Patents

Literature

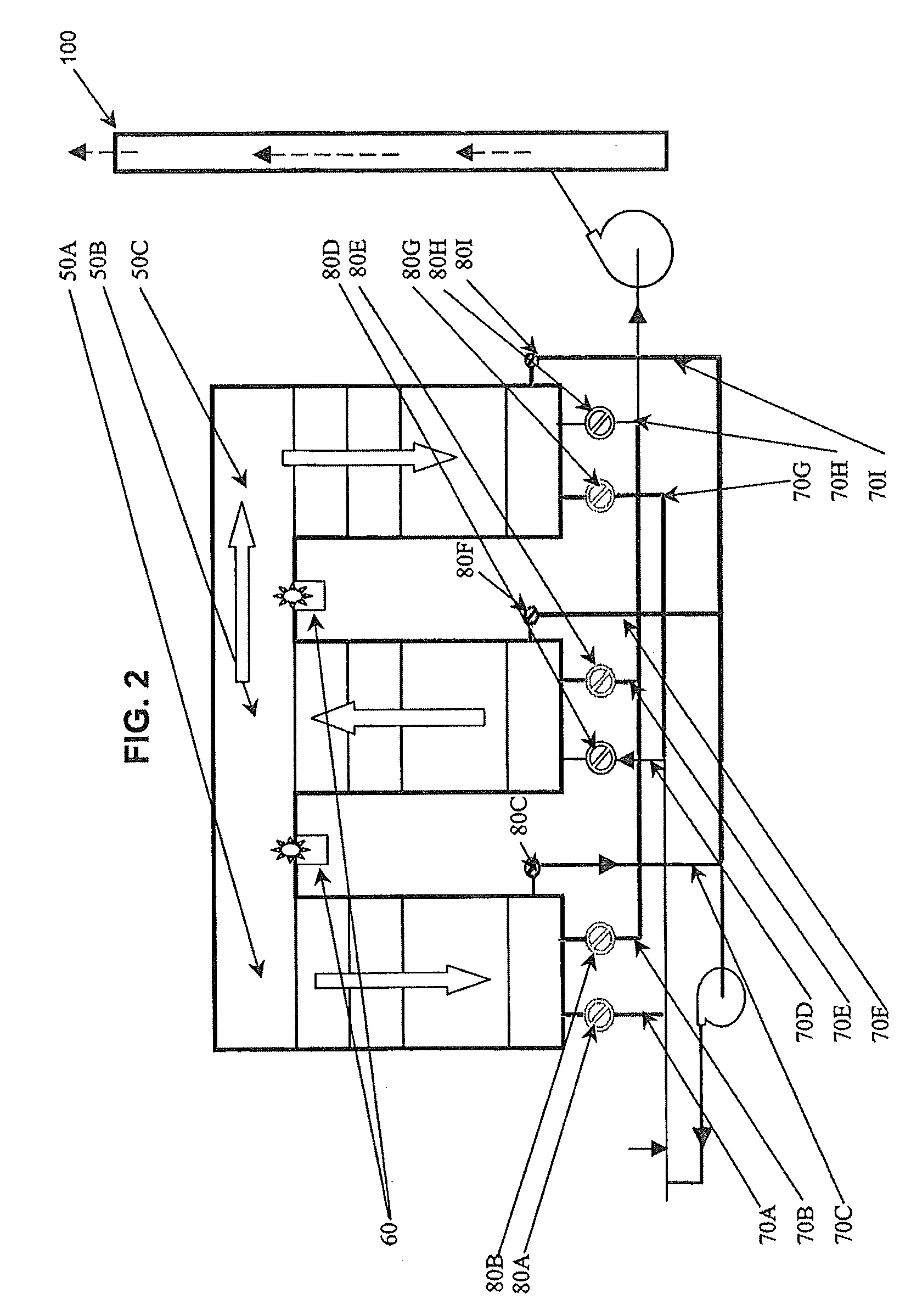

2102results about "Combustion process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

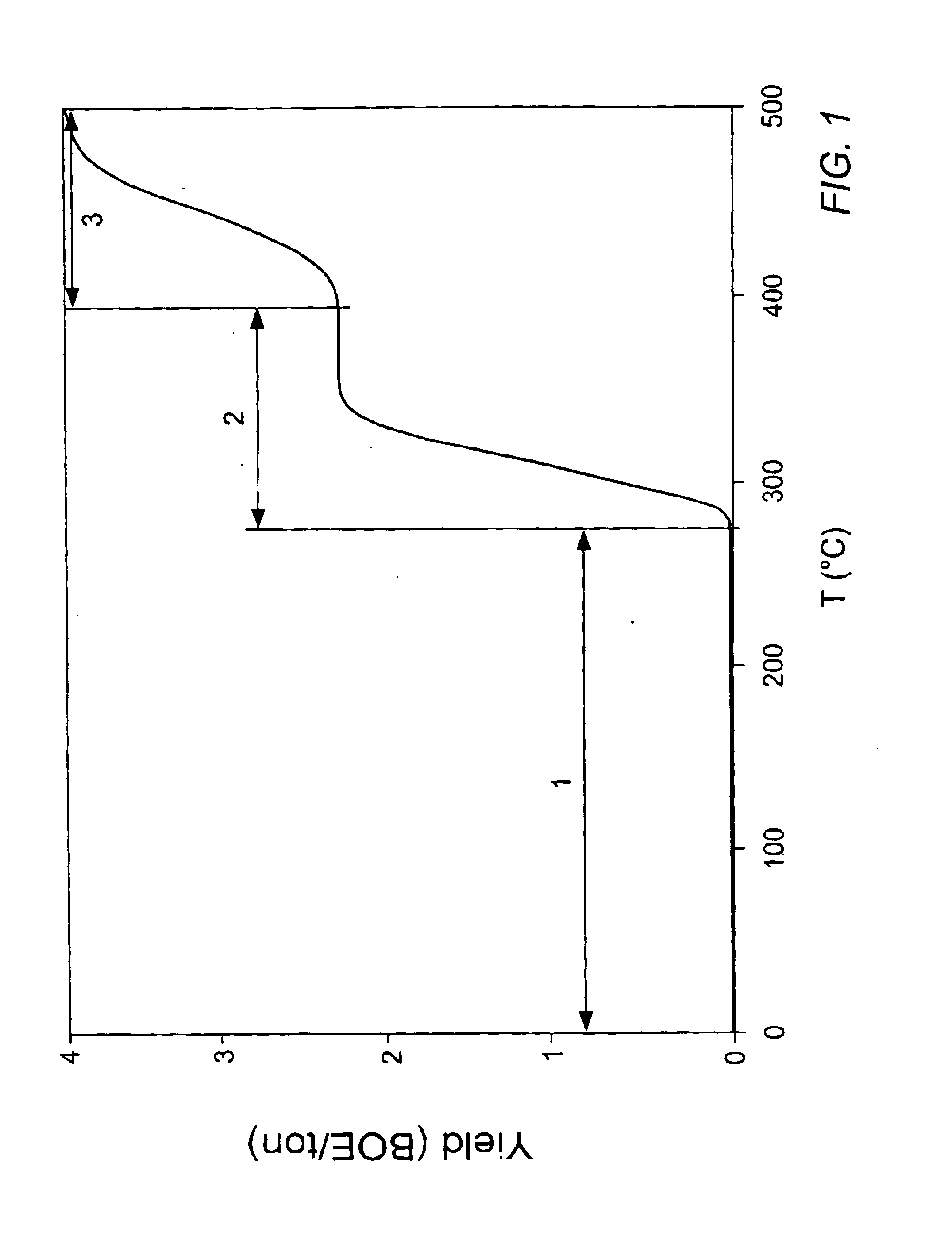

In situ thermal processing of a hydrocarbon containing formation using a controlled heating rate

InactiveUS6745837B2High calorific valueImprove the heating effectSurveyCombustion processFormation fluidHeat energy

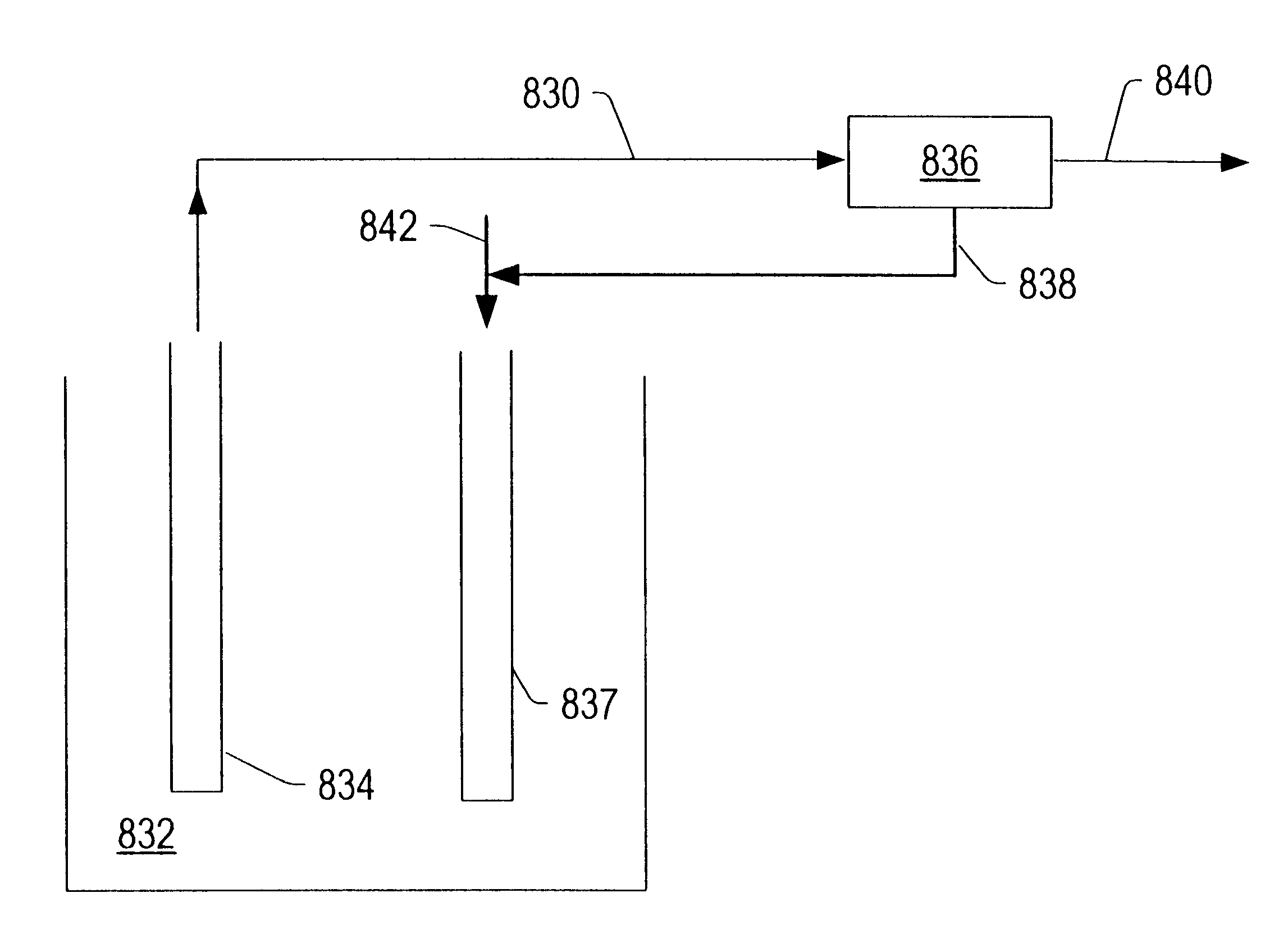

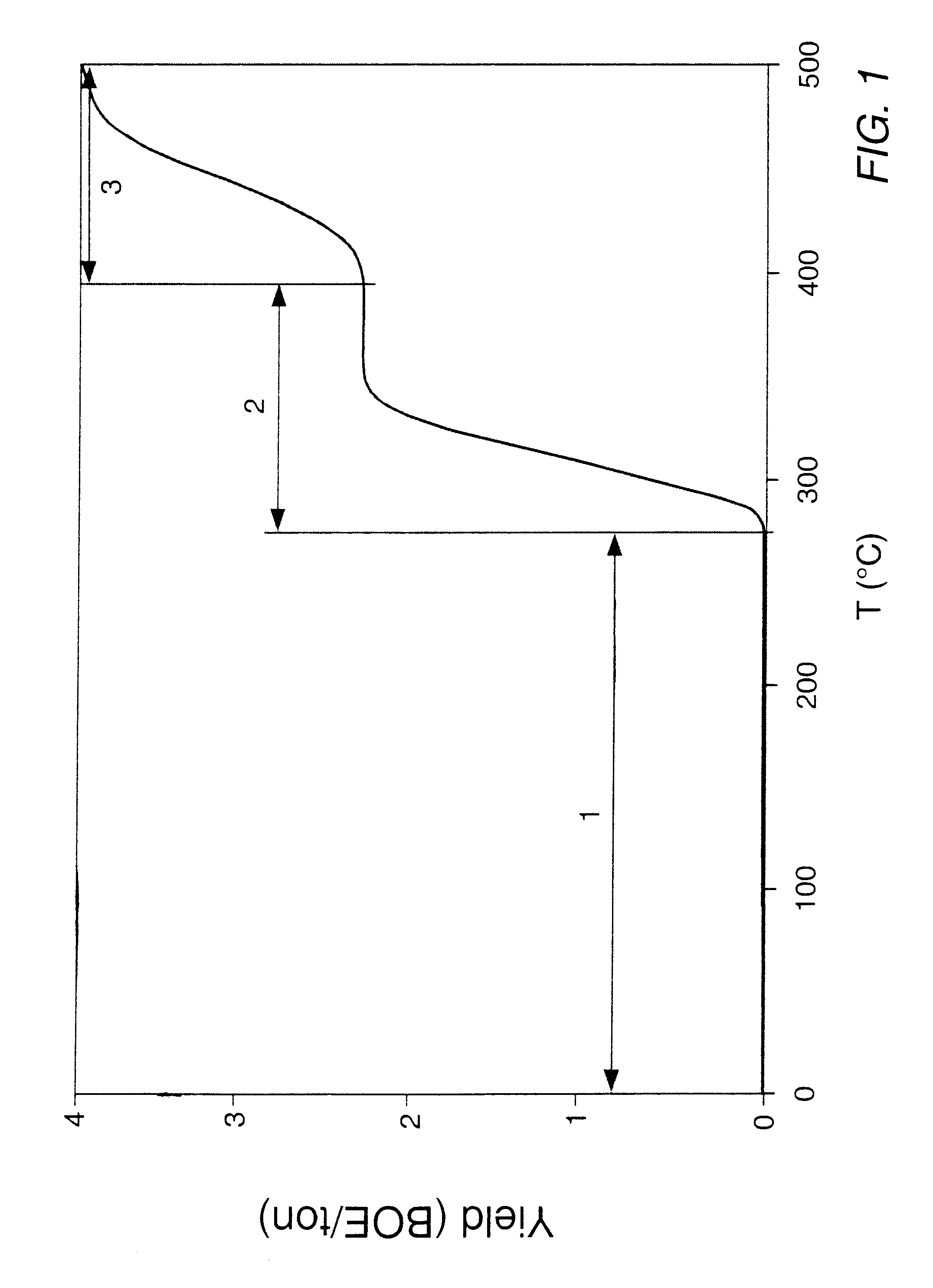

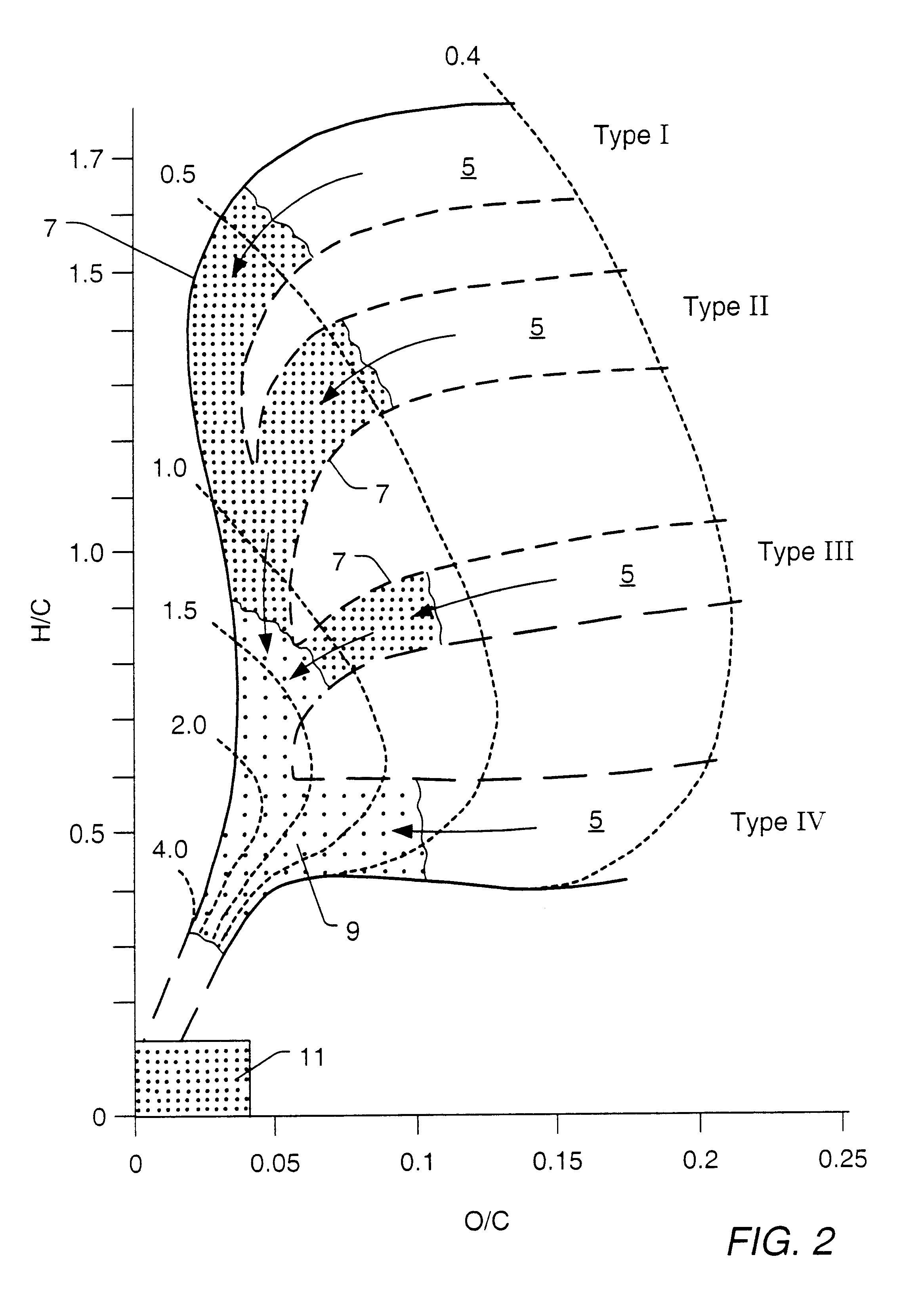

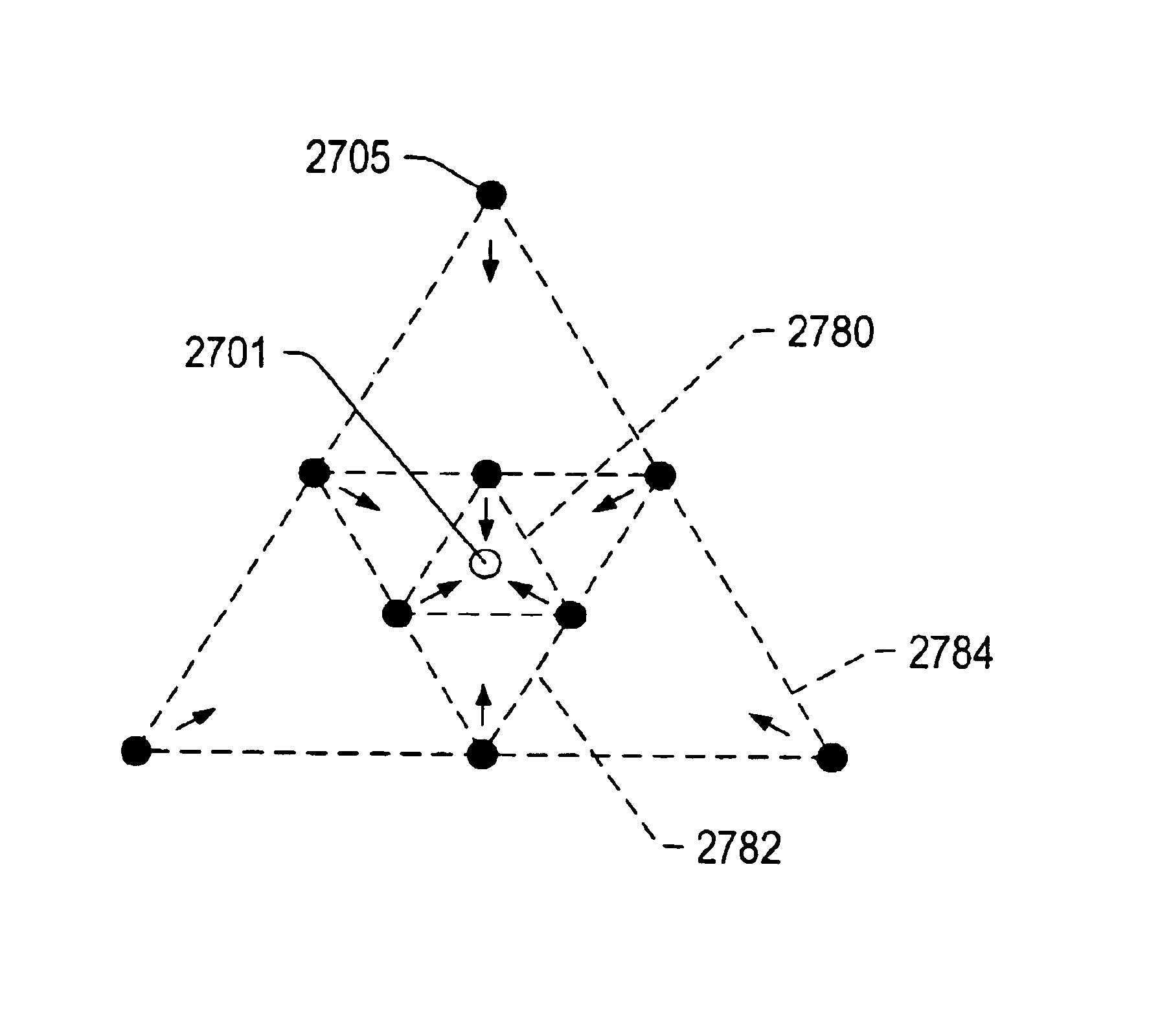

A hydrocarbon containing formation may be treated using an in situ thermal process. A mixture of hydrocarbons, H.sub.2, and / or other formation fluids may be produced from the formation. Heat may be applied to the formation to raise a temperature of a portion of the formation to a pyrolysis temperature. A heating rate to a selected volume of the formation may be controlled by altering an amount of heating energy per day that is provided to the selected volume.

Owner:SALAMANDER SOLUTIONS INC

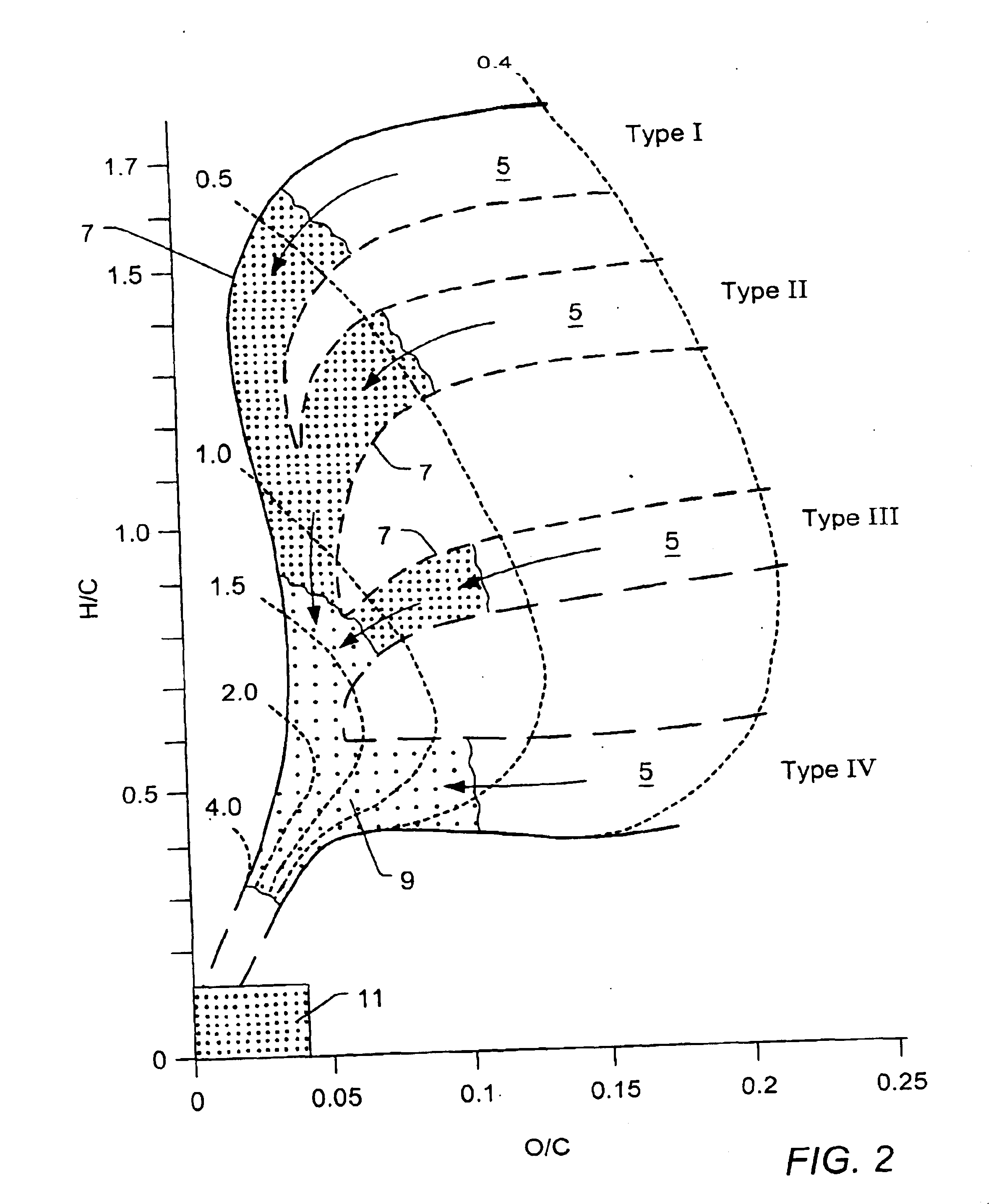

In situ thermal processing of a coal formation to increase a permeability/porosity of the formation

InactiveUS6866097B2Reduce the temperatureHigh strengthSurveyCombustion processPorosityInitial permeability

Owner:SHELL OIL CO

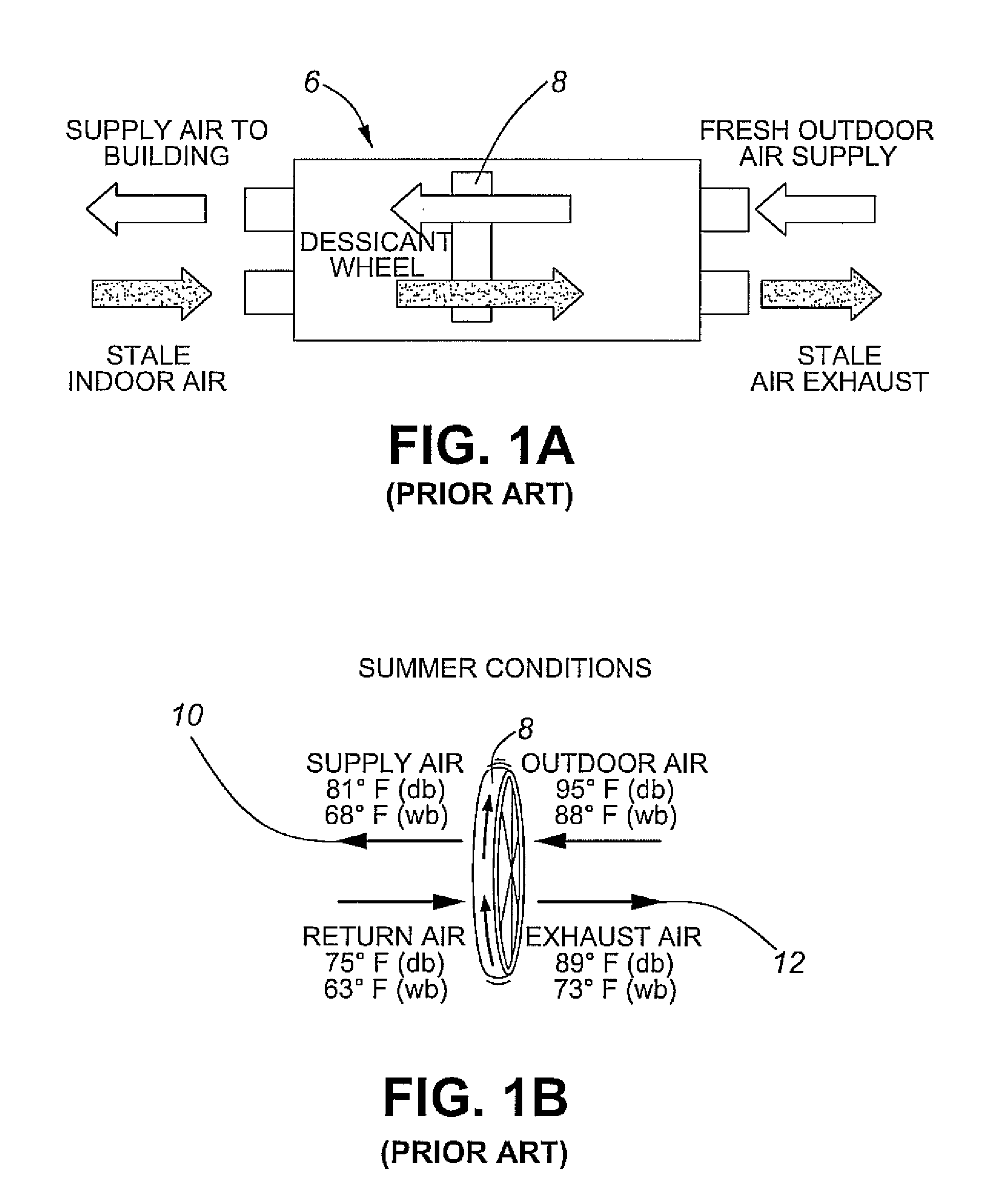

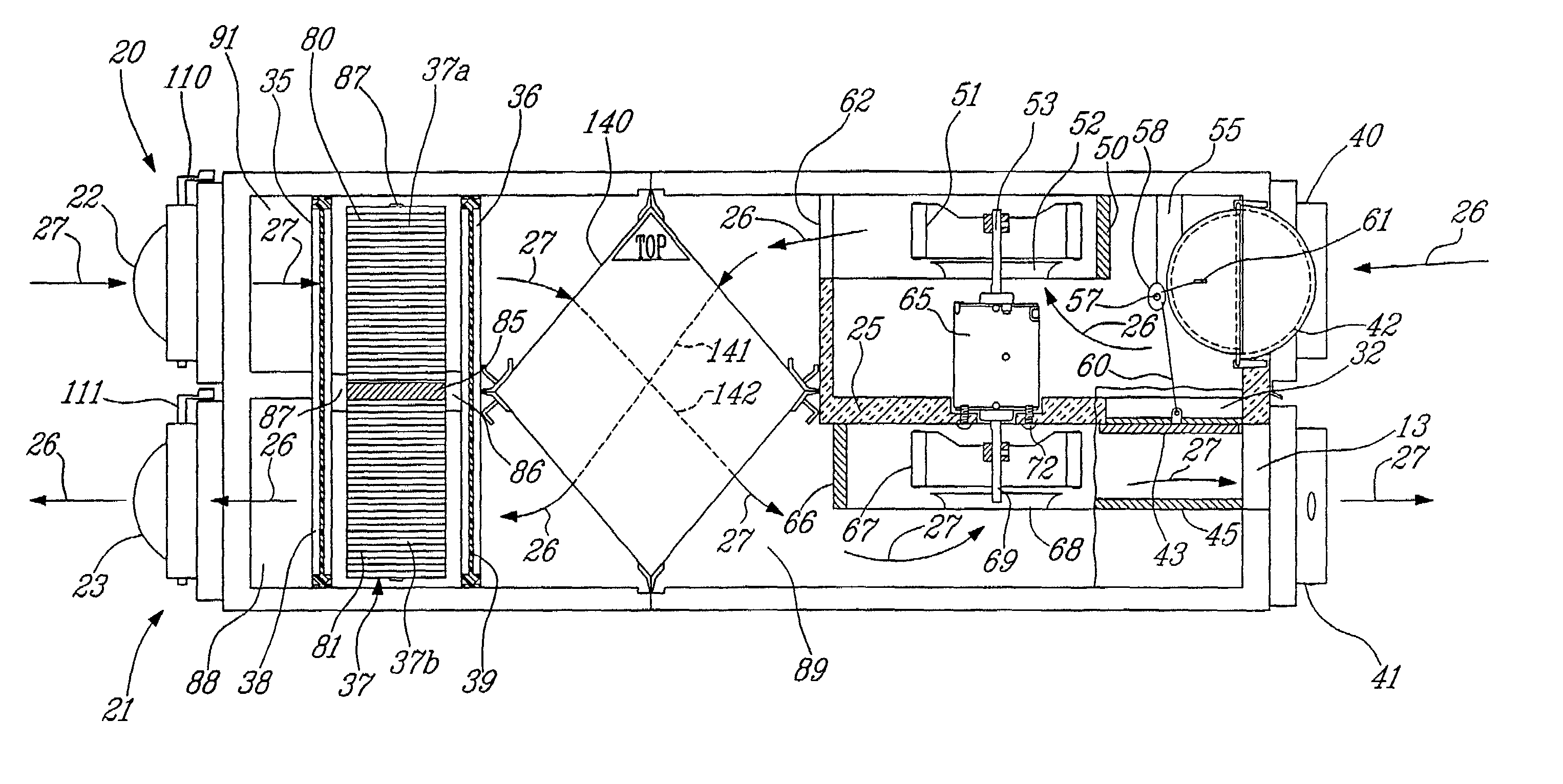

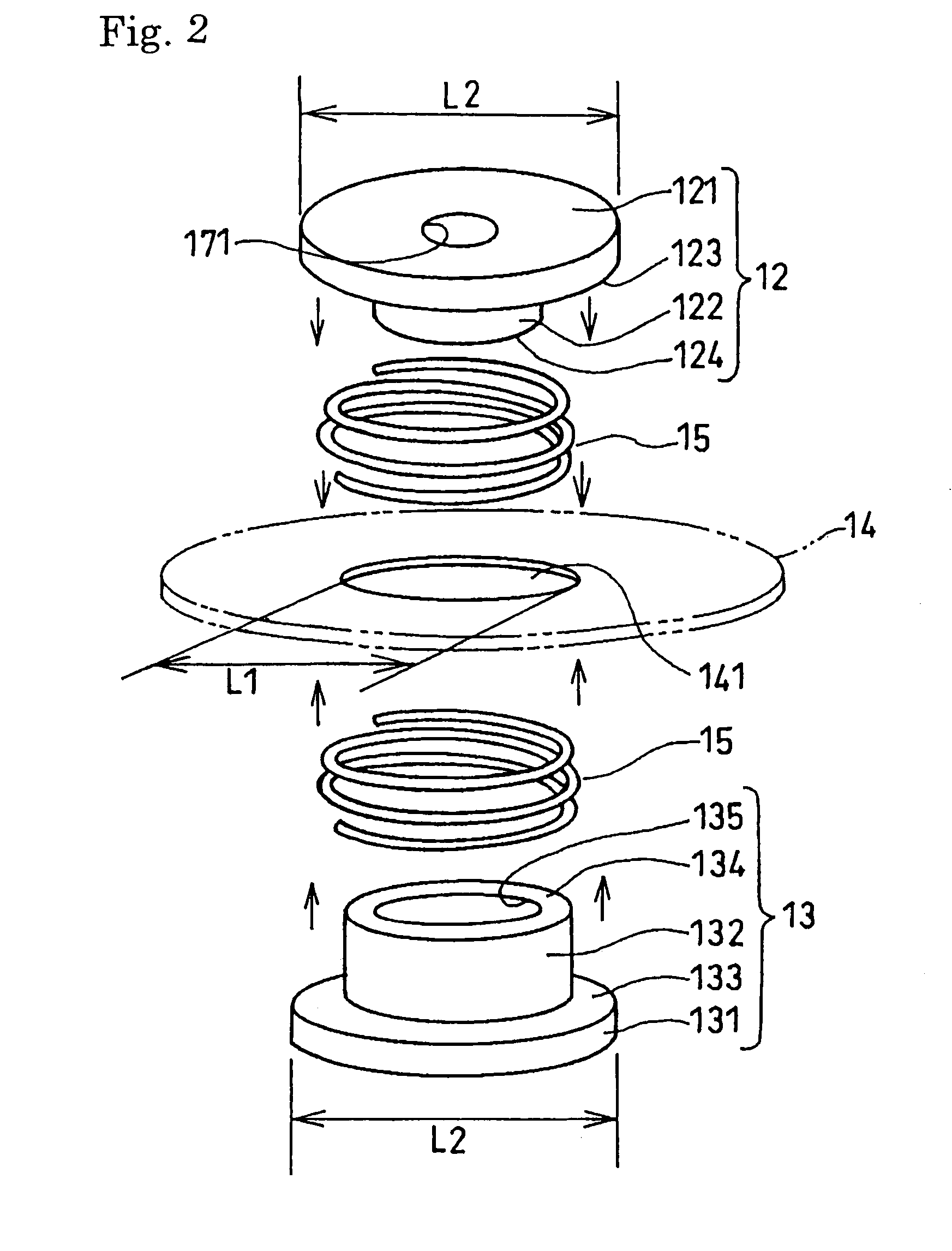

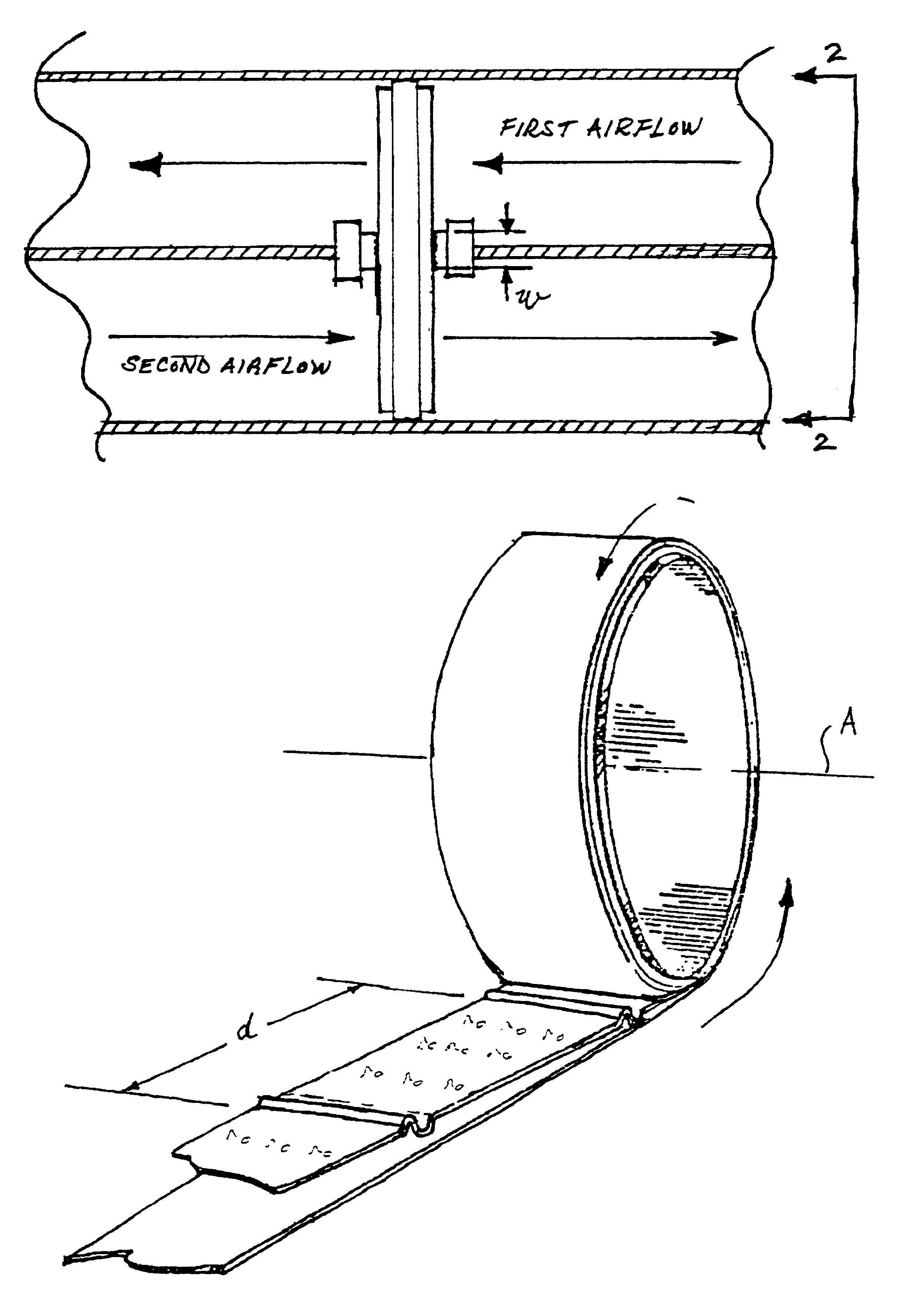

Apparatus for regenerating desiccants in a closed cycle

InactiveUS6029467AEasy and efficient to manufactureDurable and reliable constructionAir treatment detailsCombustion processDesiccantClosed loop

