Method for preparing bisphenol A nanometer silicon gel carrier surface molecule print solid phase extraction filling

A nano-silica gel and carrier surface technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as memory residue and template elution difficulties, and achieve many imprinting sites, easy chemical structure modification and design, and high rigidity and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

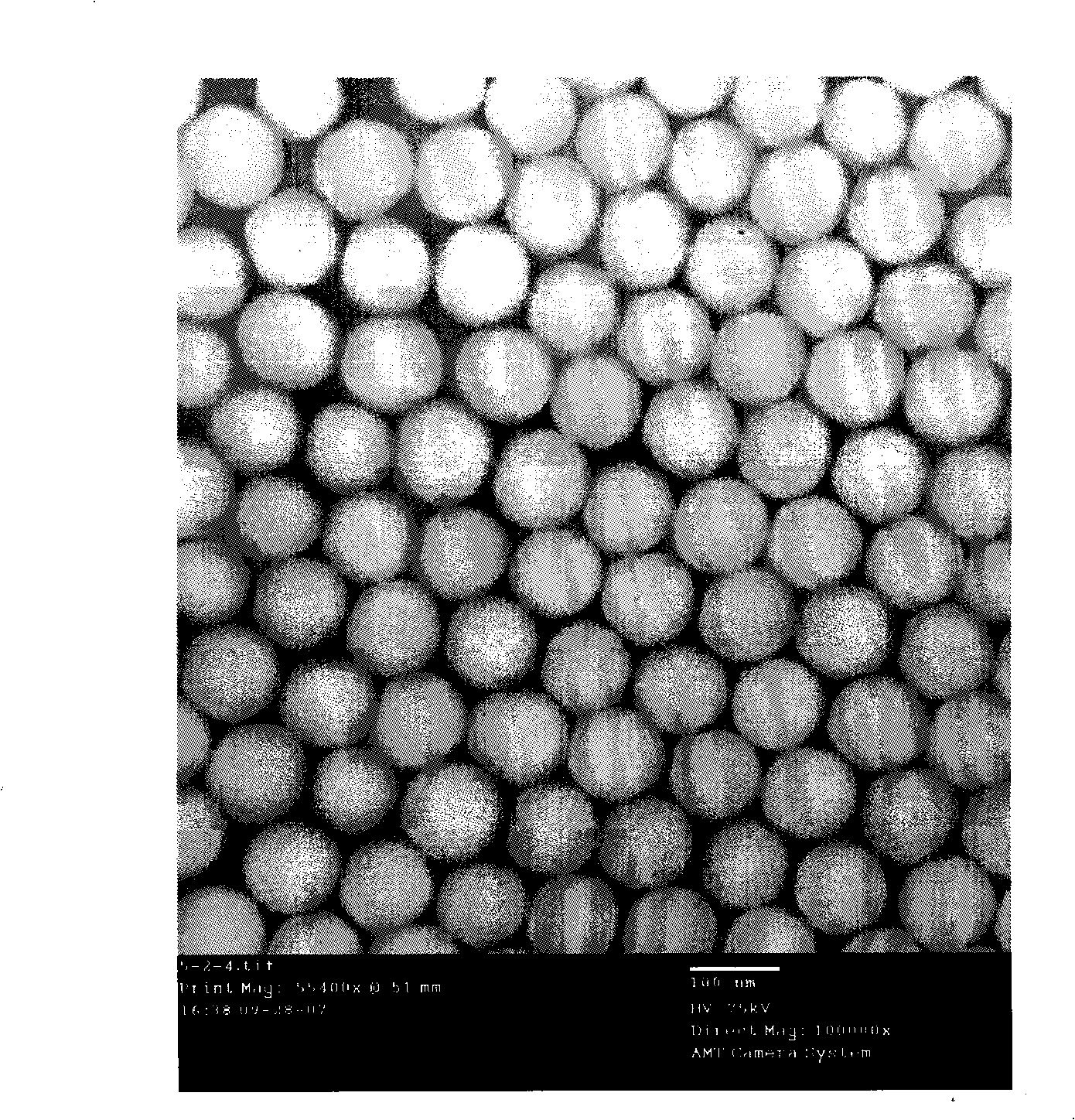

[0022] Preparation of nanoscale silica:

[0023] Preparation of 100nm silica

[0024] Add 100ml of absolute ethanol to a 250ml round bottom flask, then add 3.85ml of concentrated ammonia water and 1.8ml of distilled water, stir at 500r / min for 3min, then add 3.6ml of tetraethyl orthosilicate dropwise for 15-20h, then centrifuge at 10000r / min , discard the supernatant, and add absolute ethanol to ultrasonically wash three times to obtain 100nm silica pellets.

[0025] Preparation of 200nm silica

[0026] Add 88ml of absolute ethanol to a 250ml round bottom flask, then add 11.9ml of concentrated ammonia water, stir at 500r / min for 3min, then add 3.6ml of tetraethyl orthosilicate drop by drop, react for 15-20h, centrifuge at 10000r / min, discard After cleaning with anhydrous ethanol and ultrasonic cleaning three times, 200nm silica pellets were obtained.

