Patents

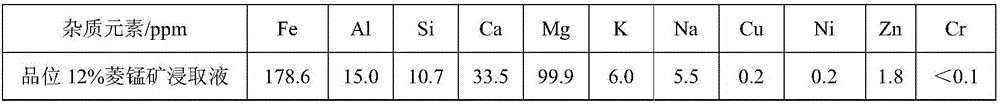

Literature

84 results about "Rhodochrosite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

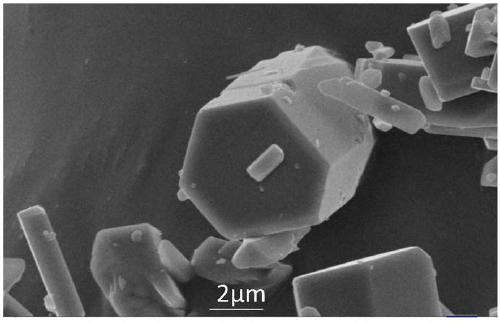

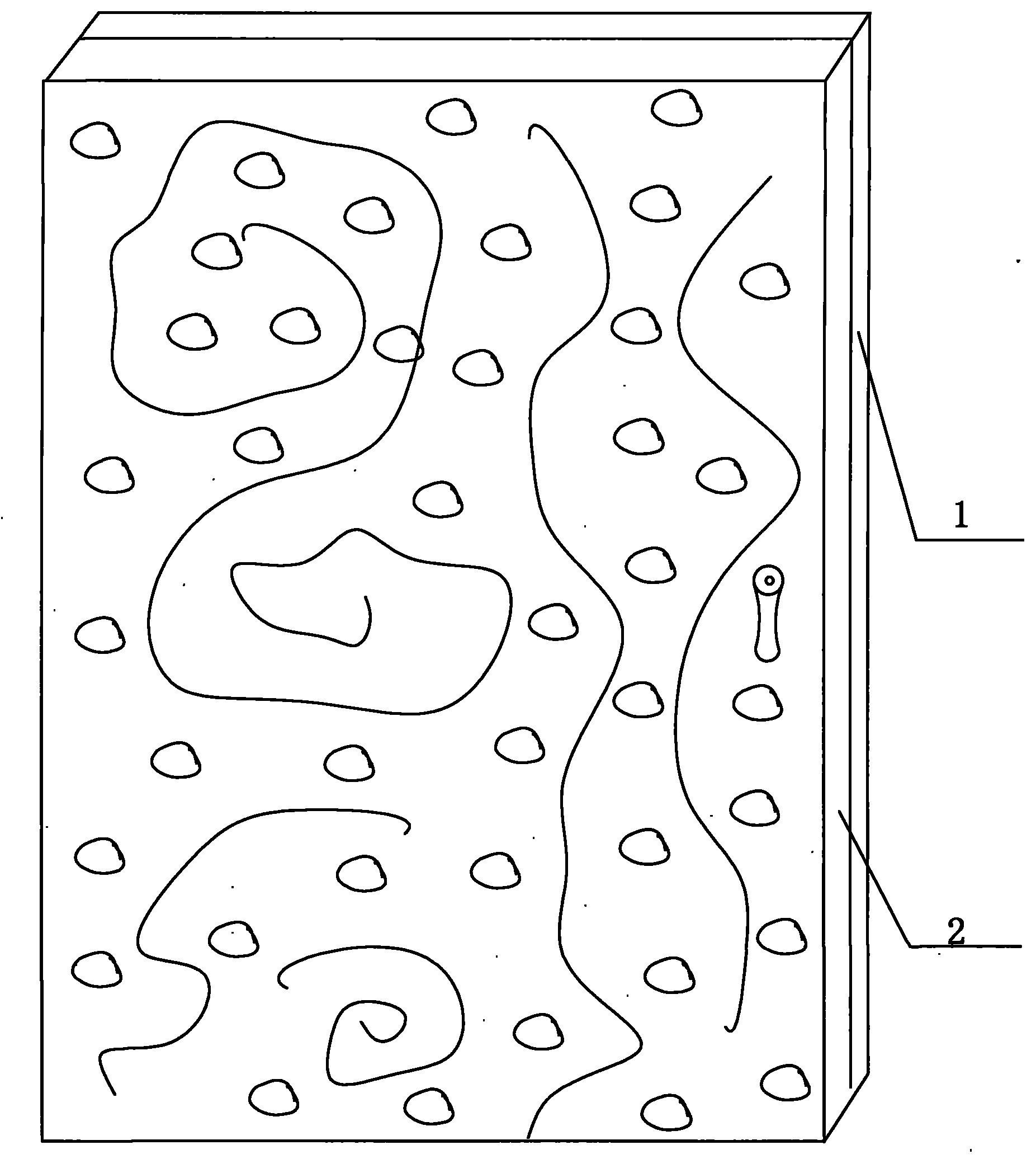

Rhodochrosite is a manganese carbonate mineral with chemical composition MnCO₃. In its (rare) pure form, it is typically a rose-red color, but impure specimens can be shades of pink to pale brown. It streaks white, and its Mohs hardness varies between 3.5 and 4. Its specific gravity is between 3.5 and 3.7. It crystallizes in the trigonal system, and cleaves with rhombohedral carbonate cleavage in three directions. Crystal twinning often is present. It is transparent to translucent with refractive indices of nω=1.814 to 1.816, nε=1.596 to 1.598. It is often confused with the manganese silicate, rhodonite, but is distinctly softer.

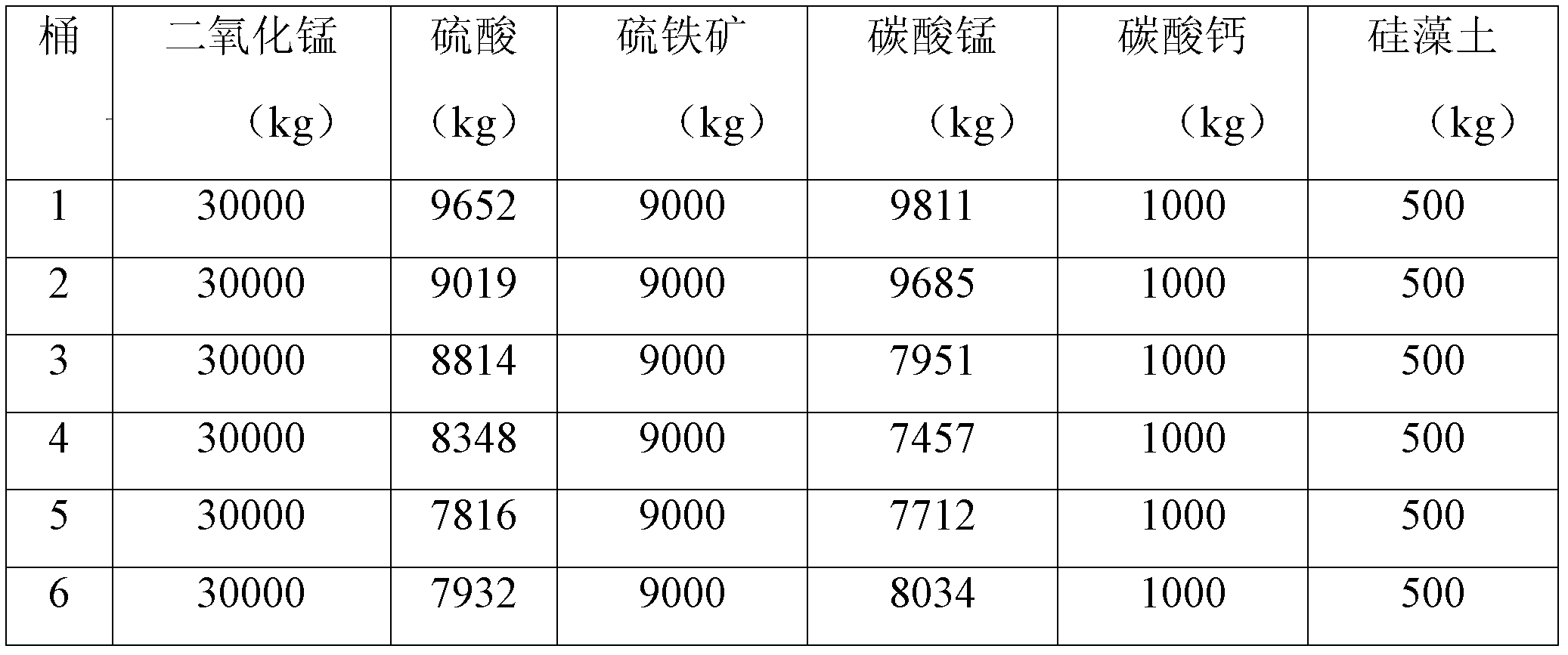

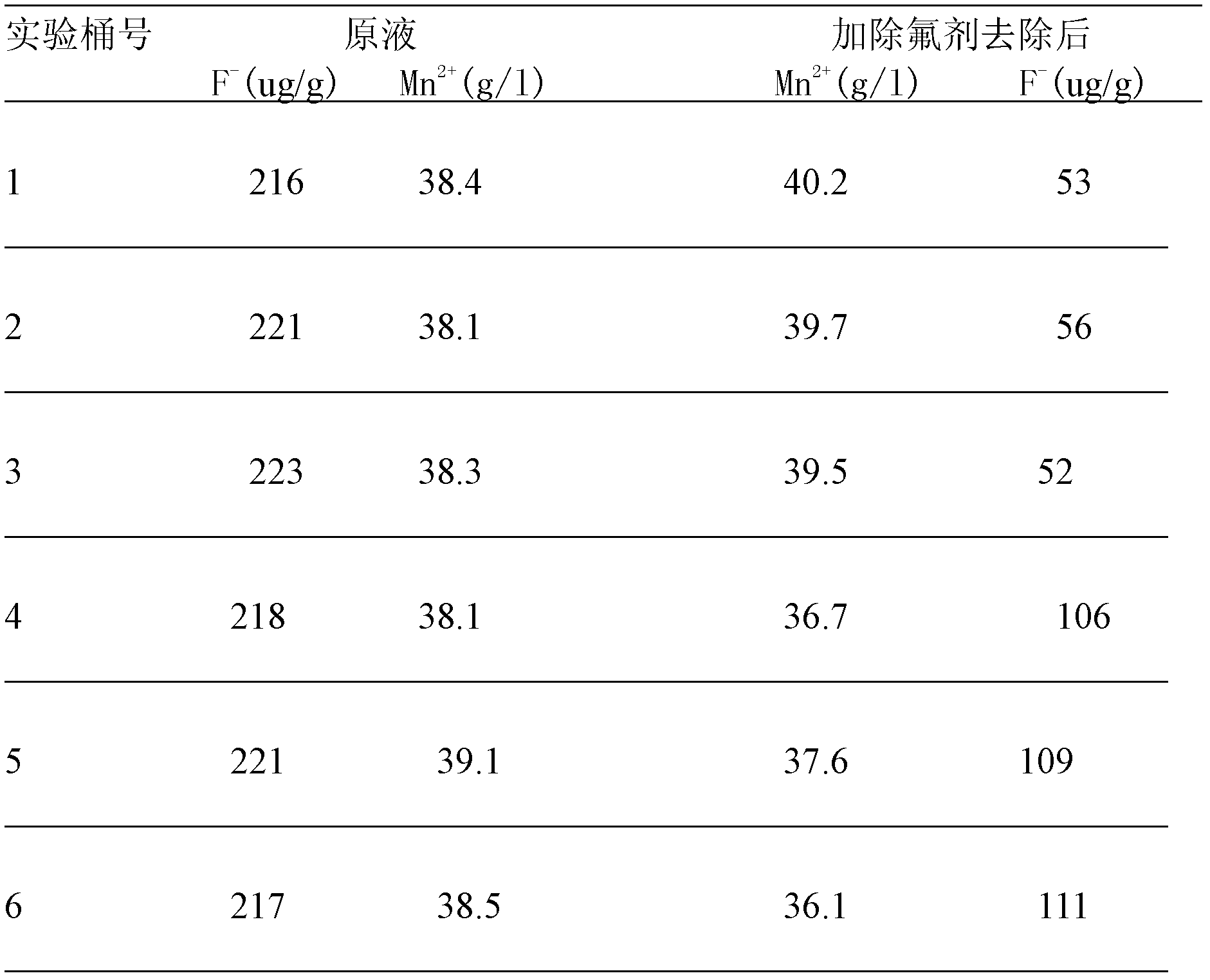

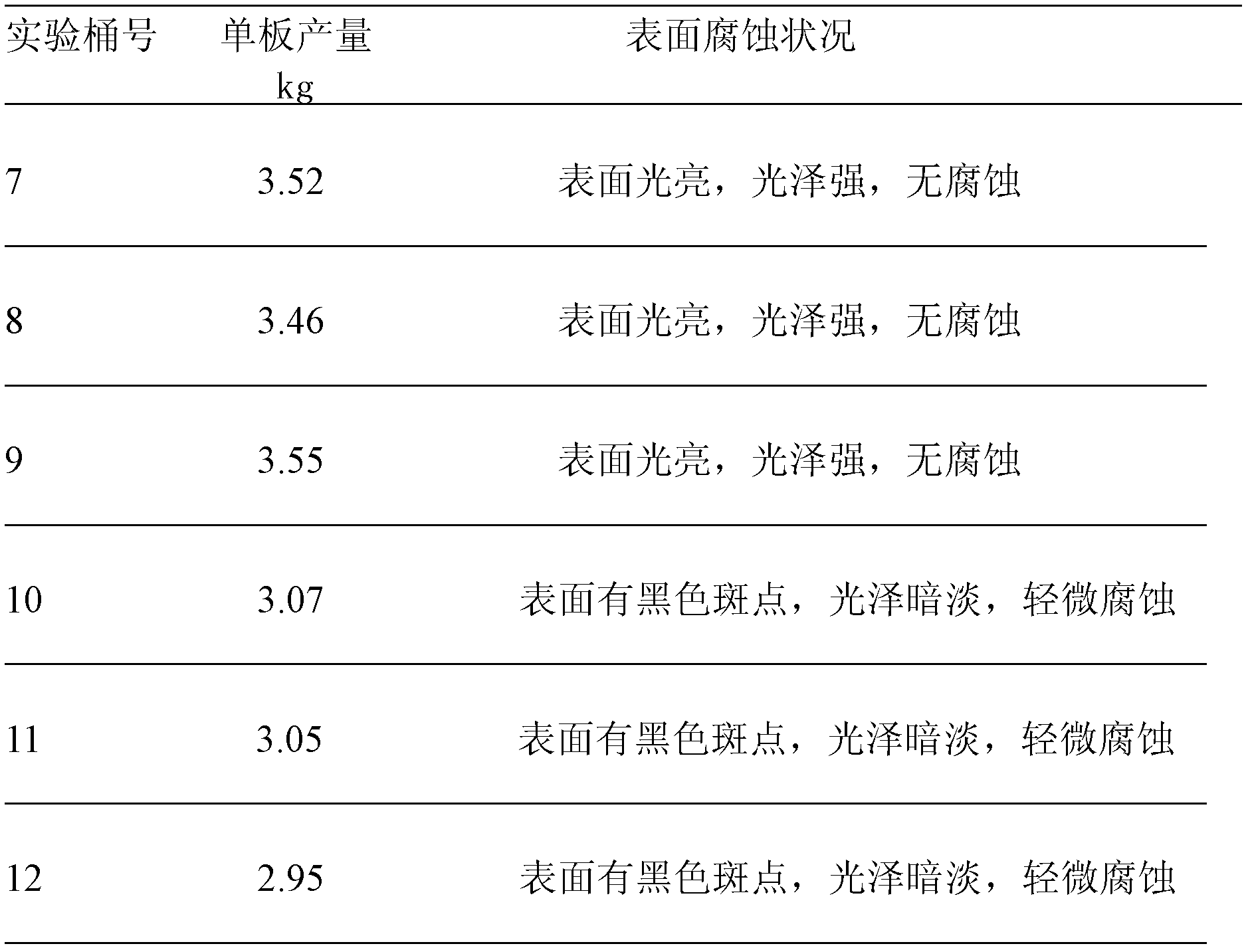

Method for removing fluorine ion from manganese sulfate solution for producing electrolytic manganese metal

