Patents

Literature

38results about How to "Good cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volatile stamping cutting oil composite for machining for machining of moderate-thickness aluminum plate and preparation method thereof

InactiveCN102199476AImprove the lubrication effectImprove rust resistanceLubricant compositionIrritationPhosphate

The invention relates to volatile stamping cutting oil composite for machining of a moderate-thickness aluminum plate and a preparation method thereof. The stamping cutting oil composite comprises the following raw materials in percentage by weight: 90-95 percent of solvent oil, 1-4 percent of antiwear additive, 1-4 percent of oiliness additive, 0.5-2 percent of antirust additive and 0.2-1 percent of antioxidant; the solvent oil has low sulphur content, low aromatic hydrocarbon content, no toxicity and smell and has the kinematic viscosity of 1.5-3.5mm<2> / s at 20 DEG C; the antiwear additive is selected from phosphates; the oiliness additive contains more than one of fatty alcohol and fatty acid methyl ester; the antirust additive is sodium alkylsulfonate; and the antioxidant is an antioxidant BHT (butylated hydroxytoluene). The preparation method of the volatile stamping cutting oil composite for the machining of the moderate-thickness aluminum plate, provided by the invention, is simple and convenient; and the composite provided by the invention does not contain a chlorine extreme pressure agent, is a biological environment-friendly product and has the advantages of excellent extreme pressure lubrication performance and favorable demoulding performance, volatilization completeness, no trace leaving, no clean, extremely low smell, no irritation to skin, time and labor saving and capability of greatly prolonging the service life of a mould.

Owner:上海德润宝特种润滑剂有限公司

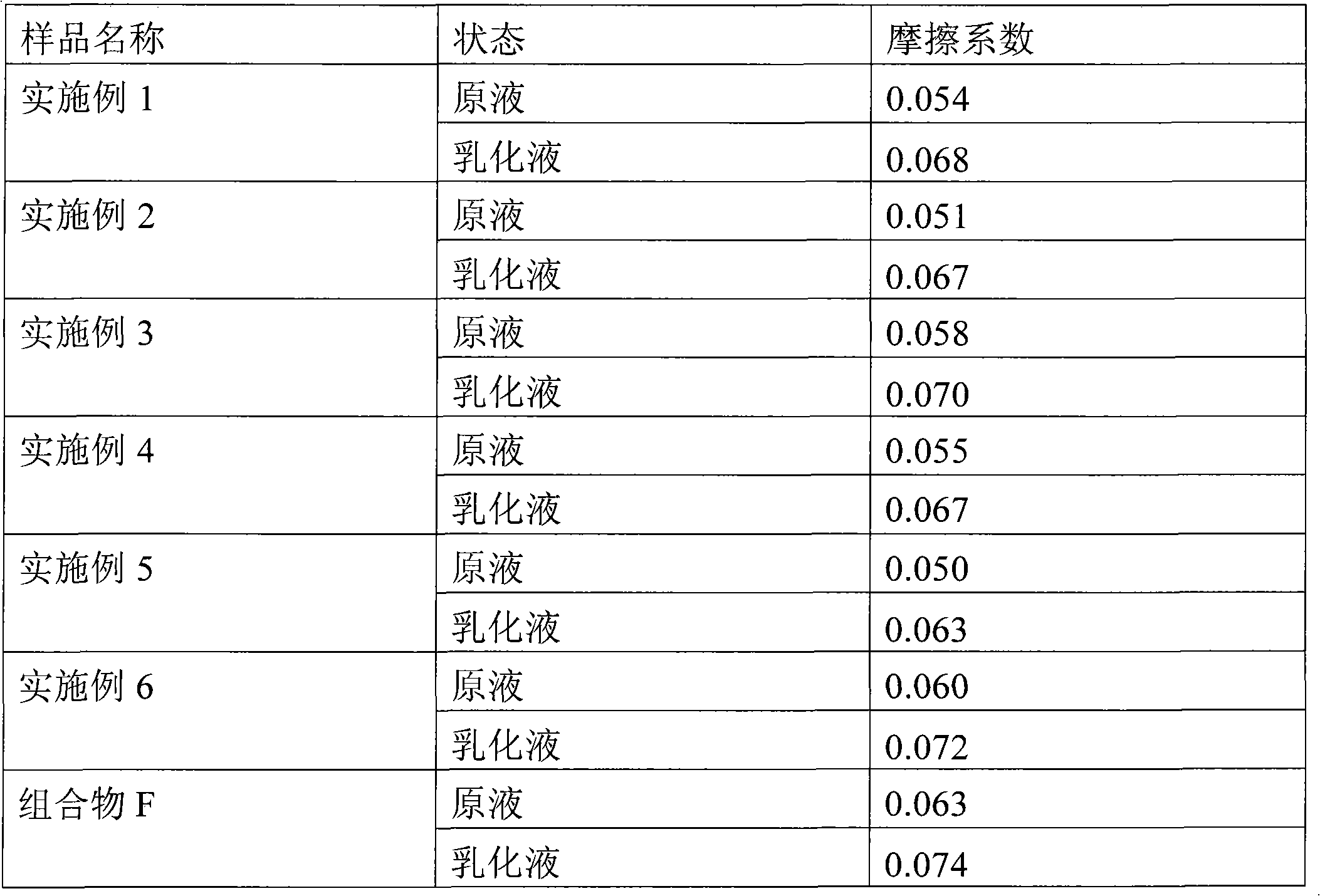

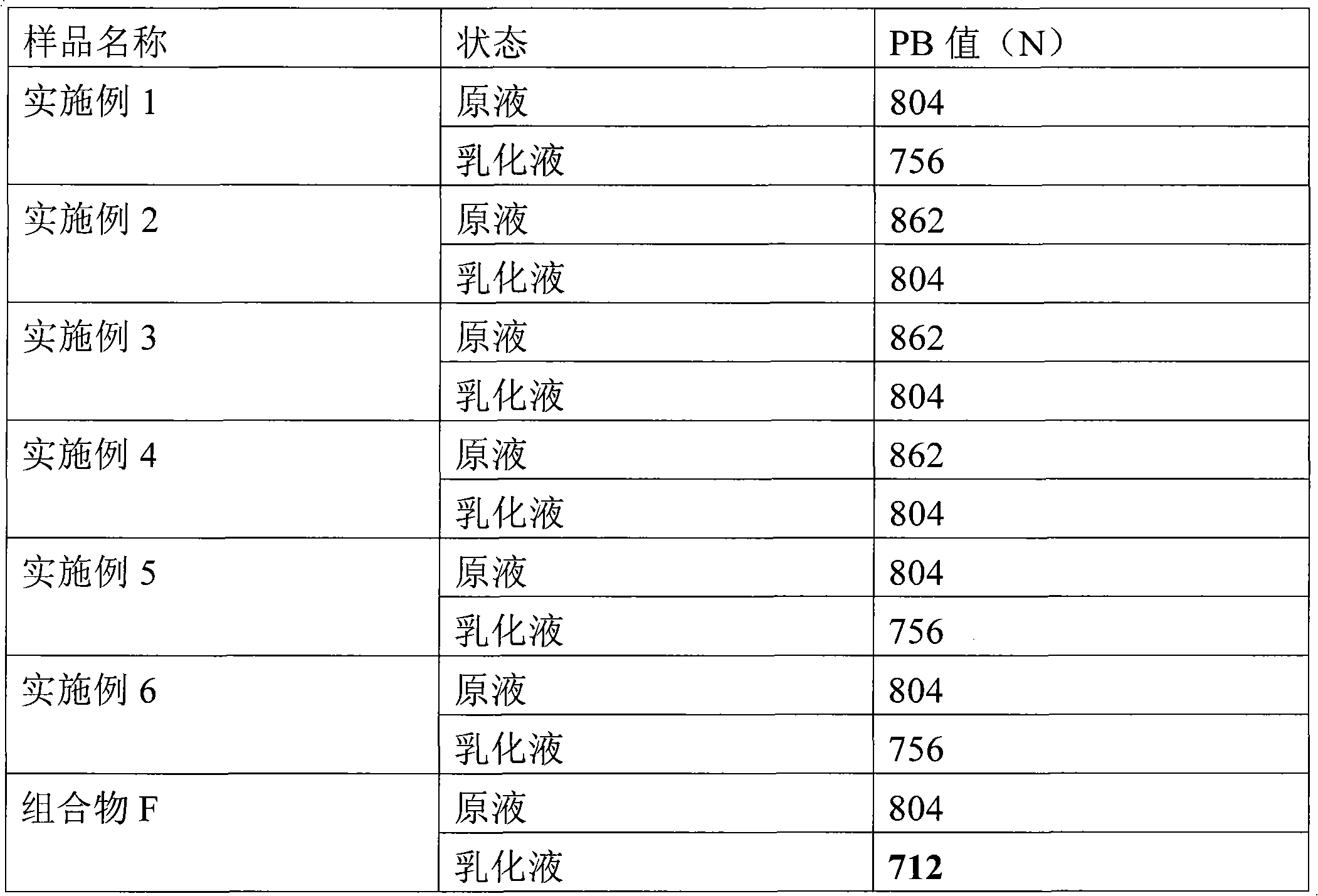

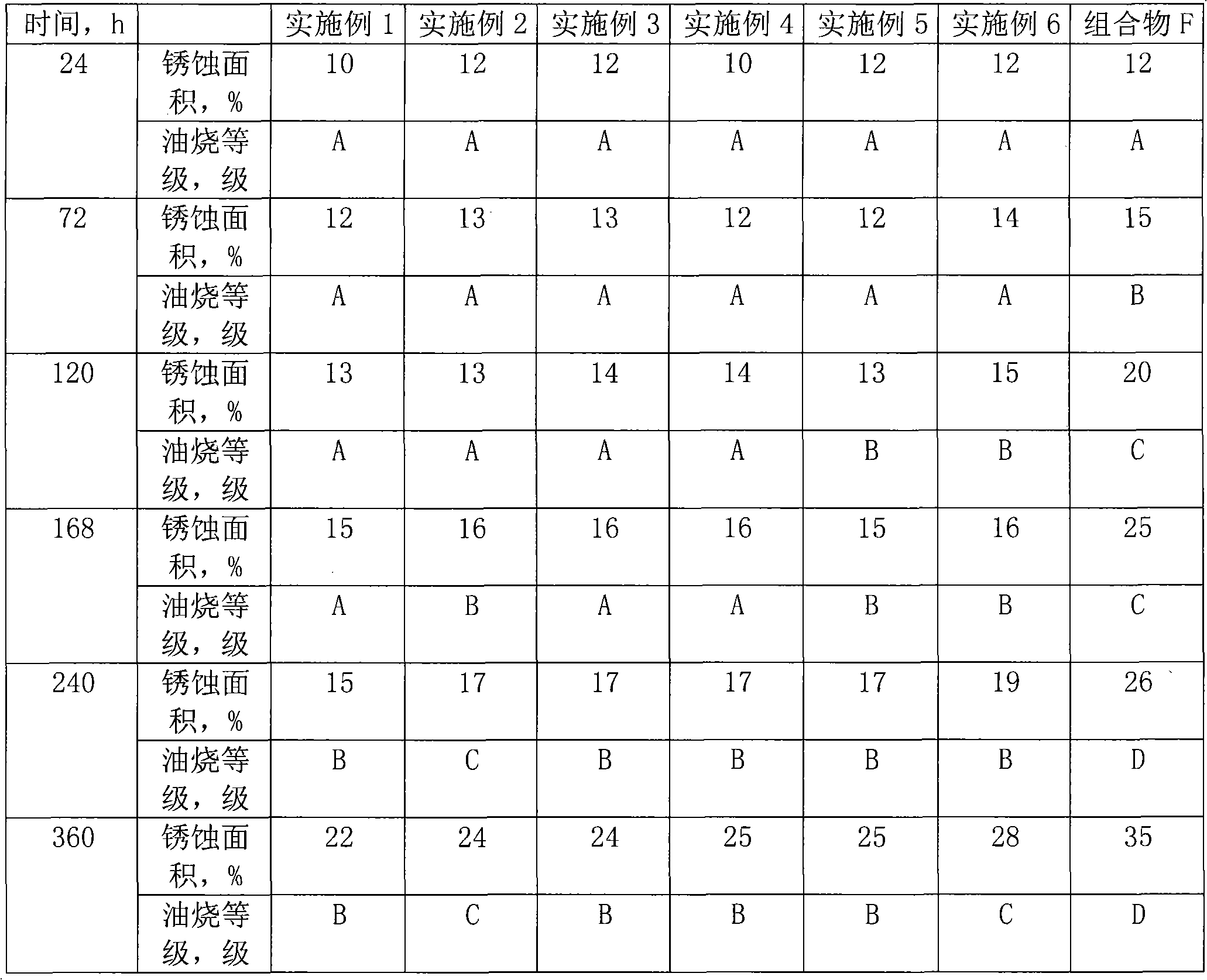

Cold rolled silicon steel rolled oil composition

The invention discloses a cold rolled silicon steel rolled oil composition. The composition comprises the following components in percentage by weight: 60 to 90 percent of alcohol ester oiliness agent, 5.0 to 12 percent of animal and vegetable oiliness agent, 2.0 to 12.0 percent of nonionic surfactant, 0.6 to 8 percent of phosphate antiwear additive and 0.5 to 8 percent of antirust additive. The rolling lubricating property of the cold rolled silicon steel rolled oil composition is high; the cleanness of the rolling environment and a memorial archway is good; and the degreasing property, the rust-proof performance and the anti-oil burn property are high.