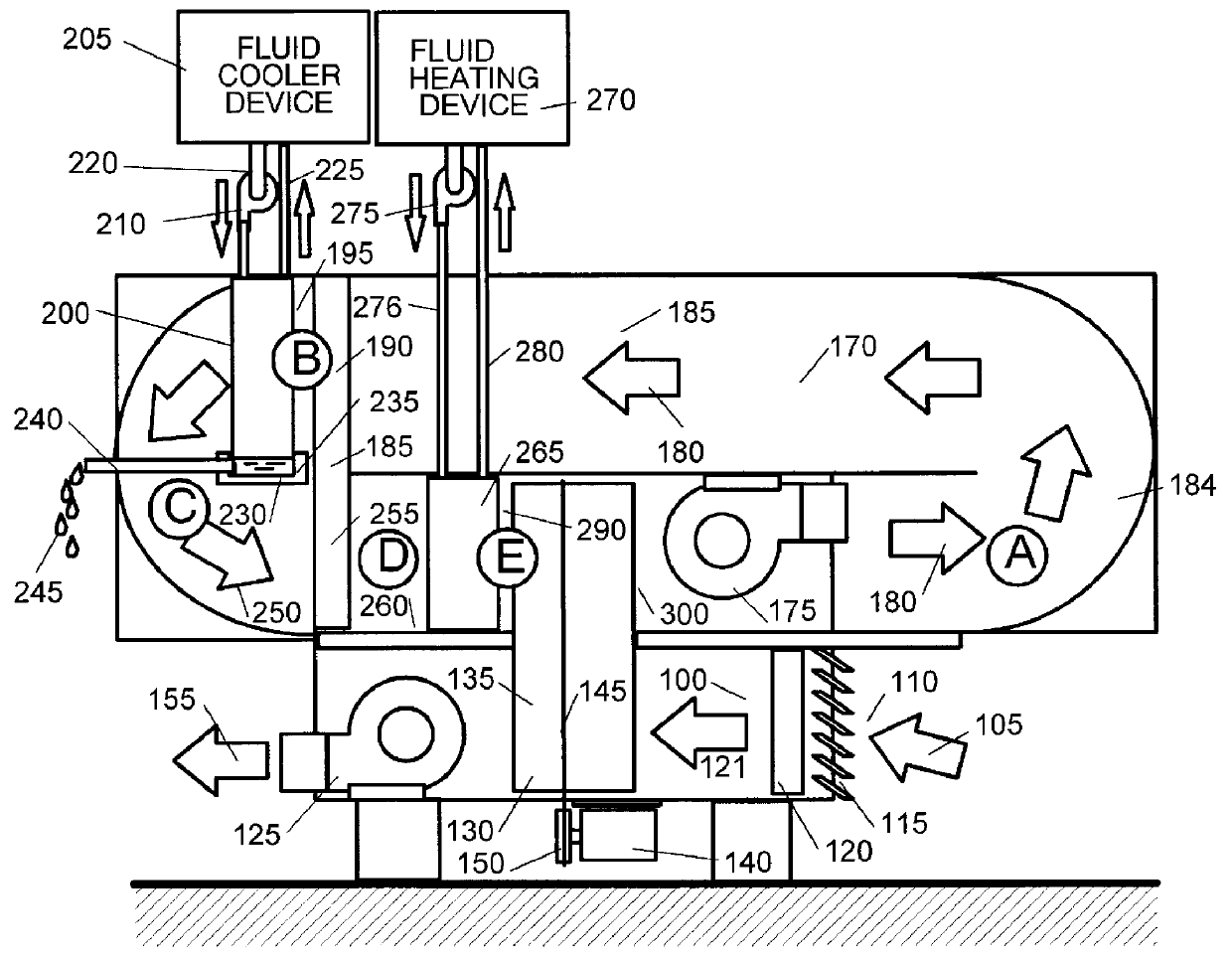

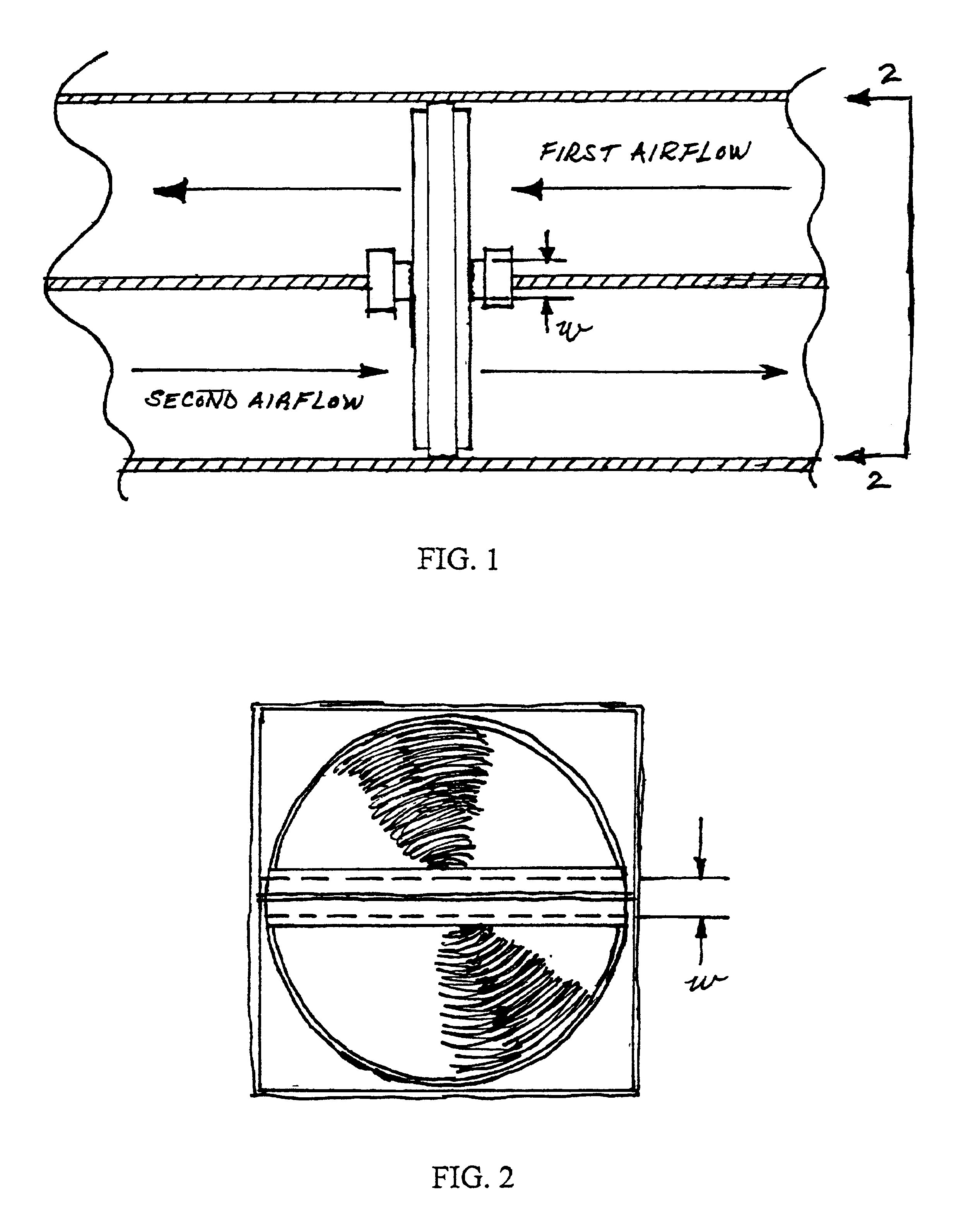

A method and apparatus for conditioning air through the removal of moisture from air to be conditioned comprising a first path for a first flow of air to be dehumidified, the first path having an input end and an output end with a first blower between the input end and the output end to effect the movement of air from the input end to the output end; a second path for a second flow of air, the second path being independent of the first path and adapted to remove moisture from the second flow of air, the second path being in a closed loop configuration with a second blower for continuously moving the second flow of air around the second path and with a plurality of temperature changing devices sequentially positioned in the second path including an air precooling device, a cooling condenser device for condensing moisture from the second flow of air, a reheating device coupled to the precooling device, and a heating device; and a desiccant wheel with a motor to rotate the wheel in a continuous path of travel through a first zone and a second zone, the first zone being in the first path of travel between the input end and the output end, the second zone being in the second path of travel between the heating device and the precooling device.

Owner:MORATALLA JOSE M

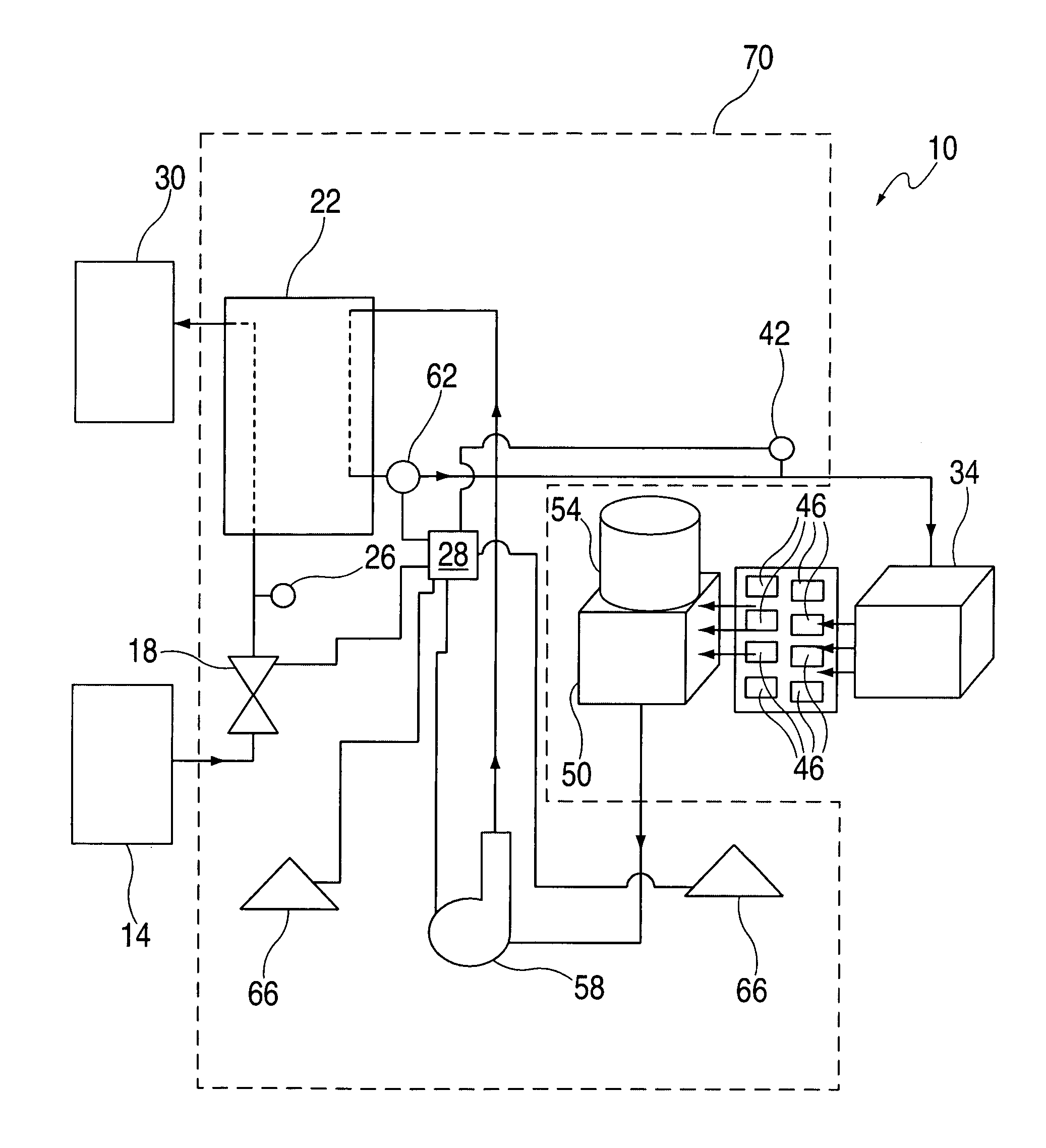

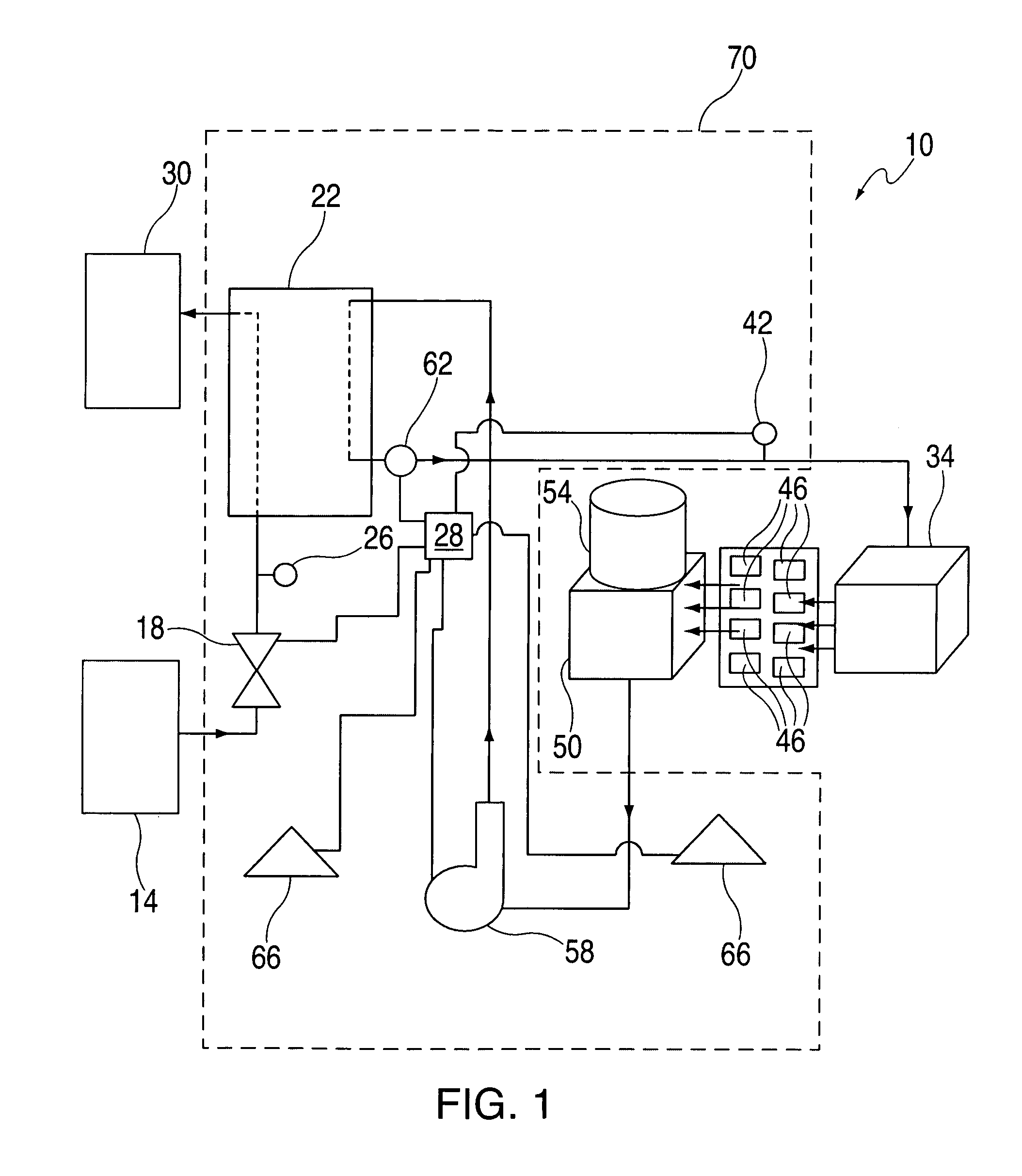

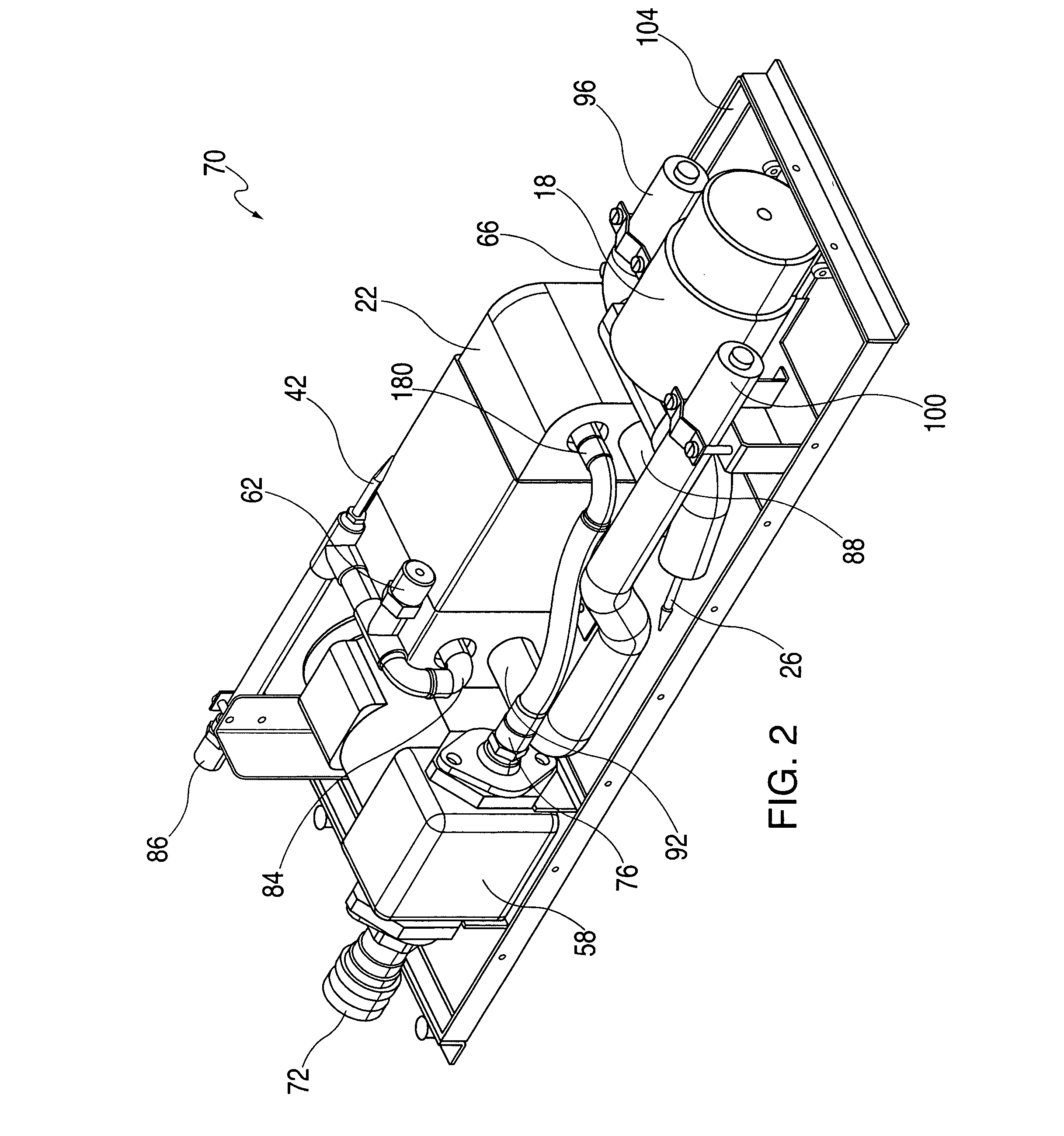

Method and apparatus for cooling electronic components

A modular fluid unit for cooling heat sources located on a rack, the modular fluid unit comprising: a heat exchanger in fluid communication a pump; and wherein the modular fluid unit is mountable within the rack and is configurable to be in fluid communication with a cold plate return manifold, a cold plate supply manifold, and an end-user fluid supply. A method for cooling electronic components in a rack, the method comprising: circulating a first liquid from a cold plate to one of a plurality of heat exchangers mounted within the rack; circulating a second liquid from a second liquid supply to the one of a plurality of heat exchangers; and transferring heat from the first liquid to the second liquid at the one of a plurality of heat exchangers.

Owner:IBM CORP

Brush-seal and matrix for regenerative heat exchanger, and method of adjusting same

InactiveUS20090000762A1Avoid mixingCombustion processIndirect carbon-dioxide mitigationEngineeringGuide tube

Disclosed is a regenerative heat exchanger including a brush-seal configuration to prevent mixing of fluid flows. The regenerative heat exchanger includes a regenerator, and at least two conduits, each conduit having a matrix end abutting a face of the regenerator matrix. The at least two conduits carrying at least two fluid flows, the fluid flows which pass through the regenerator matrix. The regenerative heat exchanger includes a plurality of brush-seals, each brush-seal located at a matrix end of each conduit without contacting the matrix, thereby sealing around a periphery of each conduit to prevent mixing of fluid flows. Also disclosed is a method for establishing a minimal gap between a regenerator matrix of a regenerative heat exchanger and a plurality of brush-seals.

Owner:WILSON SOLARPOWER CORP

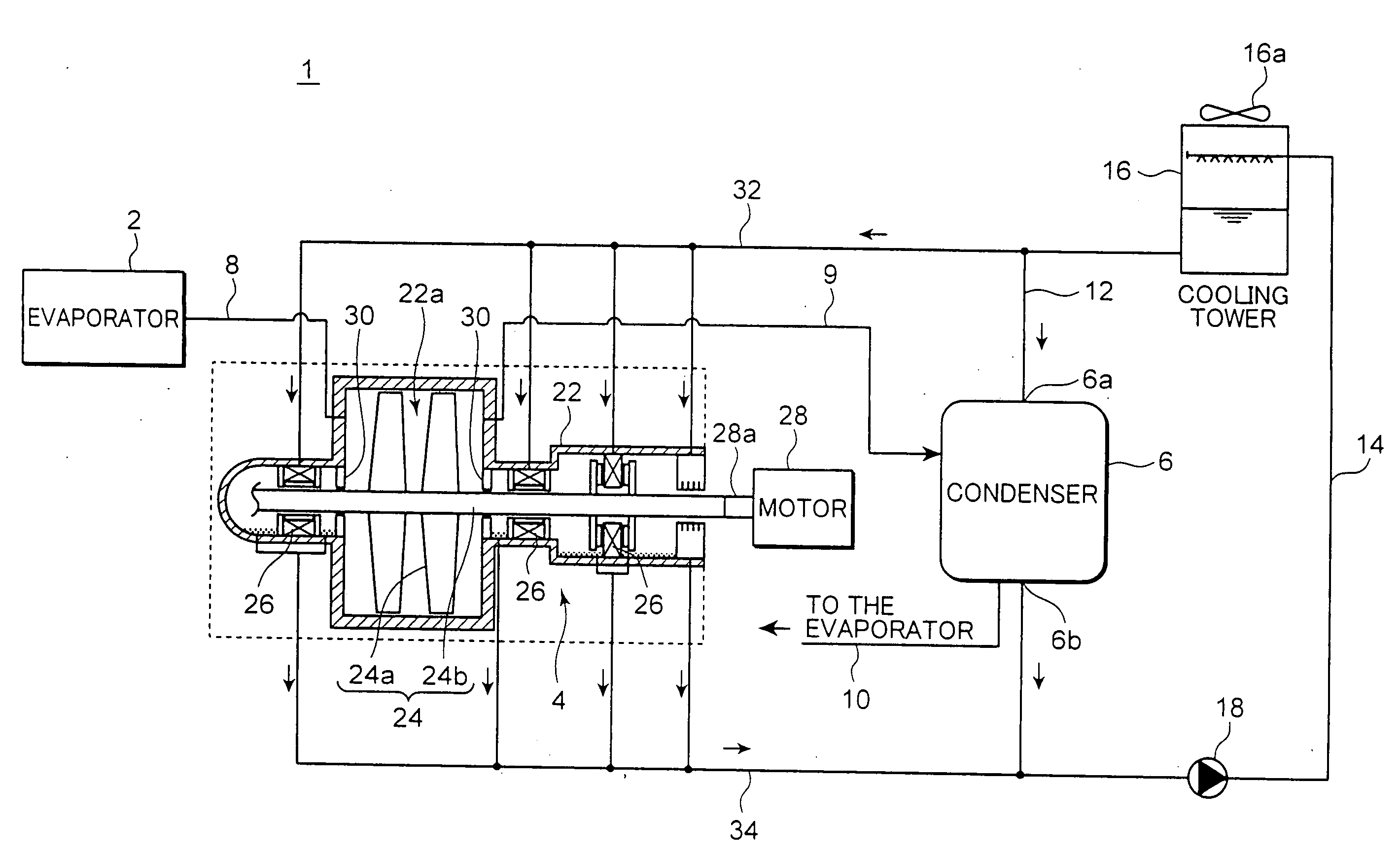

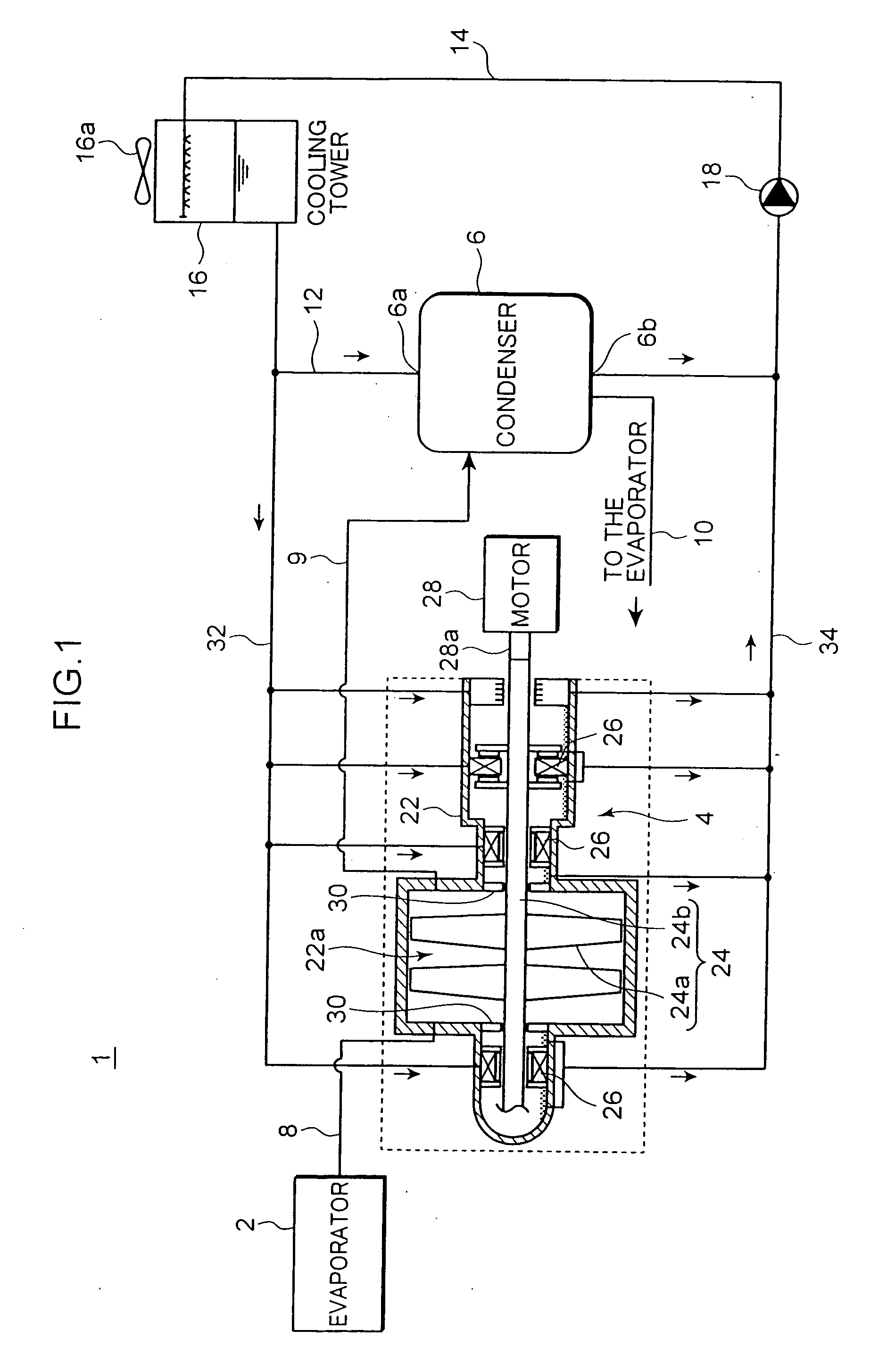

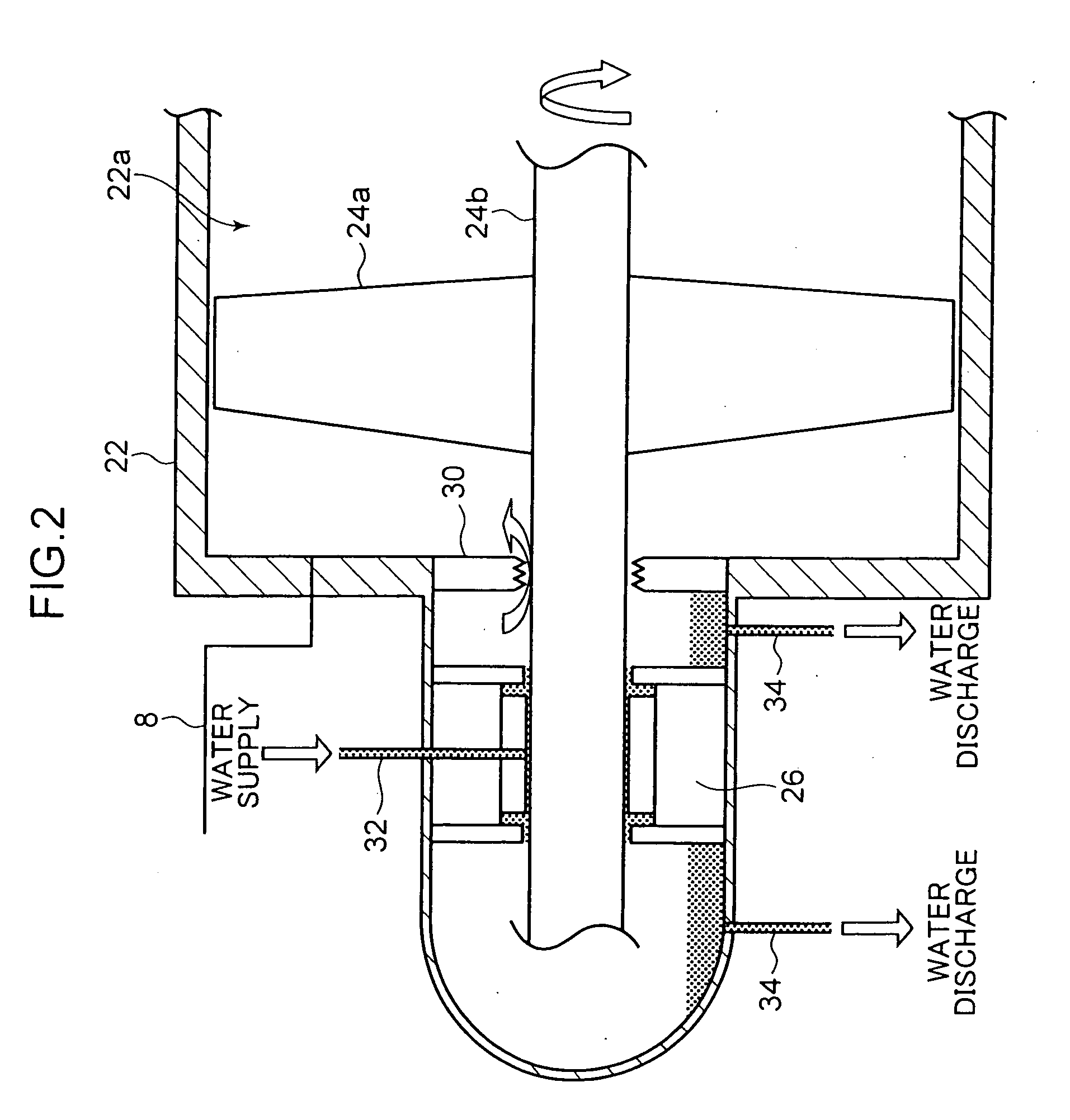

Compressor and refrigerating machine

ActiveUS20110174009A1Easy disposalSimple configurationCompressorPump componentsRotational axisWater vapor

A compressor and a refrigerating machine which enable an easy disposal of a lubricant, are friendly to the natural environment, and have simple configurations, are provided.The compressor which is used in a refrigerating machine including an evaporator and a condenser and adapted for compressing refrigerant gas evaporated in the evaporator to convey the compressed refrigerant gas to the condenser, includes: a motor; a housing having a compression chamber inside; a rotary member which has a rotating shaft and is rotated by a driving force of the motor so as to compress water vapor serving as the refrigerant gas in the compression chamber; a bearing for supporting the rotating shaft of the rotary member in the housing; and a lubricant supplier for supplying water serving as a lubricant to the bearing.

