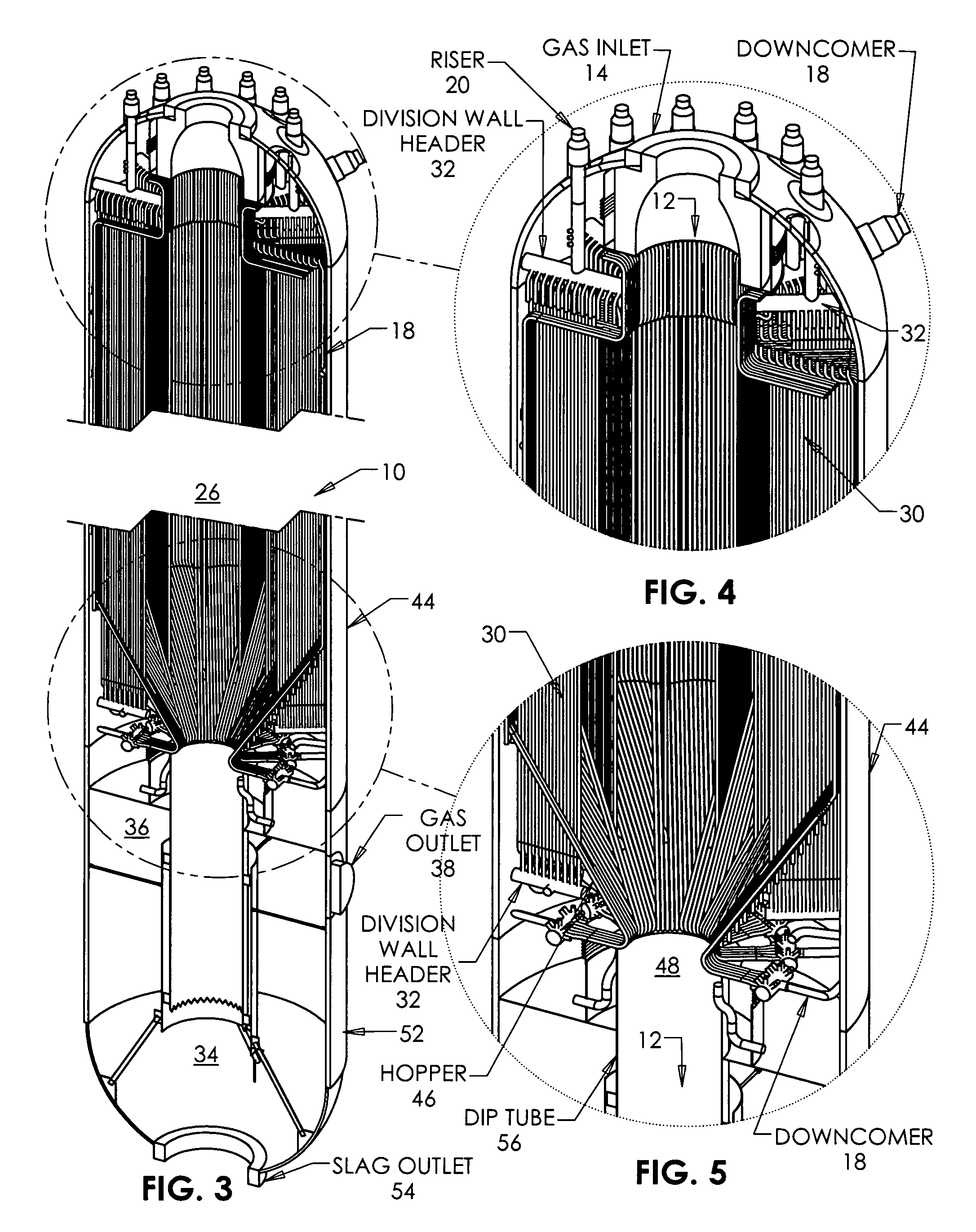

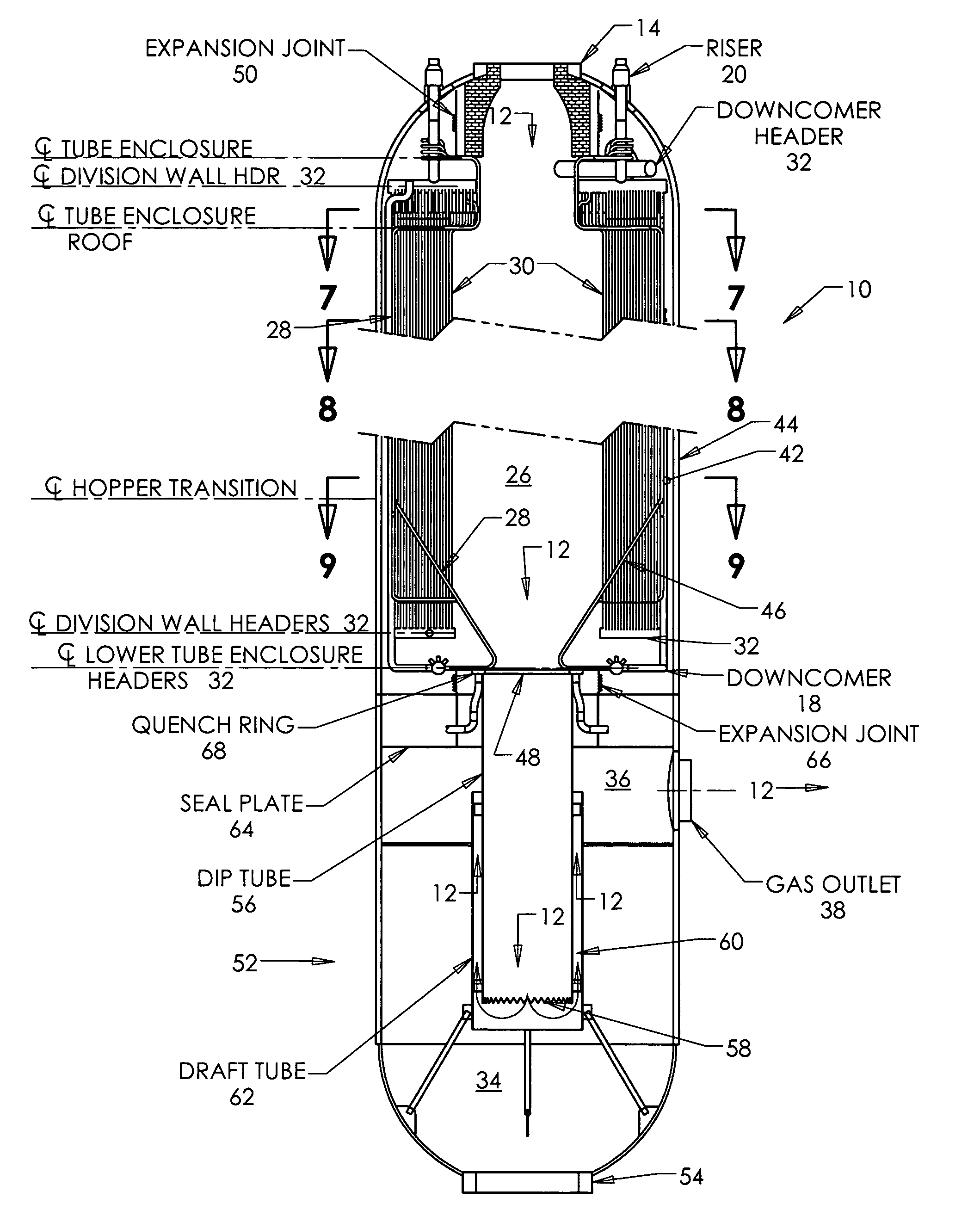

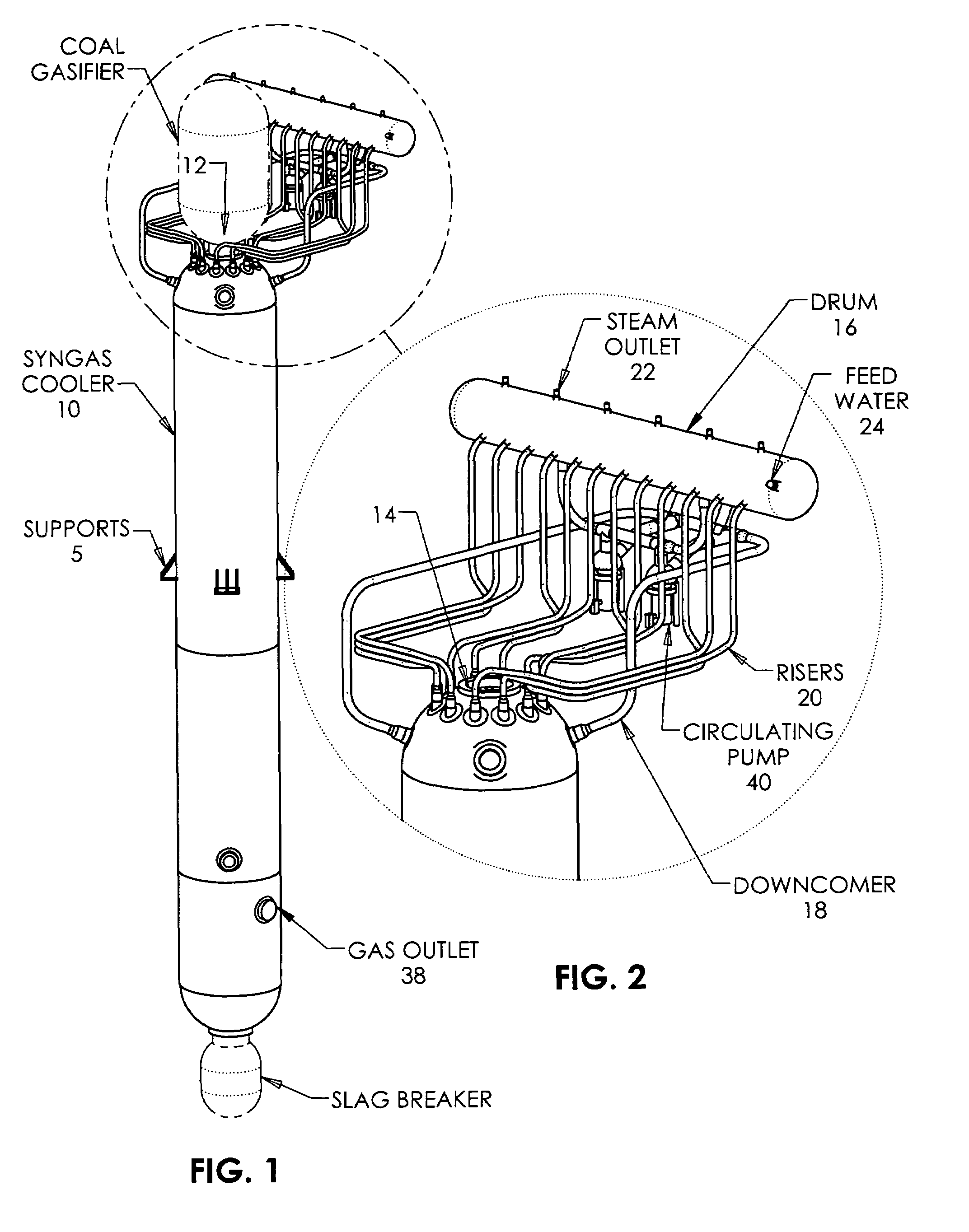

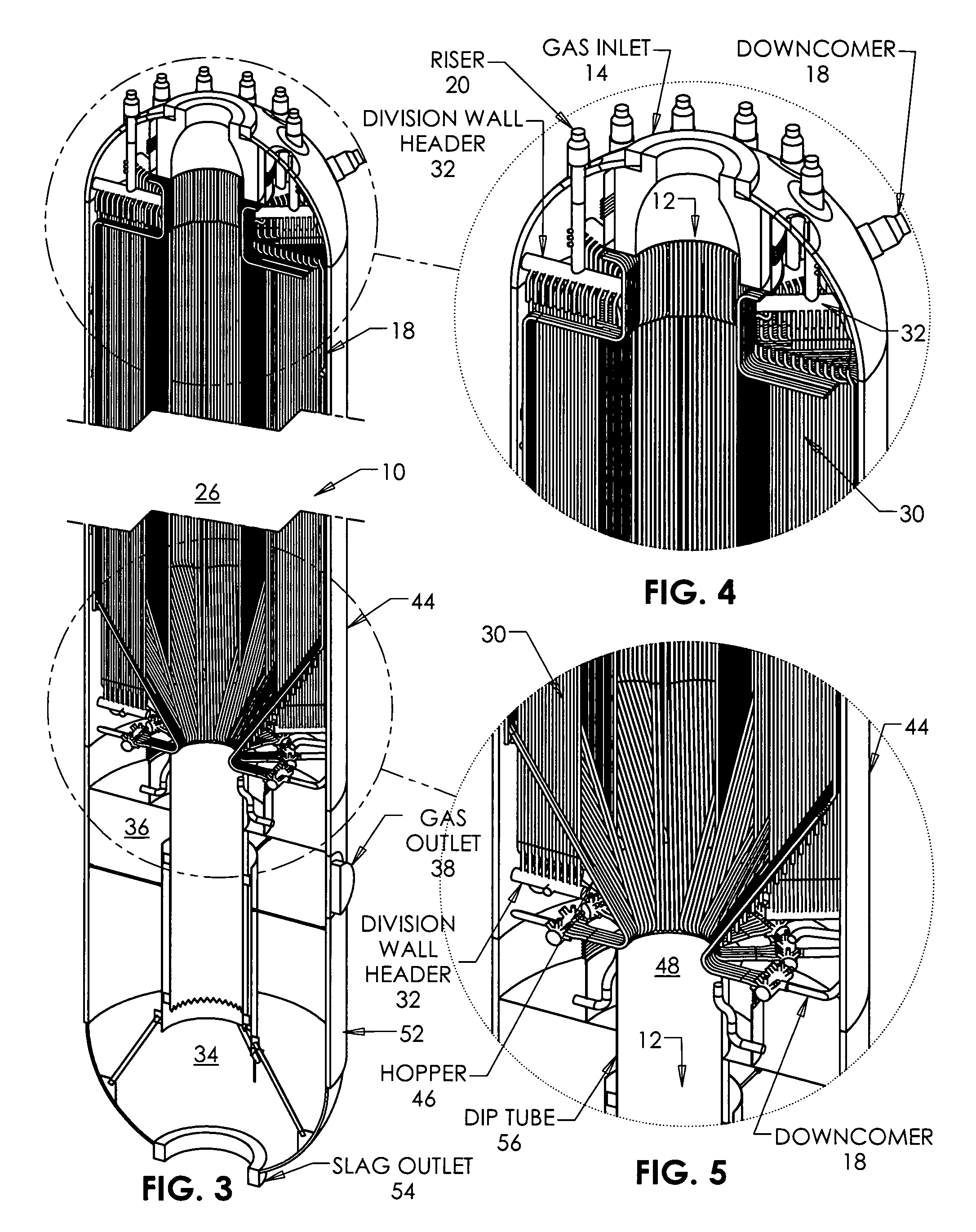

Radiant syngas cooler

A radiant syngas cooler used to contain and cool the synthesis gas produced by coal gasification processes employs radiant and convection surfaces in a specific arrangement to achieve a cost-effective, compact design.

Owner:THE BABCOCK & WILCOX CO

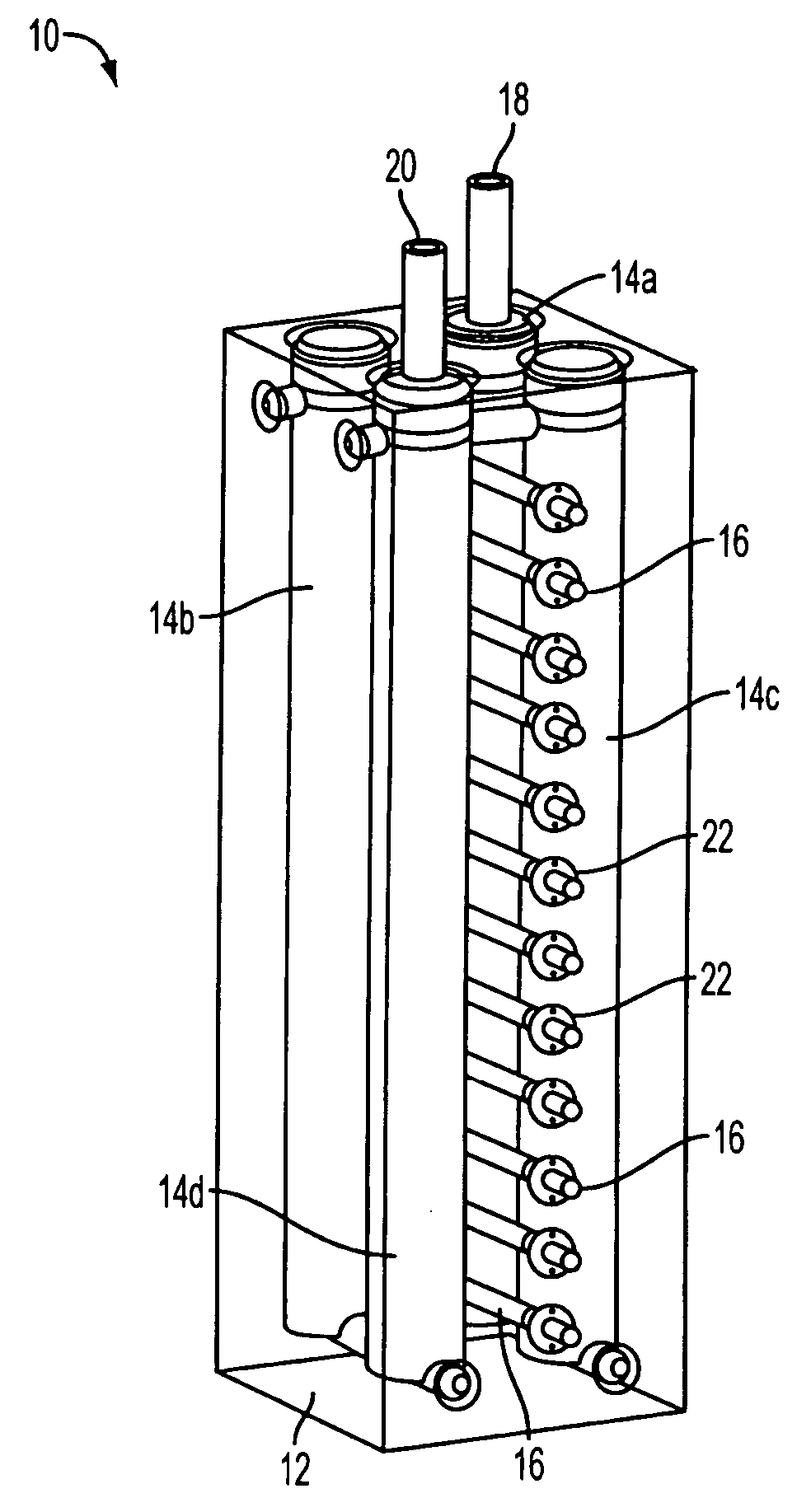

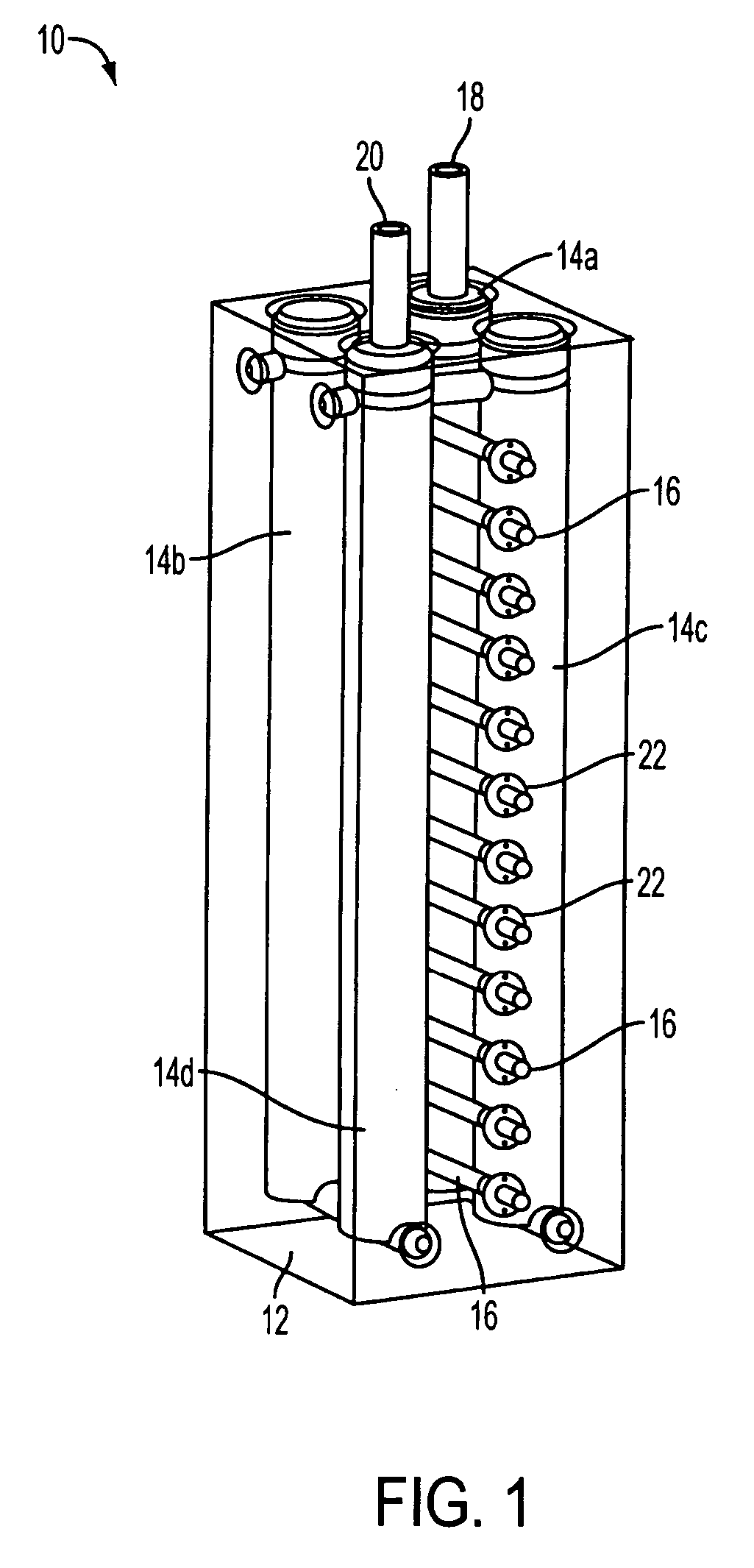

Oxygen transport membrane system and method for transferring heat to catalytic/process reactors

A method and apparatus for producing heat used in a synthesis gas production process is provided. The disclosed method and apparatus include a plurality of tubular oxygen transport membrane elements adapted to separate oxygen from an oxygen containing stream contacting the retentate side of the membrane elements. The permeated oxygen is combusted with a hydrogen containing synthesis gas stream contacting the permeate side of the tubular oxygen transport membrane elements thereby generating a reaction product stream and radiant heat. The present method and apparatus also includes at least one catalytic reactor containing a catalyst to promote the steam reforming reaction wherein the catalytic reactor is surrounded by the plurality of tubular oxygen transport membrane elements. The view factor between the catalytic reactor and the plurality of tubular oxygen transport membrane elements radiating heat to the catalytic reactor is greater than or equal to 0.5.

