Patents

Literature

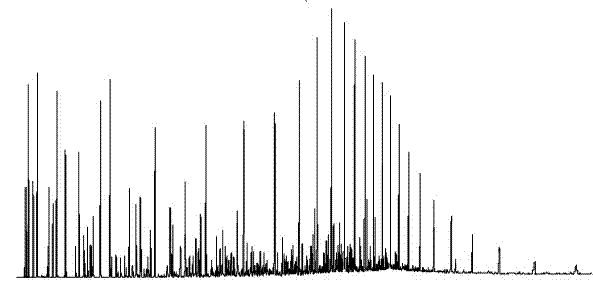

440 results about "Pellets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

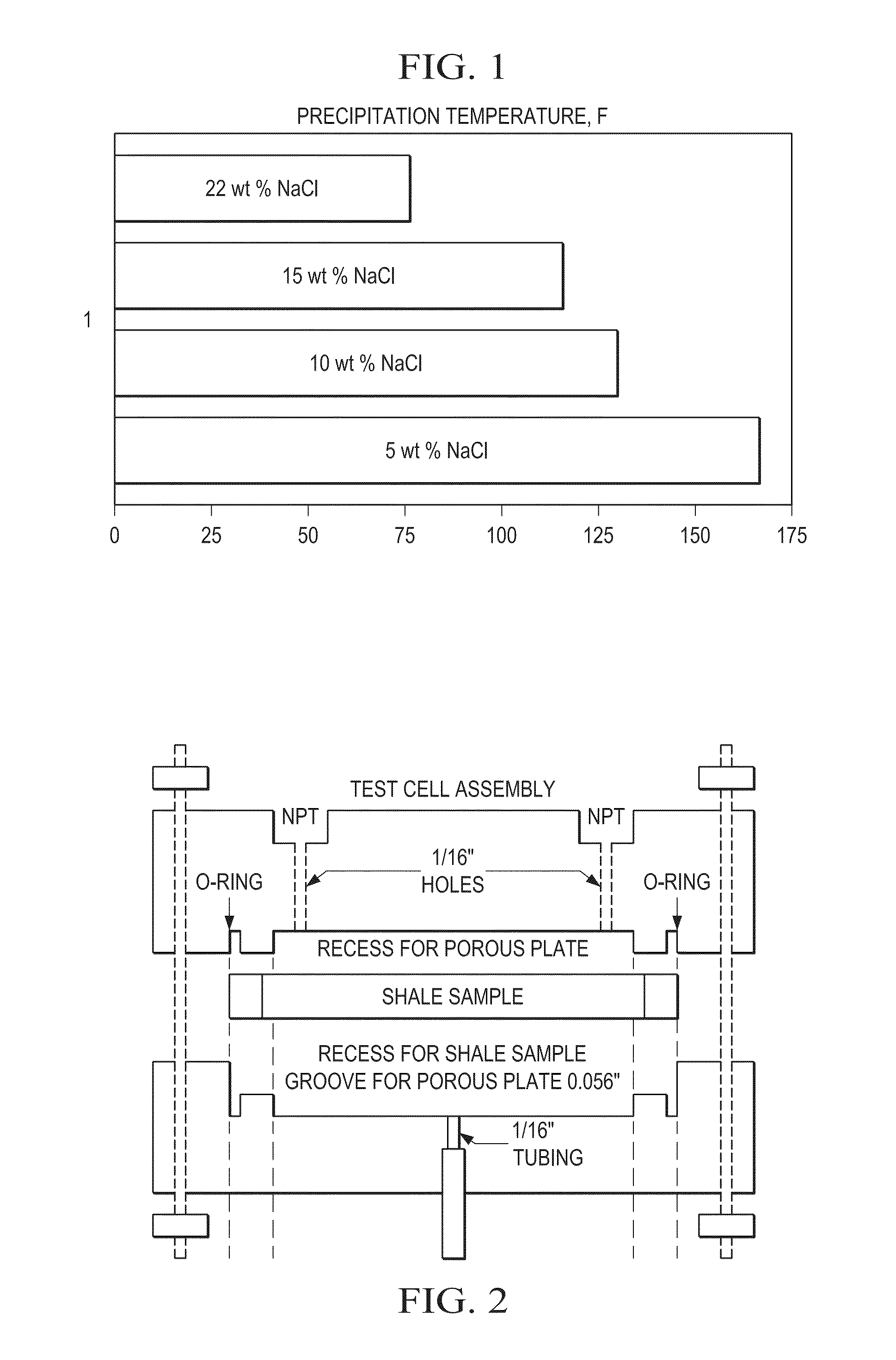

Pellets are small spherical to ovoid or rod-shaped grains that are common component of many limestones. They are typically 0.03 to 0.3 mm long and composed of carbonate mud (micrite). Their most common size is 0.04 to 0.08 mm. Pellets typically lack any internal structure and are remarkably uniform in size and shape in any single limestone sample. They consist either of aggregated carbonate mud, precipitated calcium carbonate, or a mixture of both. They either are or were composed either of aragonite, calcite, or a mixture of both. Also, pellets composed of either glauconite or phosphorite are common in marine sedimentary rocks. Pellets occur in Precambrian through Phanerozoic strata. They are an important component mainly in Phanerozoic strata. The consensus among sedimentologists and petrographers is that pellets are the fecal products of invertebrate organisms because of their constant size, shape, and extra-high content of organic matter.

Time release multisource marker and method of deployment

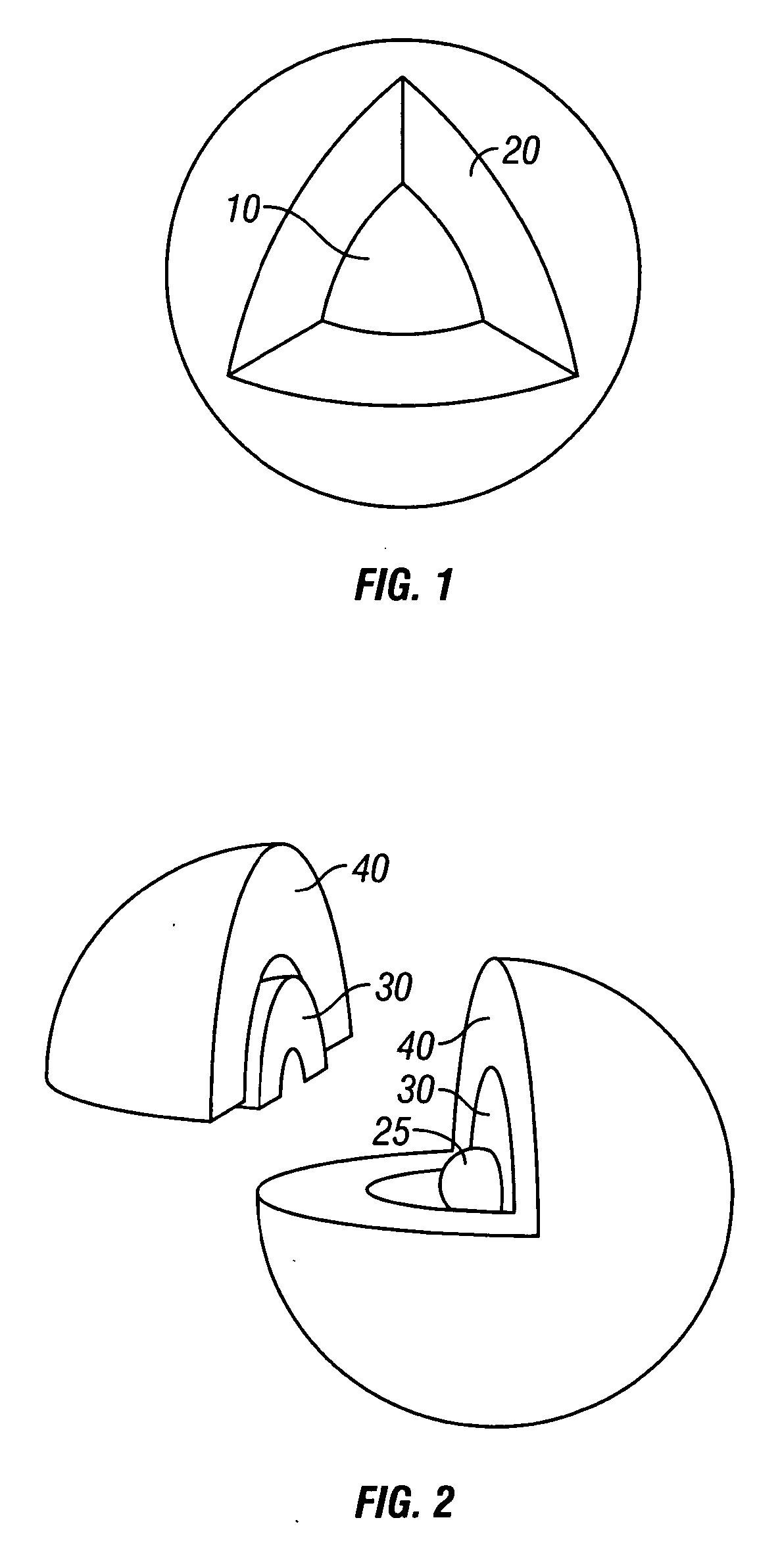

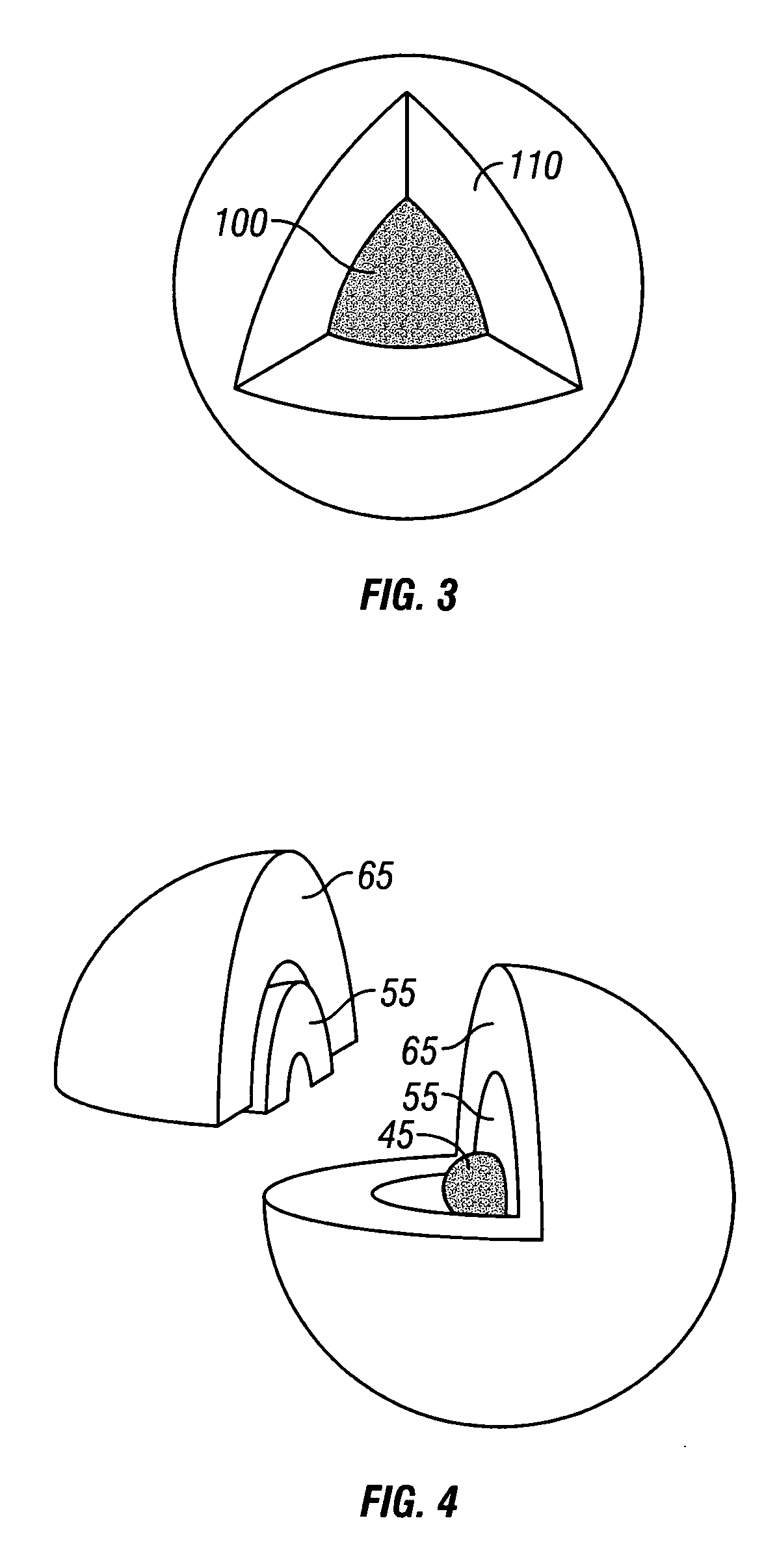

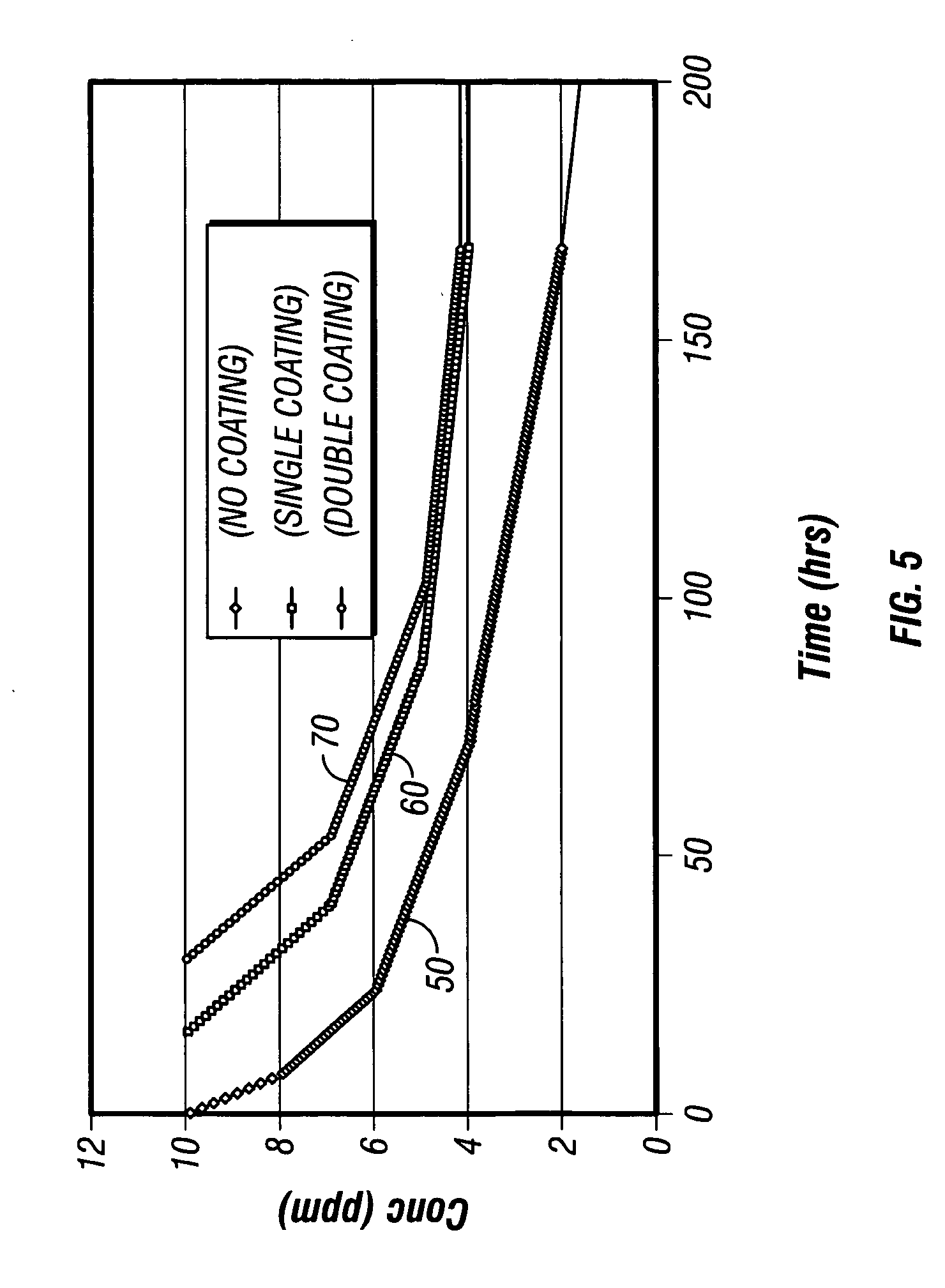

InactiveUS20060052251A1Delay releaseImprove practicalityConstructionsDrilling compositionSoil scienceMarking out

The present invention provides time released markers for use with single reservoir and commingled wells. The invention accomplishes the time release of markers by coating or encapsulating marker particles or by coating a proppant which has been saturated with a marker. After coating or encapsulation, the marker is injected into a well as is known in the art. The marker remains in the well. The marker is released after an elapsed of time. The elapsed time can be in a wide range. After the elapsed time, production is taken from the well and tested for the presence of the marker. Various types of known analyses can be performed to test for the presence and concentration of the marker in the production fluid. The concentration of the marker in the production fluid allows the apportioning of production from the reservoir. In addition, different markers may be added to each zone within a reservoir where each marker has a different elapsed time increment. The zones can be any different layer or area in the reservoir such as different strata or layer of rock, limestone or sand. Differing marker combinations allow contribution from different zones to be monitored over an extended time.

Owner:CORE LAB LP

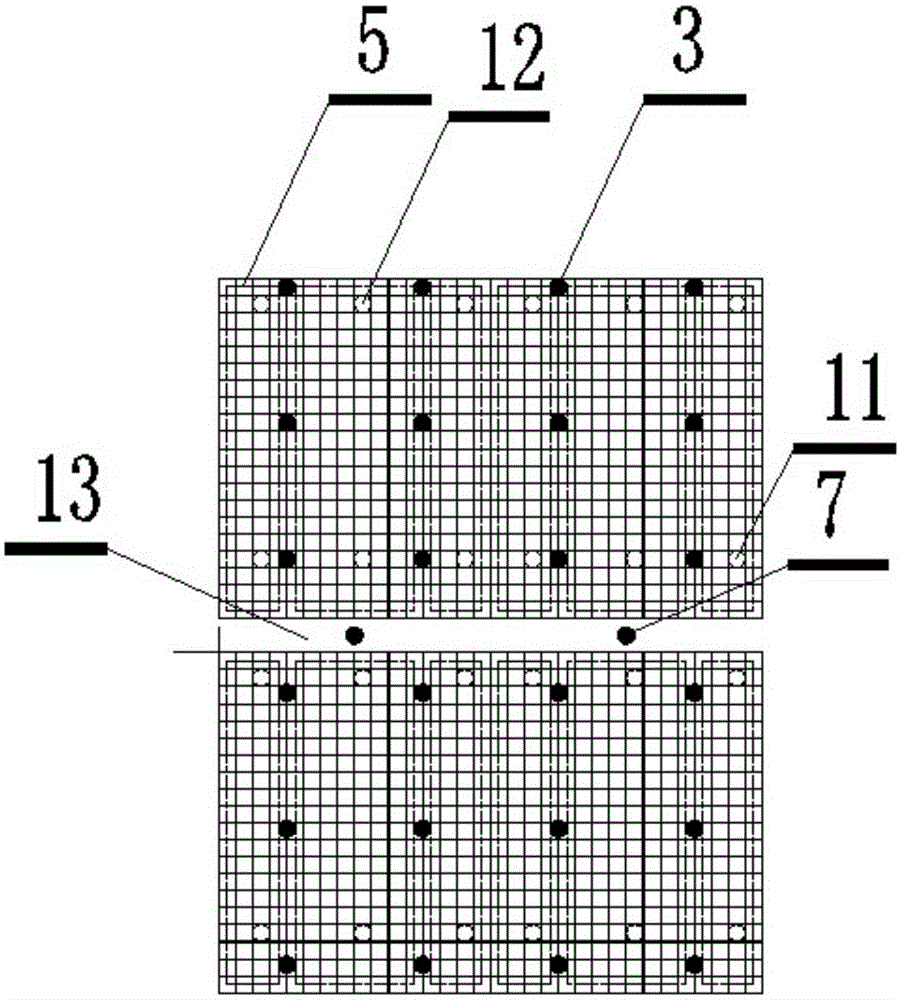

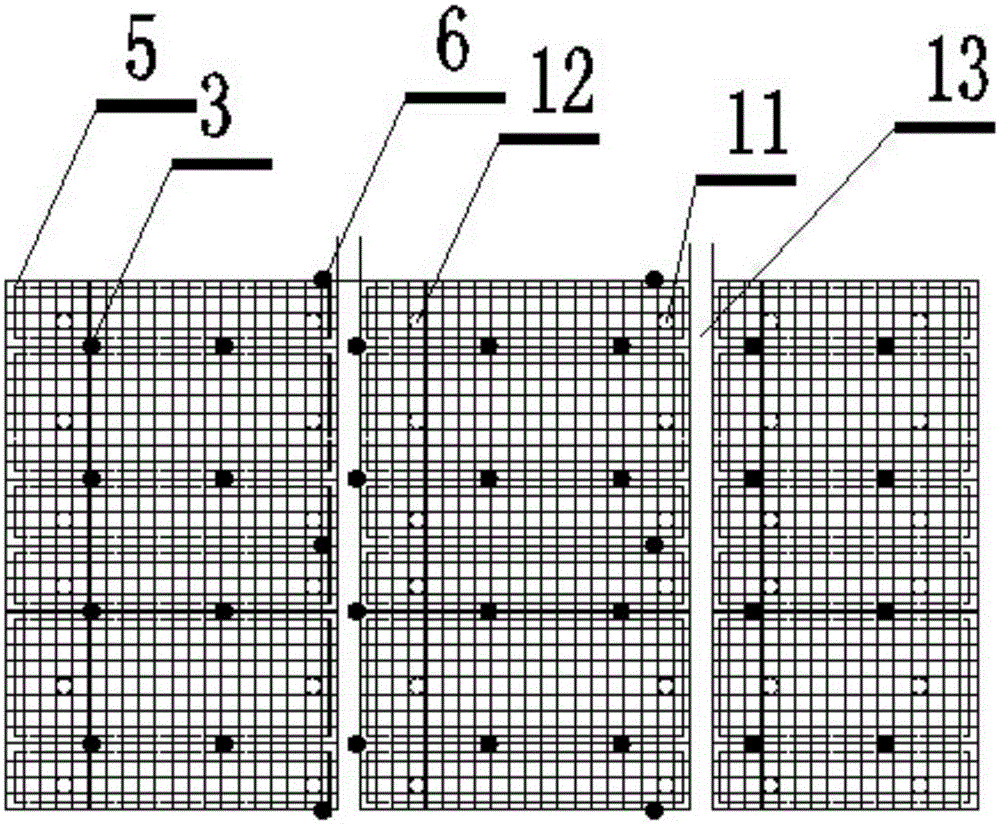

High sediment concentration waterflood river bed tearing simulation test method

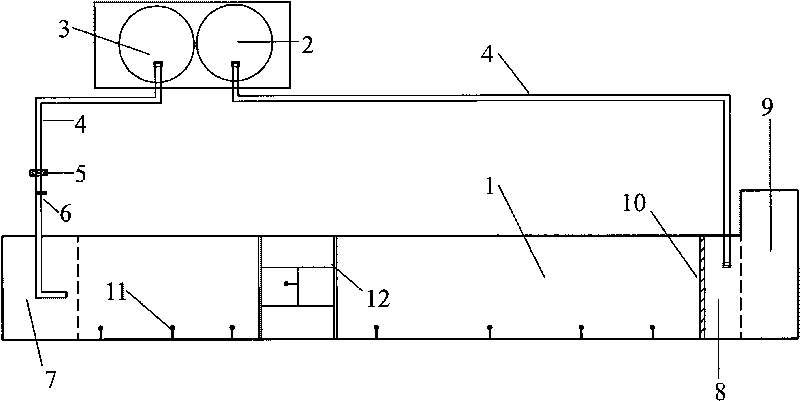

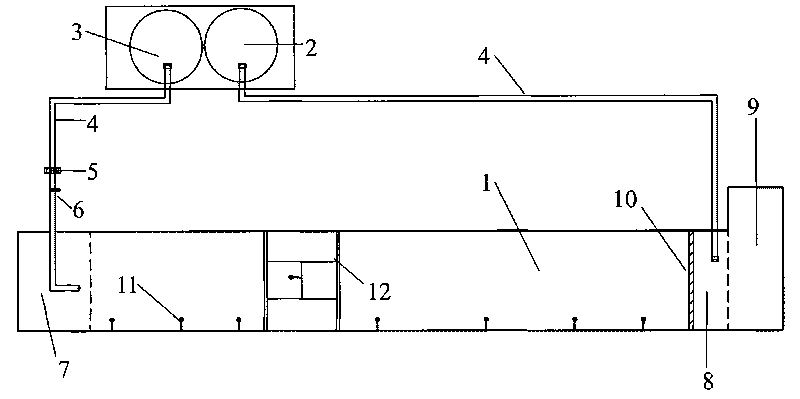

The invention relates to a hydraulic model with the international patent classification (IPC) of E02B 1 / 02, in particular to a high sediment concentration waterflood river bed tearing simulation test method. The method utilizes a special test device and adopts flyash as model sand, wherein extremely fine flyash with a median diameter being smaller than 0.01mm is adopted to simulate an adhesive mud layer of deposits, fine flyash with a median diameter of 0.03mm is adopted to simulate suspended sand, and coarse particle flyash with a median diameter of 0.05mm is adopted to simulate loose bed sand. The invention provides a feasible test method for researching the problems of a river bed tearing phenomenon of the Huang river and the breaking of consolidation cohesive soil of the water conservancy industry, lays foundations for recognizing the generation mechanism of the river bed tearing phenomenon and establishing a scouring index of river bed tearing, and plays a certain active role in the development of the subject of river sediments.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

Magnesia-calcia dry type working liner for tundish and preparation thereof

The invention relates to a magesia-calcia tundish dry working lining refractory and a method for preparing the same. The technical scheme comprises mixing 55-65wt% of particle material with a grain size of 3-0mm, 22-35wt% of powder with a grain size less than 0.088mm, 0 or 0.5-8wt% of additives and 6-12wt% of binding agent according to a theoretical content of MgO 55-85wt% and CaO 10-40wt%, baking at 200-350 DEG C after stirring and vibration molding, getting the tundish dry working lining after demoulding, wherein the particle material is one or a mixture more than one selected from the magnesia, magnesite, limestone and dolomite; the powder is one or a mixture more than one selected from the magnesia, hydrated lime, limestone, dolomite and magnestie. The invention has advantages of simple technology, convenient construction, low cost, environment friendly and saving energy, and the magesia-calcia tundish dry working lining has a good metallurgical effect and the feature of easy disintegration after use.

