Patents

Literature

115results about How to "Good wettability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long fiber filler reinforced resin pellet

InactiveUS20090081462A1Good wettabilityGood appearanceSynthetic resin layered productsCellulosic plastic layered productsEtherFiber

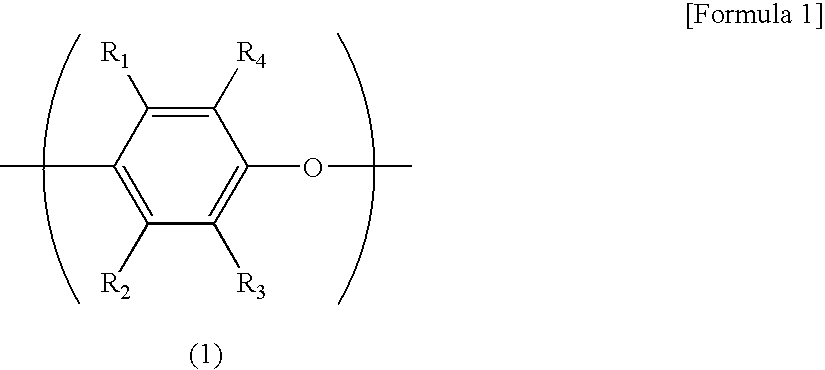

The invention provides a long fiber filler reinforced resin pellet composed of a long fiber filler and a thermoplastic resin blend. In the pellet, the long fiber filler is aligned to form a spiral with a central axis along the longitudinal direction of the pellet, and the pellet has a skin layer part with a lower content of the long fiber filler, and a core part with a higher content of the long fiber filler, thereby the cross-section of the core part is in a range of 30% to 70% of the cross-section of the pellet. The thermoplastic resin blend in the pellet is composed of polyphenylene ether and a thermoplastic resin other than polyphenylene ether.

Owner:ASAHI KASEI CHEM CORP

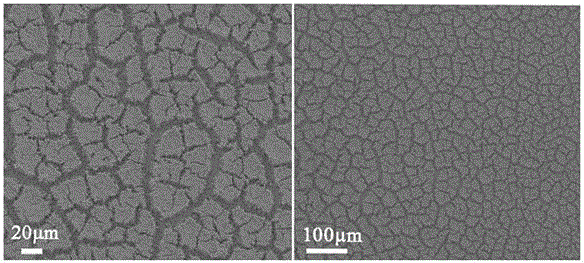

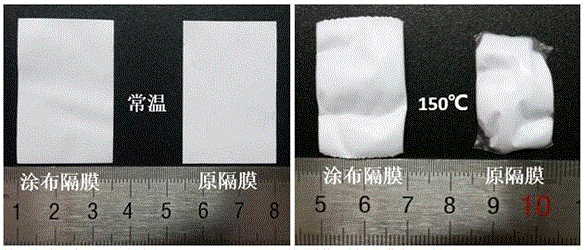

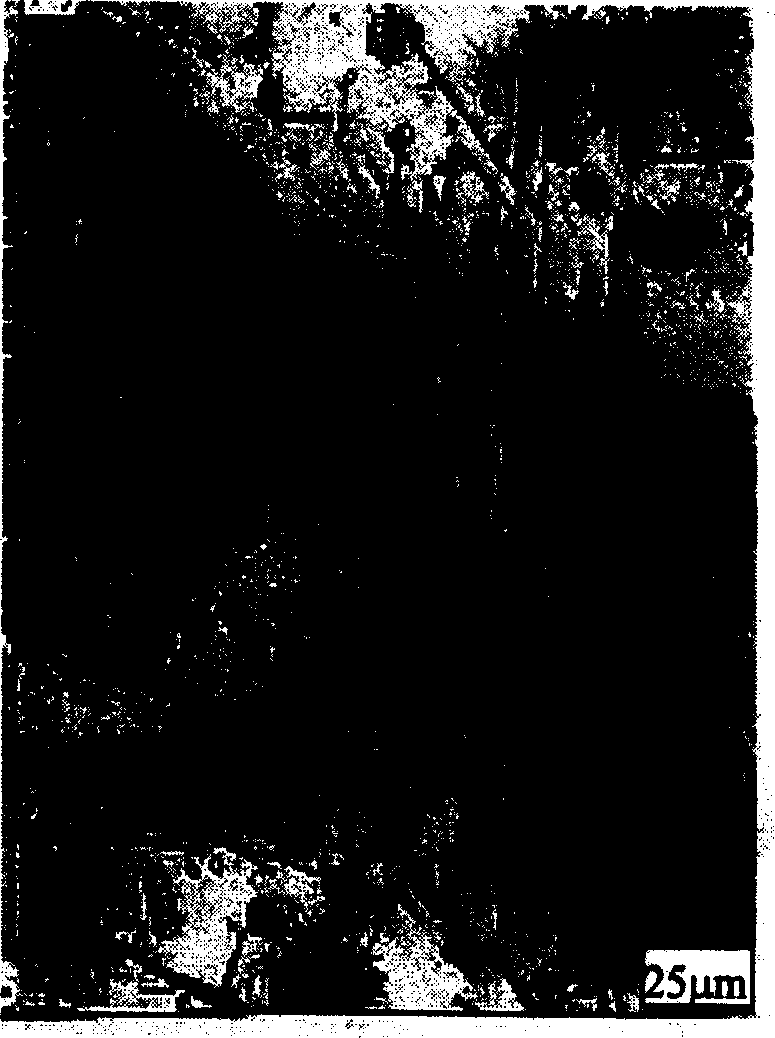

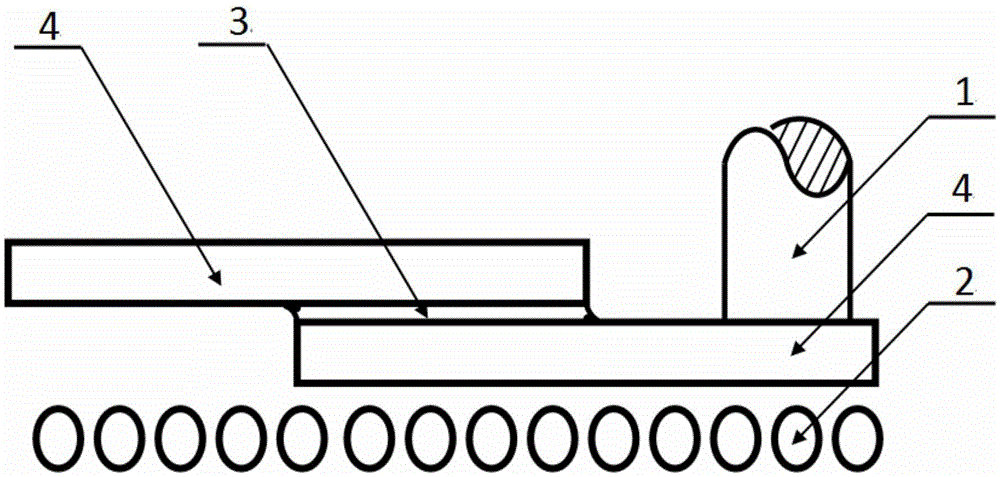

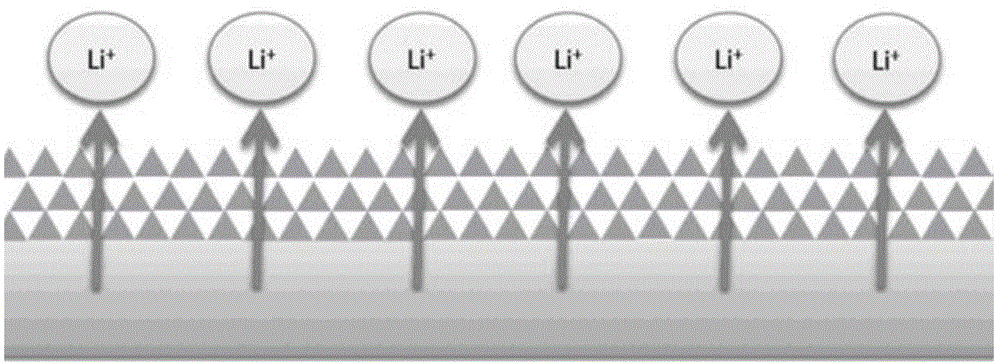

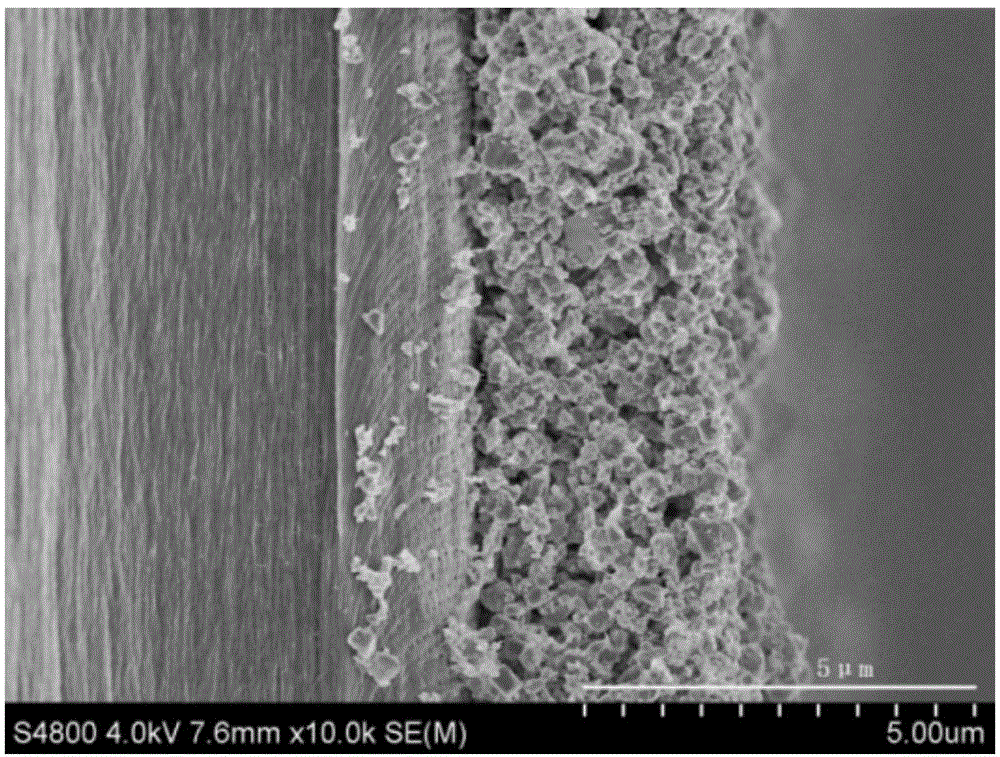

Novel hydrophobic silica aerogel composite separator for lithium ion battery

ActiveCN106450116ALight in massGood wettabilityCell component detailsCoatingsPolyolefinPolymer chemistry

The invention discloses a novel hydrophobic silica aerogel composite separator for a lithium ion battery. The separator is a hydrophobic silica aerogel coating layer coated on surfaces of conventional separators with different thicknesses, and the thickness of the silica aerogel coating layer is 1-25 micrometers. A preparation method of the hydrophobic silica aerogel composite separator comprises the steps of firstly, preparing hydrophobic silica aerogel; secondly, dispersing the hydrophobic silica aerogel into an organic solvent, and adding a certain proportion of binding agent to prepare paste; and finally, uniformly coating the obtained paste on the surfaces of the conventional separators with different thicknesses, and performing drying to obtain the hydrophobic silica aerogel composite separator. The hydrophobic silica aerogel composite separator has the advantages of light weight and good heat resistance, the silica aerogel of an organic electrolyte with high wettability is used as the coating layer material, and the heat resistance, the wettability and the electrochemical performance of a polyolefin separator are greatly improved on the premise of almost no increase on the mass of the separator.

Owner:ZHENGZHOU UNIV

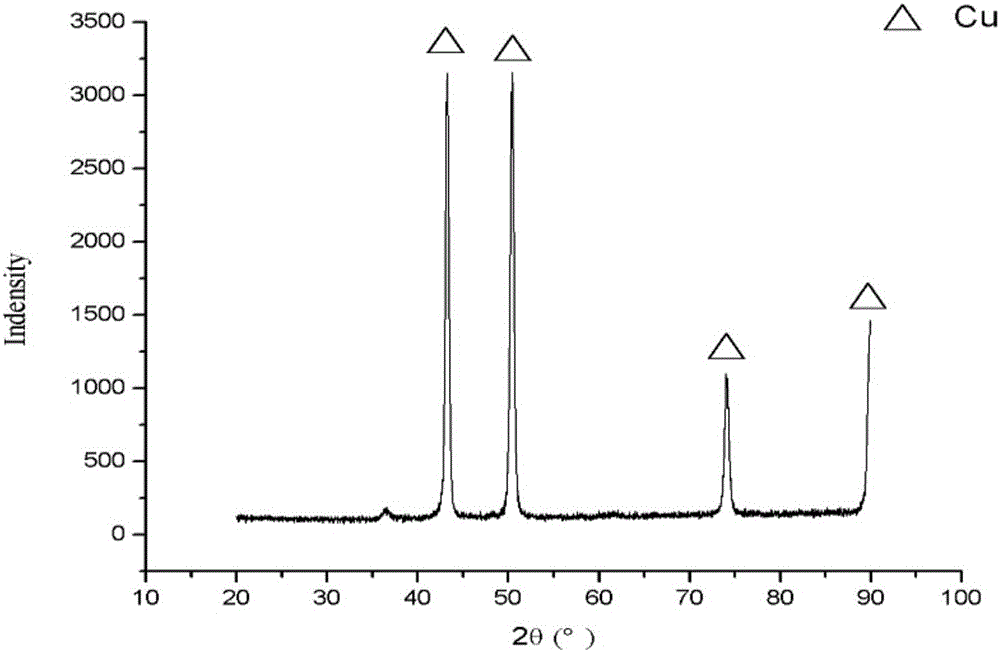

Surface or local gradient reinforced wear resistant manganese steel composite material and preparing process

InactiveCN1616706AUniform and small sizeGood wettabilitySolid state diffusion coatingWear resistantHardness

The present invention relates to surface or locally gradient reinforced antiwear composite manganese steel material and its preparation process. The composite material has matrix of austenite with relatively high toughness; reinforcing layer comprising TiC with relatively high hardness, martensite and metastable austenite; and intermediate transition layer comprising gradient varying TiC, martensite and austenite. The preparation process includes the following steps: designing metastable austenite manganese steel matrix composition with C 0.8-1.3 wt% and Mn 6-13 wt%; setting Ti-Fe alloy powder as composite medium in special parts of the cast mold and casting high temperature manganese steel melt to obtain the surface or local TiC reinforcement plus metastable austenite as-cast structure; and liquid nitrogen deep cooling the surface or local to obtain phase changed gradient martensite layer. The present invention can raise comprehensive mechanical performance of manganese steel.