Owner:THE TOKYO ELECTRIC POWER CO INC +3

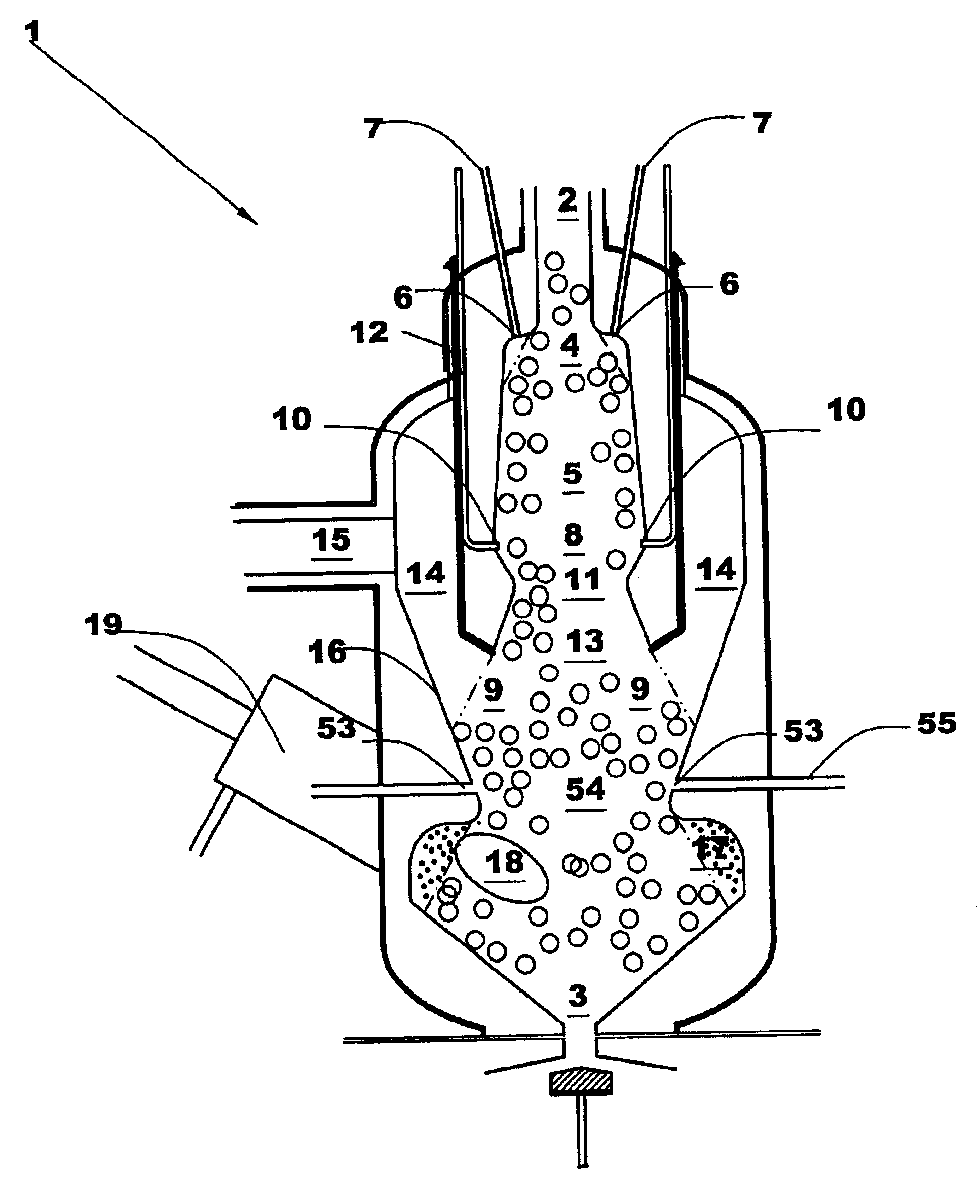

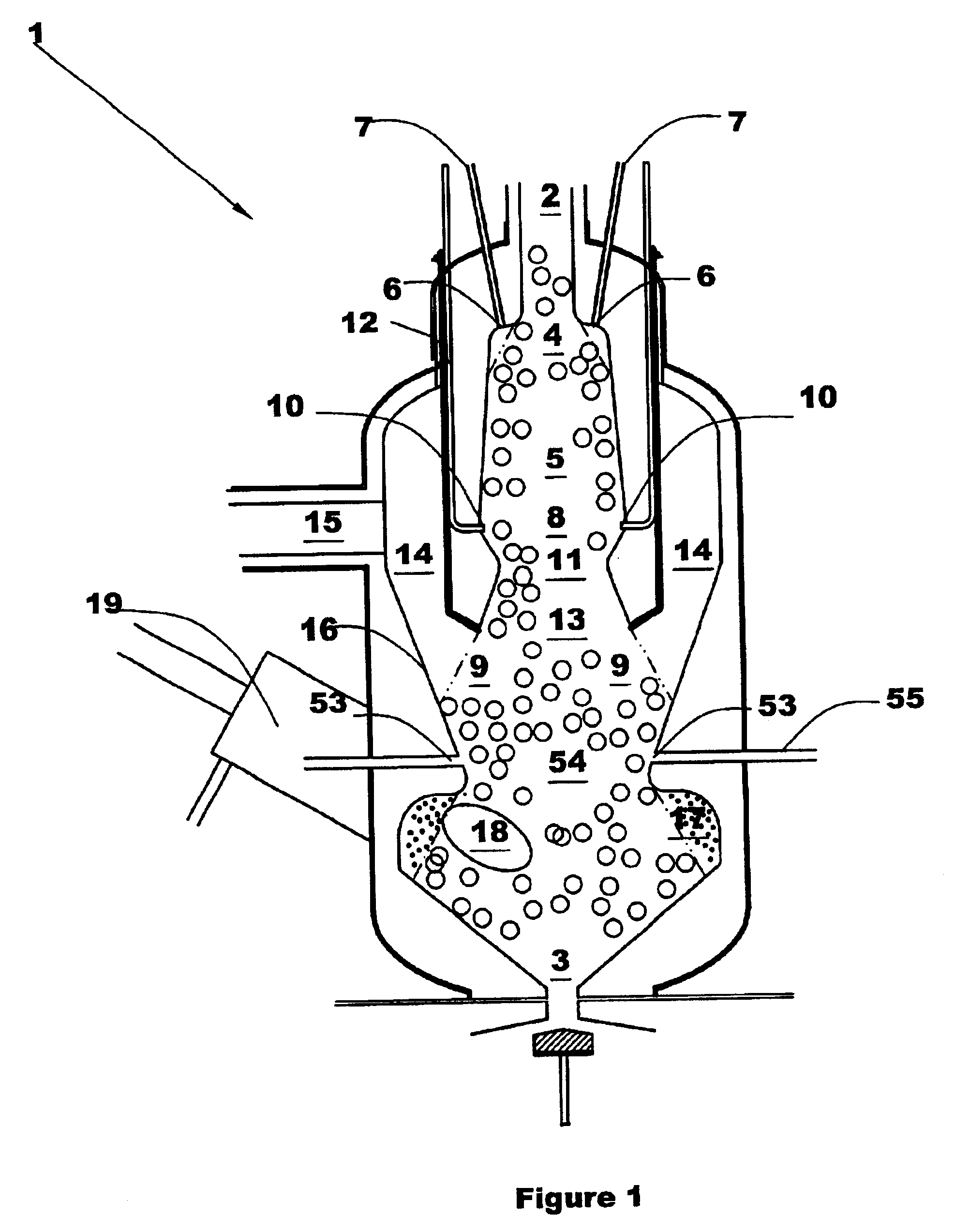

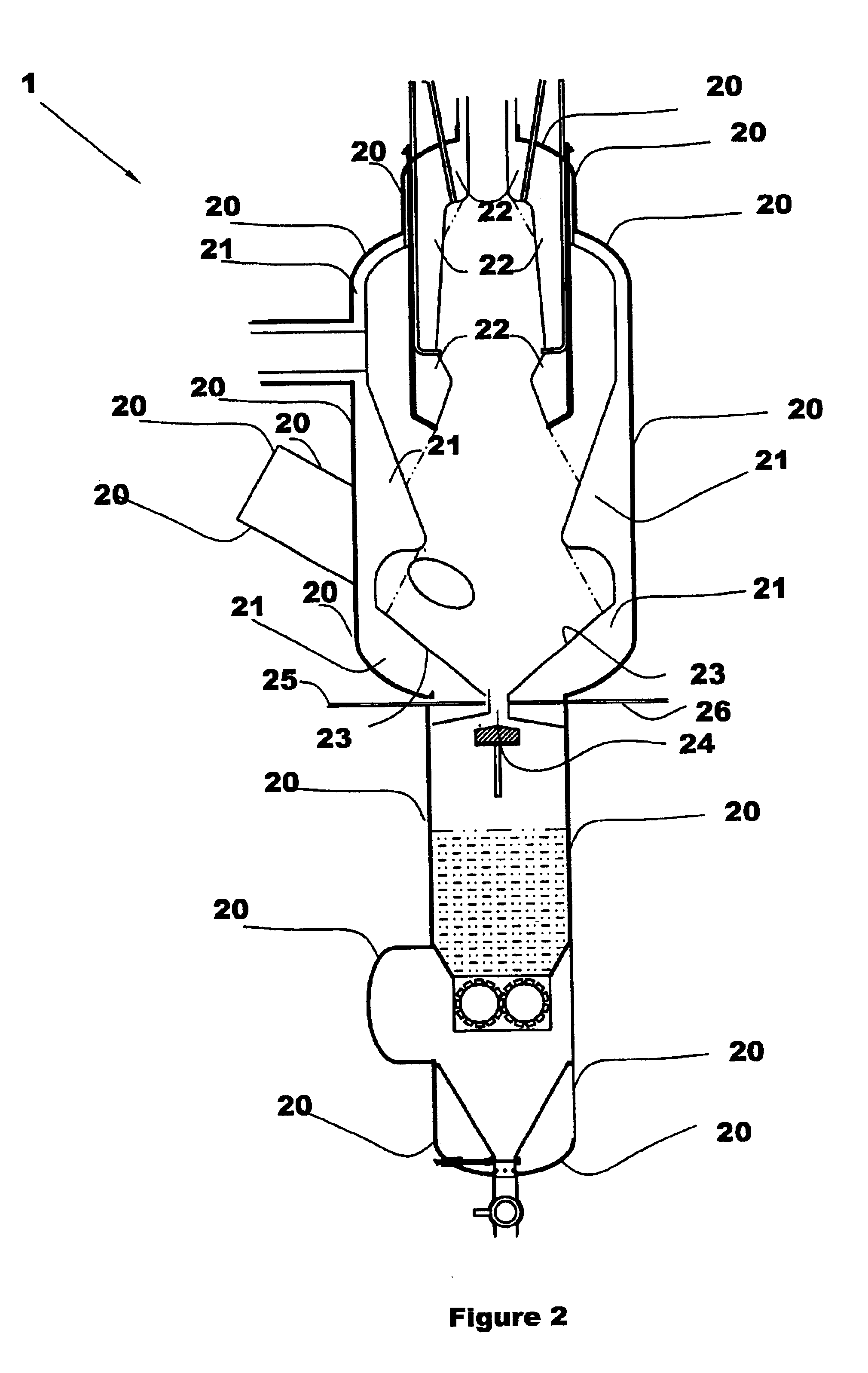

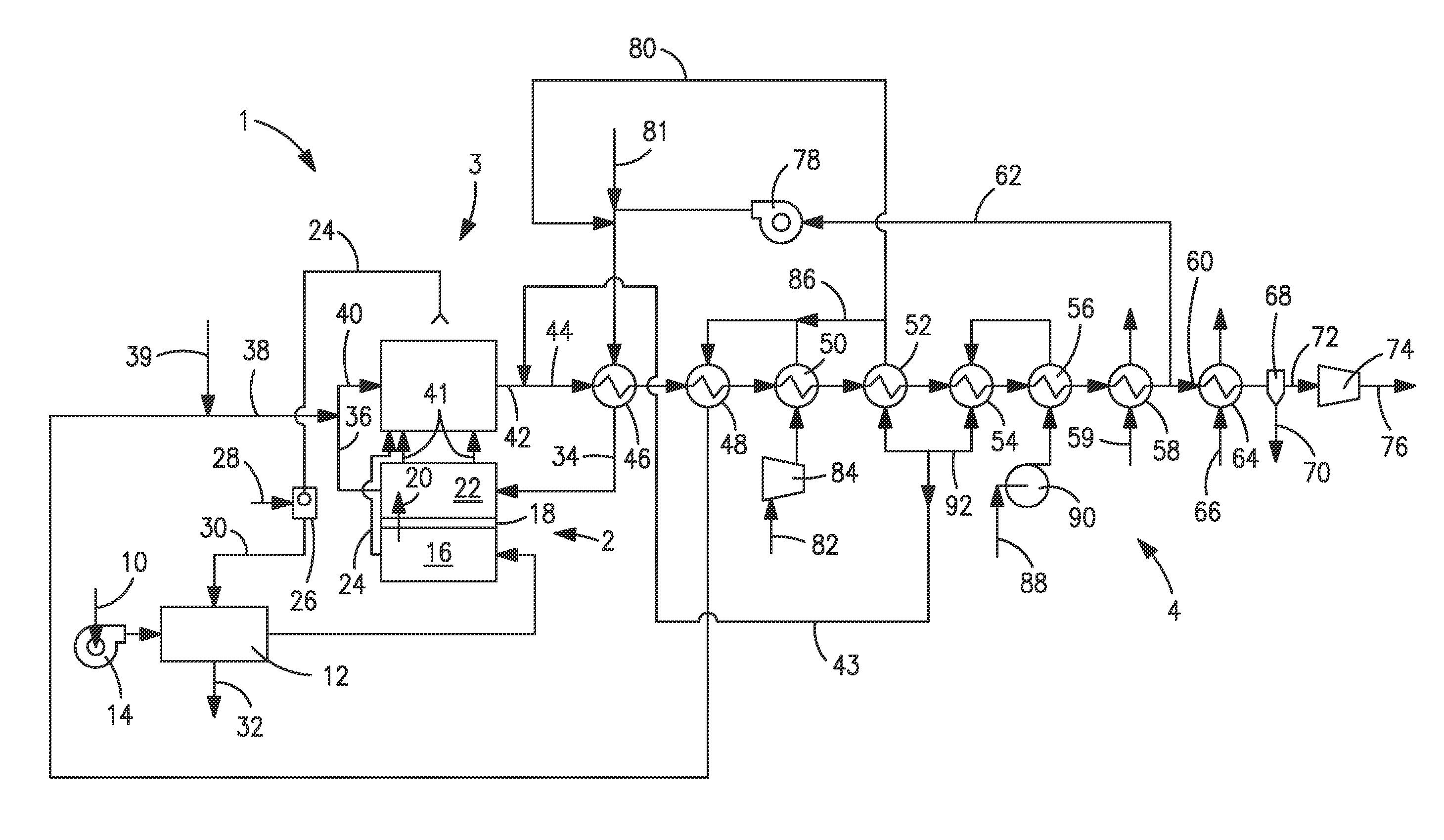

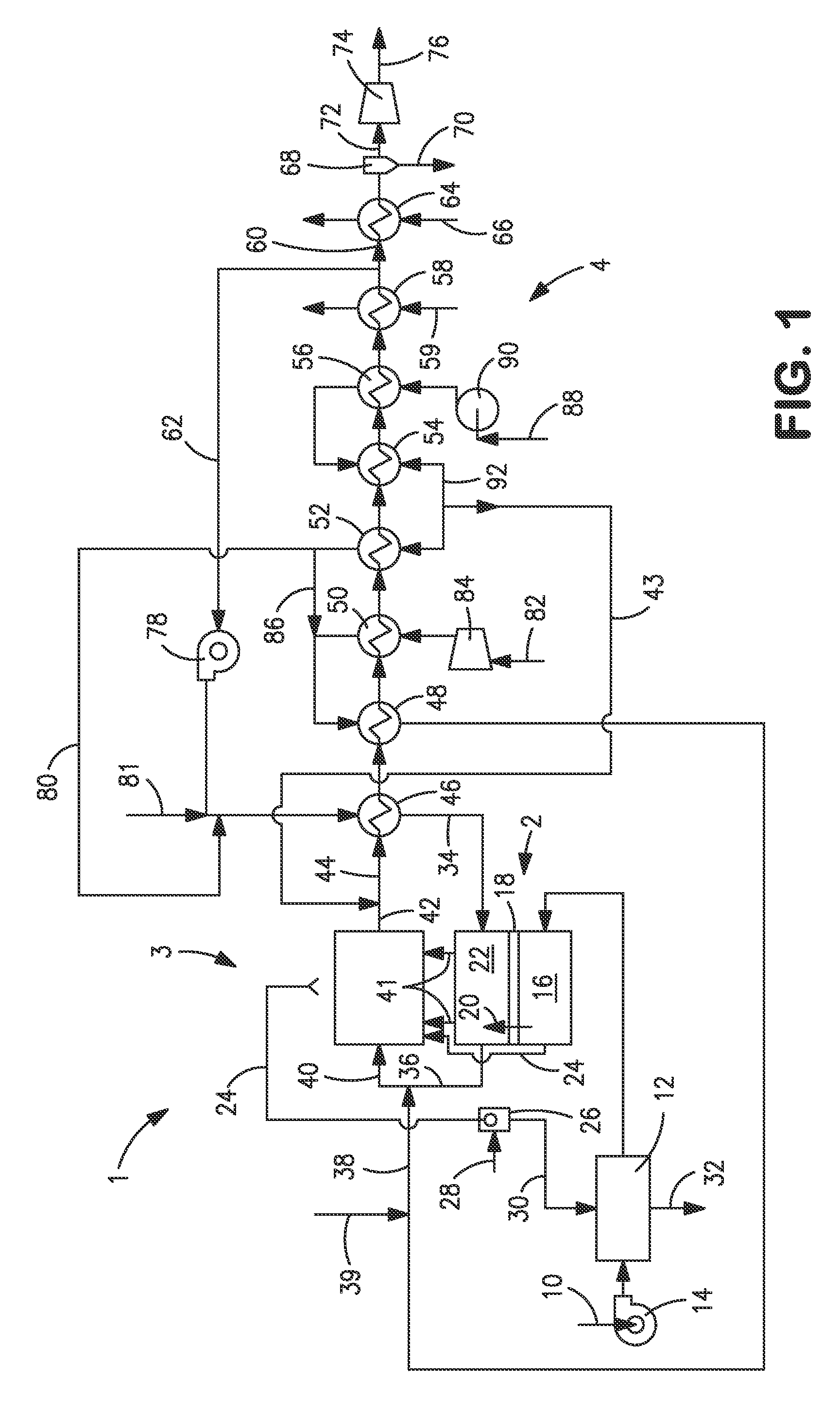

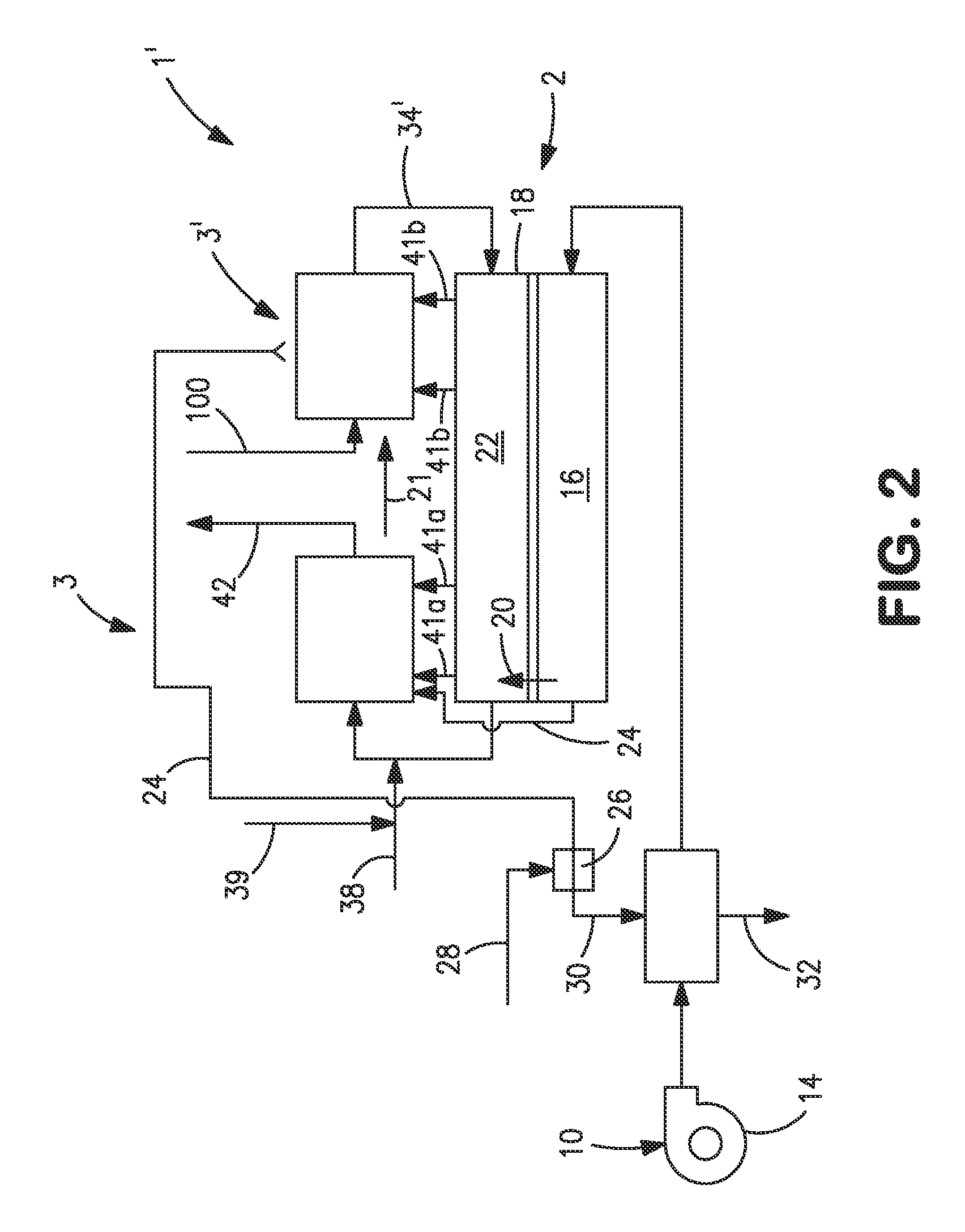

Multi-faceted gasifier and related methods

InactiveUS6960234B2Increased hydrogen productionImprove overall plant economicsLiquid degasificationCoke ovensActivated carbonInjection port

A gasifier is disclosed combining a fixed bed gasification section where coarse fuel is gasified and an entrained flow gasification section where fine fuel is gasified. The fixed bed section includes upper and lower sections. Coarse fuel is devolatilized in the upper fixed bed section and subjected to elevated temperatures sufficient to crack and destroy tars and oils in the effluent gases. The entrained flow gasification section is disposed in a lower plenum adjacent the lower fixed bed section. A plurality of injection ports are configured to introduce oxygen, steam, or air into different sections of the gasifier to control temperature and operating conditions. Activated carbon may be formed in the upper fixed bed section and in the entrained flow section. The activated carbon may be used as a sorbent to remove pollutants from the effluent gases. The gasifier may be used with various coarse and fine fuel feedstocks.

Owner:EMERY ENERGY

Oxygen transport membrane system and method for transferring heat to catalytic/process reactors

A method and apparatus for producing heat used in a synthesis gas production process is provided. The disclosed method and apparatus include a plurality of tubular oxygen transport membrane elements adapted to separate oxygen from an oxygen containing stream contacting the retentate side of the membrane elements. The permeated oxygen is combusted with a hydrogen containing synthesis gas stream contacting the permeate side of the tubular oxygen transport membrane elements thereby generating a reaction product stream and radiant heat. The present method and apparatus also includes at least one catalytic reactor containing a catalyst to promote the steam reforming reaction wherein the catalytic reactor is surrounded by the plurality of tubular oxygen transport membrane elements. The view factor between the catalytic reactor and the plurality of tubular oxygen transport membrane elements radiating heat to the catalytic reactor is greater than or equal to 0.5.