Owner:WUHAN UNIV OF SCI & TECH

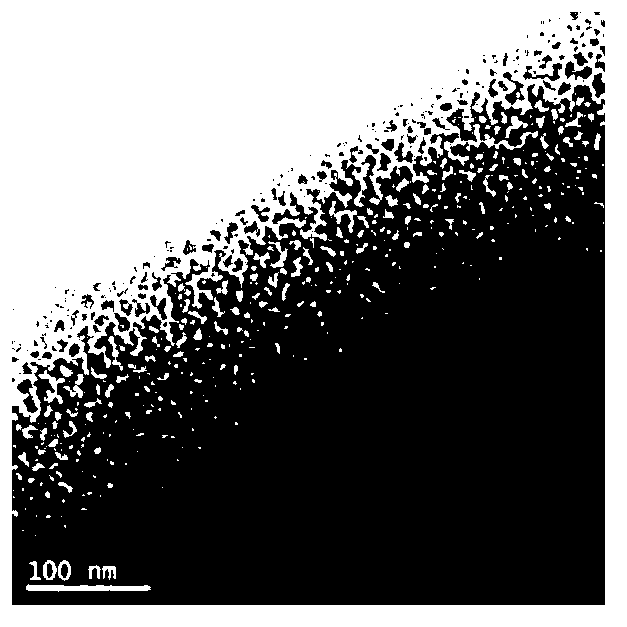

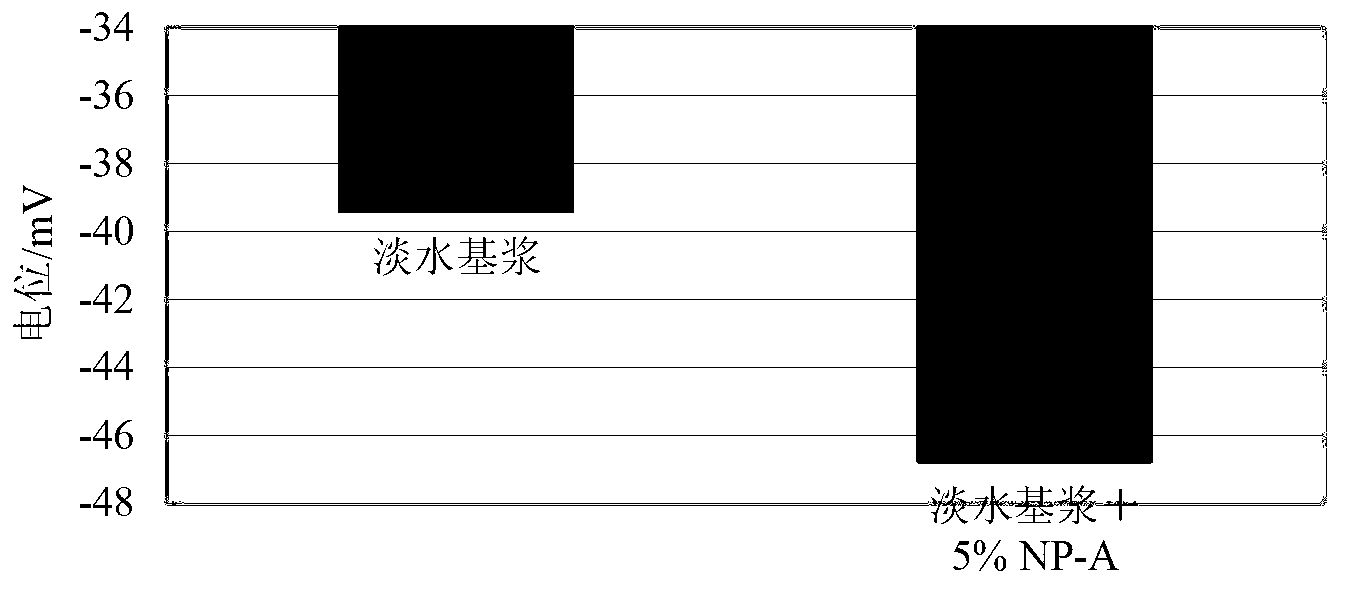

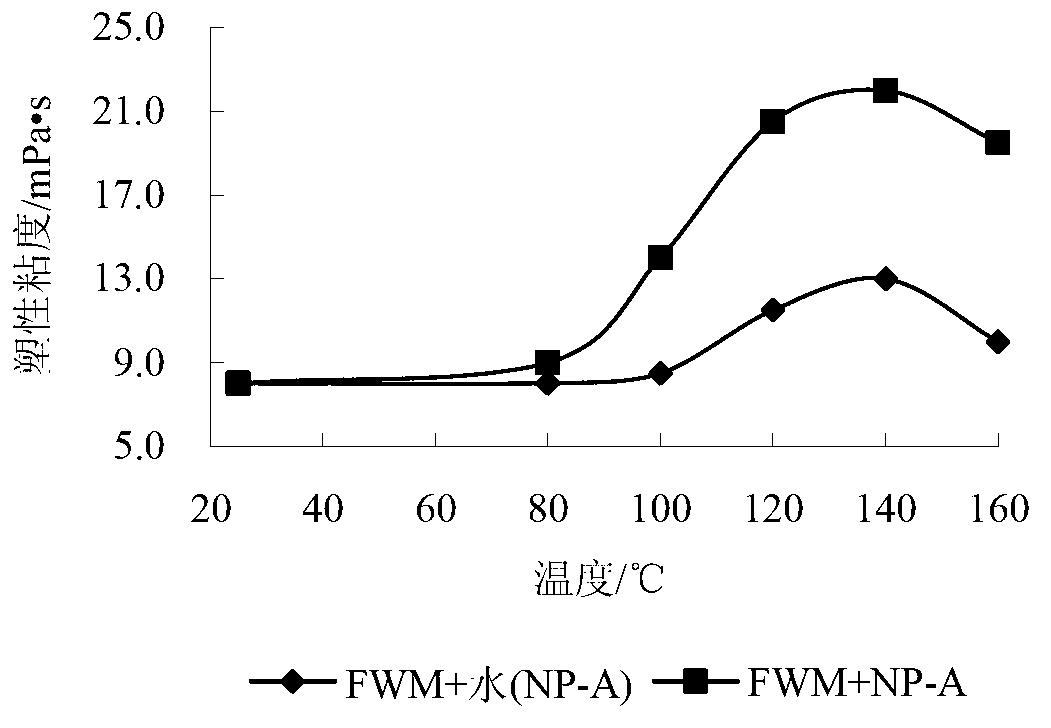

Method of utilizing nanometer silicon dioxide to improve properties of water-based drilling fluid at different temperatures

ActiveCN103013469AImprove the blocking effectImprove stabilityDrilling compositionWater basedFiltration

The invention provides a method of utilizing nanometer silicon dioxide to improve properties of water-based drilling fluid at different temperatures. The method comprises a step of adding a nanometer silicon dioxide dispersing agent into base mud, wherein the mass of the nanometer silicon dioxide particle in the nanometer silicon dioxide dispersing agent is 5-10% of total mass of the base mud and the nanometer silicon dioxide dispersing agent. Due to the nano-scale particle size, the nanometer silicon dioxide material can be filled into small holes and cracks of the shale stratum to improve the plugging effect of the water-based drilling fluid, slow down the trend of permeation of the drilling fluid to the stratum and expansion and chipping of the stratum after water absorption, and improve the stability of the borehole wall. The nanometer silicon dioxide can strengthen the stability of fresh-water base mud and bentonite base mud by increasing the negative charge level of the system. The nanometer silicon dioxide also can enable the base mud to form thinner and compact mud cakes and facilitate the de-filtration effect to be obvious.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

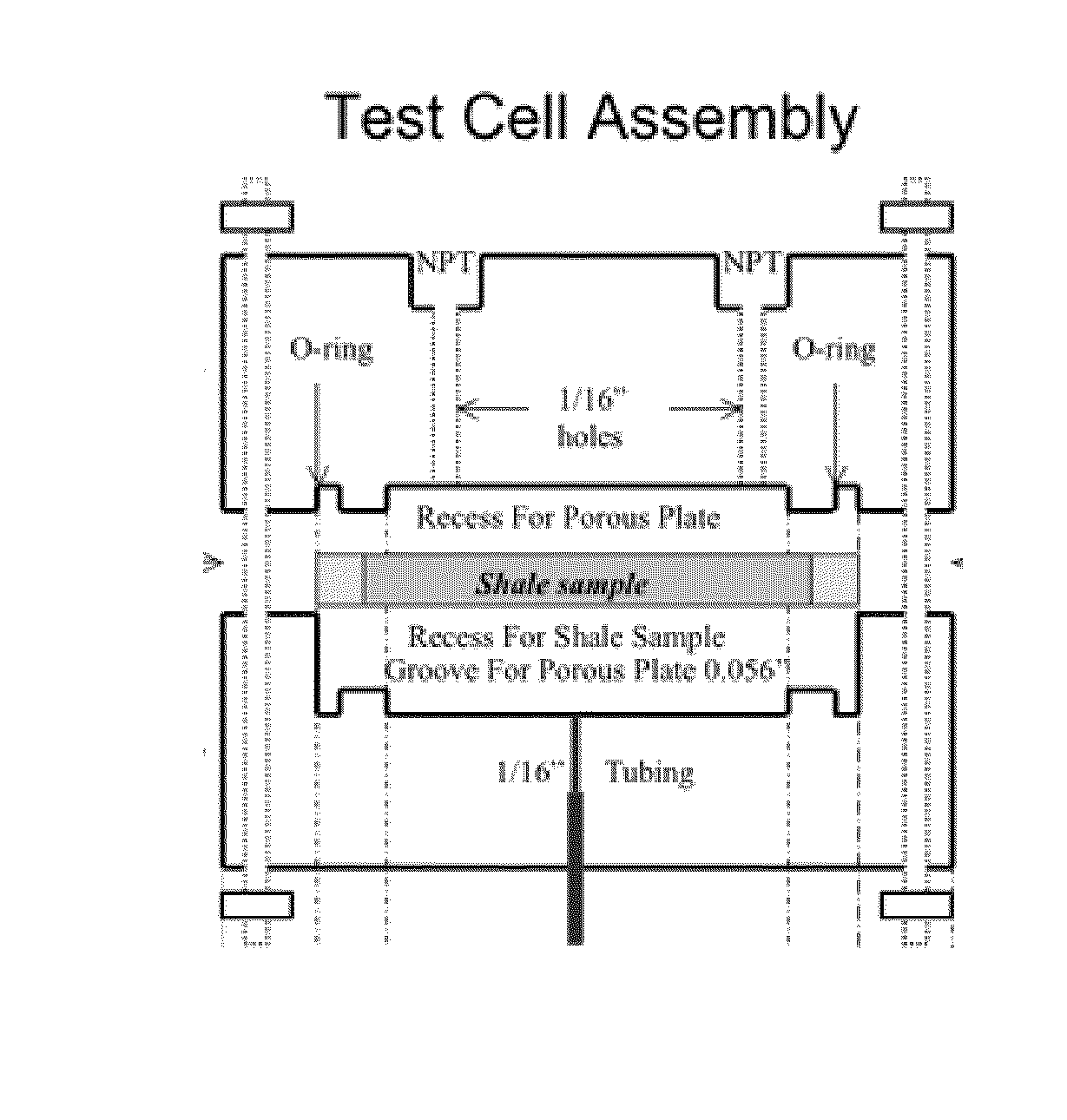

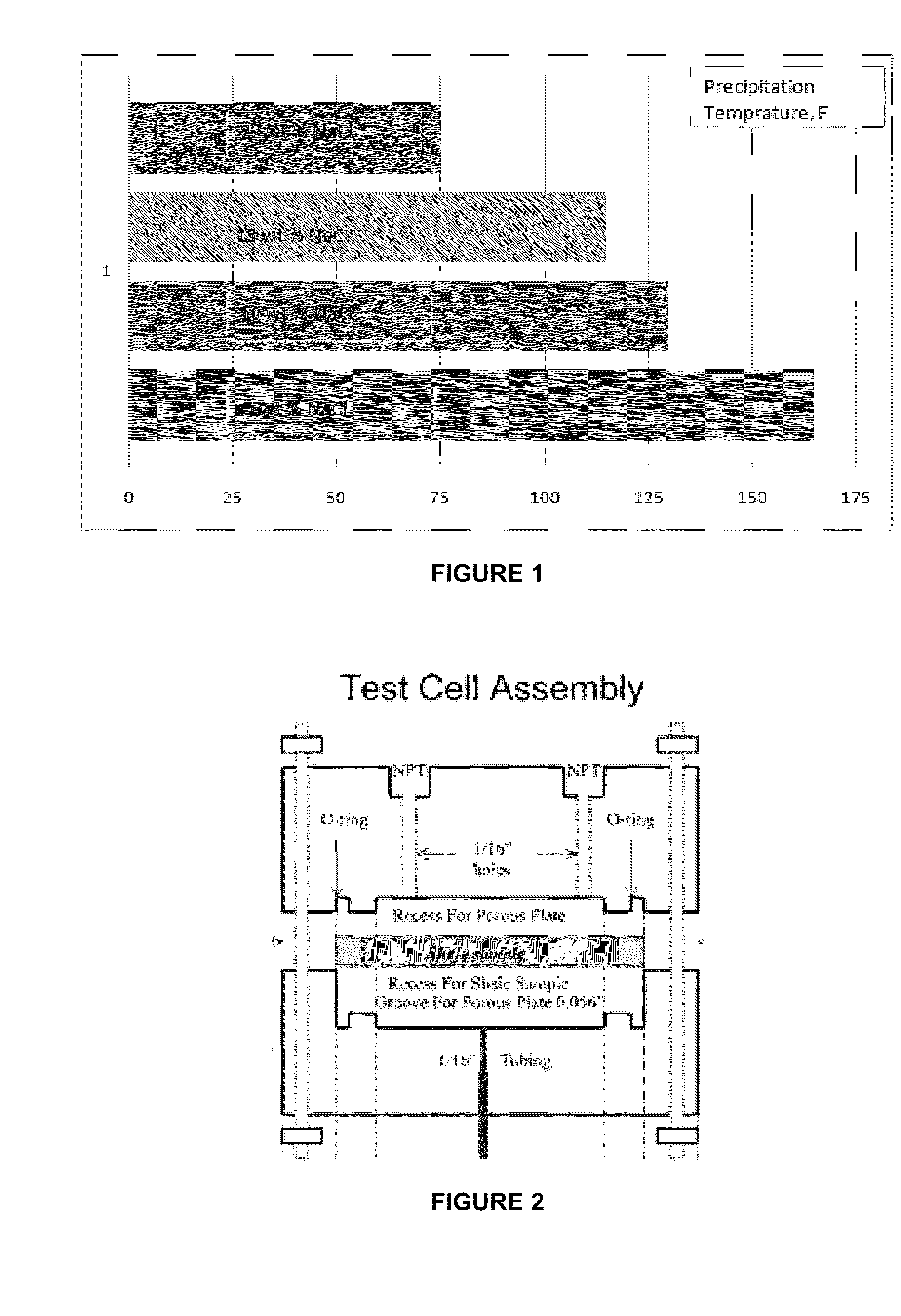

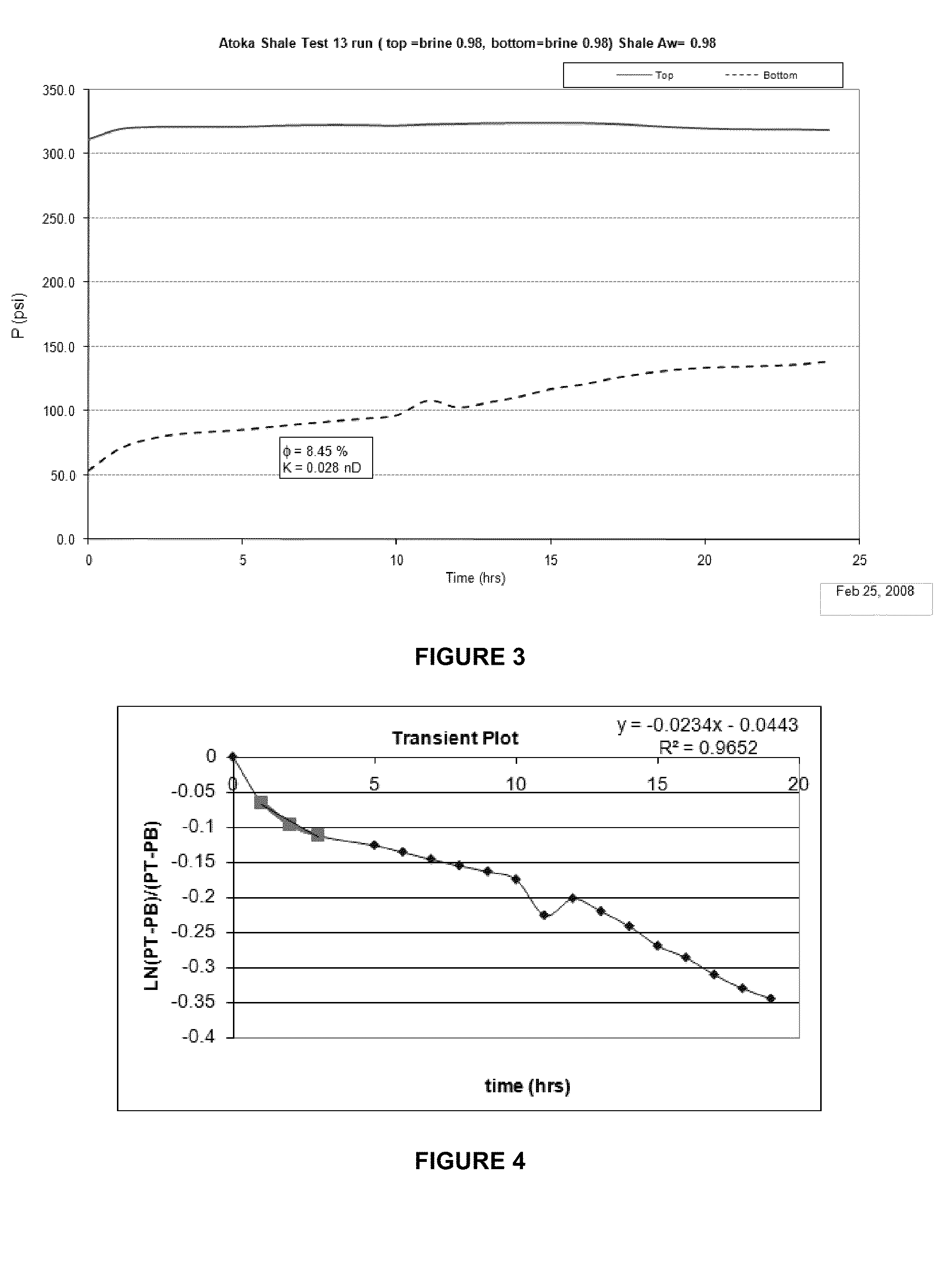

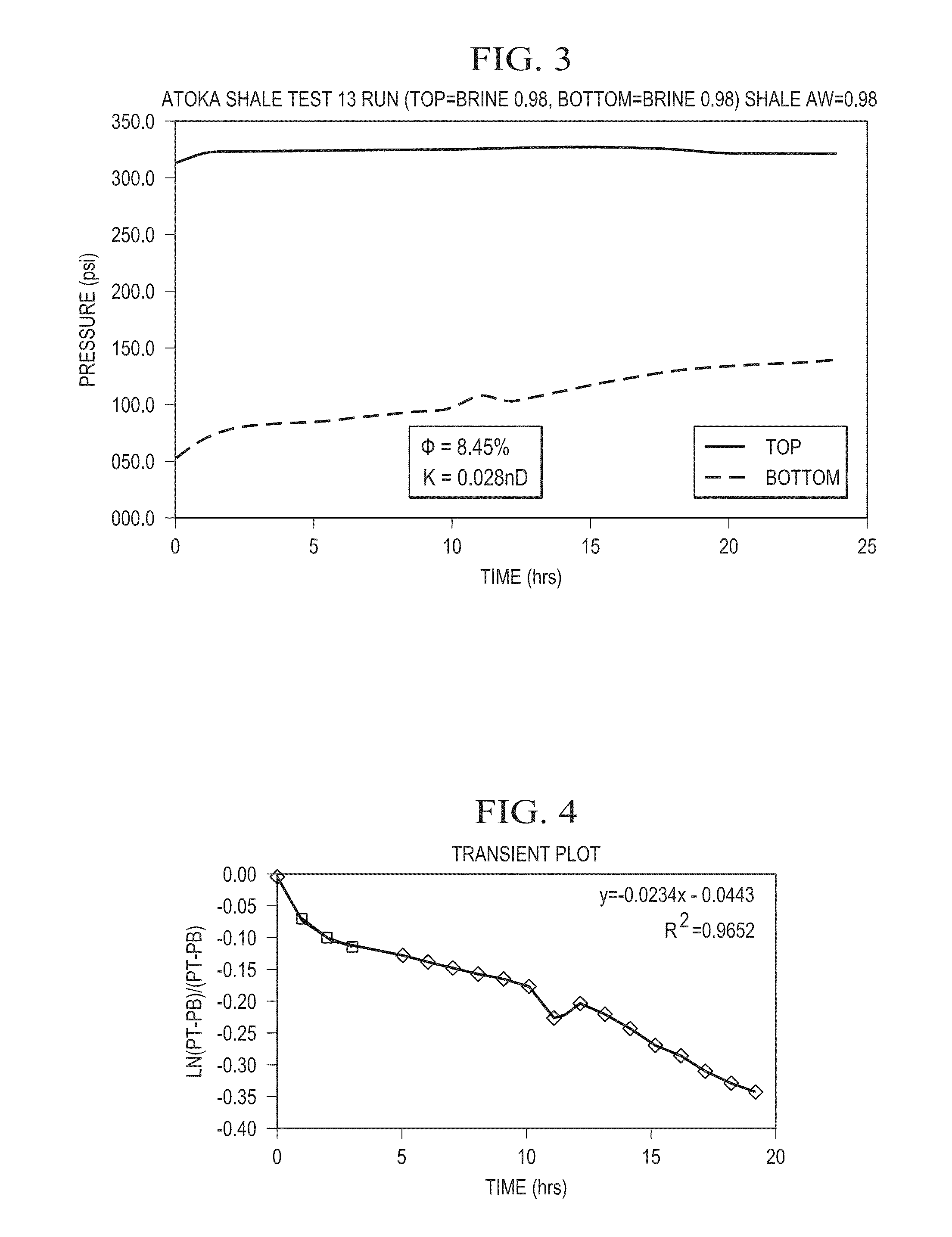

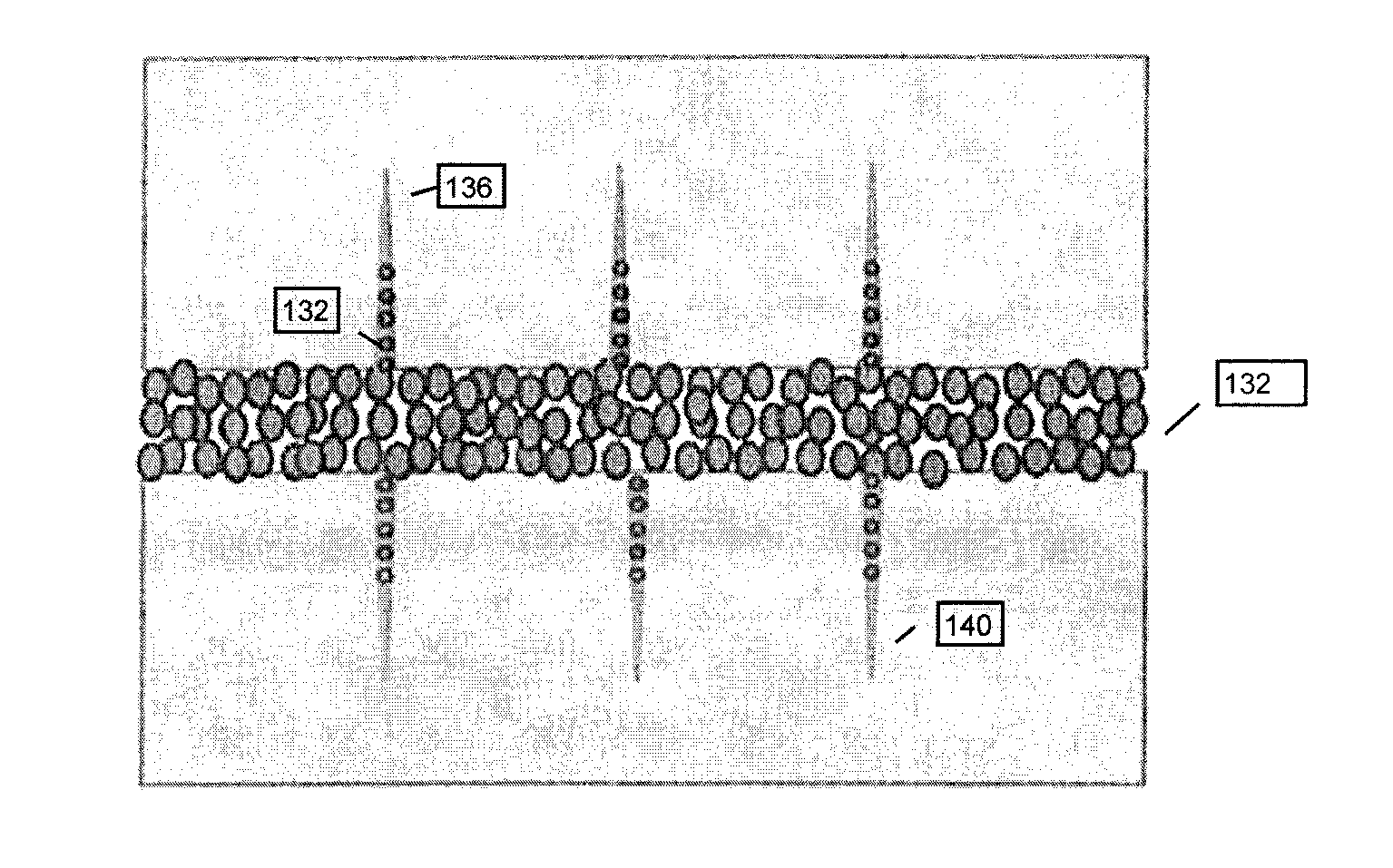

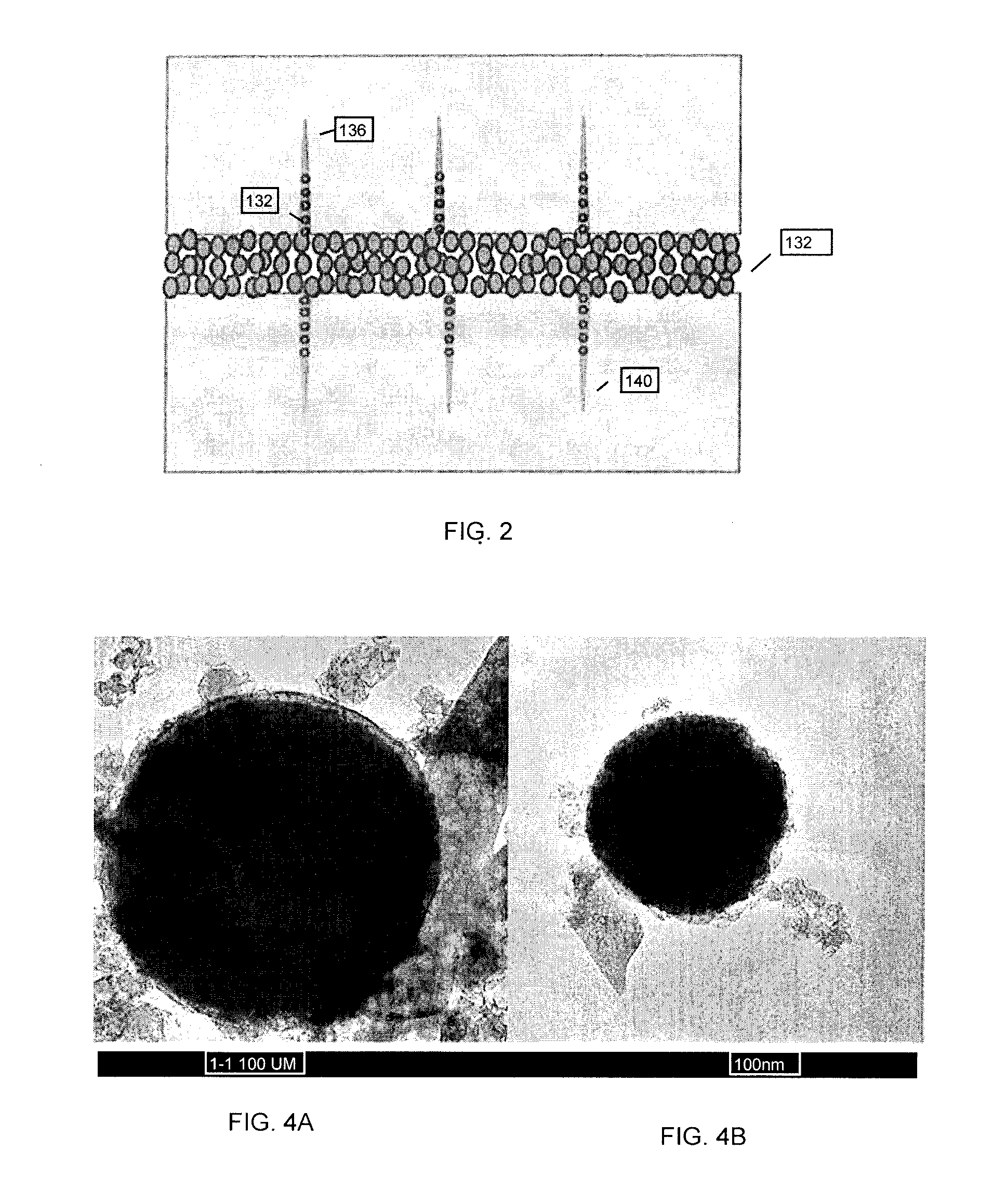

Maintaining shale stability by pore plugging

ActiveUS20090314549A1Reduces shale permeabilityReduce intrusionDrilling compositionBorehole/well accessoriesNanoparticlePhysical chemistry

