System and method for providing conditioned air to an enclosed structure

a technology of conditioned air and enclosed structure, which is applied in the direction of lighting and heating apparatus, heating types, furniture, etc., can solve the problems of system that utilizes air blowers, it takes several days, weeks, or even months to adequately dry a bin full of grain, and the supply air typically requires a significant amount of auxiliary energy. to achieve the effect of reducing the humidity level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

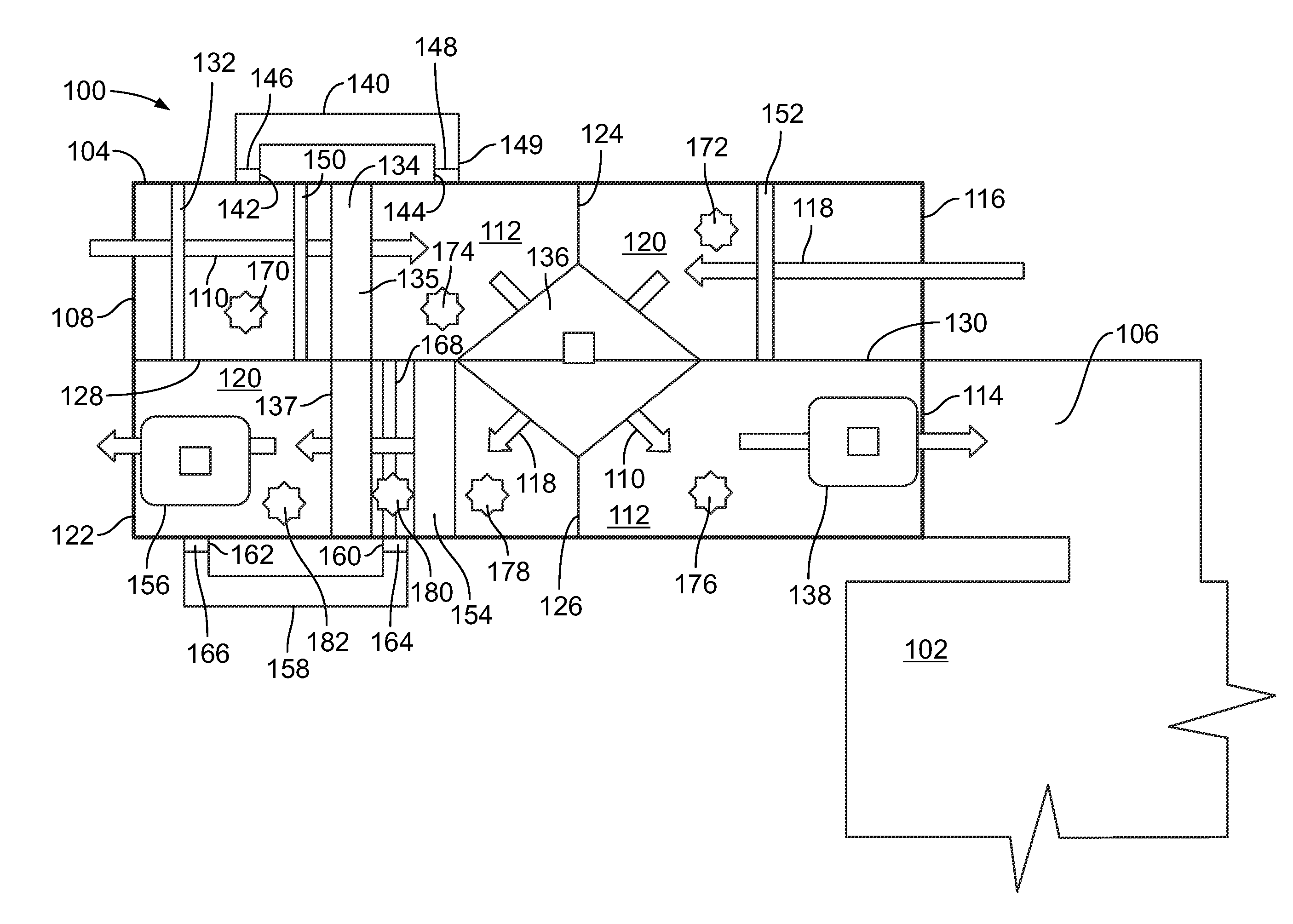

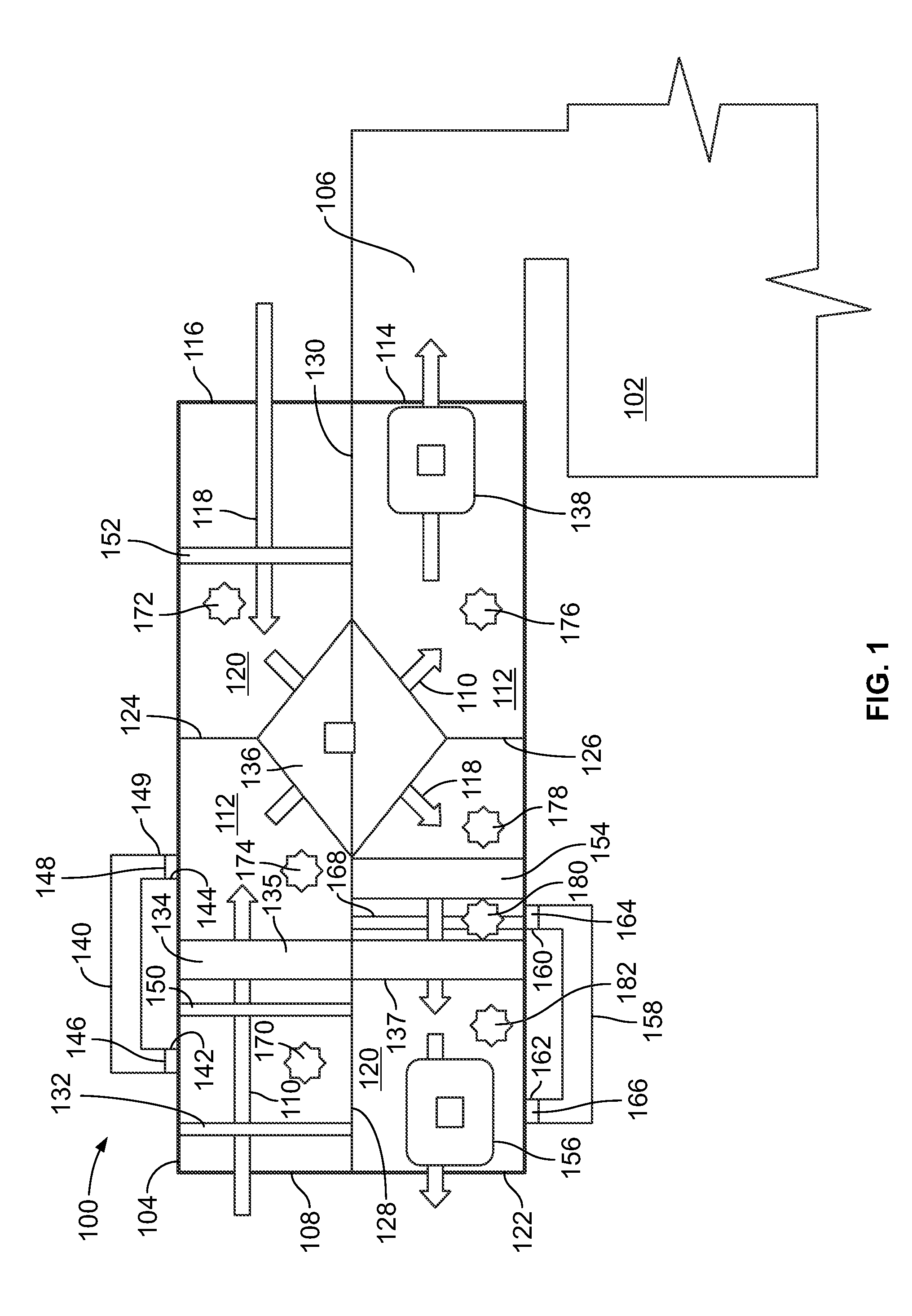

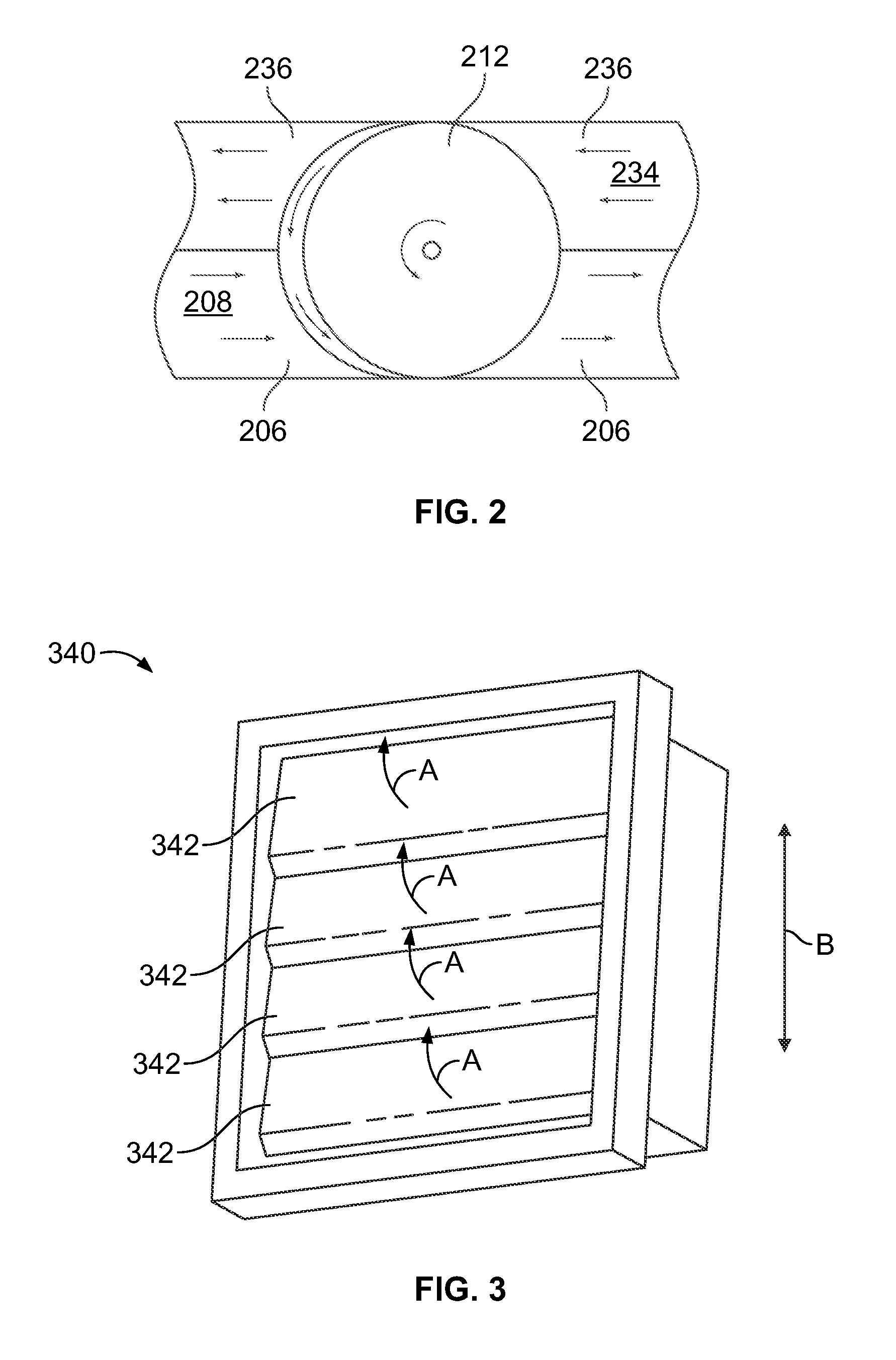

[0009]Certain embodiments of the present disclosure provide an energy exchange system configured to provide supply air to an enclosed structure. The system may include an energy transfer device having a first portion configured to be disposed within a supply air flow path and a second portion configured to be disposed within a regeneration air flow path. The energy transfer device may be configured to decrease a humidity level of the supply air. The energy transfer device is configured to be regenerated with regeneration air. The system may also include a first heat exchanger configured to be disposed within the supply air flow path downstream from the energy transfer device and within the regeneration air flow path upstream from the second portion of the energy transfer device. The first heat exchanger is configured to transfer sensible energy between the supply air and the regeneration air. The energy exchange system is configured to supply the supply air to the enclosed structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com