Owner:PRAXAIR TECH INC

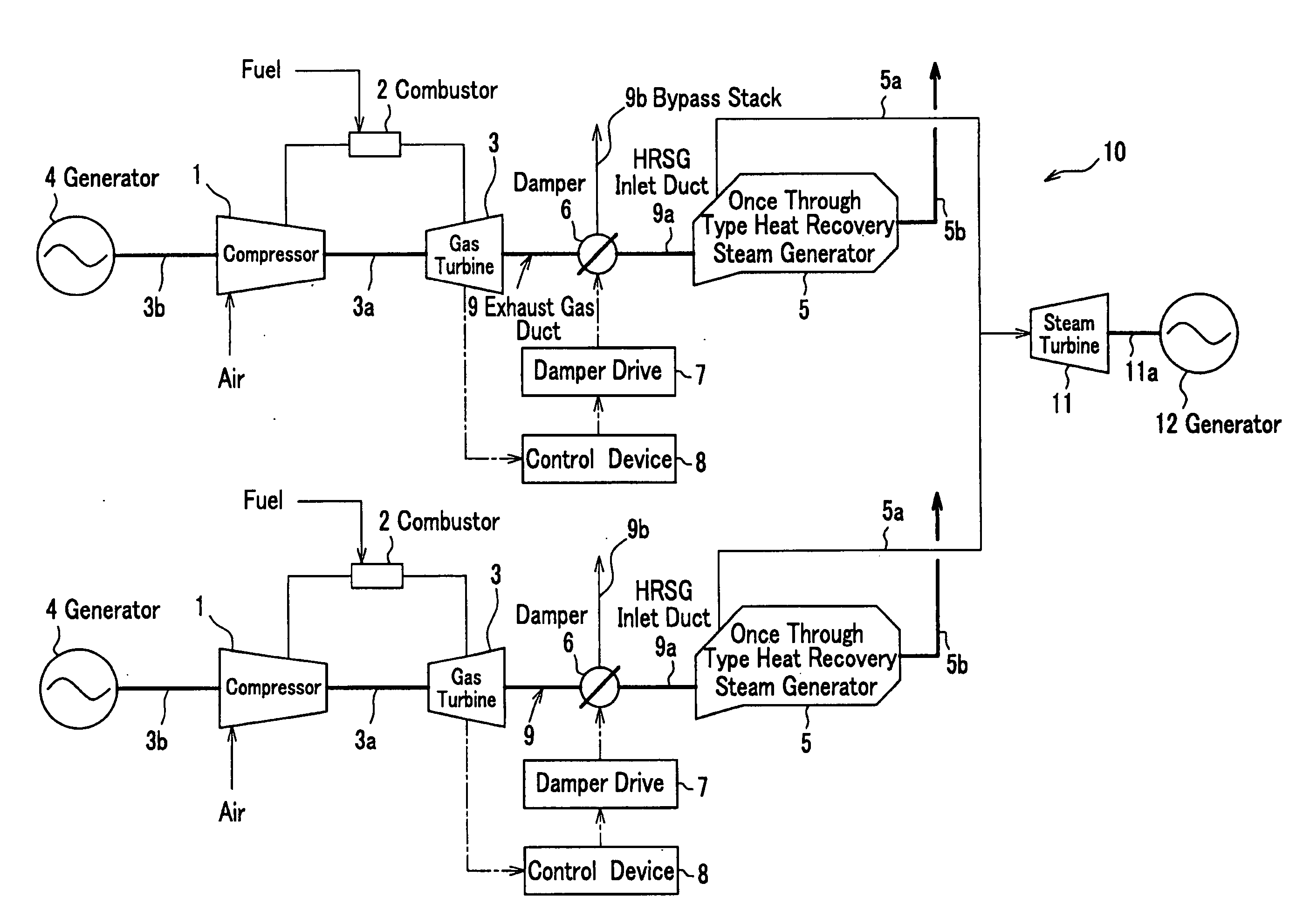

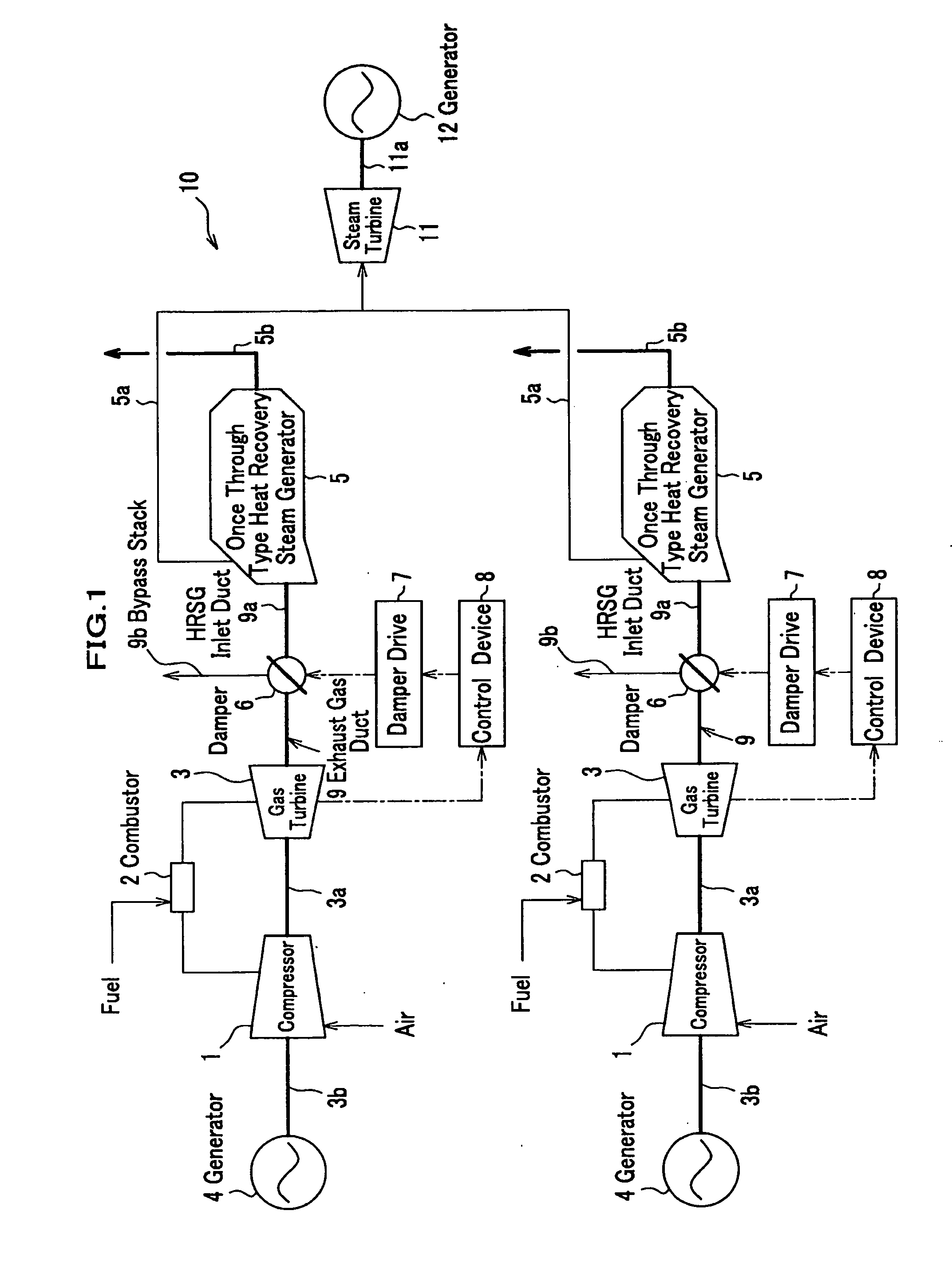

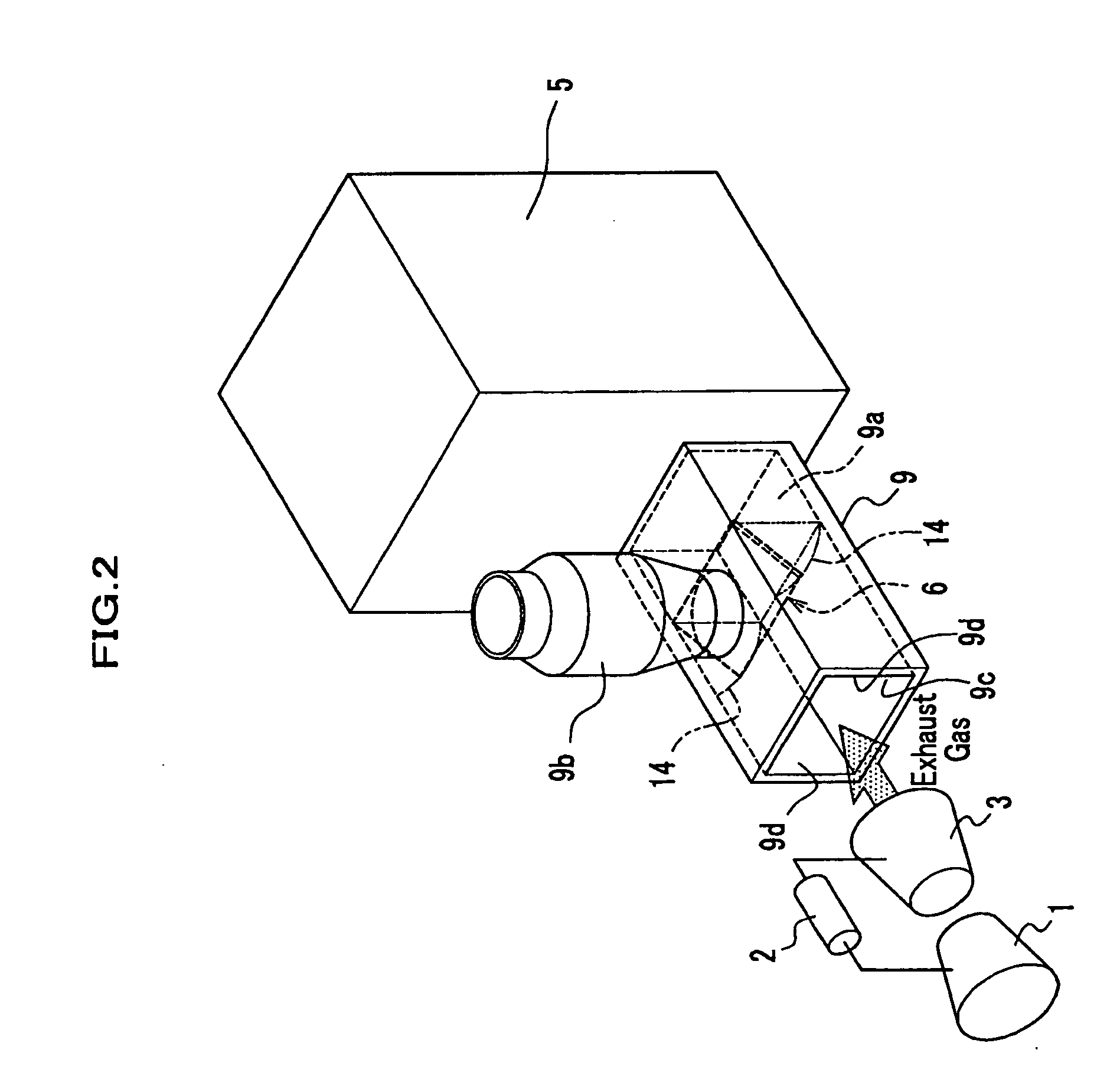

Fast start-up combined cycle power plant

InactiveUS20050268594A1Avoid vibrationReduce the amount requiredEngine fuctionsGas turbine plantsCombustorPower station

A combined cycle power plant of the present invention is configured of a compressor; a combustor for combusting compressed air compressed by the compressor together with supplied fuel; a gas turbine driven by a combustion gas exhausted from the combustor; a heat recovery steam generator for recovering high temperature exhaust heat exhausted from the gas turbine; a steam turbine driven by steam obtained from the heat recovery steam generator; and an exhaust gas duct having an HRSG inlet duct that is provided between the gas turbine and the heat recovery steam generator and introduces an exhaust passage into the heat recovery steam generator, and a bypass stack that leads the exhaust gas outside, wherein the exhaust duct is configured of a damper, a damper drive for changing any of angle and opening of the damper, and a guide mechanism for preventing a vibration of the damper.

Owner:THE TOKYO ELECTRIC POWER CO INC +1

Method for production of high pressure steam from produced water

InactiveUS7591309B2Drying using combination processesSolid sorbent liquid separationChemical treatmentWater flow

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

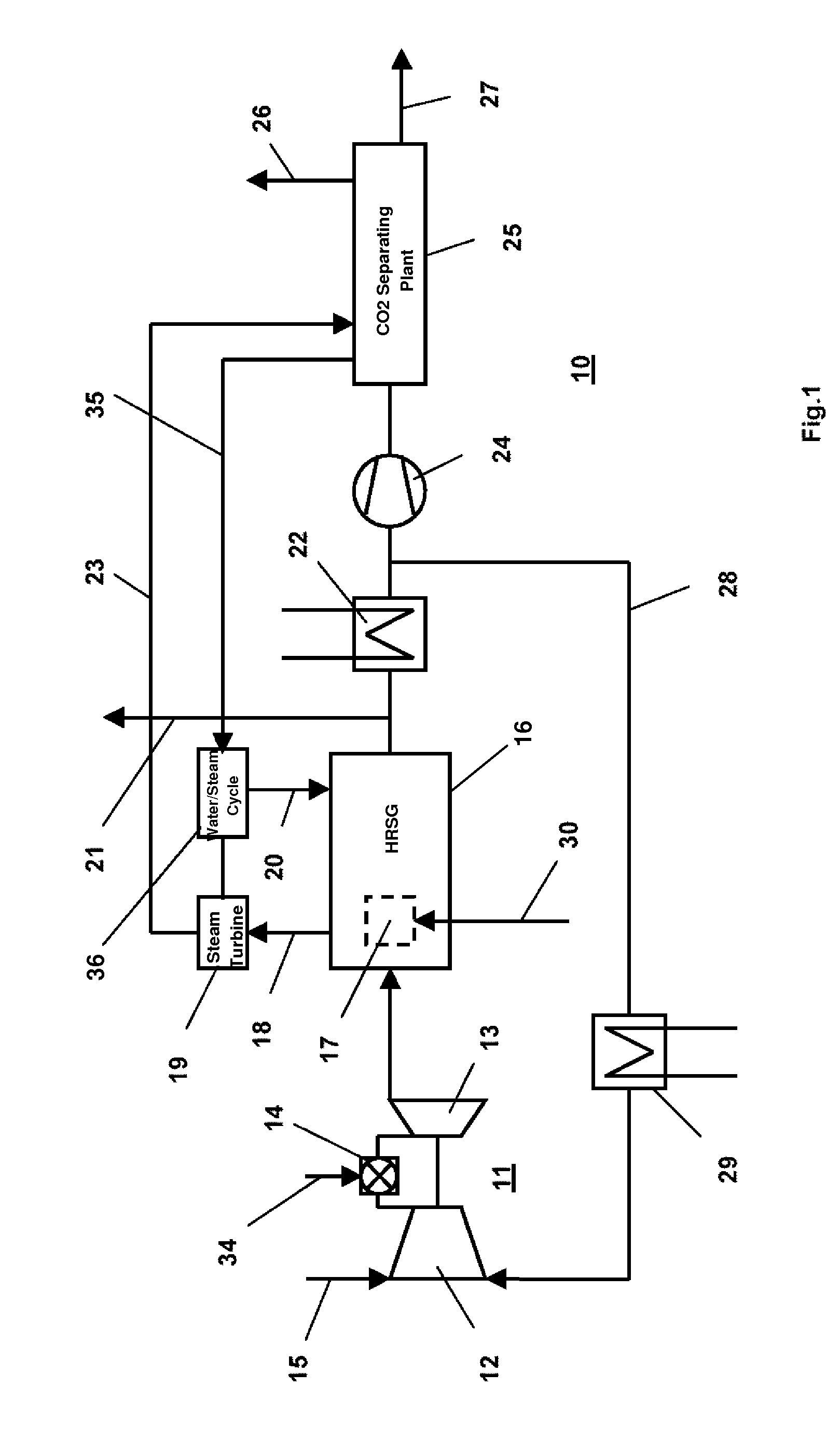

Combined-cycle power plant with exhaust gas recycling and CO2 separation, and method for operating a combined cycle power plant

InactiveUS8424282B2High outputReduce probabilityGas turbine plantsDirect carbon-dioxide mitigationPower stationExhaust fumes

Owner:GENERAL ELECTRIC TECH GMBH

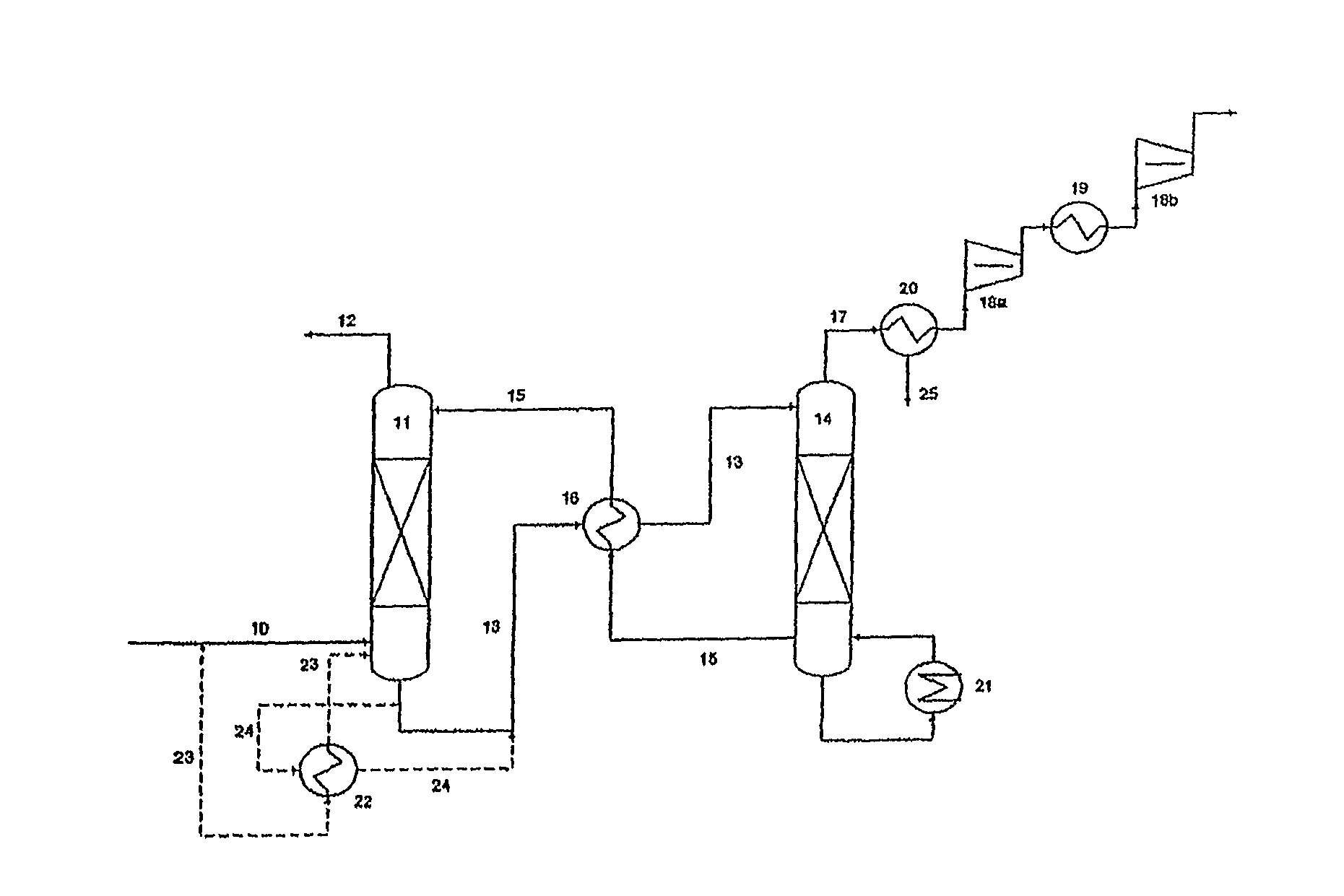

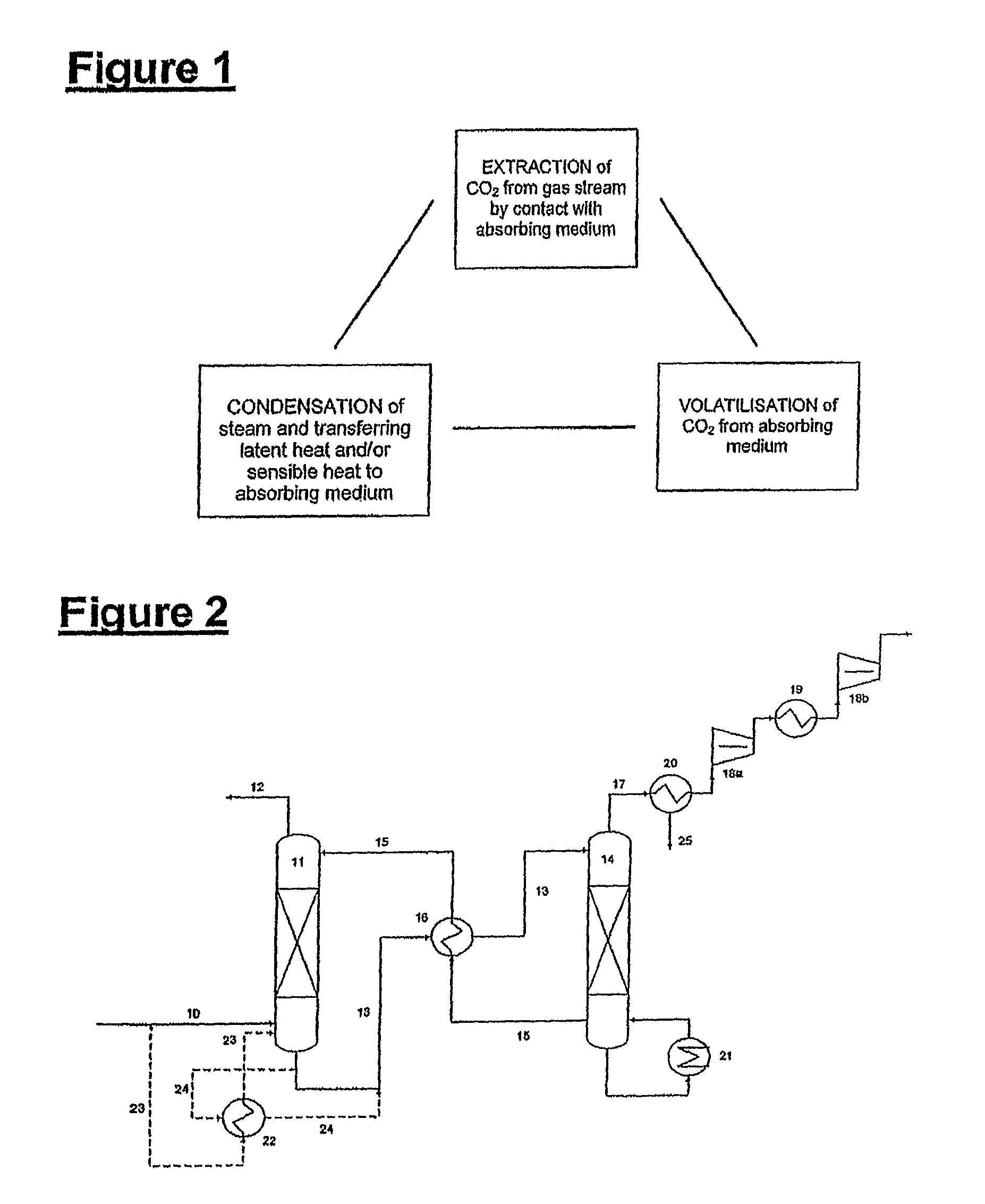

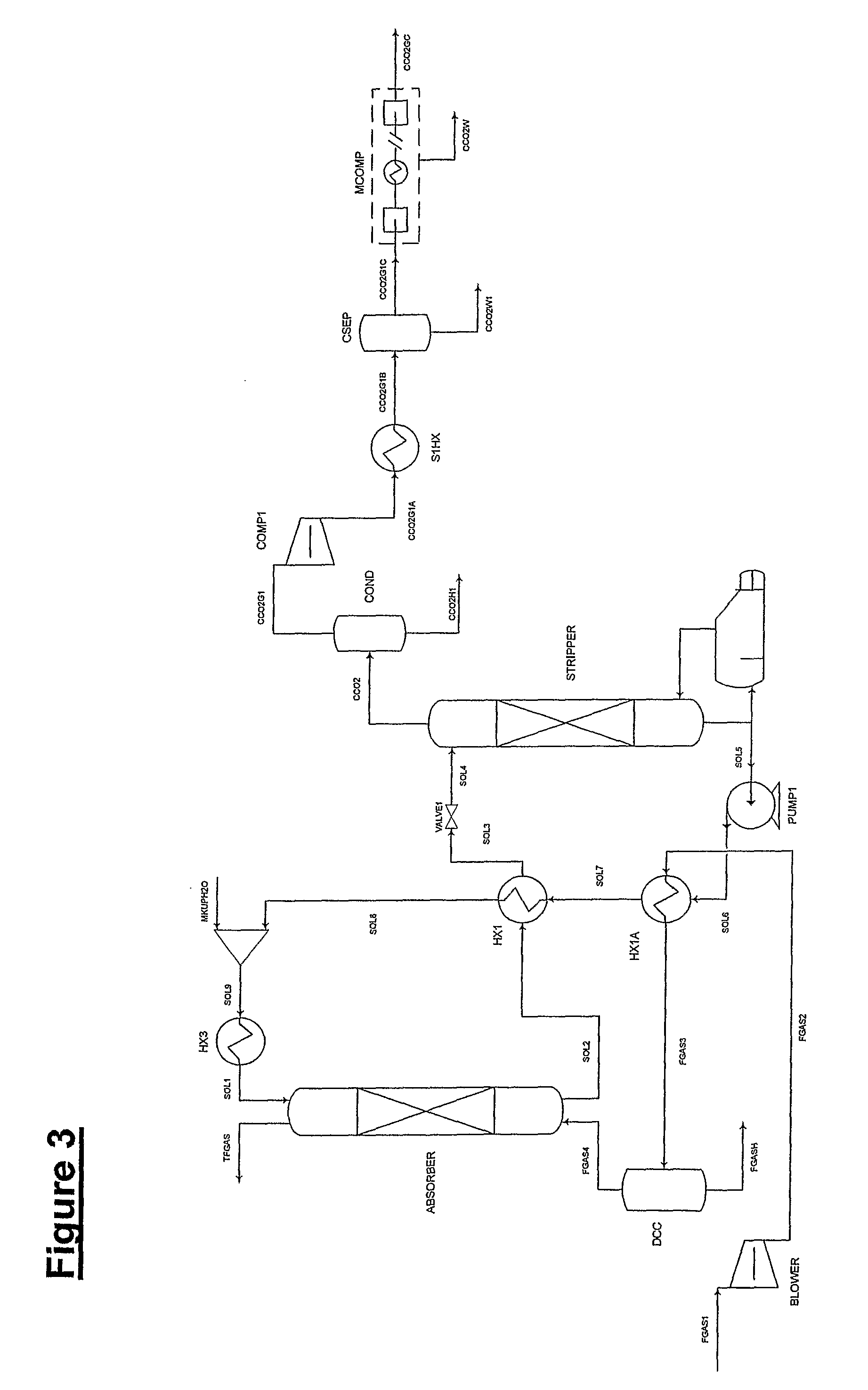

Plant and process for removing carbon dioxide from gas streams

ActiveUS7976803B2Minimizing overall energy requiredAssist in volatilizationFluidized bed combustionIndirect heat exchangersComponents of crude oilCoal