The present invention includes compositions and methods for improving wellbores stability of a hydrocarbon bearing shale formation using nanoparticles to decrease swelling and plug pore throats.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

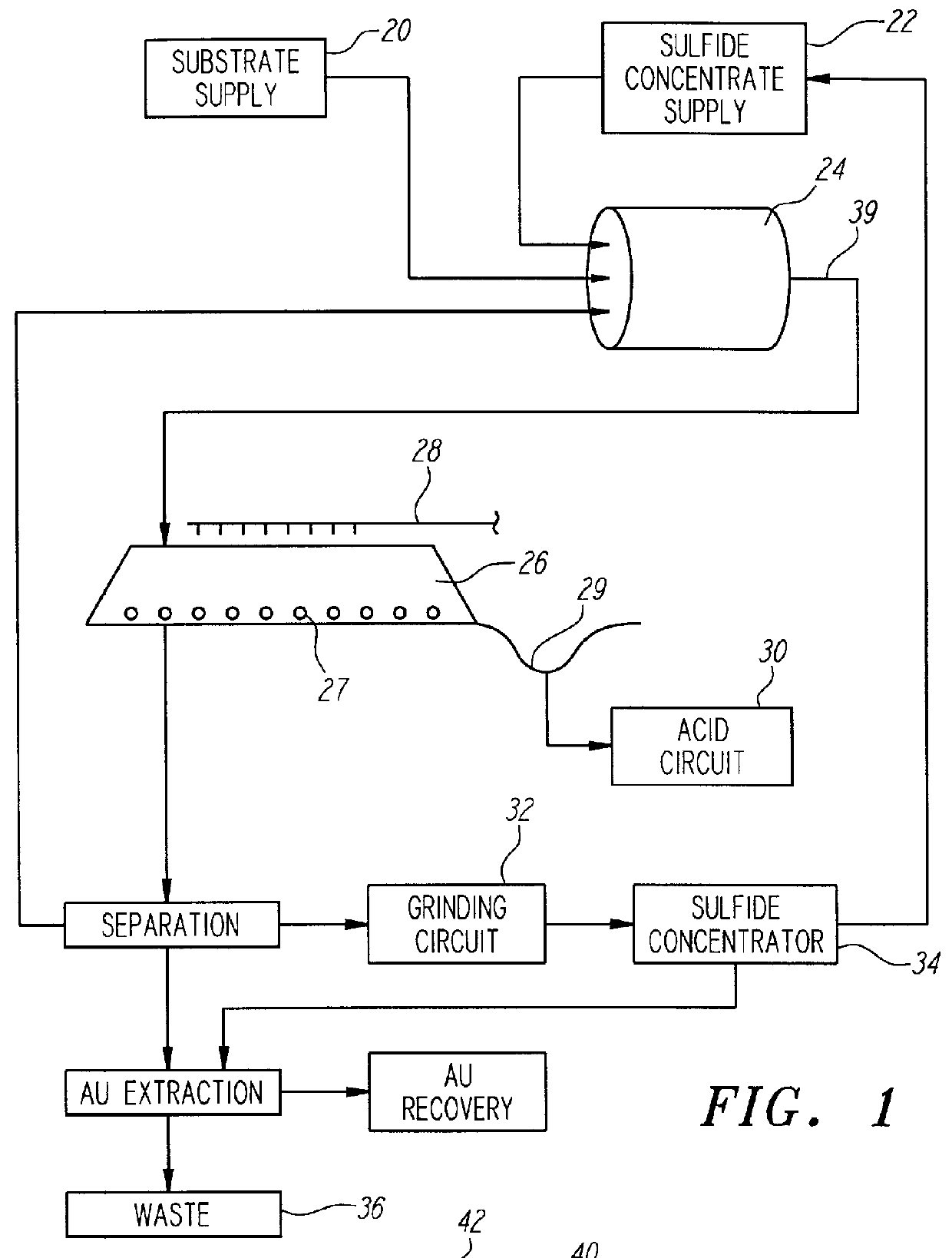

Nonstirred bioreactor for processing refractory sulfide concentrates and method for operating same

InactiveUS6083730AReduced pHIncrease equipment costSolvent extractionContaminated soil reclamationSulfide mineralsMetallic sulfide

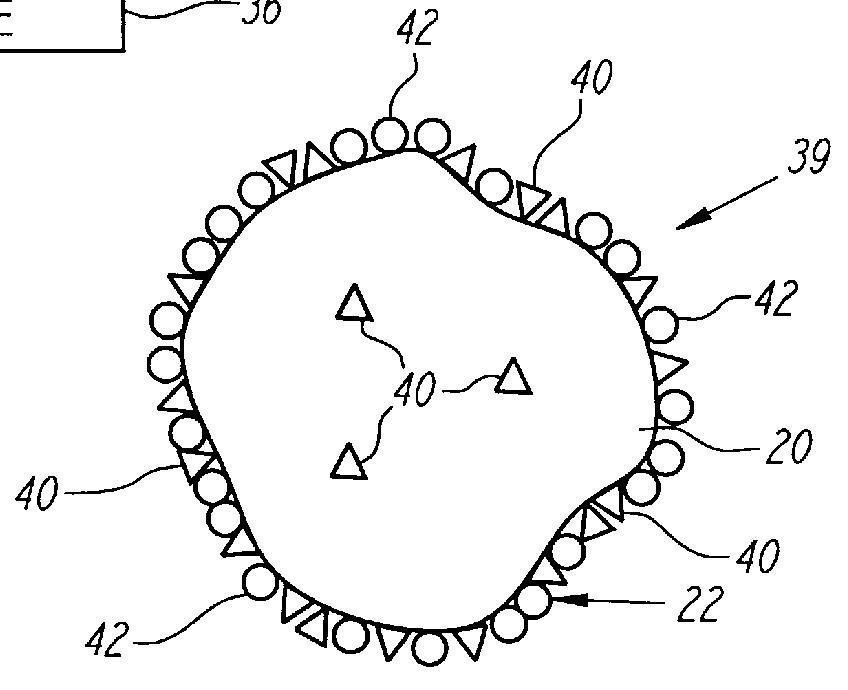

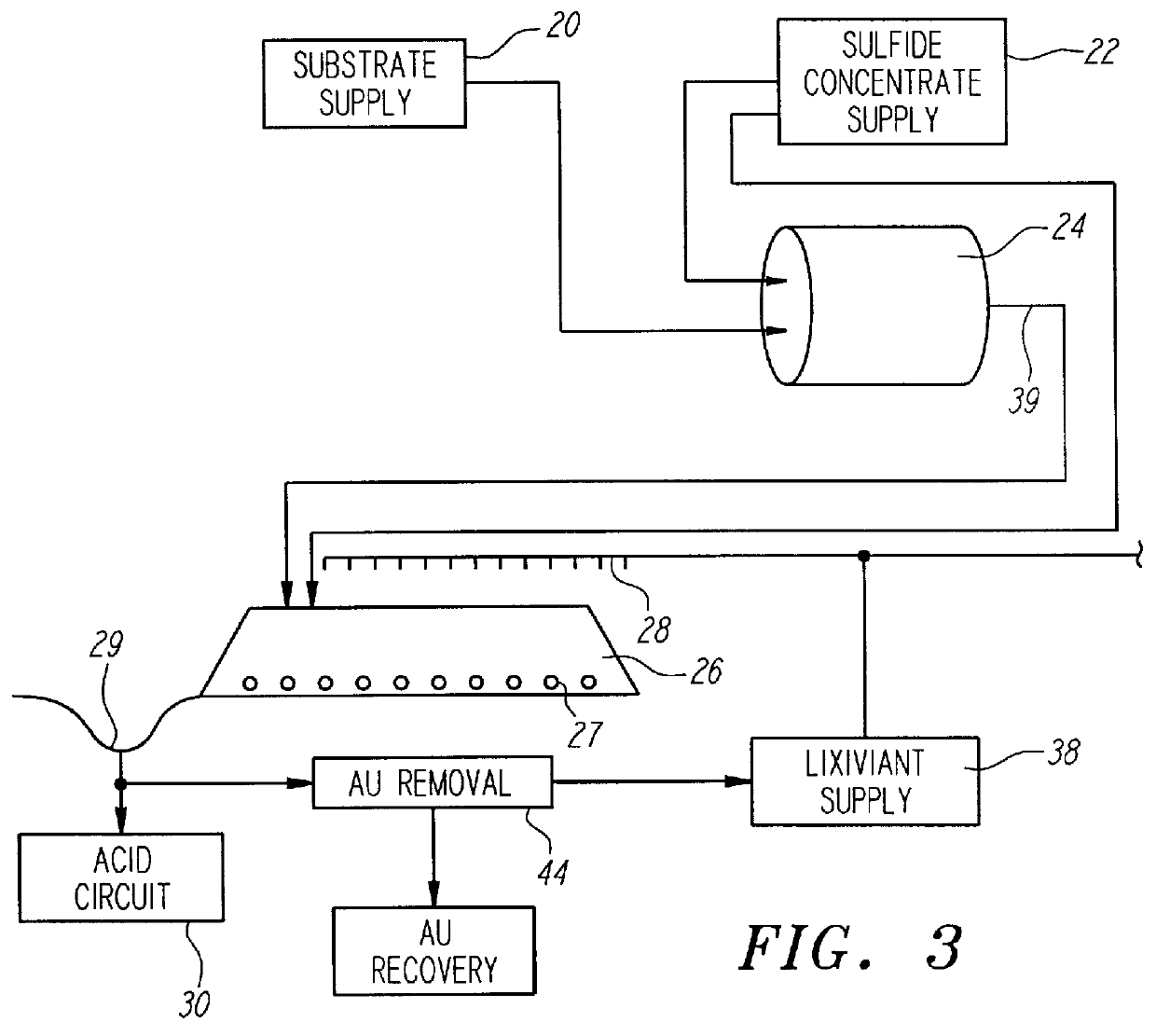

A method of biooxidizing sulfide minerals in a nonstirred bioreactor is provided. According to the disclosed method, a concentrate of sulfide minerals is coated onto a substrate, such as coarse ore particles, lava rock, gravel or rock containing mineral carbonate as a source of CO2 for the biooxidizing bacteria. After the sulfide minerals are coated onto the substrate, a heap is formed with the coated substrates or the coated substrates are placed within a tank. The sulfide minerals are then biooxidized to liberate the metal value of interest. Depending on the particular ore deposit being mined, the sulfide mineral concentrates used in the process may comprise sulfide concentrates from precious metal bearing refractory sulfide ores or they may comprise sulfide concentrates from metal sulfide type ores, such as chalcopyrite, millerite or sphalorite. The distinction being that in the former, the metal of interest is a precious metal occluded within the sulfide minerals, whereas in the latter, the metal to be recovered is copper, nickel or zinc and is present as a metal sulfide in the sulfide concentrate.

Owner:GEOSYNFUELS LLC (US)

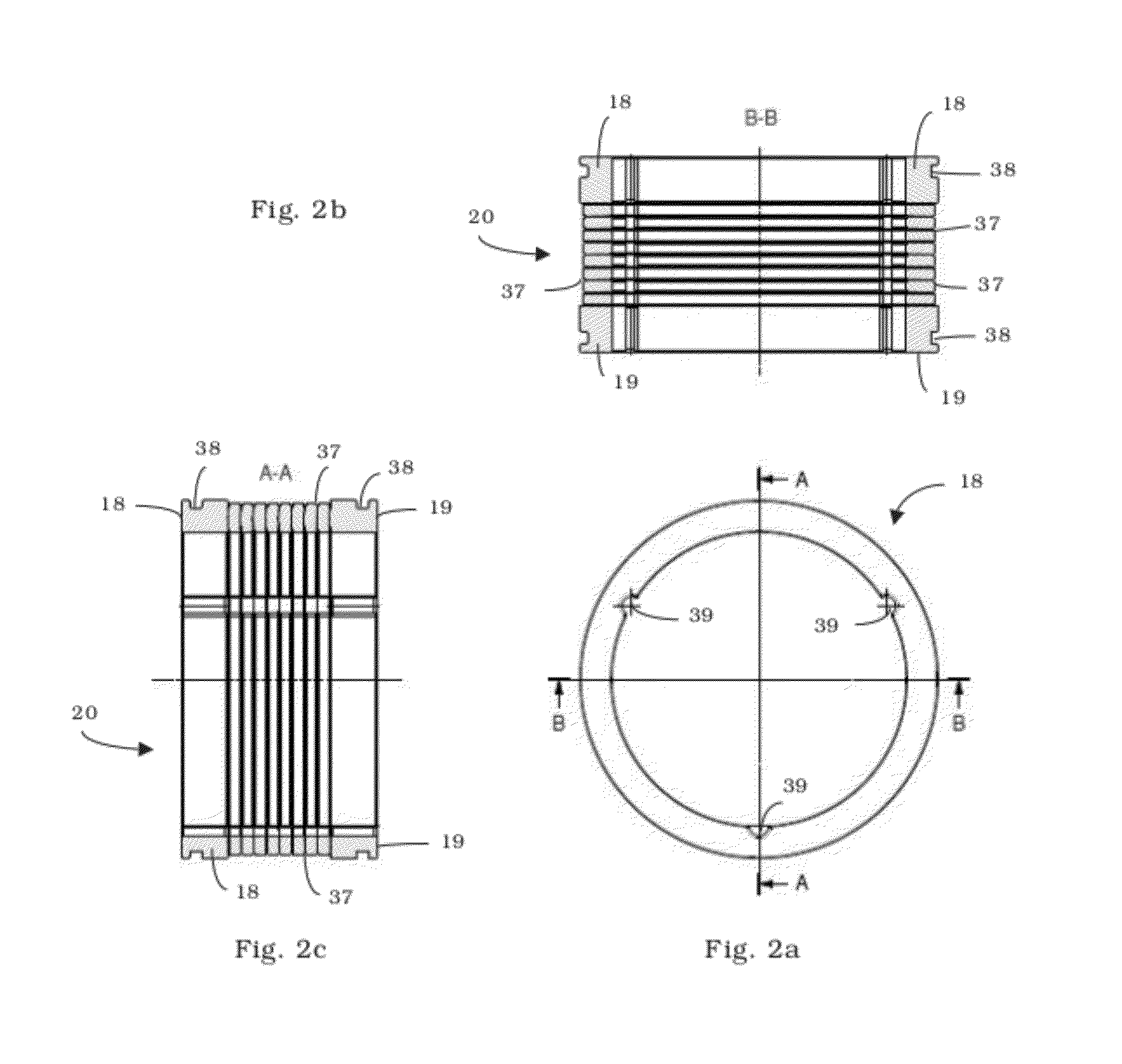

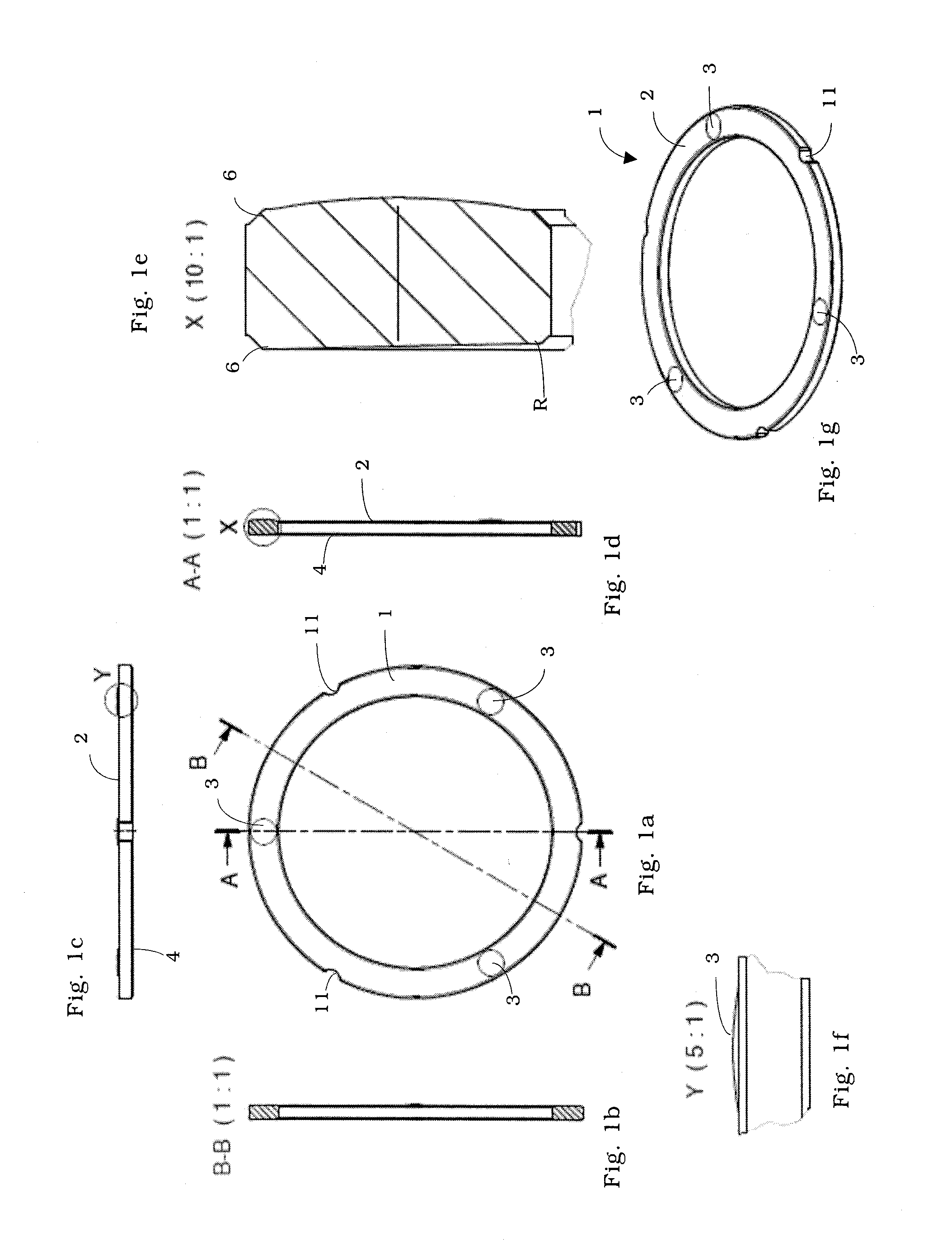

Separating device for tubular flow-through devices

ActiveUS8833447B2Good abrasionIncrease resistanceDispersed particle filtrationFluid removalWell drillingGeophysics

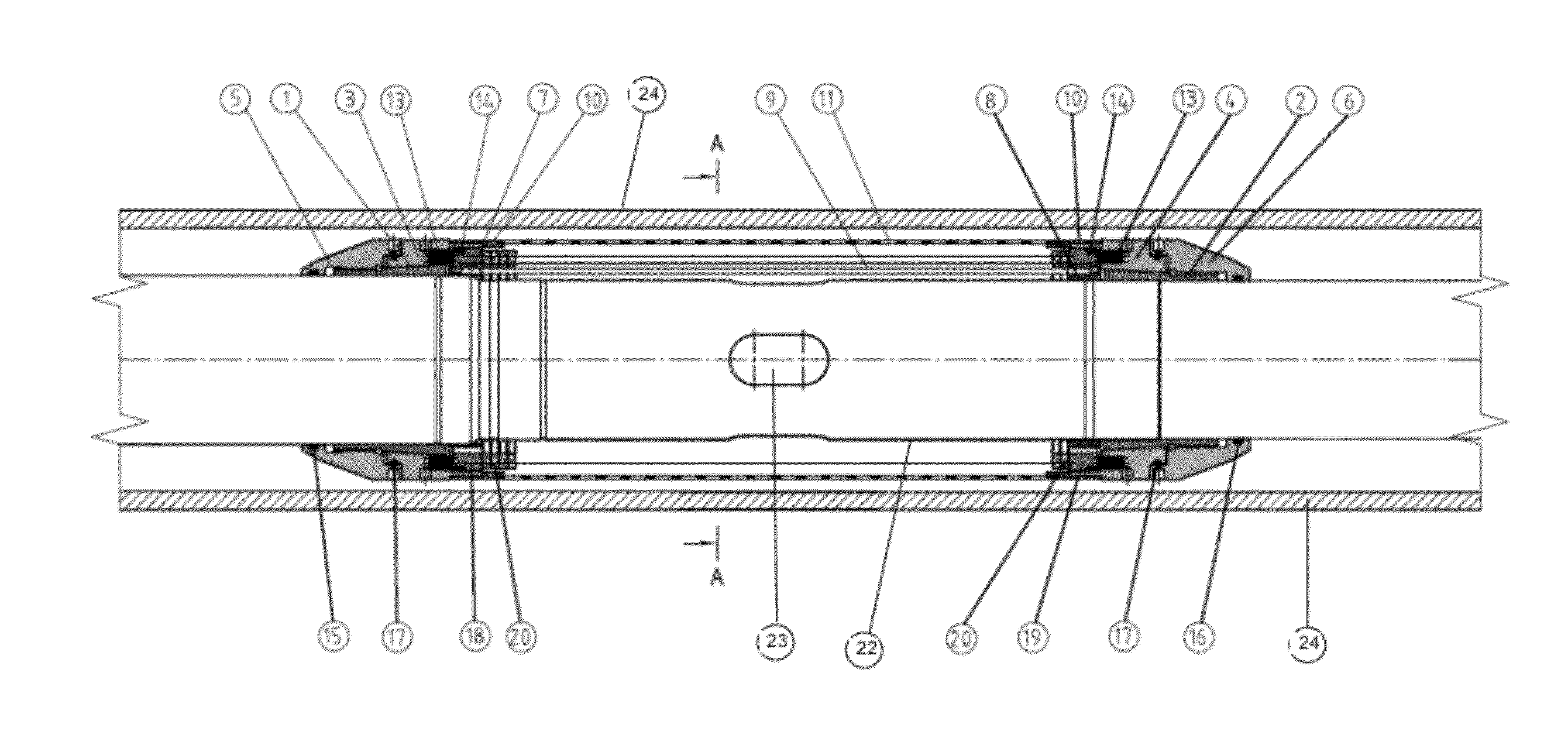

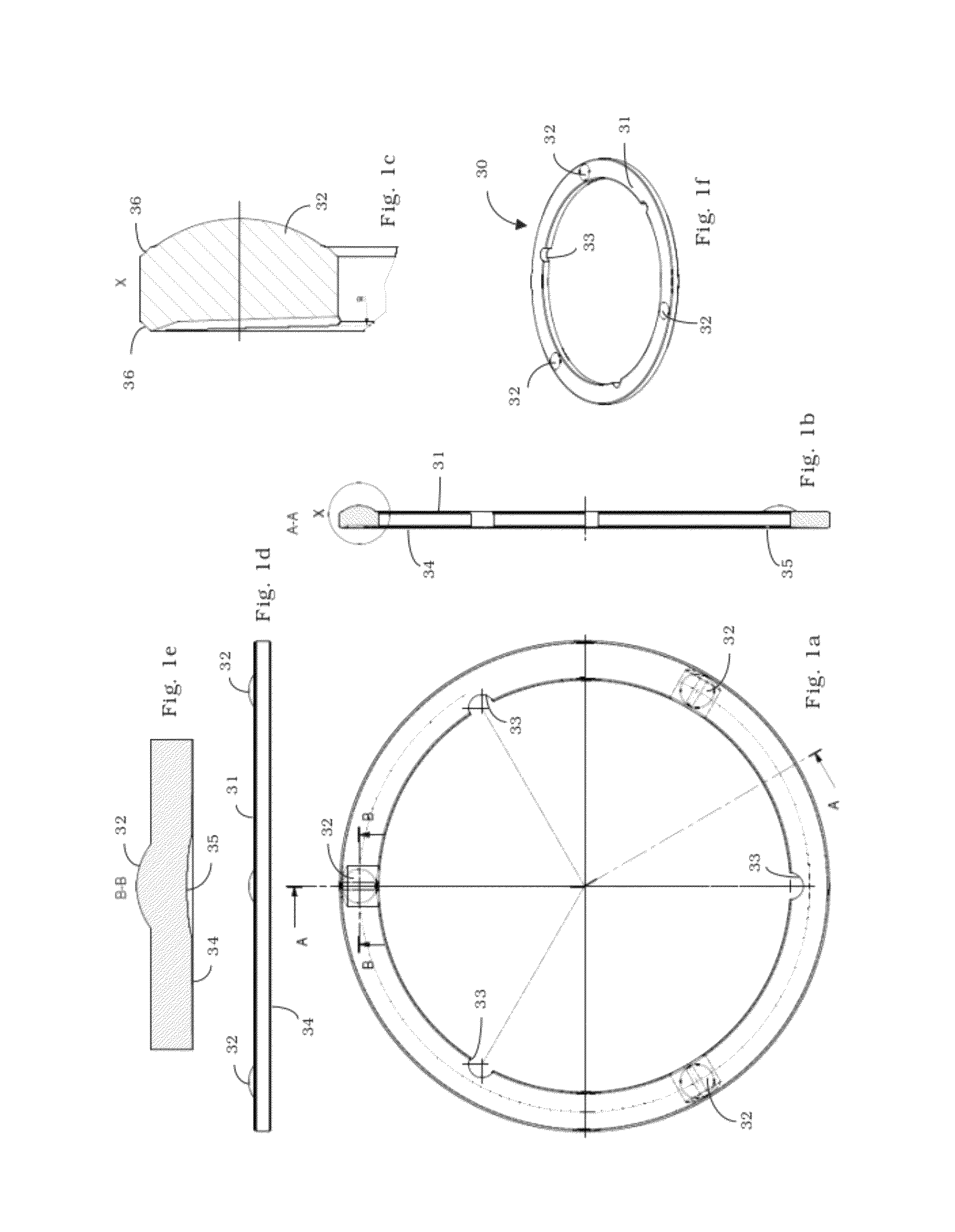

The invention relates to a separating device for tubular flow-through devices (22) which serve for the extraction of liquids or gases from wells drilled in rock or deep wells, the separating device being suitable for the removal of sand and rock particles and comprisingan annular stack (20) of brittle-hard annular disks, the disks (30) being stacked and braced in such a way that a separating gap (37) for the removal of sand and rock particles is present in each case between the individual disks (30),a coupling-on element (18, 19) at one or both ends of the annular stack (20),a clamping device at one or both ends of the annular stack (20), making it possible on the one hand to flexibly brace the brittle-hard disks (30) and on the other hand to variably fasten the annular stack (20) on the tubular flow-through device (22).

