Patents

Literature

41results about How to "Raise the hot air temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

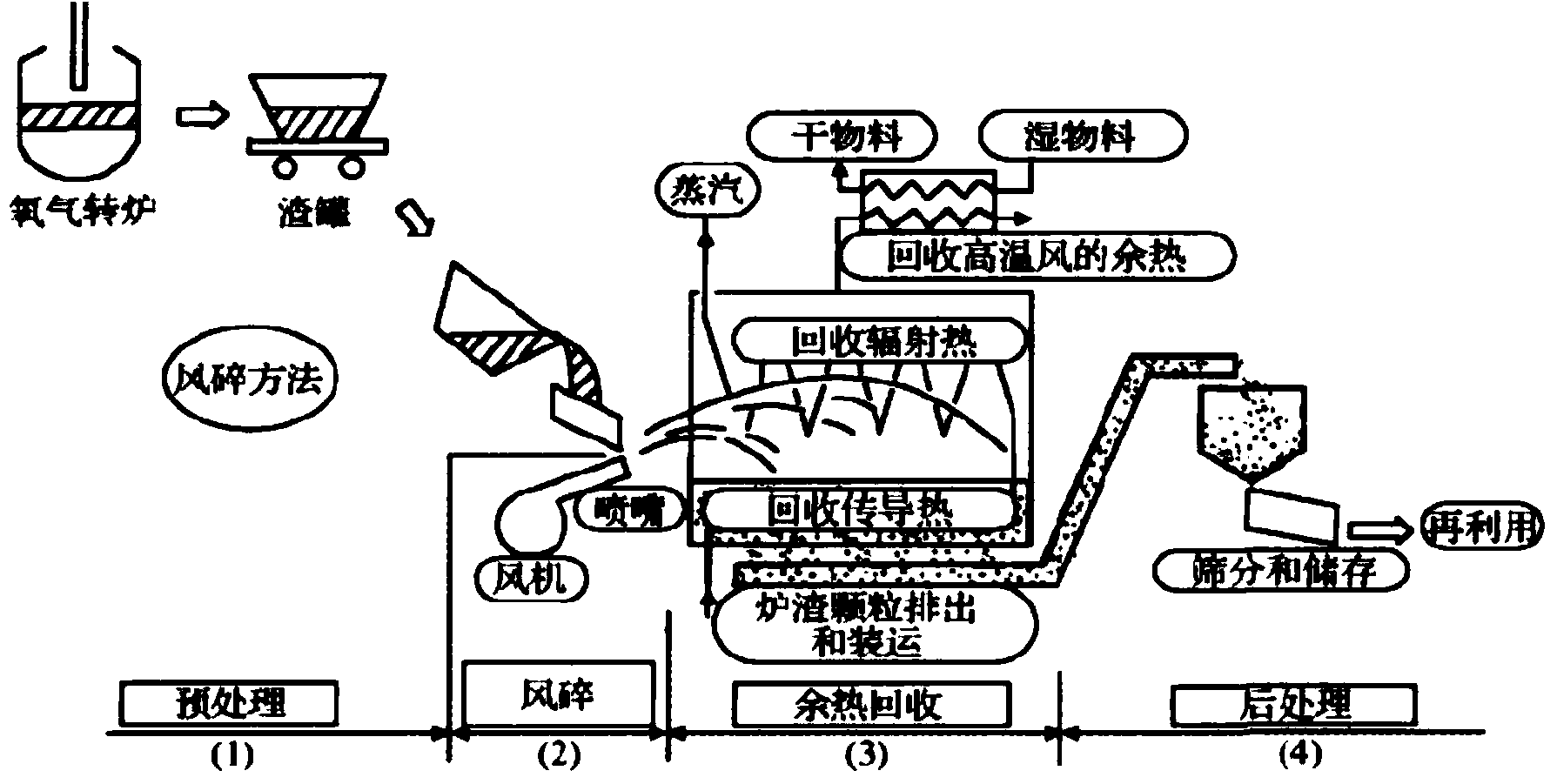

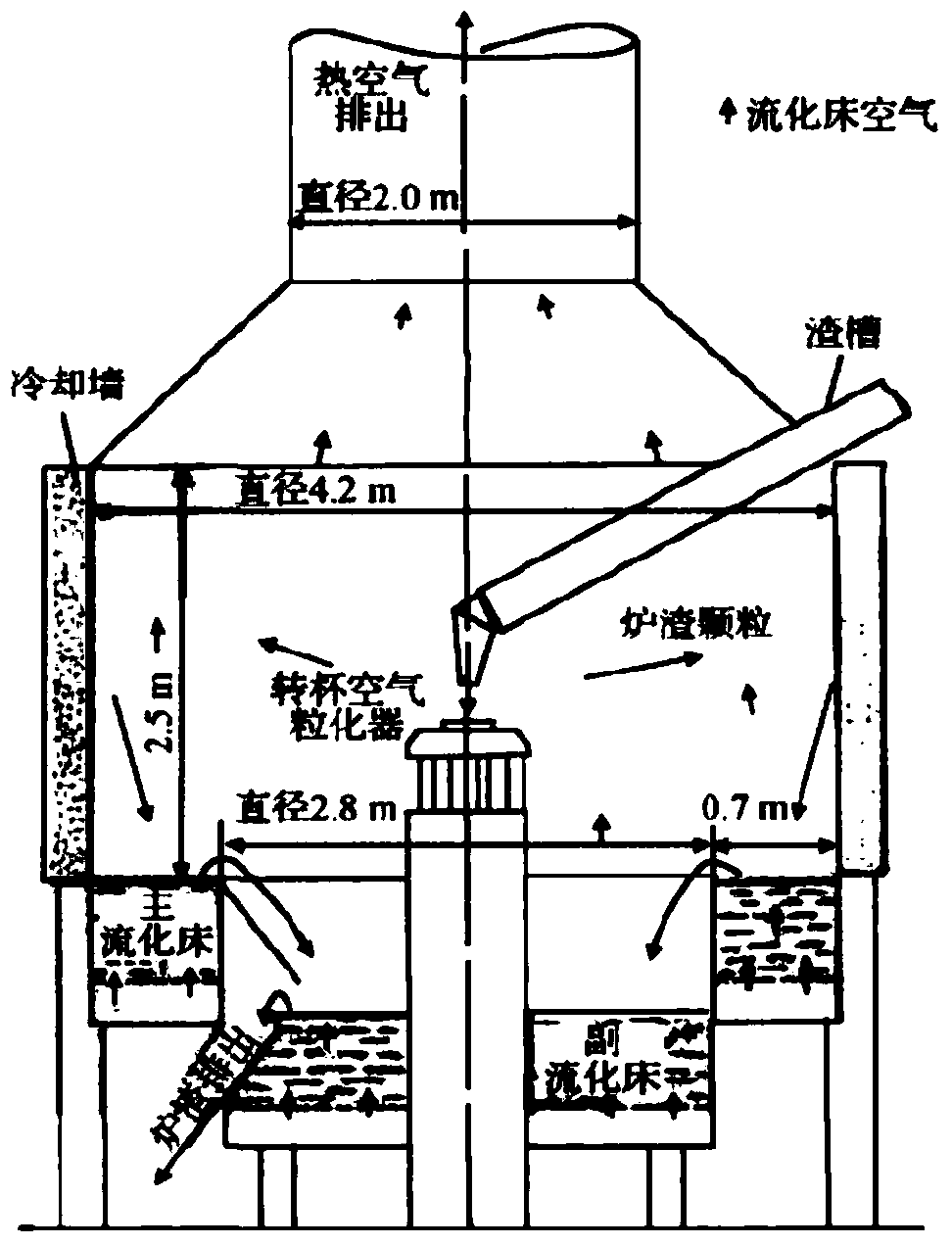

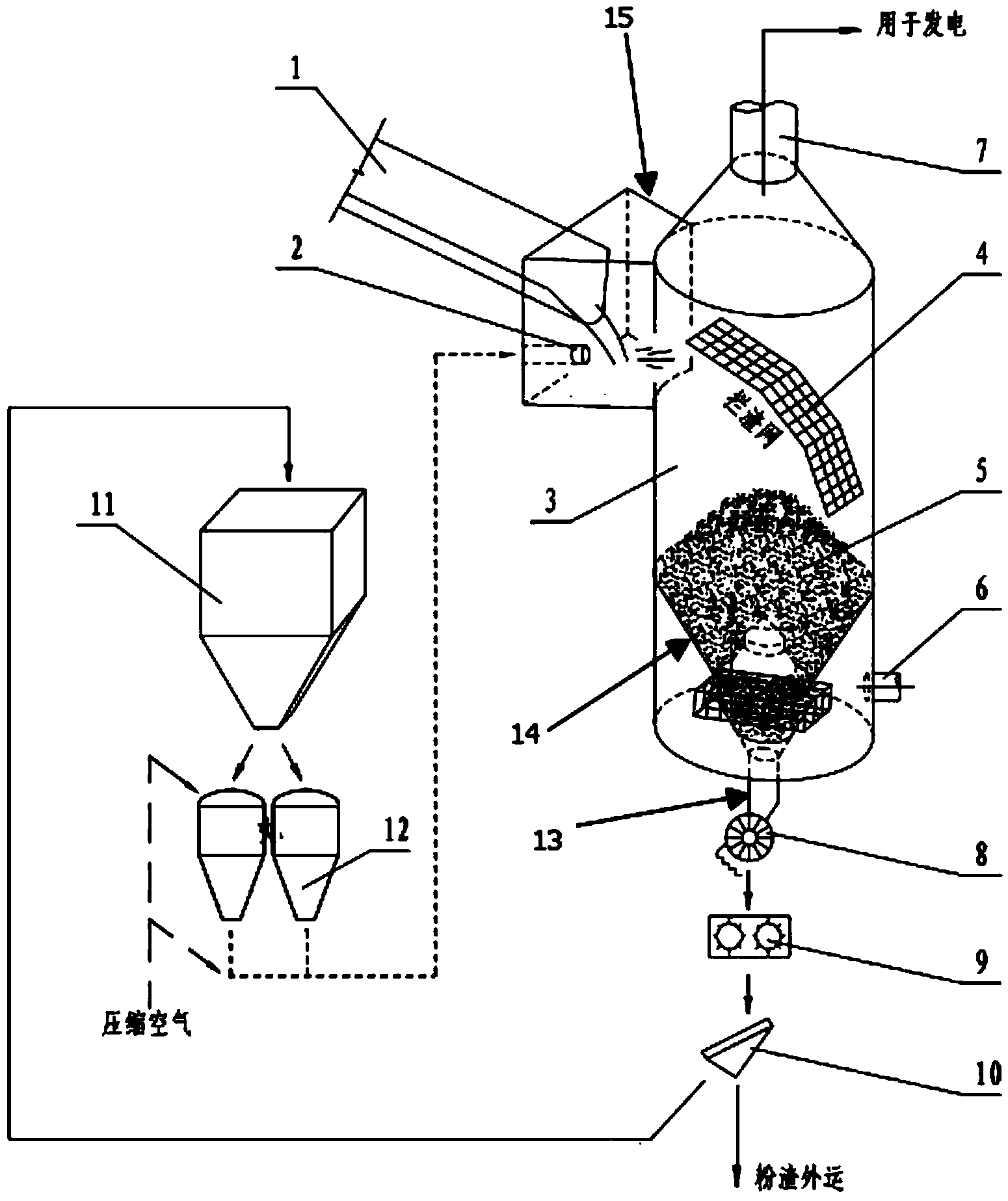

Afterheat recycling system utilizing slag-granule-jetting molten-slag-crushing process

The invention is suitable for the field of molten slag dry process treatment, and provides an afterheat recycling system utilizing a slag-granule-jetting molten-slag-crushing process. The system comprises a dry cooling tower, a granulated slag bin and a blowing tank, wherein an opening is formed in the upper end of the dry cooling tower; an air inlet is formed in the lower end of the dry cooling tower; a hot air outlet is formed in the top of the dry cooling tower; a discharging port is formed in the bottom of the dry cooling tower; an collection bin is also arranged inside the dry cooling tower; the bottom of the collection bin is communicated with the discharging port; a slag trough and a spray gun are arranged at the opening; the spray gun is positioned below the outlet of the slag trough; the outlet of the granulated slag bin is connected with the blowing tank; compressed air is used as a fluidization and transmission medium, and the outlet of the blowing tank is communicated with the spray gun. According to the afterheat recycling system utilizing the slag-granule-jetting molten-slag-crushing process, by adopting a pneumatic transmission way, slag granules are jetted so as to crush molten slag, and heat exchange on the slag granules and the molten slag can be performed, so that the flow of the cooling air is reduced; moreover, the molten slag is easily crushed by the slag granules, the obtained hot slag layer has certain voidage, and therefore, full heat exchange is facilitated. According to the system, higher temperature of the hot air can be acquired, the afterheat recycling quality is improved, and the generating efficiency is increased.

Owner:WISDRI ENG & RES INC LTD

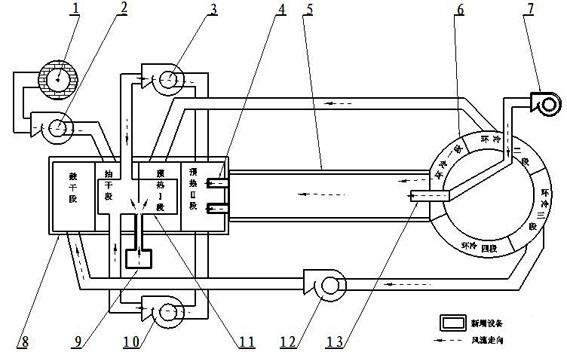

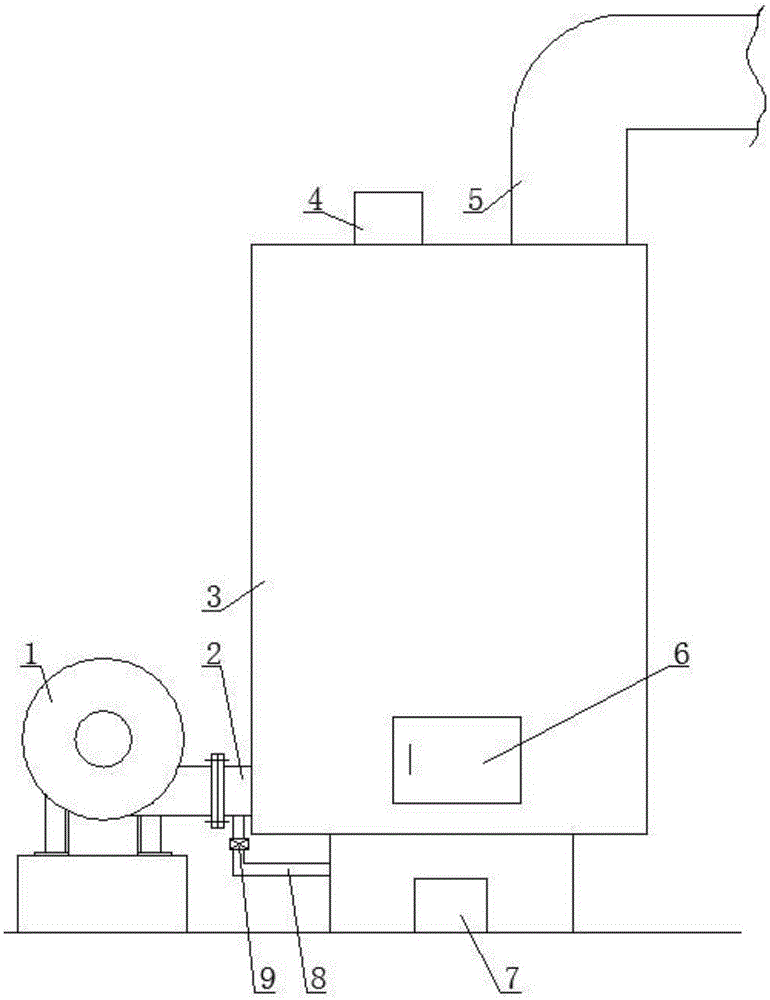

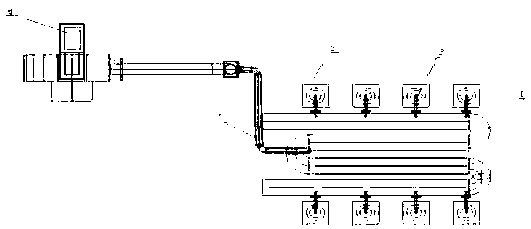

Method and system for optimizing drying grate-rotary kiln oxidate pellet thermal regulation

A method and a system for optimizing a drying grate-rotary kiln oxidate pellet thermal regulation are characterized in that a blower is adopted to pressurize the combustion air of a center burner; the pressure of the combustion air is increased to 18 to 25 KPa; the length of the flame of the center burner of a rotary kiln is controlled to be 15 to 17 m; a heat source point is added in a gas hood to increase the temperature of the preheating segment II of a drying grate by 100 to 150 DEG C; hot air of 500 to 1,000 DEG C are supplied to an air drying segment and a preheating segment I; and the system comprises a pressurizing device, the heat source point and a hot air supply device. The invention has the advantages that reasonable drying and preheating temperature gradient is formed, the drying and preheating effect is improved, energy is saved, the proportion of production of hematite is improved from the highest 40 percent to 100 percent, the hot air volume of the drying grate is sufficient, the hot air temperature is standard, the drying and preheating effect of fresh pellets is remarkably improved, the yield is increased, the consumption of coal gas is lowered, the powder entering the kiln is reduced, and the phenomenon that ring forming is liable to be caused by high-temperature powder feeding of the rotary kiln.

Owner:LIUZHOU IRON & STEEL

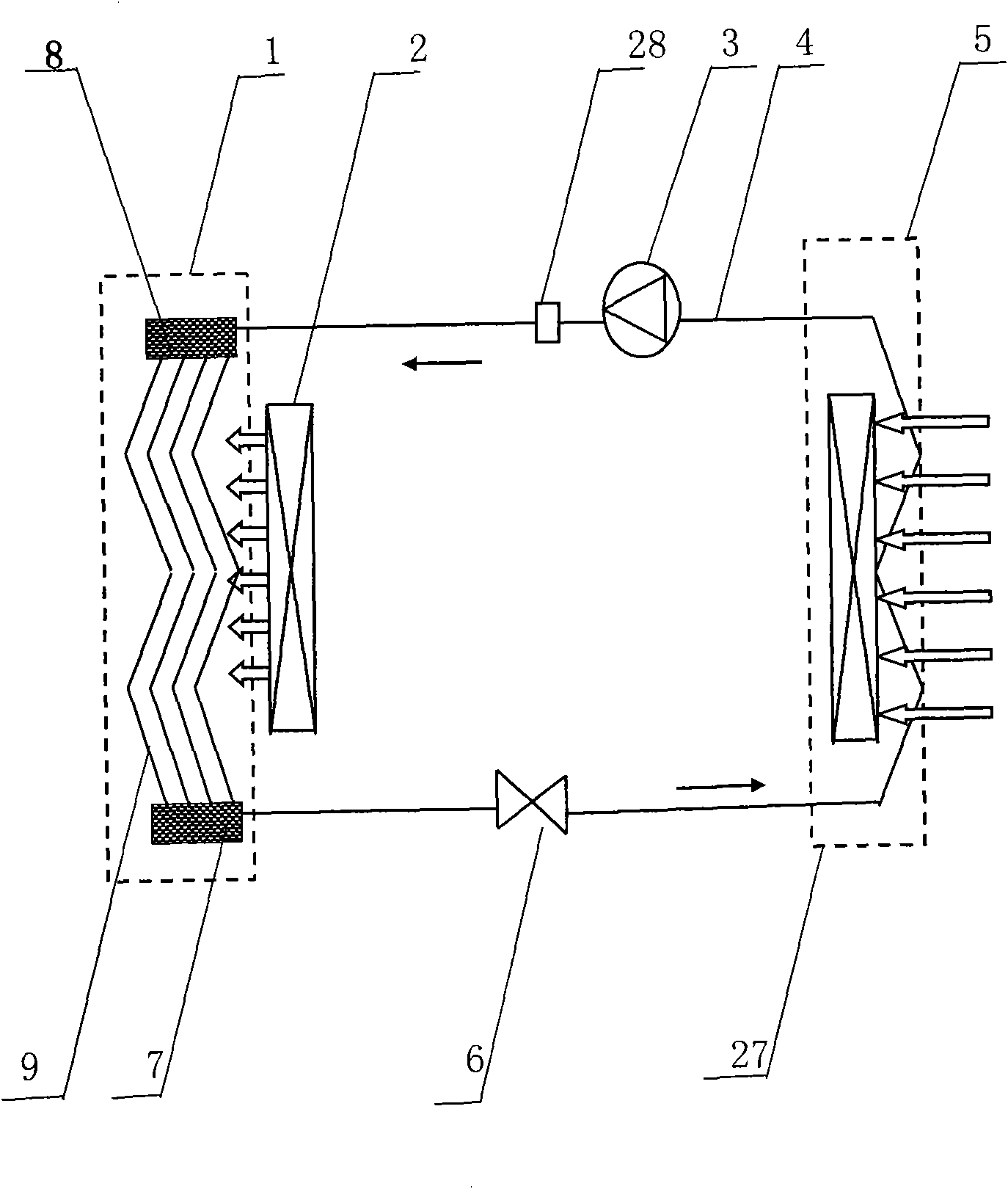

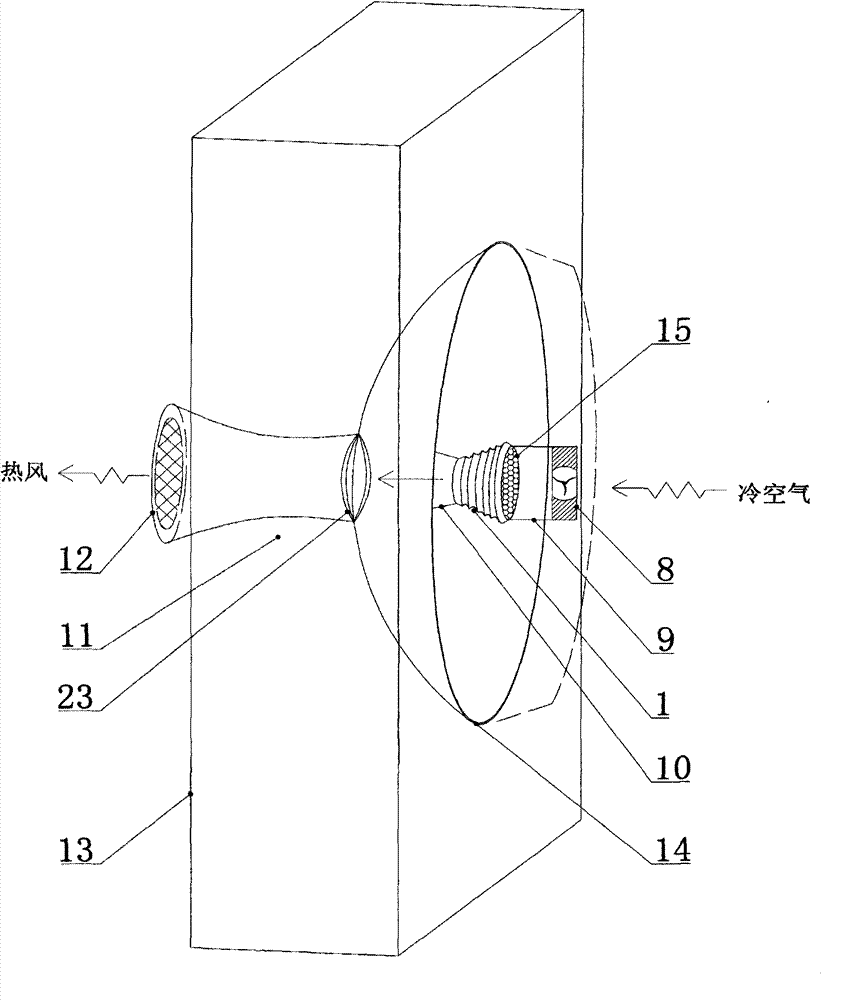

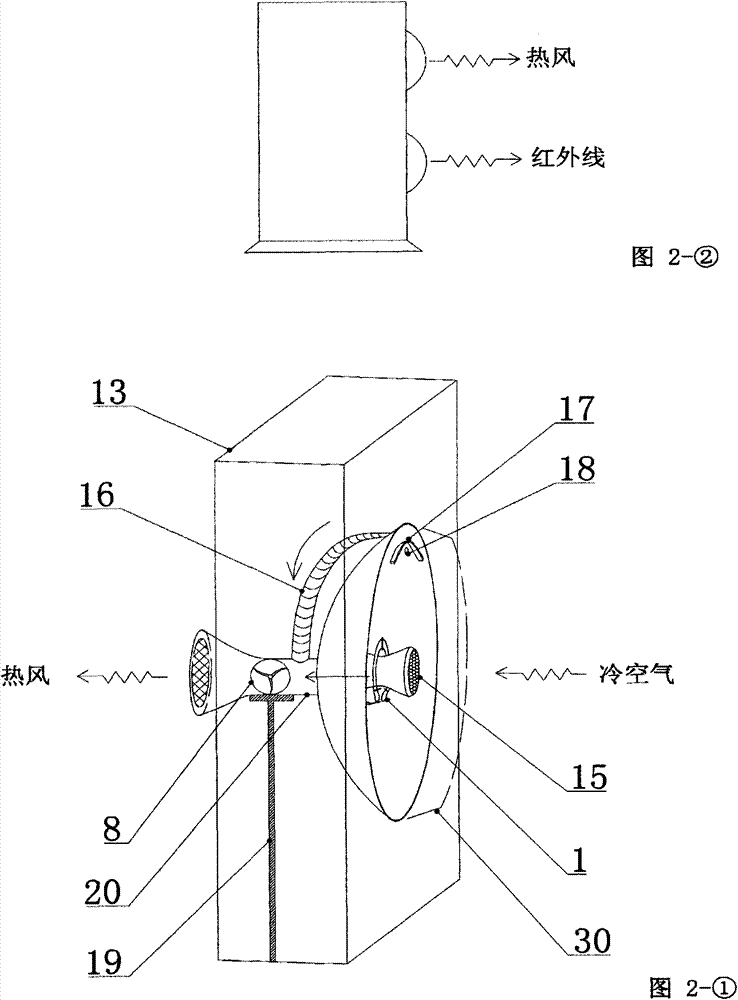

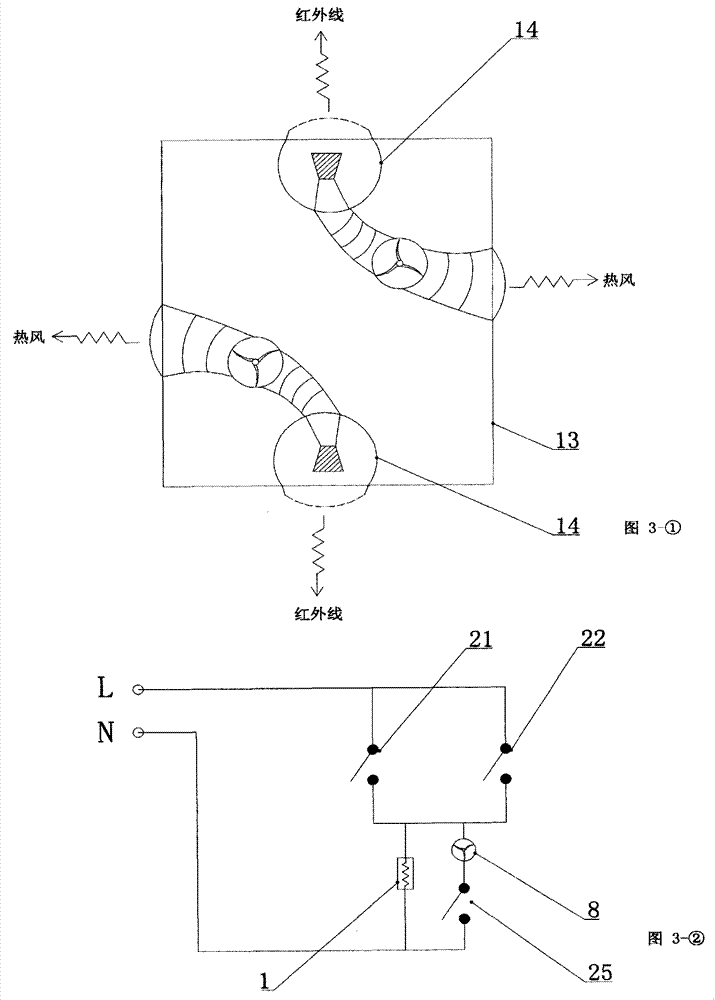

High-temperature air source heat pump air heater with evaporator with adjustable heat exchange capability

InactiveCN101639288AIncrease the heat exchange areaFull exchangeFluid heatersHeat pumpsAir volumeEngineering

The invention discloses a high-temperature air source heat pump air heater with an evaporator with adjustable heat exchange capability. The heat pump air heater comprises an air source heat pump and acondenser air blower, wherein the air source heat pump mainly comprises an evaporator, a compressor, a condenser and a throttling device which are sequentially connected by working medium circulatingpipelines; and the ratio of heat exchange area of the evaporator to the input power of the compressor ranges from 8.7 to 20m<2> / kw, the ratio of heat exchange area of the condenser to the input powerof the compressor ranges from 5.6 to 15m<2> / kw, and the evaporator is provided with the air blower with adjustable air flow. The invention improves the working capability of the heat pump air heaterin the mode of adjustable input; and under the same working condition, the air-out temperature thereof is greatly improved, the system can normally and stably run, and meanwhile, the energy efficiencyratio thereof exceeds the national standard by more than 50%. The invention provides hot-blast air with higher temperature, greatly expands the application range of the air source heat pump, and plays a positive role in energy conservation and emission reduction.

