Method and apparatus for processing sulfur-containing flue gas by lean manganese mine and rhodochrosite

A treatment method and technology for lean manganese ore, applied in chemical instruments and methods, separation methods, manganese sulfate, etc., to achieve huge social benefits, achieve harmlessness, and increase equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the embodiments and drawings, but not as any limitation to the present invention.

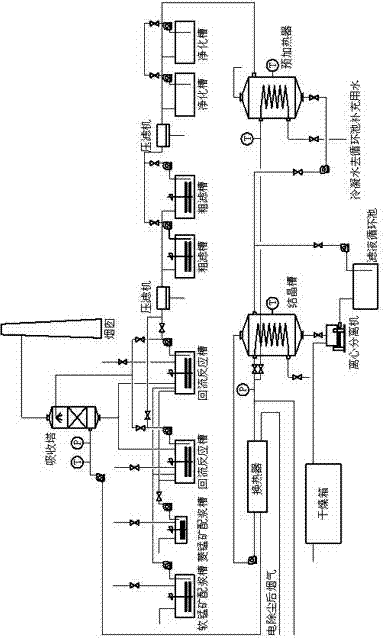

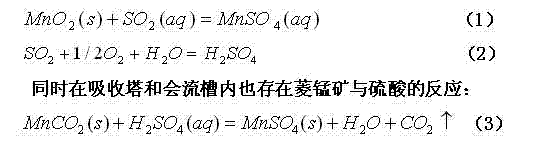

[0019] A method for treating sulfur-containing flue gas with poor manganese ore and rhodochrosite, the method includes absorption, purification, crystallization and drying processes; absorbing SO in sulfur-containing flue gas through poor manganese ore and rhodochrosite 2 ; absorb SO 2 The resulting product is purified, crystallized and dried, part of which is recycled as batching water for manganese-poor and rhodochrosite slurry, and the other part is used as a by-product. Poor manganese ore is the main desulfurizer, and rhodochrosite is the regulator of the pH value of the pulp. Poor manganese ore is prepared by adding water to the poor manganese ore mixing tank to prepare manganese ore slurry, and rhodochrosite is prepared by adding water to the rhodochrosite mixing tank to make rhodochros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com