Patents

Literature

11702results about How to "Improve drying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

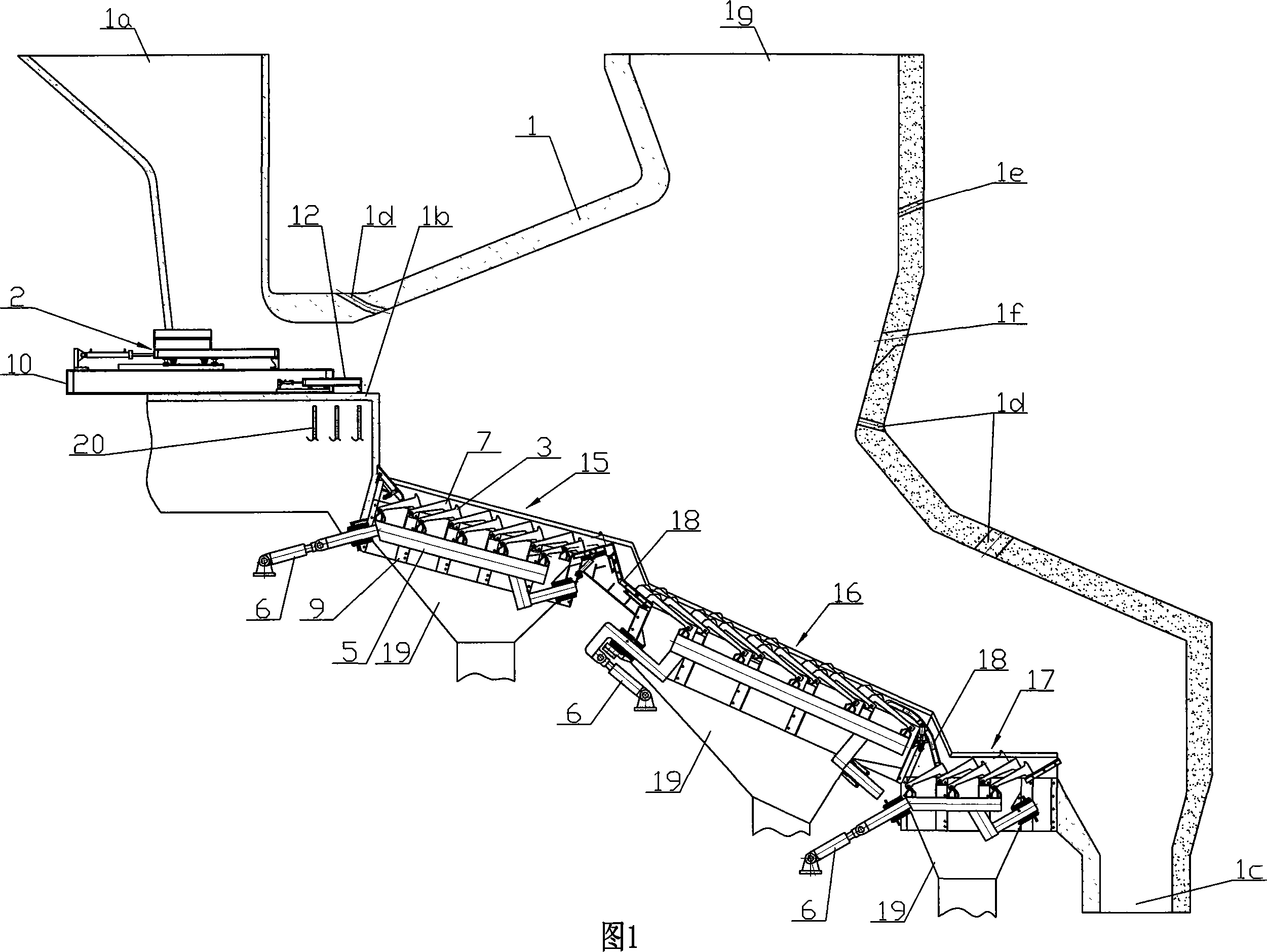

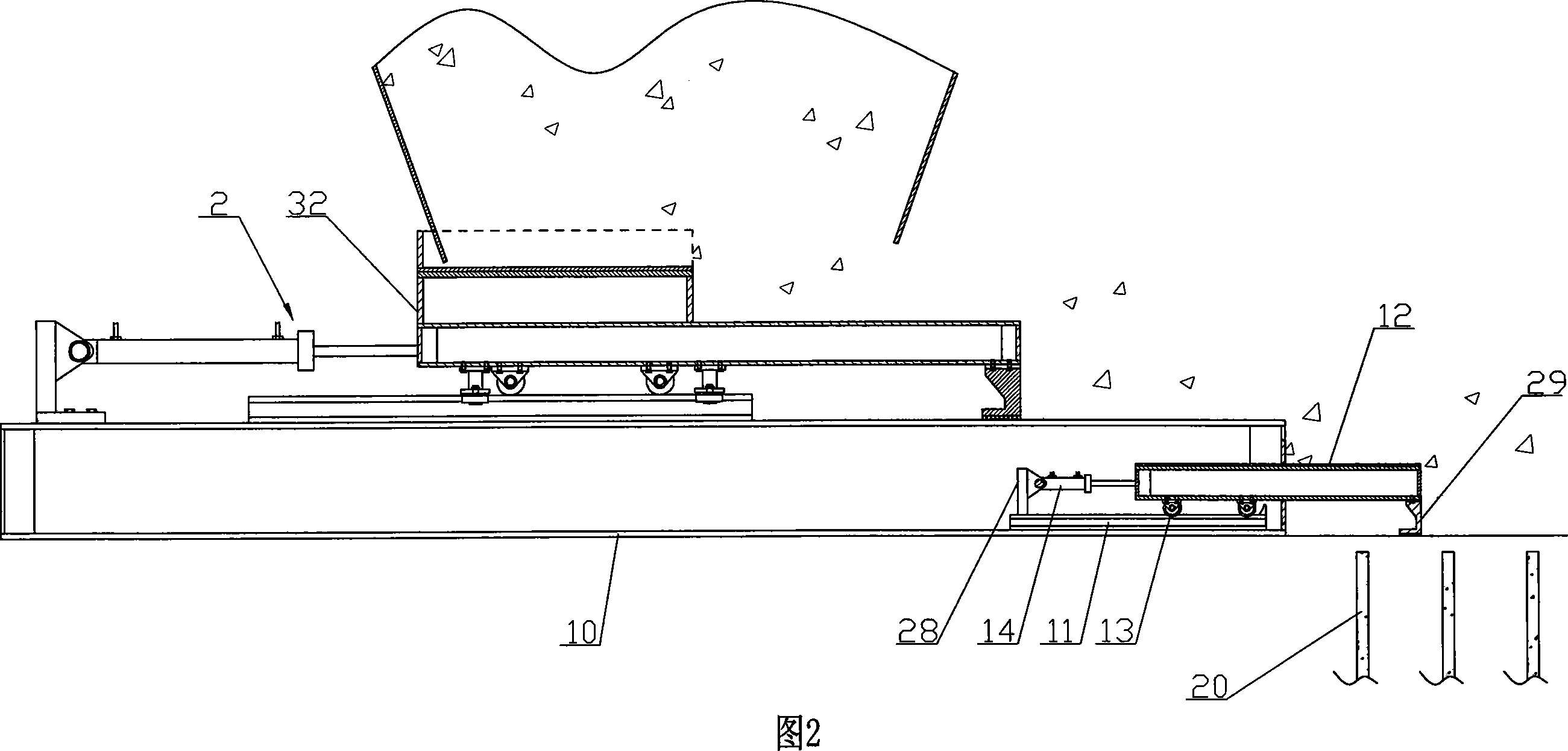

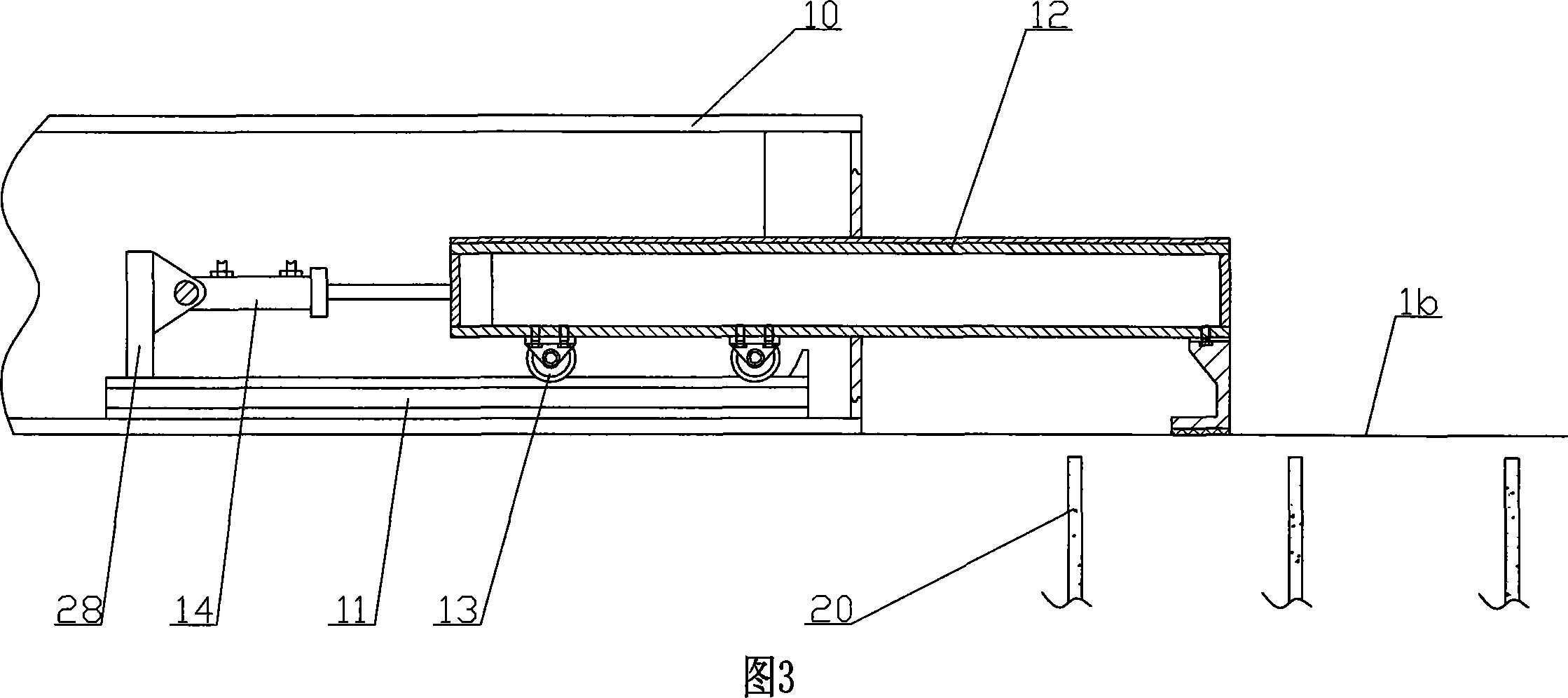

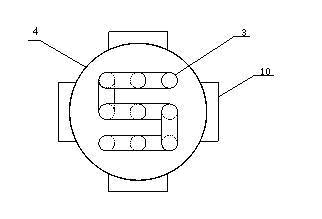

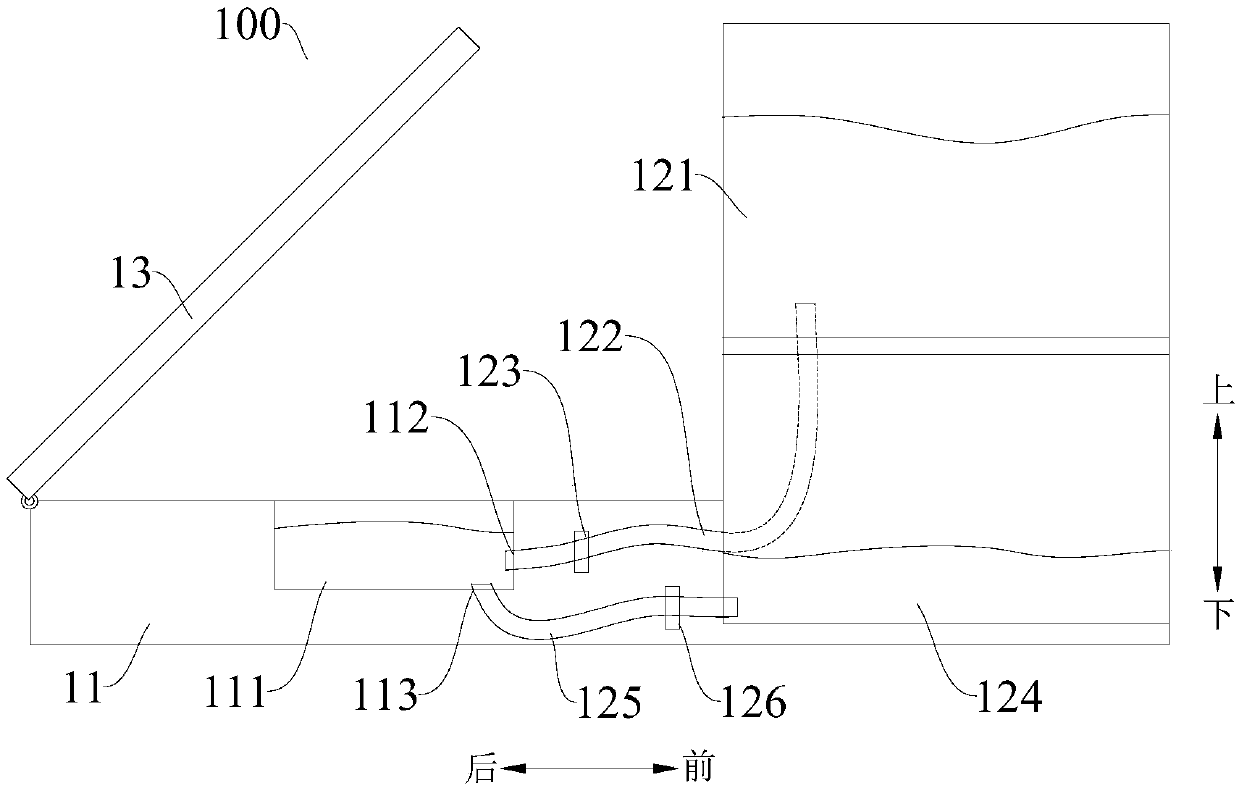

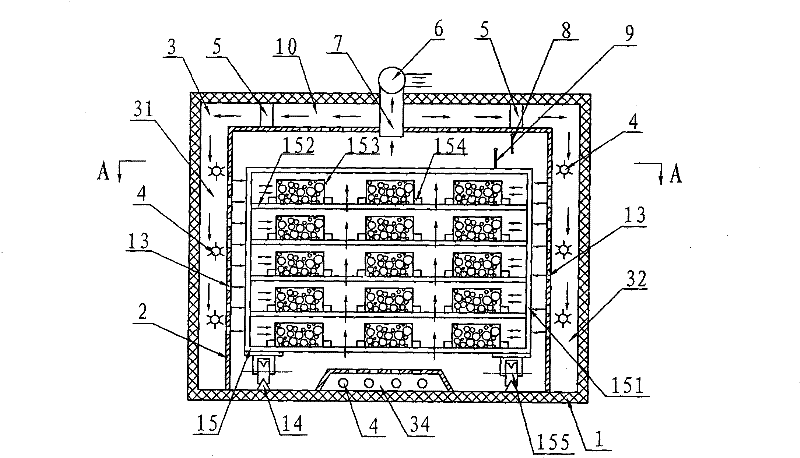

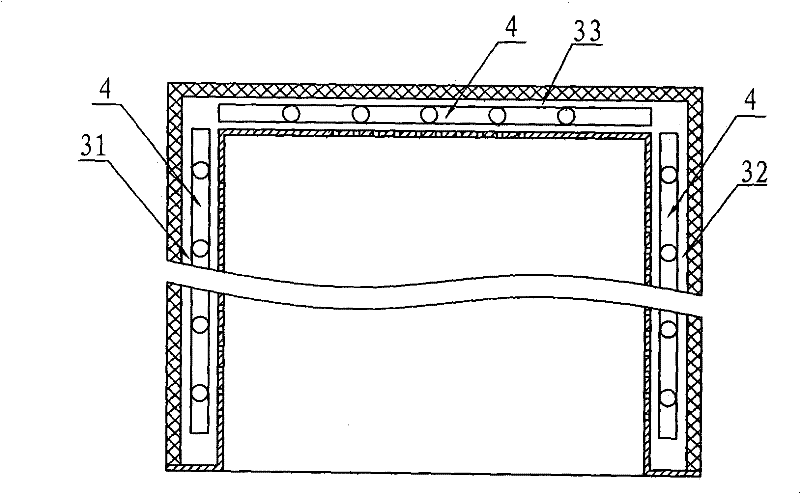

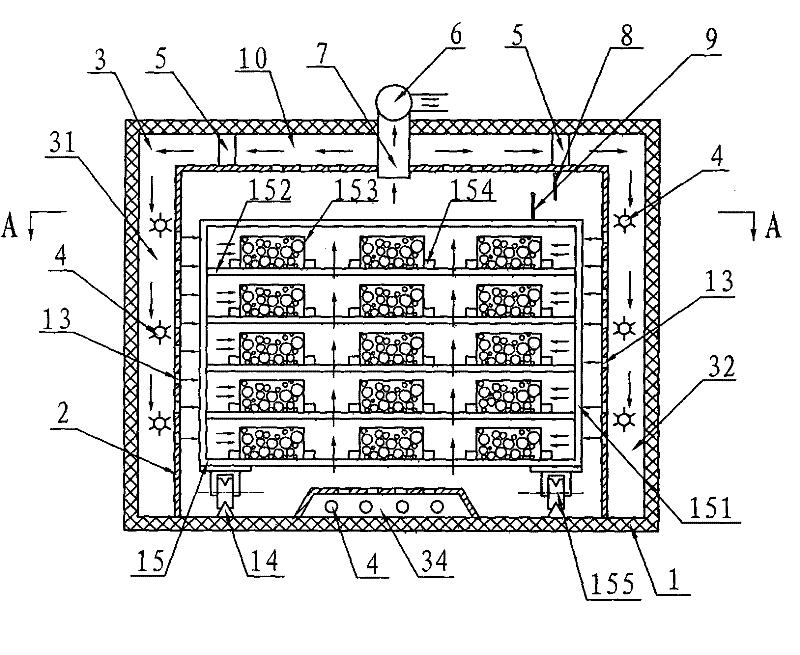

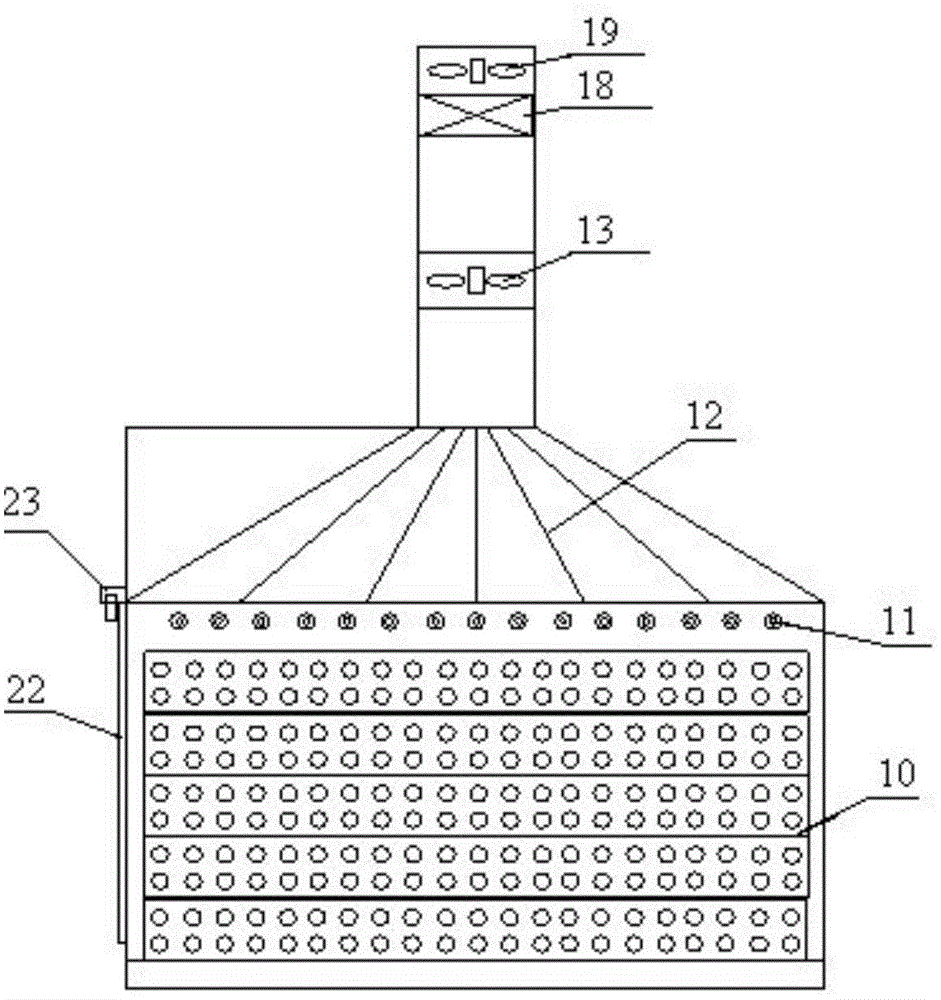

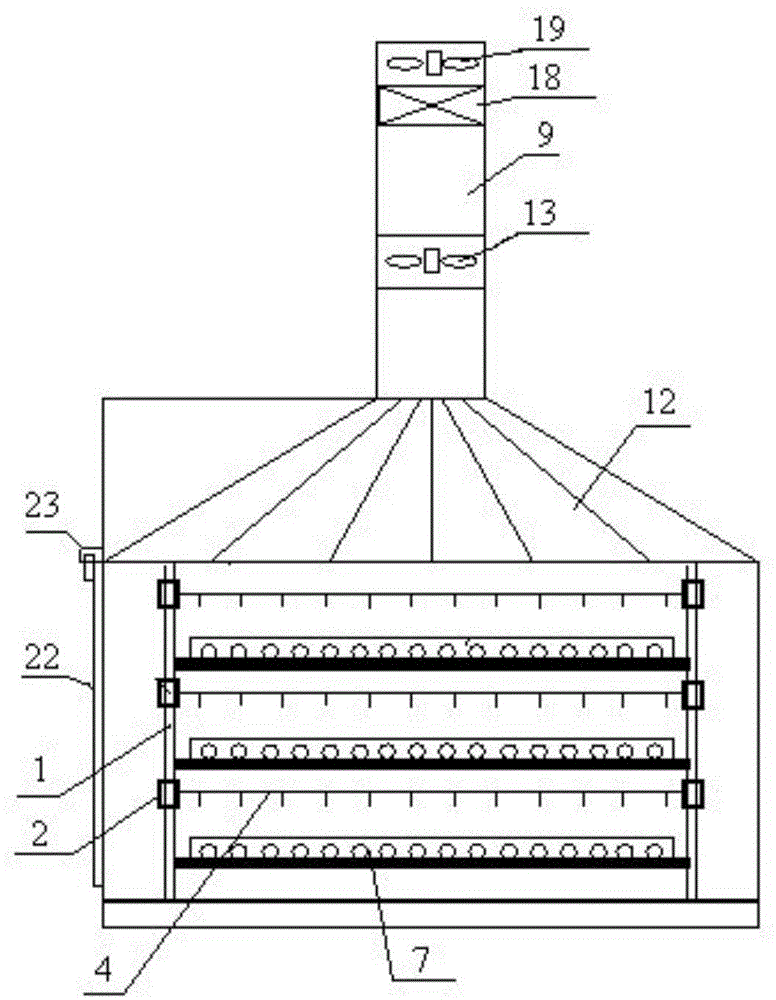

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

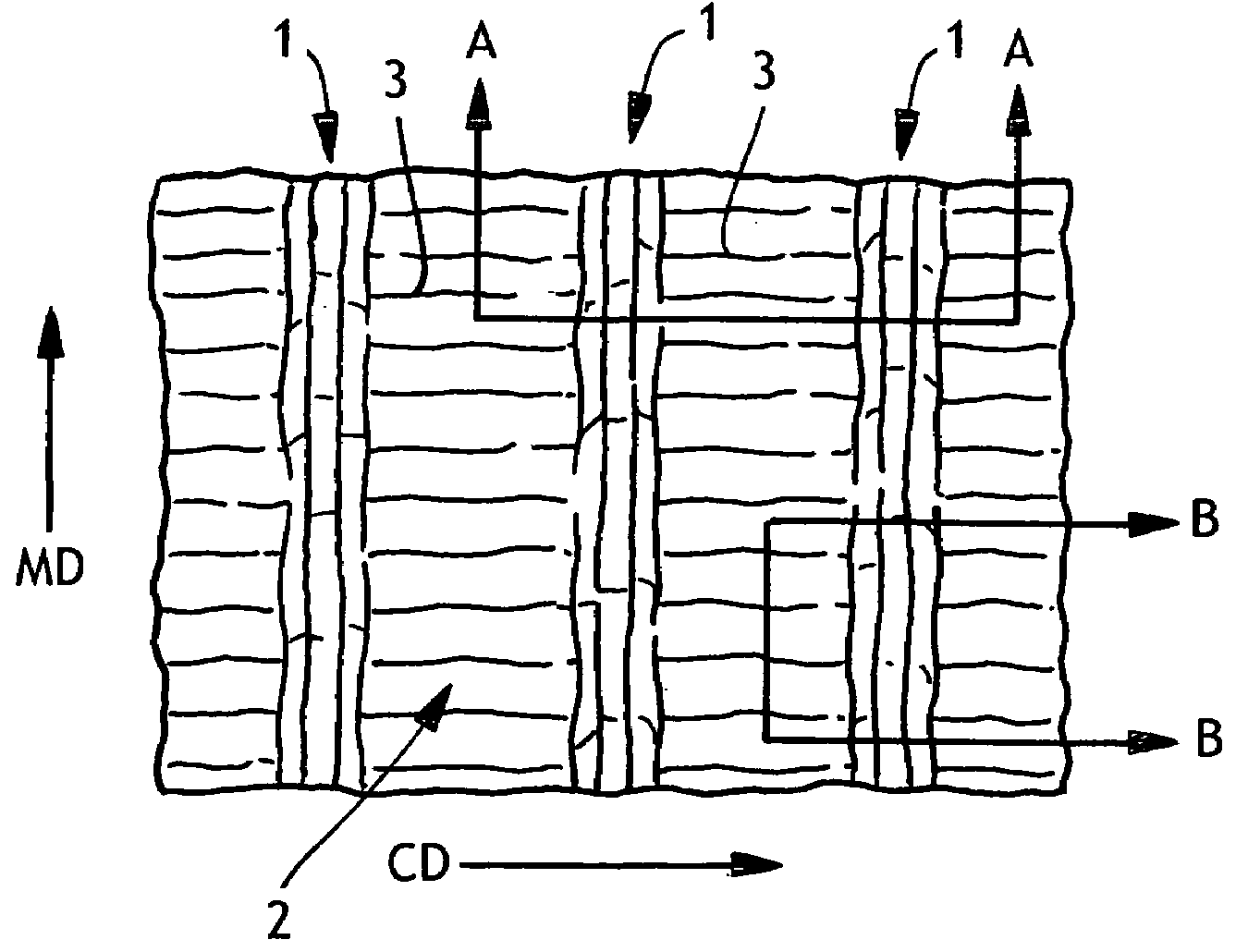

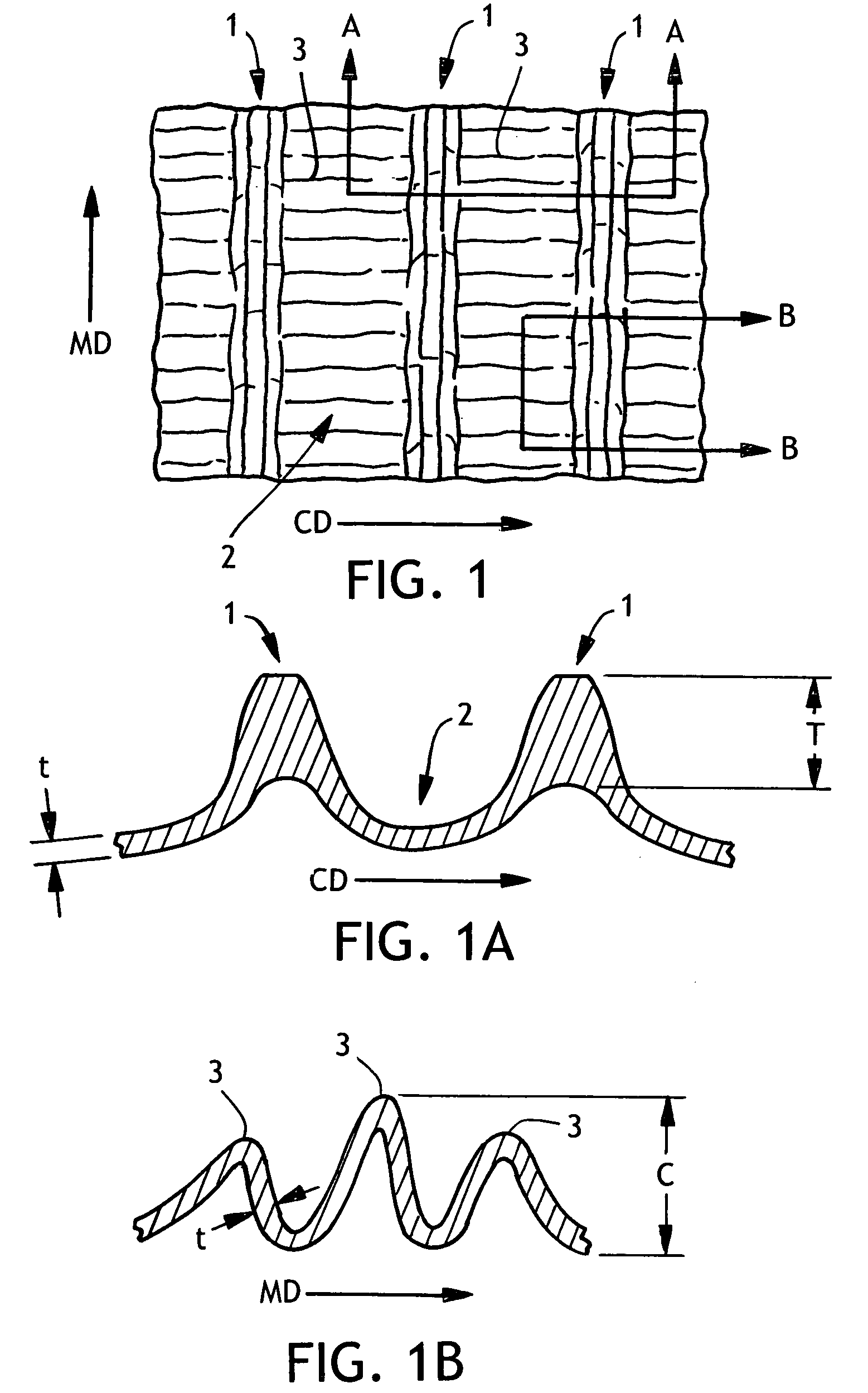

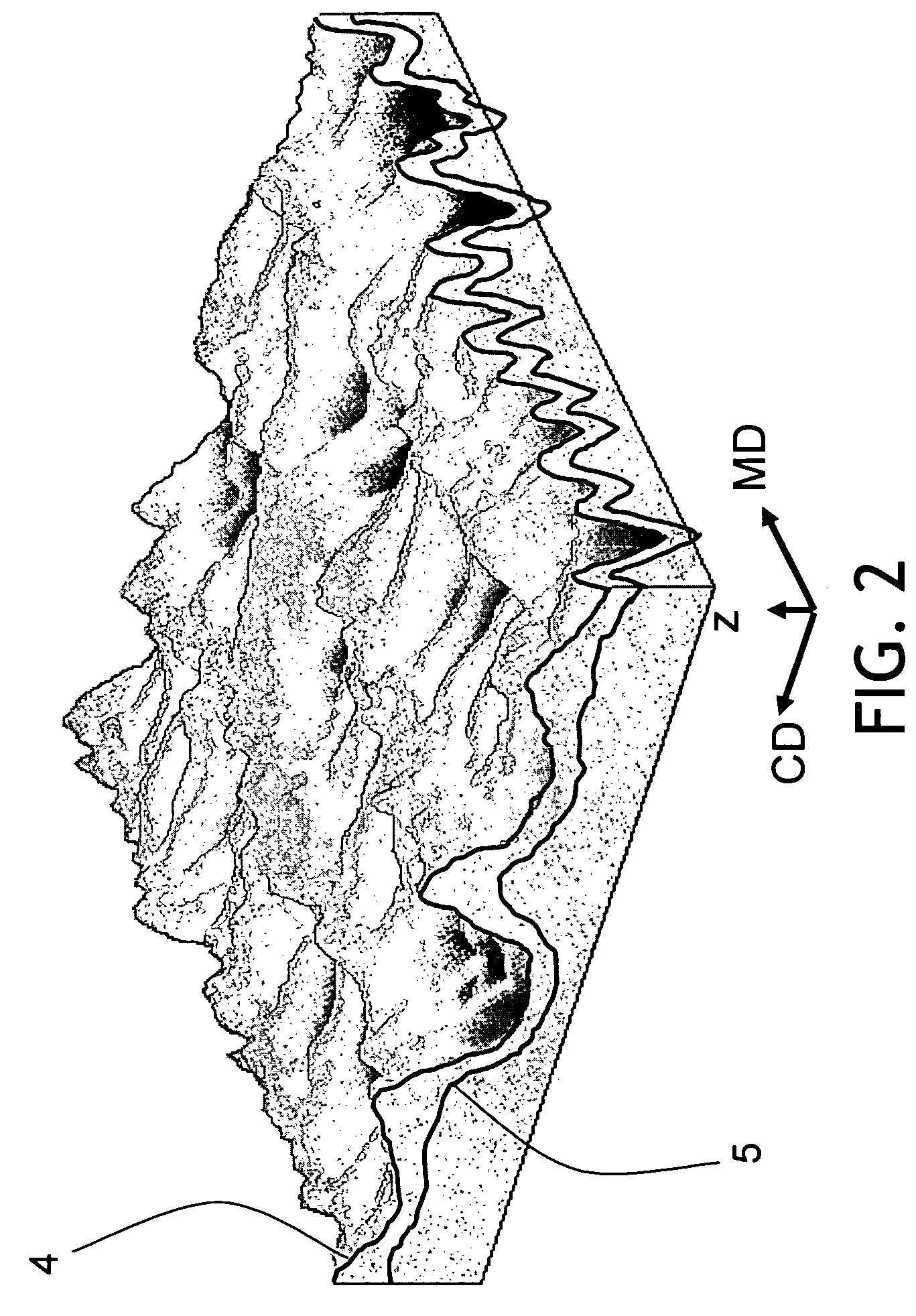

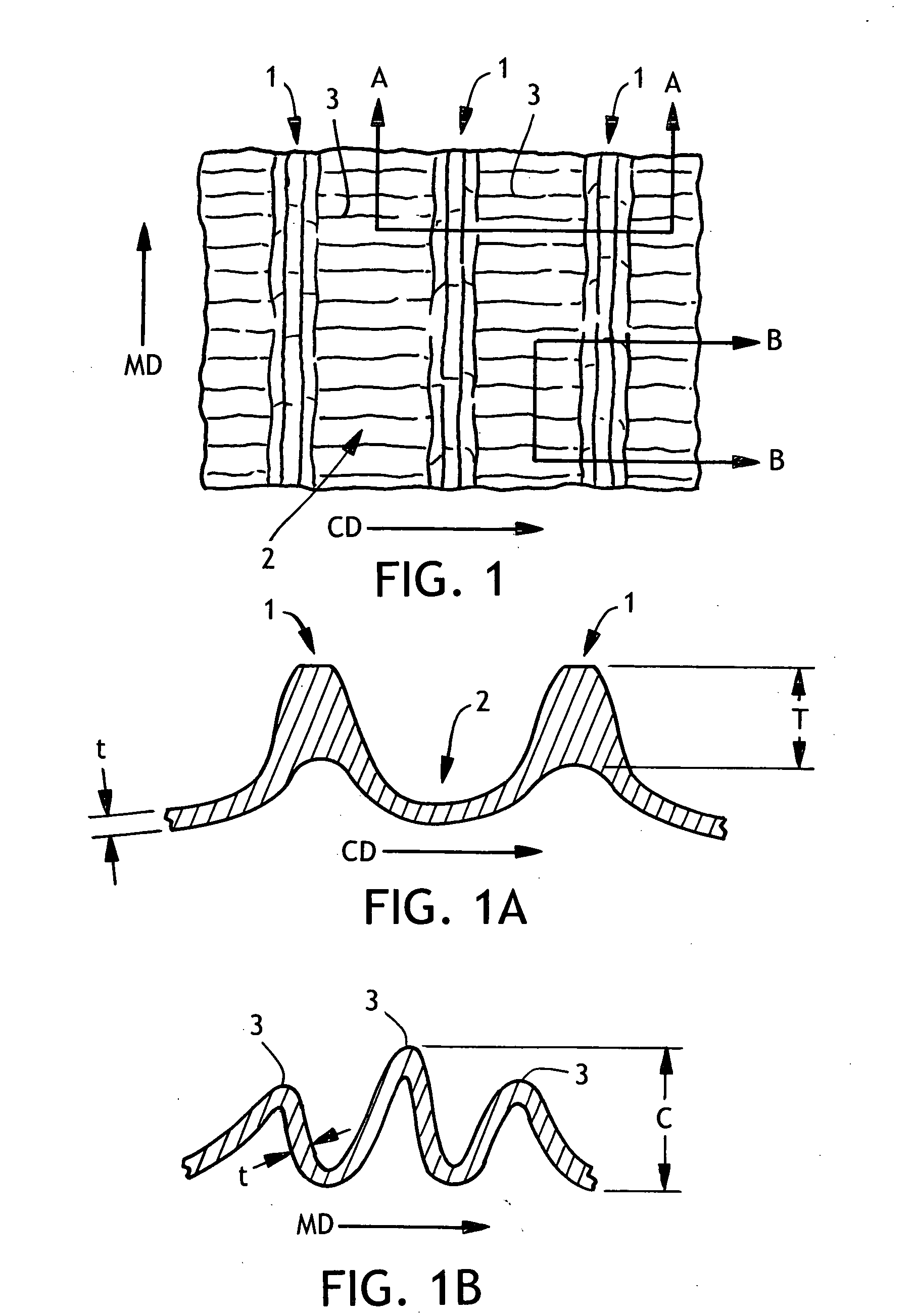

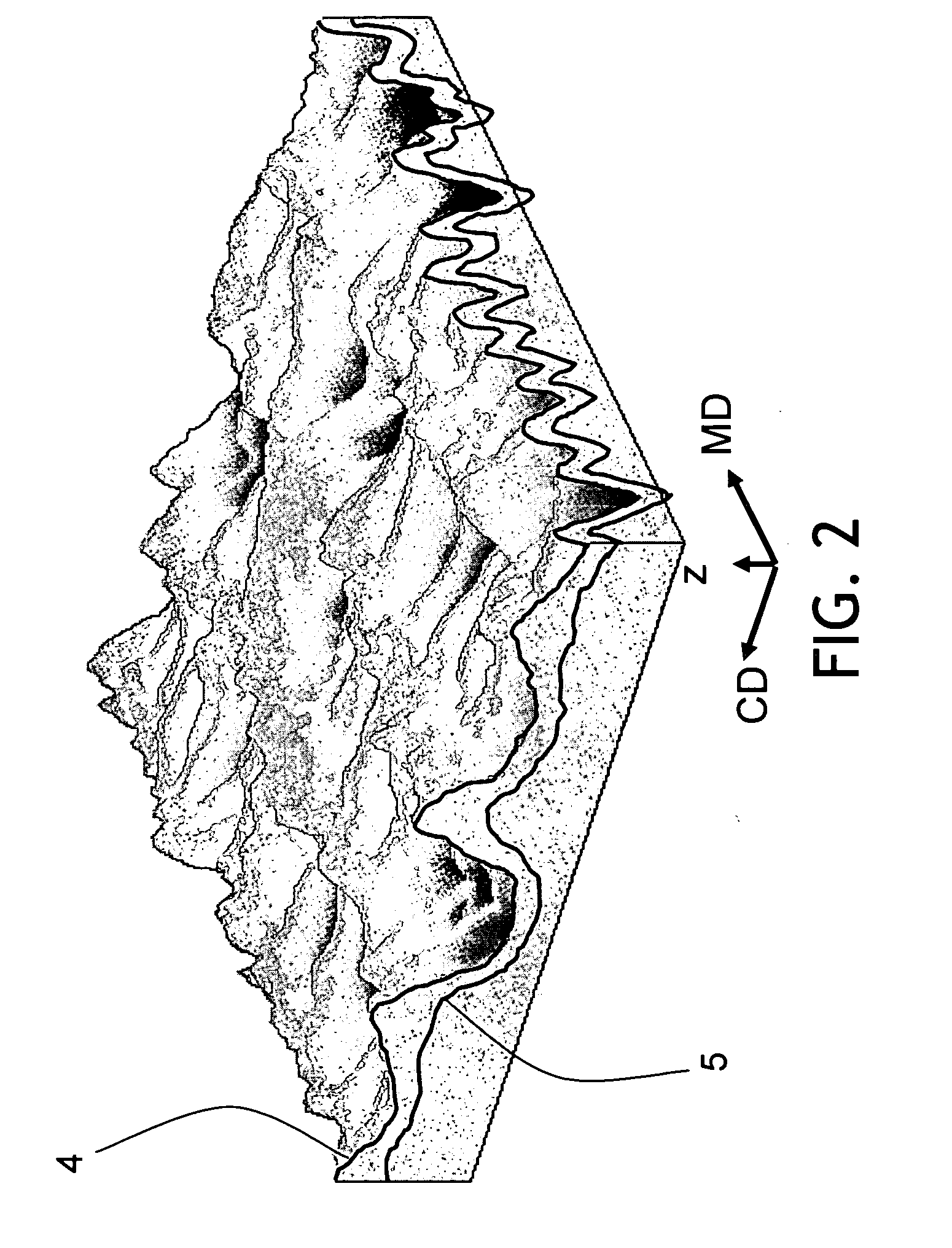

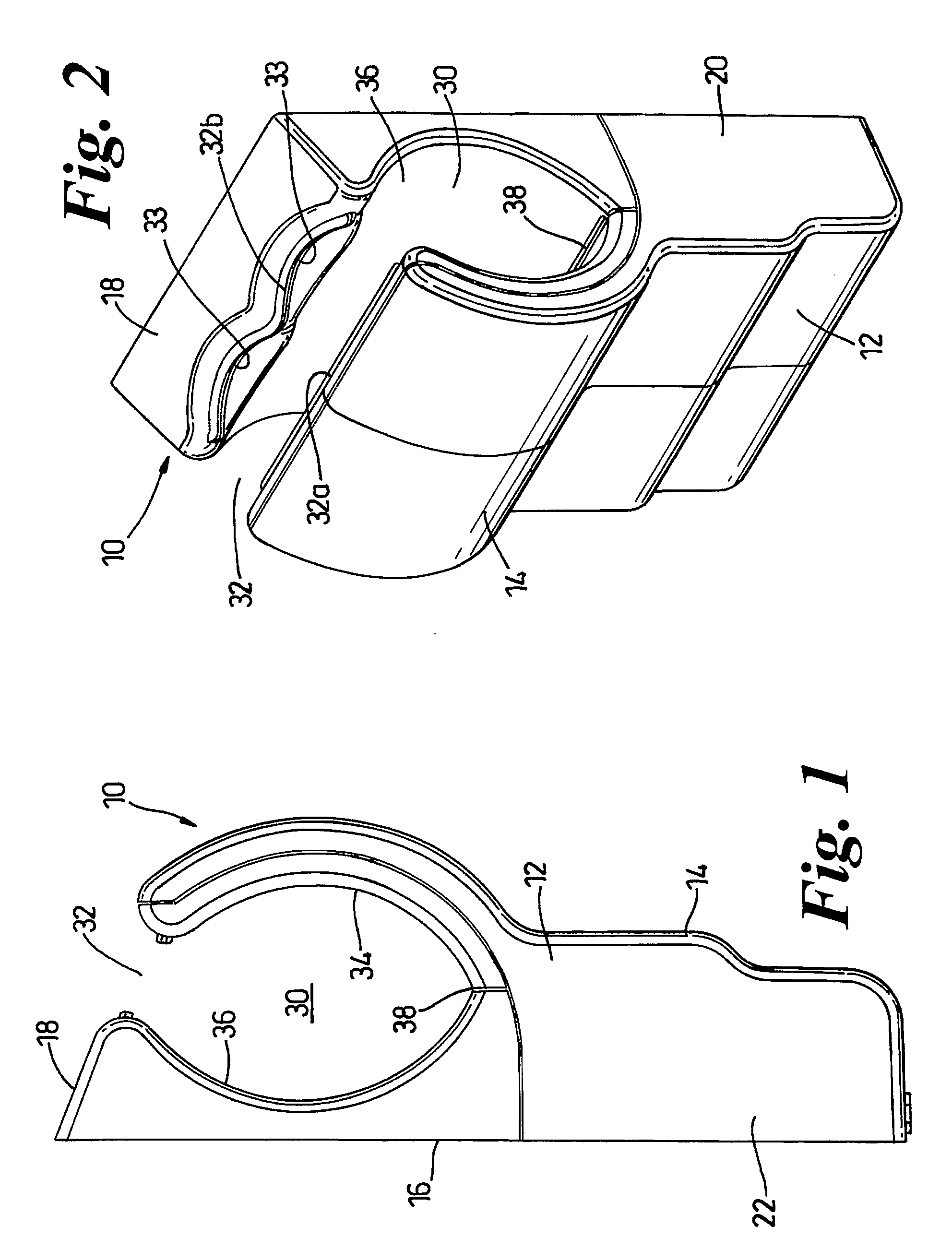

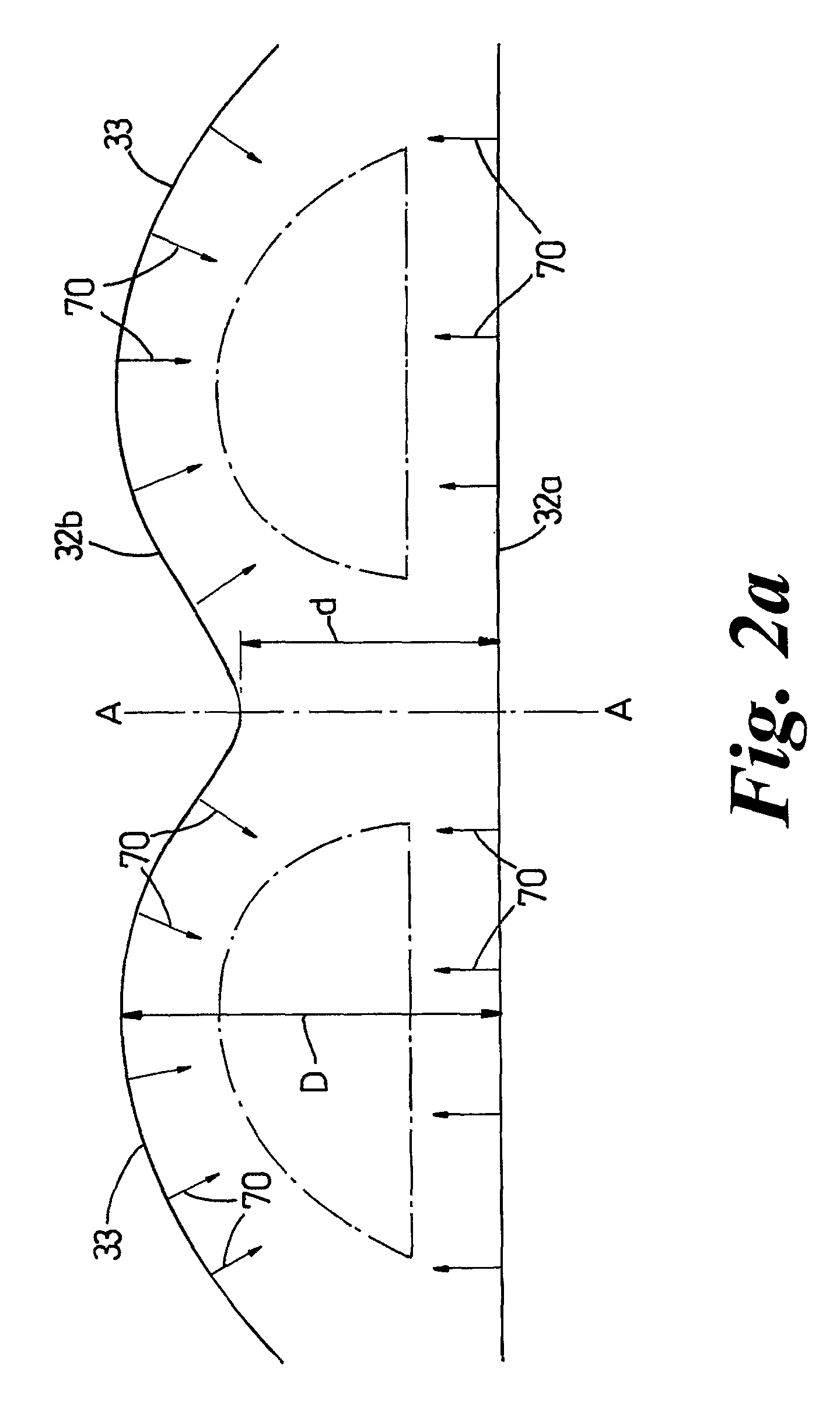

Molded wet-pressed tissue

ActiveUS7563344B2Lose weightIncrease speedNon-fibrous pulp additionNatural cellulose pulp/paperBiomedical engineeringSupport surface

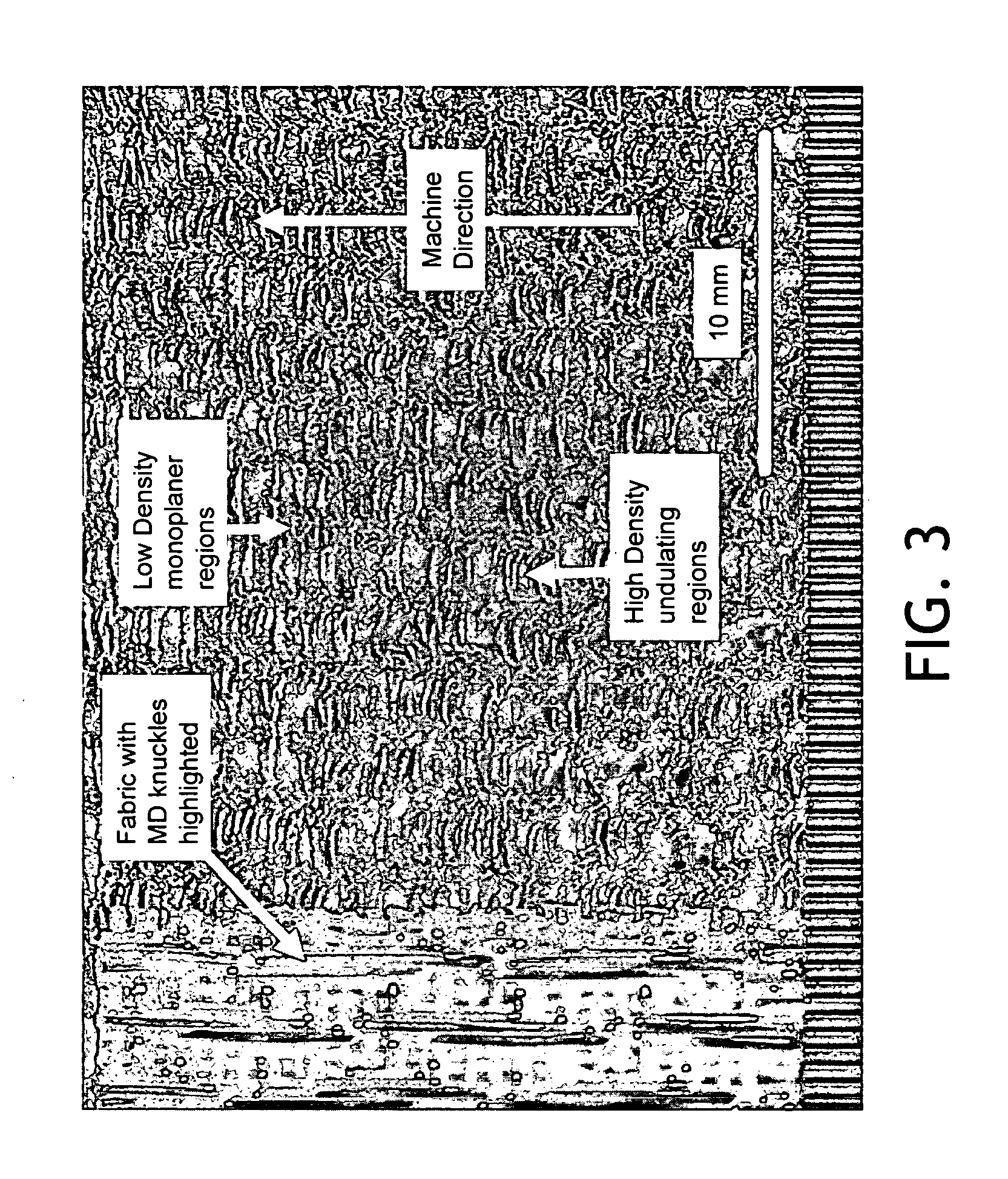

Wet-pressed creped tissue sheets exhibit continuous undulating valleys separated by continuous mono-planar macro-ridges running in the machine direction of the sheet, the macro-ridges being of a lower fiber density relative to the fiber density of the undulating valleys. The tissue structure can be created by