Patents

Literature

211results about How to "Improves strength and hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance acidic transparent silicone sealant

ActiveCN101982516AImproves strength and hardnessIncrease filling volumeNon-macromolecular adhesive additivesOther chemical processesChemistryDibutyl tin dilaurate

A high-performance acidic transparent silicone sealant belongs to the technical field of the adhesive. The sealant comprises the following components in parts by weight: 90-130 parts of hydroxyl-terminated polydimethylsiloxane, 10-60 parts of alkyl-terminated polydimethylsiloxane, 5-15 parts of crosslinking agent, 20-90 parts of silicon dioxide, 0.01-0.9 part of anti-yellowing agent and 0.005-0.15 part of catalyst, wherein crosslinking agent is the mixture of methyltriacetoxysilane and ethyltriacetoxysilane; anti-yellowing agent is one or more of ultraviolet absorbent and light stabilizer; and catalyst is dibutyltin diacetate or dibutyltin dilaurate. The invention does not depend on the foreign product and provides the high-performance acidic sealant so as to fills the gap that neutral transparent silicone sealant can not be used in the glass fishbowl; and the sealant has good bonding property to the substrate, and can not have blushing and yellowing and can have no pollution to the environment. The sealant can satisfy the demands of the specific curtain wall, glass roof and glass fishbowl.