Owner:PRAXAIR TECH INC

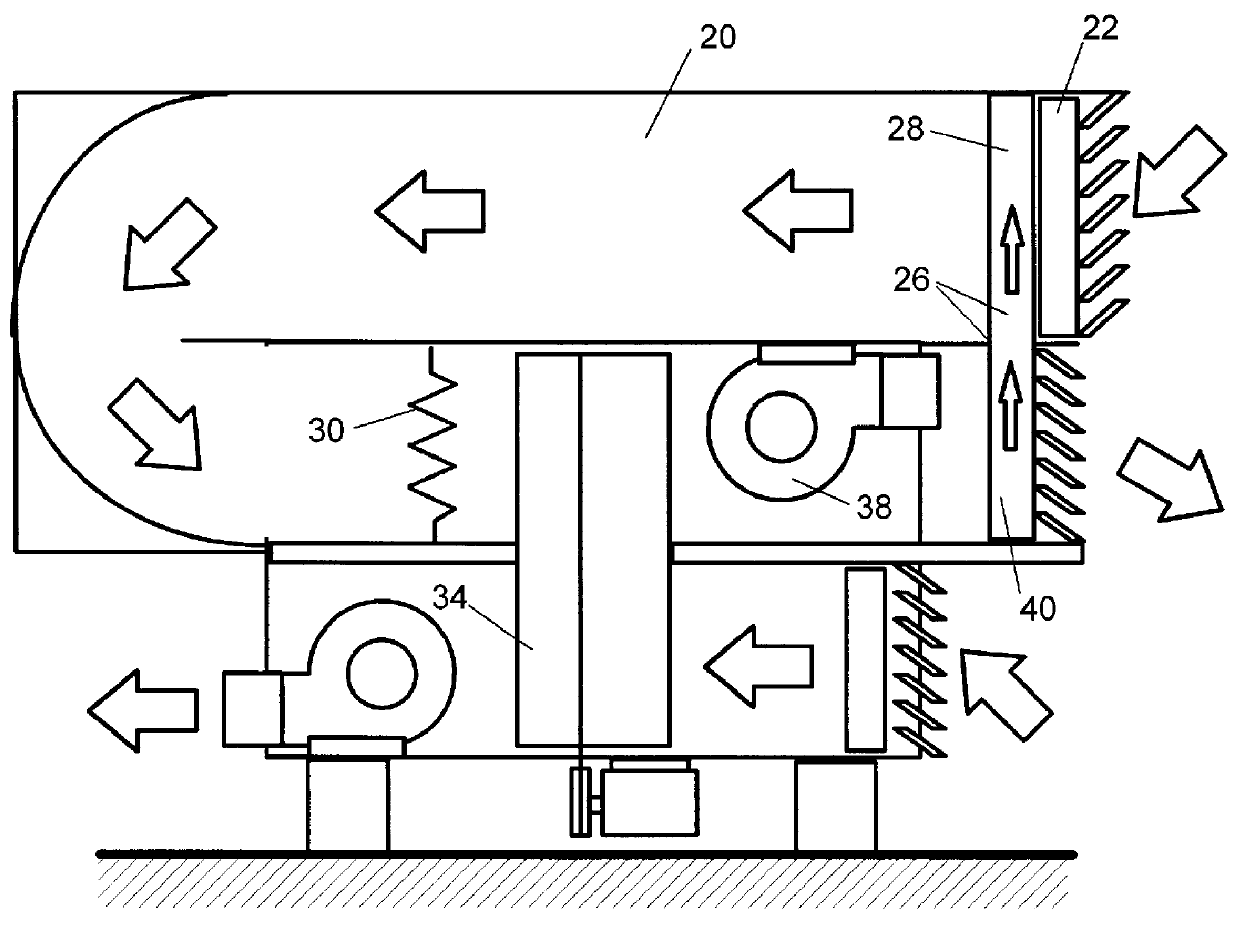

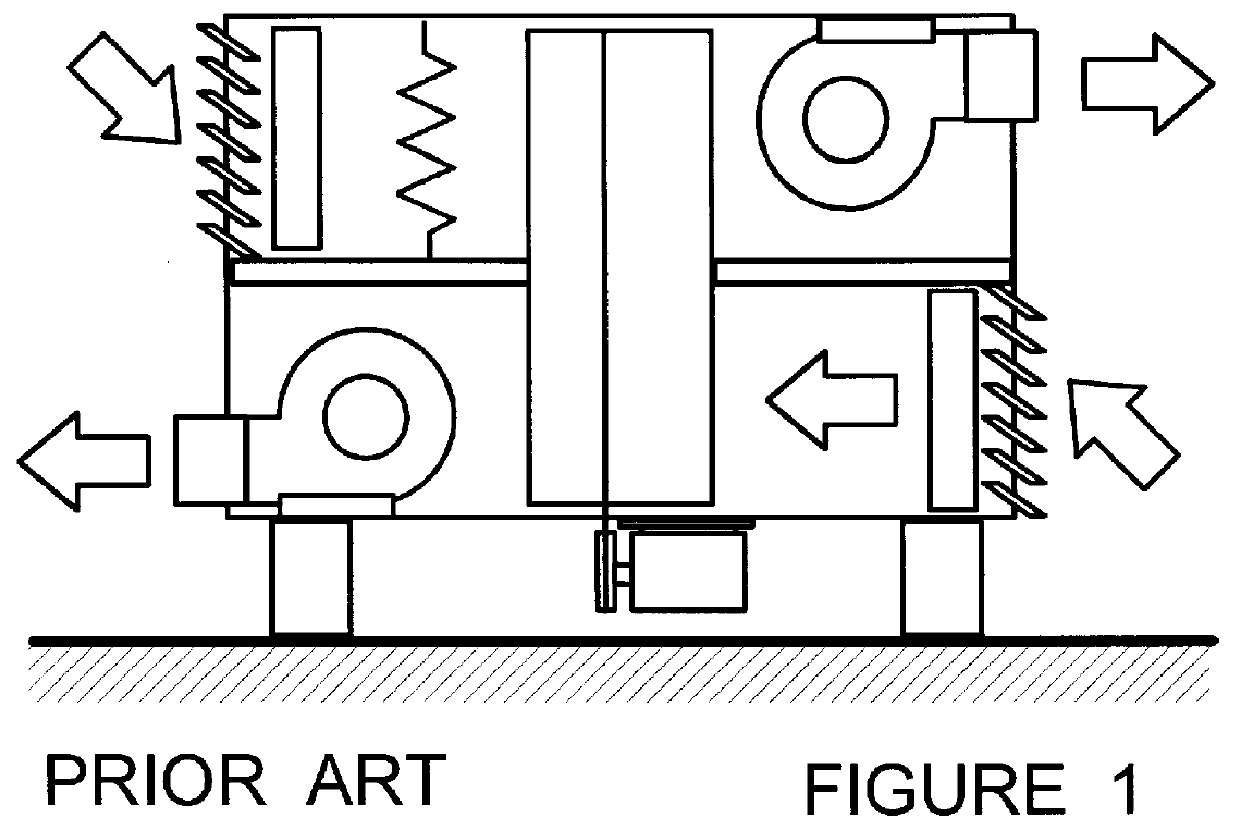

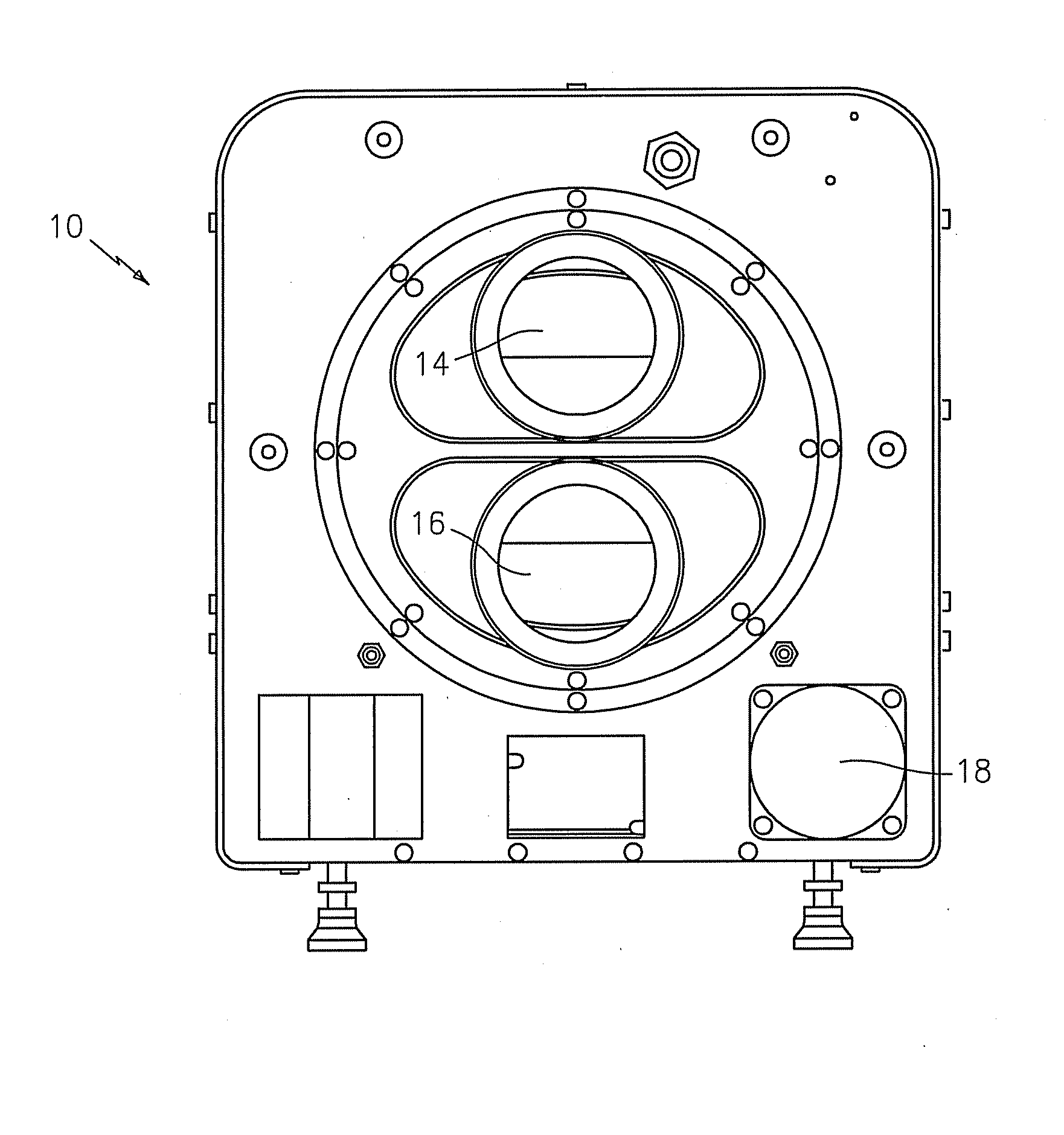

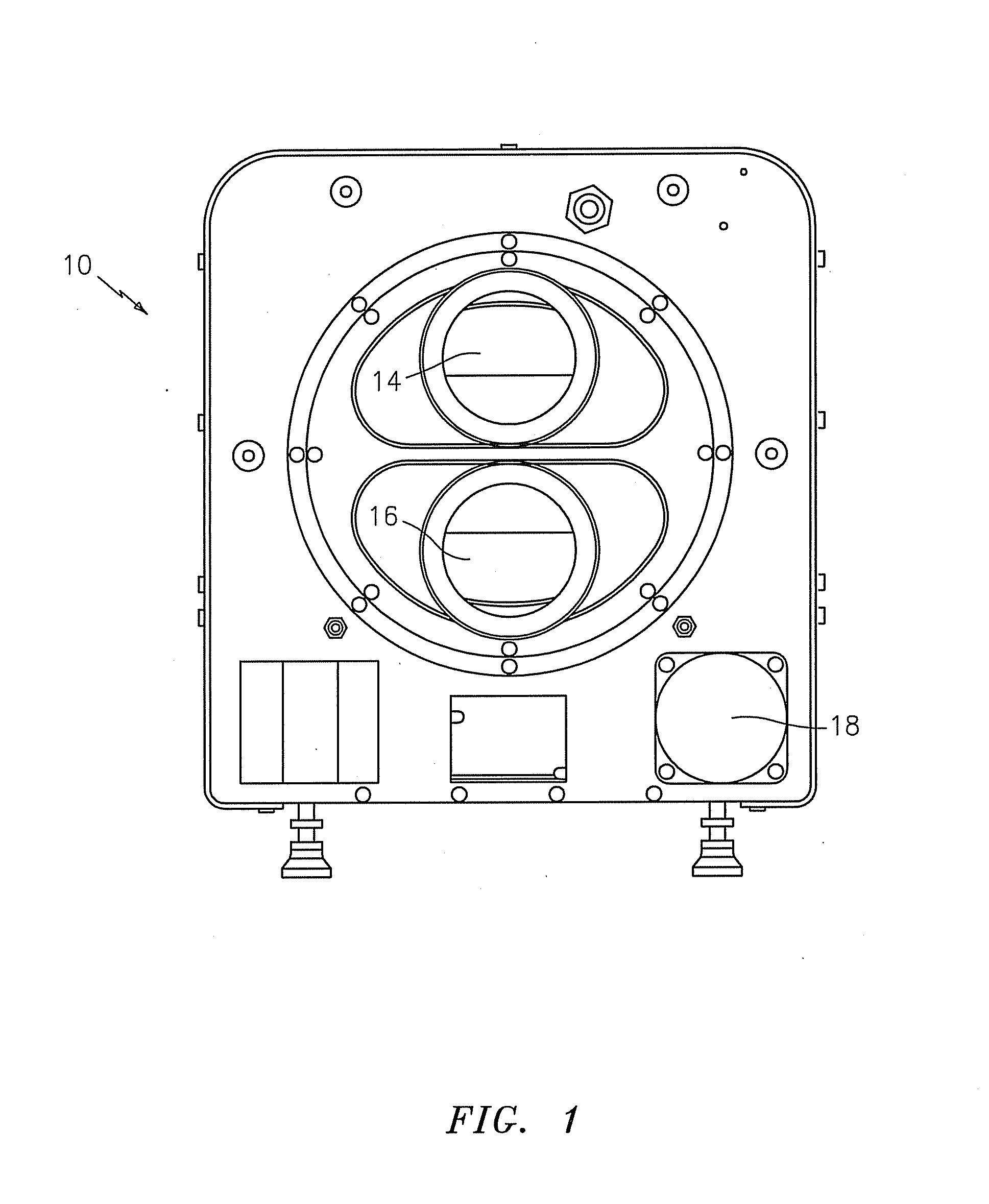

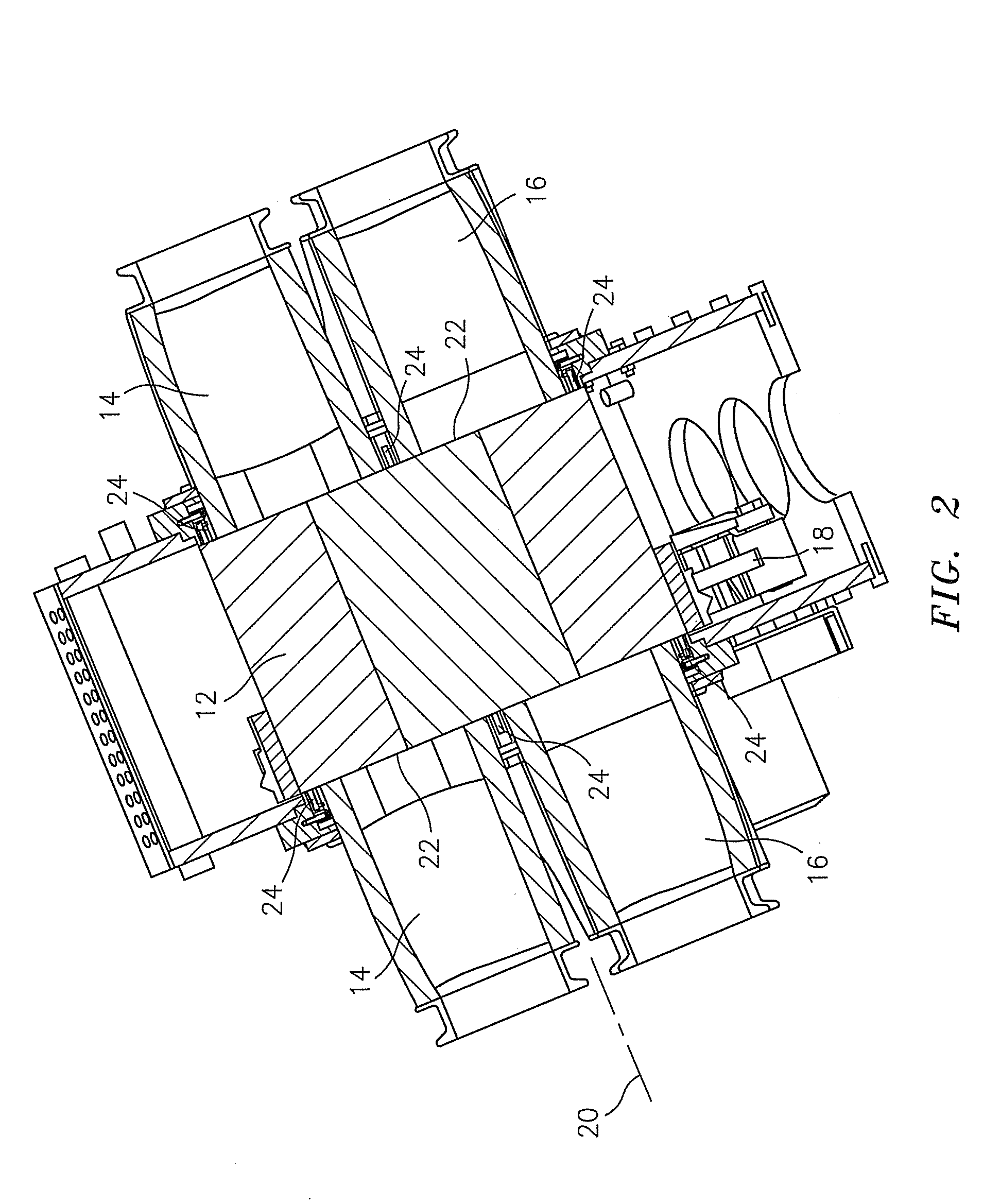

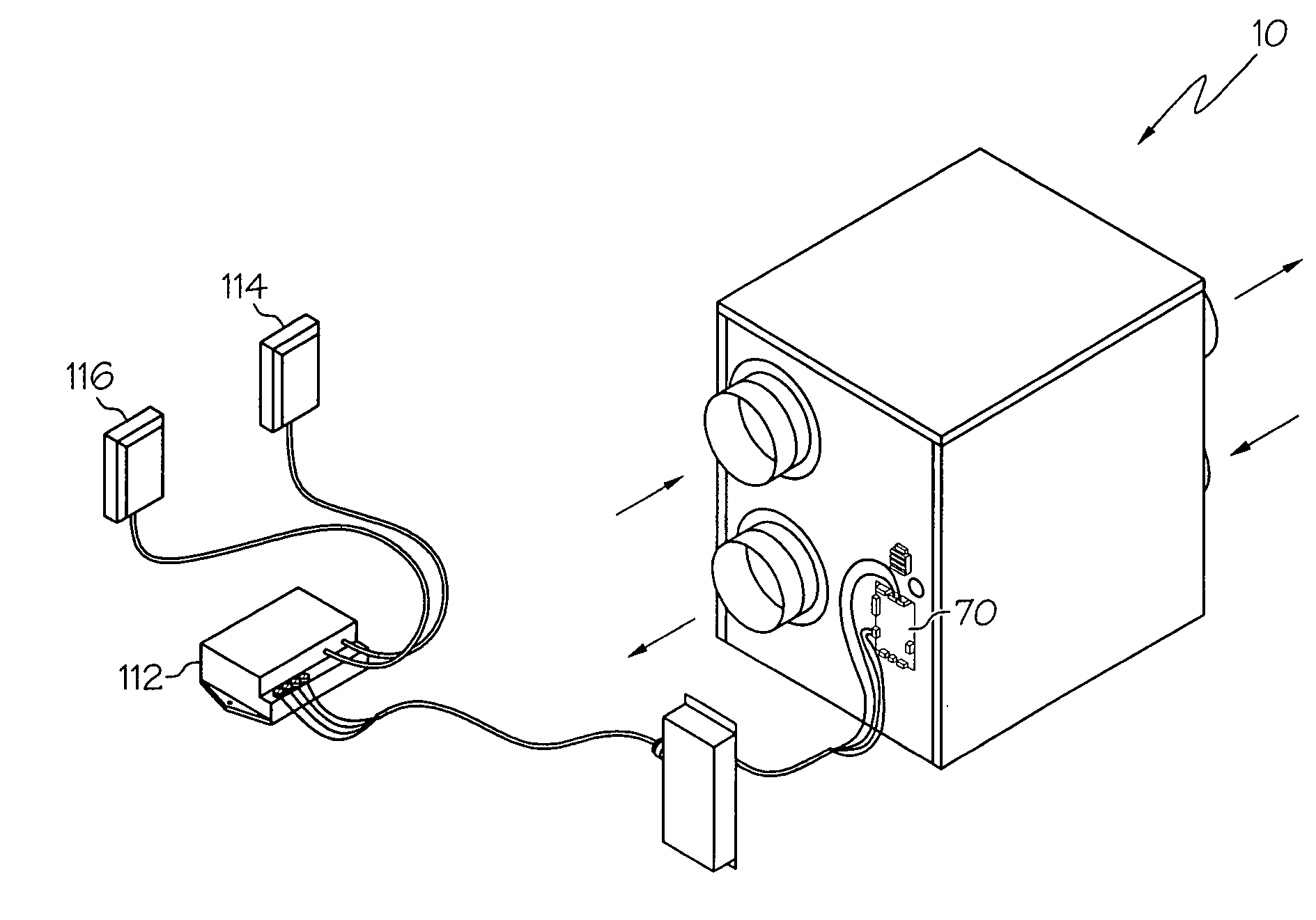

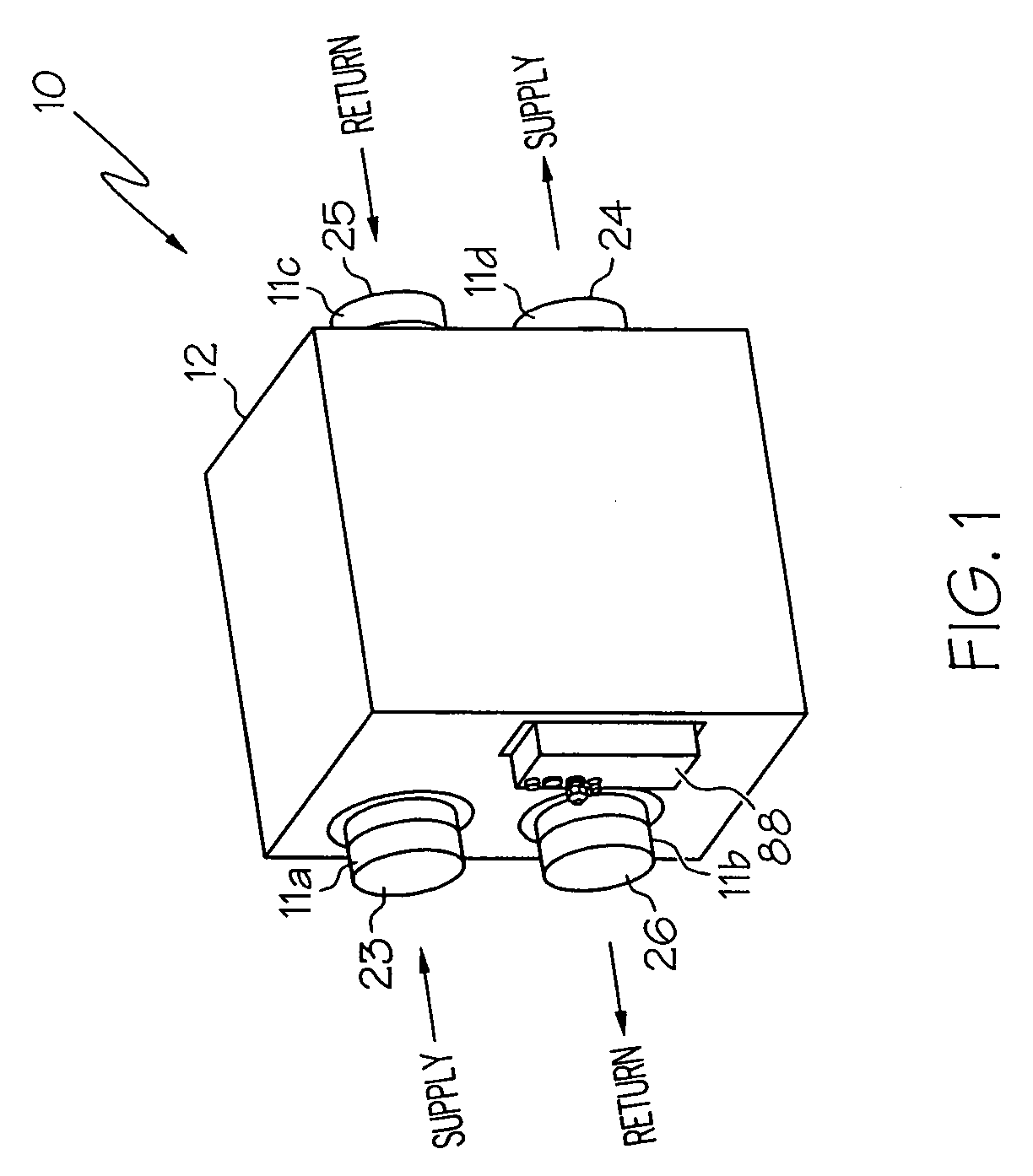

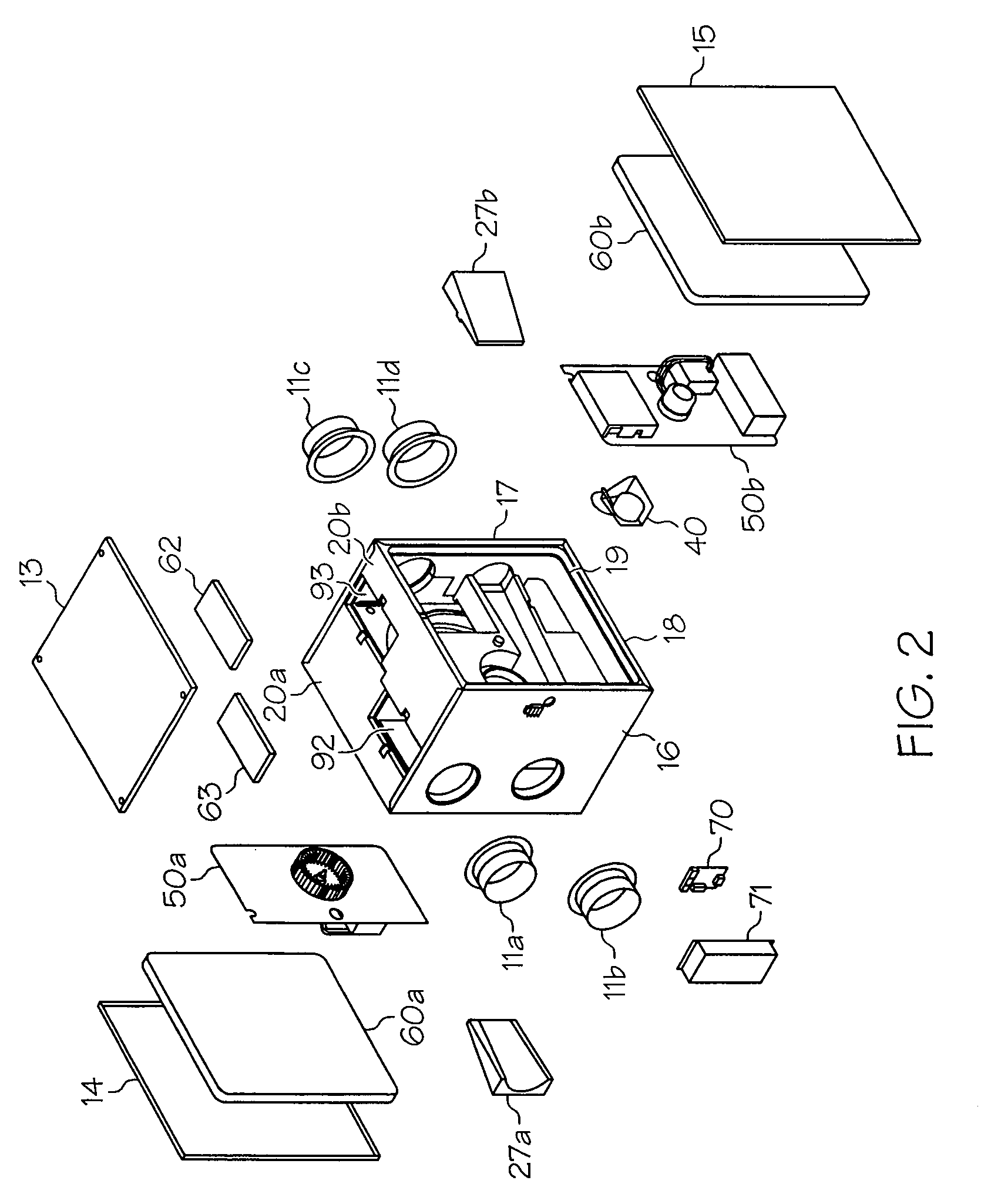

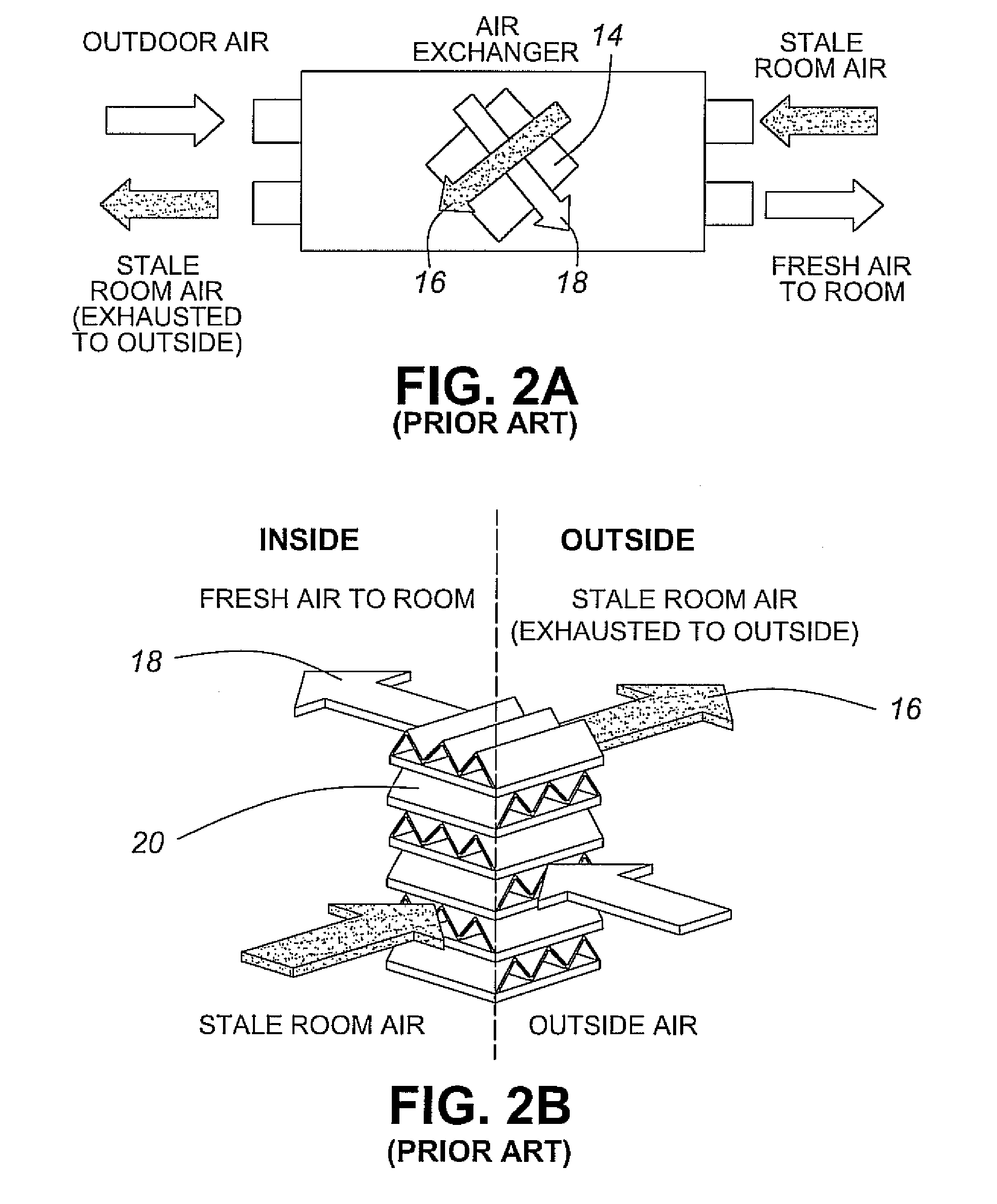

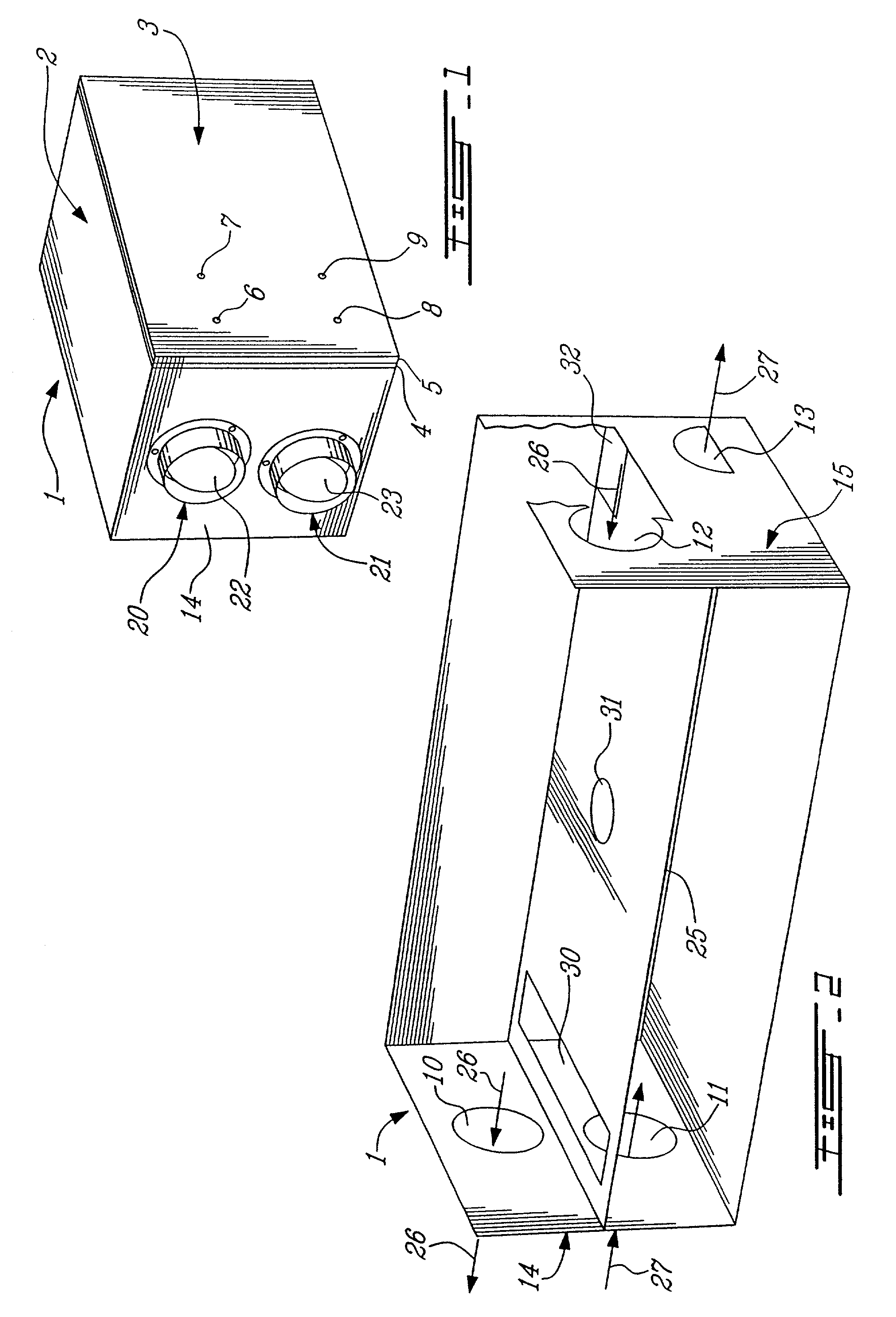

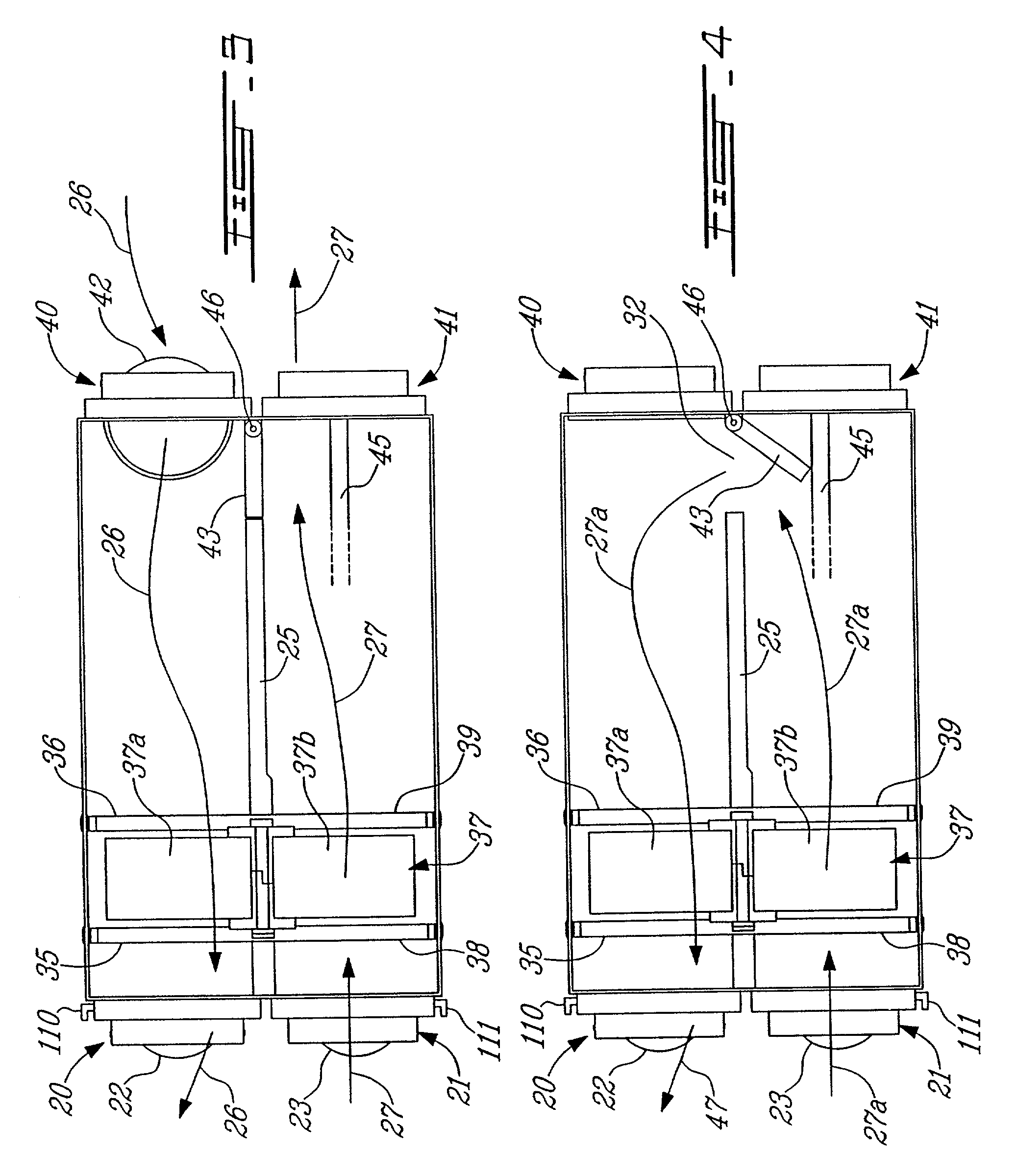

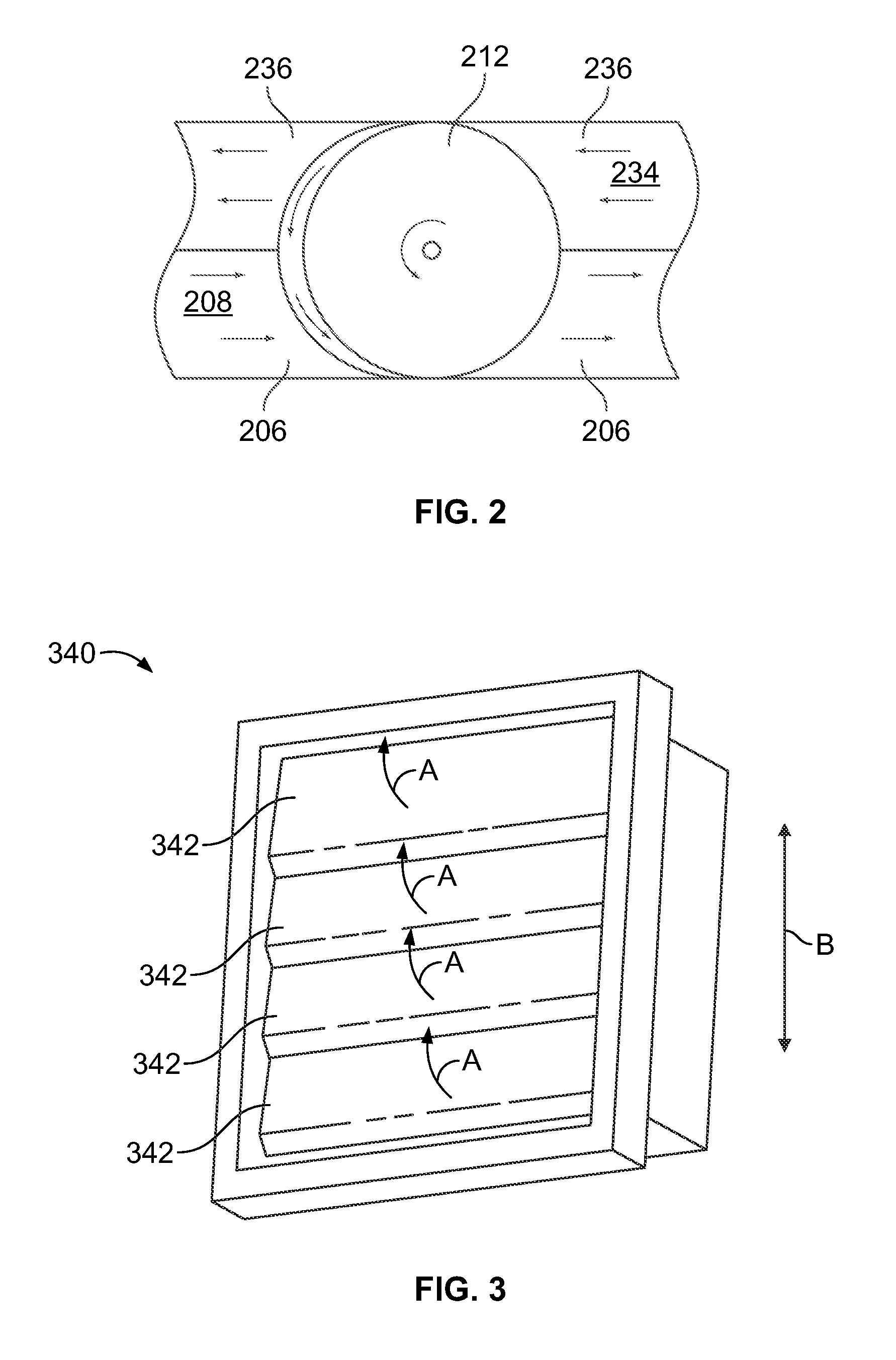

Heat and energy recovery ventilators and methods of use

InactiveUS20050236150A1Increase heightDomestic cooling apparatusHeating and ventilation casings/coversThermal energyMotor drive

An energy recovery ventilator and method for monitoring and maintaining an environmental condition inside a structure such as a house, building, or dwelling is provided. The ventilator may include a housing having mating halves of a molded polymeric material, first and second chambers disposed within the housing to convey separate first and second streams of air, a heat exchanger configured to intersect the first and second chambers, a first fan to circulate the first air stream through the first chamber, a second fan to circulate the second air stream through the second chamber, and a fan motor driving the first and second fans. The ventilator may also be configured to prevent frost build-up in or on the energy ventilator, to provide efficient cooling, and maintain one or more desired environmental conditions.

Owner:STIRLING TECH INC +1

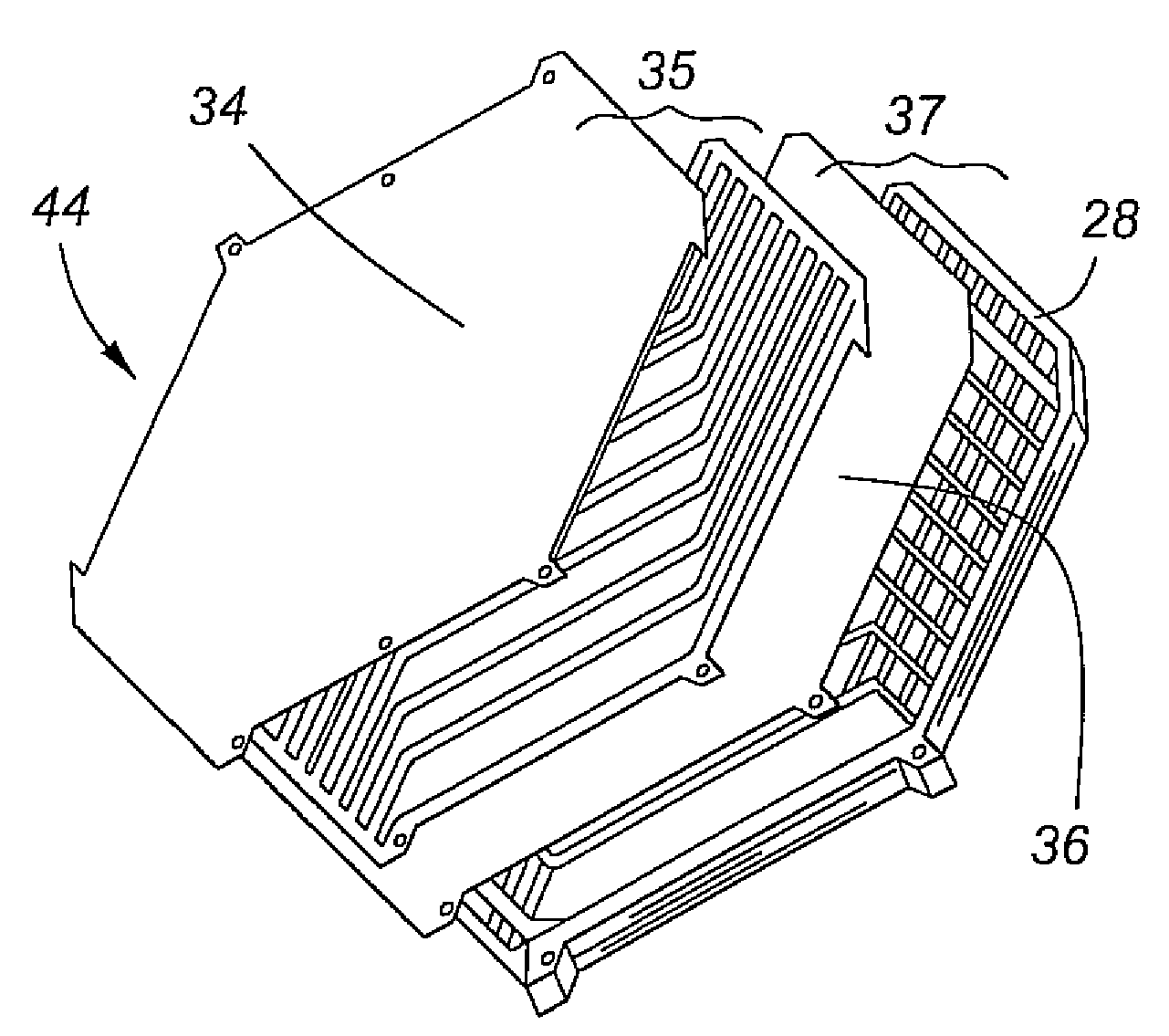

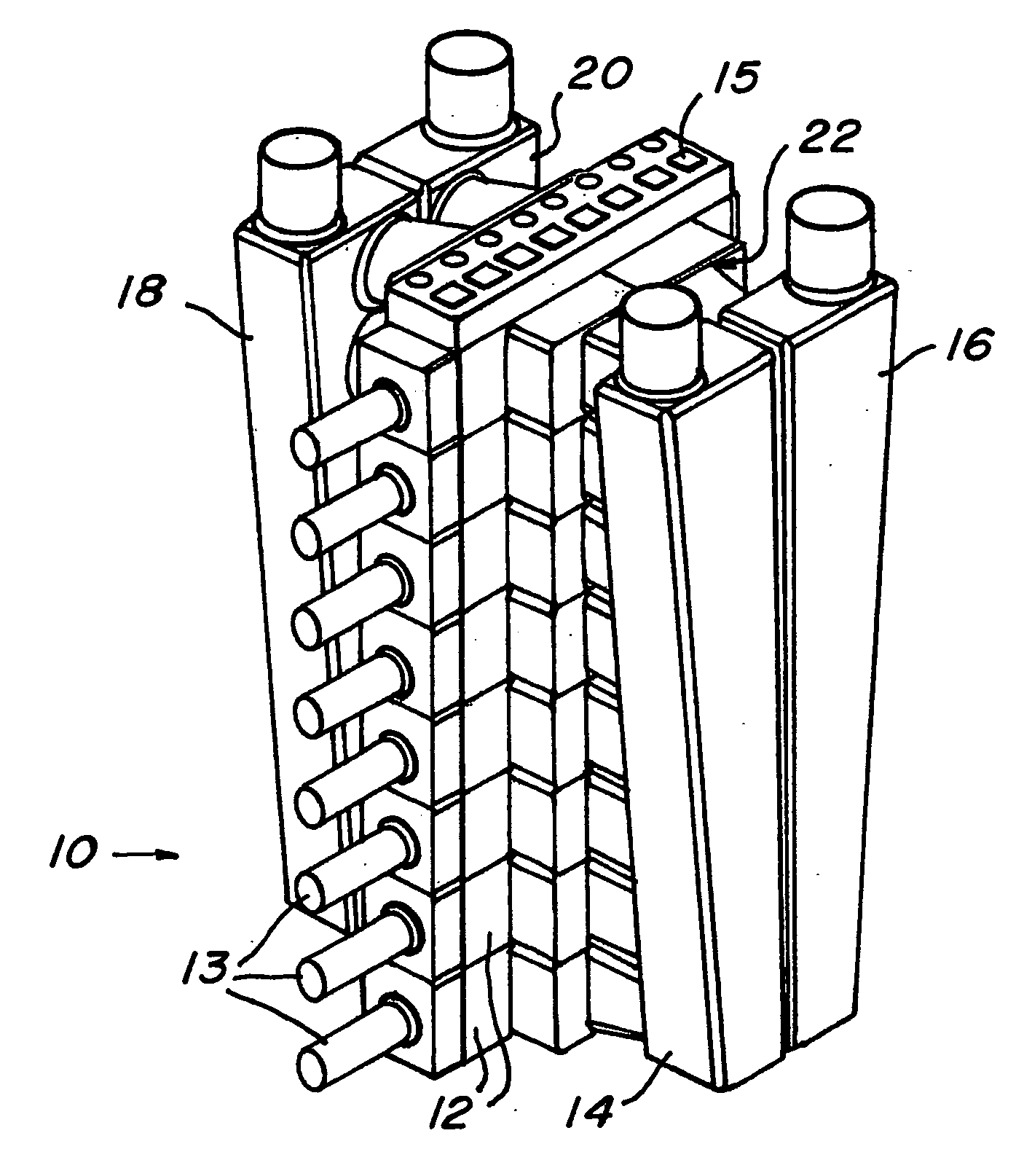

Flat plate heat and moisture exchanger

ActiveUS20090314480A1Easy to manufactureOperationally efficientFuel cell heat exchangeHeat exchanger casingsHeat and moisture exchangerEnergy recovery

This invention relates in general to air exchange systems and, in particular, to an improved energy recovery ventilator, a cross flow plate core associated therewith and a method of conditioning air for a building. In one aspect, the invention provides a cross flow plate core comprising: a left hand wafer comprising a left hand spacer with a first of a plurality of membranes bonded thereto, the left hand spacer comprising a plurality of parallel curvilinear rails which form channels for receiving a first stream of air; and a right hand wafer comprising a right hand spacer with a second of the plurality of membranes bonded thereto, the right hand spacer comprising a plurality of parallel curvilinear rails which form channels for receiving a second stream of air, wherein the left hand spacer of the left hand wafer is bonded to the top of the membrane of the right hand wafer.

Owner:ZEHNDER VERKAUFS UND VERW

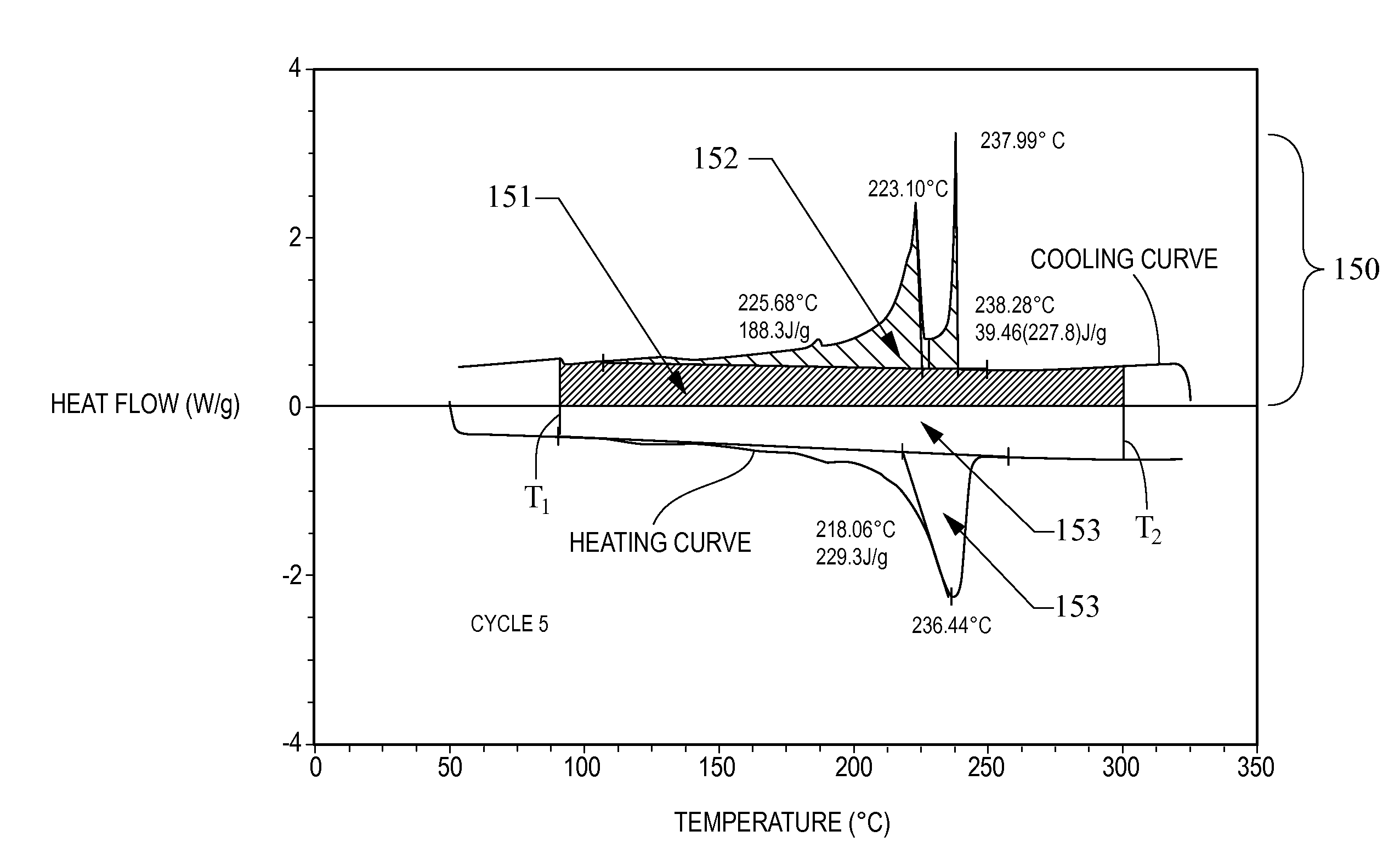

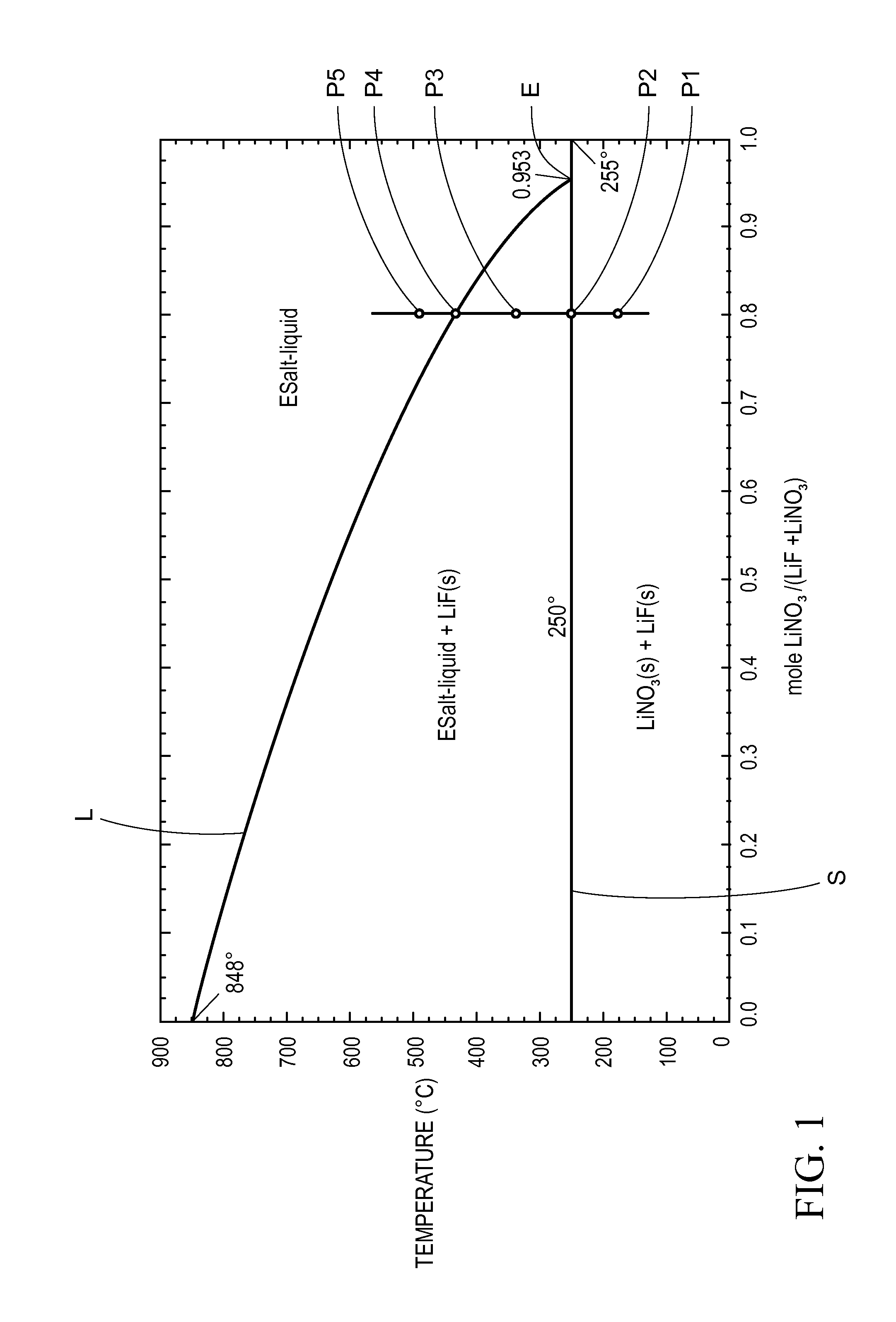

Thermal energy storage materials

A thermal energy storage material (TESM) system (and associated methods) that reproducibly stores and recovers latent heat comprising i) at least one first metal containing material including at least one first metal compound that includes a nitrate ion, a nitrite ion, or both; ii) at least one second metal containing material including at least one second metal compound; and iii) optionally including water, wherein the water concentration if any is present is less than about 10 wt. %; wherein the TESM has a liquidus temperature, TL, from about 100° C. to about 250° C.; and wherein the TESM exhibits a heat storage density from 300° C. to 80° C. of at least about 1 MJ / l; so that upon being used in a system that generates heat, at least a portion of the heat is captured and stored by the TESM and subsequently released for use, and the system is generally resistant to corrosion at temperatures of about 300° C.

Owner:DOW GLOBAL TECH LLC

Method and apparatus for cooling electronic components

InactiveUS20050247433A1Digital data processing detailsTemperatue controlEngineeringElectronic component

A modular fluid unit for cooling heat sources located on a rack, the modular fluid unit comprising: a heat exchanger in fluid communication a pump; and wherein the modular fluid unit is mountable within the rack and is configurable to be in fluid communication with a cold plate return manifold, a cold plate supply manifold, and an end-user fluid supply. A method for cooling electronic components in a rack, the method comprising: circulating a first liquid from a cold plate to one of a plurality of heat exchangers mounted within the rack; circulating a second liquid from a second liquid supply to the one of a plurality of heat exchangers; and transferring heat from the first liquid to the second liquid at the one of a plurality of heat exchangers.