pressing a densified tissue web against the surface of a Yankee dryer while the web is supported by a texturizing (molding) fabric having a web-supporting surface having highly topographic continuous or substantially continuous ridges and valleys and thereafter creping the web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

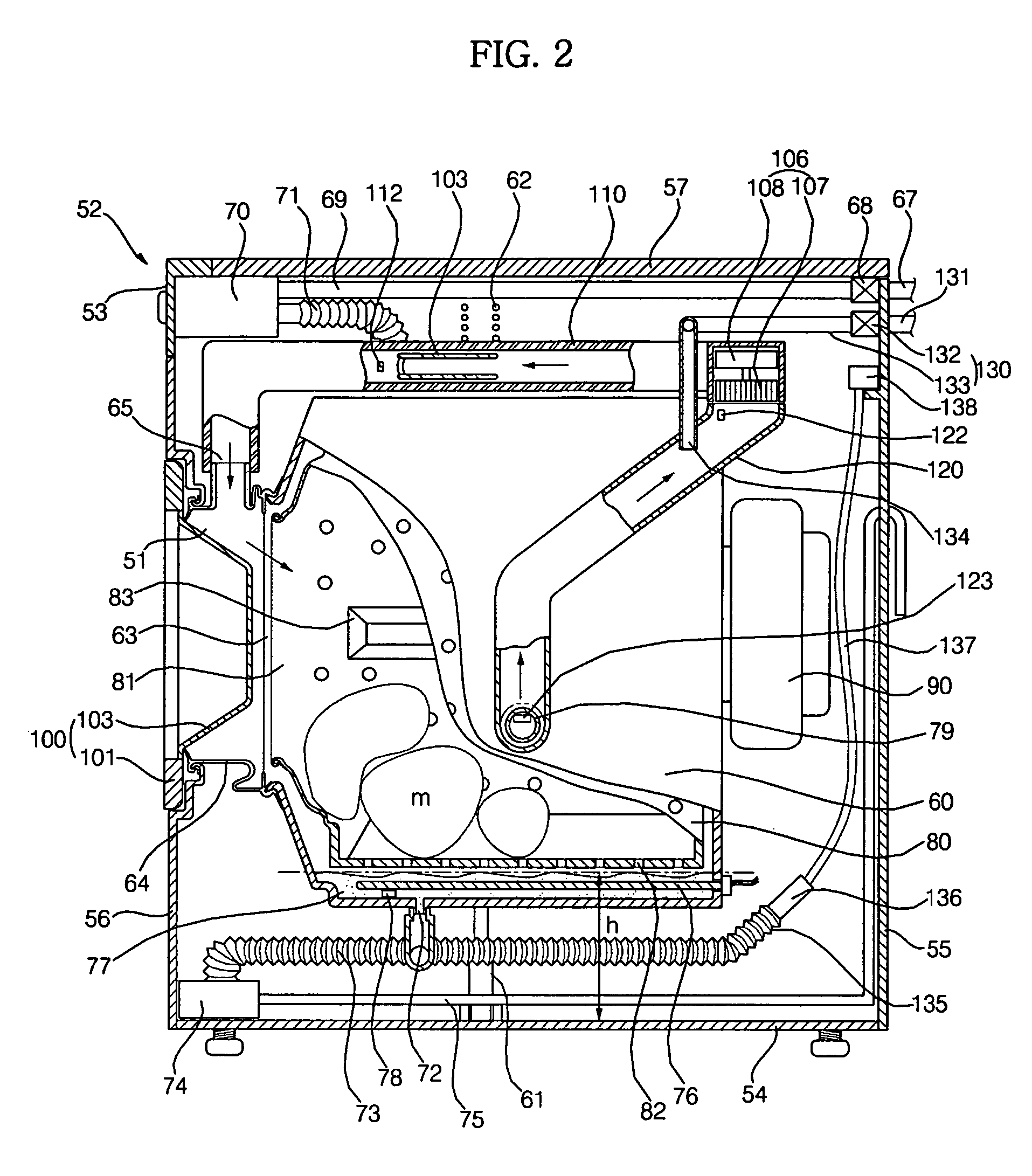

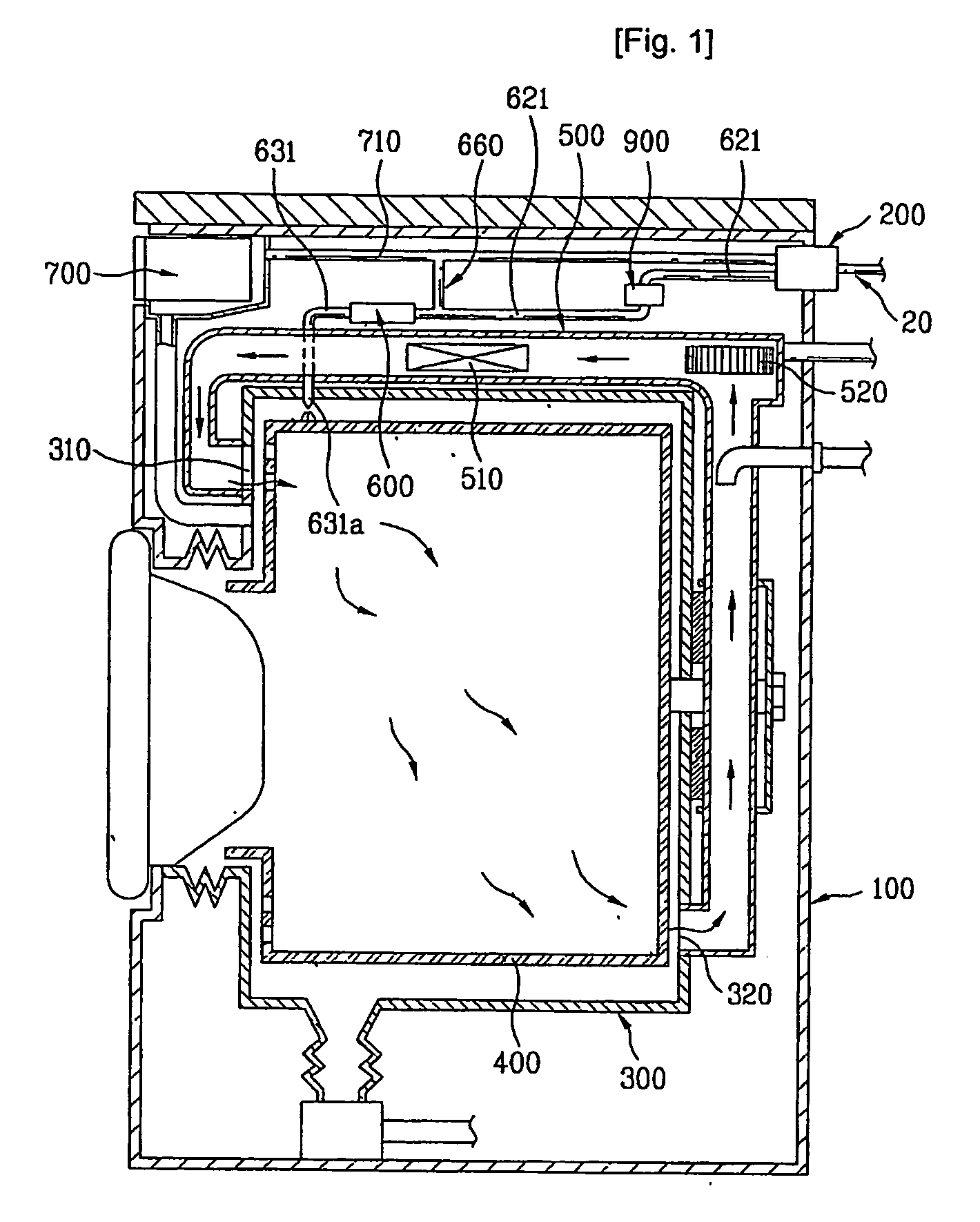

Drying control apparatus and method of washing and drying machine

InactiveUS20060137105A1Improve condensation effectMinimizing rateOther washing machinesWashing machine with receptaclesCold airProcess engineering

A drying control method and apparatus of a washing and drying machine, in which cooling water dropped from a condensation duct to a tub accelerates the condensation of moisture contained in circulated air so as to improve condensing capability, a cold air drying time is differently set according to load so that when the load is small, a drying time is shortened, and the drying of laundry is rapidly performed, a power consumption rate is minimized, or a cooling water consumption rate is minimized according to user's desire, and a drying operation is controlled using a difference between a temperature of air and a temperature of cooling water so that the drying operation is efficiently performed according to load conditions so as to improve the drying capability.