Owner:ZHEJIANG TIME NEW MATERIAL

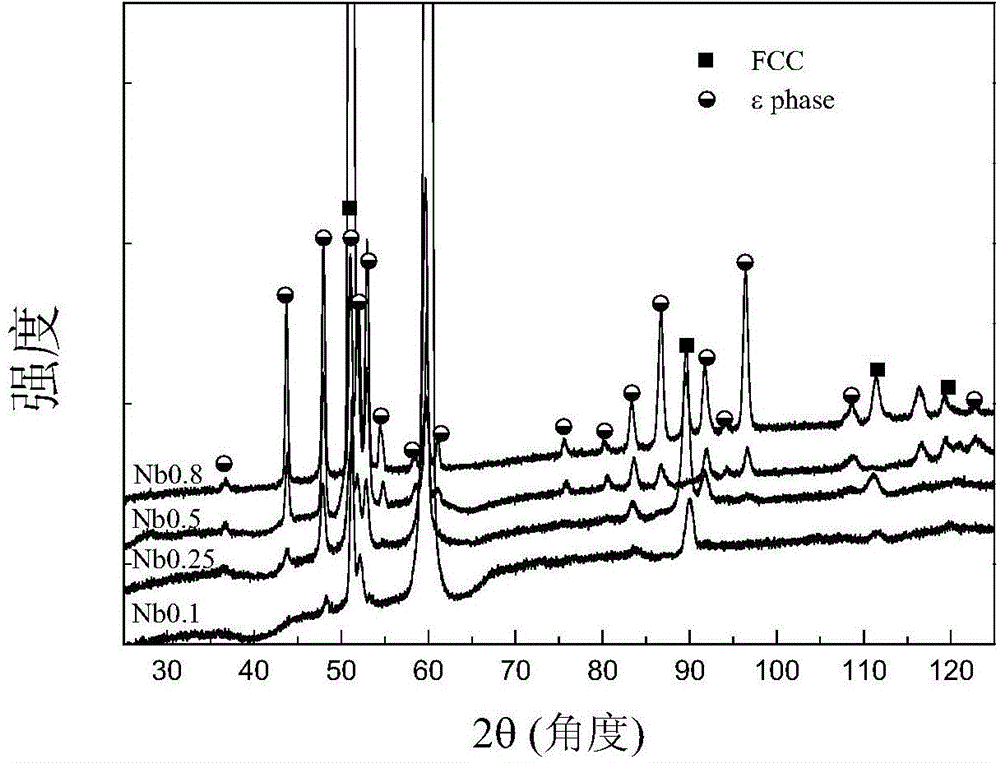

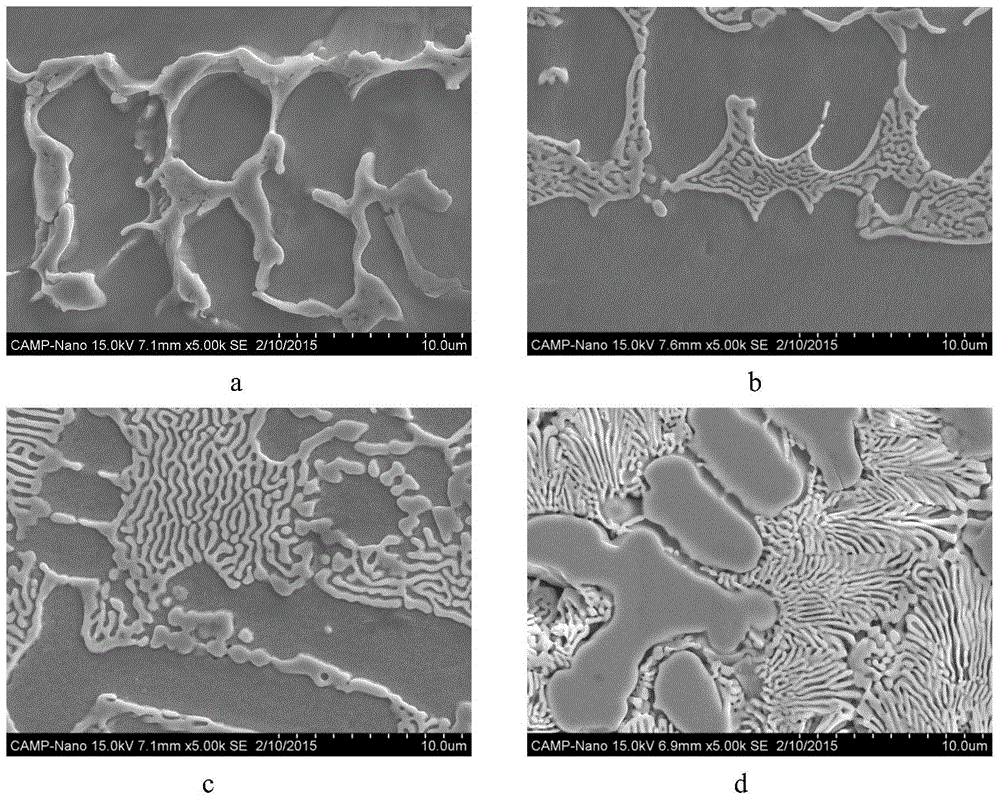

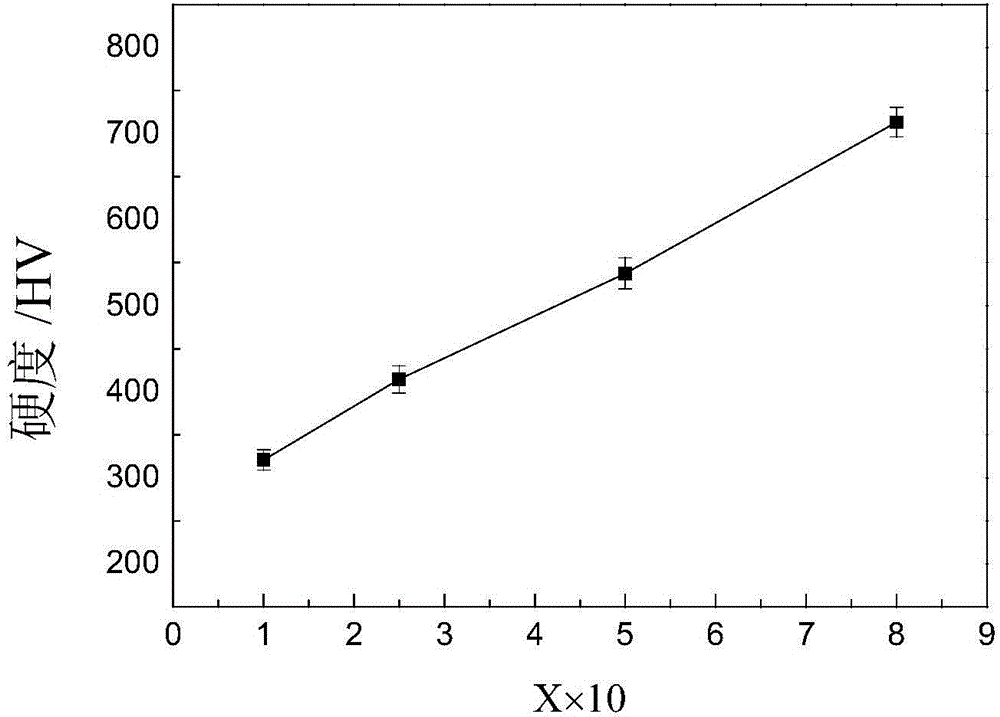

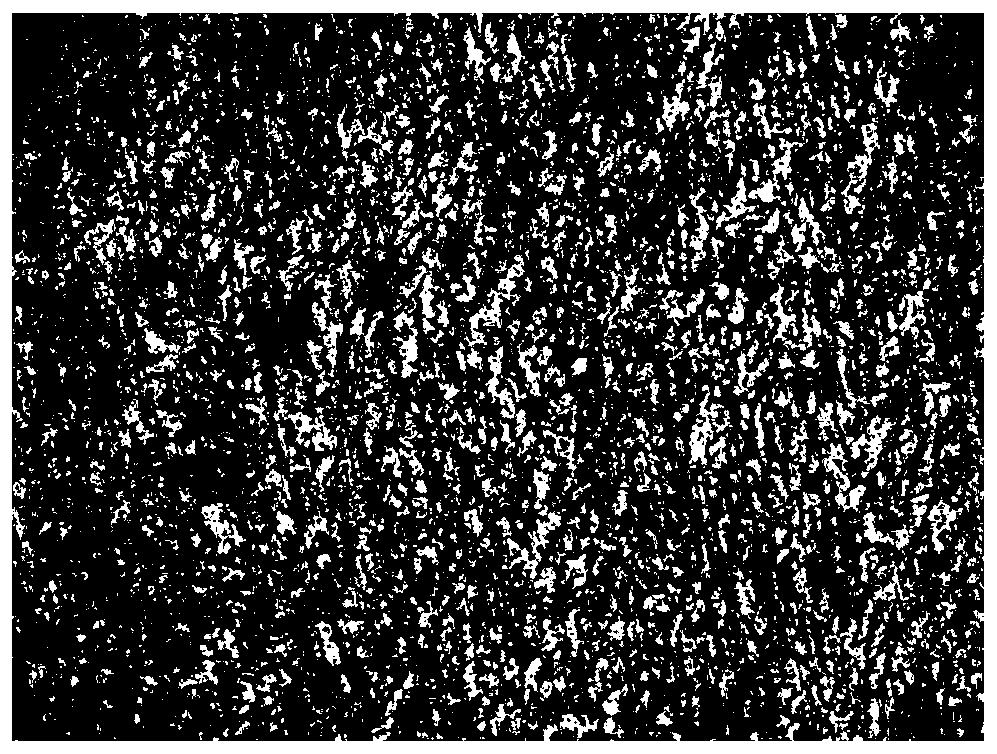

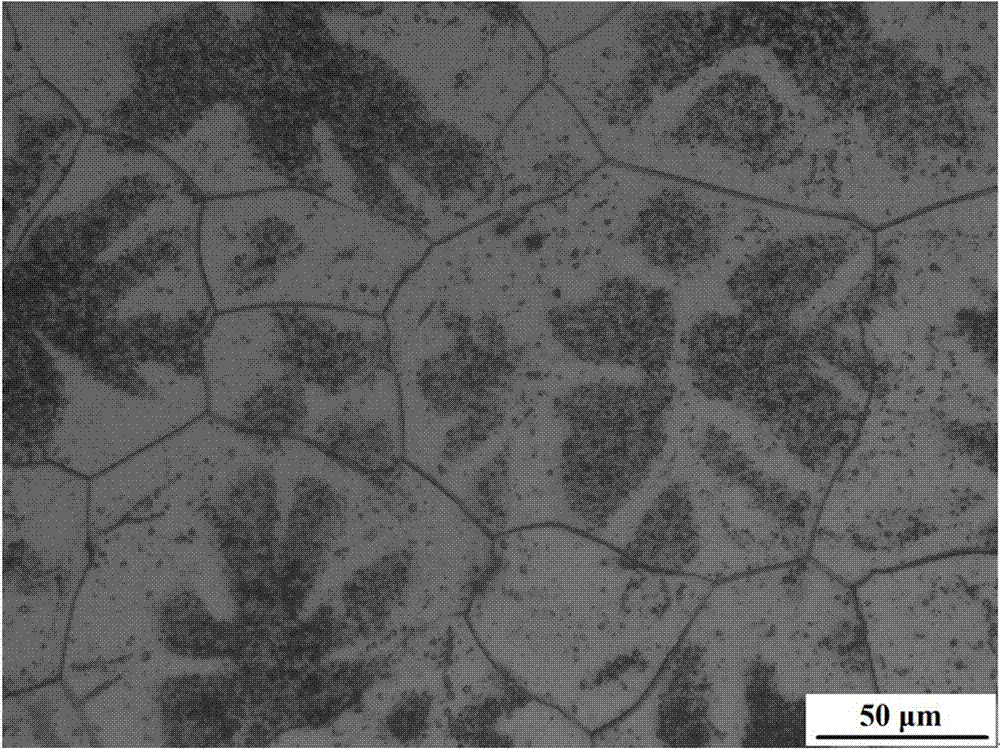

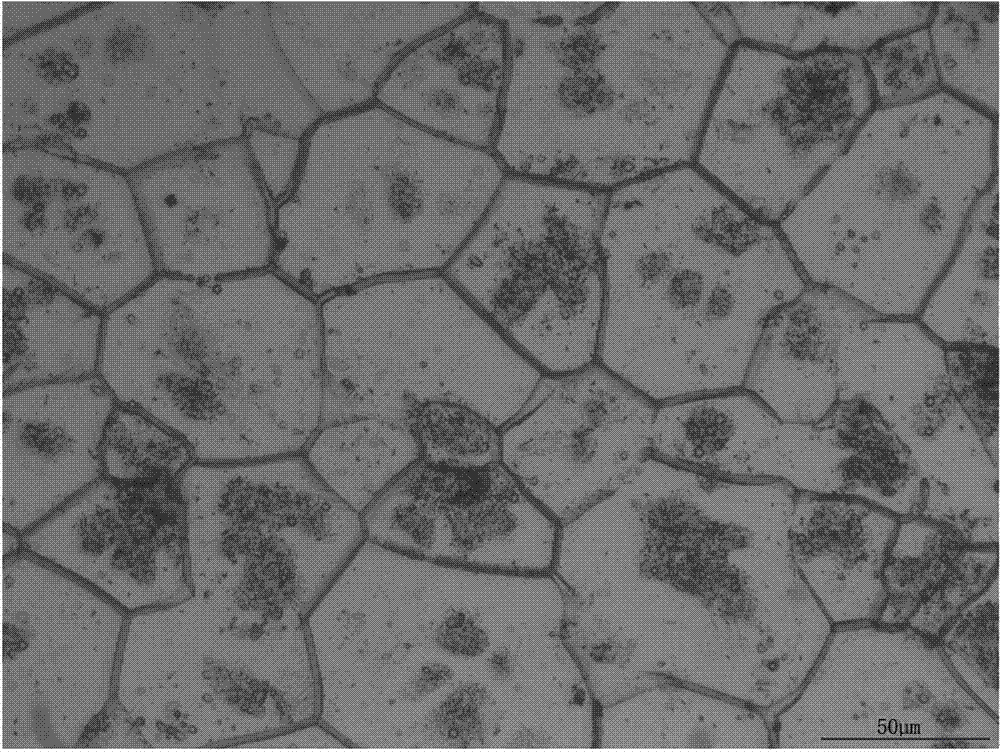

CrFeCoNiNbx high-entropy alloy and preparation method thereof

The invention discloses a CrFeCoNiNbx high-entropy alloy and a preparation method thereof. The CrFeCoNiNbx high-entropy alloy comprises Cr, Fe, Co, Ni and Nb, wherein x ranges from 0.1 to 0.8; the content of Nb is 2.4%-16.7%; Cr, Fe, Co, and Ni are equal in content; and the proportion is mole percentage. An Nb element is added to a Cr-Fe-Co-Ni quaternary alloy, a precipitated phase is formed in single FCC (face-centered cubic) solid solution phase, precipitation strengthening is performed, and the high-entropy alloy has a face-centered cubic structure, high hardness, high strength, good compression plasticity and better mechanical properties.

Owner:东莞市三航军民融合创新研究院

Polyurethane composite material having shape memory function sponge, and preparation and using method thereof

ActiveCN102807663AImproves strength and hardnessPromote blood circulationBlood circulationTemperature sense

The invention belongs to the technical field of polyurethane, and relates to a polyurethane composite material having a shape memory function sponge, and a preparation and using method thereof. The composite material comprises a component A, a component B and a component C, wherein the component A comprises polyether polyol and polymer polyol, a foam stabilizer and a foaming agent, and the component B comprises polyether polyol, isocyanate, a hardening agent and a polyether opening agent. The shape memory sponge can generate memory deformation along with temperature sensing and pressure, and has the advantages of moderate rebound speed, no obstructing and shrinkage, large physical mechanical strength, certain support strength and the like. By a mouse pad manufactured by the polyurethane composite material having the shape memory sponge, on one hand, the hardness and strength of the traditional memory sponge is improved, and the mouse pad has a certain support function for wrists; and on the other hand, the memory sponge has a temperature sensing effect and a shape memory function, so that the memory sponge can generate zero-pressure support for each part of the wrist, promote blood circulation for each part of the wrist, and relieve fatigue.

Owner:SHANDONG INOV POLYURETHANE

Davis bronze-steel composite bimetallic bearing material and manufacturing method thereof

ActiveCN101301802AImproves strength and hardnessReduce coefficient of frictionBearing componentsOther manufacturing equipments/toolsLayered structureCarbon steel

The invention provides a nickel bronze-steel compound double metal bearing material and a manufacture method thereof, in particular to a nickel bronze-steel compound double metal bearing material and a manufacture method thereof of a nickel bronze alloy sintered on the surface of a low carbon high grade plain carbon steel material. The nickel bronze-steel compound double metal bearing material of the invention is a layered structure; a basic layer is the low carbon high grade plain carbon steel material; a surface layer is the nickel bronze alloy; the nickel bronze alloy is sintered on the surface of the low carbon high grade plain carbon steel material. The manufacture method of the nickel bronze-steel compound double metal bearing material of the invention relates to a manufacture method for sintering the nickel bronze alloy on the surface of the low carbon high grade plain carbon steel material to form the nickel bronze-steel compound double metal bearing material by adopting the principle of a powder metallurgy sintering method.

Owner:SHANGHAI HEWEI IND

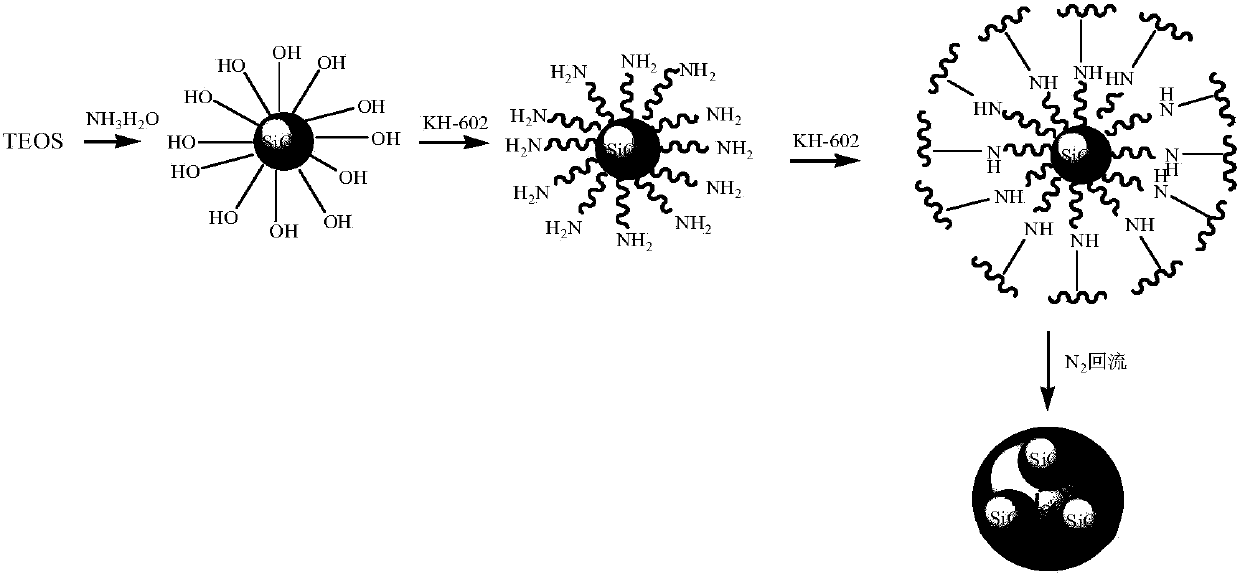

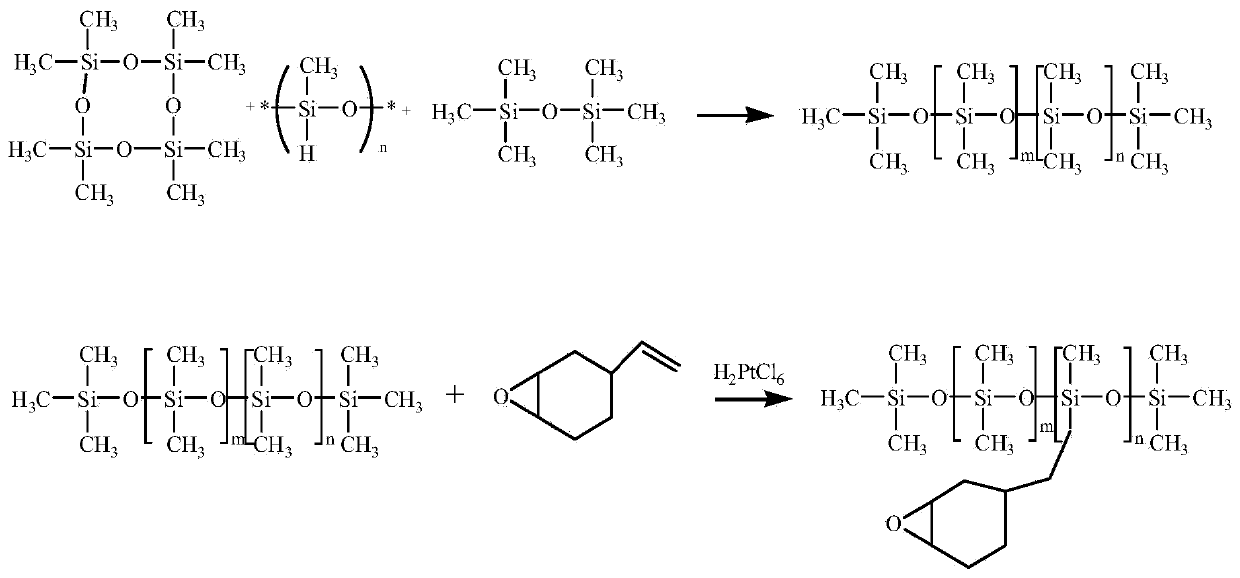

Organic and inorganic hybridization nanometer super-hydrophobic fiber membrane and preparing method thereof

ActiveCN103993423AGood fibrillationImproves strength and hardnessNon-woven fabricsElectrospinningSolvent

The invention relates to an organic and inorganic hybridization nanometer super-hydrophobic fiber membrane and a preparing method thereof. The super-hydrophobic fiber membrane is a polystyrene / polyacrylonitrile nanometer fiber membrane comprising silicon dioxide particles modified by epoxy modified polysiloxane. The preparing method comprises the steps that under the indoor temperature conditions, the polystyrene (PS) is added into solvent to be stirred and dissolved, the silicon dioxide composite nanometer particles modified by epoxy modified polysiloxane are added into the mixture to be stirred to obtain a PS spinning solution; under the indoor temperature conditions, the polyacrylonitrile (PAN) is dissolved in the solvent to be stirred and dissolved, and the silicon dioxide composite nanometer particles modified by epoxy modified polysiloxane are added into the mixture to be stirred to obtain a PAN spinning solution; double-sprayer electrostatic spinning and drying are carried out, and then the organic and inorganic hybridization nanometer super-hydrophobic fiber membrane is obtained. According to the organic and inorganic hybridization nanometer super-hydrophobic fiber membrane and the preparing method, the strength of the hydrophobic fiber can be improved to a certain degree, the hydrophobic performance can be superior without modifying the surface through fluorochemicals and other low surface potential energy substances, and the problems that an existing super-hydrophobic fiber is complex in preparing process and low in strength are solved.

Owner:DONGHUA UNIV

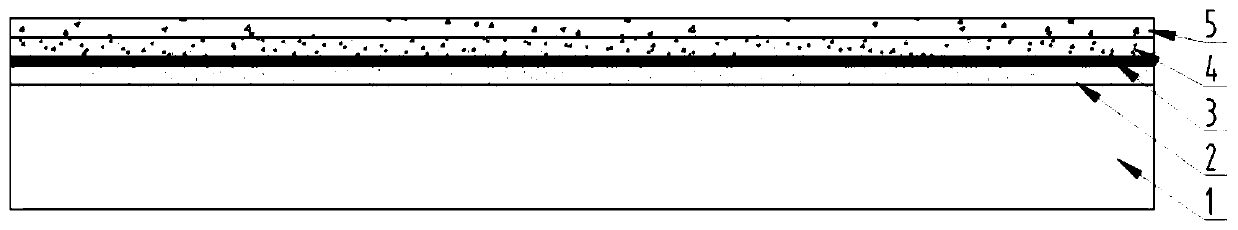

High-hardness wear-resistant low light rock plate and preparation method thereof

The invention discloses a high-hardness wear-resistant low light rock plate. The low light rock plate sequentially comprises a green body layer, a ground glaze layer, a spray-printed pattern layer, aprotective glaze layer and a dry granule glaze layer from bottom to top, wherein the formula of solid dry granules in the dry granule glaze layer comprises 49-53% of SiO2, 18-21% of Al2O3, 5-7.5% of CaO, 0.8-1.4% of MgO, 3-4% of Na2O, 2.8-3.5% of K2O, 6.5-9% of ZnO, 5.5-7% of SrO and below 2% of ignition loss and trace impurities. The materials in the above innovative process formula are combinedto prepare the ceramic rock plate with a low-light effect comfort on the surface and good physical and chemical properties.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +2

Low-nickel austenite gas valve alloy and preparation method thereof

The invention discloses low-nickel austenite gas valve alloy and a preparation method thereof. The low-nickel austenite gas valve alloy comprises the following ingredients in percentage by weight: 0.02-0.08% of C, 28.0-35.0% of Ni, 12.0-17.0% of Cr, 1.5-2.5% of Al, 2.5-3.5% of Ti, 0.4-1.02% of W and Mo, 0.3-0.9% of Nb and Cu, 0.05-0.2% of Y, 0.05-0.3% of Hf, 0.001-0.005% of B, smaller than or equal to 0.4% of Mn, smaller than or equal to 0.3% of Si, smaller than or equal to 0.02% of S, smaller than or equal to 0.02% of P, smaller than or equal to 0.02% of O, smaller than or equal to 0,02% of N and the balanced Fe and unavoidable impurities. Cu is smaller than or equal to 0.3%. The alloy has the advantages of high strength, excellent corrosion resisting property and good high-temperature performance.