Owner:IBM CORP

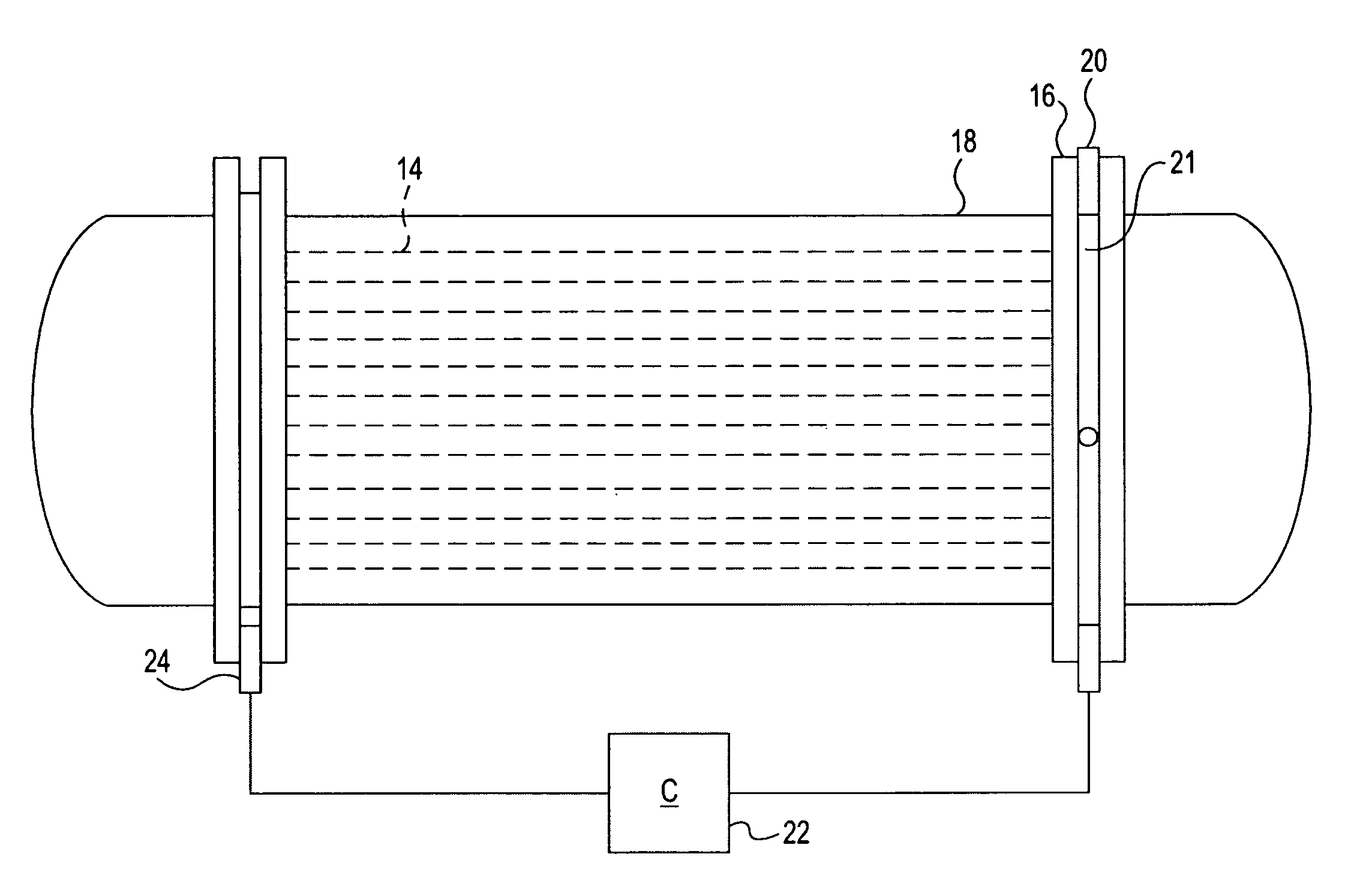

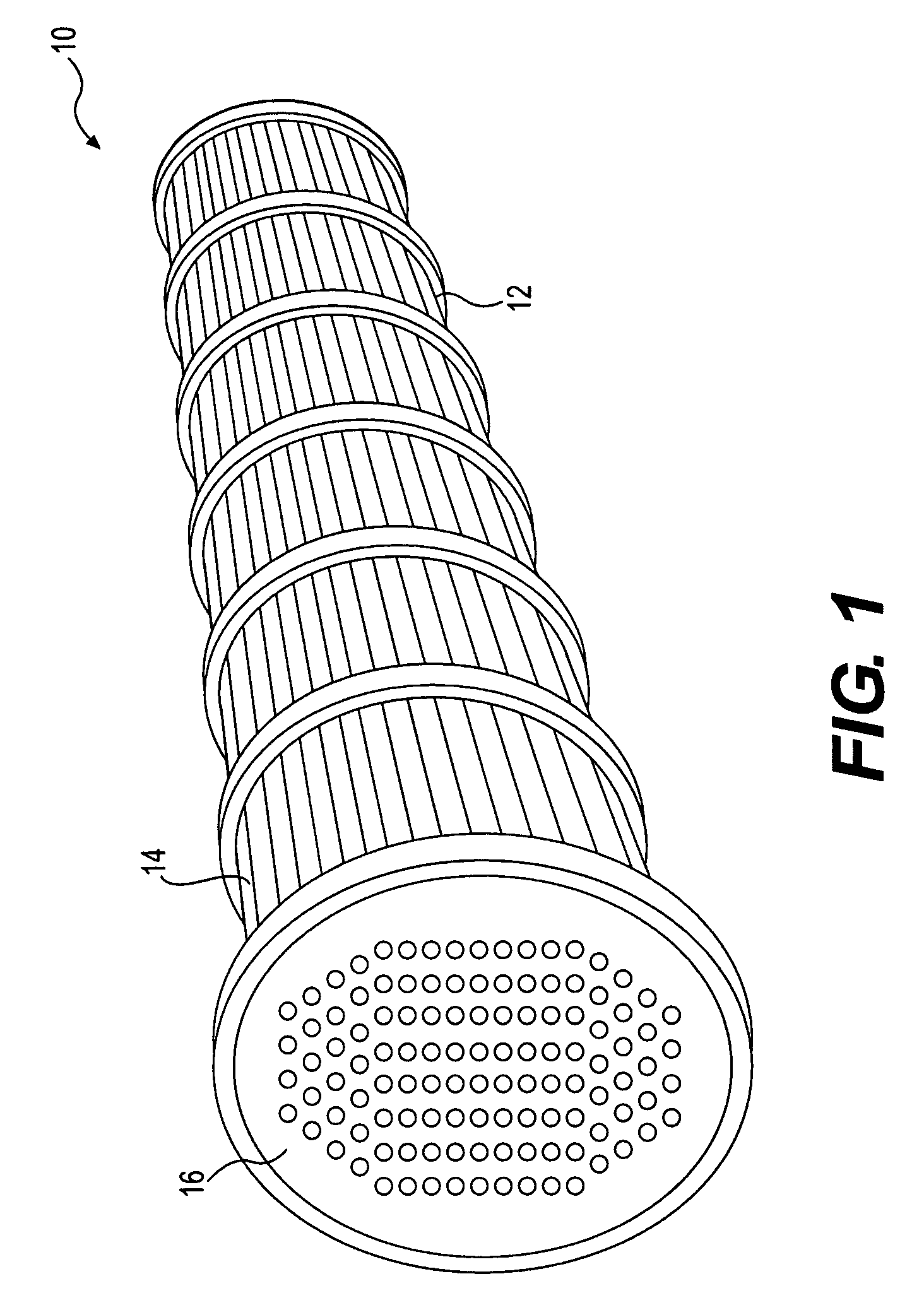

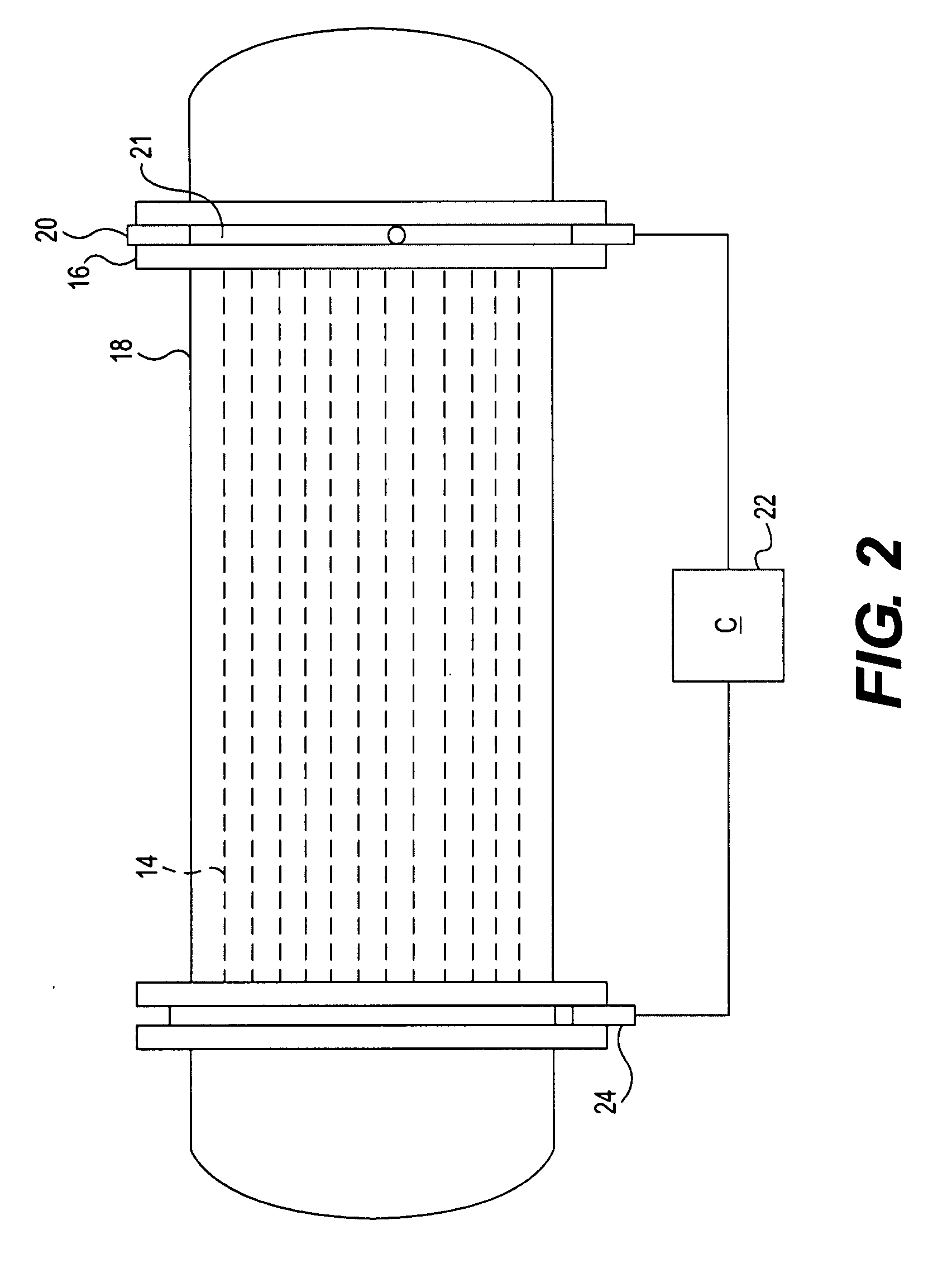

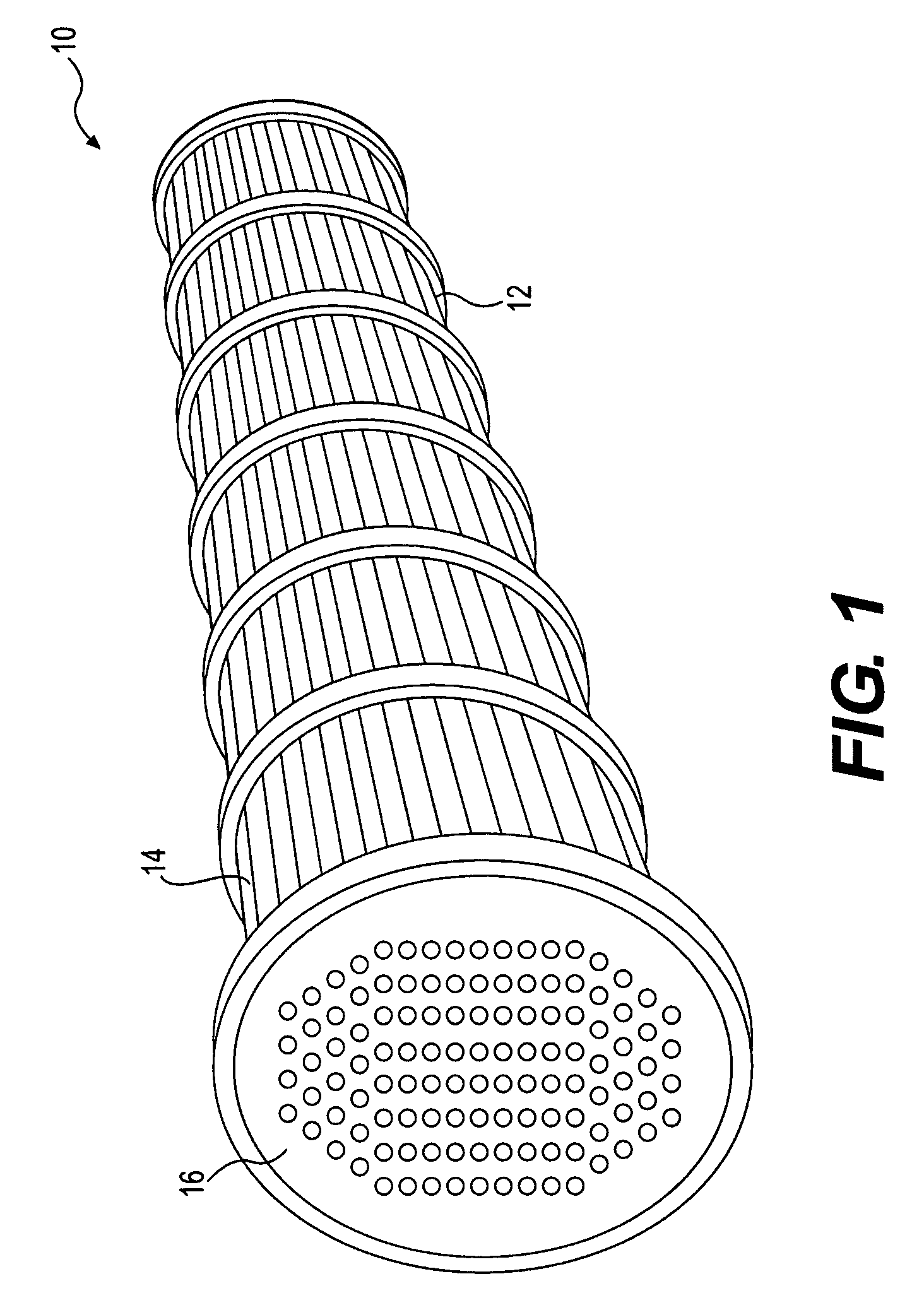

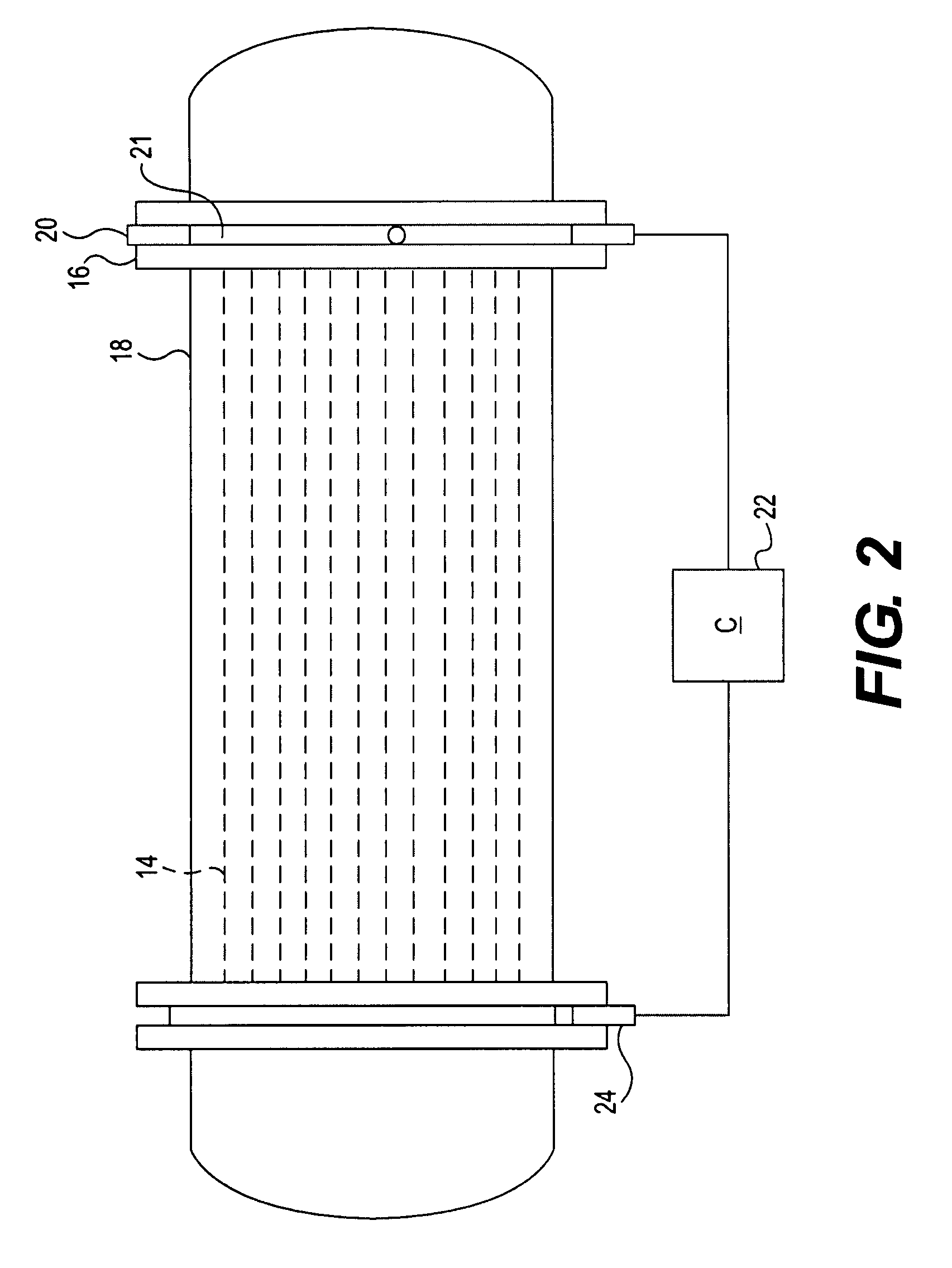

Mitigation of in-tube fouling in heat exchangers using controlled mechanical vibration

InactiveUS20070267176A1Reduce dirtCombustion processCorrosion preventionPlate heat exchangerEngineering

Fouling of heat exchange surfaces is mitigated by a process in which a mechanical force is applied to a fixed heat exchanger to excite a vibration in the heat exchange surface and produce shear waves in the fluid adjacent the heat exchange surface. The mechanical force is applied by a dynamic actuator coupled to a controller to produce vibration at a controlled frequency and amplitude output that minimizes adverse effects to the heat exchange structure. The dynamic actuator may be coupled to the heat exchanger in place and operated while the heat exchanger is on line.

Owner:EXXON RES & ENG CO

Heat exchanger containing a component capable of discontinuous movement

InactiveUSRE37134E1Reduced Seal LeakageReduce leak rateCombustion processRegenerative heat exchangersEngineeringMicro heat exchanger

Owner:MASSACHUSETTS INST OF TECH

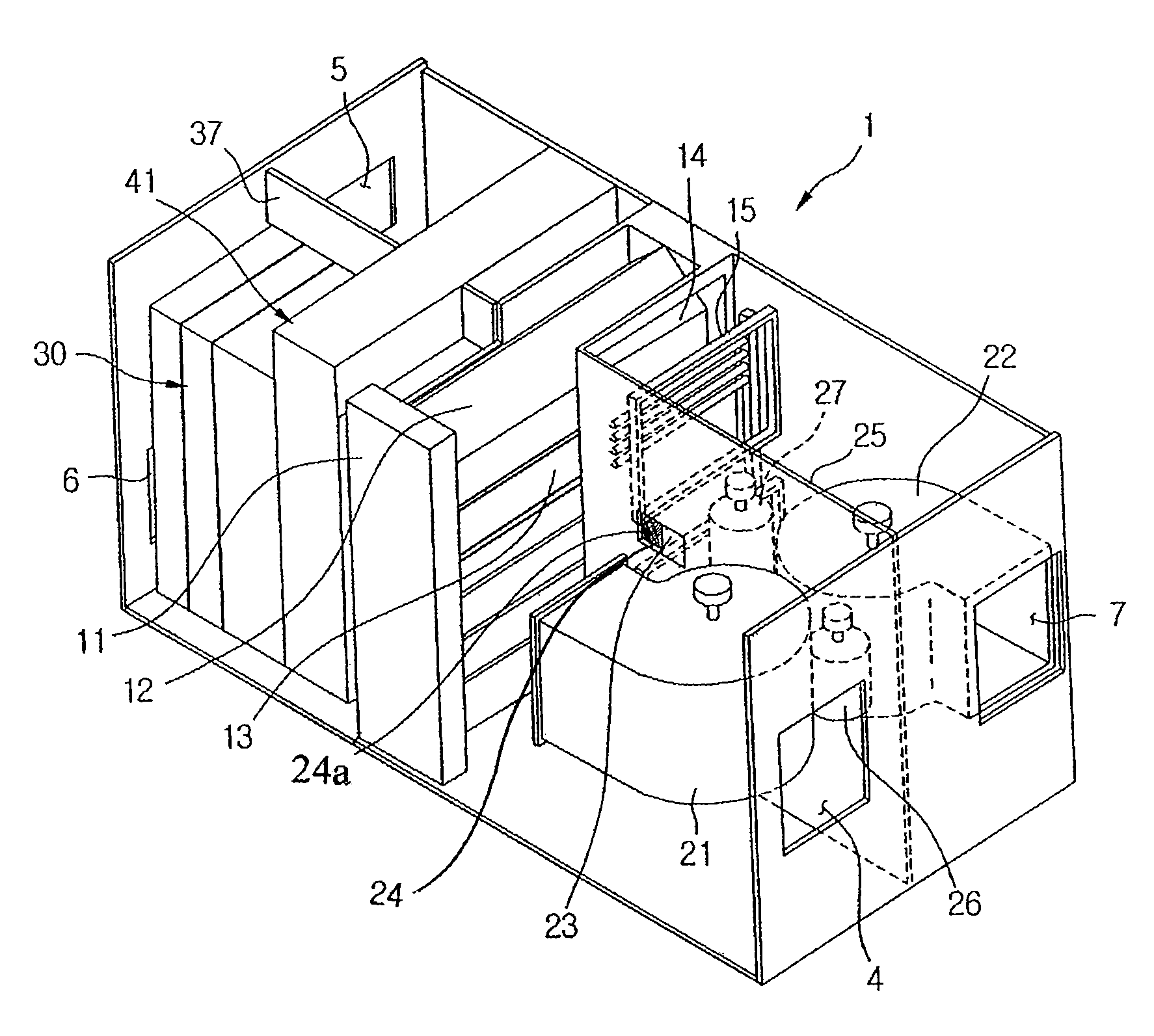

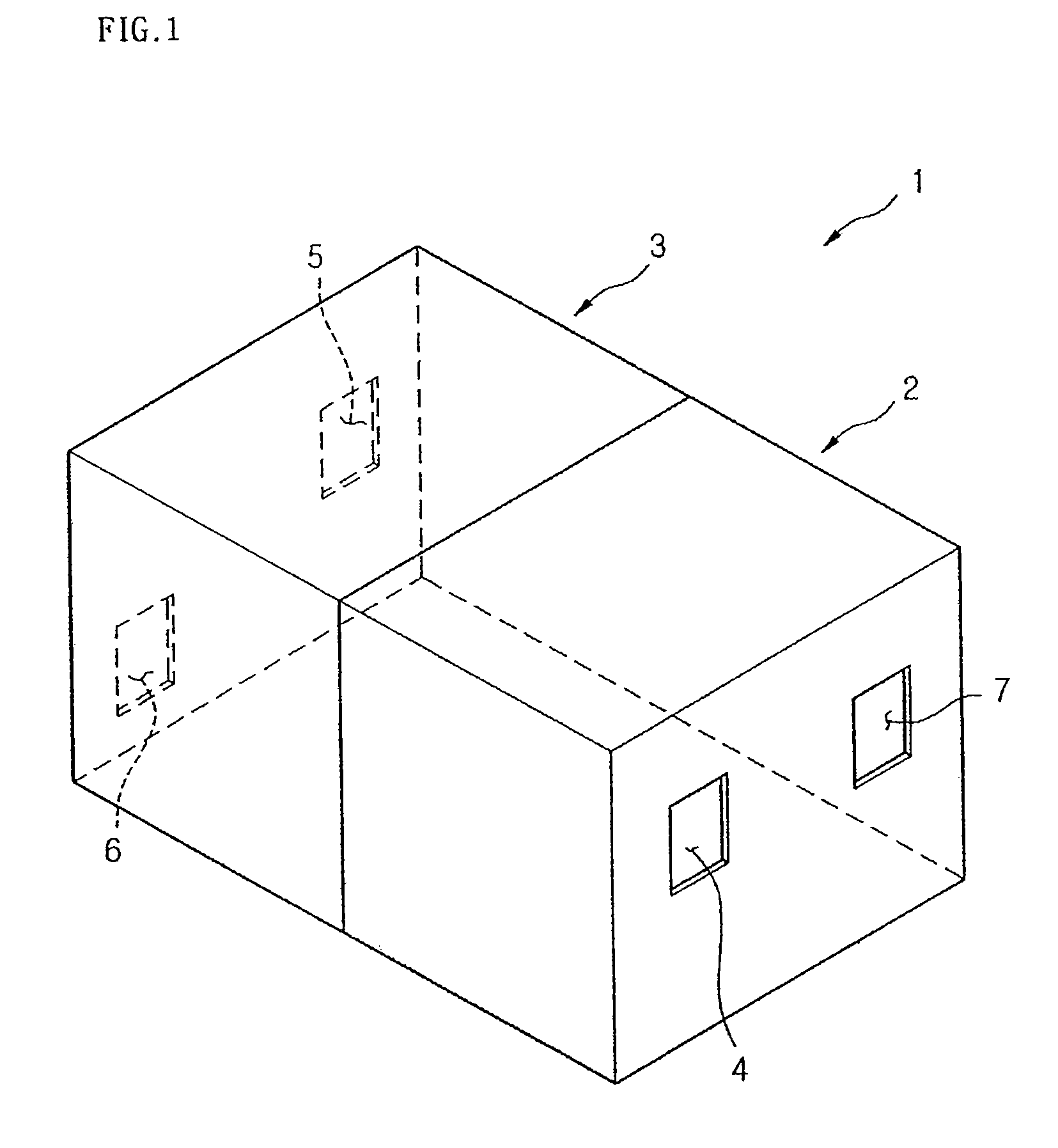

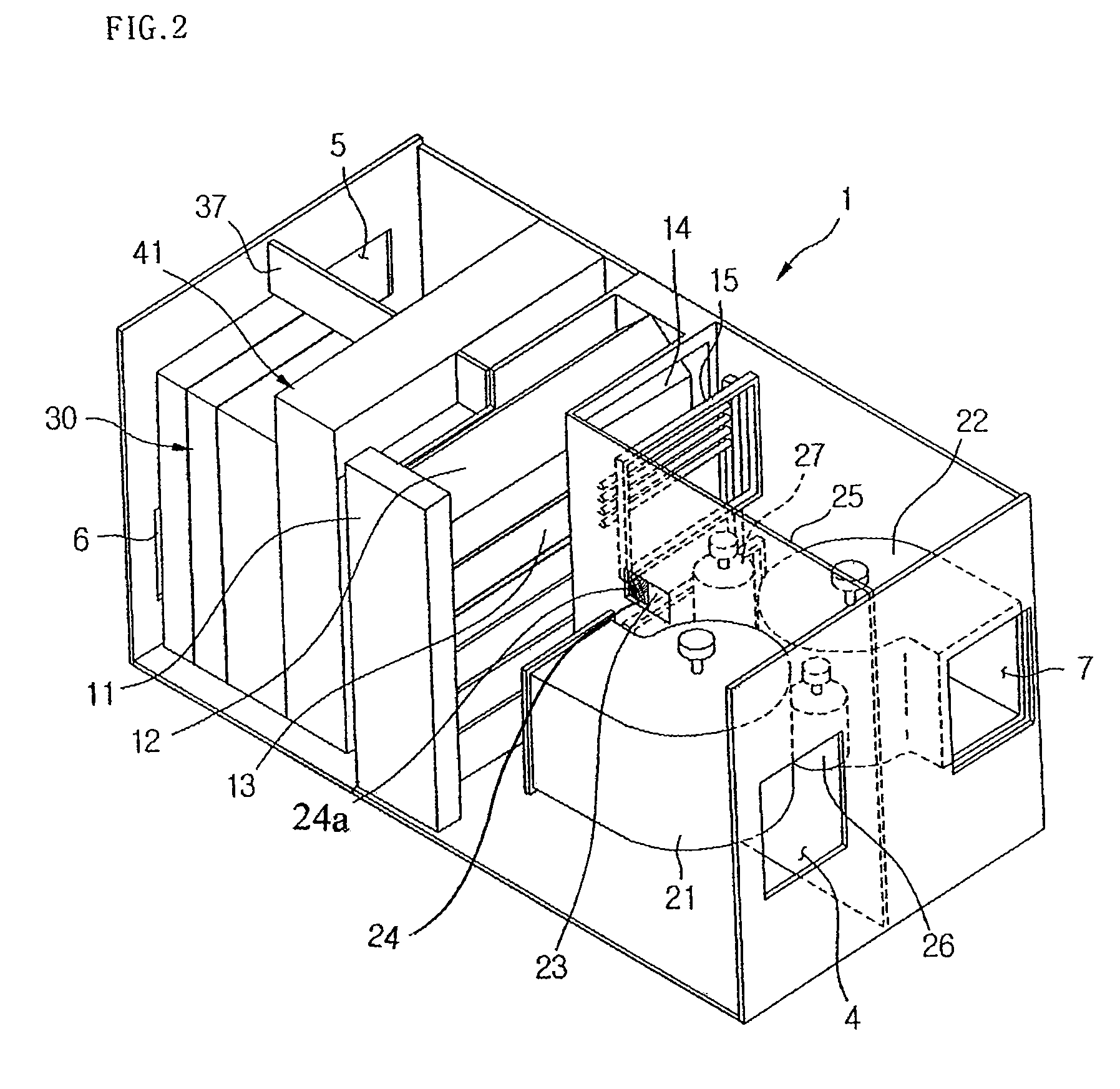

Ventilation system

InactiveUS7073566B2Low costSimple cuttingMechanical apparatusSpace heating and ventilation detailsFresh airEngineering

An apparatus for ventilation systems includes an element for the transfer of heat from warm exhaust air (taken from inside a building) to cooler exterior fresh air which is drawn into the building. The present invention in particular provides an apparatus whereby, during a defrost cycle, interior air may circulate through both of the fresh air and exhaust air paths for delivery back into the building, i.e. the warm interior air, used as defrost air, may be able to circulate from the interior of the building into the ventilation apparatus and back to the interior of the building. The apparatus can thus use interior air as defrost air while diminishing or avoiding the creation of a negative air pressure in the building.

Owner:VENMAR VENTILATION

Mitigation of in-tube fouling in heat exchangers using controlled mechanical vibration

Fouling of heat exchange surfaces is mitigated by a process in which a mechanical force is applied to a fixed heat exchanger to excite a vibration in the heat exchange surface and produce shear waves in the fluid adjacent the heat exchange surface. The mechanical force is applied by a dynamic actuator coupled to a controller to produce vibration at a controlled frequency and amplitude output that minimizes adverse effects to the heat exchange structure. The dynamic actuator may be coupled to the heat exchanger in place and operated while the heat exchanger is on line.

Owner:EXXON RES & ENG CO

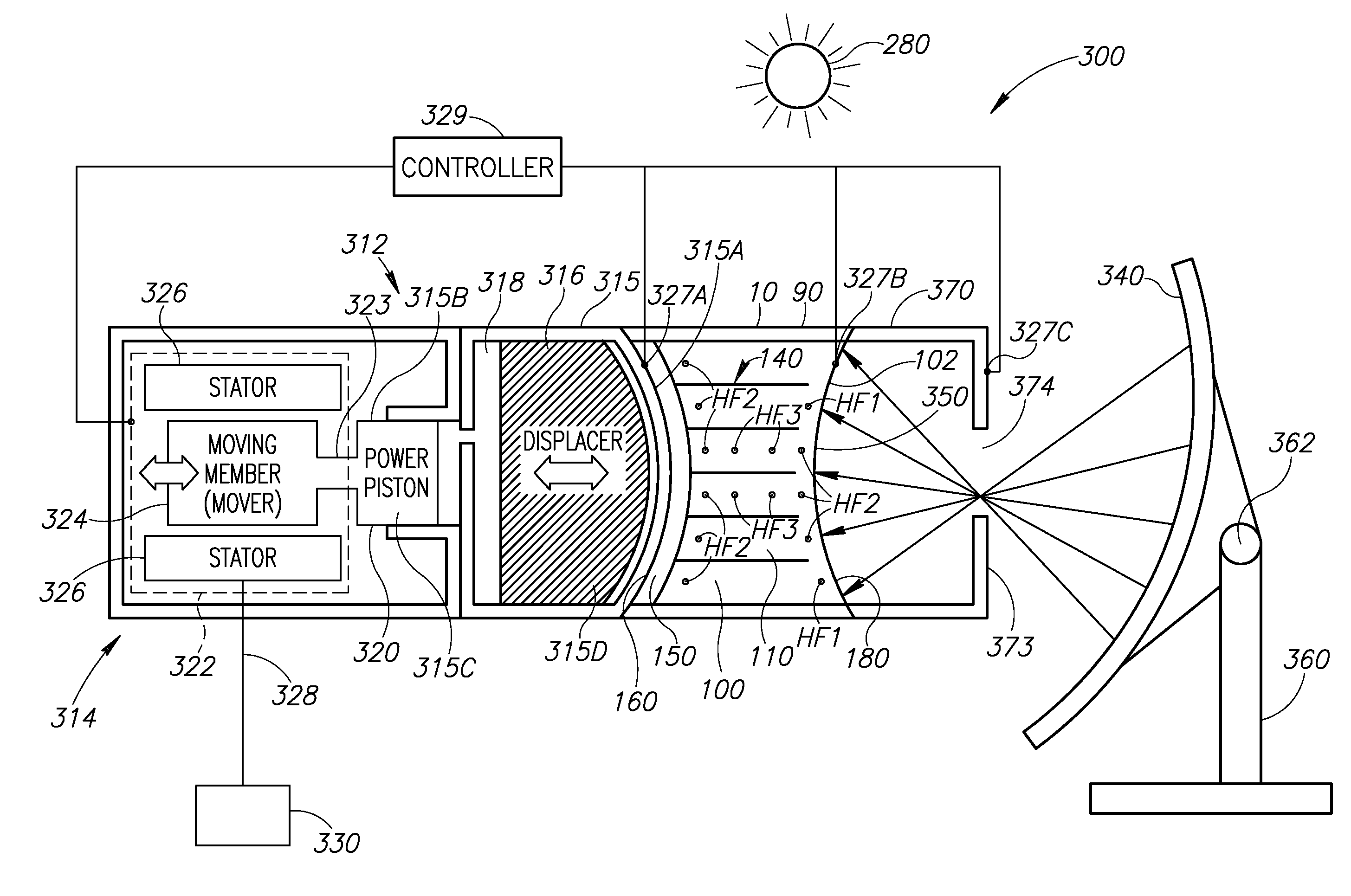

Thermal energy storage device

A thermal energy storage (“TES”) device including a vessel housing a continuous volume of a TES media, an input portion, an output portion, and a plurality of thermal energy transport members connected to the input portion and / or the output portion. The input portion receives thermal energy from a thermal energy source. The received thermal energy is transported by one or more of the thermal energy transport members to the output portion and / or the TES media for storage. One or more of the thermal energy transport members connected to the output portion transport stored thermal energy from the TES media to the output portion. The output portion is coupled to an external device, such as a Stirling engine, and configured to transfer thermal energy the external device. Optionally, selected ones of the thermal energy transport members connected to both the input and output portions may be insulated from the TES media.

Owner:RICOR GENERATION

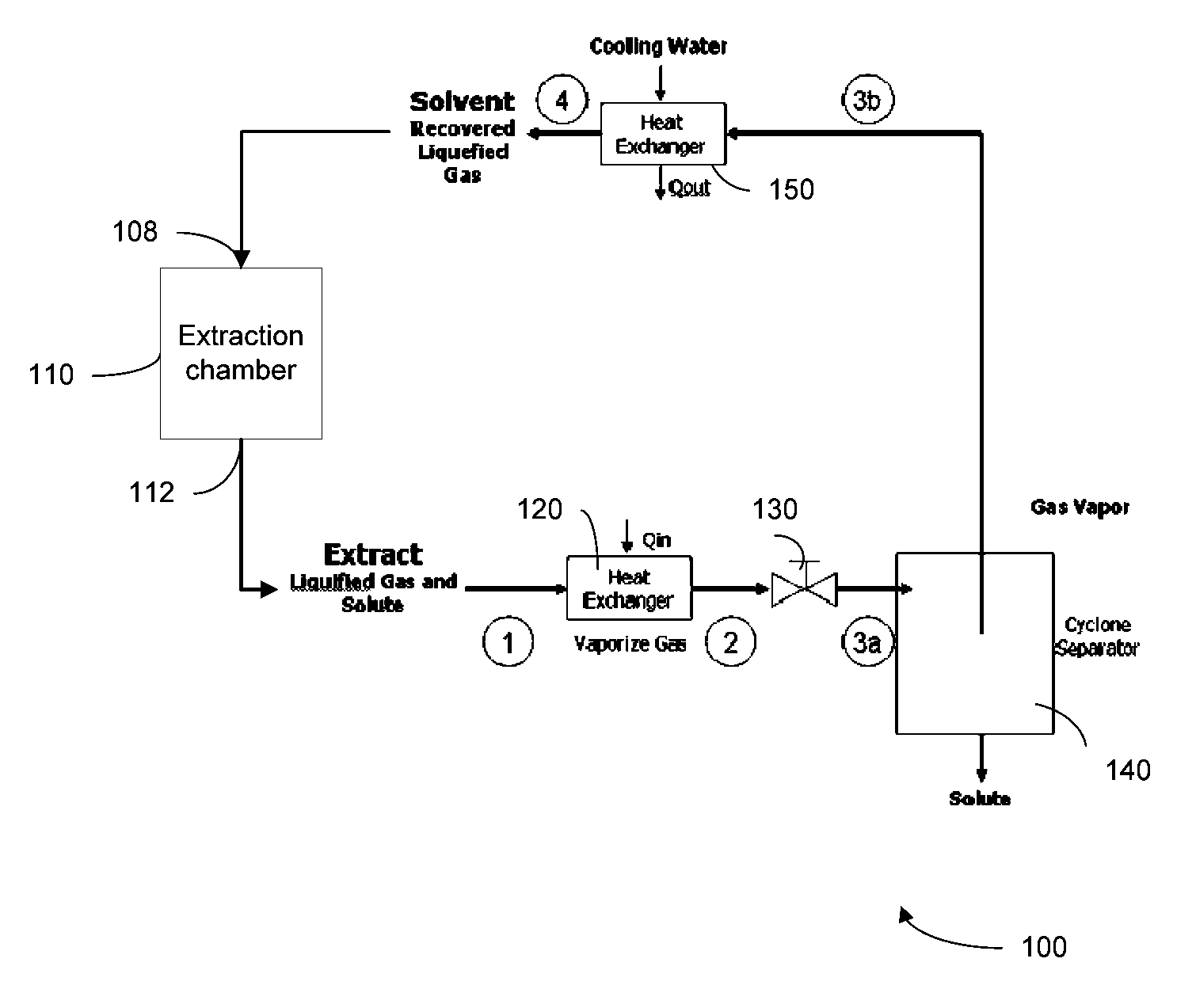

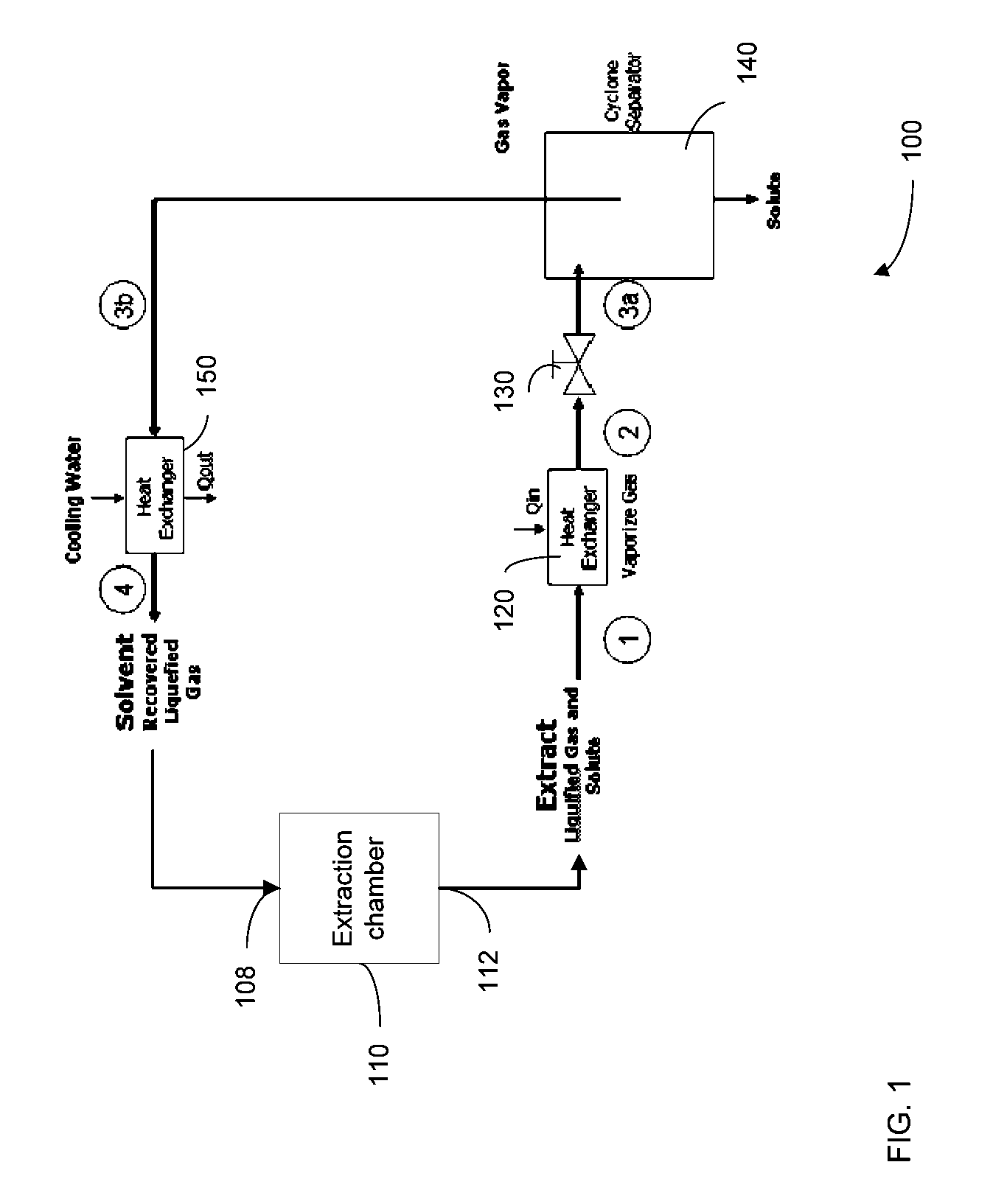

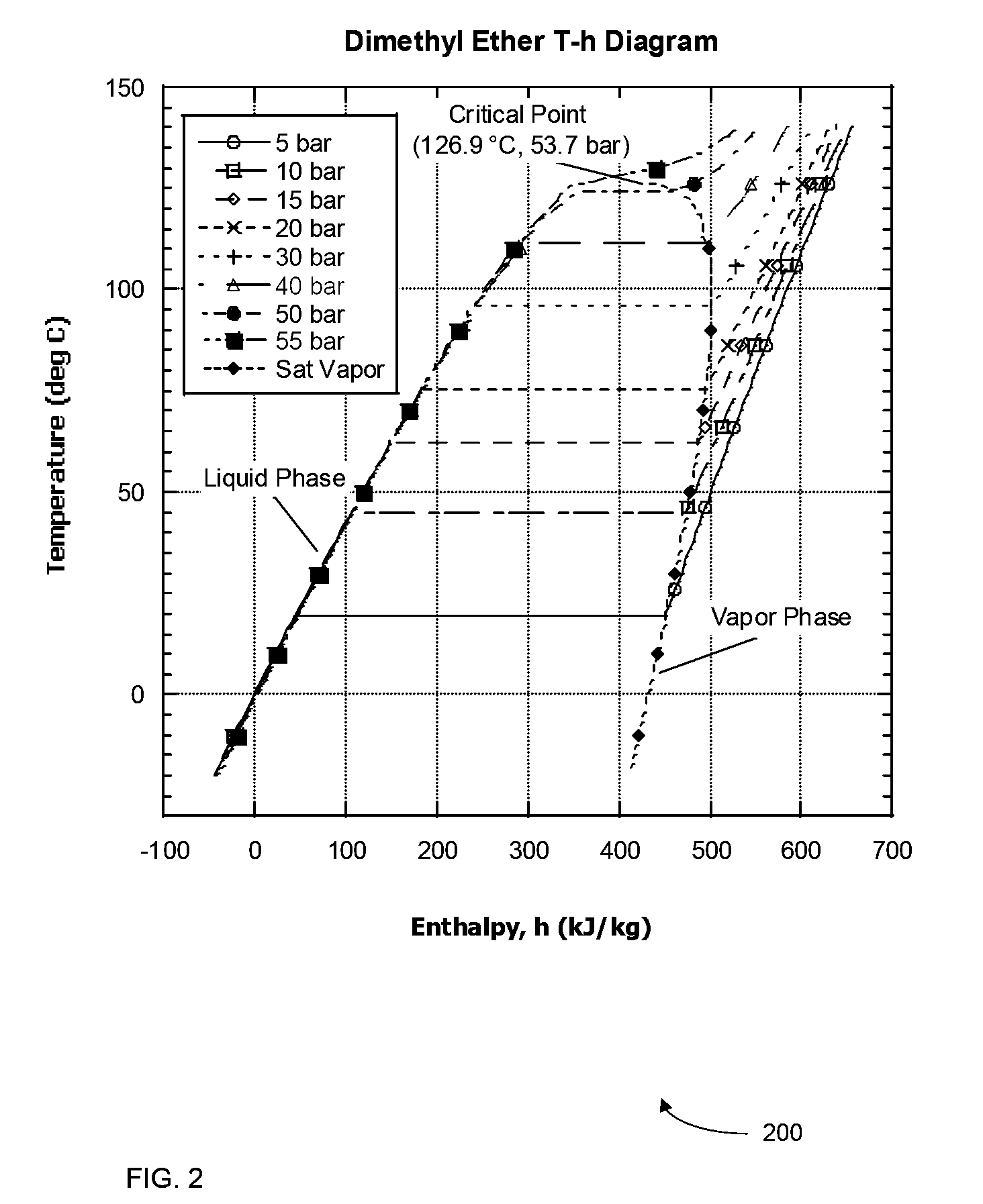

Solvent extraction and recovery

ActiveUS20090166175A1Improve solubilityReduce the amount requiredLiquid degasificationHeat recovery systemsSolubilityProduct gas

Systems and methods for improving dense gas solvent extraction of a solute and recovery of the solvent are provided. A pressure of the solvent / solute mixture obtained from an extraction chamber is increased, e.g. with a pump, thereby providing the mixture above saturation conditions. The increased pressure provides greater solubility of the solute and less solvent being vaporized in a heat exchanger. A buildup of solute in the system is reduced, thus improving system longevity. Also, process conditions of the separation process are isolated from those of the extraction process. Accordingly, the process conditions for the separating process are maintained while the process conditions of the extraction chamber vary with ambient temperature, thus saving cost and energy. This isolation also provides an ability to use, in the gas recovery cycle, a heat pump that can be used for many applications and environmental conditions while still using a conventional refrigerant.