Owner:LG ELECTRONICS INC

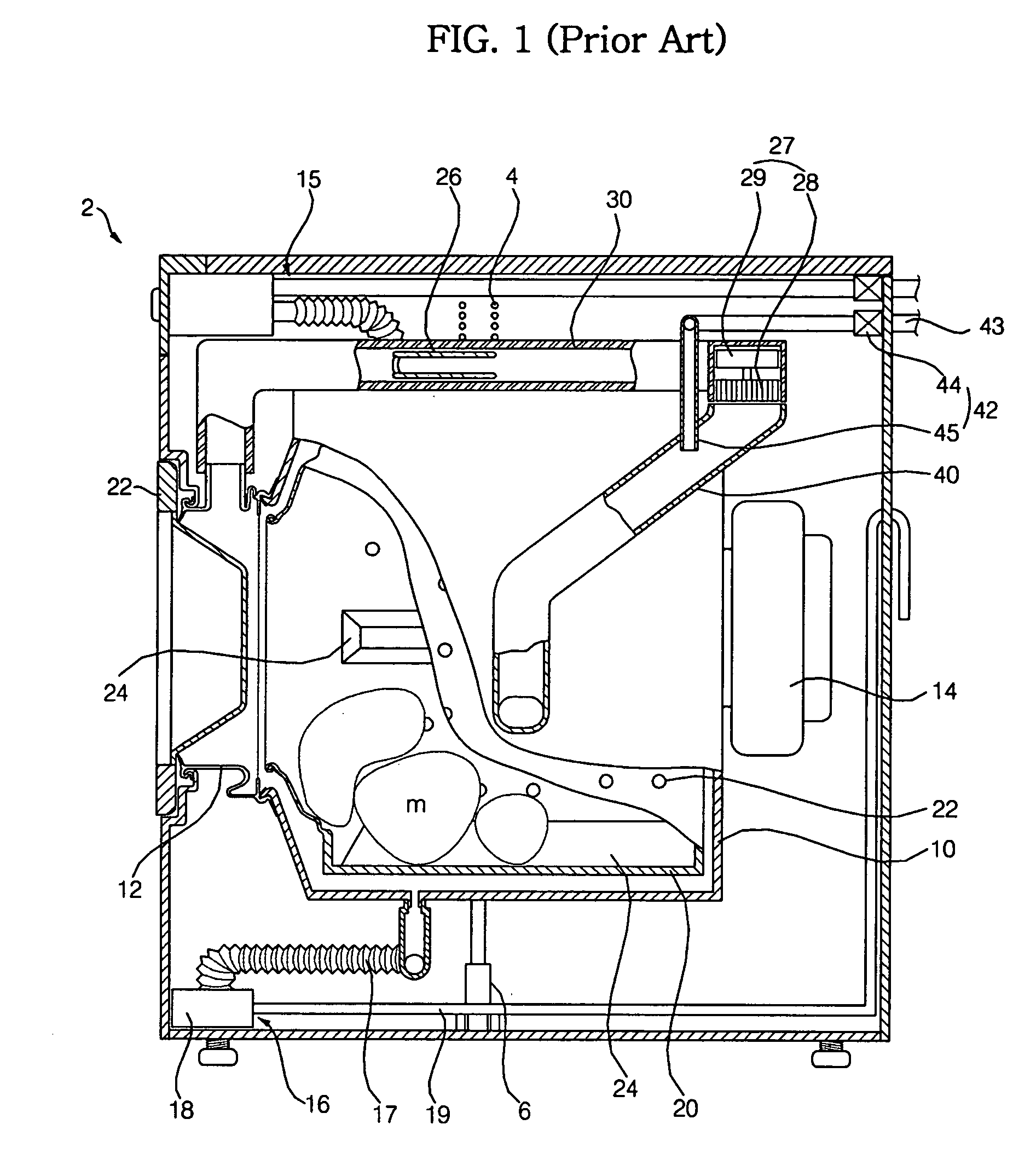

Dishwasher and method of controlling the same

InactiveUS20070006898A1Increase humidityShorten the timeTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionDrive motorControl theory

A dishwasher includes a drying fan formed on a side of the door to suck wet-vapor existing in a tub, a fan driving motor for rotating the drying fan, a sump formed on a bottom of the tube to reserve washing water, a drain motor for draining the washing water out of the sump, and a control unit for controlling the fan driving motor as well as the drain motor. The control unit controls the operation of the drain motor while the fan driving motor operates.

Owner:LG ELECTRONICS INC

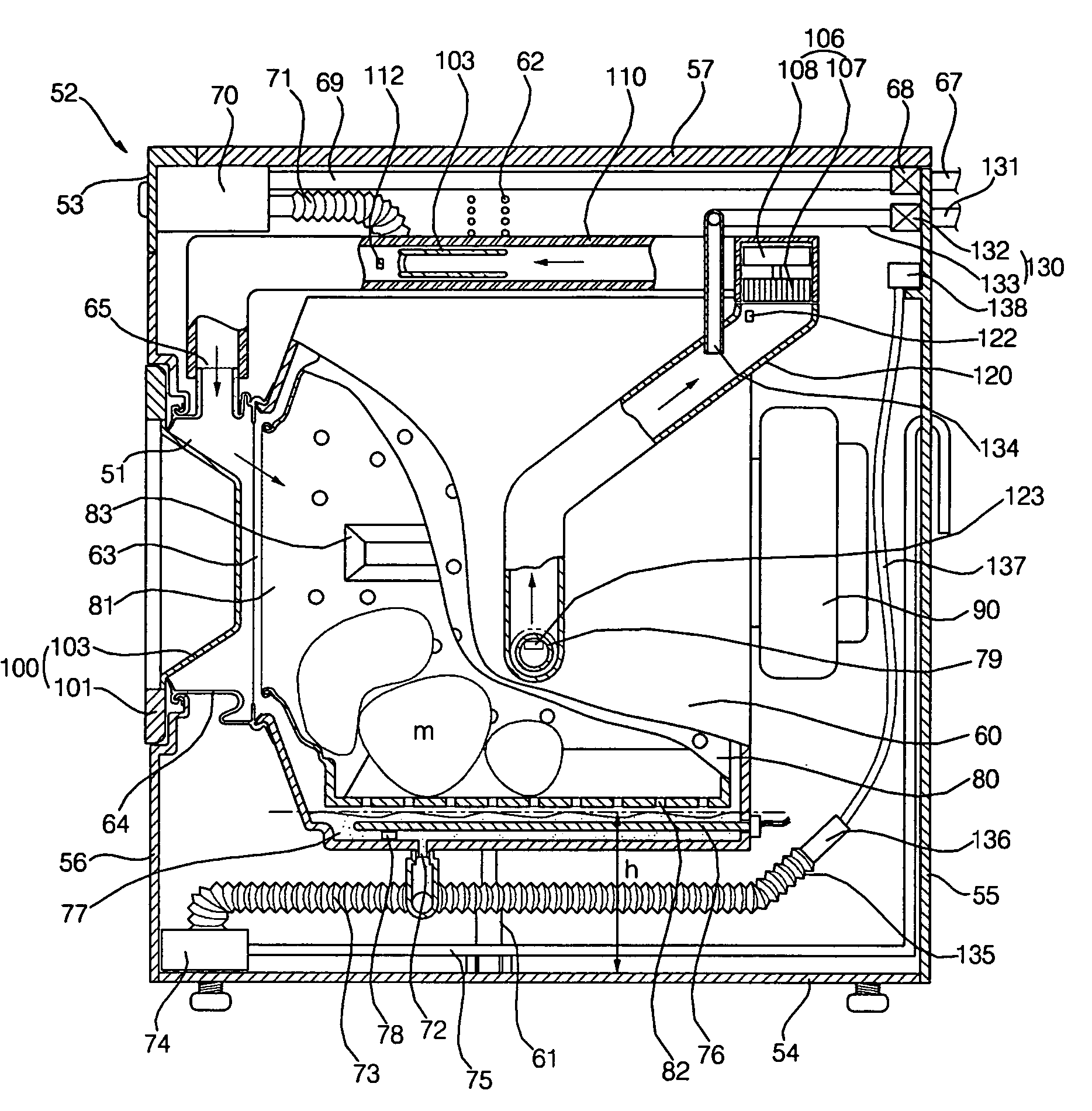

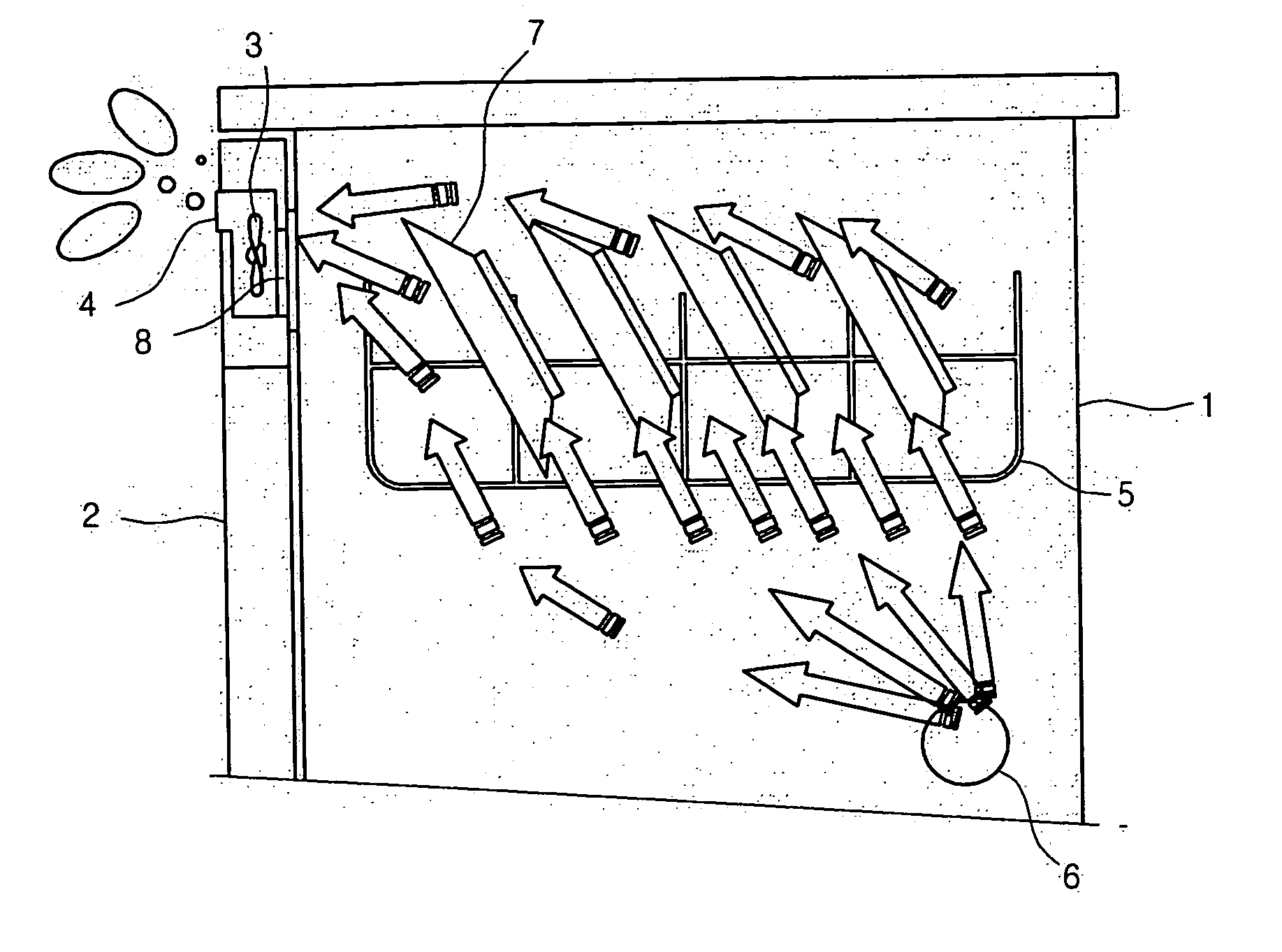

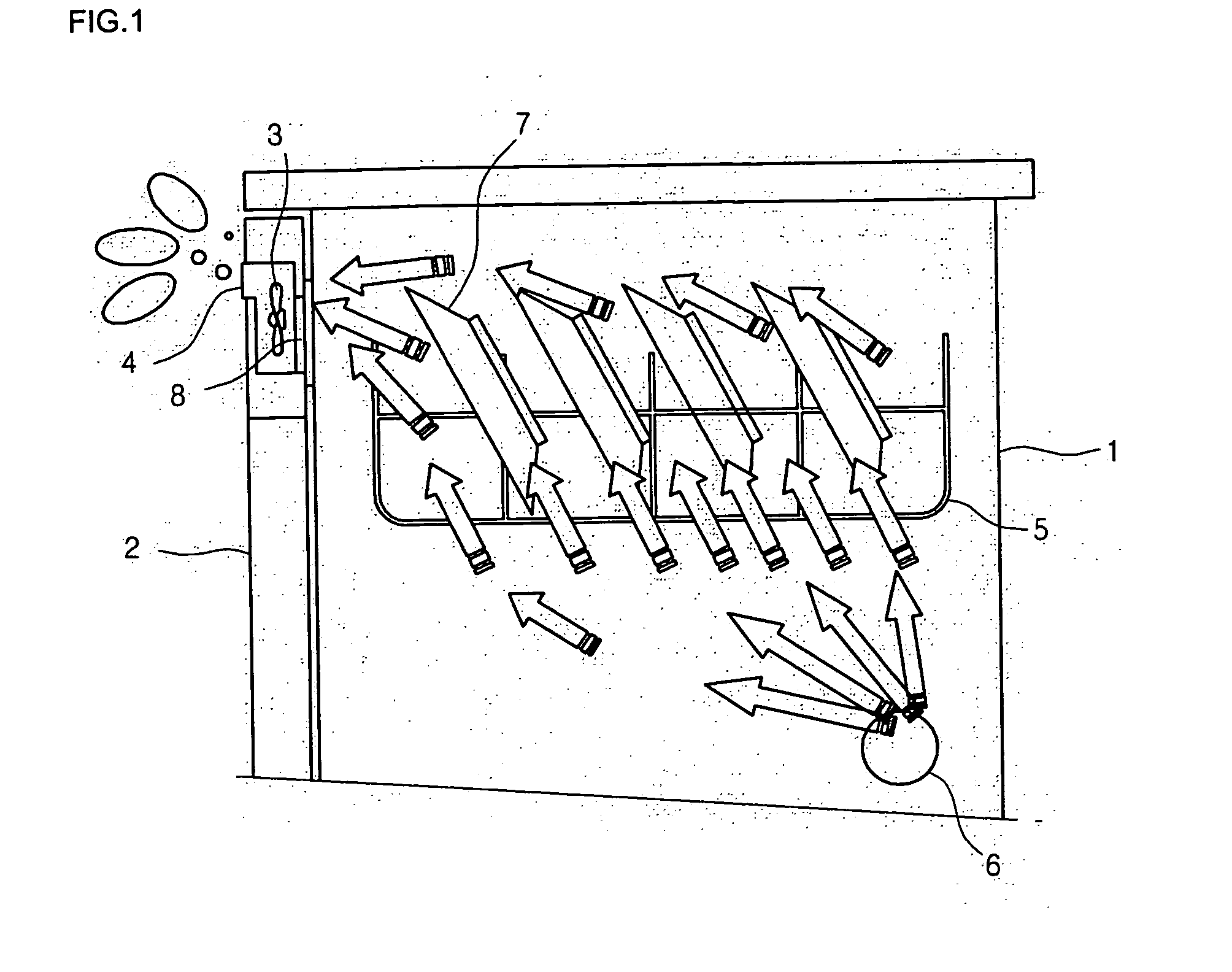

Drying machine

InactiveUS20050198852A1EfficientlyEfficient dryingDrying gas arrangementsDrying machines with non-progressive movementsAir cycleGas cooler

An object is to provide a drying machine capable of maintaining air discharged into a housing chamber while efficiently drying a matter to be dried in a short time. A drying machine provided with a housing chamber which houses the matter to be dried, and executing a drying operation of the matter to be dried in the housing chamber comprises: a gas cooler; an evaporator; a blower fan; an air circulation path for discharging air heated by the gas cooler into the housing chamber by the blower fan, sending the air passed through the housing chamber into the evaporator, and circulating the air in the gas cooler; and a closable outside air introduction port for mixing outside air with the air circulating in the air circulation path.

Owner:SANYO ELECTRIC CO LTD

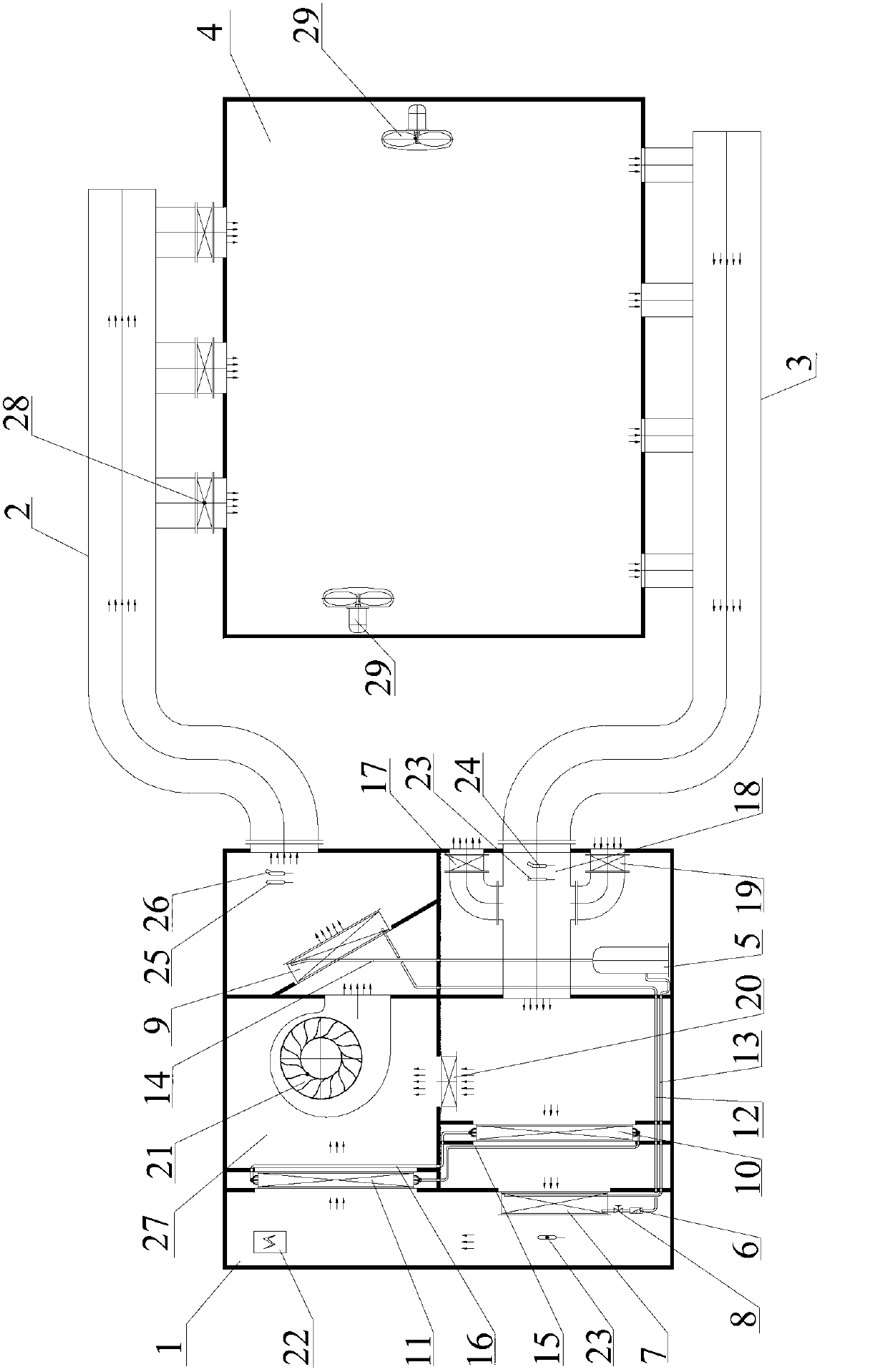

Intelligent hot-air drying control device

InactiveCN103123215AReduce energy consumptionReduced dehumidification loadDrying gas arrangementsEngineeringAir blower

The invention discloses an intelligent hot-air drying control device which comprises a heat exchange box and a drying chamber, wherein he heat exchange box is separated into multiple spaces, and the drying chamber is connected with the heat exchange box through an air supplying main pipe and a general air return pipe. A heat pump dehumidifying and heating system, a heat pipe return heat exchange system, a hot air circulating system and an intelligent control system are arranged in the heat exchange box. The heat pump dehumidifying and heating system which is composed of a compressor, a drying filter, a dehumidifying evaporator, a throttle valve and a heating condenser. The heat pipe return heat exchange system is composed of a heat pipe evaporator and a heat pipe condenser. The hot air circulating system is composed of a high-pressure refrigerant liquid connecting pipe, a low-pressure refrigerant return gas connecting pipe, a high-pressure refrigerant gas connecting pipe, a liquid refrigerant connecting pipe, a gas refrigerant connecting pipe, an air exhaust regulating valve, a mixed air box, a fresh air regulating valve, a secondary air flow regulating valve and an air blower assembly. The intelligent control system is composed of the a temperature sensor, a humidity sensor, a hot air temperature sensor and a hot air humidity sensor, wherein the temperature sensor, the humidity sensor, the hot air temperature sensor and the hot air humidity sensor are connected in the various systems. The intelligent hot-air drying control device can regulate the temperature and the humidity of drying air automatically and improve the material drying efficiency.

Owner:孙应真

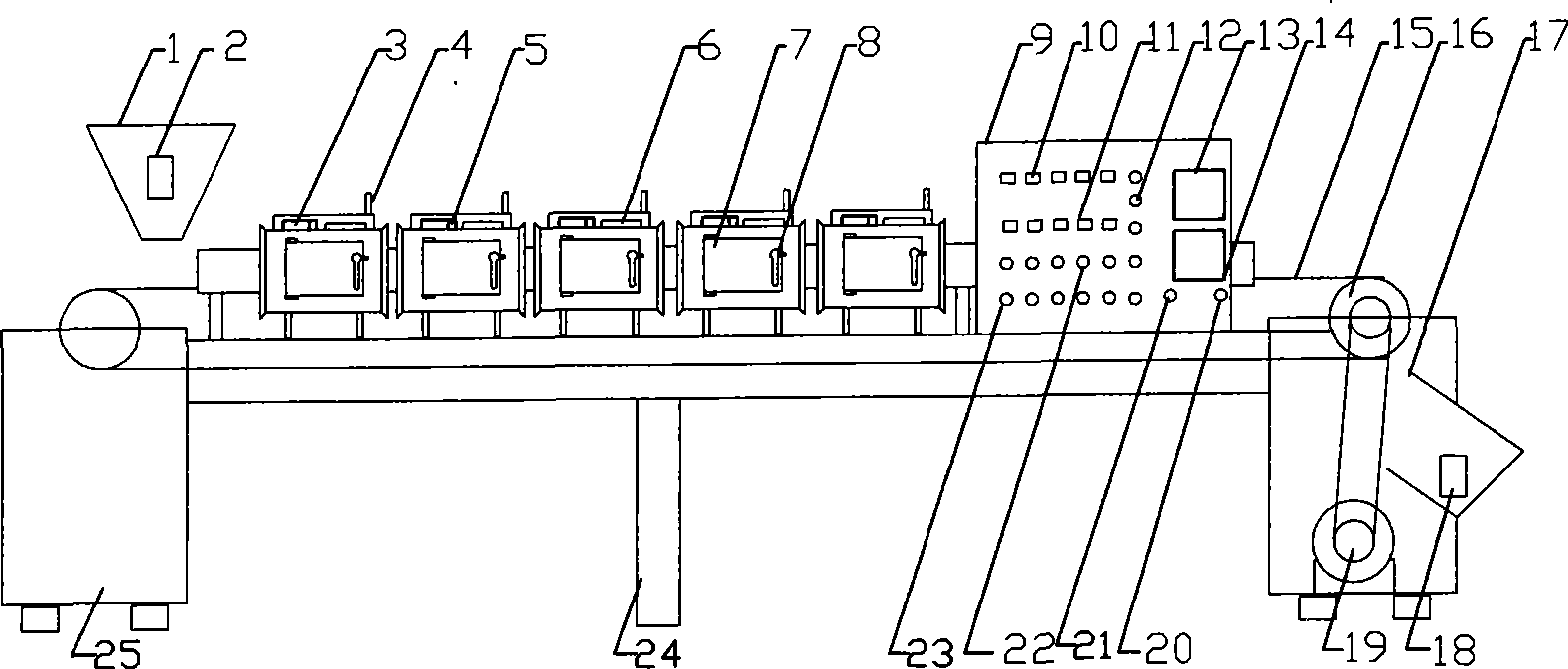

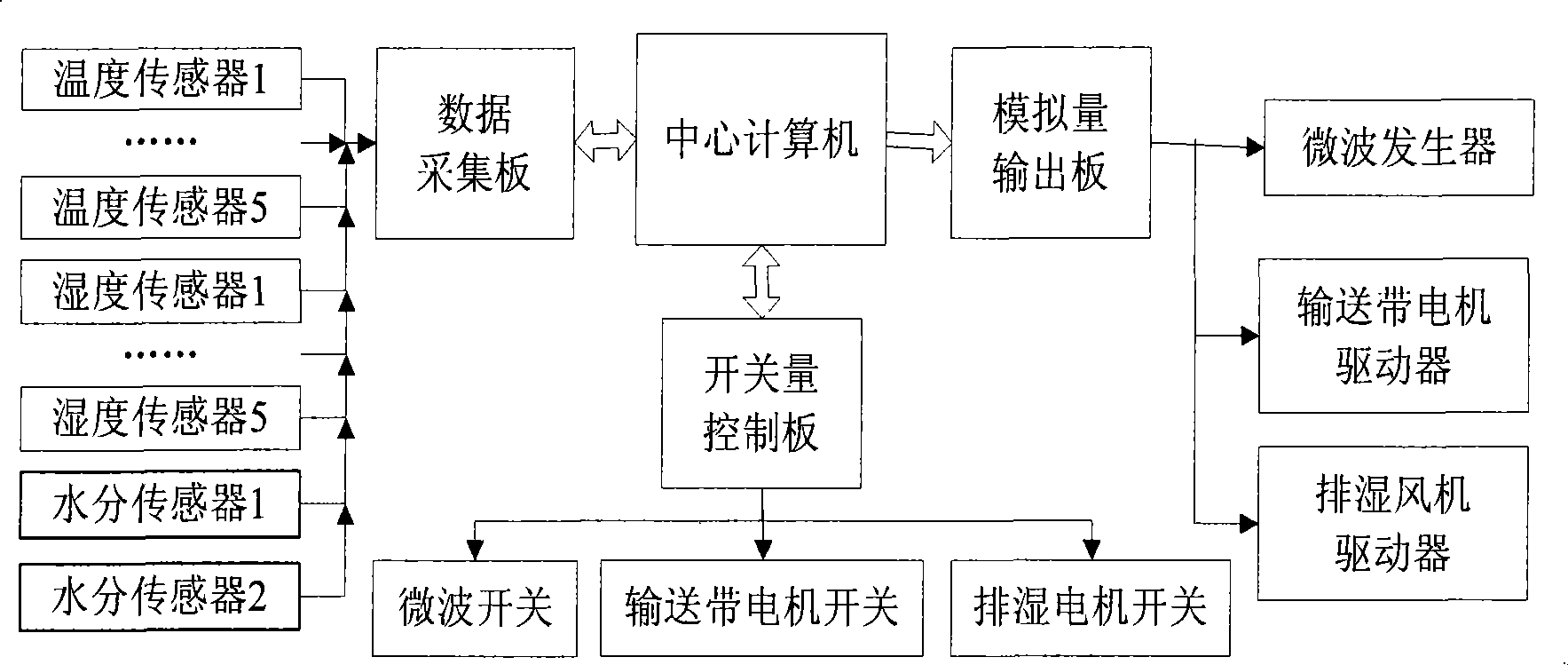

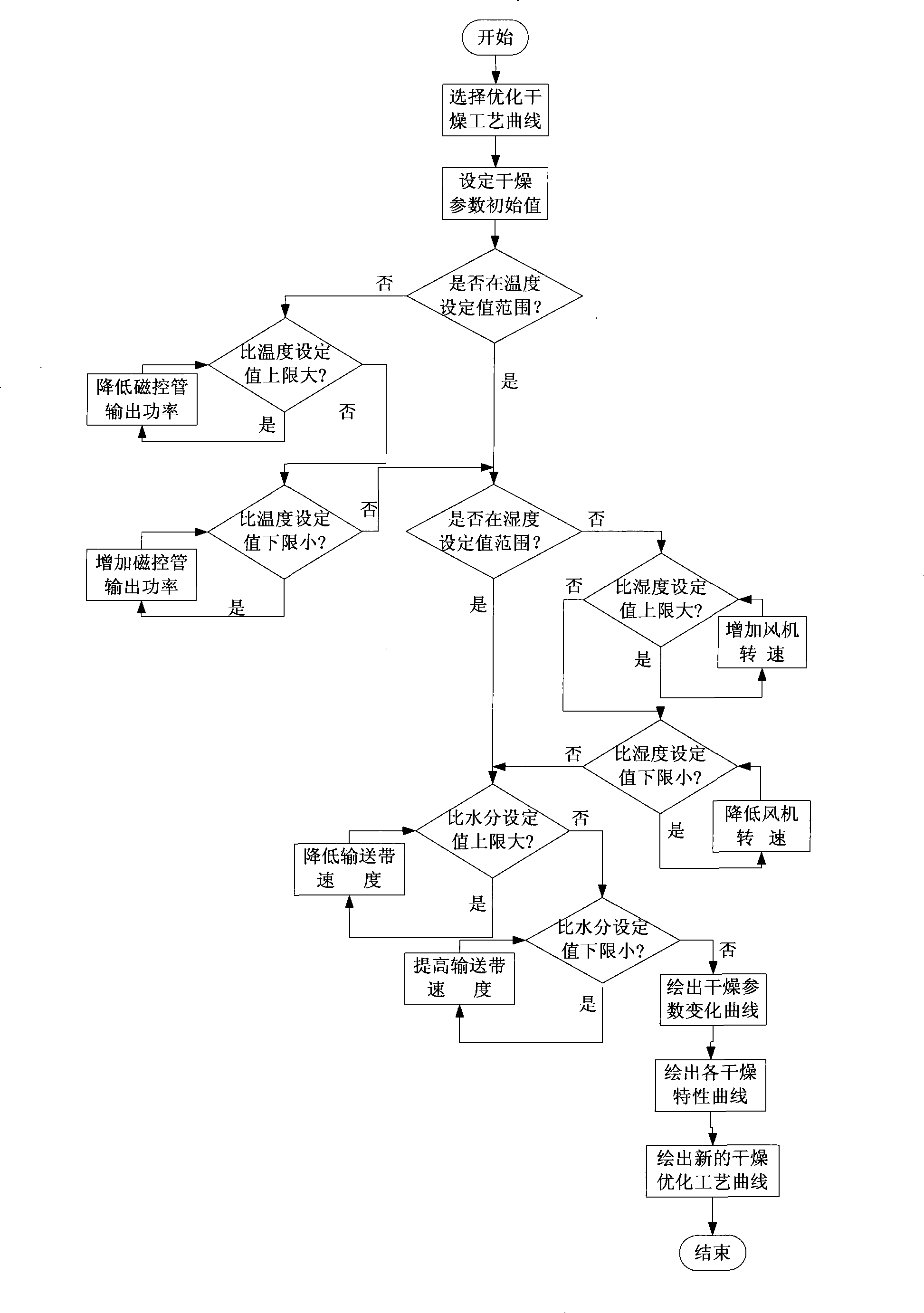

Intelligent microwave continuous drier and control method thereof

InactiveCN101382379AImprove drying qualityEasy to operateDrying solid materials with heatDrying machines with progressive movementsFrequency changerDrive motor

The invention discloses an intellectualized microwave continuous drier and a control method thereof; the drier comprises a rack, a conveying belt, a conveying belt wheel, a driving motor, an instrument control box and a computer; two ends of the conveying belt are respectively provided with a feed hopper and a discharge hopper and the conveying belt runs through a plurality of microwave drying cavities with doors; each microwave drying cavity is internally provided with a microwave magnetron, a temperature sensor, a humidity sensor and a speed-regulating fan; the feed hopper and the discharge hopper are respectively provided with a moisture sensor, and the conveying belt is driven by a speed-regulating motor controlled by a frequency converter. A control system can automatically draw variation curves of the temperature and the humidity of the materials in each drying cavity and the water content ratio of the discharged materials in the drying process of the materials in shorter time according to the collected data of the temperature, the humidity and the water content ratio of the materials in the drying process of the materials, can optimize control parameters continuously according to the change of the temperature, the humidity and the water content ratio in the drying process of the materials, and can regulate the system parameters automatically and realize the dynamic optimization of the drying technique parameters.