Owner:湖南省浏阳市择明热工器材有限公司

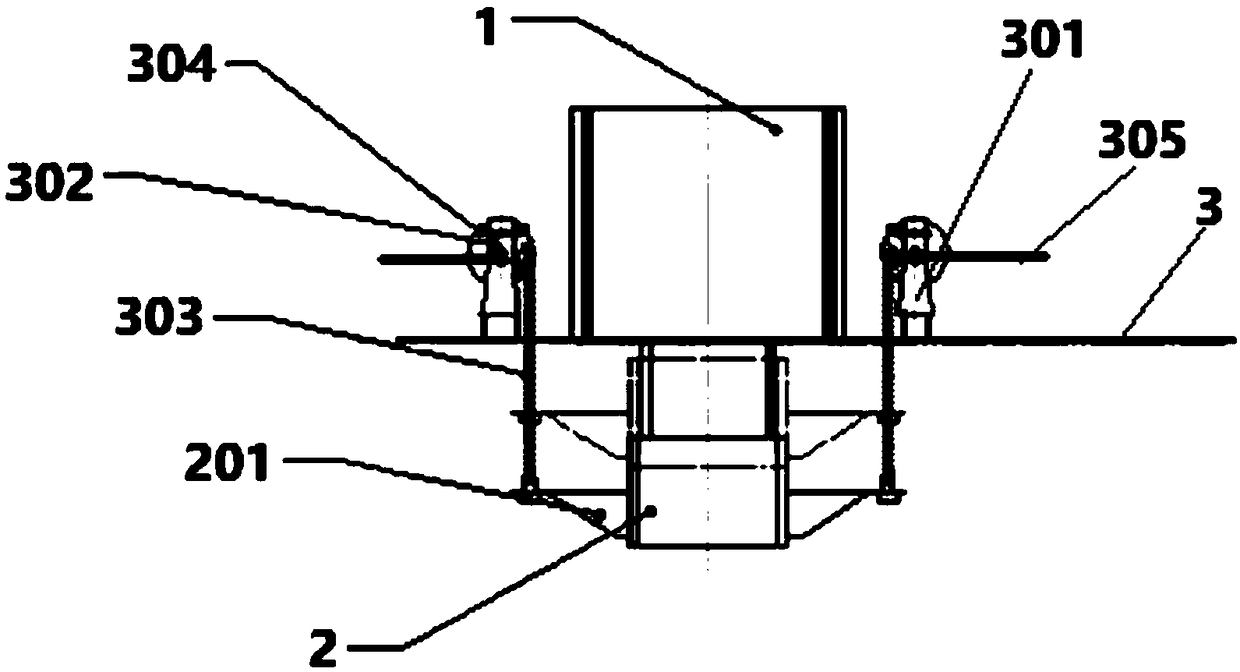

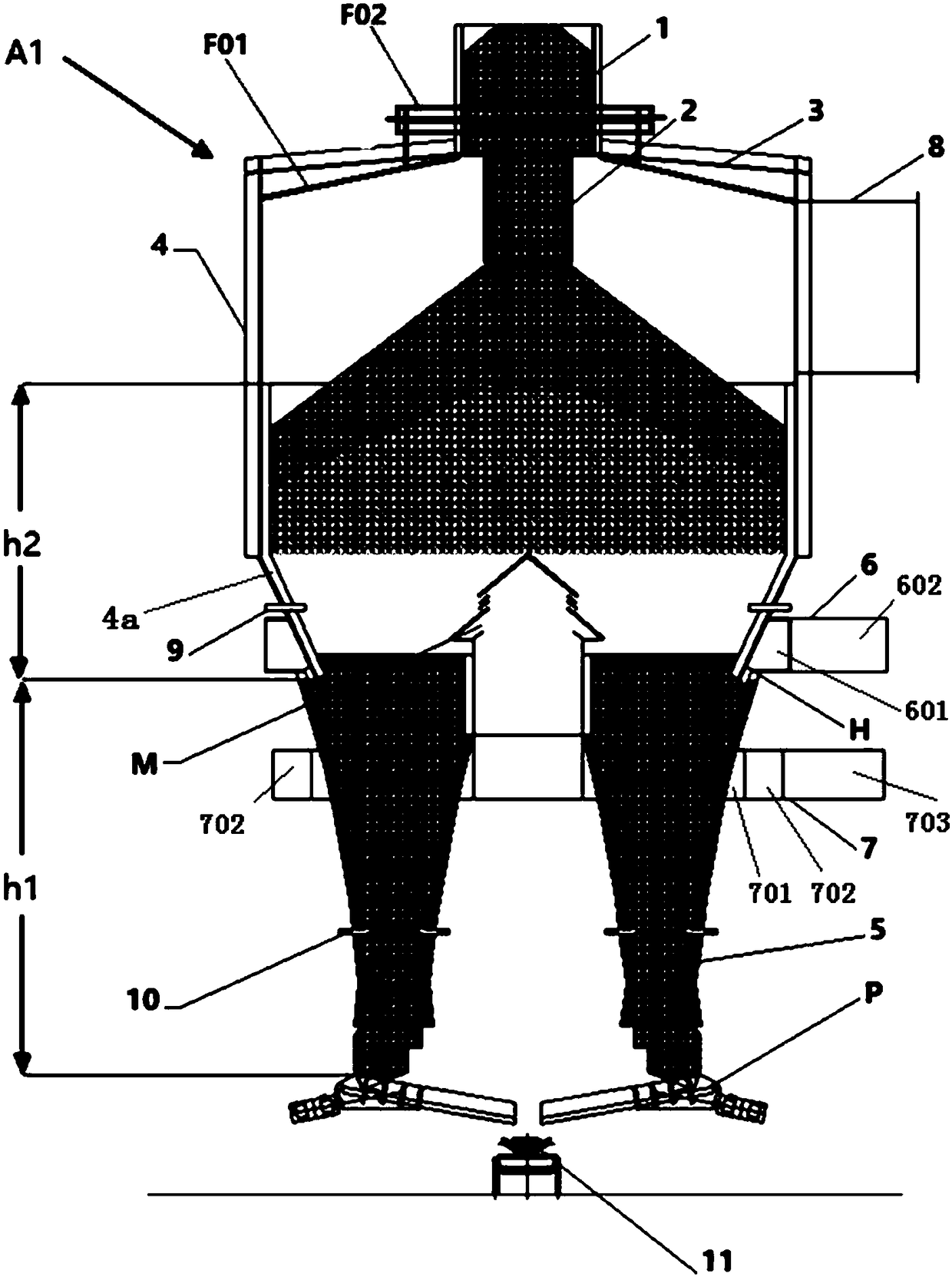

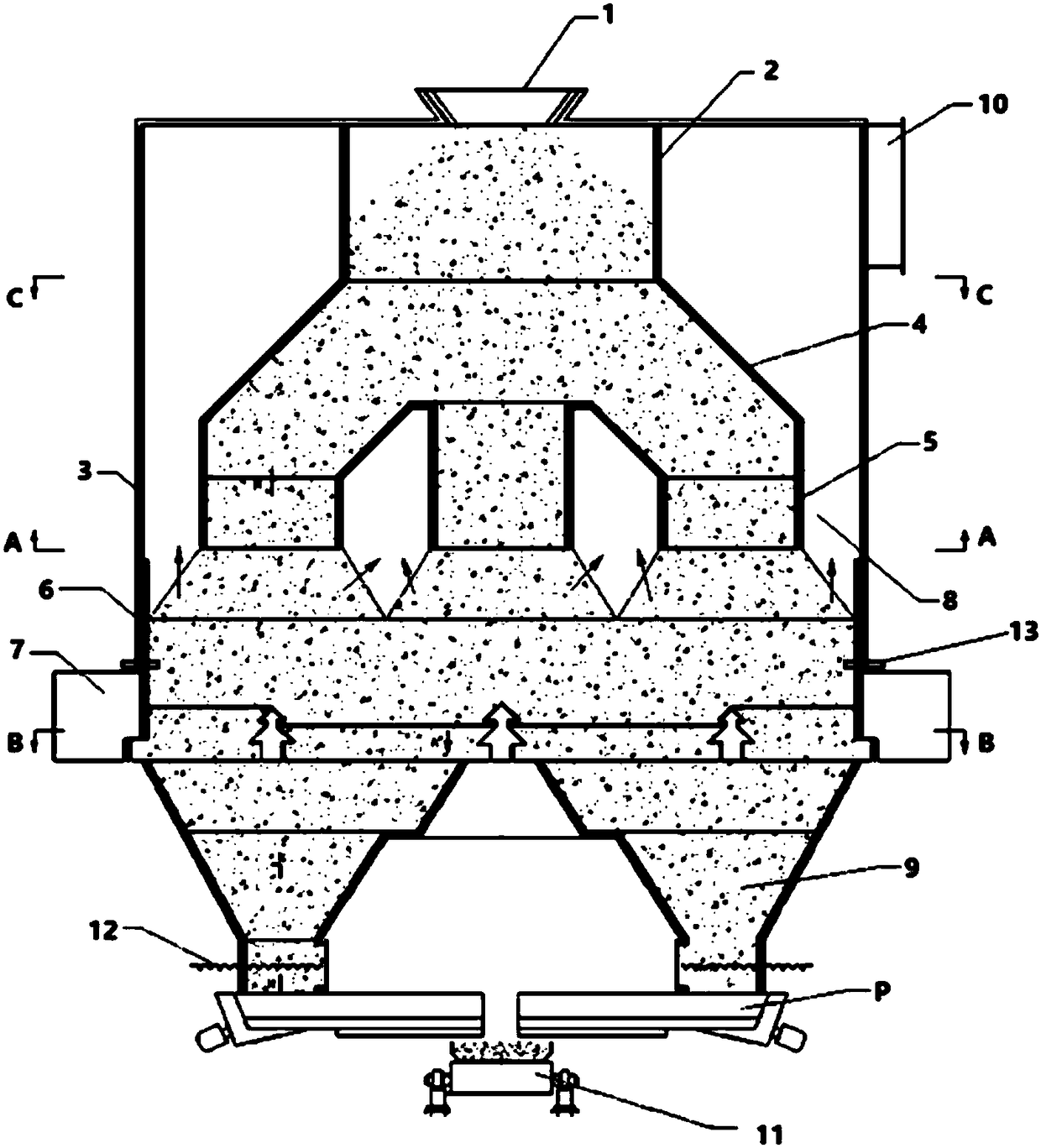

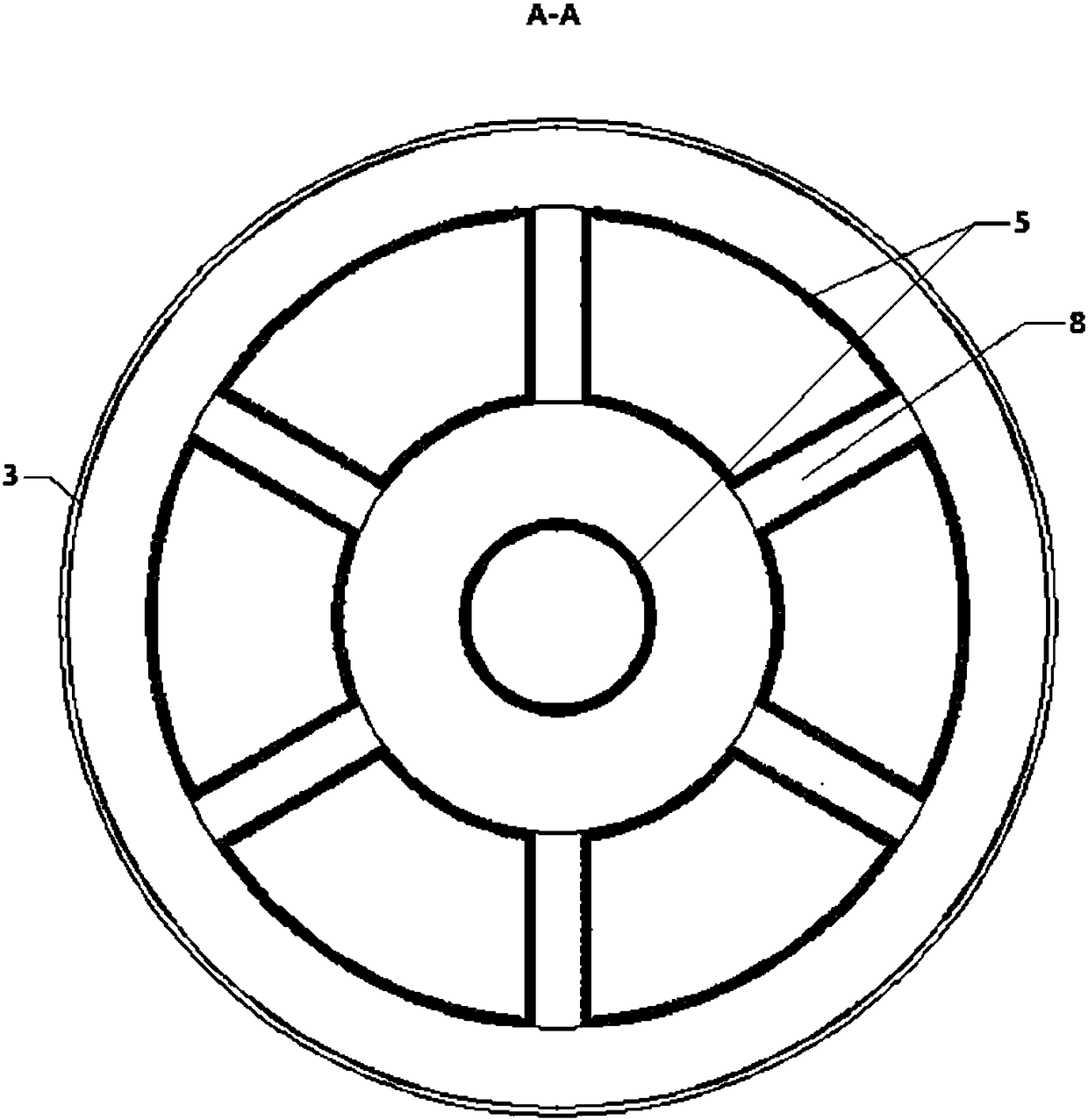

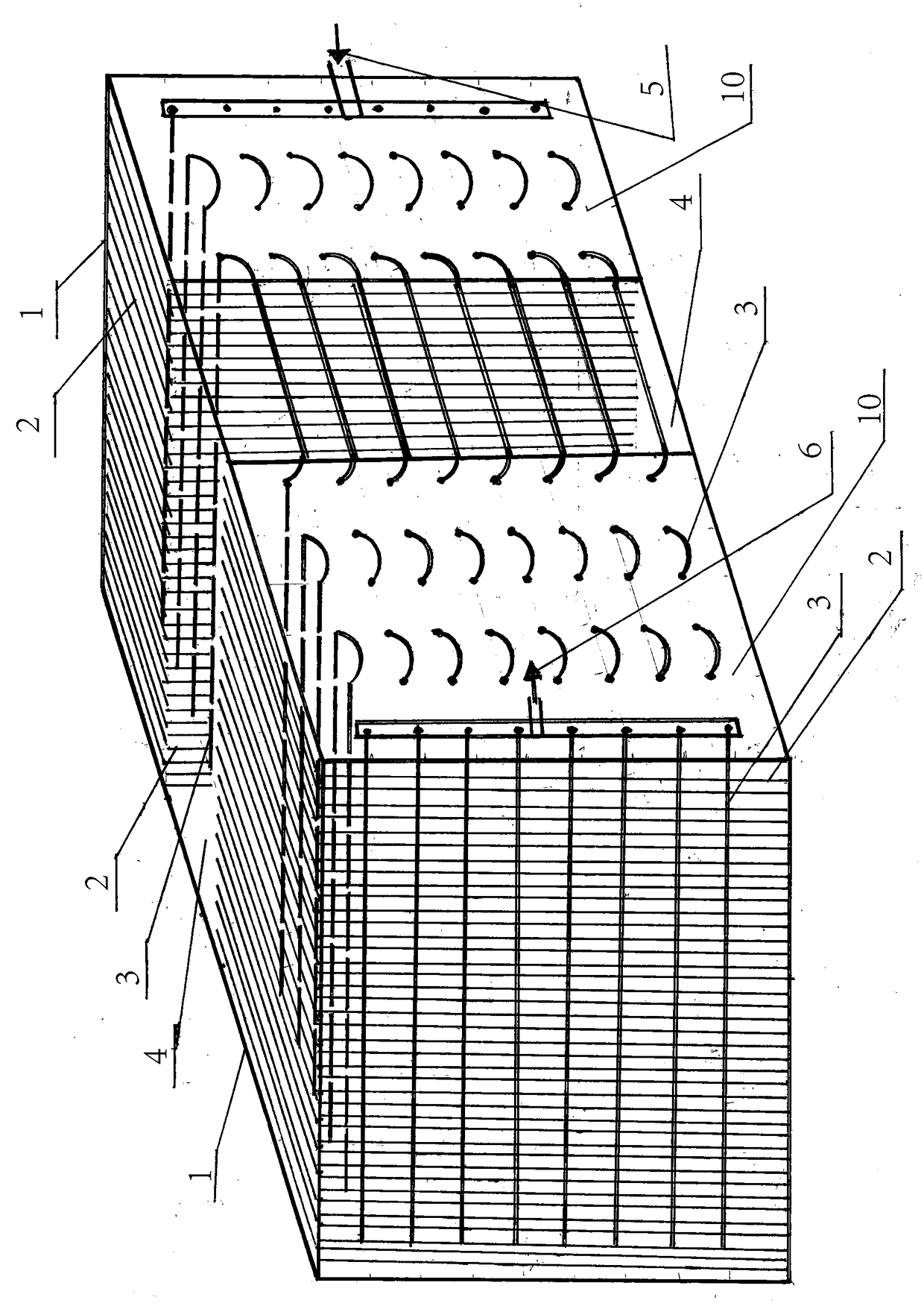

Vertical type sinter cooler with rotary distributing device and sinter cooling method

ActiveCN108955276ASimple structureImprove sealingIncreasing energy efficiencyHandling discharged materialTowerWaste management

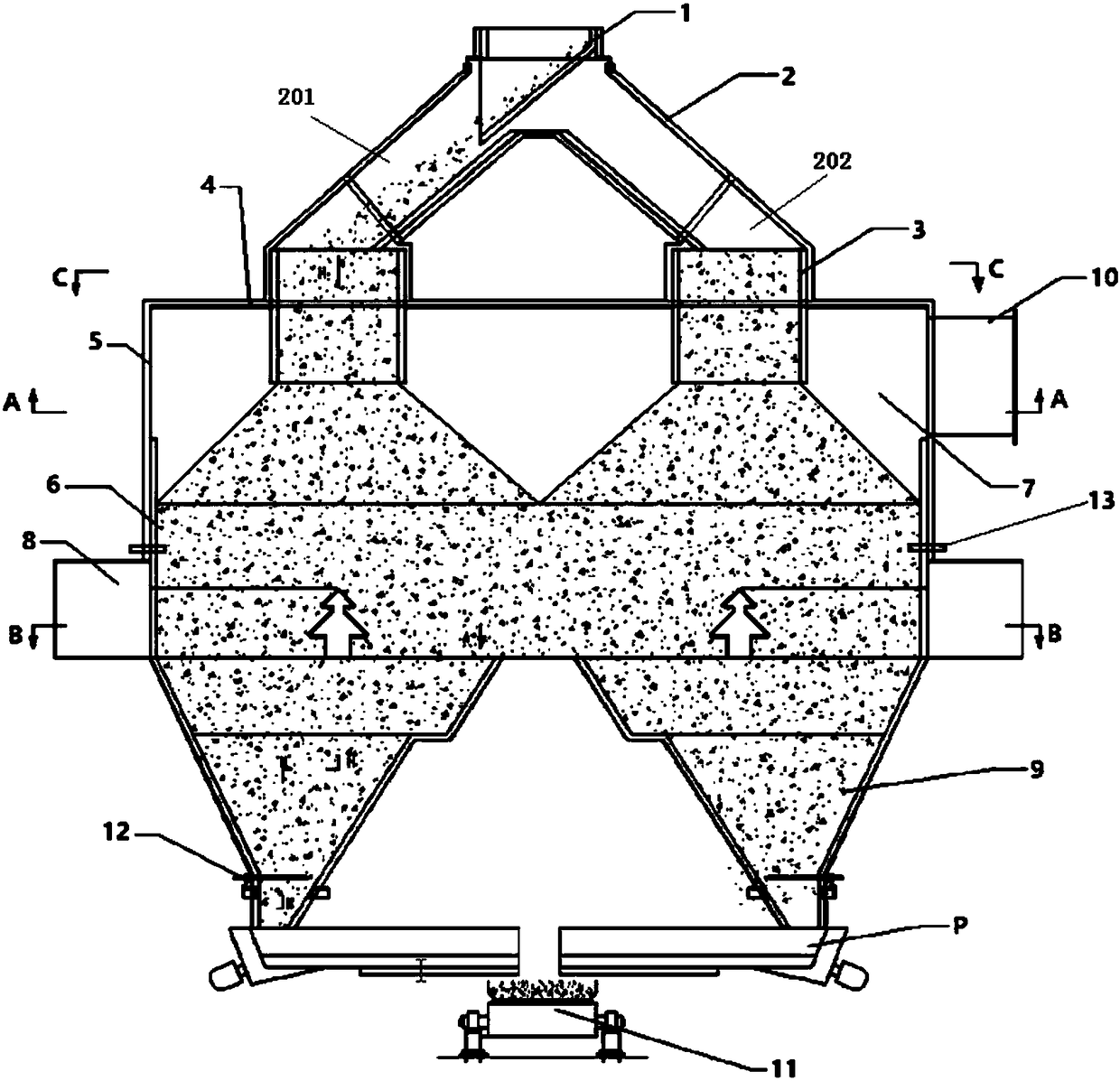

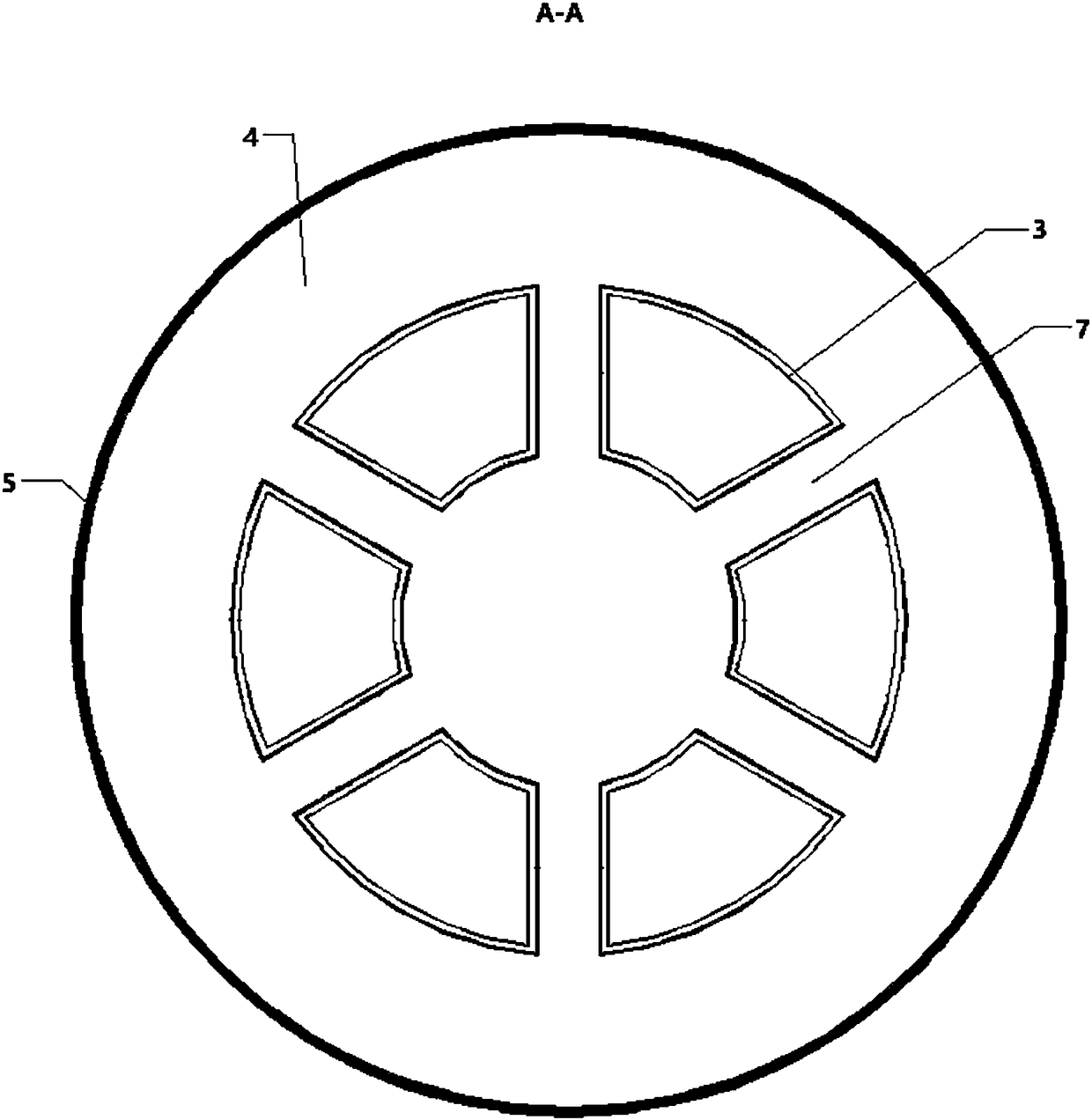

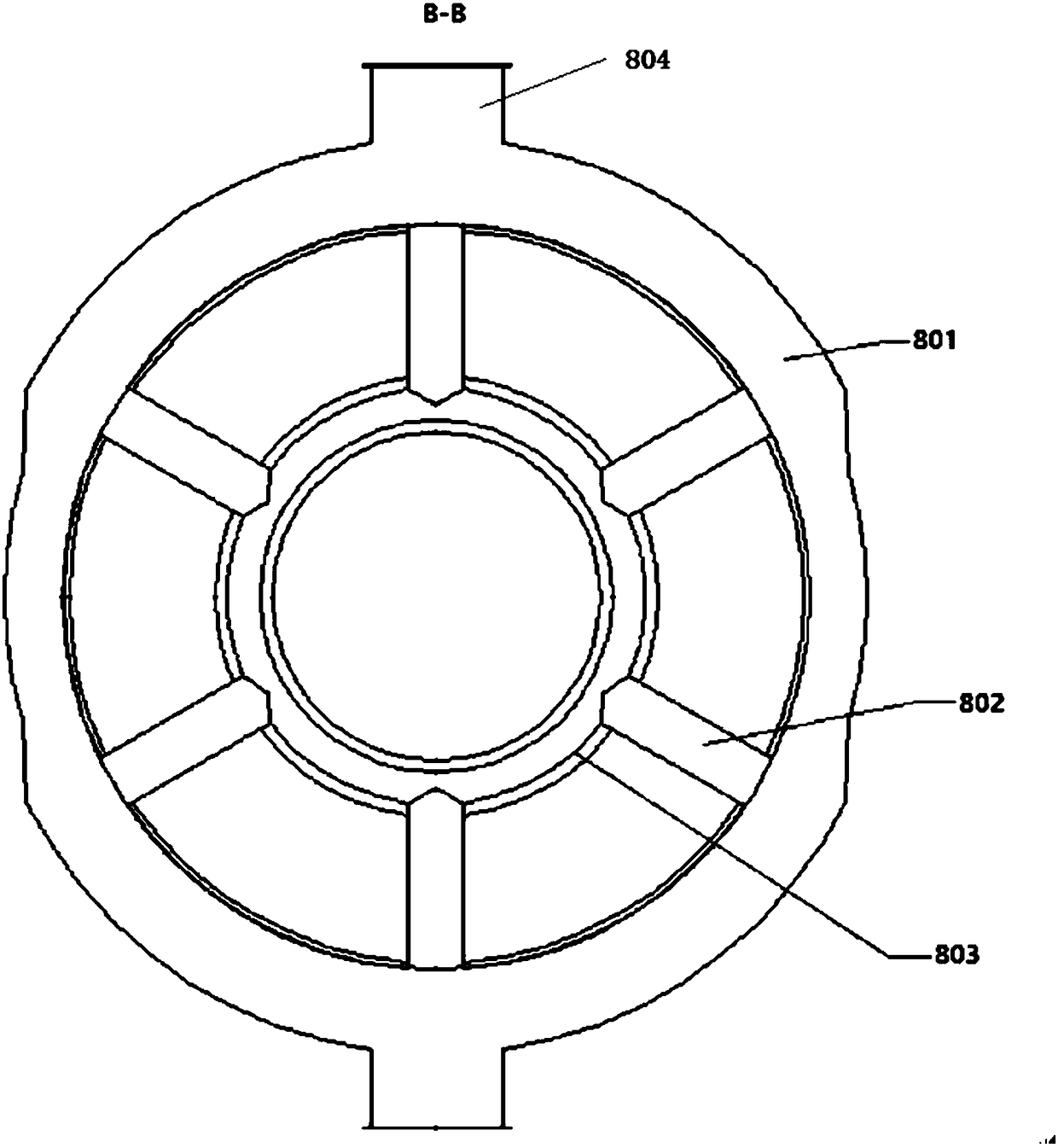

A vertical cooling machine with a rotary distributing device comprises the rotary distributing device (1), an umbrella-shaped chute (2), vertical chutes (3), a tower body, a cooling section (6) and ahot air outlet (10), wherein the tower body is composed of a tower body top cover (4) and a tower body side wall (5), and the hot air outlet (10) is formed in the upper portion of the tower body top cover or the tower body side wall. The umbrella-shaped chute (2) comprises an upper overall section (201) and a lower separated section (202), the upper end of the overall section (201) is connected with the rotary distributing device (1), each branch of the lower separated section (202) is connected with one corresponding vertical chute (3) below, and a hot air channel (7) is formed above the cooling section (6) and in a gas space between the tower body and the vertical chutes (3). A uniform air inlet device (8) is arranged below the cooling section (6), and a plurality of discharging conicalhoppers (9) are arranged on the lower side of the uniform air inlet device (8). Discharging devices are arranged on the lower sides of the discharging conical hoppers (9). The vertical cooling machineis simple in structure, reliable in sealing and high in waste heat recovery efficiency.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