The invention provides a method for removing fluorine ion from manganese sulfate solution for producing electrolytic manganese metal, which comprises the following step of: when the manganese sulfate solution for producing the electrolytic manganese metal is prepared from rhodochrosite, pyrolusite, pyrite and vitriol, adding fluorine removing agent calcium carbonate and kieselguhr to remove the fluorine ion from the solution, so that the fluorine ion content in the manganese sulfate solution is less than or equal to 60mug / g. The method is simple to operate, the loss of the manganese in the solution can be avoided when the fluorine ion is removed, a cathode can not be corroded when a metal sheet is produced by the fluorine ion-free manganese sulfate solution in an electrolysis way, and the single plate is high in yield.

Owner:广西靖西市一洲锰业有限公司

Method for preparing electronic grade non-selenium manganomanganic oxide from dialogite

InactiveCN101348280AReduce power consumptionLess investmentManganese oxides/hydroxidesLower gradeLow graded

Owner:花垣县科信新材料有限责任公司

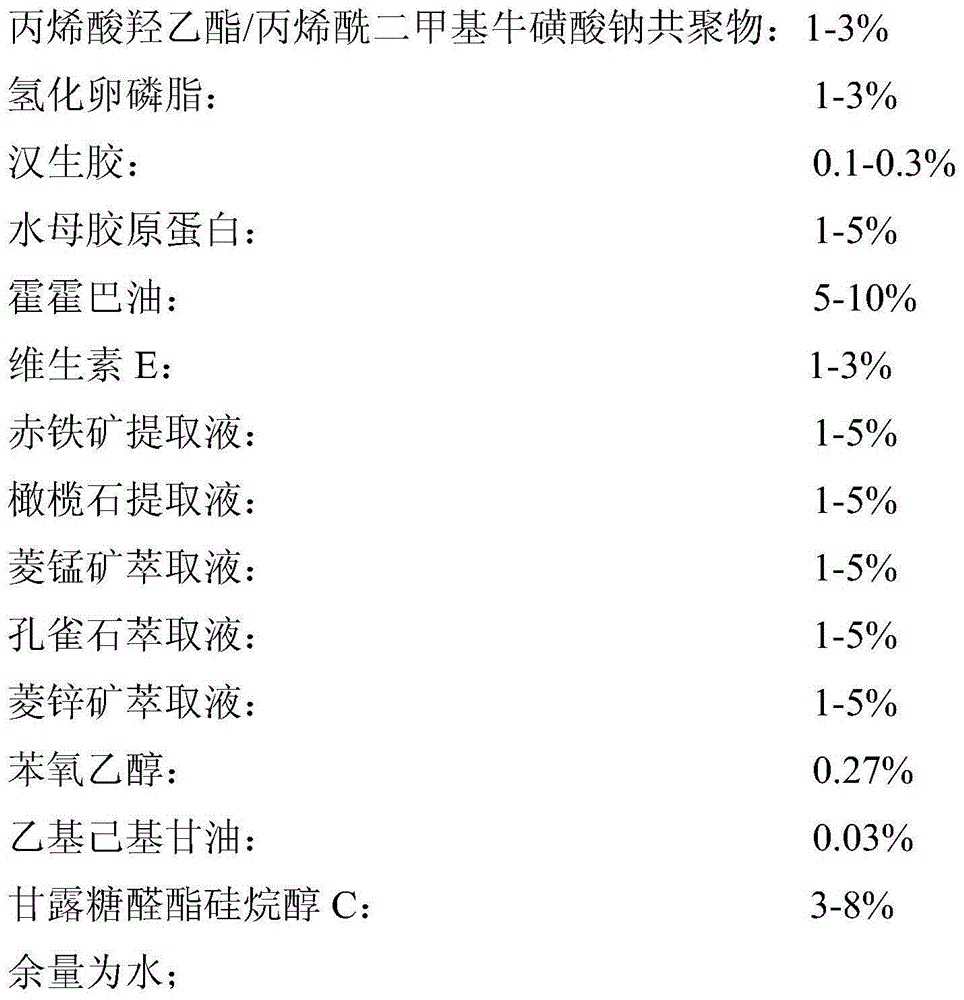

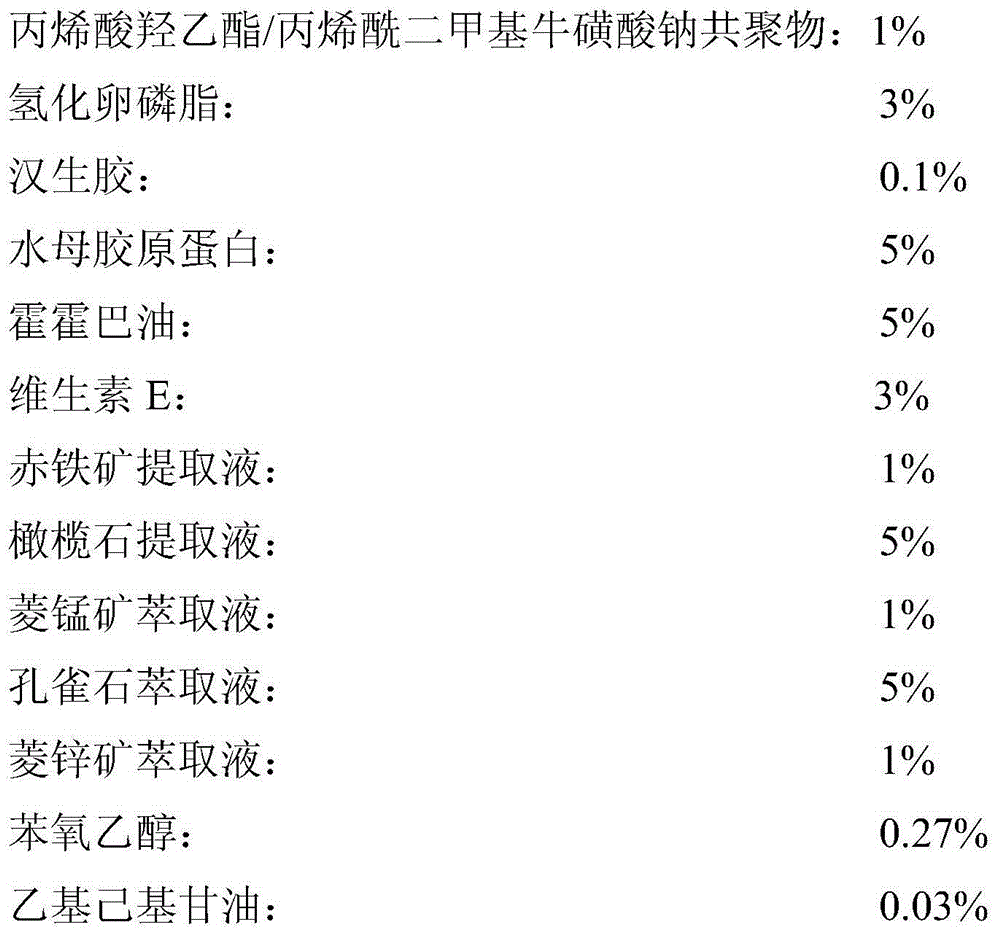

Skin comprehensive anti-aging water condensation and preparation method thereof

ActiveCN104784071ADelay agingPromote proliferation and divisionCosmetic preparationsToilet preparationsTrace elementJojoba oil

The invention discloses a skin comprehensive anti-aging water condensation and a preparation method thereof. The water condensation is prepared from a hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, hydrogenated lecithin, xanthan gum, jellyfish collagen, jojoba oil, vitamin E, a hematite extraction liquid, an olivine extraction liquid, a rhodochrosite extraction liquid, a malachite extraction liquid, a smithsonite extraction liquid, phenoxyethanol, ethylhexylglycerin, algisium C and water. The anti-aging water condensation has the main effective components being the liquid ore extracts rich in various trace elements. The anti-aging water condensation can prolong the life of cells and delay skin aging, and is a comprehensive nursing type product which can comprehensively deal with the skin aging problem.

Owner:广州丽丰化妆品制造有限公司

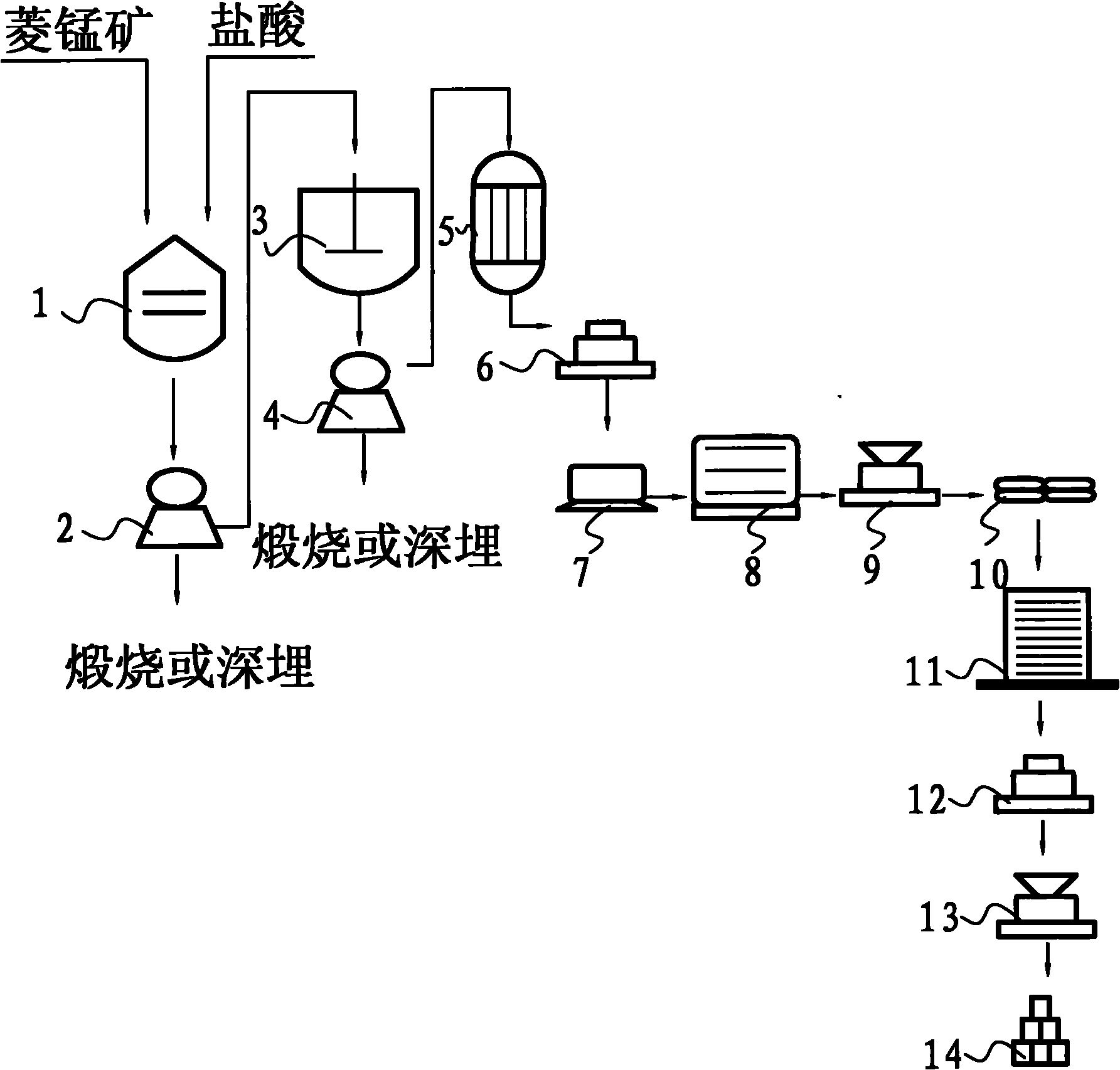

Method for preparing electronic-grade manganese carbonate from rhodochrosite

InactiveCN106145199AReduce manufacturing costEasy to operateManganese compoundsCarbonizationRhodochrosite

The invention provides a method for preparing electronic-grade manganese carbonate from rhodochrosite. According to the method, rhodochrosite with high impurity content, low manganese content, rich reserves and low price is used as a raw material; ammonia water and carbon dioxide gas are used as carburization agents; and rhodochrosite is subjected to extraction of manganese sulfate, removal of iron aluminum, removal of copper, nickel, lead, cobalt and zinc, removal of calcium and magnesium, removal of silicon and suspended solids, and carbonization of manganese sulfate so as to prepare manganese carbonate. Compared with the prior art, the method provided by the invention has the advantages that production cost is reduced by about 30%; and the method is simple to operate and convenient for large-scale production.