Owner:JIANGSU SHENYUAN SPECIAL STEEL +1

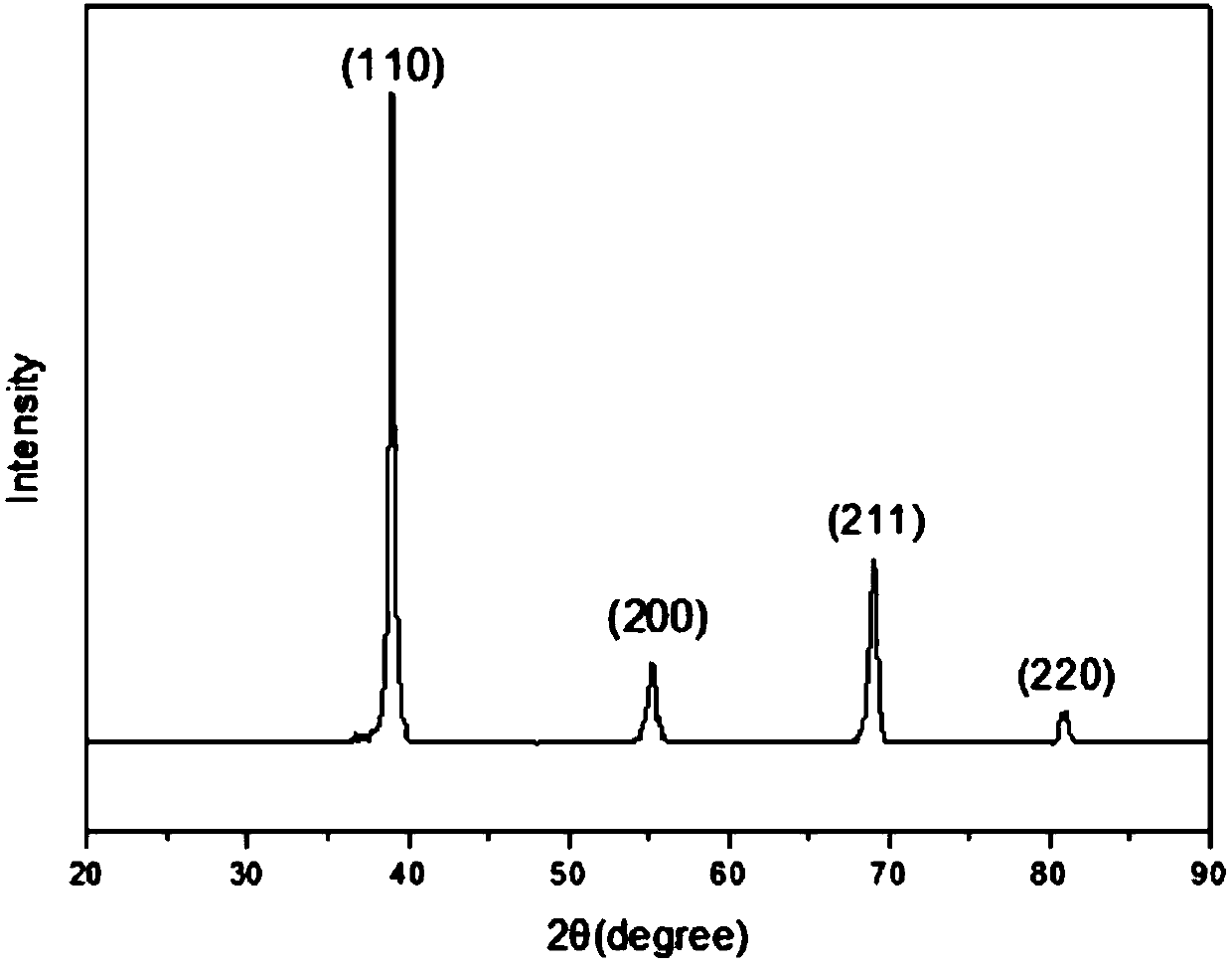

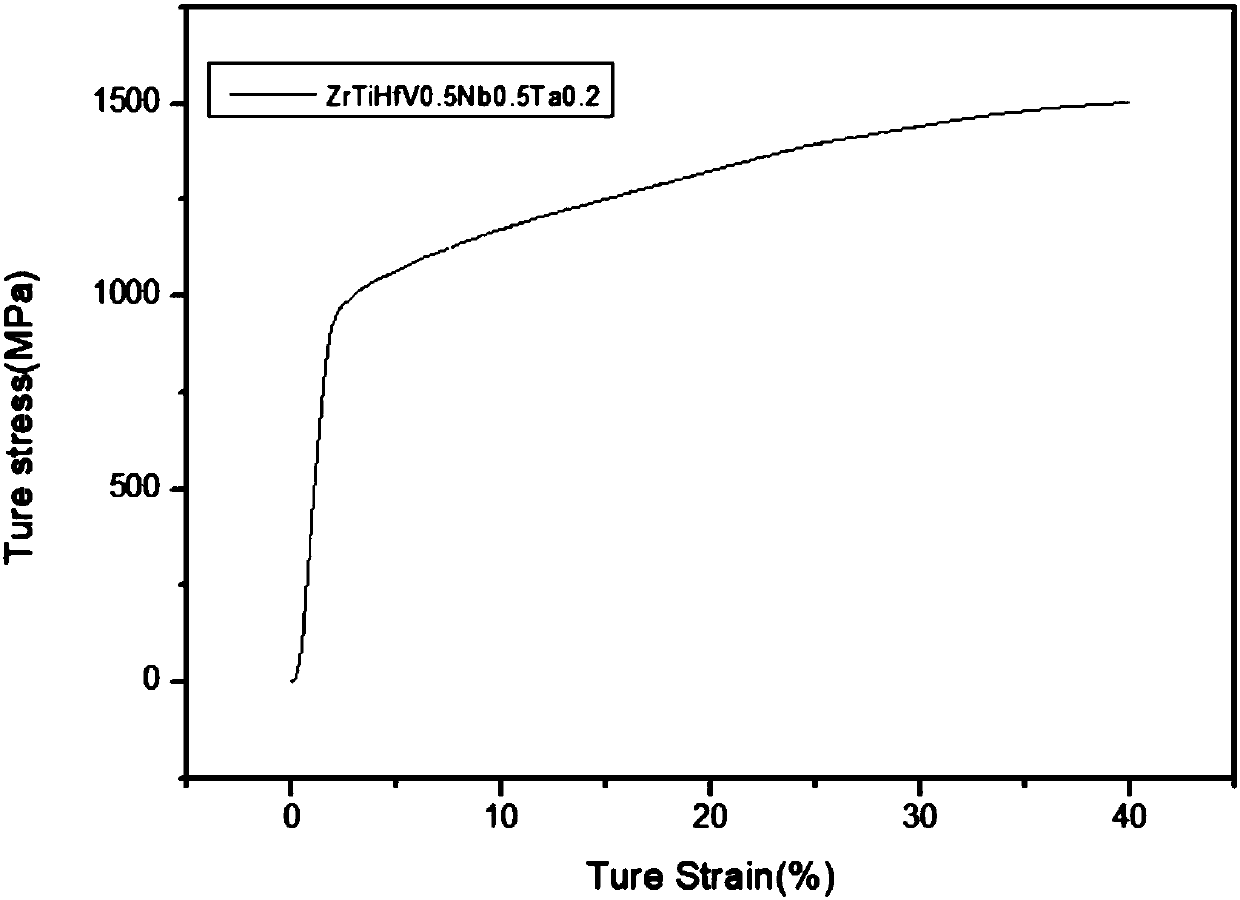

High-plasticity and high-strength hexabasic refractory high-entropy alloy and verification method thereof

InactiveCN107619982AGood mechanical propertiesGood compression plasticity at room temperatureHigh entropy alloysMetallic materials

The invention relates to high-plasticity and high-strength hexabasic refractory high-entropy alloy and a verification method thereof, and belongs to the field of metal materials. The refractory high-entropy alloy comprises components of ZraTibHfcVdNbeXf, wherein a, b, c, d, e and f are separately molar ratios corresponding to various elements, a equals to 0.2-1, b equals to 0.2-1, c equals to 0.2-1, d equals to 0.2-1, e equals to 0.2-1, f equals to 0.2-1, and X is Ta or Mo; and purities of Zr, Ti, Hf, V, Nb, Ta and Mo are 99.7wt% or above. The refractory high-entropy alloy is excellent in mechanical property, and has high compression plasticity at room temperature and high strength. The verification method of the high-plasticity and high-strength refractory high-entropy alloy is simple andreliable; the success rate of preparation of the refractory high-entropy alloy is increased; and the time for preparation of the high-entropy alloy is shortened.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-toughness 3D printing paraffin forming material and preparation method thereof

ActiveCN106118082AImprove impact toughnessImproves strength and hardnessAdditive manufacturing apparatusParaffin waxBonding strength

The invention discloses a high-toughness 3D printing paraffin forming material. The high-toughness 3D printing paraffin forming material is prepared from components of raw materials in percentage by mass as follows: 30%-50% of paraffin, 2%-5% of bee wax, 5%-10% of epoxy resin, 2%-3% of a curing agent, 2%-20% of a viscosity modifier, 20%-30% of a toughening polymer, 6%-25% of a high-hardness polymer, 2%-4% of a filling material, 0.1%-0.3% of dyes and 2%-4% of a phase transferring agent. The bee wax is added to physically modify a paraffin support material, and the impact toughness of the paraffin support material is effectively improved; meanwhile, epoxy resin and the corresponding curing agent are added, and the adding quantity of the epoxy resin and the adding quantity of the corresponding curing agent are adjusted, so that the bonding strength of the paraffin support material and a 3D printing product interface is moderate while the hardness and the strength of the paraffin support material are improved and the shrinkage is reduced, and the paraffin support material is easy to peel off, doesn't deform and doesn't affect the support function on the 3D printing product in the printing process when removed in the later period. The toughening polymer and the high-hardness polymer are added to the paraffin support material, the needle penetration of the material can be effectively reduced, the toughness of the material is improved, and the high-toughness 3D printing paraffin forming material has excellent overall properties.

Owner:佛山市晗宇科技有限公司

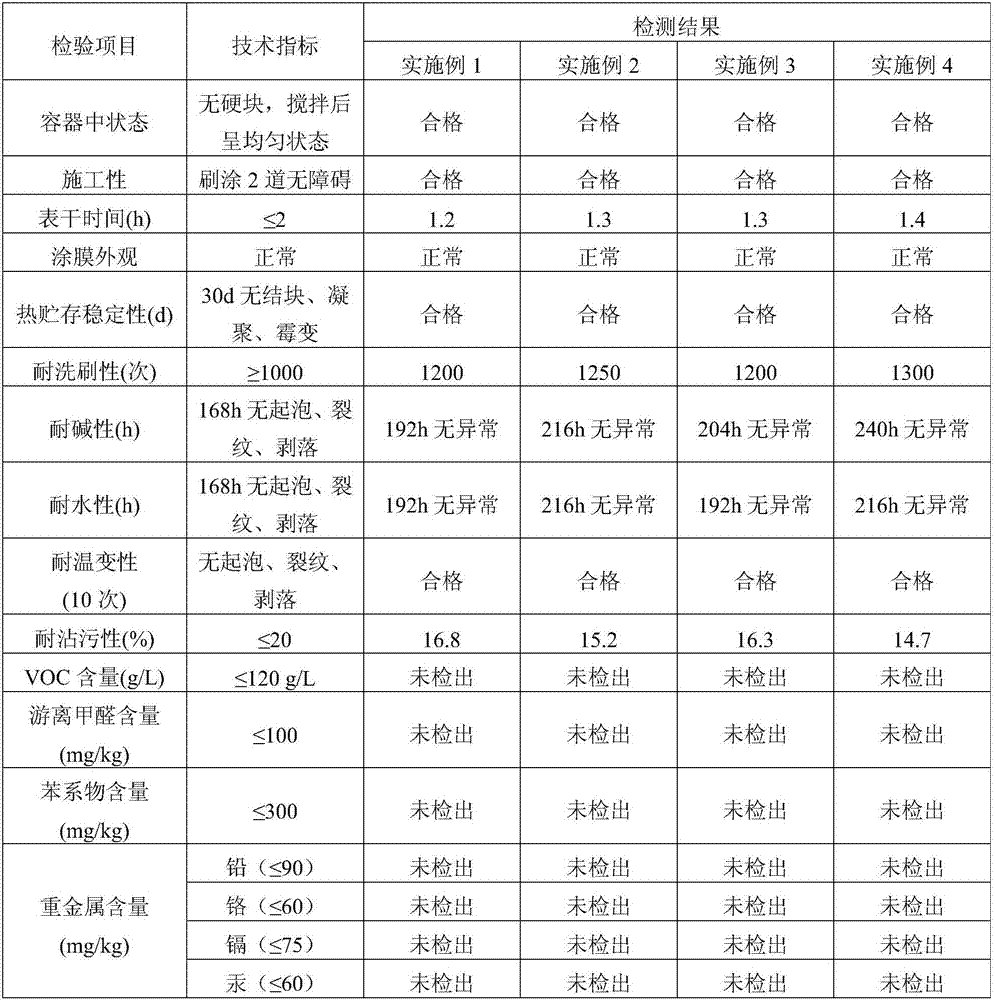

Novel environment-friendly waterborne inorganic paint and preparation method thereof

InactiveCN107266944AFire retardantAntibacterial and antifungalFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholFire resistance

The invention discloses novel environment-friendly waterborne inorganic paint and a preparation method thereof. The novel environment-friendly waterborne inorganic paint is prepared from, by weight, 55-65 parts of kaolin, 12-20 parts of sodium silicate, 20-30 parts of titanium dioxide, 1-5 parts of nano zinc oxide, 5-10 parts of ultrafine wollastonite powder, 1-10 parts of nano calcium carbonate, 1-5 parts of ultrafine white mica powder, 7-15 parts of polyvinyl alcohol, 1-4 parts of ultrafine molybdenum disulfide powder, 2-10 parts of nano silicon dioxide, 2-12 parts of nano magnesium oxide, 2-12 parts of nano aluminum oxide, 1-3 parts of magnesium chloride, 1-3 parts of a sodium silicate hardening accelerator, 2-5 parts of a pH value regulating agent, 1-8 parts of a waterproof agent, 6-10 parts of an antifoaming leveling agent, 1-3 parts of a thickening anti-settling agent and 280-310 parts of water. The novel environment-friendly waterborne inorganic paint which is environment-friendly waterborne inorganic paint for buildings is high in storage stability, excellent in water resistance and alkali resistance, strong in adhesion, high in fire resistance, high in strength and hardness, resistant to scratching and contamination, excellent in corrosion resistance and antibacterial property, free of formaldehyde, benzene compounds, VOC (volatile organic compounds) and heavy metal elements, completely environmental friendly and nontoxic, suitable for industrial production, easy for painting and convenient and quick in construction.