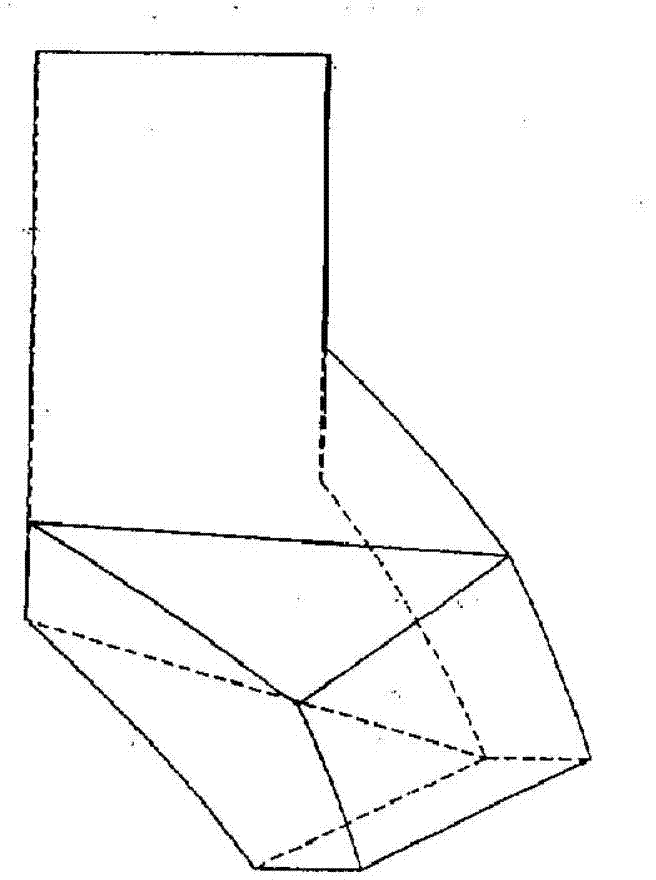

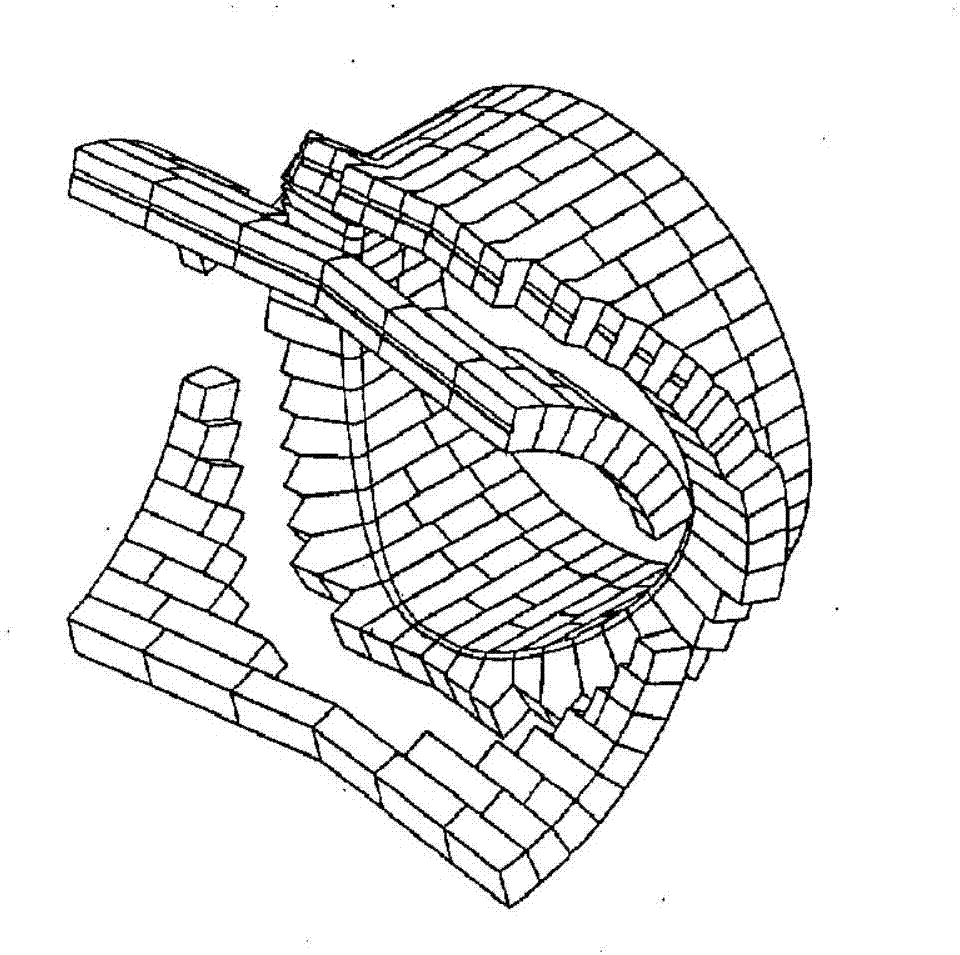

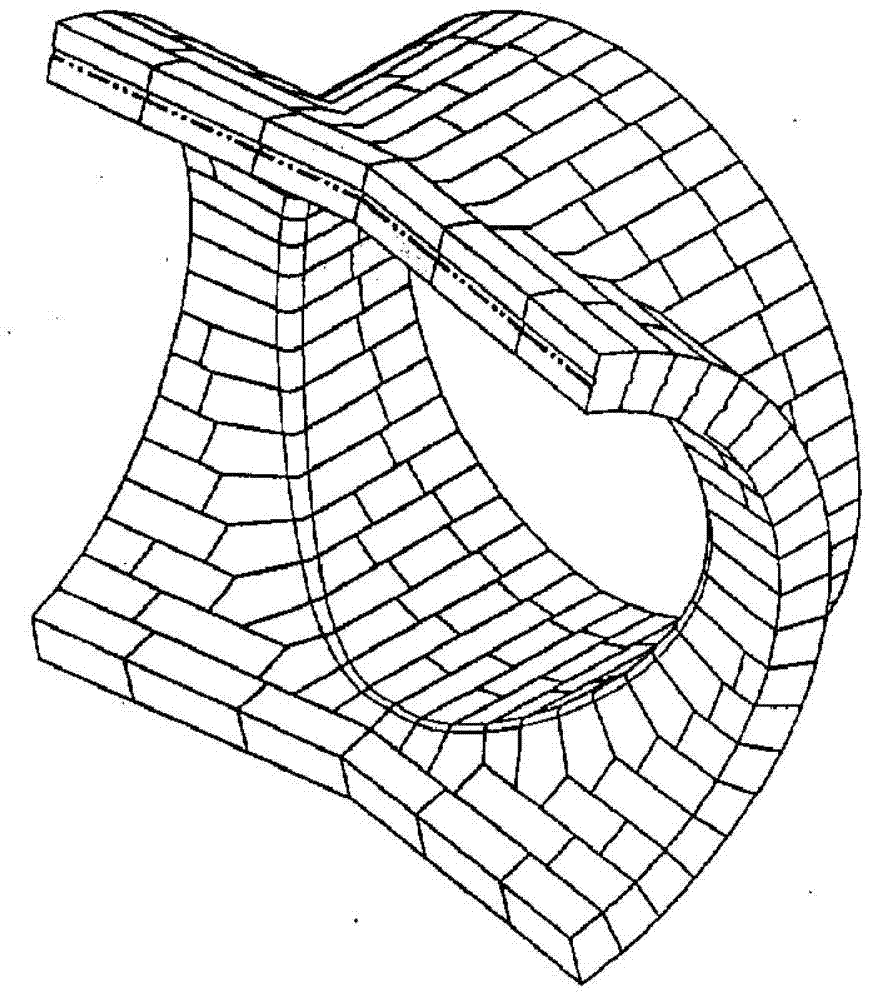

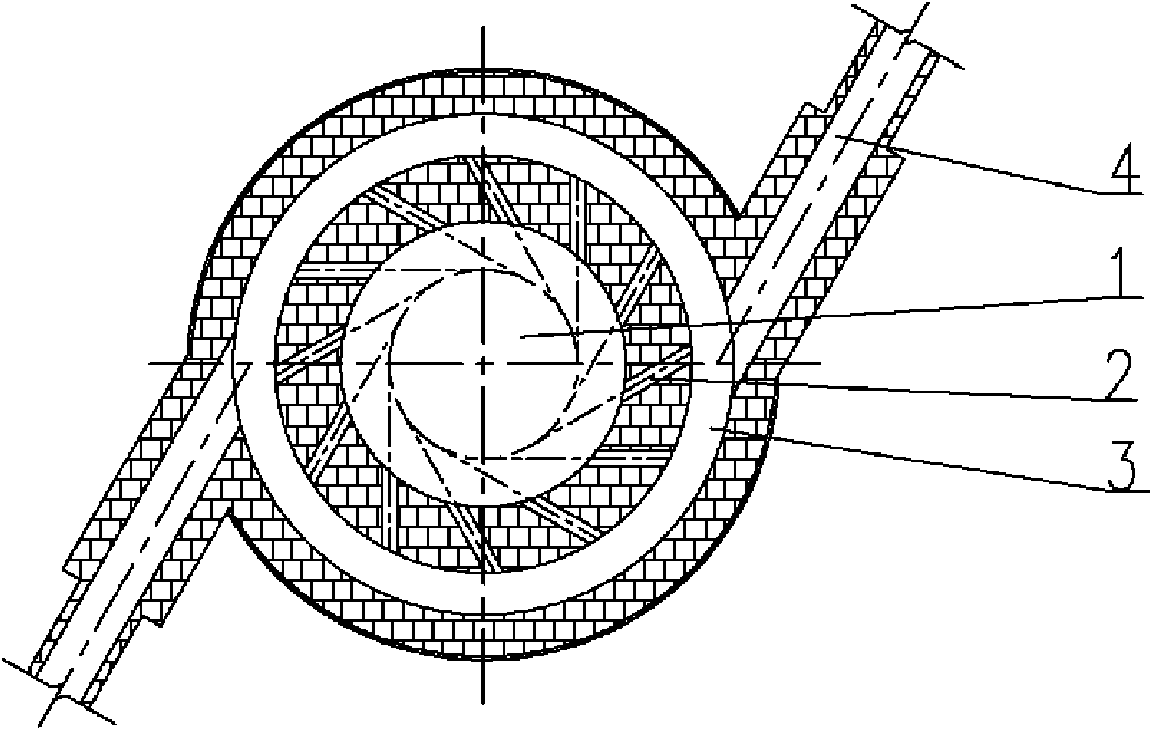

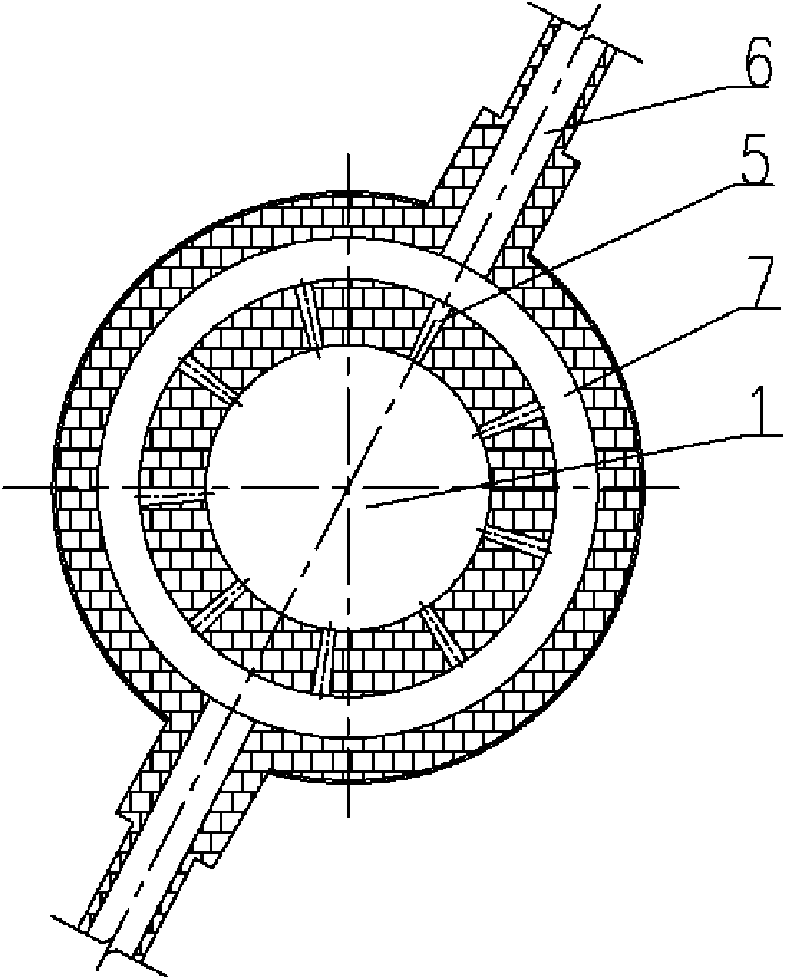

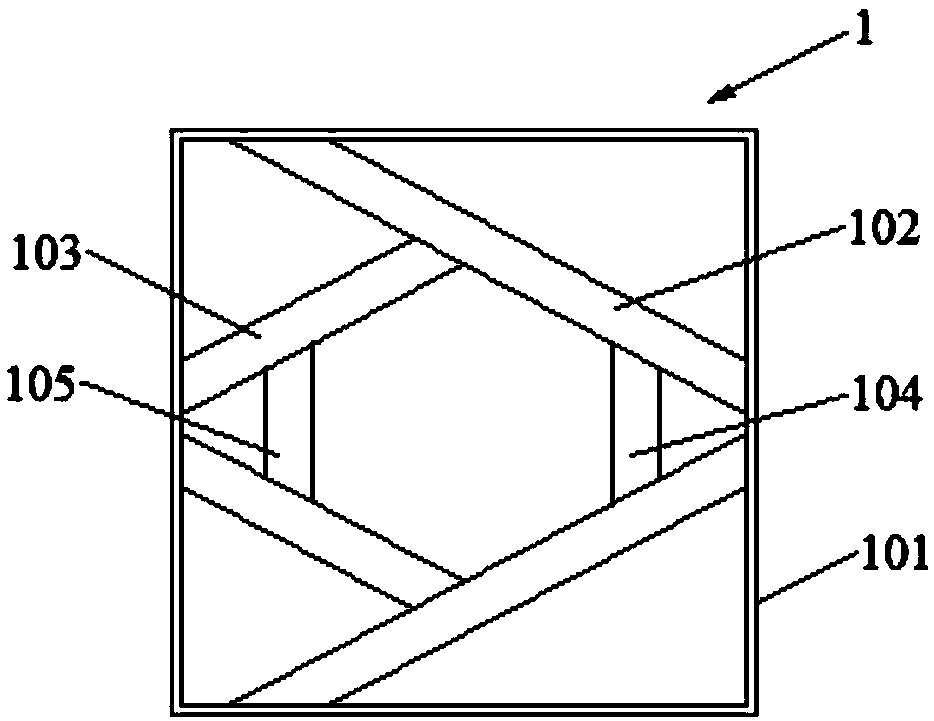

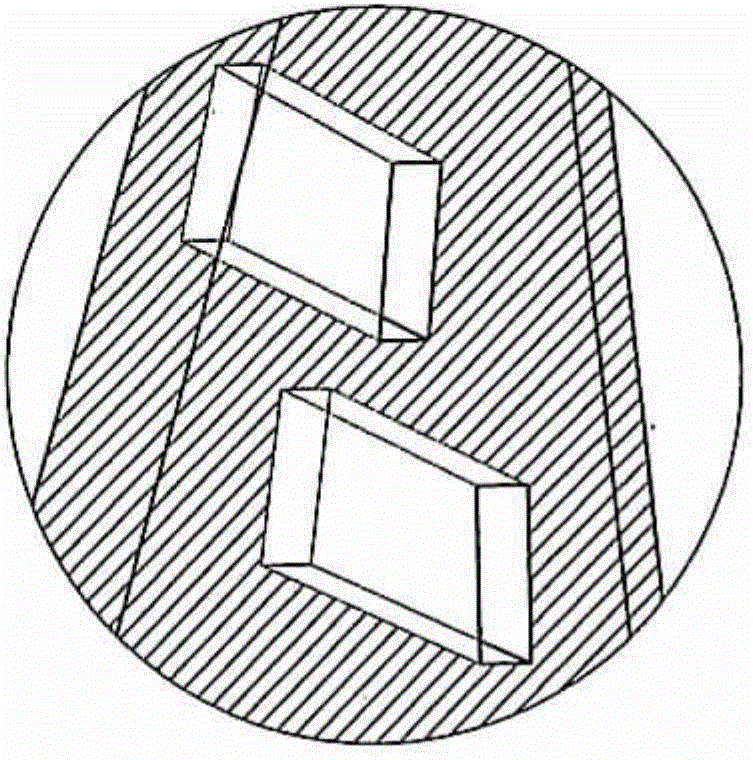

Novel combined brick structure of self-locking sealed blast furnace warm air duct intersection

ActiveCN103114167AIncrease injection volumeReduce lossBlast furnace detailsHeating stovesBrick masonryPower engineering

The invention provides a novel combined brick structure of a self-locking sealed blast furnace warm air duct intersection and relates to the technical field of thermal power engineering. A key technology of self-locking refractory brick masonry structure is adopted, self-locking refractory bricks with both flat ends and self-locking refractory bricks with one flat end and one pointed end are selected within bending angles of 1-180 degrees according to the actual condition of diameter of the intersection connecting site of a main pipe and a surrounding pipe (or branch pipe), and the self-locking refractory bricks are built to form a novel annular combined brick structure at the intersection connecting site of the main pipe and the surrounding pipe (or branch pipe) in the blast furnace warm air duct so as to eliminate the annular faulted joint at the intersection connecting site of the main pipe and the surrounding pipe (or branch pipe) in the blast furnace warm air duct and numerous triangular faulted joints of the annular faulted joint. The novel combined brick structure is applied to blast furnace warm air duct intersection structures. The novel combined brick structure has the advantages of scientific and smart design, no annular faulted joints or triangular faulted joints, severe environment resistance, high production efficiency and excellent quality.