Owner:谢文刚

Method for producing manganese metal through electrolysis

InactiveCN107858702AReduce energy consumptionReduce harmPhotography auxillary processesMetallic material coating processesEnvironmental resistanceElectrolysis

The invention relates to the technical field of manganese metal production conducted through electrolysis, in particular to a method for producing manganese metal through electrolysis. The method comprises the following steps of leaching, iron removal, heavy metal removal, purification, electrolysis, passivation, drying and peeling. When rhodochrosite is treatment through the method, the leachingrate of manganese can be increased; after impurity removal chemicals and the like are added to obtained manganese sulfate liquid for deep purification, the impurity content is low; product quality isguaranteed; an electrolysis addition agent and passivation agent adopted in the method are safe and environmentally friendly, and harm to human bodies and pollution to the environment are reduced; when the manganese metal is electrolyzed through the method, energy consumption is greatly saved, cost is lowered, and the environment is protected; and in addition, the purity of the manganese metal produced through the method reaches 99.8% or above.

Owner:DAXIN SCI & TECH INFORMATION RES INST

Method for removing magnesium in sulfuric acid leaching process of rhodochrosite

ActiveCN104928469AImprove leaching rateHigh concentration of leached residual acidProcess efficiency improvementPhysical chemistryRhodochrosite

A method for removing magnesium in sulfuric acid leaching process of rhodochrosite comprises the steps that electrolytic manganese returned anode liquor is added in a leaching tank, and then rhodochrosite powder and concentrated sulfuric acid are added to carry out high acid leaching; after sufficient leaching is carried out, liquid ammonia is added for neutralization, and a solution system is made to be neutral; air is blown into the solution system, dimethyl carbamodithioic acid is added after aeration is carried out for a while; after sufficient stirring, solid and liquid separation is carried out on obtained pulp; the filtrate obtained through the solid and liquid separation is circularly used for electrolytic manganese production; separated solid residues are recycled separately. The method is easy and convenient to operate and easy to implement, the manganese leaching rate in the electrolytic manganese production can be increased, and the concentration of magnesium in the electrolytic manganese returned anode liquor can be reduced.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing manganese sulfate from sulfur-containing waste residue

InactiveCN101811737AHigh purityAchieve recyclingSolid waste disposalManganese sulfatesForeign matterElectrolysis

The invention relates to a method for preparing manganese sulfate from sulfur-containing waste residue, i.e. acid-leaching electrolytic manganese slag and lead-zinc tailings or limestone are calcined at high temperature, stone coal vanadium-extraction acid-leaching slag and lead-zinc tailing or limestone are calcined at high temperature, or acid-leaching electrolytic manganese slag, stone coal vanadium-extraction acid-leaching slag and lead-zinc tailing or limestone are mixed to be calcined at high temperature. Sulfur dioxide and sulfur trioxide mixed gases which are produced in the calcining are dried by concentrated sulfuric acid and are mixed with air to be compressed and to be guided into a mixed solution consisting of the pyrolusite, rhodochrosite and water, the solution is mixed continuously in the whole process, the extraction time is 4 to 10 hours, the extraction temperature is 20 to 90 DEG C, and the manganese sulfate solution for electrolysis is obtained after the removal of foreign matters and filtering. The solution is evaporated, concentrated, crystallized and dried to obtain the manganese sulfate product under the temperature of 80 to 100 DEG C.

Owner:XIANGXI AUTONOMOUS PREFECTURE MINERALS & NEW MATERIAL TECHNOLOGICAL INNOVATION SERVICE CENT +1

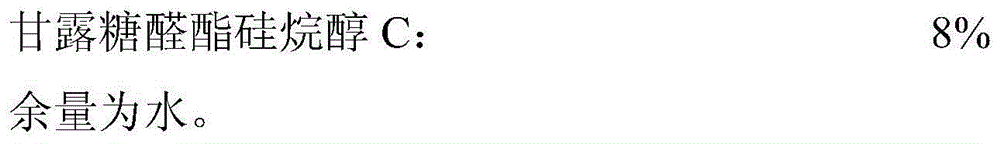

Mineral filtering material and preparation method thereof, and filtering core obtained from mineral filtering material

InactiveCN110833723ALightweightEasy to useTreatment involving filtrationWater/sewage treatment by substance additionFiberRhodochrosite

The invention discloses a mineral filtering material and a preparation method thereof, and a filtering core obtained from the mineral filtering material, wherein the mineral filtering material comprises the following raw materials by weight: 9-24 parts of secondary quartzite, 3-8 parts of feldspar quartz sandstone, 2-5 parts of rhodochrosite, 20-40 parts of zeolite, 10-30 parts of active carbon particles, 5-20 parts of active carbon fibers and 20-40 parts of a binder, wherein the rhodochrosite is a mixture of iron rhodochrosite and zinc rhodochrosite according to a weight ratio of 1-3:2, and the zeolite is a mixture of phillipsite and analcime according to a weight ratio of 1-3:1. The invention further provides a preparation method of the filtering material and a filtering core prepared from the filtering material. According to the invention, the filtering core capable of stably releasing mineral substances beneficial to growth and development of infants is obtained by utilizing natural rock materials through reasonable matching, and is environmentally friendly, free of secondary pollution and free of heavy metal exceeding the standard, wherein the TDS of the water mineralized by the filtering core is kept at 10-40 mg / L.

Owner:QINGDAO HAIER STRAUSS WATER EQUIP CO LTD

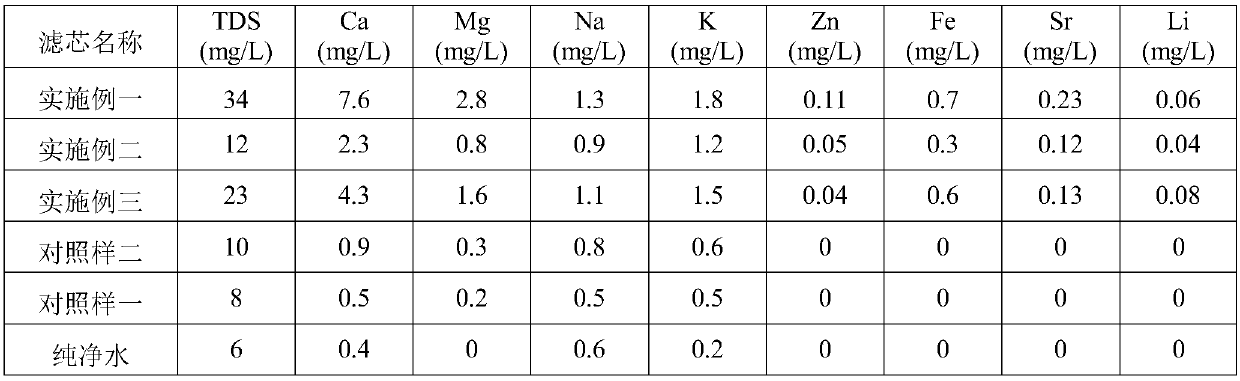

Phosphorous removal method for manganous sulfate produced from high-phosphorus rhodochrosite

InactiveCN103818965ASimple processReduce energy consumptionManganese sulfatesRhodochrositeHigh energy

The invention provides a phosphorous removal method for manganous sulfate produced from high-phosphorus rhodochrosite. The phosphorous removal method comprises the steps of (1), at the room temperature, adding ferrous sulfate and a hydrogen peroxide solution to a manganous sulfate solution produced from high-phosphorus rhodochrosite to form a mixed solution, and then carrying out an oxidization reaction in a stirring state, (2) adding stronger ammonia water to the mixed solution obtained in the step (1) to regulate the pH value to the range from 3 to 5, and then thoroughly stirring under the room temperature to obtain a mixed slurry, and (3) standing and precipitating the mixed slurry obtained in the step (2), and then filtering and separating, and obtaining the filtrate, namely, a low-phosphorus manganous sulfate solution. Compared with the prior art, the phosphorous removal method is capable of effectively avoiding the problems of complex operation, high energy consumption and / or pollution on the environment possibly caused by phosphorous removal during mineral separation, and also has the advantages of mild reaction conditions and relatively lower cost.

Owner:CHONGQING UNIV

Arsenic contaminated soil remediation agent

InactiveCN106753410ALow costGood effectContaminated soil reclamationOrganic fertilisersSoil remediationRhodochrosite

The invention discloses an arsenic contaminated soil remediation agent. The remediation agent is prepared from, by mass, 12-15 parts of hornwort, 4-5 parts of gelidium amansii lamx, 4-7 parts of rhodochrosite, 20-25 parts of western red cedar; wherein the mass ratio of hornwort and gelidium amansii lamx is 3:1; firstly rhodochrosite is crushed to have the rhodochrosite powder; hornwort, gelidium amansii lamx and western red cedar are respectively dried and crushed into powder; the western red cedar powder is added with water and soaked, then processed by a microwave, and filtered to obtain the western red cedar liquid and the western red cedar dregs, the western red cedar liquid after the process of decompression and concentration is the western red cedar extraction liquid; the western red cedar dregs are calcined to obtain the calcined western red cedar; the western red cedar extraction liquid is evenly mixed with the western red cedar powder, the hornwort powder and the gelidium amansii lamx powder to obtain the mixture pulp body; the calcined western red cedar is placed in the pulp mixture and soaked, treated and prepared. The remediation agent has the advantages of being low in consumption, low in cost, effective and free of pollution.

Owner:ZHENGZHOU BEIDOU COMM TECH

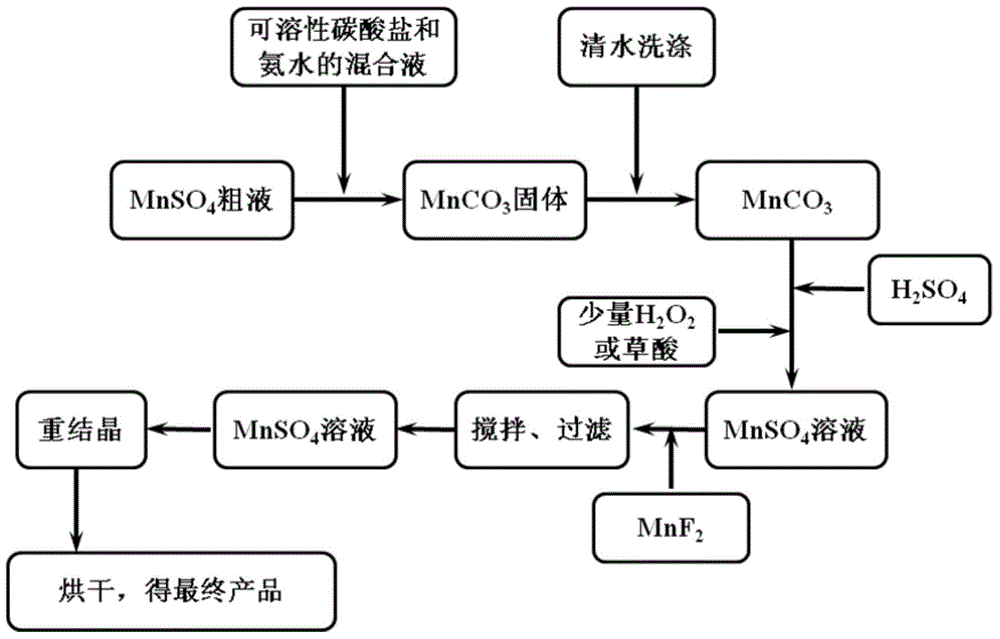

Preparation method of manganese sulfate monohydrate

The invention discloses a preparation method of manganese sulfate monohydrate, which is characterized in that a manganese sulfate solution prepared by rhodochrosite is reacted with soluble carbonate under alkalescence environment at 30-80 DEG C to generate MnCO3 deposition, sodion in the manganese sulfate solution prepared by rhodochrosite is removed, and most calcium ion, magnesium ion and other heavy metal ions are removed; sulfuric acid and MnCO3 are reacted to generate manganese sulfate, calcium ion and magnesium ion in manganese sulfate are deposited and removed by fluorinion, and finally, the manganese sulfate solution is filtered, recrystallized and dried to obtain the product. By using solubility difference of different metal ionic salt, through multitime deposition and washing process, by controlling the acid-base value of a system during a deposition washing process, impurity ion of calcium, magnesium and sodium can be removed at maximum degree, microscale Ca<2+> and Mg<2+> in the product can be removed by introducing F ion, product purity is increased by recrystallization, and manganese sulfate purification can be realized. The method has the advantages of simple and easy operation and friendly environment, and is suitable for industrial large scale production.