Owner:CHINA PETROCHEMICAL CORP +1

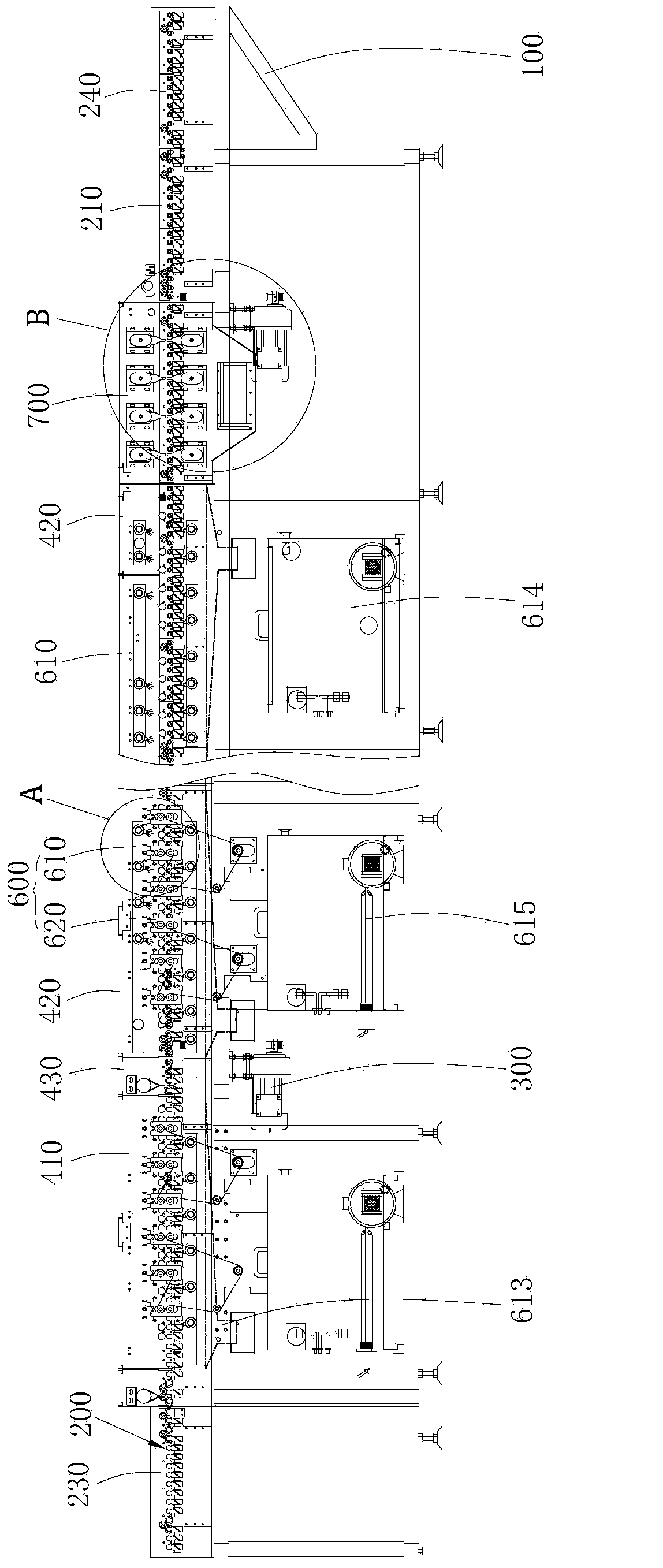

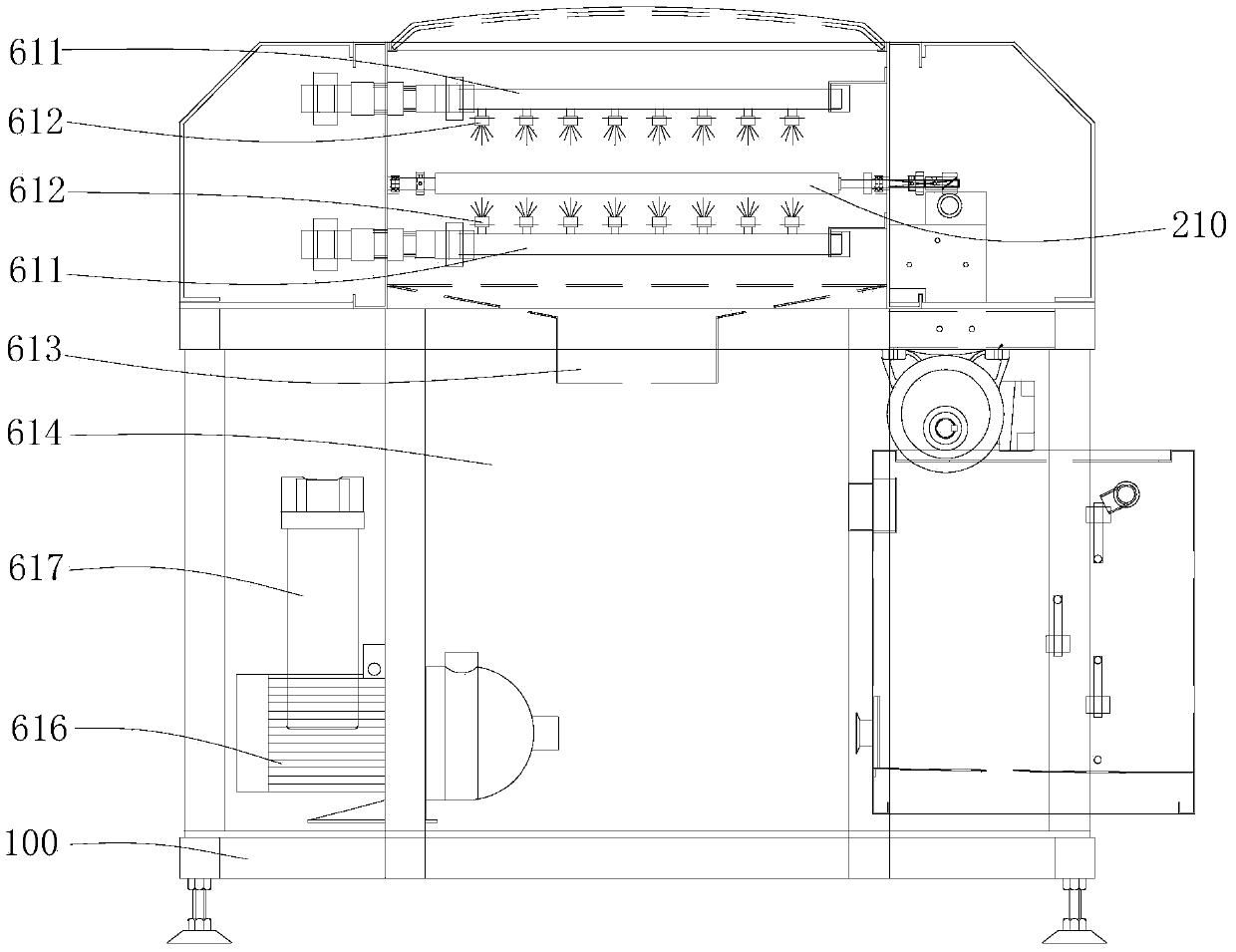

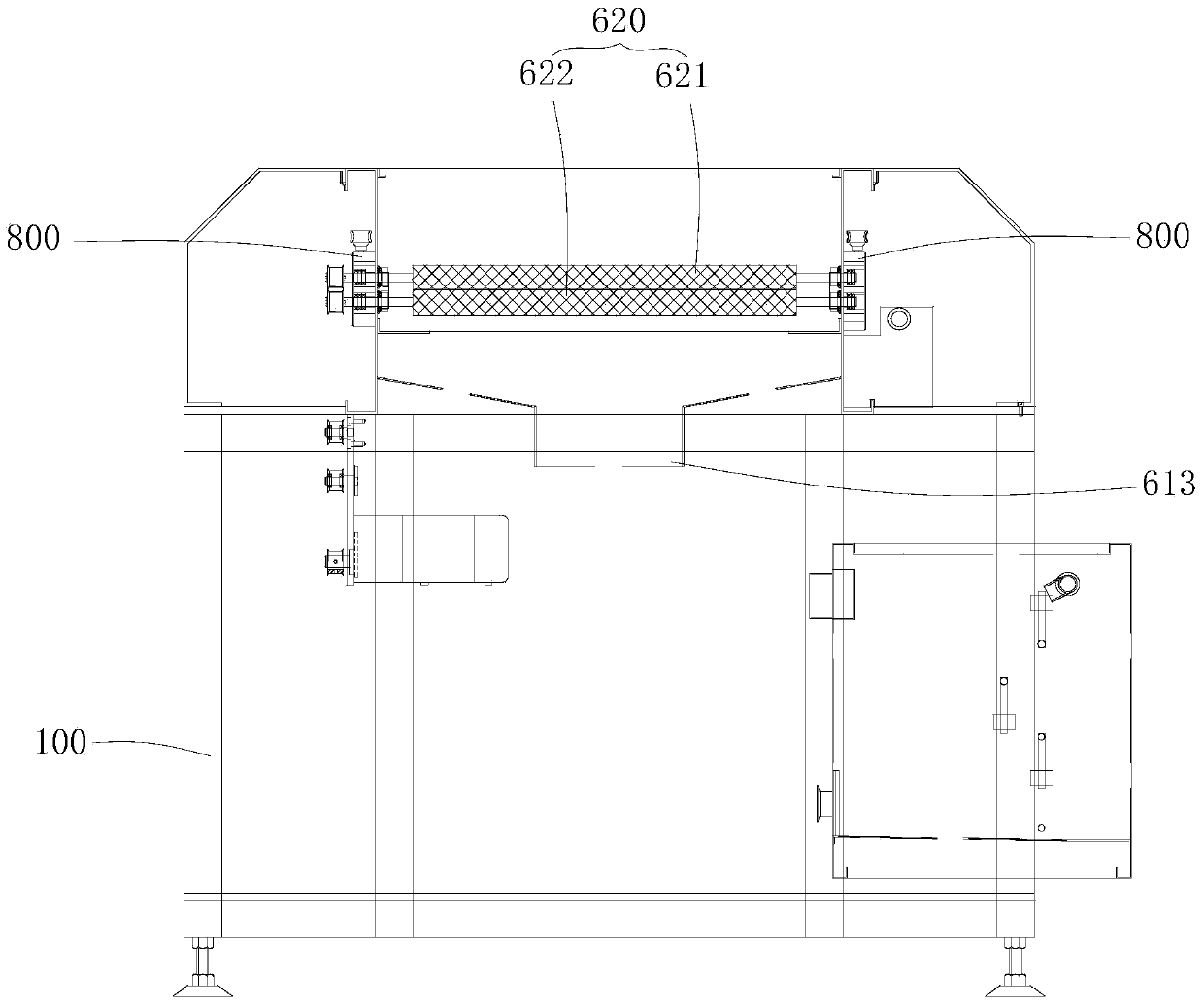

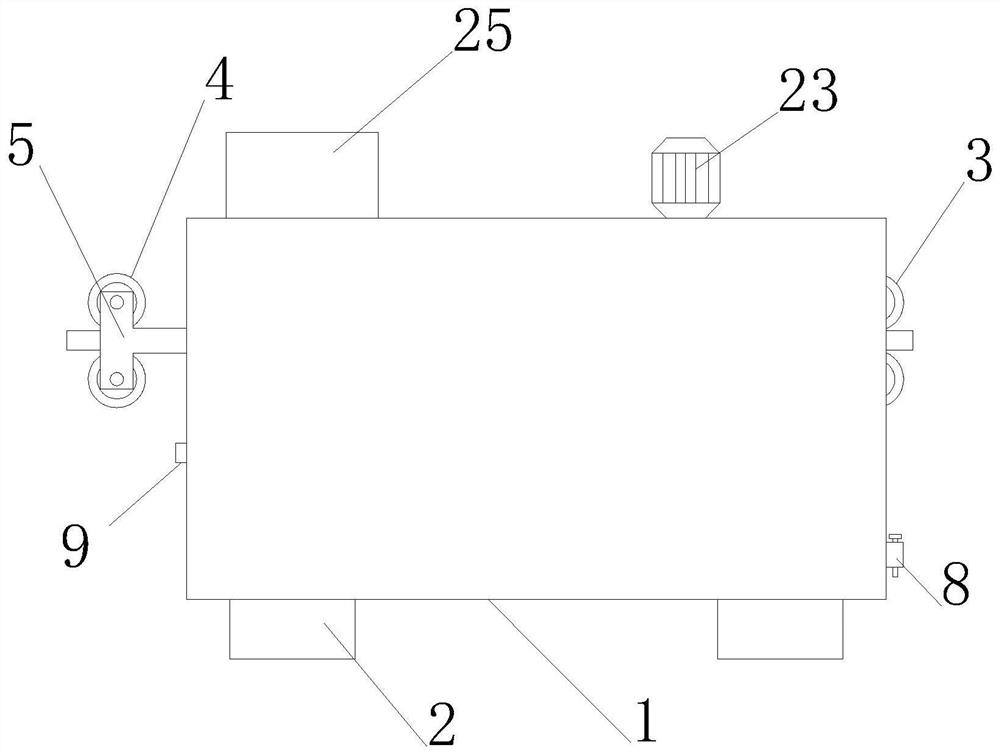

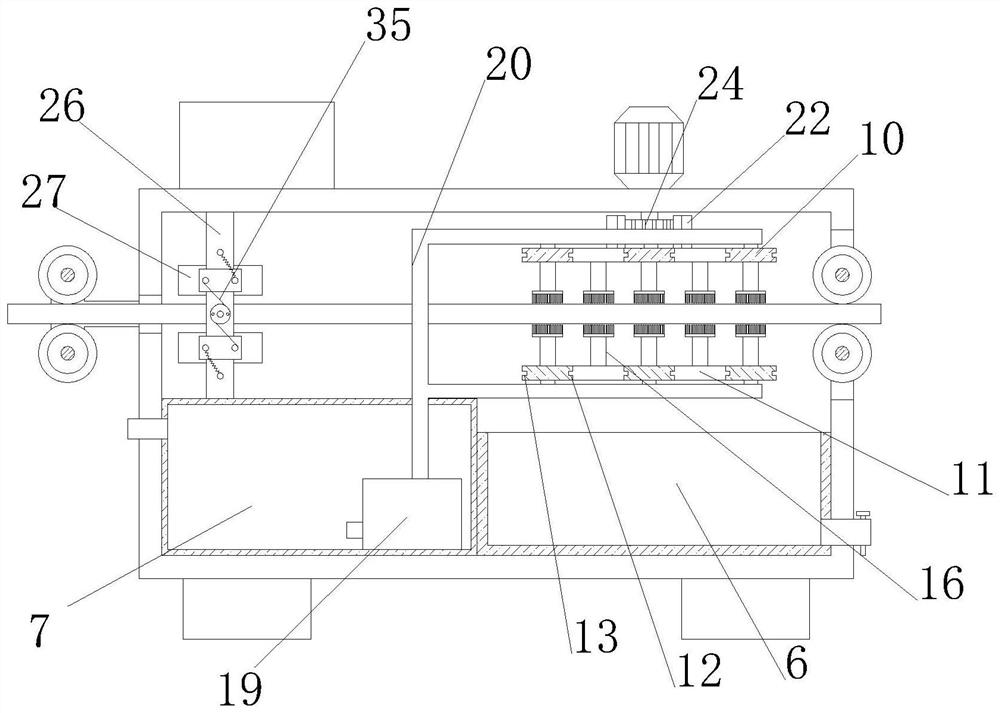

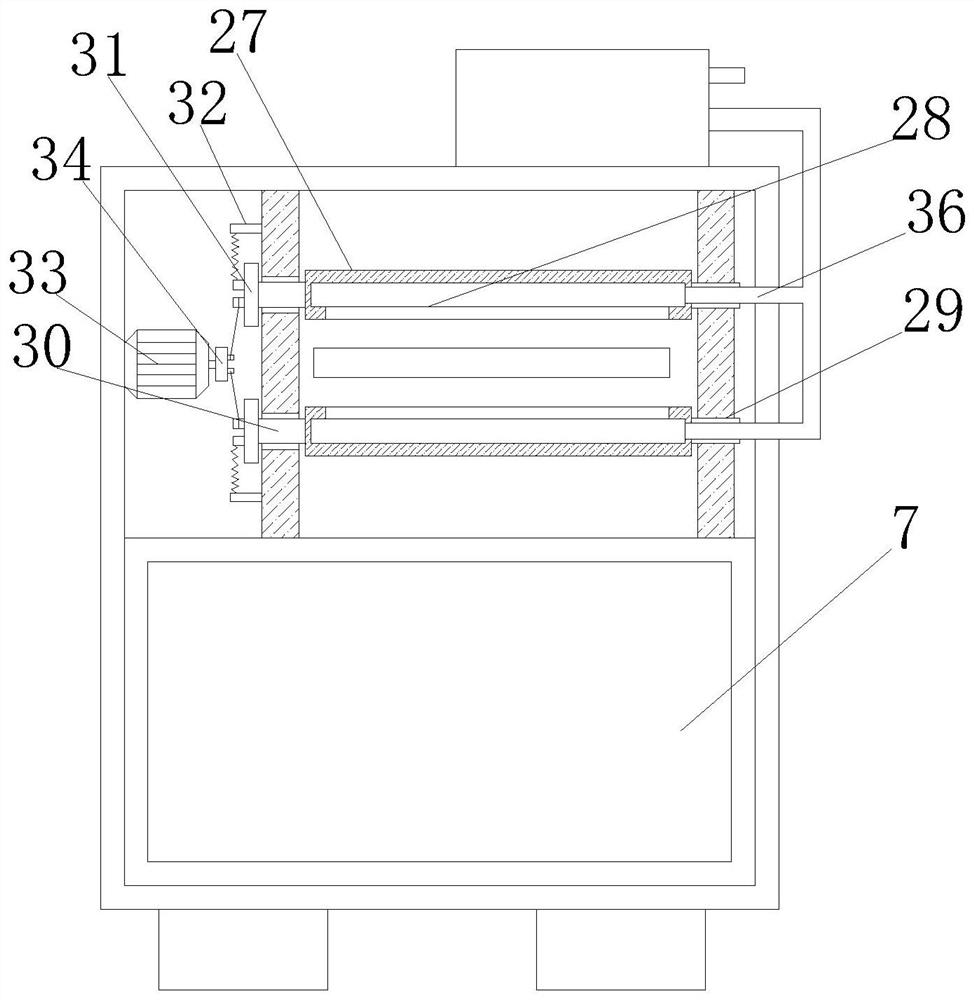

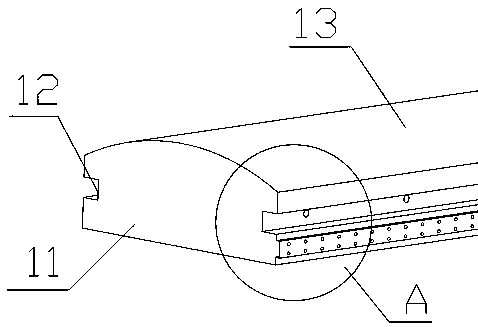

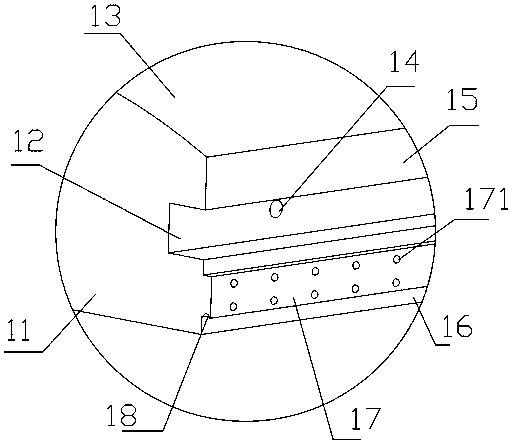

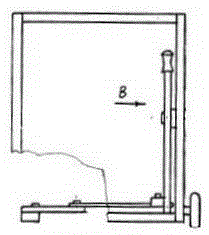

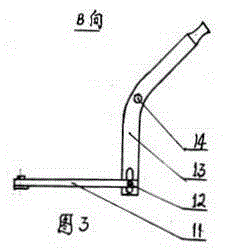

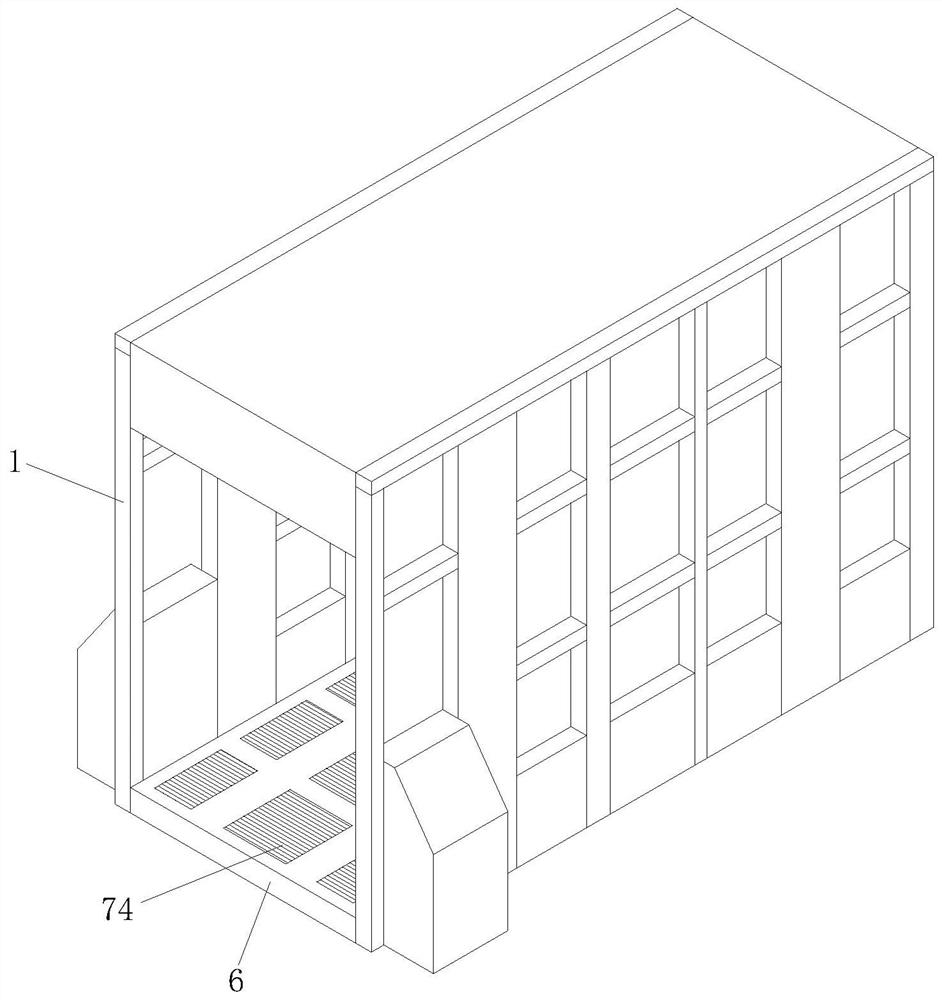

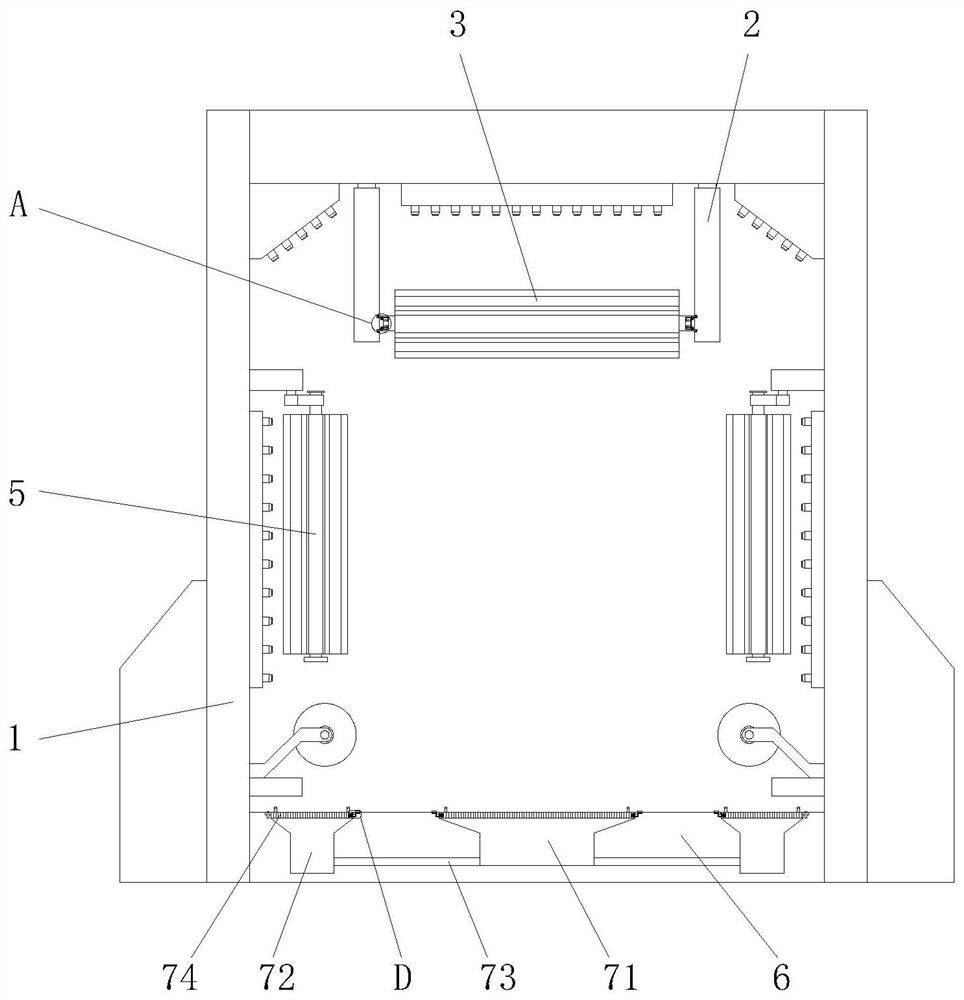

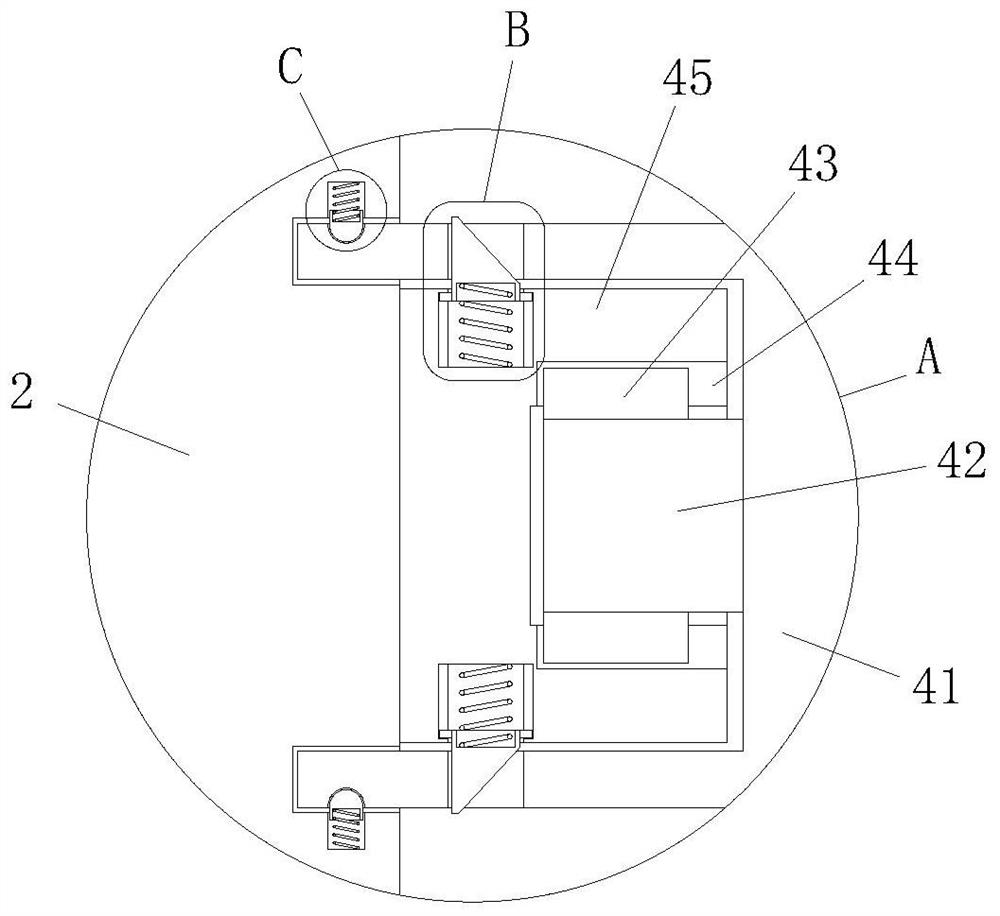

Cleaning machine

ActiveCN103990624AGood cleanlinessImprove efficiencyDrying gas arrangementsFlexible article cleaningDrive motorAir drying

The invention belongs to the field of mobile phone screen glass cleaning equipment, and discloses a cleaning machine. The cleaning machine comprises a machine frame and a plurality of conveying rubber rollers arranged on the machine frame to form a conveying channel. The machine frame is provided with a drive motor used for driving the conveying rubber rollers to rotate. One end of the conveying channel is the feeding end, the other end of the conveying channel is the discharging end, a cleaning area is formed between the feeding end and the discharging end, and the cleaning area is internally provided with a cleaning mechanism and a drying device. The cleaning mechanism comprises a spraying device and a brush assembly. The brush assembly comprises an upper brush shaft and a lower brush shaft which are arranged in parallel, the peripheral wall of the upper brush shaft and the peripheral wall of the lower brush shaft are covered with bristles, the two ends of the upper brush shaft and the two ends of the lower brush shaft are provided with brush adjusting mechanisms used for adjusting the length of a gap between the upper brush shaft and the lower brush shaft, and the drying device is connected with an air filter. The cleaning machine is high in cleaning efficiency and good in cleanliness, the brush adjusting mechanisms are arranged for adjustment to be carried out conveniently, positioning is accurate, glass screens with different thicknesses can be cleaned, and the drying device is high in air drying efficiency, and noise is low.

Owner:SHENZHEN HANDONG GLASS EQUIP MFG CO LTD

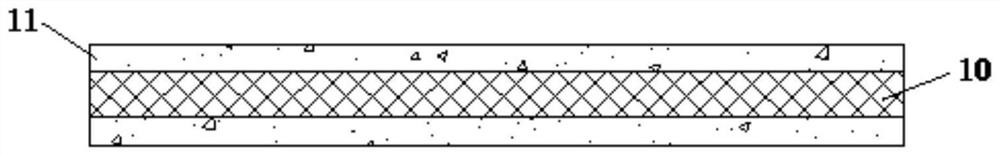

Non-woven fabric for manufacturing dust-free wiping paper and manufacturing method thereof

The invention provides a non-woven fabric for manufacturing dust-free wiping paper. The non-woven fabric for manufacturing the dust-free wiping paper comprises a non-woven fabric containing cellulosic fibers, wherein the non-woven fabric is prepared by treating a treatment solution containing polyvinyl alcohol, water-borne polyacrylate and a water-borne isocyanate cross-linking agent. The provided non-woven fabric is firm, high in cleanliness and soft. The invention also provides a method for manufacturing the non-woven fabric. The manufacturing method comprises the following steps: preparing the treatment solution containing polyvinyl alcohol, water-borne polyacrylate and a water-borne isocyanate cross-linking agent; padding the non-woven fabric containing cellulosic fibers by adopting the treatment solution, and baking. The method is simple and low in cost.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