Owner:KC8 CAPTURE TECH LTD

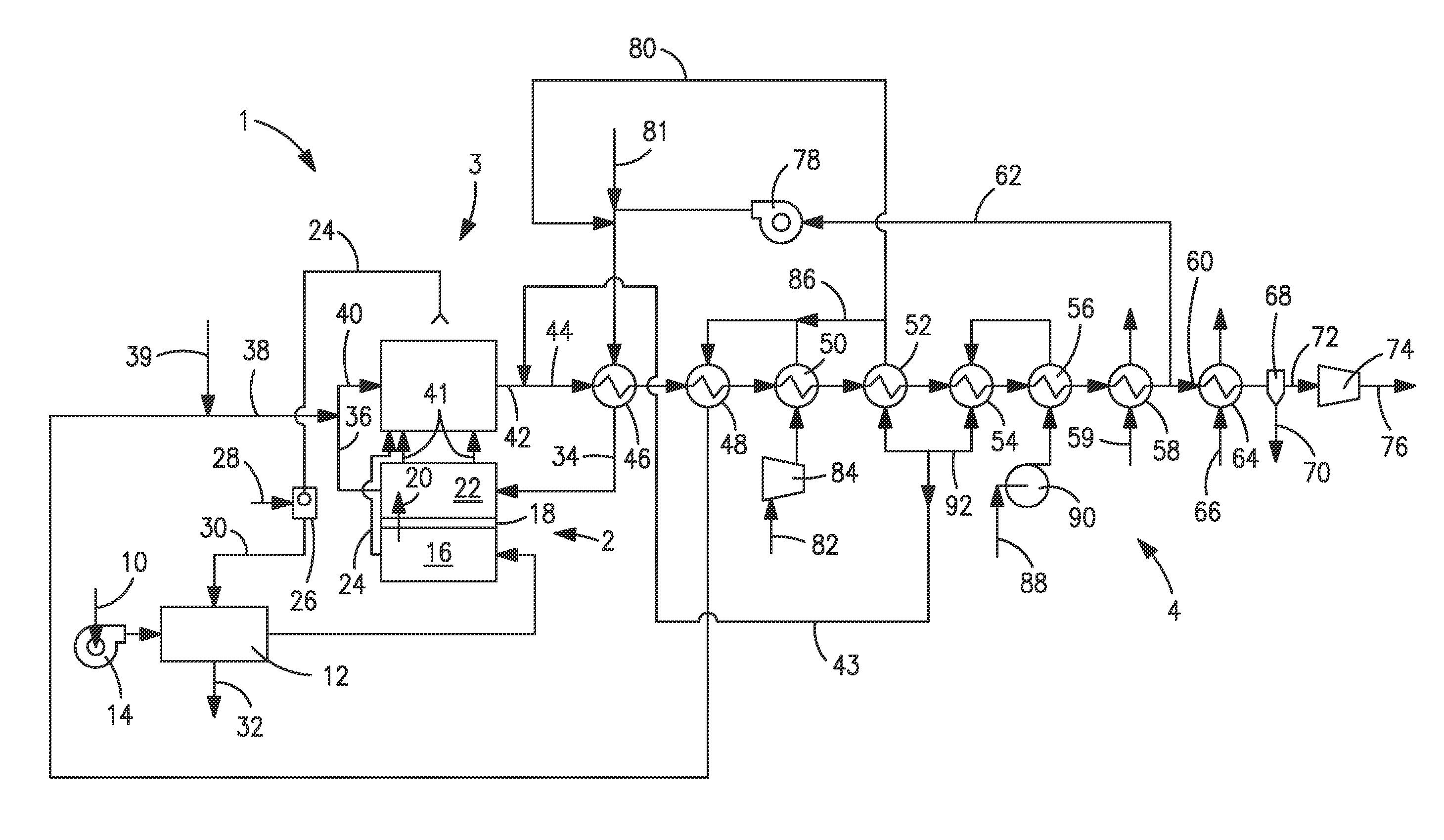

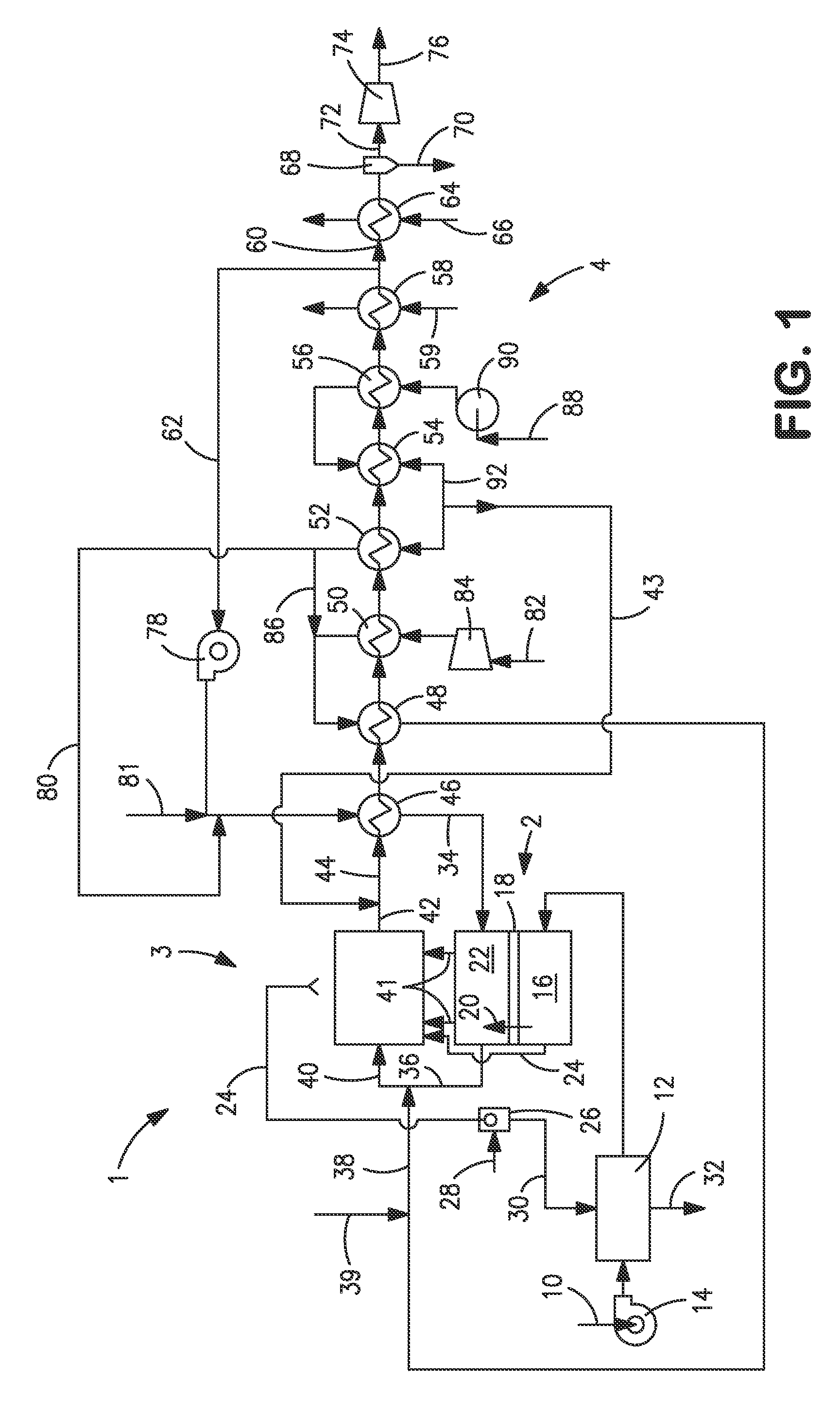

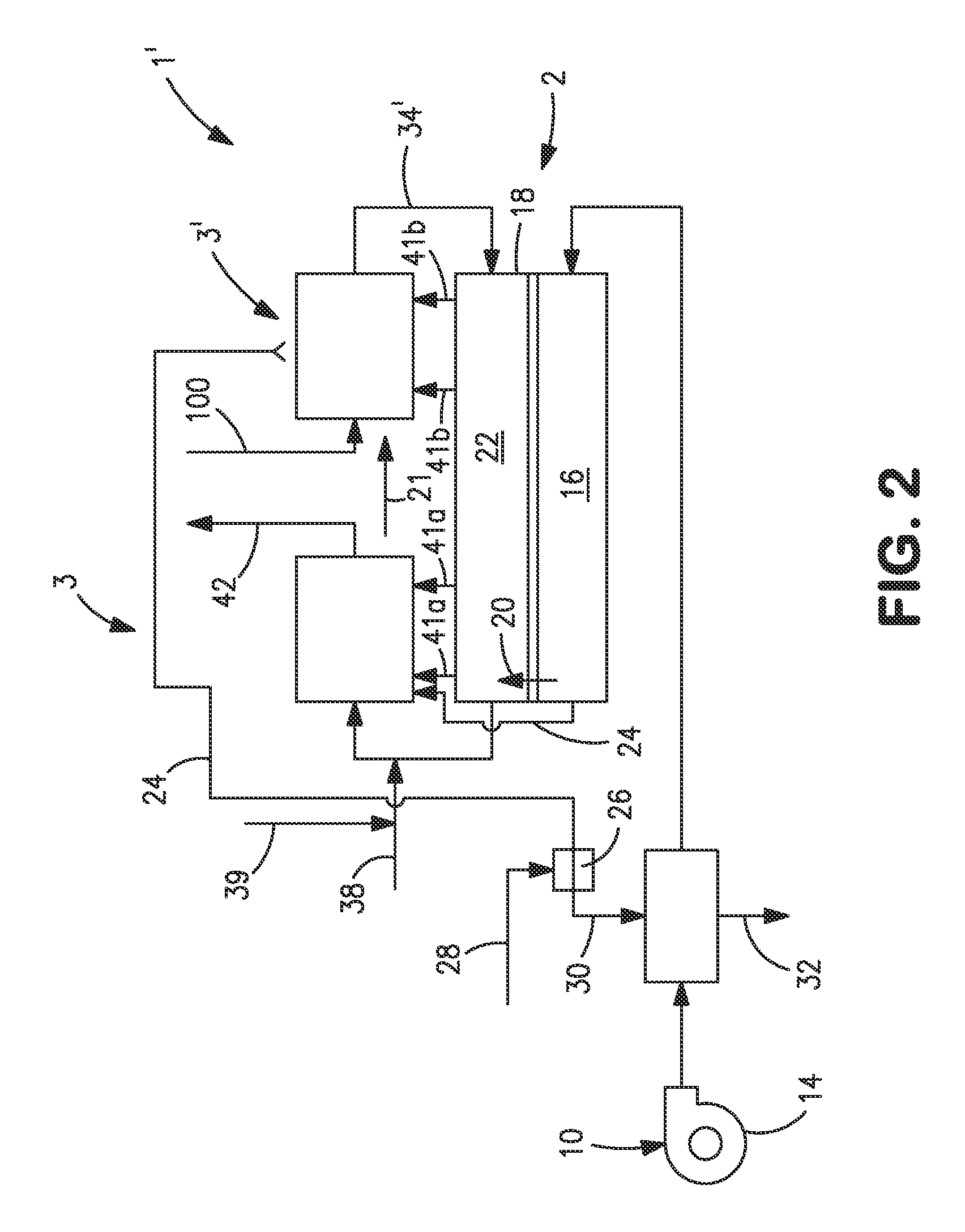

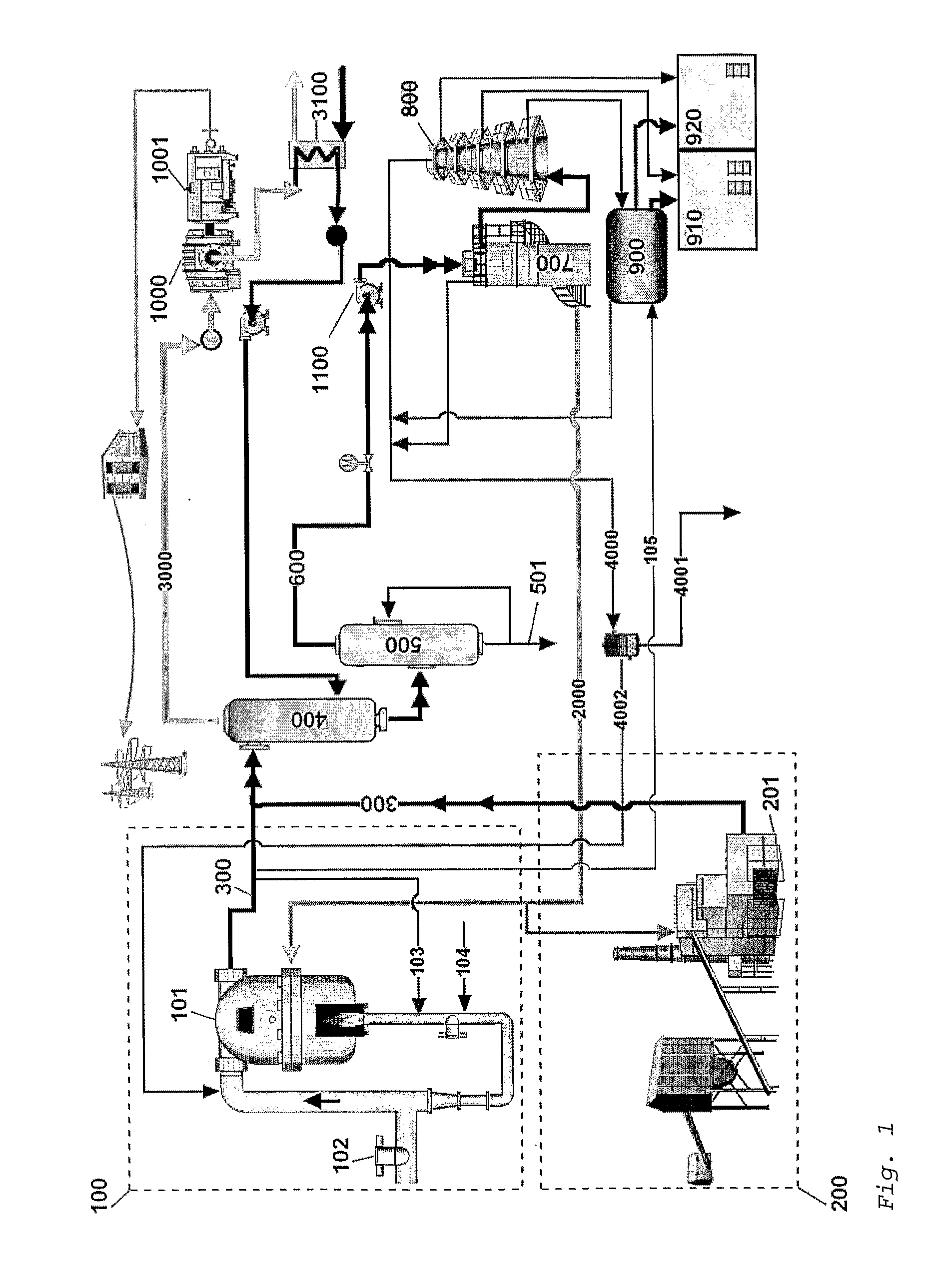

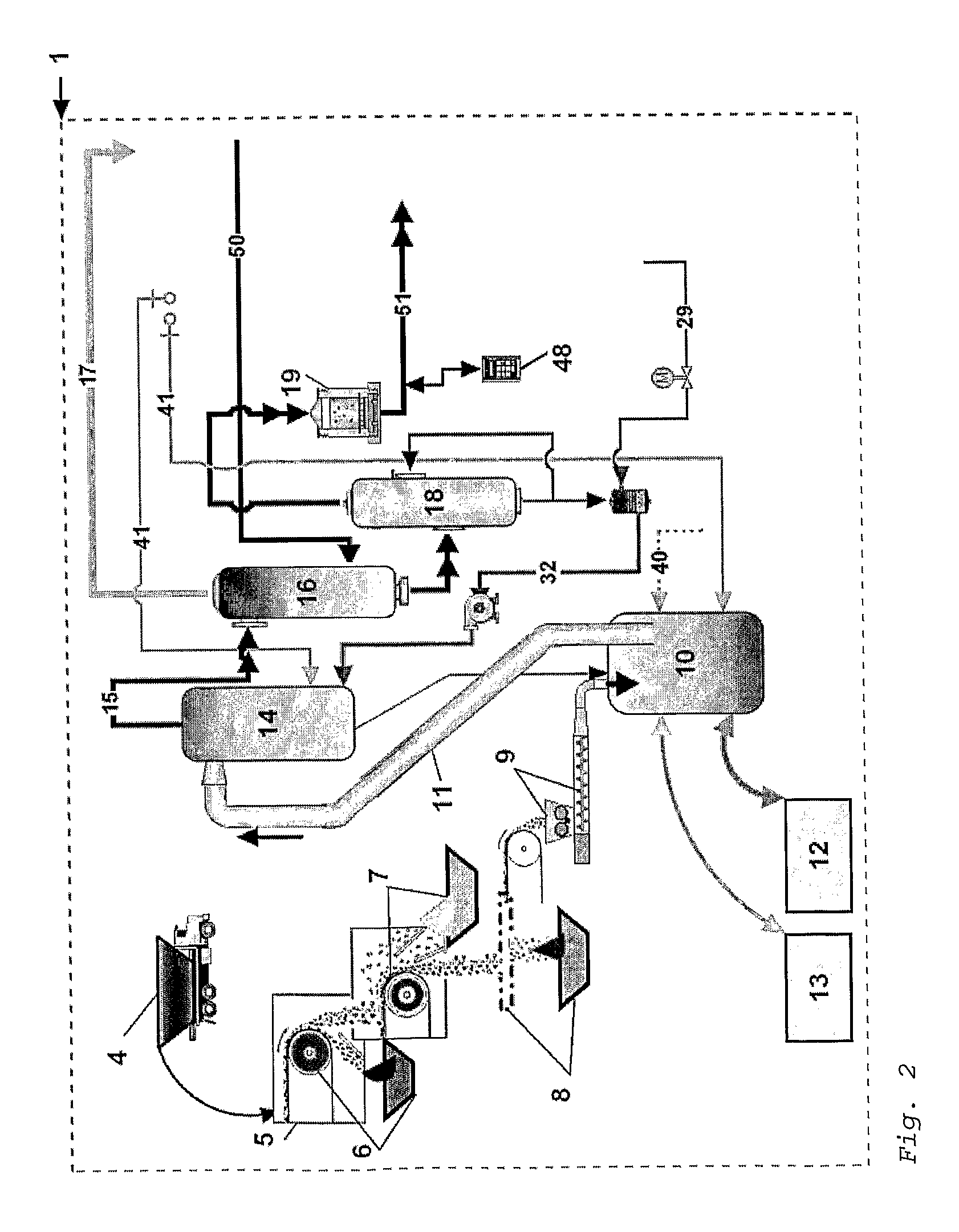

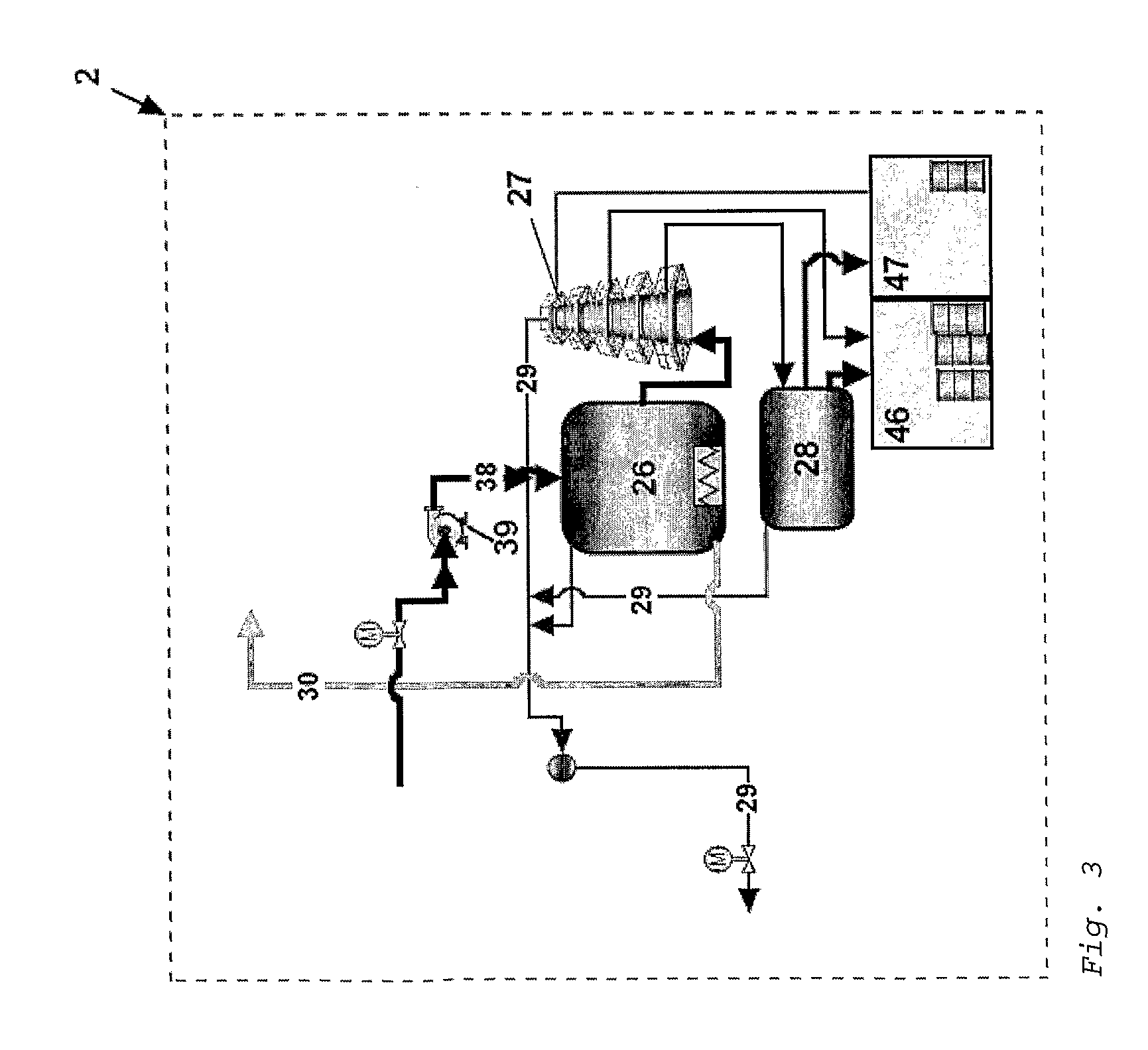

Waste to liquid hydrocarbon refinery system

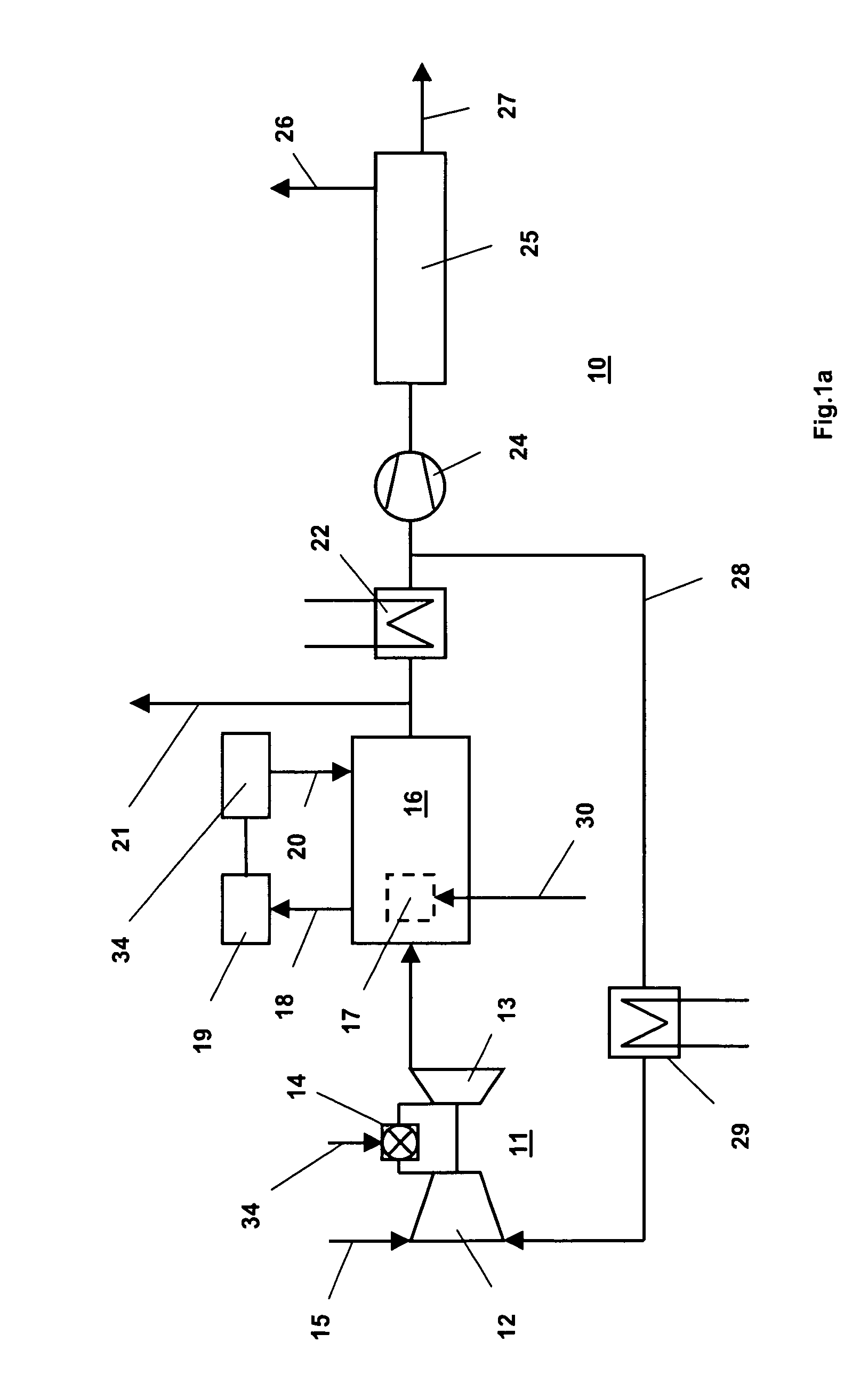

InactiveUS20110158858A1Eliminate concernsReduce dependenceDirect heating destructive distillationCombustible gas catalytic treatmentLiquid wasteCogeneration

A Waste to Liquid Hydrocarbon Refinery System that transforms any municipal solid wastes and hazardous industrial wastes, Biomass or any carbon containing feedstock into synthetic hydrocarbon, particularly, but not exclusively, diesel and gasoline and / or electricity and co-generated heat, comprising three major subsystems: i) the Pyro-Electric Thermal Converter (PETC) (10) and Plasma Arc (PA) waste and biomass gasification subsystem (1); ii) the hydrocarbon synthesis subsystem (2); and iii) the electricity generation and heat co-generation subsystem (3).