Owner:SHAANXI ZIYANG XIANGGUI MANGANESE IND CO LTD

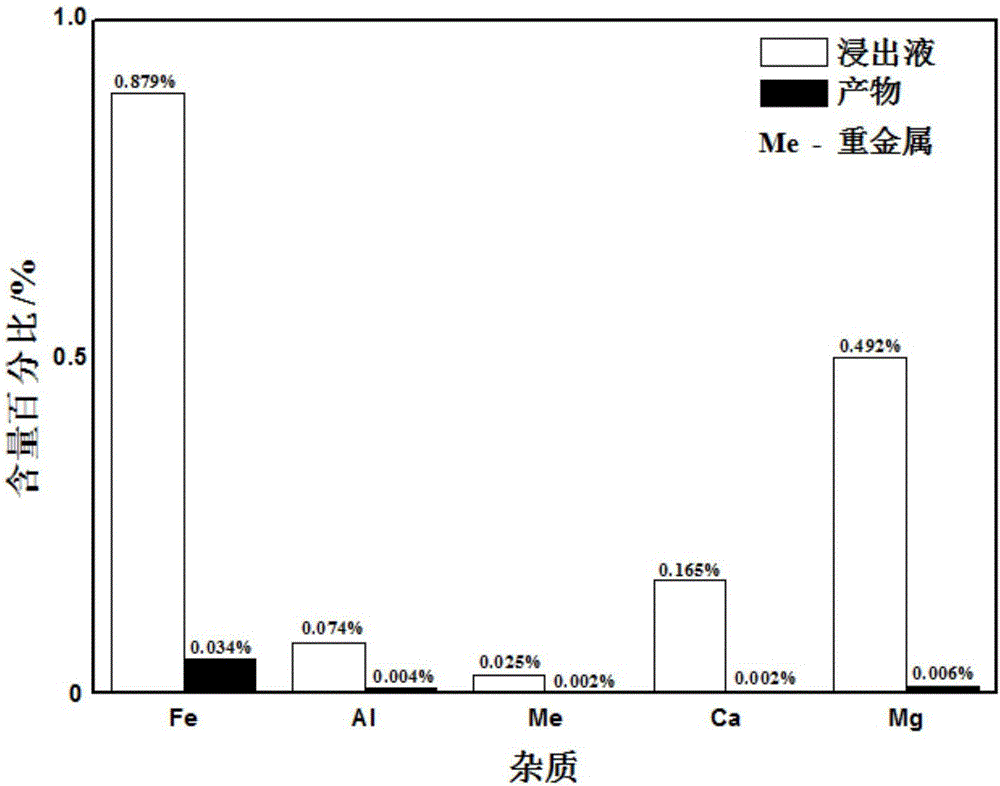

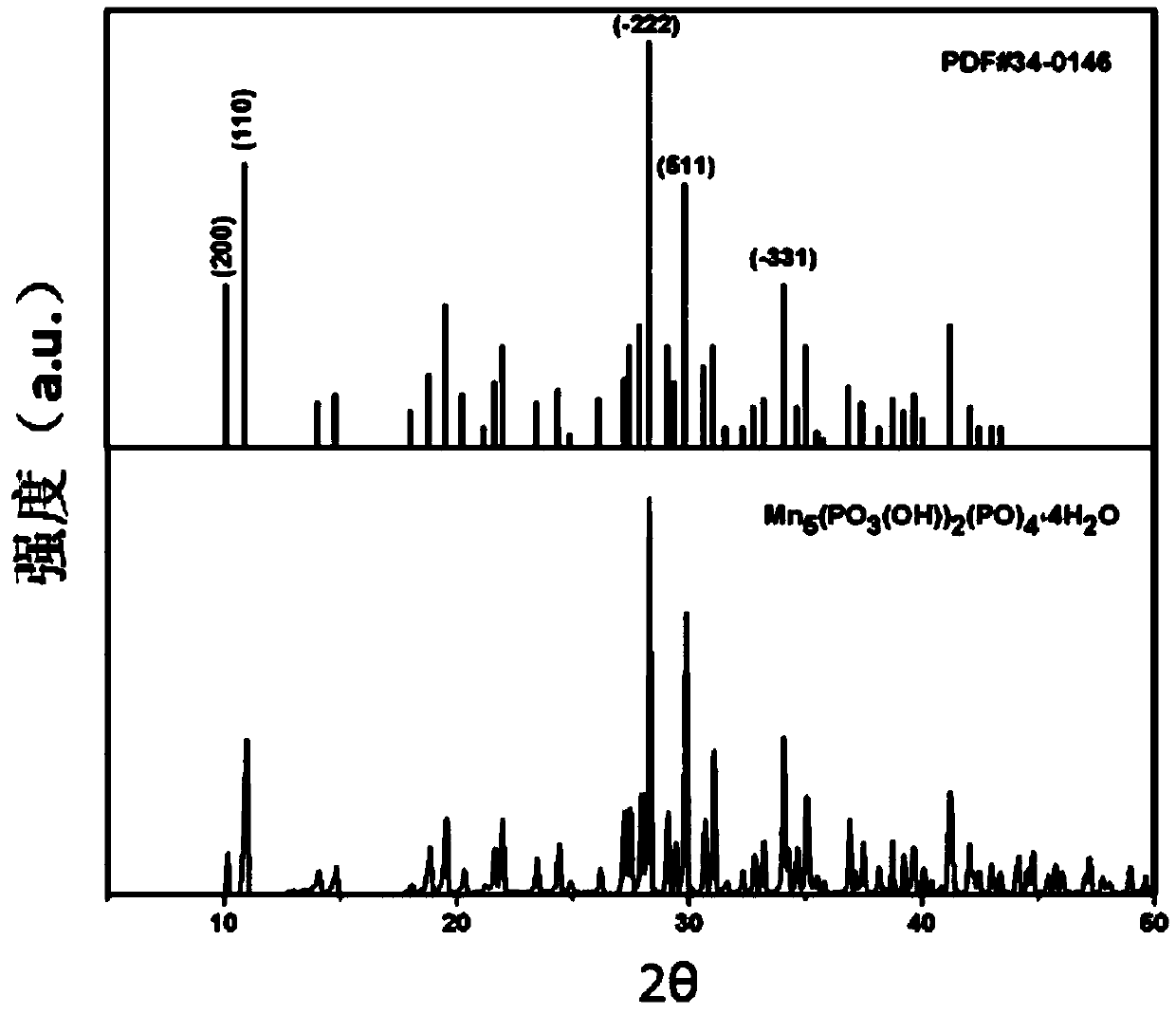

Method for preparing high-purity manganese phosphate from low-grade rhodochrosite leaching liquid

ActiveCN106381387AHigh purityLow impurity contentPhosphorus compoundsSodium phosphatesHydrometallurgy

The invention discloses a method for preparing high-purity manganese phosphate from low-grade rhodochrosite leaching liquid and belongs to the hydrometallurgy field. The impurity content of the low-grade rhodochrosite leaching liquid is high, the technical difficulty of impurity removal is high, and the process is complicated. The method for preparing the high-purity manganese phosphate from the low-grade rhodochrosite leaching liquid is short in technological process and mainly includes the following two steps that firstly, sodium phosphate is added into sulfuric acid leaching liquid of rhodochrosite, the pH value of a solution is controlled between 3 and 3.5, sufficient stirring is performed, precipitate is removed in a filtering manner, and a preliminarily purified manganese sulfate solution is obtained; and secondly, sodium phosphate continues to be added into the preliminarily purified manganese sulfate solution, a final pH value of the solution is controlled between 4.0 and 4.5, sufficient stirring is performed, filtering and repeated washing are performed, and a high-purity manganese phosphate product is obtained. The method is simple in process operation and easy to control, the prepared manganese phosphate is high in purity, feasibility of evaluation in the aspects of economy, technology, environment and the like is high, and a new path is provided for development and application of the low-grade rhodochrosite.

Owner:UNIV OF SCI & TECH BEIJING

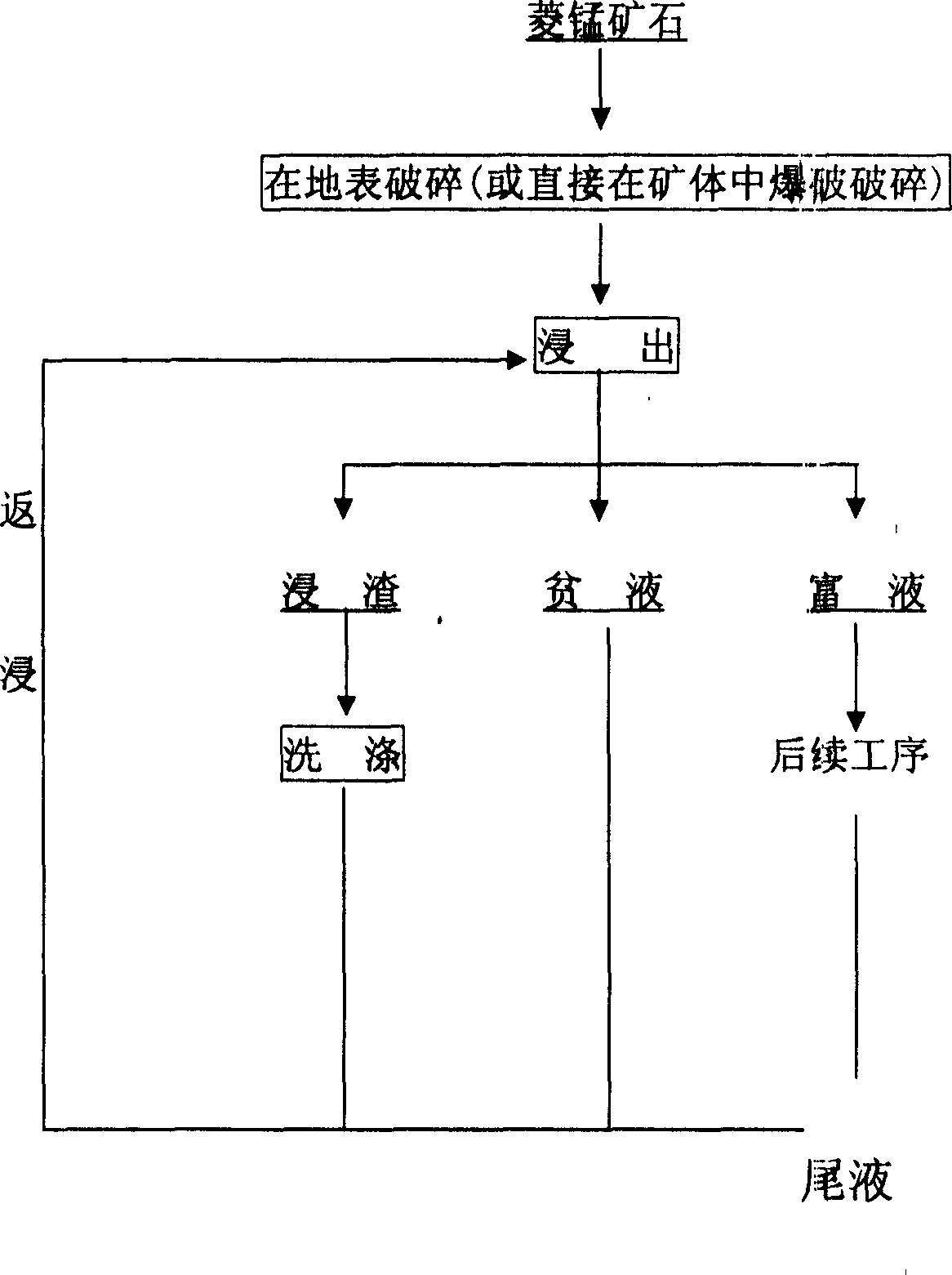

Phodochrosite leaching technology

InactiveCN1618995AReduce mining costsReduce investmentProcess efficiency improvementRhodochrositeMaterials science

An immersing extraction technology for rhodochrosite features that the deluted sulfuric acid is sprayed on the rhodochrosite ores for immersing it while extracting its active components.

Owner:周罗中

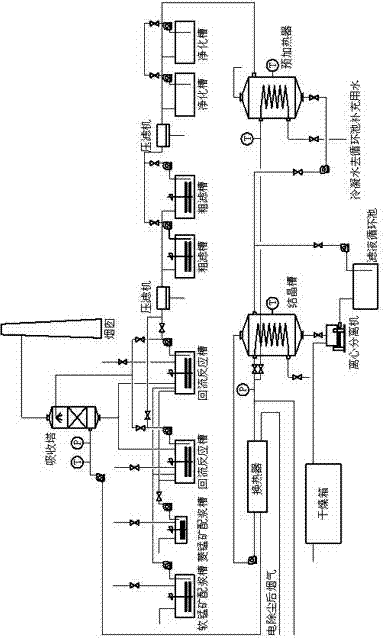

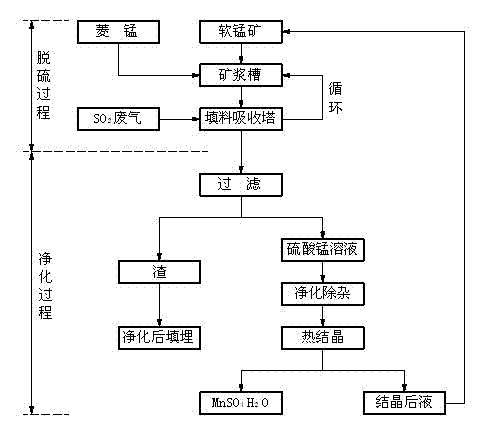

Method and apparatus for processing sulfur-containing flue gas by lean manganese mine and rhodochrosite

InactiveCN104740982AHarmlessAchieve reductionDispersed particle separationManganese sulfatesManganese sulphateFlue gas

The invention discloses a method and an apparatus for processing sulfur-containing flue gas by lean manganese mine and rhodochrosite. The method comprises the processes of absorption, purifying, crystallization and drying. SO2 in the sulfur-containing flue gas can be absorbed by lean manganese mine and rhodochrosite, a part of a resultant generated by absorption of SO2 can be purified, crystallized and dried for being as an ingredient water of the lean manganese and rhodochrosite for cycle use, and the other part is taken as a by-product. According to the invention, MnSO4 production and SO2 exhaust gas treatment are combined, harmlessness, quantitative reduction and resource of SO2 can be realized, and the method develop the market for using the lean manganese mine resource. The operation cost is low, the method is not restricted by manganese mine grade, a reduction calcination process of the manganese sulfate production is omitted, a lot of energy is saved, sulfuric acid source problem is solved, SO2 exhaust gas treatment problem can be solved, and the manganese sulfate product can reach the requirement of fertilizer grade (GB1622-86) and feed grade (GB5253-87).