Owner:JILIN UNIV

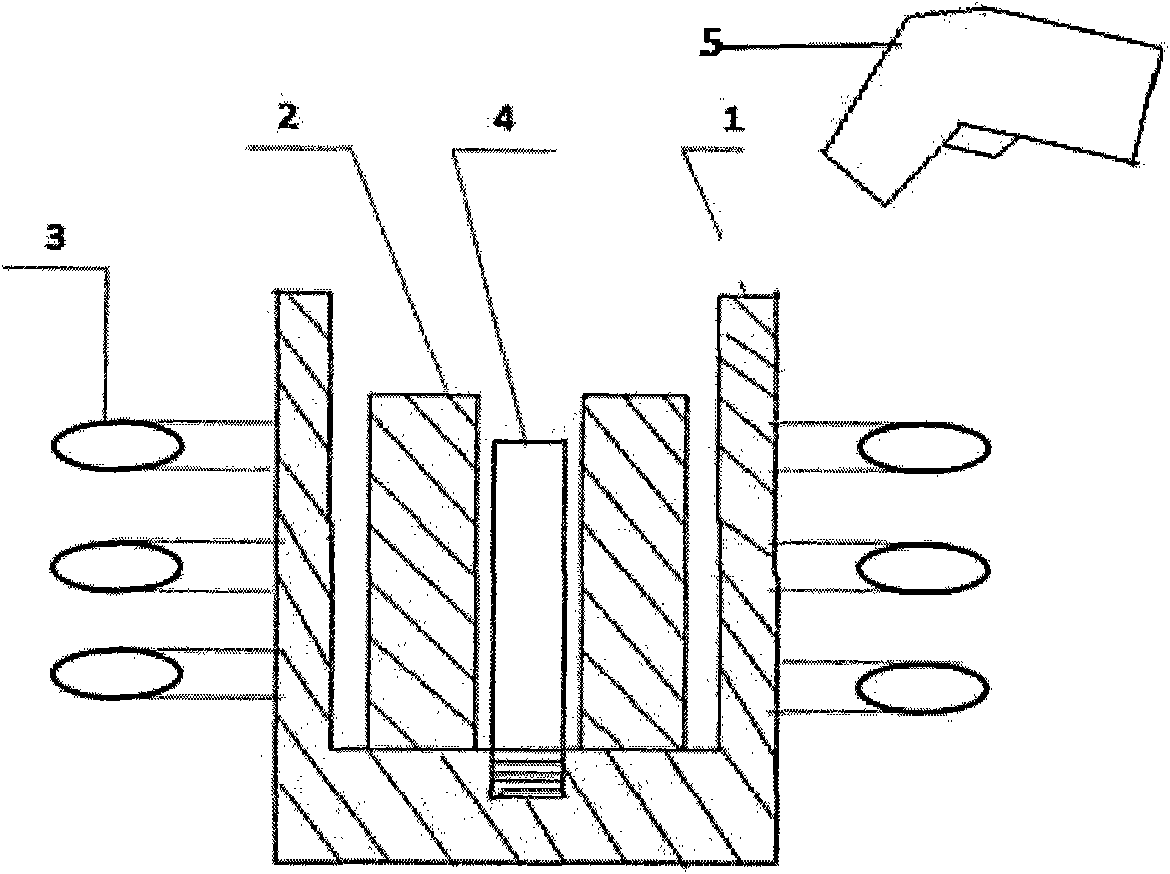

Ultrasonic-assisted low-temperature glass brazing method

ActiveCN105522244AGood wettabilityOvercoming illiquiditySoldering apparatusSolder pasteUltrasonic assisted

The invention relates to an ultrasonic-assisted low-temperature glass brazing method. The ultrasonic-assisted low-temperature glass brazing method aims at solving the problems that in the existing process of brazing through low-temperature glass, as the viscosity of fusion glass under low temperature is large and a welding line is narrow, wetting spreading is not sufficient, and air hole remaining exists. The brazing method includes the steps that (1) low-temperature sealing glass powder and a binding material are mixed to obtain low-temperature glass brazing soldering paste; (2) a to-be-soldered raw material is cut and molded; (3) a soldered piece is subject to ultrasonic washing and polishing; (4) the low-temperature glass brazing soldering paste is coated to pre-connecting positions of the soldered piece; (5) the pre-connecting positions of the soldered piece are attached to form a to-be-soldered piece; and (6) heating is carried out to fuse the low-temperature glass brazing soldering paste, secondary ultrasonic vibration is applied to the surface of the to-be-soldered piece, and furnace cooling is carried out after vibration is stopped. The low-temperature sealing glass used in the method is low in sealing temperature, effective wetting spreading on the surface of the welded piece is carried out under the ultrasonication, obtained brazing connectors are free of macroscopic defects such as cracks and air holes, the residual stress is small, the strength is high, and the gas tightness is good.

Owner:HARBIN INST OF TECH

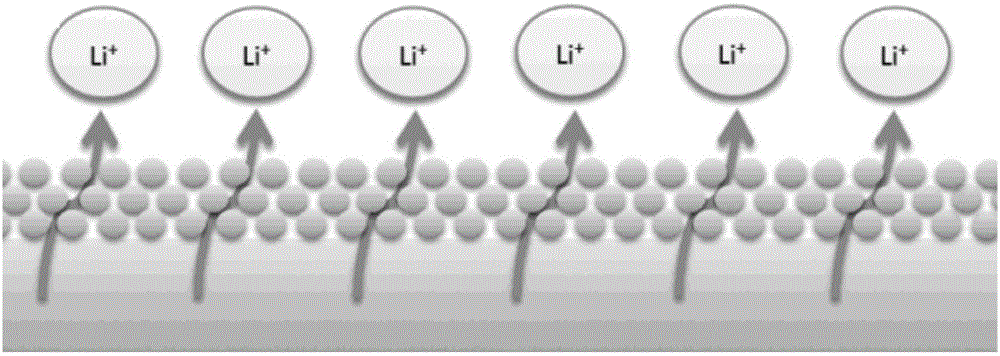

Composite separator membrane, preparation method thereof, and application thereof in lithium ion batteries

InactiveCN105990550AGood wettabilityImprove conductivitySecondary cellsCell component detailsCharge and dischargeLithium electrode

The invention provides a composite separator membrane which includes a separator membrane and a conductor material coating which is composited on the surface of the separator membrane. The conductor material coating includes a garnet conductor material. The conductor material coating on the surface of the separator membrane contains the garnet conductor material, so that during charging and discharging of a lithium ion battery, the separator membrane can supply a path for transmitting lithium ions, so that damage on the charging and discharging performance of the lithium ion battery is avoided due to existence of the path in the garnet conductor material even the surface of the separator membrane is coated with the coating and the porosity of the surface of the separator membrane is reduced, and meanwhile, a long cycle life is achieved. The invention also provides a preparation method of the composite separator membrane and an application thereof in the lithium ion batteries.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Degreasing agent for permanent magnet material

The invention relates to a degreasing agent for a permanent magnet material. The water-soluble degreasing agent comprises alkaline materials, a cleaning auxiliary agent and a surface active agent, wherein the alkaline materials are selected from at least two of sodium hydroxide, potassium hydroxide, sodium carbonate, sodium hydrogen carbonate, trisodium phosphate or sodium pyrophosphate; the cleaning auxiliary agent is selected from at least one of organic polybasic phosphonic cleaning auxiliary agents, or a mixture of at least one of the organic polybasic phosphonic cleaning auxiliary agents and at least one of inorganic phosphate cleaning auxiliary agents; and the surface active agent is a low-foam non-ionic surface active agent. According to the invention, the degreasing agent provided by the invention has good wettability, permeability and emulsibility, high degreasing speed, higher grease dirt capacity and long service life, and can prevent grease dirt from being adsorbed again; and meanwhile, by using the non-ionic surface active agent, the foam is little, the washing performance is superior, the water can be softened, and the corrosion of the permanent magnet material in the degreasing agent can be avoided.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

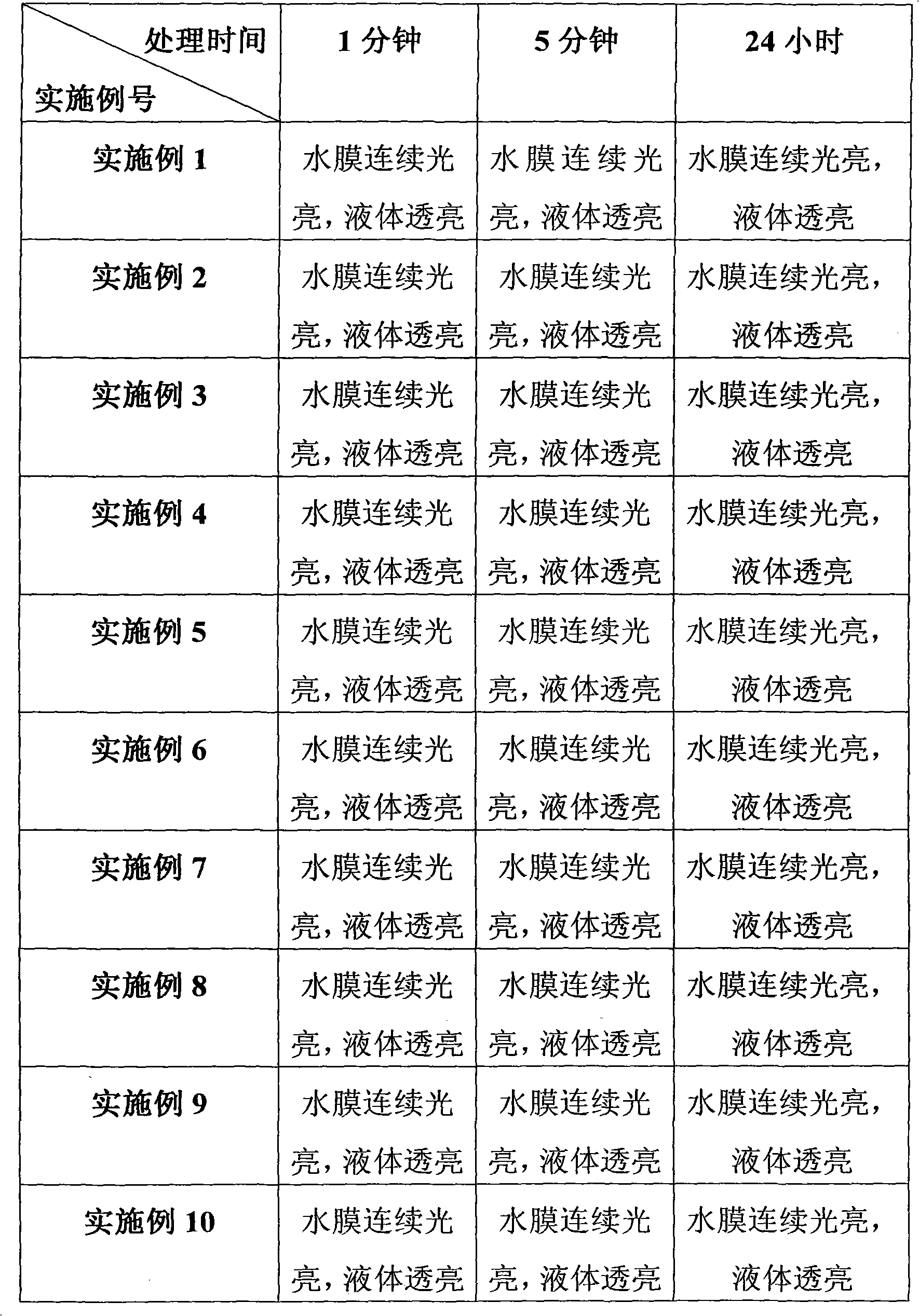

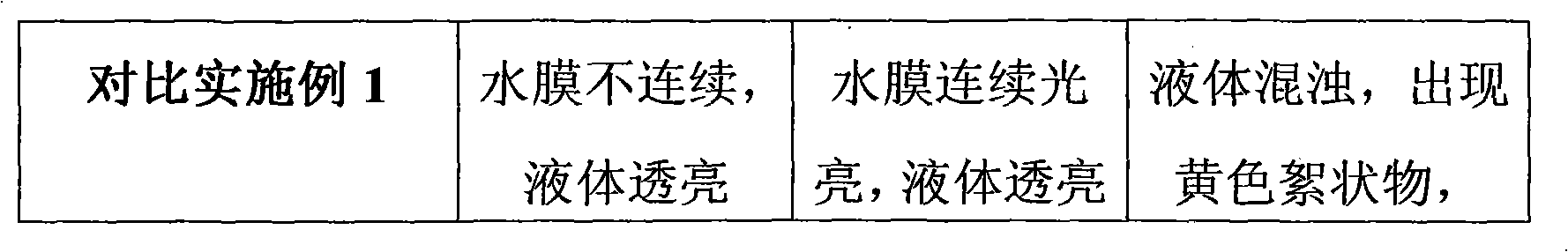

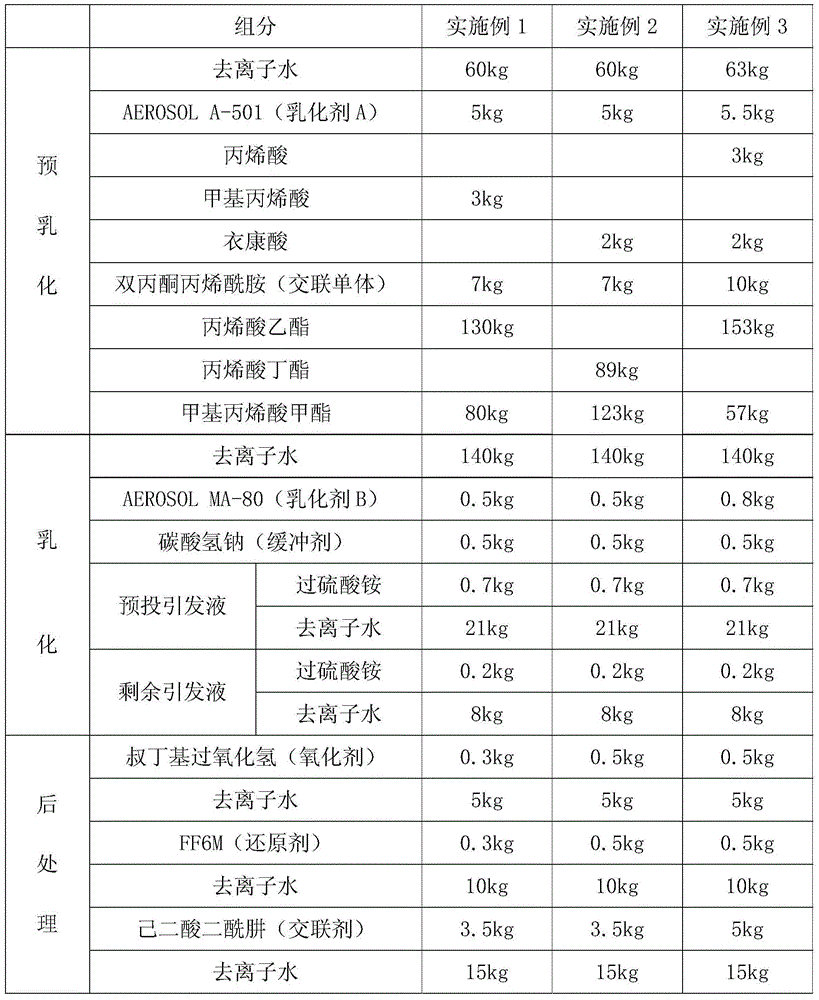

Self-crosslinking acrylate emulsion and preparation method thereof

ActiveCN103554349AImprove performanceIncrease surface areaEster polymer adhesivesFunctional monomerPotassium

The invention discloses self-crosslinking acrylate emulsion and a preparation method thereof. The self-crosslinking acrylate emulsion is prepared from (methyl) acrylate monomer, a functional monomer, a crosslinking monomer, a crosslinking agent, an emulsifying agent A, an emulsifying agent B, a buffering agent, an initiator, an oxidizer, a reducer and deionized water, wherein the reducer is an FF6M macromolecule polymerization novel reducer produced by a Bruegmann company in Germany, the emulsifying agent A is an emulsifying agent AEROSOL A-501 produced by a Cytel company in America, and the emulsifying agent B is an emulsifying agent AEROSOL MA-80 produced by the Cytel company in America; the preparation method of the self-crosslinking acrylate emulsion comprises pre-emulsification, emulsification and post treatment. A superfine glass fiber separating plate made by adopting the self-crosslinking acrylate emulsion is low in potassium hypermanganate reduzate content, high in liquid absorption speed, high in amount of absorbed liquid and excellent in performance.