Owner:ALVES RAMALHO GOMES MARIO LUIS

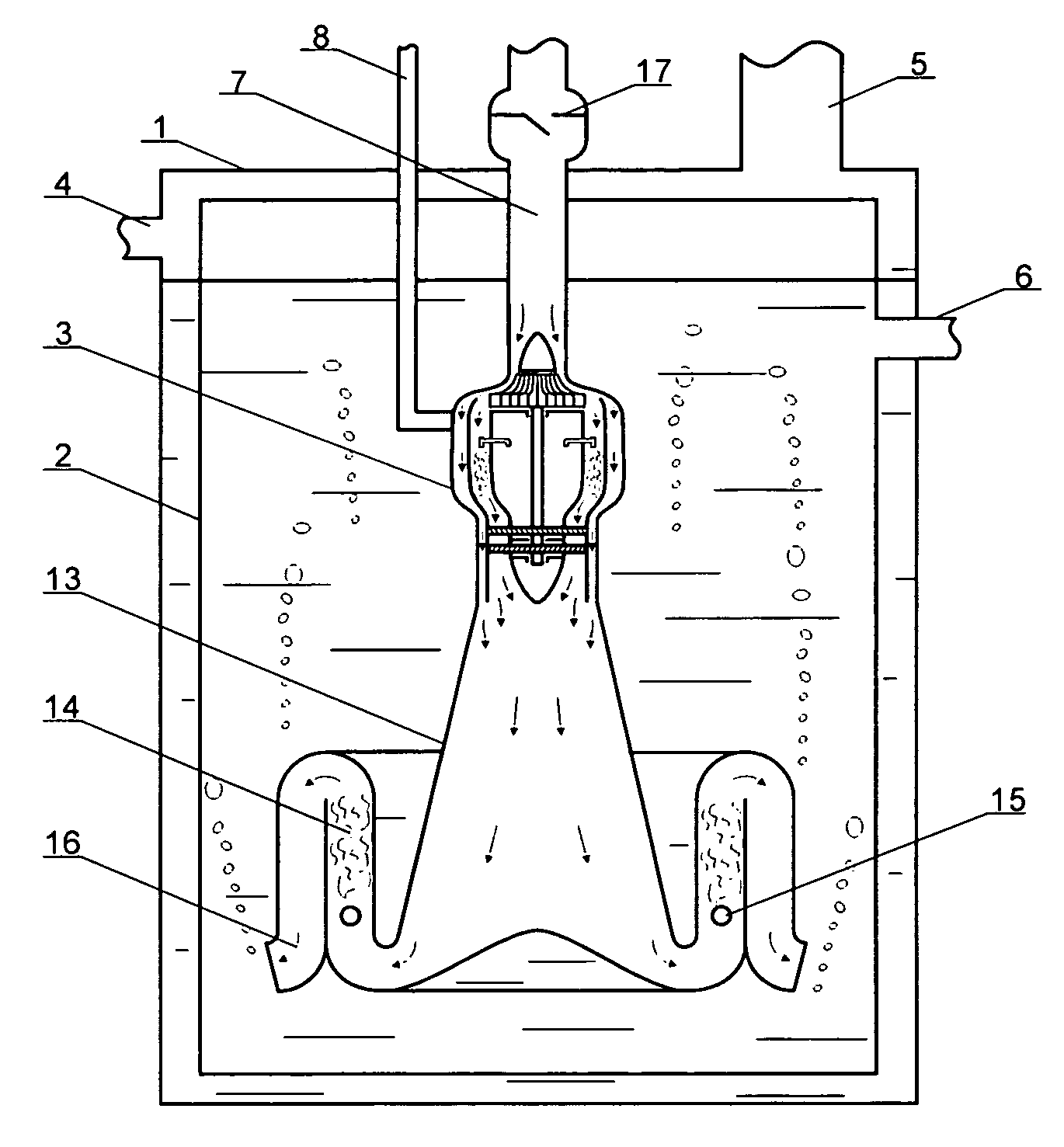

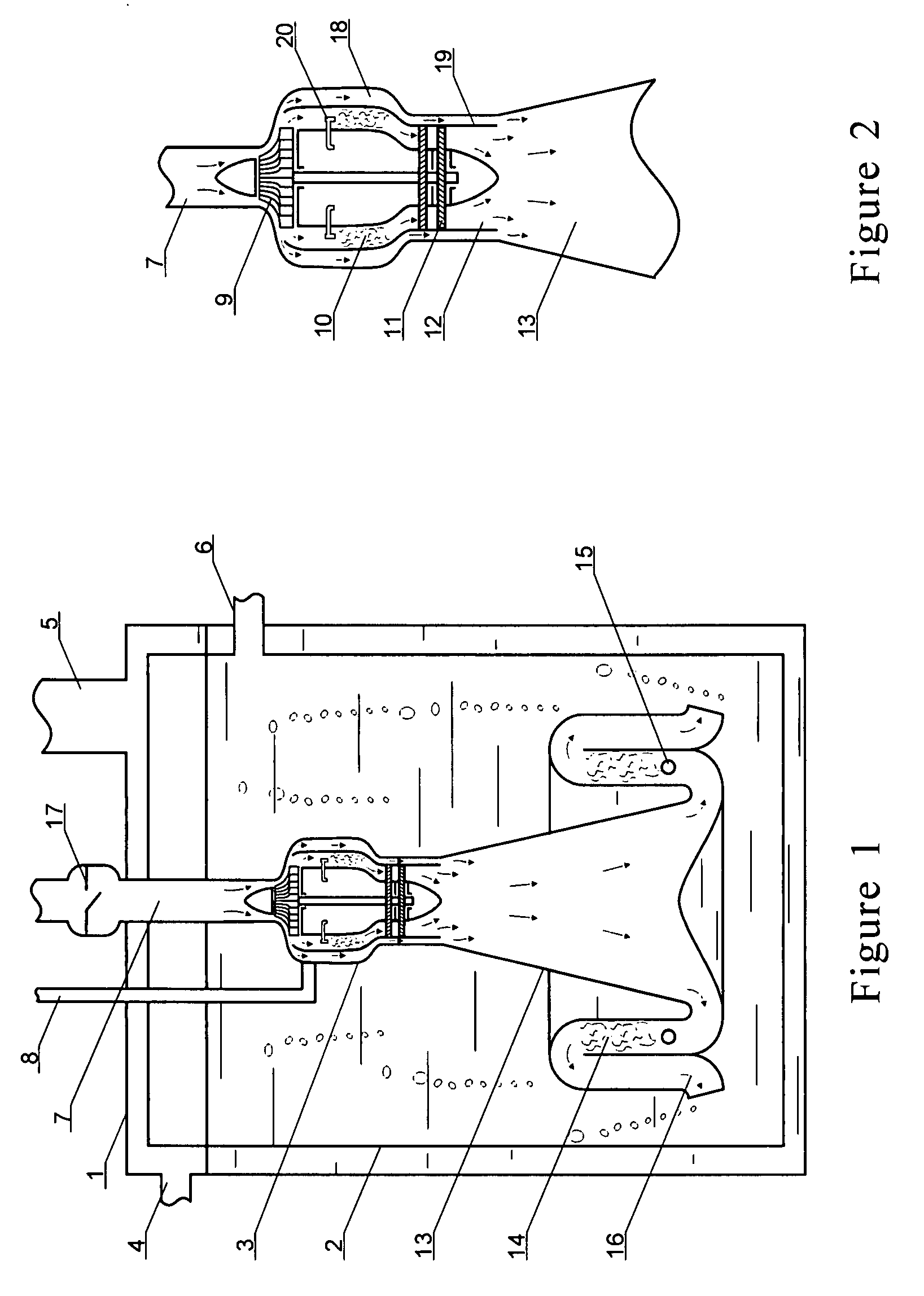

Method and device of turbine submerged combustion boiler

InactiveUS20080035078A1Improve energy efficiencySteam generation using pressureGas turbine plantsComing outHigh energy

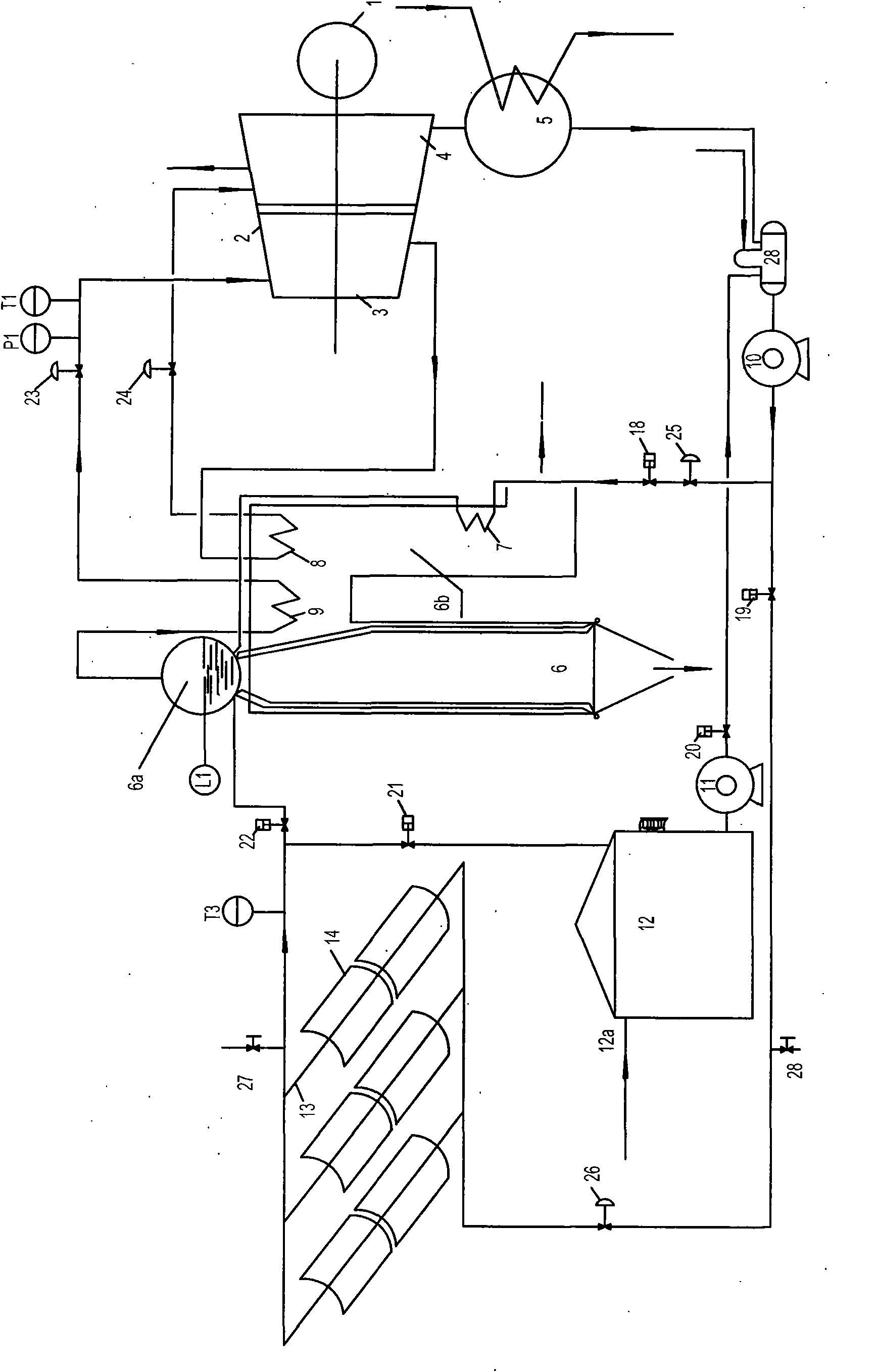

The invention is about a submerged combustion method and the device; in details, it is a submerged combustion method and the device utilizing turbine heat engine principle. In the invention, turbine power combustion means is used and substituted conventional submerged combustion system that must equip air blowing means. The high temperature gases generated from the combustion within the turbine power combustion means will do works on turbine, which will drive the air compressor means of the turbine power combustion means to induce air for combustion, and will drive the second-time complete combustion of high temperature gases and the complement fuel, and then the gases will come out from water bottom against tank water pressure and carry out heat interchange with tank water. The turbine submerged combustion boiler device of the invention need not equip air blowing means additionally which would consume energy. So it has high energy efficiency and a simple system structure. And it has features of high heat interchange rate, stable long term heat efficiency, environmental protection, etc.

Owner:LI WEICHENG

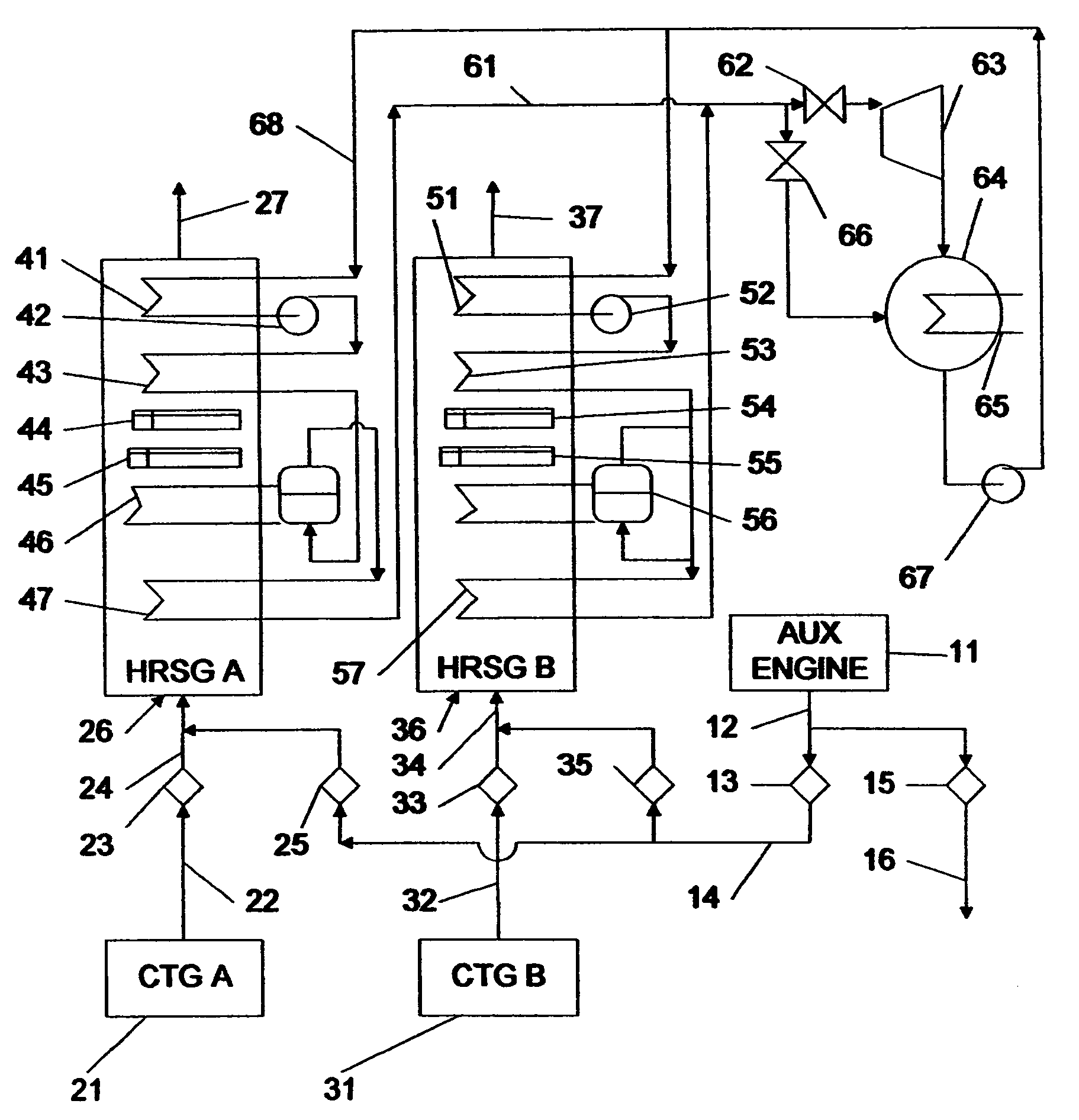

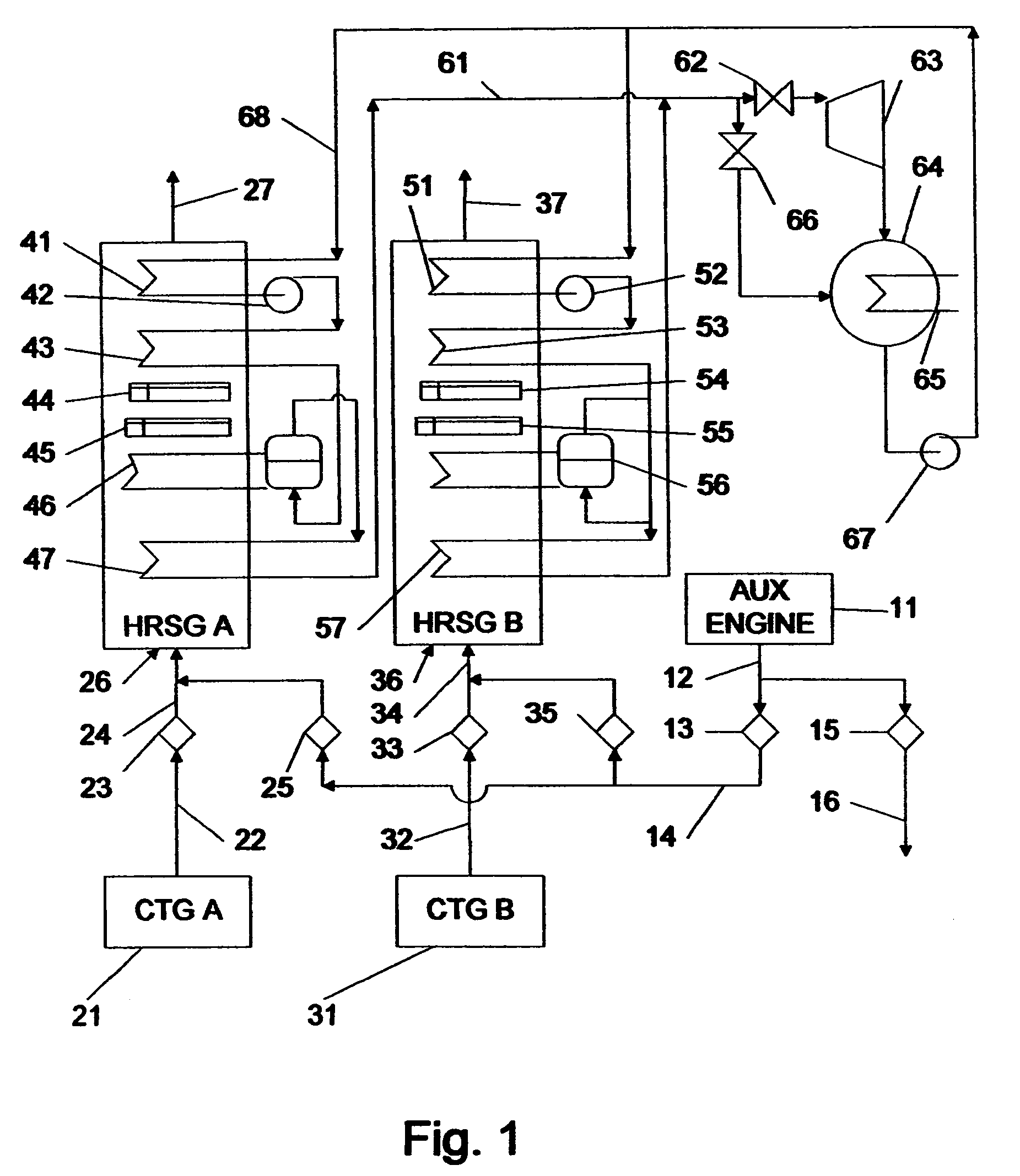

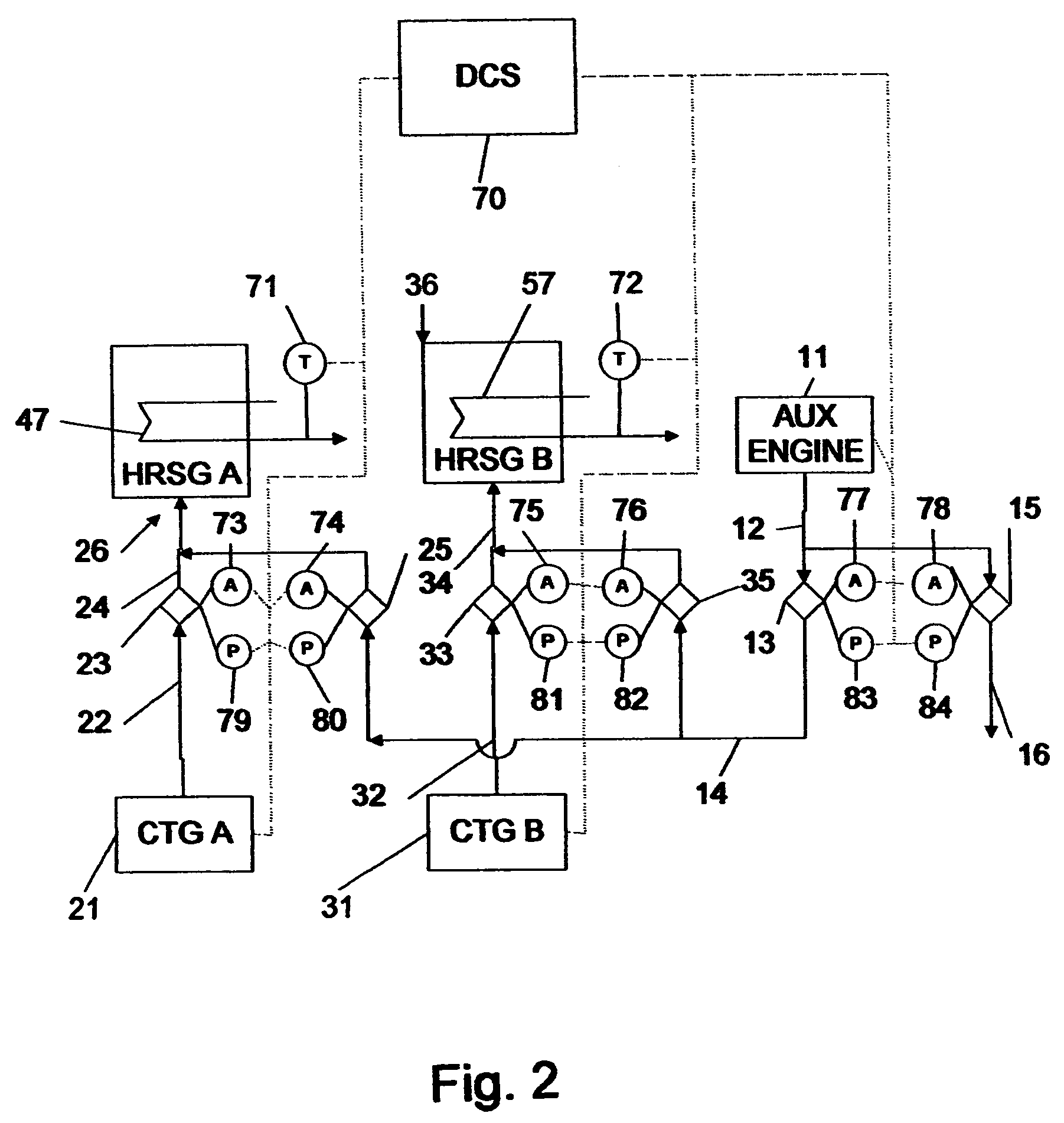

Method and apparatus for combined cycle power plant operation

InactiveUS7107774B2Stress minimizationEmission reductionTurbine/propulsion fuel supply systemsEngine fuctionsPower stationProcess engineering