Owner:ANHUI AGRICULTURAL UNIVERSITY

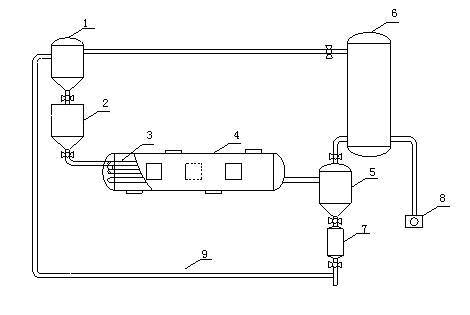

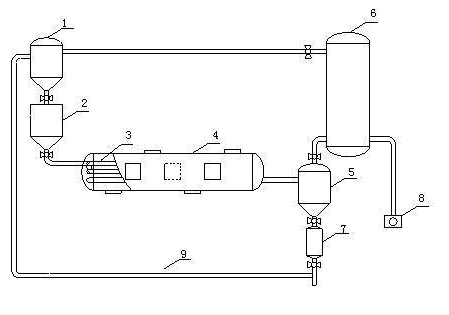

Negative-pressure microwave uniform spraying and drying device and application

ActiveCN102062525ADry evenlyAvoid uneven heatingDrying using combination processesDrying machinesMicrowaveDrying time

The invention discloses a negative-pressure microwave uniform spraying and drying device and application, belonging to the technical field of uniform drying devices. The negative-pressure microwave uniform spraying and drying device comprises a circulating material storage device, a feeder, a negative-pressure spraying pipe, a microwave heating cavity, a cyclone separator, a vacuum storage tank, a discharger, a water ring vacuum pump, a circulating pipe and microwave sources. The circulating material storage device is used for storing materials dried circularly, the feeder is used for feeding dry materials to the negative-pressure spraying pipe which is a channel for drying and circulating the materials, and the microwave sources are uniformly distributed inside the microwave heating cavity, two ends of which are sealed. The cyclone separator is connected with an outlet of the negative-pressure spraying pipe inside the microwave heating cavity and is connected with the vacuum storage tank and the discharger through a channel. The discharger is connected with the circulating material storage device through the circulating pipe. Because the materials can be sprayed under negative pressure, the device can be used for spraying, rotating and circulating the materials under a microwave vacuum drying condition so as to achieve the purpose of drying the materials efficiently and uniformly, meanwhile, is favorable for shortening the drying time by above 40% and reducing the cost of large-scale production.

Owner:JIANGNAN UNIV

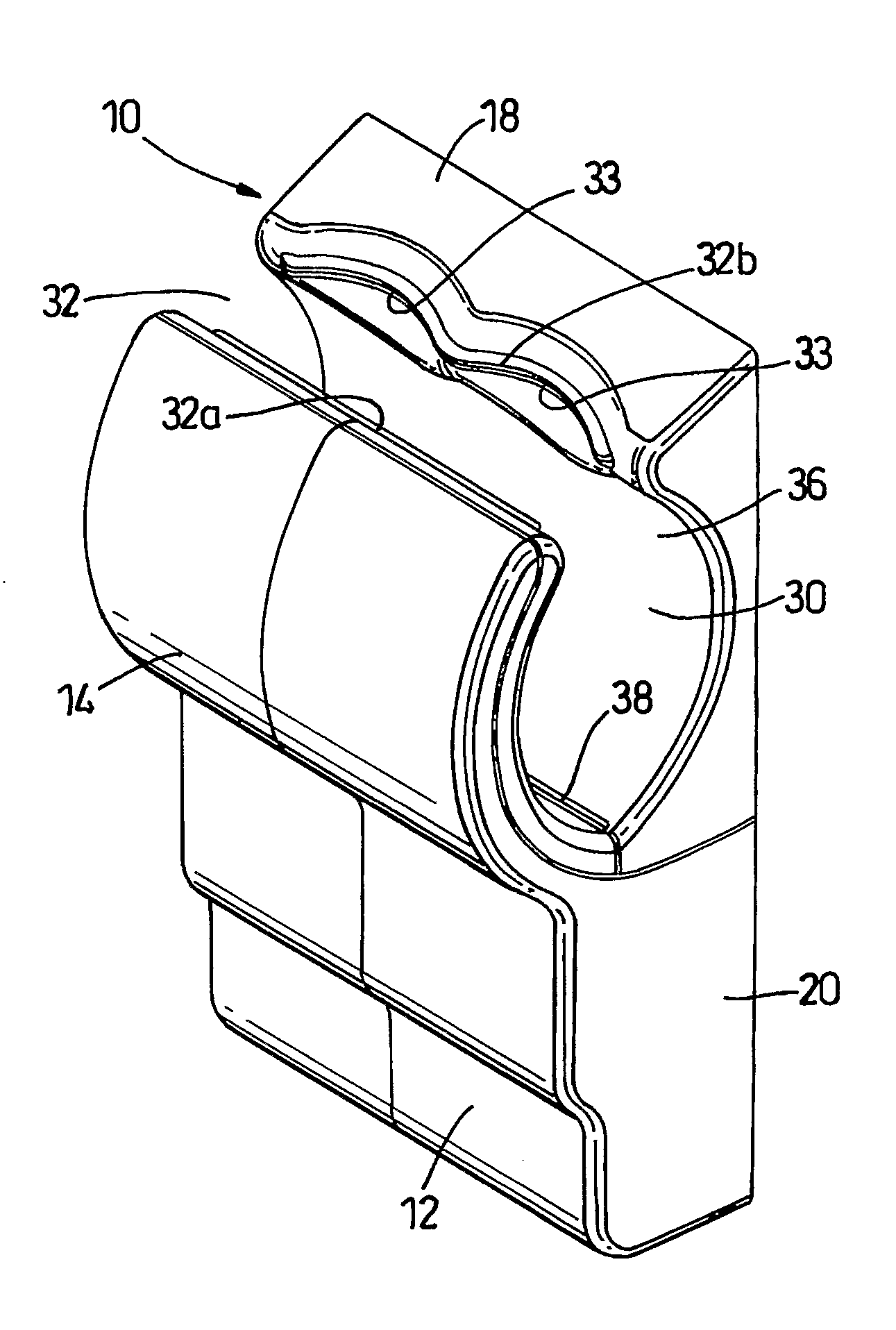

Molded wet-pressed tissue

ActiveUS20080099169A1Lose weightIncrease speedNon-fibrous pulp additionNatural cellulose pulp/paperBiomedical engineeringPaper sheet

Wet-pressed creped tissue sheets exhibit continuous undulating valleys separated by continuous mono-planar macro-ridges running in the machine direction of the sheet, the macro-ridges being of a lower fiber density relative to the fiber density of the undulating valleys. The tissue structure can be created by pressing a densified tissue web against the surface of a Yankee dryer while the web is supported by a texturizing (molding) fabric having a web-supporting surface having highly topographic continuous or substantially continuous ridges and valleys and thereafter creping the web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

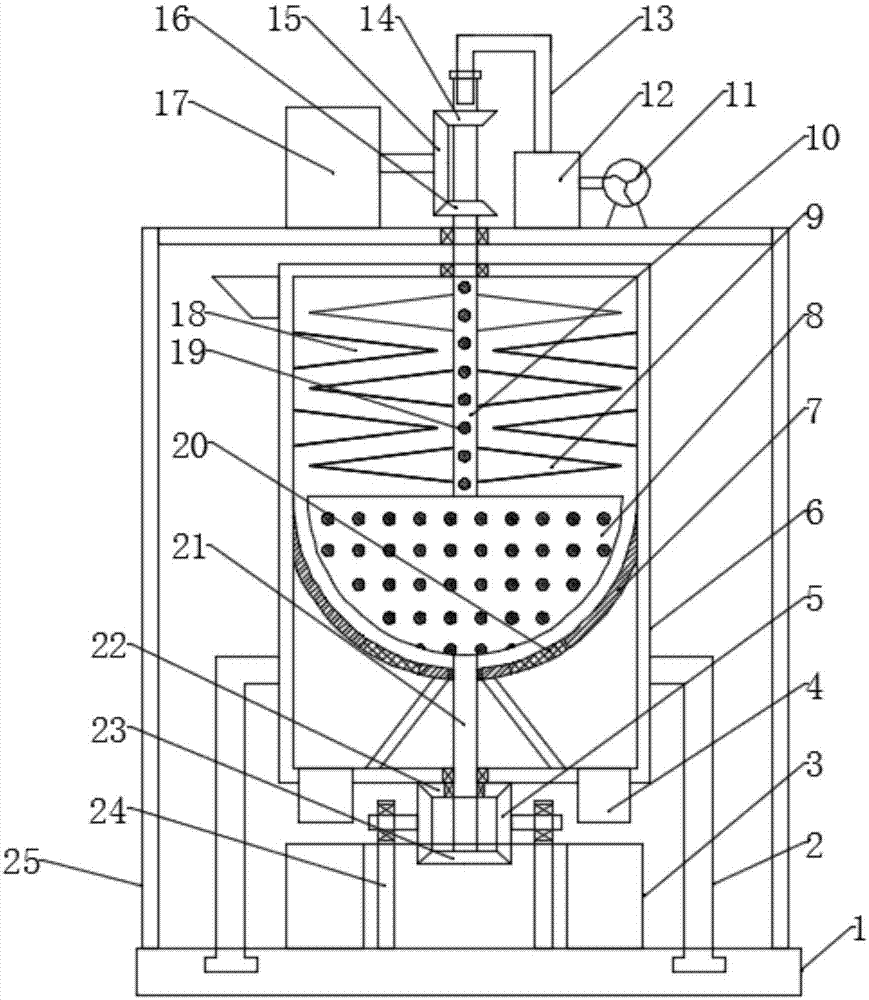

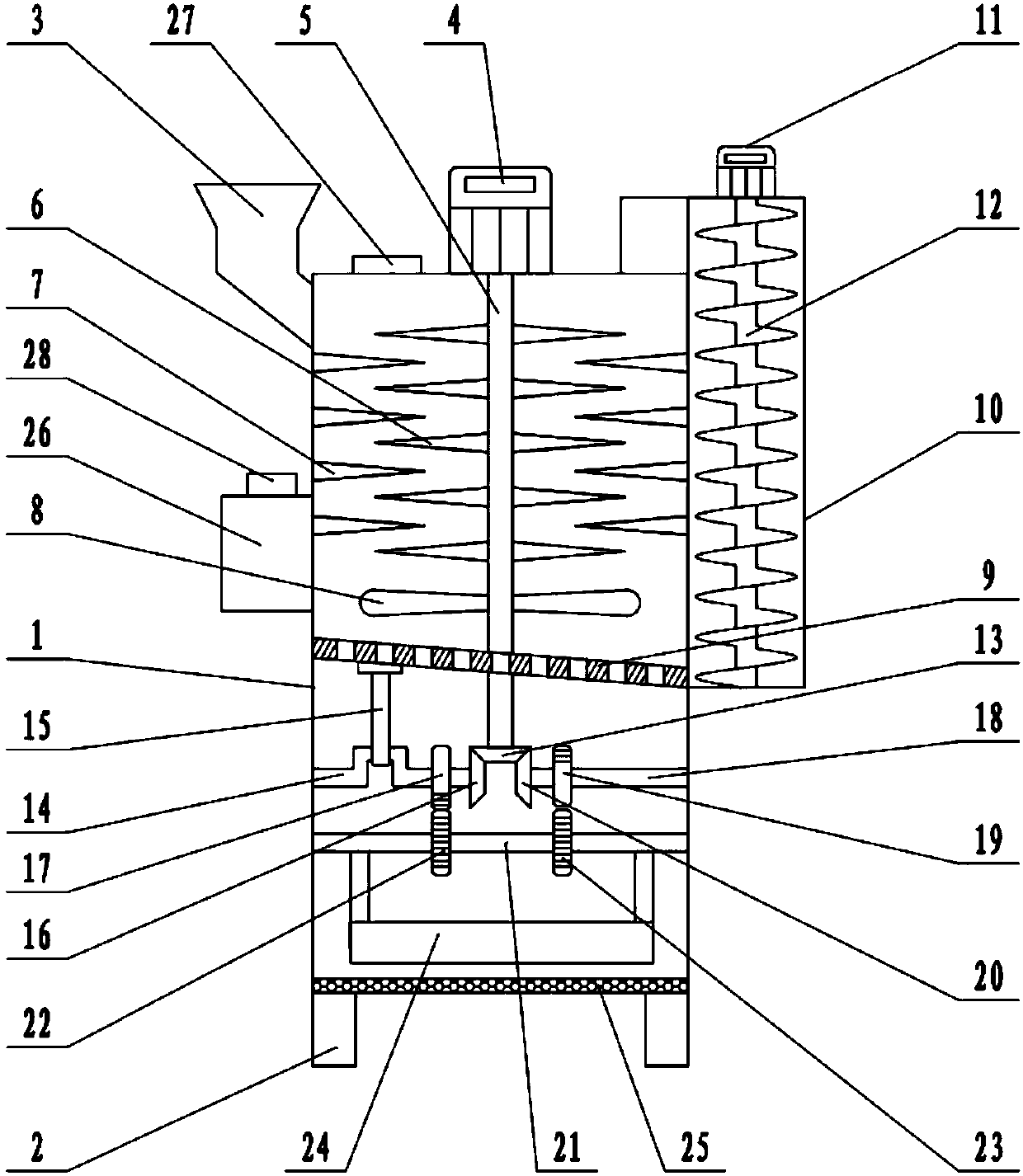

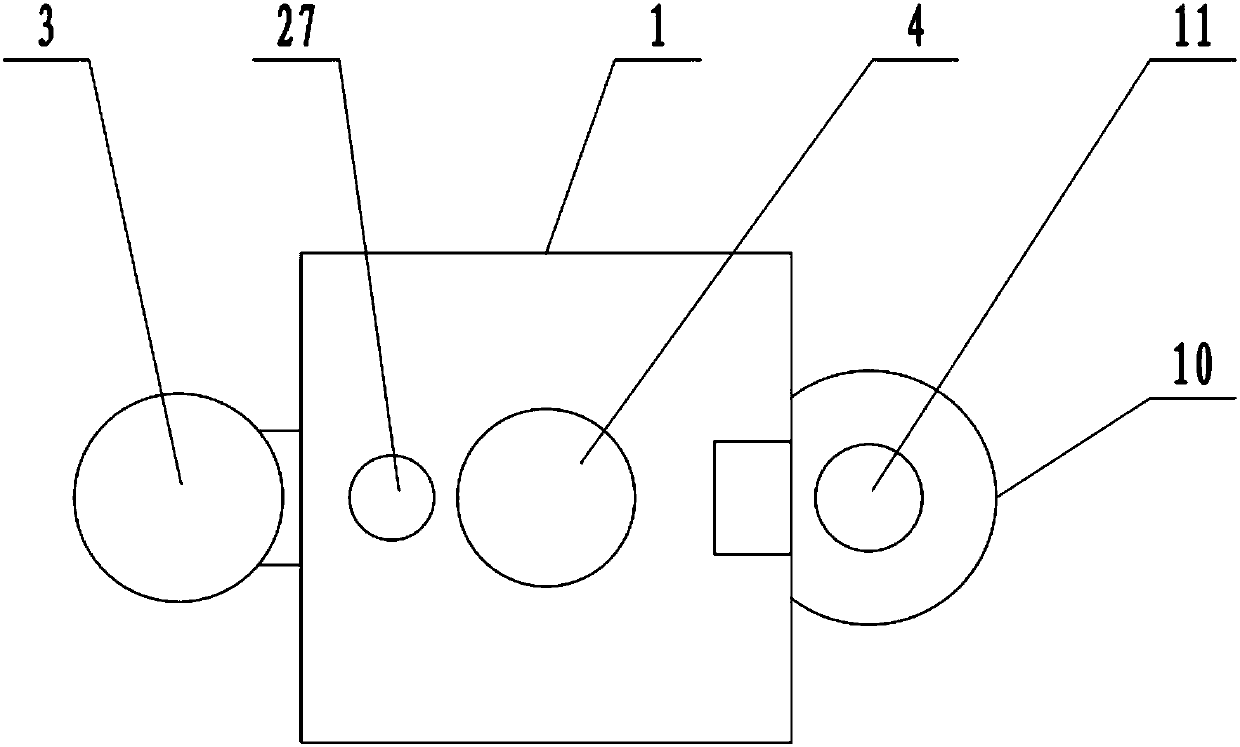

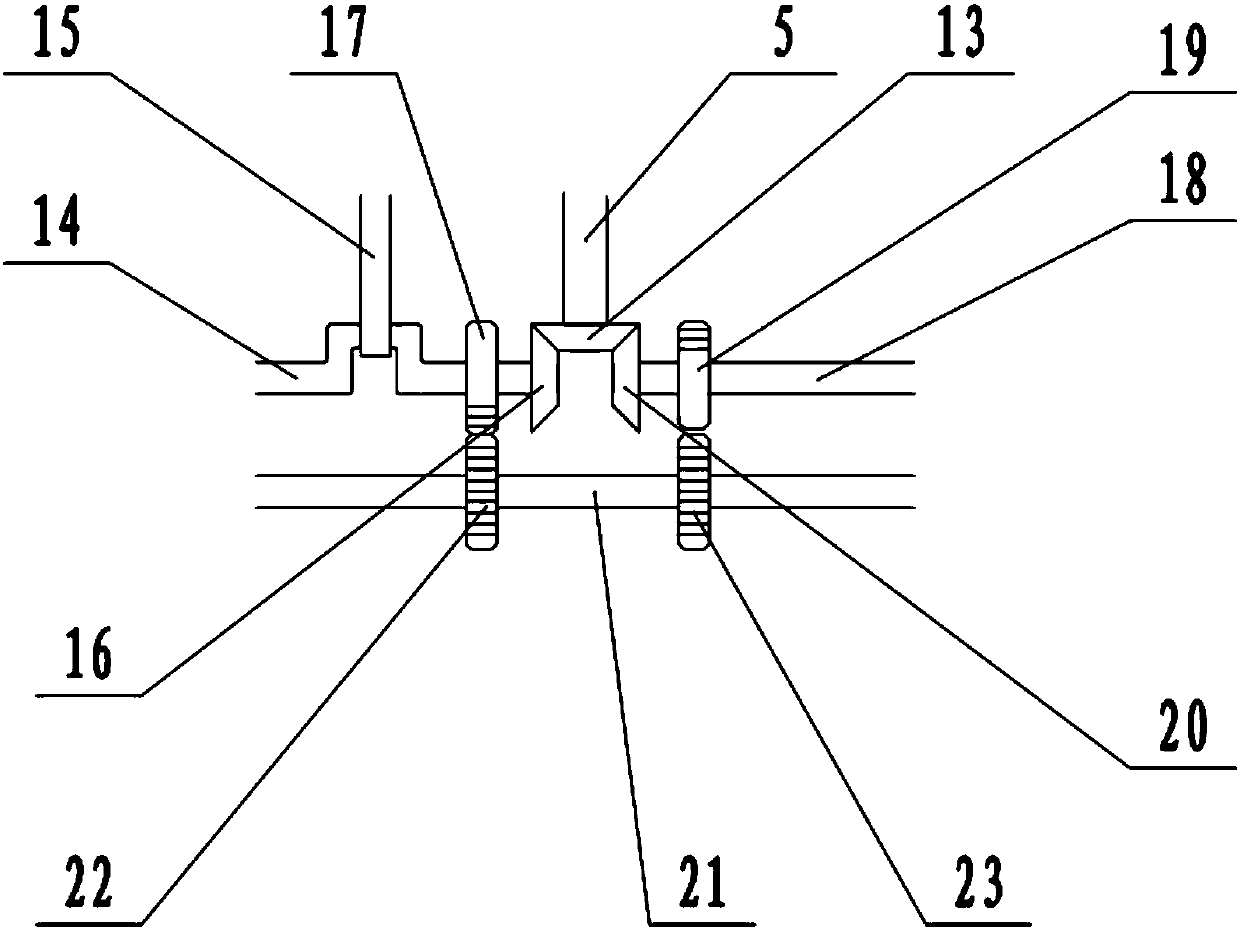

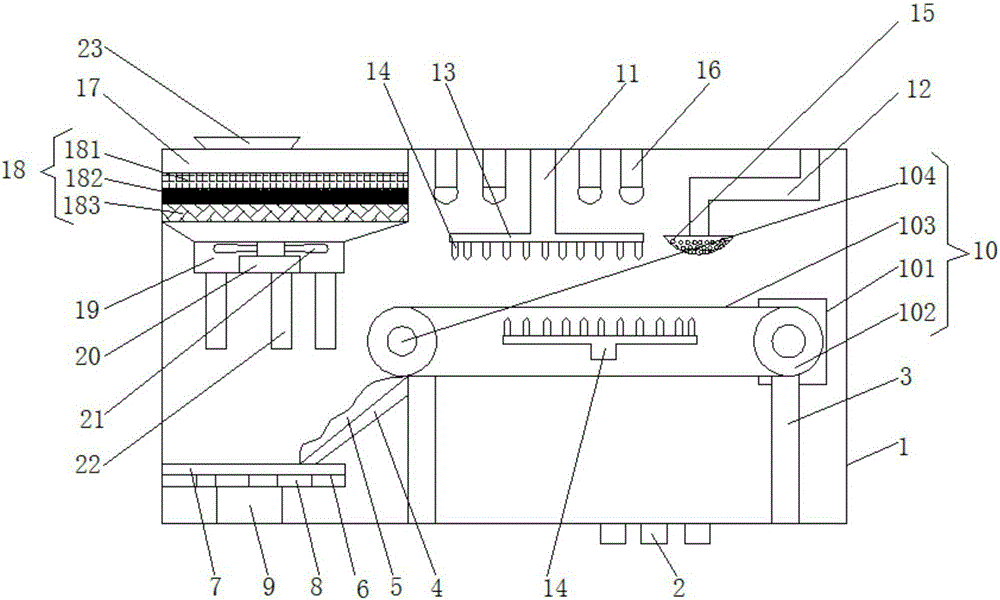

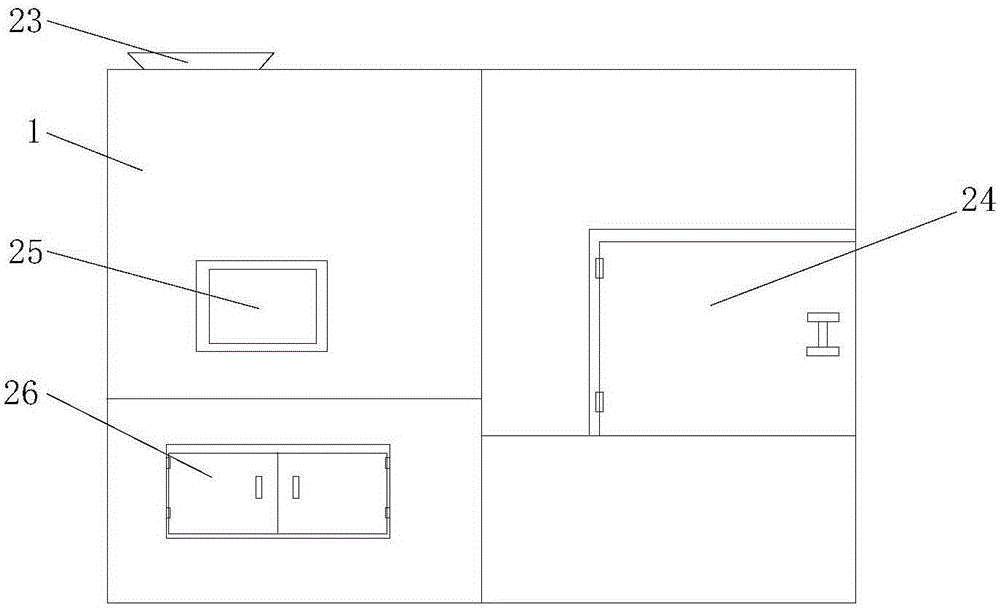

Traditional Chinese medicine smashing-grinding-drying integrated equipment

InactiveCN107570308AImprove crushing and grinding efficiencyImprove drying efficiencyDrying gas arrangementsGrain treatmentsEngineeringTraditional Chinese medicine

The invention discloses traditional Chinese medicine smashing-grinding-drying integrated equipment. The traditional Chinese medicine smashing-grinding-drying integrated equipment comprises a bottom plate, a cylinder body, a motor, an incomplete bevel gear, a first bevel gear, a second bevel gear, a hollow rotary shaft, a first smashing blade, a second smashing blade, a grinding hemisphere, a grinding shell, a filter screen, a third bevel gear, a fourth bevel gear, a fifth bevel gear and a drying device. The drying device comprises a draught fan, a heating device and air outlet holes. Accordingto the traditional Chinese medicine smashing-grinding-drying integrated equipment, the motor, the incomplete bevel gear, the first bevel gear, the second bevel gear, the hollow rotary shaft and the grinding hemisphere cooperate to drive the first smashing blade and the grinding hemisphere to rotate positively and negatively, the smashing and grinding efficiency is improved, so that traditional Chinese medicine is smashed and grinded more sufficiently and rapidly. The third bevel gear, the fourth bevel gear and the fifth bevel gear cooperate to drive the cylinder body and the hollow rotary shaft to rotate reversely, and thus the smashing and grinding efficiency is further improved. The drying device is used for drying the traditional Chinese medicine while the traditional Chinese medicineis smashed and grinded, and thus the drying efficiency is high.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

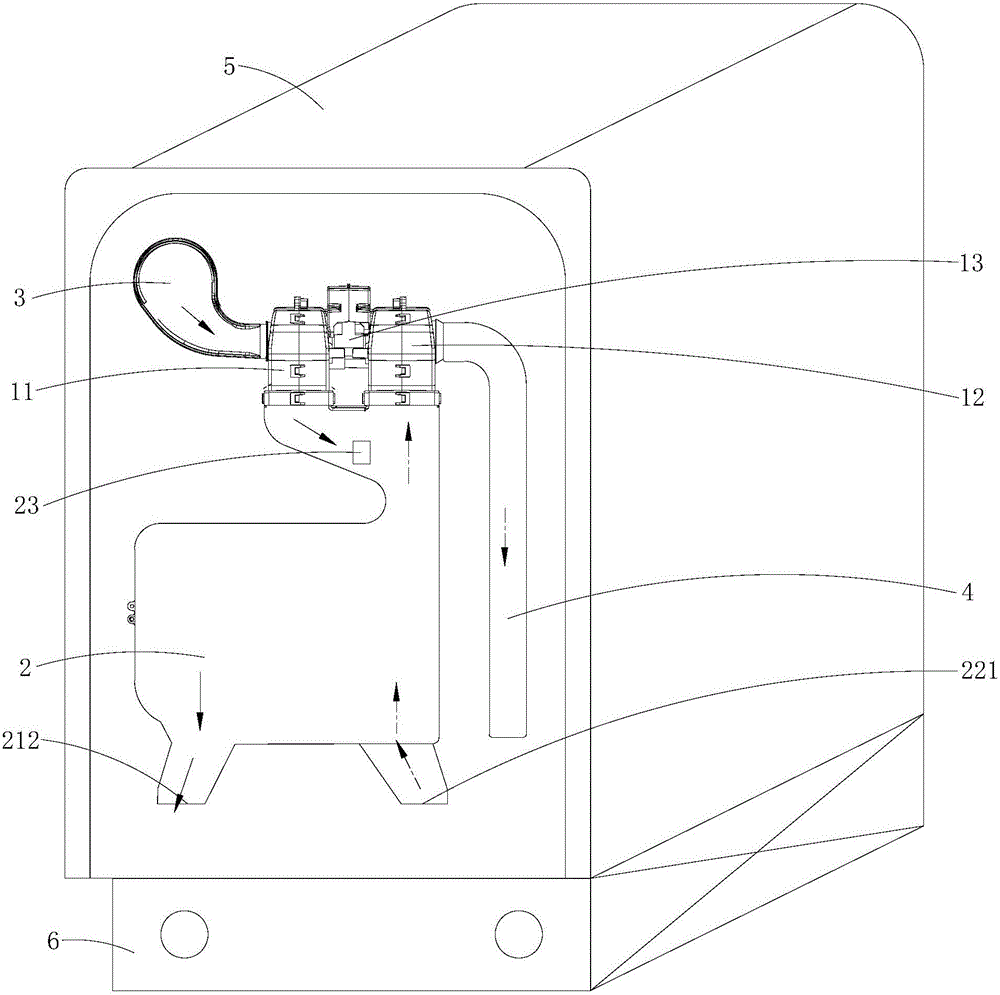

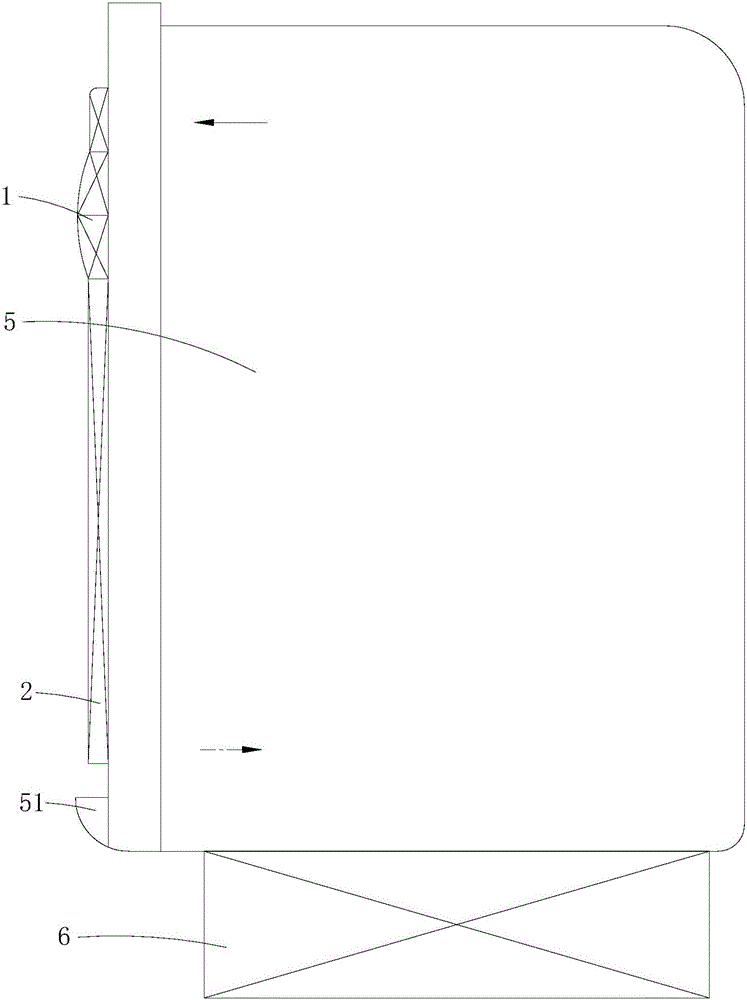

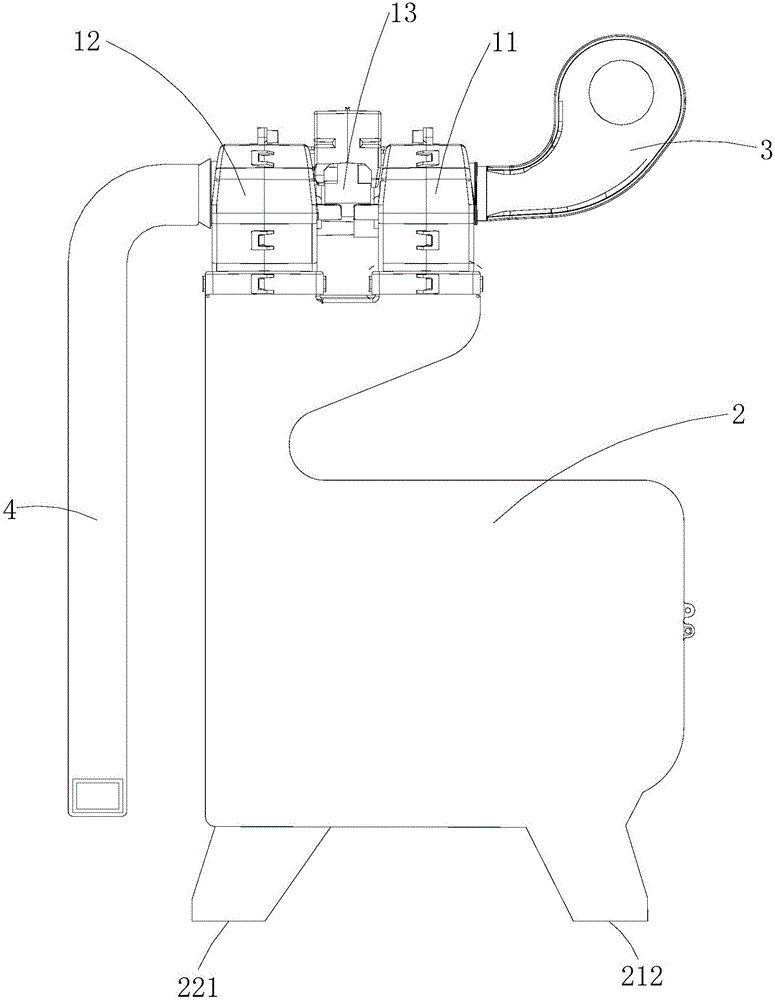

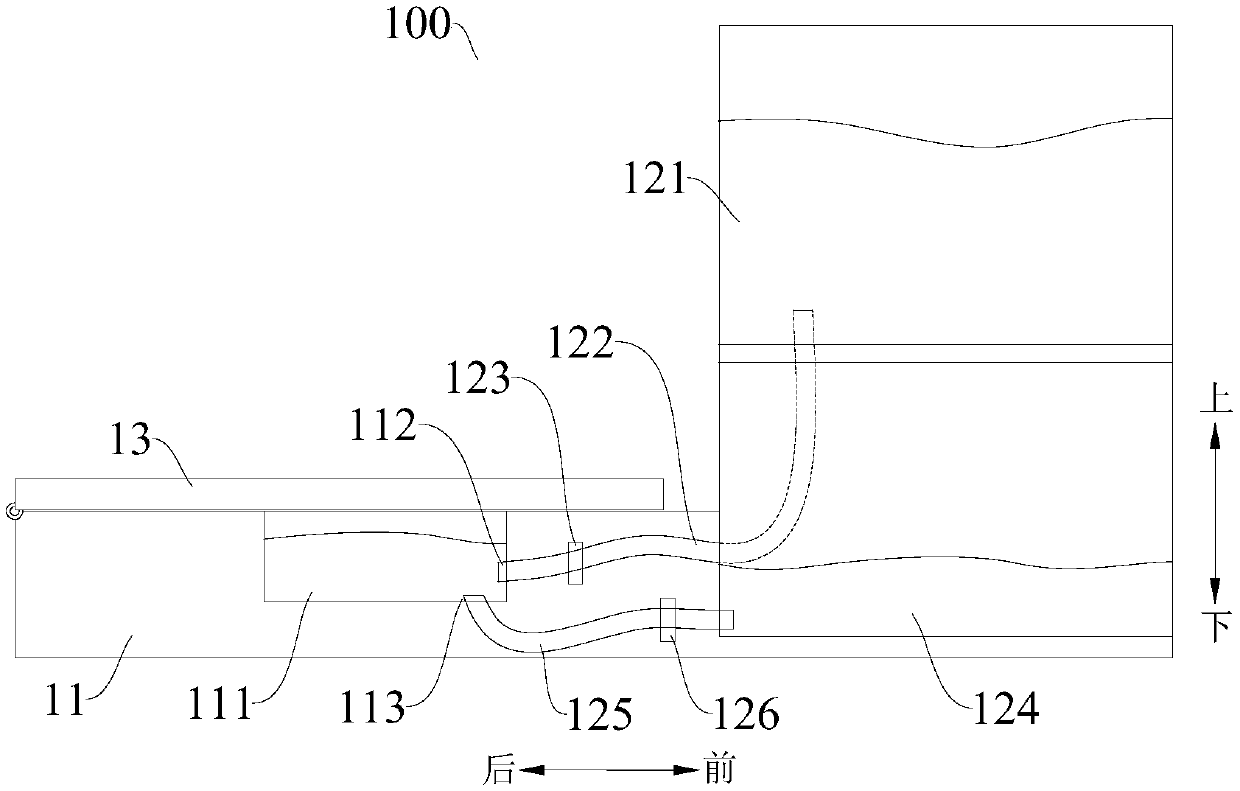

Condensing and drying device of dish-washing machine and dish-washing machine

InactiveCN105796033AKeep dryImprove drying efficiencyTableware washing/rinsing machine detailsHome appliance efficiency improvementWater flowEngineering