Owner:ZHENGZHOU ANNEC IND

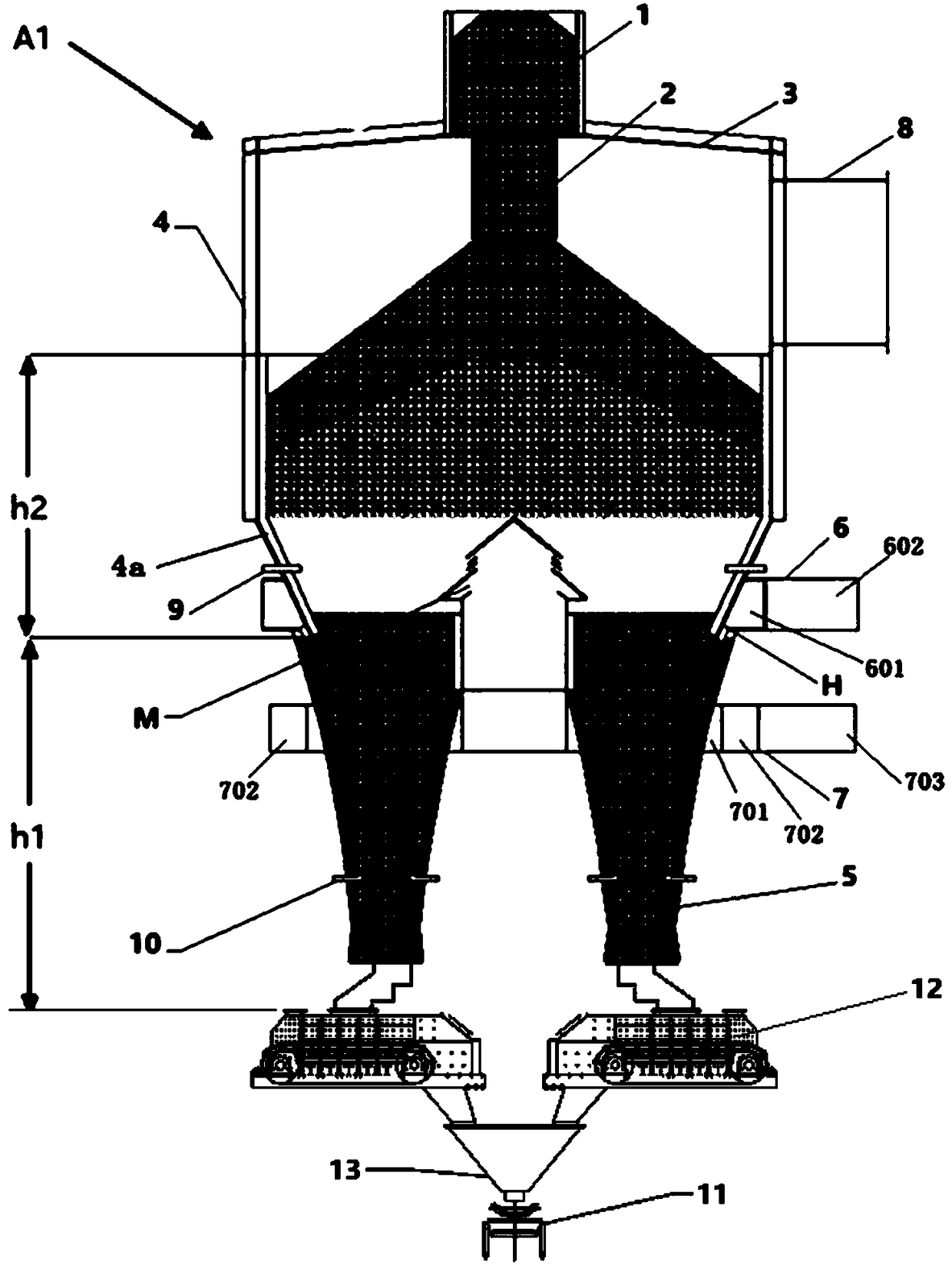

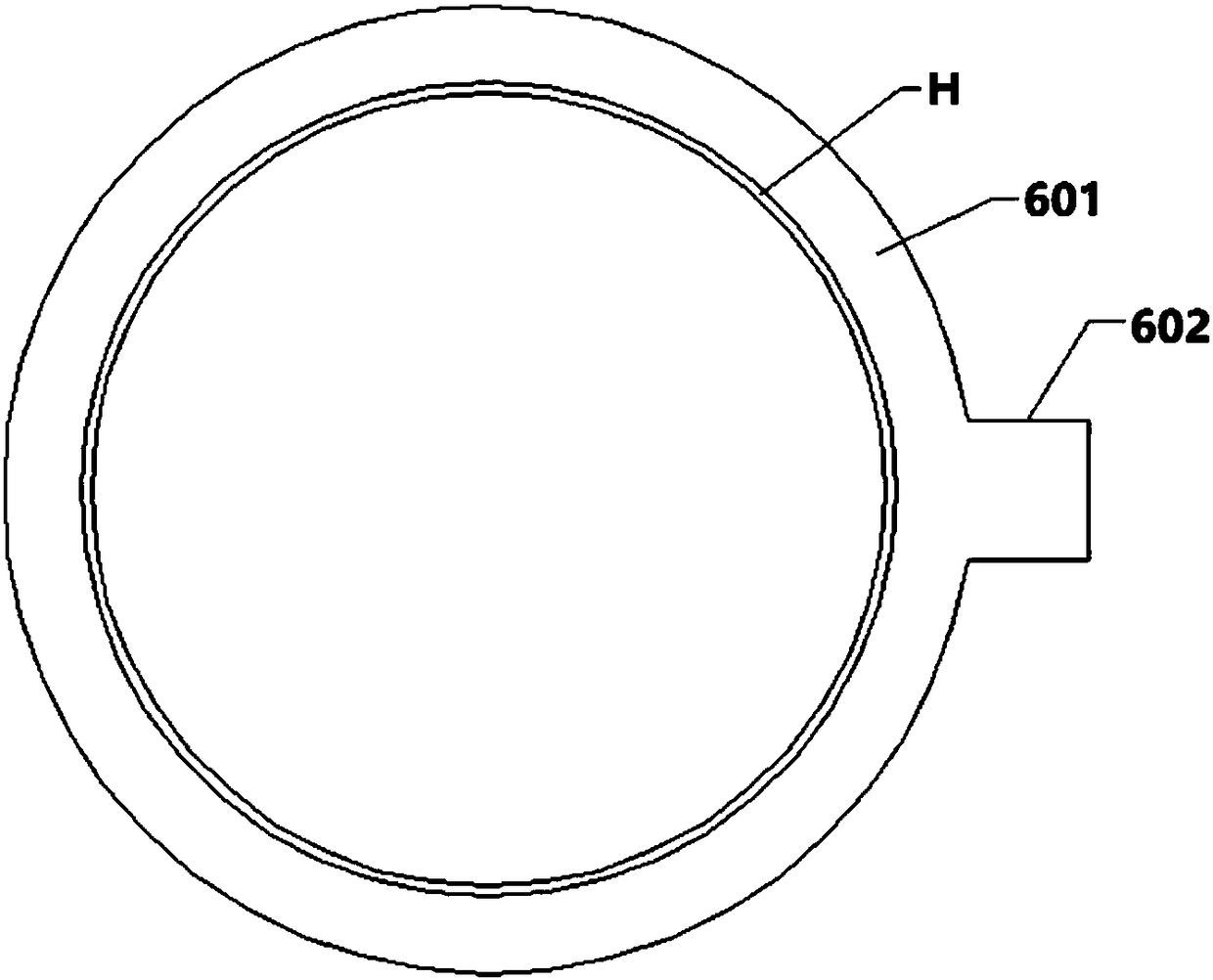

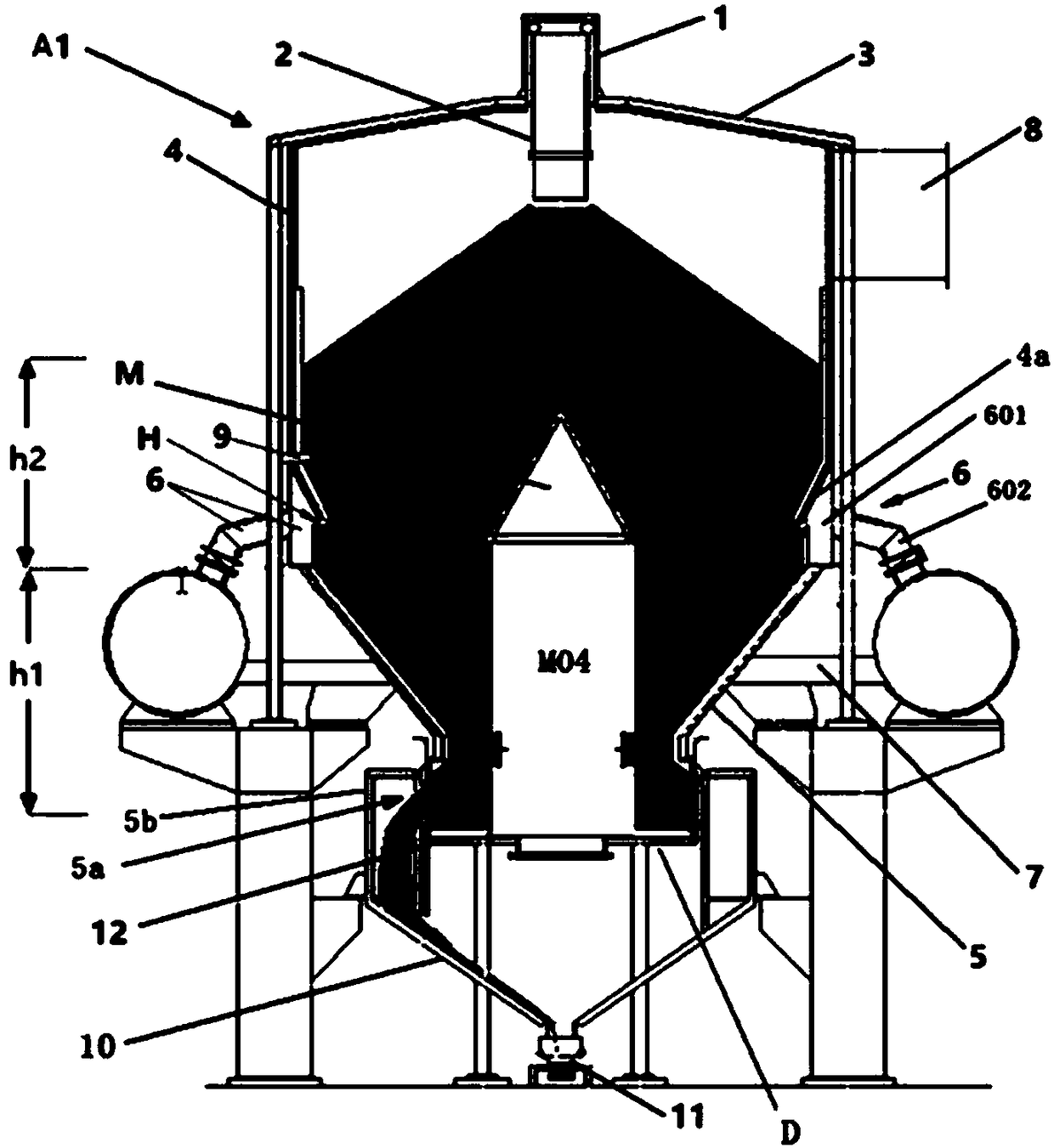

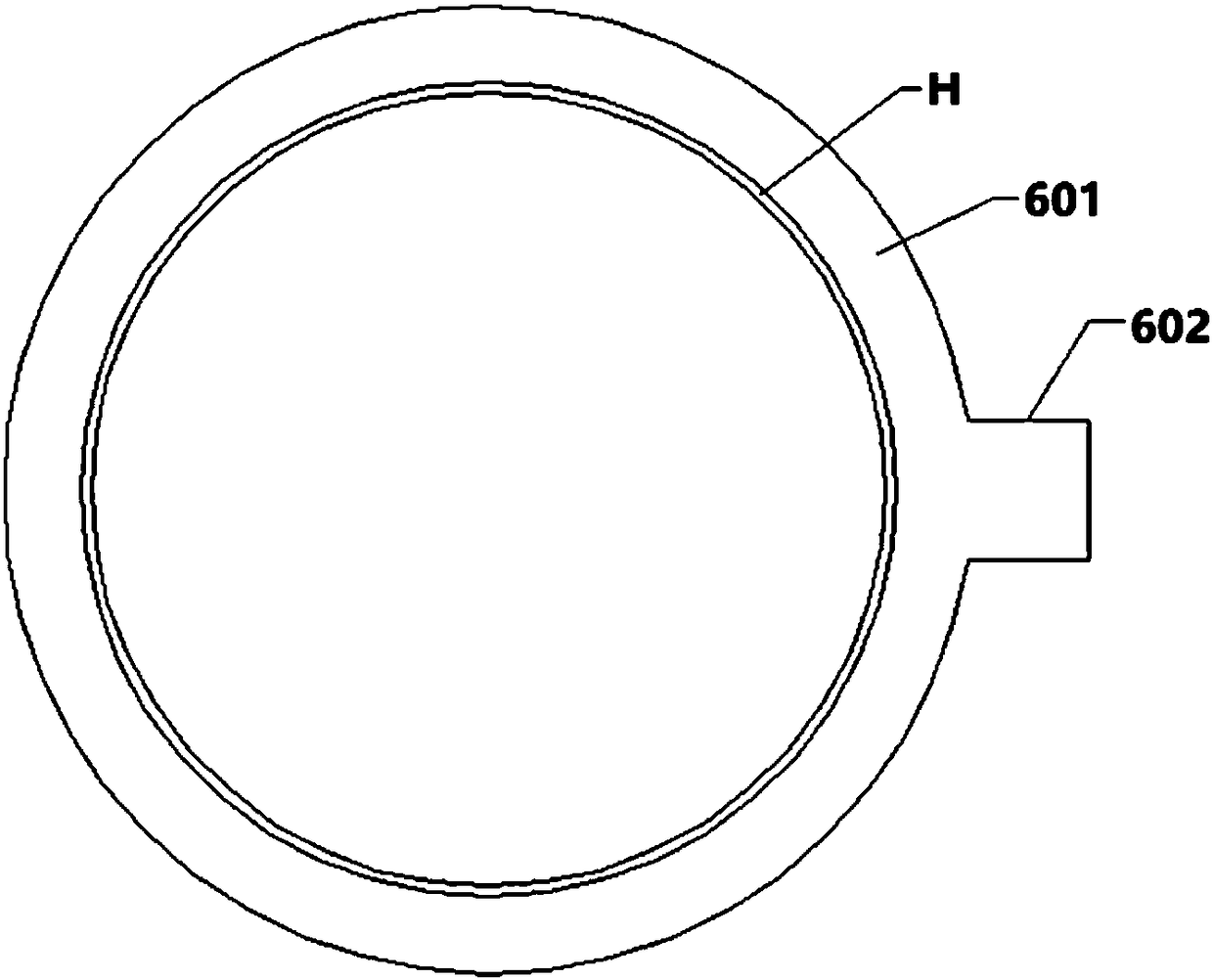

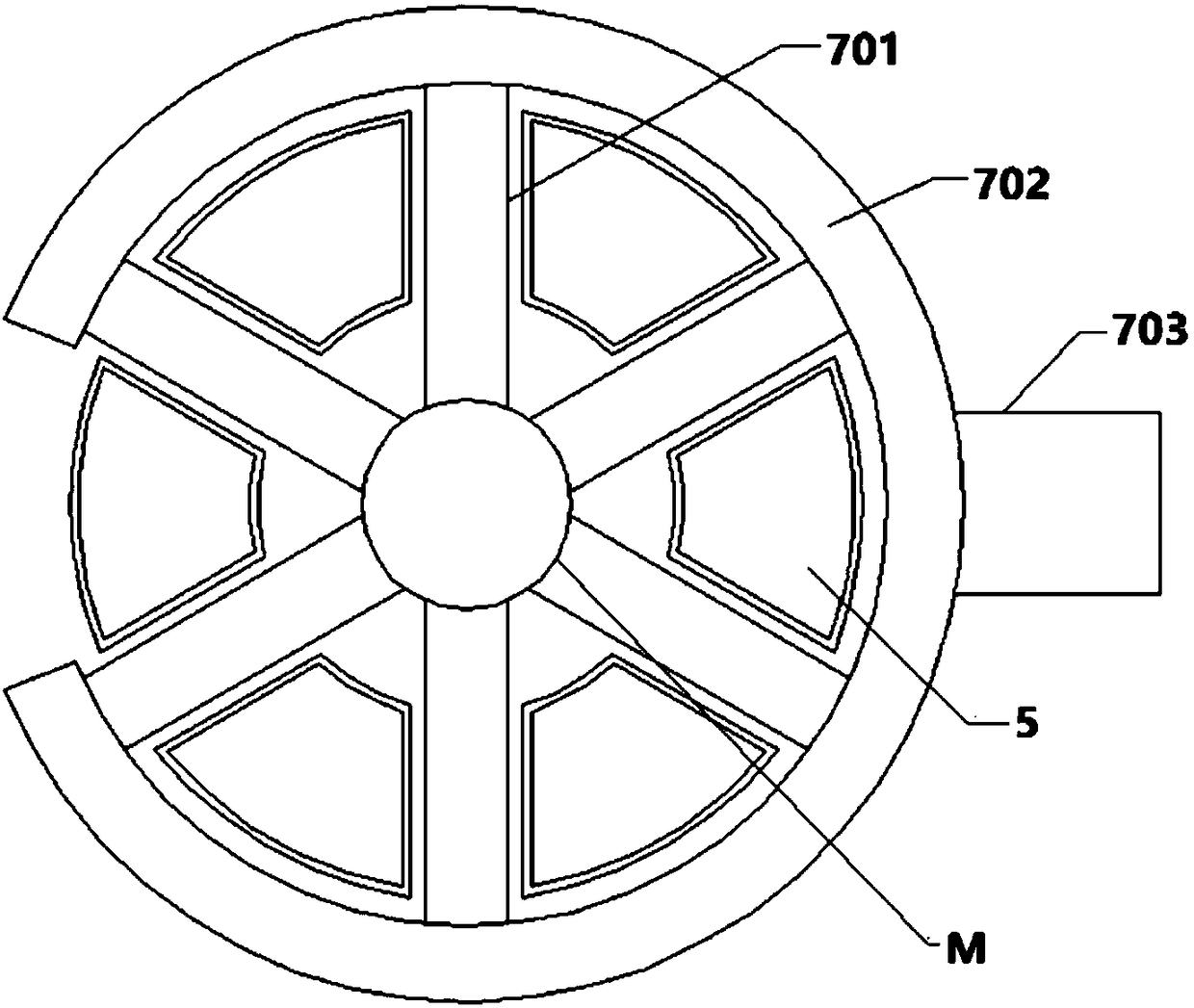

Vertical type sinter cooler and sinter cooling method

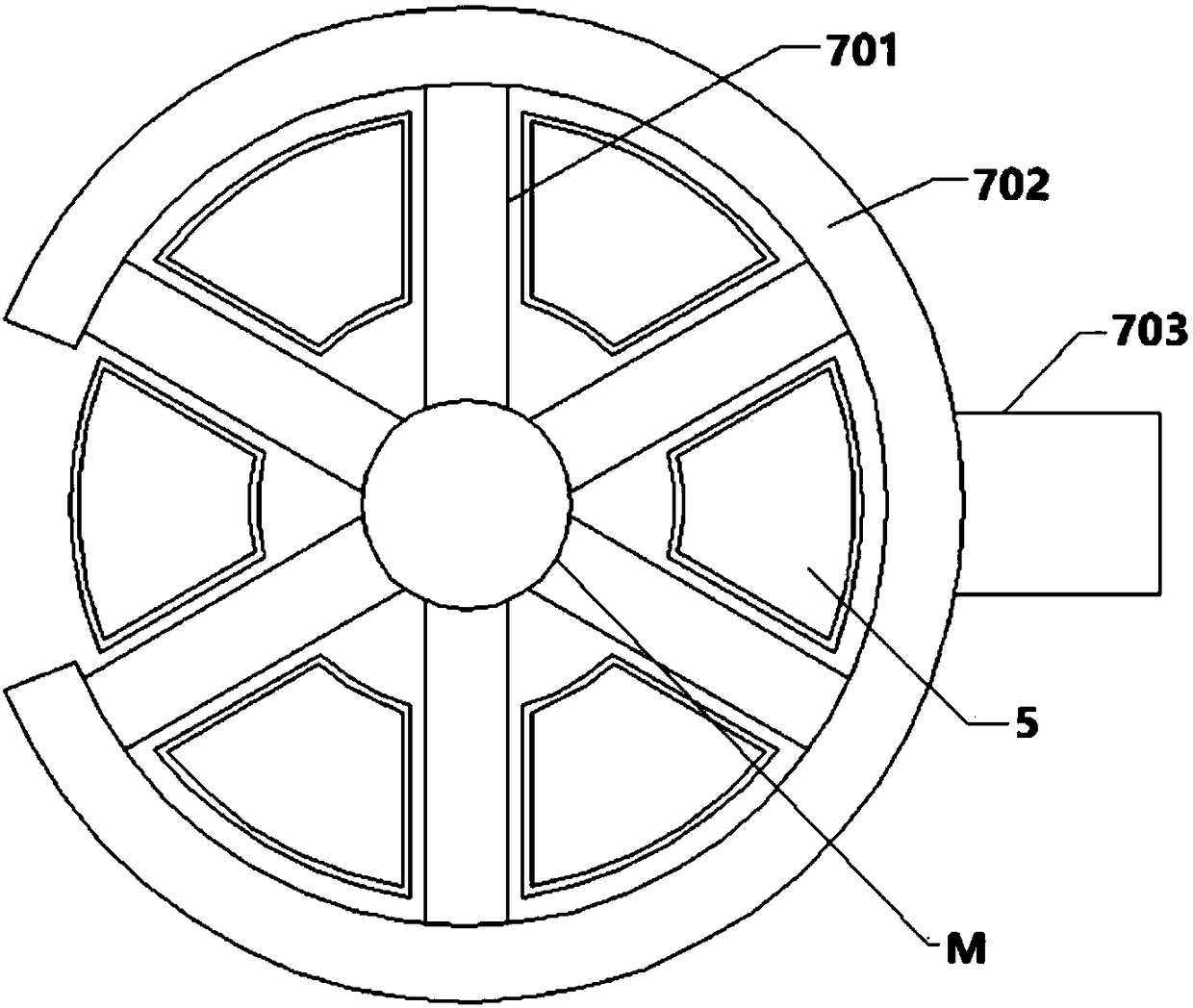

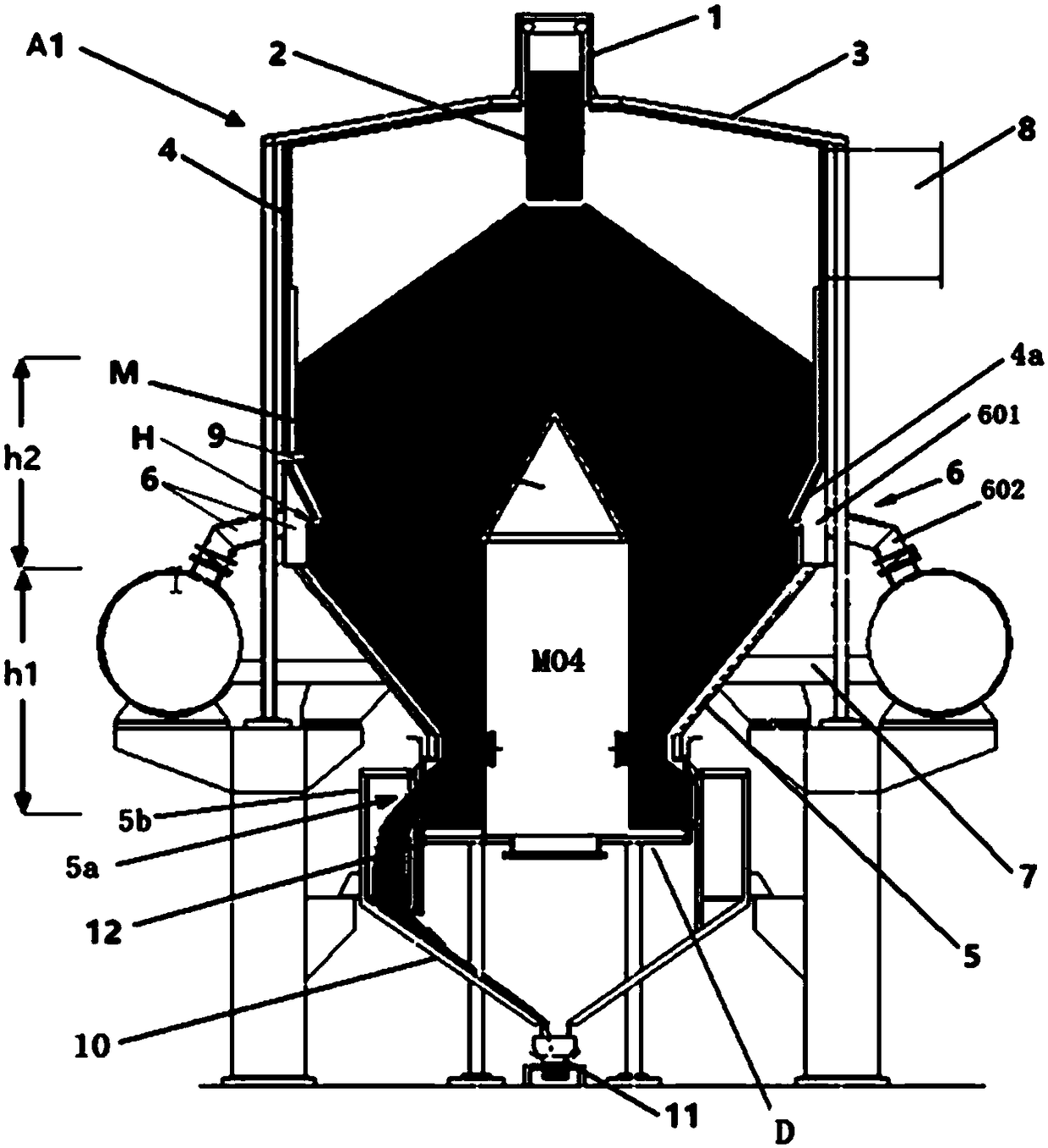

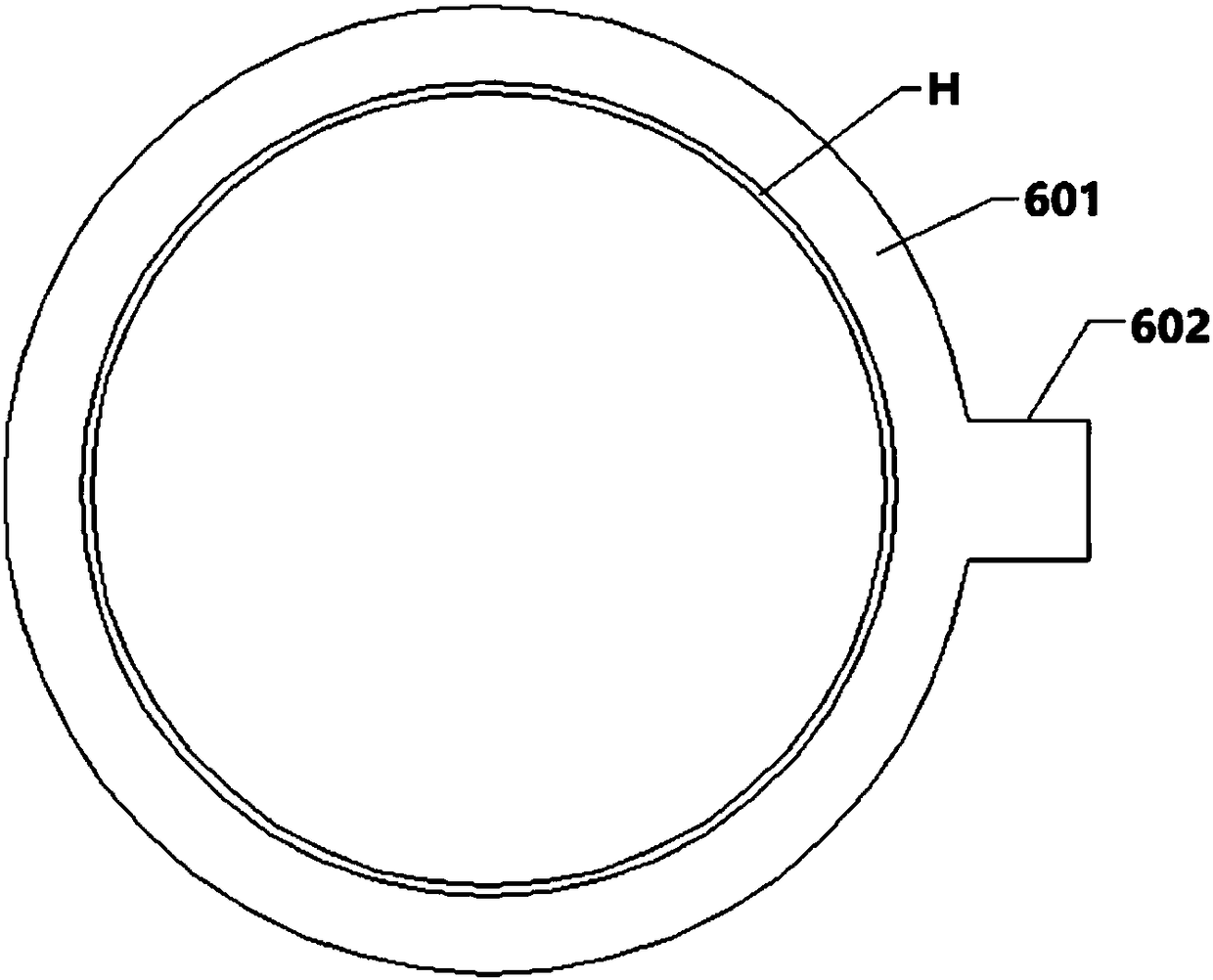

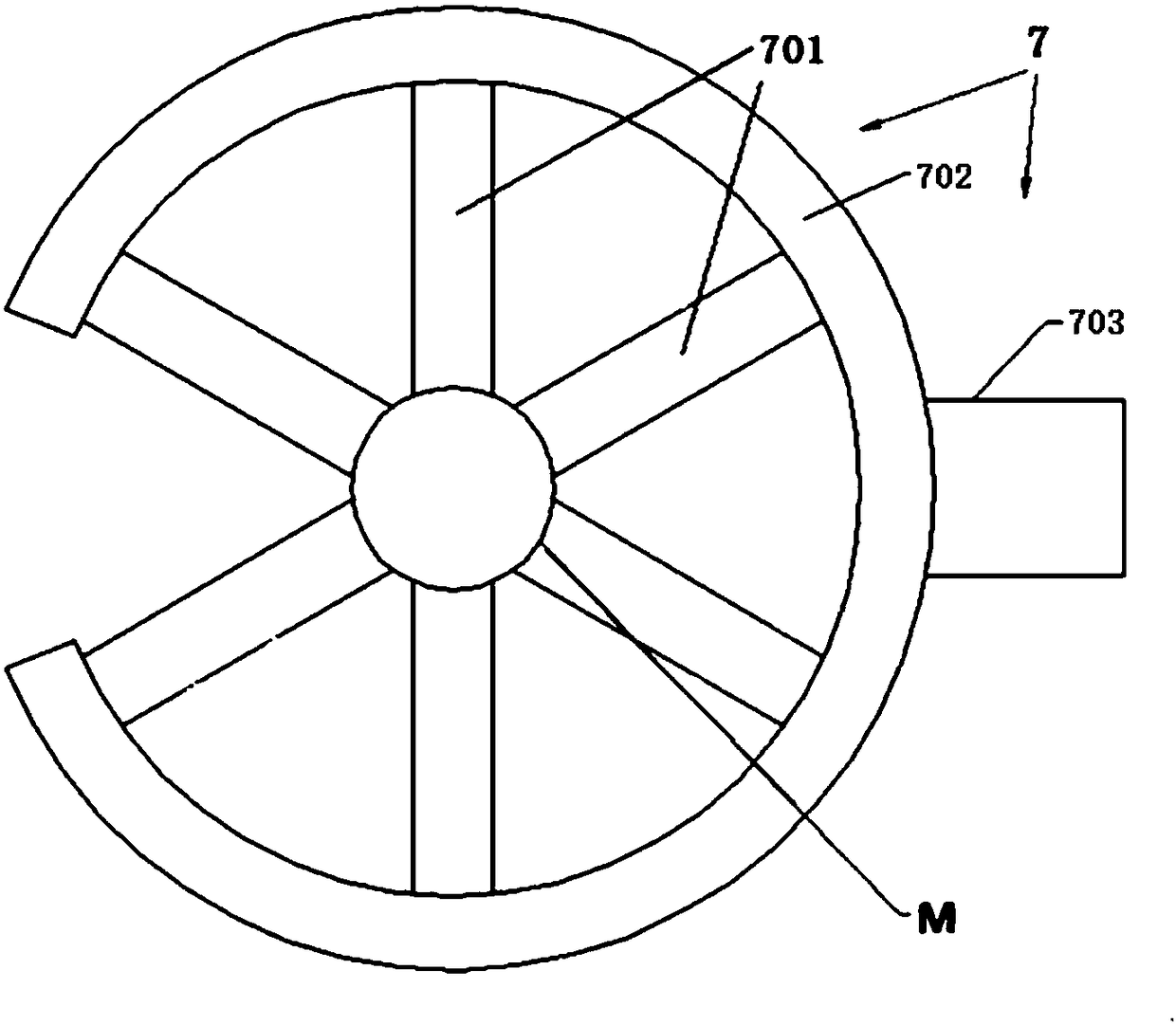

PendingCN108267019AImprove cooling effectRaise the hot air temperatureCharge treatment typeHandling discharged materialEngineeringMaterial distribution

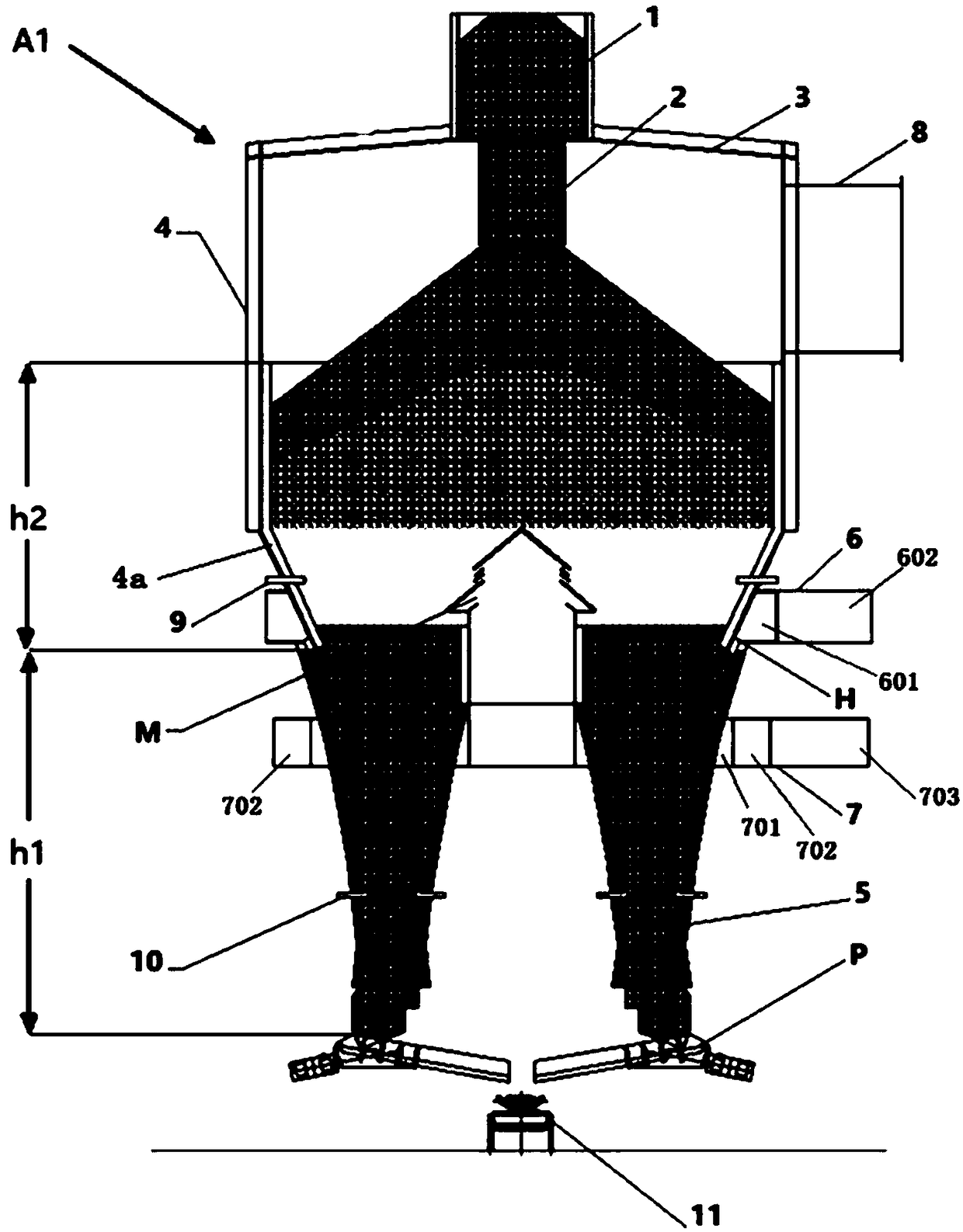

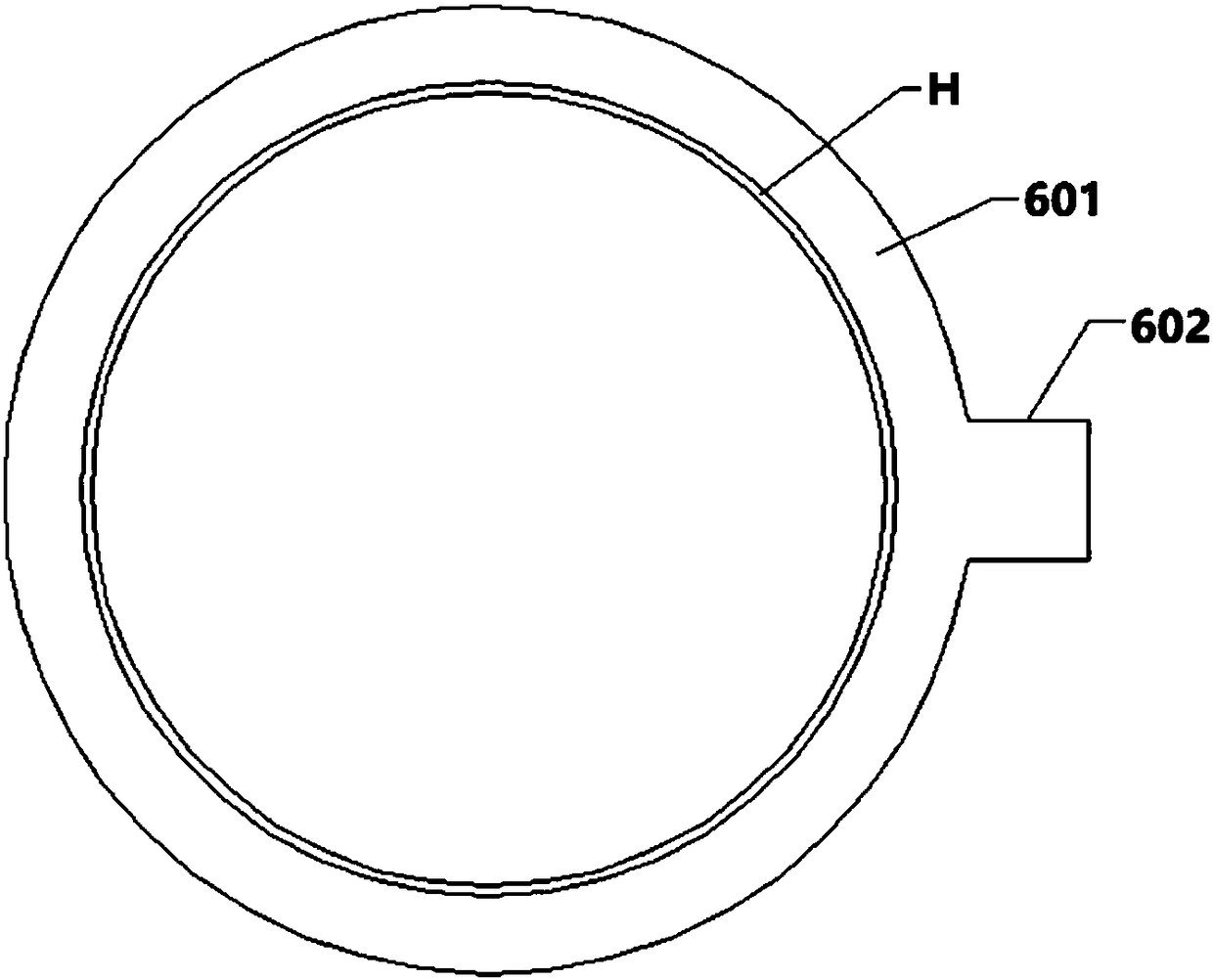

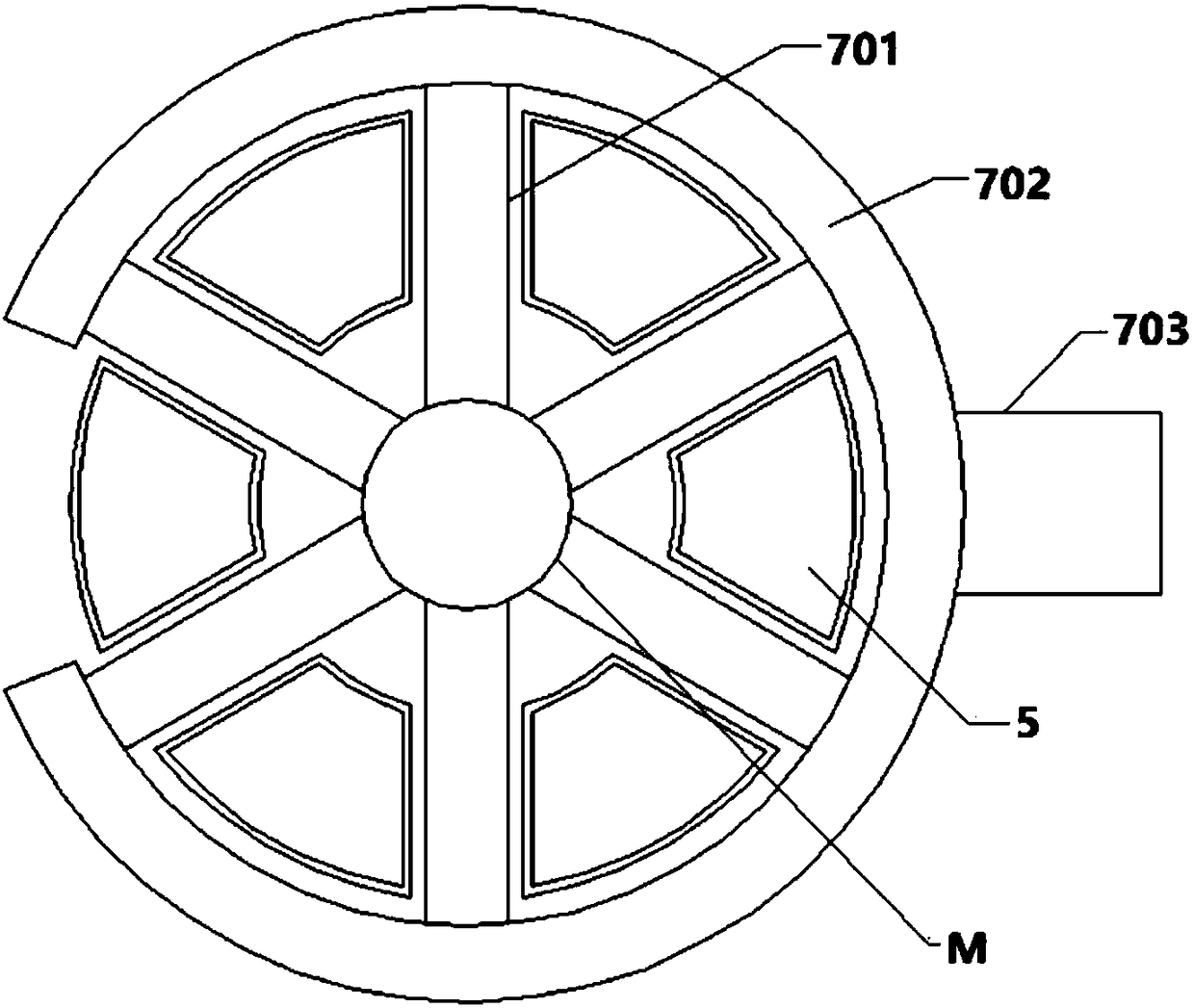

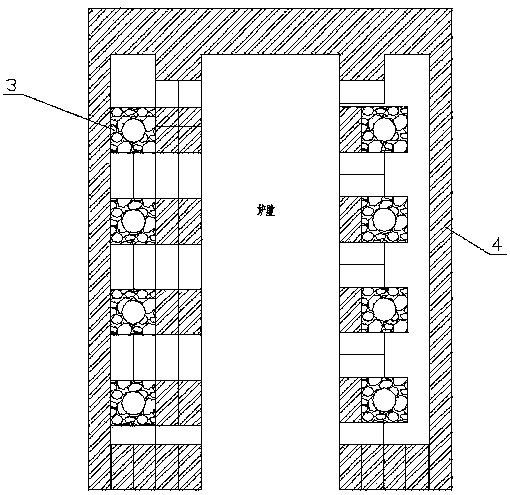

The invention discloses a vertical type sinter cooler and a sinter cooling method. A plate type ore feeder unloading type vertical cooler comprises a material bin (1), a material distribution pipe (2), a tower, a plurality of discharge conical hoppers (5), an air ring (H), an air cap (M) and a hot air outlet (8). The tower comprises a tower top cover (3) and a tower wall (4). The discharge conicalhoppers (5) are located below the tower wall (4). The hot air outlet (8) is formed in the upper portion of the tower wall (4) or in the tower top cover (3). The top cover (3) is fixedly connected with the upper end of the tower wall (4). The material bin (1) is arranged above the top cover (3). The upper end of the material distribution pipe (2) is connected with the bottom of the material bin (1). The lower end of the material distribution pipe (2) stretches into the place below the top cover. The multiple discharge conical hoppers (5) are distributed annularly at the lower end of the towerwall (4) or are distributed evenly in the peripheral direction. A circle of fixed gap is formed between the lower portion of the tower wall and the tops of the multiple discharge conical hoppers (5) and serves as the air ring (H). The air cap (M) upwards stretching into the inner space of the tower is arranged in the bottom center of the tower, and a plate type ore feeder (12) is arranged below each discharge conical hopper (5).

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

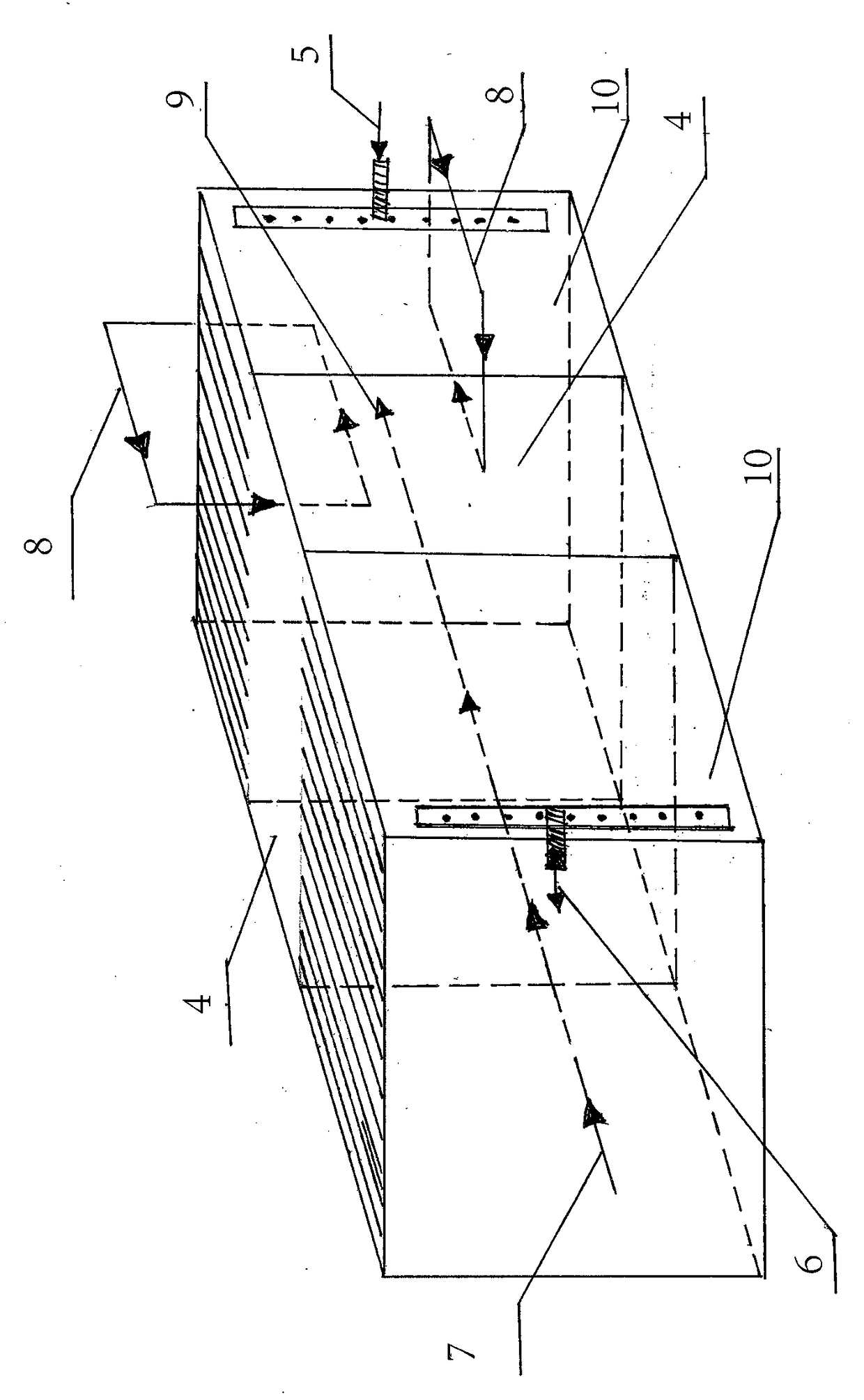

Sintering ore air draft type circulating cooling system and process thereof

PendingCN109425231ASlow coolingImprove thermal efficiencyIncreasing energy efficiencyFurnace coolingCold airEngineering

Provided is a sintering ore air draft type circulating cooling system. The system comprises an air draft type vertical cooling furnace, a waste heat boiler and power generation system, a circulating exhaust fan, a hot air conveying channel and a cold air conveying channel, wherein the air draft type vertical cooling furnace comprises a material bin, a tower body, an air inlet discharging device, adischarging unit and a discharging chute; an air draft type hot air outlet is formed in the upper portion of the tower body; a cold air inlet is formed in the side wall of the discharging chute; theair draft type hot air outlet is connected with an air inlet of the waste heat boiler and power generation system through the hot air conveying channel; and an air outlet of the waste heat boiler andpower generation system is connected with a cold air inlet through the cold air conveying channel. The cooling system and a cooling process can effectively cool sintering ores and are low in air leakage, and at the same time, after cooling air is subjected to heat exchange with the sintering ores, waste heat can be totally used to achieve circulation.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Flashboard discharging type vertical cooler and sinter cooling method

PendingCN108267018ASimple structureImprove sealingHandling discharged materialInterior spaceEngineering

The invention discloses a flashboard discharging type vertical cooler. The vertical cooler comprises a stock bin (1), a distributing tube (2), a tower body, a wind ring (H), a wind cap (M), multiple discharging outlets (5a) and a hot wind outlet (8), wherein the tower body is composed of a tower body top cover (3), a tower wall (4), a tower body cone cylinder (4) located below the tower wall (5) and a tower bottom (D), the multiple discharging outlets (5a) are arranged at the lower part of a discharge cone hopper (5), and the hot wind outlet (8) is arranged on the upper part of the tower wall(4) or the tower body top cover (3); and a fixed gap at the periphery is formed between the lower part of the tower wall (4) and the top part of the discharge cone hopper (5) and serves as the wind ring (H), the wind cap (M) extending upwards into the inner space of the tower body is arranged at the center of the tower bottom, a discharging gate or a discharging gate plate (12) is correspondinglyarranged at each discharging port (5a), and a discharging channel (10) is arranged below the discharging gate (12).