[0027] Preparation of 400nm silica

[0028] Add 44ml of absolute ethanol to a 100ml round bottom flask, then add 5.95ml of...

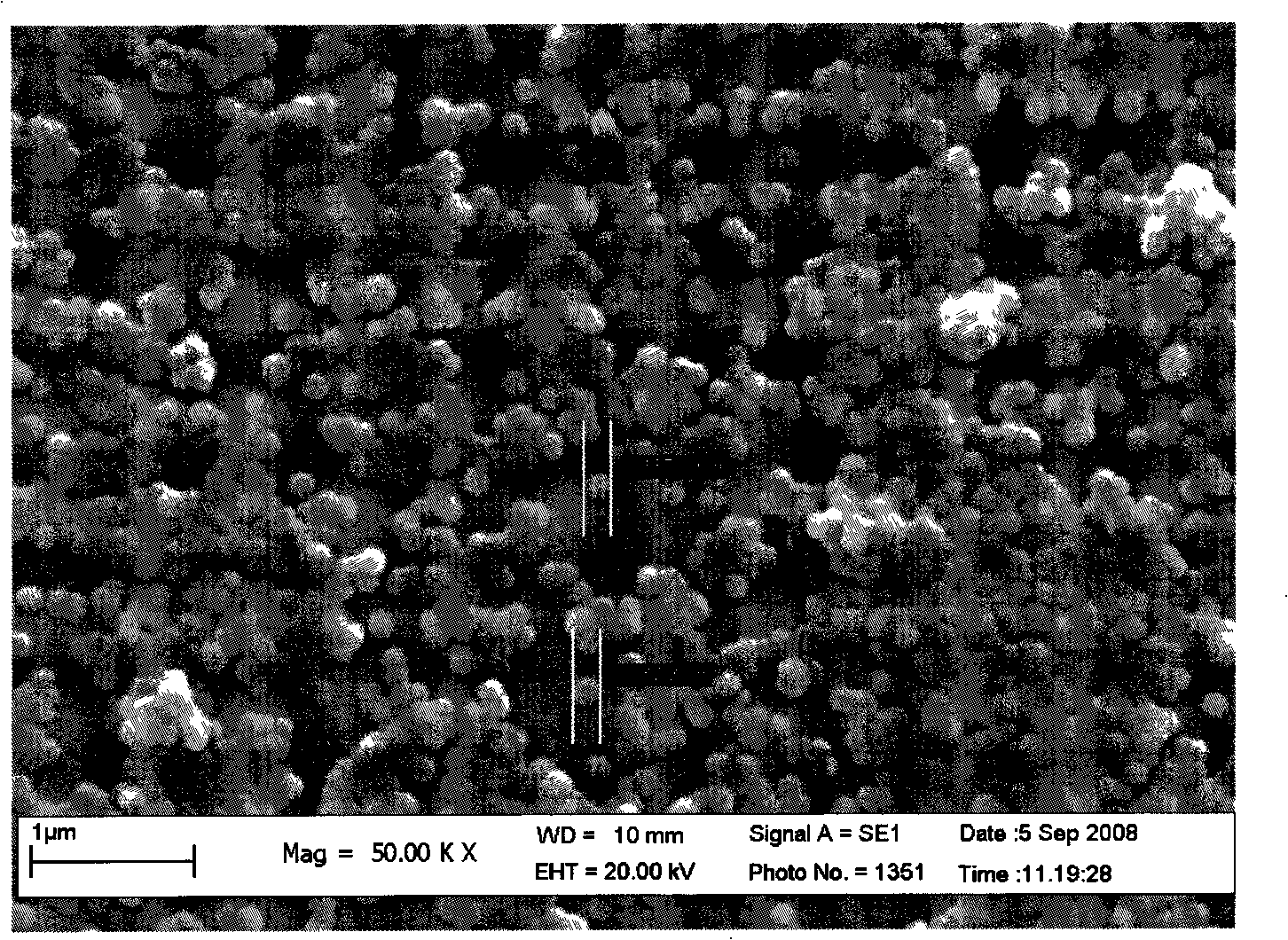

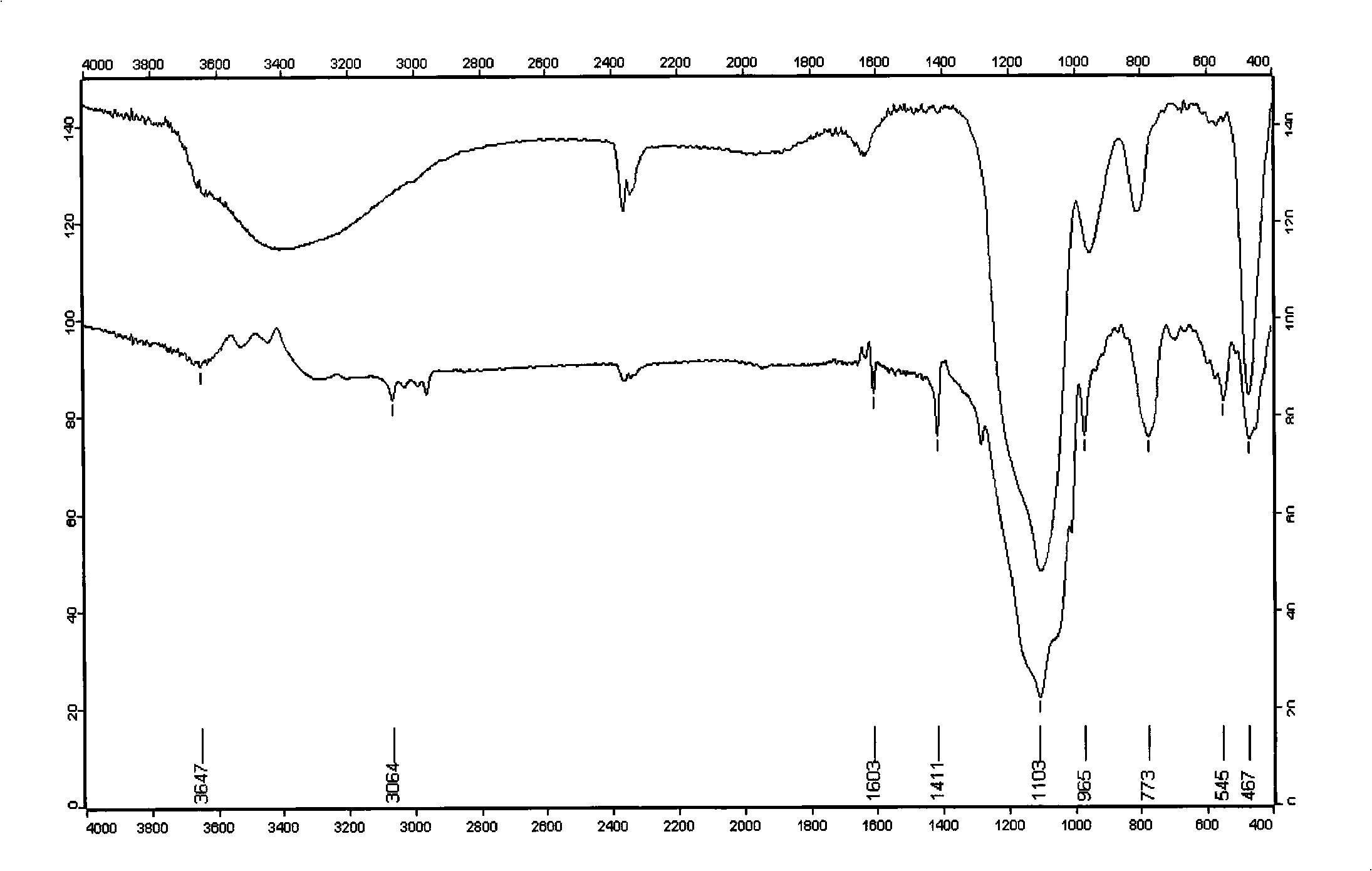

Embodiment 1

[0030] Disperse 0.1g of silica pellets with a particle size of 100nm in 20ml of toluene, add 6.6mmol of vinyltrimethoxysilane, catalyze the reaction with 1ml of concentrated ammonia water for 16h, centrifuge at 10000r / min, and wash the lower solid with toluene for 2 times, surface-grafted nano-silica spheres were obtained. Then disperse the surface-grafted nano-silica spheres in 20ml of toluene, then add 0.25mmol template molecule tetrabromobisphenol A and 2mmol functional monomer 4-vinylpyridine, after ultrasonication for 3 minutes, add 13.2mmol cross-linked Combine vinyltrimethoxysilane and 80mg initiator azobisisobutyronitrile, ultrasonically dissolve and disperse for 1min, vacuumize and fill with nitrogen, and react with stirring at 500r / min in an oil bath at 70°C for 24h. After the reaction is completed, centrifuge, and stir and wash the lower layer of solids with a mixture of methanol and acetic acid at a volume ratio of 9:1 for 12 hours, then centrifuge it, discard the ...

Embodiment 2

[0032] Disperse 0.2g of silica pellets with a particle size of 200nm in 40ml of toluene, add 13.2mmol of vinyltrimethoxysilane, catalyze the reaction with 2ml of concentrated ammonia water for 20h, centrifuge at 10,000r / min, and wash the lower solid with toluene for 3 times, surface-grafted nano-silica spheres were obtained. Then disperse the surface-grafted nano-silica spheres in 20ml toluene, then add 0.5mmol template molecule tetrabromobisphenol A and 4mmol functional monomer 4-vinylpyridine, after ultrasonication for 3 minutes, add 26.4mmol cross-linked Combine vinyltrimethoxysilane and 80 mg initiator azobisisobutyronitrile, ultrasonicate for 1 min, vacuumize and fill with nitrogen, and react with stirring at a speed of 500 r / min for 24 h in an oil bath at 70°C. After the reaction is completed, centrifuge, and stir and wash the lower layer of solids with a mixture of methanol and acetic acid at a volume ratio of 9:1 for 12 hours, then centrifuge it, discard the supernatan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com