Owner:CHANGZHOU TIANMA GROUP CO LTD

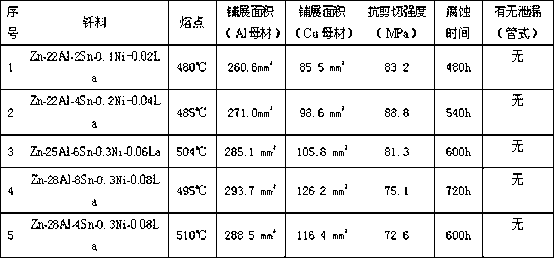

Zinc-based solder for aluminum/copper brazing and preparing method thereof

InactiveCN103317255AGood wettabilityIncreased shear strengthWelding/cutting media/materialsSoldering mediaCorrosionLanthanum

A zinc-based solder for aluminum / copper brazing and a preparing method thereof can be applied to furnace brazing and flame brazing of aluminum / copper dissimilar metals and belong to the field of solders. According to mass percent, the zinc-based solder contains 22-28% of aluminum, 1-8% of tin, 0.1-0.3% of nickel, 0.01-0.1% of raw earth lanthanum, and the balance zinc. The zinc-based solder is formed by simple substances of Zn, Al, Sn, Ni and intermediate alloy Al-La. The preparing method includes the following steps: 1 calculating and weighing raw materials; 2 smelting Zn-Al-Sn-Ni alloy; 3 adding the intermediate alloy Al-La; 4 performing heat preservation; 5 performing cooling and taking out the solder. The melting point of the zinc-based solder is 480-510 DEG C. When the zinc-based solder is used for brazing Al / Cu joints, the brazing manufacturability is good and the joints are good in corrosion resistance and high in strength.

Owner:UNIV OF SCI & TECH BEIJING +1

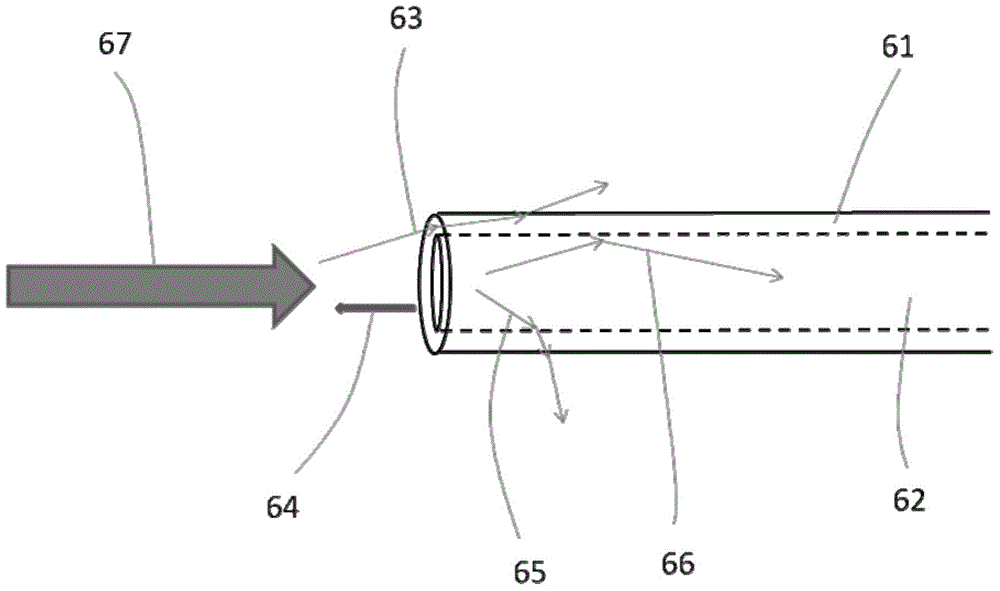

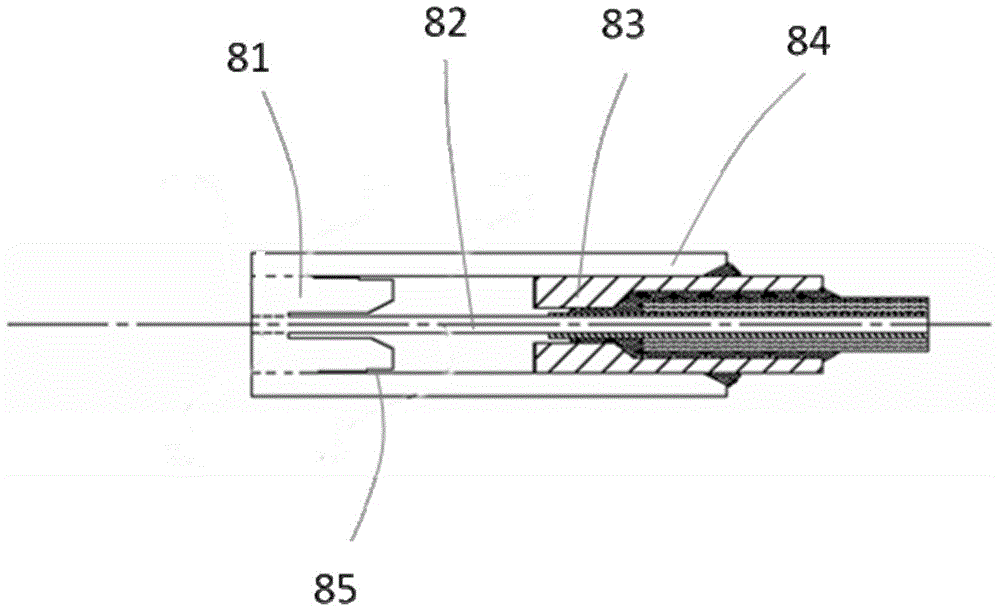

Optical fiber connector

ActiveCN103823277AGood wettabilityGood thermal conductivityCoupling light guidesOptical fiber connectorThermal conductivity

Disclosed in the invention is an optical fiber connector comprising a connector body and a segment of bare fiber penetrating the connector body. The connector body includes a metal sleeve, a first fiber fixed component fixed at one end of the metal sleeve, and a second fiber fixed component fixed at the other end of the metal sleeve. The bare fiber includes a first bare fiber passing through the first fiber fixed component and a second bare fiber passing through the second fiber fixed component. Because the metal sleeve and metal solder have good invasion, welding fixation of the optical fiber connector and a laser protection shell can be realized beneficially. Moreover, due to the good thermal conductivity of the metal, the heat can be transmitted to the air through the metal sleeve or be transmitted to the metal solder through the metal sleeve and then to the laser protection shell for dissipation, so that heat dissipation can be carried out beneficially.

Owner:天津凯普林光电科技有限公司

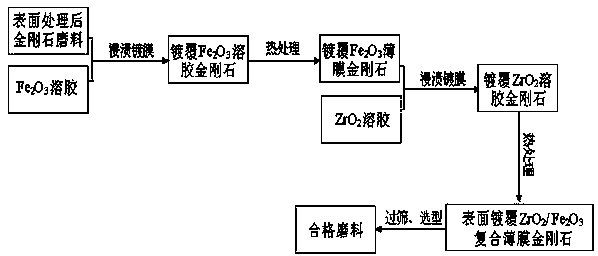

Technology for coating ZrO2/Fe2O3 composite film on surface of diamond by sol-gel method

InactiveCN103468212AGood chemical inertnessGood wettabilityOther chemical processesSurface finishingSol-gel

The invention discloses a technology for coating a ZrO2 / Fe2O3 composite film on the surface of diamond by a sol-gel method. The technology comprises the following steps of preparing stable Fe2O3 sol by FeCl3 hydrolysis, dipping a diamond abrasive subjected to surface treatment into the Fe2O3 sol, carrying out drying and calcination on the diamond abrasive to obtain a diamond abrasive of which the surface is uniformly coated with a Fe2O3 film, preparing stable ZrO2 sol by ZrOCl2 hydrolysis, dipping the diamond abrasive of which the surface is uniformly coated with the Fe2O3 film into the ZrO2 sol, and carrying out drying and calcination on the diamond abrasive to obtain the diamond abrasive coated with the ZrO2 / Fe2O3 composite film. The ZrO2 / Fe2O3 composite film can prevent the diamond abrasive from a harmful chemical reaction with a ceramic binder in sintering, improve wettability of the diamond abrasive and the ceramic binder, improve the diamond abrasive holding capacity of the ceramic binder, and prolong a service life of a diamond ceramic grinding tool.

Owner:HUNAN UNIV

Method for induction heating fusion-cast welding of copper-tungsten mold

The invention discloses a method for induction heating fusion-cast welding of a copper-tungsten mold, which comprises the following steps: cleaning and assembling a tungsten rod, a copper ring and a graphite mold, wherein the tungsten rod is fixed on the graphite mold, and the copper ring is sheathed between the tungsten rod and the graphite mold; filling protective agents in gaps and tops of the copper ring, the tungsten rod and the formed graphite mold; sheathing a cylindrical substrate induction ring outside the graphite mold to lead the height of the position to be the same as that of copper materials, then conducting graded heating to the graphite mold by utilizing the induction ring, stopping heating after the copper ring is molten, and leading the copper and the tungsten rod to generate alloy combination to complete fusion-cast welding through directional solidification. The method is simple in process, has 100 percent of welding rate, has no defects of slag inclusion, non-welding and the like on the surfaces, is zero in fusion depth, and has no dilution rate problem, and the compositions and performances of the fusion-cast layer are not influenced by substrate metal, the bonding performance is stable and the quality is excellent.

Owner:NANJING UNIV OF SCI & TECH

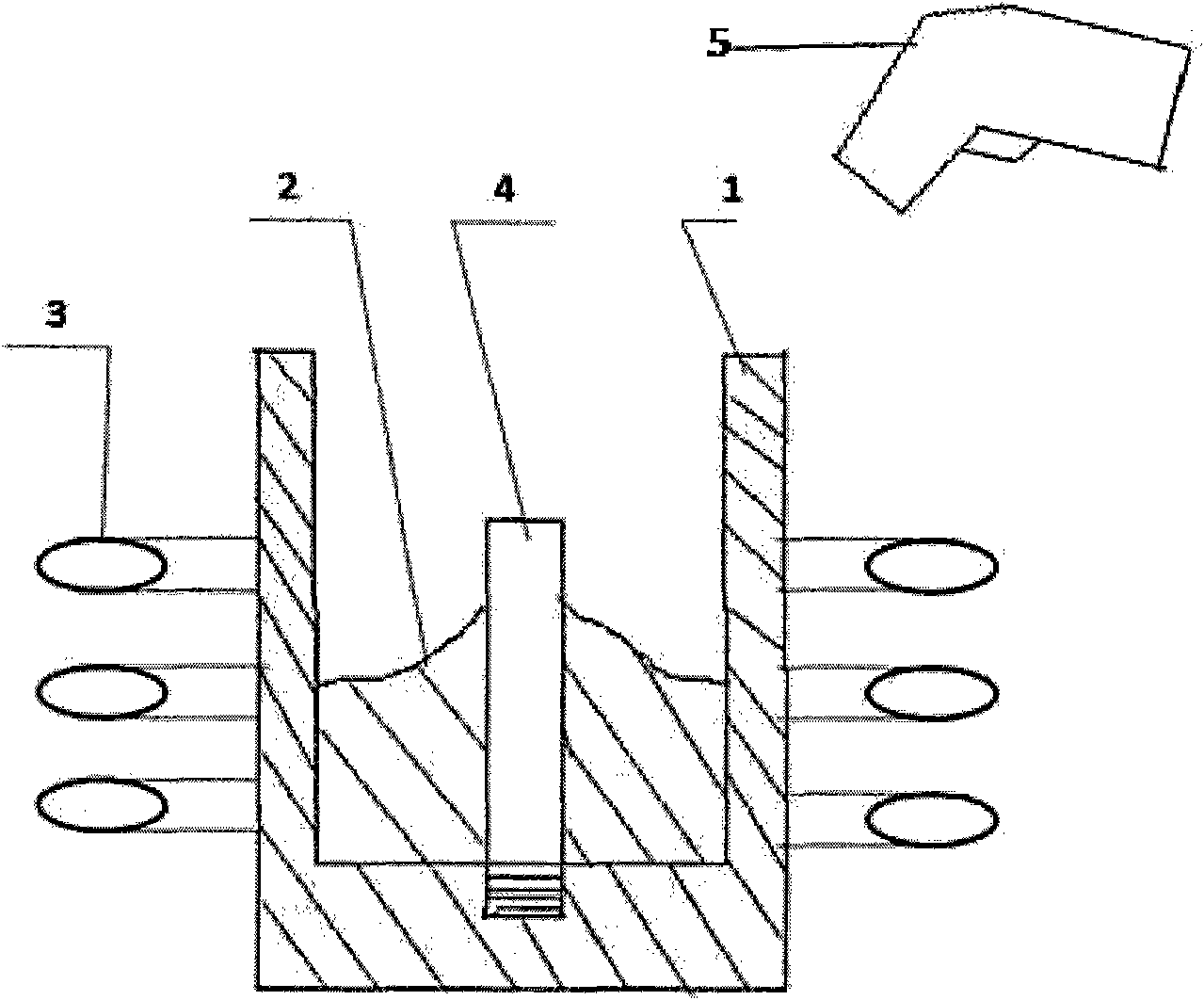

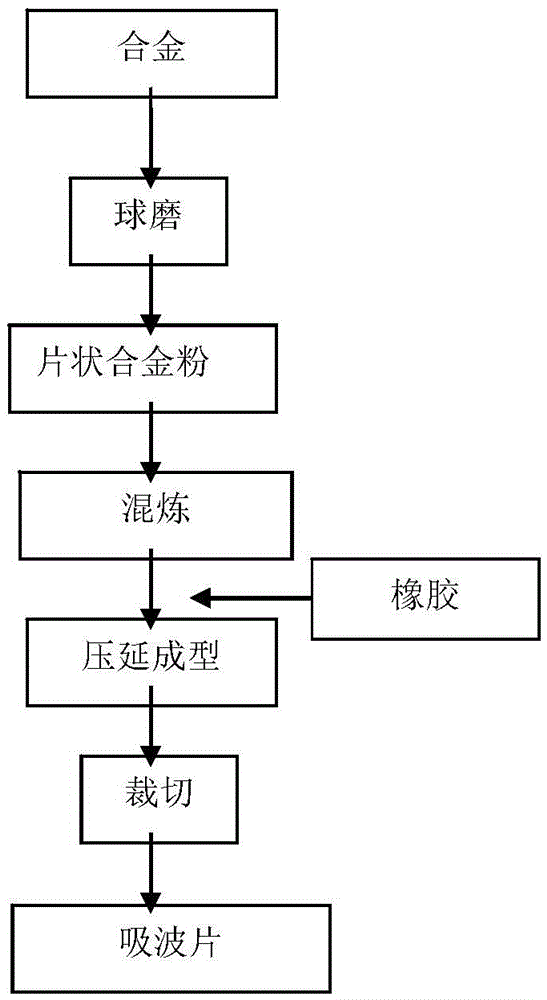

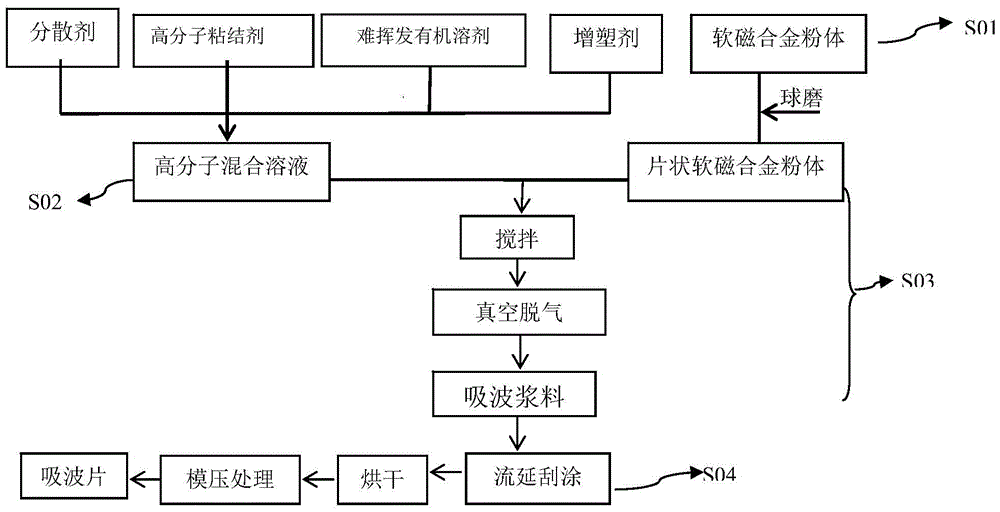

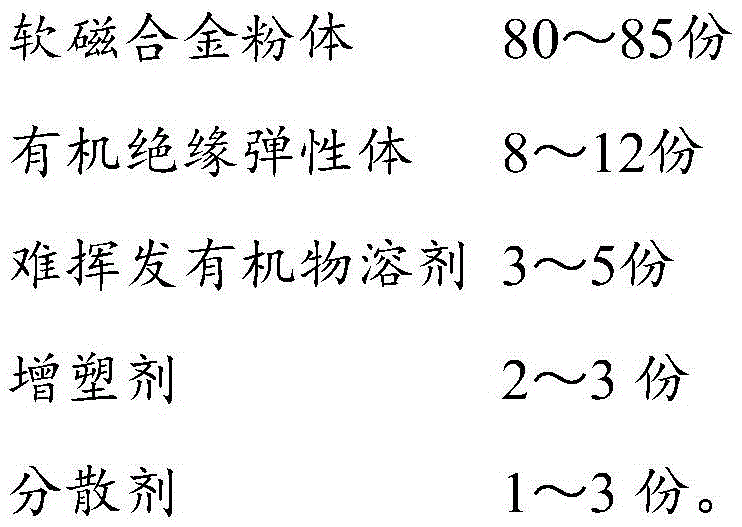

High-magnetic-conductivity wave-absorbing sheet and tape-casting slurry and preparation method therefor

The invention relates to a high-magnetic-conductivity wave-absorbing sheet and tape-casting slurry and a preparation method therefor. The tape-casting slurry for the high-magnetic-conductivity wave-absorbing sheet comprises the following ingredients in parts by weight: 80-85 parts of soft magnetic alloy powder, 8-12 parts of organic insulating elastic body, 3-5 parts of nonvolatile organic solvent, 2-3 parts of plasticizer and 1-3 parts of dispersing agent. The high-magnetic-conductivity wave-absorbing sheet is molded from the tape-casting slurry through a tape-casting process. The tape-casting slurry for the high-magnetic-conductivity wave-absorbing sheet has high wettability for the soft magnetic alloy powder; the prepared wave-absorbing sheet has high magnetic-conductivity, high resistivity and high flexibility; in addition, the preparation method is easy to control; and the prepared wave-absorbing sheet is high in yield and stable in performance.