Owner:WASHINGTON GROUP INTERNATIONAL

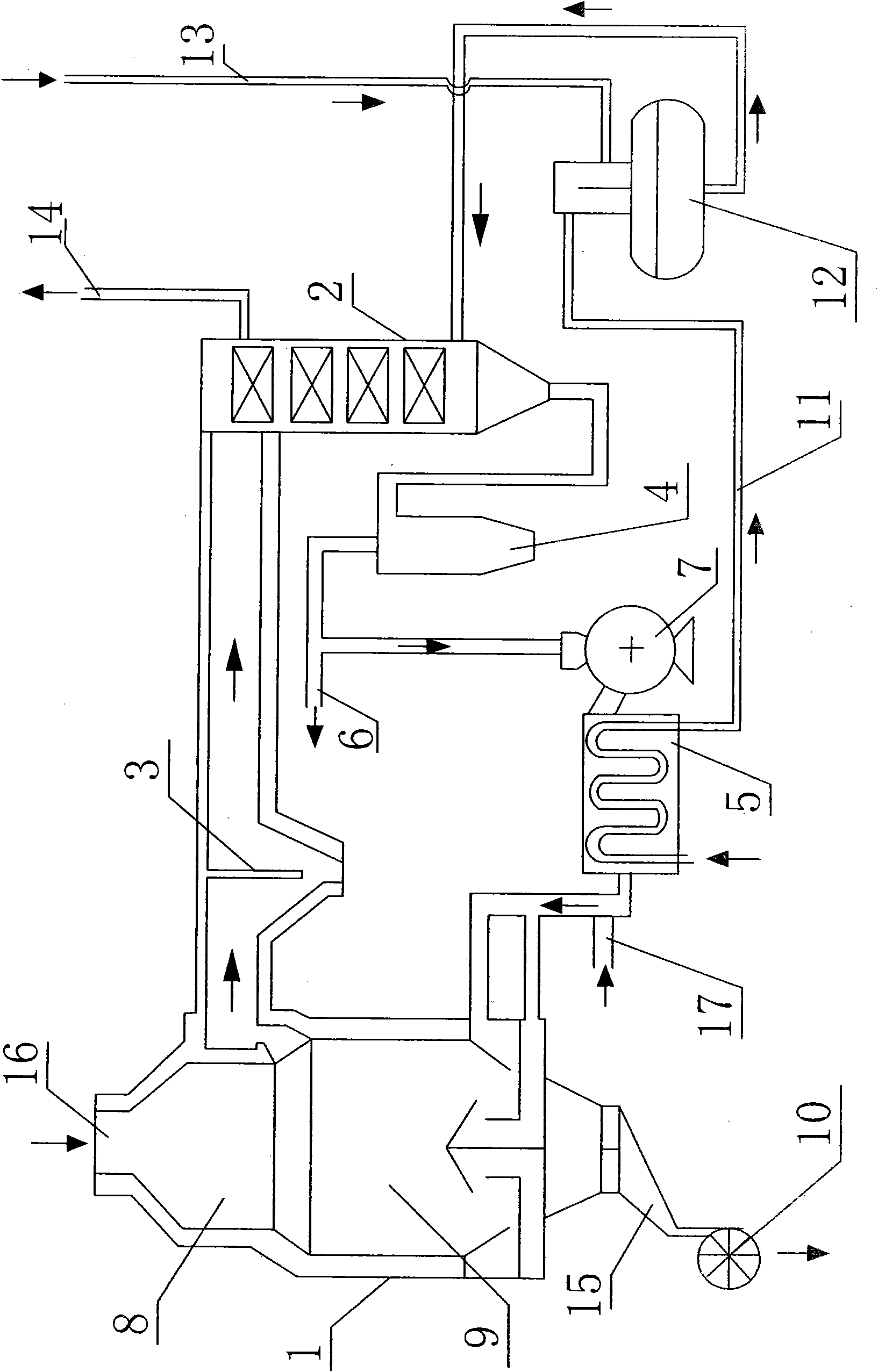

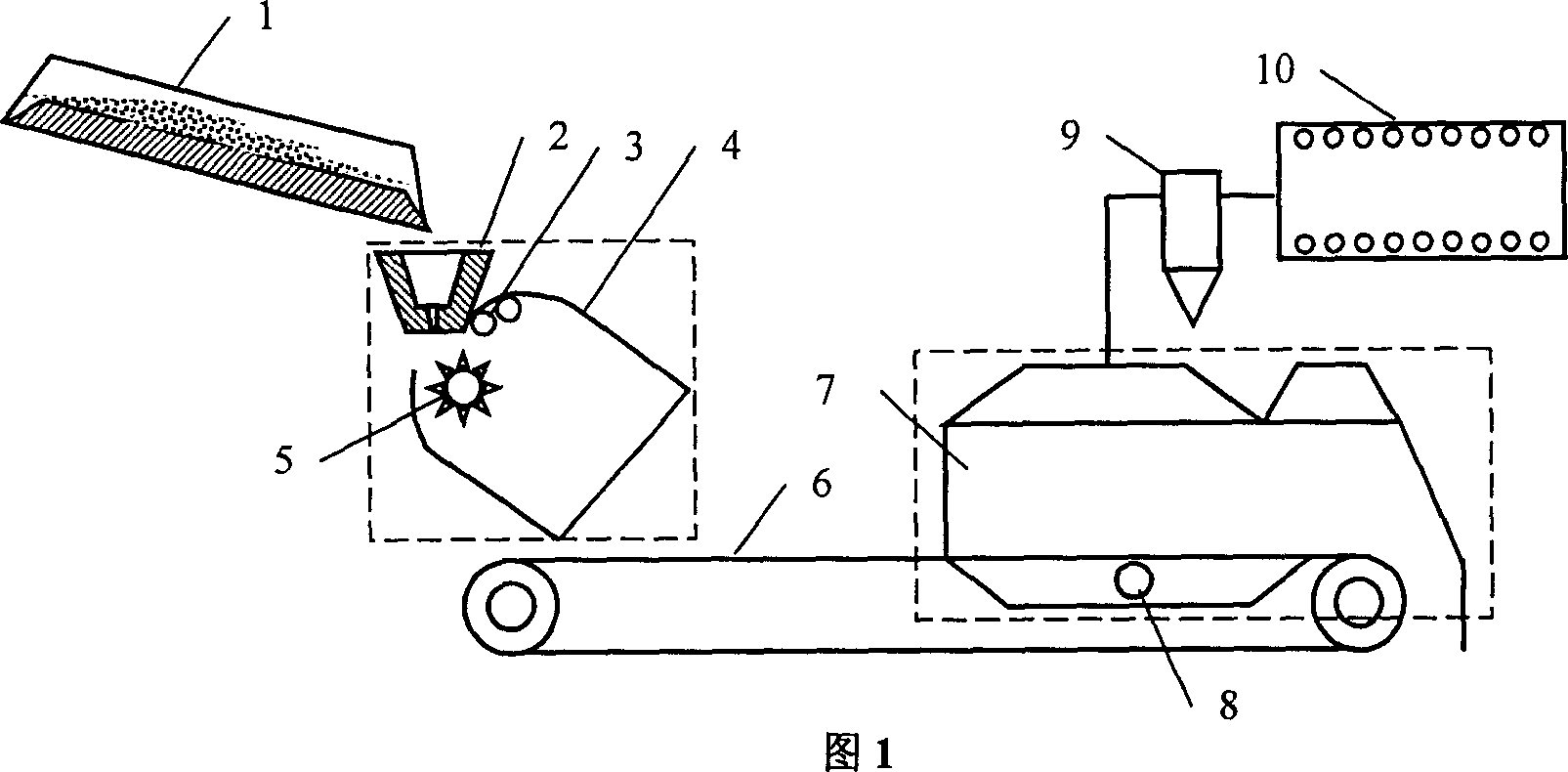

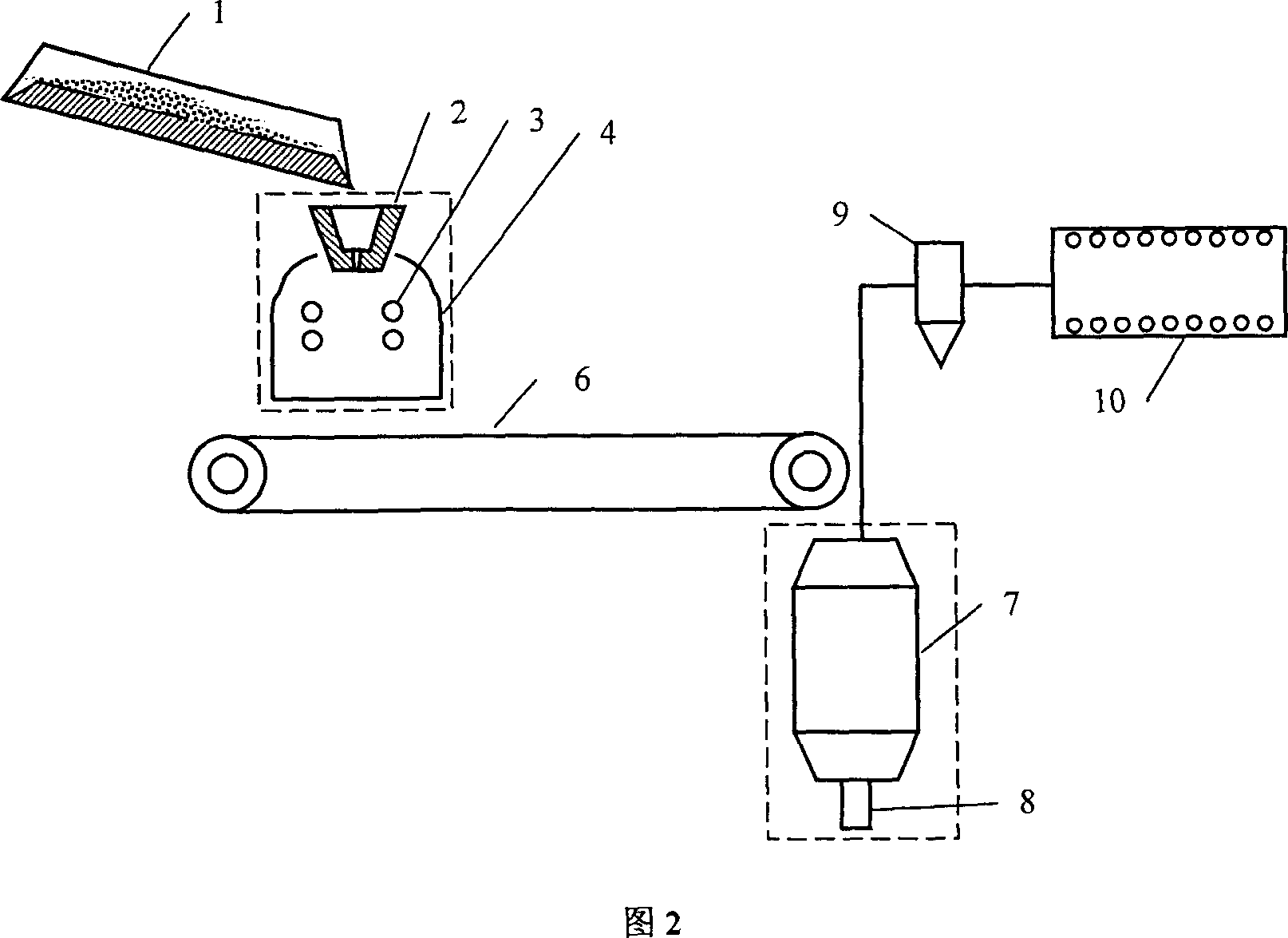

Grading recycling and cascade utilization method of residual heat resources in sintering process and device thereof

ActiveCN101655320AOvercome congenital deficienciesSolve the problem of air leakageLiquid degasificationIncreasing energy efficiencyThermodynamicsEngineering

The invention relates to a method for effectively recycling and utilizing residual heat resources in a sintering process and a device thereof. The invention has the main contents that a fiery sinter ore is filled in a vertical and sealed tank body, air is led from the tank body so as to cool the sinter ore, sensible heat of the sinter ore is almost totally carried by the air and is exhausted fromthe top of the tank body at the same time; and hot air is led into a residual heat boiler to generate steam to synchronously generate power. Compared with the prior sintering residual heat recycling and utilization technology, the invention has higher residual heat recycling utilization ratio, effectively reduces the energy consumption of the sintering procedure with reasonable and effective method, simple apparatus and easy operation, and is relatively favorable for popularization and application in the technical field of residual heat resource recycling and utilization in a metallurgy process.

Owner:NORTHEASTERN UNIV

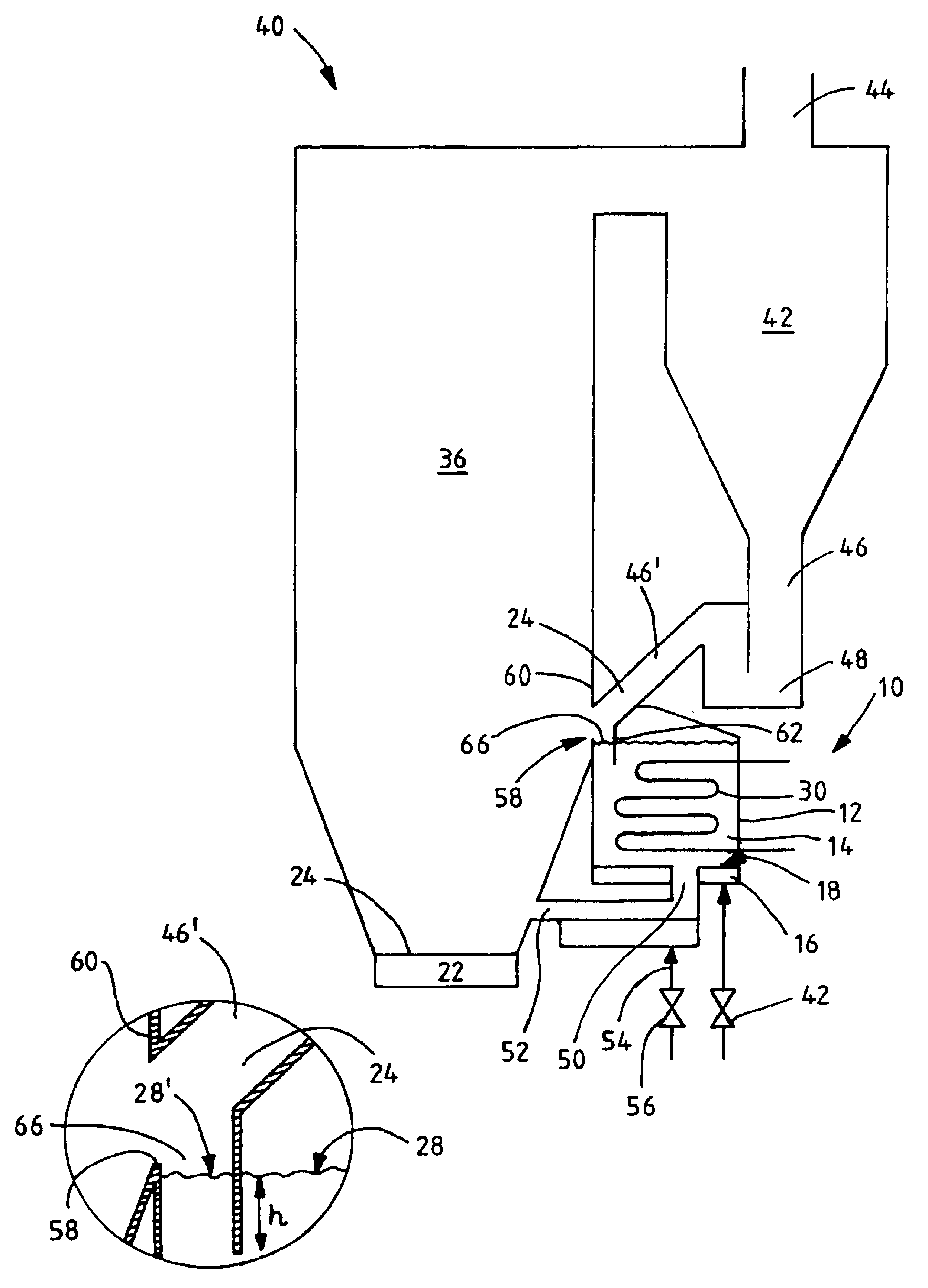

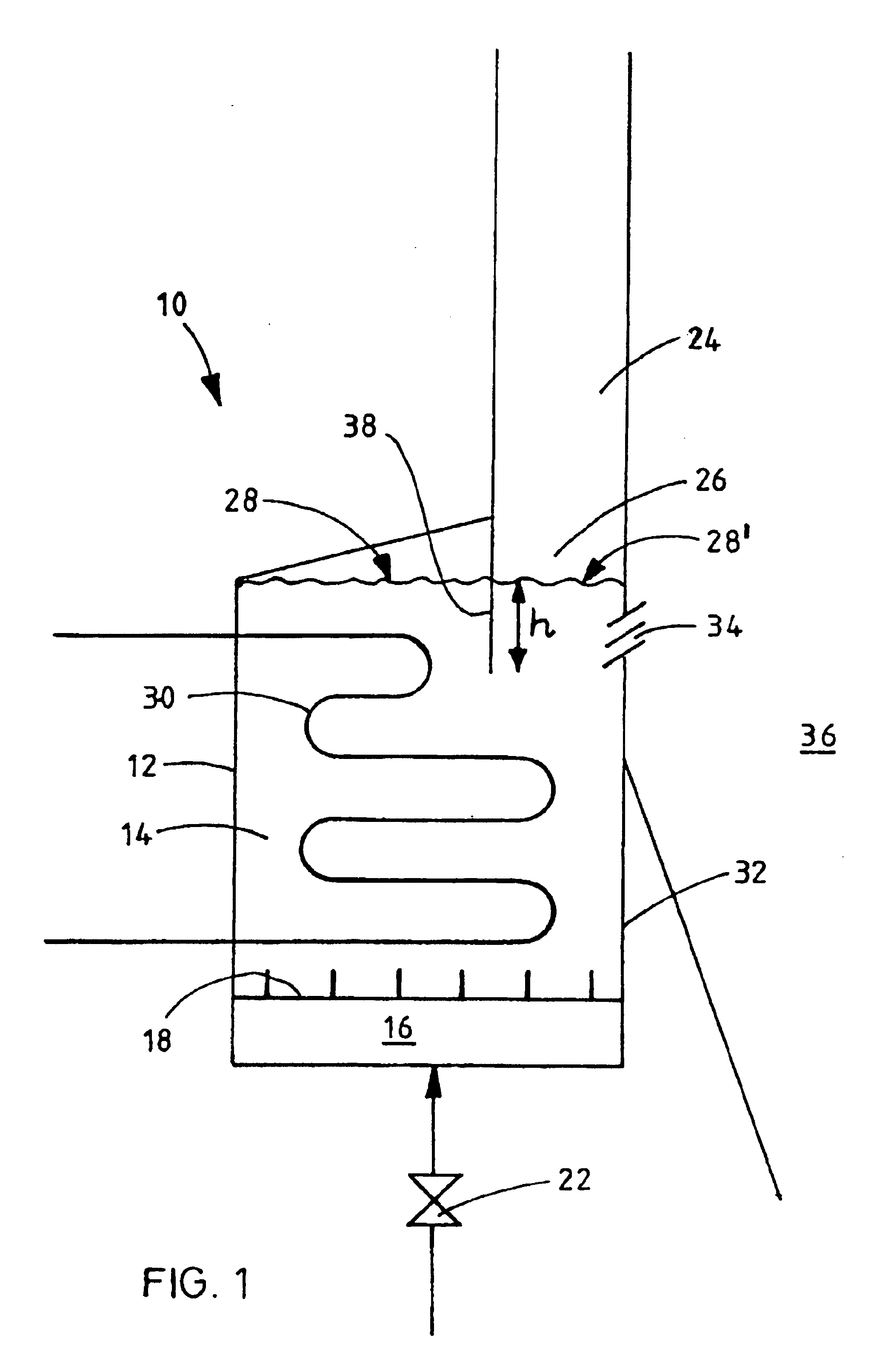

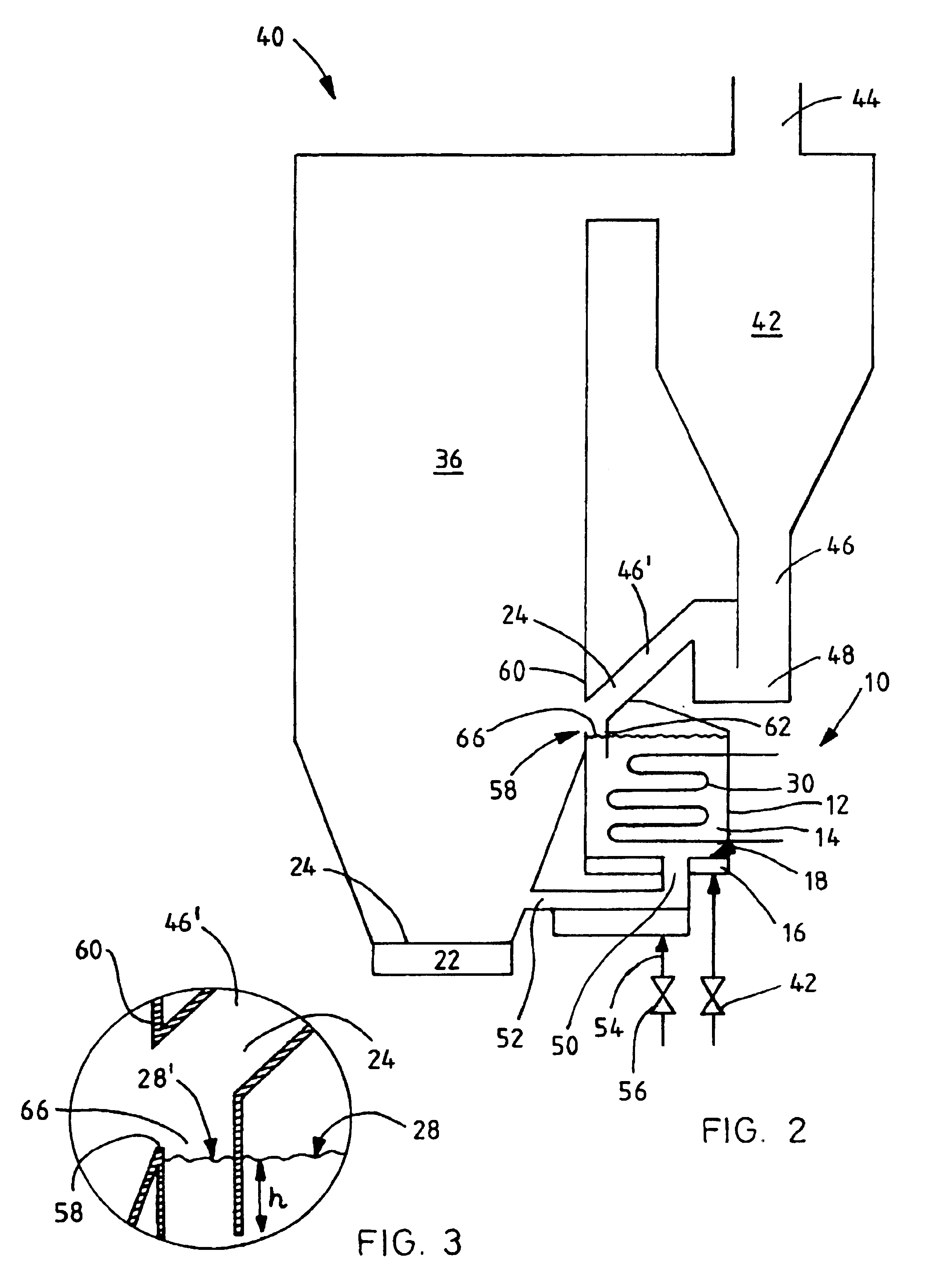

Method and apparatus in a fluidized bed heat exchanger

InactiveUS6962676B1Easy to adjustEfficient and wide-ranging adjustment of heat transferFluidized bed combustionFluidised-bed furnacesFluidized bedEngineering

A method and an apparatus in a fluidized bed heat exchanger including a heat exchange chamber having a fluidized bed of solid particles, heat transfer surfaces, an inlet, and an outlet. Particles are fed through the inlet onto the upper surface of the bed of solid particles by a guiding channel. The guiding channel, which extends from above the upper surface of the bed of solid particles to the surface thereof, or to below the surface, passes the solid particles to the restricted area of the surface. The outlet is formed in the area of the guiding channel to remove particles from the area delimited by the guiding channel. Uncooled particles can thus be removed from the heat exchange chamber.