Owner:CHENGDU POLYTECHNIC

Method for preparing decorative material by utilizing modified plant straws

InactiveCN104530735AImproves strength and hardnessImprove stabilityReed/straw treatmentCorn starchMagnesium

The invention relates to a method for preparing a decorative material by utilizing modified plant straws. The preparation method comprises the following steps: with 100 parts of plant straws by weight as a cardinal number, weighing 20 parts of waste plastic particles, 3 parts of bamboo powder, 0.5 part of curcumin, 2 parts of calcined shell, 1 part of metal magnesium powder, 5 parts of calcined kaolin, 1 part of a fire retardant, 2 parts of linear polyethylene, 0.8 part of a silane coupling agent, 1 part of hydroxypropyl methylcellulose, 0.8 part of modified corn starch, 1 part of soybean oil, 0.5 part of cyclohexanone and 2 parts of nanometer silicon dioxide; airing the plant straws, smashing, drying straw powder, sending the straw powder to a reaction kettle to react, taking out the straw powder, cooling, and sending the straw powder to a refrigerating device to obtain modified straw powder; mixing the modified straw powder and other materials, pouring the mixture to a grinding machine and grinding for 2 hours; and carrying out hot melting extrusion to mold. The decorative material has high fire resistance, corrosion resistance, moisture resistance, steeping resistance, worm-eaten resistance, dimensional stability and the like.

Owner:王旭

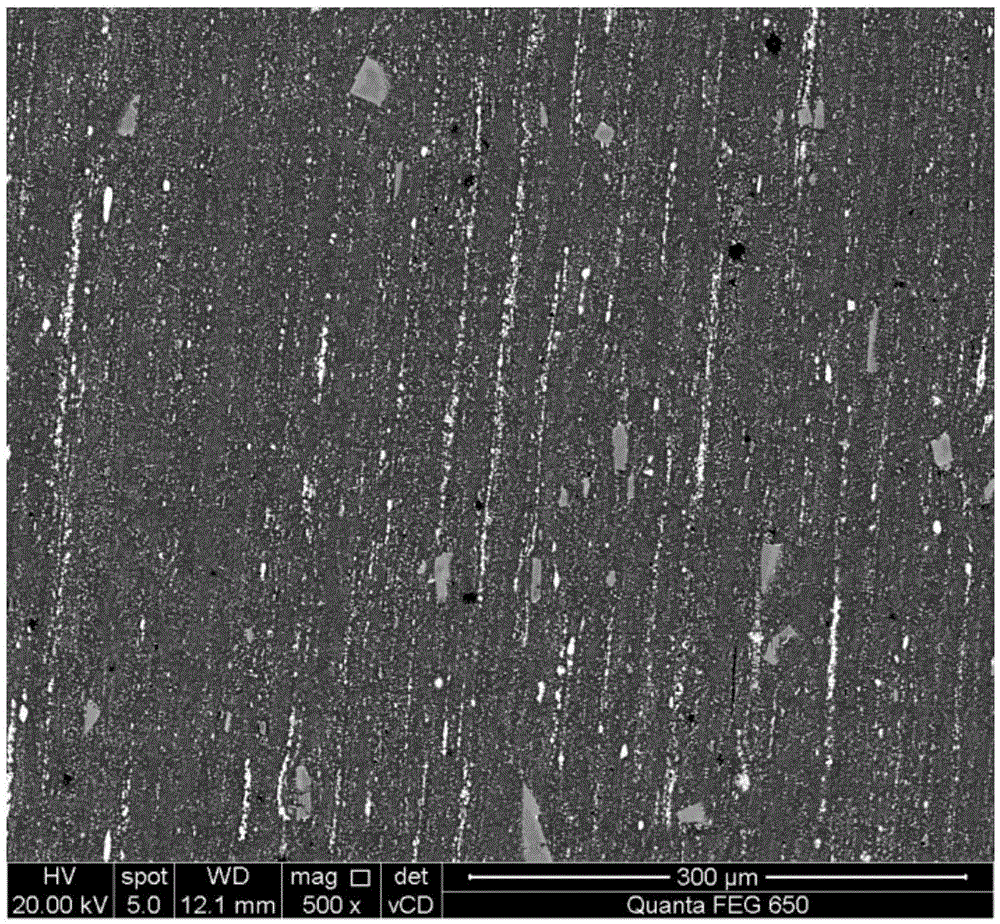

High-strength and ductility aluminum-silicon-based composite welding wire and preparation method thereof

ActiveCN110306083AImproves strength and hardnessGuaranteed toughnessAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyAlloy

The invention provides a high-strength and ductility aluminum-silicon-based composite welding wire and a preparation method thereof. The reinforcing phase of the aluminum-silicon composite material welding wire is in-situ self-generated TiB2 ceramic particles, and a matrix alloy is Al - Si - Mg, wherein the weight percentage of Al - Si is 6.5%-7.5%, the weight percentage of Mg is 0.4%-1. The preparation method comprises the following steps of taking pure aluminum, Al-Si intermediate alloy, Al-Cu intermediate alloy, Al-Mg intermediate alloy and the like as raw materials to prepare intermediatemelt, and after homogenization heat treatment, carrying out hot extrusion, drawing and surface treatment on the intermediate melt to obtain the composite material welding wire. According to the preparation method of the aluminum-silicon-based composite material welding wire, the prepared aluminum-silicon-based composite material welding wire is suitable for electric arc additive manufacturing technology.

Owner:SHANGHAI JIAO TONG UNIV

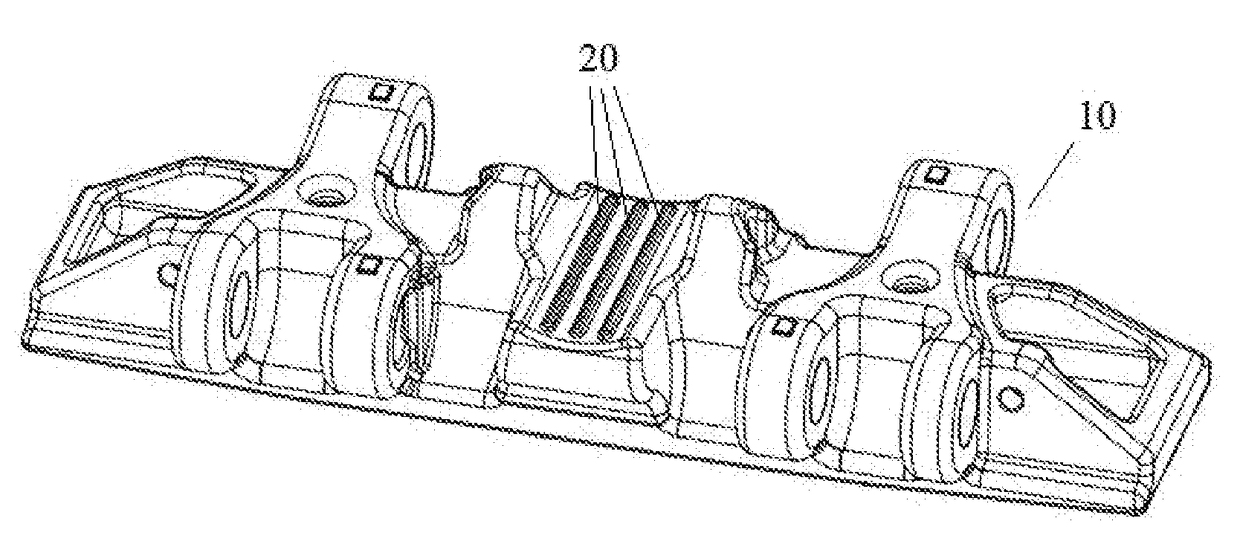

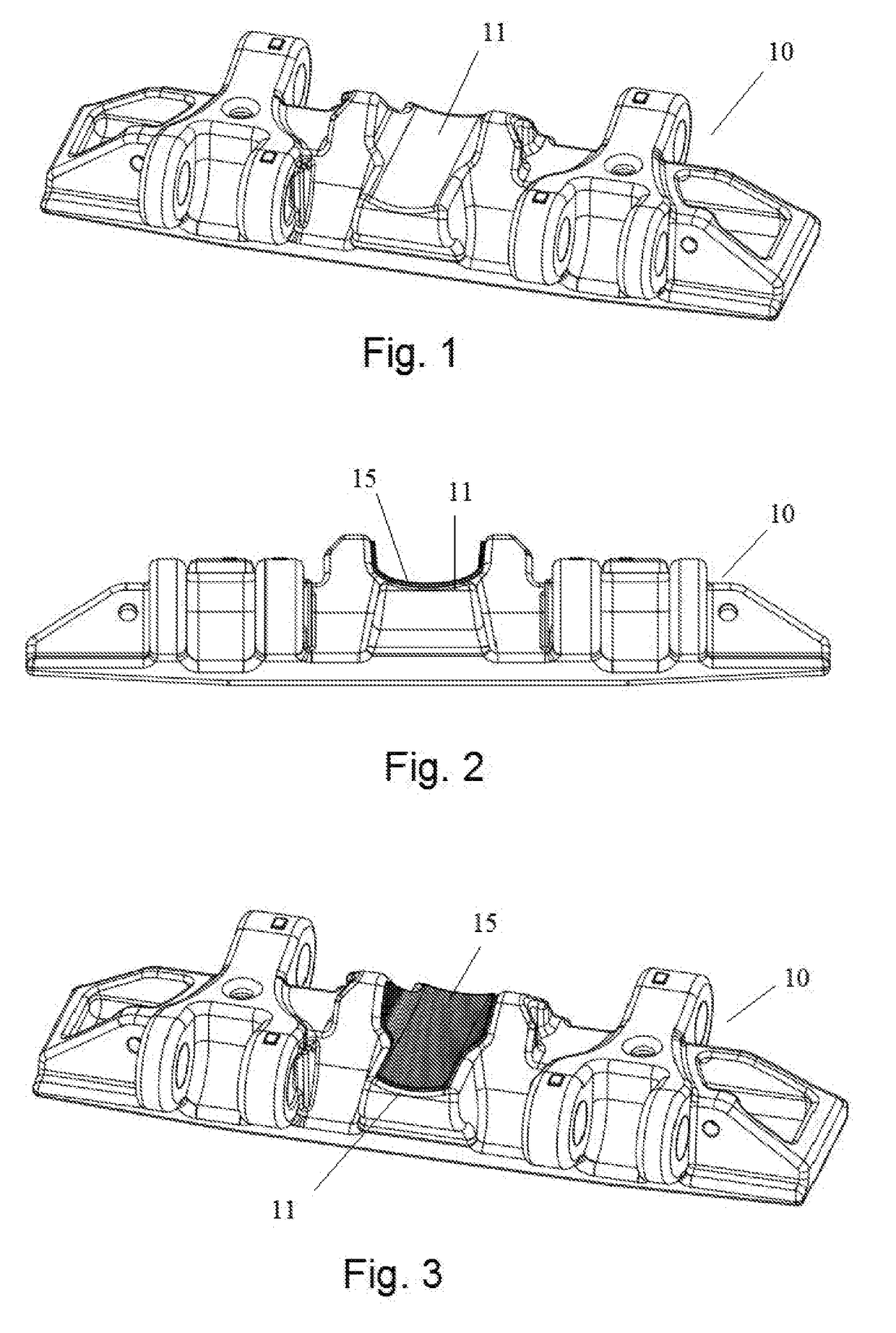

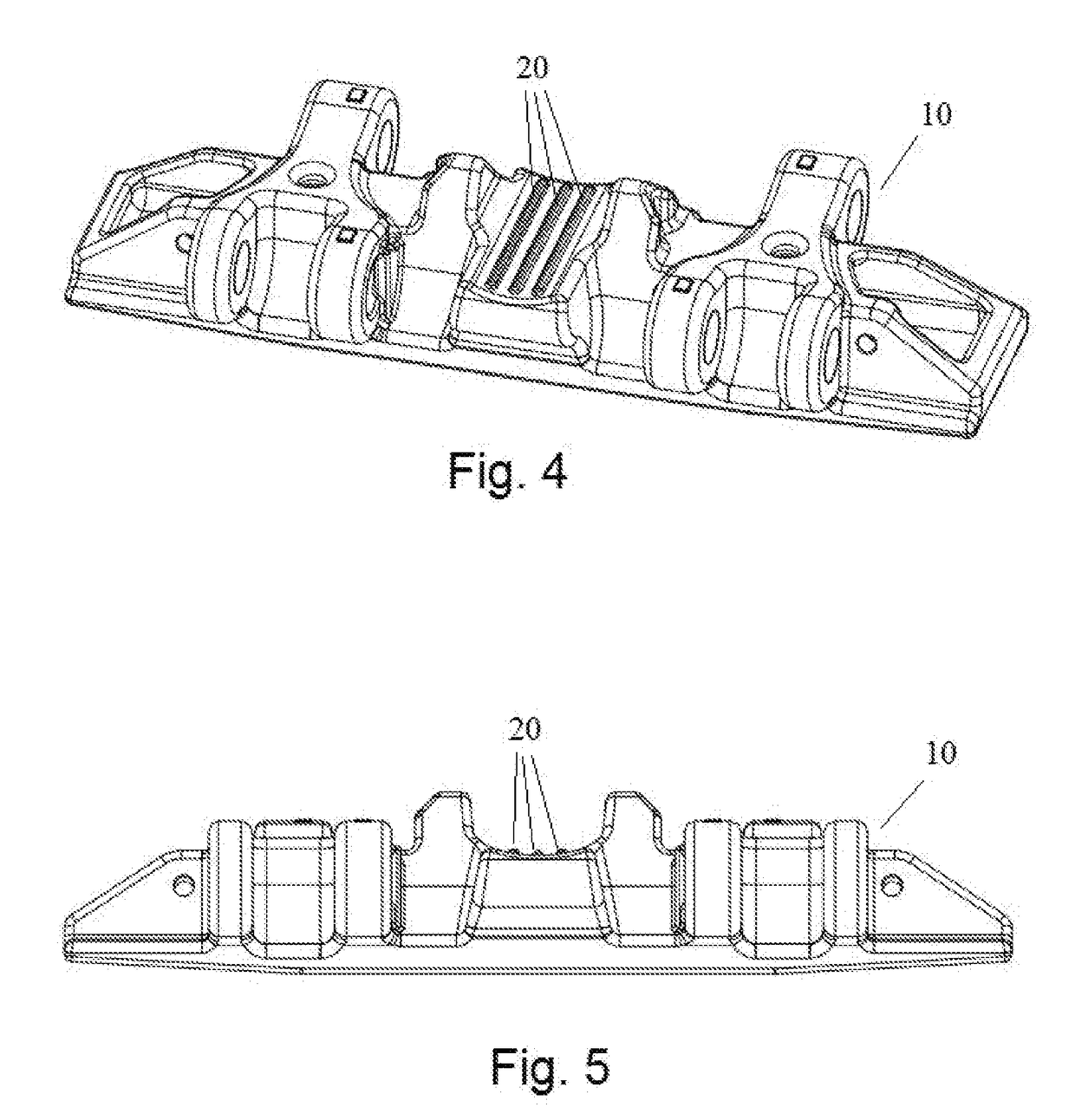

Explosive hardening of track shoes

InactiveUS20170275717A1Reduce removalReduce stressFurnace typesEndless track vehiclesShock waveEngineering