Owner:SHENZHEN PENGHUI FUNCTIONAL MATERIAL CO LTD

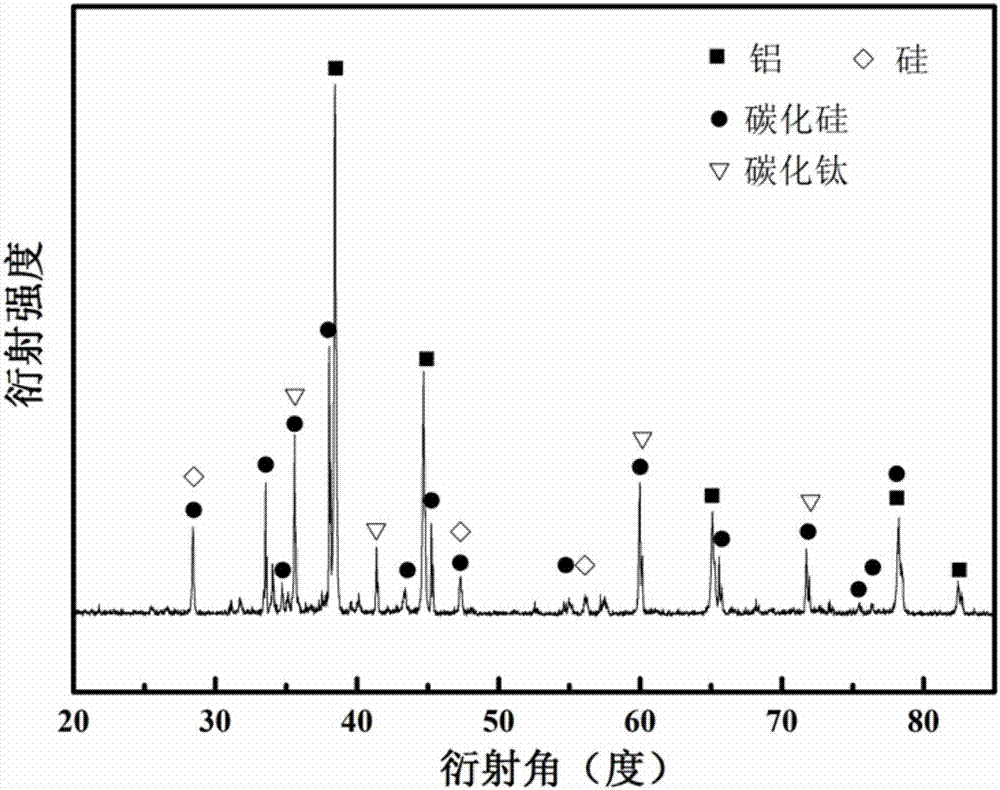

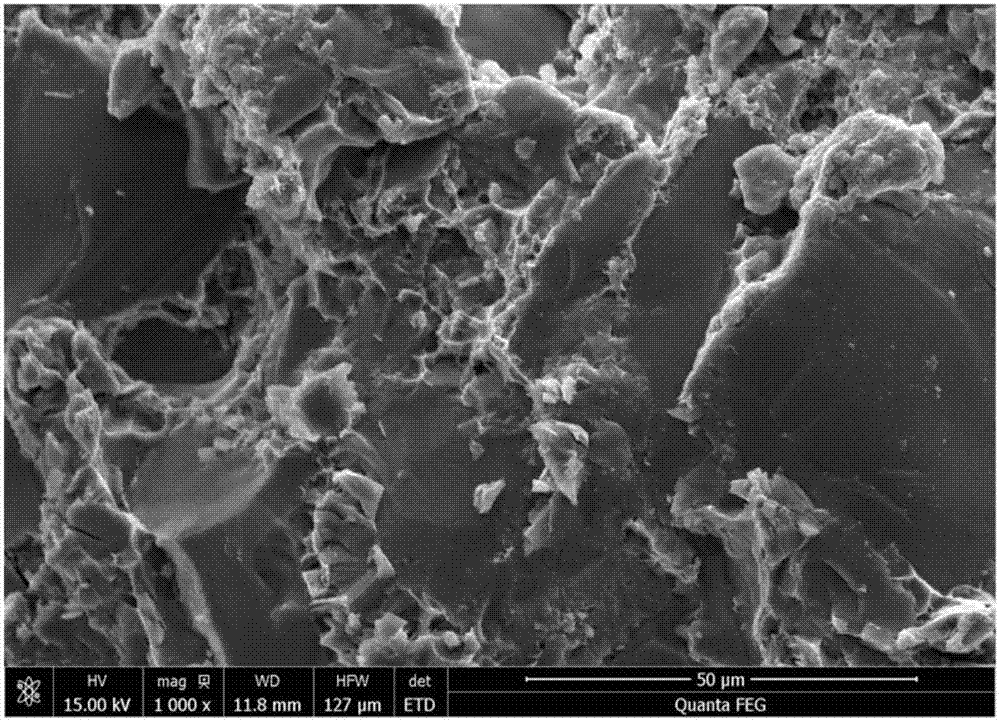

Preparation method for high-volume-fraction SiC reinforced Al-base composite material

ActiveCN106917009AGood wettabilityImprove interface bonding performanceInterfacial reactionPowder metallurgy

The invention discloses a preparation method for a high-volume-fraction SiC reinforced Al-base composite material. The preparation method comprises the steps of SiC powder oxidation treatment, TiO2 sol preparation, SiC powder surface coating, high-temperature calcination under a reducing atmosphere, mixing, forming, Ar atmosphere protection sintering and cooling. The preparation process is simple, the interface bonding between SiC particles and molten metal Al is effectively improved, an adverse interfacial reaction is avoided, the defect that the density is not high as a powder metallurgy method is adopted traditionally is overcome, and the finally prepared SiC particle reinforced Al-base composite material is excellent in performance, for example, the flexure strength ranges from 181.7 Mpa to 203.5 Mpa, the density ratio ranges from 91.0 % to 95.3 %, and the volume fraction is 56.5 %.

Owner:WUHAN UNIV OF TECH

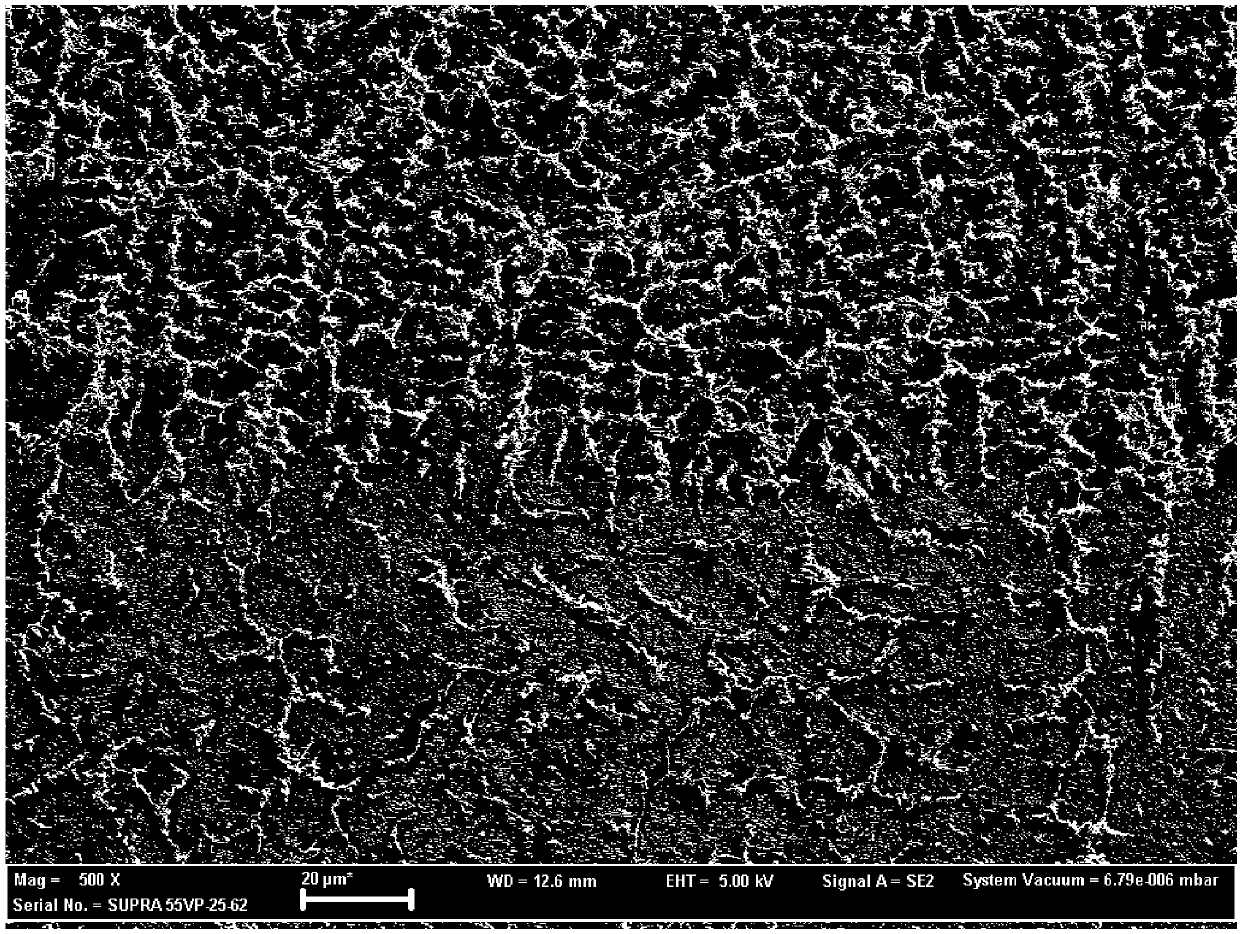

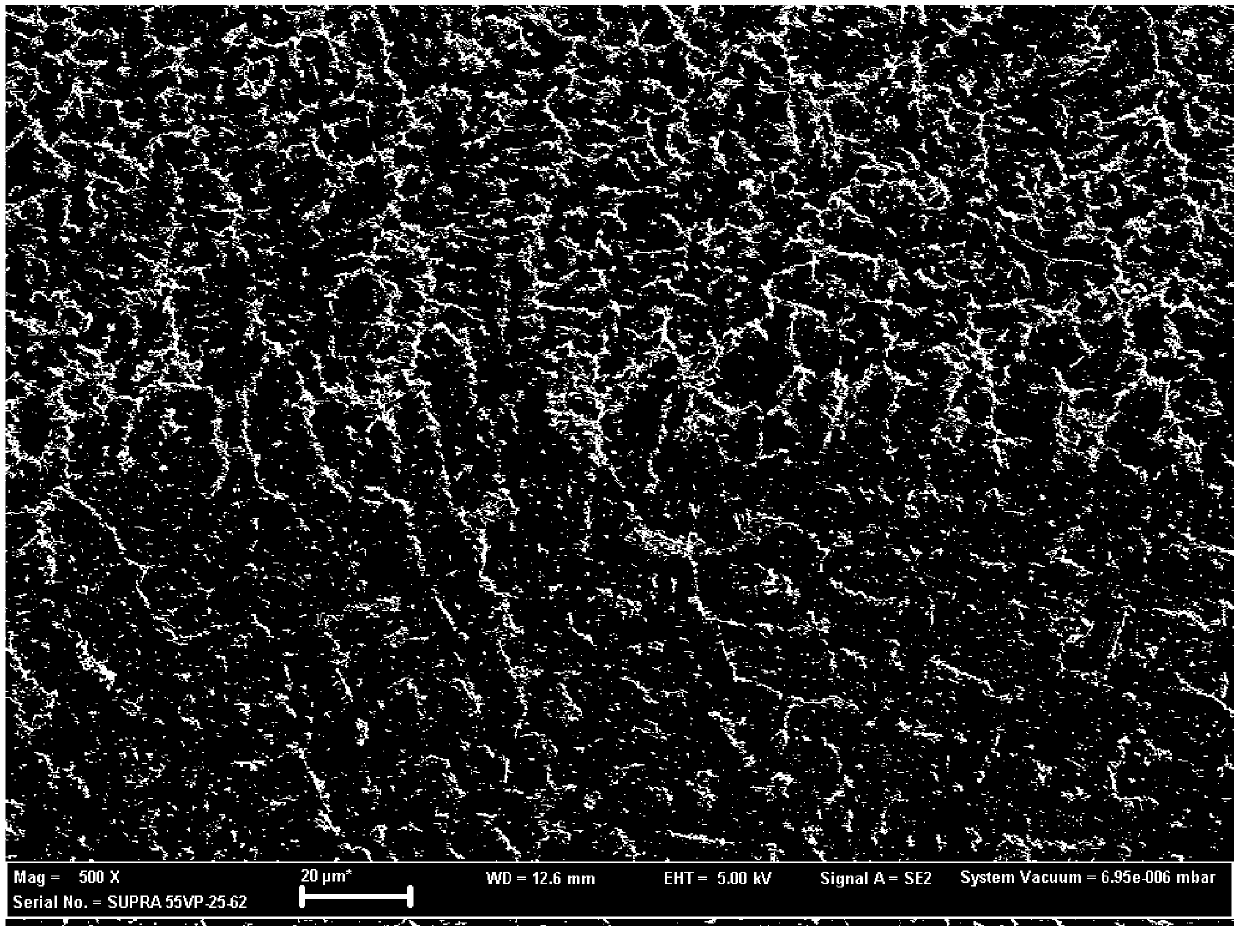

Preparation method of TC4 titanium alloy laser cladding reinforced coating

InactiveCN107723703AGood wear and corrosion resistanceGood wettabilityMetallic material coating processesLoad resistanceCorrosion

The invention provides a preparation method of a TC4 titanium alloy laser cladding reinforced coating. The preparation method comprises the steps that pretreatment is conducted on a base body; titanium carbide powder and TC4 titanium alloy powder are tiled on the surface of the base body; mixed alloy powder is clad on the surface of the base body by utilizing a high-power semiconductor laser, andthe like. The preparation method has the advantages that the alloy powder for laser cladding has both high hardness and the excellent abrasion resistance and the corrosion resistance; compared with other alloy powder, the TC4 titanium alloy powder has the good wettability, the corrosion resistance and the high-temperature self-lubricating effect, ingredients of the TC4 titanium alloy powder do notcontain chromium, and pollution to the environment in an experiment or production does not occur; titanium carbide not only is good in toughness, high in hardness and high in impact load resistance and abrasive particle abrasion ability, but also has good resistance to interfacial corrosion abrasion after being combined with base metal; and no cracks and pores exist in the combined area part of the laser cladding layer and the base body, and through experimental test, the strength of the laser cladding layer is high.