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

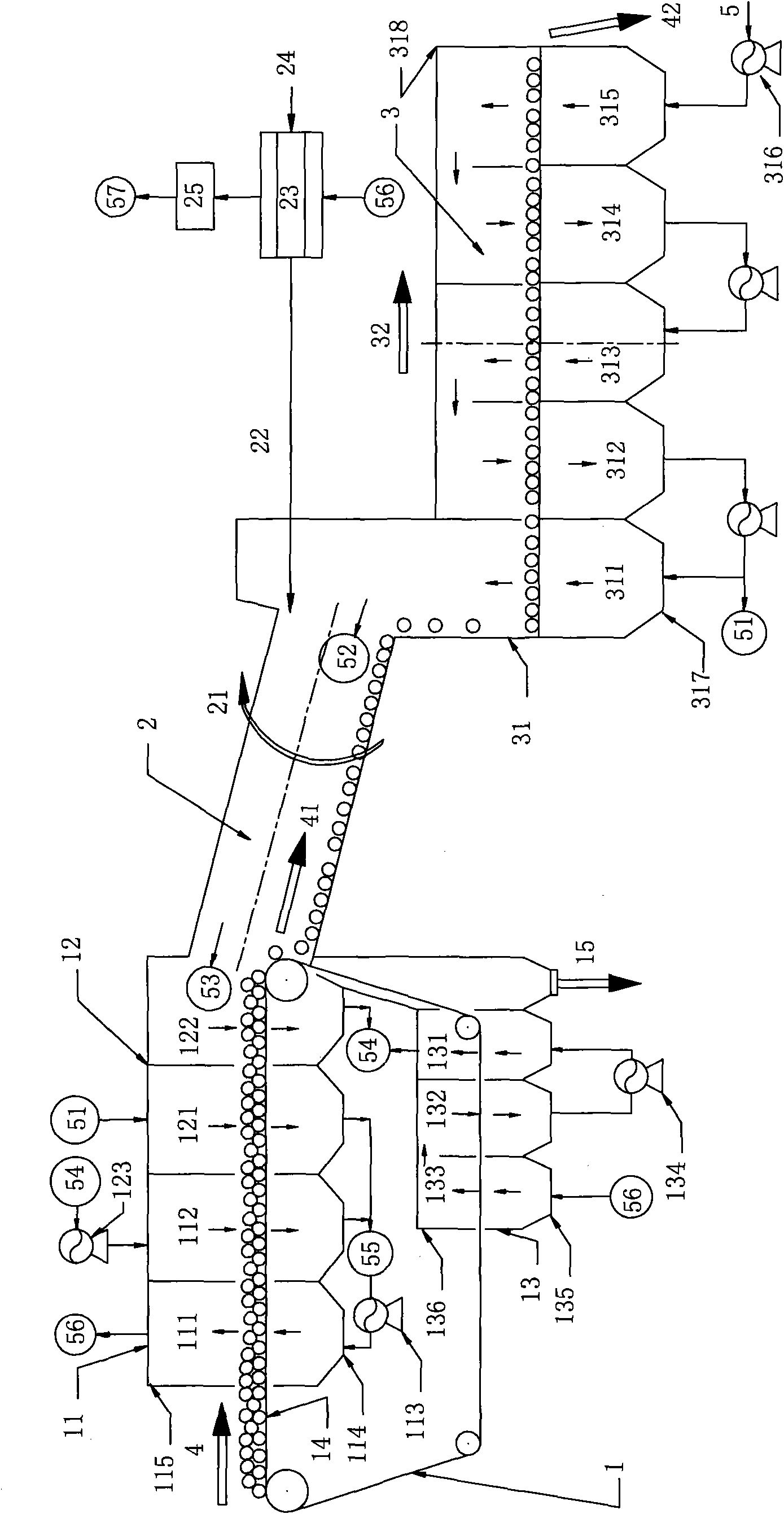

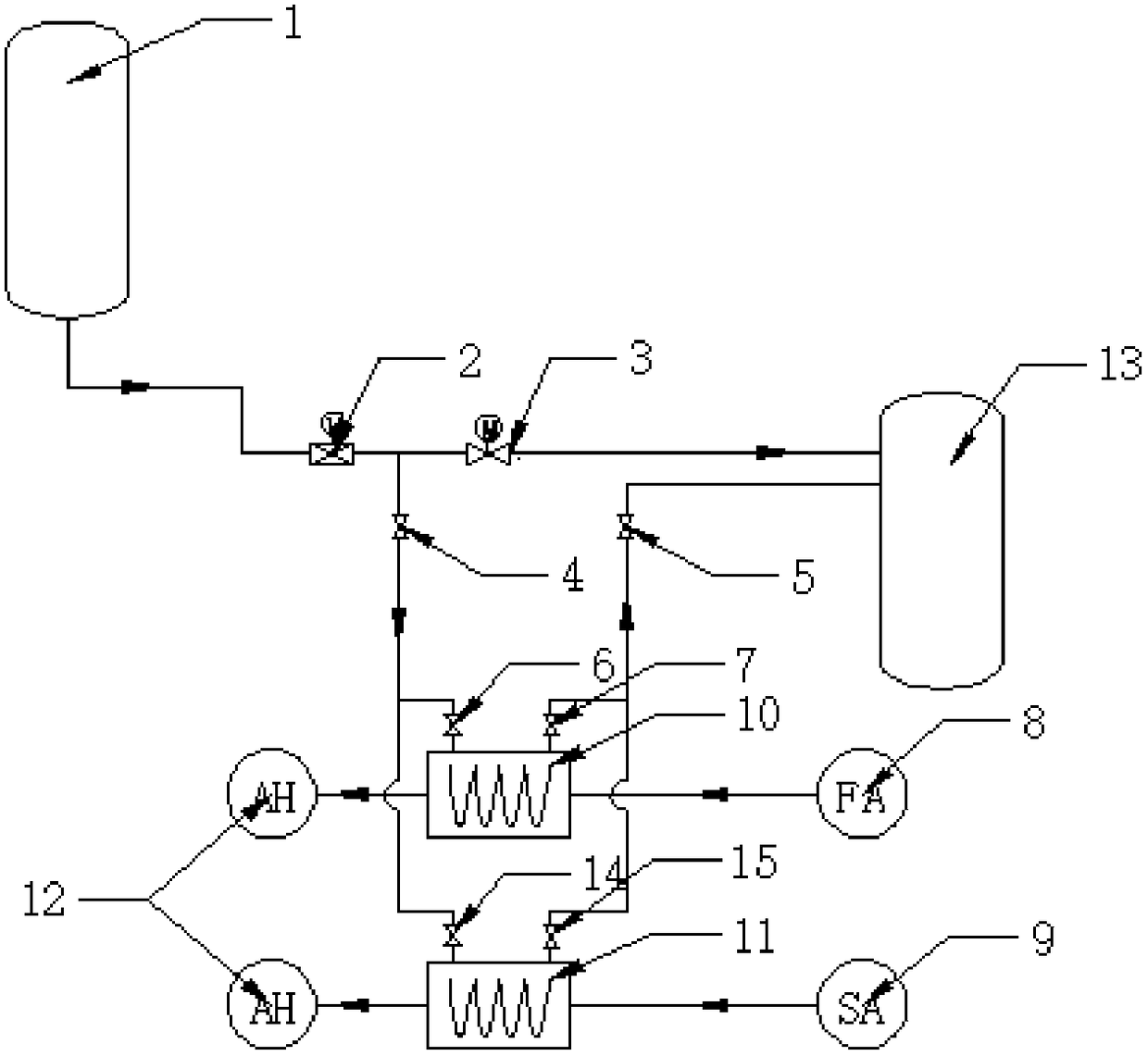

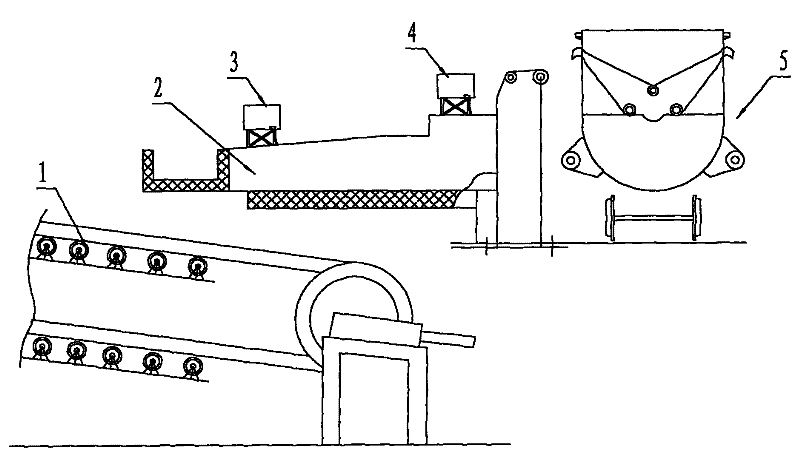

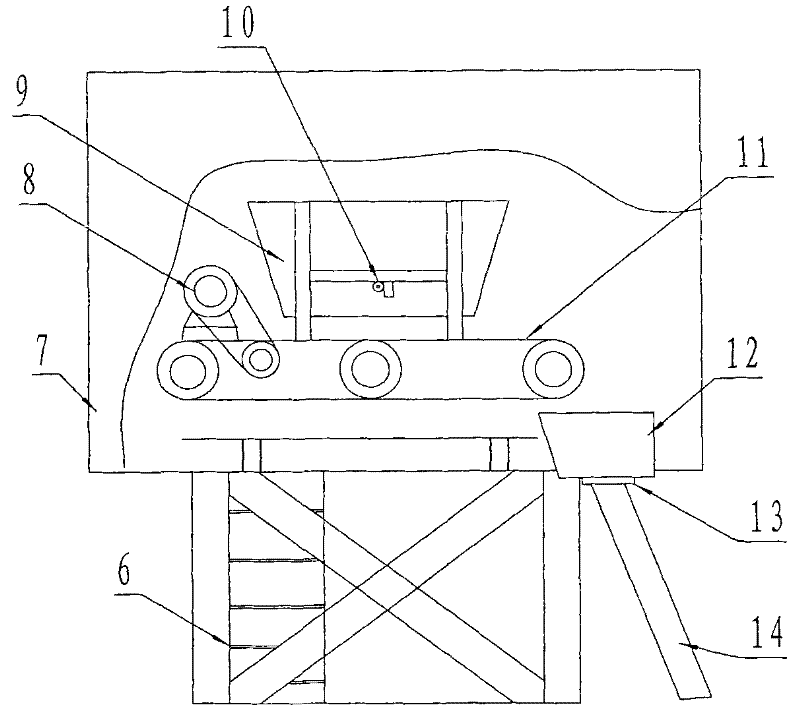

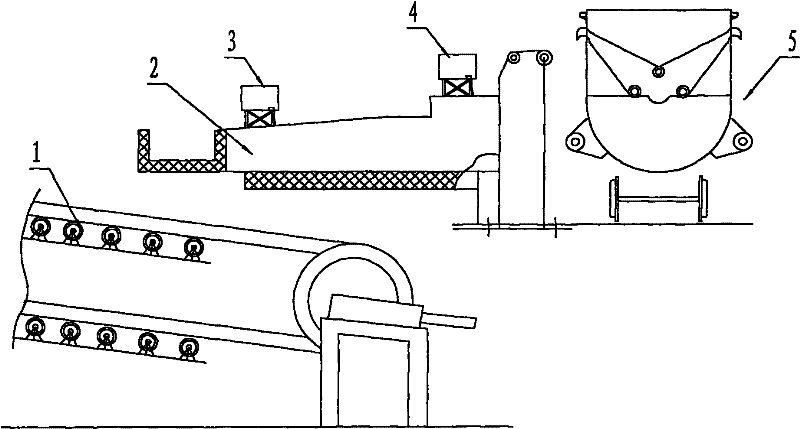

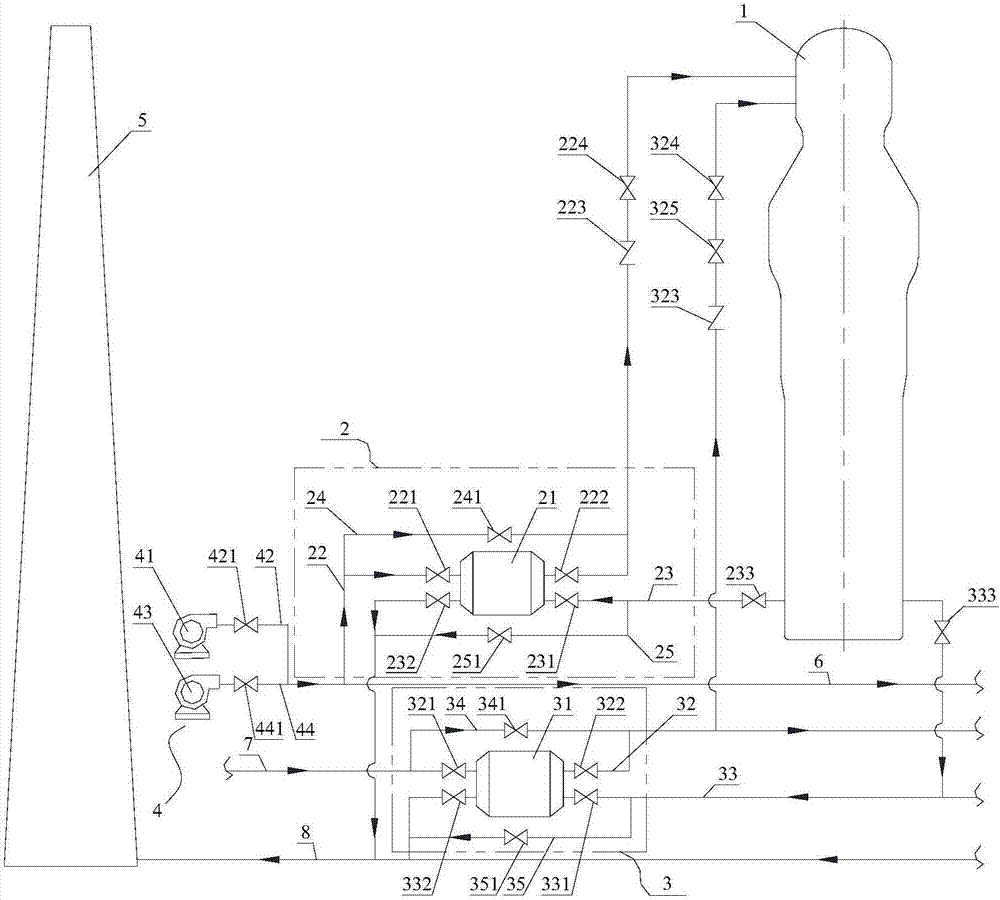

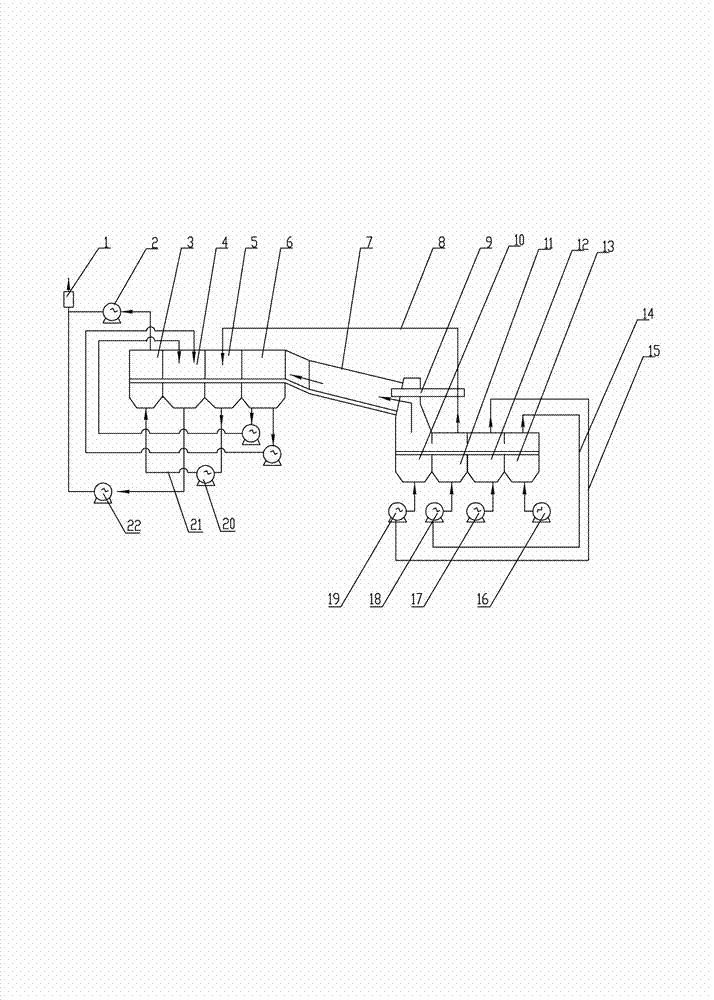

Waste heat internal and external circulation comprehensive recycling method and hot air flow system of pellet production equipment

InactiveCN101592443BIncrease efficient recyclingReduce consumptionEnergy industryDirect contact heat exchangersCoal dustHeat energy

The invention discloses a waste heat internal and external circulation comprehensive recycling method and a hot air flow system of pellet production equipment and relates to the technical field of energy conservation in the metallurgical industry. The method and the system are mainly used in a grate-rotary kiln-circular cooler pellet production process. The method and the system are characterized in that: circular cooler high-temperature pellet waste heat internal circulation high-efficiency recovery, grate high-temperature grate bed waste heat internal circulation high-efficiency recovery, inter-equipment waste heat external circulation utilization, grate preheating and drying stage heat circulation recovery and rotary kiln fire coal dust preheating improve pellet production waste heat recovery hot air temperature and heat energy, waste heat recovery efficiency, pellet production waste heat utilization rate and pellet production equipment energy-conservation and emission-reduction effect, and reduces pellet production equipment fire coal consumption.

Owner:JIANGSU UNIV

Vertical type sinter cooler and sinter cooling method

PendingCN108267020ASimple structureImprove sealingCharge treatment typeHandling discharged materialEngineeringMaterial distribution

The invention provides a vertical type cooler. The vertical type cooler comprises a stock bin (1), a material distribution pipe (2), a tower body, a plurality of discharging conical funnels (5), air rings (H), air buttons (M) and a hot air outlet (8), wherein the tower body is composed of a tower body top cover (3) and tower walls (4); the discharging conical funnels (5) are positioned below the tower walls (4); the hot air outlet (8) is formed in the upper part of one tower wall (4) or in the tower body top cover (3); the top cover (3) is fixedly connected with the upper ends of the tower walls (4); the stock bin (1) is arranged on the top cover (3); the upper end of the material distribution pipe (2) is connected with the bottom of the stock bin (1); the lower end of the material distribution pipe (2) extends to a position below the top cover; the plurality of discharging conical funnels (4) are correspondingly annularly distributed at the lower ends of the tower walls (4) or are uniformly distributed in the circumferential direction; a circle of fixed clearances are formed between the lower parts of the tower walls (4) and the tops of the plurality of discharging conical funnels(5) to form the air rings (H); the center position of the bottom of the tower body is provided with the air buttons (M) which extend up into the internal space of the tower body; and each dischargingequipment (P) is arranged below the corresponding discharging conical funnel (5).

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

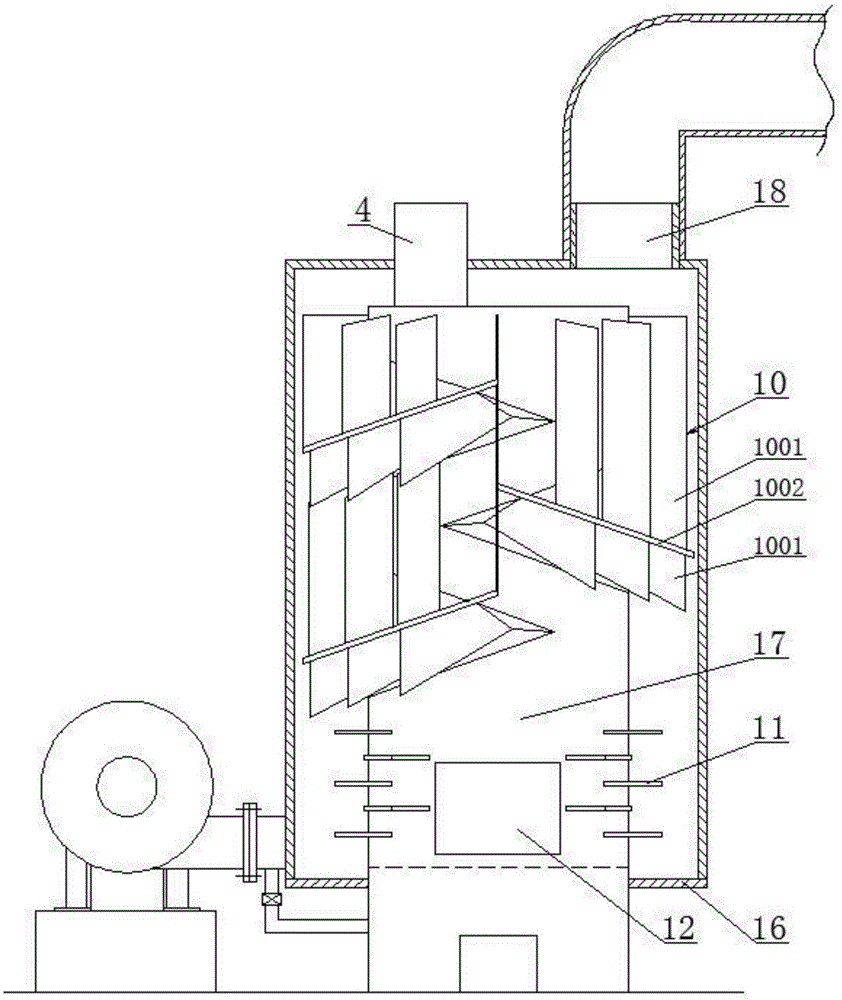

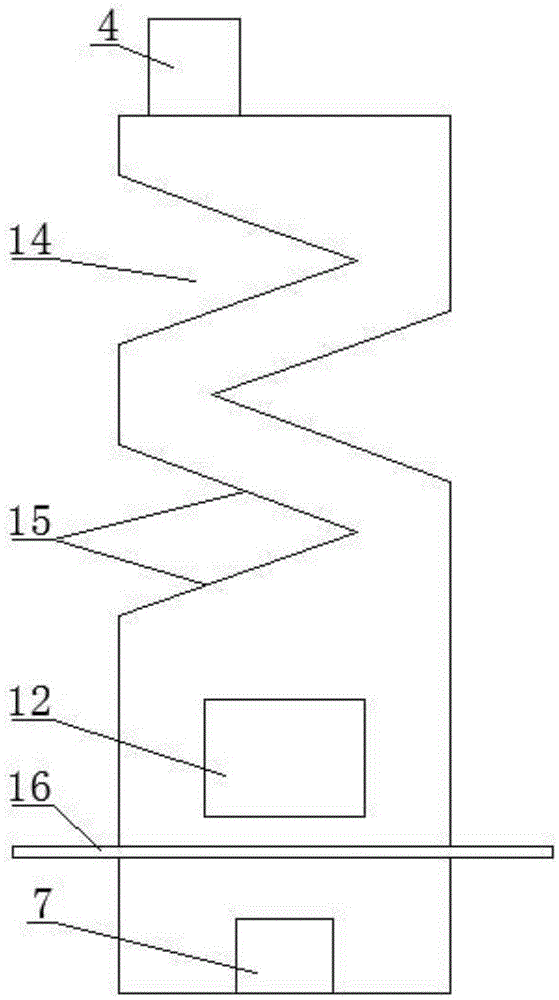

Energy-saving and temperature-control type hot-blast stove

ActiveCN105674557AIncrease the lengthIncrease the heat exchange areaAir heatersTemperature controlCombustion chamber

The invention relates to an energy-saving and temperature-control type hot-blast stove. The hot-blast stove comprises a shell and an inner container, wherein a combustion chamber and an ash unloading chamber are arranged at the lower part the inner container. The hot-blast stove is characterized in that a broken line-shaped flue is arranged at the upper part of the inner container; a flue gas outlet is formed in the tail end of the broken line-shaped flue, and a plurality of radiators are arranged on the outer wall of the broken line-shaped flue; an air inlet is formed in the lower part of the shell, a centrifugal blower is connected to the outer side of the air inlet, a branched pipeline is connected to the side wall of the air inlet, and the other end of the branched pipeline penetrates through the shell and is inserted into the ash unloading chamber; and an electromagnetic valve or a manual gate valve controlled by an indoor temperature sensor is arranged on the branched pipeline, and a hot air outlet is formed in the top of the shell. The energy-saving and temperature-control type hot-blast stove is high in heat exchange efficiency and convenient to use, and the problems of high heat exchange efficiency and energy consumption of existing agricultural hot-blast stoves are solved.

Owner:辽宁燕邦农业有限公司

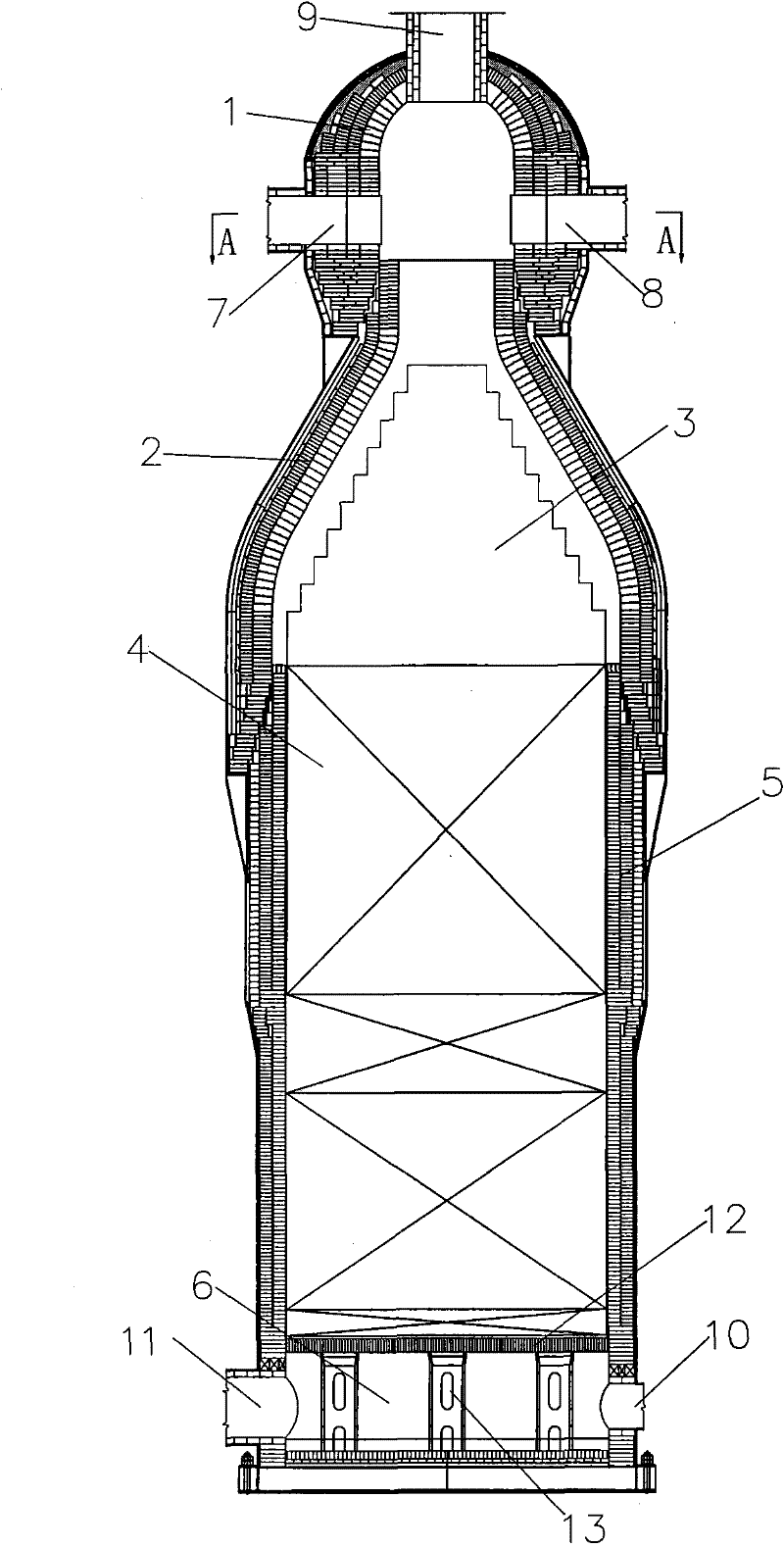

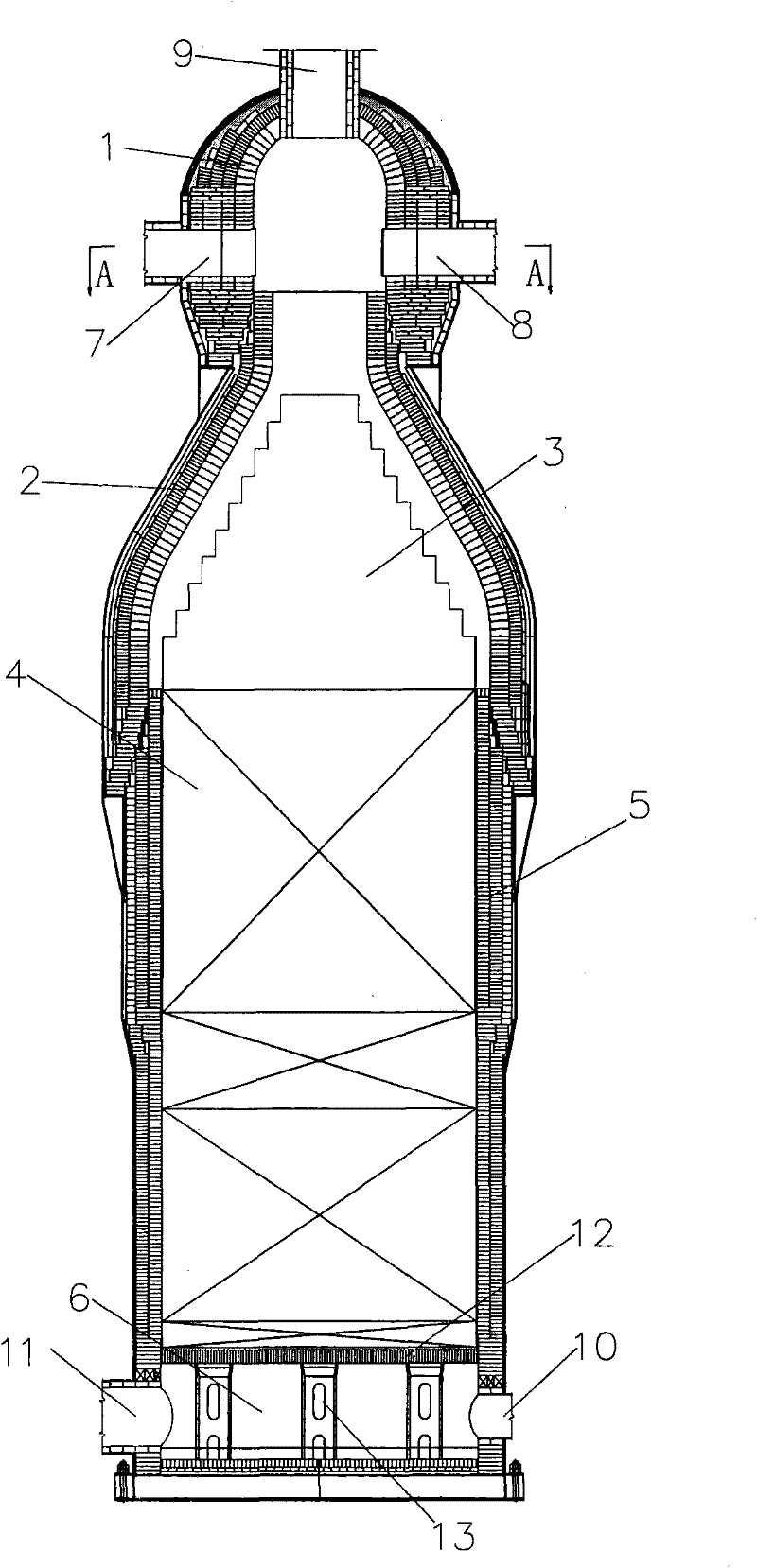

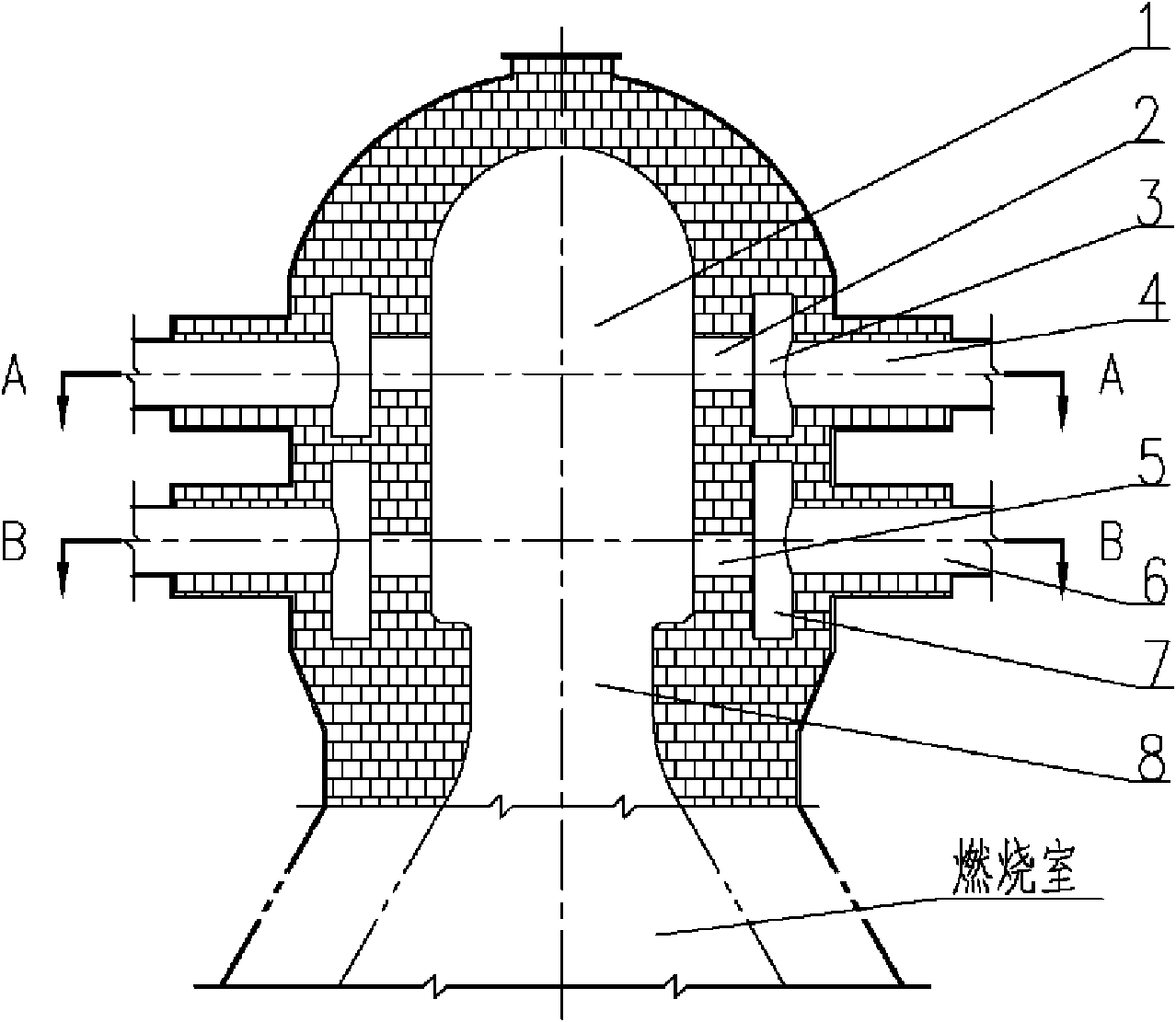

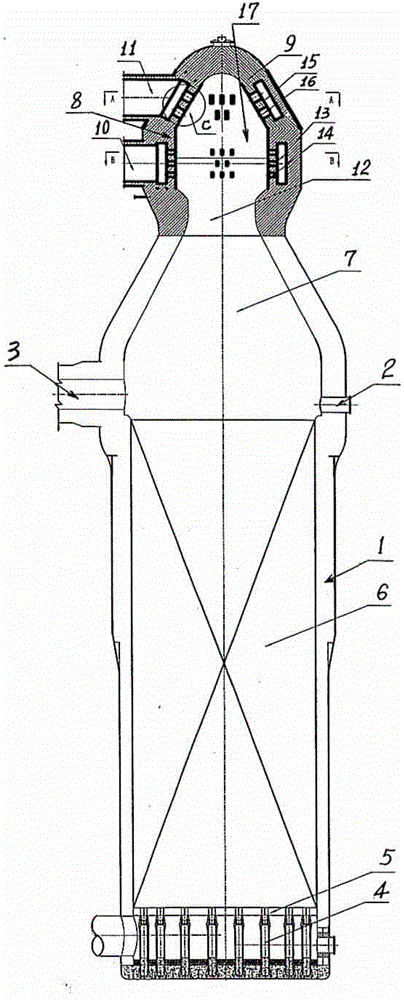

High-blast-temperature hot-blast stove burnt in convection swirling heat storage medium