A component of a crawler type machine is hardened by explosive depth hardening. The component is typically a crawler track shoe (10), and the roller path surface (11) of the track shoe and immediate underlying metal portion are pre-hardened by placing explosive charge (15) on the surface of the track shoe (10), and detonating the explosive charge to impart a high force on the surface and underlying metal portion for a short duration. The resultant shock wave causes high-velocity deformation at a high stress level, which leads to intensive development of plastic displacement at microscopic size. This increases the hardness and the strength of the surface and underlying metal portion. The surface (11) may be hardened by repetitive explosive depth hardening. Grooves (20) may also be formed in the roller path (11) to accommodate any flow of material. Explosive depth hardening can be applied to other surfaces of the track shoe (10), such as the pin bore of a connection lug, or to other components such as a drive tumbler of the crawler.

Owner:BRADKEN RESOURCES

Aluminum-silicon-based welding wire for electric arc additive manufacturing and preparation method of aluminum-silicon-based welding wire

ActiveCN110340565AHigh strengthImprove toughnessAdditive manufacturing apparatusArc welding apparatusManufacturing technologyAlloy

The invention provides an aluminum-silicon-based welding wire for electric arc additive manufacturing and a preparation method of the aluminum-silicon-based welding wire, the reinforcing mode of the aluminum-silicon-based welding wire comprises alloy compensation and alloy strengthening; and the aluminum-silicon-based welding wire is composed of the following components, in percents by mass, Al-Si(6.5%-7.5%)-Mg(0.4%-1%)-Ce(0.4%-1%)-Mn(0.4%-0.6%). The preparation method comprises the following steps that pure aluminum, Al-Si intermediate alloy, Mg particles, Al-Ce intermediate alloy and Mn powder are used as raw materials to prepare a cast blank, and after homogenization heat treatment, the cast blank is subjected to hot extrusion, drawing and surface treatment, so that the welding wire isobtained. The aluminum-silicon-based welding wire is suitable for the electric arc additive manufacturing technology.

Owner:SHANGHAI JIAO TONG UNIV

Artificial hip joint with nano and porous structure on surface and preparation method thereof

InactiveCN101496749AImproves strength and hardnessReduce stress shieldingJoint implantsFemoral headsCotyloid CavityHuman organism

The invention relates to an artificial hip joint with surface nanometer and porous structure in the technical field of medical appliance and a preparation method thereof. In the artificial hip joint, the part of a femoral head handle or / and acetabulum combined with human organism has a scale of surface layer grains of between 1 and 500nm, and has an evenly distributed porous structure; and the artificial hip joint has a gradient nanometer structure from the surface inwards, the scale of the grains gradually increase along with increase of distance with the surface, until a scale of a conventional untreated state is achieved, and the thickness of the gradient nanometer layer is between 1 and 500 mu m. The preparation method comprises the following steps that: the artificial hip joint obtains the nanometer gradient structure layer by surface high-energy treatment technology; and then, the nanometer gradient structure layer is subjected to acid treatment so as to obtain a porous structure on the surface, thereby obtaining the artificial hip joint. The artificial hip joint and the method not only can effectively reduce stress shield effect of an implant body and a bone, but also can improve interface combination of the prosthesis and the bone, effectively improve the loosened implanted prosthesis, and have excellent application in the field of biomedicine.

Owner:SHANGHAI JIAO TONG UNIV

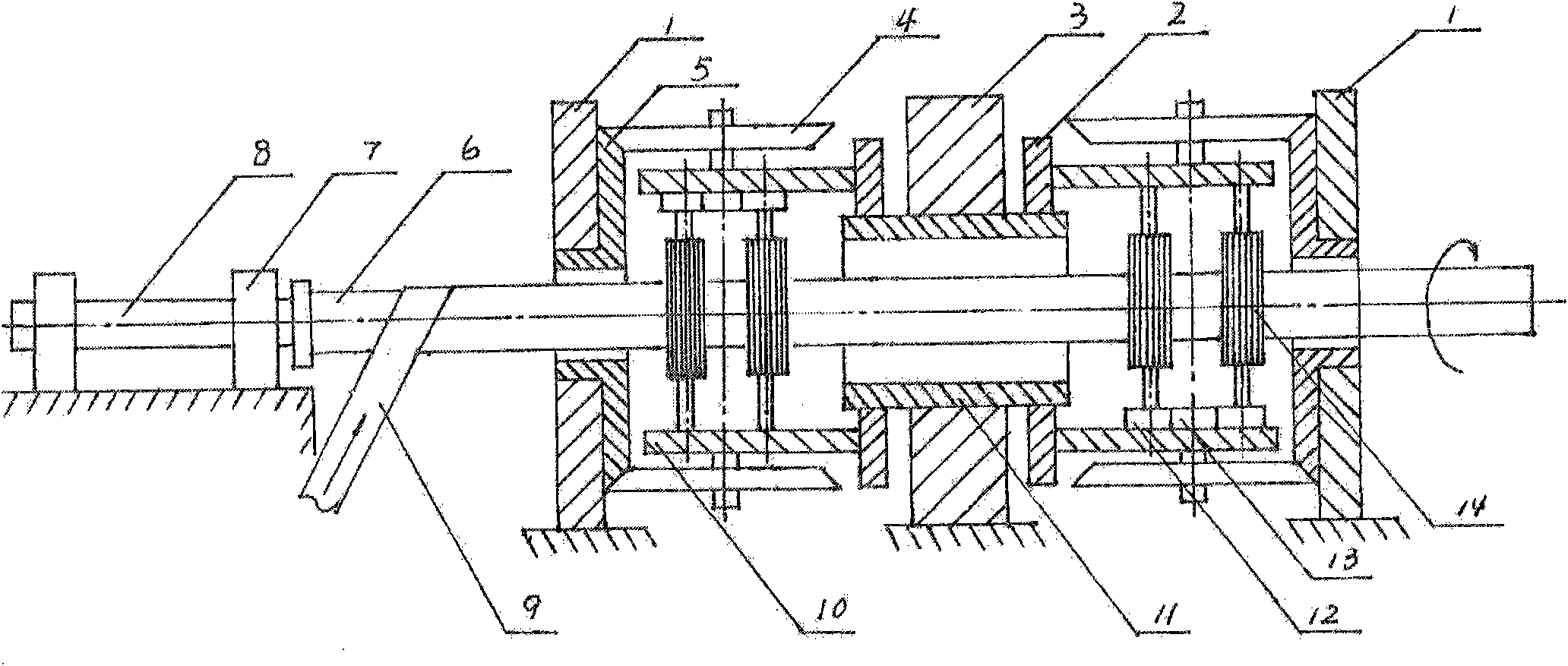

Spiral square paper tube manufacturing equipment

The invention discloses a piece of spiral square paper tube manufacturing equipment, which comprises a bevel seat, a driving chain wheel, a chain wheel seat, a driven bevel gear, a fixed bevel gear, an inner mold of a square tube, a gear connecting plate, a hollow shaft, a pinch roller shaft transmission gear, a pinch roller shaft driving gear, a pinch roller shaft, and a power device, wherein the power device drives the driving chain wheel so as to drive the pinch roller shaft to radially and axially rotate. Therefore, the manufacture of the square paper tube is finished. The problems of irregular shapes and inaccurate dimensions in the prior art are solved. The square tube manufactured by the invention has the advantages of accurate dimension, square shape, and high intensity and hardness. The length of the square tube is not limited by base paper width, and the shape of the fracture surface can be square or rectangular; and the manufactured square tube has less rebound, is not distorted or deformed, and has no special requirements on glue or other raw materials and higher production efficiency. Therefore, the spiral square paper tube manufacturing equipment and the technology have the advantages of simple structure, low investment cost, high dimension precision, high intensity and hardness, high production efficiency, and wide application range.

Owner:GUANGZHOU HAIFANG TECH CO LTD

Multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and manufacturing method thereof

ActiveCN107083508AImprove room temperature and high temperature mechanical propertiesImproves strength and hardnessRare-earth elementCorrosion resistant

The invention discloses a multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and a manufacturing method of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy. The ingredients of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy comprise pure magnesium ingots, pure zinc ingots, Mg-Gd alloy, Mg-Y alloy, Mg-Nd alloy, Mg-Ca alloy, Mg-Zr alloy and nanometer-scale NdN particles. The elements in the raw materials comprise, by mass, 3.5-5.0% of Gd, 1.0%-3.0% of Y, 0.5%-0.8% of Nd, 0.8%-1.5% of Zn, 0.3%-0.8% of Ca, 0.3%-0.6% of Zr, 0.5%-1.5% of nanometer-scale NdN particles and the balance Mg. The sequence of the mass percentage contents of the three rare earth elements of the Gd, the Y and the Nd from large to small is Gd>Y>Nd, and the mass percentage of the total addition amount of the three rare earth elements of the Gd, the Y and the Nd does not exceed 10%. The particle size of the nanometer-scale NdN particles is 80-150 nm. The steps of pretreatment and cladding of the NdN particles, preheating of the ingredients, smelting, refining, doping, pouring, sectioned solution treatment and artificial aging treatment are sequentially conducted, and then the fine, dispersive nanometer-precipitated-phase microscopic-structure heat-resistant corrosion-resistant magnesium alloy product is obtained. By the adoption of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and the manufacturing method of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy, the manufacturing cost is low, and the heat resistance and corrosion resistance of the magnesium alloy are excellent.

Owner:YANGZHOU FENG MING METAL PROD +1

Water-based heavy-duty single-component on-rust primer, and preparation method and application thereof

The invention discloses a water-based heavy-duty single-component on-rust primer, and a preparation method and application thereof. The water-based heavy-duty single-component on-rust primer is composed of deionized water, a main conversion agent, an auxiliary conversion agent, a penetrant, a film forming assistant, an antifreezing agent, a preservative, a thickener, a filler, a defoaming agent, a dispersing agent, a pH regulator, a film forming material and a substrate wetting agent. The temperature of the used substrate can not be too high, the humidity can not be greater than 85%, the one-time spray coating can not be too thick, and the position for electric welding is reserved. The product is stored at 5-40 DEG C in a ventilating cool dry place, and the construction temperature is preferably 10-40 DEG C. The primer can be applied by brush coating, roller coating, air spraying or airless spraying, the particular mode can be selected according to the on-site construction environment and climate conditions, and brush coating and airless spraying are suggested if conditions permit.

Owner:山东兴鲁化工股份有限公司

Preparation method of powder metallurgy gear with excellent performance

InactiveCN104043836AUniform composition and densityImproves strength and hardnessPowder metallurgyCarburizing

The invention discloses a preparation method of a powder metallurgy gear with excellent performance and belongs to the technical field of powder metallurgy. The method comprises the steps that 1, mixing and stirring; 2, pressing and forming: powder metallurgy mixture is placed in a pressing machine, and the mixture is pressed into green body pieces; 3, sintering: the green body pieces are placed into a sintering furnace to be sintered; 4, heat treatment: the workpieces obtained from the step 3 are quenched and then tempered, and the workpieces are subjected to carbonitriding in a carburizing furnace, the workpieces are cooled to room temperature, and finished products are obtained by finish machining. According to the preparation method of the powder metallurgy gear with the excellent performance, the rigidity and the intensity of the tooth surface of the produced gear are improved by specific composition proportion, the abrasive resistance is enhanced, coal ash and gas ash are used as specific components of the powder metallurgy gear, and metallurgy waste is subjected to resource utilization.

