Preparation method of TC4 titanium alloy laser cladding reinforced coating

A laser cladding and titanium alloy technology, applied in the field of laser additive manufacturing, can solve the problems of inability to guarantee the service life of parts, low hardness, environmental pollution, etc., and achieve the effects of easy access, good wettability, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

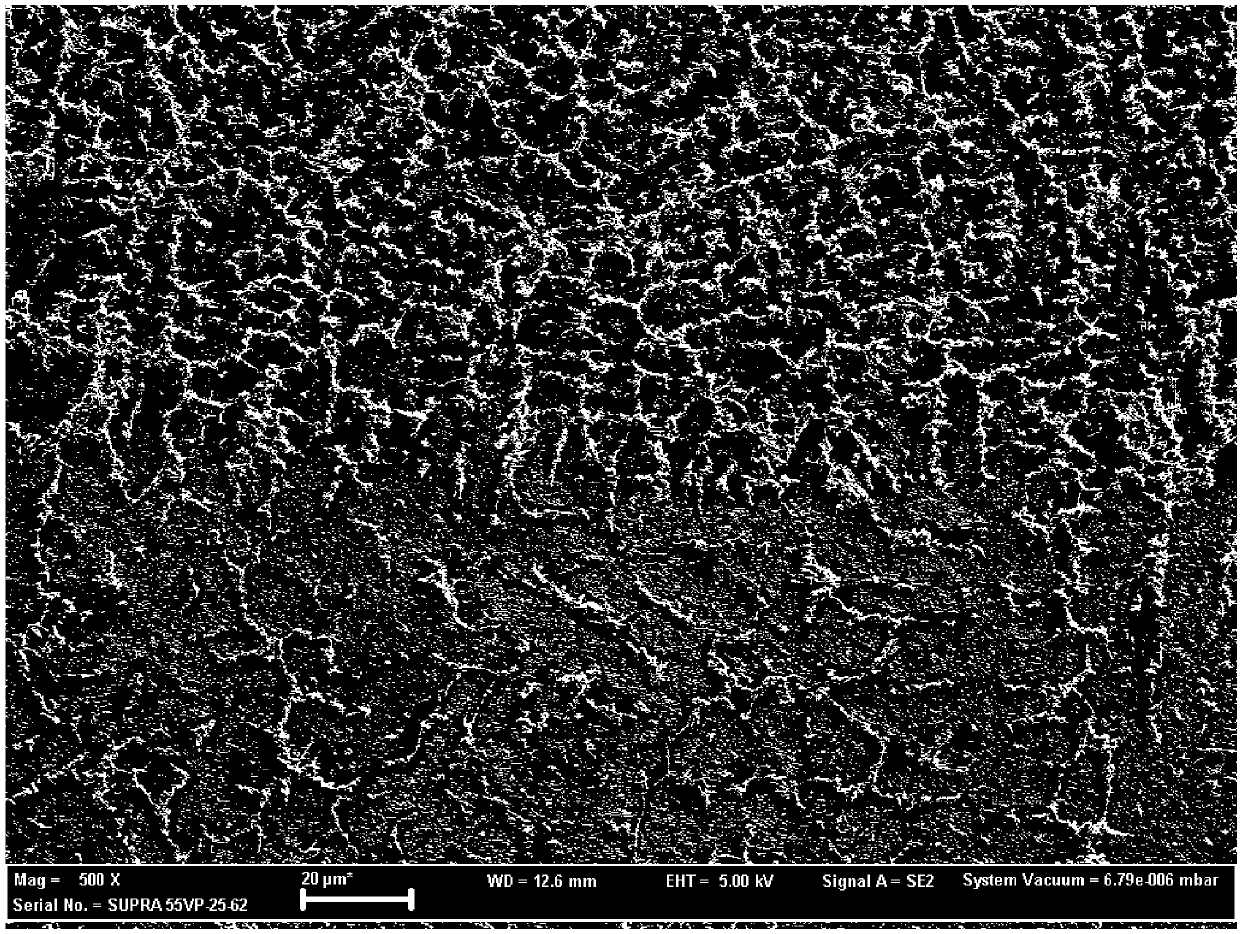

Embodiment 1

[0024] The preparation method of the TC4 titanium alloy laser cladding enhanced coating provided in this embodiment includes the following steps in order:

[0025] Step 1: Use TC4 titanium alloy material as the substrate for cladding, polish the surface with 600-grit sandpaper, and then use acetone solution to remove oil and rust on the surface to pretreat the substrate;

[0026] Step 2: mix titanium carbide powder and TC4 titanium alloy powder uniformly with a mass ratio of 20:80 to make a mixed powder, and then spread a layer of mixed alloy powder on the surface of the above-mentioned pretreated substrate; the thickness of the mixed alloy powder layer 3mm;

[0027] Step 3: Using argon as a protective gas, the above-mentioned mixed alloy powder is clad on the surface of the substrate with a high-power semiconductor laser at a spot width of 6mm, a laser power of 1200W, a scanning speed of 3mm / s, and a focal length of 160mm, and then quickly Cool to form a layer of laser cladd...