Owner:YOURST MATT T +3

Ventilation system

InactiveUS7572179B2Reduce airflow resistanceLower performance requirementsEnergy recovery in ventilation and heatingAir treatment detailsEngineeringHeat exchanger

Owner:LG ELECTRONICS INC

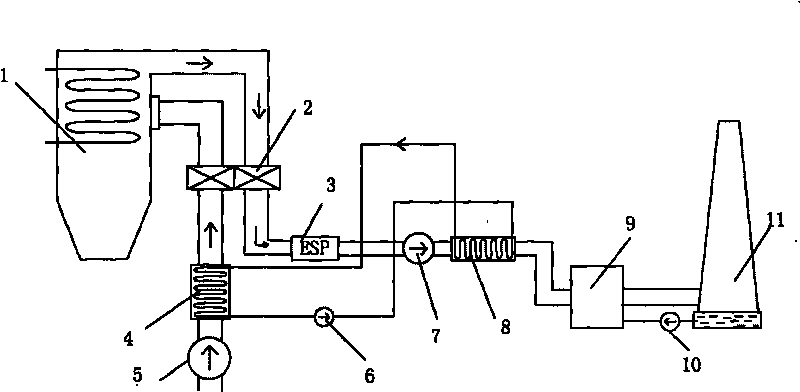

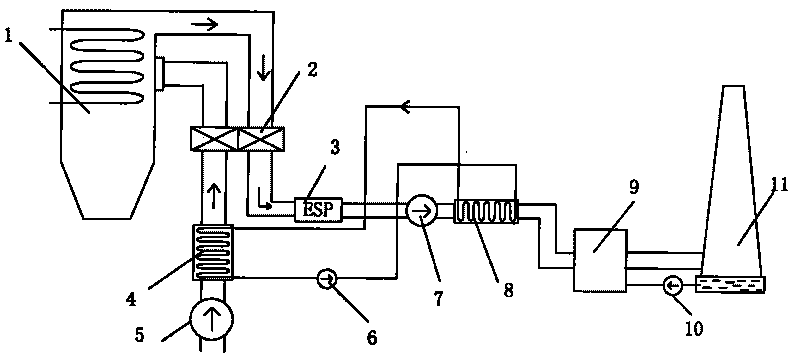

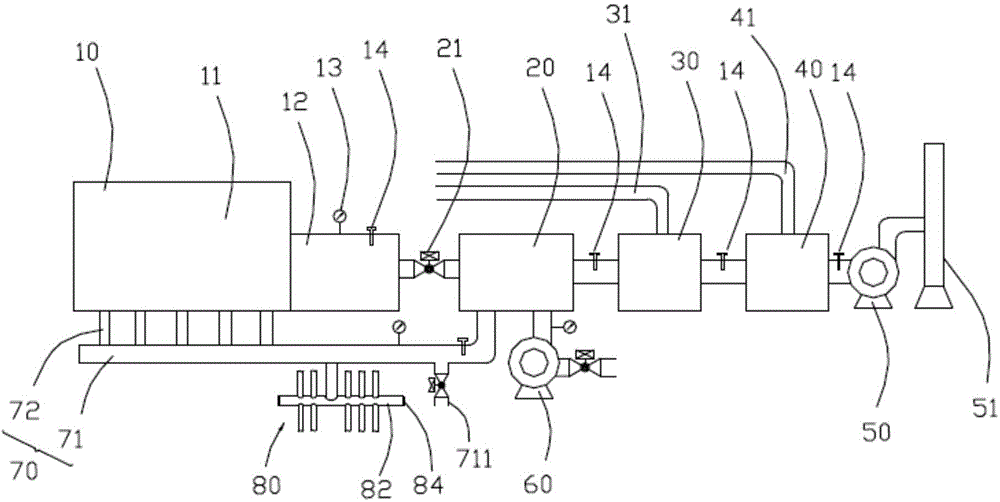

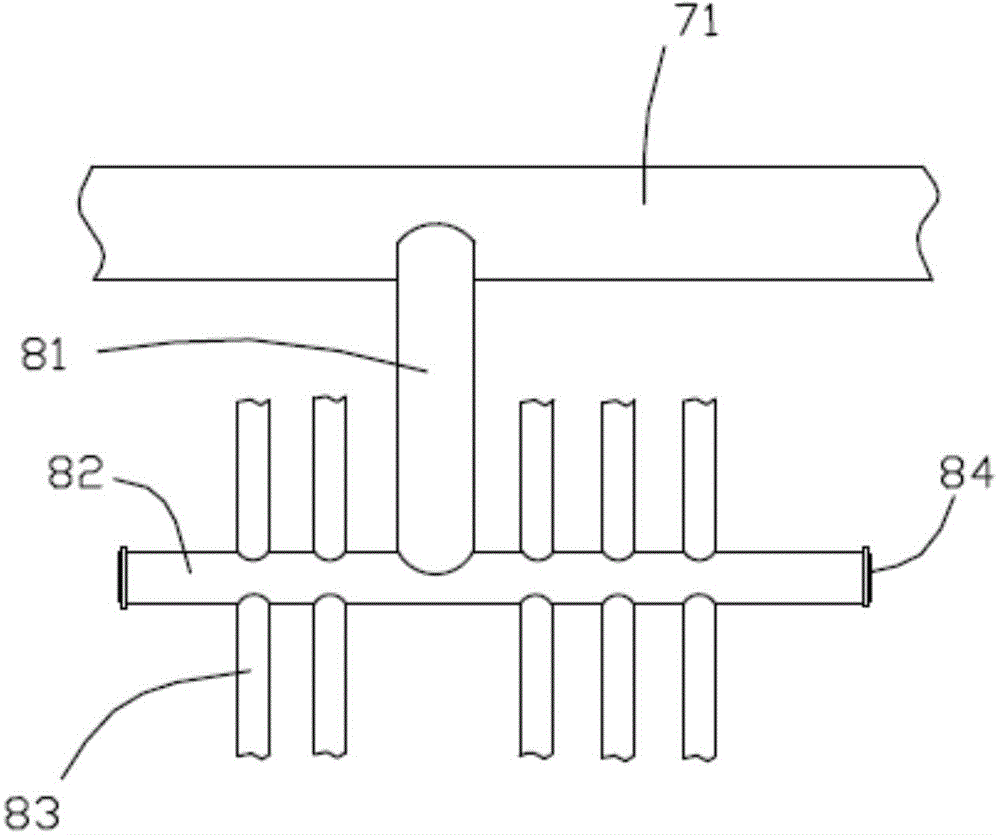

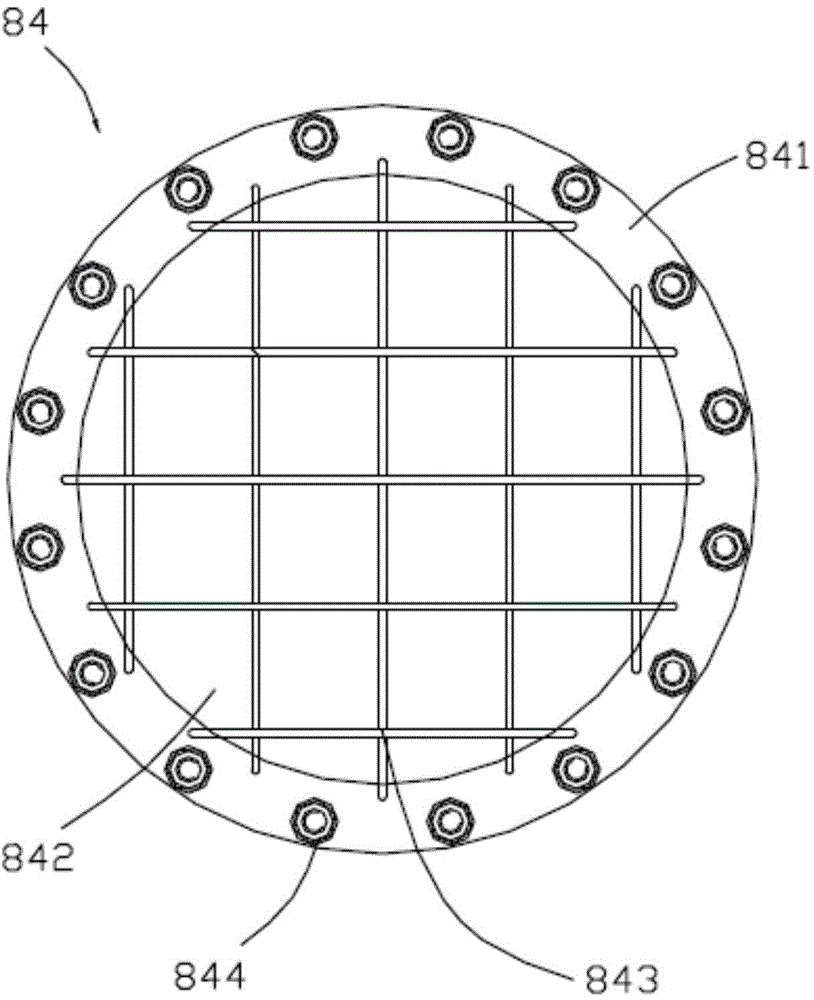

System for deep cooling and waste heat recovery of smoke gas in boiler

ActiveCN101709879AGreat effortDoes not affect normal operationCombustion processIndirect carbon-dioxide mitigationEngineeringWater circulation

The invention relates to a system for deep cooling and waste heat recovery of smoke gas in a boiler with an independent operating system, which comprises a smoke gas deep cooler, an air heater and an independent water circulation system comprising the smoke gas deep cooler and the air heater. The smoke gas of which the dust is removed by an electrostatic dust remover is used for heating the cold water in the smoke gas deep cooler to recover the waste heat of the exhausted smoke, and the hot water at the outlet of the smoke gas deep cooler is transferred to the air heater for preheating the air, thereby increasing the temperature of the combustion-supporting air in the boiler; after the smoke gas passes through the smoke gas deep cooler, the smoke gas is directly introduced into a desulfurizing tower for desulfurization and recovery processing; and finally, the smoke gas is exhausted through a wet chimney. The system of the invention does not need to change the traditional thermodynamic system of the machine unit, and the long-period safe operation of the system can not be influenced in the process of recovering the waste heat of the smoke gas, thereby lowering the temperature of the exhausted smoke, saving the desulfurization water consumption, improving the machine unit efficiency and increasing the machine unit output.

Owner:XI AN JIAOTONG UNIV +1

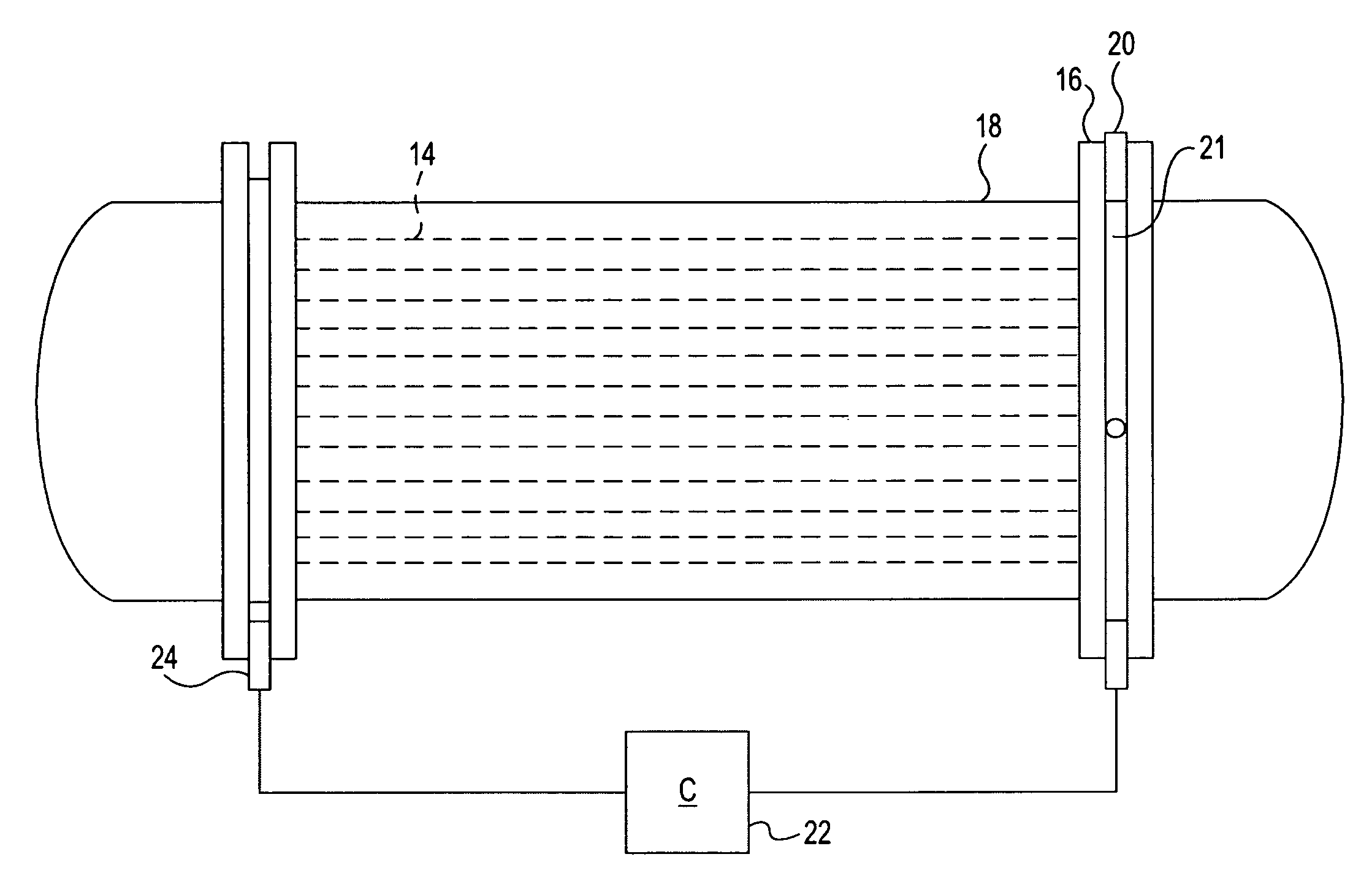

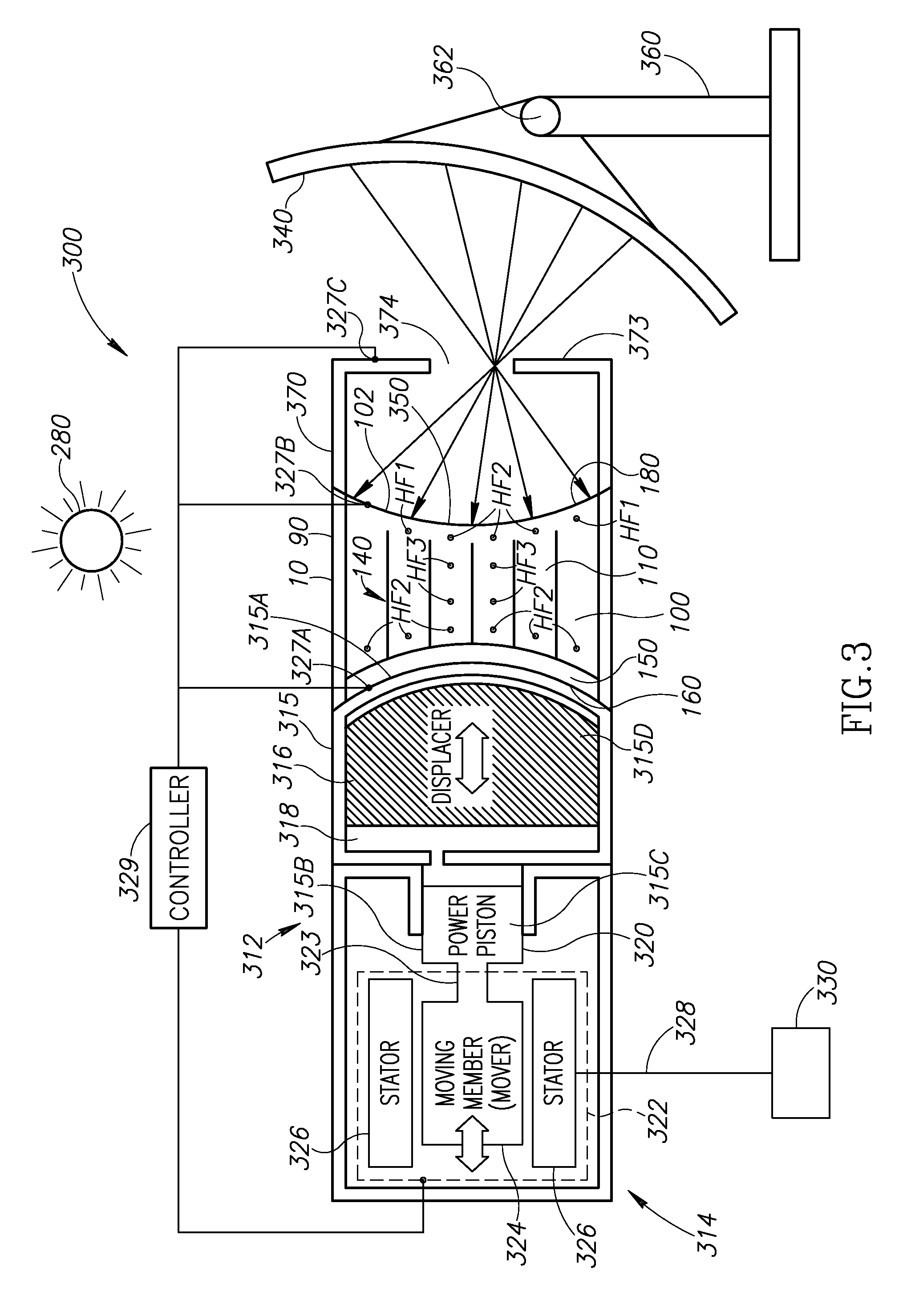

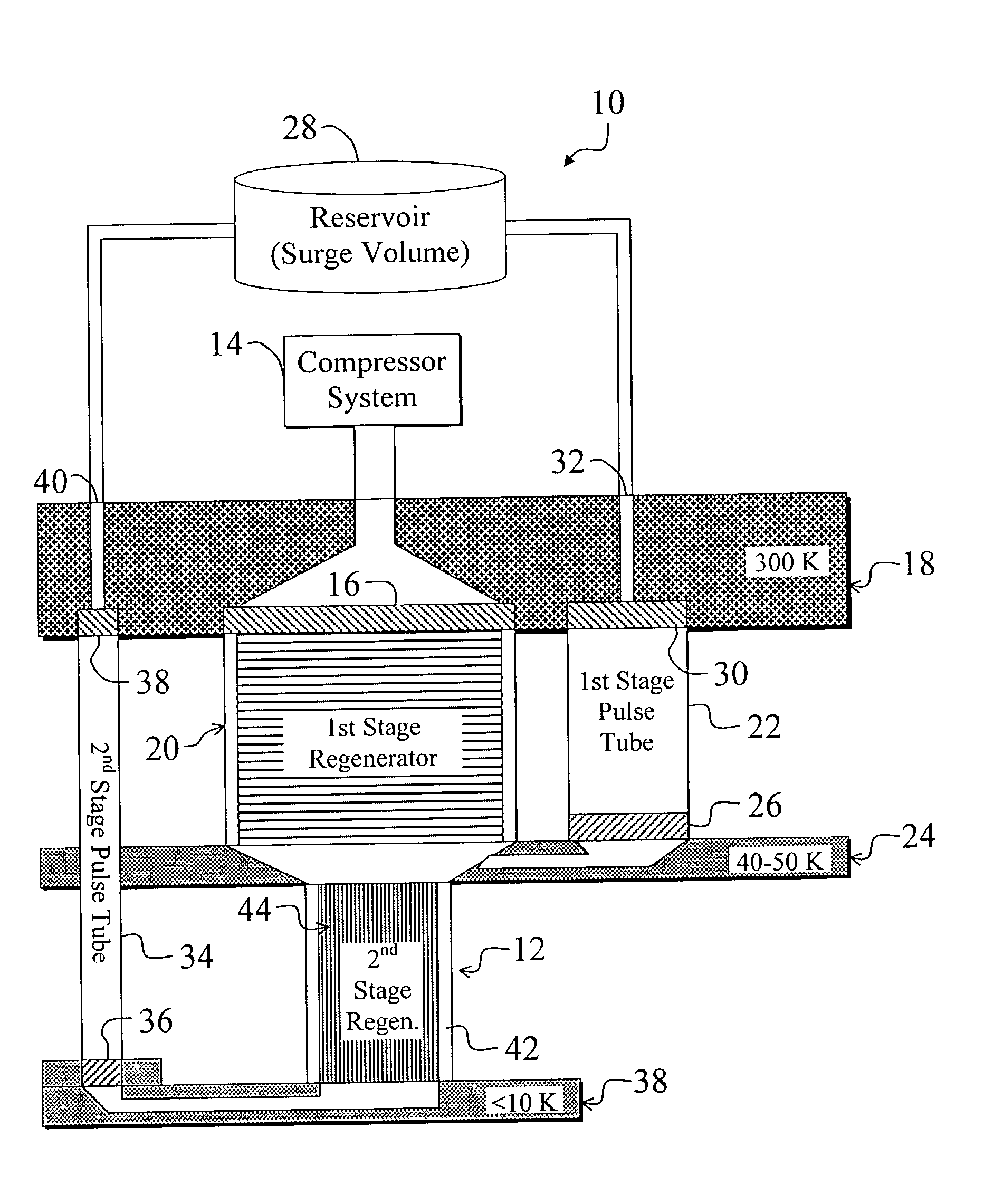

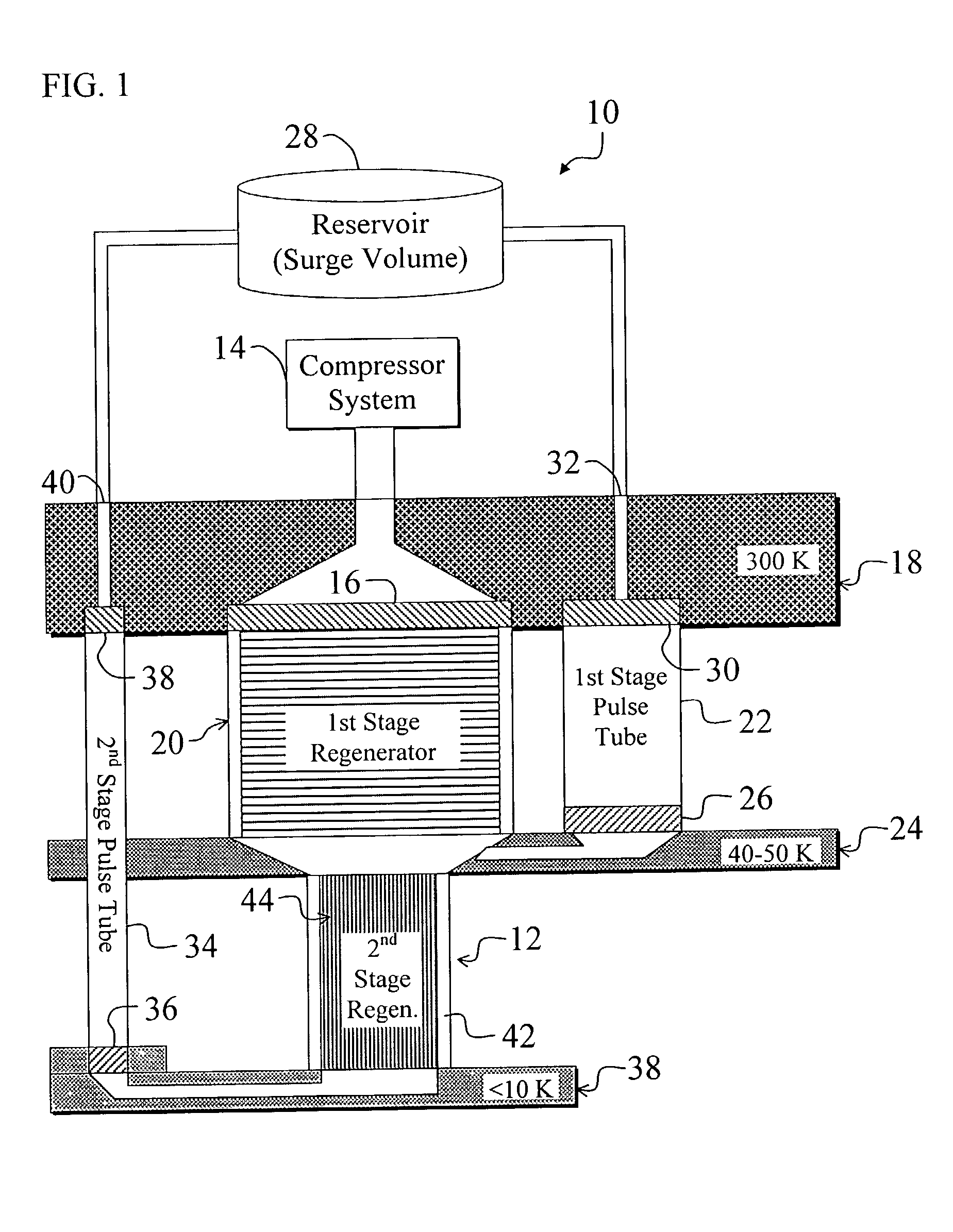

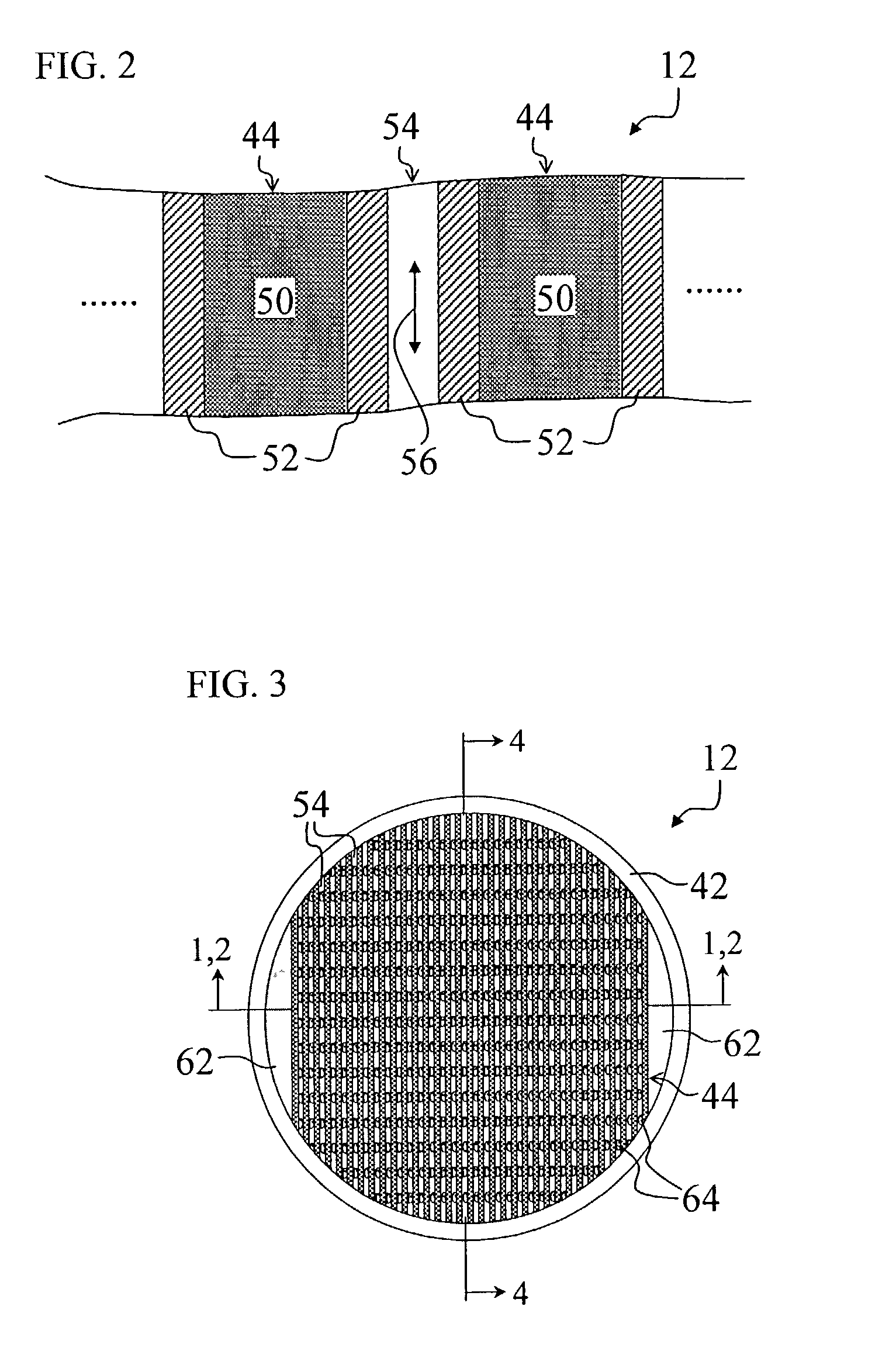

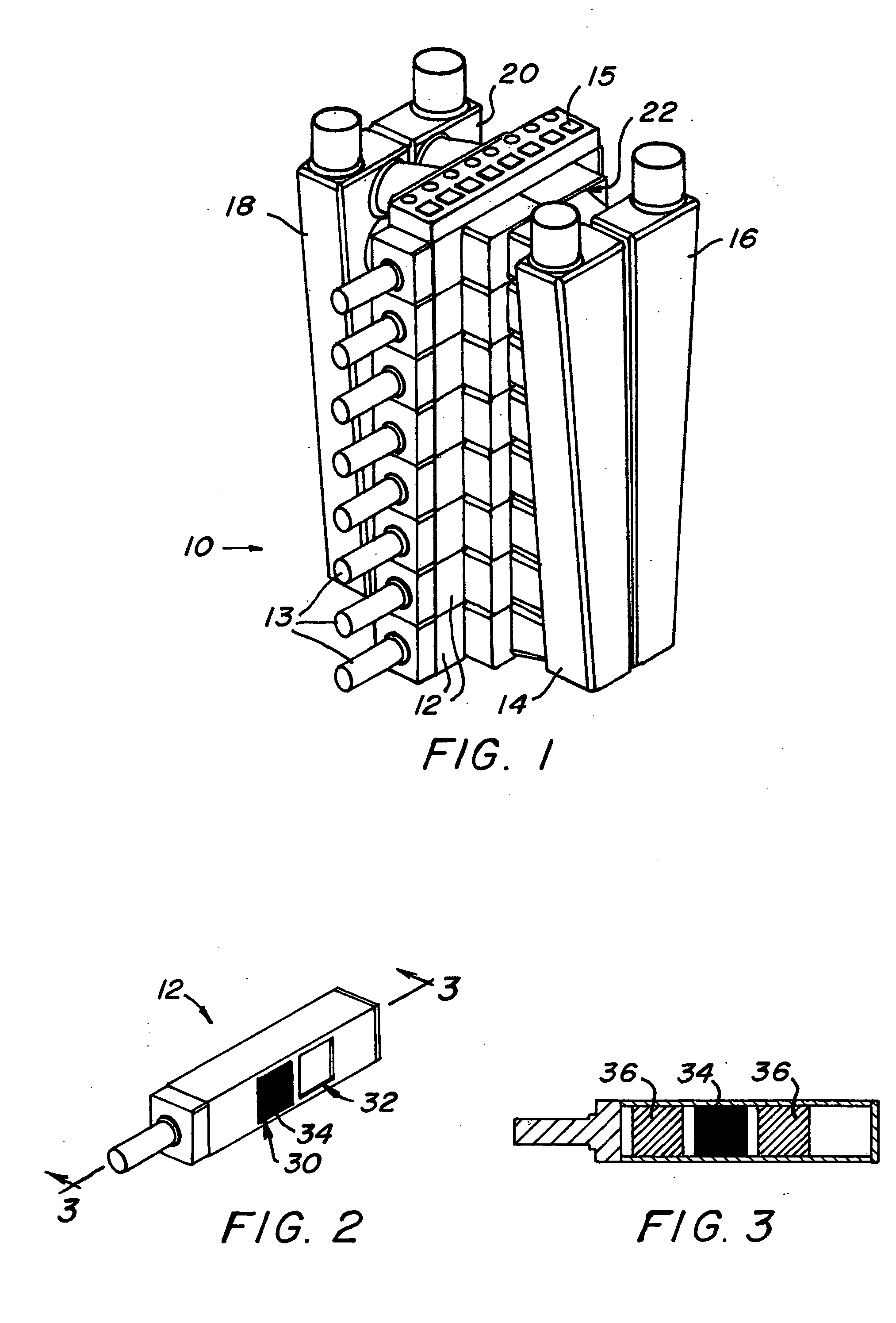

High-frequency, low-temperature regenerative heat exchanger

A high-frequency, low-temperature regenerator (12). The regenerator (12) includes a substrate (50) having rare earth material (52) disposed thereon. In a specific embodiment, the substrate (50) has channels or pores (54) therethrough or therein to facilitate gas flow through the regenerator (12). The substrate (50) is constructed from a material, such as polyimide, polyester, or stainless steel, which is sufficient to define the geometry of the regenerator (12). The rare earth material (52) is selected and deposited on the substrate (50) in a layer (52) having thermal penetration depth that is greater than the thickness of the layer (52). The thermal penetration depth is sufficiently high to enable all of the rare earth material (52) to contribute to thermal regeneration at an operating frequency of 30 Hz. In the illustrative embodiment, the thickness of the substrate (50) is less than or equal to approximately 0.001 inches. The layer of rare earth material (52) is approximately 0.0002 inches thick. The substrate (44, 50) includes a stack of plated substrates (44) that are stacked so that spaces (54) exist between the plated substrates (44), which result in a porosity of approximately 15 percent. Dimples, pleats, or other mechanisms in the plated substrates (44) preserve the spaces (54) between the plated substrates (44). In the specific embodiment, the spaces (54) are approximately 0.00025 inches wide, and the working gas is helium.

Owner:RAYTHEON CO

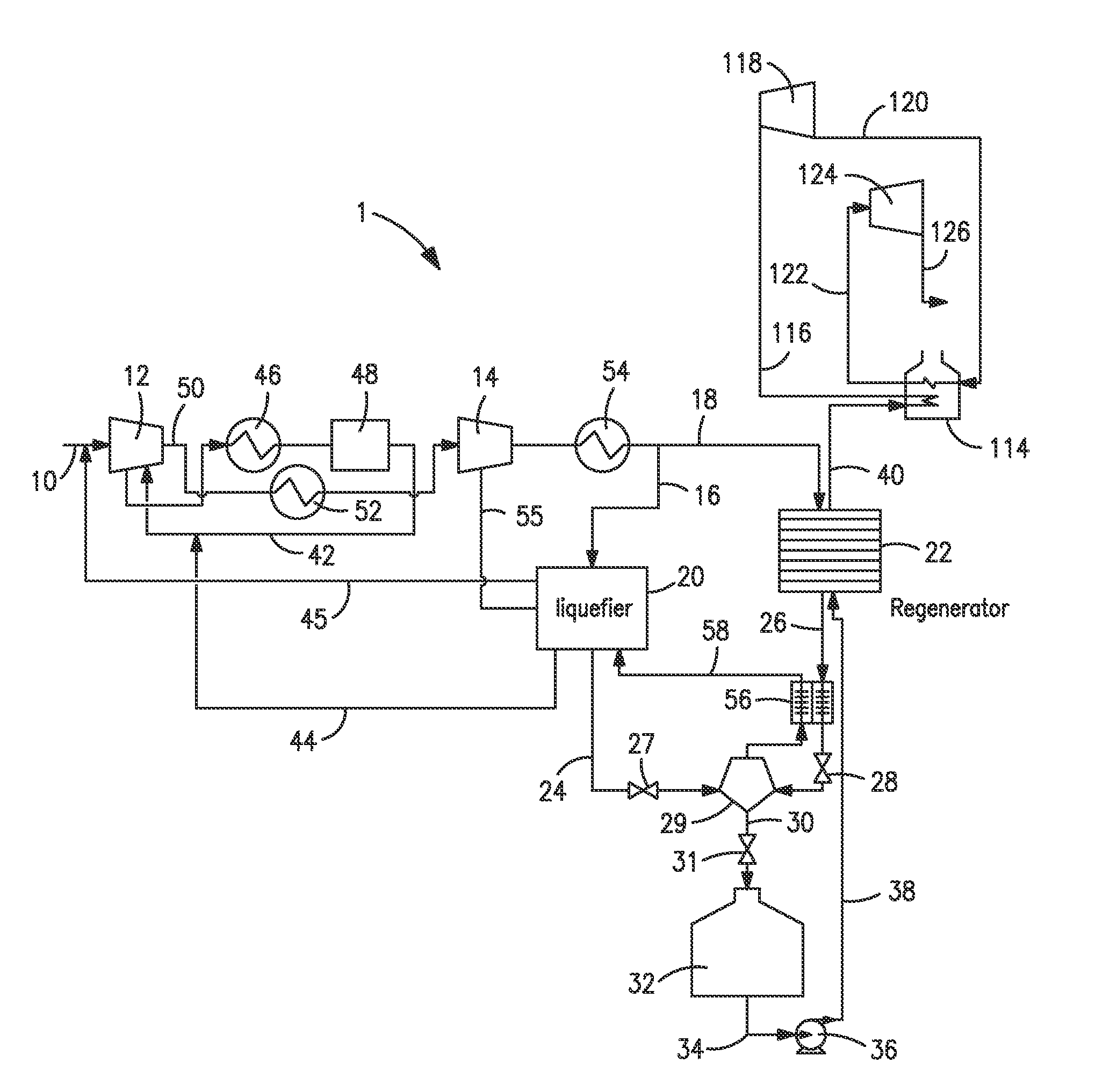

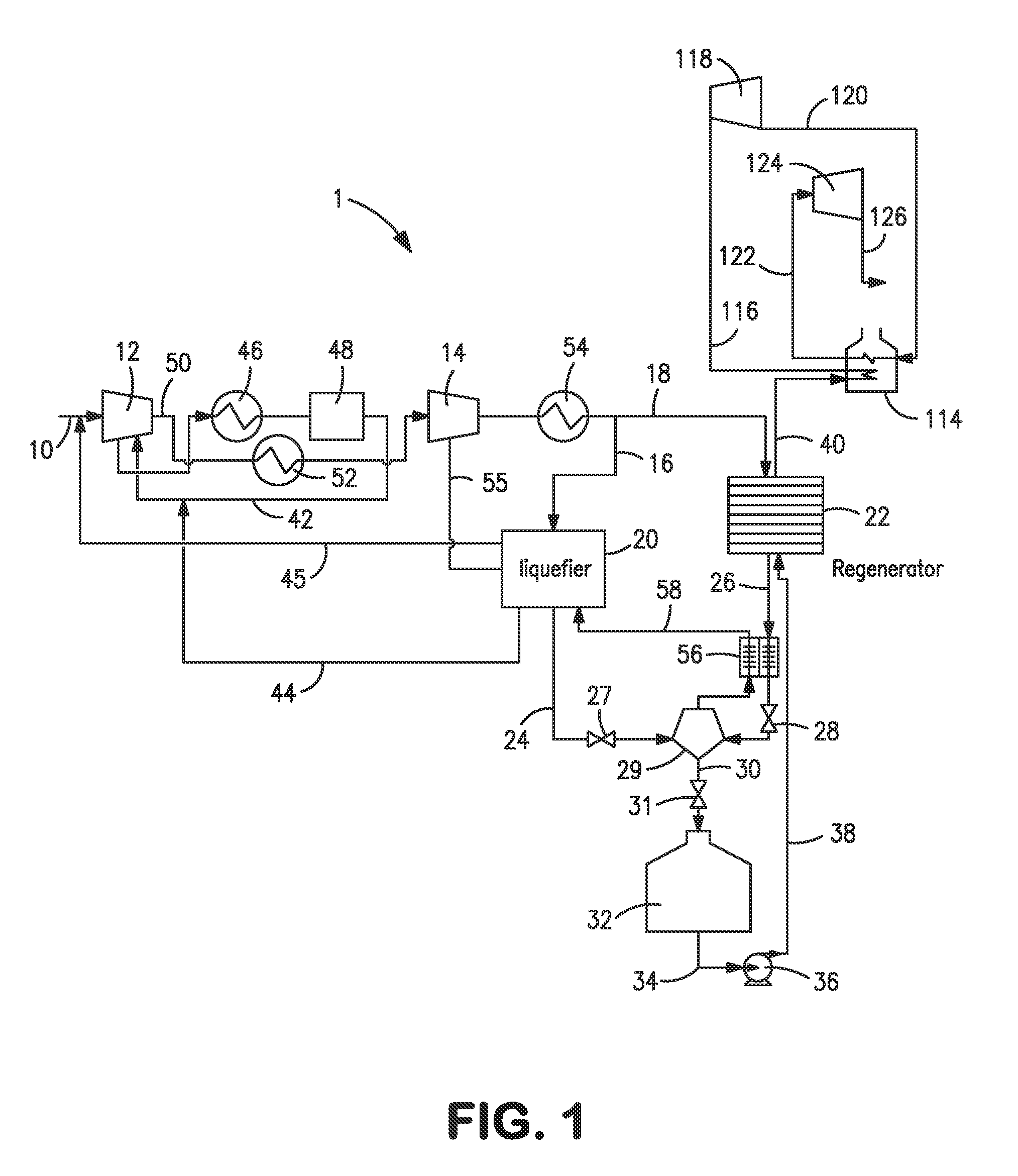

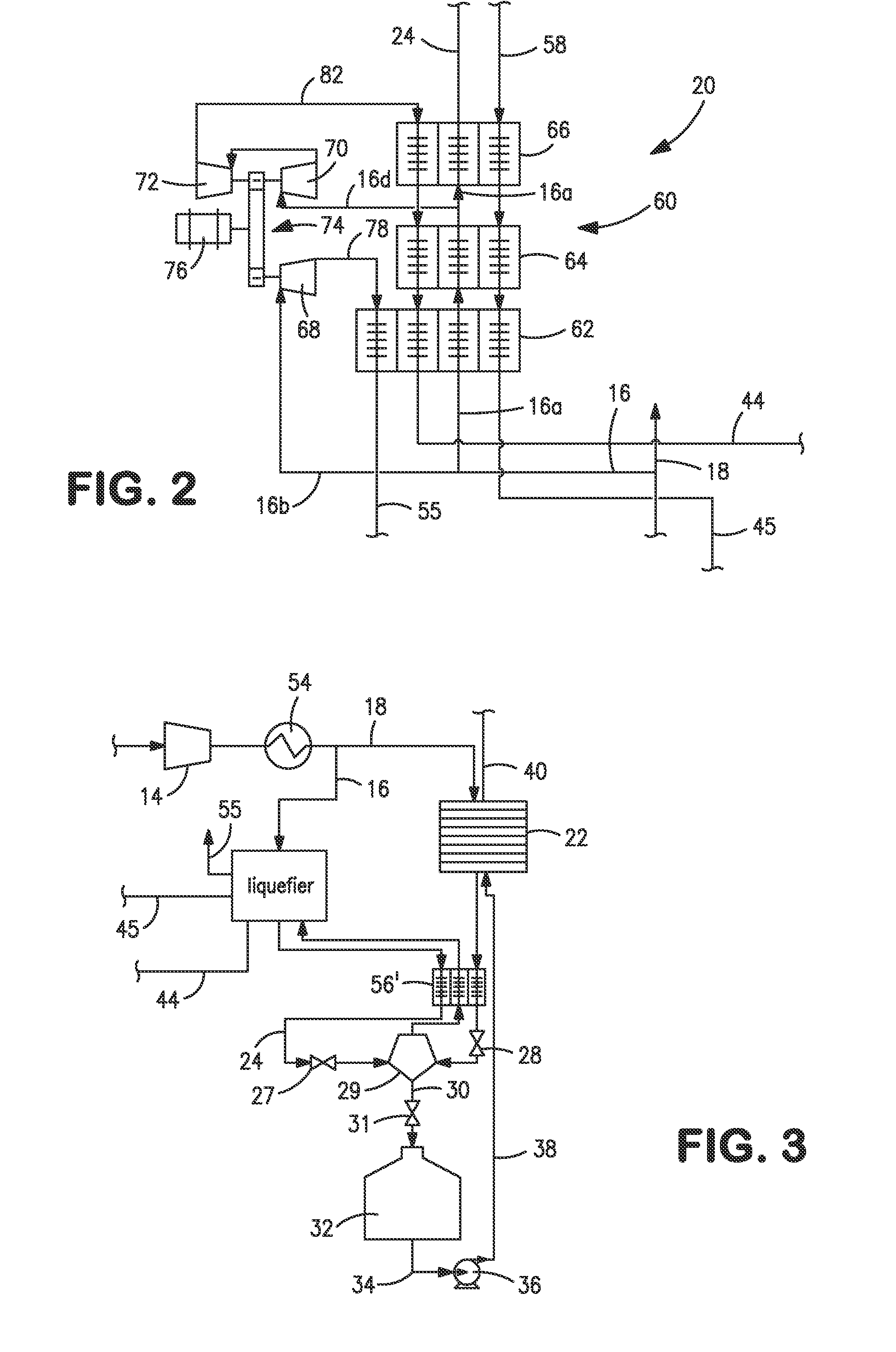

Liquid air method and apparatus

A method and apparatus in which air is liquefied and stored for later energy recovery during which the liquid air is pumped to high pressure, heated and then expanded to recover the energy. During the recovery of energy, the pumped liquid air is heated within a regenerator that stores the refrigeration within the liquid air. During the liquefaction of the air, part of the refrigeration required is obtained from the refrigeration stored in the regenerator.