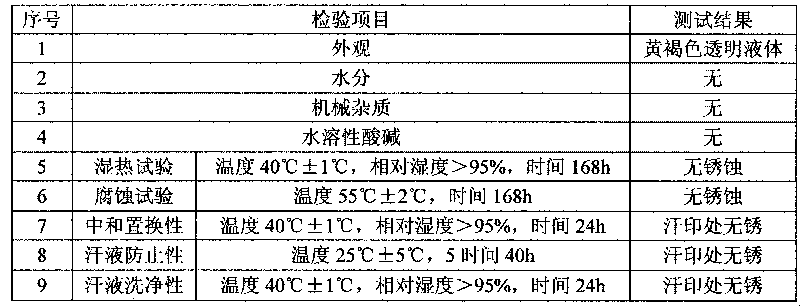

Thin-layer rust-preventative oil for engine part and method for preparing same

The invention aims to provide thin-layer rust-preventative oil for an engine part and a method for preparing the same. The rust-preventative oil is prepared from the following components in percentage by weight: 2 to 3 percent of petroleum barium sulfate, 4 to 7 percent of barium dinonyl napthalene sulphonate, 0.5 to 0.9 percent of dodecene butane diacid, 0.1 to 0.5 percent of benzotriazole, 1.0 to 5.0 percent of dibutyl phthalate, 3 to 5 percent of polyisobutene and the balance of aviation lubricating oil, wherein the ratio of the two components comprising benzotriazole to dibutyl phthalate is 1:10 to 11.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Fragrant detergent for household textiles

InactiveCN104845758AEfficient and durable antibacterialGood cleanlinessAnionic-cationic-non-ionic surface-active compoundsDetergent perfumesChemistryActive agent

The invention discloses a fragrant detergent for household textiles. The fragrant detergent for the household textiles is prepared from the following raw materials in parts by weight: 2-4 parts of rose essence, 7-14 parts of zinc sulfate, 8-16 parts of methyl acrylate, 1.2-2 parts of essence, 6-12 parts of fatty alcohol-polyoxyethylene ether, 10-16 parts of a petroleum emulsion, 7-10 parts of cetyltrimethylammonium chloride, 8-13 parts of lauryl polyoxyethylene ether sodium sulfate, 2.4-4.6 parts of honeysuckle essential oil, 1-2.1 parts of sodium sulfate, 6-9 parts of a compound surfactant, 8-13 parts of ethyl alcohol and 2-5 parts of hydroxyethyl cellulose. The fragrant detergent for the household textiles is efficient and durable in antibacterial property, excellent in cleaning property, free of influence on the hand feeling of textiles, free of toxicity and harm to the human body and free of pollution to the environment, and is capable of durably scenting fragrant smell.

Owner:青岛千帆高新技术有限公司

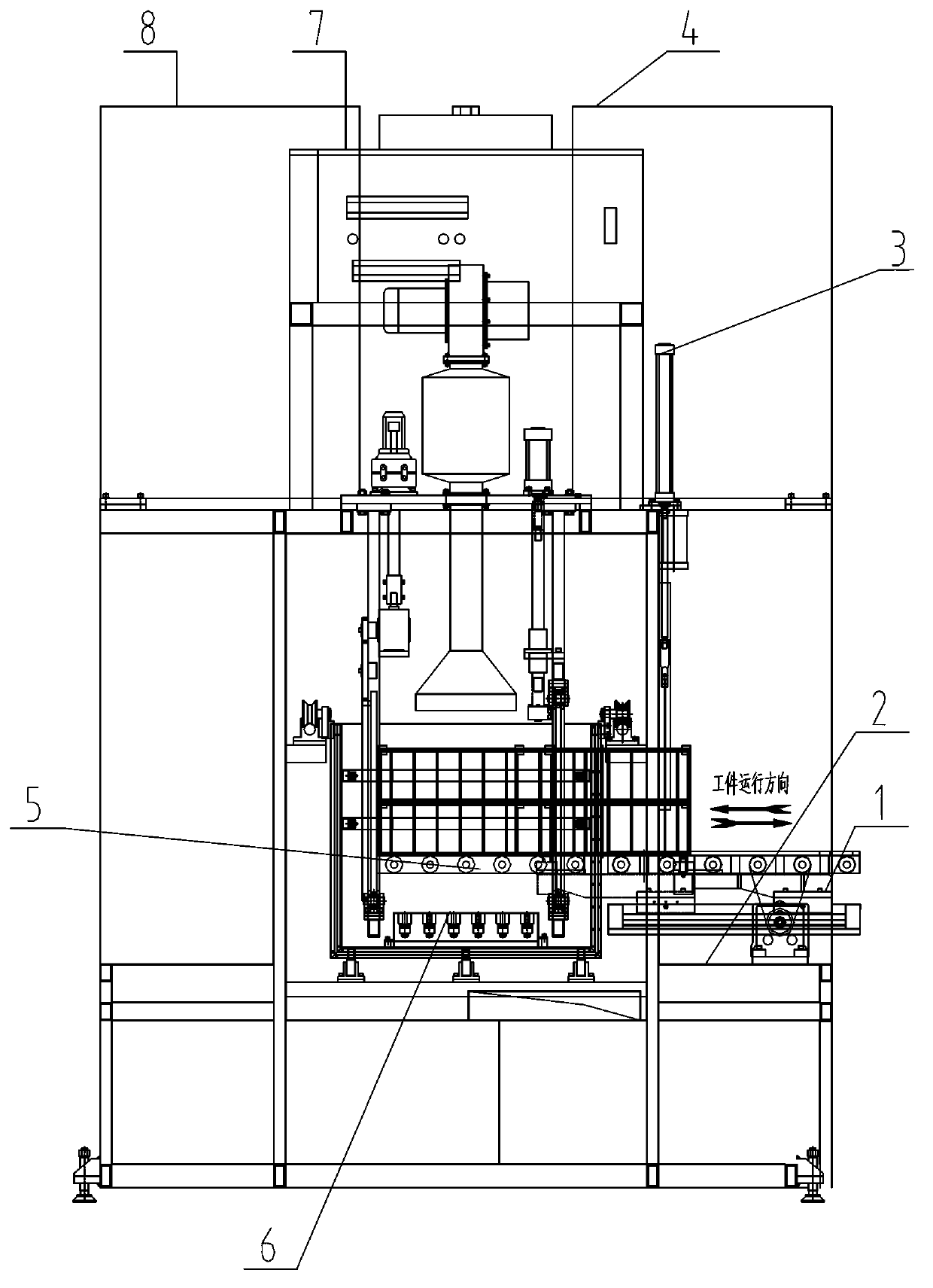

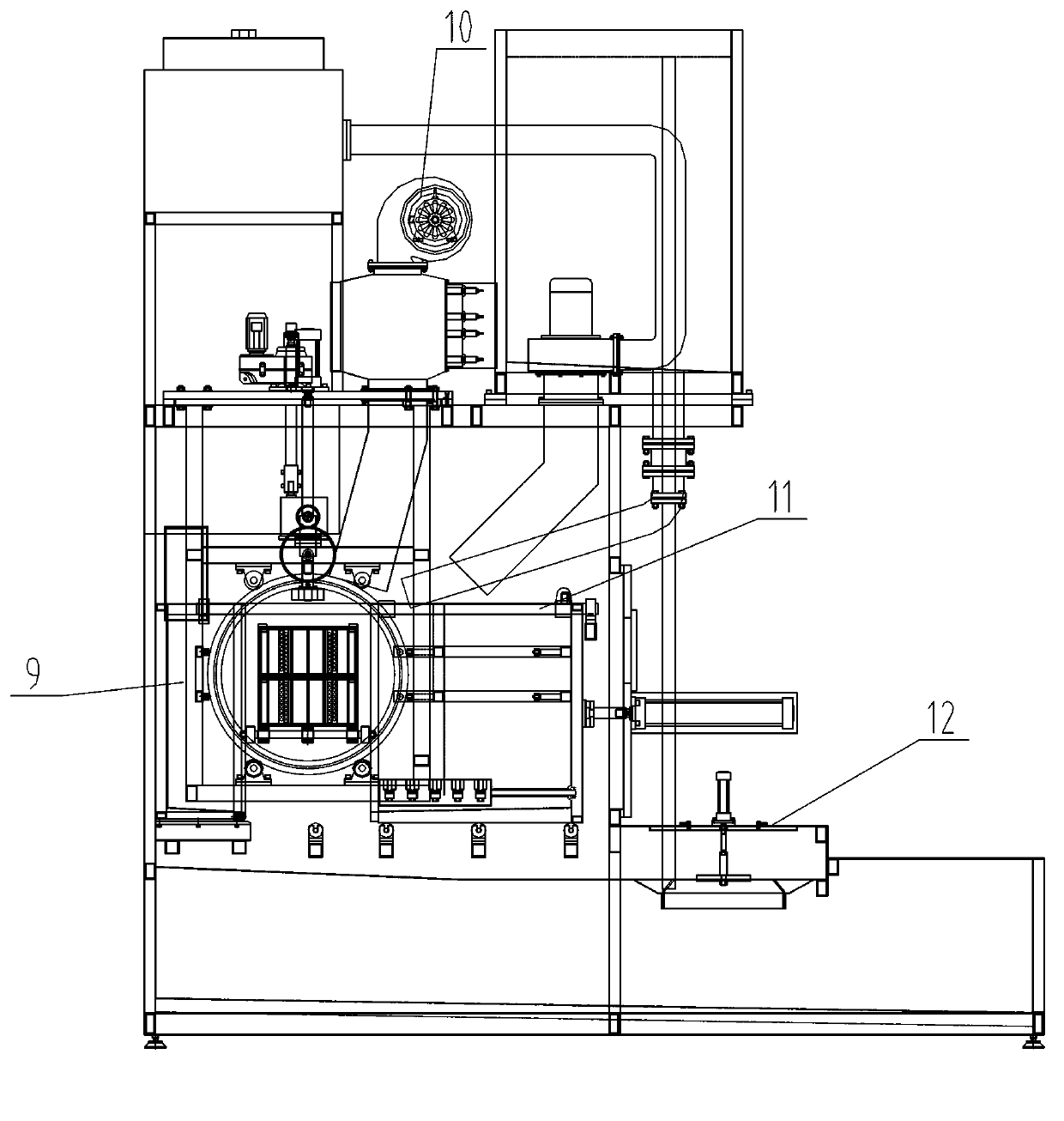

Liquid downward-jetting ultrasonic cleaning device

The invention discloses a liquid downward-jetting ultrasonic cleaning device. The liquid downward-jetting ultrasonic cleaning device comprises a rack; a cleaning water storage machine and a rinsing water storage machine are arranged on the two sides above the rack, a condensing and demisting system is arranged between the cleaning water storage machine and the rinsing water storage machine, an automatic door is arranged on one side of the rack, an automatic feeding and discharging system is arranged below the automatic door, a rotating system is arranged above the automatic feeding and discharging system, an ultrasonic wave assembly is arranged below the rotating system, a fixed half slot and a movable half slot are arranged in the rotating system, an organic liquid box is arranged at the bottom of the rack, a backwater separating system is arranged at the bottom of the rack, and a drying device is arranged in the middle upper part of the rack. The liquid downward-jetting ultrasonic cleaning device has the beneficial effects that the cleanliness of a cleaned workpiece is good, no cleaning dead angle exists, and cutting materials and sludge in deep holes and zigzag holes can be cleaned, and can be overturned to be poured out.