Owner:WUHU WATER PUMP MFG

Production process for bright titanium wire

InactiveCN102319762AReduce grinding wheel grinding processReduce acid and alkali washing processDrawing diesExtrusion cleaning devicesSocial benefitsEconomic benefits

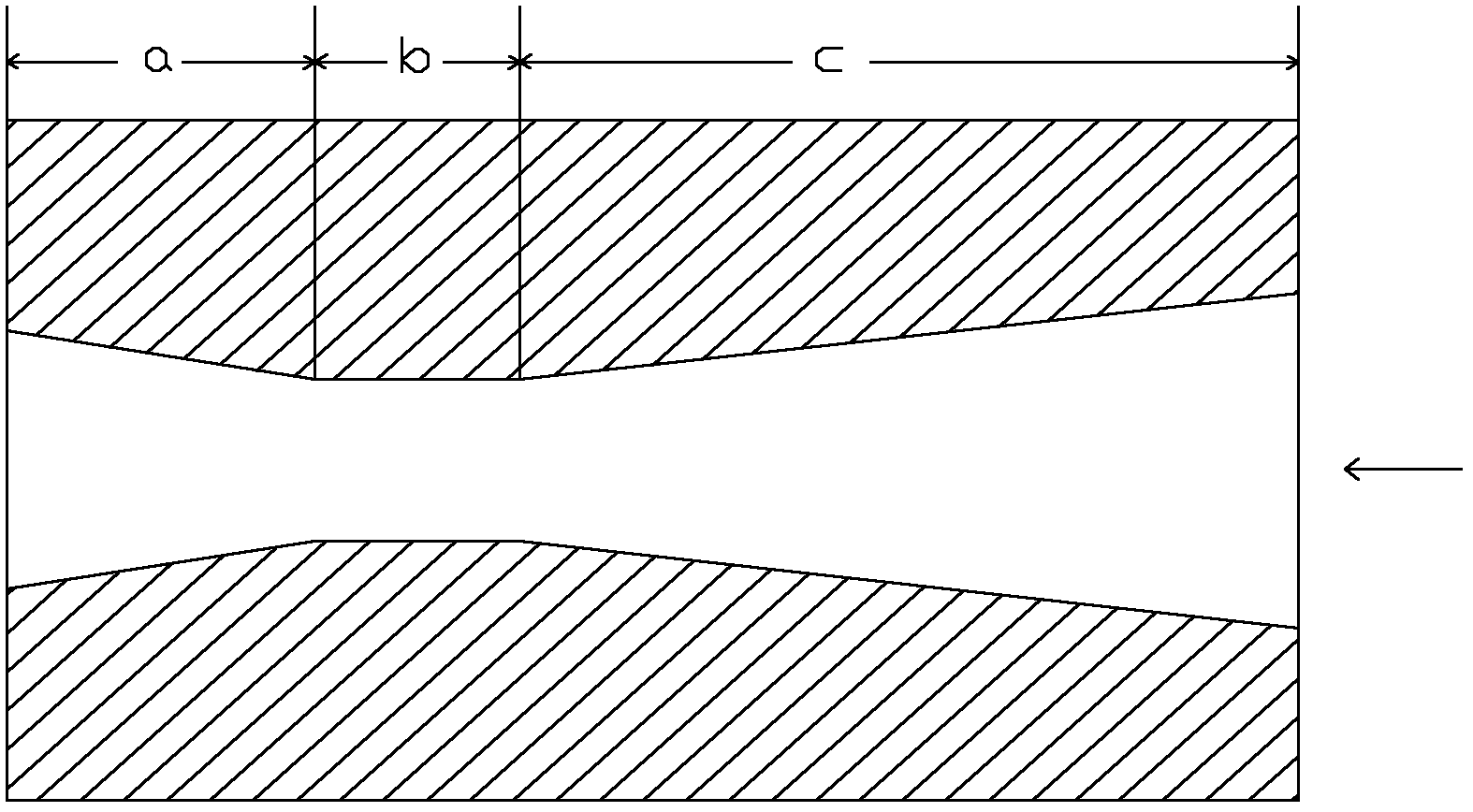

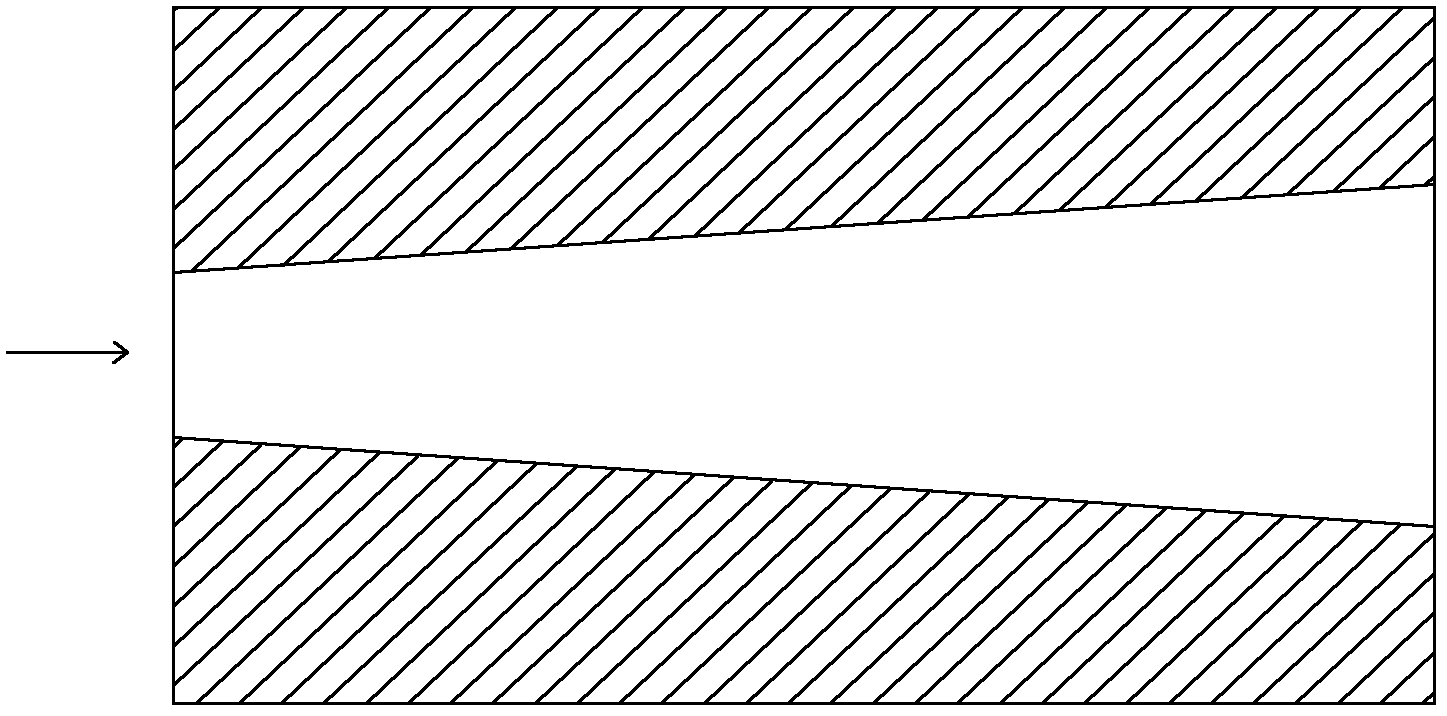

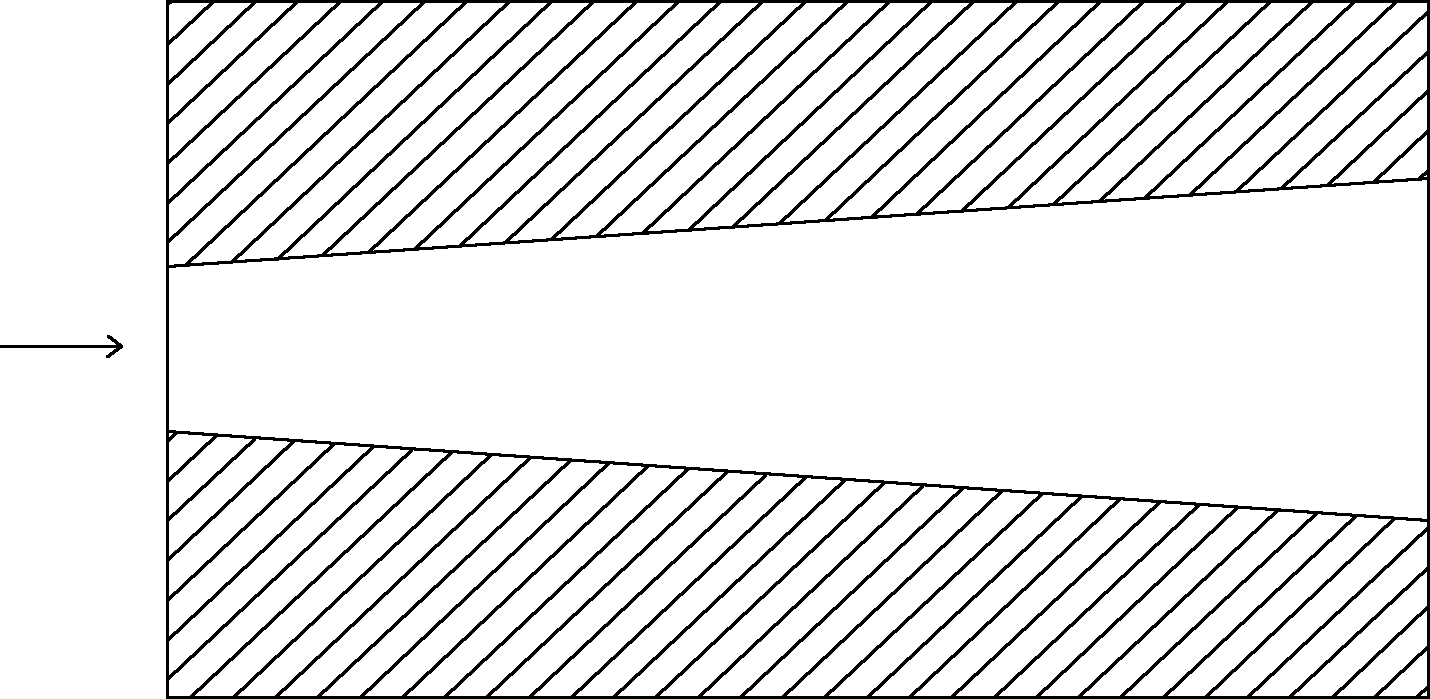

The invention aims at providing a production process for a bright titanium wire, which can be used for overcoming the defects in a traditional process. The production process comprises the process flows of cogging and rolling of titanium ingots, wire drawing, descaling and obtaining finished products, wherein the step of descaling is finished by the step that a titanium wire is introduced from a small port and drawn out of an expansion port by using a scalping die provided with a horn port in the middle. According to the improved production process for the titanium wire, a work procedure of coping a grinding wheel and an acid-alkali washing work procedure are omitted; titanium chips generated by wire drawing and scaling can be recycled; no pollution from acid and alkali is generated; and the drawn titanium wire has a bright and attractive surface, enhanced strength and hardness, favorable elasticity and more perfect service effect. In addition, the production process disclosed by the invention has a favorable economic benefit; in the known production process, about 15 percent of loss is generated and cannot be recycled; and in the improved process disclosed by the invention, about 1.3 percent of loss is generated and can be recycled. The improved production process has no pollution to the environment and a better social benefit.

Owner:BAOJI YONGXING NON FERROUS METAL MATERIALS CO LTD

High-stability coating with good thermal resistance and adhesion property

InactiveCN105969162AImproves strength and hardnessImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyAcrylic resin

The invention discloses a high-stability coating with good thermal resistance and adhesion property. The high-stability coating is prepared from the following raw materials: modified polyurethane, epoxy resin, phenolic resin, chlorosulfonated polyethylene, acrylic resin, modified epoxide resin, methyl hydroxyethyl cellulose, methyl ethyl ketone, ethyl acetate, ethyl cellulose, attapulgite, kieselguhr, zinc oxide, calcium sulfate, calcined kaolin, nano-montmorillonite, nano-aluminum hydroxide, organic bentonite, a silane coupling agent KH760, phenyl petroleum sulfonate, citrate, a defoaming agent, an anti-mold agent and a curing agent. The high-stability coating is excellent in thermal resistance, high in pencil hardness and good in adhesion property and stability.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

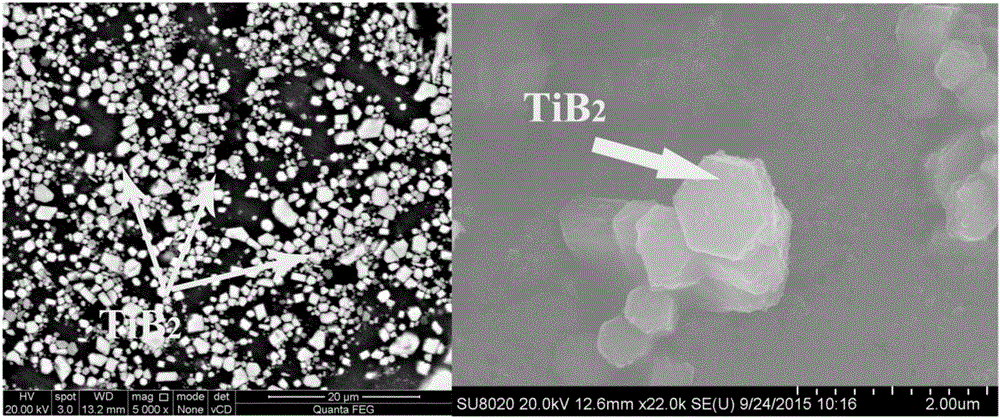

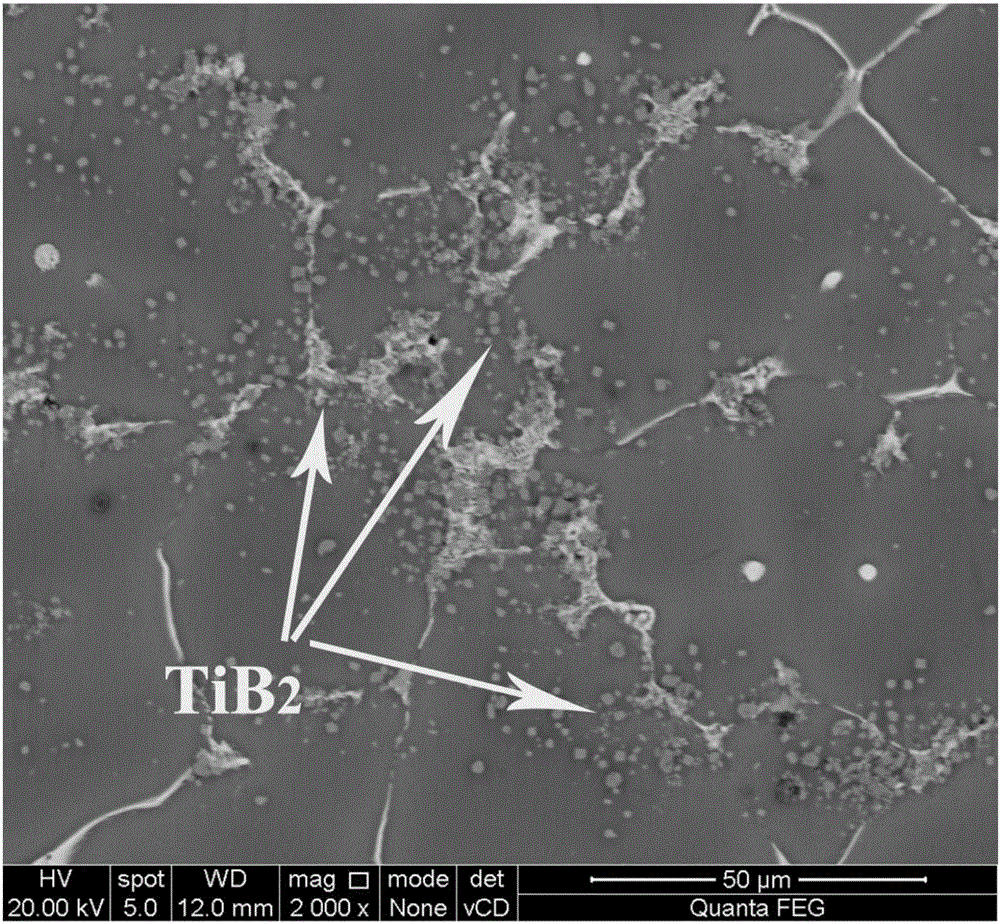

Super-high strength and high hardness TiB2 particle reinforced Al-Zn-Mg-Cu composite material and preparation method thereof