Owner:GUIZHOU UNIV

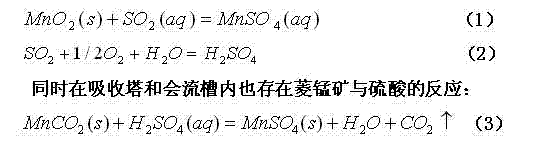

Beneficiation method for improving grade of manganese in rhodochrosite ores

InactiveCN102302977APromote monomer dissociationClean and efficient sorting methodWet separationMicrowave ovenRhodochrosite

The invention discloses a beneficiation method for improving the grade of manganese in rhodochrosite ores. The method comprises the following steps: crushing raw rhodochrosite ores, then putting the crushed powdered ores in an industrial microwave oven to carry out microwave roasting to obtain roasted powdered ores; adding water into the roasted powdered ores so as to carry out wet grinding on the powdered ores, then carrying out separation on the obtained grinded ore pulp by using a spiral chute to obtain manganic concentrates, wherein compared with the grade of manganese in the raw ores, the grade of manganese in the manganic concentrates can be increased by 5-15%, and the recovery rate of manganese is 85-90%. The beneficiation method disclosed by the invention has the following advantages that: (1) through roasting raw rhodochrosite ores by using microwaves, the monomer dissociation of monomers of various minerals in the ores can be effectively promoted, and no harmful pollution gas is produced in the process of roasting; (2) separation and enrichment is carried out on manganese minerals subjected to roasting by using a gravity separation method, and the separation method is clean and efficient without using any chemical agents; and (3) compared with the grade of manganese in raw ores, the grade of manganese in the obtained manganic concentrates can be increased by 5-15%, and the recovery rate of manganese is 85-90%.

Owner:长沙达华矿业技术开发有限公司

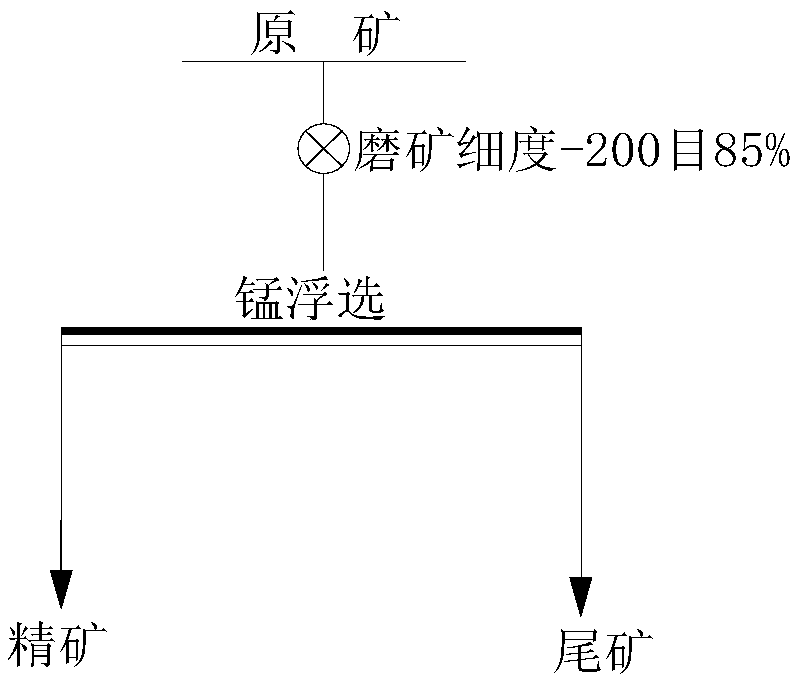

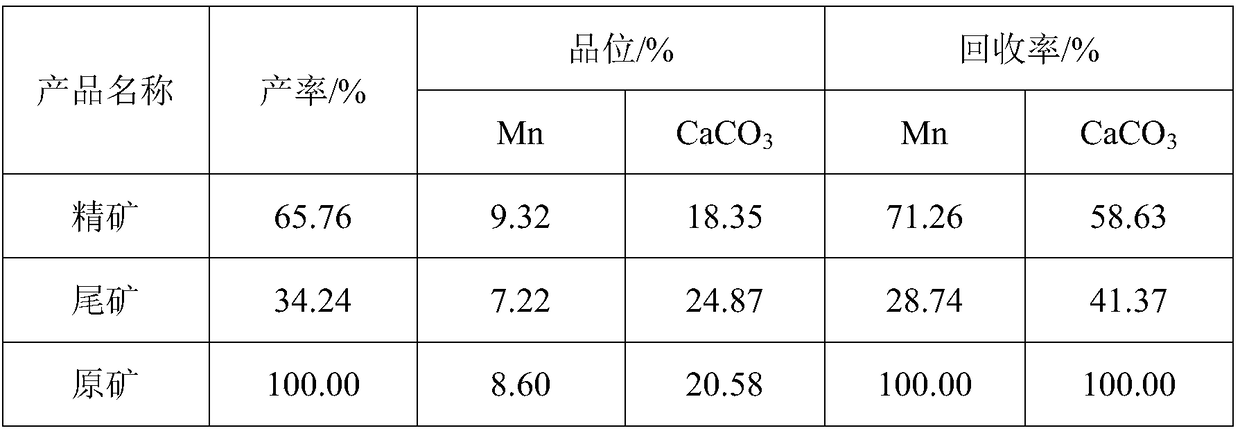

Flotation method of rhodochrosite

The invention relates to a flotation method of rhodochrosite. Ore is ground first to obtain fine ore; manganese sulfate is added into the fine ore for size mixing, then a first inhibitor and a first oxidation ore collector are added for uniform mixing, and flotation is conducted to obtain rougher tailings; a second oxidization ore collector is added into rougher tailings, and scavenging is conducted 2-5 times to obtain scavenged tailings and scavenged concentrates; the scavenged concentrates are returned to last-level operation in sequence; manganese sulfate and a second inhibitor are added into the scavenged tailings, concentration is conducted 2-5 times, obtained foam products are calcium carbonate concentrates, and the finally obtained product tailings are rhodochrosite concentrates. The method solves the problems that flotation separation of high-calcium manganese ore is difficult, the separation effect is poor, and the recovery rate of manganese concentrates is low. The recovery rate of manganese in the flotation method can reach 92% or above. According to the method, most of calcium carbonate is removed in advance, the grade of the manganese concentrates is increased, the content of calcium carbonate in the manganese concentrates is reduced, and convenience is provided for reducing the production cost of subsequent electrolytic manganese operation.