Owner:FOSTER WHEELER ENERGIA OY

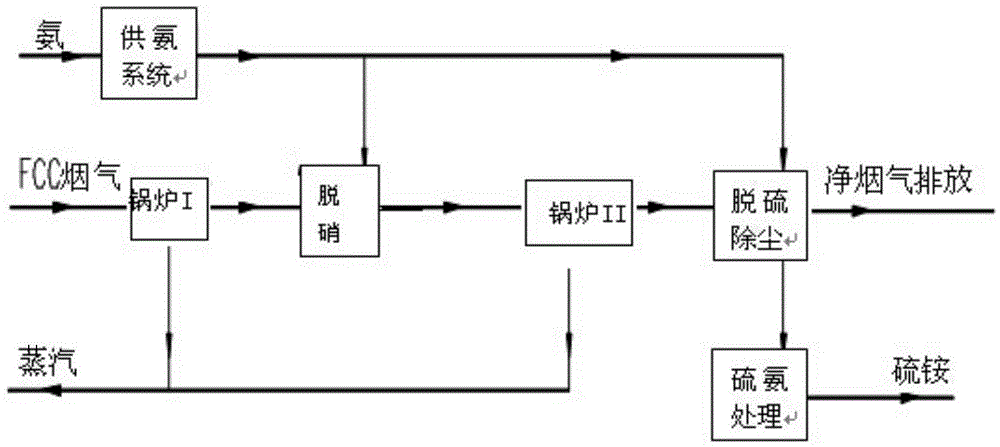

Ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas

ActiveCN104941423ALess investmentLow running costUsing liquid separation agentEnergy inputNitric oxidePetroleum

The invention relates to an ammonia desulfurization and denitrification dedusting method and device utilizing catalytic cracking regeneration flue gas, comprising the following steps: enabling high-temperature catalyst regeneration flue gas coming from a catalytic cracking unit and containing catalyst dust to firstly enter a waste heat boiler I, reducing the temperature of the flue gas to 280-430 DEG C, wherein the heat of the flue gas is externally supplied by steam produced by the waste heat boiler I; enabling flue gas at temperature of 280-430 DEG C to enter a denitrification device for denitrification and enter a waste heat boiler II through an outlet flue after sufficiently reacting on the surface of a denitrification catalyst in a denitrification reactor; removing sulfur dioxide, nitric oxide and byproduct ammonium sulfate by taking ammonia as a reactant, and removing catalyst dust in the regeneration flue gas to achieve clean gas up-to-standard release; the three waste free release purifying method can be applied to catalytic cracking catalyst regeneration flue gas treatment in oil refining.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Radiant syngas cooler

A radiant syngas cooler used to contain and cool the synthesis gas produced by coal gasification processes employs radiant and convection surfaces in a specific arrangement to achieve a cost-effective, compact design.

Owner:THE BABCOCK & WILCOX CO

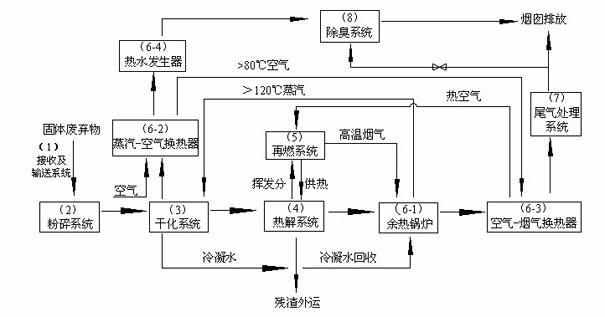

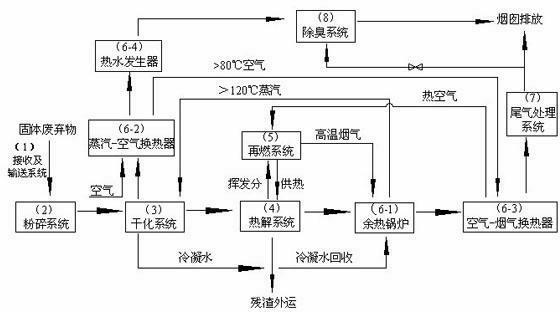

Novel process for pyrolysis of solid wastes

InactiveCN102537973AHas waste heat utilization valueAvoid consumptionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustionRoom temperature

The invention discloses a novel process for pyrolysis of solid wastes. According to the existing pyrolysis technology, the solid wastes with low calorific values and high moisture content are difficult to treat, and effects of being completely harmless, reduced and recycled cannot be achieved. The novel process provided by the invention comprises the following steps of: uniformly crushing the solid wastes by a crushing system and conveying the crushed solid wastes to a drying system to be dried; carrying out the pyrolysis in a pyrolysis system and treating a pyrolyzed product by a re-burning system to provide energy needed by the pyrolysis system; conveying high-temperature smoke into a residual heat boiler to generate saturated vapor with a temperature which is higher than 1000 DEG C; carrying out heat exchange on the vapor by a vapor-air heat exchanger; after raising the temperature of normal-temperature air, conveying the air into the vapor-air heat exchanger to carry out the heat exchange with output smoke of the residual heat boiler; conveying the hot air into the pyrolysis system and carrying out processes of cooling combustion smoke, de-acidifying and removing dust on the smoke of the residual heat boiler through an exhaust gas treatment system; receiving uncondensed gas in condensed odor vapor by the deodorization system, carrying out final treatment on the uncondensed gas and exhausting. According to the invention, the residual heat value of the high-moisture solid wastes is sufficiently utilized and the utilization is not limited by types of the solid wastes, so that the energy source and the operation cost are saved.

Owner:ZHONGCHANG ENVIRONMENT PROTECTION GROUP +1

Automatic draft control system for coke plants

ActiveUS20140048402A1Change positionCombustible gas coke oven heatingHorizontal chamber coke ovensAutomatic controlAutomatic train control

A coke oven includes an oven chamber, an uptake duct in fluid communication with the oven chamber, the uptake duct being configured to receive exhaust gases from the oven chamber, an uptake damper in fluid communication with the uptake duct, the uptake damper being positioned at any one of multiple positions, the uptake damper configured to control an oven draft, an actuator configured to alter the position of the uptake damper between the positions in response to a position instruction, a sensor configured to detect an operating condition of the coke oven, wherein the sensor includes one of a draft sensor, a temperature sensor configured to detect an uptake duct temperature or a sole flue temperature, and an oxygen sensor, and a controller being configured to provide the position instruction to the actuator in response to the operating condition detected by the sensor.

Owner:SUNCOKE TECH & DEV LLC

Apparatus and Method for Generating Power and Refrigeration from Low-Grade Heat

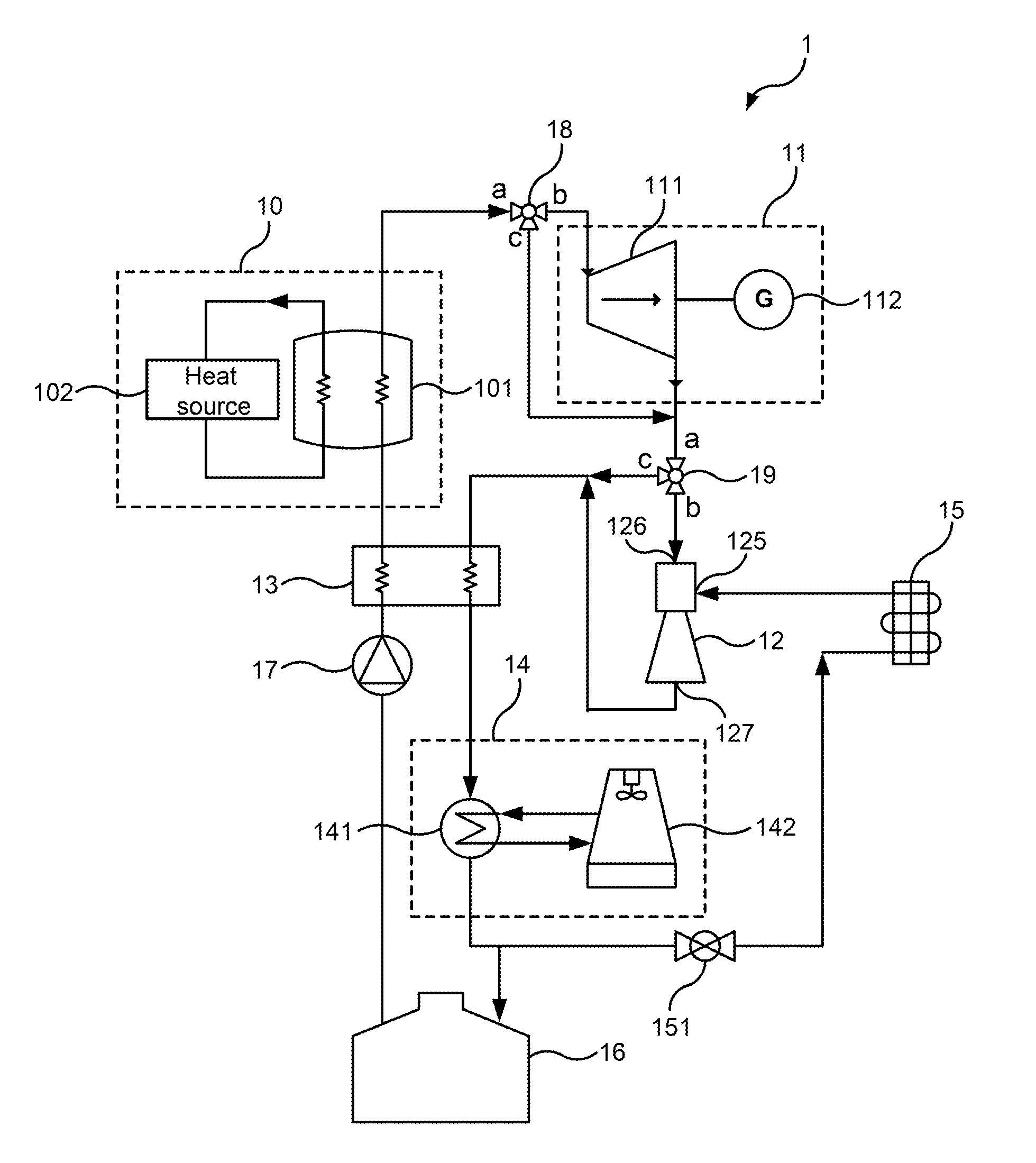

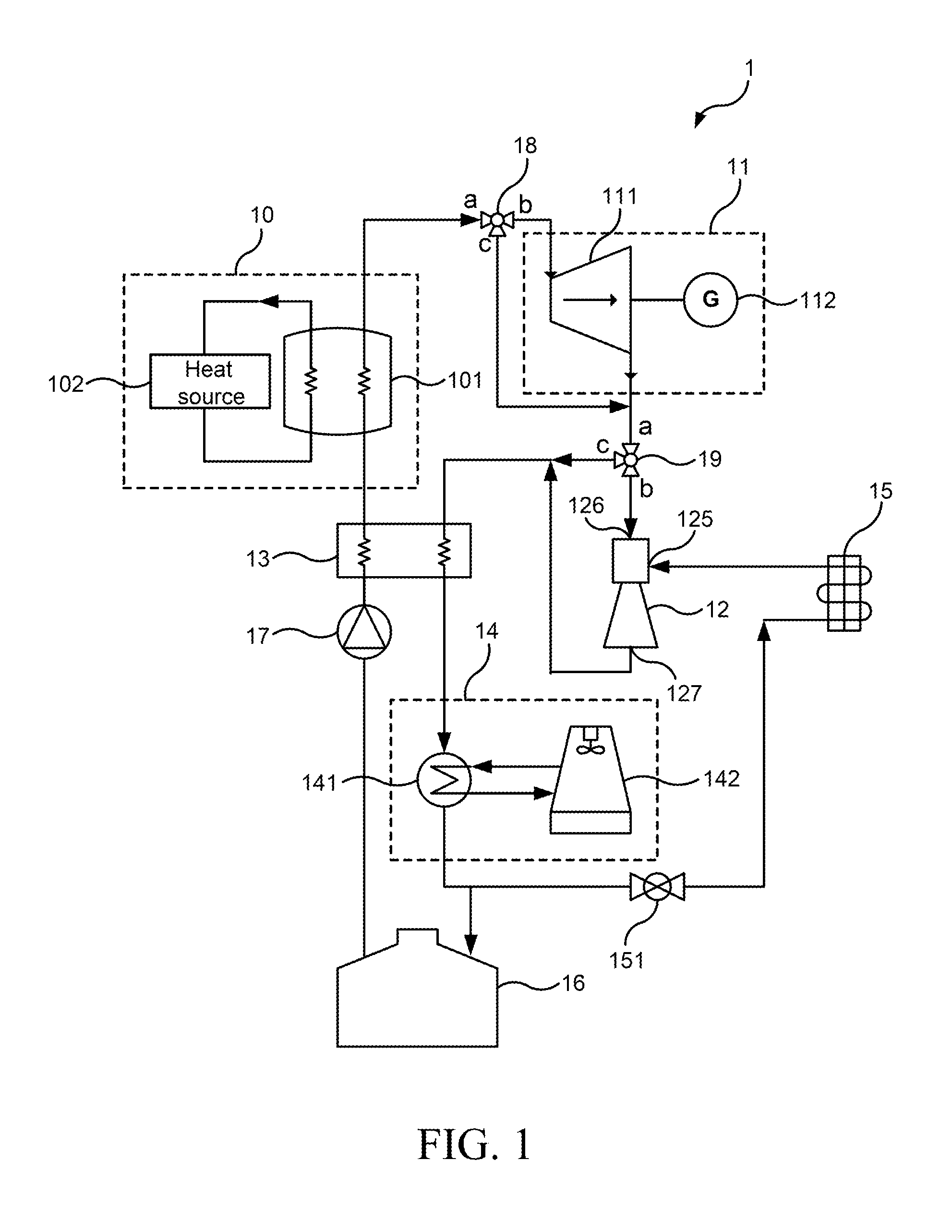

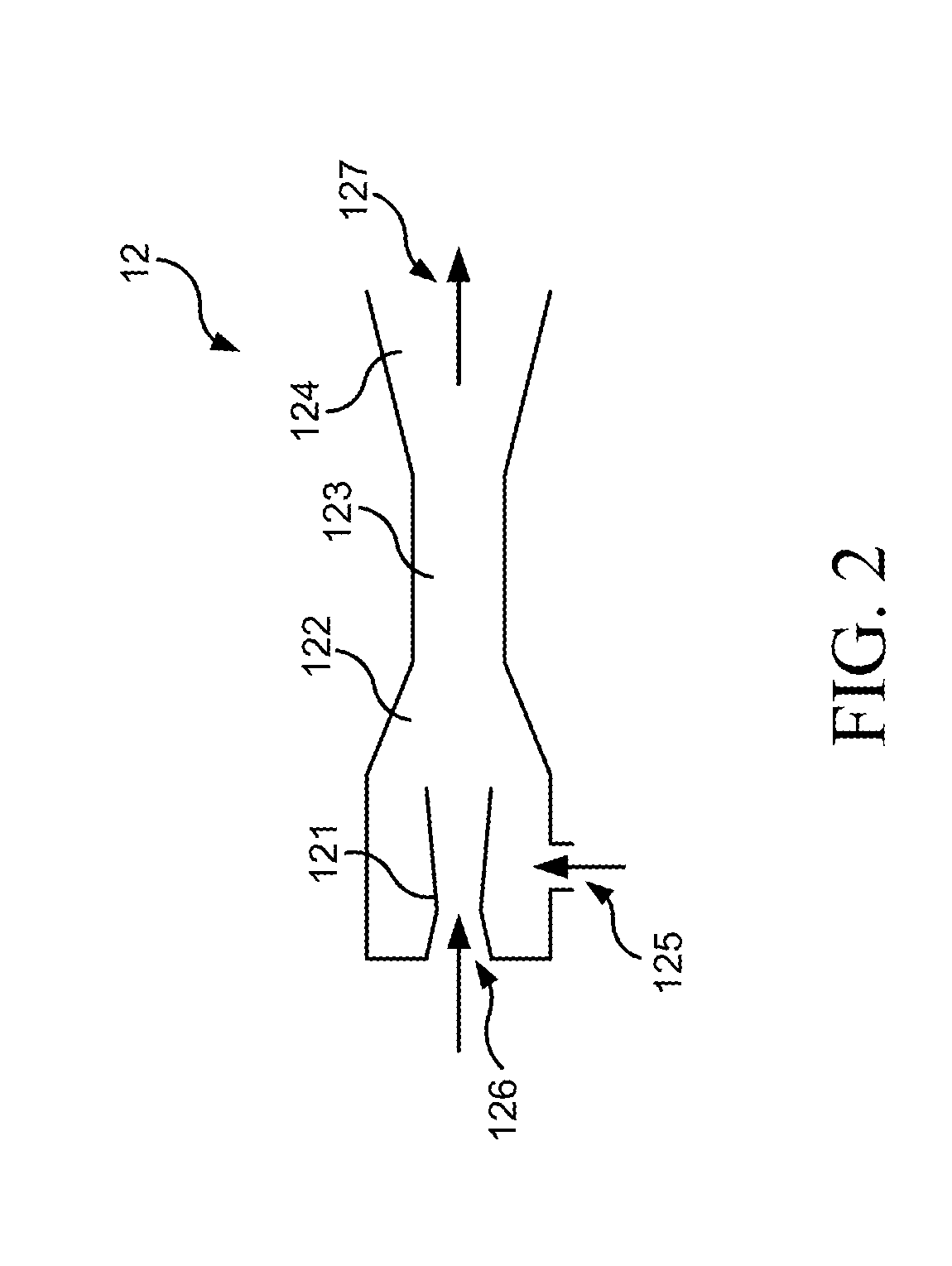

InactiveUS20120255304A1Compression machines with non-reversible cycleSteam useWorking fluidCooling tower

An apparatus and a method generate power and refrigeration from low-grade heat. The apparatus includes a heating module, a power generator module, an ejector, a heat exchanger, a condenser module, a low-temperature evaporator, a reservoir, a pressure pump and two direction controllable three-way valves. The heating module includes a heat source and a boiler. The power generator module includes an expansion turbine and a power generator. The condenser module includes a condenser and a cooling tower. The method is that the direction controllable three-way valves are operated to change the flow directions of the working fluid for executing a power generation and refrigeration mode, a power generation mode, a refrigeration mode or an idle mode.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Blast-furnace cement sensible heat recovery system and its production process

InactiveCN1920380AReduce focal ratioRaise the hot air temperatureOther heat production devicesBlast furnace componentsSlagProduct gas

The invention relates to a blast furnace slag heat recycle system and relative production, wherein it is formed by cooling-breaking, gas-slag heat exchanger, and left-heat boiler units; the slag outlet has cooling-braking unit which will cool the slag to the solidify point 1200-1300Deg. C, to be broken into the slag particles whose diameter is less than 100mm; the transmitter is connected to the gas-slag heat exchanger to heat the air to 700-800Deg. C; the slag will be cooled under 150Deg. C; the heated air will be transmitted to the left-heat boiler; the water of heating tube of boiler will adsorb the heat of gas, to generate the steam whose pressure at 0.3-0.4MPa and temperature at 260-350Deg. C. The invention can improve the energy recycle efficiency more than 70%, to reduce the energy consumption of steel production, reduce the consumption of cooling water, and reduce the environment pollution.