The invention discloses a super-high strength and high hardness TiB2 particle reinforced Al-Zn-Mg-Cu composite material and a preparation method thereof, and belongs to the field of composite materials. Al-Zn-Mg-Cu alloy serves as a matrix, TiB2 with the mass fraction being 3%-10% and with the average size smaller than 1 micron serves as reinforcing particles, and the Al-Zn-Mg-Cu alloy matrix comprises, by mass, 8%-10% of Zn, 1.0%-2.0% of Mg, 1.0%-1.5% of Cu, 0.05%-0.20% of Zr, and the balance Al. Al-TiB2 intermediate alloy is prepared through a melt self-propagating direct synthetic method, proportioning and smelting are carried out according to the design ingredients of the composite material, the Al-TiB2 intermediate alloy serves as a matrix, an Al ingot, a Zn ingot, a Mg ingot, Al-Cu intermediate alloy and Al-Zr intermediate alloy are added, standing is carried out after stirring, and casting is carried out. The TiB2 particles are uniform in distribution and small in dimension, and both the strength and hardness are remarkably improved compared with those of the matrix alloy.

Owner:BEIJING UNIV OF TECH

Smelting preparation method for anti-yielding aluminum alloy section bar

ActiveCN103103401AComposition is stableImproves strength and hardnessSurface oxidationSmelting process

The invention discloses a smelting preparation method for anti-yielding aluminum alloy section bar. The smelting preparation method comprises the following operation steps: preparing aluminum alloy melt, wherein the aluminum alloy melt is prepared from the following materials in parts by weight: 55-65 parts of 3003 aluminum ingots, 32-42 parts of waste aluminum products, 5-10 parts of boron carbide and 5-10 parts of nanometer quartz sand powder, and the fineness of the boron carbide is 5 microns to 8 microns; adding the materials to a smelting furnace; scattering a layer of covering agent to the surface of the melt to cover the melt when the furnace materials are heated up to be softened and collapsed, wherein the covering agent comprises the following components in parts by weight: 10-20 parts of CaO, 10-25 parts of Al2O3, 35-45 parts of SiO2, 12-30 parts of C and 12-23 parts of coal ashes. According to the smelting preparation method disclosed by the invention, the waste aluminum materials are added to the material ingredients for facilitating the stabilizing of the performances of the aluminum section bar and reducing the possibility that the quality of the aluminum section bar is affected by undetected materials during the smelting process of the melt. The ingredients are further optimized and the hardness and strength of the aluminum alloy are increased, so that the comprehensive performances of the aluminum alloy section bar are improved; and the chromizing treatment is carried out on the surface of the aluminum alloy section bar, so that the corrosion resistance of the oxide film on the surface of the aluminum alloy section bar and the binding force of the aluminum alloy section bar and the coating are improved.

Owner:江苏兴甬铝业科技有限公司

Iron-based electrode material with pure copper transition layer and surface pure metal molybdenum or tungsten coating and preparation method for electrode material

InactiveCN103029370AEasy to processImprove conductivitySuperimposed coating processMetal layered productsChemical platingContact resistance

The invention discloses an iron-based electrode material with a pure copper transition layer and a surface pure metal molybdenum or tungsten coating and a preparation method for the electrode material. The preparation method comprises the following steps: coating pure copper with certain thickness on the surface of an iron-based material to serve as a transition layer by electric brush plating or chemical plating and sputter plating technologies; and depositing metal molybdenum or tungsten by a sputter plating technology to form the novel iron-based electrode material with the pure copper transition layer and the surface pure metal molybdenum or tungsten coating. The iron-based material serves as the electrode material, so the electrode material has high processability, high conductivity, high strength and low cost. One layer of copper is plated on the electrode material, so the conductivity is enhanced; and the copper layer serves as the transition layer, so the film substrate bonding strength of the surface pure metal molybdenum (or tungsten) layer is enhanced; and the surface pure metal molybdenum (or tungsten) has the advantages of corrosion resistance, high strength and hardness and low electrical resistivity, so the specific energy and the specific power of the electrode can be greatly increased, the contact resistance maintains constant and the electric energy consumption is stable and low.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Blue ssuperindividual corundum and preparation method thereof

ActiveCN101906663AChemically stableNo pollution in the processPolycrystalline material growthSingle crystal growth detailsAluminium fluorideZirconium dioxide

The invention discloses a blue superindividual corundum and a preparation method thereof. The preparation method comprises the following steps of: carrying out mixing, smelting, temperature reduction solidification, blowing-in grinding, magnetic separation impurity removal, screening and secondary magnetic separation impurity removal on one ton of alumina powder, anatase titanium dioxide, titanium stone powder, aluminium fluoride and zirconium dioxide powder; and then carrying out magnetic separation by using a magnetic separator so as to obtain the blue superindividual corundum. Because iron ores are not used, the smelting process causes no smoke and odour, and the processing process of a product causes no hydrogen sulfide gas, therefore the whole production process causes no pollution to the environment; in addition, because a right amount of the zirconium dioxide is added, the zirconium dioxide and the alumina appear in a crystal combining way, therefore true specific weight and granularity are obviously increased, chemical property is more stable, strength achieves 33 N, density achieves 4.02 g / cm<3>, the content of Al2O3 contained in the blue superindividual corundum achieves more than 99.55 percent, and the content of various impurities is lower.

Owner:XIXIA ZHENGHONG MONOCRYSTALLINE CORUNDUM

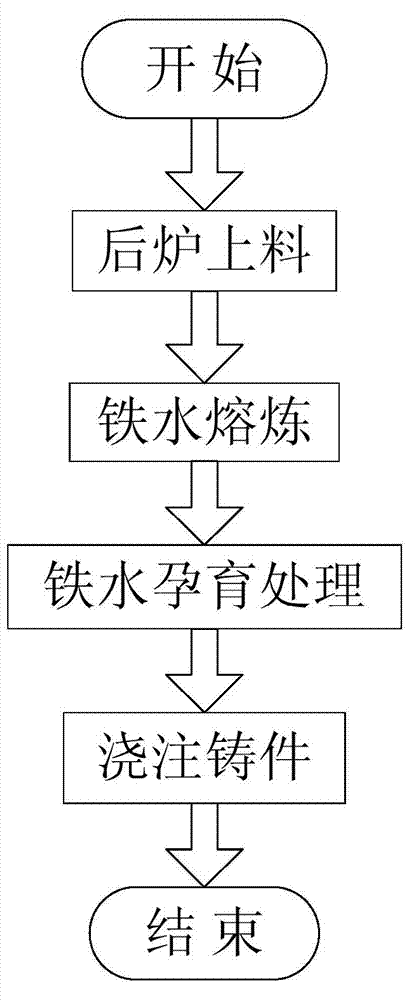

High-grade grey cast iron casting method

The invention discloses a high-grade grey cast iron casting method. The method specifically comprises the following steps: firstly, a rear-furnace charging step; secondly, a molten iron smelting step, wherein added furnace charge is molten into molten iron, molten iron high-temperature refining is carried out after components of the molten iron are adjusted, and the adjusted molten iron components include: 2.8%-3.3% of carbon, 1.6%-2.1% of silicon, 0.2%-0.4% of manganese, 0.02%-0.07% of phosphor, 0.02%-0.06% of sulfur, 0.2%-0.4% of chromium, 0.3%-0.6% of copper, and 0.04%-0.1% of tin; thirdly, a molten iron inoculation treatment step; finally, a casting piece casting step. According to the high-grade grey cast iron casting method disclosed by the invention, the strength and hardness of a casting piece are improved by lowering addition of normal alloys manganese, sulfur, copper and tin in the gray iron casting production; the noble metals are not added, so that the casting piece product is prevented from generating the defects such as cavity shrinkage and porosity shrinkage while the production cost is lowered.

Owner:GUANGXI YUCHAI MASCH CO LTD

Thermochromic glass

InactiveCN107718777AImprove light absorption capacityImproves strength and hardnessSynthetic resin layered productsGlass/slag layered productsProtective glassesSilver sulfide

The invention discloses thermochromic glass. The thermochromic glass comprises anti-scratching film layers, protective glass layers, a thermochromic layer, arc-shaped rims, filling grooves, adhesion layers and shading gratings, wherein the thermochromic layer is designed in a center layer of the thermochromic glass, the protective glass layers are adhered to the upper and lower surfaces of the thermochromic layer, the anti-scratching film layers are adhered to the outer end surfaces of the protective glass layers, and the arc-shaped rims are designed at the outer ends of the left and right sides of the thermochromic glass and are filled with the adhesion layers. The thermochromic layer of the thermochromic glass is prepared by the steps of adding a small amount of silver sulfide into sodium aluminum borate glass as a photosensitizer, adding a trace amount of copper and cadmium ions as a sensitizer, preparing glass through fusion, carrying out thermal treatment at a proper amount to accumulate silver sulfide into particles; and the thermochromic layer is capable of effectively absorbing thermal radiation or long wave light, and light transmitting the thermochromic layer under burning sun becomes soft, shady and cool, so that the light blocking and absorbing capacities of glass are enhanced, and the hardness and the strength are enhanced.

Owner:安徽光为智能科技有限公司

Aluminum alloy used for casting pot and manufacturing method of aluminum alloy

InactiveCN106011556AImproves strength and hardnessImprove wear resistanceTetraethyl orthosilicateSodium silicate

The invention discloses an aluminum alloy used for casting a pot and a preparing method of the aluminum alloy. The aluminum alloy is formed by smelting an aluminum alloy base body and an additive. The additive is composed of iron powder, magnesium oxide powder, rare earth fluoride, nano-zinc powder, potassium permanganate, rutile powder, sodium fluosilicate, modified silicon dioxide, bentonite and sodium carbonate. The modified silicon dioxide is formed by adding acetic acid into a deionized water solution of tetraethyl orthosilicate for hydrolysis. Due to the fact that the substance including the iron powder, the magnesium oxide powder, the nano-zinc powder and the like is added into the aluminum alloy base body, the potassium permanganate is decomposed to generate oxygen and manganese dioxide at a high temperature, the generated manganese dioxide can be arranged in the aluminum alloy base body in a filling manner to enhance wear resistance of the base body, furthermore, the iron powder in the aluminum alloy can be oxidized, and therefore iron oxide, magnesium oxide and aluminum oxide can be combined at the high temperature to generate wild phases similar to iron-aluminum spinel and magnesia-aluminum spinel; and the wild phases are dispersed and distributed in a whole system, and therefore the melting point, strength and wear resistance of the final aluminum alloy are improved.

Owner:PINGDINGSHAN MEIYI METAL PROD

Modified 6063T6 aluminum alloy and processing method thereof

The invention discloses a modified 6063T6 aluminum alloy and a processing method thereof. The total weight of the aluminum alloy is improved, and the modified aluminum alloy is prepared from the following chemical components: 0.45-0.50% of Si, 0.65-0.70% of Mg, 0.02-0.10% of Cu, less than or equal to 0.23% of Fe, less than 0.10% of Mn, less than 0.10% of Cr, less than 0.01% of Zn, less than 0.1% of Ti, and the balance Al. The modified 6063T6 aluminum alloy has high strength, high hardness and high elongation, has the mechanical property reaching 6061T6 standard, and can replace 6061T6 aluminumalloy, thereby reducing the production cost.