The invention is applicable to the field of dish-washing machines, and discloses a condensing and drying device of a dish-washing machine and the dish-washing machine. The condensing and drying device of the dish-washing machine is installed between an inner door and an outer door of the dish-washing machine and comprises an air-blasting assembly and a heat exchange component; a condensing cavity and a heating cavity are formed in the heat exchange component side by side, the air-blasting assembly comprises a first air-blasting component, a second air-blasting component and a power component, wherein the first air-blasting component can suck humid and hot air in an inner container of the dish-washing machine into the condensing cavity and outwards exhaust the air subjected to condensation of the condensing cavity, the second air-blasting component can suck external air located in front of the outer door into the heating cavity and exhaust the external air heated by the heating cavity into the inner container, and the power component is used for driving the first air-blasting component and the second air-blasting component to operate. According to the condensing and drying device of the dish-washing machine and the dish-washing machine, the situation that due to the fact that air exhausted from the dish-washing machine forms condensed water on the outer surface of the dish-washing machine, the condensed water sags on the outer surface of the dish-washing machine or drips onto the ground is prevented, necessary energy consumption in the drying process of the dish-washing machine is reduced, and meanwhile the internal hygiene condition of the dish-washing machine is effectively improved.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

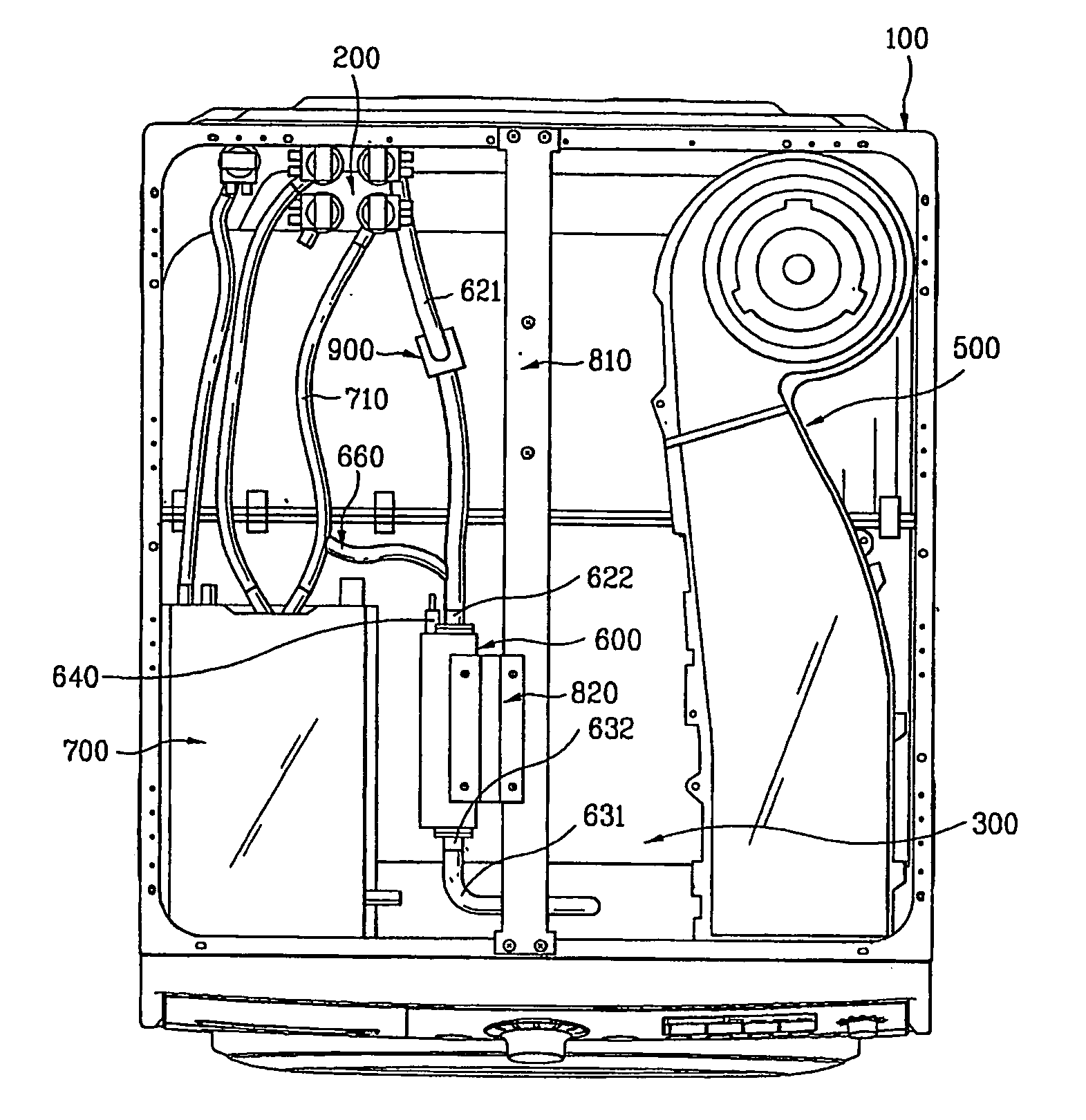

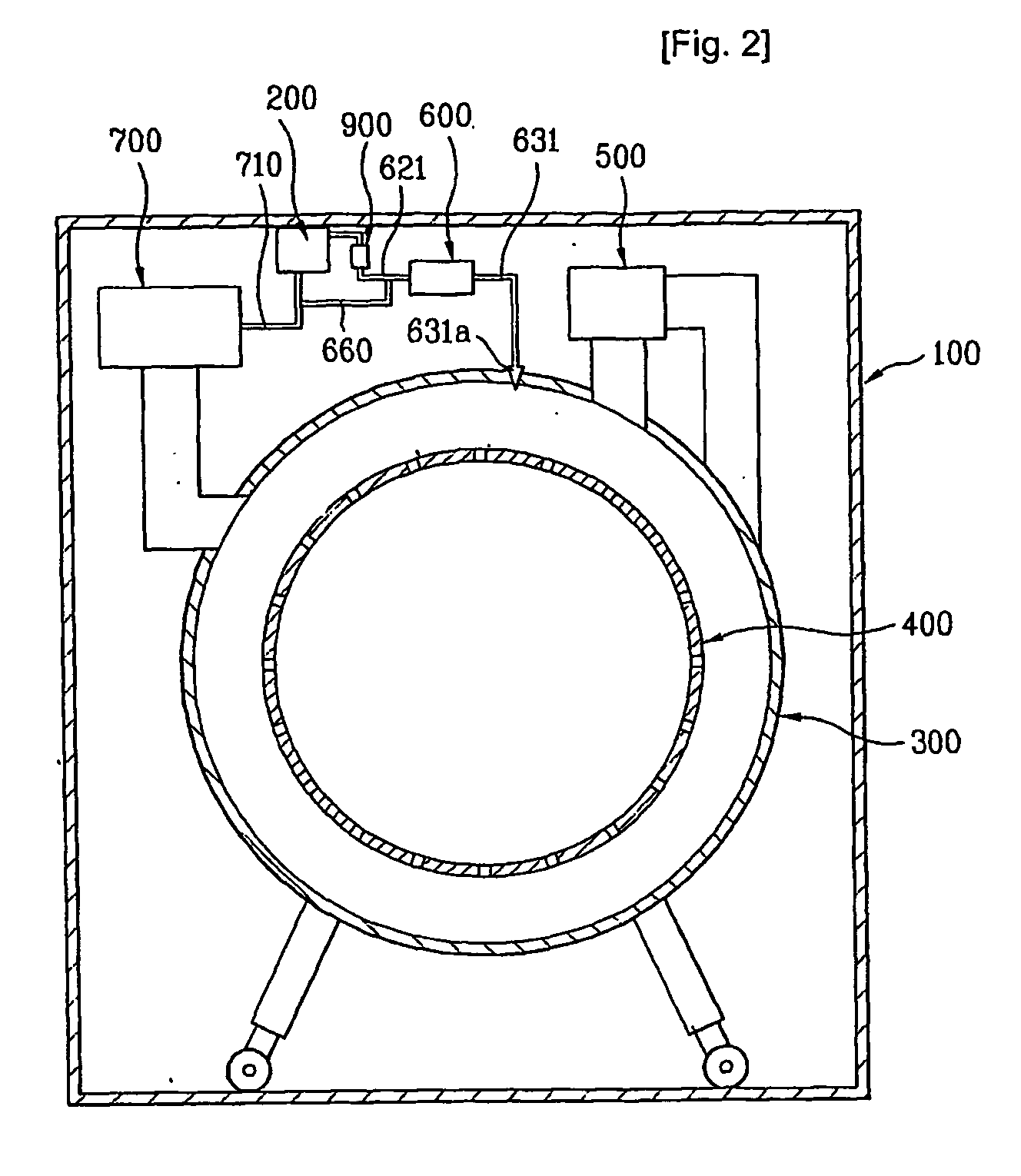

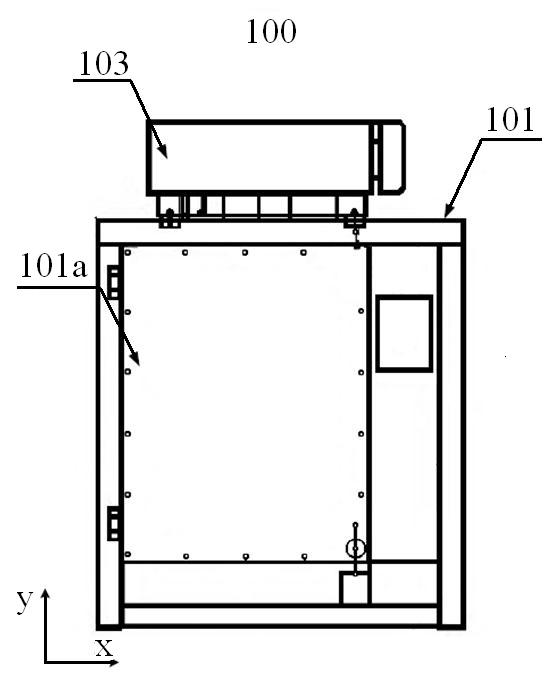

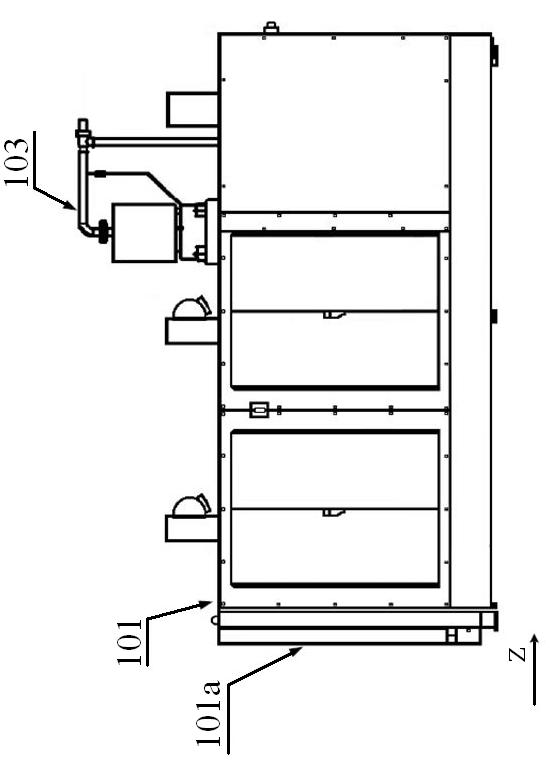

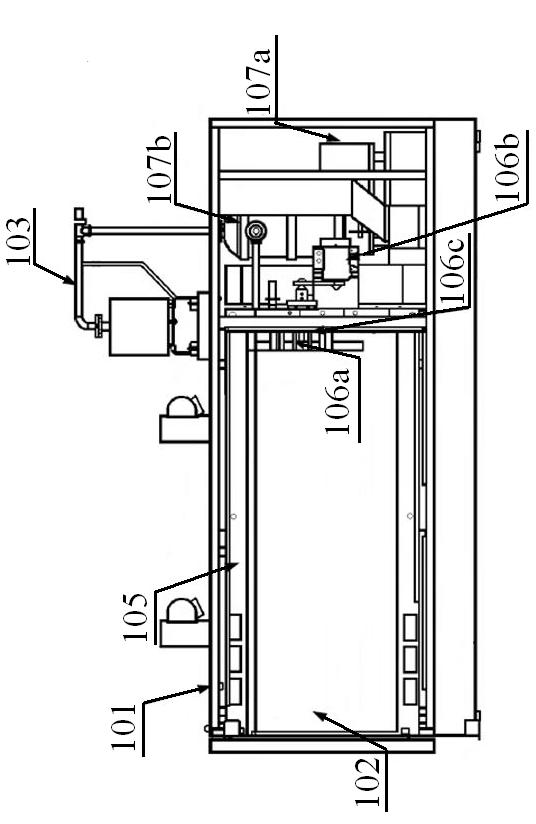

Laundry Machine

InactiveUS20080271500A1Improve washing efficiencyEconomizing in wash water in a washing cycleTextile treatment machine partsOther washing machinesProcess engineeringLaundry

A laundry machine is disclosed. A laundry machine includes a body (100) for defining an exterior, a water supply valve (200) provided in the body (100) and connected with an outer water supply device, a drum rotatably mounted within the body, at least one steam generator for supplying steam into the drum (600), and a water treatment apparatus (900) for treating water supplied to the steam generator (600). an object of the present invention is to provide a laundry machine which can perform washing and drying more quickly and efficiently as well as which has an effect of smoothing out wrinkles and sterilizing the laundry.

Owner:LG ELECTRONICS INC

Cleaning systems and base stations for cleaning systems

PendingCN110881900AImprove drying efficiencyCarpet cleanersFloor cleanersSewageMechanical engineering

The invention discloses a cleaning system and a base station of the cleaning system. The base station includes: a support platform for supporting a cleaning robot, the support platform has a cleaning tank with an open top, and the cleaning tank is used to hold water to clean the cleaning robot located above it. Flannel and / or roller brush, the cleaning tank has a water inlet and a sewage outlet; a drying component for generating hot air, the drying component is connected with the cleaning tank, and the hot air generated by the drying component is directed to the cleaning tank to dry the cleaned Clean the robot's lint and / or brush. According to the base station of the cleaning system according to the embodiment of the present invention, by setting the drying component, the flannelette and / or roller brush of the cleaning robot can be dried after cleaning, thereby speeding up the drying efficiency of the flannelette and / or roller brush, preventing the The flannel and / or roller brush dripping water on the floor will affect the effect of cleaning the floor.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

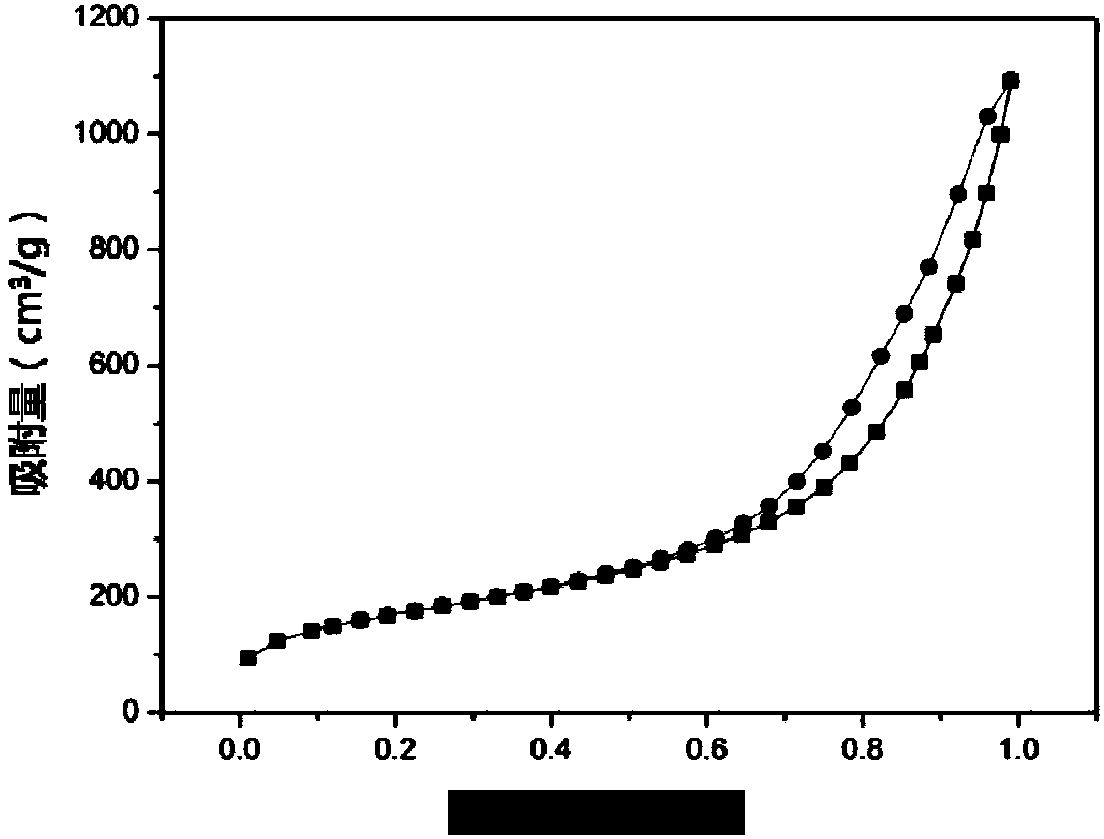

Aerogel micro powder and preparation method thereof

InactiveCN108689412AImprove drying efficiencyShorten freeze-drying timeChemical industryFerric oxidesPorosityOrganic solvent

The invention discloses aerogel micro powder and a preparation method thereof. The method comprises the following steps: a hydrogel is provided, and fragmentation is carried out on the hydrogel and dispersing the hydrogel to obtain gel fluid or gel dispersion liquid; an atomizing device is employed for performing atomization on the gel fluid or the gel dispersion liquid, gel droplets are formed, the gel droplets are collected by a low-temperature container, and the gel freezing particles are obtained; the freeze drying is carried out, and the aerogel micro powder is obtained. The aerogel micropowder can realize integration of granulation and refrigeration, pre-refrigeration is not required, rapid and continuous production of the aerogel micro powder can be realized, organic solvent displacement is not required, the preparation method has the advantages of simple process, short production period, low cost, energy saving, and environmental protection, the preparation process can be amplified to industrial production, and the obtained aerogel micro powder has the excellent physical properties of controllable morphology, uniform particle size, large specific surface area, high porosity amount, and low thermal conductivity.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

