Novel UV-LED ultraviolet crosslinked polyethylene cable material and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

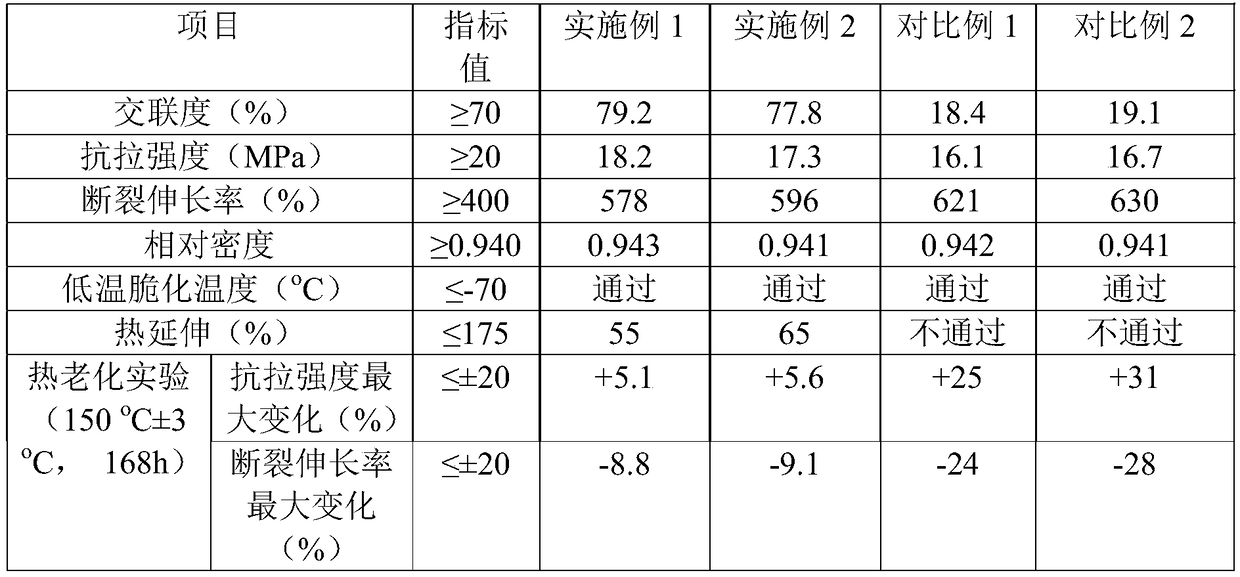

Examples

Embodiment 1

[0021] Each raw material is prepared according to the following formula: 100 parts of linear low density polyethylene (7042), 1.8 parts of TPO, 1.2 parts of TAC, 1.3 parts of epoxybutane, 0.2 part of antioxidant 1010 and 0.1 part of DLTP; Stir in the feeder at a speed of 250rpm for 5 minutes to obtain the mixture; preheat the extruder to 170°C, put in the above mixture, make the mixture fully plasticized, extrude and enter the water tank to cool, and then enter the UV-LED ultraviolet light Irradiation is carried out in the irradiation cross-linking equipment, and the irradiation time is 3s to obtain ultraviolet light irradiation cross-linked polyethylene wires and cables.

Embodiment 2

[0023] Prepare raw materials according to the following formula: 80 parts of high-density polyethylene (5000s), 20 parts of linear low-density polyethylene (7042), 1.2 parts of ITX, 1.2 parts of TMPTA, 1.0 parts of epoxybutane, 0.3 parts of antioxidant 1010 and 0.1 part of DLTP; the above raw materials were stirred in a mixer at a speed of 250rpm for 5 minutes to obtain a mixture; the extruder was preheated to 165°C, and the above mixture was put in to make the mixture fully plasticized, extruded and entered The water tank is cooled, and then enters the UV-LED ultraviolet light irradiation crosslinking equipment for irradiation, and the irradiation time is 3s to obtain ultraviolet light irradiation crosslinked polyethylene wires and cables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com