Owner:HUNAN RES INST FOR NONFERROUS METALS

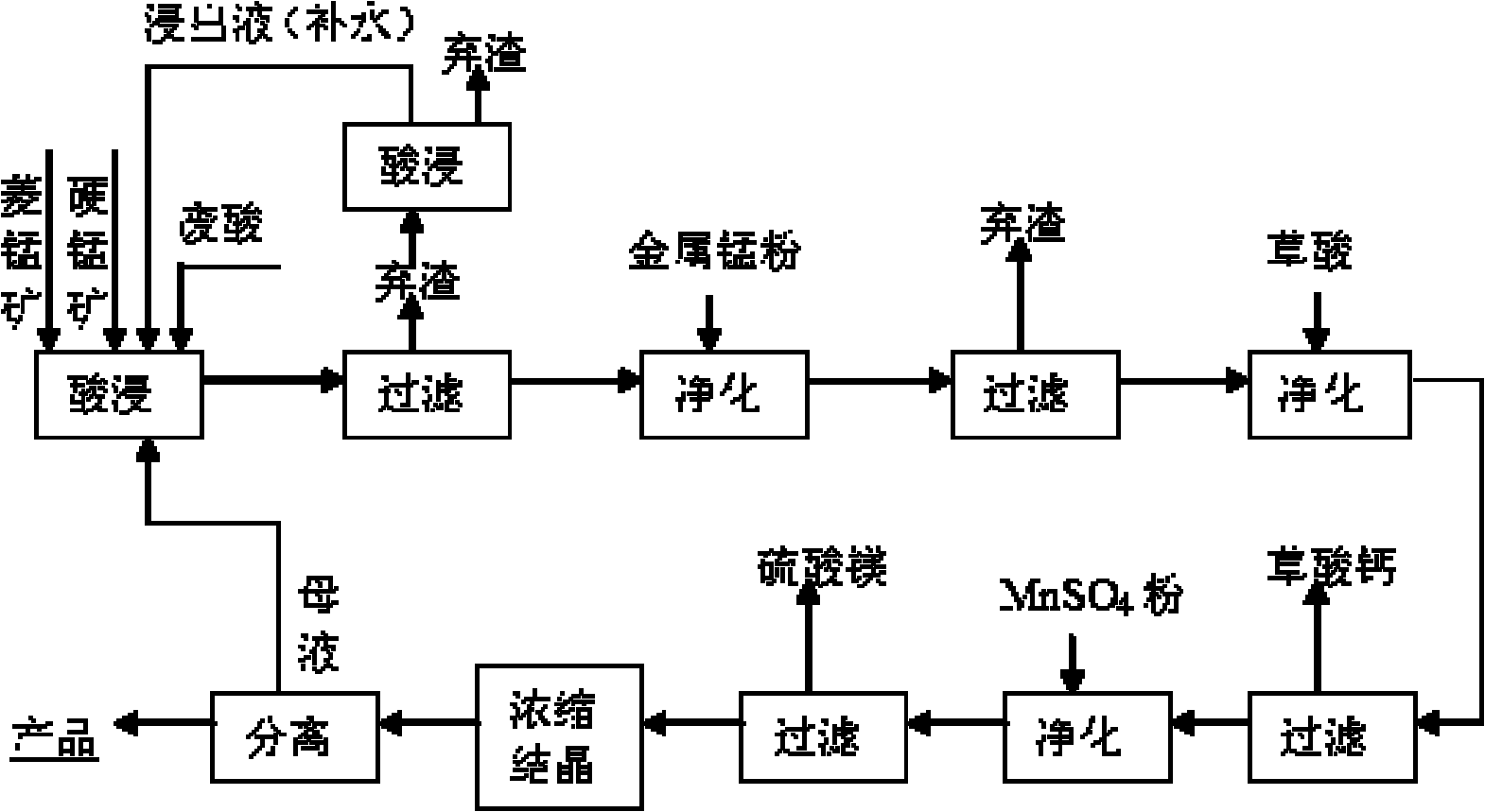

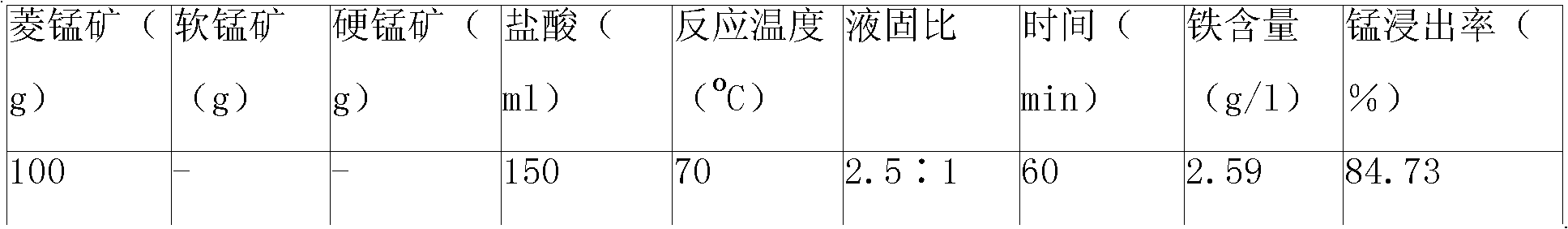

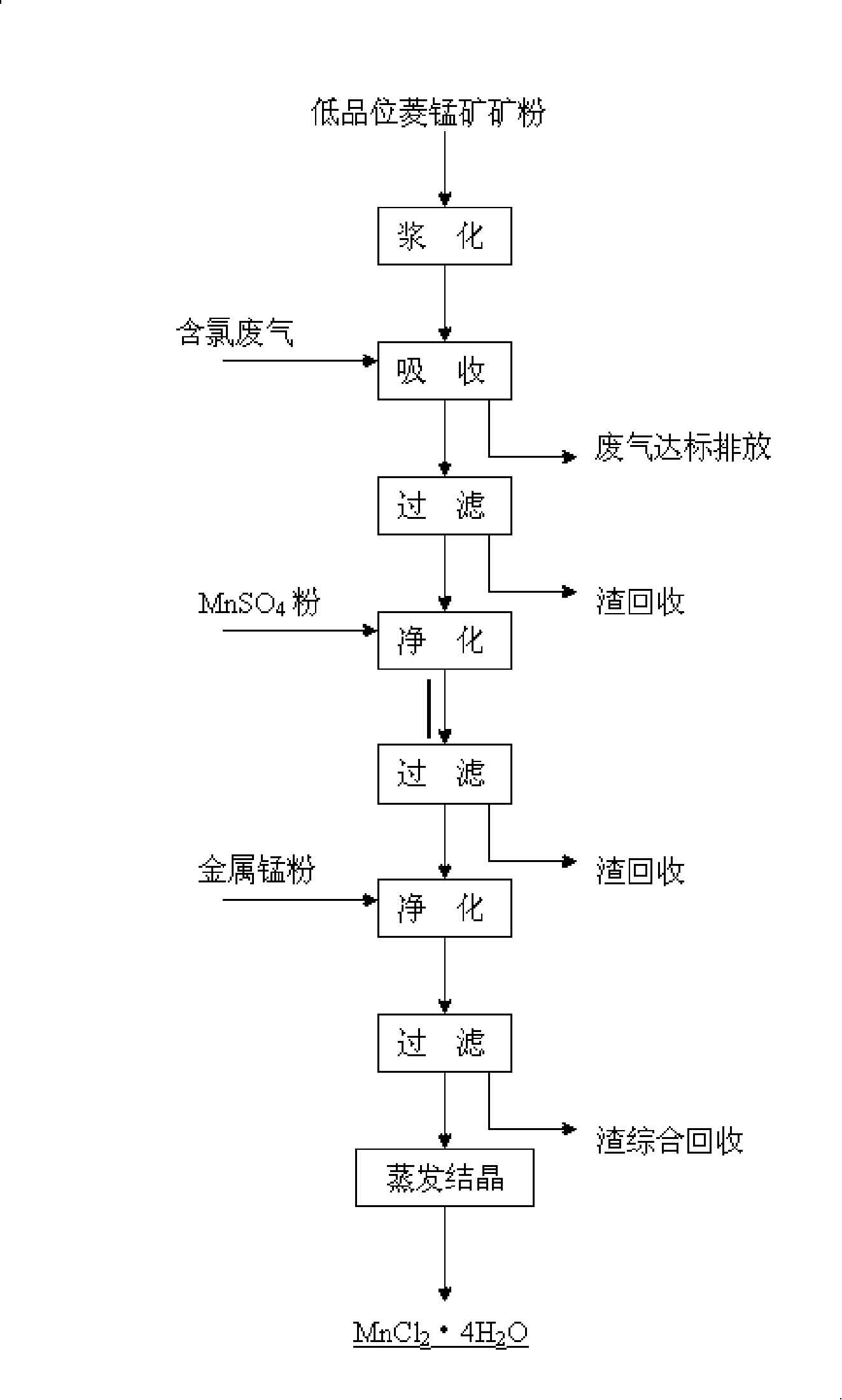

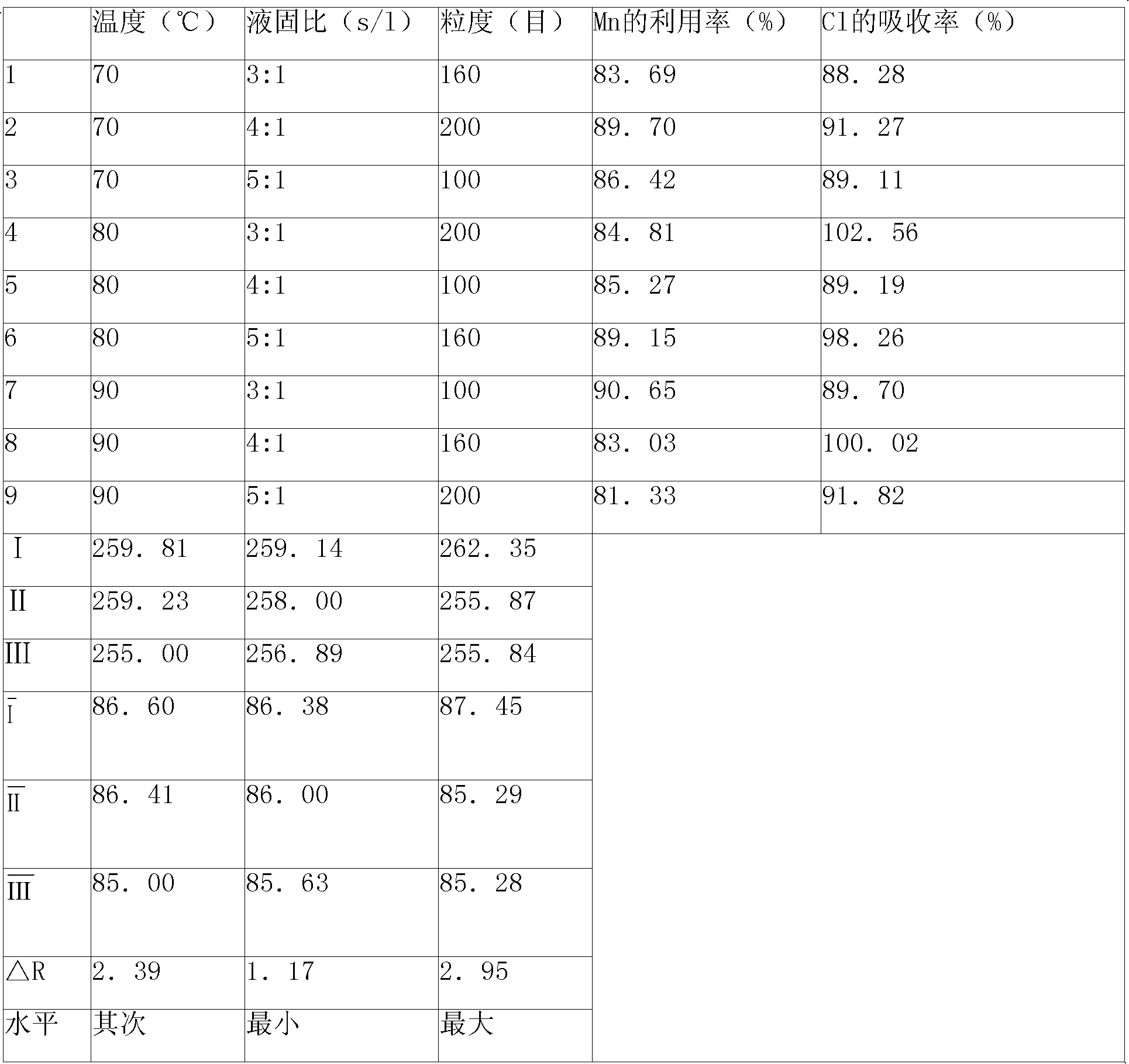

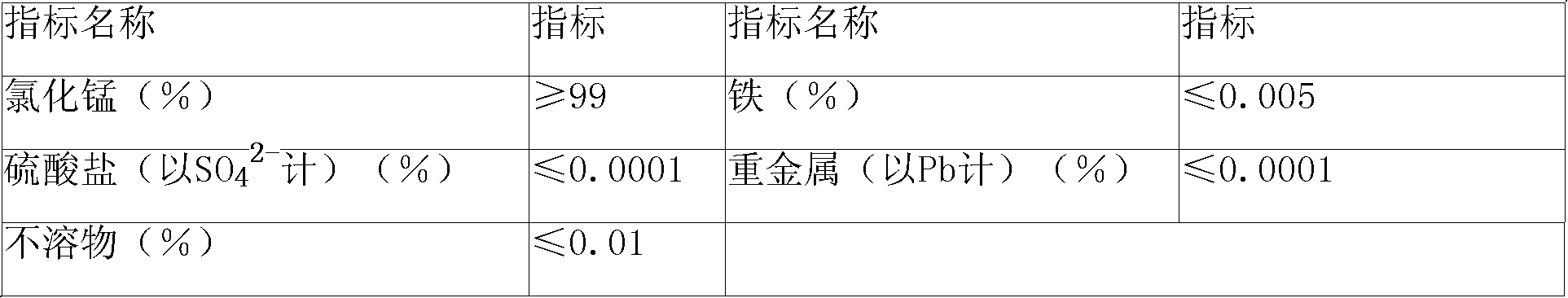

Process for preparing tetrahydrate manganese chloride by leaching out rhodochrosite with waste acid

InactiveCN102050495ATo satisfy the market's needsReduce manufacturing costManganese halidesSlagPsilomelane

The invention discloses a process for preparing tetrahydrate manganese chloride by leaching out rhodochrosite with waste acid. The process comprises the following steps of: adding waste hydrochloric acid to rhodochrosite step by step for leaching, meanwhile, adding pyrolusite or psilomelane which is used as an oxidant; filtering the generated mixed solution, and leaching the filter residue with acid once again; adding metal manganese powder to filter liquor for precipitating, filtering and abandoning slag; adding oxalic acid in the filter liquor for settling, filtering; adding manganese sulfate powder to the filter liquor for precipitating, and filtering; quantitatively adding BaCl2 to the filter liquor, standing still and filtering to remove excessive SO4 <2->; and finally, carrying out concentrating crystallization and centrifugal separation on the filter liquor to obtain a tetrahydrate manganese chloride product. Compared with the prior art, the process has the advantages of simple process flow, convenience of operation, less investment, high efficiency and easy utilization of industrialization. In the invention, low-concentration waste acid is used for leaching the rhodochrosite to produce tetrahydrate manganese chloride, which not only solves the treatment problem of waste acid, but also efficiently utilizes a large quantity of low-grade rhodochrosite resources and realizes the sustainable utilization of resources.

Owner:沈新财

Desulphurization method for sintering flue gas by using pyrolusite and rhodochrosite

InactiveCN104740990AHarmlessAchieve reductionDispersed particle separationManganese sulfatesPyrolusiteSide effect

The invention discloses a desulphurization method for sintering flue gas by using pyrolusite and rhodochrosite. The method is characterized in that production of MnSO4 and SO2 exhaust gas treatment are combined, harmlessness, quantitative reduction and resource of SO2 are realized, and utilization market of the lean manganese ore is developed. An innovation is characterized in that rhodochrosite is taken as a pH value conditioning agent, problems that limewash taken as the conditioning agent can easily lead to obstruction of an absorption system pipeline and a circulating pump, and new impurity can be brought to a leachate, slag amount is increased, so that Mn<2+> loss is increased, and the problems of preparation complex of the pH value buffering agent, higher price than that of rhodochrosite and new impurity introducing in the system can be solved, limewash is not good for purifying pyrolusite desulphurization side effect, so that equipment investment for subsequent technology is increased, energy consumption and operation cost are increased. According to the invention, desulphurization efficiency can reach as stable as more than 92%, and the manganese leaching rate can reach more than 80%.

Owner:GUIZHOU UNIV

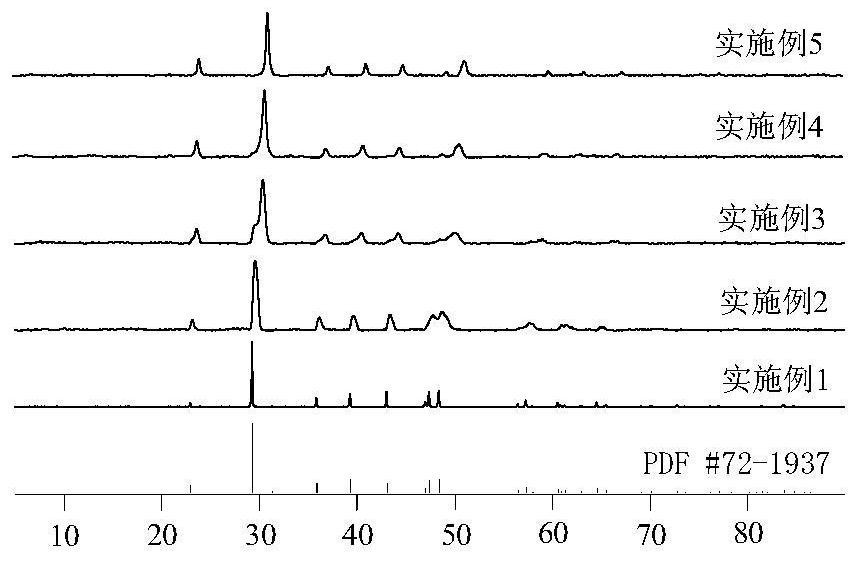

Preparation method and application of calcite-rhodochrosite solid solution

PendingCN112174180AAchieve long-term stabilityLow costCalcium/strontium/barium carbonatesCalcium/strontium/barium nitratesPhysical chemistryCrystallinity

The invention discloses a method for synthesizing calcite-rhodochrosite mixed crystal solid solution by a precipitation method. The method comprises the steps of obtaining calcite-rhodochrosite mixedcrystal solid solution with high crystallinity and good stability by using an ammonium bicarbonate preparation solution as a base solution and then adding anhydrous calcium nitrate and manganous nitrate in different molar ratios into the ammonium bicarbonate solution. Finally, a proper quantity of calcite-rhodochrosite solid solution is dissolved in three different solutions at the temperature of25 DEG C, and the rules of migration, transformation and enrichment of manganese in the environment are mastered. Compared with calcite-rhodochrosite synthesized through a traditional precipitation method, the calcite-rhodochrosite series solid solution synthesized through the method has the advantages of being low in cost, easy to control, capable of achieving long-term stable storage of manganese in the environment and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

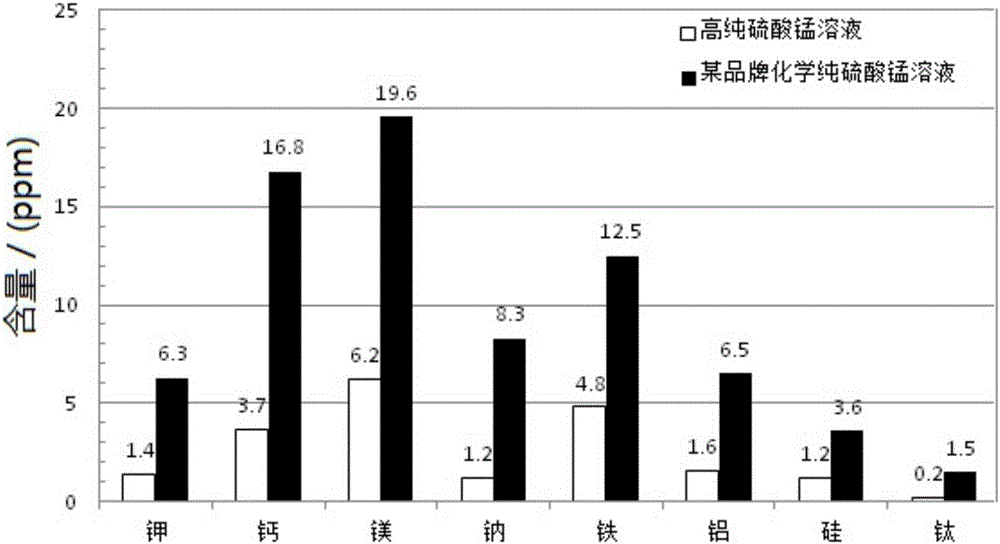

Short-process low-consumption high-purity manganese sulfate solution preparing method

The invention relates to a method for directly preparing a high-purity manganese sulfate solution from low grade rhodochrosite sulfuric acid extraction liquid. The rule that the PH value of a system is changed from small to large is implemented, and an efficient chemical coupling mechanism is played. The method includes the steps that firstly, manganese mineral powder is continuously dissolved into low grade manganese ore sulfuric acid extraction liquid, the pH value of the extraction liquid is sequentially adjusted with barium hydroxide to reach 3 to 4, then barium fluoride is added, and filtering is carried out; secondly, the pH value of filter liquor is adjusted with barium hydroxide to reach 5 to 6, then barium sulfide is added, filtering is carried out, and new filter liquor is obtained; and finally, the PH value of the new filter liquor is adjusted with barium hydroxide to reach 8, and filtering is carried out to obtain the high-purity manganese sulfate solution. The method is simple in operation, medicament waste caused by operation for repeatedly adjusting the PH value of the system in an overlapped manner is avoided, the manganese content in the prepared high-purity manganese sulfate solution is larger than or equal to 80 g / L, the main impurity contents are all smaller than or equal to 10 ppm, the heavy metal content is smaller than or equal to 1 ppm, and the short-process low-consumption free-pollution high-purity manganese sulfate solution preparing method is provided.