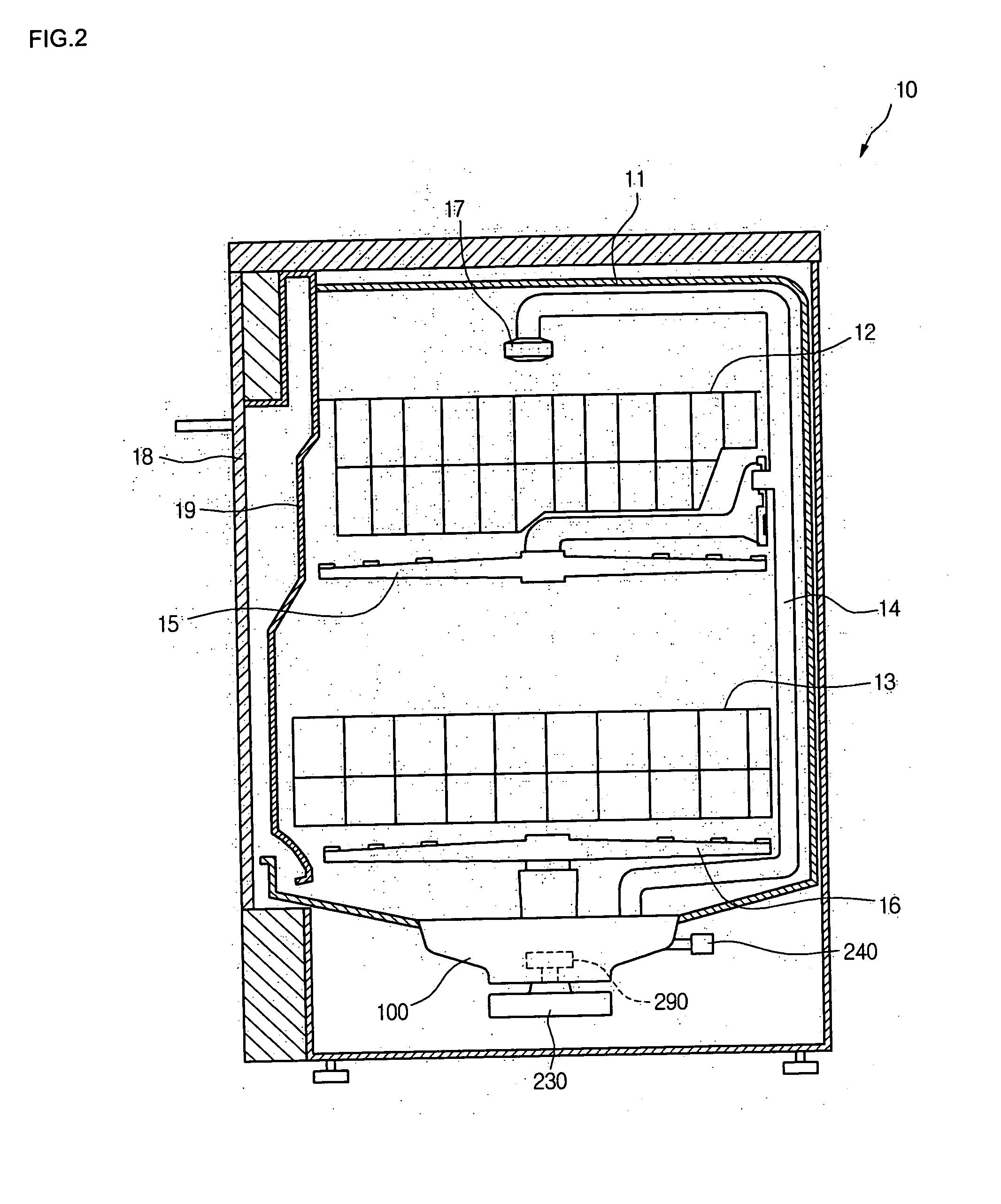

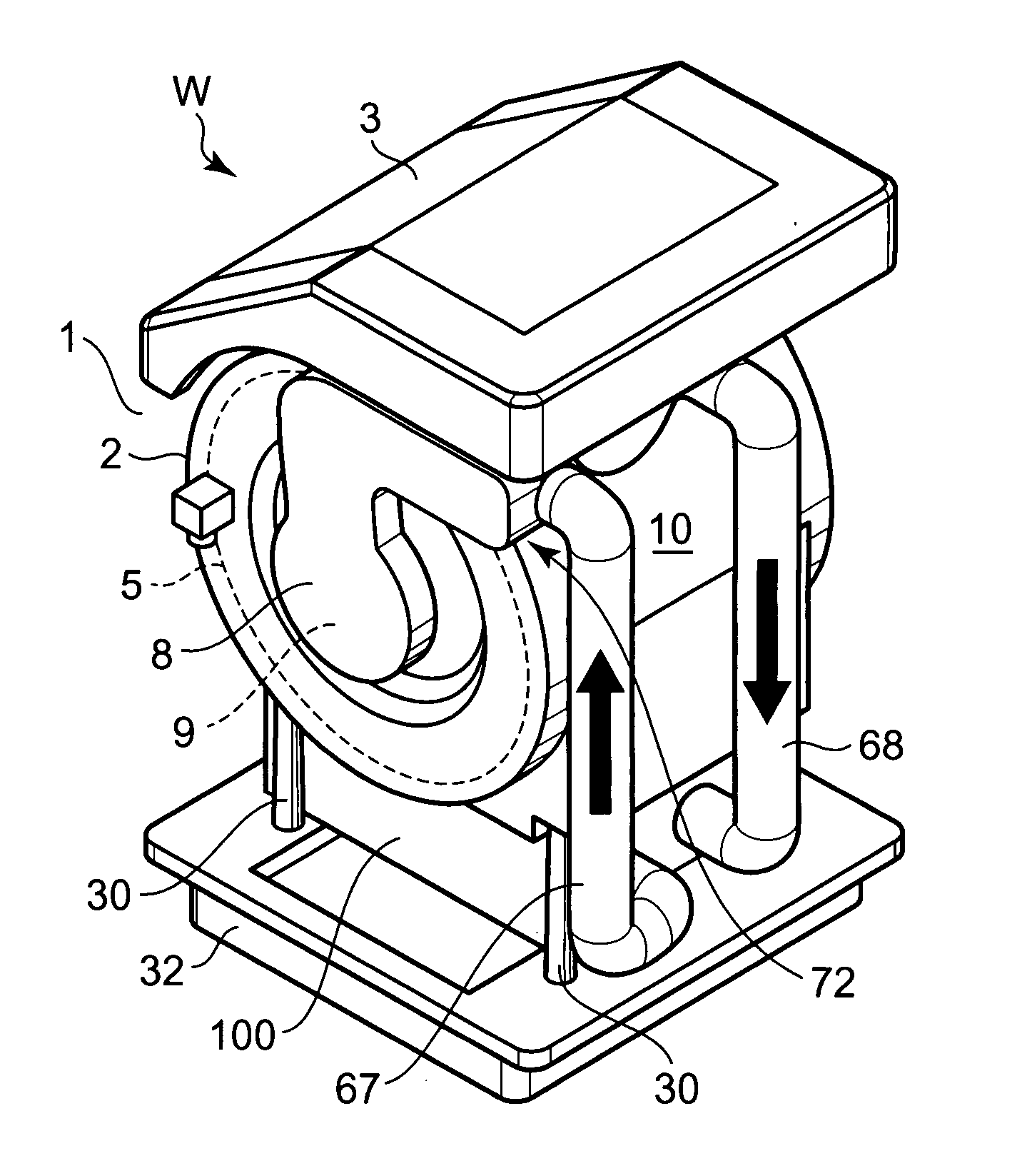

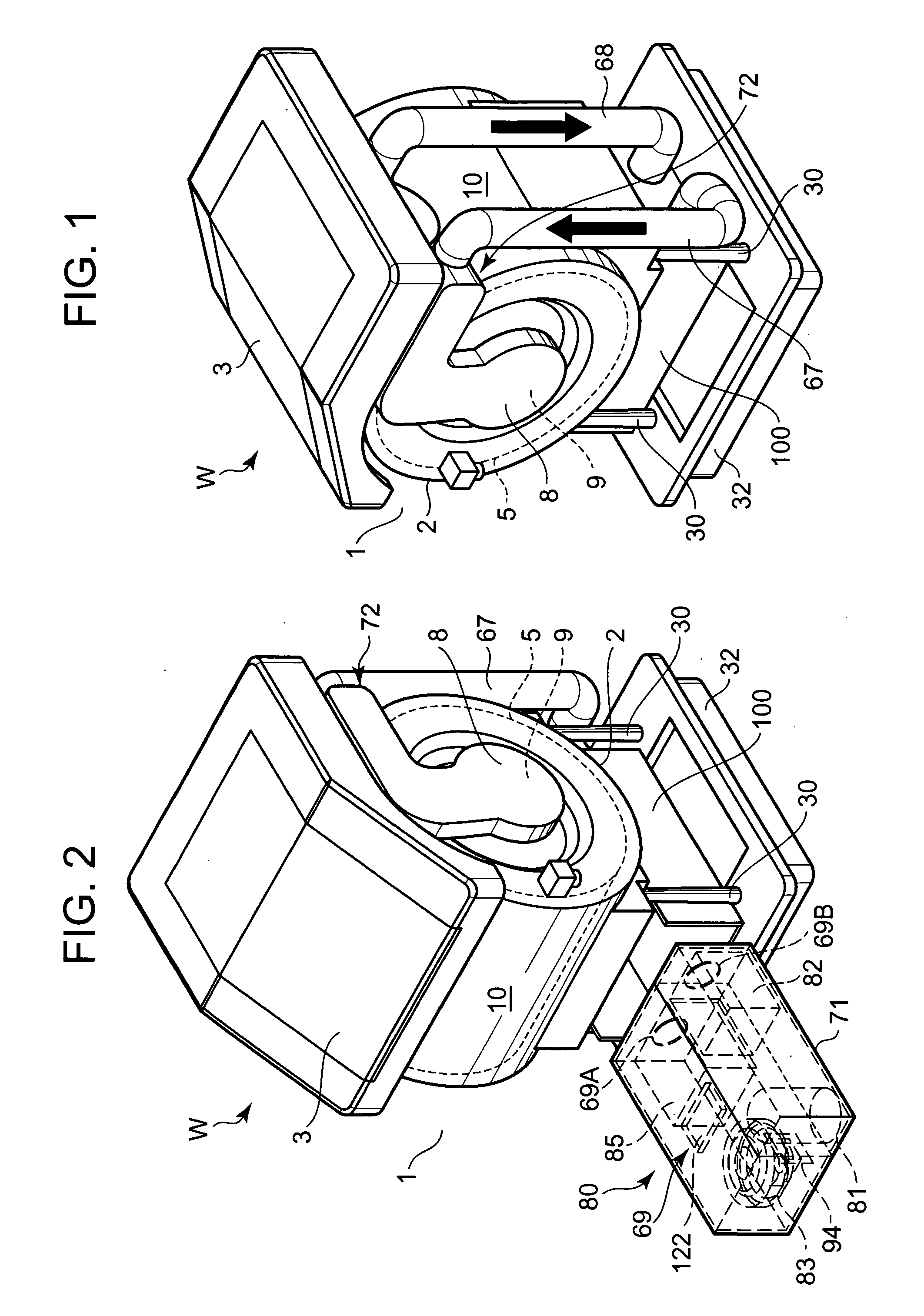

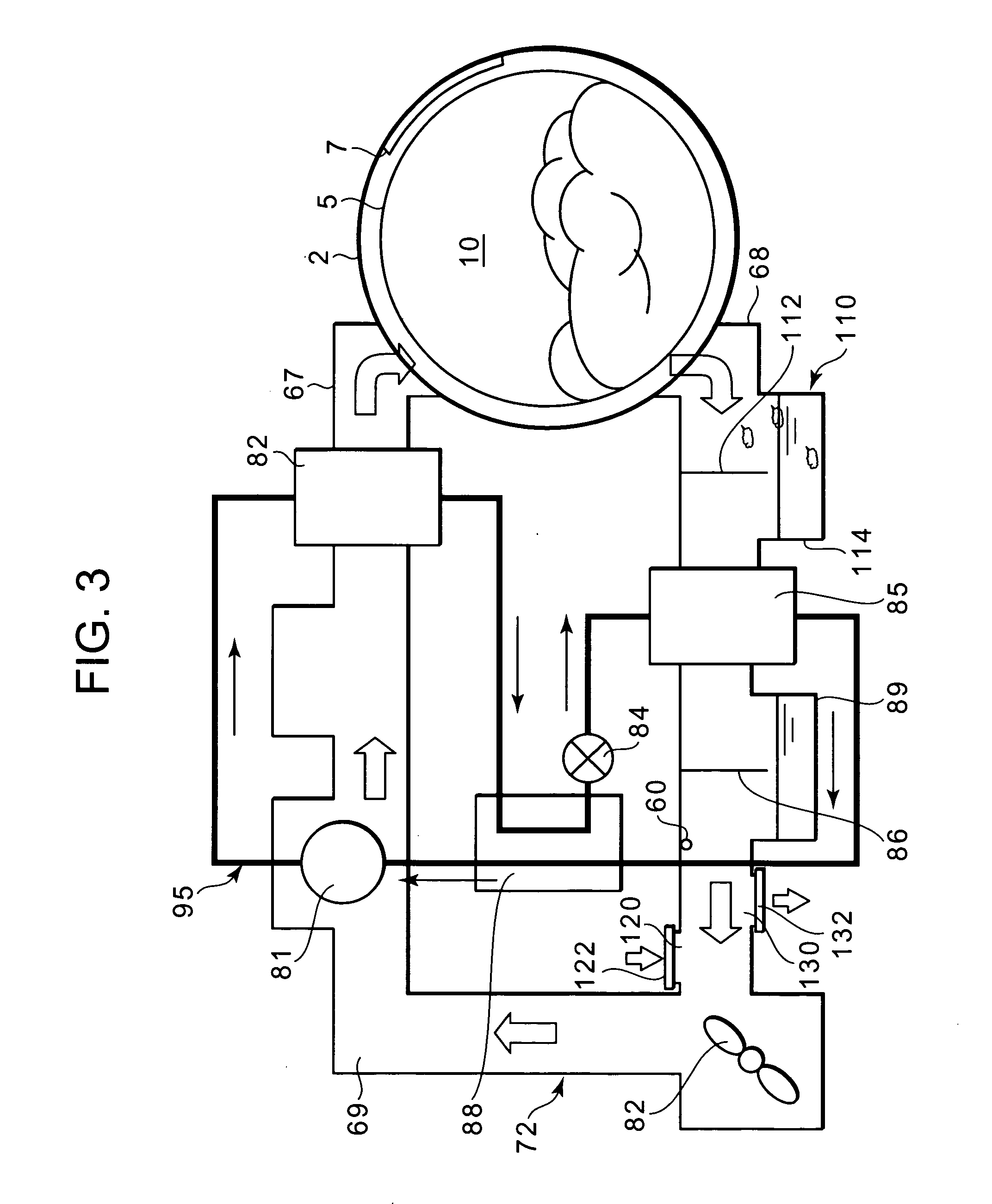

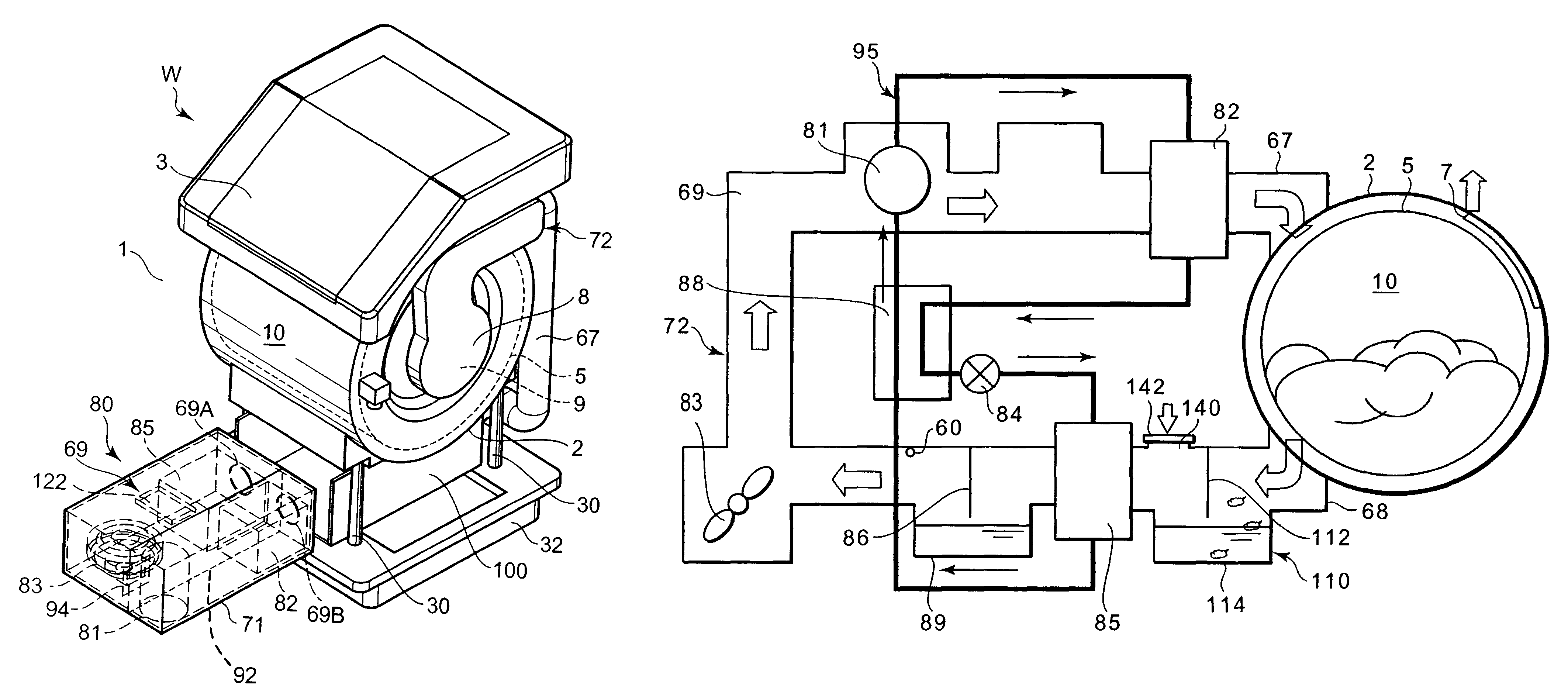

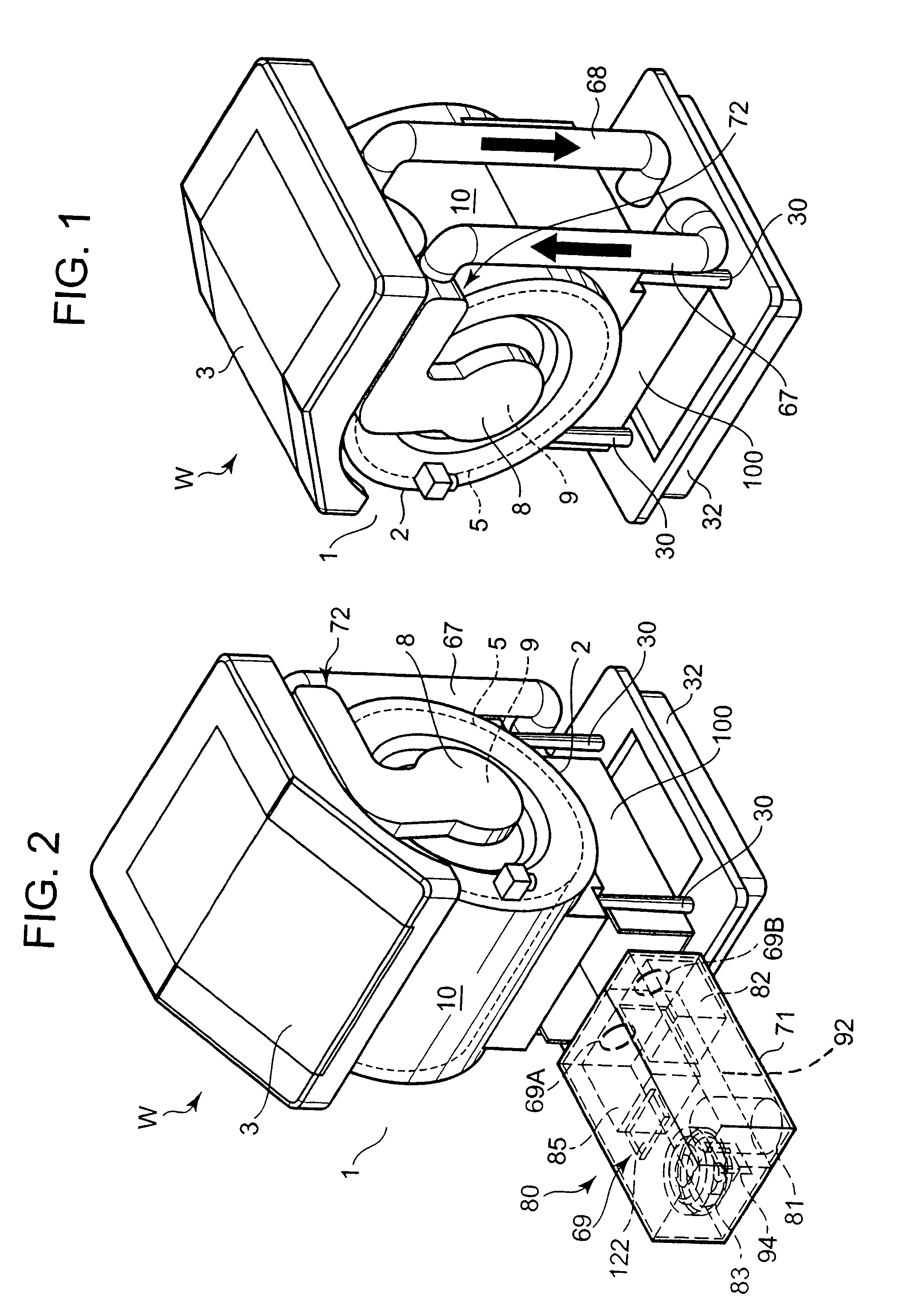

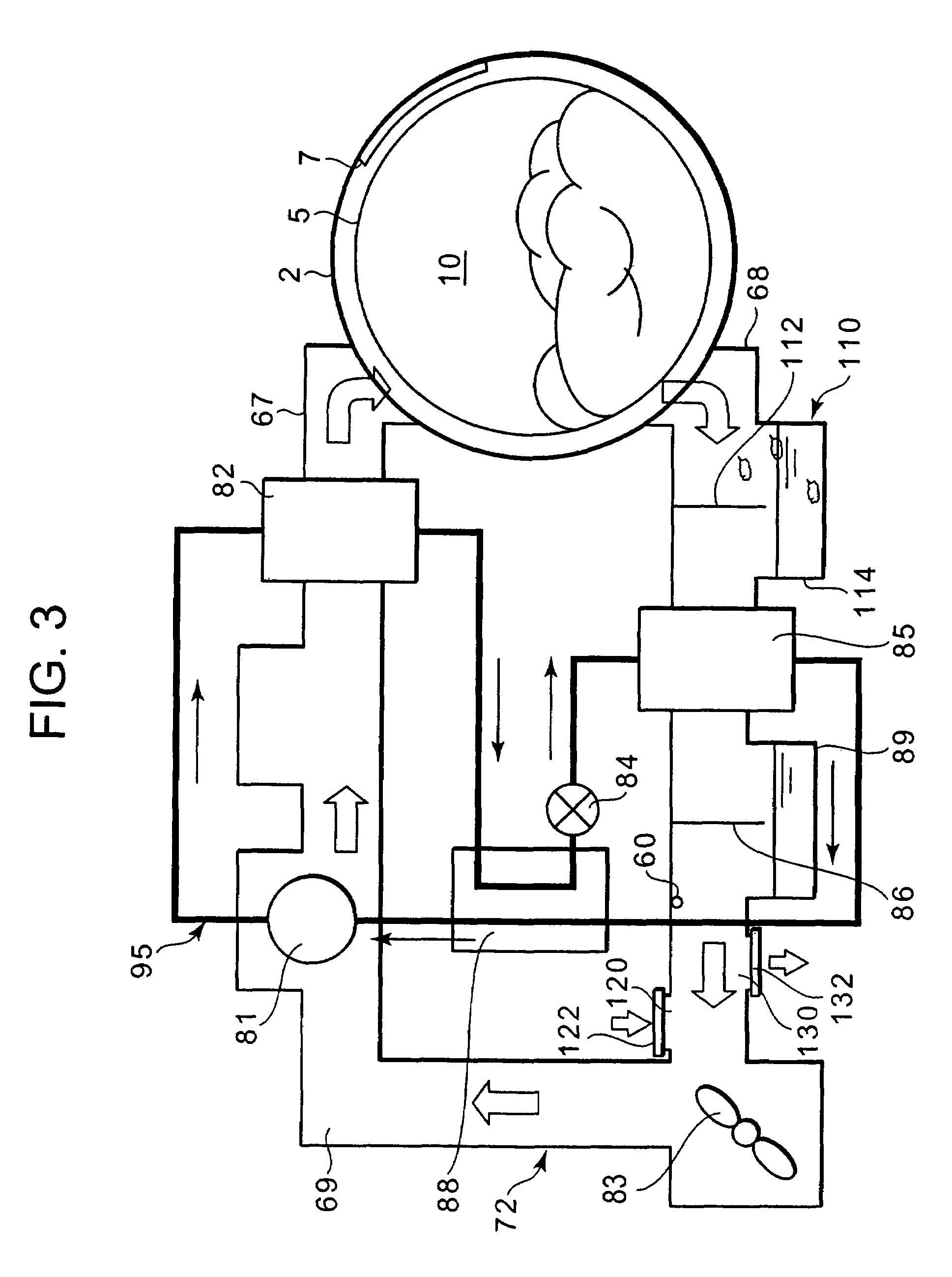

Drying machine with inner and outer drums and outside air introduction

InactiveUS7409776B2Efficient dryingShort timeDrying gas arrangementsDrying machines with non-progressive movementsAir cycleGas cooler

An object is to provide a drying machine capable of maintaining air discharged into a housing chamber while efficiently drying a matter to be dried in a short time. A drying machine provided with a housing chamber which houses the matter to be dried, and executing a drying operation of the matter to be dried in the housing chamber comprises: a gas cooler; an evaporator; a blower fan; an air circulation path for discharging air heated by the gas cooler into the housing chamber by the blower fan, sending the air passed through the housing chamber into the evaporator, and circulating the air in the gas cooler; and a closeable outside air introduction port for mixing outside air with the air circulating in the air circulation path.

Owner:SANYO ELECTRIC CO LTD

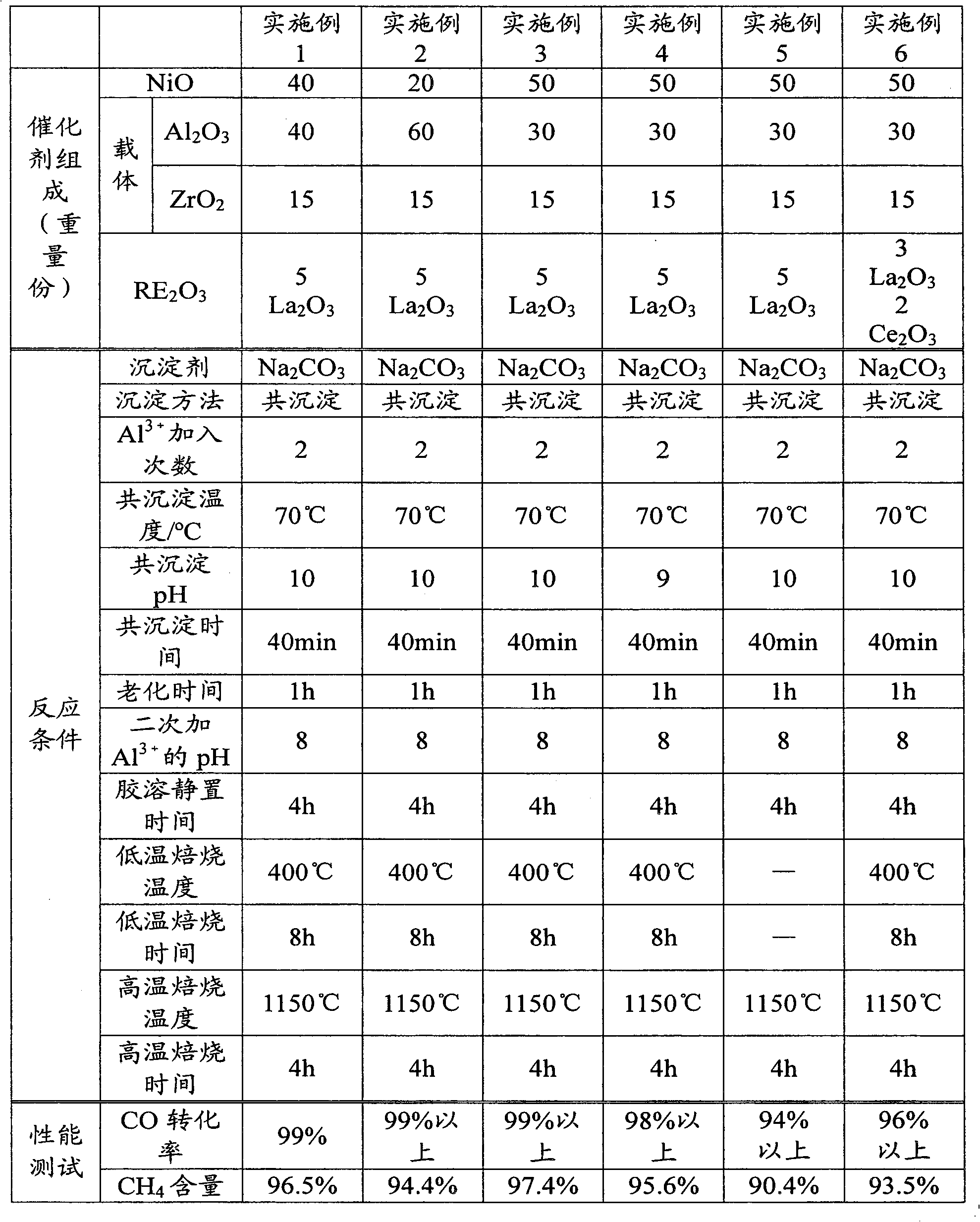

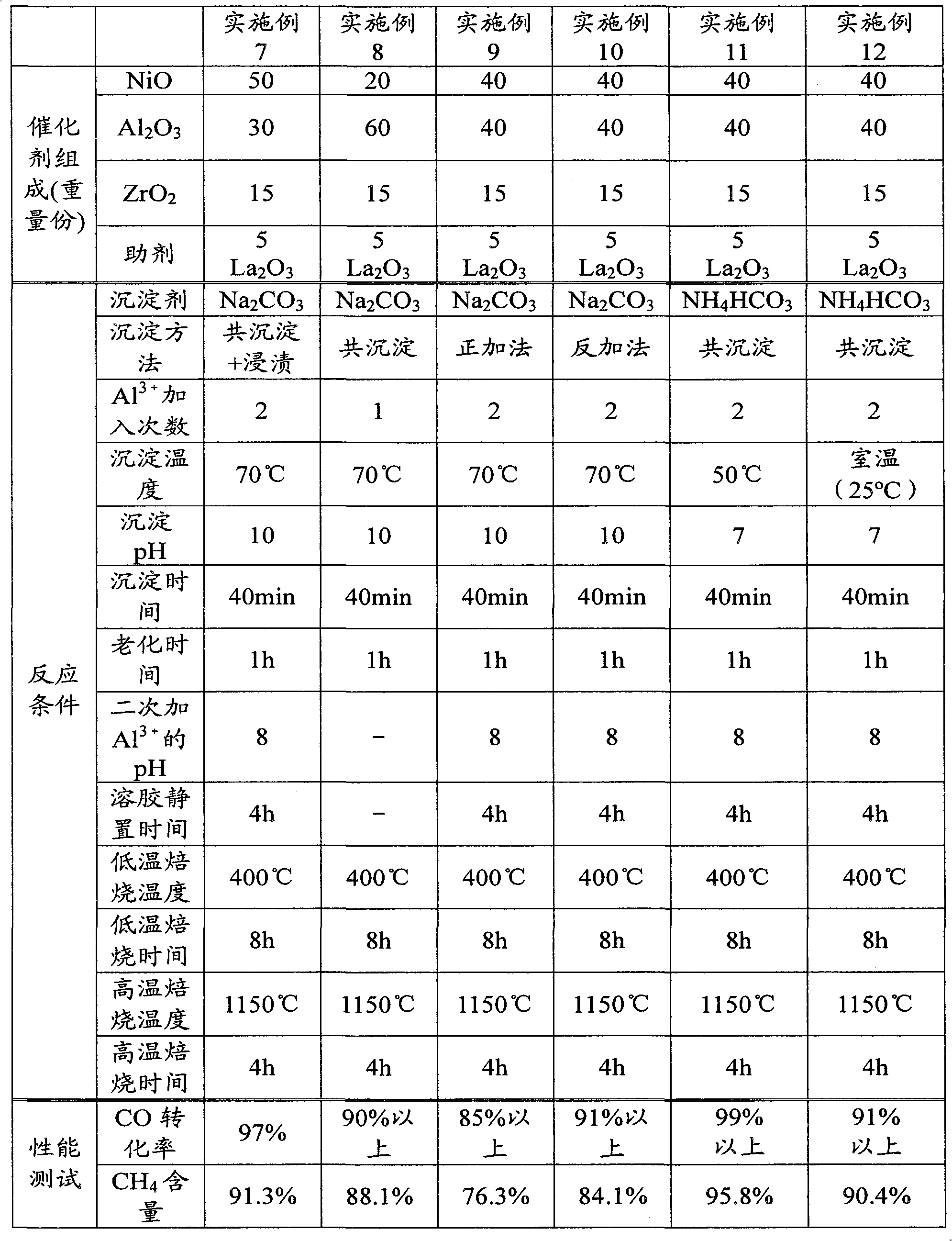

High-temperature methanation catalyst, preparation method and application thereof

ActiveCN101890353AHigh activityHigh selectivityHydrocarbon from carbon oxidesGaseous fuelsMethanationRare earth

The invention relates to a high-temperature methanation catalyst, a preparation method and application thereof. The high temperature methanation catalyst comprises the following components: a) NiO serving as an active ingredient; b) a metallic oxide carrier comprising Al2O3 and ZrO2; and c) a metallic oxide auxiliary agent which is at least one of rare-earth metallic oxide RE2O3, and metallic oxide of magnesium Mg, copper Cu and chromium Cr. The method comprises the following steps of: A) preparing an aqueous solution of water soluble salt, wherein the water soluble salt comprises Ni, the metallic oxide carrier and optional metallic cation corresponding to the metallic oxide auxiliary agent, performing precipitation reaction with a precipitator to ensure that the metallic cation in the water soluble salt is precipitated; B) separating solid from liquid to obtain a precipitated solid; and C) performing dry granulating and calcining to ensure that the metallic cation is converted into the corresponding metallic oxide, wherein the calcining comprises high-temperature calcining. The catalyst still has higher activity and selectivity at higher temperature.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

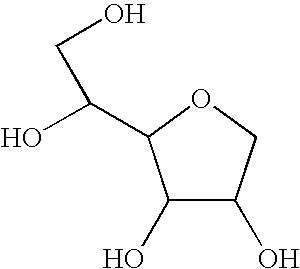

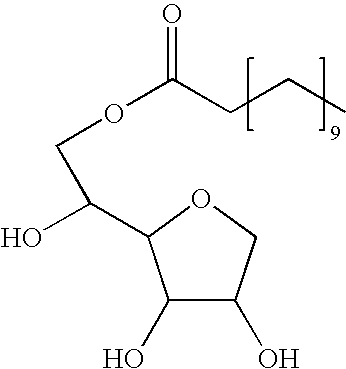

Method of drying an absorbent polymer with a surfactant

InactiveUS20070123624A1Improved pumpability and spreadabilityImprove drying efficiencyTransportation and packagingMixingPolymer scienceAcid value

A method of drying an absorbent polymer includes providing the absorbent polymer. A surfactant having a C10 to C24 ester group is incorporated with the absorbent polymer. An acid value of the surfactant is increased to further increase drying efficiency of the absorbent polymer. More specifically, after increasing the acid value of the surfactant, the absorbent polymer exhibits improved pumpability and spreadability, as compared to absorbent polymers including the surfactant without having the acid value of the surfactant increased.