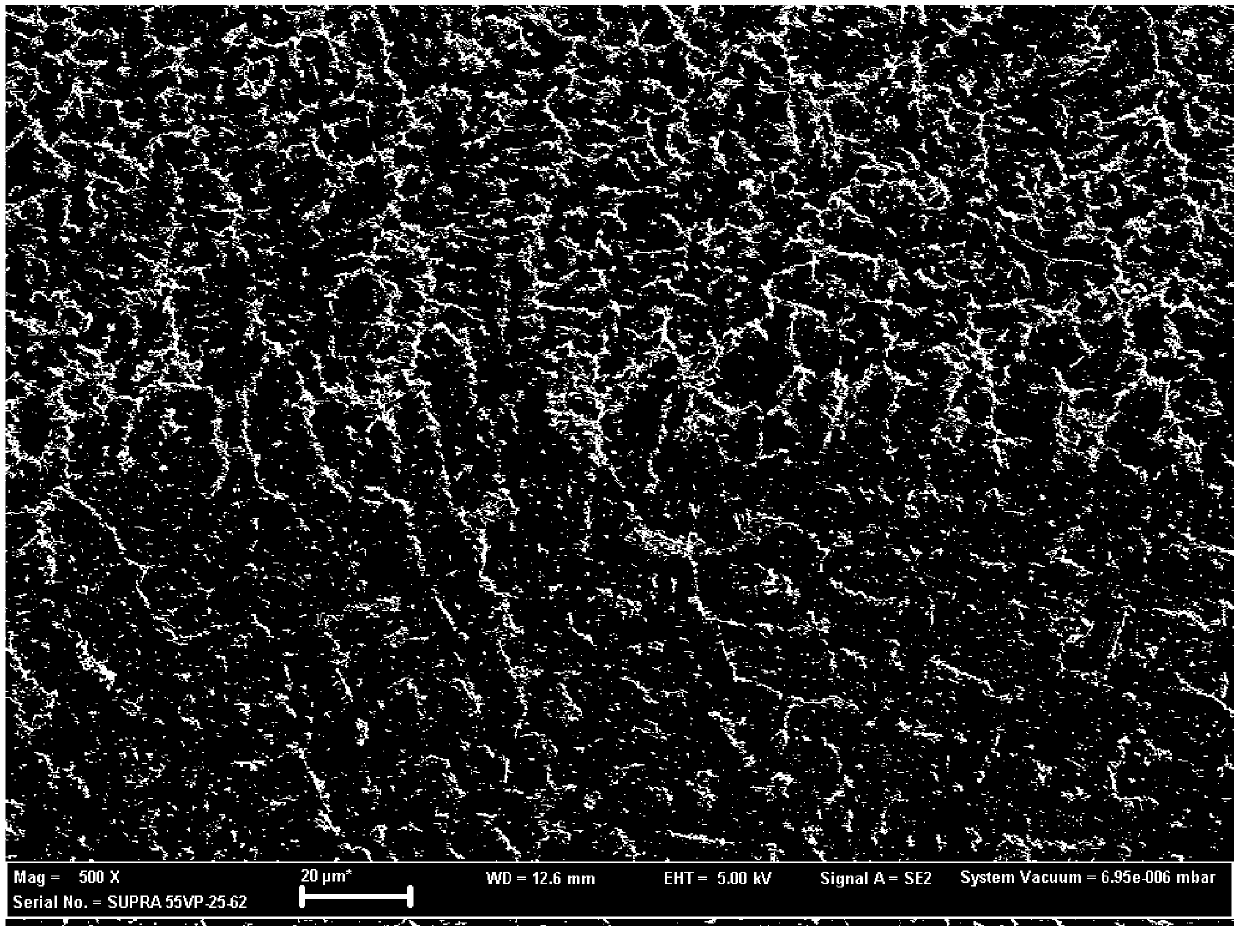

Embodiment 2

[0030] The preparation method of the TC4 titanium alloy laser cladding enhanced coating provided in this embodiment includes the following steps in order:

[0031] Step 1: Use TC4 titanium alloy material as the substrate for cladding, polish the surface with 600-grit sandpaper, and then use acetone solution to remove oil and rust on the surface to pretreat the substrate;

[0032] Step 2: mix titanium carbide powder and TC4 titanium alloy powder with a mass ratio of 30:70 to make a mixed powder, and then spread a layer of mixed alloy powder on the surface of the above-mentioned pretreated substrate; the thickness of the mixed alloy powder layer 3.5mm;

[0033] Step 3: Using argon as a protective gas, cladding the above-mentioned mixed alloy powder on the surface of the substrate with a high-power semiconductor laser at a spot width of 10mm, laser power of 1200W, scanning speed of 3mm / s, and a focal length of 160mm, and then rapidly Cool to form a layer of laser cladding coatin...

