Thermochromic glass

A color-changing glass and color-changing layer technology, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve problems such as inability to enter the ride, interfere with the driver's line of sight, and rise in temperature, so as to improve light-blocking absorption Ability, absorption and filtration effect is obvious, the effect of hardness and strength increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

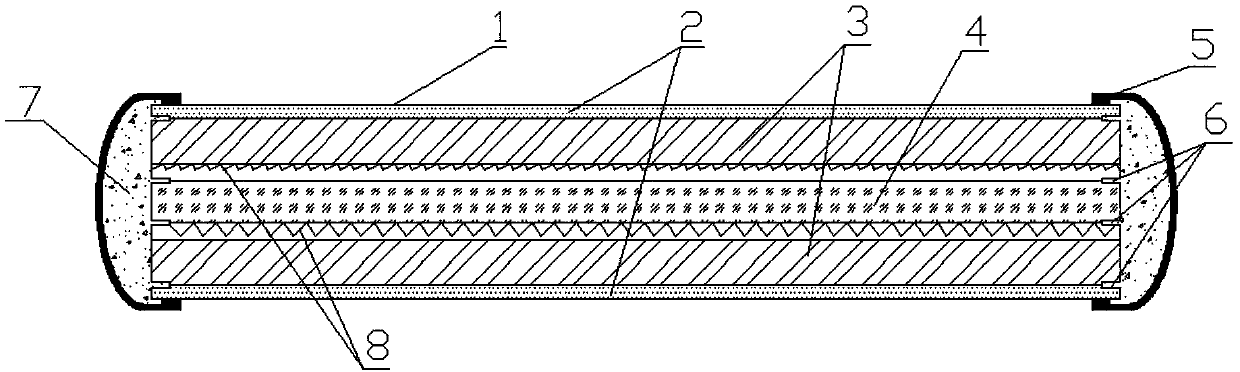

[0022] see figure 1 As shown, the present invention provides a technical solution: a color-changing glass, the color-changing glass 1 includes an anti-scratch film layer 2, a protective glass layer 3, a color-changing layer 4, an arc-shaped periphery 5, filling grooves 6, bonding Layer 7 and blocking grating 8, the central layer of the color-changing glass 1 is designed as a color-changing layer 4, the upper and lower sides of the color-changing layer 4 are pasted with a protective glass layer 3, and the outer end surface of the protective glass layer 3 is pasted with anti-scratch layer 2, the outer ends of the left and right sides of the color-changing glass 1 are designed with an arc-shaped periphery 5, and the interior of the arc-shaped periphery 5 is filled with an adhesive layer 7.

[0023] Further, a filling groove 6 is provided at the edge between each layer of the color-changing glass 1 , the length of the filling groove 6 is consistent with the width of the color-chan...

Embodiment 2

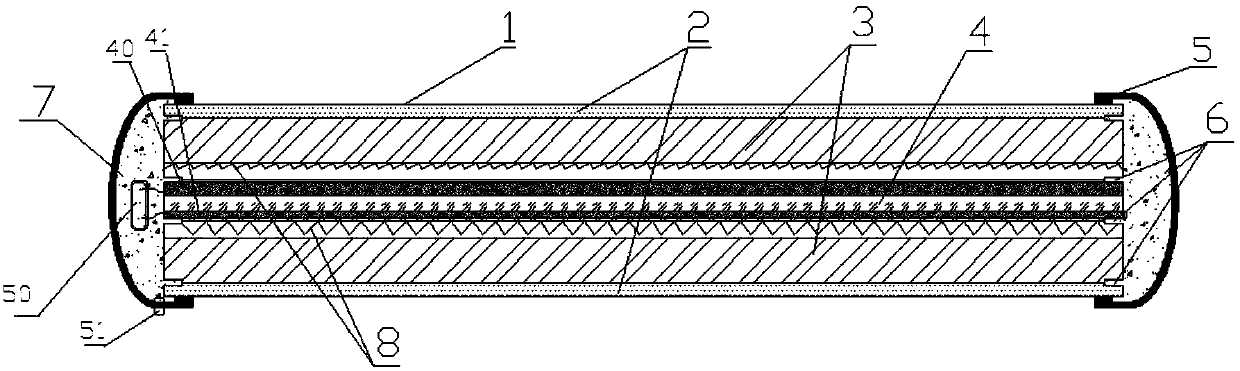

[0032] A color-changing glass. The difference between this embodiment and Embodiment 1 is that the color-changing glass 1 is designed as an anti-scratch film layer 2 , a protective glass layer 3 , a color-changing layer 4 and an anti-scratch layer 2 from outside to inside.

[0033] The reflection color measured through the surface of the color-changing glass 1 was black using a MINOLTA colorimeter CR-300, and the visible light transmittance was 11% and the ultraviolet transmittance was 1.1% using a Hitachi spectrophotometer U4000.

Embodiment 3

[0035] A color-changing glass. The difference between this embodiment and Embodiment 1 is that the color-changing layer 4 is specifically sodium aluminoborosilicate glass, and a small amount of silver sulfide and cadmium sulfide are added inside the color-changing layer 4 as photosensitizers and cuprous oxide as photosensitive agents. Sensitive agent, the thickness of color-changing layer 4 is designed to be 1~2mm.

[0036] The reflection color measured through the surface of the color-changing glass 1 was pink using a MINOLTA colorimeter CR-300, and the visible light transmittance was 15% and the ultraviolet transmittance was 1.2% using a Hitachi spectrophotometer U4000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com