Owner:OTTEN JAY +2

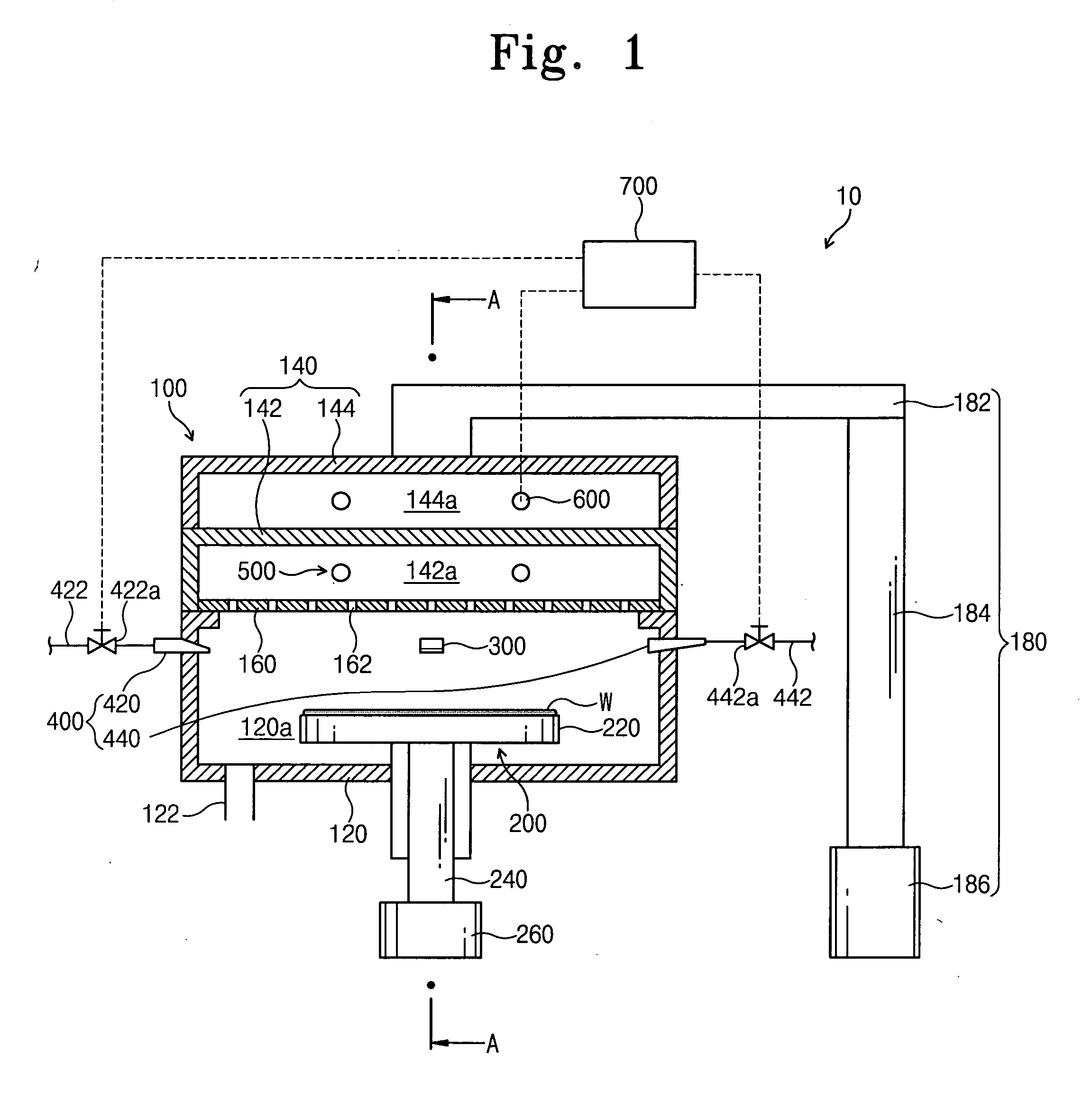

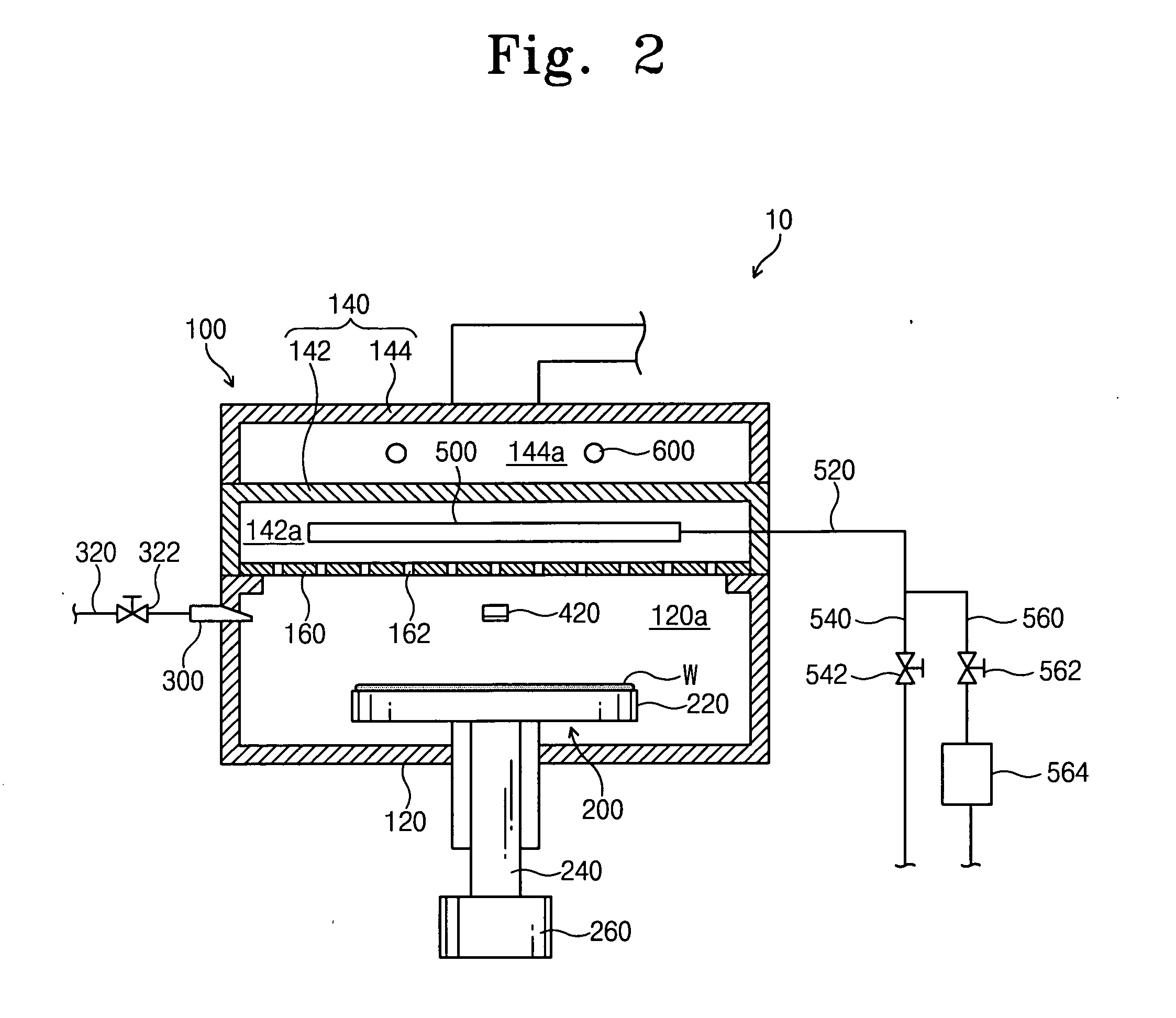

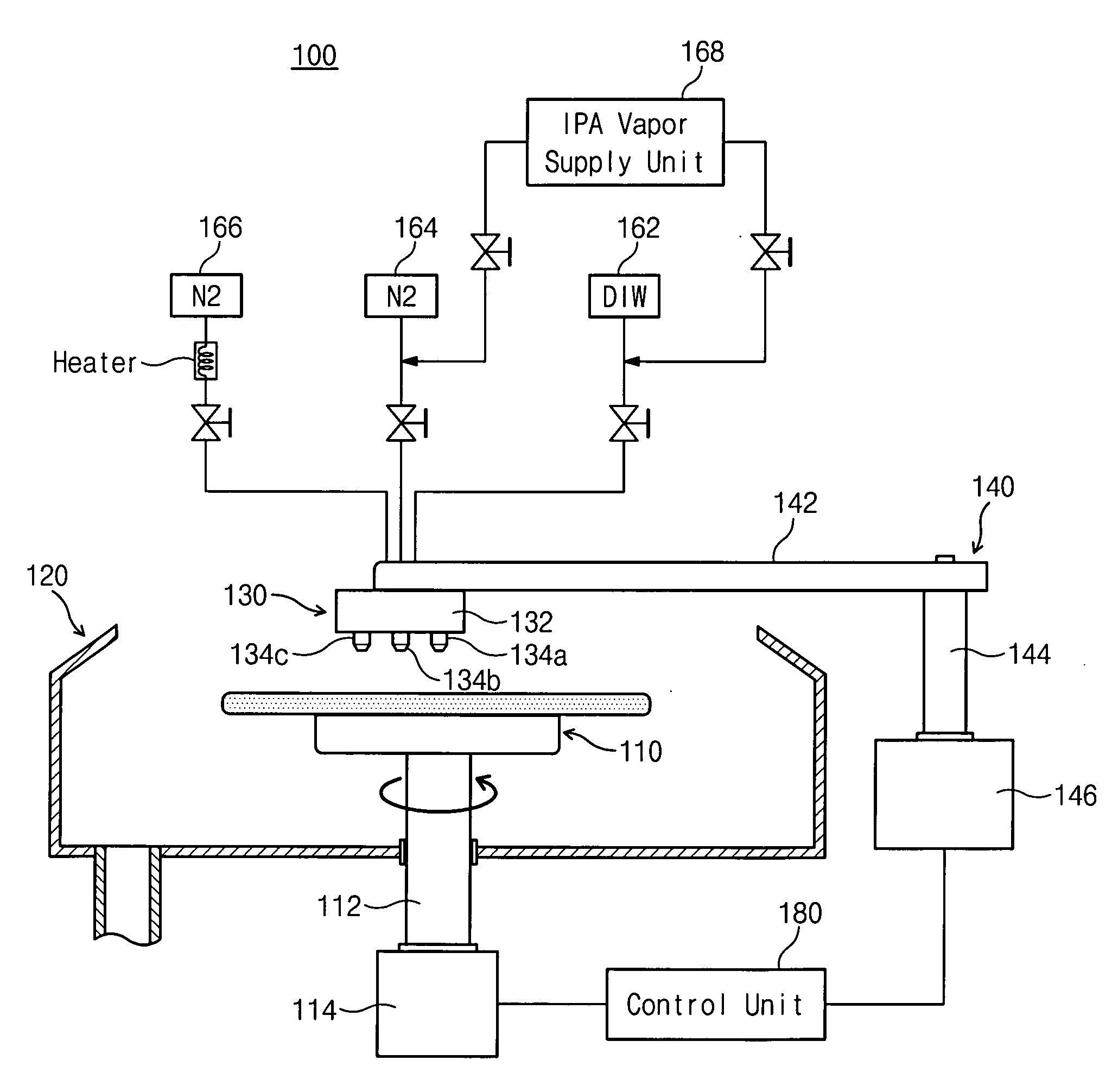

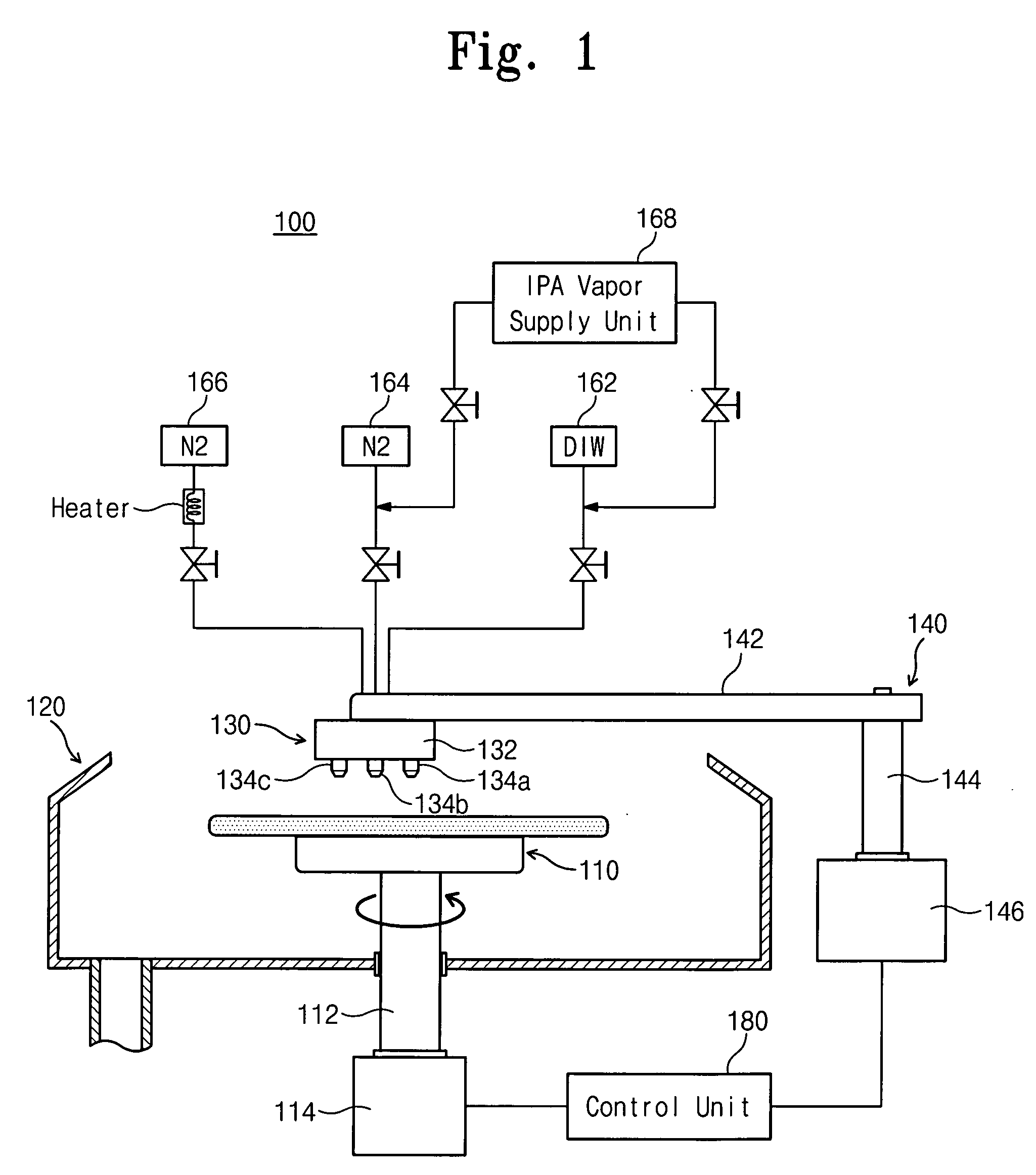

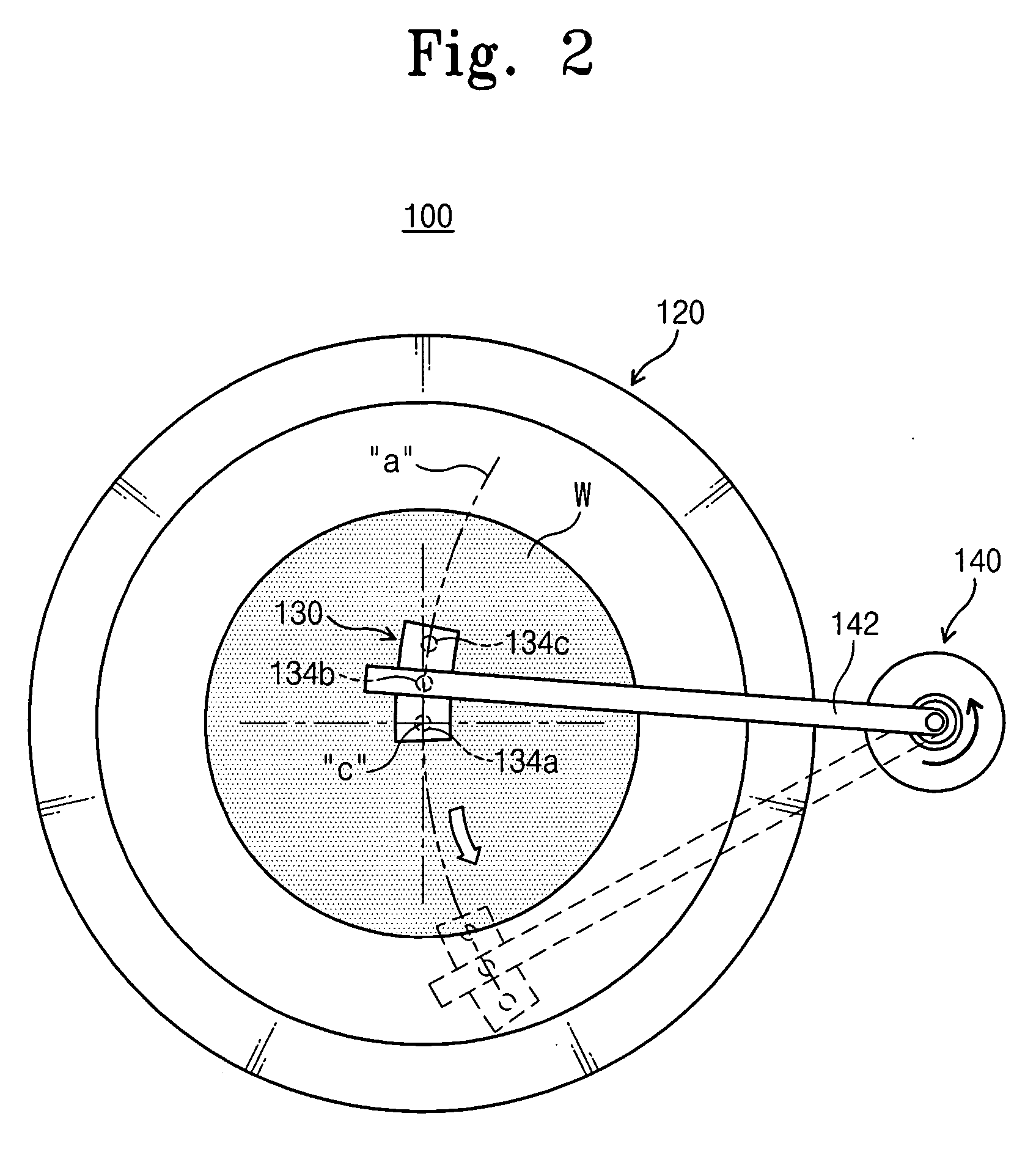

Apparatus and method for cleaning a semiconductor wafer

InactiveUS20060231125A1Easy to disassembleReduce surface tensionSemiconductor/solid-state device manufacturingToysOrganic solventProcess engineering

A cleaning apparatus is provided comprising a process chamber defining a work space, a supporter apparatus for rotating a wafer, the supporter apparatus being located in the work space and the wafer being mounted on the supporter apparatus such that a processing surface of the wafer is upwardly facing, an organic solvent supplying nozzle for supplying an organic solvent into the work space to the processing surface of the wafer mounted on the supporter apparatus, and a dry gas supplying nozzle for supplying an organic solvent vapor into the work space and forming an organic solvent atmosphere therein. Thus, water remaining on the wafer may be readily removed.

Owner:SAMSUNG ELECTRONICS CO LTD

Special baking oven and special movable material rack thereof for silicon material

InactiveCN101749928AEasy loading and unloadingFully contactedDrying solid materials with heatDrying gas arrangementsThermal insulationProcess engineering

The invention relates to a special baking oven and a special material rack thereof for silicon material. The baking oven comprises a thermal insulation shell, an inner container, a high temperature air cavity, a hot air duct, a heater, a circulating fan, a dehumidifier, a dehumidification pipe, a humidity sensor, a temperature sensor, a frame body, idler wheels and a silicon material box, wherein the high temperature air cavity is arranged on top of the inner container, the hot air duct is arranged around the inner container, the heater is arranged in the baking oven, the circulating fan is arranged between the high temperature air cavity and the hot air duct, the dehumidifier is communicated with the inner chamber of the inner container, and the humidity sensor and the temperature sensor are arranged to realize automation control of the baking oven. The movable baking shelf thereof can facilitate loading / unloading and in / out of silicon material, save baking preparation time, and has the advantages of high baking efficiency and low energy consumption. The whole silicon material box can be directly moved in the baking oven for baking, thereby greatly shortening technology preparation time and reducing labor strength of operators.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

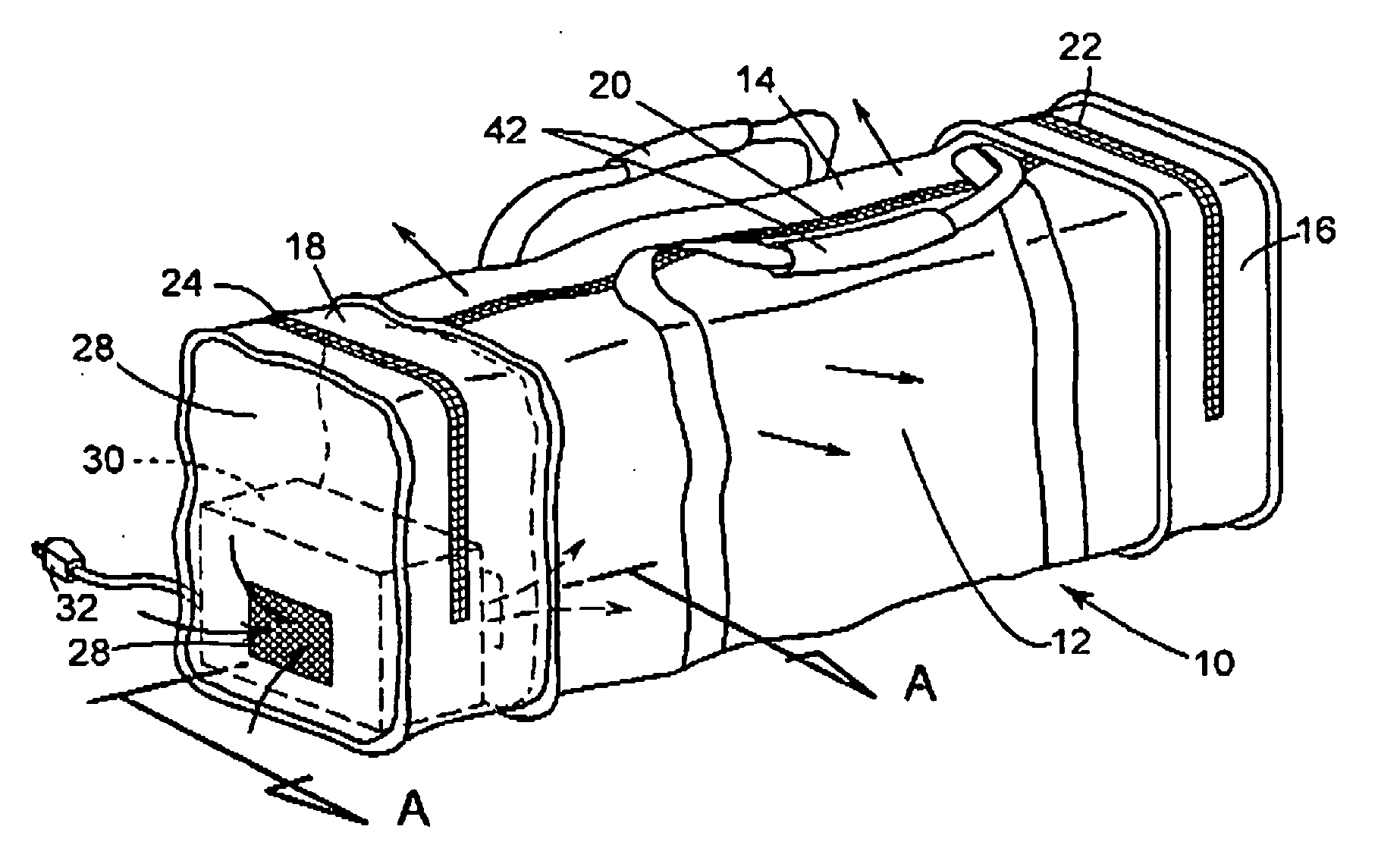

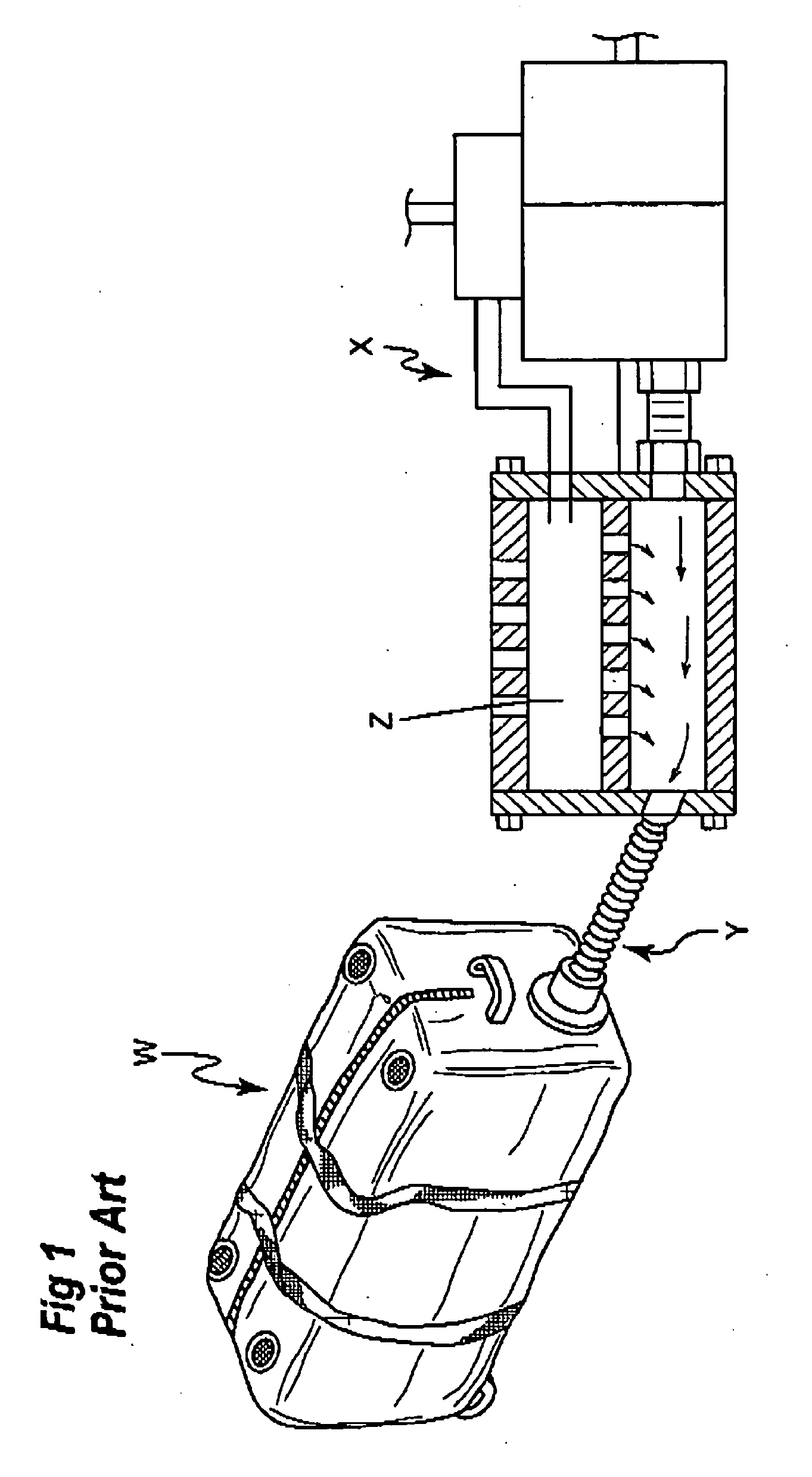

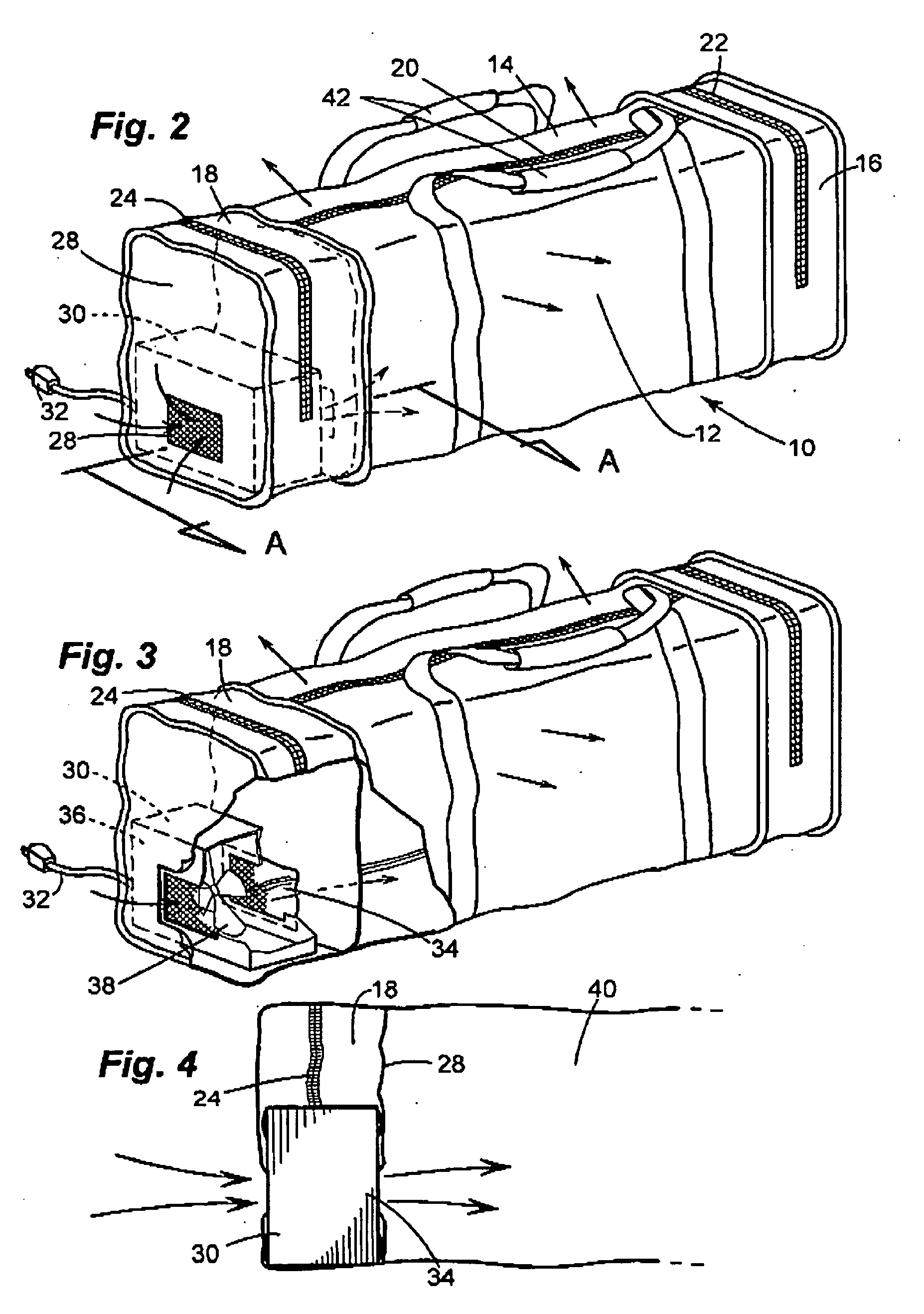

Ozone deodorizing and disinfecting portable containers

InactiveUS20080118411A1Easily modifyRemoval and neutralization of malodors and unhealthyDrying gas arrangementsDisinfectionProduct gasOzone generator

A portable storage apparatus for disinfecting, deodorizing and drying objects. The device for the apparatus comprising: a bag having at least one interior chamber formed by at least one outer wall for containing objects therein, ozone generator means for creating ozone, air distribution means for the movement and circulation of ozonated air within, throughout and out of the at least one interior chamber. The ozone generation means and air circulation means are located within or in direct circulatory contact with the one interior chamber of the bag to force ozonated air into and throughout the one interior chamber of the bag, and means on the outer wall permitting expultion of air from within the interior chamber of the bag to the environment outside the bag. Resulting in the disinfection, deodorization and drying of objects placed within the apparatus through contact with the ozone and air distributed therein.

Owner:DARINZO RALPH

Self-circulation type coffee bean grinding and drying integrated machine

InactiveCN107597329AEvenly heatedImprove drying efficiencyGrain treatmentsFood treatmentDrive shaftPulp and paper industry

The invention discloses a self-circulation type coffee bean grinding and drying integrated machine. The machine comprises a shell, support legs, a feed port, a smashing motor, a smashing shaft, main smashing blades and a heating plate. The upper surface of the shell is fixedly connected with the smashing motor. The shaft extension end of the smashing motor is fixedly connected with the smashing shaft. The main smashing blades are distributed on the sidewall of the smashing shaft. A screen plate is arranged below the main smashing blades. A crankshaft is arranged below the screen plate. The journal of the crankshaft is sleeved with a connecting rod. The upper end of the connecting rod is hinged to the lower surface of the screen plate. A transmission shaft is further arranged below the screen plate. The middle portion of the crankshaft and the middle portion of the transmission shaft are sleeved with a first semi-gear and a second semi-gear correspondingly. A rotary shaft is arranged below the transmission shaft. A scraping plate is arranged below the rotary shaft. The machine conducts cyclic smashing on coffee beans in the smashing process to make smashing more thorough. The smashed coffee beans fall onto the bottom of the shell. The screen plate vibrates up and down to make the smashed coffee beans to pass through the screen plate. The coffee beans are turned over repeatedly through the scraping plate. Accordingly, the coffee beans are heated more uniformly.

Owner:杨鹏

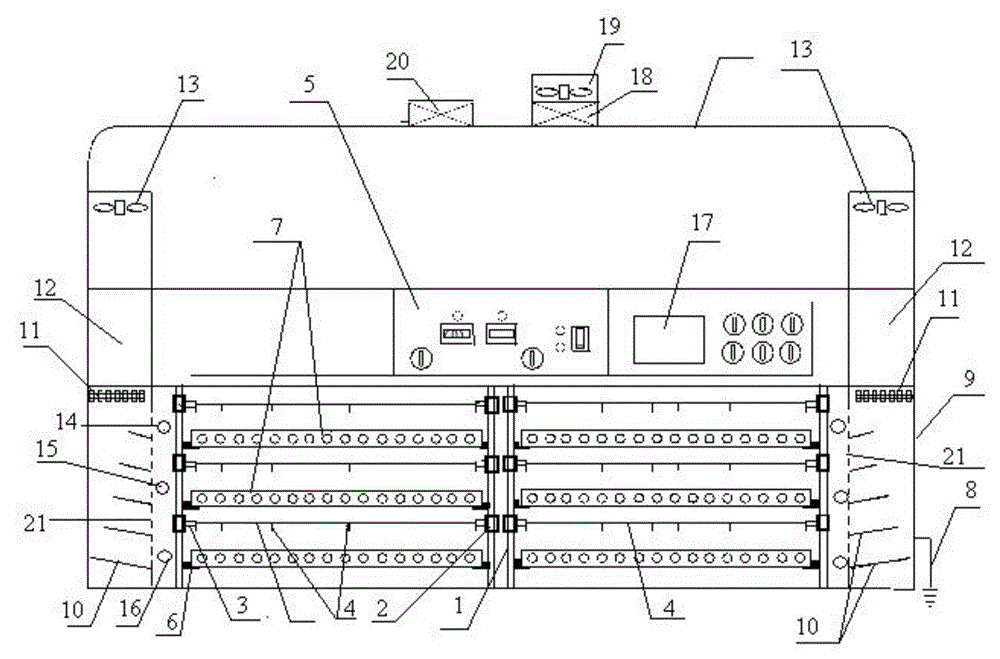

High-voltage electric field and hot air combined drying device

ActiveCN103983091AImprove retentionGood appearanceDrying gas arrangementsDrying chambers/containersThermal instabilityOperability

The invention discloses a high-voltage electric field and hot air combined drying device. The high-voltage electric field and hot air combined drying device comprises a box body, a high-voltage electric field drying system, a hot air circulation drying system and a monitoring control system, wherein the high-voltage electric field drying system, the hot air circulation drying system and the monitoring control system are arranged on the box body. According to the high-voltage electric field and hot air combined drying device provided by the invention, the structural design is reasonable, the operability is strong, and the use is convenient; compared with traditional hot air drying, the drying efficiency is high, the drying temperature is low, the drying time can be shortened by 50% than the drying time of drying by pure hot air under the same temperature, the drying energy consumption can be reduced by 51.9%, the high-voltage electric field and hot air combined drying device is particularly suitable for drying materials containing thermal-instability active components, for example, drying the materials of traditional Chinese medicine, medicinal slices, drug, agricultural products, food, biological products and the like, the appearance quality after the drying is good, the reservation degree of the active components is high, and the application range is very wide.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Dryer

ActiveUS20080222910A1Constant distanceTime required to evenly and quicklyOpening closed containersBottle/container closureEngineeringFront edge

A hand drying apparatus has a casing, a cavity formed in the casing for receiving a user's hands, a fan located in the casing and creating an airflow, and a plurality of openings communication with the fan and arranged to direct an airflow transversely across the cavity. The cavity has an entrance delimited by a front edge and a rear edge in which the openings are located. The shape of the front and rear edges is such that, when in use the user's hands are introduced to the cavity, the distance between the user's hands and the nearest opening is substantially uniform. Alternatively, one of the edges is substantially straight and the other of the said edges is curved so that the distance between the edges varies along the length of the cavity entrance. These arrangements enhance the drying efficiency of the dryer.