Owner:3M INNOVATIVE PROPERTIES CO +1

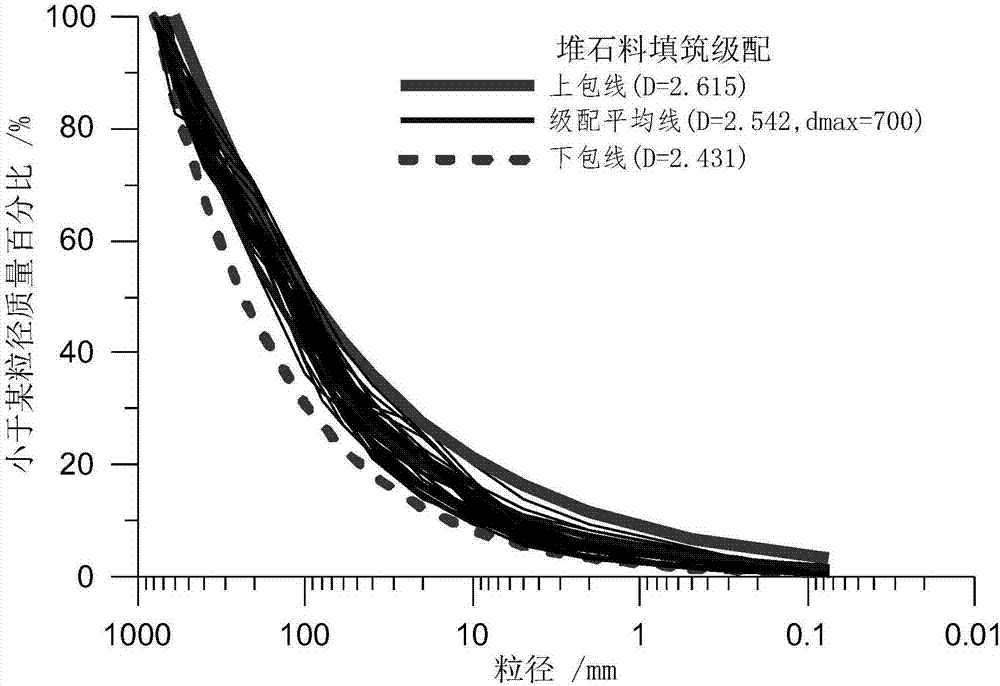

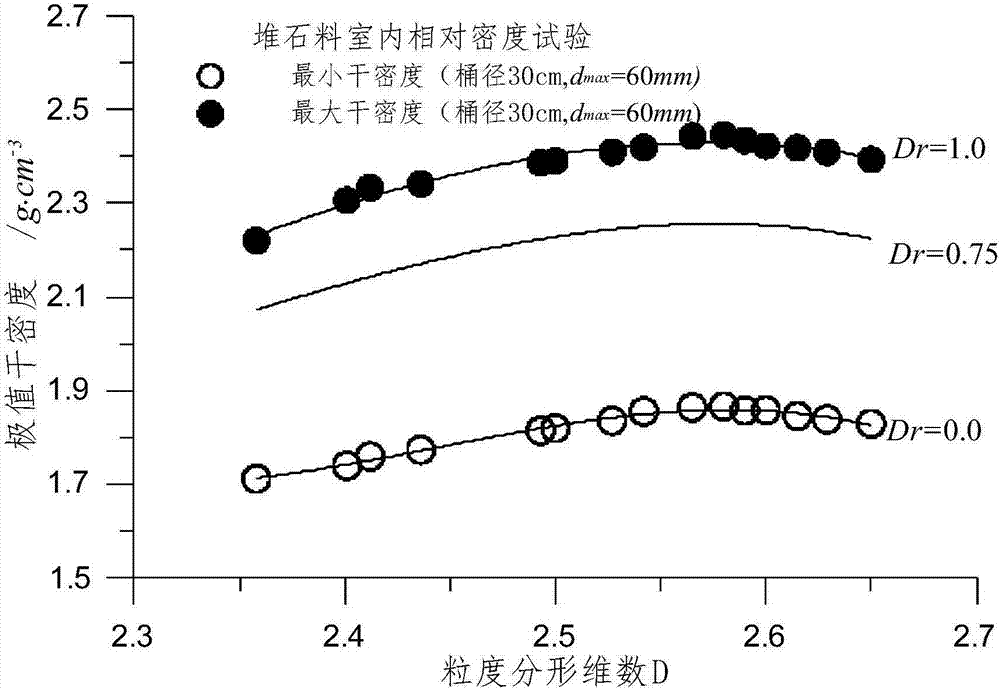

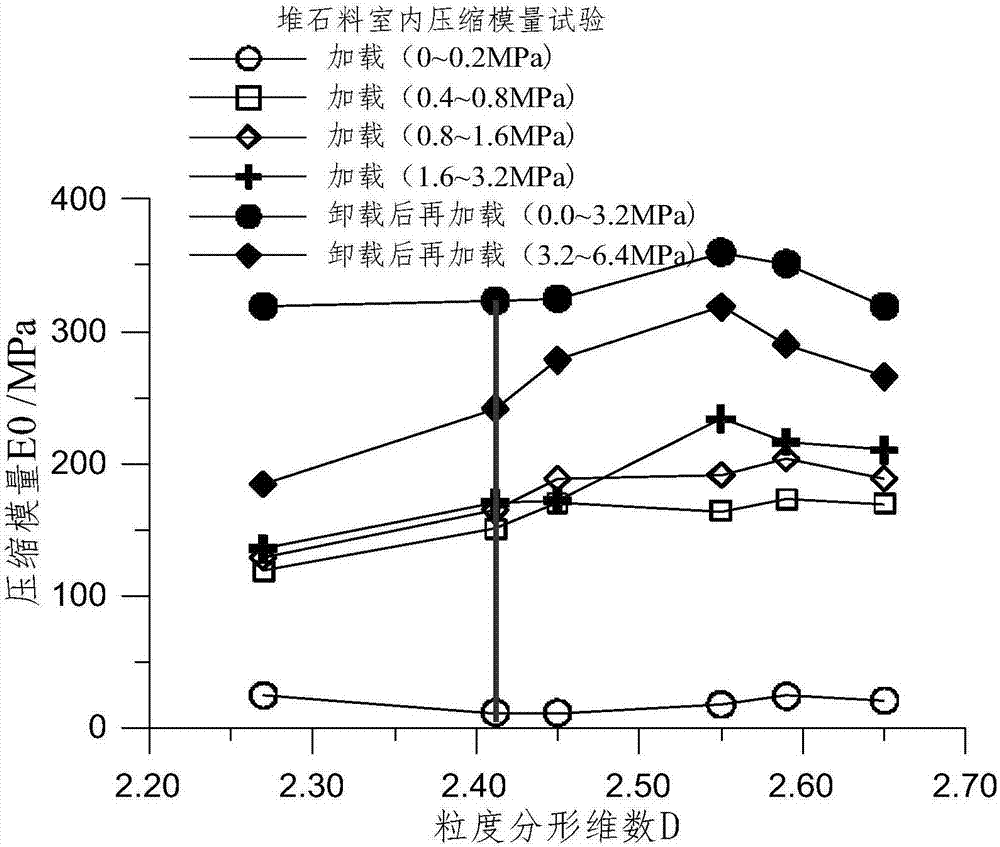

Method for determining rockfill material filling standards and detecting on-site filling quality based on fractal theory

ActiveCN107543775AControl filling qualityGuaranteed constructionParticle size analysisPermeability/surface area analysisPorosityRockfill material

The invention relates to a method for determining rockfill material filling standards and detecting on-site filling quality based on a fractal theory. The method comprises verifying a particle fractaldistribution model, building a relationship between grading parameters and dry density or porosity, building a relationship between grading parameters and a compressive modulus, determining rockfillmaterial filling grading or a grading envelope line satisfying compressive modulus requirements, acquiring a filling porosity index or an index range, carrying out a penetration test, detecting a permeability coefficient, if the permeability coefficient does not satisfy the permeability requirement, reducing and adjusting a grading range until the permeability coefficient satisfies the permeability requirement, and verifying whether the filling porosity under the condition of design relative density satisfies the filling porosity requirement. The method provides double control standards of porosity and relative density, controls rockfill body filling quality, comprehensively considers the influence produced by the grading of the rockfill material, the characteristics of the parent rock anda compaction degree on the deformability of the rockfill body, provides the reliable basis for the whole stability of the rockfill dam and effective deformation control and ensures the construction and operation safety of the dam.

Owner:HOHAI UNIV

Carbonate rock structure ingredient well logging quantitative recognition method and purpose thereof

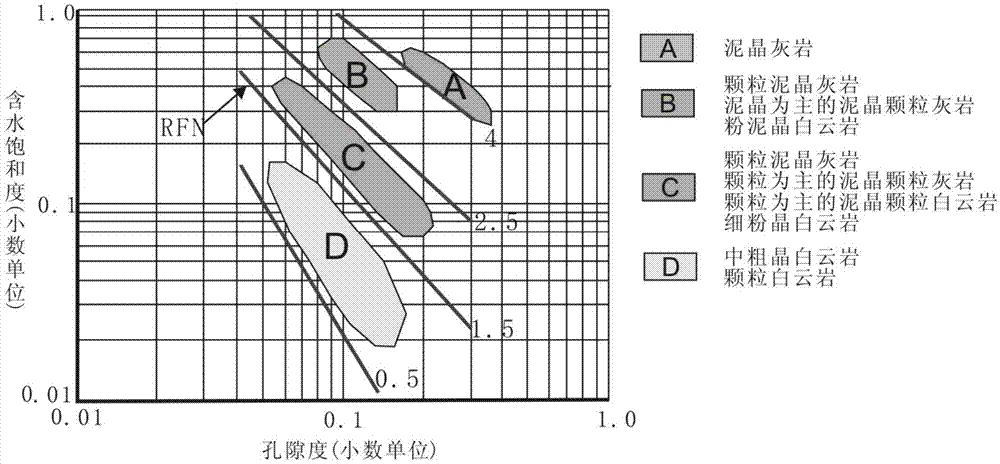

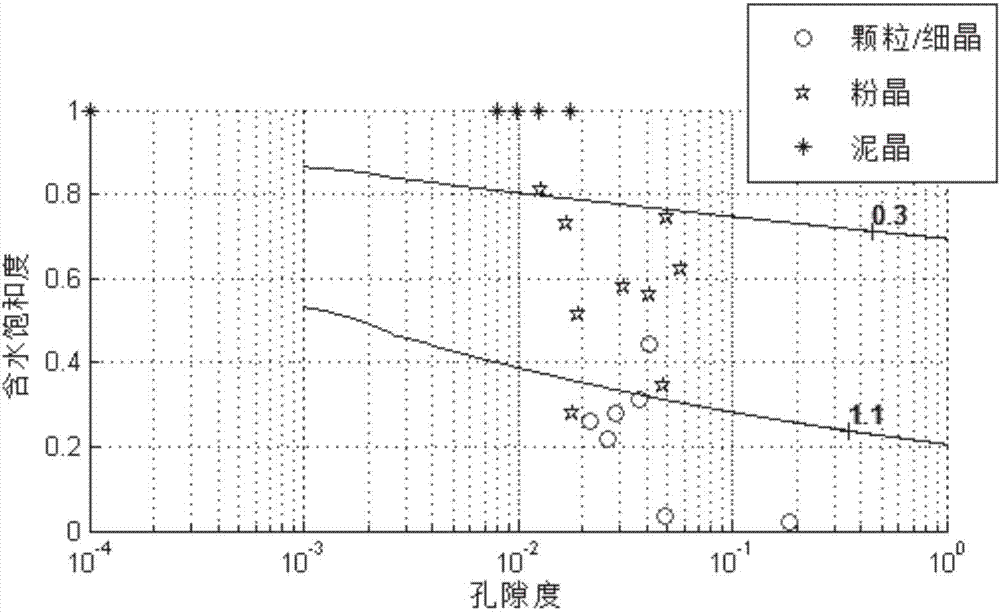

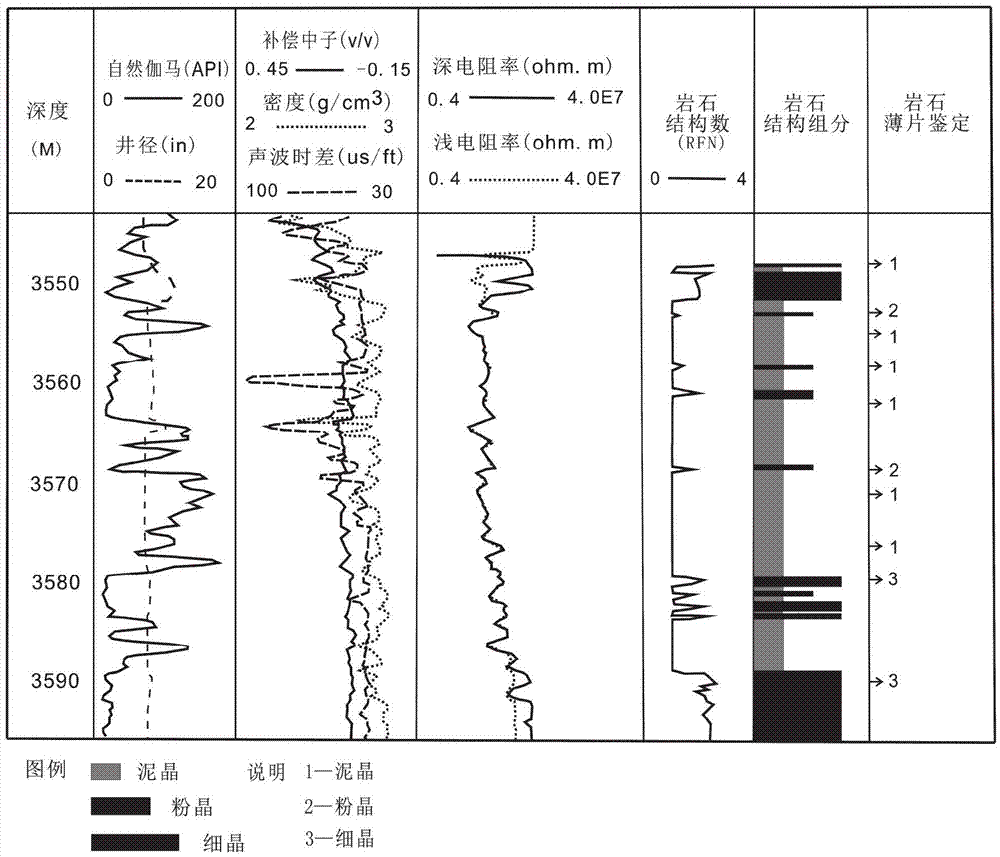

ActiveCN103698811ARealize identificationSeismic signal processingSeismology for water-loggingAdditive ingredientCrystal structure

The invention discloses a carbonate rock structure ingredient well logging quantitative recognition method and a purpose thereof. The method mainly comprises three parts including porosity and water saturation well logging calculation, rock structure number parameter calculation and rock structure ingredient identification. When RFN obtained through calculation is smaller than 0.3, the structure is a micrite structure; when the RFN is between 0.3 and 1.1, the structure is a powder crystal structure; when the RFN is greater than 1.1, the structure is a fine crystal or particle structure. The sound wave time difference logging curve is adopted for calculating the porosity, the deep lateral resistivity well logging curve and the porosity are utilized for calculating the stratum water content saturability, a rock structure number formula is utilized for calculating the rock structure number parameter, and different rock structure ingredients are identified through cutoff values. The method provided by the invention is practically applied to the stratum of Majiagou formation of Ordovician system in Wuqinan region of Ordos Basin, and a better effect is obtained.

Owner:PETROCHINA CO LTD

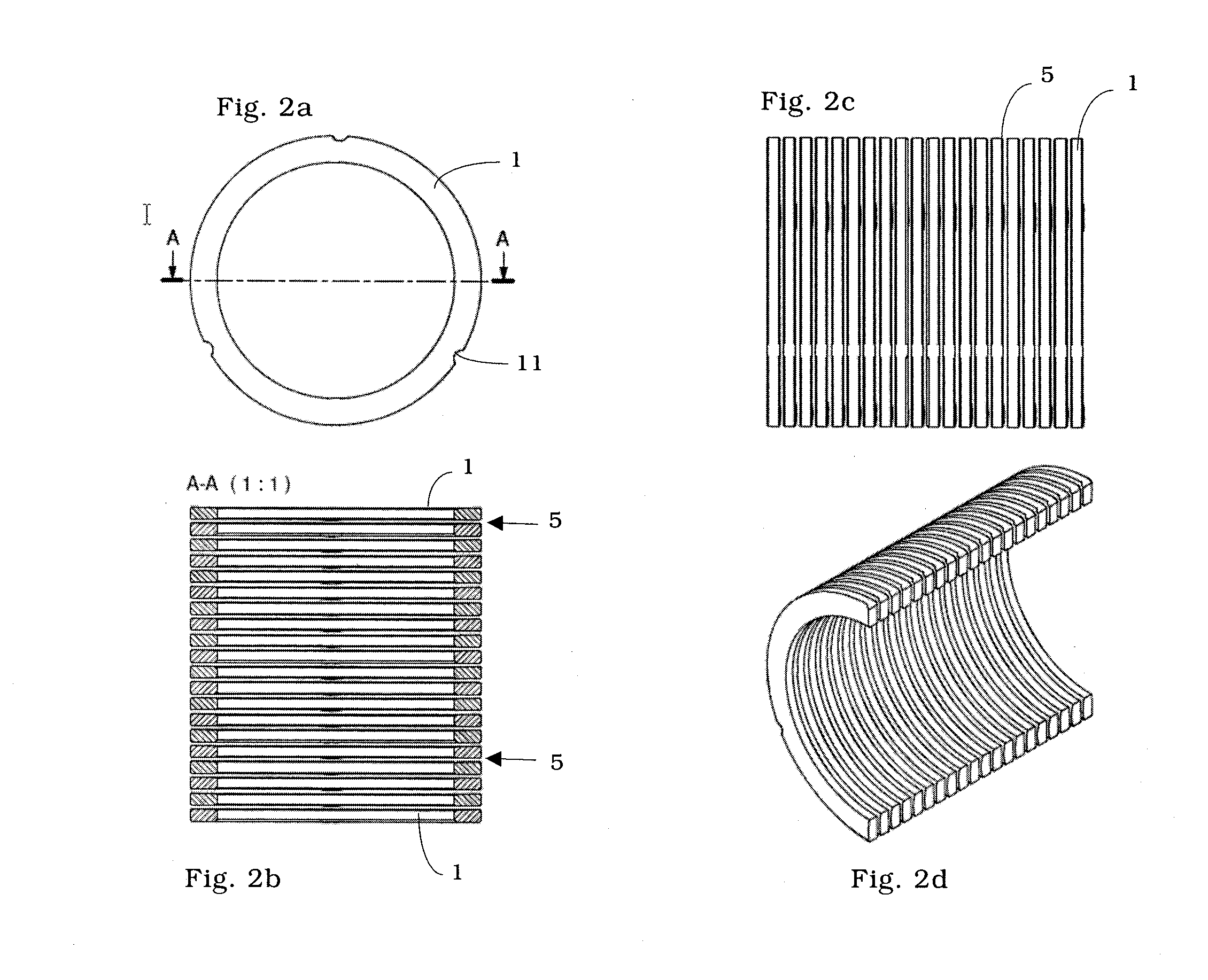

Separating device for removing sand and rock particles

ActiveUS20110220347A1Resistance of separatingWear resistanceFluid removalDrinking water installationCircular discMining engineering

According to a first embodiment, the invention relates to a separating device for removing sand and rock particles in the extraction of liquids or gases from wells drilled in rock, comprising a plurality of annular discs of a brittle-hard material stacked one on top of the other and axially braced by means of a supporting structure, the discs having on their upper side at least three spacers uniformly distributed over the circular circumference of the discs, the discs being stacked one on top of the other in such a way that the spacers respectively lie one over the other, and that a separating gap with a height of 0.05-1 mm, preferably 0.2-0.5 mm, is present in each case between the individual discs.According to a second embodiment, the invention relates to a separating device for removing sand and rock particles in the extraction of liquids or gases from wells drilled in rock, comprising a plurality of bush-shaped elements of a brittle-hard material stacked one on top of the other and axially braced by means of a supporting structure, slits with a slit width of 0.05-1 mm, preferably 0.2-0.5 mm, being formed in the bush-shaped elements.

Owner:3M INNOVATIVE PROPERTIES CO

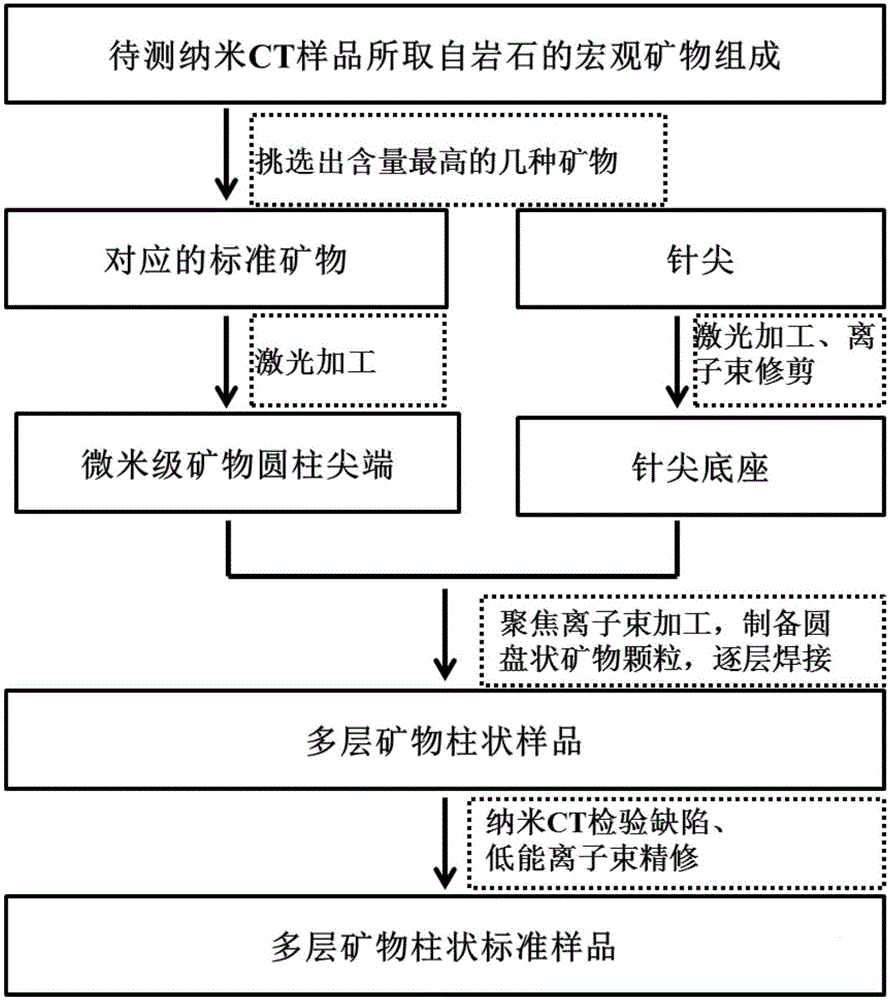

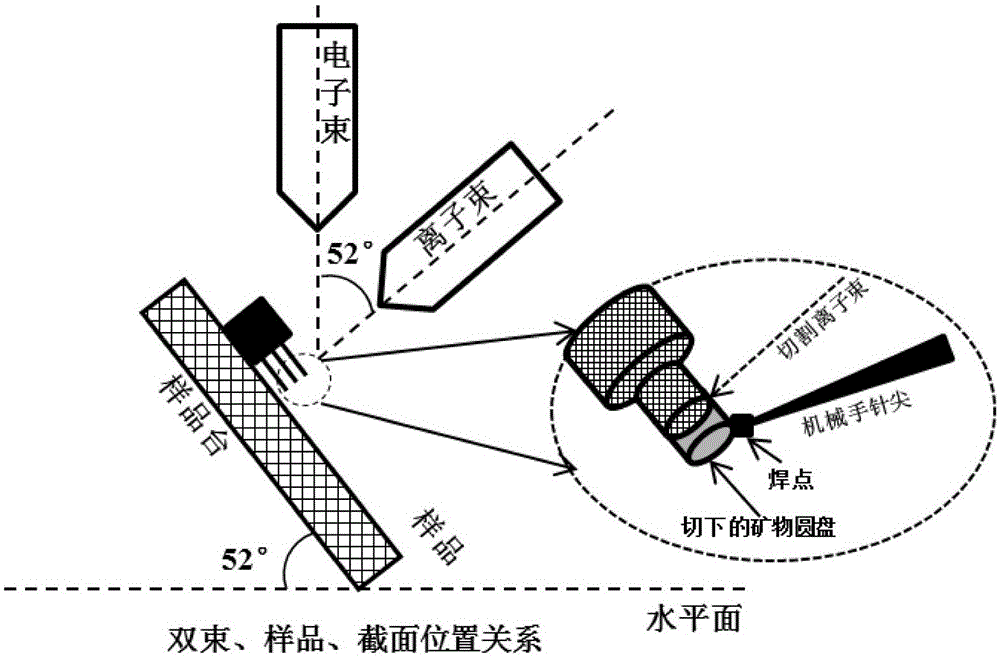

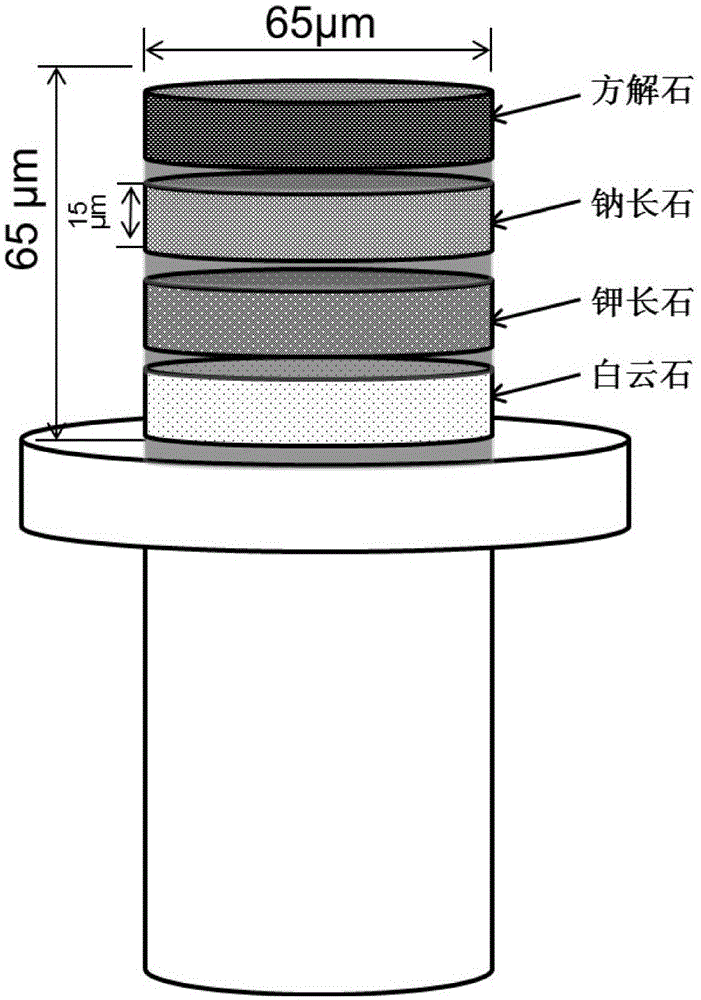

Mineral standard sample used for nanometer CT, and preparation method and application thereof

ActiveCN105067395AFill vacancyRealize one-time calibrationPreparing sample for investigationMaterial analysis by transmitting radiationMineral particlesMineral identification

The invention provides a mineral standard sample used for nanometer CT, and a preparation method and an application thereof. The preparation method of the mineral standard sample comprises the following steps: selecting standard mineral particles according to the mineral composition of a rock to be measured; respectively processing at least one of the selected standard mineral particles to form mineral sample discs; and welding one of the mineral sample discs to a pedestal, and stacking and welding all the mineral sample discs to form the mineral standard sample. When the mineral standard sample is used in mineral analysis, mineral identification is carried out by using the gray scale information of the standard mineral sample and a rock sample to make unknown mineral particles in the rock sample identified and calibrated, so the three dimensional distribution, the volume proportions and the mineral particle dimension distribution of corresponding mineral components in the rock sample are obtained. The method effectively fills up the gap in preparation methods of like standard samples, and meets urgent demands of microscopic three dimensional mineral analysis in the petroleum geology field.