Owner:TIANJIN POLYTECHNIC UNIV

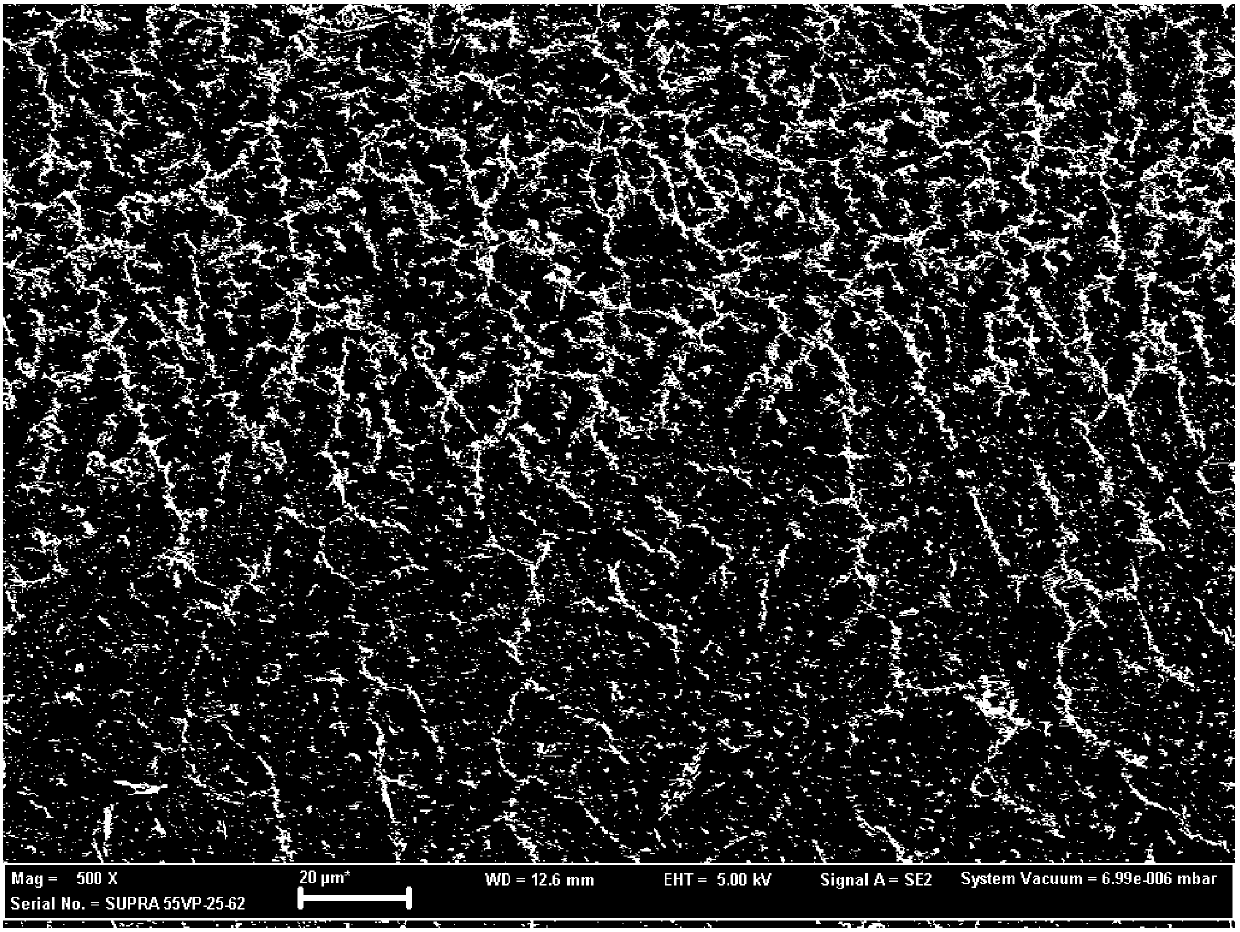

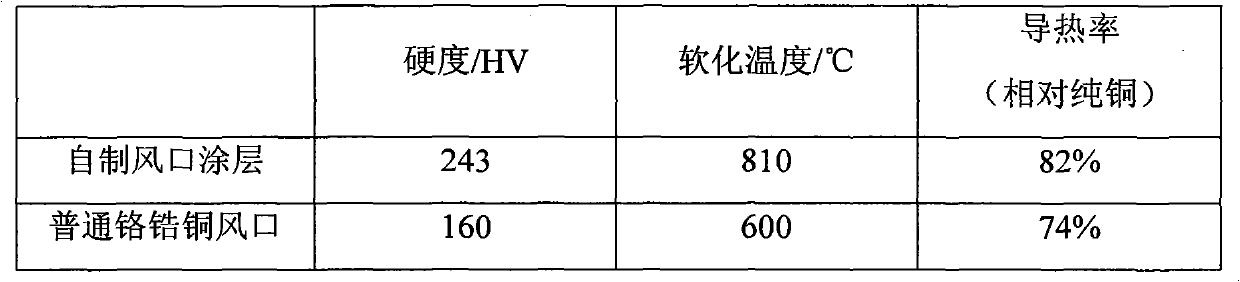

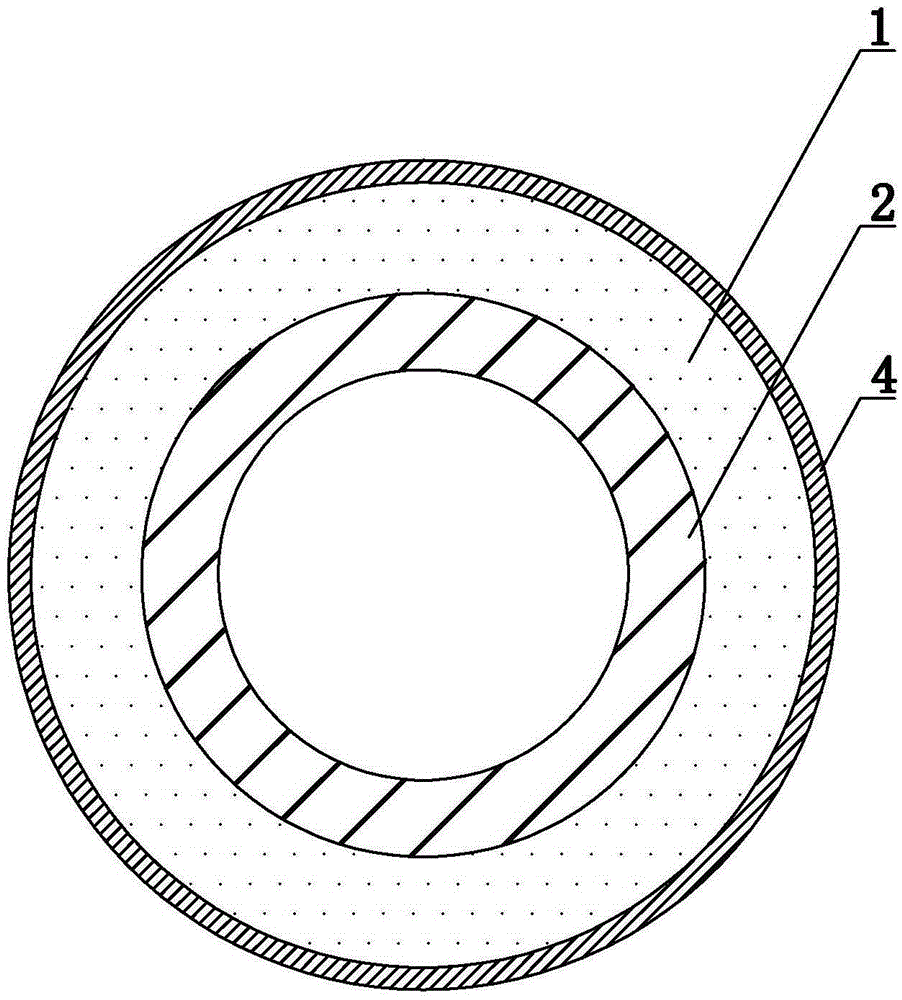

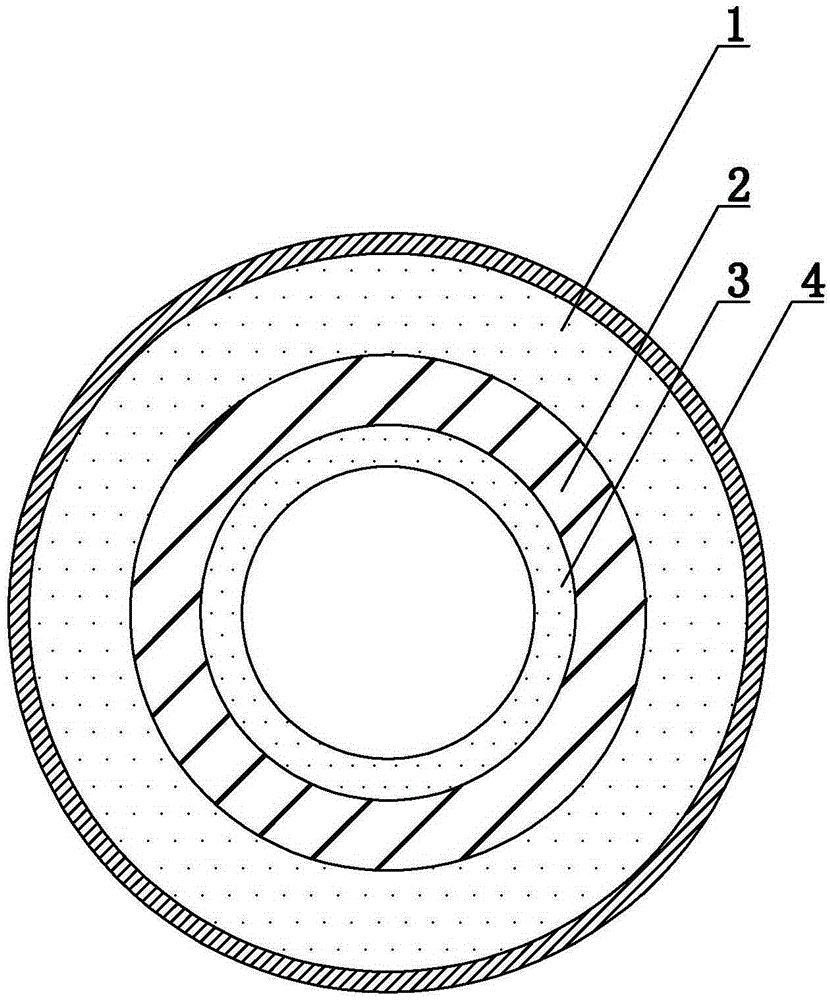

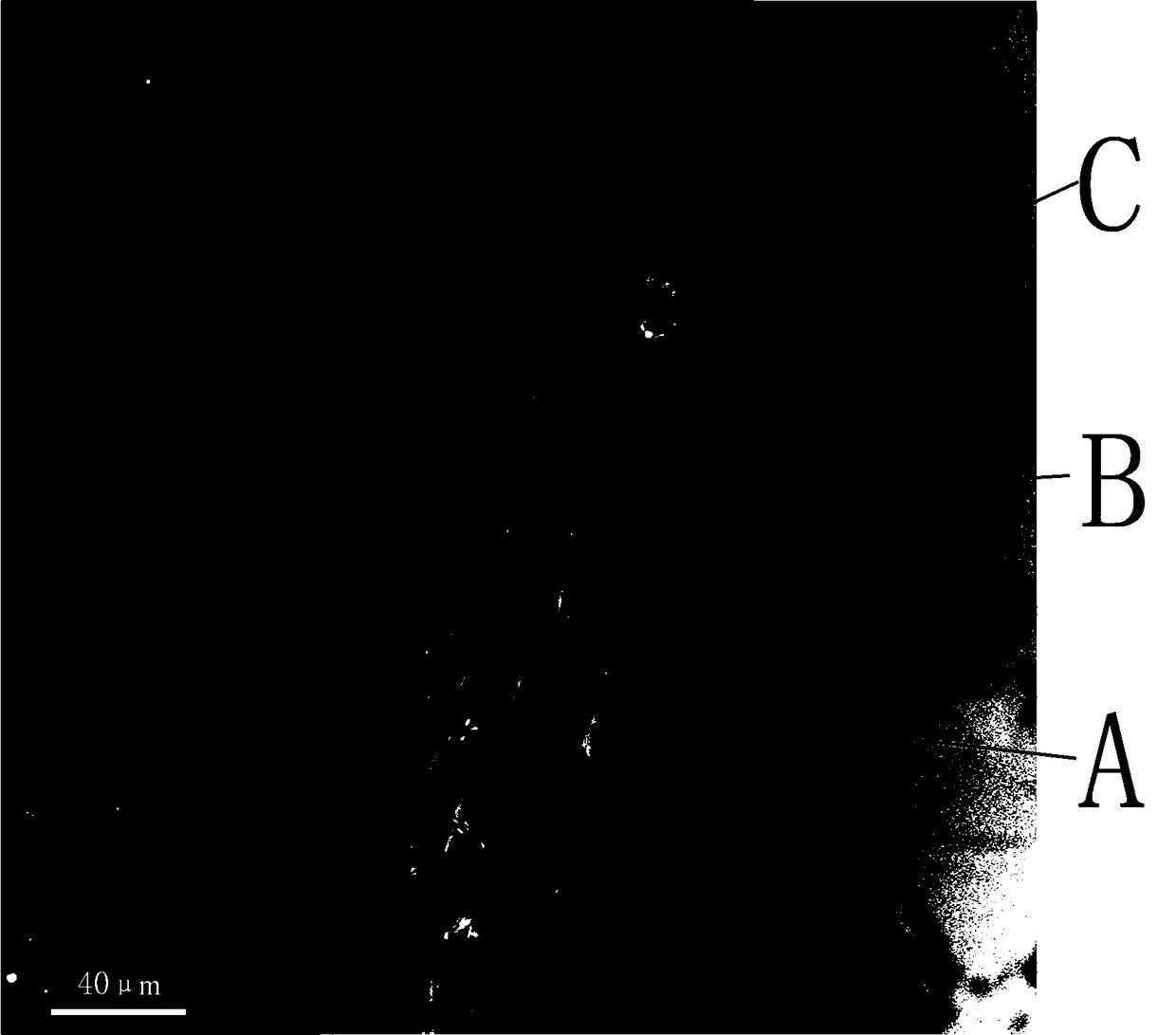

Wear-resistant anti-corrosion electric arc spraying cored wire for protecting surface of copper matrix

ActiveCN102560318AGood wettabilityHigh bonding strengthMolten spray coatingElectric arcCopper matrix

The invention relates to a wear-resistant anti-corrosion electric arc spraying cored wire for protecting the surface of a copper matrix and a preparation method and mainly solves the technical problems that in the existing spraying method for prolonging the service life of a tuyere small sleeve, the combination strength is low, a coating is easy to fall off, the mechanical impact resistance is poor and in the using process of the tuyere small sleeve, the heat conduction capacity of a tuyere is gradually reduced, the temperature of the tuyere wall is gradually risen and the melting loss is easy to generate. The invention adopts the technical scheme that the wear-resistant anti-corrosion electric arc spraying cored wire for protecting the surface of the copper matrix is characterized in that a sheath of the cored wire is a copper aluminium alloy belt, wherein the content of aluminium is 2 to 4 percent of mass of the alloy belt; and powder of the cored wire comprises the following ingredients in percentage by mass: 1 to 2 percent of metal chromium, 0.5 to 2 percent of metal zirconium, 0.1 to 1 percent of metal silver and the balance metal copper. The wear-resistant anti-corrosion electric arc spraying cored wire for protecting the surface of the copper matrix is mainly used for the erosion wear resistance of the surface of the tuyere small sleeve of a blast furnace and is low in cost.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Hydrophilic type super-lubricity urinary catheter and preparation method thereof

The invention relates to a hydrophilic type super-lubricity urinary catheter and a preparation method thereof, and belongs to the technical field of medical product processing. The hydrophilic type super-lubricity urinary catheter consists of a hydrophilic type super-lubricity coating, a polyurethane polymer outer layer and a pipe main body layer, wherein the hydrophilic type super-lubricity coating is arranged on the polyurethane polymer outer layer; the pipe main body layer is positioned at the inner side of the polyurethane polymer outer layer, and is integrally formed with the polyurethane polymer outer layer; and the hydrophilic type super-lubricity coating, the polyurethane polymer outer layer and the pipe main body layer form a concentric layer structure. The hydrophilic type super-lubricity urinary catheter provided by the invention is applied to clinical infusion and has the advantages of being integrally formed, strong in adhesive force, good in wetting property, good in water retention property, low in friction coefficient, high in mechanical strength, excellent in safety and the like.