Owner:UNIV OF SCI & TECH BEIJING

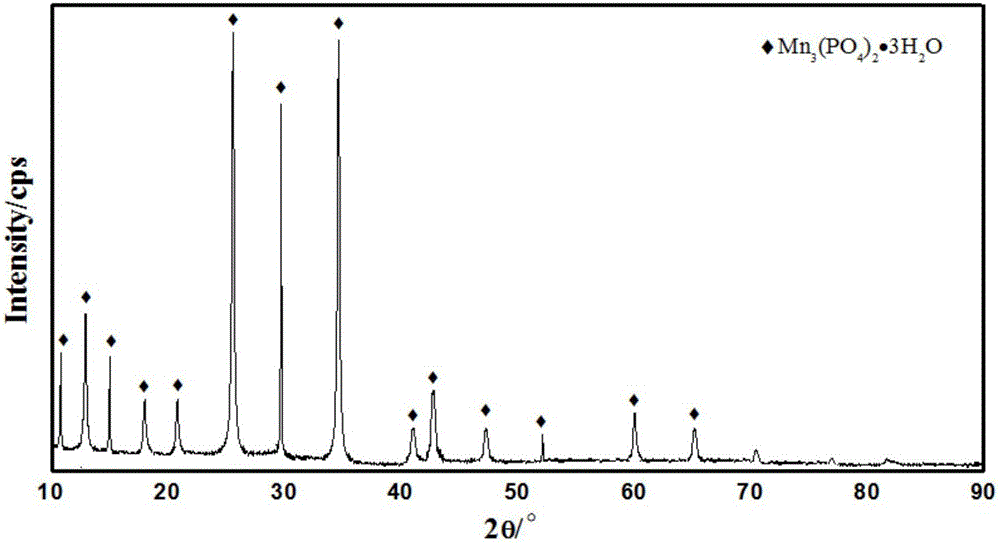

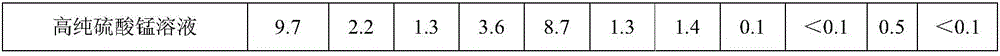

A kind of method for preparing rhodochrosite type manganese phosphate from low-grade rhodochrosite leaching solution

The invention discloses a method for preparing manganwentzelite type manganese phosphate from low grade rhodochrosite leachate. Manganwentzelite is phosphate of first-class manganese, has the characteristics of high hardness, good thermal stability and good wear resistance, and is widely used as a high-performance preservative. The low grade rhodochrosite leachate is high in impurity content, an impurity removal technical difficulty is high, and a production process for high-purity products is complicated. The method for preparing manganwentzelite type manganese phosphate from low grade rhodochrosite leachate mainly comprises the following steps: regulating the pH value of the low grade rhodochrosite leachate by using barium hydroxide, filtering to remove precipitate to obtain a primary purified manganese sulfate solution; and adding ammonium dihydrogen phosphate in the primary purified manganese sulfate solution, controlling the pH value of the solution, the reaction temperature and the reaction time, and repeatedly washing the phosphate to obtain a high-purity manganwentzelite product. The method is short in technological process, simple to operate and easy to controlled; batch production is facilitated; and the prepared product is high-purity prismatic manganwentzelite type manganese phosphate. A new way is provided for short-process development and application of low grade rhodochrosite and preparation of the high-purity manganwentzelite type manganese phosphate.

Owner:UNIV OF SCI & TECH BEIJING

Method for removing chloride impurities from rhodochrosite and eluent adopted by same

The invention discloses an eluent for removing chloride impurities from rhodochrosite. The eluent is a mixed solution of ammonium sulfate and ammonia water, wherein the mass of the ammonium sulfate accounts for 0.2-0.6% of the total mass of the mixed solution; and the concentration of the ammonia water is 0.01-0.05M. A natural ore sample is eluted and filtered by use of the eluent to obtain filtrate and an ore sample after removing chloride impurities. The dechlorination method provided by the invention is simple to operate, only requires normal-temperature stirring and filtration, and is easy to implement industrially; the eluent can prevent the dissolution loss of manganese ions; and since the components in the eluent can form precipitates with barium ions and calcium ions contained in rhodochrosite, the washing effect is better.

Owner:青海华信环保科技有限公司

Method for regulating pH of low-grade pyrolusite sintering flue gas desulfurization slurry

InactiveCN104750130AAvoid introducingImprove purification effectControlling ratio of multiple fluid flowsDispersed particle separationPyrolusiteProcess equipment

The invention discloses a method for regulating the pH of low-grade pyrolusite sintering flue gas desulfurization slurry. According to the method, low-grade pyrolusite is used as a regulator for the pH of low-grade pyrolusite sintering flue gas desulfurization slurry. The problem that the adoption of lime water as a regulator may easily cause blockage of an absorption system pipeline and a circulating pump, bring new impurities to leaching solution and cause the increase in the amount of slag and the loss of Mn2+ is solved. The problem that the investment in equipment in the subsequent process as well as the energy consumption and the running cost are increased due to the fact that a pH value buffer agent is complex in preparation and more expensive than rhodochrosite is also solved. From the point of view of technological process, the adoption of rhodochrosite as a pulp pH regulator avoids the introduction of new impurities to the system and is conductive to the purification of pyrolusite desulphurization by-products. Moreover, in the ultimate process of controlling waste gas pollution with use of low-grade ore, resourcelized utilization of ultimate disposables is realized.

Owner:GUIZHOU UNIV

High spectral image processing method for extracting information of rhodochrosite

InactiveCN105784602AReduce choiceReduce distractionsColor/spectral properties measurementsData needsRhodochrosite

The invention relates to a high spectral imaging processing method for extracting the information of rhodochrosite. According to the method, the wave bands with prominent spectral characteristics of rhodochrosite are saved; the images of wave bands (1445nm, 1535nm, 1820nm, 1940nm, 2015nm, 2045nm, 2135nm, 2165nm, 2225nm, 2360nm, and 2405nm) are extracted, and then a series of judgments and calculation are performed so as to calculate the abundance value of rhodochrosite in different areas of the image range. The provided method can remove the wave bands with unobvious characteristics, thus the spectral characteristics of rhodochrosite become more prominent during the process of information extraction, the influence of other objects or noise is reduced, the data needed to be processed is reduced, moreover, IDL program can be used to reduce artificial operation and extract the final result information, and the precision and speed of rhodochrosite information extraction are both improved.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

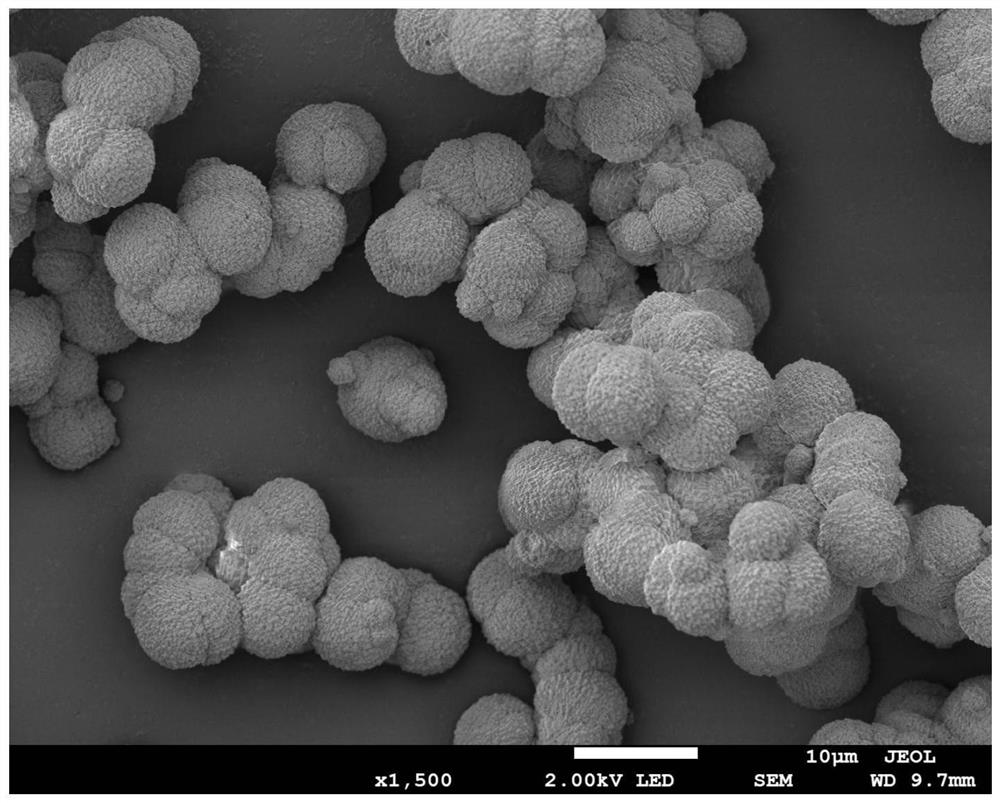

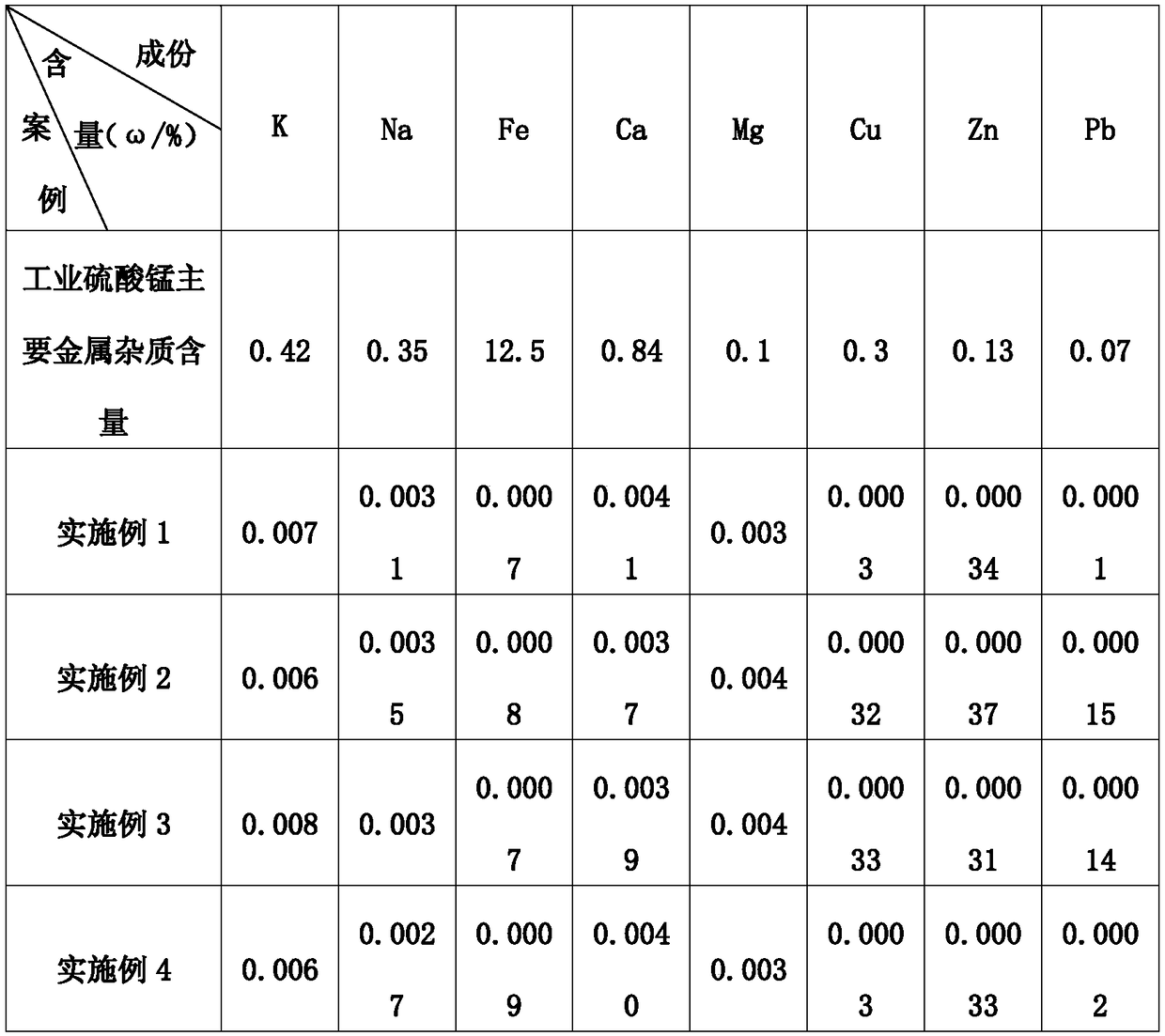

Method for preparing high-purity manganese sulfate from poor rhodochrosite

InactiveCN109319843ASmall particle sizeIncrease the effective reaction contact areaManganese sulfatesFiltrationSulfate

The invention discloses a method for preparing high-purity manganese sulfate from poor rhodochrosite. The method comprises the following steps: crushing a poor rhodochrosite material to obtain a product A; carrying out magnetic separation on the product A to obtain a product B; carrying out acid leaching on the product B to obtain a product C; carrying out pressure filtration on the product C, andtaking filtrate to obtain a product D; adding Fe2(SO4)3 and KMnO4 into the product D, stirring, standing and then filtering, and taking filtrate to obtain a product E; taking the product E, regulating PH, adding an active carbon adsorbent, stirring, standing and then filtering, and taking filtrate to obtain a product F; adding MnF2 into the product F, assisting with ultrasonic treatment, stirring, standing and then filtering, and taking filtrate to obtain a product G; adding MnS into the product G, assisting with ultrasonic treatment, stirring, standing and then filtering, and taking filtrateto obtain a product H; concentrating and crystallizing the product H to obtain high-purity battery-grade manganese sulfate. The high-purity manganese sulfate is prepared from the poor rhodochrosite;the utilization efficiency of the poor rhodochrosite is high; impurities such as calcium and magnesium in manganese sulfate are simply separated; the prepared manganese sulfate is high in purity and low in production cost.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD +1

Method for treating waste sulfuric acids by rhodochrosite to prepare high-purity manganese sulfate and hydrate thereof

The invention belongs to the technical field of treatment and utilization of chemical waste gases, waste water and waste residues, and particularly relates to a method for treating waste sulfuric acids by rhodochrosite to prepare high-purity manganese sulfate and hydrate thereof. The main technical scheme is that: the rhodochrosite is fully utilized to treat the waste sulfuric acids produced by the production of titanium dioxide by crushing the rhodochrosite, leaching manganese in the rhodochrosite with a hydrochloric acid and reacting leaching liquor with the waste sulfuric acids produced by the production of the titanium dioxide. On one hand, wastes are turned into wealth, environmental pollutions are treated and simultaneously the waste sulfuric acids are converted into the manganese sulfate with high economic values; and on the other hand, a plurality of products can be simultaneously co-produced in a process route, the manganese sulfate is produced and simultaneously the hydrate of the manganese hydrate is co-produced. The method ensures low production cost, high profits, great market needs and simple process and production equipment, is a relatively more practical treatment and utilization method, can create considerable economic values, eliminates the chemical waste residues and treats the environmental pollutions.