Owner:PRAXAIR TECH INC

Waste heat recycling system of annealing furnace

The invention provides a waste heat recycling system of an annealing furnace. The waste heat recycling system comprises the annealing furnace, an air heat exchanger, a steam boiler, a hot water boiler, an exhaust fan, a combustion fan and a combustion air pipe. The annealing furnace comprises a heating section and a preheating section, the air heat exchanger is connected with the preheating section, the steam boiler is connected with the air heat exchanger, the hot water boiler is connected with the steam boiler, the exhaust fan is connected with the hot water boiler, the steam boiler is connected with a steam pipeline, the hot water boiler is connected with a hot water pipeline, the combustion fan is connected with the air heat exchanger, the combustion air pipe comprises a main pipe and a plurality of branch pipes communicated with the main pipe, one end of the main pipe is connected with the air heat exchanger, the branch pipes are connected with the heating section, and the main pipe is provided with an exhaust pipe and a pipe explosion prevention device. According to the waste heat recycling system of the annealing furnace, waste heat produced in the annealing process can be made full use of, and safety performance of the waste heat recycling system can be fully guaranteed.

Owner:湖南宏旺新材料科技有限公司

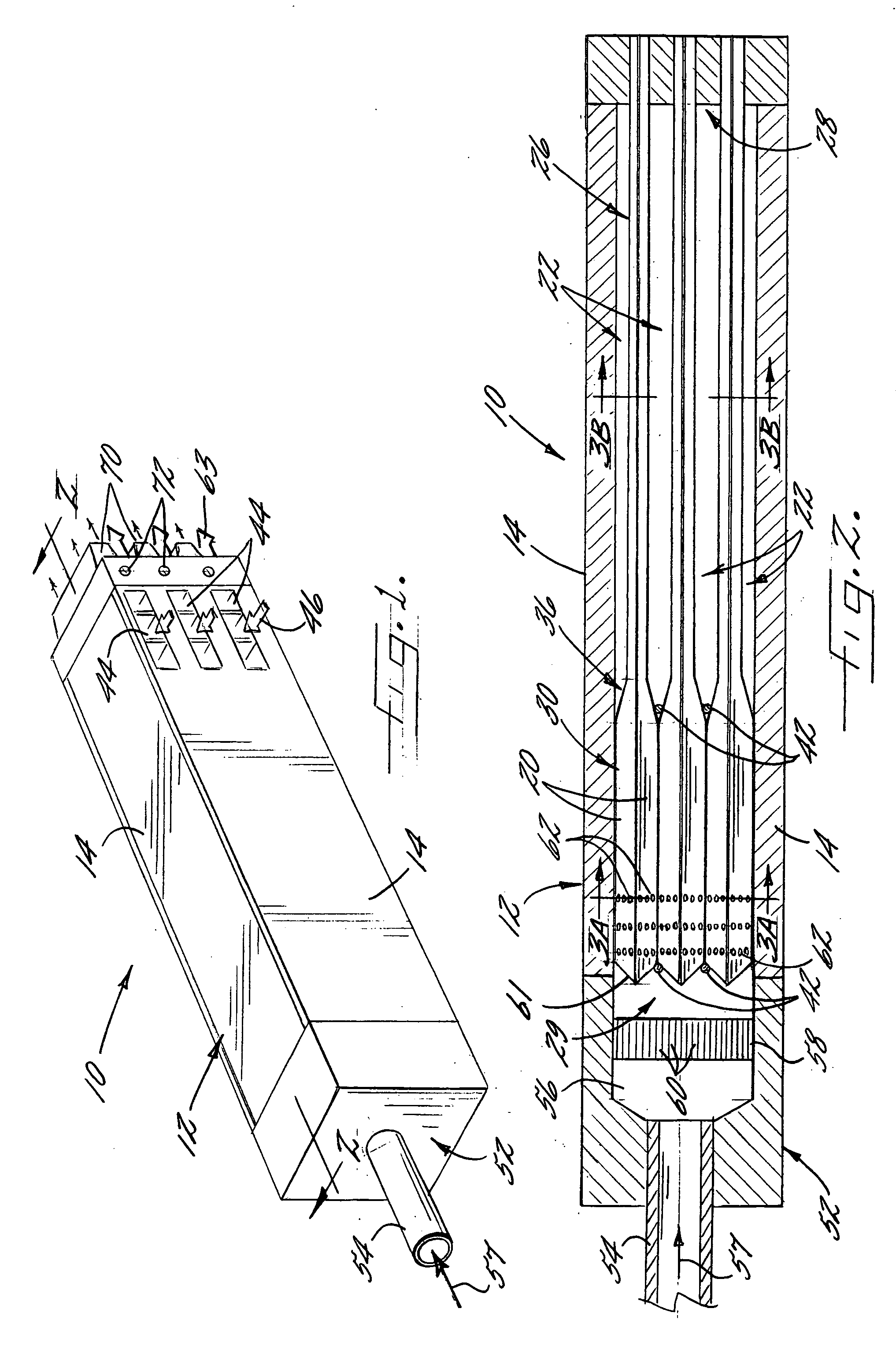

Formed sheet heat exchanger

InactiveUS20050189097A1Improve thermal efficiencyEfficient heat exchangeCombustion processIndirect carbon-dioxide mitigationThermal energyPlate heat exchanger

A formed sheet heat exchanger is provided for exchanging heat between fluids is provided. The apparatus includes flow divider sheets that are positioned in a stacked configuration and extend in a longitudinal direction so that adjacent pairs of the sheets define flow passages therebetween for receiving first and second fluids. Each of the sheets is nonuniform in the longitudinal direction, having a manifold portion and a corrugated portion. The corrugated portions of each adjacent pair of sheets define a plurality of fluid channels therebetween that are connected to the portion of the flow passage defined between the manifold portions. The fluid channels are configured to receive the first or second fluids and transfer thermal energy therebetween through the flow divider sheets.

Owner:THE BOEING CO

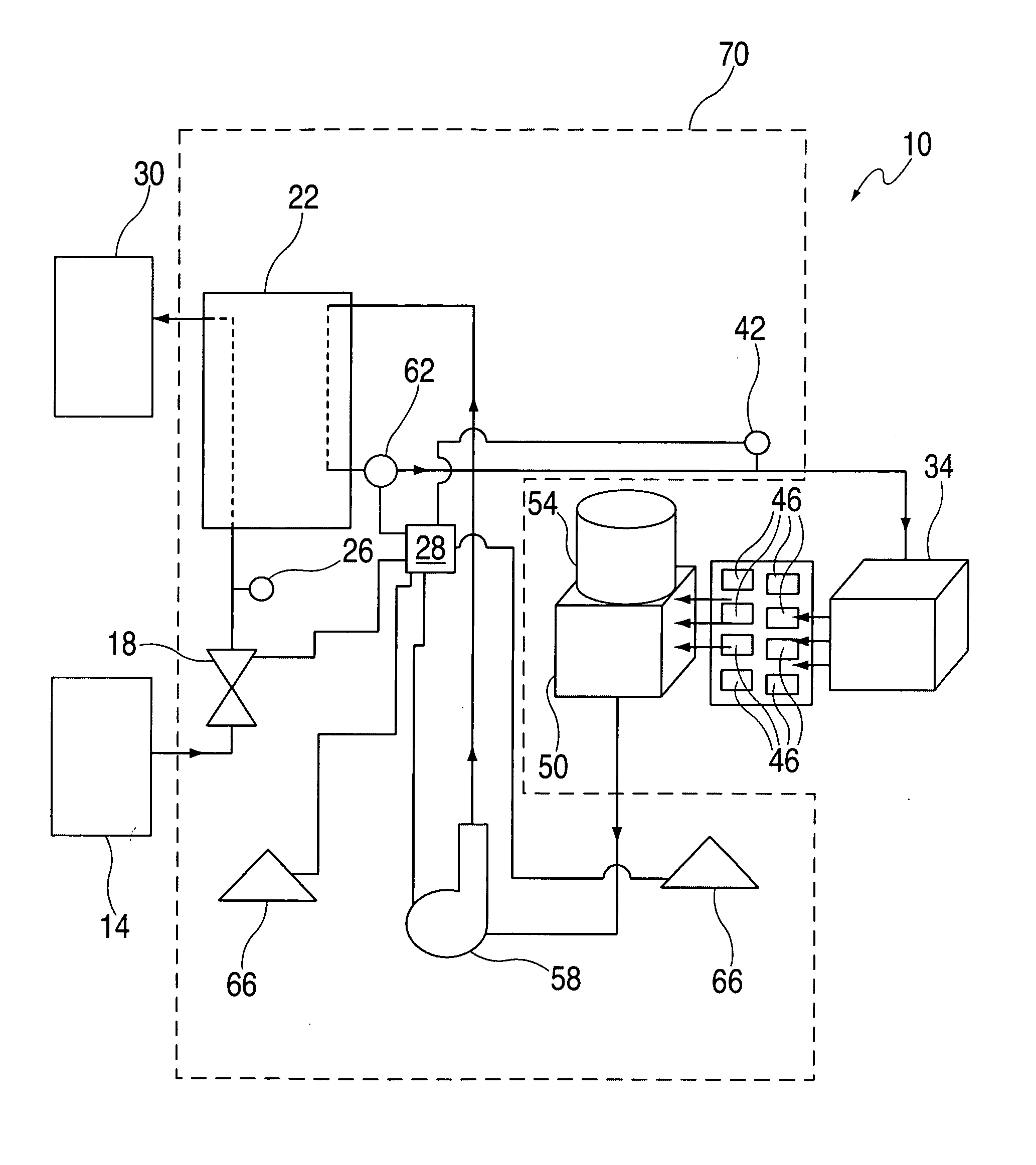

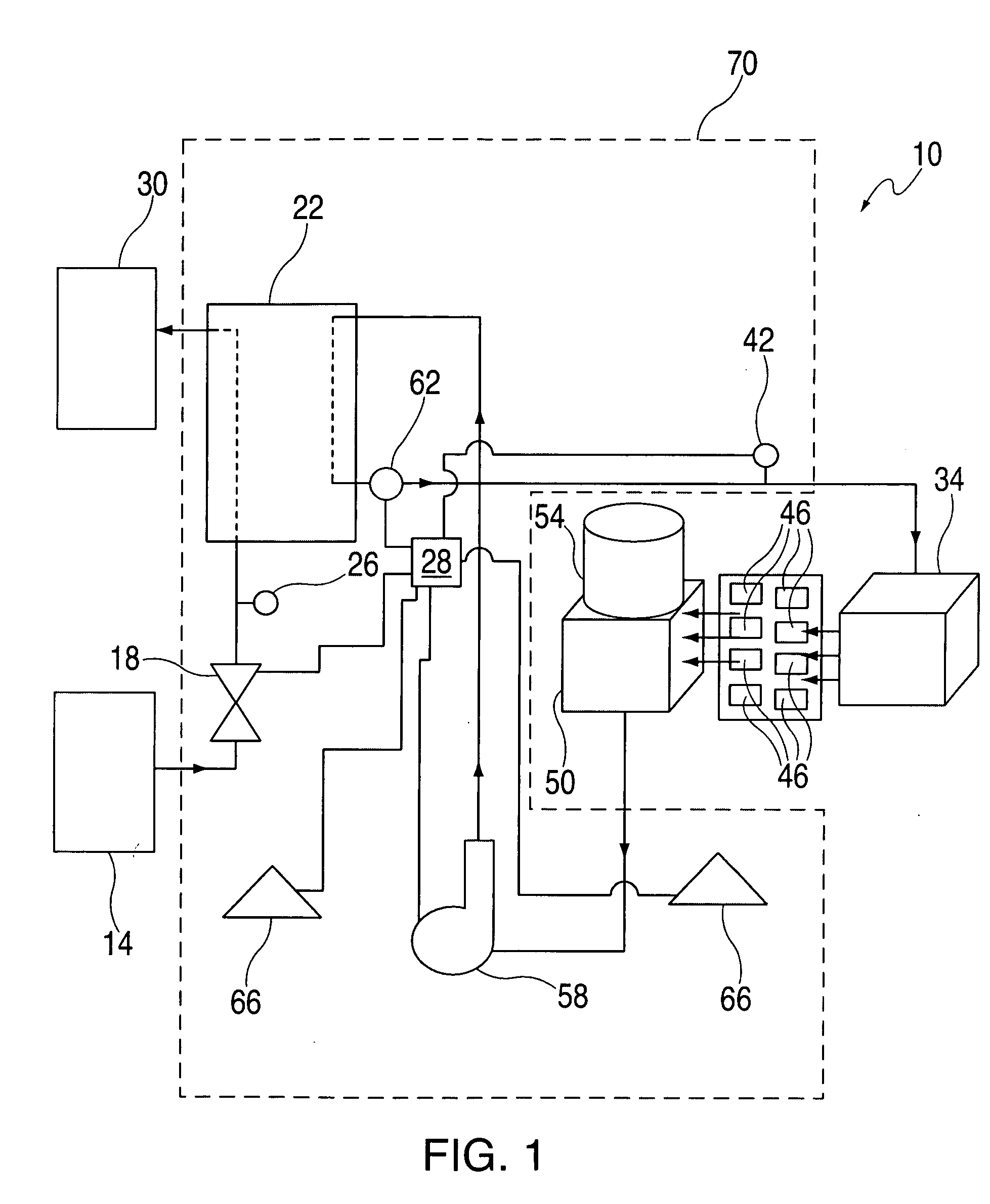

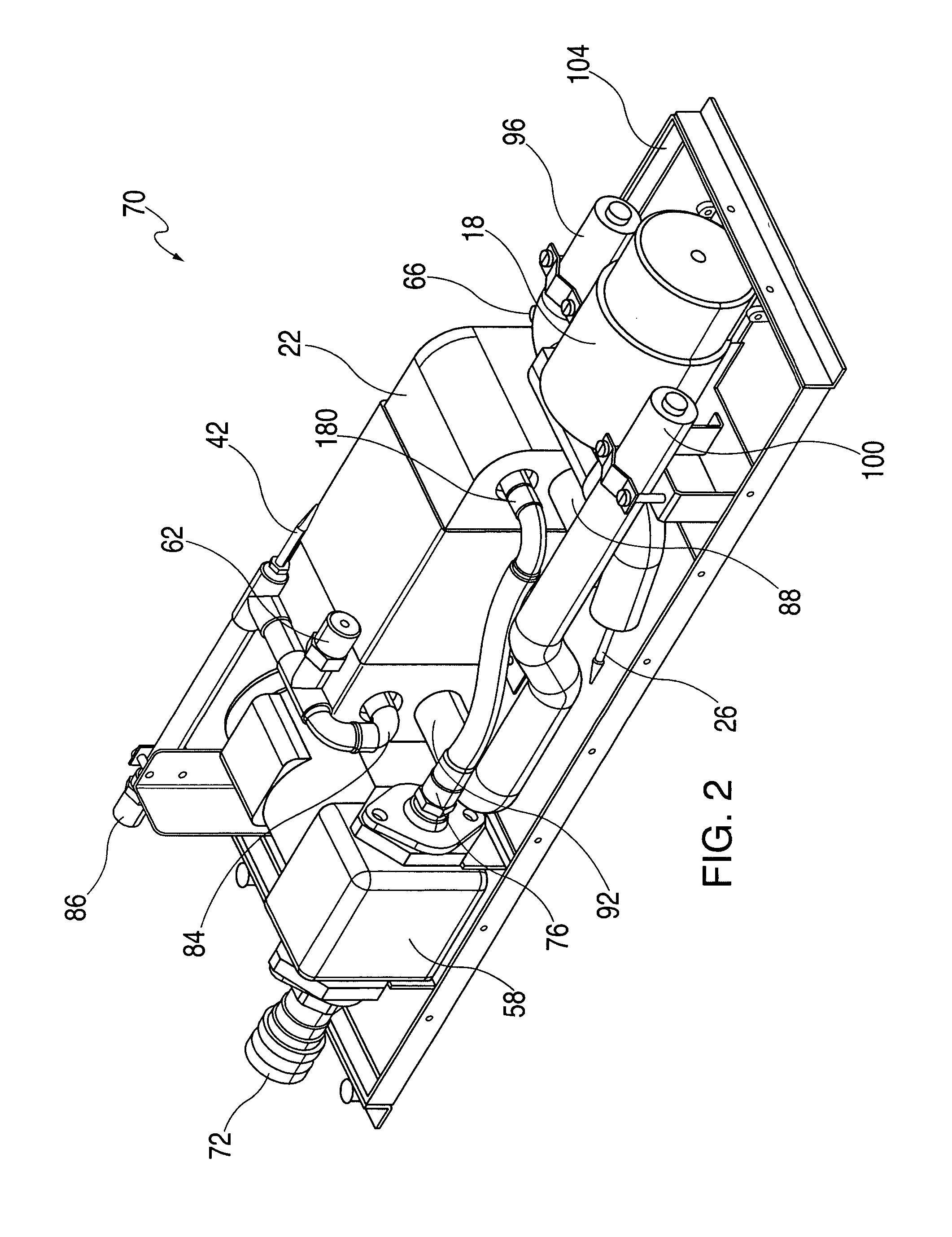

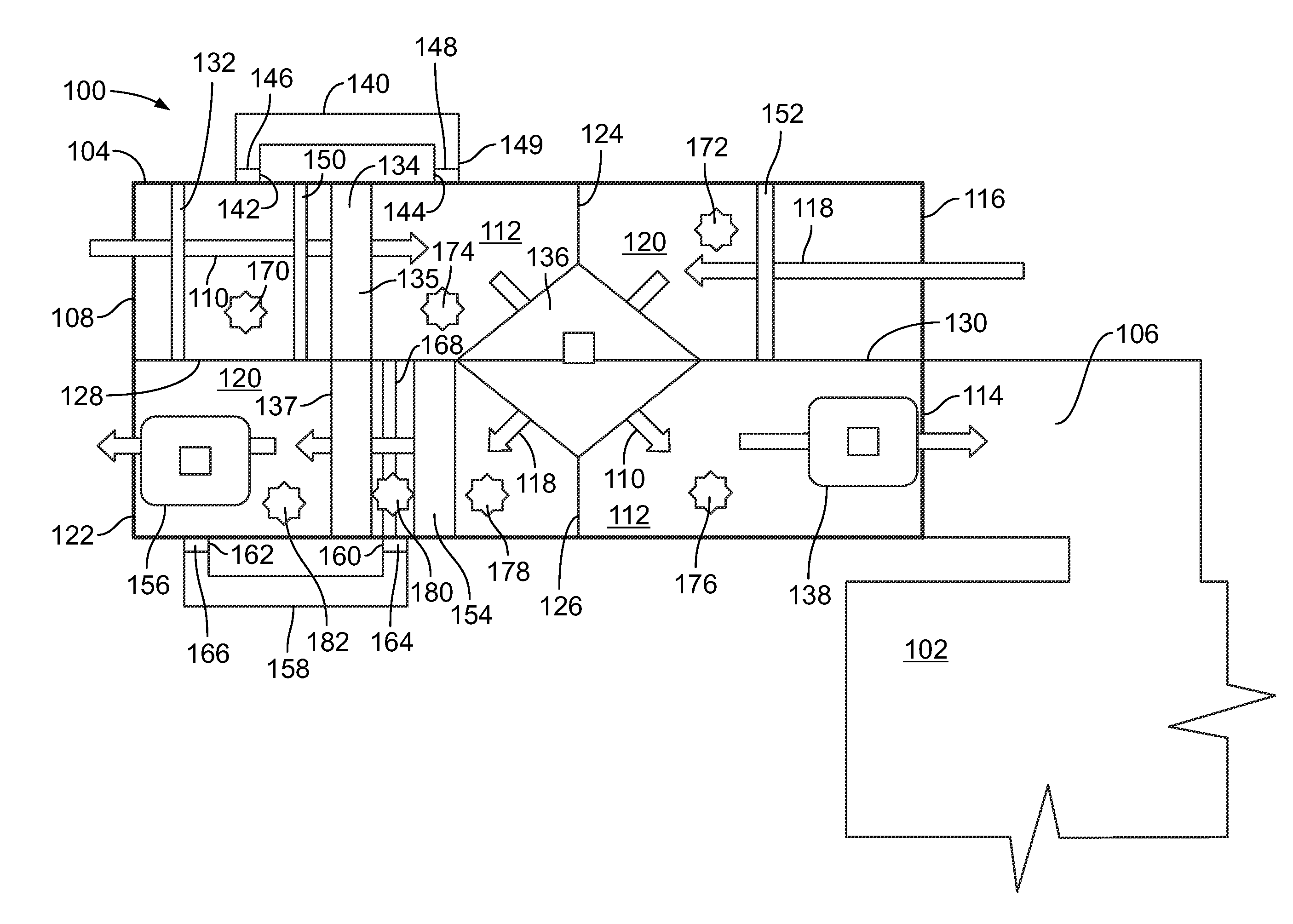

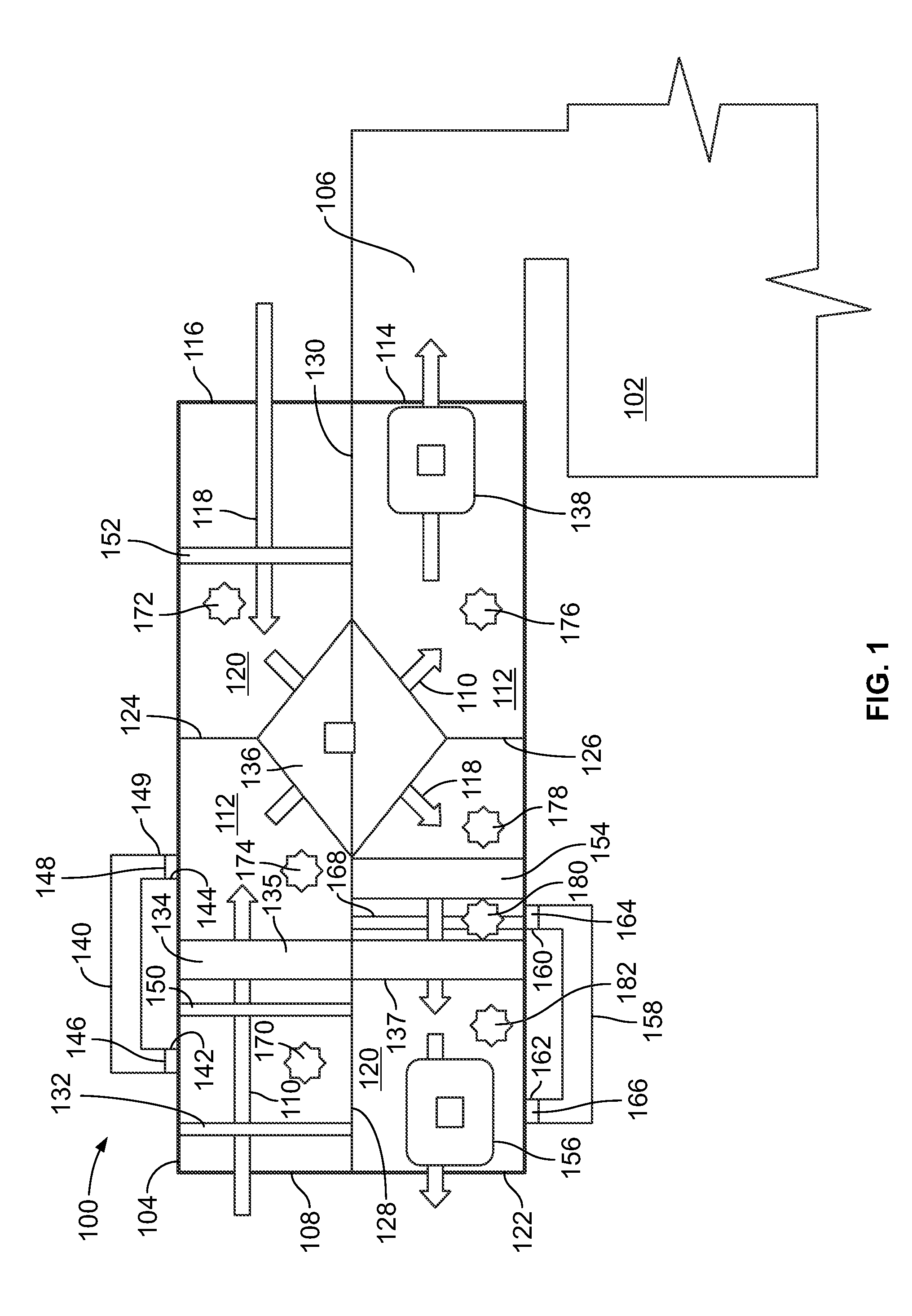

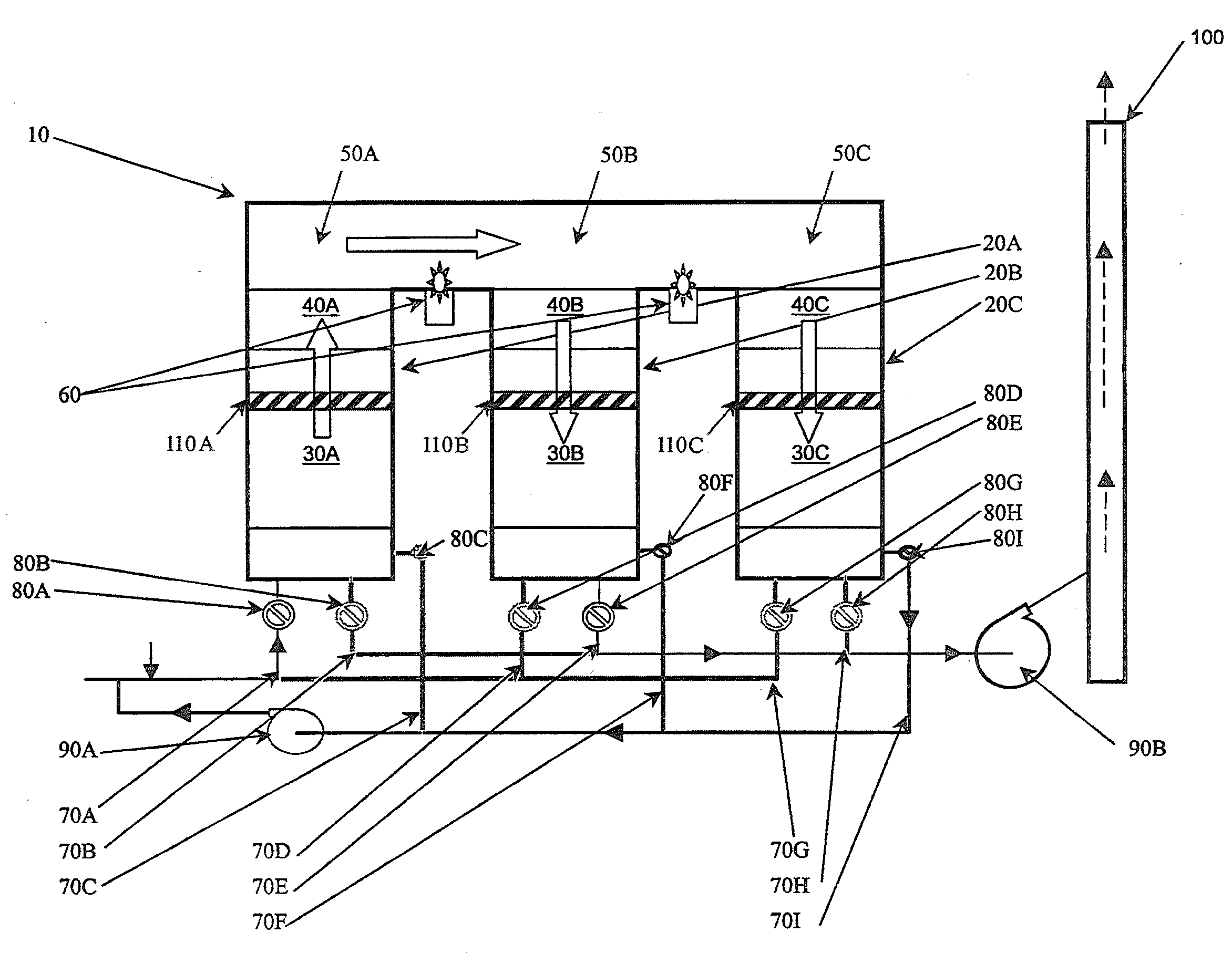

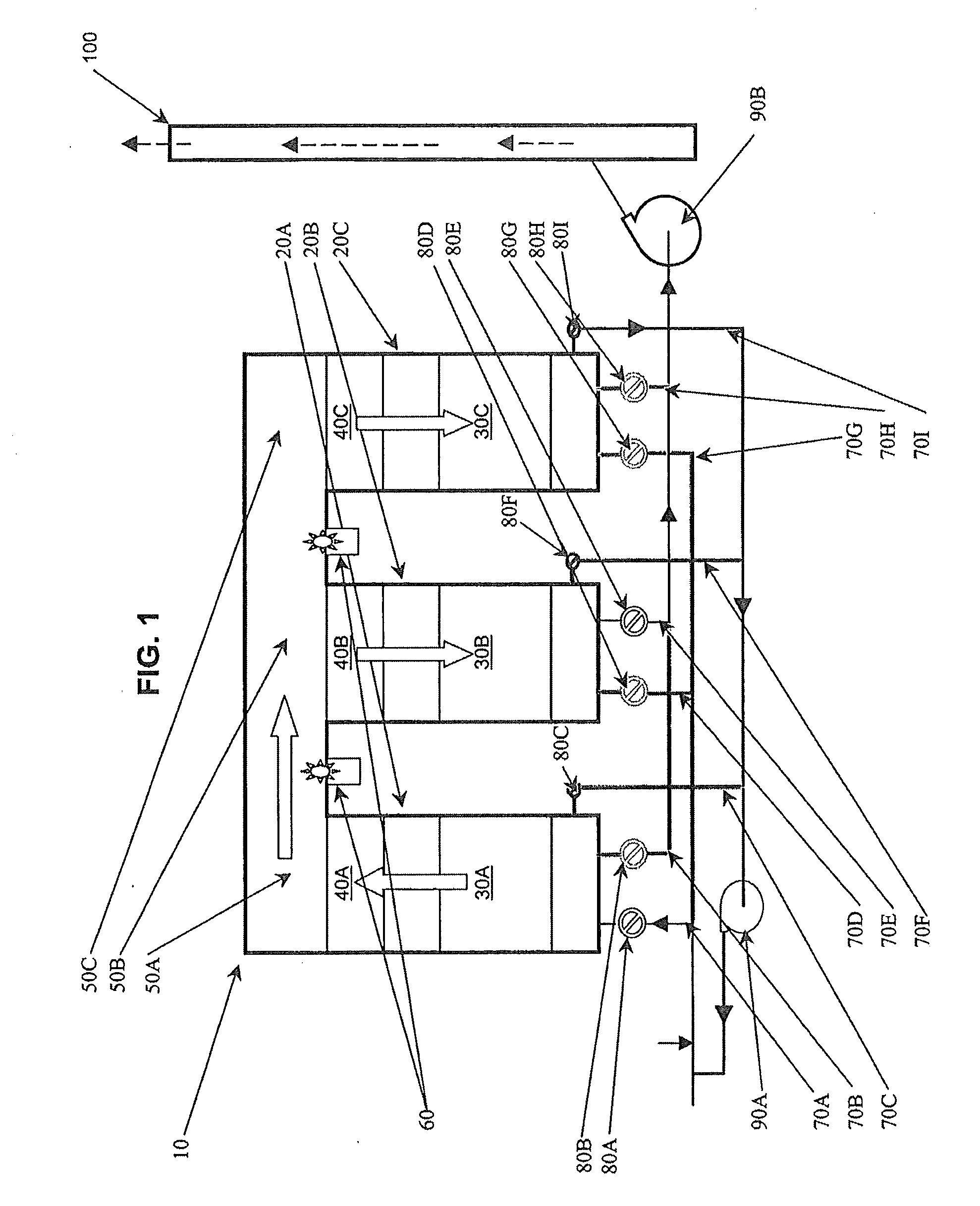

System and method for providing conditioned air to an enclosed structure

InactiveUS20140190037A1Reduce humidity levelEnergy can transferEnergy recovery in ventilation and heatingDrying solid materials with heatEnergy transferEngineering

An energy exchange system is configured to provide dry supply air to an enclosed structure. The system may include an energy transfer device having a first portion configured to be disposed within a supply air flow path and a second portion configured to be disposed within a regeneration air flow path. The energy transfer device is configured to decrease a humidity level of supply air. The energy transfer device is configured to be regenerated with regeneration air. The system may also include a first heat exchanger configured to be disposed within the supply air flow path downstream from the energy transfer device and within the regeneration air flow path upstream from the second portion of the energy transfer device. The first heat exchanger is configured to transfer sensible energy between the supply air and the regeneration air. The supply air is configured to be supplied to the enclosed structure after passing through the energy transfer device and the first heat exchanger.