Owner:SHAOXING XINYUANLI TECH CO LTD

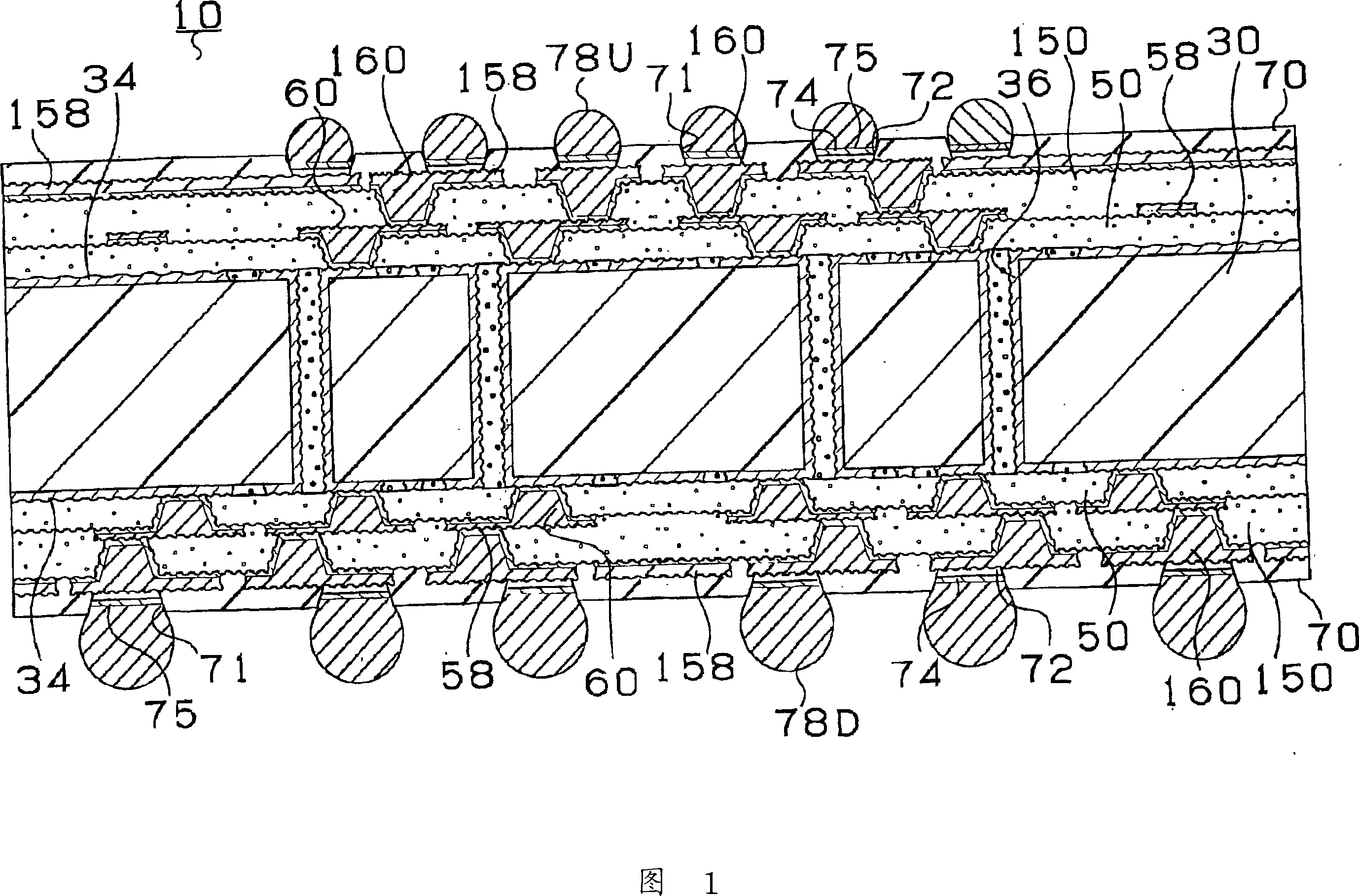

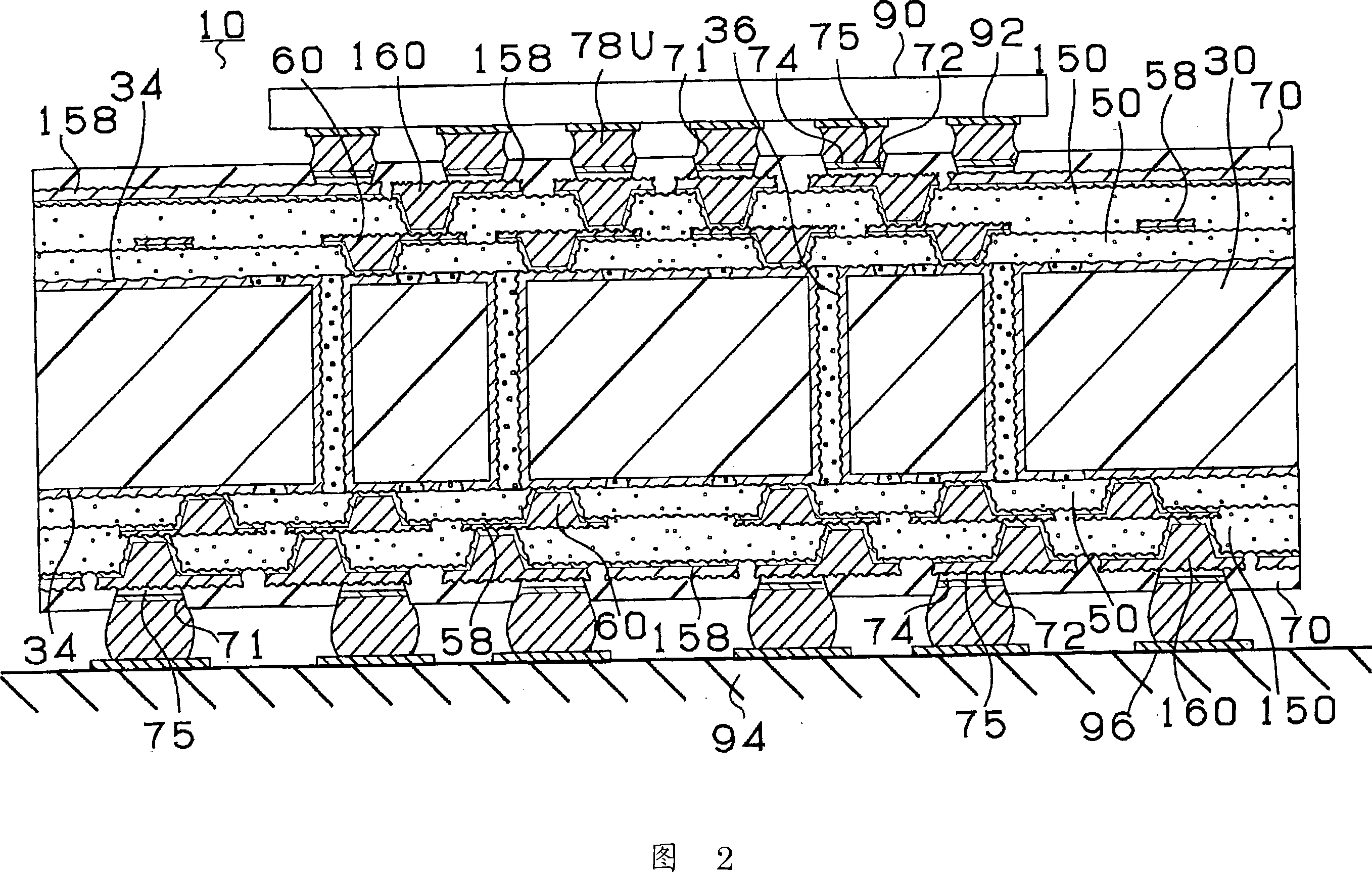

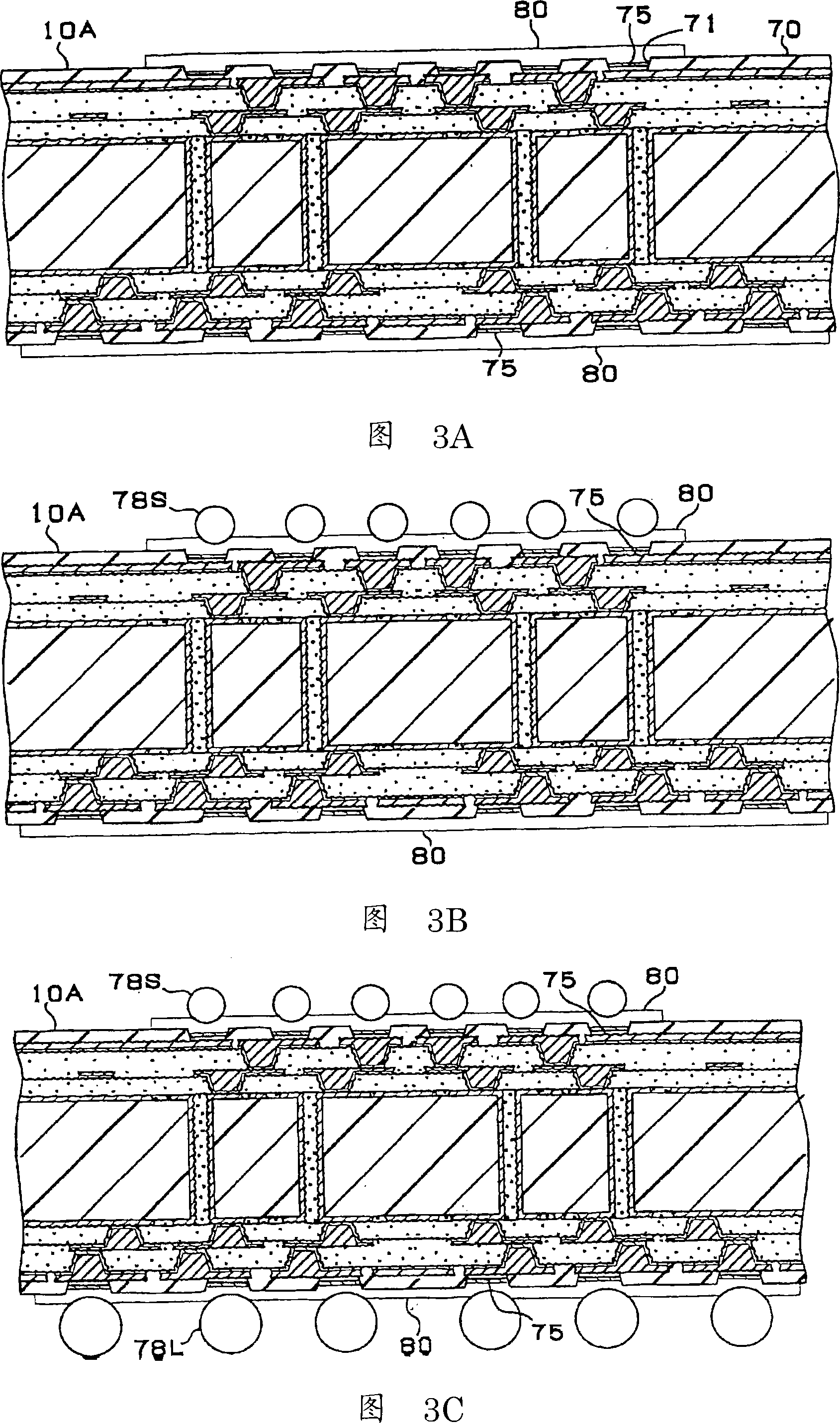

Printed wiring board

ActiveCN101171895APrevent peelingSmall insulation resistancePrinted circuit assemblingSemiconductor/solid-state device detailsResistElectrical conductor

A printed wiring board comprises a wiring substrate provided with at least one conductor circuit, a solder resist layer provided on the surface of the wiring substrate, at least one conductor pad formed from a part of the conductor circuit exposed from an opening provided in the solder resist layer, and at least one solder bump for mounting electronic parts on the conductor pad. In the printed wiring board, since the at least one conductor pad is aligned at a pitch of 200 µm or less, and a ratio (W / D) of a diameter W of the solder bump to an opening diameter D of the opening formed in the solder resist layer is within a range of 1.05 to 1.7, connection reliability and insulation reliability can be easily improved.