Owner:ANGANG STEEL CO LTD +1

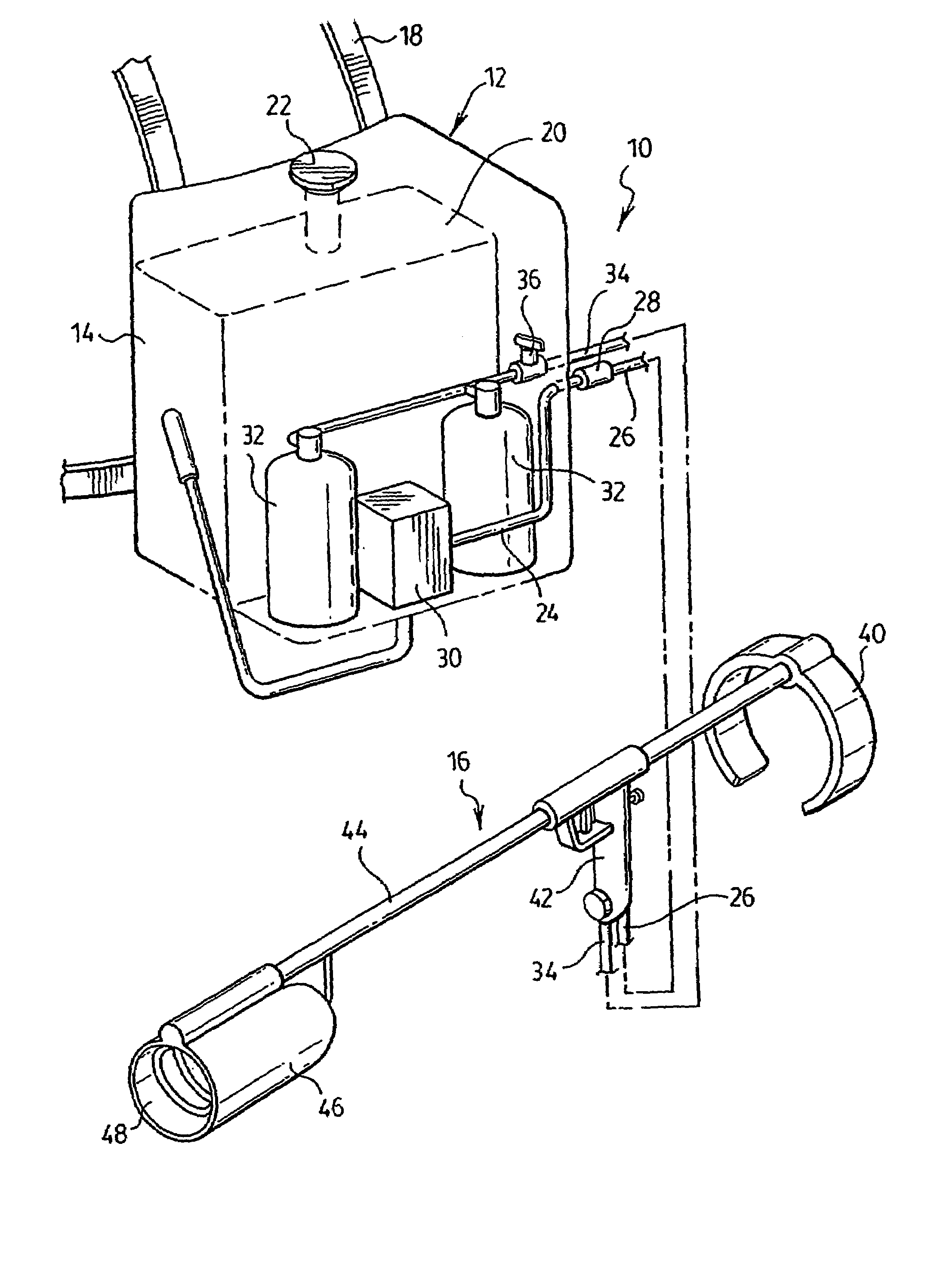

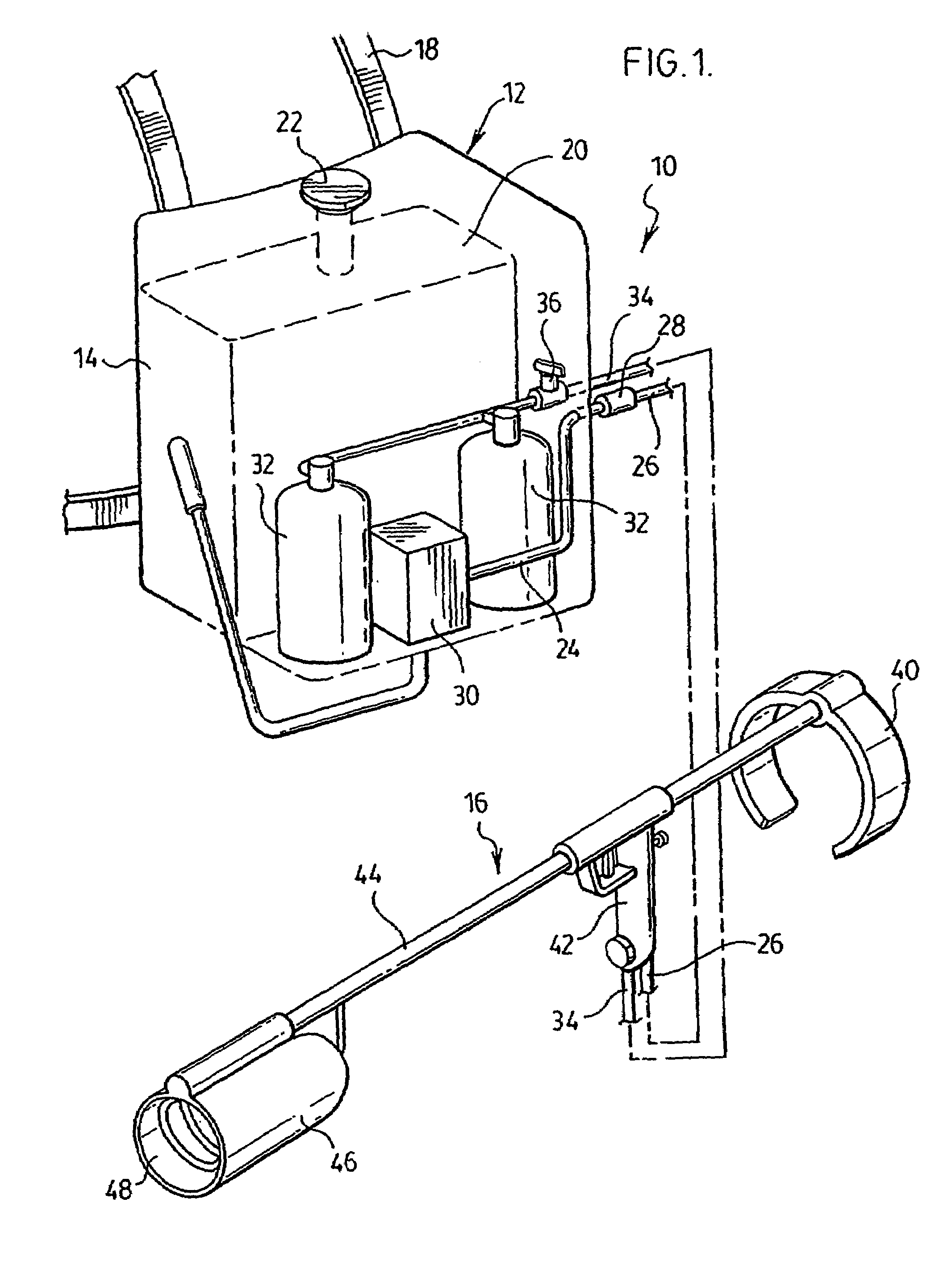

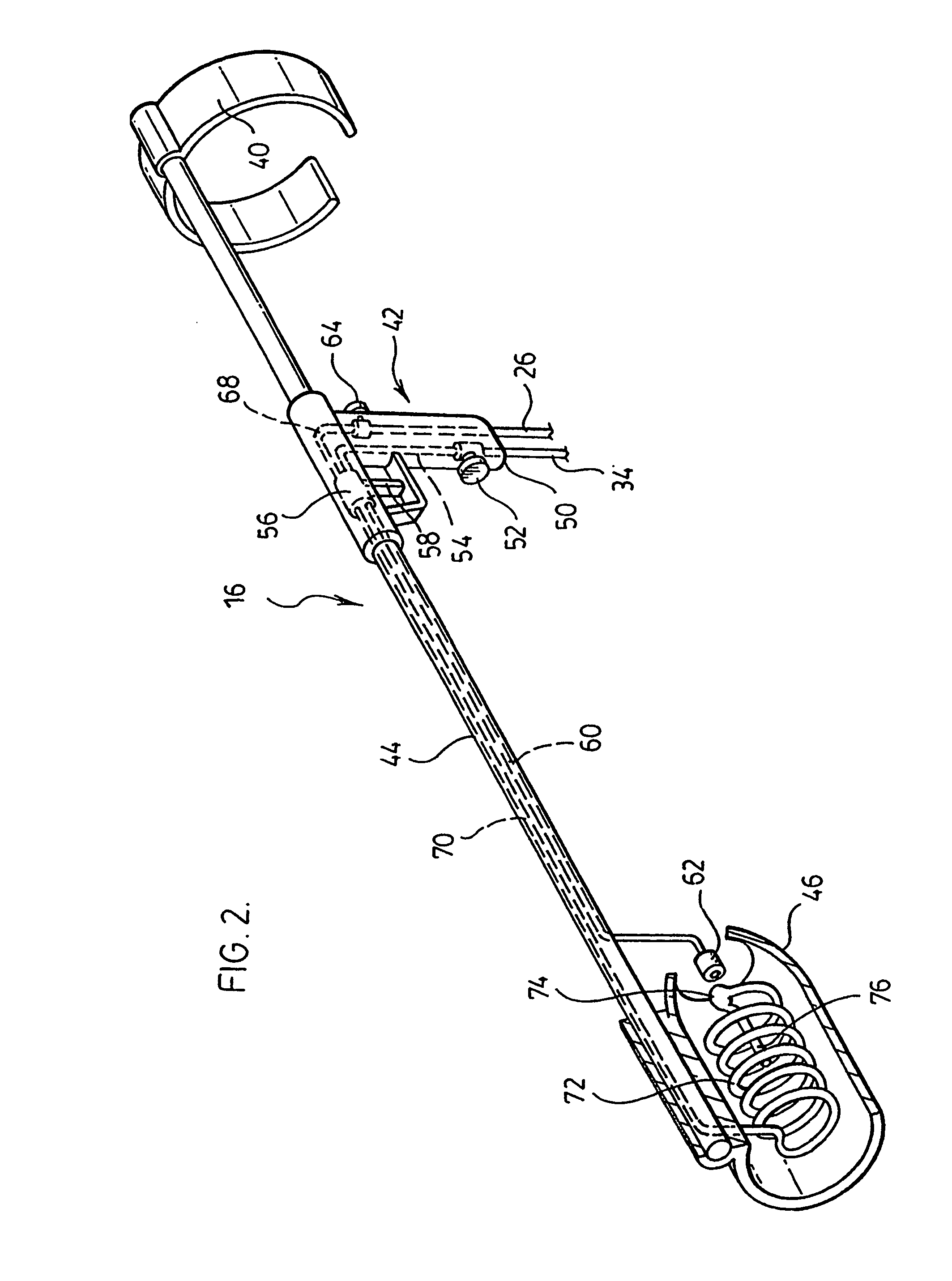

Portable steam and heat generator

The present invention is directed to an apparatus for directing steam, hot water or hot water vapor and hot air onto a target area, the apparatus comprising a water container and a fuel container connected and supplying water and fuel to an applicator wand with an applicator head which generates steam and heat for application adjacent to the target area of application to the unwanted vegetation. Steam is generated immediately adjacent to the target area within the applicator head and combined with surplus heat from the steam generation process to produce heated steam and water vapor for application to the target area. In a preferred embodiment of the invention, the applicator wand is hand held, the applicator head having an inlet, an outlet and a body therebetween, the water and fuel being supplied to a steam generator and burner within the body of the applicator head which generates steam and hot air adjacent to the target area for application through the outlet to the target area.

Owner:GREENSTEAM

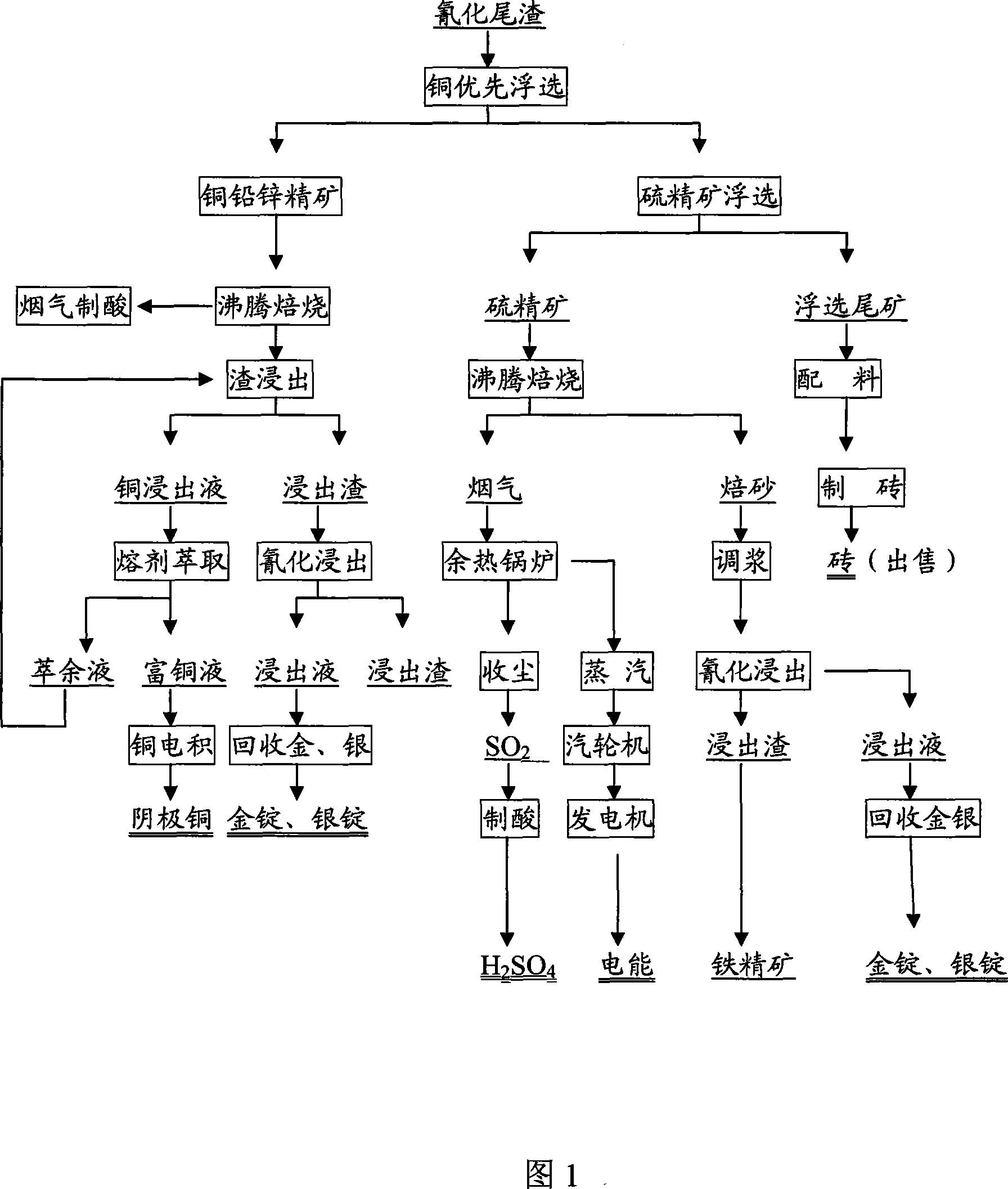

Integrated utilization technique for cyanidation gold-extracted waste slag

InactiveCN101078051AReduce energy consumptionTake advantage ofSolid waste managementSulfur compoundsBrickSlag

The invention relates to a method of complex utilization of the waste residue that from gold extraction with cyanidation. This invention belongs to the field of metallurgy and chemical technology. Firstly, the waste residue that from gold extraction with cyanidation is pretreated with acid. The floatation process is adopted here. The first step is to concentrate cuprum, plumbum, zincum and argentum; Secondly, collect 47%-52% of the high-grade sulfur and concentrate gold and argentums; Then roast the high-grade sulfur concentrate, the gas is utilized to produce acid, and the waste heat is utilized to produce electricity, and the waste residue is utilized to extract gold with cvanidation. After washing by water, the leavings which contains 62%-68% iron can be used as iron concentrate. Finally, produce slag brick with the refuse. The technology which could reclaim the elements, such as Fe, S, Cu, Pb, Zn, Au, Ag, complex utilizes the waste residue that from gold extraction with cyanidation. The invention takes full advantage of resource. The effect of integrated utilization of resource and the economic benefit are enhanced and the environmental pollution is lessened by this way.

Owner:SHANDONG GUODA GOLD

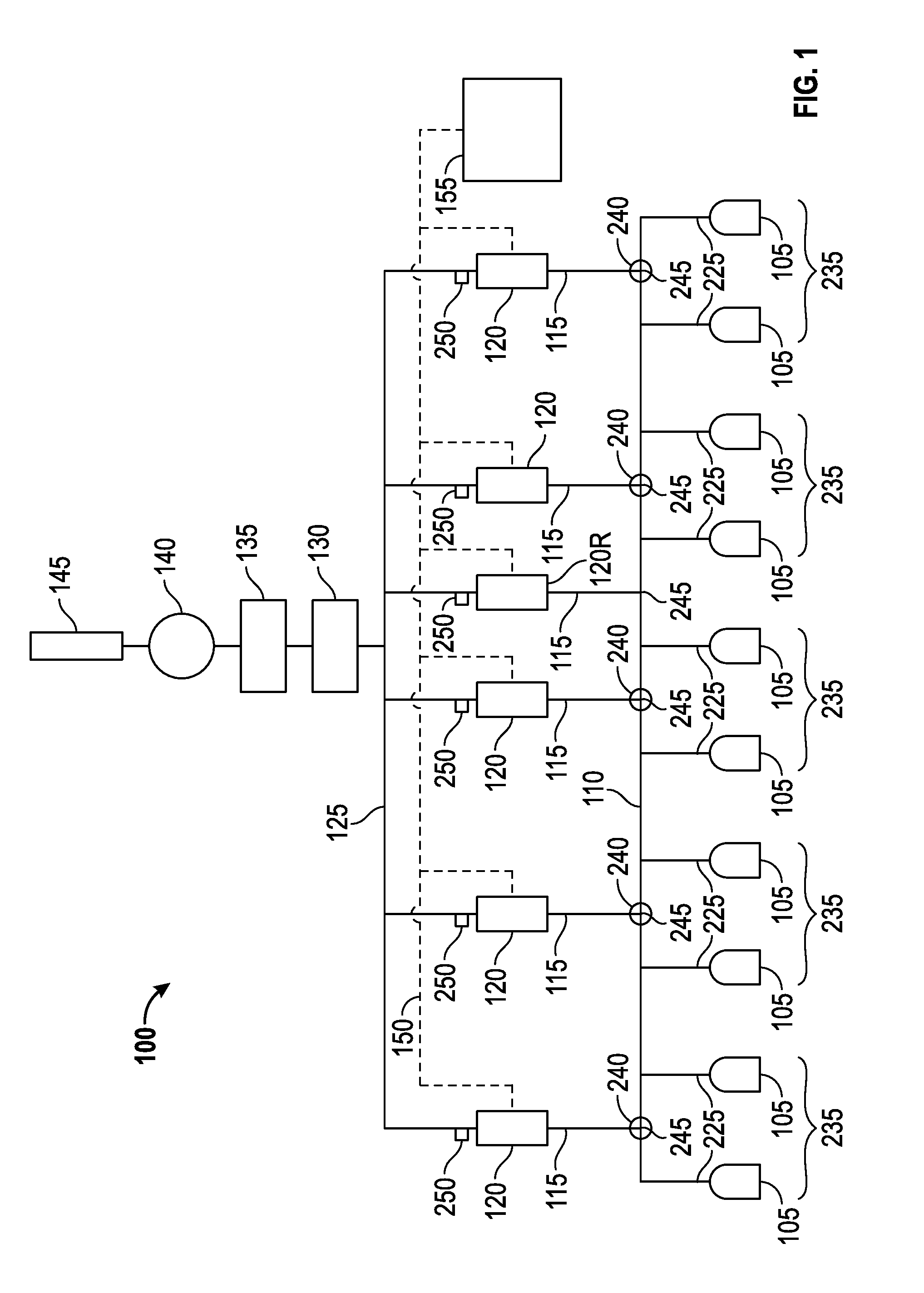

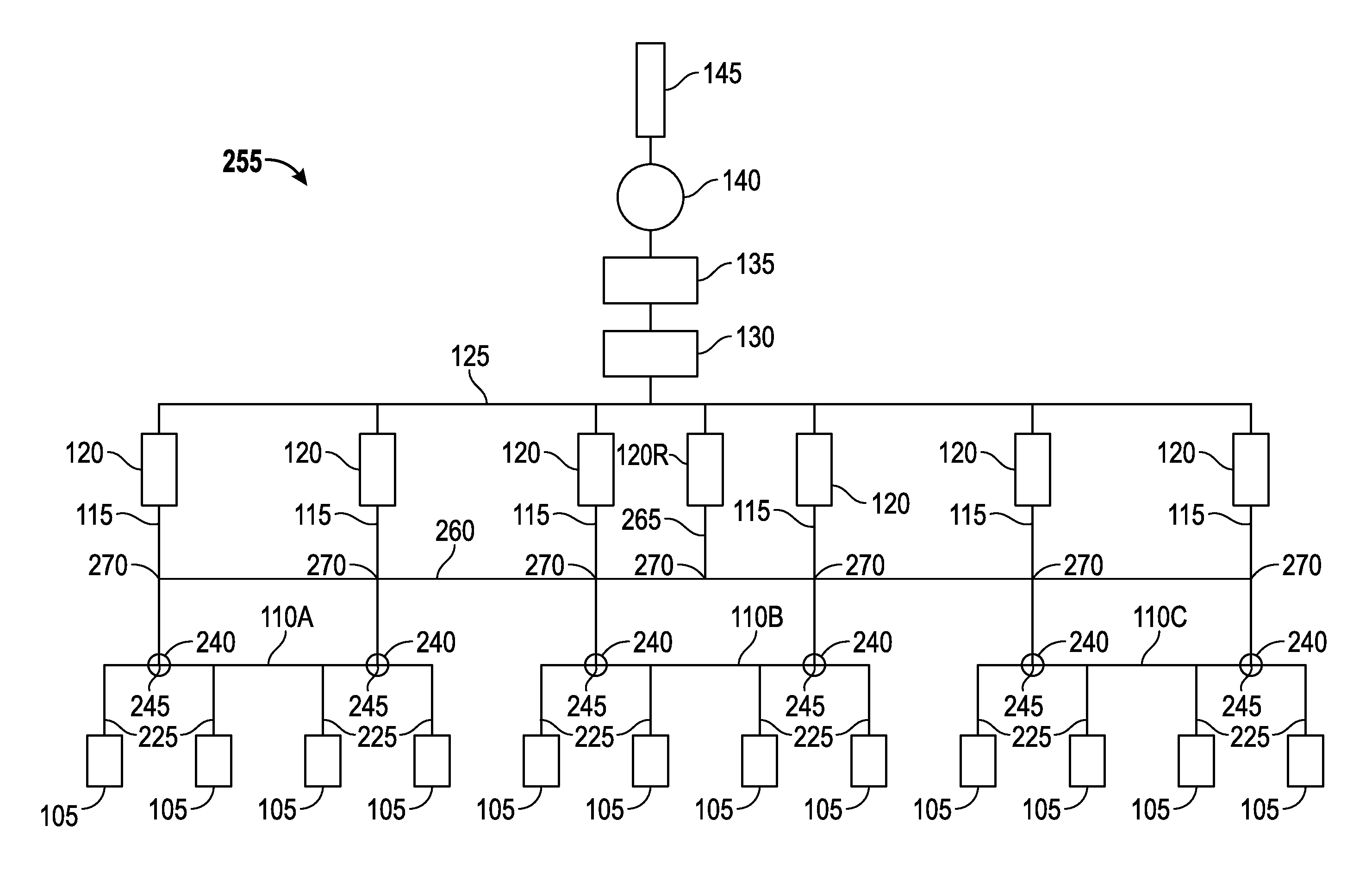

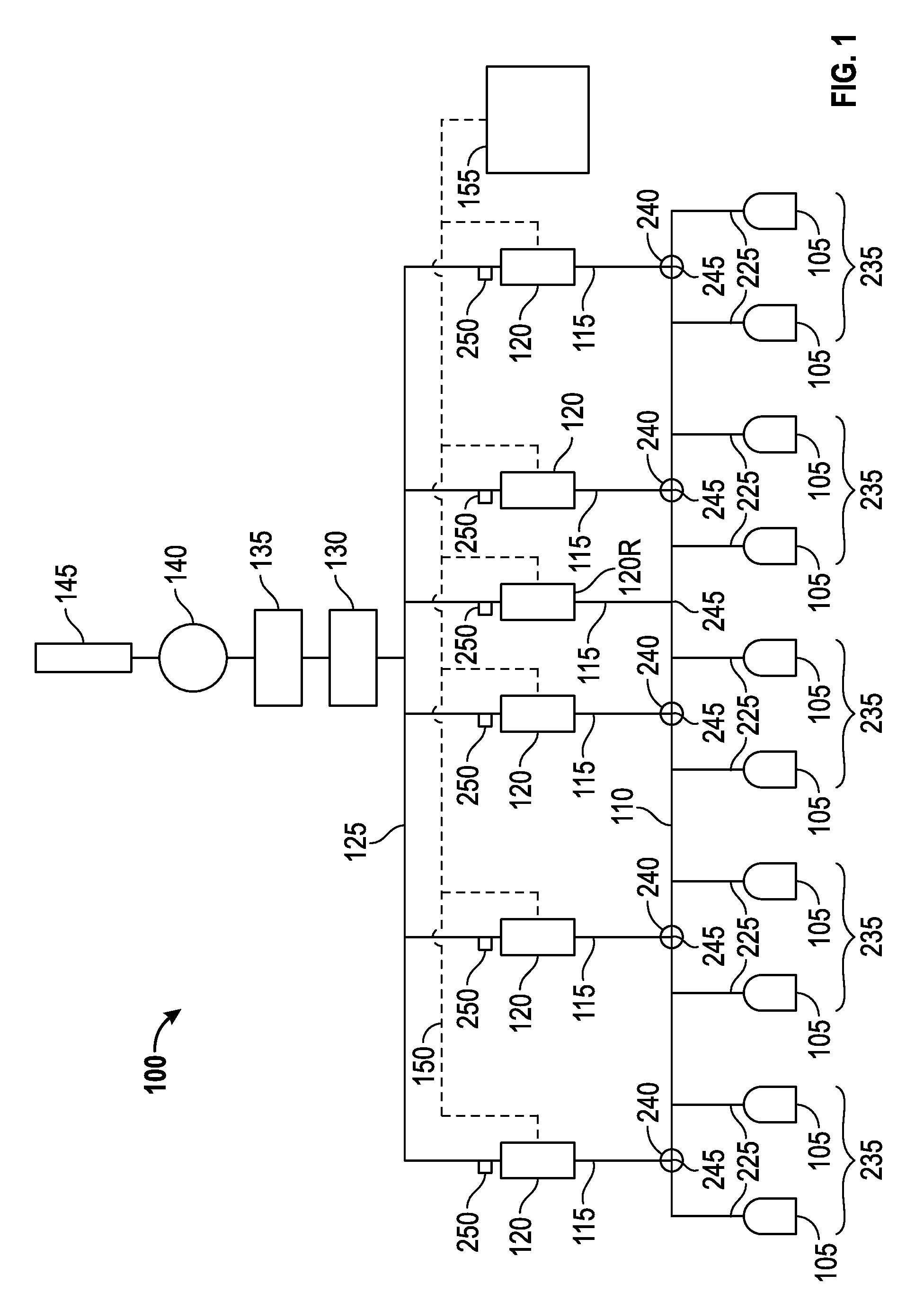

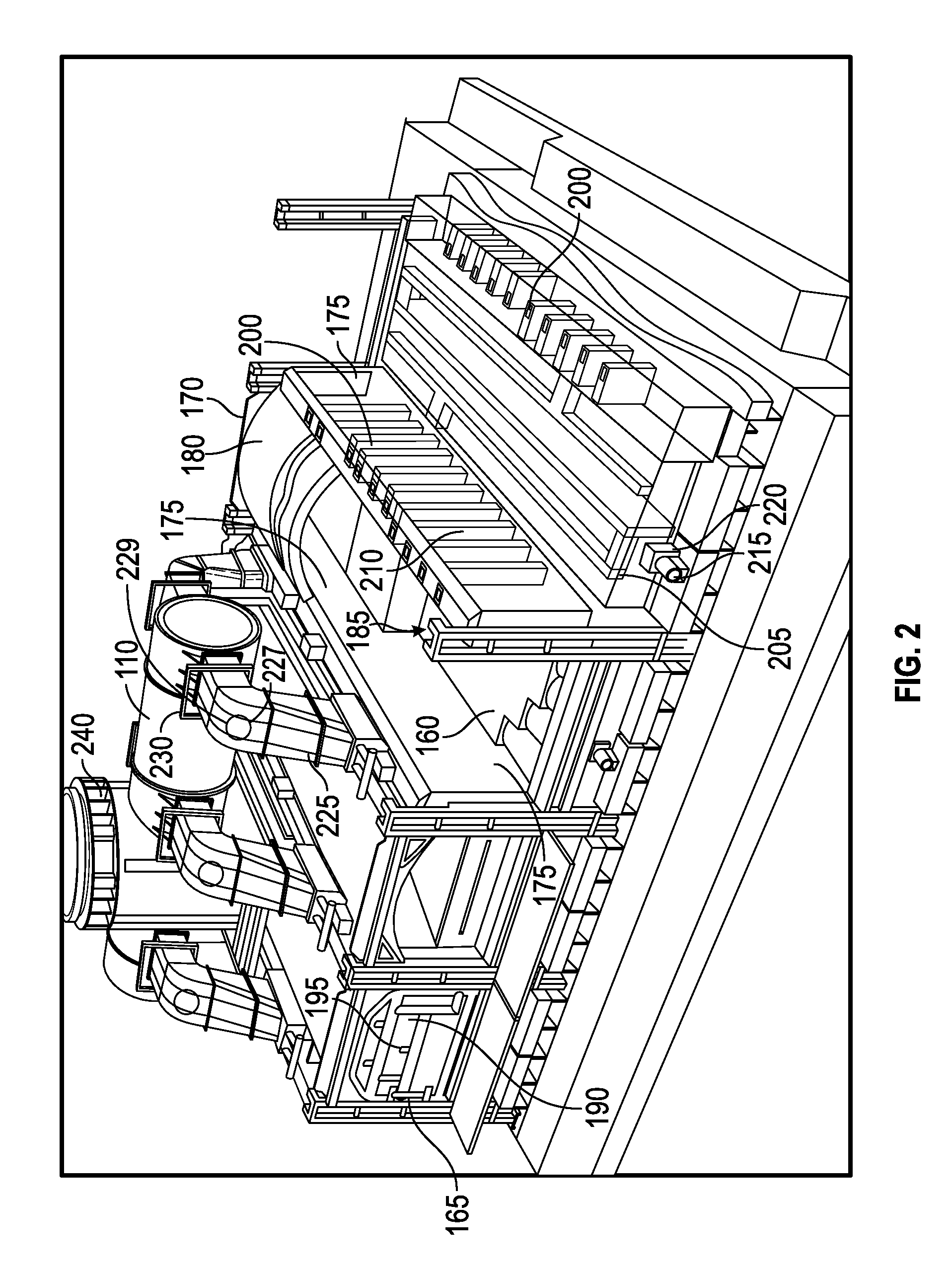

Coke plant including exhaust gas sharing

ActiveUS9243186B2Coke oven safety devicesHorizontal chamber coke ovensExhaust fumesProcess engineering

A coke plant includes multiple coke ovens where each coke oven is adapted to produce exhaust gases, a common tunnel fluidly connected to the plurality of coke ovens and configured to receive the exhaust gases from each of the coke ovens, multiple standard heat recovery steam generators fluidly connected to the common tunnel where the ratio of coke ovens to standard heat recovery steam generators is at least 20:1, and a redundant heat recovery steam generator fluidly connected to the common tunnel where any one of the plurality of standard heat recovery steam generators and the redundant heat recovery steam generator is adapted to receive the exhaust gases from the plurality of ovens and extract heat from the exhaust gases and where the standard heat recovery steam generators and the redundant heat recovery steam generator are all connected in parallel with each other.