Owner:NORTEK AIR SOLUTIONS CANADA INC

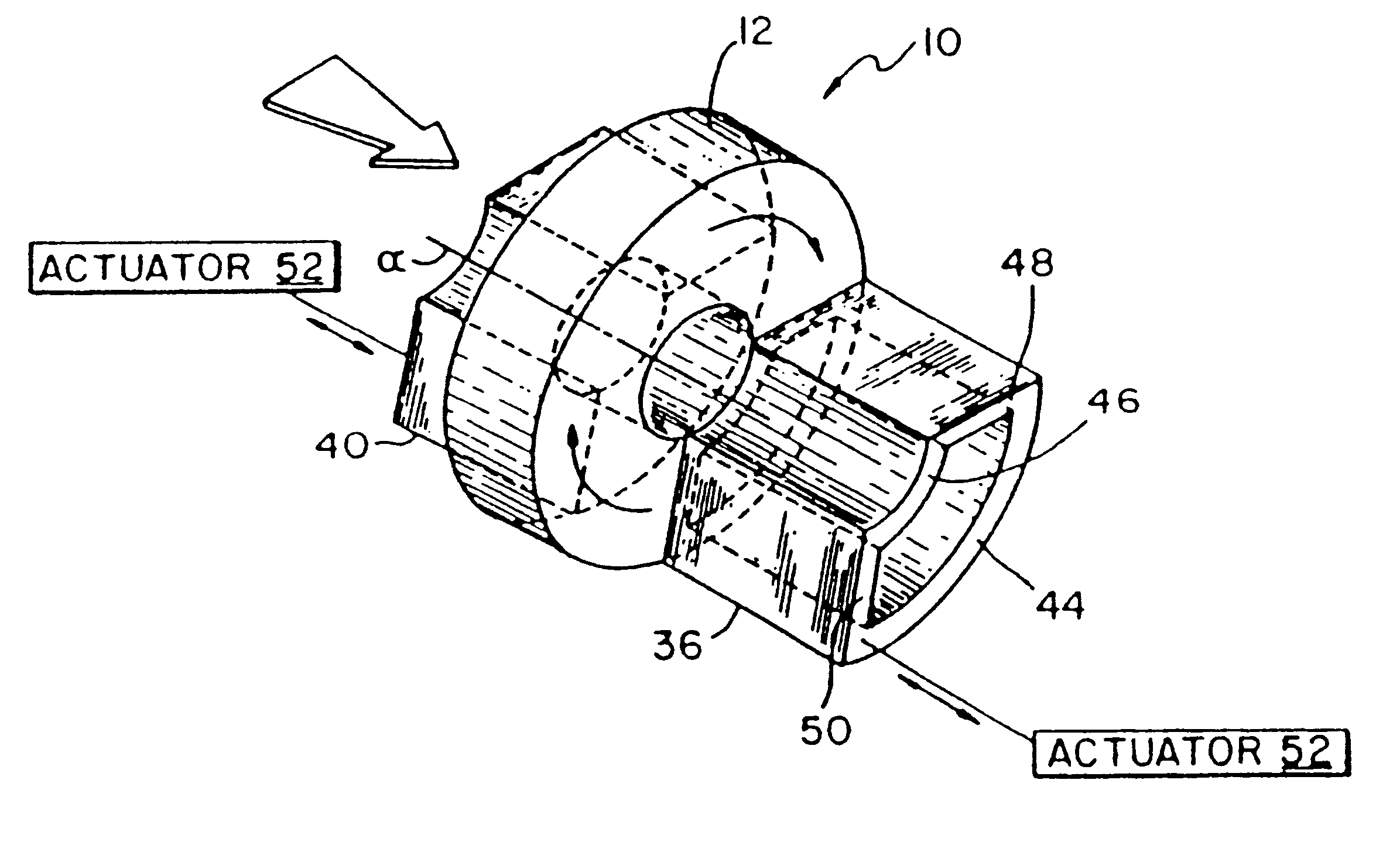

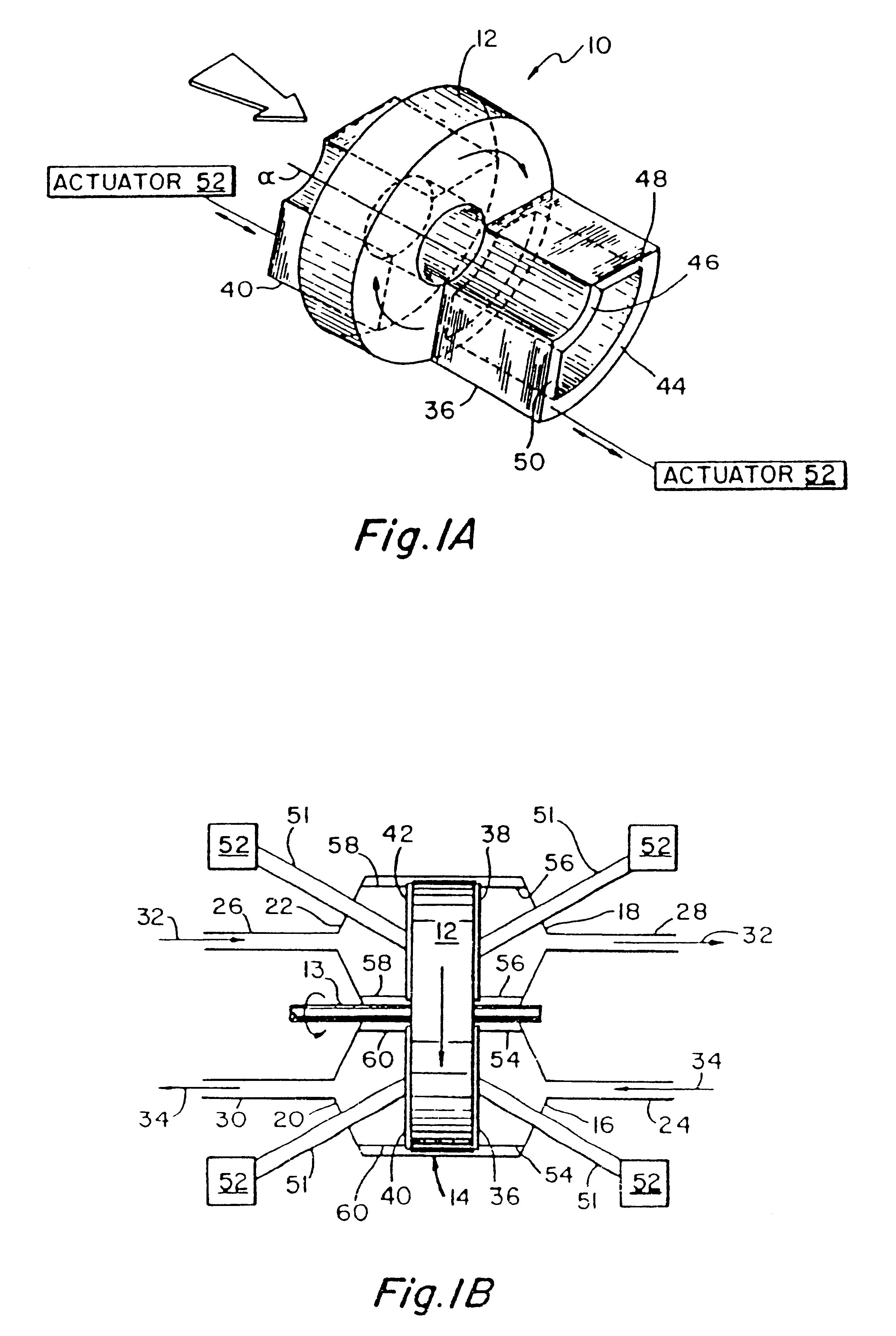

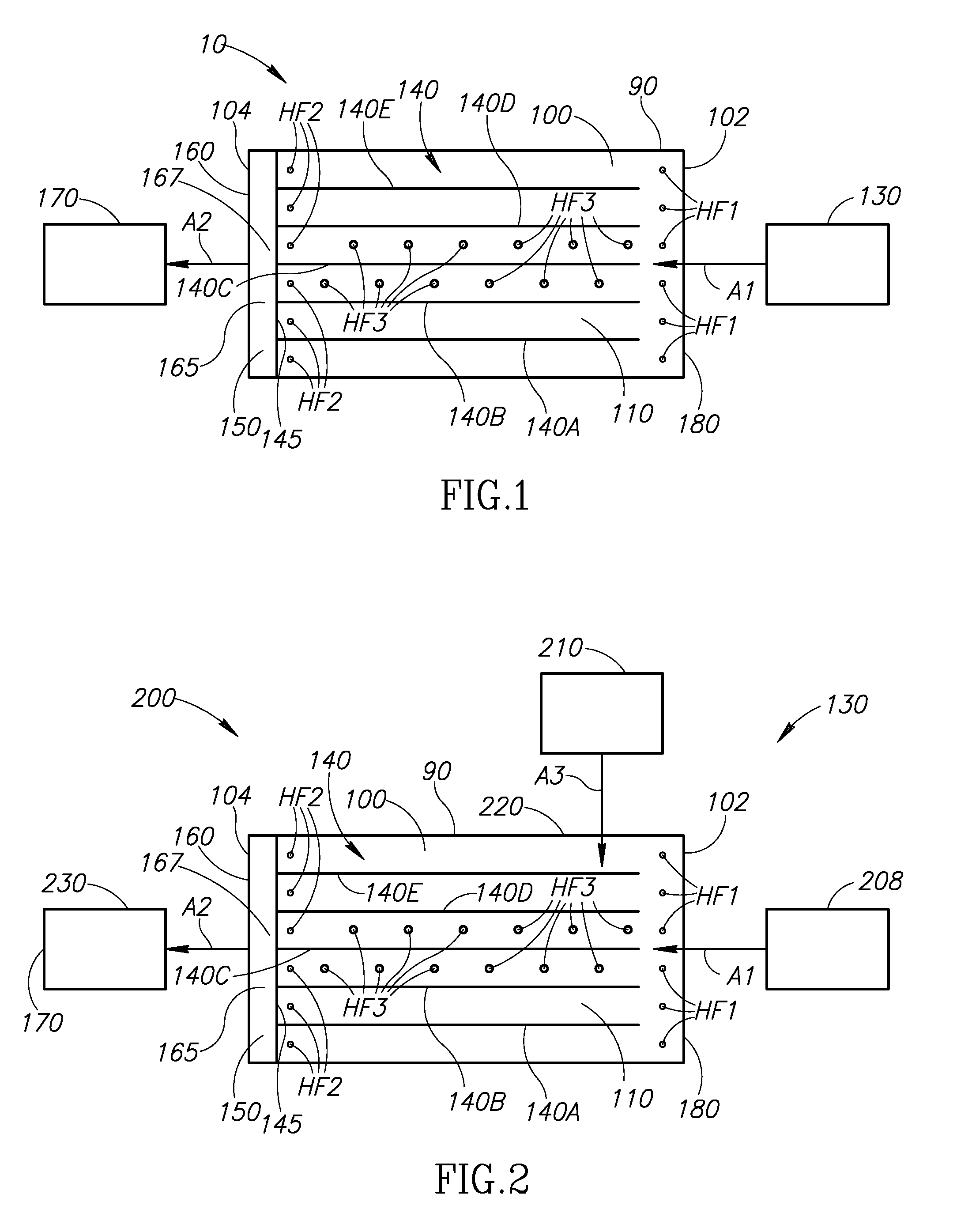

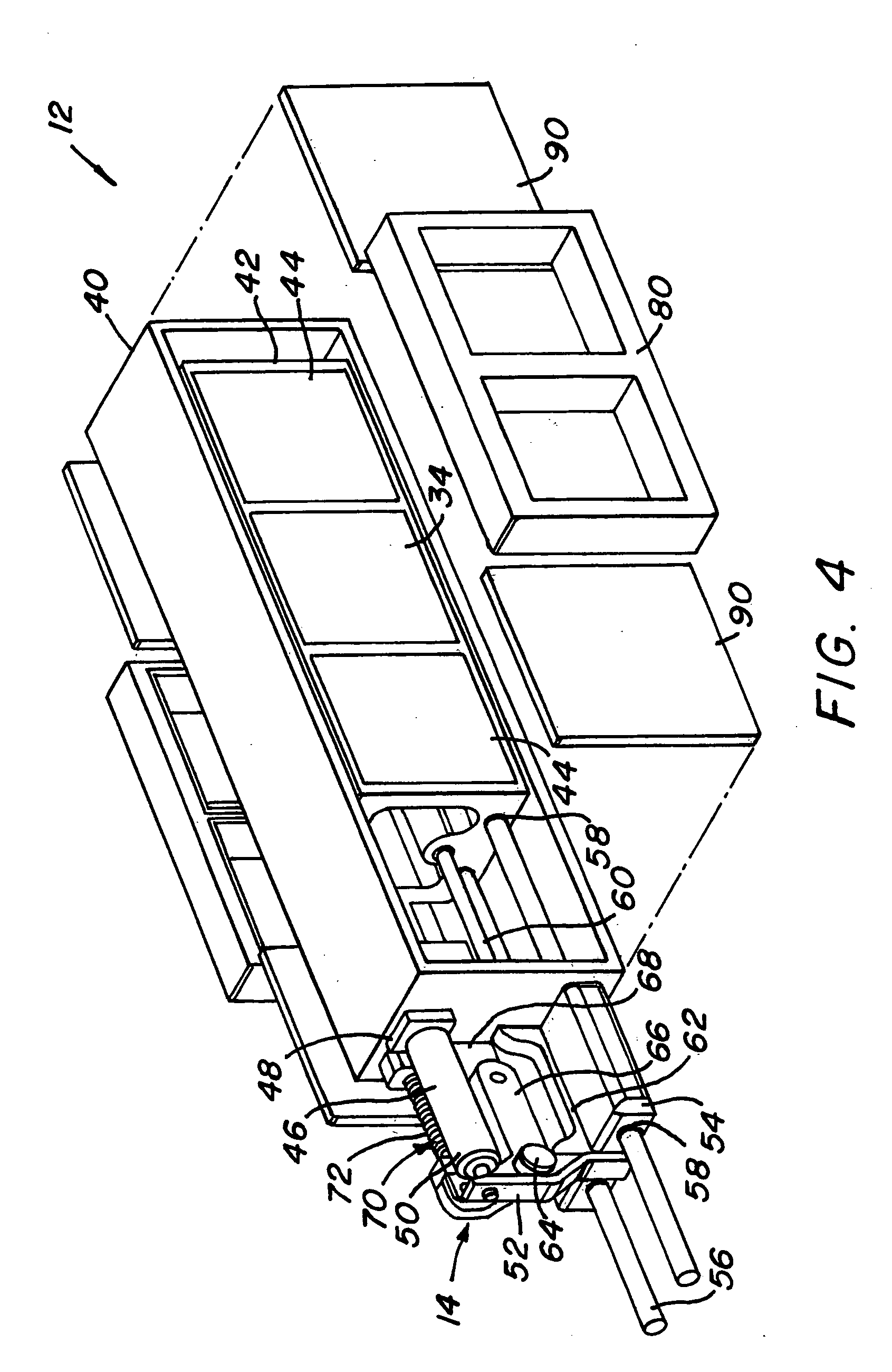

Variable area mass or area and mass species transfer device and method

Disclosed herein is a-variable-area or mass or area and mass ratio species transfer device, one embodiment with a plurality of species transfer masses. At least one actuator is disposed in communication with the species transfer masses, capable of selectively moving one or more of the masses independently of other one or more of the masses into at least contact with a first fluid stream and into contact with a second fluid stream. Yet further disclosed herein is a method for controlling species transfer in a species transfer device. The method includes: selecting an appropriate mass / area ratio between a portion of a variable area or mass or area and mass ratio species transfer device exposed to a higher-temperature fluid and a portion of the species transfer device exposed to a lower-temperature fluid; exposing one selected portion of the species transfer device to the higher-temperature fluid; and exposing another selected portion of the species transfer device to the lower-temperature fluid.

Owner:WILSON SOLARPOWER CORP

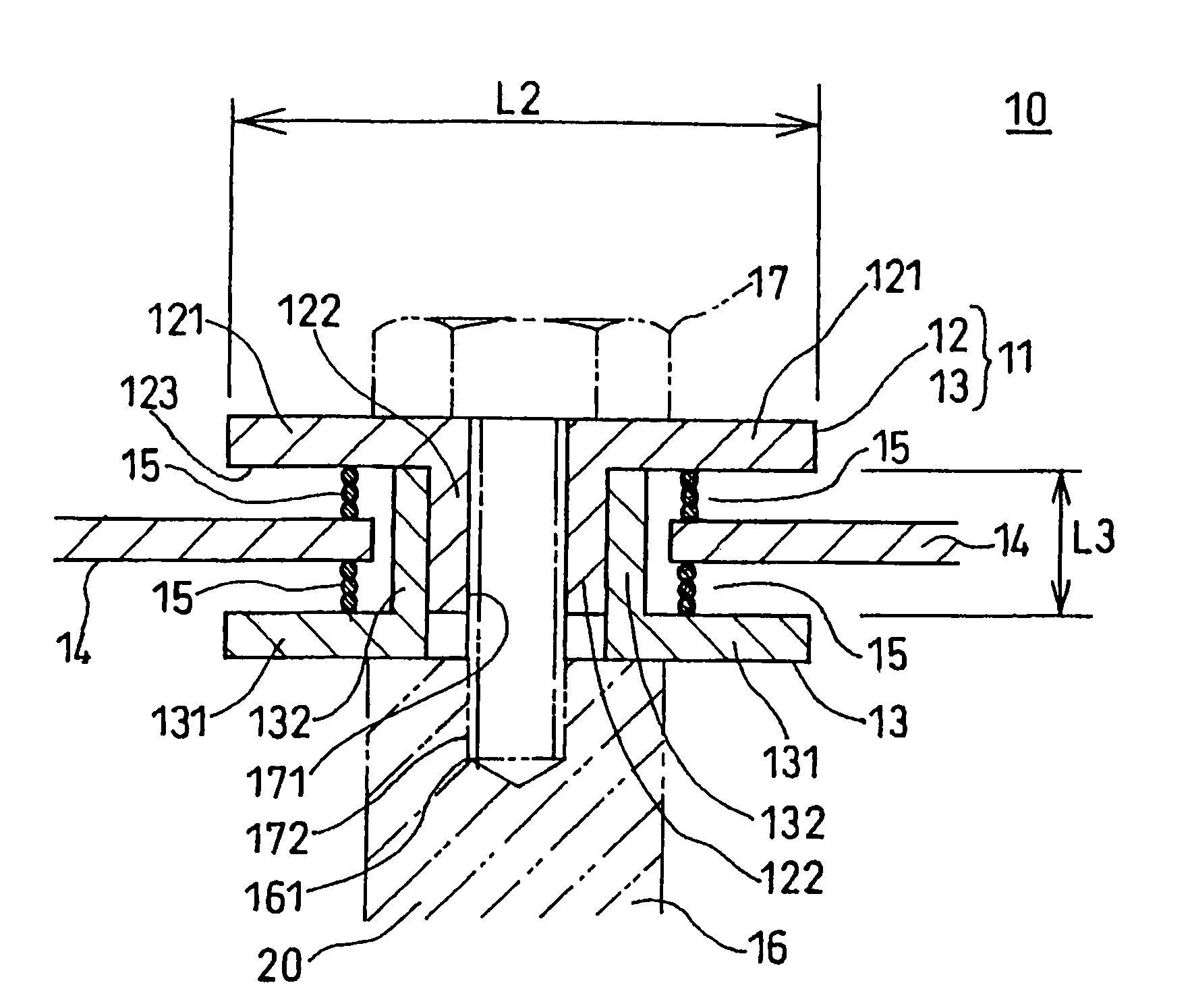

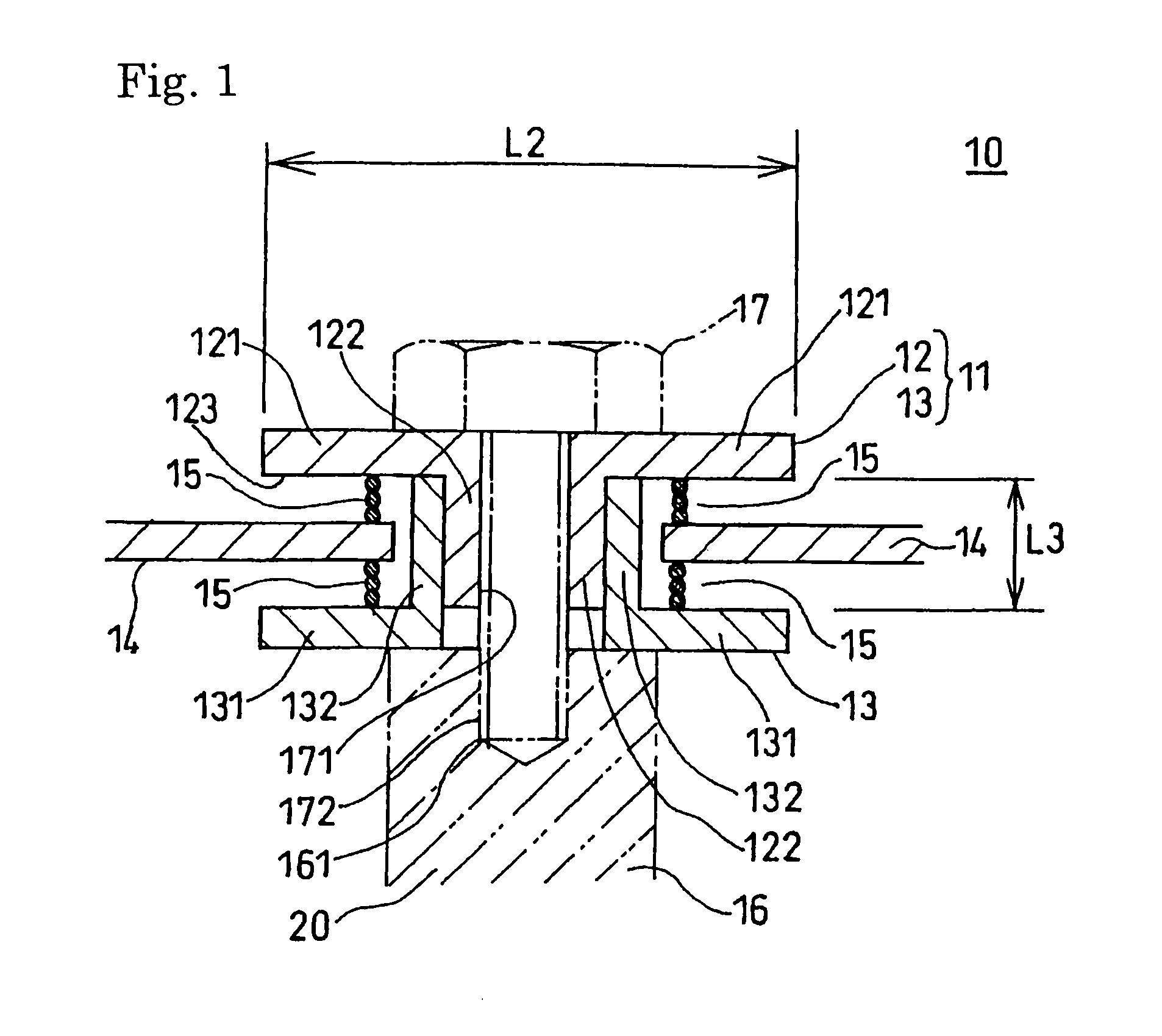

Vibration and heat insulating board

ActiveUS7065963B2Efficient processReduce in quantityExhaust apparatusNon-rotating vibration suppressionSource surfaceVibration source

A vibration and heat insulating board fixed so as to cover at least part of a heat source while forming a gap against the heat source surface, in order to lessen diffusion of heat from the heat source fixed in a vibration source, in which the heat source and the vibration and heat insulating board are coupled by means of a collar member having a pair of locking pieces fitted to the vibration and heat insulating board main body and bolted to a mounting part of the heat source, and ring-shaped coil members interposed between the pair of locking pieces of the collar member and the vibration and heat insulating board main body.

Owner:NICHIAS CORP

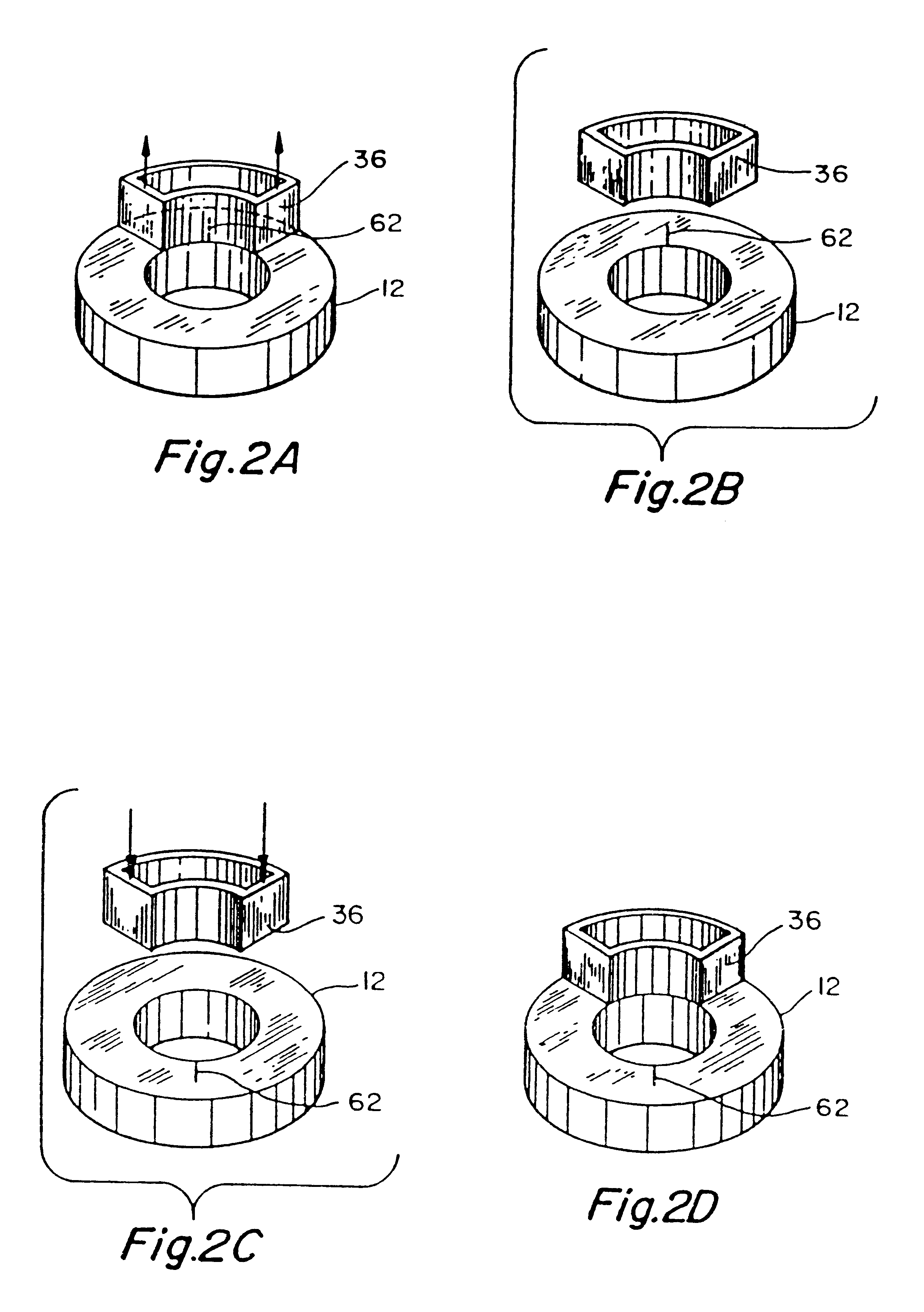

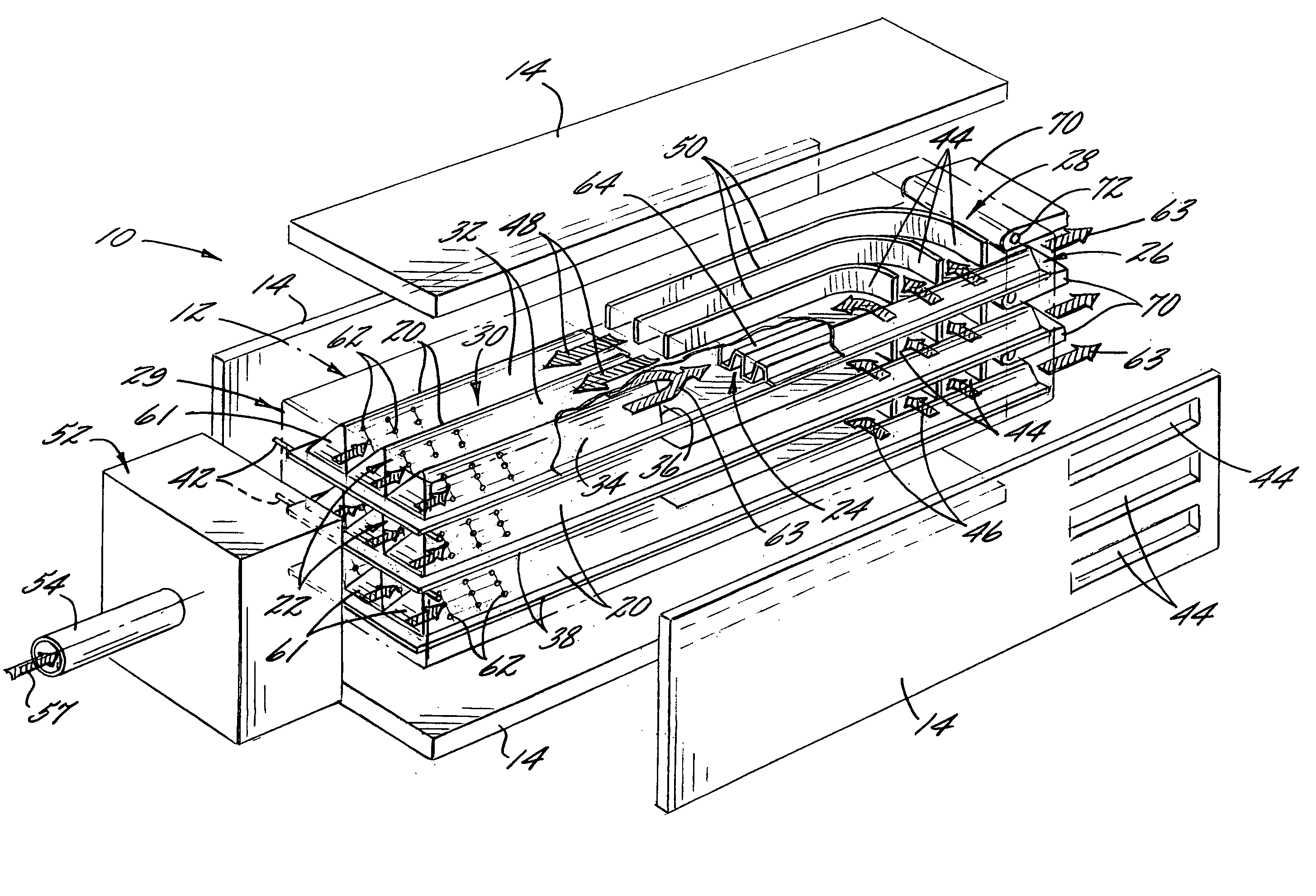

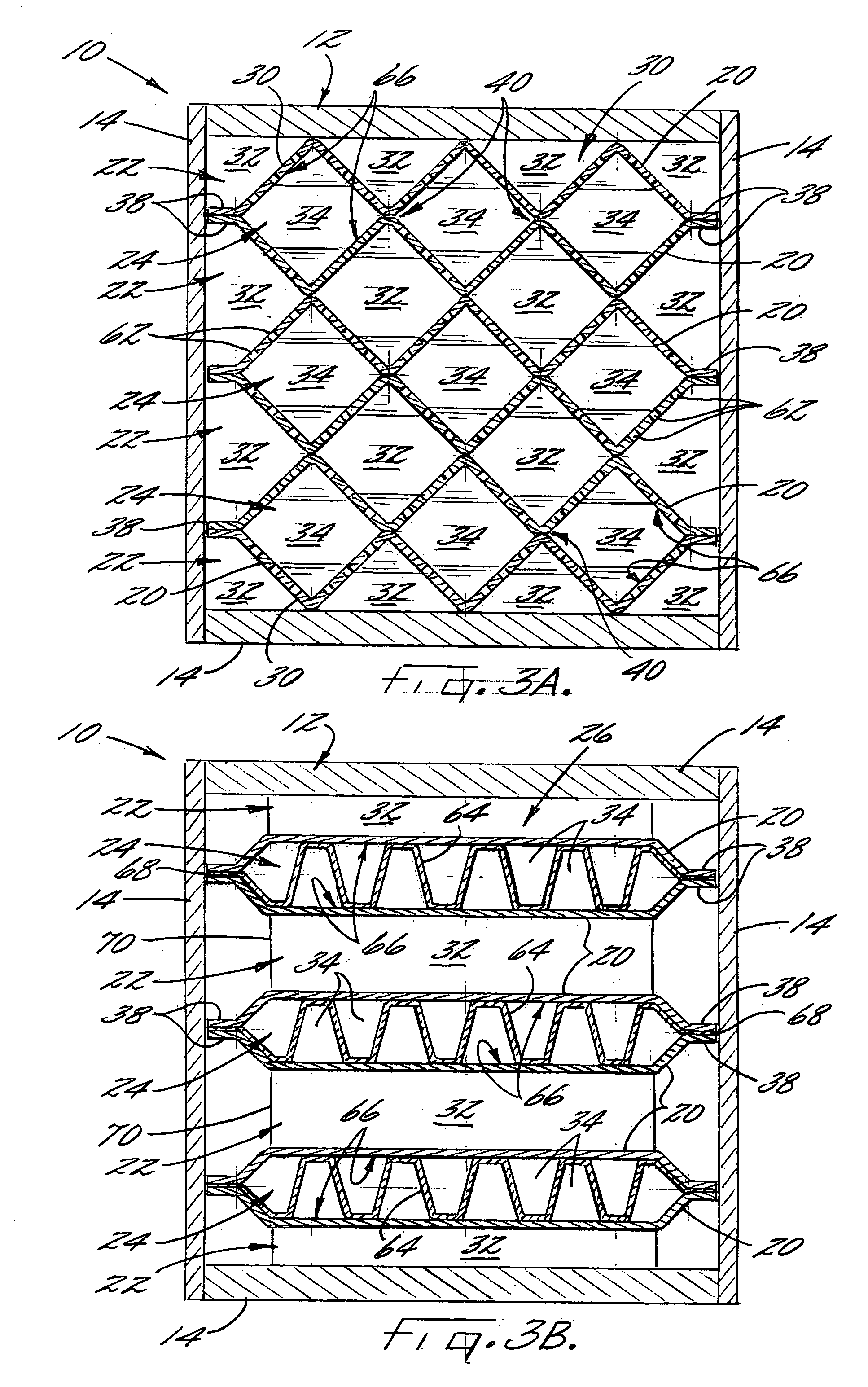

Embossed regenerator matrix for heat exchanger

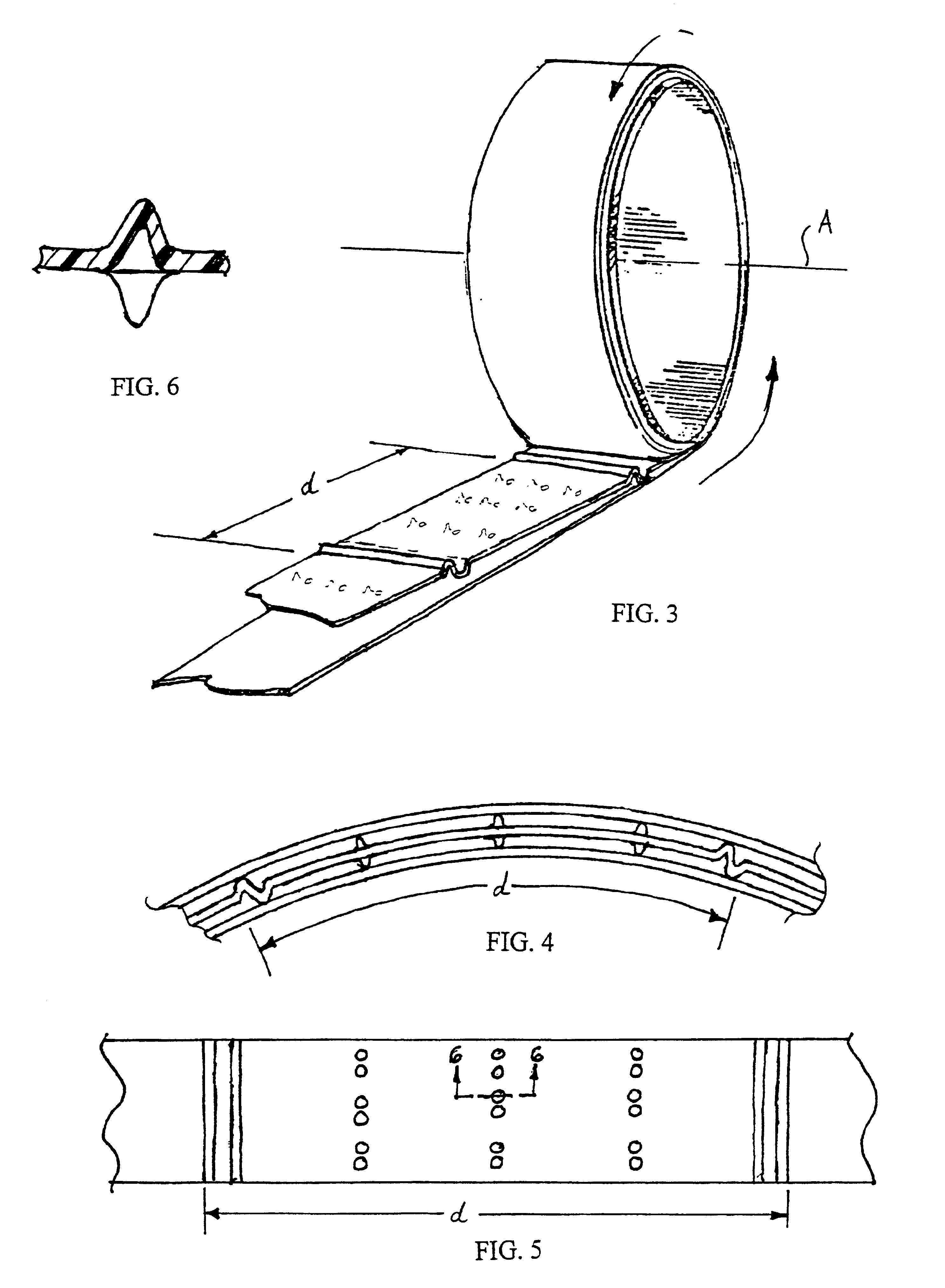

InactiveUS6892795B1Uniform heightImprove heat exchange efficiencyAir treatment detailsCombustion processPlate heat exchangerCounter flow

A regenerator matrix for effecting the transfer of heat between two counter-flowing air streams separated in part by face seals. The matrix includes strips of material wound about an axis so as to provide a plurality of layers. The matrix also includes embossments located on at least some of the layers and providing interlayer spaces between at least some of the layers, such that the interlayer spaces extend through the matrix substantially parallel to the axis. The embossments have a uniform height and include primary and secondary embossments. The primary embossments extend substantially parallel to the axis to divide the interlayer spaces into gas passageways and substantially resist circumferential gas leakage between the gas passageways. The primary embossments are also for aligning with the face seals to prevent circumferential gas leakage between the two counter-flowing air streams, and are successively spaced so that at most two successive primary embossments will align with the face seals. The secondary embossments maintain the interlayer spaces at a substantially uniform spacing between the primary embossments, yet allow circumferential gas flow within the gas passageways.

Owner:AIRXCHANGE

Systems and Methods for Removing Materials From Flue Gas Via Regenerative Selective Catalytic Reduction

InactiveUS20090130011A1Improve performanceLower levelGas treatmentNitrogen compoundsFlue gasProduct gas

Regenerative selective catalytic reduction (RSCR) systems and processes are provided whereby NOx and CO levels in gases are reduced by mixing the gas with a reactant and then introducing the gas into an RSCR apparatus for treatment that entails heating the gas, causing the gas to undergo one or more catalytic reactions, and then directing the gas through a heat transfer area, to which the gas provides heat for use in connection with successive cycles of the RSCR process.

Owner:BABCOCK POWER ENVIRONMENTAL INC (US)

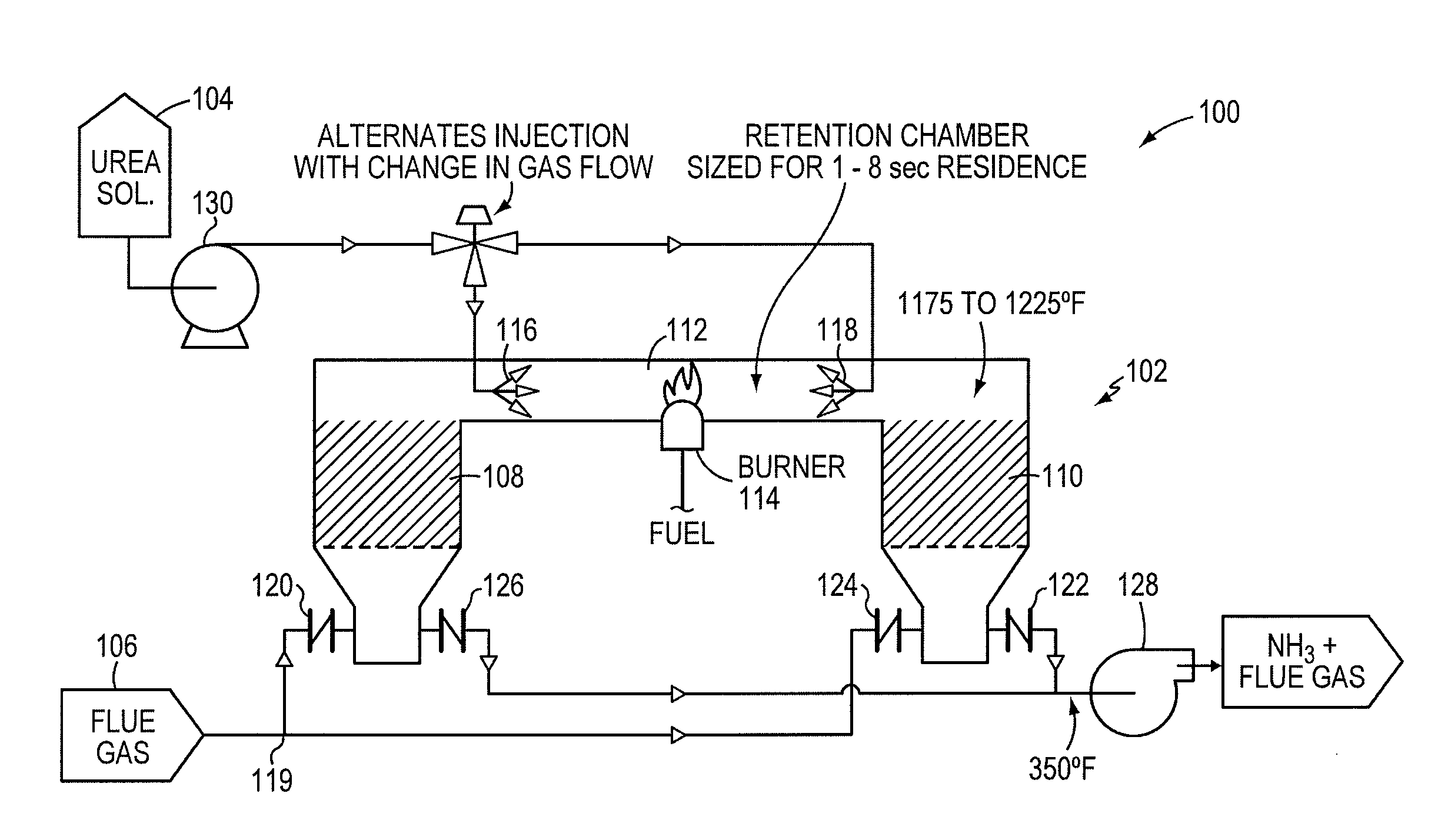

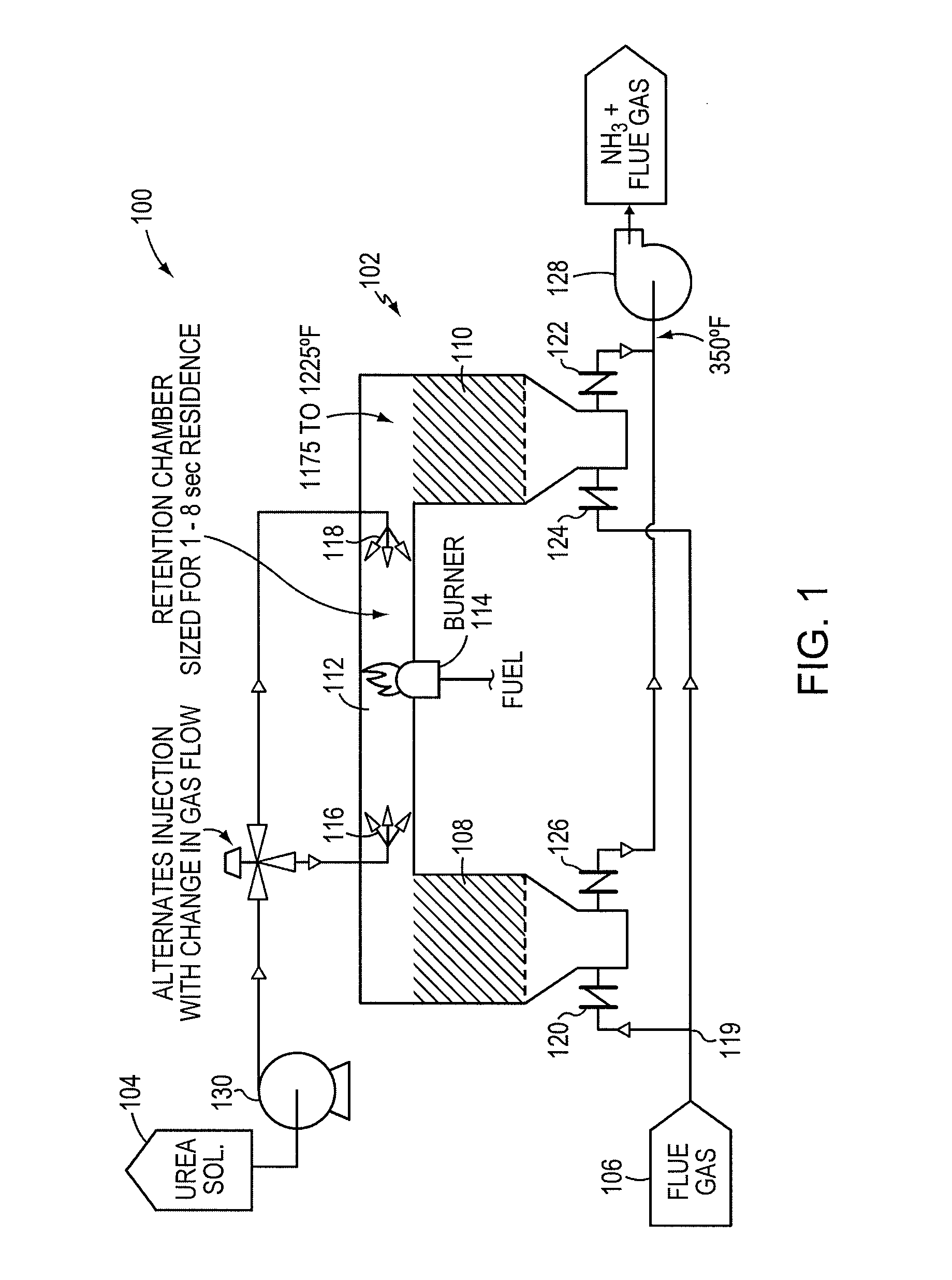

Thermal Decomposition of Urea in a Side Stream of Combustion Flue Gas Using a Regenerative Heat Exchanger

InactiveUS20080050297A1Avoid insufficient temperatureImprove thermal efficiencyNitrogen compoundsExhaust apparatusFlue gasThermal efficiency

This invention relates generally to the treatment of NOx in combustion flue gas. In certain embodiments, the invention relates to the use of a regenerative heat exchanger (RHE) to convert urea to ammonia in a side stream of flue gas. Ammonia and / or other urea decomposition products exit the heat exchanger, are mixed with the rest of the flue gas, and enter a selective catalytic reduction (SCR) unit for reduction of NOx in the flue gas. The use of an RHE significantly improves the thermal efficiency of the overall process. More particularly, in certain embodiments, the regenerative heat exchanger is a dual chamber RHE.

Owner:BABCOCK POWER ENVIRONMENTAL INC (US)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com