Owner:IBIDEN CO LTD

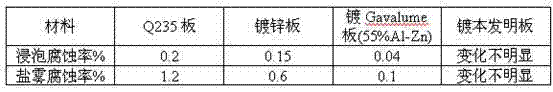

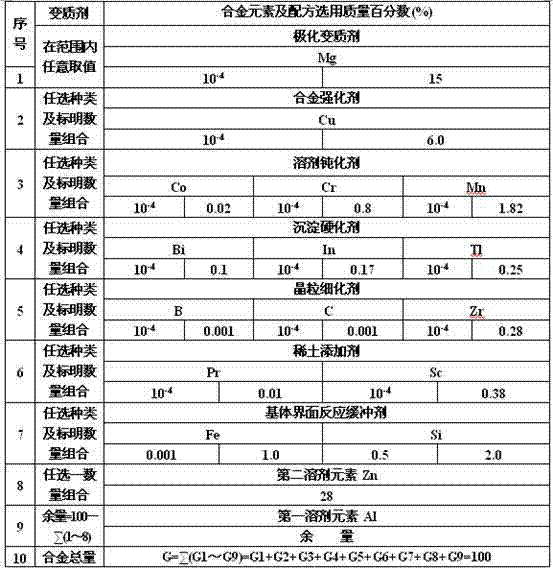

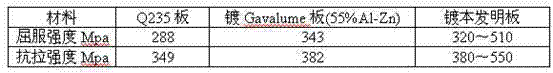

Mg-contained multi-combination modified low-zinc hot-dipping aluminium-plated alloy plating material and preparation method thereof

InactiveCN102650025AGood wettabilityStrong combinationHot-dipping/immersion processesAluminium industryWetting

The invention discloses a Mg-contained multi-combination modified low-zinc hot-dipping aluminium-plated alloy plating material and a preparation method thereof. The low-zinc hot-dipping aluminium-plated alloy plating material comprises the following elements by weight percent: Zn 28, Mg 10<-4> to 15, alloy reinforcer 10<-4> to 6.0, solvent passivator 10<-4> to 1.0, precipitation hardener 10<-4> to 0.5, grain refiner 10<-4> to 1.0, rare earth additive 10<-4> to 1.0, matrix interface reaction buffer 0.001 to 2.0, and Al and inevitable trace impurities in balancing amount. The low-zinc hot-dipping aluminium-plated alloy plating material enables a plating liquor and a plating to have good wetting properties and strong adhesive force to a matrix, has a favorable prospect to replace hot dipping and zinc alloys, can enhance the balanced development between the iron steel industry, and the aluminium industry and the zinc industry, and realizes a breakthrough development on low-cost industrialized application of novel plating materials.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

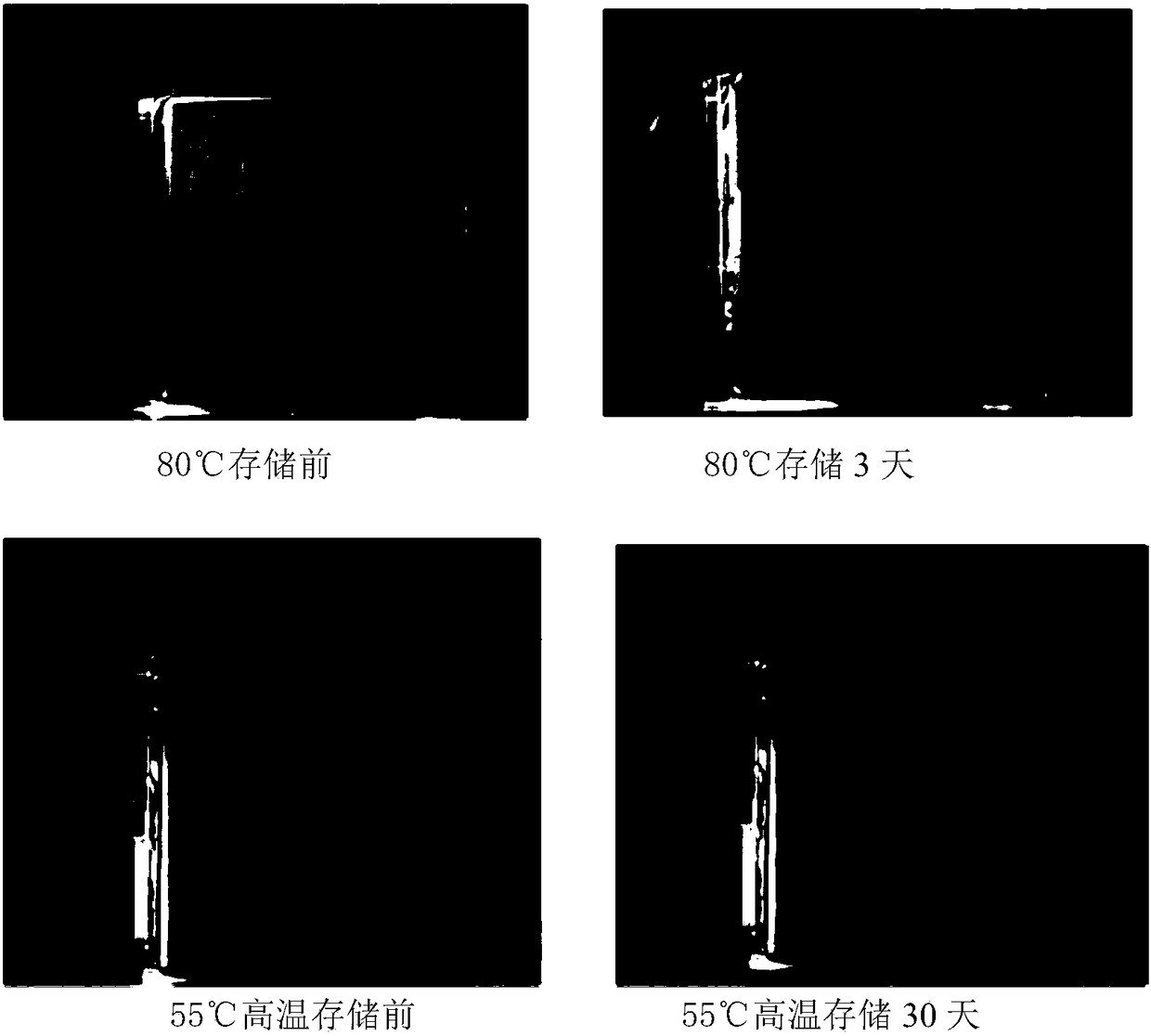

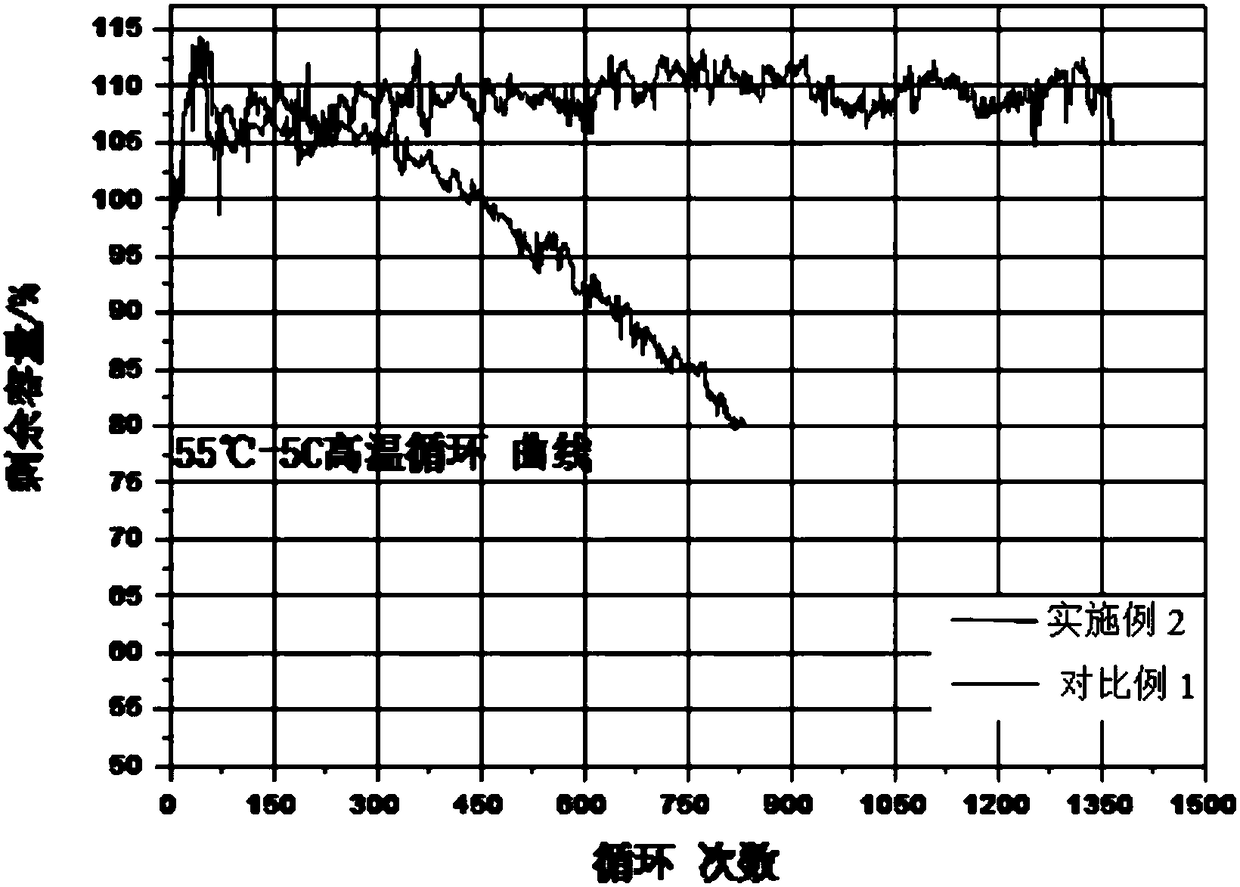

High temperature resistant lithium titanate battery and formation and aging method thereof

ActiveCN108172894AGood wettabilityGood spatial stability and leveling performanceFinal product manufactureElectrolyte accumulators manufactureSolventLithium electrode

The invention relates to the technical field of lithium ion batteries, in particular to a high temperature resistant lithium titanate battery and a formation and aging method thereof. The lithium titanate battery comprises a positive plate, a negative plate, a diaphragm, an electrolyte and an outer packaging film, wherein an active substance on the positive plate is a ternary material or a mixed material of the ternary material and a lithium salt; an active substance on the negative plate is lithium titanate; the diaphragm is a PE diaphragm; the electrolyte solvent is organic carbonic ester; and LiPF6 is contained inside the electrolyte. By adopting a special material system and the formation and aging technology, the gas production problem of the lithium titanate battery is effectively solved, the high-temperature storage capacity of the lithium titanate battery is improved, and the recycling service life of the lithium titanate battery is prolonged.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

In-situ synthesized metal coating silver brazing rod and preparation method thereof

ActiveCN108406162AGood wettabilityGood liquidityWelding/cutting media/materialsSoldering mediaFiller metalPolystyrene

The invention relates to an in-situ synthesized metal coating silver brazing rod and a preparation method thereof. The in-situ synthesized metal coating silver brazing rod is composed of a strip-shaped silver brazing filler metal core and a coating coated on the outer part of the silver brazing filler metal core, wherein the silver brazing filler metal core consists of the following components inpercentage by weight: 10-50% of Ag, 15-45% of Cu, 17-40% of Zn, 1-3% of Sn, 0.1-0.5% of P, 0.5-2% of Ni, 0.1-0.3% of Si and 0.1-0.3% of Li; and the coating consists of the following components in percentage by weight: 5-10% of elemental boron micro powder, 5-10% of sodium borohydride, 15-30% of potassium fluoborate, 25-40% of boric anhydride, 10-30% of sodium fluoride, 2-4% of potassium bifluoride, 1-5% of copper sulfate, 0.1-2% of polystyrene and 0.2-2% of dibutyl phthalate. The brazing filler metal core of the coating sliver brazing rod is good in wettability, is good in liquidity, has self-brazing effect, and enables zinc to be not liable to volatilize; and moreover, the coating has the advantages of being high in activity, weak in moisture absorption, less in carbon residues, good in plasticity and toughness, and the like, and is especially suitable for assemblies such as brazing stainless steel and manganese brass.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Aluminum alloy matrix composite material, preparation method and application

InactiveCN105970147AGood wettabilityHigh bonding strengthMolten spray coatingBonding strengthElectrical conductor

The invention discloses an aluminum alloy matrix composite material, a preparation method and application. The aluminum alloy matrix composite material comprises an aluminum alloy matrix; the surface of the aluminum alloy matrix is sequentially coated with a bonding layer and a functional layer from inside to outside; the bonding layer is an aluminum nickel alloy layer made from aluminum-coated nickel composite powder; and the functional layer is a copper coating. According to the aluminum alloy matrix composite material, the surface of the aluminum alloy matrix is sequentially coated with the bonding layer and the functional layer from inside to outside, modification of the surface of the aluminum alloy matrix is achieved, the bonding layer is made from the aluminum-coated nickel composite powder, has good wettability and can be well bonded with the aluminum alloy matrix and the copper coating, the bonding strength between the copper coating and the aluminum alloy matrix is greatly improved, and good bonding performance of the copper coating and the aluminum alloy matrix is guaranteed; and the functional layer is the elementary copper coating, the using performance of the material is guaranteed, the conductivity of the material is improved, and the aluminum alloy matrix composite material is applicable to conducting of high-current conductor parts.

Owner:PINGGAO GRP +1

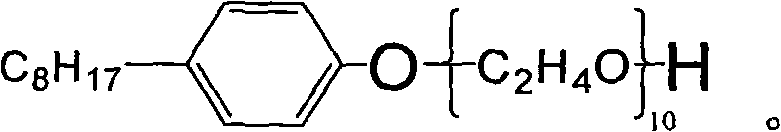

Crude oil demulsifier

InactiveCN104479732AGood surface properties and penetrating abilityGood wettabilityDewatering/demulsification with chemical meansSurface-active agentsEther

The invention provides a crude oil demulsifier which is characterized by comprising the following components by weight, 30-40% of a polyoxyethylene ether dry agent, 5-15% of a wetting agent, 5-10% of lauryl sodium sulfate, 4-10% of ammonium chloride, 6-12% of polyether modified trisiloxane and 20-30% of methanol. The polyoxyethylene ether dry agent is polysiloxane-polyoxyethylene polyoxypropylene dodecanol ether and propanediol poly-oxypropylene polyoxyethylene ether. The polyoxyethylene ether crude oil demulsifier has good surface properties, permeability and excellent wettability, can be quickly dispersed in crude oil to replace and neutralize an emulsifier originally on oil-water interface to form an unstable adsorption film for change of wettability of particles, so that water molecules connected by a surface active agent can rapidly agglomerate, the polyoxyethylene ether crude oil demulsifier has has good demulsification performance on crude oil emulsion, and can save time, manpower and material resources.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

Dipping liquid used for dipping glass fiber twistless roving at external layer of steel rail polishing grinding wheel, and its preparation method

The invention discloses a dipping liquid used for dipping a glass fiber twistless roving at the external layer of a steel rail polishing grinding wheel, and its preparation method. The dipping liquid has a very high bonding ability and has a high wettability to the glass fiber twistless roving, so the glass fiber twistless roving enables a winding layer to be firmly bonded with the body of the grinding wheel when the glass fiber twistless roving subjected to the dipping in the dipping liquid is wound on the outer circumferential surface of the grinding wheel body, the winding layer does not shred after long-term use, the strength of the grinding wheel is substantially enhanced, and the winding layer can protect the grinding wheel body during the whole service life period, thereby the service life of the grinding wheel is prolonged.

Owner:江苏新砺河磨具科技有限公司

Composite CuNiIn powder, preparation method and application thereof

ActiveCN108425085AHigh strengthImprove the binding effectMolten spray coatingTransportation and packagingThermal sprayingUltimate tensile strength

The invention discloses composite CuNiIn powder, a preparation method and an application thereof. The composite CuNiIn powder comprises a dispersion strengthening phase and a self-lubricating phase. The preparation method comprises the following steps that ball milling and mixing on In powder, nickel-coated molybdenum disulfide powder and A12O3 dispersion strengthening Cu powder are carried out soas to prepare mixed raw materials; a spray drying granulator is adopted to carry out centrifugal atomization granulation on the mixed raw materials to prepare dried granules; and vacuum sintering iscarried out on the dried particles, and then the dried particles are crushed and screened to obtain the composite CuNiIn powder. The composite CuNiIn powder can be prepared into a composite CuNiIn coating containing the dispersion strengthening phase and the self-lubricating phase by adopting a thermal spraying method. The distribution state of the self-lubricating phase is changed, the strength and the toughness of the coating are improved, the generation of micro-cracks of the coating is effectively avoided, the self-lubricating service life of the coating is prolonged, and the composite CuNiIn powder has a good application value in the industries of aviation engines, gas turbines and the like.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Copper-based active solder for brazing diamond grinding tools

InactiveCN109465568AGood wettabilityLow melting pointWelding/cutting media/materialsSoldering mediaDiamond grindingMetallic Nickel

The invention relates to copper-based active solder for brazing diamond grinding tool. The copper-based active solder is prepared by adding active elements such as nickel, chromium and phosphorus in acopper-tin-titanium-based alloy. The active elements include, by weight, 52% to 68% of copper, 17% to 23% of tin, 5% to 11% of titanium, 5% to 9% of nickel, 3% to 5% of chromium, and 0.5% to 1.5% ofphosphorus. The obtained active solder has the characteristics of low brazing temperature, good wettability, high caulking capacity and high wear resistance. Under the action that nickel has a solid solution strengthening effect and chromium is made from carbide, a diamond and a matrix can form a solid metallurgical bond, so that the holding force of the diamond is enhanced. The joint shearing strength of graphite / 45# steel brazed by using the active solder can reach 360 MPa. The addition of phosphorus makes the melting point lower, and the obtained solder can obtain a complete liquid phase at760 DEG C.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