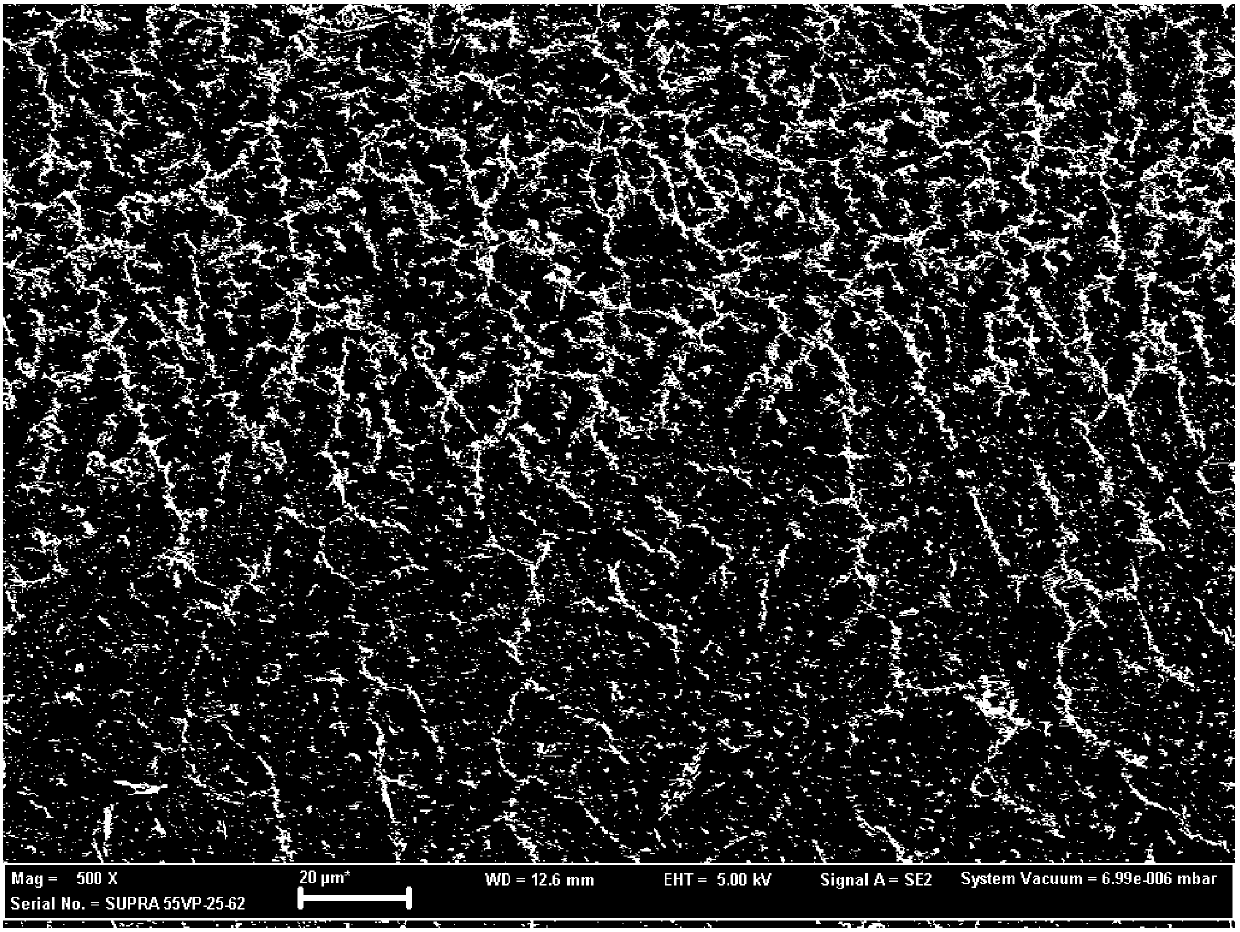

Embodiment 3

[0036] The preparation method of the TC4 titanium alloy laser cladding enhanced coating provided in this embodiment includes the following steps in order:

[0037] Step 1: Use TC4 titanium alloy material as the substrate for cladding, polish the surface with 600-grit sandpaper, and then use acetone solution to remove oil and rust on the surface to pretreat the substrate;

[0038] Step 2: mix titanium carbide powder and TC4 titanium alloy powder uniformly with a mass ratio of 40:60 to make a mixed powder, and then spread a layer of mixed alloy powder on the surface of the above-mentioned pretreated substrate; the thickness of the mixed alloy powder layer 4mm;

[0039] Step 3: Using argon as a protective gas, cladding the above mixed alloy powder on the surface of the substrate with a high-power semiconductor laser at a spot width of 8mm, laser power of 1200W, scanning speed of 3mm / s, and a focal length of 160mm, and then quickly Cool to form a layer of laser cladding coating. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com