Owner:WUXI BAOHE MACHINERY EQUIP

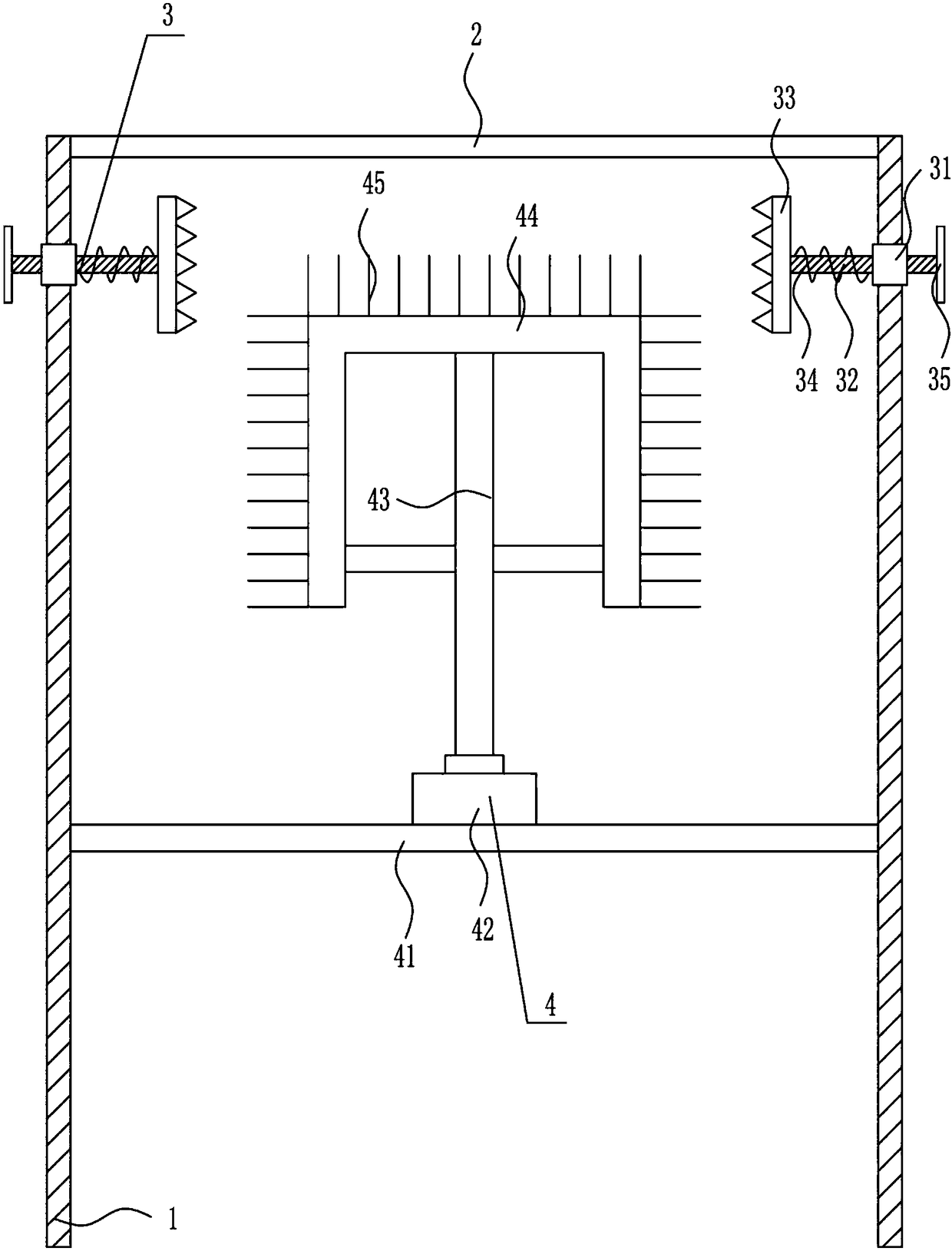

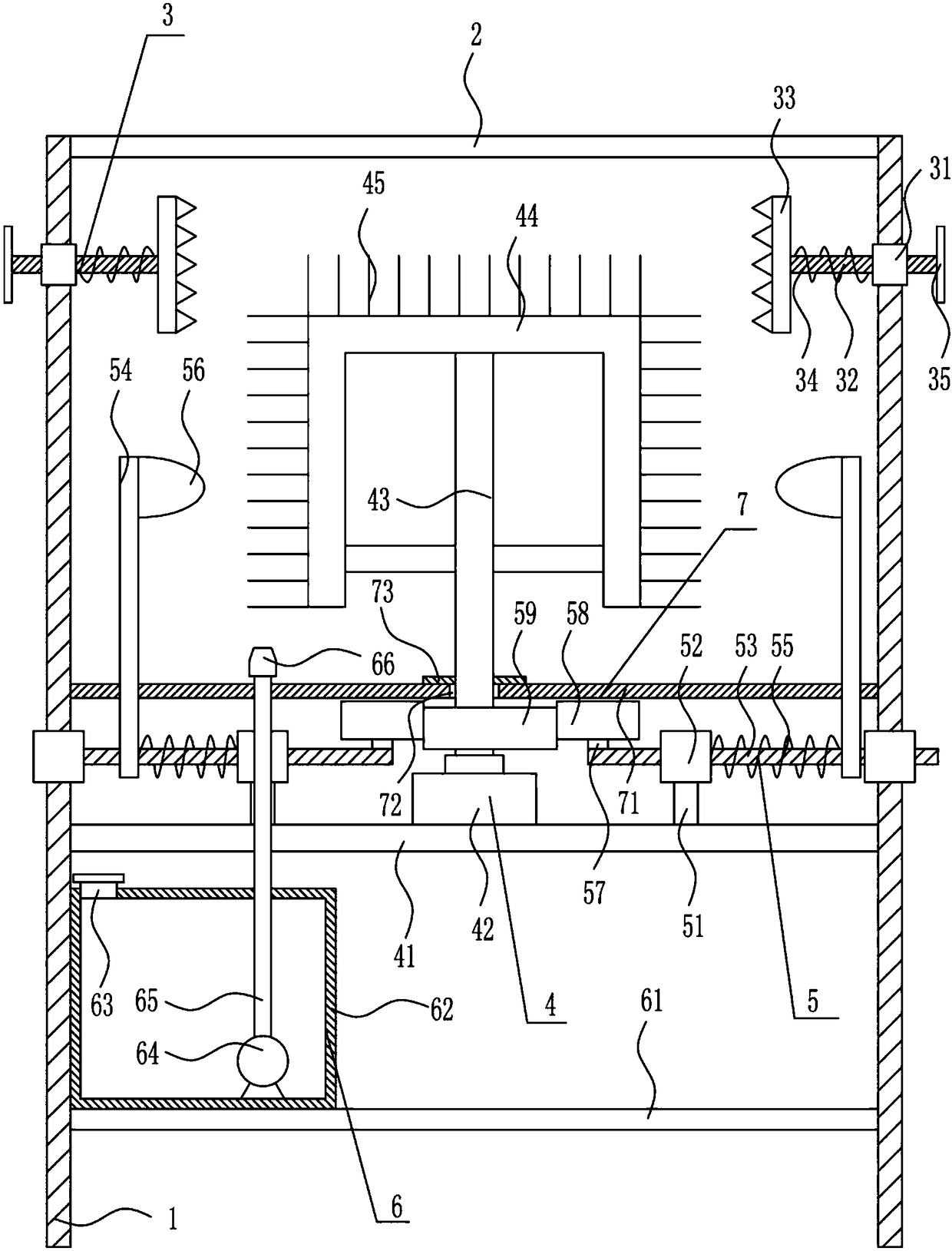

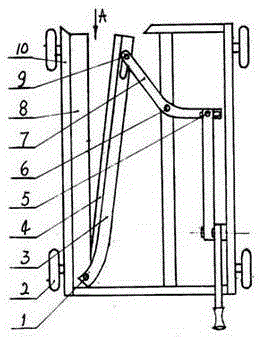

Cleaning device of cement carrying bucket for constructional engineering

InactiveCN108393321AEasy to cleanAchieve left and right movementHollow article cleaningArchitectural engineeringCement

The invention relates to a cleaning device, in particular to a cleaning device of a cement carrying bucket for constructional engineering. The cleaning device of the cement carrying bucket for constructional engineering can automatically clean a cement bucket, and is short in time and good in cleanliness. The cleaning device of the cement carrying bucket for constructional engineering comprises supporting legs and the like, a connecting rod is connected between the top portions of the left and right side supporting legs, fixing mechanisms are installed on the supporting legs, and a cleaning mechanism is installed at the bottom between the left and right side supporting legs. The fixing mechanisms are matched with the cleaning mechanism, the cement bucket can be fully cleaned, and the optimization of a knocking mechanism and a spraying mechanism is used for achieving the effects of automatic cleaning of the cement bucket, short time and good cleanliness.

Owner:刘桂兰

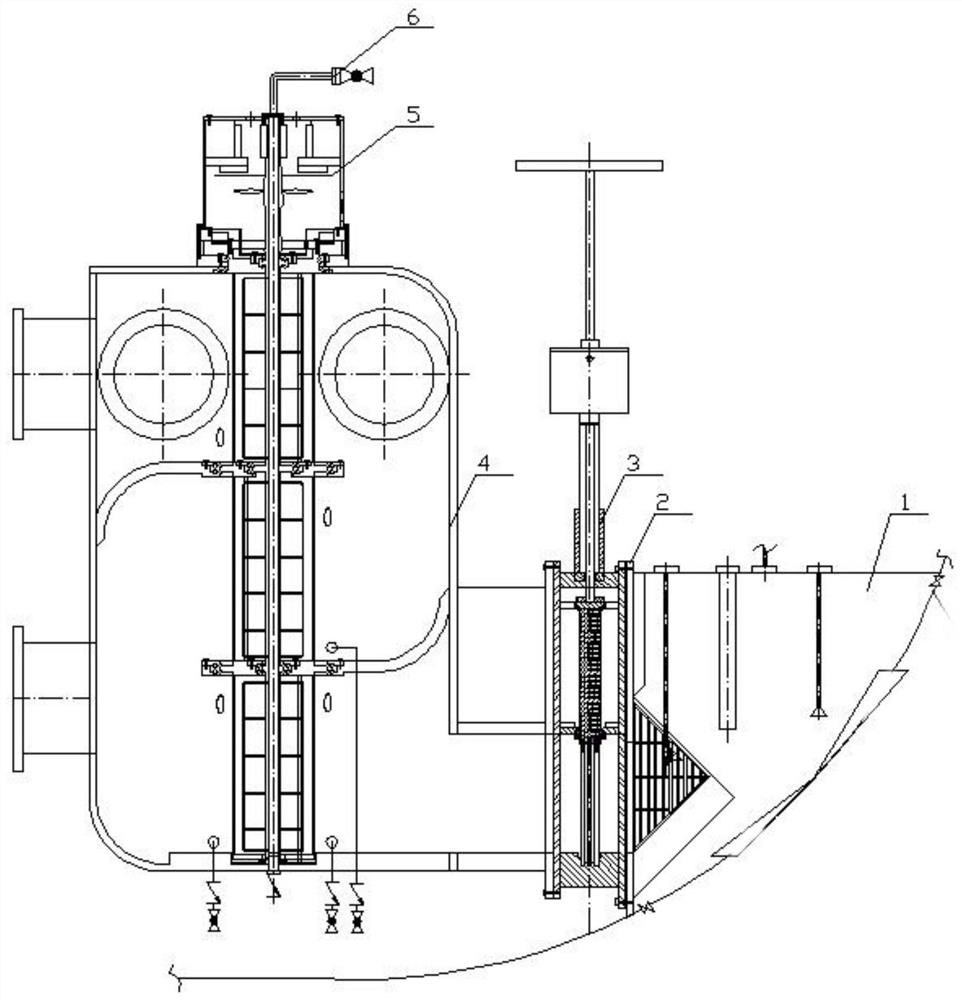

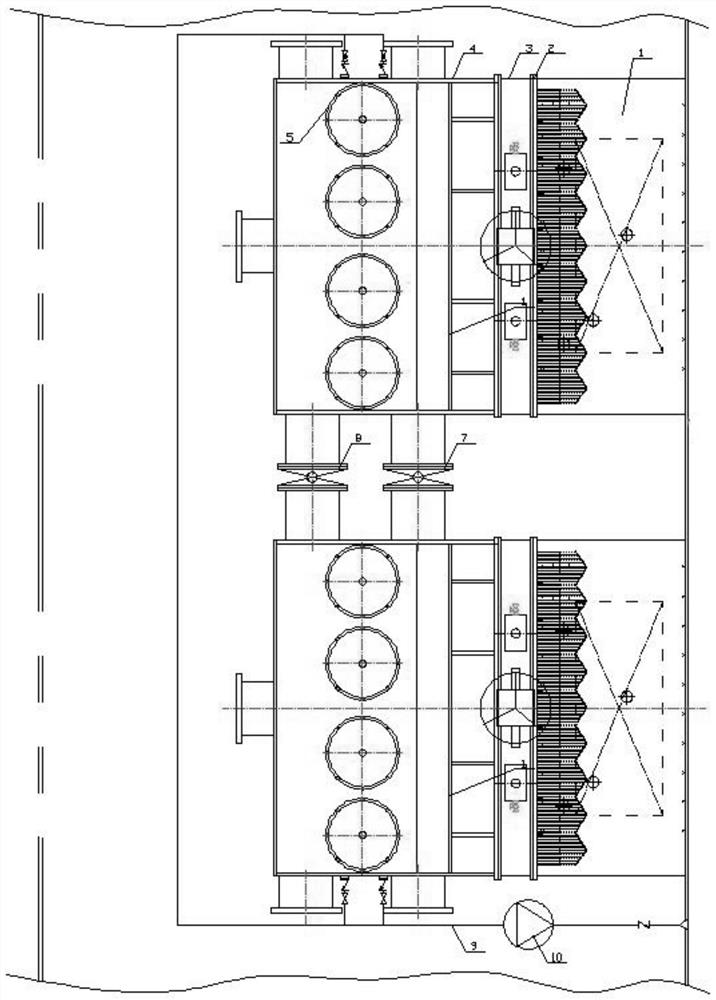

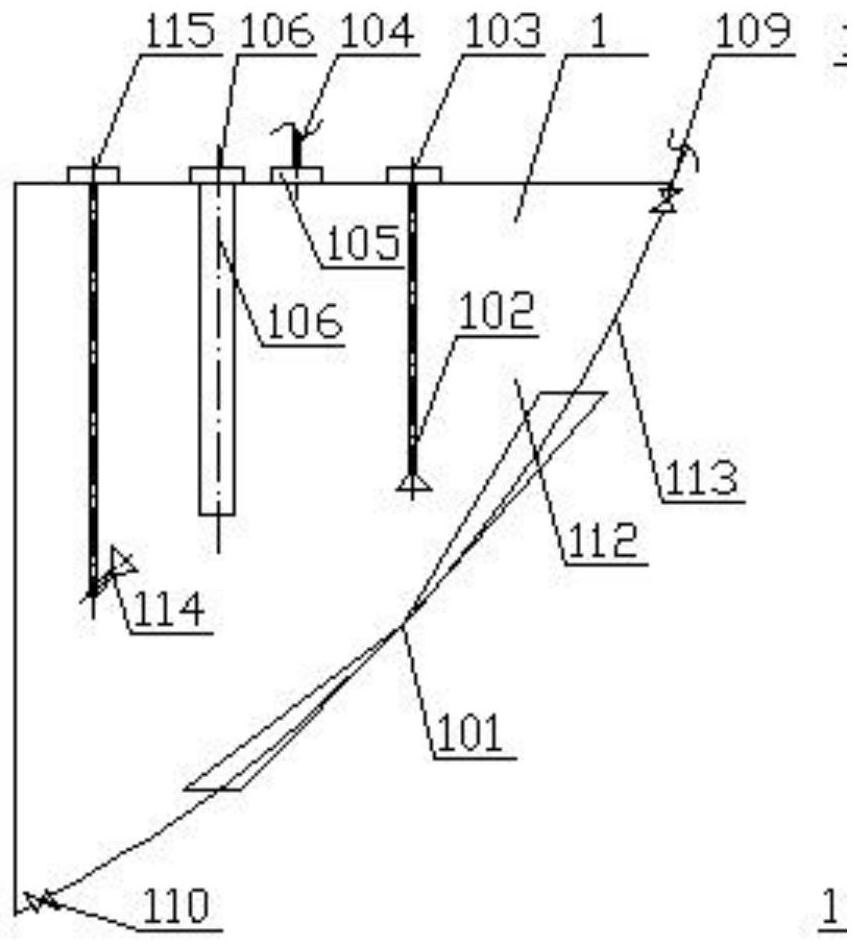

Sea chest, seawater filter and use method

ActiveCN113086085AStrong filtering performanceGood cleanlinessVessel partsFiltration circuitsSeawaterHull

The invention belongs to the technical field of seawater filters, and discloses a sea chest, a seawater filter and a use method. The sea chest comprises a sea chest body, a ship body outer plate, a sea grid, a connecting flange I, a seawater filtering grid assembly, a sea gate valve, a first compressed air pipe and a second compressed air pipe; the device is small in size, multifunctional and suitable for the technical field of ships and ocean engineering, is used for extracting sufficient seawater for a seawater system, a ballast system and other ship auxiliary systems of a ship or ocean engineering platform, effectively prevents marine litter or dirt from entering the ship system and effectively discharges the marine litter or dirt, and prevents ship system faults.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Production technology of canned tuna

The invention relates to the technical field of can production and especially relates to a production technology of canned tuna. The production technology of canned tuna comprises the following steps: step one, steaming and dewatering; step two, showering and cooling; step three, removing skin and bone; step four, cutting the cooked tuna into pieces and packaging in a can. The production technology may also comprise a step A of raw-material treating before the step one; the production technology may also comprise a step five of vacuum-sealing and a step six of sterilizing and cooling after the step four. According to the production technology of canned tuna, water is showered onto the steamed tuna body obtained in the step one for a certain time period, so that the purpose of cooling the steamed fish body is achieved; therefore, the skin of the fish body is separated from the fish-meat by instantaneous temperature difference, so that the surface-skin of the fish body can be easily removed in the step three of removing skin and bone and the fish-skin removal cleanliness is good.