Owner:湖南海铝汽车工业有限公司

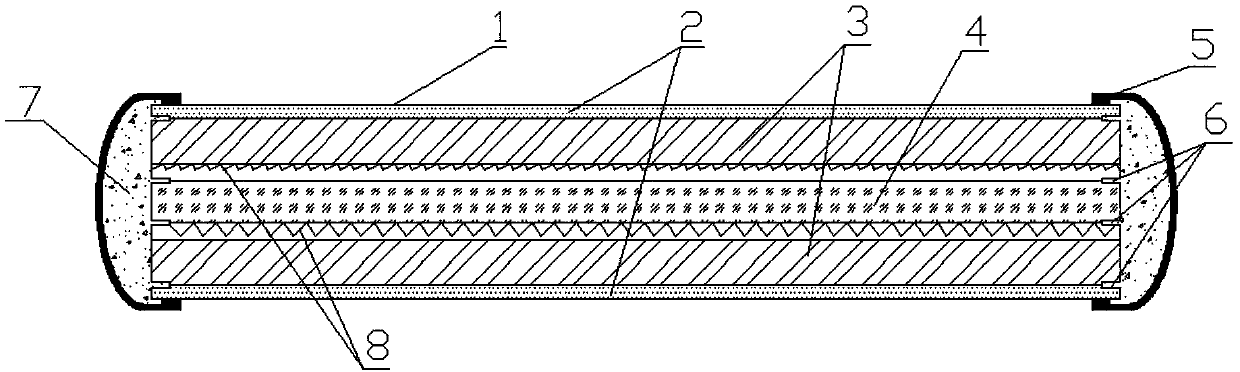

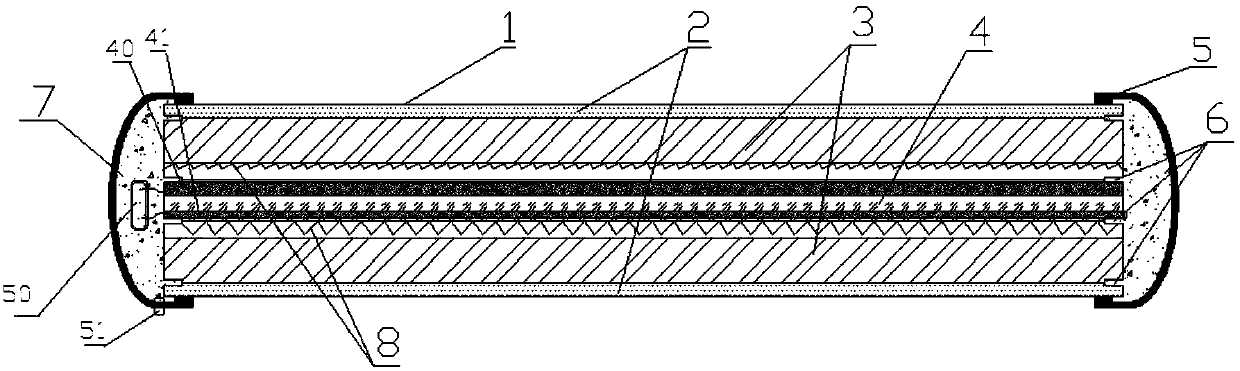

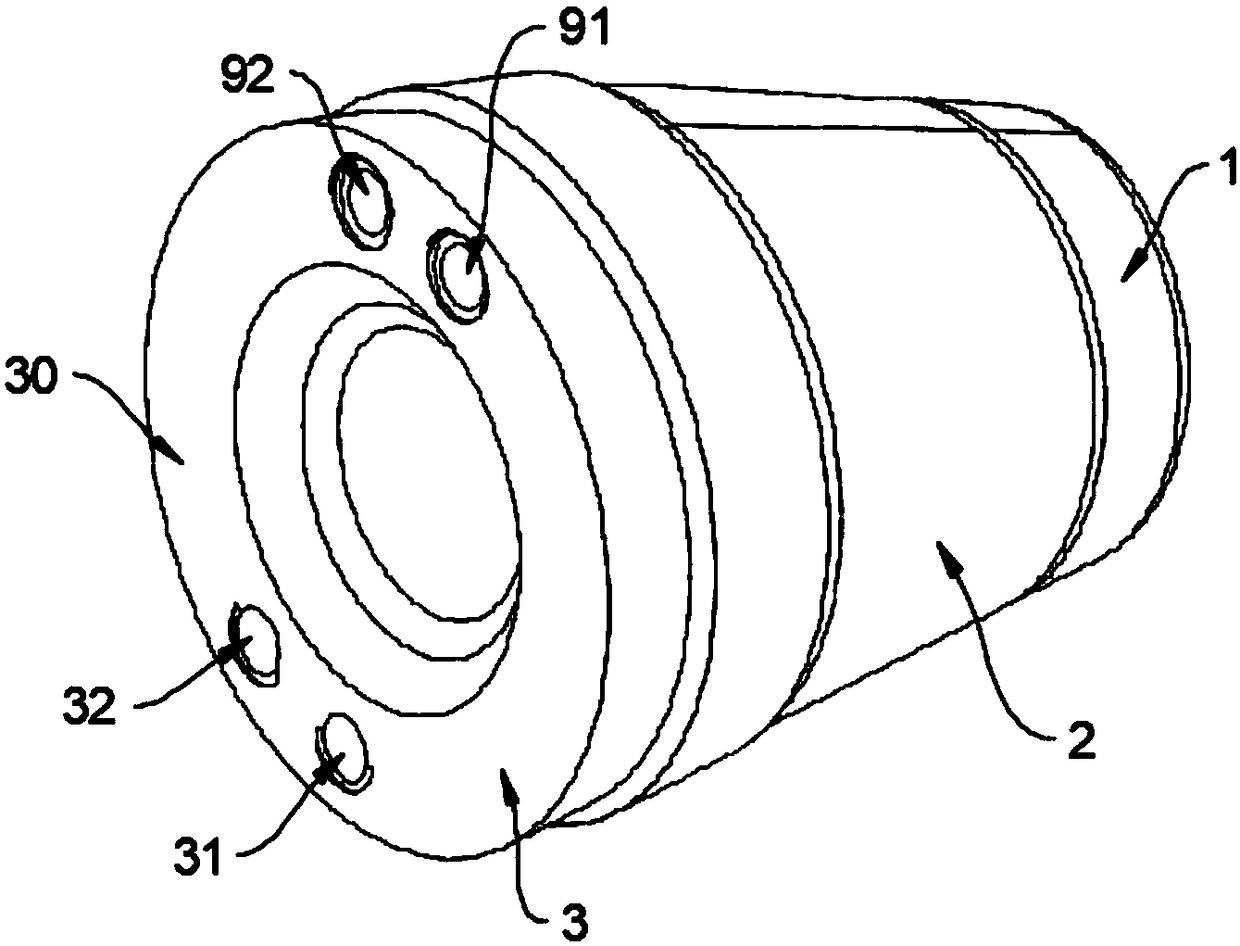

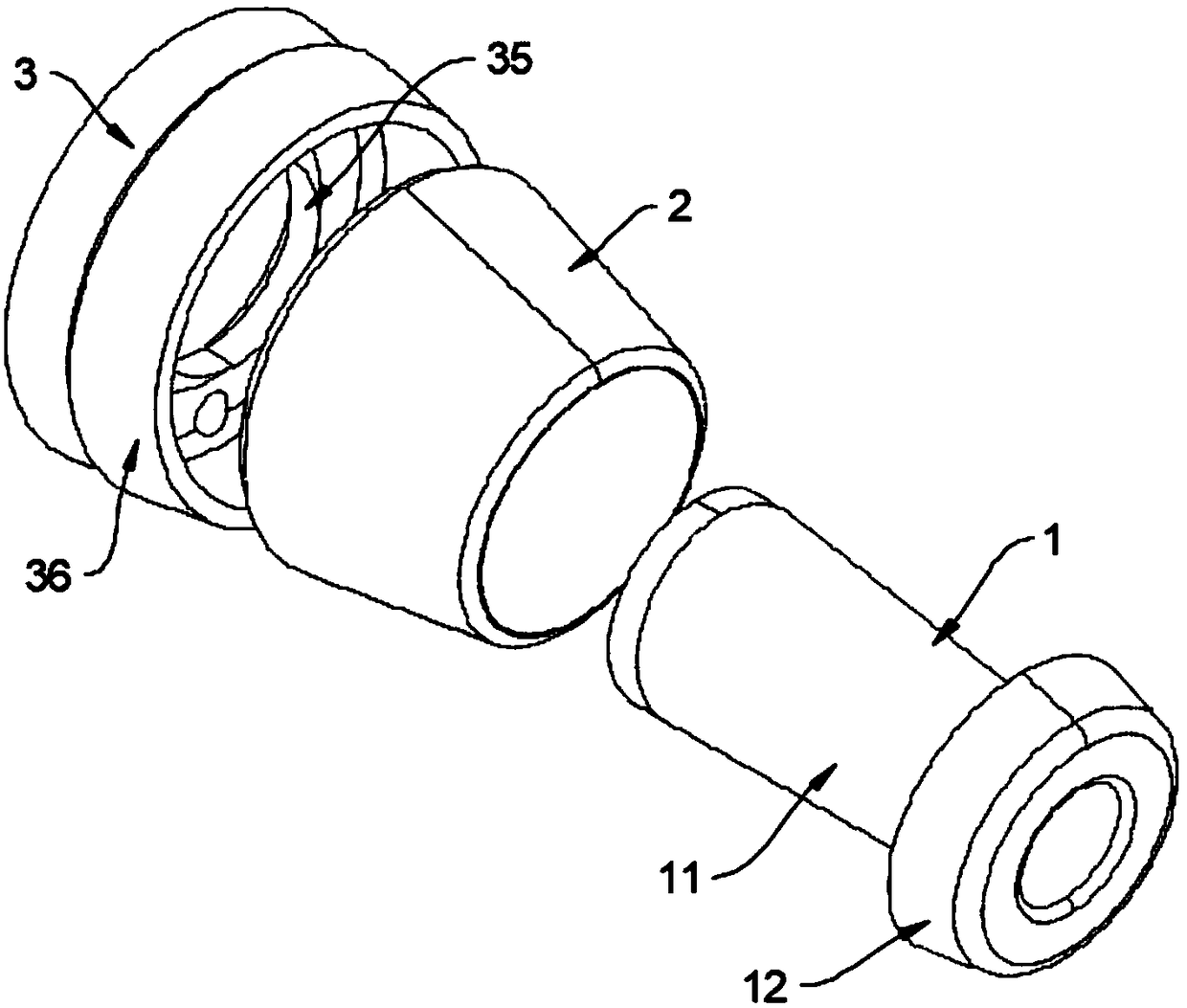

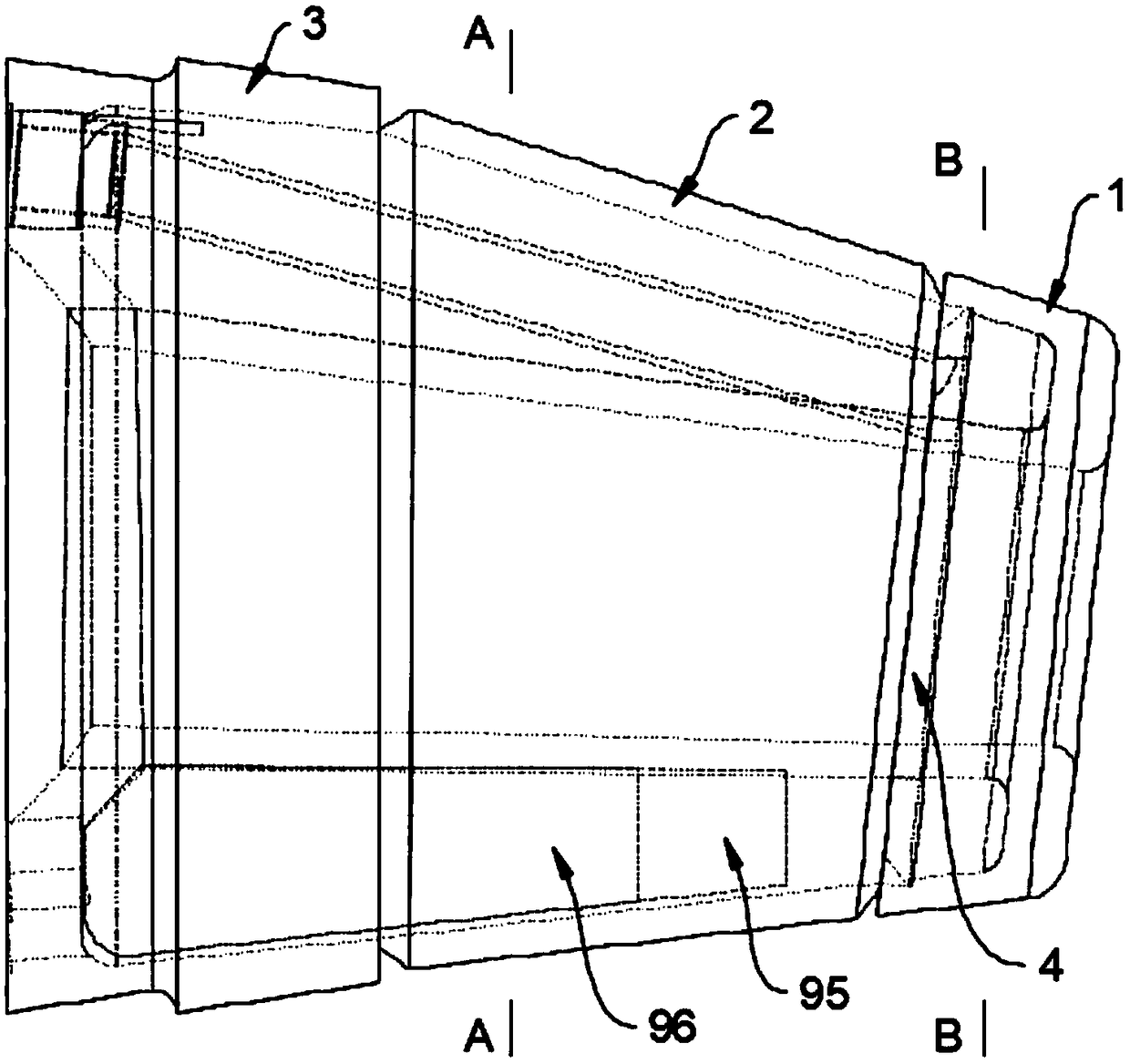

Blast furnace cooling tuyere

Disclosed is a blast furnace cooling tuyere. The blast furnace cooling tuyere comprises a front cap, a middle cap and a rear cap, wherein a cavity structure is enclosed by the front cap, the middle cap and the rear cap. A partition plate is arranged between the front cap and the middle cap to divide the cavity structure into a front cavity and a rear cavity. A cooling water inlet pipe and a cooling water outlet pipe are arranged in the rear cavity. The partition plate is provided with a partition plate water inlet hole and a partition plate water outlet hole. The cooling water inlet pipe and the cooling water outlet pipe communicate with the partition plate water inlet hole and the partition plate water outlet hole correspondingly. The front cavity is internally provided with a front cavity partition plate, and the front cavity partition plate is positioned between the partition plate water inlet hole and the partition plate water outlet hole. The cooling capability of a tuyere small sleeve can be improved, and the hidden danger of water leakage caused by a traditional casting structure can be eliminated, so that the service life of the tuyere can be prolonged, and the service quality and the combustion rate are improved.

Owner:常州市武进长虹结晶器有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com