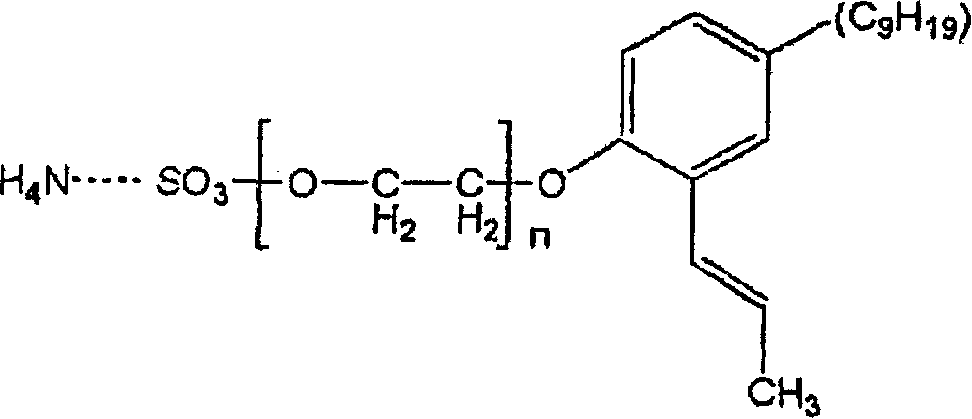

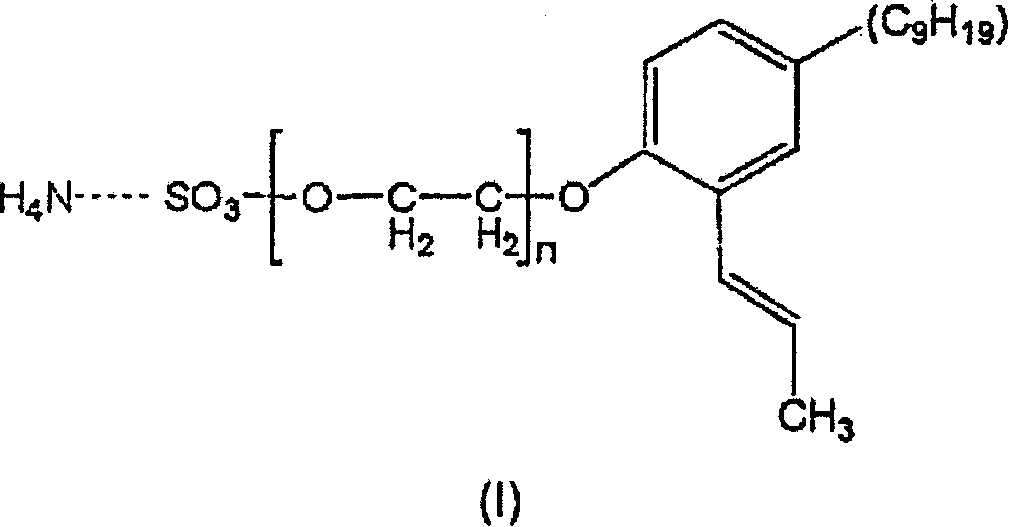

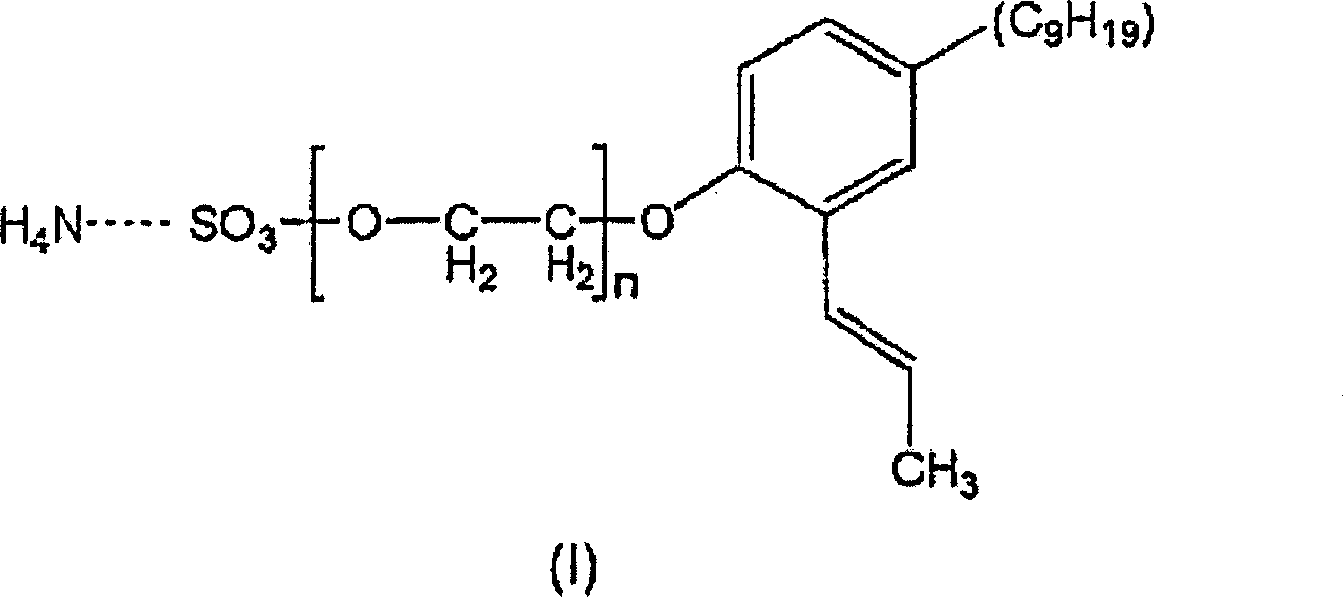

Water-whitening resistant latex emulsion pressure sensitive adhesive and its production

InactiveCN1823150AGood wettabilityUnsaturated ether polymer adhesivesEster polymer adhesivesPressure sensitiveEmulsion

An aqueous, blush-retardant pressure sensitive adhesive (PSA) is made from an aqueous latex emulsion having an average particle size diameter of not substantially above about 100 nm and emulsified in the presence of an emulsifier consisting essentially of: Formula (I) wherein n is an integer ranging from 1-200.

Owner:ASHLAND LICENSING & INTPROP LLC

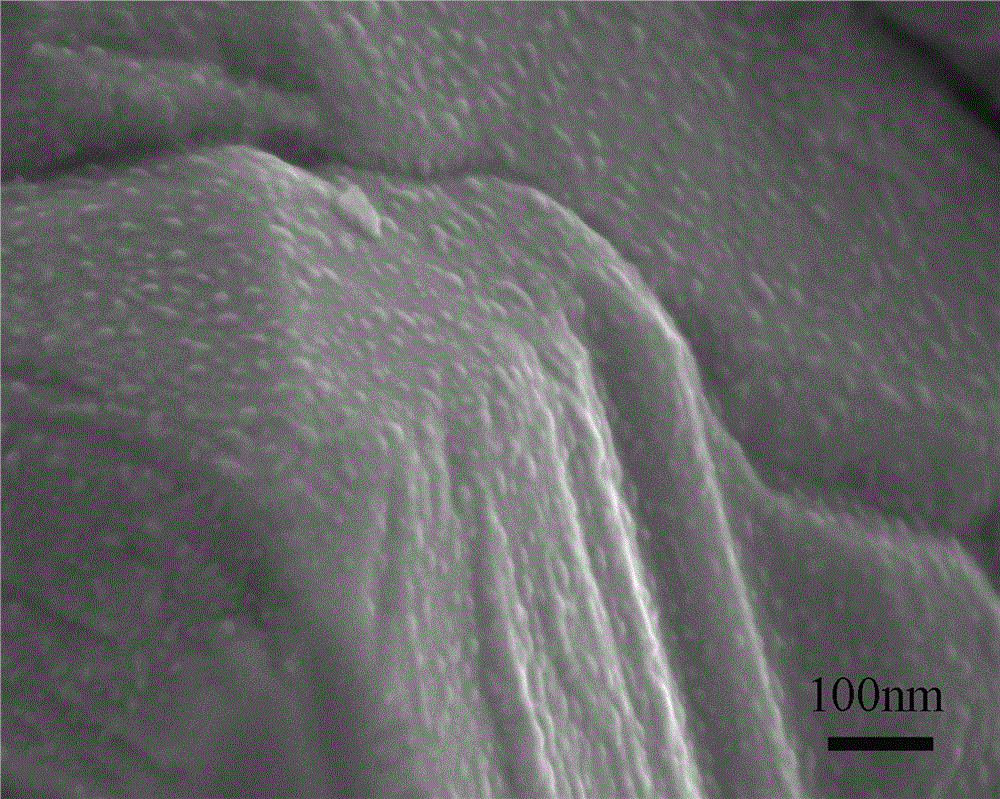

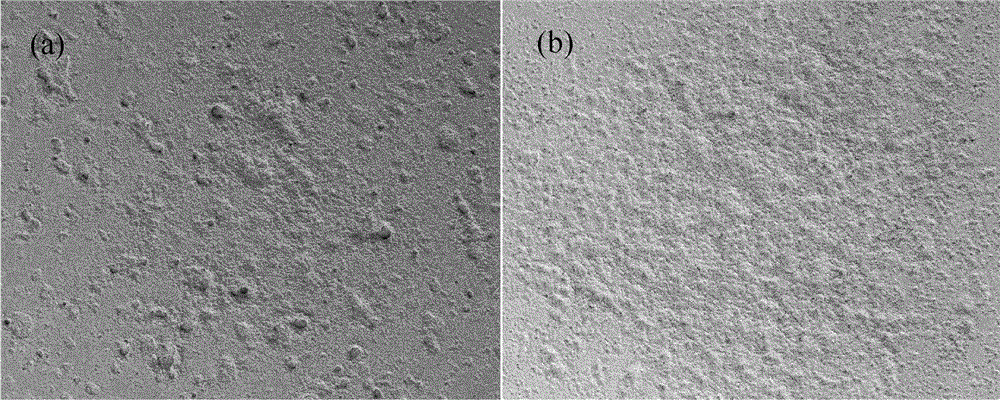

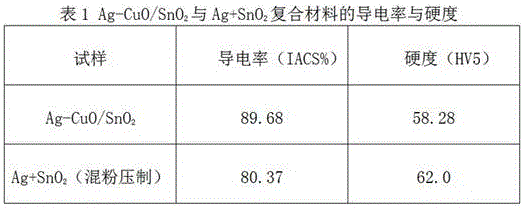

Copper oxide doped silver tin oxide composite and preparation method thereof

ActiveCN106086495AGood wettabilityGood microstructure uniformityTransportation and packagingMetal-working apparatusMicrostructureMetallic materials

The invention relates to the technical field of silver-based metal materials, in particular to a low-voltage electric contact material, and particularly discloses a copper oxide doped silver tin oxide composite. The copper oxide doped silver tin oxide composite comprises, by weight, 4.9%-18.5% of tin oxide, 0.1%-1.5% of copper oxide, and the balance silver. A preparation method of the copper oxide doped silver tin oxide composite comprises the steps that a silver-copper composite body is prepared, the silver-copper composite body is mixed with tin oxide powder, then compression forming is conducted, and sintering is conducted. The silver copper composite body comprises silver powder and a copper oxide precursor arranged on the surface of the silver powder in a coating mode. The copper oxide doped silver tin oxide composite has the advantages of being uniform in microstructure, good in processing performance, low in electrical resistivity and the like, is suitable for the electric contact material, and has good stability and long service life. The preparation method of the copper oxide doped silver tin oxide composite has the advantages of being simple, convenient and easy to conduct, high in production efficiency, free of environmental pollution and the like.

Owner:SHIJIAZHUANG TIEDAO UNIV

Filler-free halogen-free flame-retardant epoxy resin composition

The invention relates to a flame-retardant composite material formed by multiple techniques, particularly a filler-free halogen-free flame-retardant epoxy resin composition. The filler-free halogen-free flame-retardant epoxy resin composition comprises a component A and a component B. The component A comprises the following components in percentage by weight: 55-75% of low-halogen bisphenol A epoxy resin 128, 5-15% of bisphenol F epoxy resin 170, 10-30% of phosphorus-nitrogen flame retardant and 10-20% of phosphate flame retardant. The component B comprises the following components in percentage by weight: 10-20% of polyetheramine curing agent D230, 50-70% of isophorone diamine (IPDA) and 20-30% of N-aminoethyl piperazidine. The component A and component B are mixed according to the weight ratio of 100:(19-21) to obtain the composition. On the premise of ensuring various physiochemical properties of the cured resin and especially the mechanical properties and halogen-free flame retardancy, the composition does not use any filler-type flame retardant, and satisfies the operating requirements for multiple techniques.

Owner:WELLS ADVANCED MATERIALS SHANGHAI

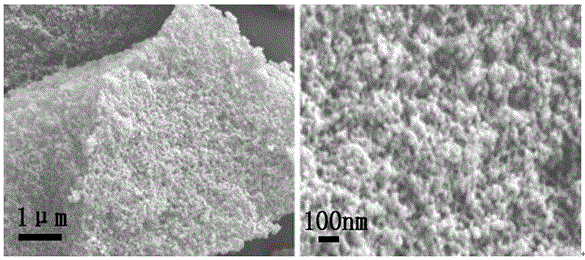

Preparation method for nanoporous carbon

ActiveCN106587047AEasy to prepareGood wettabilityCarbon compoundsHybrid capacitor electrodesChemistryCarbon source

The invention relates to a preparation method for nanoporous carbon. The preparation method comprises the following steps: dissolving a resin carbon source, a curing agent, a pore-forming template agent and a proppant with a solvent, and performing gelatination and curing at 0 to 150 DEG C to obtain a cured material; removing the solvent from the cured material, crushing the cured material into granules of 20 to 100 meshes, and performing heating treatment on the granules in an air atmosphere or oxygen atmosphere of 170 to 330 DEG C to obtain a pretreated material; placing the pretreated material in a carbonization reaction chamber, controlling the temperature to rise to 700 to 1,000 DEG C under gas protection at the rate of 1 to 15 DEG C per min, performing constant temperature treatment for 30 to 300min at a temperature rising endpoint, and performing cooling to room temperature to obtain the nanoporous carbon. The nanoporous carbon prepared by the method has the advantages of simplicity of the preparation method, easiness for regulation and control of pore diameters and the like, has a pore diameter adjustable within the range of 0.5 to 100nm and a specific surface area of 600 to 1,600m<2> / g, and can be used for an electrode material of a super capacitor, an electrode material of a lithium ion battery, an electrode material of capacitive desalination equipment, blood purification, a catalyst carrier, water treatment, gas purification, solvent recovery and the like.

Owner:ZHANGJIAGANG SMARTGRID FANGHUA ELECTRICAL ENERGY STORAGE RES INST +1

Positive plate with improved infiltration capacity and lithium ion battery

ActiveCN110504409AGood wettabilityShorten the resting timeElectrode rolling/calenderingElectrode thermal treatmentCurrent collectorLithium electrode

The invention provides a positive plate with improved infiltration capacity. The positive plate comprises a current collector, and n active matter layers with the same thickness are arranged on two sides of the current collector, wherein n is larger than or equal to 1 and smaller than or equal to 10; the contact angle of the surface of the current collector is theta 0, COS(theta 0) is larger thanor equal to 0.50 and smaller than 0.99, the contact angle of the surfaces of the active matter layers is theta n, and theta n is smaller than or equal to 30 degrees; when COS(theta 0) is larger than or equal to 0.50 and smaller than 0.94, theta 1 is equal to half of theta 0, and theta n is equal to the product of theta 1 and 0.9<n+1>; and when COS(theta 0) is larger than or equal to 0.94 and smaller than 0.99, theta 1 is equal to theta 0, and theta n is equal to the product of theta 1 and 0.9<n+1>. The positive plate with improved infiltration capacity obtains good plate infiltration, standingtime of a cell after the battery is injected with an electrolyte is shortened, the infiltration rate of the electrolyte for the positive plate with the improved infiltration capacity is increased, the production efficiency and yield are increased, a prepared battery electrode interface state is more uniform, and interfacial current density in the charging-discharging process is more uniform.

Owner:TIANJIN ENERGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com