Owner:广东鹰金钱海宝食品有限公司

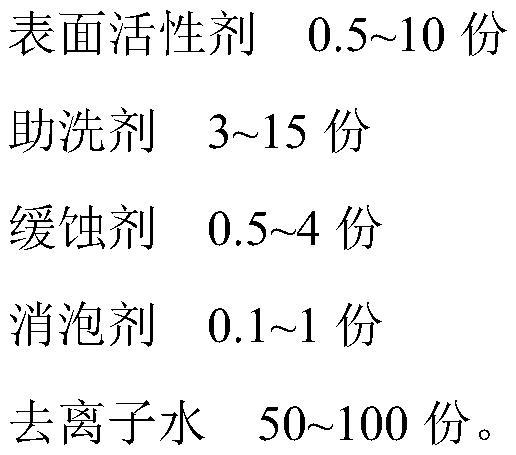

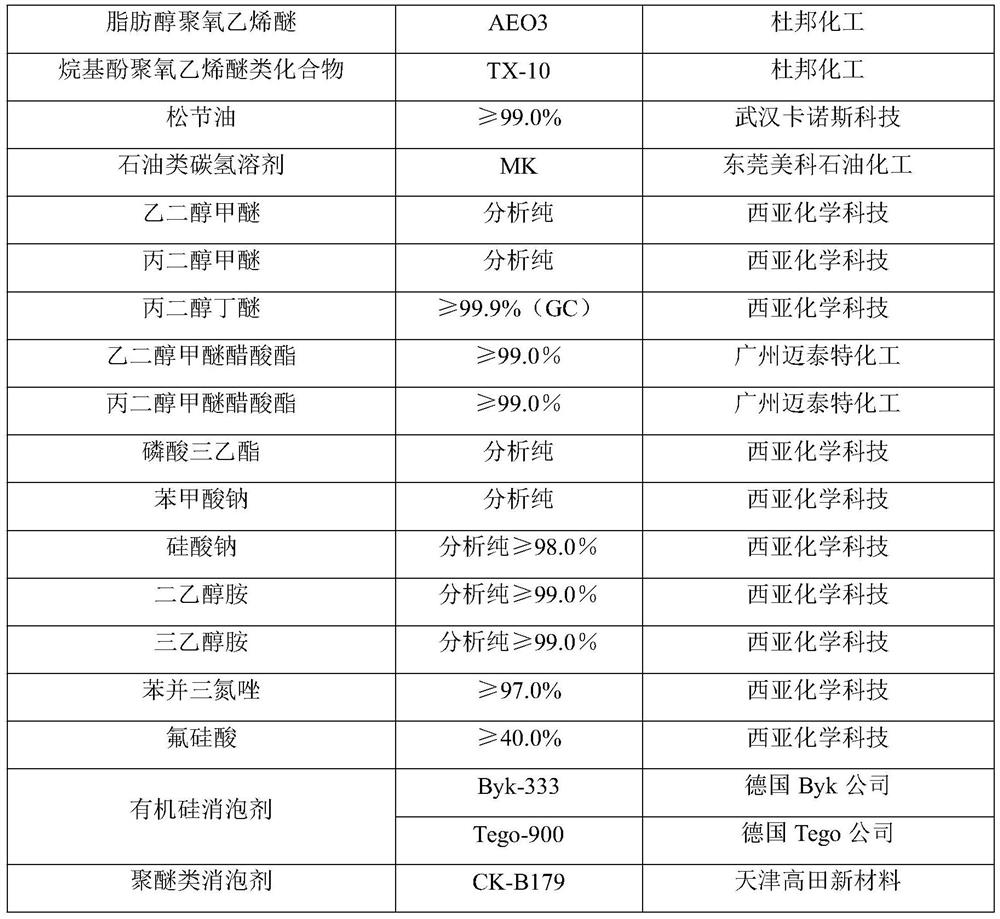

Neutral water-based cleaning agent for cleaning PCB and preparation method of neutral water-based cleaning agent

InactiveCN112522037AGood cleanlinessGood cleaning efficiencyInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentEnvironmental engineering

The invention relates to an electronic industry cleaning agent, in particular to a neutral water-based cleaning agent for cleaning a PCB and a preparation method of the neutral water-based cleaning agent. The invention discloses a neutral water-based cleaning agent for cleaning a PCB. The neutral water-based cleaning agent comprises the following preparation raw materials in parts by mass: 0.5-10part of a surfactant; 3-15 parts of a builder; 0.5-4 part of a corrosion inhibitor; 0.1-1 part of a defoaming agent; 50-100 parts of deionized water; the invention further discloses a preparation method of the neutral water-based cleaning agent for cleaning the PCB, which comprises the following steps: adding the surfactant, the builder, the corrosion inhibitor and the defoamer into deionized water according to a mass ratio, regulating the pH value to 7.0-8.0, and stirring at 40 DEG C for 15-30 minutes. The prepared neutral water-based cleaning agent has the advantages of being good in cleaning effect, high in cleaning efficiency and low in corrosivity to a PCB, and the preparation method is simple, easy to implement and convenient to operate.

Owner:苏州柯仕达电子材料有限公司

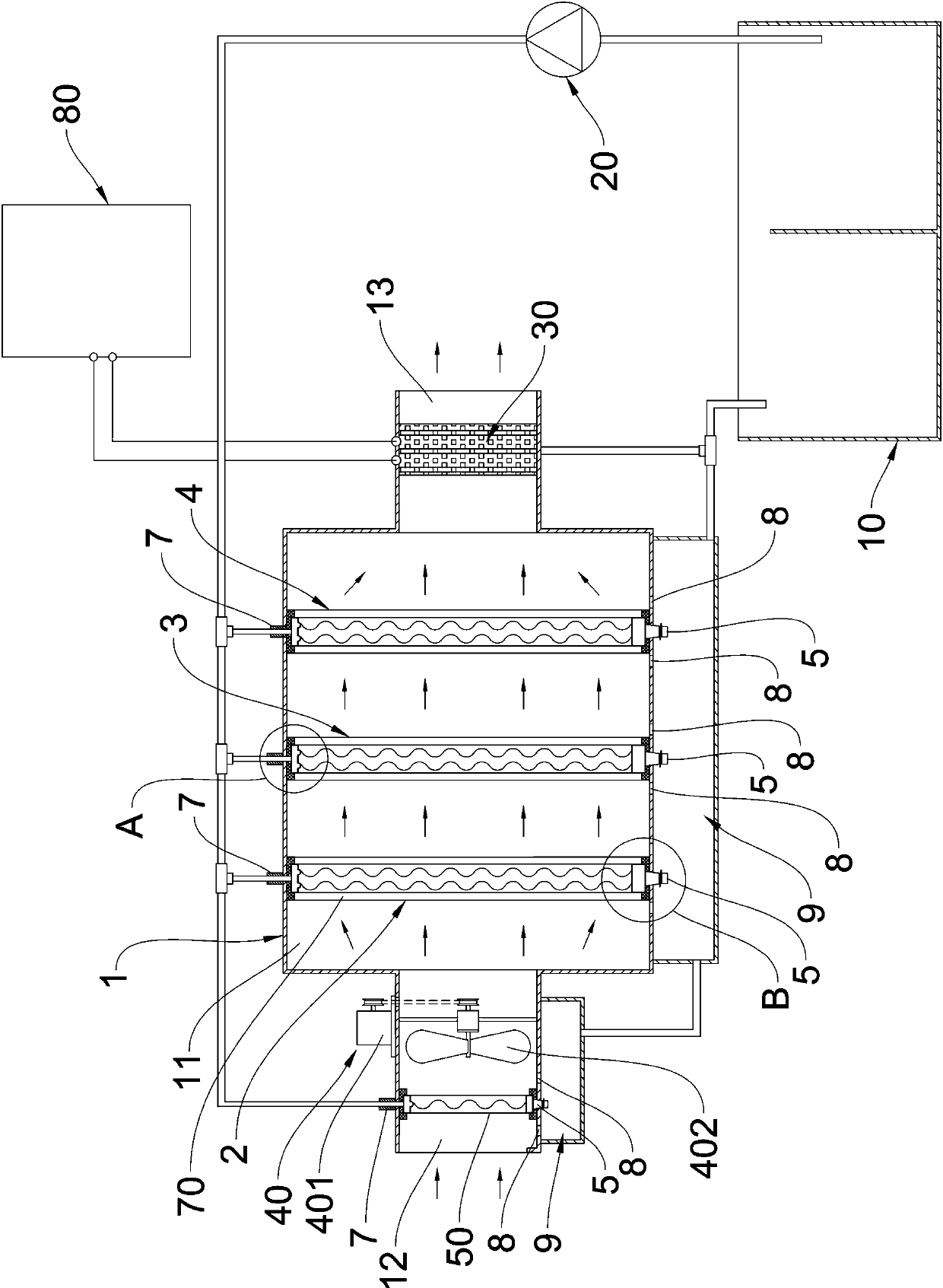

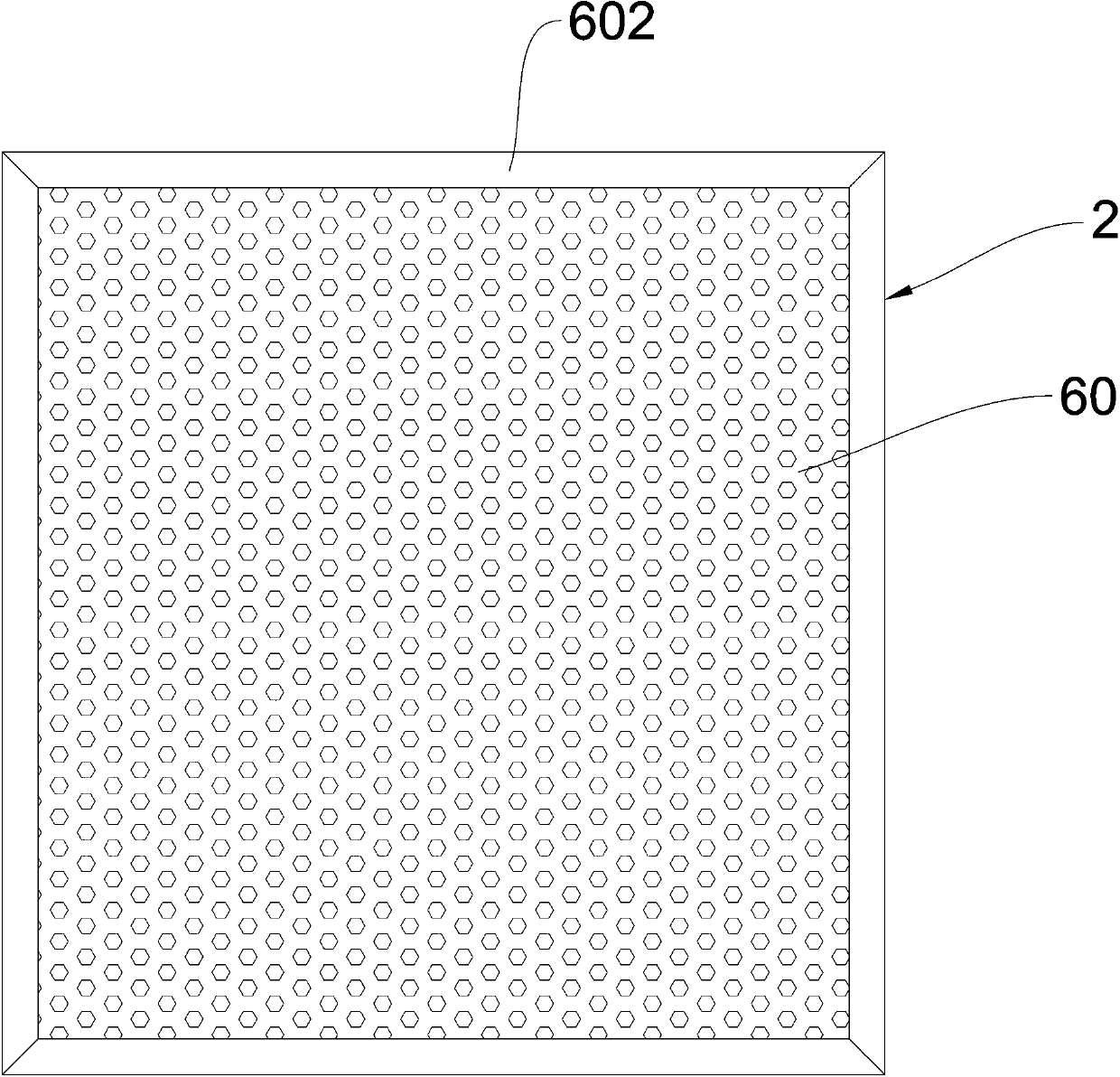

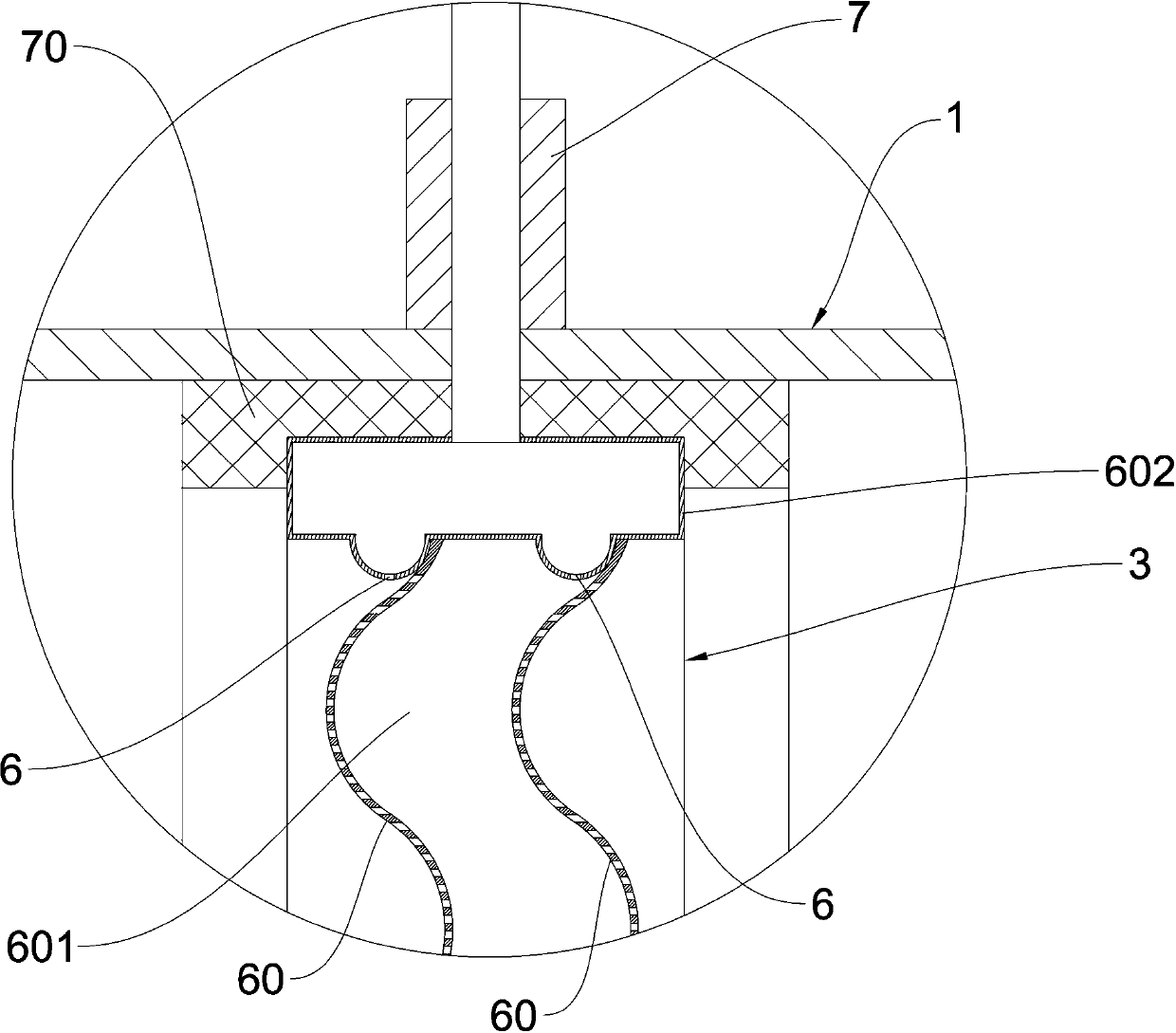

Ultrasonic wave environment purifier

InactiveCN110871000AGood cleanlinessImprove purification efficiencyDispersed particle filtrationTransportation and packagingAir cleaningEngineering

The invention relates to an ultrasonic wave environment purifier including: a case, at least one filter screen plate, and ultrasonic transducers; a purification chamber is formed in the case; an air inlet and an air outlet are respectively disposed at the two ends of the case; the filter screen plates are vertically installed in the purification chamber in order; the ultrasonic transducers are respectively on the side edges of the filter screen plates so that the filter screen plates are subjected to ultrahigh-frequency cutting vibration filter movement; a water curtain slot and a water inletjoint are arranged above each filter screen plate and spray water to form a water curtain on each filter screen plate; a water outlet hole is formed in the bottom of the case. The environment purifieris free of replacement of filter screens and is zero-consumption, wherein the filter screens have self-cleaning function, so that the filter screens are free of cleaning and maintenance. The environment purifier can work uninterruptedly for long period. The environment purifier is high in air purification degree and purification efficiency, is simple in structure, is easy to achieve, is reliableand durable and is suitable for air purification under different environments.