Owner:PETROCHINA CO LTD

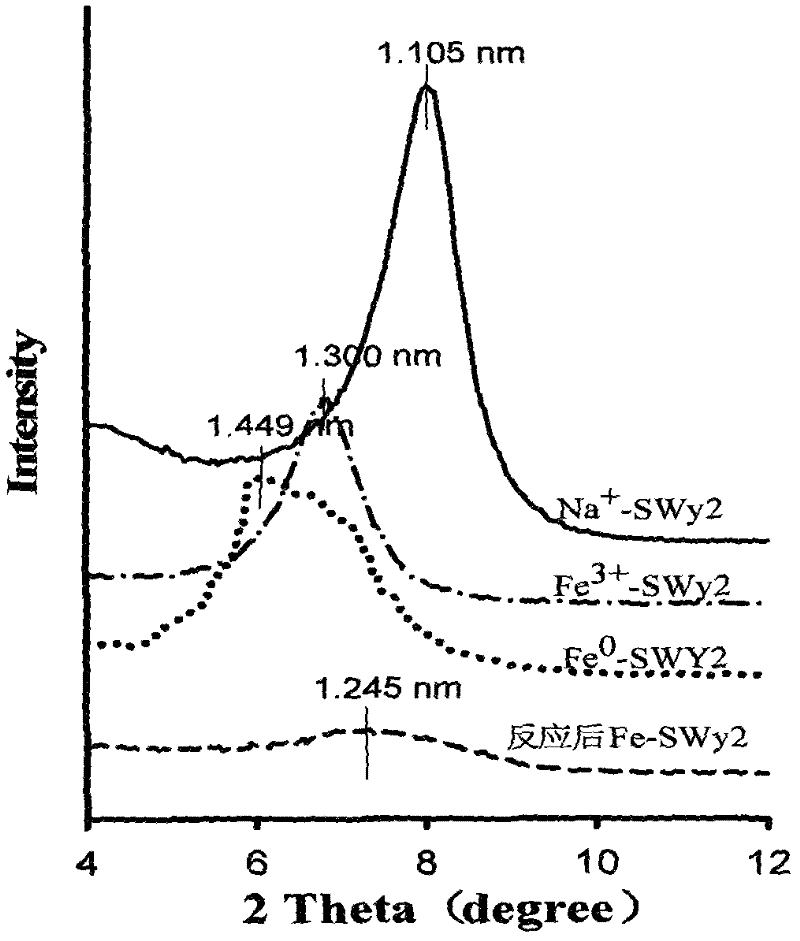

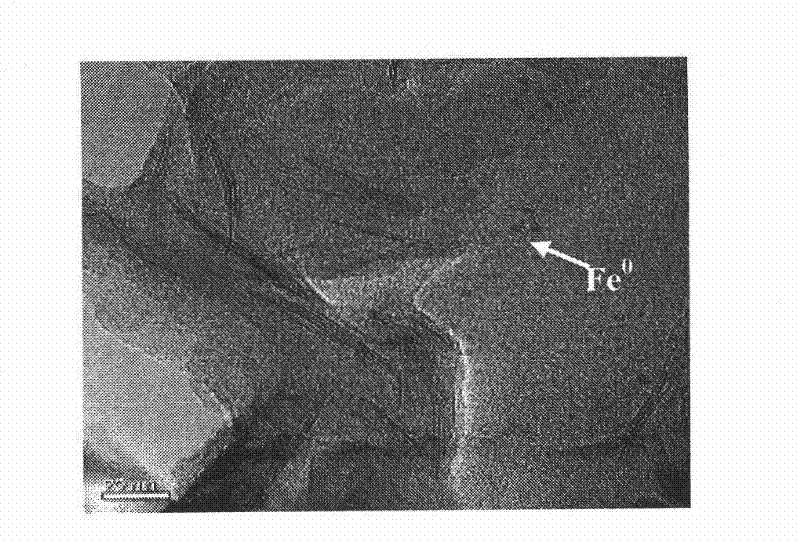

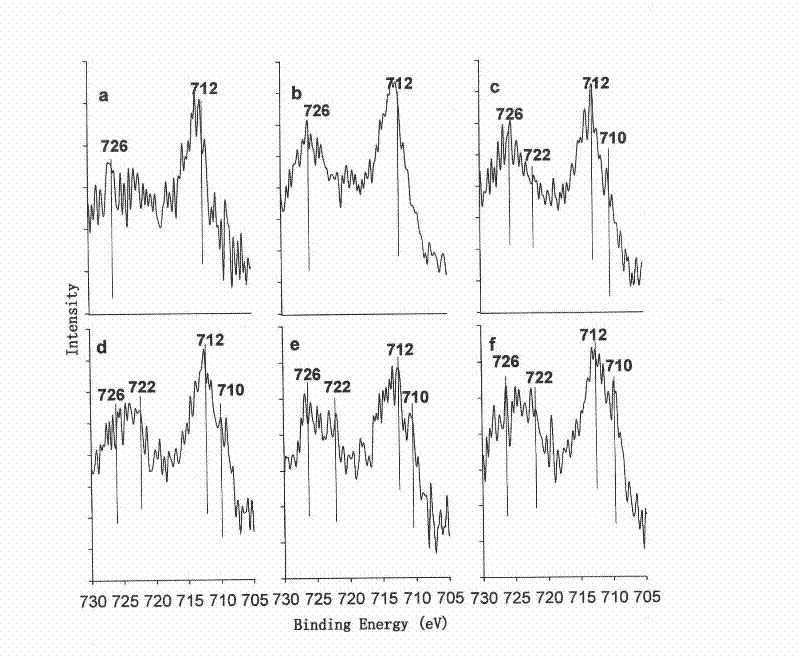

Method for preparing montmorillonite in situ intercalation type nanoscale zero-valent iron

InactiveCN102344194AAvoid reunionImprove liquidityWater/sewage treatment by sorptionWater/sewage treatment by reductionMontmorilloniteMaterials science

The present invention relates to a method for preparing montmorillonite in situ intercalation type nanoscale zero-valent iron. According to the method, a template is adopted, wherein the template is prepared through adopting montmorillonite clay as nanoscale zero-valent iron; the in situ intercalation method is adopted to prepare the montmorillonite-loaded nanoscale (sub-nanometer) zero-valent iro; the montmorillonite in situ intercalation type nanoscale zero-valent iron is prepared through the following preparation steps: pretreatment of montmorillonite, preparation of Fe<3+> saturated montmorillonite, acidification of Fe<3+> saturated montmorillonite and preparation of montmorillonite-loaded zero-valent iron. The nanoscale zero-valent iron in the prepared montmorillonite-loaded type zero-valent iron composite material through the method provided by the present invention is positioned between the montmorillonite layers, and exists in nanometer or sub-nanometer atom cluster scale; compared to other nanoscale zero-valent irons, the nanoscale zero-valent iron provided by the present invention has higher reaction activity and higher reducing effectiveness. According to the present invention, with the template prepared through adopting the montmorillonite as the zero-valent iron, the agglomeration of the zero-valent iron particles can be prevented, the fluidity of the zero-valent iron is enhanced, the zero-valent iron can be protected to a great degree, such that the oxidation of the zero-valent iron due to water molecules can be avoided; with the method, the problems of easy agglomeration, easy oxidation due to the water and poor fluidity during the synthesis and the application process of the nanoscale zero-valent iron are solved; an effective material and technology is provided for environmental pollution treating.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Method of using shaped compressed pellets in treating a well

ActiveUS9010430B2Speed up the flowEasily obstructedCleaning apparatusFluid removalParticulatesSorbent

Shaped particulates which have been compressed from a composite of a well treatment agent and adsorbent in a matrix may be introduced into horizontal or deviated oil or gas wells. The well treatment agent of the shaped pellets may be used to prevent and / or control the formation of deposits in a production well.

Owner:BAKER HUGHES INC

Determining and Tracking Downhole Particulate Deposition

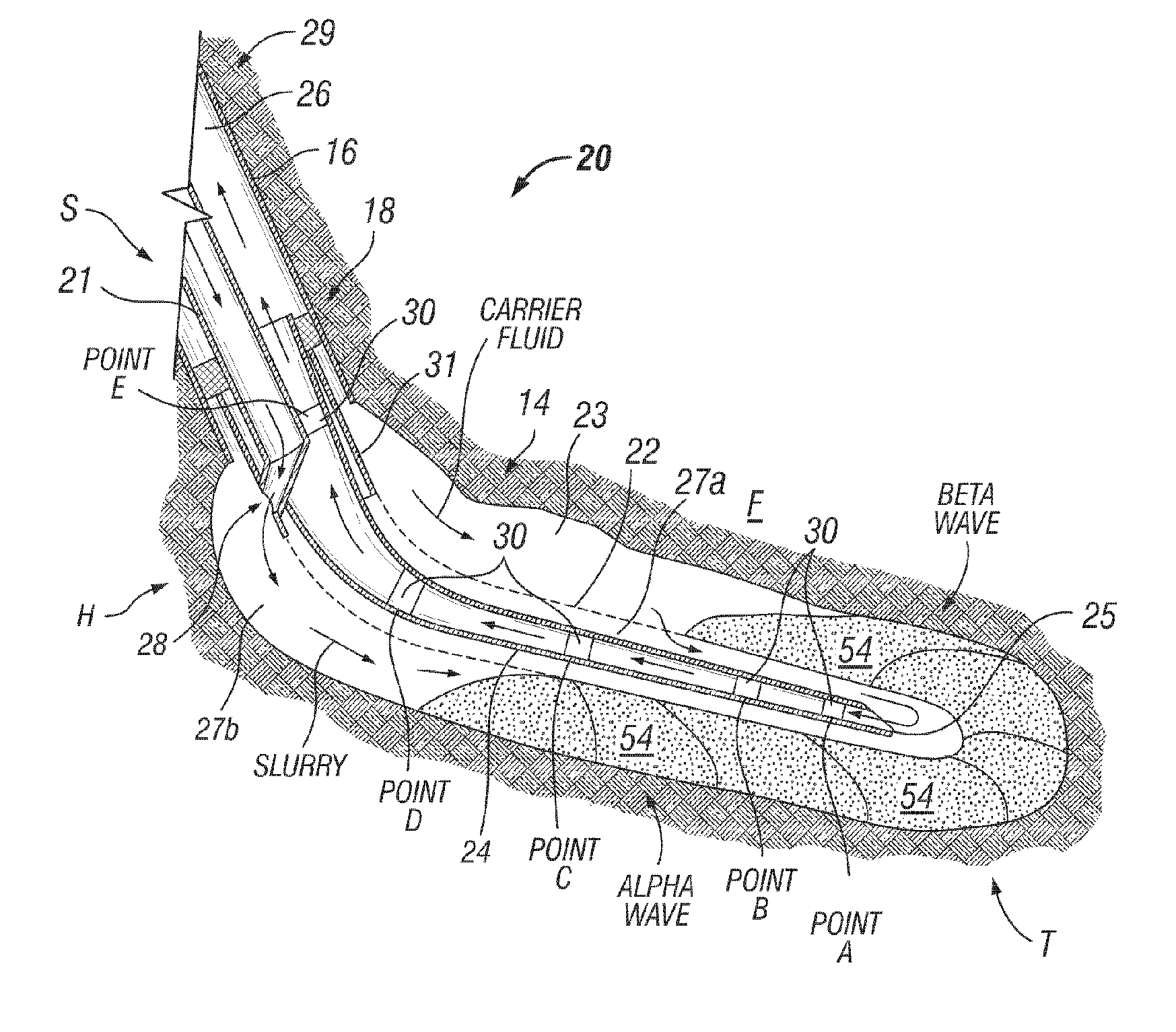

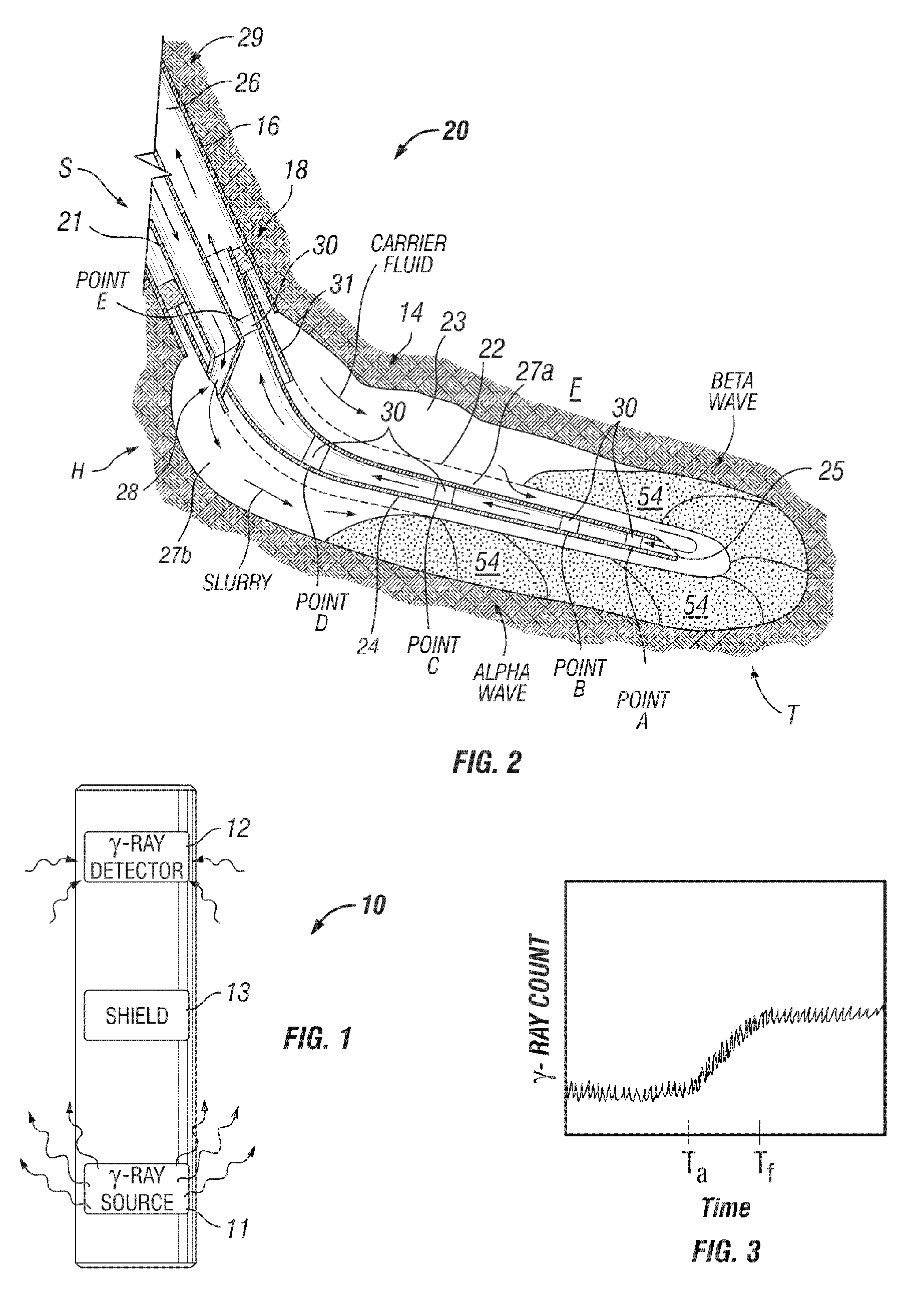

InactiveUS20070017673A1Easy to “ track ”Useful characteristicSurveyFluid removalParticulatesCarrier fluid

Methods and apparatus provide for the characterization of injected fluid flow within a wellbore. Particular embodiments include injecting a slurry comprising a particulate material and a carrier fluid into an isolated wellbore annulus and acquiring composite density readings at one or more discrete locations along the annulus while depositing the particulate material. Interpreting the acquired composite density readings provides an evaluation of the placement of the deposited particulate material within the isolated wellbore annulus. A further step may include determining when the slurry reaches each of the discrete locations as indicated by increases in the composite density reading at each of the discrete locations and furthermore, acquiring a maximum composite density reading at each of the discrete locations along the tubular member as an indication of the quantity of deposited particulate material at each of the discrete locations. Apparatus includes a plurality of densimeters secured at discrete axial locations within a tubular member for acquiring composite density readings within an isolated wellbore annulus.

Owner:SCHLUMBERGER TECH CORP

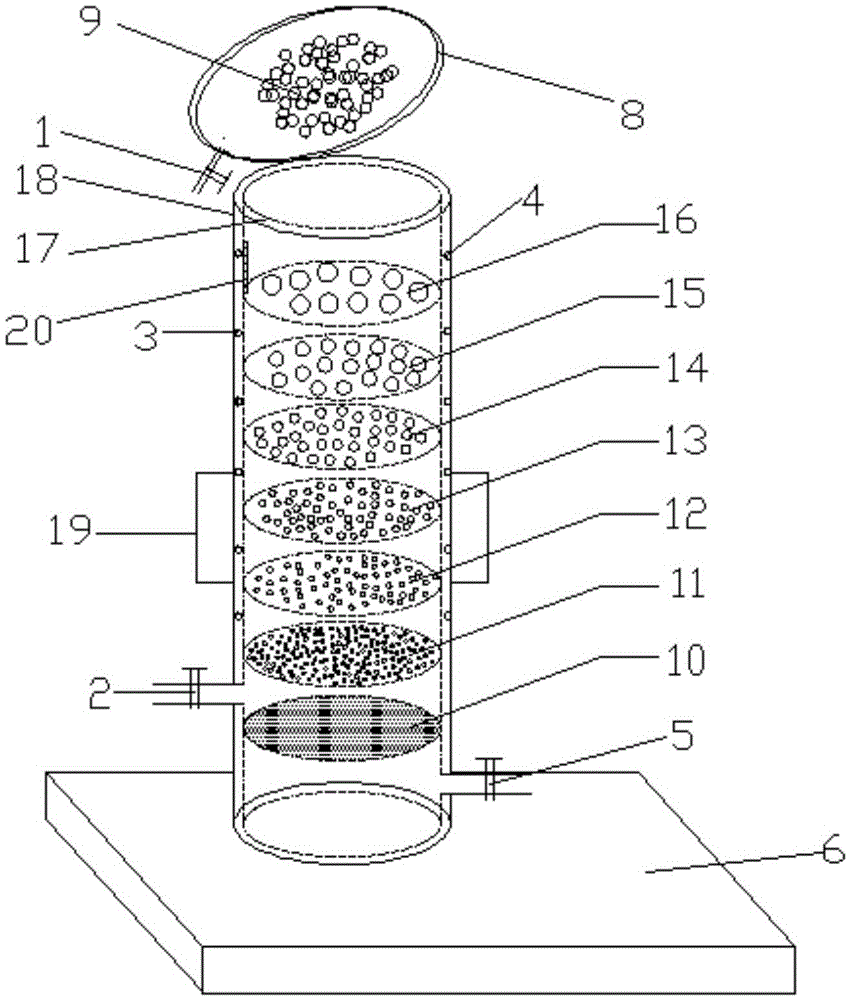

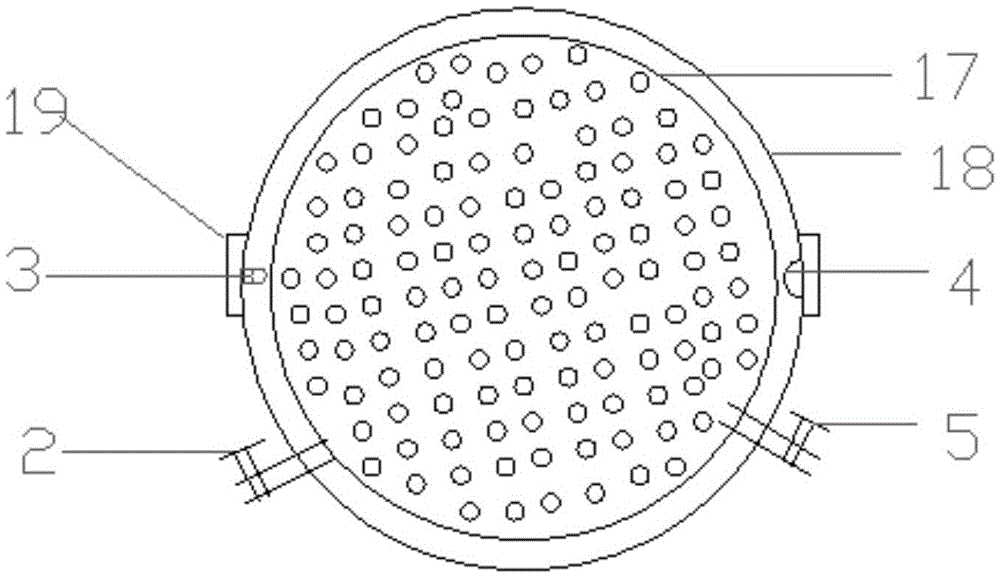

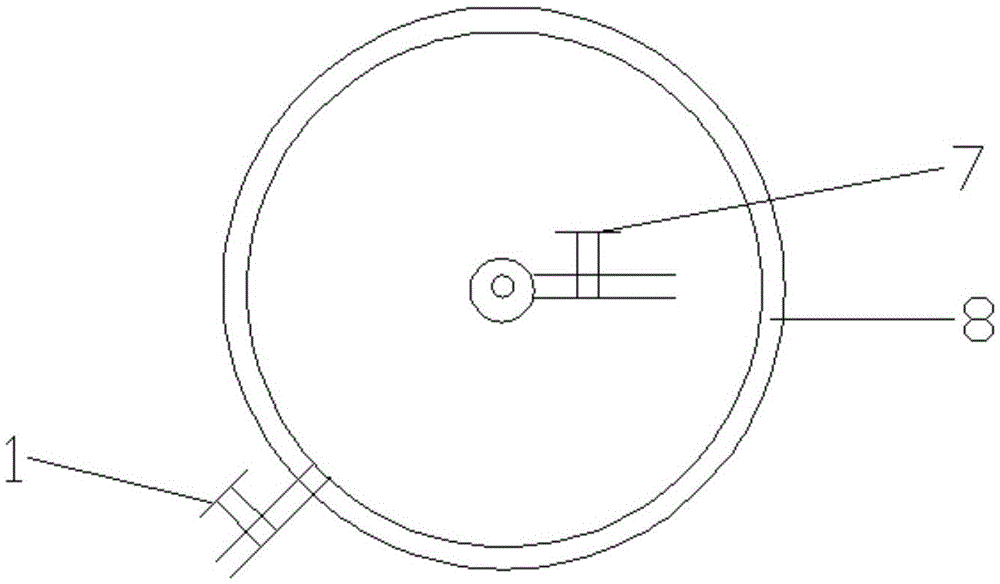

Soft rock weathering and breaking experimental apparatus and experimental method thereof

InactiveCN105628595AStrong operabilityReal-time measurementWeather/light/corrosion resistanceMaterial weighingGeotextileRock weathering

The invention discloses a soft rock weathering and breaking experimental apparatus and an experimental method thereof. The soft rock weathering and breaking experimental apparatus is placed on a frequency modulatable vibrating table and is provided with a transparent inner barrel and an outer barrel. A required volume of water can be added by a water inlet on a barrel upper cover; a water outlet and a gas delivery opening are formed at the bottom of the experimental apparatus; a plurality of layers of round hole sieve plates are arranged in the inner barrel; hole diameters of the round hole sieve plates are sequentially decreased from top to bottom according to a standard sieve hole size of a laboratory; micro high-strength frequency modulatable fluorescent lamps and monitoring probes are placed in the interval between the inner barrel and the outer barrel above each sieve; geotechnical cloth is arranged for isolating soil and filtering water. According to the soft rock weathering and breaking experimental apparatus and experimental method which are disclosed by the invention, effects of variable natural factors on soft rocks are controlled in a room by simulation so as to research influence of each factor on soft rock weathering; by the monitoring probes, the weathering and breaking process of each layer of soft rock particles can be observed and recorded, and the weathered broken rock particles can be automatically sieved and are continuously weathered and broken; the soft rock weathering and breaking experimental apparatus and experimental method have the advantages of being visual, convenient, rapid, accurate and the like.

Owner:CHANGAN UNIV

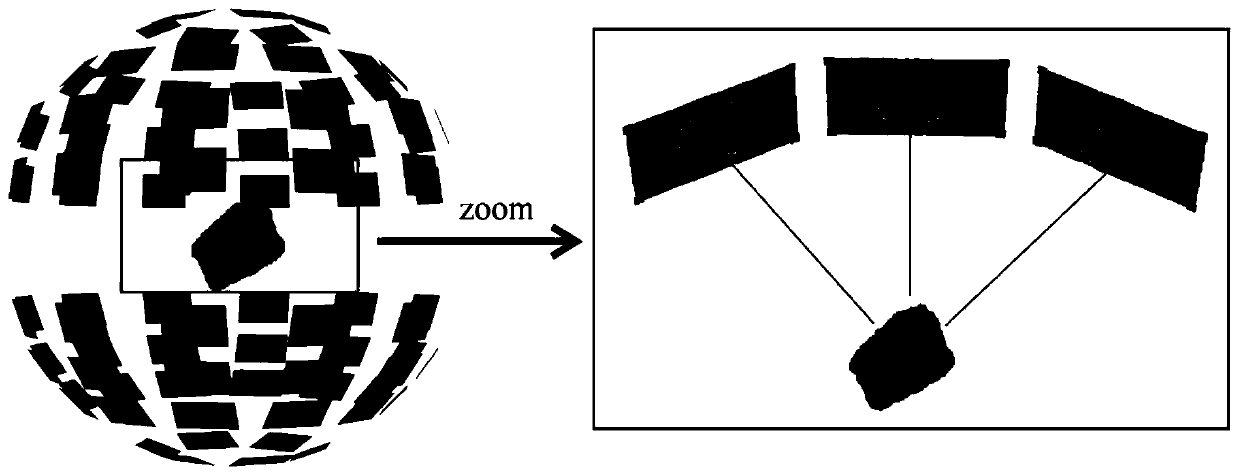

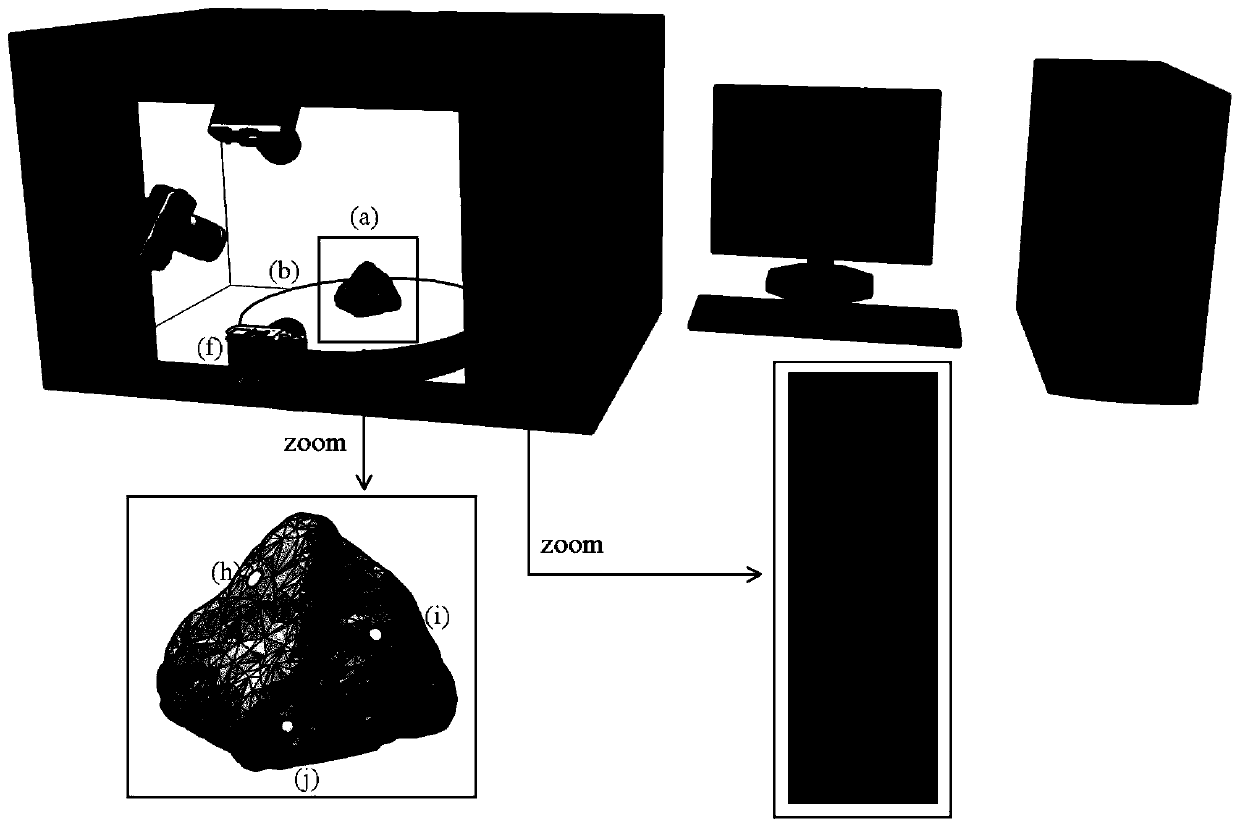

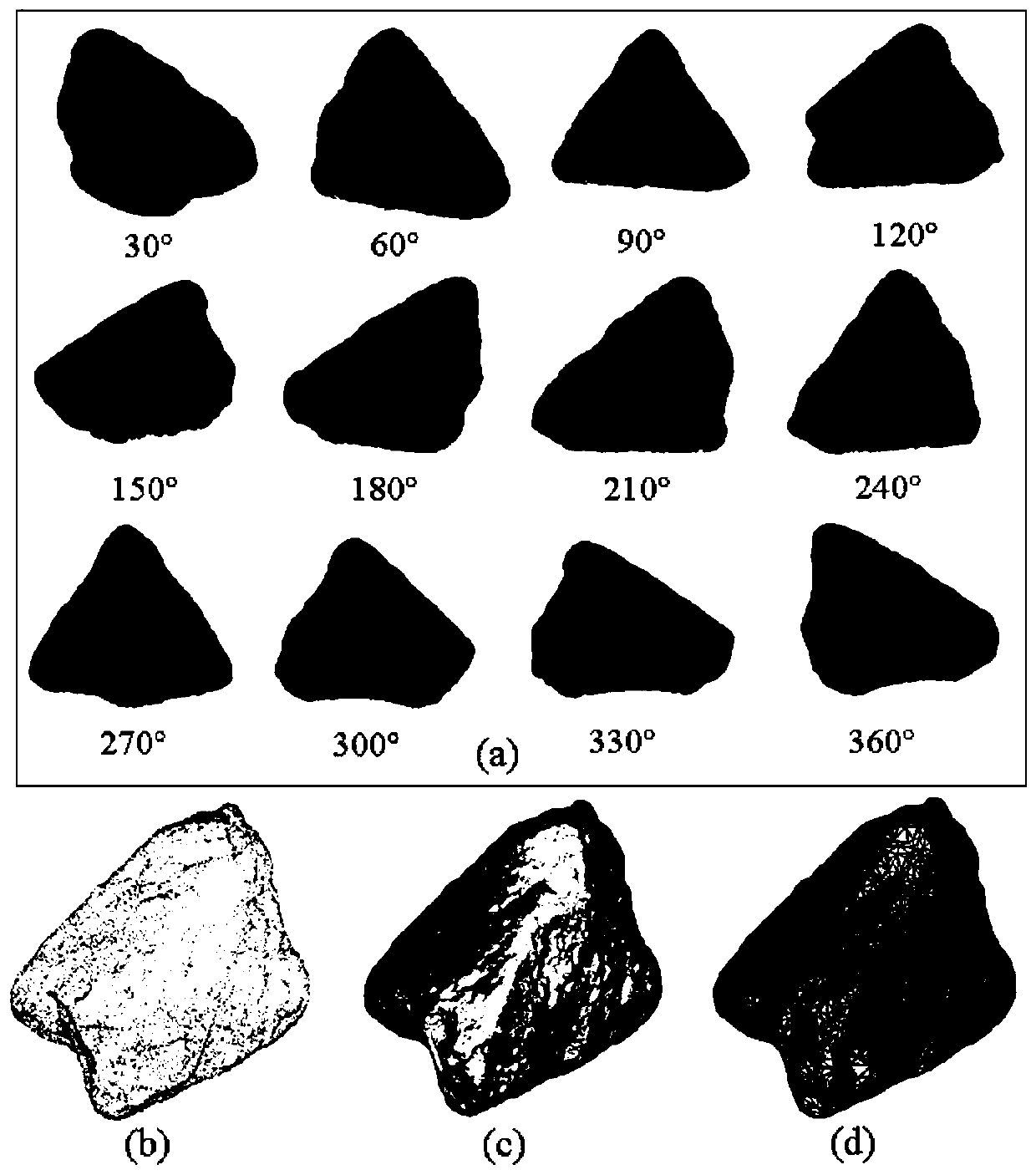

Rock particle three-dimensional geometrical morphology information extraction system and method

The invention discloses a rock particle three-dimensional geometrical morphology information extraction system and a rock particle three-dimensional geometrical morphology information extraction method. The rock particle three-dimensional geometrical morphology information extraction method comprises the steps of: photographing a plurality of feature images of each surface of a rock particle at different height visual angles from a plurality of visual angles at different heights, so as to obtain all feature points of the surface of the rock particle; performing three-dimensional modeling according to the plurality of feature images of each surface of the rock particle at different height visual angles to obtain a three-dimensional model of the rock particle; and extracting contour information of the rock particle from the three-dimensional model, and further calculating three-dimensional geometrical morphology information of the rock particle according to the contour information. Compared with the prior art, the rock particle three-dimensional geometrical morphology information extraction method and the rock particle three-dimensional geometrical morphology information extraction system have the advantages that the precision of the three-dimensional model of the rock particle acquired by the method and the system is higher, and the local three-dimensional geometrical morphologyinformation of the rock particle can be acquired.