Owner:王嘉兴

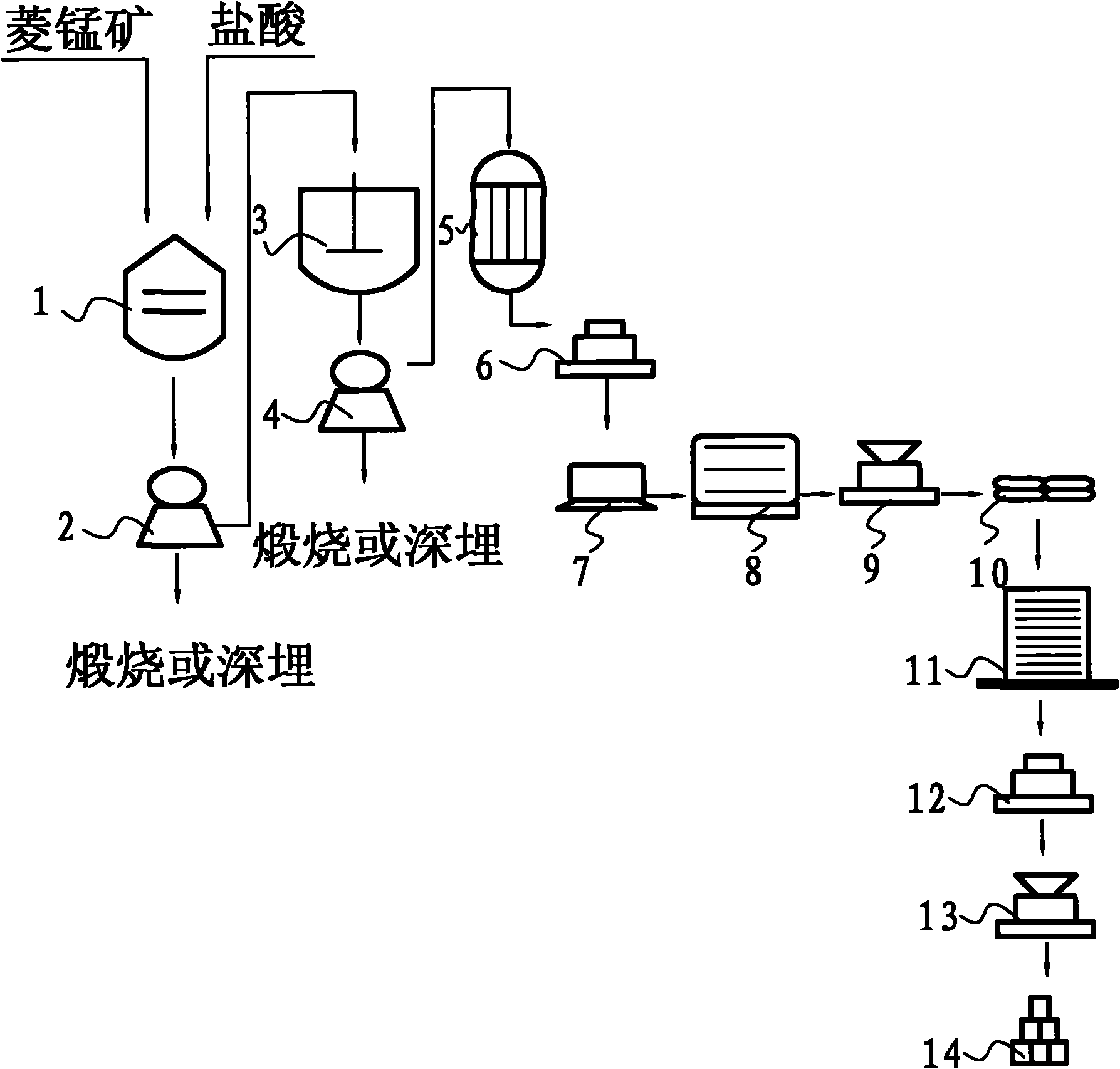

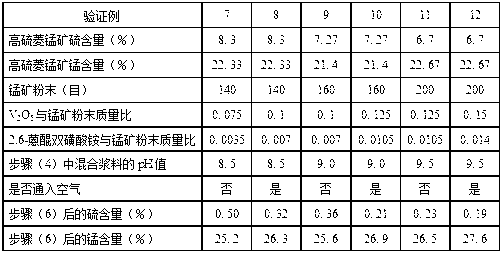

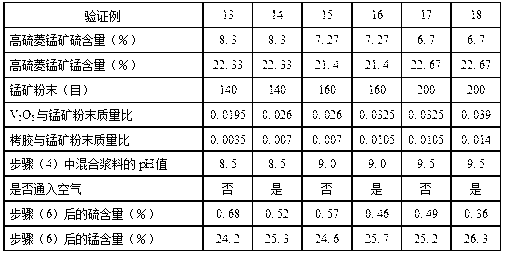

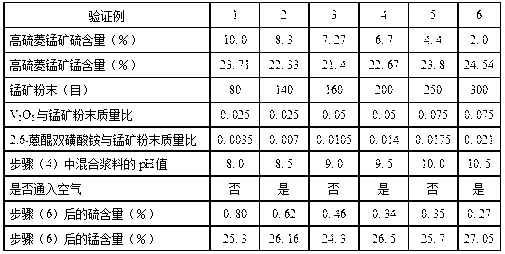

Desulfurizing method for high-sulfur rhodochrosite

The invention relates to a desulfurizing method for high-sulfur rhodochrosite, which comprises the following steps: (1) pulverizing and screening high-sulfur rhodochrosite, (2) feeding water to make a mixed sizing agent under a condition of room temperature, (3) adding vanadic oxide and 2.6-anthraquinone double ammonium sulphonate or adding vanadic oxide and tannin extract into the mixed sizing agent, (4) adjusting the pH value of the mixed sizing agent to be 8 to 10 by dilute aqua ammonia, and then stirring under the condition of keeping the temperature of 55 to 65 DEG C, (5) filtering and separating the mixed sizing agent gained after the step (4), and gaining a precipitate and a filter liquor, and (6) washing the precipitate and then drying to gain manganese mineral powder with low sulphur content. The method has the advantages of low energy consumption, simple technology, easiness in operation, low environmental pollution and high desulfurizing efficiency, and can improve the manganese content of the pre-processed alabandite.

Owner:CHONGQING UNIV

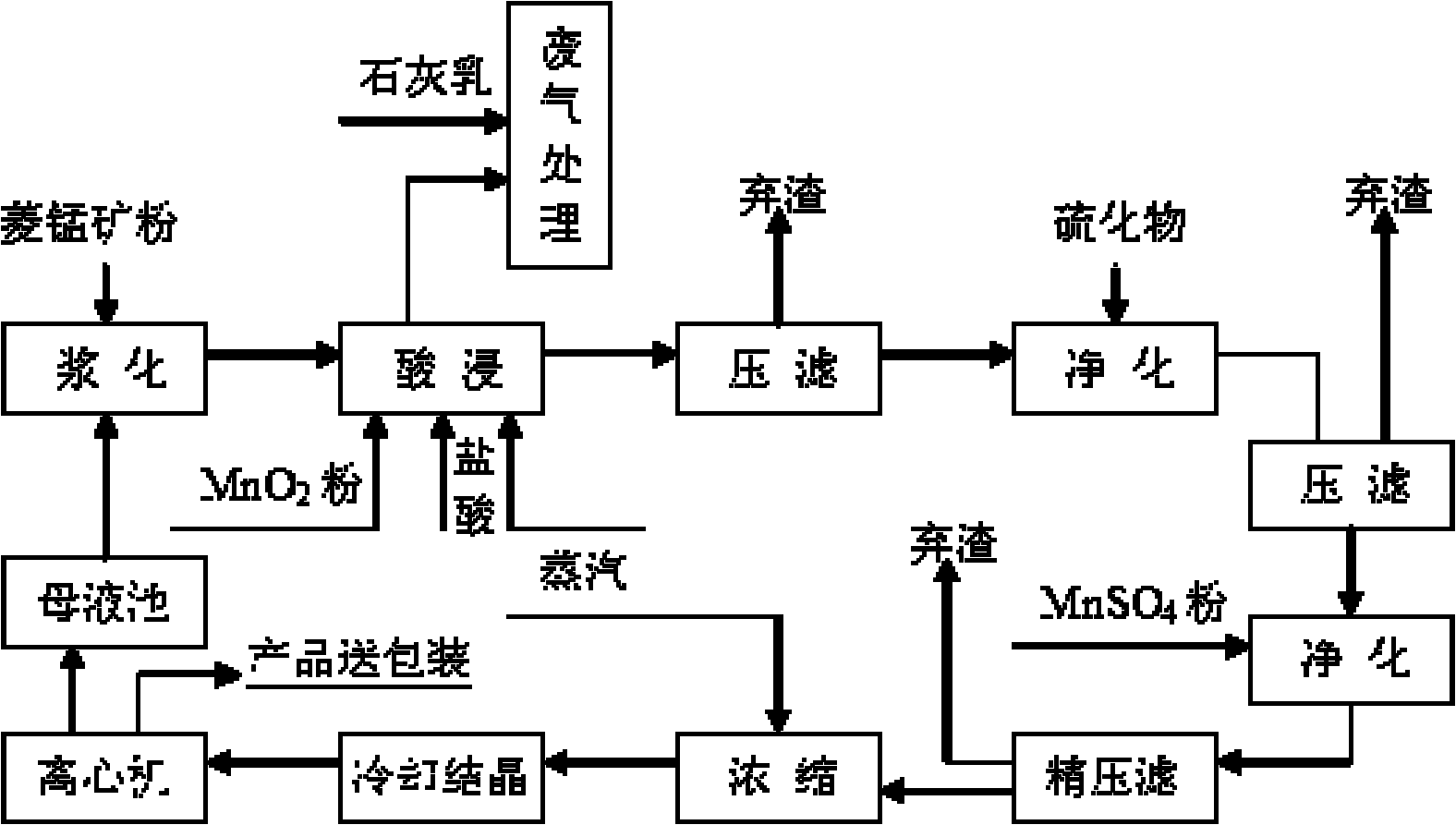

Technique for manufacturing tetrahydrate manganese chloride low ore grade rhodochrosite absorption of chlorine containing waste gas

The invention discloses a process for preparing manganese chloride tetrahydrate by absorbing waste gas containing chlorine by low-taste rhodochrosite. Powder of the low-taste rhodochrosite is prepared to be ore pulp with water; the ore pulp carries out absorption reaction with the waste gas containing the chlorine; the obtained ore pulp is carried out filtration; manganese sulfate powder and metal manganese powder are sequentially added in the filtrate to carry out the purification and the filtration; after the filtrate is evaporated and crystallized, solid MnCl2 4H2O product is obtained. Compared with the prior art, the invention has simple technological process and is convenient to operate. The invention solves the problem of treating the waste gas containing the chlorine, makes full use of the oxidizability without adding oxidant and can also highly effectively use a large amount of low-taste rhodochrosite resource which is difficult to use, which realizes sustainable utilization of resources and reutilization of secondary resources and has good application prospect in industry. By adopting ways of displacement of the metal manganese powder and reduction of the manganese sulfate when purifying and eliminating heavy metals, the invention not only has obvious effect but also reduces secondary pollution to the product and saves process of secondary impurity removal.

Owner:GUIZHOU UNIV

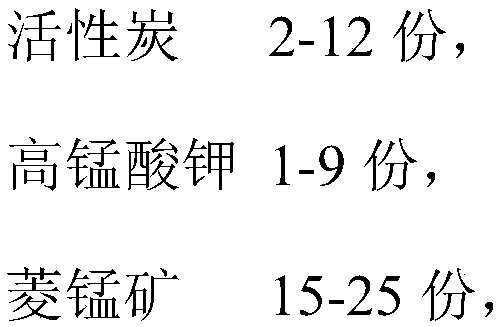

Flue gas denitration agent

PendingCN109224801AImprove adsorption capacityImprove denitrification performanceDispersed particle separationActivated carbonFlue gas

The invention relates to a flue gas denitration agent and production and application methods thereof. The denitration agent is prepared from the following components in parts by weight: 2 to 12 partsof activated carbon, 1 to 9 parts of potassium permanganate, 15 to 25 parts of rhodochrosite, 2 to 12 parts of magnesium oxide, 0.2 to 3.8 parts of silicon oxide, 24.5 to 34.5 parts of urea and 24.5 to 34.5 parts of sodium carbonate. The denitration agent provided by the invention contains the activated carbon and the adsorption effect of the denitration agent can be increased; the added urea canreact with NO and can react with water to form NH3; the NH3 can react with the NO and also can react with NO2; the denitration effect is improved and the denitration rate can reach 95 percent or more;when the same denitration effect is realized, the dosage can be reduced when being compared with that of other denitration agents and the denitration cost is reduced.

Owner:常州泰聚环保科技有限公司

Compound crystal energy intervention material

The invention relates to a compound crystal energy intervention material. Some of the additional environment-friendly indoor decorative materials can also release dangerous and harmful substances to harm human bodies. The compound crystal energy intervention material is prepared from the following materials by weight part: 30-50 parts of anion, 10-20 parts of aetite, 10-20 parts of stone needles,5-10 parts of kallaite, 5-10 parts of graystone, 5-10 parts of void stone, 5-10 parts of sugilite, 5-10 parts of rhodochrosite, 5-10 parts of amber, 10-20 parts of pearl and 10-20 parts of coral. The invention is used as a coating additive.

Owner:关伟 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com