Owner:彭志军

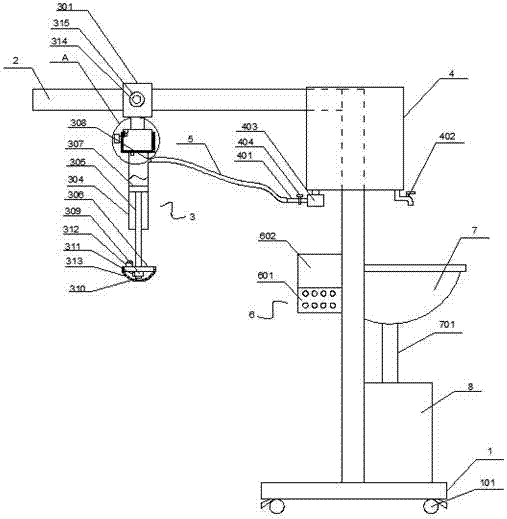

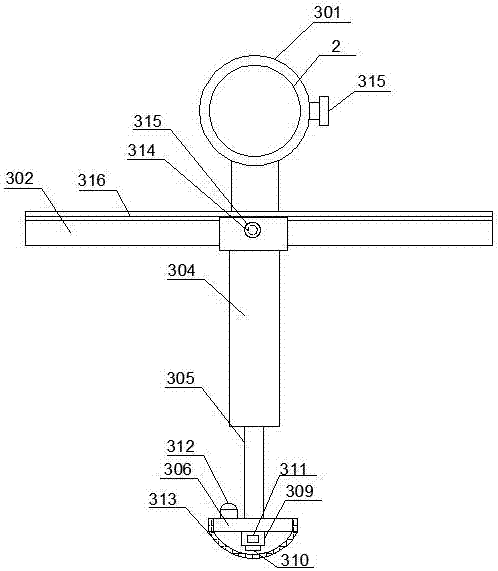

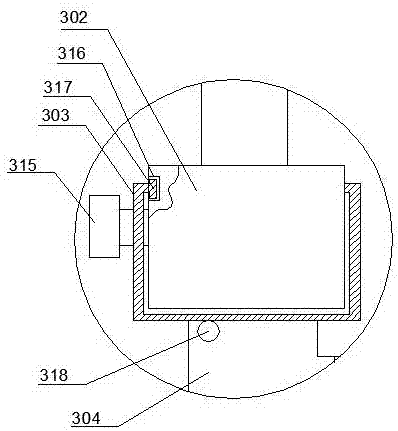

Device for stopping bleeding for department of cardiology

InactiveCN107485423AGood precisionImprove controllabilitySurgeryCatheterEngineeringMedicine.cardiology

The invention provides a device for stopping bleeding for the department of cardiology. The device comprises a base plate, a support rod, a bleeding stopping structure and a water tank; the support rod is arranged on the base plate, the water tank is arranged on the side wall of the support rod, a water outlet pipe is arranged at the lower end of the water tank, the bleeding stopping structure is arranged on the support rod in a sliding mode, the bleeding stopping structure comprises a sliding ring, a cross rod, a sliding frame, a syringe cylinder, a shaft lever and a bleeding stopping block, the sliding ring can be arranged on the support rod in a sliding and sleeving mode, the cross rod is connected to the lower end of the sliding ring through a connecting rod, the sliding frame is arranged on the cross rod in a sliding and sleeving mode, the syringe cylinder is arranged at the lower end of the sliding frame, a piston is arranged in the syringe cylinder, and the shaft lever and the bleeding stopping block are connected to the lower end of the piston in sequence, a liquid inlet pipe is arranged on the side wall of the upper portion of the syringe cylinder, the liquid inlet pipe is communicated with a liquid outlet pipe through a rubber hose, and a control structure is arranged on the side wall of the support rod. The device is high in positioning flexibility, capable of feeding back the bleeding stopping situation in time and good in cleaning and finishing.

Owner:刘岩

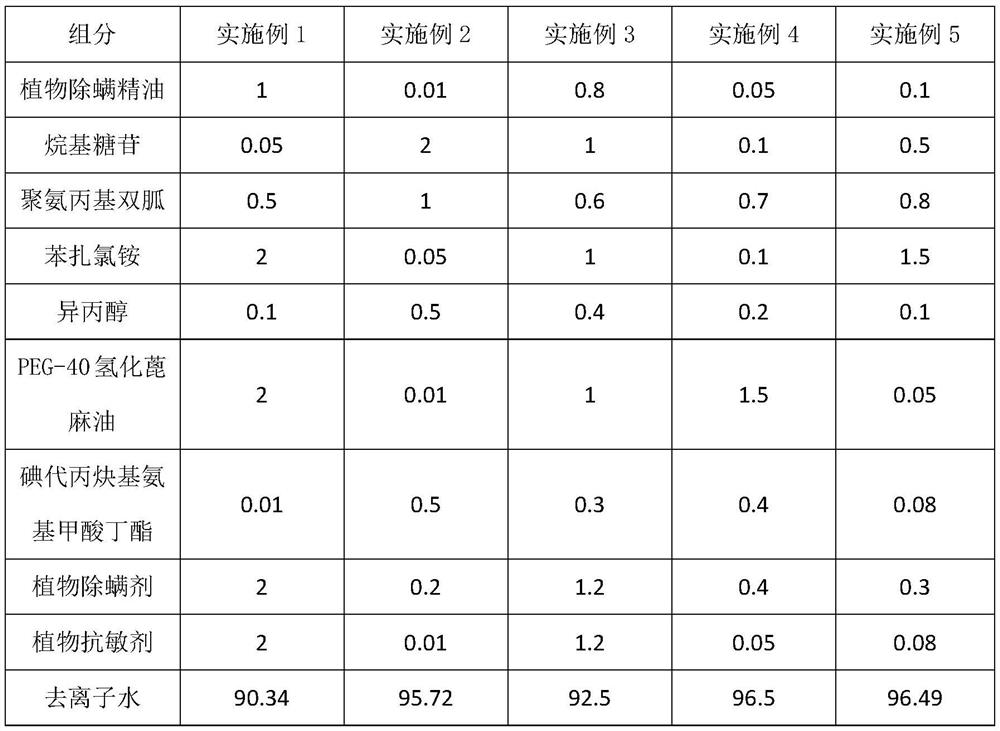

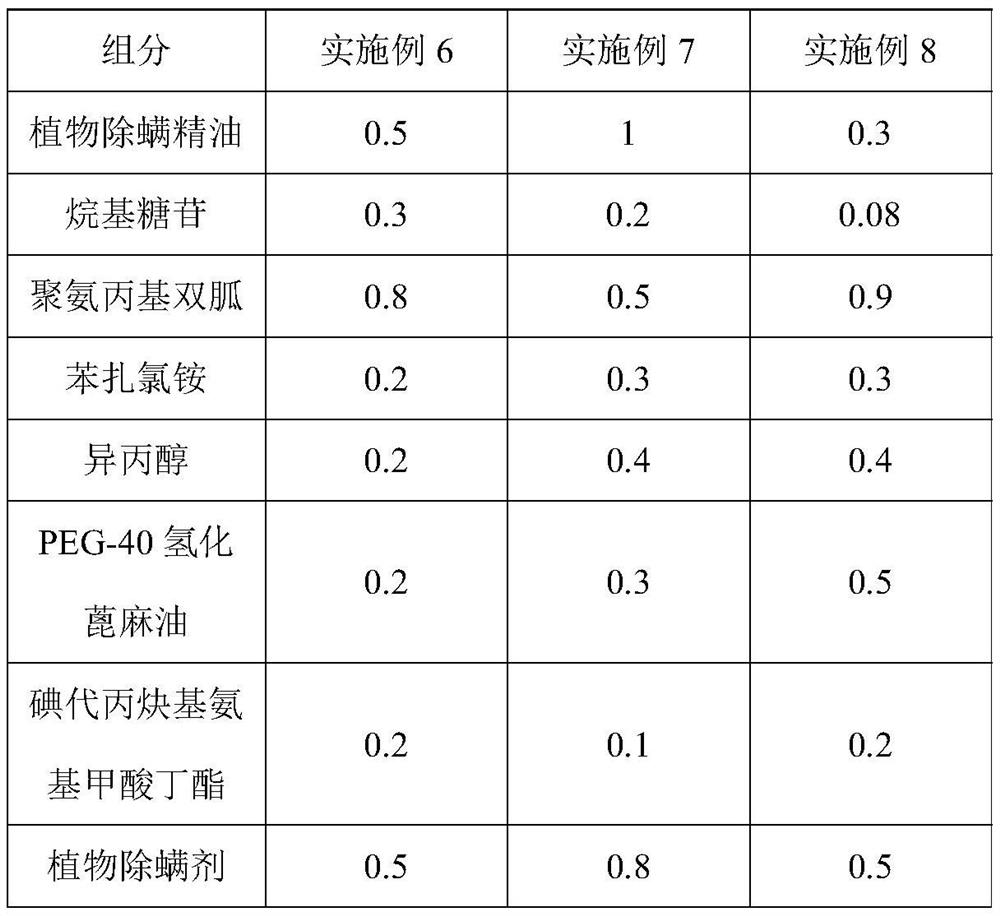

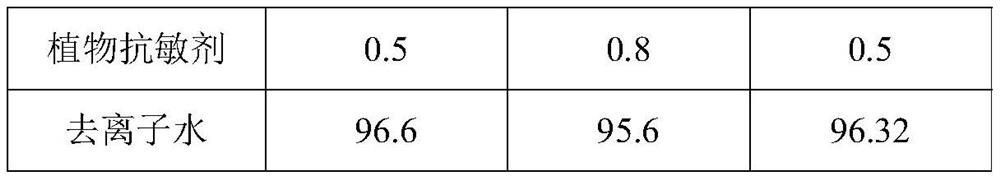

Household sterilizing, cleaning and acarus killing wet tissue

ActiveCN112852556AGood antibacterial and anti-mite effectEasy to cleanOrganic detergent compounding agentsNon-ionic surface-active compoundsGlycosideMicrobiology

The invention discloses a household sterilizing, cleaning and acarus killing wet tissue which comprises a wet tissue body and wet tissue liquid sprayed and dripped on the wet tissue body, and the wet tissue emulsion is sterilizing and acarus killing emulsion and comprises plant acarus killing essential oil, alkyl glycoside, polyaminopropyl biguanide, benzalkonium chloride, isopropanol, PEG-40 hydrogenated castor oil, iodopropynyl butyl carbamate, a plant acarus killing agent, a plant anti-allergy agent and deionized water. The mass ratio of the alkyl glycoside to the polyaminopropyl biguanide to the benzalkonium chloride to the iodopropynyl butyl carbamate is (0.08-0.3): (0.5-0.9): (0.2-0.3): (0.1-0.2). The household sterilizing, cleaning and acarus killing wet tissue is high in cleaning capacity and good in sterilizing and acarus killing effects, meanwhile, the compatibility problem of emulsion and floor plastic is solved, damage to a floor in the cleaning process is avoided, and the household sterilizing, cleaning and acarus killing wet tissue is wide in application.

Owner:MAOMING ZHANGSHI SCI & TECH DEV CO LTD

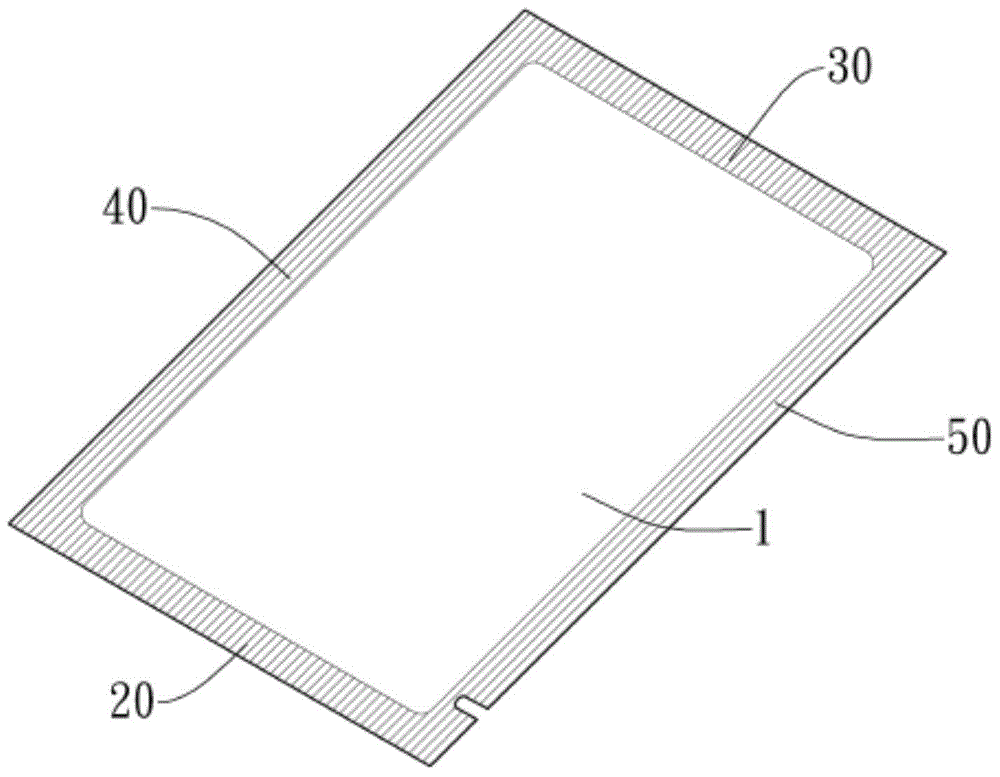

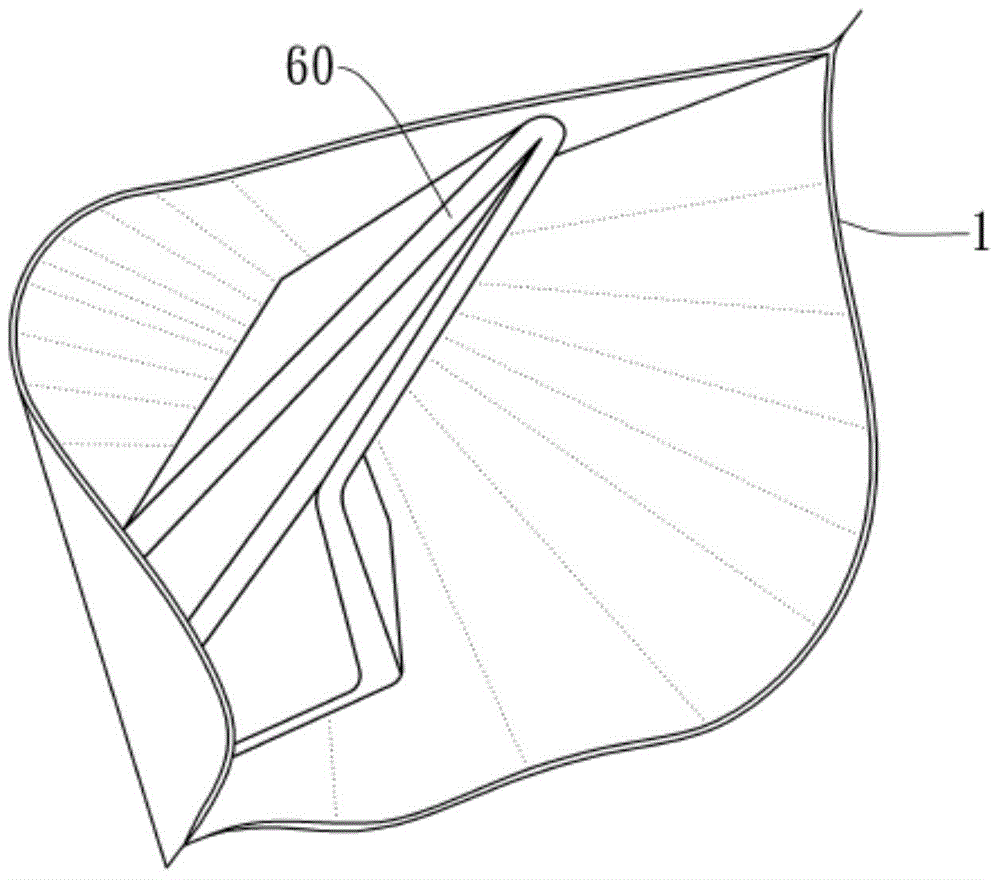

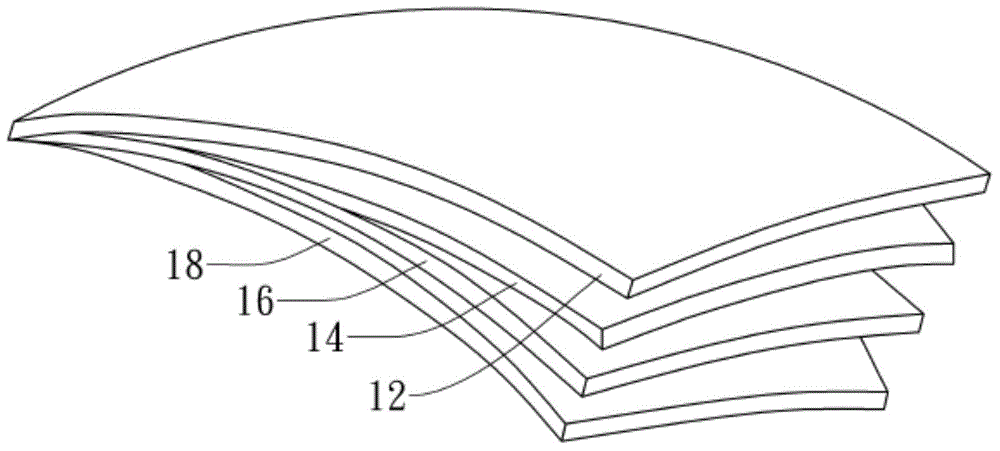

Package body for enhancing glass surface processing agent, glass product and manufacturing method thereof

InactiveCN104556722AEasy to carryThe carrier that carries the strengthening glass surface treatment agent is convenient to use byPackagingEngineeringSurface processing

The invention provides a package body for enhancing a glass surface processing agent, a glass product, and a manufacturing method thereof. The package body comprises a body and a carrier carrying an enhanced glass surface processing agent. The carrier is combined with the body. The enhanced glass surface processing agent comprises fluorine compounds. The user can evenly coat or paste the carrier carrying an enhanced glass surface processing agent on the glass panels of various electronic products so as to keep the glass panel clean and prevent dust, dirt, water drop from being adhered on the automobile glass, thus the driver view cannot be affected, and the safety is guaranteed. The provided glass product comprises a glass panel, and a film, which comprises the enhanced glass surface processing agent and is formed on the glass panel surface to form an enhancing glass surface processing agent layer; wherein the enhancing glass surface processing agent comprises fluorine compounds.