InactiveCN101906496BImprove heat transfer performanceIncrease profitBrick-hot blast stovesCold airCombustion chamber

The invention relates to a high-blast-temperature hot-blast stove burnt in a convection swirling heat storage medium, effectively solving the problems of complicated structure, non-uniform gas mixing, insufficient burning, environmental pollution and energy waste. The stove adopts the structure that a pre-burning chamber of a bell jar on the top of a ball and a taper-section barrel-shaped burningchamber below the pre-burning chamber are connected by using a labyrinth without stress action; the taper-section burning chamber is sufficiently filled with porous heat storage bodies; a coal gas inlet pipe and an air inlet pipe are distributed on the vertical wall of the pre-burning chamber; a barrel-shaped heat storage chamber is arranged below the burning chamber, and checker brick heat storage bodies are stacked on grates in the heat storage chamber; a cold air chamber is arranged below the heat storage chamber, and a smoke exhaust pipe and a cold air inlet pipe are connected to the wall; the grates for holding the heat storage bodies are mutually spaced with expansion gaps, put on a beam and supported by grate supporting posts; the supporting posts are fixed on a rigid base of the hot-blast furnace; and a central vault line of the pre-burning chamber is provided with a hot-blast outlet pipe coaxial with the hot-blast furnace. The invention has the advantages of simple structure,high mixed burning intensity, good air flow heat exchange effect and raised hot-blast temperature.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

Flashboard unloading-type vertical cooler with material position adjusting device and sintering ore cooling method

PendingCN108692576AAchieve height changeEasy to operateHandling discharged materialTowerWaste management

A flashboard unloading-type vertical cooler comprises a bin (1), a material height adjusting device (2), a tower composed of a tower top cover (3), a tower wall (4), a tower cone barrel (5) and a tower base (D), a wind ring (H), a wind cap (M), a plurality of discharge outlets (5a) formed in the lower portion of the discharge cone bucket (5), and a hot air outlet (8) formed in the upper portion ofthe tower wall (4) or in the tower top cover (3), wherein the tower cone barrel (5) is located on the lower portion of the tower wall (4). A circle of fixed gap is formed between the lower portion ofthe tower wall (4) and the top of the discharge cone bucket (5) to serve as the wind ring (H). The center of the tower base is provided with the wind cap (M) which upwards extends into the inner space of the tower. Discharge gates or discharge flashboards (12) are arranged at the discharge outlets (5a) accordingly, and a discharge channel (10) is formed below the discharge gates (12).

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Sinter cooler with radiation heat recoverer and cooling method

ActiveCN108267021ASimple structureImprove sealingCharge treatment typeHandling discharged materialEngineeringMaterial distribution

The invention disclose a vertical type cooler. The cooler comprises a material bin (1), a material distribution pipe (2), a tower body composed of a tower body top cover (3) and a tower wall (4), a plurality of discharging cone hoppers (5) located below the tower wall (4), a wind ring (H), a wind cap (M), a radiation heat recoverer (F01) located under the tower body top cover (3) and is close to the tower body top cover (3) and a hot wind outlet (8) arranged above tower wall (4) or on the tower body top cover (3), wherein the top cover (3) is fixedly connected with the upper end of the tower wall (4), the material bin (1) is arranged above the top cover (3), the upper end of the material distribution pipe (2) is connected with the bottom of the material bin (1), and the lower end of the material distribution pipe (2) extends into the positon below the top cover (3); and the plurality of discharging cone hoppers (5) are annularly distributed below the tower wall (4) or are uniformly distributed in the circumferential direction, a circle of fixed clearance is formed between the lower part of tower wall (4) and the tops of the plurality of discharging cone hoppers (5) and serves as the wind ring (H), the wind cap (M) extending upwards into the inner space of the tower body is arranged at the center of the bottom of the tower body, and discharging equipment (P) is arranged below each of the discharging cone hoppers (5).

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Device and method utilizing start-up system drained water as heating source of air heater

PendingCN108224465ALower drain temperatureReduce heatCombustion processIndirect carbon-dioxide mitigationAir preheaterCombustion

The invention provides a device and method utilizing start-up system drained water as a heating source of an air heater. The device comprises two connecting paths connected between a start-up system water storage tank and a flash vessel; according to one connecting path, the start-up system water storage tank is connected with the flash vessel through a water storage tank body and an air heater by-pass valve; according to the other connecting path, the start-up system water storage tank is connected with water inlets of both a primary-air air heater and a secondary-air air heater through the water storage tank body and an air heater valve correspondingly, and water outlets of both the primary-air air heater and the secondary-air air heater are connected with the flash vessel through an airheater back-water valve; a primary fan is connected with an air inlet of the primary-air air heater, a secondary fan is connected with an air inlet of the secondary-air air heater; and air outlets ofboth the primary-air air heater and the secondary-air air heater are connected with an air preheater. According to the device and method utilizing start-up system drained water as the heating sourceof the air heater, heat discharged by a start-up system can be effectively utilized, the heat loss is reduced, and the primary air temperature and the secondary air temperature are increased; and combustion of a boiler can be enhanced, and secondary burning and low-temperature corrosion of a train flue of a unit and the air preheater can also be weakened and avoided.

Owner:中国能源建设集团西北电力试验研究院有限公司

Method for smelting ultra-low sulfur, silicon and titanium grey nodular cast iron by pig iron

ActiveCN101775452BImprove utilization factorIncreased ductile iron ratioBlast furnace detailsSulfurNitrogen

The invention discloses a method for smelting ultra-low sulfur, silicon and titanium grey nodular cast iron by pig iron, belonging to the technical filed of steel making, and used for solving the problem of stably producing the ultra-low sulfur, silicon and titanium grey nodular cast iron by a blast furnace with the pig iron. The method comprises the following steps: a, blast furnace raw materialselection; b, low silicon smelting; c, stokehole silicon addition; d, stokehole desulfuration treatment; e, nitrogen spraying and stirring; and f, pig machine inoculation. The invention utilizes the treatment techniques of blast furnace raw material selection, low silicon smelting, stokehole silicon addition, stokehole desulfuration treatment, nitrogen spraying and stirring and pig machine inoculation, thus solving the technical problem of problem of stably producing ultra-low sulfur, silicon and titanium grey nodular cast iron by the blast furnace with the pig iron. The product realizes not only low Si, low Ti and super low S but also gray, and is particularly suitable for producing large-scale cast ferritic nodular cast iron and large-scale high grade nodular iron pieces such as containers for wind power generation and nuclear fuel storage, and the like, thus filling the gap of the products of the type.

Owner:河北龙凤山铸业有限公司

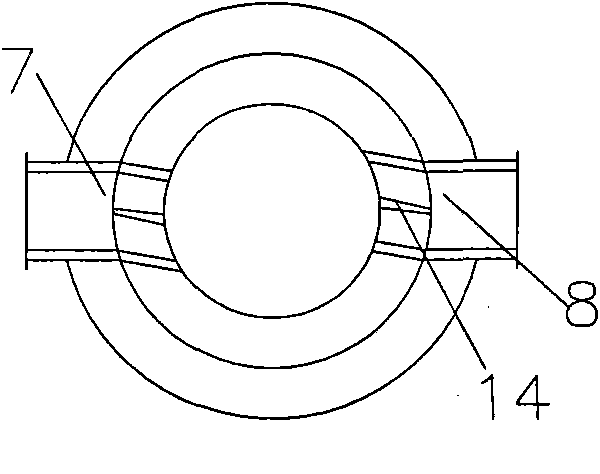

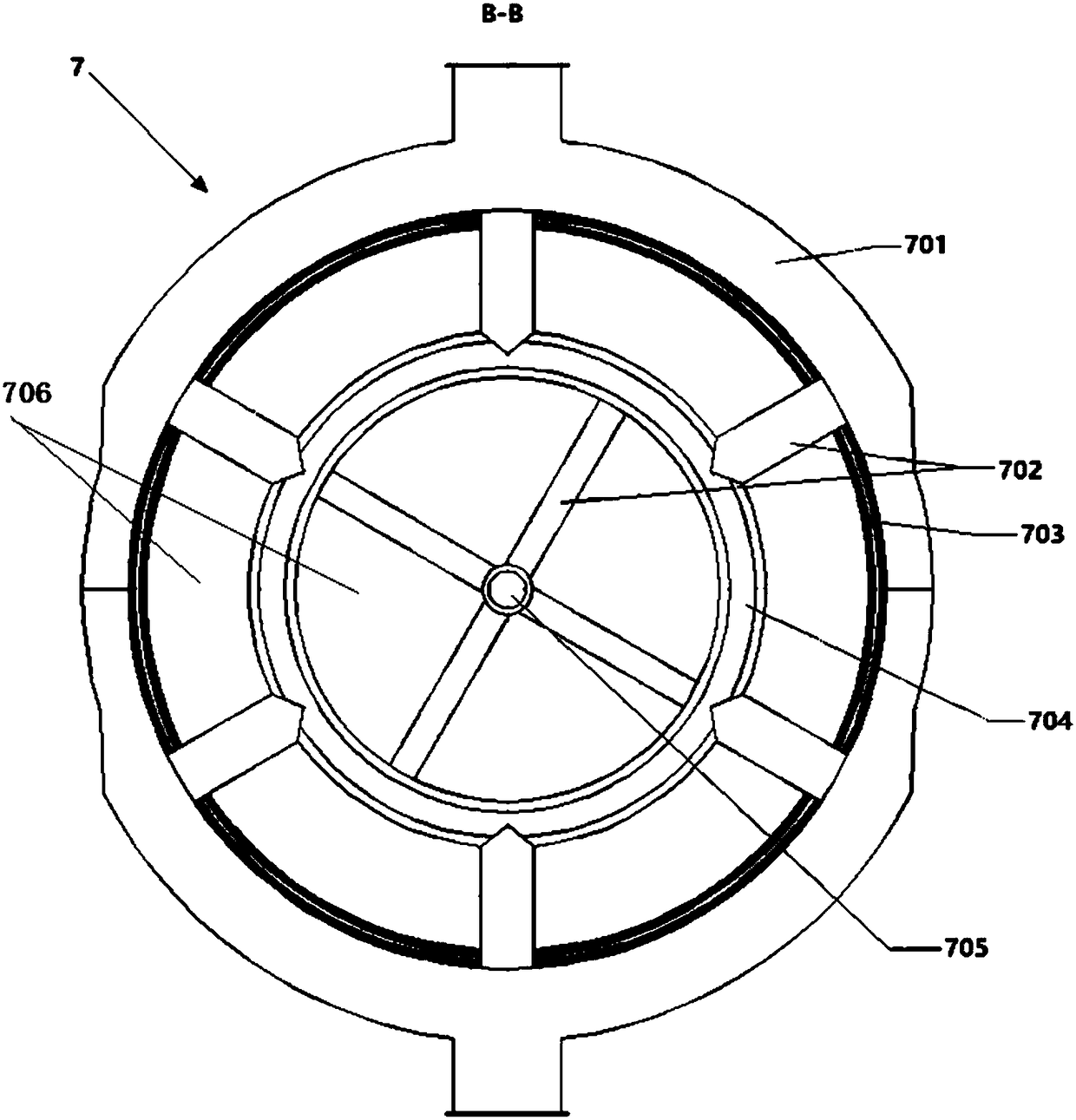

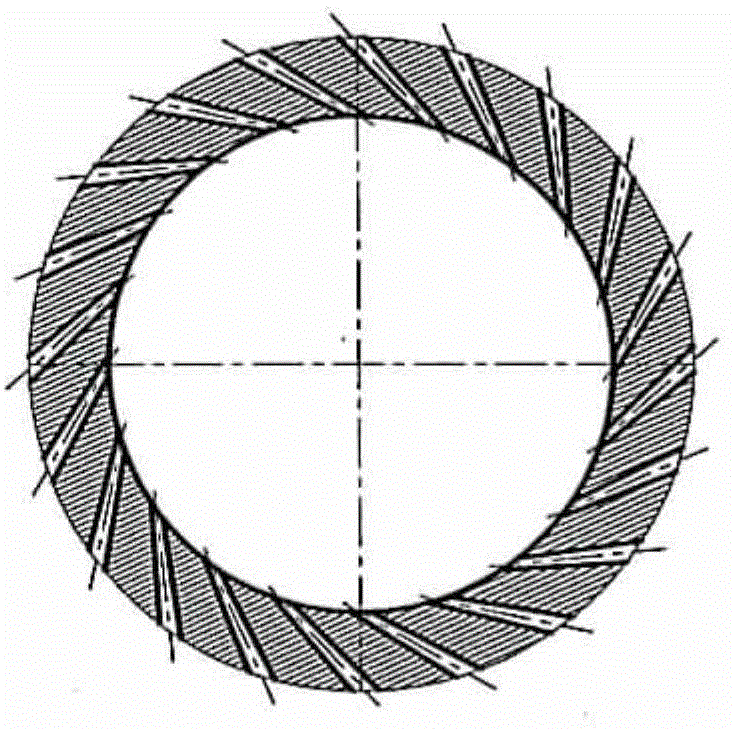

Double-channel vortex ceramic burner

The invention relates to a double-channel vortex ceramic burner (namely, the number of coal gas inlets is two and the number of air inlets is two) which is vertically installed at the upper part of a burning chamber of a hot air stove and comprises a vortex chamber 1, a throat mouth 8, coal gas inlets 4, a coal gas ring path 3, a coal gas nozzle 2, air inlets 6, an air ring path 7 and an air nozzle 5, wherein the vortex chamber 1 is positioned at a central area, and the throat mouth 8 is arranged between the vortex chamber 1 and the burning chamber; the coal gas nozzle 2 is arranged on the inner wall of the coal gas ring path 3, and two coal gas inlets 4 are arranged on the outer wall of the coal gas ring path 3; the air nozzle 5 is arranged on the inner wall of the air ring path 7; and the two air inlets 6 are arranged on the outer wall of the air ring path 7. The double-channel vortex ceramic burner can transform the top-burning hot air stove of the traditional level sleeve type burner into a vortex top-burning hot air stove under the condition that the burning chamber and the pipeline of the hot air stove is rarely transformed. The double-channel vortex ceramic burner has the characteristics of raising the hot air temperature, prolonging the service life of the hot air stove, reducing the burning consumption, and reducing the investment.

Owner:ZHENGZHOU ANNEC IND

Hot-blast stove system of blast furnace

PendingCN107227382AIncrease vault temperatureIncrease temperatureBlast furnace detailsHeating stovesCombustionFlue gas

The invention provides a hot-blast stove system of a blast furnace. The hot-blast stove system comprises a plurality of hot-blast stoves, a plurality of first heat exchange units, at least one second heat exchange unit, a combustion-supporting device, a chimney, a main air pipe, a main coal gas pipe and a main flue gas pipe. The multiple hot-blast stoves and the multiple first heat exchange units are arranged in a one-to-one correspondence mode. All the hot-blast stoves communicate with the main flue gas pipe and one of the main coal gas pipe and the main air pipe through the corresponding first heat exchange units, and all the hot-blast stoves communicate with the main flue gas pipe and the other one of the main coal gas pipe and the main air pipe through the second heat exchange units. The main flue gas pipe communicates with the chimney. The main air pipe communicates with the combustion-supporting device. By means of the hot-blast stove system of the blast furnace, at least one of coal gas and combustion-supporting air can be preheated with waste flue gas of one single hot-blast stove, high-temperature waste flue gas heat which is generated by last-phase combustion can be effectively utilized so that the coal gas and / or the combustion-supporting air can reach 280-310 DEG C, and thus the arch crown temperature and hot-blast temperature of each hot-blast stove can be further raised.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

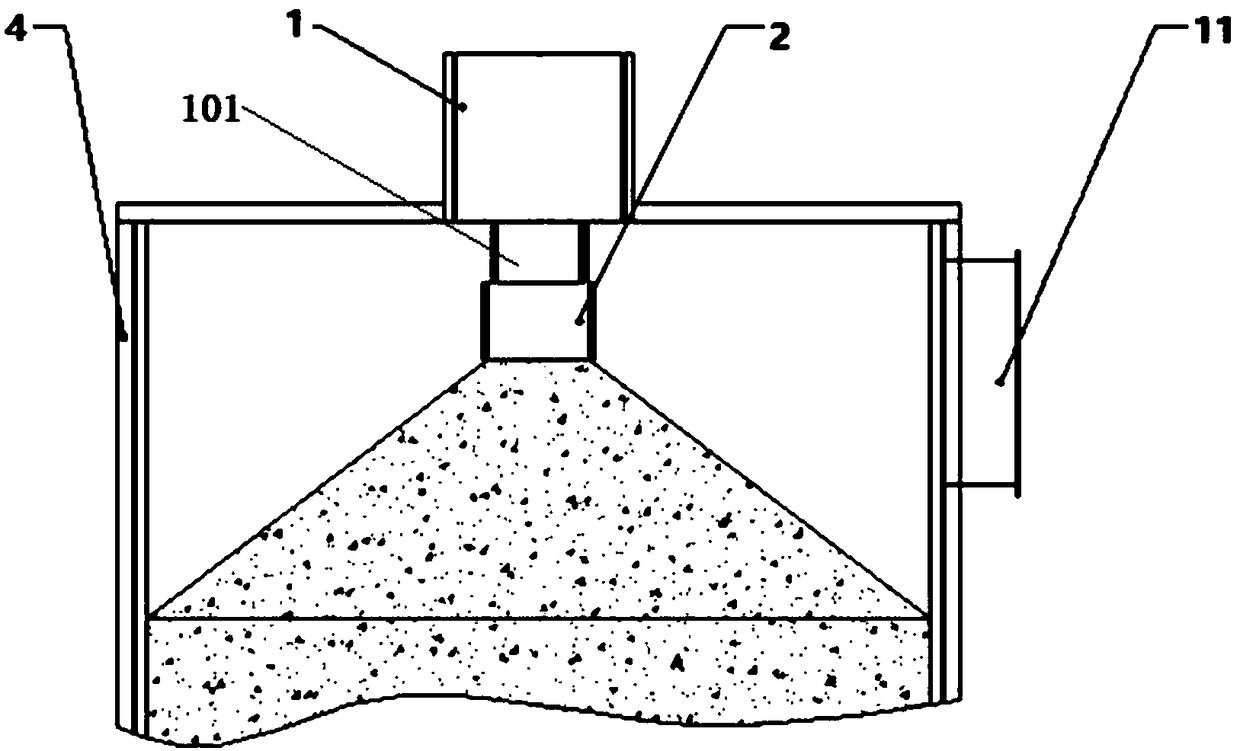

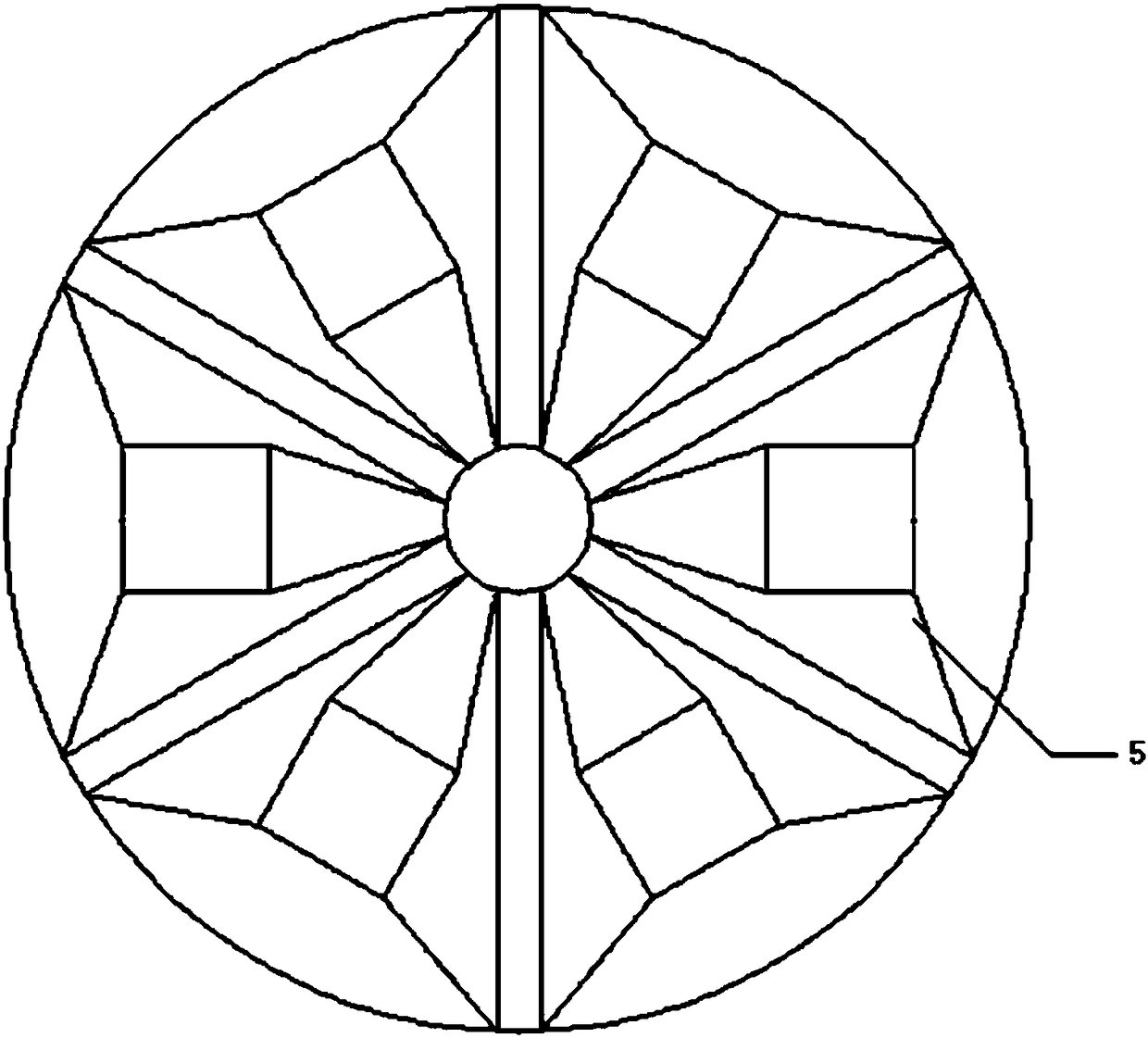

Vertical type sinter cooler with chute type distributing device and sinter cooling method

ActiveCN108955275ASimple structureImprove sealingCharge manipulationCharge treatment typeTowerWaste management

The invention discloses a vertical type cooler with a chute type distributing device. The vertical type cooler comprises a feed inlet (1), a stock bin (2), a tower body (3), an umbrella-shaped chute (4), vertical chutes (5), a cooling section (6) and a hot air outlet (10) in the upper portion of the tower body (3). The feed inlet (1) is formed in the upper portion of the tower body (3), the upperend of the stock bin (2) is connected with the feed inlet (1), the lower end of the stock bin (2) is connected with the upper end of the umbrella-shaped chute (4), the lower ends of branches of the umbrella-shaped chute (4) are connected with the upper ends of the corresponding vertical chutes (5), and the lower portions of the vertical chutes (5) are provided with the cooling section (6). A uniform air inlet device (7) is arranged below the cooling section (6), a plurality of discharging conical hoppers (9) are arranged on the lower side of the uniform air inlet device (7), and the lower sideof each discharging conical hopper (9) is provided with a discharging device. The cooler is simple in structure, reliable in sealing and high in waste heat recovery efficiency.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