Owner:CENT SOUTH UNIV

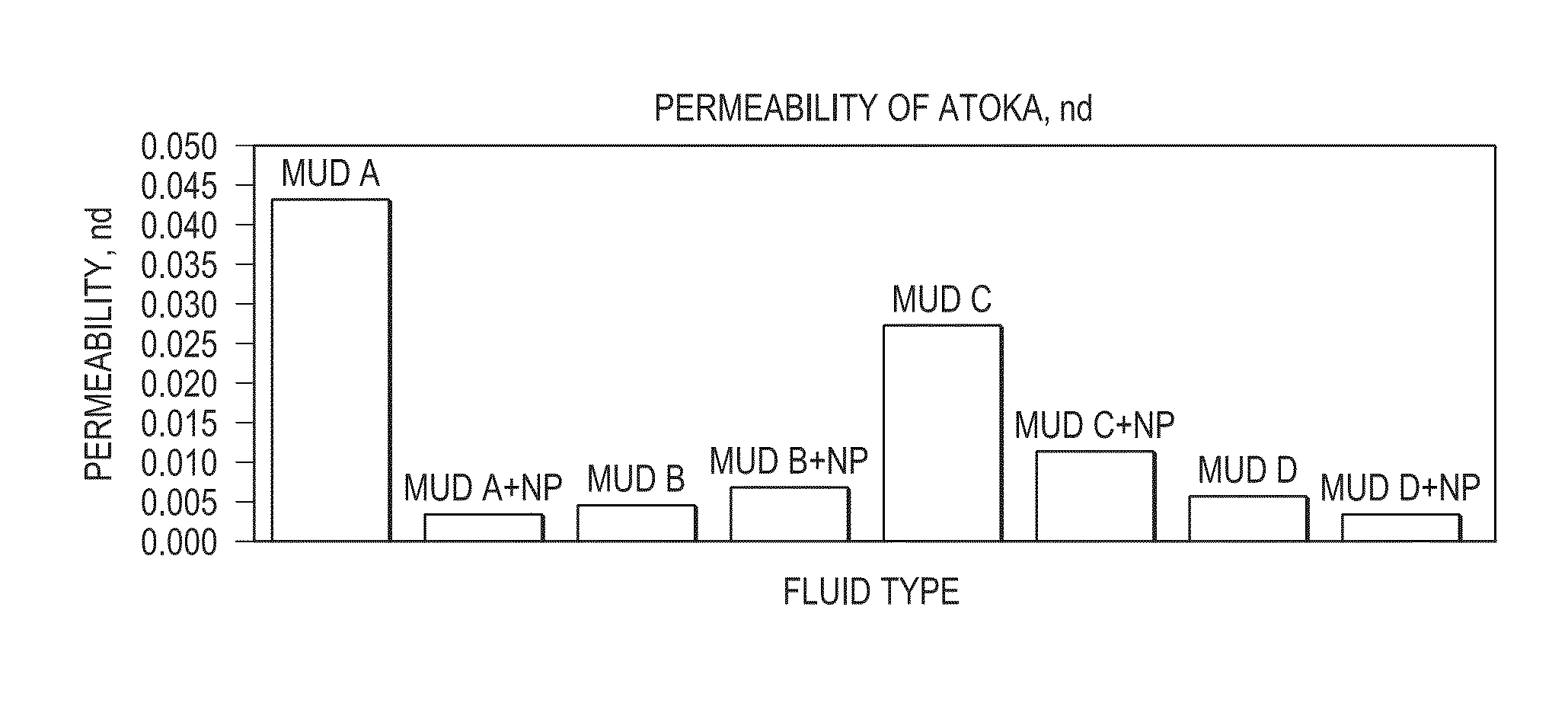

Maintaining shale stability by pore plugging

Compositions and methods for improving wellbores stability of a hydrocarbon bearing shale formation using nanoparticles to decrease swelling and plug pore throats.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

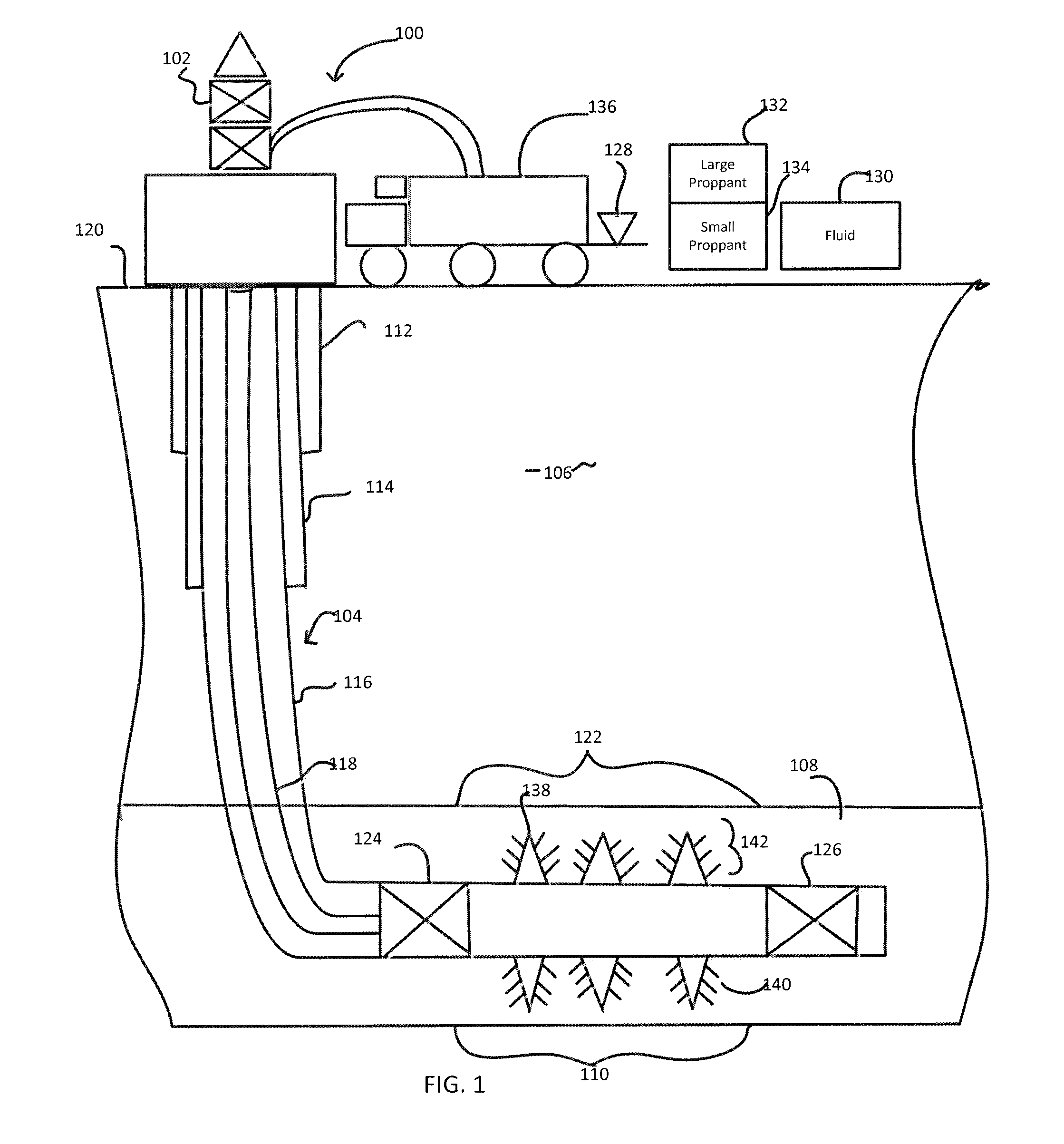

Nano-proppants for fracture conductivity

InactiveUS20160355727A1Increase the extension lengthImprove conductivityFluid removalDrilling compositionMetallurgyFracturing fluid

Methods of hydraulic fracturing are disclosed. One method of hydraulic fracturing which is performed on a geologic stratum includes using a nano-proppant dominantly formed of particles having an average diameter of less than 1 μm dispersed in a fracturing fluid. A material for use in hydraulic fracturing may include a fracturing fluid and a nano-proppant dominantly formed of particles having an average diameter of less than 1 μm dispersed in the fracturing fluid.

Owner:UNIVERSITY OF KANSAS

Metallurgical auxiliary material fluxing agent and preparation method thereof

InactiveCN101748235APlay a role in fluxingFlux benefitsBlast furnace detailsManufacturing convertersMaterials scienceCalcium ferrite

The invention relates to the field of metallurgical technology, in particular to a metallurgical auxiliary material fluxing agent which is characterized in that the melting point of the fluxing agent is 1100 DEG C-1150 DEG C, and the fluxing agent contains, by weight percent, 40-50 Fe2O3, 45-50 CaO, 2.0-6.0 AL2O3, 0-5.0 SiO2 and 0-1.5CaF2. The preparation method is as follows: crushing the compositions to 0-20mm grains, mixing, melting at high temperature of 1200 DEG C -1550 DEG C so as to get calcium ferrite after the melting reaction, cooling and then grinding the calcium ferrite to 200-mesh powder. The fluxing effect can be best when the amount of the fluxing agent added is 4-6% by weight percent of the agglomerate or pellets reduced in a rotary kiln, and after being added, the fluxing agent is mixed with the agglomerate or pellets. The invention has the advantages that: firstly, the fluxing agent not only has fluxing function but also participates in the metallurgical reaction, and secondly, the melting point of the fluxing agent is 1150 EDG C which is lower than that of the fluxing agent of fluorite, so the fluxing agent has better fluxing action to the auxiliary material and is stable in fluxing effect, low in unit and environment-friendly.

Owner:LIAONING TIANHE TECH

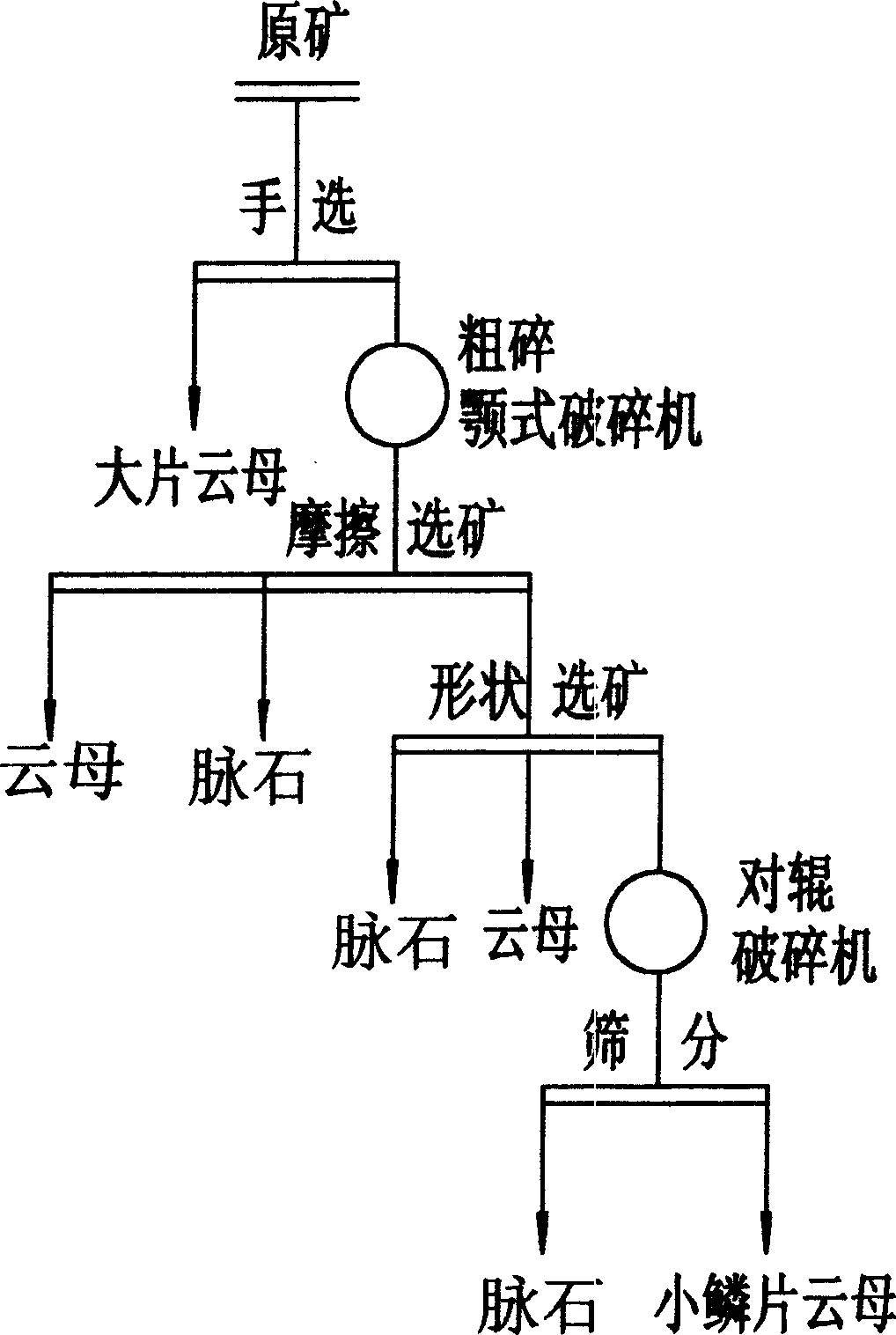

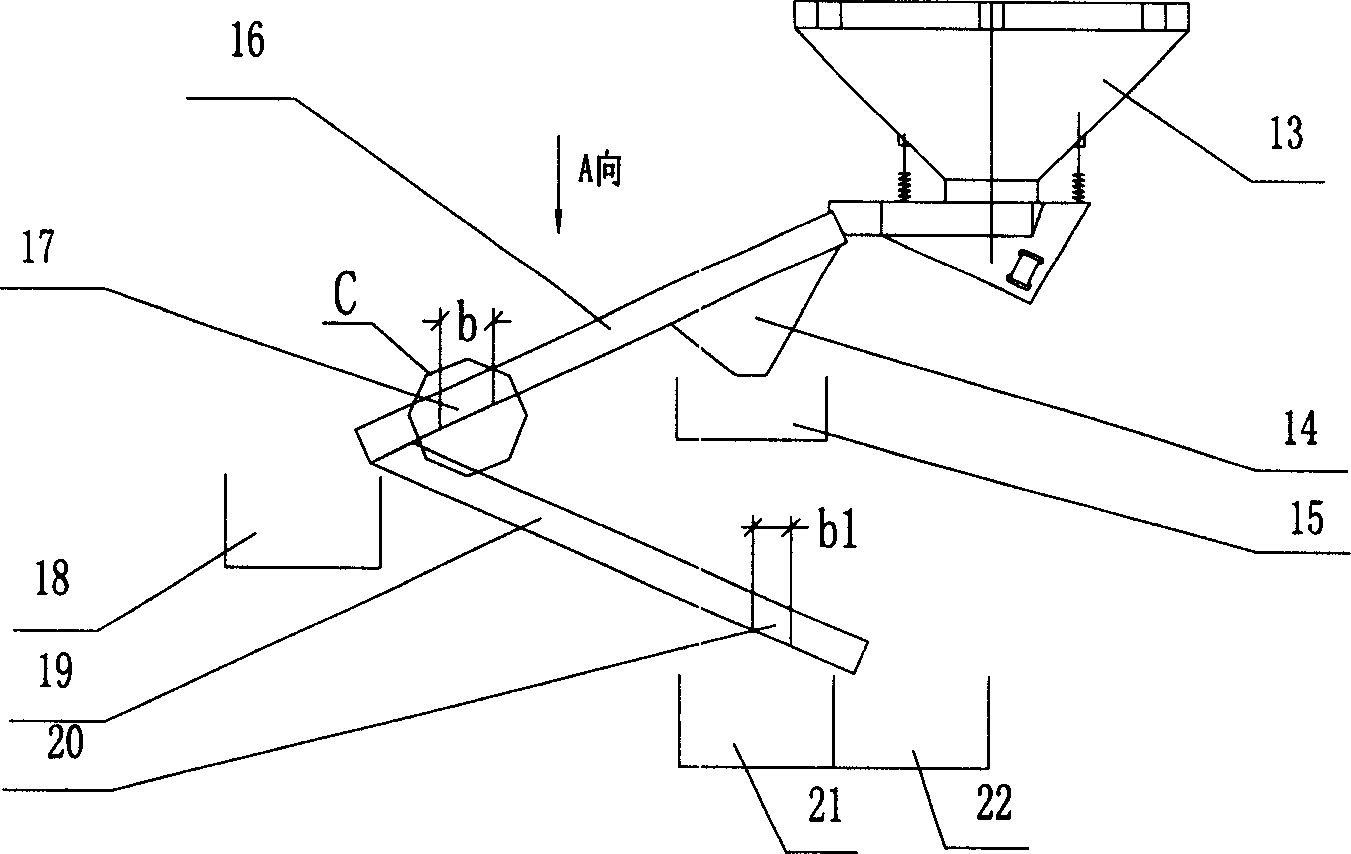

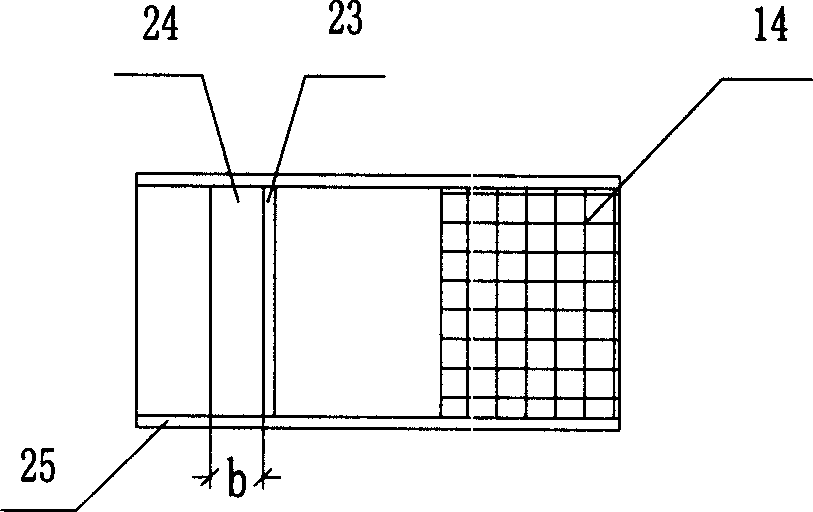

Ore selecting method of anthrophyllite and its friction concentrator

The invention involves a kind of mica dressing method, one mica dressing method, its characteristic is it includes the following step: 1) PE400X600jaw type breaker; 2) Friction dressing; The ore first through rubs front end the concentrator slanting to sieve,screens out finely ground particles mica which is smaller than the 20mm and barren rock, enters undressed ore recycling bunker which is smaller than the 20mm ; Is bigger than the 20mm ore to continue along the sloping plate to glide down, when arrives rubs the concentrator the batardeau board, divides elects, the final final with barren rock separates, 3) Is smaller than the 20mm finely ground particles mica and barren rock gives into the universities the mica grate, the inner layer linearity, strainer through product, the outer layer hole shape strainer on thing is the mica, the outer layer hole shape strainer under thing for the small lamella mica to the finely ground particles barren rock mixture; 4)Highly effective mica grate all levels of other disappears the crisp piece mica and the finely ground particles barren rock mixtureseparately enters to the roller breaker to break,the sieves separately with barren rock and the mica, obtains the different rank small lamella mica.The invention may recycle the small lamella micais which is smaller than the 20mm, has a protection function to the mica crystal.