Owner:GOTOP ELECTRONICS TECH

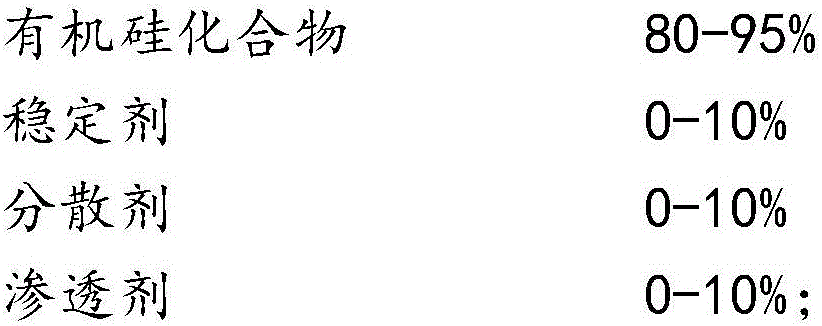

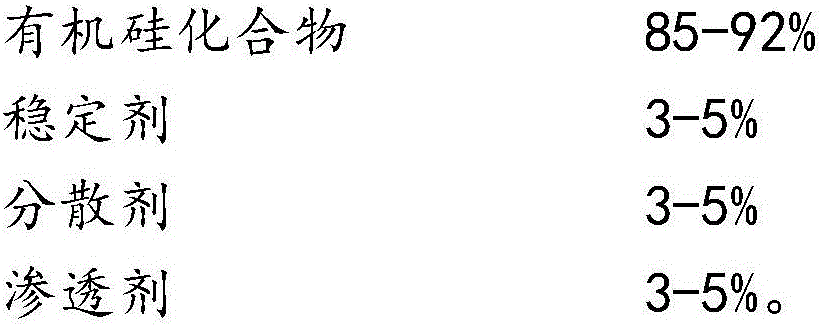

Surface tension increasing agent for hydrocarbon cleaning agent as well as preparation method and use method of surface tension increasing agent

InactiveCN106350326AWide range of applicationsGood cleanlinessNon-ionic surface-active compoundsOrganic detergent compounding agentsSurface tensionCleanability

The invention provides a surface tension increasing agent for a hydrocarbon cleaning agent. The surface tension increasing agent is characterized by consisting of or being prepared from the following ingredients in percentage by mass: 80-95% of an organic silicon compound, 0-10% of a stabilizer, 0-10 parts of a dispersant and 0-10% of a penetrant, wherein the ingredients certainty include at least one of the stabilizer, the dispersant and the penetrant. The product provided by the invention is wide in application range, has favorable cleanability, and is capable of effectively preventing secondary pollution of washed-off oil stain. The surface tension increasing agent is also capable of reducing the cleaning agent brought away by workpieces, and reducing losses in a cleaning process.

Owner:诺而曼环保科技(江苏)有限公司

Metal equipment detergent

The invention relates to a metal equipment detergent which is prepared from the following raw materials in parts by weight: 8-14 parts of fatty alcohol polyethenoxy ether, 3-5 parts of lauryl sodium sulfate, 3.2-4.6 parts of quaternary ammonium salt lignin flocculant, 1.2-3.6 parts of calcium propionate, 7-10 parts of dimethylformamide, 3-6 parts of penetrant, 2.3-3.5 parts of stabilizer, 3.2-4.5 parts of polyacrylamide, 2.4-4.6 parts of amino acid, 2-5 parts of sodium gluconate, 3-6 parts of castor oil potash soap, 3.4-5.6 parts of thiadiazole derivative, 2-3 parts of cellulose acetate, 2-8 parts of polyoxyethylene sorbitan monooleate and 1.2-1.6 parts of chromate. The metal equipment detergent has the advantages of high cleaning efficiency and high corrosion resistance, and can well protect metal equipment.

Owner:青岛千帆高新技术有限公司

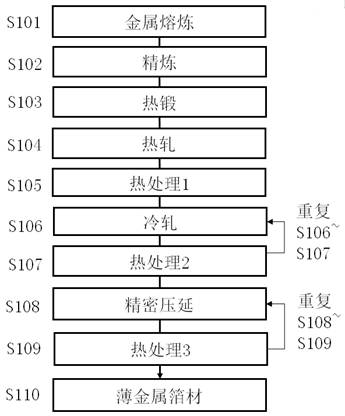

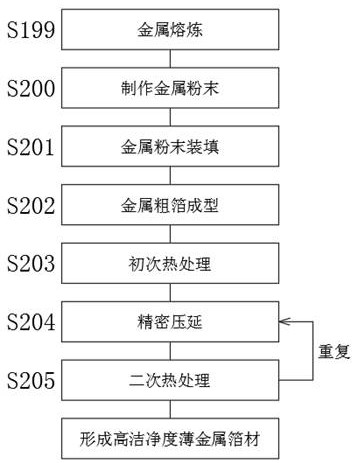

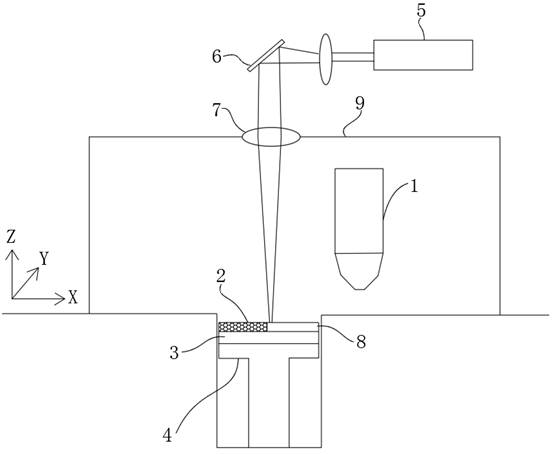

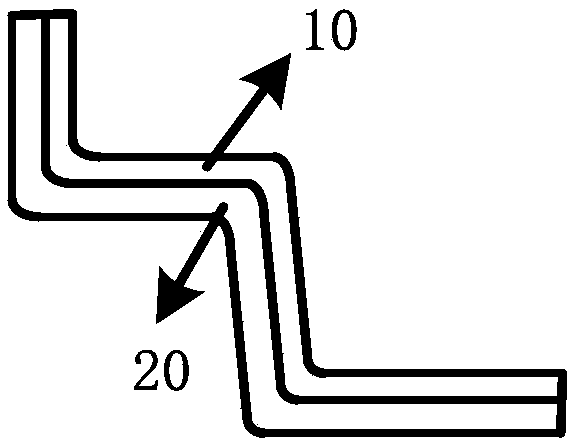

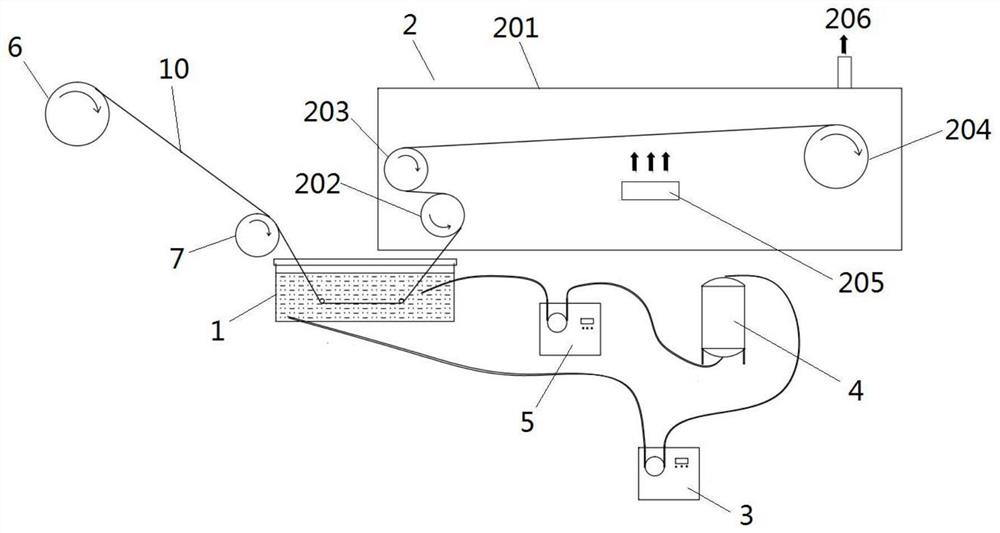

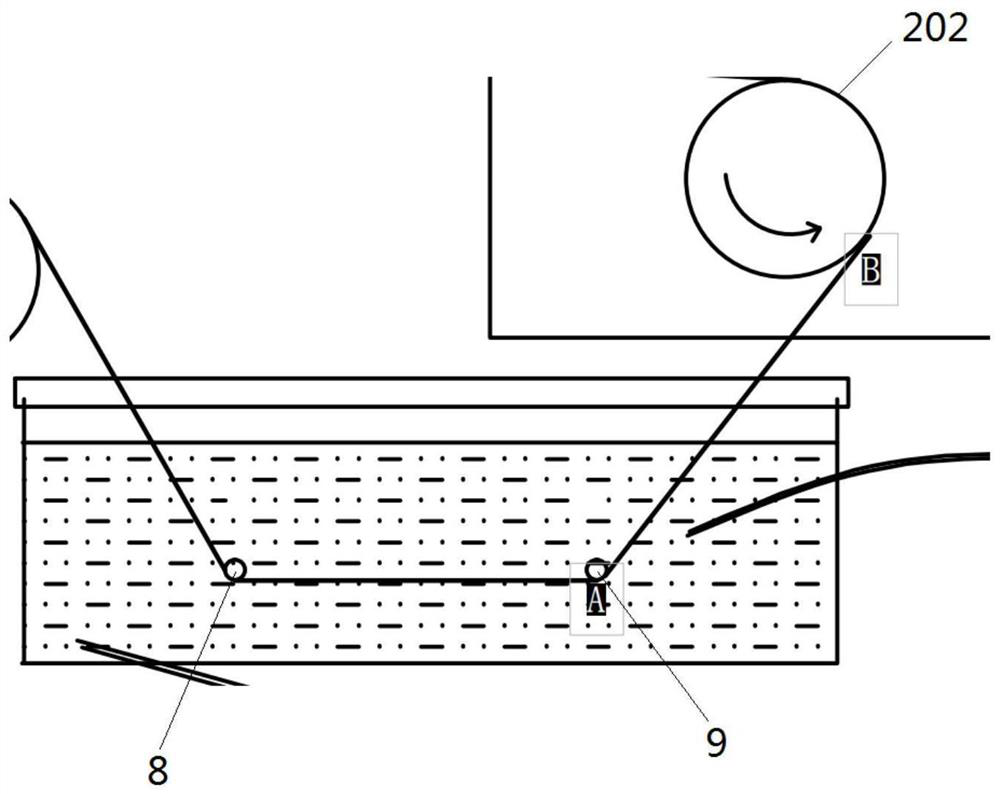

Preparation method of high-cleanliness metal foil and preparation method of metal mask plate strip

PendingCN114433847AImprove cleanlinessLess investmentVacuum evaporation coatingSputtering coatingThin metalMetal foil

The invention discloses a preparation method of a high-cleanliness metal foil and a preparation method of a metal mask plate strip. The preparation method comprises the following steps: filling metal powder into a metal powder dispensing device of laser welding processing equipment; welding the metal powder layer into a metal coarse foil by using a laser plane scanner in laser welding processing equipment; primary heat treatment; precisely rolling; rolling the crude metal foil raw material subjected to primary heat treatment into a required high-cleanliness thin metal foil material in a normal-temperature precise cold rolling manner; performing secondary heat treatment; the high-cleanliness metal foil obtained through the high-cleanliness metal foil preparation method is used for preparing precision metal mask plate strips, metal foil pattern processing is carried out after cleaning, and the precision metal mask plate strips are cut and formed after patterning processing is completed; the manufacturing process has the advantages of few procedures, low production cost, and high cleanliness and yield of the metal foil.

Owner:MAGIC STAR TECHNOLOGY (NINGBO) CO LTD

Towel cleaning agent

InactiveCN104862094AGood cleanlinessGood sterilizationInorganic/elemental detergent compounding agentsSurface-active detergent compositionsActive agentSurface-active agents

Disclosed is towel cleaning agent. The towel cleaning agent is prepared from raw materials of, by weight part, 12-26 parts of surface active agent, 4-7 parts of citric acid, 6-9 parts of sodium chloride, 3-7 parts of sulfonic acid, 5-10 parts of cocoanut fatty acid diethanolamine, 6-11 parts of tween-80, 18-22 parts of purified water, 4-7 parts of glycerin, 4-8 parts of hydrophilic solvent, 7-9 parts of sorbitol, 5-7 parts of potassium permanganate, 8-16 parts of rhizoma smilacis glabrae, 6-9 parts of radix sophorae flavescentis and 5-10 parts of jasmine flowers. The towel cleaning agent has good clean ability and germicidal activity, is nontoxic and harmless on a human body, and can sterilize deeply.

Owner:青岛海蓝海洋复合功能材料科技有限公司

Thin film battery cleaning device

ActiveCN111618012ASave time at workGood cleanlinessDrying gas arrangementsCleaning using toolsLiquid storage tankElectrical and Electronics engineering

The invention relates to the technical field of cleaning devices and discloses a thin film battery cleaning device. The thin film battery cleaning device comprises a cleaning box. The two ends of thecleaning box are provided with feeding rollers and discharging rollers. A dirty water tank and a liquid storage tank are arranged in the cleaning box. The bottom face of the dirty water tank and the bottom face of the liquid storage tank are fixedly connected with the bottom face in the cleaning box. Fixed cleaning plates and movable cleaning plates are horizontally arranged in the cleaning box and are staggered. The front end and the back end of each fixed cleaning plate are fixedly connected with the contact positions of the inner wall of the cleaning box. The bottom faces of the fixed cleaning plates are fixedly connected with the top face of a liquid passing plate. The thin film battery cleaning device accelerates the continuous updating rate of the contact interface between cleaning liquid and a thin film battery in the cleaning process, continuously and efficiently cleans and removes matter insoluble with the surface of the thin film battery, promotes and enhances the thin film battery cleaning effect, improves the cleaning efficiency of the thin film battery, shortens the cleaning travel of the thin film battery, lowers equipment configuration cost and production and operation cost, saves energy and lowers consumption.