Owner:SUNCOKE TECH & DEV LLC

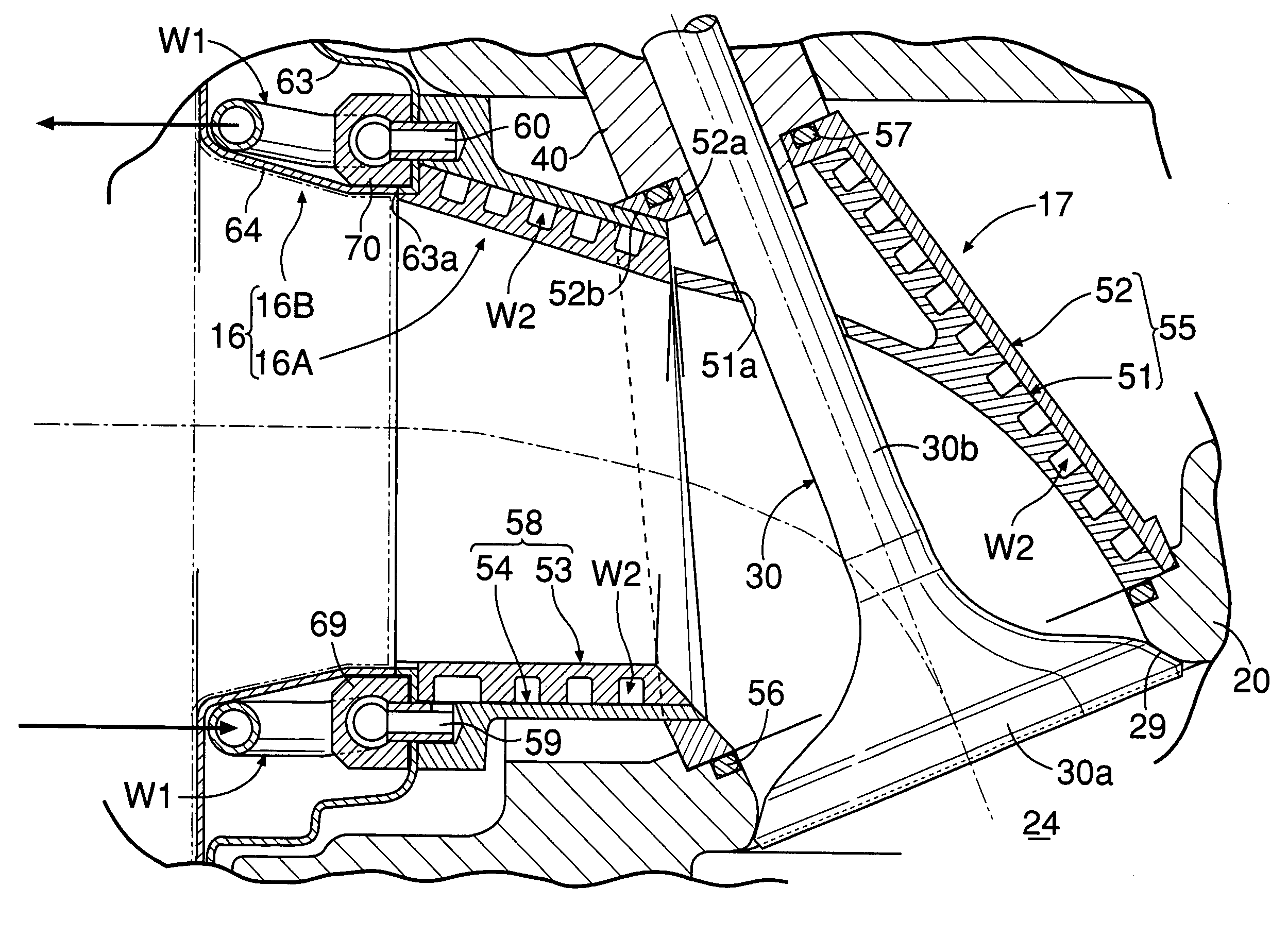

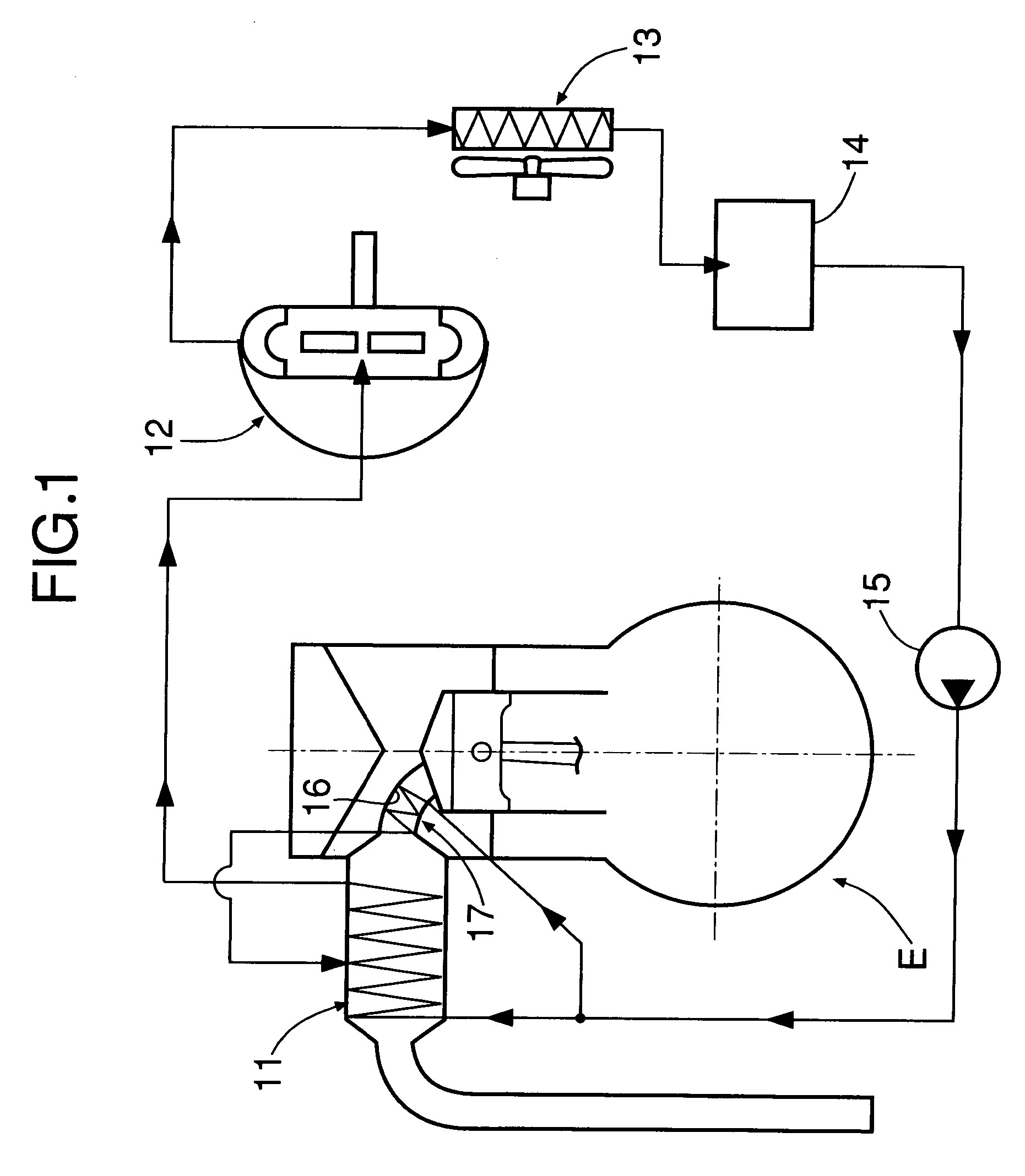

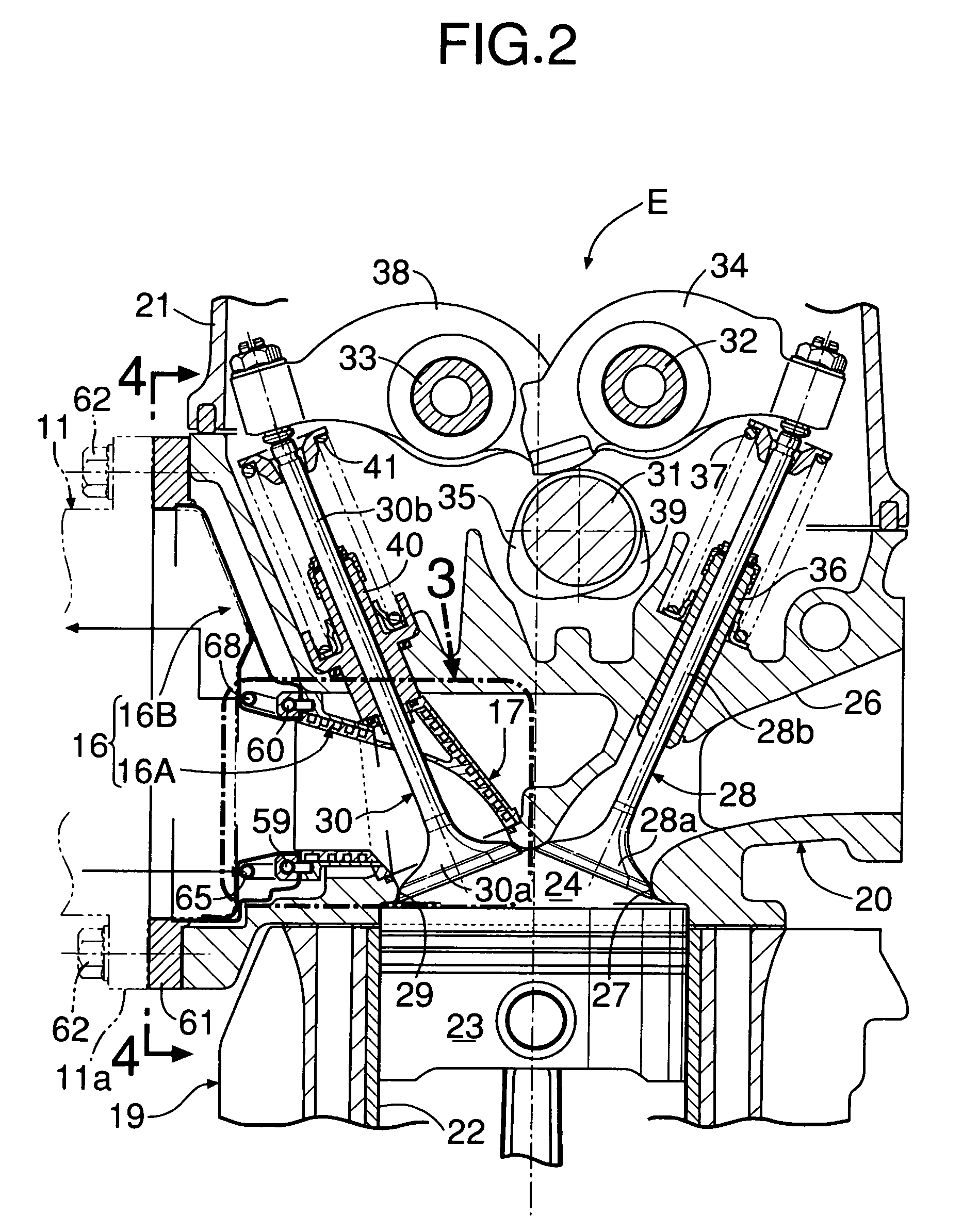

Internal combustion engine

InactiveUS7069884B2Improve cooling effectWaste heat recoveryLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

An internal combustion engine is provided in which an exhaust port communicating with a combustion chamber formed in a cylinder head is formed from independent exhaust ports, which are positioned on the upstream side, and a grouped exhaust port, in which the plurality of independent exhaust ports are combined. Water supplied from a supply pump passes through a water passage of the grouped exhaust port and a water passage of the independent exhaust ports while cooling the exhaust port, and a valve seat and valve guide on the periphery of the exhaust port, which have high temperatures, thus heating the water itself and thereby recovering waste heat of the internal combustion engine. The heated water carries out heat exchange with exhaust gas in an evaporator provided in an exhaust passage and turns into high temperature, high pressure steam, which drives an expander of a Rankine cycle system. It is thereby possible to maximize the recovery of heat transferred from the exhaust port to the cylinder head of the internal combustion engine.

Owner:HONDA MOTOR CO LTD

Method and system for converting waste heat from cement plant into a usable form of energy

Methods and systems for converting waste heat from cement plant into a usable form of energy are disclosed. The methods and systems make use of two heat source streams from the cement plant, a hot air stream and a flue gas stream, to fully vaporize and superheat a working fluid stream, which is then used to convert a portion of its heat to a usable form of energy. The methods and systems utilize sequential heat exchanges stages to heat the working fluid stream, first with the hot air stream or from a first heat transfer fluid stream heated by the hot air stream and second with the flue gas stream from a second heat transfer fluid stream heated by the hot air stream.

Owner:KALINA POWER LTD +1

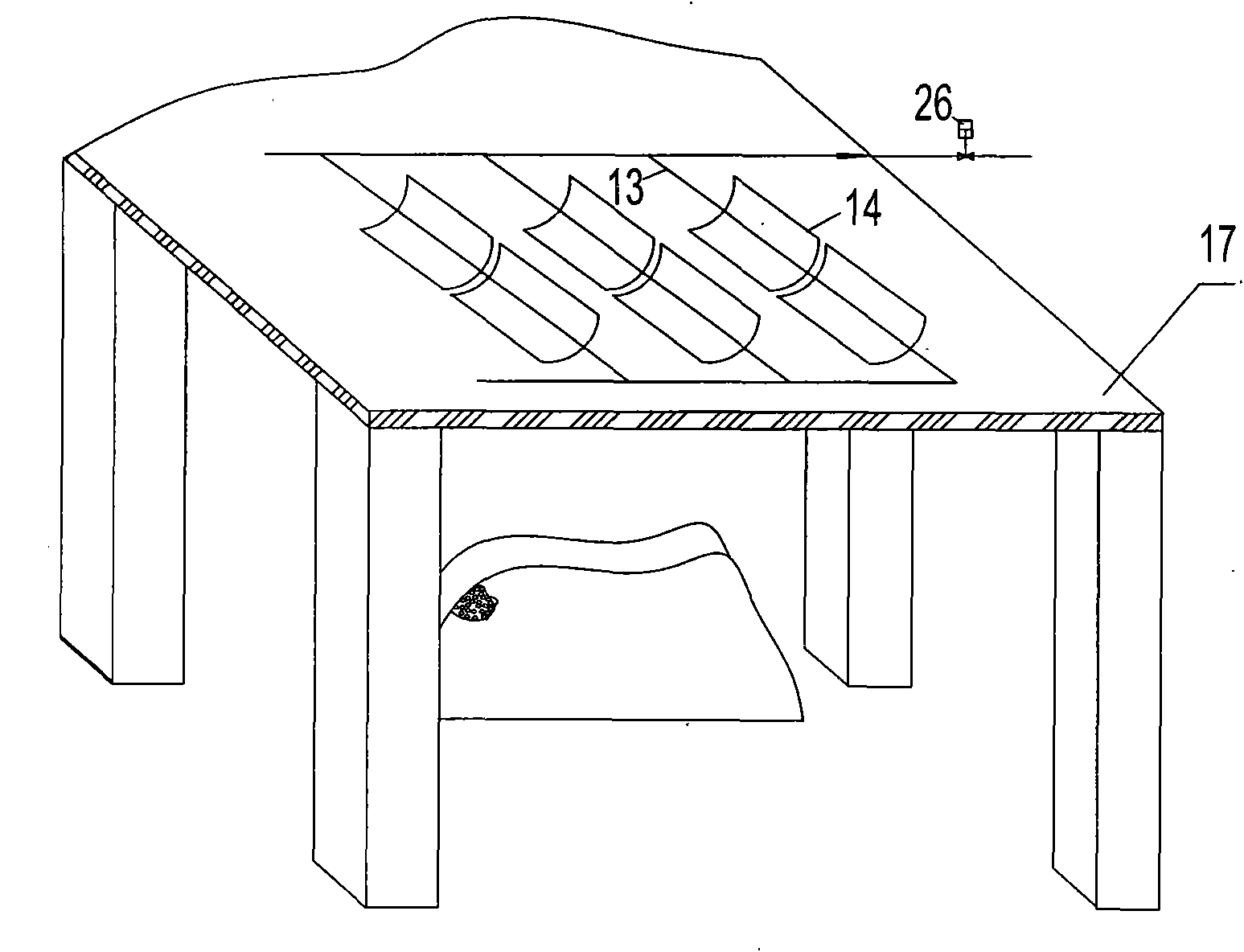

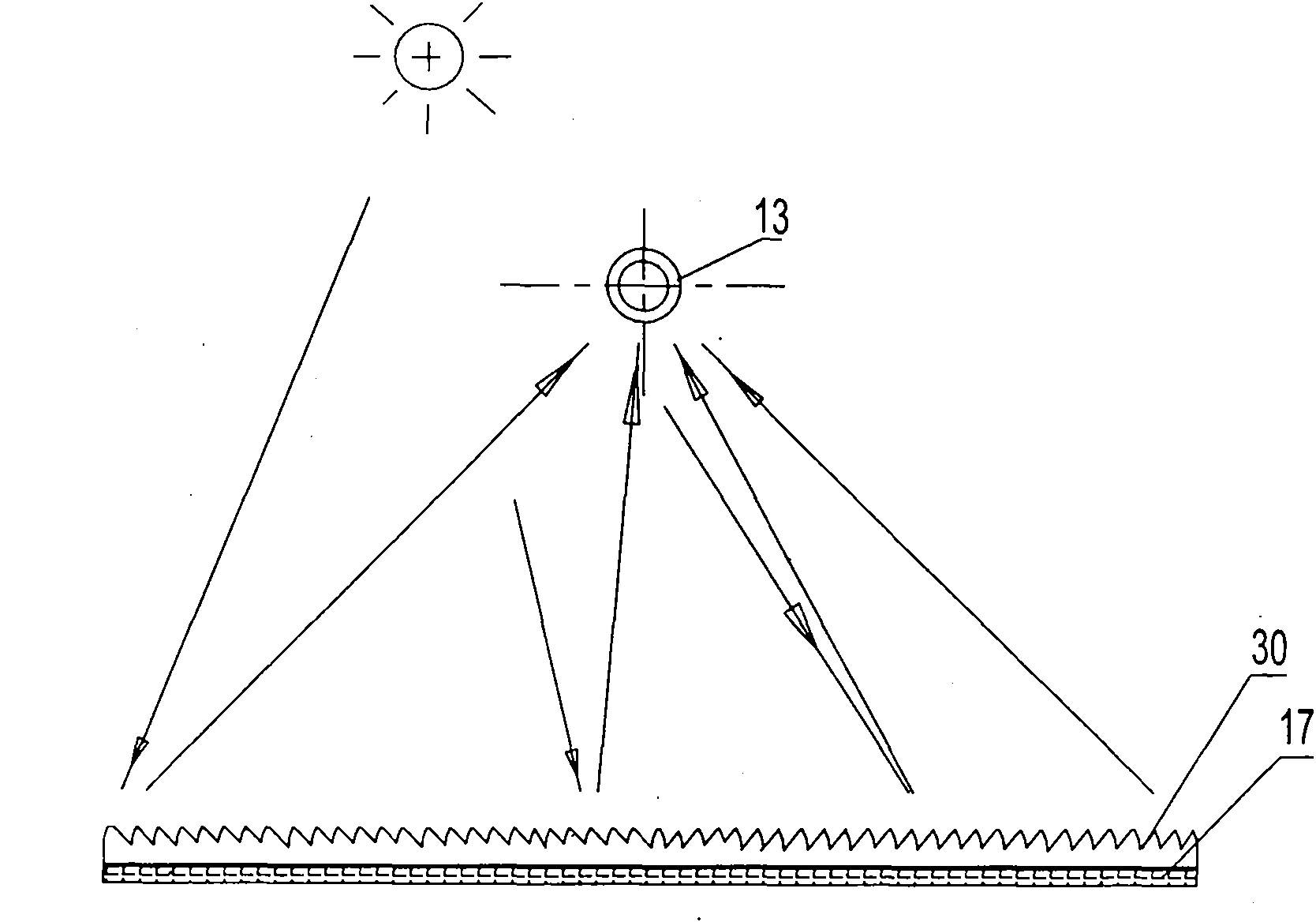

Solar power generation method and system taking biomass boiler as auxiliary heat source

ActiveCN101968041ASolve the problem of antifreeze in winterHigh thermal efficiencySolar heating energyFrom solar energyWater storage tankEngineering

The invention discloses a solar power generation method and a solar power generation system taking a biomass boiler as an auxiliary heat source. The system comprises a solar condensation heat collecting device, a biomass boiler device and a steam turbine generator system, wherein the solar condensation heat collecting device takes water as a medium and is combined by adopting medium-pressure solar vacuum heat collecting pipes in a series-parallel matrix; the outlet of the solar condensation heat collecting device is communicated with the bottom of a steam pocket of the biomass boiler; and the steam outlet of the steam pocket of the biomass boiler is connected with a cylinder of a steam turbine generator. A de-aerator and a water supply pump are connected in series in the water inlet pipeline of the solar condensation heat collecting device. A steam re-heater is connected in series in the connected pipeline of the steam outlet of the steam pocket of the biomass boiler and the cylinder of the steam turbine generator; the steam re-heater is connected to the cylinder of the steam turbine generator; and the steam re-heater is placed in a flue of the biomass boiler. A water supply tank is a desalting water storage tank, and the desalting water storage tank is connected with the de-aerator through the water supply pump and connected with the outlet of the solar condensation heat collecting device through a first control valve.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Methods and systems for heating thermal storage units

InactiveUS20050279292A1Small sizeReduced standby lossesStorage heatersWater heatersPower applicationControl system

Methods and systems for heating a thermal storage unit (TSU) are provided. A thermal storage system is provided that includes a system of heaters removably disposed at least partially within the TSU, a control system for adjusting power provided to the heaters, and a removal tool for removing one or more of the heaters from the TSU when the TSU is still hot. The thermal storage system may be used in a thermal and compressed air storage system for backup power applications.

Owner:ACTIVE POWER INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com