Owner:WUHAN UNIV OF TECH

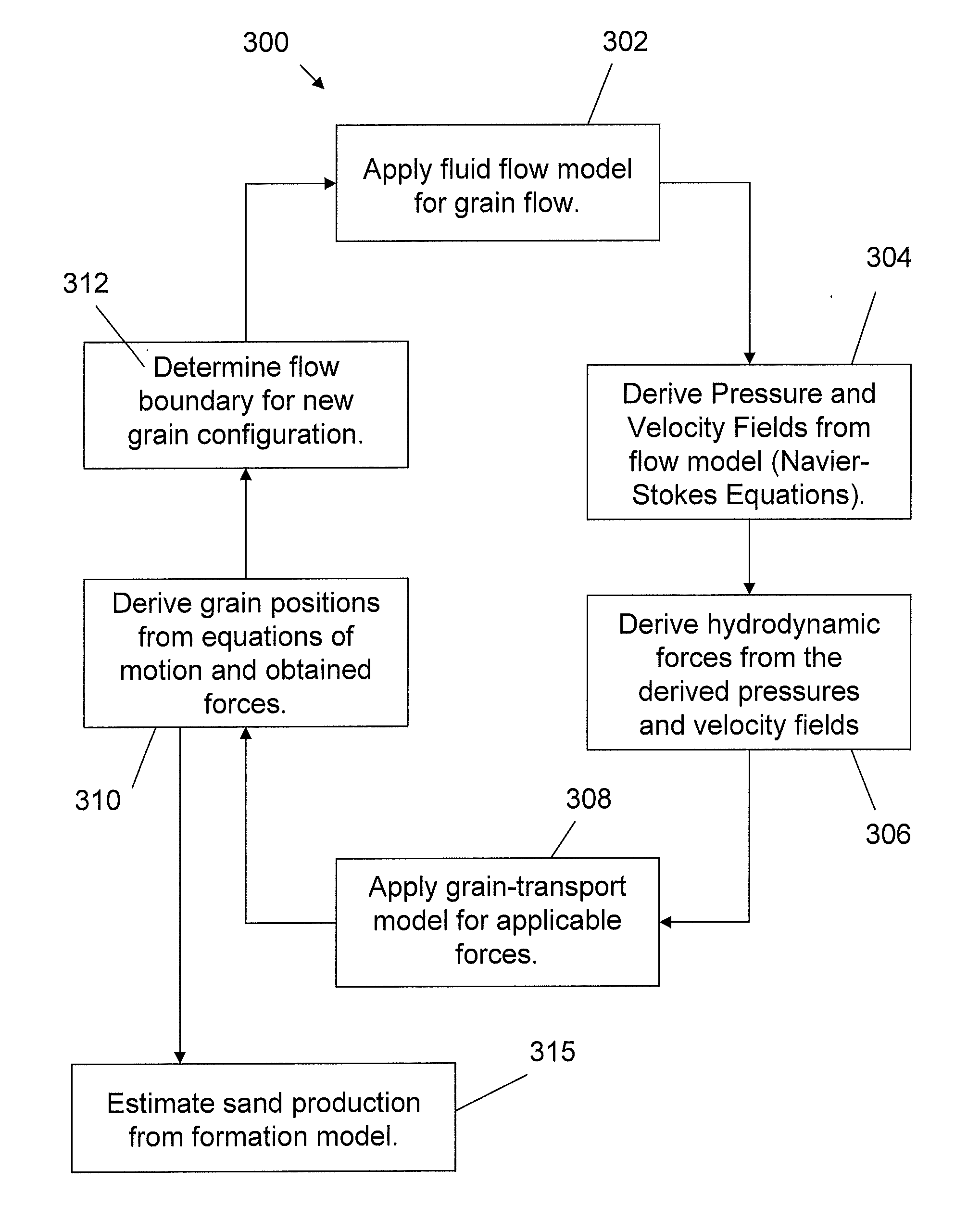

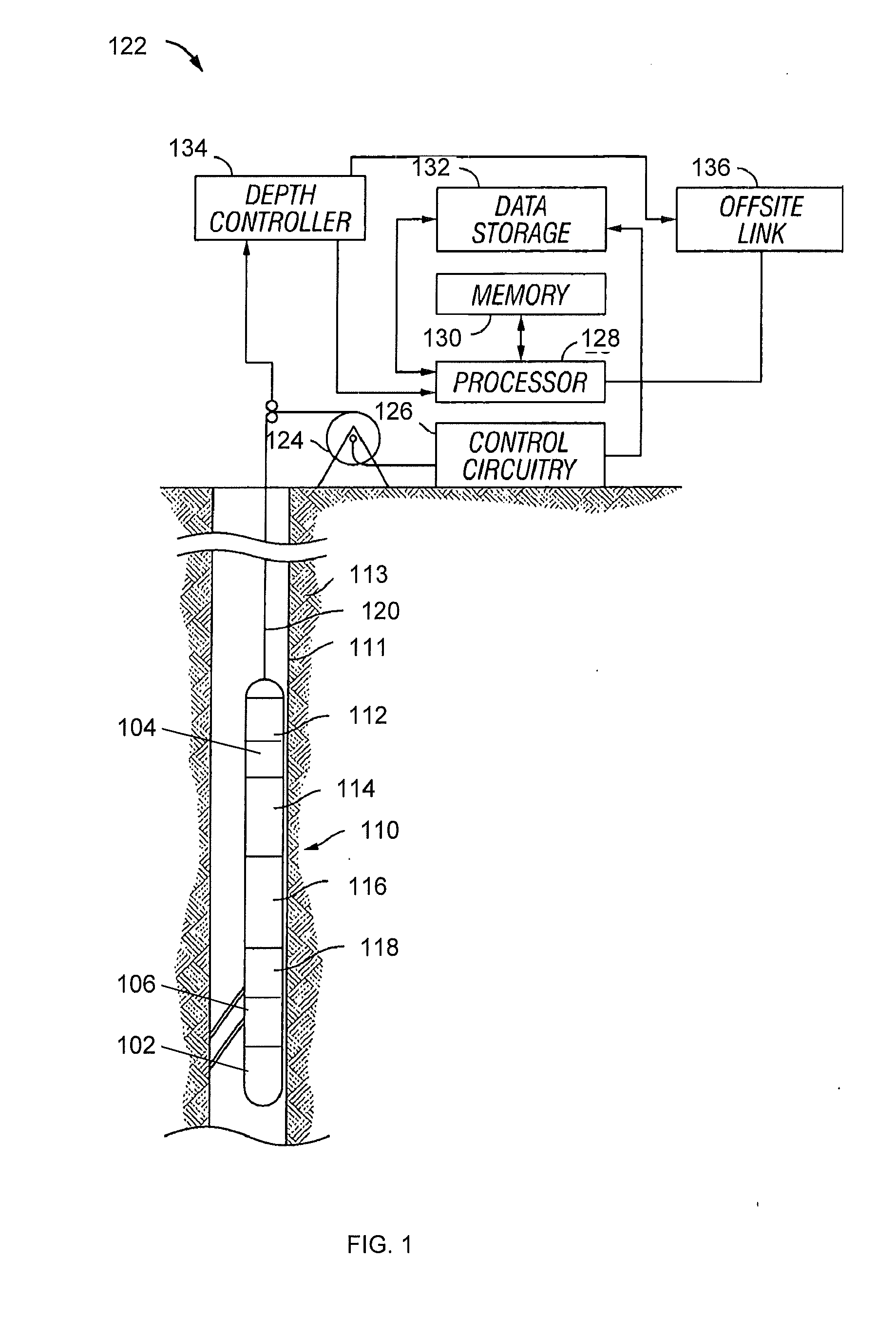

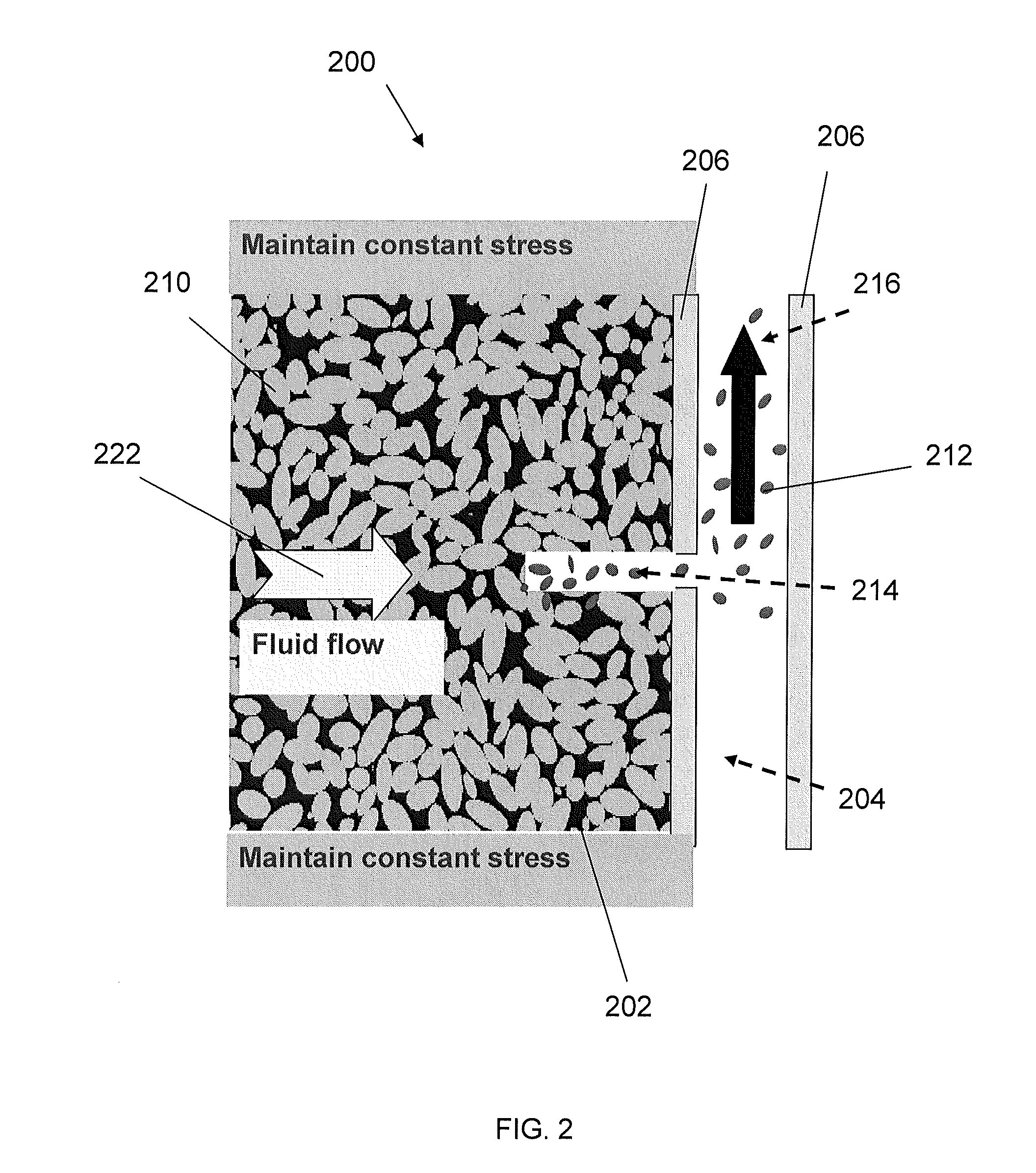

Predicting Downhole Formation Volumetric Sand Production Using Grain-Scale Rock Models

Owner:BAKER HUGHES INC

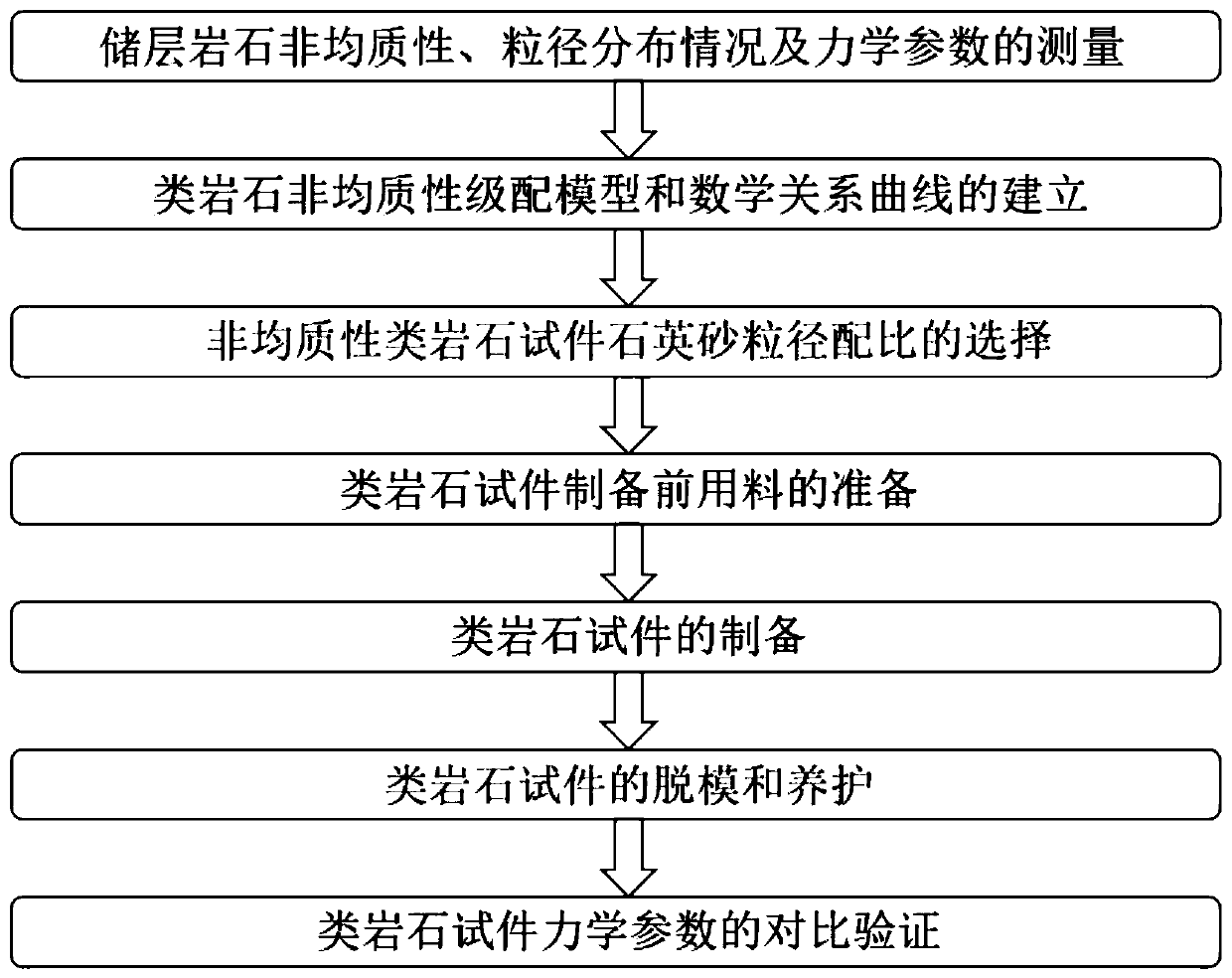

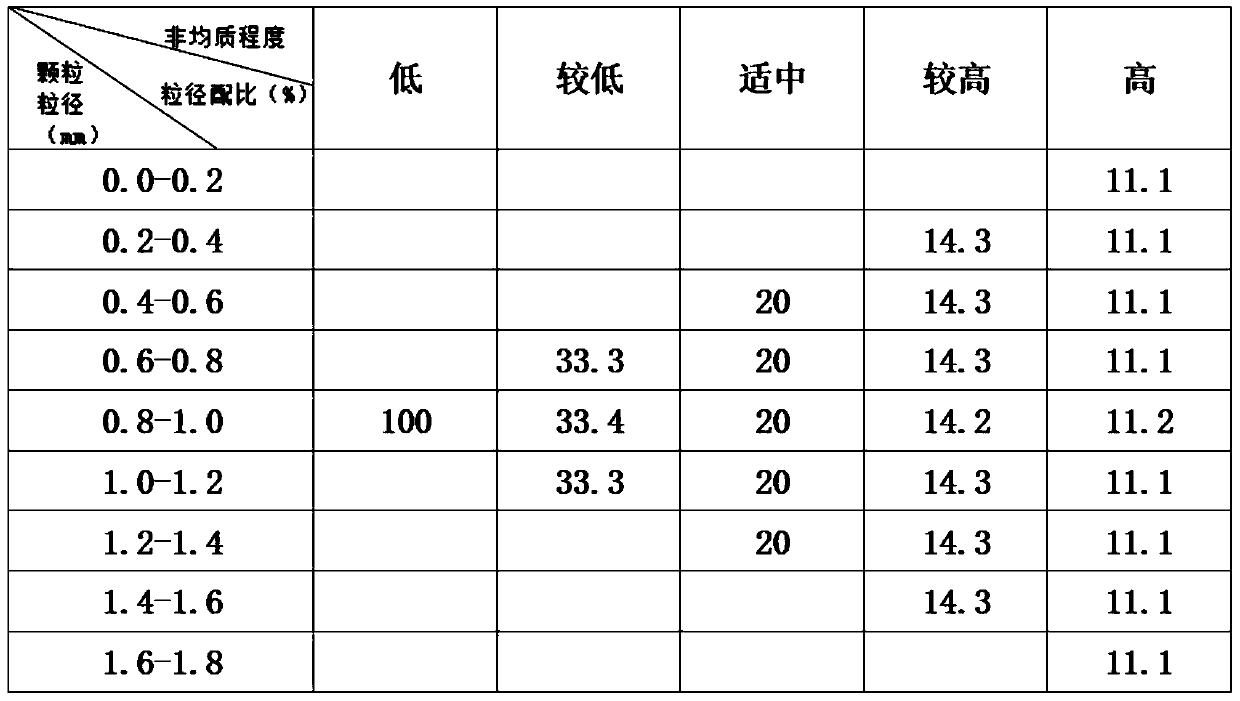

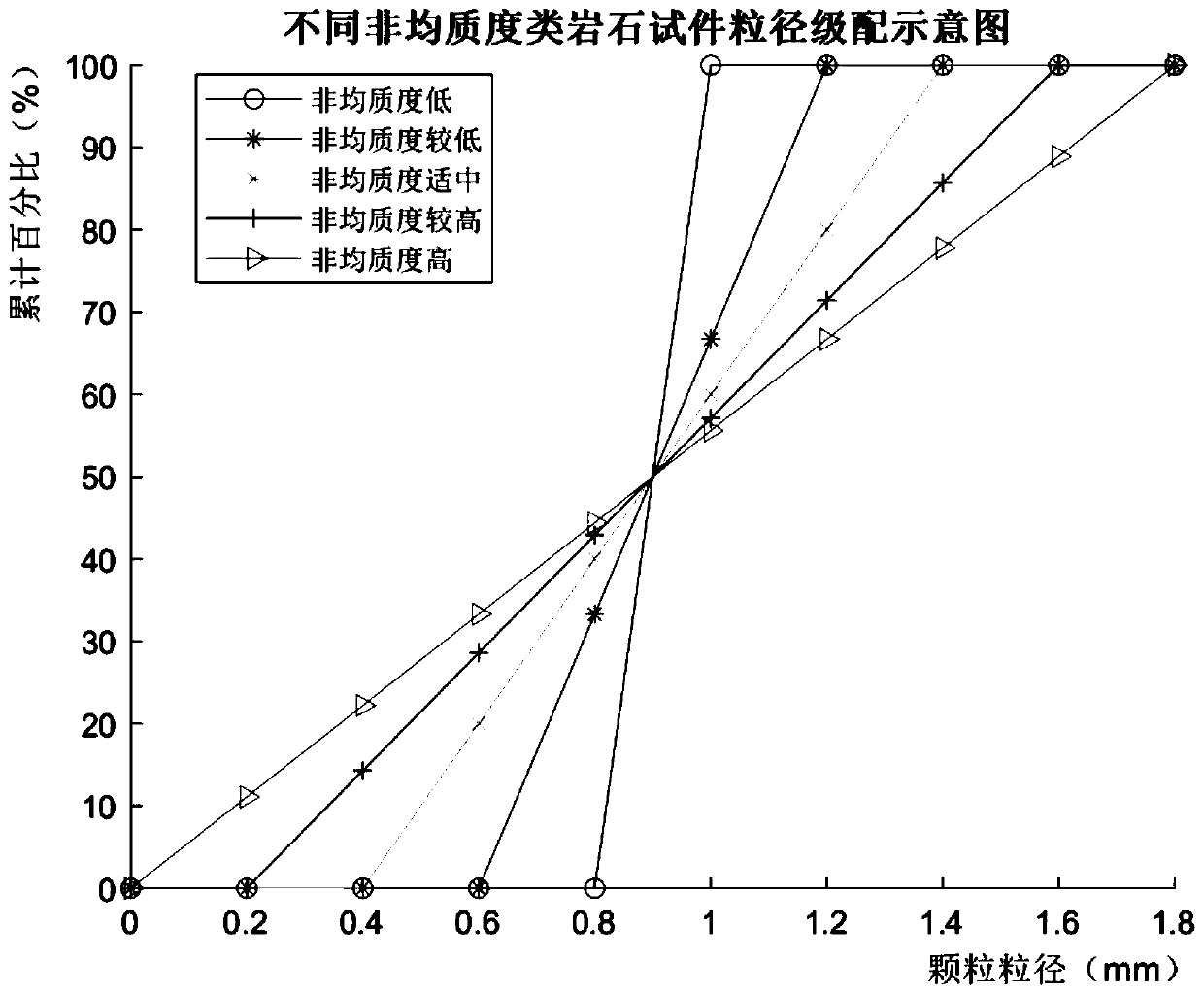

Rock-like material for simulating reservoir rock heterogeneity and test piece preparation method

ActiveCN111579374AEasy to makeLow costPreparing sample for investigationMaterial strength using tensile/compressive forcesPelletsParticle-size distribution

The invention relates to a rock-like material for simulating reservoir rock heterogeneity and a test piece preparation method, and belongs to the field of rock-like material preparation. The method comprises the following steps: measuring reservoir rock heterogeneity, particle size distribution condition and mechanical parameters; analyzing the influence of the particle size ratio degree on the reservoir rock heterogeneity and the mechanical parameter sensitivity of the rock-like material, and establishing a grading model and a mathematical relationship curve of the rock-like material with different heterogeneity degrees under different particle size ratio conditions by taking the particle size of the quartz sand particles as an index; referring to a fracturing test, and selecting quartz sand particles with corresponding particle sizes to perform aggregate proportioning by using a heterogeneous degree of rock and a rock-like specimen aggregate particle size grading schematic table; preparing a rock-like test piece by taking the quartz sand particles as aggregate, and carrying out maintaining and demolding operation to obtain the rock-like material. The heterogeneous rock-like material provided by the invention can well reflect the control effect of the particle size on the rock heterogeneity, and can accurately describe heterogeneity characteristics of a complex lithologic stratum.

Owner:SHANDONG UNIV

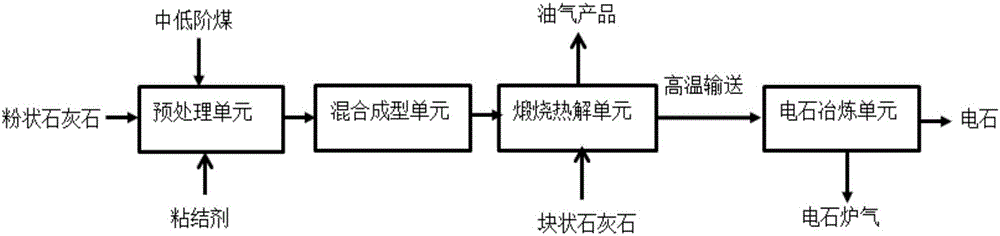

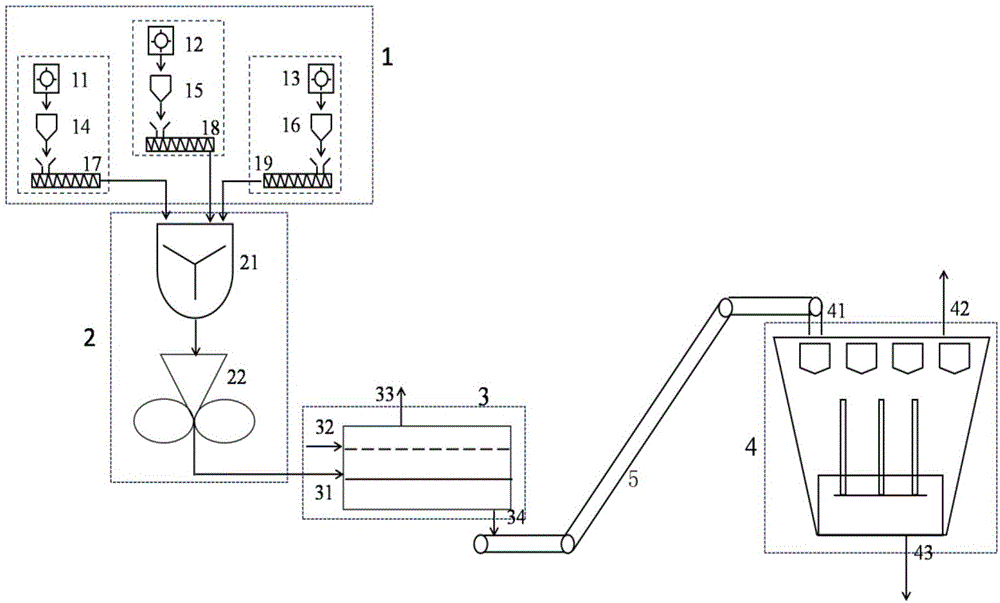

Method and system for producing calcium carbide by utilizing limestone

InactiveCN106430208ASolve cokingEliminate the calcination processCalcium carbideSpecial form destructive distillationAdhesiveCoal

The invention relates to a method and system for producing calcium carbide by utilizing limestone. The method comprises the following steps: molding mixture of finely powdered medium and low-rank coal, limestone and adhesive into pellets; layering and pyrolyzing the pellets and massive limestone in a dual-layer revolving bed, putting the pellets below the massive limestone, calcining the massive limestone while catalytically cracking raw gas generated by pyrolyzing the pellets in the lower layer, and calcining and pyrolyzing to obtain high-temperature massive quicklime, oil-gas products and high-temperature active pellets; and insulating the high-temperature massive quicklime and high-temperature active pellets, and feeding into a calcium carbide melting furnace to generate calcium carbide and calcium carbide furnace gas. According to the method and system for producing calcium carbide by utilizing limestone, powdered limestone can be sufficiently utilized, and pyrolysis gas generated by pyrolyzing pellets is catalytically cracked and filtered while the massive limestone is used as a raw material, so that the caking problem of radiant tubes can be solved.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

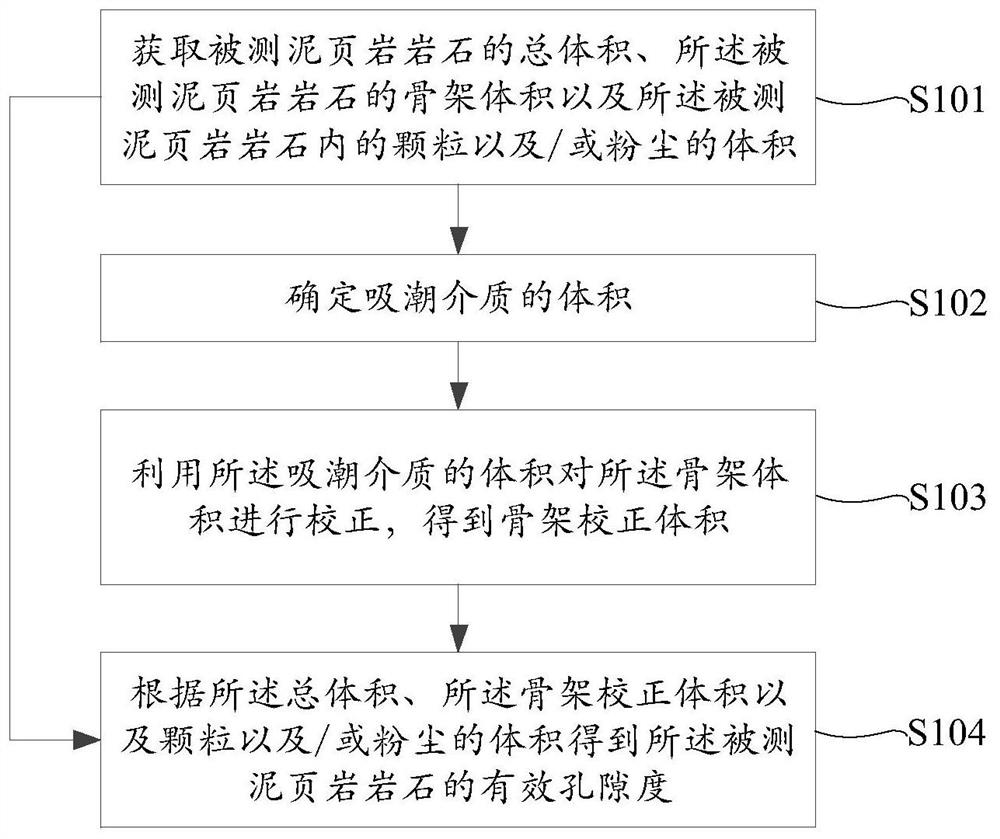

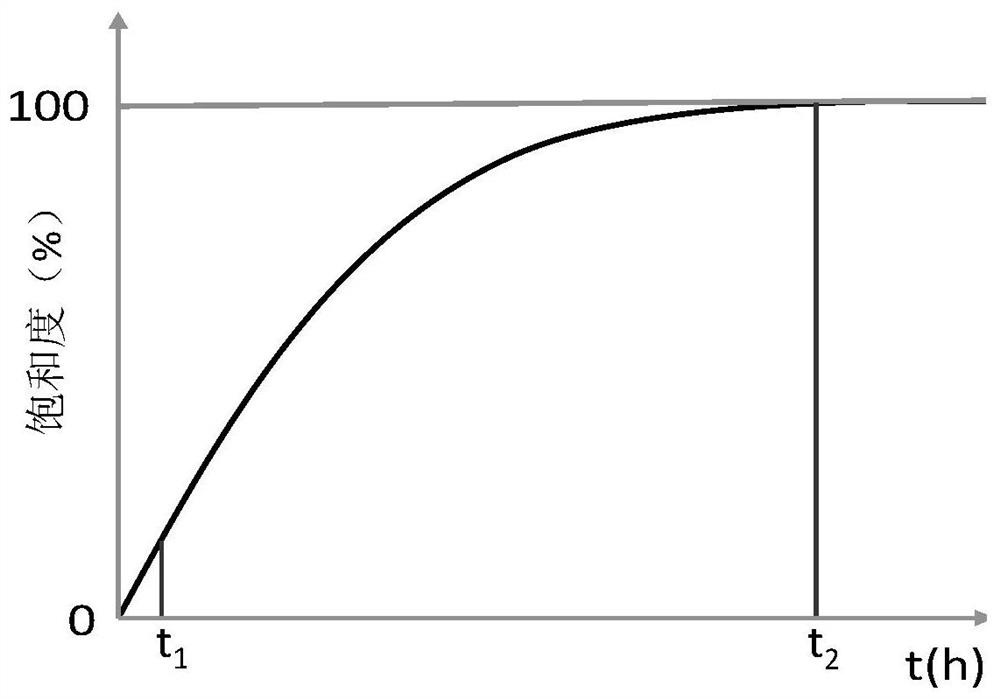

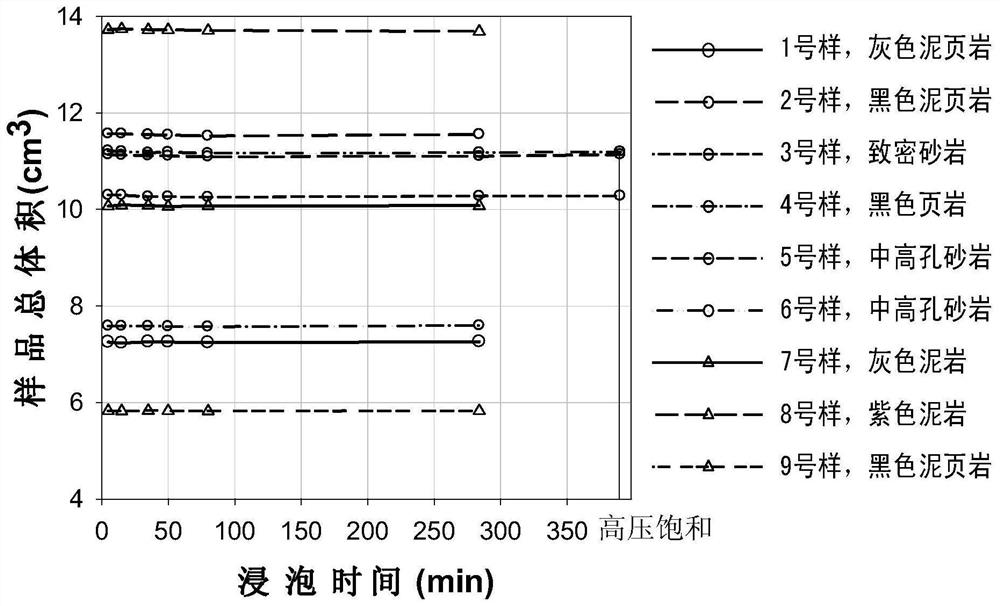

Method and device for measuring effective porosity of shale rock

ActiveCN111650108ASolve the problem of inaccurate determination of effective porosityPermeability/surface area analysisSpecific gravity measurementMoisture absorptionPellets

The invention discloses a method and a device for measuring effective porosity of shale rock, which relate to the field of oil and gas exploration and development experiment testing. The method for measuring the effective porosity of shale rockcomprises the following steps of obtaining the total volume of the measured shale rock, the skeleton volume of the measured shale rock and the volume of particles and / or dust in the measured shale rock,determining the volume of the moisture absorption medium,correcting the skeleton volume by utilizing the volume of the moisture absorption medium to obtain a skeleton correction volume,and obtaining the effective porosity of the measured shale rock according to the total volume, the skeleton correction volume and the volume of the particles and / or dust. The problem that determination of the effective porosity of shale rock is inaccurate is solved.