Owner:昆山倩超亮光伏科技有限公司

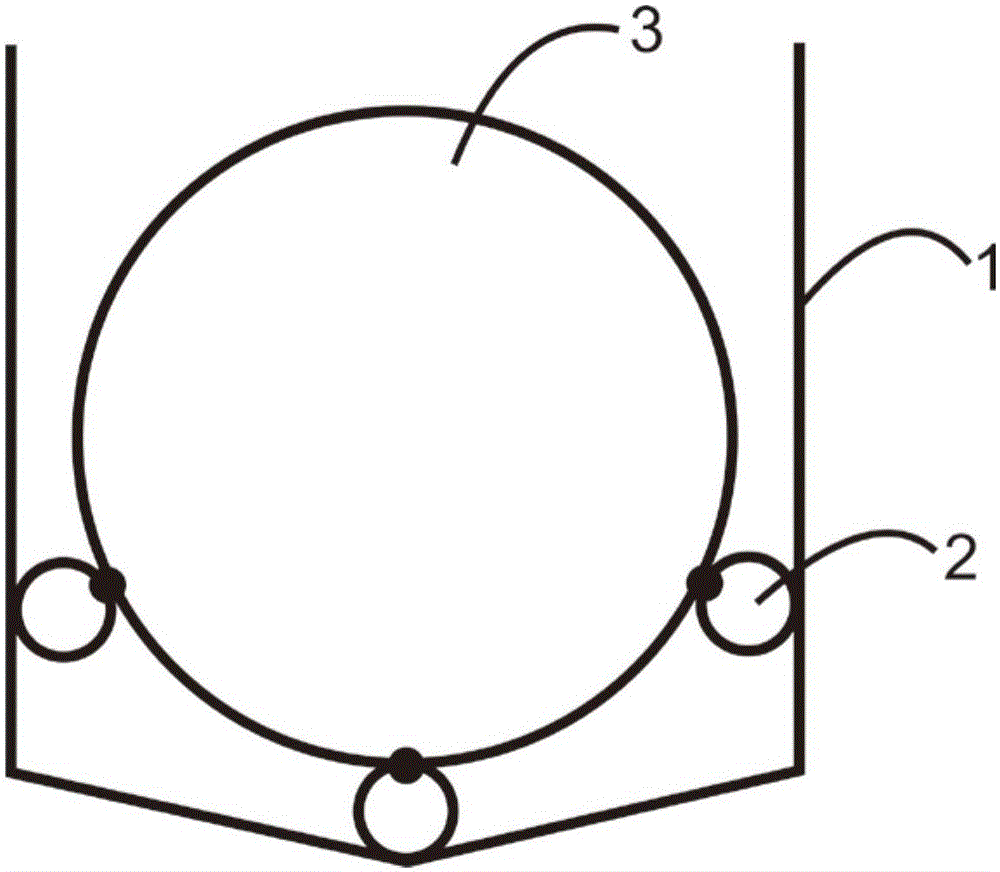

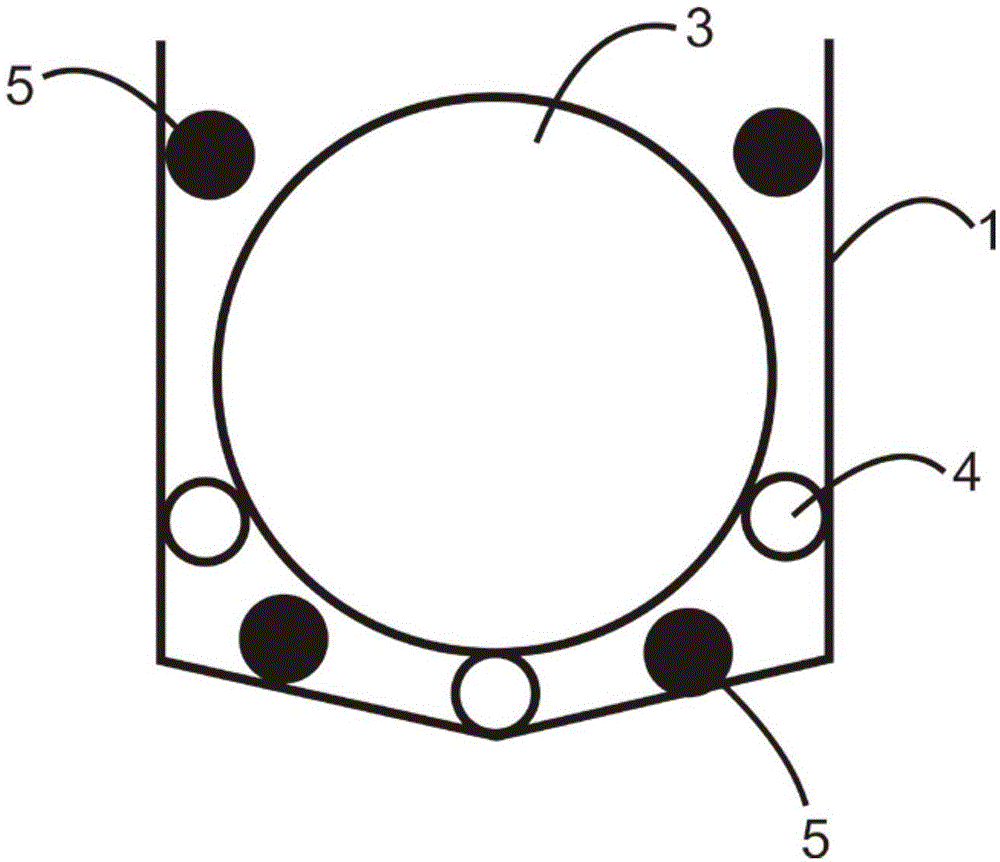

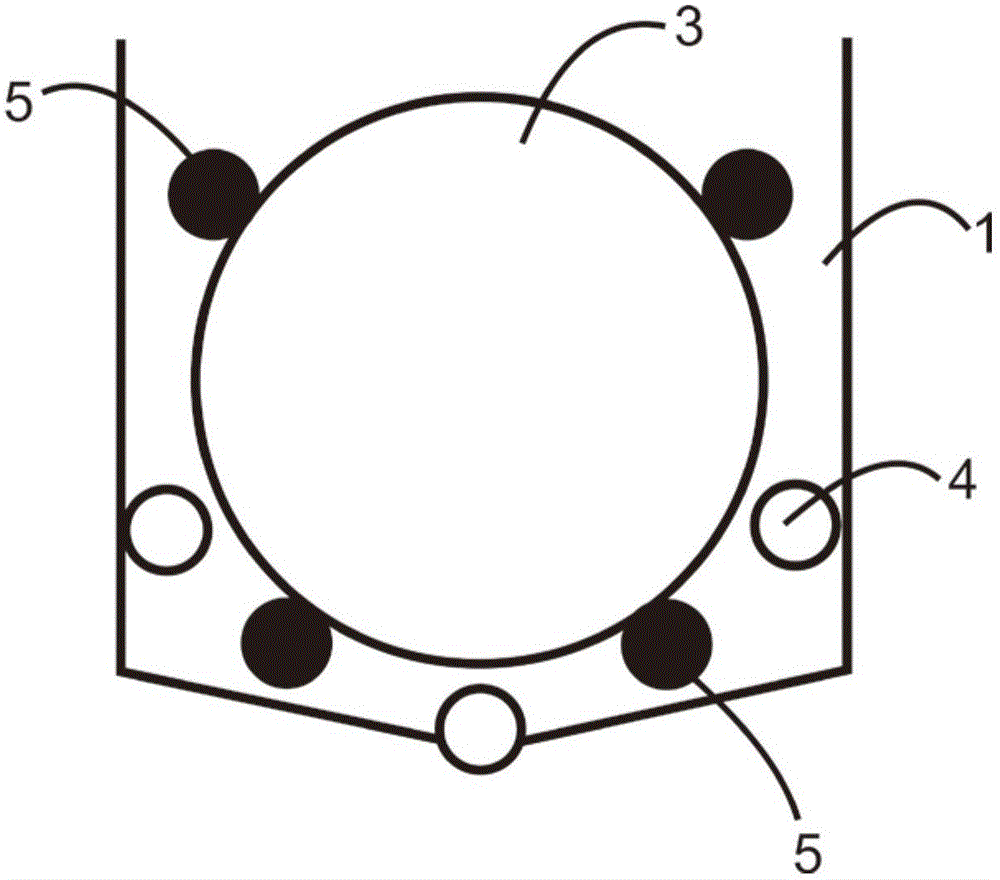

Washing device and method for wafer supporting pieces

ActiveCN105080892AGood cleanlinessAvoid pollutionCleaning using liquidsElectrical and Electronics engineering

The invention discloses a washing device and method for wafer supporting pieces. The washing device comprises the first set of wafer supporting pieces and the second set of wafer supporting pieces. The first set of wafer supporting pieces and the second set of wafer supporting pieces are used alternately, and when the first set of wafer supporting pieces are in the stretch-out state, the second set of wafer supporting pieces are in the retracting state, or when the first set of wafer supporting pieces are in the retracting state, the second set of wafer supporting pieces are in the stretch-out state. Due to the fact that the first set of wafer supporting pieces and the second set of wafer supporting pieces are used alternately, when wafers are supported by one set of wafer supporting pieces, the other set of wafer supporting pieces make full contact with washing liquid, the good cleanliness of the wafer supporting pieces is kept all the time, dirt on the wafer supporting pieces is prevented from contaminating the wafers, the defects of the wafers are reduced, and the yield of the wafers is increased.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

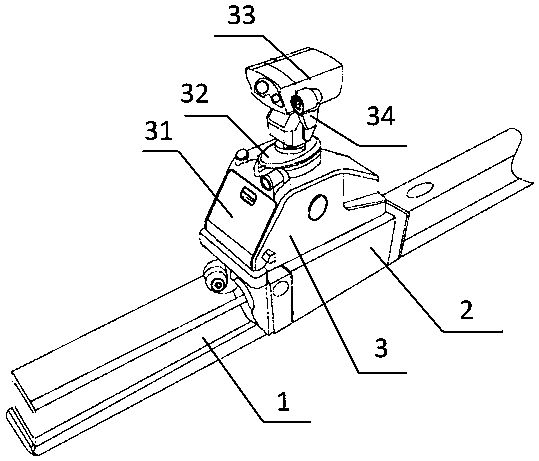

Internet of Things visual optimization monitoring equipment

PendingCN110430402AHigh degree of automationGood cleanlinessTelevision system detailsColor television detailsComputer visionInternet of Things

The invention relates to the field of infrared monitoring equipment, in particular to Internet of Things visual optimization monitoring equipment. According to the technical scheme, the Internet of Things visual optimization monitoring equipment comprises a guide rail, a sliding block sliding on the guide rail and a camera shooting assembly installed on the sliding block, the camera shooting assembly comprises a main body, and a real-time infrared camera shooting device comprises a transparent shell. The Internet of Things visual optimization monitoring equipment comprises a camera shooting purification device used for cleaning a transparent shell, and the camera shooting purification device comprises an upper connecting base, a wiping lifting strip connected with the upper connecting baseand a wiping soft block driven by the wiping lifting strip to reciprocate to wipe the surface of the transparent shell. The invention aims to provide Internet of Things visual optimization monitoringequipment, which can move and adjust the monitoring range in real time, clean a transparent shell outside a camera and optimize a shot picture in real time.

Owner:福州市协成智慧科技有限公司

System for harvesting high-stalk crops

The invention discloses a system for harvesting high-stalk crops. The system comprises four small wheels, a box, a cutting bottom plate, a cutter blade and a four-rod and six-shaft mechanism. The system is simple to manufacture, low in cost, high in harvesting efficiency, good in harvesting degree and safe to use, labor intensity can be greatly reduced, and the system serving as a harvesting farm tool is suitable for harvesting of high-stalk crops such as wheat, rice, foxtail millet and soybeans of rural individual farmers.

Owner:周琳桓

Semi-closed automatic car washing machine

PendingCN113895407AGood cleanlinessAvoid harmCleaning apparatus for vehicle exteriorsStationary filtering element filtersAutomotive engineeringManufacturing engineering

The invention belongs to the field of car washing machines, and particularly relates to a semi-closed automatic car washing machine which comprises a protective wall, a mechanical arm, a brush, lateral cleaning modules and a base; the mechanical arm is fixedly connected to the top end of the interior of the protective wall, the brush is arranged at the bottom end of the mechanical arm, the lateral cleaning modules are arranged on the two sides of the interior of the protective wall, the base is arranged at the bottom end of the interior of the protective wall, and a connecting mechanism is arranged between the brush and the mechanical arm; the connecting mechanism comprises a fixing shaft, a sleeve block, an inserting block, an inserting groove, a connecting shaft, a limiting assembly and a positioning assembly, one side of the fixing shaft is fixedly connected to the two sides of the brush, the side, away from the brush, of the fixing shaft is arranged in the mechanical arm, the sleeve block is fixedly connected with the fixing shaft, the sleeve block is inserted into the connecting shaft, and the connecting shaft is fixedly connected with the mechanical arm; and the effect of conveniently disassembling and replacing the brush after long-time use is achieved through the connecting mechanism.

Owner:亿力清洗科技(苏州)有限公司

Composite profile and preparation method thereof

ActiveCN110450489AInhibit surface bacterial growthGood cleanlinessSynthetic resin layered productsChemistryResin composite

The invention provides a composite profile and a preparation method thereof. The composite profile comprises a resin surface layer and a resin inner layer which are overlapped, wherein materials for forming the resin surface layer comprise ABS resin, materials for forming the resin inner layer comprise at least one thermoplastic resin other than ABS resin, and an antibacterial agent is contained in the resin surface layer and / or the resin inner layer. Through the composite profile, bacterial reproduction on the surface can be inhibited, good cleanliness and a good appearance of products can bemaintained, and meanwhile, the resin inner layer is formed by using the thermoplastic resin different from the ABS resin so as to enhance the resin inner layer according to application requirements,so that the antibacterial ABS resin composite material with good wear resistance and high strength is provided.

Owner:PETROCHINA CO LTD

Process for pretreating part to be plated in electroplating process

The invention discloses a process for pretreating a part to be plated in the electroplating process. The process comprises the steps that degreasing and etching procedures are carried out on the part to be plated, a chemical degreasing solution adopted in the degreasing procedure is prepared from sodium hydroxide, sodium phosphate tribasic dodecahydrate, sodium carbonate and sodium metasilicate, and a chemical etching solution adopted in the etching procedure is prepared from 150 g / L to 200 g / of 98% sulfuric acid, 0.6 g / L to 0.9 / L of rodine and 50 g / L to 100 g / L of sodium chloride. In this manner, according to the process, grease and a passive film on the surface of the plated part can be removed, so that the surface of the plated part and a plating solution have good wetability, the surface of the plated part which is not electroplated is very good in state and high in clean degree, the obtained plated part is long in service time, and the plating peeling off phenomenon is avoided.

Owner:苏州市华婷特种电镀有限公司

Flexible material with self-cleaning function and preparation method and application thereof

InactiveCN113234384AWith self-cleaning functionImprove waterproof performanceFibre treatmentPolyether coatingsPolymer scienceFluoride

The invention provides a flexible material with a self-cleaning function and a preparation method and application thereof.The flexible material comprises a base layer and a self-cleaning coating layer, the self-cleaning coating layer is arranged on the surface and / or inside the base layer, and the self-cleaning coating layer is made of fluorine-containing hydrophobic and oleophobic coating and an antistatic agent. The flexible material is good in waterproof performance, high in oil stain resistance and capable of self-cleaning accumulated dust, the oil repellent grade is 3-8, meanwhile, the flexible material has stable sound transmission and air permeability, and has stable frequency response within the range of 100-10 KHz, and fluoride and an antistatic agent which are excellent in performance are adopted in the preparation method of the flexible material; the material with better hydrophobic, oleophobic and self-cleaning properties is obtained by controlling a plurality of process parameters such as the solid content of the fluorine-containing hydrophobic and oleophobic coating in the self-cleaning solution in the dip-coating process of the base layer material, the solid content of the antistatic agent, the liquid outlet angle of the base layer, the feeding speed, the drying temperature and the like.

Owner:TIANJIN RIJIN TECH +1

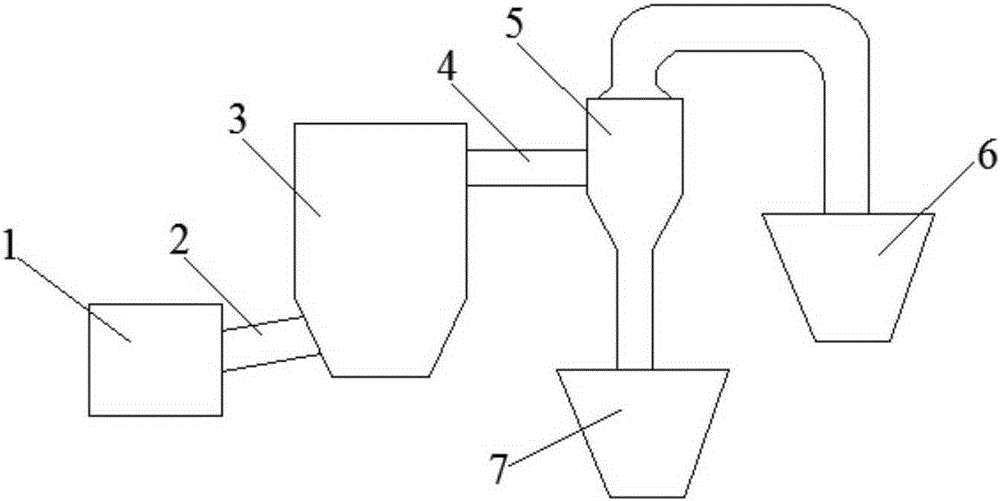

Scattered evaporation type drying machine

InactiveCN106622500AGood cleanlinessFull collection of productsGrain treatmentsDrying machinesSpecific gravityEngineering

The invention discloses a scattered evaporation type drying machine and belongs to the technical field of mechanical device design. The scattered evaporation type drying machine comprises an air blowing device, an air pipe, a drying machine, a connecting pipe, a discharging device, a dust collecting box and a particle collecting box. The left side of the drying machine is connected with the air blowing device through the air pipe. Hot air blown out from the interior of the air blowing device enters the drying machine through the air pipe to heat and dry raw materials in the drying machine. The right side of the drying machine is connected with the discharging device through the connecting pipe. The raw materials enter the discharging device from the connecting pipe after being dried in the drying machine. Dust with the low specific gravity in the discharging device enters the dust collecting box from the connecting pipe on the top of the discharging device, and particles with the large specific gravity enters the particle collecting box from an outlet in the bottom of the discharging device. According to the scattered evaporation type drying machine, the raw materials are sufficiently smashed, porcelain zirconium balls are not likely to be broken, the product cleanliness is good, the porcelain zirconium balls jump and extrude and rub sufficiently, and the products are sufficiently collected.

Owner:CHIZHOU DAHENG BIOCHEM

Clean lubricating oil

InactiveCN104830448AGood cleanlinessAntioxidantLubricant compositionEnvironmental geologyTrimethylolpropane

A clean lubricating oil is prepared from, by weight, 3-4 parts of fatty acid, 2-5 parts of calcium carbonate, 4-5 parts of trimethylol propane, 3-6 parts of metal dialkyl dithiocarbamate, 1-3 parts of polyisobutylene succimide, 4-8 parts of methyl benzoate, 8-14 parts of silicone oil, 2-3 parts of a metal antirust agent, 2-4 parts of a dispersant, 1-2 parts of polytetrafluoroethylene, 1-3 parts of lithium soap, 1.5-2.5 parts of red lead and 2-4 parts of butylenes. The clean lubricating oil has the advantages of oxidation resistance, sterilization property, extreme pressure wear resistance and extremely good cleaning property.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

Quickly cooled machining cleaner

InactiveCN107118867AGood cleanlinessReduce the temperatureOrganic detergent compounding agentsAnionic-cationic-non-ionic surface-active compoundsChemistryPolyacrylamide

The invention provides a quickly cooled machining cleaner, and particularly relates to the field of machining. The cleaner is prepared from the following raw materials in parts by weight: 4 to 6 parts of polyethylene glycol, 5 to 9 parts of potassium sodium tartrate, 7 to 11 parts of a lubricating oil additive, 4 to 7 parts of zinc naphthenate, 2 to 4 parts of diethylene glycol, 8 to 12 parts of disodium ethylate tetraacetic acid, 4 to 8 parts of polyacrylamide, 5 to 10 parts of mineral oil, 3 to 6 parts of an extreme pressure additive, 3 to 6 parts of an antioxidant, 4 to 10 parts of oil diethylene glycol ester, 6 to 9 parts of diisopropyl sodium sulfonate and 7 to 10 parts of castor amide. Through cooperation of all raw material components, the quickly cooled machining cleaner is obtained; the cleaner is extremely high in cleaning property and further can effectively reduce temperature of mechanical equipment, prolong the service life of the mechanical equipment and increase the economical benefit; moreover, the cleaner is high in biodegradability, can effectively remove oil dirt from the mechanical equipment, is harmless to the skin and is safe and environmentally-friendly.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com