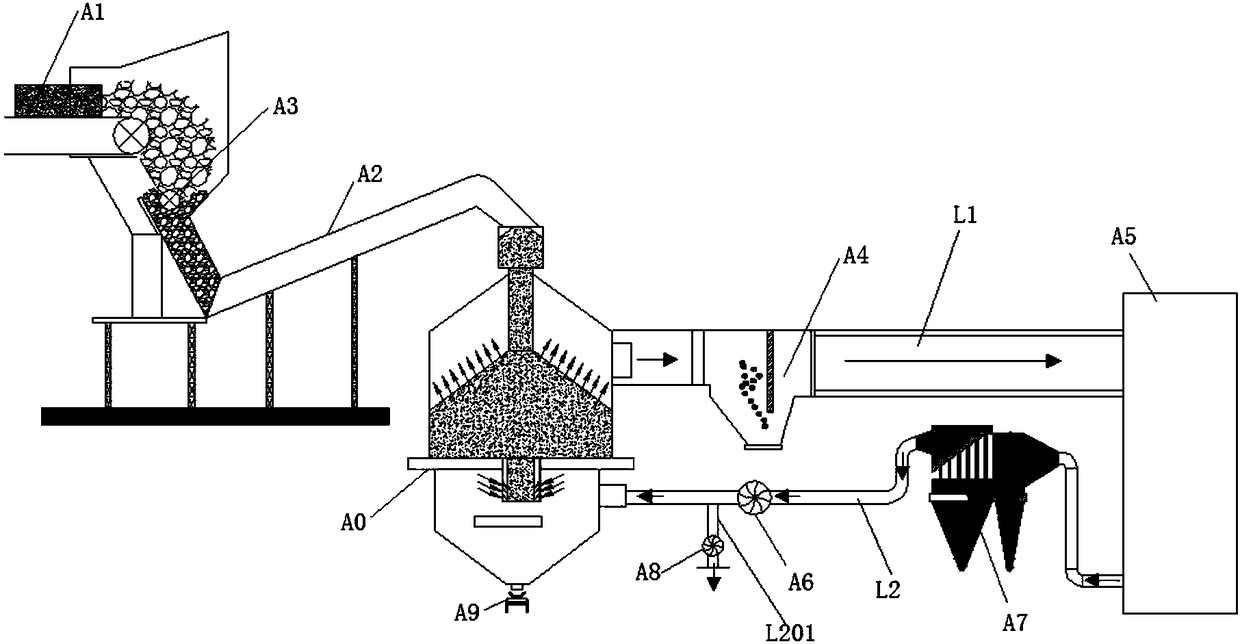

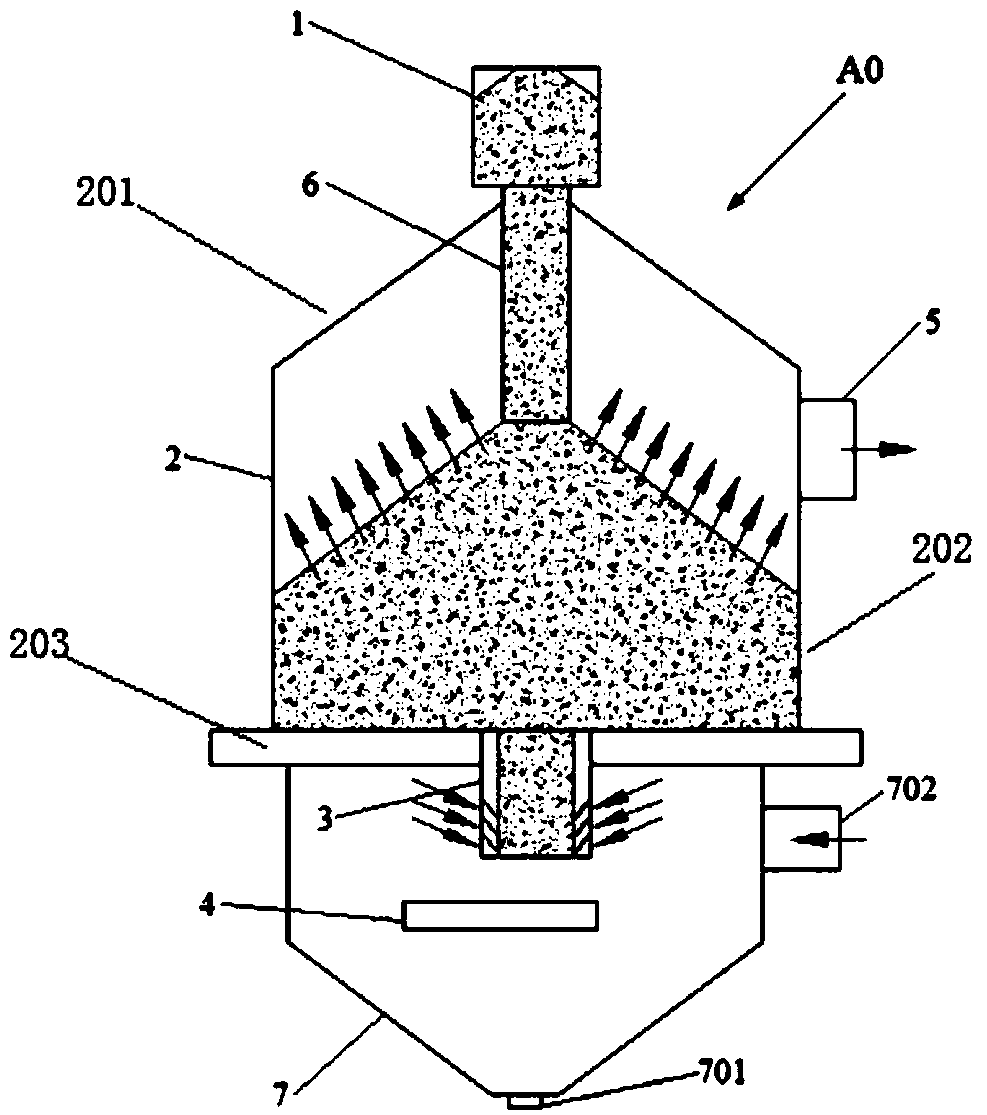

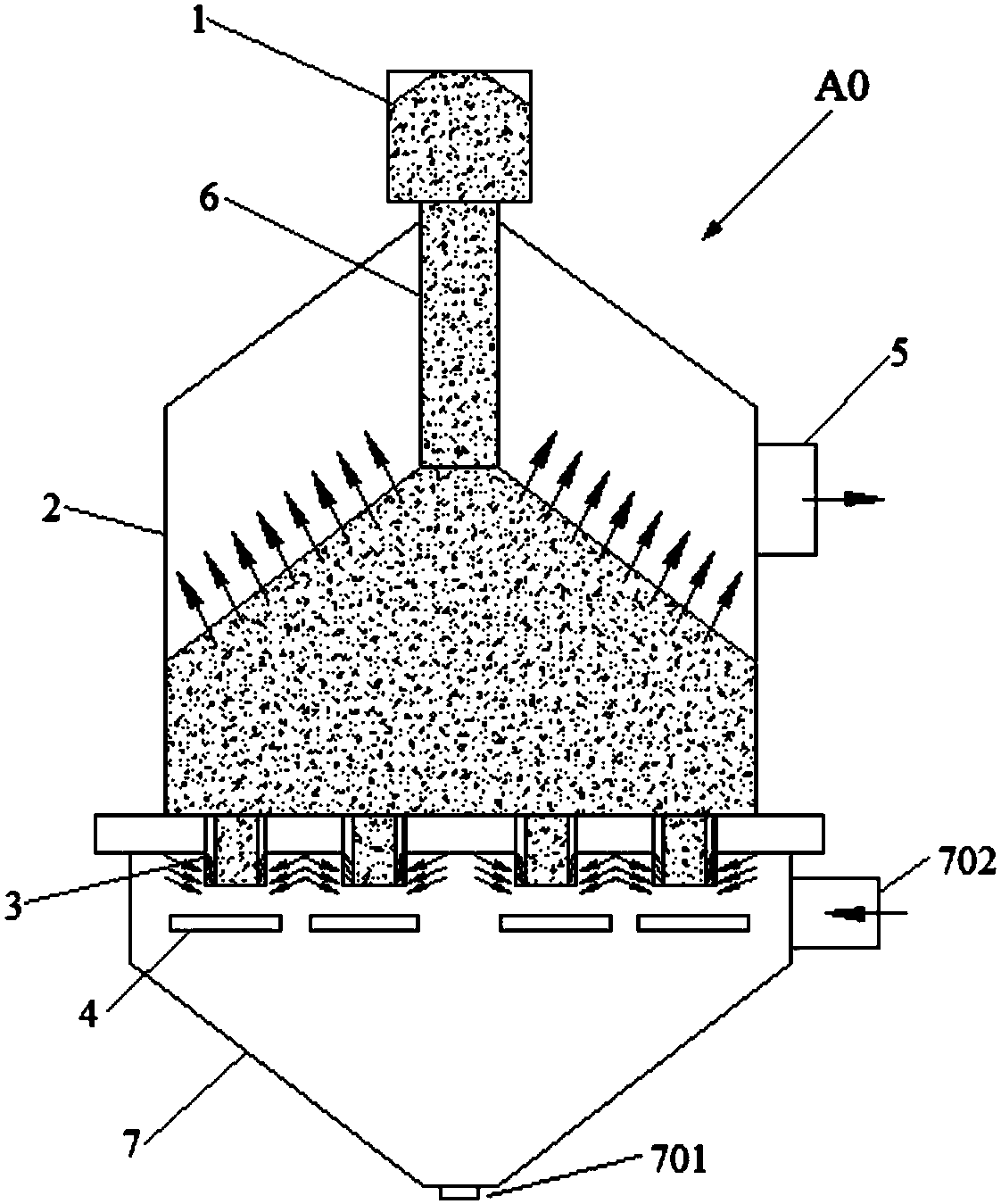

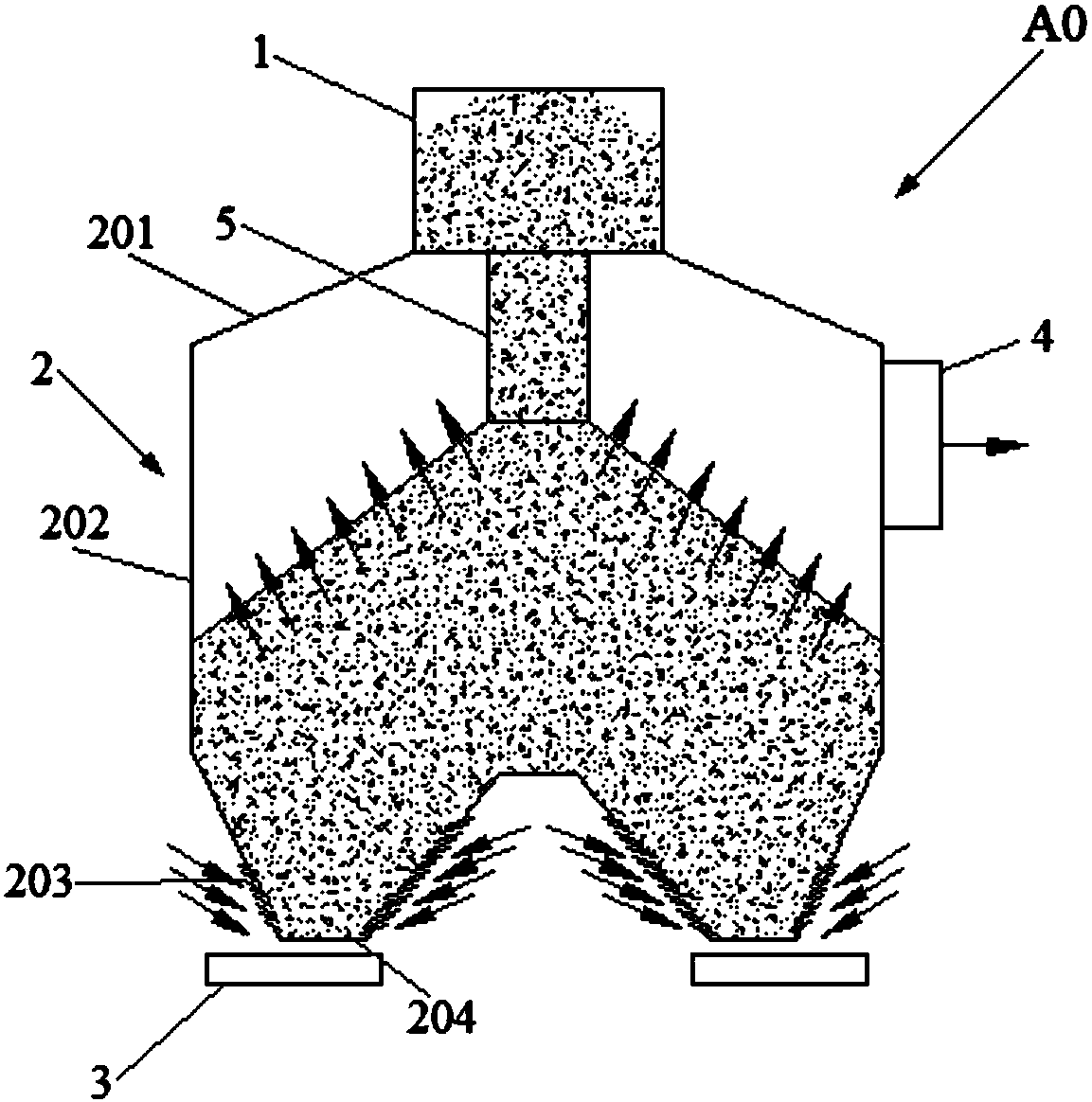

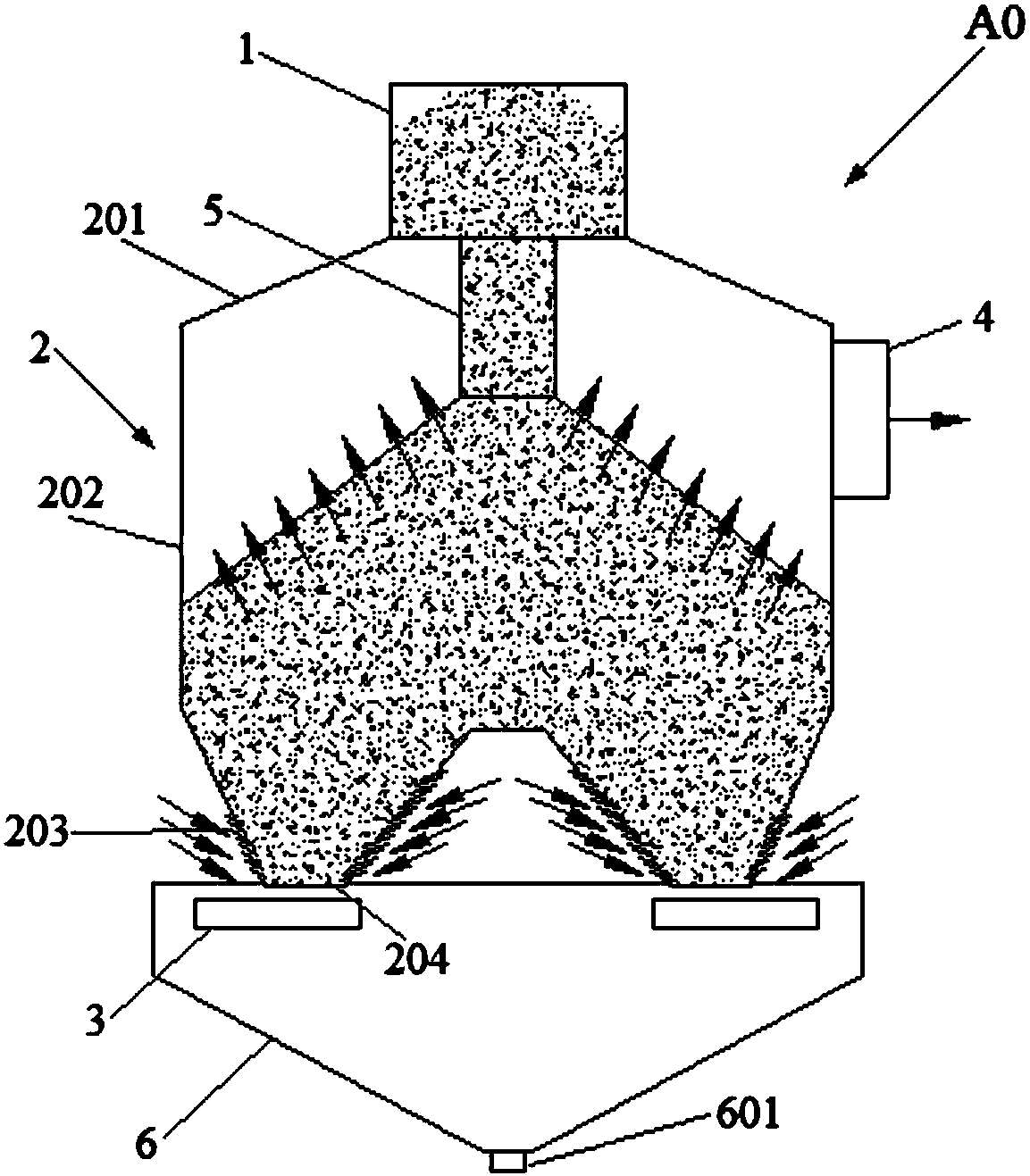

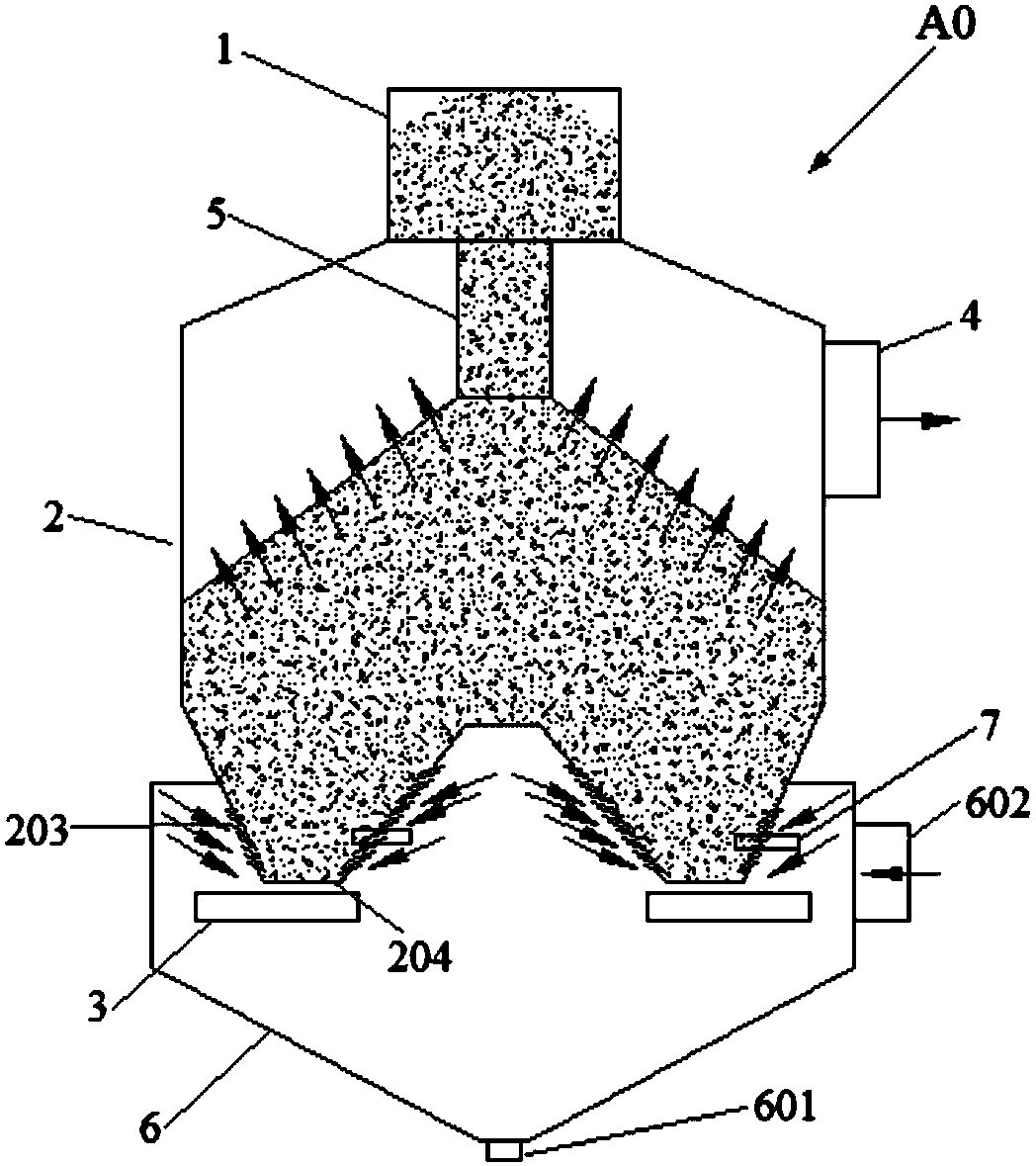

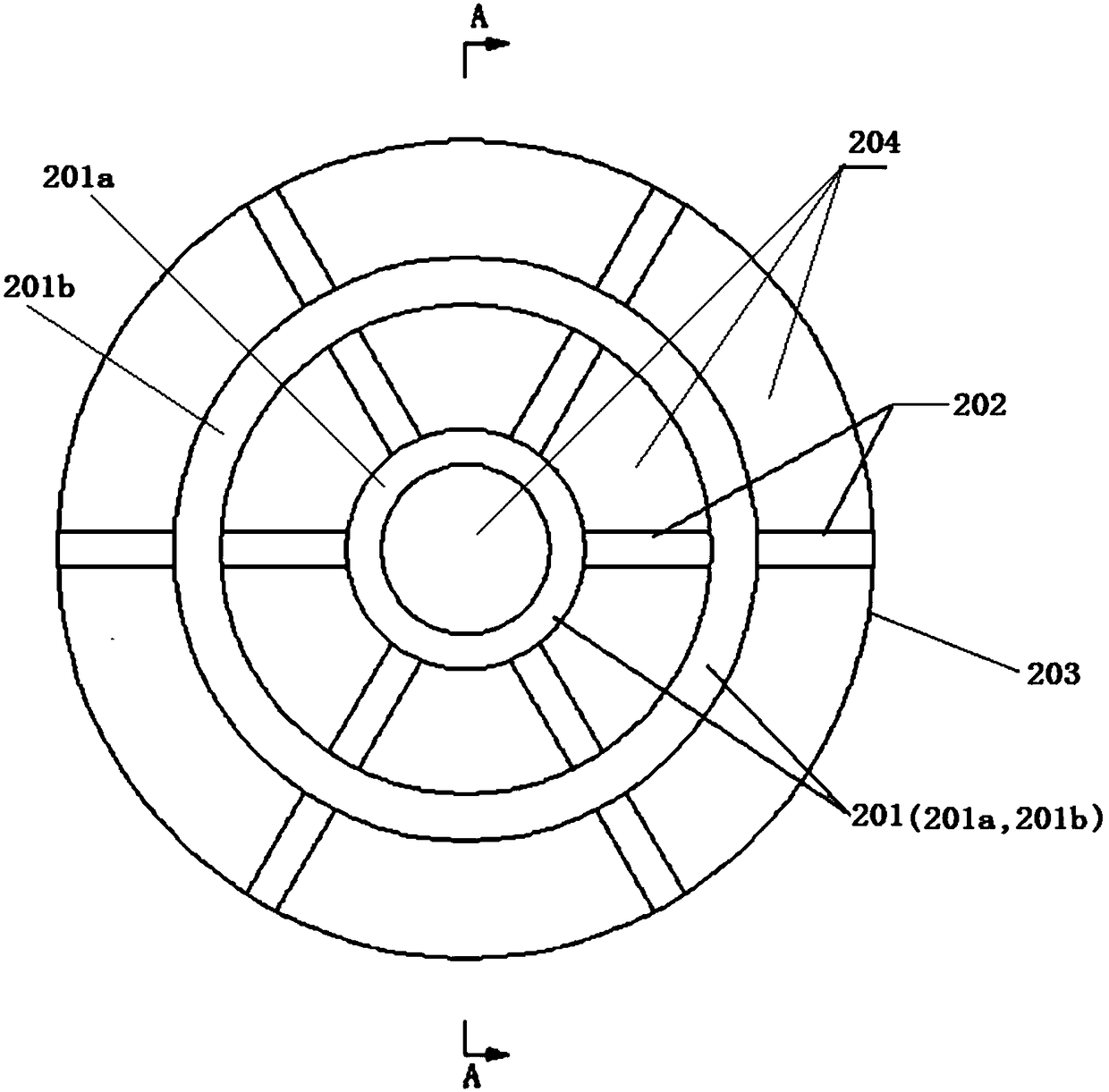

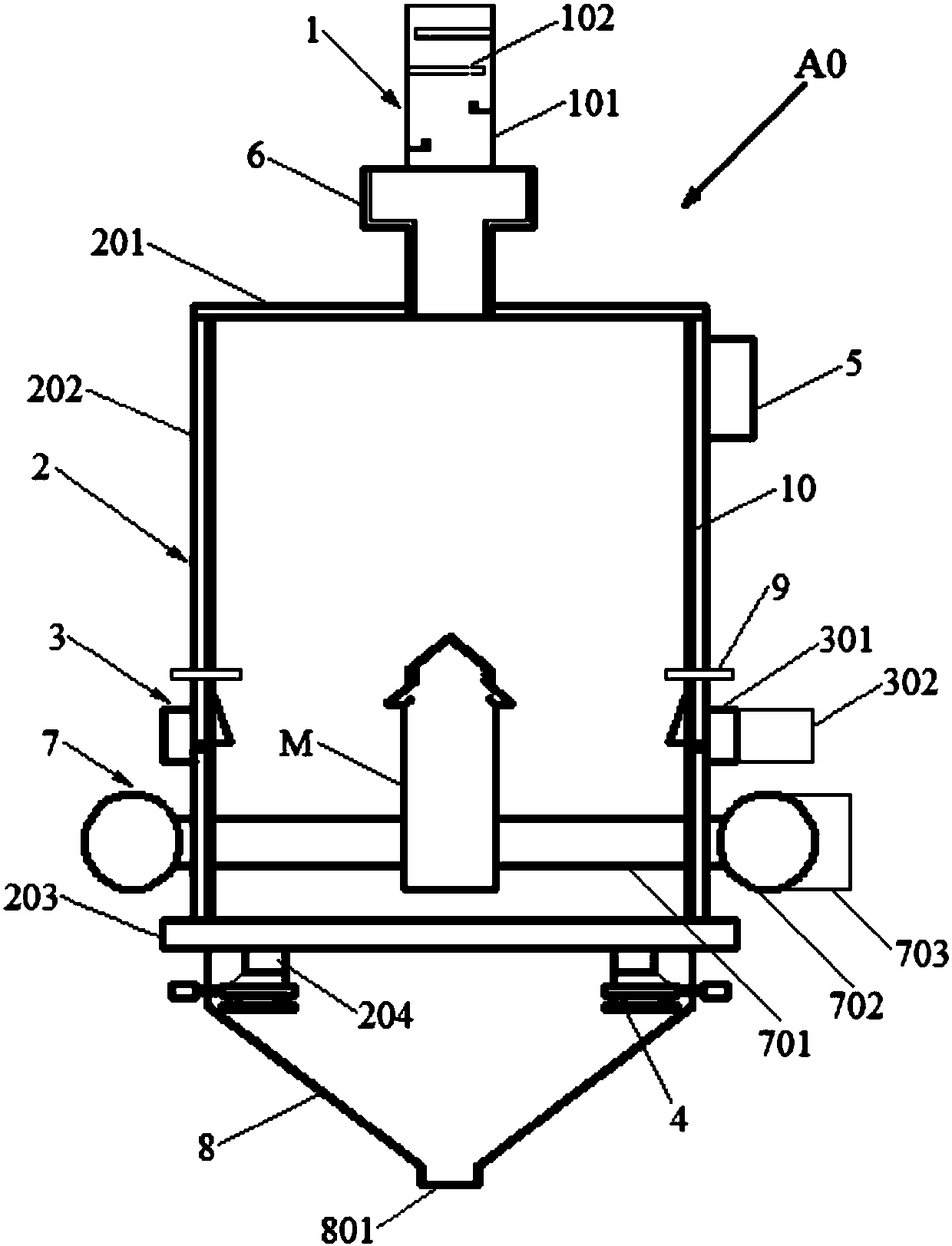

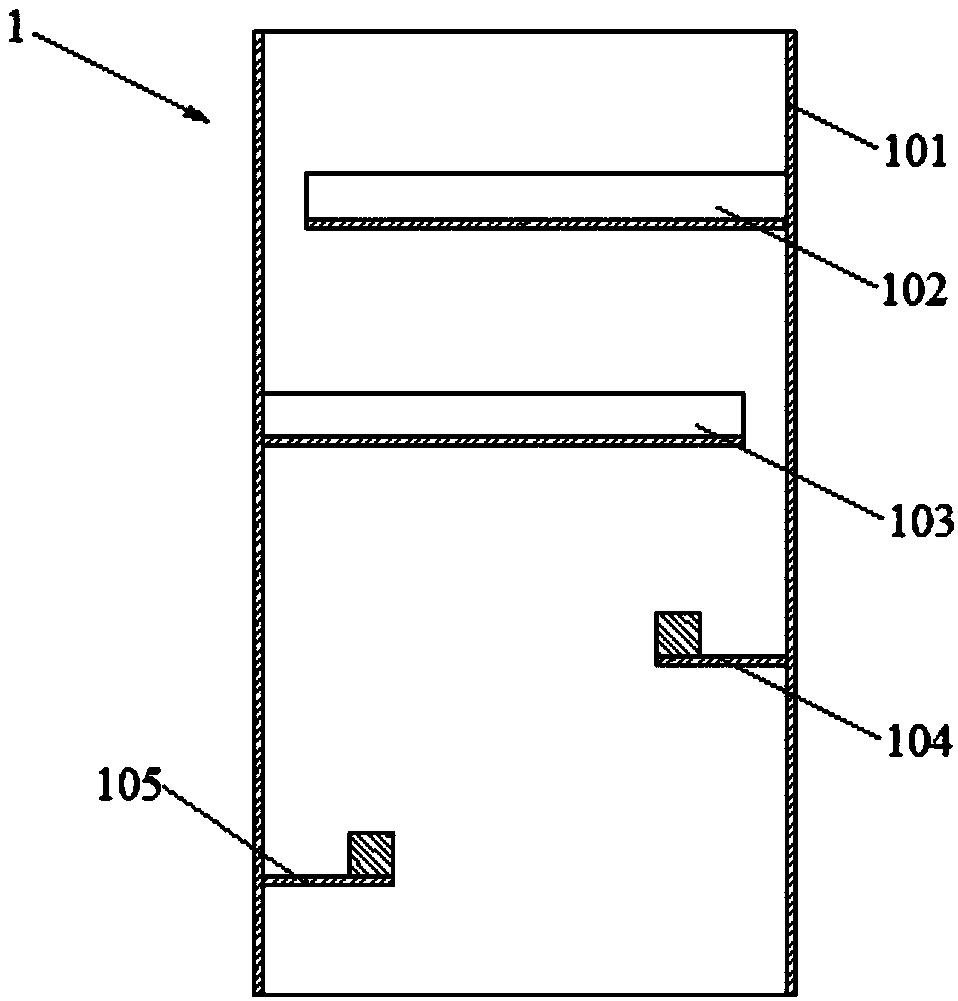

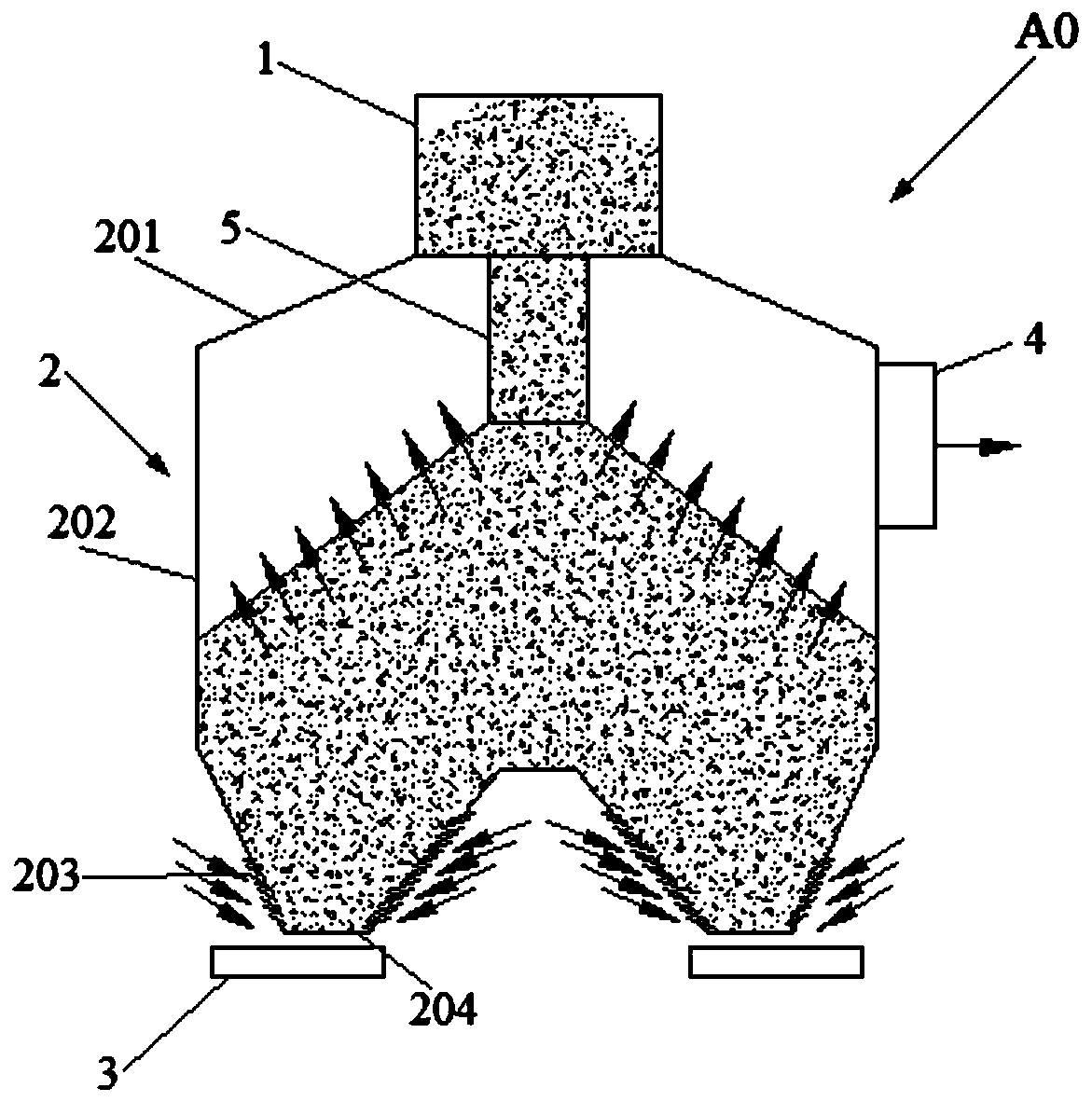

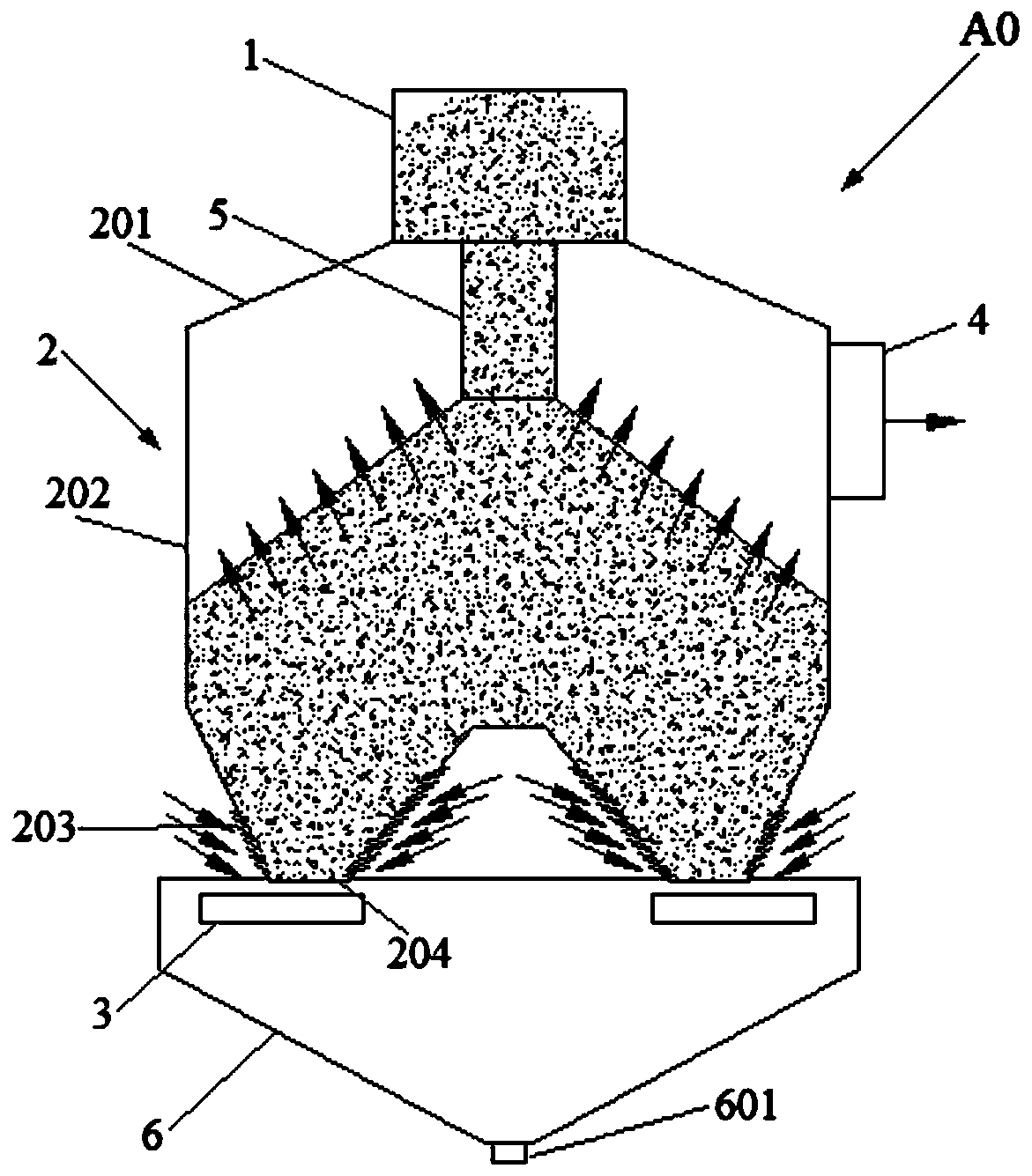

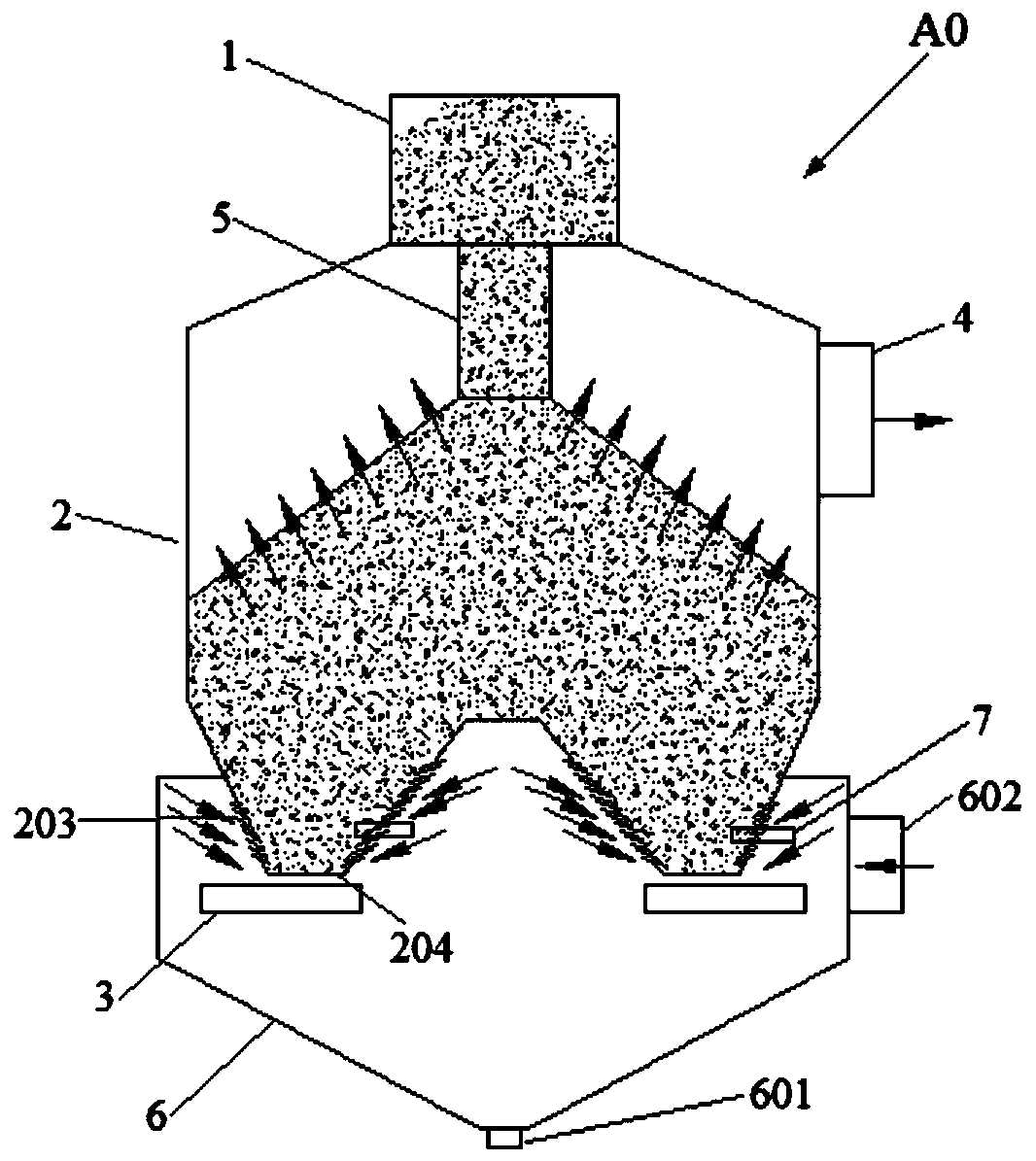

Sinter air drafting type vertical cooling furnace and sinter cooling method

ActiveCN109654893ASlow coolingIncrease temperatureCharge treatment typeIncreasing energy efficiencyEngineeringTower

The invention discloses a sinter air drafting type vertical cooling furnace. The vertical cooling furnace (A0) comprises a stock bin (1), a tower body (2) and discharging equipment (3). The tower body(2) comprises a tower top (201), a tower wall (202) and an air inlet segment (203). The tower top (201) is arranged on the top of the tower wall (202), and the air inlet segment (203) is arranged onthe lower part of the tower wall (202). The stock bin (1) is arranged on the upper part of the tower top (201) and communicates with the interior of the tower body (2). The bottom of the air inlet segment (203) is provided with a discharge port (204). The discharging equipment (3) is arranged below the discharge port (204). The tower top (201) or the upper part of the tower wall (202) is providedwith an air drafting hot air outlet (4). The vertical cooling furnace has the advantages that the sinter cooling speed is low, the cooling air capacity consumed per ton is small, the exhaust gas quantity is relatively small, the exhaust gas temperature is high, the boiler thermal efficiency is high, cooling waste gas can be completely utilized by a boiler, and the sensible heat recovery rate of sinter generally can reach about 70 %.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

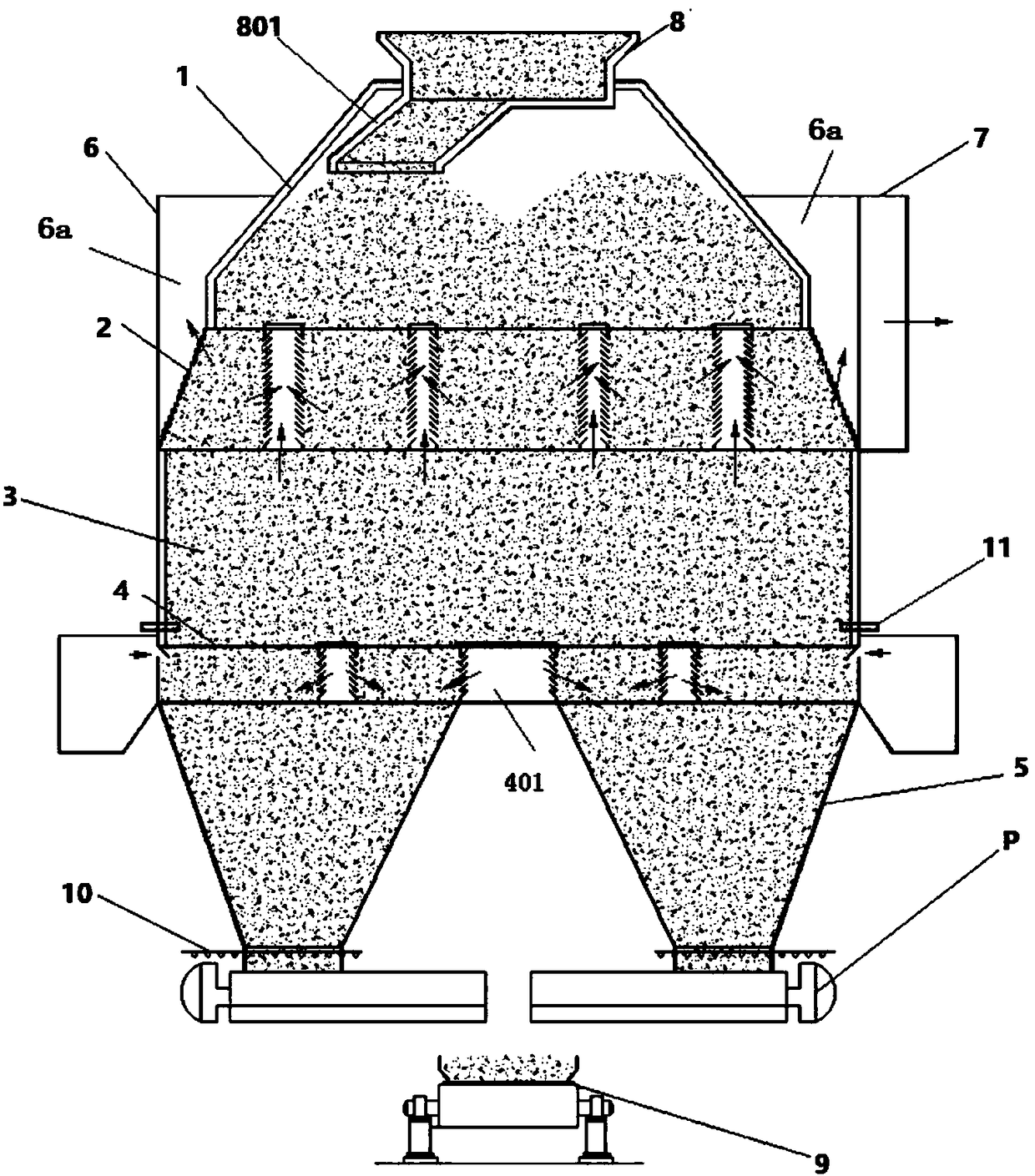

Tower-type sinter cooler with fixing distributing device, and sinter cooling method

PendingCN108931140ASimple structureReliable sealingHandling discharged materialIncreasing energy efficiencyCooling methodsWaste heat

A tower-type cooler comprises a tower body constituted by a feeding section (1), a uniform distributing air-outlet section (2), a cooling section (3) and a uniform discharging blast section (4). A rotating distributing device (8) is arranged at the top end of the feeding section (1), and a discharging outlet (801) of the rotating distributing device (8) downwards extends into the feeding section (1). The uniform distributing air-outlet section (2) is connected with the lower end of the feeding section (1); a hot air annular air channel (6) is arranged on the lower portion of the feeding section (1) and the periphery of the outer side of the uniform distributing air-outlet section (2); the cooling section (3) is arranged below the uniform distributing air-outlet section (2); the uniform discharging blast section (4) is arranged below the cooling section (3); and a plurality of discharging cone hoppers (5) are annularly distributed at the lower end of the uniform discharging blast section (4) or uniformly distributed in the circumferential direction, and discharging equipment is arranged below each discharging cone hopper (5). The tower-type cooler is simple in structure, reliable insealing and high in waste heat recovery efficiency.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Vertical-type cooling machine with rectifying device and cooling method

PendingCN109990605AMeet the requirements of the cooling processUniform clothIncreasing energy efficiencyFurnace coolingAir volumeEngineering

The invention discloses a vertical-type cooling machine with a rectifying device. The vertical-type cooling machine comprises the rectifying device, a tower body, an edge air supply device and discharging devices. The tower body comprises a tower top, a tower wall and a tower bottom. The tower top is arranged at the top of the tower wall, and the tower bottom is arranged at the bottom of the towerwall. The rectifying device is arranged above the tower top and further communicates with the inside of the tower body. The edge air supply device is arranged on the lower middle portion of the towerwall. The tower bottom is provided with discharging outlets. The discharging devices are arranged below the corresponding discharging outlets. A hot-blast air outlet is formed in the upper portion ofthe tower top or the tower wall. The vertical-type cooling machine disclosed by the invention has the cooling beneficial effects that the cooling speed of agglomerate is low, ton consumption coolingblast capacity is small, the exhausted air amount is relatively small, the exhausted air temperature is high, the heat efficiency of a boiler is high, the cooled exhausted gas can be fully utilized bythe boiler, and the sensible heat recovery rate of the agglomerate can reach about 7%.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

A sinter draft type vertical cooling furnace and a sinter cooling method

ActiveCN109654893BSlow coolingIncrease temperatureCharge treatment typeIncreasing energy efficiencyAir volumeExhaust fumes

The invention discloses a sinter air drafting type vertical cooling furnace. The vertical cooling furnace (A0) comprises a stock bin (1), a tower body (2) and discharging equipment (3). The tower body(2) comprises a tower top (201), a tower wall (202) and an air inlet segment (203). The tower top (201) is arranged on the top of the tower wall (202), and the air inlet segment (203) is arranged onthe lower part of the tower wall (202). The stock bin (1) is arranged on the upper part of the tower top (201) and communicates with the interior of the tower body (2). The bottom of the air inlet segment (203) is provided with a discharge port (204). The discharging equipment (3) is arranged below the discharge port (204). The tower top (201) or the upper part of the tower wall (202) is providedwith an air drafting hot air outlet (4). The vertical cooling furnace has the advantages that the sinter cooling speed is low, the cooling air capacity consumed per ton is small, the exhaust gas quantity is relatively small, the exhaust gas temperature is high, the boiler thermal efficiency is high, cooling waste gas can be completely utilized by a boiler, and the sensible heat recovery rate of sinter generally can reach about 70 %.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Multifunctional small solar heater structure based on excess and waste heat utilization technology

The invention discloses a multifunctional small solar heater structure based on excess and waste heat utilization technology. An air outlet of an air supply pipe (11) is directly fixed or fixed below the outside of a reflecting cover through a movable hook (31), a safety protecting net (12) and an additionally-made movable pipe orifice fastening cover are arranged at the pipe orifice of the air supply pipe, and a pipe body of the air supply pipe (11) is fixedly or movably butted with a pipeline led from a foot and hand heating device (27) via a three-way branch pipe (26). Without increasing power consumption and reducing original infrared heating effect, original rising lost hot air and heat energy carried by a heat source carrier form hot air through the fan, the hot air is blown or sucked onto the heating device specially used for feet and hands, excess and waste heat is fully utilized to solve the problem about heating of feet and hands of another person outside an infrared radiation area, electric heat utilization rate of a heater is doubled, and energy-saving effect is remarkable.