Owner:PETROCHINA CO LTD +1

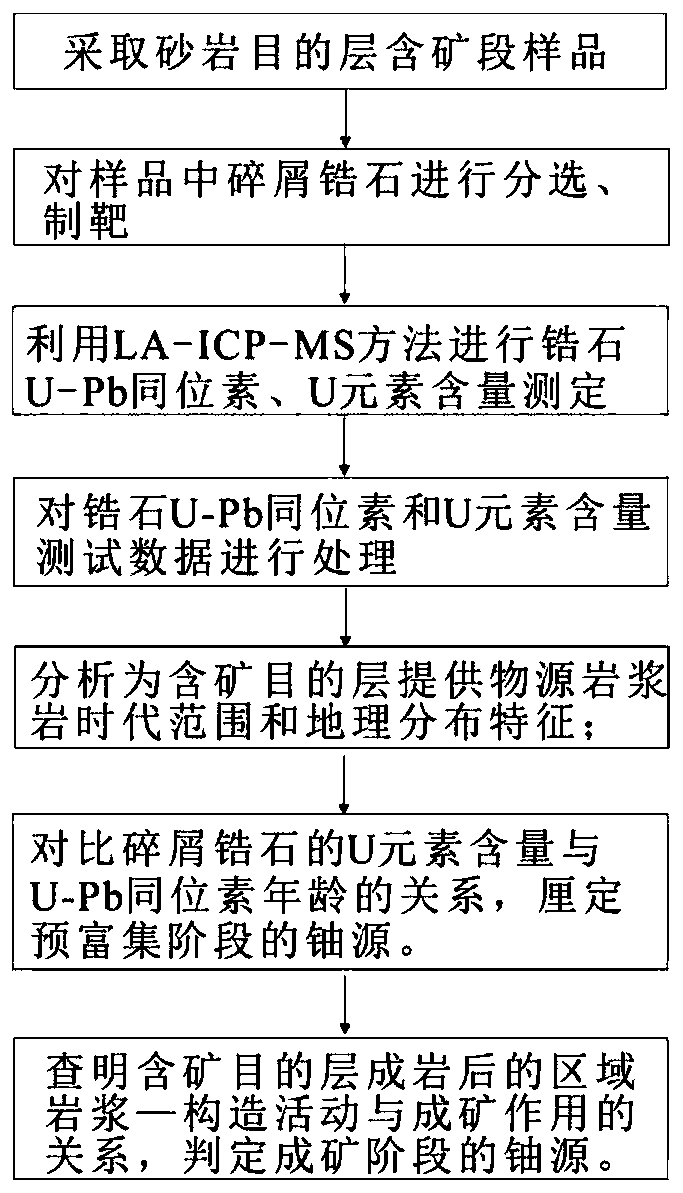

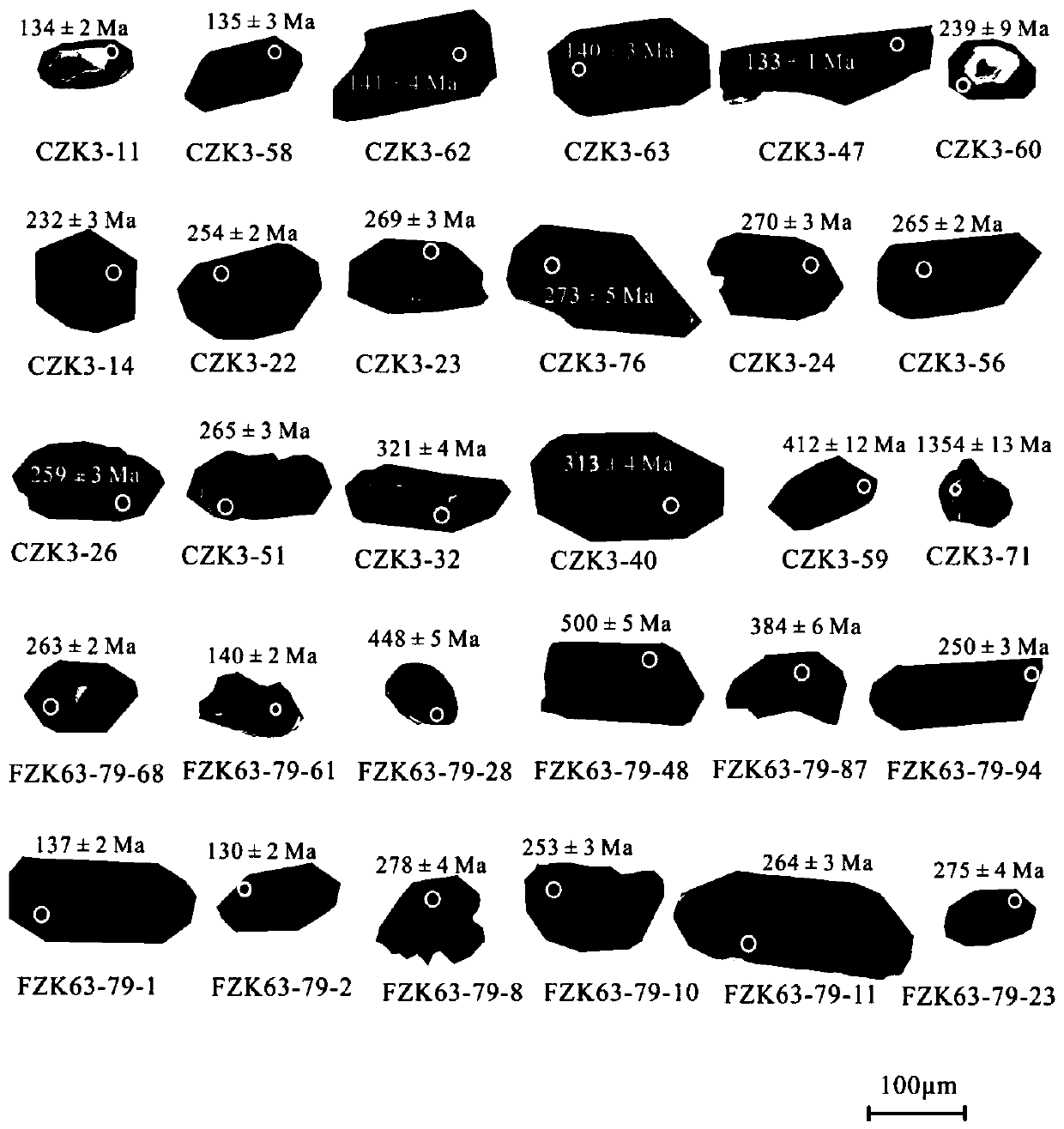

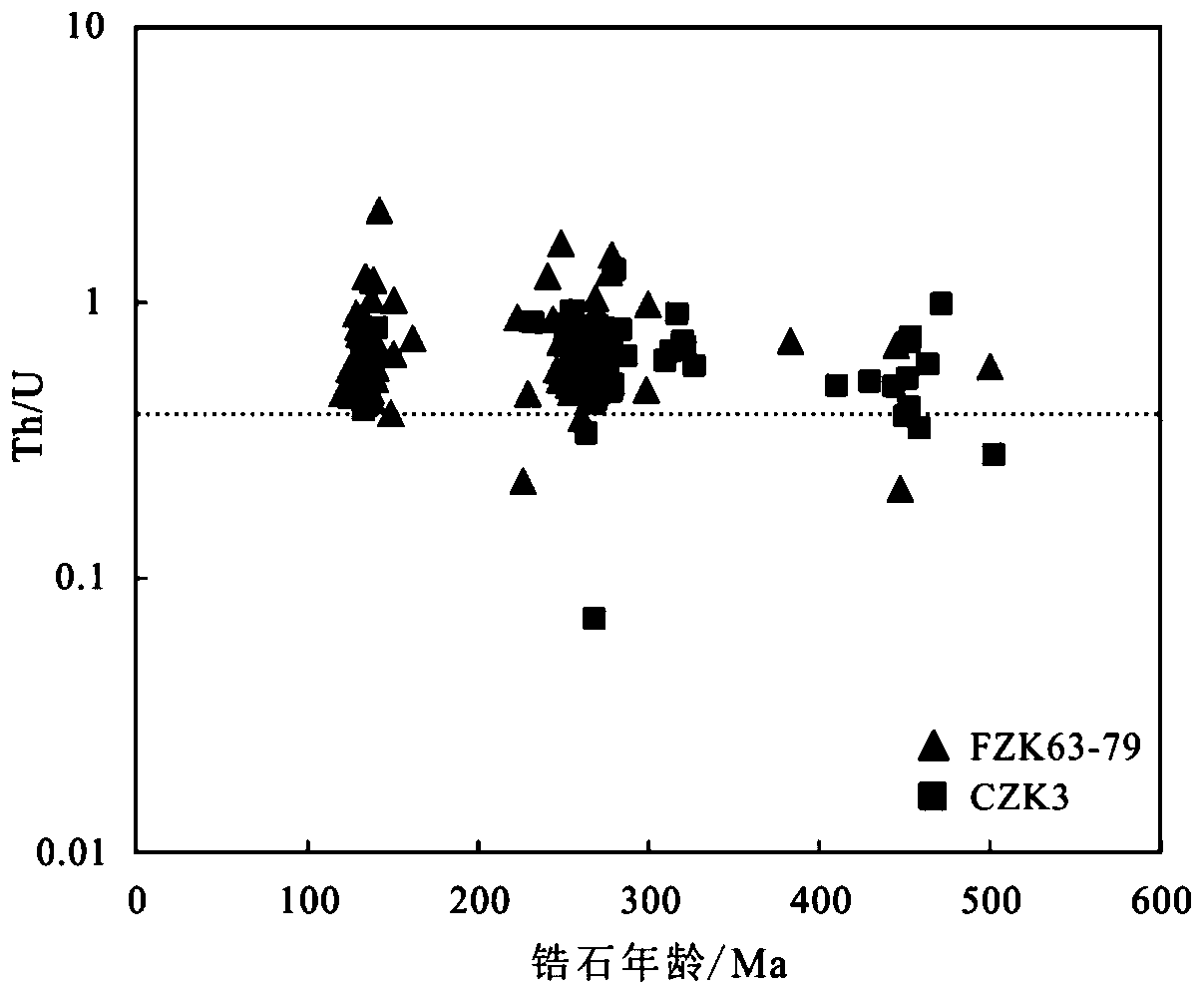

Evaluation method suitable for judging ancient river valley sandstone type uranium ore uranium source

InactiveCN111044708ACredible and valid evaluationPreparing sample for investigationMaterial analysis by electric/magnetic meansMetallogenyIsotope

The invention belongs to the technical field of uranium ore mineralization potential evaluation, and particularly discloses an evaluation method suitable for judging a sandstone type uranium ore uranium source in a basin. The evaluation method comprises the steps of: (1) collecting an ore-containing target layer sandstone sample; (2) selecting chippings zircon in the sample to prepare a zircon target; (3) testing the U-Pb isotope and U element content of zircon; (4) acquiring a zircon isotopic age histogram and a zircon U-Pb isotopic age and U content element diagram according to the U-Pb isotope and the U element content; (5) providing a source magmatic rock age range and geographical distribution characteristics for the ore-bearing target stratum sandstone according to the analysis in the step (4); (6) finding out the age range of the detritus zircon with the highest U content and particle number ratio according to the U-Pb isotopic age of the zircon and the U content element diagram, and determining a uranium source in a pre-enrichment stage in combination with the step (5); and (7) determining a uranium source in the mineralization stage according to the steps (5) and (6). Theevaluation method provided by the invention can be used for judging uranium sources in sedimentary diagenetic and mineralization action stages of the ore-bearing target layer.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

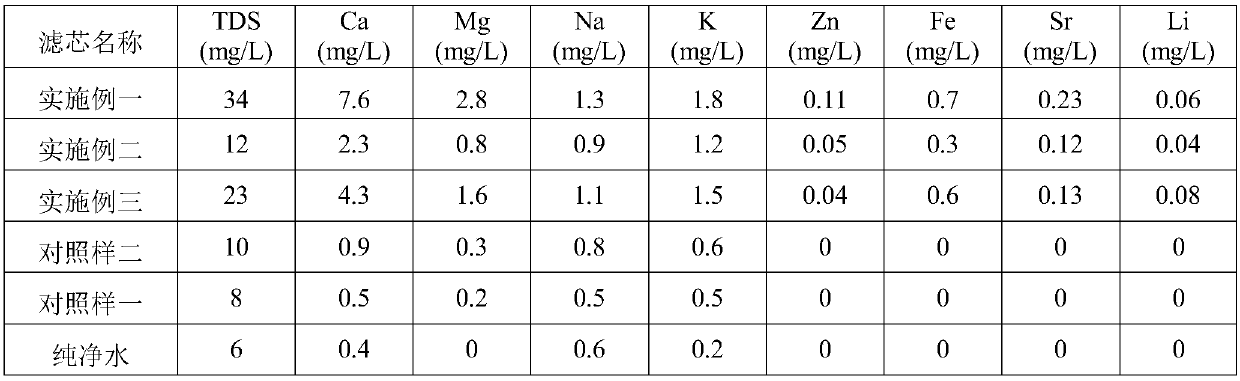

Mineral filtering material and preparation method thereof, and filtering core obtained from mineral filtering material

InactiveCN110833723ALightweightEasy to useTreatment involving filtrationWater/sewage treatment by substance additionFiberRhodochrosite

The invention discloses a mineral filtering material and a preparation method thereof, and a filtering core obtained from the mineral filtering material, wherein the mineral filtering material comprises the following raw materials by weight: 9-24 parts of secondary quartzite, 3-8 parts of feldspar quartz sandstone, 2-5 parts of rhodochrosite, 20-40 parts of zeolite, 10-30 parts of active carbon particles, 5-20 parts of active carbon fibers and 20-40 parts of a binder, wherein the rhodochrosite is a mixture of iron rhodochrosite and zinc rhodochrosite according to a weight ratio of 1-3:2, and the zeolite is a mixture of phillipsite and analcime according to a weight ratio of 1-3:1. The invention further provides a preparation method of the filtering material and a filtering core prepared from the filtering material. According to the invention, the filtering core capable of stably releasing mineral substances beneficial to growth and development of infants is obtained by utilizing natural rock materials through reasonable matching, and is environmentally friendly, free of secondary pollution and free of heavy metal exceeding the standard, wherein the TDS of the water mineralized by the filtering core is kept at 10-40 mg / L.

Owner:QINGDAO HAIER STRAUSS WATER EQUIP CO LTD

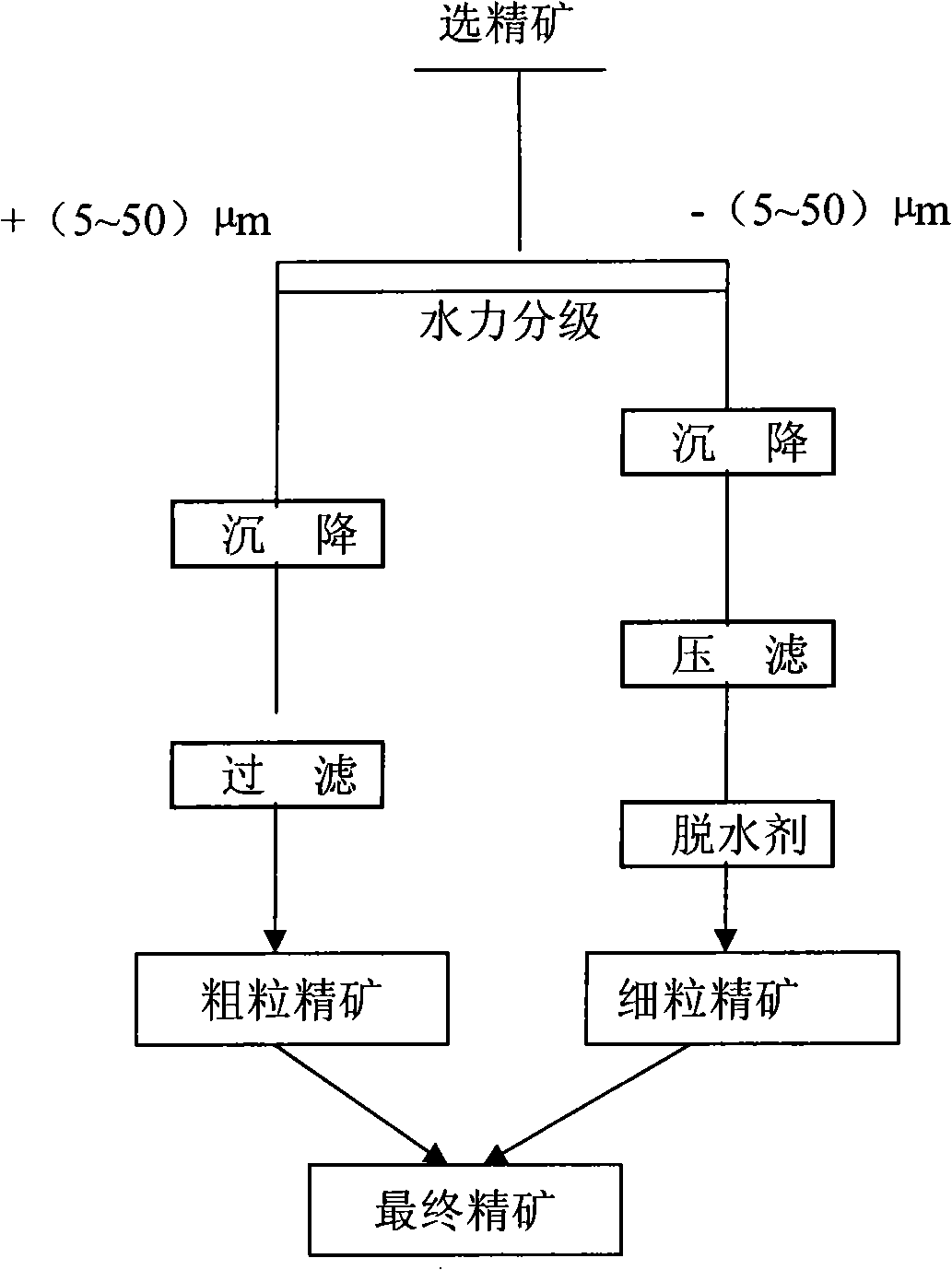

Dewatering process screening fine ore of alumyte

InactiveCN101254375AAccelerated settlementImprove filtering effectAluminium compoundsFiltration circuitsCycloneEngineering

The invention relates to a dewatering method for bauxite concentrate, and the method is used in the solid-liquid separation processes of a diasporite positive flotation concentrate product. The method comprises the operations such as classification, sedimentation, filtration, etc. The invention is characterized in that the diasporite positive flotation concentrate product is classified by adopting classifying equipment such as a hydraulic cyclone, etc., the classification size is 5 to 50 micrometer; after the classification the coarse concentrate and the fine-sized concentrate undergo the sedimentation and the filtration respectively, and are combined into the final concentrate. The method of the invention is simple and feasible, and can obviously improve the sedimentation and the filtration performances as well as the filter cake moisture of the bauxite concentrate, thereby greatly reducing the energy consumption and the mineral processing cost of the aluminum oxide production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

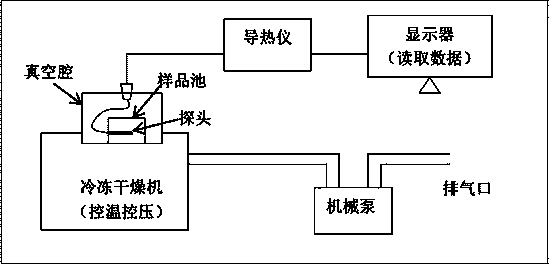

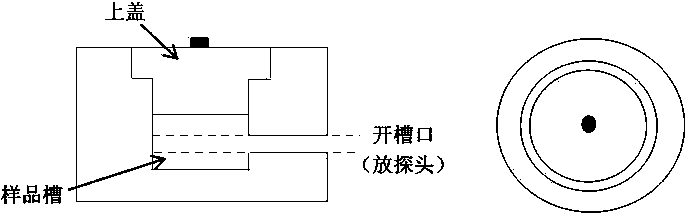

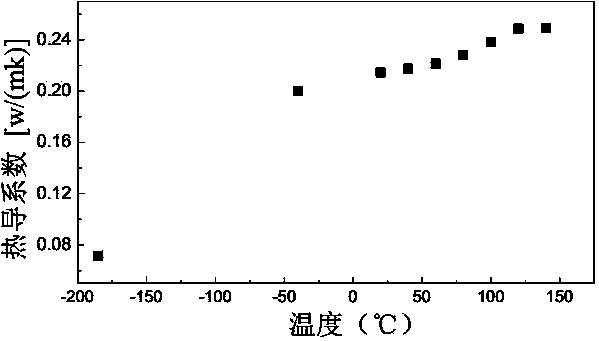

New method for measuring heat conductivity coefficient of micro powder sample under variable temperature and variable pressure conditions

The invention belongs to the field of mineral and rock materials and in particular relates to a new method for measuring a heat conductivity coefficient of a micro (gram-scale) mineral and rock powder sample in a vacuum environment under variable temperature and variable pressure conditions. The needed volume of the micro powder sample is in a range from 1.0cm<3> to 20.0cm<3> during test. The method is performed under vacuum conditions and comprises the following test steps: (1) performing sample pretreatment, namely preparing the sample into a powder sample with the particle size of not more than 1mm according to own needs, ensuring that the sample is uniformly mixed, and drying the sample before measurement; (2) mounting the sample, namely selecting sample cells of different sizes and volumes according to the sample quantity, putting the pretreated sample and a test probe into the sample cells for fixing, and finally arranging the sample cells in a vacuum cavity of a freezer dryer; and (3) testing the sample, namely vacuumizing the vacuum cavity of the freezer dryer, adjusting the pressure to be in a range from 1Pa to 1.013*10<5>Pa, and adjusting the temperature in the cavity, wherein the adjustable temperature ranges from 190 DEG C below zero to 200 DEG C. After the pressure and temperature reach the specified values, the heat conductivity coefficient value of the sample under specified testing conditions is obtained through operation of thermal conductance meter related software.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

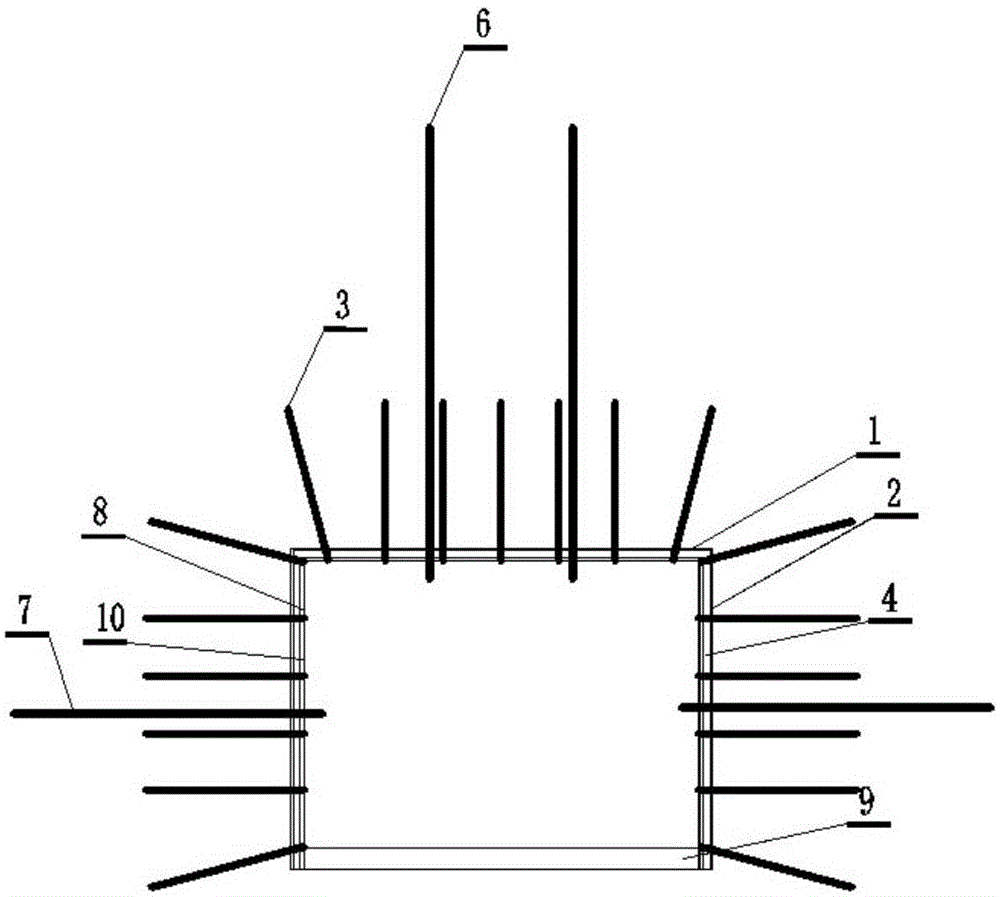

Poorly consolidated formation roadway support method and system

InactiveCN105114099ALimit deformation damageImprove support strengthUnderground chambersTunnel liningPre stressPellets

The invention relates to a poorly consolidated formation roadway support method and system. The poorly consolidated formation roadway support method and system are suitable for poorly consolidated formation rock in west mining areas, wherein the poorly consolidated formation rock has the disadvantages that strength is low, the consolidation performance is poor and the poorly consolidated formation rock is disintegrated when encountering water; due to the influences of excavation disturbance, the shallow part surrounding rock of a roadway is wide in destruction range within a short period of time, and the phase change phenomenon from rock to gravel particles happens during destruction; stability can hardly be effectively controlled through traditional anchor net support and bolting and grouting reinforcement. The poorly consolidated formation roadway support method includes the steps of firstly, prefabricating a hollow shell, arranging the shell on the surface of the excavated roadway through bolt supporting, and exerting certain pre-tightening force on surrounding rock through anchor rods; secondly, injecting expansibility grout in a filling bag of the hollow shell, exerting pre-tightening force on the surrounding rock through the grout in the solidification process due to the expansion effect, and limiting deformation of the surrounding rock; thirdly, implementing full-fracture-surface grouting and bottom plate concrete pouring. The method is easy to operate and convenient to construct, and is mainly applied to poorly consolidated formation roadway support projects.

Owner:内蒙古伊泰广联煤化有限责任公司 +1

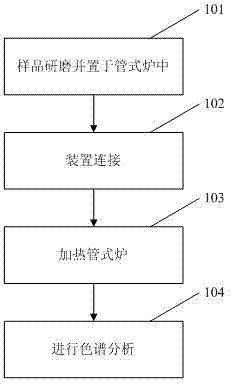

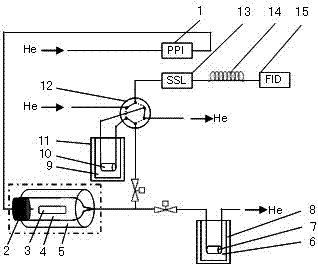

Mud shale thermal release C5-C14 hydrocarbon preparation and online chromatographic analysis method

InactiveCN104749303AAvoid incomplete pyrolysisOvercome residualComponent separationChromatographic columnTube furnace

The present invention provides a mud shale thermal release C5-C14 hydrocarbon preparation and online chromatographic analysis method, which comprises that: 1, a mud shale sample is grinded into particles, and are in the quartz sample boat of a tubular furnace; 2, the tubular furnace is heated under helium gas purging, and hydrocarbon components of the sample are enriched in a liquid nitrogen cold trap; and 3, after completing the enriching, a chromatograph is started, the online enriching tube is rapidly heated, and the thermal release hydrocarbon enters the chromatographic column through a high temperature six-way valve along with carrier gas so as to separate. With the mud shale thermal release C5-C14 hydrocarbon preparation and online chromatographic analysis method of the present invention, the incomplete heavy-component thermal release caused by the large sample particles or the low thermal release temperature is avoided, the online chromatographic analysis and the sample preparation for other analysis items can be concurrently performed, the oil-rock comparative study can be performed, the mud shale can be subjected to quantitative evaluation, and advantages of convenience and environmental protection are provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com