Owner:DYSON TECH LTD

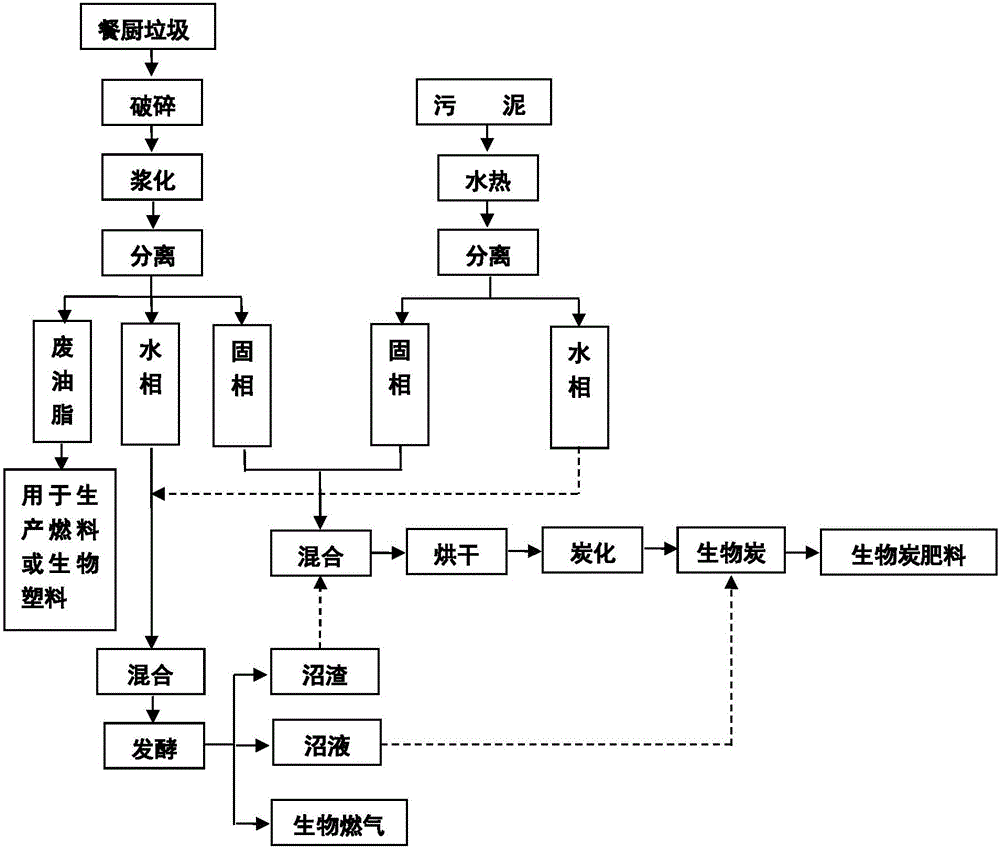

Method for processing sludge and kitchen wastes

ActiveCN105855275AImprove system stabilityLow running costSludge treatment by de-watering/drying/thickeningSolid waste disposalFertilizerNutrient

The invention relates to a method for processing sludge and kitchen wastes. The method comprises the following steps: by utilizing sludge and kitchen wastes as principal raw materials; separating waste oil from kitchen wastes to be taken as the raw material of fuel or bioplastics; taking biological fuel gas, which takes methane as main material and is generated through fermentation, as an external fuel supply; absorbing the nutrient in biogas slurry by the charcoal generated through pyrolysis and then taking the charcoal as a charcoal fertilizer. The method for processing sludge and kitchen wastes provided by the invention meets the increasingly urgent requirement of processing the sludge and kitchen wastes in China at present; the method can be used for efficiently solving the problems of separately processing sludge and kitchen wastes; the classification and valuable utilization of by-products are realized; various by-products are low-carbon high-efficient cleanly utilized; the purposes of best use, energy conservation, environment protection and cost lowering are achieved; the method has excellent economic benefit and environmental benefit.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Cleaning and drying device for medical instruments

InactiveCN105170527AQuick washQuick cleaningDrying gas arrangementsCleaning using liquidsLap jointEngineering

The invention discloses a cleaning and drying device for medical instruments. The cleaning and drying device comprises a box. Water outlets are formed in the bottom of the inner wall of the box. A support is fixedly arranged at the bottom of the inner wall of the box. One side of the support is fixedly connected with a lower sliding plate. The surface of the lower sliding plate is covered with a water absorption sponge. The bottom end of the lower sliding plate is in lap joint with the upper surface of a bearing plate. A containing groove is formed in the upper surface of the bearing plate, and a heating piece is arranged in the bearing plate. According to the cleaning and drying device for the medical instruments, a high-pressure spray head is arranged, so that the medical instruments are cleaned fast; ultraviolet lamps are arranged, so that the effect of disinfecting the medical instruments is achieved; the sliding plate and the water absorption sponge are arranged, so that the effects of sliding down and water absorption on the instruments are achieved; a filter device is arranged in an air chamber, so that the effect of filtering out impurities in air is achieved; and the heating piece is arranged, so that the effect of heating the bearing plate and the instruments on the bearing plate is achieved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Vacuum baking oven for pole pieces of battery

ActiveCN102072620AImprove work efficiencyImprove performanceDrying using combination processesElectrode manufacturing processesPole pieceEngineering

The invention relates to a vacuum baking oven for pole pieces of a battery. The vacuum baking oven comprises a box body, a baking room, a vacuumizing component, a heating component, a heat transfer component, a gas flow circulating component and a protective gas supply component, wherein the baking room is positioned in the box body and used for accommodating and baking the pole pieces; the vacuumizing component is positioned outside the box body and communicated with the baking room; the heating component is positioned in the box body and arranged around the outside of the baking room; the heat transfer component is in contact with and around the outside of the baking room and is used for quickening the transfer of the heat from the heating component to the baking room; the gas flow circulating component is positioned in the box body and used for circulating the gas in the baking room; and the protective gas supply component is positioned outside the box body and communicated with the baking room to blow protective gas into the baking room. The vacuum baking oven can reduce the water content of the pole pieces and enhance the baking efficiency and the safety.

Owner:FUJIAN NANPING NANFU BATTERY

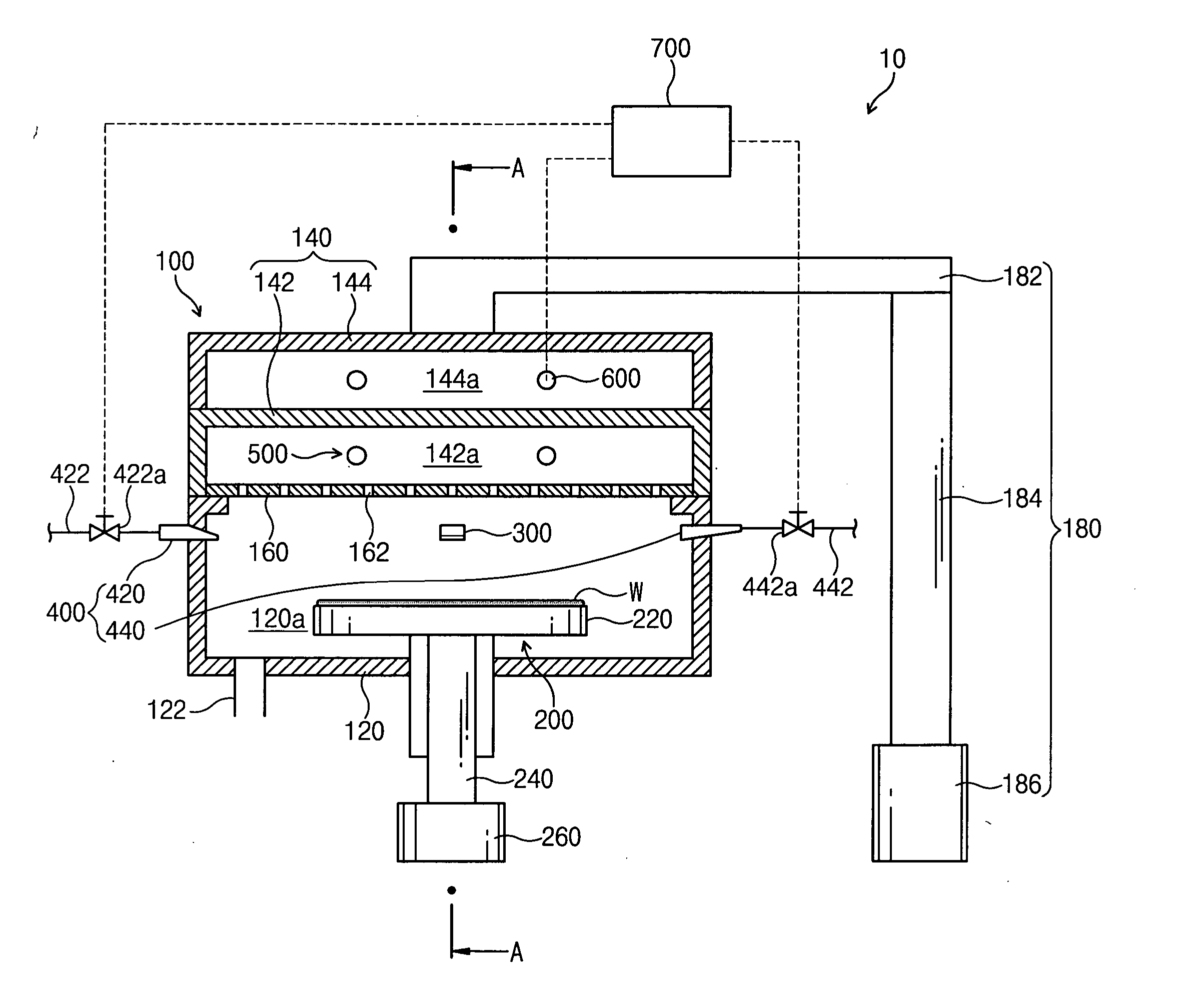

Method and apparatus for cleaning and drying wafers

InactiveUS20060081269A1Improve drying efficiencyShorten drying timeElectrostatic cleaningSemiconductor/solid-state device manufacturingInjection portEngineering

The present invention is directed to a method and an apparatus for cleaning and drying wafers. The apparatus includes an injection unit having first and second injection ports configured for injecting different fluids and arranged in a moving direction of the rose or on a line adjacent to the moving direction. The injection unit migrates straightly from the center of a wafer to the edge thereof, and the first and second injection ports are linearly arranged on a moving line of the nozzle.

Owner:SEMES CO LTD

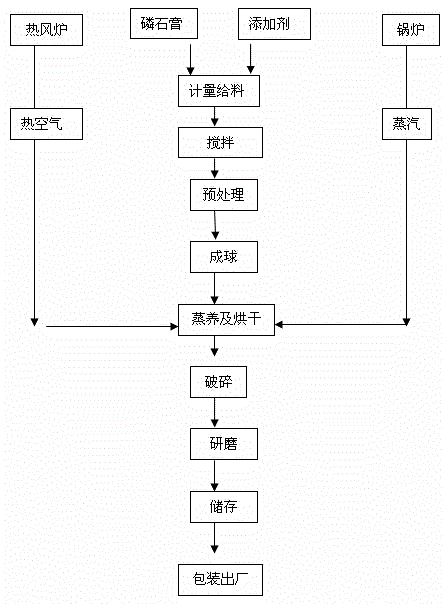

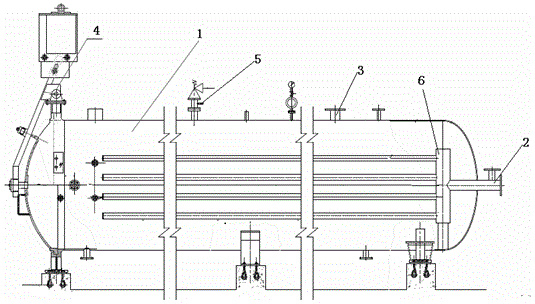

Method and device for preparing high-strength alpha hemihydrate gypsum by using phosphogypsum

The invention discloses a method for preparing high-strength alpha hemihydrate gypsum by using phosphogypsum. The method comprises the following steps of: mixing the phosphogypsum, a pretreatment additive, water and a crystal modifier, stirring to be uniform, forming balls after aging treatment, then finishing steam curing and drying in a stilling kettle, and preparing the high-strength alpha hemihydrate gypsum. The method disclosed by the invention has the advantages that the process flow is simple, the industrialization is easy, the phosphogypsum can be greatly utilized and consumed, and the conversion rate is high; and simultaneously, the invention provides the stilling kettle capable of realizing integration of steam curing and drying, the alpha hemihydrate gypsum can be better prepared, and the high-quality building material or wall-body material can be better prepared.

Owner:KUNMING UNIV OF SCI & TECH

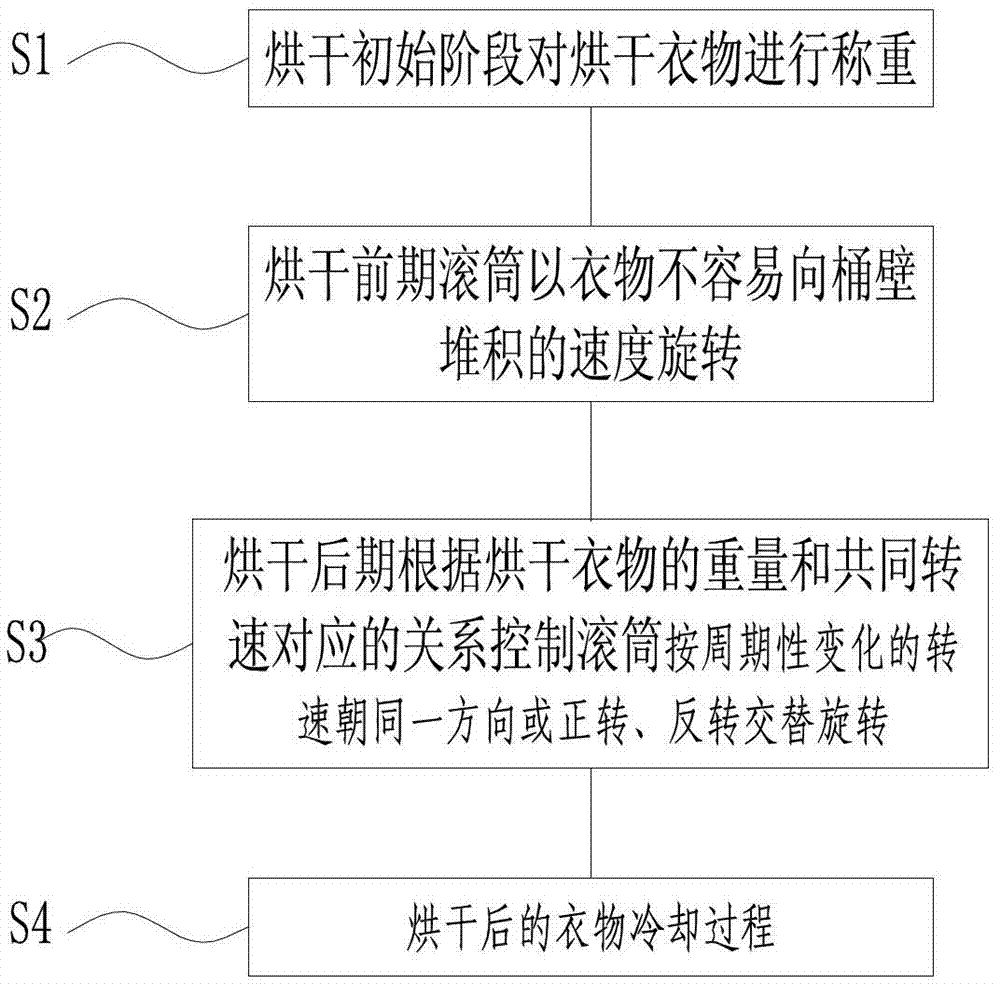

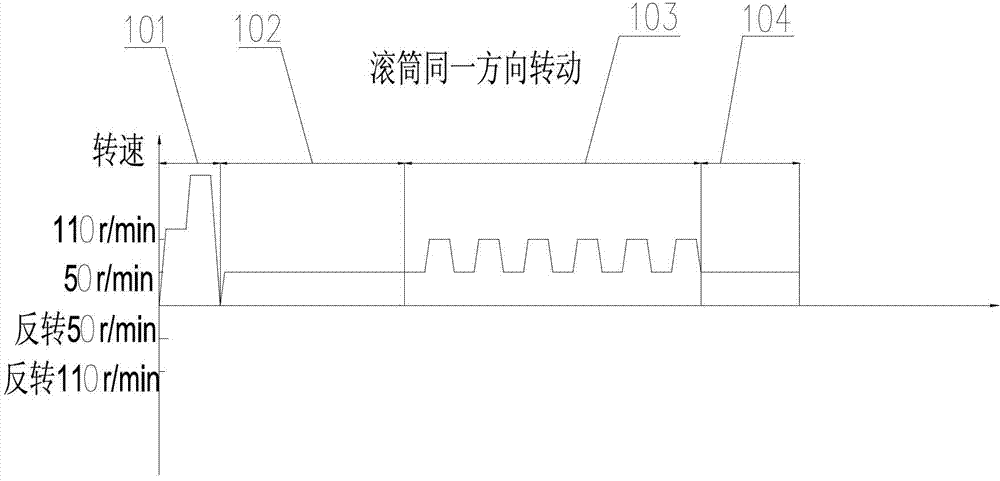

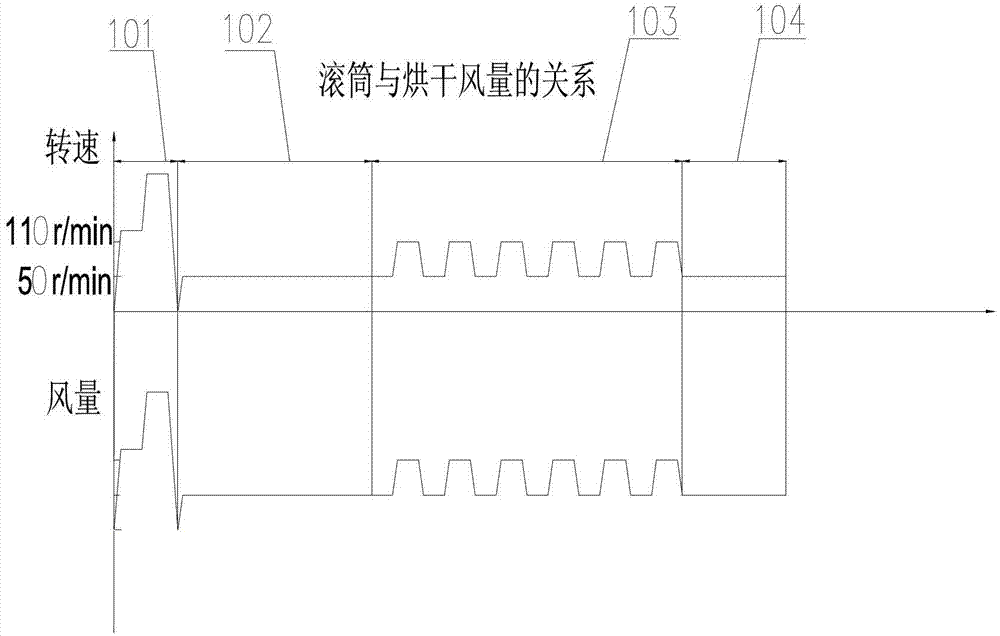

Method for improving drying effect of clothes through speed change of roller and clothes drying machine

ActiveCN102899871AImprove drying effectImprove drying efficiencyTextiles and paperLaundry driersPulp and paper industry

The invention discloses a method for improving drying effect of clothes through speed change of a roller and a clothes drying machine. The method comprises the following steps of: at a primary stage of drying, detecting the weight and / or unit weight of the clothes to be dried; at an earlier stage of drying, due to the fact that the clothes are relatively moist, rotating the roller based on the speed enabling the clothes to uneasily accumulate to a roller wall; at a later stage of drying, controlling the roller to rotate towards the same direction or forwards and backwards rotate alternately according to the periodically changed rotating speed based on the corresponding relation of the weight and / or the unit weight of the clothes and the rotating speed of the roller, wherein the periodically changed rotating speed at least comprises two different kinds of rotating speed; and a process of cooling the dried clothes, according to the method, controlling the roller to rotate towards the same direction or forwards and backwards rotate alternately according to the periodically changed rotating speed by measuring the weight and / or the unit weight of the clothes, and the corresponding relation of the weight and / or the unit weight of the clothes and the rotating speed of the roller, so that the clothes can be completely extended to realize the uniform and complete drying effect of the clothes and further improve the drying effect of the clothes with large weight.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Cleaning machine

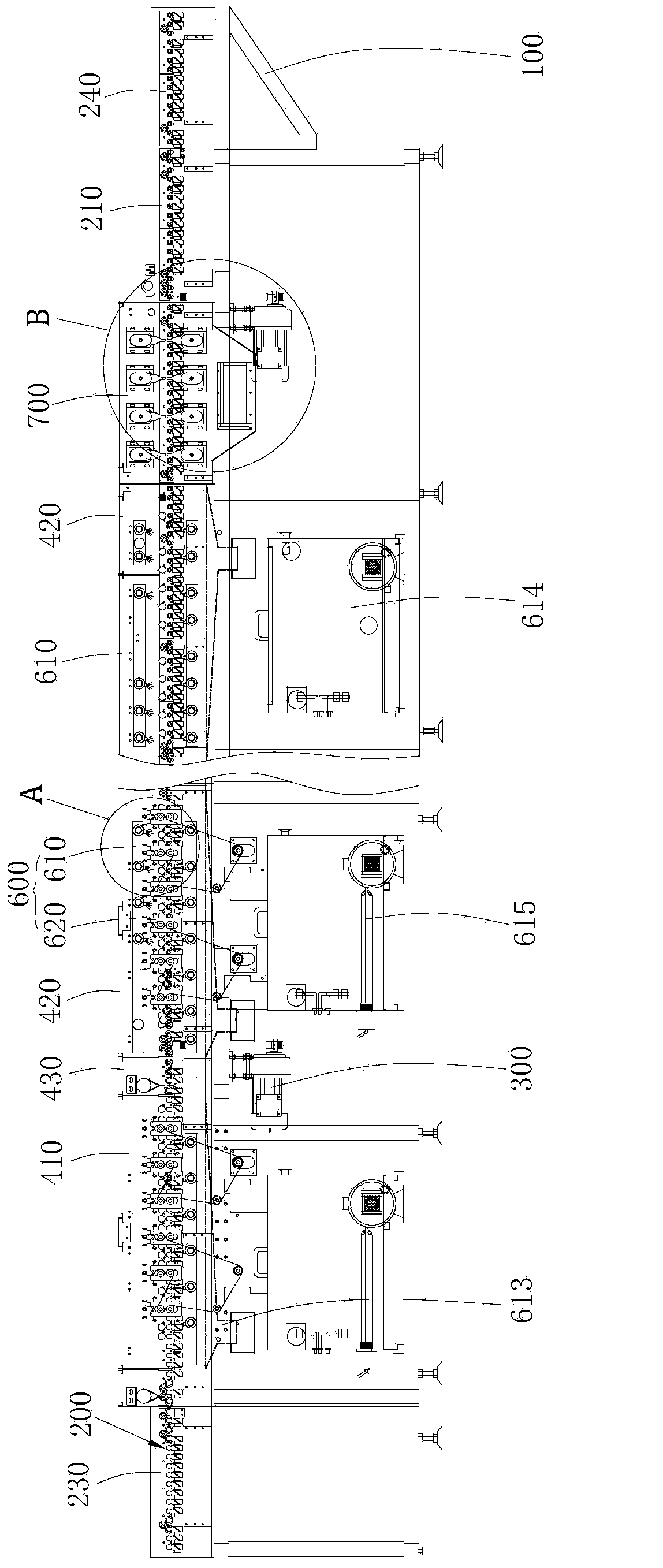

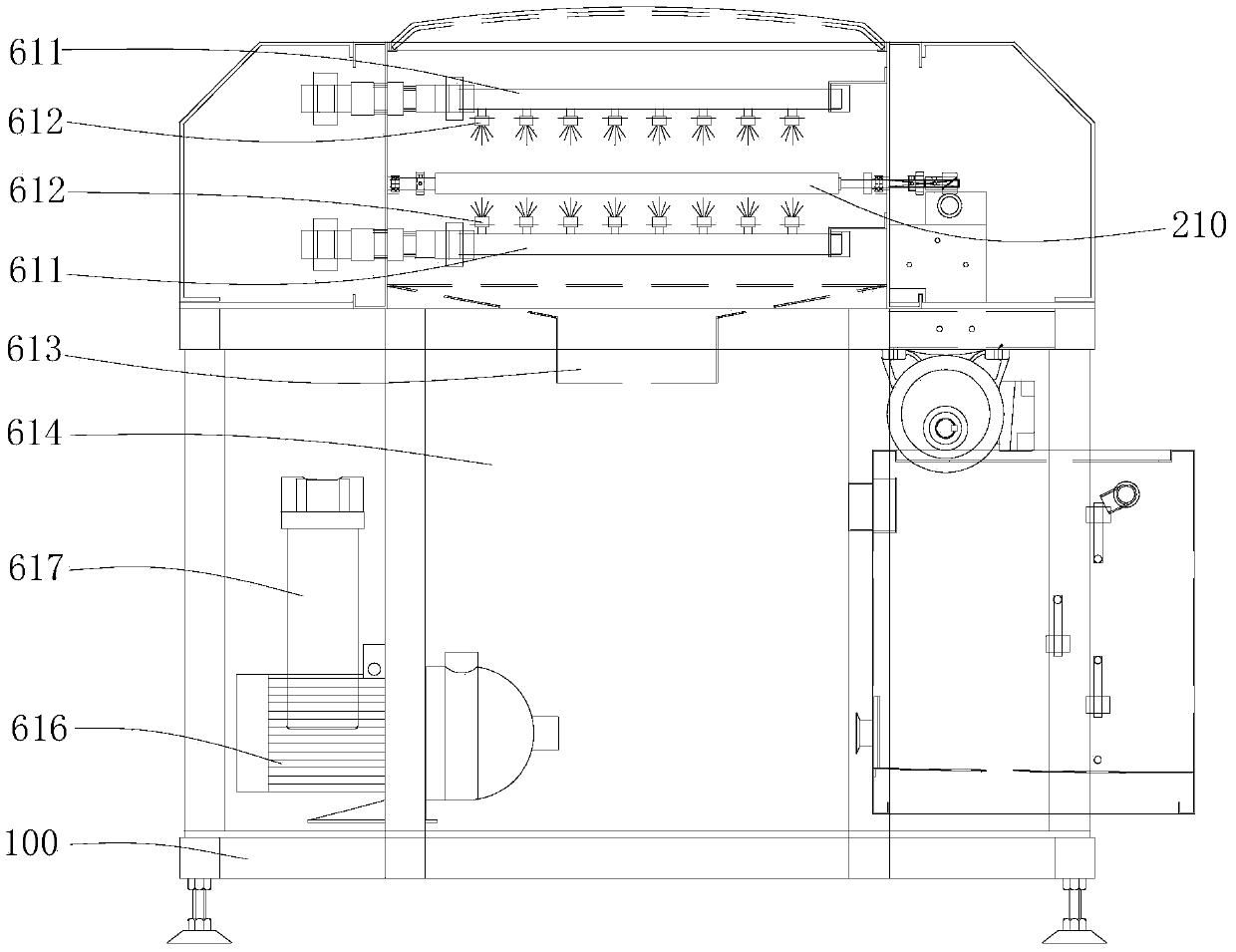

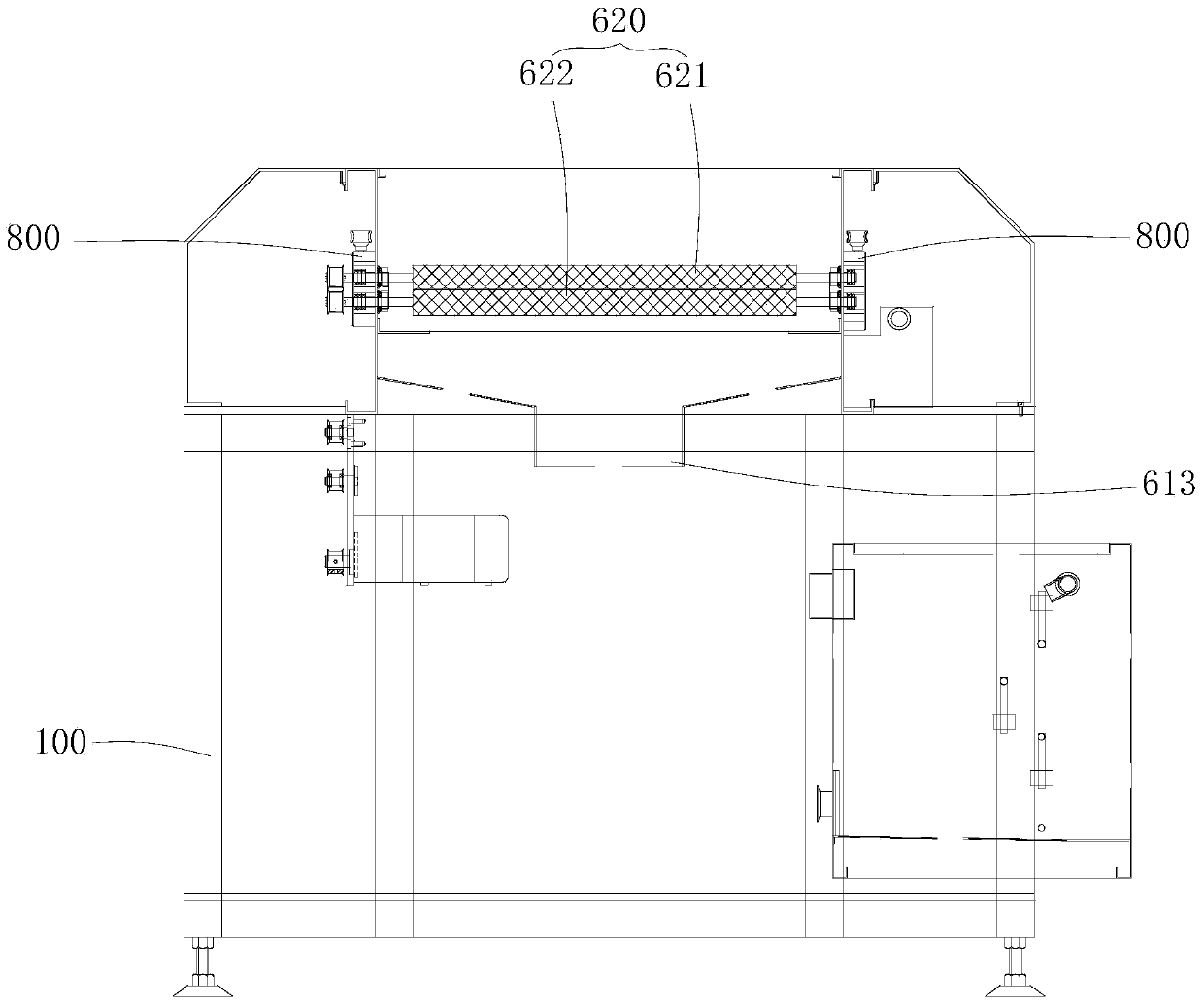

ActiveCN103990624AGood cleanlinessImprove efficiencyDrying gas arrangementsFlexible article cleaningDrive motorAir drying

The invention belongs to the field of mobile phone screen glass cleaning equipment, and discloses a cleaning machine. The cleaning machine comprises a machine frame and a plurality of conveying rubber rollers arranged on the machine frame to form a conveying channel. The machine frame is provided with a drive motor used for driving the conveying rubber rollers to rotate. One end of the conveying channel is the feeding end, the other end of the conveying channel is the discharging end, a cleaning area is formed between the feeding end and the discharging end, and the cleaning area is internally provided with a cleaning mechanism and a drying device. The cleaning mechanism comprises a spraying device and a brush assembly. The brush assembly comprises an upper brush shaft and a lower brush shaft which are arranged in parallel, the peripheral wall of the upper brush shaft and the peripheral wall of the lower brush shaft are covered with bristles, the two ends of the upper brush shaft and the two ends of the lower brush shaft are provided with brush adjusting mechanisms used for adjusting the length of a gap between the upper brush shaft and the lower brush shaft, and the drying device is connected with an air filter. The cleaning machine is high in cleaning efficiency and good in cleanliness, the brush adjusting mechanisms are arranged for adjustment to be carried out conveniently, positioning is accurate, glass screens with different thicknesses can be cleaned, and the drying device is high in air drying efficiency, and noise is low.

Owner:SHENZHEN HANDONG GLASS EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com