Owner:CIXI FUYUN ELECTRIC APPLIANCE

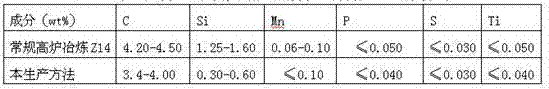

A kind of production method of hypoeutectic casting pig iron

ActiveCN104561409BSolve genetic problemsSolve puzzlesBlast furnace detailsAlkalinityChemical composition

The invention discloses a production method for hypoeutectic cast pig iron. The production method is characterized in that the pig iron comprises the following chemical elements by mass fraction: 3.400-4.000% of C, less than or equal to 0.600% of Si, less than or equal to 0.100% of Mn, less than or equal to 0.040% of P, less than or equal to 0.030% of S and less than or equal to 0.040% of Ti. The production method comprises the following working procedures: (1), blast furnace smelting: 65-70 wt% of a high basicity sinter and 30-35 wt% of pellets are taken as raw materials, and the basicity of the high basicity sinter is 1.90-2.00; during smelting, the content of Si is controlled to be less than or equal to 0.50 wt%, and the furnace slag binary basicity R2 is controlled to be from 1.15 to 1.20; (2), electric furnace smelting: an electric furnace is heated to smelt iron by utilizing a blast furnace molten iron and waste steel method; a first inoculation treatment is performed when the iron is discharged, and the addition amount of an inoculant is controlled in a range of 2-3 kg / t molten iron; (3), casting moulding: the inoculant is added along an iron flow during casting to perform second inoculation treatment, and the addition amount of the inoculant is less than or equal to 2 kg / t molten iron. According to the production method for the hypoeutectic cast pig iron, factors, such as utilization factors, yield and hot air temperature, are improved; furthermore, the comprehensive coke ratio is remarkably reduced; the problem of thick graphite heredity in casting industry is solved.

Owner:河北龙凤山铸业有限公司

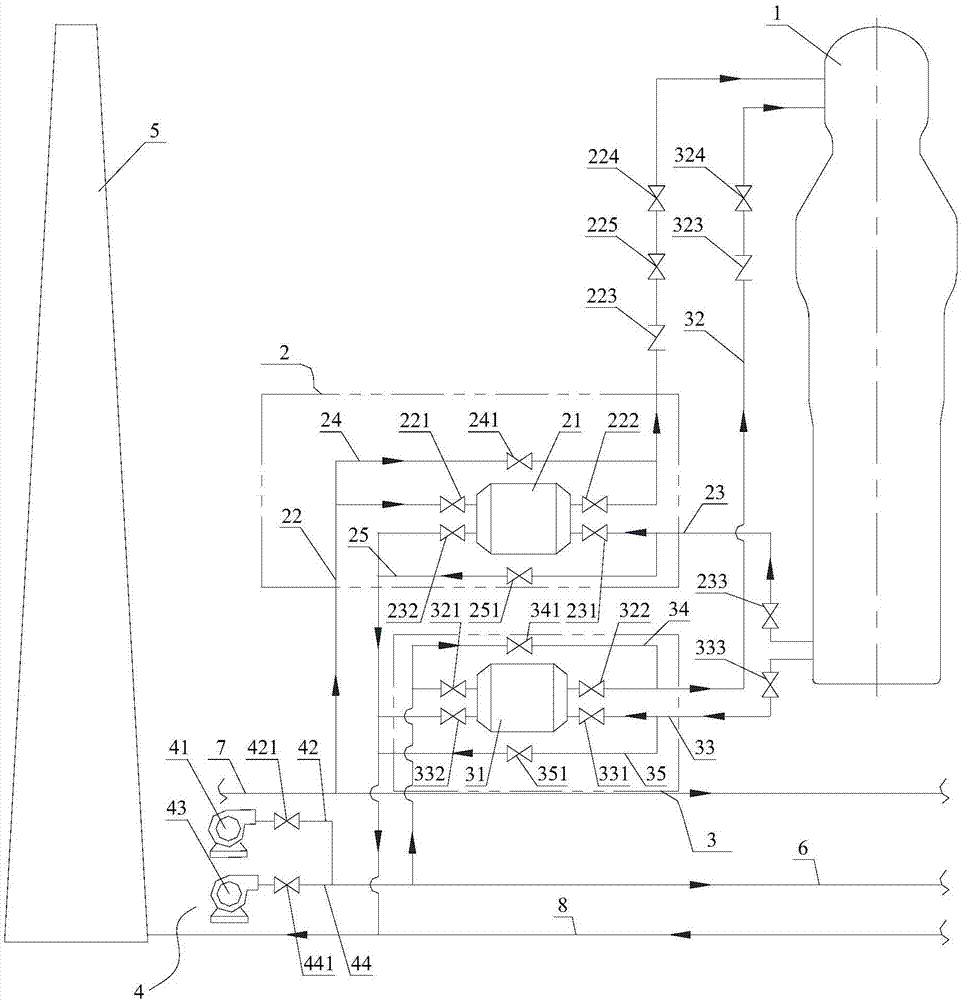

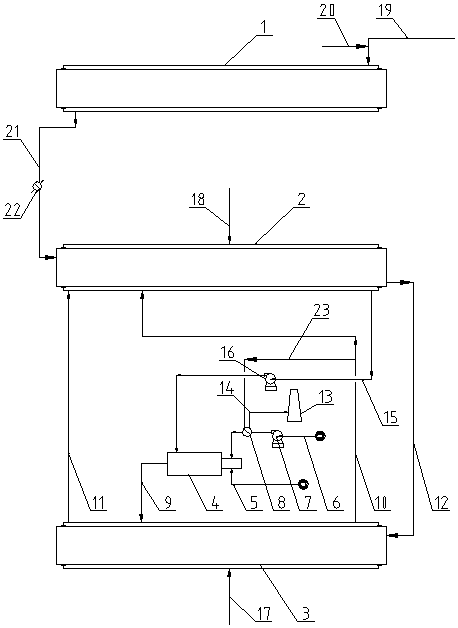

Rotary Reactor Furnace Hot Air Heating System

ActiveCN106091672BRaise the hot air temperatureHeating fastCombustion processRotary drum furnacesEconomic benefitsEngineering

The invention relates to a rotary-reactor hot-air heating system which comprises a recovery furnace (1), a dewater furnace (2) and a thermal decomposition furnace (3). A warm air gas furnace (4) is arranged outside the thermal decomposition furnace (3), a gas inlet pipe (5) and an air inlet pipe (6) are connectively arranged on the warm air gas furnace (4), the jacket of the warm air gas furnace (4) and the jacket of the thermal decomposition furnace (3) are connected through a hot-air outlet pipe (9), the jacket of the thermal decomposition furnace (3) and the jacket of the dewater furnace (2) are connected through a first connecting pipe (10) and a second connecting pipe (11), and the jacket of the dewater furnace (2) and the warm air gas furnace (4) are connected through a return duct (15) therebetween. The rotary-reactor hot-air heating system is high in hot-air temperature and rapid in material heating, thermal efficiency is as high as 85%, energy sources can be effectively saved, energy consumption can be reduced, and economic benefit of products can be finally improved.

Owner:江苏柯恒石化电力机械有限公司

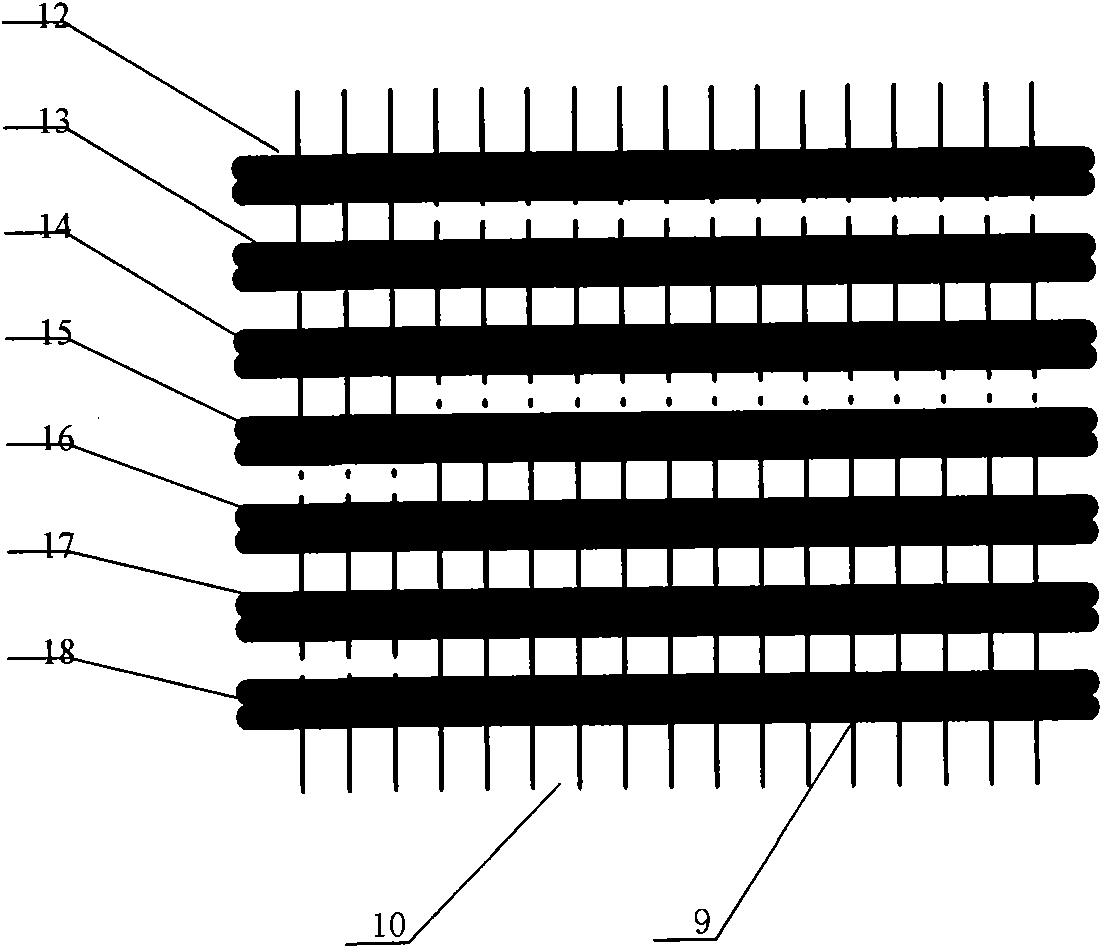

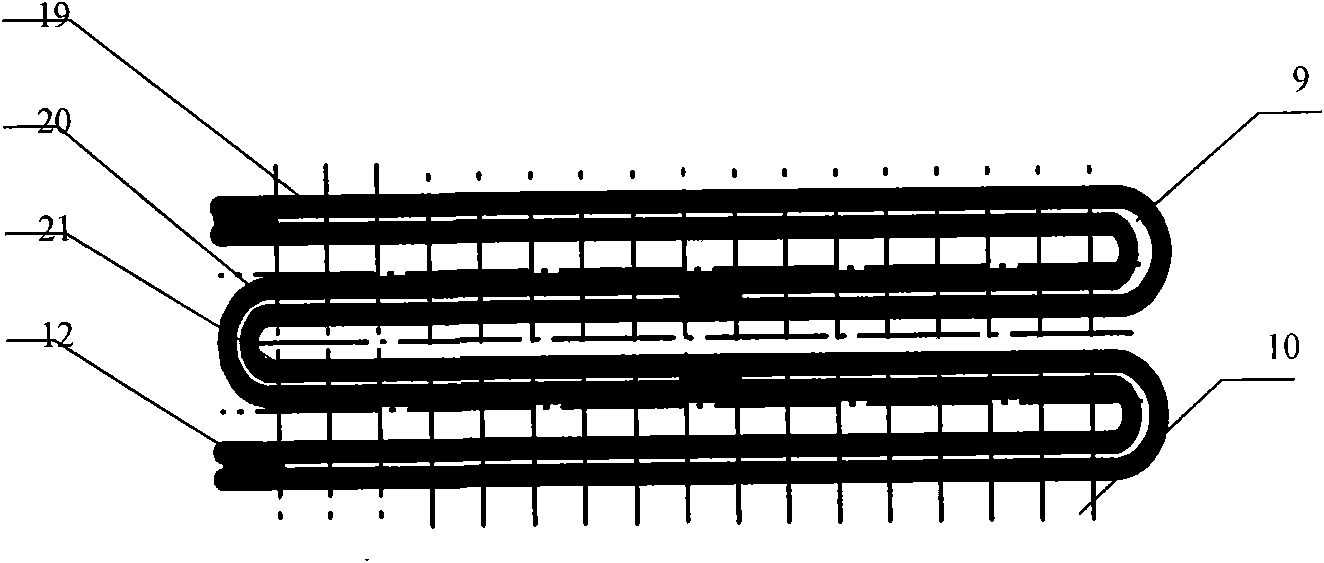

Air energy condenser or evaporator

The invention discloses an air energy condenser or evaporator which comprises a support, metal sheets, metal pipes, one or more single bodies, return air inlets, a refrigerant inlet, a refrigerant outlet, an air inlet and an air outlet. The support, the metal sheets and the metal pipes are connected to form the single bodies, the gaps between the single bodies are arranged as the return air inletswhich return air enters, the metal pipes in the single bodies are sequentially connected in a layered mode from left to right, one end of the connected metal pipes is arranged as the refrigerant inlet, the other end of the connected metal pipes is arranged as the refrigerant outlet, one end of the refrigerant inlet is arranged as the air outlet, and one end of the refrigerant outlet is arranged as the air inlet. The air energy condenser or evaporator is characterized in that the single bodies formed by connecting the metal sheets with the metal pipes and the return air inlets are connected toform the air energy condenser or evaporator.

Owner:张诗华

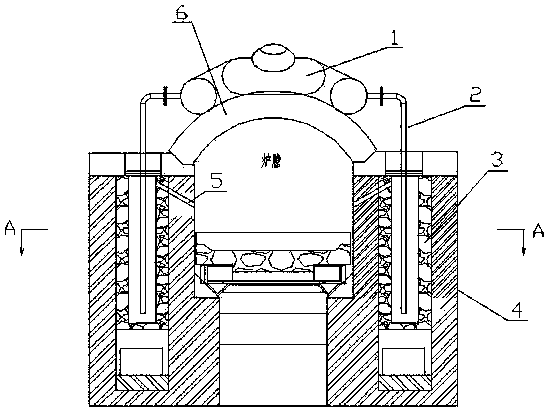

Top-burning hot-blast stove with cone-column composite vault structure

The invention discloses a top-burning hot-blast stove with a cone-column composite vault structure, and belongs to the field of heat energy technology. The top-burning hot-blast stove with the cone-column composite vault structure comprises a stove body and a combustor, wherein the stove body is composed of an inlet, a hot wind outlet, supporting columns, a grate, a regenerative chamber, and a combustion chamber; column chamber walls above the combustor and cone top walls are integrated to form a mixing chamber; one side of the column chamber walls is provided with an air inlet, the column chamber walls are provided with an air circuit, and the inner side of the air circuit is provided with air nozzles; and one side of the cone top walls is provided with a gas inlet, the cone top walls are provided with a gas circuit, and the inner side of the gas circuit is provided with gas nozzles. The top-burning hot-blast stove is used for heat accumulation of wind supply to blast furnaces. Combustion is sufficient, thermal efficiency is high, and cost is low.

Owner:ZHENGZHOU ANNEC IND

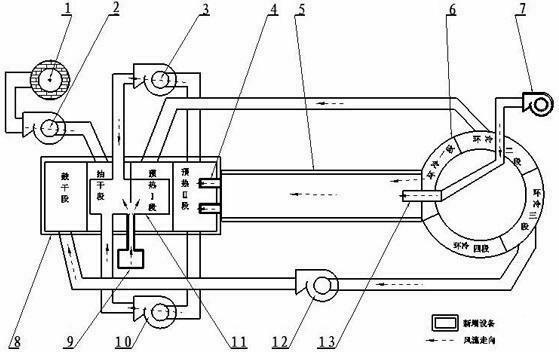

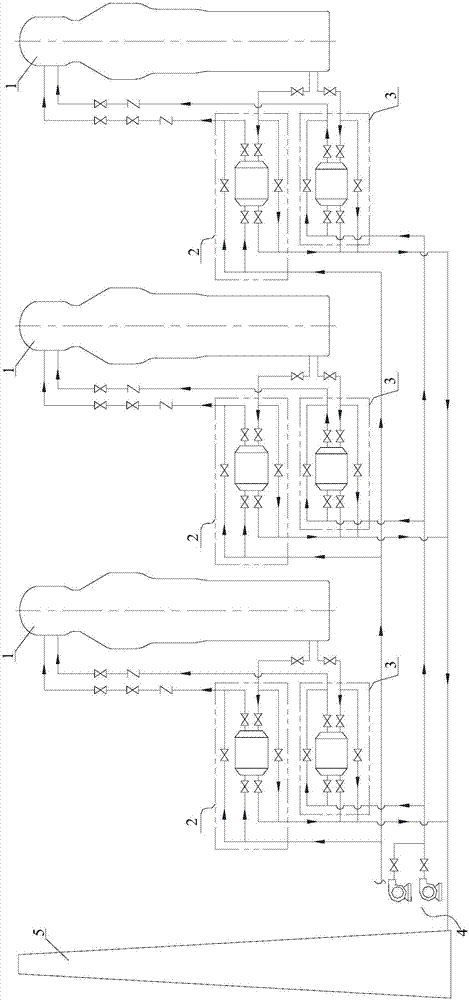

Novel waste heat utilization and emission reduction process for hot air systems of chain grate machine, rotary kiln and circular cooler

ActiveCN102252530BLow running costLittle resistance lossWaste heat treatmentFriction lossExhaust fumes

The invention relates to a waste heat utilization and emission reduction process for hot air systems of a chain grate machine, a rotary kiln and a circular cooler. The process is characterized by comprising the following steps of: supplying hot air in a preheating zone I to a blowing drying zone to dry the material in the blowing drying zone; supplying the waste gas in a four-cooling zone to a secondary cooling zone to cool the material in the secondary cooling zone; and supplying waste gas from a three-cooling zone to a first cooling zone to cool the material in the first cooling zone. By the process, waste heat and heat of pellet hot air systems of the chain grate machine and the rotary kiln can be fully utilized, the resistance loss of hot air is low, the operating cost of a fan can be reduced, circulating waste heat utilization of hot waste gas to be exhausted is realized, energy is saved, and emission is reduced.

Owner:NORTHERN ENG & TECH CORP MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com